Patents

Literature

650results about How to "Avoid quality defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

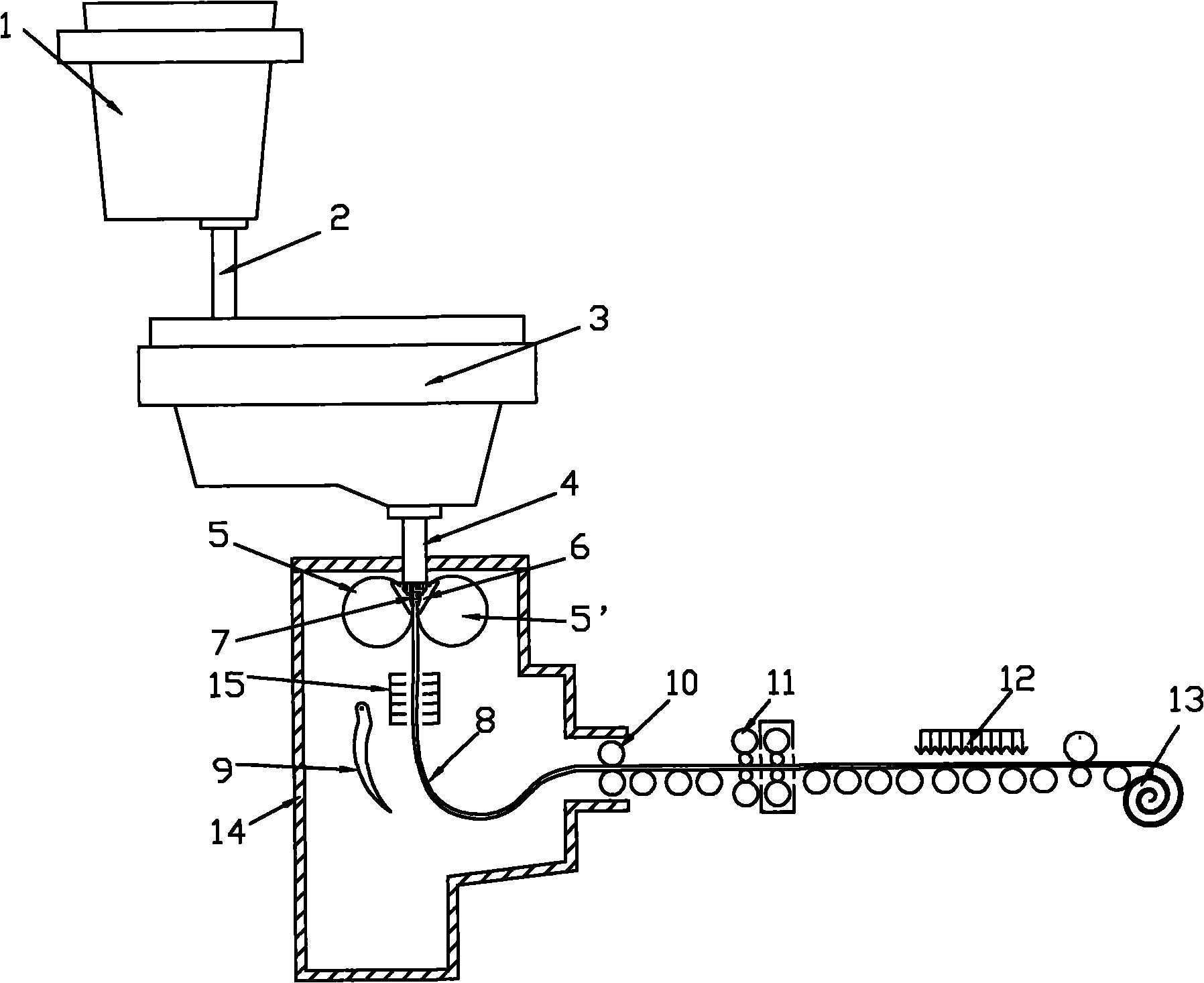

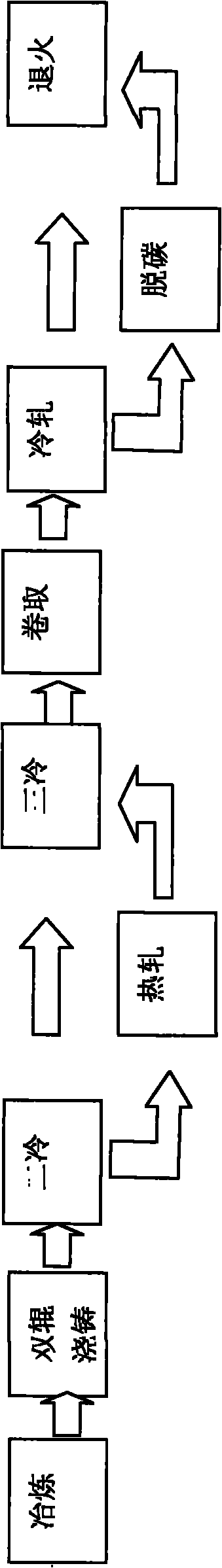

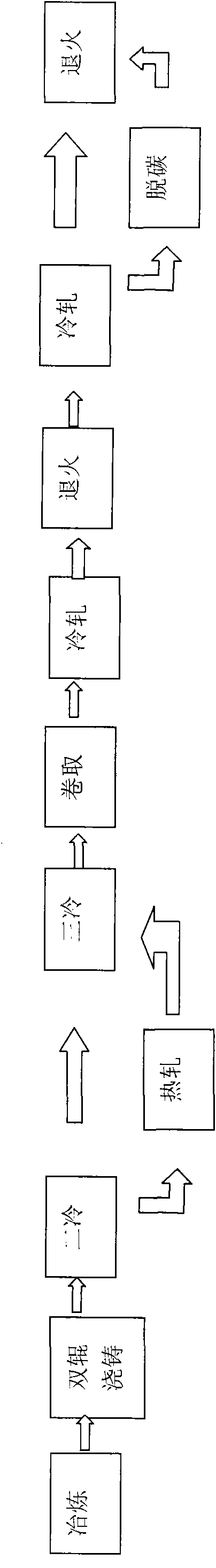

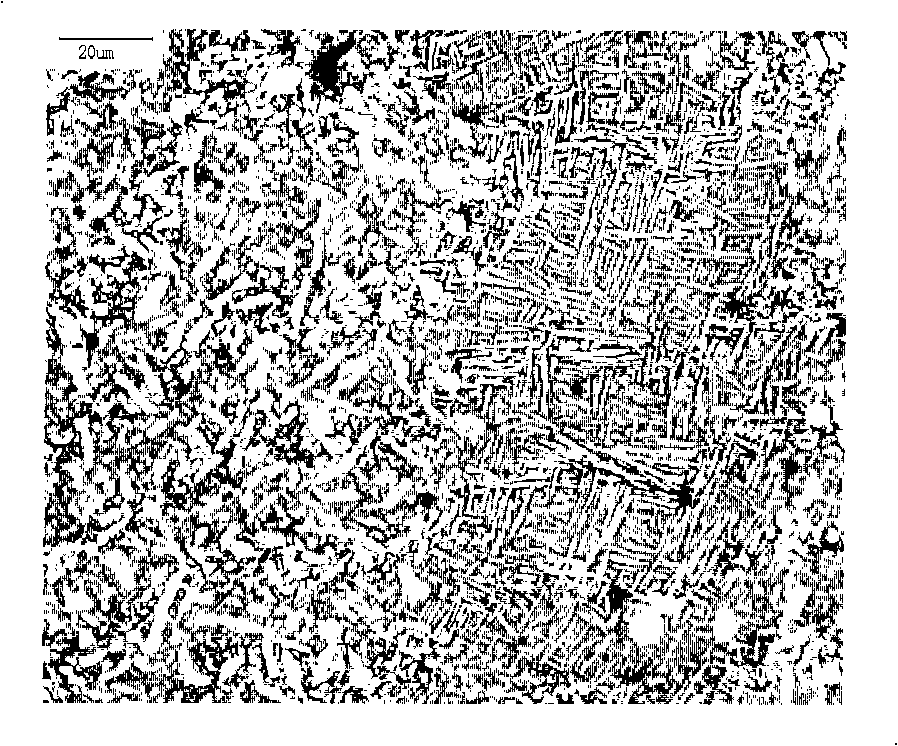

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

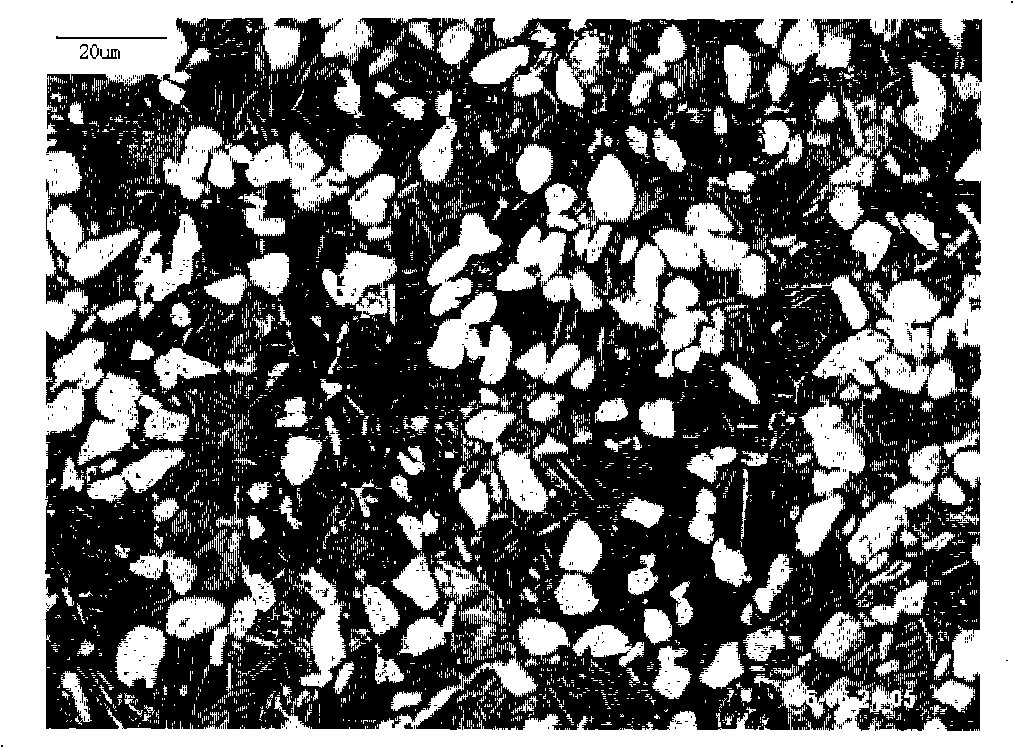

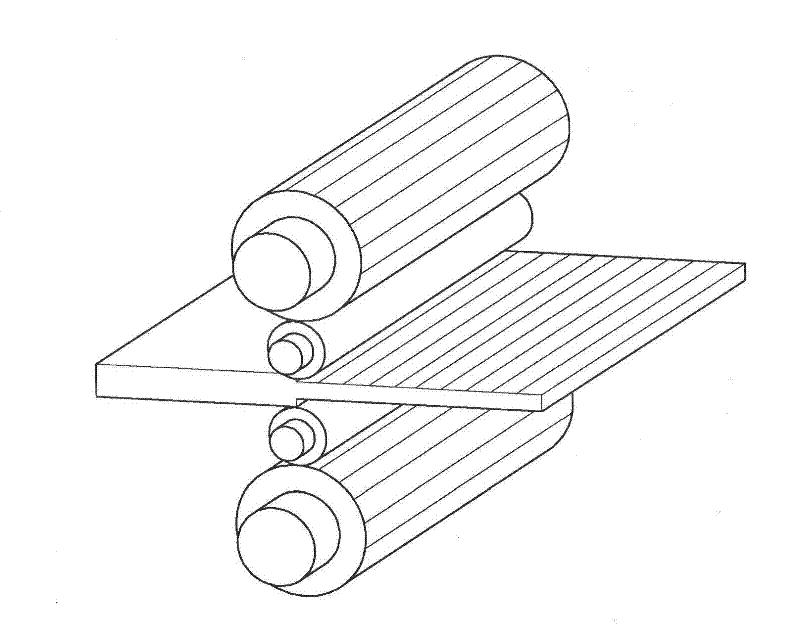

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

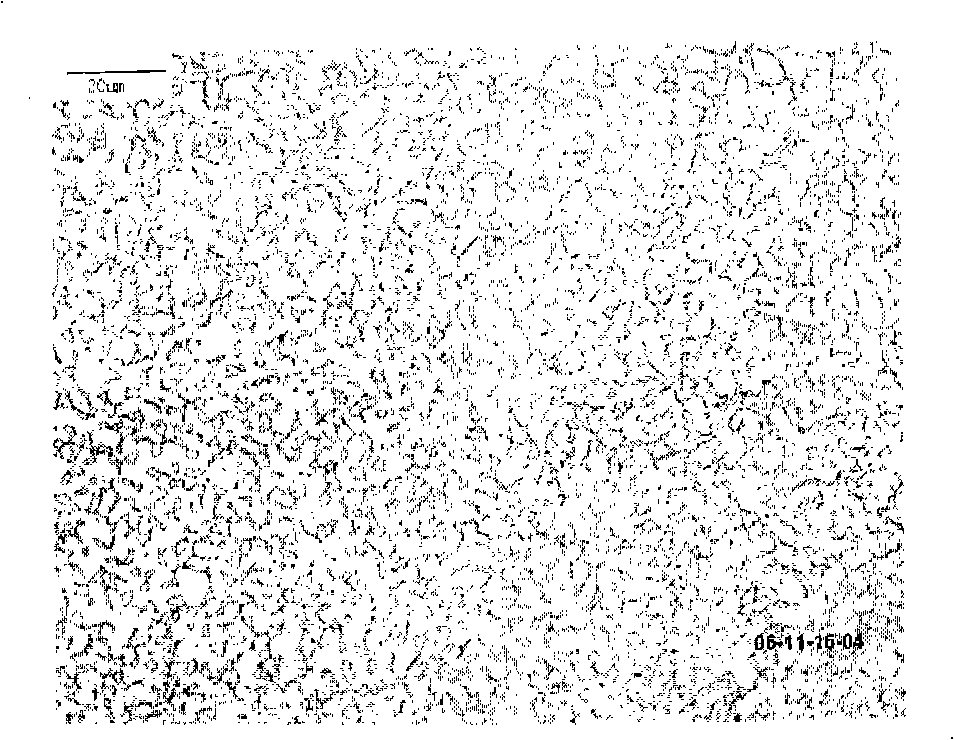

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

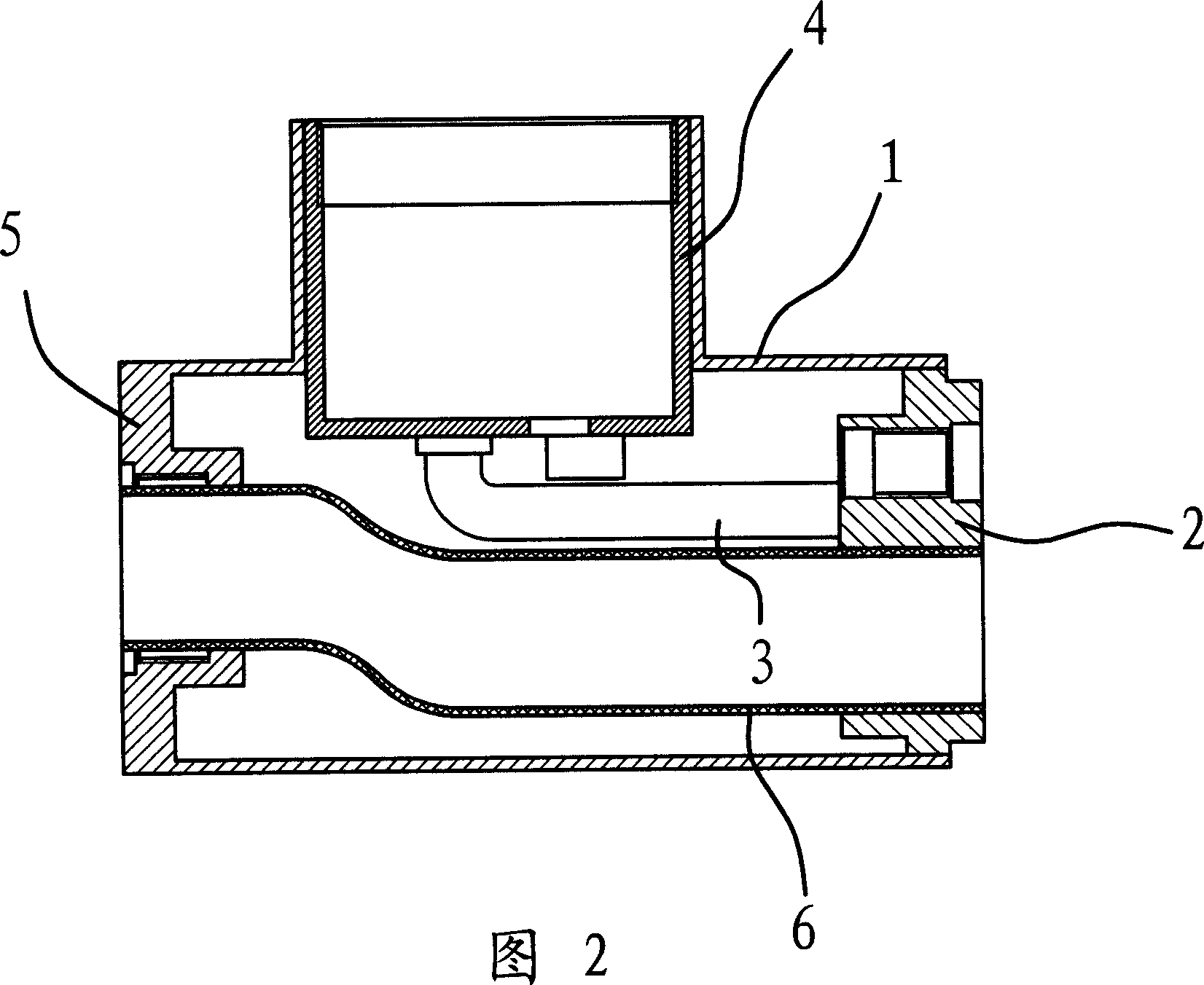

Elastic thread supply device

Owner:UNI CHARM CORP

Elastic thread supply device

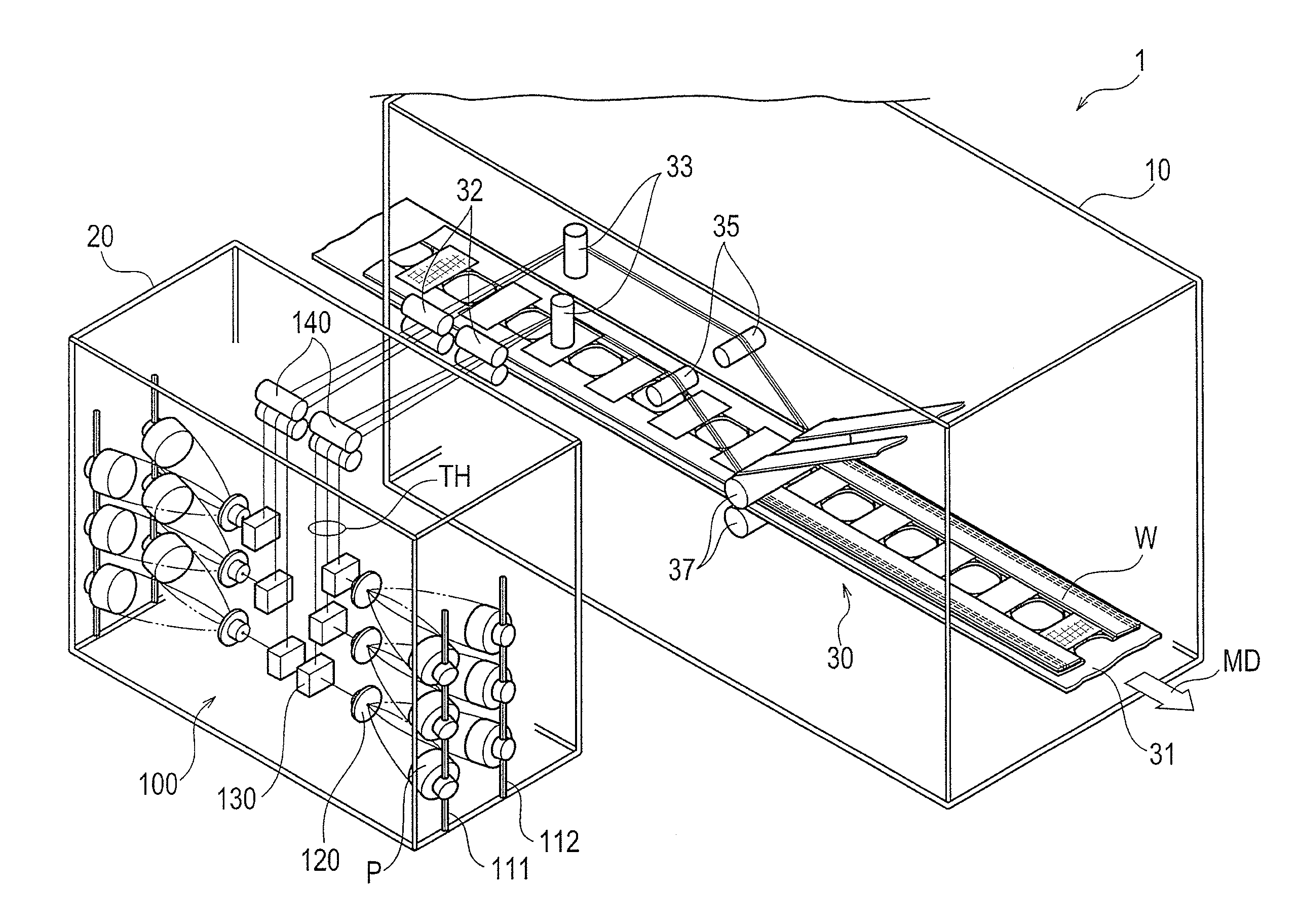

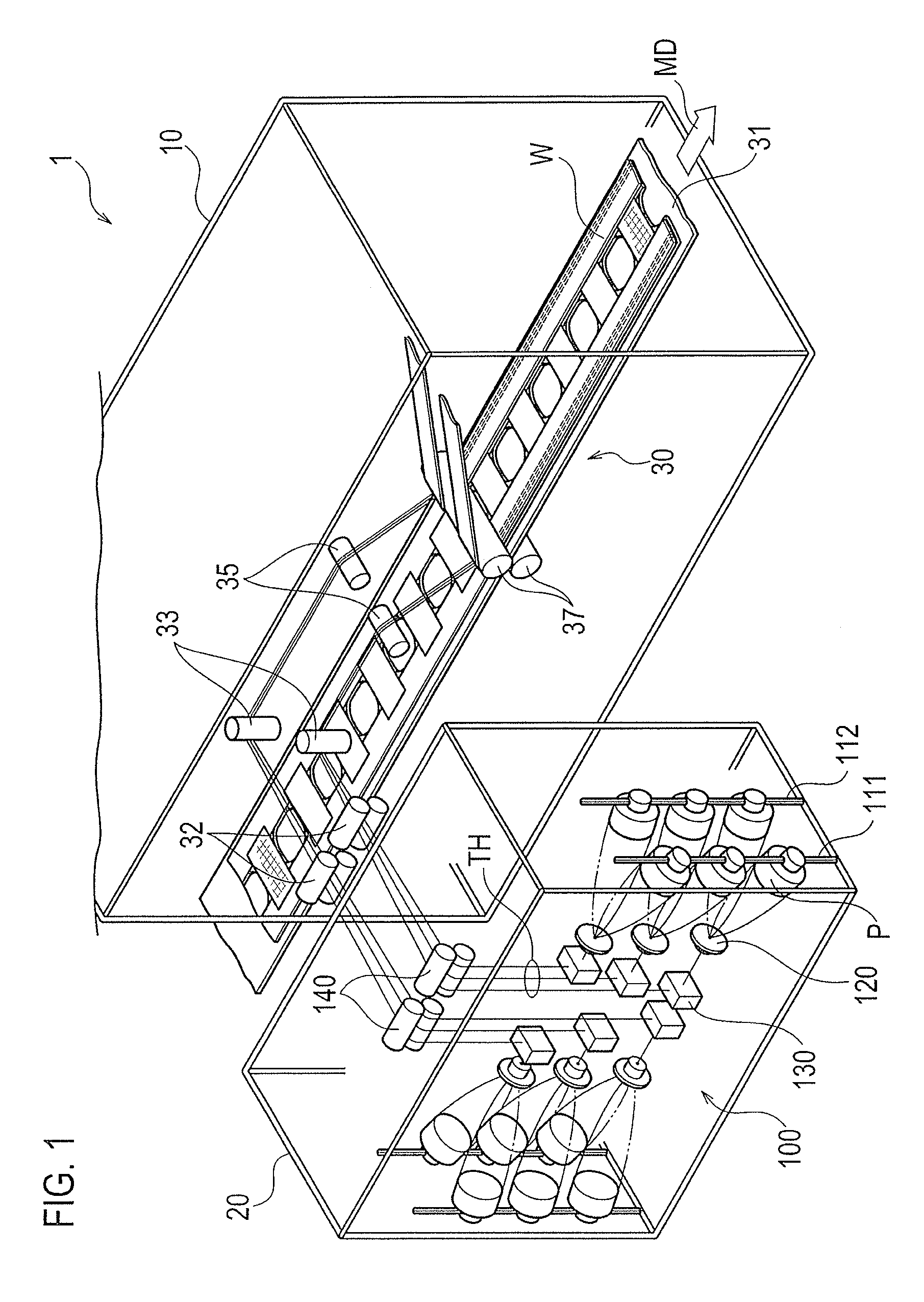

An elastic thread supply device including a tension controller configured to control the stress acting upon an elastic thread drawn from an elastic thread package, and a drive roll configured to supply the elastic thread dispensed from the tension controller to a processing line. The drive roll operates at a supply velocity slower than a conveyance velocity of a web, and increases or decreases the supply velocity depending on the fluctuation in the conveyance velocity.

Owner:UNI CHARM CORP

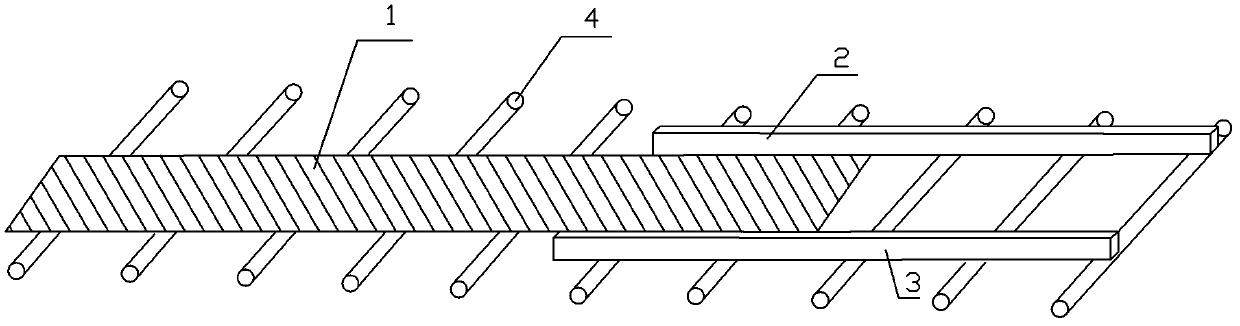

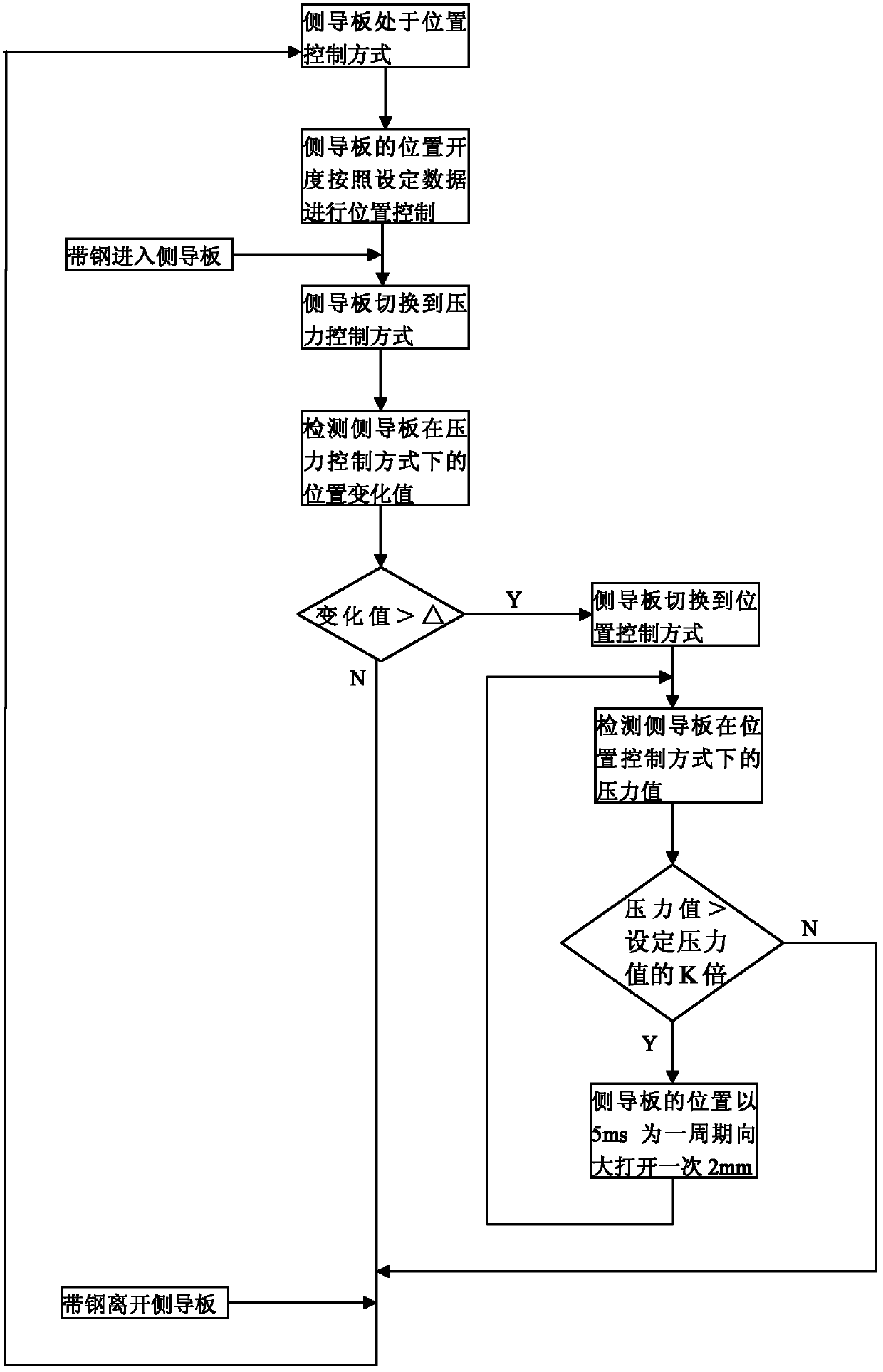

Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

ActiveCN102896180AReduce the amount of reworkReduce manufacturing costControl mannerPressure feedback

The invention relates to a control method of a hot-rolling side guide plate in the metallurgy field, and relates to a control method of a hot-rolling rolled side guide plate for improving hot-rolling roll shape quality. The side guide plate is in a position ring control mode before the band steel enters into the rolling side guide plate; the control mode of side guide plate is switched to a pressure control mode from the position control mode after the band steel enters into the side guide plate; during the pressure control process, when the detected position change of the side guide plate exceeds [Delta]X mm, the control mode of side guide plate is switched to the position control mode from the pressure control mode; and if the position change does not exceed [Delta]X mm, the side guide plate is at the pressure control mode all the time; after the control mode of side guide plate is switched to the position control mode from the pressure control mode, a pressure feedback value of the side guide plate is detected; if the pressure feedback value exceeds K times of a pressure setting value in the pressure control mode, the position of the side guide plate is opened 2 mm with 5 s as a period, until the pressure feedback value of the side guide plate is lower than K times of a pressure setting value in the pressure control mode; and when the band steel leaves the side guide plate; the side guide plate enters into the position control mode. The method effectively solves the problems of quality defects such as layer offset, edge protrusions and edge cracks of roll shapes when rolling supplied material of the band steel swims or has cambers.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

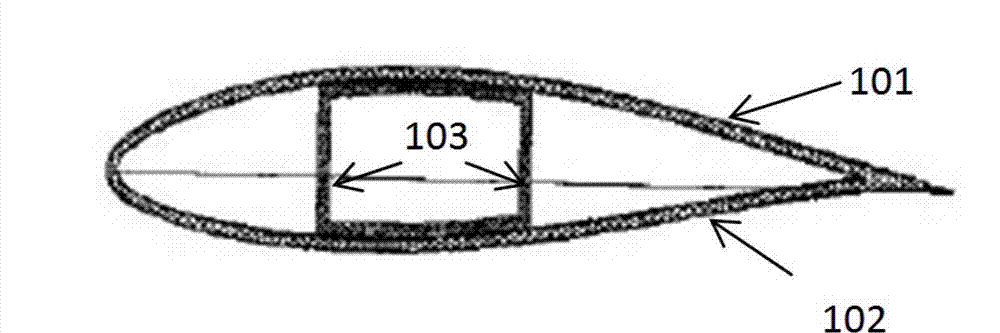

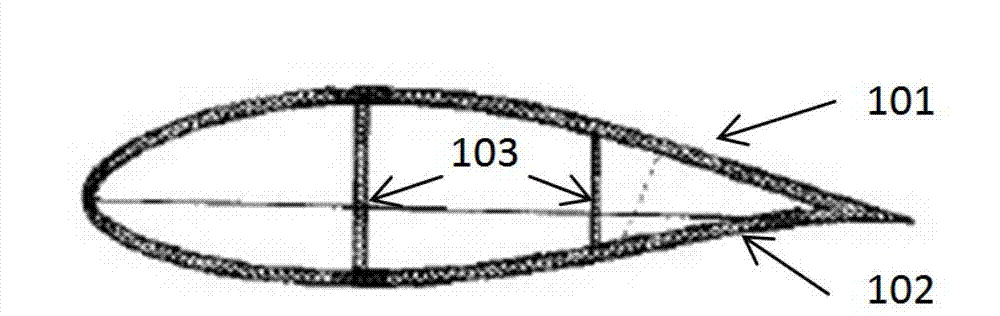

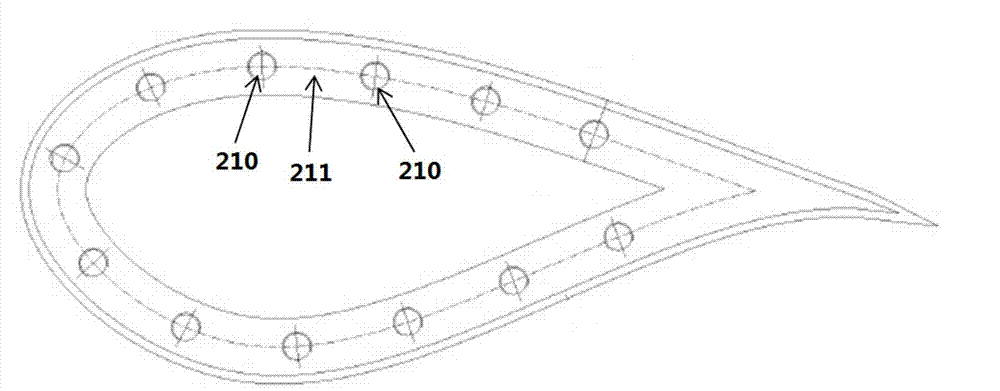

Integrated forming method and device for segmented blade

ActiveCN103042700ASolve the problem of integrated moldingImprove finished product qualityDomestic articlesElectricityPositive pressure

The invention relates to a manufacturing process method for integrated formation of a horizontal shaft segmented wind power blade and an integrated device applicable to the method. The wind power blade at least comprises two segments of composite material blade segments. A metal bolt sleeve is embedded into the connecting part of the two adjacent segments during manufacturing, and integrated formation is realized by a positive pressure auxiliary vacuum perfusion mode, so the defects of the traditional perfusion process are overcome, and the manufacturing problem of the segmented blade is solved. In addition, the integrated formation process avoids various disadvantages and risks caused by that the traditional process shell adopts adhesive to adhere.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

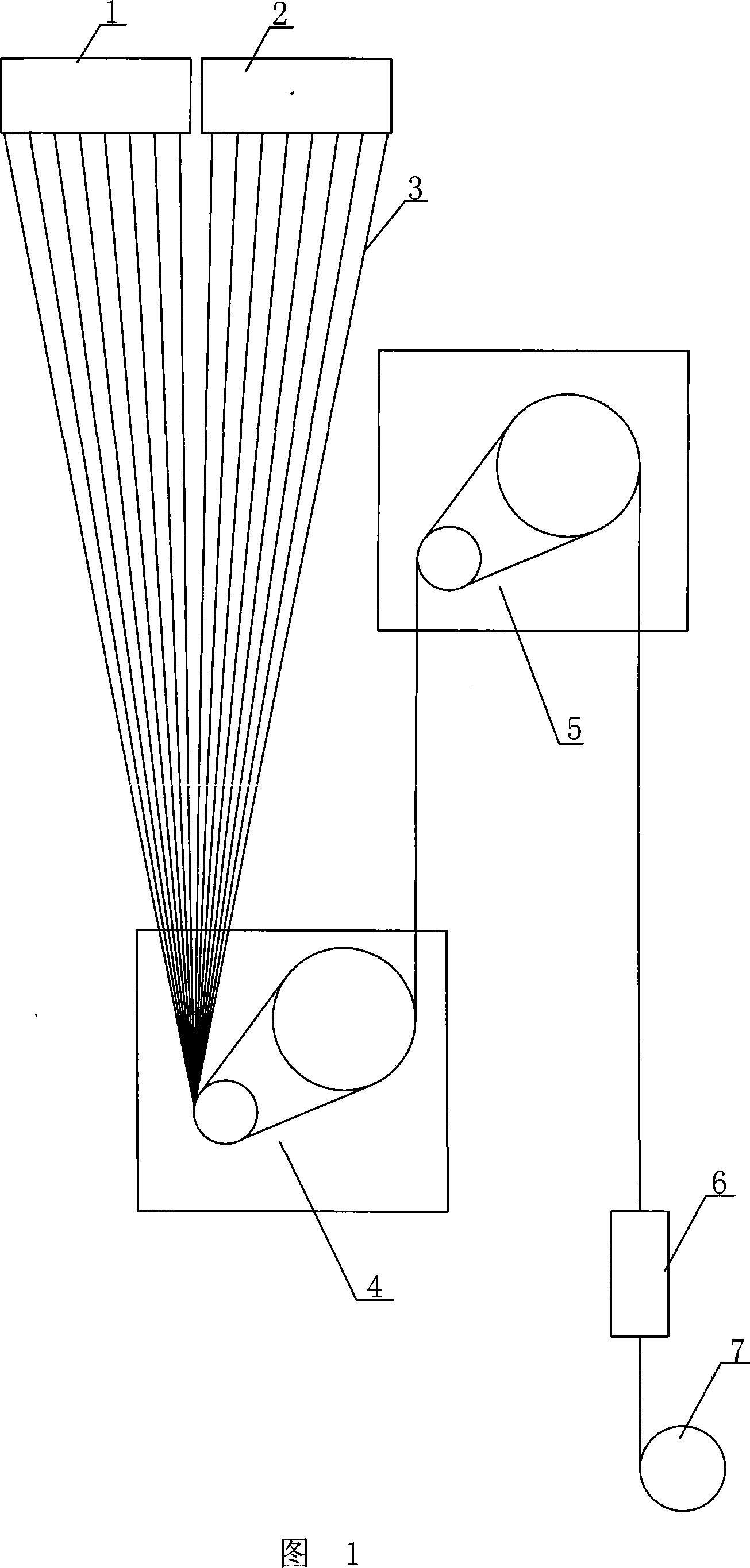

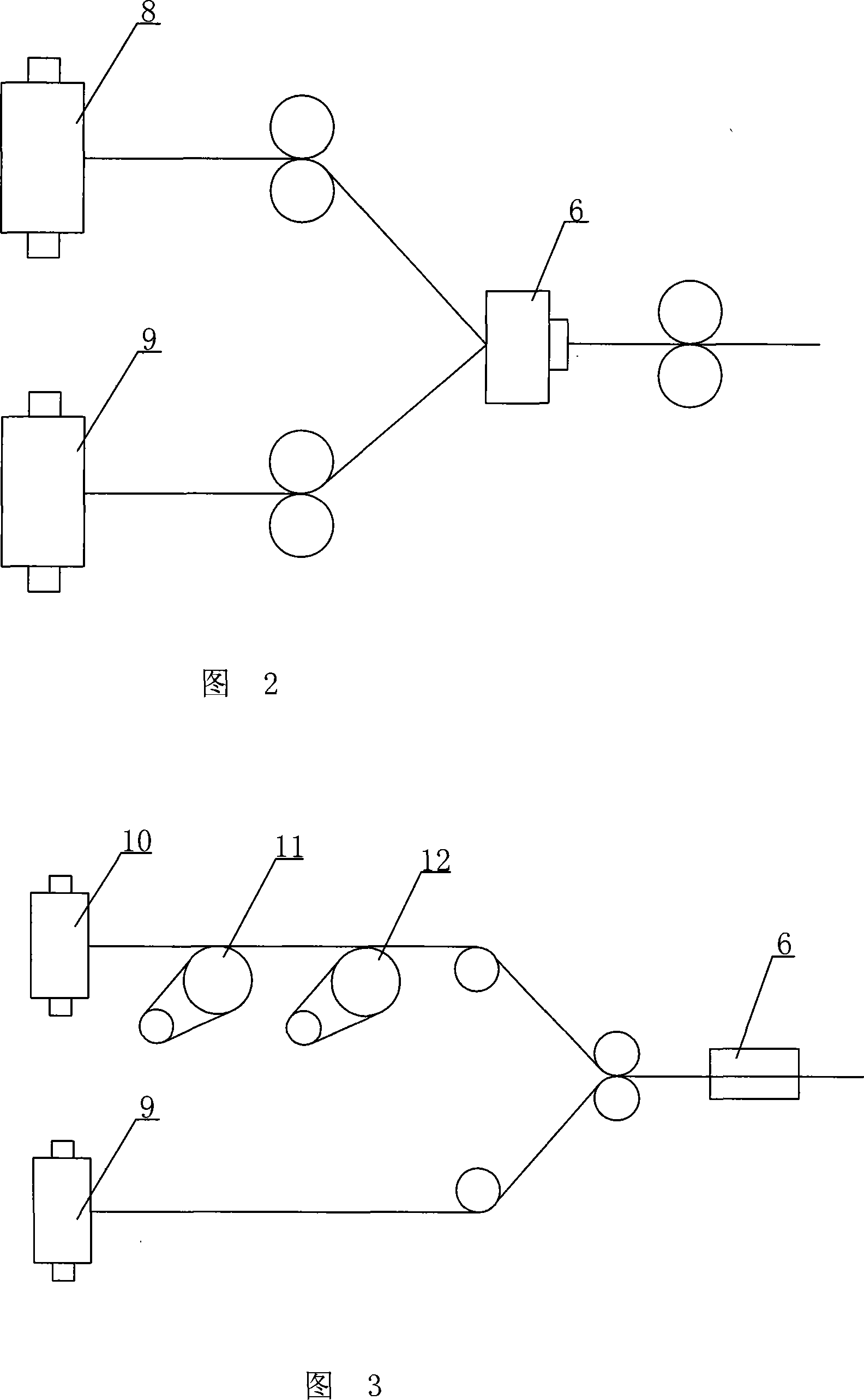

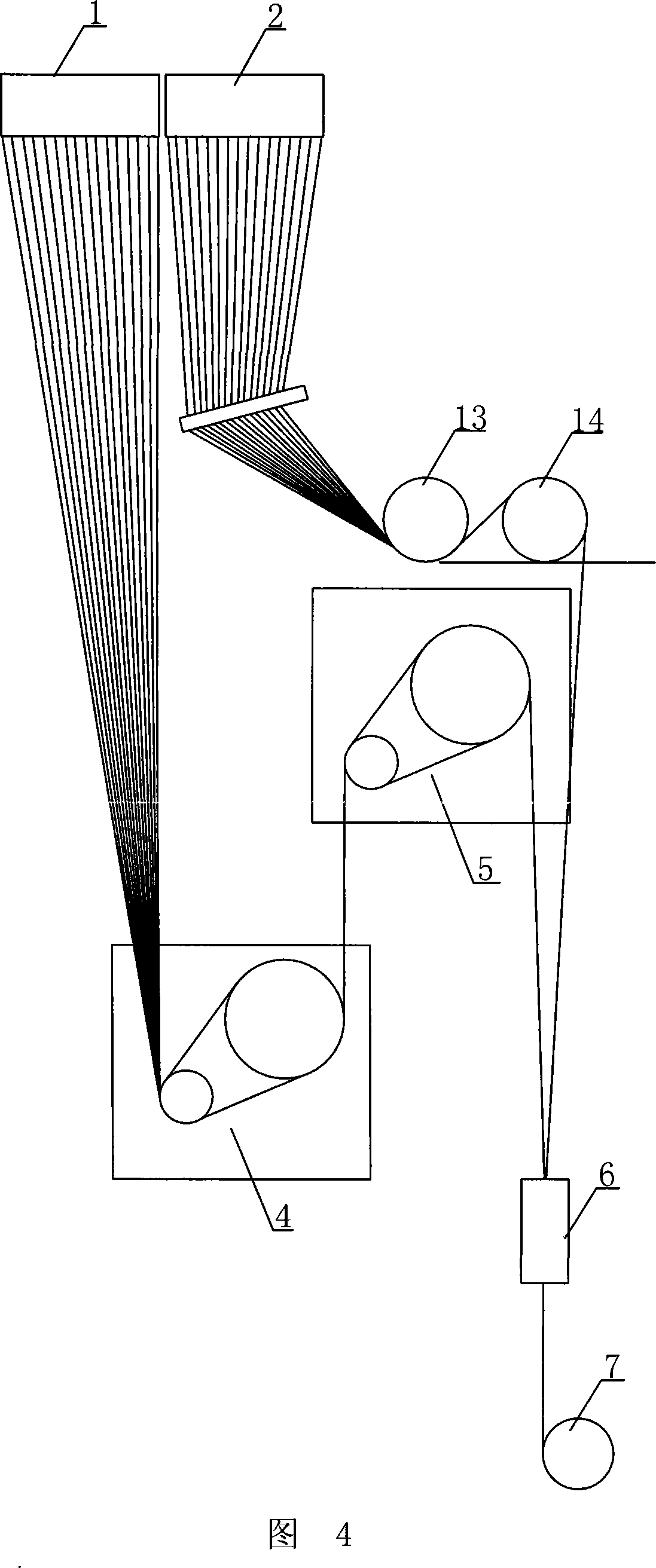

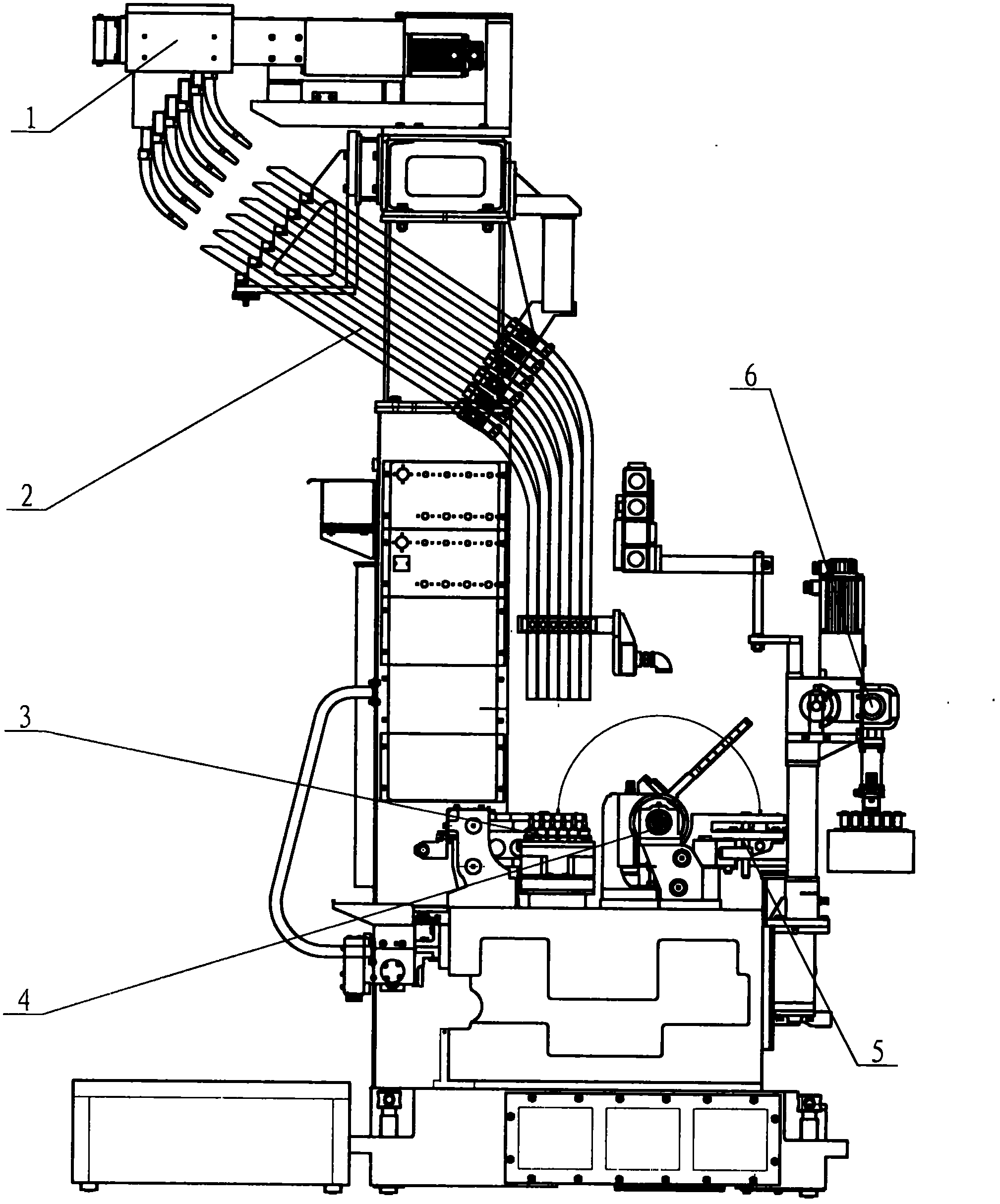

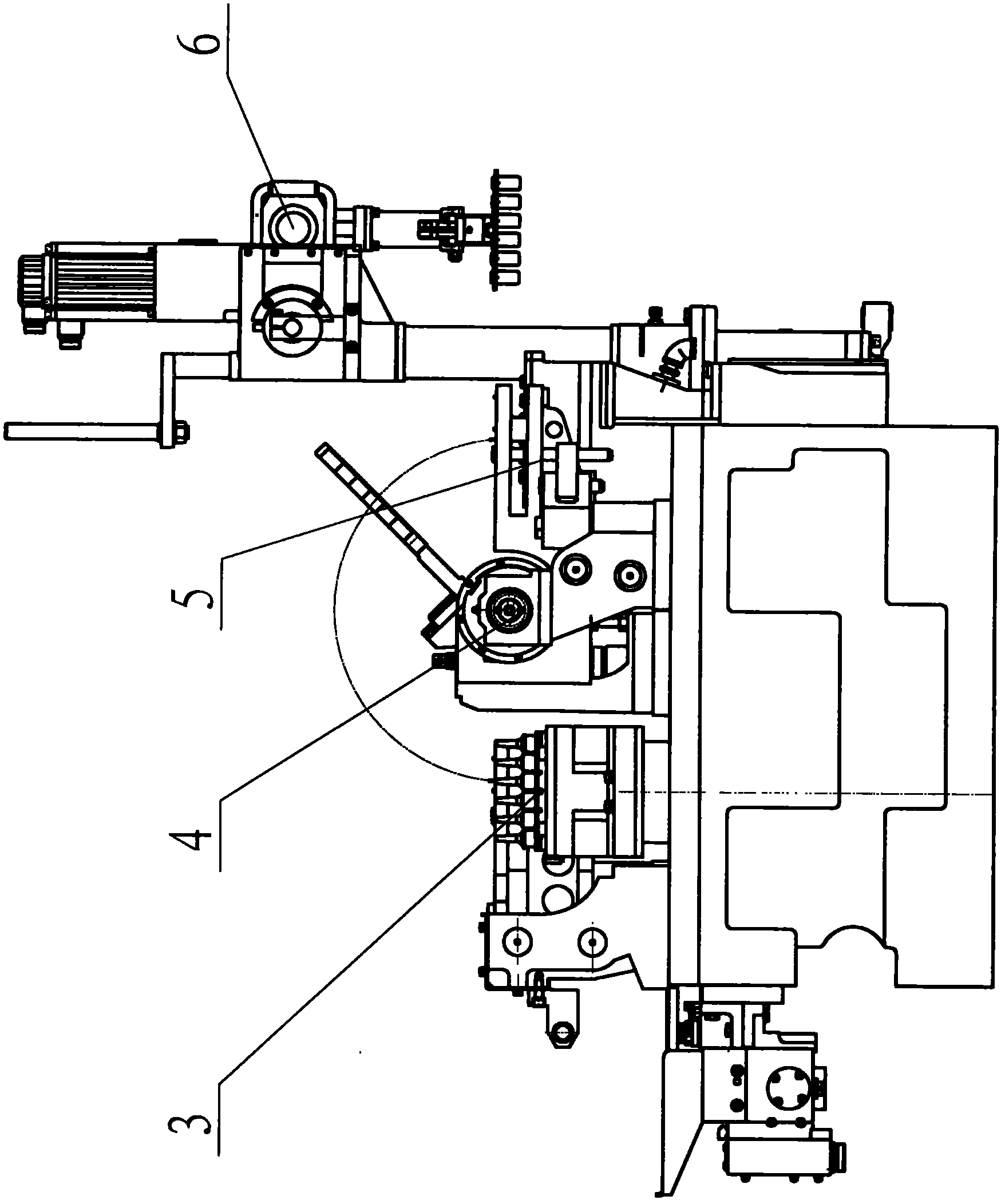

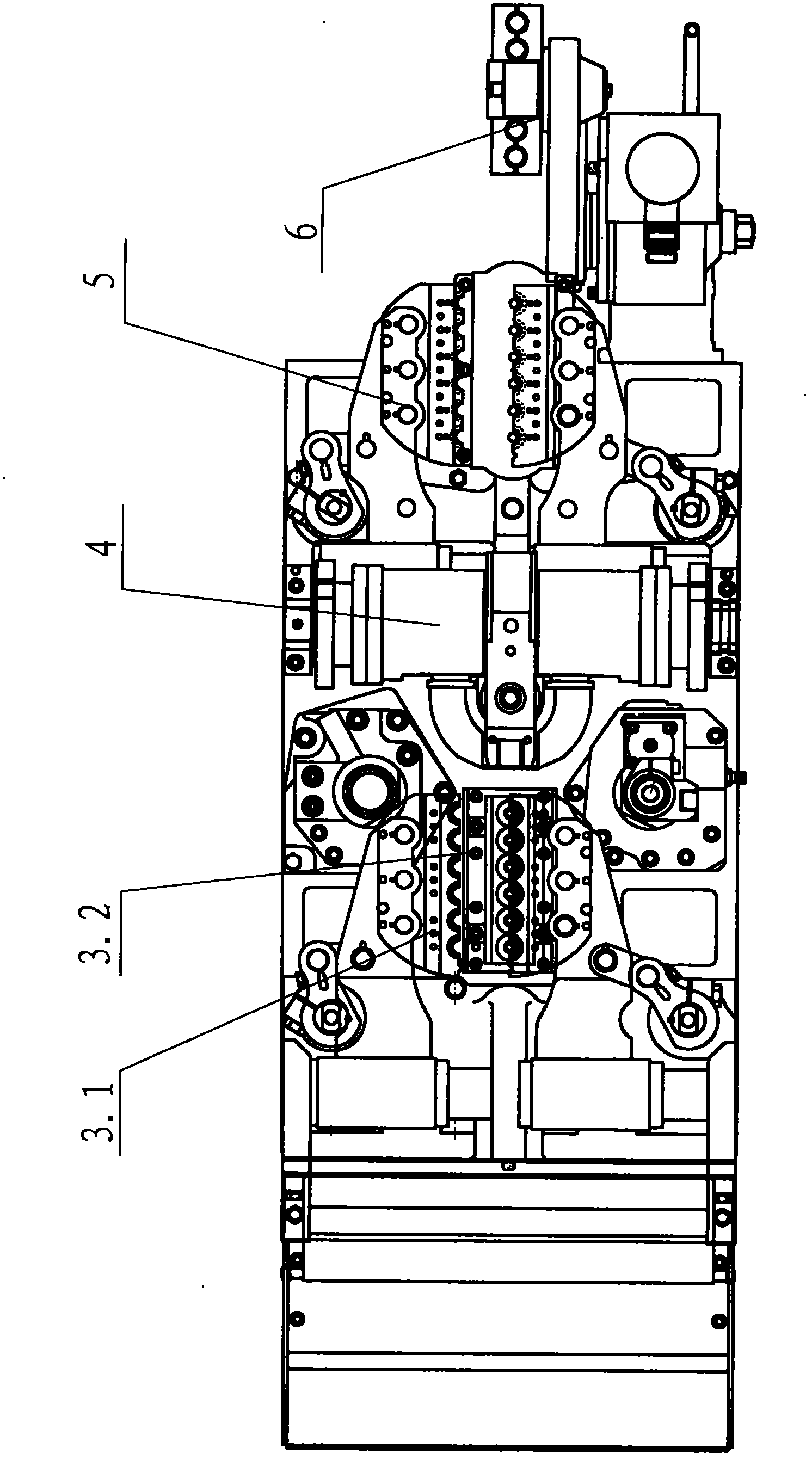

Method and device for manufacturing fully drawn yarn/pre-oriented yarn stranding composite yarn by one-step process

ActiveCN101200826AReduce consumptionSolve technical problemsSpinnerette packsFilament manufactureEngineeringRaw material

The invention discloses a one-step preparation method of stranding composite yarn of fully drawn yarn / pre-oriented yarn and a device thereof. The method includes that an FDY filament device is adopted to haul part tow on the back of a spinning box to two clod godet rollers to obtain POY yarn. The left tow is hauled to two hot godet rollers to obtain FDY yarn. The two tows are winded with a speed of 2800-3200m / min after being networked through a network device to obtain multi-strands of stranding composite yarn of fully drawn yarn / pre-oriented yarn. The device is to add two cold godet rollers on the filament device. The network device and a winding device are arranged to the back of the cold godet rollers and two hot godet rollers. The invention shortens the production process, reduces theequipment occupying space, lowers the consumption of the production cost, raw materials and energies and effectively solves the technical problem of finishing the spinning and the stranding in one step. The whole process is stable. The product quality is reliable. The quality defect that monofilament in yarn is easy to appear in a composite yarn product can be completely eliminated. The yield is three times of that of the prior art. And the production efficiency can be improved greatly.

Owner:WUJIANG FUDONG TEXTILE GROUP

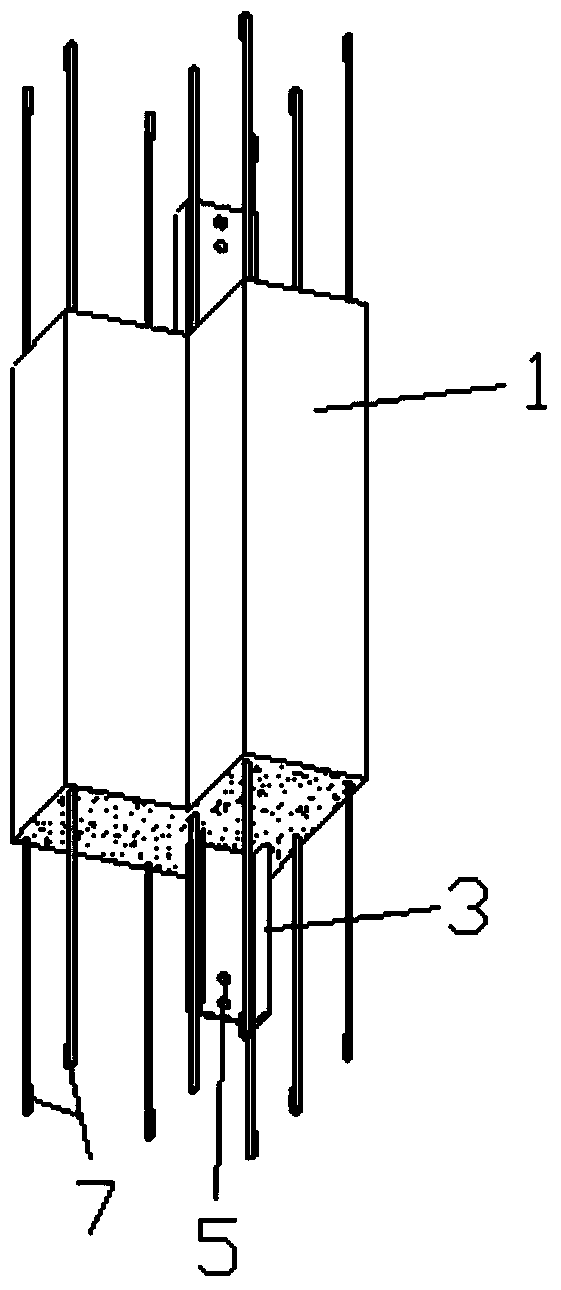

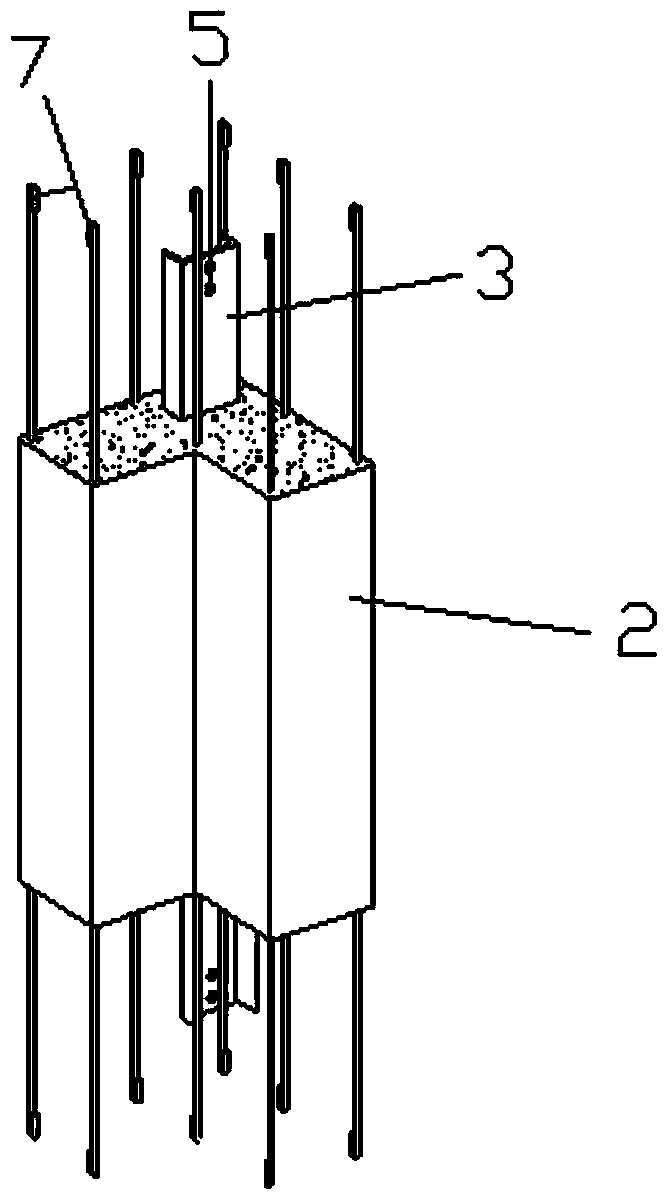

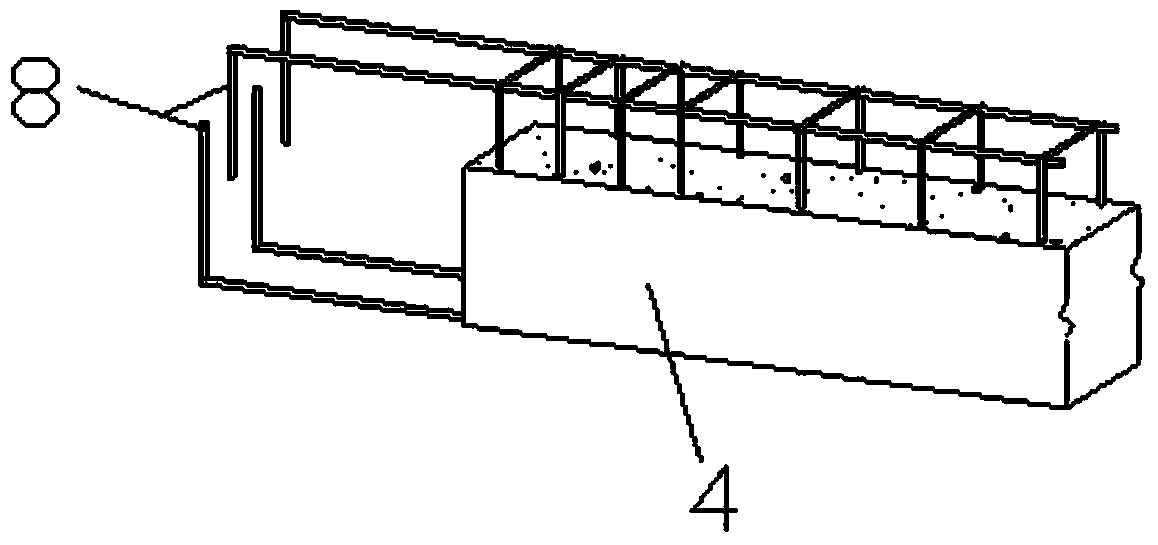

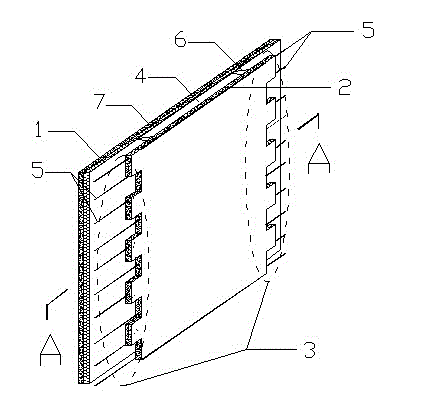

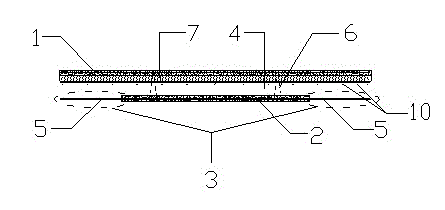

Prefabricated, assembled and integrated type special-shaped column structure and jointing construction method thereof

InactiveCN103850350AImprove integrityEliminate weaknessBuilding material handlingWhole bodyBolted joint

The invention discloses a prefabricated, assembled and integrated type special-shaped column structure and a jointing construction method of the column structure. The prefabricated, assembled and integrated type special-shaped column structure comprises a prefabricated upper column, a prefabricated lower column and a prefabricated laminated beam, wherein the prefabricated upper column and the prefabricated lower column are respectively provided with channel steel in an embedding manner, reserved bolt holes are formed in each channel steel, the adjacent prefabricated upper column and prefabricated lower column are connected through the channel steel by bolts to form an upper and lower through special-shaped column provided with a cast-in-place area, and reinforcing hoops are arranged in the cast-in-place area; the prefabricated laminated beam is anchored in the abnormal column through a longitudinal rib of the prefabricated laminated beam; cast-in-place concrete is injected in the cast-in-place areas of the adjacent two prefabricated upper column and prefabricated lower column and a part, not pouring the concrete, of the prefabricated laminated beam, so as to form a beam and column combined whole body. According to the prefabricated, assembled and integrated type special-shaped column structure and the jointing construction method of the column structure, which are disclosed by the invention, the problems that the vibration of concrete in joint core area of the special-shaped column is not dense and is difficult can be remarkably modified, so that the vibration resistance of joints can be improved; furthermore, the construction speed further can be increased, the construction period is shortened, and the development of building industrialization is facilitated.

Owner:NANJING TECH UNIV +1

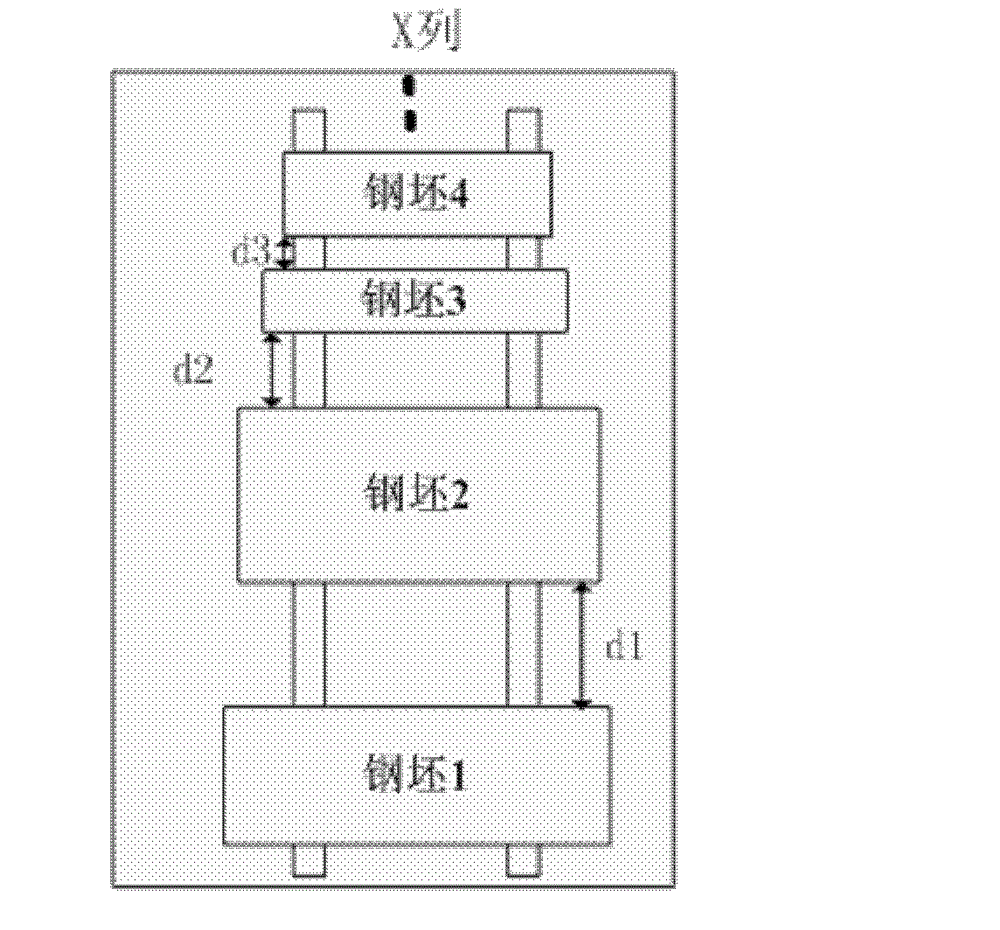

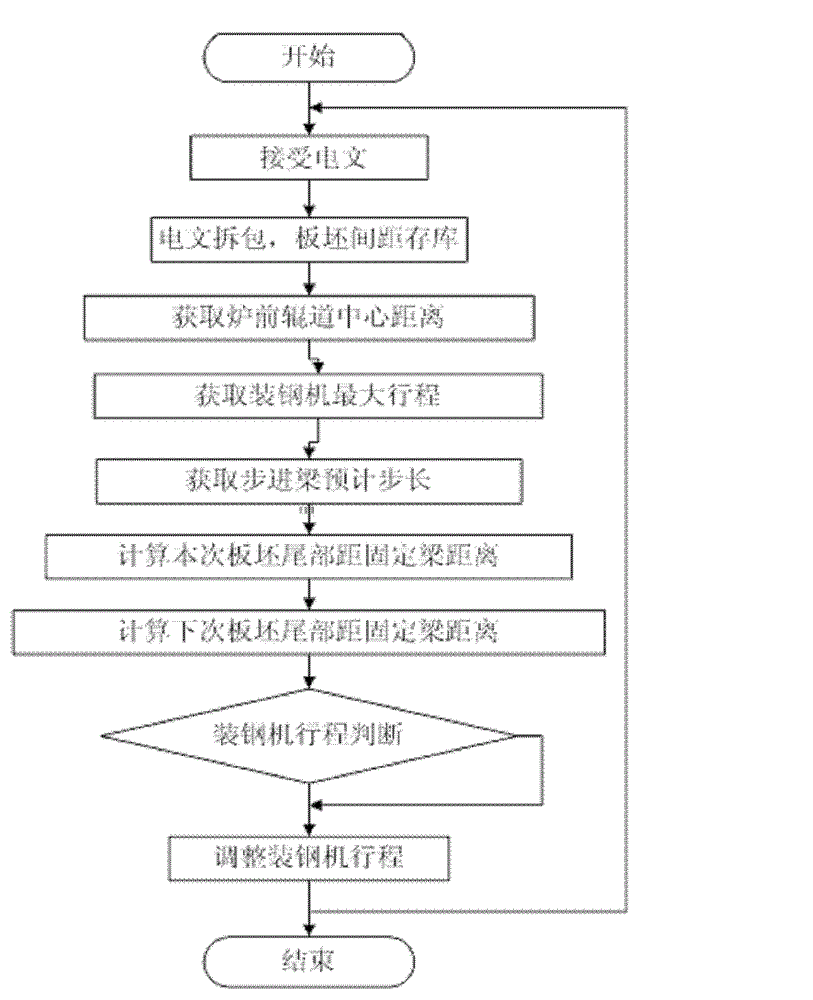

Method for controlling steel slab gap in heating furnace

ActiveCN102747216AReduce quality defectsReduces the frequency of sticking and slab heating non-uniformitiesFurnace typesHeat treatment process controlSlagSheet steel

The invention relates to a method for controlling the steel slab gap in a heating furnace. The method comprises the steps of steel stroke control, steel vacancy control and furnace map position track, wherein a formula that A=A1+A2-A3-A4 is adopted in the steel vacancy control step; A is a distance from a next steel slab to the tail of a fixed beam, and is in mm; A1 is a distance between the last slab on the fixed beam and the tail of the fixed beam, and is in mm; A2 is a step pitch of a stepping beam, and is in mm; A3 is a slab gap and is in mm; and A4 is a slab width. The slab spacing in the slag heating furnace is dynamically adjusted and tracked through the steel stroke control, the steel vacancy control and the furnace map position track according to the method for controlling the steel slab gap in the heating furnace of the invention, so slab surface quality defects caused by the slab gap are reduced. The heating non-uniformity generation frequency of bonding steel and the slabs is substantially reduced, the slab heating quality is ensured, and the production efficiency is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

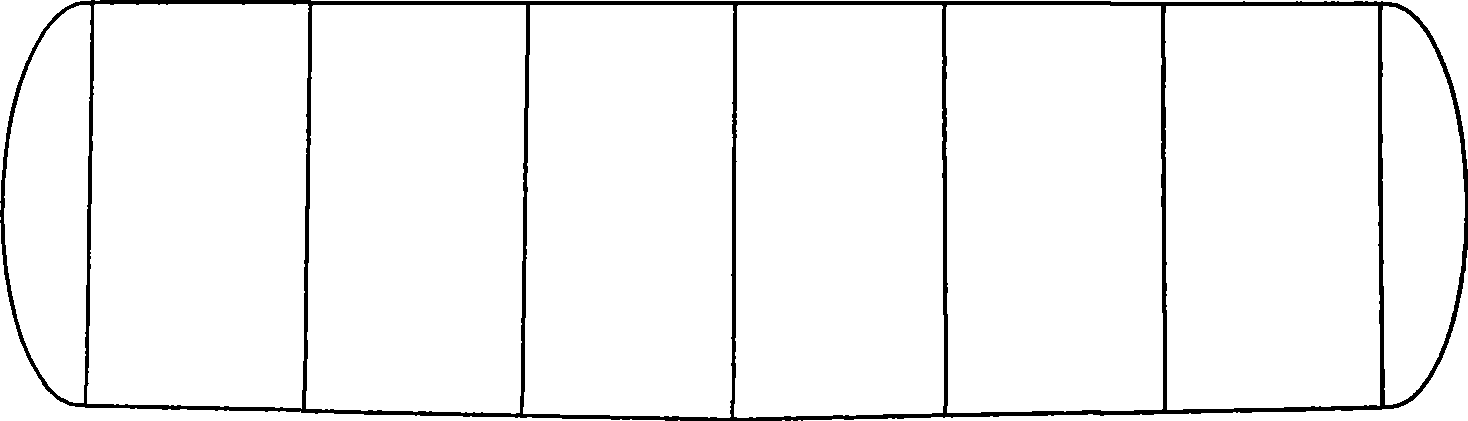

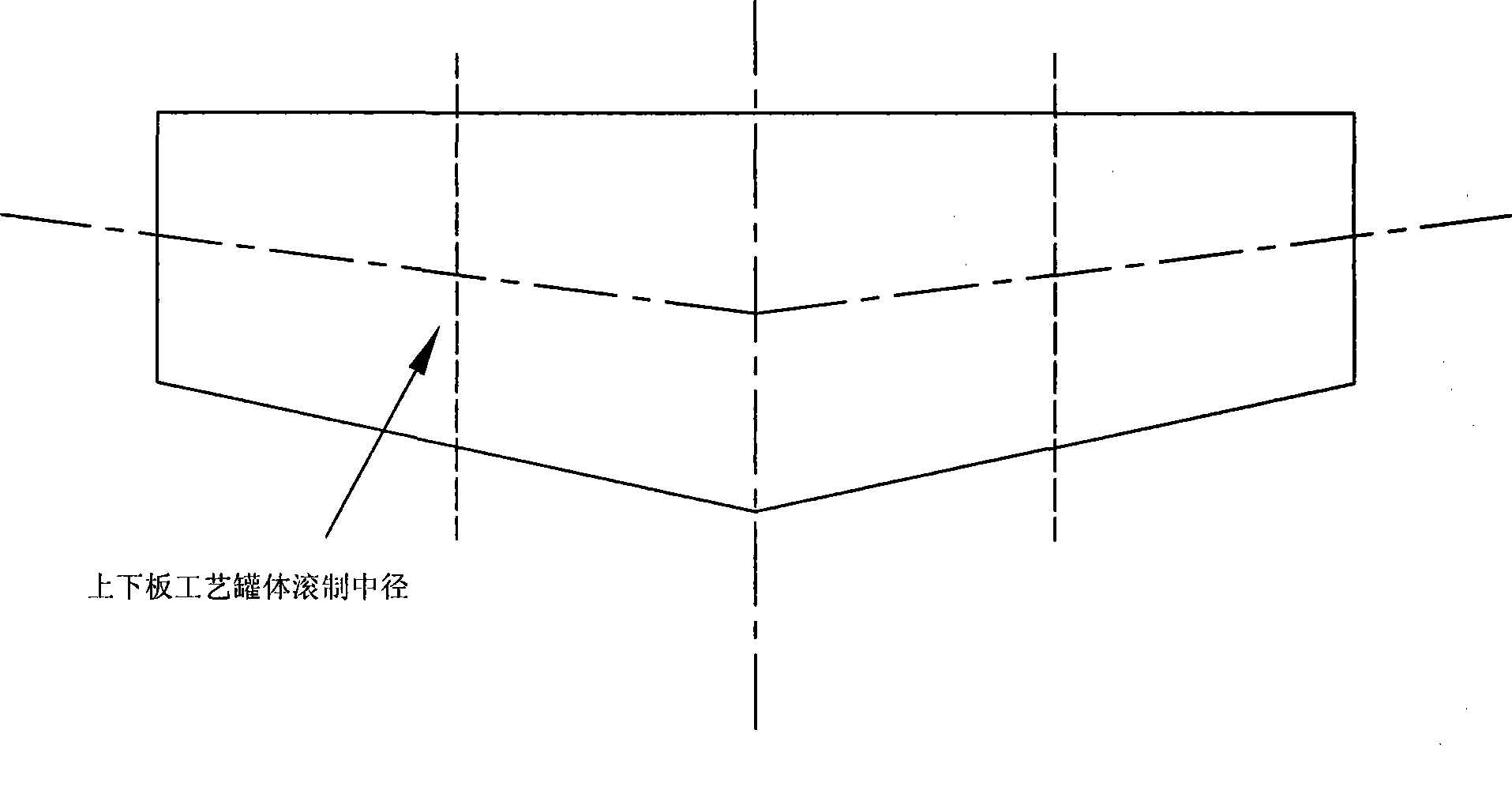

Cylindrical shell sloping-bottom tank car body manufacture technique

ActiveCN101417381AAvoid quality defectsMeet the design requirementsLarge containersArc welding apparatusEngineering

The invention relates to a manufacturing technique of a tank body of a cylindrical shell section sloping bottom tank car, comprising three steps of rolling cylindrical shell section cones, fitting up the cylindrical shell section cones and forming the tank body. The invention has reasonable step design; and the manufactured tank body of the sloping bottom tank is completely consistent with the design requirements, thus fundamentally eliminating the quality defect of the sloping bottom tank body caused by the technique method and greatly improving the welding quality; and the invention is applicable to the production of various cylindrical shell section sloping bottom tank cars and can be produced on scale.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

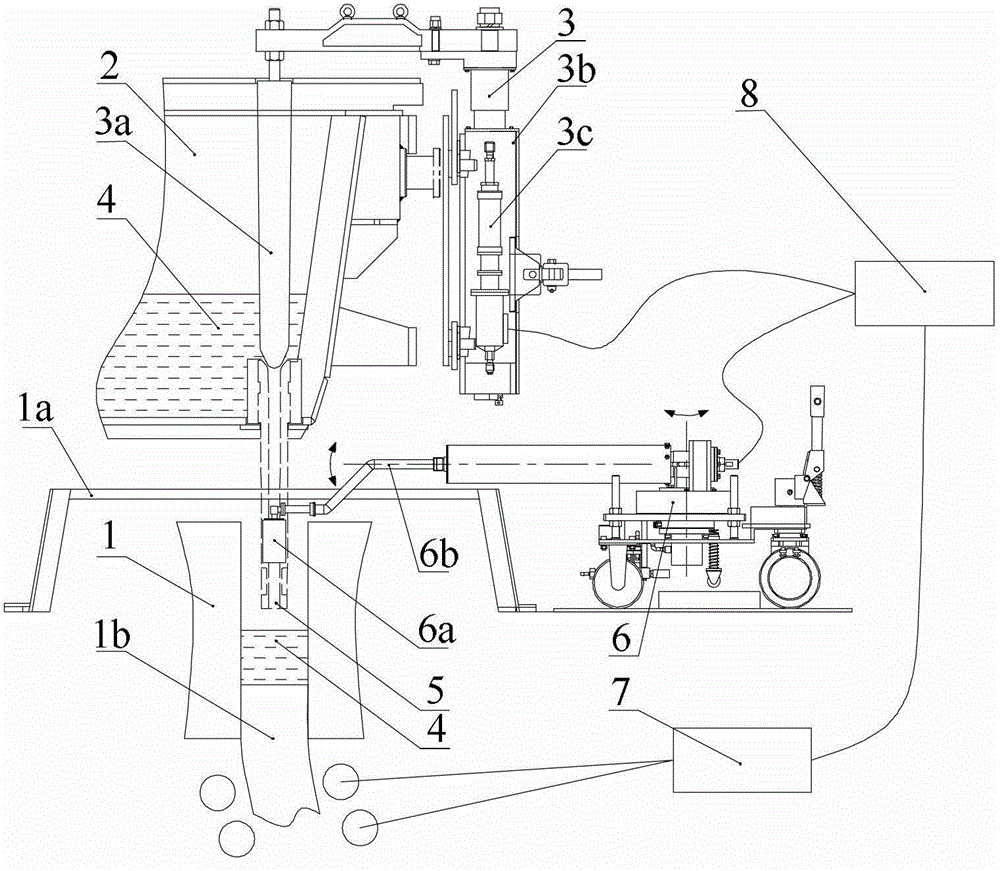

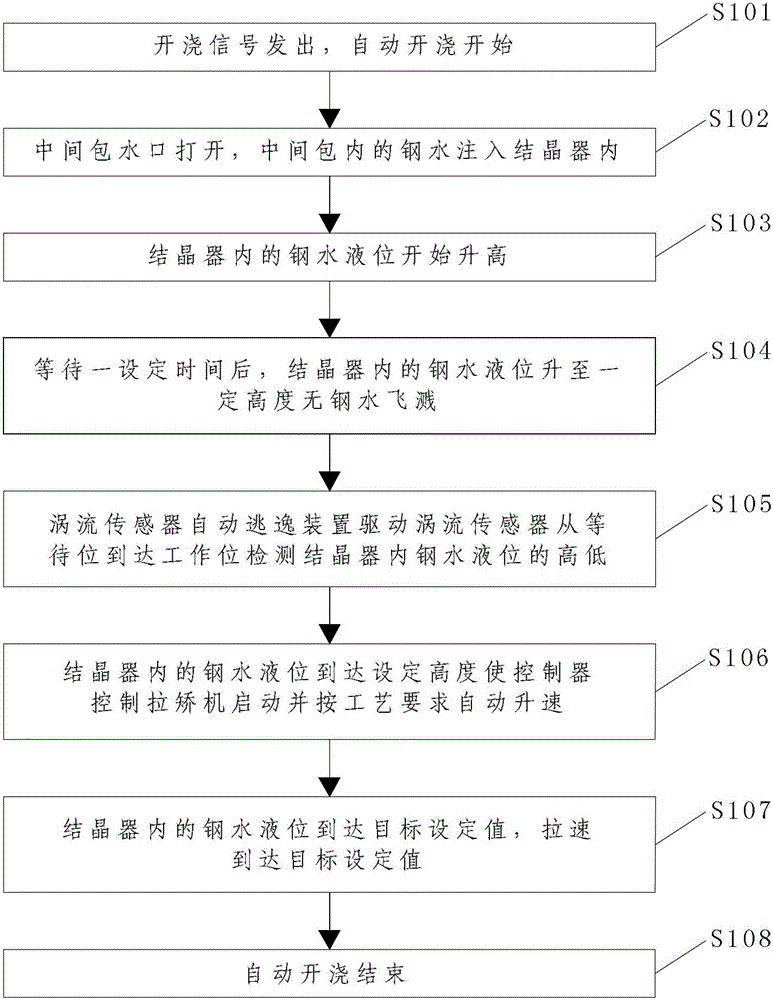

Automatic plate blank continuous casting machine tundish pouring method and automatic pouring system

InactiveCN102717039AReduce the risk of breakoutsImprove the success rate of pouringFlow transducerSlab caster

The invention discloses automatic plate blank continuous casting machine tundish pouring method and an automatic pouring system. The pouring method comprises the following steps of: a) opening a water gap of a tundish, and pouring molten steel in the tundish into a crystallizer; b) after the water gap of the tundish is opened for certain time, leading a vortex flow transducer to automatically move to a work station from a waiting station so as to detect height of the molten steel level in the crystallizer by utilizing an automatic escape device; and c) when the vortex flow transducer detects that the molten steel level in the crystallizer reaches a set height, starting a withdrawl and straightening machine and promoting the casting speed to a target set value according to the process requirement. The automatic plate blank continuous casting machine tundish pouring method and the automatic pouring system can solve the problem that the plate blank continuous casting machine of the existing vortex flow molten steel level detector can not realize automatic pouring, reduce the risk on pouring breakout, improve the pouring success rate, and saving the cost.

Owner:田志恒 +2

Method for manufacturing outer graphics of electronic circuit board by encapsulation method

The invention discloses a method for manufacturing outer graphics of an electronic circuit board by an encapsulation method, comprising the following steps: 1. electro-plating an entire panel: the entire panel is electro-plated to the desired thickness for one time; 2. pretreating a dry film on the outer layer (namely, cleaning); a. sticking the dry film on the outer layer; 4. registering and exposing the film: the film is drawn according to the graphics design and is arranged on the dry film by registration according to the requirement of the design, the desired graphic parts on the corresponding circuit board of the films are non-lighttight, and the undesired graphic parts are lighttight, the dry film under the non-lighttight parts of the film can react after being exposed; 5. developing the outer layer: the dry films which are exposed are retained, and the dry films which are not exposed are developed away; 6. etching the outer layer: acid itching liquid is used for itching the exposed metal on the board; 7. removing the film on the outer layer: the dry films on the graphics are removed; 8. inspecting the panel. The invention reduces the operational links, and further reduces the quality defects appearing in the operational links, reduces the use of devices and decreases the production cost.

Owner:JIANGSU SUHANG ELECTRONIC CO LTD

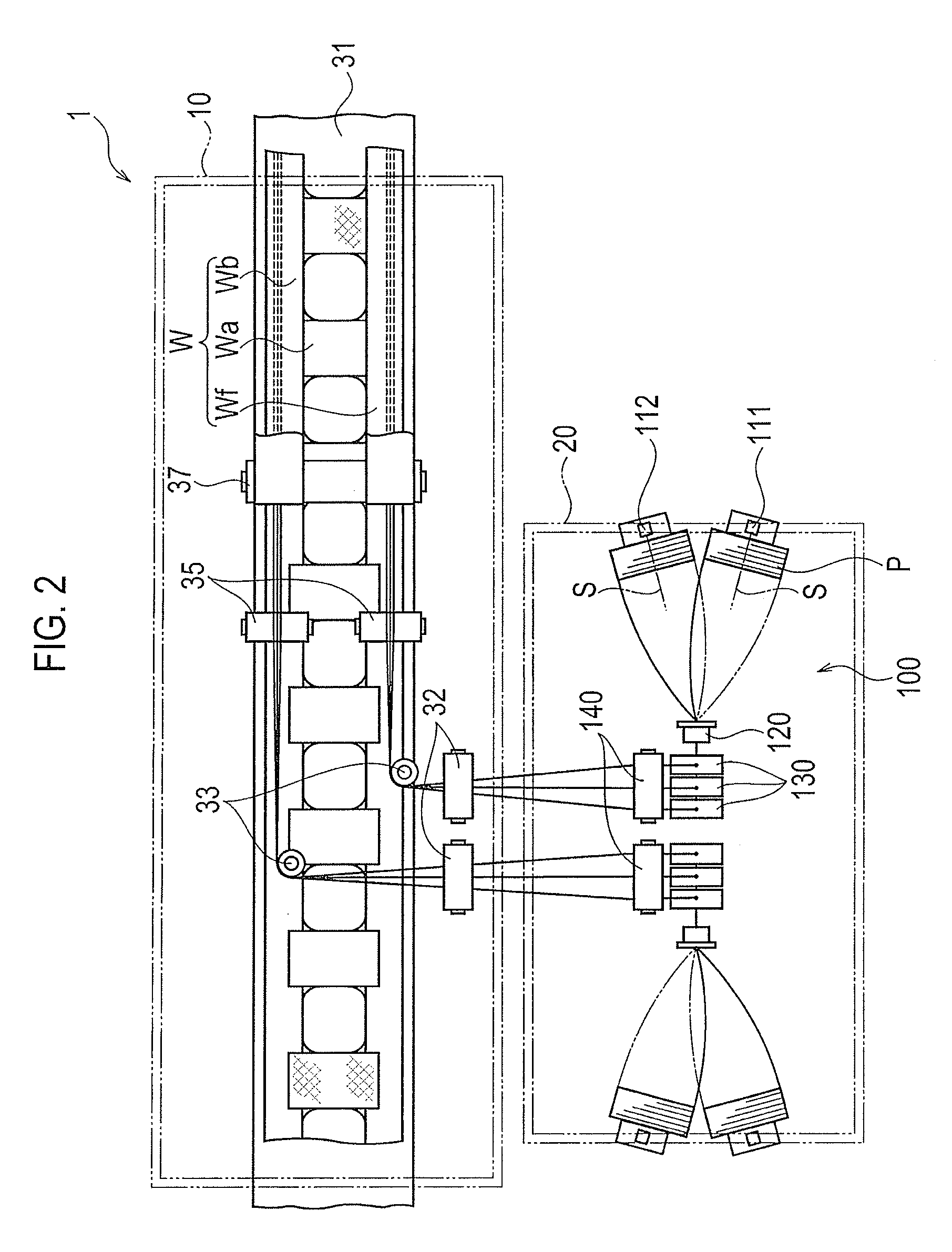

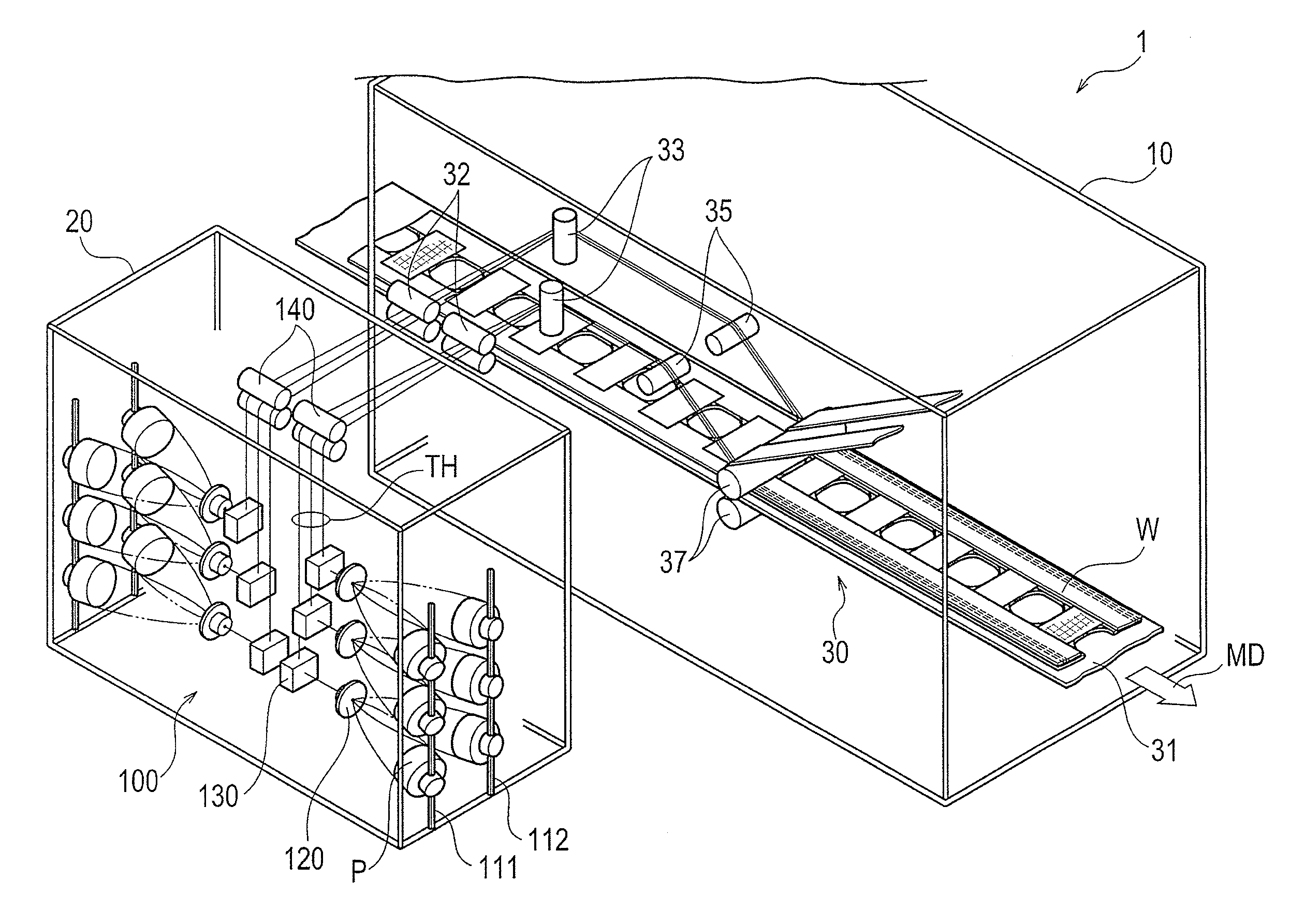

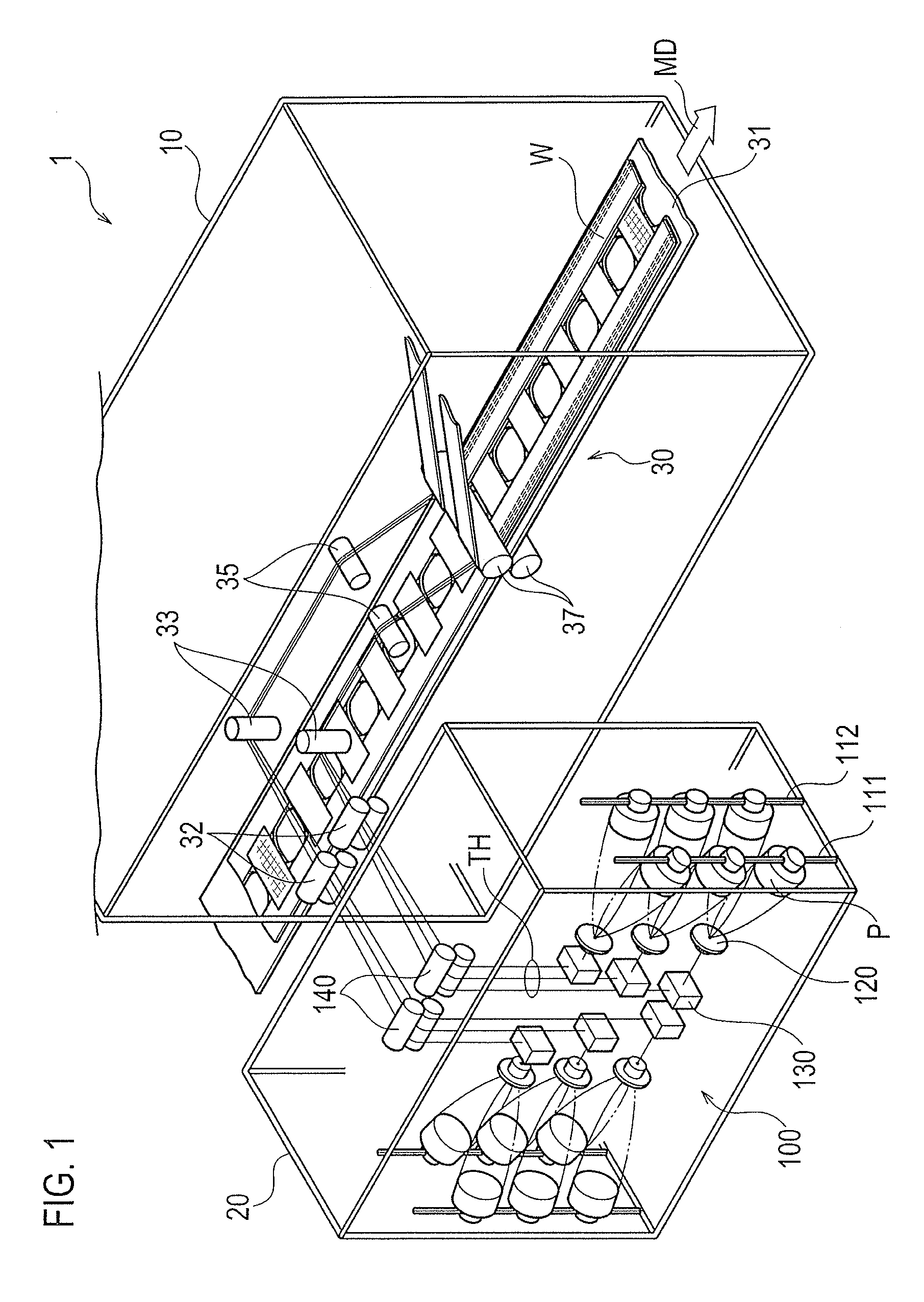

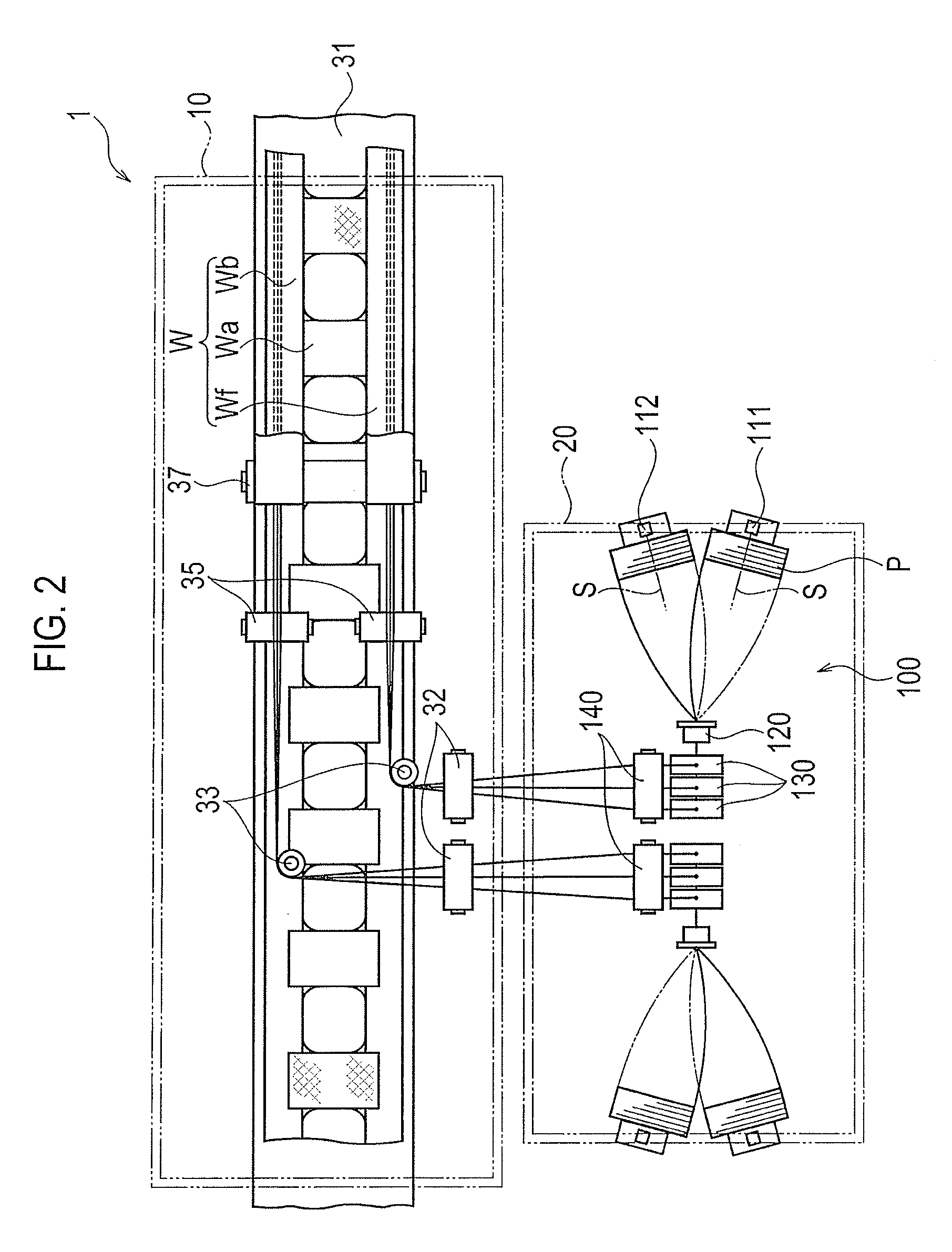

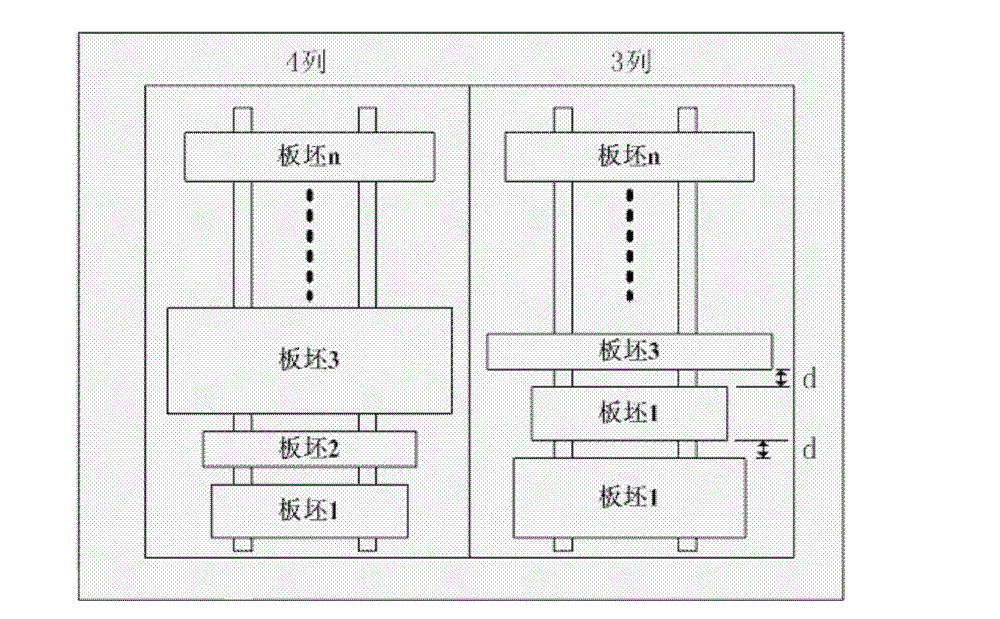

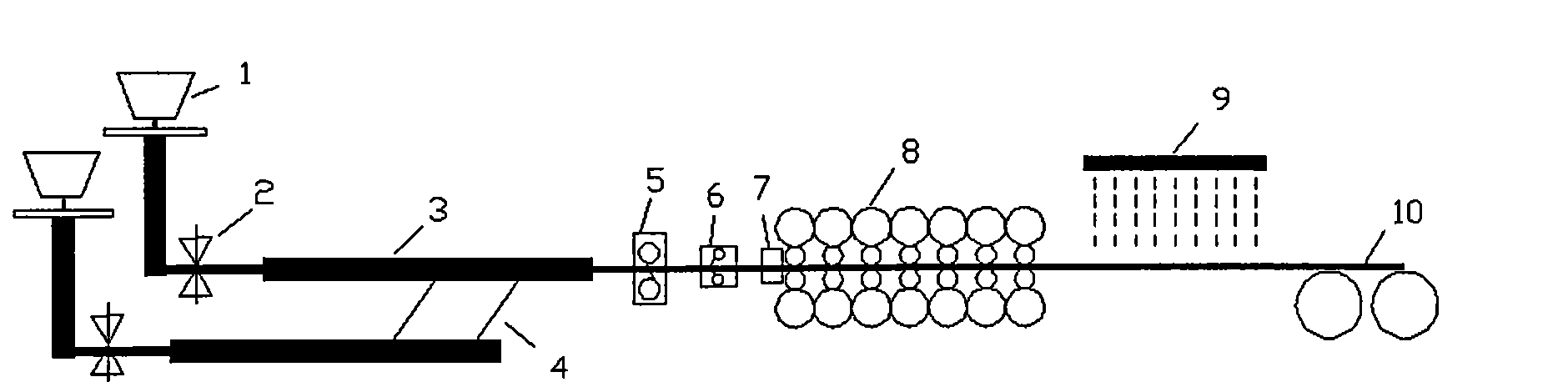

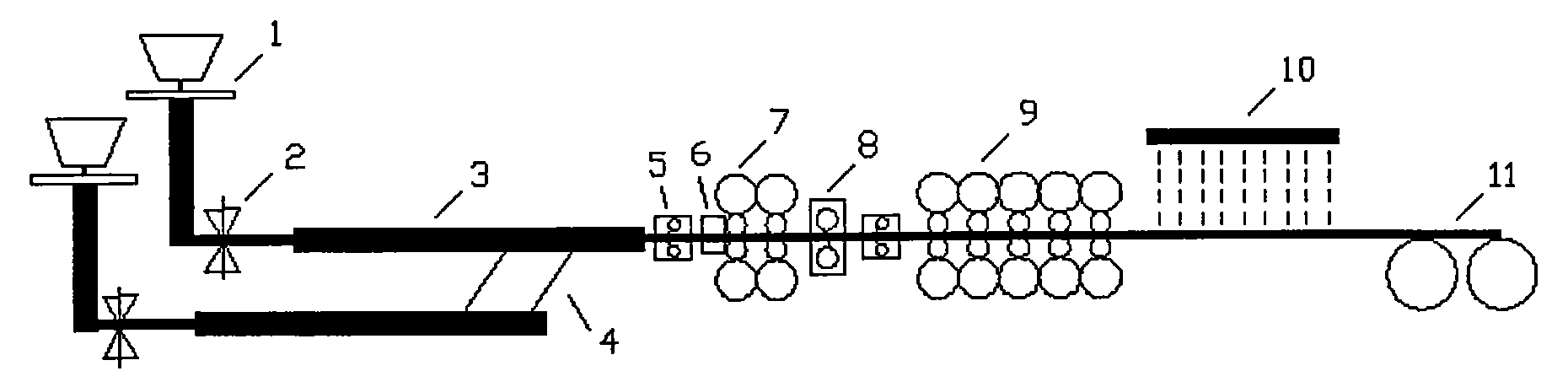

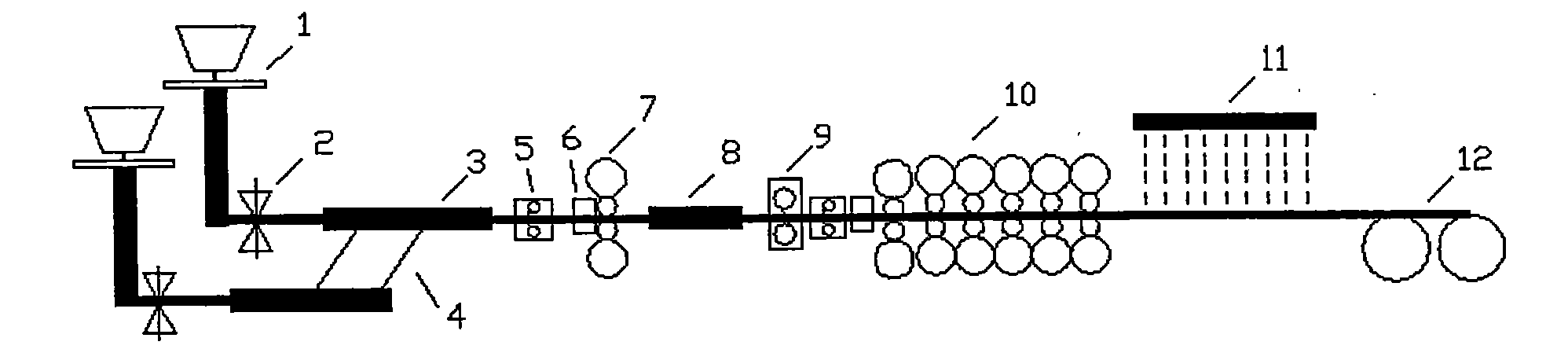

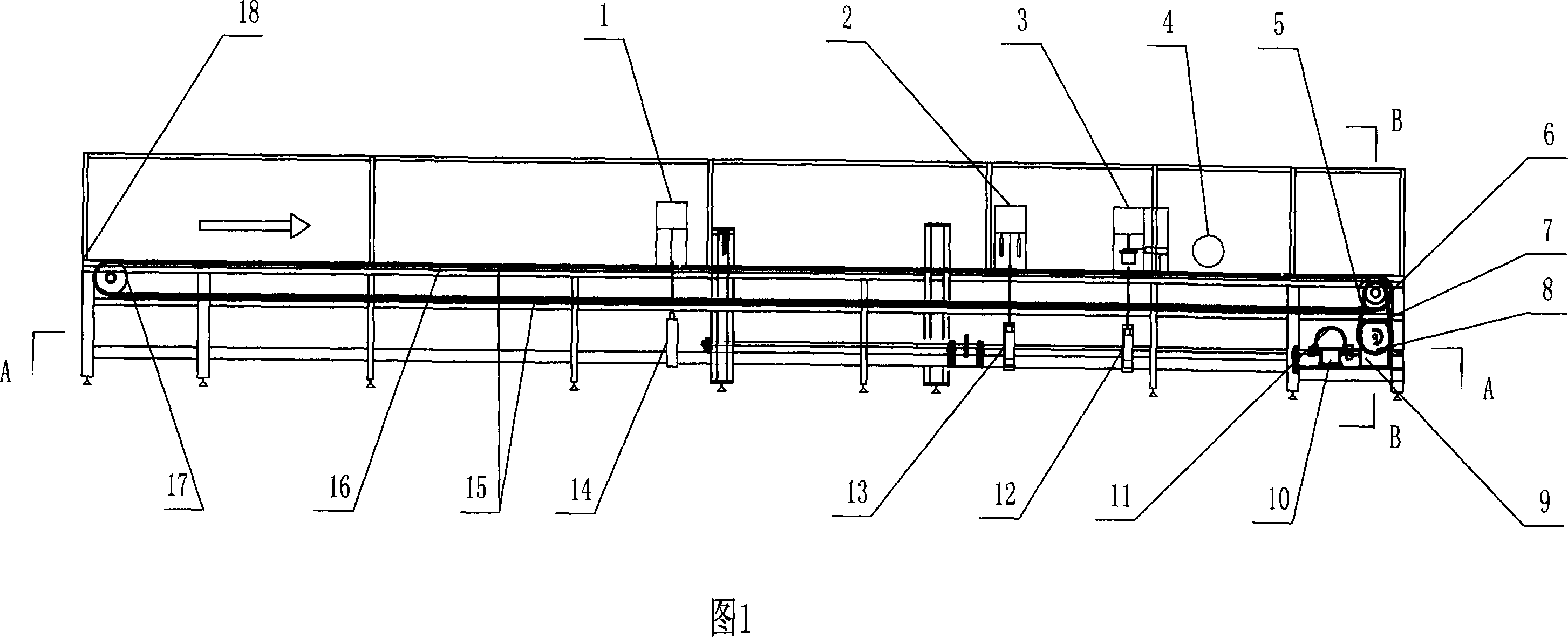

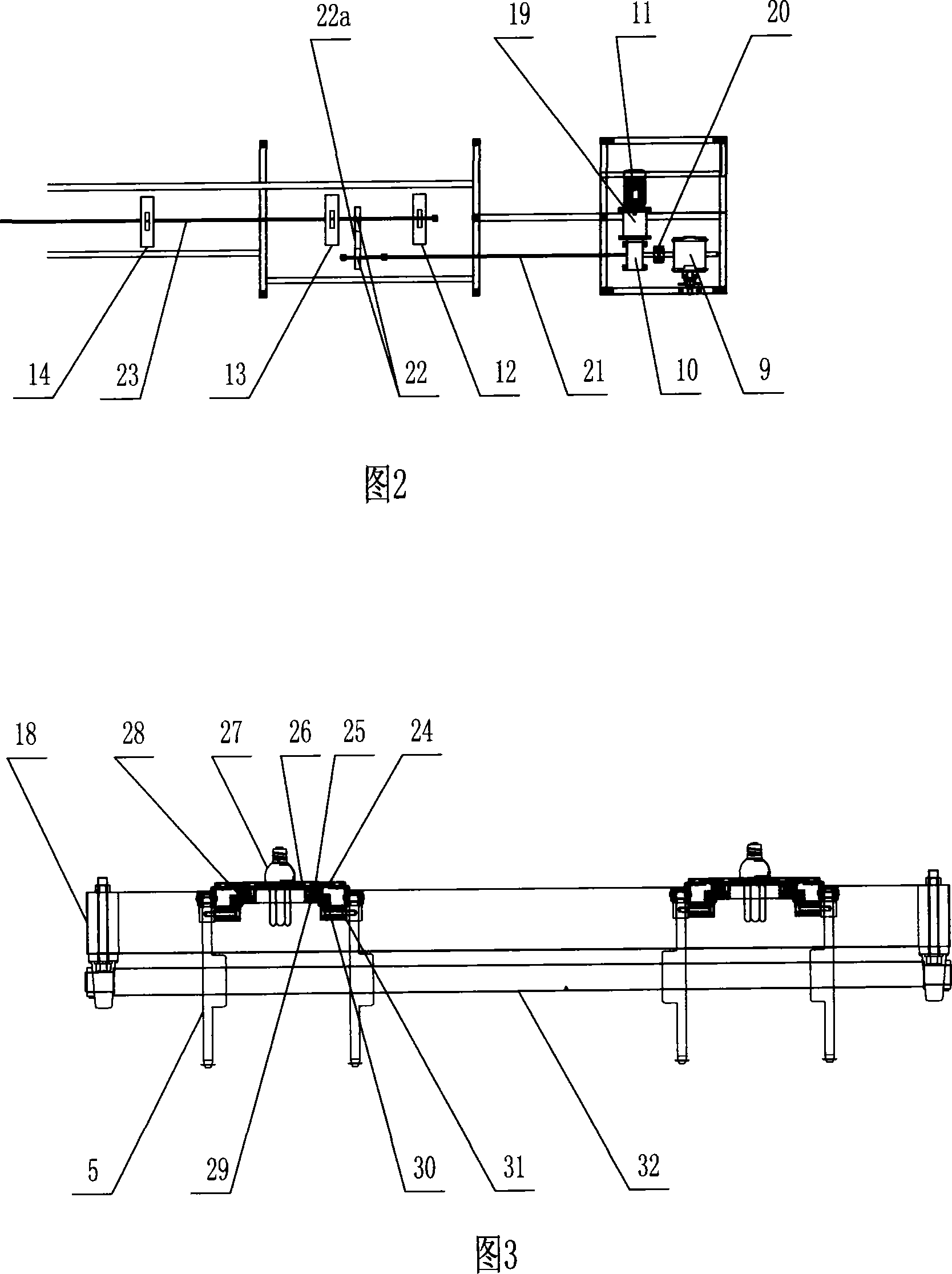

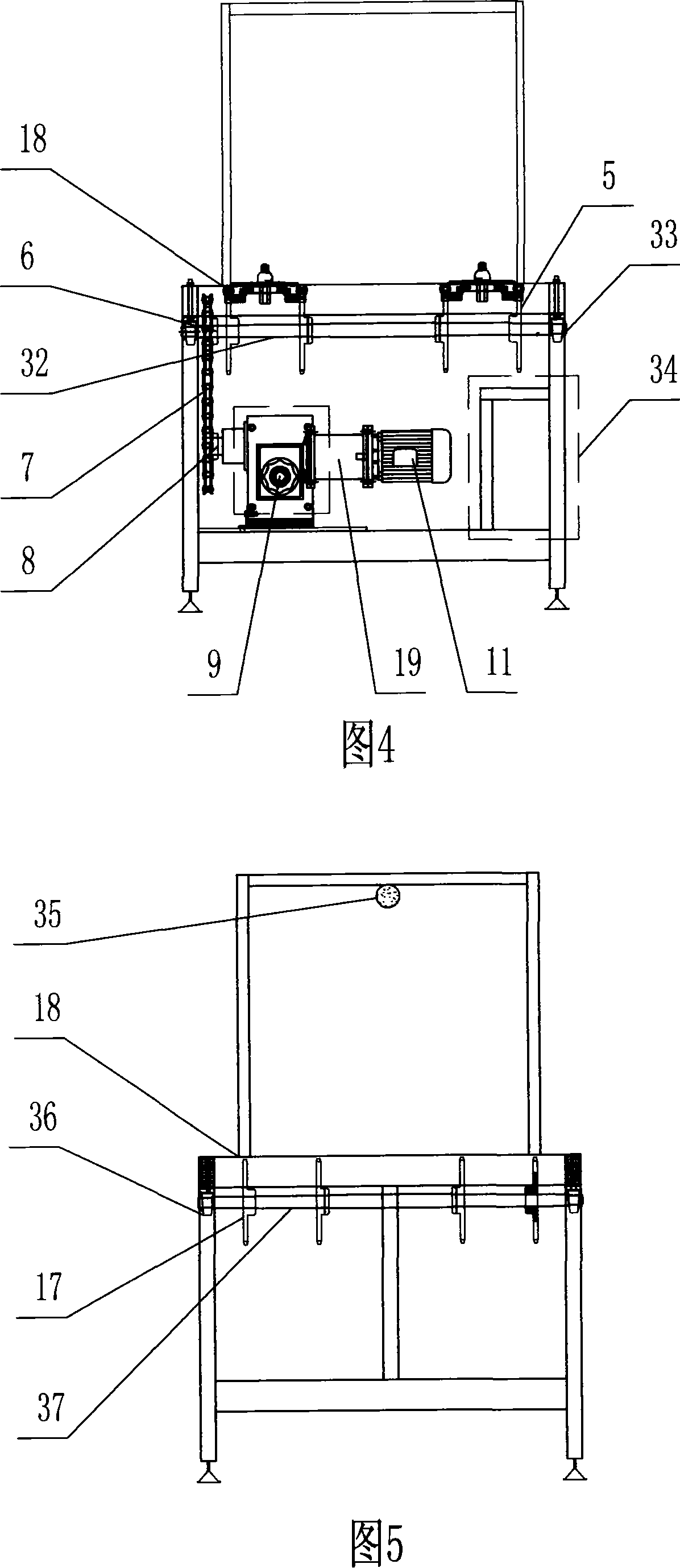

Sheet billet continuous casting and rolling production line

InactiveCN101658860AHigh speedReduce baking timeWork treatment devicesMetal rolling arrangementsProduction lineHearth

The invention relates to a sheet billet continuous casting and rolling production line and mainly solves the technical problems of high rigidity and low surface quality of produced sheet billets of the prior production line. The invention adopts a technical scheme that: the sheet billet continuous casting and rolling production line is sequentially provided with the following production line equipment: a continuous casting machine, swinging shears, a roller-hearth tunnel furnace, a descaling unit, a vertical roll, a rough mill, a coil box, a ultrafast water-cooling device, flying shears, a finishing mill, a laminar flow-cooling and ultrafast water-cooling device and a coiling machine, wherein a secondary descaling unit can be arranged between the flying shears and the finishing mill; and the continuous casting machine adopts two double flow roller-hearth tunnel heating furnaces, combines two flows of the two continuous casting machines into one flow through a transverse moving machineand is connected with a rolling line. The invention is mainly used for continuous casting and rolling of sheet billets.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Six-drop individual section bottle-making machine and pressing and blowing production technology thereof

ActiveCN101913754AReduce weightMaintain strengthPress and blow machinesGlass productionMoulding devicePiston

The invention discloses a six-drop individual section bottle-making machine and pressing and blowing production technology thereof, belongs to the field of bottle-making machines, in particular to a multi-drop bottle-making machine and bottle-making technology thereof. The bottle-making machine comprises a frame, a parison mold molding mechanism, a molding mold molding mechanism and a bottle poking mechanism, and is characterized in that: a molding device of the parison mold molding mechanism is an integral multi-cavity stamping device which comprises a driving cylinder, a combined cylinder, a punch, a piston push-pull plate and a piston, wherein the piston is connected with the piston push-pull plate; six punches are arranged at the upper end of the piston push-pull plate; mold switching devices of the parison mold molding mechanism and the molding mold molding mechanism adopt a parallel switching mode in a horizontal plane; the bottle poking mechanism is driven by two stepping motors; and the two stepping motors drive a rotating disc and bottle poking arms of the bottle poking mechanism through a synchronous belt. The technology comprises six steps of separating materials, producing parison, turning, molding, clamping bottles and poking the bottles. The bottle-making machine has the advantages of high bottle-making yield, good molding quality and capacity of manufacturing high-grade glass bottles in multiple specifications.

Owner:SHANDONG JIAFENG GLASS MACHINERY

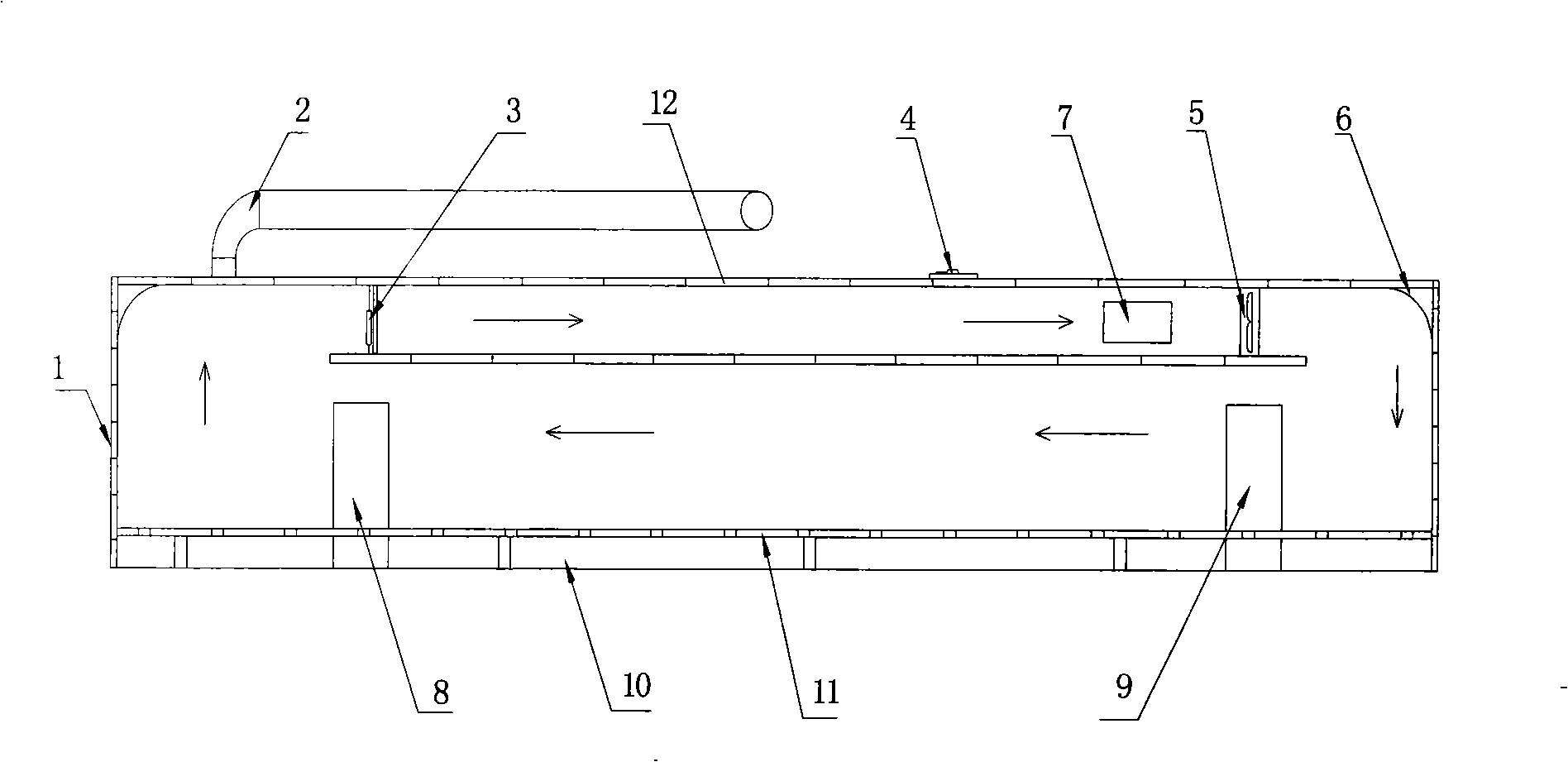

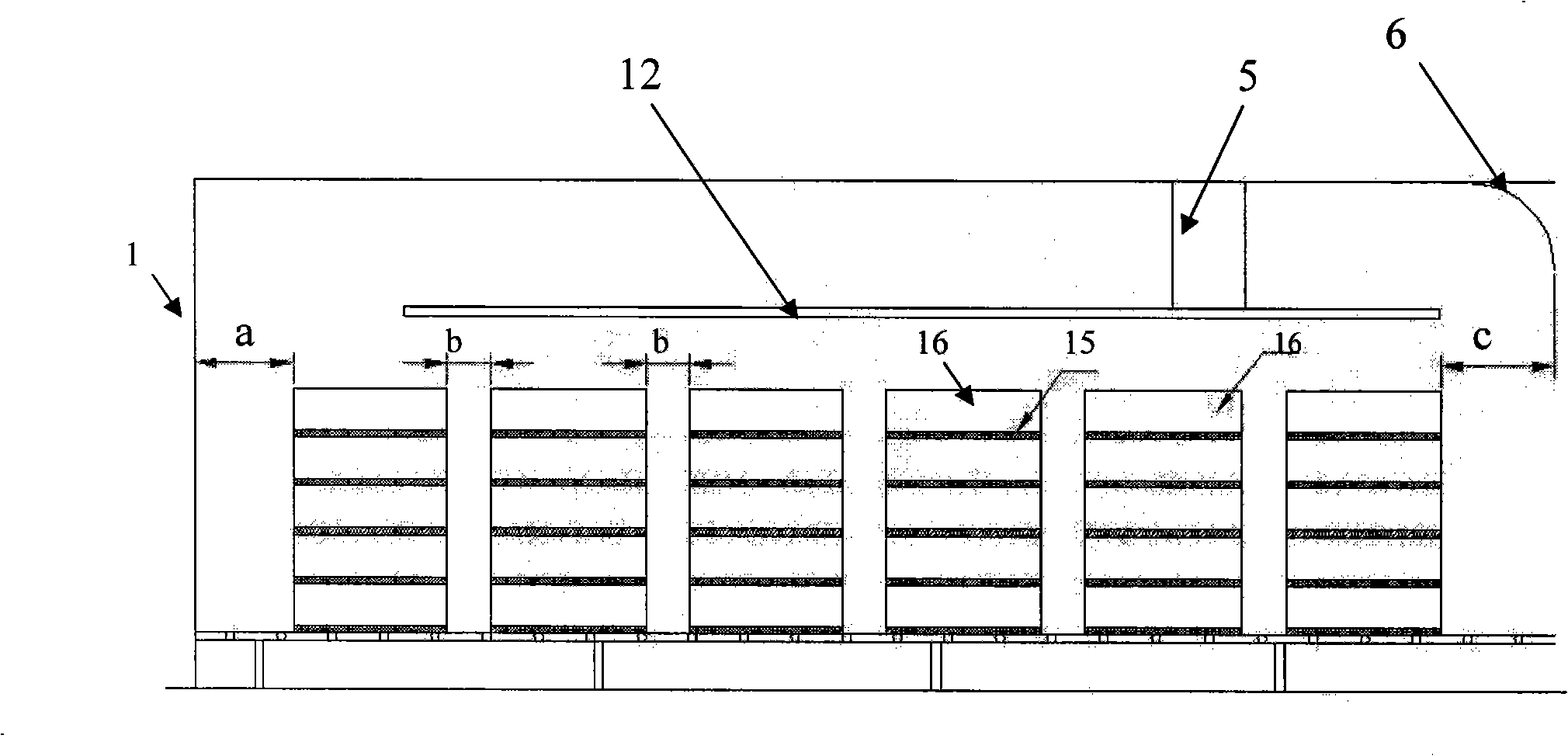

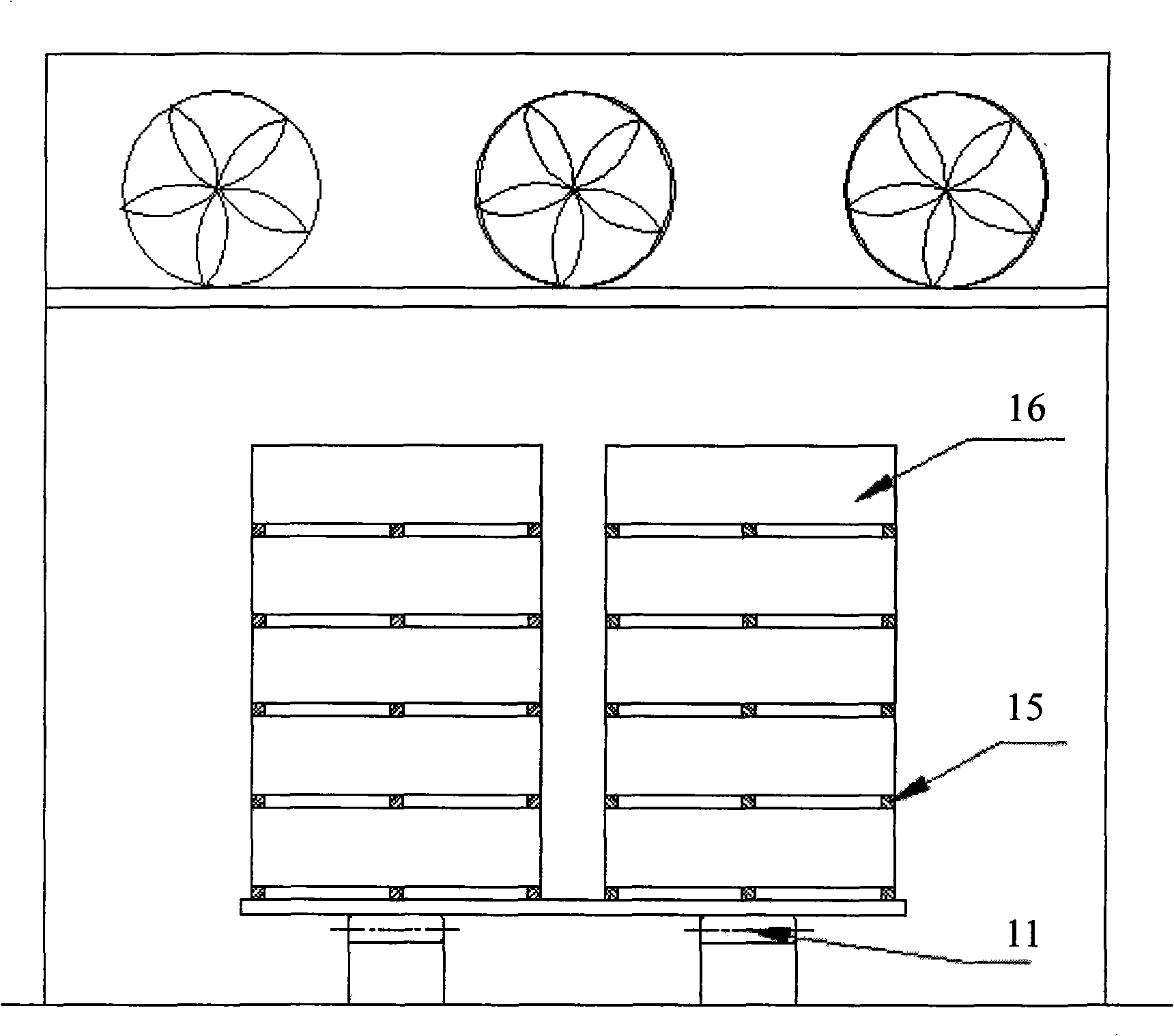

Board balance health-preserving chamber and board health-preserving method

InactiveCN101491907AImprove yieldImprove quality stabilityOther plywood/veneer working apparatusWood dampingWater contentProduct gas

The invention relates to a board balance reconditioning chamber and a method for reconditioning boards. The inside of the board balance reconditioning chamber is provided with a dehumidifier, a humidifier and temperature control equipment, and the middle part of the board balance reconditioning chamber is provided with an air flow guide device. The method for reconditioning boards comprises the following steps: 1) piling boards in the board balance reconditioning chamber; 2) adjusting the temperature and humidity of the board balance reconditioning chamber and determining the board processing time according to the preset water content range of the boards to balance the water content of all parts of the boards and to release the inner stress of the boards in a constant temperature and humidity environment; and 3) determining the water content of the boards and completing the reconditioning treatment when the water content of the boards reaches a preset value. The invention provides the constant temperature and humidity environment with flowing air to balance the water content of all parts of the boards, to release the inner stress of the wood fibers and to reduce the drawbacks of wood floors such as deformation and bending, thereby improving the percentage of cut-turn and the stability of the quality of the wood floors.

Owner:GUANGDONG YINGRAN WOOD IND

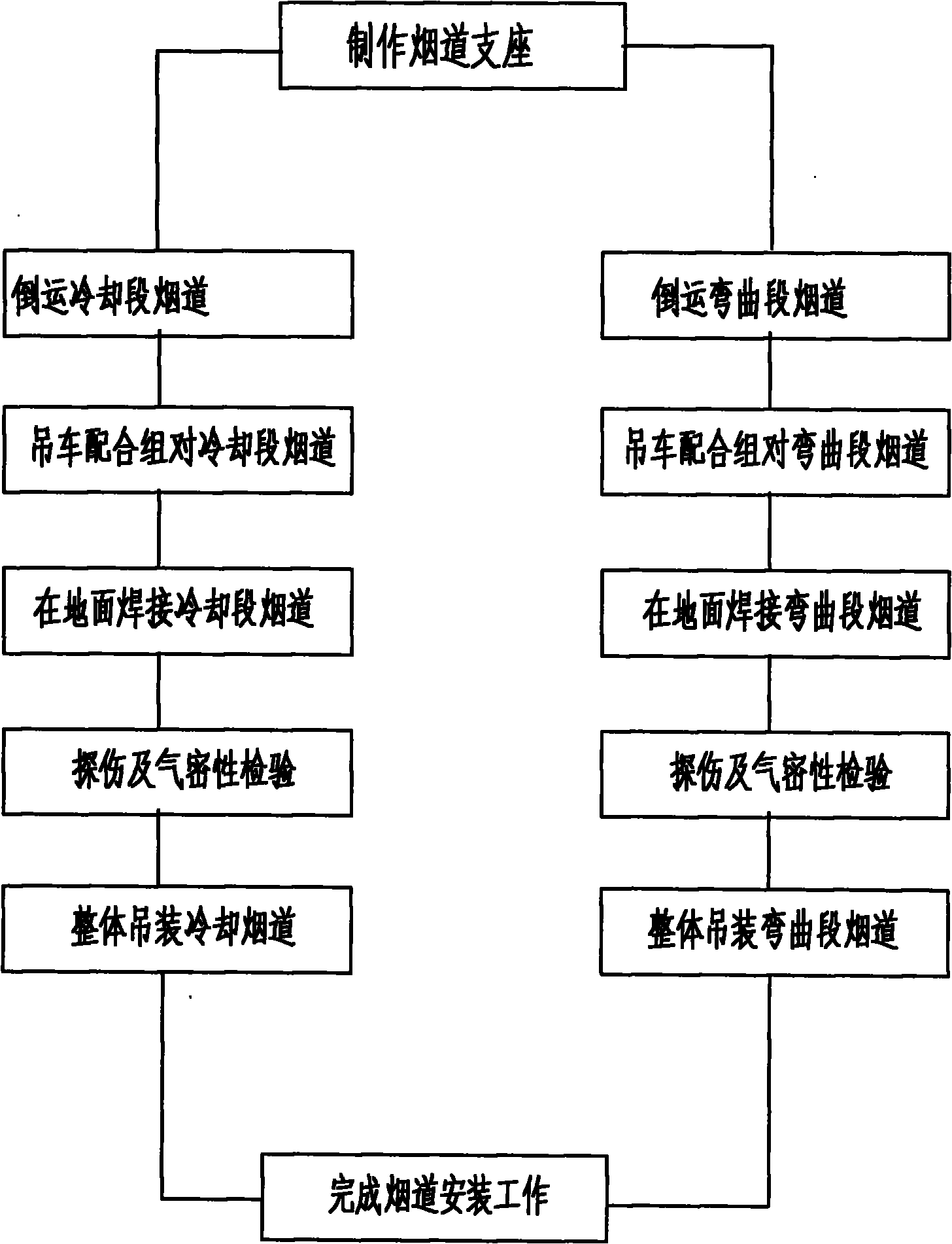

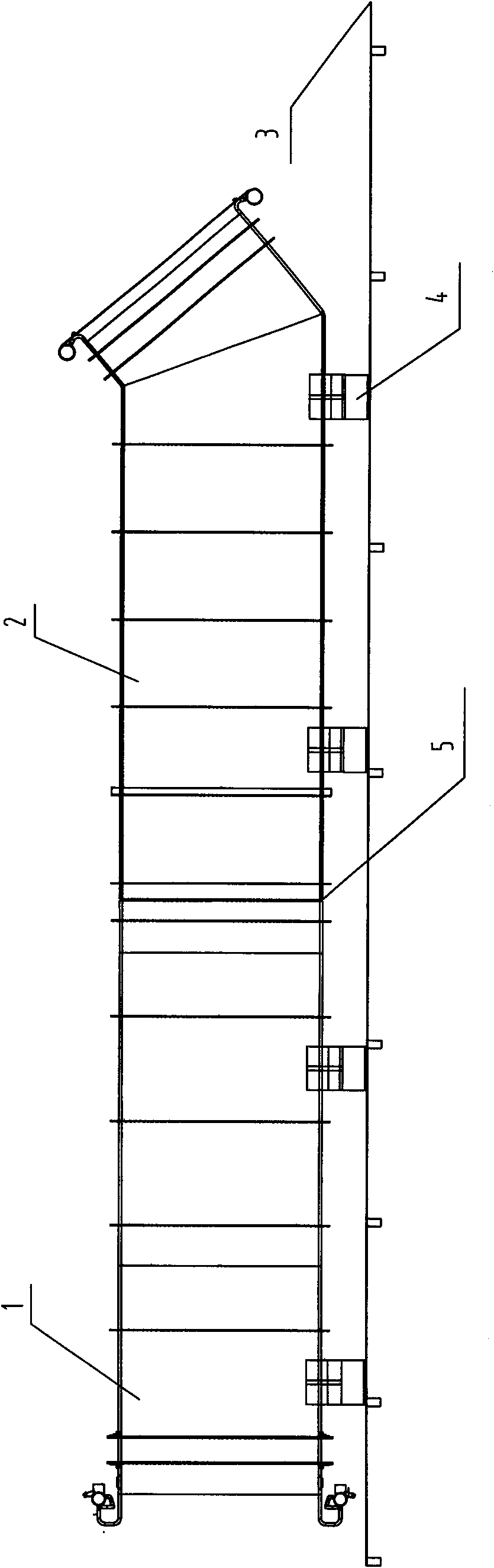

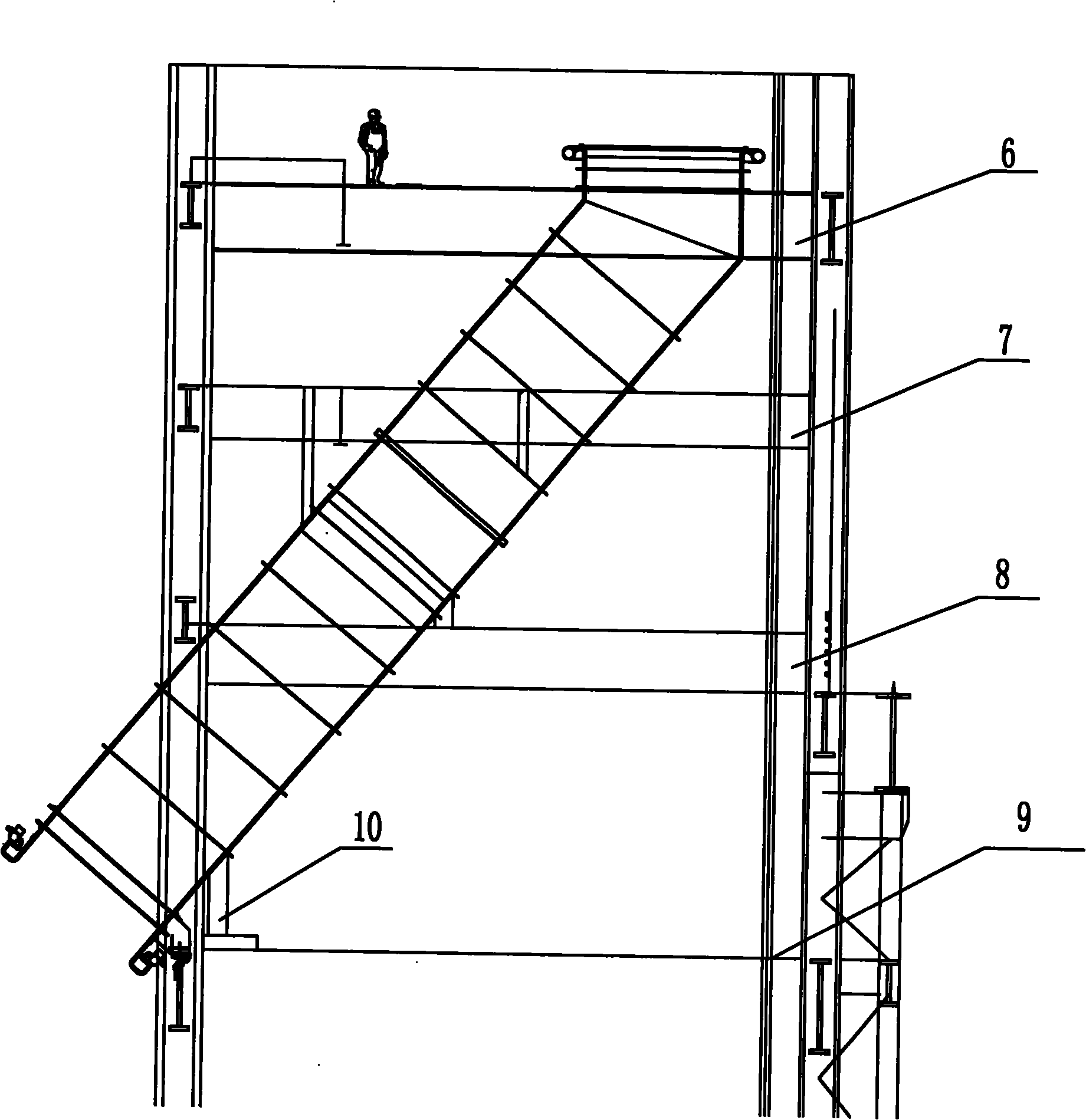

Ground assembling and welding integral installation and construction technology for vaporization-cooling chimney

ActiveCN101804501AImprove construction qualityExtended service lifeArc welding apparatusManufacturing convertersArchitectural engineeringVaporization

The invention relates to installation project construction of a vaporization-cooling chimney of a large converter, in particular to ground assembling and welding integral installation and construction technology for the vaporization-cooling chimney. The technology comprises the following steps: laying a steel platform and making a chimney support by using steel plates; transporting a cooling chimney to an installation site by using a large-tonnage flat truck; assembling the cooling chimney by using a large-tonnage crane; performing all-position ground welding on the vaporization-cooling chimney by adopting argon tungsten arc welding; performing 25 percent of radiographic detection and a corresponding airtight test on the welded chimney according to construction specifications; hoisting the chimney integrally; and fixing chimney system equipment according to the following sequence: curved chimney, cooling chimney and movable chimney so as to complete the installation of the chimney. The technology ensures the welding quality of the vaporization-cooling chimney, reduces the workload of overhead construction, reduces potential safety hazard during the construction, greatly improves the working efficiency of the installation of the vaporization-cooling chimney, reduces the duration of the construction, and increases the service life of the vaporization-cooling chimney.

Owner:CHINA 22MCC GROUP CORP

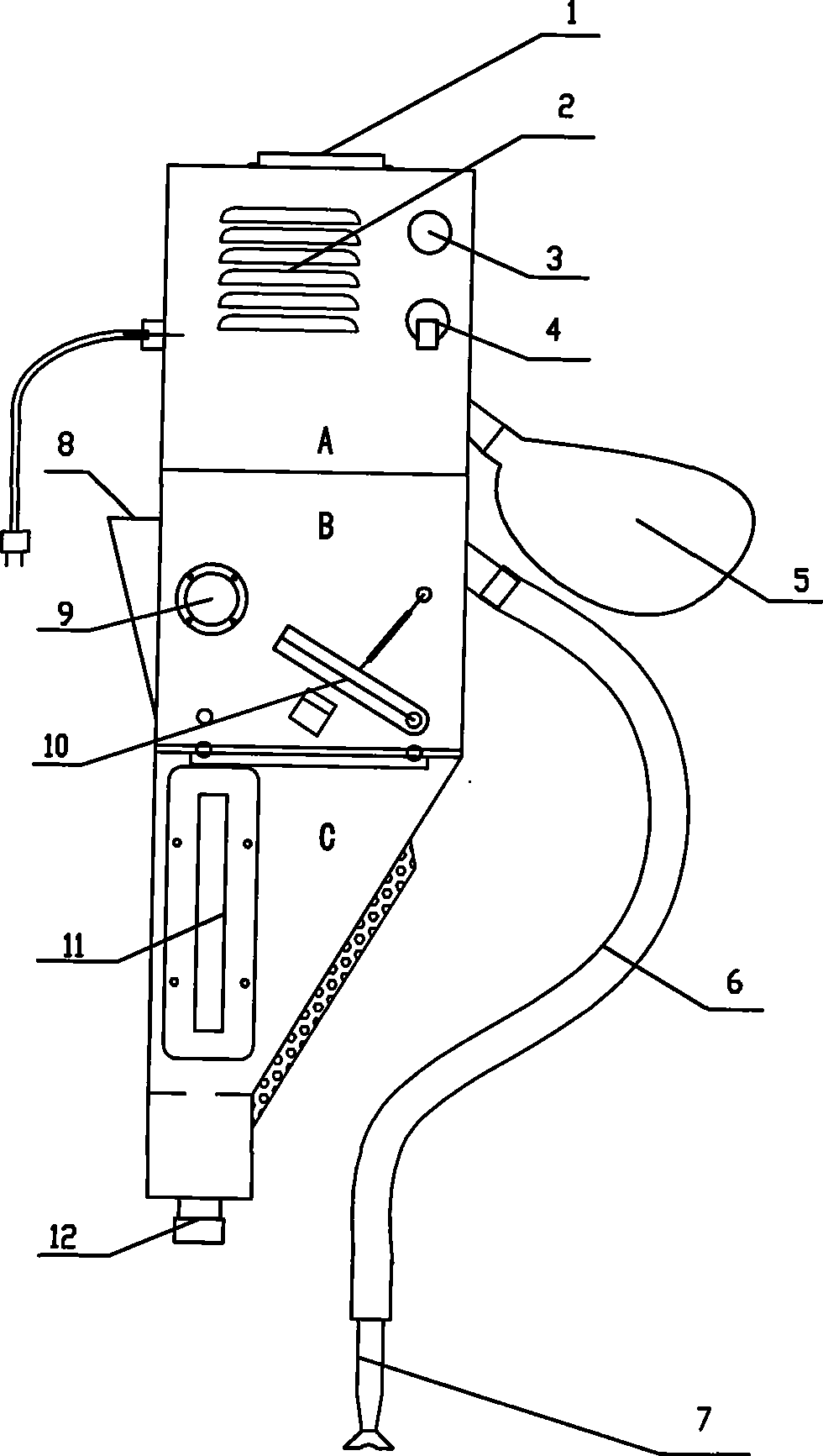

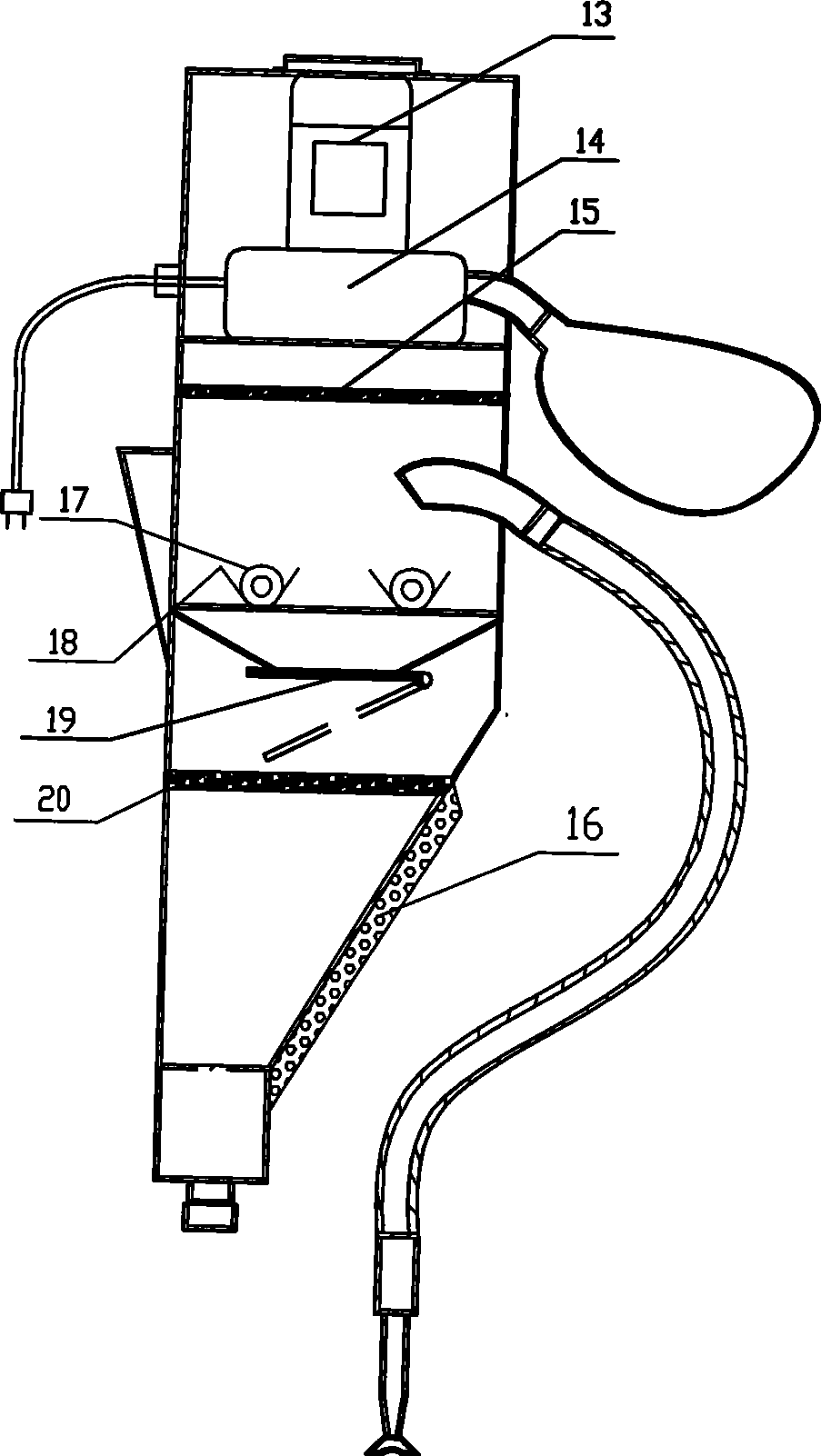

Submerged arc flux recovery device

ActiveCN101386104AKeep dryAvoid quality defectsMagnetic separationWelding accessoriesEngineeringStorage material

The invention provides a submerged arc-welding flux recovering device, comprising a wind suction hopper which provides negative pressure for the flux recovery and a storage material hopper which is used for storing flux; the wind suction hopper is internally provided with a wind sucker; the submerged arc-welding flux recovering device is characterized in that a magnetic-selection separation material hopper is arranged between the wind suction hopper and the storage material hopper; the magnetic-selection separation material hopper is respectively communicated with the storage material hopper and the wind suction mouth of the wind suction hopper; the wind suction hopper, the magnetic-selection separation material hopper and the storage material hopper are integrated into a whole; the magnetic-selection separation material hopper is connected with a flux recovery pipeline; the storage material hopper is provided with a heating device; the flux recovered by the submerged arc-welding flux recovering device contains no iron chippings or vapor; when the recovered flux is re-used for welding, the gained surface of the submerged arc-welding seam is smooth and level and generates no air bubbles, and quality defects existing when the submerged arc-welding flux recovering device is carried out by the recovered flux in the prior art can be effectively solved; the wind suction hopper, the magnetic-selection separation material hopper and the storage material hopper are integrated into a whole, thus occupying few areas, thereby reducing the manufacture cost and being small and practical.

Owner:中焊自动化科技(无锡)有限公司

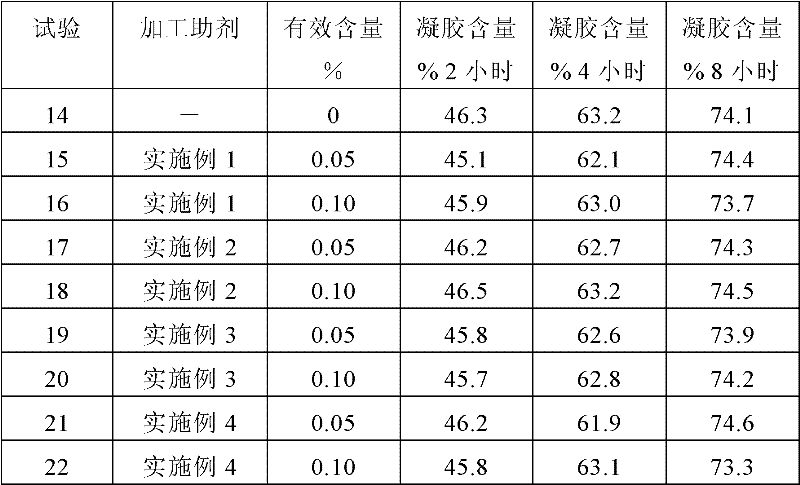

Fluoropolymer processing aid, silane-crosslinked polyethylene composition containing same and application thereof

ActiveCN102286157AInhibition of pre-crosslinkingIncrease extrusion speedCoatingsSurface finishProcedure Agents

The invention provides a fluoropolymer processing aid. The fluoropolymer processing aid is particles which are formed by a core part and a shell part and have average particle diameter of 0.2 to 1 micron, wherein the core part is made of fluorocarbon polymer, the shell part is made of MQ silicon resin, the ratio of M to Q is 0.5 to 0.9, and the weight ratio of the core part to the shell part is 20:80-45:55. The invention also provides a silane cross-linked polyethylene composition containing the processing aid and application of the fluoropolymer processing aid in silane cross-linked polyethylene extrusion molding. Not only the silane cross-linked polyethylene added with the fluoropolymer processing aid has high extrusion velocity, but also the extruded product has high surface finishment.

Owner:上海鲁聚聚合物技术有限公司

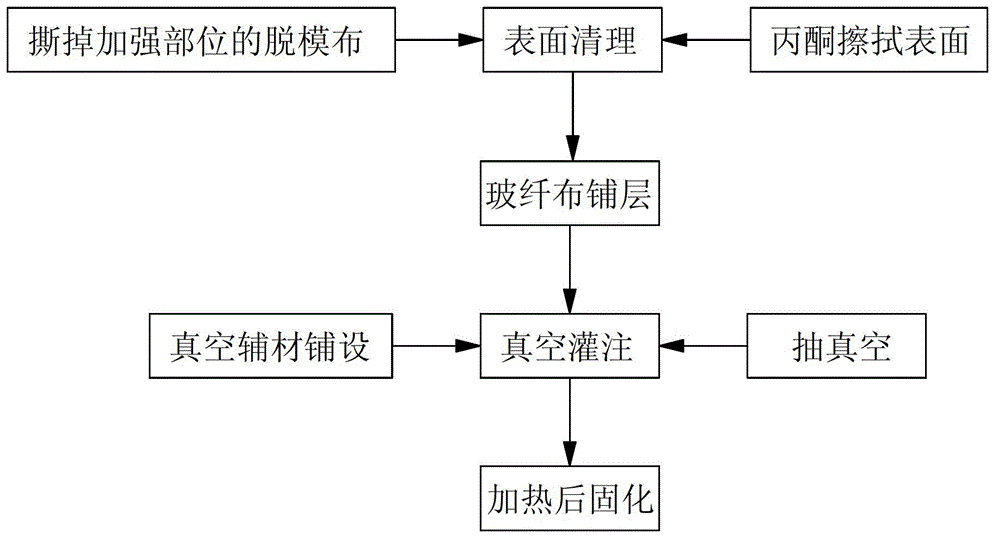

Outside reinforcing, vacuum filling and heat curing molding process on front edge and back edge of blade

The invention discloses an outside reinforcing, vacuum filling and heat curing molding process on the front edge and back edge of a blade. The process comprises the following steps of: firstly laying glass fiber cloth at reinforcing parts on the front edge and back edge of the blade, and then performing vacuum filling and heating curing molding. By performing vacuum filling for outside reinforcement of the front edge and back edge of the blade, the quality defects of reinforcement layering, bubbles, adhesive fillets and the like on the front edge and back edge of the blade can be greatly reduced, and the reliability of the blade is improved; and simultaneously, the curing of resin can be accelerated by curing after heating, and the production efficiency is improved.

Owner:CHONGQING GENERAL IND (GRP) LTD

Full-automatic assembly production chain of energy-saving lamp

InactiveCN101083190ANovel ideaReasonable process structure designSequential operation station machinesCold cathode manufactureProduction chainEngineering

The invention relates to the energy-saving lamp full automatic-assembly assembly line. It belongs to the energy-saving lamp manufacture equipment technology area. Its characteristic lies in that the rack intermediate deck coordinate installs the work piece conveying appliance by the transmission chain drive, the one output end of the decelerator which installs on the sublayer of the rack and connects the motor driver connects the dynamic major axis which coordinates the cam major axis driver, another output through the cam dismember coordinates to the work piece conveying appliance, above the work piece conveying appliance fit establishes automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment, compression moulding cam, soldering lamp base cam, dial nail cam which installs on the cam major axis separately connects the automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment. The line flow has rational design, the automation pattern substitutes manual work, reduces the suggestion factor of the quality flaw, enormously raises the production efficiency and the product quality, creates the scale effect, take a foundation for promoting the enterprise brand image.

Owner:王佩诚

Method for processing persimmon cake

InactiveCN101558841AOptimize the drying processOvercome quality defectsFood preservationFood preparationWater contentNutrient content

The invention discloses a method for processing persimmon cake, which leads hot-air drying and microwave drying and sterilizing to be combined and applied to the processing production of the persimmon cake, wherein the hot-air drying is performed by the following step: a plastic plate loaded with mashed fruit is placed in a hot-air dryer and is kept for 5-8h at a heating temperature of 65-75 DEG C so as to lead the water content of the material to be lowered at 30-35 percent; the microwave drying and sterilizing is performed by the following step: the plastic plate loaded with the mashed fruit is placed in a microwave drying sterilization machine and is kept for 5-8min at a heating temperature of 60-65 DEG C so as to lead the water content of the material to be lowered at 20-25 percent and play a role of sterilization. The technical scheme overcomes the shortcomings of the prior method for drying the persimmon cake and the quality defect of the product, effectively lightens the damage of the drying process to nutrient content in the persimmon cake, optimizes the processing procedure, greatly shortens the processing time, is beneficial to lower the energy consumption and the production cost, and improves the efficiency.

Owner:广州市从化龙丰园果子食品厂

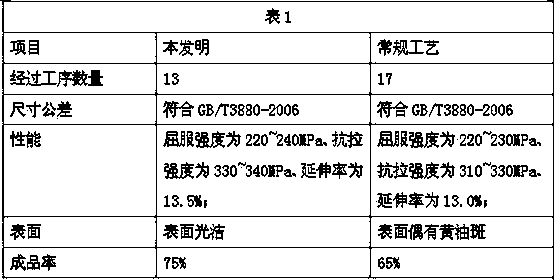

Production method of aluminum alloy plate for coal gondola car

The invention discloses a production method of an aluminum alloy plate for a coal gondola car. The production method comprises the steps of: (1) burdening: the aluminum alloy plate comprises the following components in percentage by weight: not more than 0.2% of Si, not more than 0.3% of Fe, not more than 0.1% of Cu, not more than 0.8% and not less than 0.6% of Mn, not more than 4.8% and not less than 4.5% of Mg, not more than 0.2% and not less than 0.15% of Cr, not more than 0.1% and not less than 0.05% of Zn, not more than 0.15% and not less than 0.1% of Ti, not more than 0.15% and not less than 0.1% of Sc, not more than 0.15% and not less than 0.1% of Zr, and the balance of Al; (2) smelting; (3) refining; (4) crystal grain refinement; (5) degassing; (6) filtering; (7) casting; (8) sawing; (9) surface milling; (10) uniform heating; (11) hot rolling; (12) straightening of a cut plate at a transverse sheared edge; and (13) checking. A trace of a rare earth element scandium and a transitional element zirconium are newly added, so that the alloy strength is improved; the thickness of a finished product is directly rolled through hot rolling; compared with a traditional production method, the production method, provided by the invention, reduces four procedures, and is high in production efficiency; and the thickness of the finished product is directly rolled through hot rolling, so that the quality defect of panel butter spots in a traditional method is prevented.

Owner:DALISHEN ALUMINUM

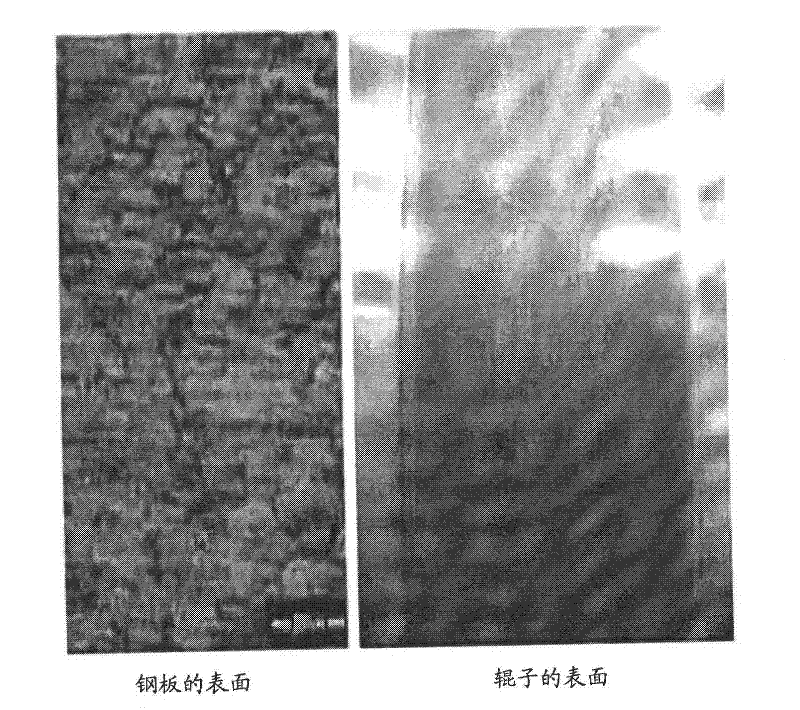

Method and system to control quality in cold rolling system

InactiveCN102179413AQuality improvementEasy transferMeasurement devicesMeasuring devicesSheet steelCurrent sensor

The invention discloses a method and a system to control quality in a cold rolling system capable of preventing frequent chatter masks and hot cracks in the continuous cold rolling process. Meanwhile, the distortion and cutting of steel plates due to the roughness difference between the upper and lower surfaces of steel plates is also prevented. More specifically, the invention discloses a system and a method for detecting the quality abnormality in a cold rolling system, wherein a vibration sensor, a torque sensor, a temperature sensor and a current sensor are arranged inside a rolling mill. The information measured by the above sensors are used for detecting signals which cause defects, which are also used for minimize the defect ratio of the steel plates being rolled.

Owner:POHANG IRON & STEEL CO LTD

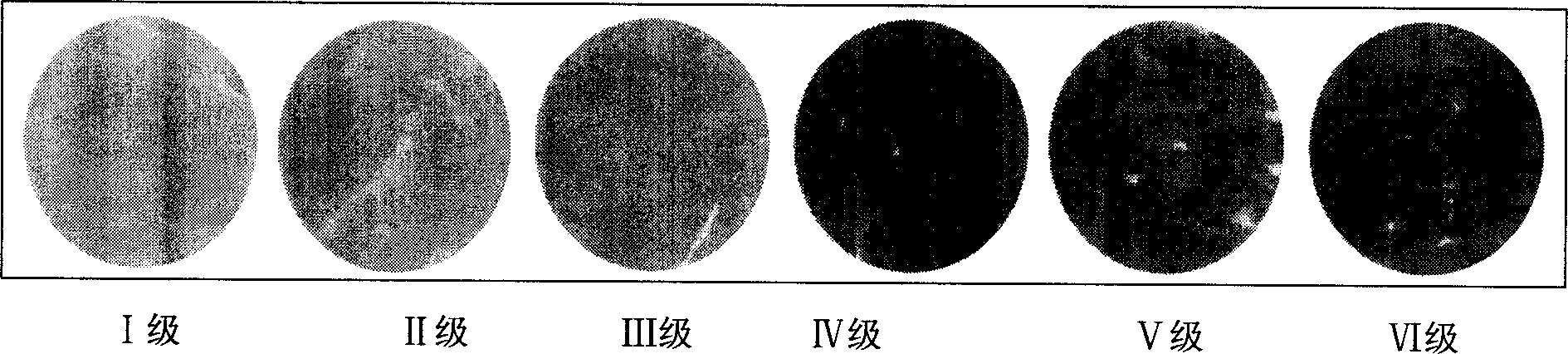

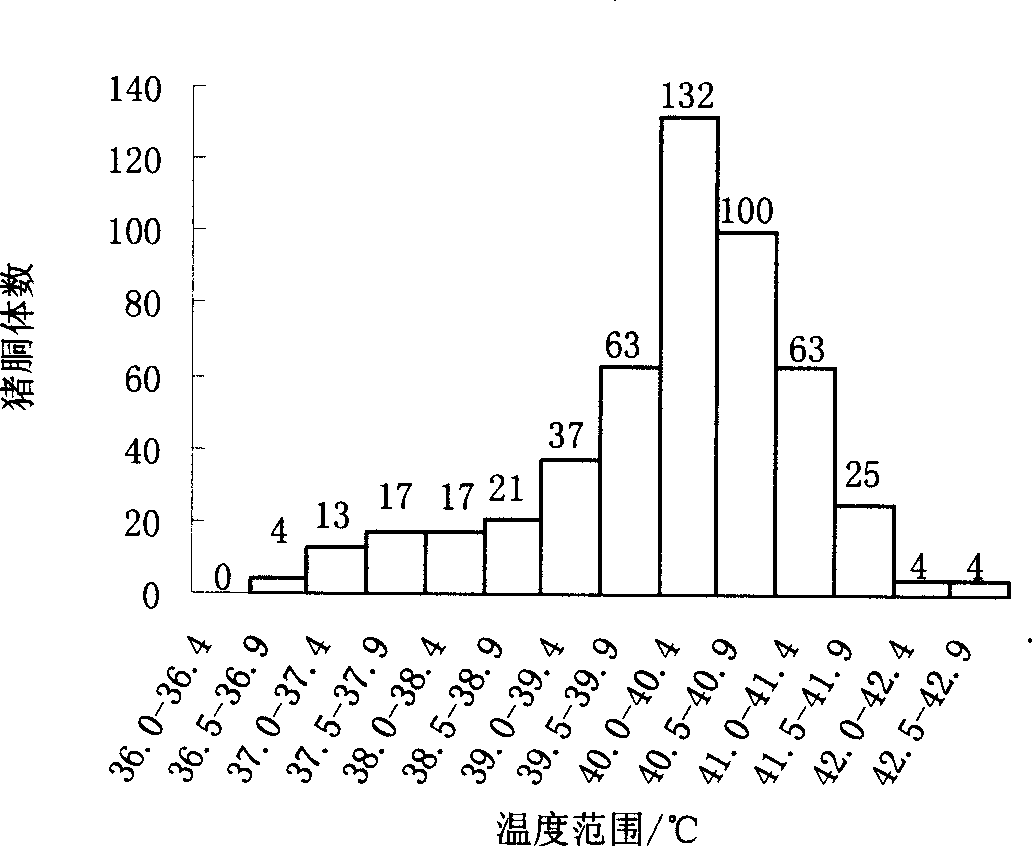

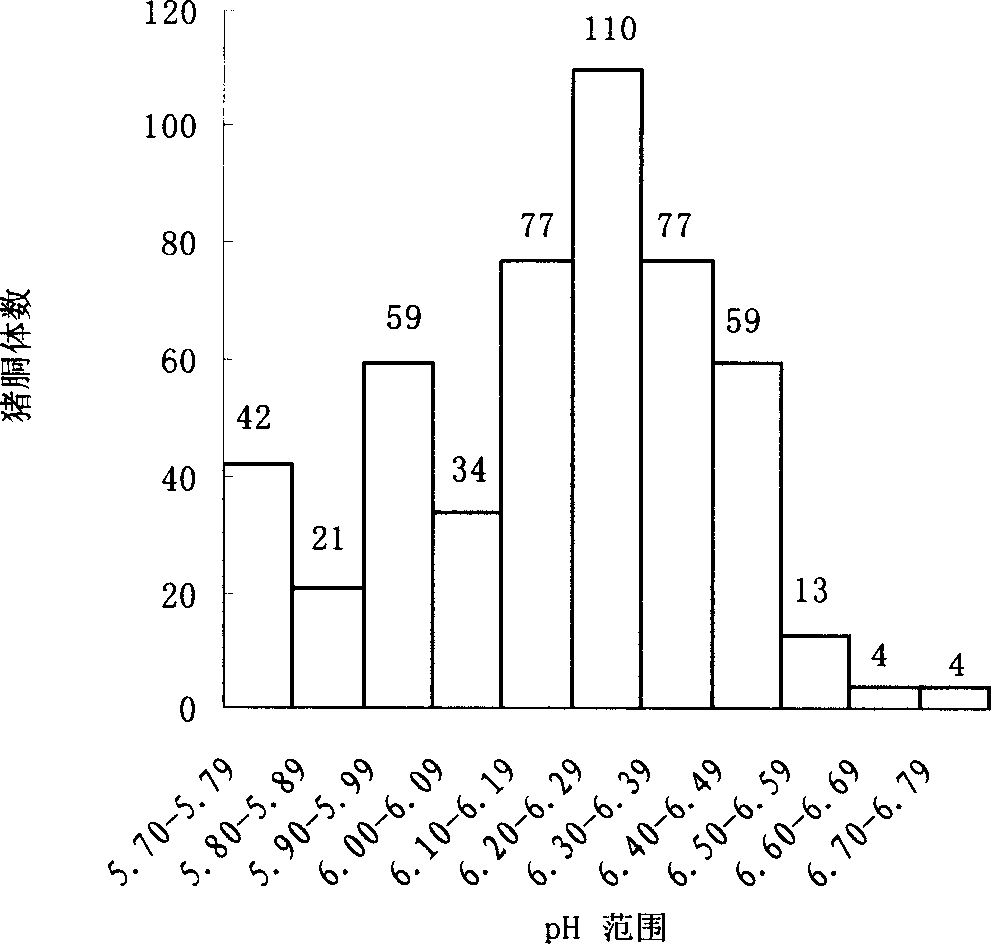

Method for grading pork based on its color and quality

A method based on the computer visualization technique for classifying the quality of pork by its color includes such steps as preparing the standard color map according to the color space recommended by CIE, taking the pork specimen, and comparing it with said standard color map to determine its quality.

Owner:NANJING AGRICULTURAL UNIVERSITY

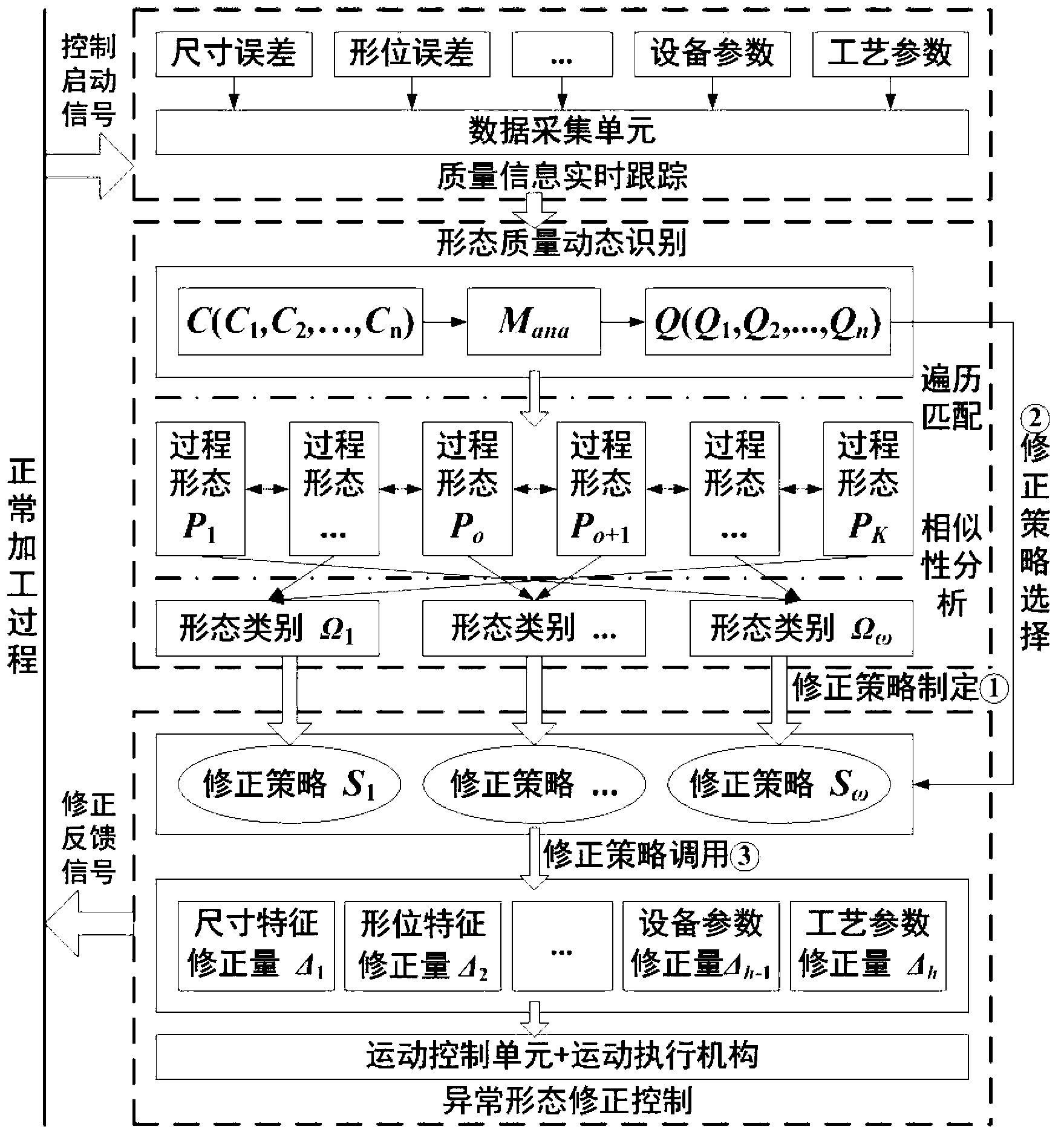

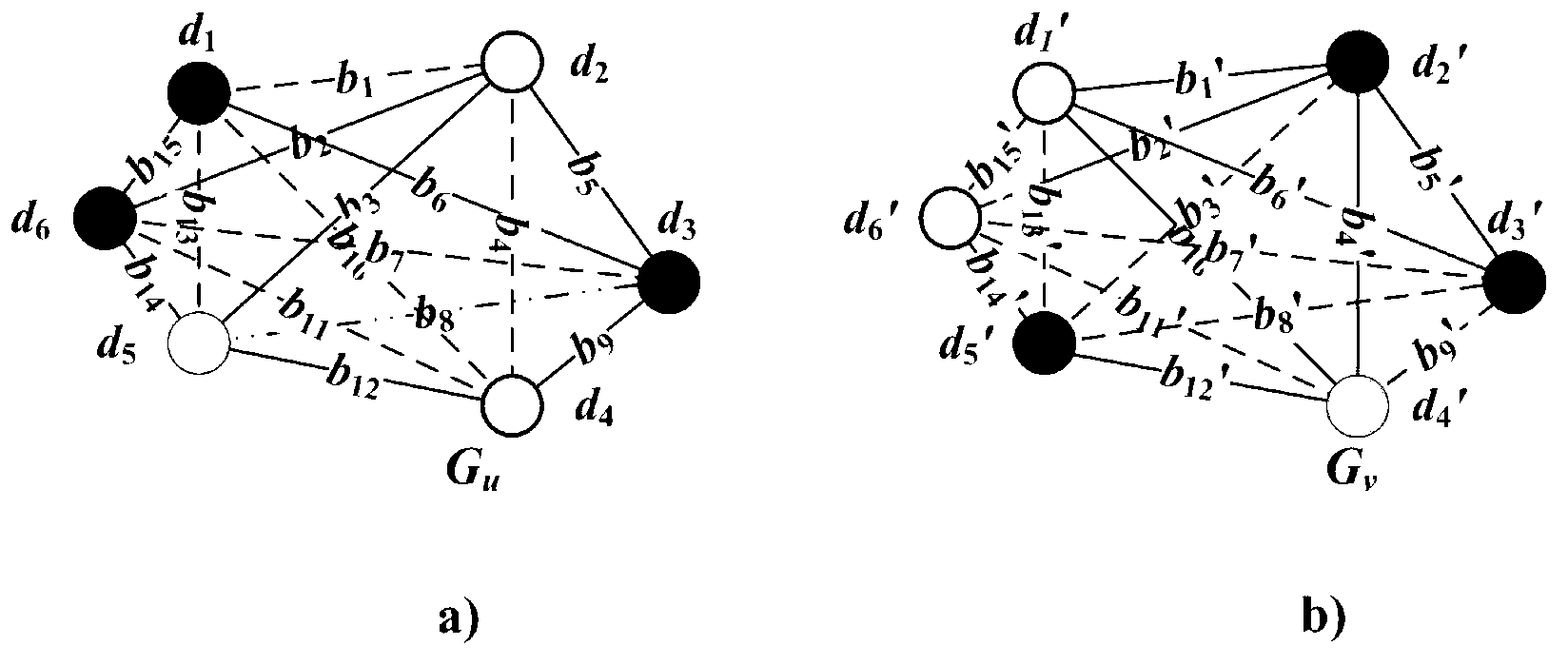

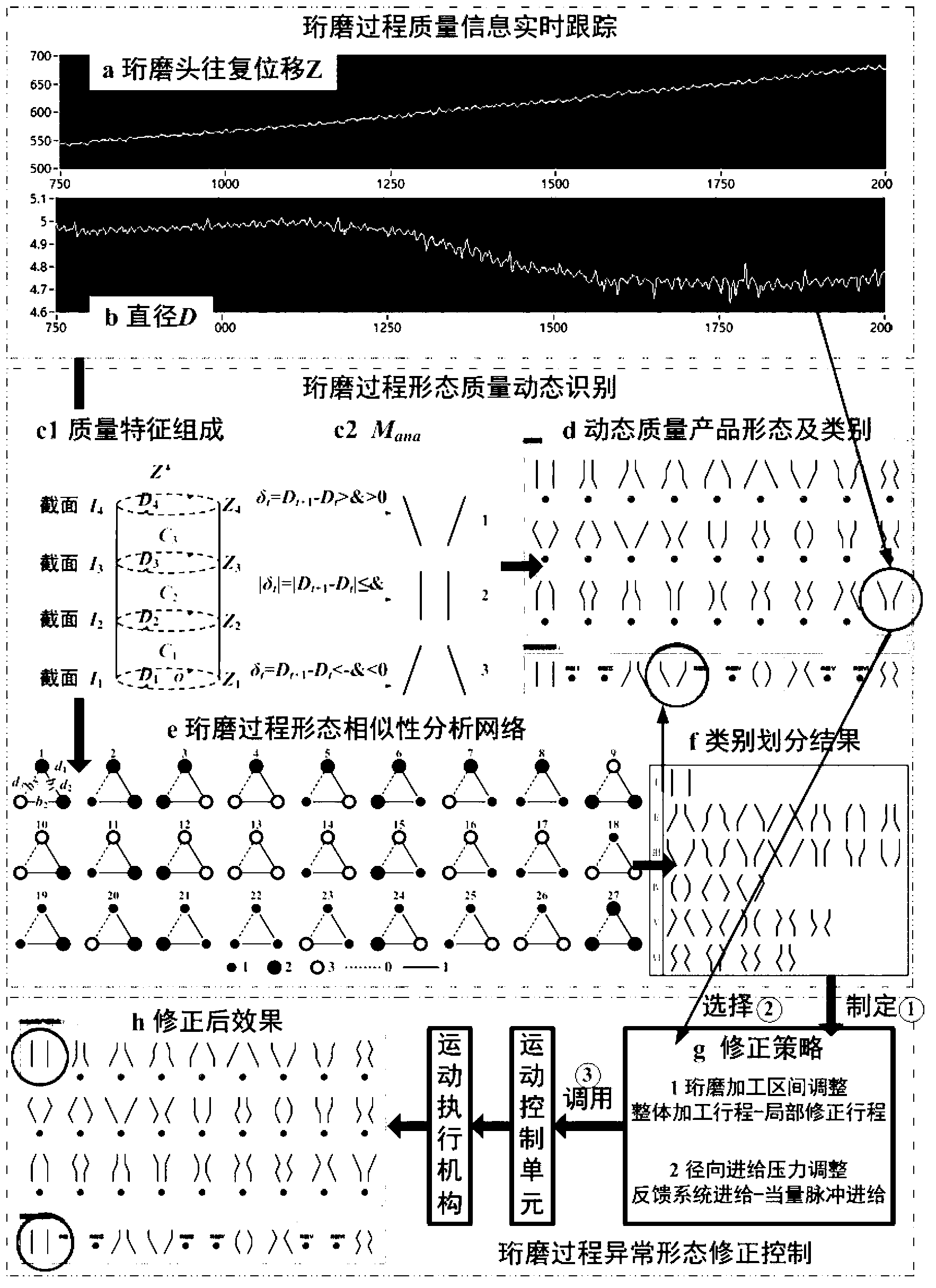

Form quality dynamic identification and modification control method in machining process

ActiveCN103257615AClear control processAvoid reprocessingProgramme controlComputer controlSimilarity analysisEconomic benefits

The invention discloses a form quality dynamical identification and modification control method in machining process. The form quality dynamical identification and modification control method in the machining process comprises the steps of (1) quality information real-time tracking, (2) form quality dynamic identification and (3) unusual form modification control, wherein the quality information real-time tracking is used for meeting the requirement that a large amount of bottom-layer data can reflect a present quality state of a workpiece form in the process of dynamic identification and modification, the form quality dynamic identification is used for carrying out data processing on acquired form quality information to acquire a dynamical quality product form, searching a form which is matched with the dynamical quality product form through an ergodic process form set and determining a belonging form type of the dynamical quality product form through similarity analysis, and the unusual form modification control is used for adopting a modification strategy ' deciding+choosing+calling' mechanism, dynamically carrying out modification control on a process exception form through a motion control unit and a motion executing mechanism. By the adoption of the form quality dynamical identification and modification control method in the machining process, the improvement of machining quality is benefited, the defects of quality is overcome in advance, quality cost is reduced, the improvement of production efficiency is benefited, off-line detection is avoided, sub-quality products can be machined again, and the economic benefit of an enterprise is improved.

Owner:XI AN JIAOTONG UNIV

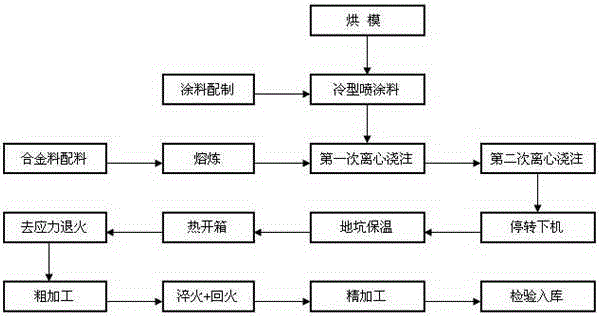

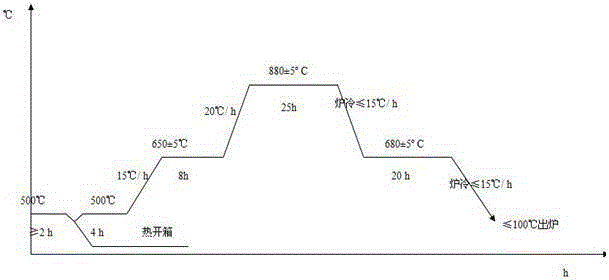

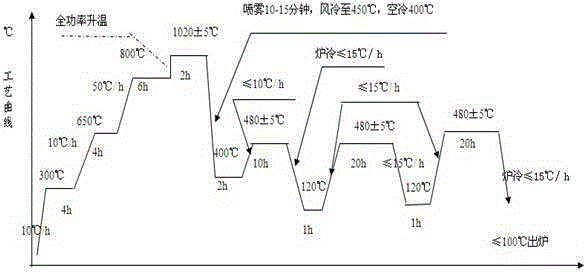

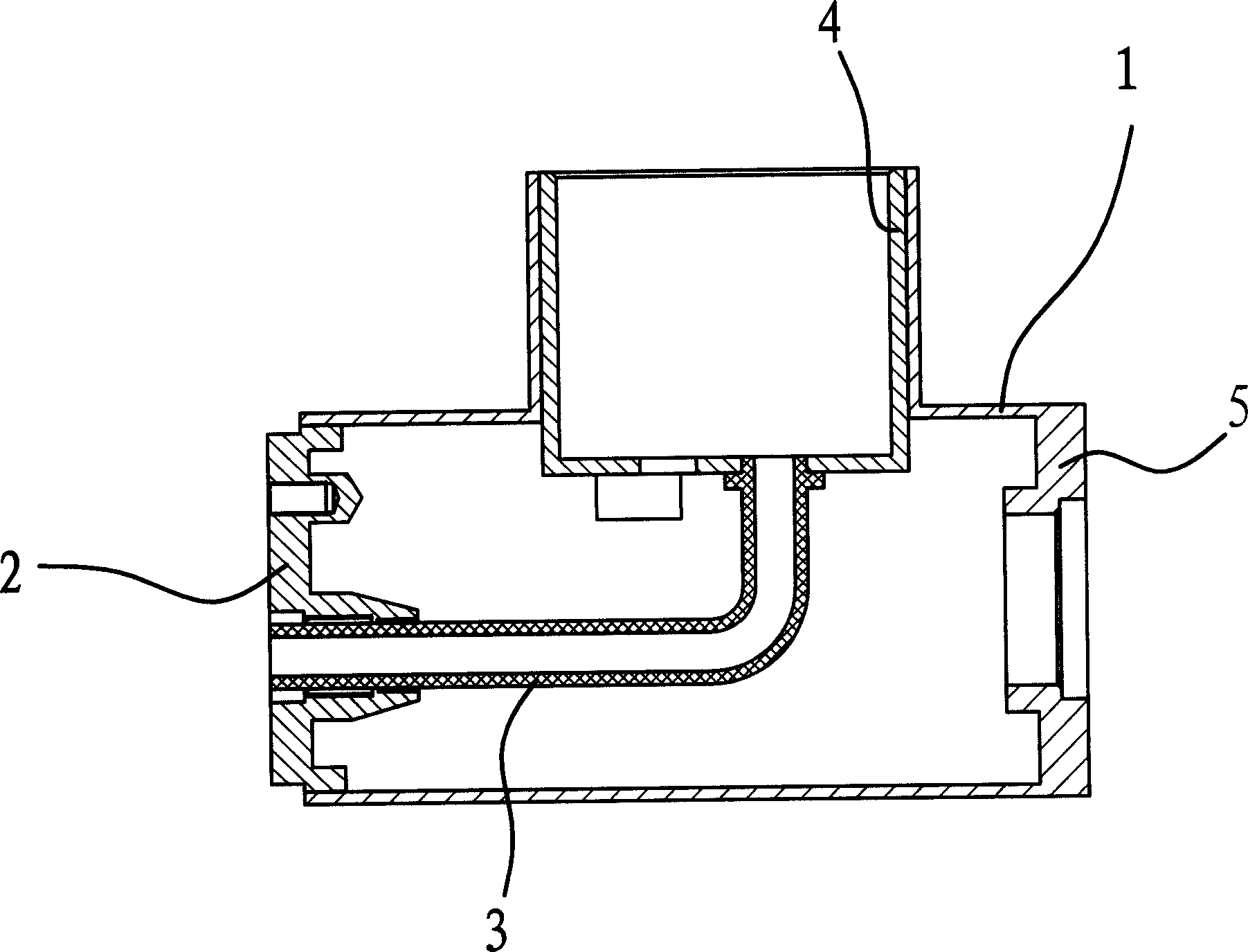

Centrifugal cast Cr12MoV shape steel straightening roll and production technology thereof

InactiveCN105177447ASolve the problem of axial crack failureAvoid quality defectsMolten steelMechanical engineering

The invention discloses a centrifugal cast Cr12MoV shape steel straightening roll and a production technology thereof. A centrifugal layer of a roll ring comprises a work layer and an inner layer and is cast through two times of centrifugal casting in an interval mode. The material of the work layer is Cr12MoV. The material of the inner layer is graphitic steel. The production technology comprises the steps that molten steel is subjected to the processing procedures of component design, stokehold molten steel treatment, spraying of cold type coating, smelting, centrifugal pouring, pit heat preservation, hot box opening and heat treatment, and the Cr12MoV shape steel straightening roll is obtained. According to the centrifugal cast Cr12MoV shape steel straightening roll and the production technology thereof, the problems that the roll face of a forged straightening roll axially cracks and loses efficacy in the using process are solved. The centrifugal cast Cr12MoV shape steel straightening roll has the characteristics of being high in abrasion resistance and long in service life, and the manufacture cost of the straightening roll is reduced.

Owner:TANGSHAN IRON & STEEL GROUP

Manufacturing method of tap valve body

The invention provides a method for manufacturing hydro-valve body, comprising the steps of: a. part machining; b. welding; and c. fine machining. And it moulds case, water inlet base, inner water pipe, valve core seat, and water outlet base and weld them together. And it compromises the advantages of hot forging and casting processes, saving large number of materials, reducing manufacturing cost and easy to control.

Owner:李仁波 +1

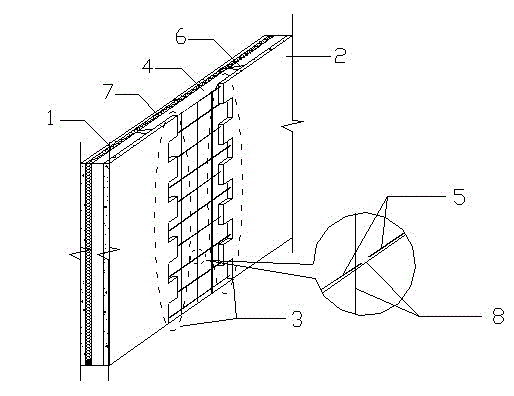

Precast wall casing structure of reinforced concrete superposed shear wall and splicing method thereof

InactiveCN102747796AImprove integrityImprove carrying capacityWallsHeat proofingReinforced concreteThermal insulation

The invention discloses a precast wall casing structure of a reinforced concrete superposed shear wall and a splicing method thereof. The precast wall casing structure of the reinforced concrete superposed shear wall comprises a reinforced concrete precast wall casing, a bump gap of the precast wall casing, a wall hollow cavity, rebars of the bump gap of the precast wall casing, a rebar bracket, an additional constructional rebar and a thermal insulation layer. The invention further discloses a splicing constriction method of the precast wall casings. With the precast wall casing structure of the reinforced concrete superposed shear wall and the splicing method of the precast wall casing structure provided by the invention, the horizontal joint junction of the reinforced concrete superposed shear wall is remarkably improved and therefore the integrity, the bearing capacity and the earthquake resistant behaviour of the junction joint of the reinforced concrete superposed shear wall are enhanced. The invention realizes that the reinforced concrete superposed shear wall is equal to a common entire cast-in-site shear wall, and can produce higher social and economic benefits.

Owner:NANJING UNIV OF TECH +1

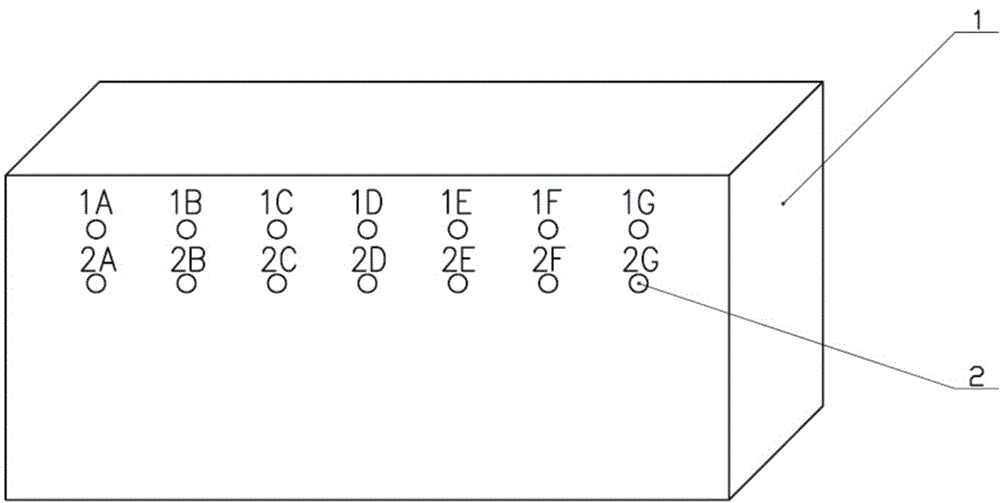

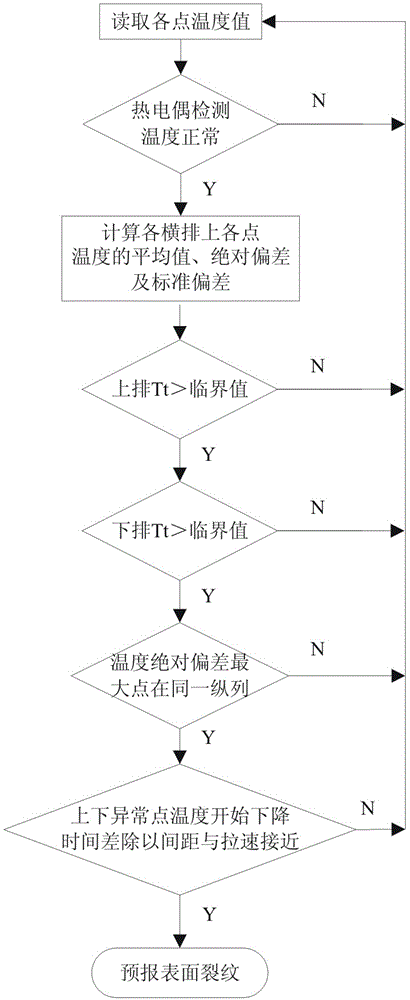

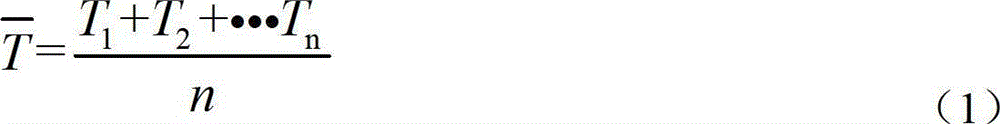

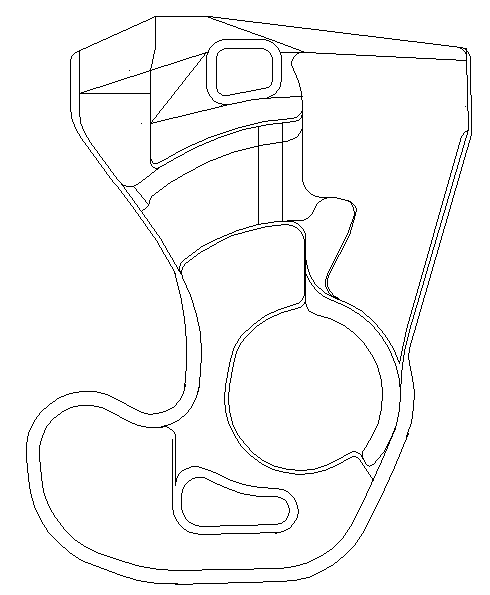

Control method for online predication of surface crack of continuous casting sheet billet

The invention relates to a control method for online predication of a surface crack of a continuous casting sheet billet. The online predication of the surface crack is carried out by building a temperature detection system on thermocouples on the wall surface of a crystallizer and comparatively analyzing the temperature change conditions in different positions in the heat transfer direction, so that the predication accuracy is high, the surface crack of the continuous casting sheet billet and the specific location of the surface crack are accurately predicted, and the control method is used for guiding on-site production to reduce the quality defects and improve the quality of the continuous casting sheet billet.

Owner:WISDRI ENG & RES INC LTD

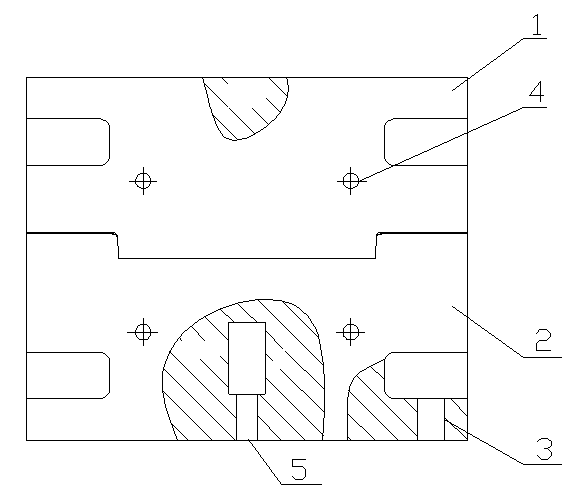

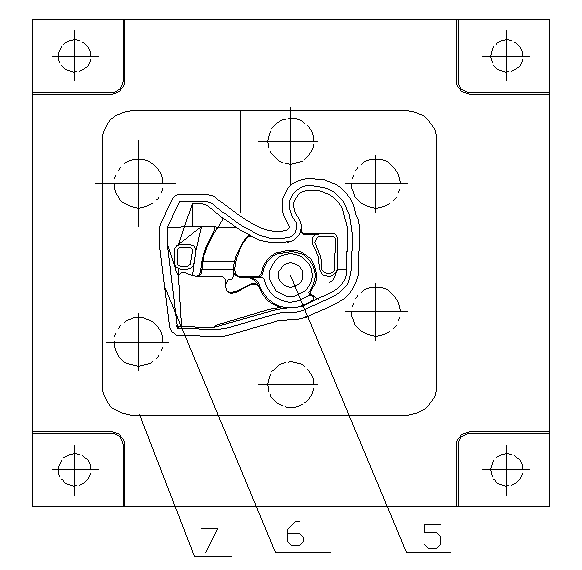

Special-shaped deep-cavity hot-forging precision coupler knuckle die and processing method thereof

ActiveCN103286253AImprove performanceAvoid quality defectsForging/hammering/pressing machinesEngineeringLinear section

The invention discloses a special-shaped deep-cavity hot-forging precision coupler knuckle die comprising an upper die and a lower die. Templates of the upper die and the lower die are both cuboids and flexibly connected, cavities of the upper die and the lower die are in the same shape and size, the cavities and a coupler knuckle are of the same shape, and the cavities are positioned at the centers of the templates. Each cavity is formed by enclosing of a plurality of circular arc sections and linear sections so as to form the shape of the coupler knuckle. The invention further discloses a processing method of the die. The processing method includes the specific steps of (1) forging, (2) planer milling, (3) drilling, (4) numeric control milling, (5) heat treatment, (6) finish milling, (7) polishing to remove burrs and sharp corners, and (8) assembling, die assembly, debugging, packaging and acceptance inspection. The die substitutes for an original casting die and a casting process, quality defects of existing coupler knuckle castings are overcome, and accordingly production efficiency and overall performance of processed coupler knuckles are improved.

Owner:MAANSHAN CITY ZHONGYE MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com