Centrifugal cast Cr12MoV shape steel straightening roll and production technology thereof

A technology of centrifugal casting and production technology, which is applied in the field of metallurgy, can solve the problems of inability to forge the inner hole, low service life, and high cost of use, and achieve significant economic and social benefits, high wear resistance, service life, and improved accident resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Produced straightening roller rings with a specification of Φ1300×350 for a steel factory section steel wire (one blank can process three straightening roller rings). The total amount of molten steel is 6600kg, of which the amount of molten steel in the working layer is 4400kg, which is smelted by a 7T intermediate frequency induction furnace, and the amount of molten steel in the inner layer is 2200kg, which is smelted by a 3T intermediate frequency induction furnace.

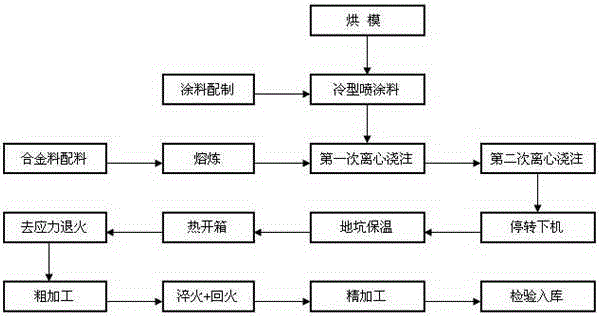

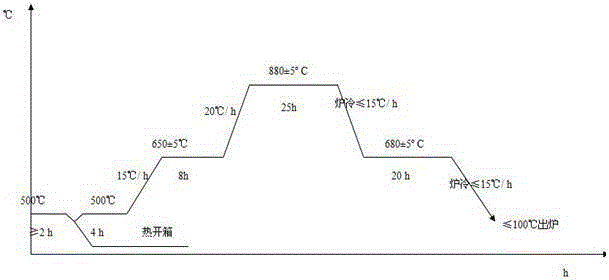

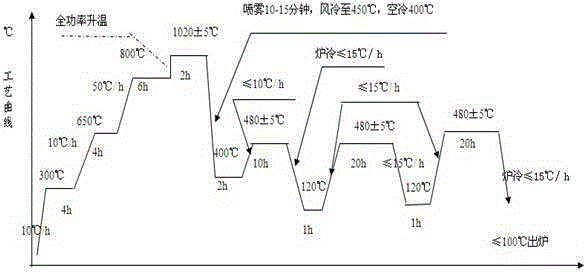

[0061] The specific process of the production process of the Cr12MoV centrifugal casting straightening roller is as follows:

[0062] A. Composition design: The material of the working layer is Cr12MoV, and the material of the inner layer is graphite steel. The chemical composition and mass percentage are shown in Table 1;

[0063] B. Molten steel treatment before the furnace: working layer Cr12MoV material: 15 minutes before tapping, add ferro-vanadium in the furnace. The particle size of the vanadium-...

Embodiment 2

[0076] The chemical composition and mass percentage of the working layer and inner layer of the straightening roller ring are shown in Table 1. The performance of the straightening roller ring is shown in Table 2.

[0077] The production process difference with embodiment 1 only lies in:

[0078] B. Molten steel treatment before the furnace: working layer Cr12MoV material: 15 minutes before tapping, add ferrovanadium in the furnace, and the particle size of the ferrovanadium is 20mm.

[0079] C. Spraying of cold-type paint: Baking of paint: bake at 150±30°C for 4 hours, heat up to 250±30°C for 3 hours, heat up to 440°C for 8 hours, cool to below 340°C and leave the oven.

Embodiment 3

[0081] The chemical composition and mass percentage of the working layer and inner layer of the straightening roller ring are shown in Table 1. The performance of the straightening roller ring is shown in Table 2.

[0082] The difference with the production process of Example 1 is only: B, molten steel treatment before the furnace: working layer Cr12MoV material: 15 minutes before tapping, iron vanadium was added in the furnace, and the grain size of the iron vanadium was 40mm.

[0083] C. Spraying of cold paint: Baking of paint: bake at 150±30°C for 4 hours, heat up to 250±30°C for 3 hours, heat up to 460°C for 8 hours, cool to below 340°C and leave the oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com