Patents

Literature

34results about How to "Eliminate weak links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt-based non-curable heat-resistant waterproof sealant and preparation method thereof

ActiveCN102775956AImprove adhesionAdhesiveNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePolyolefin

The invention relates to an asphalt-based non-curable heat-resistant waterproof sealant and a preparation method of the sealant. The sealant comprises the following components in percentage by weight: 10-35% of asphalt, 5-15% of rubber oil, 1-3% of polyolefin processing modifier, 20-30% of 30Mu-100Mu glue powder, 5-10% of tackifier, 10-30 of sodium bentonite, and 3-5% of wetting dispersant reagent. The sealant has the following characteristics of good bonding property, high percentage elongation, good self-healing property, good creep property, possible construction of knife coating, spray coating or grouting, no need to maintain, capability of being constructed on wet foundation surface even under condition of (-40) DEG C and thus effectively shortening the construction period, no organic solvent, low energy consumption in construction, safety, environmental friendliness, no pollution, high-temperature resistance (not flowing at 110 DEC C), low-temperature resistance (not cracking at (-40) DEG C), stable property, good stickiness, and capability of sealing base layer cracks and pores so as to avoid water channeling phenomenon.

Owner:中建材苏州防水研究院有限公司 +1

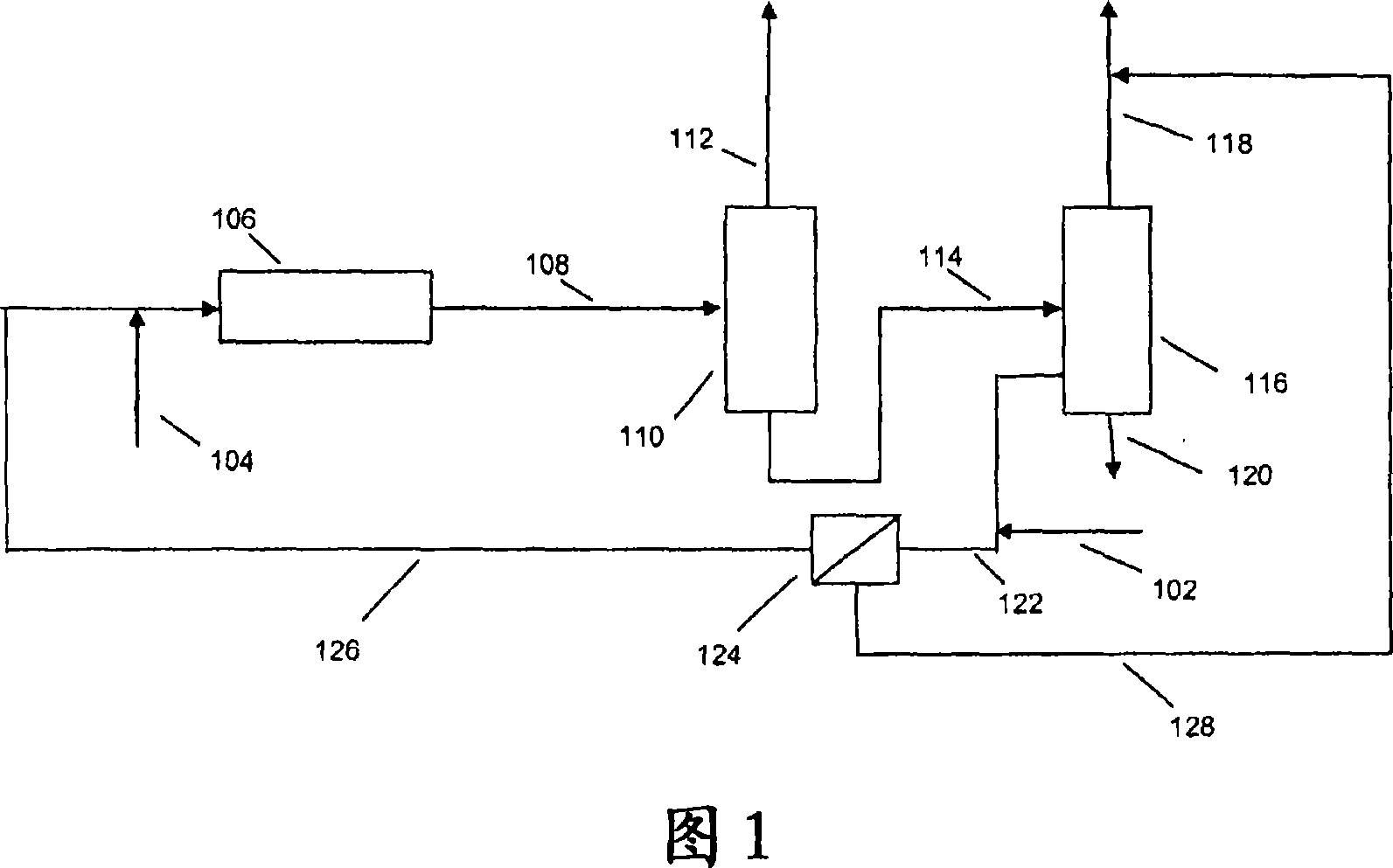

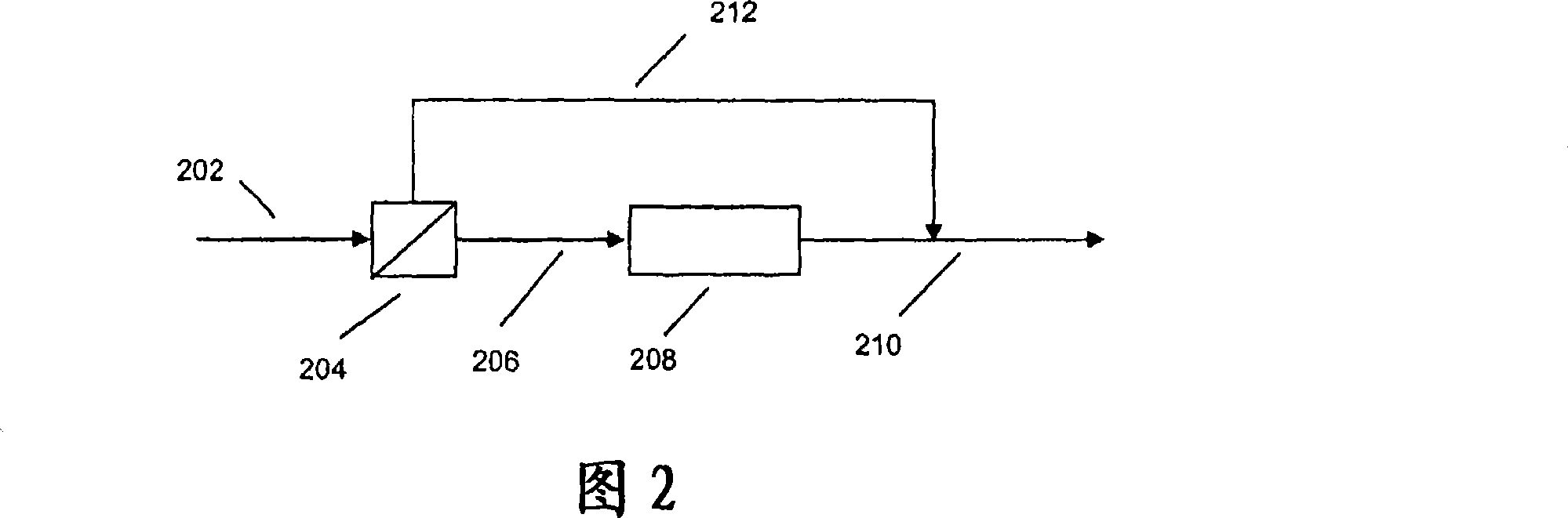

Processes for the isomerization of normal butane to isobutane

InactiveCN101171213AReduce loadEliminate weak linksSemi-permeable membranesHydrocarbon by isomerisationPermselective membraneBoiling point

In a normal butane isomerization process where the isomerization effluent (108, 114) is fractionated in a deisobutanizer (116) operated such that a lower boiling fraction (118) is provided containing at least 80 mass-% isobutane and a higher boiling fraction (122) containing normal butane and at least 10 mass-% isobutane. The higher boiling fraction (122) is contacted with a selectively permeable membrane (124) to provide a permeate (126) containing normal butane-containing and a retentate (128) containing at least 80 mass-% isobutane. The preferred membranes are sieving membranes having a C4 Permeate Flow Index of at least 0.01 and a C4 Permeate Flow Ratio of at least 1.25:1.

Owner:UOP LLC

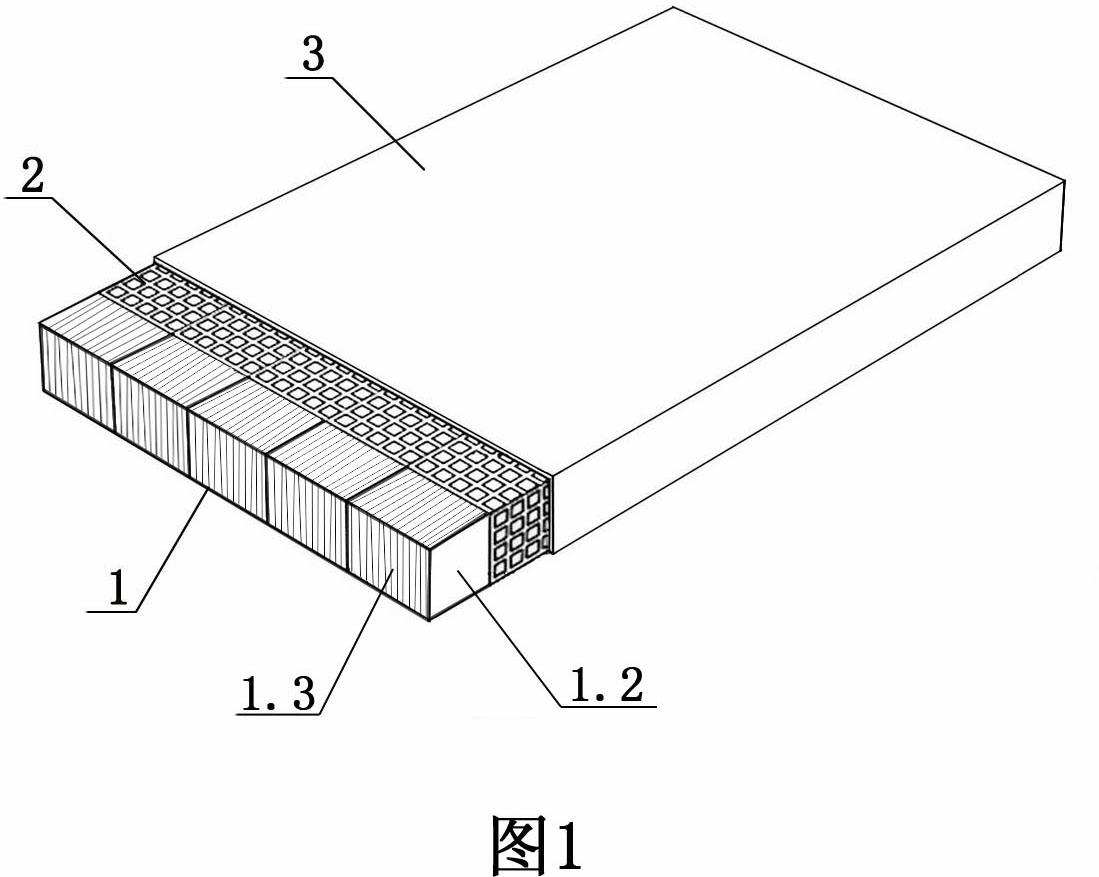

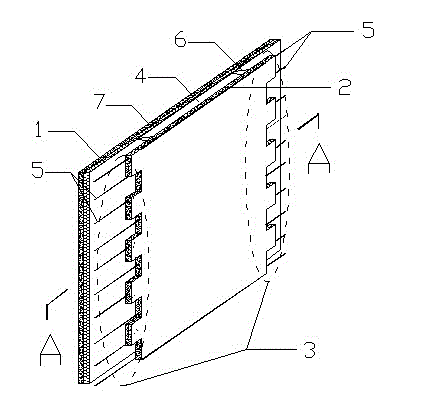

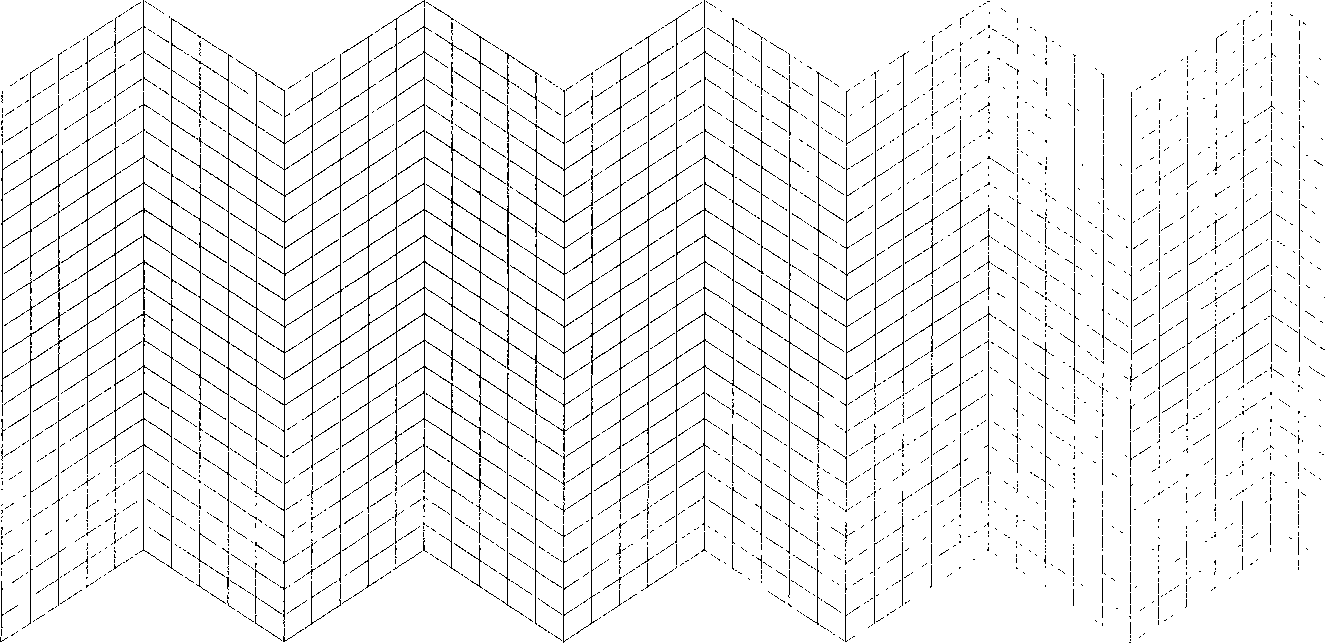

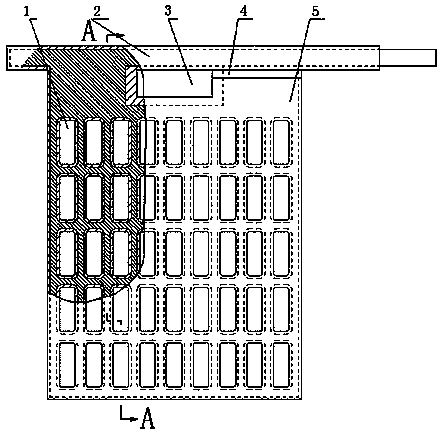

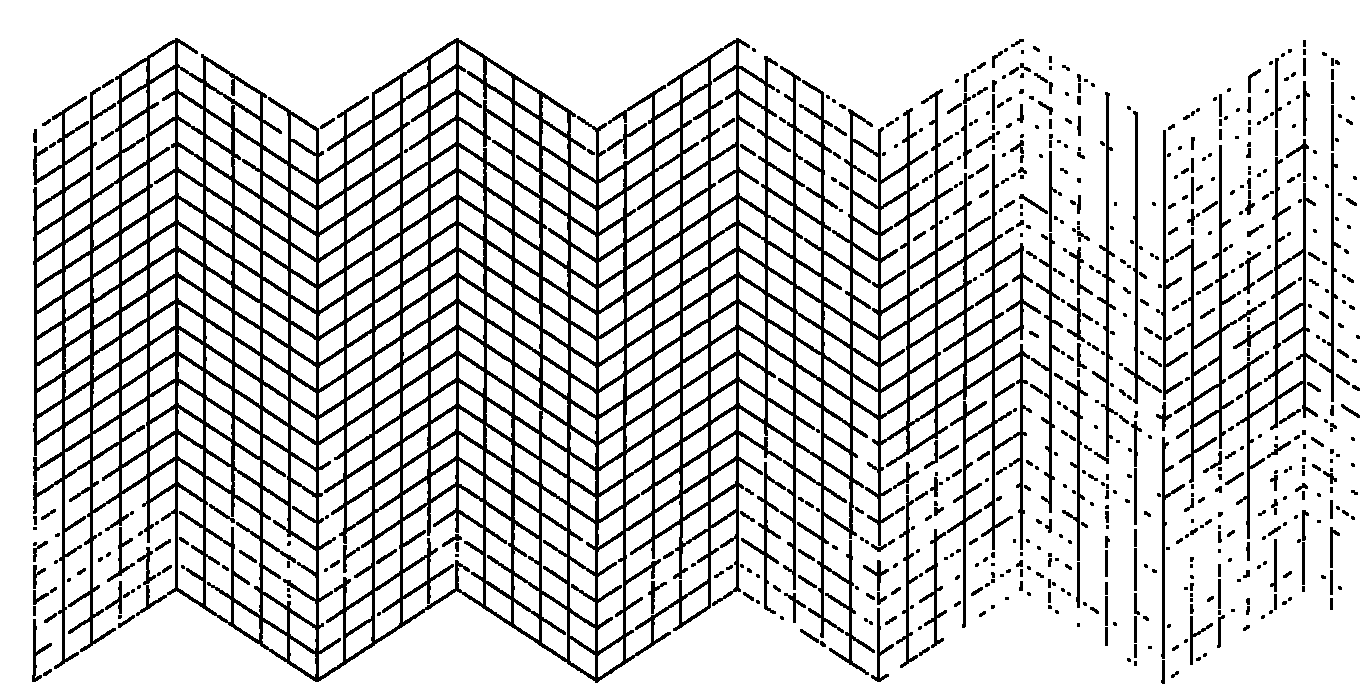

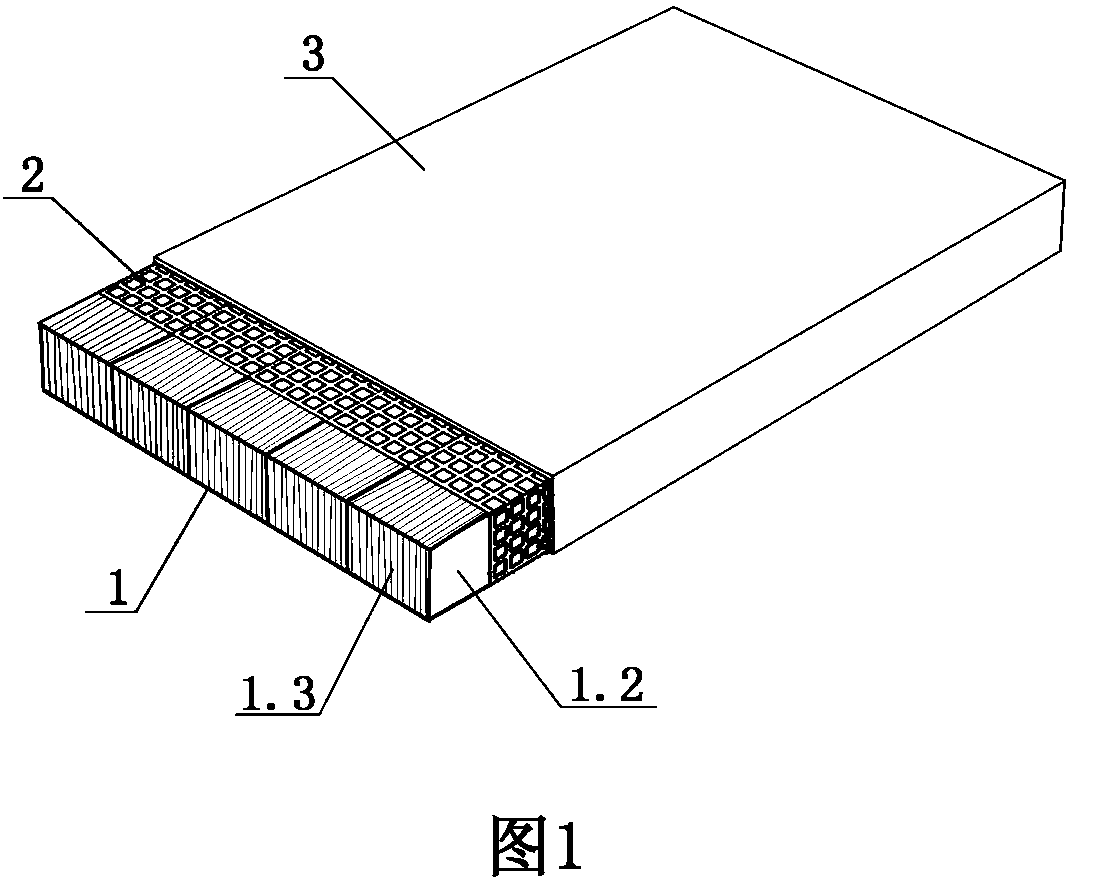

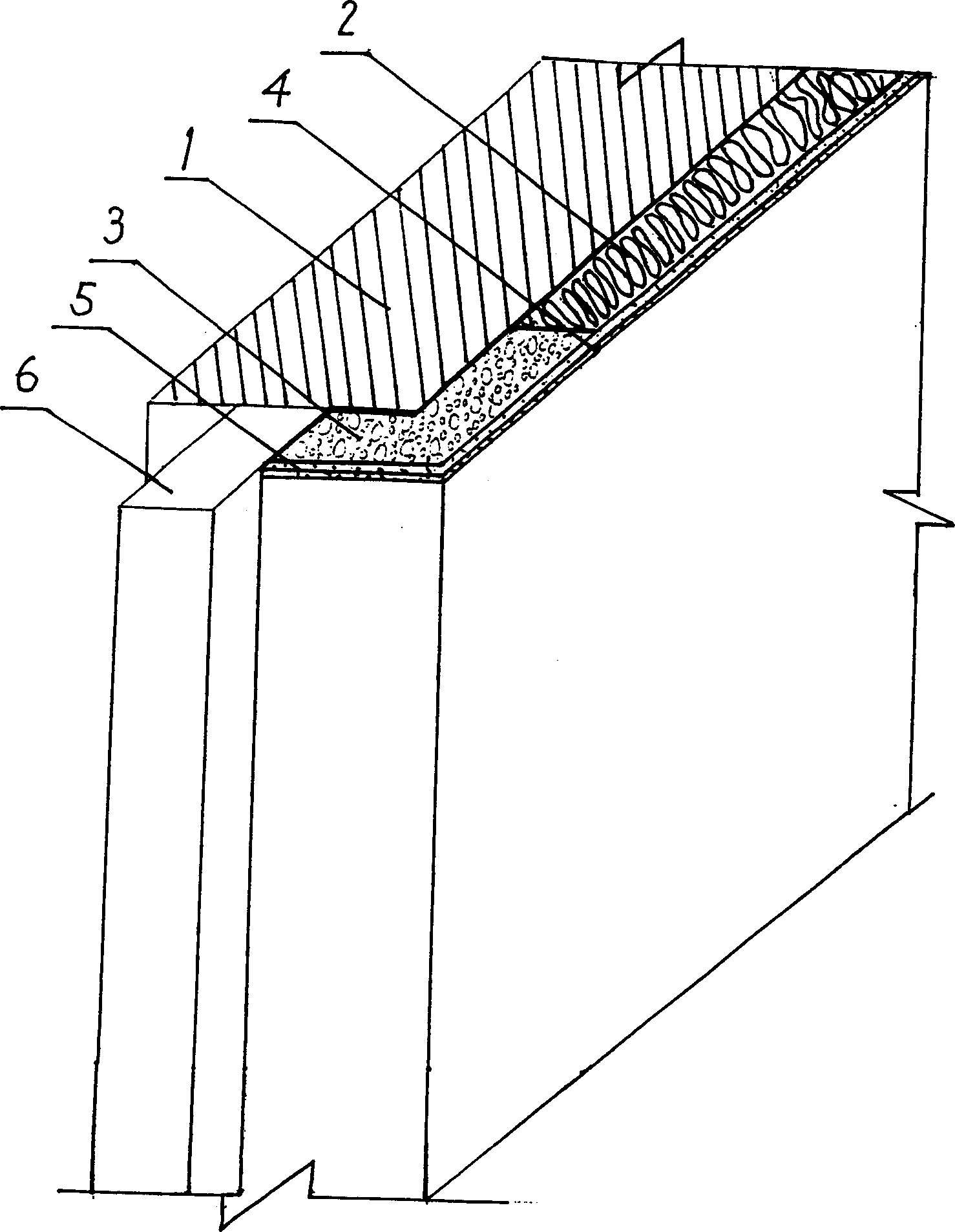

Composite rock wool reinforcement plate and preparation method for composite rock wool reinforcement plate

ActiveCN102635172AHigh strengthEliminate weak linksHeat proofingNatural mineral layered productsYarnHigh intensity

The invention discloses a composite rock wool reinforcement plate and a preparation method for the composite rock wool reinforcement plate. The composite rock wool reinforcement plate comprises a core plate; wherein the core plate is composed of at least two rock wool slivers which are arranged side by side; the arrangement direction of fiber yarns of the rock wool slivers is in parallel with the thickness direction of the composite rock wool reinforcement plate; the four surfaces of the core plate in the length direction are wrapped by a layer of reinforced fiber layer; and the outer surface of the reinforced fiber layer is coated by a layer of mortar protecting layer. According to the composite rock wool reinforcement plate and the preparation method, the shortcomings of low tensile strength and low compression strength of common rock wool plate are overcome, the weak link of stress is eliminated, and the safety of the system is improved; and the composite rock wool reinforcement plate has the advantages of good heat insulating effect, high intensity, good fire-proof and humidity resistant performances, simple construction and long service life, so that the composite rock wool reinforcement plate can be widely applied to the fields of outer wall constructions of buildings.

Owner:北京振利节能环保科技股份有限公司

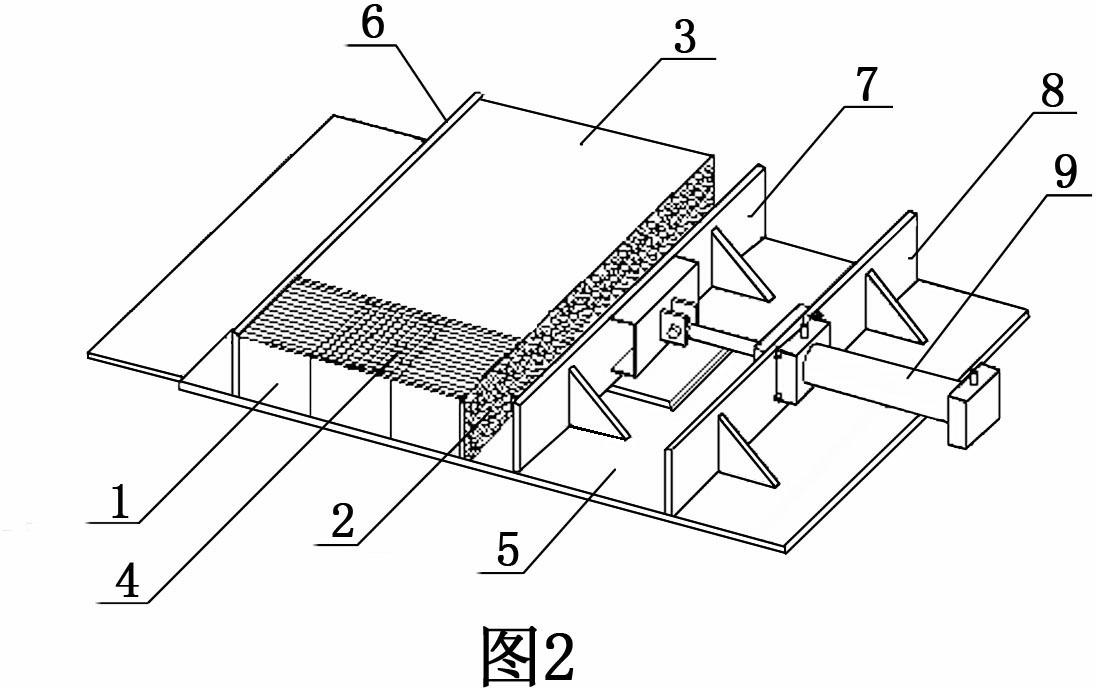

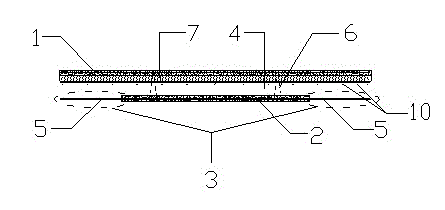

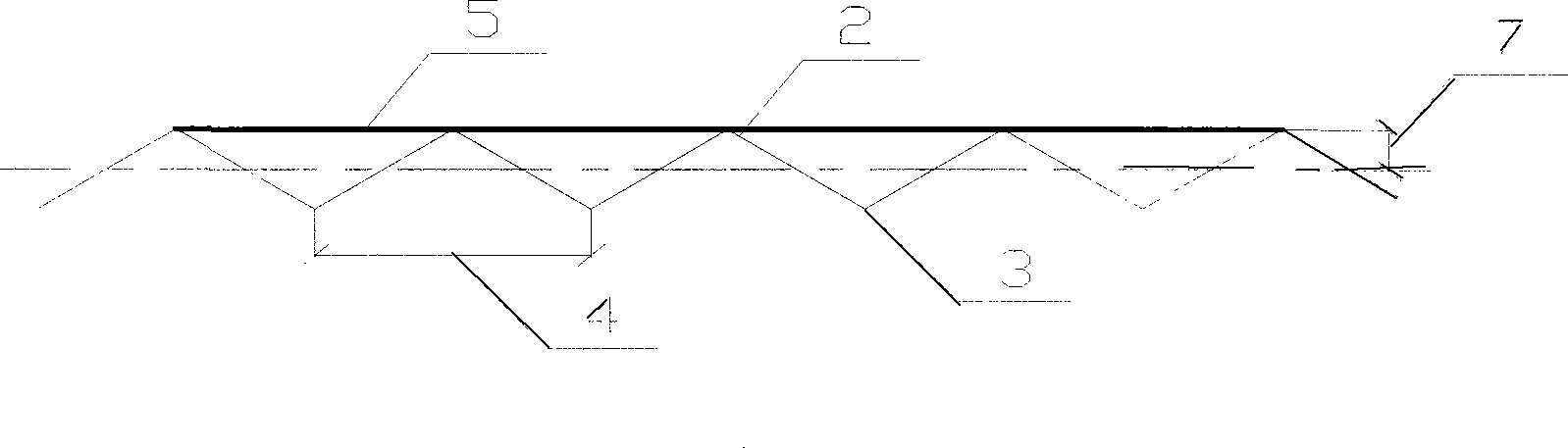

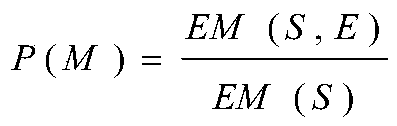

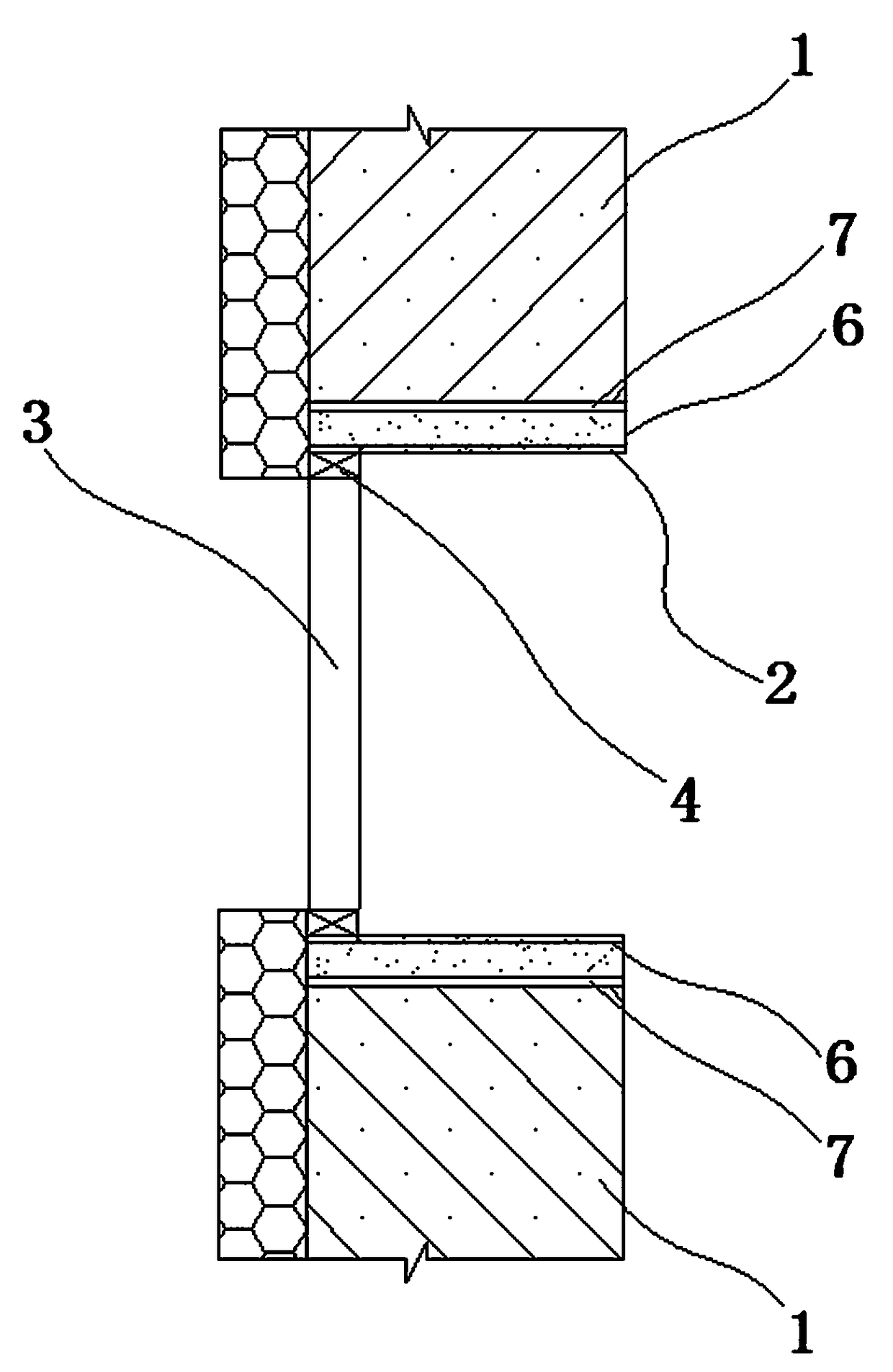

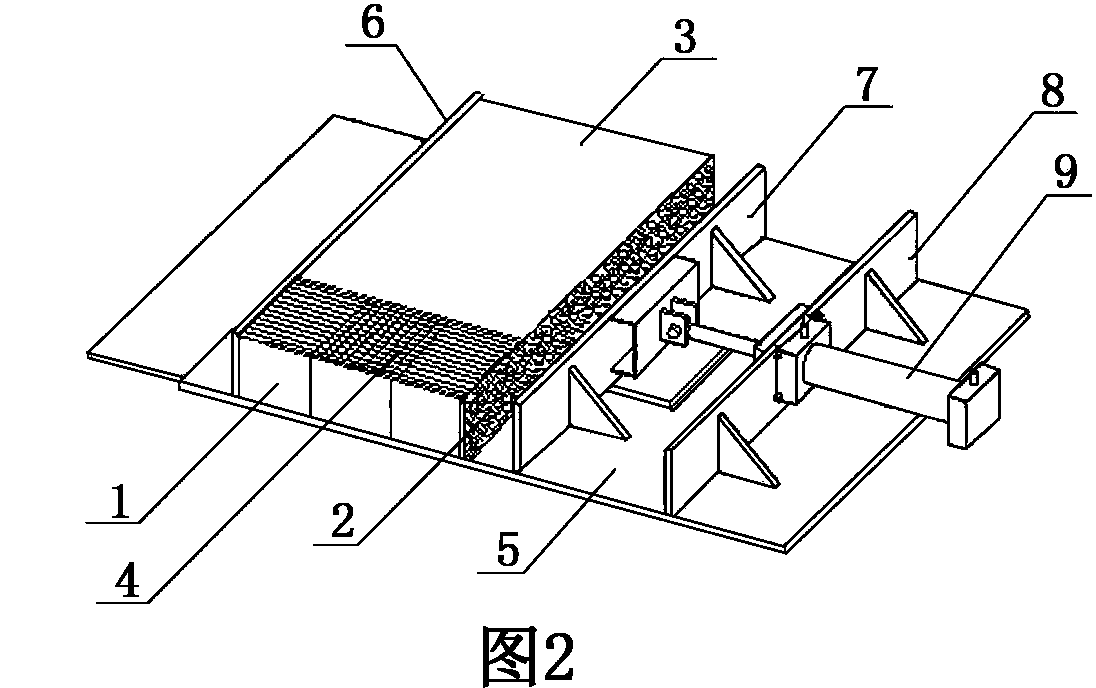

Precast wall casing structure of reinforced concrete superposed shear wall and splicing method thereof

InactiveCN102747796AImprove integrityImprove carrying capacityWallsHeat proofingReinforced concreteThermal insulation

The invention discloses a precast wall casing structure of a reinforced concrete superposed shear wall and a splicing method thereof. The precast wall casing structure of the reinforced concrete superposed shear wall comprises a reinforced concrete precast wall casing, a bump gap of the precast wall casing, a wall hollow cavity, rebars of the bump gap of the precast wall casing, a rebar bracket, an additional constructional rebar and a thermal insulation layer. The invention further discloses a splicing constriction method of the precast wall casings. With the precast wall casing structure of the reinforced concrete superposed shear wall and the splicing method of the precast wall casing structure provided by the invention, the horizontal joint junction of the reinforced concrete superposed shear wall is remarkably improved and therefore the integrity, the bearing capacity and the earthquake resistant behaviour of the junction joint of the reinforced concrete superposed shear wall are enhanced. The invention realizes that the reinforced concrete superposed shear wall is equal to a common entire cast-in-site shear wall, and can produce higher social and economic benefits.

Owner:NANJING UNIV OF TECH +1

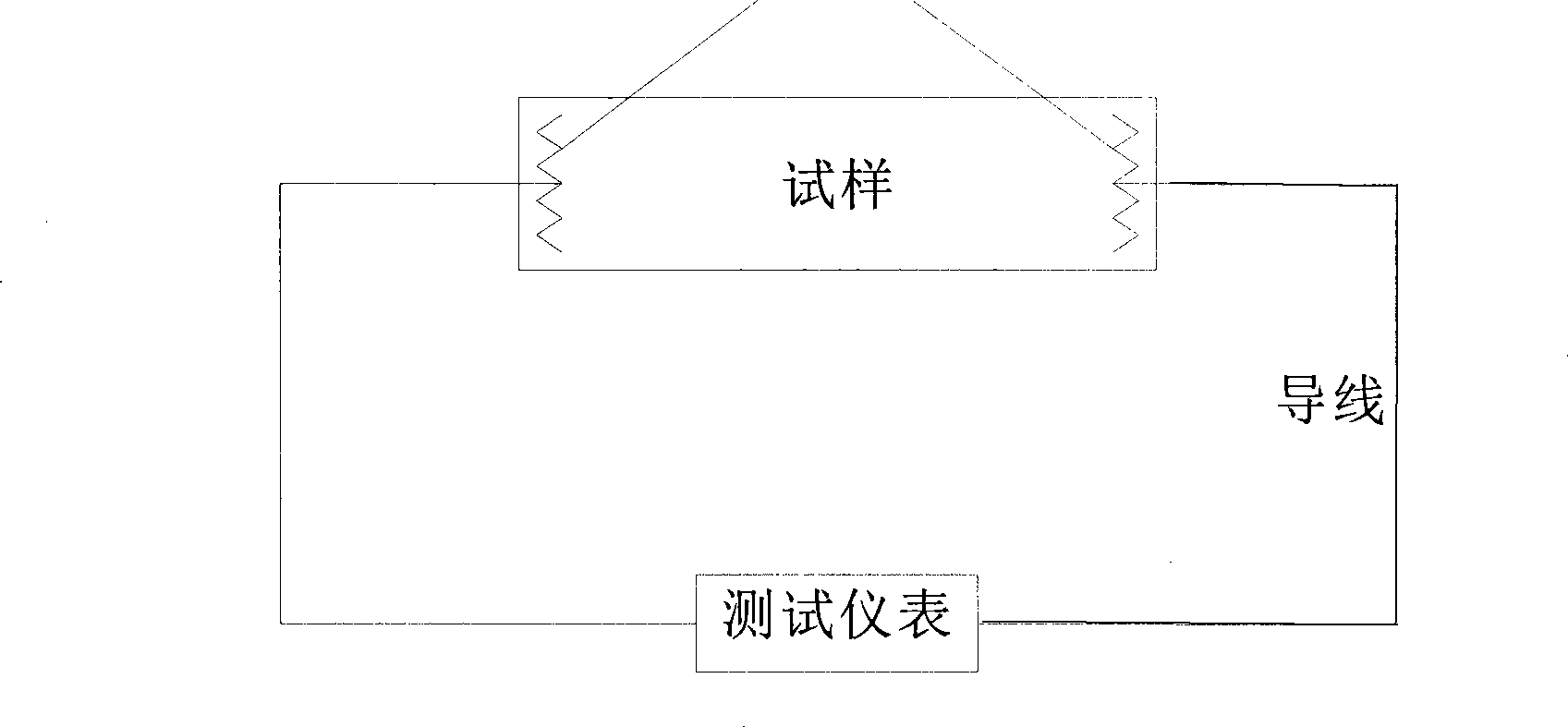

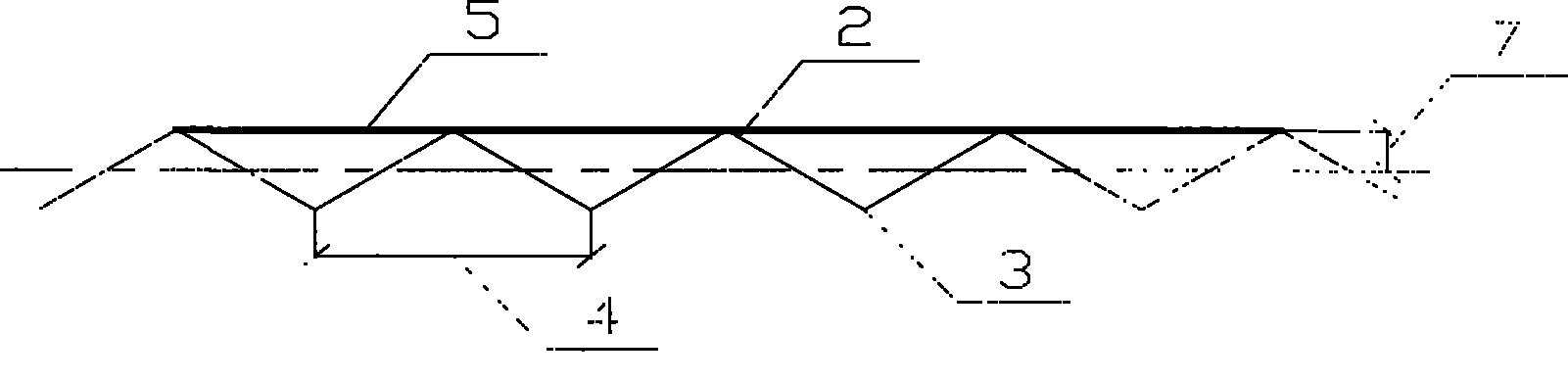

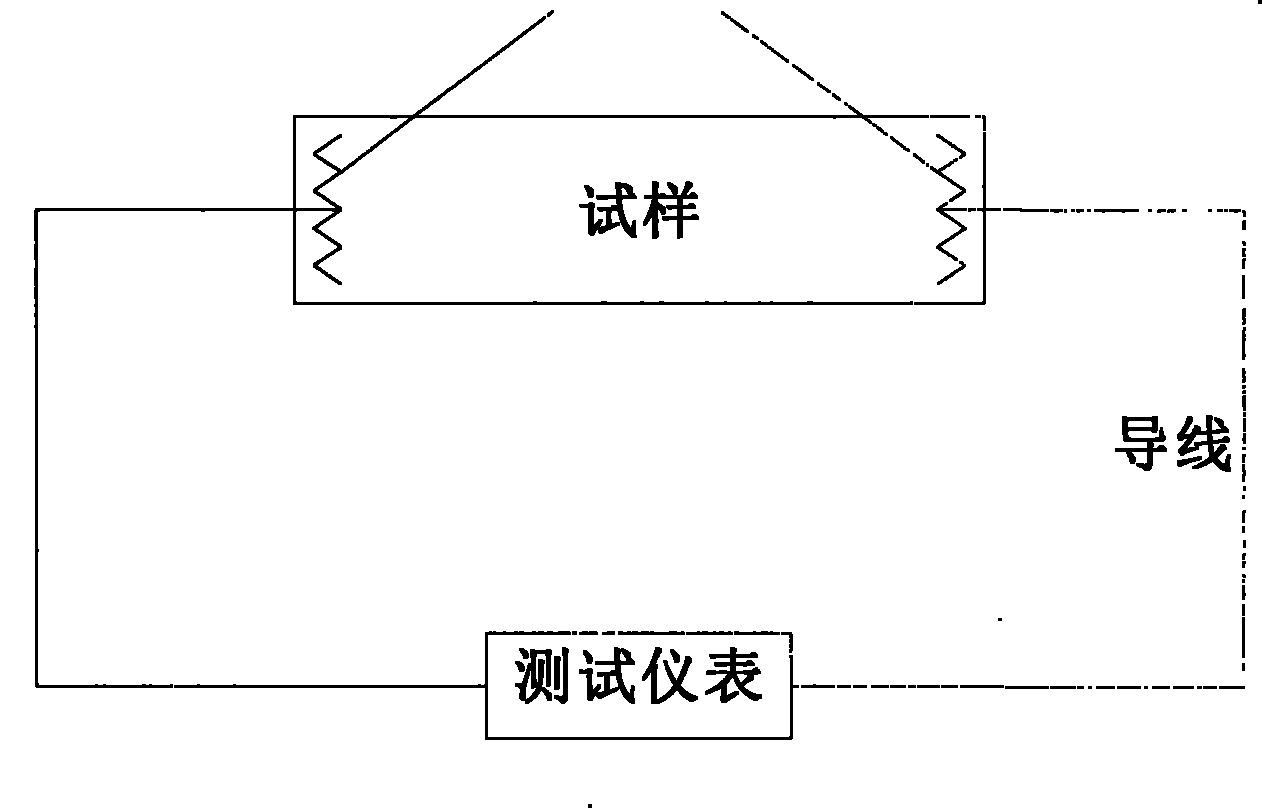

Manufacturing process for electrode of cement based conductive composite material

InactiveCN101478085AReduce the impact of accuracyElimination of Weak Links Created by EmbeddingResistance/reactance/impedenceMaterial resistanceFiberCarbon nanotube

The invention discloses a method for manufacturing cement-base conducting composite materials, which belongs to the technical field of civil engineering. The method is characterized in that a plane stainless steel net is manufactured into a solid stainless steel net of different waveforms. When a cement-base conducting composite material specimen is manufactured, the wave crests of the electrodes of two solid stainless steel nets are arranged oppositely; and as the basal body of the cement-base conducting composite material can be made of cement paste, cement mortar or concrete, and the conductive phases incorporated can be carbon fiber, powdered carbon, steel fiber, steel scrap, plumbago or carbon nanometer tubes, the grid sizes of the plane stainless steel net, the waveforms, the cycles and the amplitudes of the waveforms of the electrodes of the solid stainless steel nets can be selected on a rational basis according to the types of the material of the base body and the conducting material besides considering the type and the size of the specimen in practical application. The invention has the advantages that the contact resistance between the electrodes and the base body can be reduced; the influence of polarization effect is reduced; the bonding effect of the electrodes and aggregate is improved; and the accuracy of the resistance test of the cement-base conducting composite material is improved.

Owner:DALIAN UNIV OF TECH

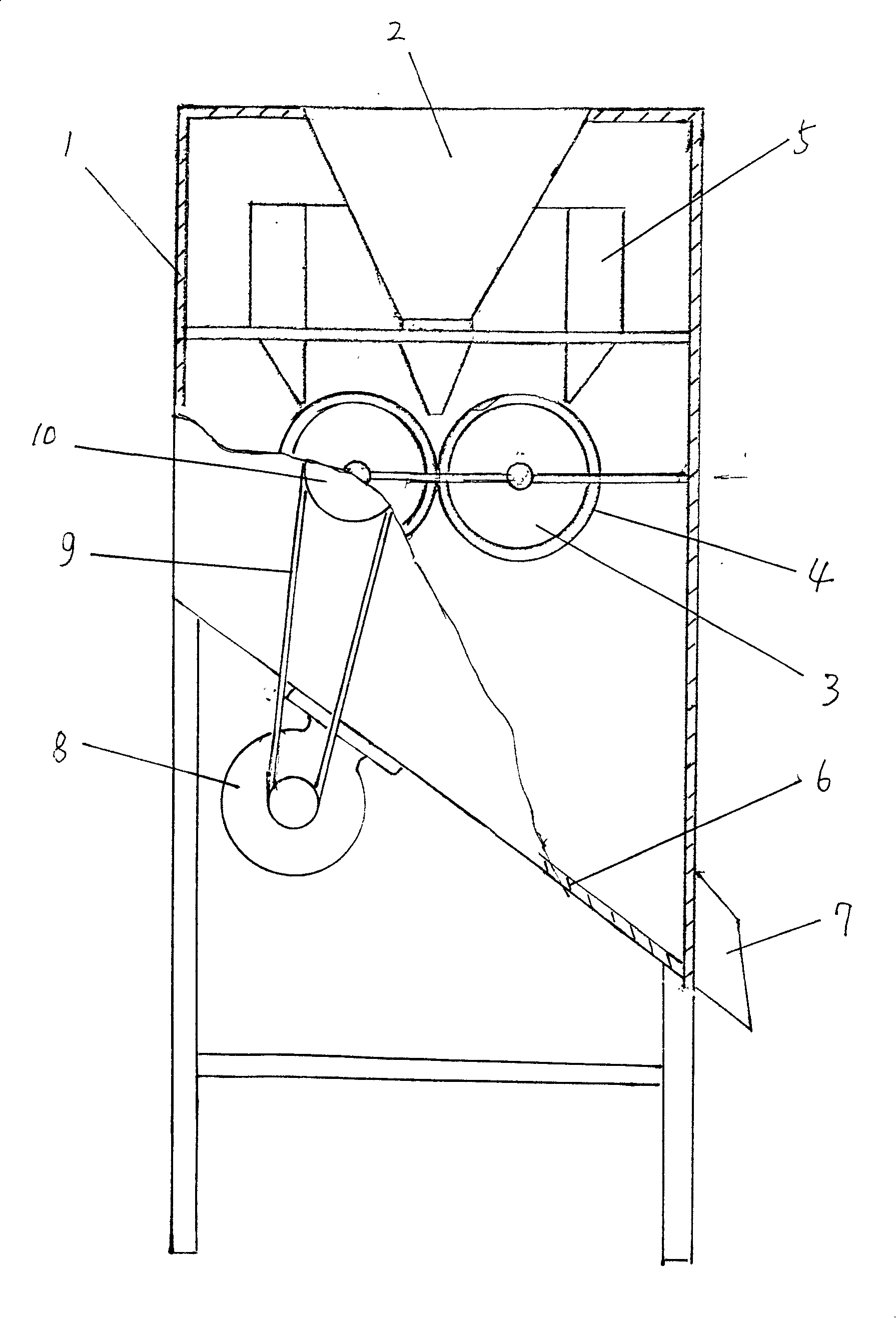

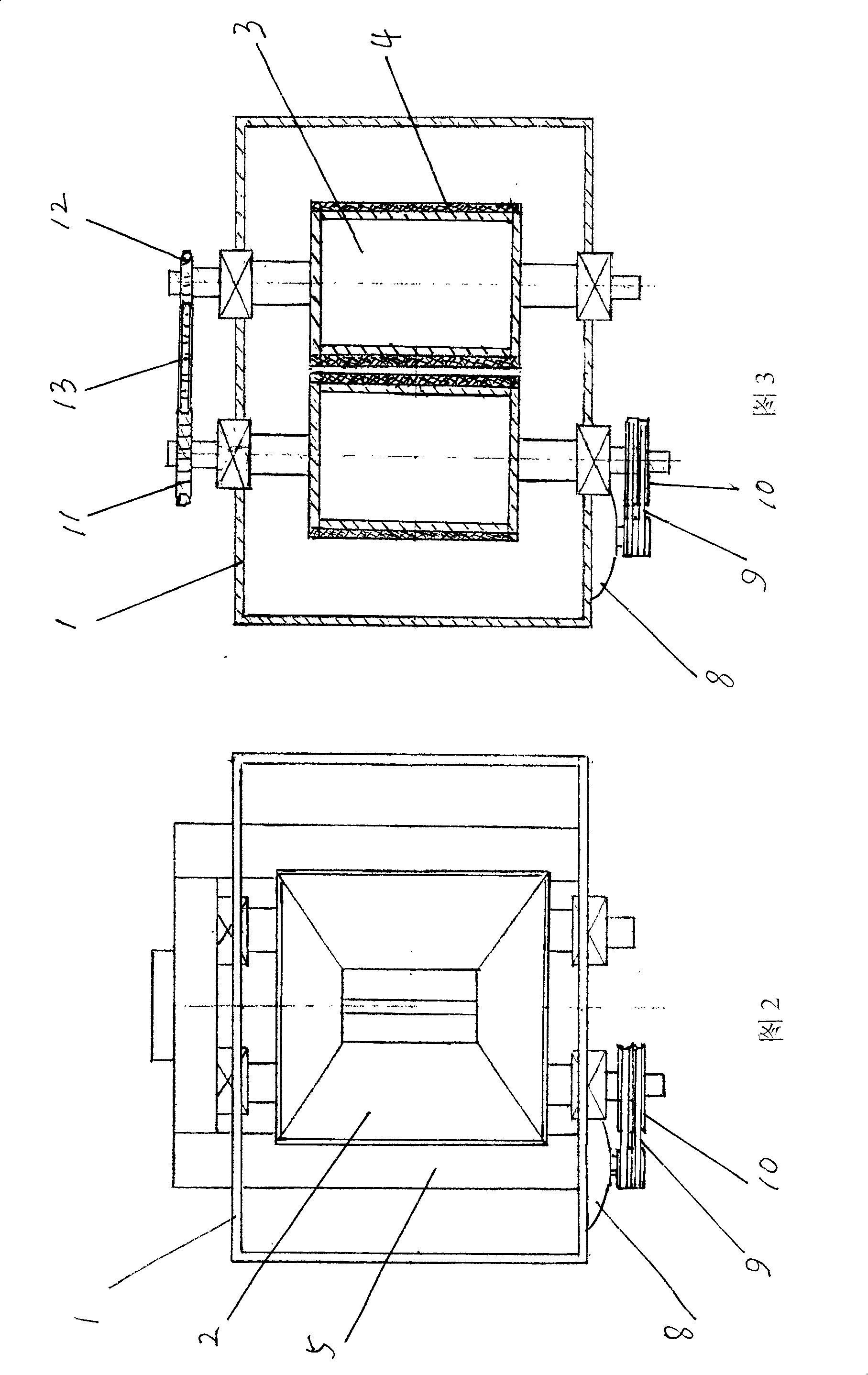

Pinenut kernel testa stripping machine

InactiveCN101204245AAchieve mechanical peelingImprove work efficiencyHuskingHullingRubber materialHigh volume manufacturing

The invention discloses a pine nut peeling machine, relating to a peeling device for seed capsules of nutlets. The invention comprises a fuselage, a feeder funnel arranged on the up end of the fuselage, an entwisting structure arranged down the discharge gate on the feeder funnel inside the fuselage, a discharge gate arranged down the entwisting structure on the fuselage and an actuating motor of the entwisting structure. The entwisting structure is a running entwisting roller with the surface of soft rubber material and a structure of fixed entwisting board which is close to the entwisting roller or two closed entwisting roller structures with the surface of soft rubber material. The effective result of the invention is that a mechanized peeling of seed capsules of pine nut is realized in the peeling process of a mechanical arm imitating hands of people, which significantly improves the peeling efficiency in the production of pine nut food. The invention is also characterized in that the seed capsule of the pine nut that goes through a peeling mechanism is entirely peeled without crashing the nut, which removes the weakest process in the mass production of the pine nut food.

Owner:赵义民

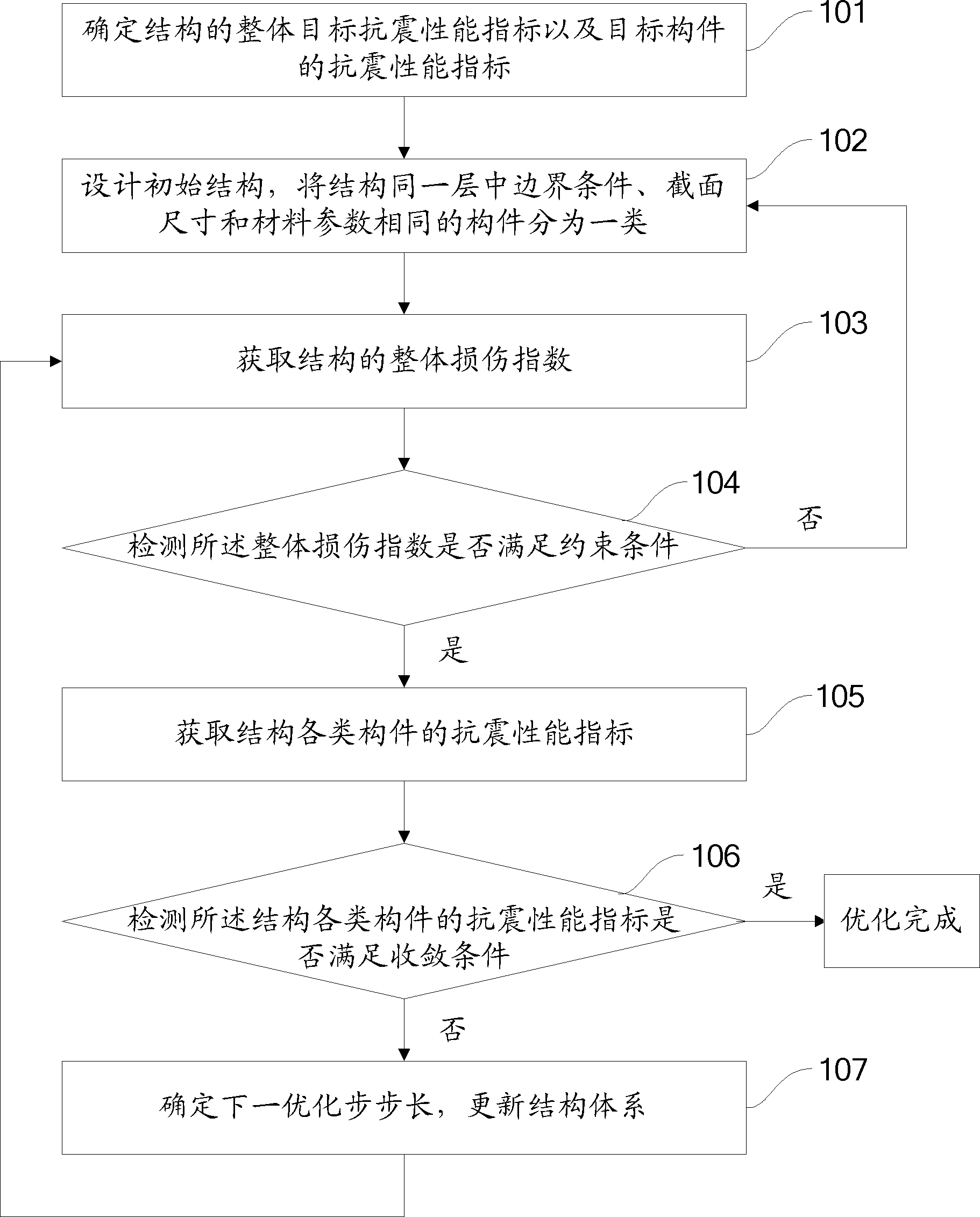

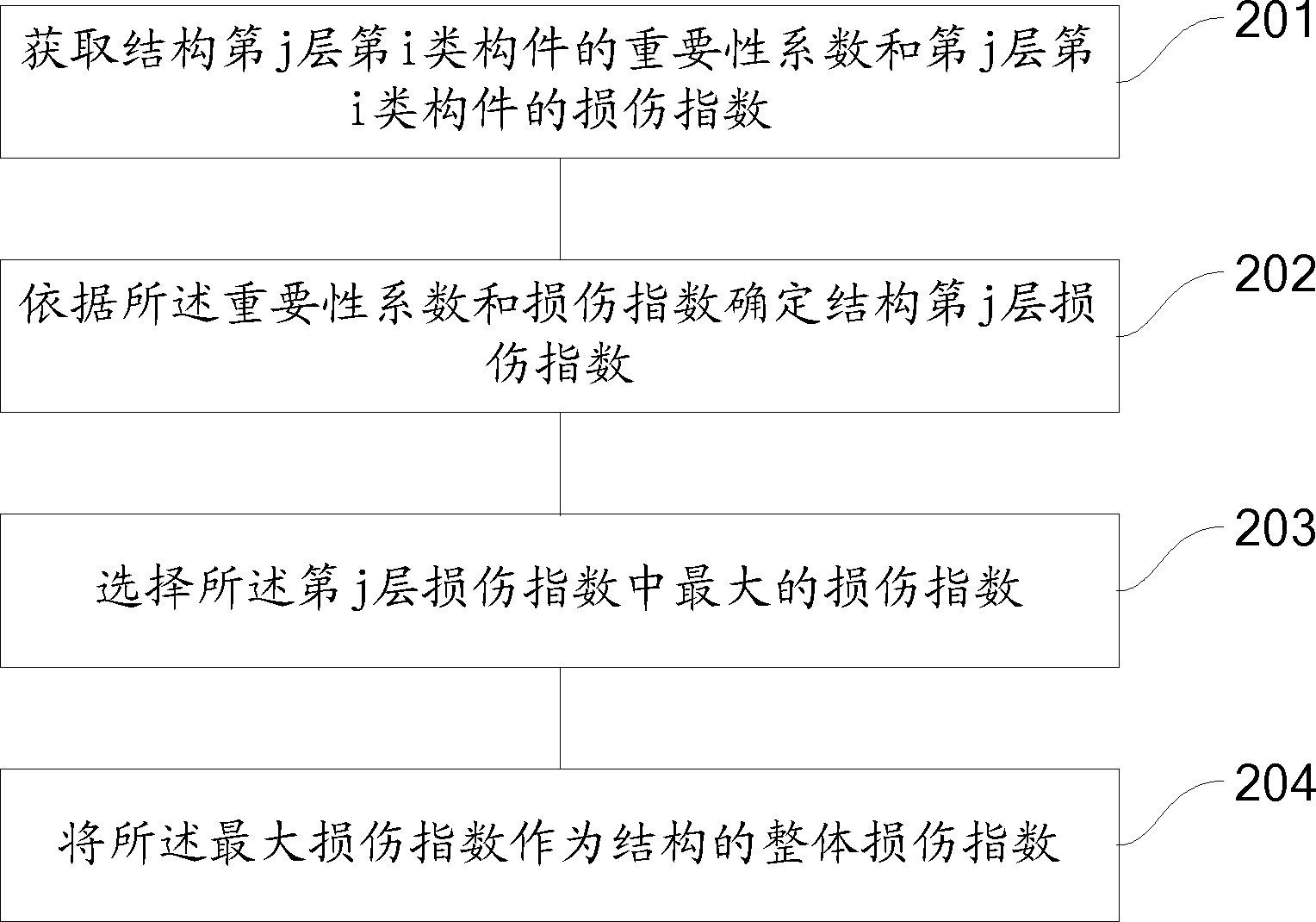

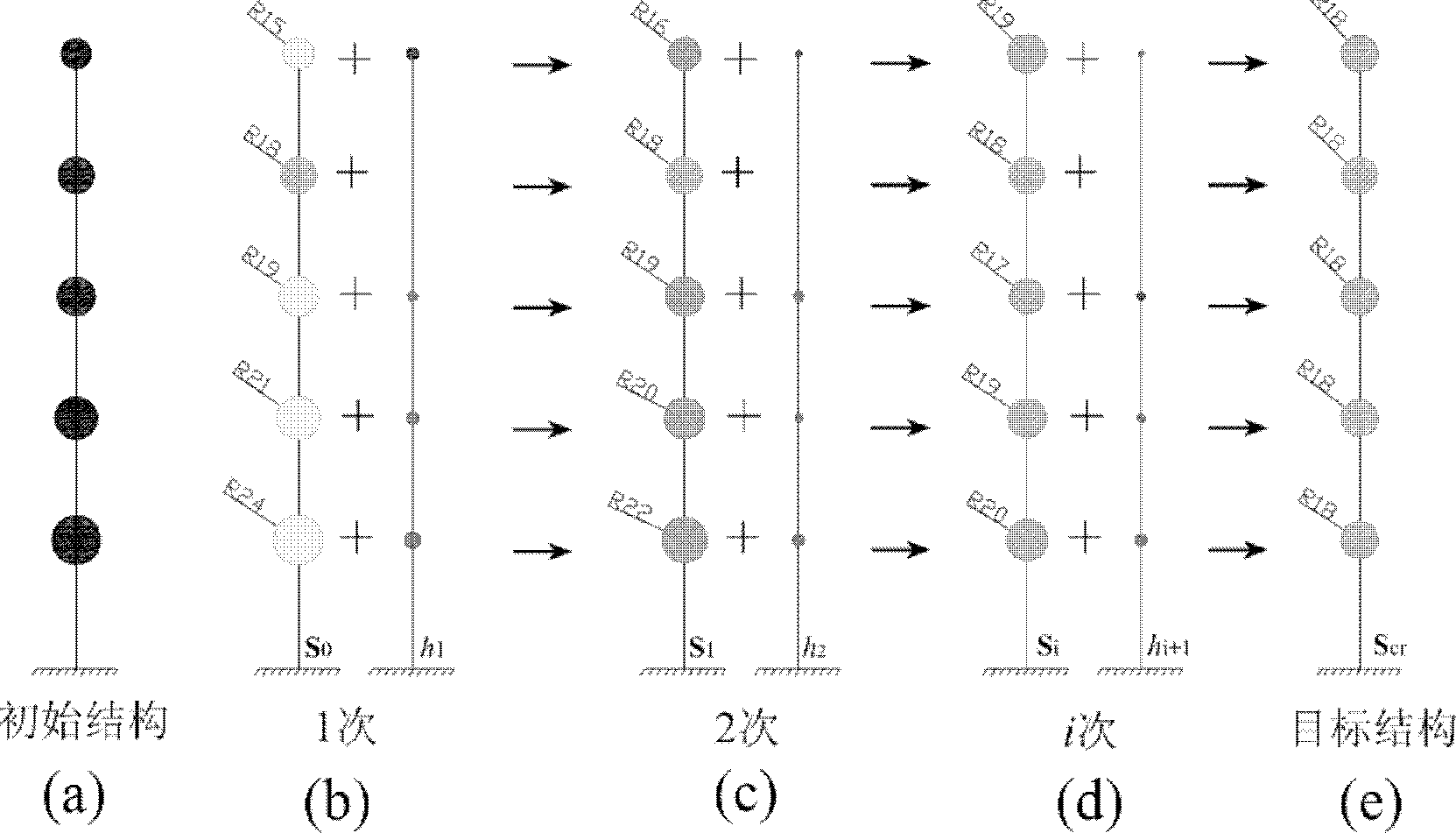

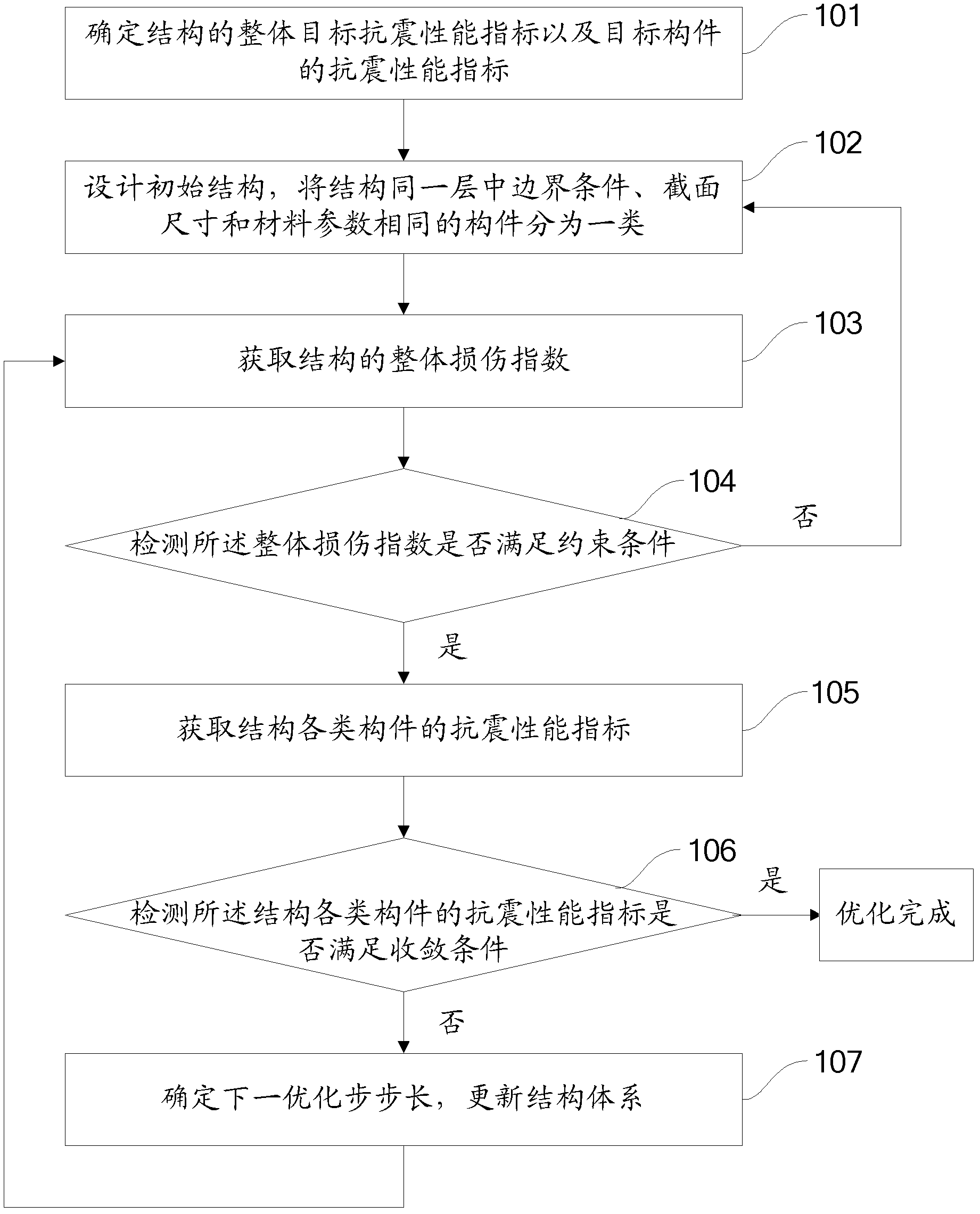

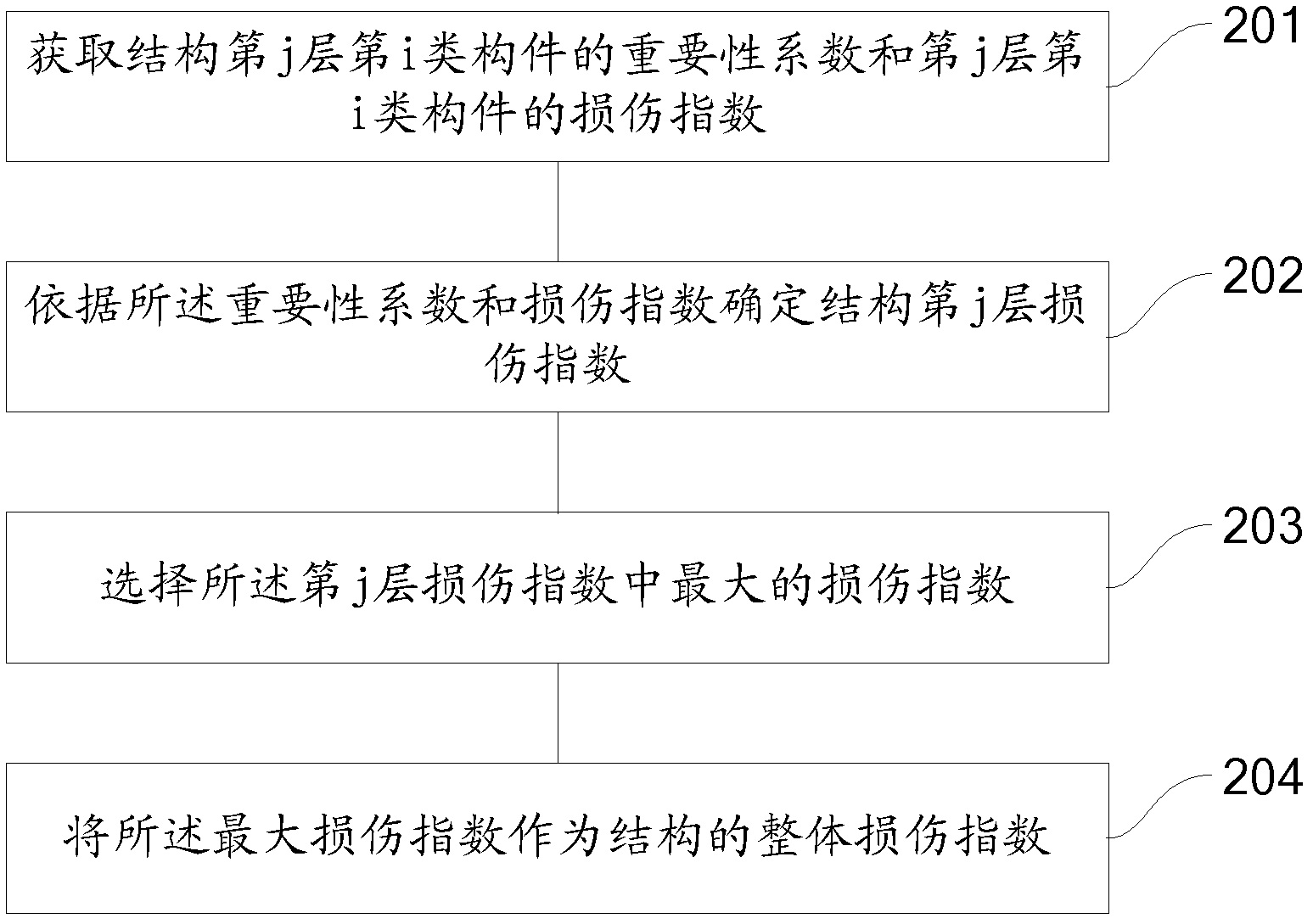

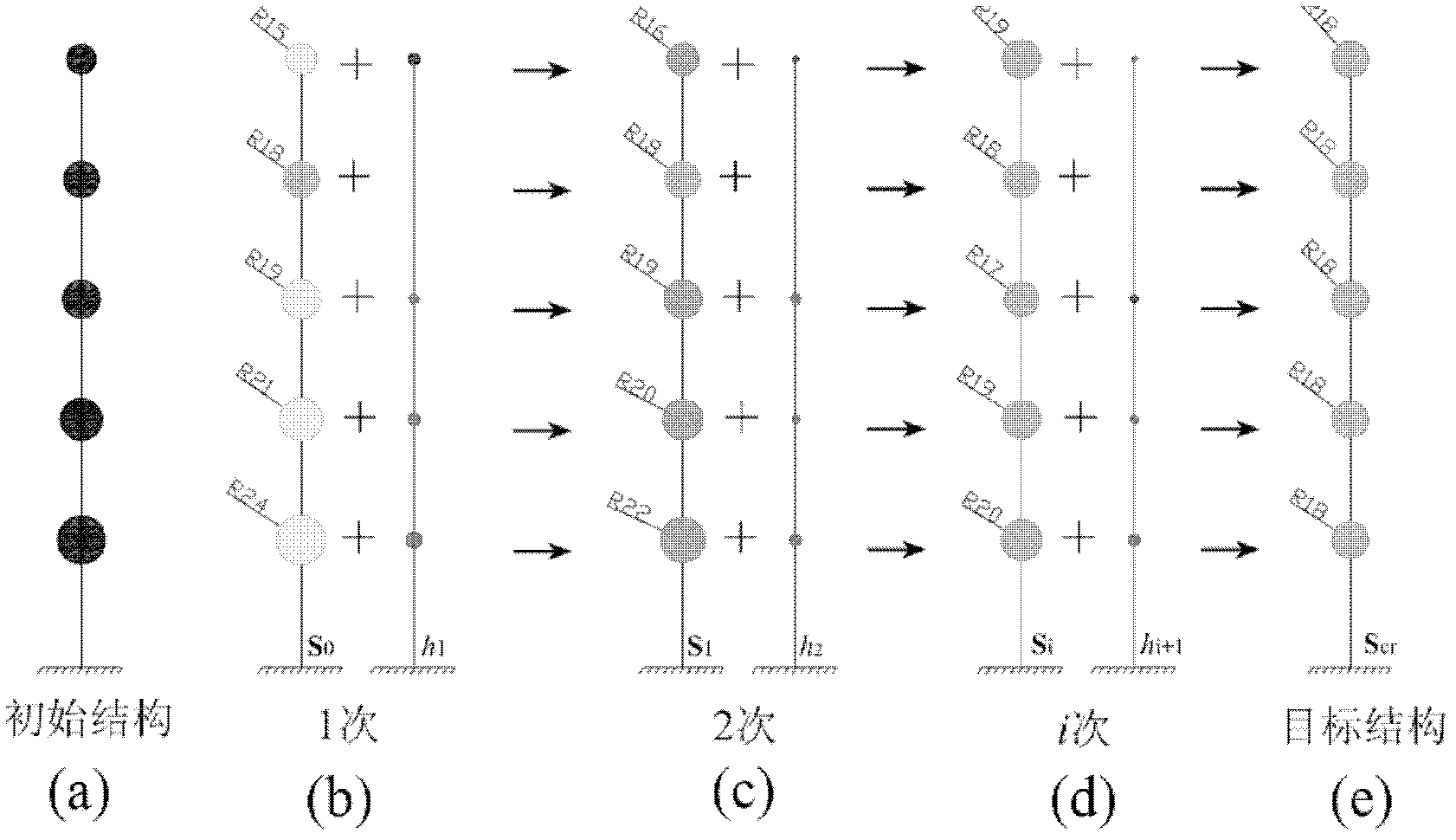

Seismic behavior based optimization method and system for building structure

ActiveCN102493569AImprove seismic performanceEliminate weak linksShock proofingStructural systemBuilding construction

The invention provides a seismic behavior based optimization method and system for a building structure. The seismic behavior based optimization method comprises the following step: A1, determining the integral target seismic behavior index of the structure and the seismic behavior index of a target construction member; A2, designing an initial structure, and dividing the construction members with the same boundary condition, the same cross section size and the same material parameter in the same layer of the structure into one class; A3, obtaining the integral damage index of the structure; A4, detecting whether the integral damage index satisfies a constraint condition, if so, performing step A5, and if not performing step 2; A5, obtaining the seismic behavior index of various classes of construction members of the structure; A6, detecting whether the seismic behavior index of various classes of construction members of the structure satisfies a condition of convergence, if so, finishing the optimization, and if not, performing step A7; and A7, determining the step size of next optimization step, updating a structural system, and returning step A3.

Owner:BEIJING JIAOTONG UNIV

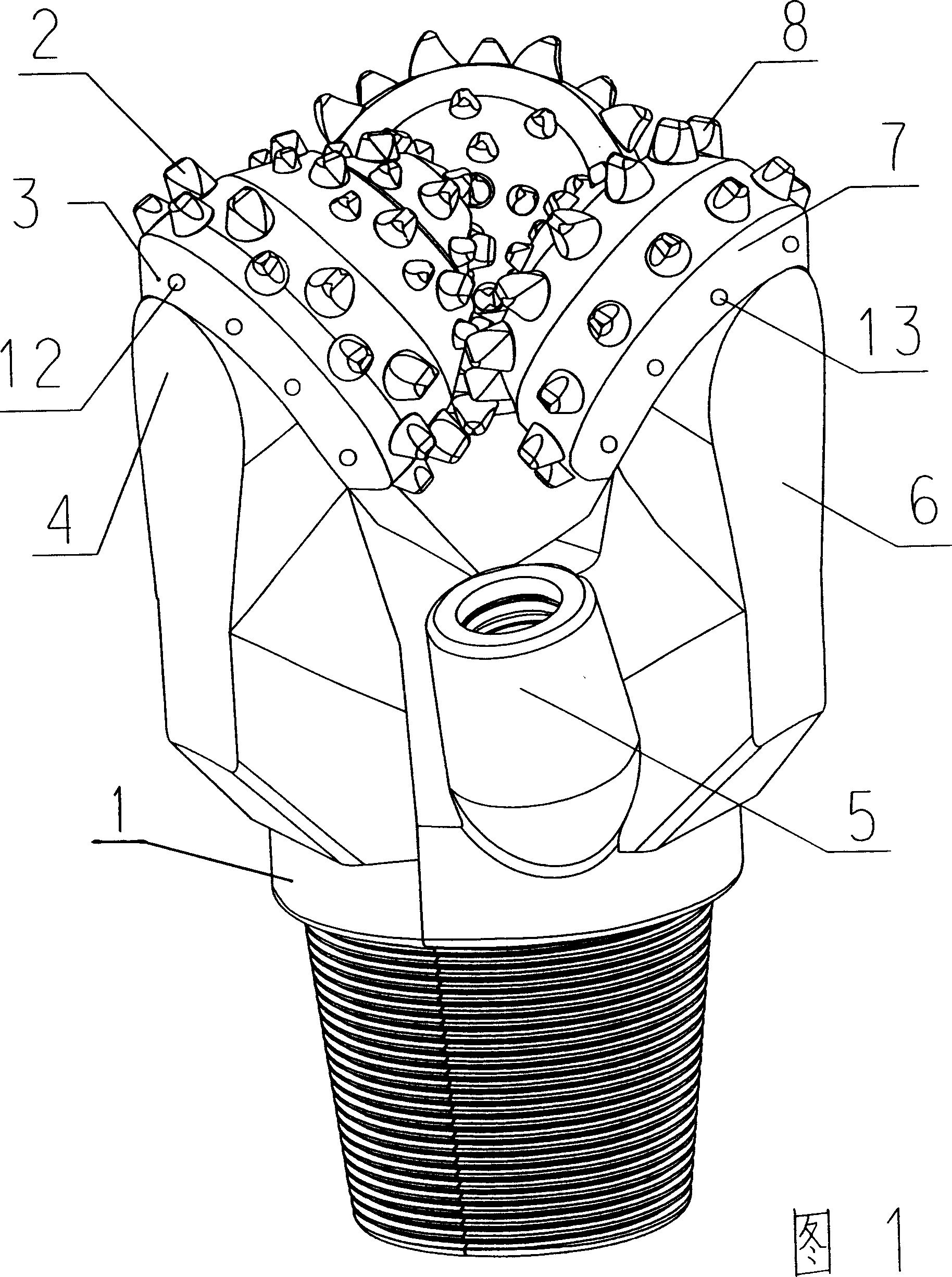

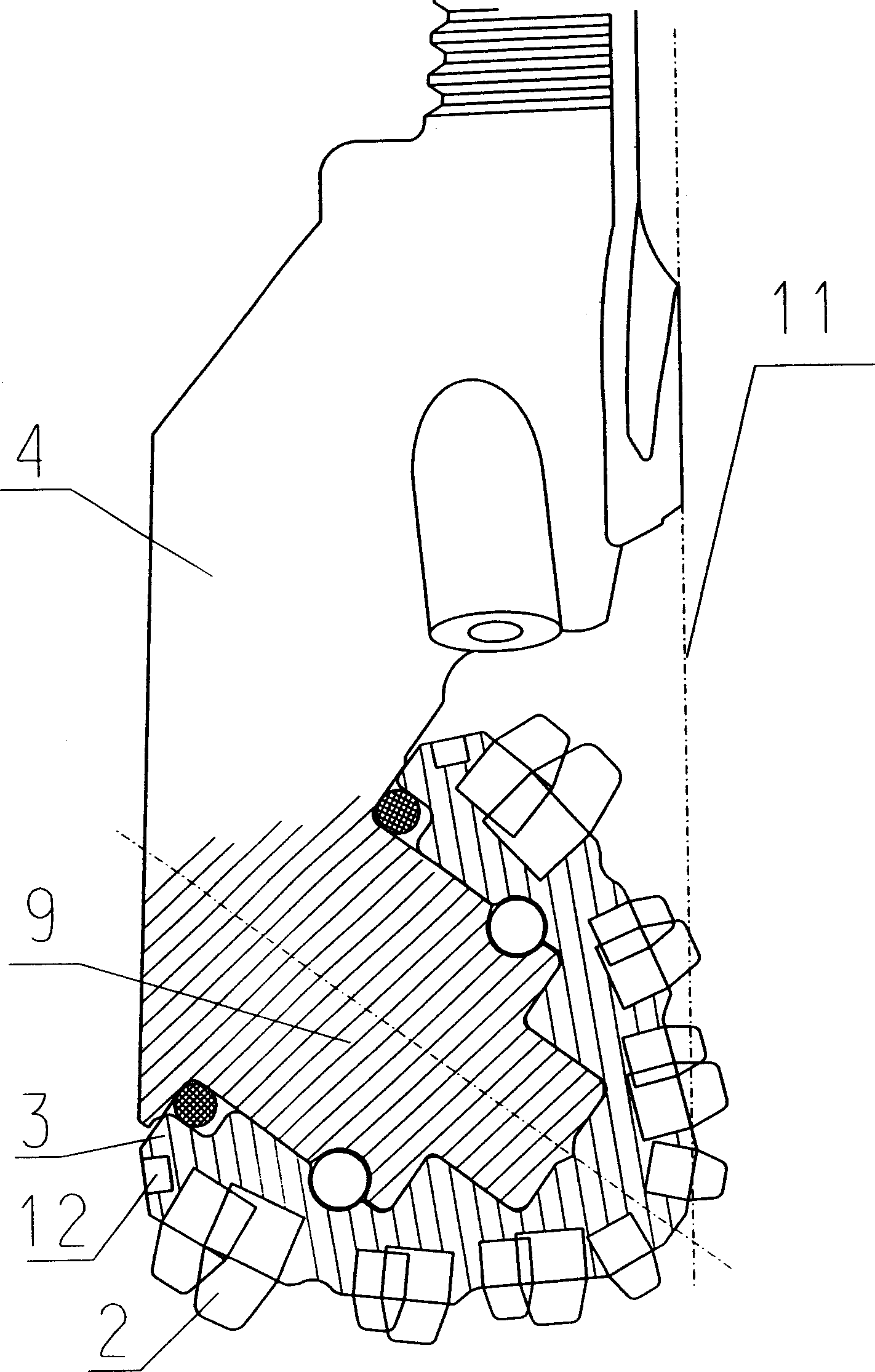

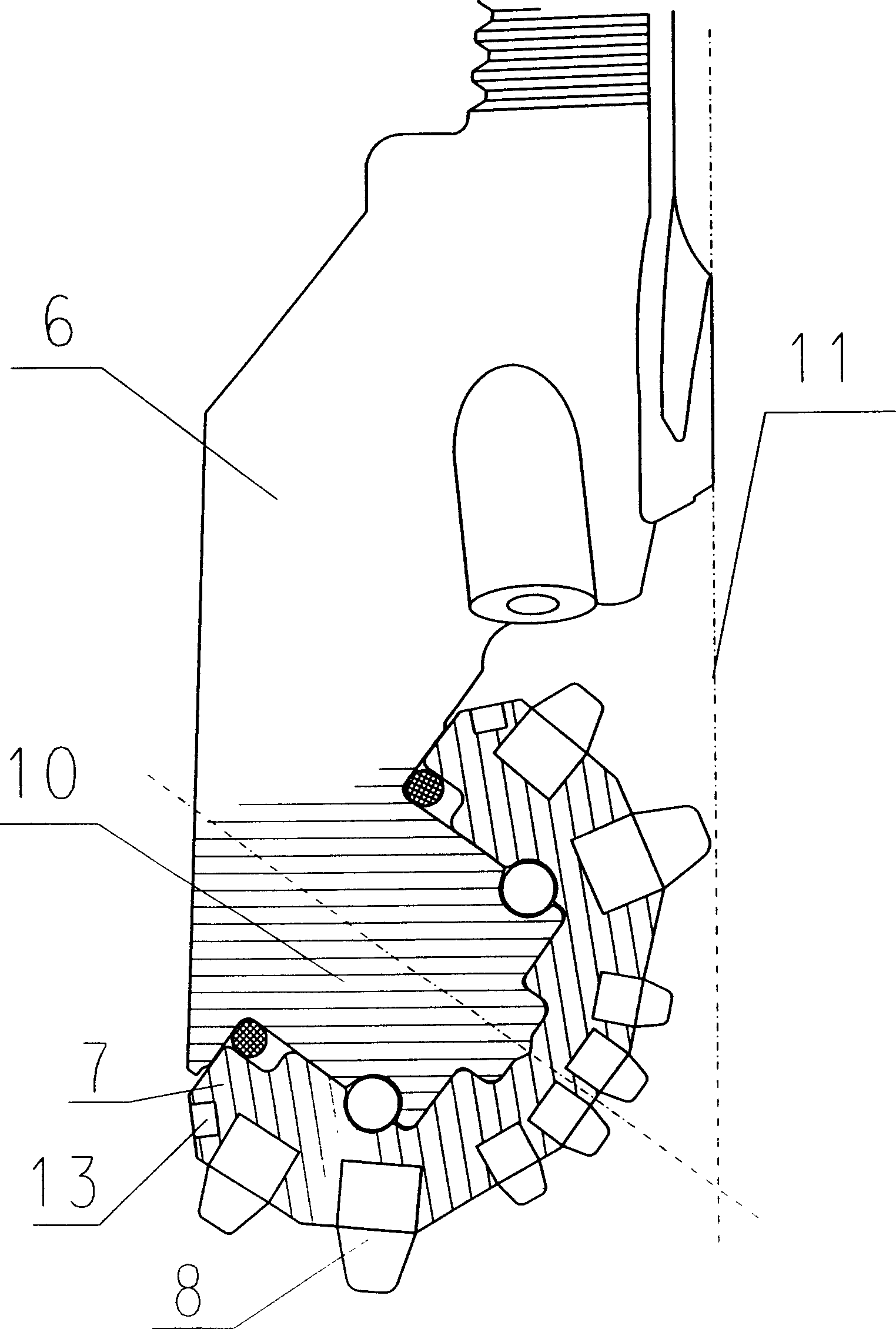

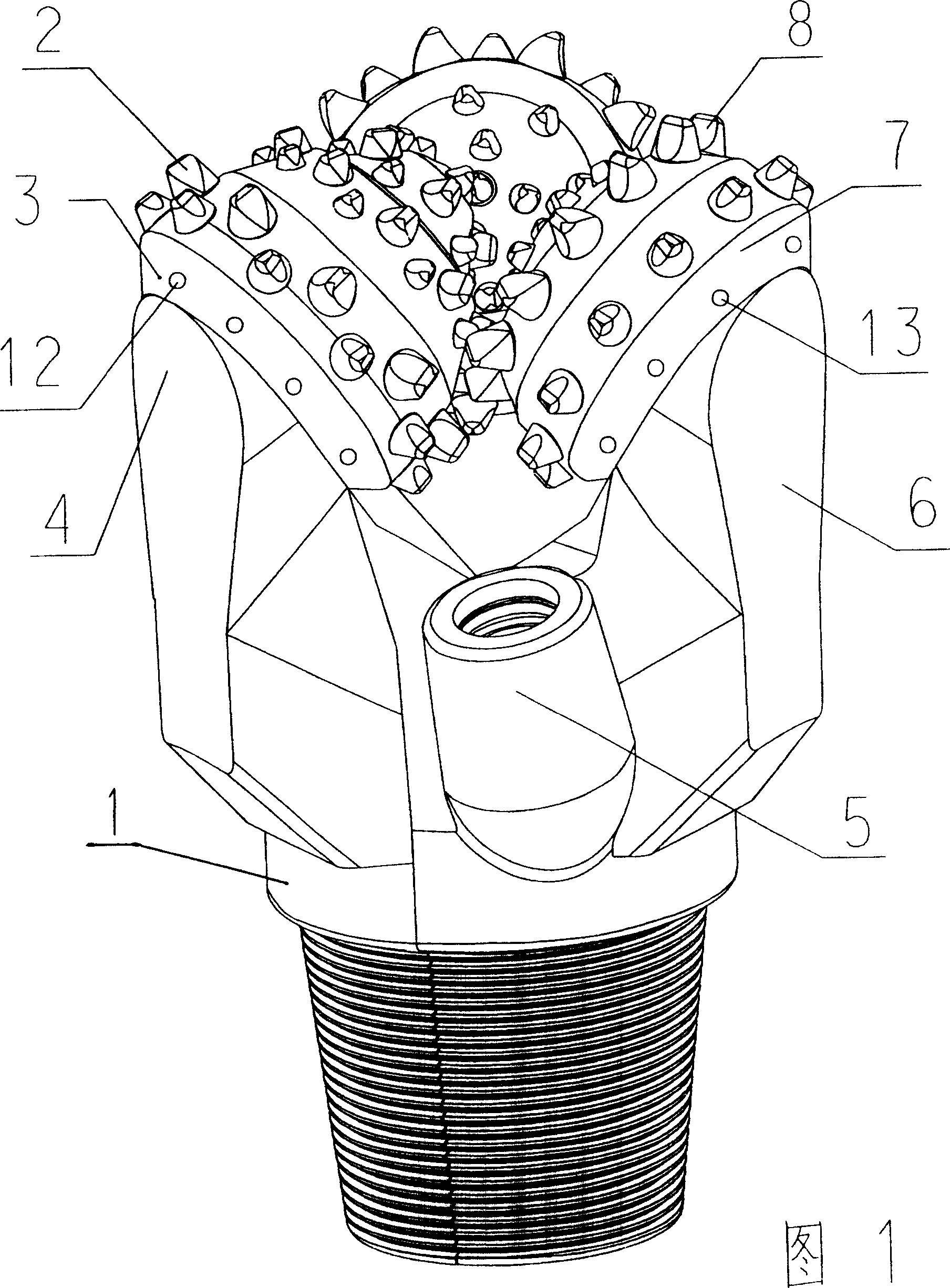

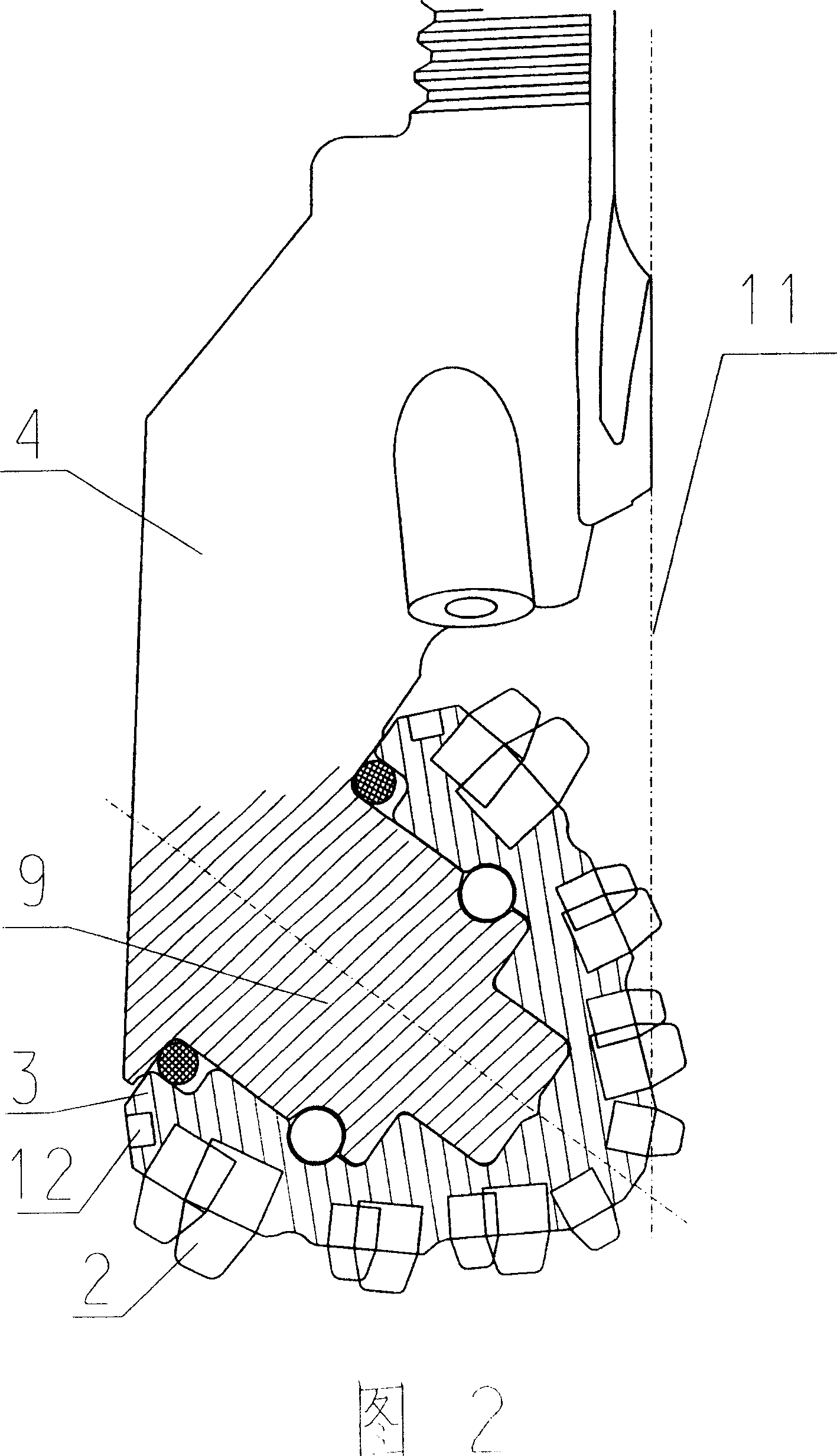

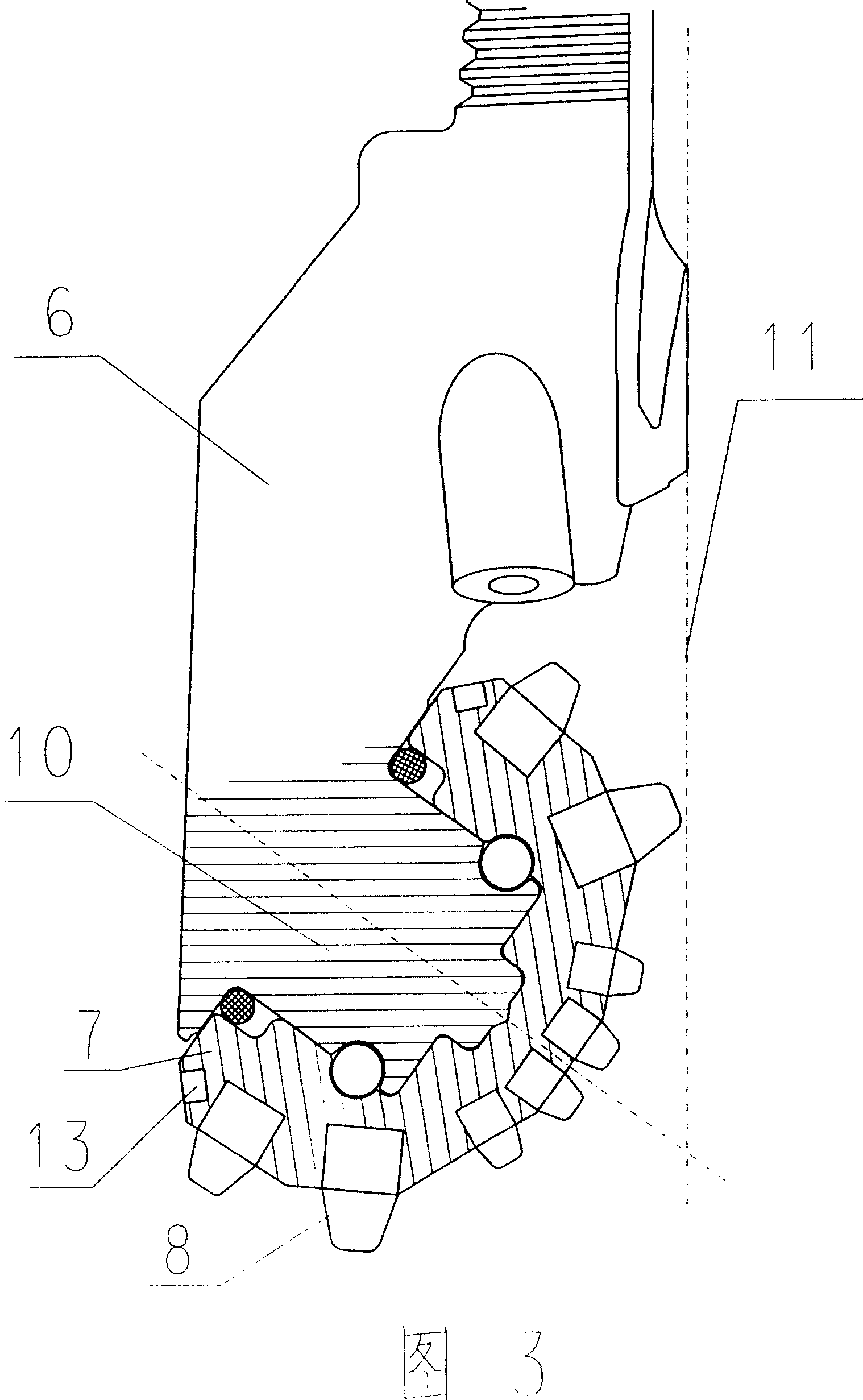

High strength antiwear drilling bit of multiple rollers

A high-strength antiwear multi-toothed-roller drill bit for drilling well has two or more palms whose upper parts are connected to form a whold drill bit body and whose lower parts are jibaxle, and multiple toothed rollers installed onto said jibaxle. Said toothed rollers is composed of the rollers with big tip on tooth and the roollers with flat front end on tooth. It has long service life.

Owner:SINOPEC OILFIELD EQUIP CORP

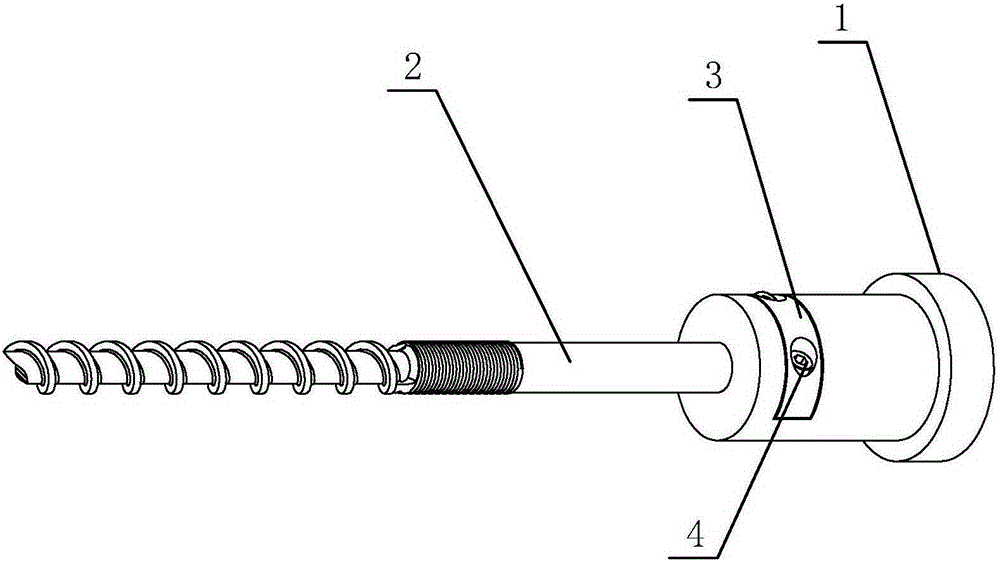

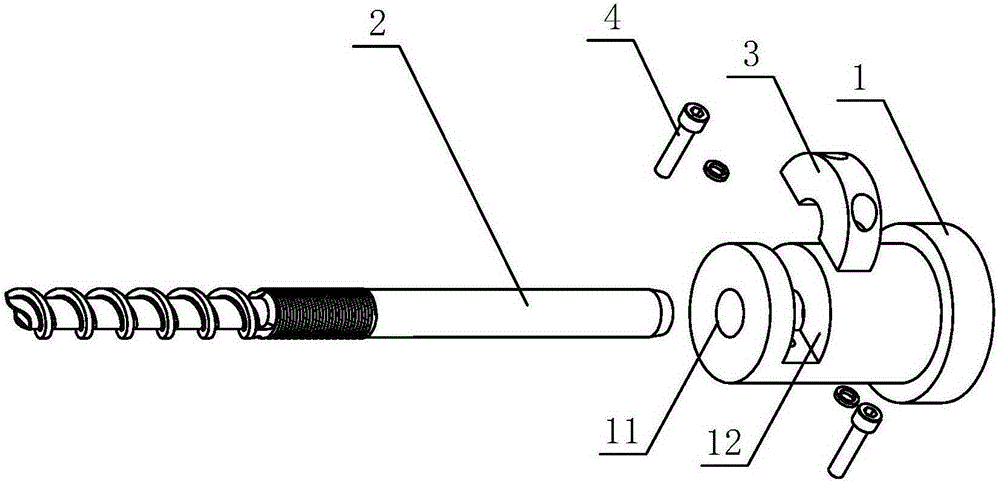

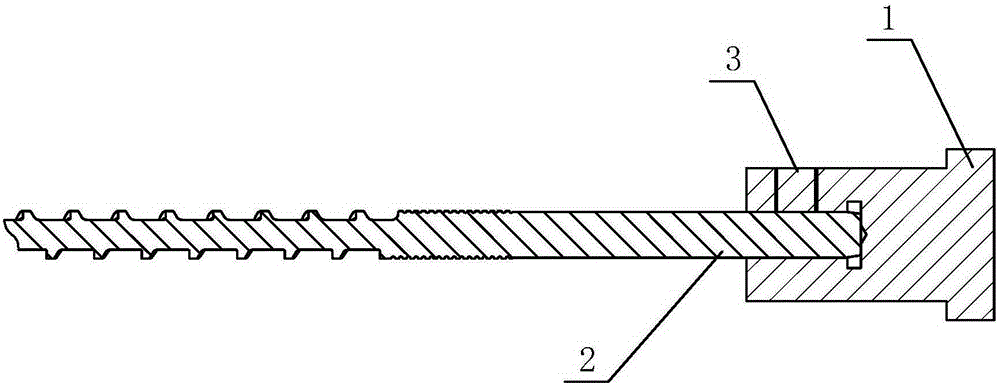

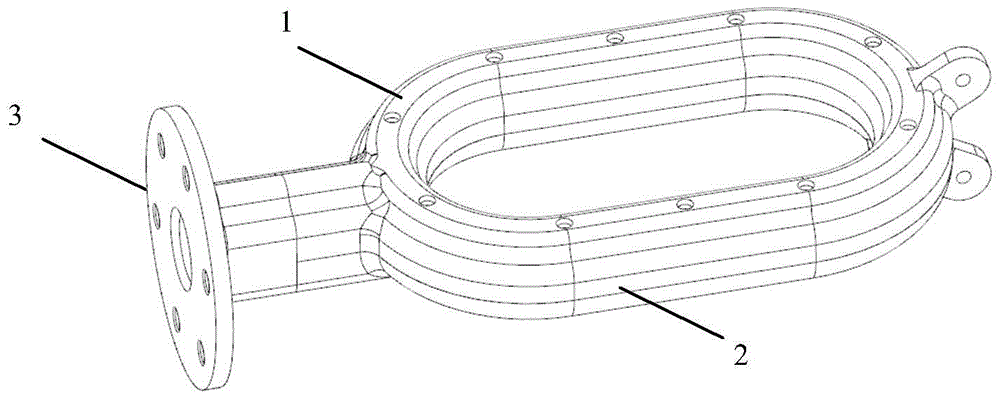

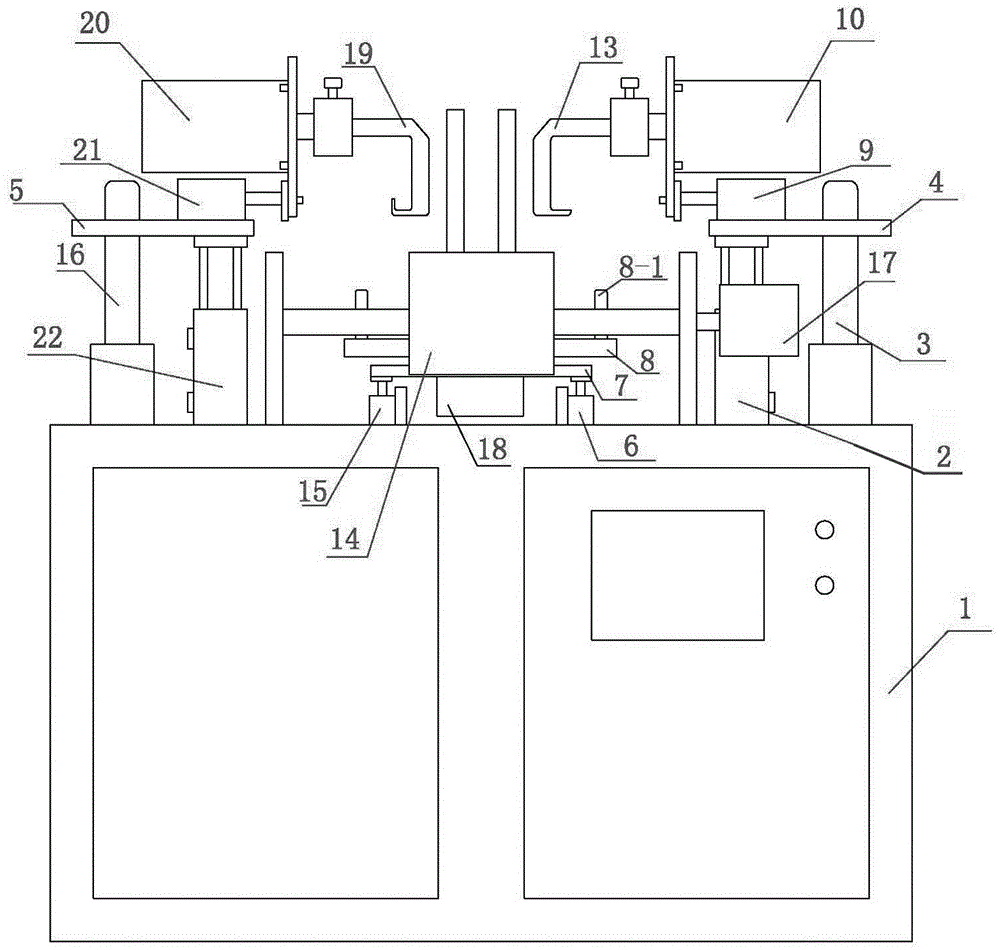

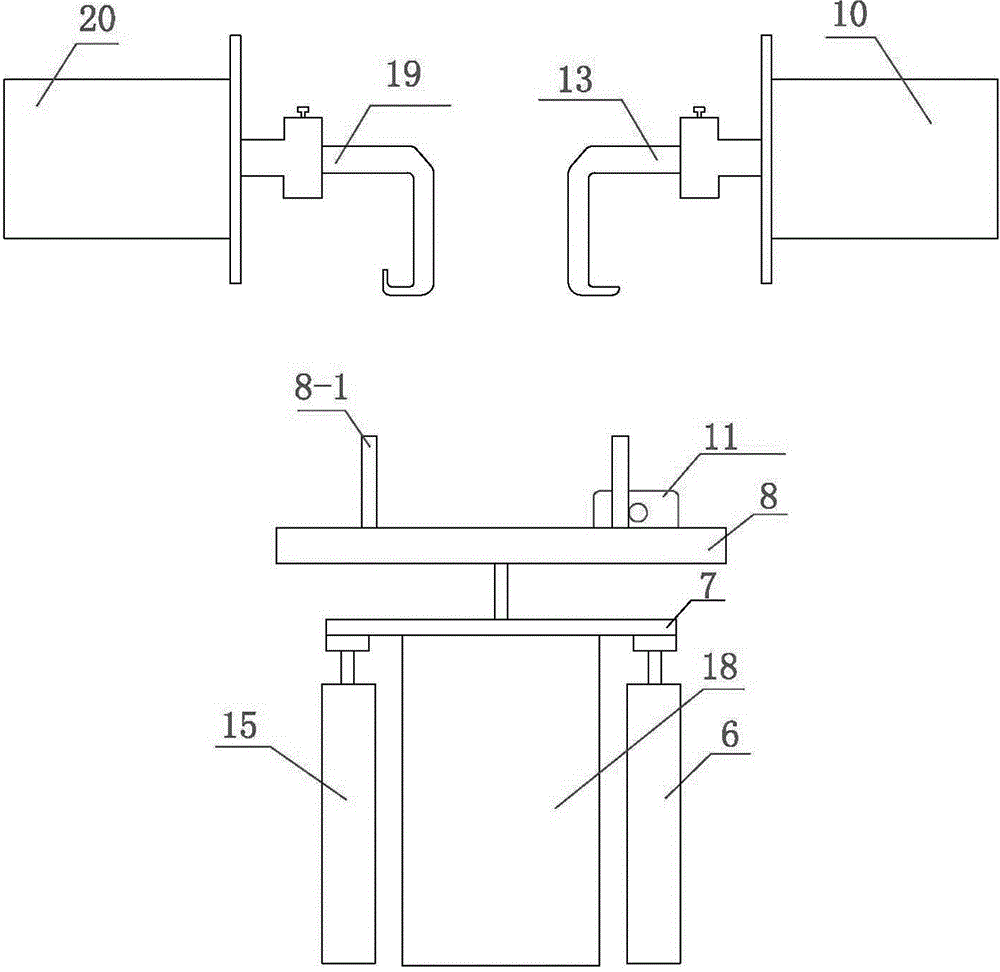

Screw rod installation structure of injection molding machine

ActiveCN105328862AEliminate weak linksHigh strengthCouplings for rigid shaftsInjection molding machineUltimate tensile strength

The invention discloses a screw rod installation structure of an injection molding machine. The screw rod installation structure comprises a rotation shaft and a screw rod. A connection shaft hole is formed in the end of the rotation shaft, and the screw rod is inserted into the connection shaft hole for shaft connection. The rotation shaft is provided with a clamping ring capable of adjusting and hooping the screw rod in the connection shaft hole in the radial direction, and the clamping ring and the rotation shaft are fixedly connected with the screw rod hooped in the radial direction through bolts. According to the screw rod installation structure, the rotation shaft and the clamping ring are used for clasping, the bolts are used for compression, and therefore the clasping structure can be tightly attached to the surface of the screw rod; torque and axial force are transmitted through compression deformation, the stressing weak link of the screw rod is eliminated, and therefore the strength of the screw rod is improved; for disassembling or assembling the screw rod, just the bolts need to be loosened and do not need to the detached, then the screw rod can be disassembled, and therefore frequent replacement of the screw rod is convenient. The screw rod installation structure has the advantages of being simple in structure and convenient to disassemble, assemble and use and lowering the machining and manufacturing cost.

Owner:DONGHUA MACHINERY

In-situ SiC particle reinforced Ti6Al4V preparation method

The invention discloses an in-situ SiC particle reinforced Ti6Al4V preparation method. The method comprises the following steps: (1) putting Si powder and C powder into high-energy grinding equipment for mechanical alloying, grinding for 8-48 hours, wherein the mass ratio of the Si powder to the C powder is (2-3):1, then adding SiO2 powder which accounts for 5-20% of the total mass of the Si powder and the C powder, and further grinding for 4-10 hours to obtain a mixed material; (2) uniformly mixing titanium powder, master alloy powder and the mixed material, wherein the addition amount of the titanium powder accounts for 80-95% of the total mass of the titanium powder and the master alloy powder, the addition amount of the master alloy powder accounts for 5-20% of the total mass of the titanium powder and the master alloy powder, the addition amount of the mixed material accounts for 5-40% of the titanium powder and the master alloy powder, and compression molding to produce blanks; and (3) sintering the blanks in a vacuum sintering furnace for two stages at 700-900 DEG C for 0.5-3 hours, then heating to be 1300-1500 DEG C and sintering in an argon atmosphere for 0.5-3 hours. The reinforcement phase of a composite material obtained by the method is produced in situ, interfaces are densely connected together, and the composite material has high strength and is suitable for industrial scale.

Owner:ZHONGYUAN ENGINEERING COLLEGE

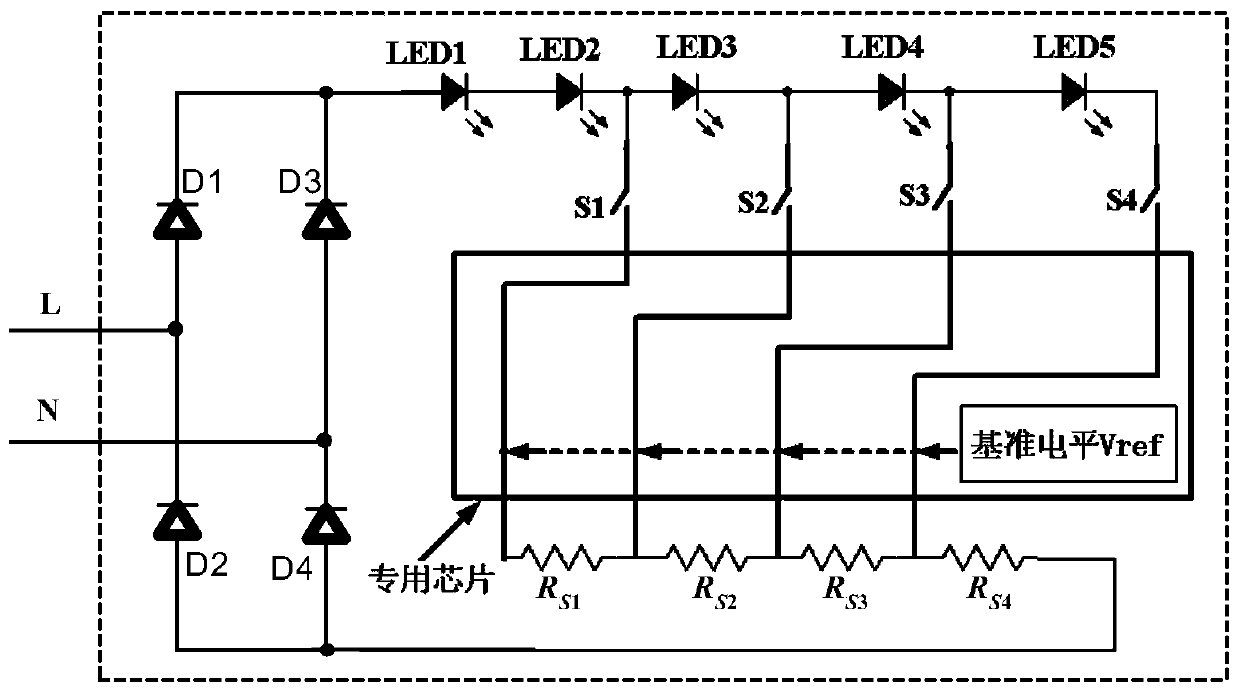

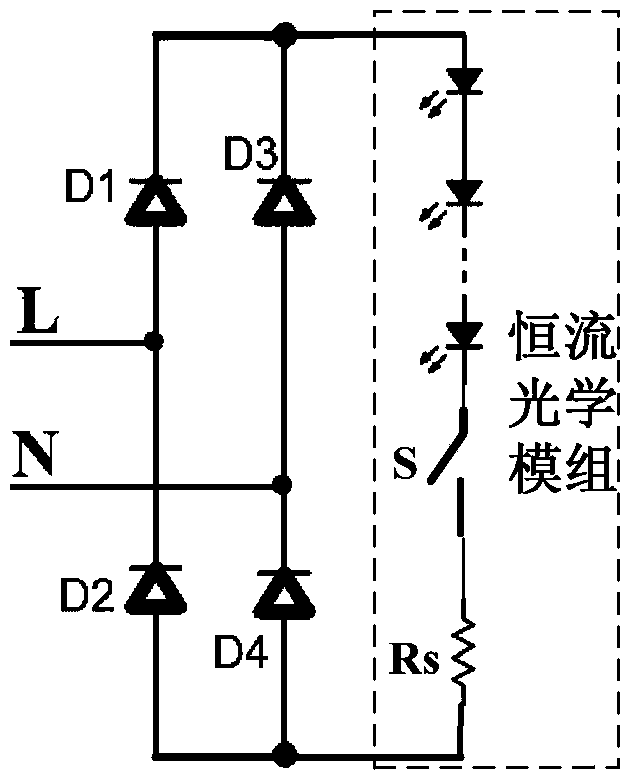

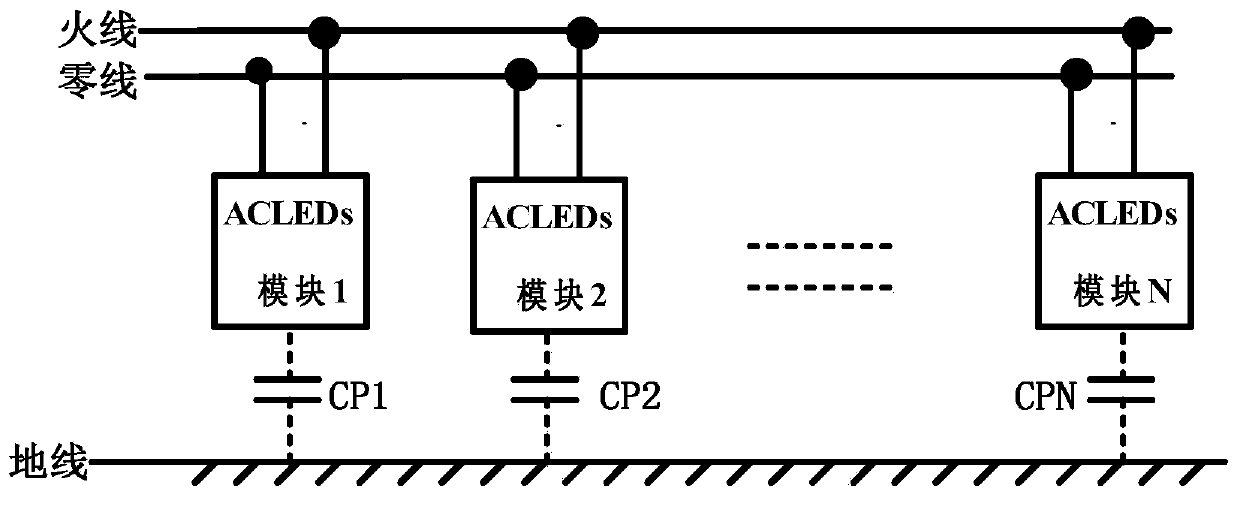

Linear power driving LED lamp and thunder-proof linear power driving LED lamp

InactiveCN103813592AConsistent response speedEliminate weak linksElectric light circuit arrangementEngineeringAlternating current

The invention discloses a thunder-proof power driving LED lamp. The thunder-proof linear power driving LED lamp comprises a thunder prevention module, a rectifying module and a linear power driving light emitting diode illumination module, wherein the thunder prevention module is used for limiting lightning transient surge current which passes through the LED lamp when a lightning stroke is occurred to the LED lamp, the rectifying module is used for rectifying alternating current and outputting pulsatile direct current, the linear power driving light emitting diode illumination module comprises N constant-current optical units which are used for regulating the pulsatile direct current output from the rectifying module into constant current source, responding to the lightning transient surge current and averaging the lightning transient surge current simultaneously. The ACLEDs module in the thunder-proof linear power driving LED lamp only comprises the constant-current optical modules rather than bridge rectifiers; when the lightning stroke is occurred to the lamp in the door or out of door, the response speed of each ACLEDs module to the lightning transient surge current is approximately consistent so that the lightning transient surge current is divided uniformly, and the weak thunder-proof link is eliminated. When the linear power driving LED lamp is used in the door, the thunder prevention module can be omitted so as to save cost.

Owner:SHANGHAI YAMING LIGHTING

High strength antiwear drilling bit of multiple rollers

A high-strength antiwear multi-toothed-roller drill bit for drilling well has two or more palms whose upper parts are connected to form a whold drill bit body and whose lower parts are jibaxle, and multiple toothed rollers installed onto said jibaxle. Said toothed rollers is composed of the rollers with big tip on tooth and the roollers with flat front end on tooth. It has long service life.

Owner:SINOPEC OILFIELD EQUIP CORP

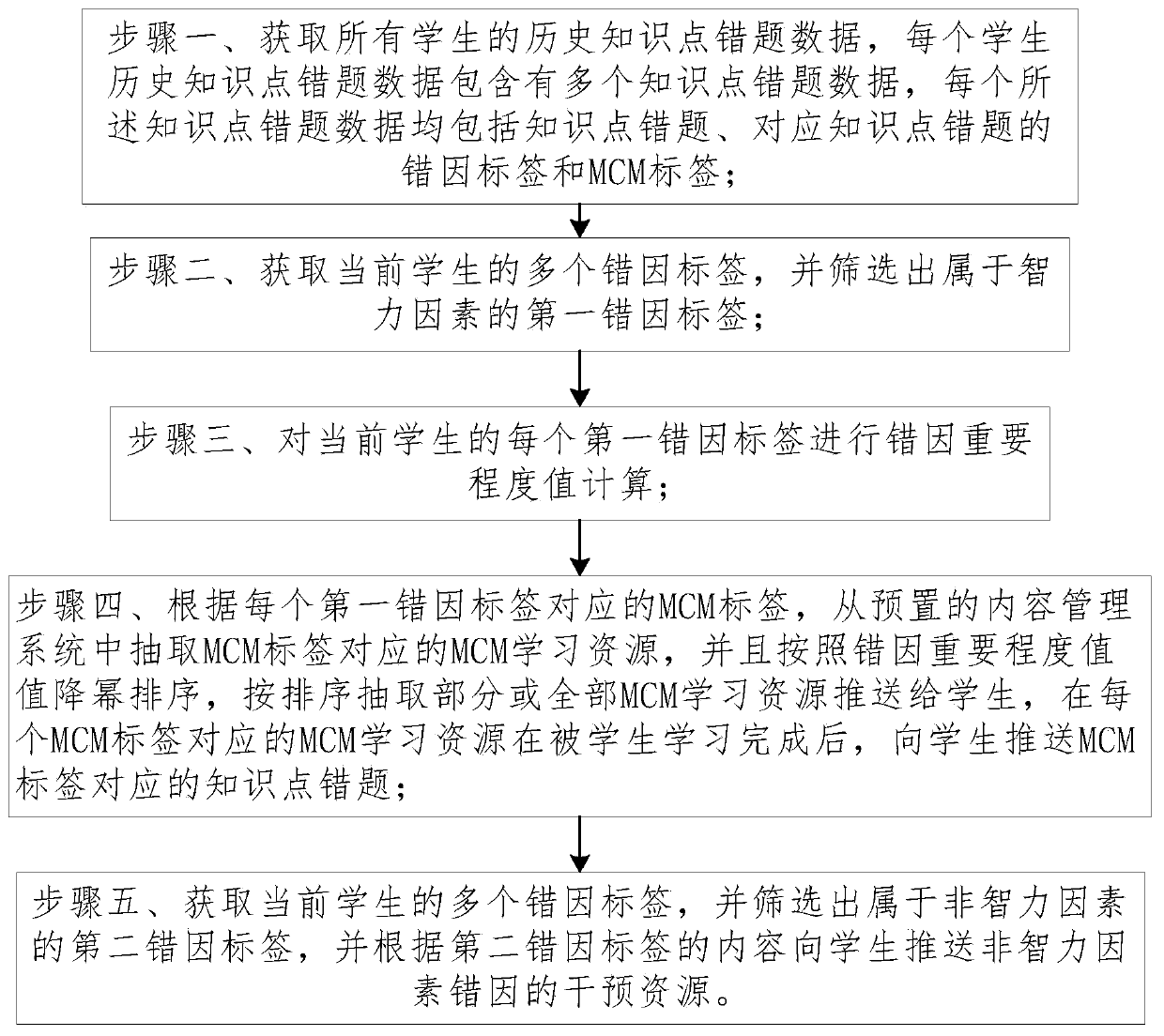

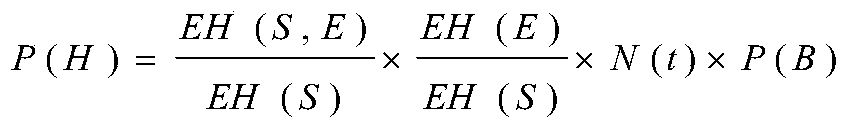

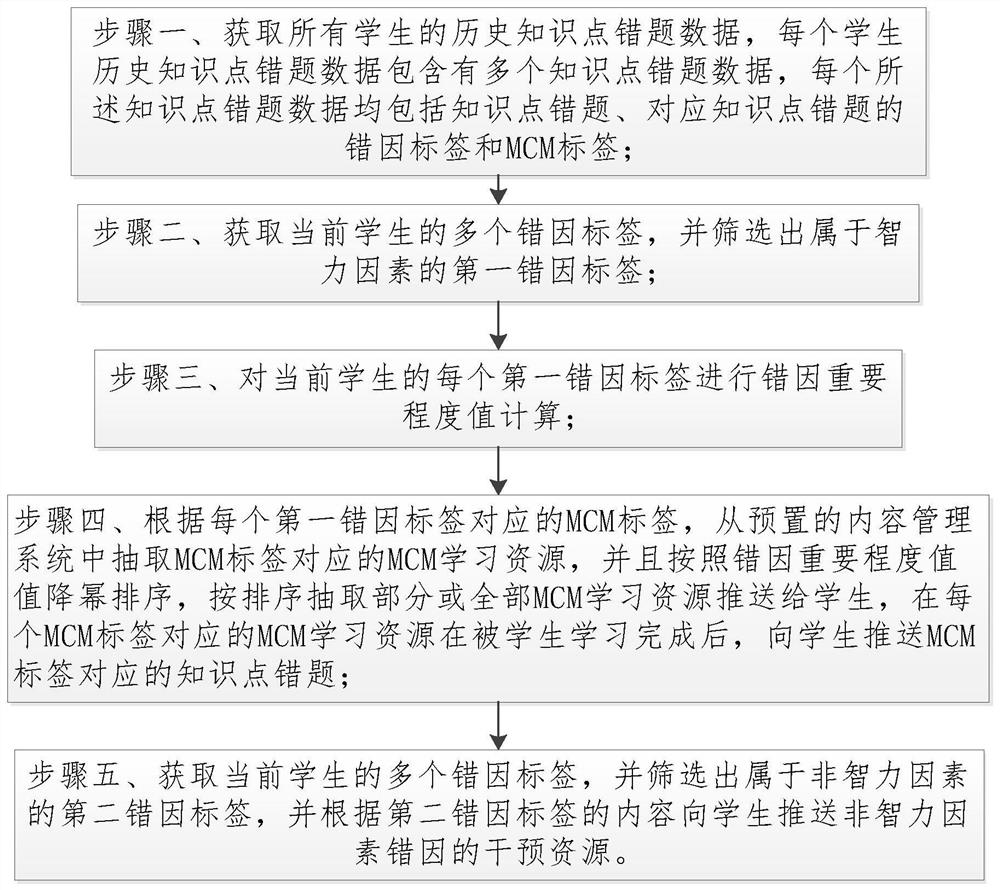

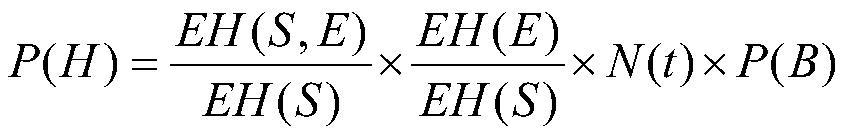

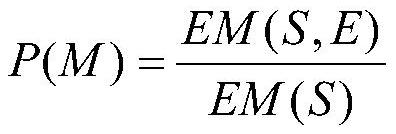

MCM-based intelligent adaptive review resource pushing method

ActiveCN111428058ASpotting weaknessesEliminate weak linksData processing applicationsDigital data information retrievalEngineeringArtificial intelligence

The invention discloses an MCM-based intelligent adaptive review resource pushing method. The method comprises the steps of obtaining historical knowledge point wrong question data of all students; obtaining a plurality of error cause labels of the current student, and screening out a first error cause label belonging to the intelligence factor; calculating an error cause importance degree value P(E) of each first error cause label of the current student; according to the MCM label corresponding to each first error factor label, obtaining a second error factor label, extracting MCM learning resources corresponding to the MCM label from a preset content management system; and performing power reduction sorting according to the error cause importance degree value P (E), extracting part or all of the MCM learning resources according to the sorting, pushing the MCM learning resources to the students, and pushing knowledge point errors corresponding to the MCM tags to the students after the MCM learning resources corresponding to each MCM tag are learned by the students. According to the invention, the problems that the symptoms are not treated during reviewing and the learning level of students is difficult to truly improve are solved.

Owner:SHANGHAI SQUIRREL CLASSROOM ARTIFICIAL INTELLIGENCE TECH CO LTD

Construction method for strengthening perforated plate and floor slab

ActiveCN103362319AEnhance horizontal connection abilityImprove carrying capacityBuilding repairsEpoxySurface layer

The invention discloses a construction method for strengthening a perforated plate and a floor slab. The construction method is characterized by comprising the following construction steps: (1) a mortar surface layer of the perforated plate and a mortar surface layer of the floor slab are removed; (2) filler in seams between the perforated plate and a wall body is removed, and the removal range reaches the top surface of a ring beam; (3) a steel linear plate is mounted; (4) a hole is drilled in the wall body, and a steel strand passes through the drilled wall hole and is fixed on the steel linear plate through an anchorage device; (5) the steel strand is fixed on the steel linear plate through the anchorage device after being stretched, and a gap between the steel strand and the wall hole is sealed through high-strength epoxy resin; (6) a seam between the perforated plate and the wall body is filled with expansive concrete; (7) a waterproof layer is constructed; (8) a fine aggregate concrete layer is poured on asphalt felt. The construction method for strengthening the perforated plate and the floor slab is convenient to operate and low in construction cost.

Owner:蚌埠尚维知识产权运营有限公司

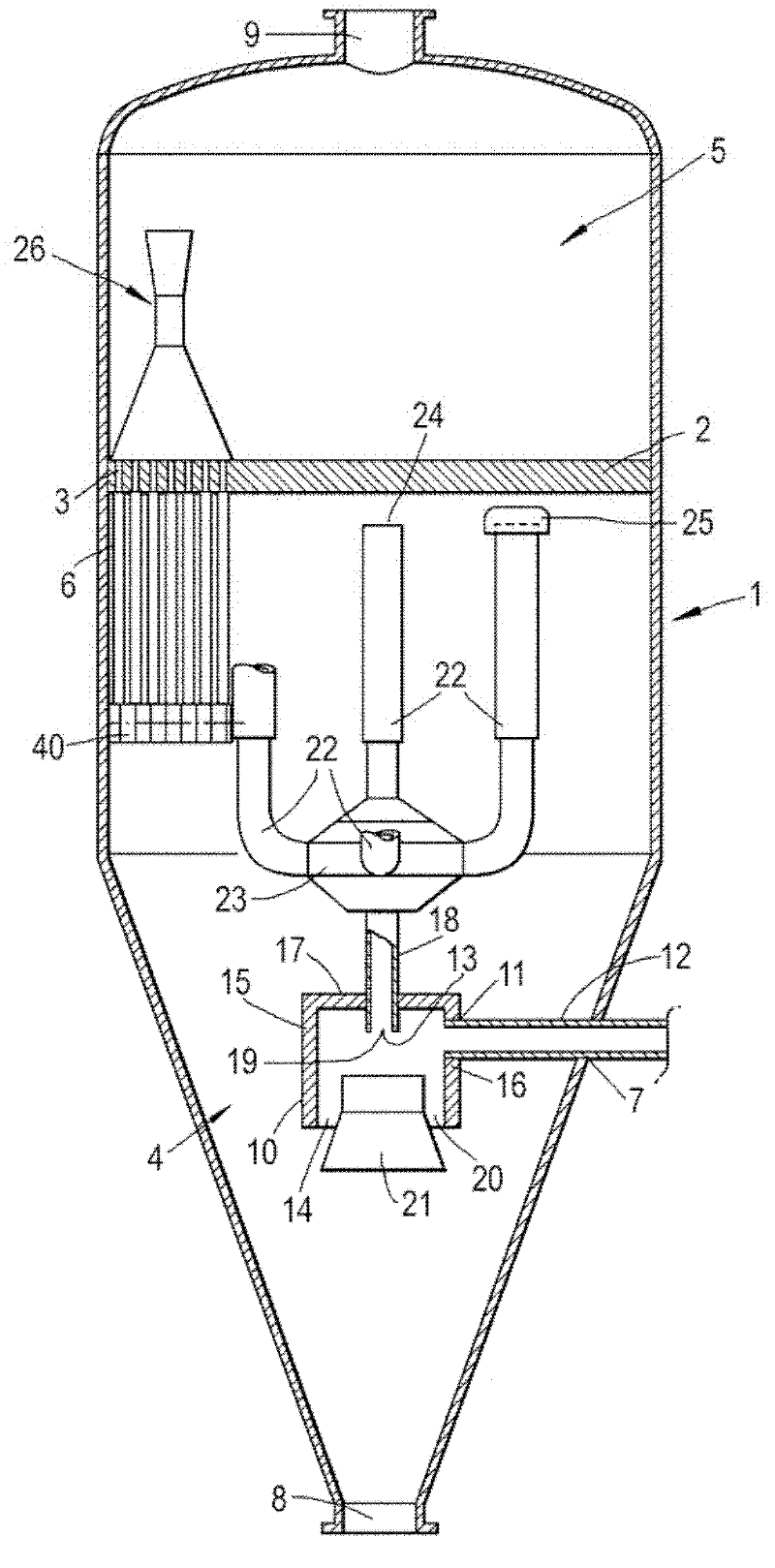

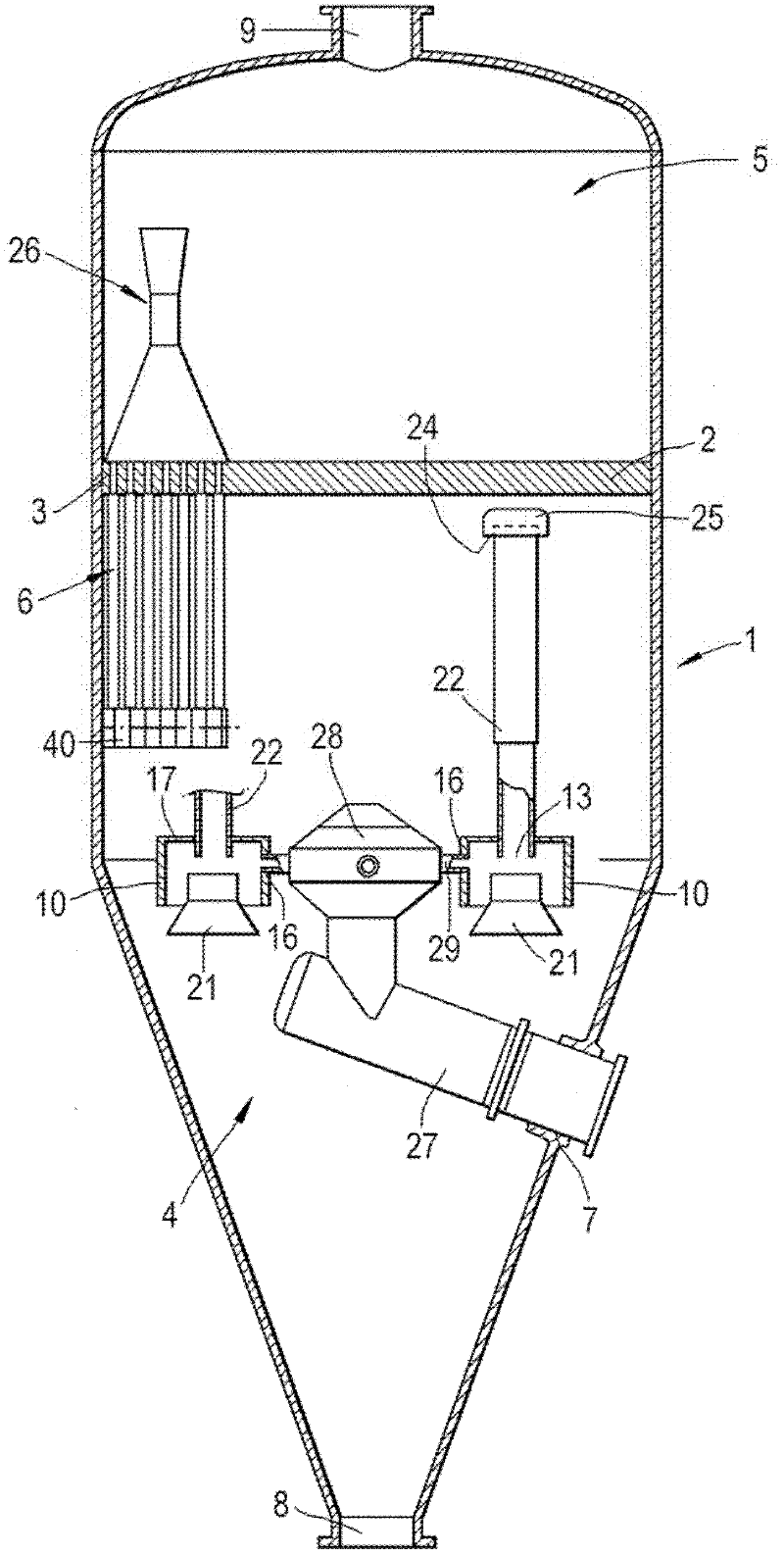

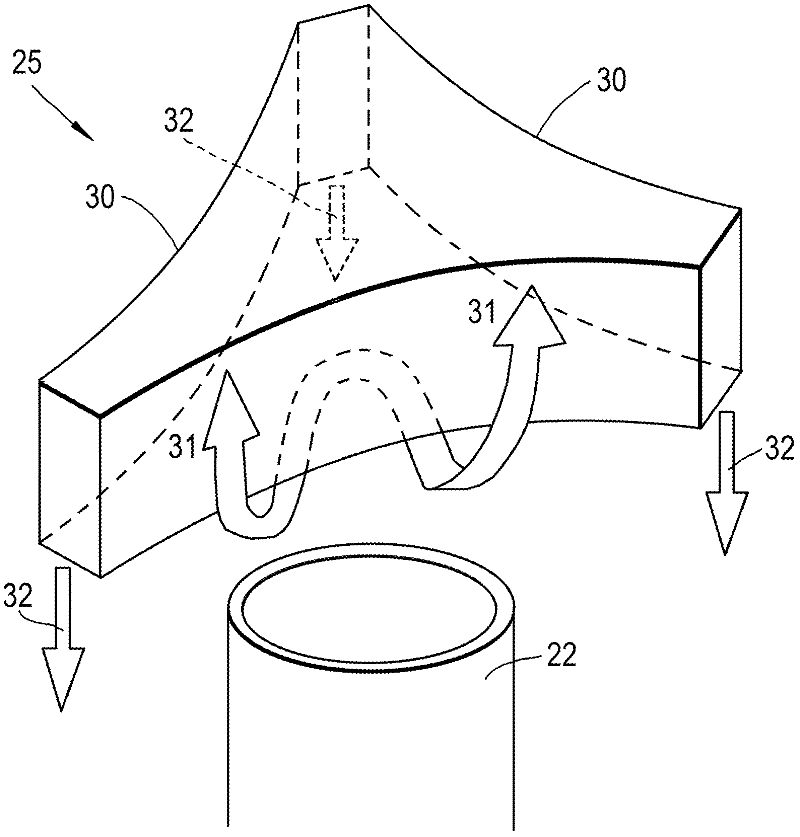

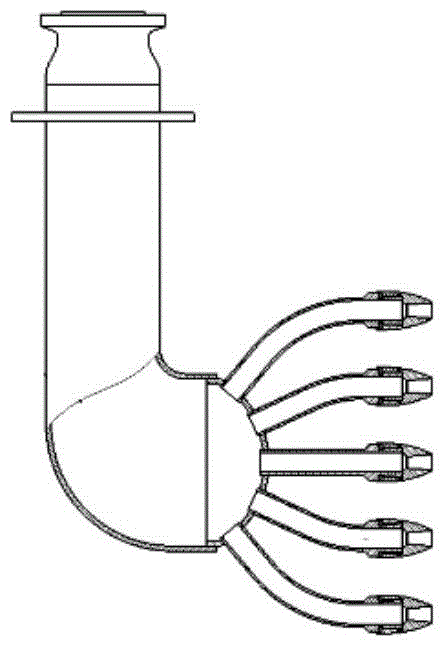

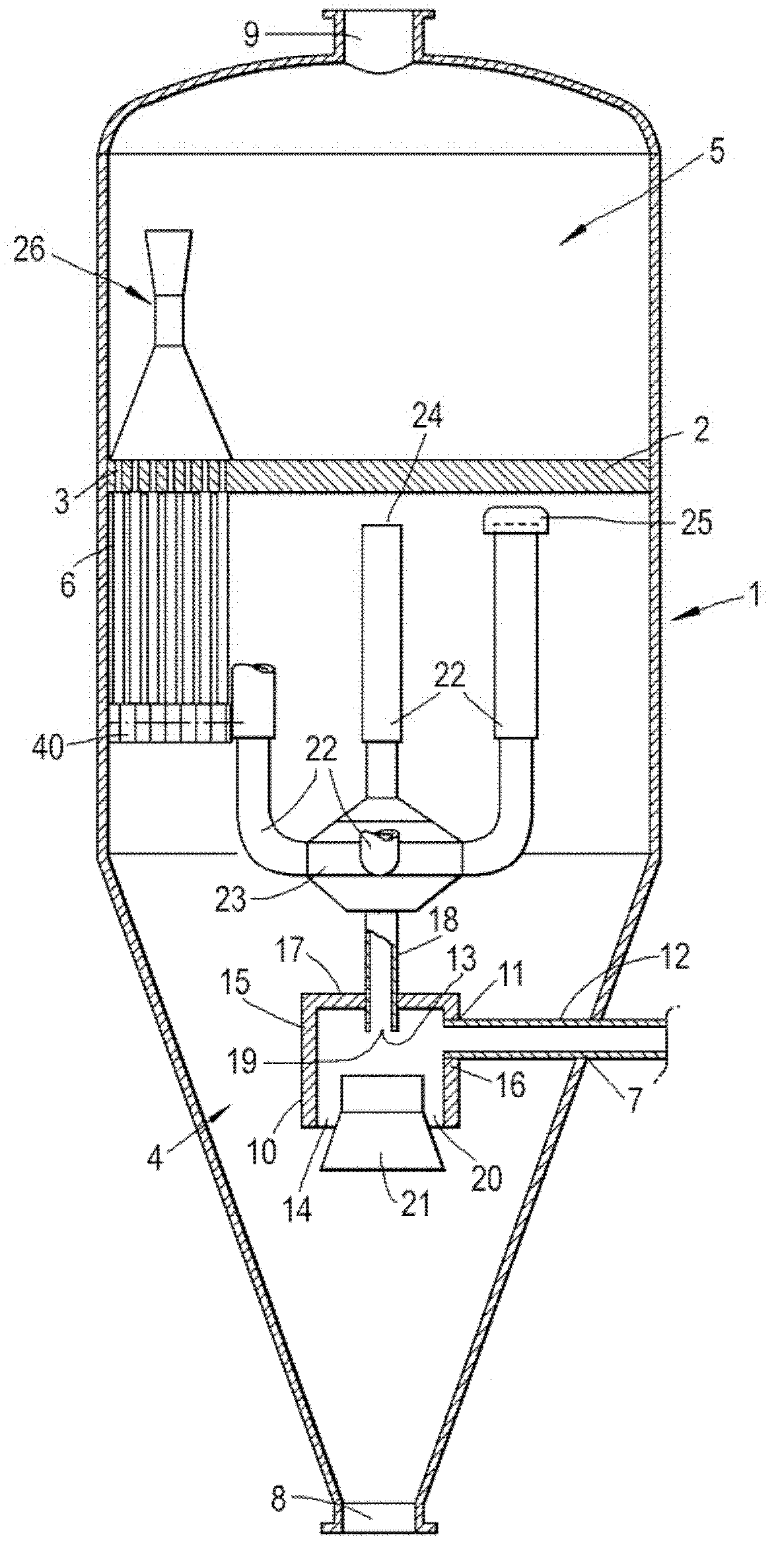

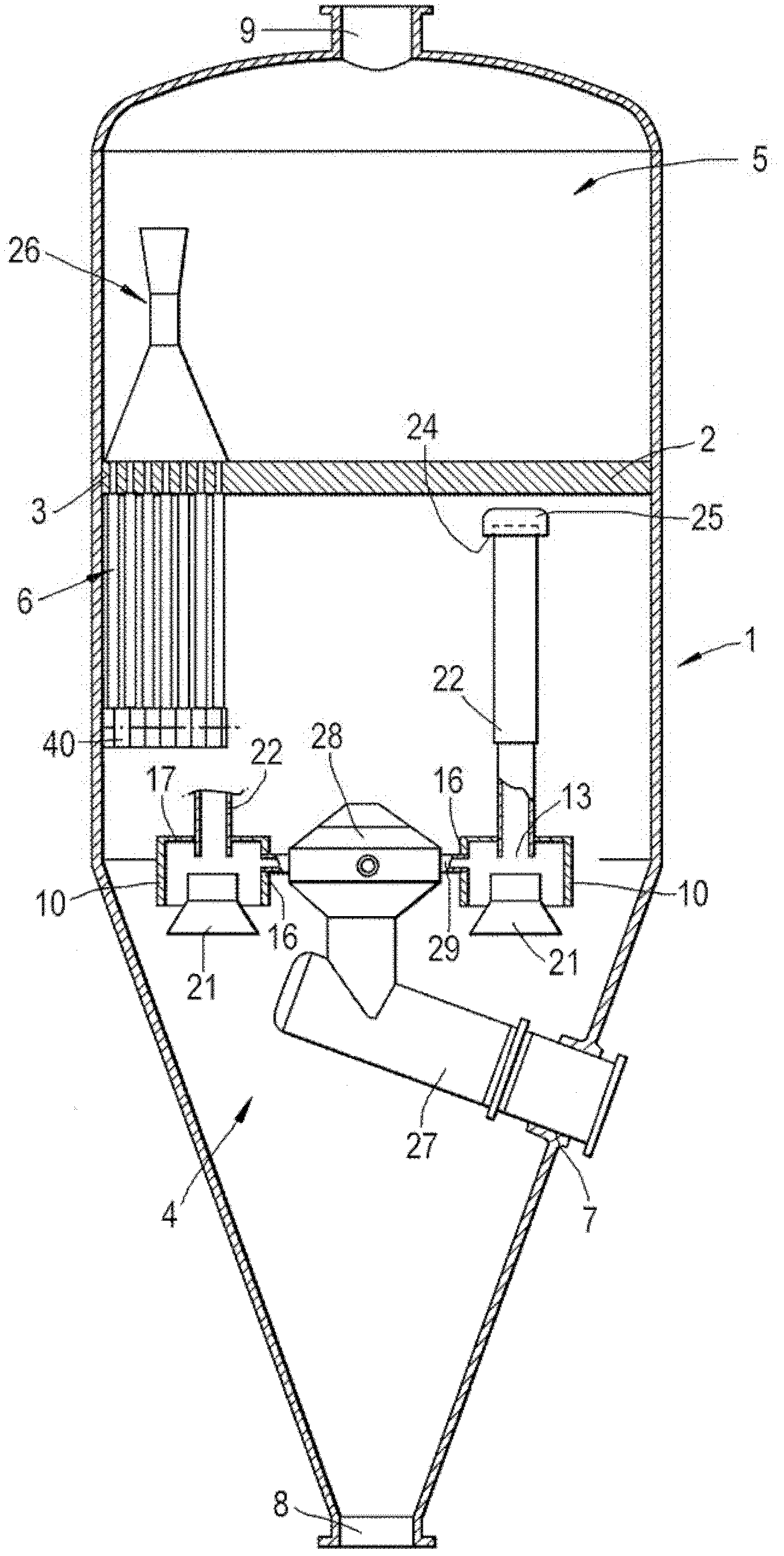

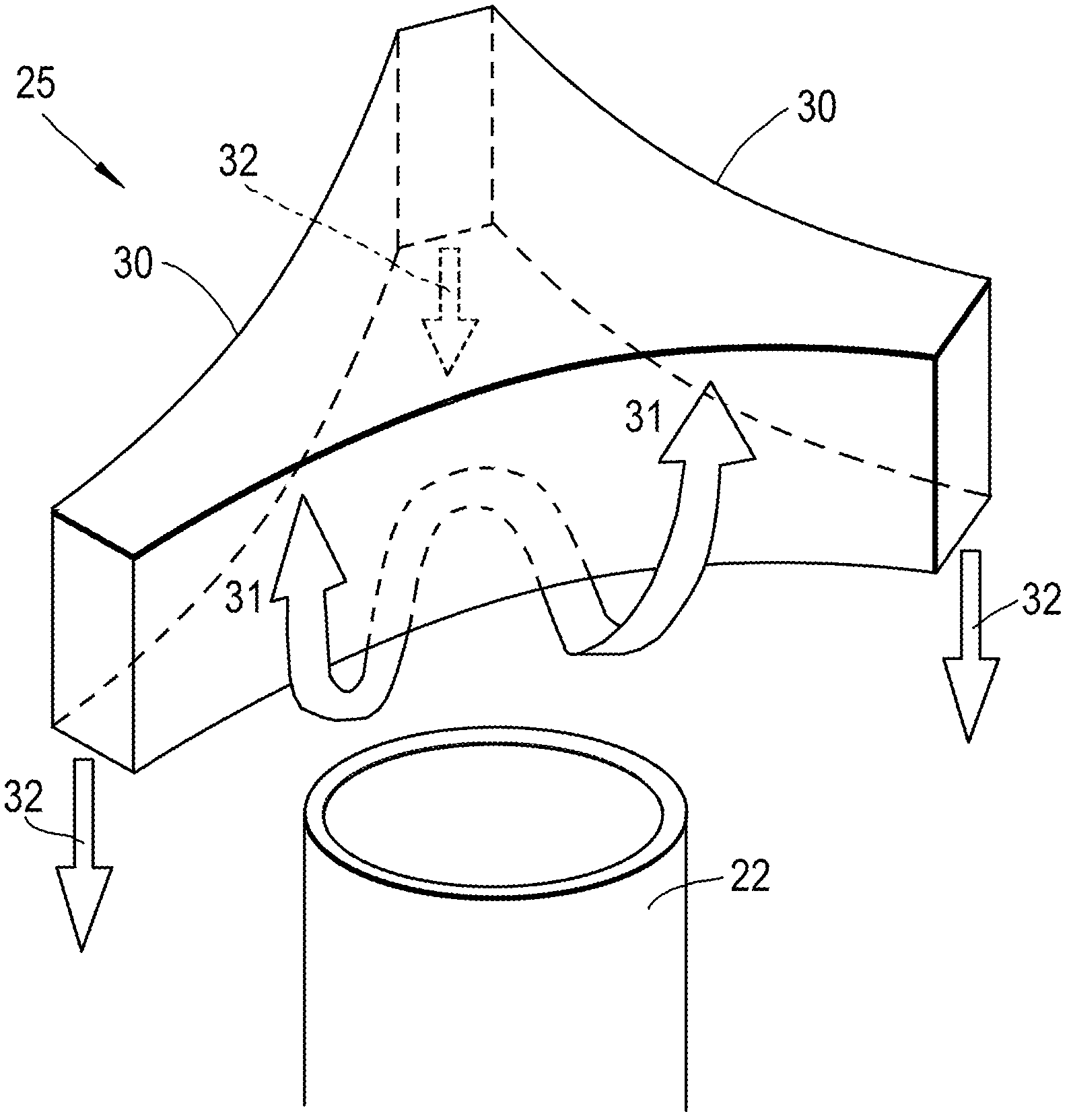

Vessel for removing solid particles from gases

ActiveCN102361676AReduce solid loadClosely spacedCombination devicesDispersed particle filtrationCycloneMarine engineering

The invention is directed to a vessel for separating solid particles from a gas containing solid particles, said vessel comprising a plate provided with openings across the vessel such that the plate divides the vessel in a first and second space, a number of filter elements extending from the openings into the first space, a vessel opening for receiving the gas containing solid particles, fluidly connected to the first space, an vessel outlet opening for discharge of solids, fluidly connected to the first space and a vessel outlet opening for gas, fluidly connected to the second space. The first space further comprises one or more cyclone separation devices having an inlet fluidly connected to the vessel opening for receiving the gas containing solid particles, a cyclone gas outlet fluidly connected to the first space and a solids cyclone outlet.

Owner:AIR PROD & CHEM INC

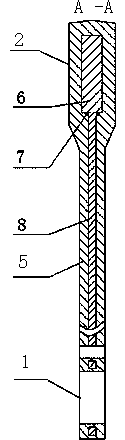

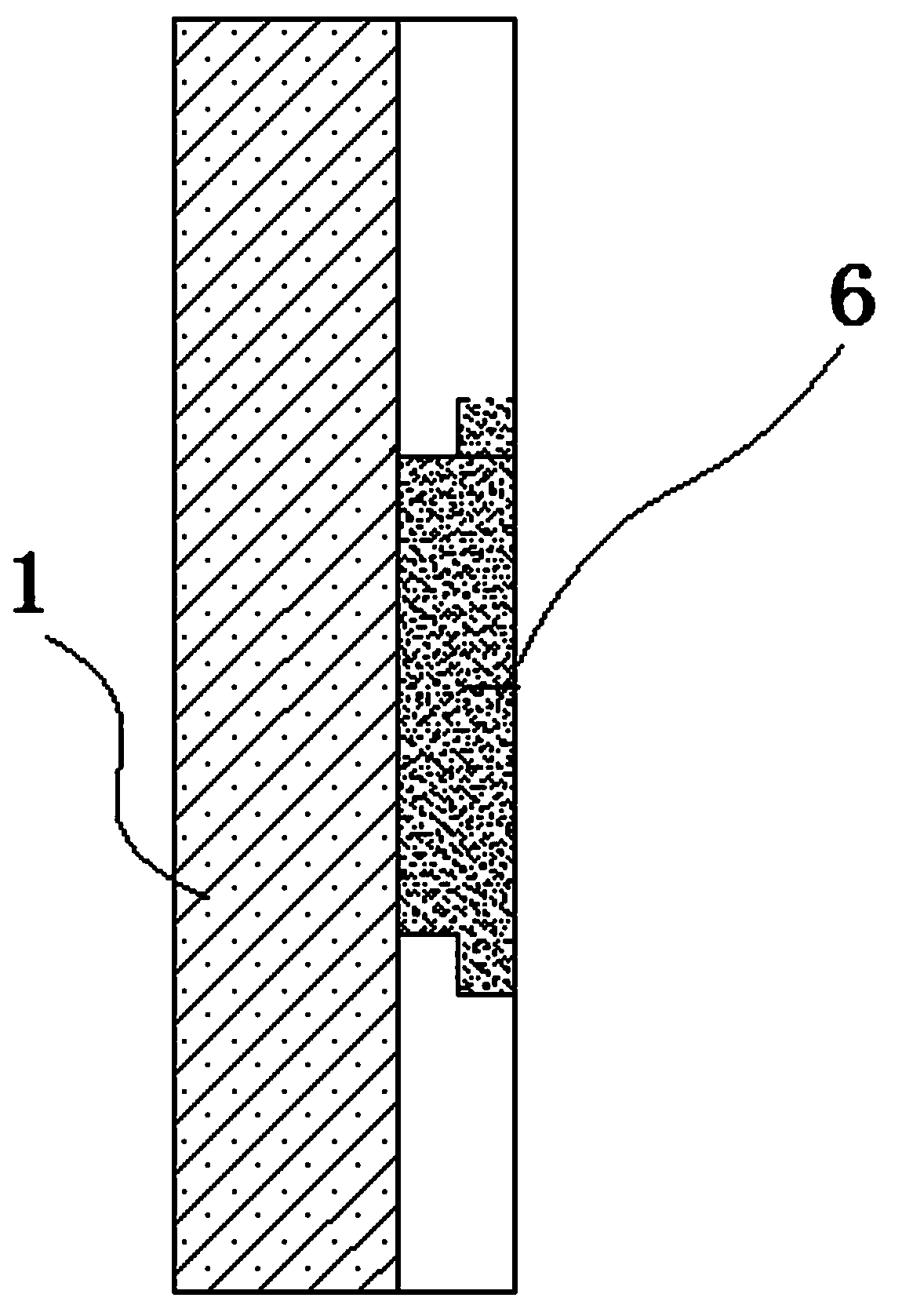

Novel sandwich electrolytic manganese anode plate and fabrication method thereof

PendingCN108301022AEliminate weak linksHigh purityPhotography auxillary processesElectrodesAnodeCopper

The invention discloses a novel sandwich electrolytic manganese anode plate and a fabrication method for the novel sandwich electrolytic manganese anode plate. The novel sandwich electrolytic manganese anode plate is characterized by comprising an anode conducting beam (2), a lead alloy anode main plate (5) and a conducting copper row (6), the lead alloy anode main plate (5) and the anode conducting beam (2) are formed by integrated pouring casting, the lead alloy anode main plate (5) internally contains a sandwich copper plate (8) with the thickness being 2-3 mm, the sandwich copper plate (8)and the conducting copper row (6) are welded together to form a whole, the sandwich copper plate (8), the conducting copper row (6) and a welding mouth (7) are entirely buried in the lead alloy anodemain plate (5), the middle of the position between the anode conducting beam (2) and the lead alloy anode main plate (5) is provided with a through hole which is taken as a hoisting hole (3), and thelead alloy anode main plate (5) is provided with a plurality of square holes which are taken as circulating holes (1). The novel sandwich electrolytic manganese anode plate is light in weight and high in conductivity and mechanical strength, and by means of the novel sandwich electrolytic manganese anode plate and the fabrication method for the novel sandwich electrolytic manganese anode plate, the electrolytic effect and electrolytic efficiency can be greatly improved.

Owner:GUIZHOU R & D CENT ON MODERN MATERIALS

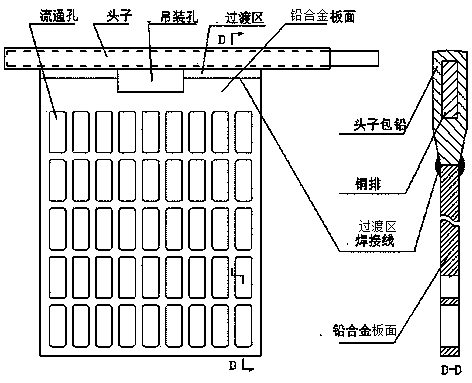

Anti-seepage system and drainage shaft lap structure for second-type storage and disposal site

PendingCN109356204AEliminate weak linksImprove reliabilitySewerage structuresProtective foundationGeomembraneEnvironmental engineering

The invention provides an anti-seepage system and drainage shaft lap structure for a second-type storage and disposal site. The structure comprises a drainage shaft. The drainage shaft comprises a shaft foundation and a shaft wall on one side of the shaft foundation. An HDPE connection lock is embedded in the shaft well foundation. The other side of the shaft foundation is provided with an anti-seepage system. The two sides of the anti-seepage system are correspondingly provided with a shaft sidewall anchoring trench and a reservoir area anchoring trench. The shaft sidewall anchoring trench isconnected with the shaft foundation. The structure eliminates the weak link of connection between the anti-seepage system and the drainage shaft, and ensures the safety and reliability of the anti-seepage system. By adopting the combined structure of the double-layer anti-seepage system, an auxiliary anti-seepage system and an anti-seepage protection system, the anti-seepage system and drainage shaft lap structure takes geomembrane as a main material, thereby promoting the reliability of the anti-seepage system in the reservoir area of the storage and disposal site of second-type general industrial solid waste, and also having a certain reference significance for the projects of domestic waste landfill and safe landfill disposal site of hazardous waste.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

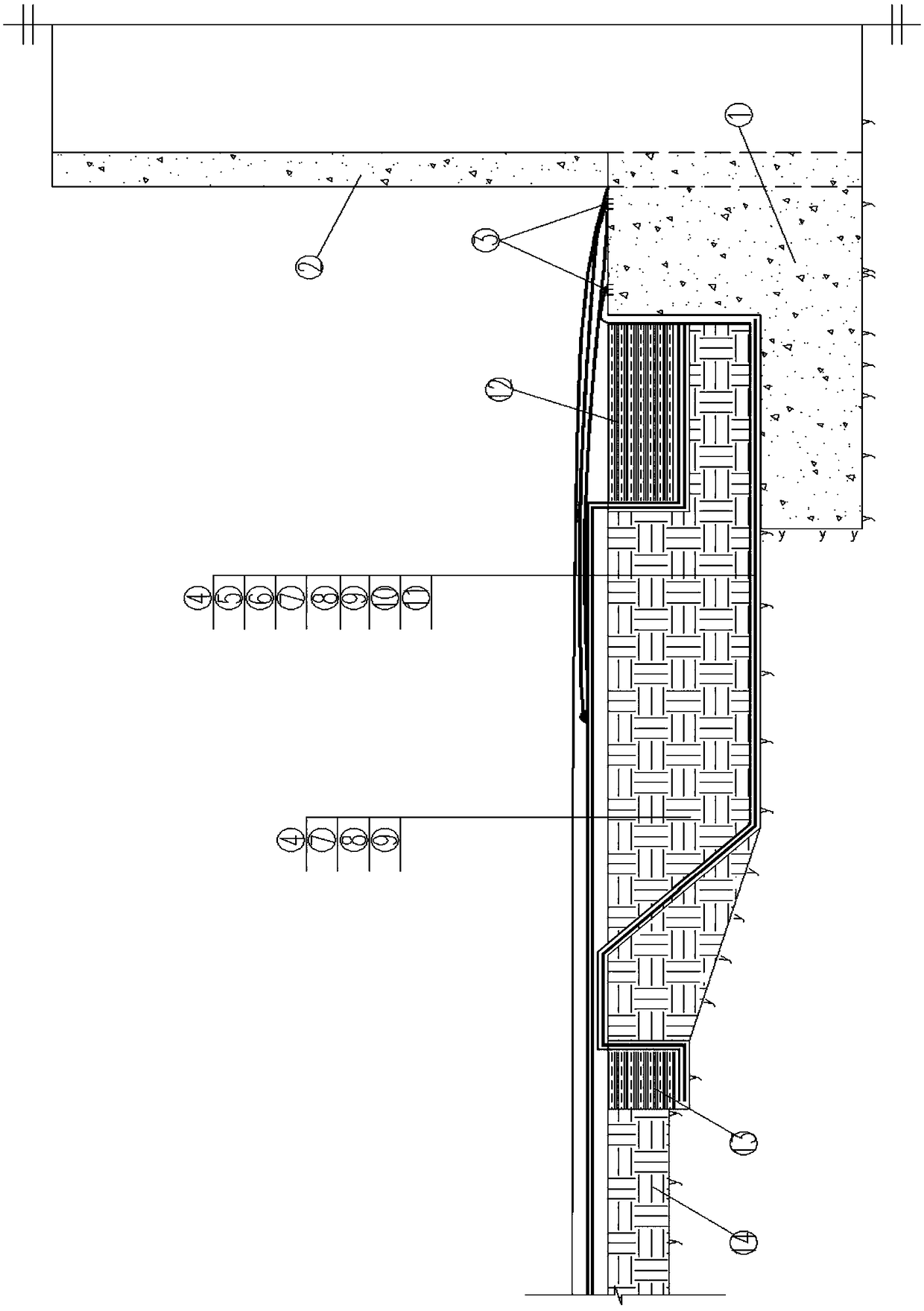

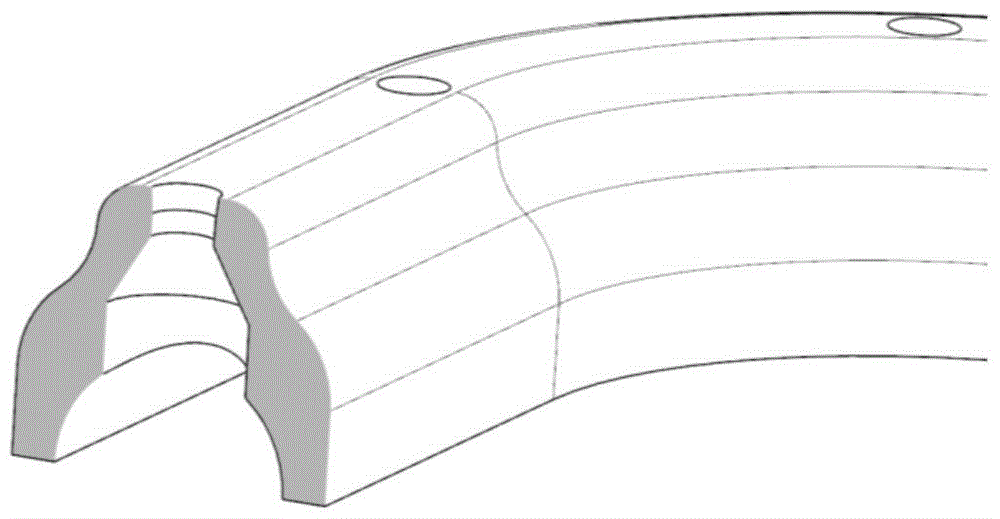

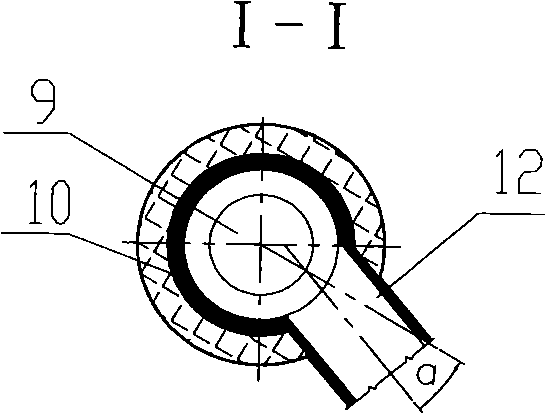

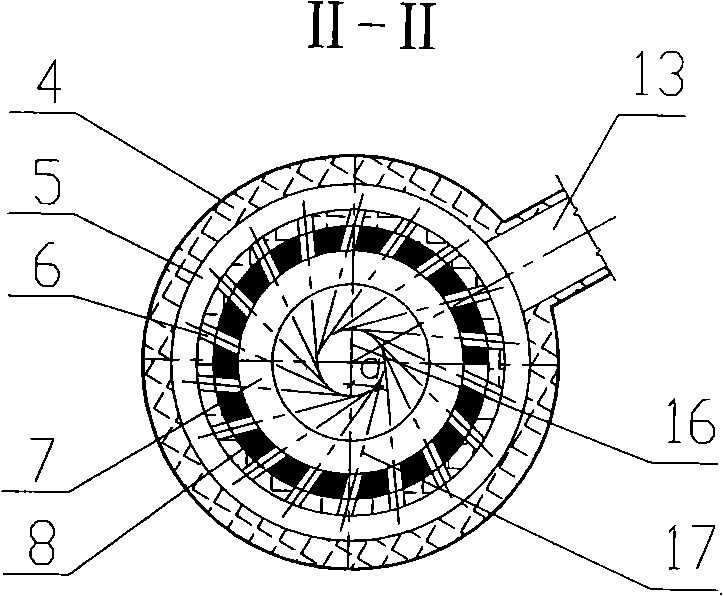

An annular multi-nozzle injection structure

ActiveCN104406338BHigh strengthImprove ejection abilityMechanical apparatusFluid circulation arrangementClassical mechanicsUltimate tensile strength

The present invention is a new ejection structure, most of the models installed and used at present are centralized ejection structures. This type of ejector has the characteristics of simple structure and high strength, but the disadvantage is that the ejection ratio is low and the performance is slightly poor. The technical solution of the present invention is to divide the injection structure into a nozzle ring, a rear sealing ring and a flange joint, and the three parts are all formed by integral machining, and then welded to form the injection body. This structure improves the injection performance, avoids the problem of insufficient strength of the overhanging nozzle, reduces the number of welds, eliminates weak links, and improves its overall reliability.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

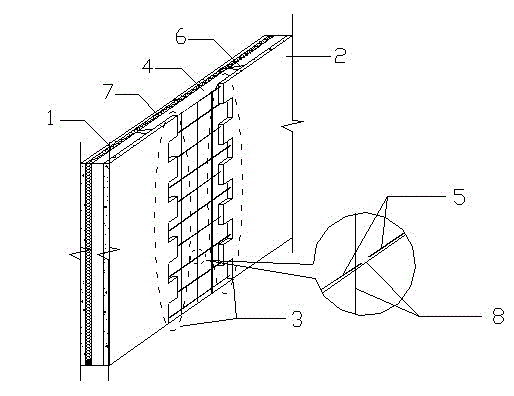

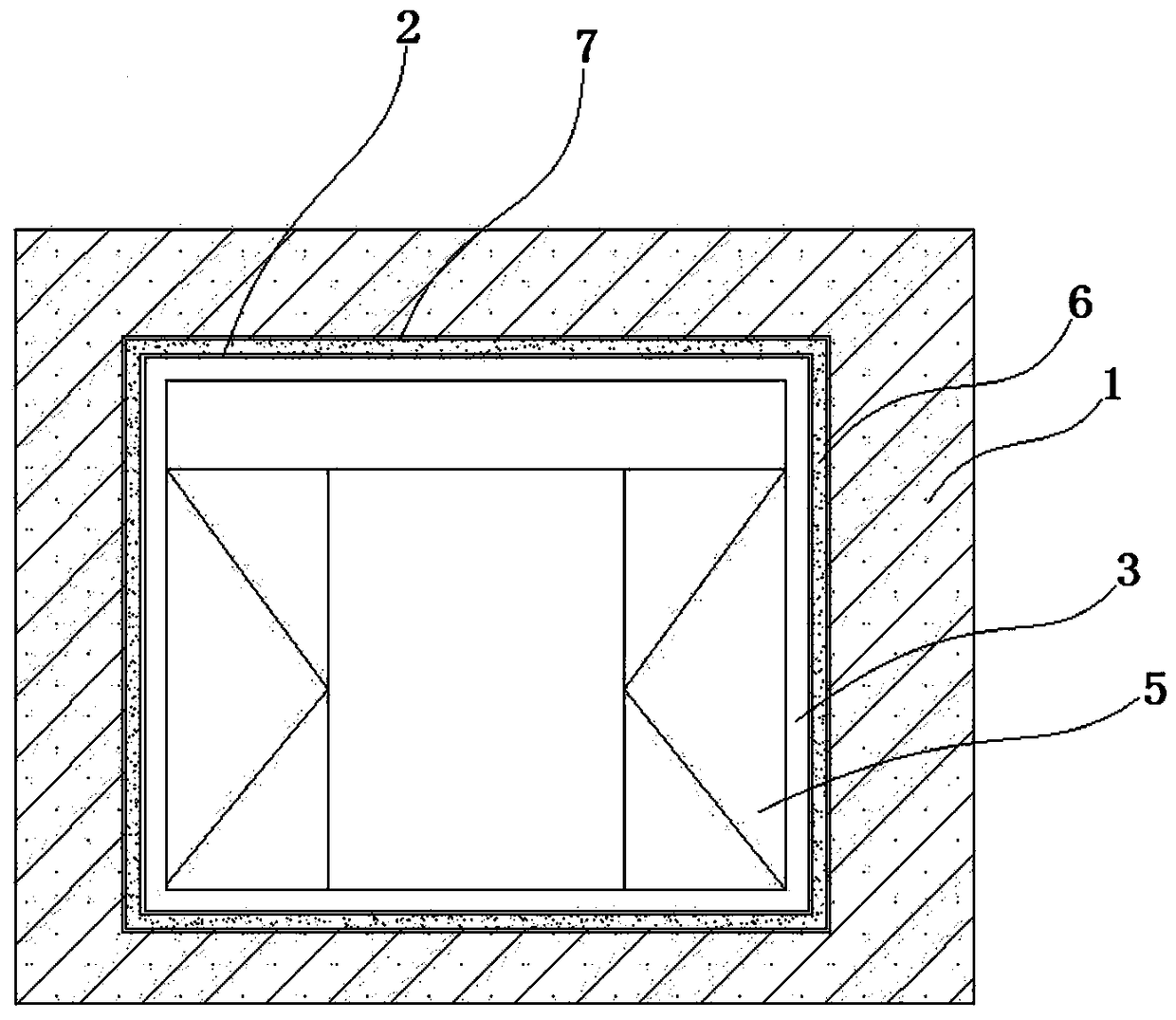

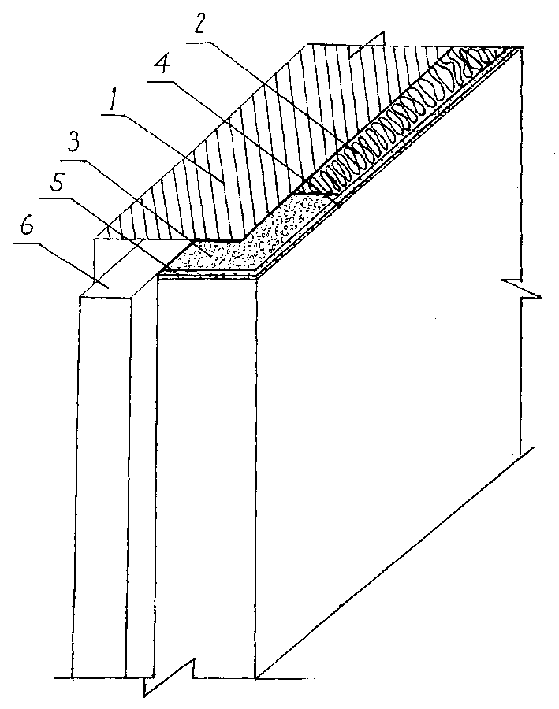

Fireproof node for building door or window opening and construction method

InactiveCN109024956AImprove fire insulation performanceEliminate weak linksFrame fasteningFire proofingSurface layerWindow opening

The invention relates to a fireproof node for a building door or window opening and a construction method. The node includes a door or window opening surface layer on the main structure, a door or window frame installed at the opening, a sealing layer between the opening and the door or window frame, and a door or window sash arranged on the door or window frame. The improvement is: a layer of foamed ceramic sheet refractory structure layer is added on the surface layer of the door or window opening. The construction method comprises the following steps of: coating cement-based polymer rubbercement at the opening of the door or window, sticking a foamed ceramic plate door or window frame into a stacked and foamed ceramic plate frame, filling the reserved gap with polyurethane foam, coating cement mortar protection surface layer. By increasing the foaming ceramic plate fireproof structure layer on the inner surface of the door or window opening, the fireproof and isolation performancesof the door or window opening node is improved, the weak link of the inner and outer fireproof and isolation of the building is eliminated. When fire happens outdoors, the danger to indoor personneland properties is reduced and longer evacuation time is left.

Owner:JILIN YUNTING ENERGY SAVING TECH CO LTD

Manufacturing process for electrode of cement based conductive composite material

InactiveCN101478085BReduce the impact of accuracyElimination of Weak Links Created by EmbeddingResistance/reactance/impedenceMaterial resistanceFiberPlumbago

The invention discloses a method for manufacturing cement-base conducting composite materials, which belongs to the technical field of civil engineering. The method is characterized in that a plane stainless steel net is manufactured into a solid stainless steel net of different waveforms. When a cement-base conducting composite material specimen is manufactured, the wave crests of the electrodesof two solid stainless steel nets are arranged oppositely; and as the basal body of the cement-base conducting composite material can be made of cement paste, cement mortar or concrete, and the conductive phases incorporated can be carbon fiber, powdered carbon, steel fiber, steel scrap, plumbago or carbon nanometer tubes, the grid sizes of the plane stainless steel net, the waveforms, the cyclesand the amplitudes of the waveforms of the electrodes of the solid stainless steel nets can be selected on a rational basis according to the types of the material of the base body and the conducting material besides considering the type and the size of the specimen in practical application. The invention has the advantages that the contact resistance between the electrodes and the base body can be reduced; the influence of polarization effect is reduced; the bonding effect of the electrodes and aggregate is improved; and the accuracy of the resistance test of the cement-base conducting composite material is improved.

Owner:DALIAN UNIV OF TECH

Vessel for removing solid particles from gases

ActiveCN102361676BReduce solid loadClosely spacedCombination devicesDispersed particle filtrationEngineeringSolid particle

The invention relates to a vessel for separating solid particles from a gas containing them, said vessel comprising: a plate provided with a plurality of openings traversing the vessel such that the plate divides the vessel into a first space and a second space; a plurality of filter elements extending from the plurality of openings to the first space; a container opening for receiving gas containing solid particles, the container opening being in fluid communication with the first space a container outlet opening for discharging solids, the container outlet opening being in fluid communication with the first space; and a container outlet opening for gas being in fluid communication with the second space. The first space also includes one or more cyclonic separation devices having: an inlet fluidly connected to a container opening for receiving gas containing solid particles; a cyclone fluidly connected to the first space; flow gas outlet; and solid swirl outlet.

Owner:AIR PROD & CHEM INC

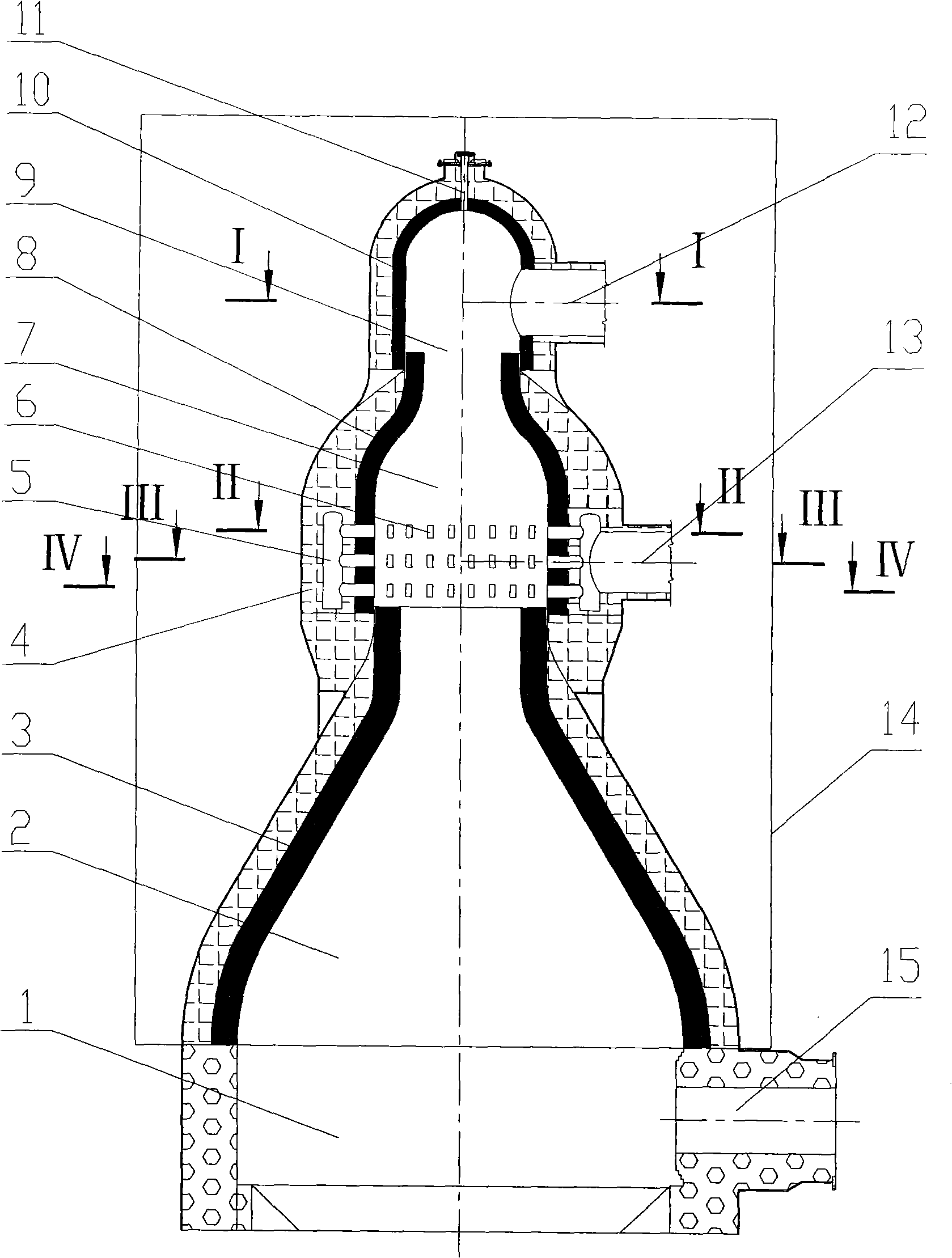

Top-fired air heating furnace

ActiveCN101644481BImprove securityPrevent blowbyAir heatersGaseous fuel burnerCombustorCombustion chamber

The invention belongs to the technical field of metallurgy industry, and in particular relates to a top-fired air heating furnace. A combustor of the top-fired air heating furnace is positioned above an air heating furnace heat storage body with a hot-blast air outlet, and is a vault part of the top-fired air heating furnace. The combustor has a three-segment type structure; a first segment is a combustion chamber which is positioned at the lower part of the combustor and is directly seated on the air heating furnace body; the upper end of a working inner lining of the combustion chamber is in a shape of a contracting mouth and vertically stretches into a gas swirl premixing chamber of the middle part without contacting a working inner lining of the gas swirl premixing chamber, and can expand freely; a second segment is the gas swirl premixing chamber positioned at the middle part of the combustor; and a third segment is an air chamber positioned at the upper part of the combustor. The top-fired air heating furnace does not generate the mutual blow-by between air and gas, and has the characteristics of no gas residues at the combustor vault, higher swirl strength, and better stability and service life of the masonry of the combustor vault. The top-fired air heating furnace can be widely applied to the air heating furnace to heat blast furnace blast media.

Owner:CISDI ENG CO LTD

Seismic behavior based optimization method and system for building structure

ActiveCN102493569BImprove seismic performanceEliminate weak linksShock proofingStructural systemBuilding construction

The invention provides a seismic behavior based optimization method and system for a building structure. The seismic behavior based optimization method comprises the following step: A1, determining the integral target seismic behavior index of the structure and the seismic behavior index of a target construction member; A2, designing an initial structure, and dividing the construction members with the same boundary condition, the same cross section size and the same material parameter in the same layer of the structure into one class; A3, obtaining the integral damage index of the structure; A4, detecting whether the integral damage index satisfies a constraint condition, if so, performing step A5, and if not performing step 2; A5, obtaining the seismic behavior index of various classes of construction members of the structure; A6, detecting whether the seismic behavior index of various classes of construction members of the structure satisfies a condition of convergence, if so, finishing the optimization, and if not, performing step A7; and A7, determining the step size of next optimization step, updating a structural system, and returning step A3.

Owner:BEIJING JIAOTONG UNIV

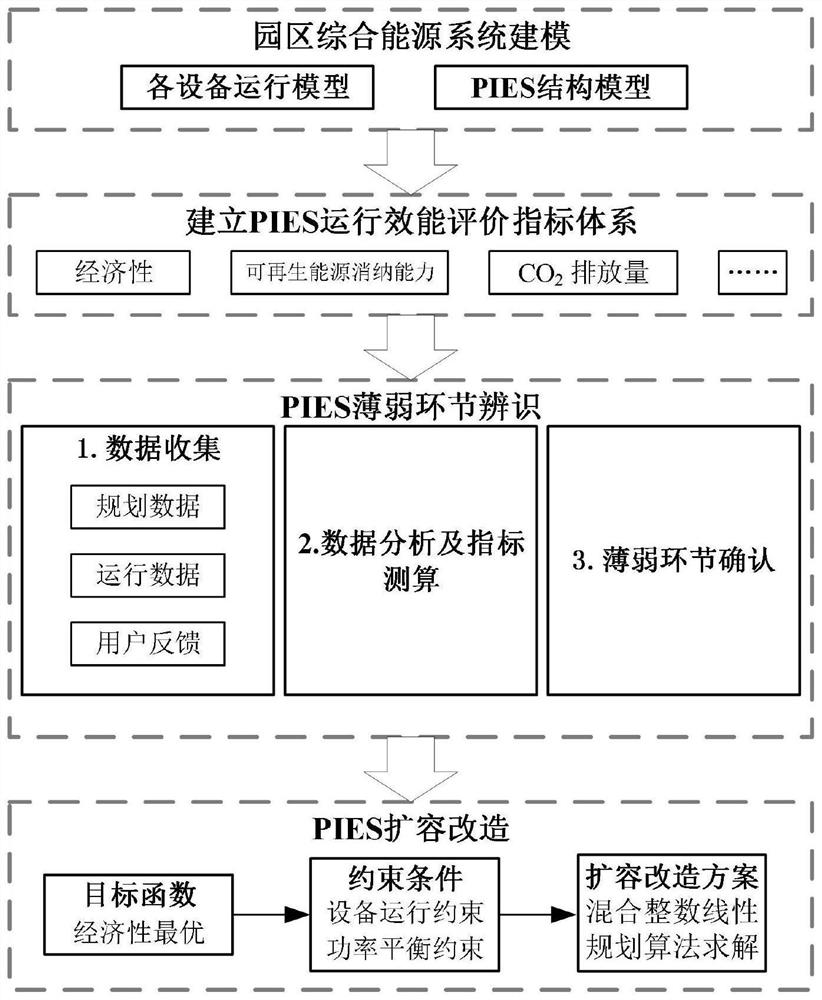

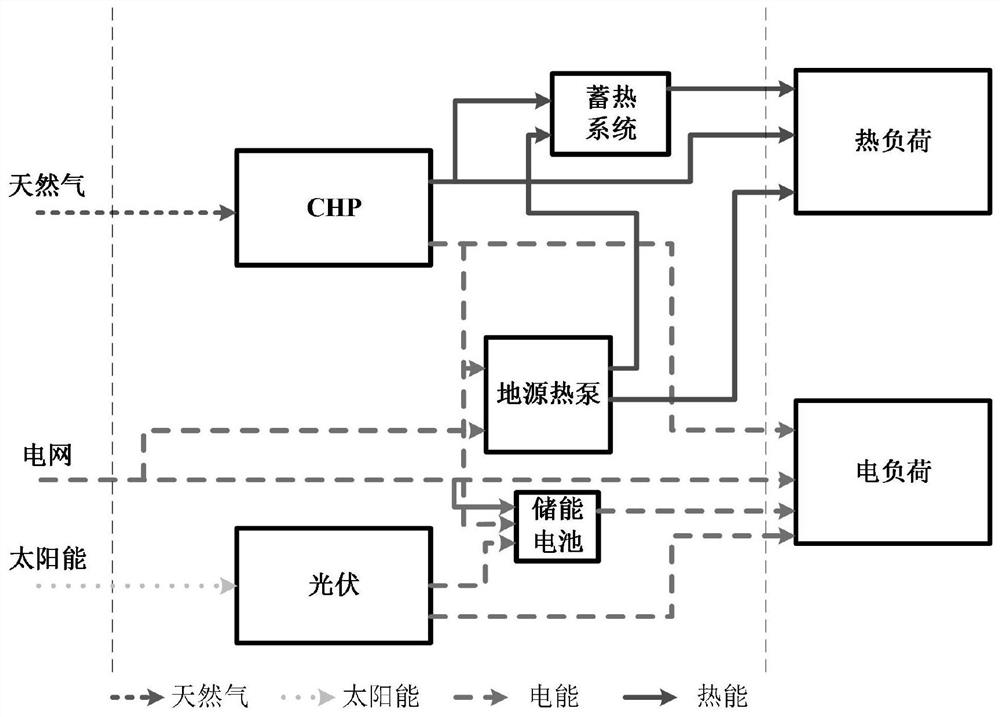

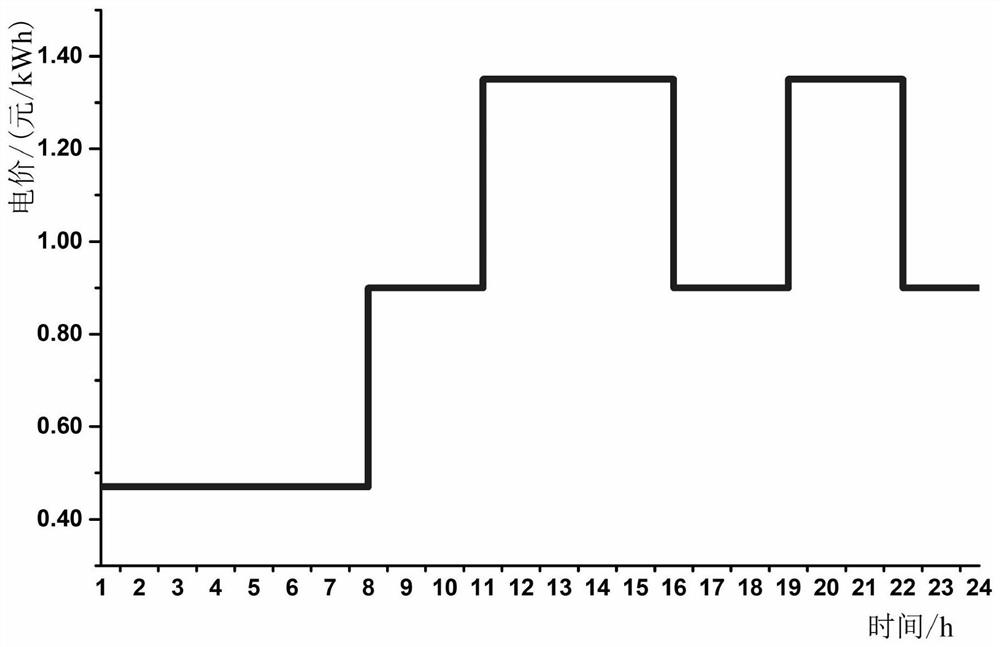

Weak link identification and capacity expansion transformation method for park integrated energy system

PendingCN112200347AAccurate identificationGuaranteed uptimeForecastingResourcesPower efficientIntegrated energy system

The invention relates to a weak link identification and capacity expansion transformation method for a park integrated energy system. The method comprises the following steps: 1) modeling PIES and each device; 2) constructing a PIES operation efficiency evaluation index system; 3) identifying the weak link of the existing PIES through three stages of data acquisition, data analysis, index measurement and calculation and the weak link; and (4) enabling the existing PIES to be subjected to expansion transformation, so that the efficiency of the PIES in the aspects of operation economy, energy conservation, emission reduction, renewable energy consumption promotion and the like is improved. According to the weak link identification and capacity expansion transformation method for a park integrated energy system, the problems of poor coherence between an existing PIES planning stage and an operation stage, unreasonable equipment type selection and capacity configuration, large difference between the PIES actual operation effect and an initial design target and the like are solved, the weak link of the system is identified starting from existing PIES operation efficiency analysis, and existing PIES is planned and transformed, the potential of the system is mined, and the operation economy and environmental protection property of the system are improved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Composite rock wool reinforcement plate and preparation method for composite rock wool reinforcement plate

ActiveCN102635172BHigh strengthEliminate weak linksHeat proofingNatural mineral layered productsYarnHigh intensity

The invention discloses a composite rock wool reinforcement plate and a preparation method for the composite rock wool reinforcement plate. The composite rock wool reinforcement plate comprises a core plate; wherein the core plate is composed of at least two rock wool slivers which are arranged side by side; the arrangement direction of fiber yarns of the rock wool slivers is in parallel with the thickness direction of the composite rock wool reinforcement plate; the four surfaces of the core plate in the length direction are wrapped by a layer of reinforced fiber layer; and the outer surface of the reinforced fiber layer is coated by a layer of mortar protecting layer. According to the composite rock wool reinforcement plate and the preparation method, the shortcomings of low tensile strength and low compression strength of common rock wool plate are overcome, the weak link of stress is eliminated, and the safety of the system is improved; and the composite rock wool reinforcement plate has the advantages of good heat insulating effect, high intensity, good fire-proof and humidity resistant performances, simple construction and long service life, so that the composite rock wool reinforcement plate can be widely applied to the fields of outer wall constructions of buildings.

Owner:北京振利节能环保科技股份有限公司

A gas-proof and corrosion-proof connection method for lead-sheathed submersible cables

ActiveCN105161944BGuaranteed performance consistencyExtended service lifeLine/current collector detailsInsulating conductors/cablesGlass fiberInsulation layer

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Asphalt-based non-curable heat-resistant waterproof sealant and preparation method thereof

ActiveCN102775956BImprove adhesionAdhesiveNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePolyolefin

The invention relates to an asphalt-based non-curable heat-resistant waterproof sealant and a preparation method of the sealant. The sealant comprises the following components in percentage by weight: 10-35% of asphalt, 5-15% of rubber oil, 1-3% of polyolefin processing modifier, 20-30% of 30Mu-100Mu glue powder, 5-10% of tackifier, 10-30 of sodium bentonite, and 3-5% of wetting dispersant reagent. The sealant has the following characteristics of good bonding property, high percentage elongation, good self-healing property, good creep property, possible construction of knife coating, spray coating or grouting, no need to maintain, capability of being constructed on wet foundation surface even under condition of (-40) DEG C and thus effectively shortening the construction period, no organic solvent, low energy consumption in construction, safety, environmental friendliness, no pollution, high-temperature resistance (not flowing at 110 DEC C), low-temperature resistance (not cracking at (-40) DEG C), stable property, good stickiness, and capability of sealing base layer cracks and pores so as to avoid water channeling phenomenon.

Owner:中建材苏州防水研究院有限公司 +1

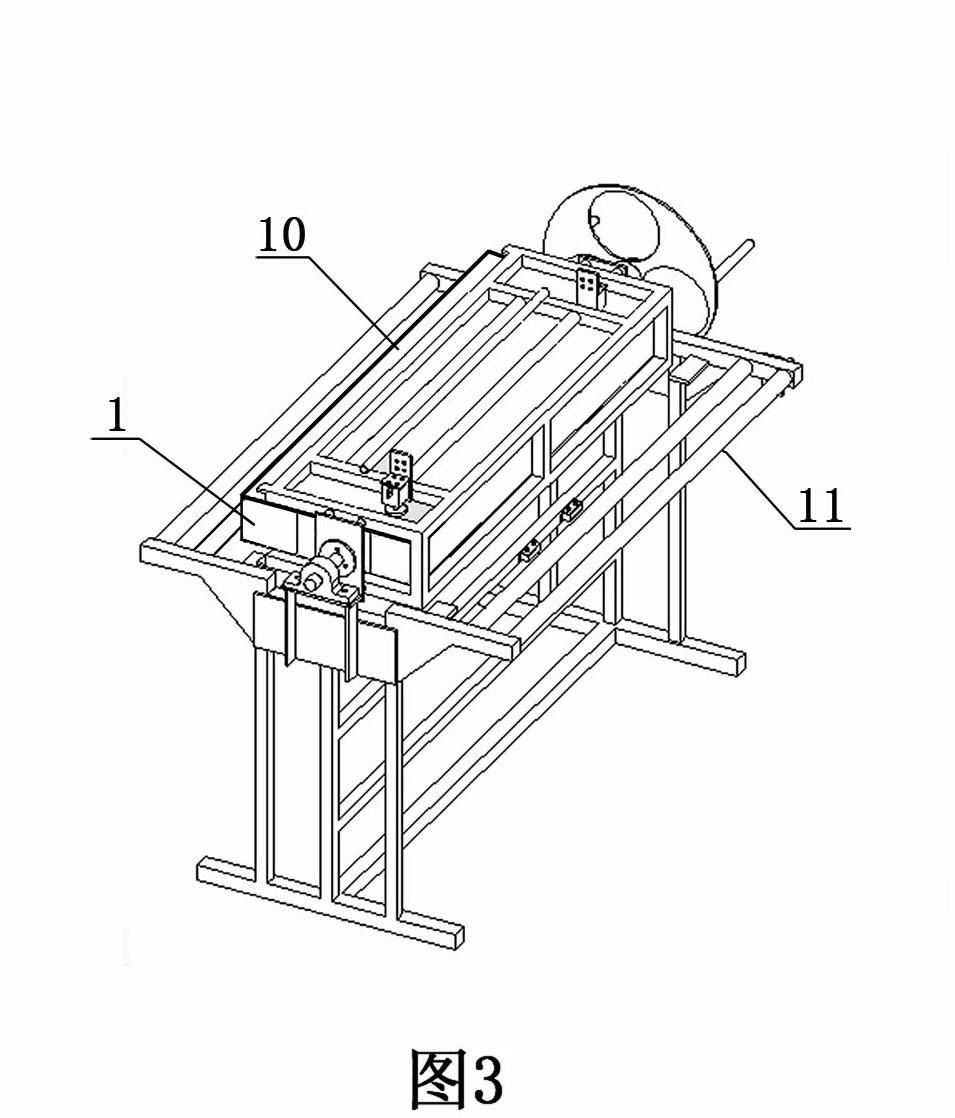

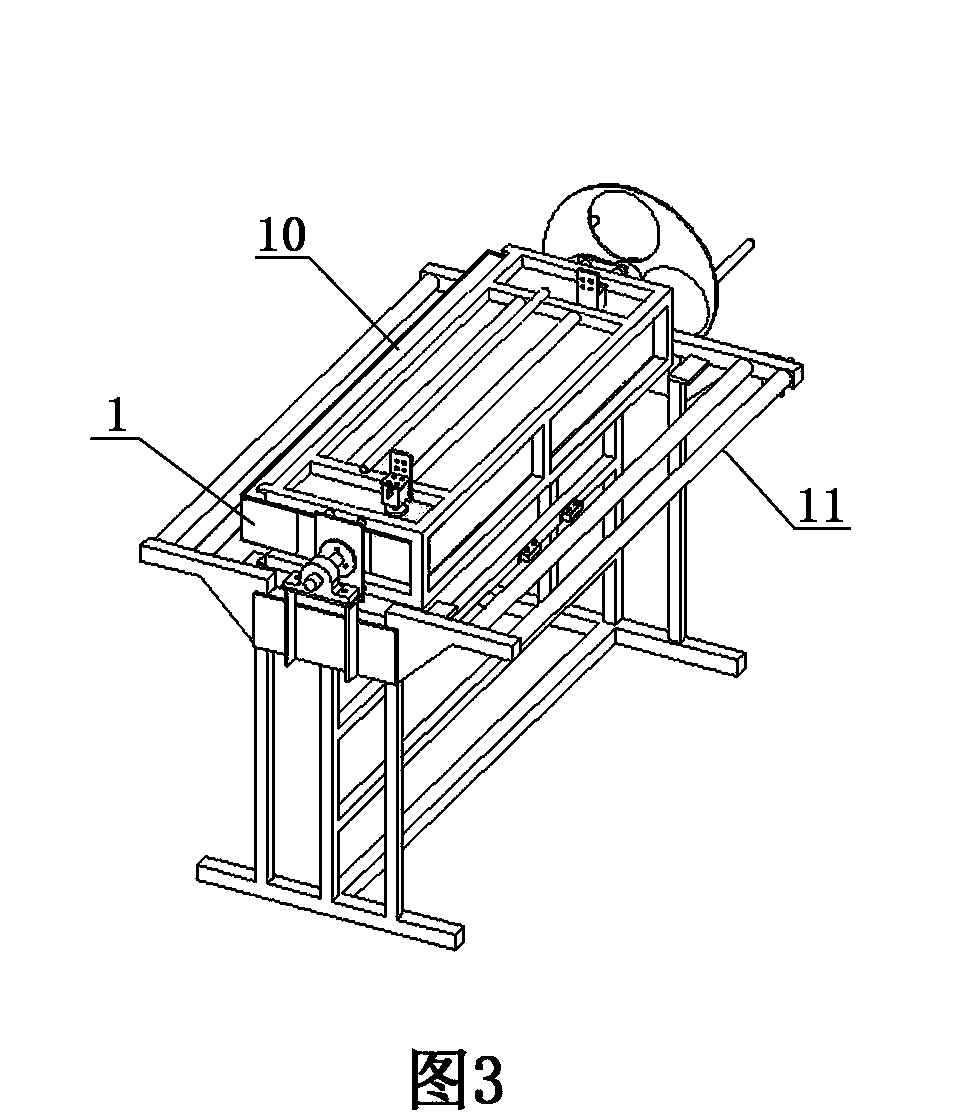

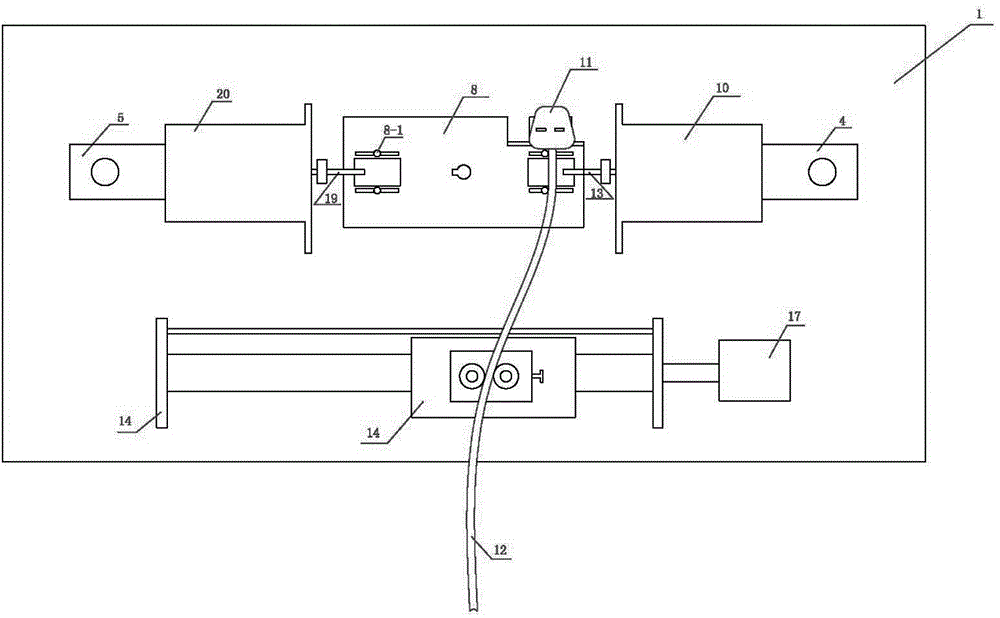

Winding machine for row socket power harness and method for winding power harness

InactiveCN103441403BNeat appearanceAdaptableLine/current collector detailsWinding machineElectric machinery

A wire harness winding machine for a socket row power supply and a method for winding a power wire harness. The preparation and hooking mechanism of the main wire harness of the power cord and the continuous winding mechanism on the main wire harness; A line hook to obtain the trunk harness; the second step is to continuously wind coils on the trunk harness to become a power harness with a plug. Using this machine to wind the power wire harness, the products are uniform, beautiful and strong, the production efficiency can be increased by more than three times, and the weak link in the socket row production line is eliminated.

Owner:傅国钢 +1

Polyphenyl plate, polyphenyl particle plastered composite thermal-insulating wall and construction process

InactiveCN1142349CEliminate weak linksImprove insulation effectHeat proofingThermal bridgeEngineering

Owner:北京振利节能环保科技股份有限公司

MCM-based intelligent adaptive review resource push method

ActiveCN111428058BSpotting weaknessesEliminate weak linksData processing applicationsDigital data information retrievalEngineeringRoot cause

The invention discloses an intelligent adaptive review resource pushing method based on MCM, which includes obtaining the historical knowledge point wrong question data of all students; obtaining multiple wrong cause labels of the current student, and screening out the first wrong cause label belonging to the intelligence factor; For each first error label of the current student, the error importance degree value P(E) is calculated; according to the MCM label corresponding to each first error label, the MCM learning corresponding to the MCM label is extracted from the preset content management system. The resources are sorted in descending order according to the P(E) value of the error cause, and some or all of the MCM learning resources are extracted and pushed to the students according to the order. The knowledge point corresponding to the MCM label is wrong. The invention solves the problems that the review can cure the symptoms but not the root cause, and the students' learning level is difficult to really improve.

Owner:SHANGHAI SQUIRREL CLASSROOM ARTIFICIAL INTELLIGENCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com