Cylindrical shell sloping-bottom tank car body manufacture technique

A manufacturing process and a technology of barrel joints, which are applied in the field of manufacturing process of tank car tanks with inclined bottoms of barrel joints, can solve the problems of difficult welding quality assurance, poor tank body forming quality, and poor cutting quality, so as to achieve reliable welding seam forming quality, Strong adaptability, convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

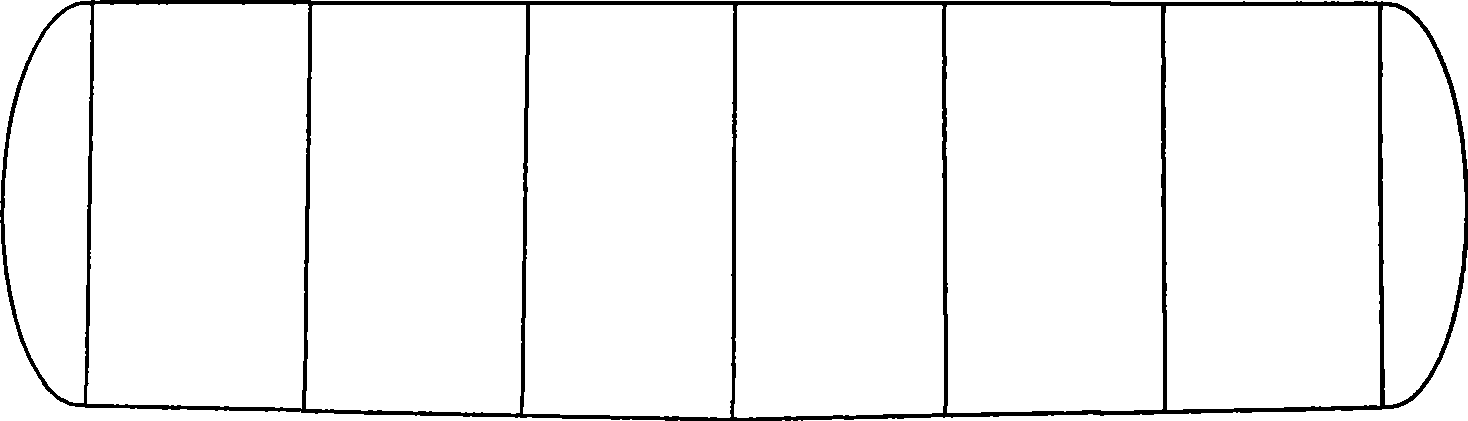

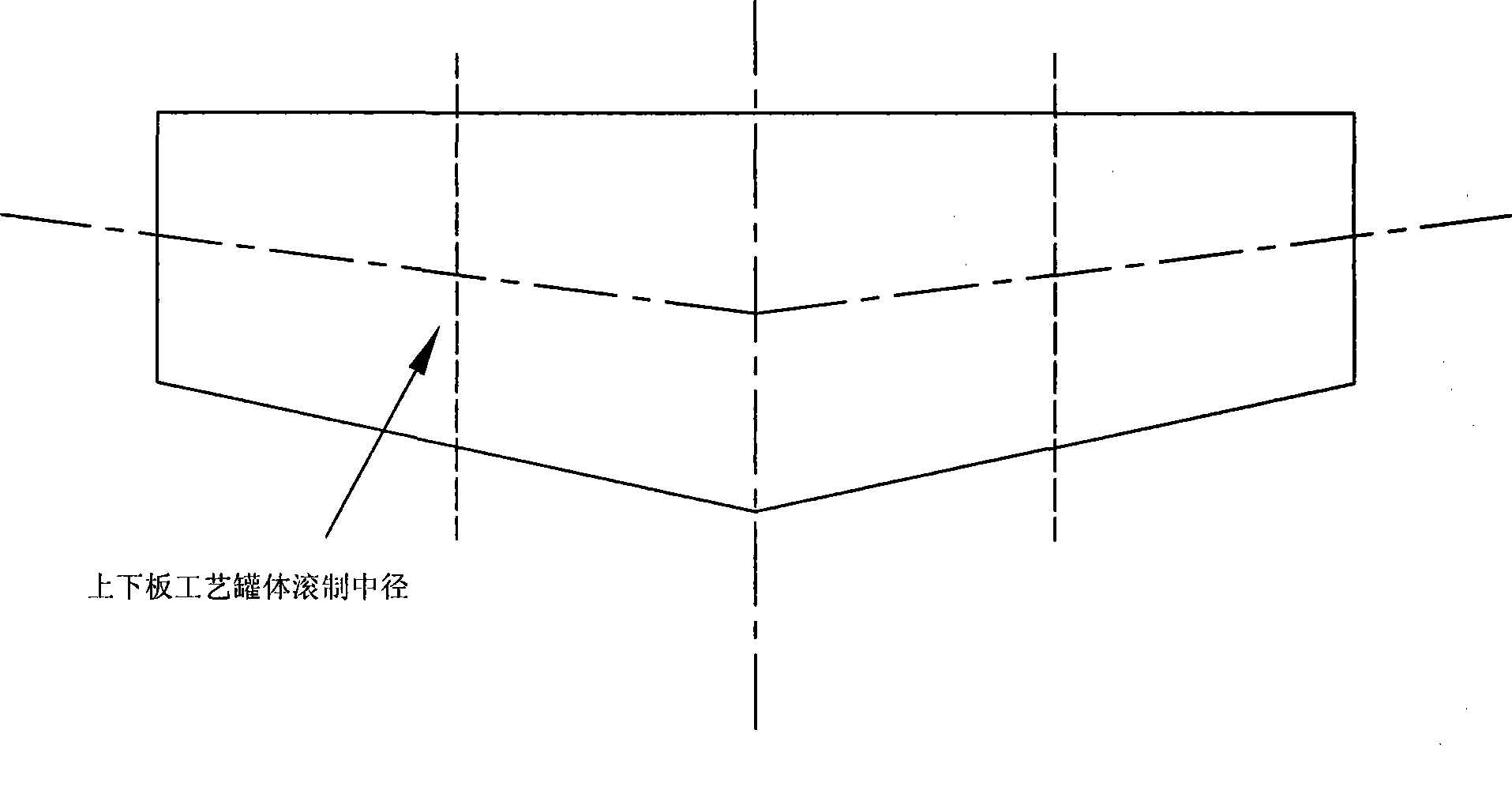

[0046] see figure 1 , a manufacturing process for a tank car with a barrel section and inclined bottom, the manufacturing process comprises the following steps:

[0047] 1) Rolling barrel pitch cone

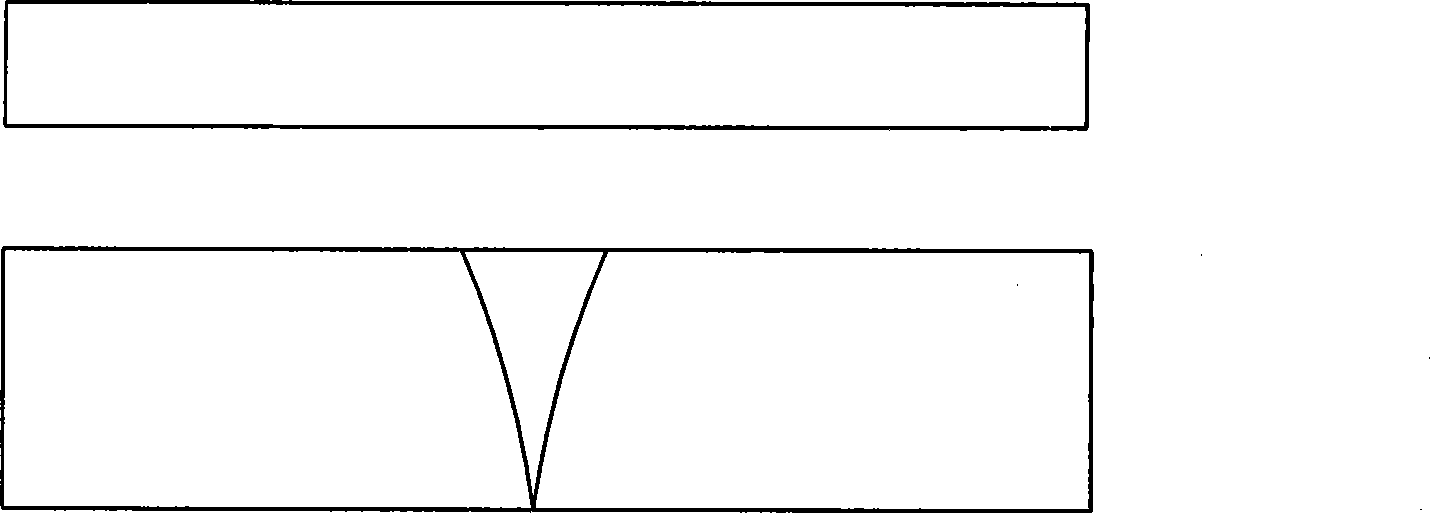

[0048] 1.1) Take two straight conical sheets, roll and bend them with a rounding machine respectively, and then weld the longitudinal seam of the cylindrical section to obtain the first frustum-conical cylindrical section and the second frusto-conical cylindrical section

[0049] The cones of the first and second truncated conical barrel joints are all right cones with the same inclination, the top surface of the frustum of the second truncated conical barrel joint the bottom surface have the same diameter;

[0050] 1.2) Take a piece of sheet material that is obliquely cut and unfolded by a normal cone, roll and bend it with a spheroid machine, and then weld the longitudinal seam of the cylinder section to obtain the third right-angle oblique cone cylinder section;

[0051] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com