Method and device for breaking work, method for scribing and breaking work, and scribing device with breaking function

A technology for cutting devices and workpieces, applied in glass cutting devices, electrical components, manufacturing tools, etc., can solve problems such as fragmentation, lack of small pieces, workpiece distortion, etc., to achieve the effect of reducing friction, easy handling, and preventing chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

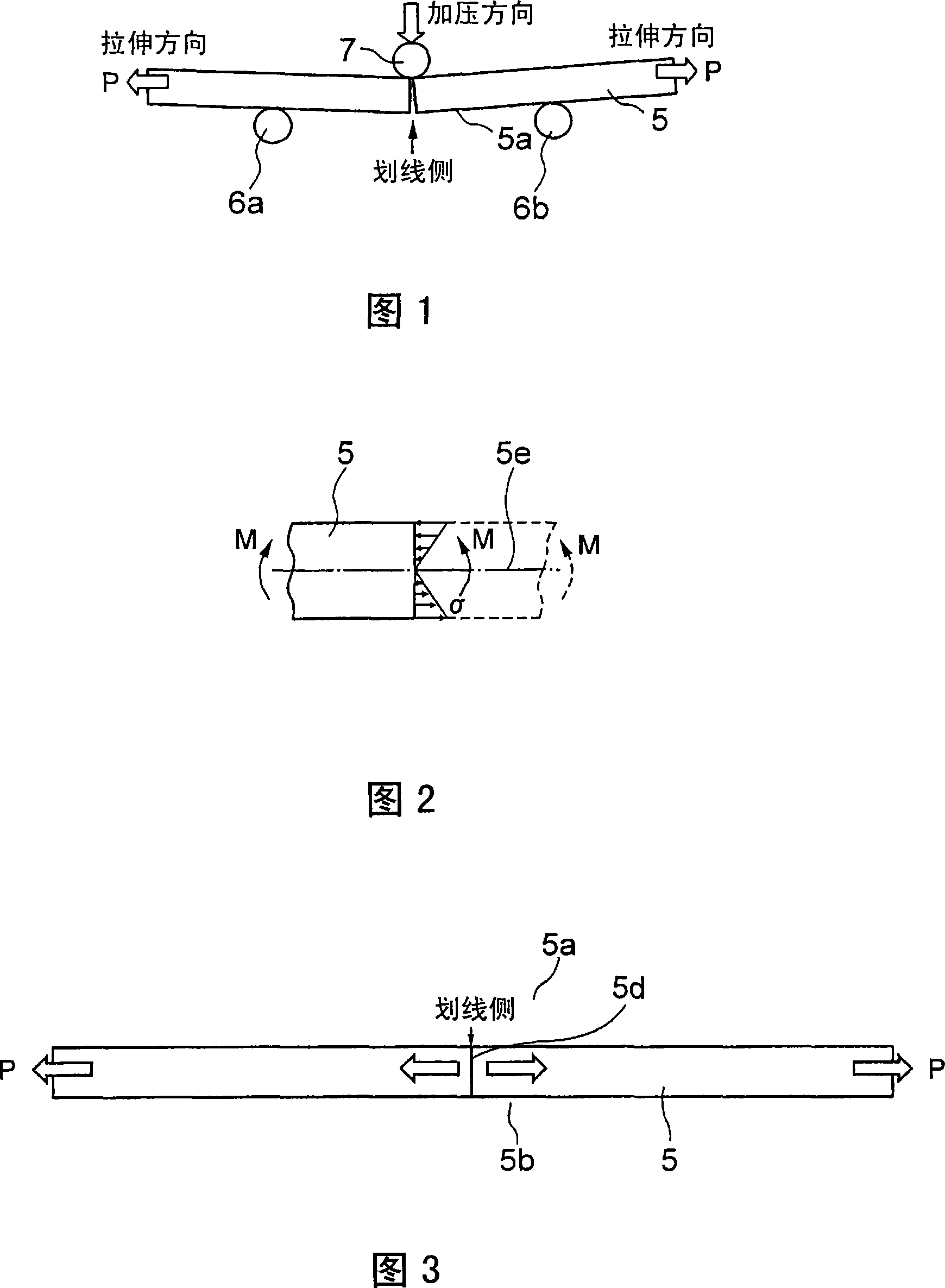

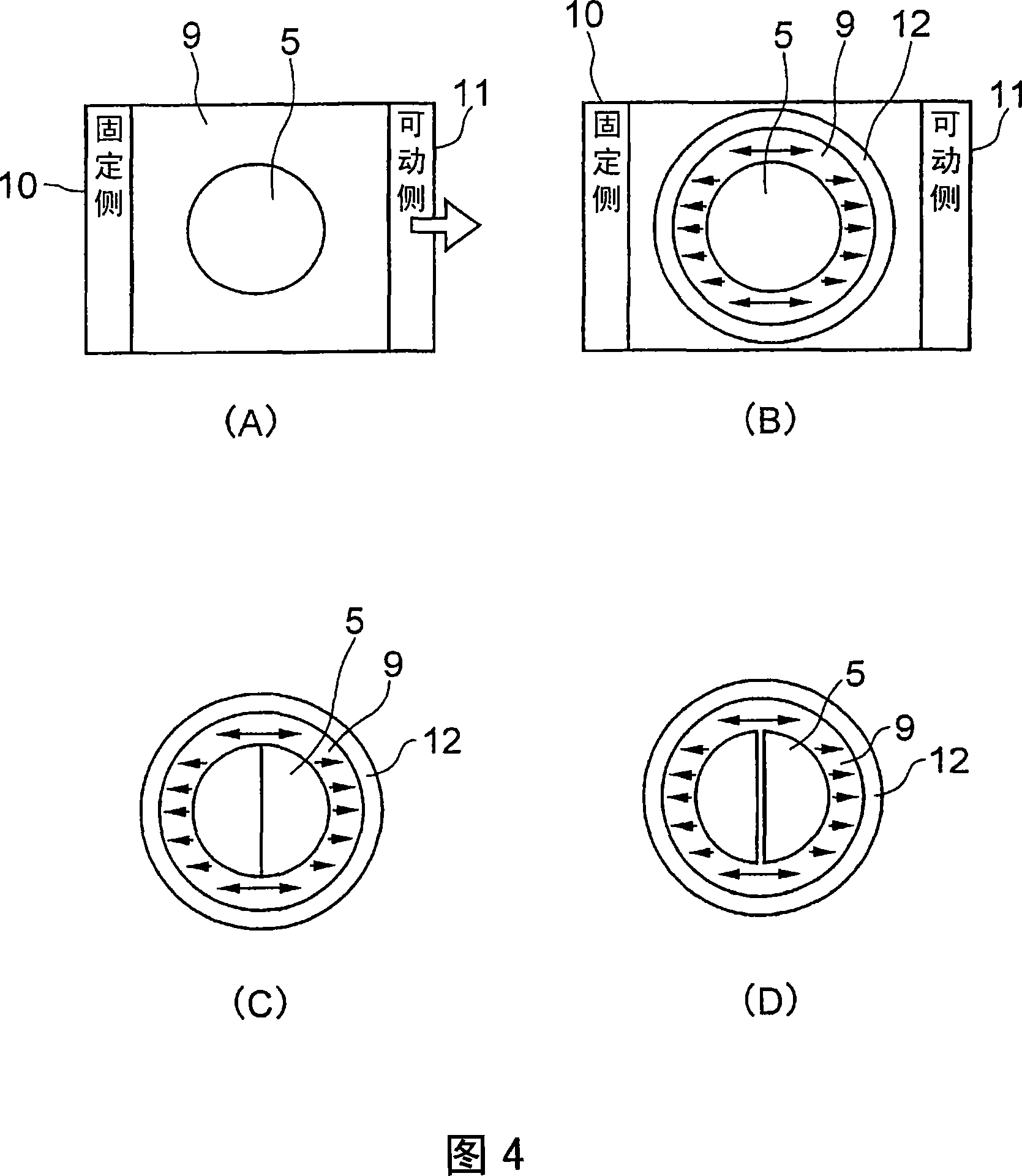

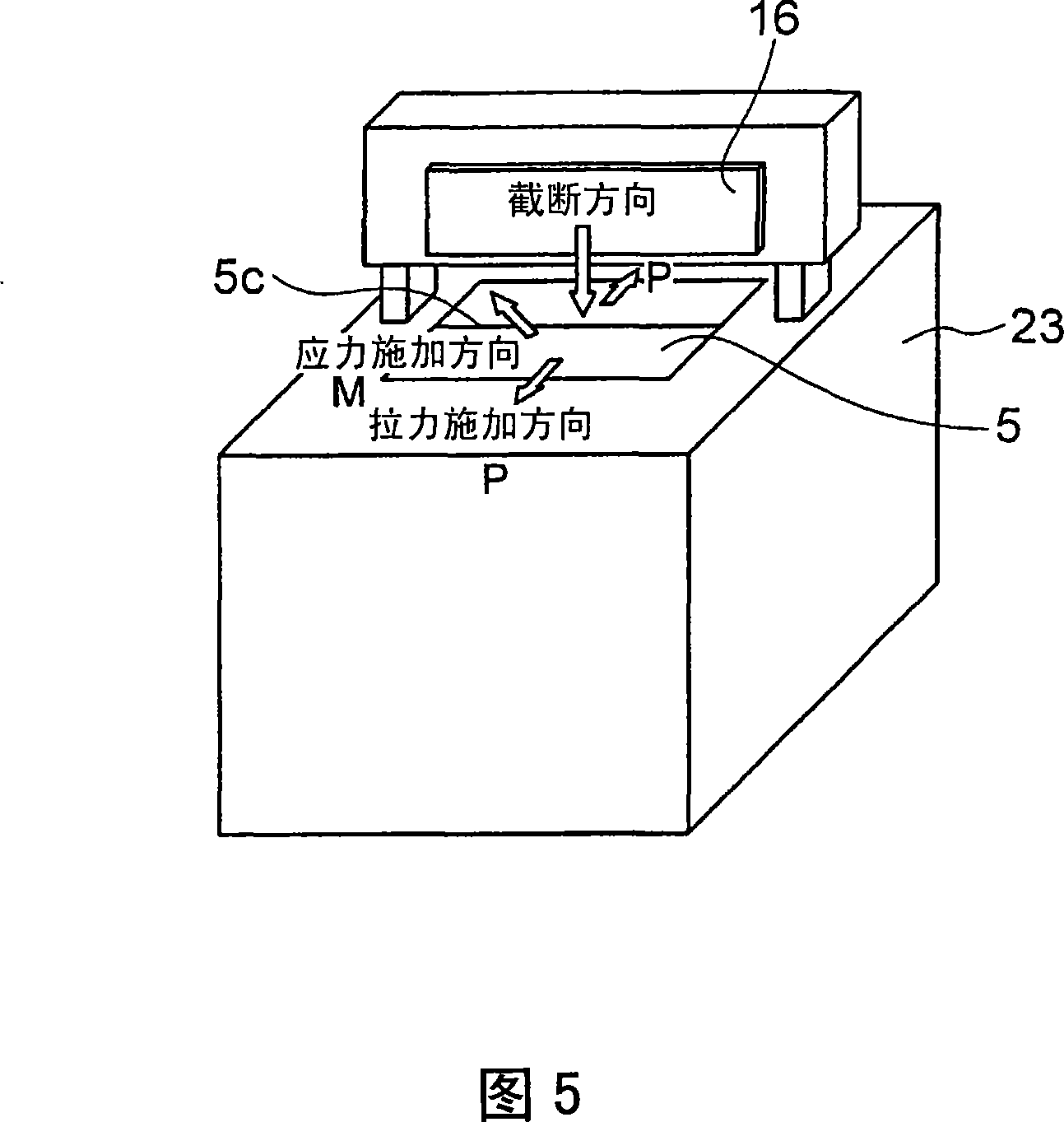

Method used

Image

Examples

Embodiment

[0118] (1) Device overview

[0119] In order to investigate the expansion effect, only the test tool of the expansion mechanism was produced as a trial (Fig. 13). Its appearance size is 410mm×450mm. In this test tool, tension can be applied to the workpiece only in the X direction, and in a compound direction of the X-Y direction. The clamping of the sheet is achieved by combining grooved plates and fixing them with bolts. The entire range of foils can be clamped by means of the grooved plate. While looking at the scale, adjust the tension with the bolt of the "tension part" in the picture.

[0120] (2) Outline of slices suitable for expansion

[0121] Dicing tapes used were D-650 and D-675 (manufactured by Lintec (Adwill) Co., Ltd., width 300 mm, thickness 80 μm) for expansion, which are generally used when dicing silicon wafers. Cut these tapes to the appropriate length for use.

[0122] (3) Expansion effect when truncating the wafer

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com