LED backlight module

A technology of backlight module and light source, applied in optics, light guide, light source and other directions, can solve the problems of dark area and large mixing distance, and achieve the effect of saving cost, reducing light mixing distance and reducing the number of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

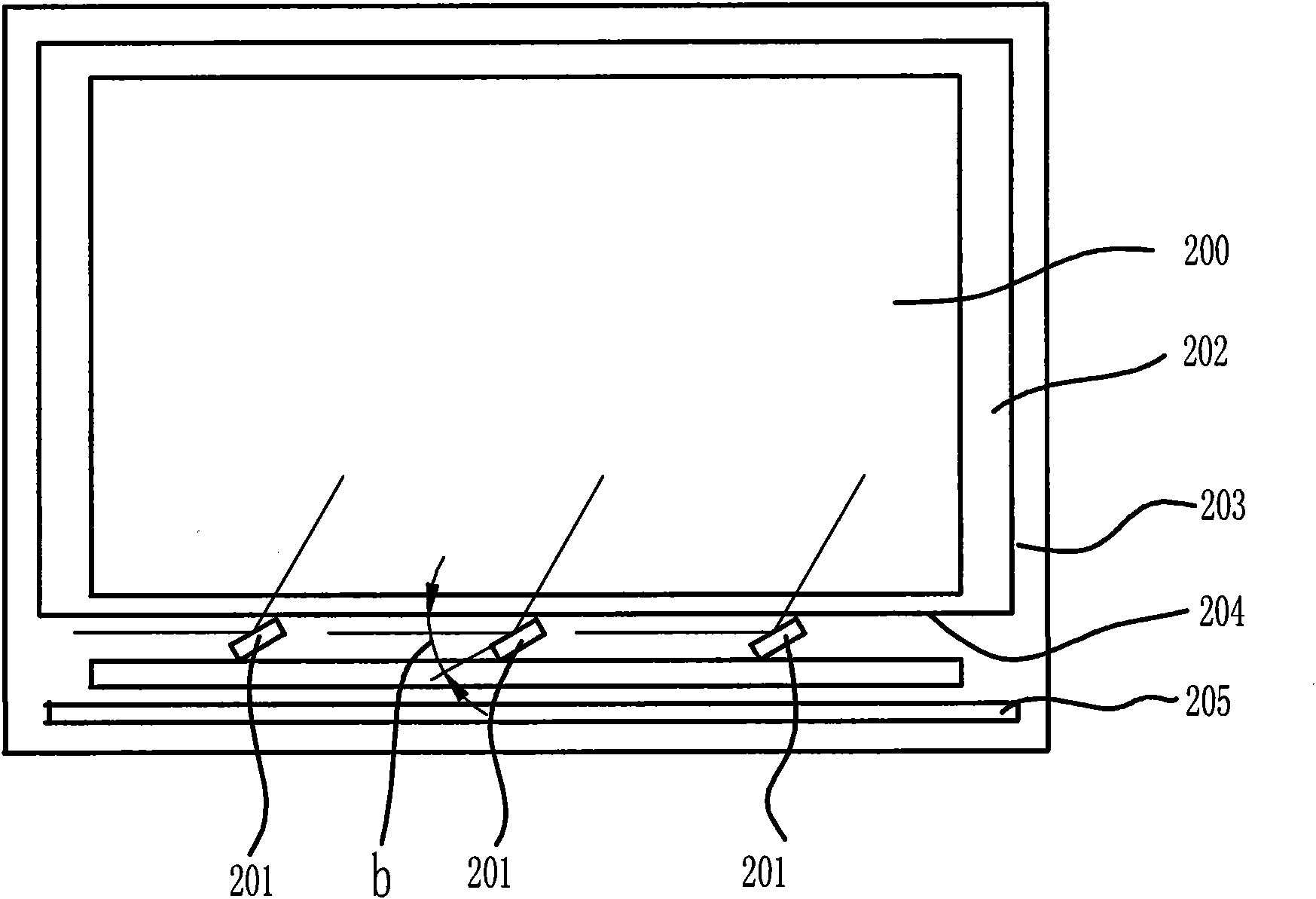

[0033] figure 2 It is a top view of the structure of the first embodiment of the present invention, as figure 2 As shown, the backlight module 200 includes at least one LED light source 201, a reflector 205, a rectangular light guide plate 202, a frame 203 and a set of optical films (not shown). The light guide plate 202 has a light incident surface 204 , and the reflection surface of the reflection device 205 is disposed opposite to the light incident surface 204 of the light guide plate 202 . The LED light source 201 is arranged between the reflection device 205 and the light incident surface 204 of the light guide plate 202, and the light output surface of the LED light source 201 is inclined towards the light incident surface 204 of the light guide plate 202 and arranged at a certain angle b, and the angle b is greater than 0 ° and less than 90°.

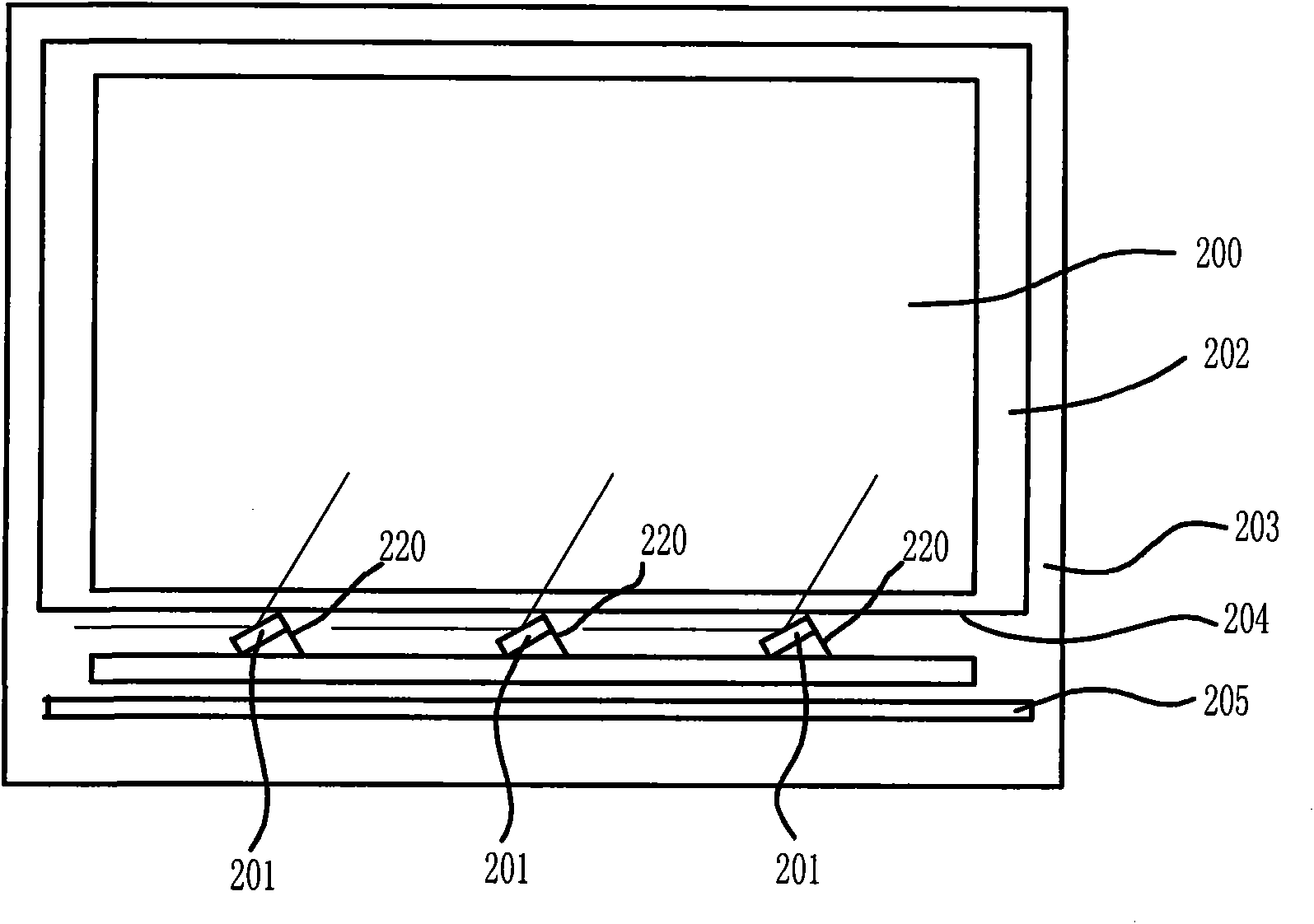

[0034] image 3 yes figure 2 Schematic diagram of the improved arrangement of the LED light source 201 in the middle, s...

Embodiment 2

[0038] Such as Figure 8 As shown, the backlight module of the present invention includes: at least one LED light source 310, the appearance of the LED light source 310 has a light output surface inclined towards the light incident surface 204 of the light guide plate 202; a reflection device 205, a light guide plate 202, a frame 203 and a set of optical films (not shown). The LED light source 310 is disposed between the reflection device 205 and the light incident surface 204 of the light guide plate 202 , and the light output surface of the LED light source 310 is inclined toward the light incident surface 204 of the light guide plate 202 . In this embodiment, the LED light source 310 has a trapezoidal shape in cross section.

[0039] Figure 9 yes Figure 8 Another improved structure schematic diagram of the LED light source 310 in the middle, such as Figure 9As shown, the appearance of the LED light source 320 with this structure has a light-emitting surface on an obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com