Patents

Literature

169results about How to "Shorten the mixing distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

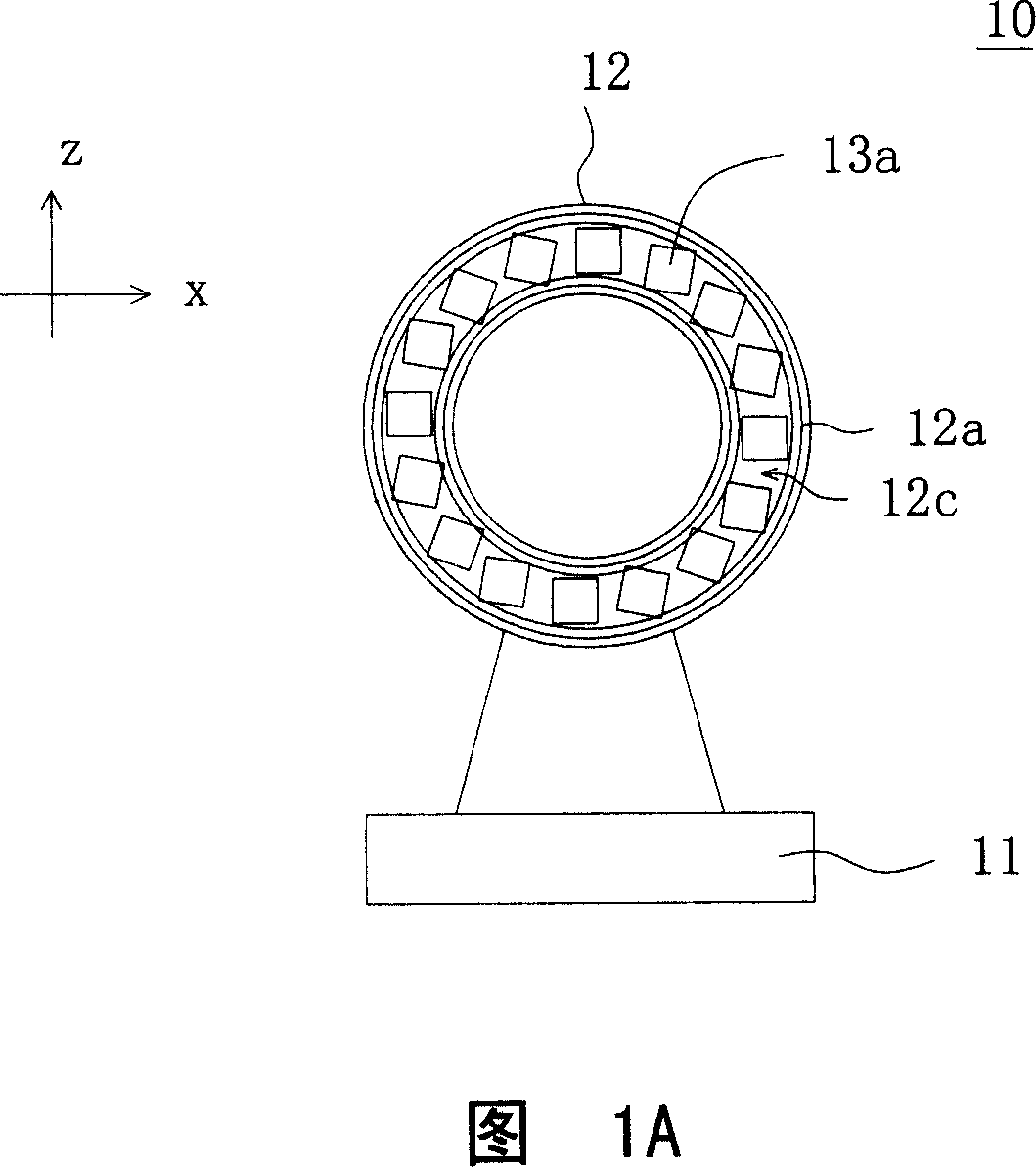

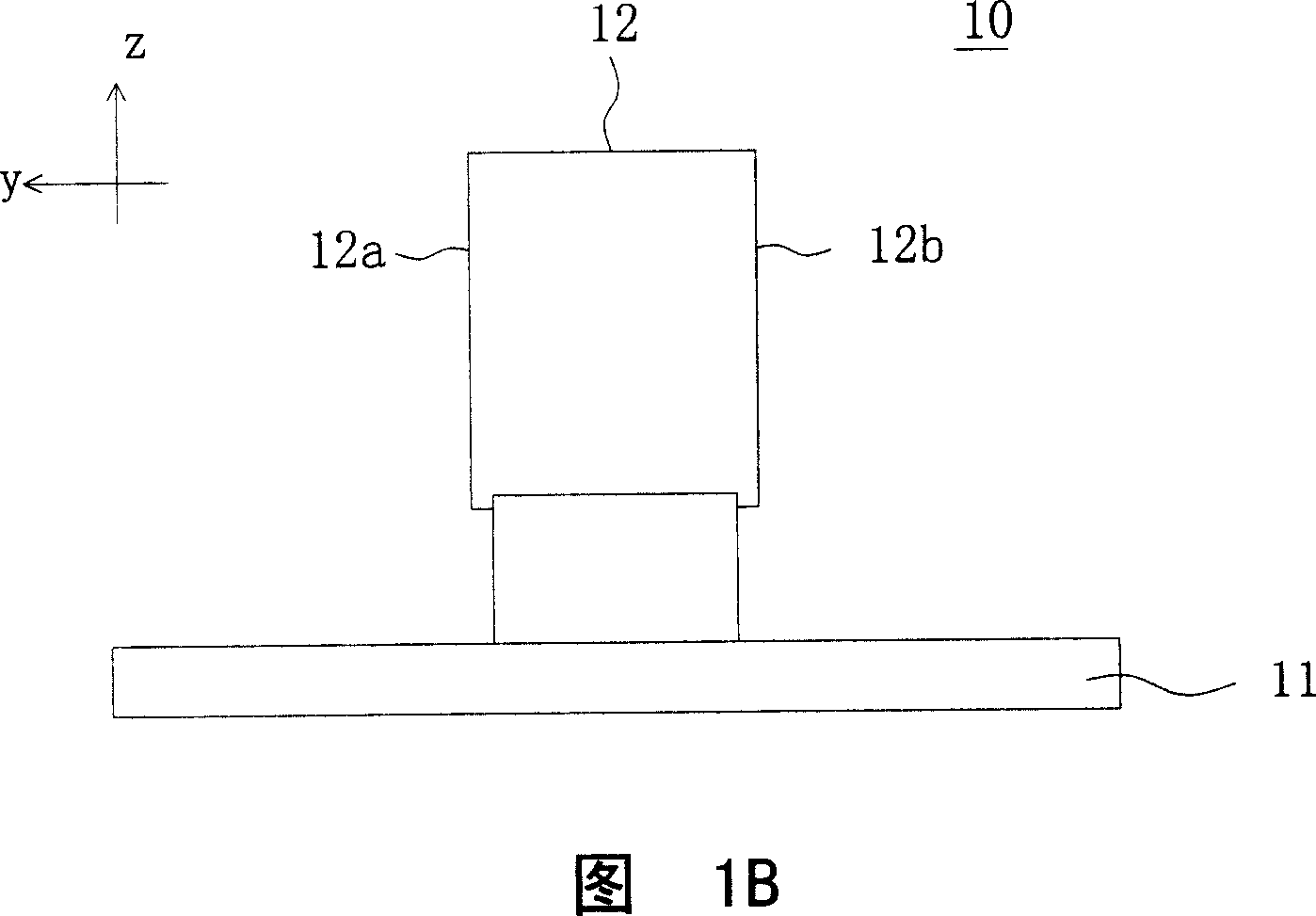

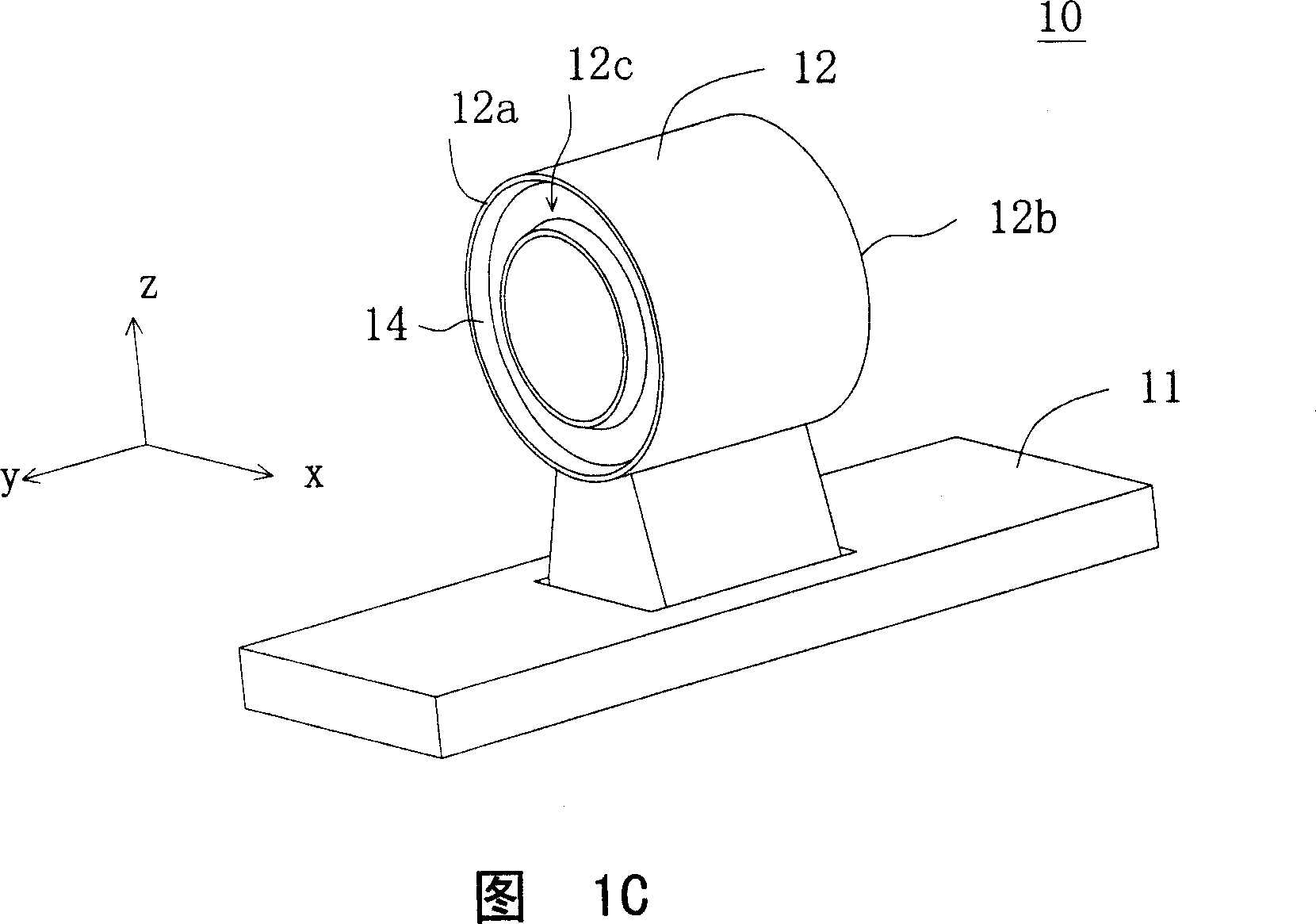

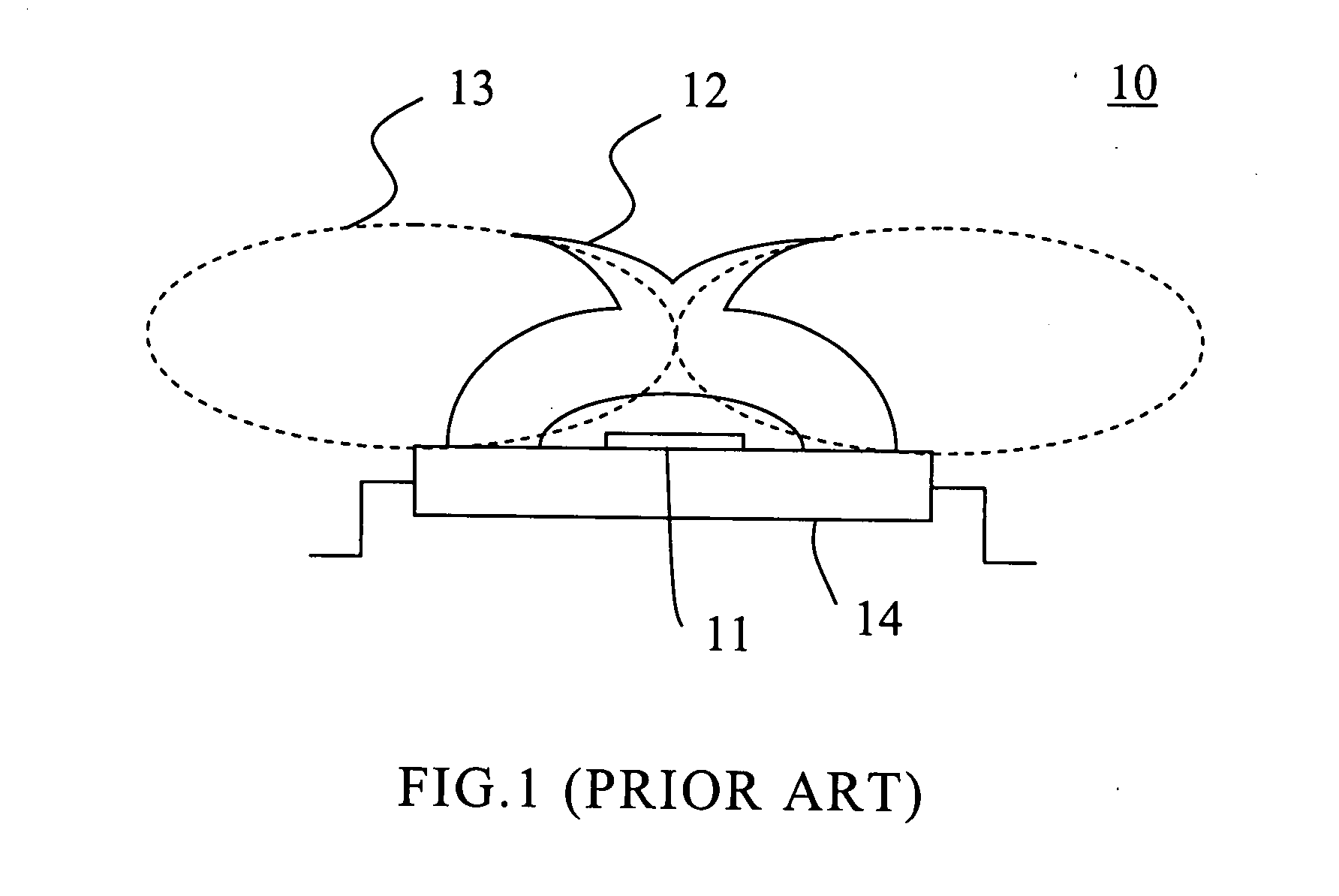

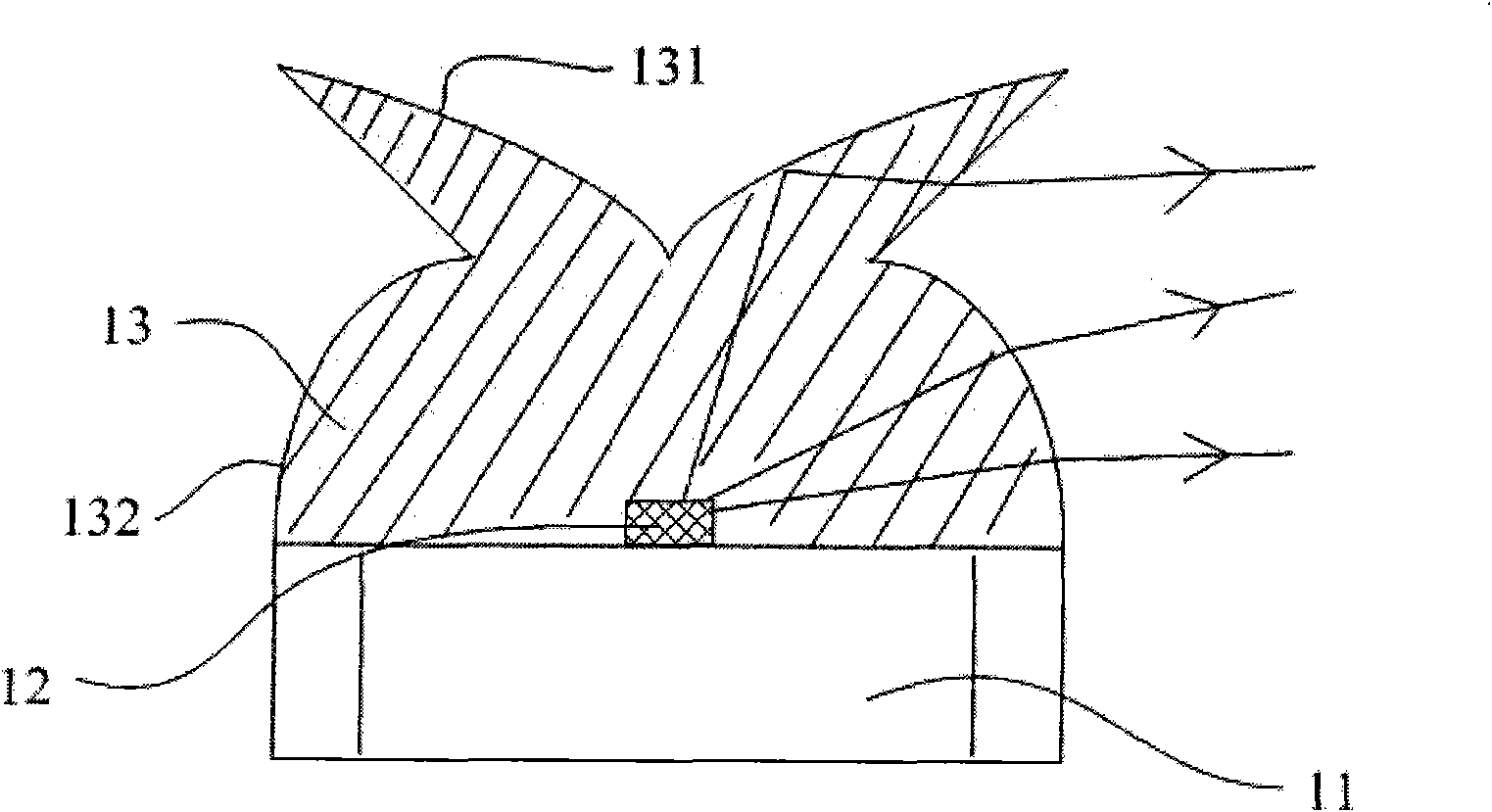

Structure for packing light-emitting diodes, light-conducting pipe and liquid crystal display device thereof

ActiveCN101075605AReduce thicknessImprove practicalityStatic indicating devicesSolid-state devicesLiquid-crystal displayPrism

A LBD packing structure includes a base, noumenon and several LBD. The noumenon is installed on the base with a circle groove on one side. LBD are fixed in the groove to supply a lateral light for the packing structure. The invention also provides an optical pipe which includes a column and several prisms. The column is of an outer side and an inner reflecting side. The prisms are installed in between the outer and inner sides. By combining the LBD package and the optical pipe, the package is capable of generating diffusion light and be used in apheliotropic module and LCD displayer.

Owner:INNOLUX CORP

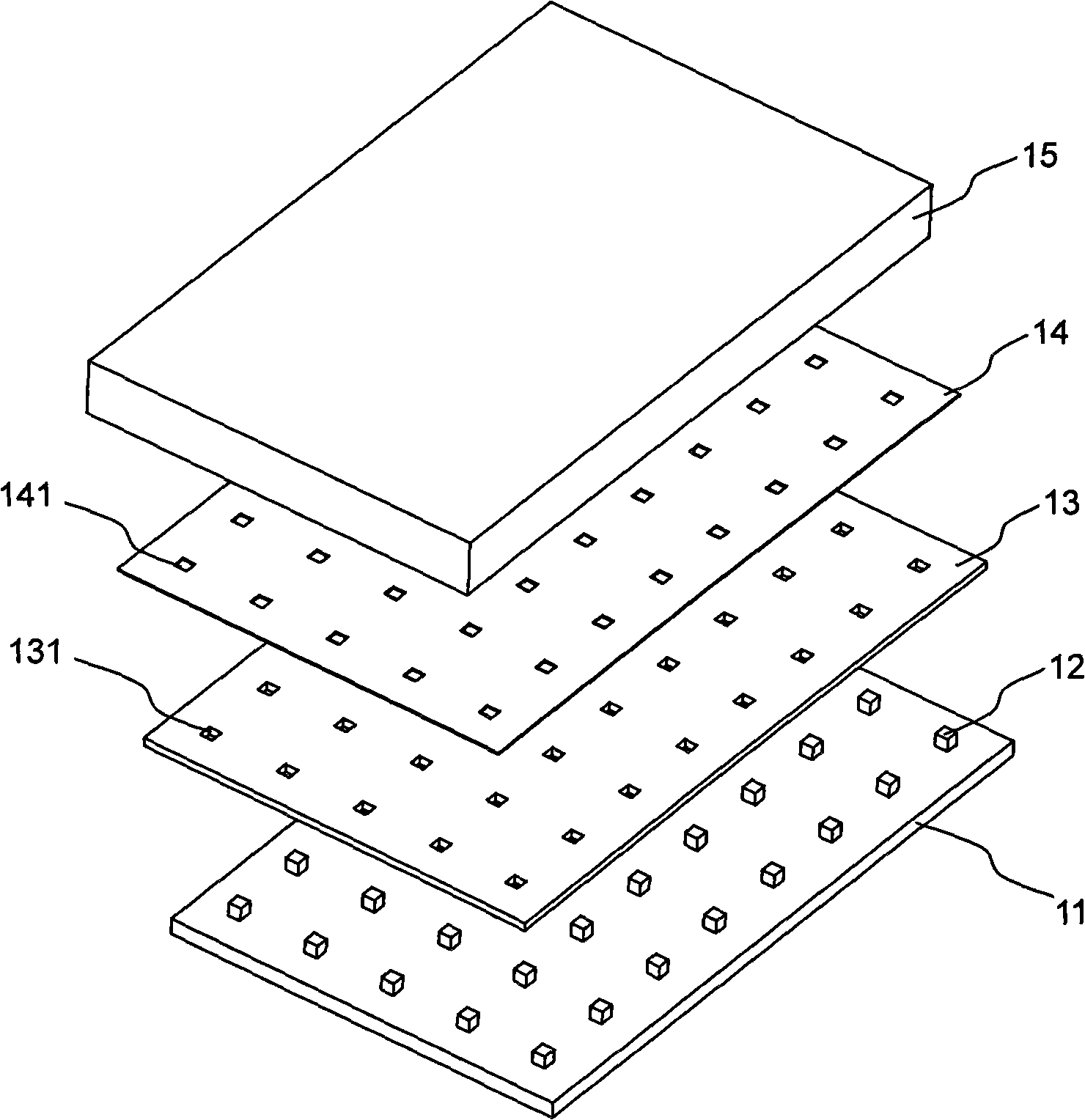

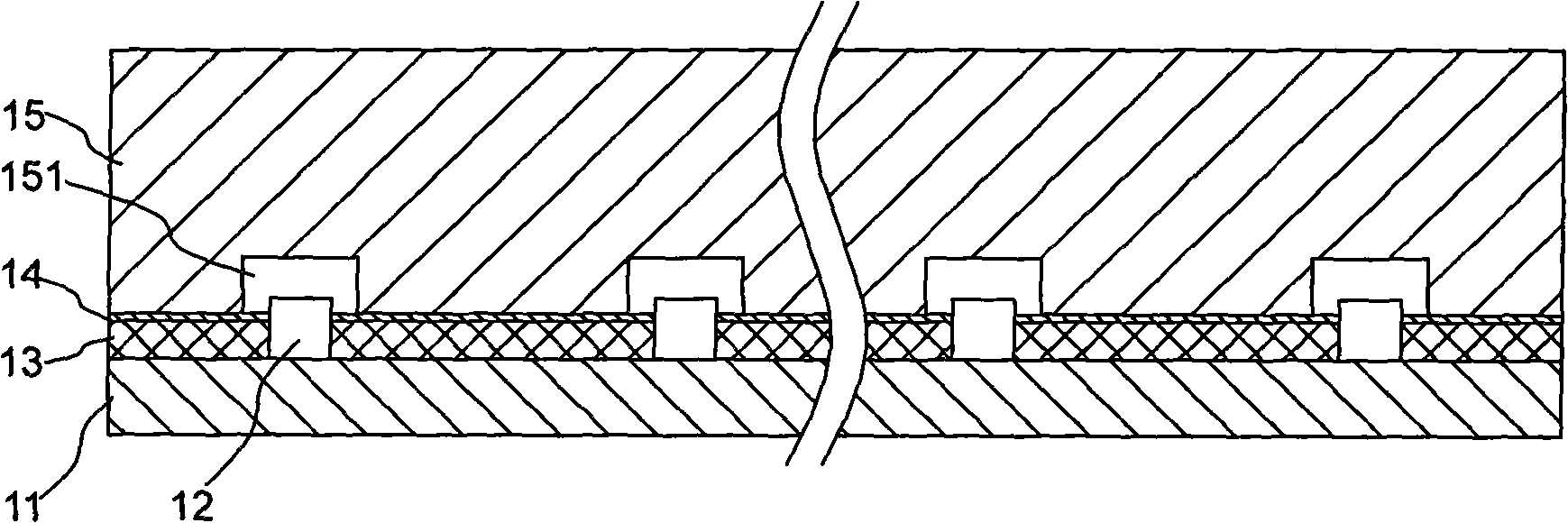

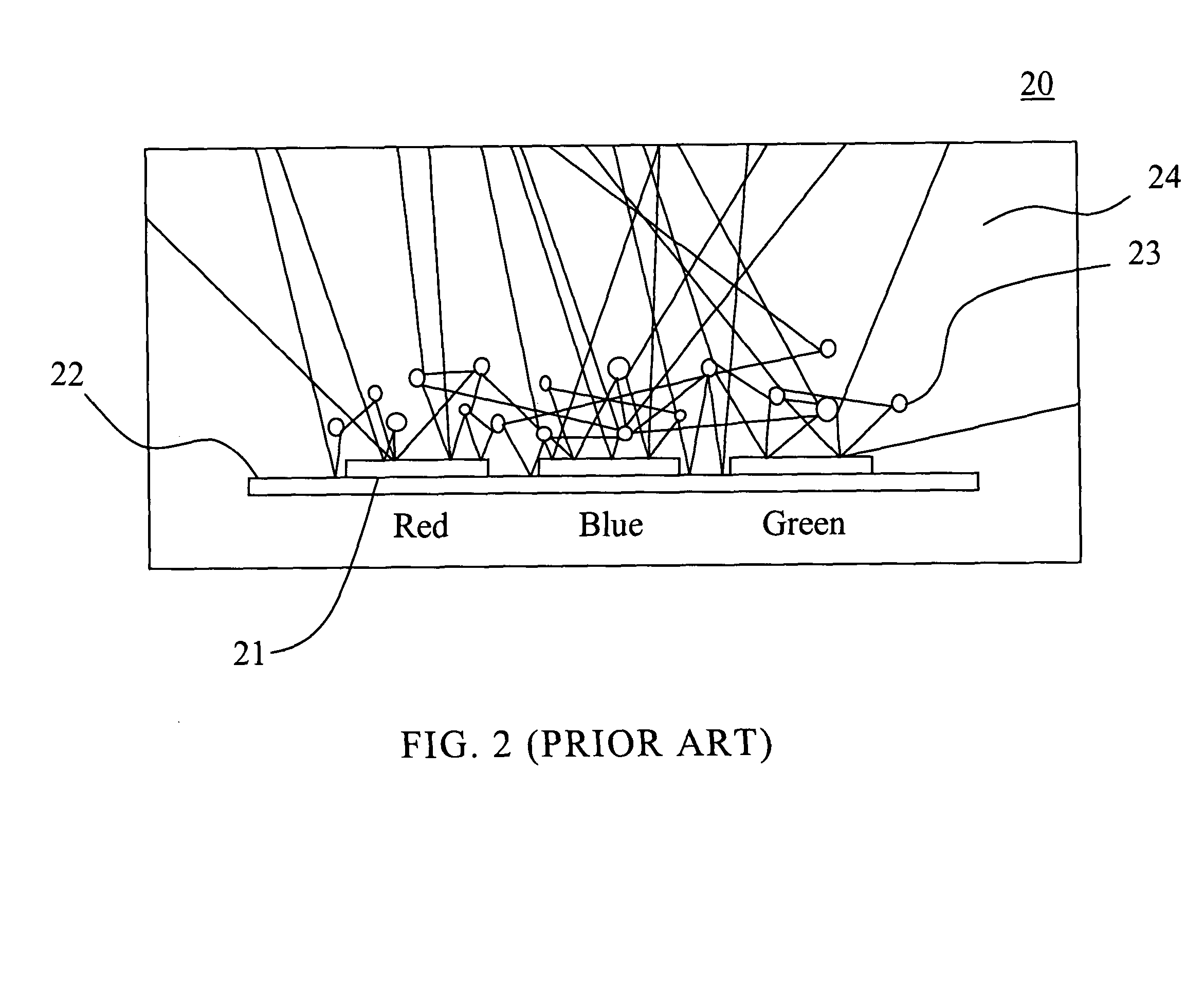

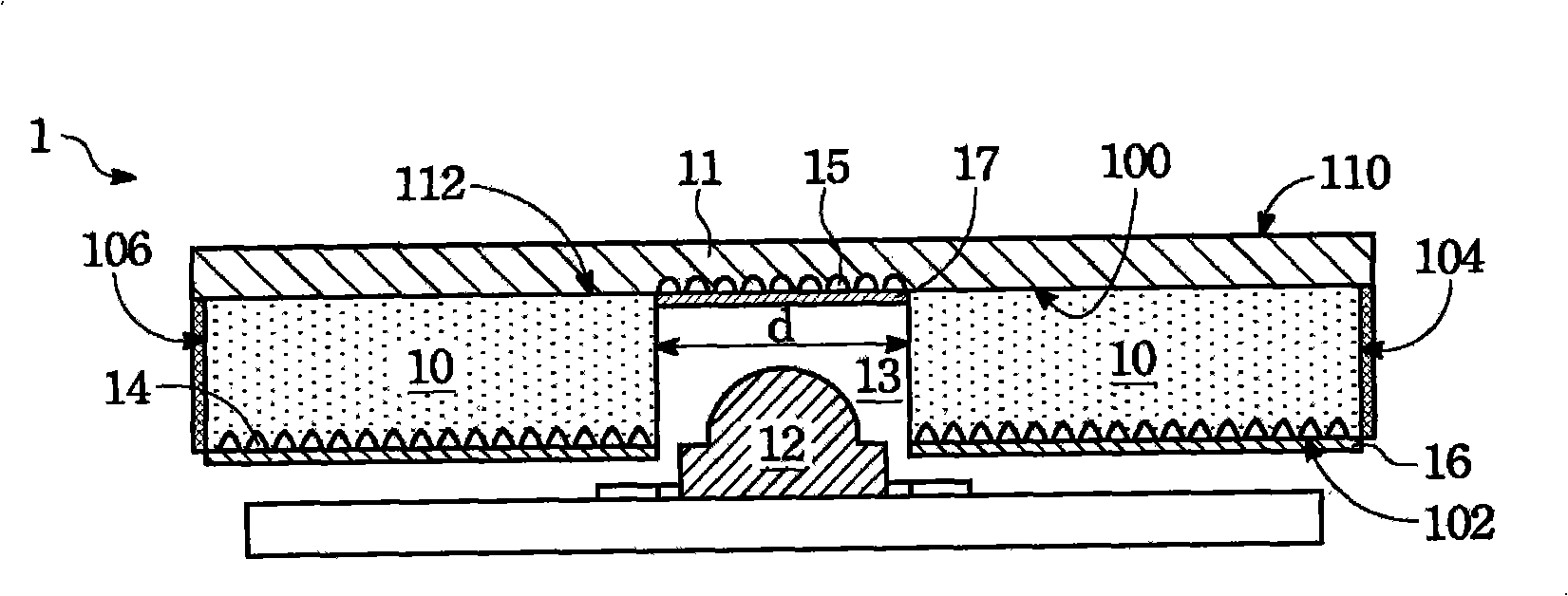

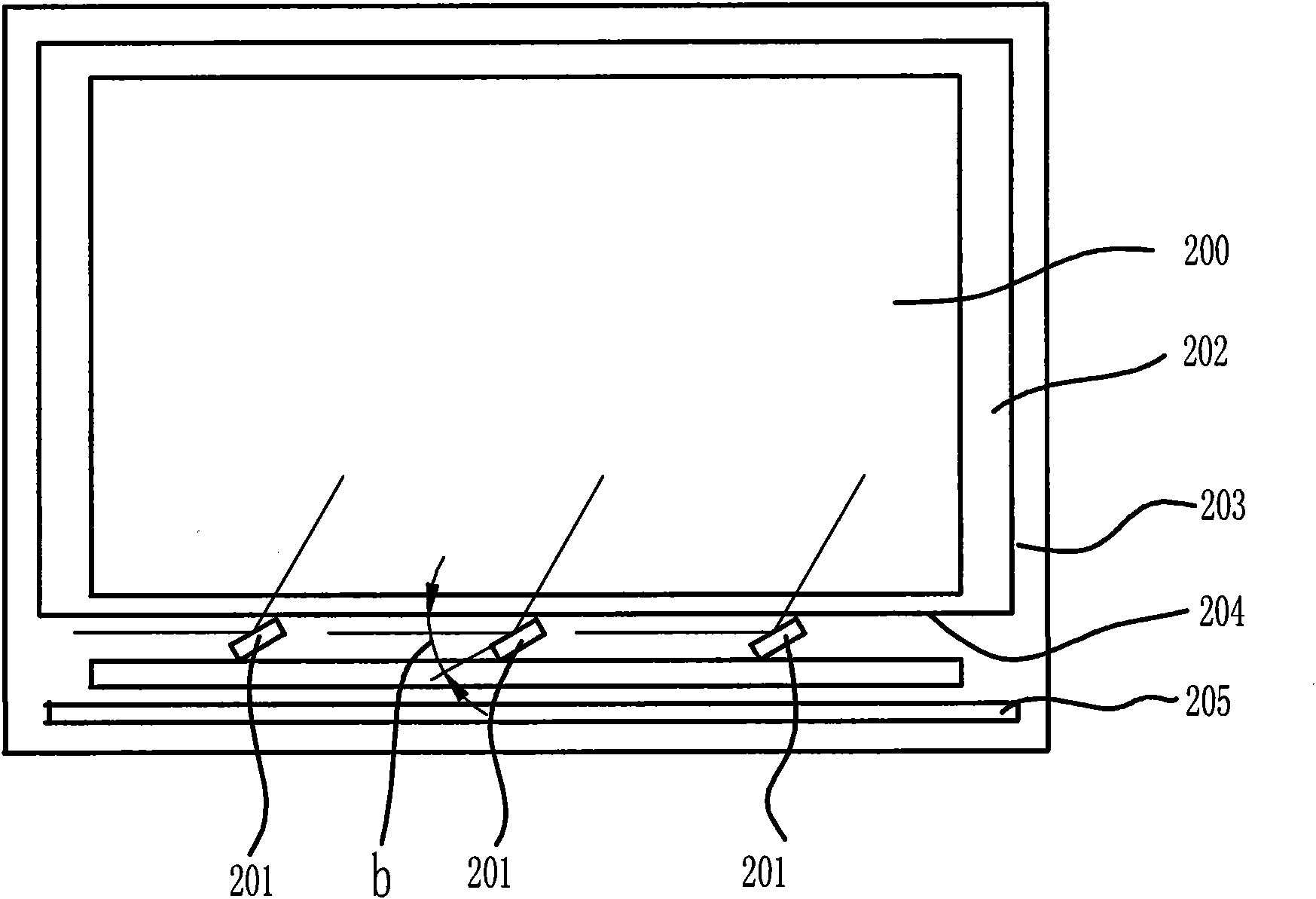

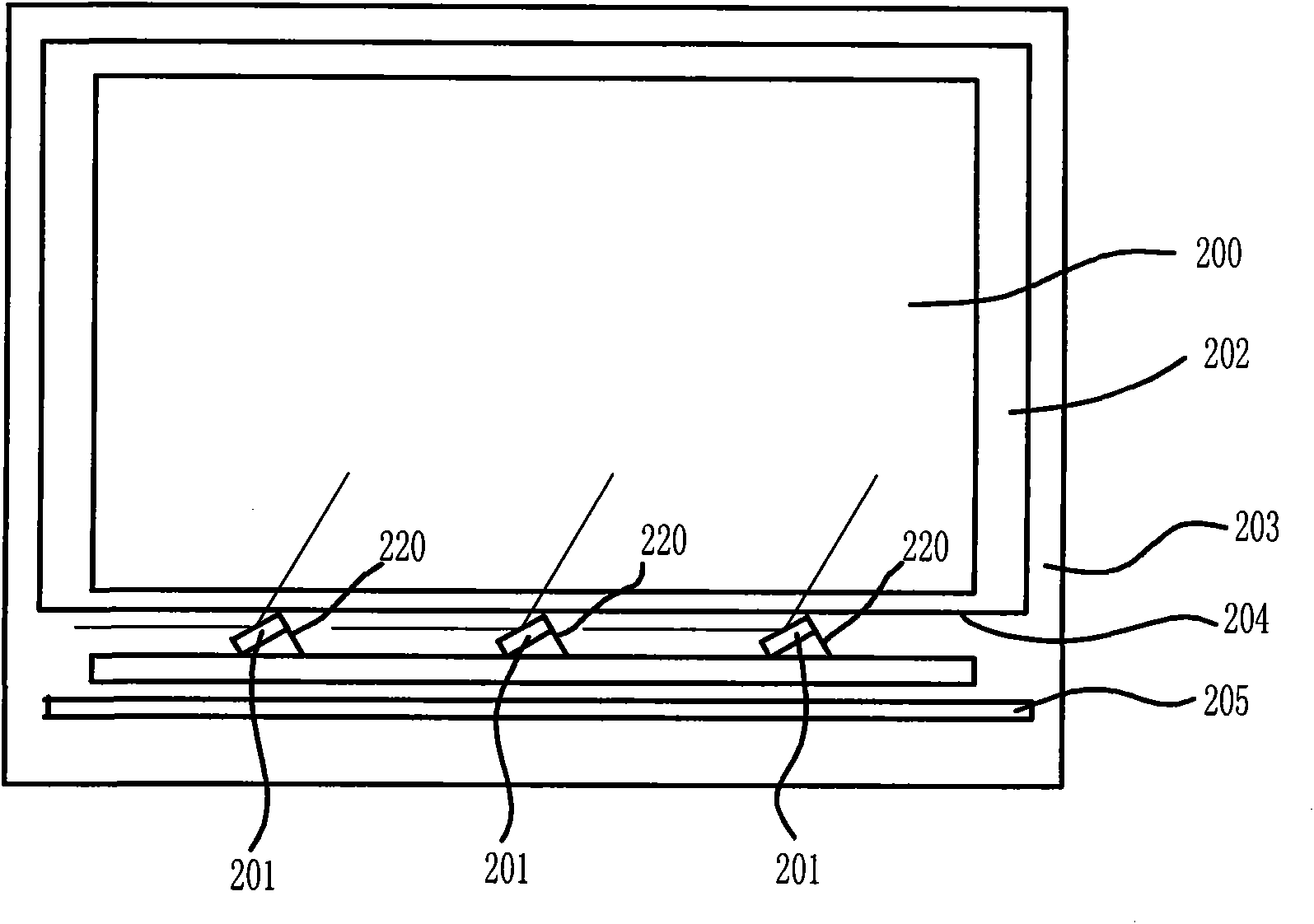

Directly-down backlight module unit

InactiveCN101256307AReduce thicknessConducive to ultra-thinMechanical apparatusPoint-like light sourceDirect illuminationLiquid-crystal display

The invention discloses a direct illumination-type backlight module using the LED light source. The direct illumination-type backlight module comprises a backplate; a plurality of LED light sources adhesive to the backplate; a printed circuit board above the backplate and electrically connected with the LED light source and provided with an opening for the LED light source at the corresponding position of the LED light source; a reflection piece above the printed circuit board and provided with an opening for the LED light source at the corresponding position of the LED light source; a guide light device comprising a bottom and a light extraction face on the reflection piece and provided with a column groove at the corresponding position of the LED light source at the bottom, wherein the groove bottom of the column groove is of conoid and is coated with the reflection material. The direct illumination-type backlight module is favourable to the ultra thinning processe of the liquid crystal display device with good heat emission effect.

Owner:上海广电光电子有限公司

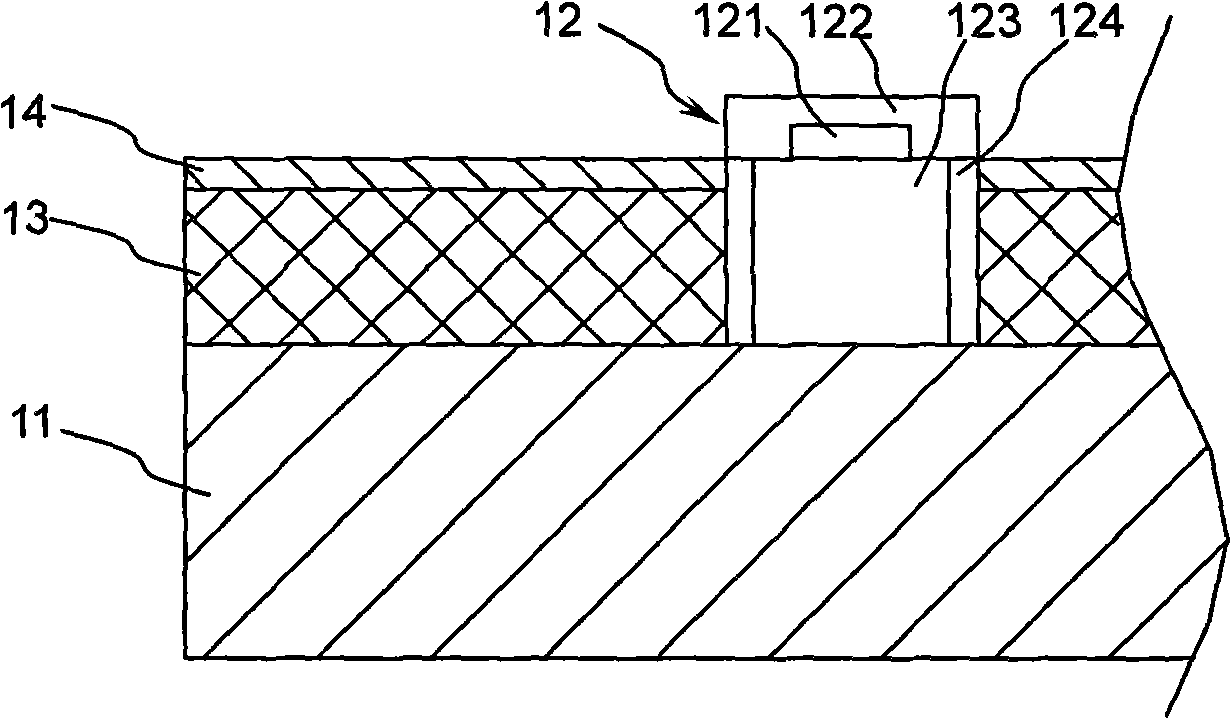

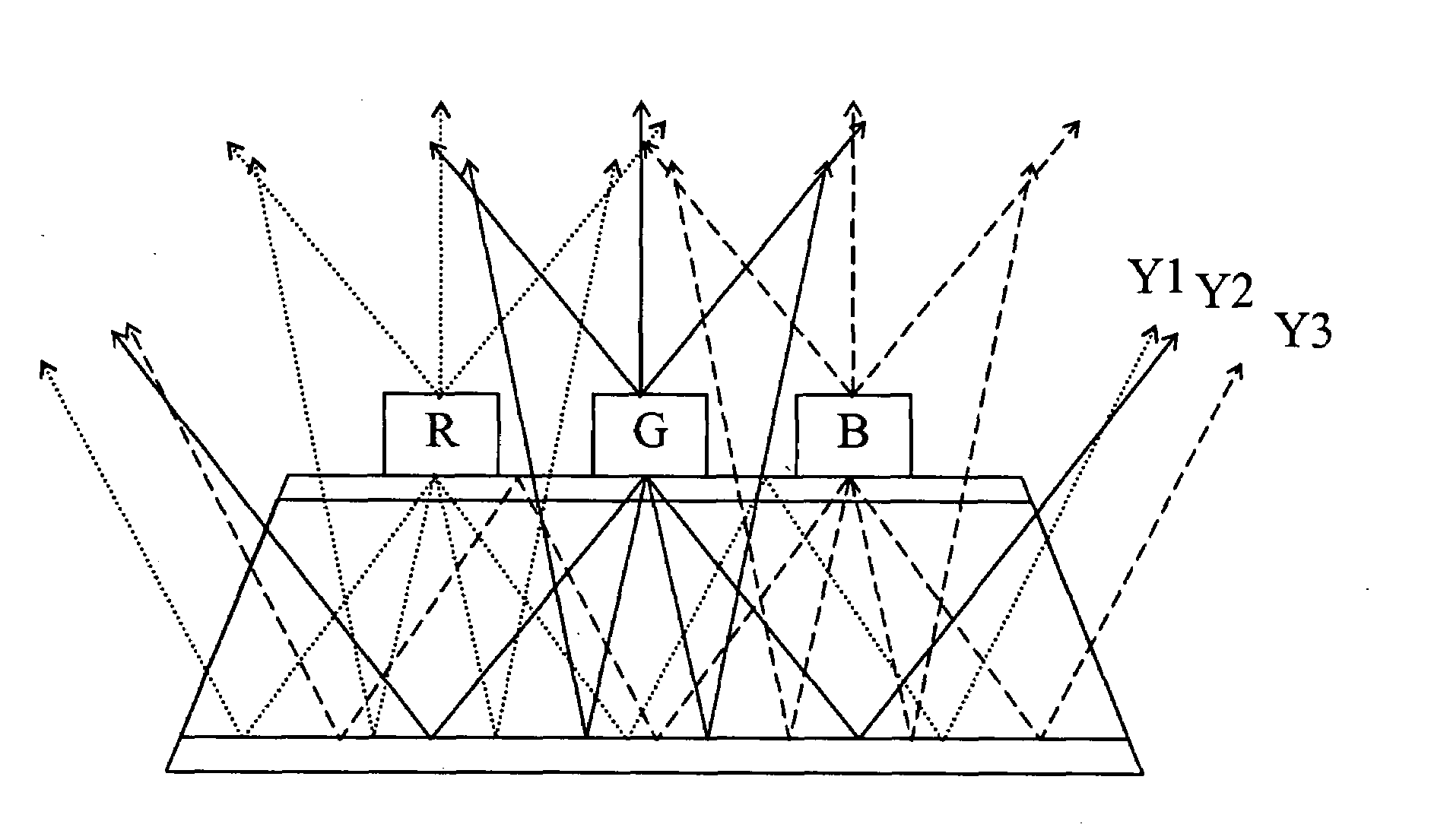

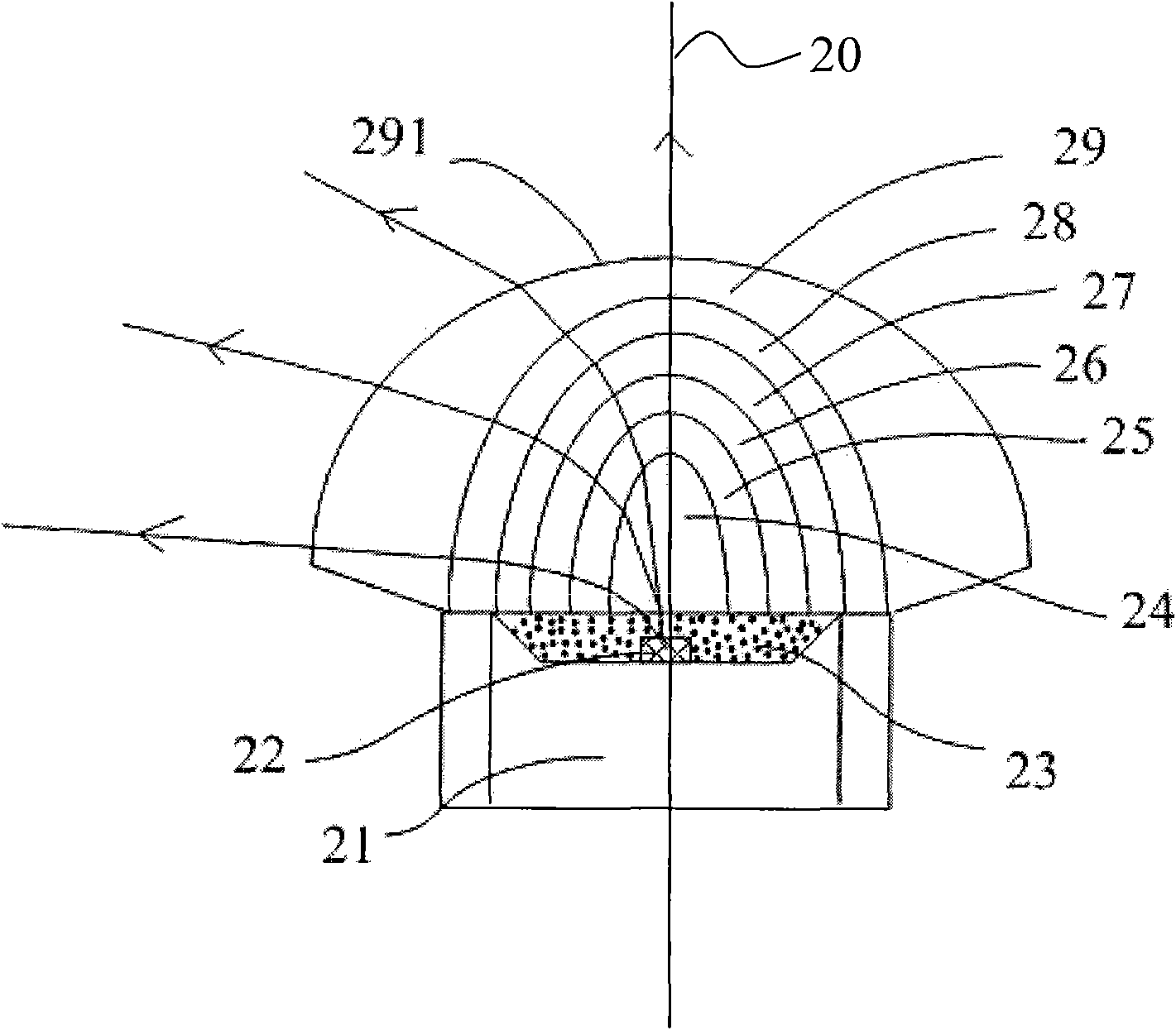

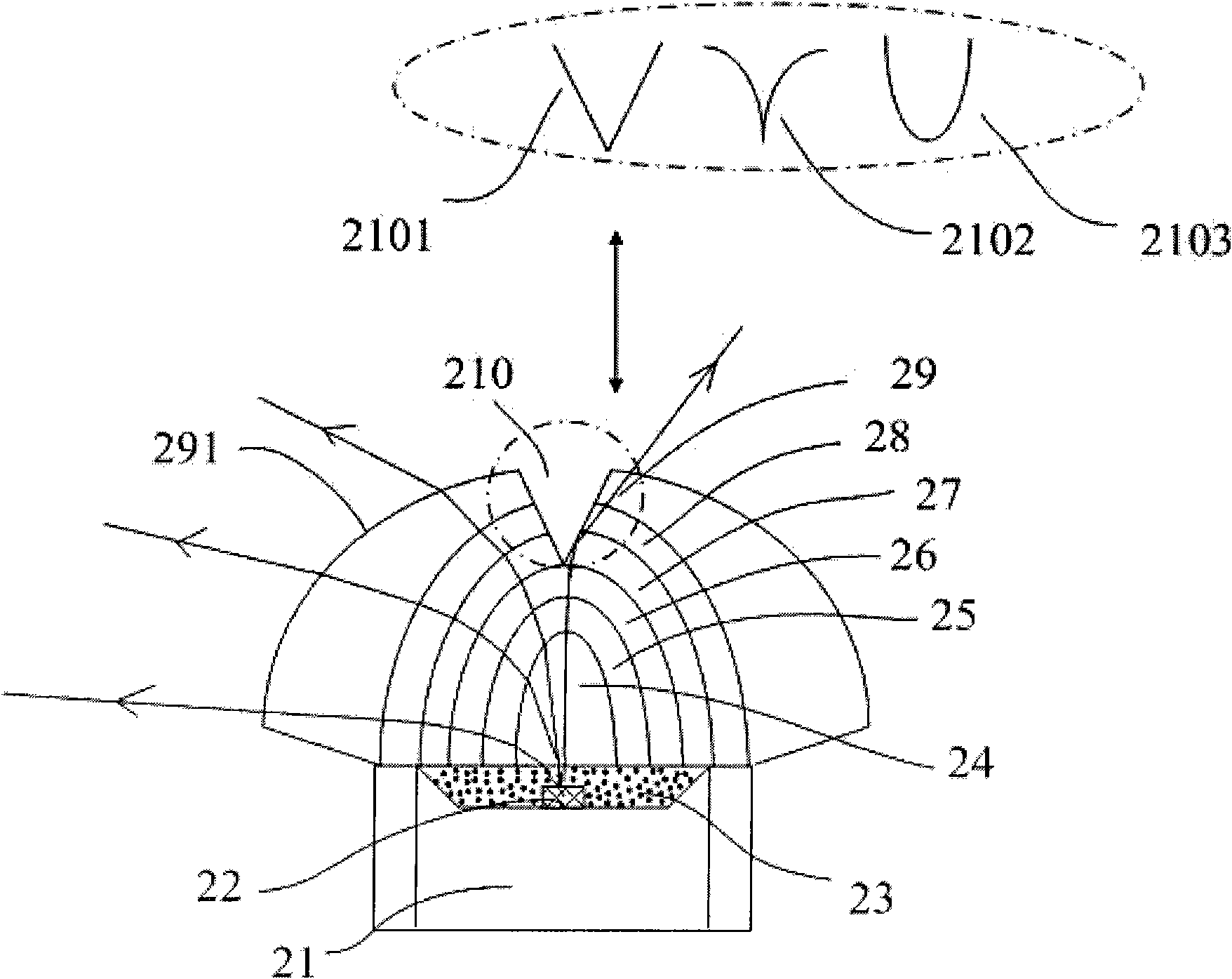

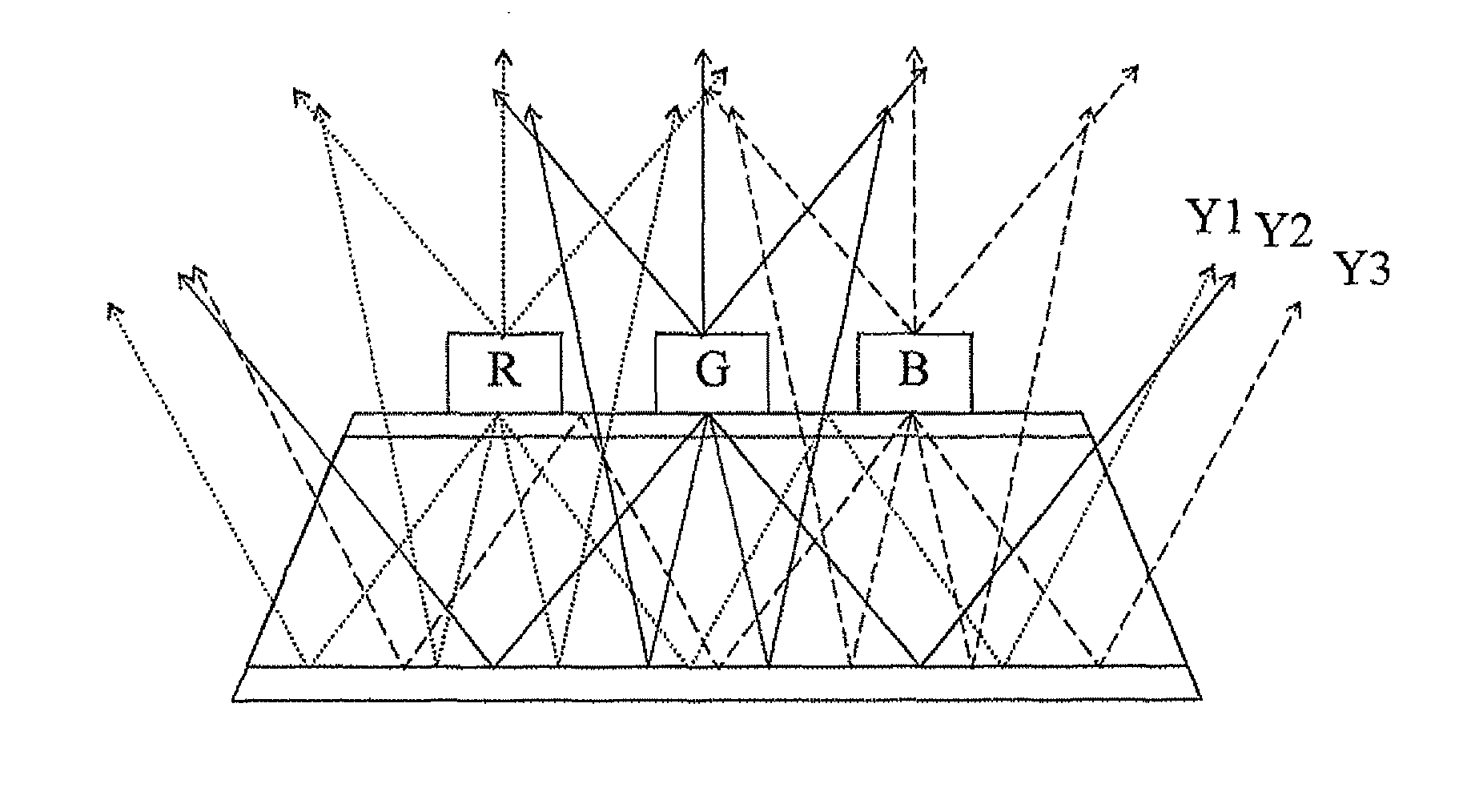

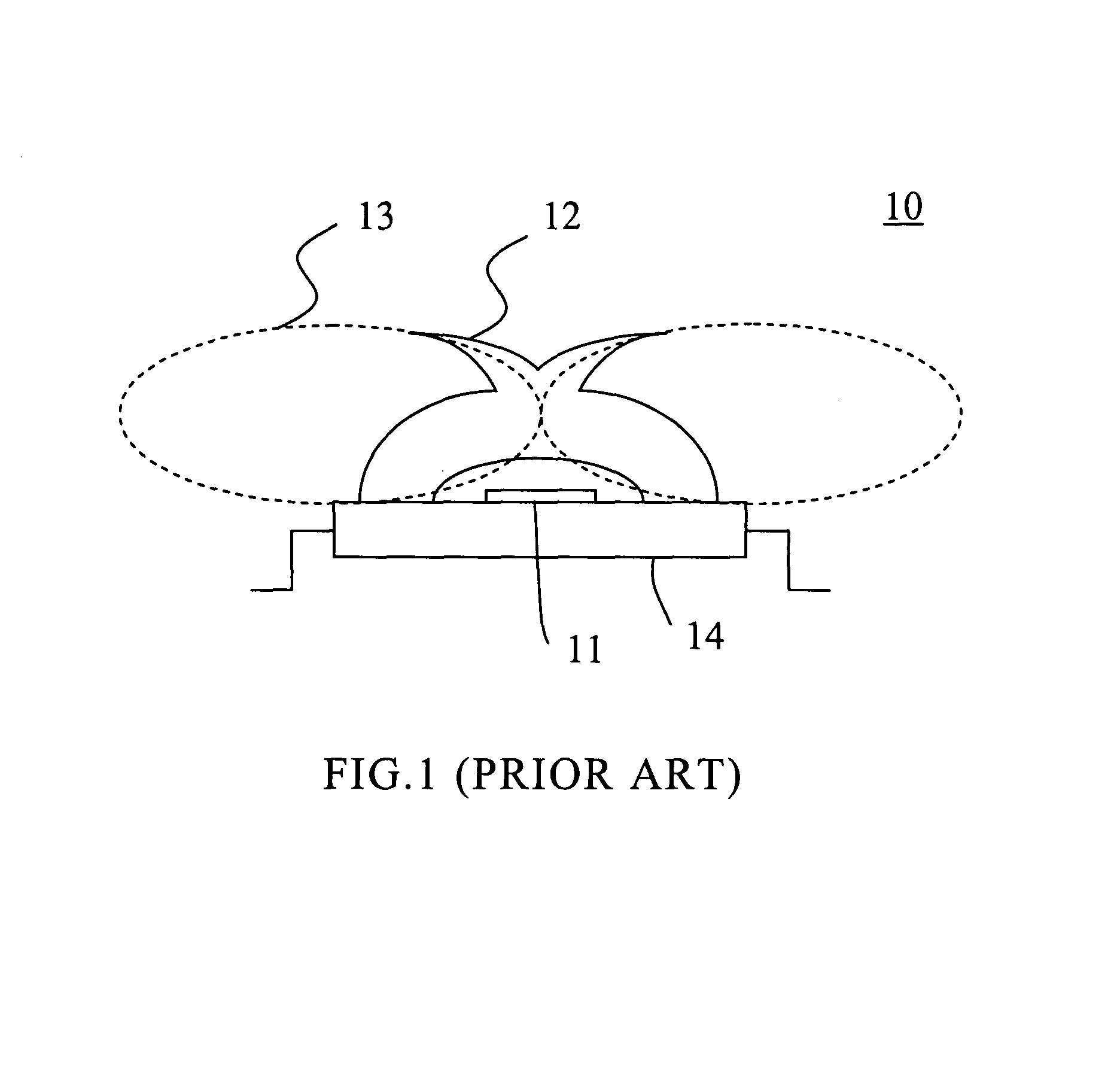

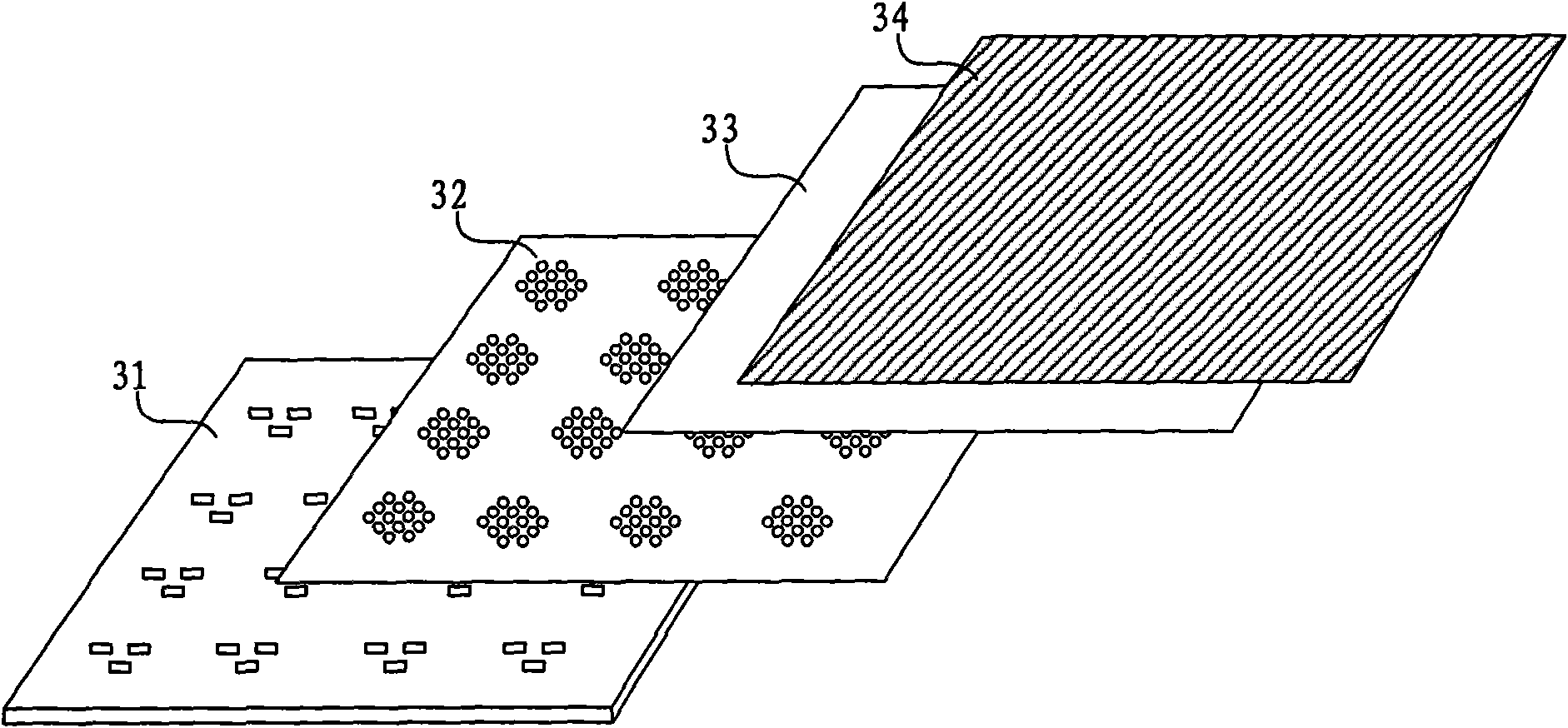

Light-mixing type light-emitting apparatus

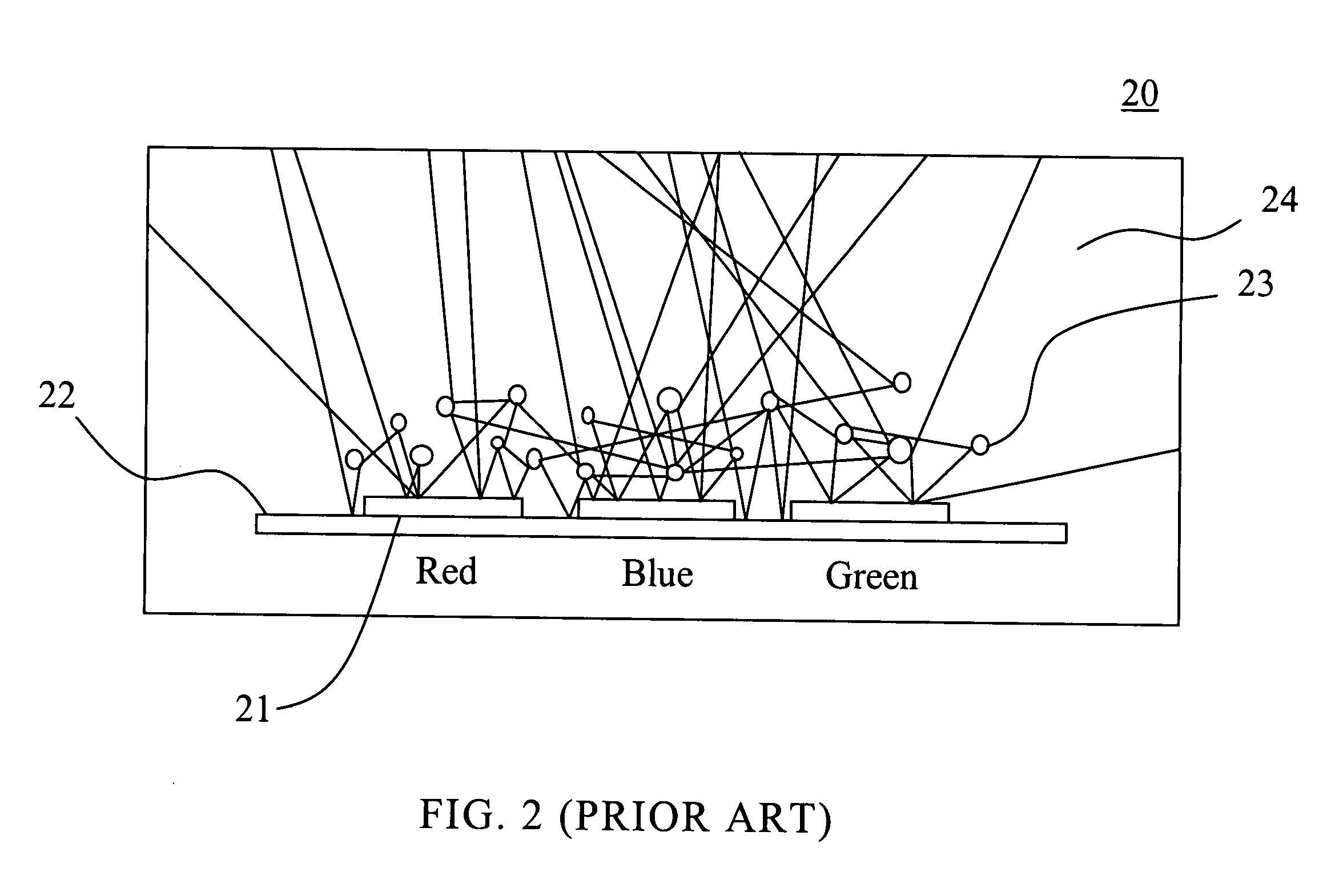

ActiveUS20070263384A1Improve efficiencyShorten the mixing distanceSolid-state devicesSpectral modifiersHybrid typeLight beam

A light-mixing type light-emitting apparatus comprises a plurality of light-emitting diodes (LEDs) formed on a transparent carrier, wherein each of the LEDs with a transparent substrate emits light of a distinct color when driven, and the light beams generated from the LEDs are mixed to form a specific color. The transparent carrier setting forth in the present invention provides a mixing zone underlying the plurality of LEDs for the light beams to mix uniformly so as to improve the light-mixing efficiency of the light-emitting apparatus and shorten the mixing distance.

Owner:EPISTAR CORP

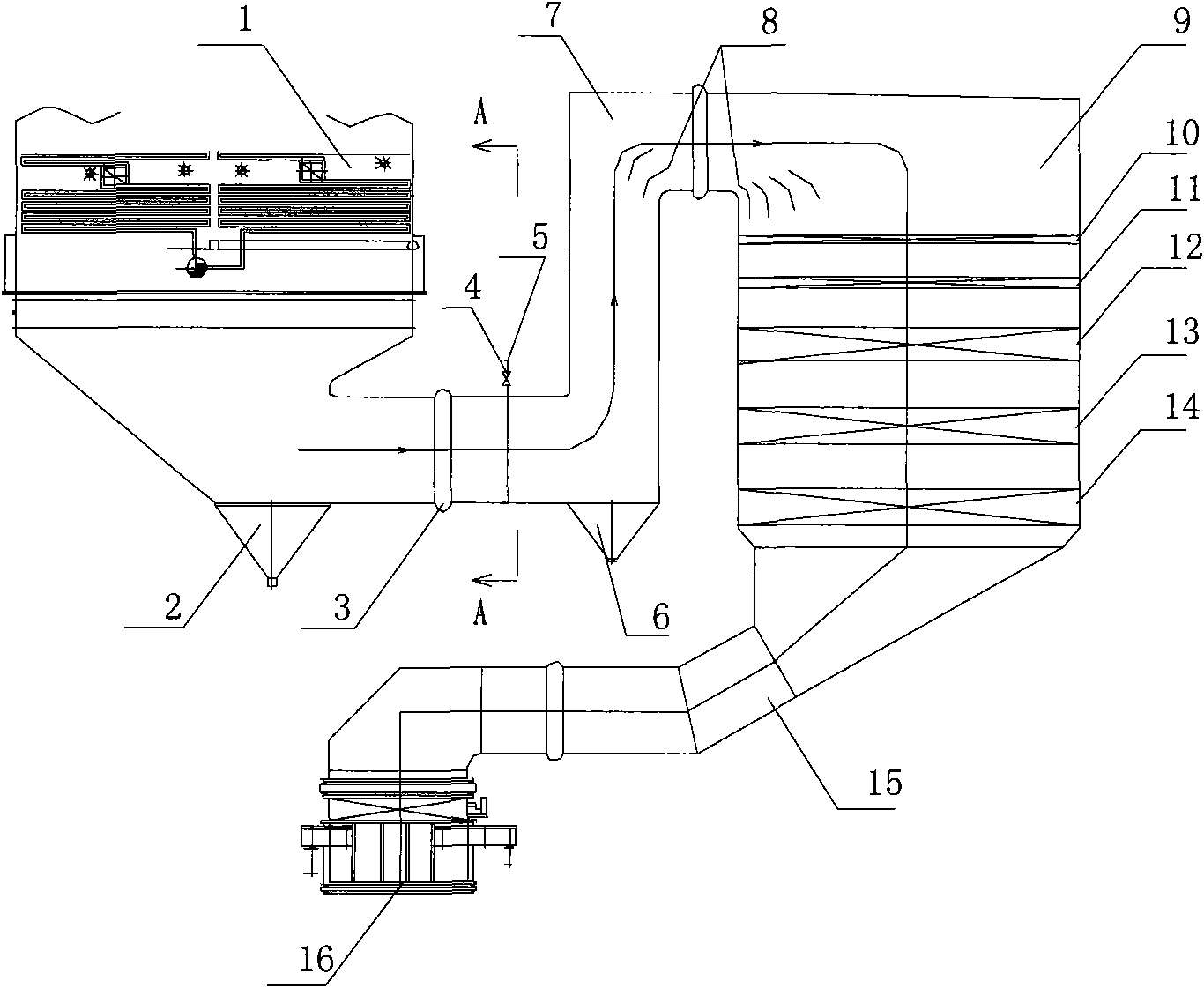

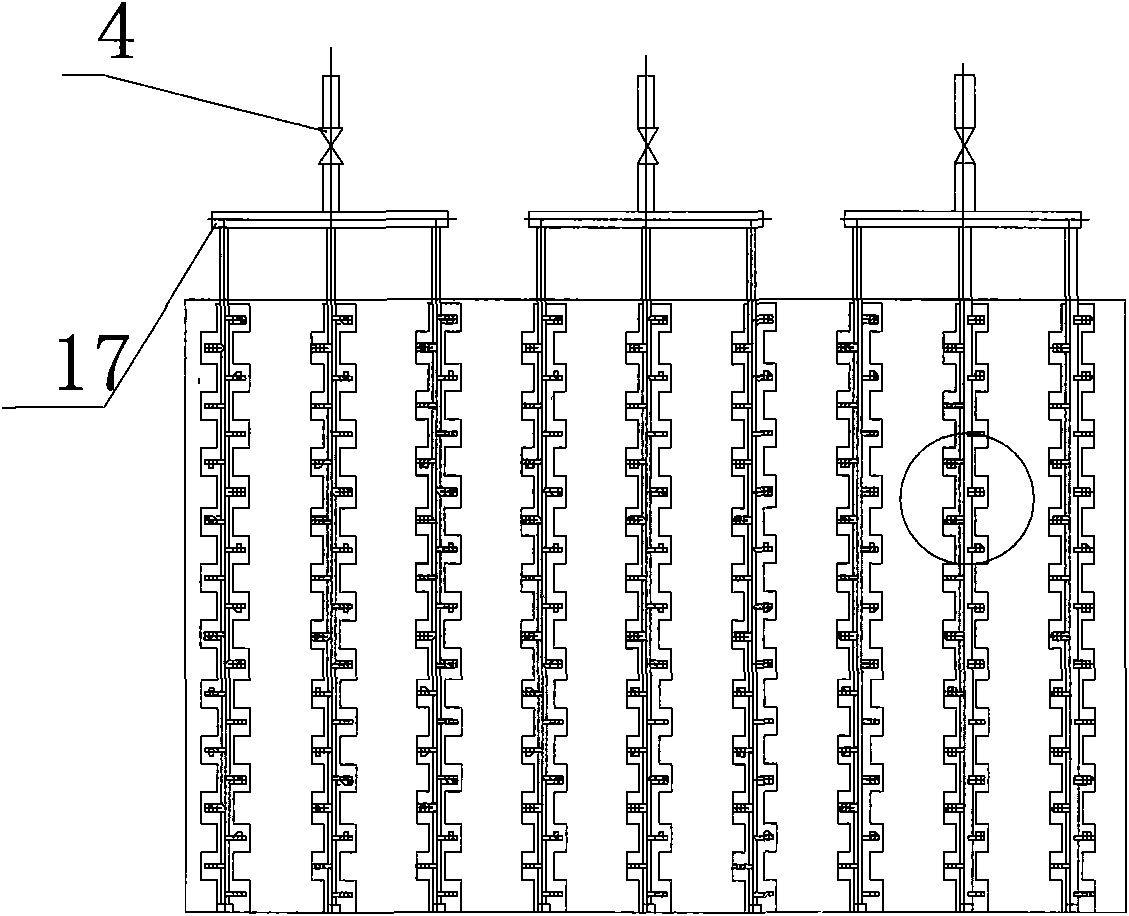

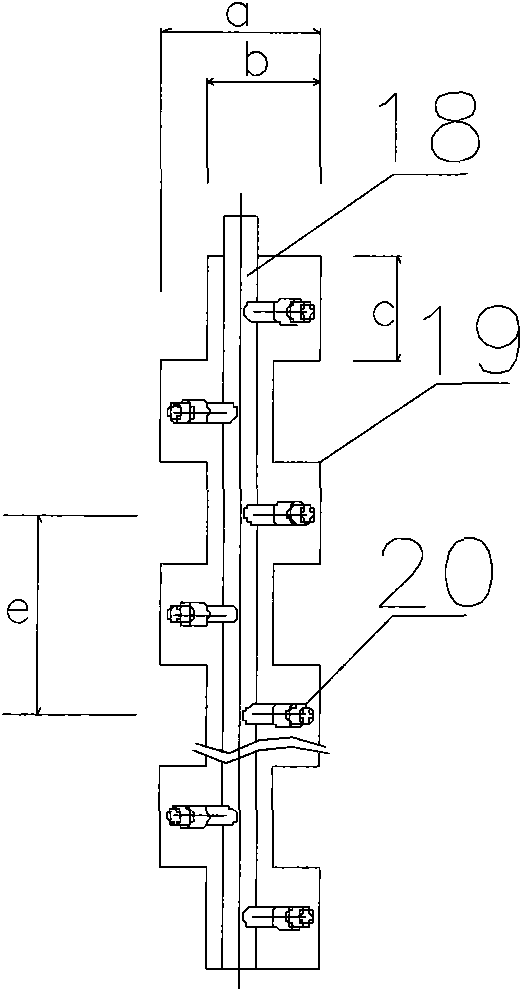

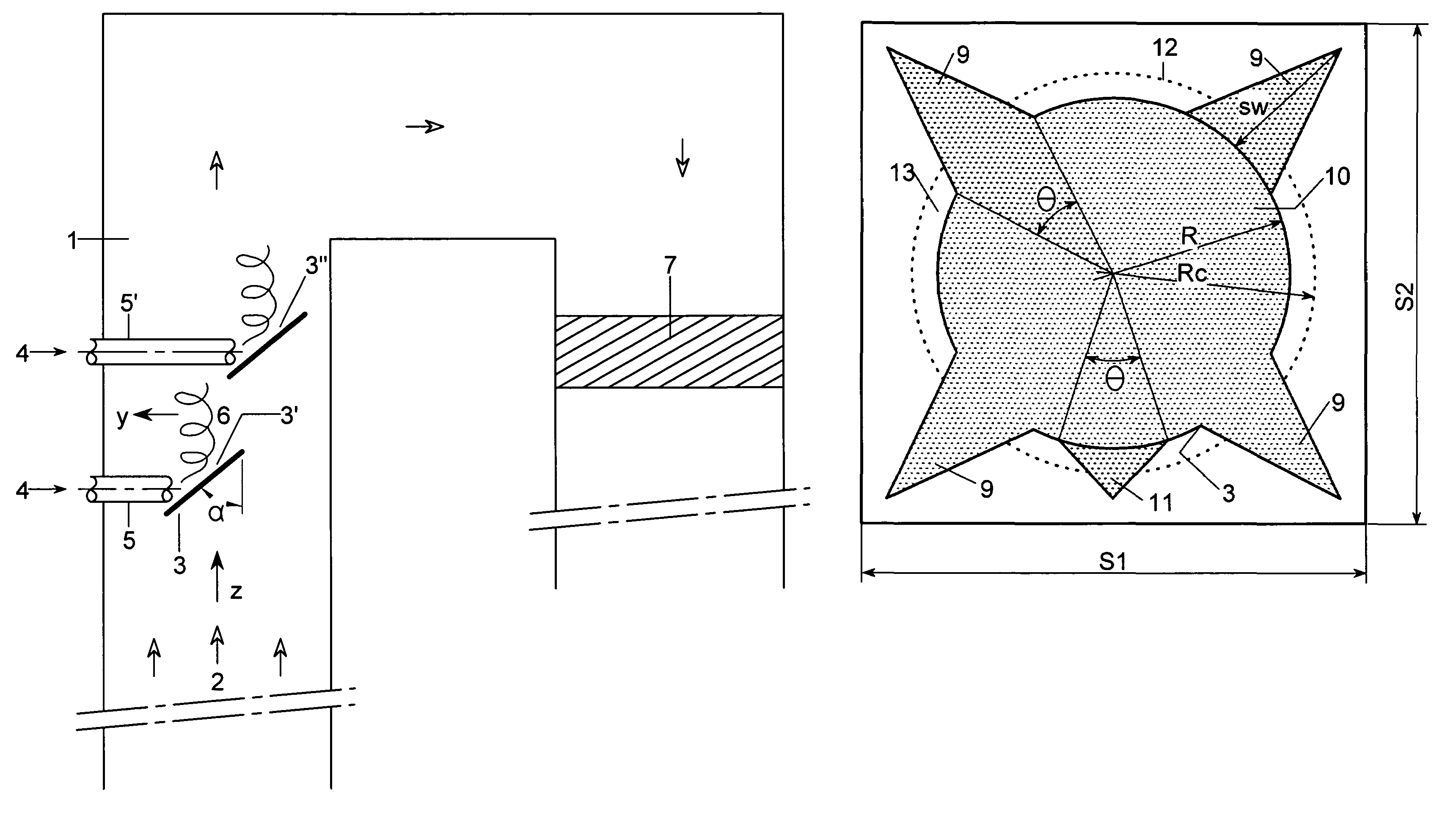

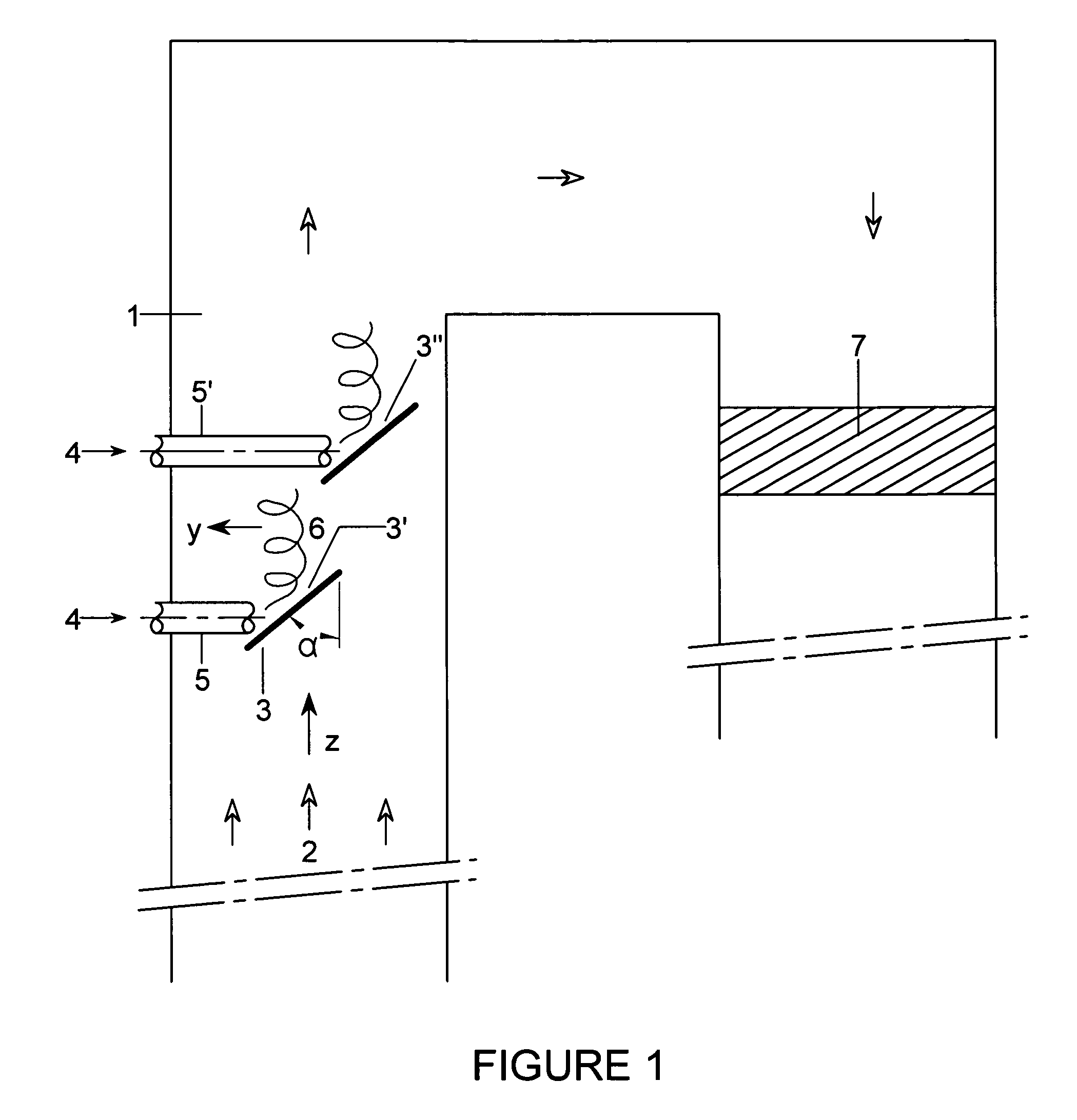

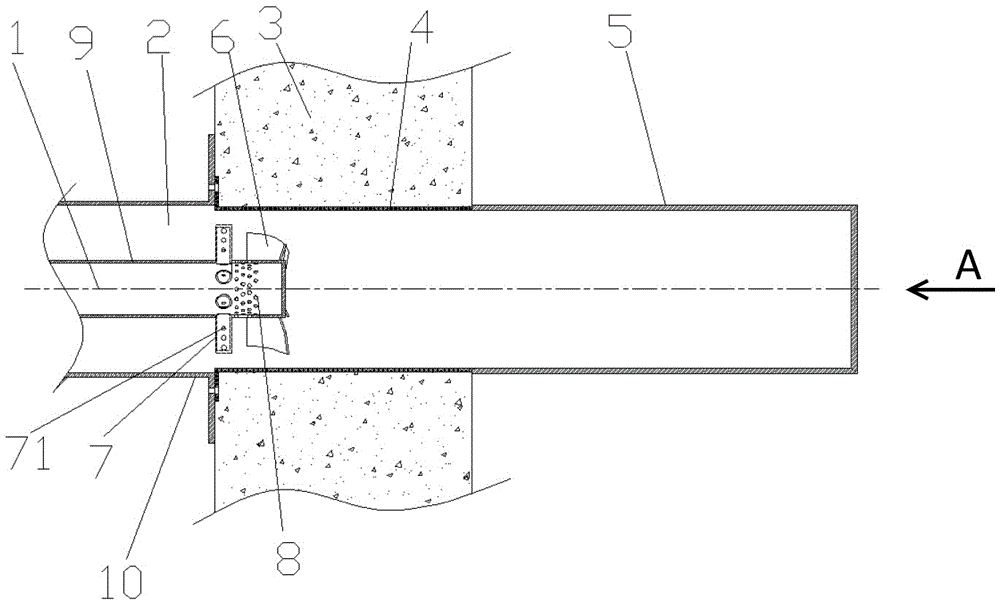

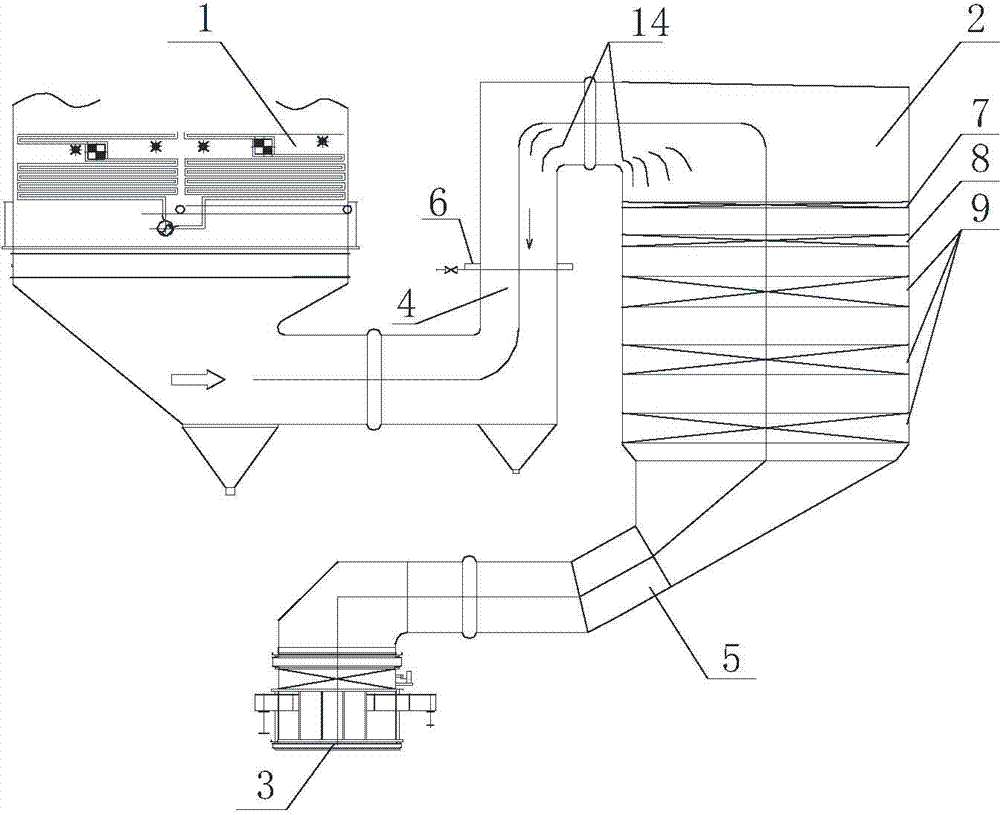

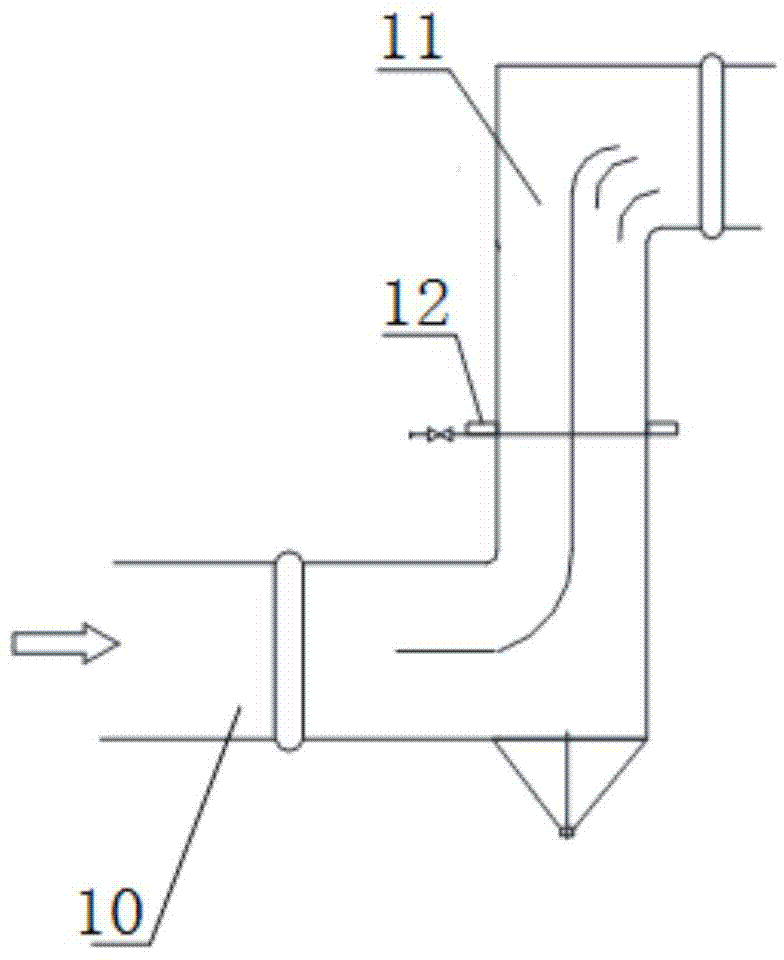

Ammonia-spraying grid device for SCR-method flue gas denitrification, and SCR-method flue gas denitrification process

ActiveCN101601965ASolve the resistanceReduce resistanceNitrous oxide captureDispersed particle separationFlue gasProduct gas

The invention discloses an ammonia-spraying grid device for SCR-method flue gas denitrification, which comprises an ammonia-spraying grid consisting of bundles of metal pipes, wherein each metal pipe is provided with a nozzle in the radial direction; the nozzle is communicated with the metal pipe; and the included angle between the opening direction of the nozzle and the flow direction of flue gas is between 0 and 90 degrees. The invention also discloses an SCR-method flue gas denitrification process adopting the ammonia-spraying grid device. The process adopts the ammonia-spraying grid to distribute ammonia / air gas mixture sprayed into an inlet flue of a denitrification reactor, and adjusts ammonia spray distribution according to the concentration of NOx in the inlet flue of the reactor so as to mix the NOx in the flue gas with NH3 sprayed in well, thus the mixing effect of the NH3 and the flue gas as well as denitrification efficiency can be effectively improved. A grid-type ammonia spraying-distributing-mixing device of the invention has the advantages of simple structure, low mixture resistance, good distribution effect, insusceptibility to ash deposition, capability of effectively protecting ammonia-spraying grid nozzles from wear, reducing the mixture distance of ammonia and the flue gas in an inlet of the denitrification reactor, improving the utilization rate of denitrification catalysts, reducing the height of the denitrification reactor and reducing the resistance of a flue gas denitrification system, thereby greatly reducing the unit cost of flue gas denitrification.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH

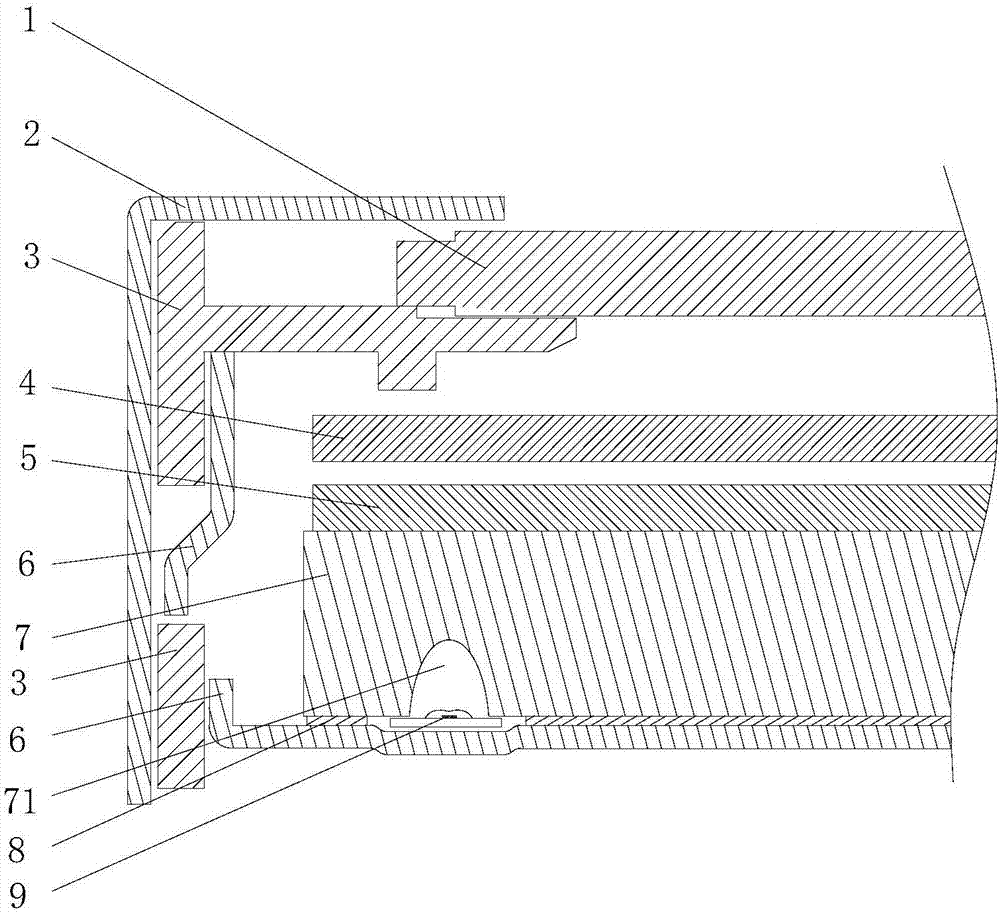

LED light source with wide-angle lens

InactiveCN101556023AImprove refraction effectImprove light utilizationPoint-like light sourceSemiconductor devices for light sourcesRefractive indexStigmatism

The invention relates to an LED light source with a wide-angle lens, comprises a base, an LED luminescence chip and a lens; the LED luminescence chip and the lens have same central axis; wherein the lens is made of a plurality of layers of mediums which have same central axis; and the index of refraction of the plurality of layers of mediums increases sequentially and outward along the central axis. The LED light source with a wide-angle lens has a plurality of layers of mediums with the gradually changing index of refraction, effectively widens the angle of diffused light, reduces the distance of mixed light and realizes thinning of the backlight module.

Owner:上海广电光电子有限公司

Light-mixing type light-emitting apparatus

ActiveUS8882290B2Improve efficiencyShorten the mixing distanceMeasurement apparatus componentsSolid-state devicesLight beamLight-emitting diode

A light-mixing type light-emitting apparatus comprises a plurality of light-emitting diodes (LEDs) formed on a transparent carrier, wherein each of the LEDs with a transparent substrate emits light of a distinct color when driven, and the light beams generated from the LEDs are mixed to form a specific color. The transparent carrier setting forth in the present invention provides a mixing zone underlying the plurality of LEDs for the light beams to mix uniformly so as to improve the light-mixing efficiency of the light-emitting apparatus and shorten the mixing distance.

Owner:EPISTAR CORP

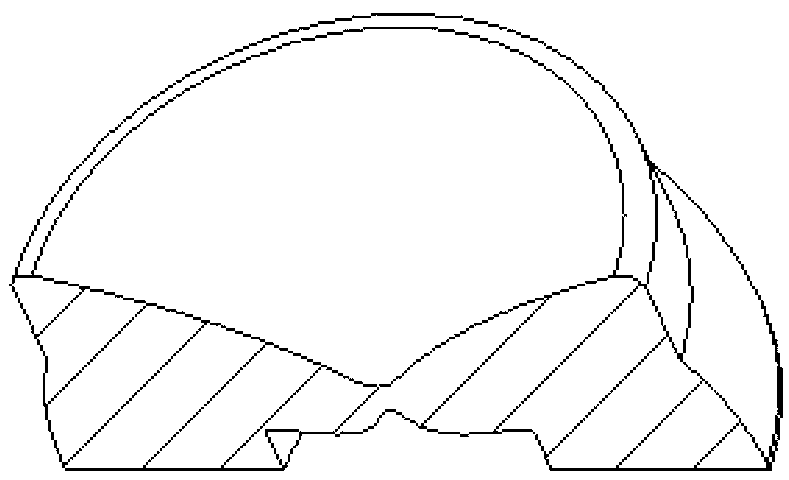

Optical lens

ActiveCN103277739ASimple designImprove light extraction efficiencyPoint-like light sourceRefractorsBeam angleLight beam

The invention discloses an optical lens. The optical lens comprises a lens body. A light-incidence curved surface with the center sunk upwards for incidence of light is formed on the bottom of the lens body. A first light-exit curved surface with the center sunk downwards is formed on the top of the lens body. A second light-exit curved surface is formed on the side portion of the lens body. After incidence of the light through the lens body is finished, an included angle between the first light-exit curved surface and the axis of the lens body is 42 degrees as a critical angle, light beams between a central light beam and 42 degrees are refracted through the first light-exit curved surface, and light beams between 42 degrees and 85 degrees are refracted through the second light-exit curved surface after being totally refracted through the first light-exit curved surface. According to the optical lens, a catadioptric way is adopted for beam angle diffusion, and brightness uniformity on a receiving surface is improved.

Owner:北京易美新创科技有限公司

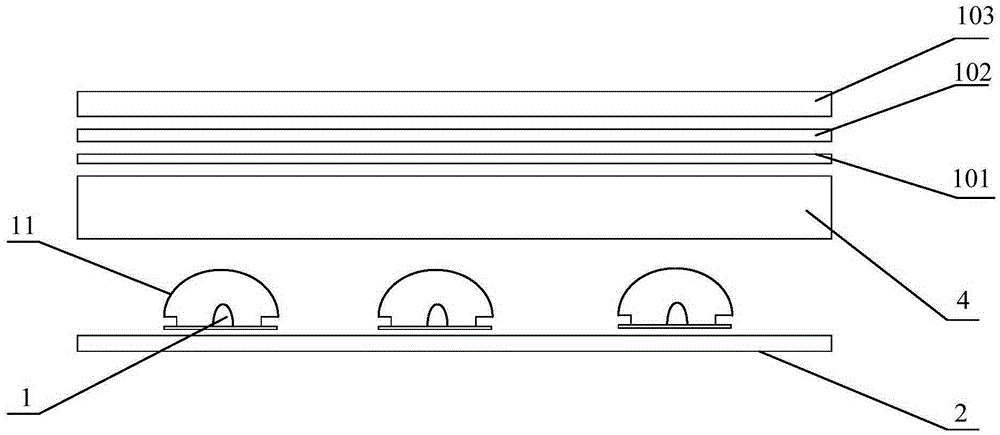

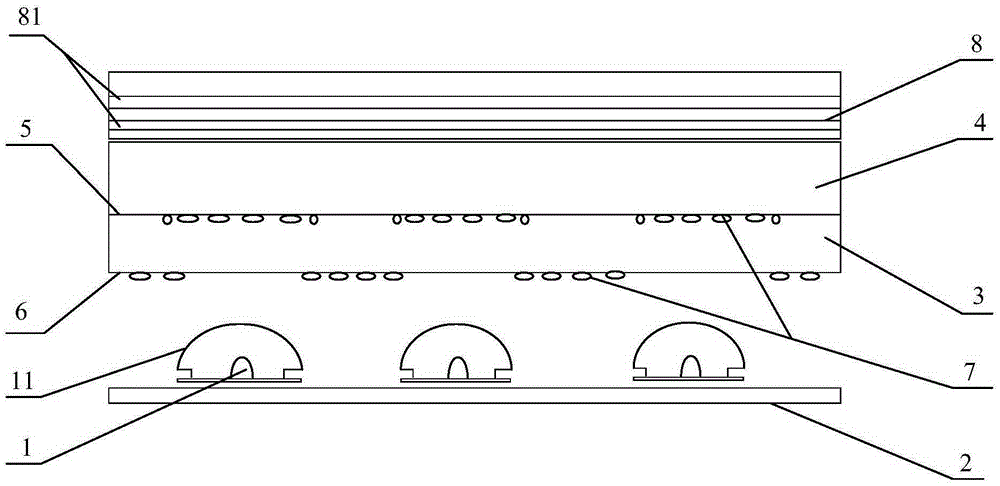

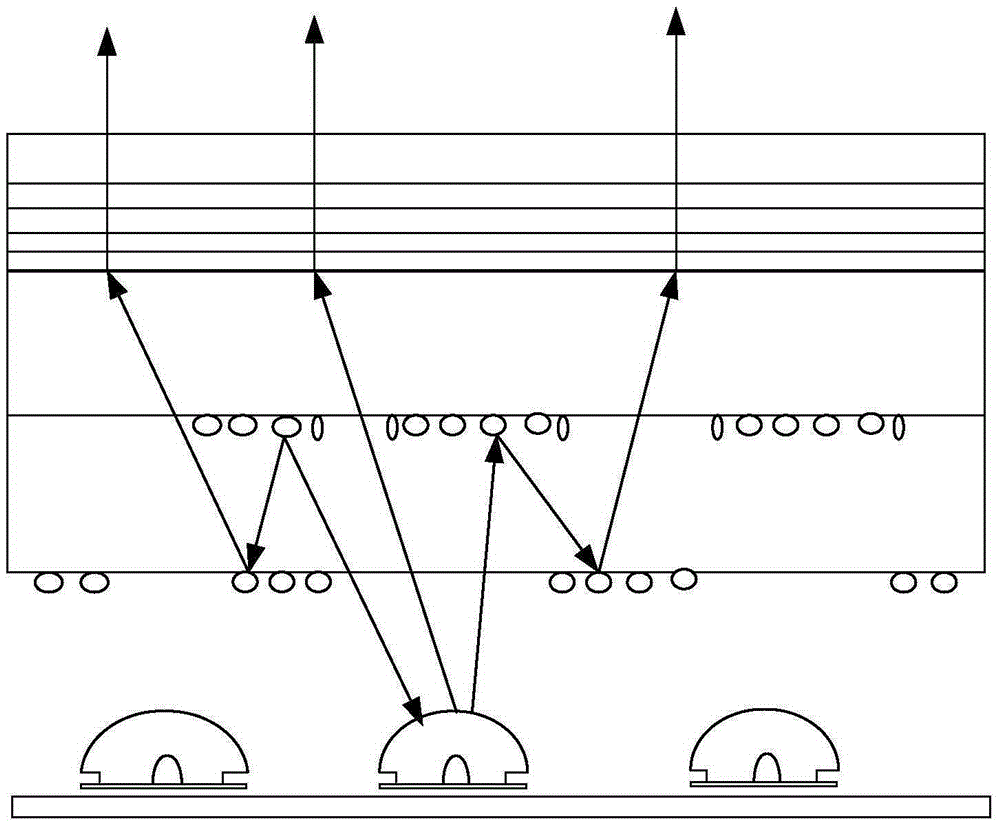

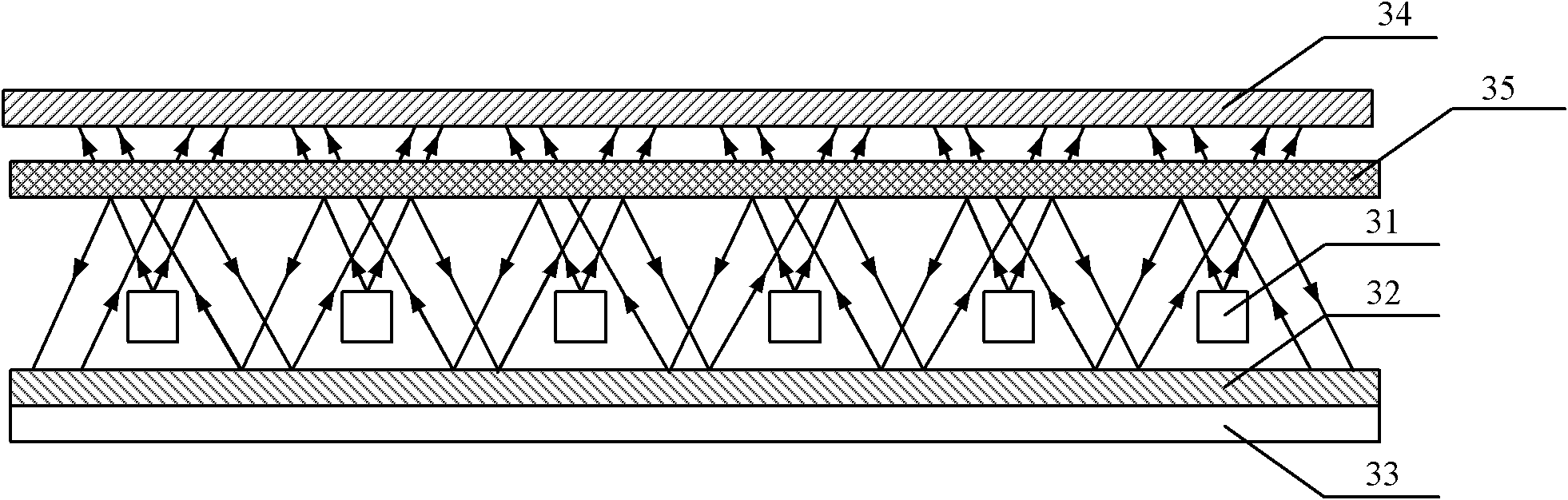

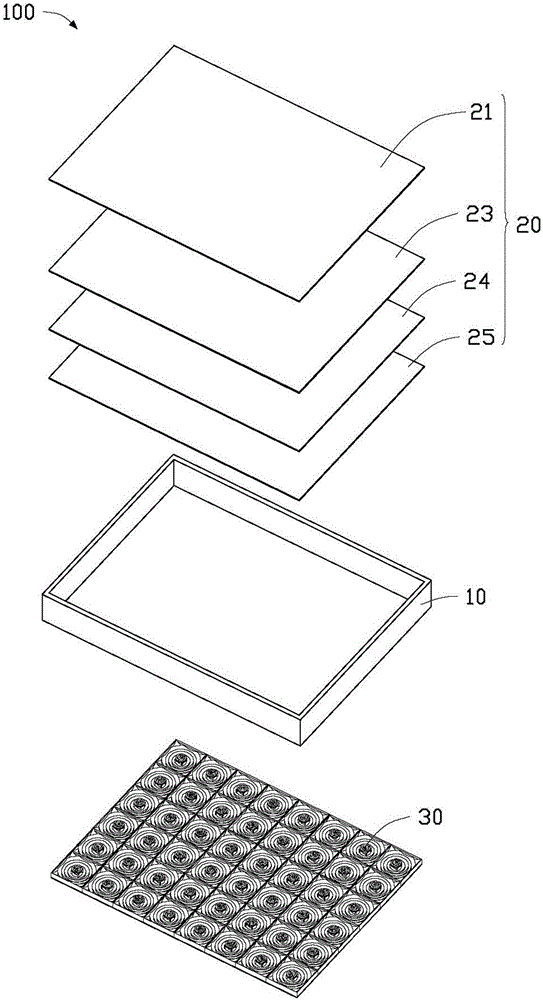

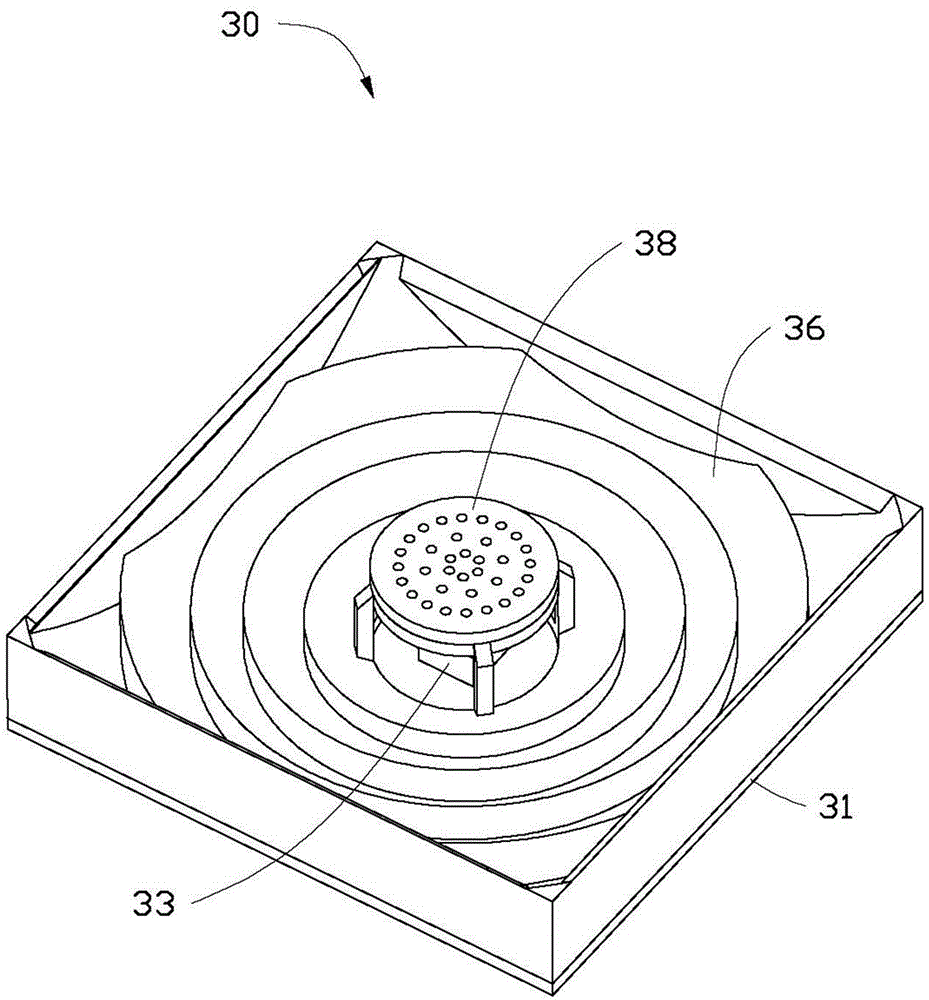

Backlight module set and display device

The invention provides a backlight module set and a display device. The backlight module set comprises an LED lamp, a reflection plate, a light guide layer and a diffusion plate, wherein the reflection plate is arranged on one side of the LED lamp; the other side of the LED lamp is orderly provided with the light guide layer and the diffusion plate; the light guide layer is arranged between the light guide layer and the diffusion plate; and lattice points capable of reflecting light rays are arranged on a connection surface between the diffusion plate and the light guide layer, and the bottom surface of the light guide layer and facing the LED lamp. Mixed spectrum distance of the direct backlight module set can be reduced and a super-thinning display device can be achieved.

Owner:HISENSE VISUAL TECH CO LTD

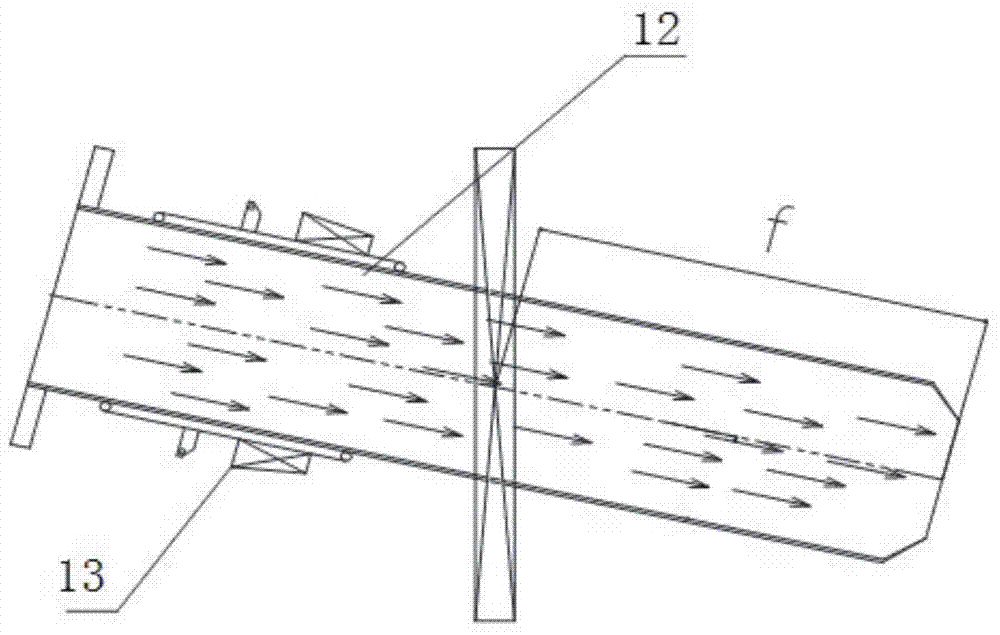

Method for mixing fluid streams

A method for the mixing of fluid streams in a duct comprising positioning at least one mixing device having a front side and a back side within said duct through which a first major stream travels, the at least one mixing device determining a total cross-sectional area which is significantly lower than that of the duct so as to allow for the passage of said first major stream, whereby the at least one mixing device is a solid plate provided with one or more protrusions extending outward from the main solid plate body.

Owner:UMICORE AG & CO KG

Direct type backlight source

InactiveCN102644883AIncrease the working distanceShorten the mixing distanceNon-linear opticsRefractorsReflectivityLight source

The invention discloses a direct type backlight source comprising a light-emitting body, a reflection sheet located below the light-emitting body, a back plate located below the reflection sheet, and a diffusion plate located above the light-emitting body. The direct type backlight source further comprises a semi-transparent semi-reflecting layer arranged between the diffusion plate and the light-emitting body, wherein the reflection rate of the semi-transparent semi-reflecting layer is more than 0 and less than 1. With the adoption of the technical scheme, the thickness of the direct type backlight source is effectively reduced.

Owner:BOE TECH GRP CO LTD +1

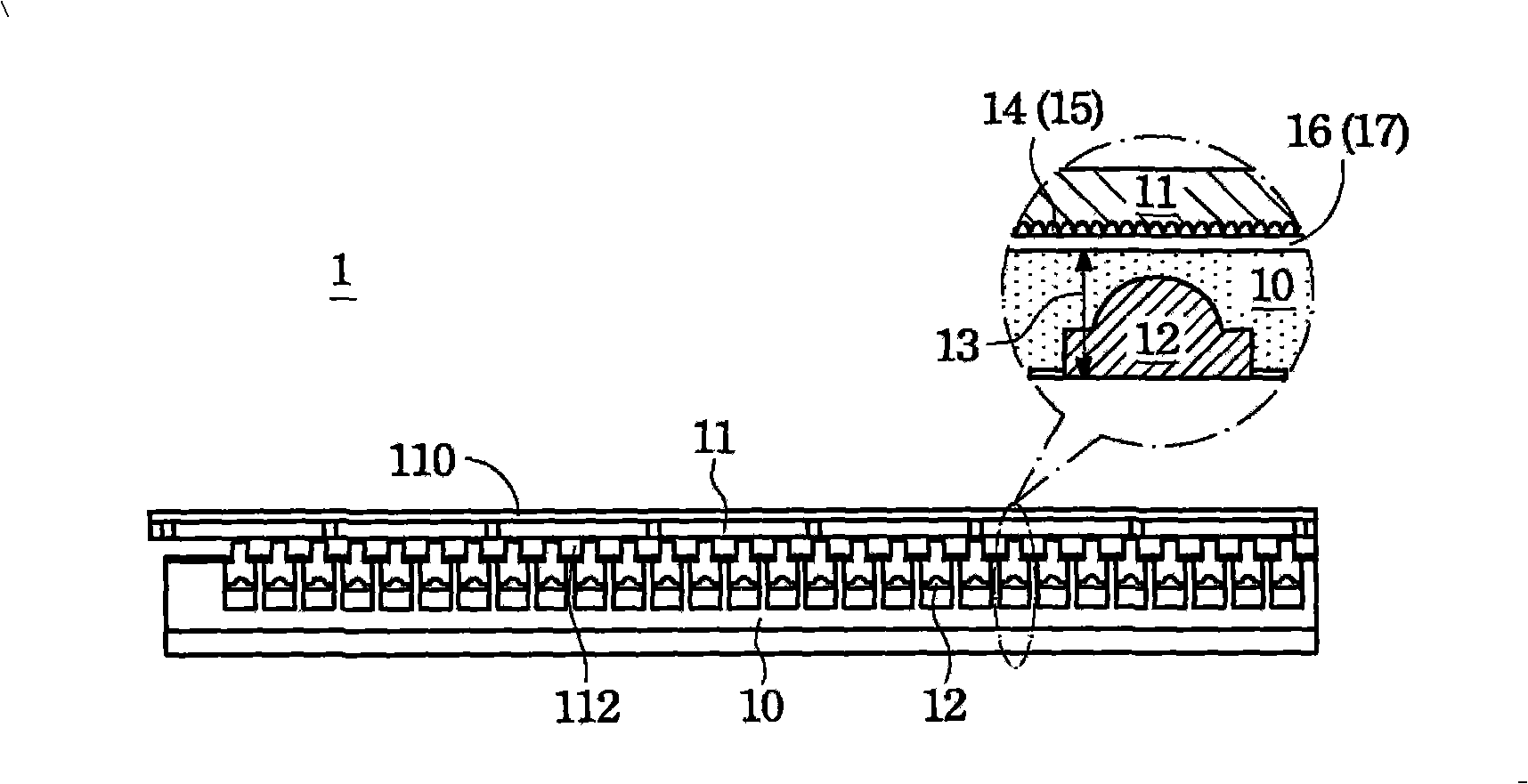

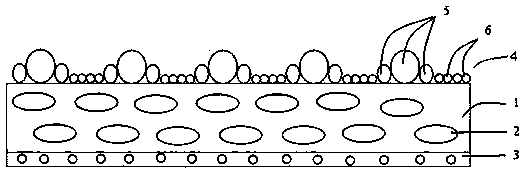

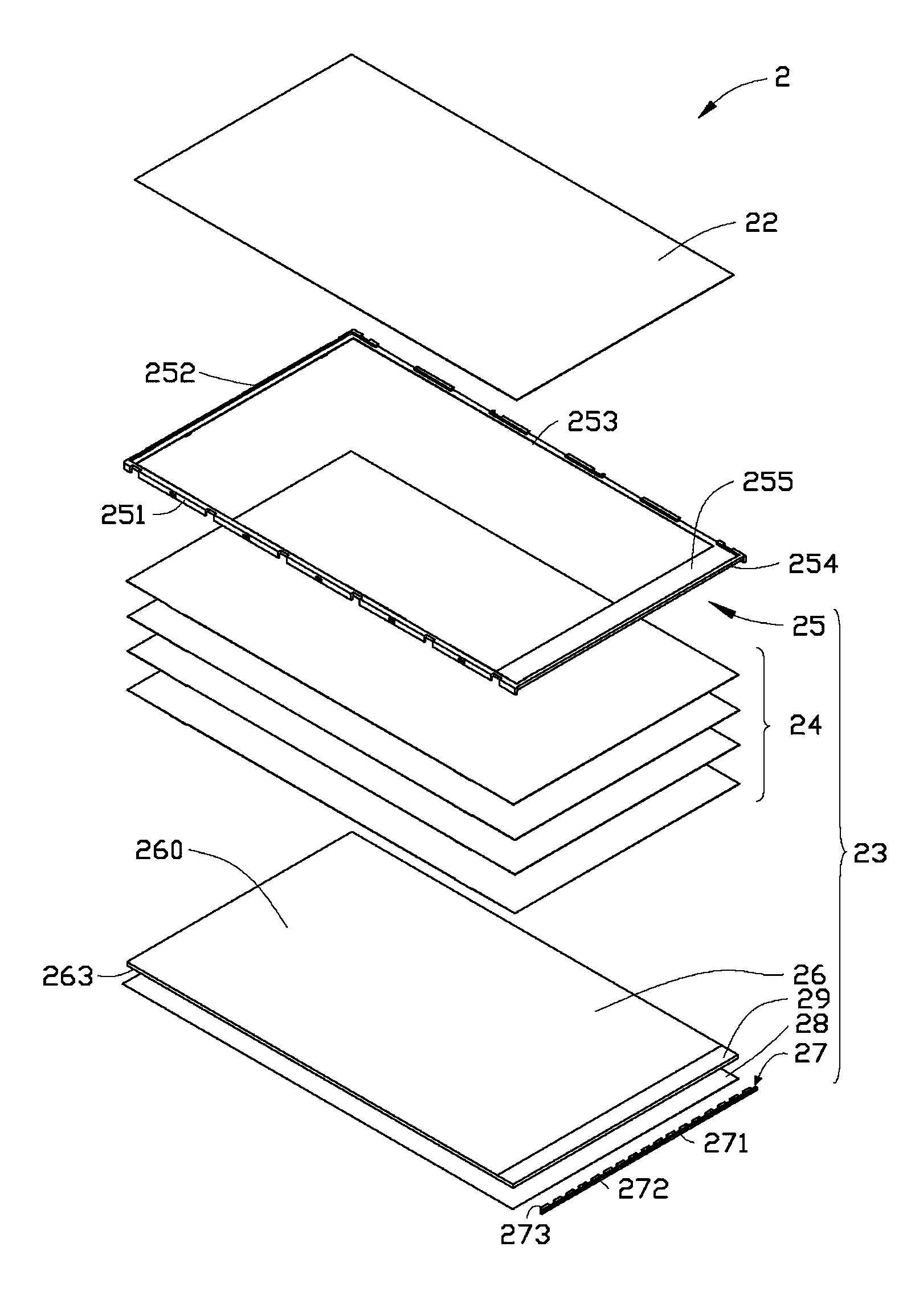

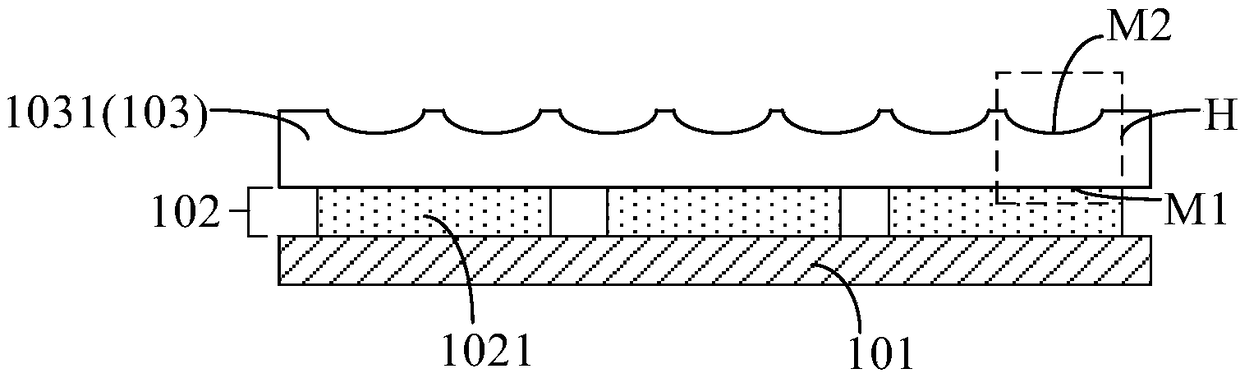

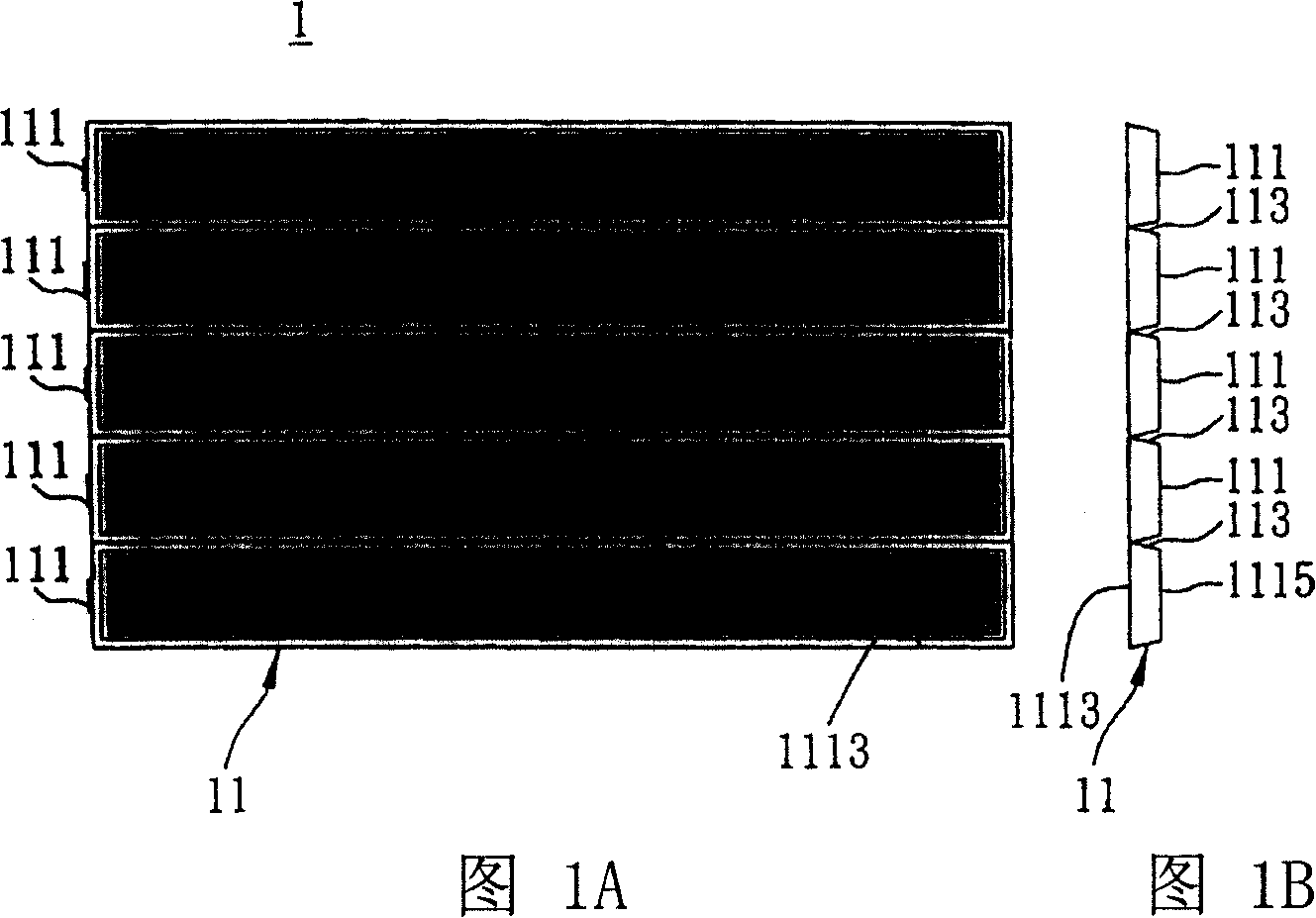

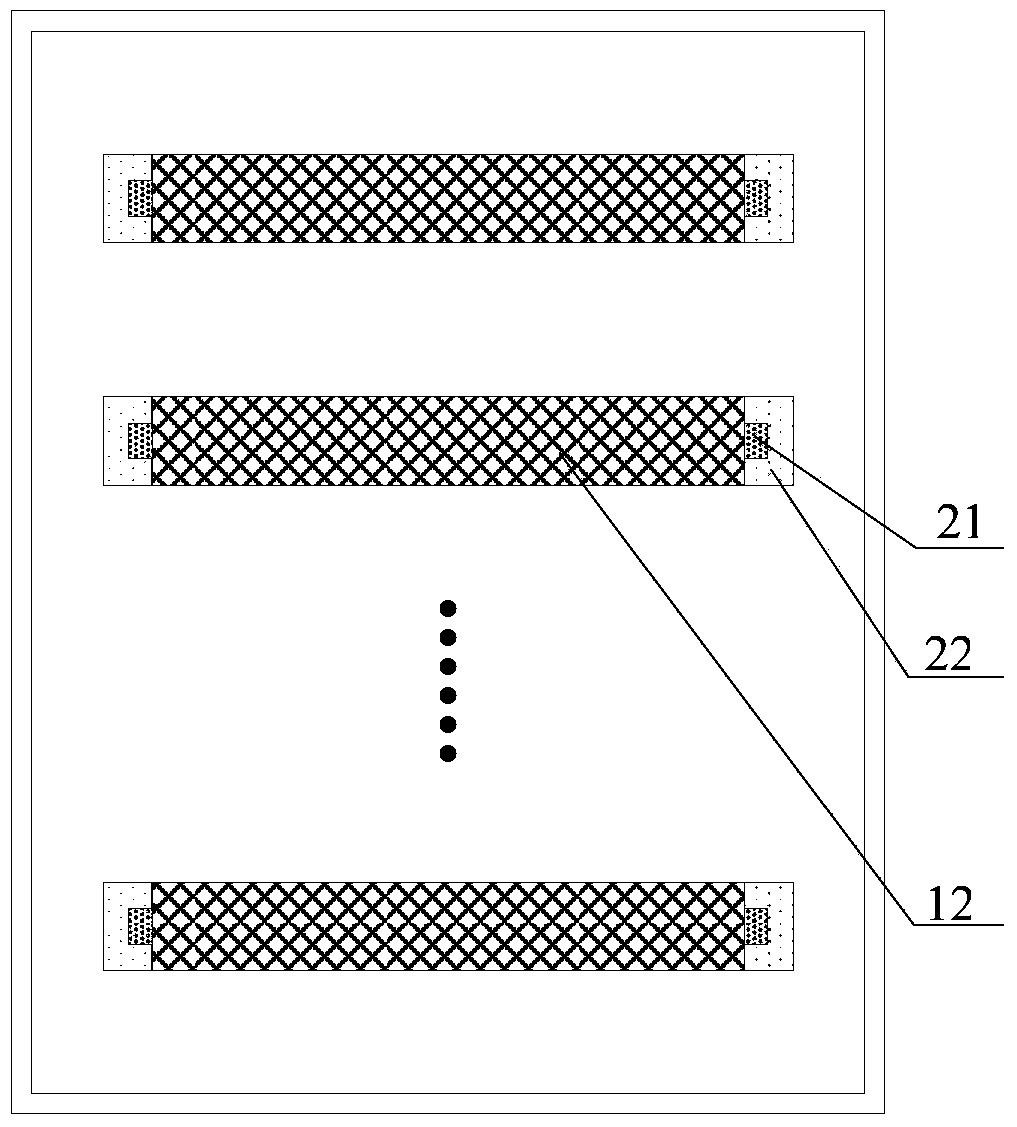

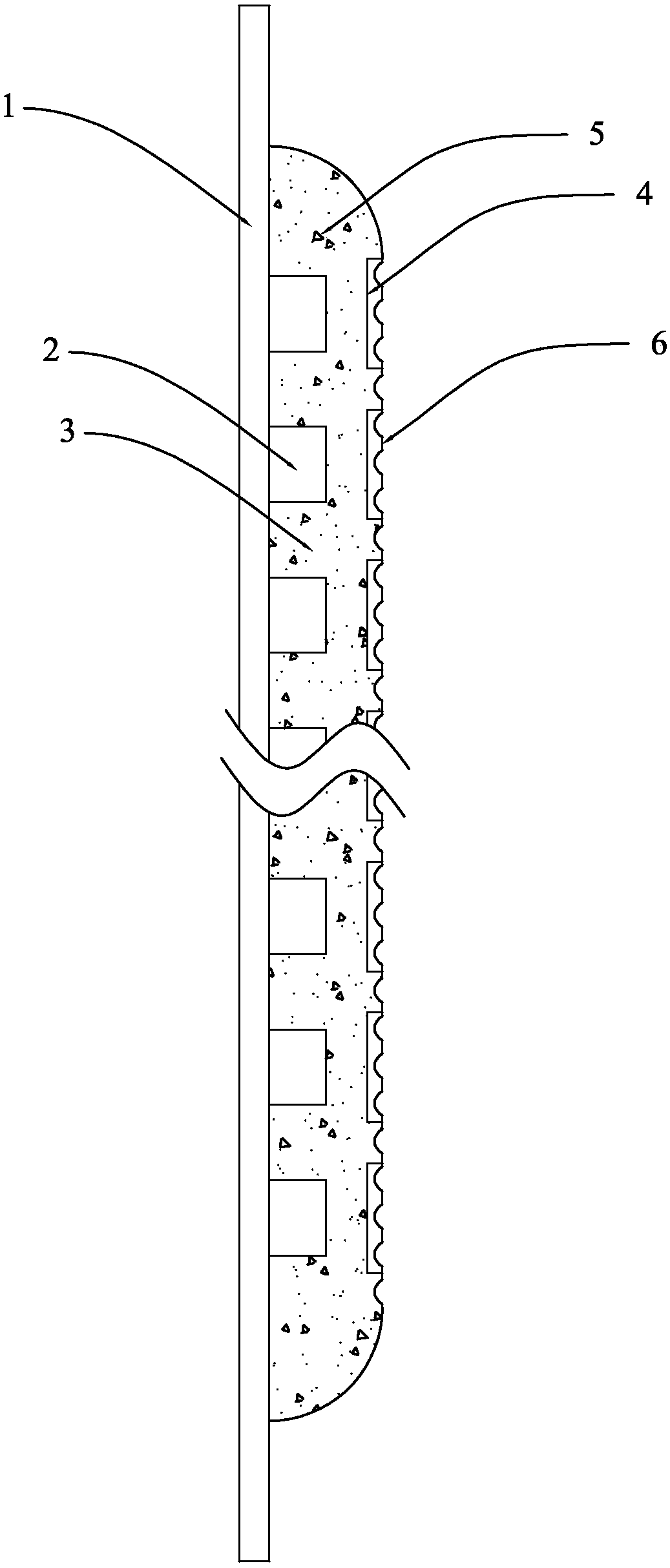

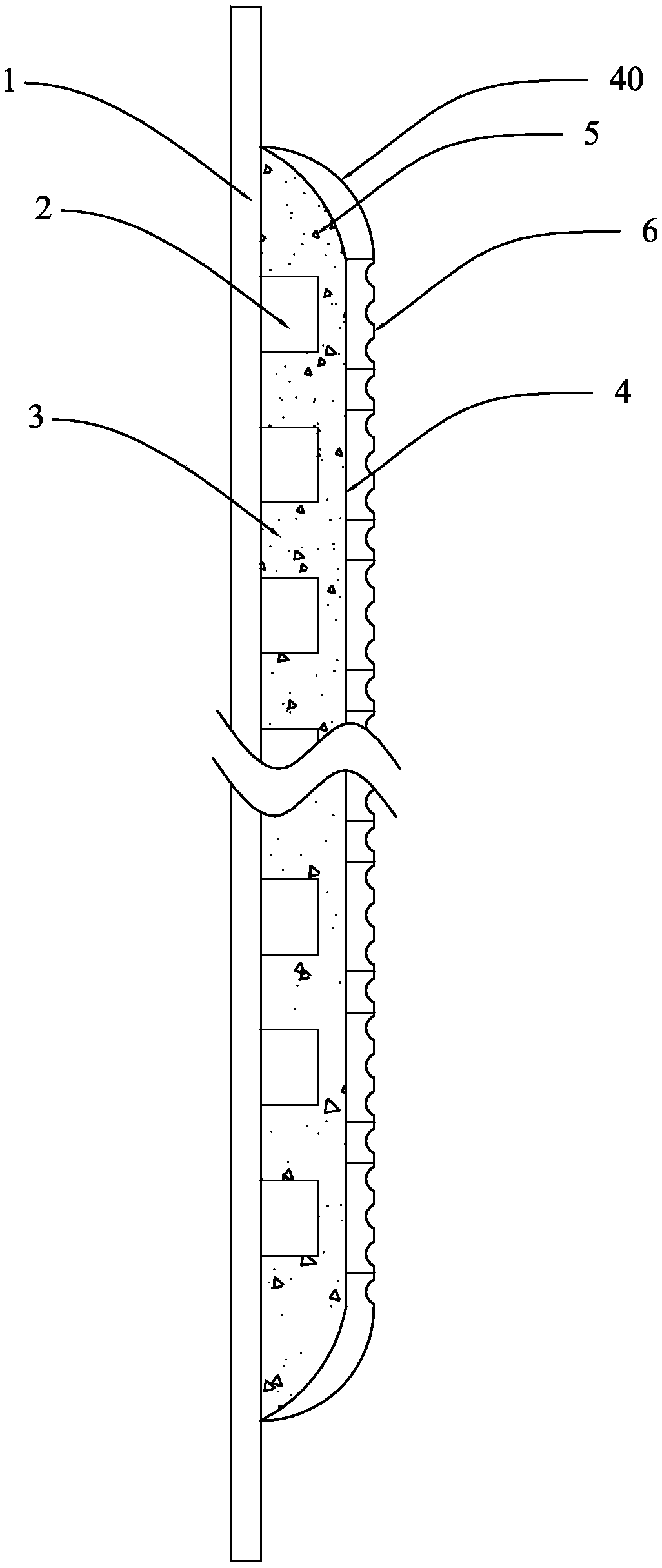

Illuminating device, backlight module with the illuminating device, lamp box module or digital electronic device and manufacturing method thereof

InactiveCN101329472AReduce thicknessShorten the mixing distanceOptical light guidesNon-linear opticsOptical reflectionDiffusion

The invention provides a light source light emitting device, a direct-type backlight module with the light-emitting device, a light box module, a planar light radiator, an LCD picture screen, a digital electronic device and a manufacturing method of the light-emitting device and the related products. The light emitting device comprises a plurality of long strip-shaped first light guide structures, a second light guide structure and a light source, the second light guide structure is adjacently spliced with two first light guide structures for receiving and containing the light source in a space which is combined by the two adjacent first light guide structures and the second light guide structure, wherein, patterned reflection layers are formed on the surfaces of the first light guide structures and the second light guide structure which are positioned at the same side of the light source and close to the periphery and the bottom part of the light source, at least optical reflection structures are additionally covered on the patterned reflection layers which are positioned at the bottom surfaces of the first light guide structures and the second light guide structure, thereby allowing light rays emitted by the light source to pass through the patterned reflection layers and the optical reflection structures for diffusion and reflection, improving the light uniformity, promoting the color mixing and reducing the occurrence of a dark band.

Owner:CHI LIN OPTOELECTRONICS CO LTD

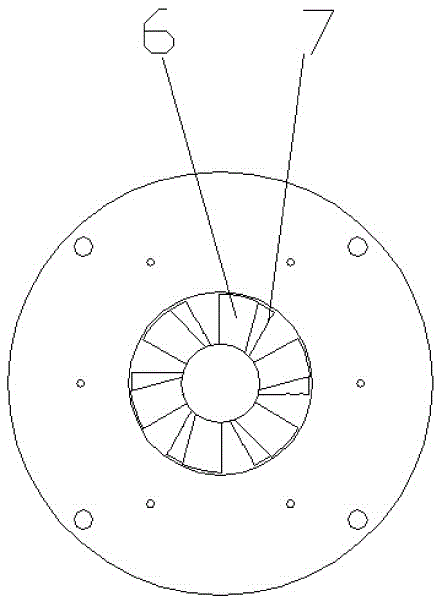

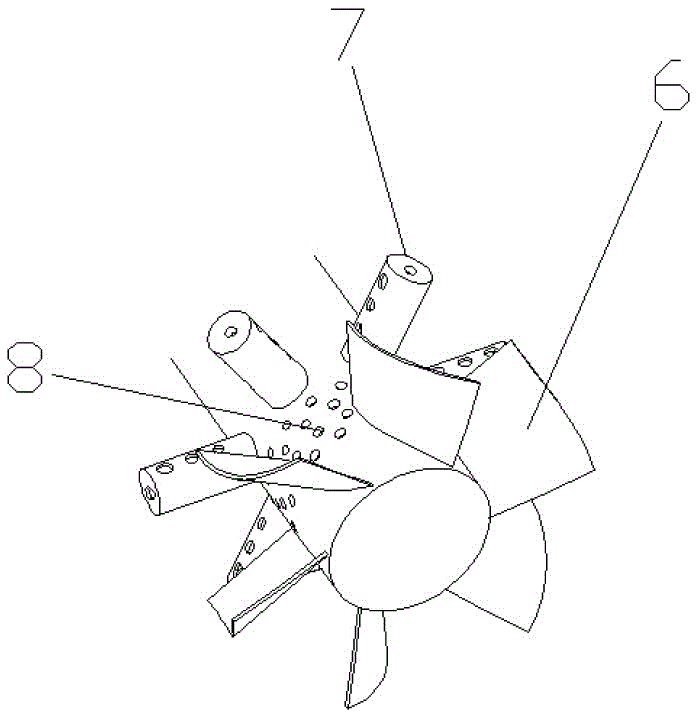

Metal surface combustor and gas premixing method thereof

InactiveCN105546533AShorten the mixing distanceImprove mixing uniformityGaseous fuel burnerCycloneCylindrical channel

The invention discloses a metal surface combustor and a gas premixing method thereof, solves the technical problem that the combustor can uniformly mix gas with combustion air in a shorter premixing channel, and belongs to the technical field of combustion of metal surface combustors. The metal surface combustor is characterized in that a metal throat is a cylindrical channel; the outer side surface is connected with a boiler front wall; one part extending into a hearth is an end-sealed microhole metal cylinder; the other end is connected with an air pipe as a whole; multiple gas spray guns and multiple cyclone blades are arranged at the tail end of the gas pipe in sequence; the gas uniformly enters the throat by spray holes in the gas spray guns and gas pipe holes in the gas pipes; meanwhile, the combustion air and the gas are hedged and uniformly mixed in the throat; and under stirring of the cyclone blades at the end part of the gas pipe, the uniform mixing is further accelerated, so that the mixing distance is shortened, the flame temperature nonuniformity caused by nonuniform gas mixing is effectively prevented, and the NOx emission is reduced.

Owner:新疆海天祥瑞环保工程有限公司

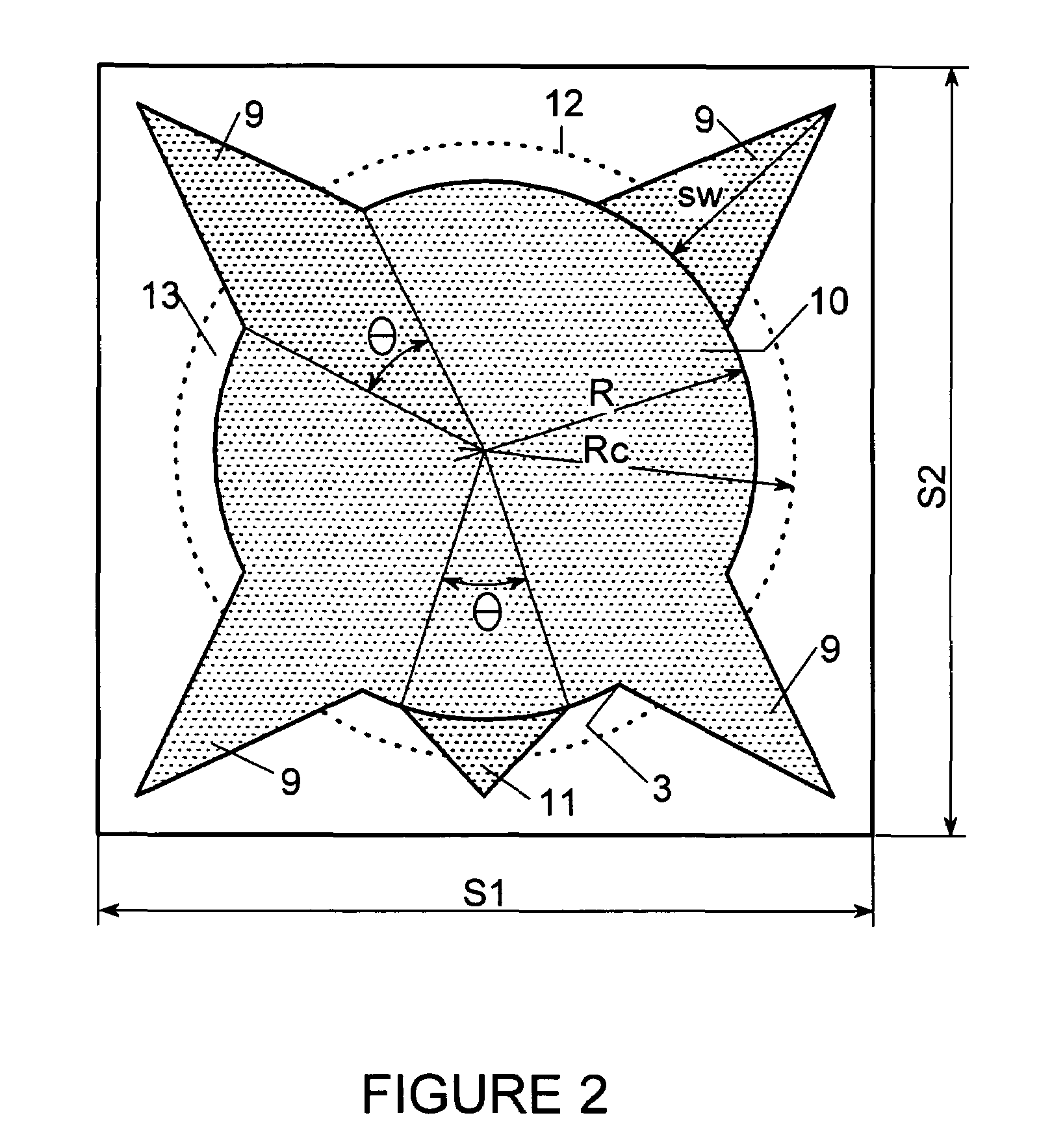

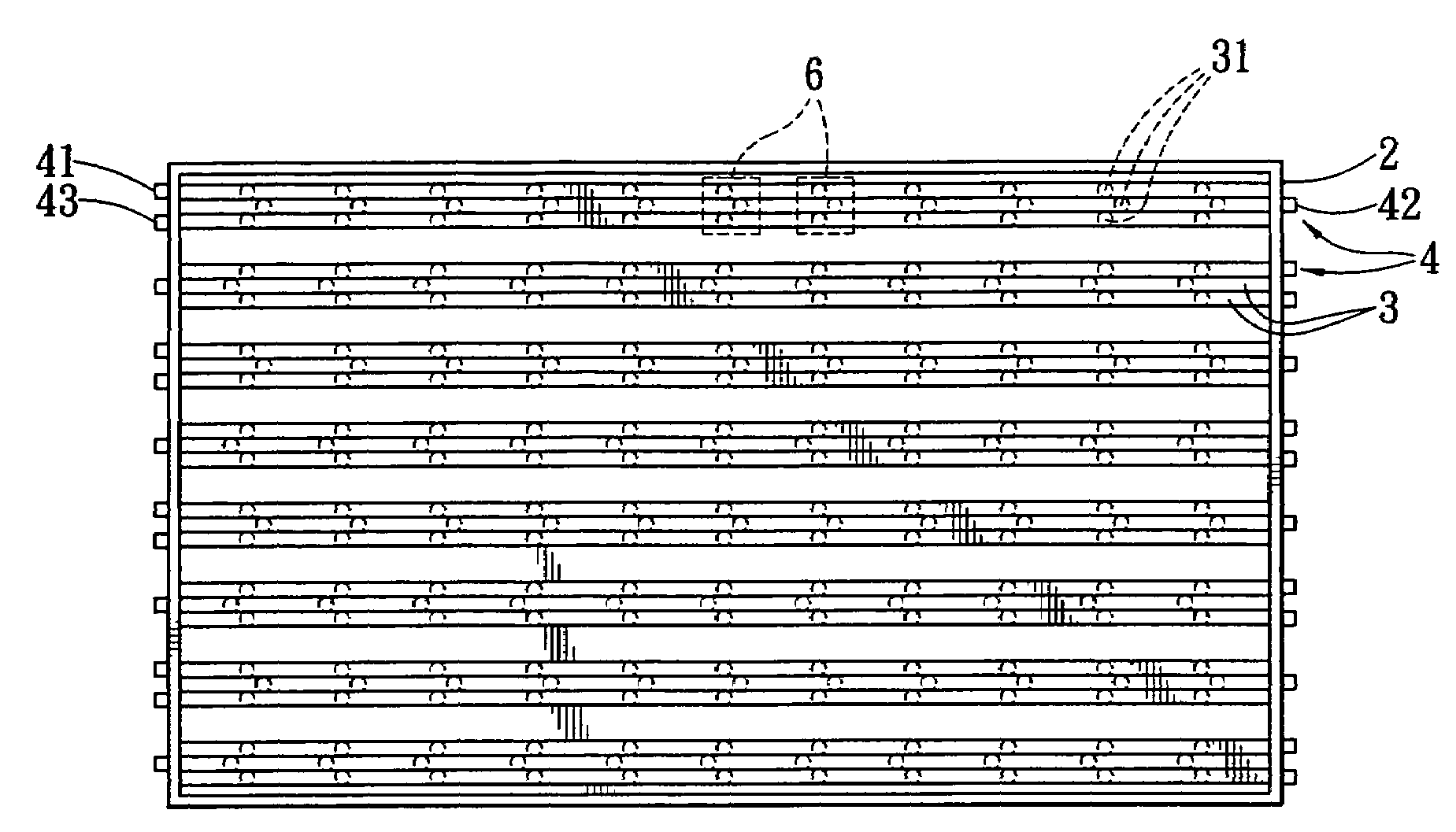

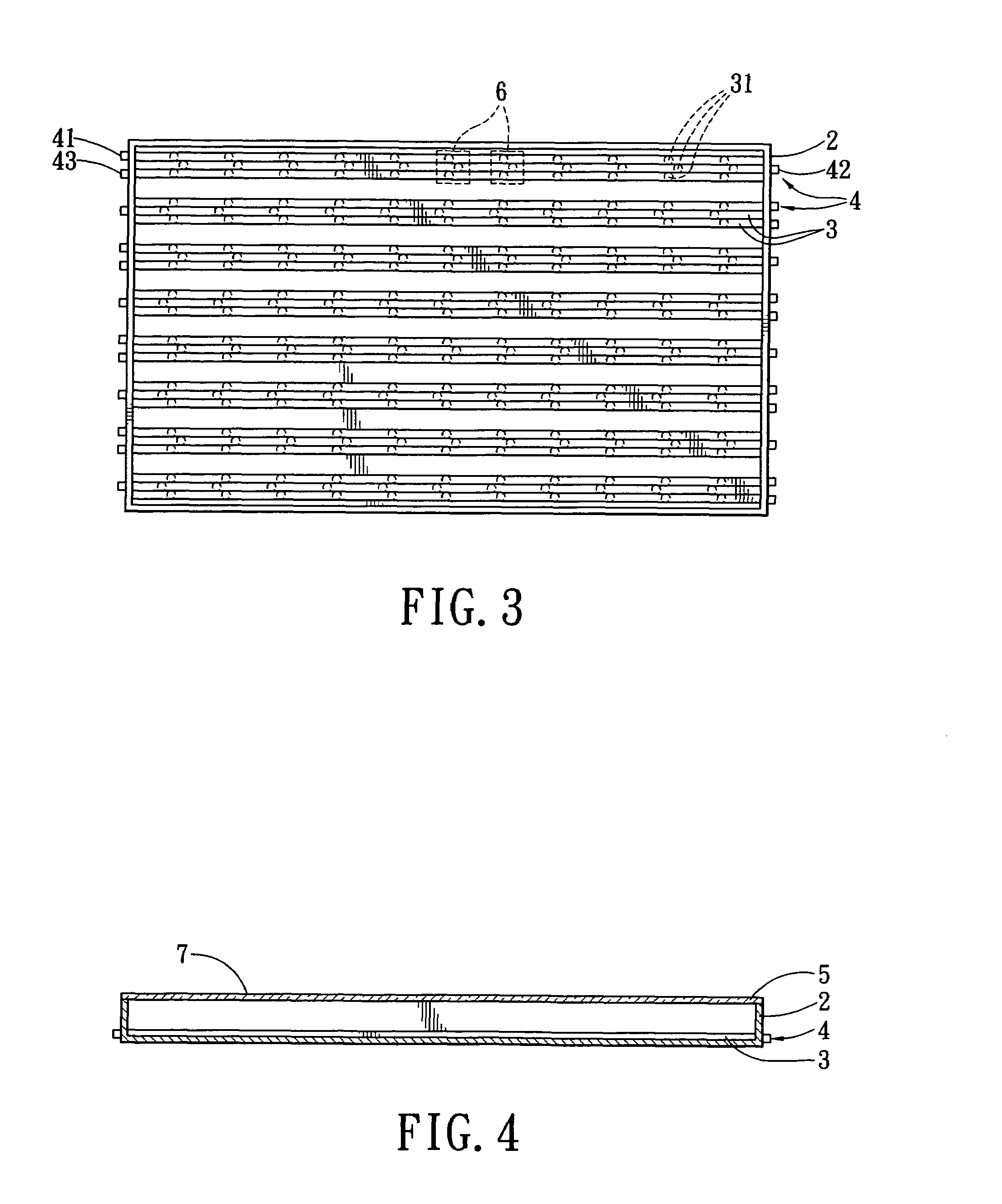

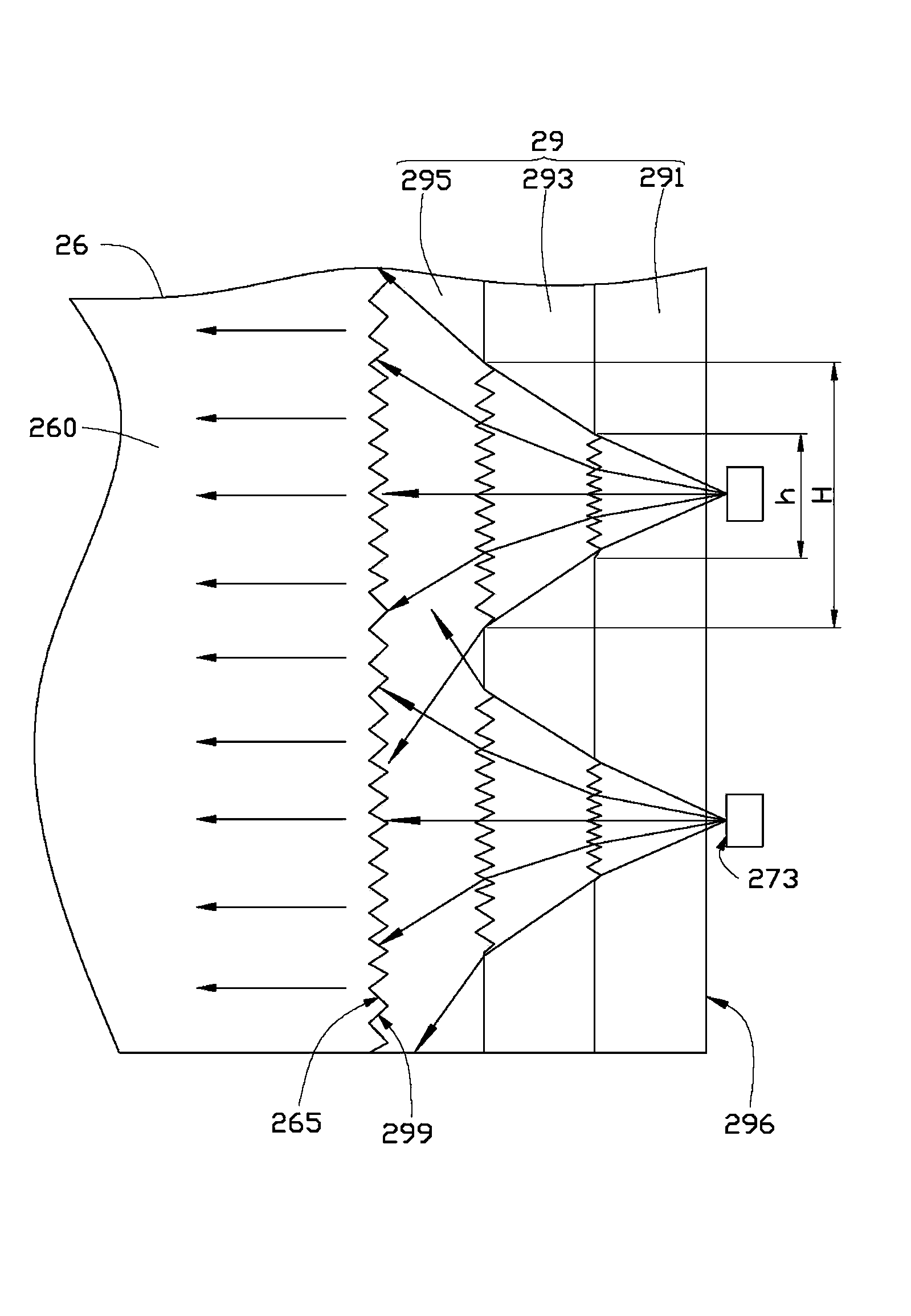

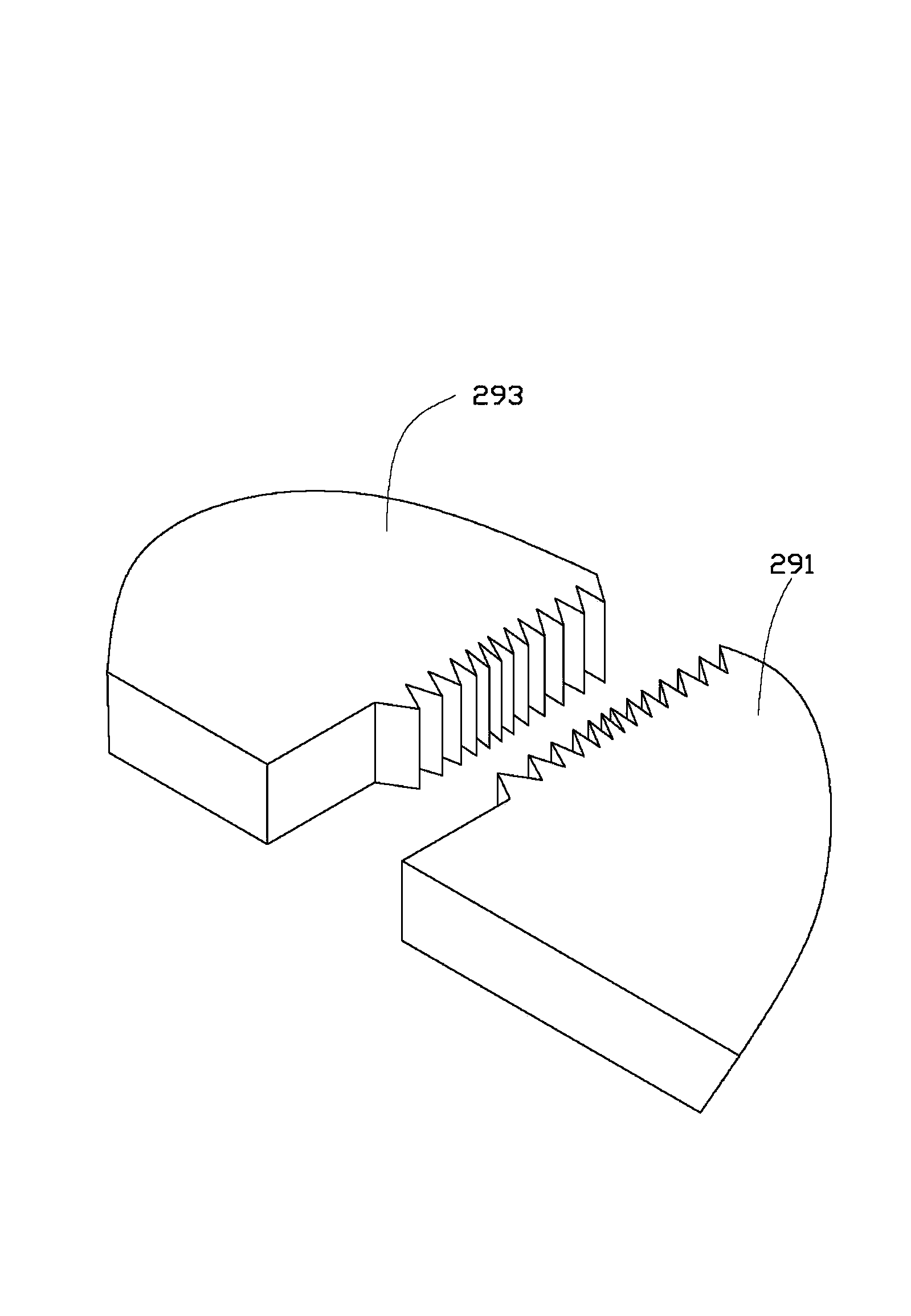

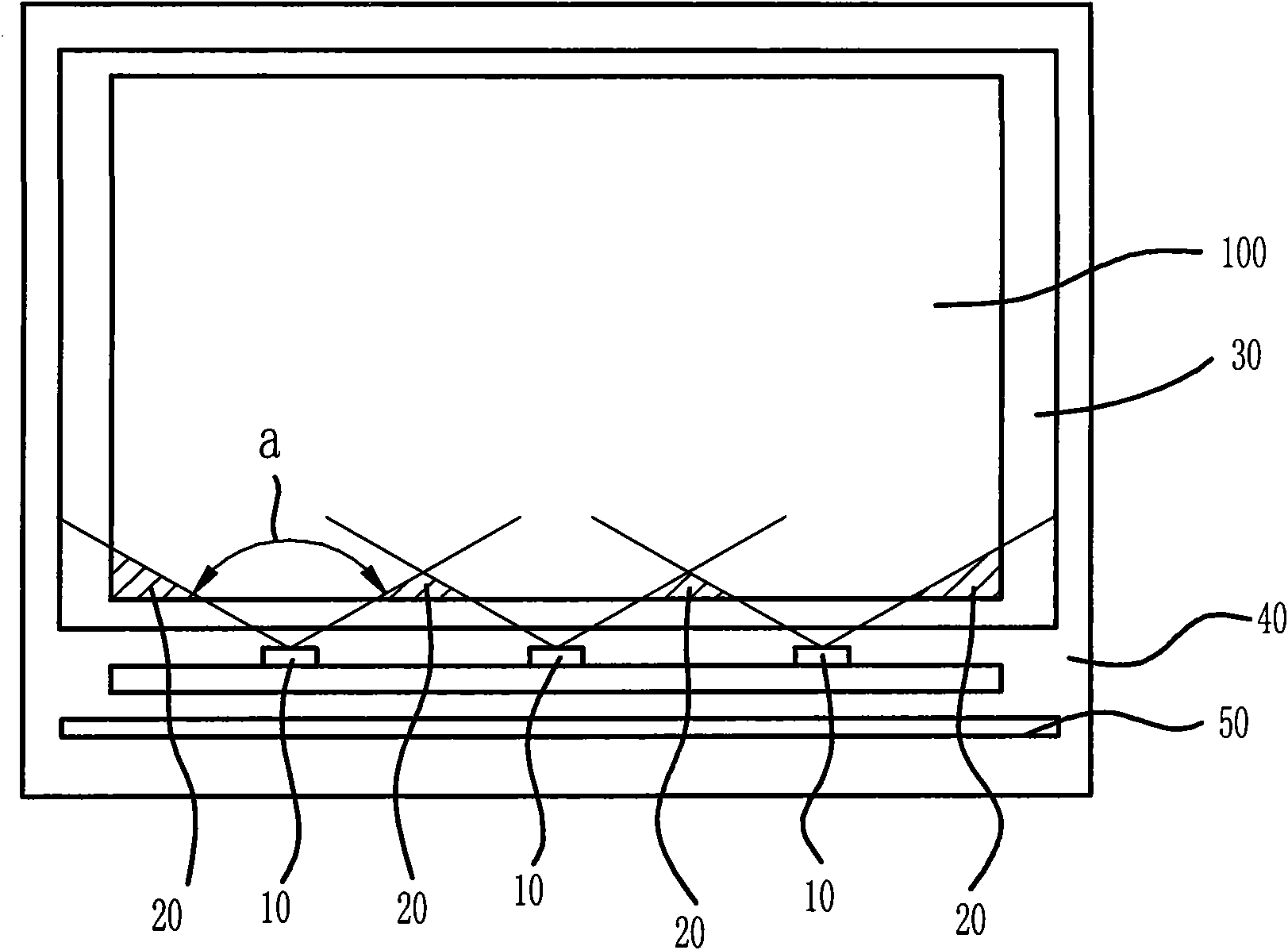

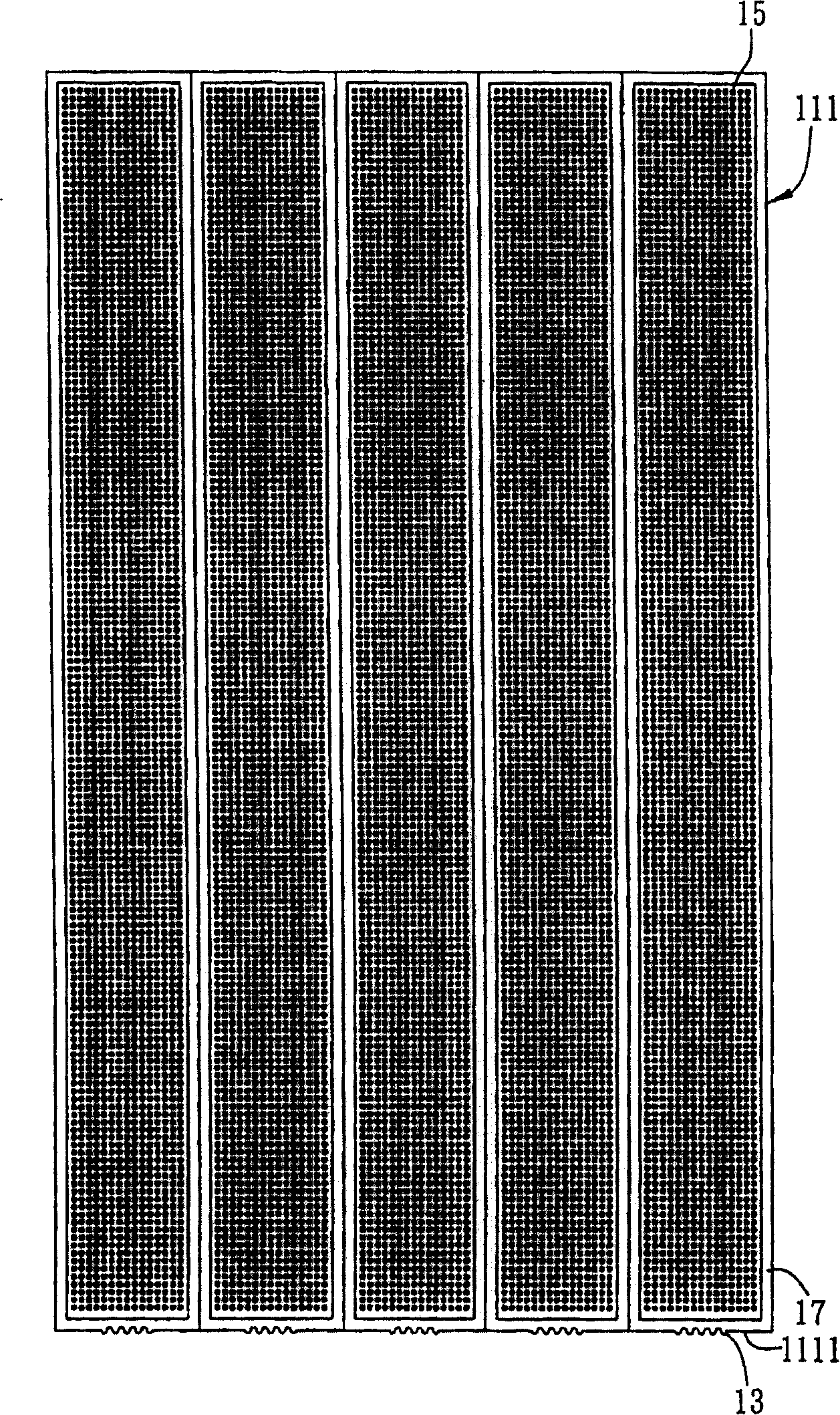

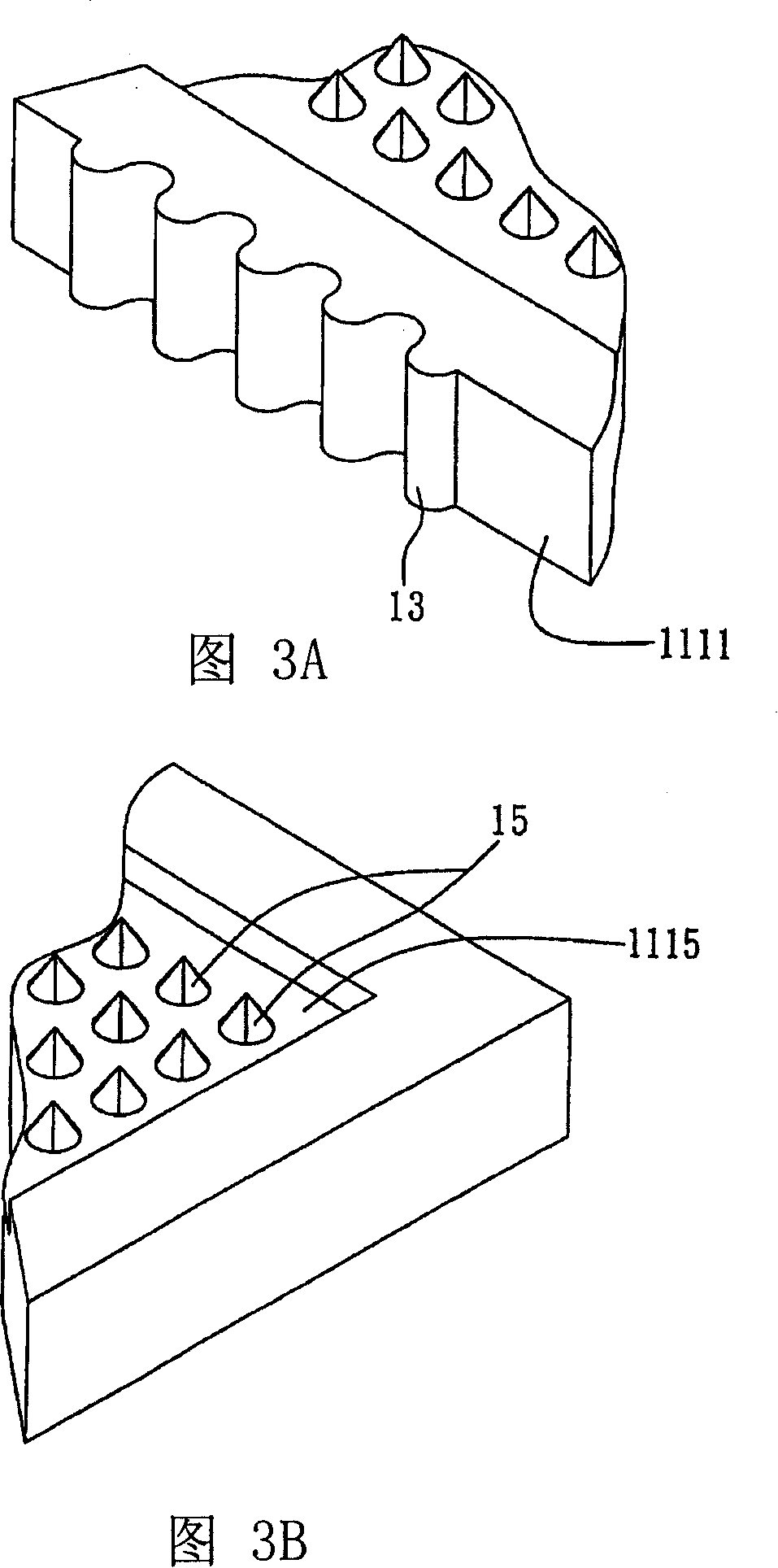

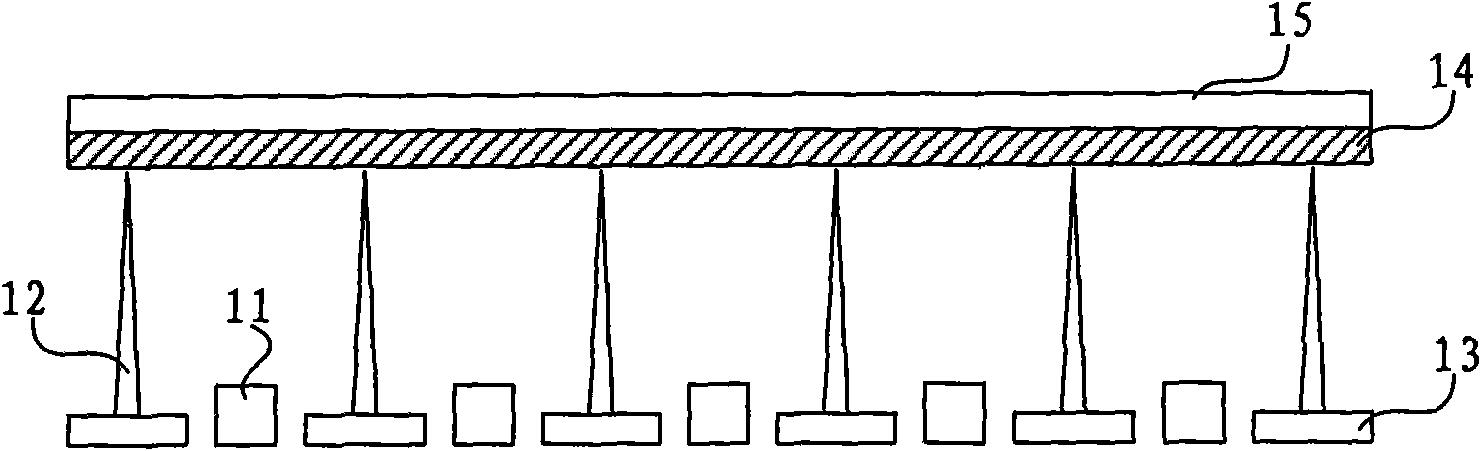

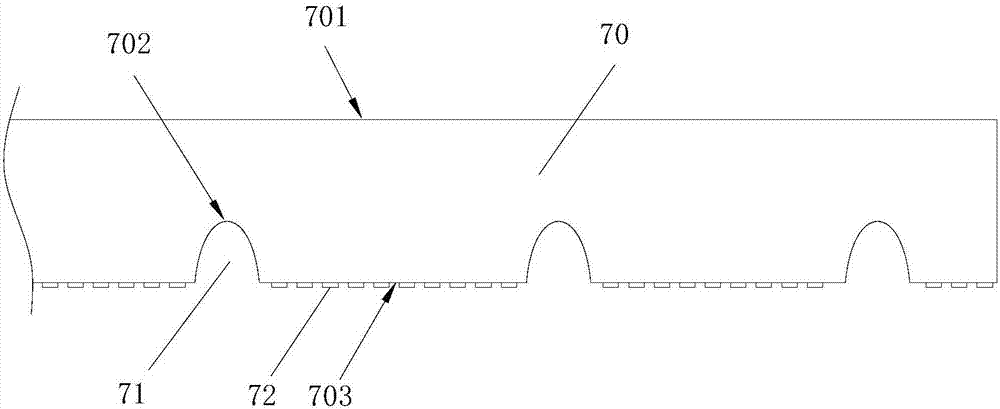

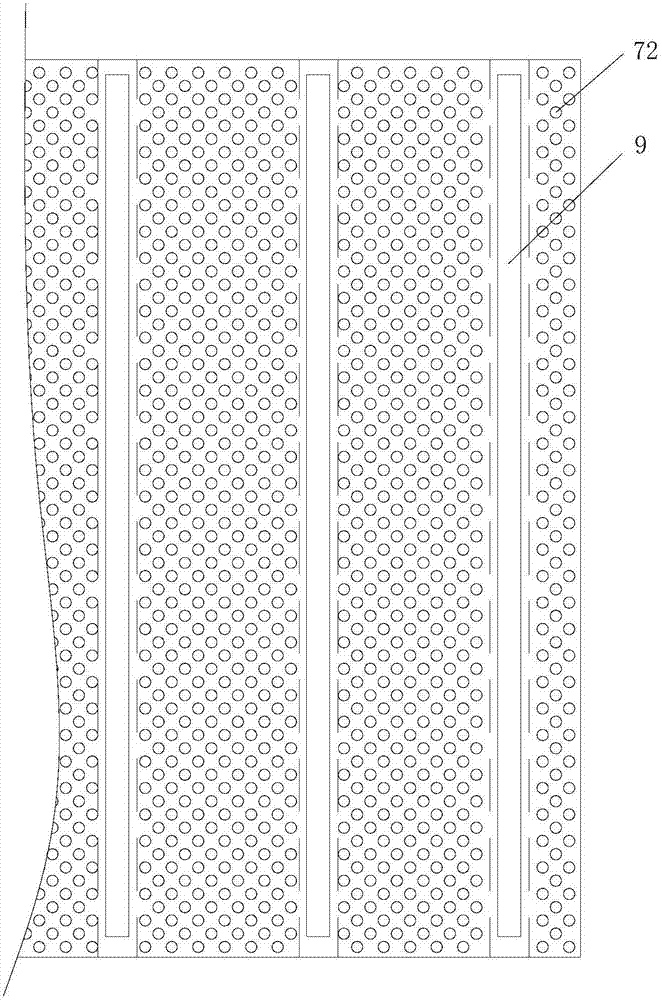

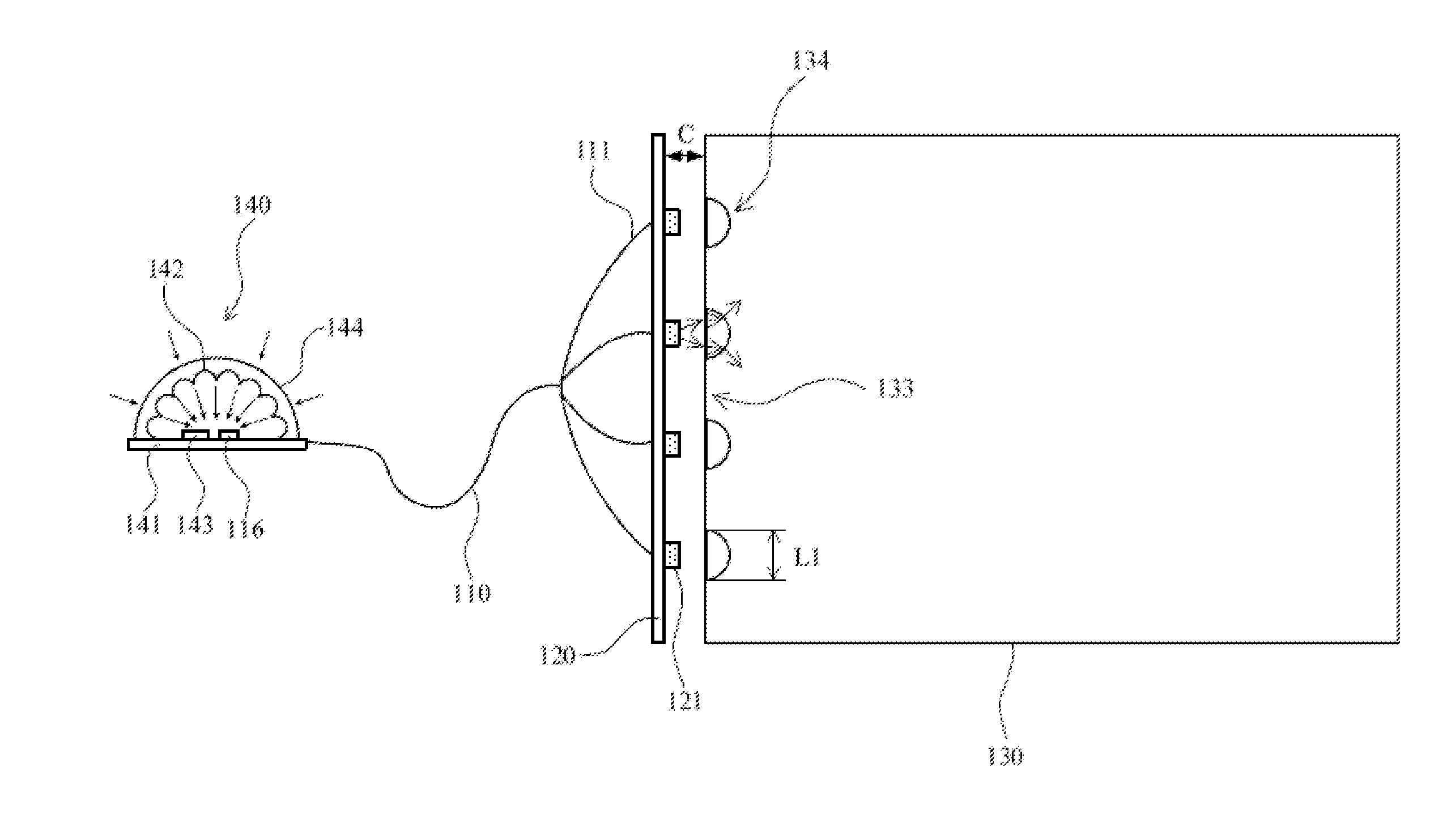

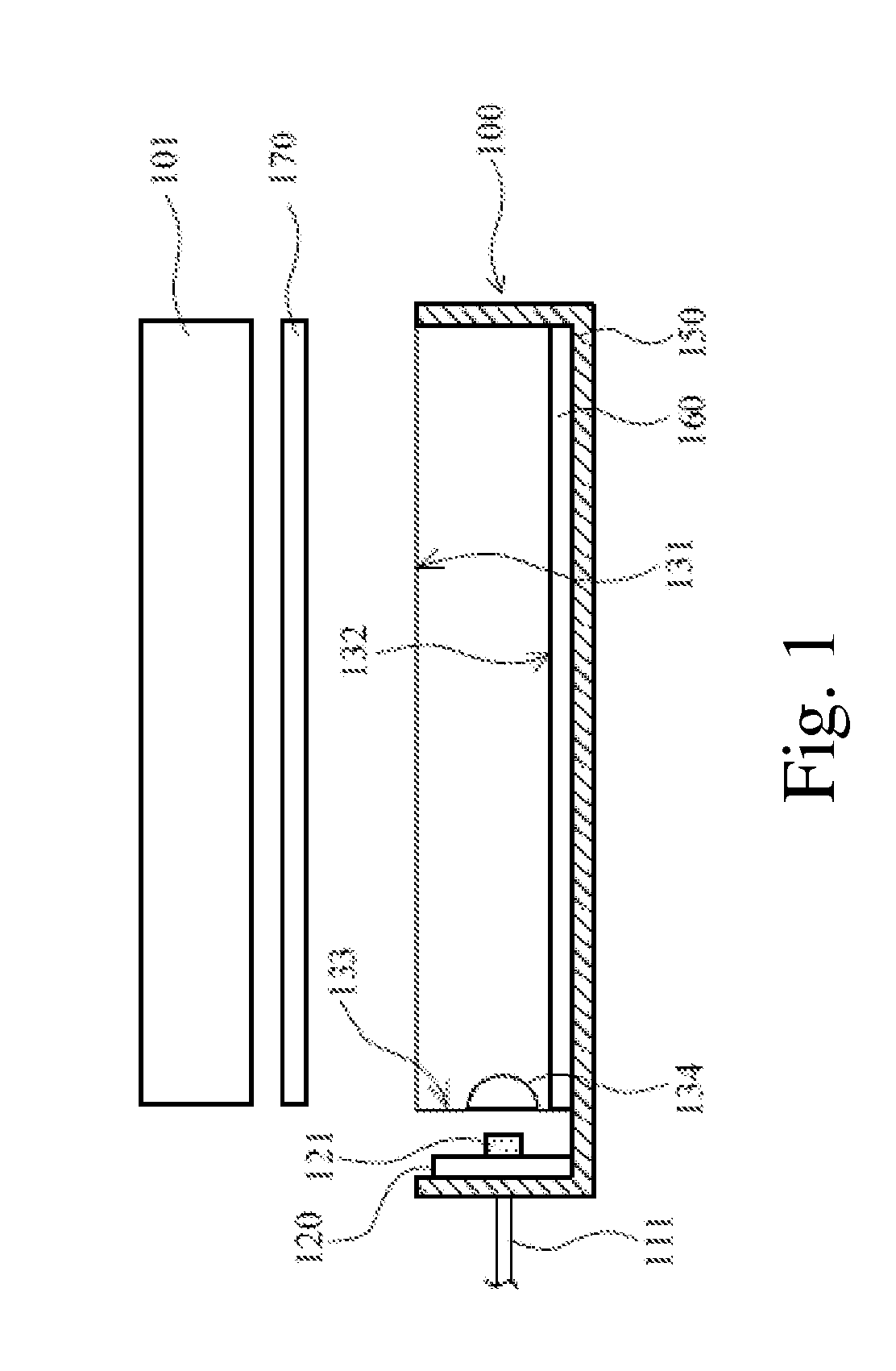

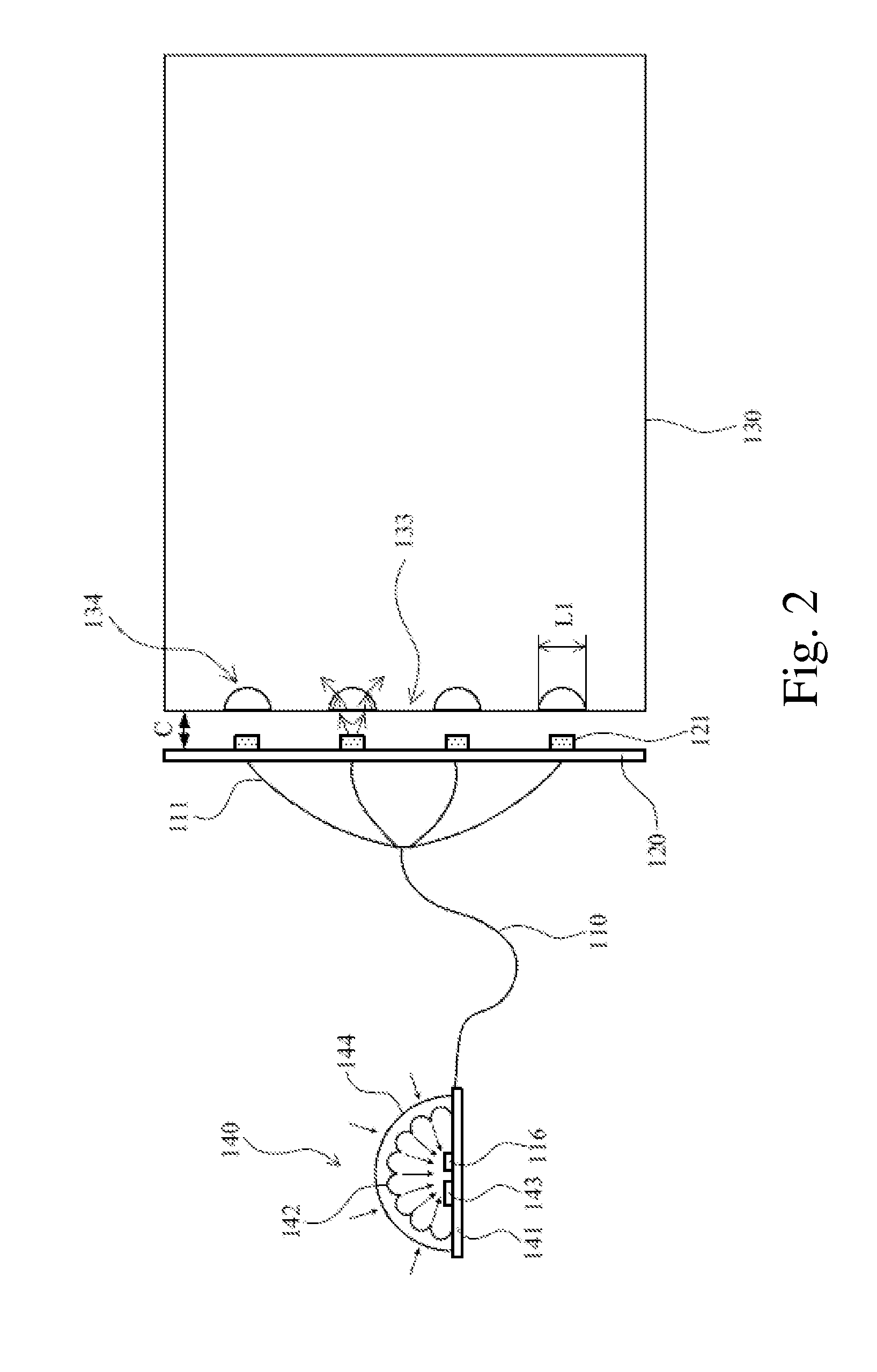

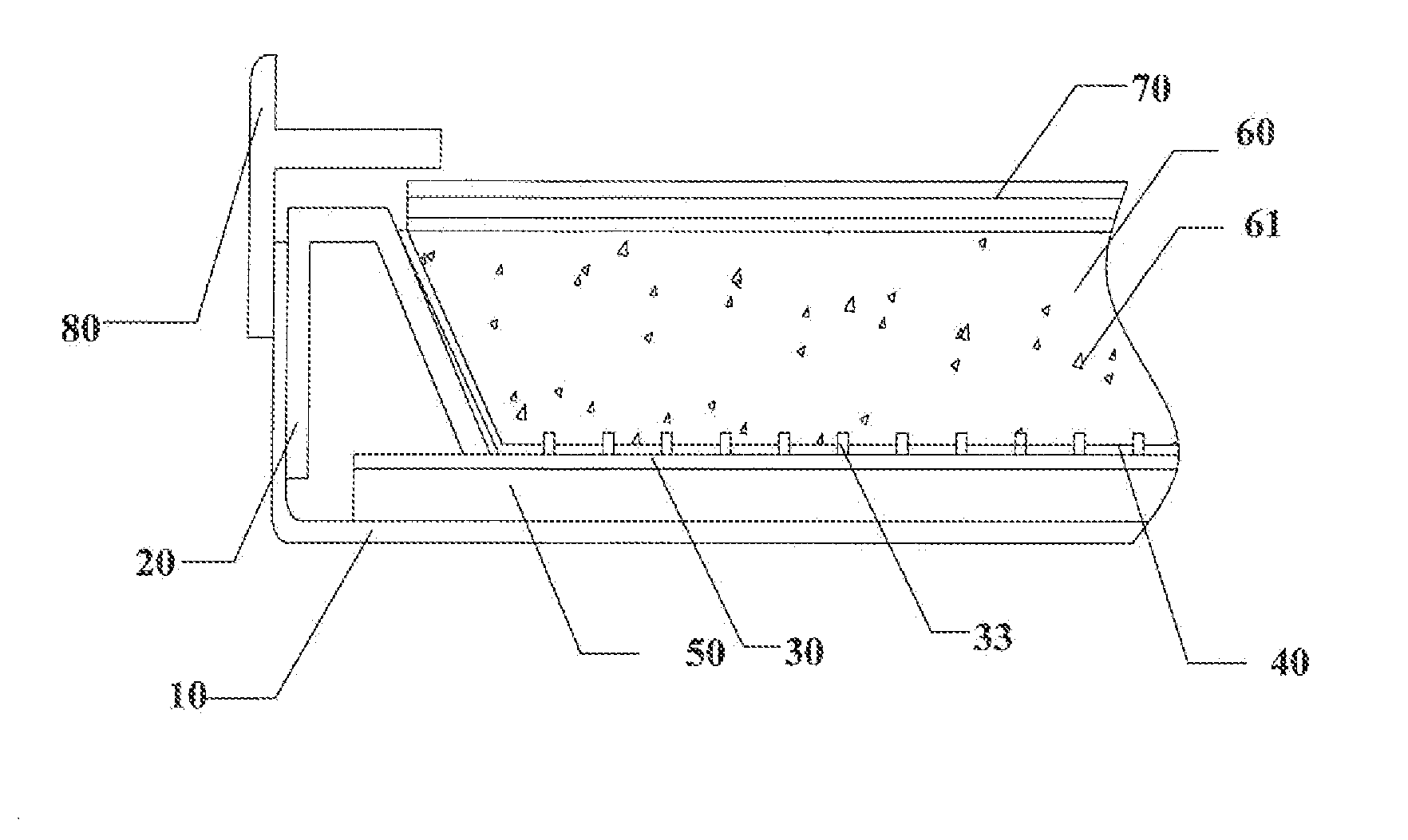

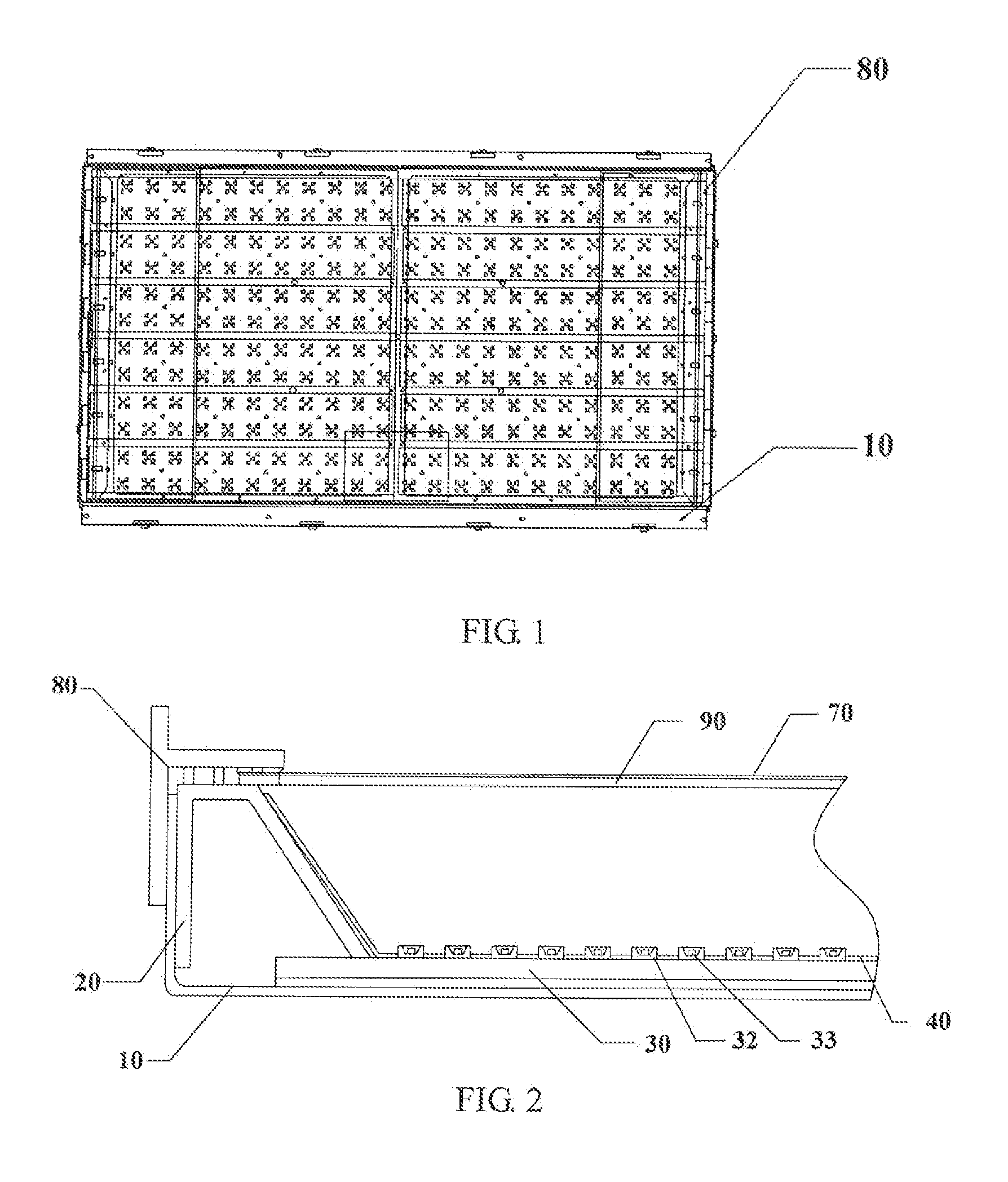

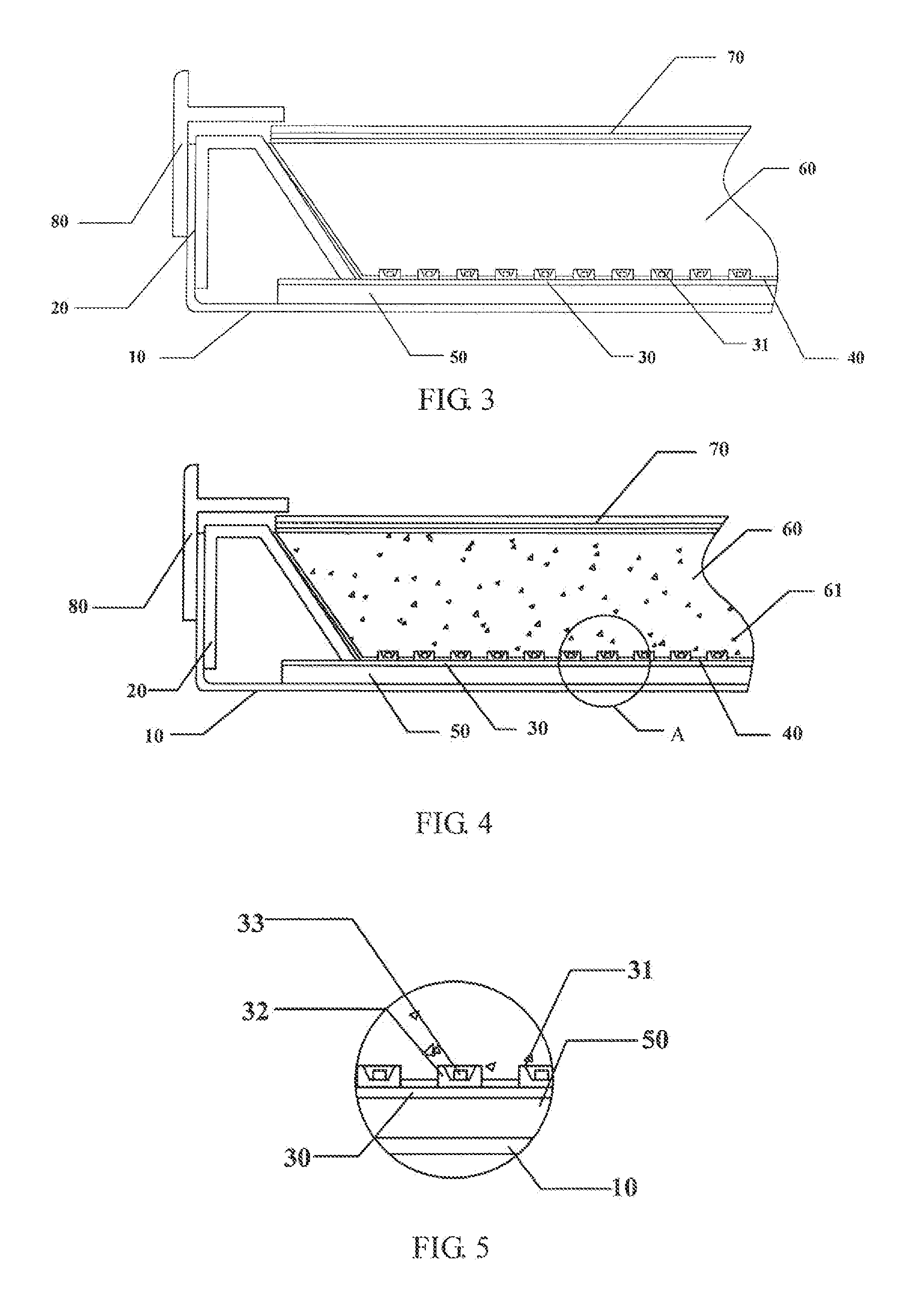

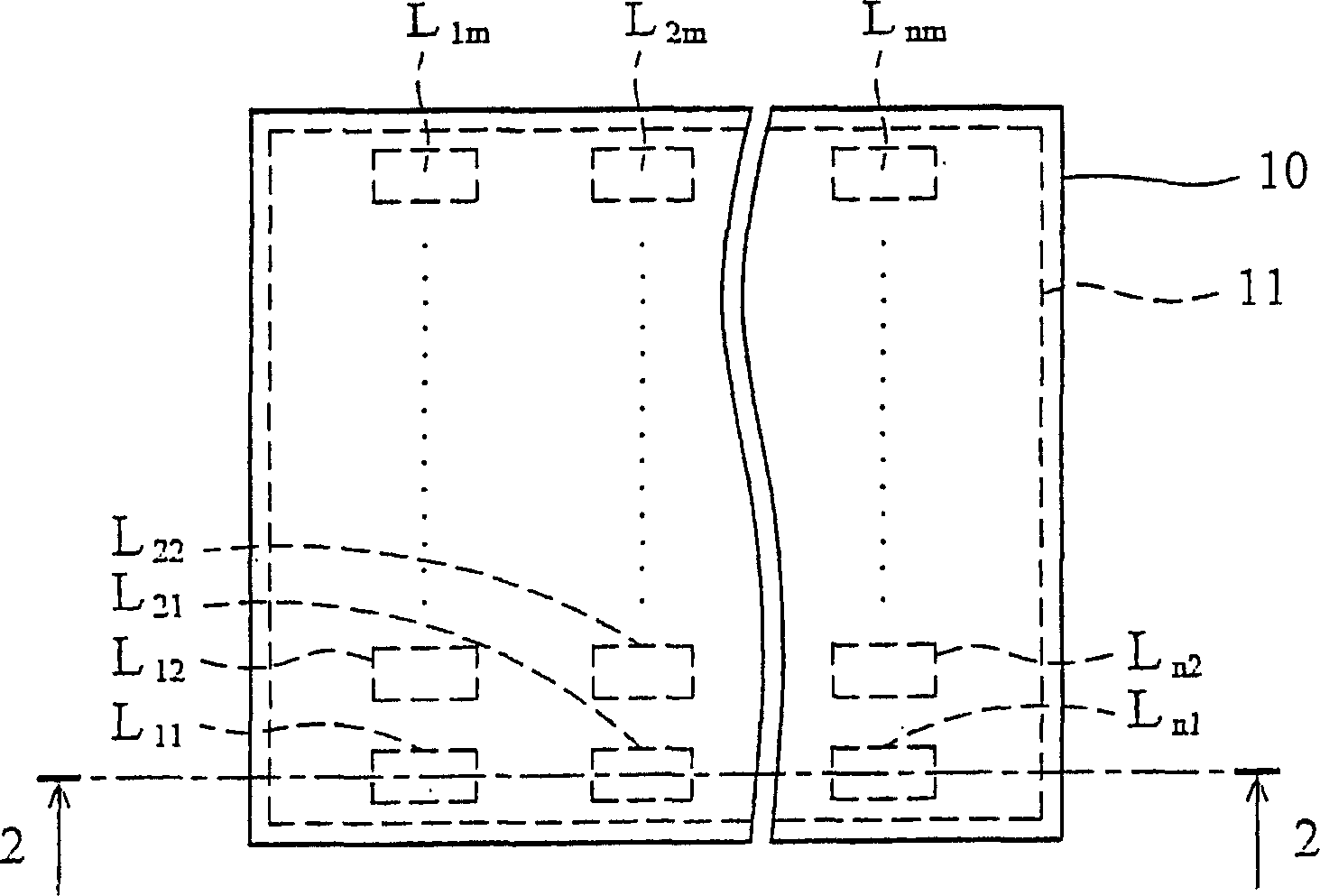

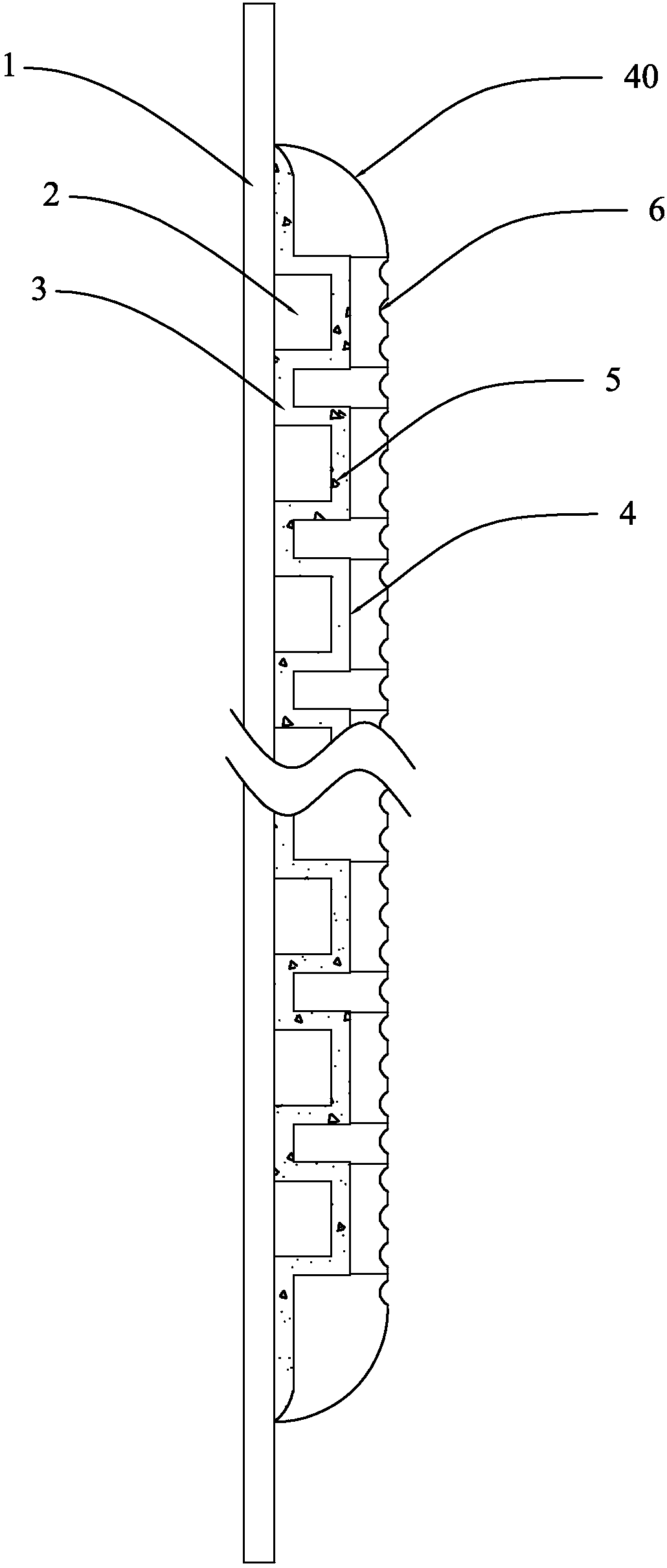

Backlight module

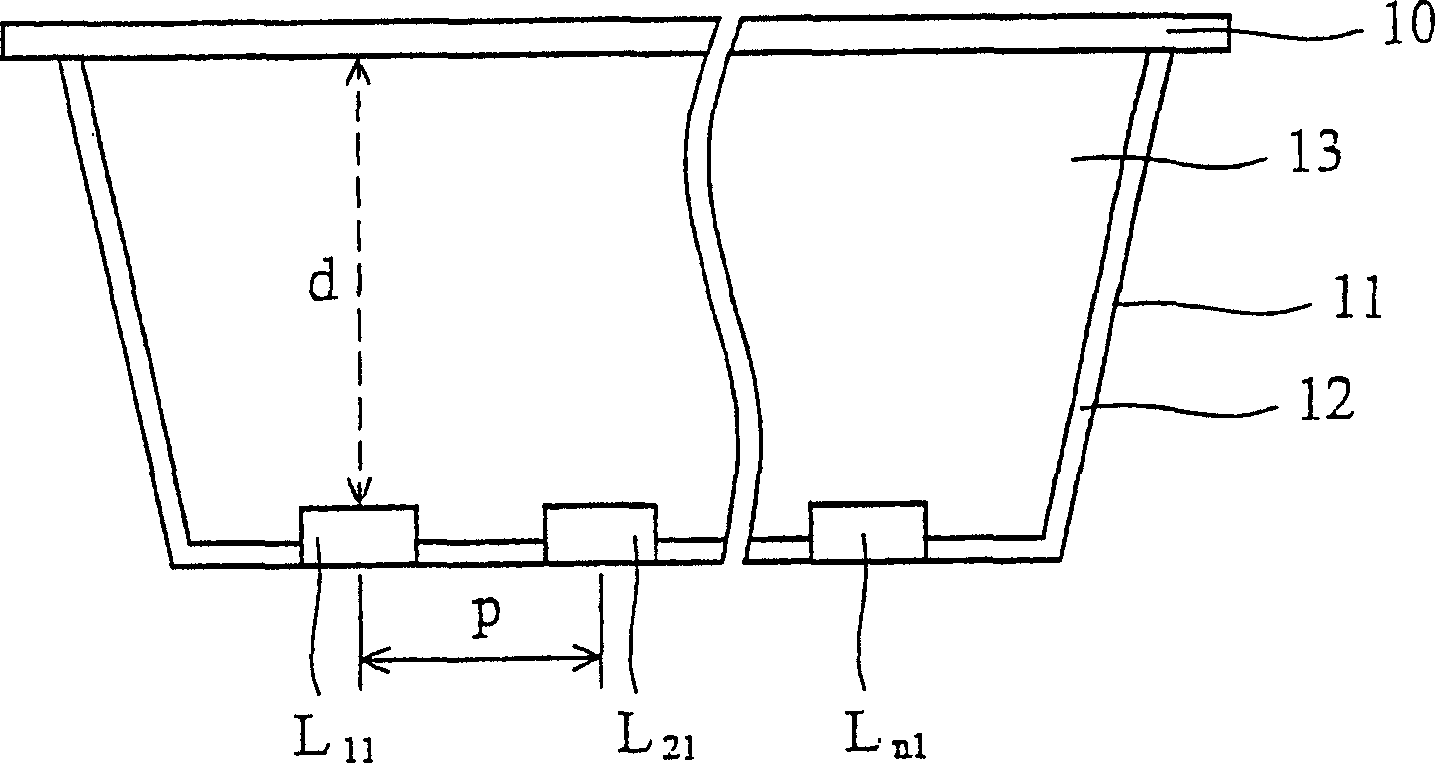

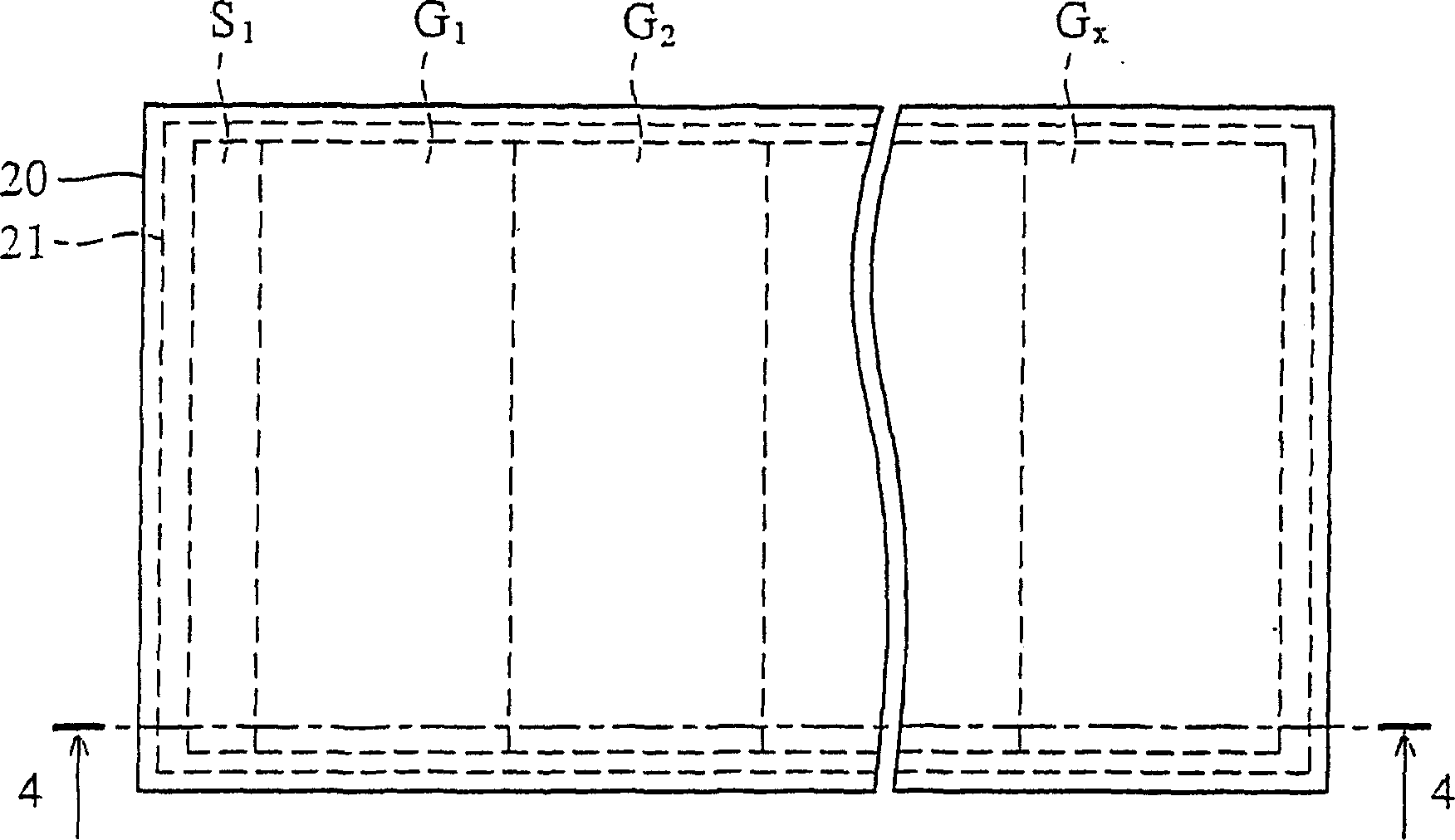

ActiveUS7534022B2Improve light mixing effectShorten the mixing distanceThermometer detailsMeasurement apparatus componentsLight guideLight beam

A backlight module includes a light box, at least one light guide tube, and at least one light source. The light box has a light exit side. The light guide tube has a plurality of microstructures which are spaced apart along a length of the light guide tube. The light guide tube and the microstructures are disposed in the light box in a particular arrangement so that the microstructures are placed substantially in a matrix array within the light box. The light source is disposed adjacent to the light guide tube, and is operable so as to emit a light beam to the light guide tube. The microstructures disperse the light beam from the light guide tube.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

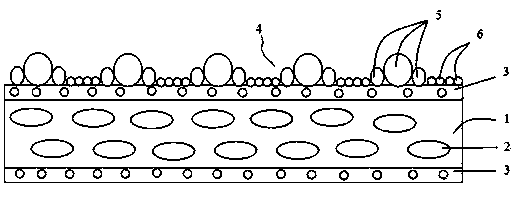

Efficient diffuse reflection film and preparing method thereof

ActiveCN103969723AGood diffuse reflectivityReduce surface glossMirrorsDiffusing elementsAcetic acidMicrobubbles

An efficient diffuse reflection film comprises a reflection film body, wherein microbubbles are distributed in the reflection film body provided with a diffuse reflection coating; the diffuse reflection coating is composed of, by mass, 20 parts of butanone, 12 parts of ethyl acetate, 10 parts of acrylate resin, 1 part of isocyanate, 1-5 parts of diffusion particles with the particle diameter ranging from 20 microns to 50 microns, and 0.5-5 parts of extinction powder. A preparing method comprises the steps: A, preparing master batches of the reflection film body; B, preparing master batches of an anti-adhesive layer; C, preparing a bidirectional tension film; and D, preparing the diffuse reflection coating and performing coating. The efficient diffuse reflection white film has extremely low surface gloss and excellent diffuse reflectivity, and therefore the reflection performance is extremely good.

Owner:NINGBO DXC NEW MATERIAL TECH

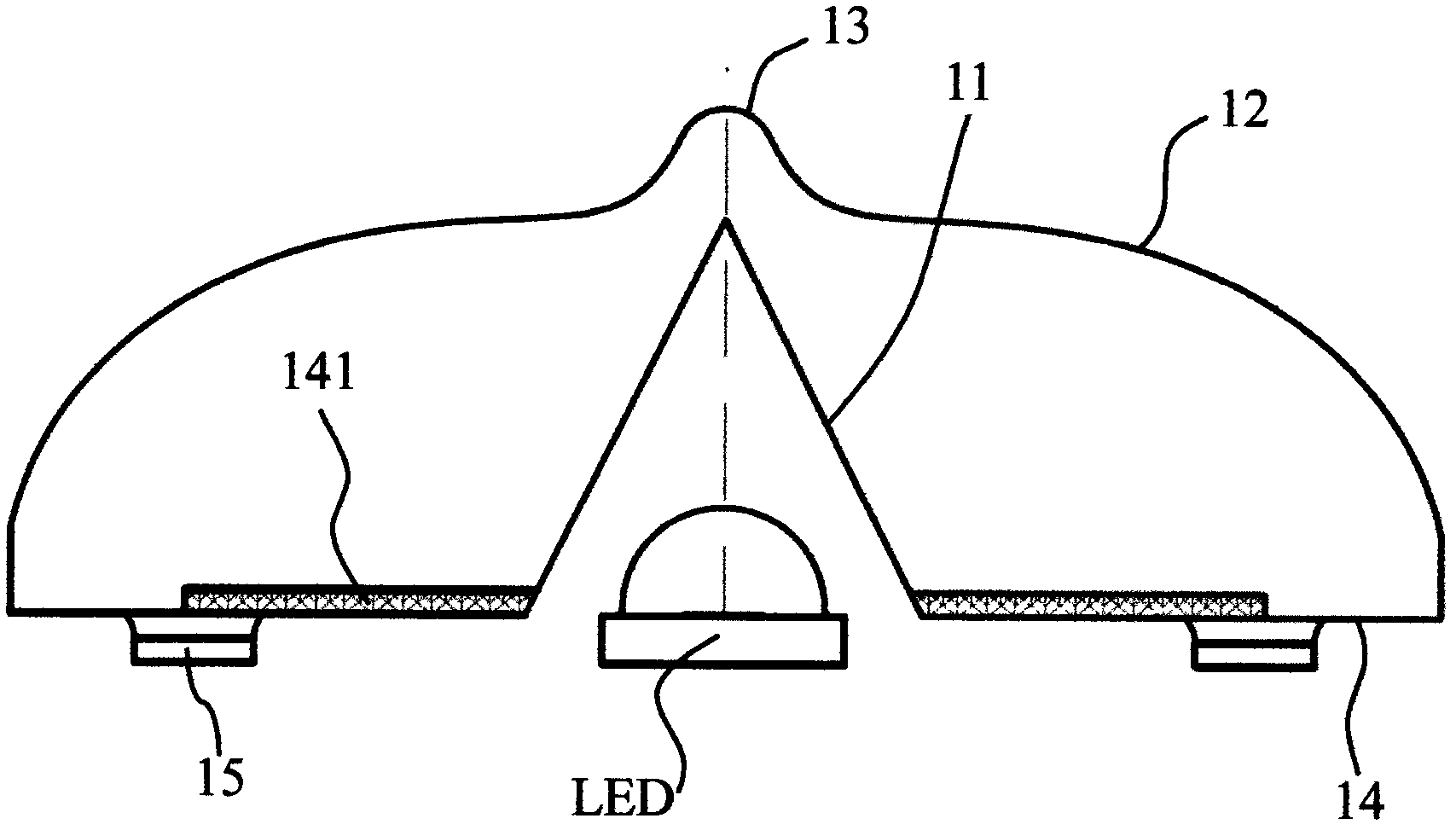

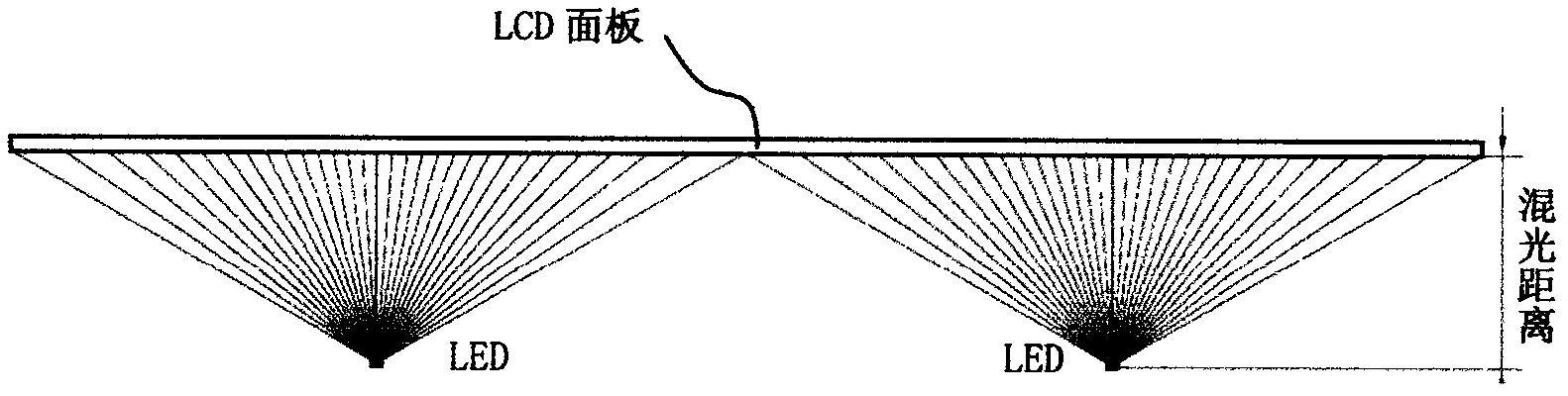

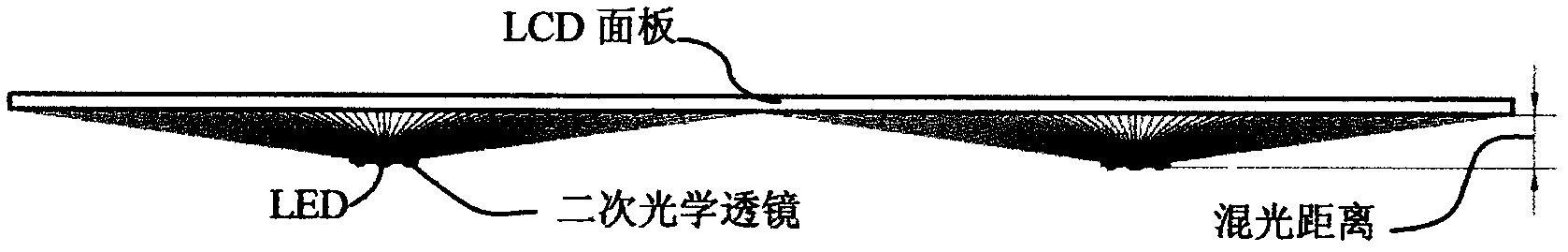

Secondary optical lens of LED backlight system for flat liquid crystal display

InactiveCN103322504AReduce lossShorten the mixing distancePoint-like light sourceNon-linear opticsBeam angleLiquid-crystal display

The invention discloses a secondary optical lens of an LED (Light Emitting Diode) backlight system for flat liquid crystal display. The secondary optical lens comprises a light distribution curved surface used as an exit surface and a bottom surface positioned at the bottom of the light distribution curved surface, an inner concave surface of the incident surface is formed by concaving upwards from the bottom surface, and an upward projected bulge is formed in the center of the top part of the light distribution curved surface, so that the full beam angle of the secondary optical lens to be larger than or equal to 160 degrees, and the incident light can pass through the concave surface and the light distribution curved surface and then to be shot. The secondary optical lens is provided with a beam angle larger than 160 degrees, and can shoot most of the light of the LED in the side surface direction of the optical lens, the direction of the maximum light intensity is above a position where an angle of plus or minus 80 degrees is formed with the optical axis, uniformly distributed light with the same range can be generated on the LCD (Liquid Crystal Display) panel by adopting a very short mixing light distance, the mixing light distance can be decreased below one third of that of the prior art, and light energy loss can be decreased effectively.

Owner:MIKOLTA OPTICAL TECH CO

Backlight module, liquid crystal display device and light source module

InactiveCN103511913AUniform light outputNarrow borderDiffusing elementsPlanar/plate-like light guidesPoint lightLiquid-crystal display

The invention relates to a backlight module, a liquid crystal display device and a light source module. The backlight module comprises at least two point light sources and a light guiding element which receives light emitted by the at least two point light sources. The backlight module further comprises a light diffusing component which comprises a first light transmittance layer and a second light transmittance layer. The refractive index of the first light transmittance layer is larger than that of the second light transmittance layer. The refractive index of the second light transmittance layer is larger than the refractive index of the light guiding element. Light rays generated by the at least two point light sources enter the light diffusing component through the first light transmittance layer, then the light rays are refracted through the interface of the first light transmittance layer and the second light transmittance layer and then enter the second light transmittance layer, the second light transmittance layer emits the light rays out of the light diffusing component, and the light rays enter the light guiding element. A frame of the backlight module is narrow.

Owner:XINCHENG TECH CHENGDU +1

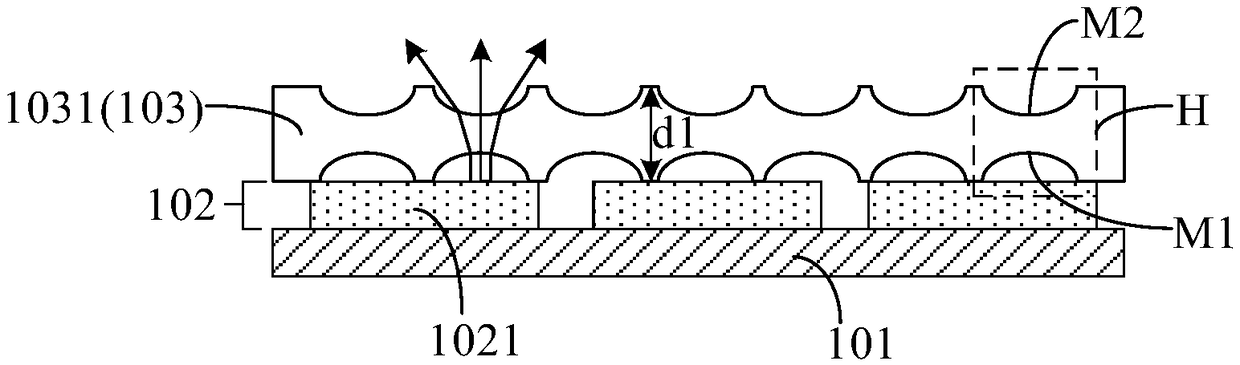

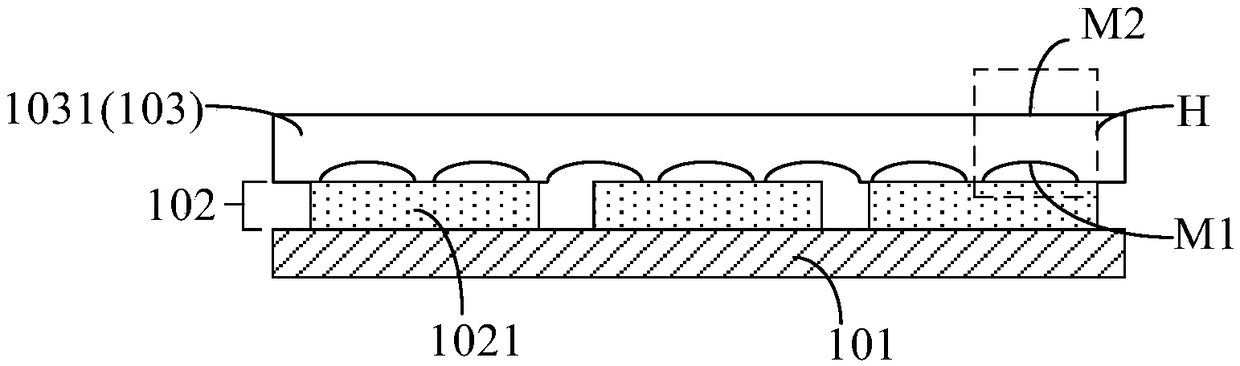

Backlight module and display device

ActiveCN109061945AImprove the problem of starry skyLarge light angleNon-linear opticsDisplay deviceLight-emitting diode

The invention discloses a backlight module and a display device. The backlight module comprises a substrate layer, a light source layer and a light mixing layer, wherein the light source layer is arranged on a substrate, and comprises a plurality of mini LEDs (Light Emitting Diodes) distributed in an array; the light mixing layer is arranged on one side of the light source layer far away from thesubstrate layer, and comprises a first light mixing layer; the first light mixing layer comprises a plurality of light mixing structures; each mini LED corresponds to a plurality of light mixing structures; the light mixing structure comprises a first surface close to one side of the light source layer and a second surface far away from one side of the light source layer; and the first surface protrudes toward a direction far away from the light source layer, and / or the second surface protrudes toward a direction close to the light source layer in the light mixing structure. According to thebacklight module and the display device, the uniformity of the brightness of the whole surface of the backlight can be improved, thereby improving the problem that the backlight module is filled withstark.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

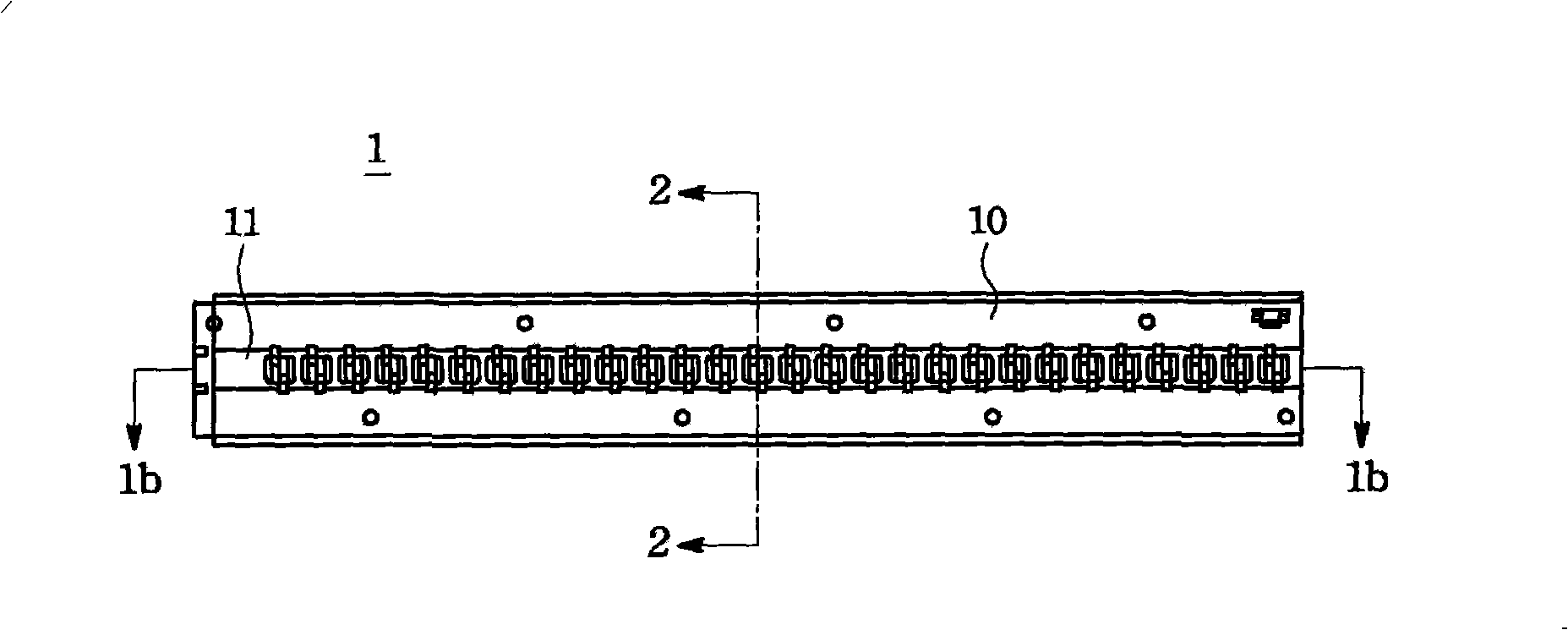

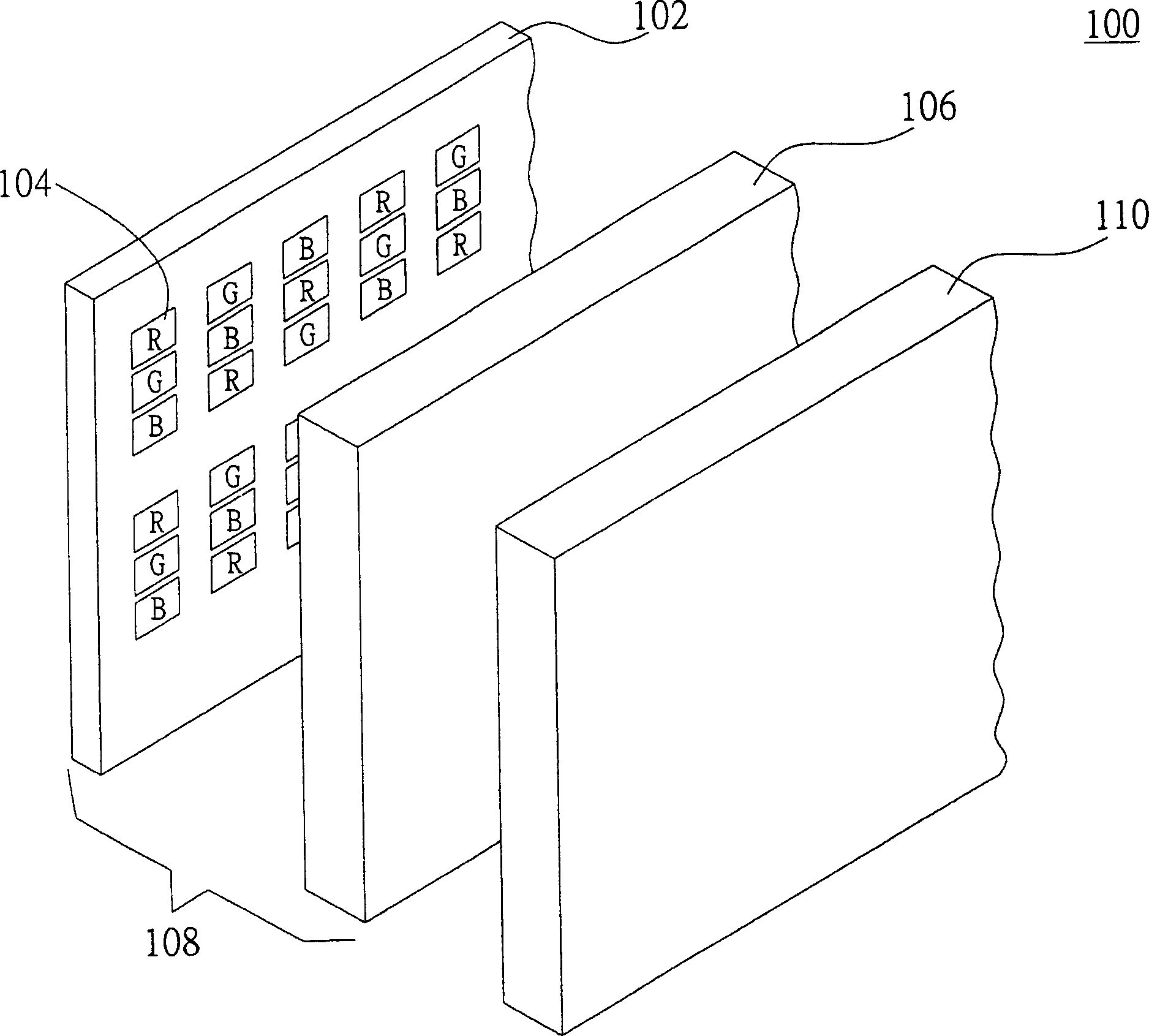

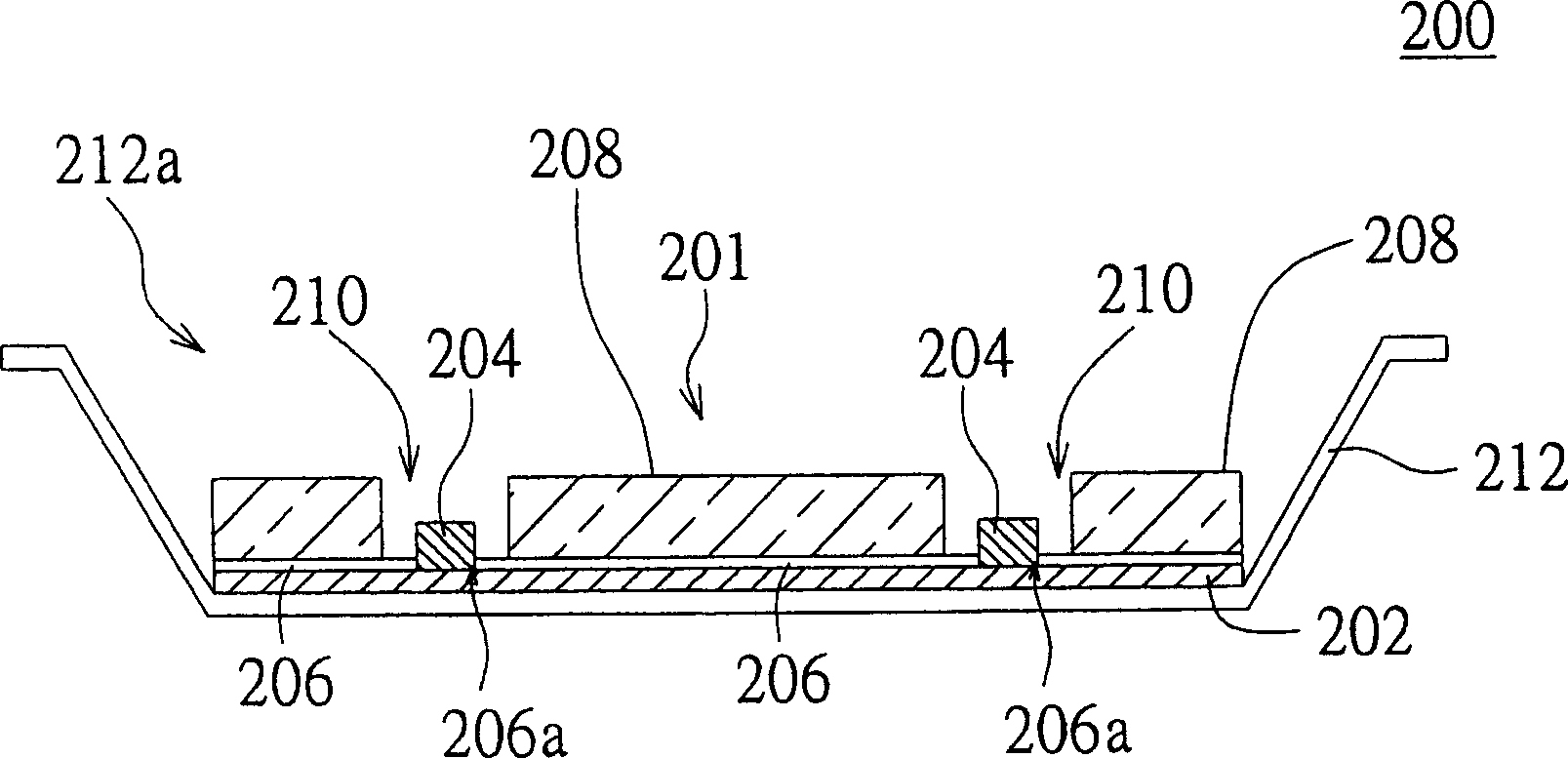

Backlight modular

A backlight module is disclosed in the invention in order to reduce light-mixing distance for light-emitting diode. In the new design, a light guiding plate is setup around light-emitting diodes for mixing light evenly in short distance so as to reduce size of the back light module. The back light module includes a frame, a circuit board, multiple light-emitting diodes and a light-guiding plate. The circuit board is installed in a space formed inside the frame. Light-emitting diodes connected to the circuit board are extended out of the board. The light-guiding plate setup on the circuit board possesses at least one opening to accommodate light-emitting diodes.

Owner:AU OPTRONICS CORP

LED backlight module

ActiveCN101571264AShorten the mixing distanceReduce the amount usedMechanical apparatusPoint-like light sourceLight guideLight emission

The invention discloses an LED backlight module which comprises a light guide plate and at least one LED luminous source, wherein the light guide plate is at least provided with a light incidence surface; the LED luminous source is arranged opposite to the light incidence surface of the light guide plate; the LED luminous source is provided with a light emission surface facing to the light incidence surface of the light guide plate and at least arranged at one side of the light guide plate; the light emission surface of the LED luminous source forms an inclination angle of larger than 0 DEG and less than 90 DEG relatively to the light incidence surface of the light guide plate. The LED backlight module can reduce a mixed light distance between adjacent LEDs in the prior LED backlight source art, reduce and even eliminate a dark area, save the cost and reduce the heat emission of the module.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Light conductive board and the backlight module possessing same

InactiveCN101165515AShorten the mixing distanceLess discomfortOptical light guidesNon-linear opticsGratingLight guide

The invention is a backlight module comprising a transparent substrate partitioned into multi areas, a grating structure located at the incident face of each area, and astigmatism structure of optical face used for receiving the incident light. The transparent substrate can be used to make partition sequential scan so as the grating structure can shorten the light-mixing distance; said astigmatism structure can evenly scatter the light out of the light-guiding plate.

Owner:IND TECH RES INST

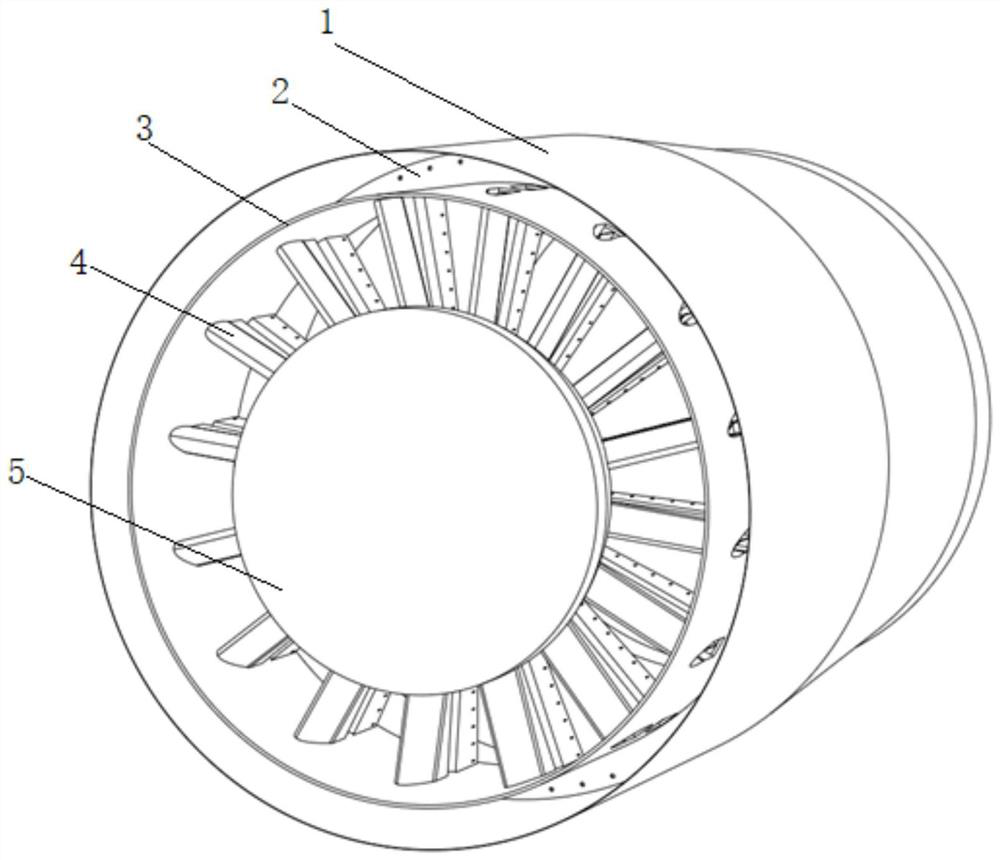

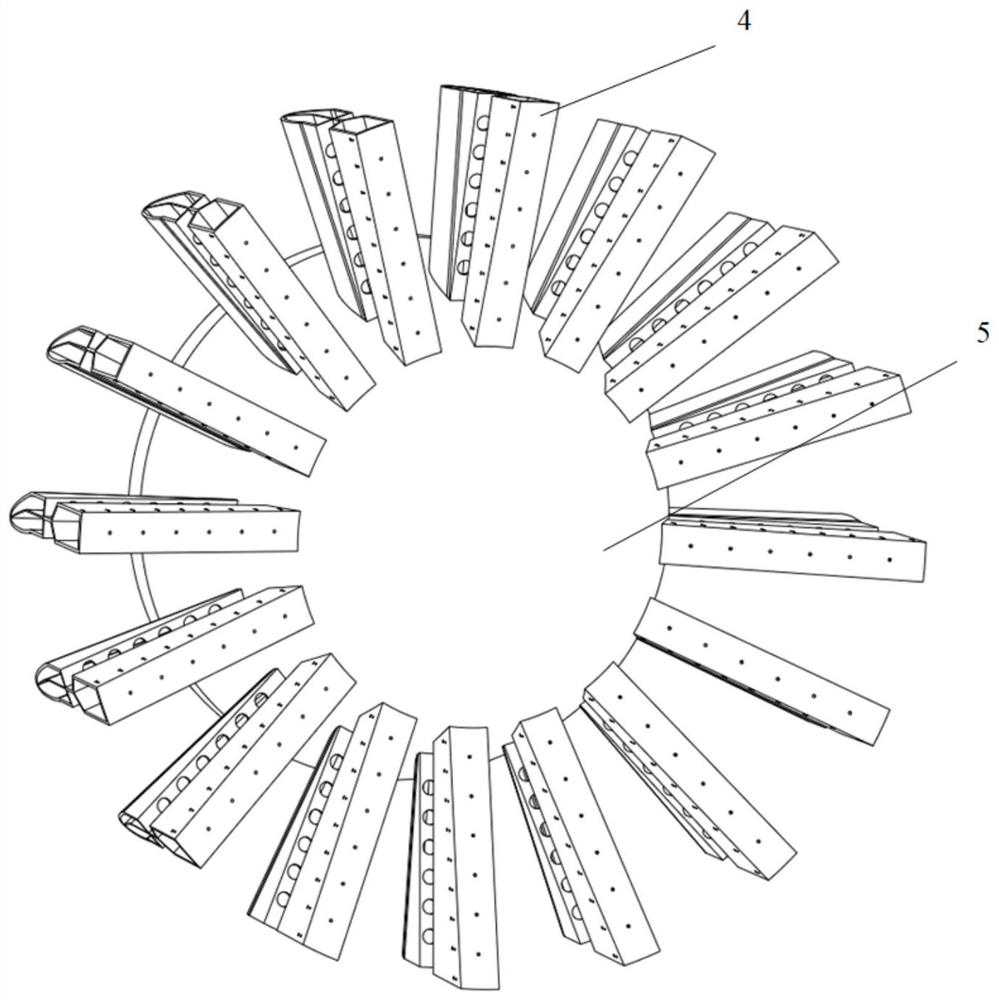

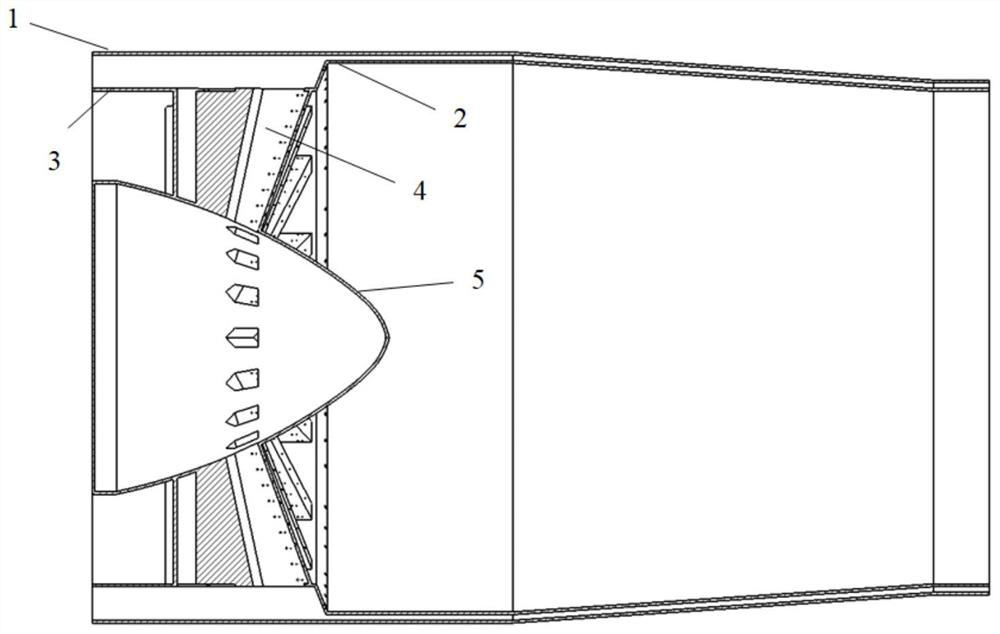

Support plate stabilizer with gas mixing function and integrated afterburner

ActiveCN114738795ASimple structureRealize integrated designContinuous combustion chamberEfficient propulsion technologiesCombustion chamberEngineering

In order to solve the problems that according to an existing afterburner integrated design scheme, a backflow area and a combustion area move forwards, consequently, combustion is insufficient, and the difficulty of ignition and flame stabilization is increased, the invention provides a supporting plate stabilizer with a gas mixing function and an integrated afterburner. The two symmetrical open type concave cavities are formed in the middle of the supporting plate stabilizer, the open type concave cavities have the gas mixing function and can replace a mixer in a traditional afterburner, and the structure of the afterburner is simplified; in addition, due to the fact that the oxygen content of the outer culvert air flow is higher than that of the inner culvert air flow, the oxygen content of the mixed air is increased after the outer culvert air flow and the inner culvert air flow are mixed, the outer culvert air flow and the inner culvert air flow are combusted while being mixed, and the combustion efficiency is improved. Therefore, combustion is more sufficient, and flame stability and combustion efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

SCR (Selective Catalytic Reduction) flue gas denitration device and flue gas denitration method

InactiveCN104741001ASolve the resistanceReduce resistanceLighting and heating apparatusDispersed particle separationAir preheaterFlue gas

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration device and a flue gas denitration method. The SCR flue gas denitration device comprises a coal economizer (1), a denitration reactor (2) and an air preheater (3), wherein the bottom of the coal economizer (1) is connected with the top of the denitration reactor (2) by an inlet flue (4), the bottom of the denitration reactor (2) is connected with the air preheater (3) by an outlet flue (5), an ammonia spraying device (6) is arranged in the inlet flue (4), and an ash crushing device (7), a rectifying layer (8) and a catalyst layer (9) are sequentially arranged in the denitration reactor (2) from top to bottom. The denitration method comprises the steps of ammonia gas mixture preparation, ammonia spraying, denitration and exhausting. According to the invention, through the reasonable setting of a nozzle, an effect of mixing sprayed ammonia with flue gas is better, and the uniformity of a temperature field in a flue can be effectively guaranteed, thereby improving the denitration efficiency.

Owner:CHINA HUADIAN ENG +1

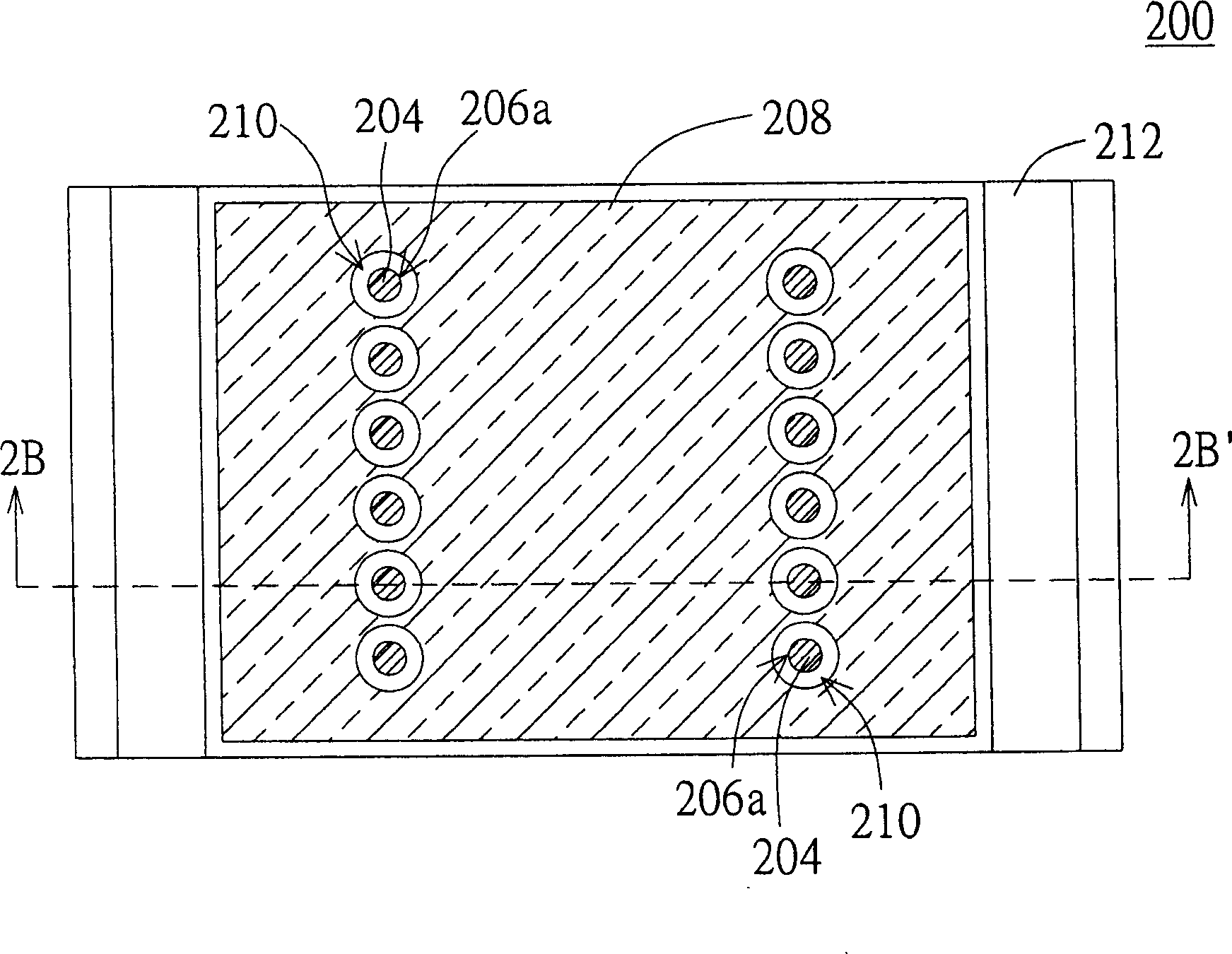

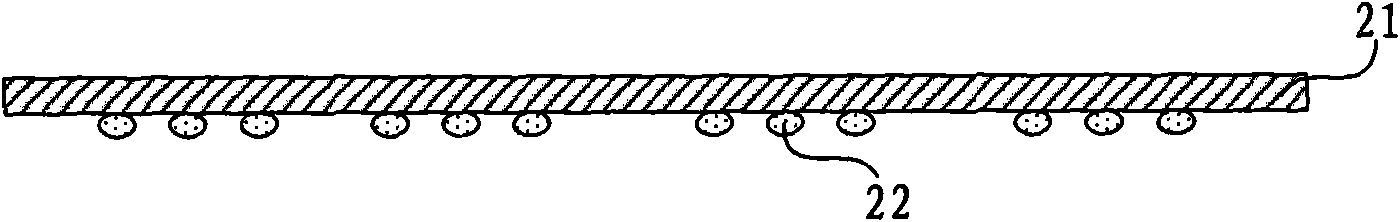

Light mixing film for mixing light from light emitting diode backlight source and light emitting diode backlight source

InactiveCN101684921AShorten the mixing distanceMeet ultra-thin requirementsPoint-like light sourceElongate light sourcesShortest distanceBright spot

The invention relates to a light mixing film for mixing light from a light emitting diode (LED) backlight source and an LED backlight source. The light mixing film comprises a substrate and mesh points arranged on the substrate, wherein the substrate is manufactured by a light-transparent material; and the mesh points are used for scattering light. The LED backlight source comprises the light mixing film, wherein the light mixing film is arranged between an LED and a diffusing sheet; and the mesh points on the light mixing film are at least arranged on the substrate right above the LED. Through the light mixing film, stronger light rays emitted by the LED can be partially transmitted and partially reflected back to the bottom reflecting film, thereby reducing the production of bright spots; and thus, light rays can be evenly mixed within a shorter distance, thereby reducing the light mixing distance of the direct LED backlight source and meeting the ultra-thin requirement for the direct LED backlight source.

Owner:BOE TECH GRP CO LTD

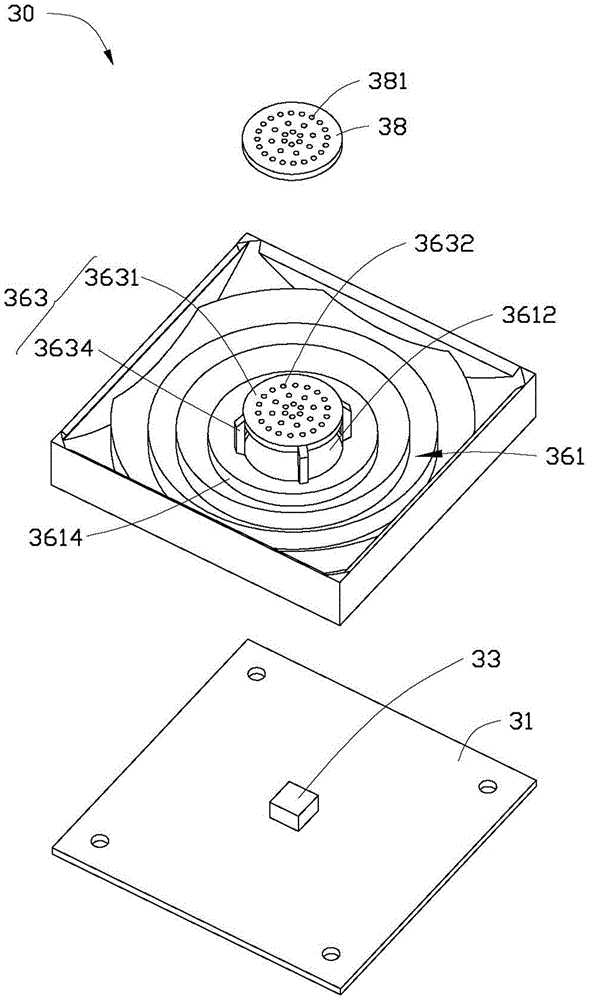

Backlight module and light source assembly thereof

ActiveCN104696780AUniform light outputAvoid problemsPoint-like light sourceDiffusing elementsLight guideEngineering

A light source assembly includes a base plate, a light source secured on the base plate, a first reflection member, a second reflection member, and a diffusion plate. The first reflection member includes a base portion secured on the base plate and a plurality of protrusions with reflection surfaces inclined to the base plate. A through hole is defined on the base portion to receive the light source. Each protrusion protrudes from a side of the base portion away from the base plate and extends around the through hole. The second reflection member includes a reflection portion defining a plurality of light holes. The diffusion plate covers the second reflection member. Light emitting from the light source transmits to the light guide assembly via the reflection portion and the reflection surfaces.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU

Light guide plate, backlight module and display device

InactiveCN107092051AImprove light mixing effectReduce thicknessOptical light guidesNon-linear opticsLight guideDisplay device

The invention provides a light guide plate, a backlight module using the light guide plate and a display device using the backlight module, wherein the light guide plate comprises a light guide plate body; the light guide plate body is provided with a light incoming surface and a light outgoing surface arranged oppositely; an optical dent for refracting and diffusing light is arranged on the light incoming surface; a refracting surface for coating a light source is formed on the inner surface of the optical dent; and the surface of the light incoming surface is also provided with a plurality of optical dots for reflecting light. Due to the light guide plate, the thickness of the backlight module and the thickness of the display device are reduced, and ultra-thin design of the display device is realized.

Owner:HEFEI HUIKE JINYANG TECH

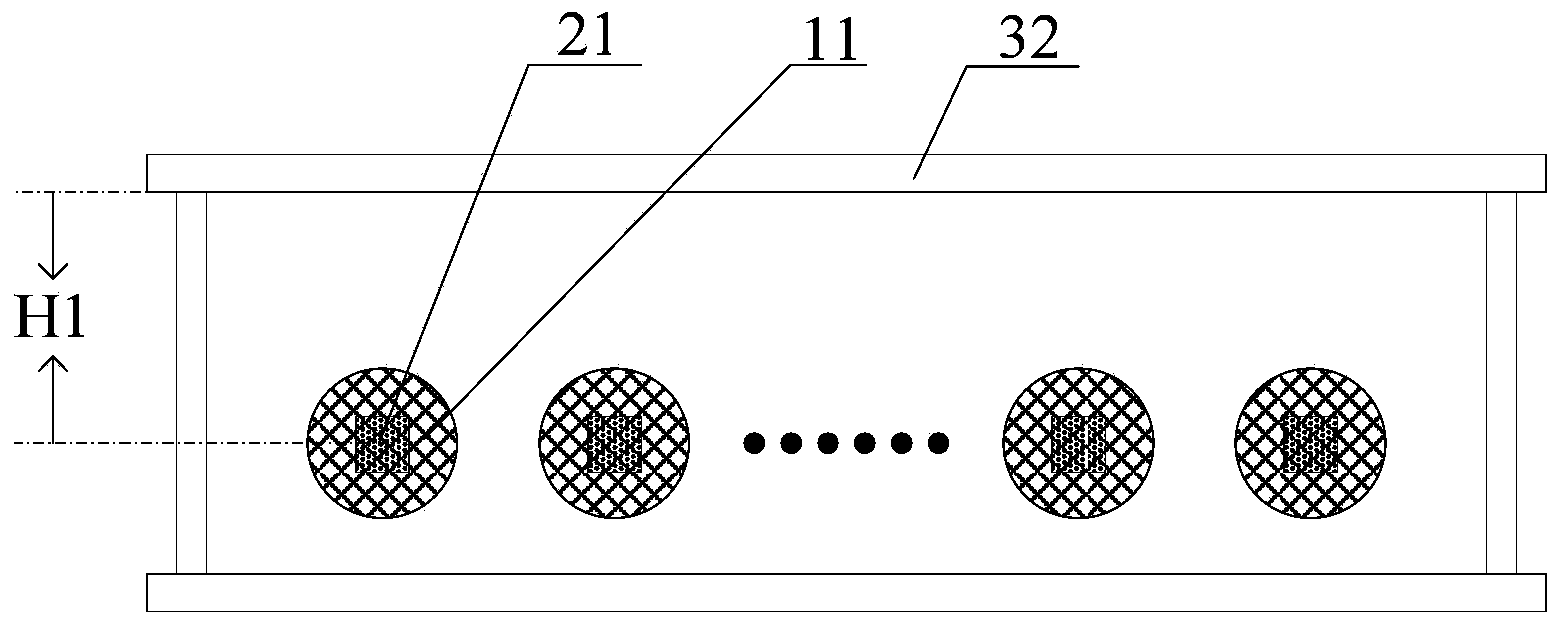

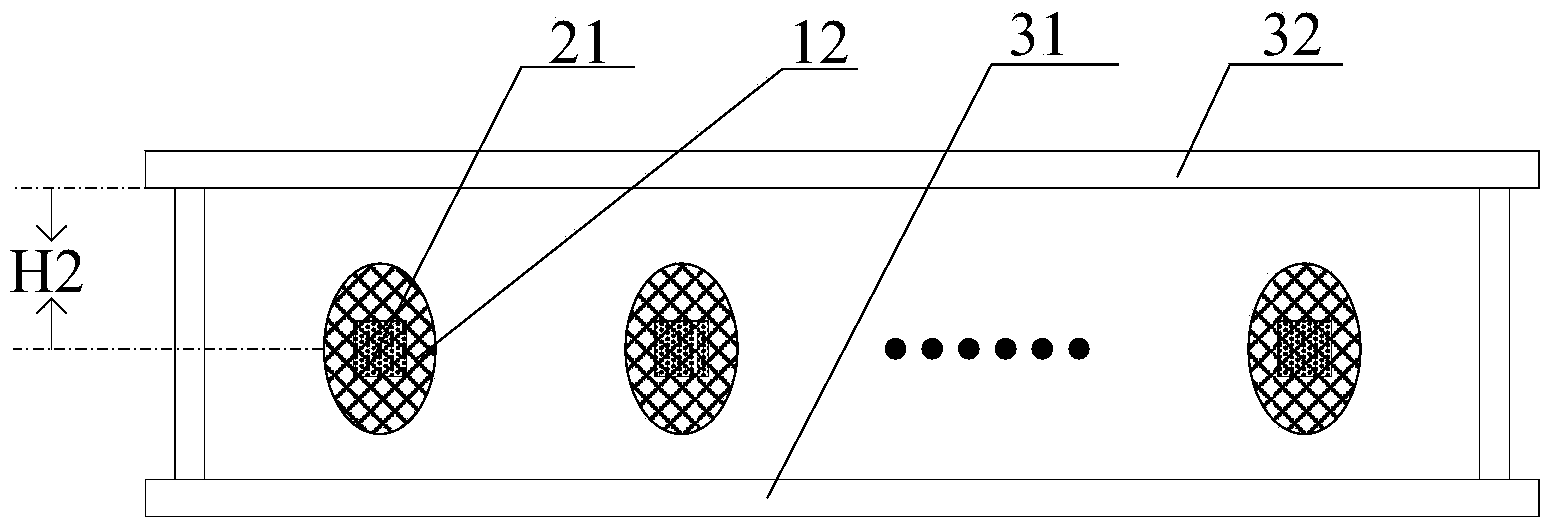

Line light source, backlight module and display device

InactiveCN103672745AReduce thicknessGuaranteed display qualityMechanical apparatusPoint-like light sourceLight guideDisplay device

The invention relates to the technical field of display, in particular to a line light source, a backlight module adopting the line light source and a display device adopting the backlight module. The line light source comprises an elliptic cylinder type light guide rod and a point light source, wherein the point light source is arranged at the end of the elliptic cylinder type light guide rod. According to the line light source, the elliptic cylinder type light guide rod is arranged, and the point light source is arranged at the end of the elliptic cylinder type light guide rod which is used for converting light which passes through the point light source in an incident mode into the line light source. Due to the utilization of the elliptic cylinder type light guide rod, light can be diffused to a larger angle, when the line light source is applied to the backlight module, on the premise that display quality is guaranteed, the light mixing distance can be further reduced, the thickness of the backlight module can be reduced, and a powerful technical support is provided for achieving the ultra-thin direct type display device.

Owner:BOE TECH GRP CO LTD

Backlight module and display apparatus

ActiveUS20140125920A1Reduce energy consumptionWide color gamutMechanical apparatusFibre light guidesFiberLight guide

The present invention provides a backlight module and a display apparatus. The display apparatus comprises the backlight module and a display panel. The backlight module comprises a light collector, optical fibers, a fiber light-outputting substrate and a light guide plate. The optical fibers are connected between the light collector and the fiber light-outputting substrate. The light guide plate is disposed at one side of the fiber light-outputting substrate. The light guide plate includes light diffusion recessions, and the light diffusion recessions face the light-outputting openings of the fiber light-outputting substrate. The present invention can use ambient light rays to form a backlight source.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Direct Type Backlight and Display Device

InactiveUS20140168949A1Improve display qualityReduce thicknessMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The present invention provides a direct type backlight and a display device provided with the direct type backlight. The direct type backlight includes: a backplate; a printed circuit board fixed on the backplate; a number of LED lamp units fixed on the printed circuit board; side frames fixed on inner side walls of the backplate; reflection sheets covering inner wall of cavity formed by the printed circuit board and the side frames, said reflection sheets have lamp holes matching the LED lamp units; outer frames fixed on upper sides of the backplate and the side frames; said direct type backlight further including: a silica gel light guide plate which this the cavity formed by the printed circuit board and the side frames to cover the reflection sheets and the LED lamp units; and optical film disposed on upper surface of the silica gel light guide plate and located between the upper surface of the silica gel light guide plate and the outer frames. By diffusing the light rays emitted from the LED lamps through the silica gel light guide plate, the mixing distance of the LED lamp is shortened, thus the thickness of the direct type backlight is reduced and the display device becomes much thinner.

Owner:BOE TECH GRP CO LTD +1

Backlight module

InactiveCN1558283AReduce thicknessWell mixedMechanical apparatusMeasurement apparatus componentsLight guideOptoelectronics

A backlight module. The backlight module includes a diffuser plate, a first light guide plate, a second light guide plate, a plurality of first light sources, and a plurality of second light sources. The first light sources are disposed adjacent to the first light guide plate and emit light through the first guide plate to the diffuser plate. The second light sources are disposed adjacent to the second light guide plate and emit light through the second light guide plate to the diffuser.

Owner:AU OPTRONICS CORP

Direct-type macro LED package structure and direct-type macro LED light mixing device

PendingCN107819063AReduce thicknessIncrease light mixing efficiencySemiconductor devicesFluorescenceReflective layer

The invention discloses a direct-type macro LED package structure and a direct-type macro LED light mixing device and belongs to the technical field of backlight sources. The direct-type macro LED package structure comprises a PCB substrate and a plurality of LED chips fixedly arranged on the PCB substrate, wherein a light mixing layer is also fixedly arranged on the PCB substrate and coats the plurality of LED chips; the light mixing layer is filled with a fluorophor; a plurality of reflecting layers which correspond to the plurality of LED chips one by one are also fixedly arranged at the upper end of the light mixing layer; and the reflecting layers are arranged opposite to the corresponding LED chips. The direct-type macro LED light mixing device comprises the direct-type macro LED package structure, a lower diffusion film, a bright enhancement film, an upper diffusion film and a reflecting frame. According to the direct-type macro LED package structure, the light mixing distance can be significantly reduced and the thickness of the package structure is reduced. The direct-type macro LED light mixing device is smaller in thickness and more uniform in light emitting.

Owner:SHENZHEN REFOND OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com