Patents

Literature

544results about How to "No friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

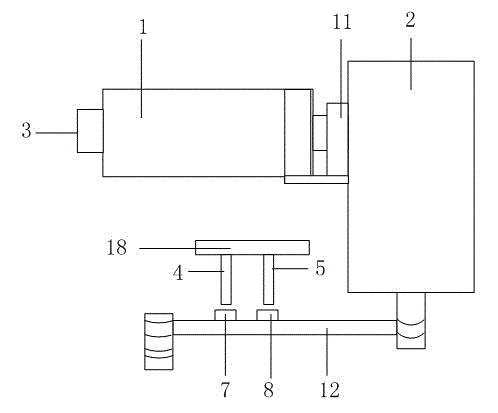

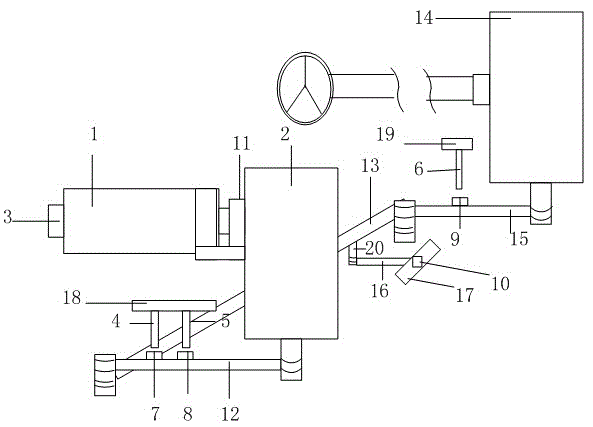

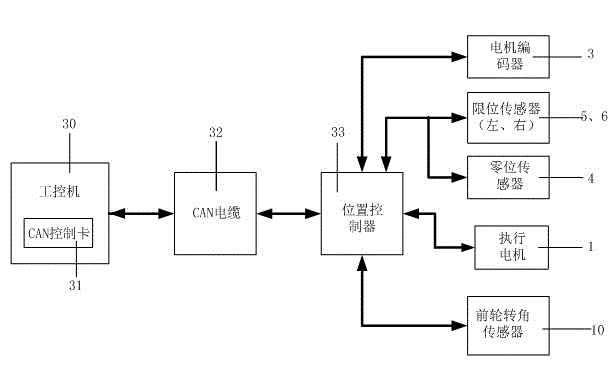

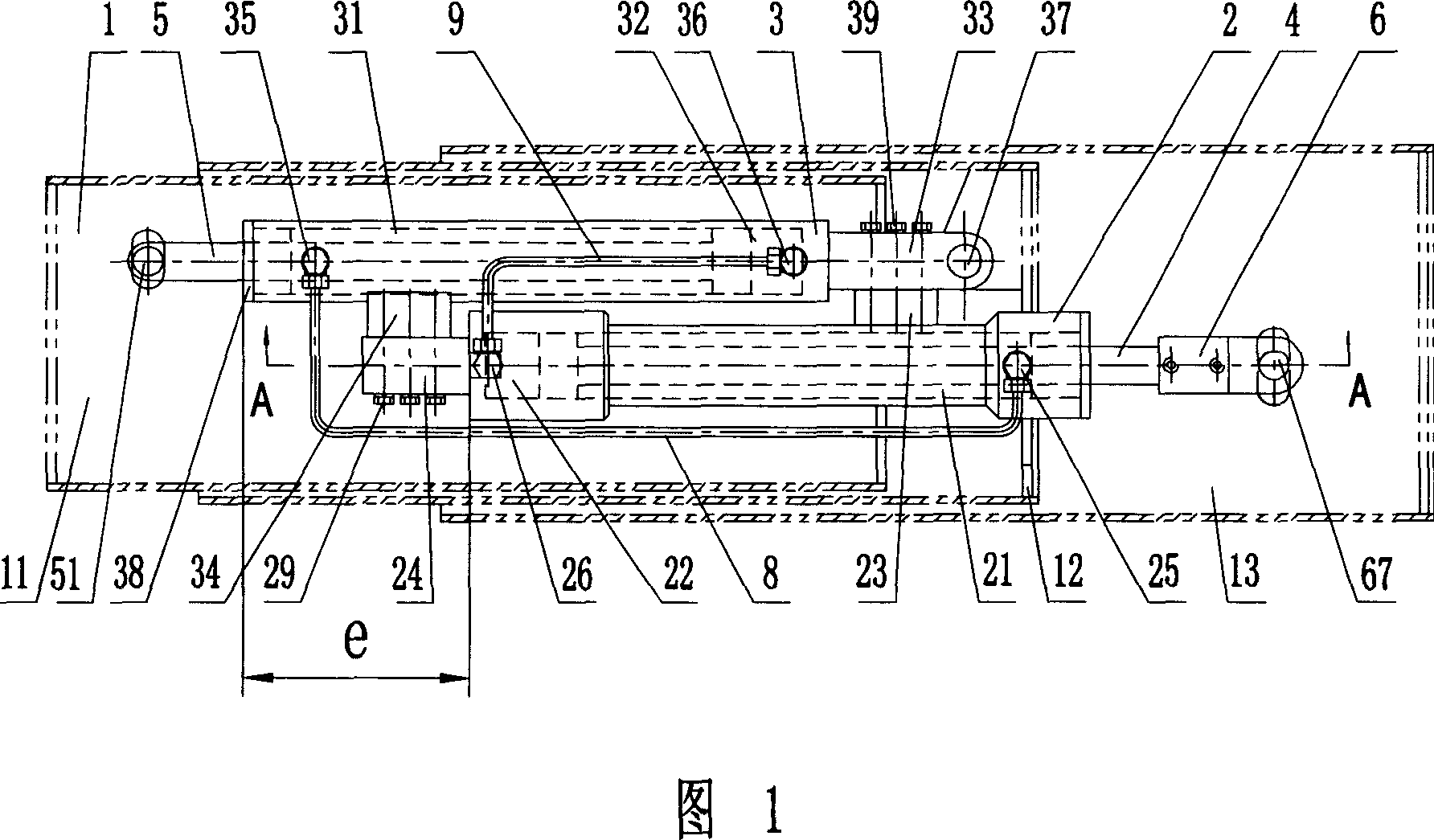

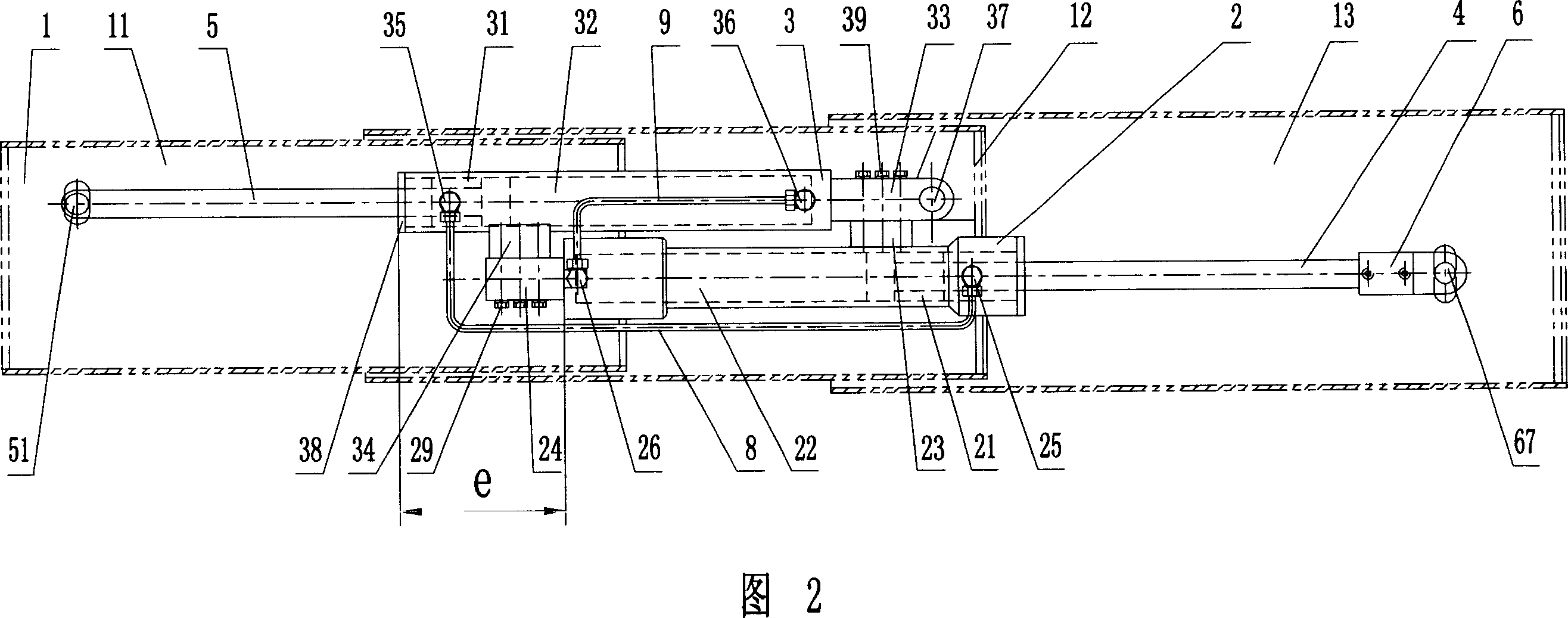

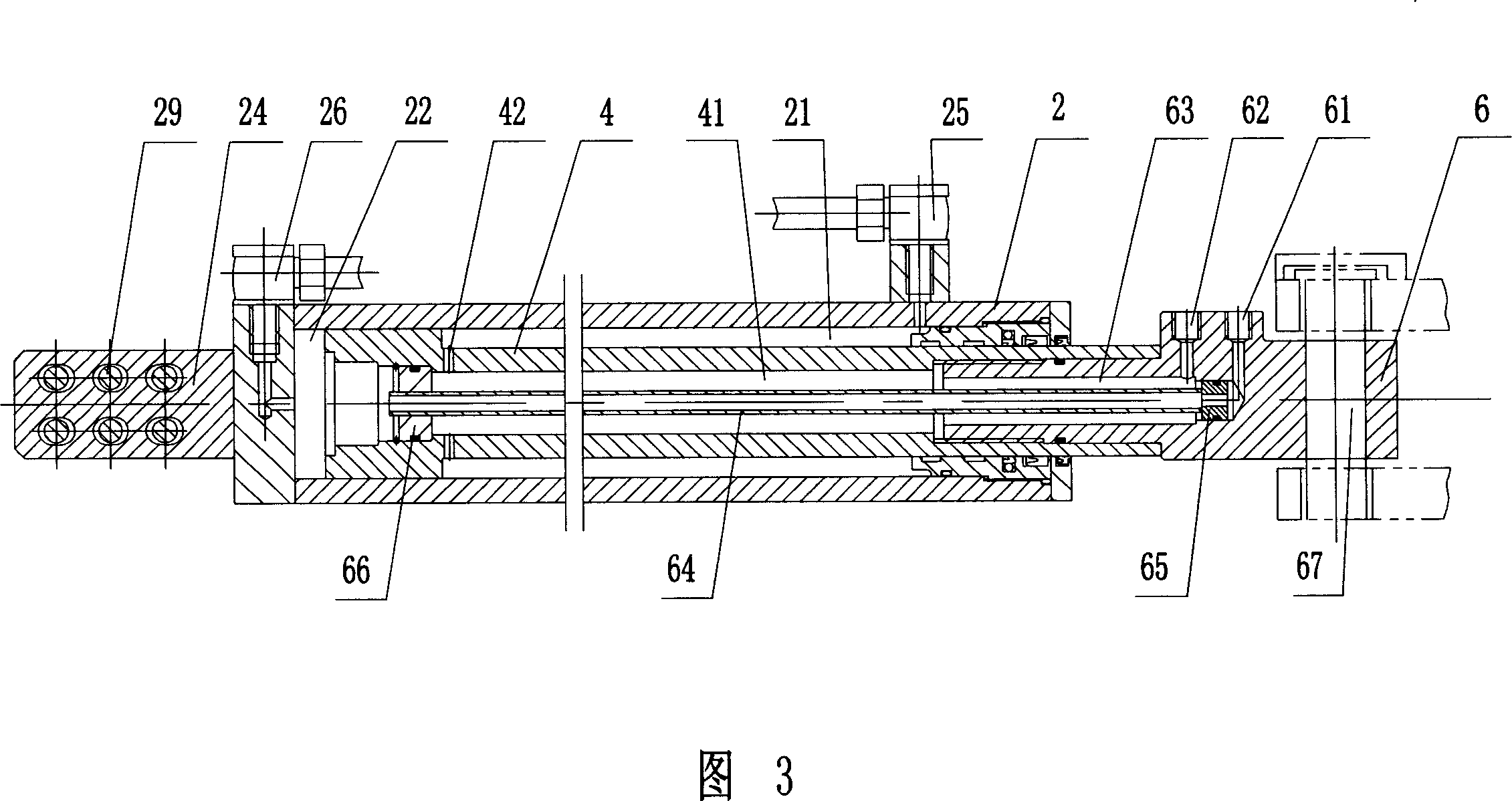

Unmanned vehicle steering system and control method thereof

ActiveCN102941876AHigh precisionImprove transmission efficiency and accuracySteering linkagesAutomatic steering controlSteering systemContact type

The invention discloses an unmanned vehicle steering system and a control method thereof. The system comprises an execution motor, a steering machine, a motor coder, a non-contact type zero position detection mechanism, a non-contact type left limiting detection mechanism, a non-contact type right limiting detection mechanism, a front wheel absolute corner mechanism and a front wheel corner double closed loop control system. The execution motor is a steering driving mechanism, and the input end of the execution motor is connected with the output end of the steering machine. The motor coder is connected with an output shaft at the back end of the execution motor. The unmanned vehicle steering system is favorable for improving steering control accuracy of unmanned vehicles, adopts a selector switch to switch the control process of manual driving / automatic driving, facilitates program debugging and ensures vehicle and personnel body safety under the emergency condition.

Owner:NANJING UNIV OF SCI & TECH

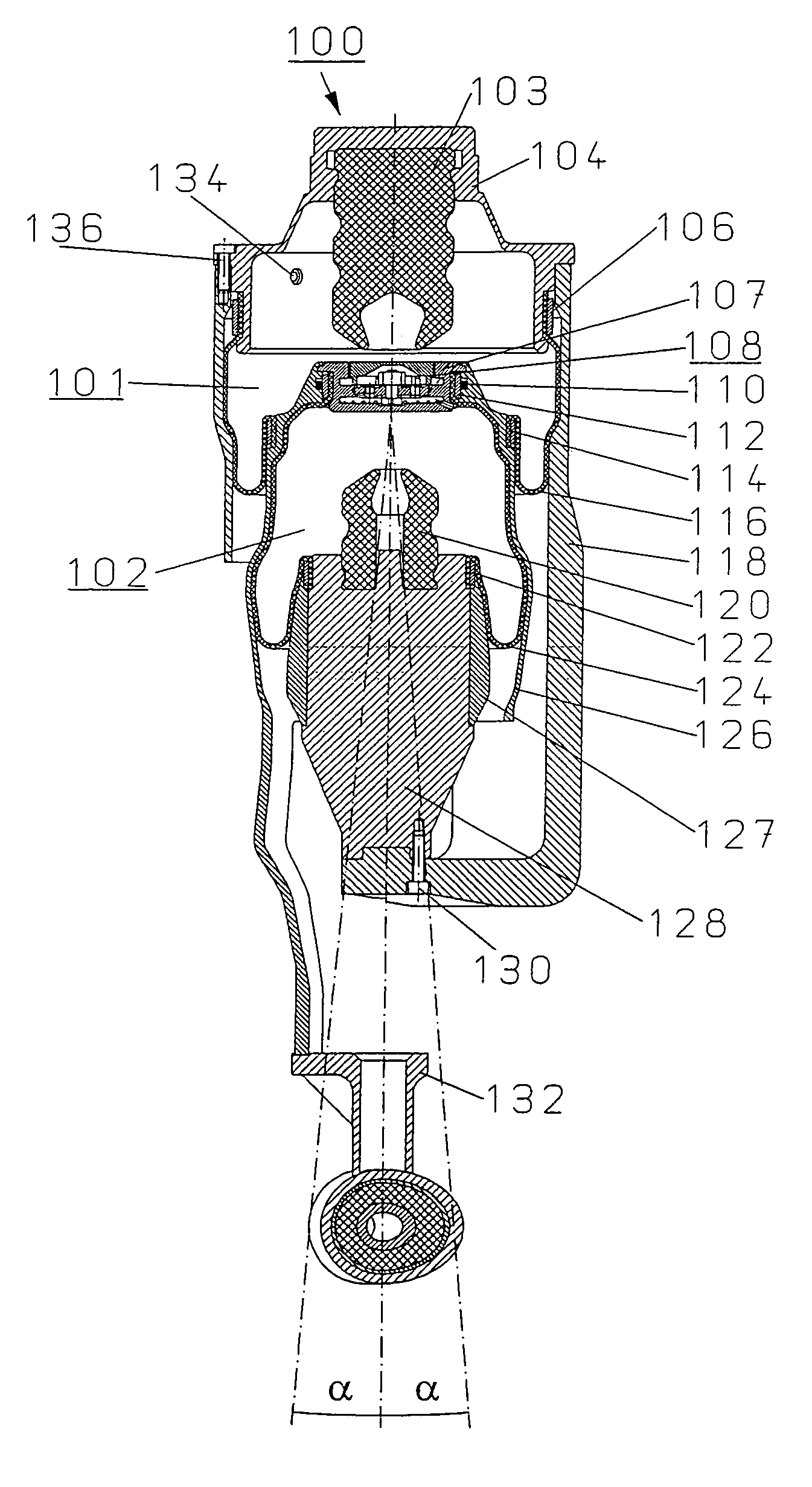

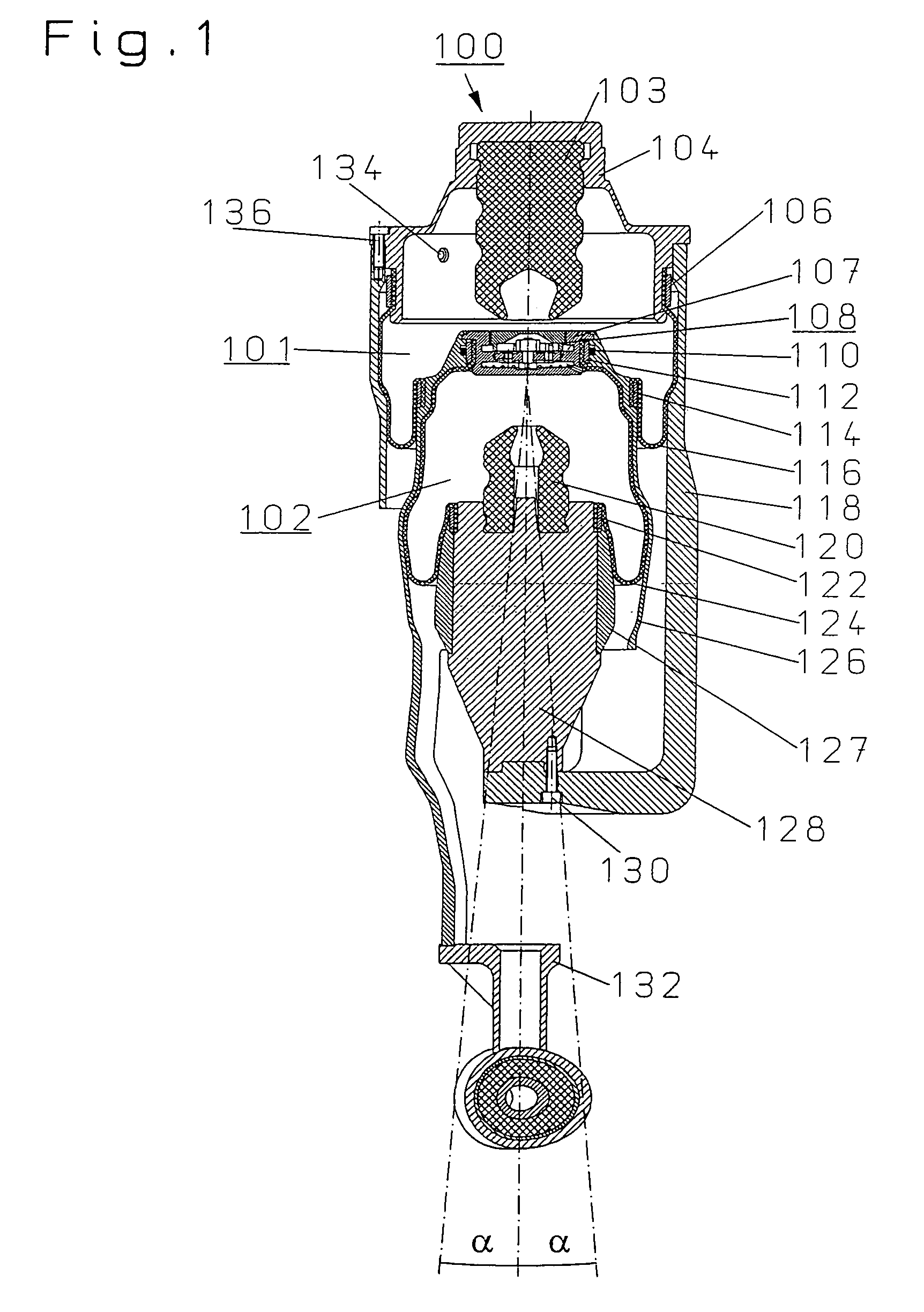

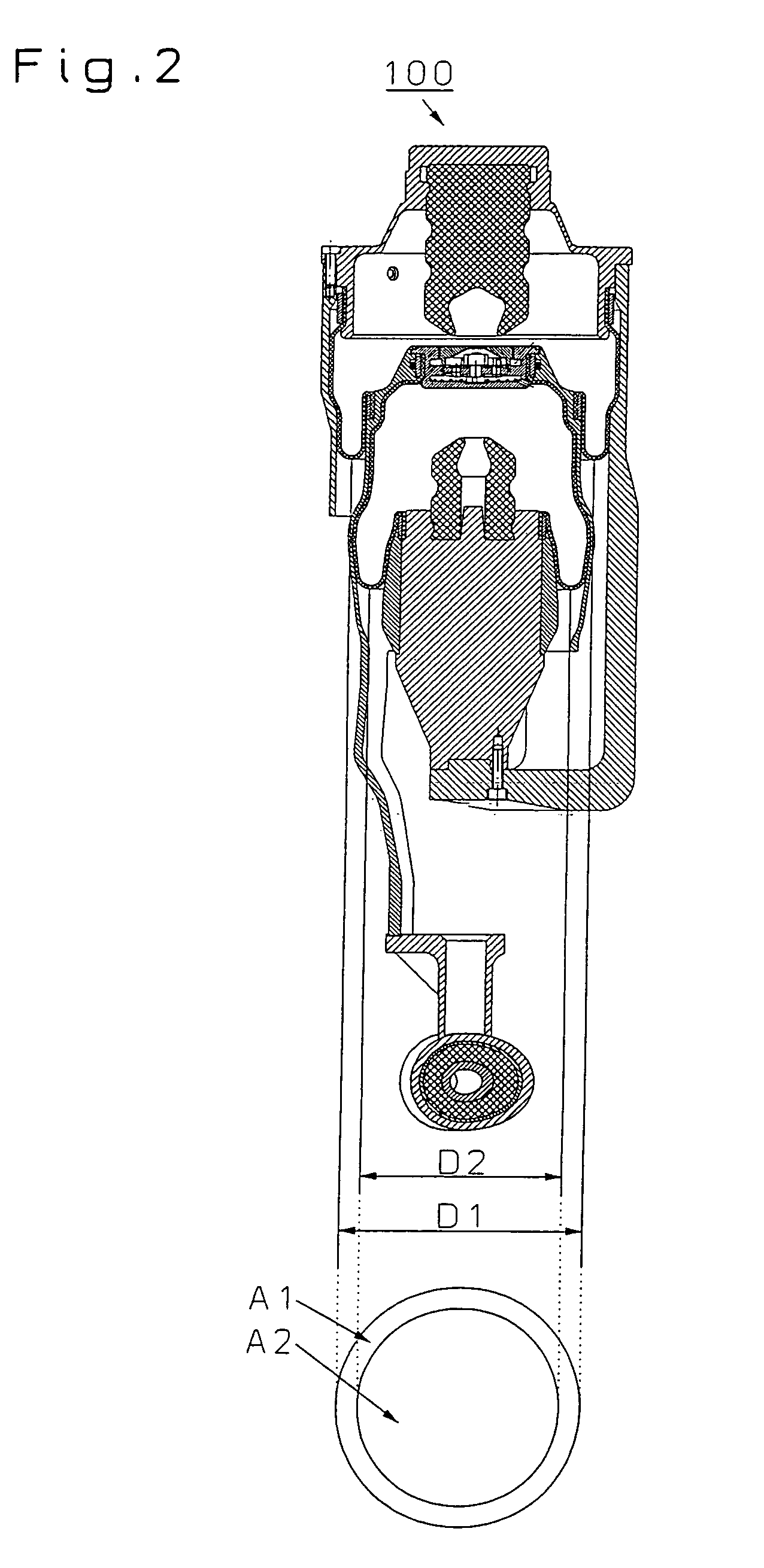

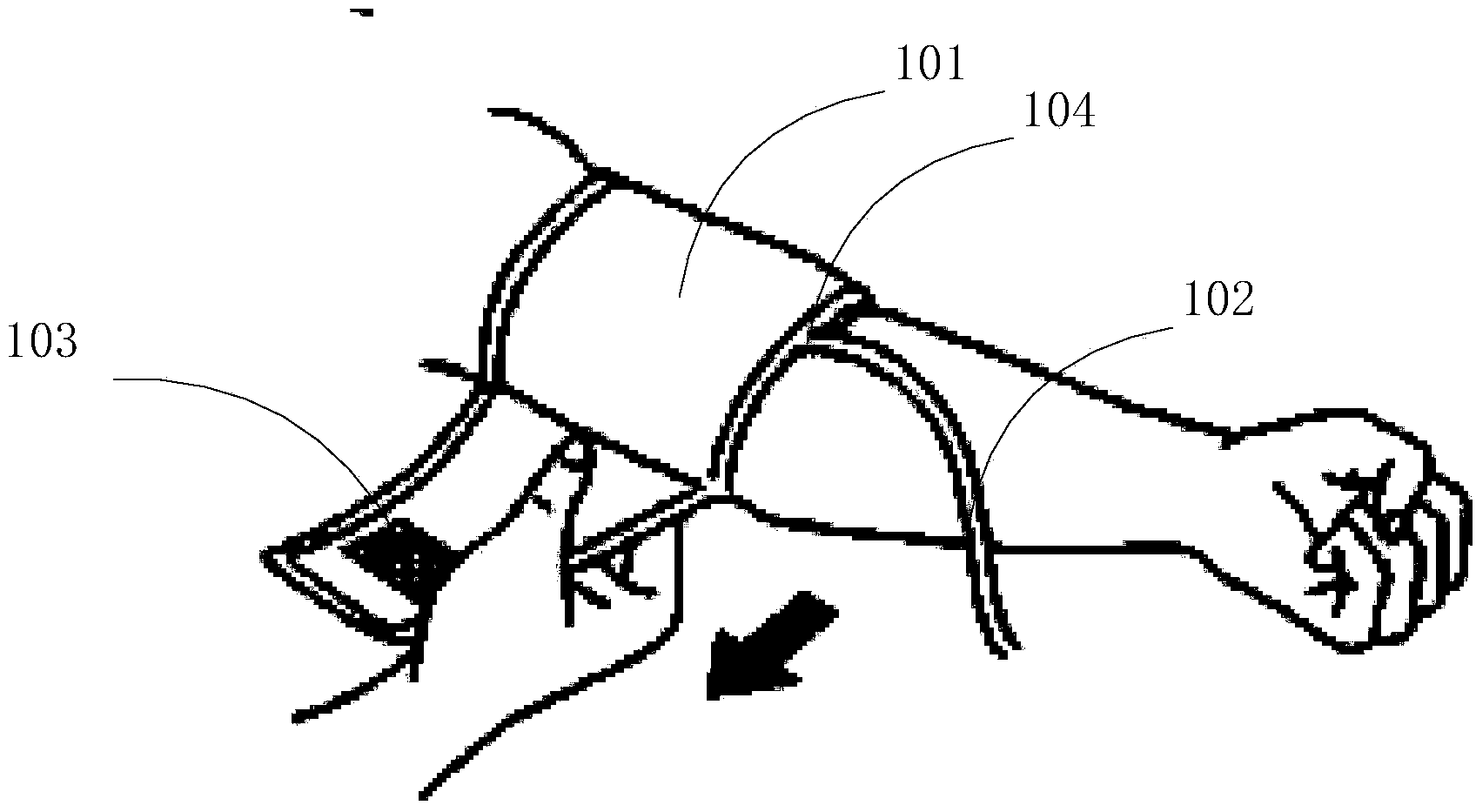

Pneumatic suspension and damping arrangement

InactiveUS7213799B2Built very short and compactNo frictionLiquid springsResilient suspensionsAir springEngineering

A pneumatic suspension and damping arrangement (100) is fixedly mounted on the chassis at the upper region and to the wheel mount at the lower region thereof. The arrangement includes two hermetically closed air springs (101, 102) filled with pressurized gas, whose volumes can be changed and which are connected via an air connection (134) to a pressurized gas source. The air springs are each enclosed by a movable wall formed by a flexible member (116, 124) and each roll off on a roll-off contour and are connected to each other via a throttle element (108) through which the gas can flow in two directions. The air springs are arranged one above the other and the roll-off contour of the first air spring (101) is defined in such a way by the second air spring (102) that the first air spring (101) rolls off on the second air spring (102). A connecting element of the upper cover (104) ) with the roll-off piston (128) of the second air spring (102) runs outside of the two air springs (101, 102).

Owner:CONTINENTAL AG

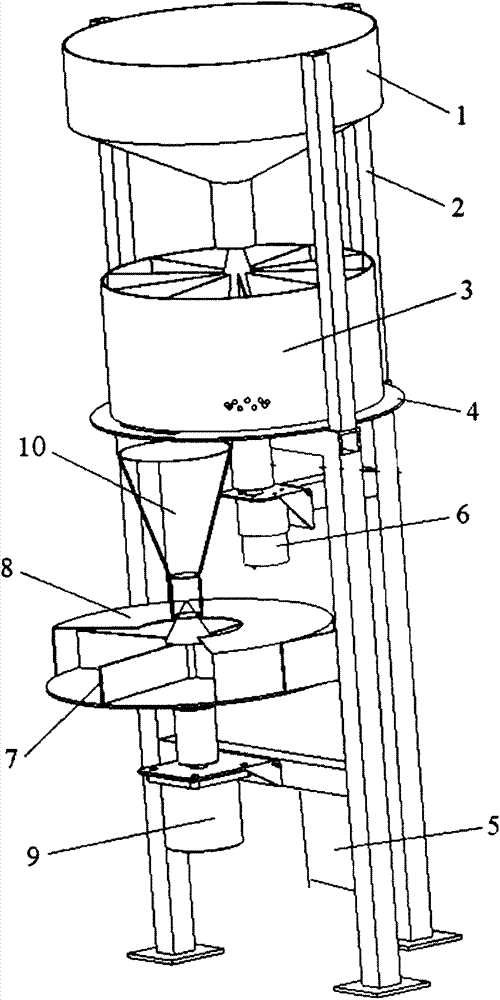

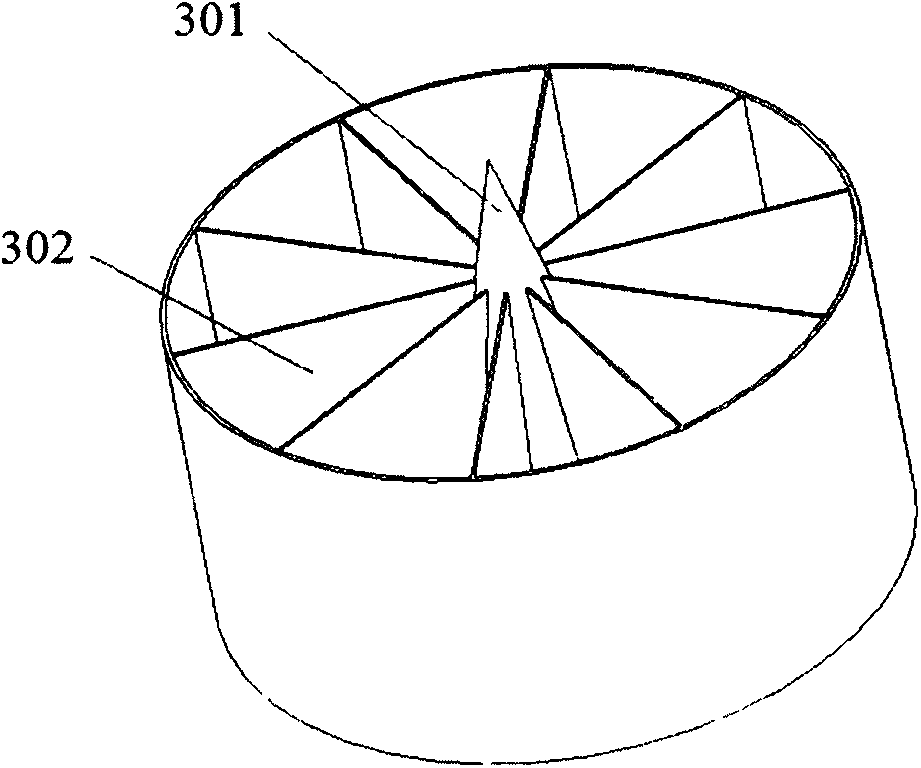

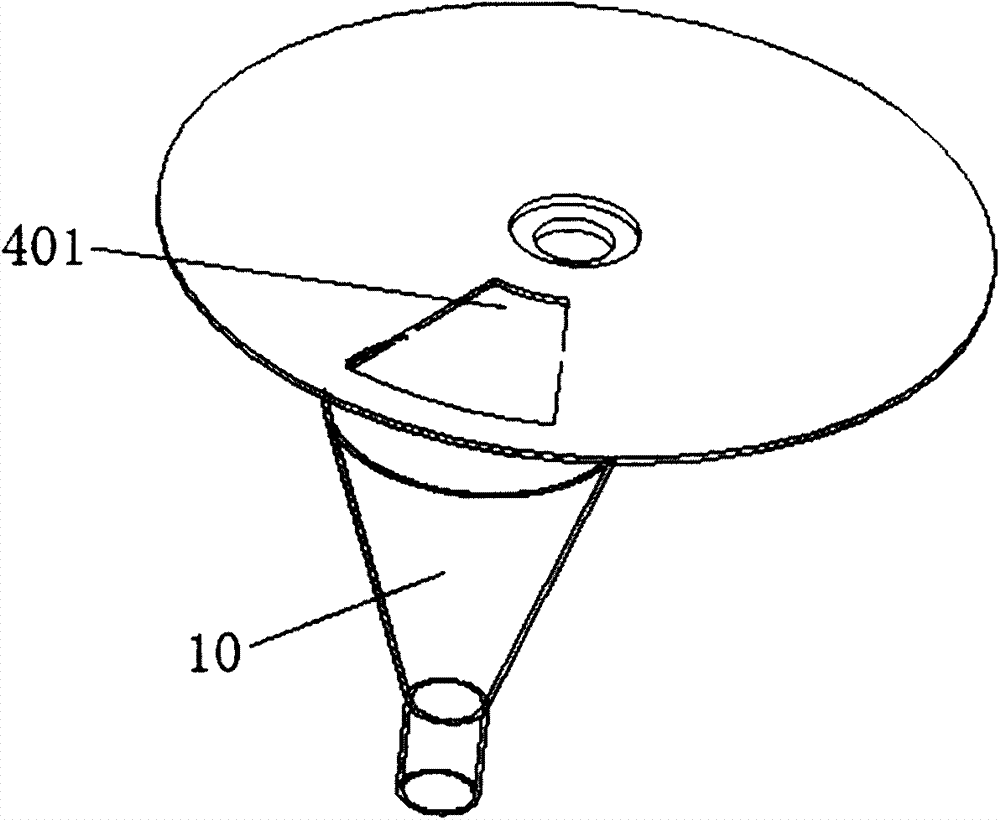

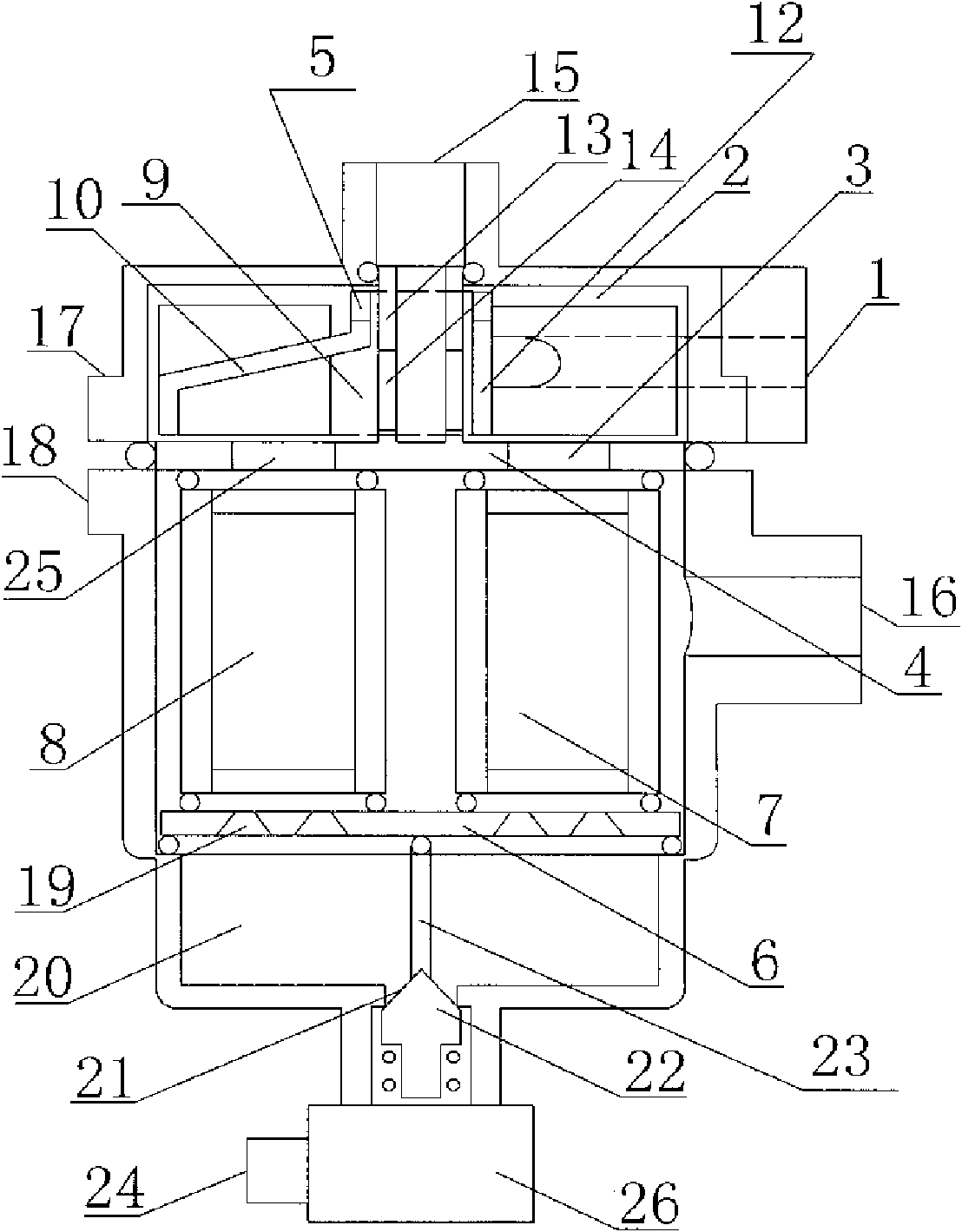

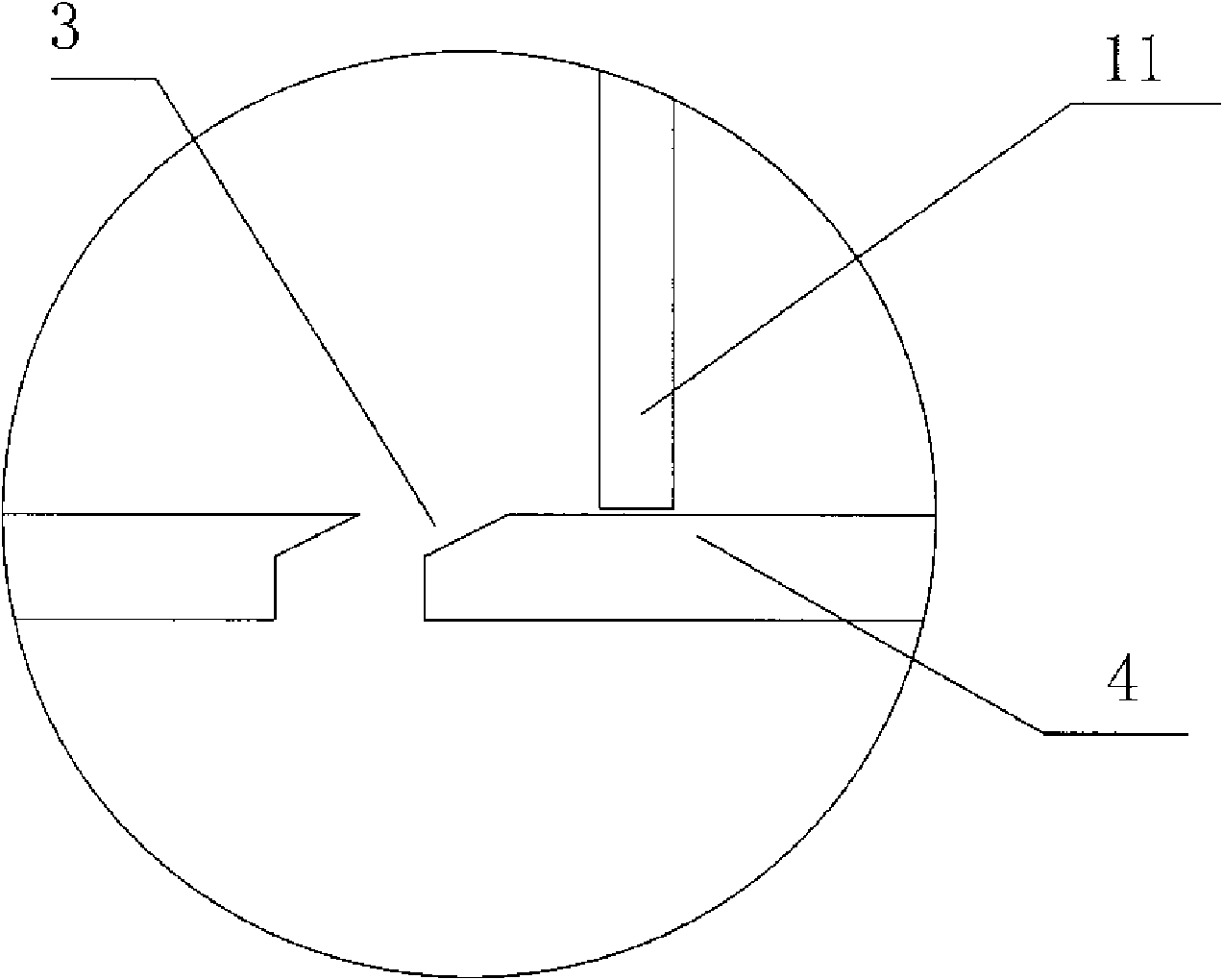

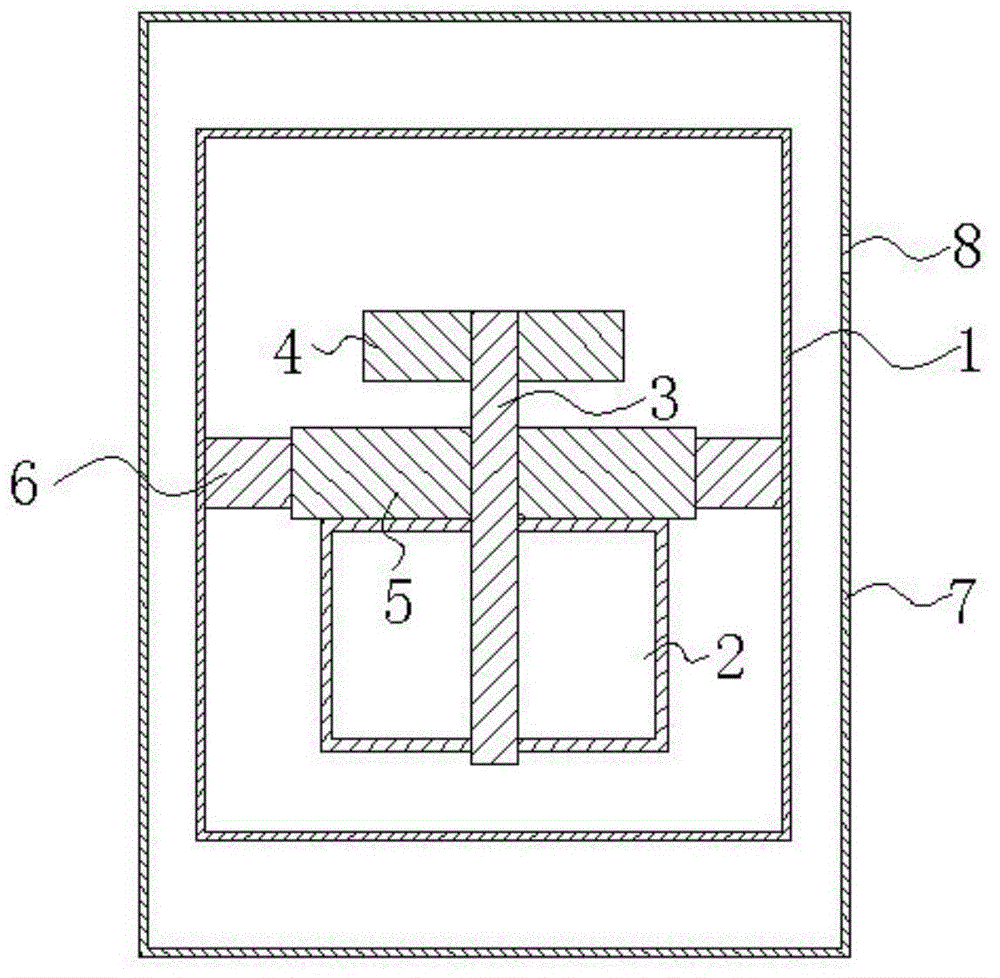

Quantitative material throwing device for aquaculture

InactiveCN103875579ASimple structureLow manufacturing costPisciculture and aquariaEngineeringAquaculture

The invention discloses a quantitative material throwing device for aquaculture and belongs to the field of aquaculture equipment. The device comprises a storage bin, a support, a quantitative bin, a quantitative tray, a conveying pipe, a feeding motor, a throwing tray, a throwing protection cover and a throwing motor, wherein the storage bin is fixedly installed on the top of the support, the quantitative bin is installed below the storage bin and is connected with the feeding motor, the quantitative tray is arranged on the bottom of the quantitative bin and is fixedly installed on the support, a quantitative hole is formed in the quantitative tray, the conveying pipe is arranged below the quantitative hole, the throwing tray is arranged below the conveying pipe and is connected with the throwing motor, and the throwing protection cover is arranged on the throwing tray in a covering mode. According to the device, the problem of uneven feed throwing is solved, even throwing all over the pond is realized in the true sense, the use efficiency of feed is improved, and the influence of aquaculture on the environment is reduced. Furthermore, the device is simple in structure and low in manufacturing cost and is worth popularization.

Owner:常州智能农业装备研究院有限公司

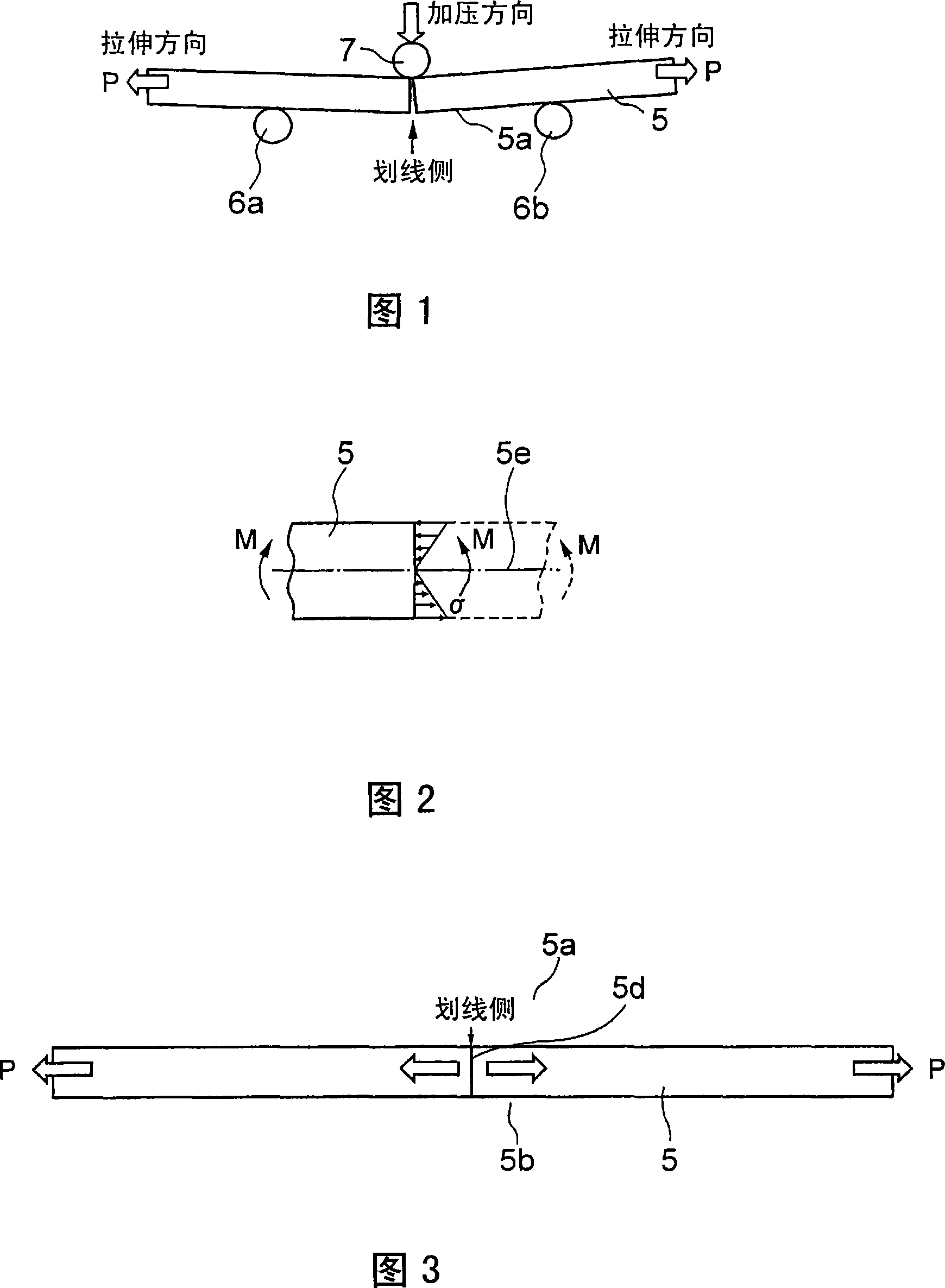

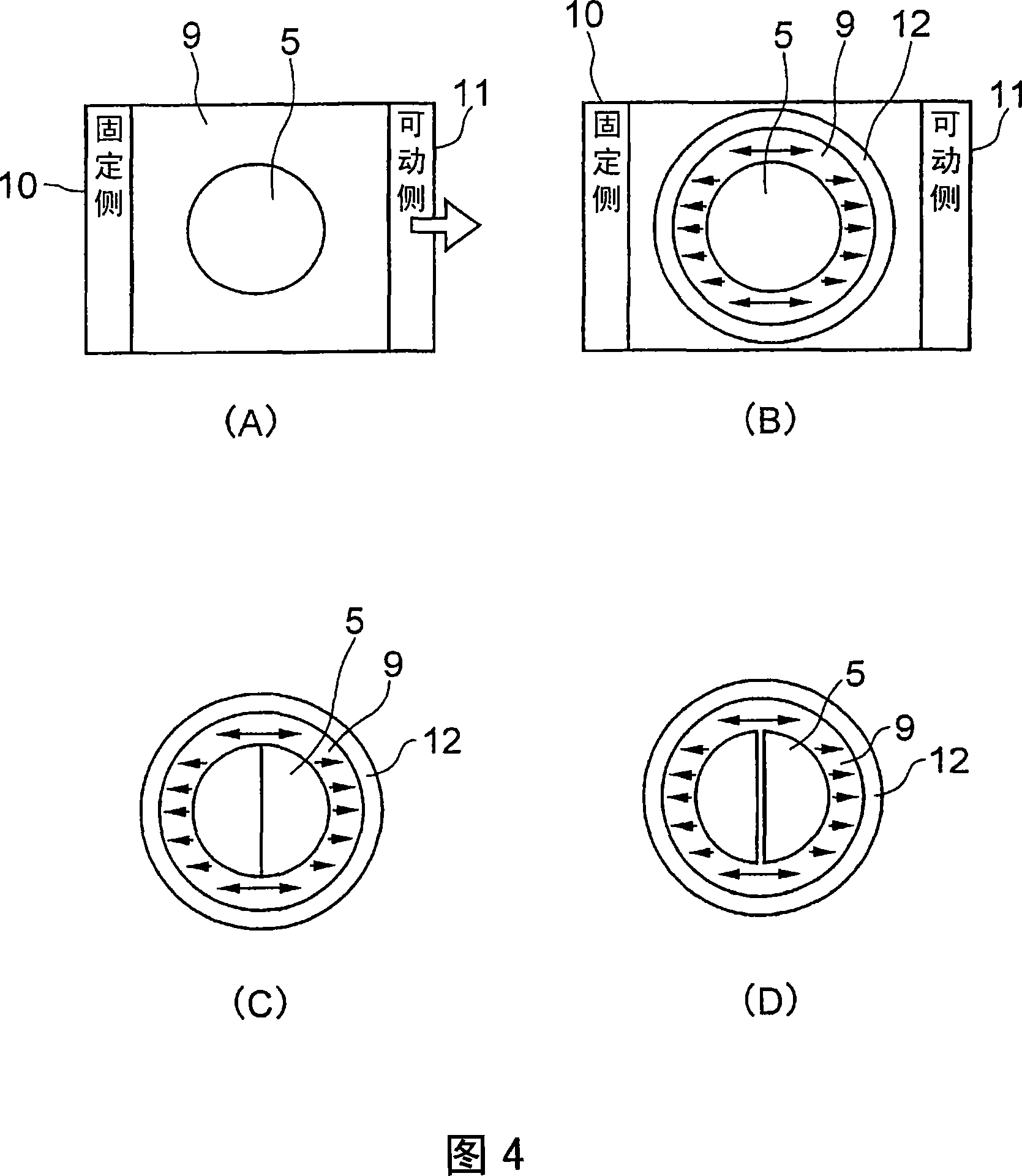

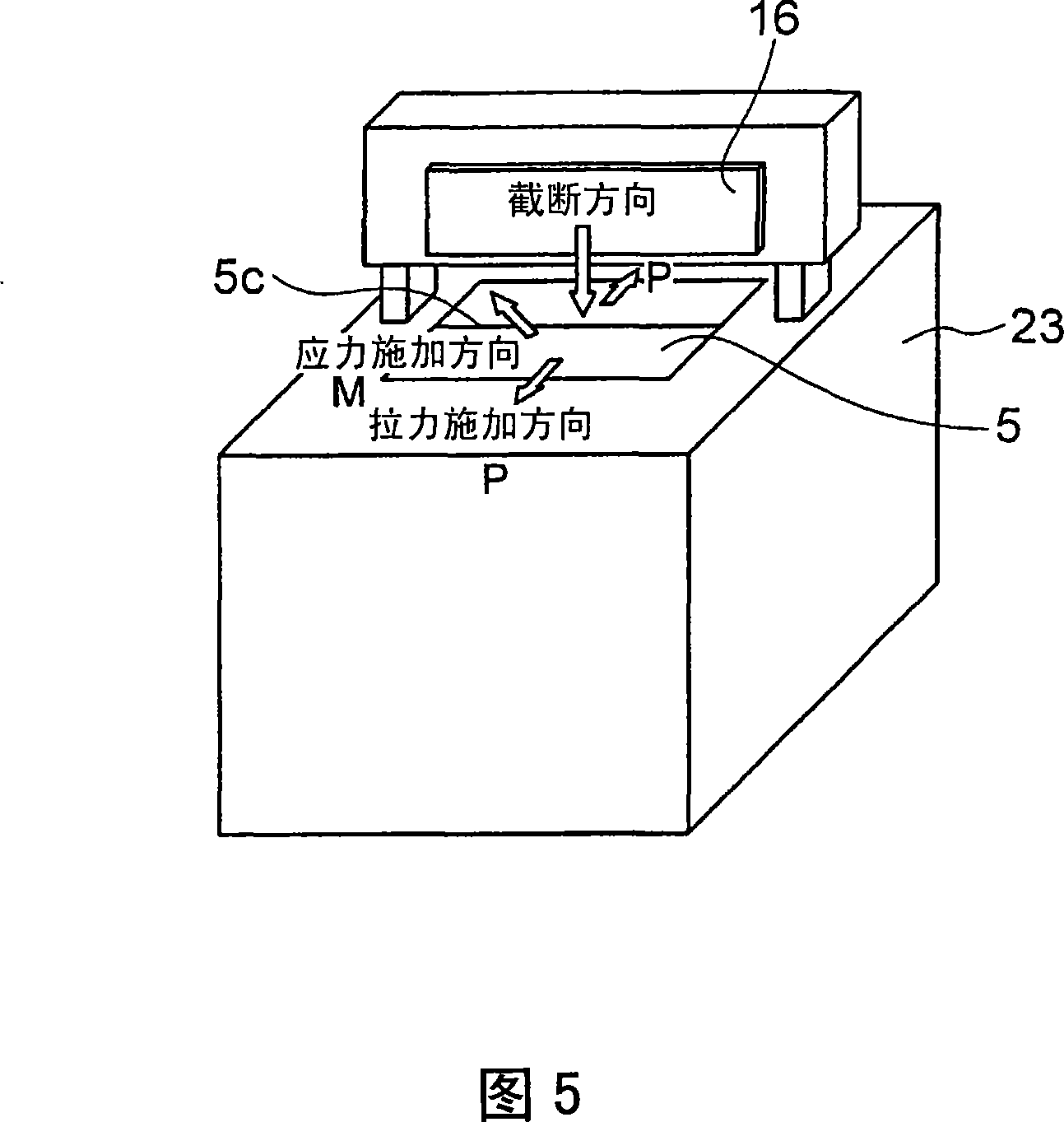

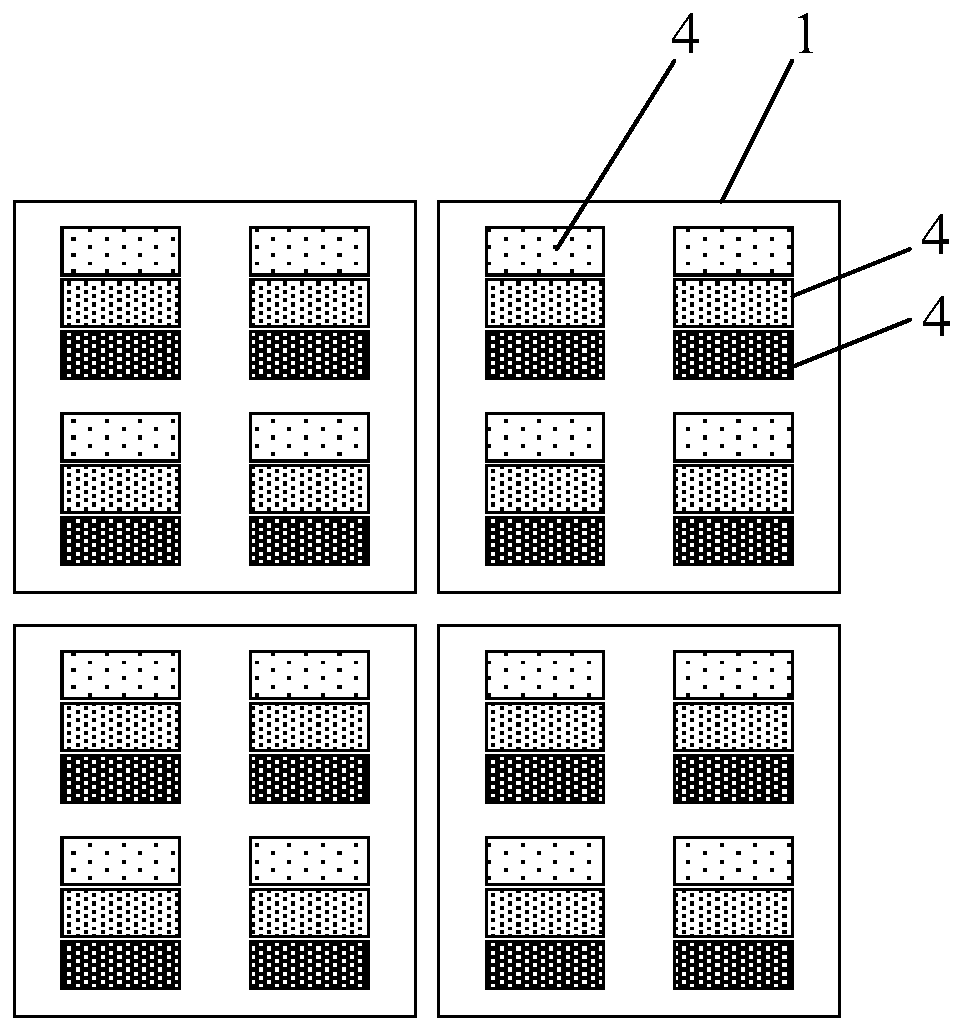

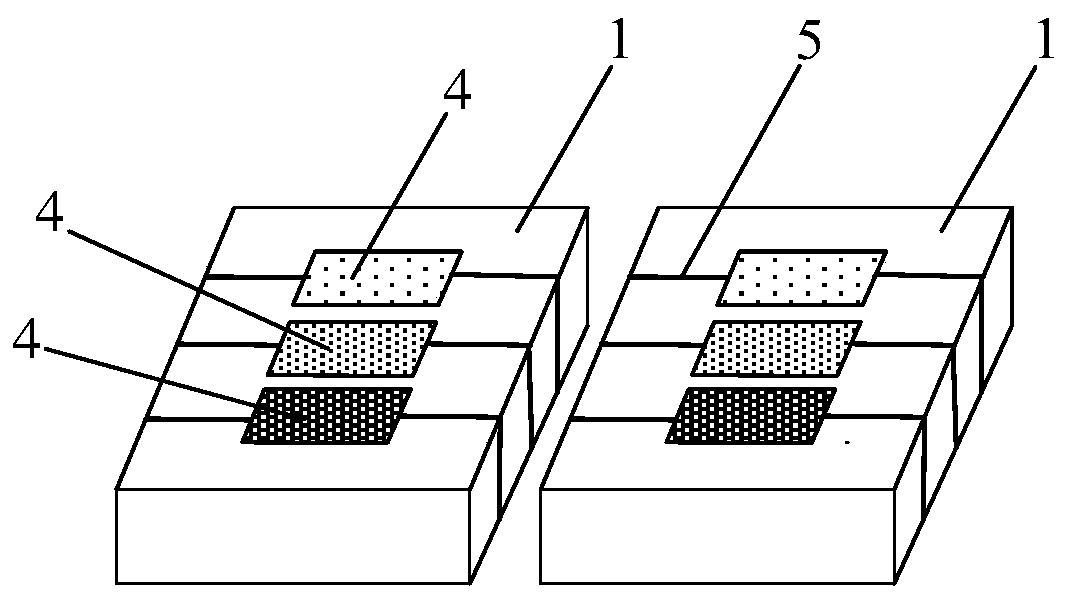

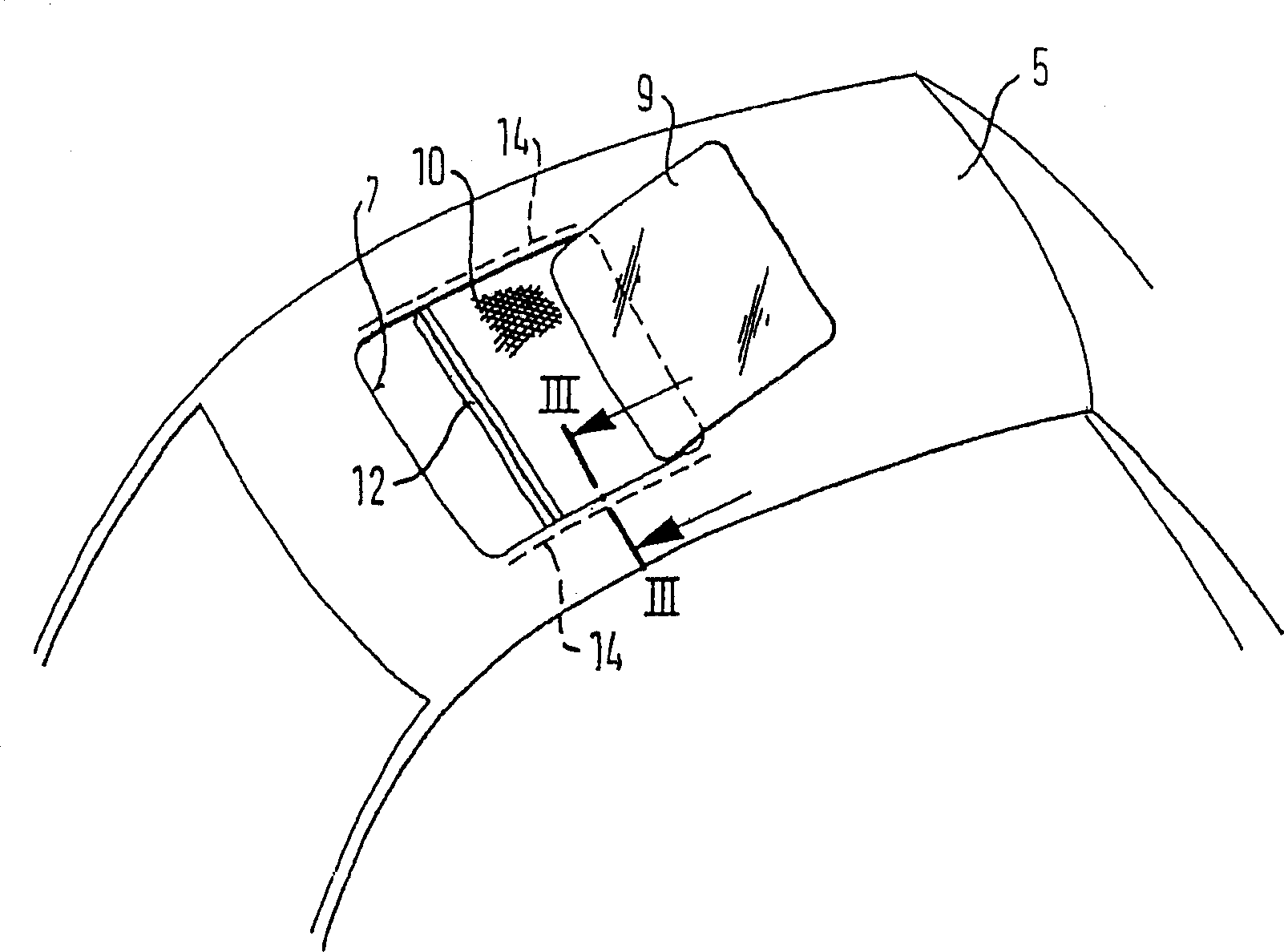

Method and device for breaking work, method for scribing and breaking work, and scribing device with breaking function

ActiveCN101099228AReduce frictionNot scatteredSemiconductor/solid-state device manufacturingGlass severing apparatusEngineeringRubbing

A method and a device for breaking a work, a method for scribing and breaking the work, and a scribing device with a breaking function. The method for breaking the work (5) capable of preventing chipping from occurring on the rear surface of the work due to rubbing when the work having a scribe line marked on the surface thereof is broken comprises a work adhering step for stamping the rear surface of the work (5) on an extensible sheet (9), a sheet pulling step for pulling the sheet (9) on which the work (5) is stamped, and a work parting step for moving the scribe line (5c) to the rear surface of the work (5) in the pulled state of the sheet (9). Since the work (5) is pulled off immediately after the work (5) is parted by the tensile force of the sheet (9), the rubbing of the parted work (5) is reduced and the chipping can be prevented from occurring on the rear surface of the work. Also, since the tensile force provided to the work (5) assists in parting the work, the work (5) can be parted with a smaller force.

Owner:THK CO LTD +1

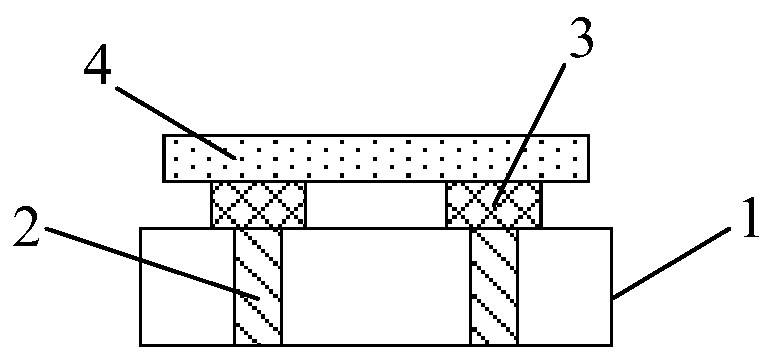

Circuit substrate, manufacturing method thereof, display substrate and splicing display device

ActiveCN109950226ANo frictionAvoid damageSemiconductor/solid-state device detailsSolid-state devicesPunchingDisplay device

The invention discloses a circuit substrate, a manufacturing method thereof, a display substrate and a splicing display device, relates to the technical field of display, and aims to solve the problems that when a glass substrate is adopted for manufacturing Micro LED and mini LED backlight substrates or display substrates, the processability of the glass substrate is poor, and the glass substrateis prone to damage during high-precision punching; and when the Micro LED and mini LED backlight substrates or the display substrates are used for splicing, the conductive connecting parts on the side surfaces of the substrates are easy to wear, resulting in the reduction of the reliability of the product. The circuit substrate comprises a substrate provided with a plurality of grooves in the surface; a driving circuit which is arranged on the substrate base plate and comprises a signal line located on the top surface of the substrate, a signal line lead located on the bottom surface of the substrate and a conductive connecting part, wherein the conductive connecting part is connected with the corresponding signal line lead and the corresponding signal line lead respectively. The circuitsubstrate provided by the invention is used for manufacturing a backboard or a splicing display screen.

Owner:BOE TECH GRP CO LTD +1

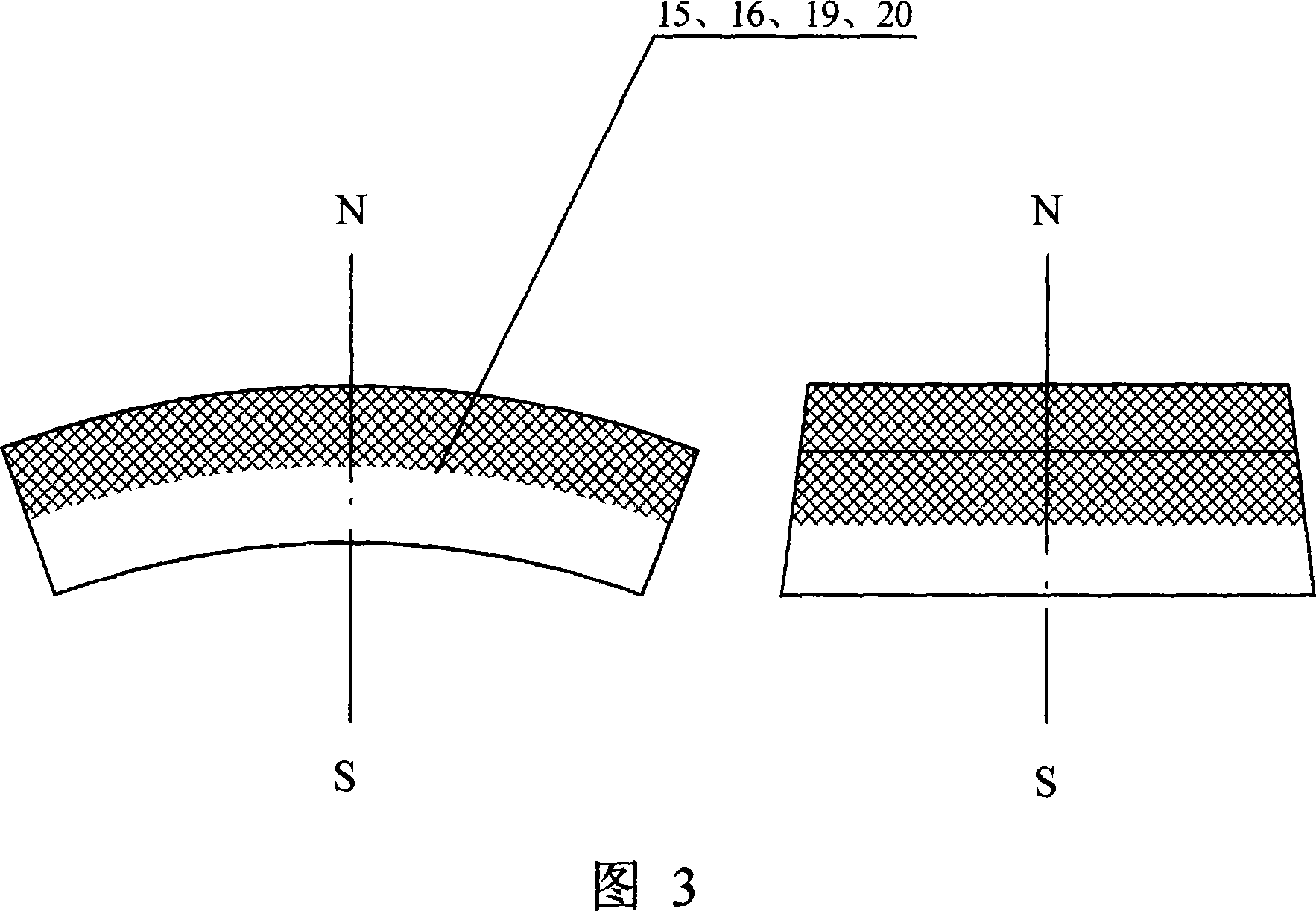

Permanent-magnetic clutch device

The invention is concerned with permanent-magnet clutch equipment, relating to main axis and driven axis, connecting with main and driven turntables, main and driven springs, axis-joining wheel, operate perch and wheel, bearing frame, main and driven inside and outside magnetism blocks. When the main axis is moving, the main and driven inner and outside magnetism blocks work through gas-gap magnetism induction action, and the magnetizations direction to south and north poles of the main and driven inner and outside magnetism blocks is the radial, the amount is same even and the south and north poles are opposite located towards to the middle to produce the attracting and excluding shear around the movement direction of axes between the main and driven magnetism blocks that moves in synchronous according to shear. The radial suction face and excluding power face is same between the main and driven magnetism blocks to balance the attracting and excluding shear along the movement direction of axes. The main and driven magnetism blocks do not drive the revolving and driving force, so the revolving and driving force can joint and separate with each other between the main and driven axes.

Owner:赵荣伟

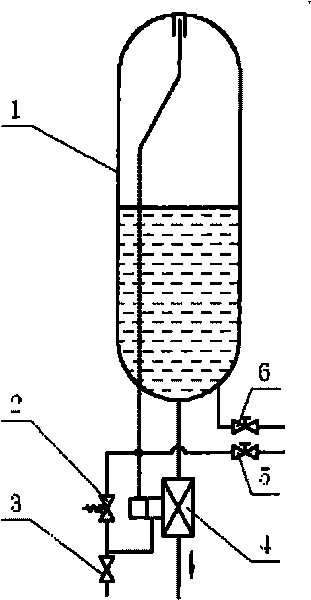

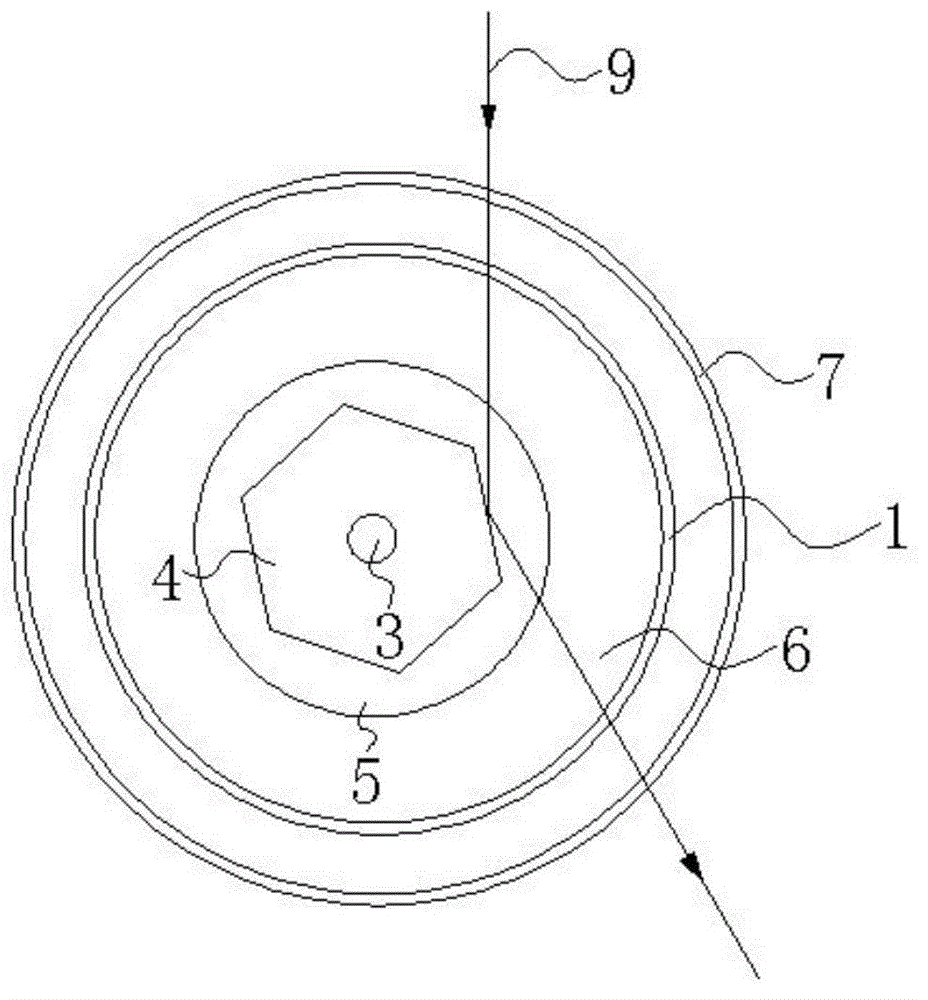

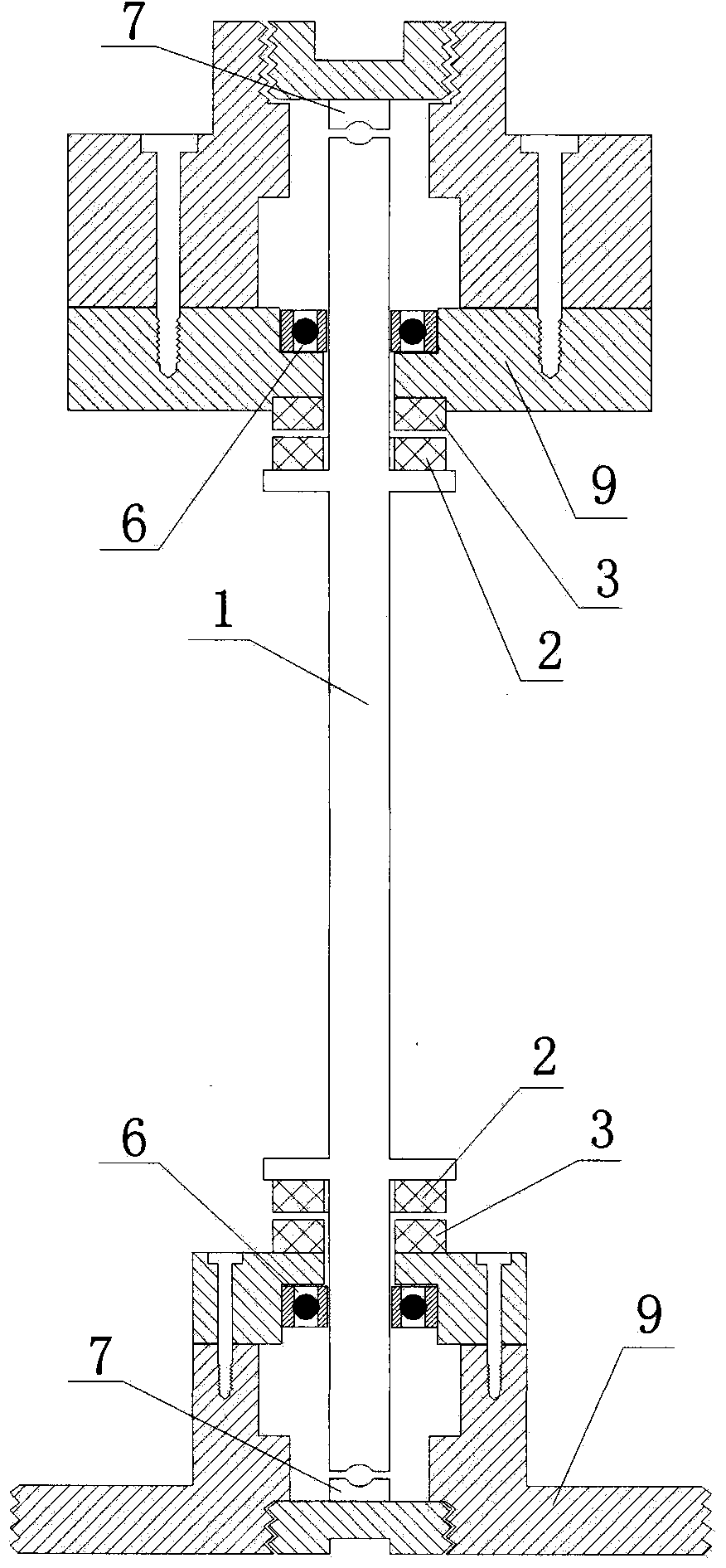

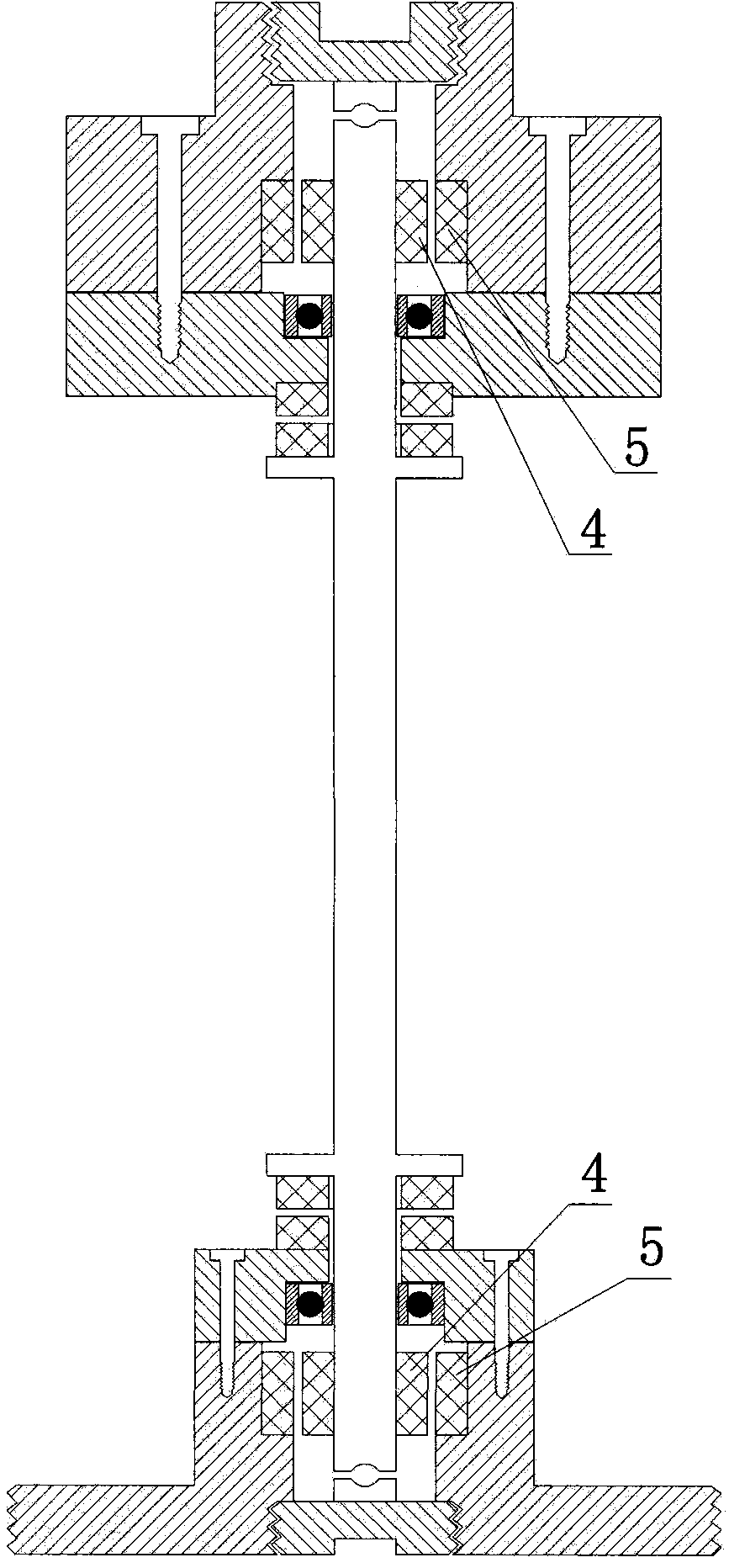

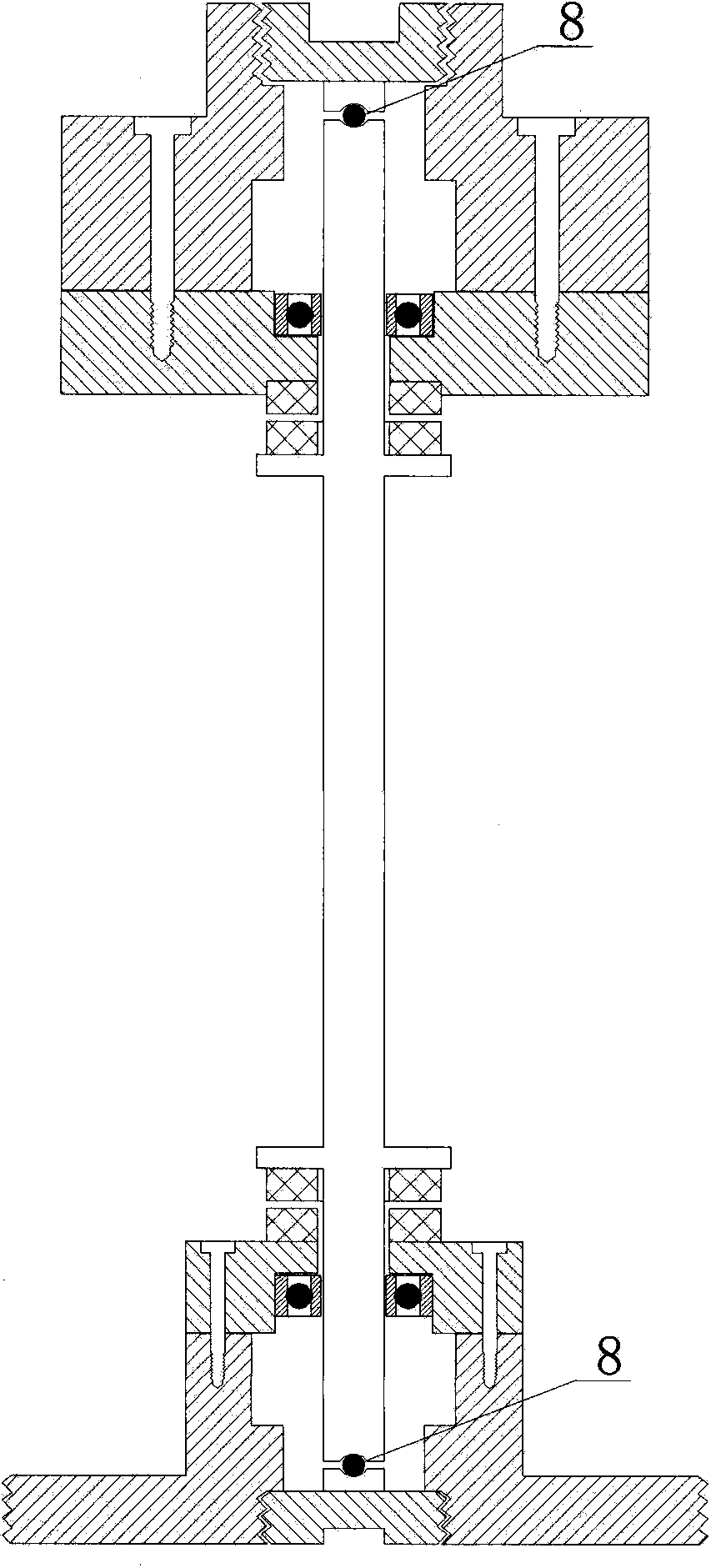

Liquid propellant conveying system of blow-down rocket engine

InactiveCN101737199APrevent accidental openingHigh sensitivityRocket engine plantsControl valvesControl circuit

The invention relates to a liquid propellant conveying system of a blow-down rocket engine, belonging to the field of the conveying system of the rocket engine. The conveying system comprises a conduit head (1), an electric explosion valve (2), an orifice (3), a flow control valve (4), a pressure increasing valve (5), a filling valve (6), a connecting pipeline and an electric explosion valve control circuit. The manipulation gas of the flow control valve (4) is the gas in the conduit head (1); the flow control valve is in the closing state before being started; the flow control valve (4) is started by the electric explosion valve (2); and the flow control valve (4) can control the flow after being started; when the pressure of the conduit head (1) falls, a valve core (8) is controlled to move by the pressure of the conduit head (1) so as to increase the valve opening and regulate the orifice size of the valves, thereby achieving the goal of flow stability; the orifice can prevent the valves from being opened, thereby improving the system reliability. The propellant conveying system has simple structure and low cost.

Owner:BEIHANG UNIV

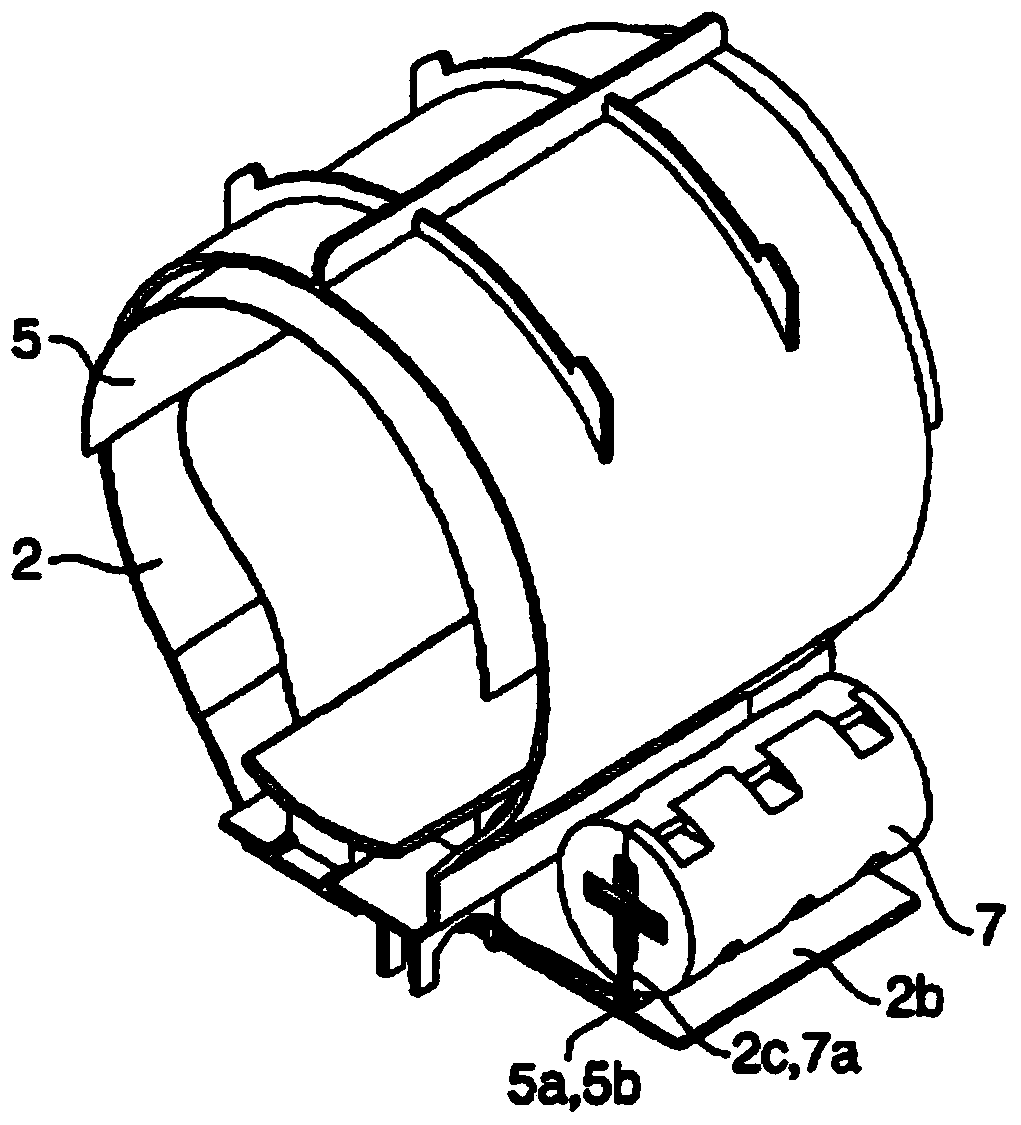

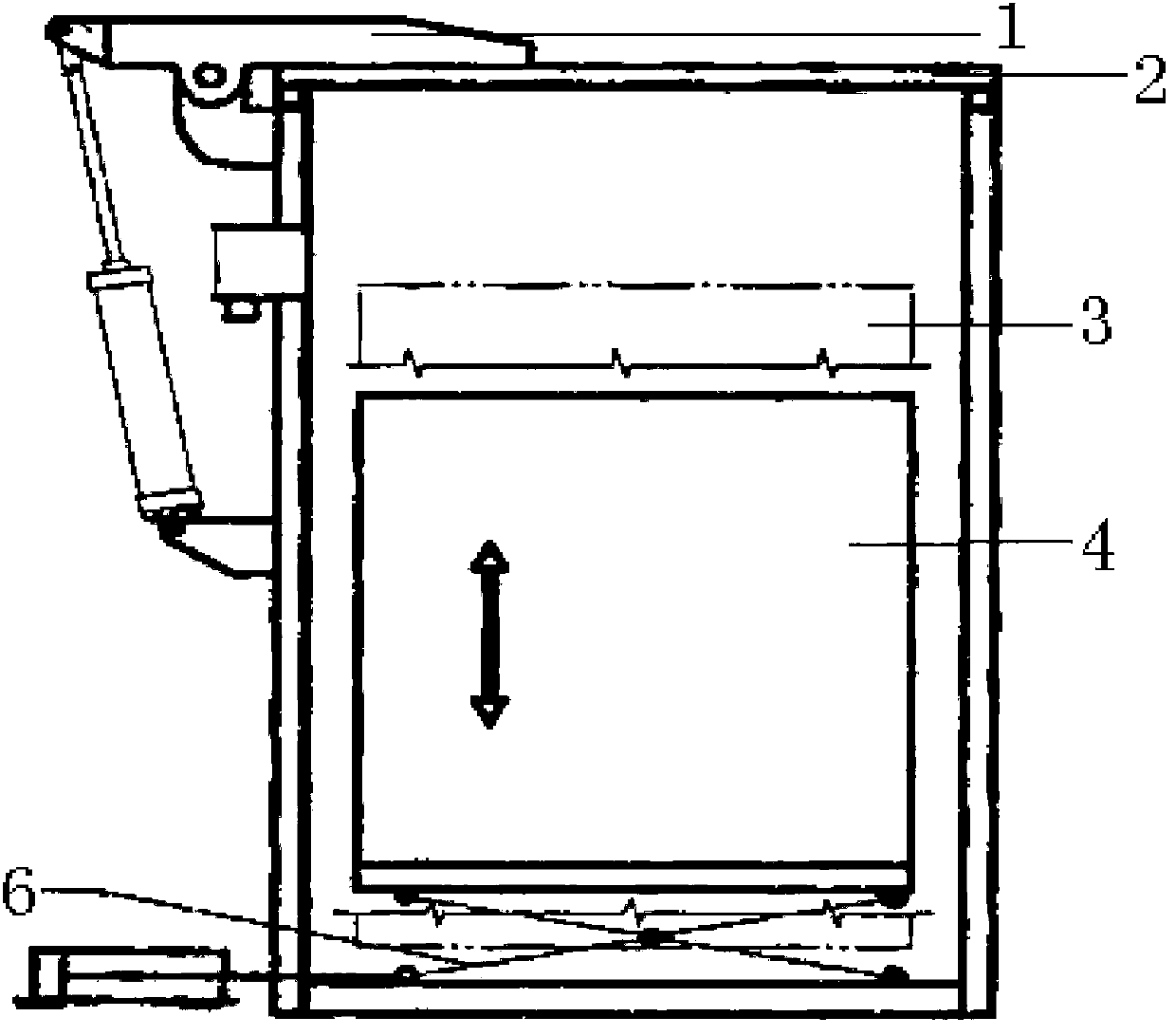

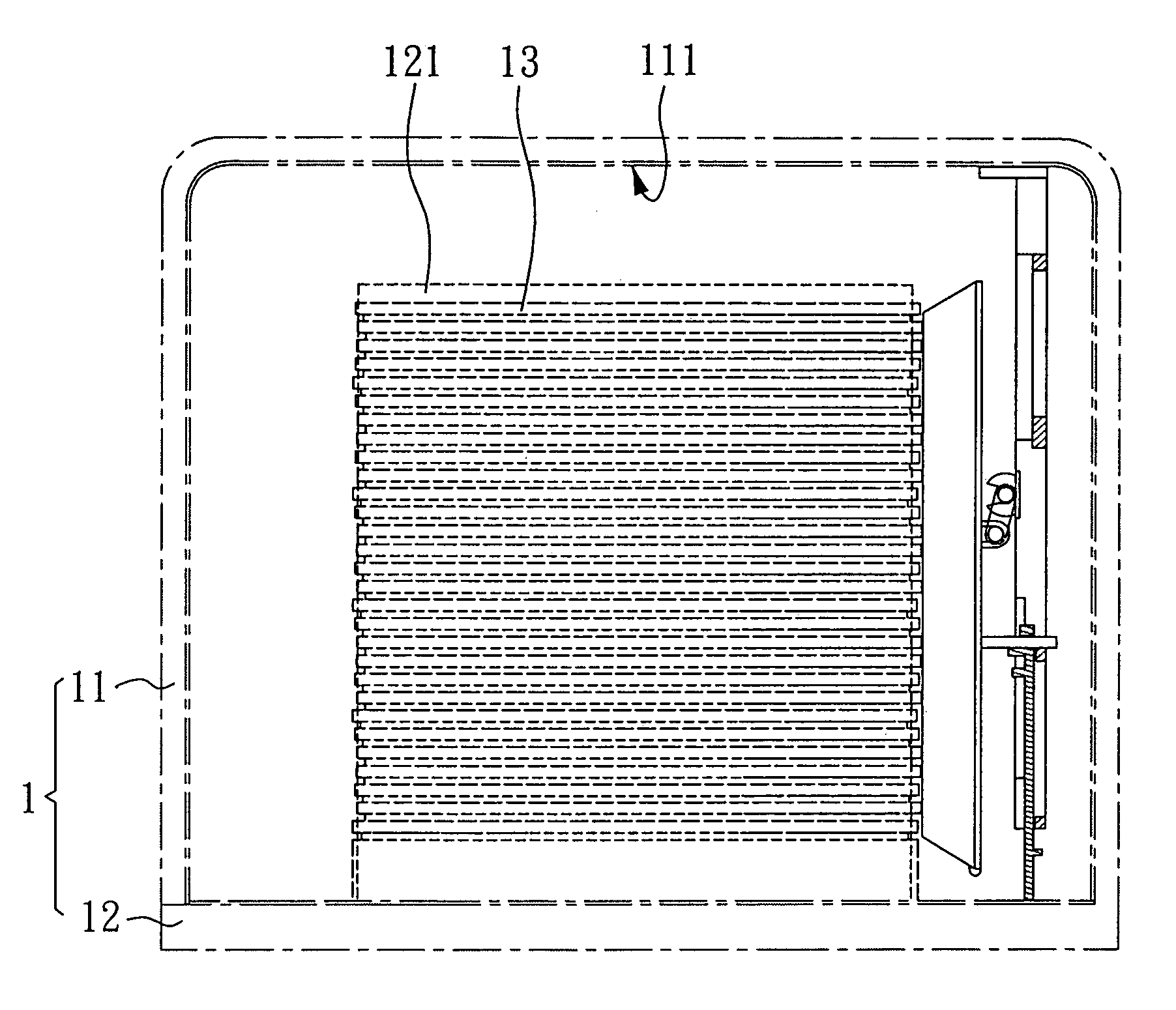

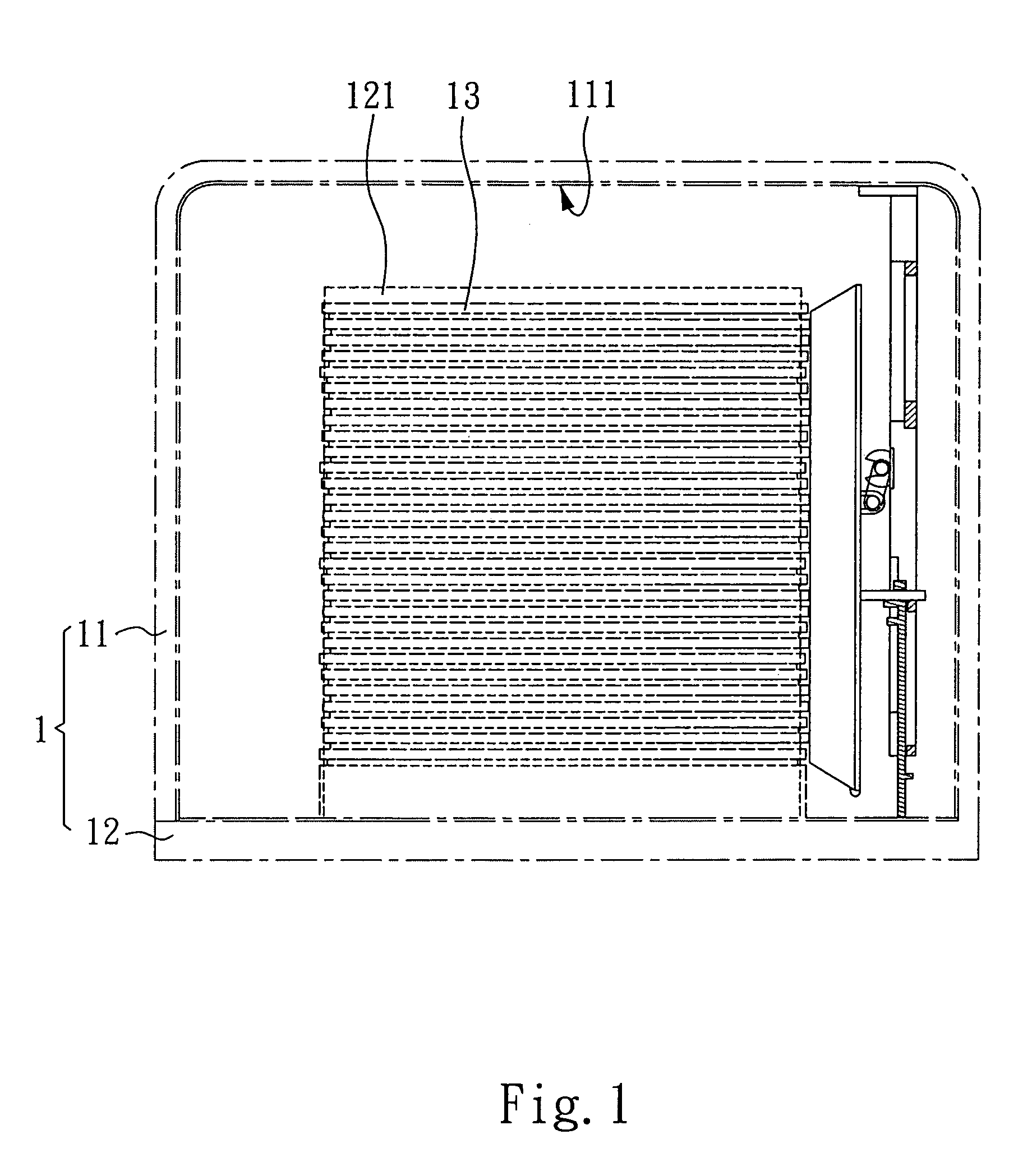

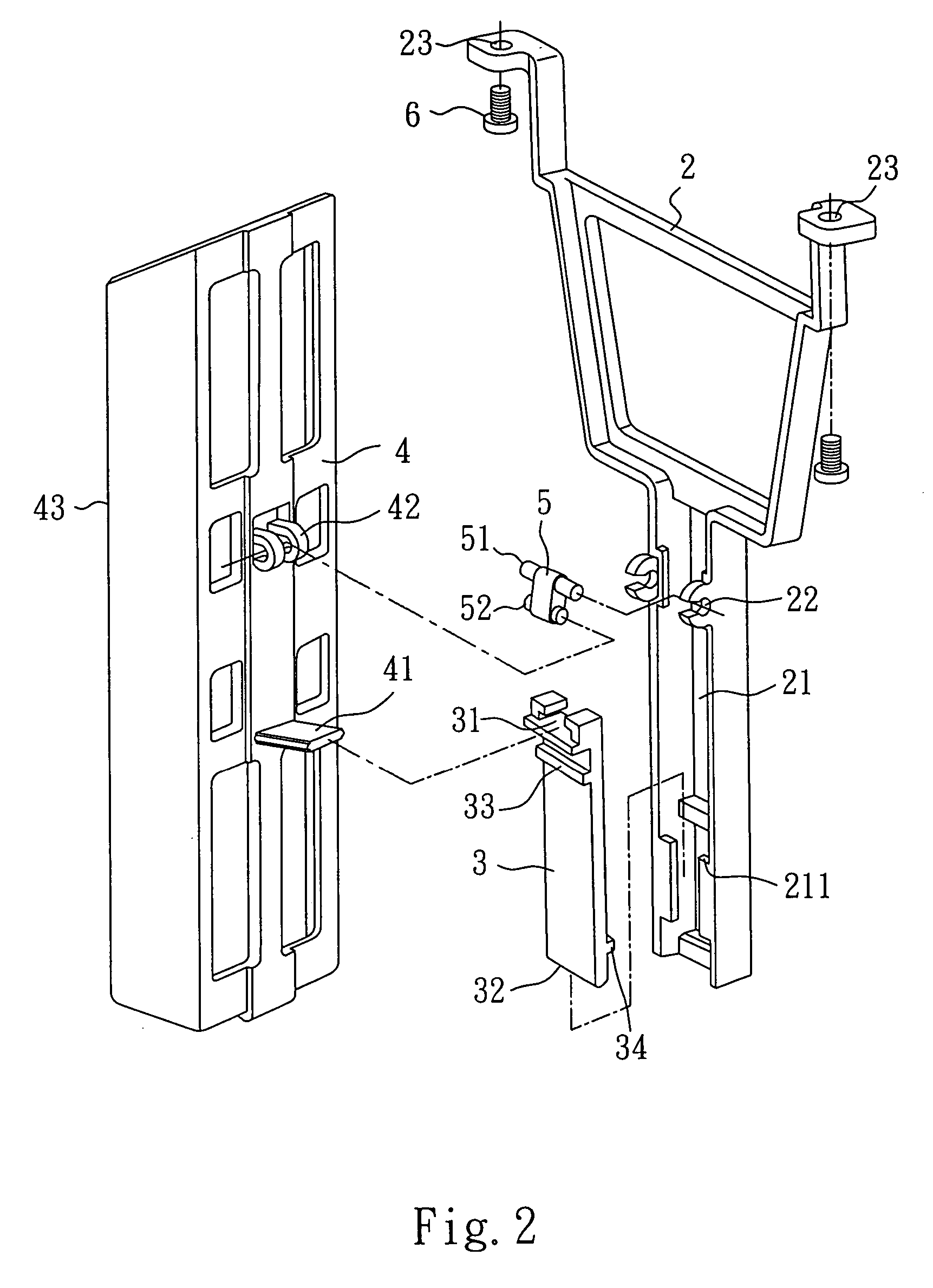

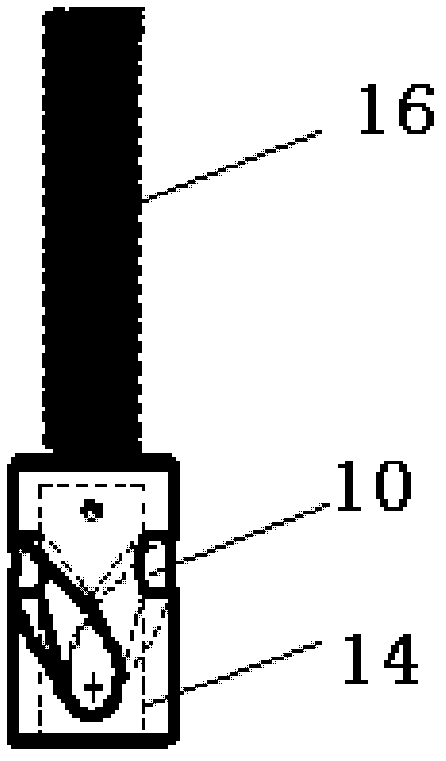

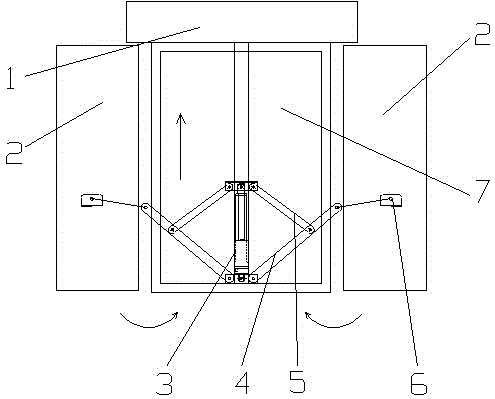

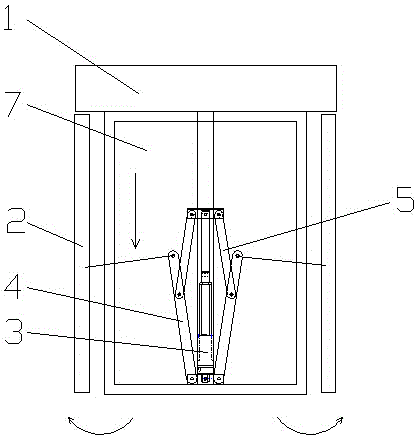

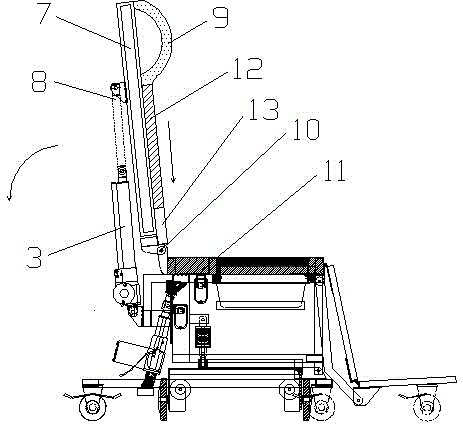

Device and method for winding or unwinding cuff

ActiveCN103932690ASolve the problem that the measurement posture cannot be adjusted according to the height and arm length of the measured objectAvoid measurement errorsEvaluation of blood vesselsAngiographyBarrel Shaped

The invention provides a device and method for winding or unwinding a cuff. The device for winding or unwinding the cuff comprises a winding mechanism, the cuff attached to the inner portion of the winding mechanism and a control part used for controlling the winding mechanism to carry out winding or unwinding. The device is characterized in that the winding mechanism is made to carry out winding or unwinding in a barrel shape through the control part to wind or unwind the cuff in the winding mechanism, so that the cross section area of the winding mechanism is changed.

Owner:BEIJING CHIOY MEDICAL TECH CO LTD

Bearing machining method

InactiveCN102518668AGuaranteed grinding precisionGuaranteed deformationBearing componentsBall bearingEngineering

The invention relates to a thin wall bearing, in particular to a heavy-duty thin wall deep groove ball bearing. A bearing machining method comprises five processes of machining an outer ring, machining an inner ring, machining a retainer, machining a seal ring, and assembling the outer ring, the inner ring, the retainer and the seal ring. The method has the advantages that: the grinding accuracy of the inner and outer rings, the deformation of the retainer and a space between the retainer and the seal ring are ensured, so that the inner and outer rings, the retainer and the seal ring are not contacted with each other and do not generate friction, and the service life of the bearing is prolonged; and moreover, noise is avoided, and the requirement on a heavy load of the bearing is met under the condition that the overall size of the bearing is not changed.

Owner:NINGBO WANFENG BEARING

Cylinder set for use in retraction mechanism

ActiveCN1963239AOvercoming the Difficulty of PipingImprove structural strengthConcrete transportationFluid-pressure actuatorsEngineeringMechanical engineering

Owner:SANY HEAVY IND CO LTD (CN)

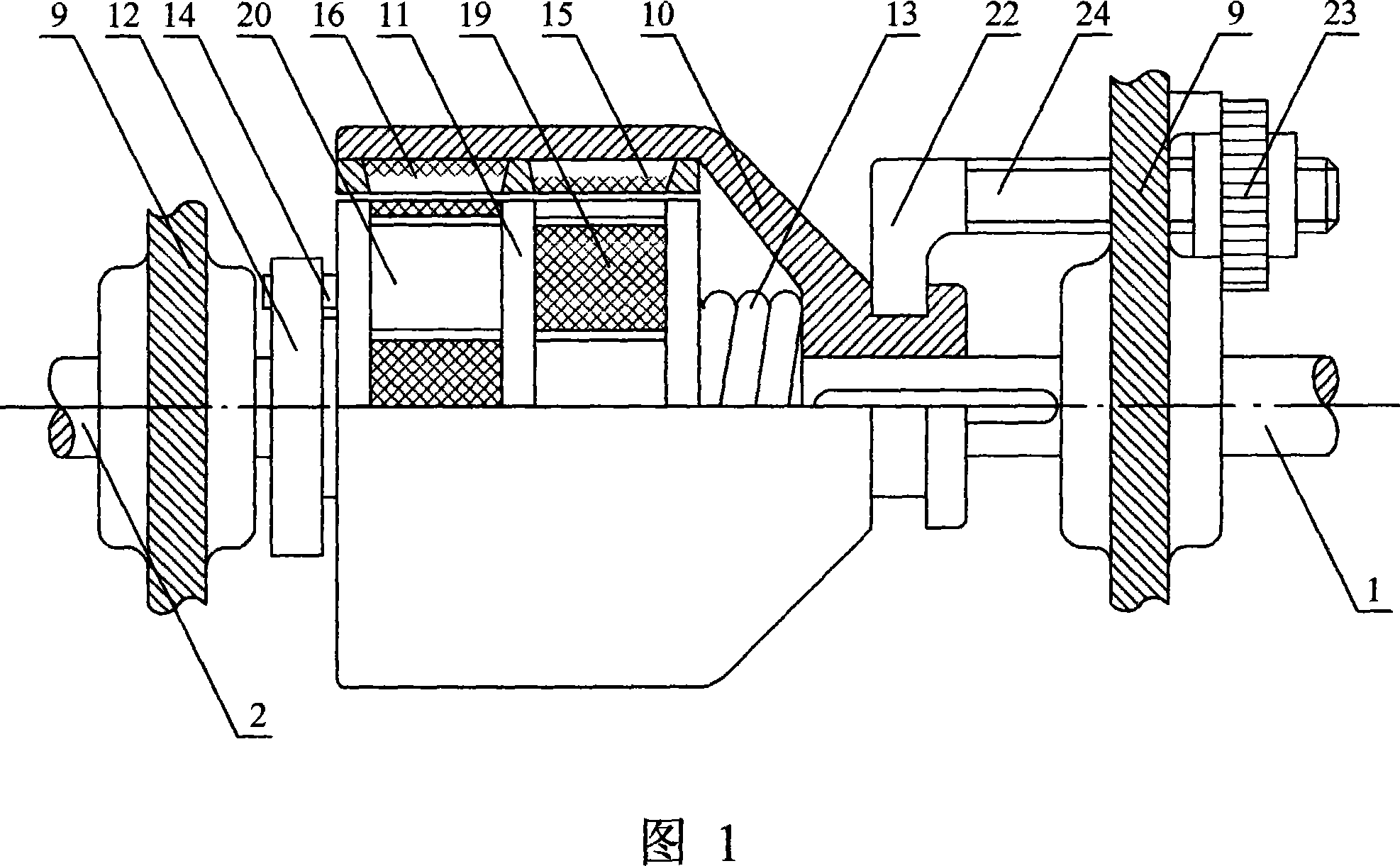

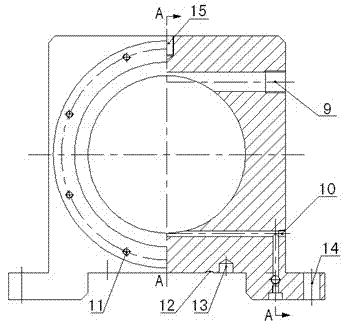

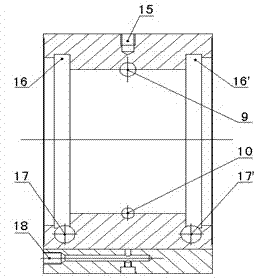

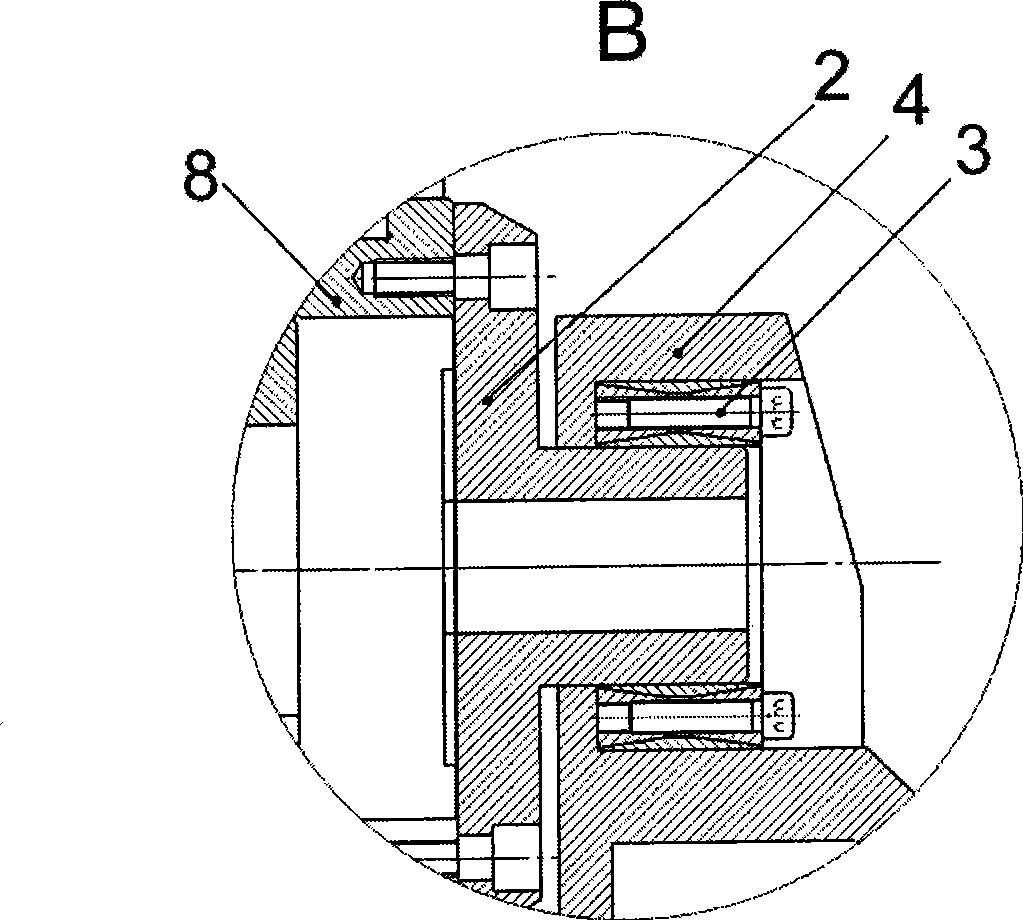

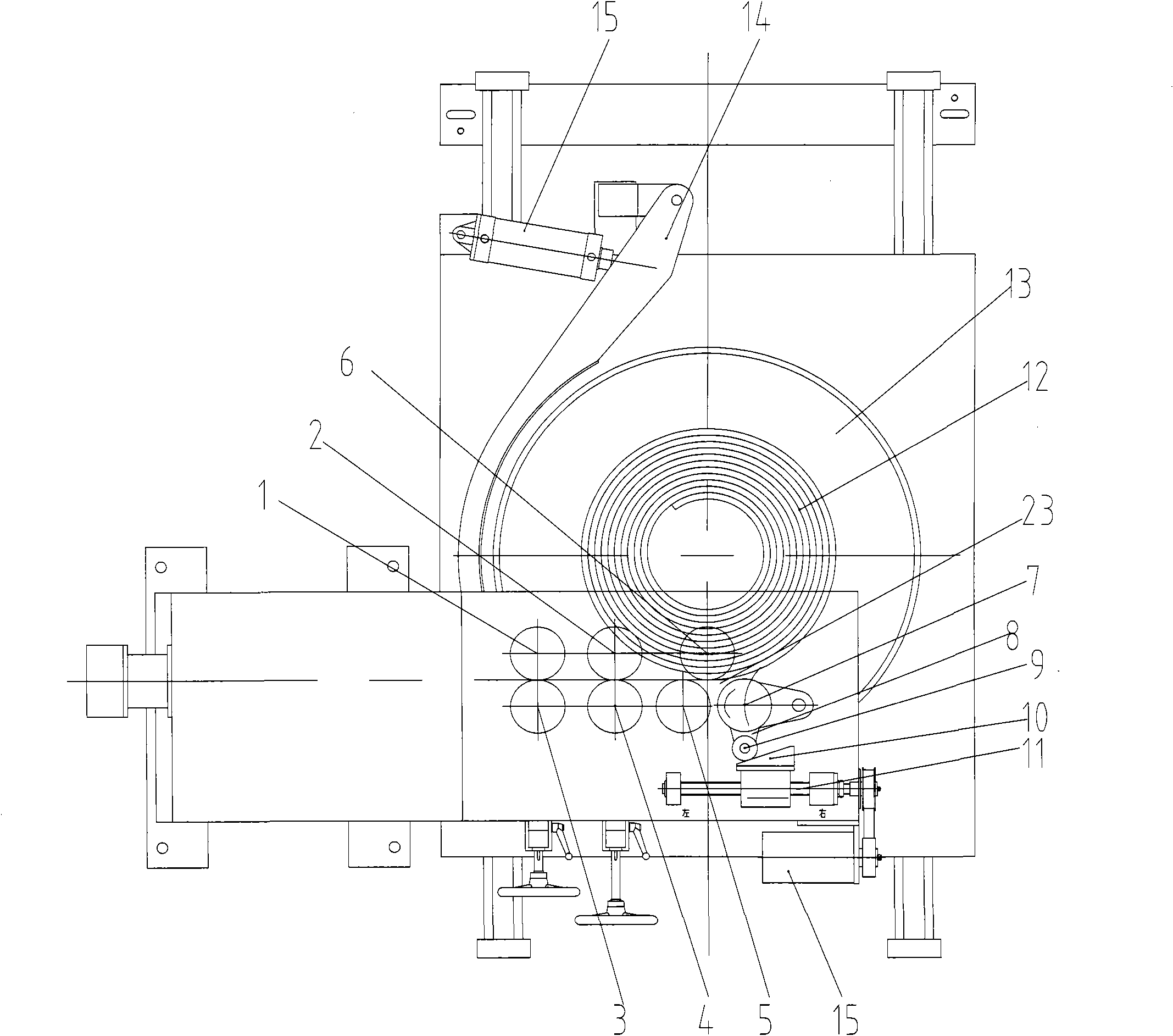

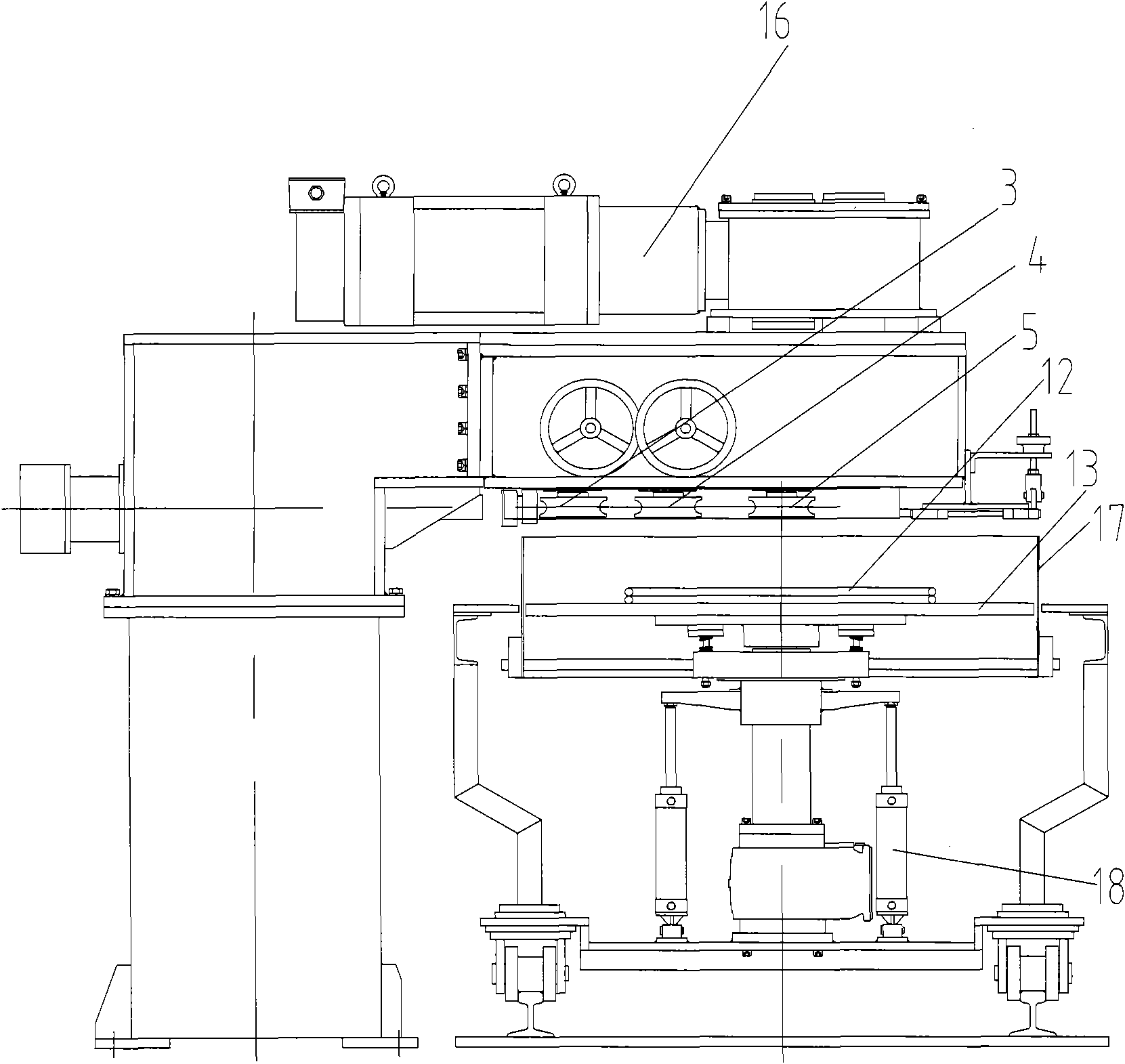

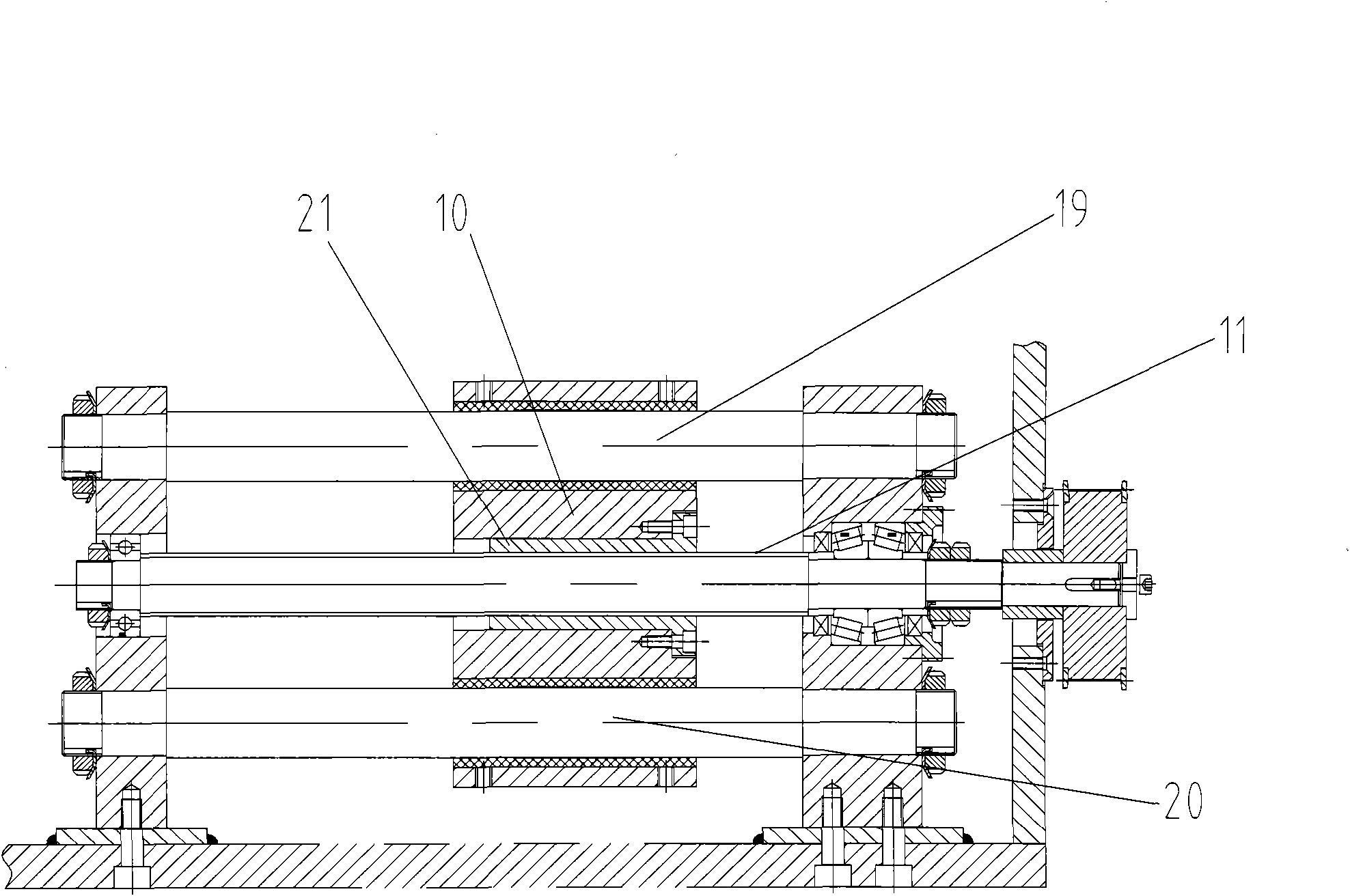

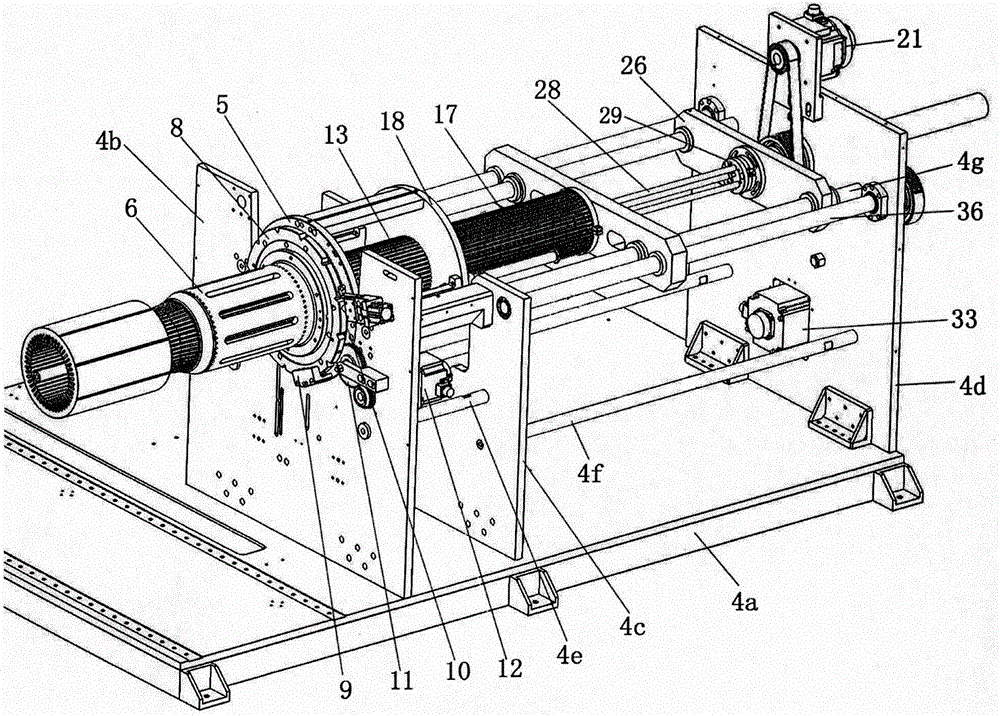

Comprehensive test device of oil film bearing

ActiveCN102854013AImprove poor oil circuit designNo frictionMachine bearings testingMiddle lineOil film

A comprehensive test device of an oil film bearing belongs to the technical field of the oil film bearing. The structure is as follows: a left bearing, a middle bearing and a right bearing are sequentially arranged from left to right; a shaft connected with a motor through a coupling is arranged inside a bearing hole; an oil path of the left bearing is provided with a dynamic press-in oil hole and a static press-in oil hole at upper and lower top points of a bearing block; oil grooves are arranged inside axle holes at the left end and the right end; the bottom part of each oil groove is communicated with an oil return hole; the dynamic press-in oil hole and a dynamic press-in oil cavity are arranged at the upper part of a vertical center line of a bush; the static press-in oil hole and a static press-in oil cavity are arranged at the lower part; the oil grooves communicated with the oil return hole are arranged on the inner surfaces of the axle holes of a left end cover and a right end cover; the oil path of the middle bearing is respectively provided with the dynamic press-in oil hole at the front and rear top points of the bearing block; the oil grooves are arranged inside the axle holes at the left end and the right end; the bottom part of each oil groove is communicated with the oil return hole; the dynamic press-in oil hole and the dynamic press-in oil cavity are arranged at the front end part and the rear end part of a radial center line of the bush; and the oil grooves communicated with the oil return hole are arranged at the inner surfaces of the axle holes of the left end cover and the right end cover.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

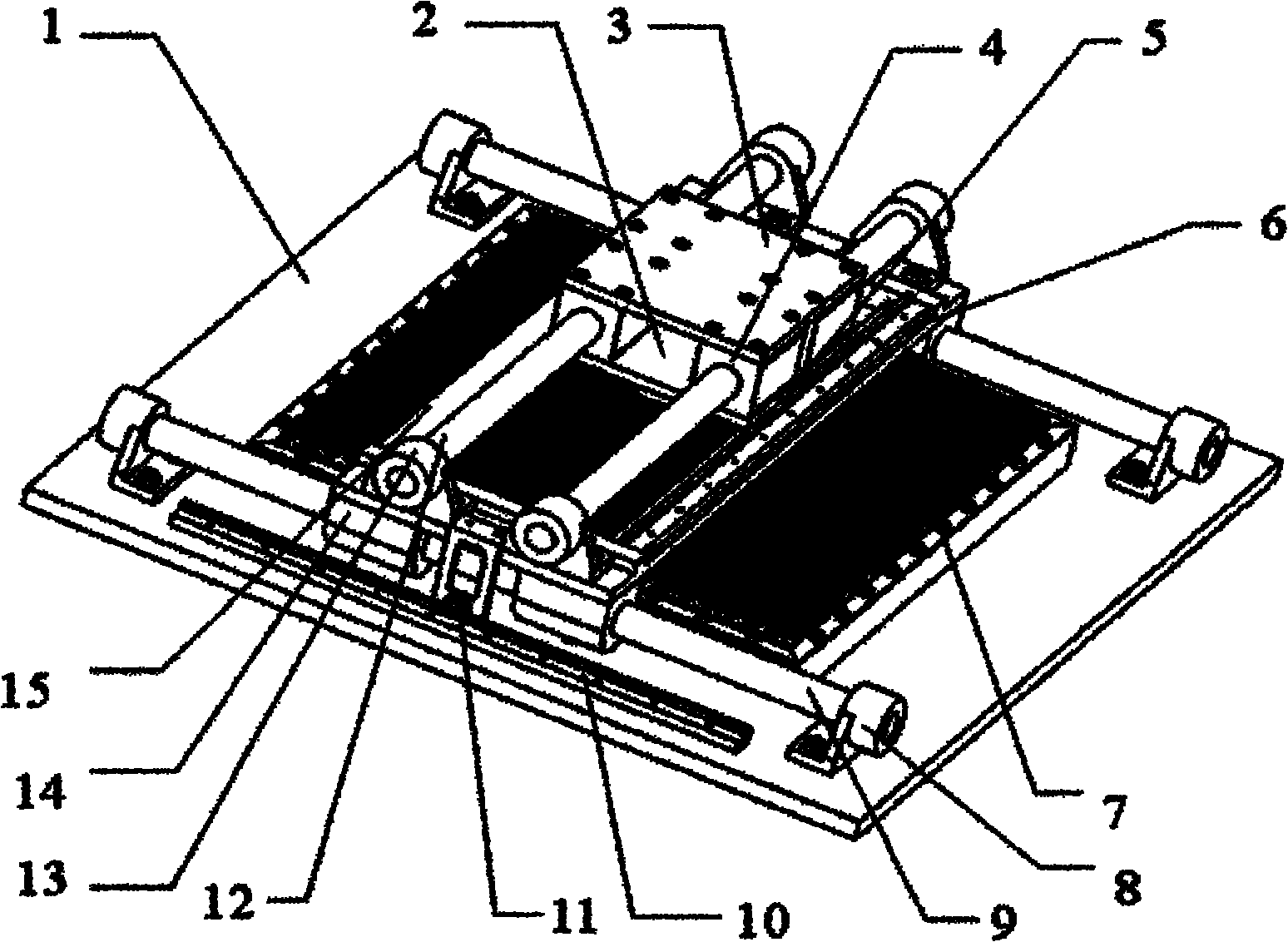

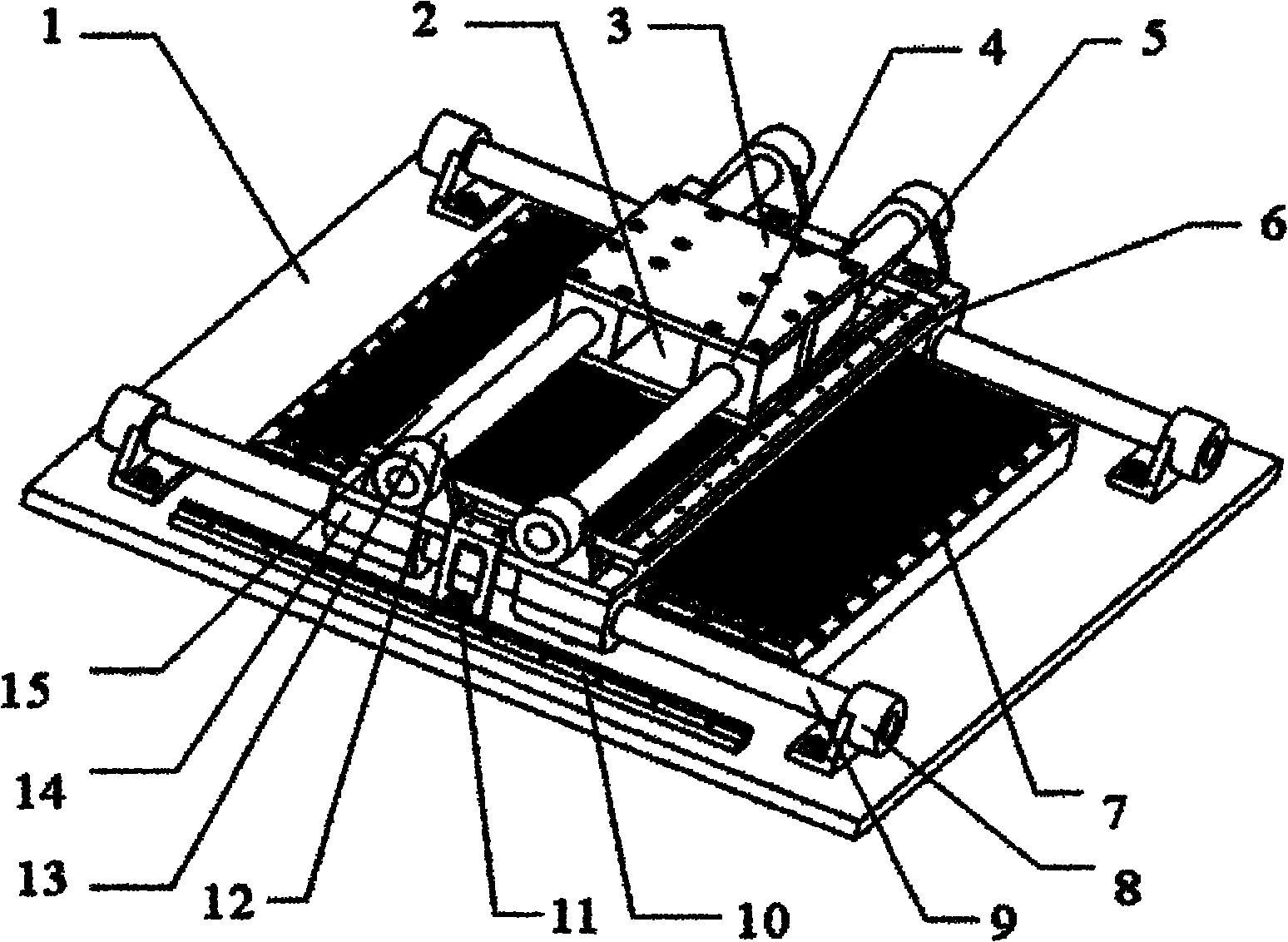

Magnetic-suspension planar feed motion device

InactiveCN102176649APrecise feed movementImprove stabilityMagnetic holding devicesGratingThree-phase

The invention discloses a magnetic-suspension planar feed motion device, which is characterized in that a planar motor is adopted to drive; a stator platform is provided with a square raised head array stator which is formed by silicon sheets evenly; a Y-direction movable platform is provided with two sets of mutually orthorhombic three-phase exciting winding rotors; magnetic-suspension sliding sleeves in two directions are used for supporting a rotor platform respectively; the magnetic-suspension sliding sleeves are arranged on cylindrical guides in the X and Y directions; coil currents in the magnetic-suspension sliding sleeves are controlled to suspend the rotor platform, thus improving the stability and the efficiency of planar motion; excitation voltages are exerted on the three-phase exciting winding rotors by regulation to generate electromagnetic driving power so as to control the planar motion direction of the rotor platform; and grating sensors in two motion directions are utilized to detect motion positions so as to realize accurate planar feed motion. The magnetic-suspension planar feed motion device can be applied to special equipment for manufacturing photoelectrons,micro-electronics and the like, and has wide market prospects.

Owner:CENT SOUTH UNIV

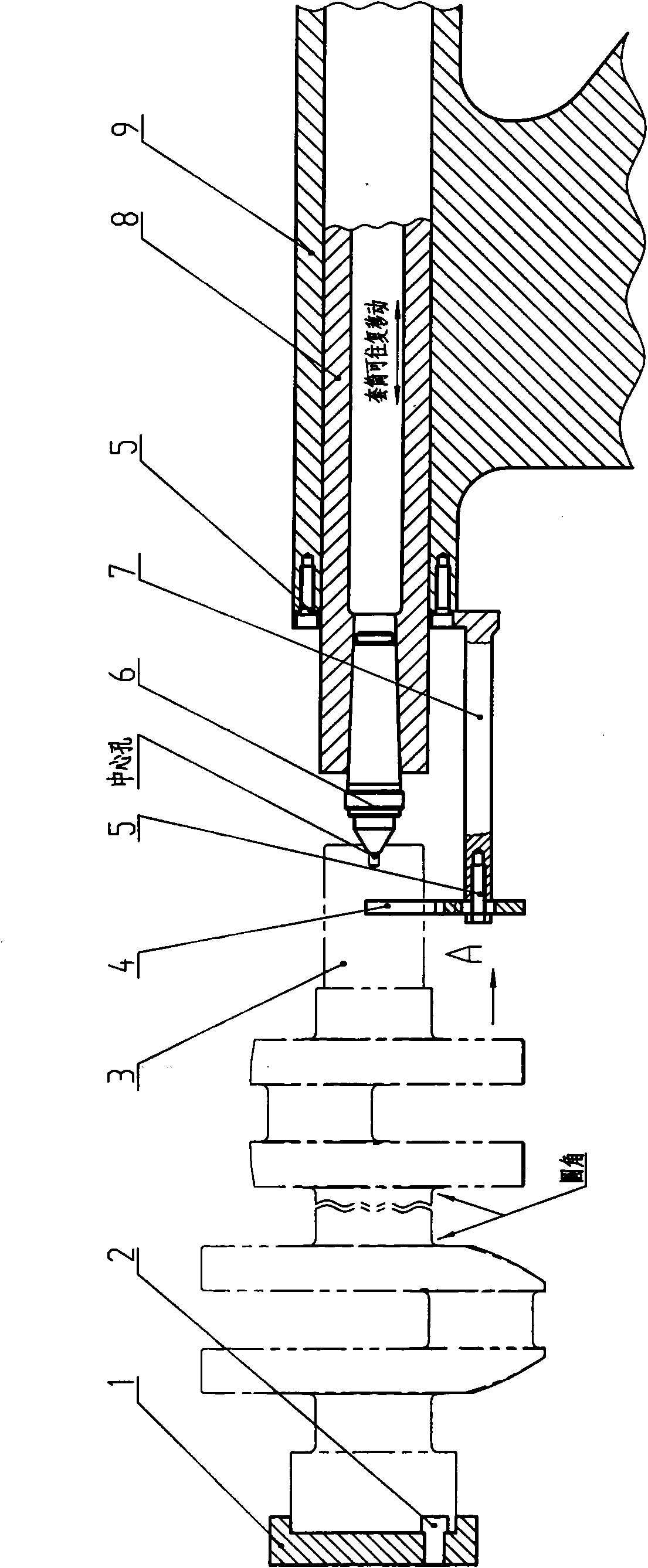

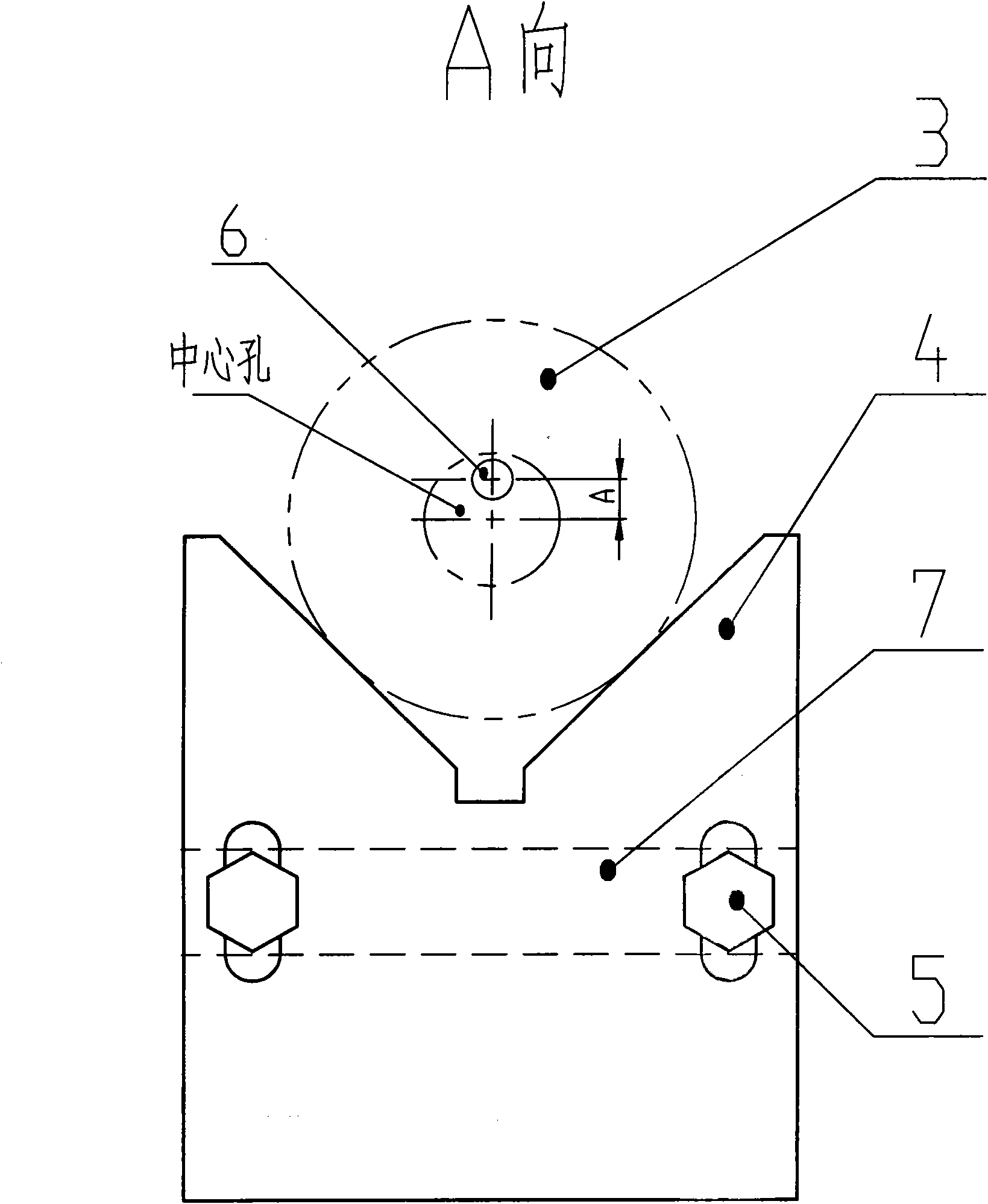

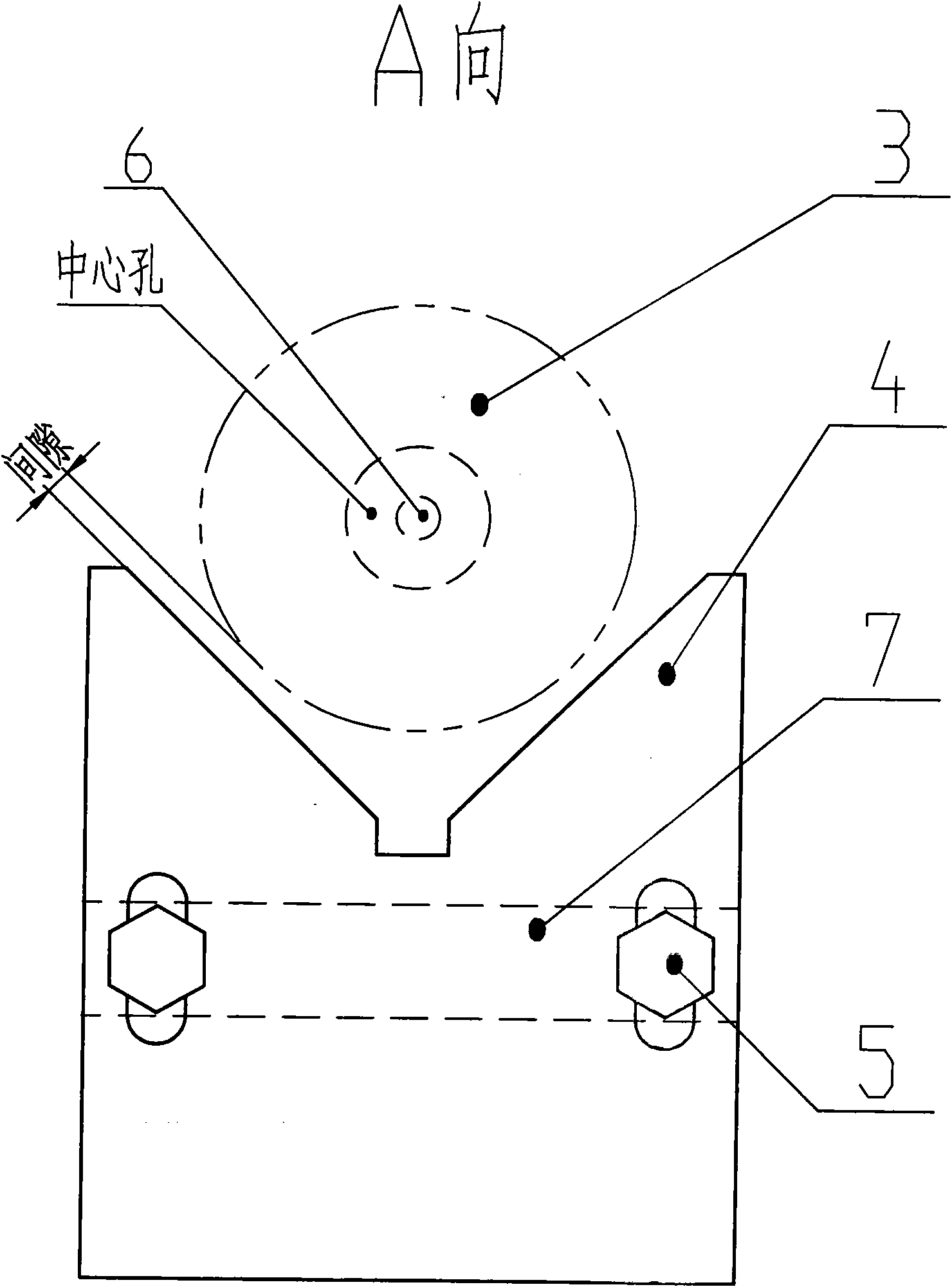

Rolling crankshaft fillet quick clamping bracket

InactiveCN102069396AQuick clampingReasonable structurePositioning apparatusGrinding work supportsEngineeringTailstock

The invention relates to a rolling crankshaft fillet quick clamping bracket which comprises a drive disk and a supporting device, wherein the drive disk is arranged at the big-head end of a crankshaft, a positioning pin corresponding to a process positioning hole at the big-head end of the crankshaft is arranged on the drive disk, the supporting device is arranged at the small-head end of the crankshaft and comprises a supporting plate, a bracket body, a core clamper, a sleeve and a tailstock, the bracket body is fixedly arranged at the front end of the tailstock by using a bolt, the tailstock is internally provided with the sleeve capable of moving front and back, the front end of the sleeve is provided with the core clamper corresponding to a center hole at the small-head end of the crankshaft, the supporting plate is fixedly arranged at the front end of the bracket body by using a bolt, and a V-shaped opening for supporting the shaft neck of the small-head end of the crankshaft is arranged above the support plate. The drive disk rotates, the crankshaft rotates with the drive disk, and a rolling mechanism is started so that a crankshaft fillet can be rolled. The invention has the advantages of reasonable structure, convenience of operation, and high clamping speed, and is suitable for clamping various crankshaft rolling fillets.

Owner:TIANRUN IND TECH CO LTD

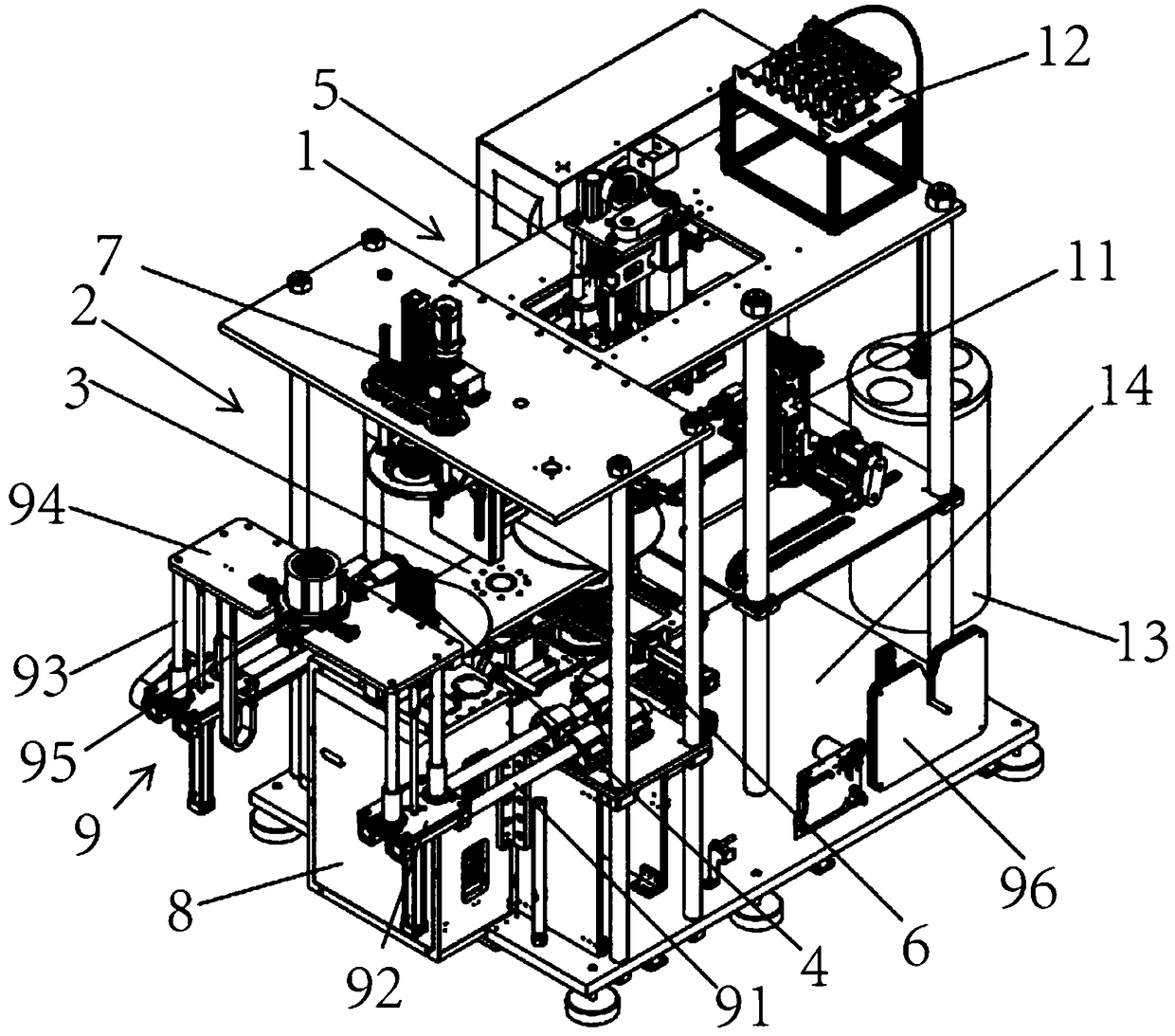

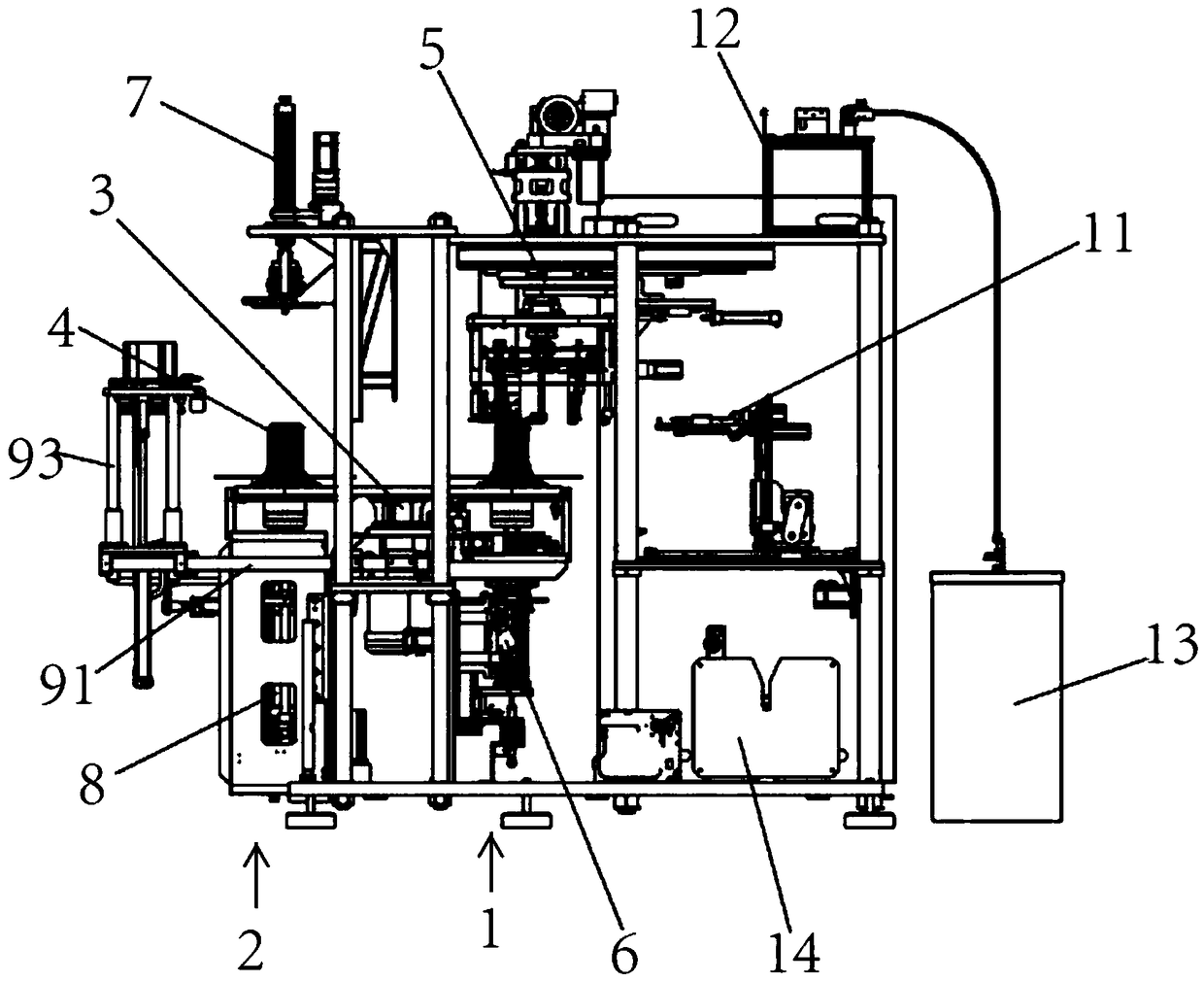

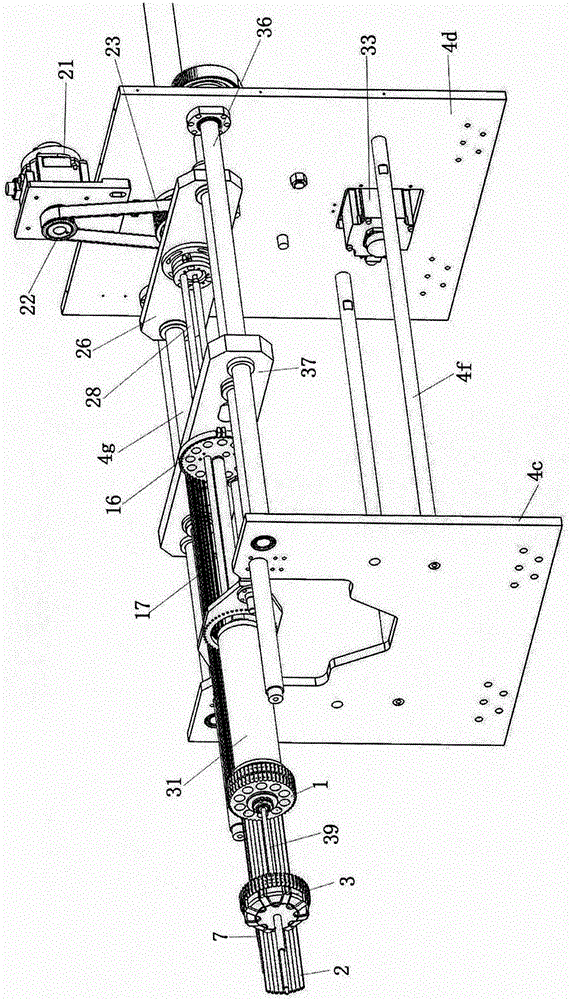

Automatic winding and embedding integrated device

ActiveCN108631524ANo frictionImprove product qualityManufacturing dynamo-electric machinesEngineeringProduction quality

The invention discloses an automatic winding and embedding integrated device which comprises a winding part, an embedding part, a paper material library part and an indexing turntable; a movable wireembedding mold is arranged on the indexing turntable, and the winding part is used for winding the wire on the movable wire embedding mold; the paper material library part is used for transferring theformed paper into the movable wire embedding mold; the embedding part is used for transferring the wire on the movable wire embedding mold and the paper in the movable wire embedding mold into a stator iron core; the movable wire embedding mold comprises a tooth protecting outer shell body, a storage strip is arranged on the tooth protecting outer shell body, a guide strip push seat is arranged in the tooth protecting outer shell, a copper head connecting rod is arranged in the guide strip pushing seat, the bottom of the guide strip pushing seat penetrates through the bottom of the tooth protecting outer shell, a limiting table is arranged between the guide strip pushing seat and the tooth protecting outer shell, a guide strip assembly is arranged at the top of the guide strip pushing seat, a copper head mold is arranged at the top of the copper head connecting rod, and the guide strip assembly and the copper head mold can synchronously move, or asynchronous move. The processed wire is protected, and the production quality is improved.

Owner:JIANGSU NIDE AUTOMATION TECH

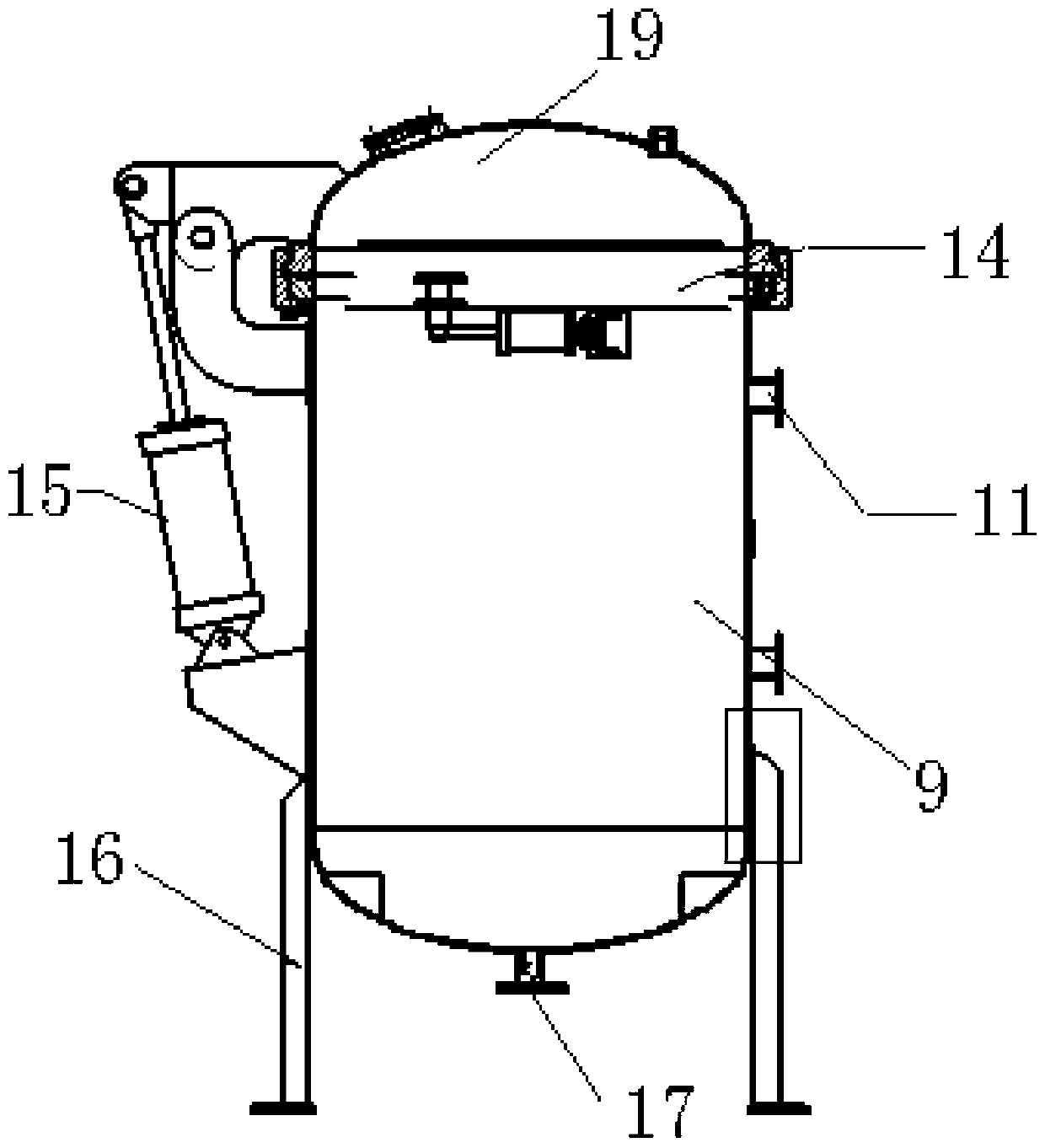

Infiltration technique and device

ActiveCN103341434AHigh surface finishHigh shape and size accuracyLiquid surface applicatorsCoatingsCooking & bakingRelative motion

The invention relates to an infiltration technique and device. The technique comprises three phases, namely infiltration preprocessing, infiltration processing and infiltration postprocessing. The infiltration device comprises an infiltration basket, a hoist hook, a degreasing pot, a cleaning pot, a centrifugal pot, a baking oven, an infiltration pot, a vacuum pump, a glue storing pot, an air compressor, a washing pot, a solidifying pot and a pressure test device, wherein all the components are arranged in a straight line. Due to the fact that the infiltration pot is cylindrical, influence of sewage on a production site can be effectively avoided. Due to the fact that the infiltration pot is locked with a method that a sealing lock ring is inflated by a lock ring cylinder and both a toothed ring of a pot cover and the lock ring are manufactured with whole materials, sealing performance is good, operation is safe and fast, the pot cover can be opened and closed automatically and fast, no relative motion exists between the pot cover and a sealing ring, friction does not exist, opening is flexible, and the service life is long. The infiltration technique and device have the advantages that the device is compact and reasonable in structure, the whole production site is beautiful, logistics is smooth, and fixed location management and civilization and cleanliness of the production site can be ensured.

Owner:NANTONG NINGYUAN AUTOMATION TECH

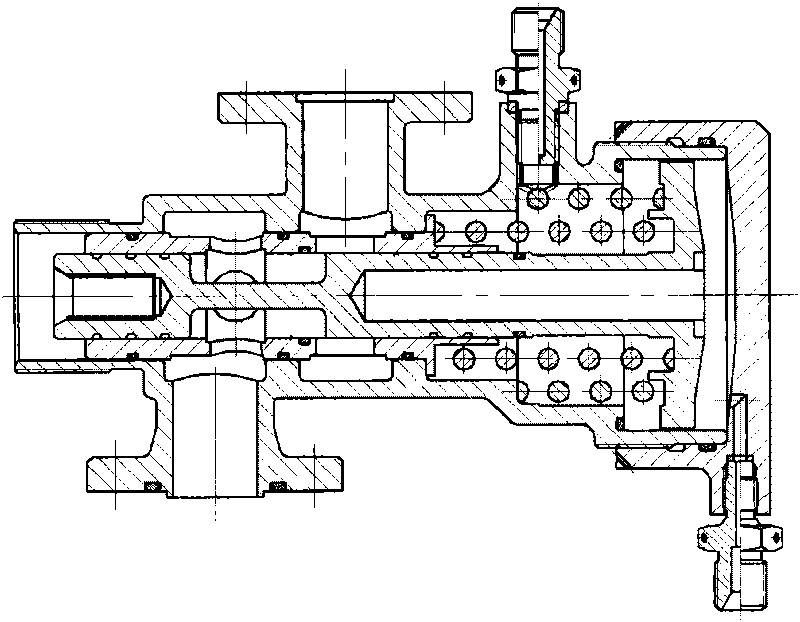

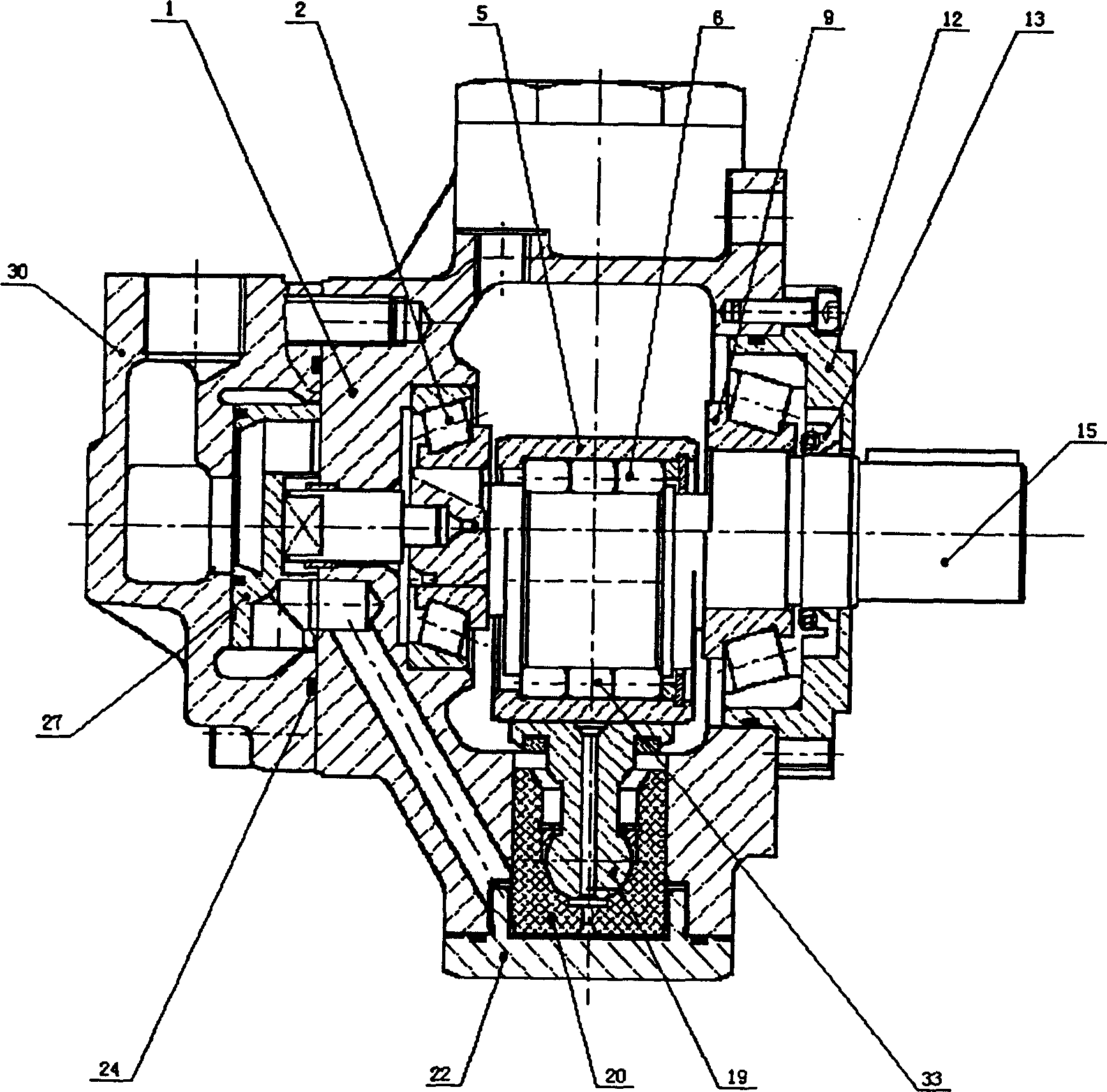

Crankshaft link hydraulic motor

InactiveCN1189673CReduce noiseReduce energy consumptionFluid-pressure actuatorsHydraulic motorEngineering

The crankshaft connecting rod type hydraulic motor includes a shell body with hydraulic channel and oil disk, front cover and plunger cover which are fixed on the shell body, in the interior of the shell body the plunger-connecting rod component, crankshaft and its support bearing and oil-distributing plate connected with one end of crankshaft are mounted, in which between the connecting rod and crankshaft eccentric wheel there are rollers and bearing sleeve, and the rollers are mounted in the roller groove of cartridge, said ring cartridge is halt-and-half separated or is made into body-separated structure with several equant portions, also can be made into double-face recess structure of also can be made into single-face recess structure.

Owner:NINGBO HOYEA MACHINERY MFG

Workpiece holder for clean container

InactiveUS7032758B2Well protected against contaminationAvoid it happening againSemiconductor/solid-state device manufacturingOther accessoriesMagnetic tapeEngineering

Owner:IND TECH RES INST

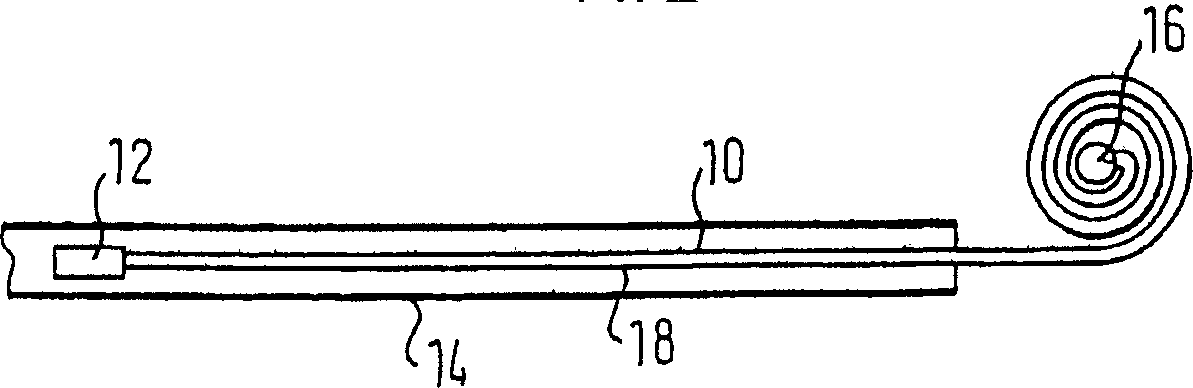

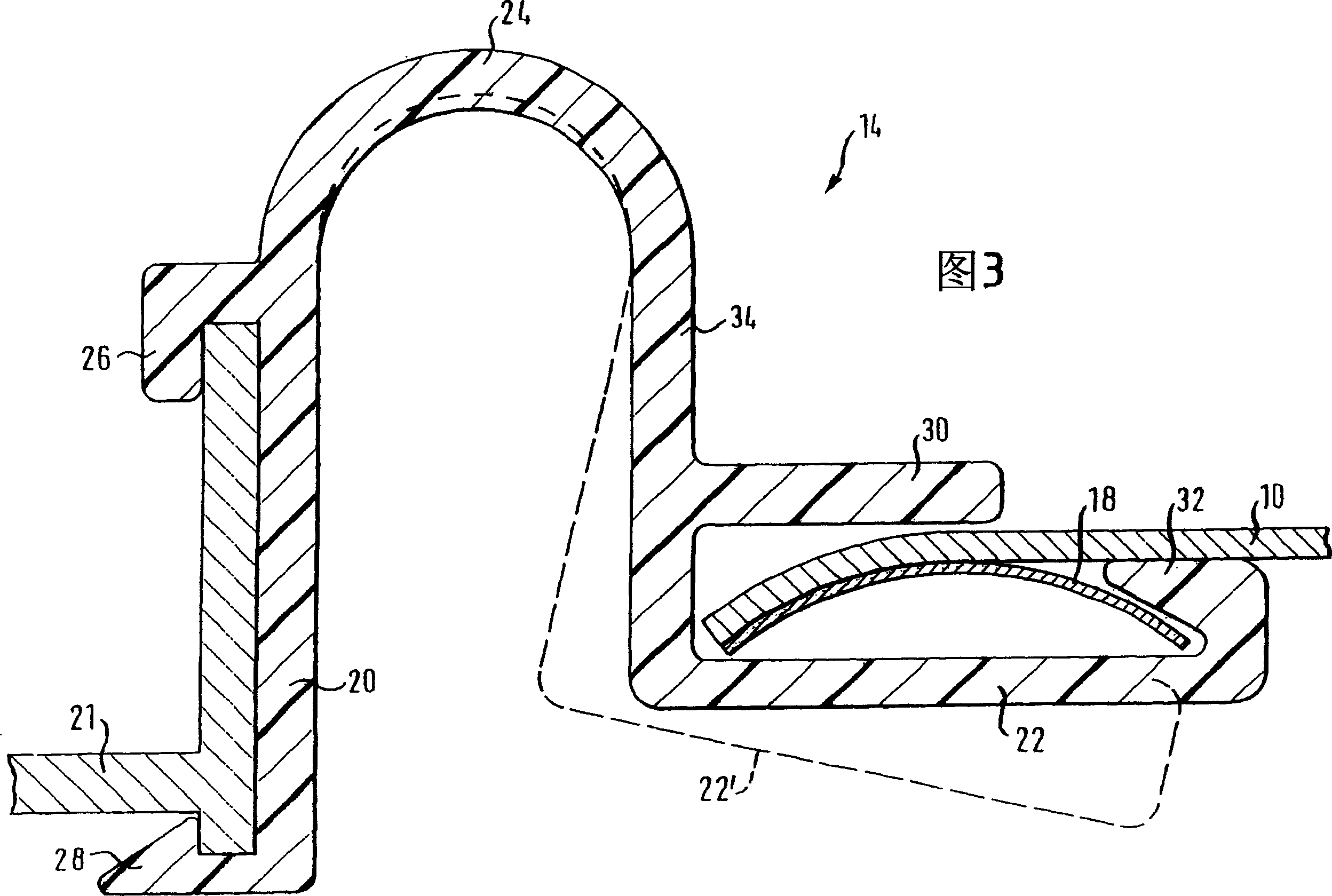

Guide raid for window shade of slide cover system

The invention relates to a guide way (14) of a blind curtain (10), which is used on a sliding roof system. The invention includes a keeping part (20), a guiding part (22) and an elastic connecting part (24) arranged between the keeping part (20) and the guiding part (22). The guide way (14) can be fixed tightly on the vehicle by the keeping part. The blind curtain (10) can be arranged into the guiding part (22).

Owner:天窗系统(德国)有限公司

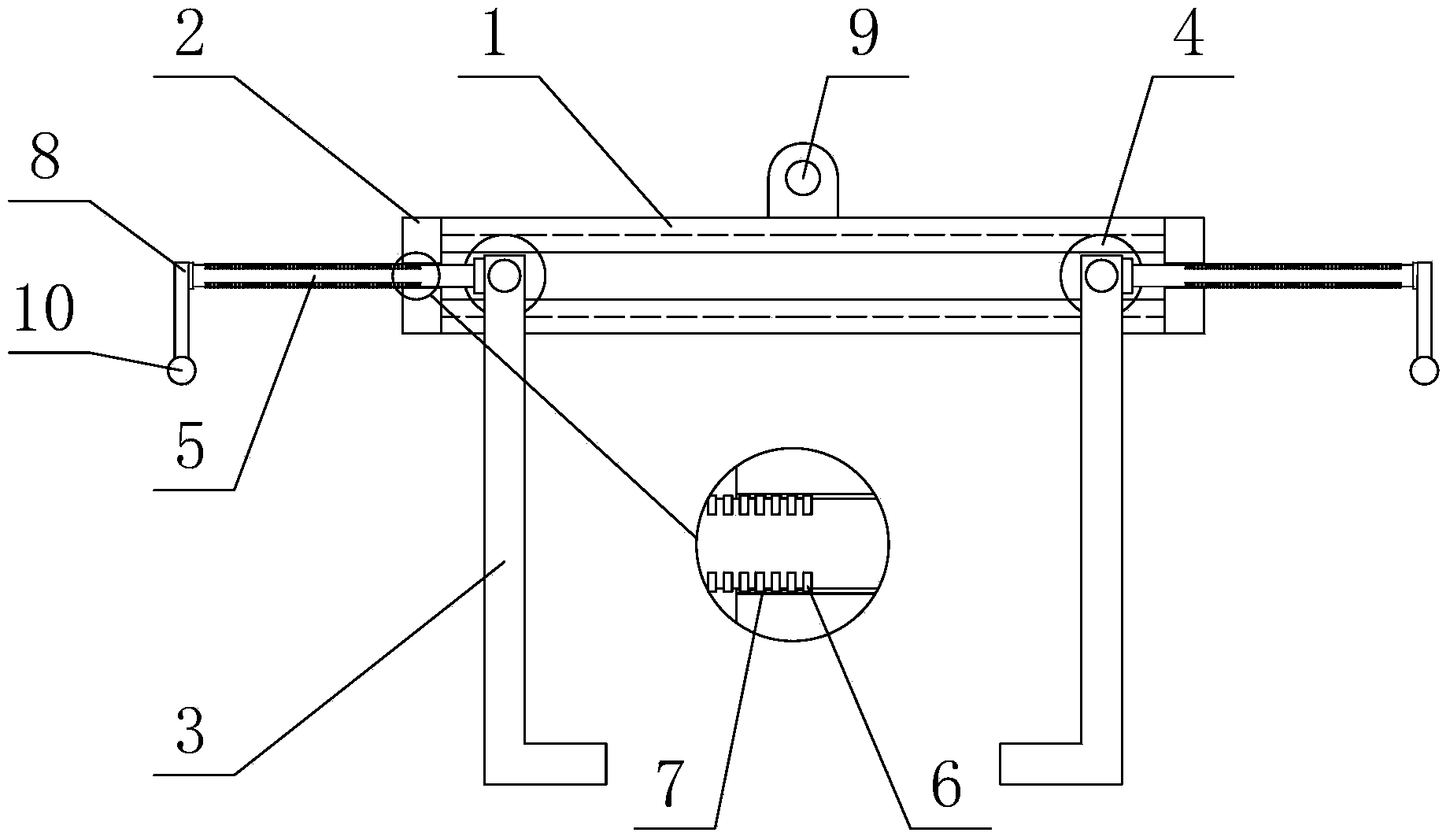

Steel coil hoisting tool

InactiveCN103626022AHoisting process safetyImprove hoisting efficiencyLoad-engaging elementsPush pullEngineering

The invention relates to a steel coil hoisting tool which comprises two parallel hoisting beams and end plates, wherein the end plates are used for connecting the two hoisting beams and are respectively positioned at both ends of the hoisting beams; each hoisting beam is a c-shaped steel with a long slot; the long slots of the two hoisting beams are opposite; two L-shaped hangers are arranged between the two hoisting beams; the L-shaped hangers are mounted between the two hoisting beams through rollers respectively embedded in the long slots of the two hoisting beams; two rollers are coaxial; through holes are respectively formed in the two end plates; push-pull rods in parallel to the hoisting beams are respectively inserted in the through holes; a plurality of latches are uniformly distributed on the push-pull rods in the axial direction; clamping grooves matched with the latches are formed in the inner sides of the through holes; the two push-pull rods are respectively connected with the two L-shaped hangers; handles perpendicular to the push-pull rods are mounted at the end parts outside the push-pull rods. The steel coil hoisting tool has the advantages of simple structure, convenience in use, firm structure, avoidance for damage to a steel coil, improvement on hoisting efficiency and elimination for potential safety hazards.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE

Reflow backwashing mechanism for automatic filtration of fluid

ActiveCN101658741ASmooth rotationSafe and reliable workDispersed particle filtrationTransportation and packagingHollow coreEngineering

The invention discloses a reflow backwashing mechanism for automatic filtration of fluid. The reflow backwashing mechanism is characterized in that: a fluid inversion chamber (2) is internally provided with a hollow shaft sleeve (12), a blade and a baffle plate are connected with the hollow shaft sleeve (12) which is provided with an opening at a position of the lower part of the baffle plate of the hollow shaft sleeve (12), the hollow shaft sleeve (12) is internally provided with a hollow core shaft (13) with an upward opening, and a shaft wall of the hollow core shaft (13) is distributed with a through hole (14). The reflow backwashing mechanism is provided with a guide through hole with obliquity, thus being capable of fully utilizing composite force of reflow backwashing produced by normal fluid flow and fluid flow out of the oblique guide through hole to quicken rotation frequency of the inversed fluid. The inversed fluid is more stable due to dependence on the core shaft for rotation and arrangement of a counterweight balance, thus the reflow backwashing mechanism has advantages of causing the whole system to have safe and reliable operation and greatly improving automatic filtration effect.

Owner:浙江瑞孚电气有限公司

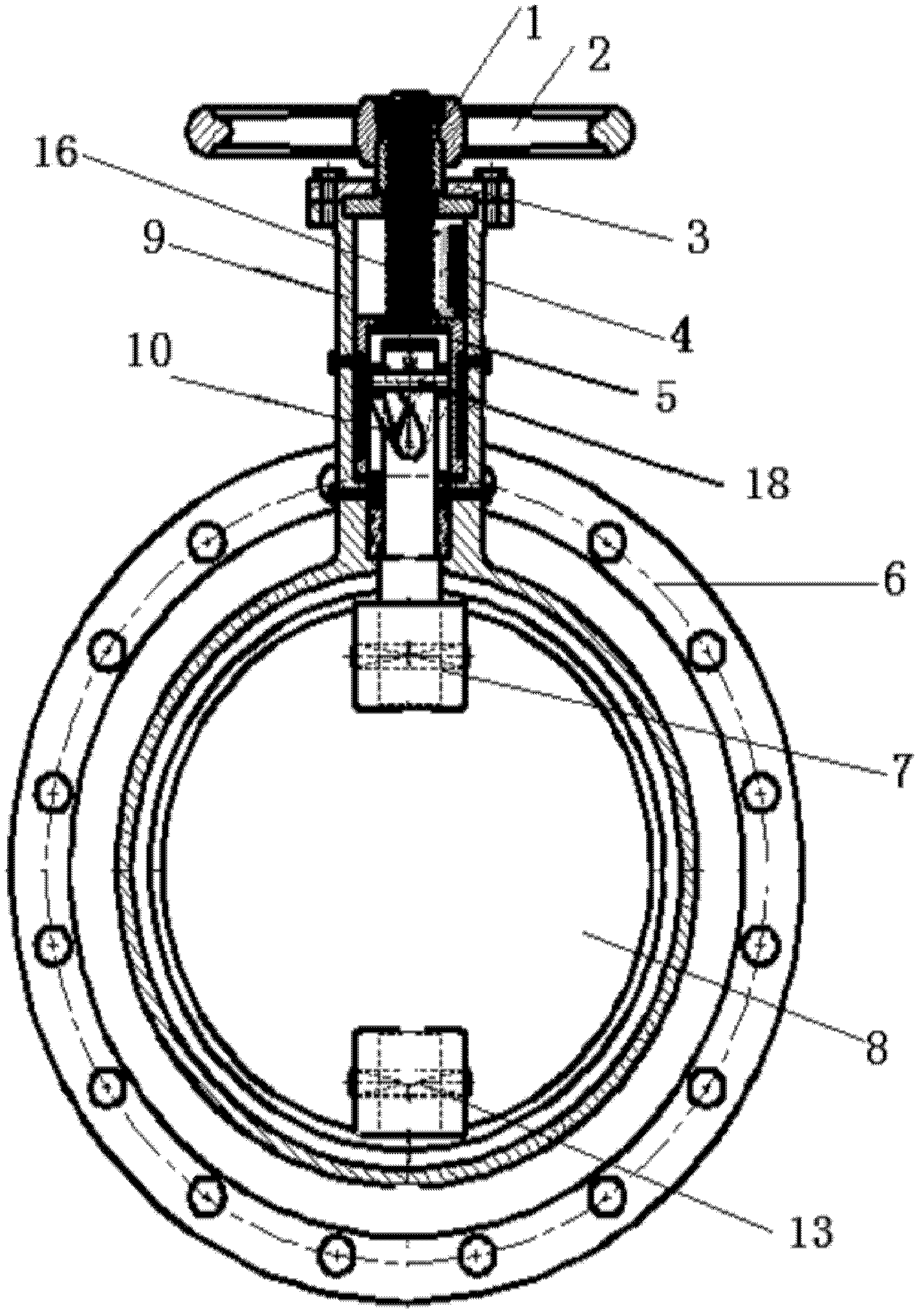

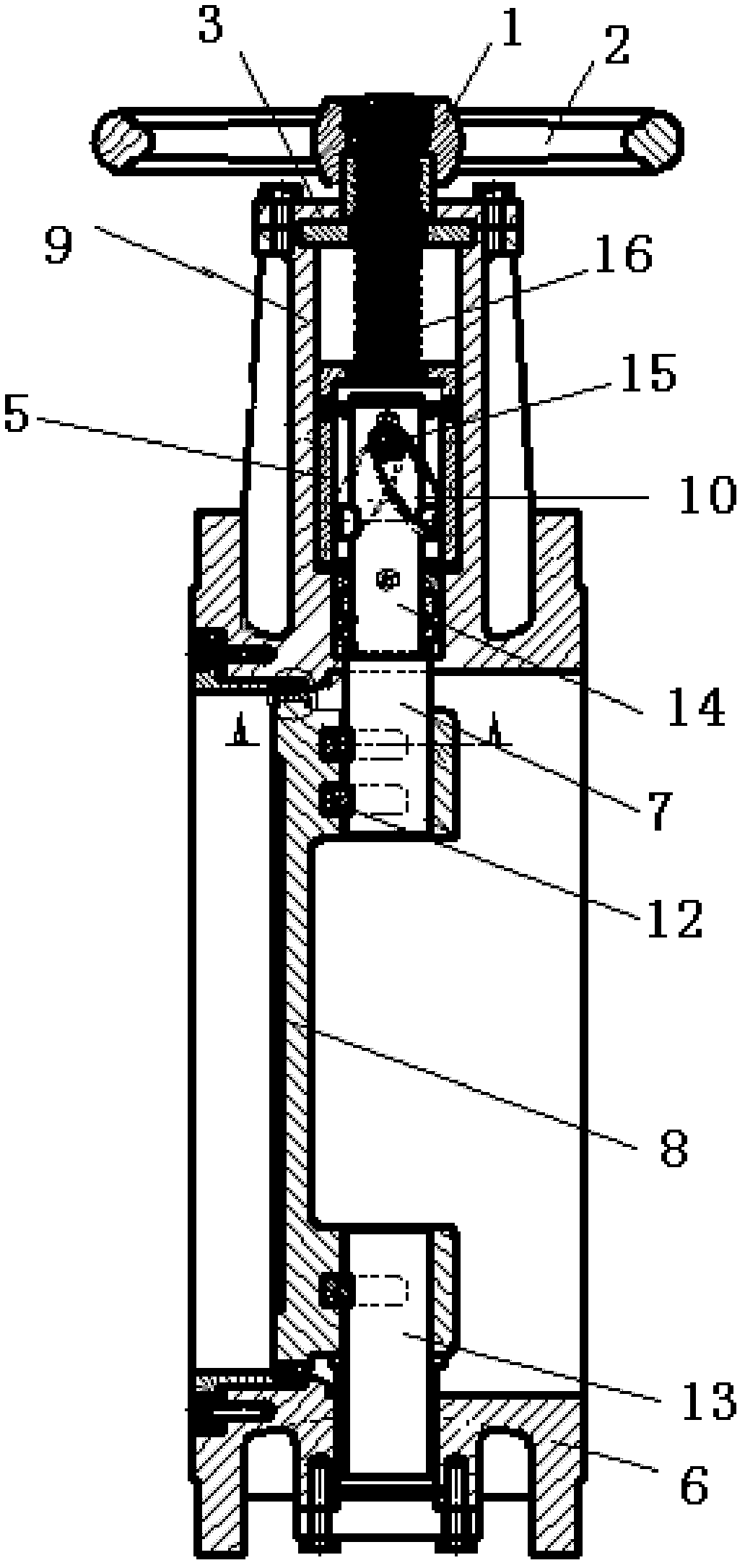

Track-torsion connecting bidirectional hard sealing butterfly valve

ActiveCN102537379AReduce torqueEliminate frictionOperating means/releasing devices for valvesLift valveStart timeEngineering

The invention provides a track-torsion connecting bidirectional hard sealing butterfly valve, which resolves the problems that an existing track butterfly valve is long in starting time and a valve plate is prone to water leakage when beaten and pressed reversely and mainly comprises a valve body, a valve body inner valve plate and a rotary device for controlling rotation of a valve plate. The rotary device comprises a hand wheel, a screw and a nut matched with the screw rod. The butterfly valve is characterized in that the nut is fixed on a rotary sleeve of the valve body, a guide sleeve is positioned in the rotary sleeve and in threaded connected with the screw, the guide sleeve can only move up and down in the rotary sleeve, a spiral torsion track is arranged on the outer surface of a polish rod and the screw, one end of a shaft on the valve plate is in clearance fit with the torsion track on the polish rod of the screw through a guide shaft, and an upper shaft and a lower shaft of the valve plate are respectively in contact with an eccentric wheel on one side of a guide pin in the valve plate. The on-off sensitivity of the valve is improved, and sealing performance of the valve plate is improved.

Owner:ANHUI TONGDU FLOW TECH

Back extrusion preventing and two-wing extending device of intelligent electric wheelchair bed

InactiveCN106137586ANo frictionNo damageWheelchairs/patient conveyanceNursing bedsElectricityFriction effect

The invention discloses a back extrusion preventing and two-wing extending device of an intelligent electric wheelchair bed. The back extrusion preventing and two-wing extending device comprises a back extending plate, two-wing extending plates, a floating back plate, a connecting rod drive mechanism, a connector, a rising pillow, a hinge part, a seat plate and an elastic soft curtain. The connecting rod drive mechanism is composed of an electric push rod, connecting rods and auxiliary connecting rods, one end of the connecting rod drive mechanism is fixed to the seat plate, and the other end of the connecting rod drive mechanism is connected with the back extending plate and the two-wing extending plates. According to the back extrusion preventing and two-wing extending device of the intelligent electric wheelchair bed, ergonomic design is adopted, when a bed posture and a sitting posture are switched, a user is in a comfortable state all the time, the angle between the user and the floating back plate is automatically adjusted, no friction effect is caused to the user, damage to the organism is avoided, electricity is adopted as power, and safety and reliability are achieved.

Owner:天津双源电力设备制造有限公司

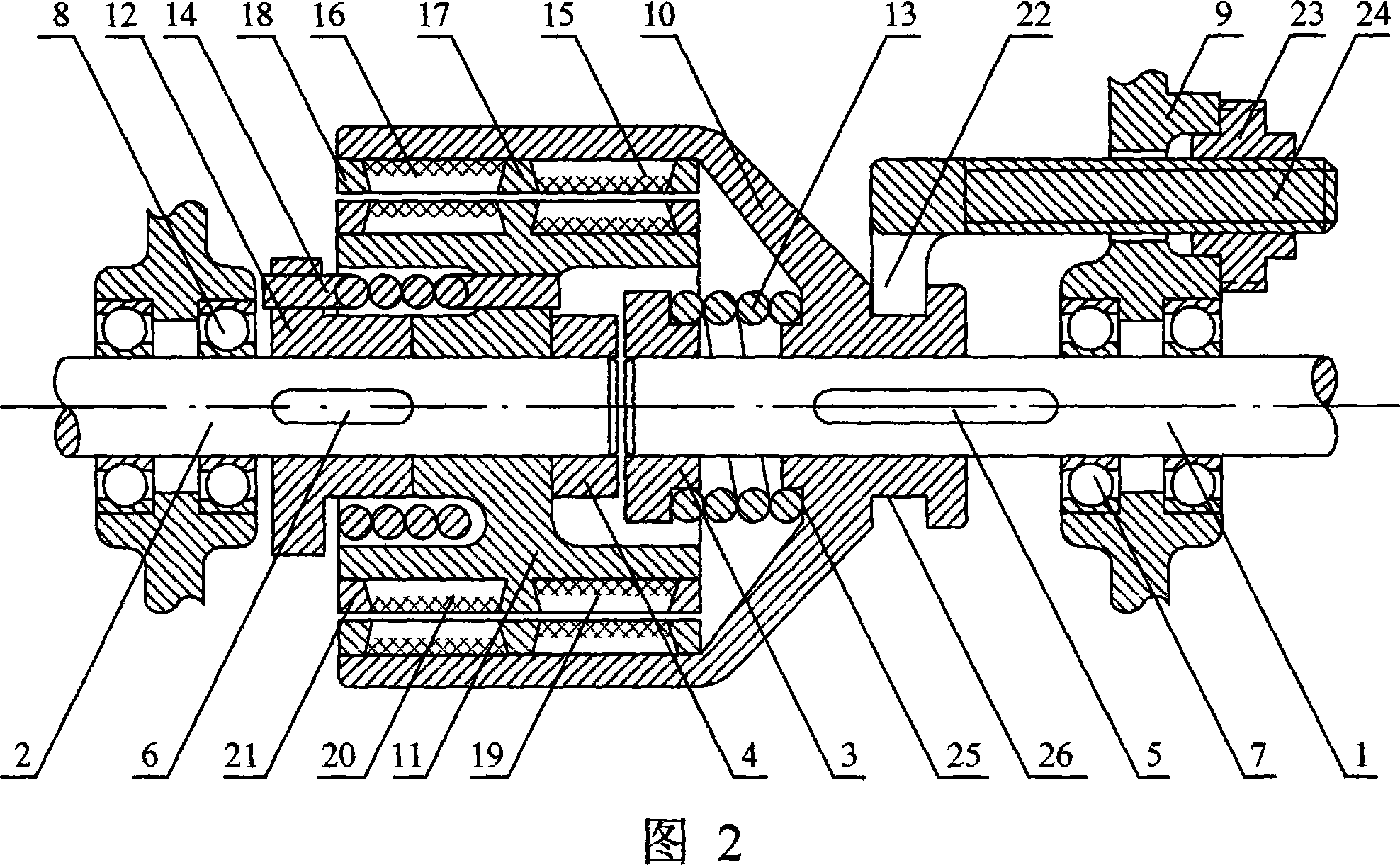

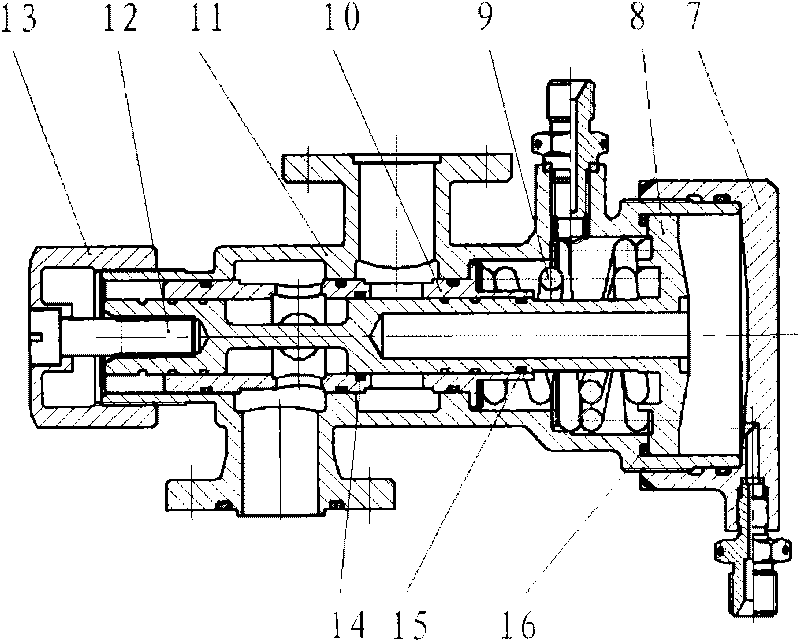

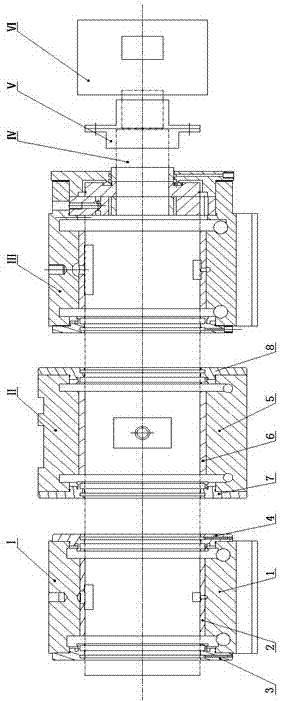

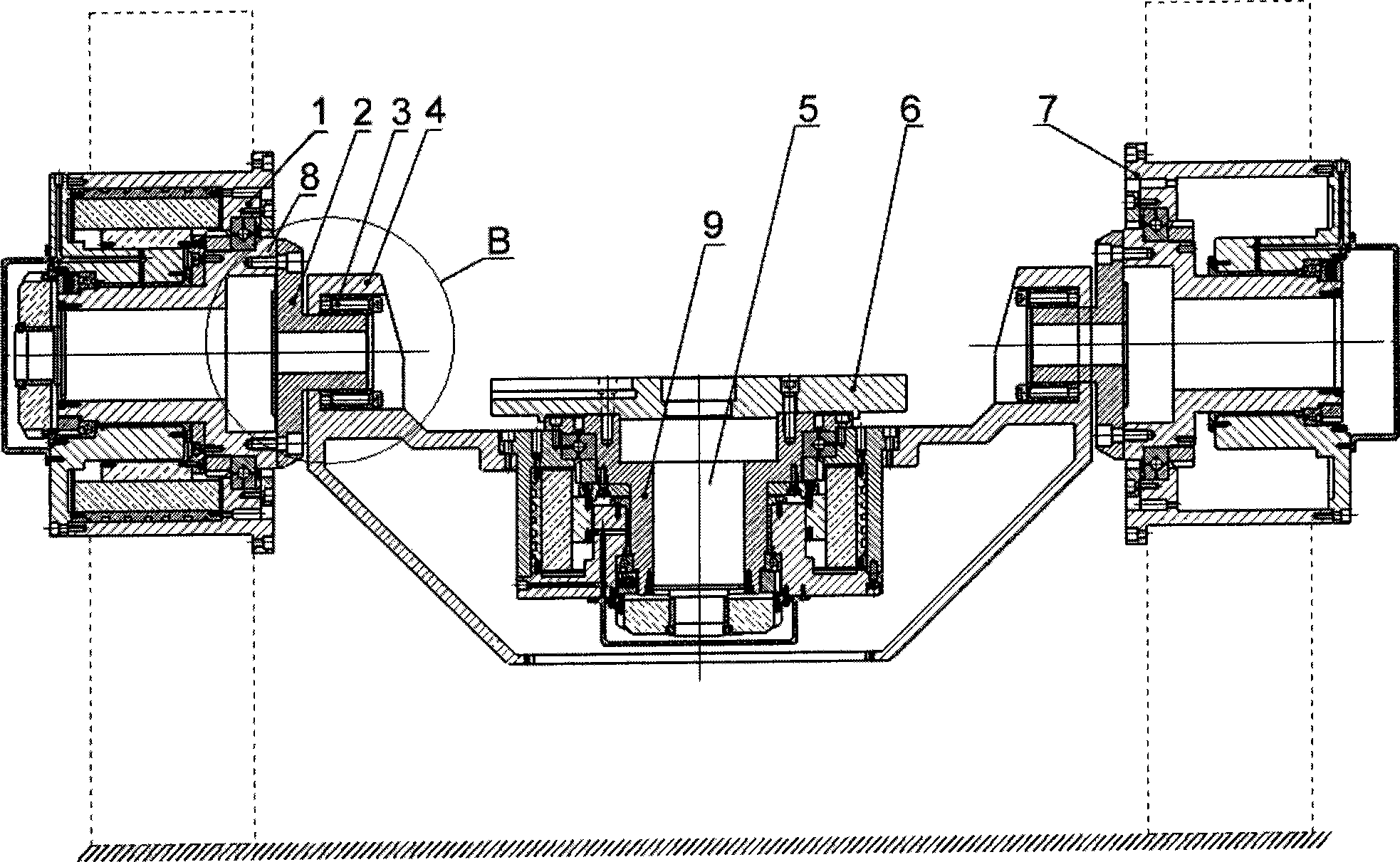

Direct driving type dual spindle accurate rotating platform

InactiveCN101486147AHigh transmission precisionHigh load rigidityLarge fixed membersDual axisMachine tool

The invention discloses a directly-driven double-shaft precise rotating platform, which comprises an A-shaft moment motor (1) which is connected to a machine tool and a C-shaft frame (4), wherein a main shaft (8) of the A-shaft moment motor (1) can perform A-shaft rotation, and the C-shaft frame (4) is connected to the main shaft (8) of the A-shaft moment motor (1); and the C-shaft frame (4) is provided with a C-shaft moment motor (5), and the main shaft of the C-shaft moment motor (5) is provided with a workbench (6). The main shaft (8) of the A-shaft moment motor (1) is fixedly connected with a connecting flange (2) which is fixedly connected with the C-shaft frame (4) through an expansion bush (3). The directly-driven double-shaft precise rotating platform has the advantages of simple structure, high workbench transmission precision and high speed. A moving shaft of the machine tool has higher dynamic performance, adjusting performance, positioning precision and repeated positioning precision, so that the directly-driven double-shaft precise rotating platform provides the optimal condition for the free curved surface of a machining mold.

Owner:三六零安全科技股份有限公司 +2

Ultrahigh-speed laser rotating scan mirror

ActiveCN102944933AAchieve ultra-high-speed rotationReduce frictionOptical elementsElectric machineryLaser printing

The invention relates to an ultrahigh-speed laser rotating scan mirror and belongs to the technical field of laser rotating scan mirrors. The ultrahigh-speed laser rotating scan mirror comprises a mirror casing, and a magnetic levitation motor, a rotating multi-face scanning mirror, a magnetic levitation bearing and a bearing support plate are arranged in the mirror casing. The rotating multi-face scanning mirror is sleeved on an output shaft of the magnetic levitation motor to complete interference fit. The magnetic levitation bearing located below the rotating multi-face scanning mirror is sleeved on the output shaft, the bearing support plate is sleeved on the magnetic levitation bearing, and an outer edge of the bearing support plate is fixedly connected with the mirror casing. The ultrahigh-speed laser rotating scan mirror has the advantages of being capable of achieving ultrahigh-speed laser rotating scanning, enabling rotating speed of the scan mirror to achieve 300000 circles / minutes to 2000000 circles / minutes, and accordingly enabling scanning speed of the ultrahigh-speed laser rotating scan mirror to improve 10-200 times compared with the prior art when the ultrahigh-speed laser rotating scan mirror is used in the technical fields such as laser radars, laser three-dimensional mopping, laser printers, laser phototypesetting printing, laser storing and laser marking.

Owner:凌昆

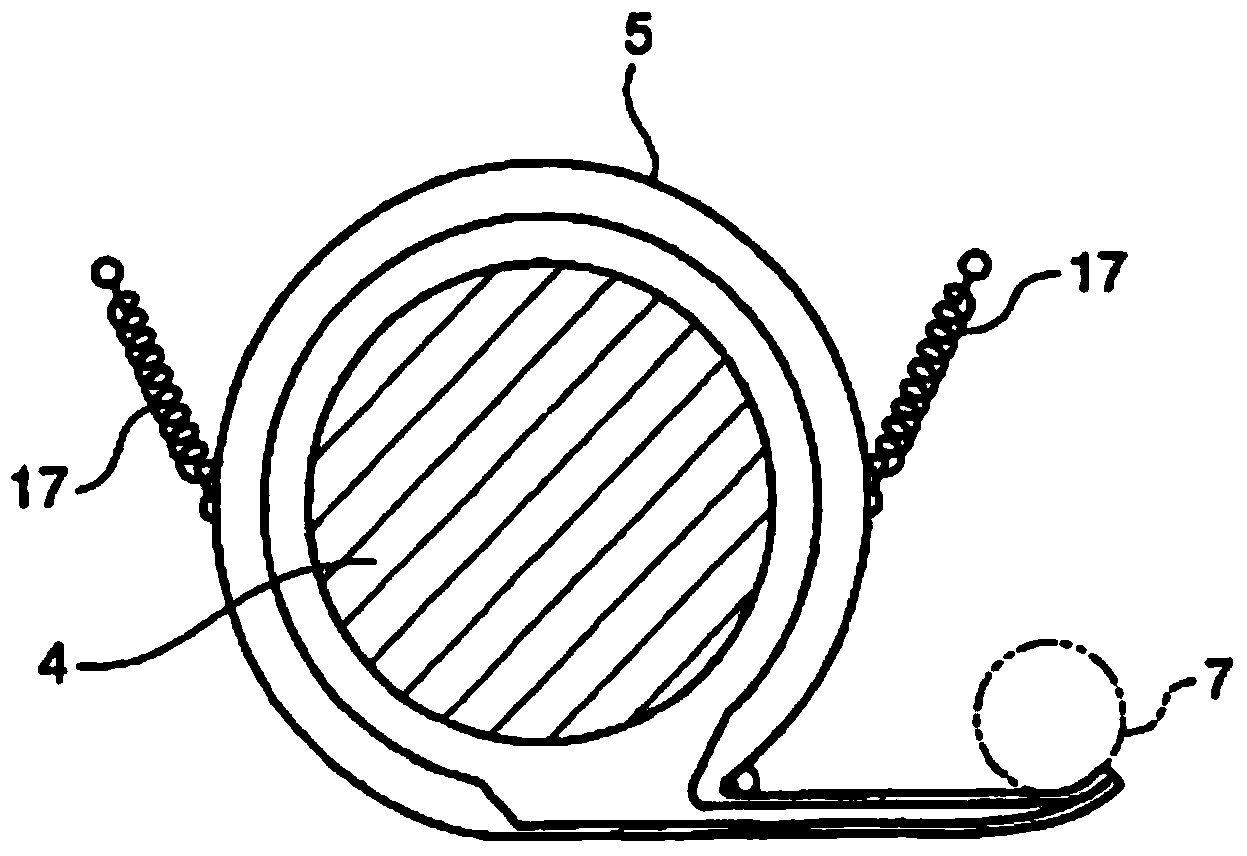

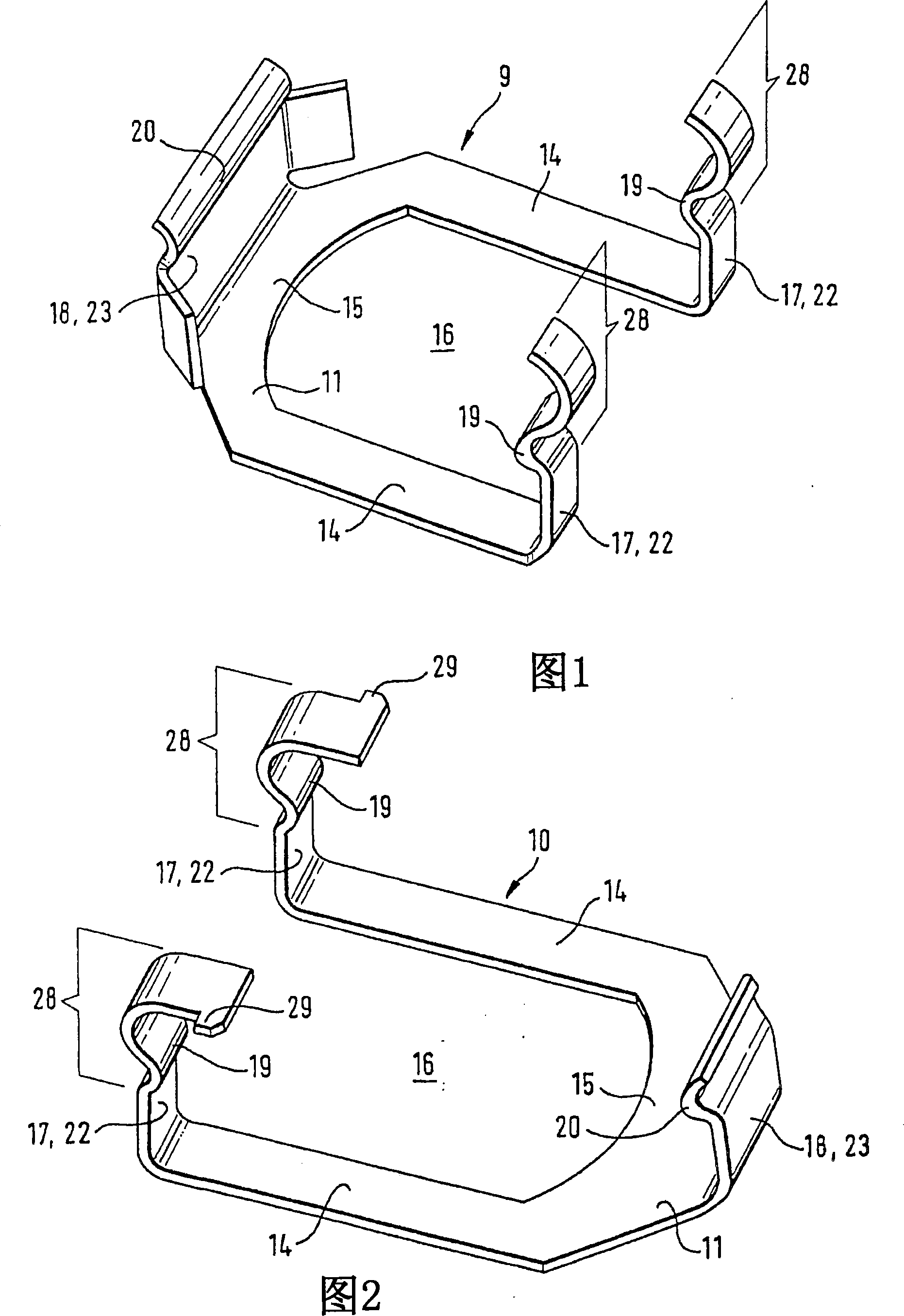

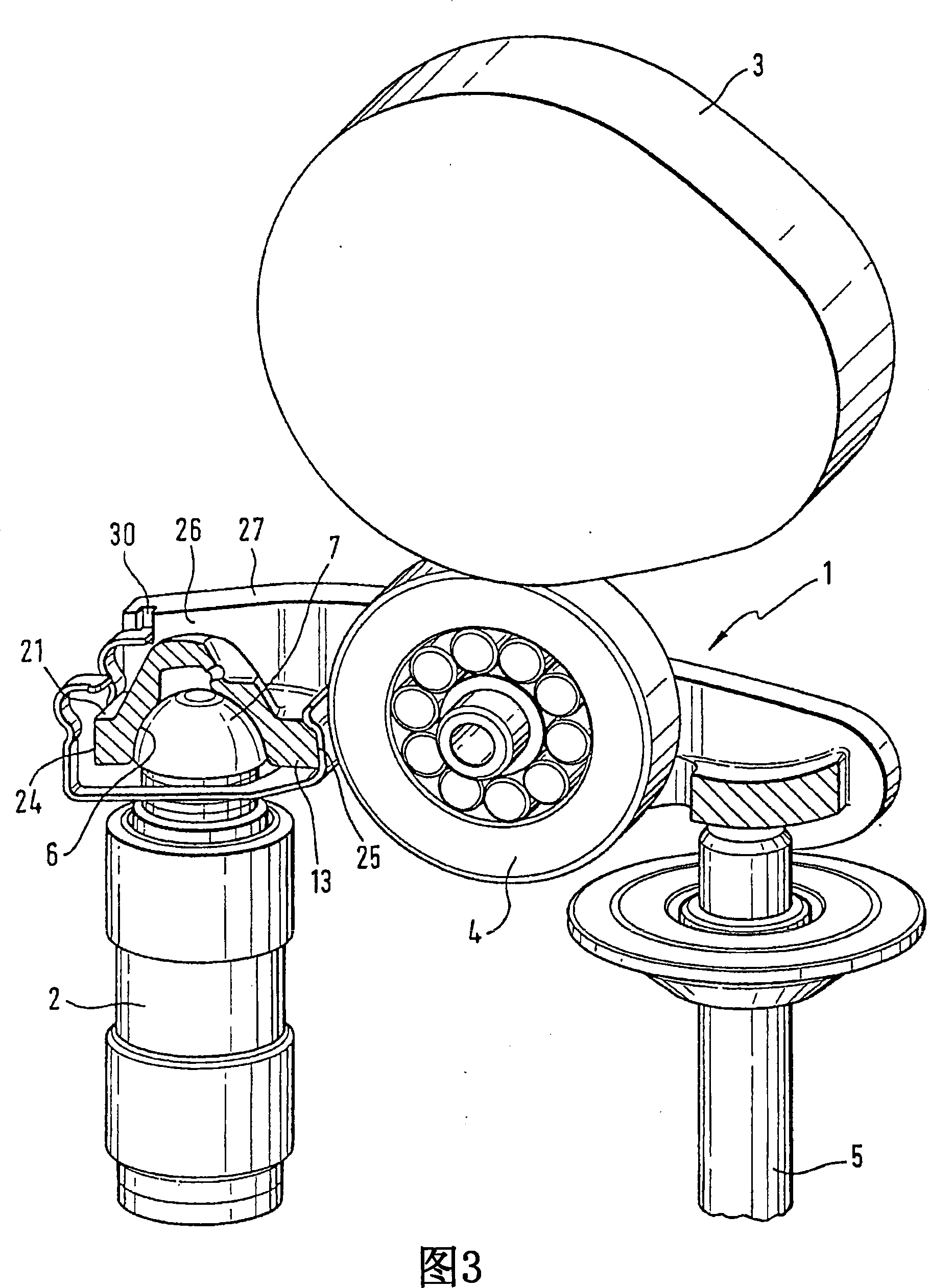

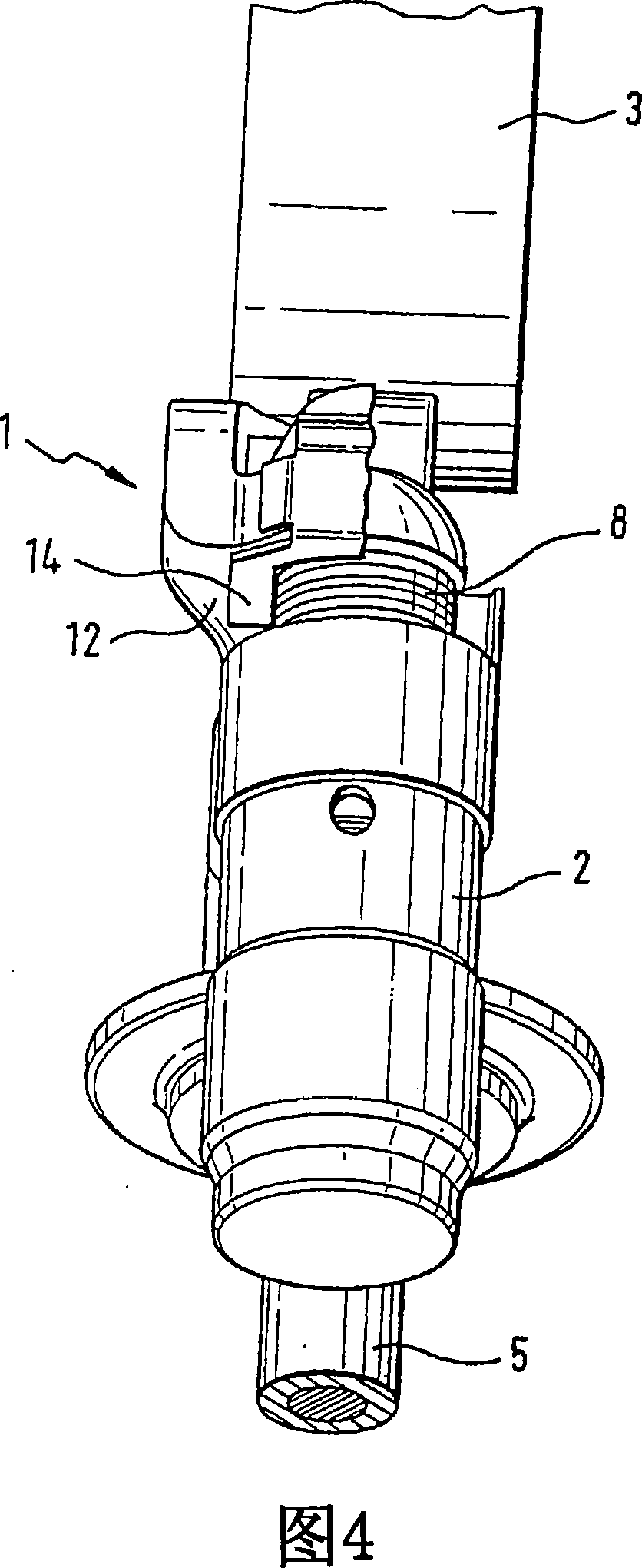

Connection element for the captive mounting of a lever-like cam follower

InactiveCN101010491ALess likely to tilt verticallyNo frictionValve arrangementsMachines/enginesEngineeringSupporting wall

The invention relates to a connection element (9, 10) for the captive mounting of a lever-like cam follower (1) which is used to actuate a gas exchange valve (5) of an internal combustion engine, on a support element (2). Said support element comprises a spherical end (7) whereon the cam follower (1) is pivotably mounted by means of a concave moulding (6). The connection element (9, 10) is made of a flat material and is arranged, with a central section (11), on a lower side (12) of the base (13) which is oriented towards the support element (2), which surrounds the concave moulding (6) and is connected to the lateral walls (27) of the cam follower (1). The central section (11) forms, with two limbs (14) which are arranged at a distance from each other, in addition to a web connected thereto (15), a U-shaped recess (16) which extends in the longitudinal direction of the cam follower (1), which is used to surround, in an essentially play-free manner, the annular-shaped groove (8) below the spherical end (7) in a fork-like manner and orthogonal in relation to the direction of pivoting of the cam follower (1). The limbs (14) extend in the form of retaining grips (17) about an approximately 90 DEG angle and the web (15) extends in a support wall (18) about an approximately 90 DEG angle. Retaining lugs (19, 20) are engaged on an upper side (21) of the base (13) which is orientated away from the support element (2), in order to fix the connection element (9, 10) to the cam follower (1). The retaining lugs (17) are supported on the inner side (26) of the lateral walls (27) of the cam follower (1) such that the U-shaped recess (16) is essentially fixed in relation to the perpendicular position thereof to the cam follower (1) and the shape thereof.

Owner:SCHAEFFLER TECH AG & CO KG

Magnetic push suspension bearing unit

InactiveCN103790962AReduce frictionPrevent mutual friction and fireBearingsBearing load reliefElectrical polarityEngineering

The invention discloses a magnetic push suspension bearing unit, comprising a shaft, an inner magnetic ring, an outer magnetic ring, an auxiliary bearing, a limiting block and a bracket, wherein the inner magnetic ring is arranged at the near end part of the shaft; the corresponding outer magnetic ring is arranged on the bracket; the adjacent surfaces of the two magnetic rings are the same in polarity; an inner magnetic barrel for magnetizing in a radial manner is arranged on the shaft; the inner magnetic barrel is sleeved with an outer magnetic barrel for magnetizing in the radial manner, and the outer magnetic barrel is fixedly arranged on the bracket; the adjacent surfaces of the two magnetic barrels are the same in polarity; the auxiliary bearing is also arranged between the shaft and the bracket; corresponding limiting block and limiting ball are arranged at the end of the shaft; a direct contact rolling body is not formed between the shaft and the bracket; the shaft and the bracket form a suspension state by virtue of a magnetic push shaft; the shaft and the bracket are free of friction, free of abrasion, high in transmission efficiency, free of cooling and lubricating, and long in service life, and the magnetic push suspension bearing unit has high applicable value in high-speed fields of aerospace and the like.

Owner:BEIJING LIANGMING TONGCHUANG WATER TREATMENT EQUIP DEV CENT

Coil-type forming device of mosquito incense piping

The invention discloses coil-type forming device of mosquito incense piping. The device comprises a clamping and conveying roller, a forming roller, a rotating seat, a rolling piece, an oblique sliding block, a rotatable screw rod, a rotating tray, a rotating pushing plate and a material bucket, wherein the clamping and conveying roller is used for clamping and conveying the piping; the forming roller is arranged at the downstream of the clamping and conveying roller and used for bending piping and can automatically rotate, the rolling piece is arranged on the rotating seat; the oblique sliding block is in rolling contact with the rolling piece through an oblique slope so as to push the rotating seat to rotate; the rotatable screw rod penetrates through a threaded through hole at the bottom of the oblique sliding block; the rotating tray is arranged below the clamping and conveying roller and the forming roller and used for bearing the coil piping; the rotating pushing plate is used for pushing the coiled piping out of the rotating tray; the material bucket is provided with an upward opening, can lift up and down and is used for containing the rotating tray and the coil piping; and the coil piping, the rotating tray and the material bucket synchronously rotate. Compared with a traditional coil-type forming device of mosquito incense piping, the coil-type forming device of mosquito incense piping can ensure the high feeding speed of the piping, the forming accuracy of the piping and unlimited forming layer number.

Owner:SUZHOU AOZHI INTELLIGENT EQUIP CO LTD

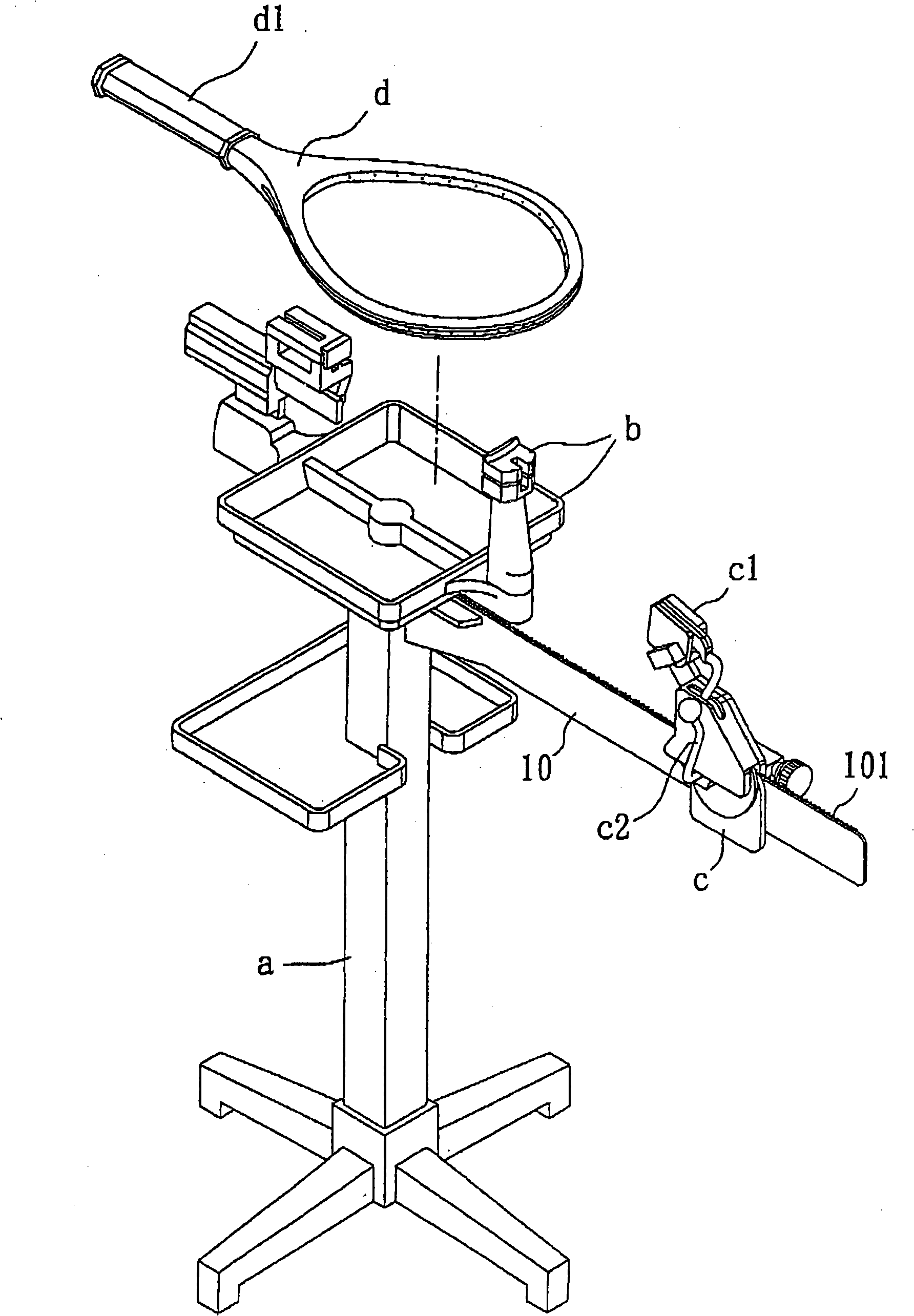

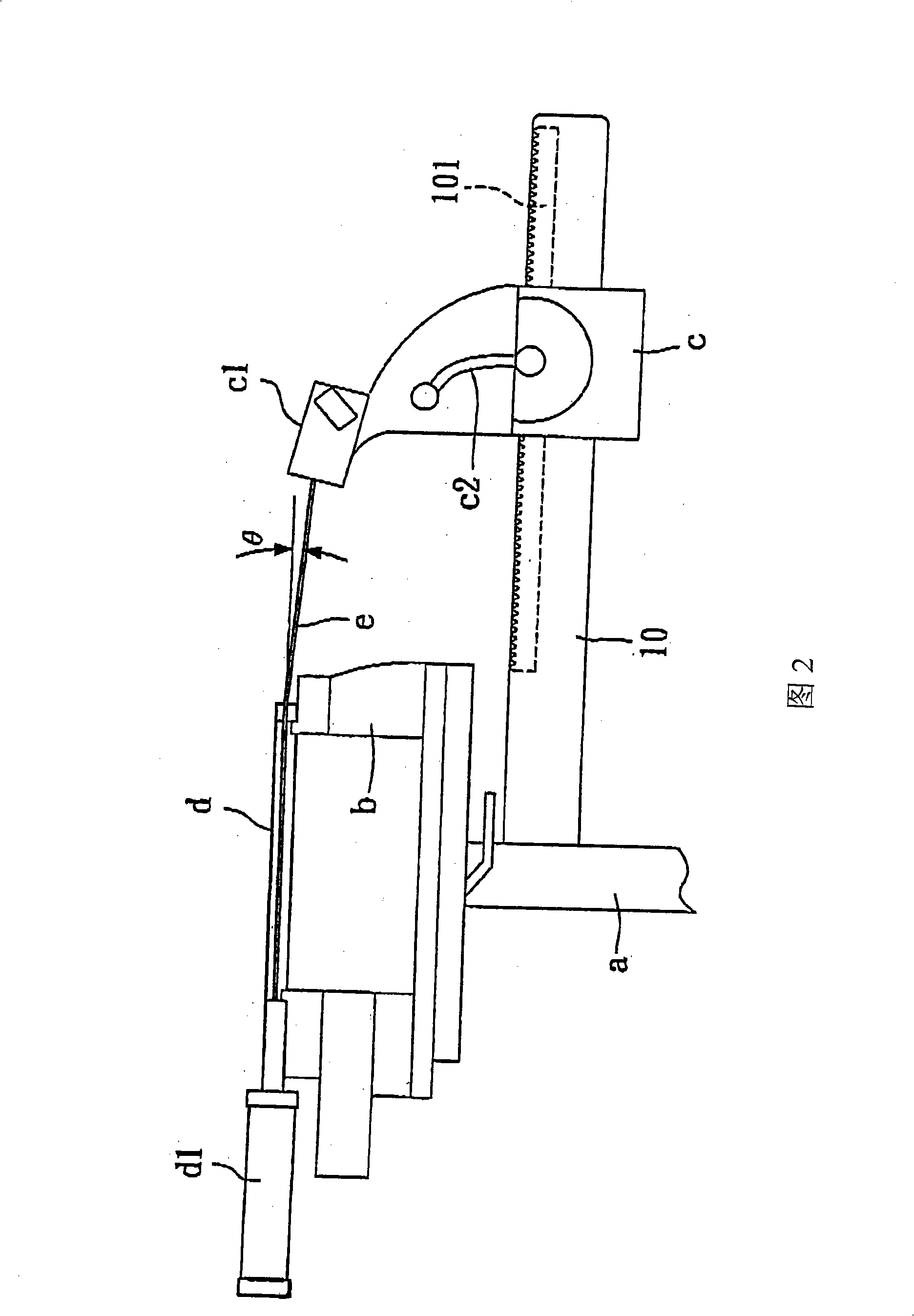

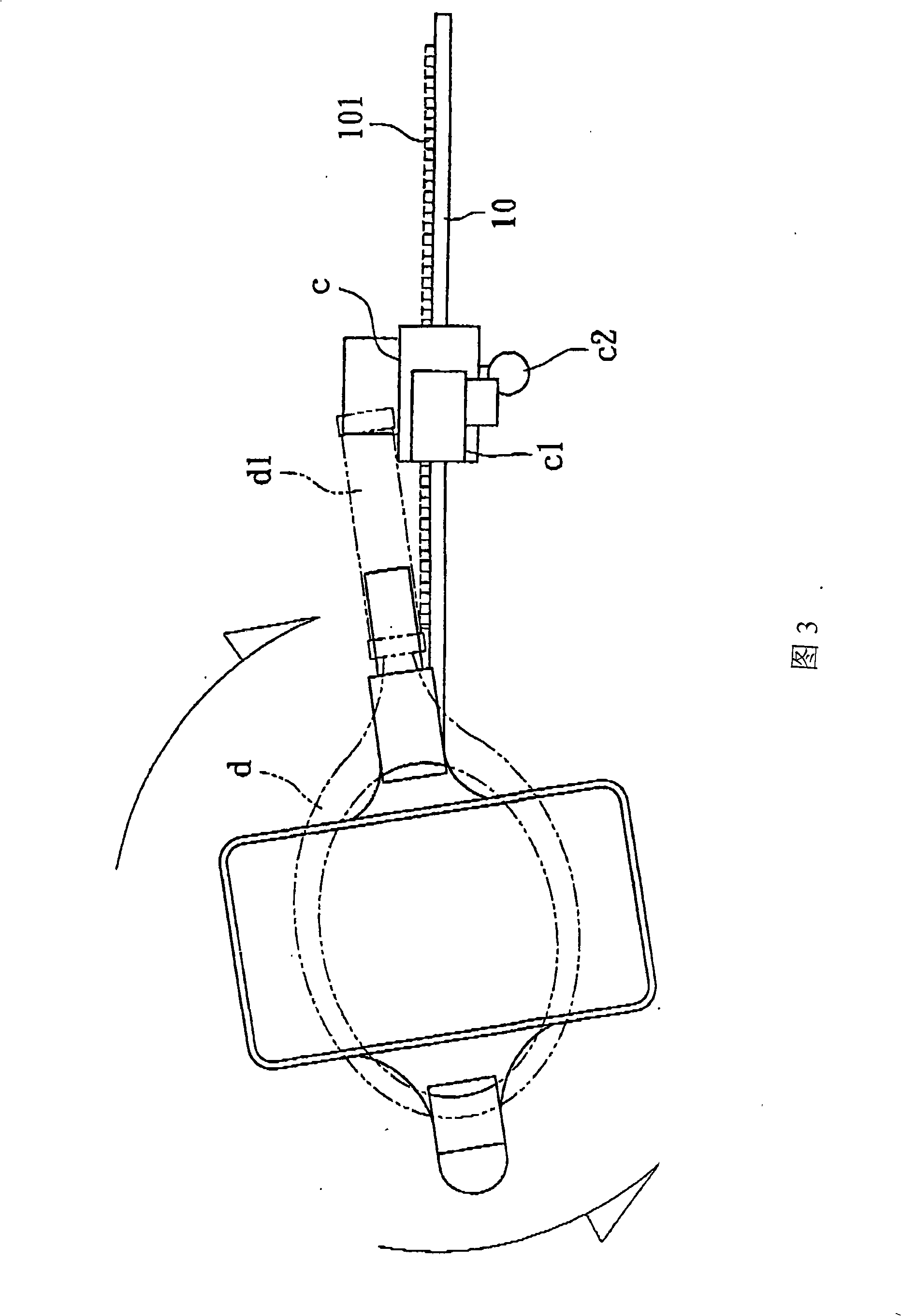

Wire-drawing device height adjustment device of wire-drawing device head of racket wiring device

The invention provides a device for adjusting the height of the string grip of the string drawing machine head of a racket stringing machine. The base body of string drawing machine head is divided into an upper base and a lower base, the string grip is connected on the upper base, and the a connection base is obliquely fixed on the base of the lower base; a slide rail is disposed on the connected base; and the upper base is pivotally connected with the slide rail via a sliding base, so that the height of the string grip can be adjusted when the string grip moves on the sliding base. Therefore, according to the stringing operations of racket frames with different thicknesses, the racket frame and the string of the string grip of the string drawing machine head can be adjusted at the same level, thereby preventing the racket string from being worn and the racket frame from being damaged, the stringing poundage is accurate; and the racket can not collide against the string grip when turning.

Owner:李 俊杰 +1

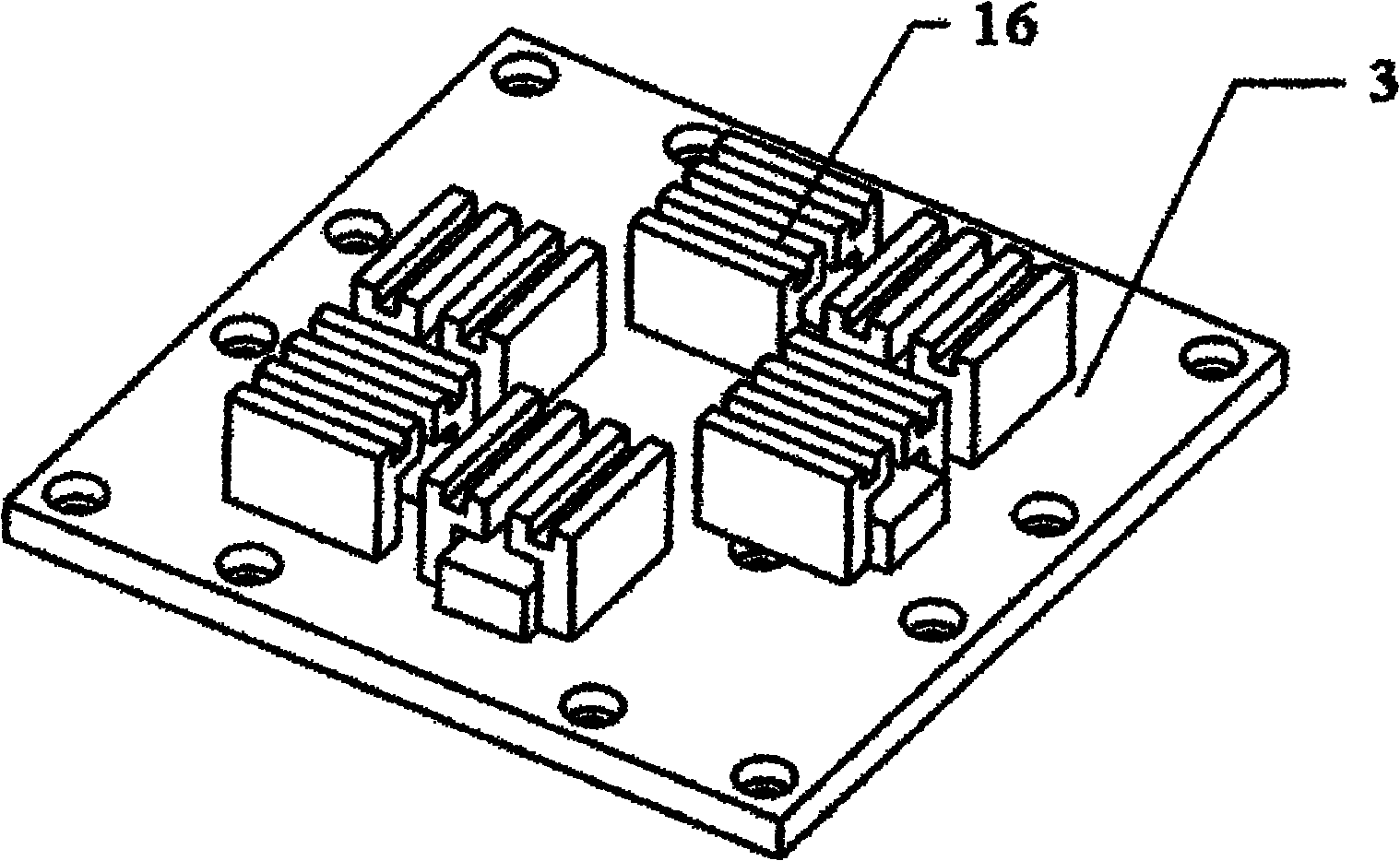

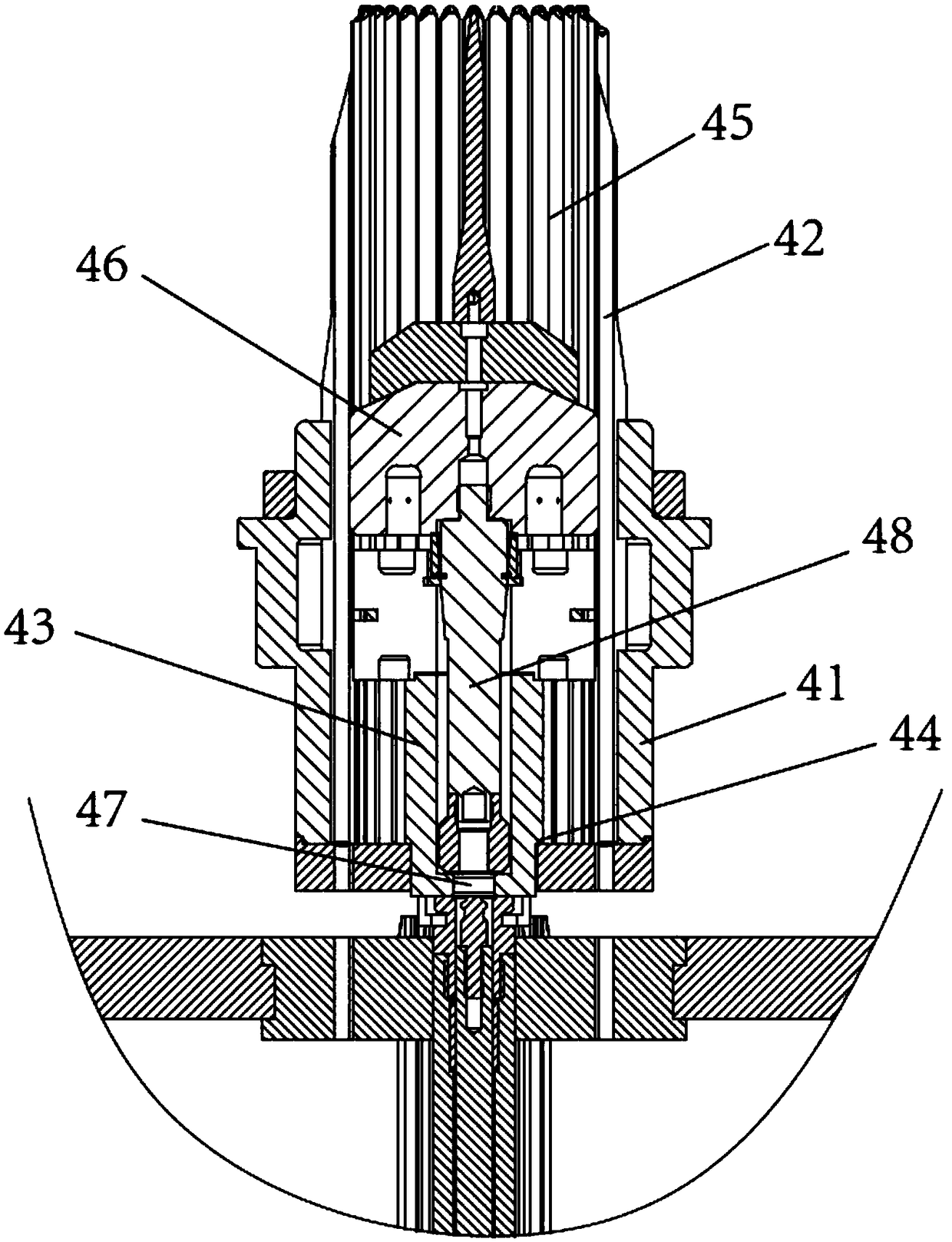

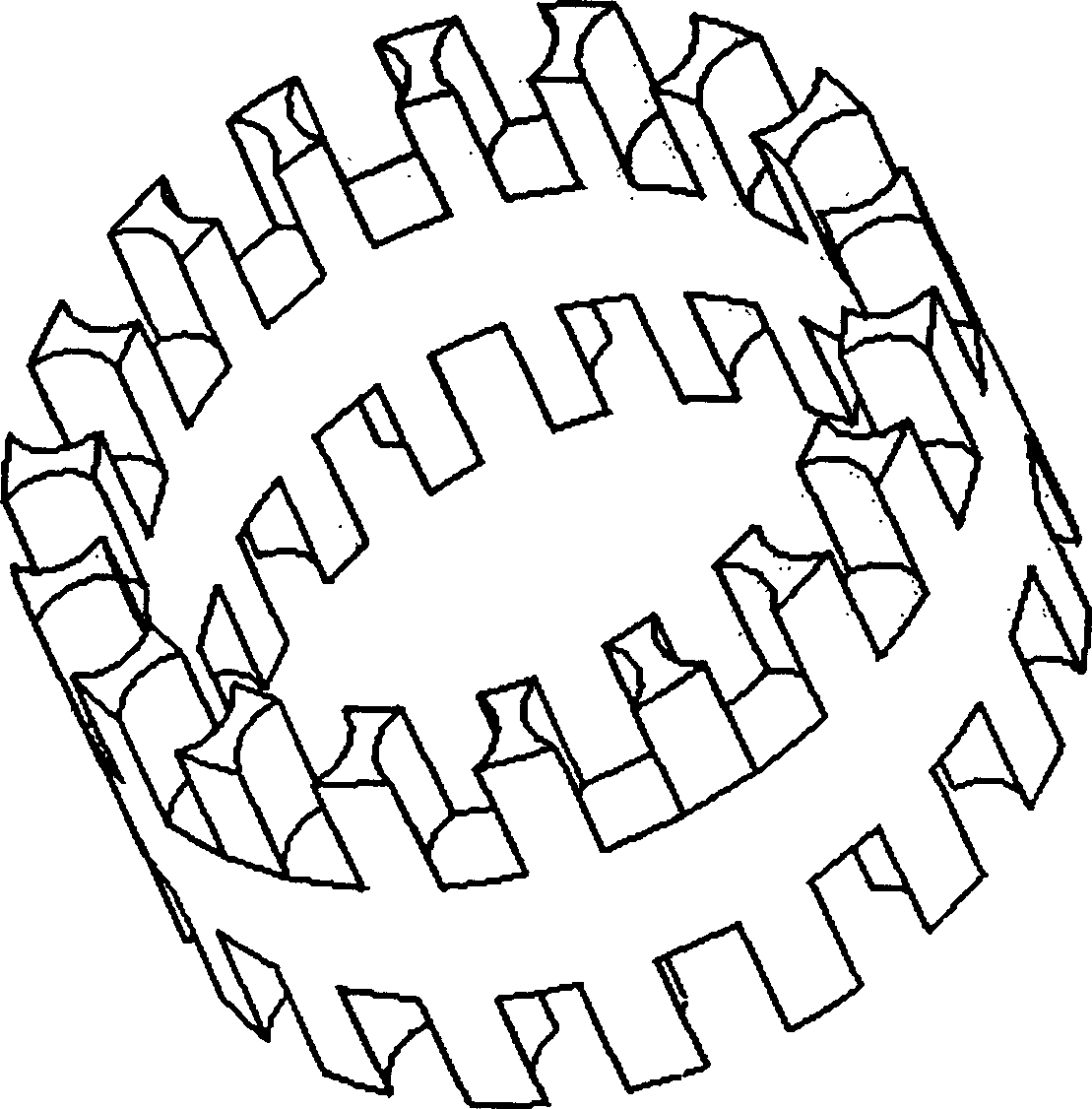

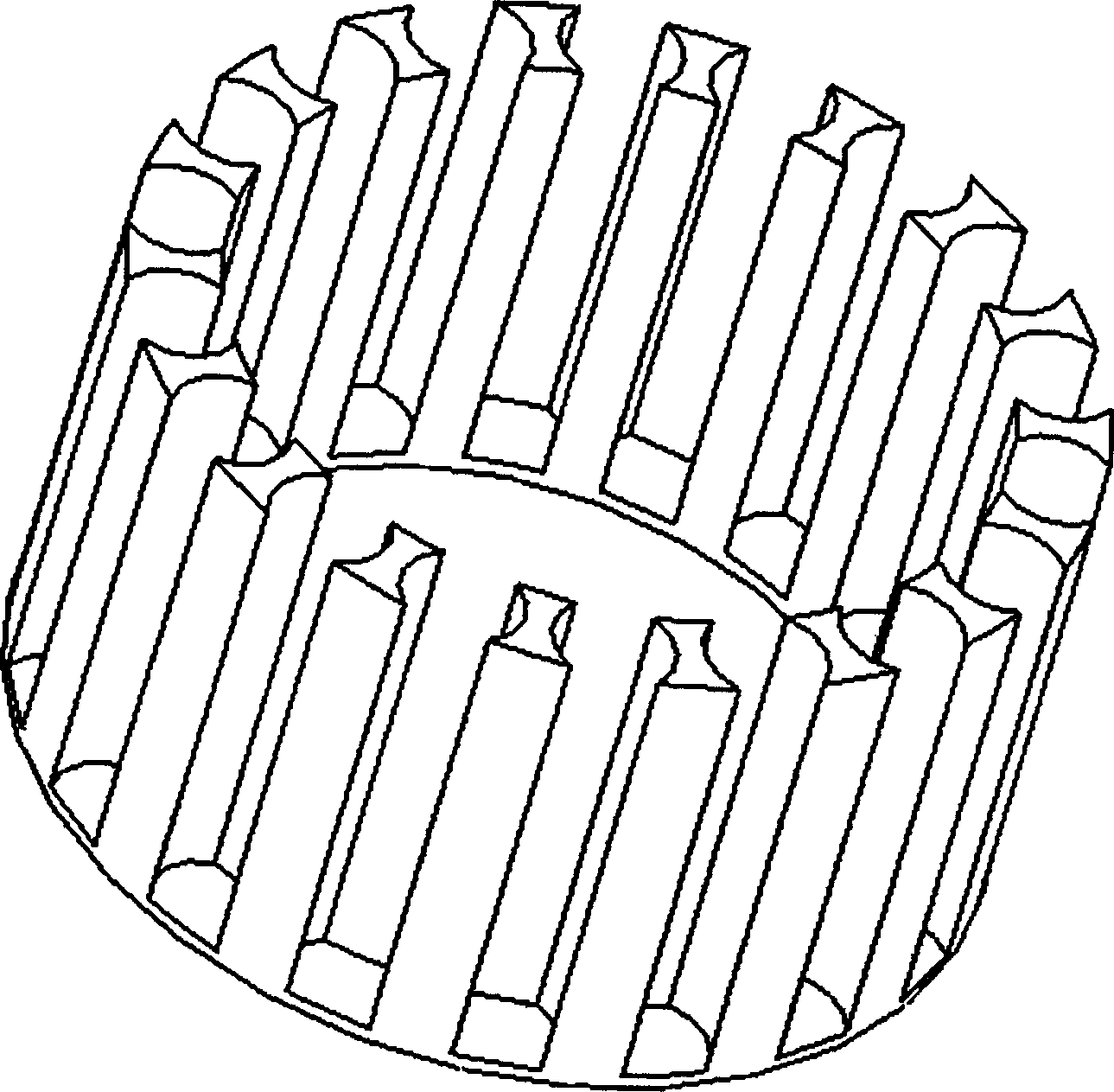

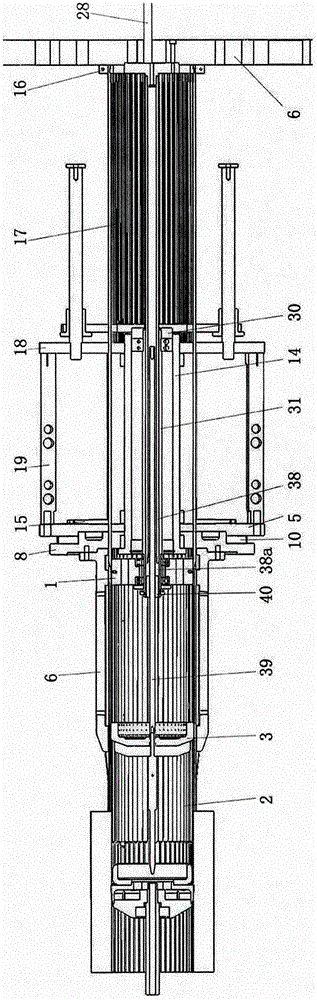

Stator wire embedding mold and stator wire embedding device

The present invention discloses a stator wire embedding mold. The stator wire embedding mold comprises a guide bar mounting seat, a plurality of guide bars and a push head; one end of each guide bar is evenly distributed at intervals and fixed on the peripheral surface of the guide bar mounting seat to form a non-closed ring-shaped space; the push head is located in the non-closed ring-shaped space; the stator wire embedding mold further comprises a connecting pipe, a mounting base, an insulating paper storage device and a paper push mechanism; one end of the push head is connected with one end of the guide bar mounting seat through the connecting pipe; one end of the insulating paper storage device is mounted at one end of the mounting base; the insulating paper storage device surrounds the guide bars; an interval into which the paper push mechanism can be inserted is arranged on the peripheral surface of the insulating paper storage device, wherein the interval is distributed along the axial direction of the insulating paper storage device; through holes through which insulating paper goes through are formed in the axial end surfaces of the mounting base and the insulating paper storage device; and the paper push mechanism is located at one end of the mounting base, wherein the one end of the mounting base is opposite to the end of the mounting base which is provided with the insulating paper storage device. With the stator wire embedding mold of the invention adopted, relative movement between the guide bars and enameled wires can be avoided in a stator wire embedding process.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

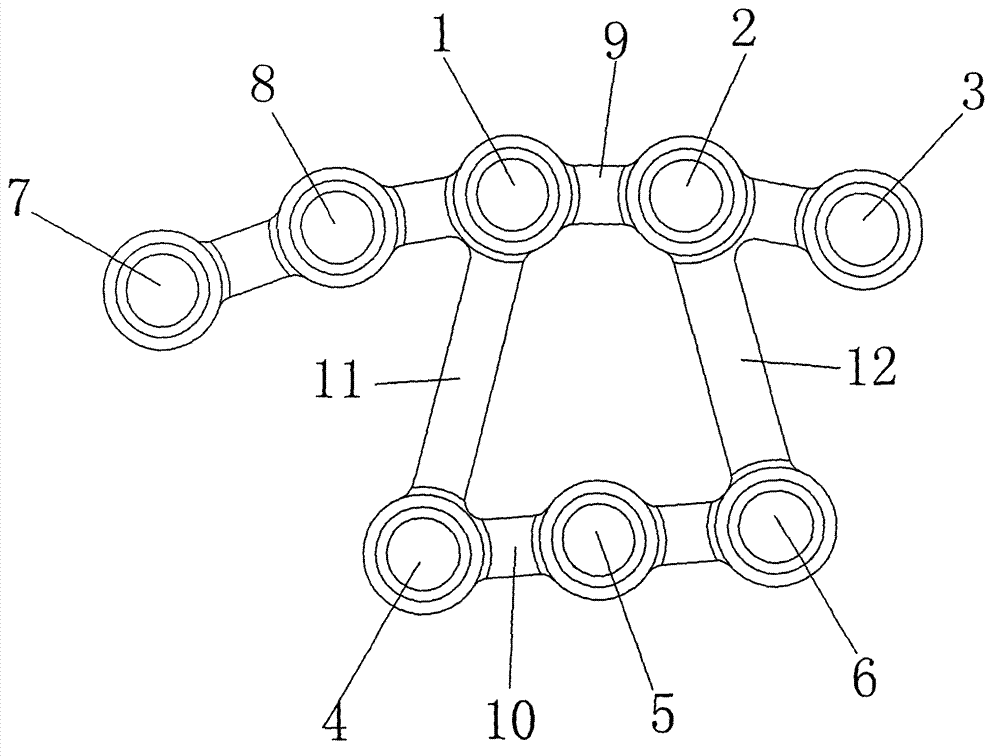

Special anatomic locking bone plate for peripherical joint fusion of foot bone and talus

A special anatomic locking bone plate for peripherical joint fusion of foot bone and talus comprises a first locking plate and a second locking plate; a first locking screw hole, a second locking screw hole and a third locking screw hole are formed on the first locking plate in sequence from left to right; a fourth locking screw hole, a fifth locking screw hole and a sixth locking screw hole are formed on the second locking plate in sequence from left to right; the first locking plate at the first locking screw hole is connected with the second locking plate at the fourth locking screw hole through a first bone plate; the first locking plate at the second locking screw hole is connected with the second locking plate at the sixth locking screw hole through a second bone plate; and both the first bone plate and the second bone plate incline outwards. The anatomic locking bone plate conforms to surface configuration of bones of the peripherical joints of normal foot bone and talus of a healthy Chinese, and ensures the angle stability after joint fusion.

Owner:徐仲棉 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com