Precast wall casing structure of reinforced concrete superposed shear wall and splicing method thereof

A technology of reinforced concrete and laminated shear walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of reduced rigidity of reinforced concrete laminated shear walls, complicated stress state, and inability to realize horizontal connections, etc. Achieve the effects of convenient construction, enhanced integrity, and easy inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

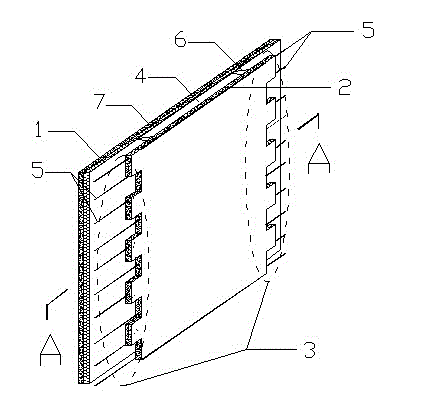

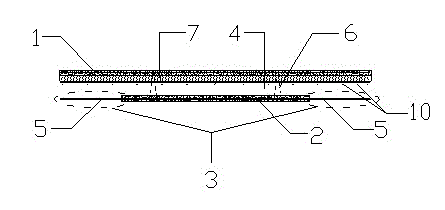

[0028] like figure 1 , 2 , Shown in 3 and 4: a kind of prefabricated wall shell structure of reinforced concrete laminated shear wall, this shell structure is formed by the horizontal connection of a plurality of wall shell units;

[0029] Each of the wall shell units includes a reinforced concrete prefabricated wall outer side layer 1, a reinforced concrete prefabricated wall inner side layer 2, a cavity 4, concave-convex gaps 3 and prefabricated steel bars 5, and the reinforced concrete prefabricated wall outer side The layer 1 and the inner side layer 2 of the reinforced concrete prefabricated wall are connected together through the steel bracket 6 to form a shell structure with the cavity, and the edges on both sides of the inner side layer 2 of the reinforced concrete prefabricated wall are prefabricated with Concave-convex gap 3, prefabricated steel bar 5 is arranged at concave-convex gap 3;

[0030] An additional structural steel bar 8 is provided at the gap between t...

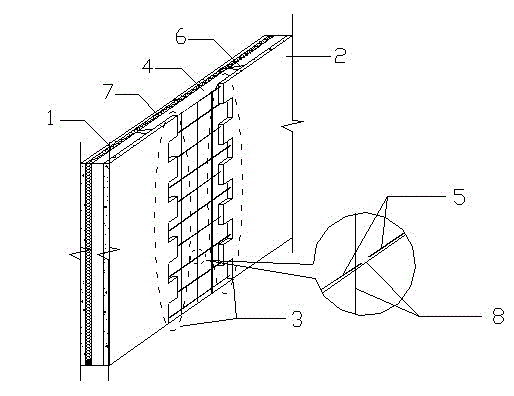

Embodiment 2

[0035] A prefabricated wall shell structure of reinforced concrete laminated shear walls, such as Figure 5 shown. The difference between this embodiment and embodiment 1 is:

[0036] The two side edges of the outer side layer 1 of the reinforced concrete prefabricated wall are also prefabricated with the concave-convex gap 3, the prefabricated steel bars 5 are arranged at the concave-convex gap 3, and the outer side layer 1 of the reinforced concrete prefabricated wall is provided with a force-bearing Rebar 10.

[0037] In embodiment 1, the shell structure of the prefabricated wall contains an insulating layer, and the thickness of the insulating layer can be set according to the heat preservation and energy saving requirements of the building. In this embodiment, the inner wall is not provided with an insulating layer; the reinforced concrete prefabricated wall in embodiment 1 The outer side layer is only used as the protective layer of the insulation layer, and a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com