Patents

Literature

1644results about How to "Avoid chipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard multilayer coated tool having increased toughness

InactiveUS6309738B1Improve toughnessLower resistancePigmenting treatmentVacuum evaporation coatingTitaniumToughness

A hard multilayer coated tool including: (a) a substrate; and (b) a multilayer coating covering the substrate, the multilayer coating comprising first and second coating layers which are alternately laminated on the substrate, each of the first coating layers having and average thickness of 0.10-0.50 mum and containing titanium therein, each of the second coating layers having and average thickness of 0.10-0.50 mum and containing aluminum therein, the multilayer coating having and average thickness of 0.50-10.0 mum.

Owner:OSG

Direct compression metformin hydrochloride tablets

InactiveUS6117451AGood compressibilityImproved flowabilityPowder deliveryBiocideMetformin HydrochlorideHigh doses

Metformin Hydrochloride (herein referred to as metformin HCl) that may be 98.5%-100% pure is a high dose drug capable of being directly compressed with specific excipients into tablets having desired, hardness, disintegrating ability, and acceptable dissolution characteristics. Metformin HCl is not inherently compressible and thus presents formulation problems. Excipients used in the formulation enhance the flow and compaction properties of the drug and tableting mix. Optimal flow contributes to uniform die fill and weight control. The binder used ensures sufficient cohesive properties that allow metformin HCl to be compressed using the direct compression method. The tablets produced provide an acceptable in-vitro dissolution profile.

Owner:PHARMALOGIX

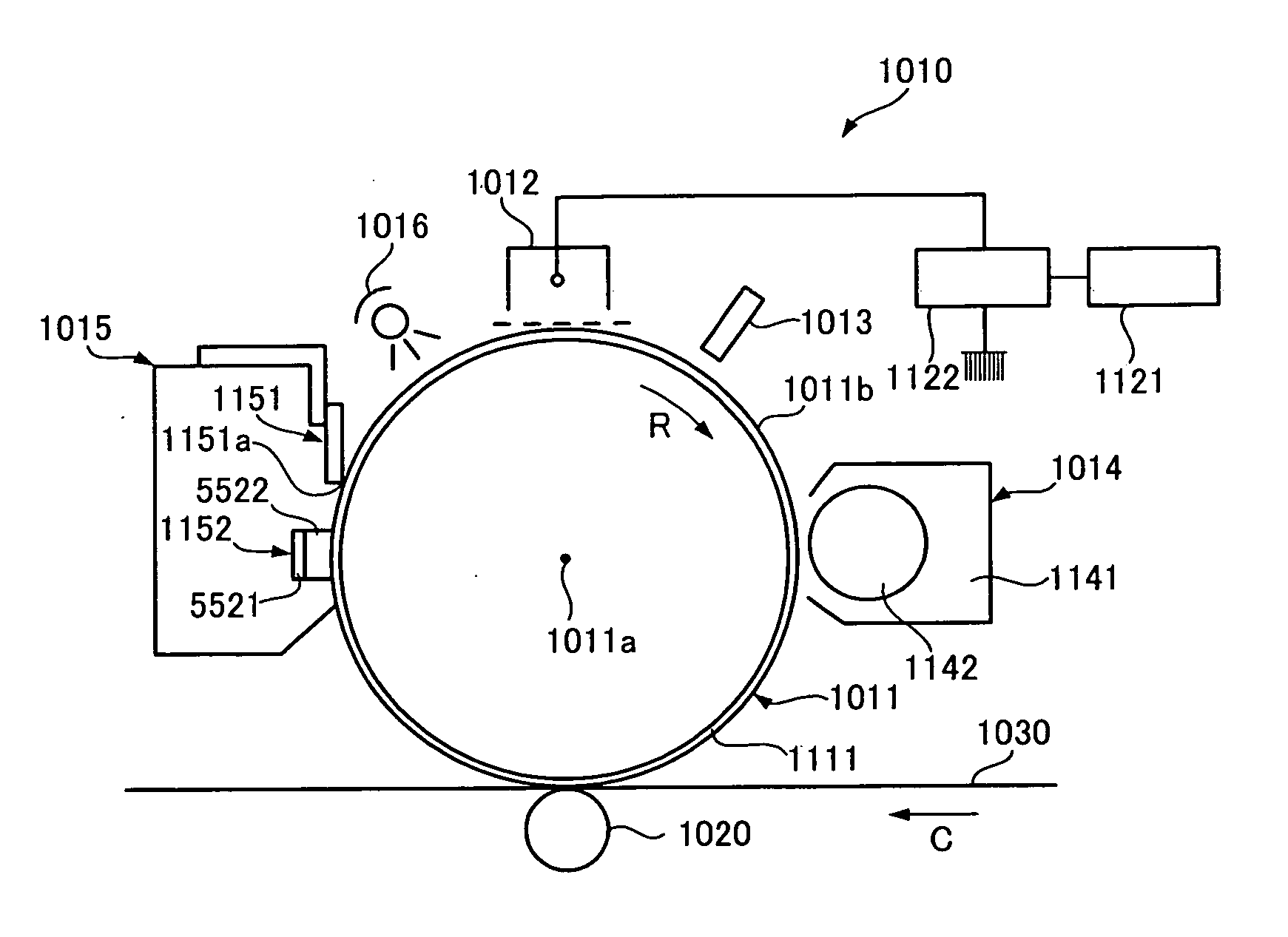

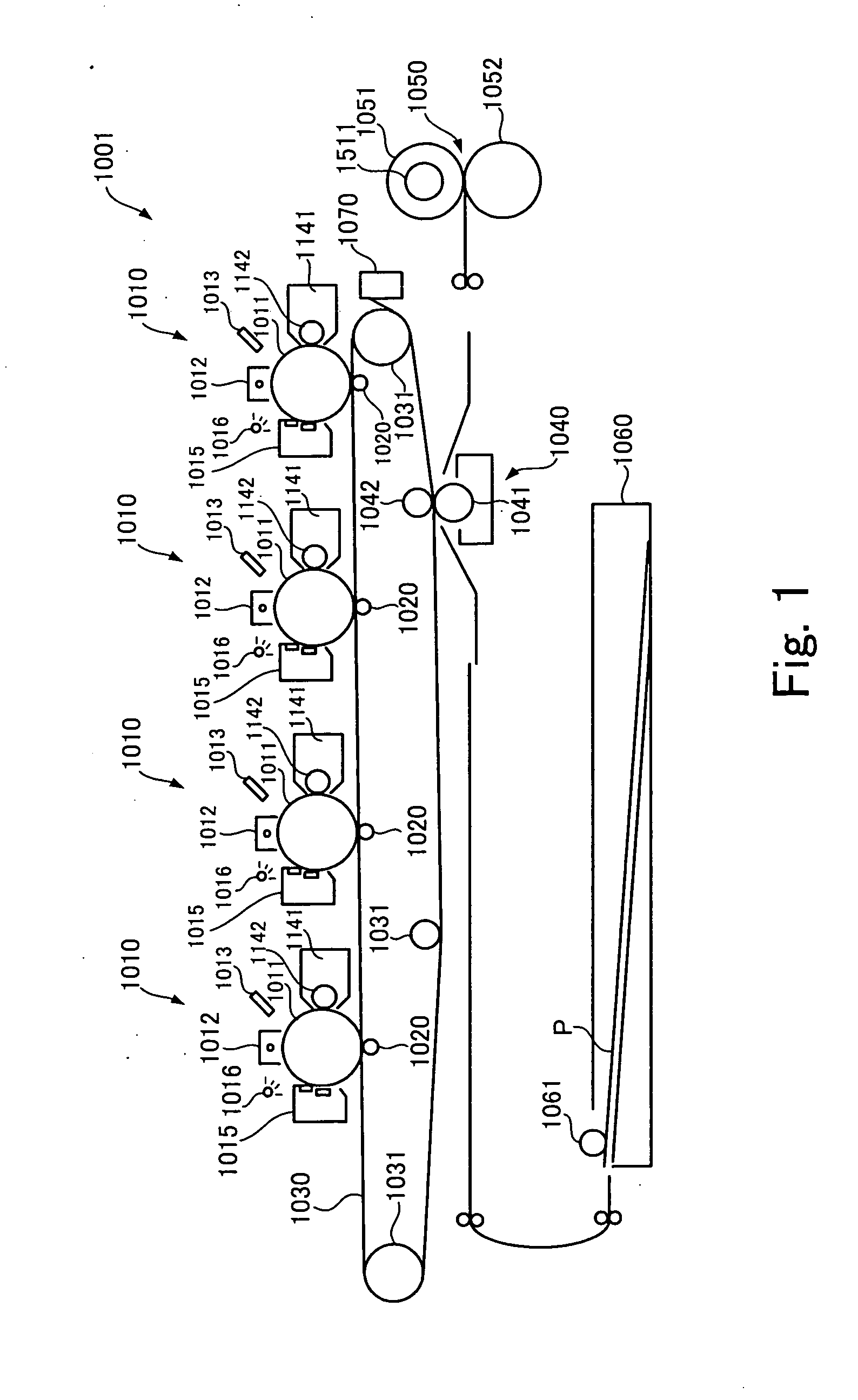

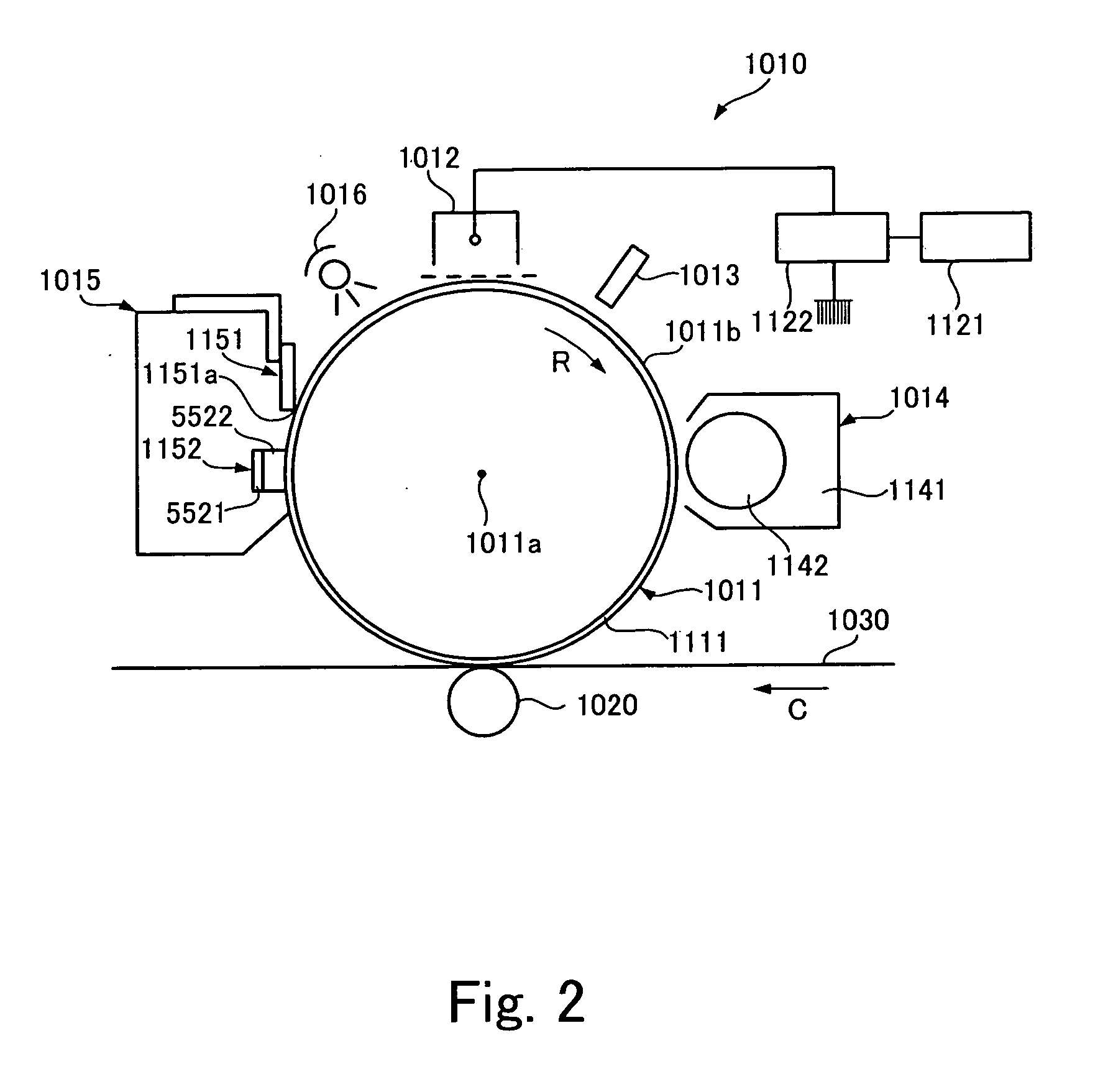

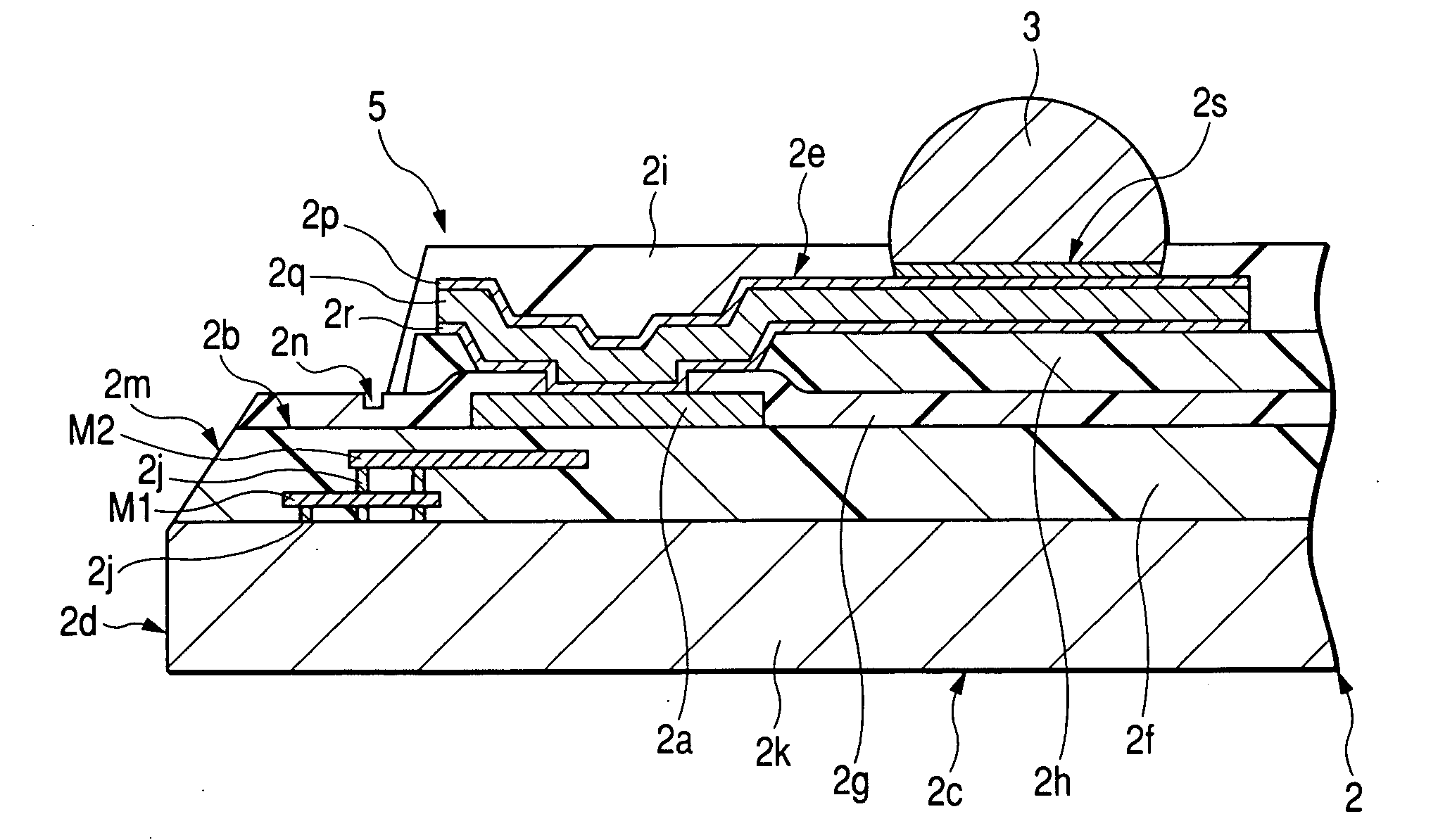

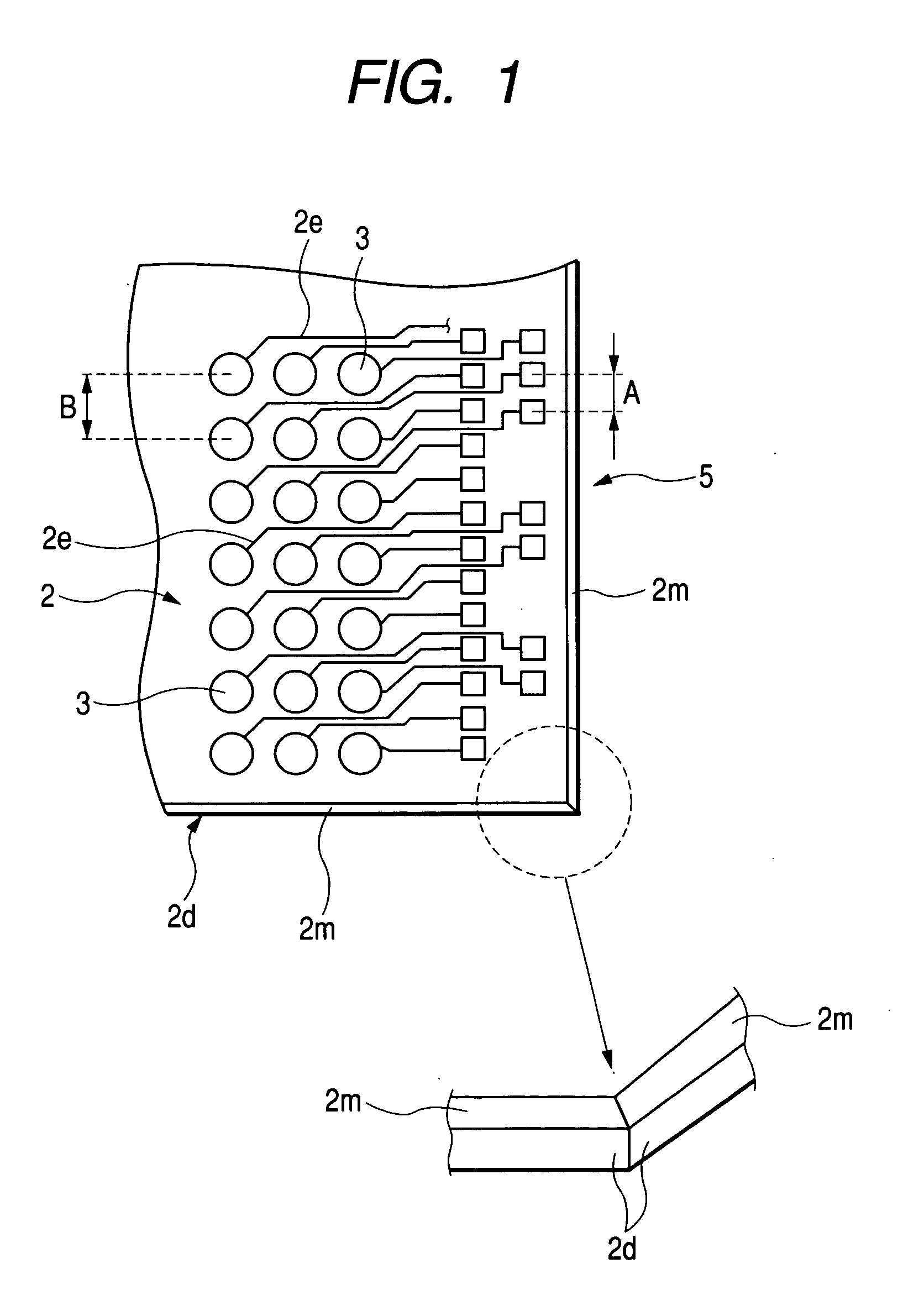

Cleaning unit and image forming apparatus

This invention relates to a cleaning unit comprising: a cleaning blade that keeps a front end of rubber material in contact with the surface with a pressure so as to scrape residual toner left on the surface of the photoreceptor and a fiber body having multiple fibers in contact with the surface of the photoreceptor in the upstream in the cyclic moving direction of the surface of the photoreceptor with respect to the cleaning blade, wherein the cleaning blade satisfies conditions A≧−2.5×B+102 and 6.3≦B≦19.6, where A designates a contact angle (°) with pure water under 23° C., 55% RH and B designates 100% modulus (MPa) at 23° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

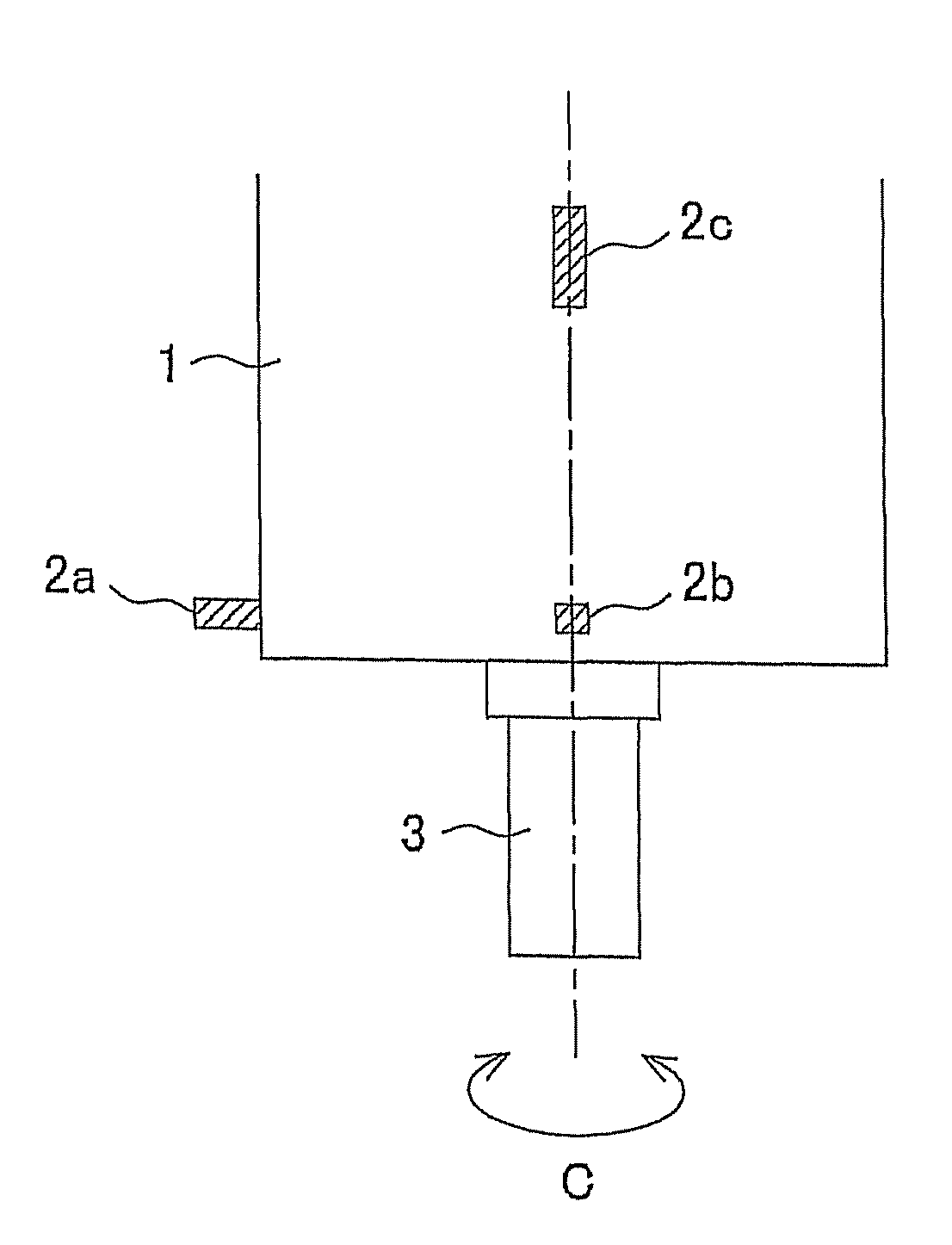

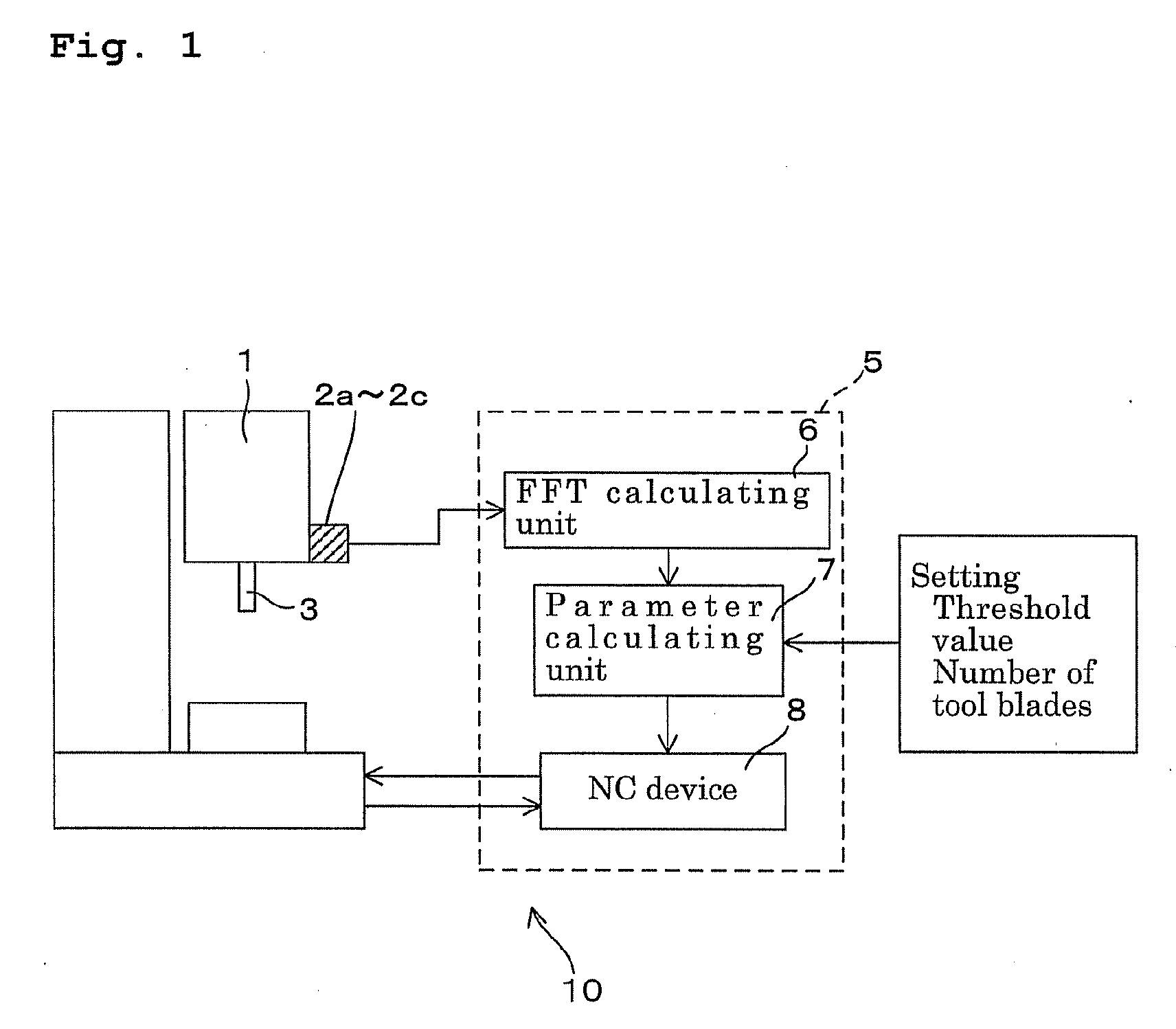

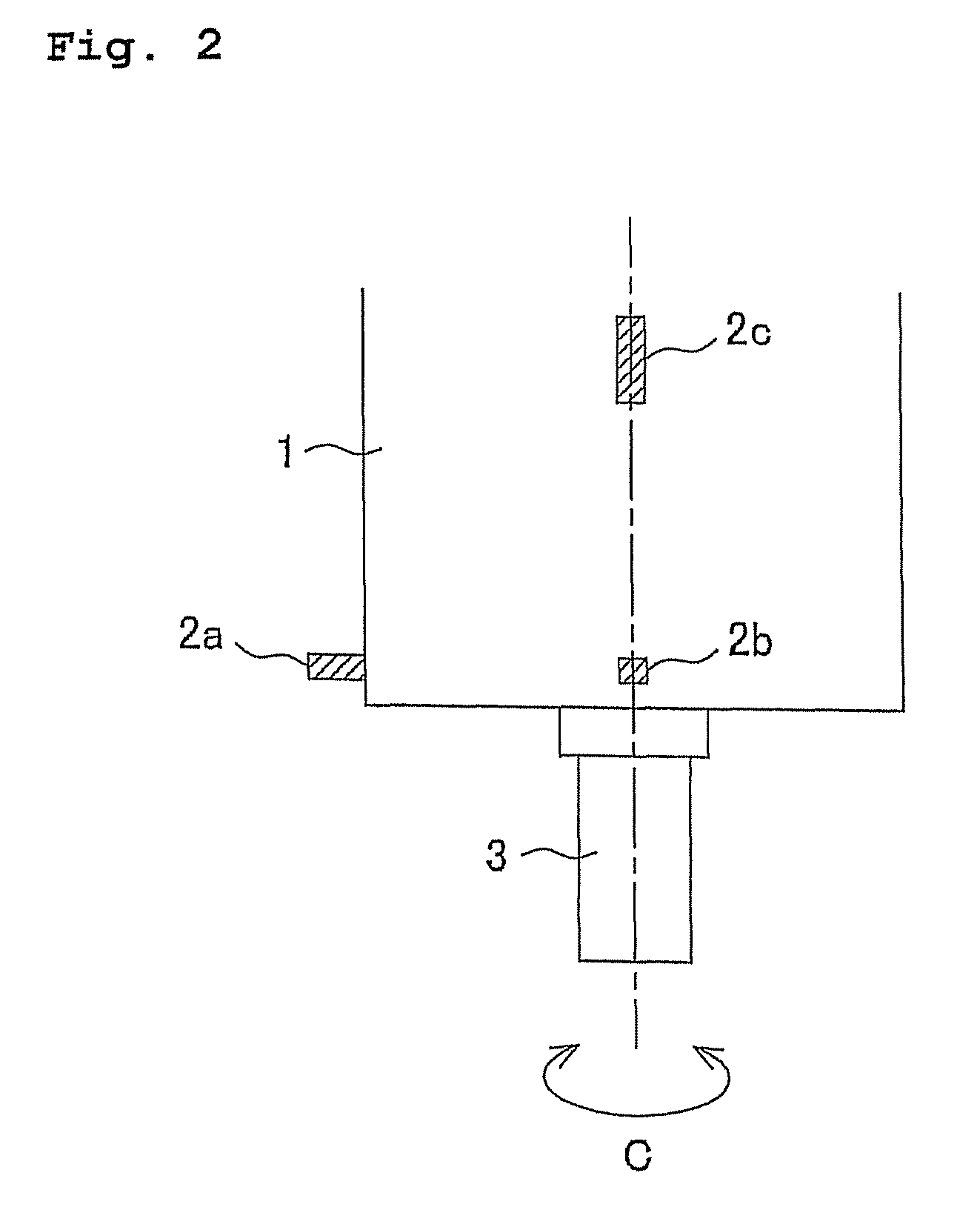

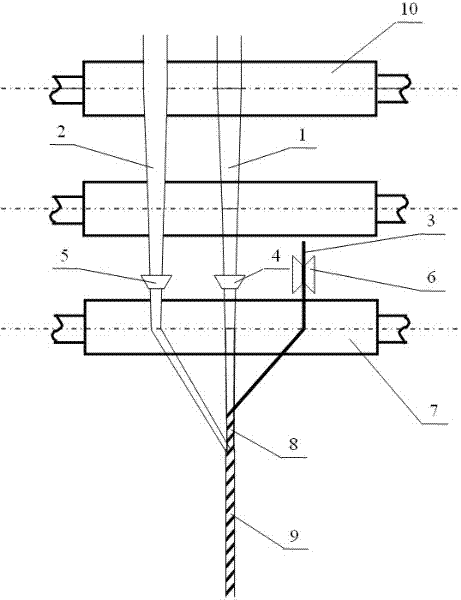

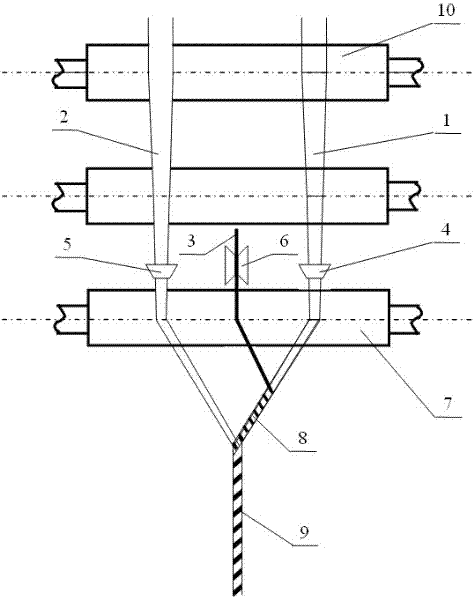

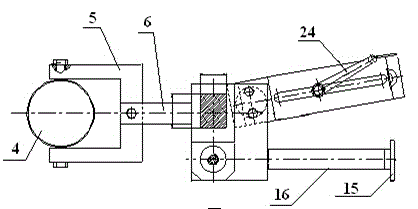

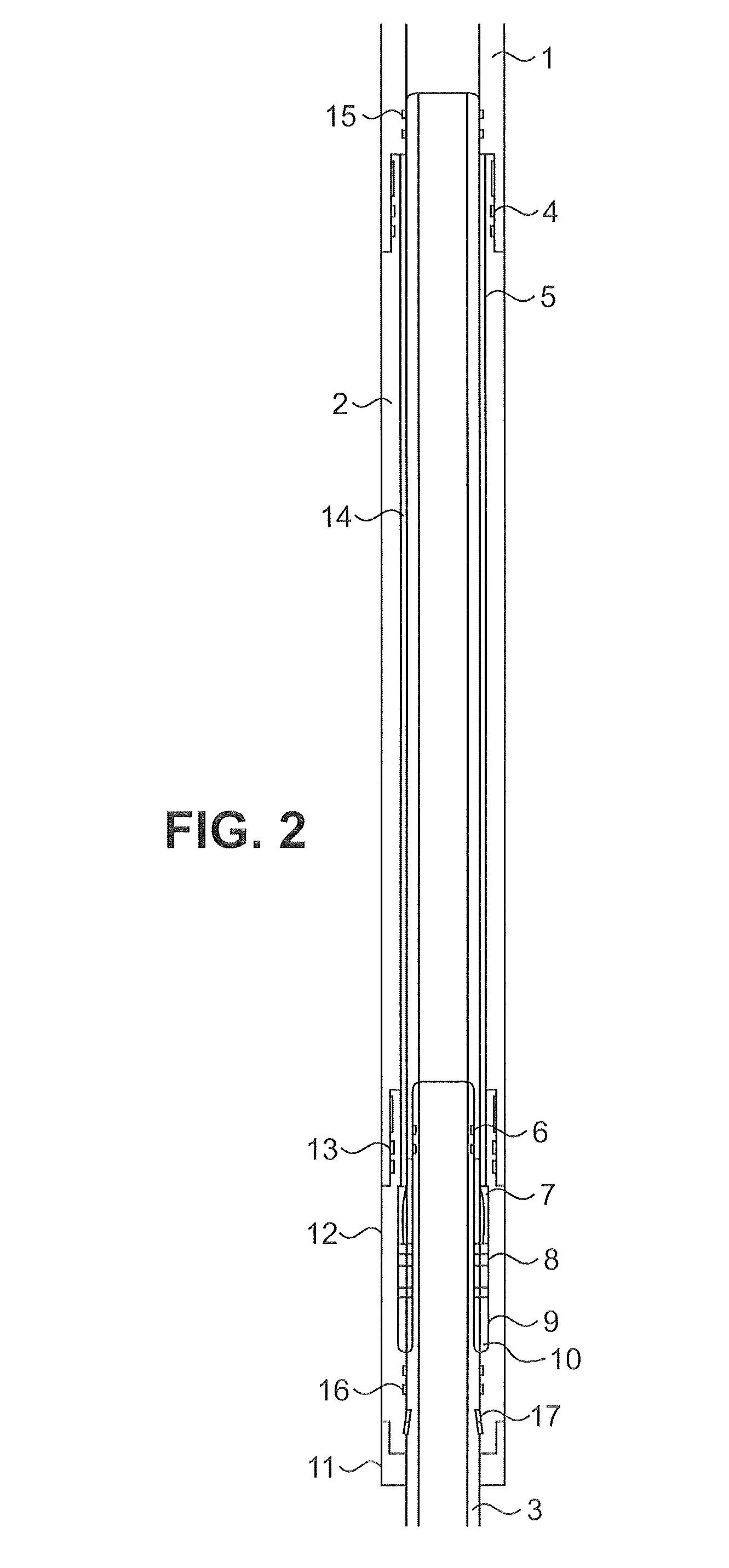

Vibration suppressing device and vibration suppressing method for machine tool

InactiveUS20080289923A1Improve machining accuracyAccurate calculationThread cutting machinesMilling machinesTime domainChatter vibration

A vibration suppressing device and a vibration suppressing method that are capable of obtaining an accurate optimum rotation speed and shortening a time period from generation of chatter vibration to calculation of the optimum rotation speed are provided. The vibration suppressing device 10 includes: vibration sensors 2a to 2c for detecting time-domain vibrational accelerations of a rotary shaft 3 in rotation; and a control device 5 for calculating a chatter frequency and a frequency-domain vibrational acceleration of the rotary shaft 3 at the chatter frequency on the basis of the time-domain vibrational accelerations detected by the vibration sensors 2a to 2c, and when the calculated frequency-domain vibrational acceleration exceeds a predetermined threshold value, calculating an optimum rotation speed on the basis of a predetermined parameter, and rotating the rotary shaft 3 at the calculated optimum rotation speed.

Owner:OKUMA CORP +1

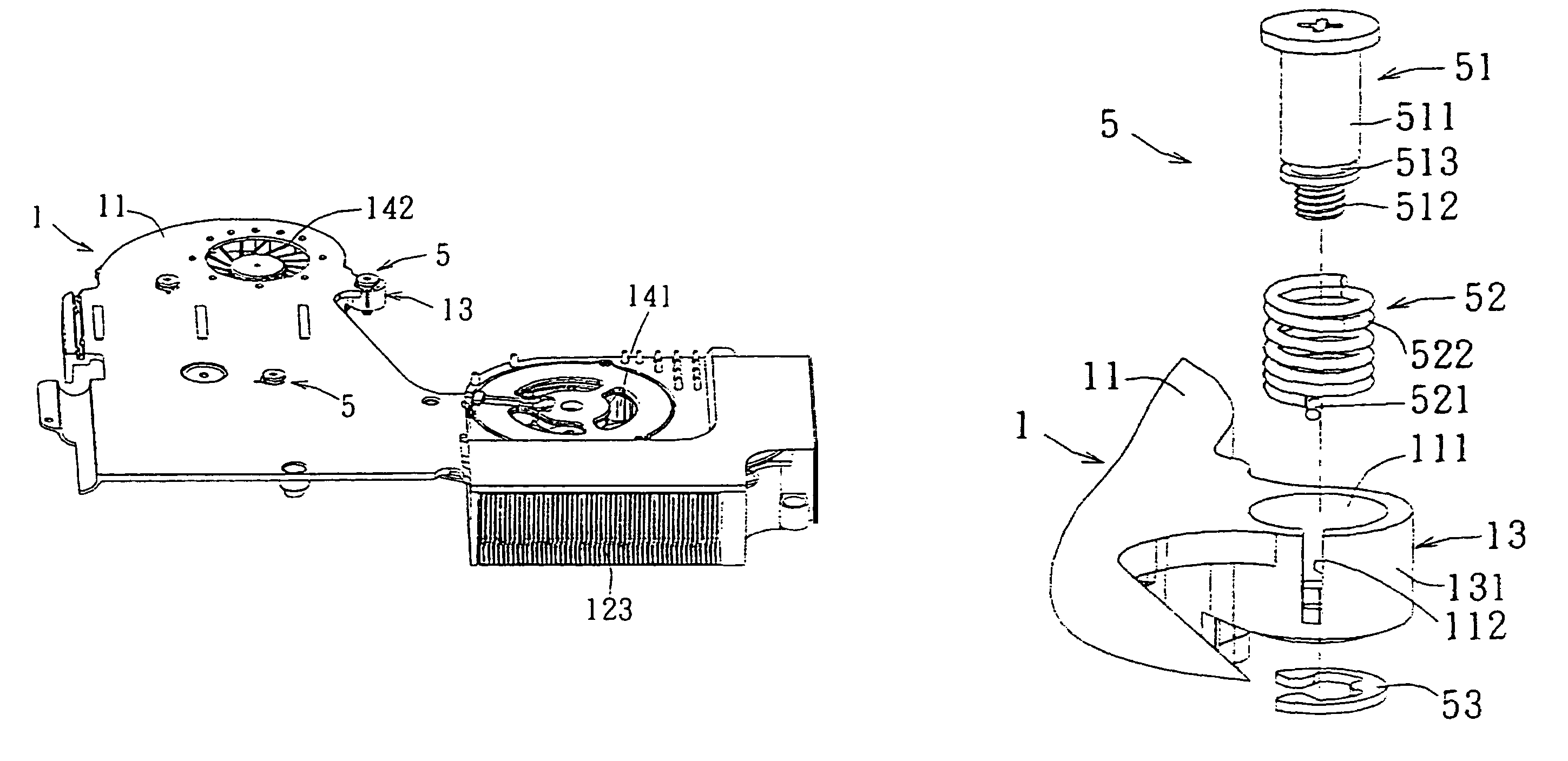

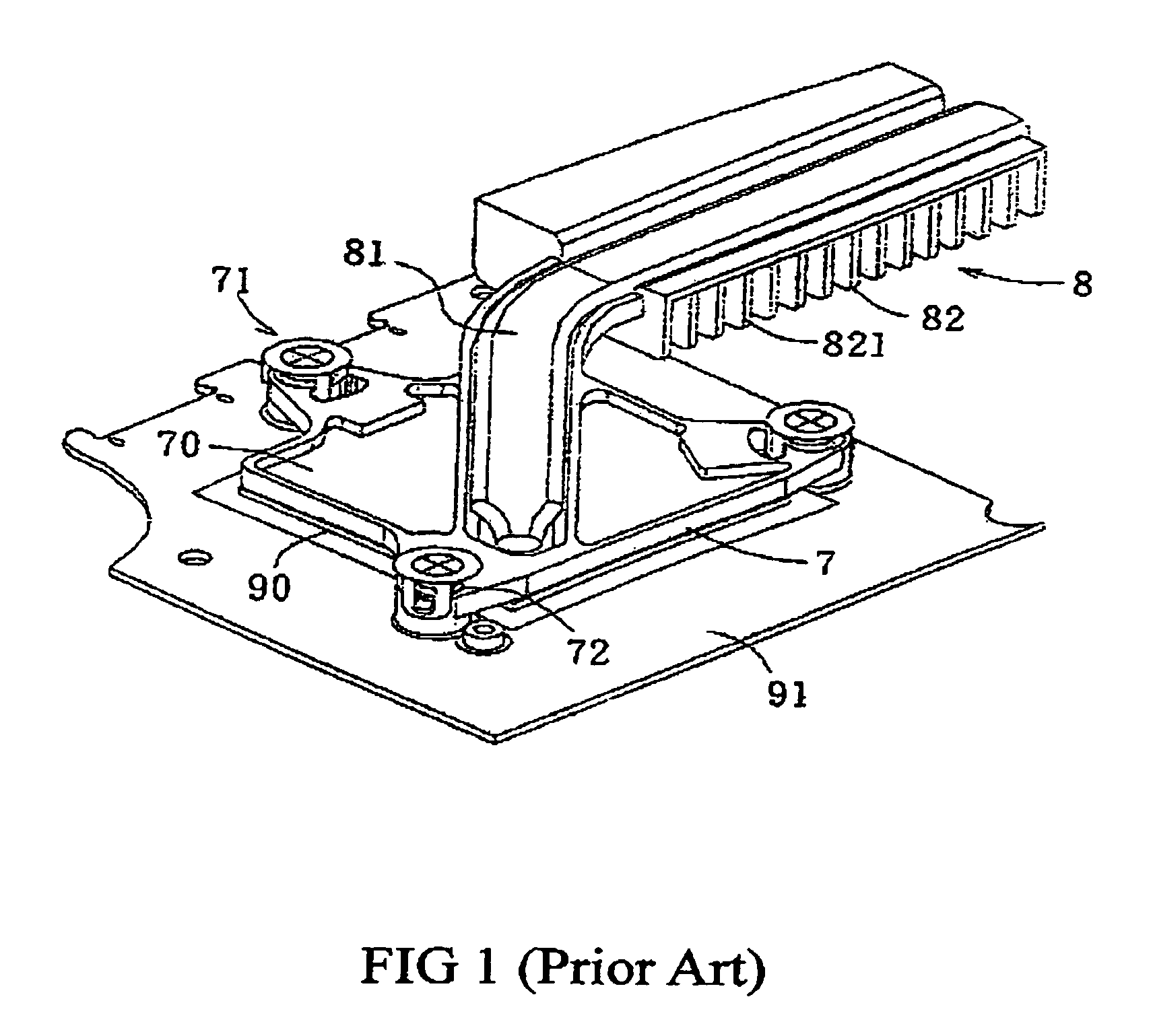

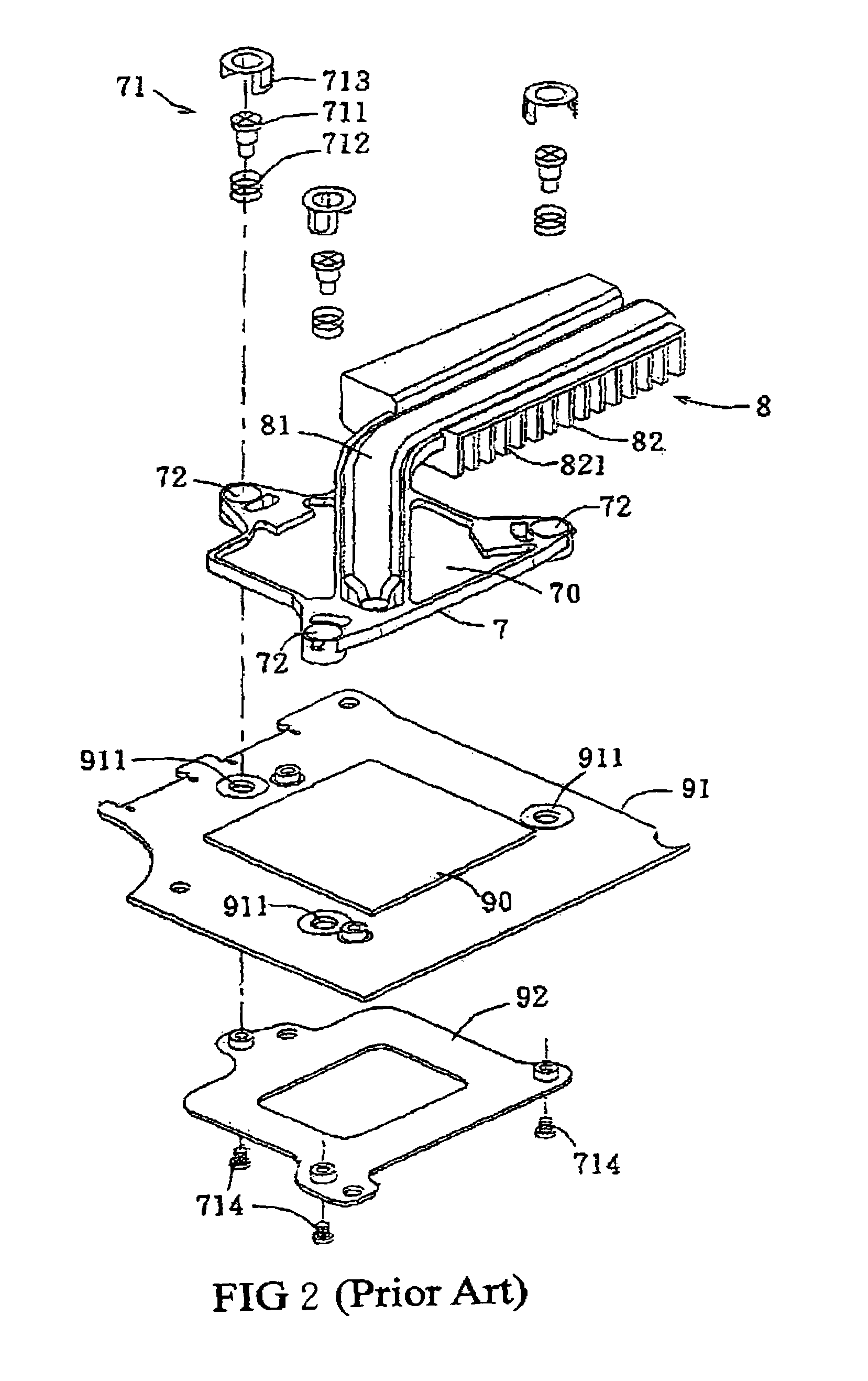

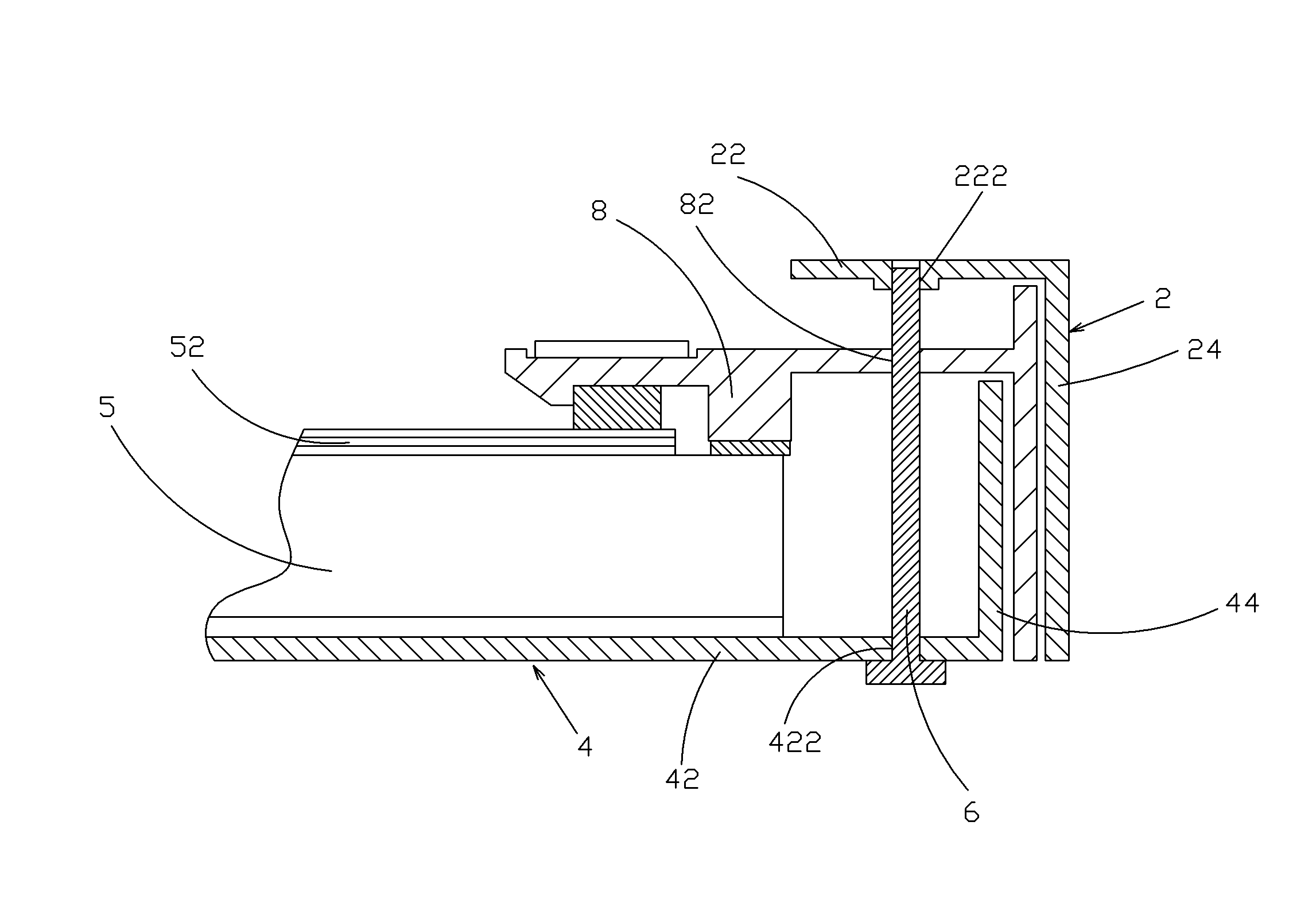

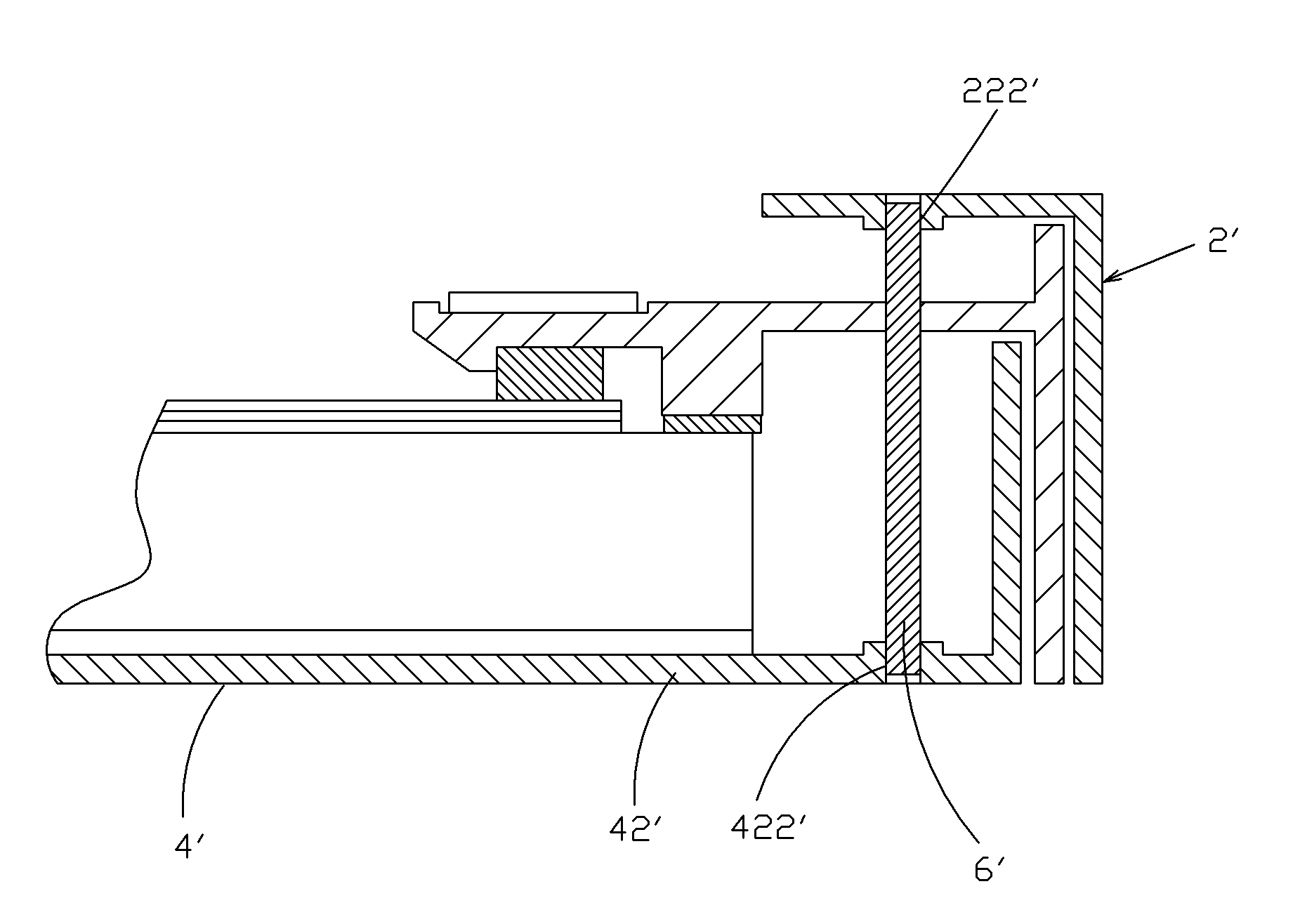

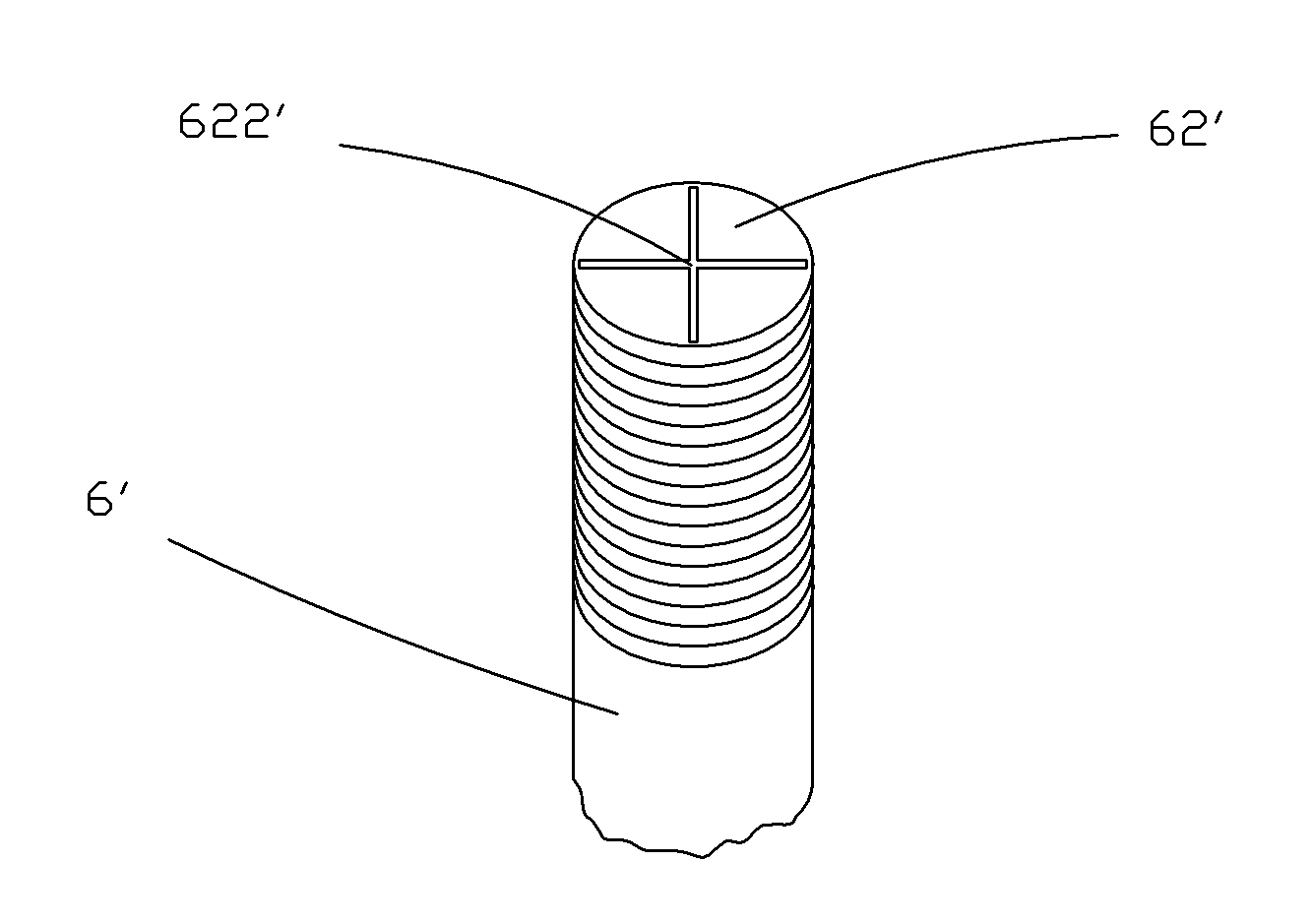

Means for securing a cooling device

InactiveUS7057897B2Avoid chippingAvoid wear and tearSnap fastenersSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

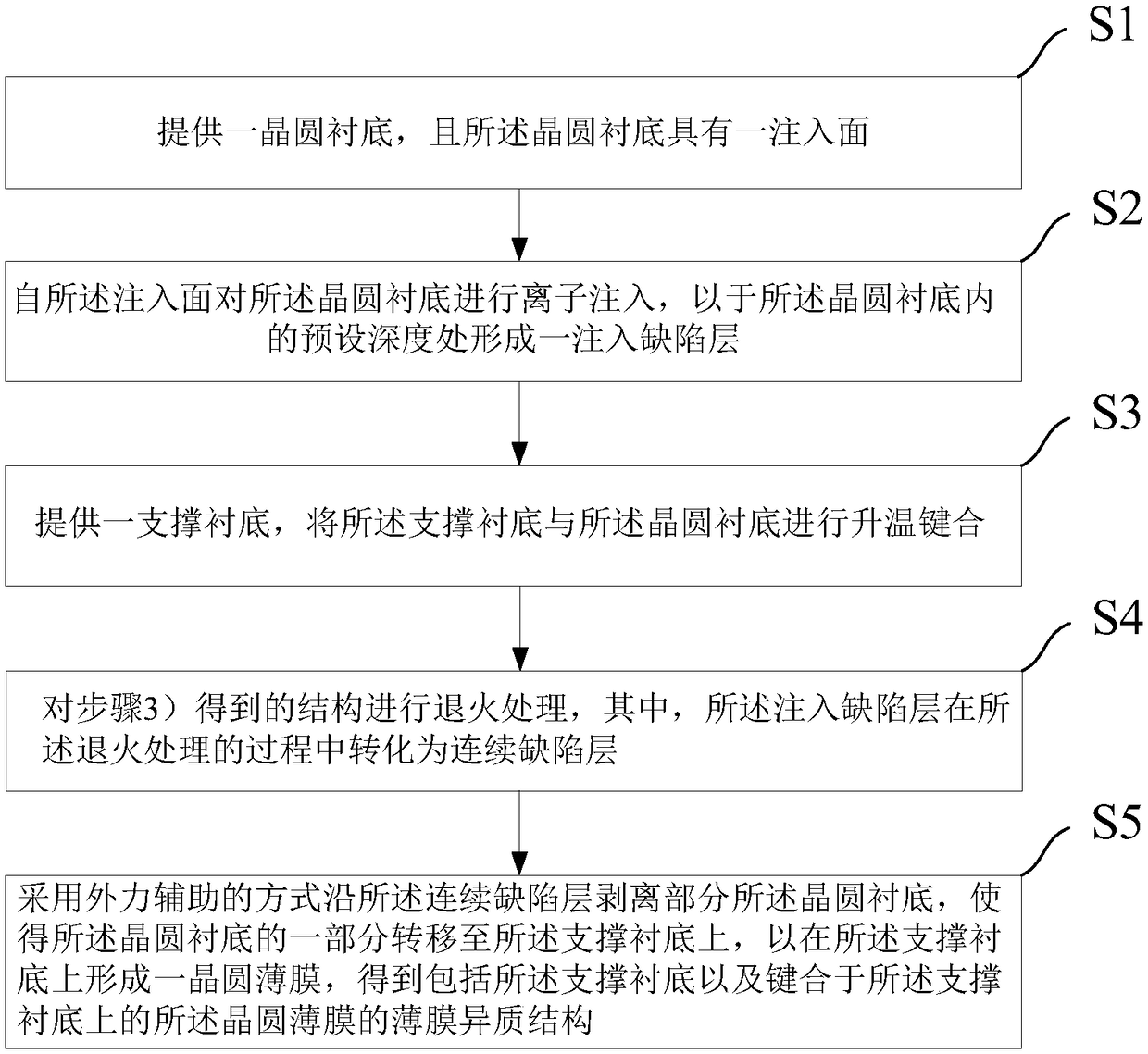

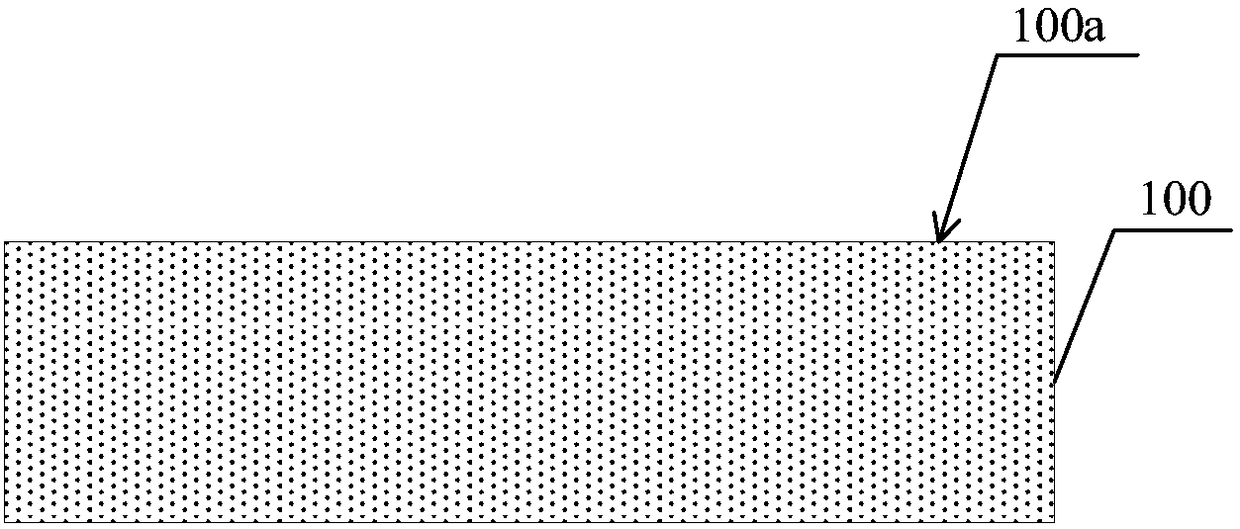

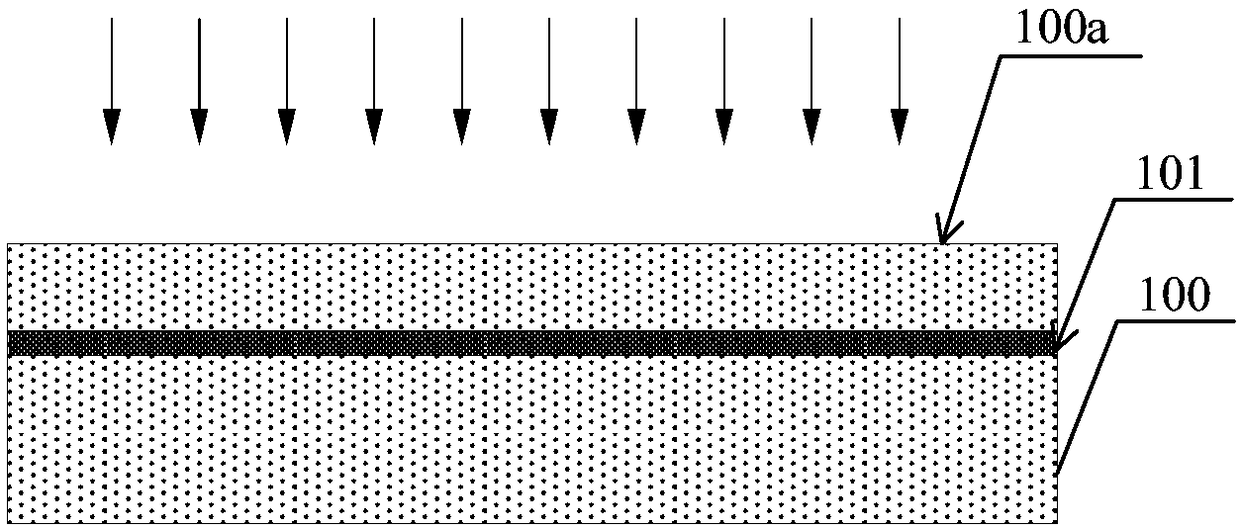

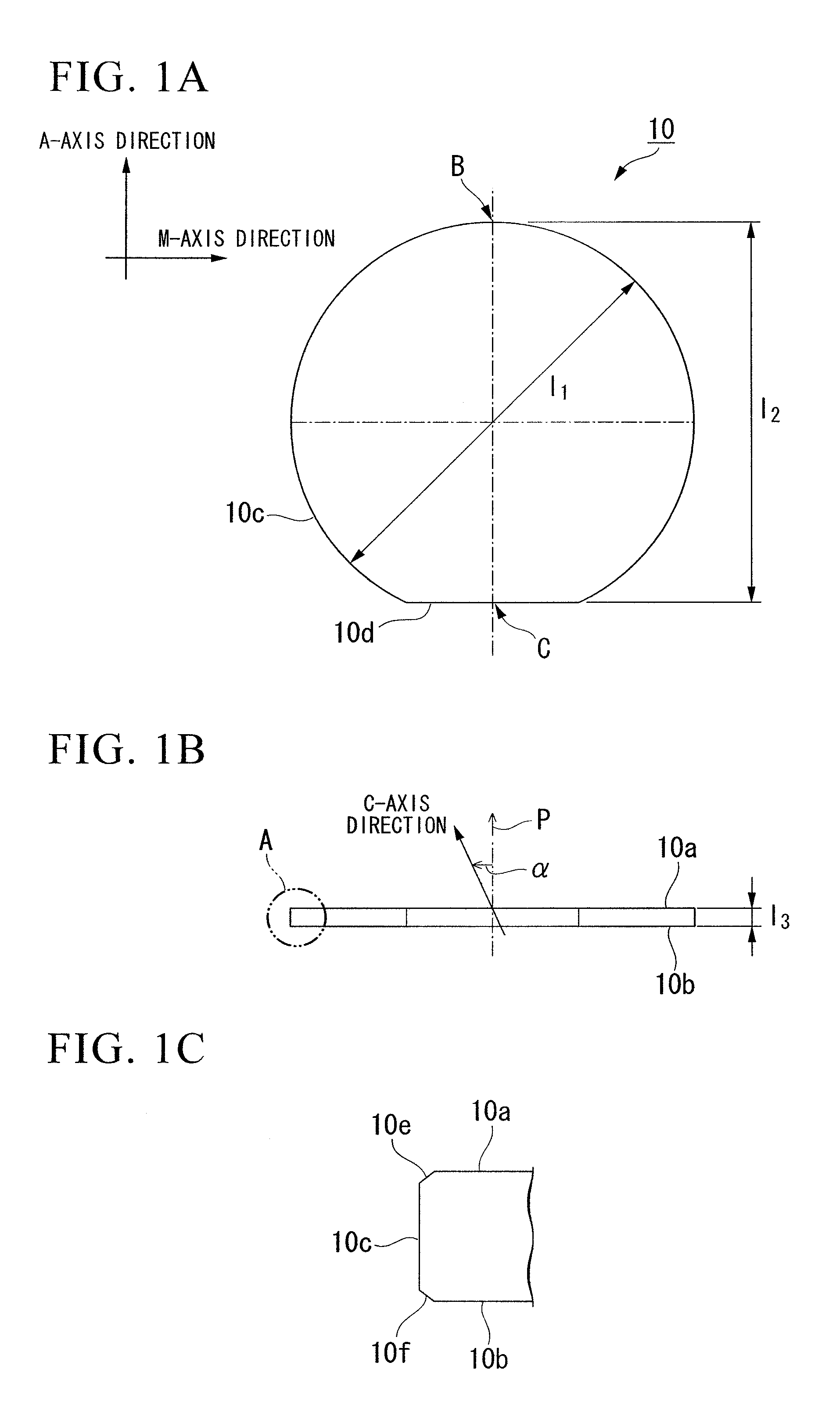

Method for preparing thin film heterostructure

InactiveCN108336219AReduce thermal strainAvoid chippingPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsIon implantation

The invention provides a method for preparing a thin film heterostructure. The method comprises the steps of providing a wafer substrate with an injection surface; conducting ion injection from the injection surface on the wafer substrate to form an injection defect layer at the predetermined depth of the wafer substrate; providing a support substrate, and performing temperature rising bonding onthe support substrate and the wafer substrate; annealing a obtained structure to form a continuous defect layer; stripping part of the wafer substrate through external force assisting, and forming wafer film on the wafer substrate to obtain a thin film heterostructure including the support substrate and the wafer film. The method can reduce the thermal strain of a bonding structure through the temperature rising bonding, so that the bonding structure remains stable and complete in the high-temperature process, and avoid the problem of film cracking caused by thermal mismatch in the stripping process, the bonding structure is separated from the continuous defect layer through the external force assisting method, so that no effect is caused on a bonding interface, and an external force assisting stripping method can reduce stripping temperature and stripping time, thereby reducing the cumulative effect of thermal stress in a piezoelectric crystal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

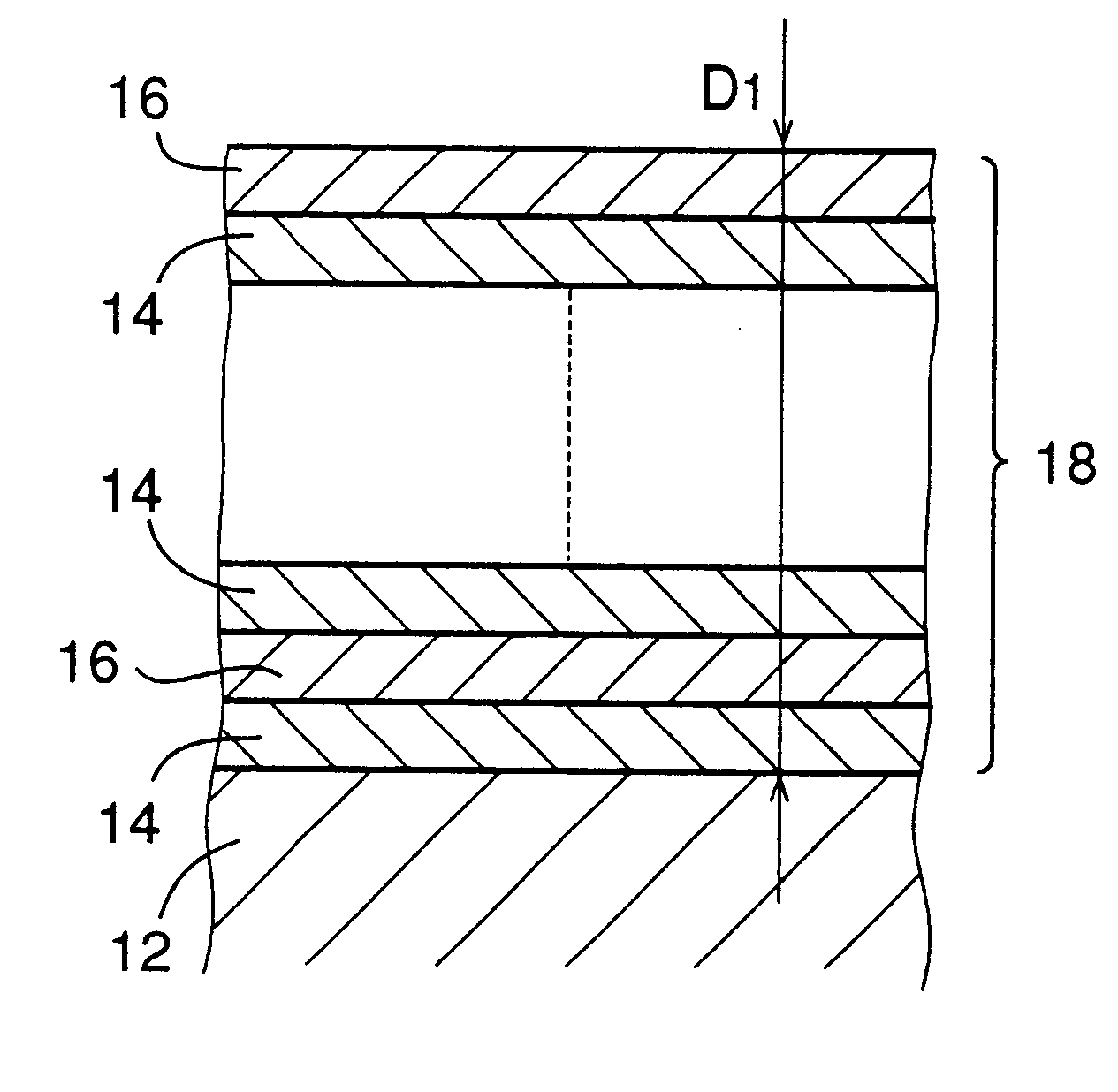

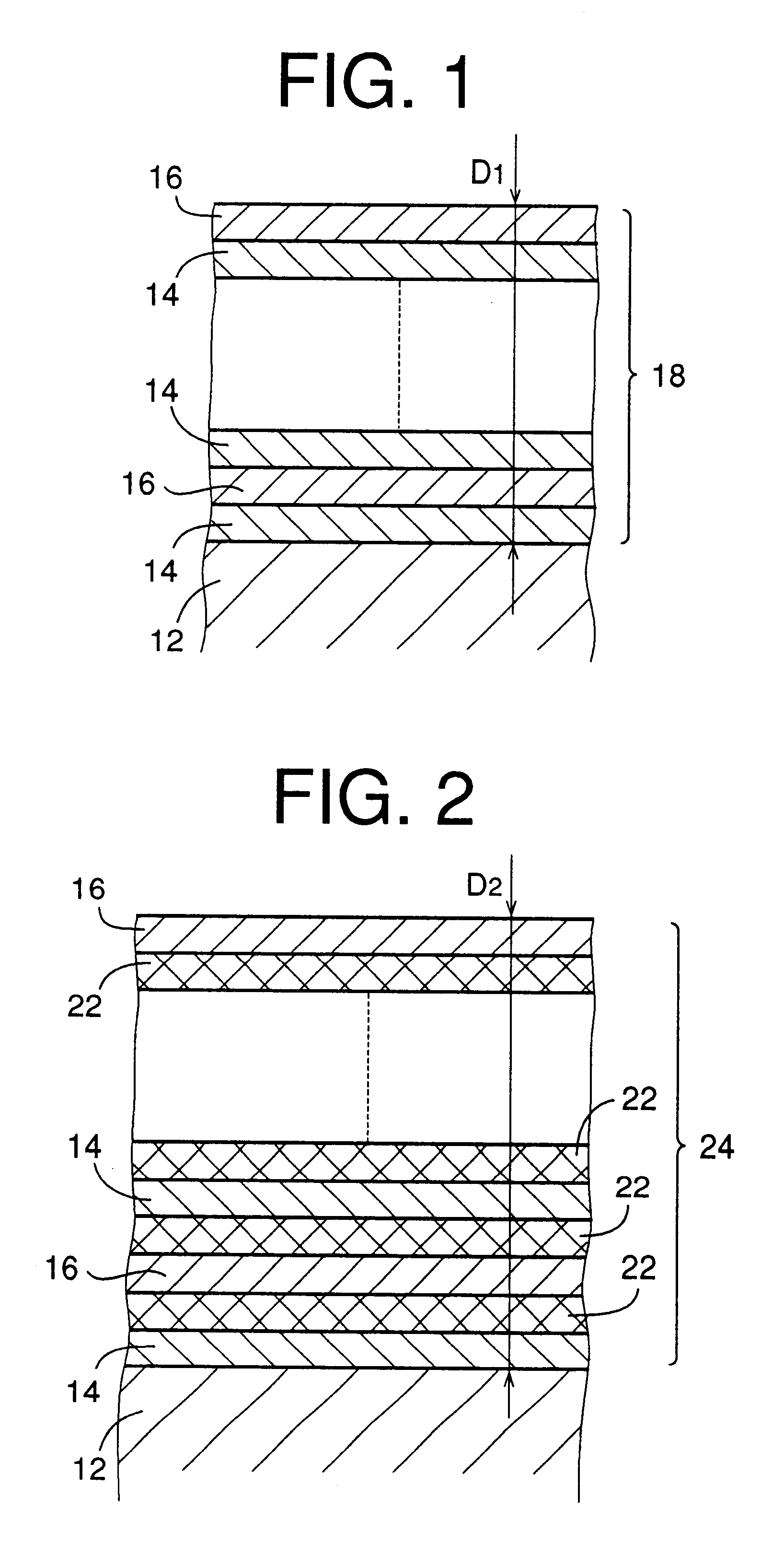

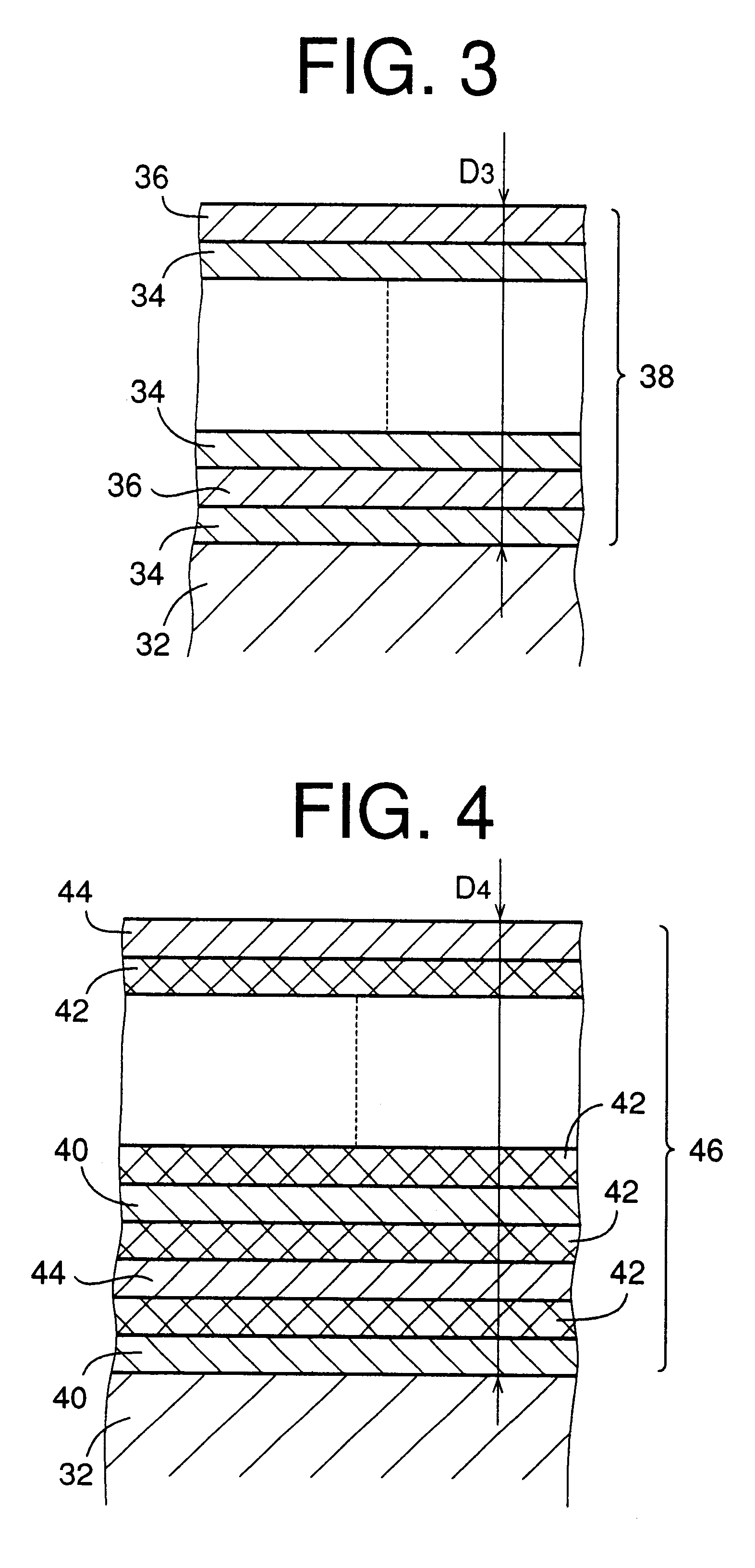

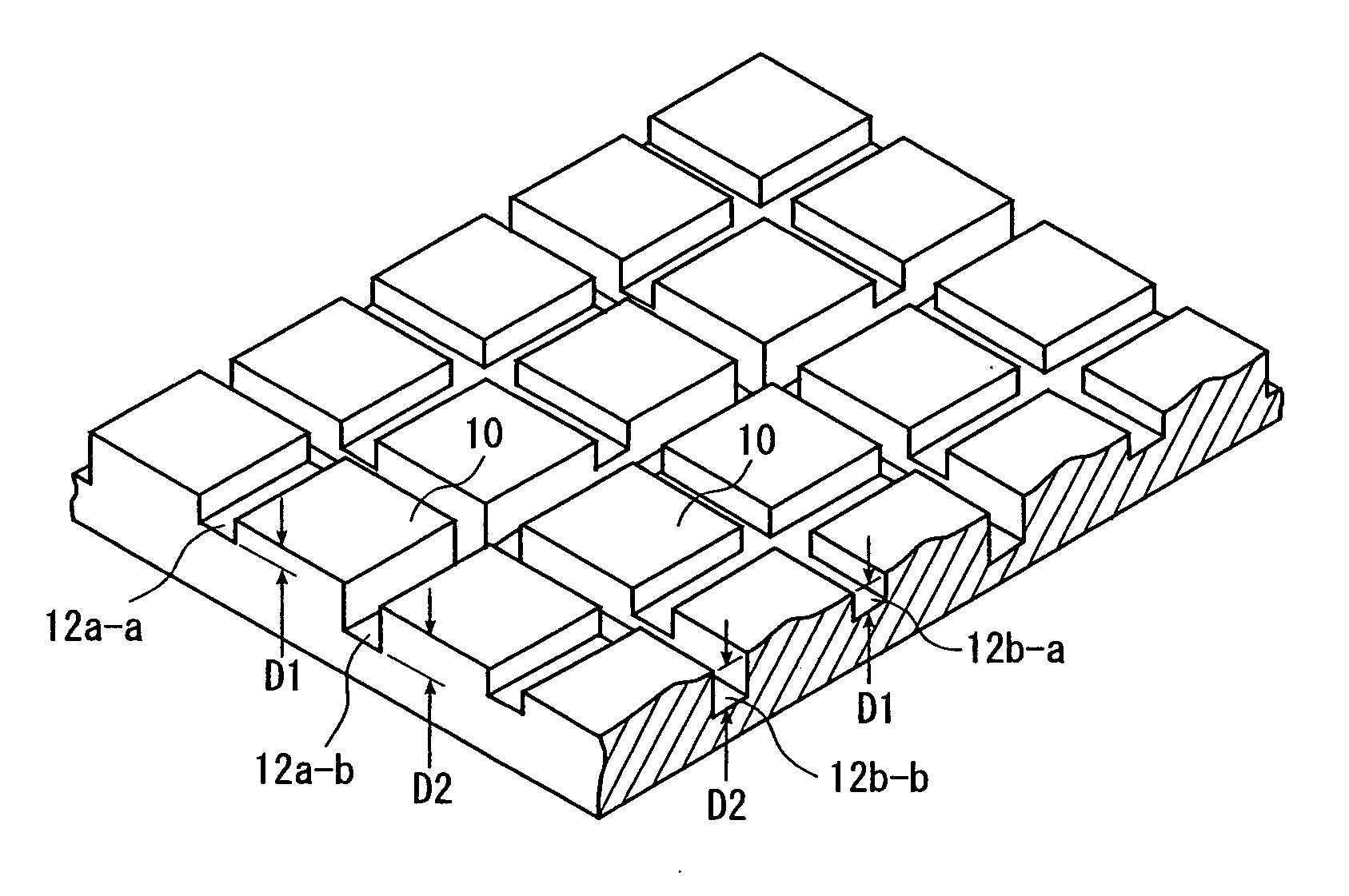

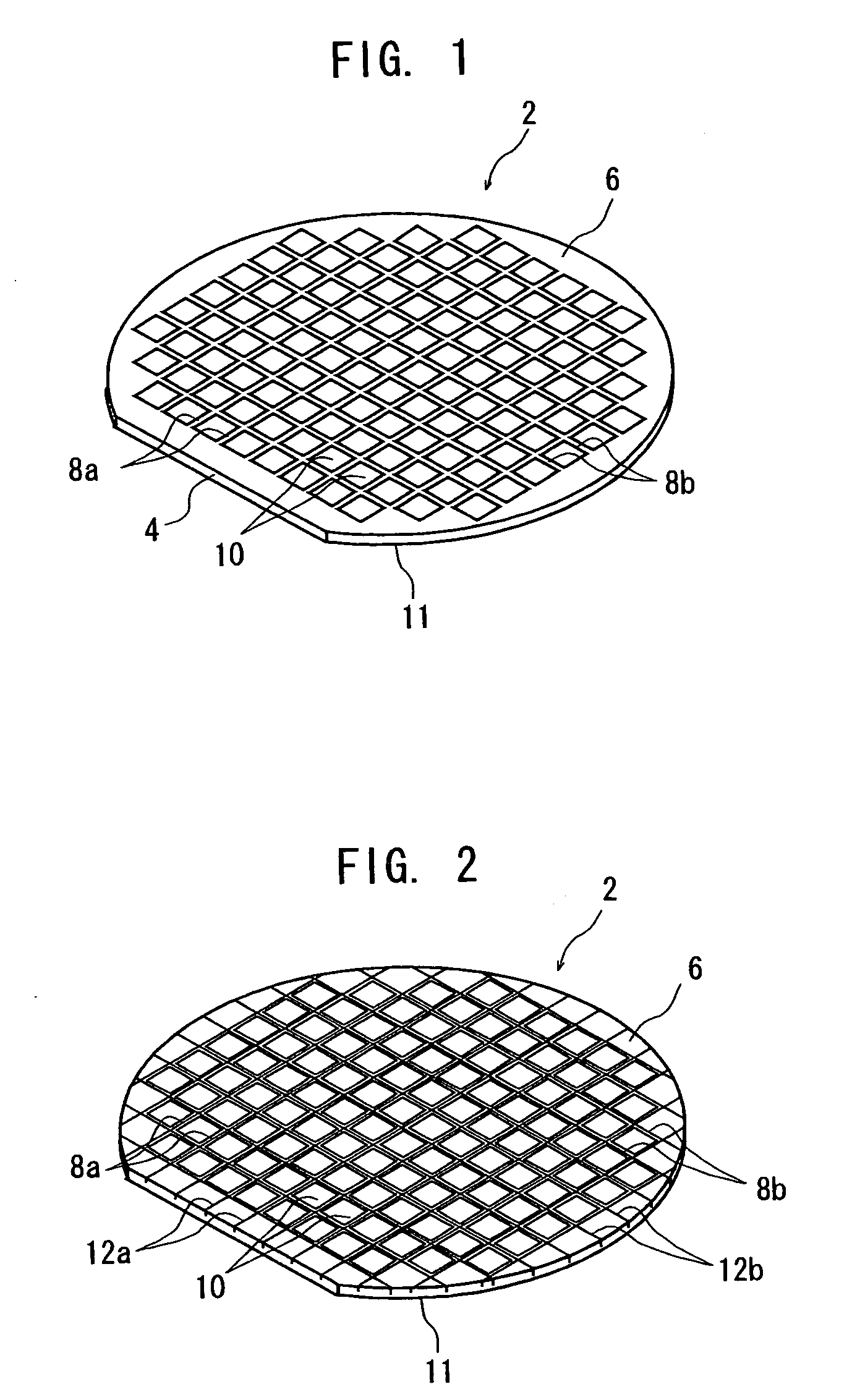

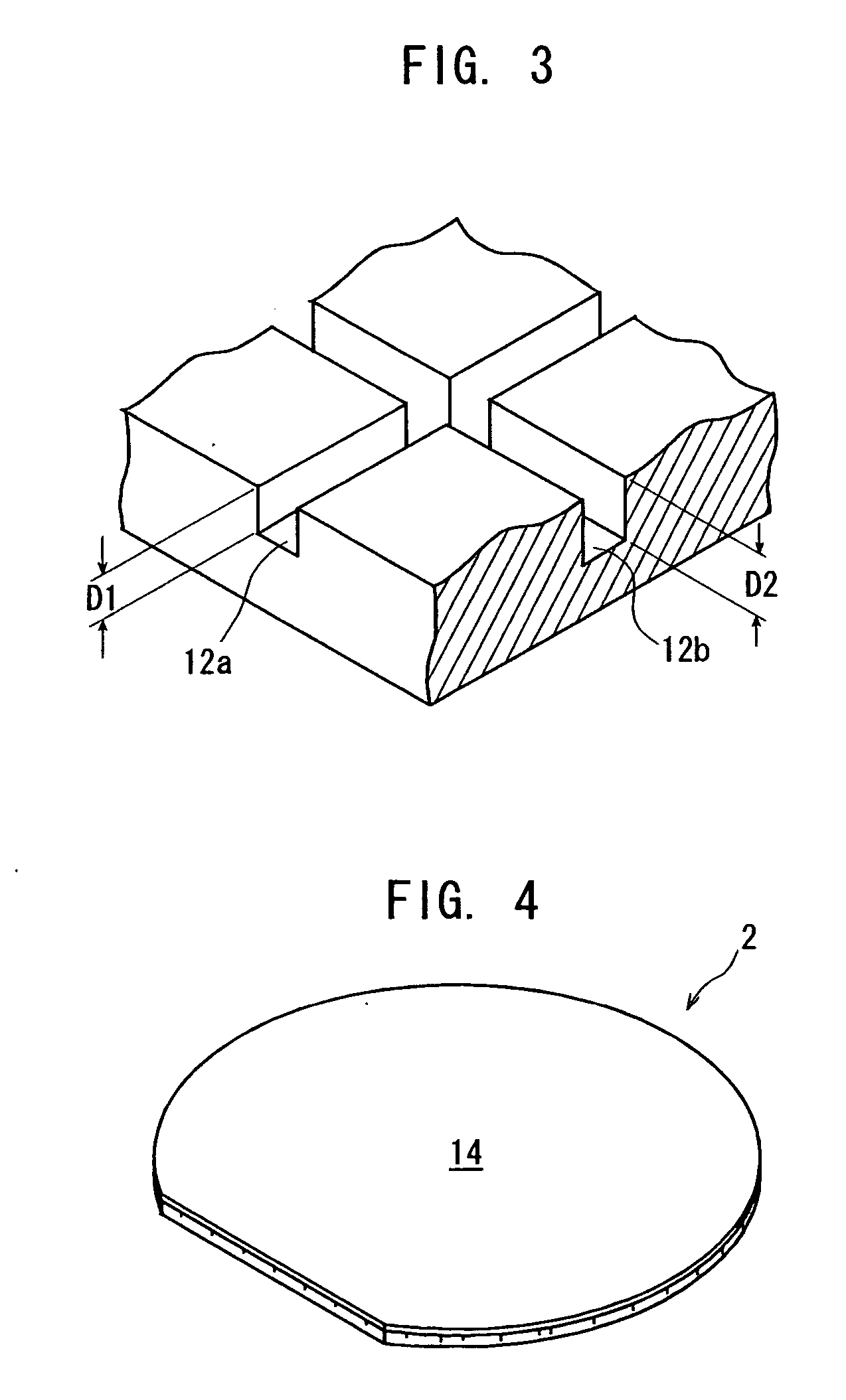

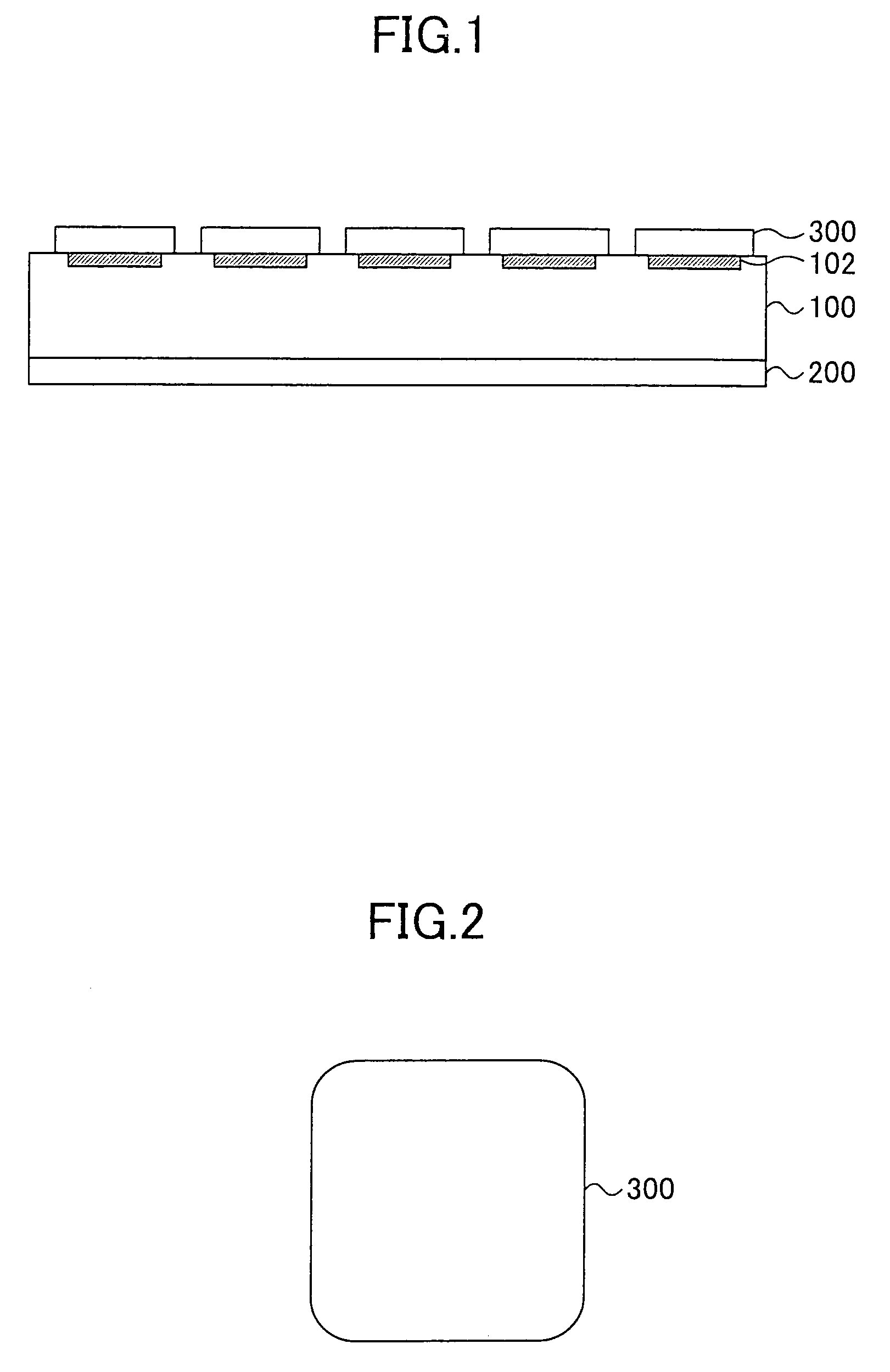

Wafer dividing method

ActiveUS20060003552A1Simple methodChipping of the semiconductor device can be avoidedSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

A wafer dividing method for dividing a wafer along a first set of plural streets extending parallel to each other, and a second set of plural streets extending parallel to each other and extending perpendicularly to the first set of the streets, the wafer having a plurality of rectangular regions defined on the face thereof by these streets. The wafer dividing method includes a groove forming step of forming grooves along the streets on the face of the wafer, and a grinding step of grinding the back of the wafer after the groove forming step. The grooves formed by the groove forming step include grooves having a first depth D1, and grooves having a second depth D2 which is greater than the first depth D1 (D2>D1).

Owner:DISCO CORP

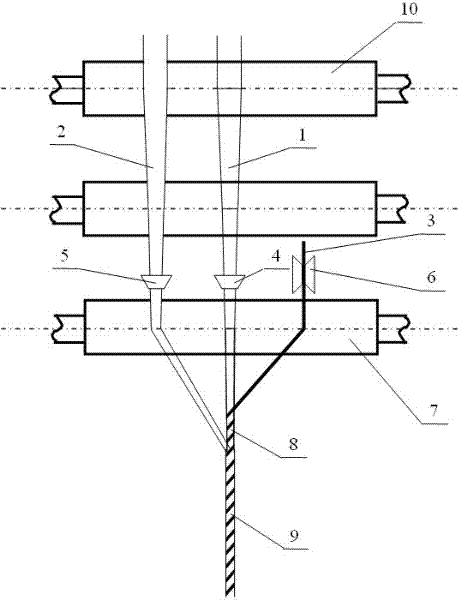

Three-axis-system composite spinning device and spinning method for tow-apt-to-fall staple

The invention provides a three-axis-system composite spinning device and a spinning method for tow-apt-to-fall staple. The three-axis-system composite spinning method is characterized in that the method comprises the steps of: feeding roving silvers containing the tow-apt-to-fall staple and cotton roving silvers into the back roller of a ring spinning machine, and conducting drafting to form a tow-apt-to-fall staple strand and a cotton strand which stretch straight in parallel; after the tow-apt-to-fall staple strand and the cotton strand are respectively positioned by using a tow-apt-to-fall staple strand positioner and a cotton strand positioner, feeding the tow-apt-to-fall staple strand and the cotton strand into the jaw of a front roller and directly feeding filament adjustable tension pulley into the jaw of the front roller; and after the tow-apt-to-fall staple strand, the cotton strand and the filament are output from the jaw of the front roller, twisting the tow-apt-to-fall staple strand and the filament at a first converging point outside the jaw of the front roller to form a structural section, and twisting the structural section and the cotton strand at a second converging point to form a three-axis-system composite yarn. The device and the method provided by the invention has the advantages that not only can the content of the tow-apt-to-fall staples in the spun composite yarn be improved, but also the situations of fiber damage and tow falling can be effectively avoided.

Owner:DONGHUA UNIV

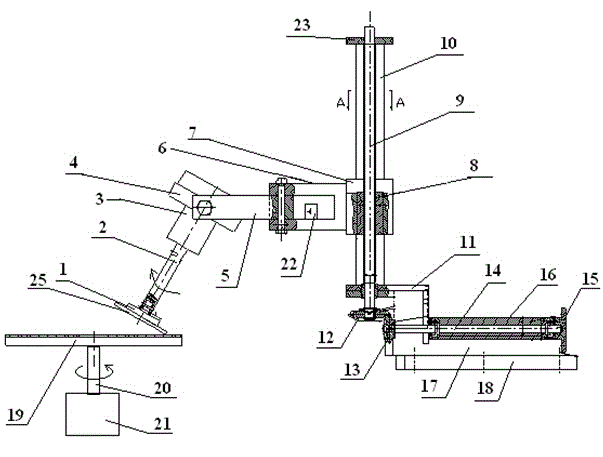

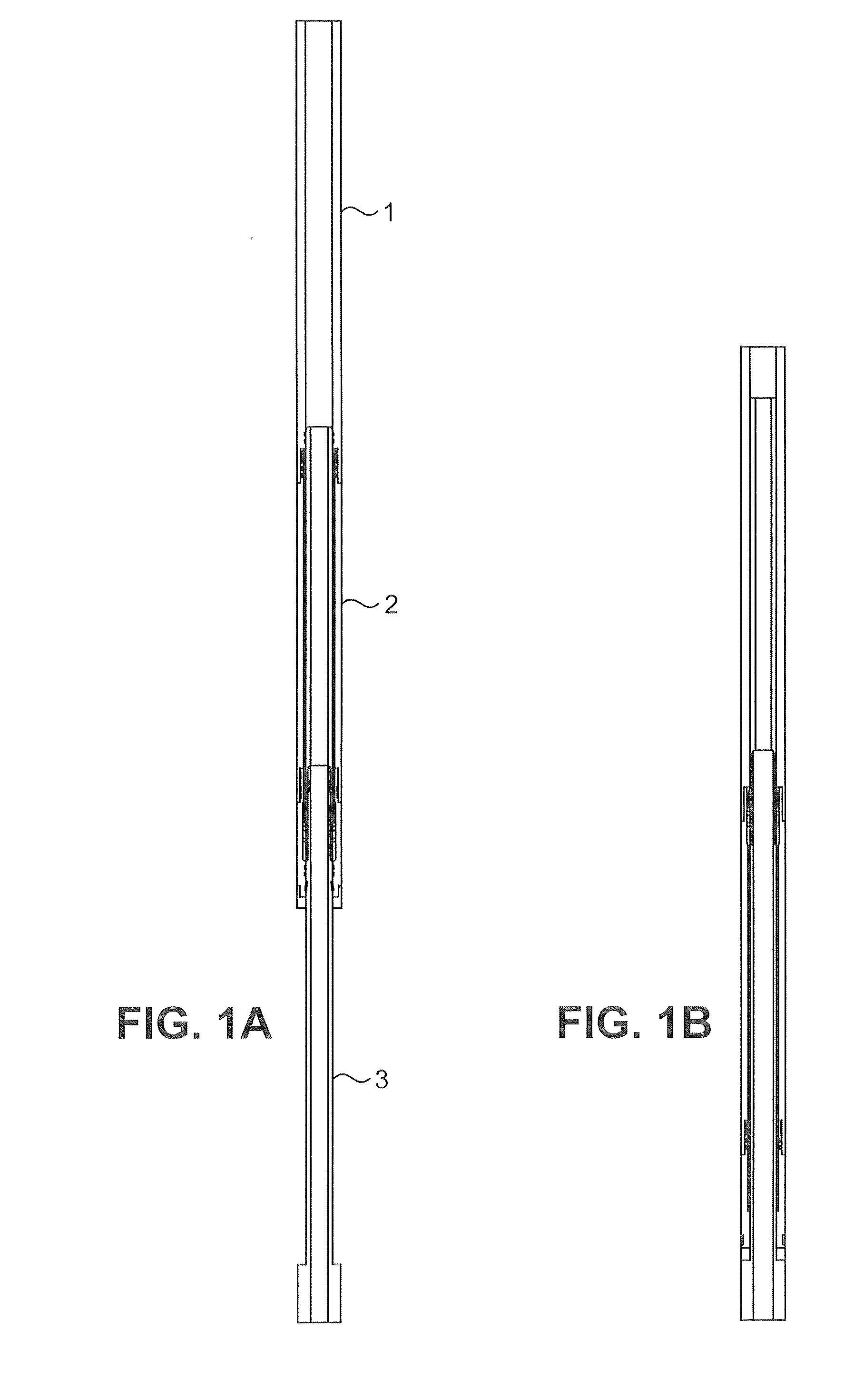

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

Semiconductor chip and fabrication method thereof

ActiveUS7052975B2Improve integration and yieldShorten production timeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:SHINKO ELECTRIC IND CO LTD

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS20050028890A1Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

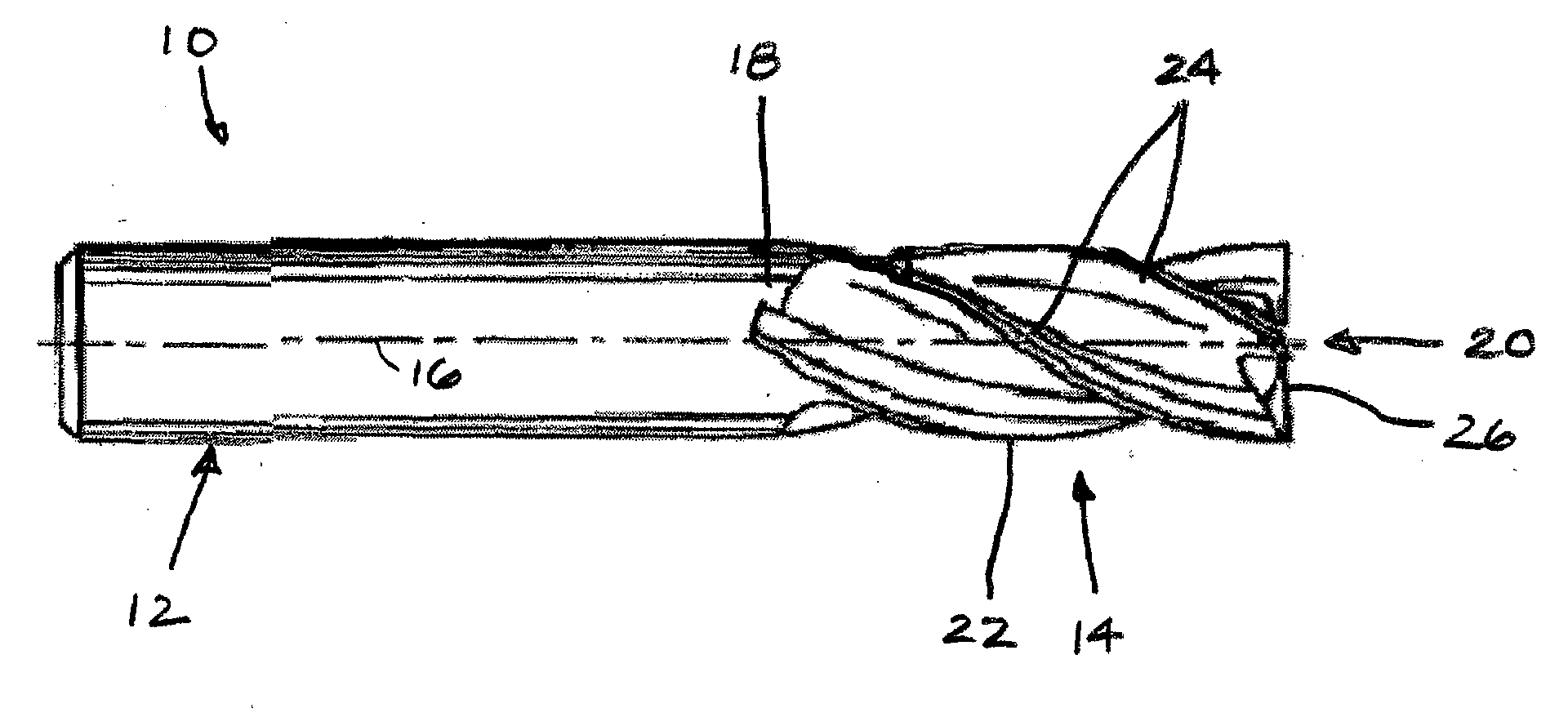

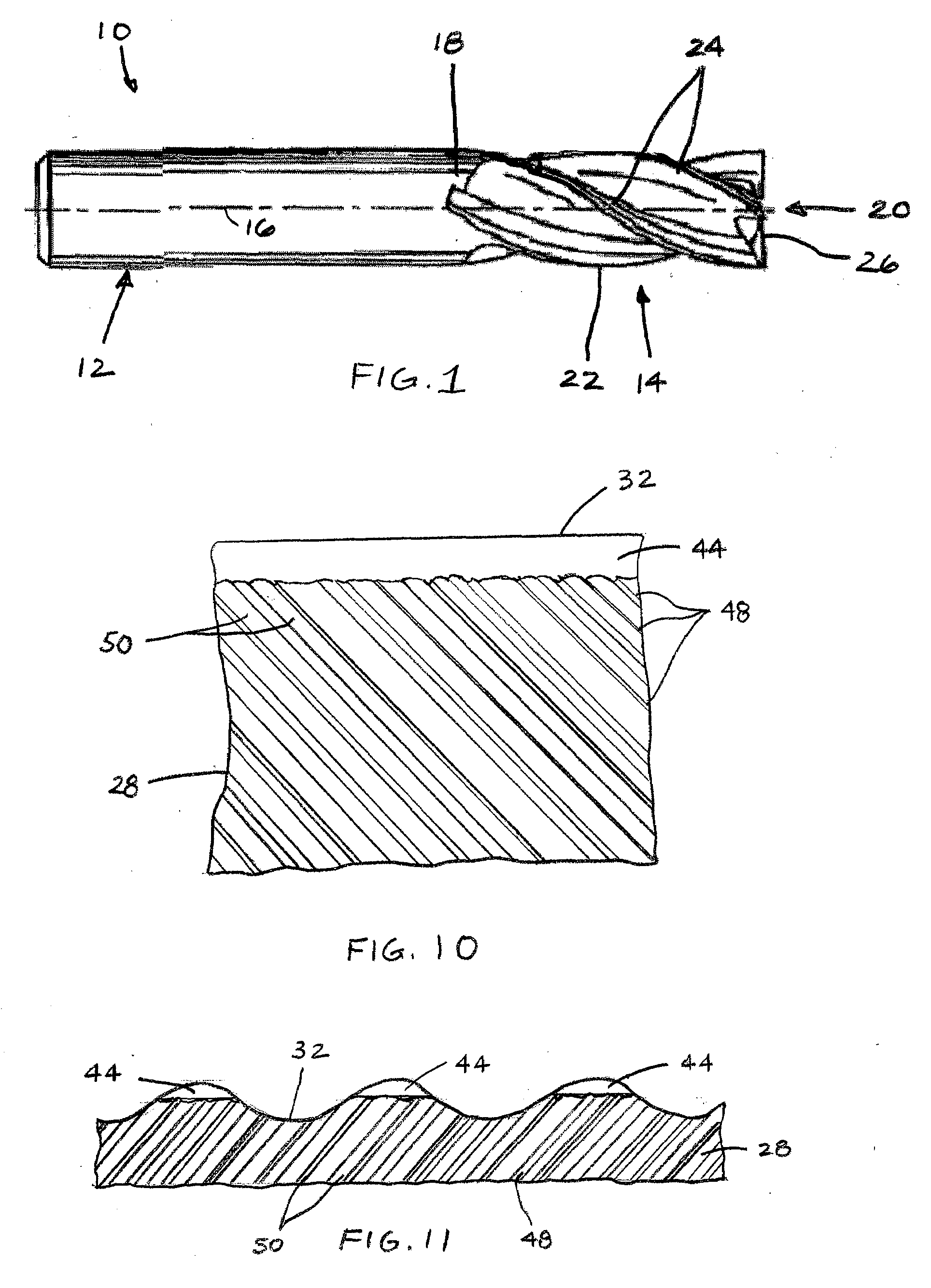

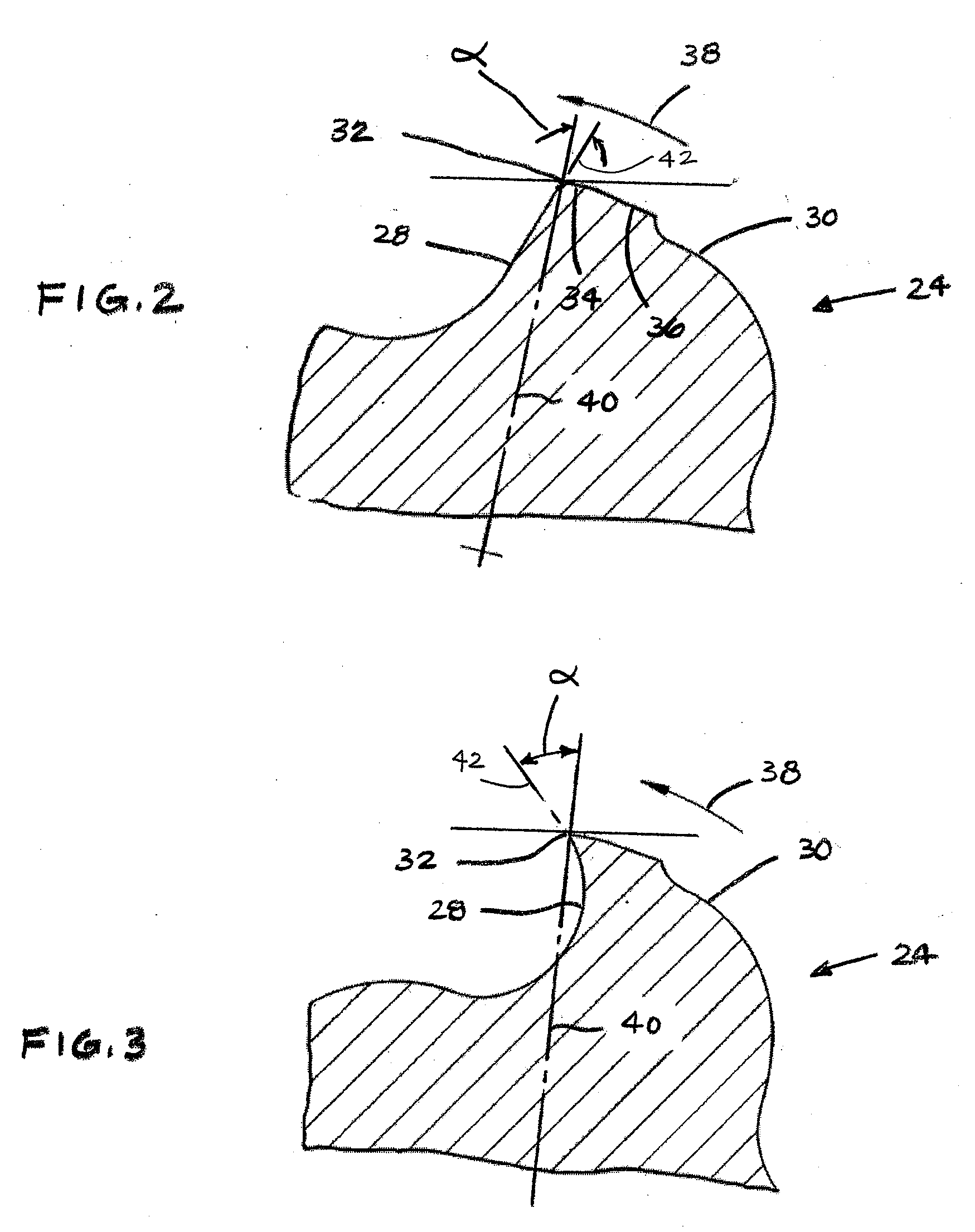

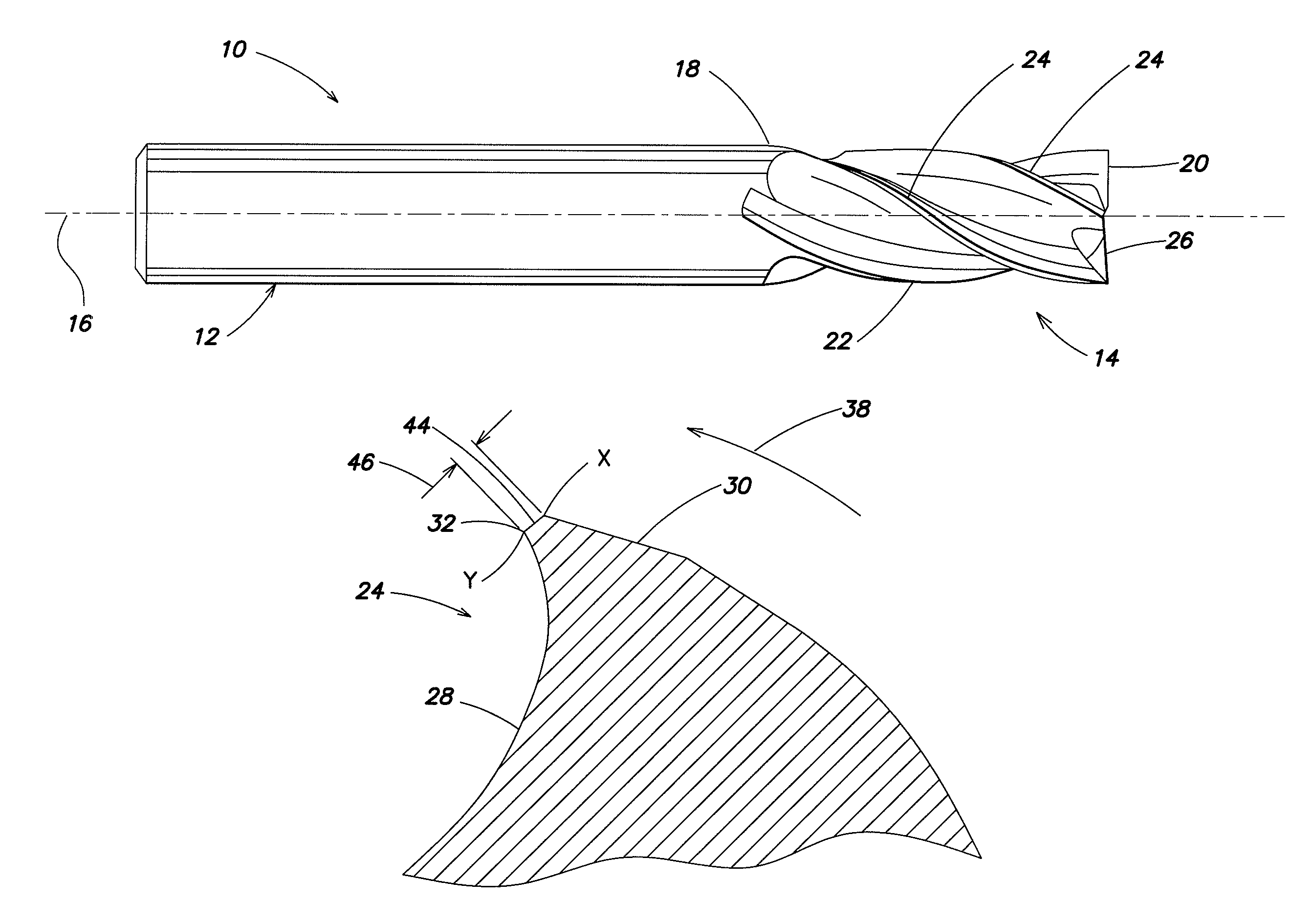

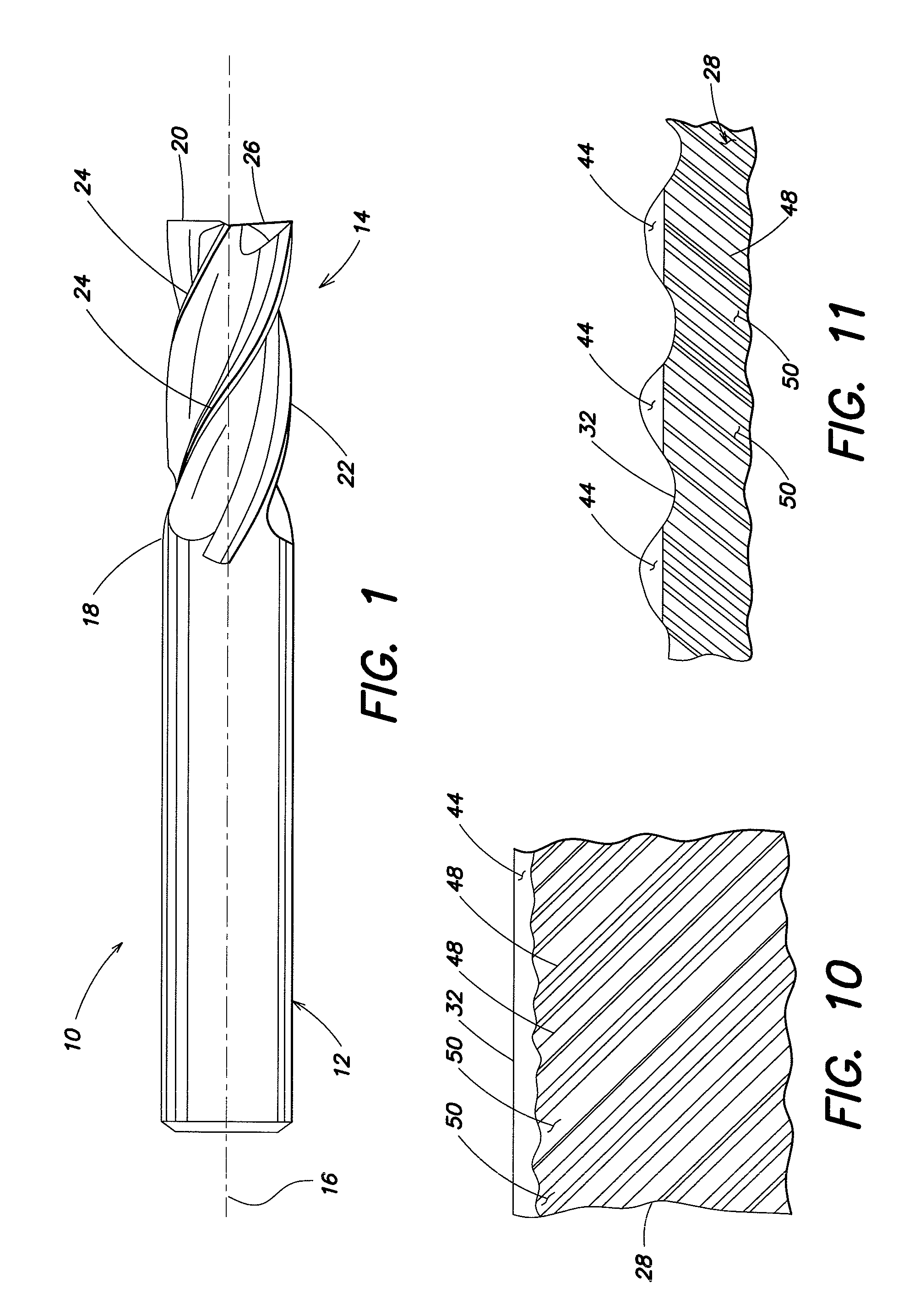

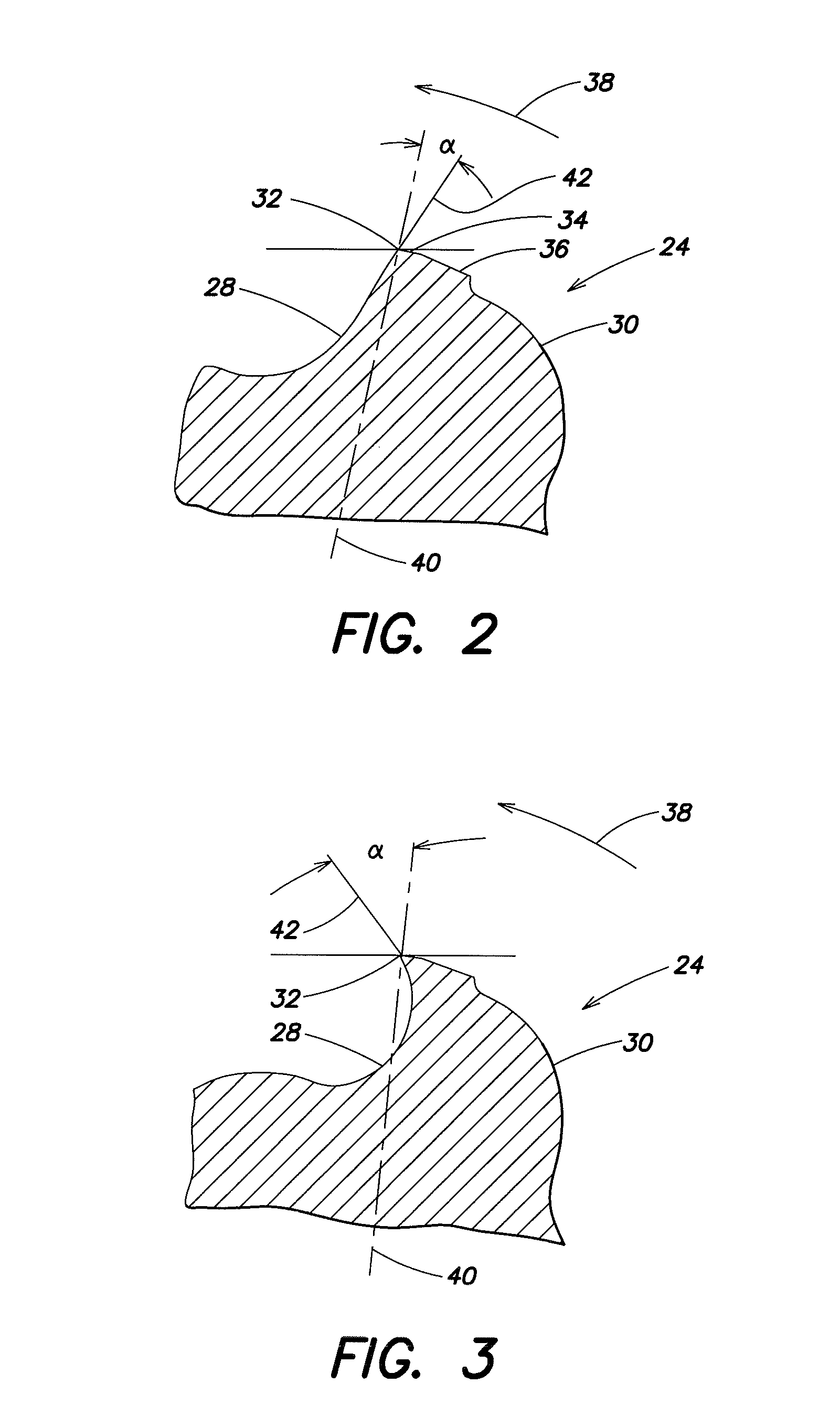

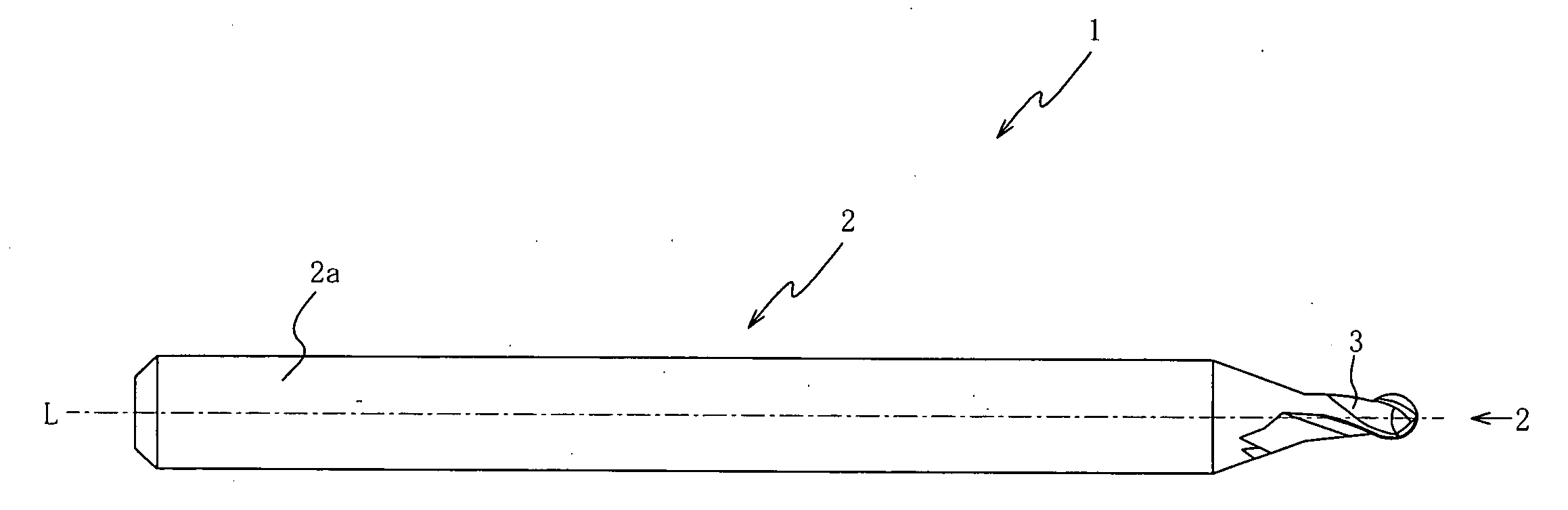

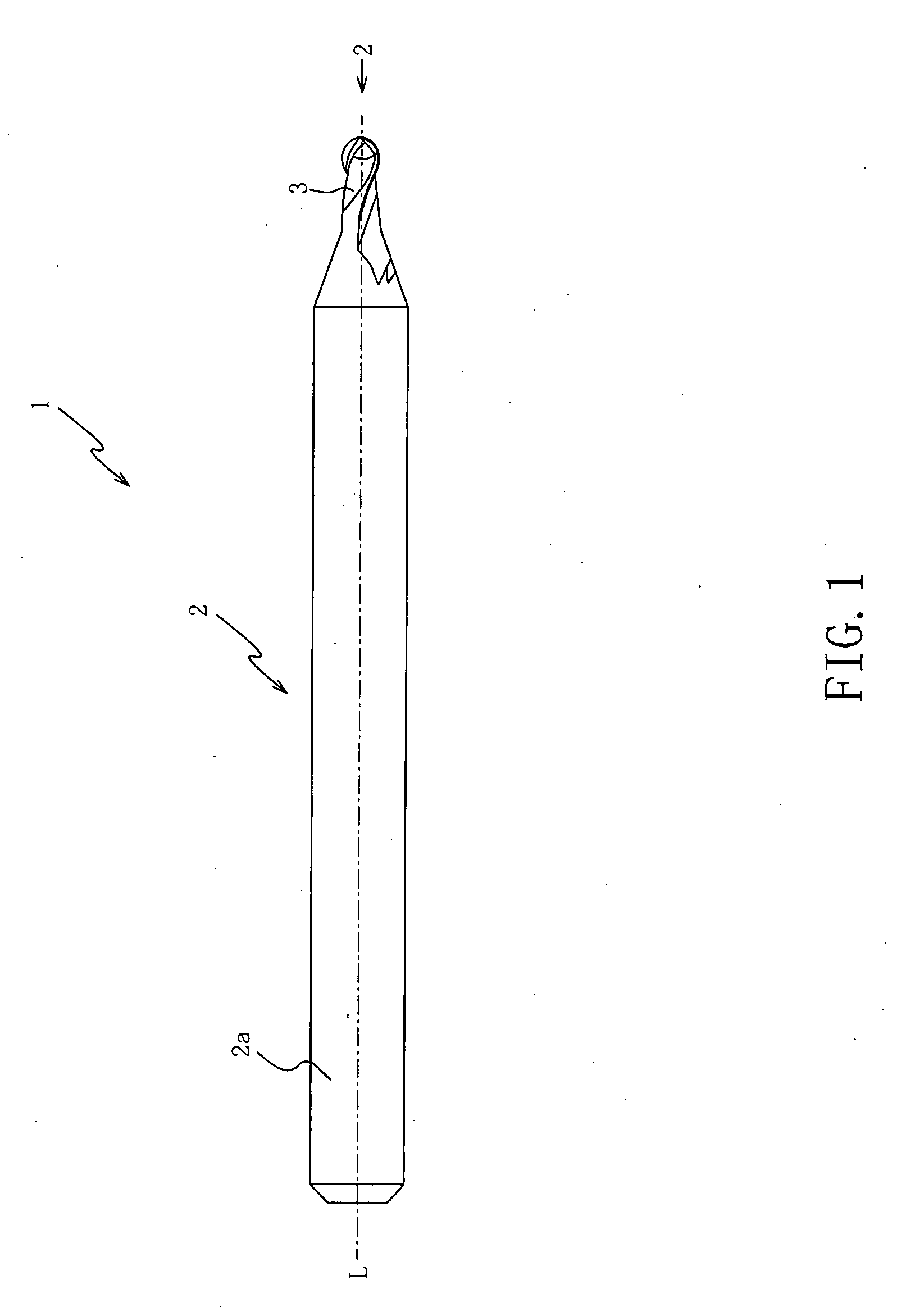

End mill

ActiveUS20080219782A1Improved cutting edgeAvoid chippingMilling cuttersShaping cuttersRotational axisMilling cutter

An end mill is provided having an axis of rotation, a shank section and a fluted section, each extending along the axis of rotation, and a plurality of helical teeth. The fluted section has a first end attached to the shank section and a second end. The plurality of helical teeth is disposed within the fluted section. Each helical tooth has a cutting edge, a relief surface, a cutting surface, and an edge preparation surface. The edge preparation surface is contiguous with the cutting edge of the respective tooth.

Owner:BERKSHIRE PRECISION TOOL

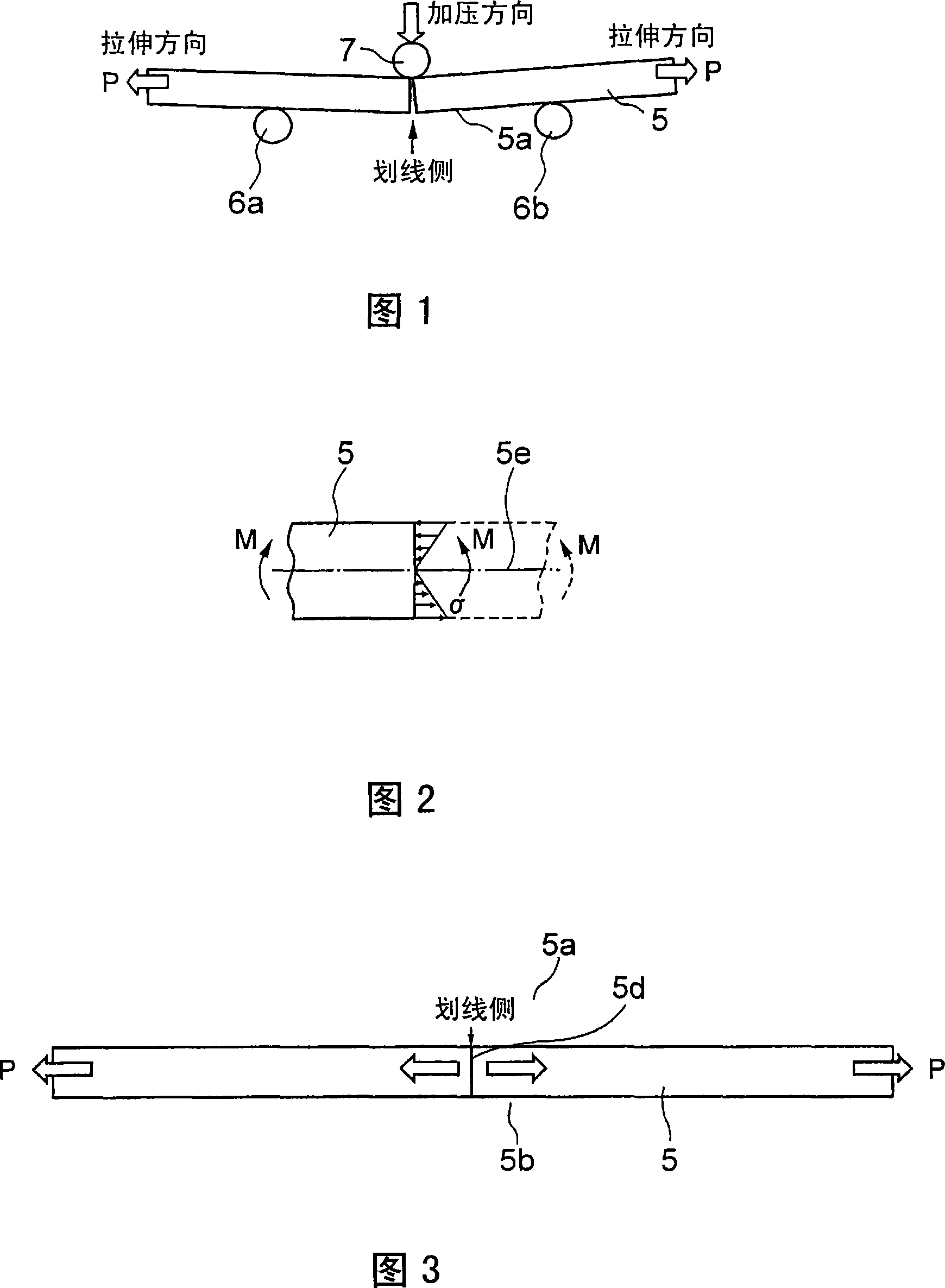

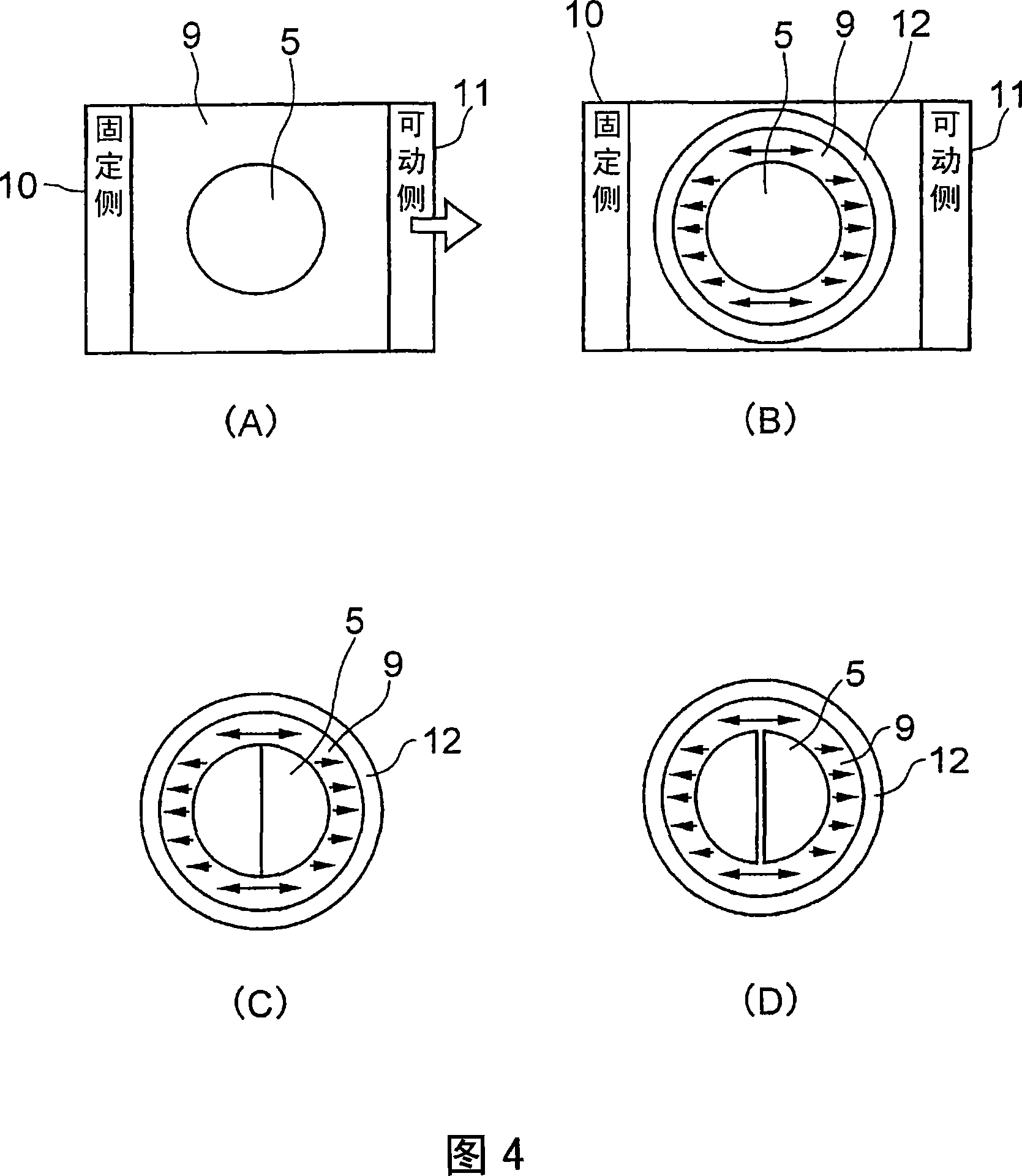

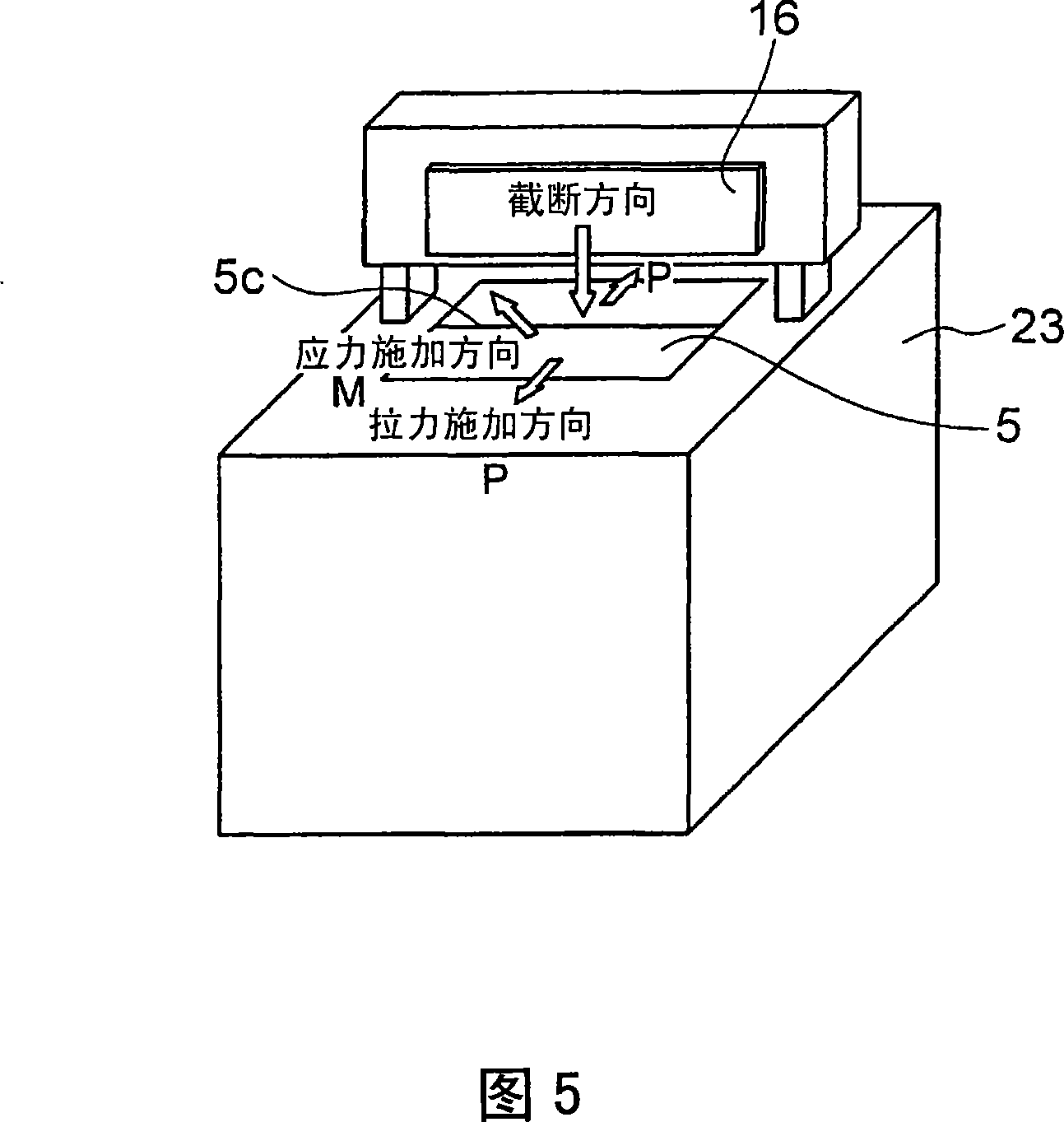

Method and device for breaking work, method for scribing and breaking work, and scribing device with breaking function

ActiveCN101099228AReduce frictionNot scatteredSemiconductor/solid-state device manufacturingGlass severing apparatusEngineeringRubbing

A method and a device for breaking a work, a method for scribing and breaking the work, and a scribing device with a breaking function. The method for breaking the work (5) capable of preventing chipping from occurring on the rear surface of the work due to rubbing when the work having a scribe line marked on the surface thereof is broken comprises a work adhering step for stamping the rear surface of the work (5) on an extensible sheet (9), a sheet pulling step for pulling the sheet (9) on which the work (5) is stamped, and a work parting step for moving the scribe line (5c) to the rear surface of the work (5) in the pulled state of the sheet (9). Since the work (5) is pulled off immediately after the work (5) is parted by the tensile force of the sheet (9), the rubbing of the parted work (5) is reduced and the chipping can be prevented from occurring on the rear surface of the work. Also, since the tensile force provided to the work (5) assists in parting the work, the work (5) can be parted with a smaller force.

Owner:THK CO LTD +1

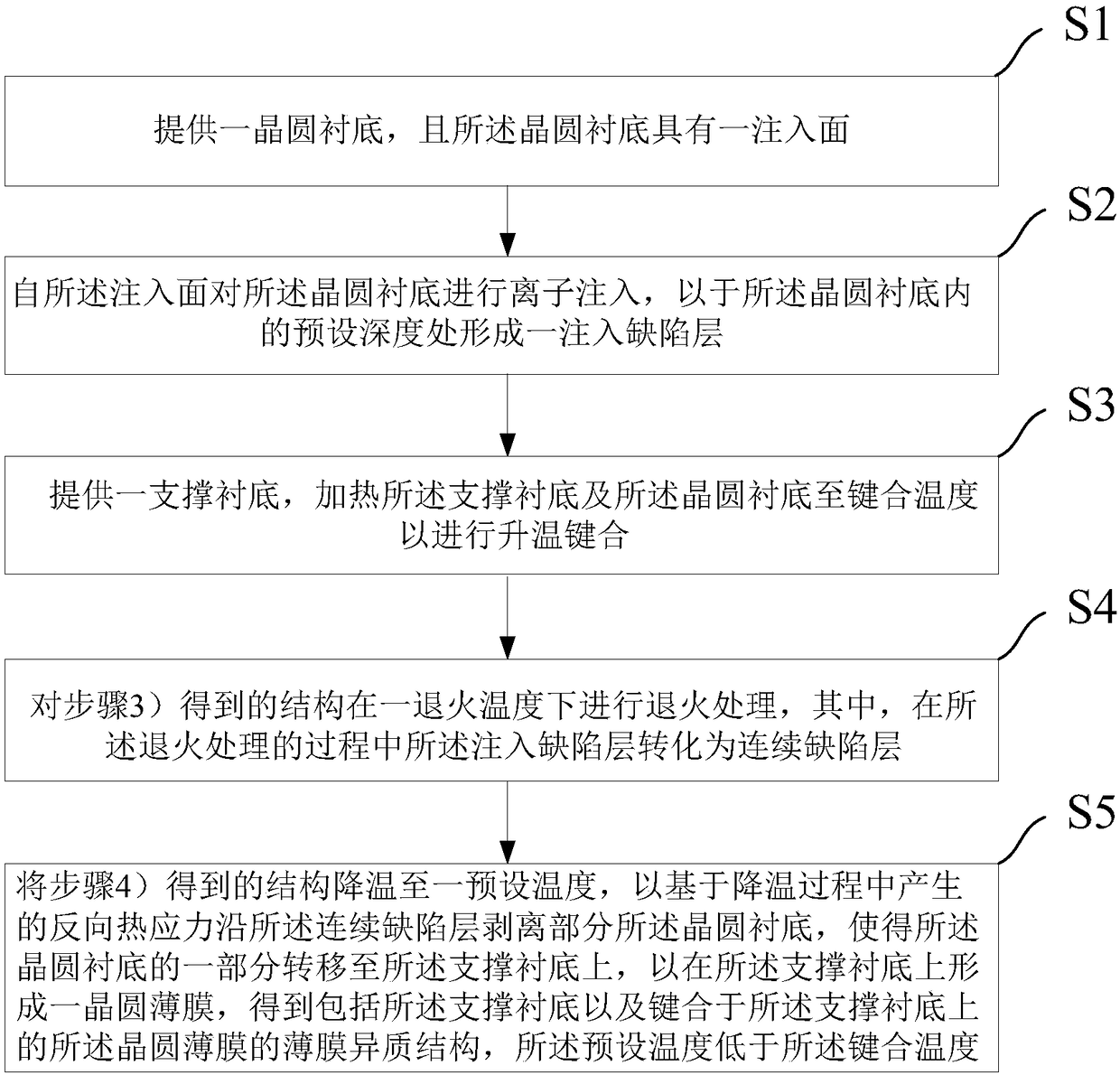

Thin film heterostructure preparation method

ActiveCN108493334ALow annealing temperatureShorten process timePiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsHigh-temperature corrosion

The invention provides a thin film heterostructure preparation method. The method comprises steps: a wafer substrate with an injection surface is provided; ion implantation is carried out on the wafersubstrate from the injection surface, and an injection defect layer is formed at a preset depth in the wafer substrate; a support substrate is provided, and the support substrate and the wafer substrate are subjected to temperature rise bonding; the obtained structure is subjected to annealing treatment to form a continuous defect layer; the temperature of the obtained structure is reduced to a preset temperature, reverse thermal stress generated based on temperature reduction strips part of the wafer substrate along the continuous defect layer, and a thin film heterostructure comprising thesupport substrate and the wafer thin film is obtained, wherein the preset temperature is lower than the bonding temperature. In the temperature rise bonding mode, the thermal stress of the bonding structure can be reduced, the bonding structure can keep stable and complete in a high temperature process, the problem of wafer crack generated by thermal mismatch in the stripping process can be effectively solved, and through the reverse thermal stress assisting method, the bonding structure is separated at the continuous defect layer and a bonding interface is not influenced.

Owner:上海新硅聚合半导体有限公司

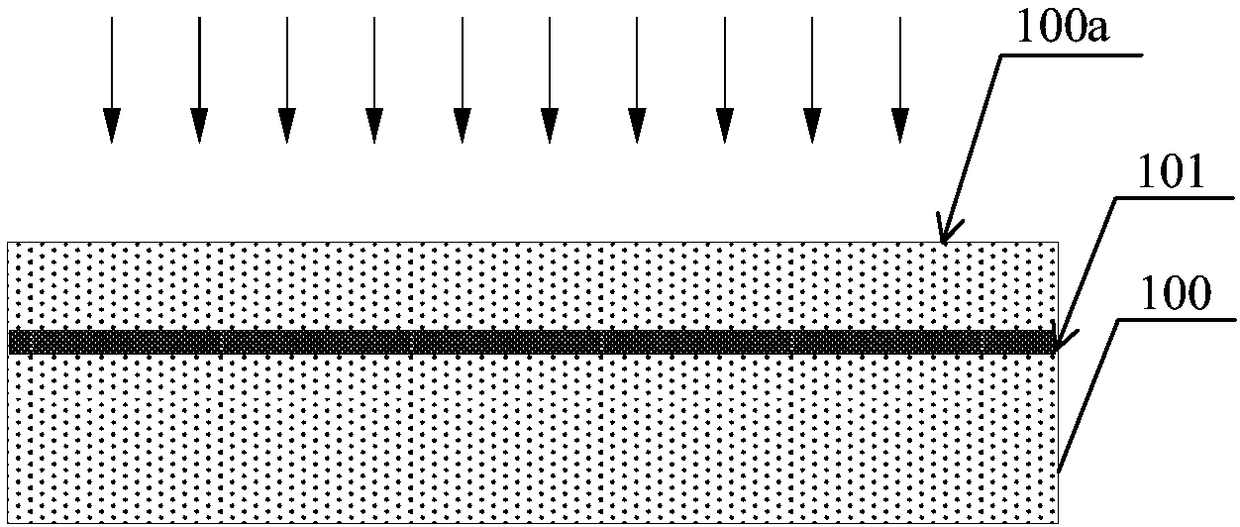

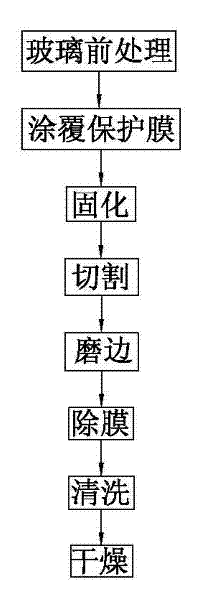

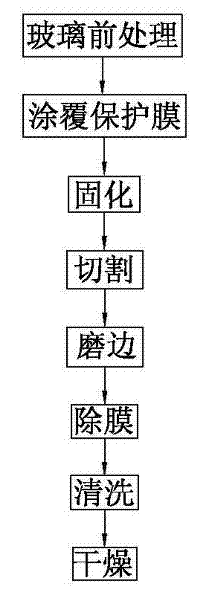

Processing technology of glass protection

InactiveCN102351409AAvoid chippingReduce processEdge grinding machinesGlass severing apparatusTectorial membraneEngineering

The invention provides a processing technology of glass protection. According to the processing technology, a protection film is added on the surface of glass before the processing operation of glass cutting or edging, so as to avoid problems such as scraping, corner-chipping, adherence, stain-bonding and the like during glass cutting or edging, save technological processes of coarse grinding and polishing, greatly reduce production cost and improve the yield.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

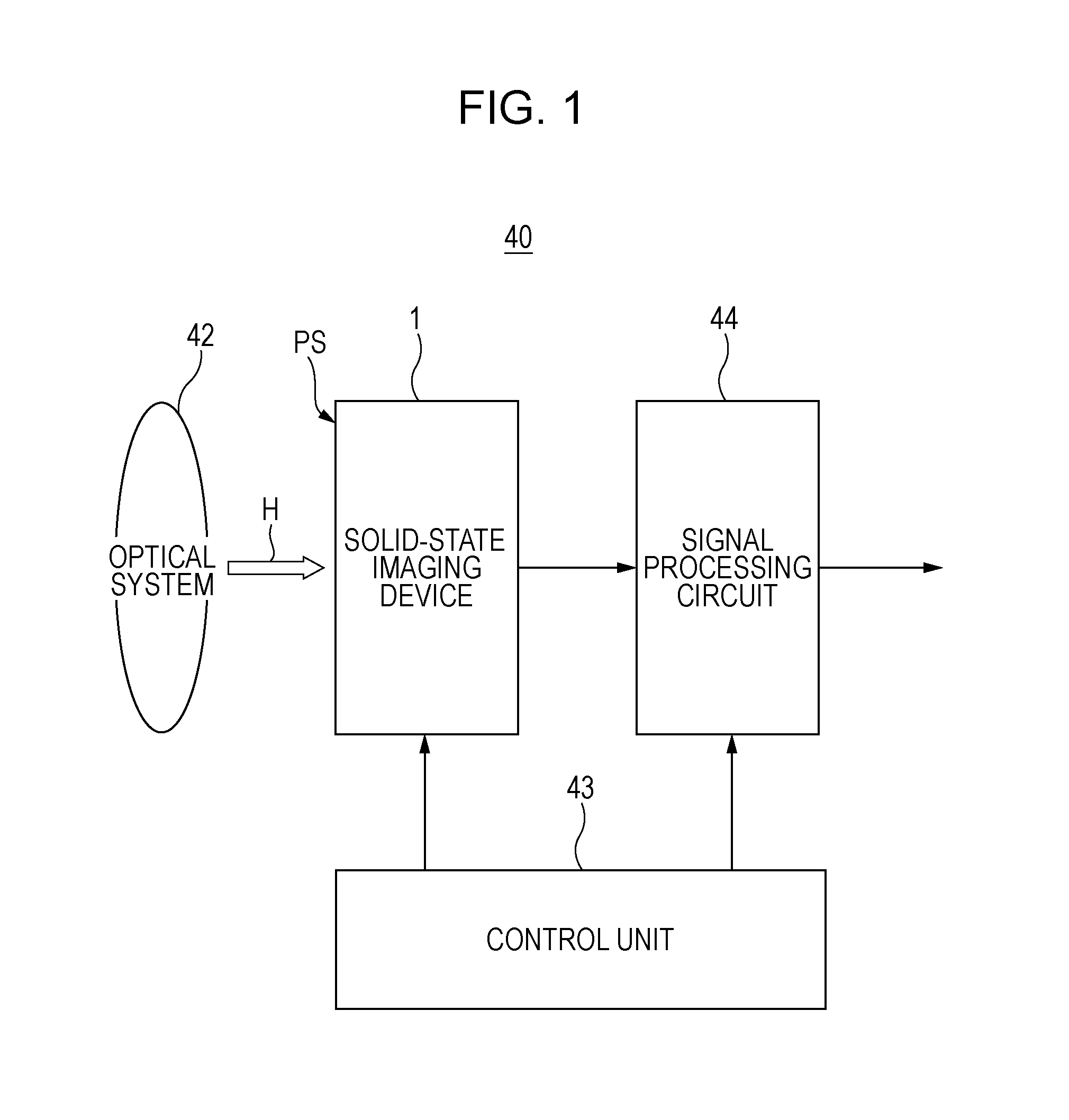

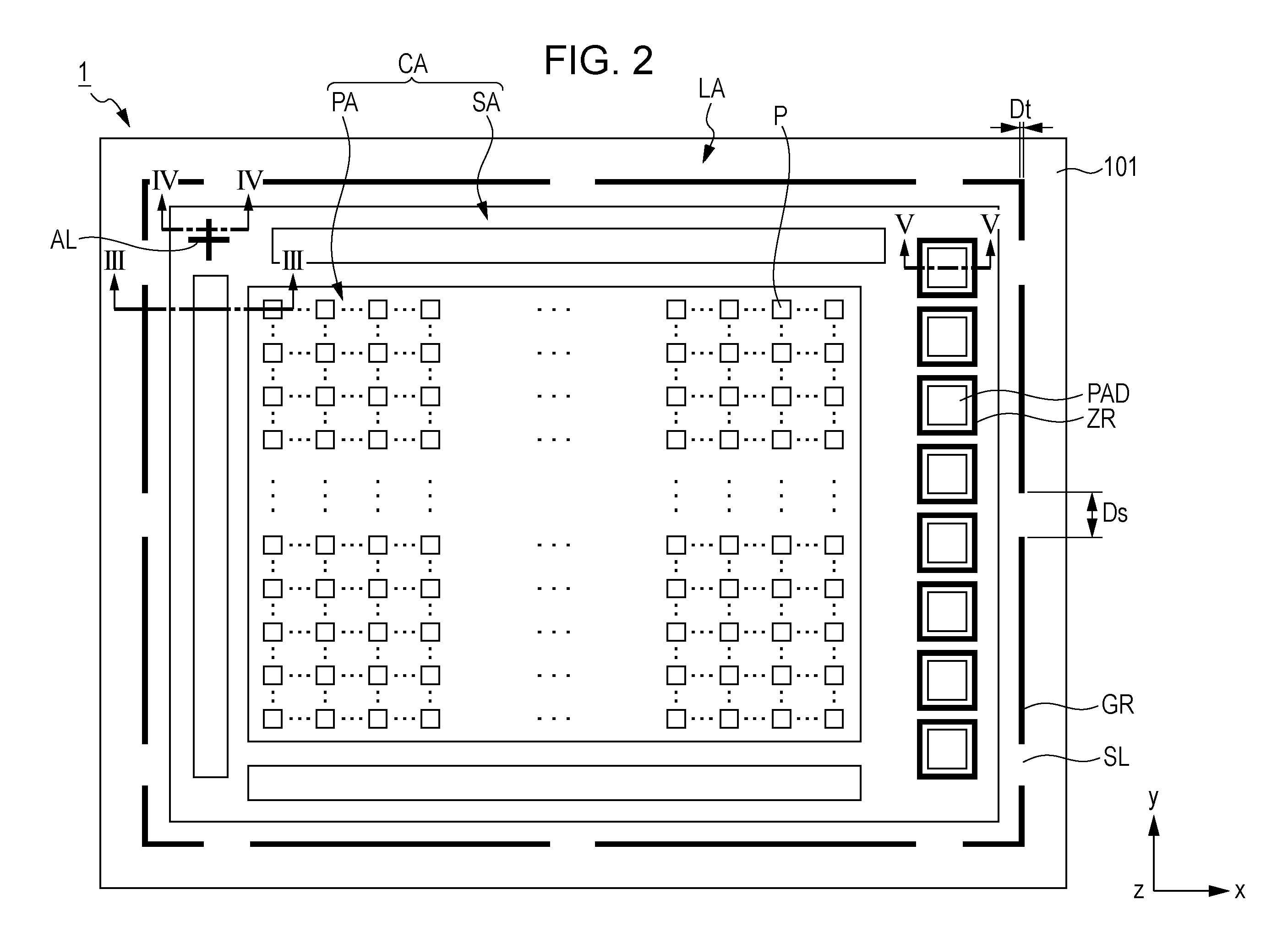

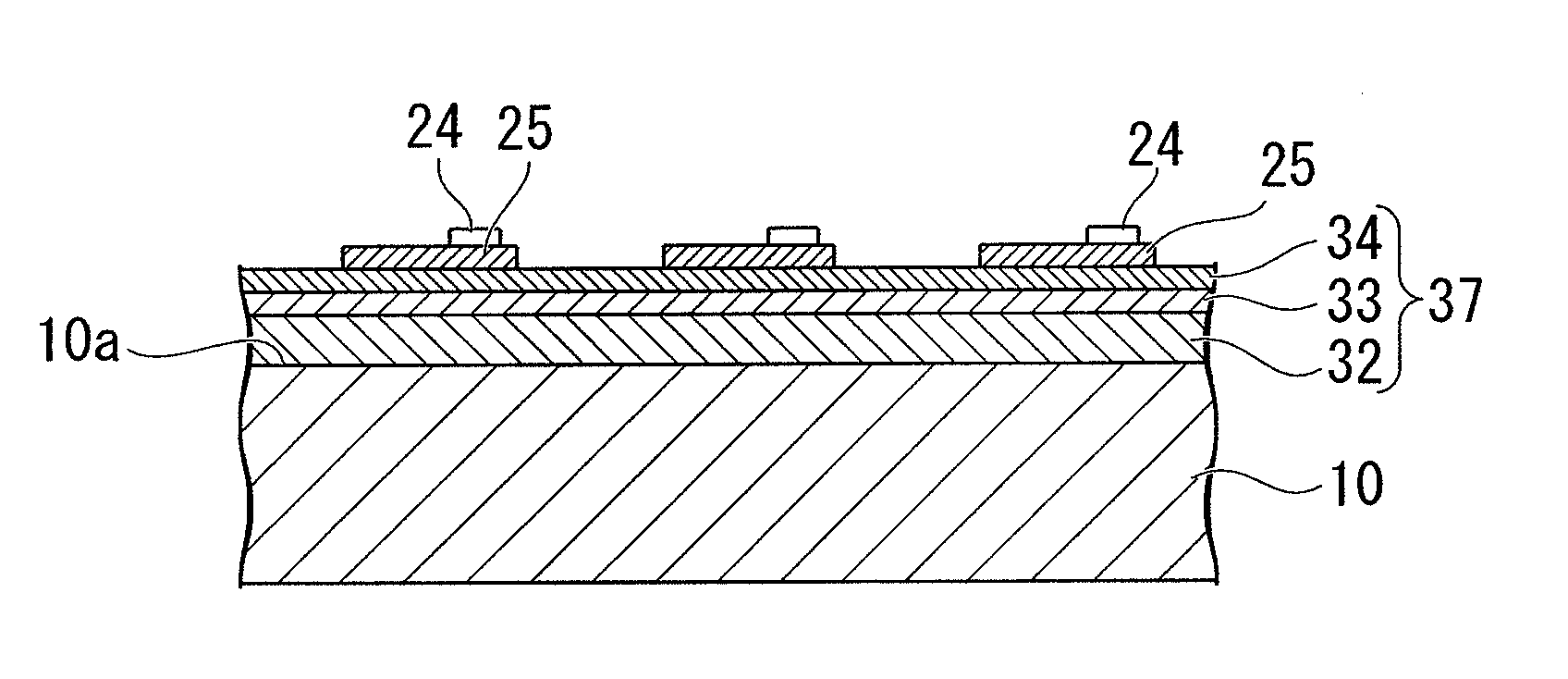

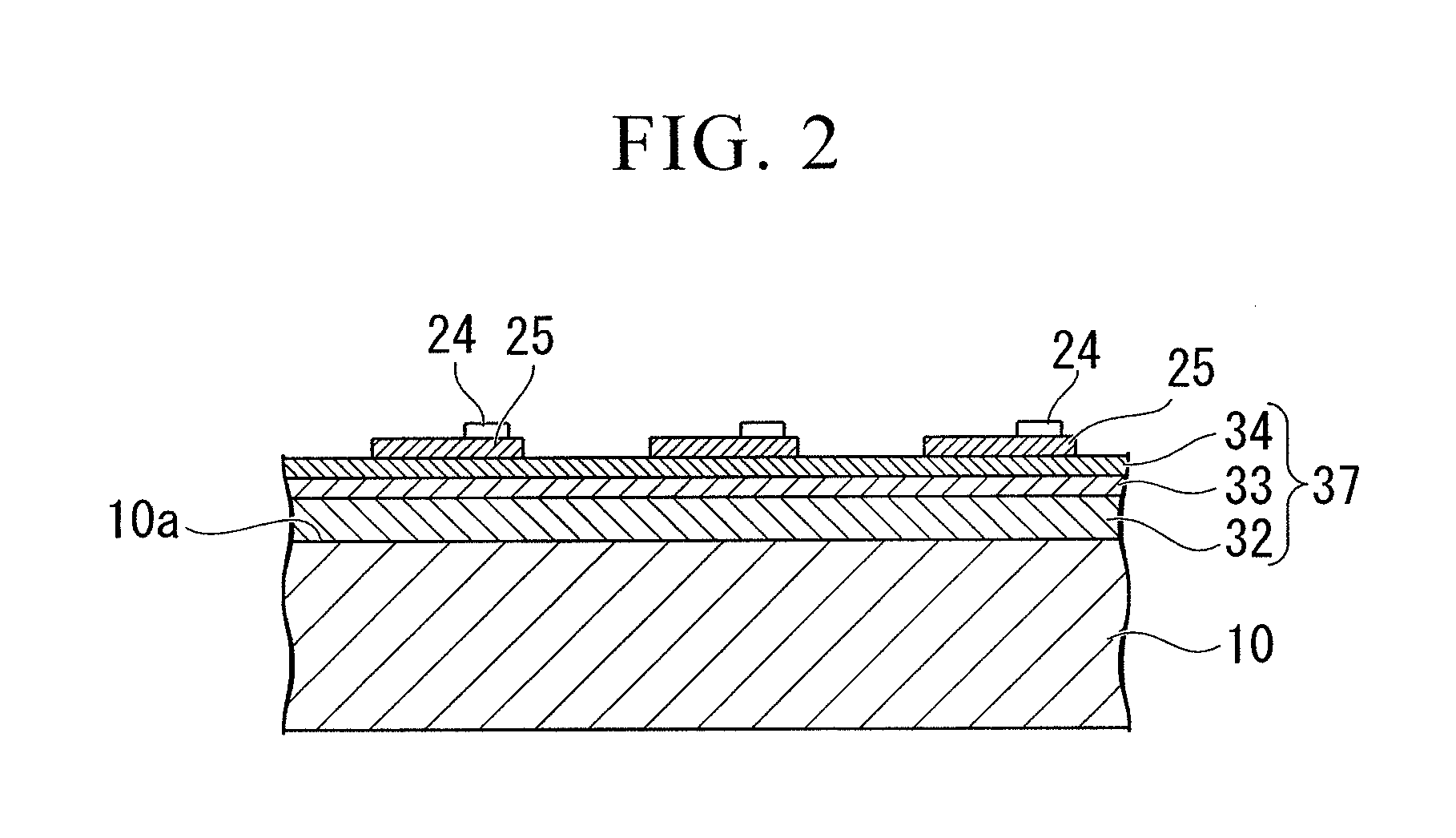

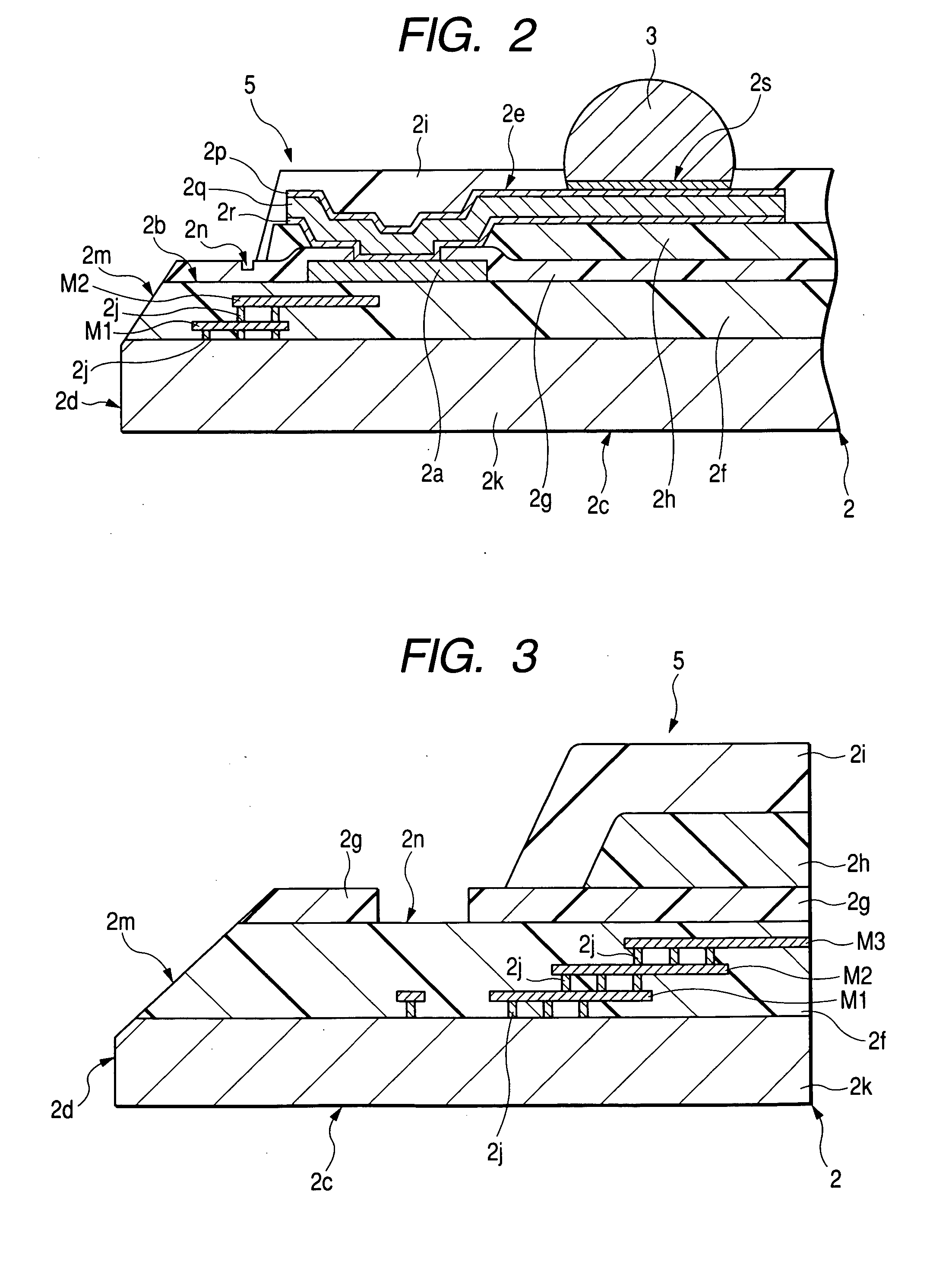

Solid-state imaging device, manufacturing method thereof, electronic apparatus, and semiconductor device

ActiveUS20110186917A1Improve production yieldSolve low manufacturing efficiencyFinal product manufactureSemiconductor/solid-state device detailsEngineeringGuard ring

A semiconductor device includes a substrate, a region including a semiconductor element on the substrate, and at least one guard ring structure provided around the region. The guard ring structure includes a guard ring and at least one portion comprised of the substrate.

Owner:SONY SEMICON SOLUTIONS CORP

Surface-coated cutting tool

ActiveCN1845808AImprove overall lifespanAvoid chippingTransportation and packagingMilling cuttersHardnessIndentation hardness

A surface-coated cutting tool having a base material and, formed thereon, a coating film, wherein the coating film has a hard layer comprising a compound selected from among a nitride, a carbonitride, a nitroxide and a carbonitroxide of one or more first elements selected from the group consisting of metals belonging to 4a, 5a and 6a Groups of the Periodic Table and B, Al and Si, and wherein the hard layer satisfies the followings: (a) in the nano indentation hardness test, (hmax - hf) / hmax is 0.2 to 0.7, wherein hmax represents the maximum indentation depth, and hf represents the indentation depth after the removal of a load (impression depth), (b) the hard layer has a film thickness of 0.5 to 15 mum, and (c) a hardness according to the nano indentation method is 20 to 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

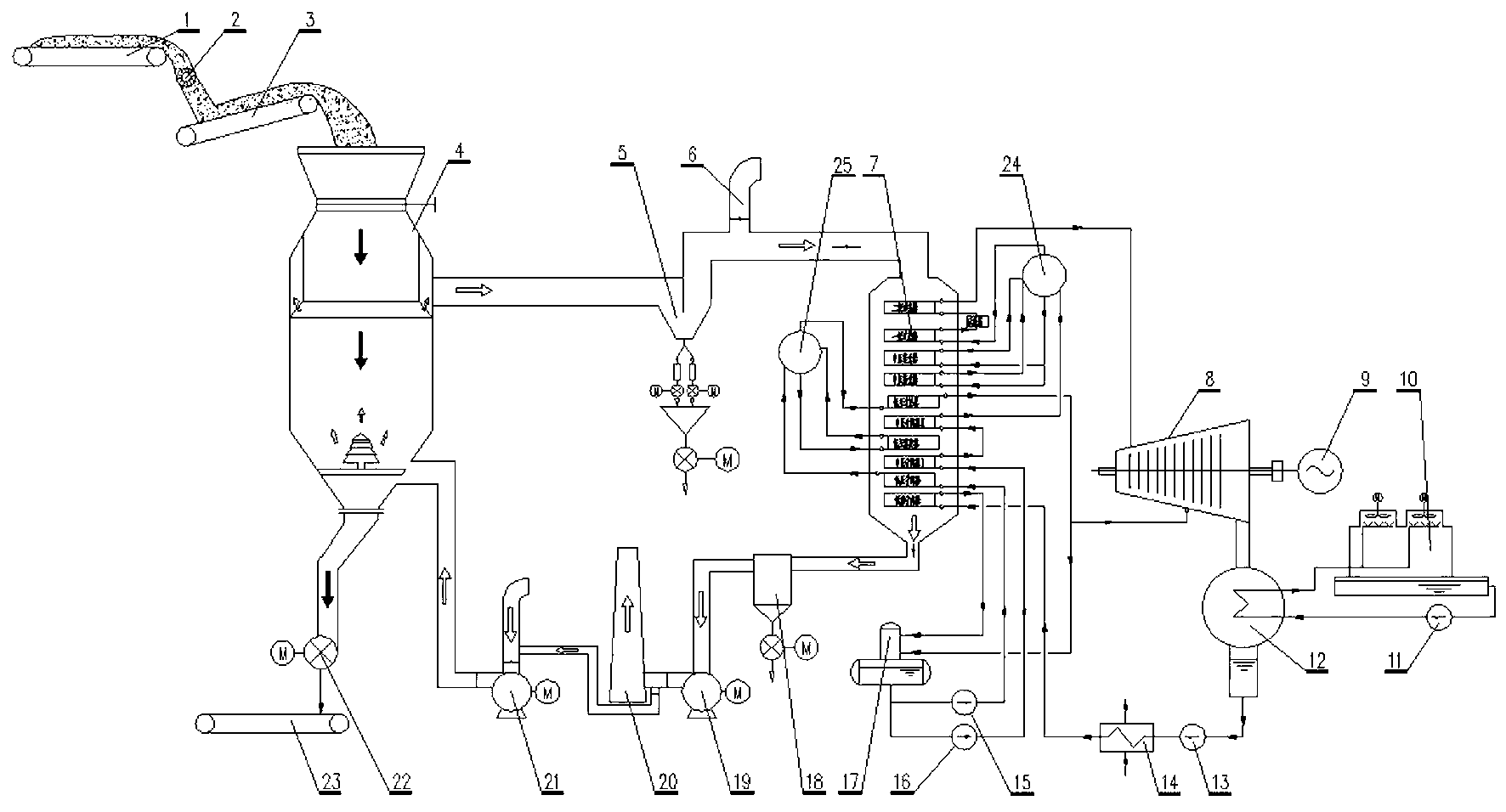

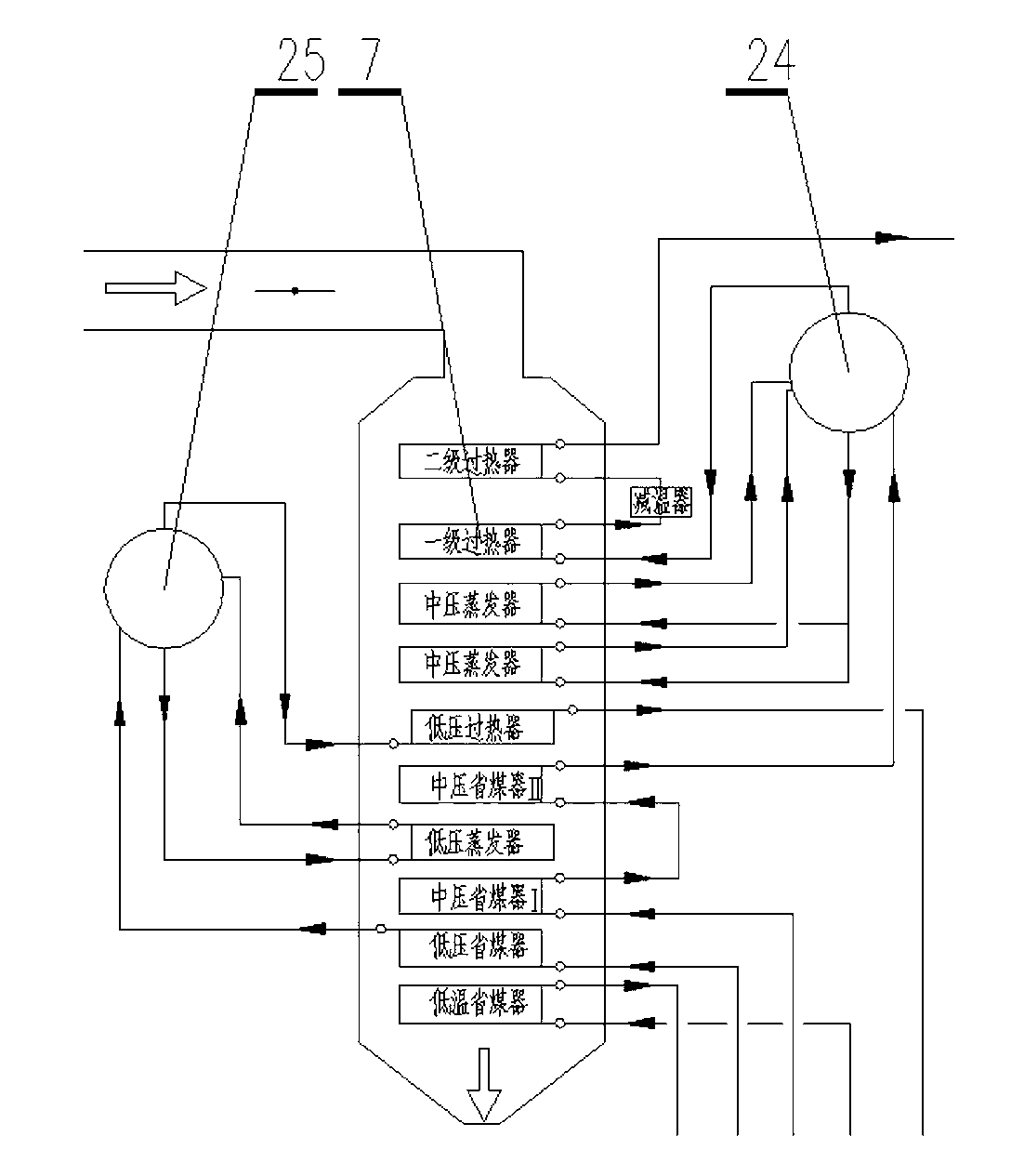

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method of manufacturing semiconductor light-emitting device

ActiveUS20110275172A1Avoid it happening againPrevent leakageSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLight emitting device

A method of manufacturing a semiconductor light-emitting device which includes the steps of forming a plurality of light-emitting device sections (40), having an approximately rectangular shape in plan view, on a substrate (10) in a matrix shape, forming a first dividing groove (61) between the long sides (41) of the light-emitting device sections (40) so that the long side (41) of the light-emitting device section (40) is along an easily cleaved plane of the substrate (10), forming a second dividing groove (62), having a larger width than the width of the first dividing groove (61), between short sides (42) of the light-emitting device sections (40), and dividing the substrate (10) along a first dividing groove (61) and a second dividing groove (62) to cut out the light-emitting device section (40).

Owner:TOYODA GOSEI CO LTD

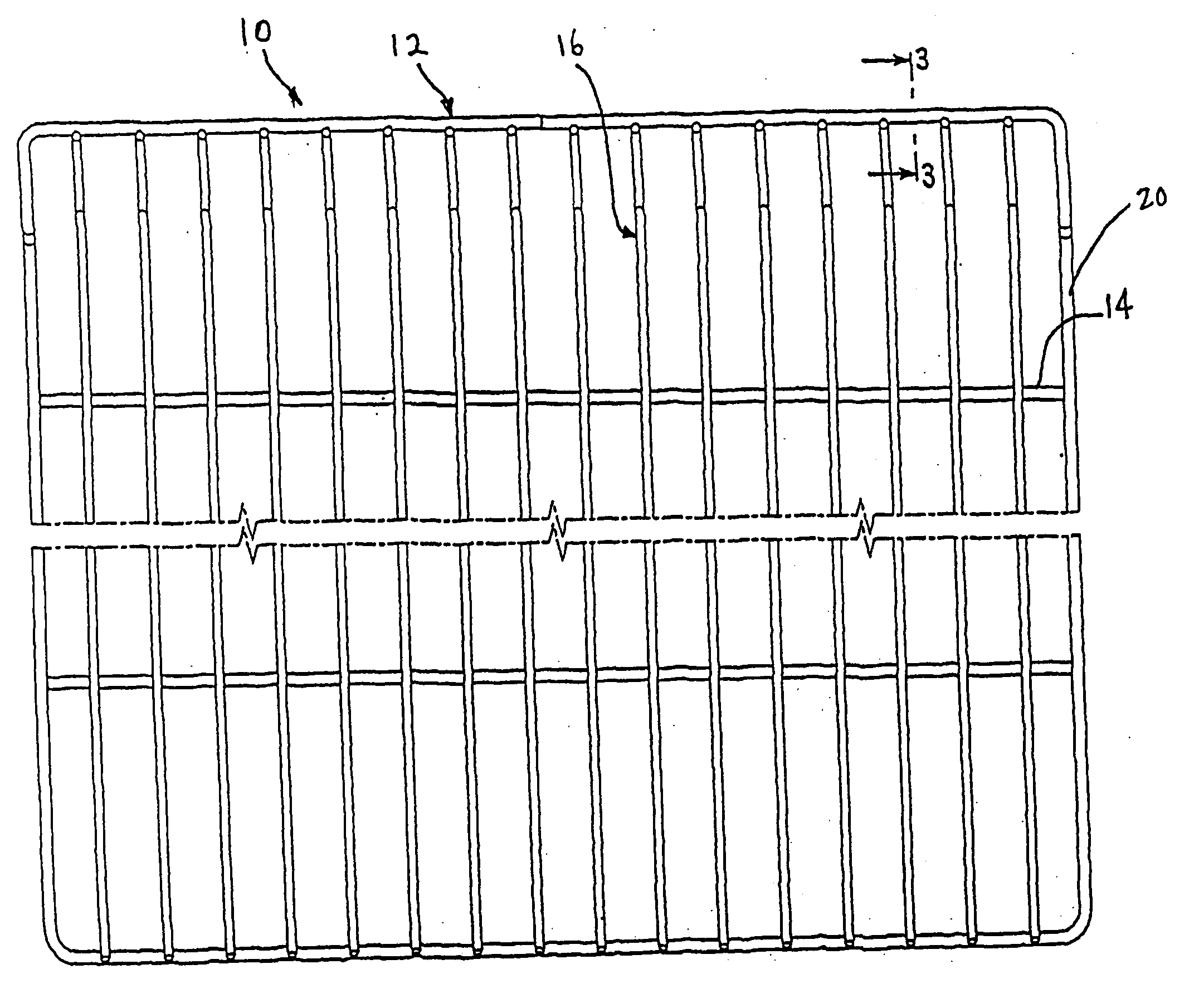

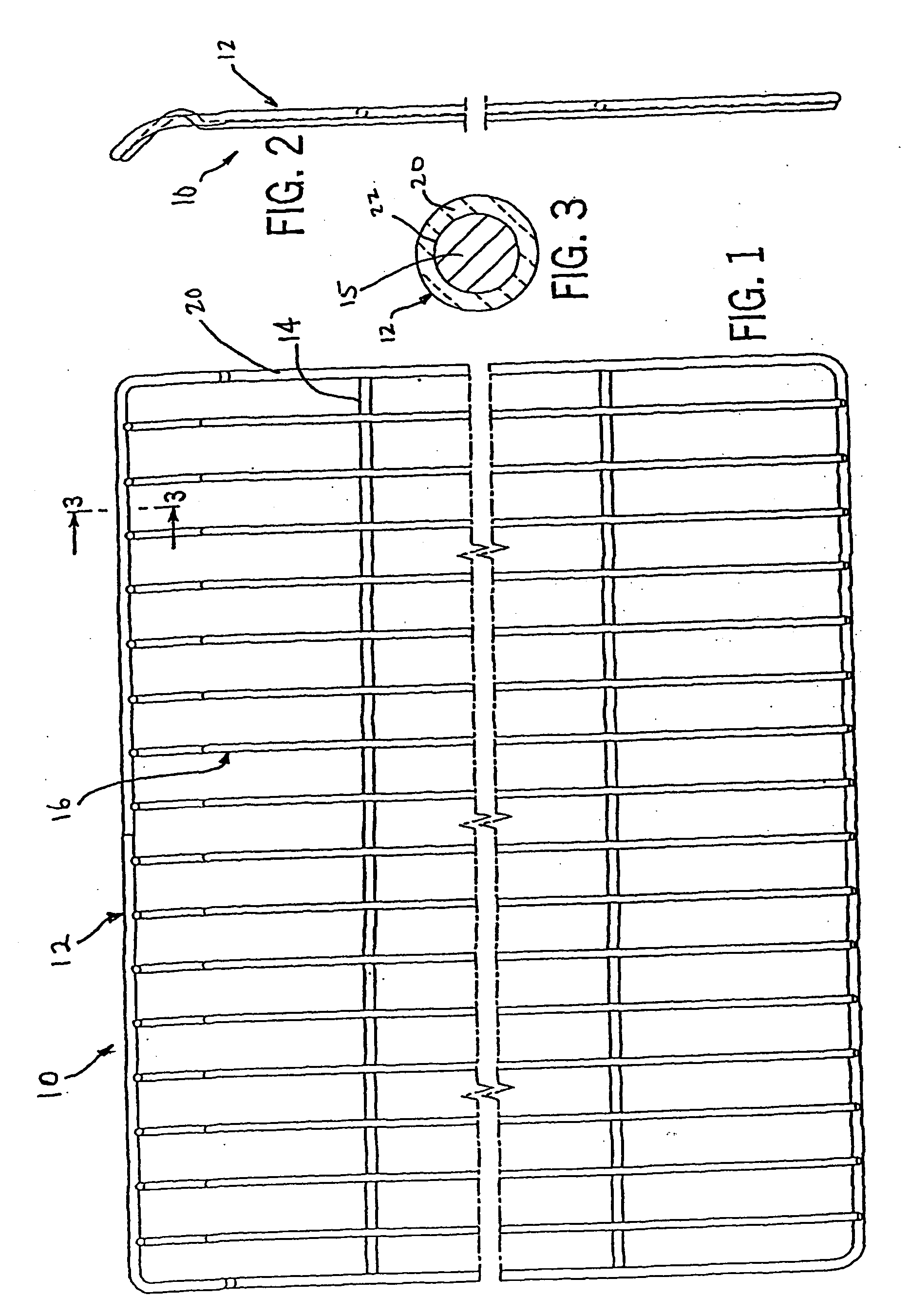

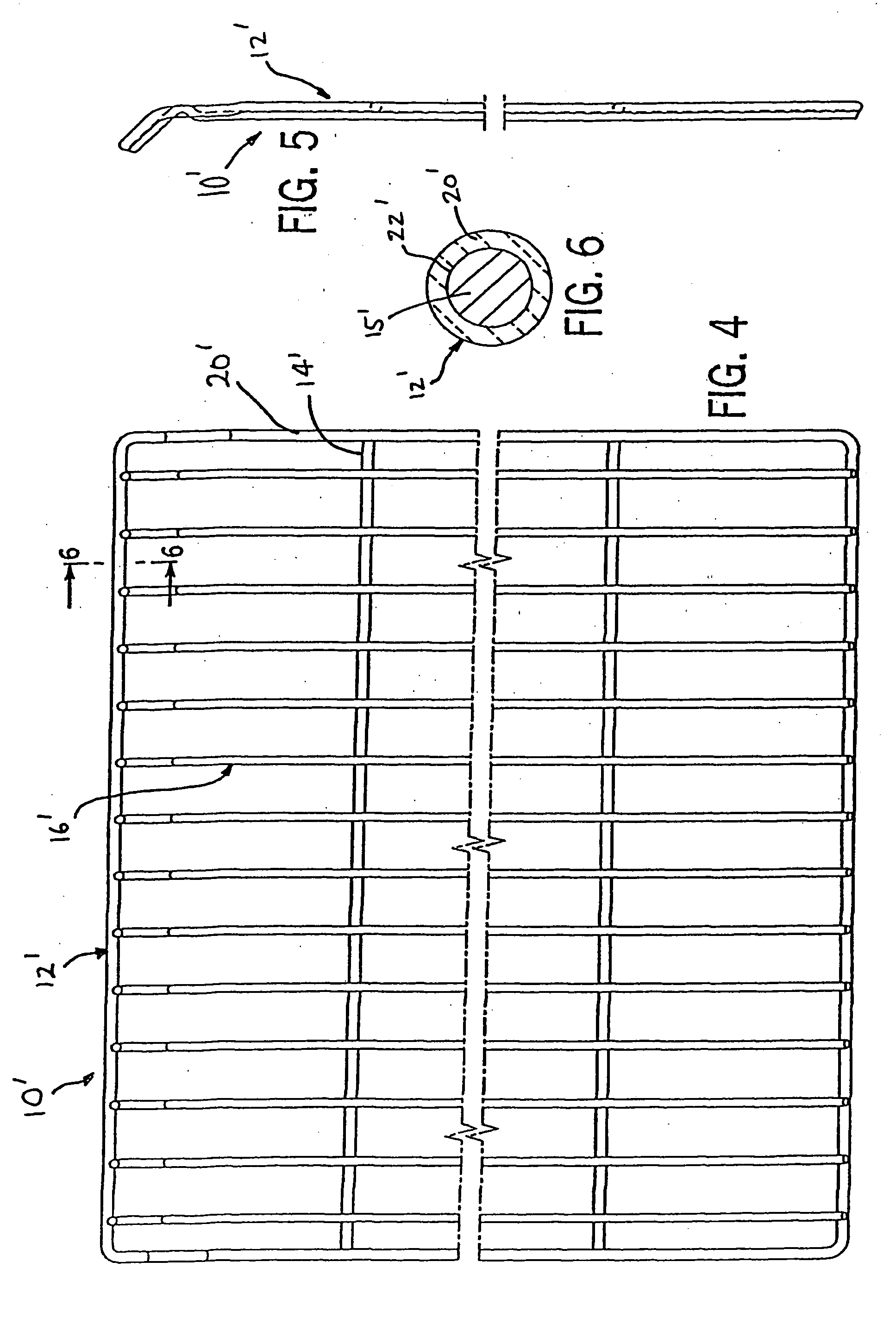

Oven rack having an integral lubricious, dry porcelain surface

InactiveUS20070272231A1Avoid chippingReduce the overall diameterDomestic stoves or rangesStoves/ranges shelves or racksDiamond-like carbonAntimony trioxide

A lubricious porcelain coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a cold drawn steel rod material containing from about 80 to about 99.9% by weight of iron, up to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. In a preferred embodiment, the porcelain surface of the oven rack includes a dry lubricant selected from carbon; graphite; boron nitride; cubic boron nitride; molybdenum (IV) sulfide; molybdenum disulfide; molybdenum sulfide; molybdenum (IV) selenide; molybdenum selenide; tungsten (IV) sulfide; tungsten disulfide; tungsten sulfide; silicon nitride (Si3N4); TiN; TiC; TiCN; TiO2; TiAlN; CrN; SiC; diamond-like carbon; tungsten carbide (WC); zirconium oxide (ZrO2); zirconium oxide and 0.1 to 40 weight % aluminum oxide; alumina-zirconia; antimony; antimony oxide; antimony trioxide; and mixtures thereof.

Owner:SSW ADVANCED TECH LLC

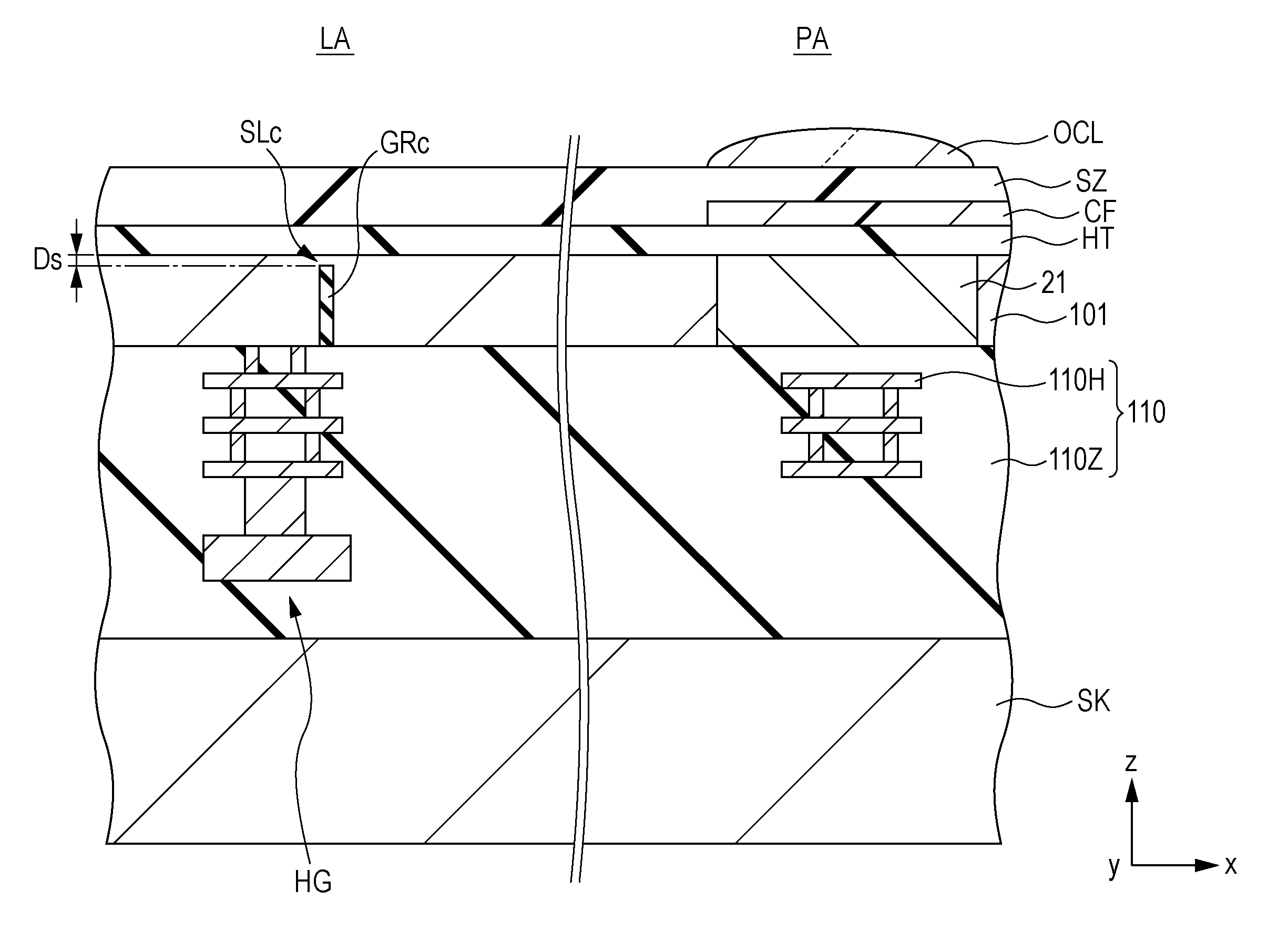

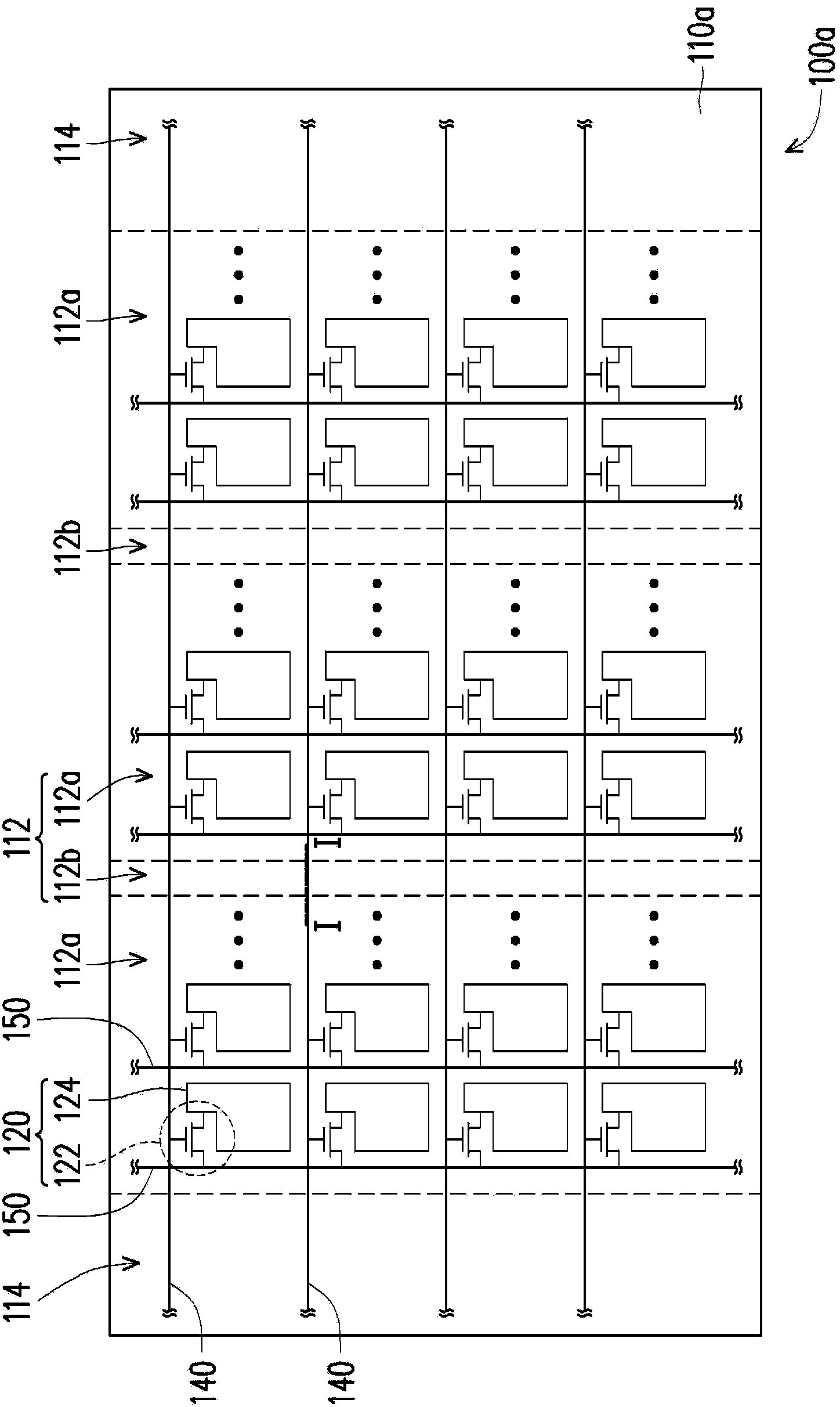

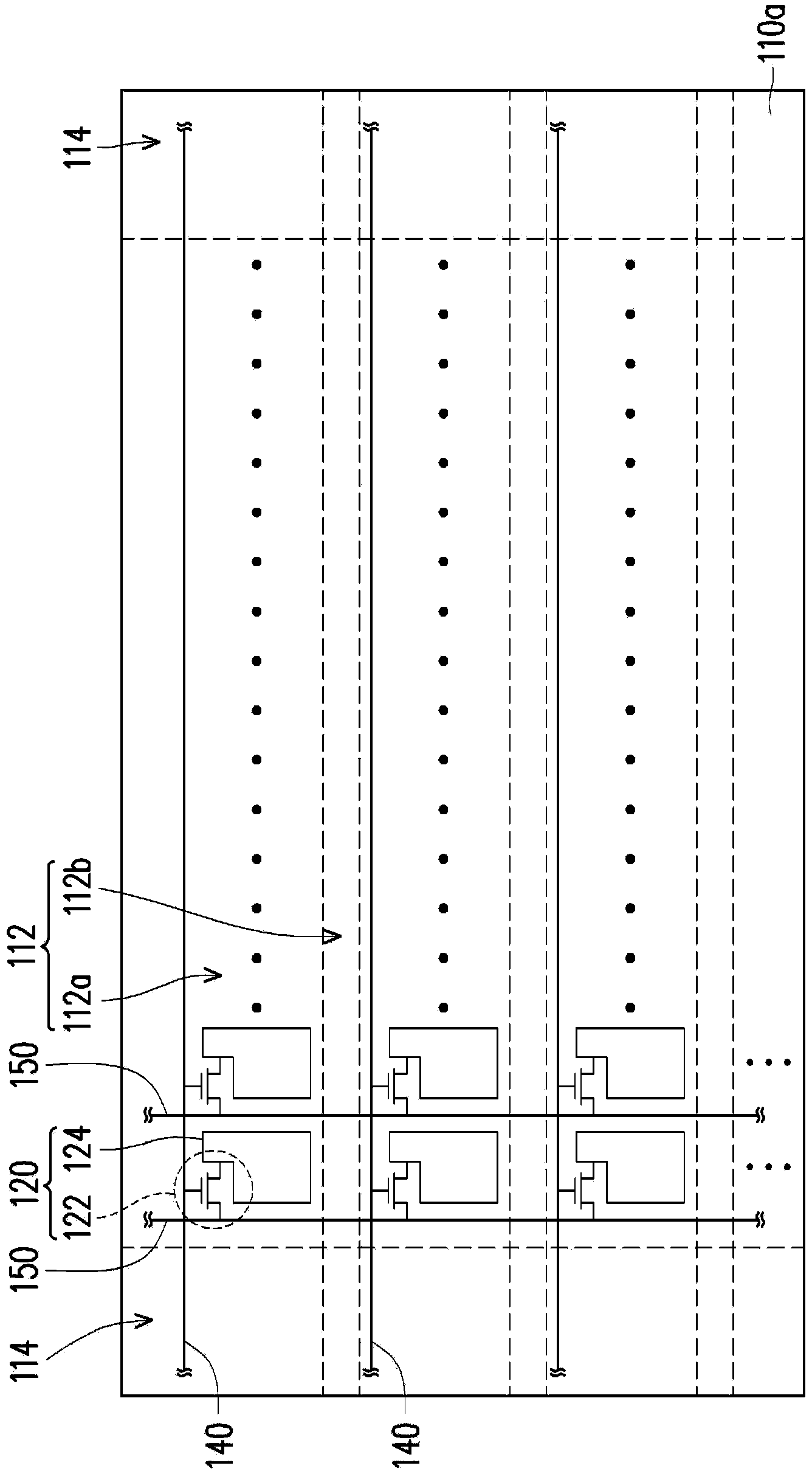

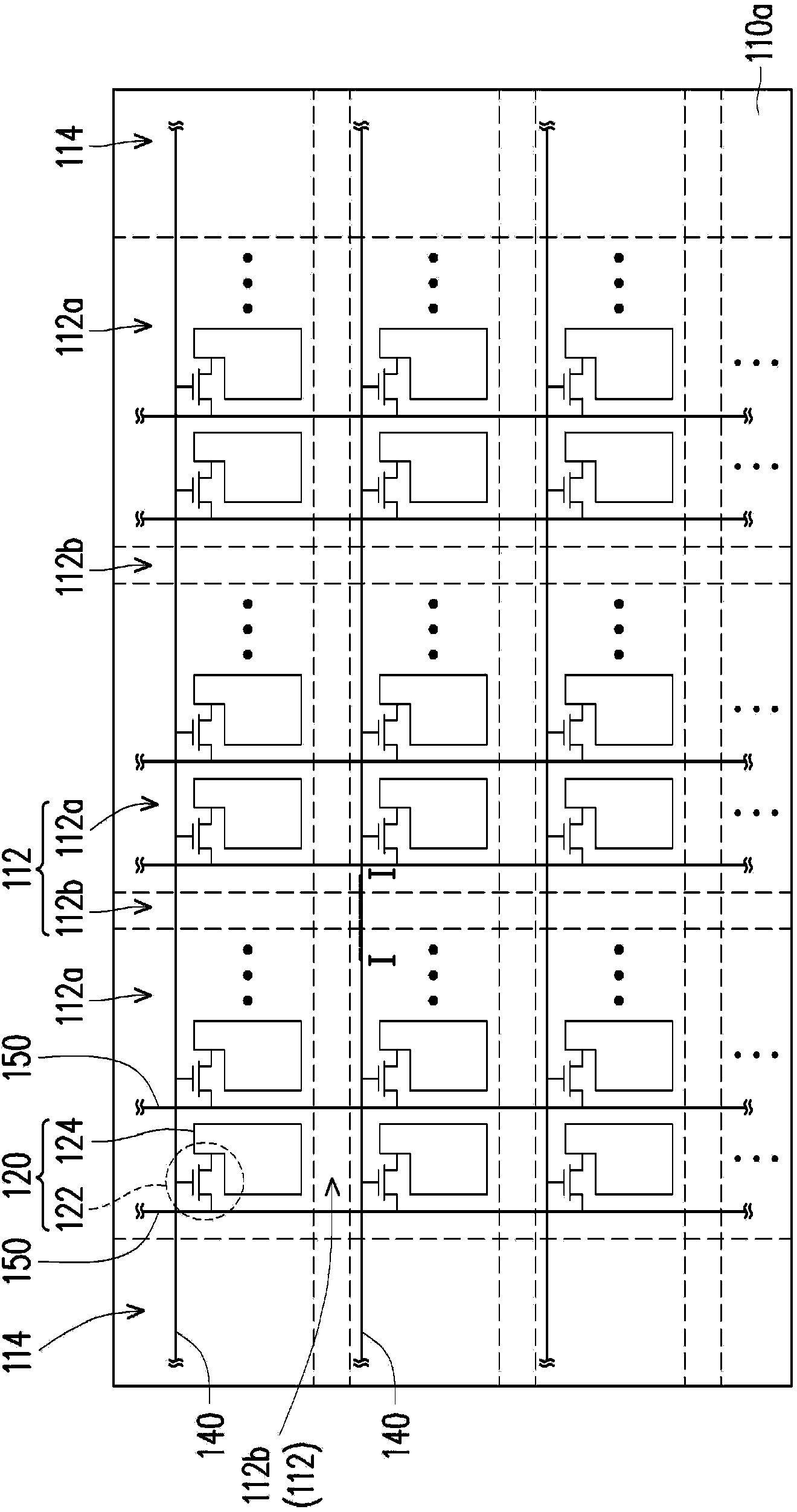

Pixel Array Substrate And Panel

ActiveCN104269417AGood structural reliabilityHigh structural reliabilitySolid-state devicesSemiconductor devicesEngineeringPixel array

A pixel array substrate includes a substrate, a plurality of pixel units and an organic insulating layer. The substrate is provided with an active zone and a peripheral zone arranged on the periphery of the active zone. The active zone includes a plurality of pixel unit zones and a bending zone arranged on at least one side of the pixel unit zone. Each pixel unit includes an active assembly and a pixel electrode connected with the active assembly electrically. The pixel electrode is arranged in the pixel unit zone correspondingly. The organic insulating layer includes a first organic insulation pattern and a second organic insulation pattern arranged in the pixel unit zone and the bending zone respectively. The thickness of the first organic insulation pattern is greater than that of the second organic insulation patter. The pixel array substrate has comparatively good flexibility.

Owner:AU OPTRONICS CORP

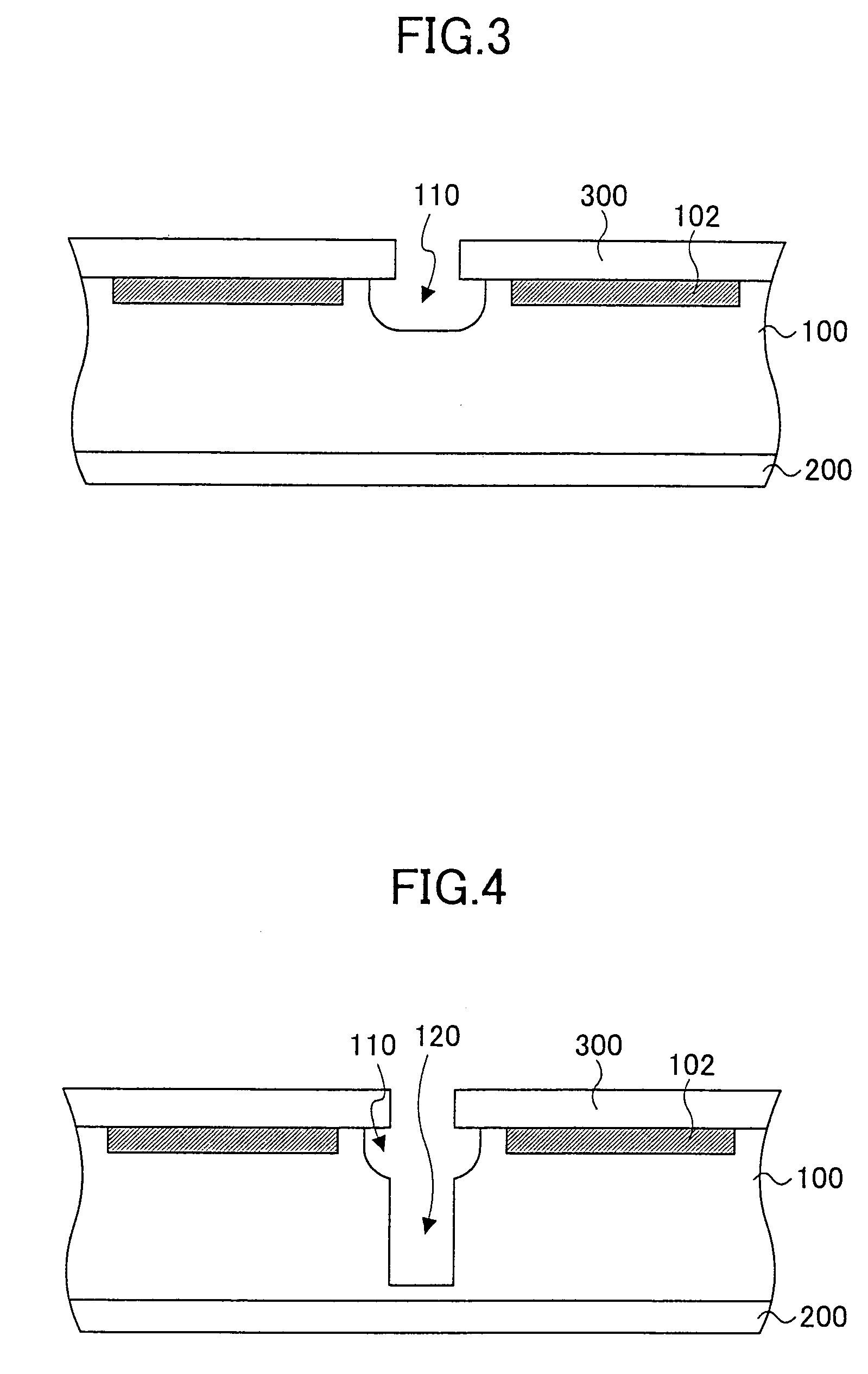

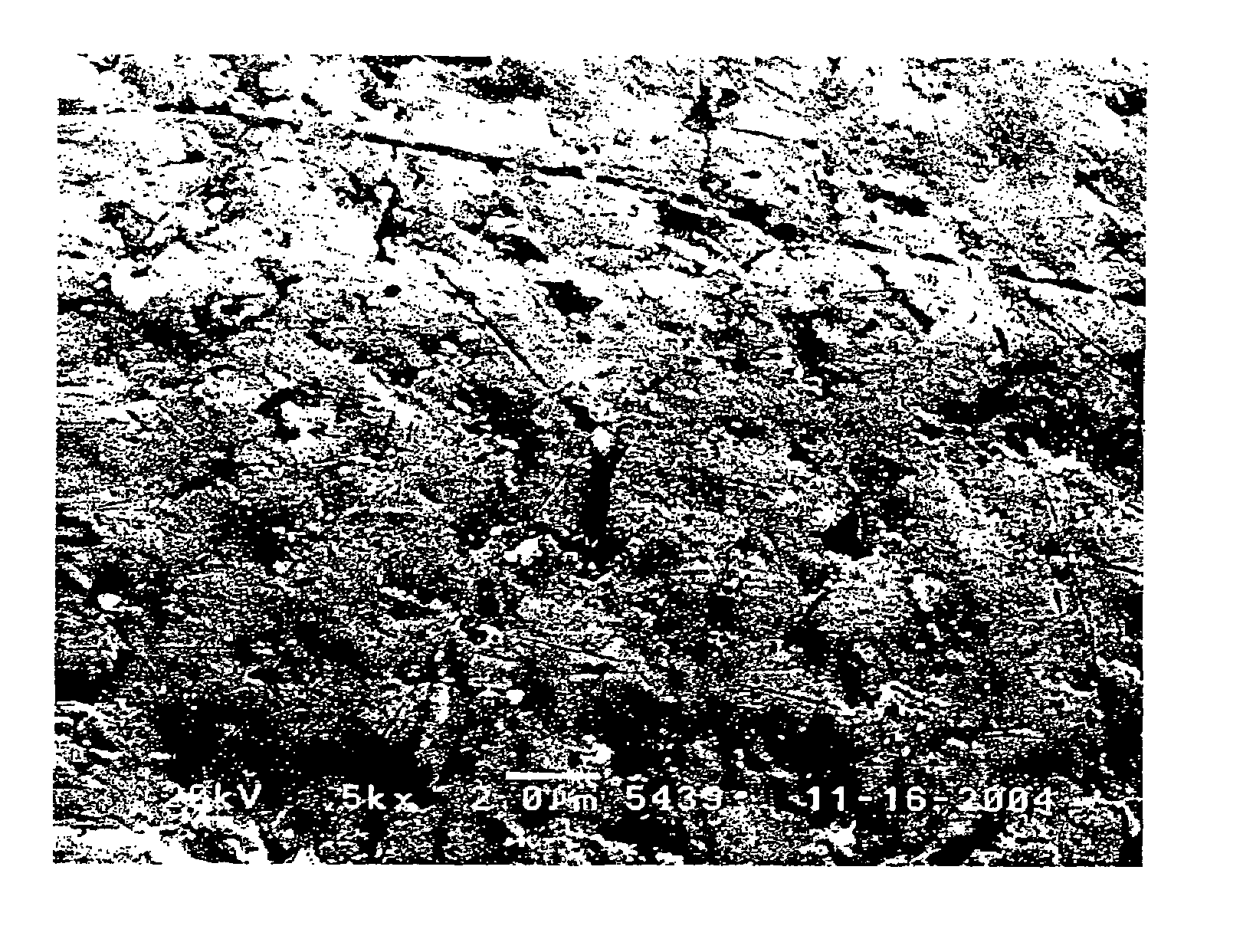

Cutting tool having high toughness and abrasion resistance

ActiveUS20060127671A1Improve toughnessIncrease the residual compressive stressPigmenting treatmentMolten spray coatingGas phaseCeramic cutting tool

Disclosed herein is a cutting tool having high toughness and abrasion resistance, in which a coated cutting tool including a cemented carbide substrate, a cermet substrate or a ceramic substrate coated with a hard coating film by means of chemical vapor deposition, moderate temperature-chemical vapor deposition or physical vapor deposition, and / or a cemented carbide cutting tool, a cermet cutting tool or a ceramic cutting tool are subjected to wet blasting using 10-300 μm sized particles to decrease residual tensile stress or increase residual compressive stress, thereby improving toughness, and also, reducing surface roughness of the cutting tool, thus remarkably increasing chipping resistance and flaking resistance.

Owner:KORLOY

Backlight module with narrow frame of liquid crystal display device

InactiveCN102384413AConducive to narrow borderGuaranteed structural strengthOptical light guidesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a backlight module with a narrow frame of a liquid crystal display device. The backlight module comprises the frame, a back plate, a connection piece and a rubber frame which is arranged on the back plate; the frame comprises a bottom plate opposite to a front panel; the front panel of the frame concaves inwards to form a first tapping hole with an inner thread; the bottom plate of the back plate is provided with a hole part corresponding to the tapping hole; the rubber frame is provided with a through hole corresponding to the hole part; the connection part passes through the through hole; and both ends are respectively in a fit connection with the first tapping hole on the front panel of the frame and the hole part on the bottom plate of the back plate so that the frame is locked with the back plate. According to the backlight module provided by the invention, space positions of the rubber frame and the back plate are saved; meanwhile, material is avoided be cut by the rubber frame in a large area to avoid convex hulls on the frame and the back plate, therefore, the structure intensity of the rubber frame is ensured, and the frame of the backlight module is easy to narrow.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Thermal-shock resistant fireproof brick and production process thereof

The invention relates to a heat shock resistance firebrick and the manufacture method. The method is that it adopts mullite, corundum, alpha-Al2O3 powder, andalusite and clay as base material, adding 3-15wt% binding agent. The process includes the following steps: adding binding agent into the base material, grinding to equal, molding, sintering at 1450 degree centigrade. The invention has good heat shock resistance, long useful life, etc. It has great economic and social benefits.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

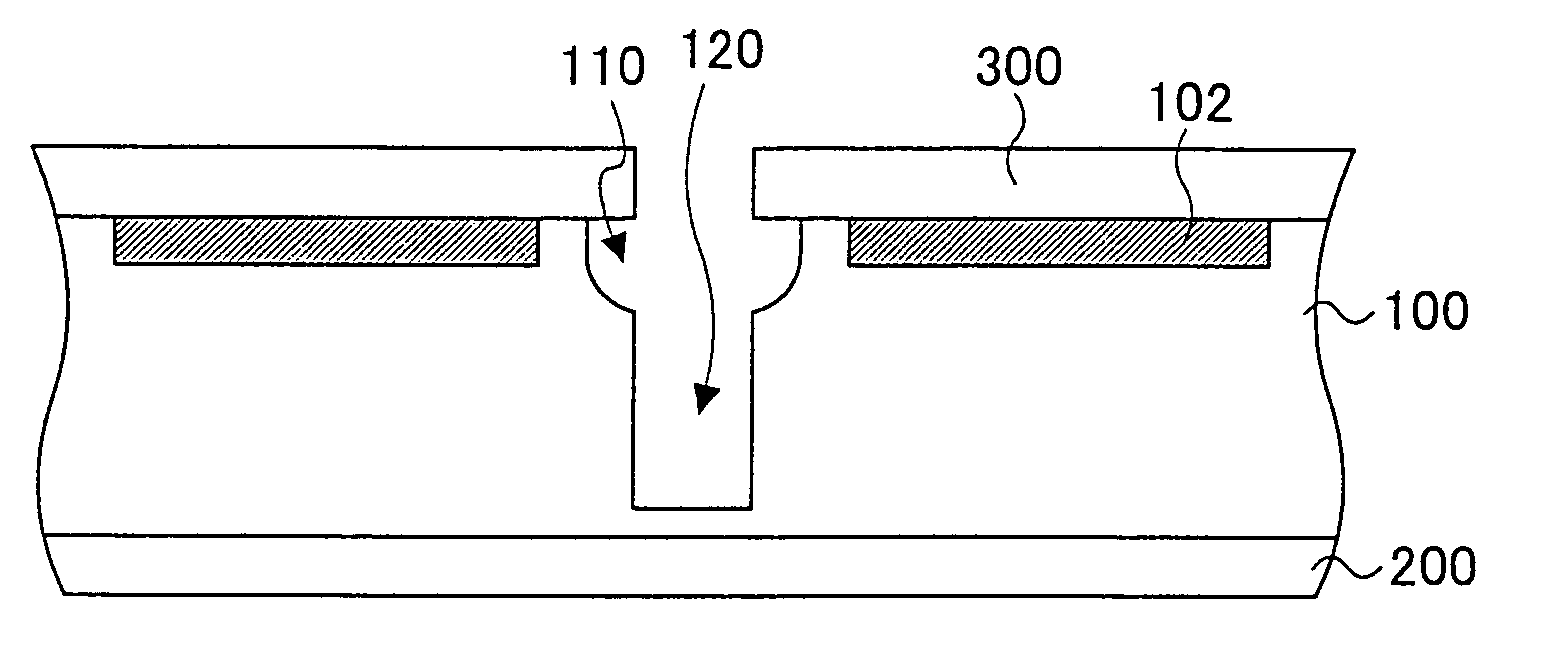

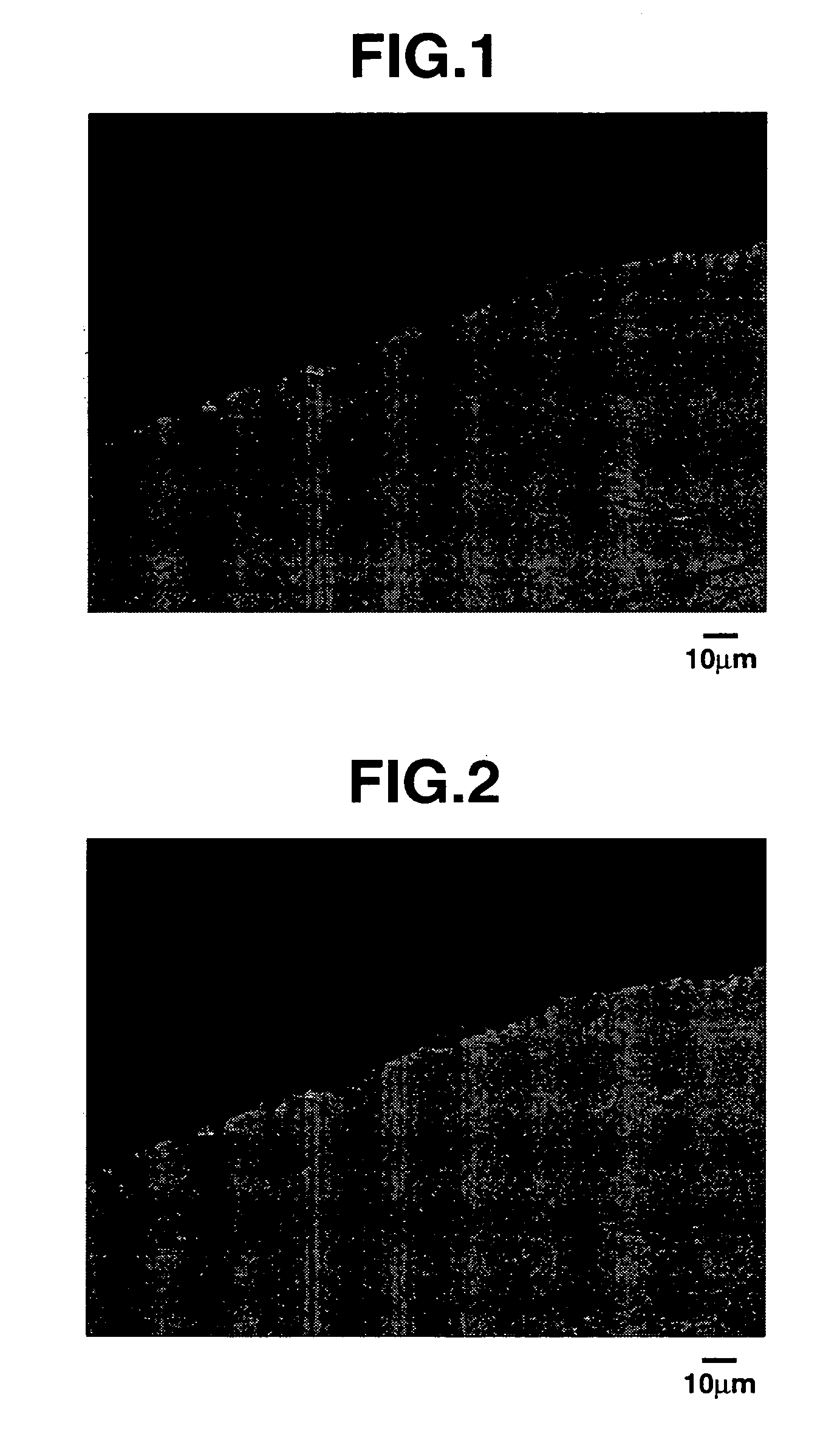

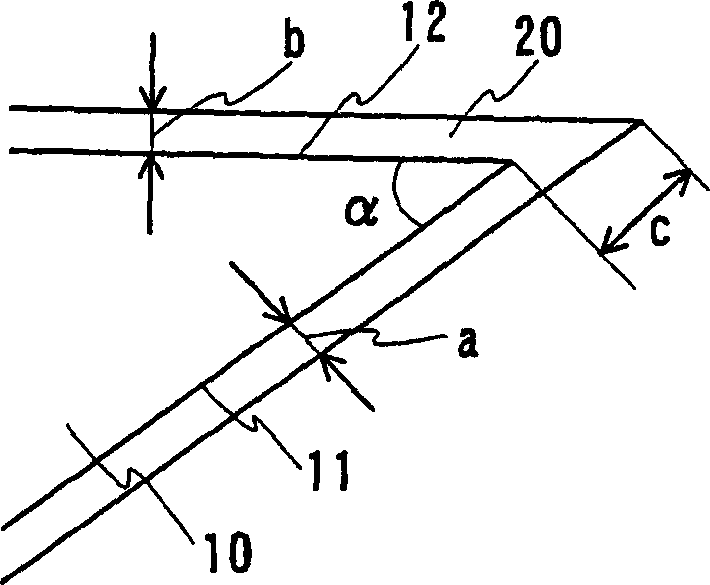

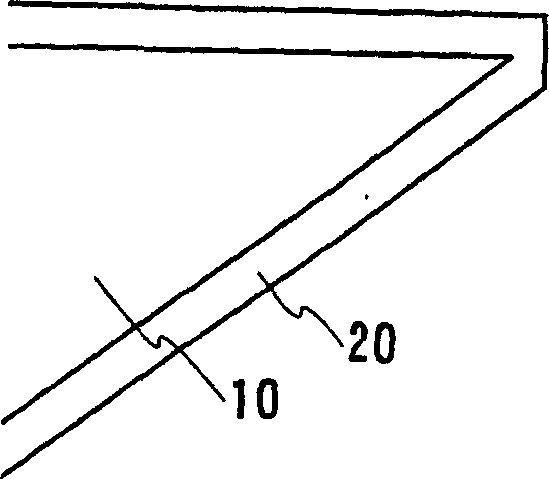

Method of manufacturing a semiconductor device

ActiveUS20050140006A1Reduce contact resistanceAvoid chippingSemiconductor/solid-state device testing/measurementElectronic circuit testingTectorial membraneDevice material

Chipping of semiconductor chips is to be prevented. A semiconductor device comprises a semiconductor chip having a main surface, a plurality of pads formed over the main surface, a rearrangement wiring formed over the main surface to alter an arrangement of the plurality of pads, and a protective film and an insulating film formed over the main surface, and a plurality of solder bumps each connected to the rearrangement wiring and arranged differently from the plurality of pads. The presence of a bevel cut surface obliquely continuous to the main surface and formed on a periphery of the main surface of the semiconductor chip prevents chipping.

Owner:RENESAS ELECTRONICS CORP

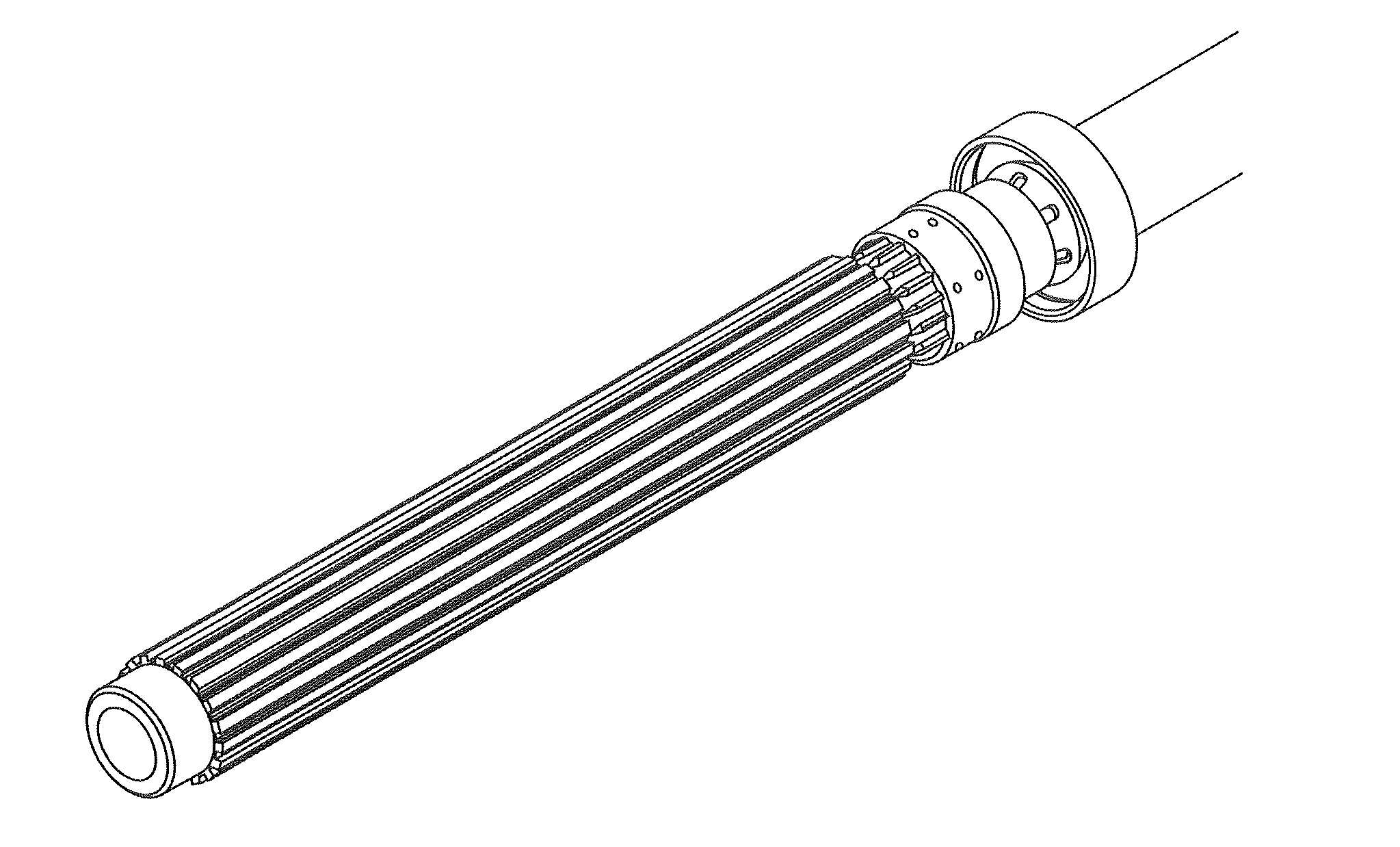

System and method for providing a downhole mechanical energy absorber

InactiveUS20100132939A1Maximizes limit loadMinimizing shock loadingPortable framesDrilling rodsMechanical energyEngineering

A system and a method are disclosed for providing a downhole mechanical energy absorber that protects downhole tools from impact loads and shock loads that occur during run-in contacts, tool drops, perforating blasts, and other impact events. A continuous localized inelastic deformation of a tube is a primary energy absorber in a load limiting design of the downhole mechanical energy absorber.

Owner:STARBOARD INNOVATIONS

End mill

ActiveUS7588396B2Improved cutting edgeLess susceptible to undesirable chatterMilling cuttersShaping cuttersRotational axisMilling cutter

An end mill is provided having an axis of rotation, a shank section and a fluted section, each extending along the axis of rotation, and a plurality of helical teeth. The fluted section has a first end attached to the shank section and a second end. The plurality of helical teeth is disposed within the fluted section. Each helical tooth has a cutting edge, a relief surface, a cutting surface, and an edge preparation surface. The edge preparation surface is contiguous with the cutting edge of the respective tooth.

Owner:BERKSHIRE PRECISION TOOL

Cutting tool having high toughness and abrasion resistance

ActiveUS7691496B2Improve toughnessIncrease the residual compressive stressPigmenting treatmentMolten spray coatingGas phaseSurface roughness

Disclosed herein is a cutting tool having high toughness and abrasion resistance, in which a coated cutting tool including a cemented carbide substrate, a cermet substrate or a ceramic substrate coated with a hard coating film by means of chemical vapor deposition, moderate temperature-chemical vapor deposition or physical vapor deposition, and / or a cemented carbide cutting tool, a cermet cutting tool or a ceramic cutting tool are subjected to wet blasting using 10-300 μm sized particles to decrease residual tensile stress or increase residual compressive stress, thereby improving toughness, and also, reducing surface roughness of the cutting tool, thus remarkably increasing chipping resistance and flaking resistance.

Owner:KORLOY

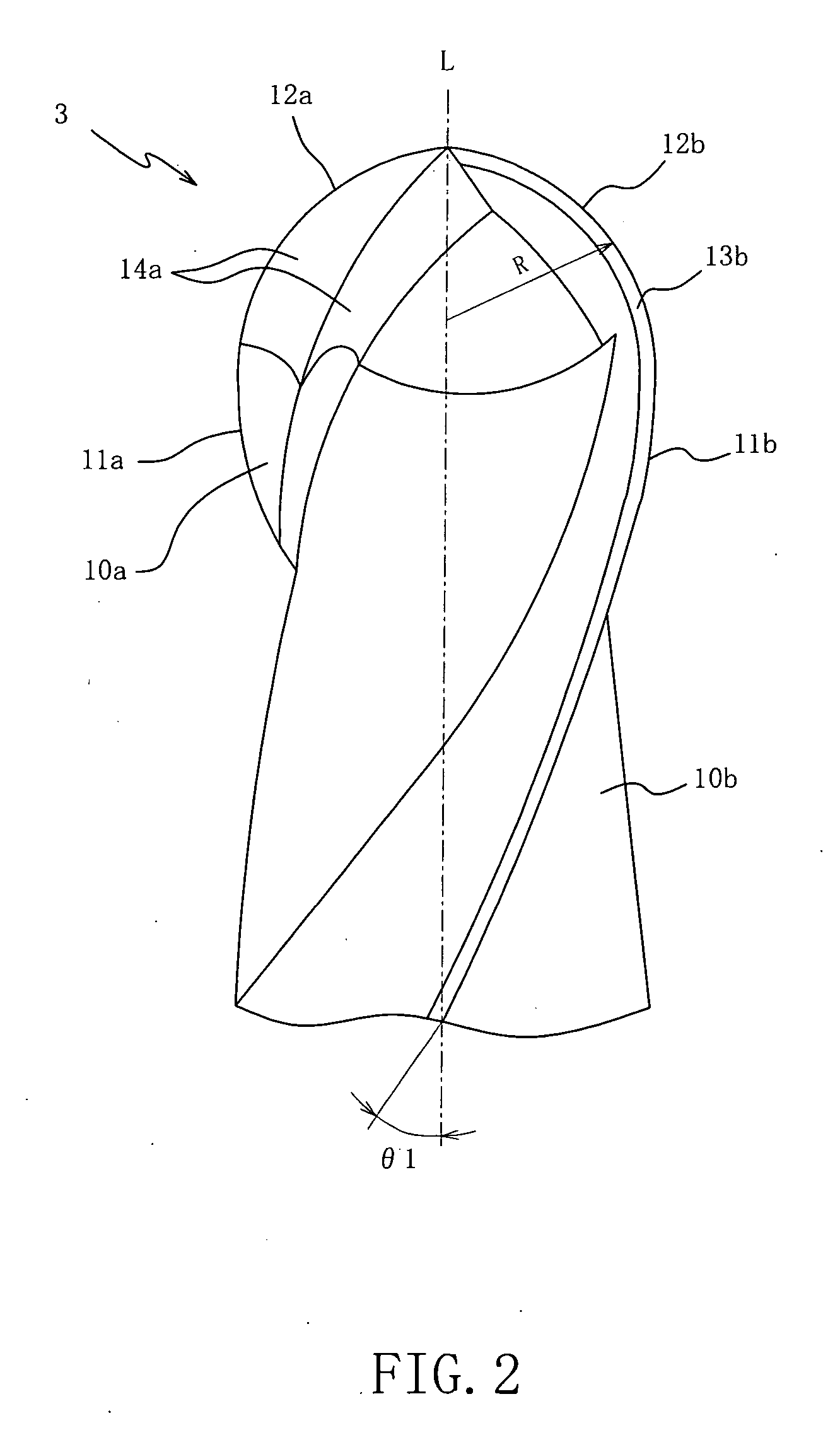

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

Whole grain compound rice containing embryo and fabrication technique

InactiveCN103168997AHigh nutritional valueAvoid chippingFood preparationHorticultureArtificial foods

The invention relates to the field of artificial food, and particularly relates to compound rice, namely whole grain compound rice containing embryo. The whole grain compound rice comprises the raw materials of rice and wheat with embryo, wherein the raw material is extruded into granules after being crushed, and prepared into the whole grain compound rice; and a rice milk layer is coated at an outer layer of the whole grain compound rice. The broken rice which is neglected and abandoned by people in the past and other side grain ingredients are taken as raw materials and processed into healthy and delicious whole grain compound rice by a high-tech craft technique. The whole grain compound rice is green and environment-friendly, and the production cost can be reduced; nutritional ingredients of the whole grain compound rice are more abundant and balanced than those of common rice; and the requirements of human health are met.

Owner:SHANGHAI YIYANGTANG FOOD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com