Backlight module

A backlight module and backside technology, applied in the direction of optics, light guides, optical components, etc., can solve the problems of dark corners of liquid crystal panels, increasing the thickness and volume of liquid crystal display backlight modules, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above-mentioned objects, features and advantages of the present invention more comprehensible, a preferred embodiment is given below and described in detail with accompanying drawings.

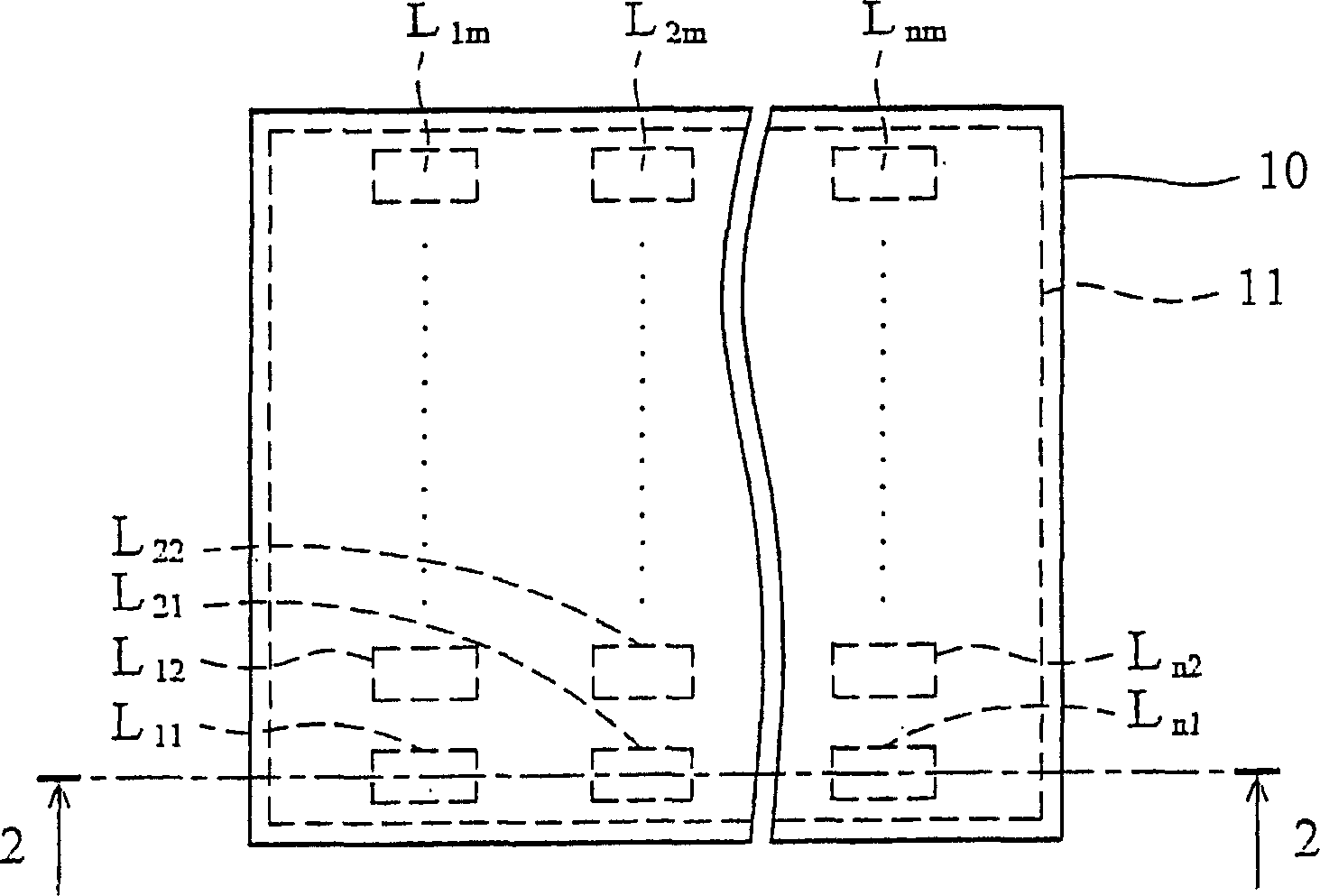

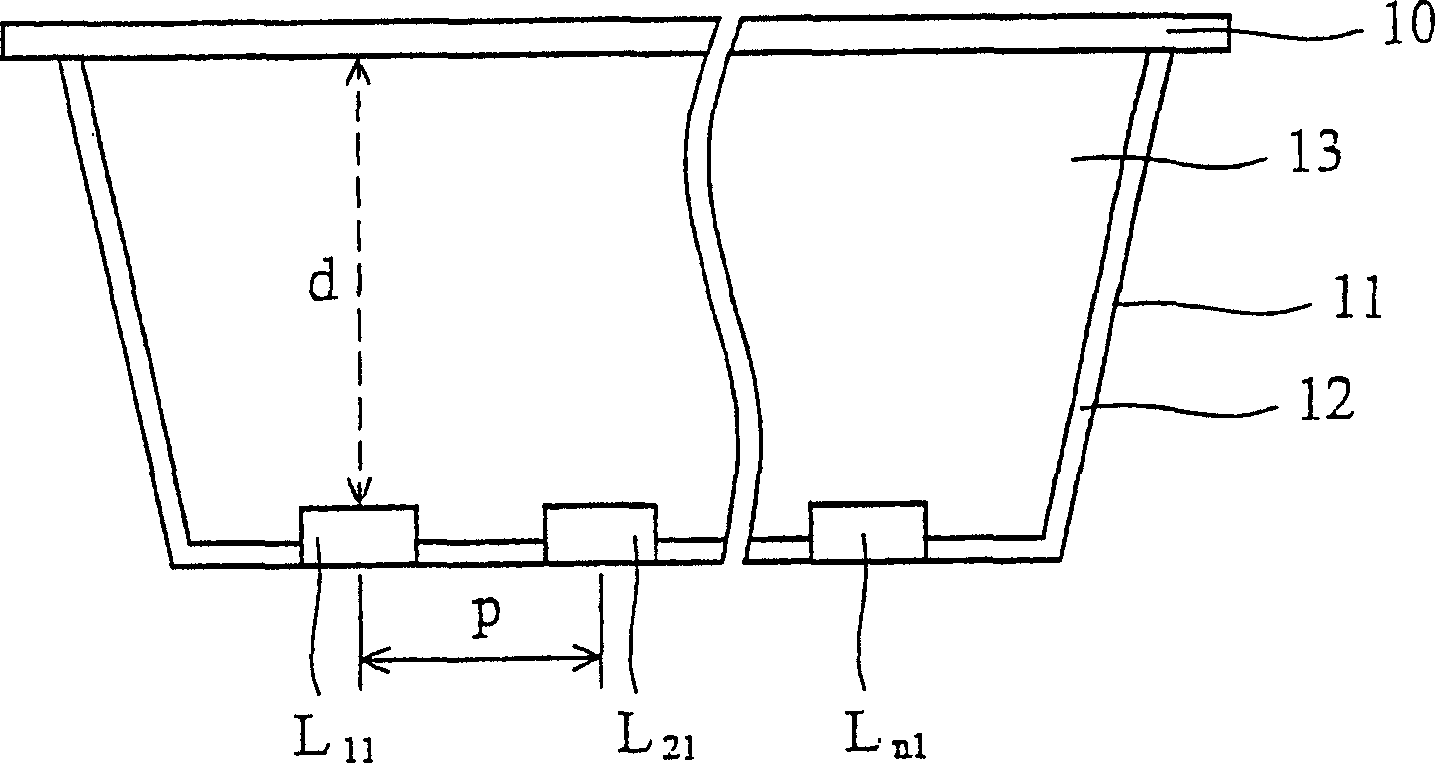

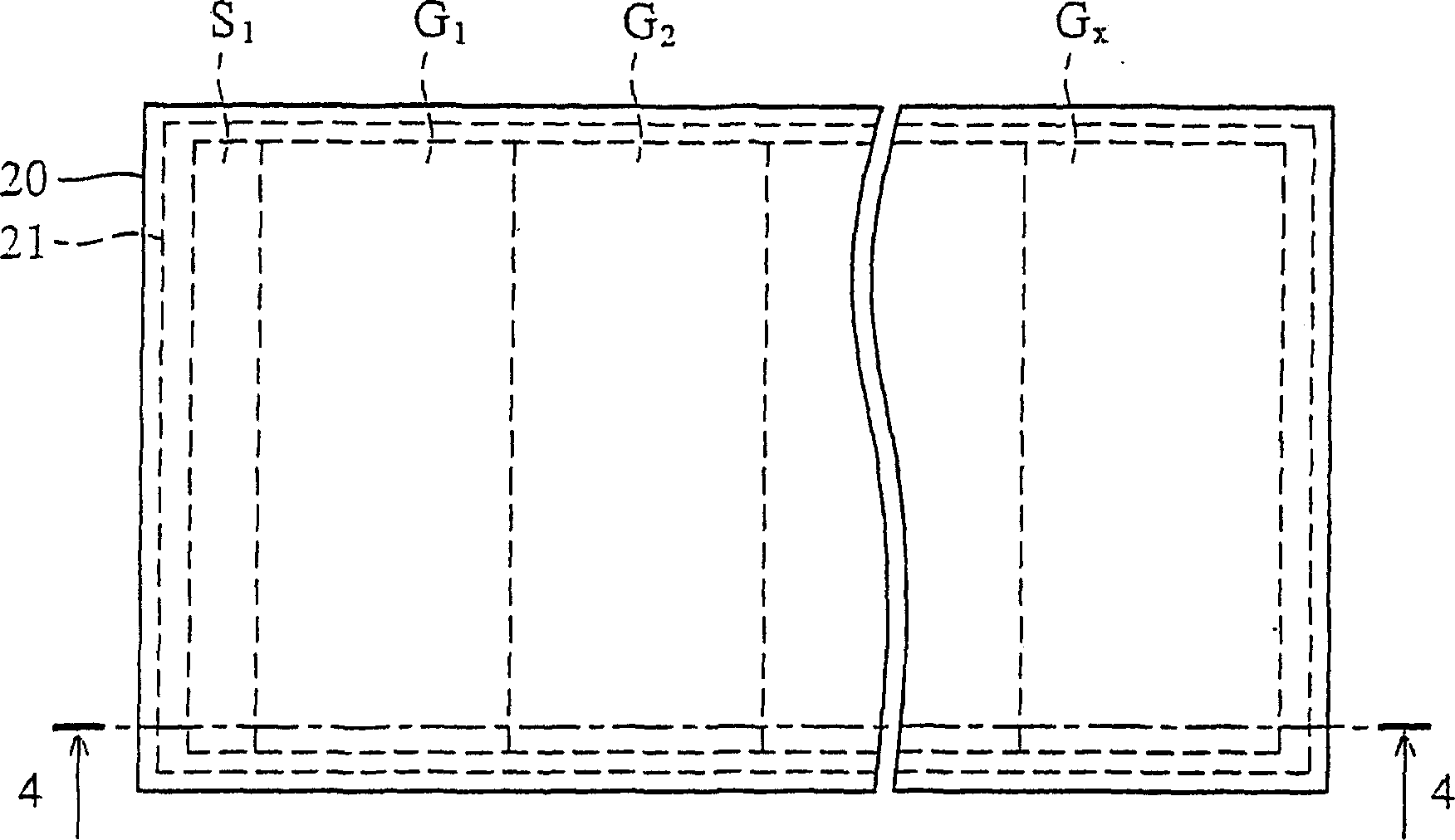

[0014] image 3 It is a schematic plan view showing the direct type backlight module of the liquid crystal display of the present invention. Figure 4 express image 3 A schematic cross-sectional view along the tangent line 4-4 in . The backlight light source of the present invention uses red, green and blue light-emitting diodes to mix into white light to provide to the liquid crystal panel. refer to image 3 and Figure 4 , the direct type backlight module of the present invention has a diffusion plate 20, an outer frame 21, a light guide plate G 1 to G x , Shade S 1 to S x and multiple light emitting diodes. A space 23 is formed between the outer frame 21 and the diffusion plate 20, and the light guide plate G 1 to G x , Shade board S 1 to S x And a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com