Patents

Literature

2556results about How to "Efficient mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

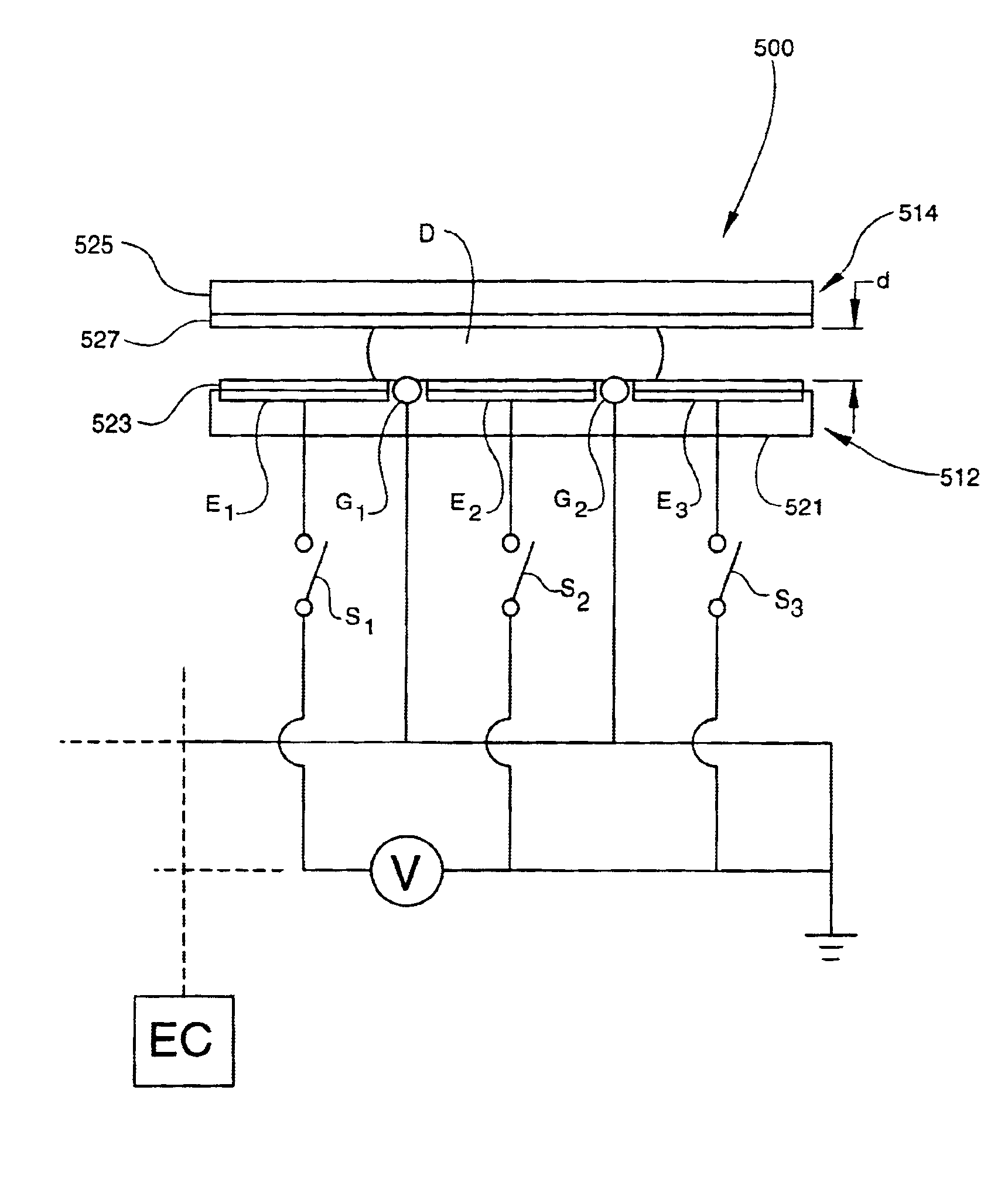

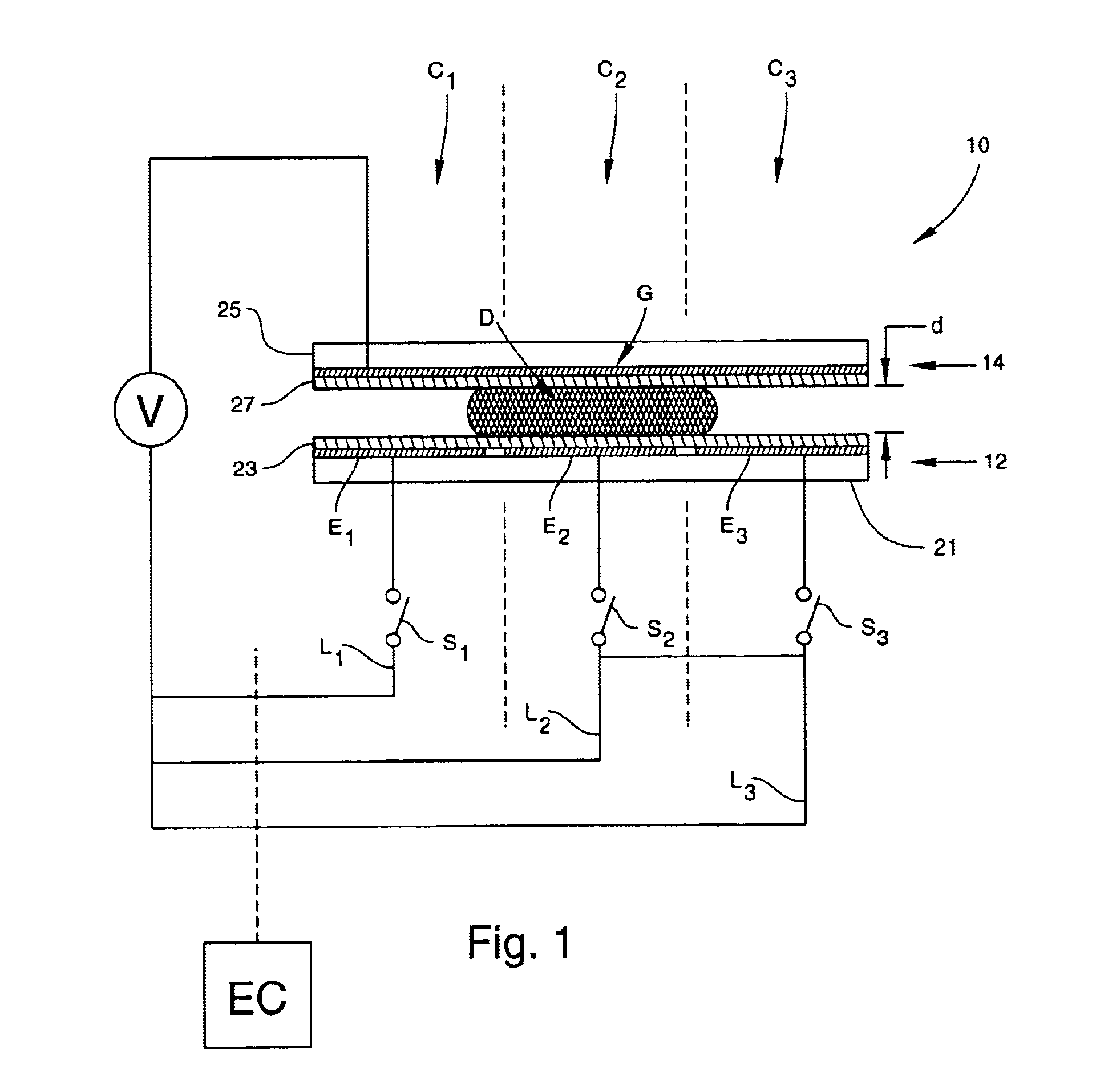

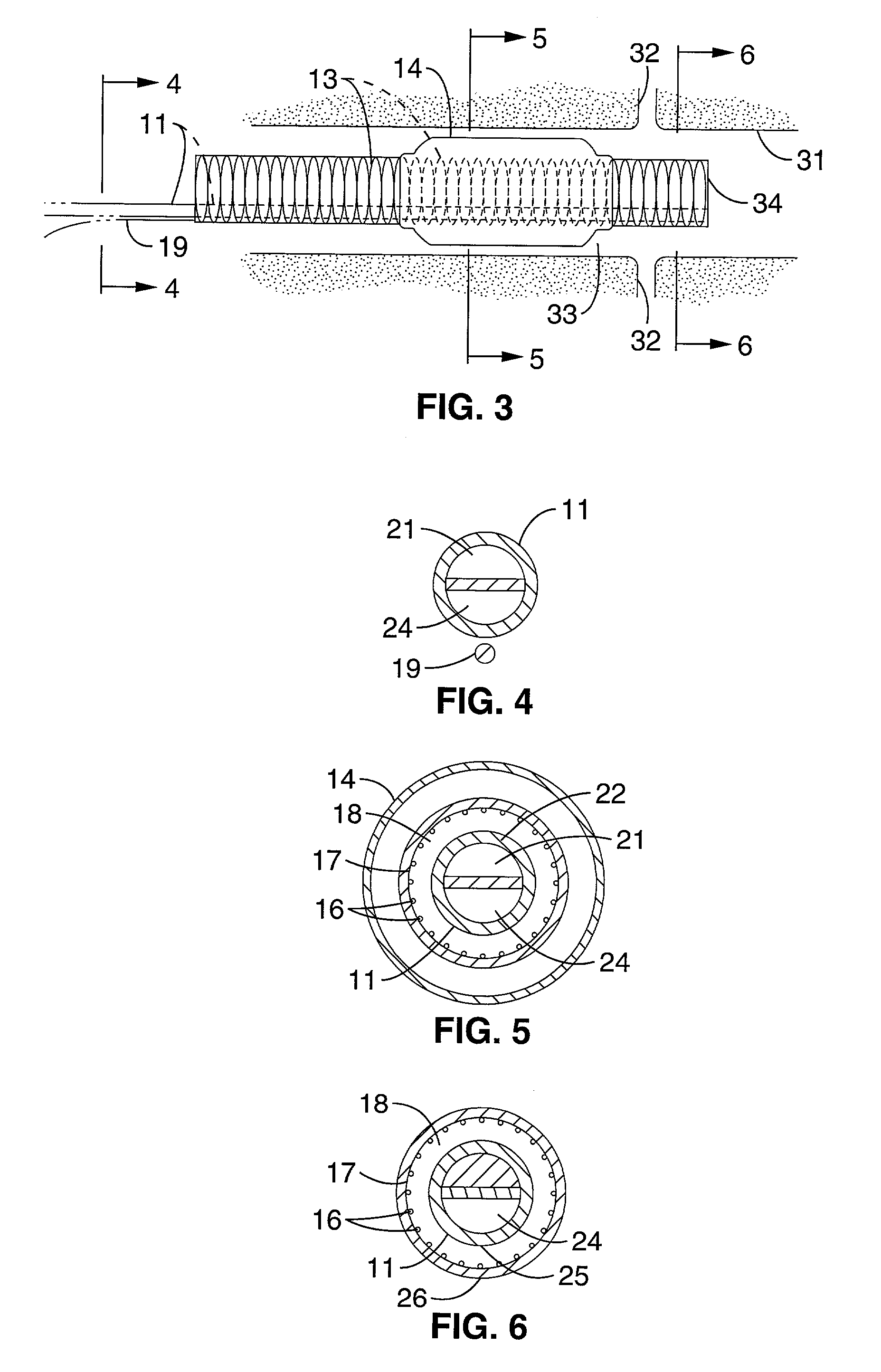

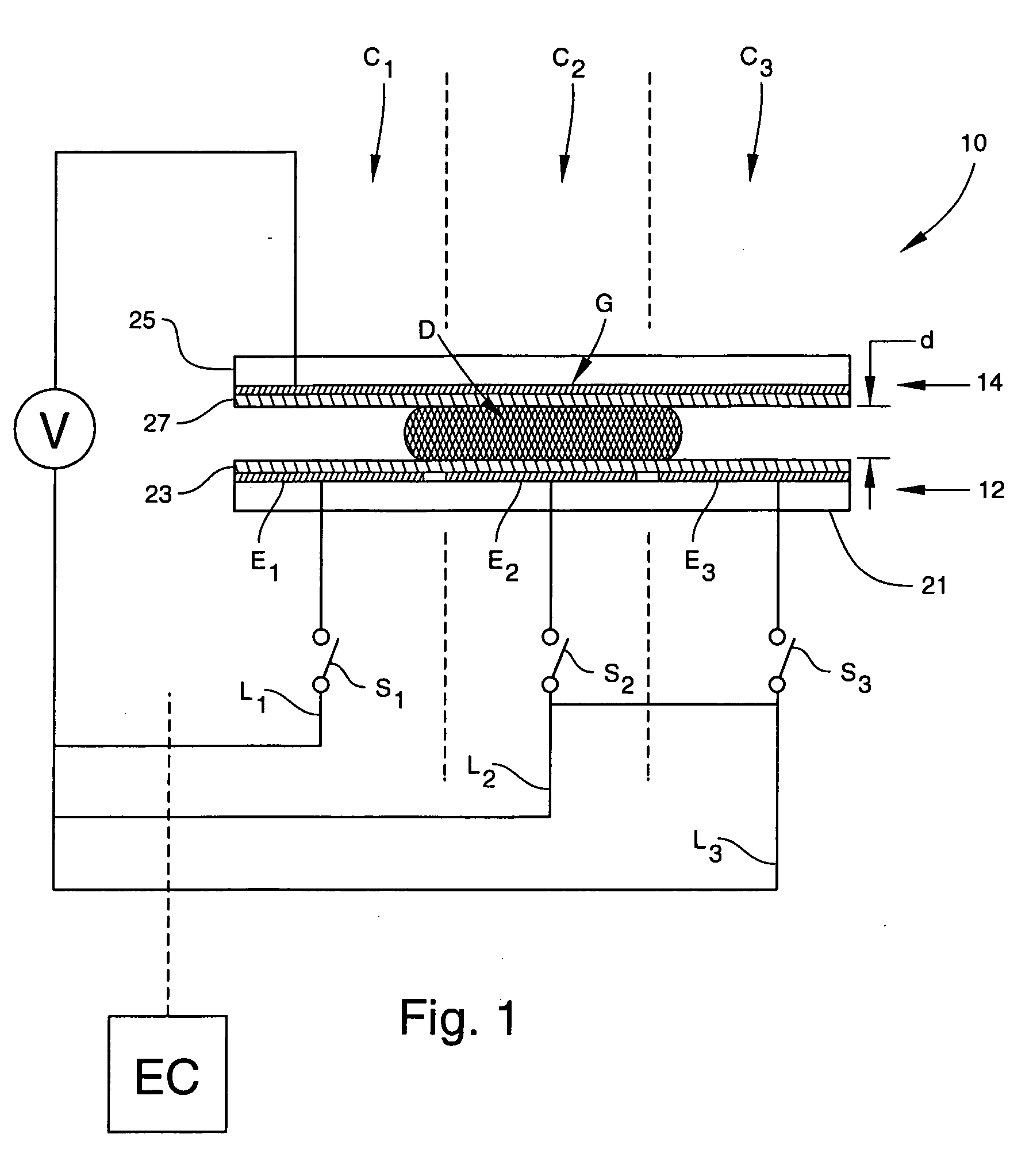

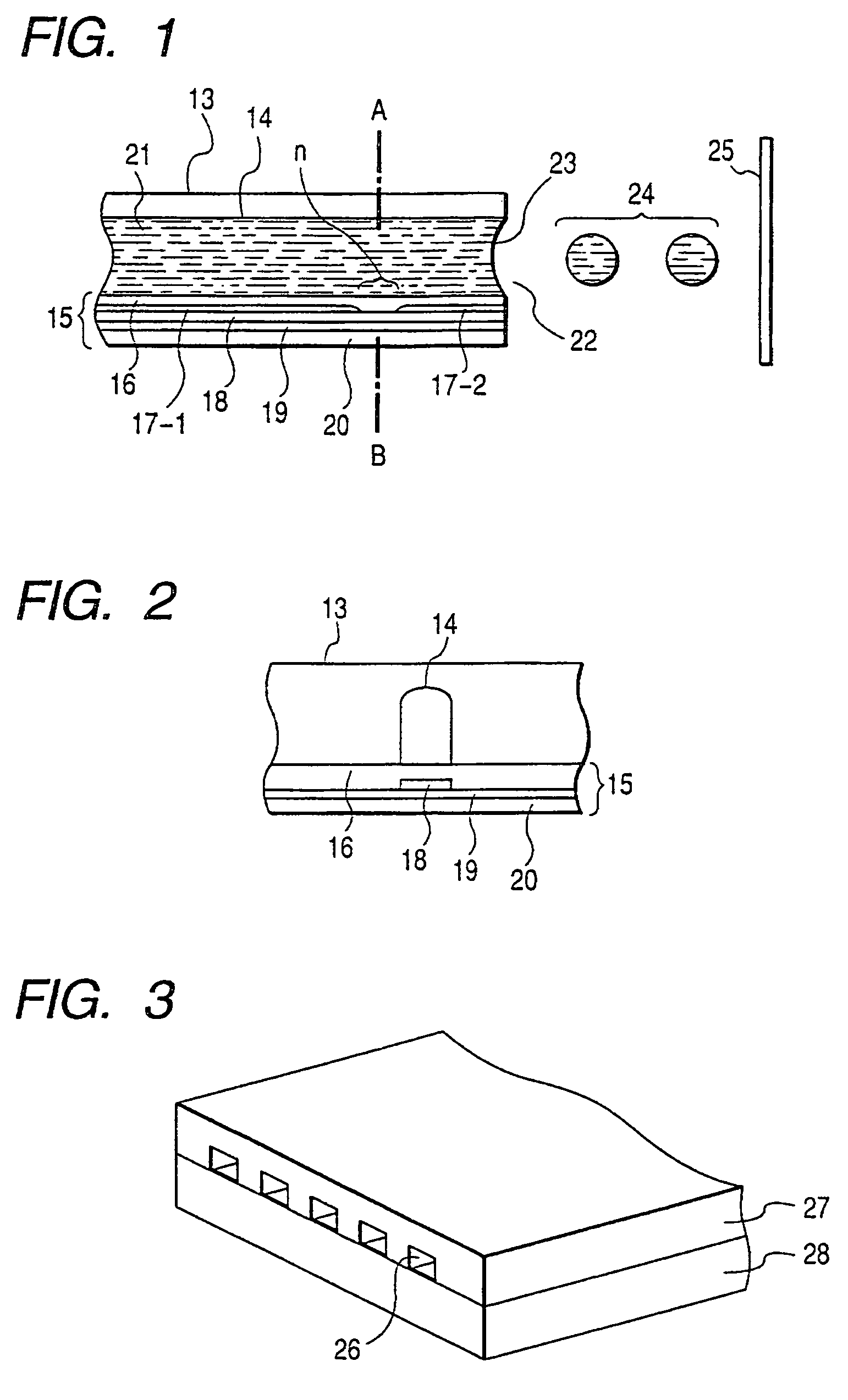

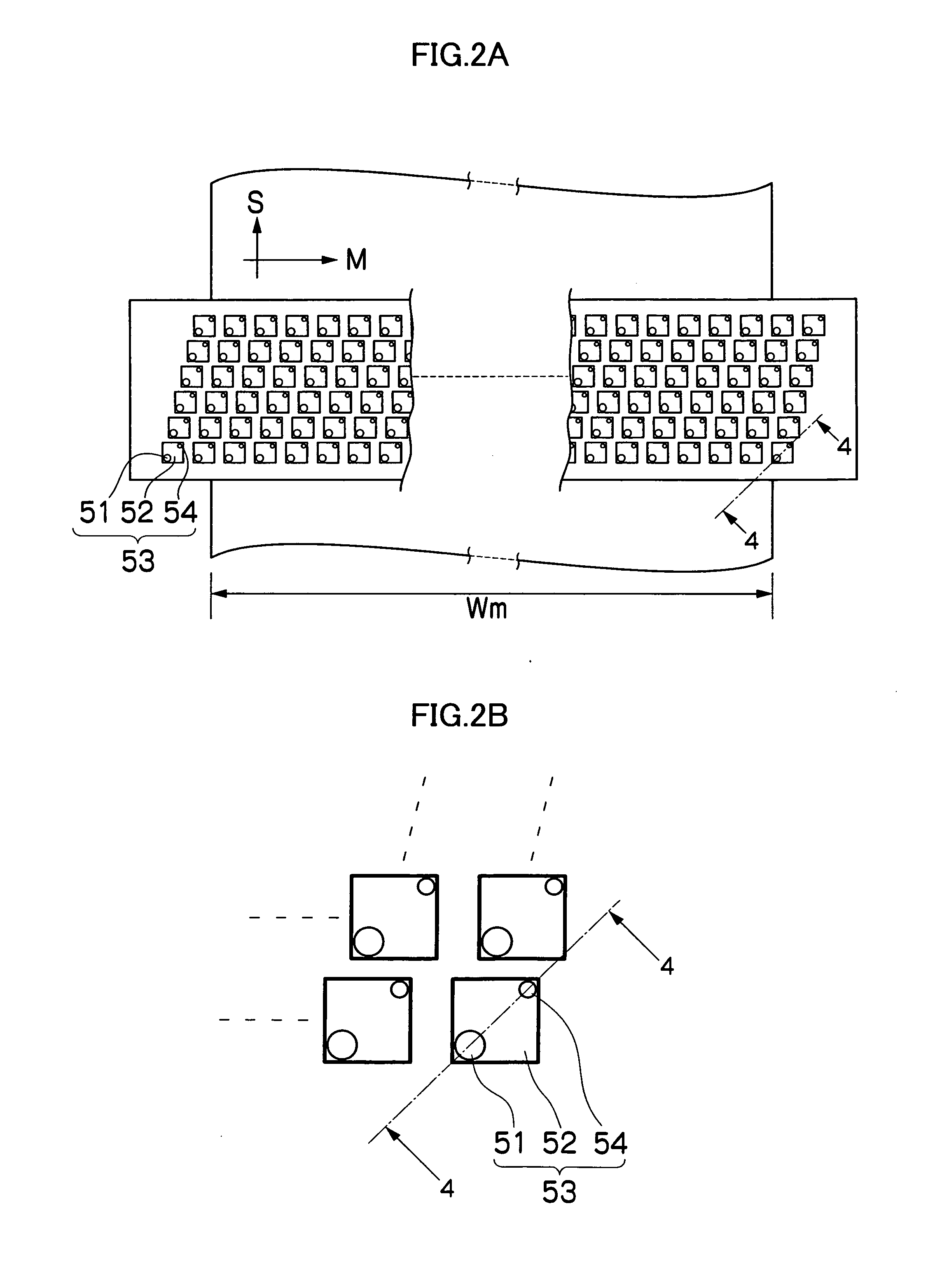

Apparatus for manipulating droplets by electrowetting-based techniques

InactiveUS6911132B2Improve controllabilityImprove accuracyBurnersElectrostatic separatorsElectricityControl manner

An apparatus is provided for manipulating droplets. The apparatus is a single-sided electrode design in which all conductive elements are contained on one surface on which droplets are manipulated. An additional surface can be provided parallel with the first surface for the purpose of containing the droplets to be manipulated. Droplets are manipulated by performing electrowetting-based techniques in which electrodes contained on or embedded in the first surface are sequentially energized and de-energized in a controlled manner. The apparatus enables a number of droplet manipulation processes, including merging and mixing two droplets together, splitting a droplet into two or more droplets, sampling a continuous liquid flow by forming from the flow individually controllable droplets, and iterative binary or digital mixing of droplets to obtain a desired mixing ratio.

Owner:DUKE UNIV

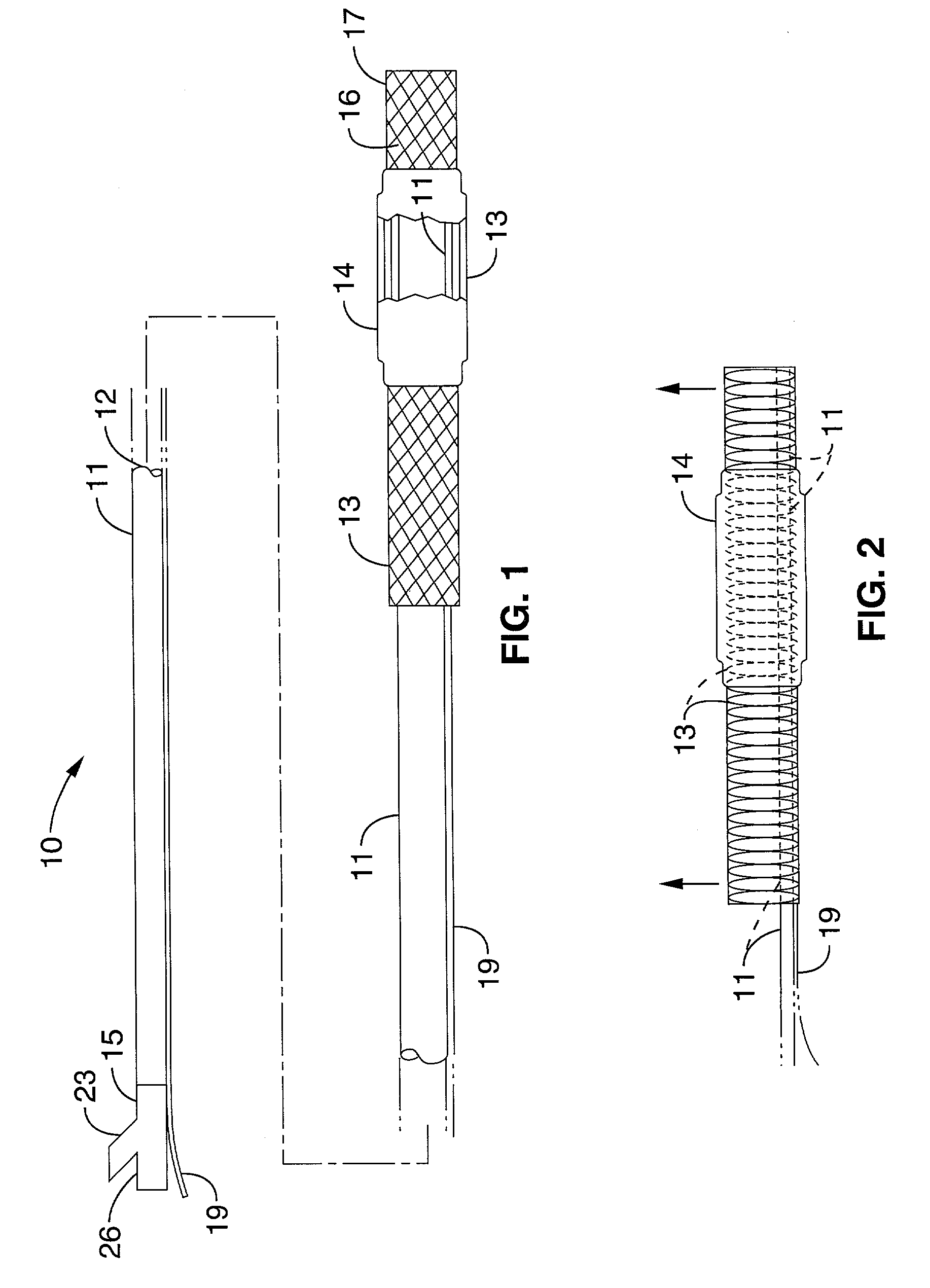

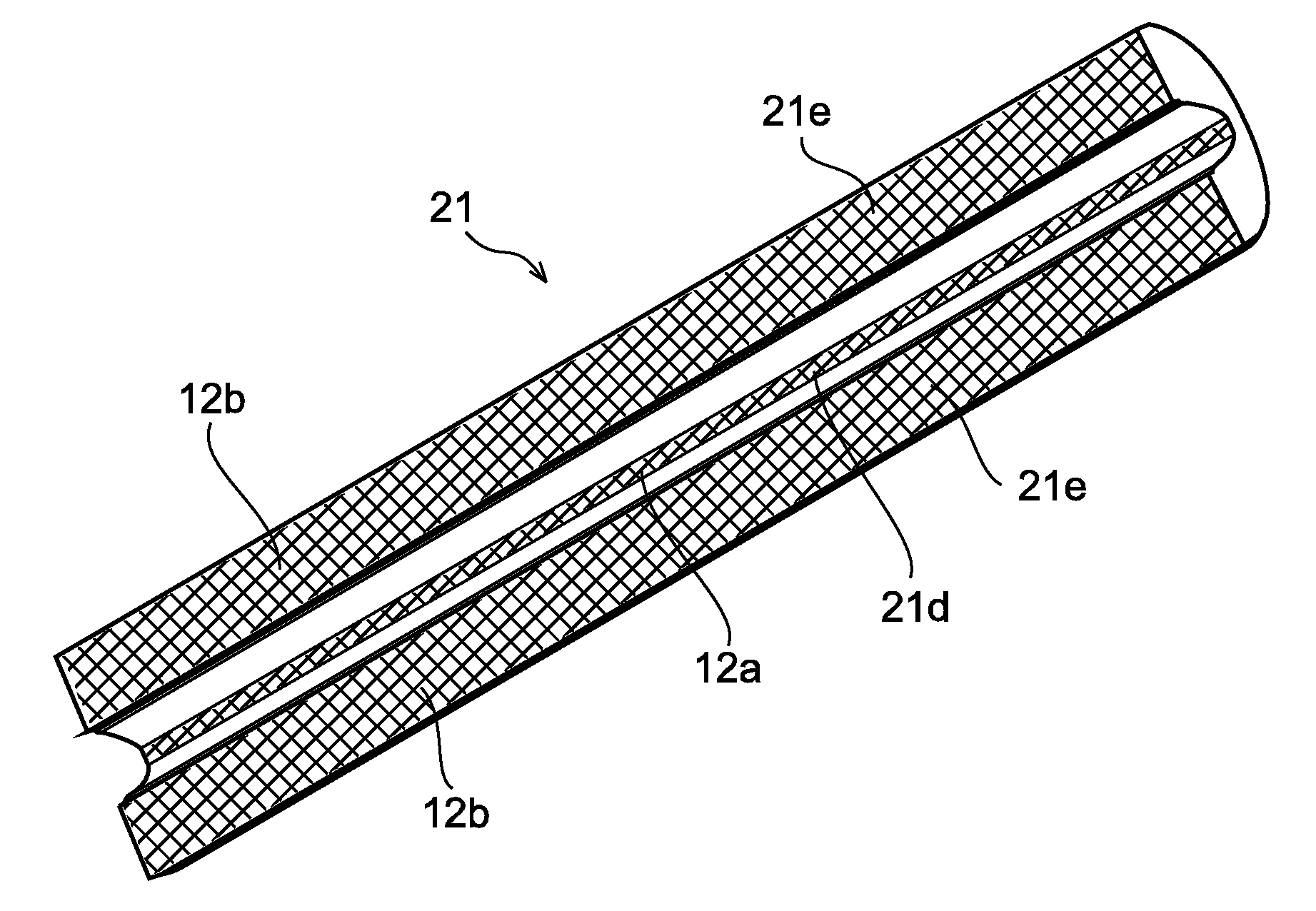

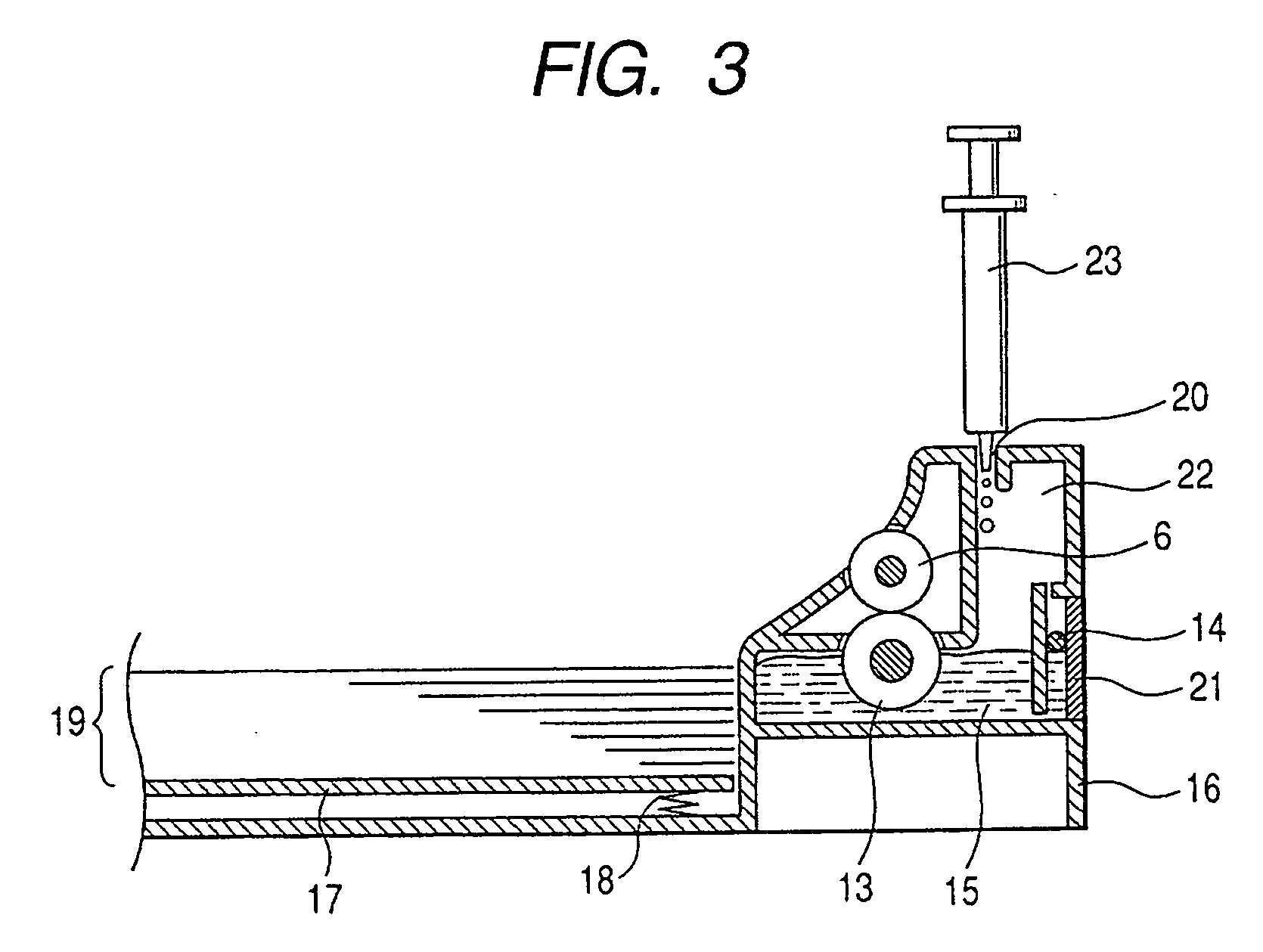

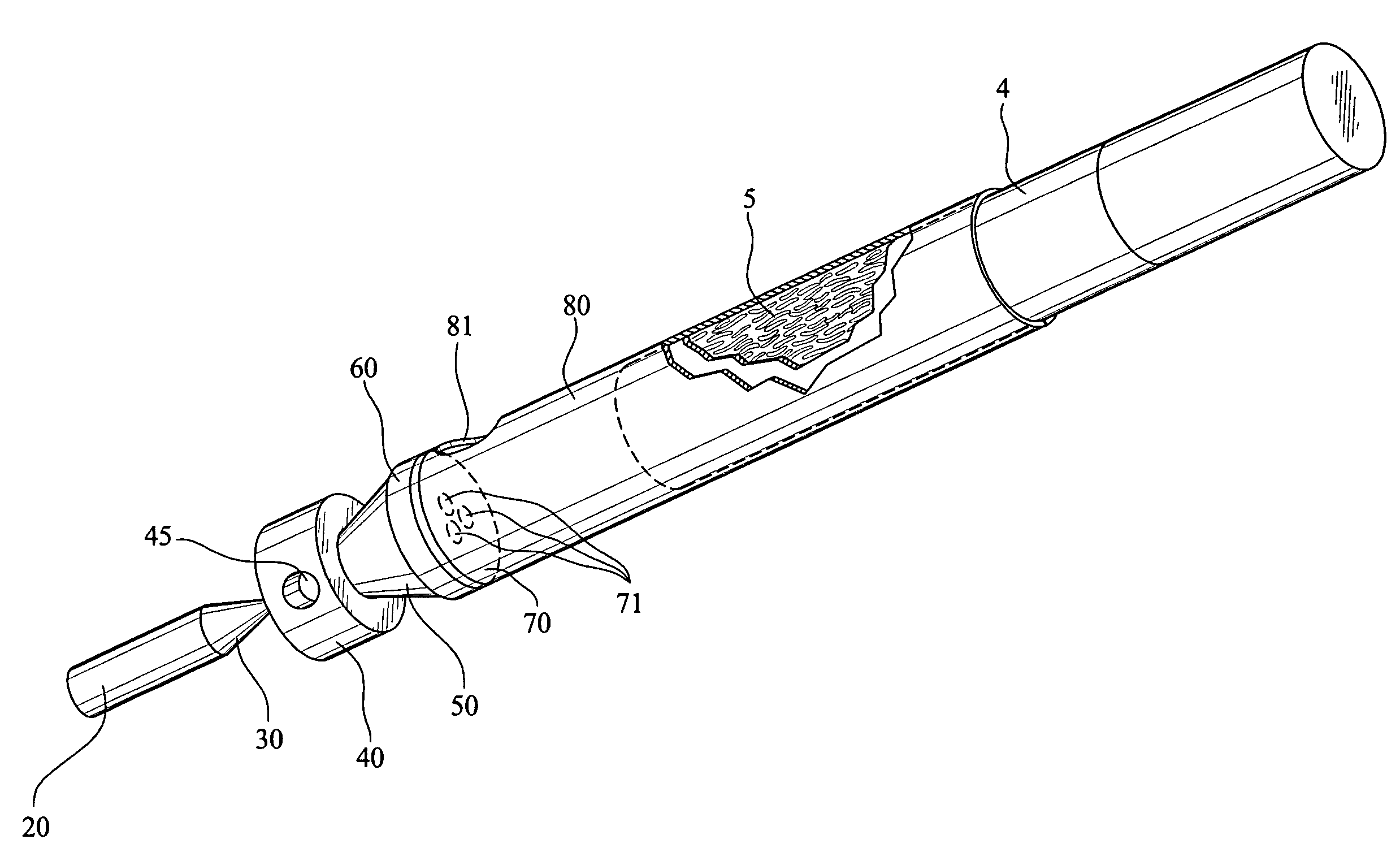

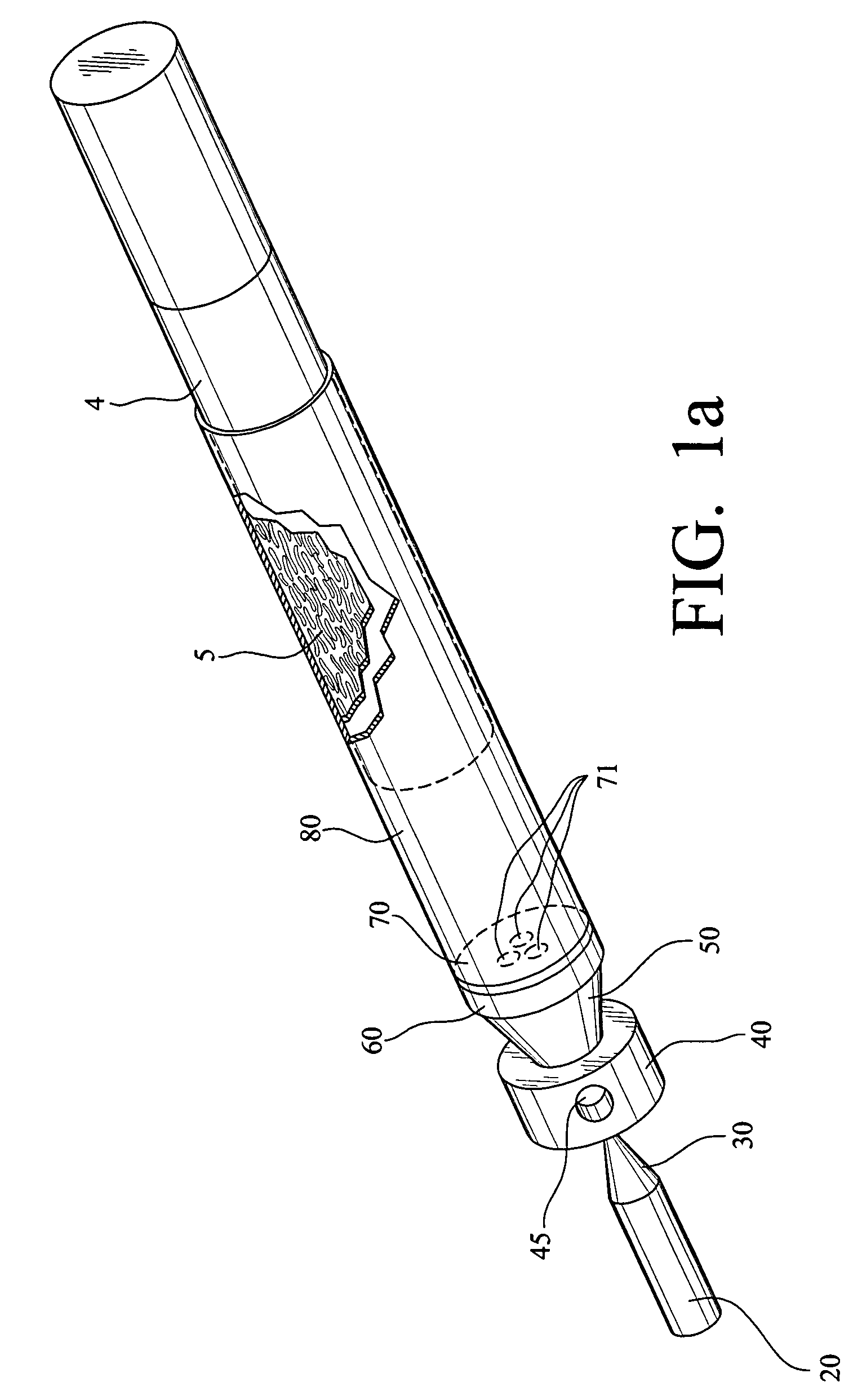

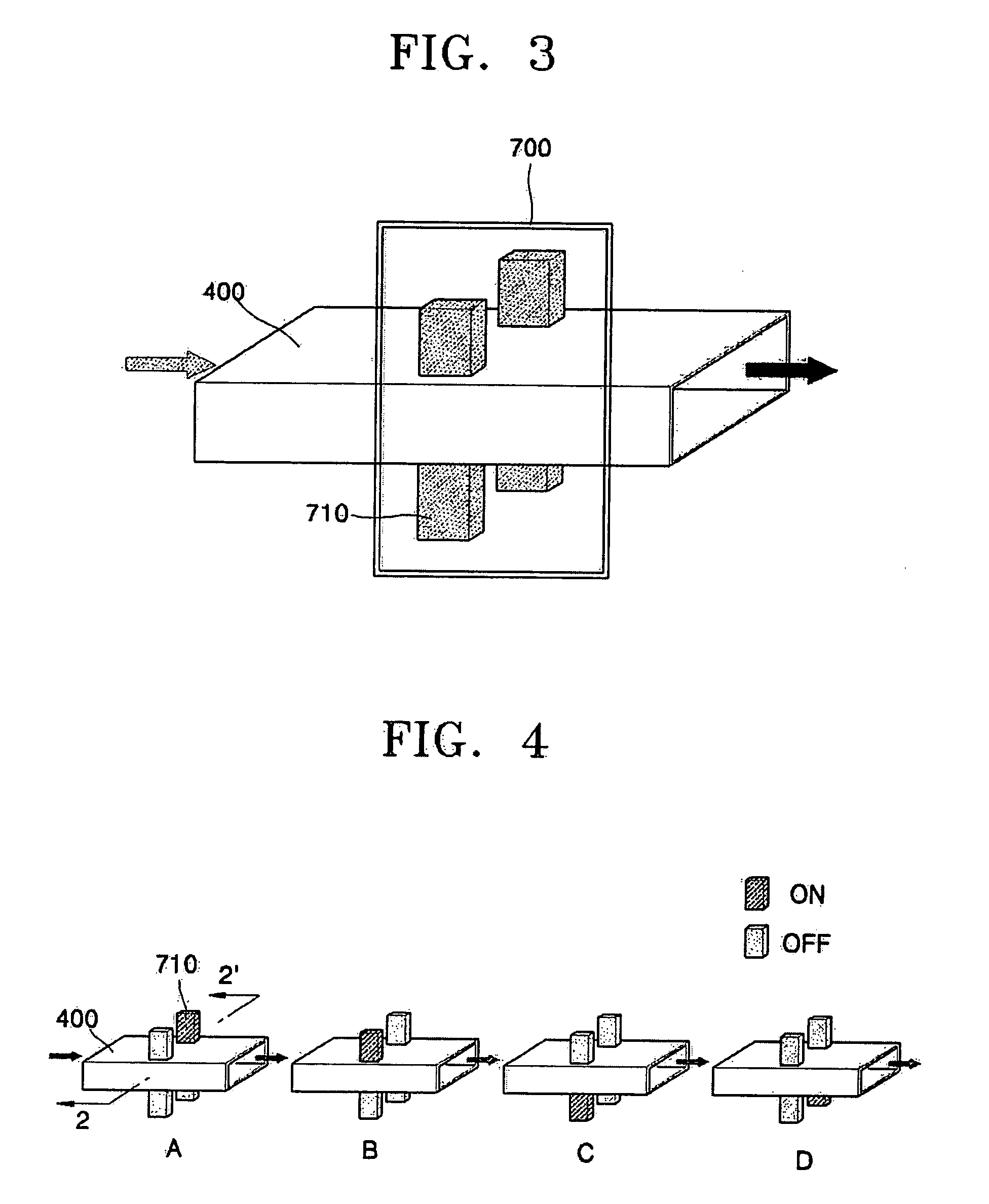

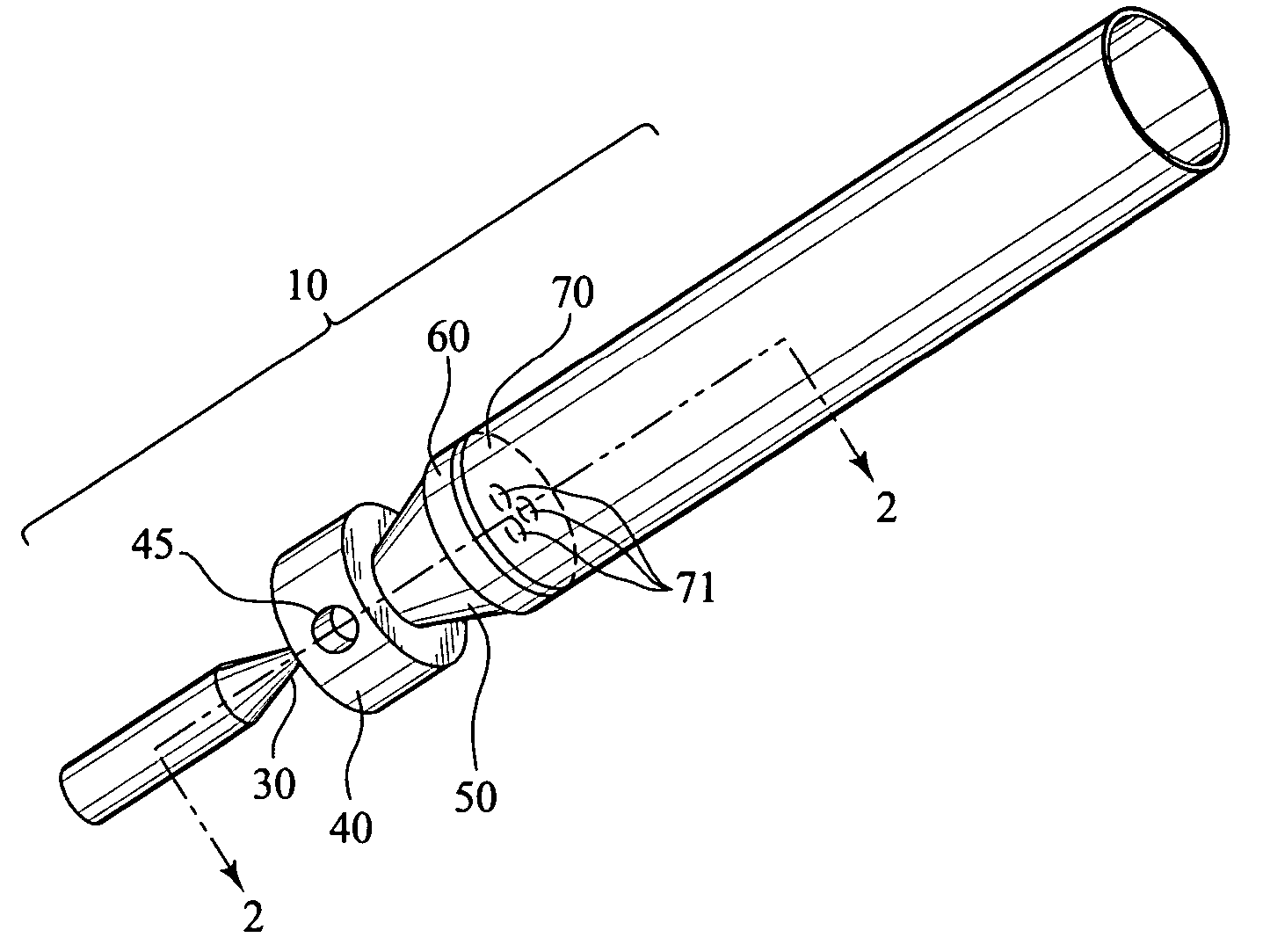

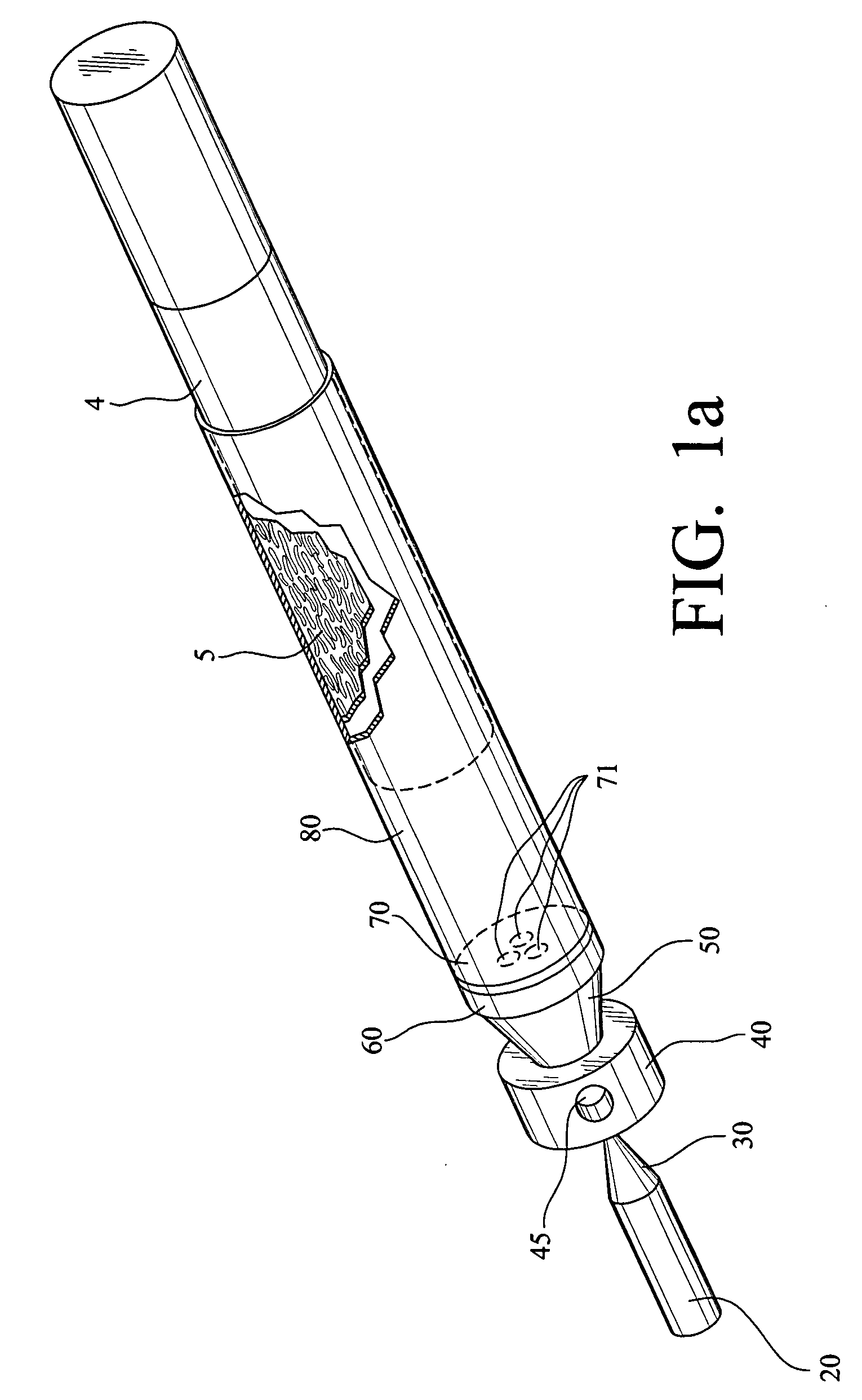

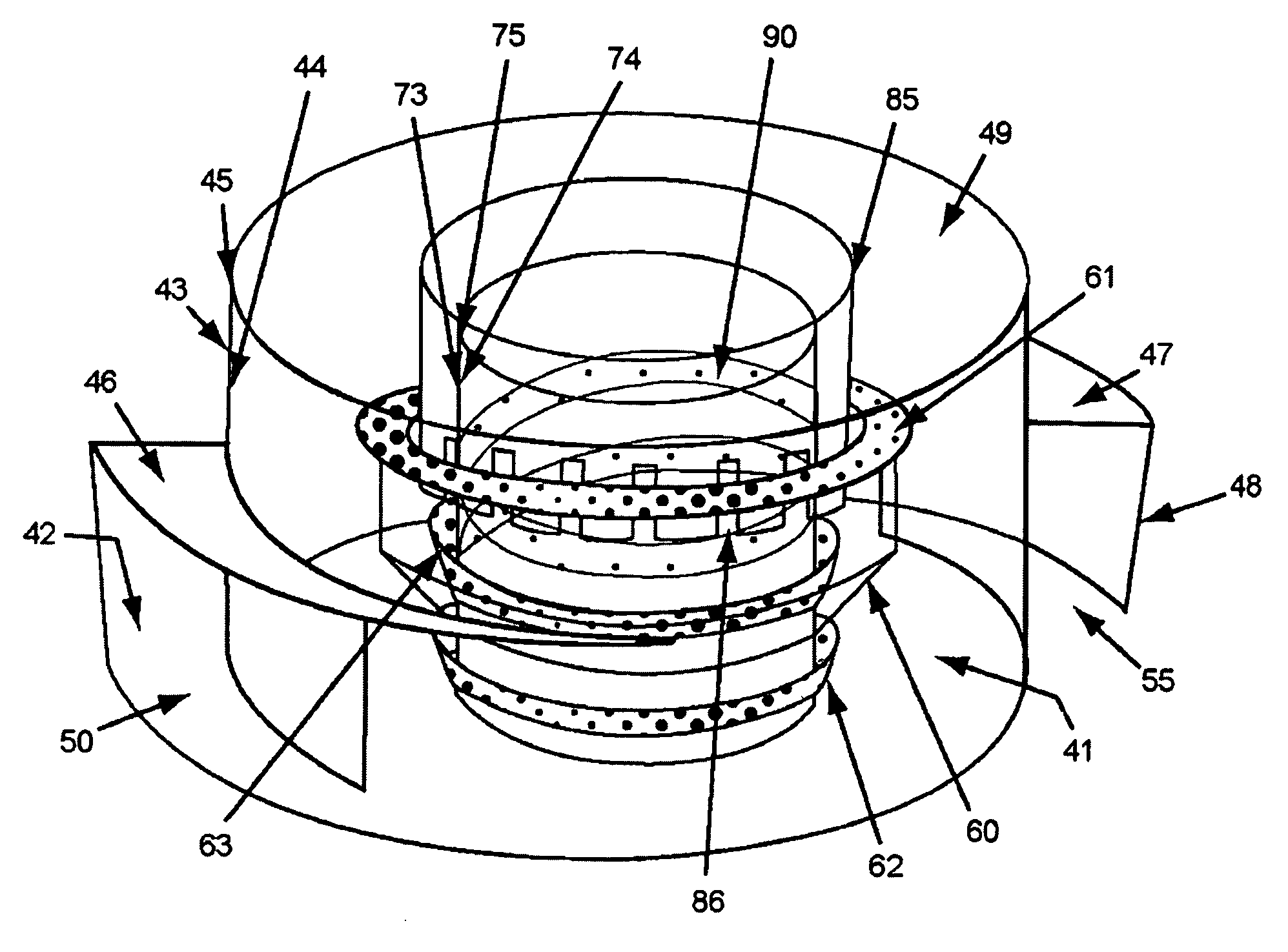

Intra-aortic renal delivery catheter

InactiveUS7063679B2Significant mixingIncreased taper pitchGuide needlesStentsPuncture WoundBoth kidneys

A renal flow system and method direct fluid into renal arteries from a location within the aorta. A renal flow assembly has a tapered tube that is adjustable between a radially collapsed condition for delivery to the location through a delivery sheath and a radially expanded condition that divides aortic flow into exterior and interior paths. The tube's wall is made from a sheet of flexible material, such as PTFE or ePTFE. Two, nickel-titanium rings radially support the tube's ends and are connected by a longitudinal spine support. A fluid delivery assembly injects drug to flow along the exterior flow path and the tubular wall directs the agent into the renal artery ostium. The tube's taper has localized shape for circumferential agent mixing to infuse both kidneys' renals. The flow assembly allows an interventional device, e.g. delivery catheter, to advance across the location while directing blood into the renals and perfusing downstream circulation. The renal flow assembly and distal device are used within a common guide sheath through a single puncture wound. Vasodilators, antioxidants, or diuretics are delivered to the kidneys to treat / prevent RCN, CHF, or ARF.

Owner:ANGIODYNAMICS INC

Methods for manipulating droplets by electrowetting-based techniques

InactiveUS20060054503A1Improve controllabilityImprove accuracySludge treatmentShaking/oscillating/vibrating mixersElectricityEngineering

Methods are provided for manipulating droplets. The methods include providing the droplet on a surface comprising an array of electrodes and a substantially co-planer array of reference elements, wherein the droplet is disposed on a first one of the electrodes, and the droplet at least partially overlaps a second one of the electrodes and an intervening one of the reference elements disposed between the first and second electrodes. The methods further include activating the first and second electrodes to spread at least a portion of the droplet across the second electrode and deactivating the first electrode to move the droplet from the first electrode to the second electrode.

Owner:DUKE UNIV

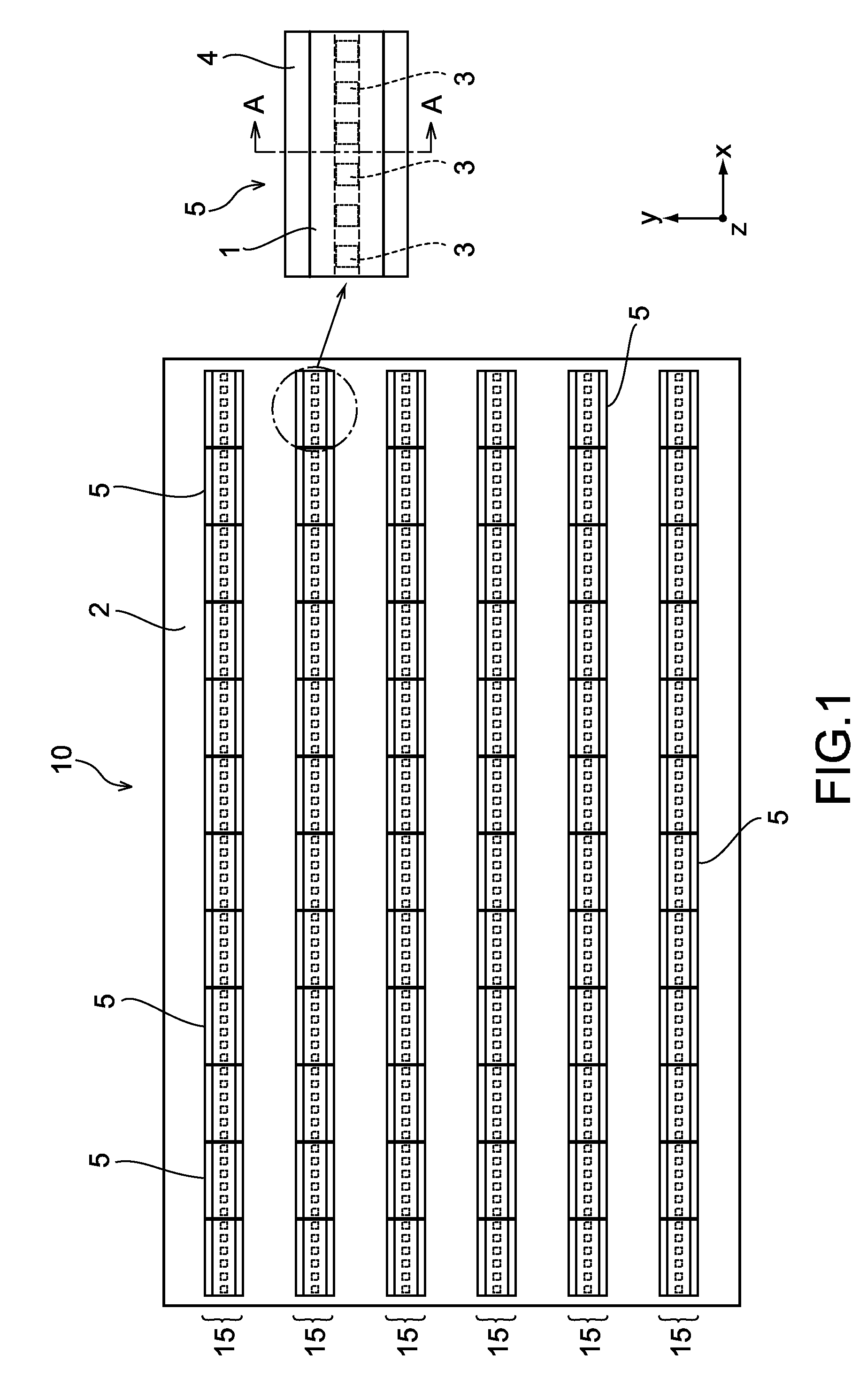

Display backlight with improved light coupling and mixing

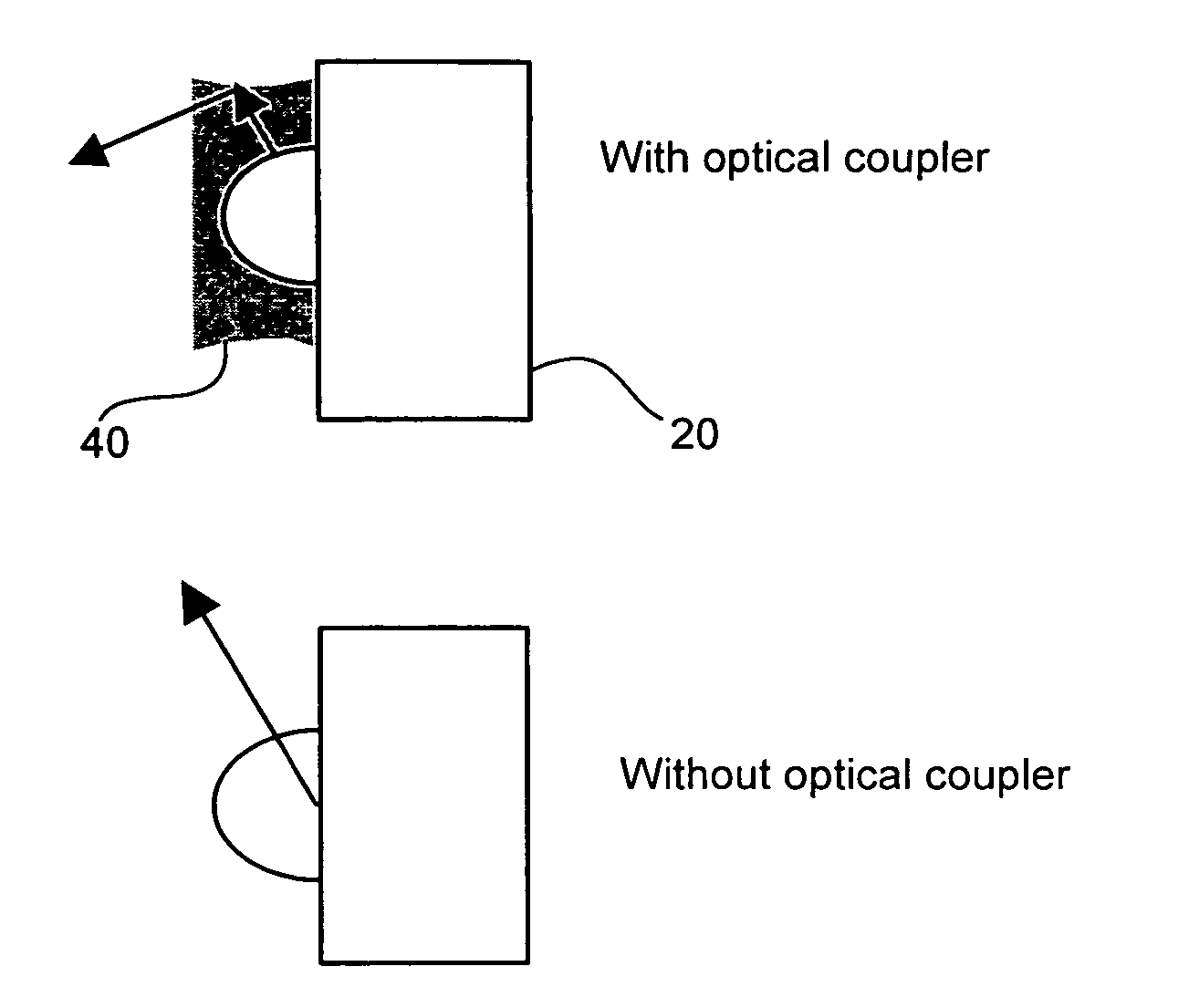

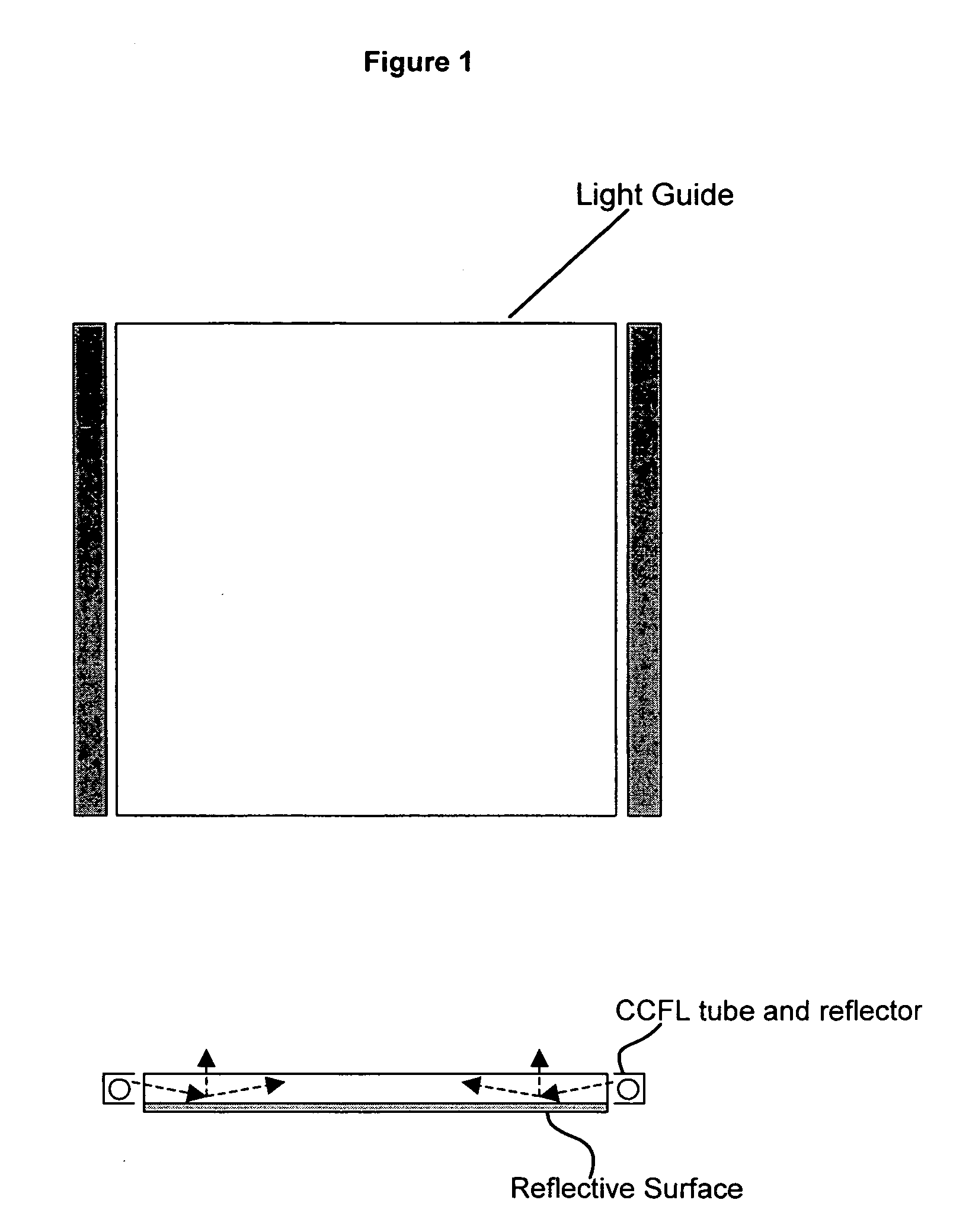

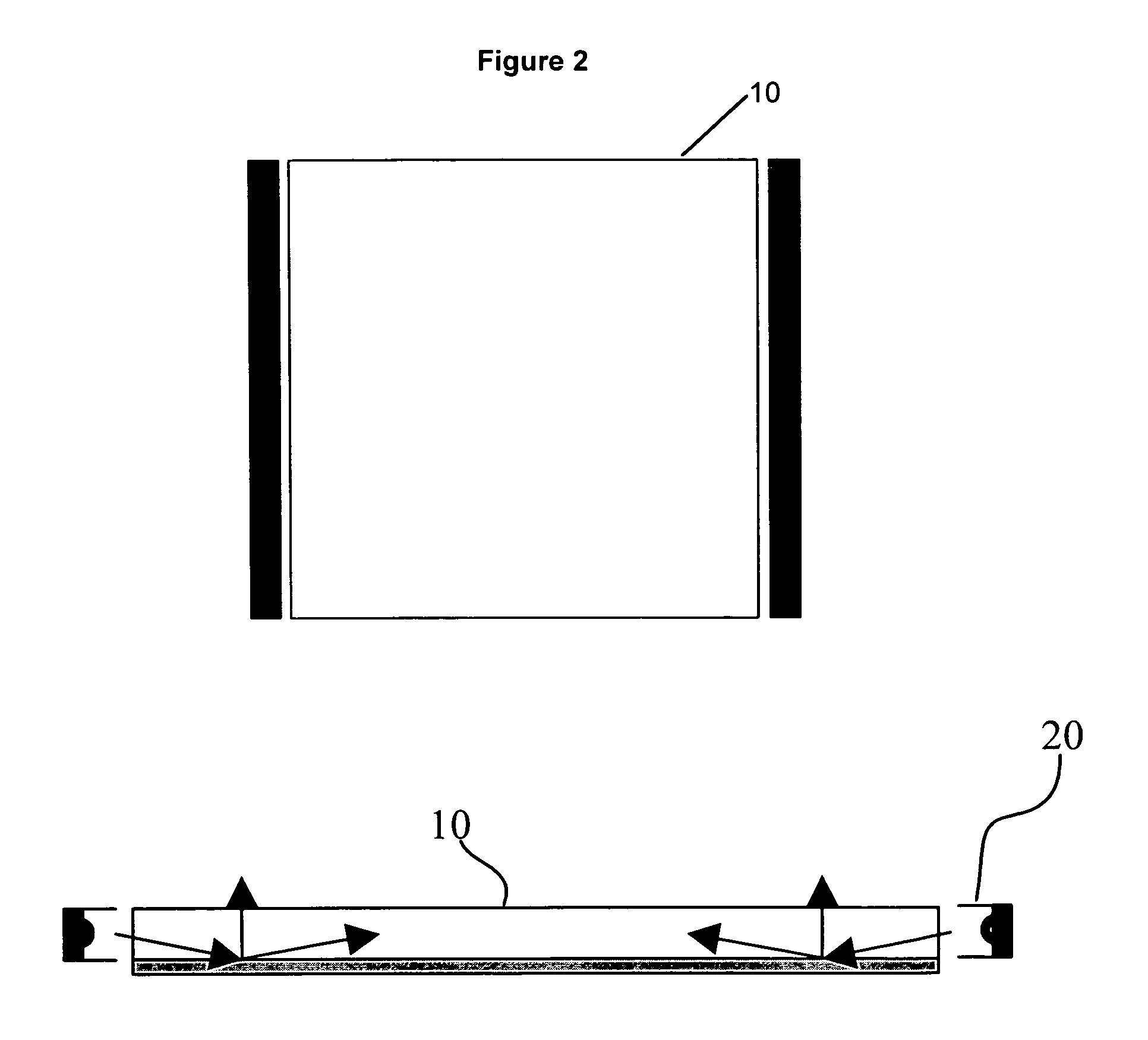

ActiveUS20070081360A1Enhanced couplingWell mixedIlluminated signsOptical light guidesLight guideDisplay device

A display backlight assembly providing improved optical coupling between a solid state light source and a display optical light guide. The assembly includes an optical coupler to couple the solid state light source and display optical light guide together. In addition, the optical coupler may include a light mixing element for improved mixing of the multi-colored or mono-chromatic light produced by the solid state light source.

Owner:LIGHTING SCI GROUP

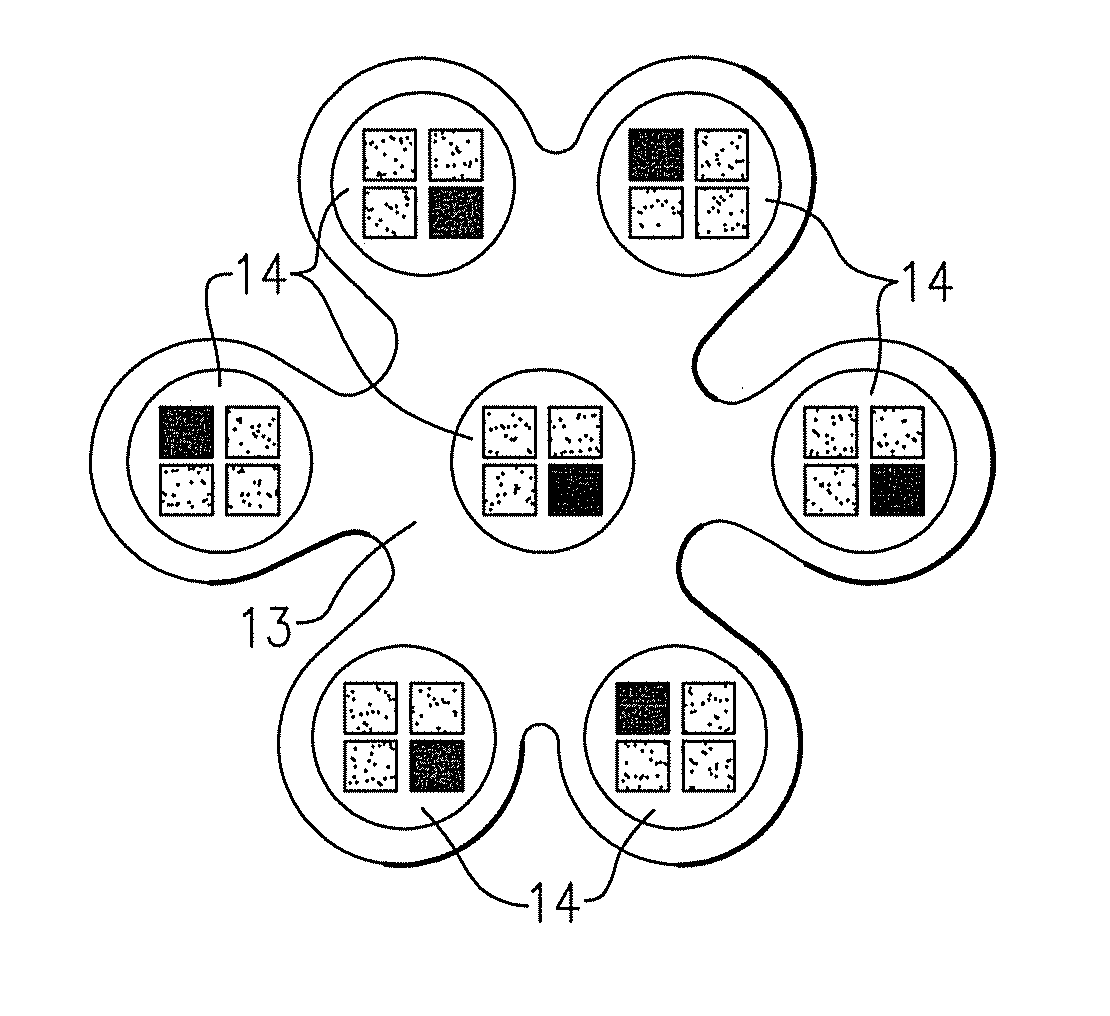

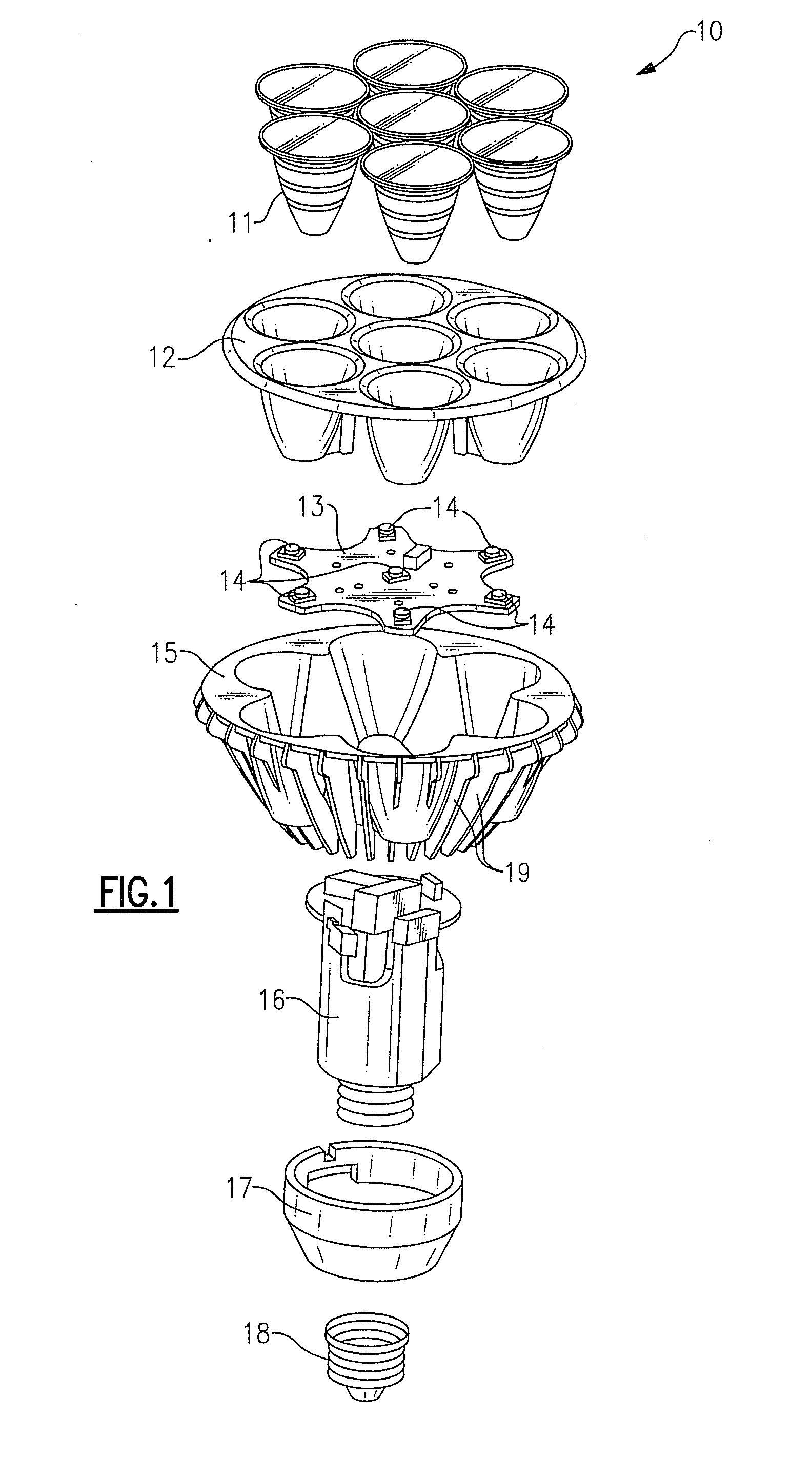

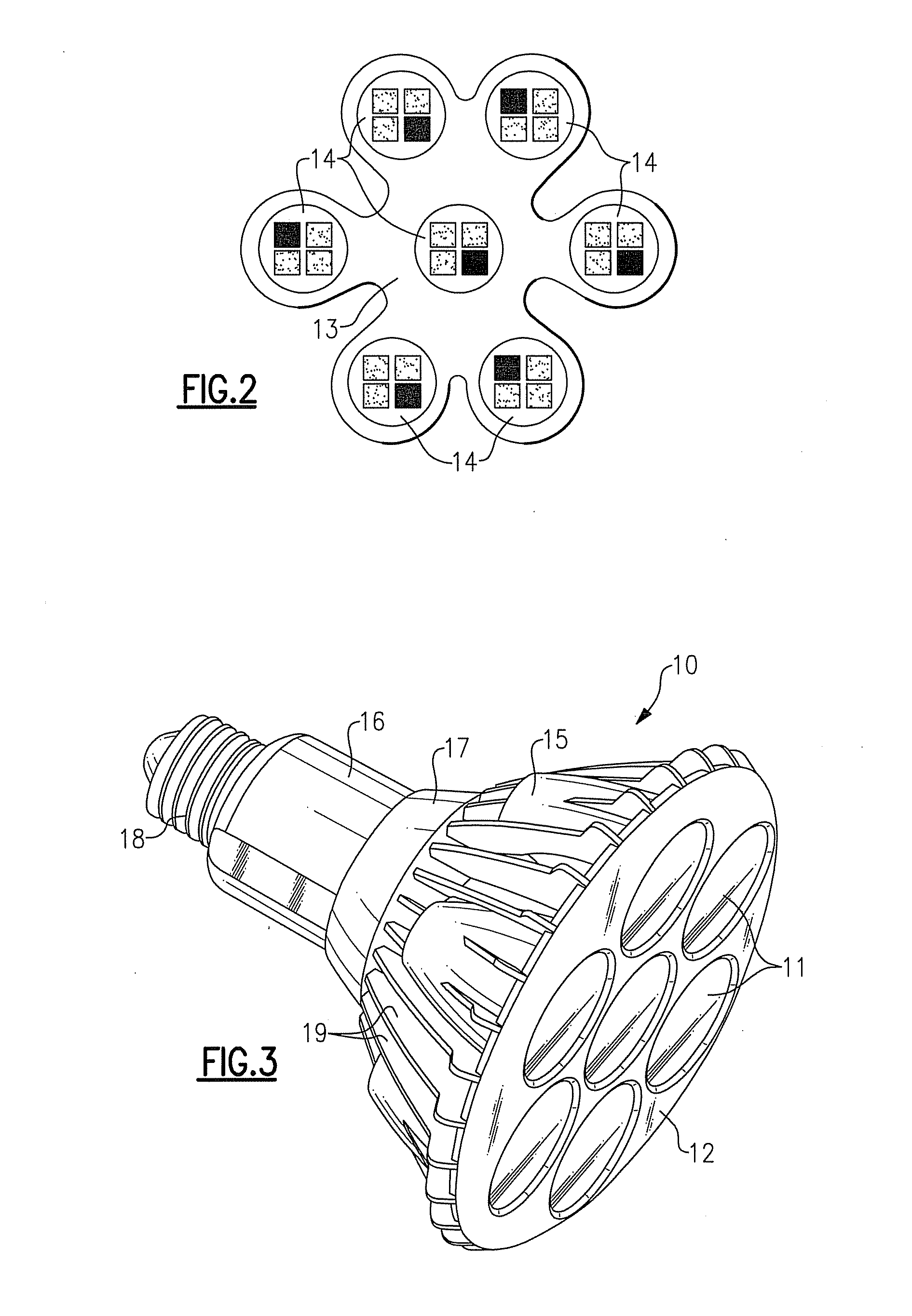

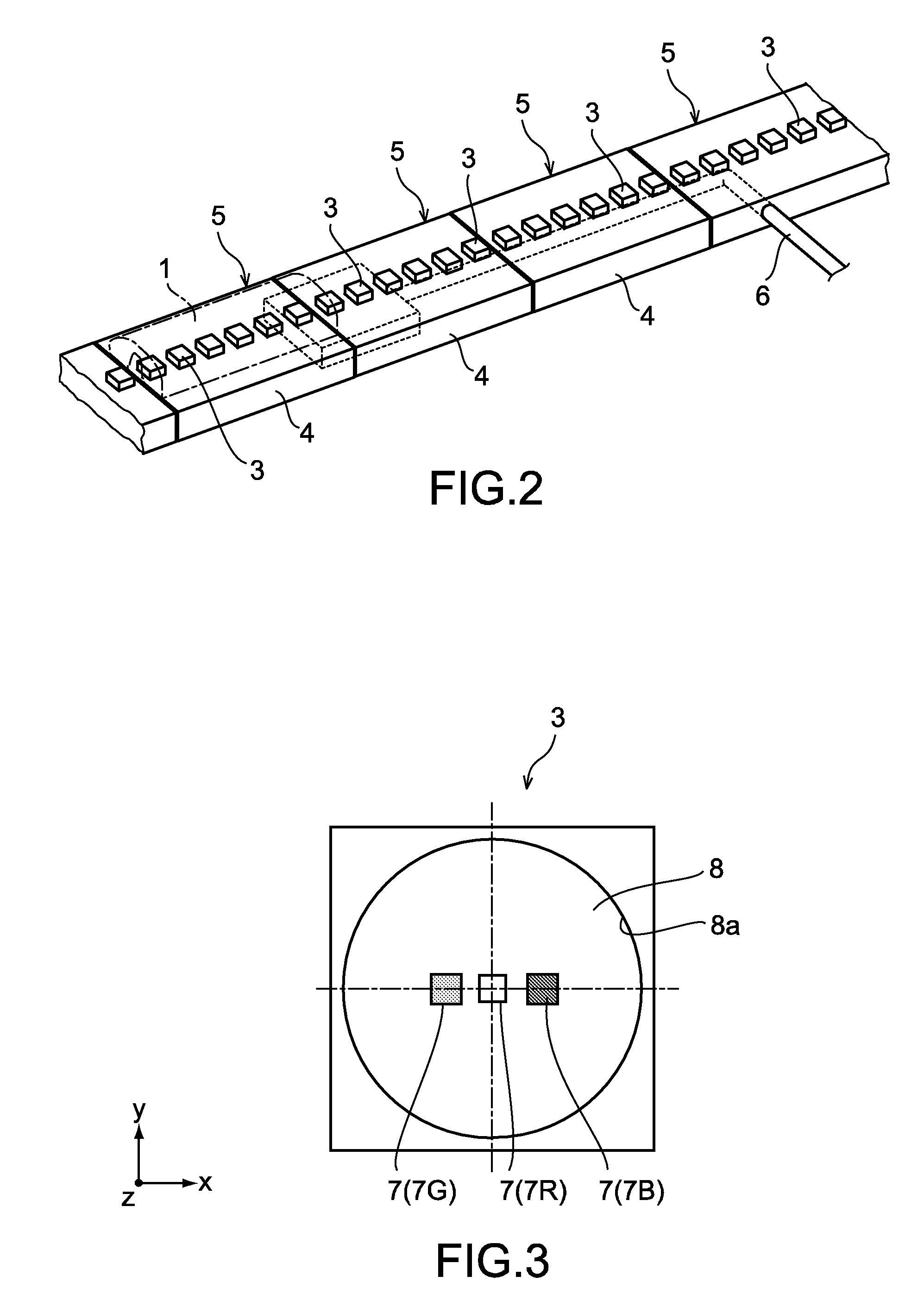

Lighting device with multi-chip light emitters, solid state light emitter support members and lighting elements

ActiveUS20110182065A1Improve color mixingImprove color uniformityPlanar light sourcesLight source combinationsEffect lightHue

A lighting device in which a solid state light emitter in a first multi-chip light emitter is spatially offset relative to a solid state light emitter in a second multi-chip light emitter. A lighting device comprising first, second and third multi-chip light emitters, in which any solid state light emitter in the second multi-chip light emitter that is spatially offset relative to a first solid state light emitter on the first multi-chip light emitter by less than 10 degrees emits light of a hue that differs from the hue of light emitted by the first solid state light emitter by more than seven MacAdam ellipses. A solid state light emitter support member comprising a center region and at least first, second and third protrusions extending from the center region. A lighting device comprising at least a first housing member, and means for emitting substantially uniform light.

Owner:IDEAL IND LIGHTING LLC

Direct compression metformin hydrochloride tablets

InactiveUS6117451AGood compressibilityImproved flowabilityPowder deliveryBiocideMetformin HydrochlorideHigh doses

Metformin Hydrochloride (herein referred to as metformin HCl) that may be 98.5%-100% pure is a high dose drug capable of being directly compressed with specific excipients into tablets having desired, hardness, disintegrating ability, and acceptable dissolution characteristics. Metformin HCl is not inherently compressible and thus presents formulation problems. Excipients used in the formulation enhance the flow and compaction properties of the drug and tableting mix. Optimal flow contributes to uniform die fill and weight control. The binder used ensures sufficient cohesive properties that allow metformin HCl to be compressed using the direct compression method. The tablets produced provide an acceptable in-vitro dissolution profile.

Owner:PHARMALOGIX

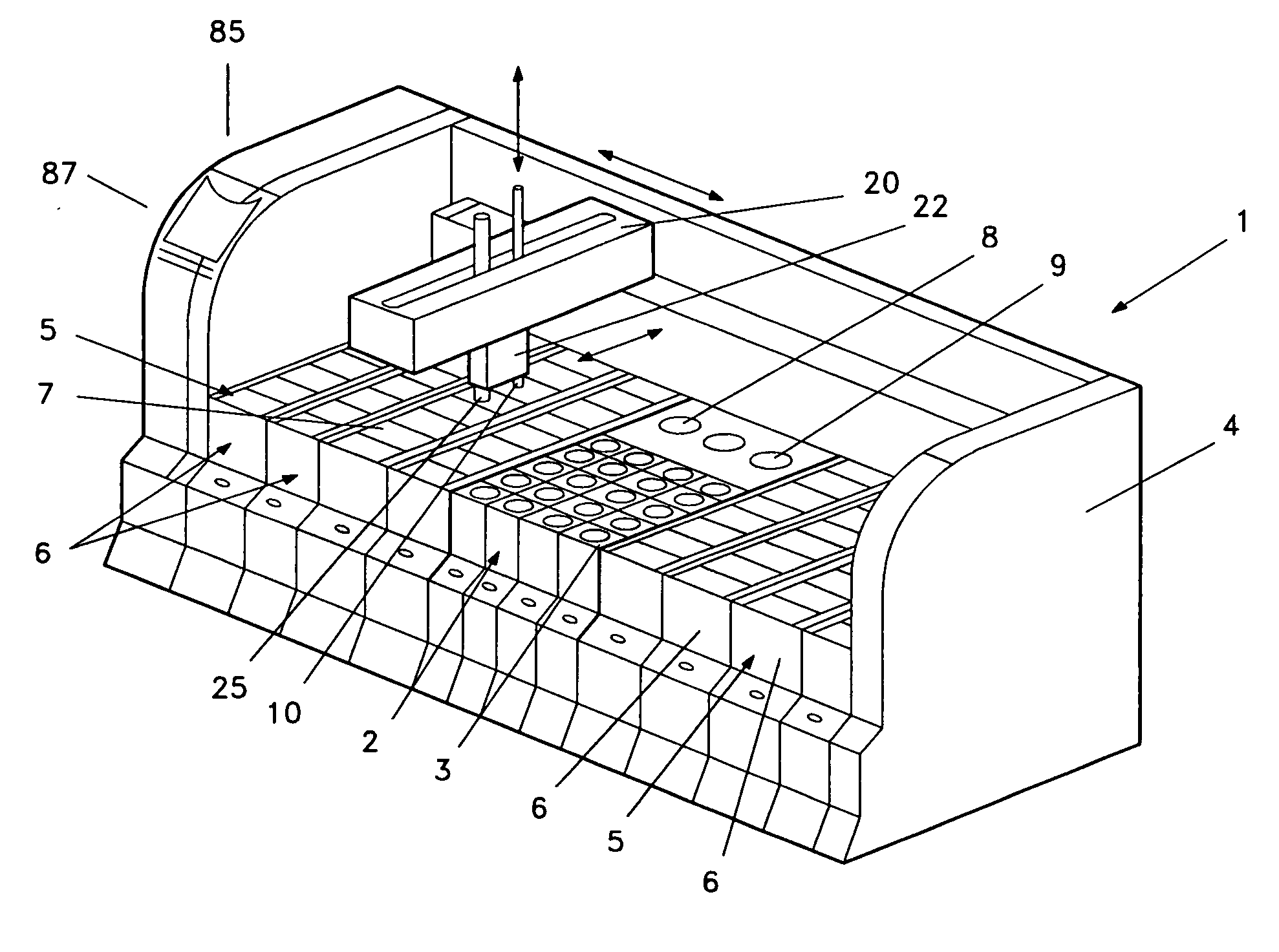

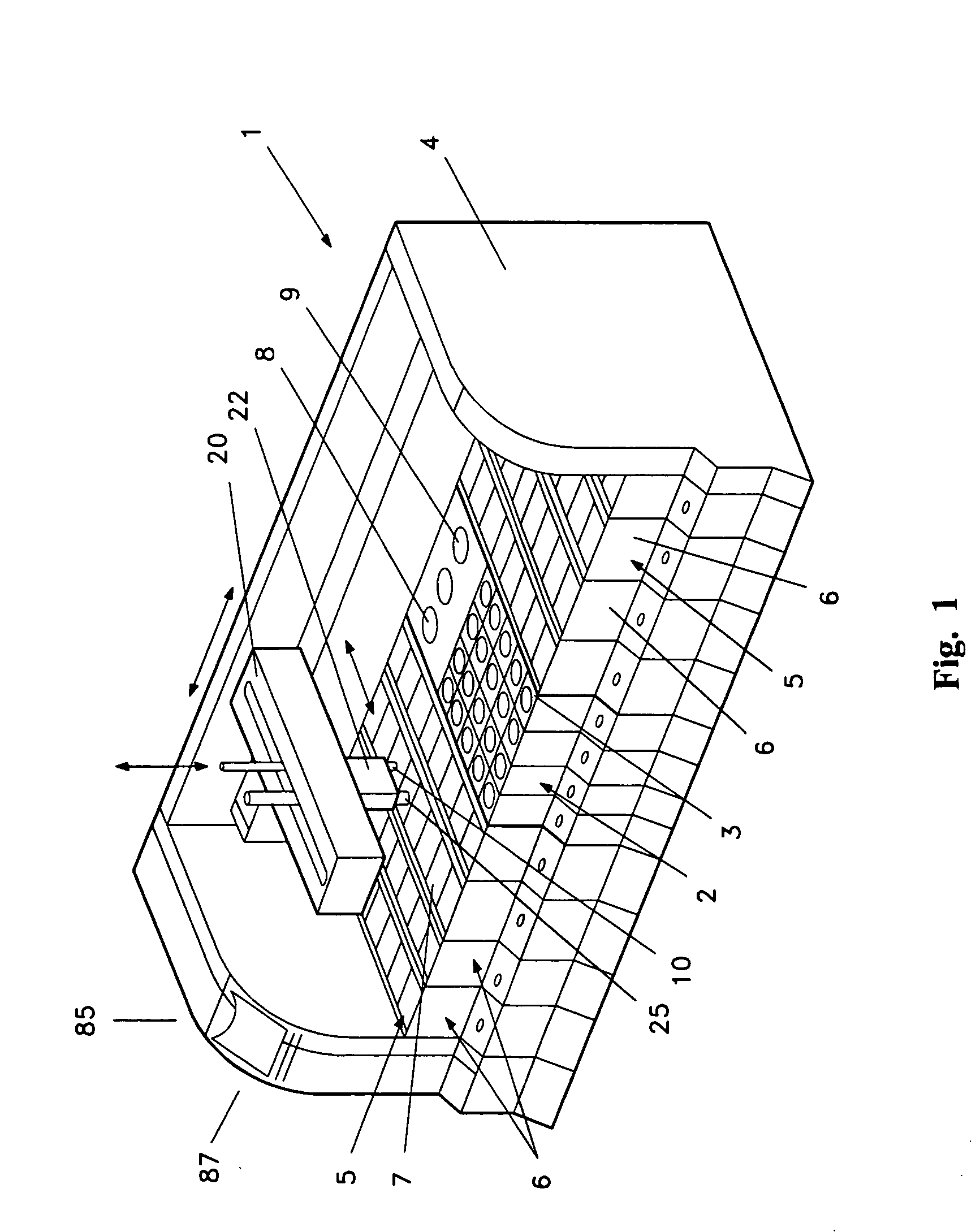

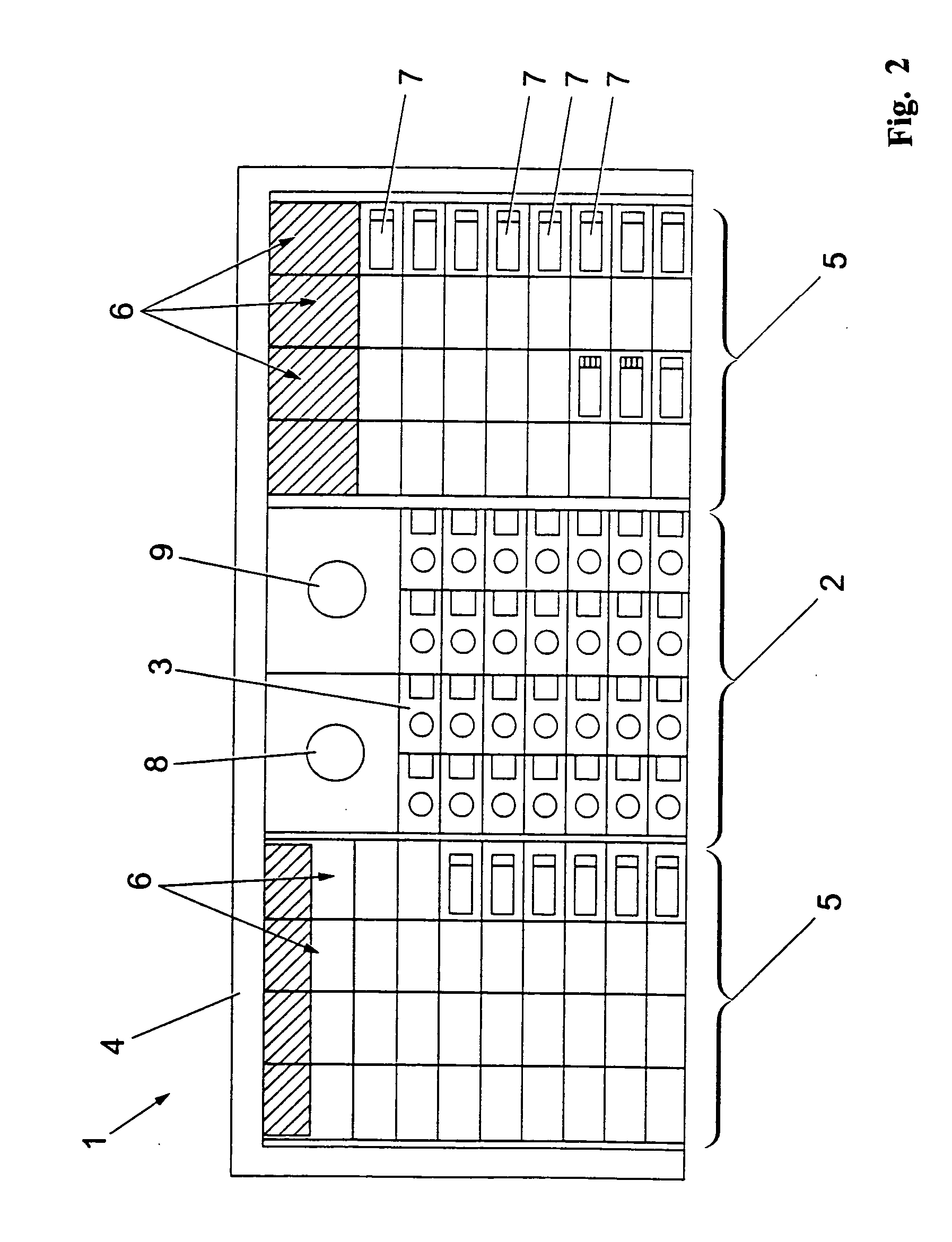

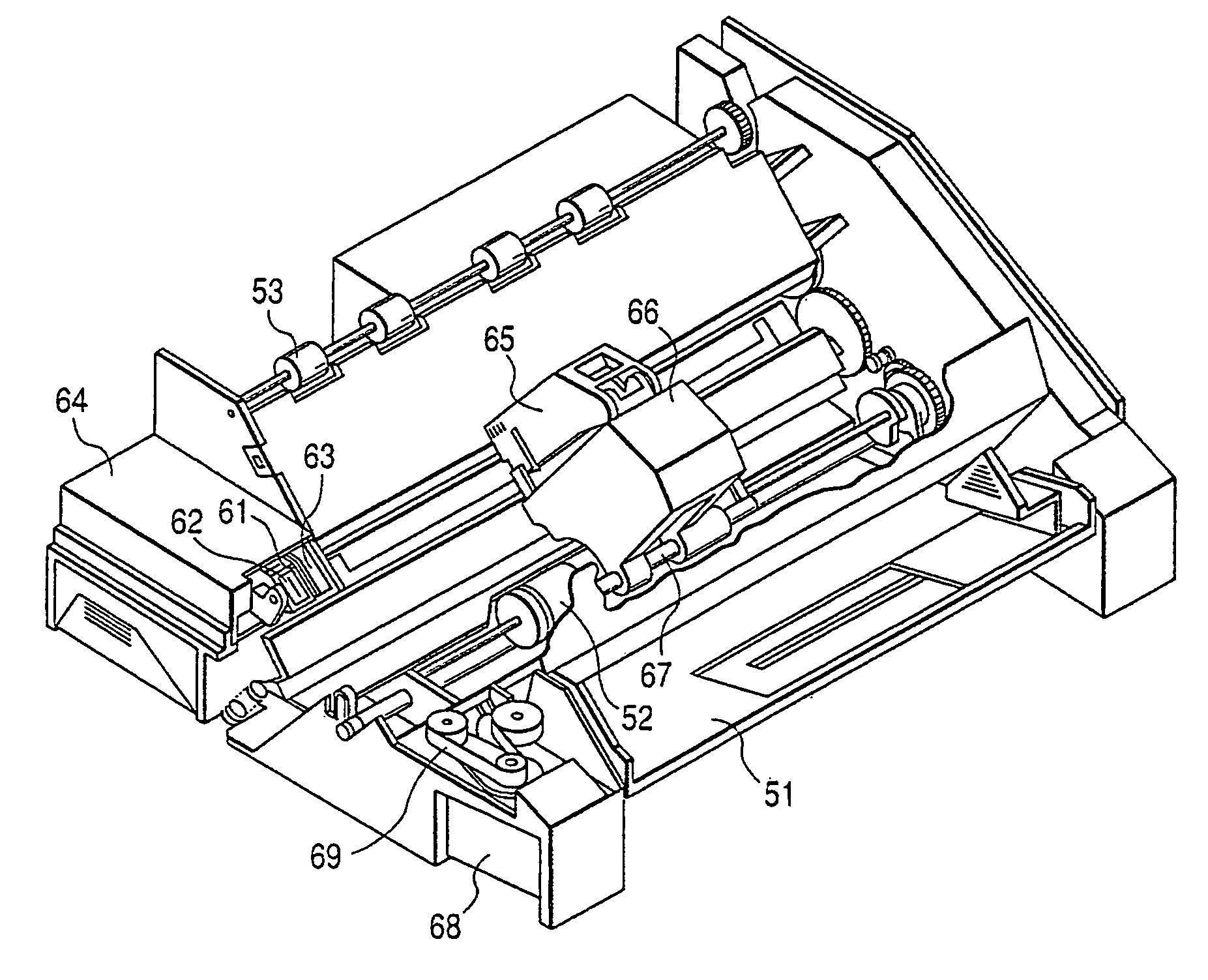

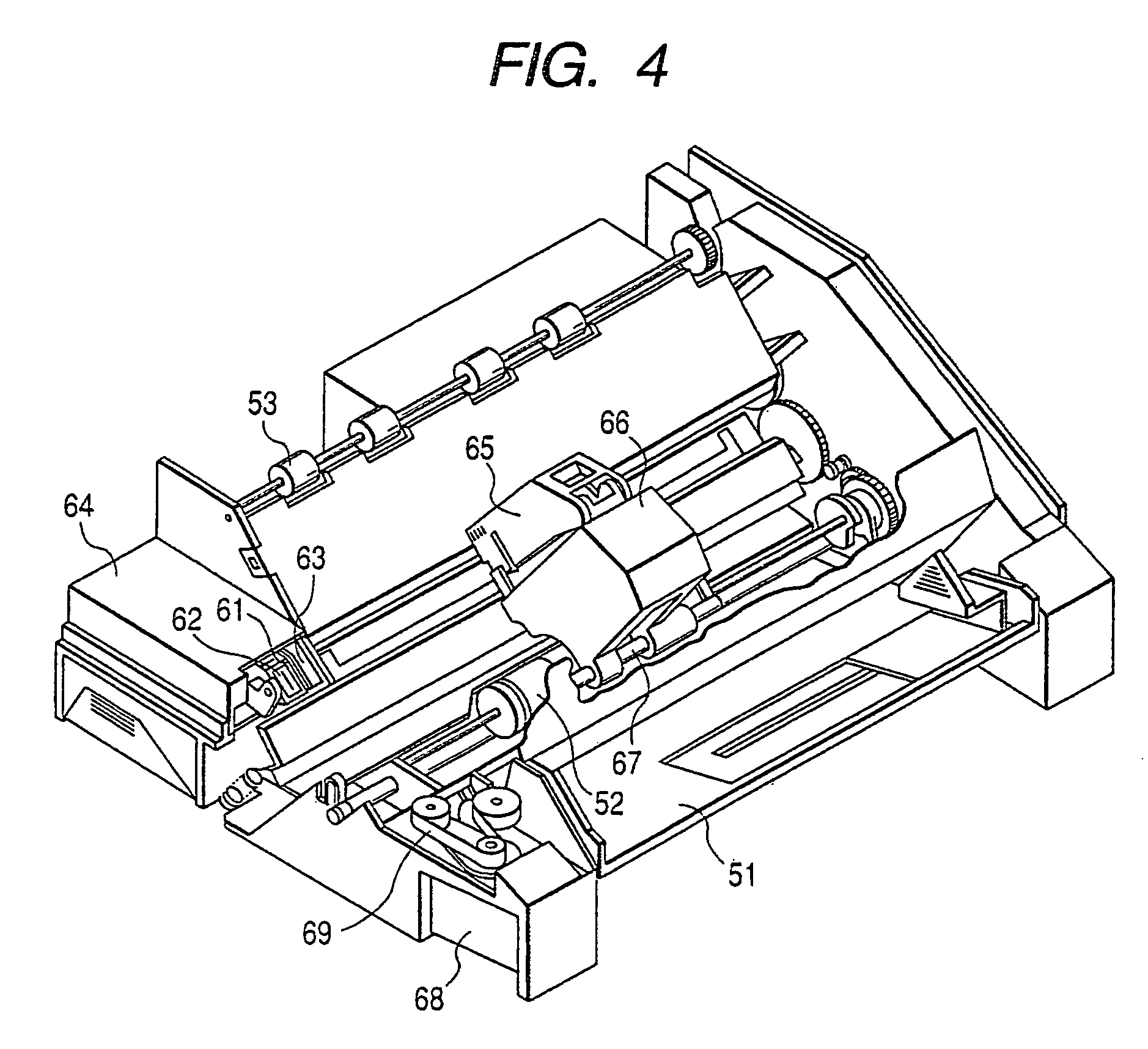

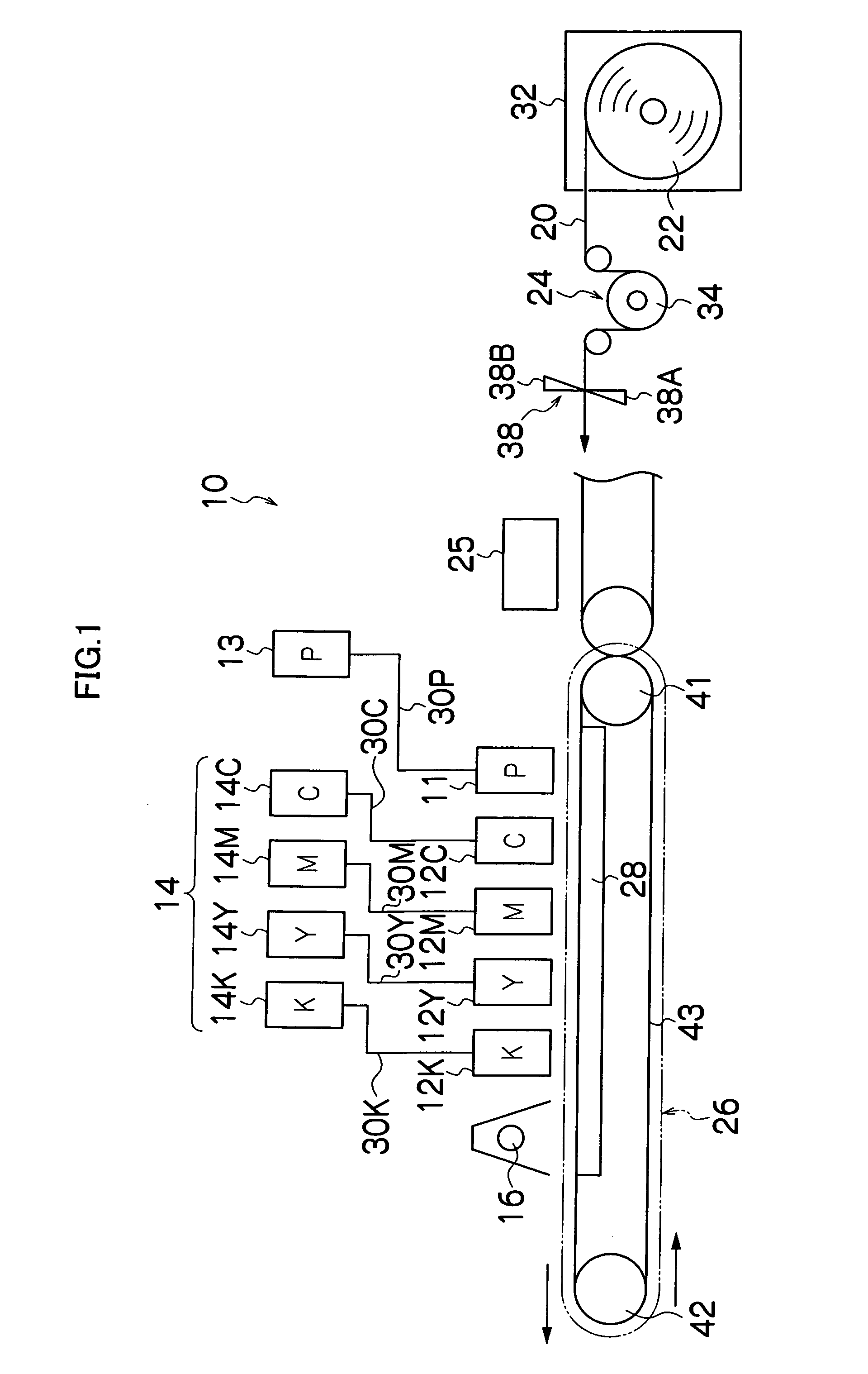

Automated sample processing apparatus and a method of automated treating of samples and use of such apparatus

InactiveUS20040266015A1Quality improvementTimely controlLayered productsStatic/dynamic balance measurementEngineeringAutomatic processing

An automated staining apparatus and a method for treating samples arranged on a carrier is disclosed, in which portions of two or more selected reagents from a first station containing the reagents are collected individually by a robot arm handling a probe and dispensed in a mixing station of the apparatus. After mixing the reagents in the mixing station, e.g. by shaking or rotating the mixing cup containing the reagents, the reagent mixture is applied to selected samples by the robot arm and a probe.

Owner:DAKOAS

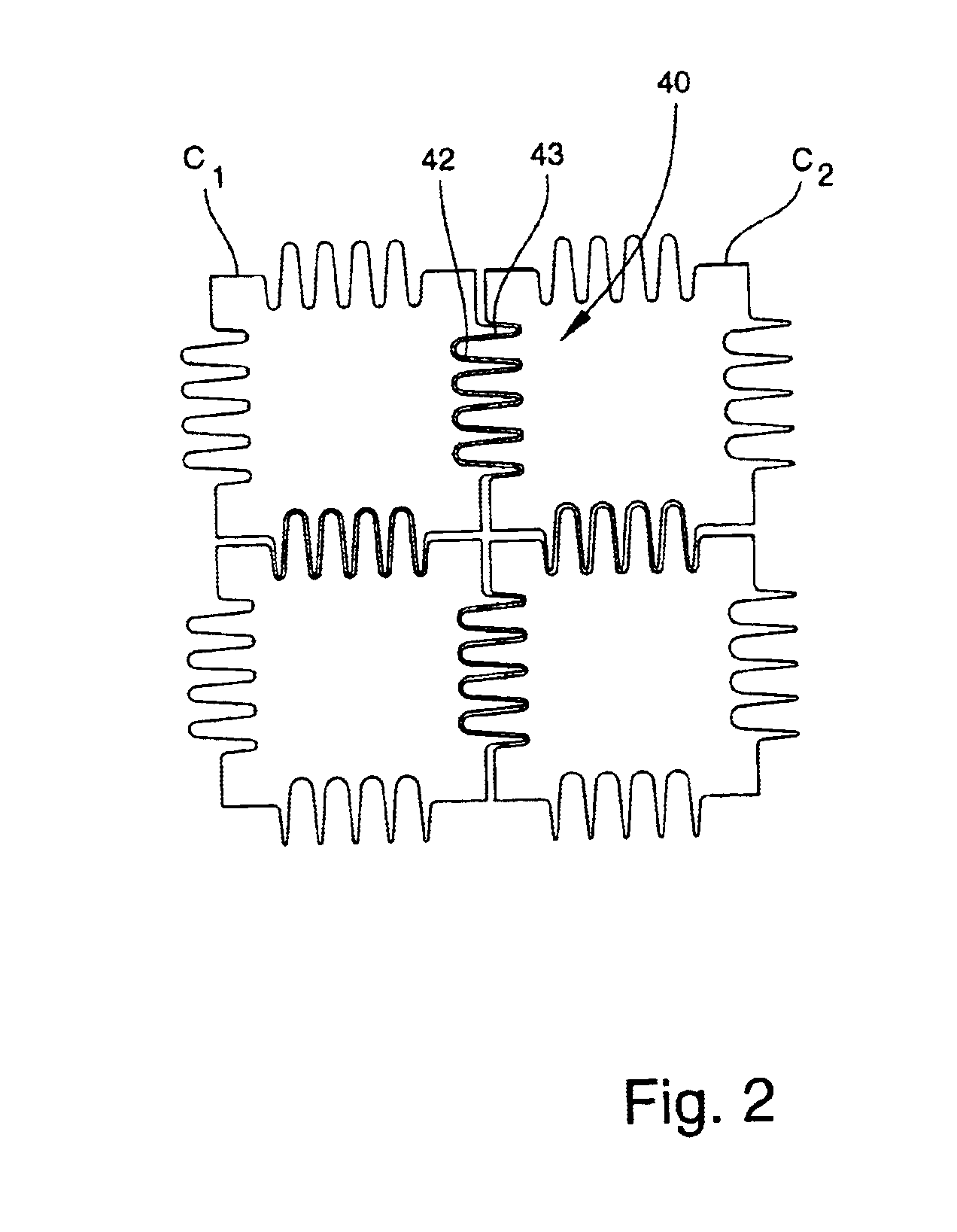

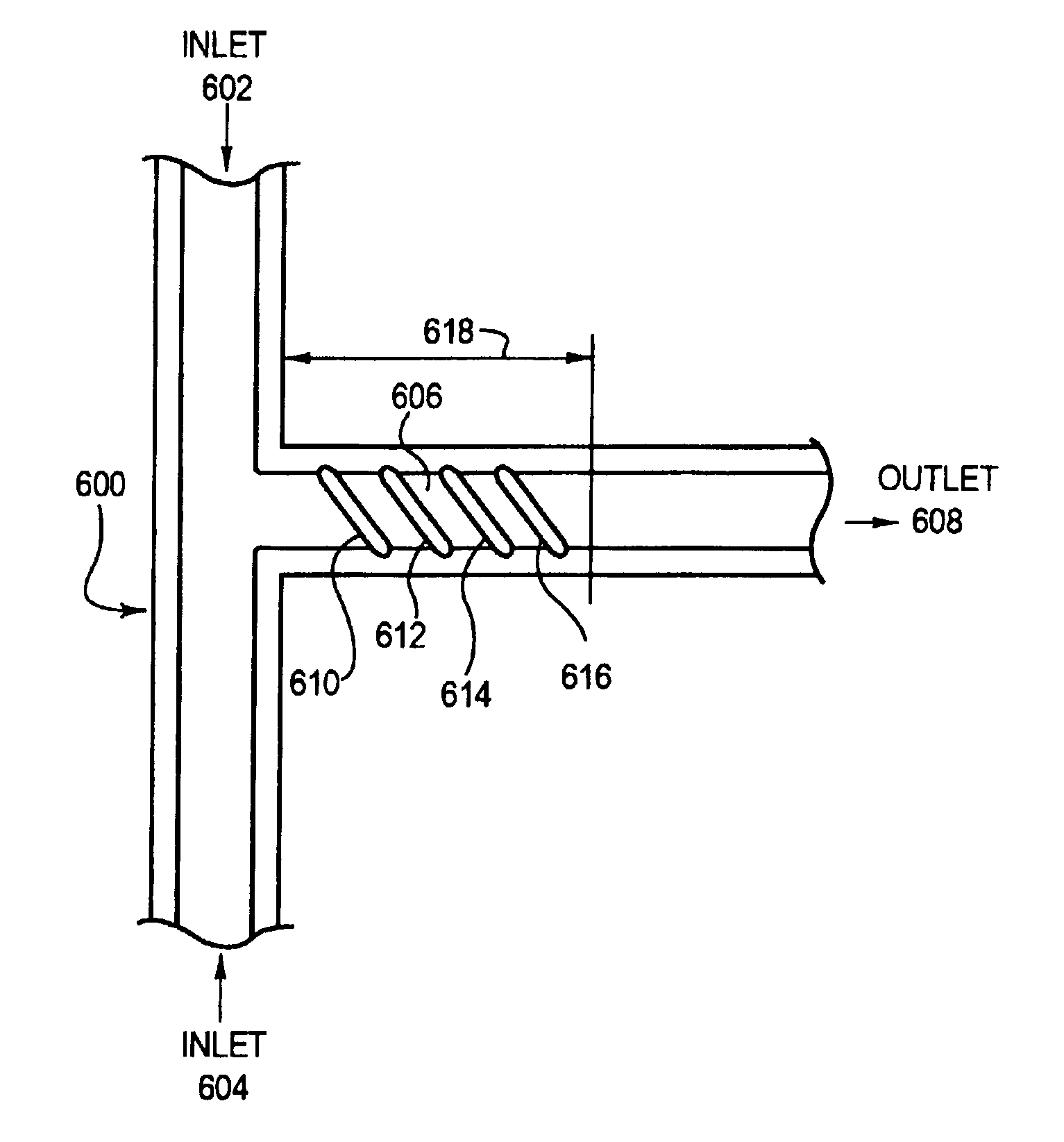

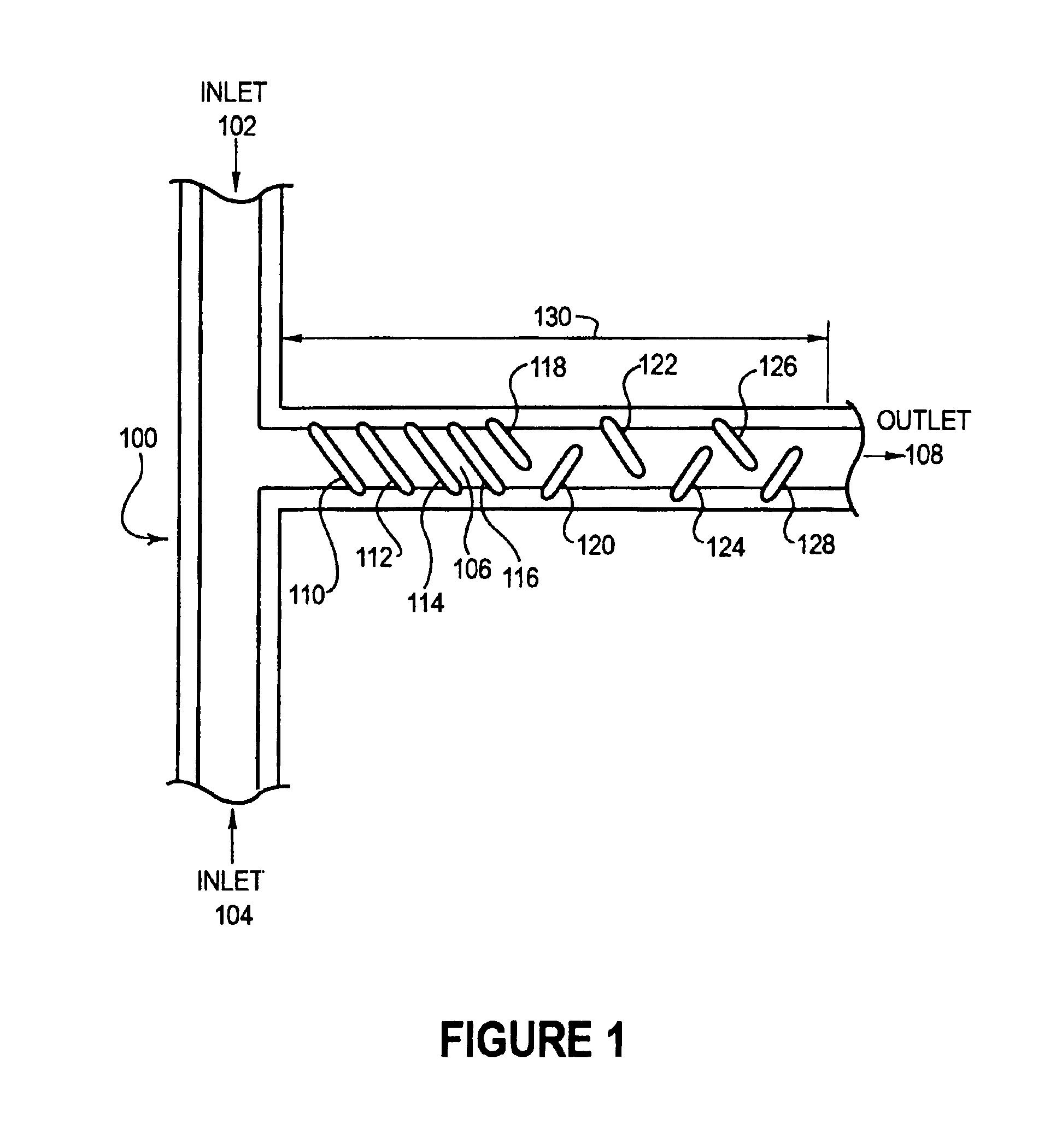

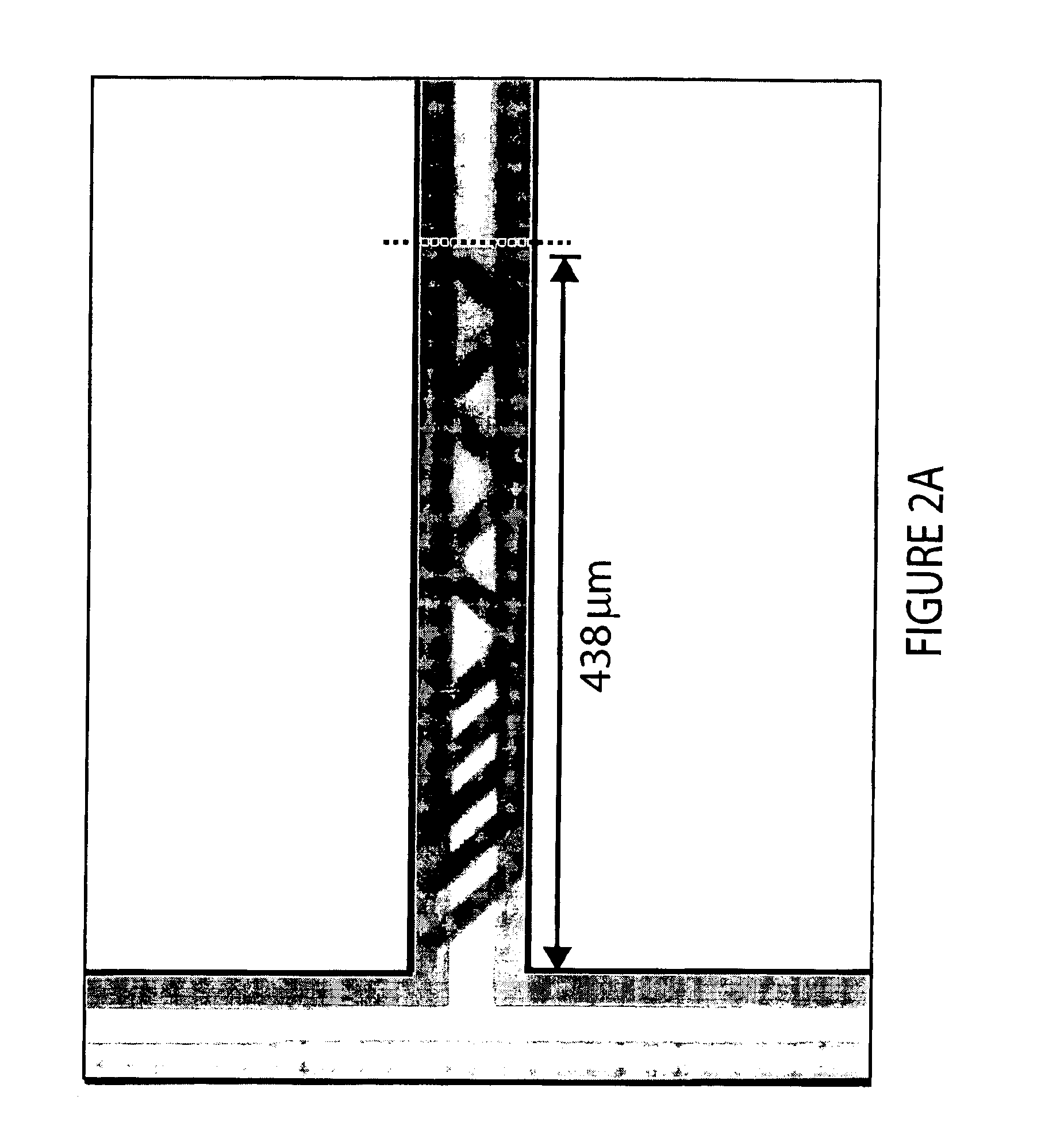

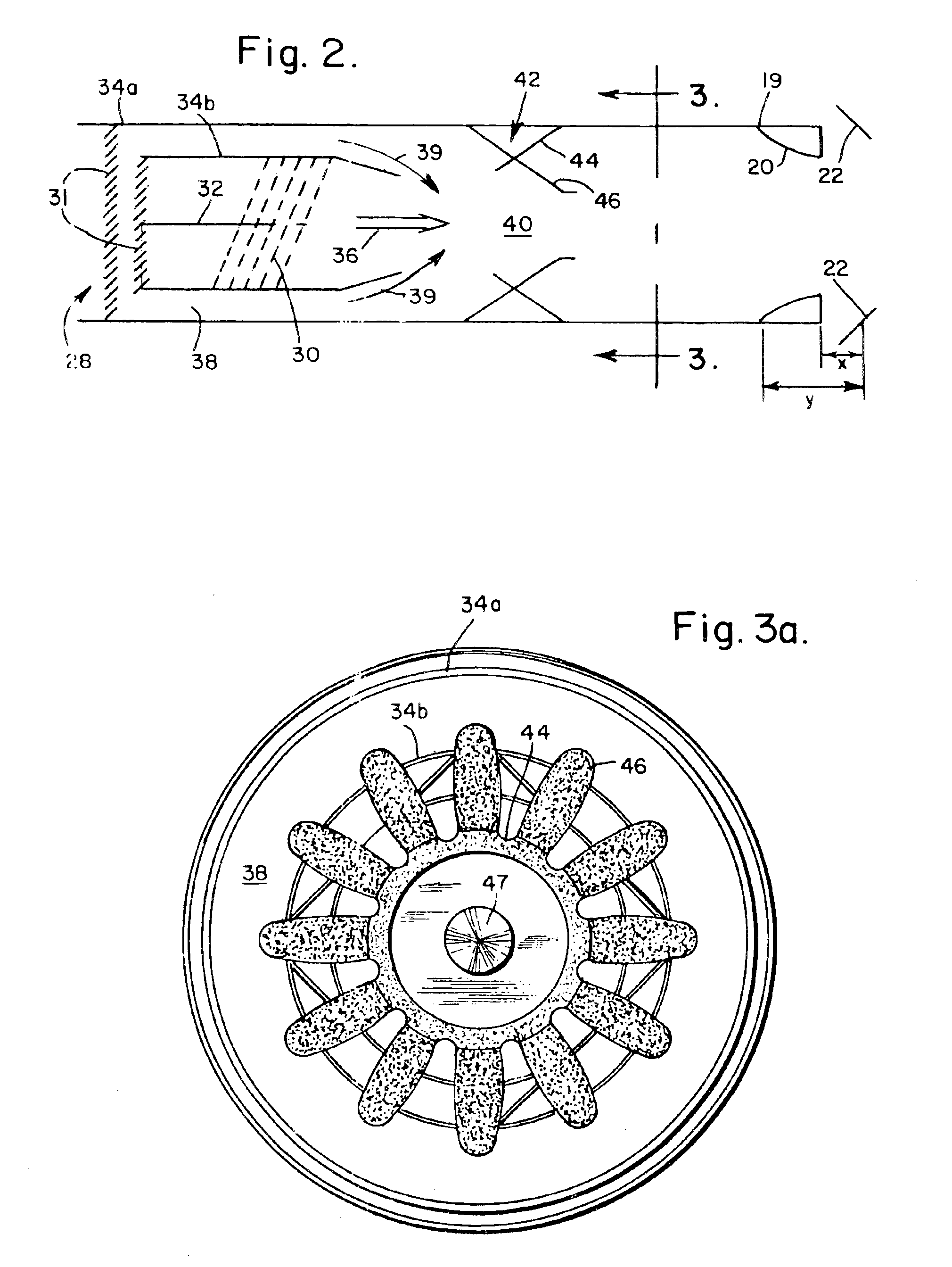

Method for microfluidic flow manipulation

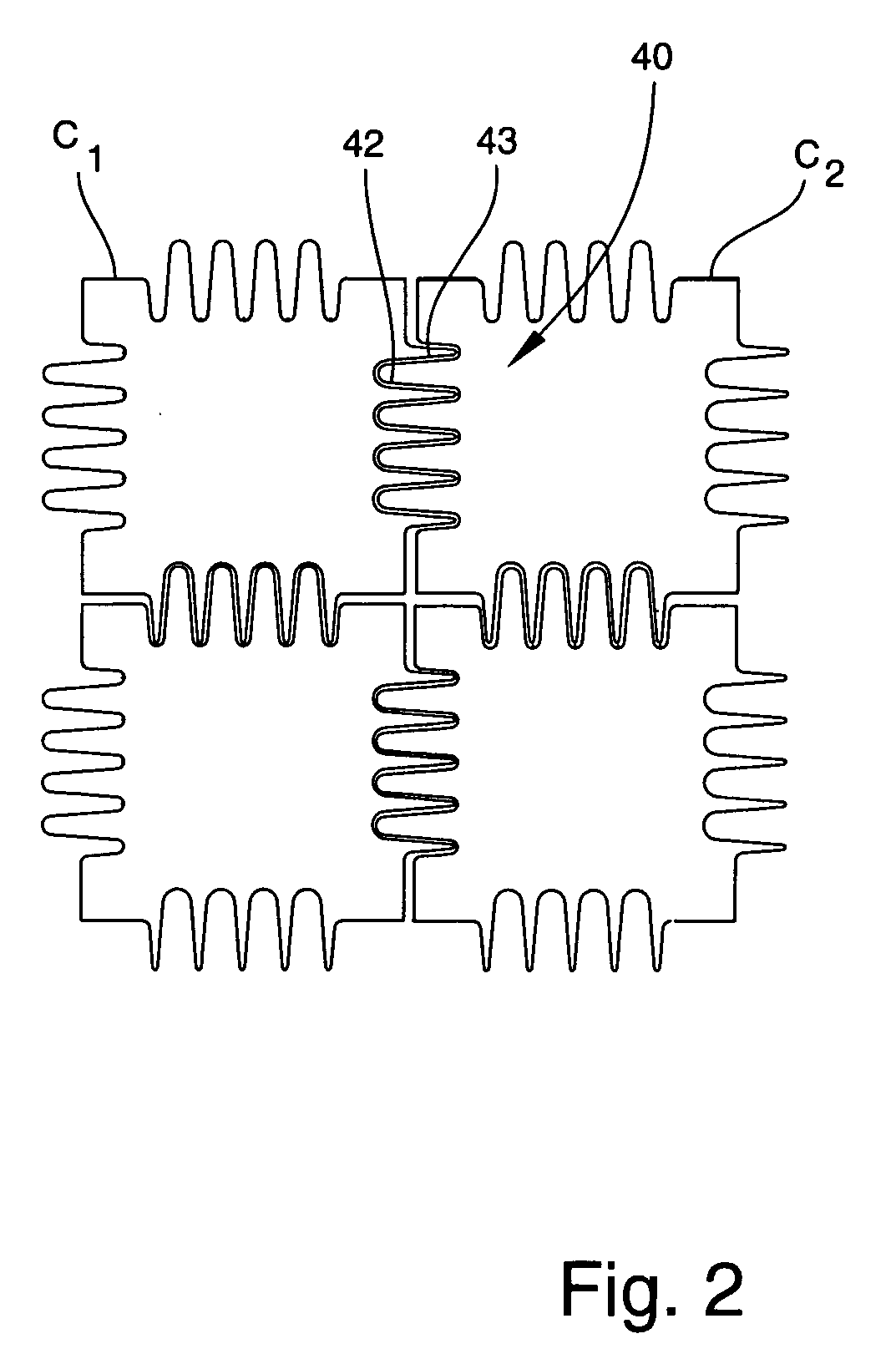

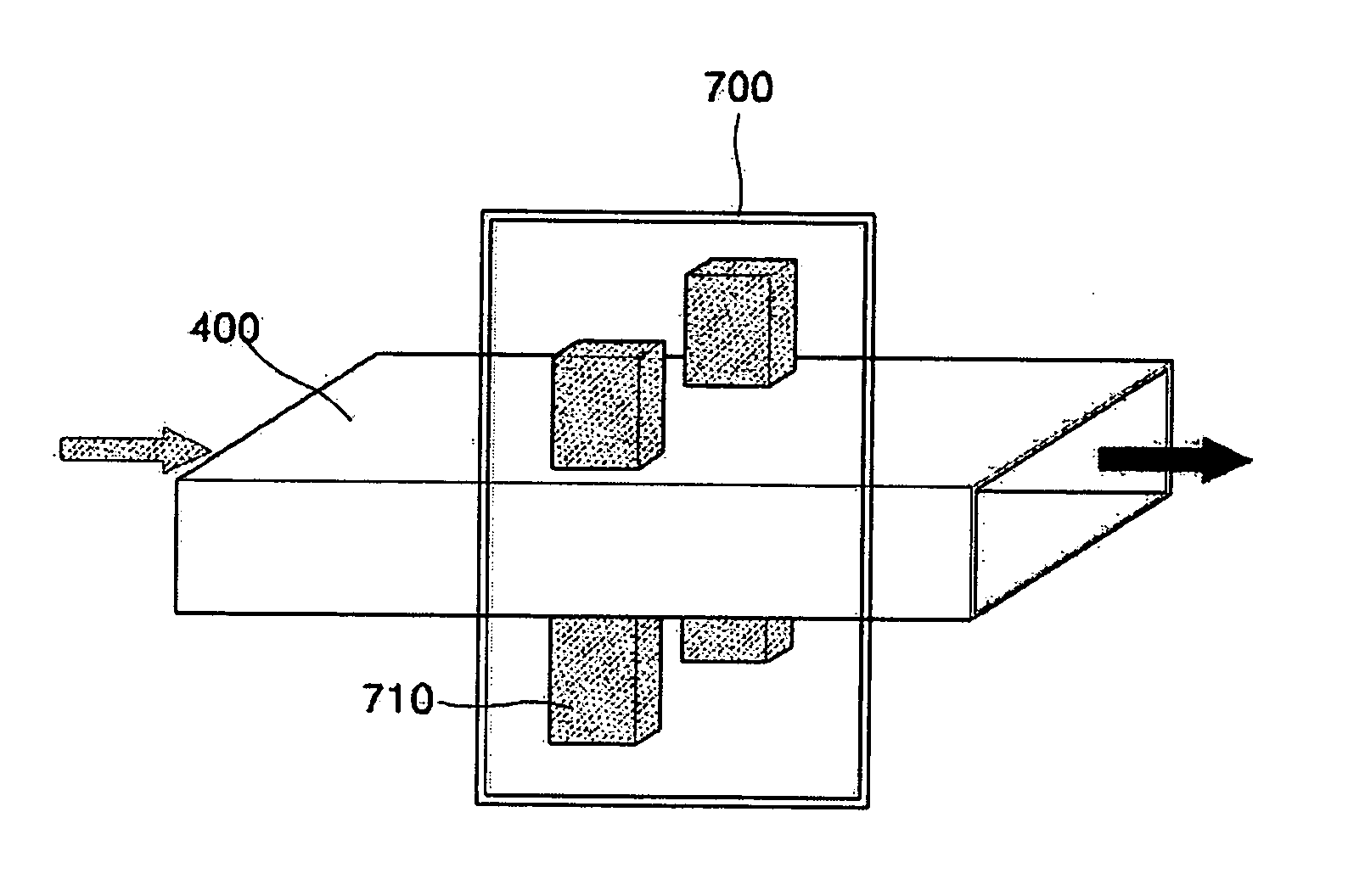

InactiveUS6907895B2Efficient mixingShorten the lengthFlow mixersOther chemical processesEngineeringPressure-driven flow

Disclosed is an apparatus and method for the mixing of two microfluidic channels wherein several wells are oriented diagonally across the width of a mixing channel. The device effectively mixes the confluent streams with electrokinetic flow, and to a lesser degree, with pressure driven flow. The device and method may be further adapted to split a pair of confluent streams into two or more streams of equal or non-equal concentrations of reactants. Further, under electrokinetic flow, the surfaces of said wells may be specially coated so that the differing electroosmotic mobility between the surfaces of the wells and the surfaces of the channel may increase the mixing efficiency. The device and method are applicable to the steady state mixing as well as the dynamic application of mixing a plug of reagent with a confluent stream.

Owner:COMMERCE UNITED STATES OF AMEICA AS REPRESENTED BY THE SEC OF THE

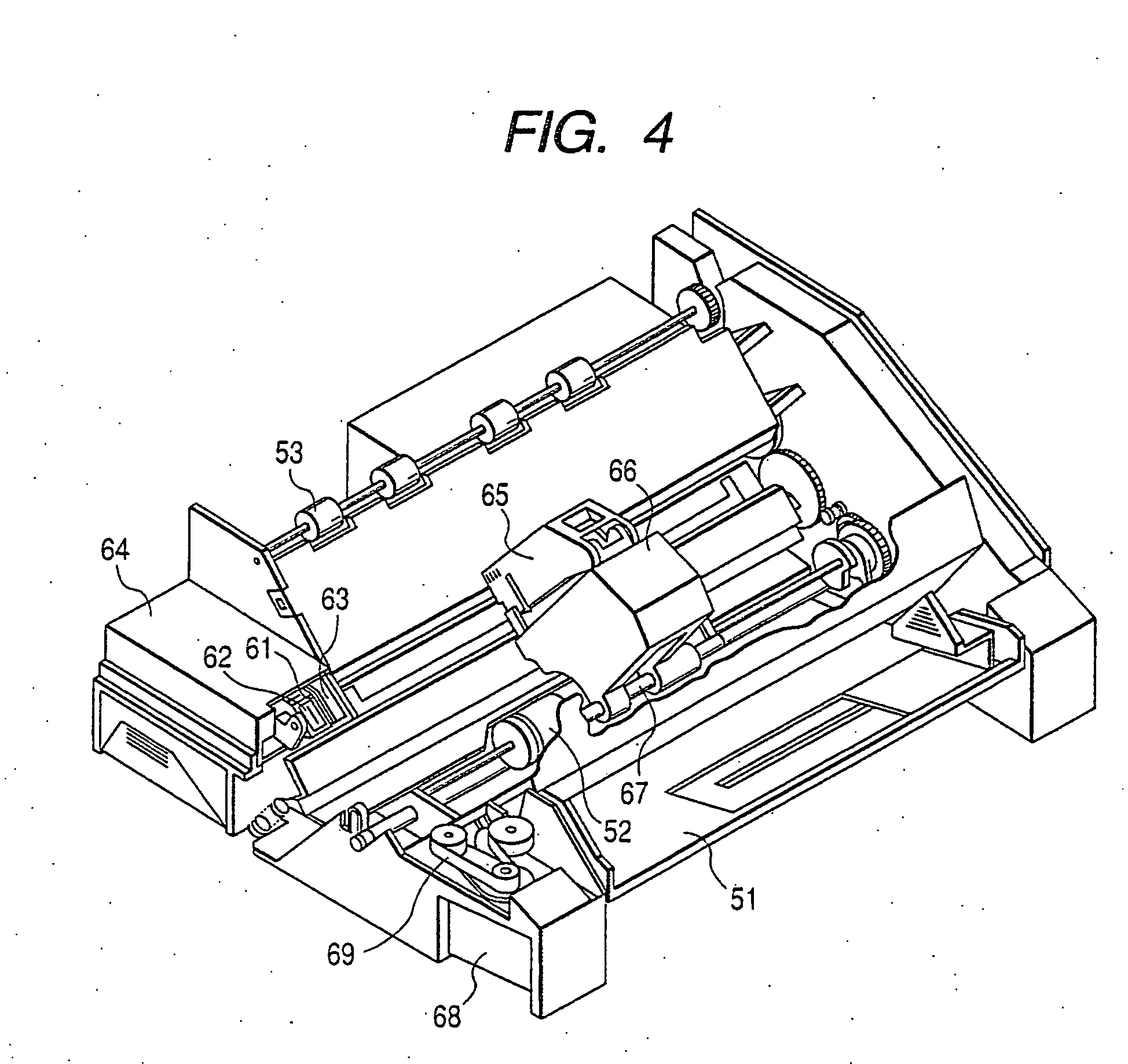

Lens, light source unit, backlight apparatus, and display apparatus

InactiveUS20090207586A1Reduce thicknessSuppressing luminance variability variabilityPlanar light sourcesPoint-like light sourceCamera lensLight guide

A lens diffusing light emitted from a light source includes a concave light-incident surface, a light guide portion, and a light-emitting surface. The light-incident surface includes a plane portion opposed to the light source and an optical function portion that is formed on the plane portion and one of scatters and diffuses the light. The light emitted from the light source enters the light-incident surface. The light that has entered the light-incident surface passes through the light guide portion. The light-emitting surface emits the light passed through the light guide portion.

Owner:SATURN LICENSING LLC

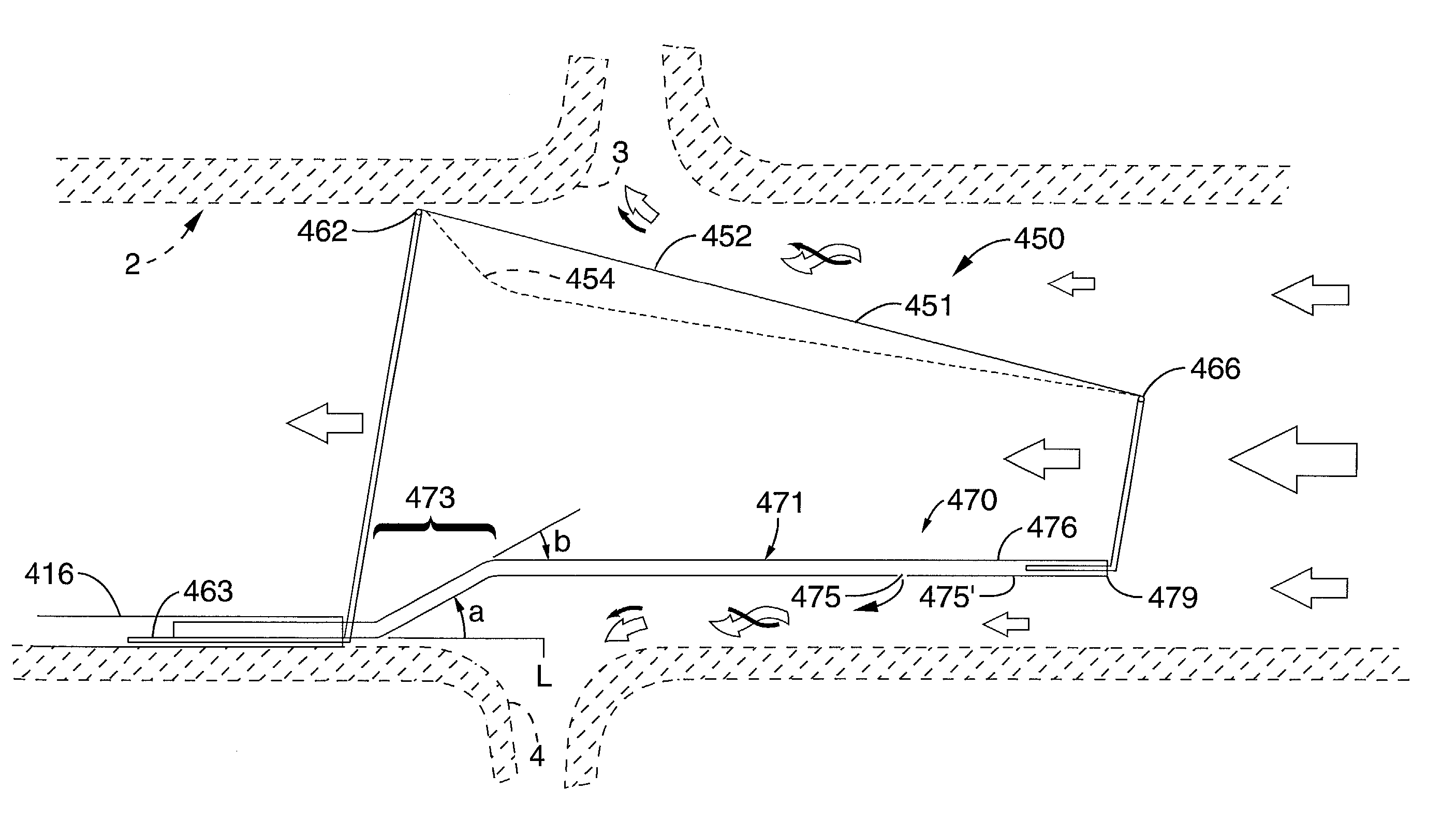

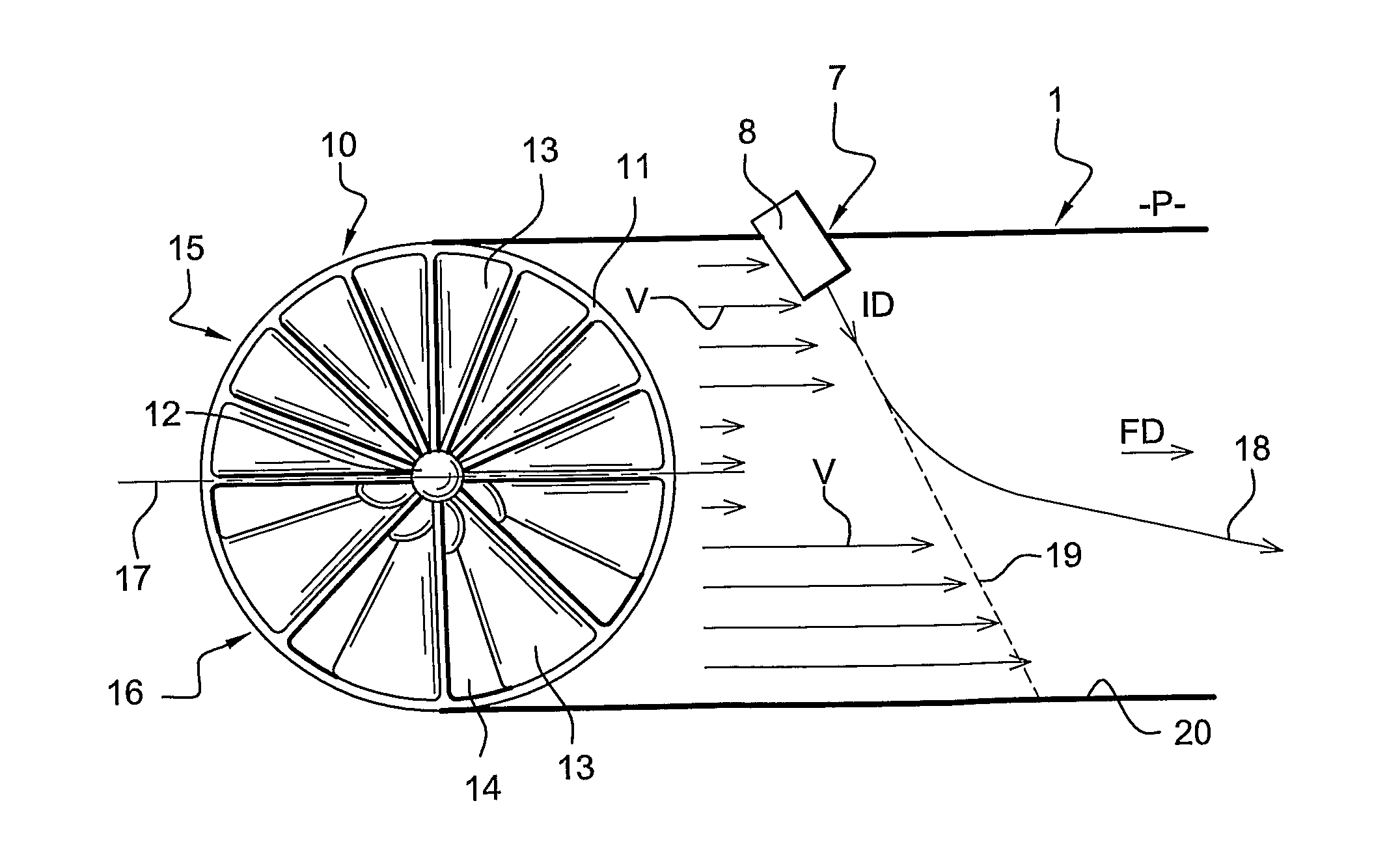

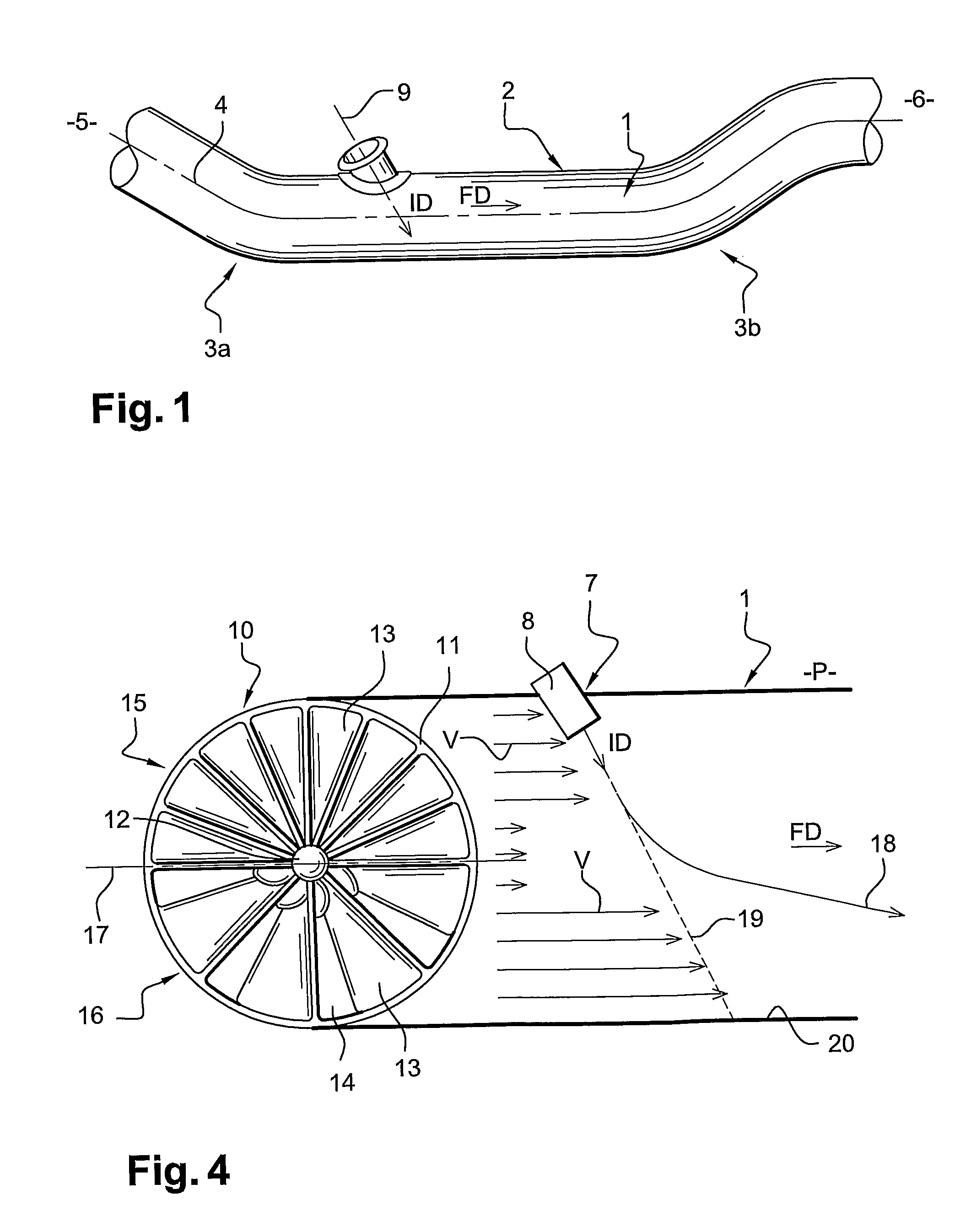

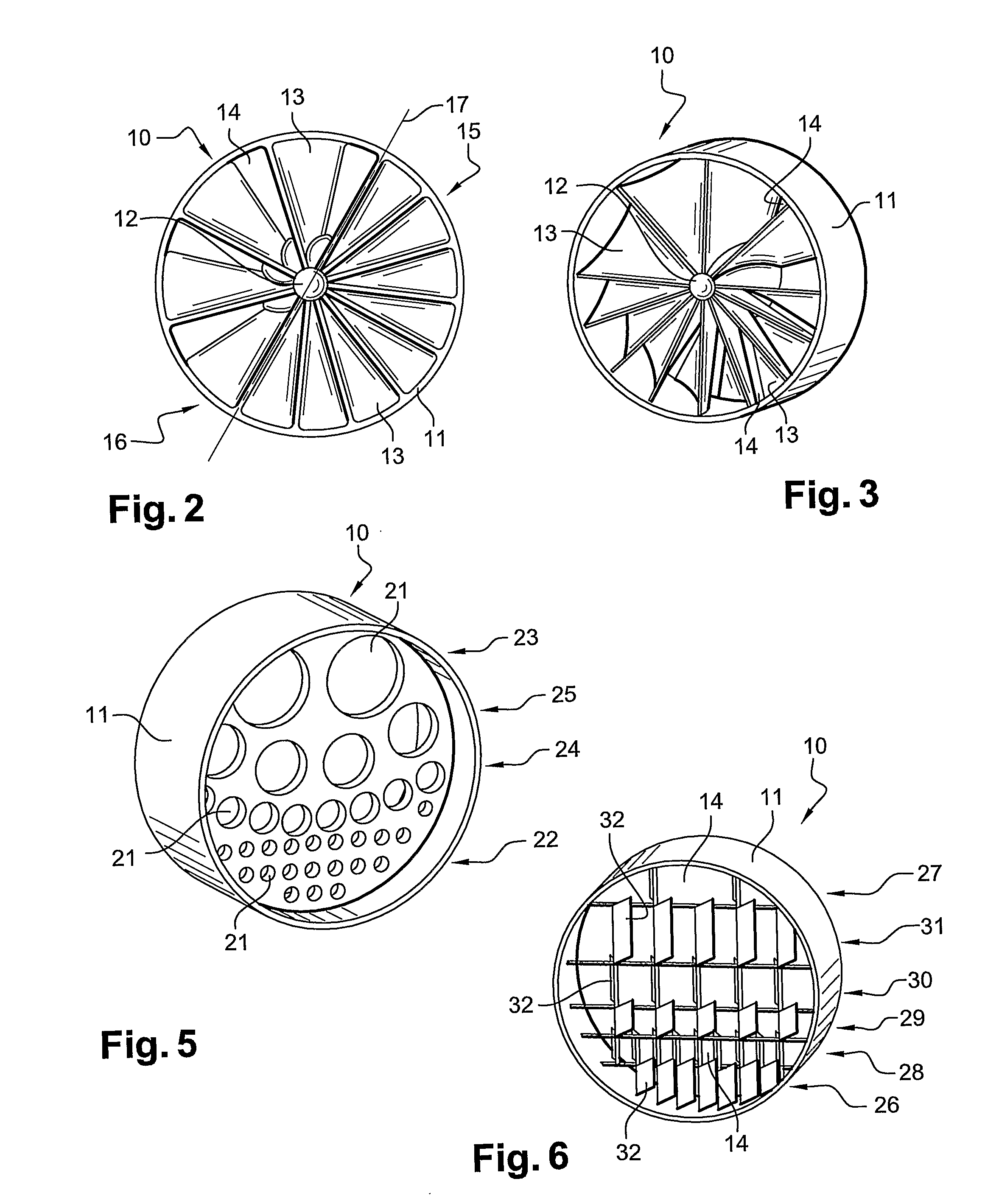

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

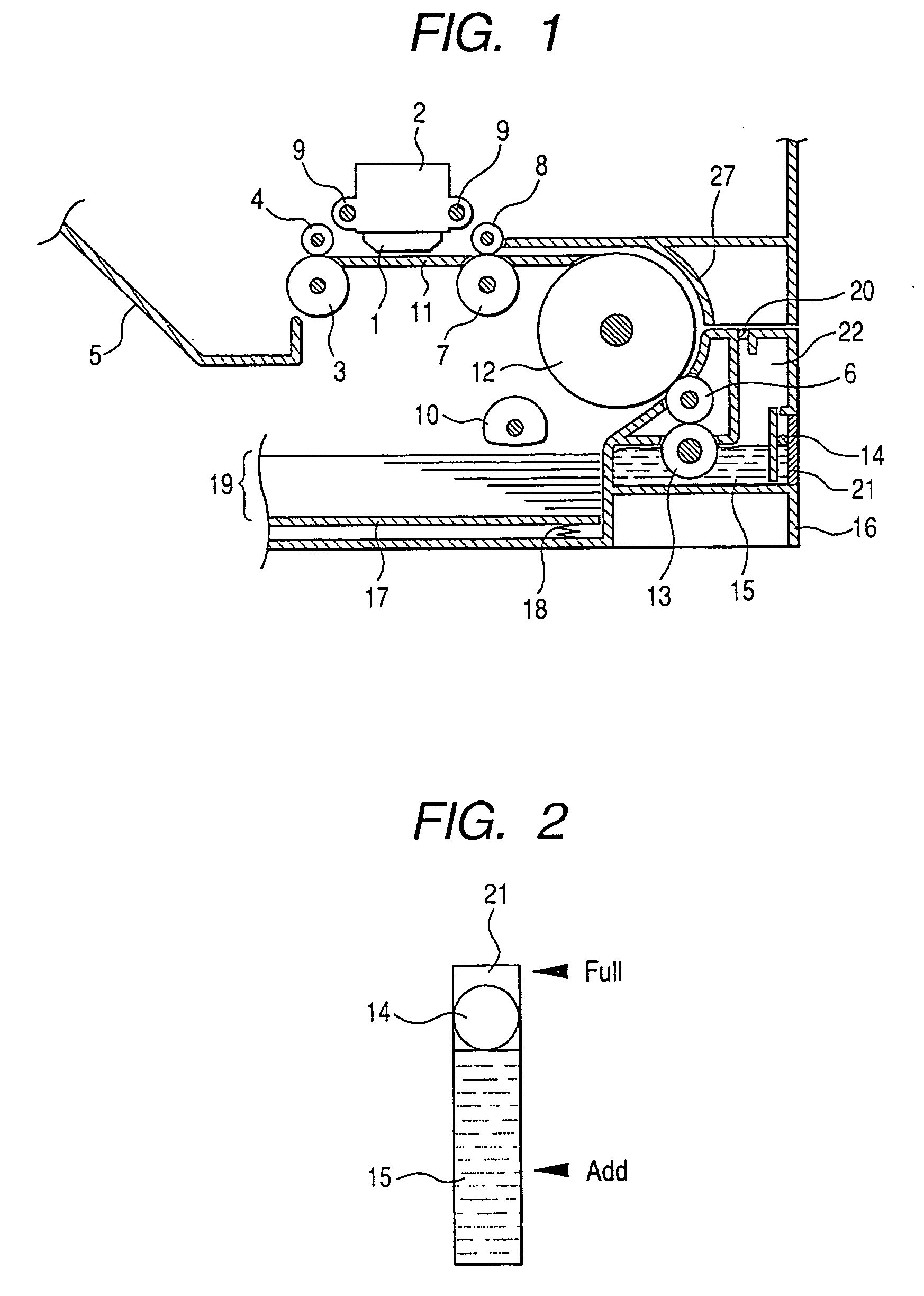

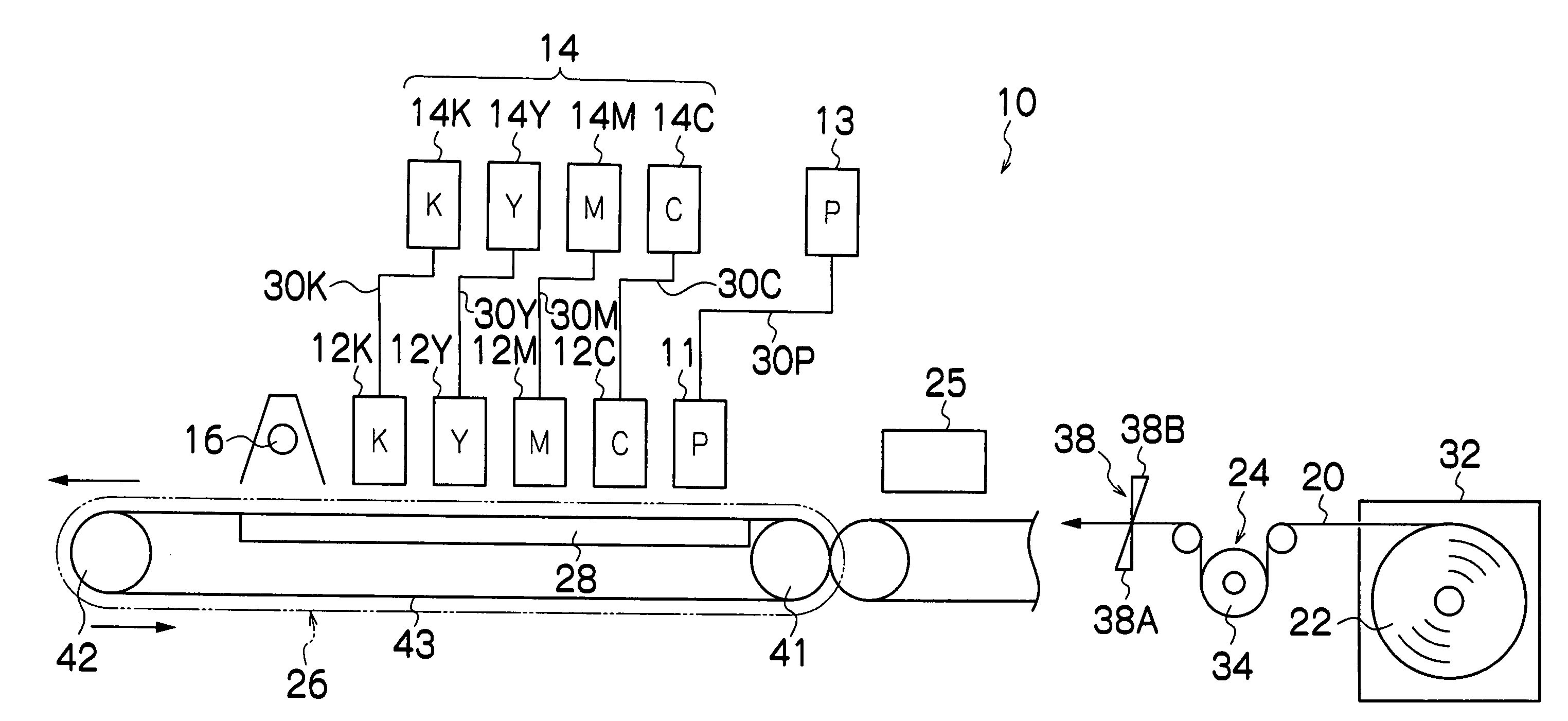

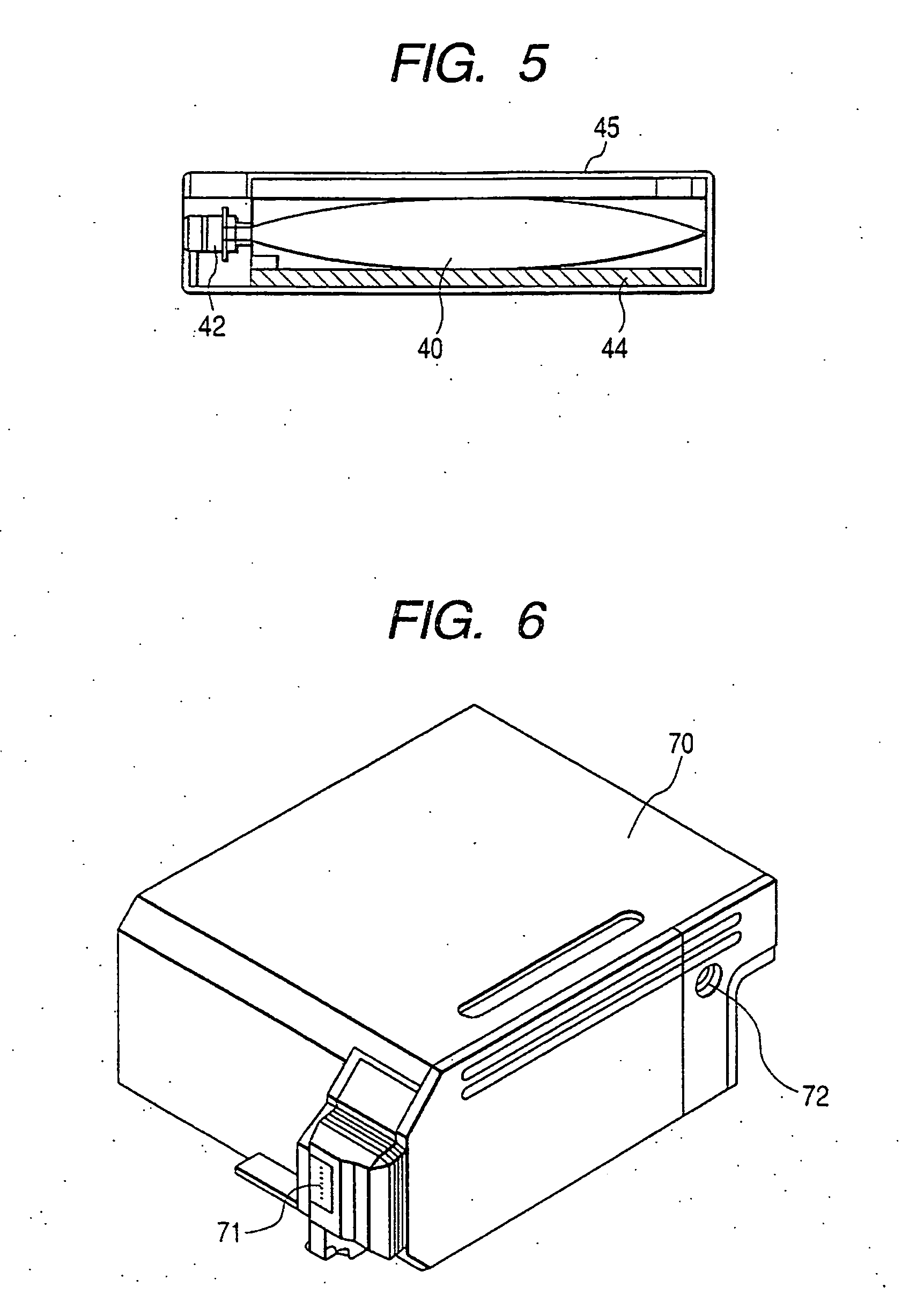

Recording method, ink cartridge, and image-forming method

InactiveUS20060103704A1Large area factorDegrading graininess of imageMeasurement apparatus componentsInksOrganic solventHigh density

A recording method is provided which enables formation of an image with high image density and low graininess. The recording is conducted by using a recording method using a first aqueous ink for higher-density recording and a second aqueous ink for lower-density recording, characterized in that the first aqueous ink comprises at least water, a water-insoluble coloring material, and plurality of water-soluble organic solvents, the plurality of water-soluble organic solvents including a good medium or good mediums for the water-insoluble coloring material and a poor medium or poor mediums for the water-insoluble coloring material, the ratio B / A in the second aqueous ink being less than the ratio B / A the first aqueous ink, where A denotes the total content (mass %) of good medium based on the total mass of the aqueous ink and B denotes the total content (mass %) of poor medium based on the total mass of the aqueous ink; and the second aqueous ink has the same hue as the first aqueous ink.

Owner:CANON KK

Full ring fuel distribution system for a gas turbine combustor

InactiveUS6282904B1Convenient lightingEnhancing quality and integrityBurnersContinuous combustion chamberCombustion chamberCombustor

A fuel nozzle system for use in a combustor utilized in a combustion turbine for reducing nitrogen oxides and other pollutants including an annular fuel distribution manifold separately mounted away from a diffusion nozzle, said annular manifold having a plurality of fuel emitting passages or holes disposed along the downstream side of the manifold, said manifold being mounted in a position away from the diffuser nozzle body to allow air to stream around the manifold on all sides allowing for a thorough mixture of fuel and air around the annular manifold for better premixing in the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

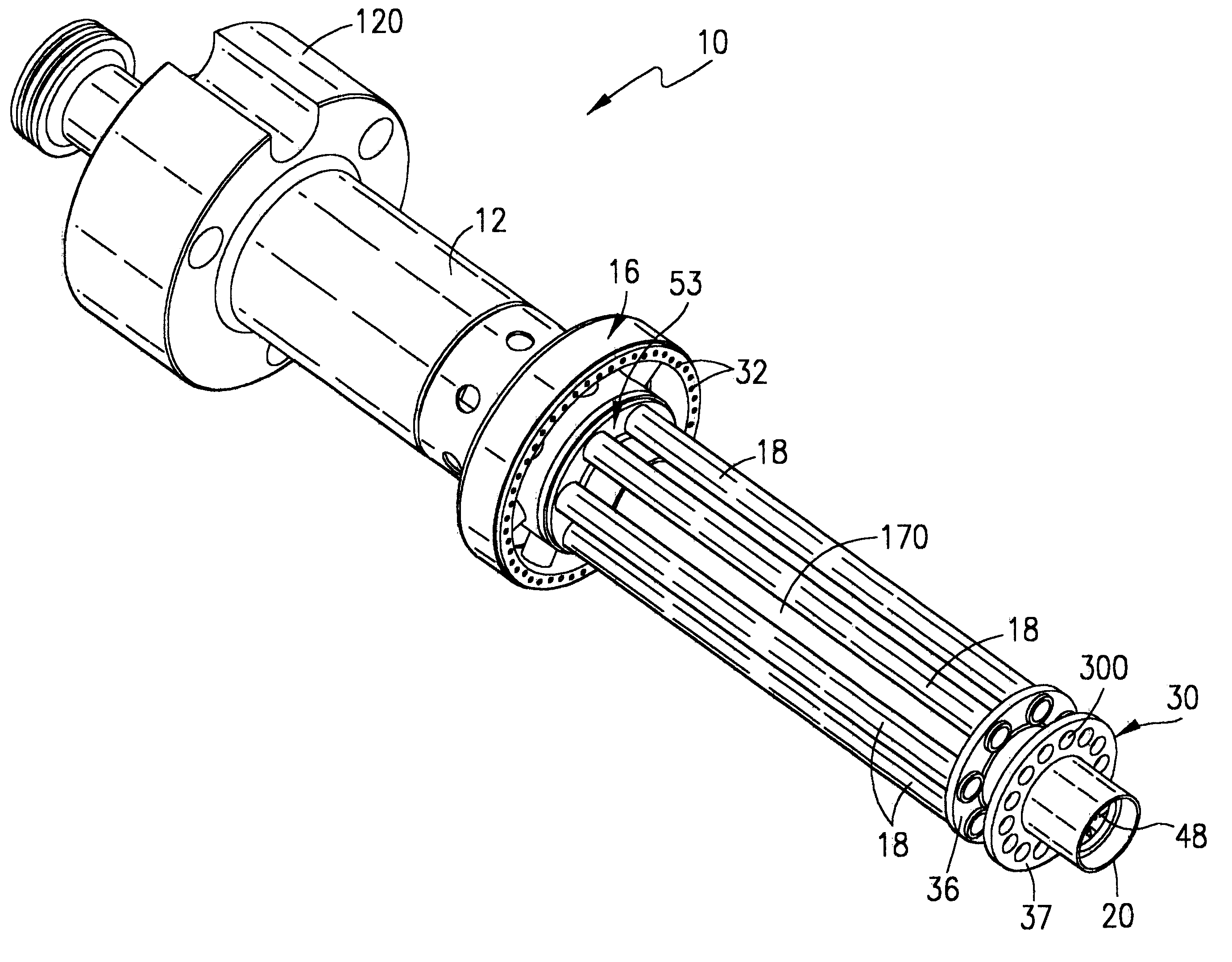

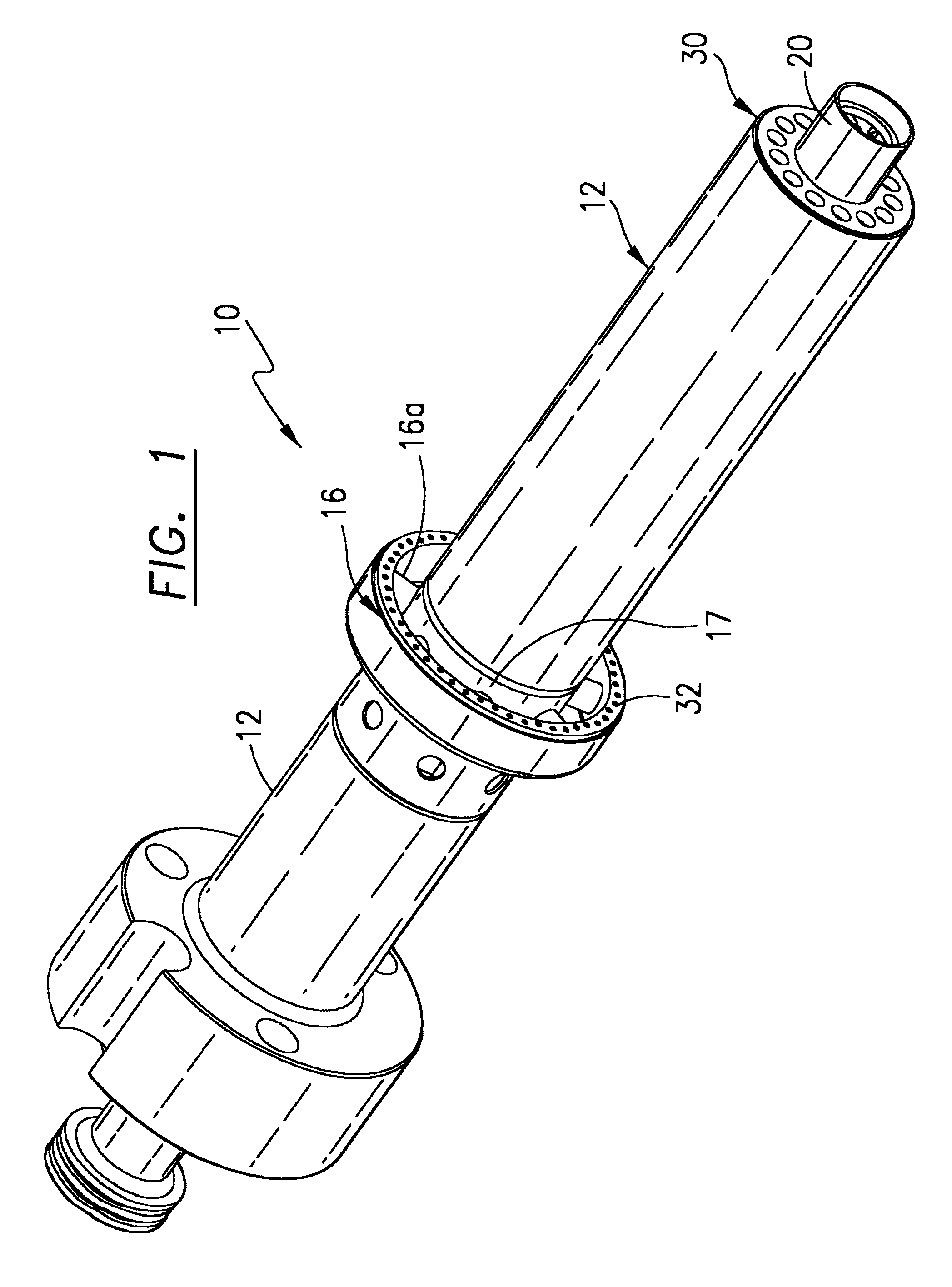

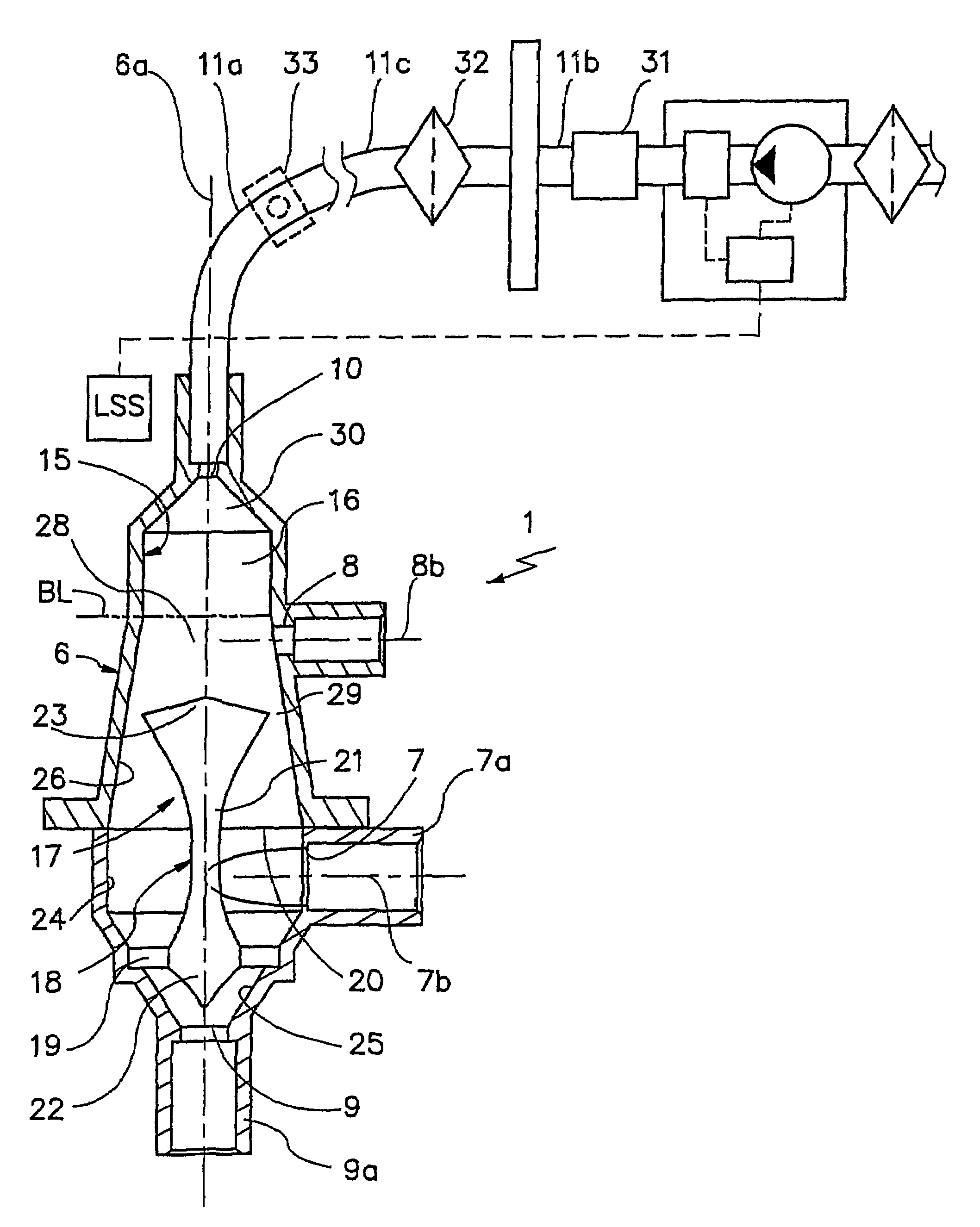

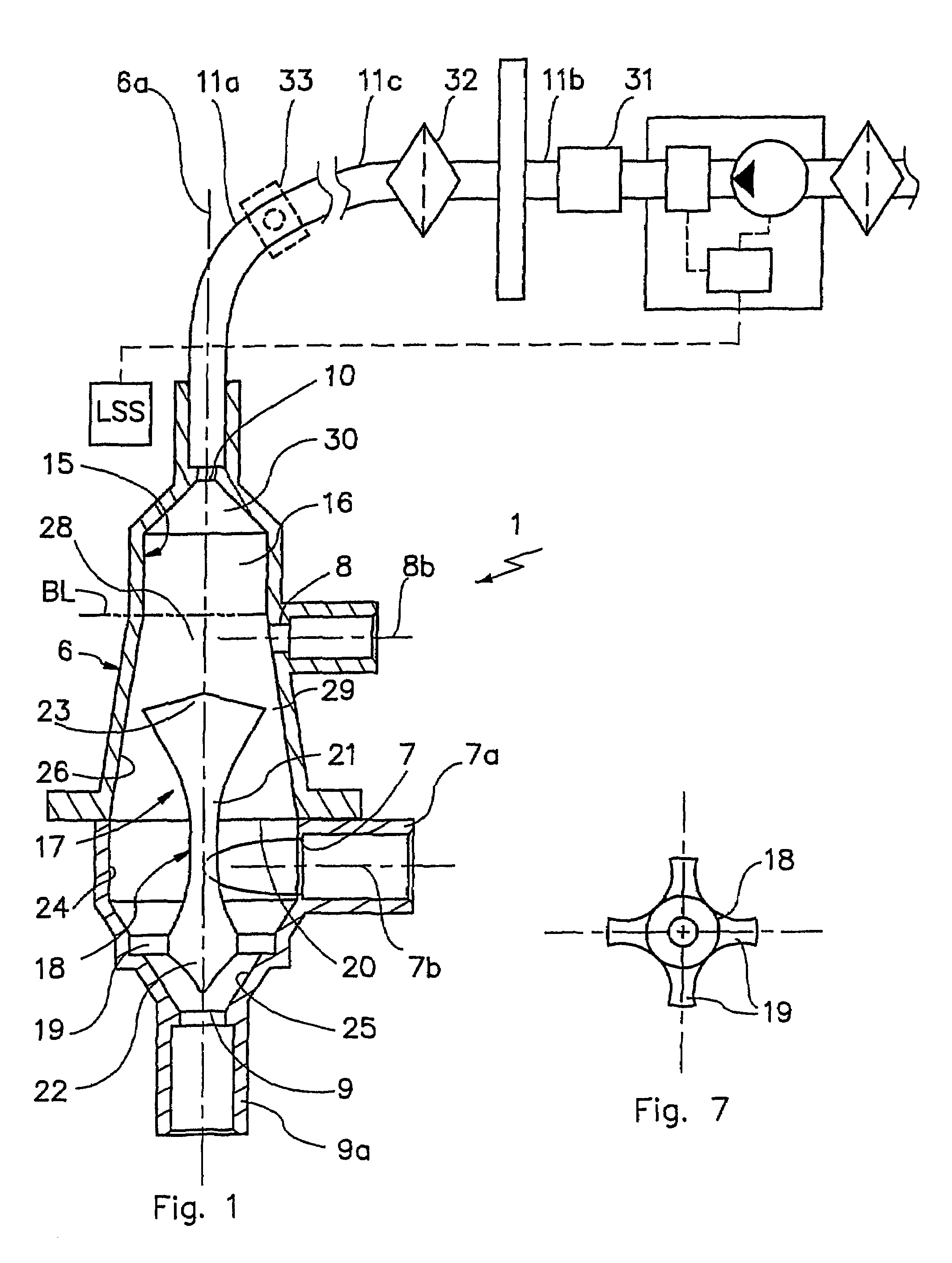

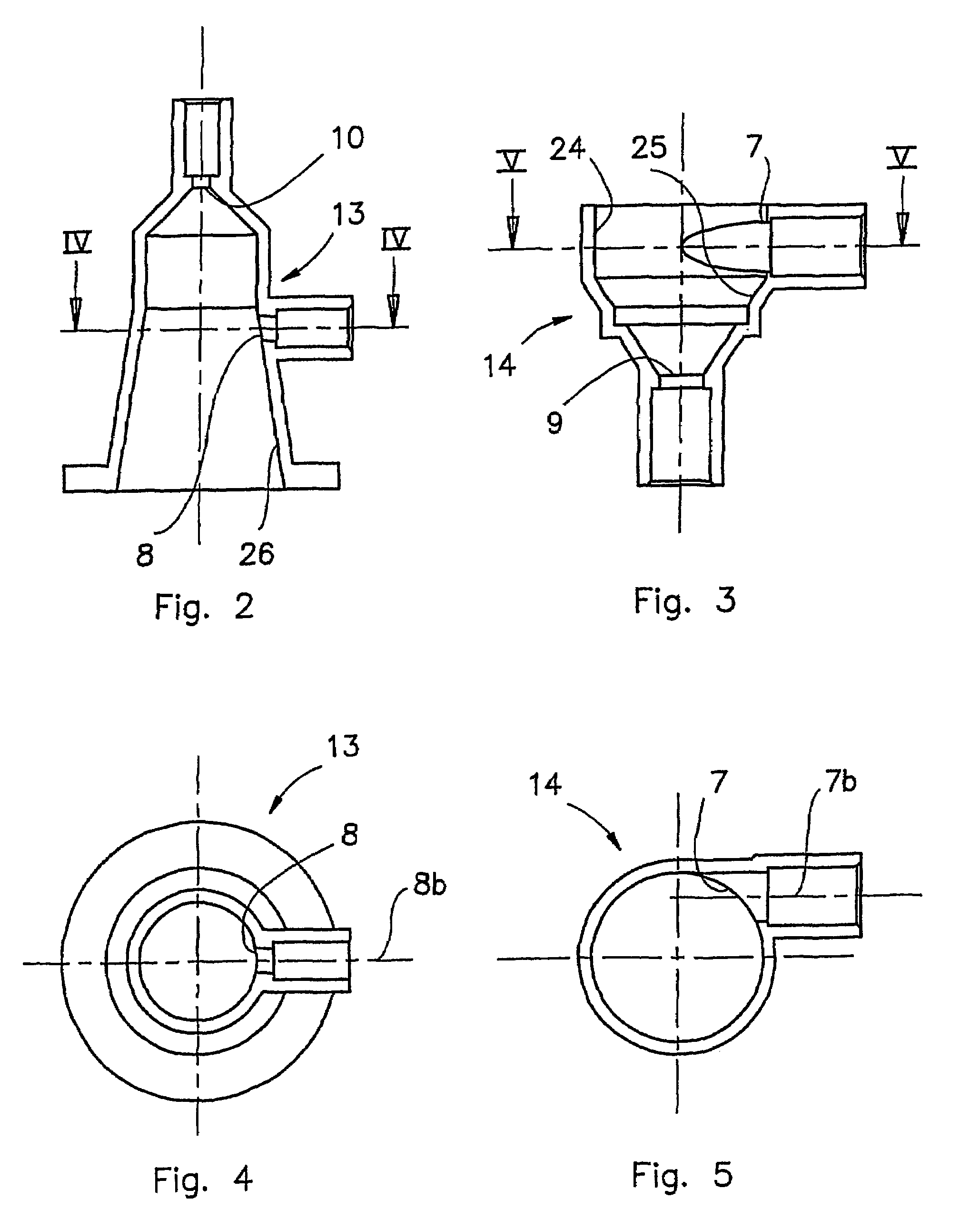

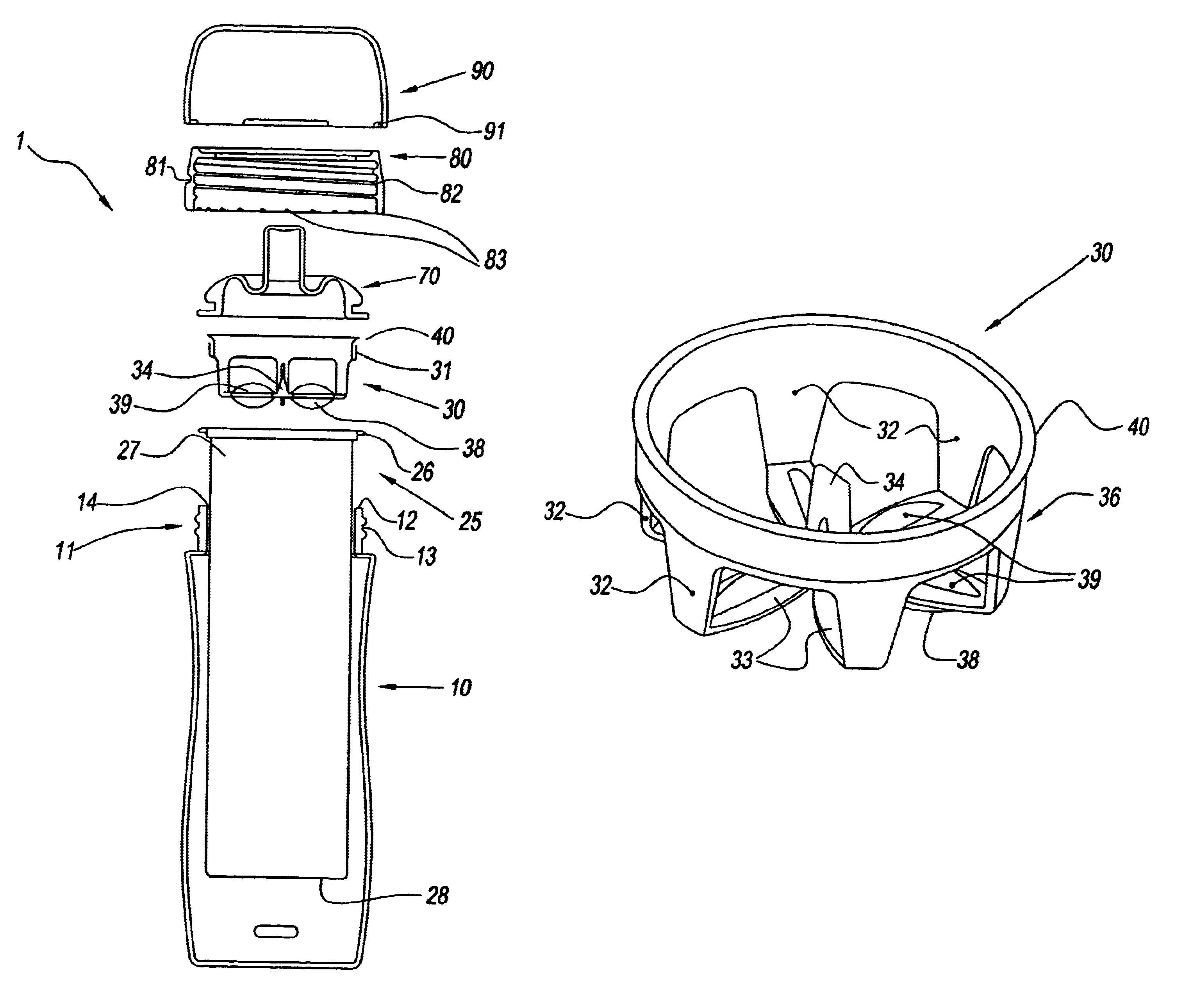

Gas separation devices

ActiveUS7517387B2Minimized volumeEasy to operateLiquid degasificationReversed direction vortexPhysiological fluidEffective surface

A description is given of a gas separation device for a physiological fluid, comprising a containing body (6) having at least a first inlet aperture (7) for a physiological fluid, positioned with a tangential direction of access, at least one outlet aperture (9) for the said fluid, spaced apart from the said inlet aperture, and a guide element (17) housed within the said body. The guide element (17) has a continuous active surface (15) designed to contact and guide the said fluid and delimits, together with the containing body (6), a first annular chamber (20) into which the first inlet aperture (7) opens directly.

Owner:GAMBRO LUNDIA AB

Aqueous ink, ink-jet recording method, ink cartridge, recording unit, ink-jet recording apparatus and image forming method

ActiveUS7276112B2Increase the areaHigh print densityDuplicating/marking methodsInksOrganic solventAtomic group

Disclosed is an aqueous ink comprising at least water, a plurality of water-soluble organic solvents and a coloring material. The coloring material is a pigment, and, it contains a pigment particle having at least one ionic group bonded to a surface of the pigment particle directly or via another atomic group. The plurality of water-soluble organic solvents have a good medium or good mediums for the pigment and a poor medium or poor mediums for the pigment. The poor medium does not solvate perfectly or substantially the pigment. The ionic group undergoes perfectly or substantially no ionic dissociation in the poor medium. Also, among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method, the Ka value of the poor medium is maximum.

Owner:CANON KK

Image forming apparatus and method, and ink set

InactiveUS20070046720A1Reliable curingEasy to fixMeasurement apparatus componentsDuplicating/marking methodsImage formationRadiation exposure

The image forming apparatus comprises: a treatment liquid deposition device which deposits treatment liquid onto a recording medium, the treatment liquid containing a polymerization initiator and particles introducing electrorheological properties; an electric field application device which applies an electric field to the treatment liquid having been deposited on the recording medium; an ink ejection device which ejects ink toward the recording medium on which the treatment liquid has been deposited, the ink containing a coloring material and a radiation-curable polymerizable compound; and a radiation irradiation device which irradiates radiation to cure the ink having been deposited on the recording medium.

Owner:FUJIFILM CORP

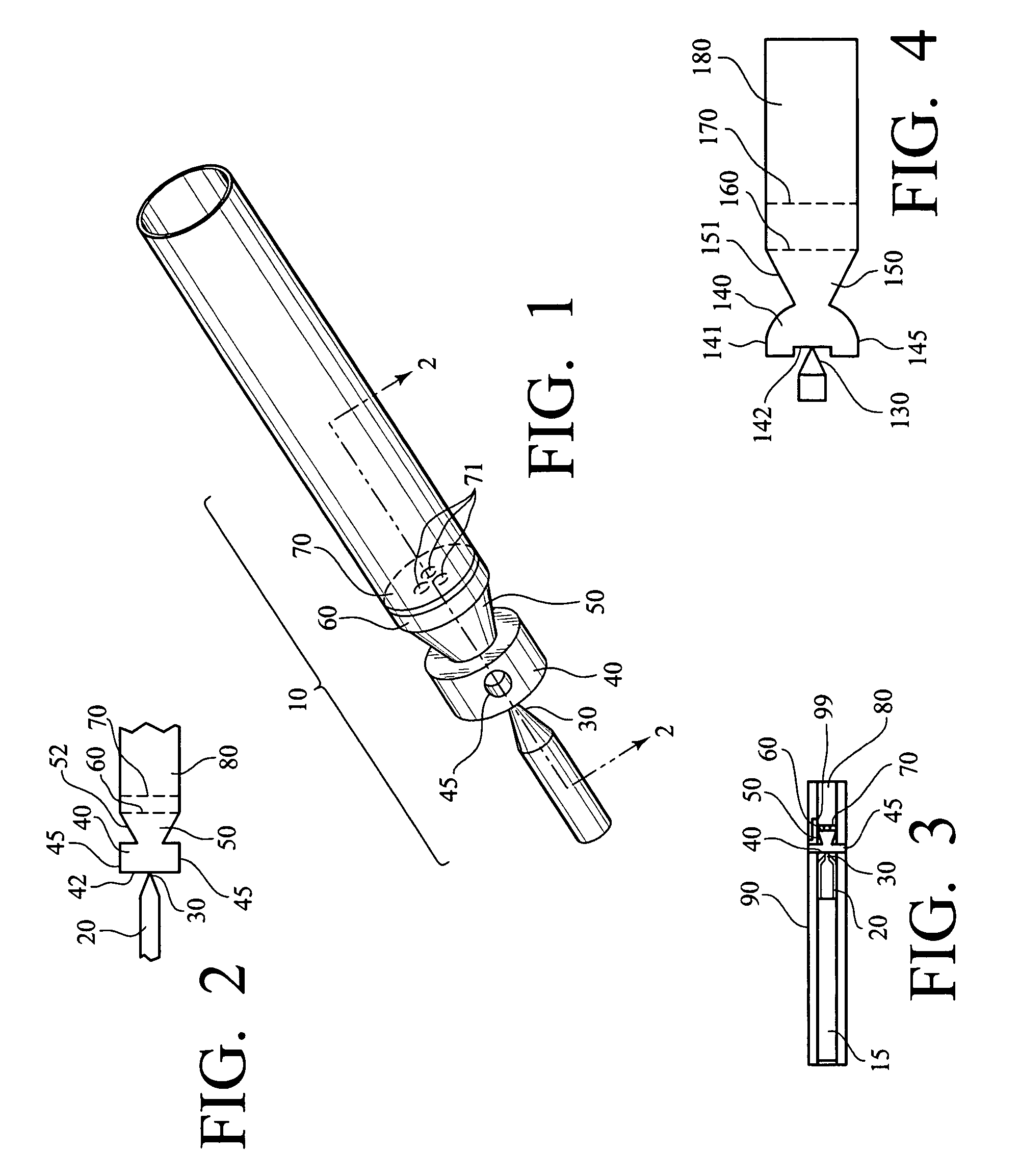

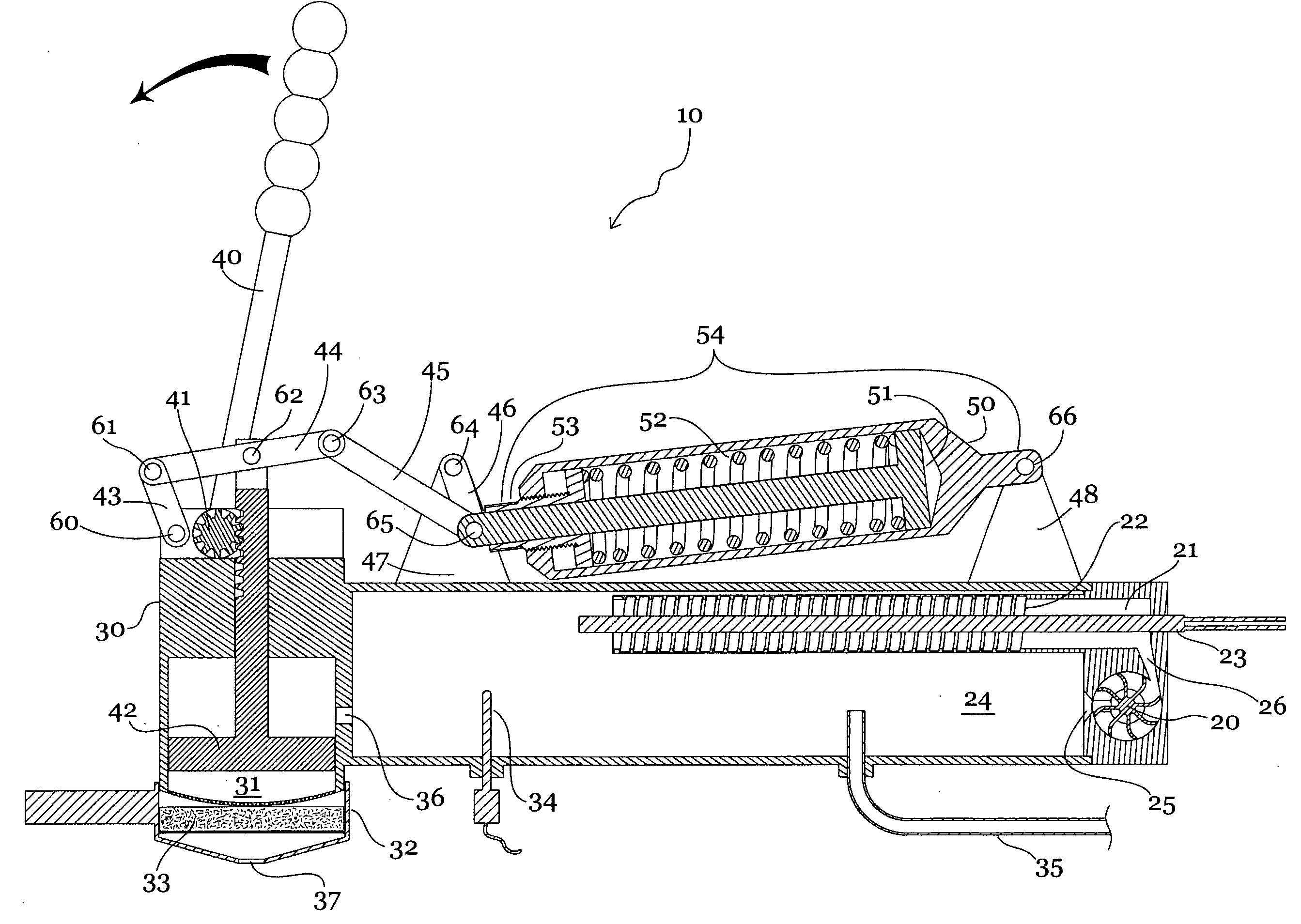

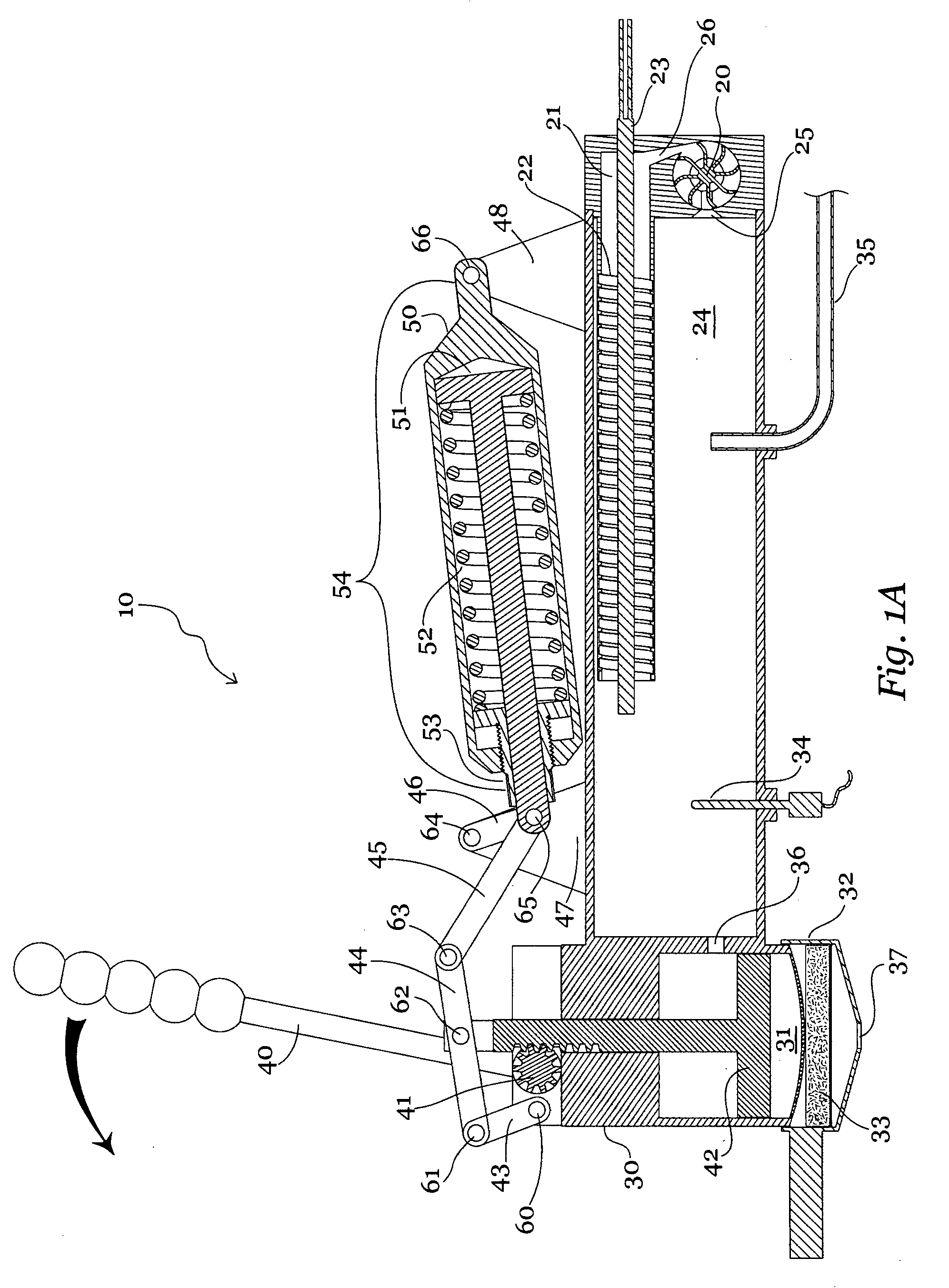

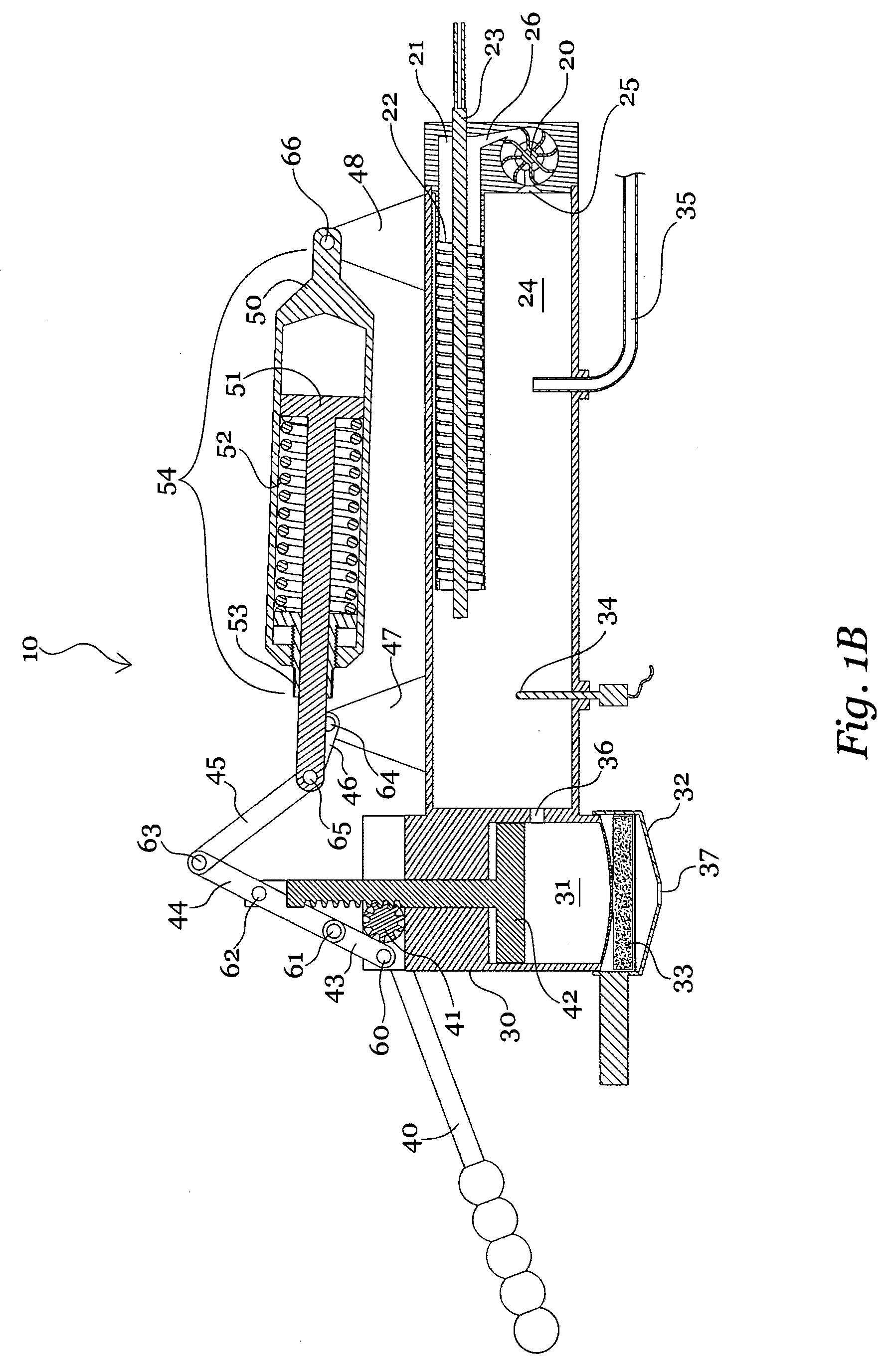

Gas micro burner

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

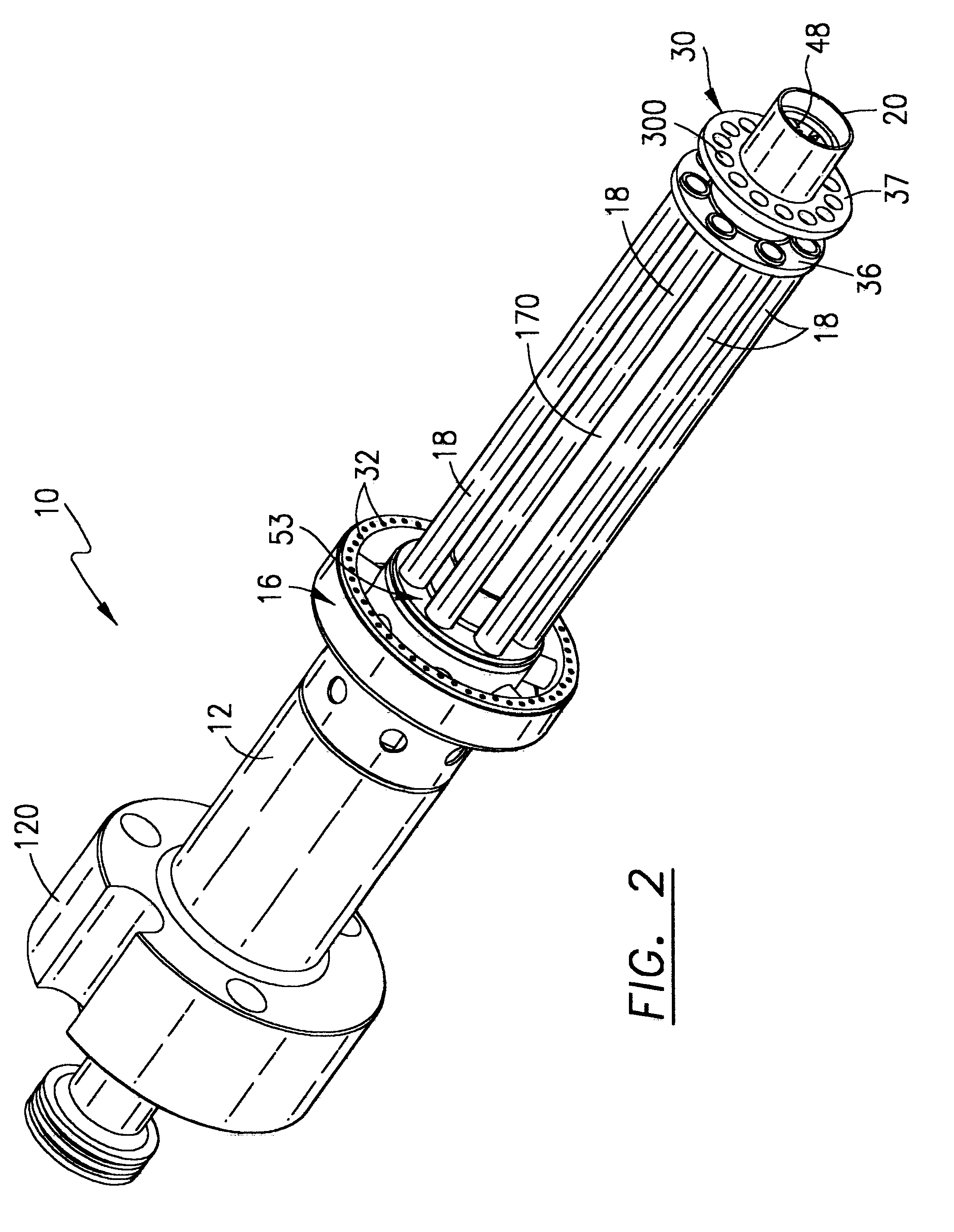

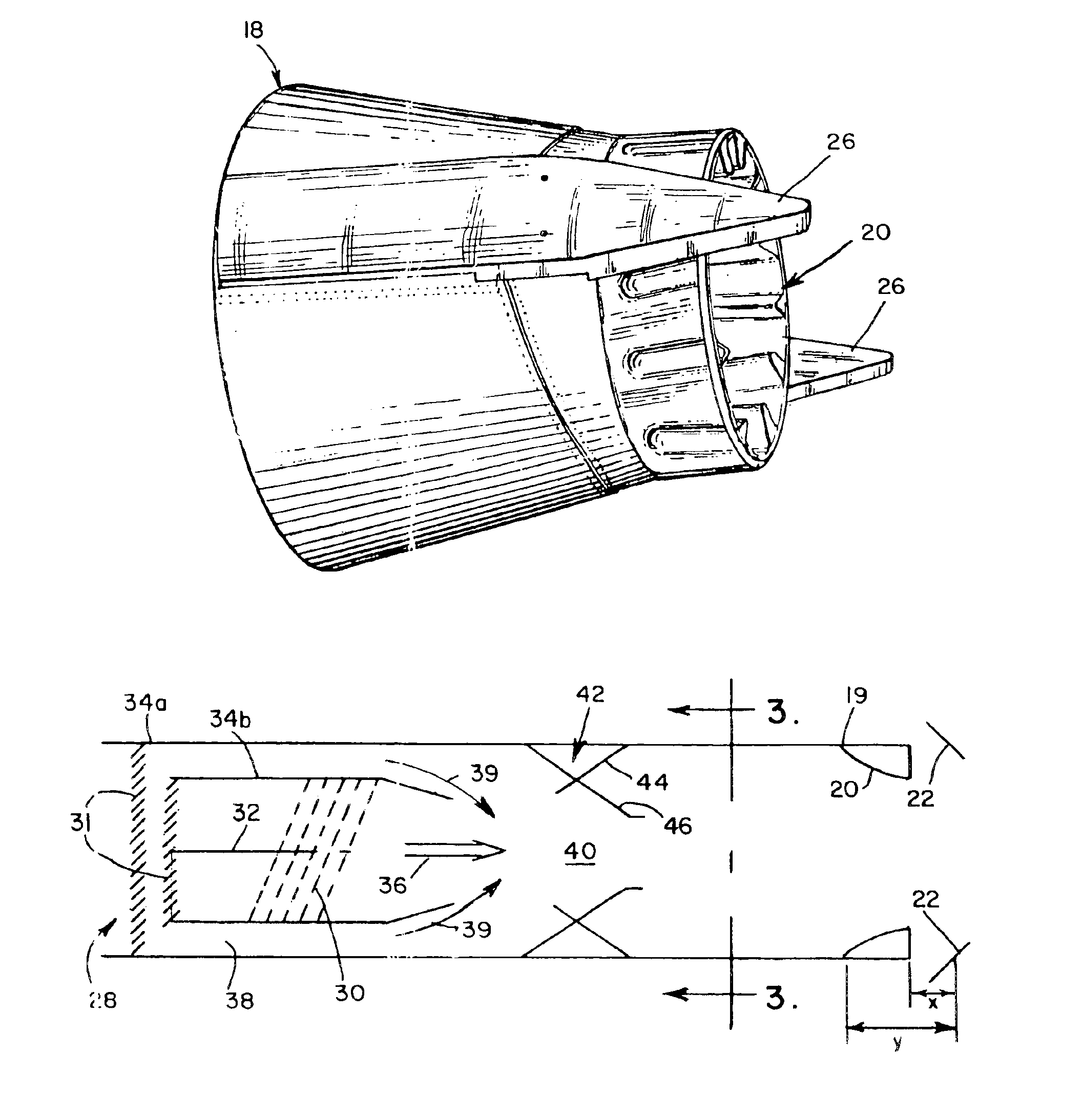

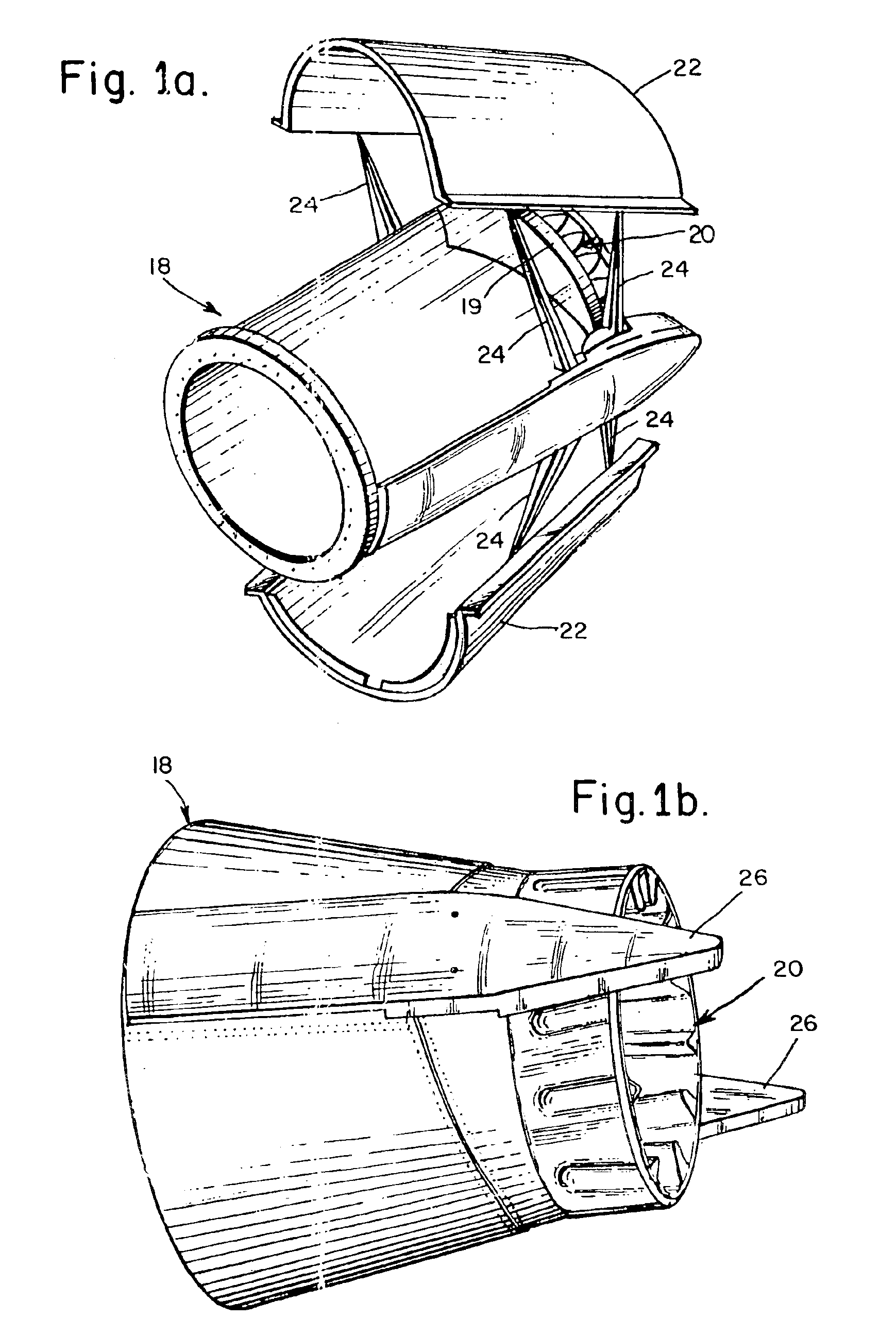

Jet nozzle mixer

InactiveUS6854260B2Reduce noiseAvoid problemsAircraft navigation controlCosmonautic vehiclesJet engineThrust efficiency

An external jet nozzle mixer (20) includes identically formed lobes (48), equal in number those of the internal mixer (42). External mixer (20) works with internal mixer (42), further to mix the engine internal bypass flow with the internal jet engine core flow, to level the disparate exhaust flow velocities, to reduce the peak velocities from the jet engine core and increase the lower bypass velocities of the engine internal bypass flow, and thereby to reduce noise. The internal lobe contours act as lifting flutes, causing mixing of the primary hot and cold flows before exiting the nozzle. The external lobe contours act as venturi chutes, accelerating the cooler ambient air secondary flow. The lobes thus act collectively as an injector to force the cooler ambient secondary flow into the previously mixed primary flow as it exits the nozzle. Also obtained is an increased thrust efficiency and a consequently decreased fuel consumption and engine emissions.

Owner:COMTRAN LTD

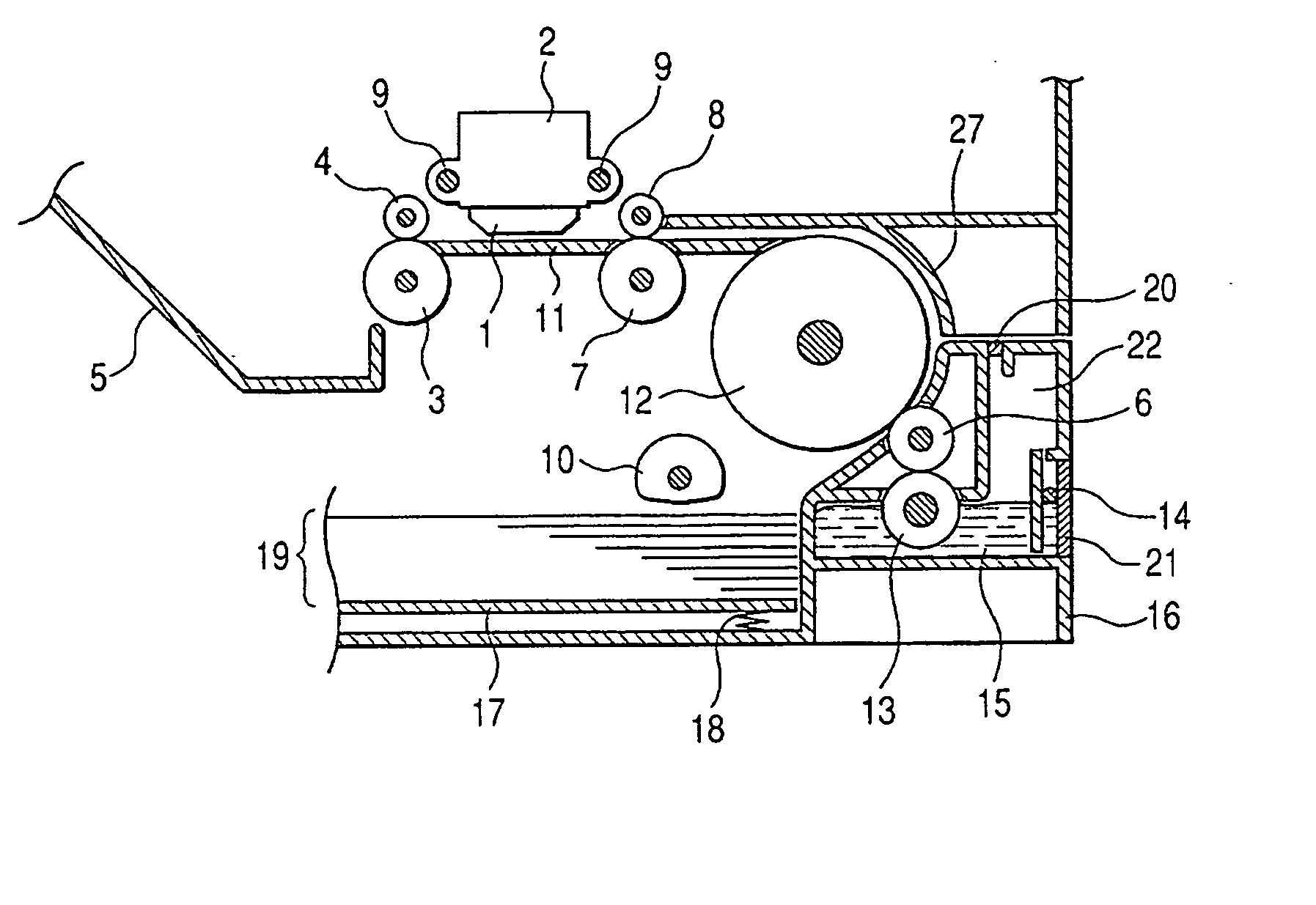

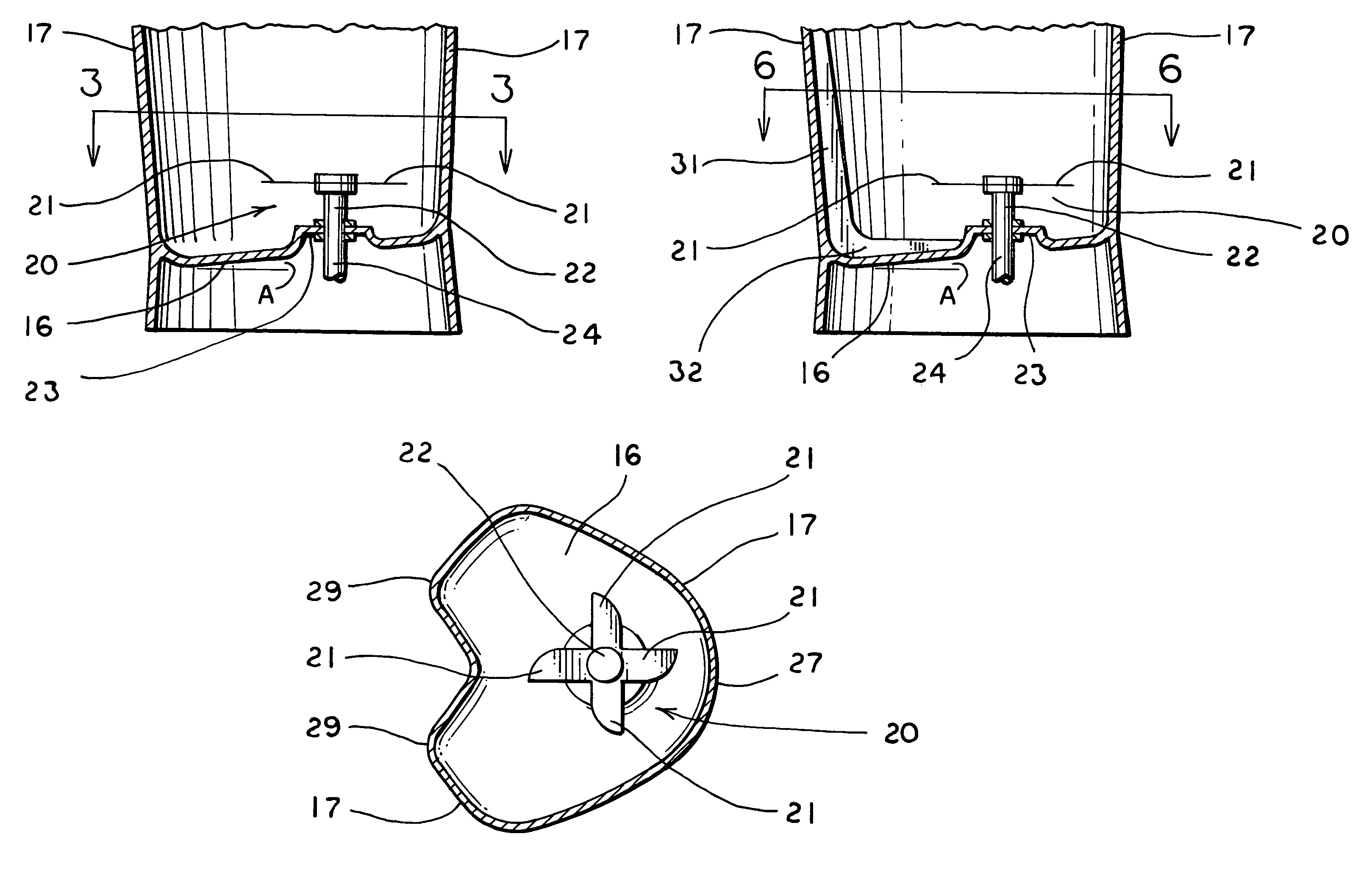

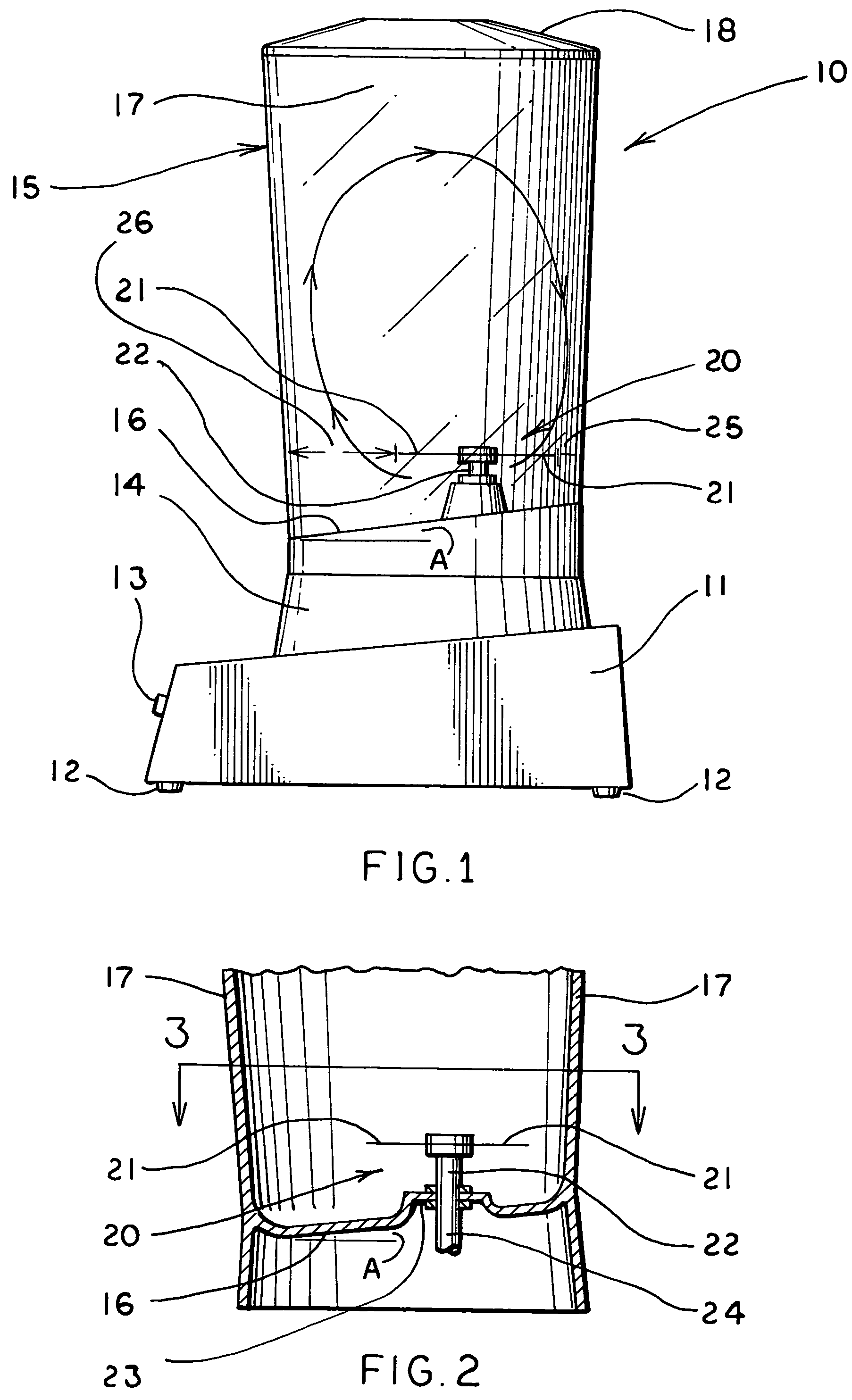

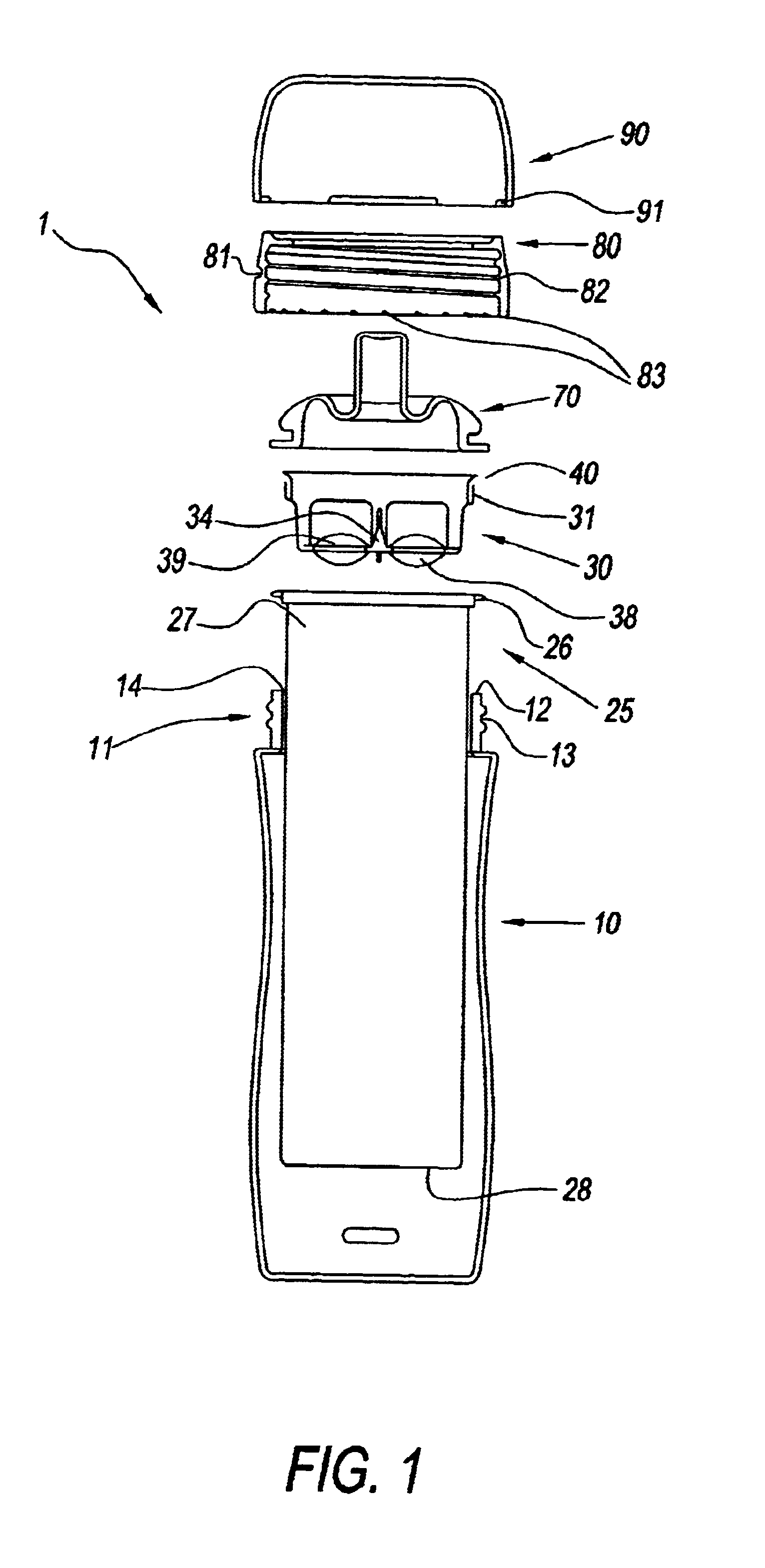

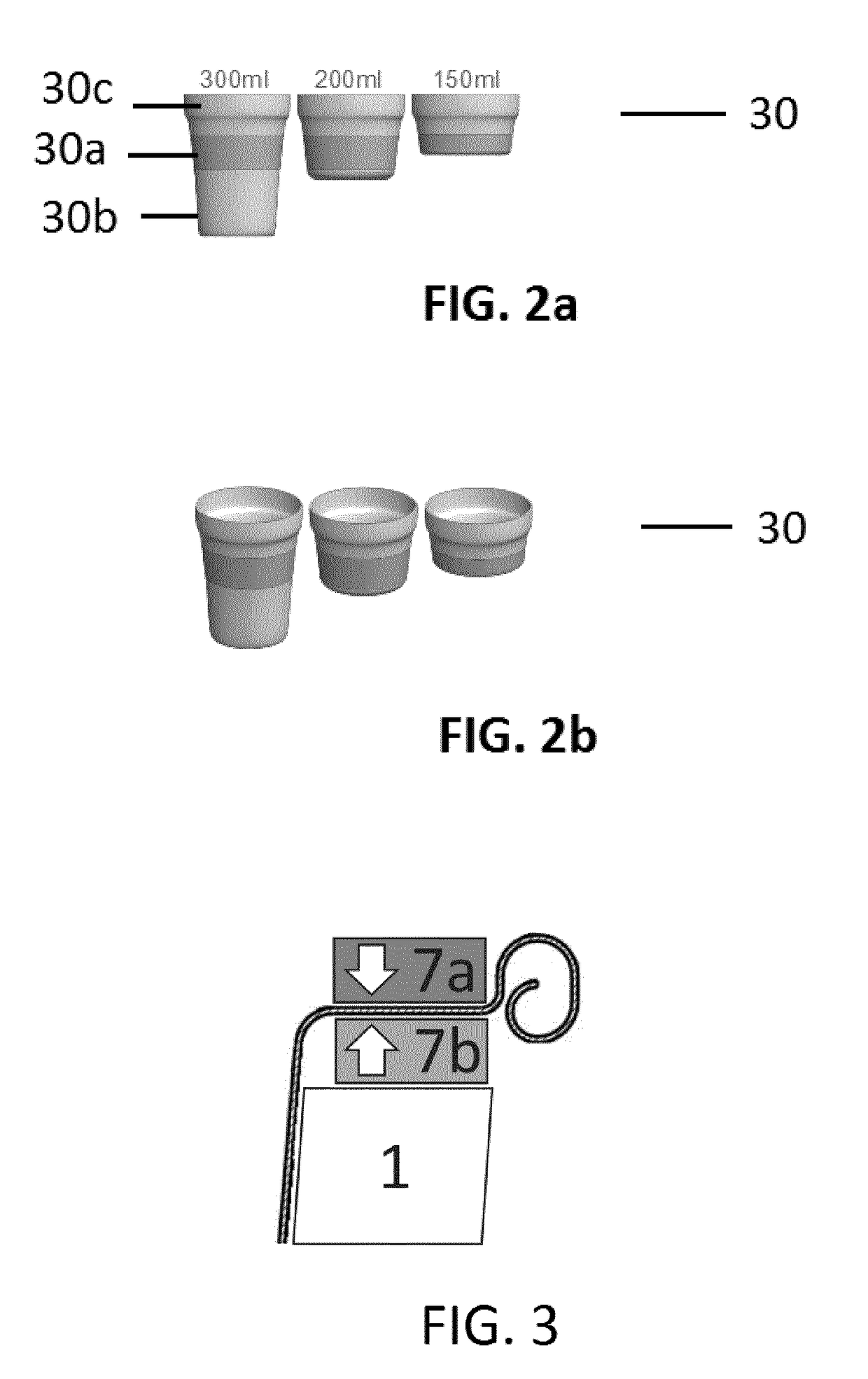

Container for a blender

InactiveUS7063456B2Inhibition formationEfficient mixingRotary stirring mixersKitchen equipmentMechanical engineeringEngineering

A container (15) for a blender (10) includes a bottom surface (16) having a non-symmetrically shaped perimeter. A side wall (17) extends upwardly from the perimeter of the bottom surface (16). A mixing blade assembly (20) having a plurality of blades (21) is located above the bottom surface (16) and is rotatable on an axis which is displaced from the center of the bottom surface (10). Nonuniform spaces (25, 26) are thus created between the ends of the blades (21) and the side wall (17). The bottom surface (16) is inclined at an angle relative to the plane normal to the axis of rotation of the blade assembly (20), and it, as well as the side wall (17), may be provided with a plurality of spaced vanes (31, 32).

Owner:VITA MIX MANAGEMENT

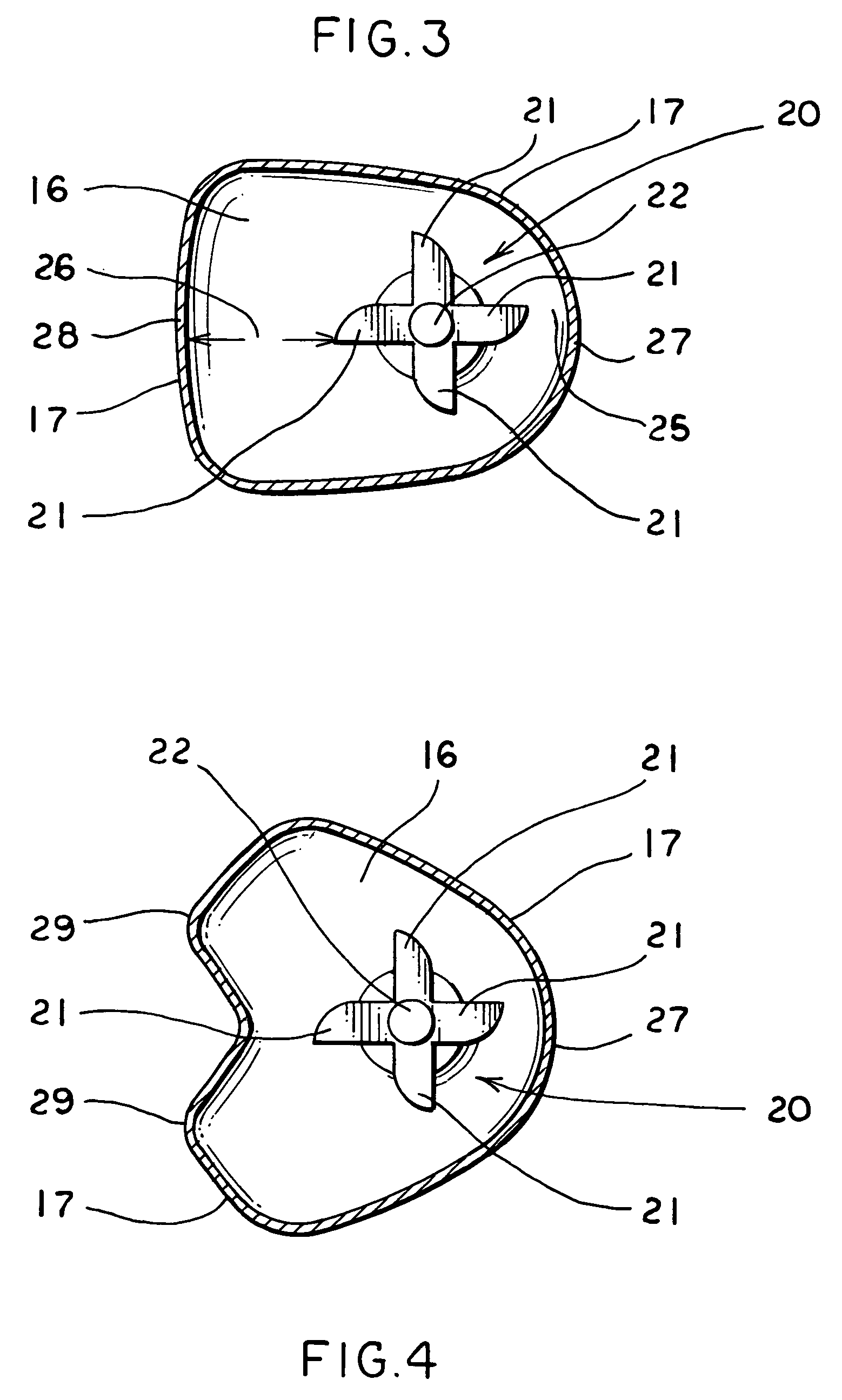

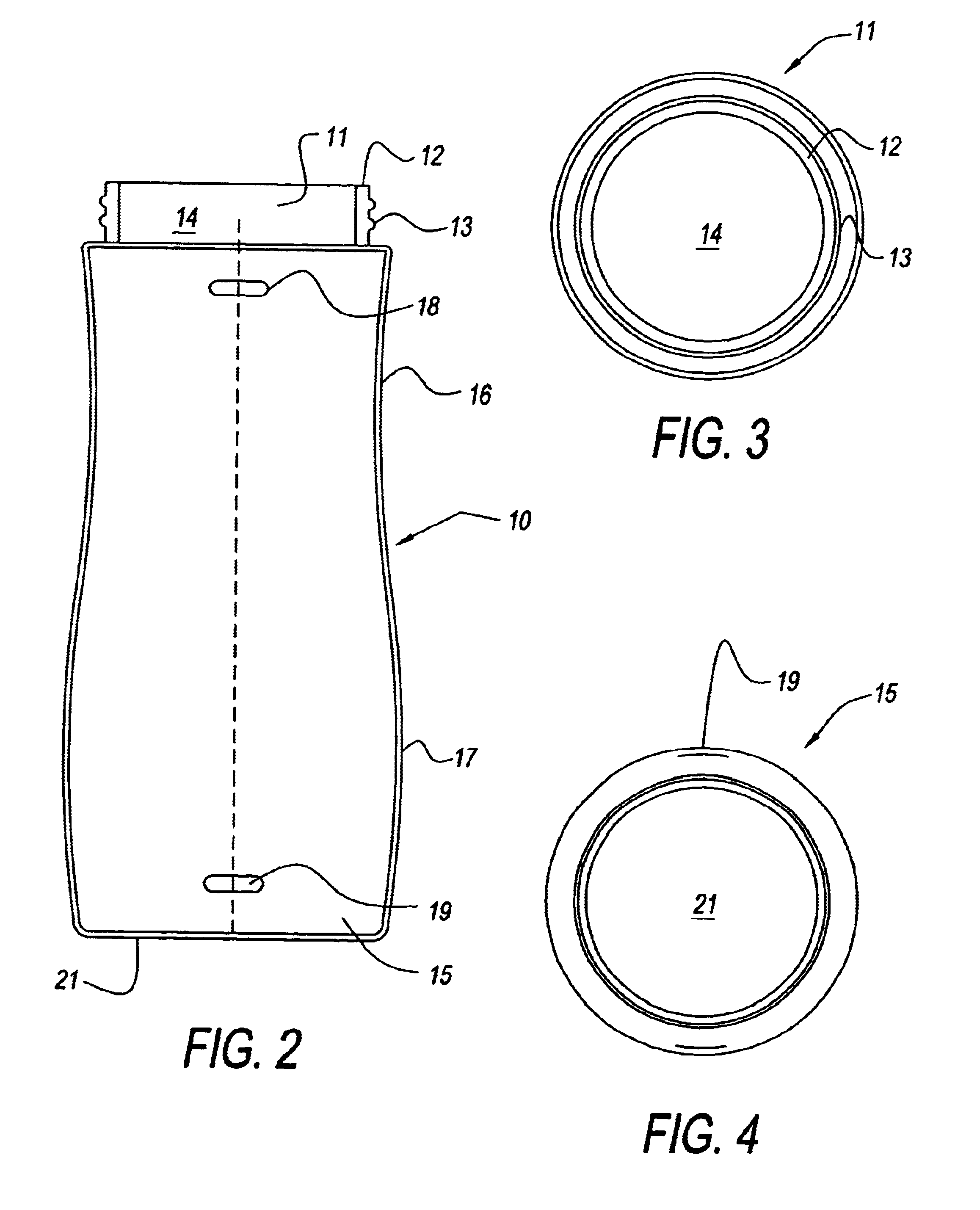

Bottle with mixing system

InactiveUS6616319B2Efficient mixingShaking/oscillating/vibrating mixersFlow mixersEngineeringMixing effect

There is provided an infant feeding bottle system having an agitator for mixing a powder substance with a liquid in a non-rigid disposable liner. The bottle system permits a user to mix powdered formula directly inside a non-rigid liner. The bottle system enhances the mixing effect, resulting in improved solubility, and provides for a self-contained uninterrupted mixing and feeding process.

Owner:JMBH HLDG LLC

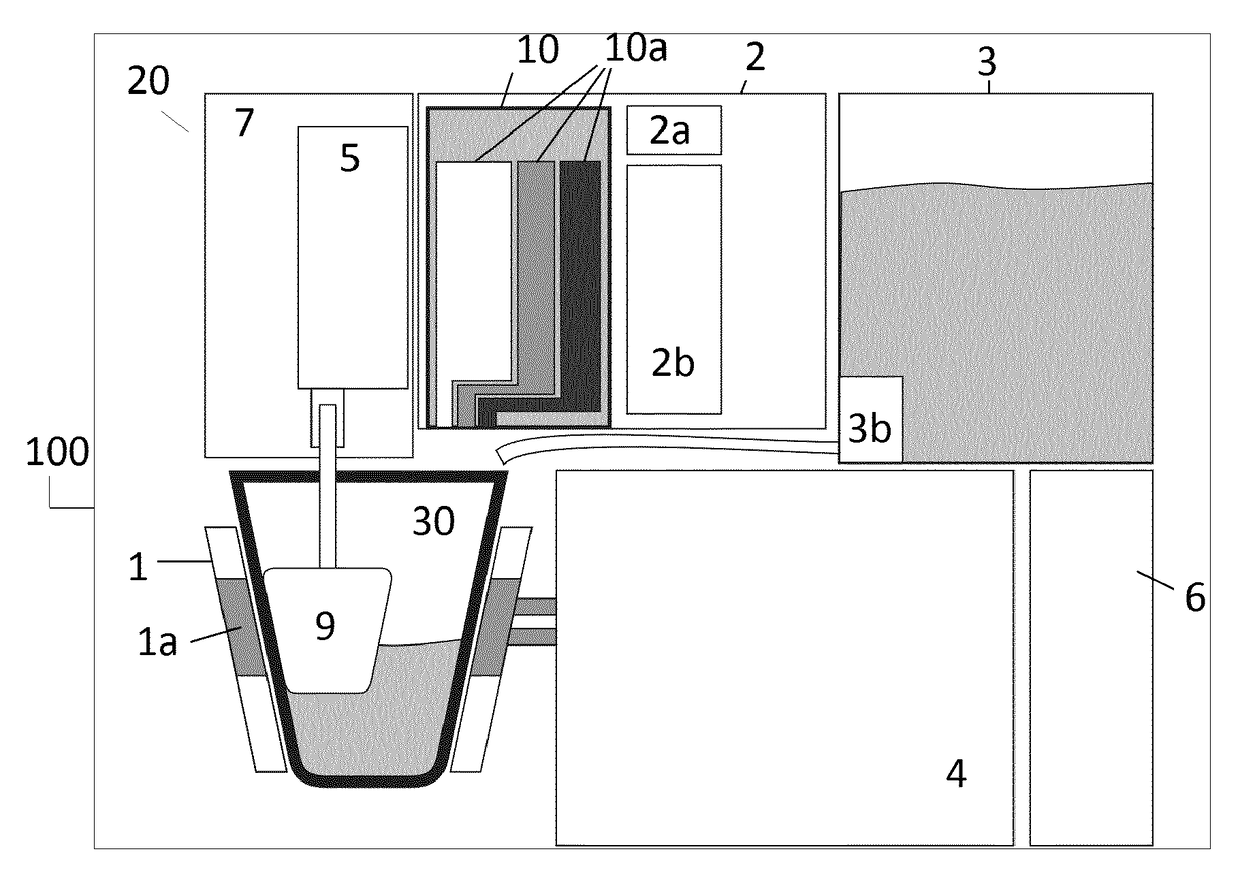

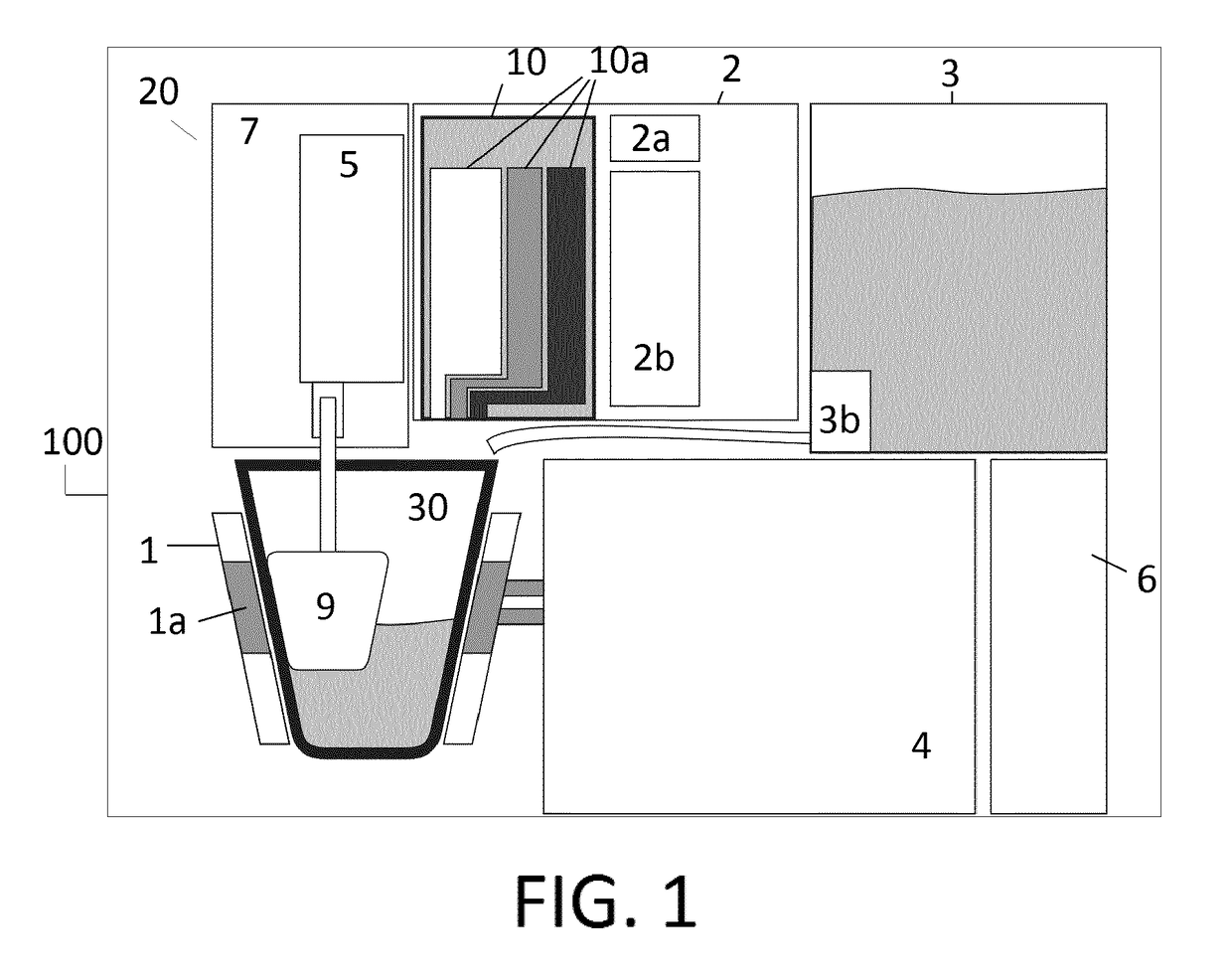

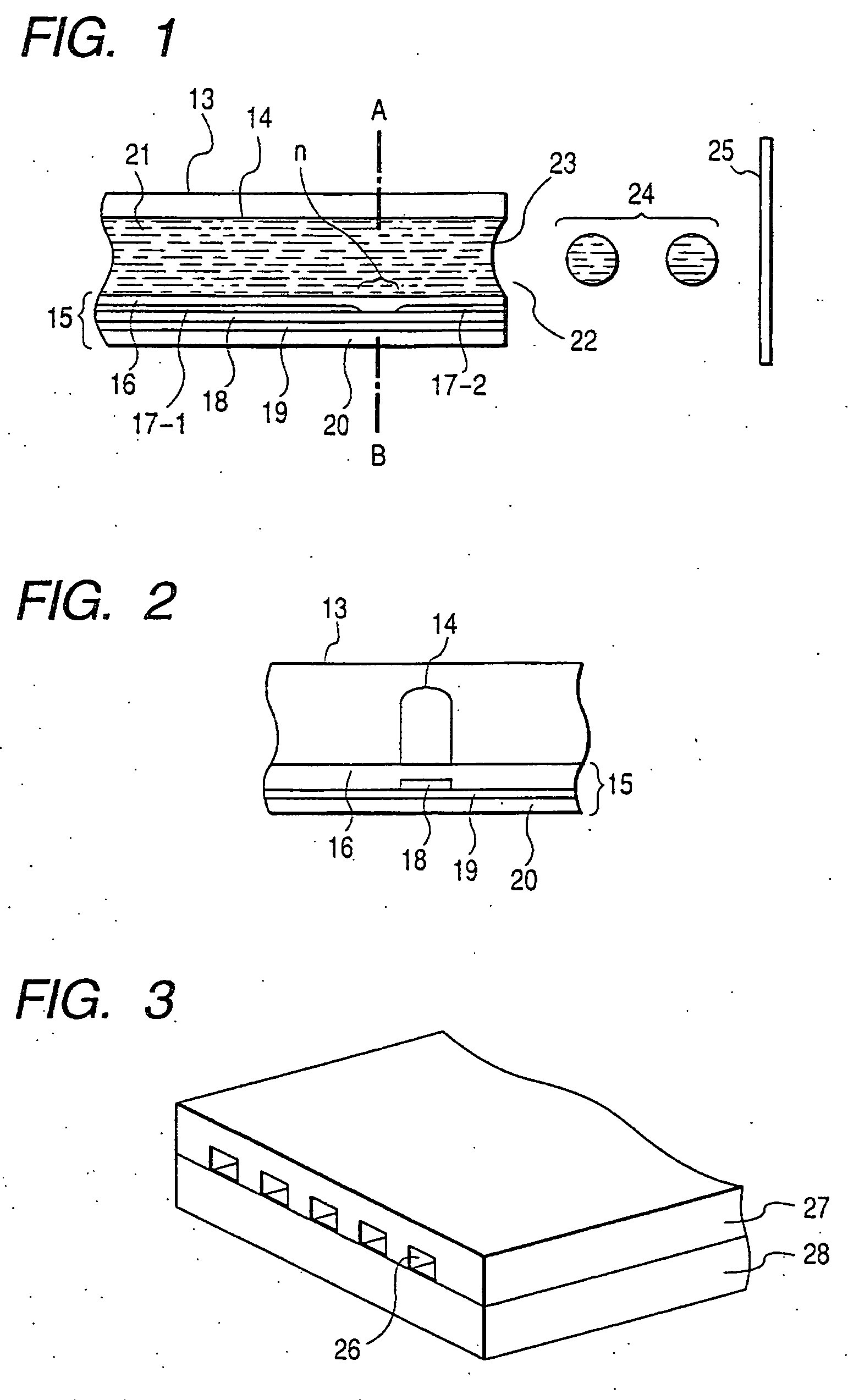

System for preparing chilled or frozen products

InactiveUS20170215456A1Quality improvementIncrease contrastReady-for-oven doughsFrozen sweetsAdditive ingredientEngineering

A single-use dispensing container (10) designed for being inserted into a device (20) where chilled and / or frozen products are prepared in a processing container (30), the dispensing container (10) comprising a plurality of ingredient compartments (10a) each comprising at least one ingredient for the preparation of the chilled or frozen product, wherein the dispensing container (10) comprises identification means providing the device (20) with information of the parameters for dispensing, cooling, texturizing and mixing the ingredients of the plurality of ingredient compartments (10a), such that the ingredients from the plurality of ingredient compartments (10a) are dispensed directly into the processing container (30), the dispensing of the ingredients being done either sequentially or simultaneously for the plurality of ingredient compartments (10a), as a function of the chilled or frozen product targeted.

Owner:NESTEC SA

Aqueous ink, ink-jet recording method, ink cartridge, recording unit, ink-jet recording apparatus and image forming method

ActiveUS20060100311A1Large area factorSuperior stabilityDuplicating/marking methodsInksWater solubleIonic dissociation

Disclosed is an aqueous ink comprising at least water, a plurality of water-soluble organic solvents and a coloring material. The coloring material is a pigment, and, it contains a pigment particle having at least one ionic group bonded to a surface of the pigment particle directly or via another atomic group. The plurality of water-soluble organic solvents have a good medium or good mediums for the pigment and a poor medium or poor mediums for the pigment. The poor medium does not solvate perfectly or substantially the pigment. The ionic group undergoes perfectly or substantially no ionic dissociation in the poor medium. Also, among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method, the Ka value of the poor medium is maximum.

Owner:CANON KK

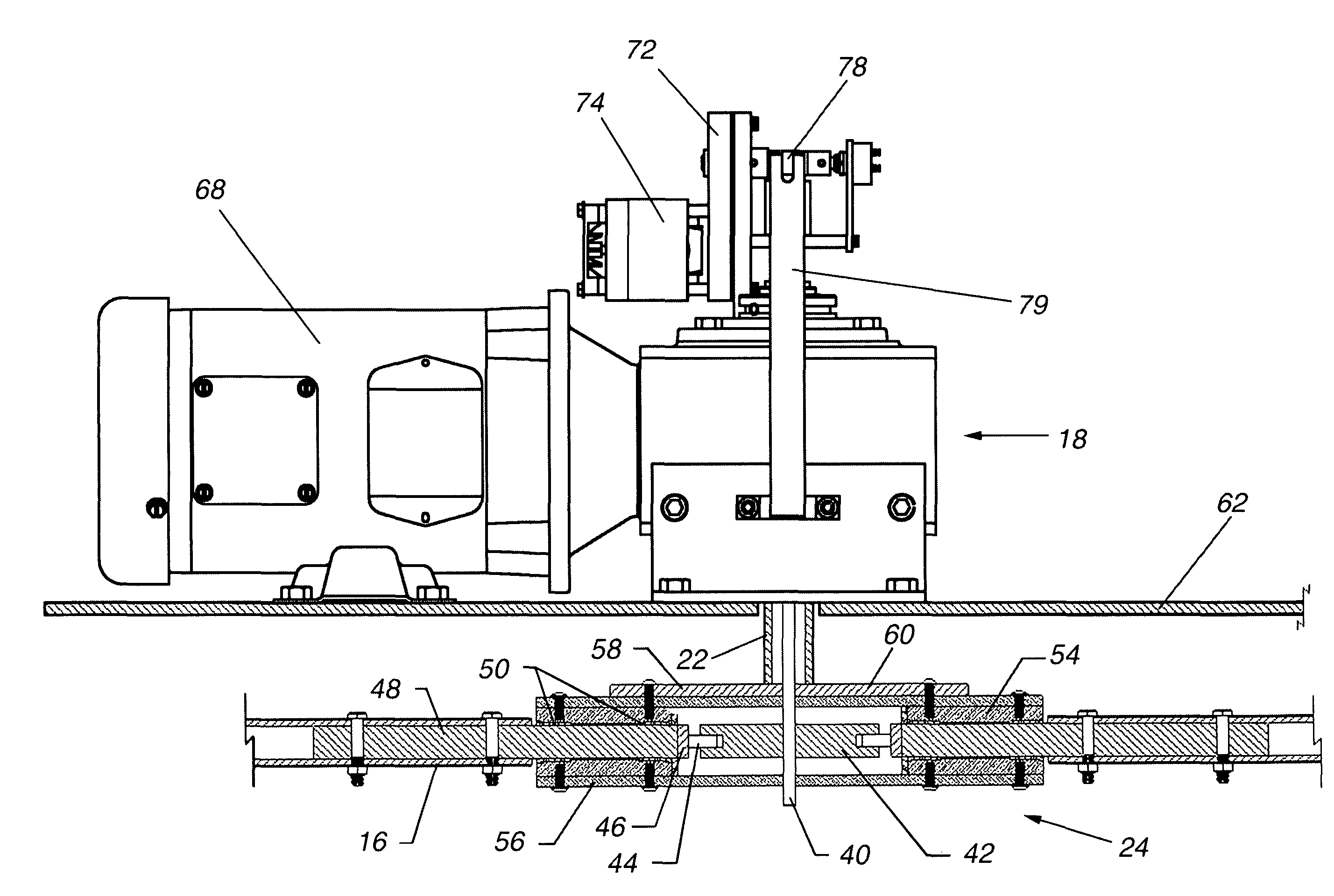

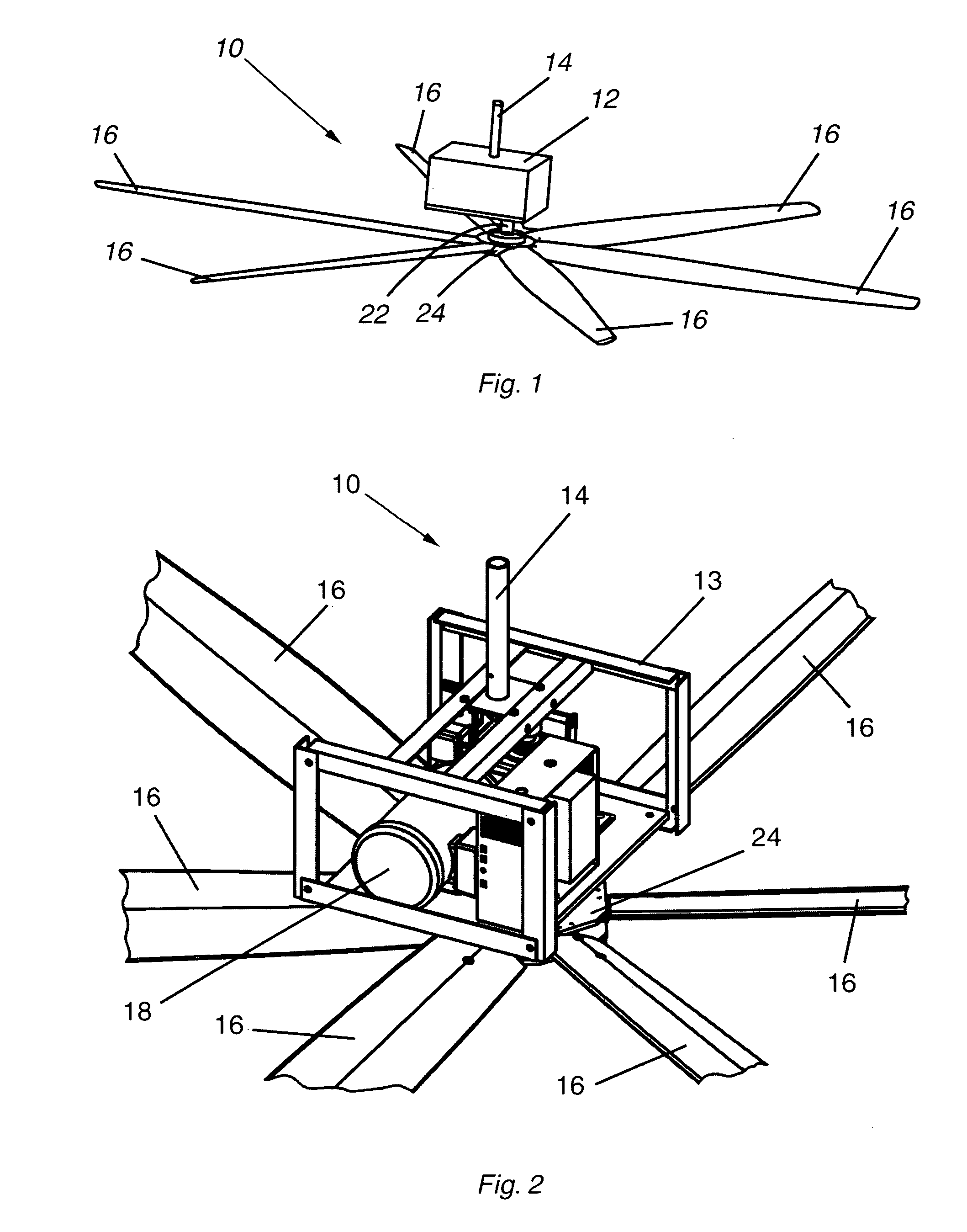

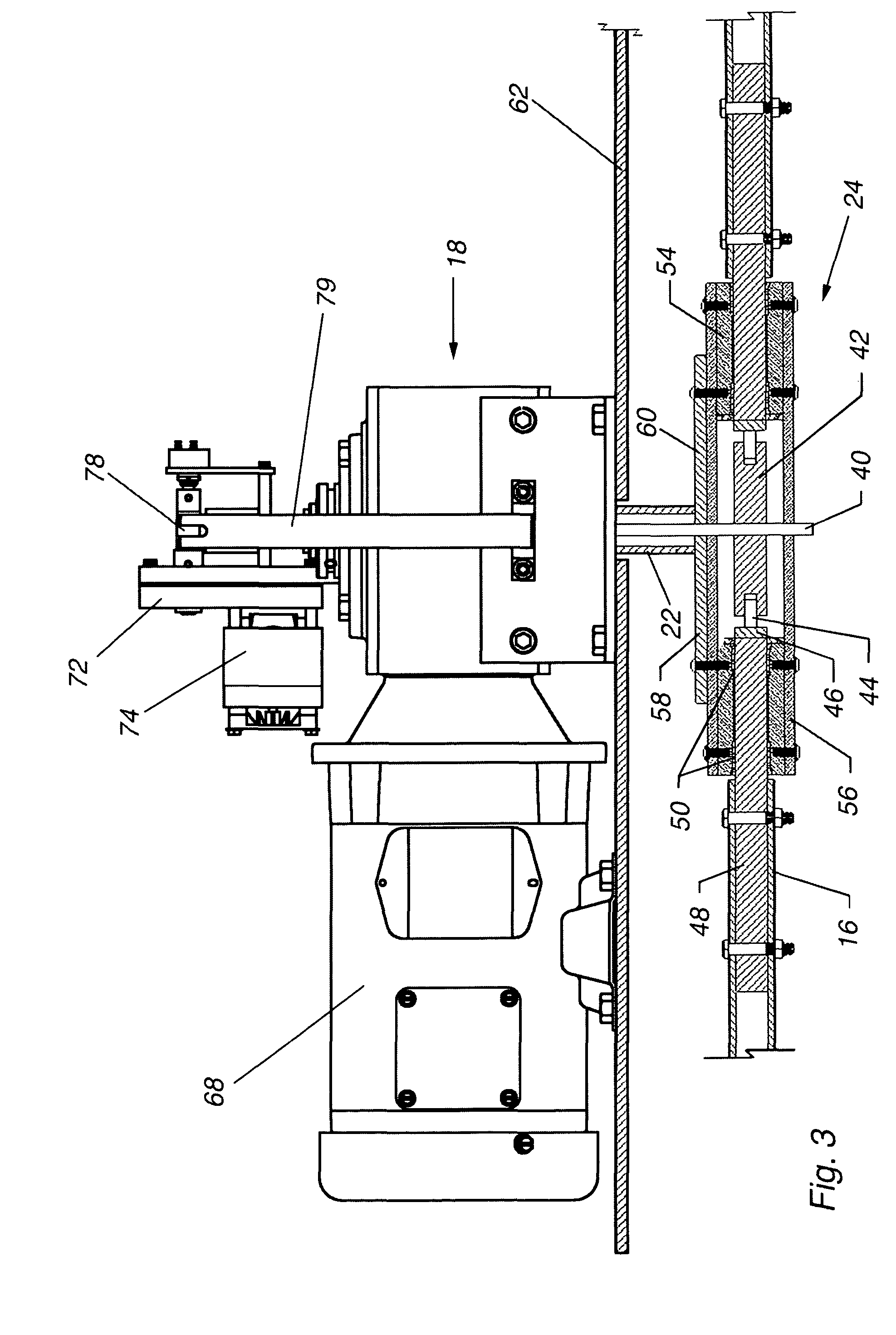

High volume low speed fan

ActiveUS8066480B2Promote circulationEasy to controlDynamo-electric brakes/clutchesPropellersAir cycleLow speed

A high volume low speed (HVLS) fan provides improved air circulation and thermal control in a building by incorporating composite fan blades pivotable to both positive and negative pitch angles. The blades are molded of polymer material over a metal tube core for strength and ease of attachment to the fan hub, and have a symmetrical airfoil shape to produce an efficient bi-directional conical airflow. The fan includes a control unit providing manual and automated intelligent control over blade angle and rotational speed, as well as startup with approximately zero blade angle for more economical power consumption and less motor wear. The fan structure and mounting system allows the fan to be installed at an optimal height inside a variety of buildings to provide increased efficiency of air destratification and air mixing. An array of multiple HVLS fans with alternating directions of airflow can further increase efficiency of air movement.

Owner:AIRMOTION SCI

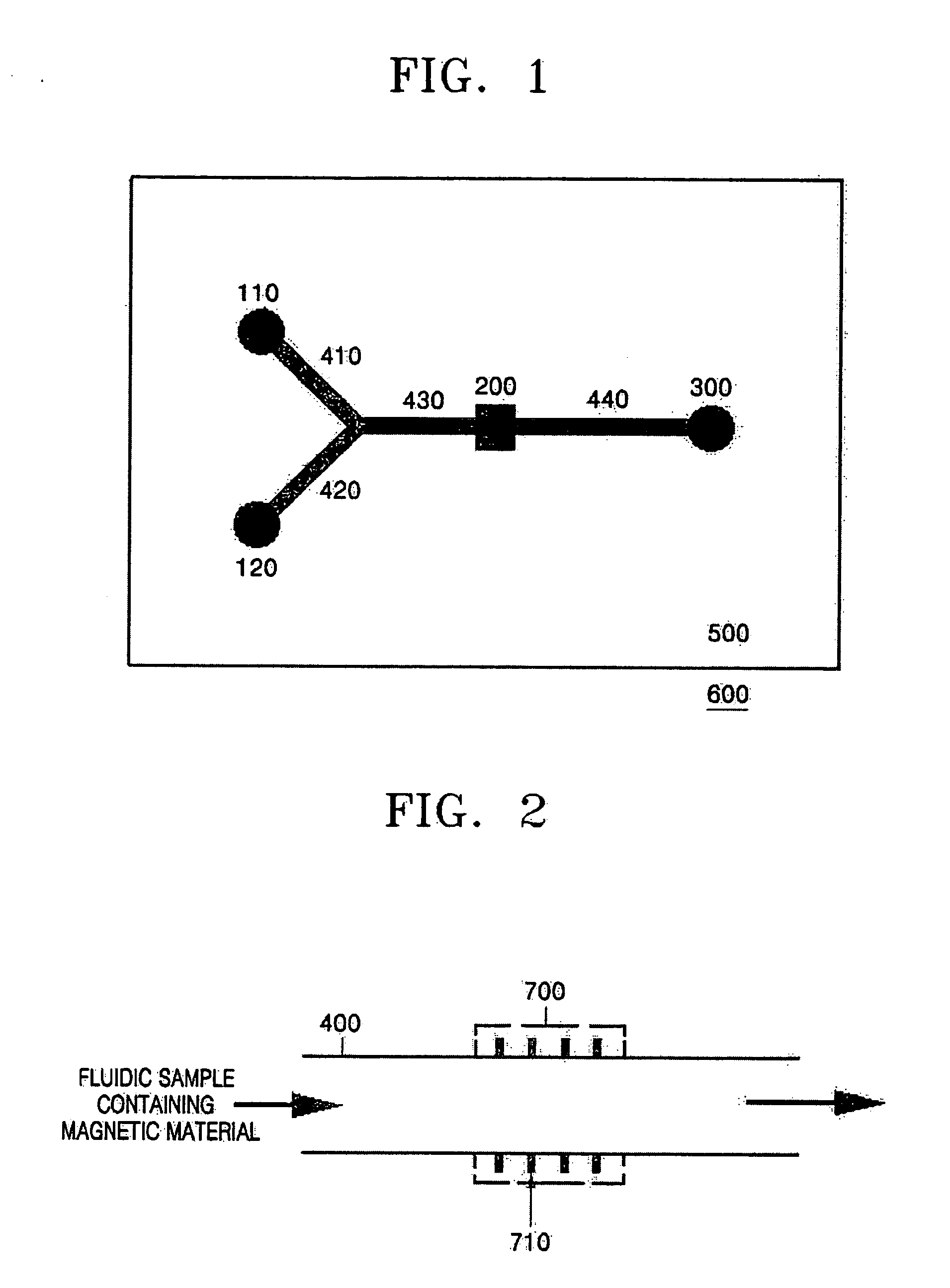

Microfluidic device including microchannel on which plurality of electromagnets are disposed, and methods of mixing sample and lysing cells using the microfluidic device

InactiveUS20060140051A1Efficient mixingEfficientlyTransportation and packagingMicroorganism lysisEngineeringElectromagnet

Owner:SAMSUNG ELECTRONICS CO LTD

Gas micro burner

InactiveUS20050069831A1Low fuel mass flow rate requirementLow mass flow rateFuel lightersBurner material specificationsGas burnerProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

Espresso coffee-making machine and associated method

InactiveUS20070227363A1Improve stabilityGood repeatabilityBeverage vesselsEspresso coffeeEngineering

An espresso-coffee making apparatus comprising a brew water tank at least one heating device for the purpose of heating the brew water, and a pump operatively engaged to the brew water tank with both its inlet and outlet. The pump outlet is attached to a housing such that the pump's discharge moves past the heating device for effective mixing at the heat source. The housing may also include turbulators for further enhanced mixing. Thus, maximum temperature homogeneity within the brew water tank is achieved. The apparatus may further comprise a biasing device operatively engaged to a piston-type pump via a linkage mechanism. Wherein the biasing device is energized by the operator, by means of a lever and the pressurized water produced used to brew espresso. Further, the pressure of the water produced by the pump is modified by the linkage mechanism such that the brew pressure as a function of displaced liquid is controlled. Thus more optimal brewing pressure profiles can be achieved.

Owner:VERNA RAFFAELLO

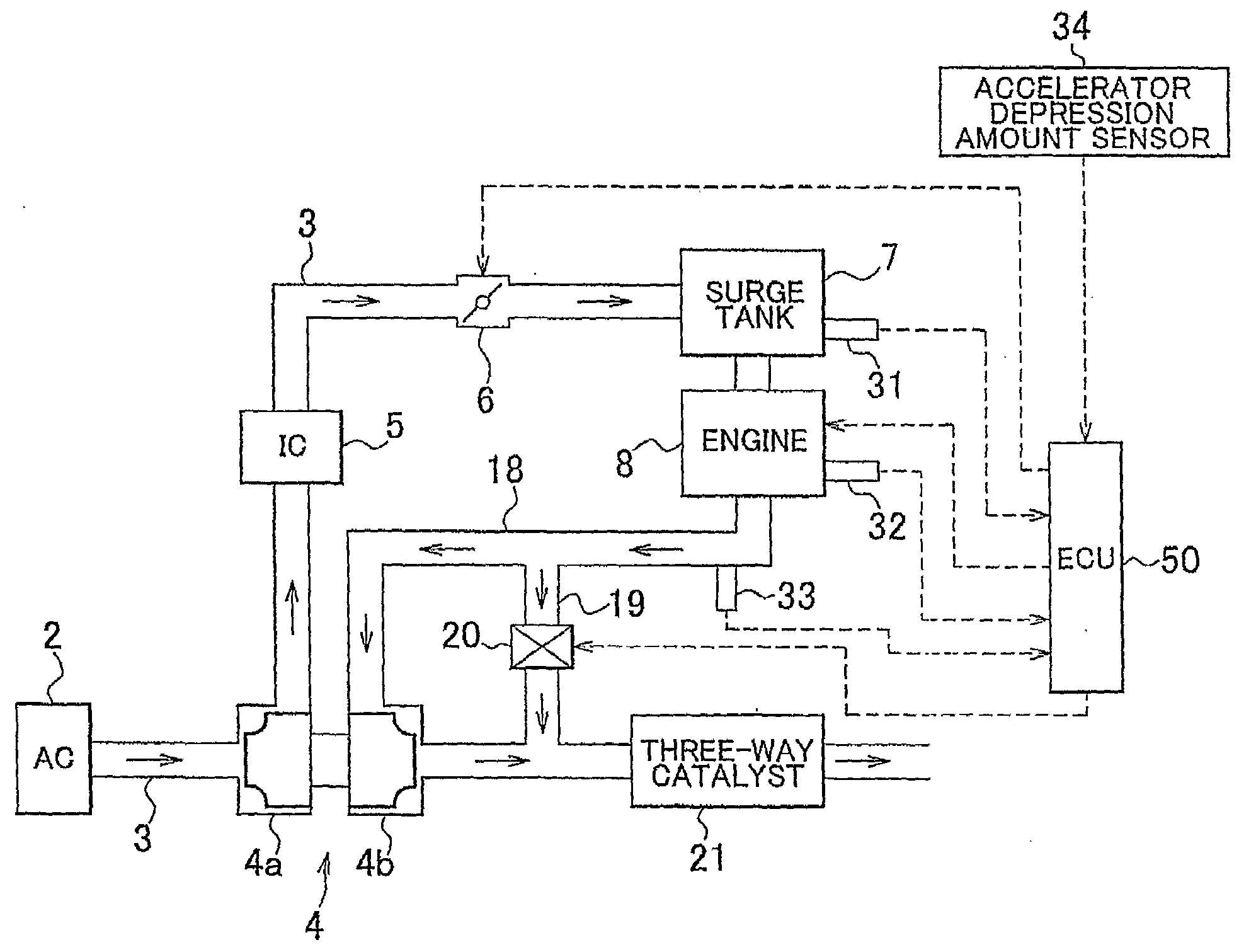

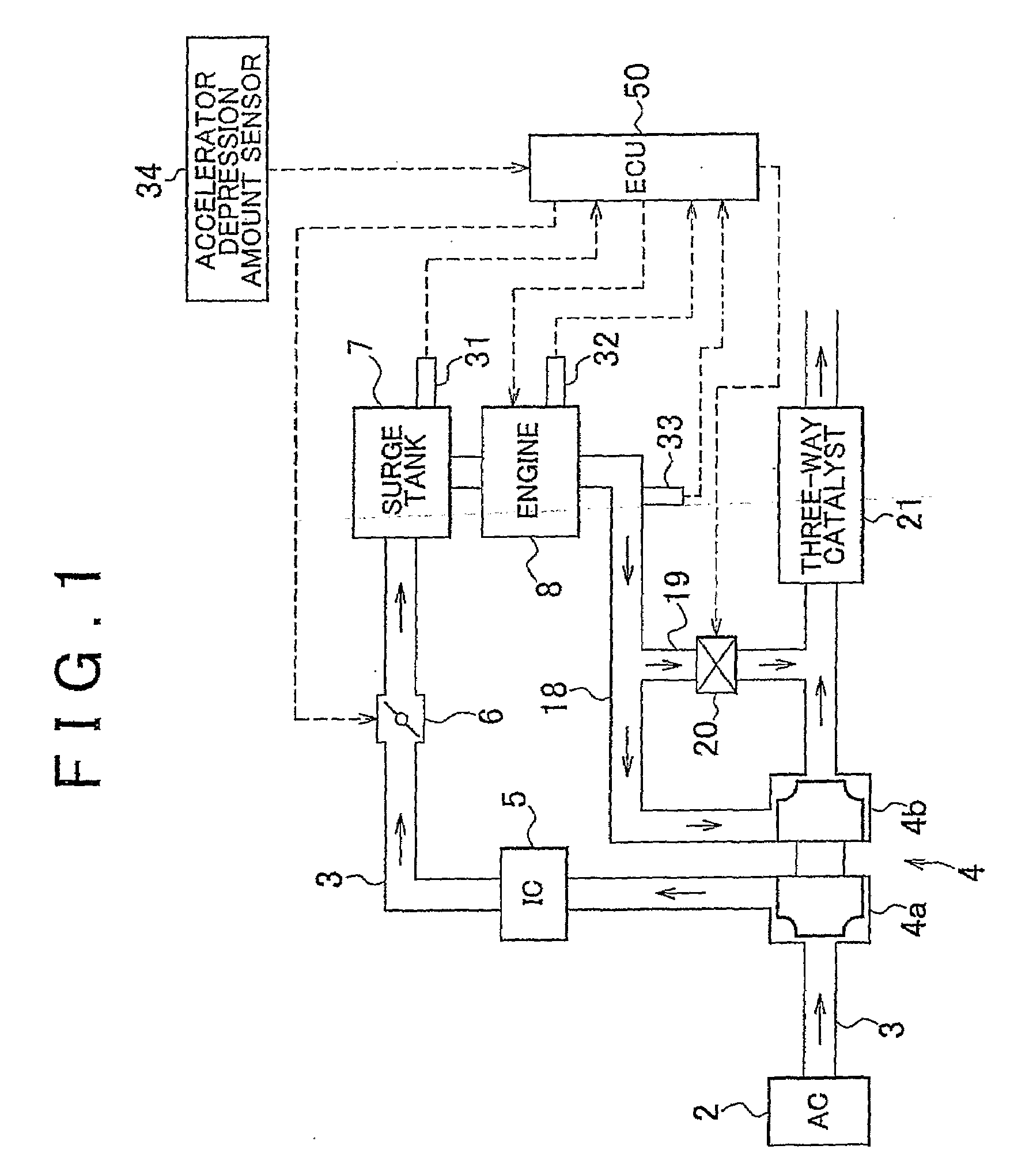

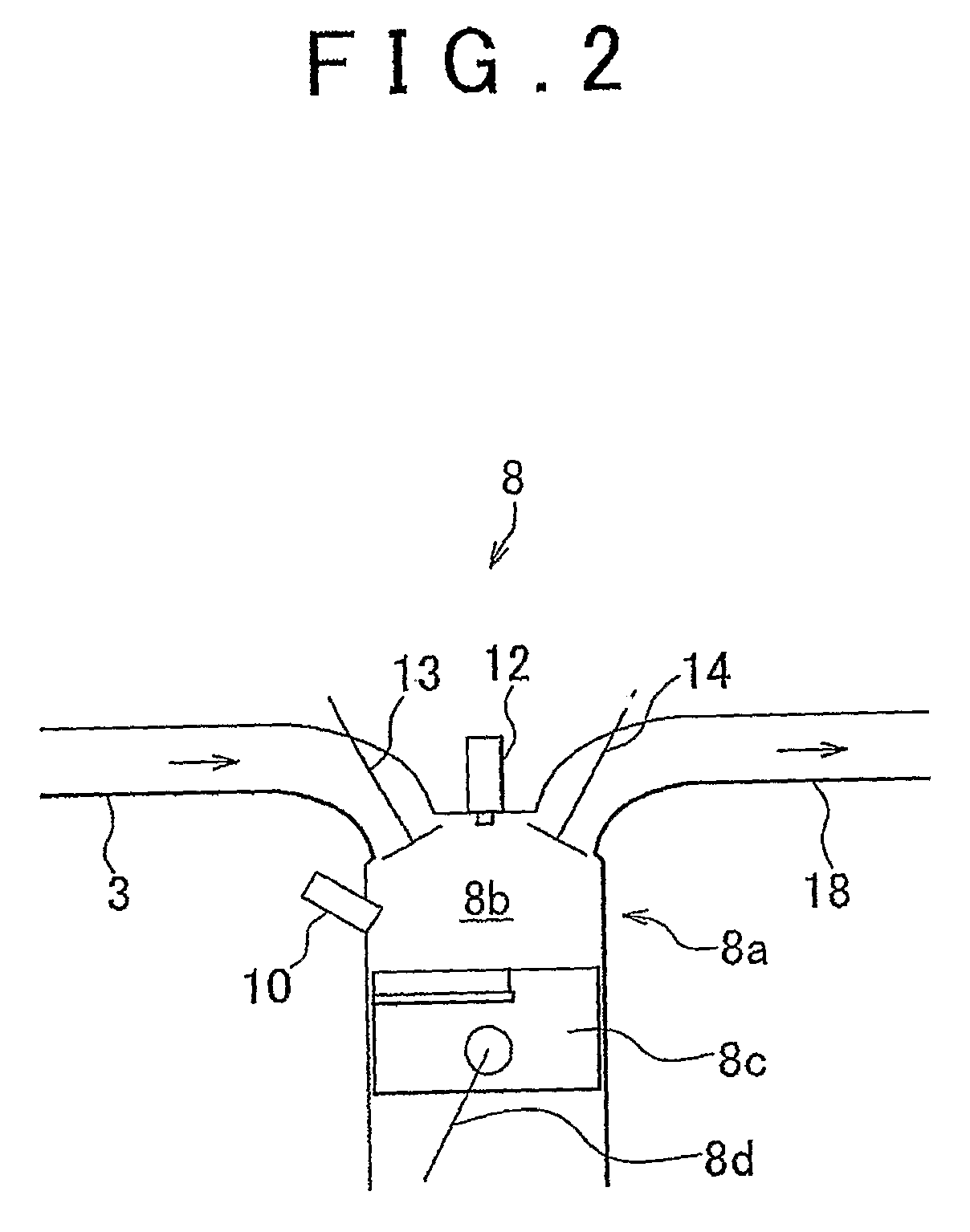

Control apparatus and control method of internal combustion engine

InactiveUS20090292446A1Efficient mixingReliable combustionElectrical controlInternal combustion piston enginesLean combustionWarming up

A control apparatus of an internal combustion engine performs control to warm up a catalyst. More specifically, the control apparatus keeps a wastegate valve open when the temperature of the catalyst is less than a predetermined temperature and closes the wastegate valve when the temperature of the catalyst becomes equal to or greater than the predetermined temperature. The control apparatus executes control to increase and decrease the fuel injection quantity such that the internal combustion engine alternately switches between lean burn and rich burn when the wastegate valve is closed. Accordingly, rich gas and lean gas can be reliably mixed in the catalyst, and CO can be reliably combusted in the catalyst. Therefore, the catalyst can be promptly warmed up while CO, HC, and the like can be appropriately suppressed from flowing through the catalyst.

Owner:TOYOTA JIDOSHA KK

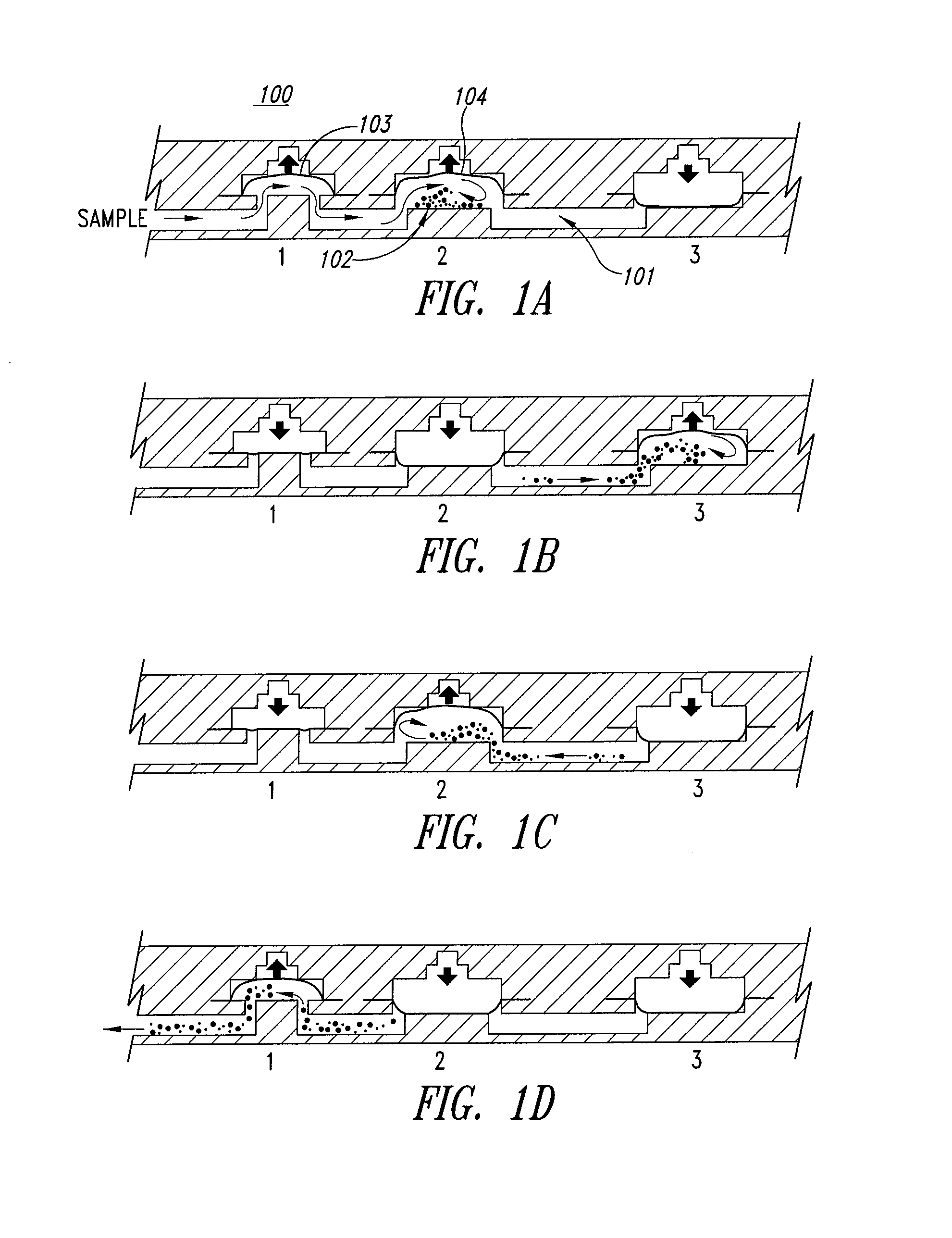

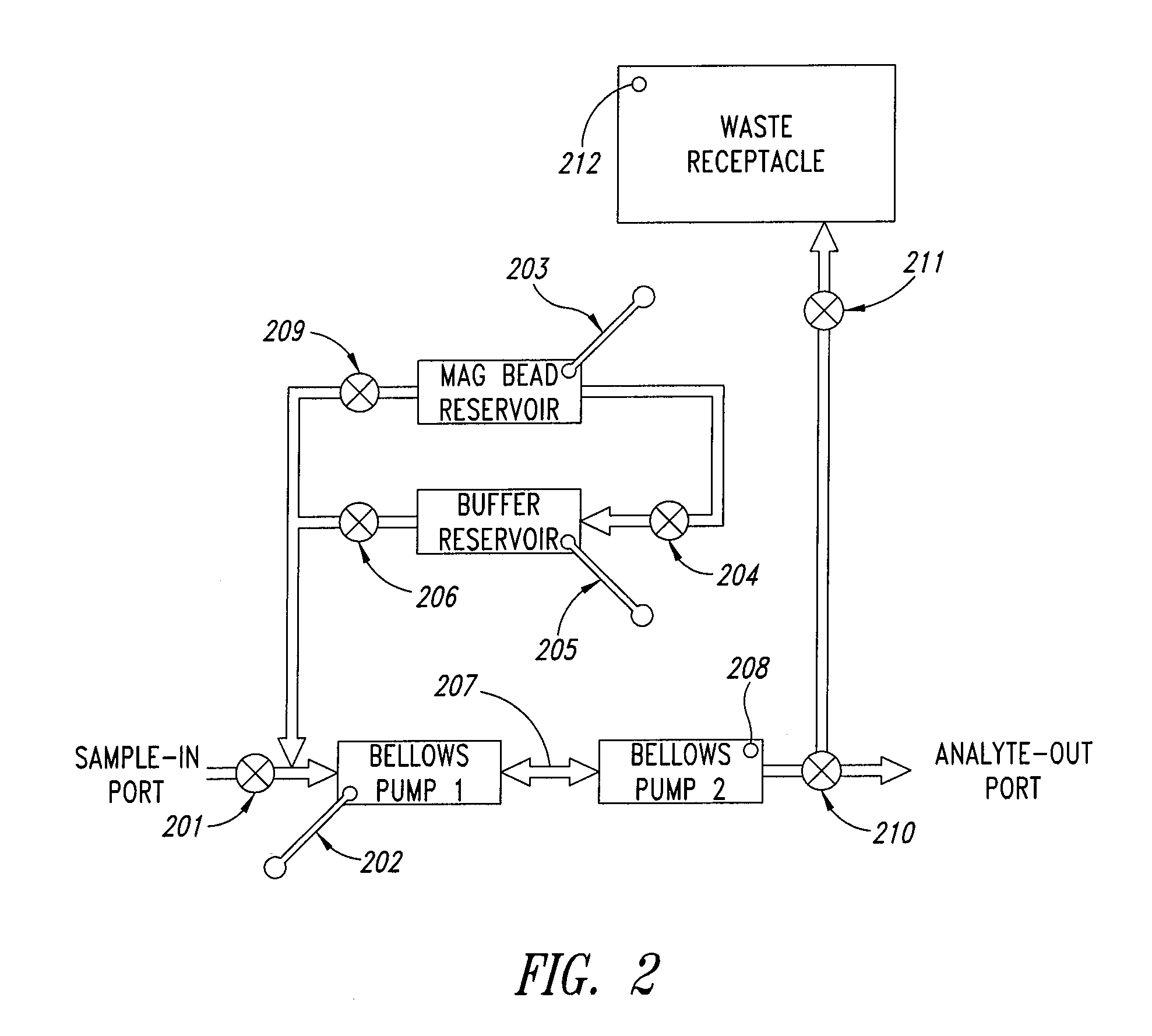

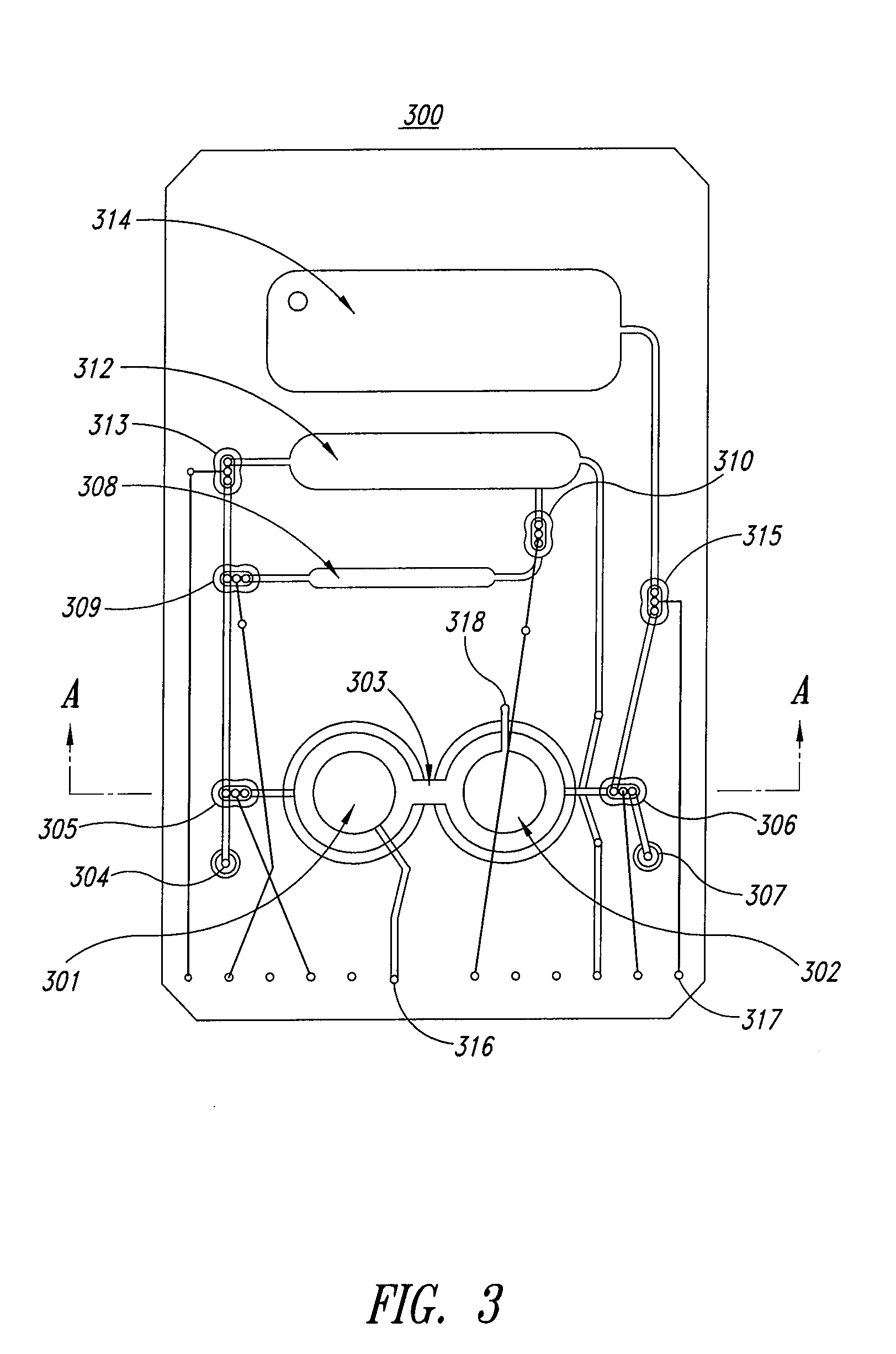

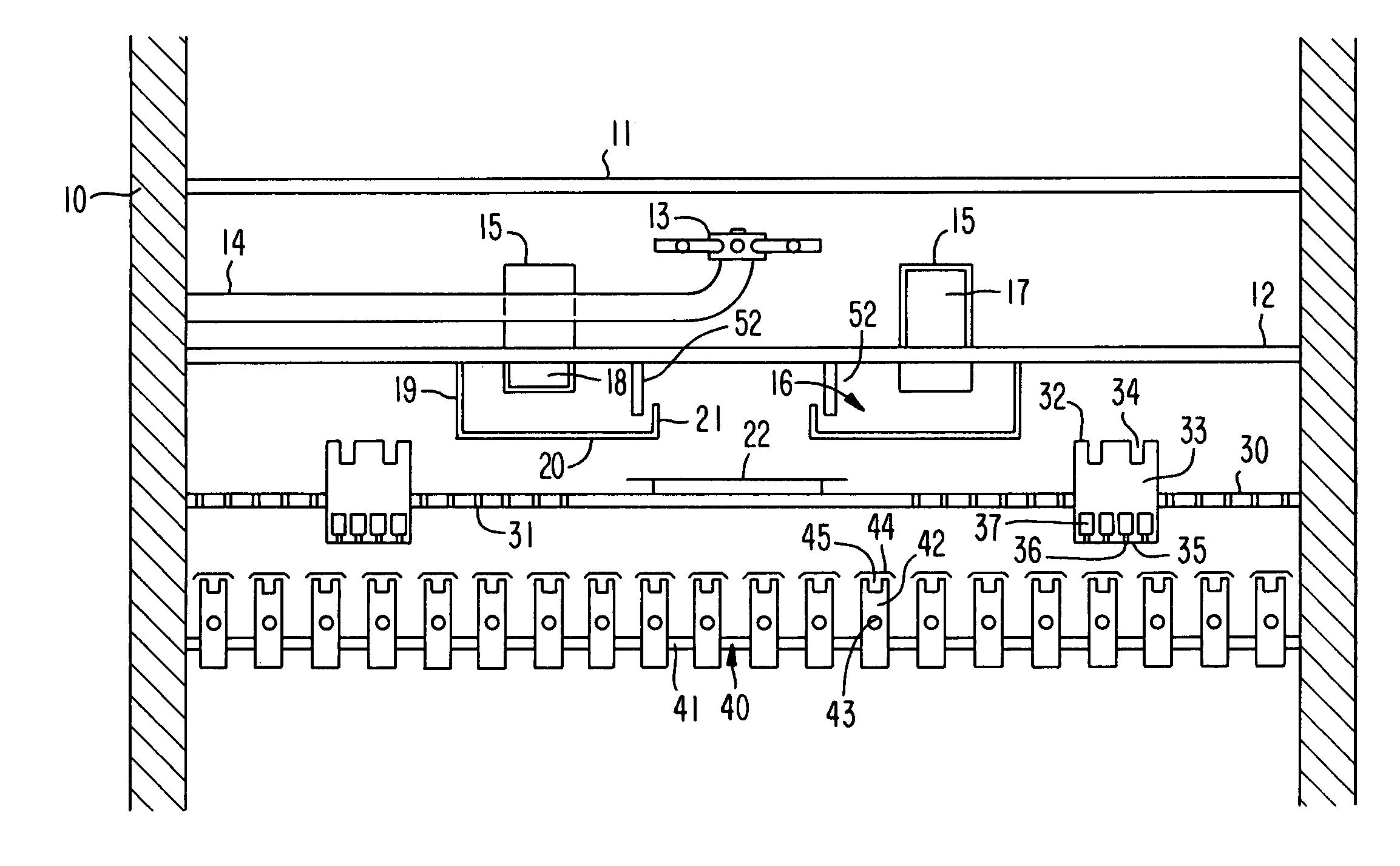

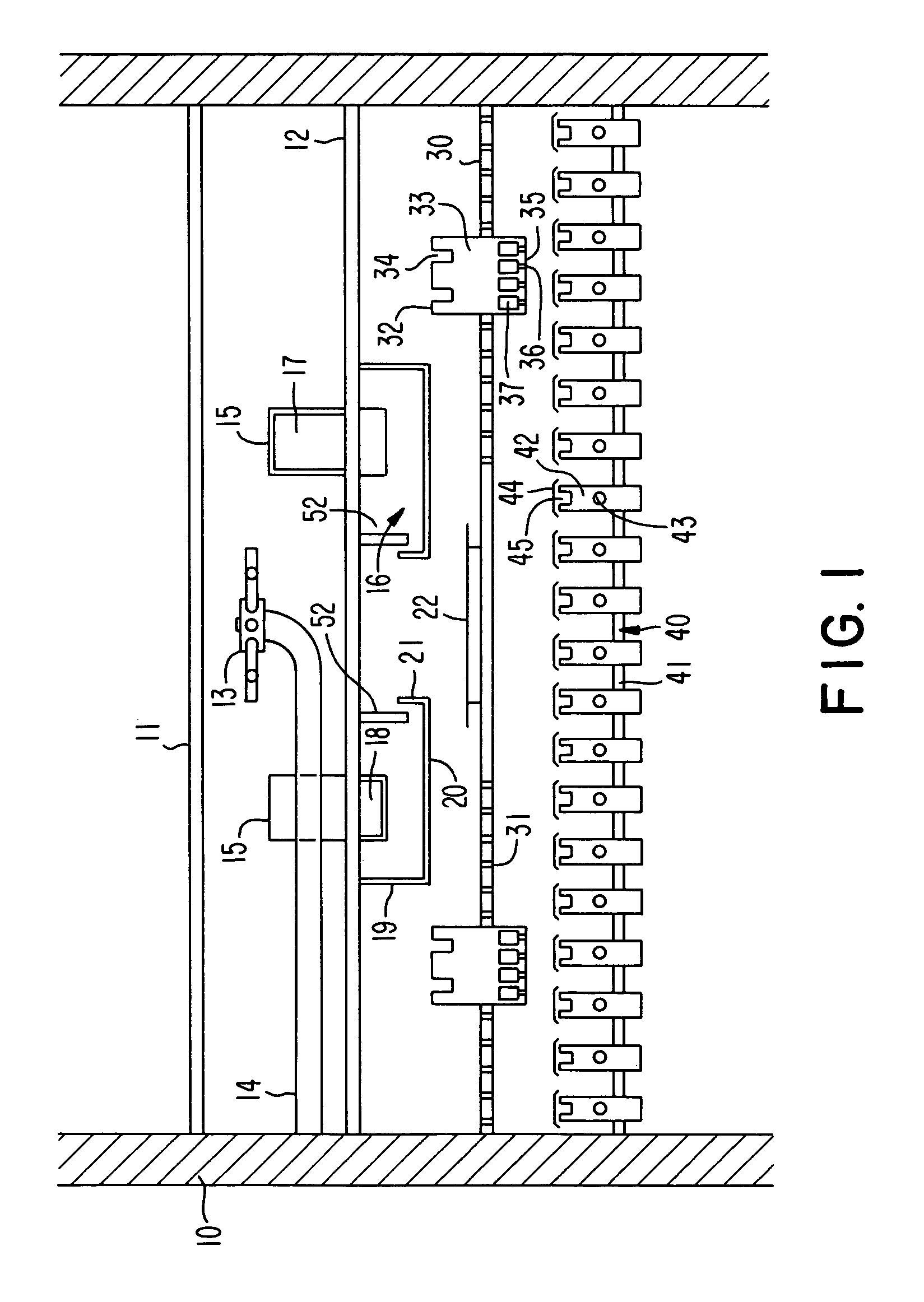

Microfluidic mixing and analytical apparatus

InactiveUS20100167384A1Efficient mixingWell mixedBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersMagnetic beadEngineering

Disclosed herein is a device comprising a pair of bellows pumps configured for efficient mixing at a microfluidic scale. By moving a fluid sample and particles in suspension through an aperture between the paired bellows pump mixing chambers, molecular collisions leading to binding between the particles and ligands in the sample are enhanced. Such devices provide an alternative for mixing that does not use a vent and can be used with a variety of particles in suspension such as magnetic beads to capture or purify useful cells and molecules.

Owner:PERKINELMER HEALTH SCIENCES INC

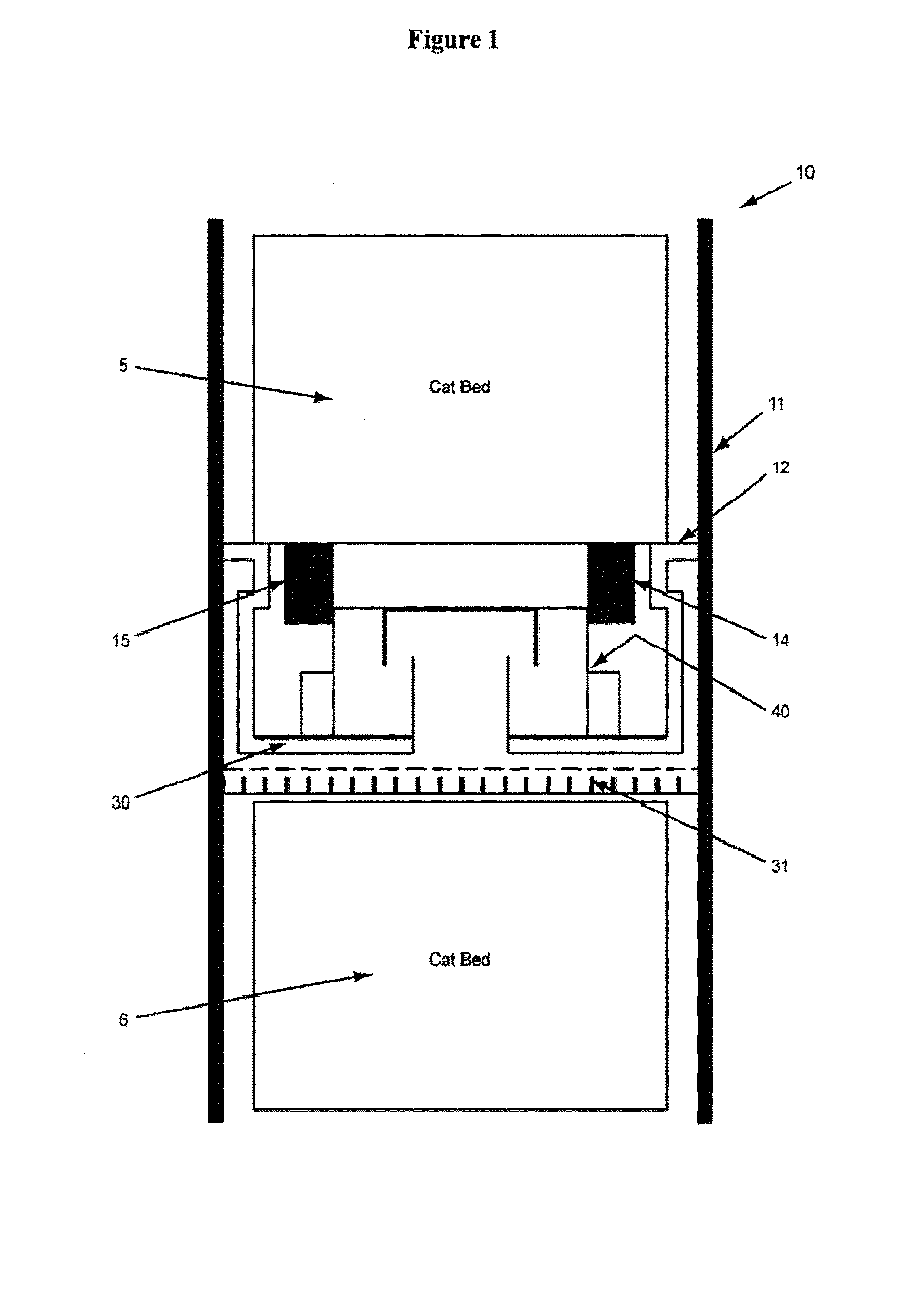

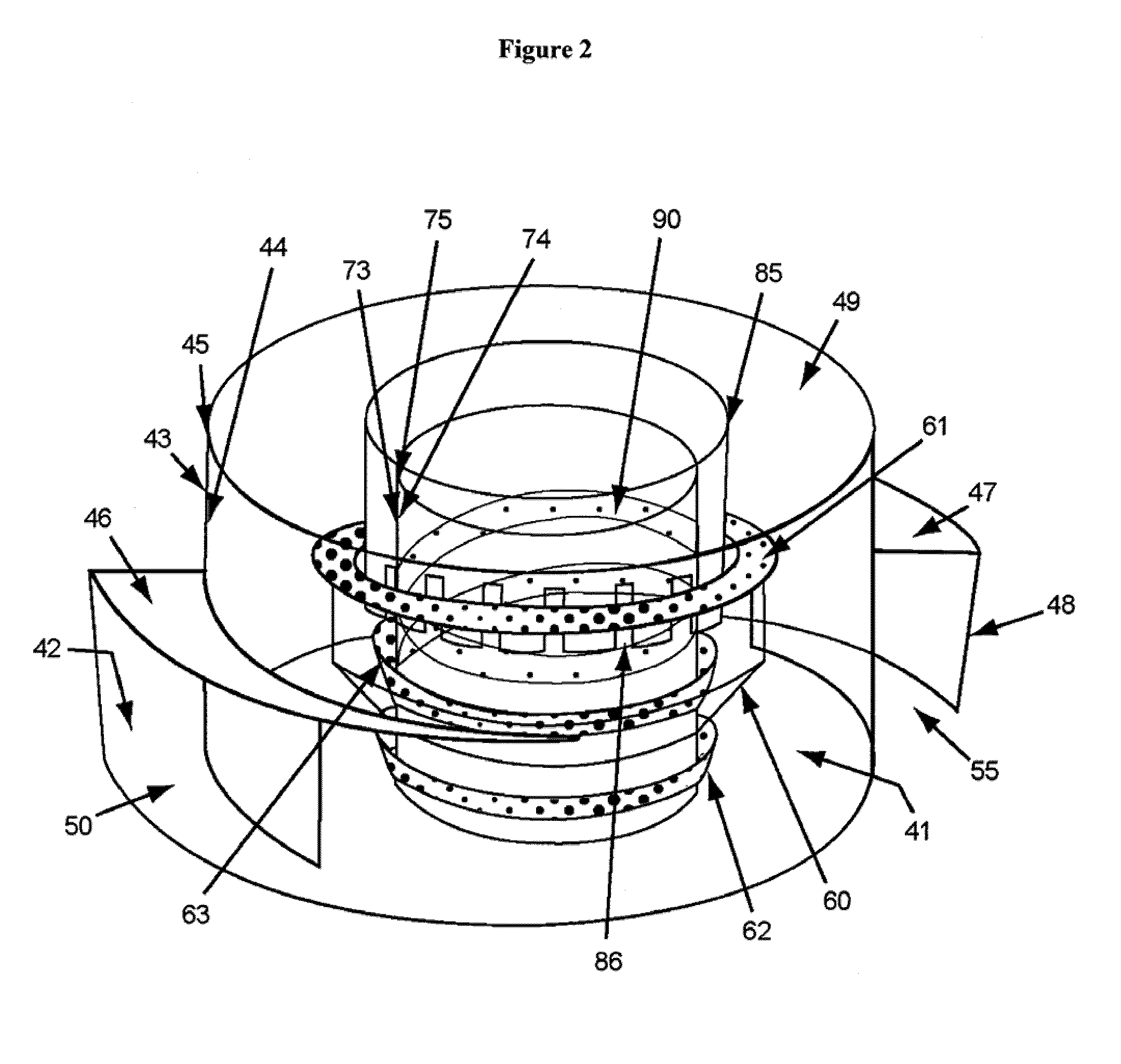

Multiphase mixing device with baffles

ActiveUS7045103B2Smooth connectionIncrease volumePhysical/chemical process catalystsMixing methodsGas phaseEngineering

The present invention provides a novel means to provide more effective mixing of quench gas and process fluids in a height constrained interbed space of a catalytic reactor without increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase of two-phase systems. According to the present invention, the quench zone hardware contained within the reactor includes a substantially vertical continuous perimeter solid baffle attached to the underside of the collection tray.

Owner:EXXON RES & ENG CO

Mixing device for a down-flow reactor

ActiveUS8017095B2Improve efficiencySmall sizePhysical/chemical process catalystsFlow mixersGas phaseProcess engineering

The present invention provides a novel means to provide more effective mixing of gas and fluids in a height constrained interbed space of a catalytic reactor without increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase and liquid phase of two-phase systems. According to the present invention, the mixing device helps create a highly arcuate flow to incoming effluents and a high degree of mixing within a constrained interbed space of a catalytic reactor.

Owner:CHEVROU USA INC

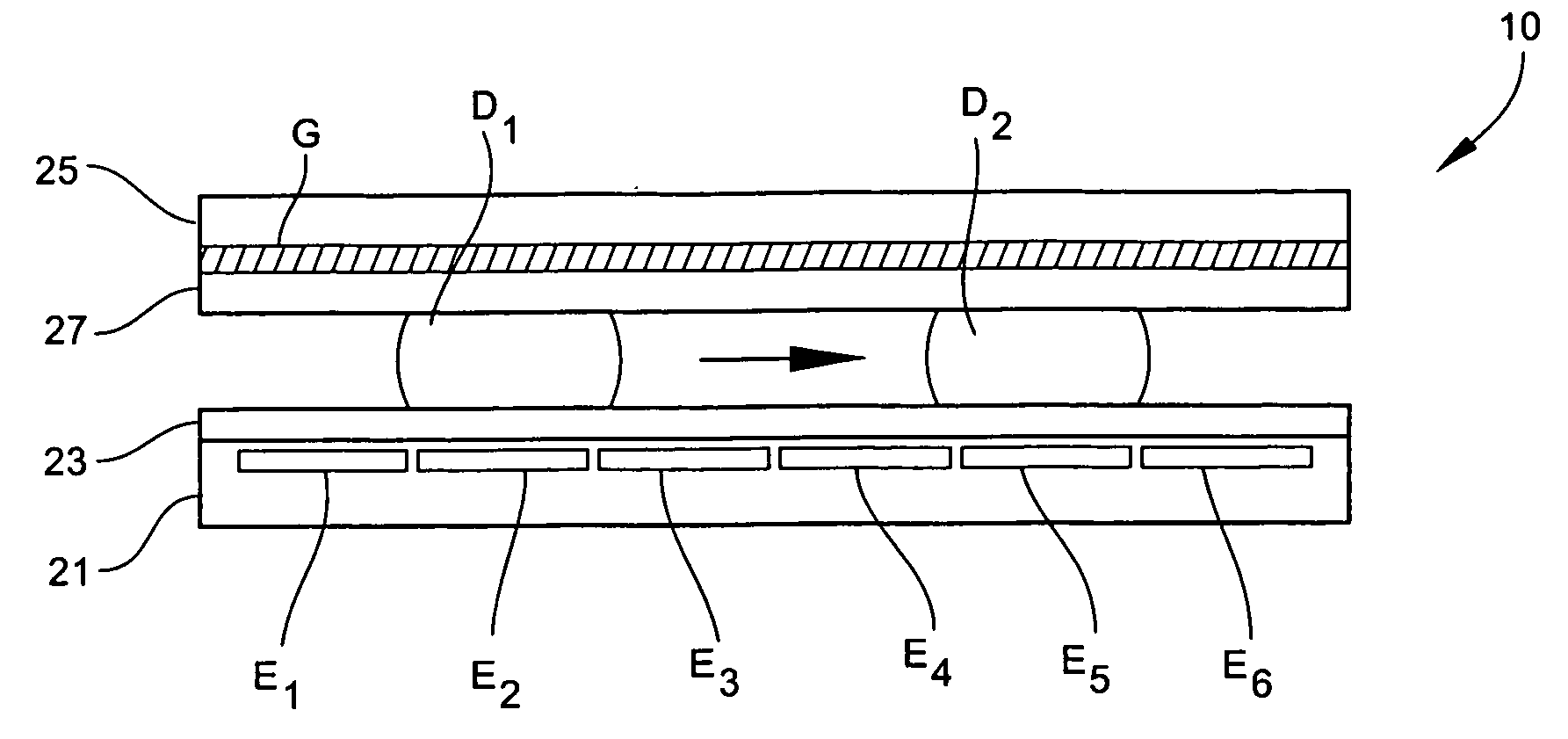

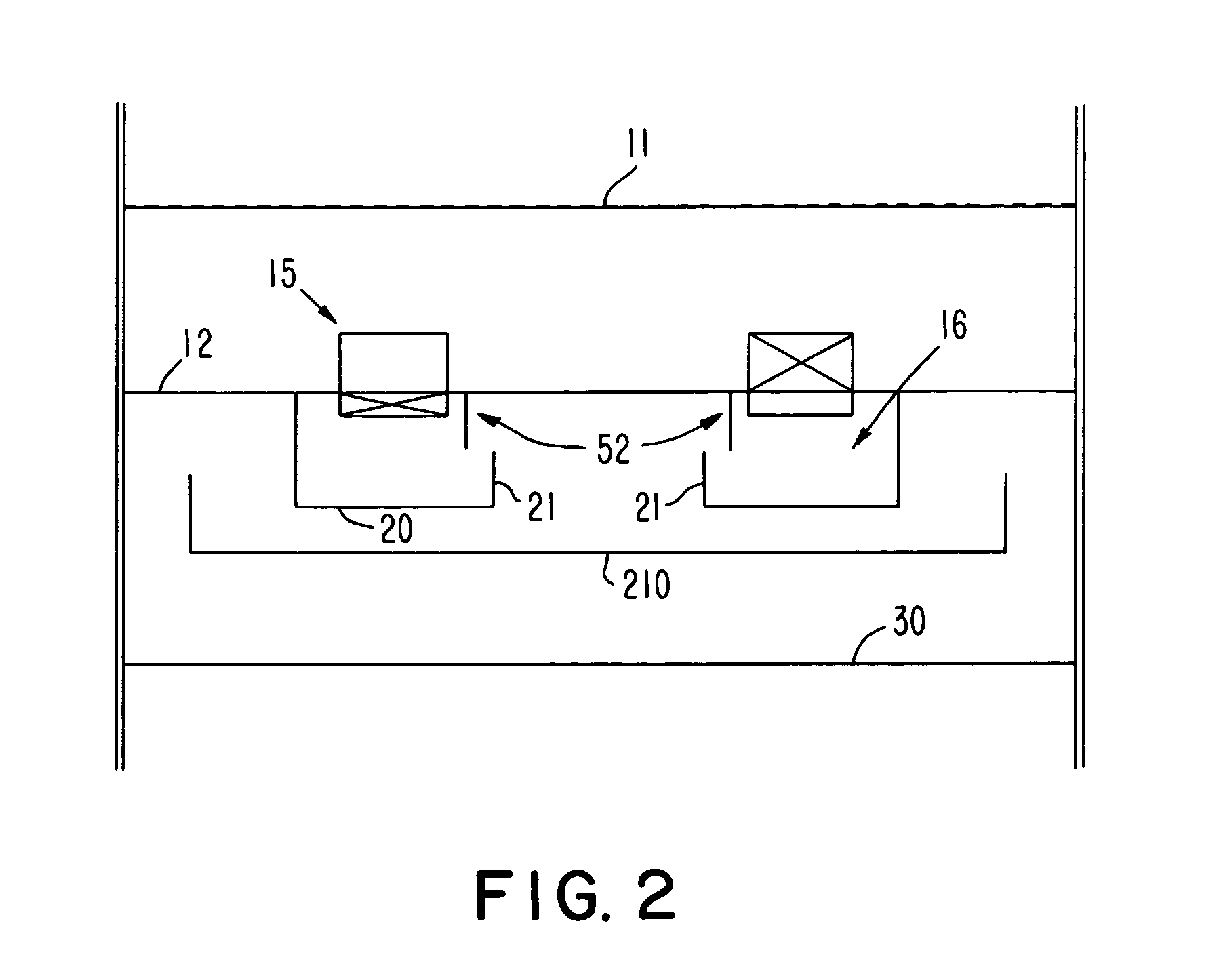

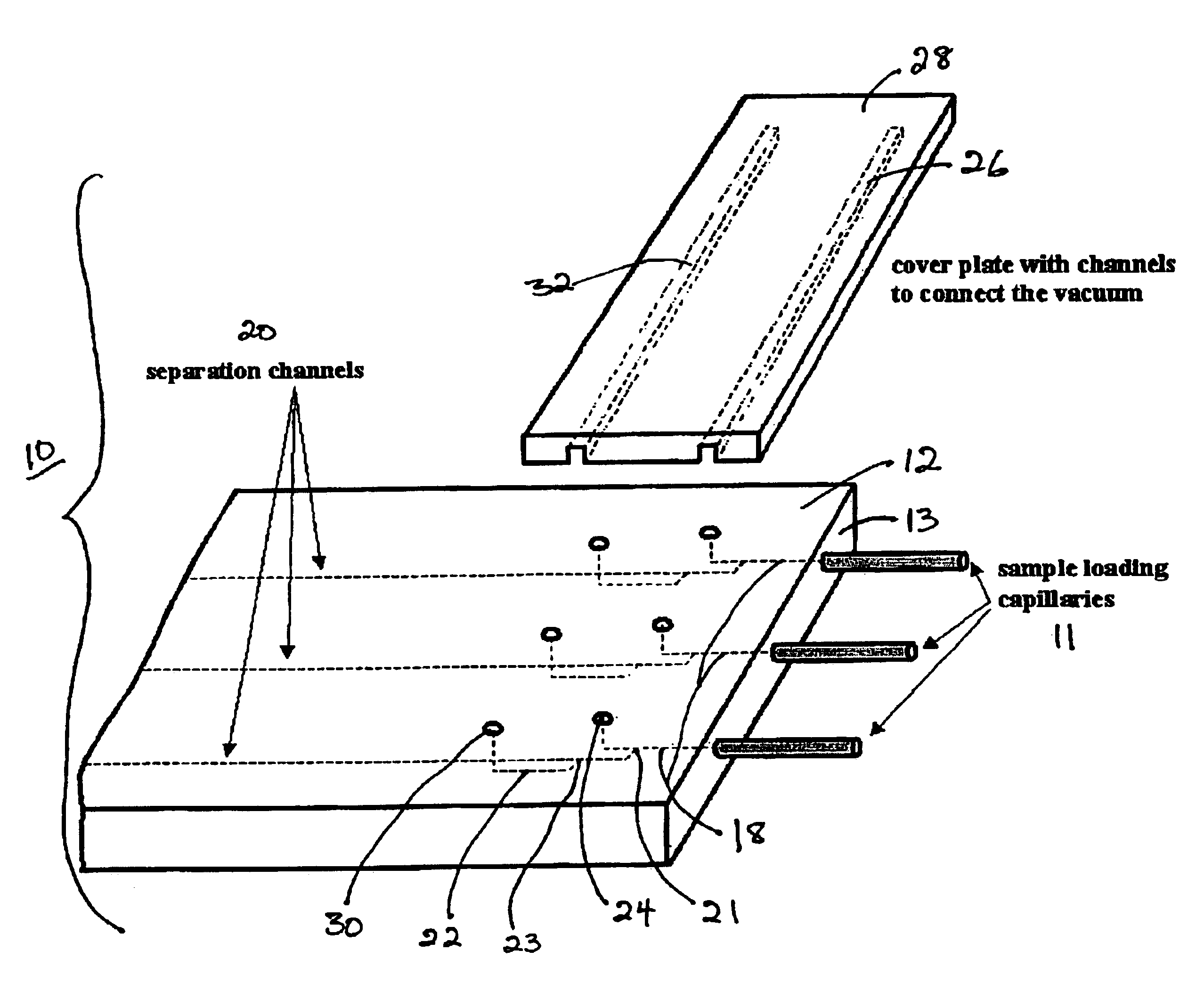

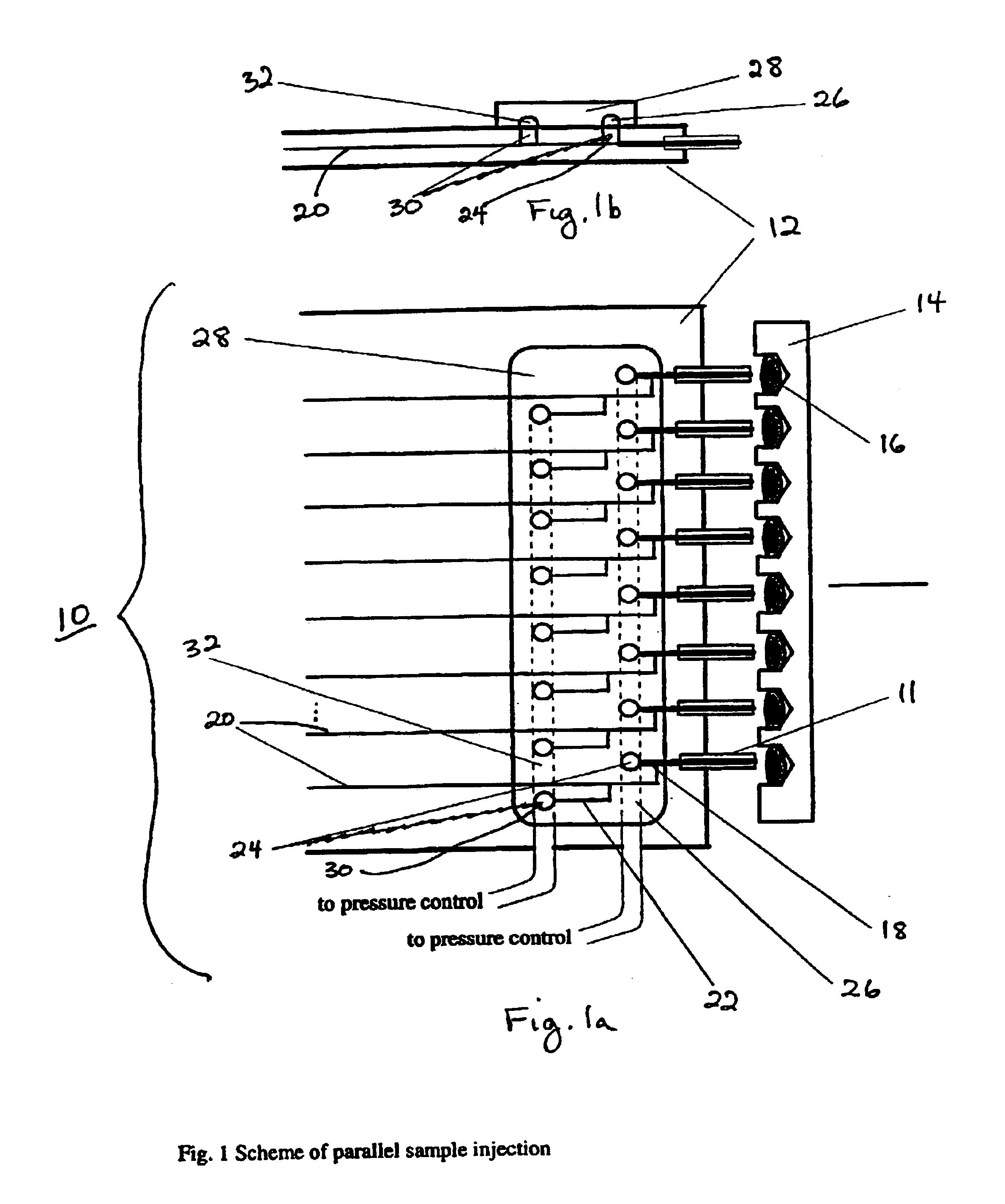

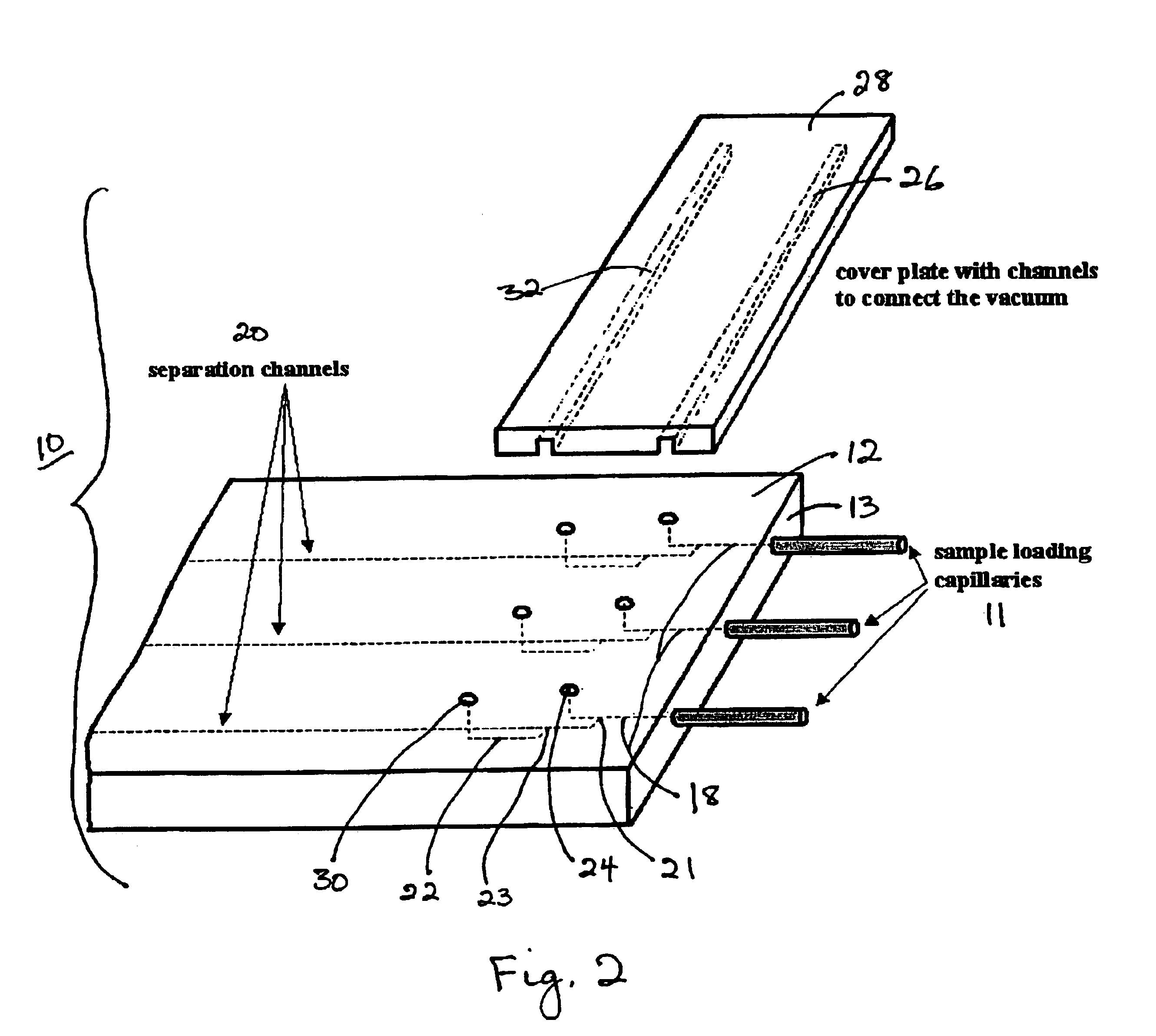

Parallel sample loading and injection device for multichannel microfluidic devices

InactiveUS6939452B2Large specific surface areaEfficient mixingSludge treatmentVolume/mass flow measurementInjection devicePhysics

A sample load and injection device (10) includes sample introduction capillaries (11) attached to a microfluidic device (12). Sample introduction capillaries (11) are connected to sample introduction channels (18). Sample introduction capillaries (18) are connected to separation channels (20) at connection points (21). At a defined distance along the separation channels (20), auxilliary channels (23) originate at connection points (24). The sample load and injection device includes cover plate (28) which has connecting channels (26, 32). Connecting channel (26) is associated with ends (24) of sample introduction channels (18). Connecting channel (32) is associated with ends (20).

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com