Top-fired air heating furnace

A hot blast stove and top-fired technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of shortening the life of masonry, and achieve the effects of no NOx generation, reduced N2 consumption, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

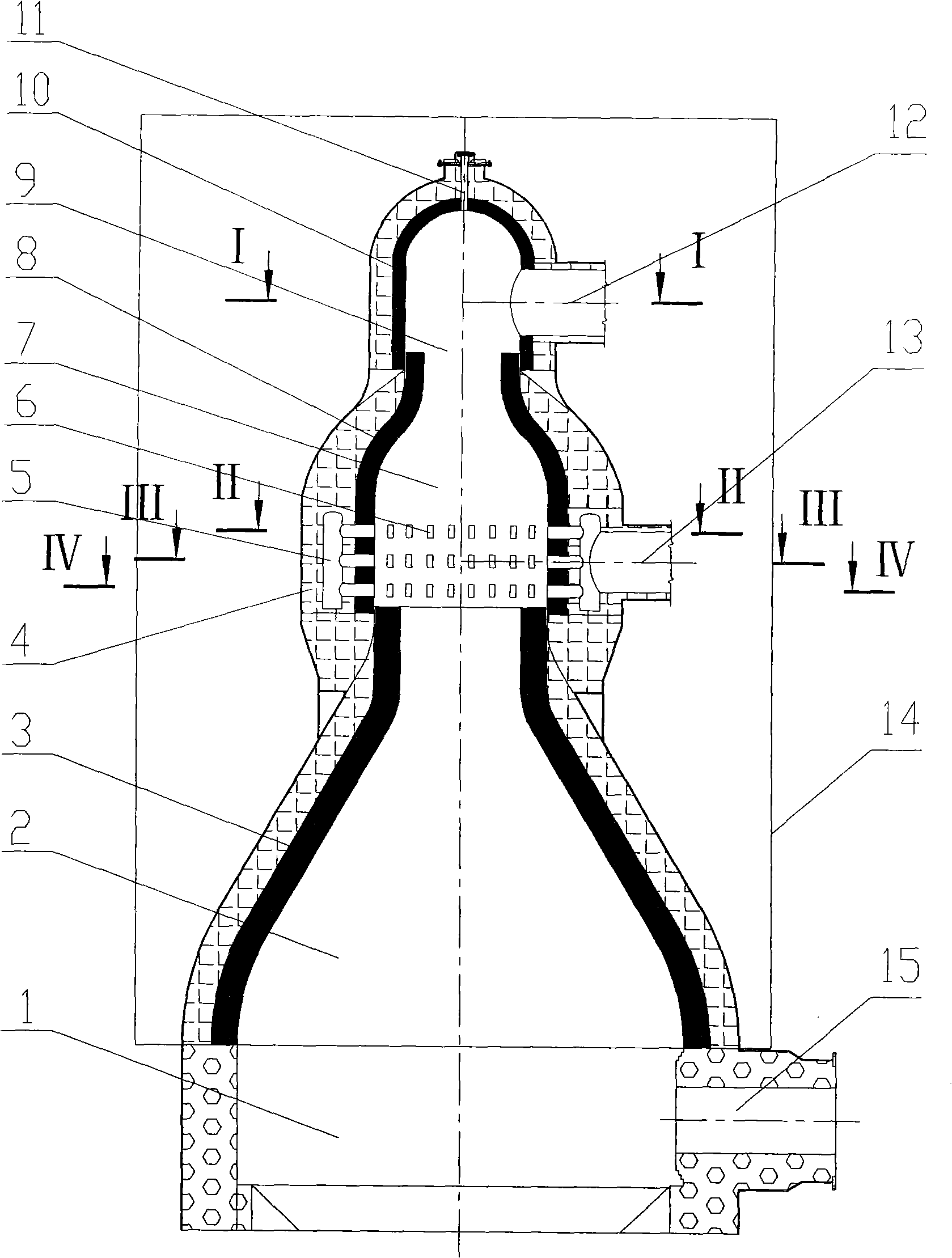

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

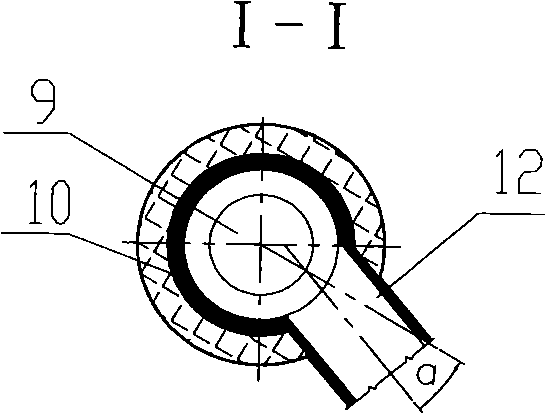

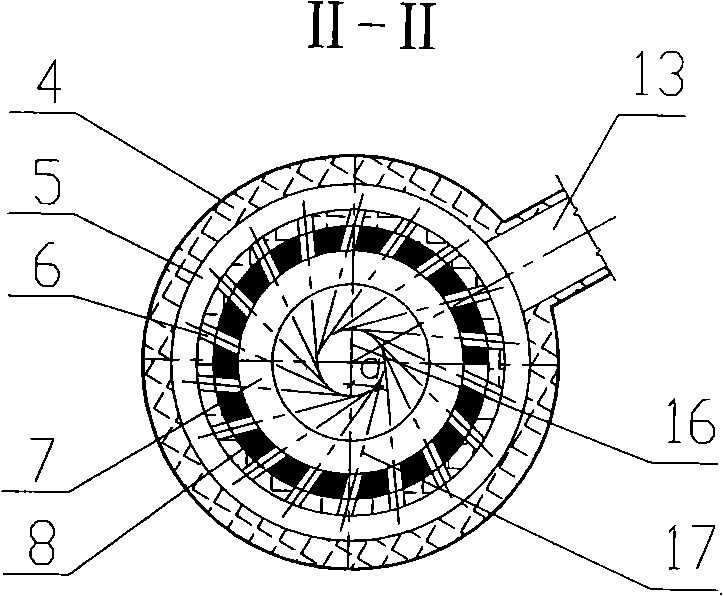

[0022] A top-fired hot blast stove of the present invention is composed of a hot blast stove heat storage body 1 with a hot blast outlet 15 and a burner 14 . The burner 14 has a three-stage structure. The first section is the combustion chamber 2, which is located at the bottom of the burner 14 and is the vault part of the top-fired hot blast stove; the second section is the gas swirl premixing chamber 7, which is located at the bottom of the burner. 14 middle part; the third section is the air chamber 9, which is at the top of the burner 14.

[0023] In the first section, the working lining 3 of the combustion chamber 2 sits directly on the heat storage body 1 of the hot blast stove. It is not in contact with the working lining 8 of the gas cyclone premixing chamber 7 and can expand freely.

[0024] In the second section, a ring of refractory material masonry gas ring 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com