Patents

Literature

182results about How to "No solvent required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance conducting resin and preparation method thereof

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

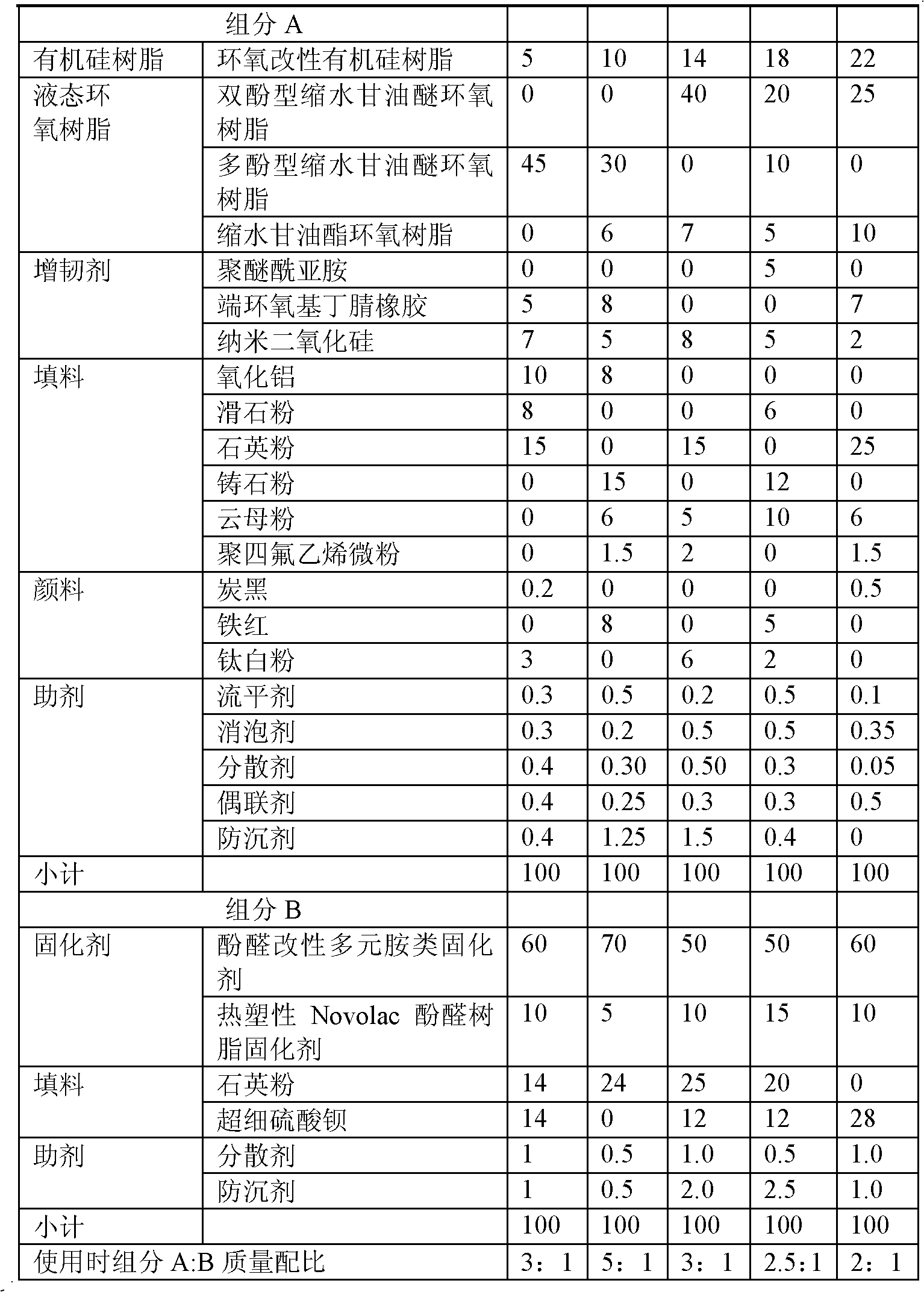

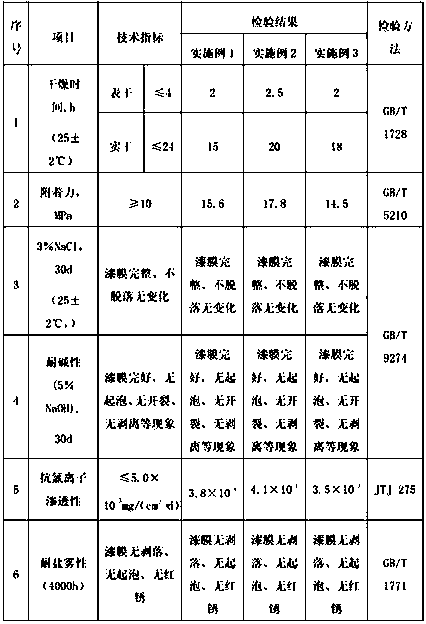

Anti-drag and anticorrosion coating for inner wall of natural gas/condensed liquid pipeline and preparation method thereof

InactiveCN102146251ANo air bubblesQuick releaseAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses an anti-drag and anticorrosion coating for an inner wall of a natural gas / condensed liquid pipeline and a preparation method thereof. The coating comprises an ingredient A and an ingredient B according to a mass ratio of (2-4):1, wherein the ingredient A comprises the following ingredients in parts by mass: 5-30 parts of liquid organic silicon resin, 30-55 parts of liquid epoxy resin, 1-15 parts of flexibilizer, 0.1-2 parts of leveling agent, 0.1-1.5 parts of defoaming agent, 0.05-1.5 parts of dispersing agent, 0.1-2 parts of coupling agent, 0.0-2 parts of anti-settling agent, 0-15 parts of pigment and 10-60 parts of filler; the ingredient B comprises the following ingredients in parts by mass: 40-70 parts of modified polyamine curing agent, 5-35 parts of phenolic resin curing agent, 0.5-2.5 parts of dispersant, 0.5-2.5 parts of anti-settling agent and 15-50 parts of filler; and the ingredient A and the ingredient B in the coating are packaged in a binary manner. The coating has the advantages of good resistance to high pressure natural gas or gas-liquid decompression and bubbling, shear resistance, high bonding strength, good wear resistance, resistance to corrosion of natural gas condensed liquid, smoothness and compactness of the coating, no solvent, quick drying and the like below 50 DEG C, and is suitable for mining requirements under anti-drag, anticorrosion and wear-resistant environments.

Owner:CHINA NAT OFFSHORE OIL CORP +2

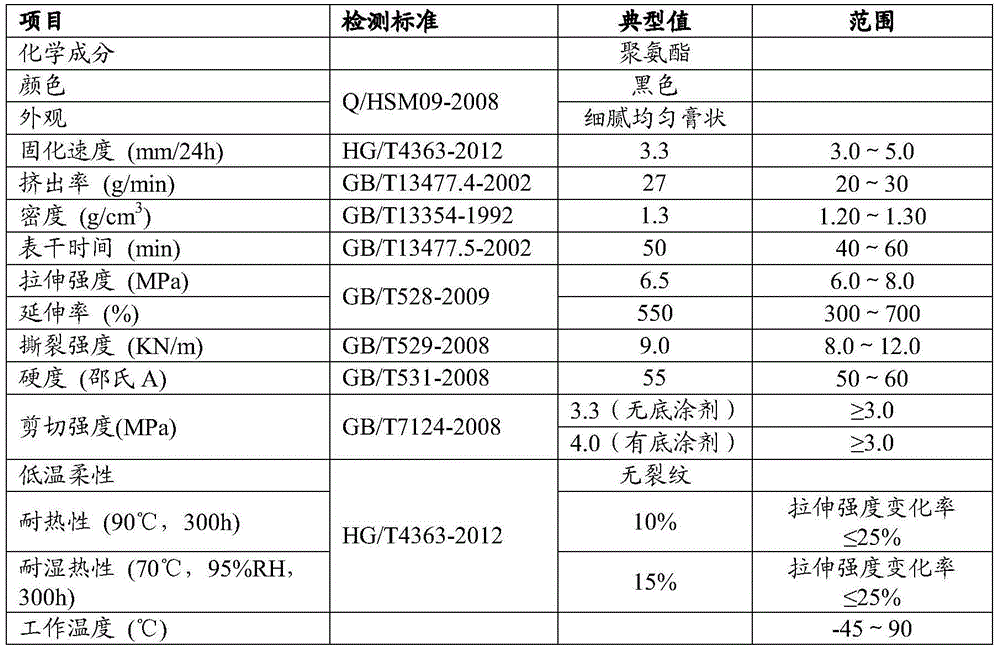

Fast-curing one-component polyurethane sealant and preparation method thereof

InactiveCN101818040AFast curingEasy to dryNon-macromolecular adhesive additivesOther chemical processesAntioxidantPolystyrene

The invention relates to a sealant, in particular to a fast-curing one-component polyurethane sealant and a preparation method thereof. The fast-curing one-component polyurethane sealant is characterized by comprising 30%-60% of prepolymer containing silyl-terminated polyurethane, 0.2%-5% of silane coupling adhesion promoter, 0.301%-0.35% of catalyst, 10%-40% of plasticizer, 10%-60% of filler and 0.05-1% of antioxidant, wherein the content of each component is represented by the weight percent. The fast-curing one-component polyurethane sealant has the advantages of fast surface drying, fast curing speed, avoidance of impacts caused by the environmental temperature and the humidity, high cross-linking density, high elongation ratio, good adhesion strength, no solvent, environmental protection and excellent adhesive performance to base materials, such as metal, ceramics, glass, silica PVC, ABC, polystyrene, polyacrylate and the like.

Owner:PUYANG CITY WANQUAN CHEM

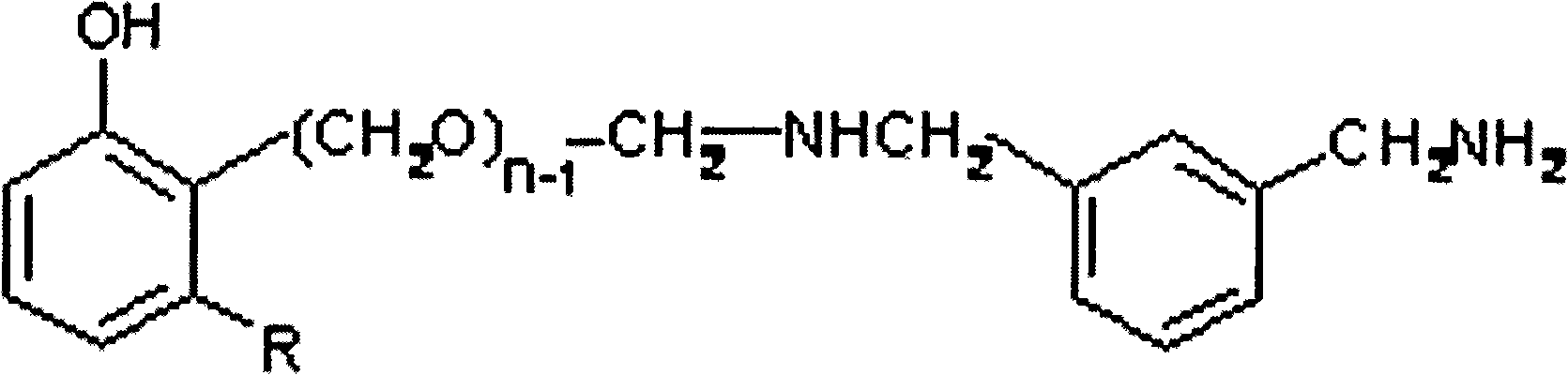

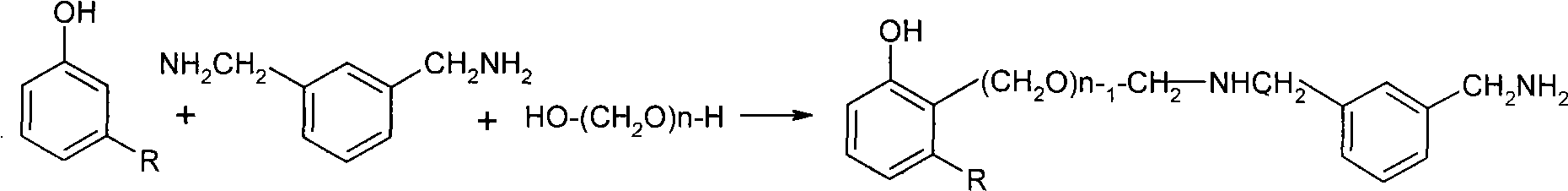

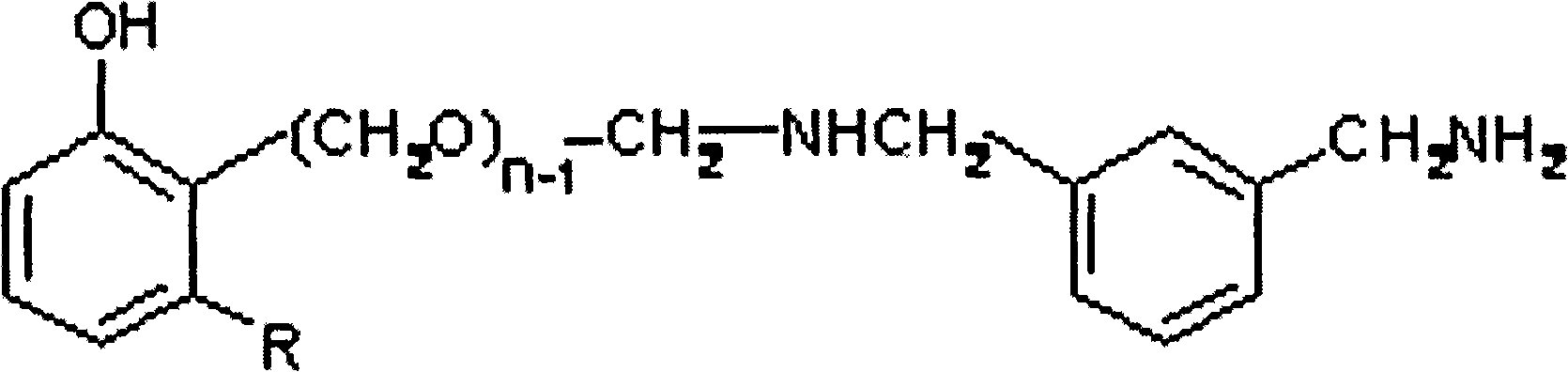

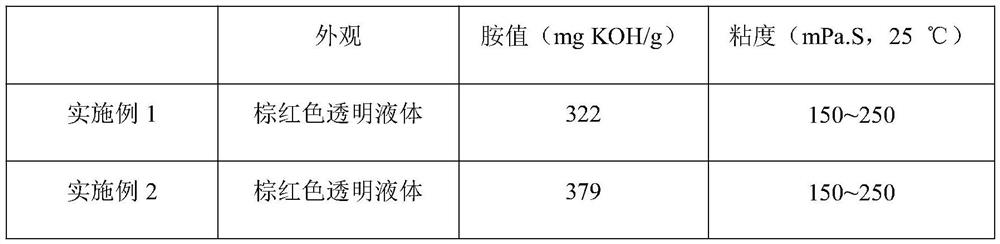

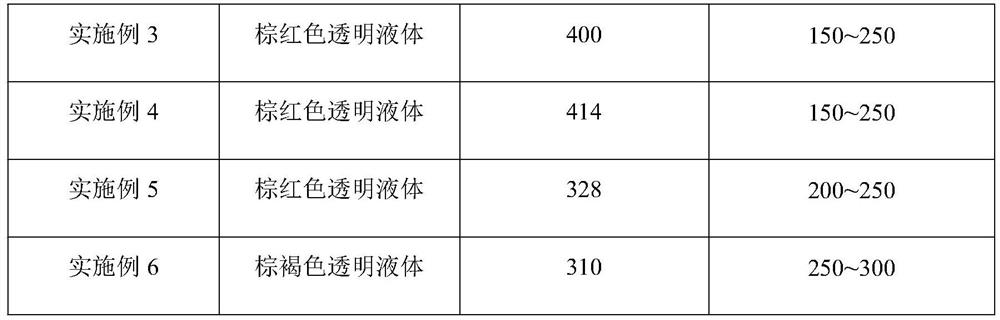

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

Spherical forming Cu base metal organic skeleton-graphene oxide composite material and preparation method of spherical forming Cu base metal organic skeleton-graphene oxide composite material

ActiveCN104226256AShort reaction timeNo solvent requiredOther chemical processesAlkali metal oxides/hydroxidesMetal-organic frameworkOxide composite

The invention belongs to the technical field of metal organic skeleton material forming and discloses a preparation method of the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The method comprises the following specific steps: proportionally mixing water, methyl hydroxypropyl cellulose and silicate resin with Cu base organic skeleton-graphene oxide composite porous material powder which is synthesized by using a mechanical ball milling method so as to obtain a mixture, adding the mixture into a pelletizer, pelleting, and drying, so as to obtain the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The spherical forming Cu base metal organic skeleton-graphene oxide composite material prepared by using the preparation method has the advantages of relatively large surface area, open pore structure and the like and has the special appearance, volume, mechanical strength, toughness and water resistance which are necessary for an actual industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

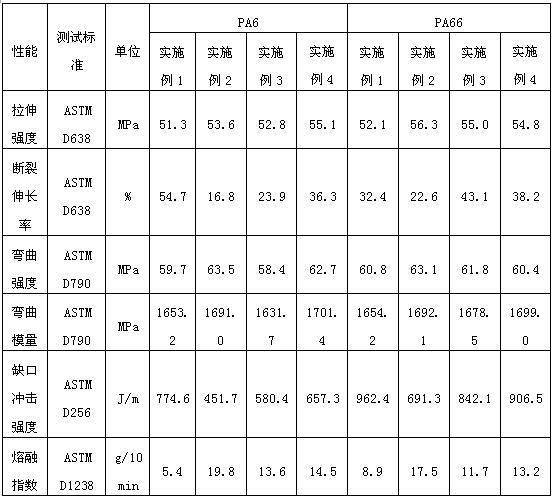

Ultrahigh-mobility propenyl elastomer grafting copolymer and preparation method thereof

The invention relates to an ultrahigh-mobility propenyl elastomer grafting copolymer and a preparation method thereof. The copolymer comprises the following components in percentage by weight (wt%): 50-100wt% of propenyl elastomer resin, 0-50wt% of polyolefin resin, 0.5-5wt% of grafted monomer, 0.01-2wt% of initiator, 0.1-1wt% of crosslinking inhibitor, 0.1-1wt% of antioxygen and 0.1-2wt% of liquid accessory ingredient, wherein other components except the initiator are mixed in a high-speed mixer at a certain ratio and are added into a double-screw extruder by main feeding; the initiator is added into the extruder by side feeding; and a product is obtained by fusing, plastifying, kneading, mixing, extruding from a handpiece, bracing, cooling, pelletizing and drying. Compared with the prior art, the ultrahigh-mobility propenyl elastomer grafting copolymer disclosed by the invention has the advantages of higher product grafting ratio, lower gel content, excellent comprehensive performance and excellent impact performance by the side feeding technology, and is especially suitable for thin-wall products and large producing pieces in the fields, such as interior / exterior trim parts ofautomobiles, bumpers, railway equipment and the like.

Owner:SHANGHAI SUNNY

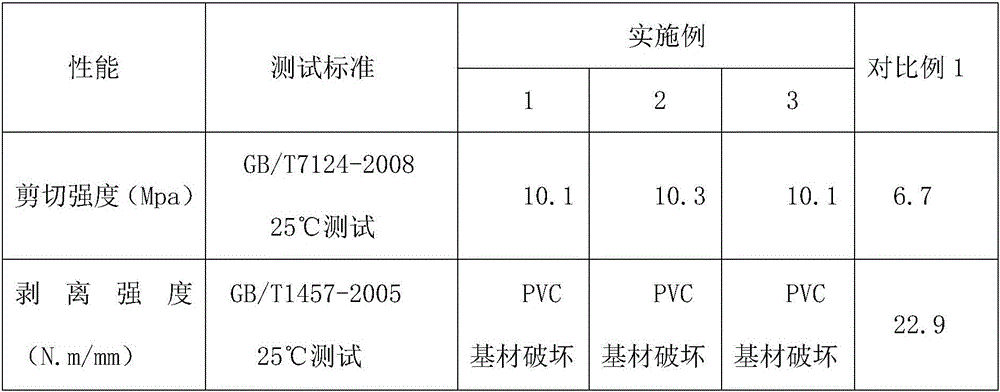

Polyurethane adhesive for compositing two-component PVC plate

ActiveCN105925236AGuaranteed dimensional stabilityHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistancePolyester

The invention discloses a polyurethane adhesive for compositing a two-component PVC plate. The adhesive is composed of a component A and a component B according to the mass ratio of (1-4):1, and the component A is composed of, by weight, 10%-25% of castor oil, 10%-20% of polyether polyol, 1%-5% of coupling agent, 0.5%-2.5% of fumed silica, 30%-60% of filler and 5%-10% of drying agent; the component B is composed of, by weight, 50%-80% of isocyanate, 5%-15% of polyether polyol, 10%-30% of polyester polyol and 1%-4% of chain extender. A preparation method of the polyurethane adhesive for compositing the two-component PVC plate comprises the following steps of preparation of the component A, preparation of the component B and mixing of the component A and the component B. The polyurethane adhesive is used for bonding PVC with a plate. The polyurethane adhesive has the advantages of being free of solvent evaporation, large in initial adhesion, excellent in adhesive force on PVC, high in strength, wide in environmental adaptability, long in storage life, high in stability, environmentally friendly in raw material, capable of obtaining the raw materials conveniently and the like.

Owner:上海都昱新材料科技有限公司

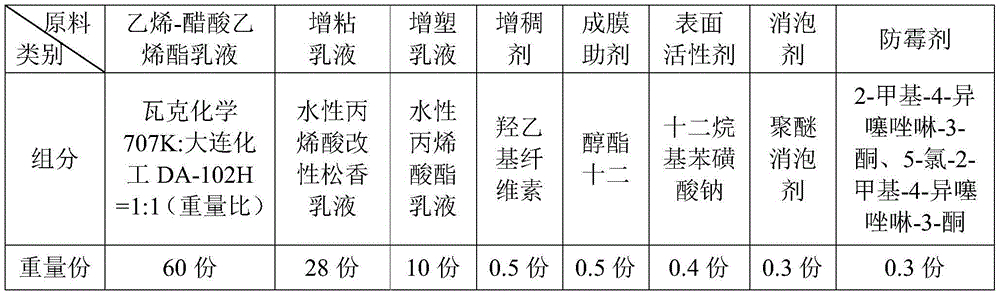

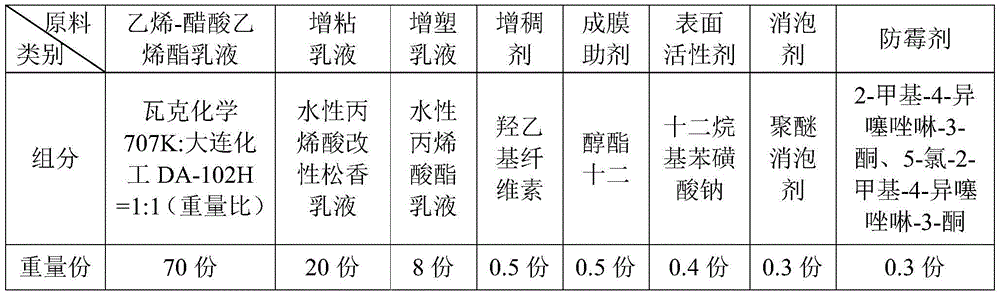

Hat box, environmentally-friendly water-based adhesive and preparation method of environmentally-friendly adhesive

ActiveCN105462519ALow VOC contentLow film forming temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAdhesive

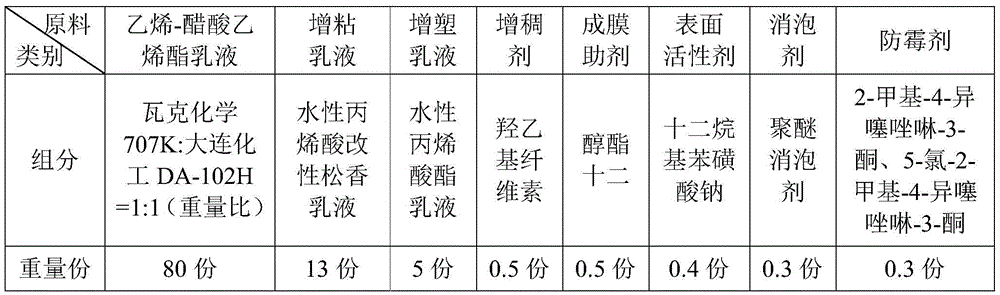

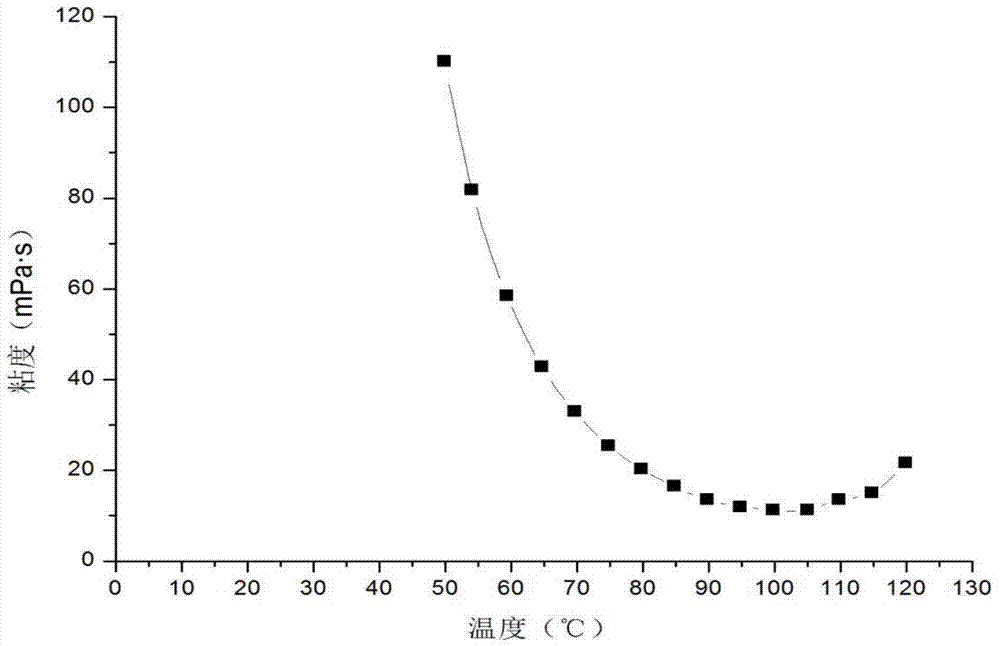

The invention relates to the technical field of adhesives, in particular to an environmentally-friendly water-based adhesive. The environmentally-friendly water-based adhesive is prepared from, by weight, 60-80 parts of ethylene-vinyl acetate emulsion, 10-30 parts of tackifying emulsion, 5-10 parts of plastifying emulsion, 0.1-1 part of thickening agent, 0.1-1 part of coalescing agent, 0.1-0.5 part of surface active agent, 0.1-0.5 part of defoaming agent and 0.1-0.5 part of mildewing preventive. The invention further discloses a preparation method of the adhesive and a hat box. Compared with the prior art, the adhesive has the advantages that with the ethylene-vinyl acetate emulsion quite low in VOC content being a basic material, water-based acrylate emulsion and water-based acrylate modified rosin emulsion low in VOC content are added to prepare the environmentally-friendly adhesive with ultra-low VOC content, and the VOC content is as low as 0.8 g / L-1.5 g / L and reaches European Union VOC emission standards for imported water-based adhesives.

Owner:东莞铭丰生物质科技有限公司 +1

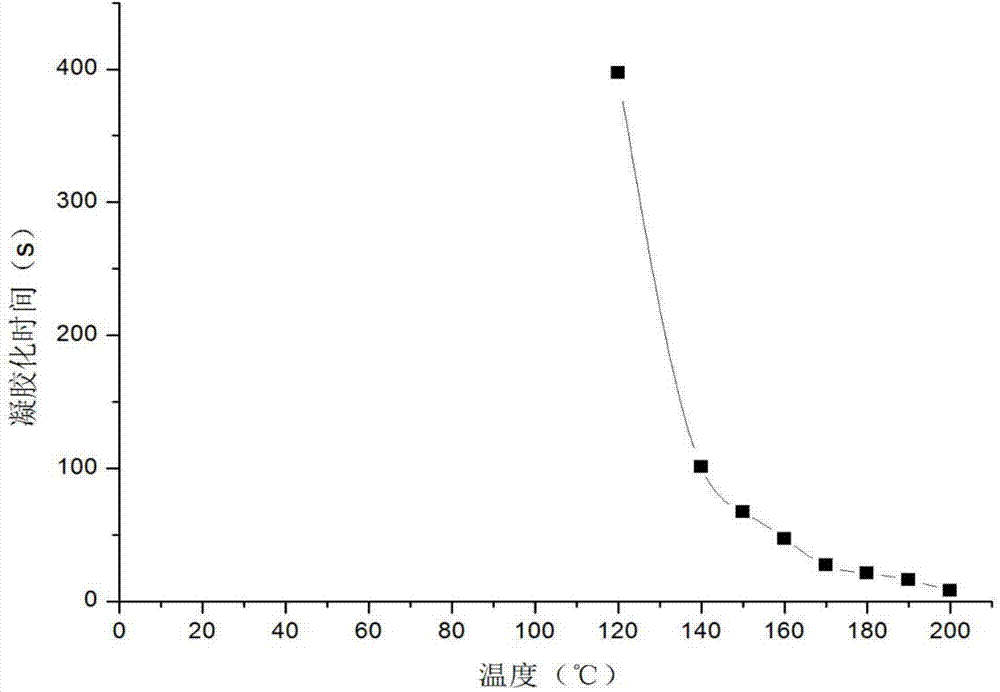

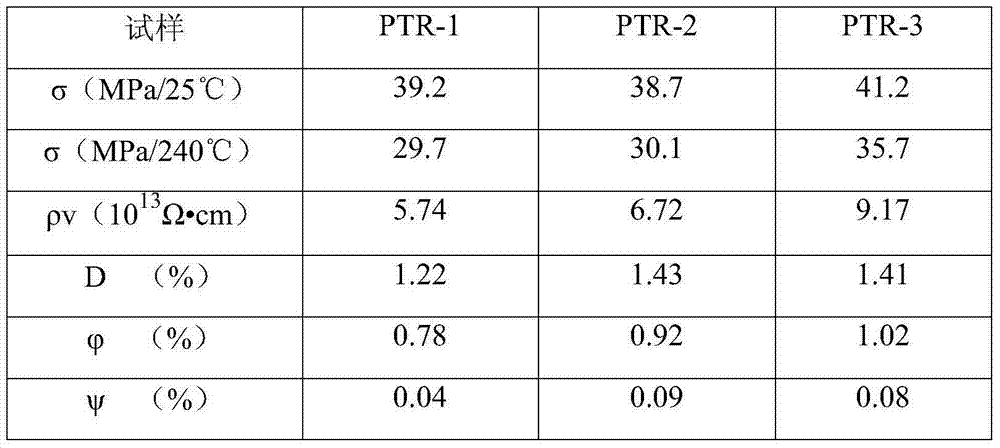

Pultrusion resin for high temperature-resistant carbon fiber-reinforced cable core and preparation method of pultrusion resin

The invention relates to pultrusion resin for a high temperature-resistant carbon fiber-reinforced cable core and a preparation method of the pultrusion resin. The resin comprises hydroxyl-containing and carboxyl-containing active polyimide resin (HCPI), polyfunctional epoxy resin, SR22000 organic silicon resin, thermoplastic bisphenol A phenolic resin, maleic anhydride, an active diluent, a curing agent and an accelerator. The preparation method comprises the following steps: putting polyfunctional epoxy resin, hydroxyl-containing and carboxyl-containing active polyimide resin, SR22000 organic silicon resin, thermoplastic bisphenol A phenolic resin and maleic anhydride into a reaction kettle, performing stirring reaction, adding the active diluent, performing the stirring reaction, then adding the curing agent and the accelerator, and uniformly stirring. The pultrusion resin provided by the invention has the advantages of convenient raw material sources, no solvent, environment friendliness, simple operation process and excellent comprehensive performance, is very suitable for a pultrusion process, is very suitable for manufacturing a high temperature-resistant carbon fiber-reinforced cable core composite material with excellent comprehensive performance by pultrusion, and has broad application prospects.

Owner:DONGHUA UNIV +1

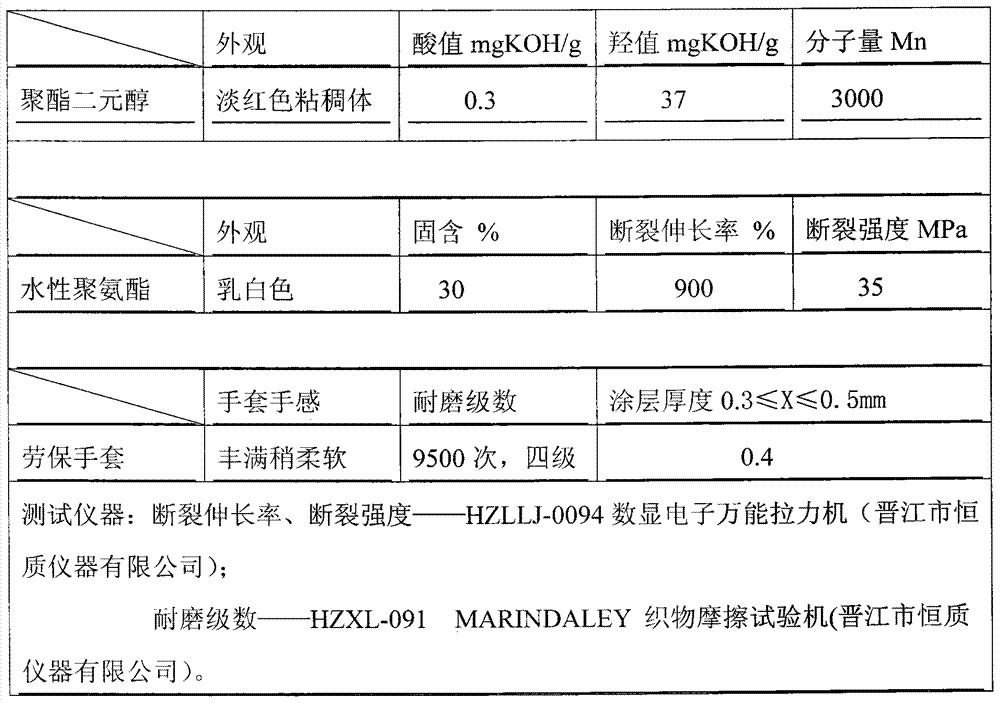

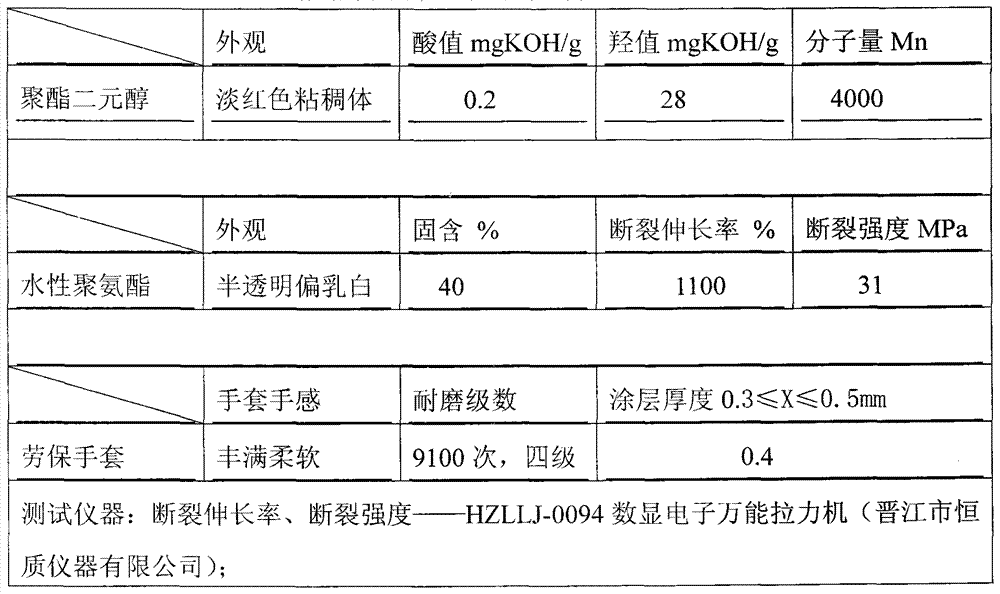

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

Adherence substance, pressure sensitive adhesive sheet and its use

InactiveUS20110151250A1Low viscosityGood paintabilityPolyureas/polyurethane adhesivesThin material handlingSilylenePolyol

To provide an adherence substance which has a low viscosity and good coatability, can be made solvent free, has a low adhesive strength, of which increase with time is small, has good adhesion to a substrate, has excellent adhesion to an adherend and excellent removability, and has a good wettability.An adherence substance which is obtained by curing a curable composition comprising a silyl group-containing polymer (S) obtained by introducing a hydrolyzable silyl group to a molecular terminal of a polyurethane prepolymer obtained by reacting a polyol compound with a polyisocyanate compound, and which has a peel adhesive strength of at most 8N / 25 mm.

Owner:ASAHI GLASS CO LTD

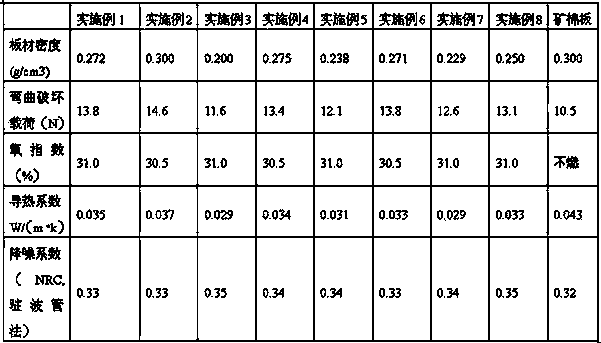

Preparation method of environment-friendly PU (polyurethane) ceiling with flame retardant and sound absorption functions

The invention discloses a preparation method of an environment-friendly PU (polyurethane) ceiling with flame retardant and sound absorption functions. The preparation method comprises the following steps: adopting polyester isocyanate prepolymer as an adhesive; uniformly mixing the polyester isocyanate prepolymer with crushed waste PU rigid foam granules; carrying out mould pressing to manufacture the environment-friendly PU ceiling with the flame retardant and sound absorption functions. The ceiling comprises 5-10 parts of the polyester isocyanate prepolymer and 90-95 parts of the crushed waste PU rigid foam granules by weight; the polyester isocyanate prepolymer is isocyanate prepolymer which is prepared through reaction between diisocyanate and polyester polyatomic alcohol in 60-80 DEG C and contains 10-30% of NCO. The preparation method adopts the polyester isocyanate prepolymer as the adhesive; a product prepared according the method is excellent in performance, out of solvent and formaldehyde, safe, and environment-friendly; a large quantity of waste polyurethane rigid foam can be treated by adding a small quantity of the polyester isocyanate prepolymer; meanwhile, a pressed plate is low in density, material consumption and comprehensive cost.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

Adherence substance, pressure sensitive adhesive sheet and its use

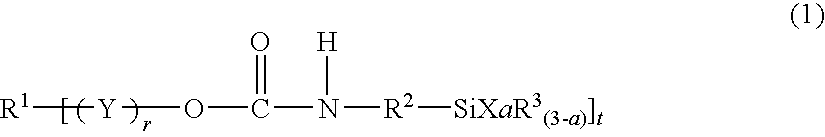

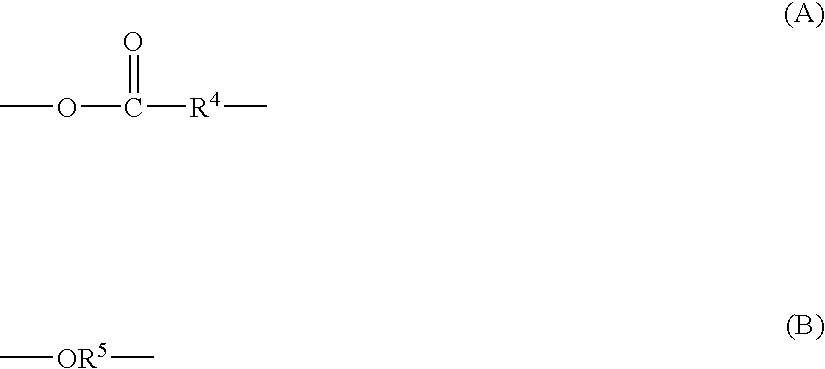

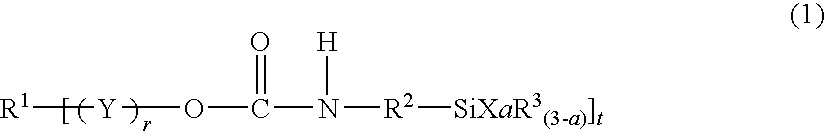

InactiveUS20100015443A1Low viscosityGood paintabilityDiffusing elementsSynthetic resin layered productsPolymer scienceChemical compound

To provide an adherence substance which has a low viscosity and good coatability, can be made solvent free, has good adhesion to an adherend and at the same time has excellent removability, can suppress peel electrostatic charge and is excellent in high speed peeling performance.An adherence substance which is obtainable by curing a curable composition comprising a silyl group-containing polymer (S) represented by the following formula (1):in the formula (1), R1 represents a t-valent residue obtained by removing all hydroxy groups from a compound having t pieces of hydroxy groups in the molecule; R2 represents a bivalent organic group; R3 represents a monovalent organic group having from 1 to 20 carbon atoms; X is a hydroxy group or a hydrolyzable group; Y represents a bivalent group represented by the following formula (A) or a bivalent group represented by the following formula (B); a represents an integer of from 1 to 3; r represents an integer of from 1 to 1,000; t represents an integer of from 1 to 8;in the formula (A), R4 represents an alkylene group having from 2 to 8 carbon atoms; and in the formula (B), R5 represents an alkylene group having from 2 to 4 carbon atoms.

Owner:ASAHI GLASS CO LTD

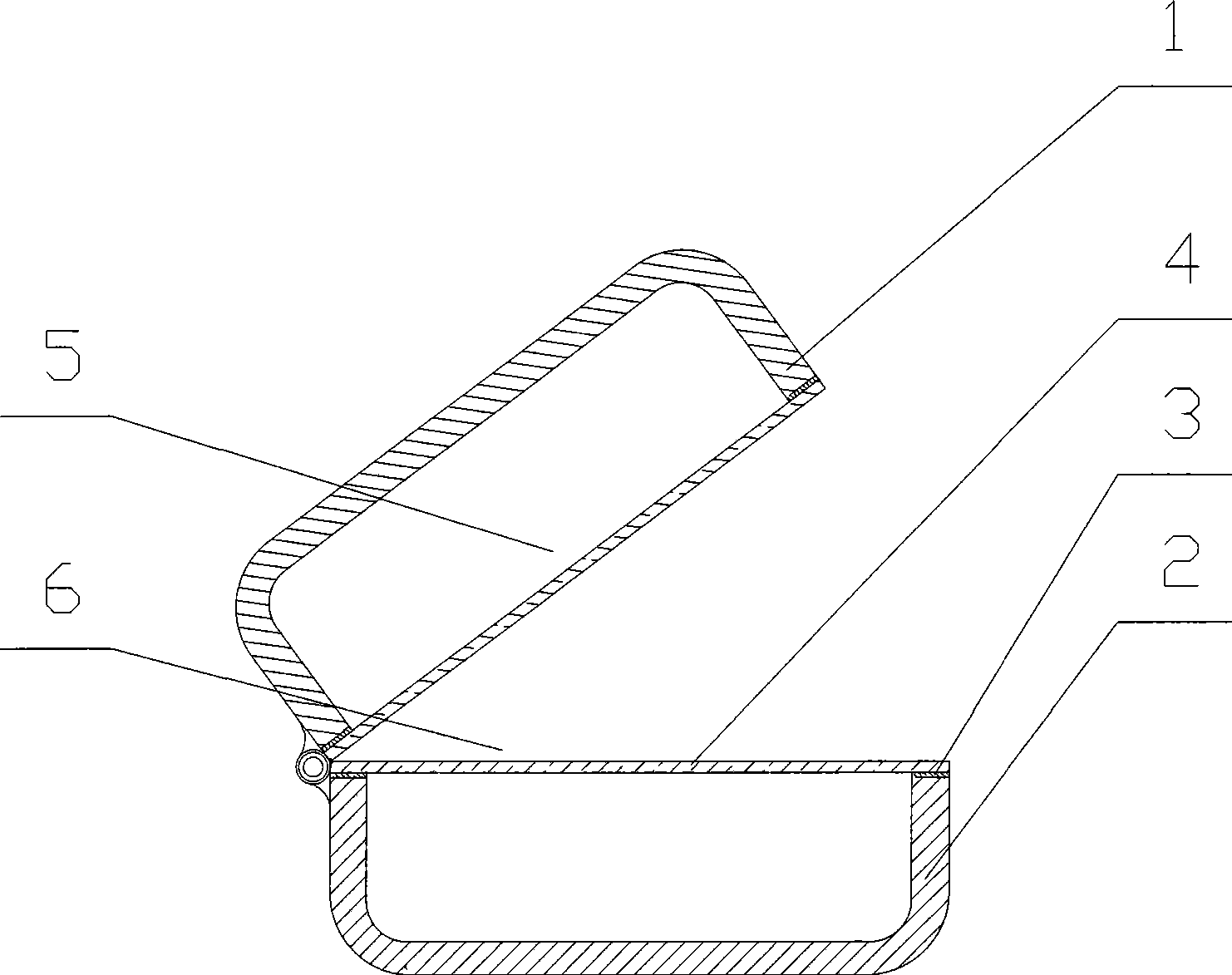

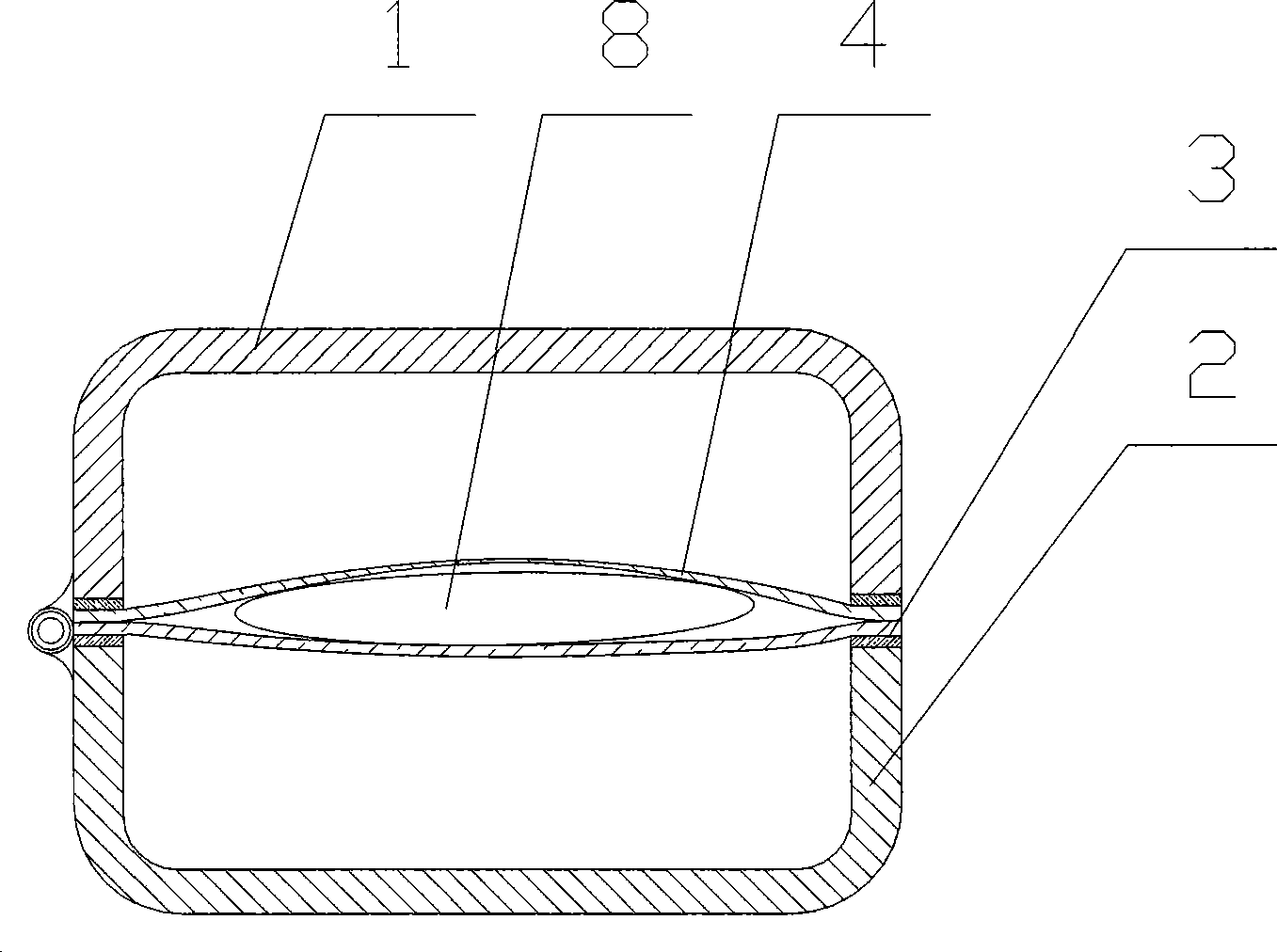

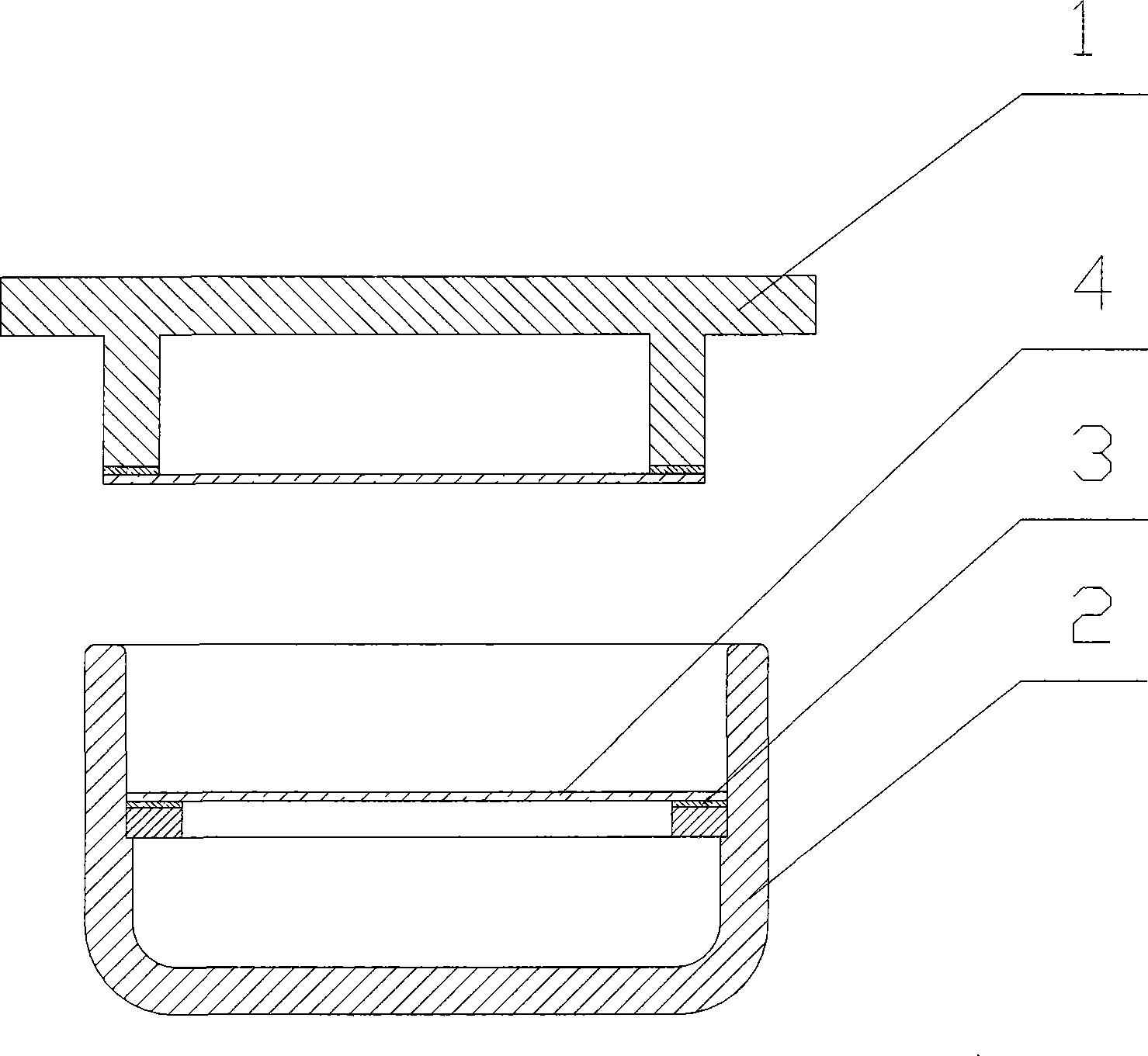

Novel packaging box and manufacturing technology thereof

ActiveCN101362529AFast curingReaction is easy to controlClosure with auxillary devicesBoxesManufacturing technologyAdhesive

The invention relates to a novel packing case and the manufacturing process thereof, which is characterized in that the novel packing case comprises an upper casing body and a lower casing body which are oppositely covered, and an elastic tensioning diaphragm which can elastically clip objects when the casing bodies are oppositely covered is respectively adhered to the upper casing body and the lower casing body by adopting UV adhesive. The novel packing case has the advantages that the structure is simple, the design is reasonable, is in favor of simplifying the production processes, reducing the production cost and re-utilization. Due to the advantages of the UV adhesive, the elastic tensioning diaphragm which is adhered by adopting the adhesive has the significant advantages of high bonding strength, high speed and high degree of automation, etc.

Owner:福州康派克光电科技有限公司

High-fluidity ethylene-alpha-octene graft copolymer and preparation method thereof

The invention relates to a high-fluidity ethylene-alpha-octene graft copolymer and a preparation method thereof. The copolymer is a graft copolymer, and comprises the following components by weight part: 100 parts of high-fluidity ethylene-alpha-octene copolymer (POE) resin, 0.5 to 5 parts of graft monomer, 0.01 to 2 parts of initiator, 0.1 to 1 part of lubricant, 0.1 to 1 part of antioxidant and 0.1 to 2 parts of liquid additive. Other components except the initiator are put in a high-speed mixer to be mixed in proportion and are added to a twin-screw extruder through a main feeder, and the initiator is added to the extruder through a side feeder to granulate to obtain a product. Compared with the prior art, through the side feeding technology, the high-fluidity POE graft copolymer has higher grafting yield and lower gel content; and in addition, because of the high fluidity of the graft copolymer, after being applied to nylon, the graft copolymer has better fluidity than that of the traditional toughener after the toughener is applied to the nylon, and has excellent comprehensive mechanical properties and impact properties.

Owner:SHANGHAI SUNNY

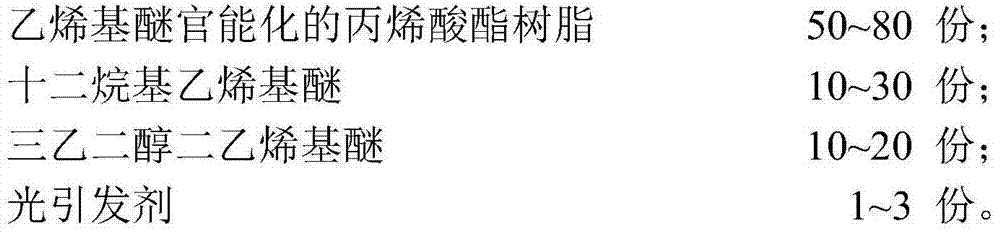

Ultraviolet light cured non-silicon release agent and preparation method thereof

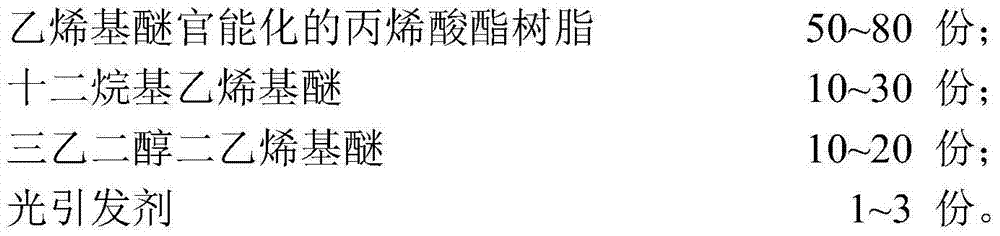

The invention discloses an ultraviolet light cured non-silicon release agent, which is composed of the following components in parts by weight: 50 to 80 parts of vinyl ether functionalized acrylic resin, 10 to 30 parts of dodecyl vinyl ether, 10 to 20 parts of triethyleneglycol divinyl ether, and 1 to 3 parts of photoinitiator. The preparation method comprises the following steps: step one, synthesizing vinyl ether functionalized acrylic resin; step two, adding 10 to 30 parts of dodecyl vinyl ether and 10 to 20 parts of triethyleneglycol divinyl ether into the 50-80 parts of vinyl ether functionalized acrylic prepolymer; step three, stirring and evenly mixing, then adding 1 to 3 parts of photoinitiator, stirring and evenly mixing so as to obtain ultraviolet light cured non-silicon release agent; step four, painting the obtained ultraviolet light cured non-silicon release agent on a film, and carrying out radiation curing by placing the film under an ultraviolet lamp. The invention aims to provide a non-mobility solvent-free ultraviolet light cured non-silicon release agent with a stable releasing performance and a preparation method thereof.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Primer-free polyurethane glass cement and preparation method thereof

ActiveCN104449534AImprove curing effectAvoid foamingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPrepolymer

The invention belongs to the technical field of high polymer materials and preparation thereof, and particularly relates to primer-free polyurethane glass cement. The primer-free polyurethane glass cement comprises the following components in percentage by weight: 19-20% of dioctyl phthalate, 35-40% of polyurethane prepolymer, 17-20% of calcium carbonate, 5.0-6.0% of spherical silica powder, 2.5-3.0% of titanium dioxide, 1.0-5.0% of calcium oxide, 10.0-14.0% of carbon black, 5.0-6.0% of gas-phase silica, 0.03-0.06% of dibutyltin dilaurate and 0.3-0.6% of glycidoxy propyl trimethoxy silane KH560. The primer-free polyurethane glass cement provided by the invention can be adhered in a primer-free manner, thereby being environmental-friendly, economical and solvent-free, and the primer-free polyurethane glass cement has the advantages of high bonding strength, high curing speed, high thixotropy, etc. The primer-free polyurethane glass cement is widely used for adhering and sealing windshield glass and side window glass of railway vehicles, cars and ships with matrix iron plates and aluminum plates.

Owner:山东汉斯曼高分子材料有限公司

Photo-setting adhesive for press key bonding injection moulding

InactiveCN101475779APracticalNo solvent requiredNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceAdhesive

The invention discloses a photocuring adhesive for key-press splicing and injection molding. The photocuring adhesive comprises the following compositions in percentage by weight: 30 to 80 percent of organosilicon acrylate, 5 to 30 percent of acrylate oligomer, 2 to 30 percent of acrylate monomer, 0.1 to 10 percent of light evocating agent, 0.1 to 10 percent of aerosil, 0.1 to 10 percent of coupling agent and 0.1 to 5 percent of additive. The invention also discloses a method for preparing the photocuring adhesive for key-press splicing and injection molding, application of the adhesive to a key-press part and a simple injection molding process. The photocuring adhesive has good splicing property, elasticity, solvent resistance, and excellent electrical performance and weather resistance; and a product has good maneuverability such as levelling, defoaming, easy demoulding, and the like in injection molding.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

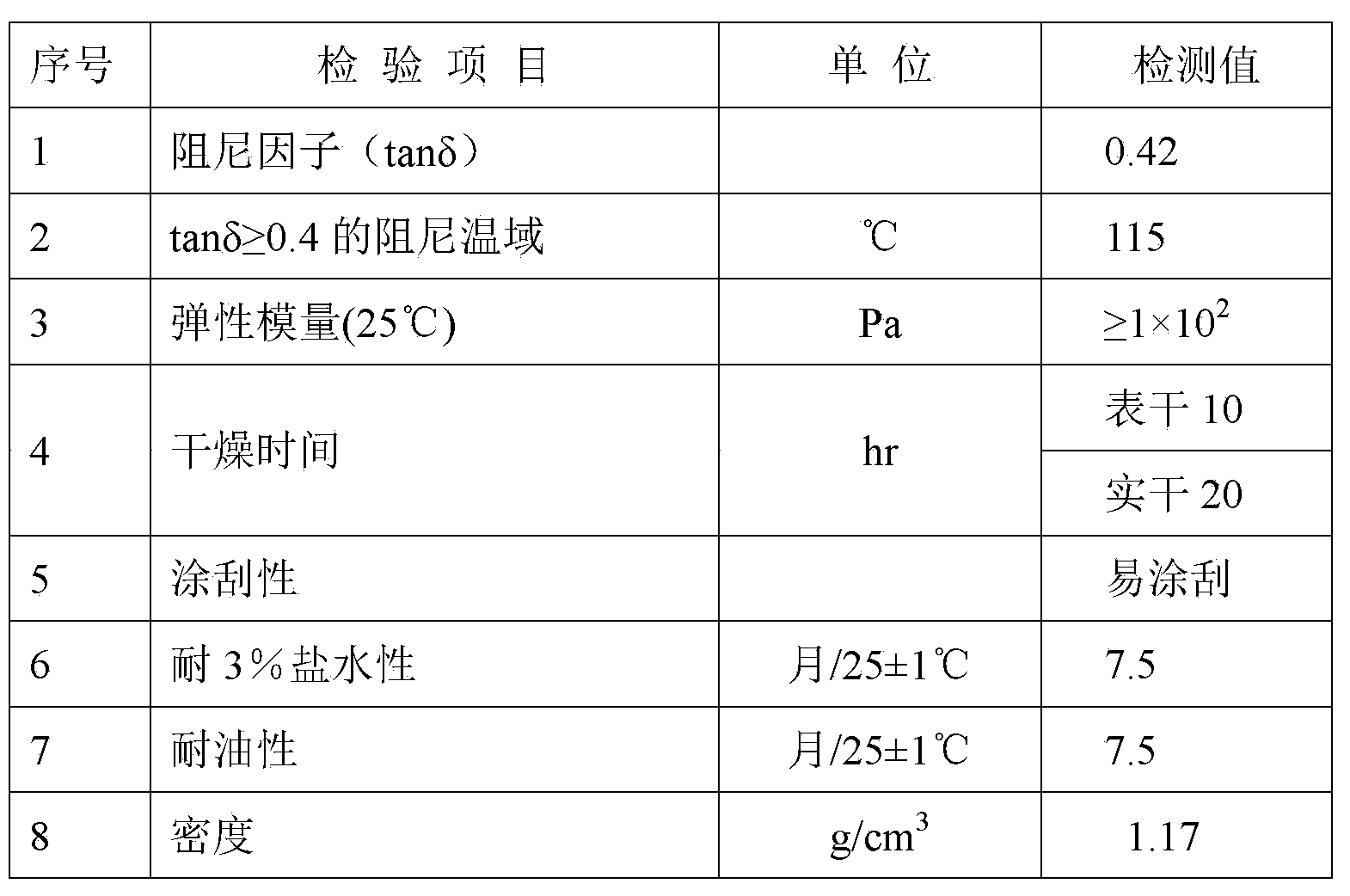

Noise reduction damping paste and preparation method thereof

ActiveCN103360938AExcellent damping, vibration and noise reductionImprove sound insulationPolyurea/polyurethane coatingsThermal insulationSolvent free

The invention provides a noise reduction damping paste, which is prepared by mixing a component A and a component B together, wherein the component A accounts for 30-50%, the balance being component B. The component A is synthesized from the following materials: polyether 2000, polyether 3050, and 15%-20% of TDI. The component B is composed of hydrated alumina, mica powder, white carbon black, silicone oil, ethylene glycol, dibutyl ester, and moca. The present invention also provides a preparation method of the noise reduction damping paste. The noise reduction damping paste can effective suppress structural vibration and noises caused by the vibration, and has excellent damping performances like noise reduction, sound insulation, sealing, and thermal insulation. The noise reduction damping paste is solvent-free, non-toxic, good in flame resistance, and strong in adhesion, has no cracking and detachment, and is suitable for complex surfaces of steel basic layer with a thickness no more than 5 mm.

Owner:湖北海风新材料股份有限公司

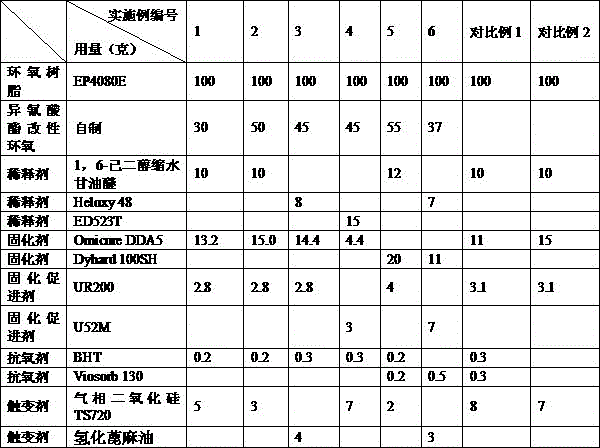

LED-used single-component epoxy insulated solid crystal glue and preparation method thereof

ActiveCN106753138AGood resistance to yellowingGood toughness and impact resistanceEpoxy resin adhesivesSemiconductor devicesIsocyanateSolvent

The invention discloses LED-used single-component epoxy insulated solid crystal glue. The LED-used single-component epoxy insulated solid crystal glue comprises the following components in parts by weight: 100 parts of epoxy resin, 25-60 parts of isocyanate modified epoxy resin, 5-20 parts of a diluent, 8-25 parts of a curing agent, 1-10 parts of a curing accelerator, 0.1-1 part of an antioxidant and 1-10 parts of a thixotropic agent. The LED-used single-component epoxy insulated solid crystal glue provided by the invention has the following advantages: firstly, excellent yellowing resistance, good tenacity and impact resistance, high bonding strength and suitability for high-speed dispensing process are achieved; secondly, owing to adoption of self-prepared isocyanate modified epoxy resin, the shortcomings of insufficient yellowing resistance, poor tenacity and the like in traditional epoxy solid crystal glue are overcome; thirdly, a method for preparing isocyanate modified epoxy resin is simple in condition, solvent-free, pollution-free to the environment and low in cost.

Owner:上海汉司实业有限公司

Novel polyurethane hot-melt adhesive paint and preparation method thereof

ActiveCN103013320AGood flexibilityIncrease productivityPolyurea/polyurethane coatingsPrepolymerIsocyanate

The invention discloses a polyurethane hot-melt adhesive paint. The polyurethane hot-melt adhesive paint comprises at least one polyurethane prepolymer which is prepared by the reaction between a polyalcohol component and isocyanate. The preparation method comprises the following steps in sequence: feeding three polyester polyols, antioxidant and ultravioresistant agent into a reacting kettle based on the ratio; reacting; adding diisocyanate until the reaction is ended; and then adding chain extender and catalyst to react to obtain the polyurethane hot-melt adhesive paint. The polyurethane hot-melt adhesive paint is simple in preparation process, fast in surface drying speed, excellent in transparency, high in resistance to heat and UV (Ultraviolet), and excellent in environmental friendliness.

Owner:嘉兴市恒泰化工科技有限公司

Epoxy grout and preparation method thereof

ActiveCN105176465AImprove adhesionImprove performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolyamideSlurry

The invention discloses epoxy grout, comprising a component A and a component B by weight; the resin component A comprises bisphenol F epoxy resin, epoxy resin octyl group glycidyl ether, bisphenol A type 128 epoxy resin, a reactive diluent AGE, an organic silica coupling reagent, fumed silica, cement C35 type, silica powder, titanium dioxide, talcum powder and epoxy black slurry; the curing agent component B comprises the following components in ratio by weight: a polyamide curing agent, a cashew nut shell oil-modified curing agent, DMP-30 (Tris(dimethylaminomethyl)phenol), organobentonite, silica micropowder and superfine mica powder; a ratio of the resin component A to the curing agent component B is 3-6:1. The invention also discloses a preparation method of the epoxy grout. The compressive resistance and bonding strength of the expoxy grout after long-term curing are higher, and the water resistance is higher than that of expoxy grout on the market, and the expoxy grout is wide in ratio, has no solvent and non-transferability plasticizer and solvent and is excellent in comprehensive performance.

Owner:HUNAN QUANCHEN TECH

Nanometer solvent-free epoxy antirust paint and preparation method thereof

ActiveCN103709901AGood wear resistanceEasy to maintainAnti-corrosive paintsEpoxy resin coatingsSolventCardanol

The invention discloses nanometer solvent-free epoxy antirust paint and a preparation method thereof. The nanometer solvent-free epoxy antirust paint comprises the following raw material components in parts by weight: component A: 20-40 parts of E-44 epoxy resin, 5-15 parts of active diluent, 10-20 parts of zinc phosphate, 5-20 parts of mica powder, 10-20 parts of nanometer alumina, 10-20 parts of ferric oxide powder and 5-10 parts of aluminum triphosphate; component B: alicyclic amine or anacardol serving as a curing agent. The weight ratio of the component A to the component B is (6-8): 1. The nanometer solvent-free epoxy antirust paint disclosed by the invention is good in antirust property, environment-friendly, free of VOC emission, not harsh in construction conditions and low in requirements on base material, and the paint can be thickly coated once; the nanometer solvent-free epoxy antirust paint can be widely applied to a variety of fields, for example, bridge, guardrail steel structure, building material, machinery, etc.

Owner:FOSHAN GAOMING FULITE CHEM CO LTD

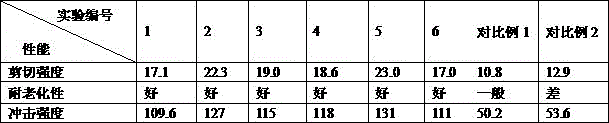

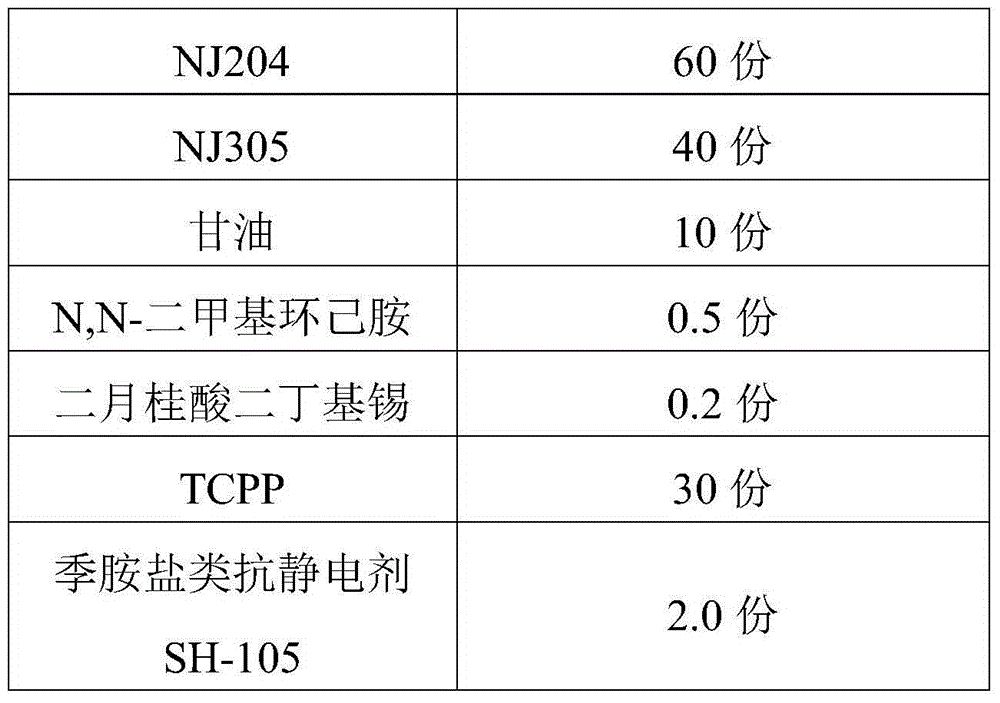

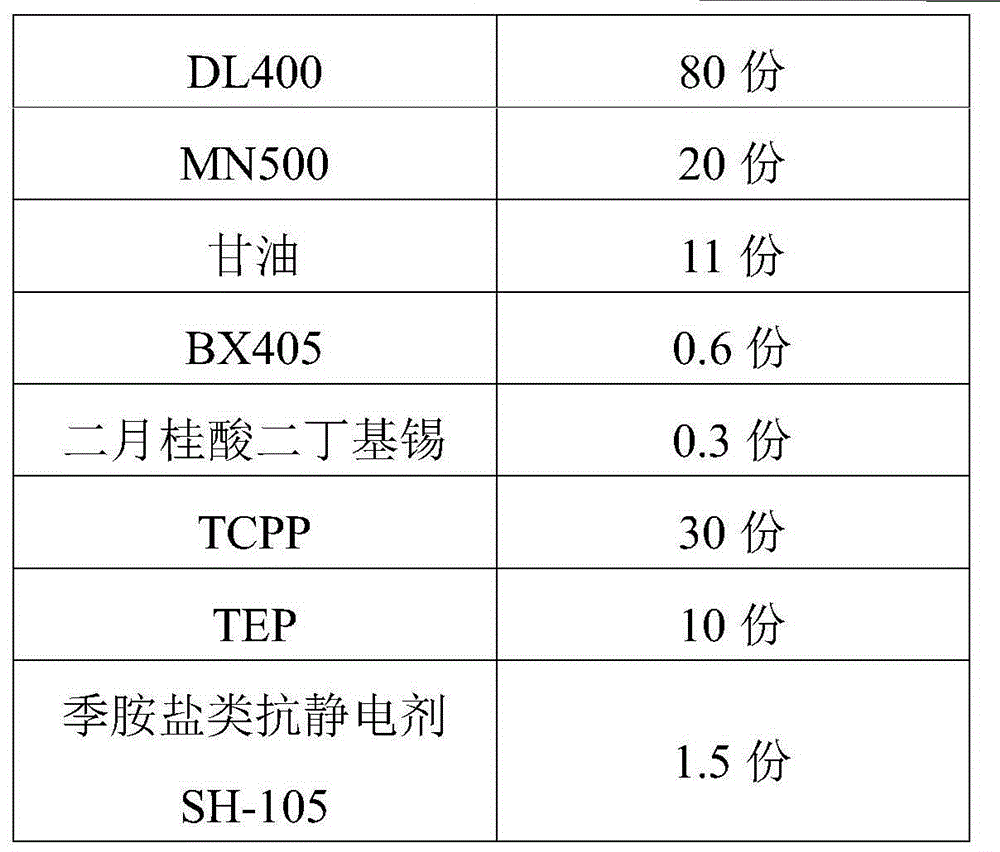

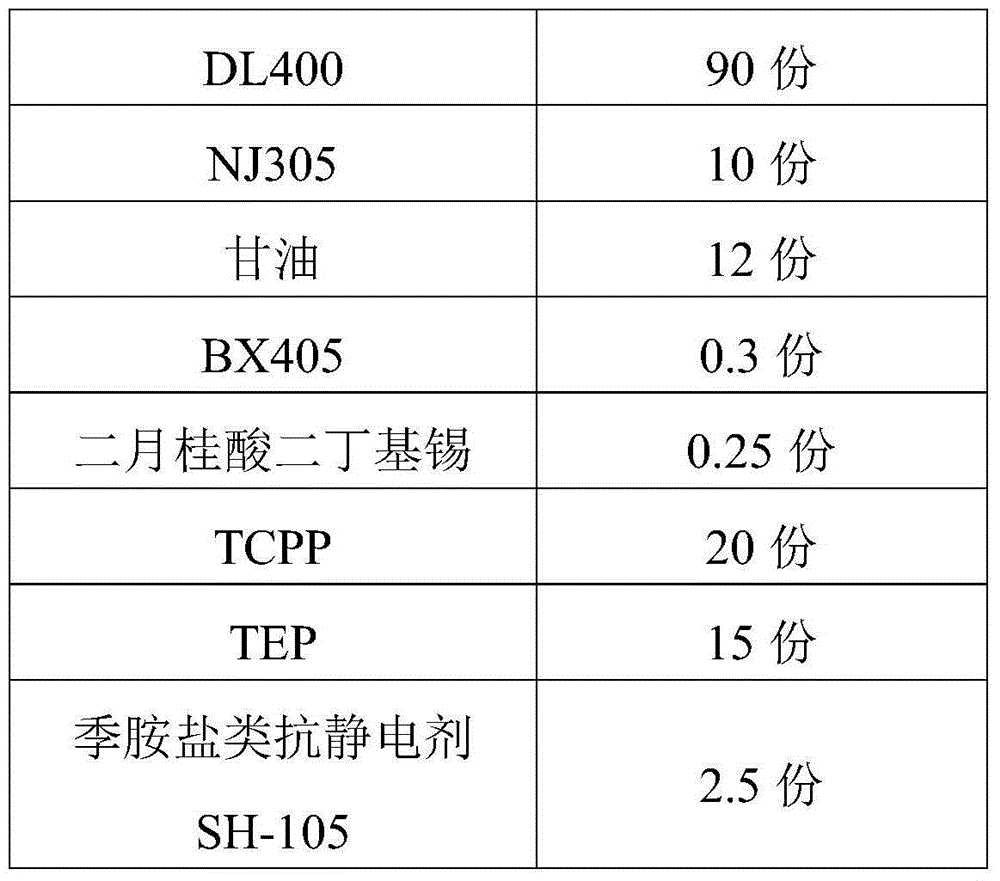

Raw material combination combined by polyether and polyurethane reinforcement materials and preparing method thereof

The invention discloses a combination polyether which comprises, by weight, the components of 60-90 parts of polyether polyol A, 10-40 parts of polyether polyol B, 7-12 parts of cross-linking agents, 0.3-1.0 part of amine catalyst, 0.1-0.3 part of metal catalyst, 20-40 parts of flame retardant agents and 1.5-2.5 parts of antistatic agents. The polyurethane reinforcement materials have solvent-free performance and non-volatilization performance, raw materials are easy to obtain, raw material price is low, flame retardant effect is good, antistatic effect is good, a danger coefficient is small during using in underground, safety and innocuity are achieved on an operator and an environment, and the combination is suitable for industrialization large-scale production. The preparing method of the polyurethane reinforcement materials is easy to operate, and three wastes are low. When the polyurethane reinforcement materials are used in the field of mining reinforcement, operation is easy, using is convenient, flexibility is high, a security coefficient is high, and safety and innocuity are achieved on the operator and the environment.

Owner:SHANGHAI DONGDA CHEM

Cardanol modified amine epoxy resin curing agent as well as preparation method and application thereof

InactiveCN111793195AImprove hydrophobicityGood flexibilityOrganic compound preparationAmino-hyroxy compound preparationPolymer sciencePtru catalyst

The invention belongs to the technical field of epoxy resin curing agents, and discloses a cardanol modified amine epoxy resin curing agent as well as a preparation method and application thereof. Thecuring agent is prepared by the following steps: mixing cardanol and phenols, heating to 30-40 DEG C, stirring, adding alkali, heating to 60-70 DEG C, adding an acid catalyst, stirring to dissolve, heating to 80-90 DEG C, reacting, standing, separating liquid, and vacuumizing to obtain an intermediate product; and heating the intermediate product to 30-40 DEG C, stirring, adding aldehyde, controlling the temperature to be less than 50 DEG C, dropwise adding amine at 30-40 DEG C after the aldehyde is added, stirring, heating to 115-175 DEG C, cooling to 90-95 DEG C after the reaction is finished, and carrying out vacuum dehydration under reduced pressure. The curing agent has good hydrophobicity, flexibility and protective function, mild heat release and moderate curing speed, avoids degradation of the toughness of epoxy resin in the fast curing process, and is applied to the field of quick curing or toughening of epoxy resin.

Owner:SOUTH CHINA AGRI UNIV

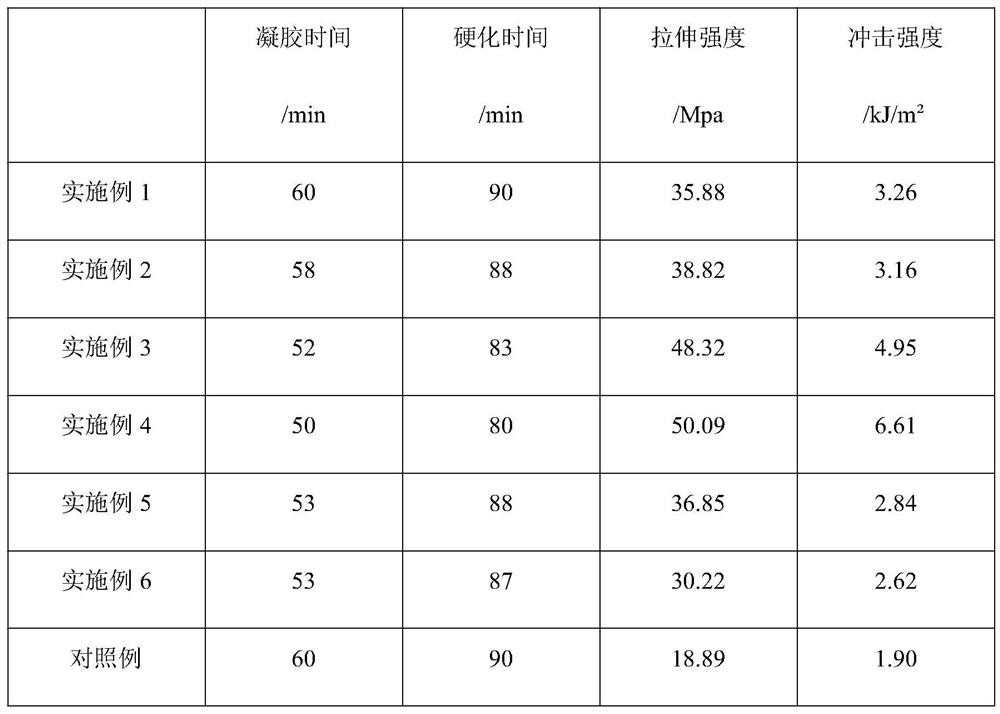

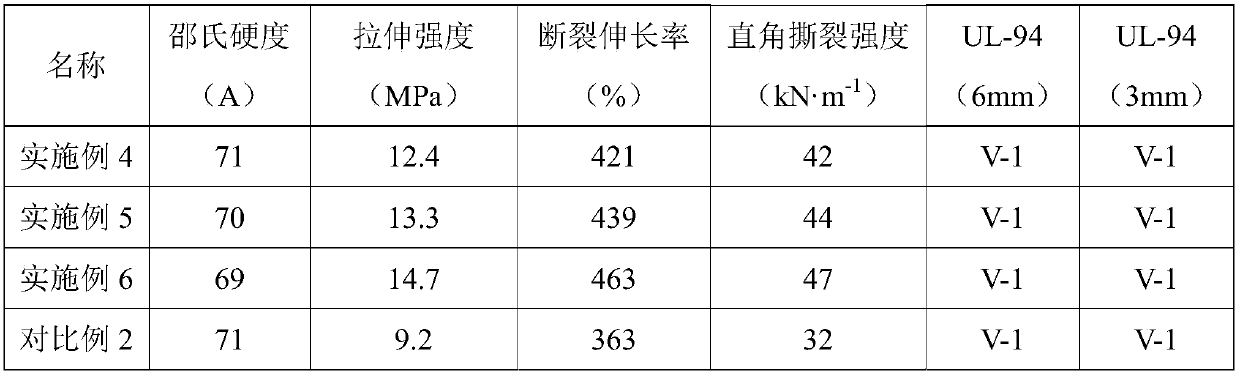

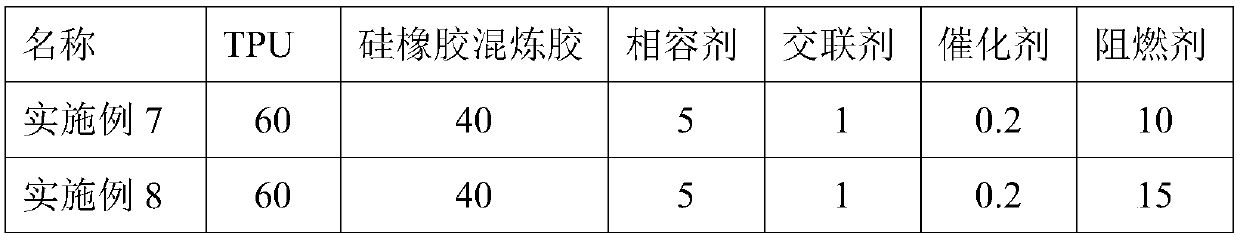

Flame-retardant thermoplastic dynamic silicon-sulfide rubber and preparation method thereof

The invention discloses flame-retardant thermoplastic dynamic silicon-sulfide rubber and a preparation method thereof. The flame-retardant thermoplastic dynamic silicon-sulfide rubber comprises the following raw materials of: thermoplastic polyurethane elastomer, silicon-rubber mixture, a flame-retarding agent, a crosslinking agent, a compatilizer and a catalyst. Simultaneously, the invention alsodiscloses a method for preparing the flame-retardant thermoplastic dynamic silicon-sulfide rubber by dynamic sulfurization. The vulcanization. The flame-retardant thermoplastic dynamic silicon-sulfide rubber disclosed by the invention has the characteristics of good flame retardance, comfortable handfeel, recoverability and excellent dynamic property and the like, can be widely applicable to thefields of electronics, electrics, automobiles, military industry and communication and the like.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

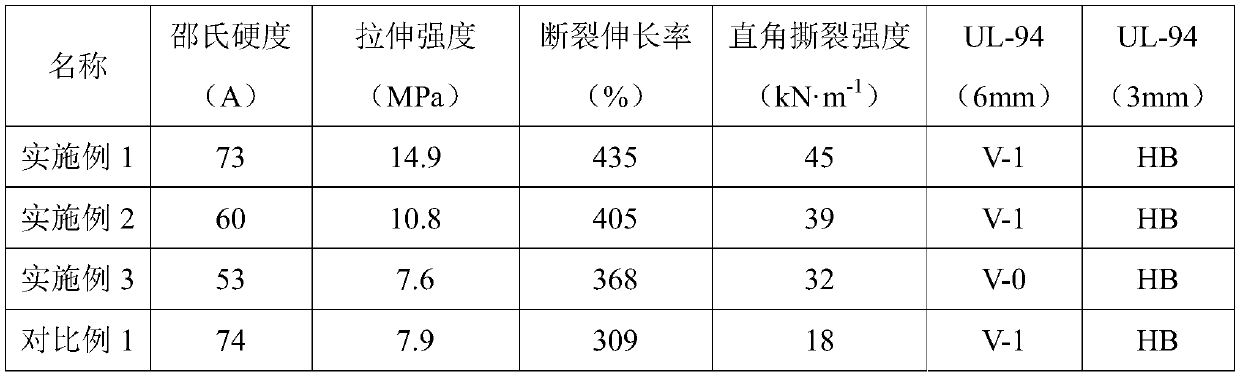

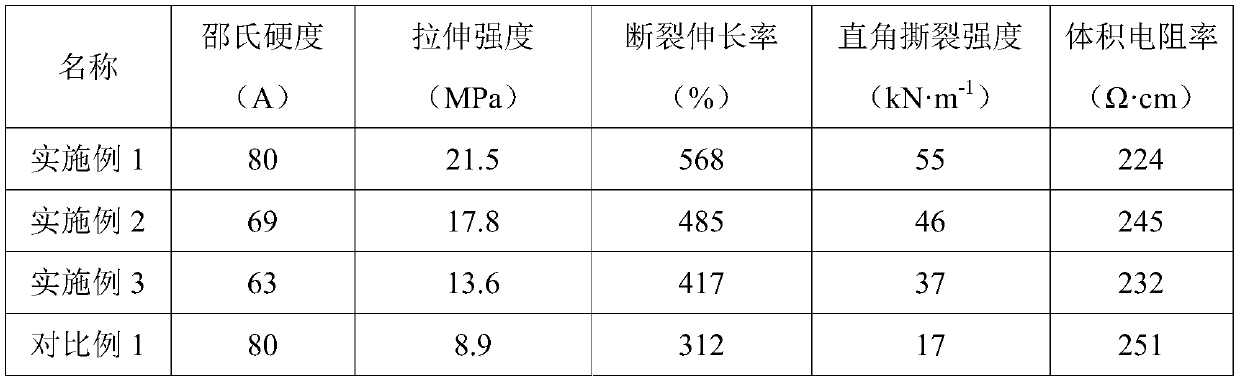

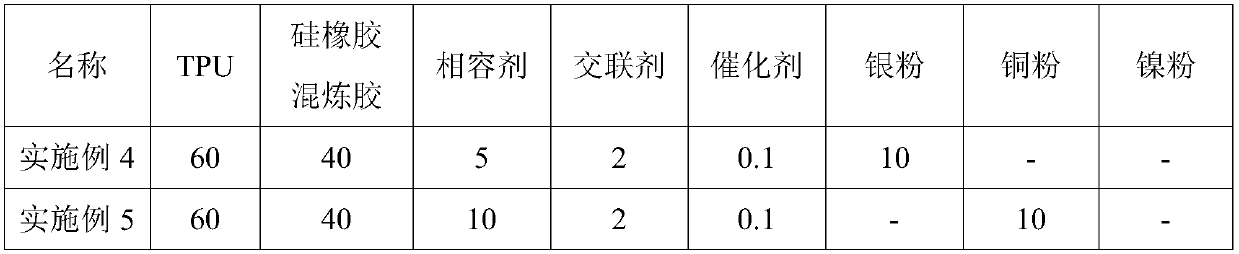

Conductive thermal plastic dynamic vulcanizing silicone rubber and preparation method thereof

The invention discloses conductive thermal plastic dynamic vulcanizing silicone rubber and a preparation method thereof. The conductive thermal plastic dynamic vulcanizing silicone rubber is preparedfrom the following raw materials of themoplastic urethane elastomers, rubber mixings of silicone rubber, conductive filling materials, crosslinking agents, compatilizers and catalysts. Meanwhile, theinvention also discloses a dynamic vulcanizing preparation method of the conductive thermal plastic dynamic vulcanizing silicone rubber. The prepared conductive thermal plastic dynamic vulcanizing silicone rubber has the characteristics of good conduction performance, comfortable hand feeling, recovery performance, excellent mechanical performance and the like. The conductive thermal plastic dynamic vulcanizing silicone rubber can be widely applied to the fields of electronics and electricity, automobiles, war industry, communication and the like.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

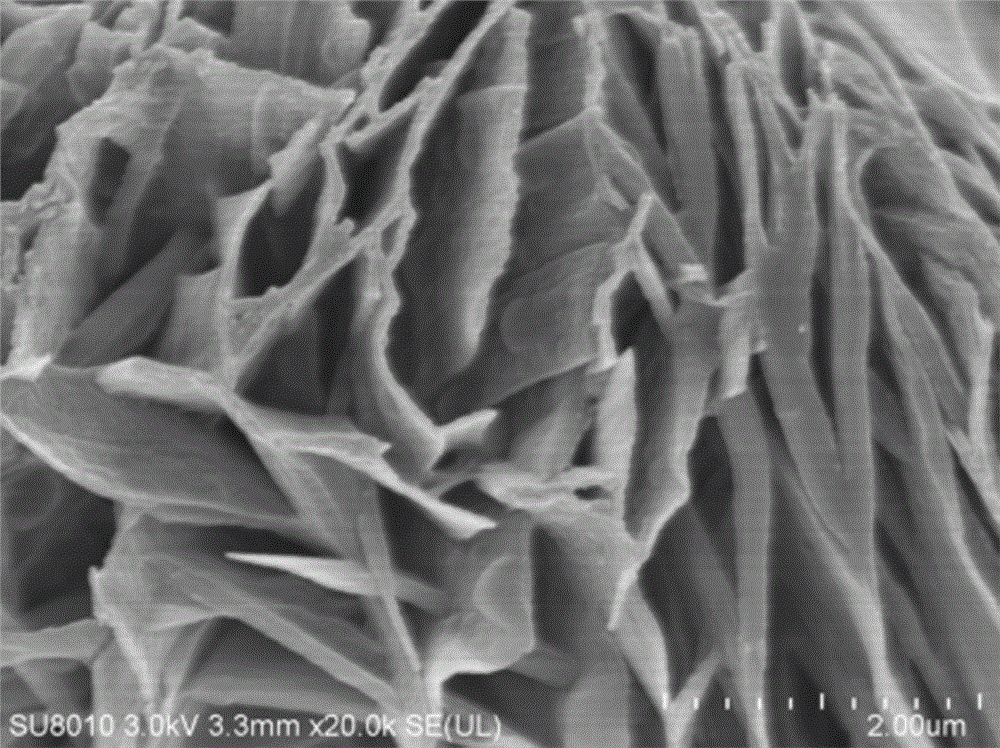

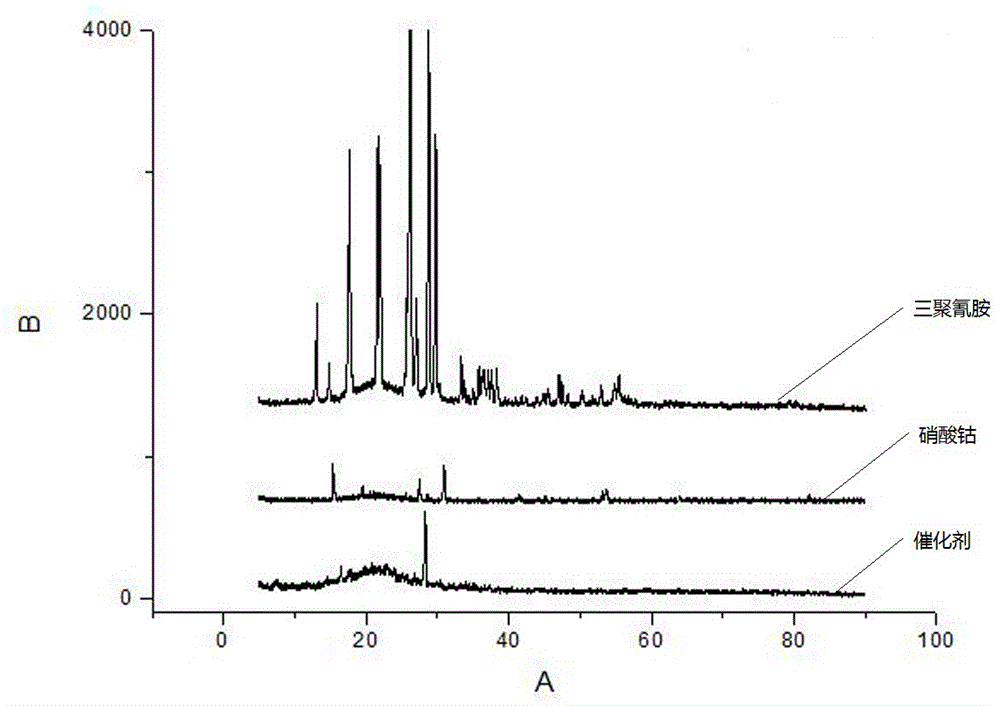

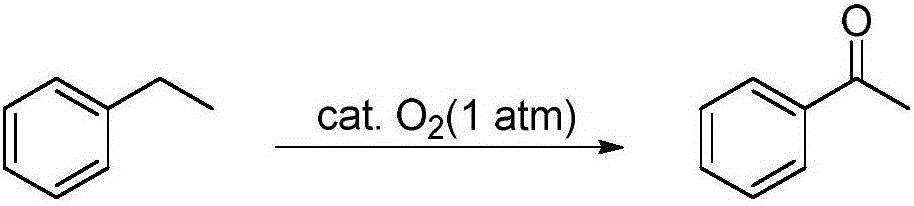

Co-N-C catalyst, and preparation method and applications thereof

ActiveCN106391082AEasy to synthesizeSynthetic safetyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRoom temperatureCobalt salt

The invention discloses a Co-N-C catalyst. According to a preparation method of the Co-N-C catalyst, the Co-N-C catalyst is prepared at room temperature via grinding, or ball milling, or grinding-sintering of a cyanamide compound and a cobalt salt at a mass ratio of (1-20):1. The invention also discloses applications of the Co-N-C catalyst. In applications, the Co-N-C catalyst is mainly used for selective oxidation of the benzyl positions of aromatic hydrocarbons and the allyl position C-H bonds of olefins. The synthesis process of the Co-N-C catalyst is simple, is easy to control, and is safe; and at the same time, coordination of the cyanamide compound with the cobalt salt is firm, the cost of metal Co is relatively low, requirements on equipment used in catalyst synthesis are simple, the equipment is easily available; efficiency is high; no additive is added; no solvent is added; conditions of the Co-N-C catalyst in application process are mild; and cycling performance is excellent.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Underwater-curing long-acting anticorrosive coating for marine steel structures, and preparation method thereof

ActiveCN107603423ACuring shrinkage is smallGood film-forming performance and adhesionAnti-corrosive paintsEpoxy resin coatingsSolventCorrosion

The invention discloses an underwater-curing long-acting anticorrosive coating for marine steel structures, and a preparation method thereof. The coating comprises a component A and a component B according to a weight ratio of 1.5:1 to 3:1; the component A comprises, by weight, 20-50 parts of phenolic modified epoxy resin, 3-8 parts of an active diluent, 25-55 parts of a filler, 0.2-1 part of a thixotropic agent, 0.3-1 part of a wetting dispersant, 0.3-0.8 part of an antifoaming agent and 0.3-1 part of a coupling agent; and the component B comprises, by weight, 20-70 parts of a curing agent Iand 30-80 parts of a curing agent II. A paint film produced by using the coating can be fast cured in a wet and even water environment, contains no solvents, has no pollution to the environment, and has good application properties. The coating has the advantages of excellent water curing and underwater curing performances, excellent corrosion resistance, excellent chloride ion permeation resistance, excellent adhesion, and excellent impact resistance.

Owner:洛阳双瑞防腐工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com