Patents

Literature

304results about "Concrete transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

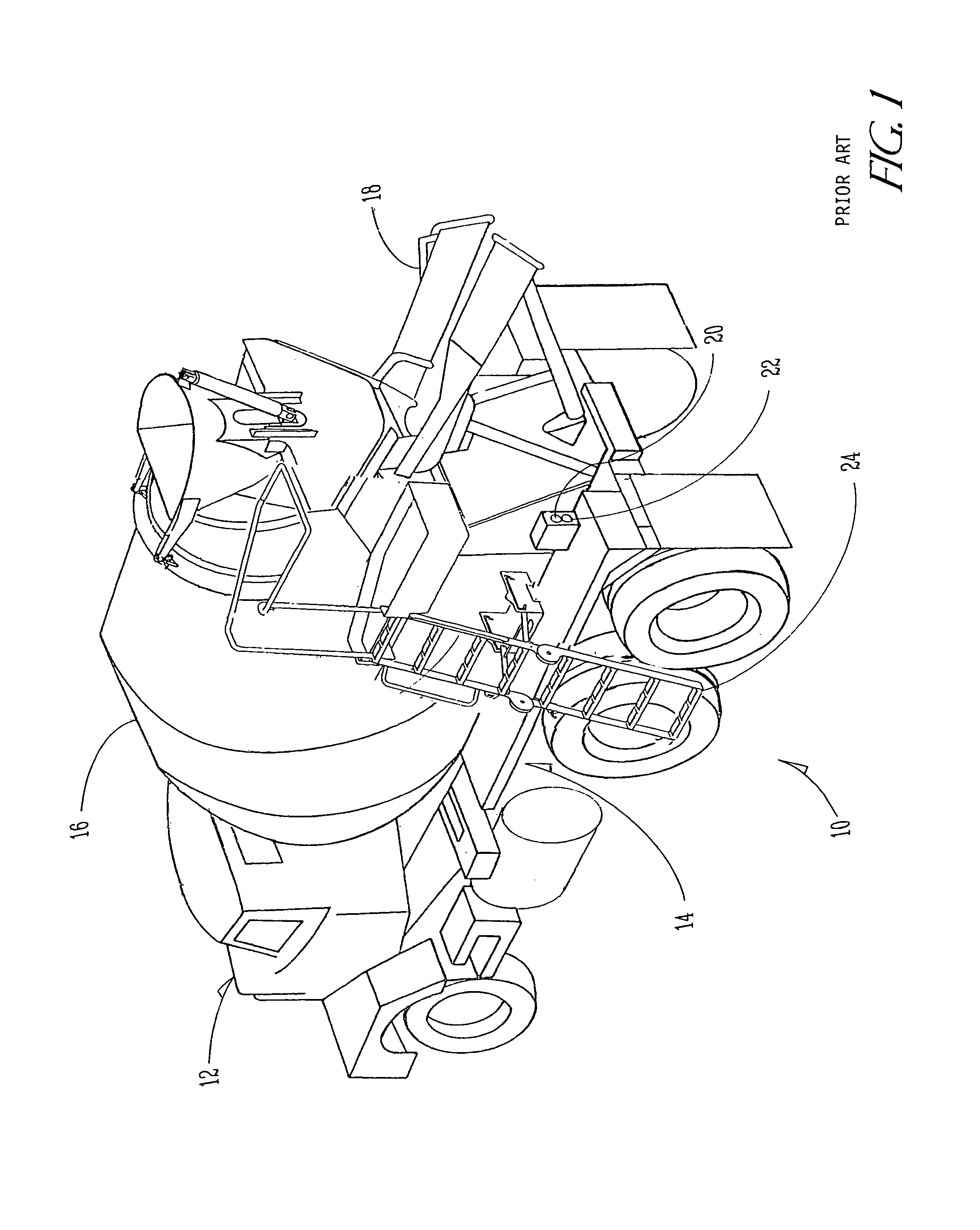

Concrete mixing truck anti-rollover system

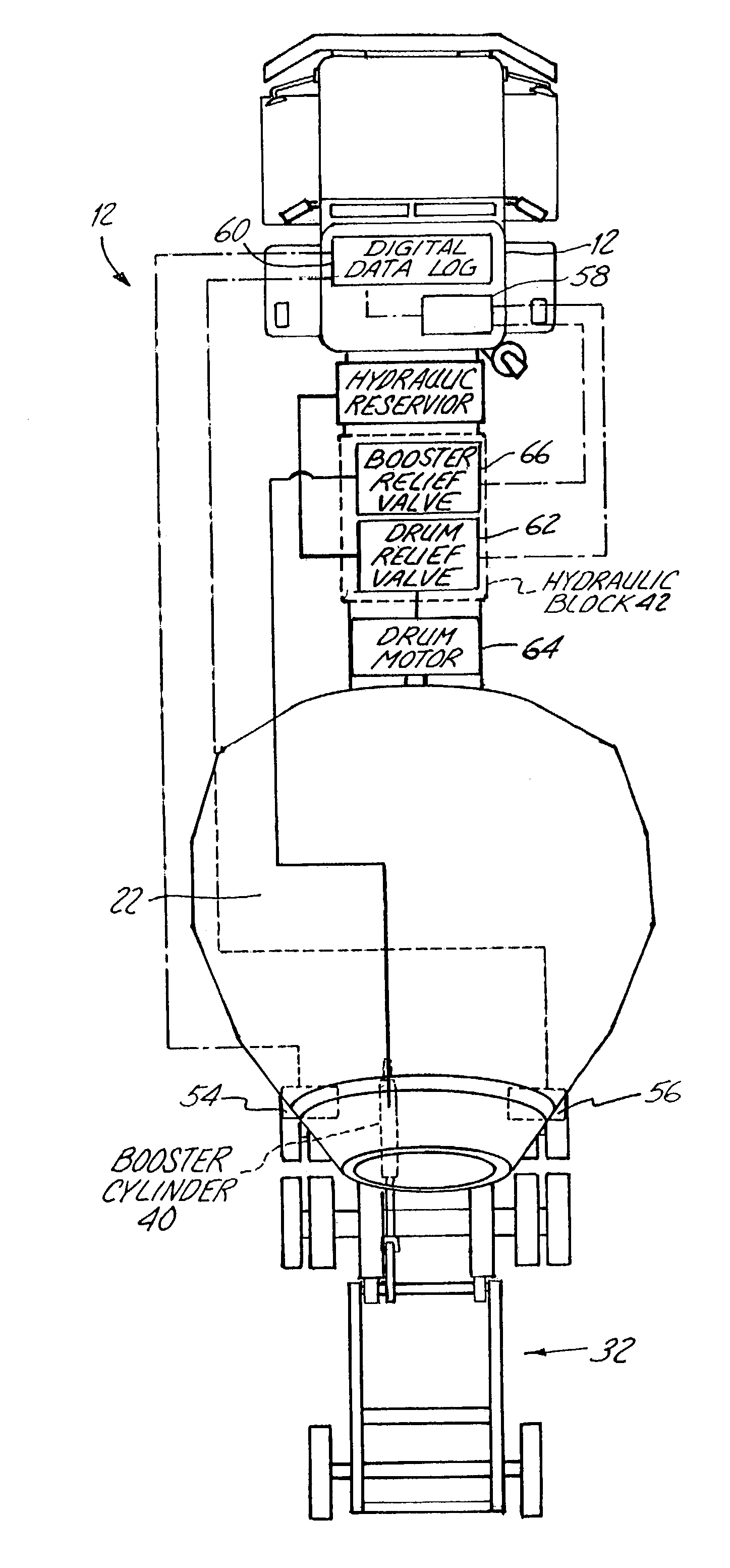

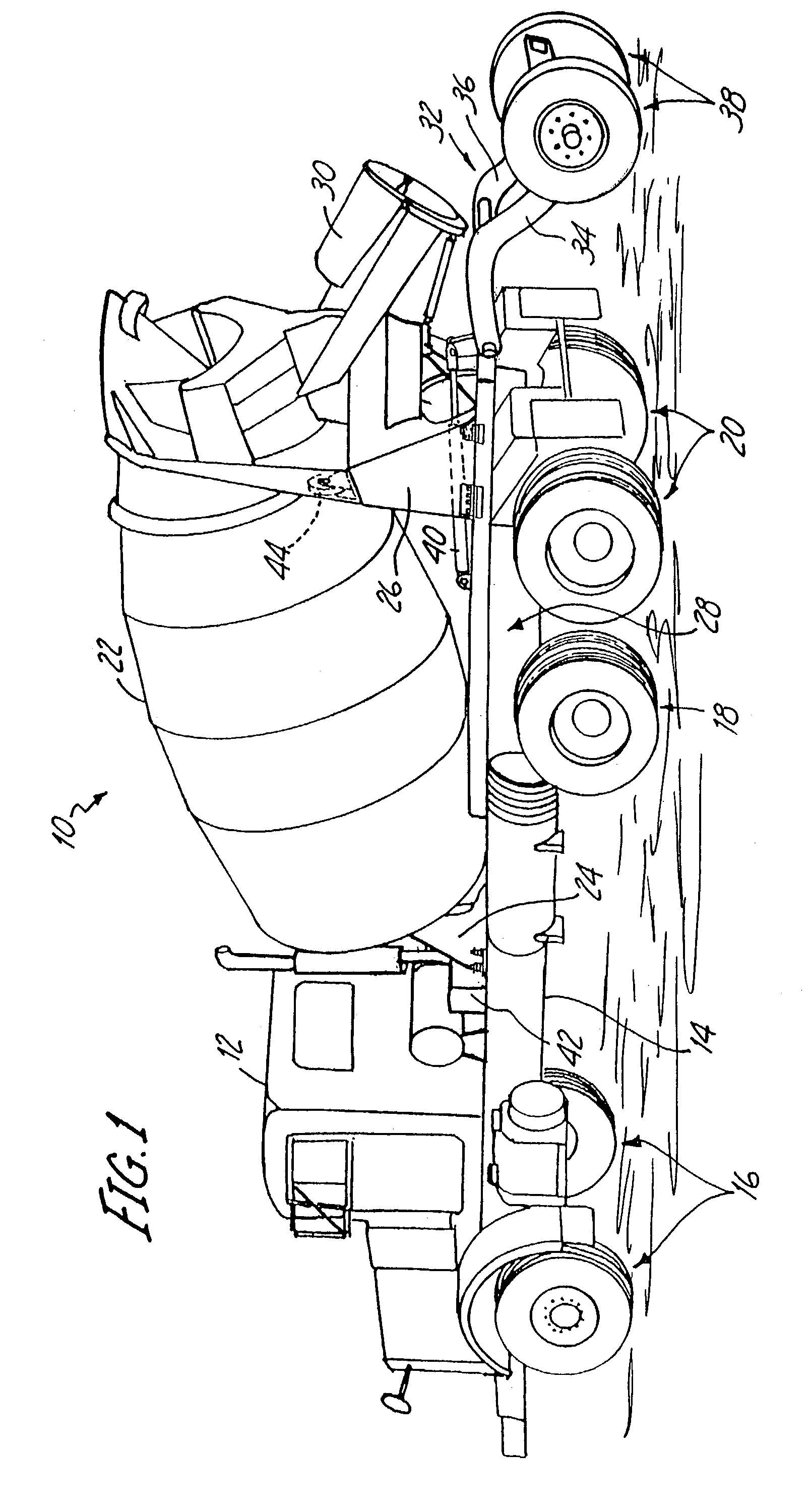

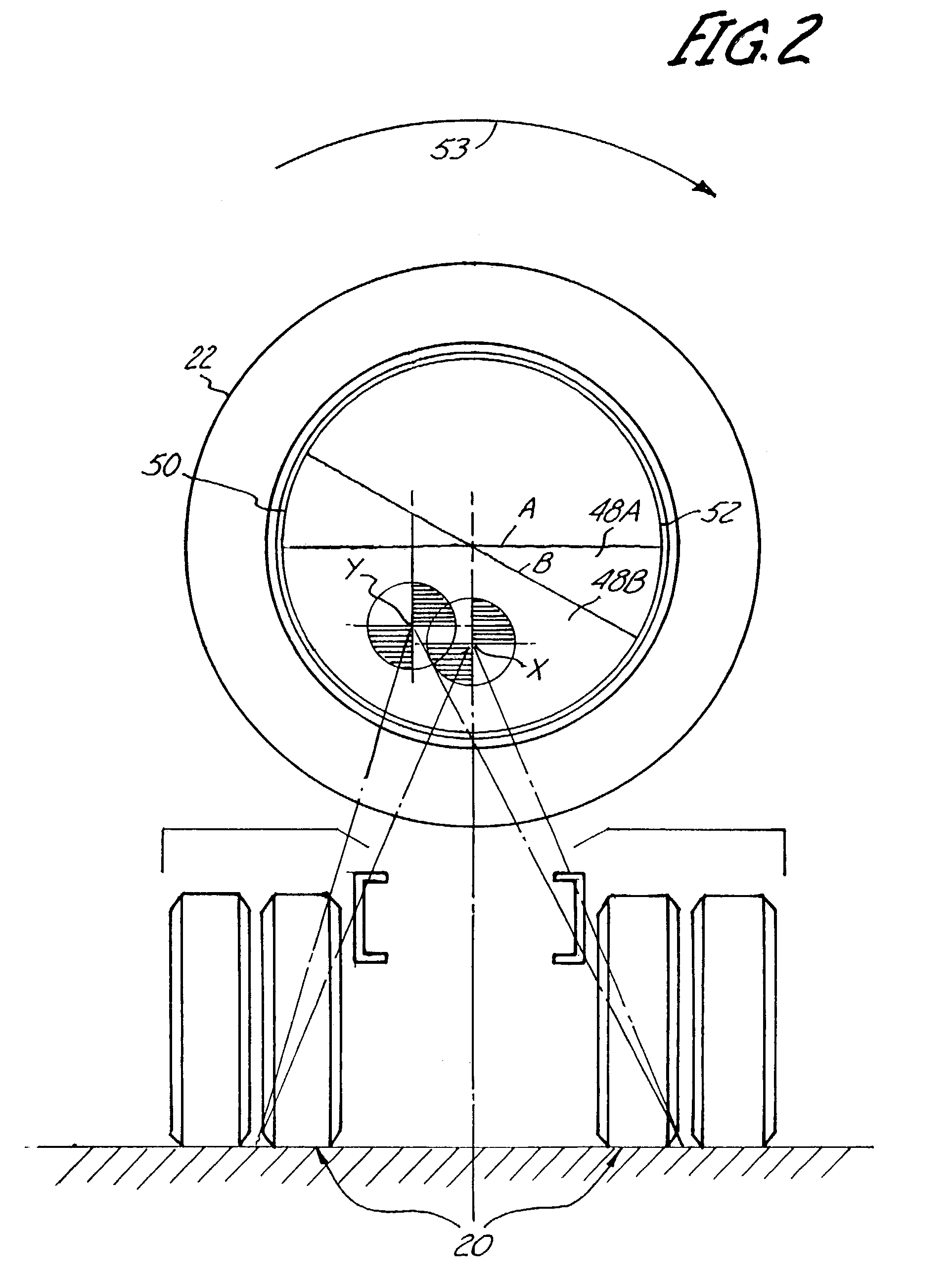

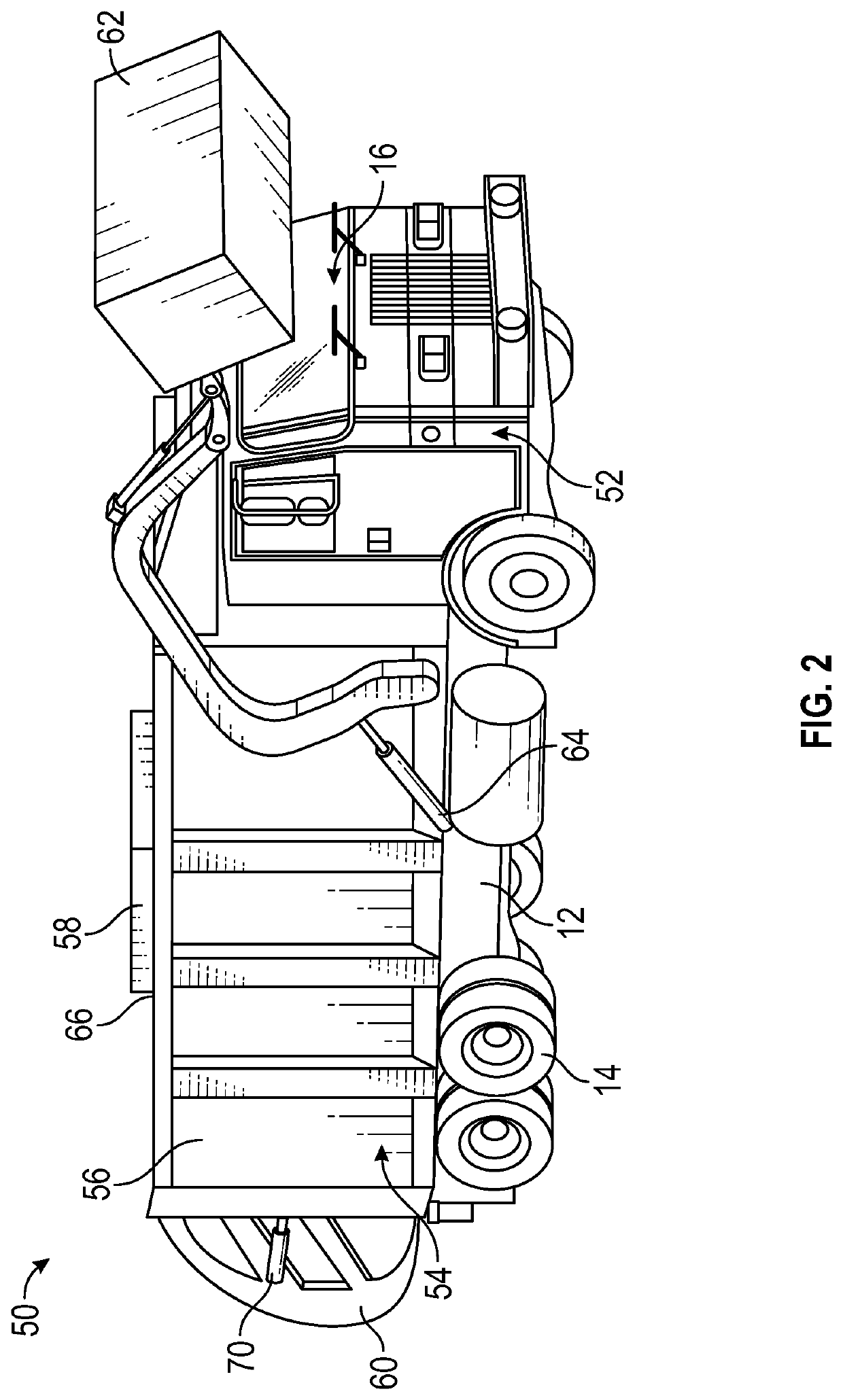

An anti-rollover system is used with a concrete mixing truck with a mixing drum, in particular during turning maneuvers, for preventing rollovers by the truck. The anti-rollover system is comprised of one or more sensors on the truck which generate an input signal representative of the truck's operating conditions indicative of a rollover condition. The system compares the sensor signal against stored data indicative of rollover conditions and if necessary initiates corrective action to prevent the truck from rolling over. Corrective action includes stopping, or in some circumstances slowing, rotation of the drum carrying a concrete load. With mixing trucks including a booster axle system, corrective action may additionally or separately include unloading the booster axle.

Owner:SCHWING AMERICA

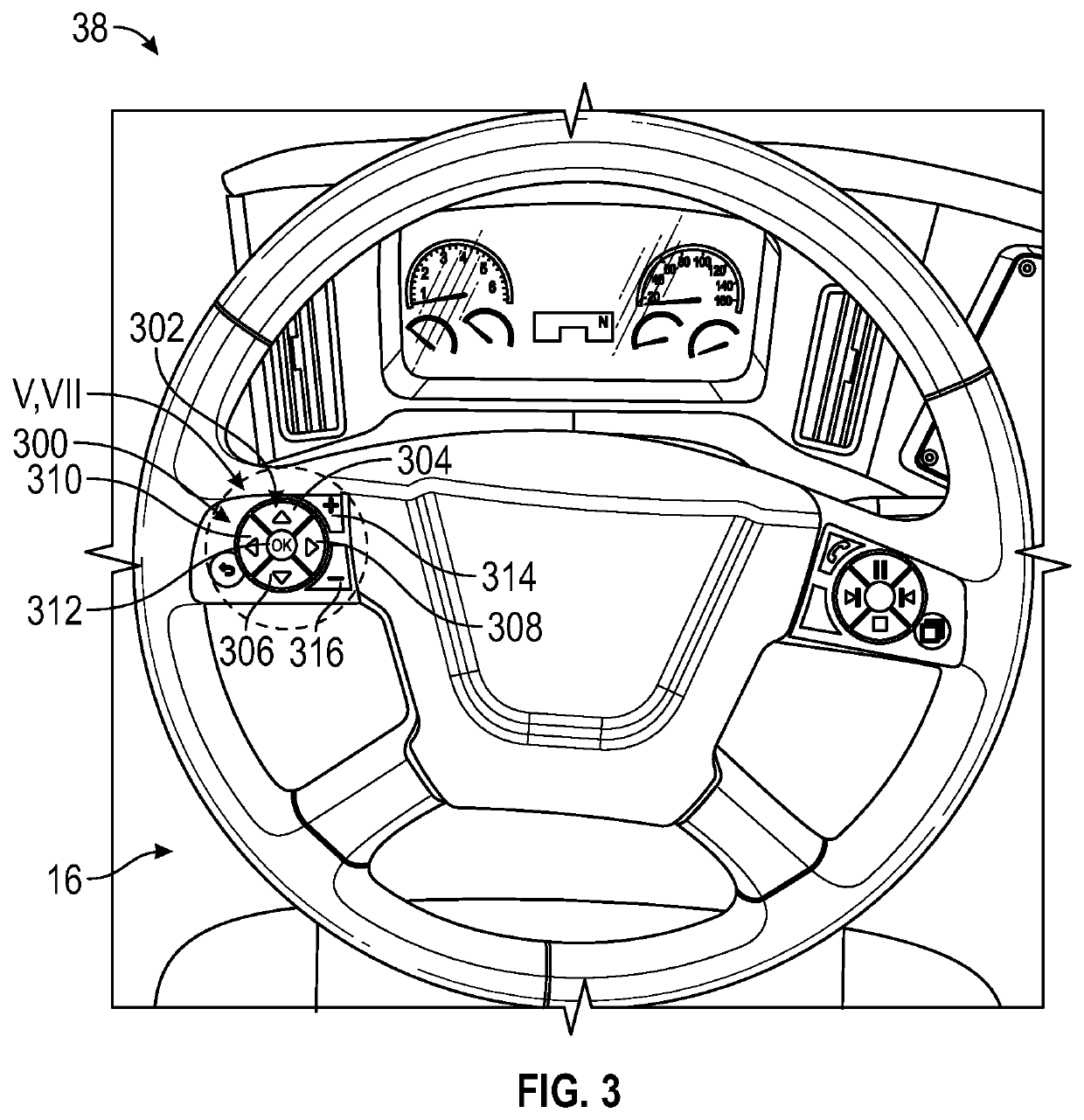

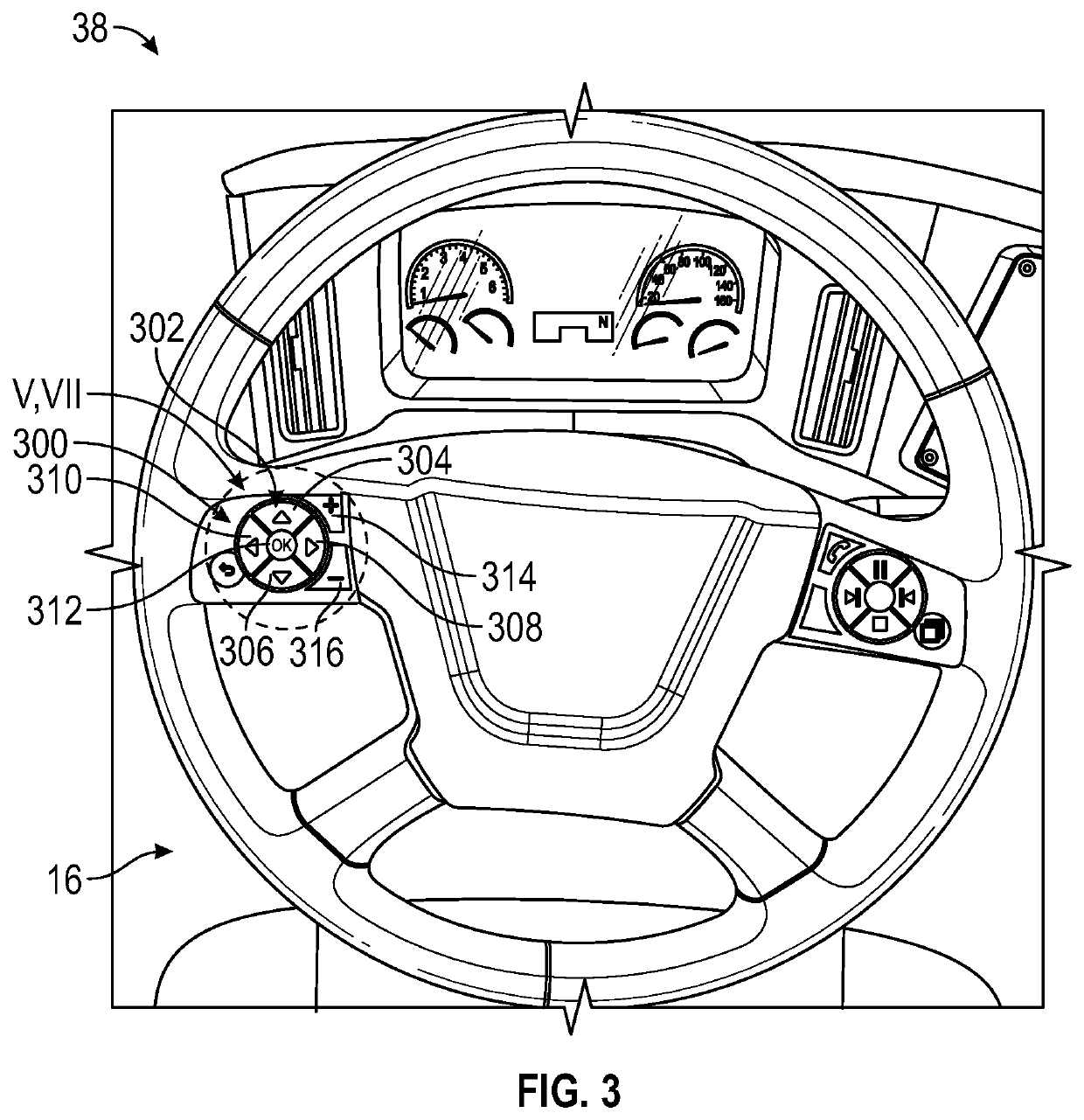

Integrated operator centric controls

PendingUS20200262366A1Facilitate transit operationMechanical power/torque controlConcrete transportationControl theoryRolling chassis

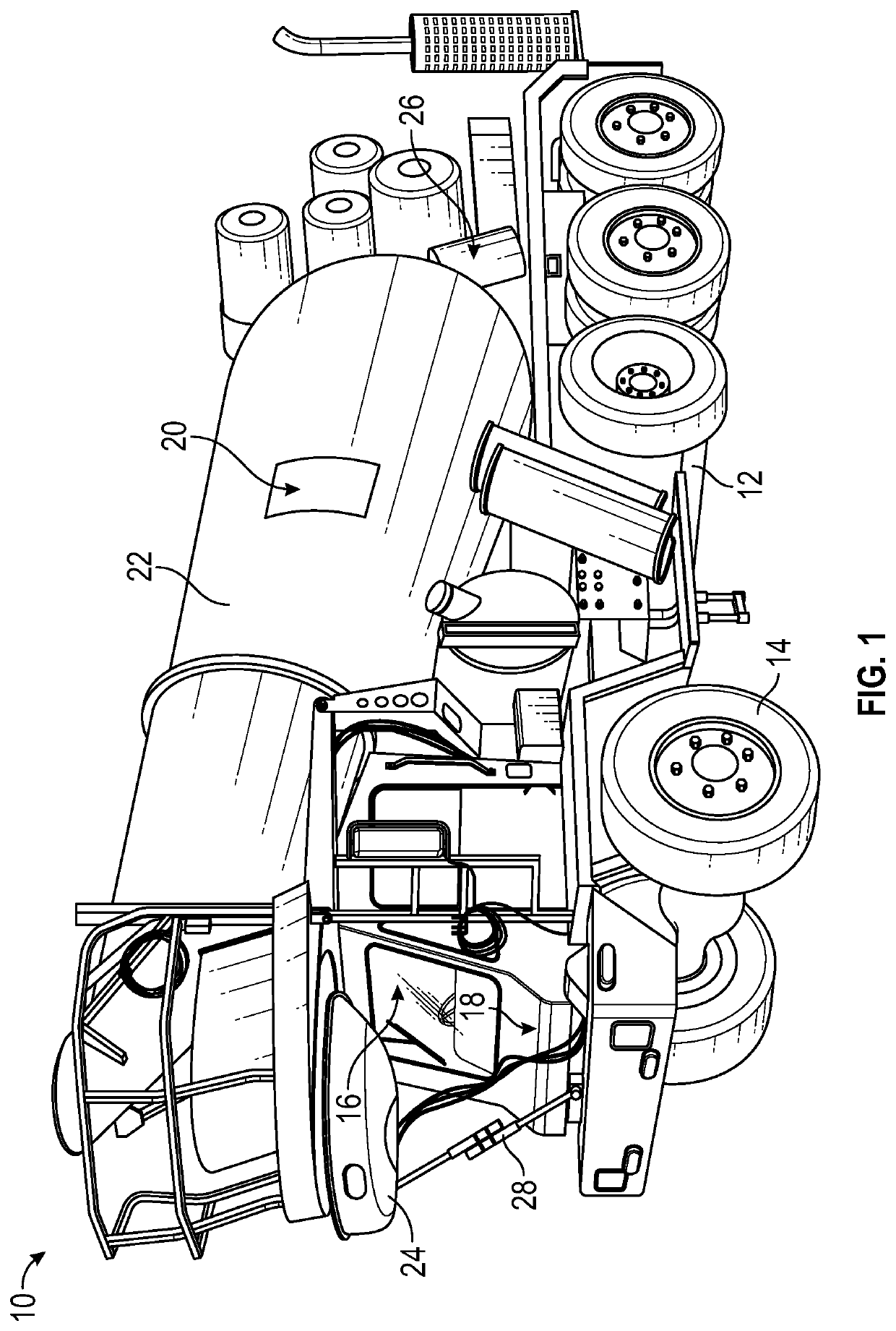

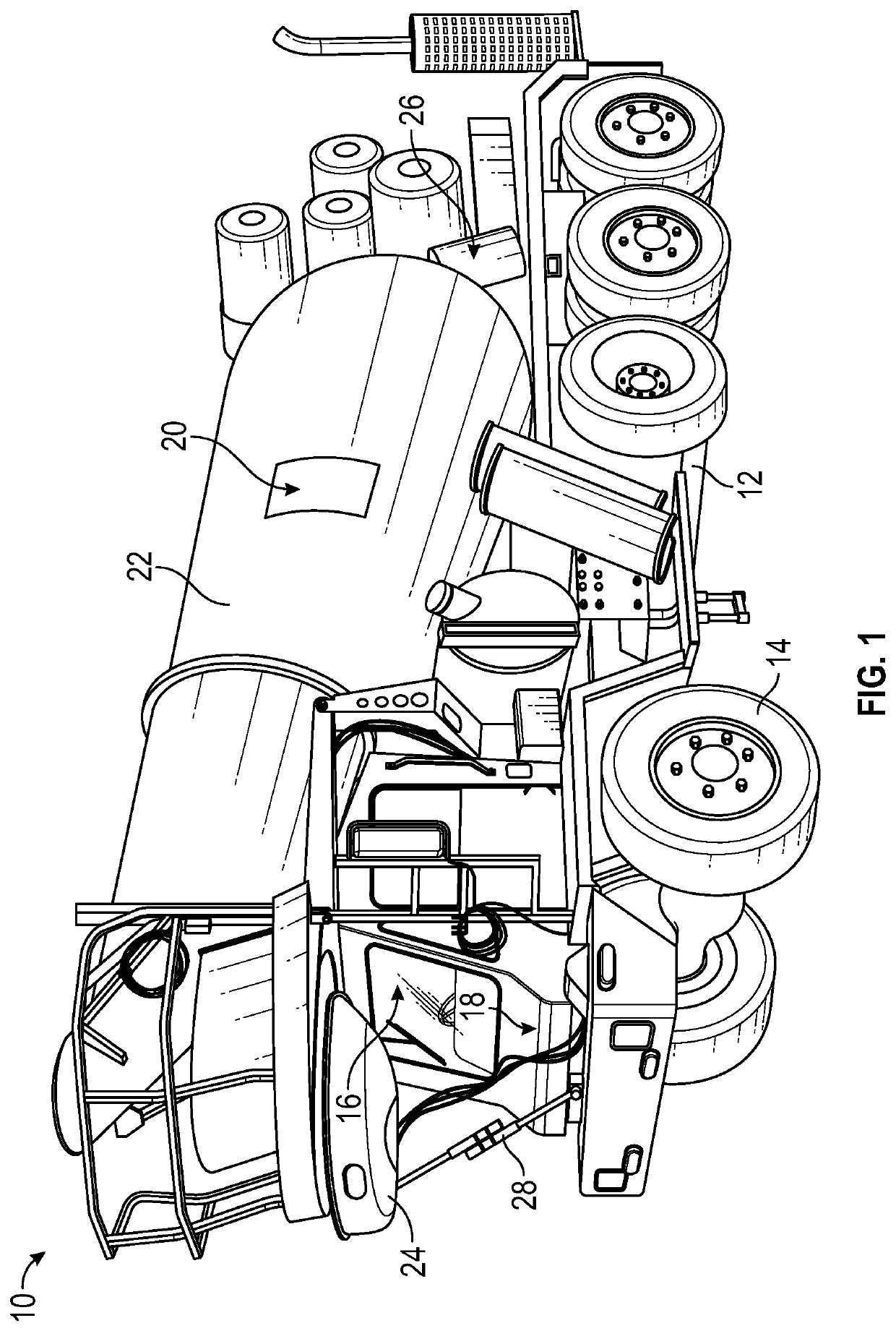

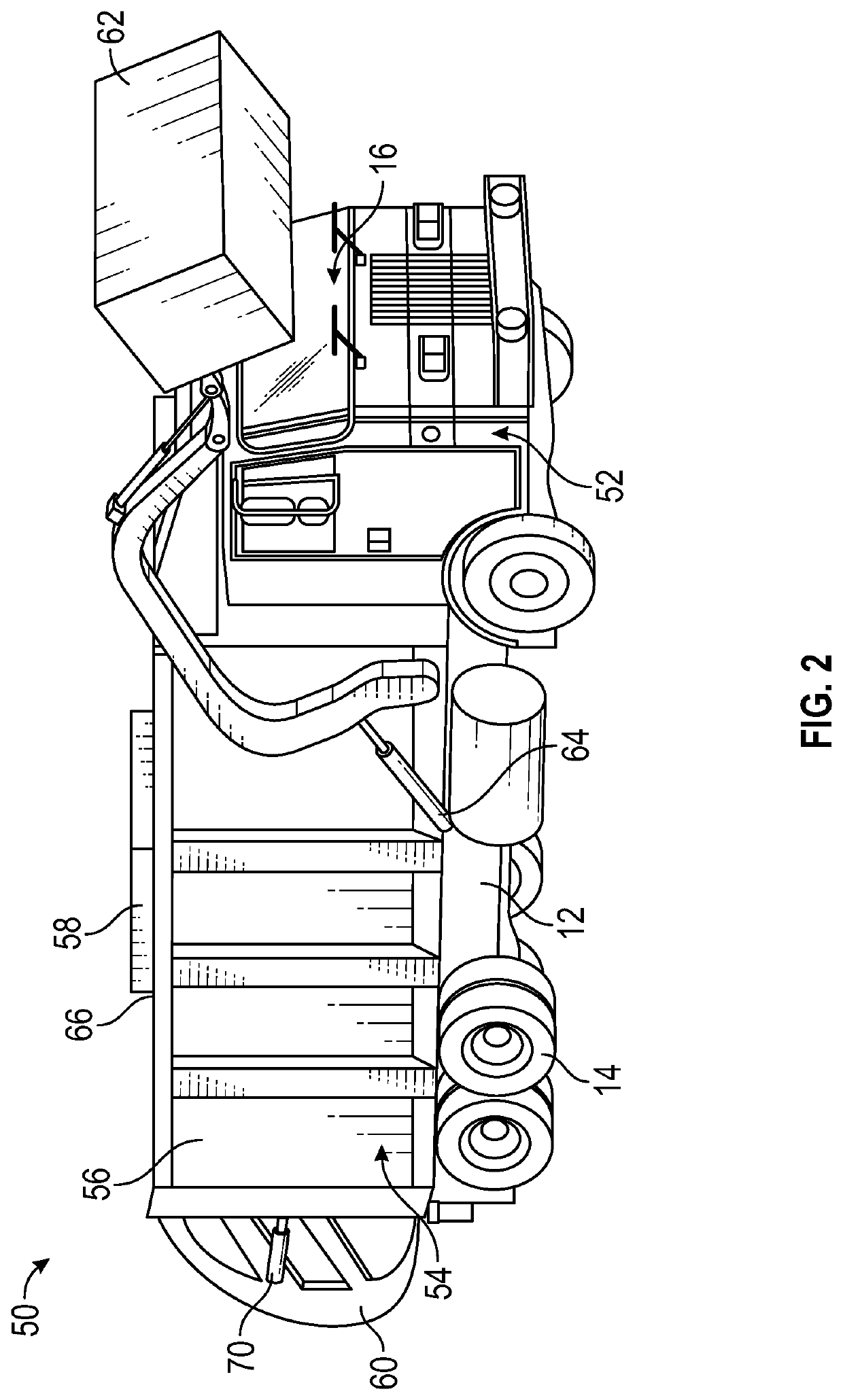

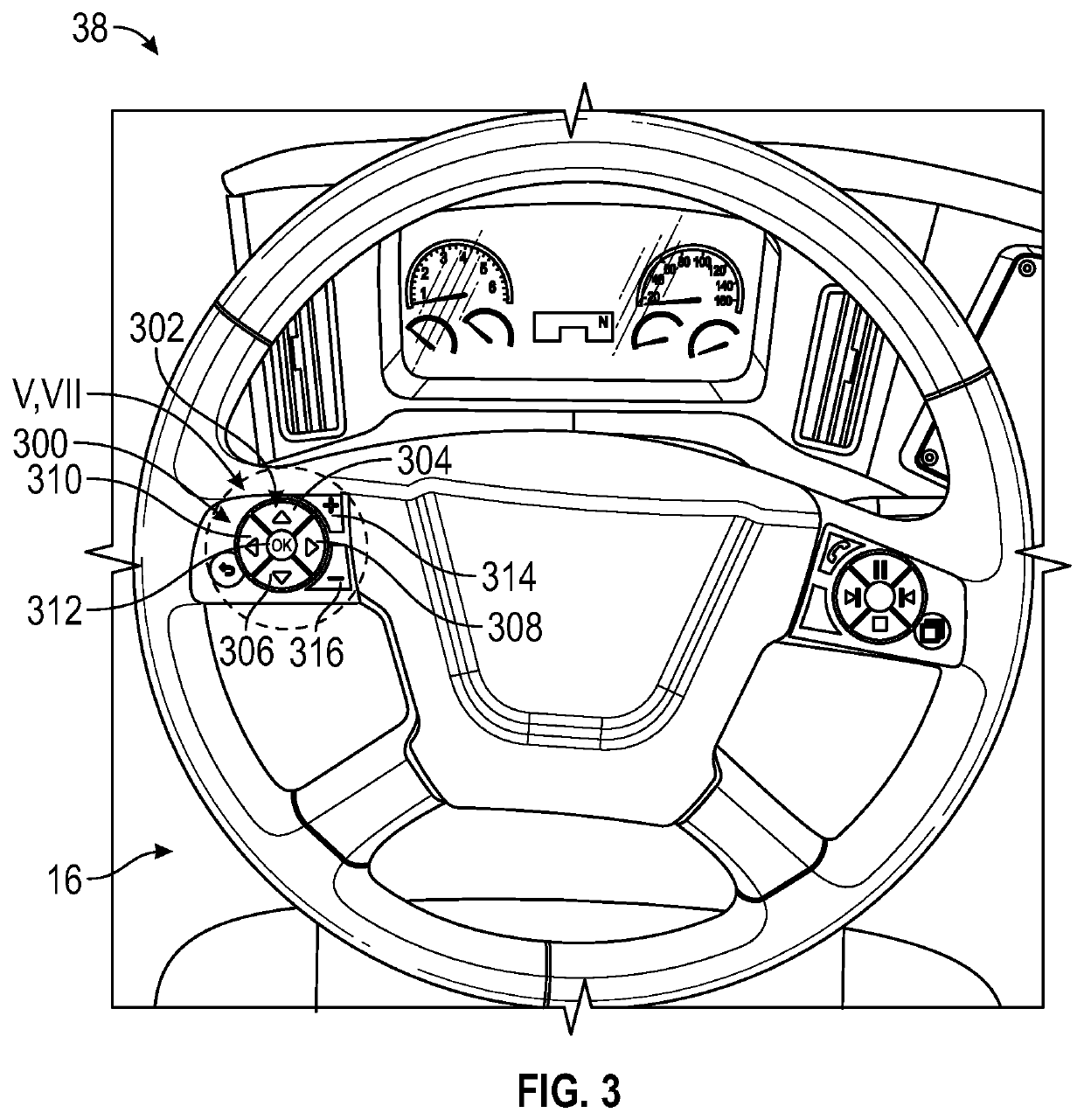

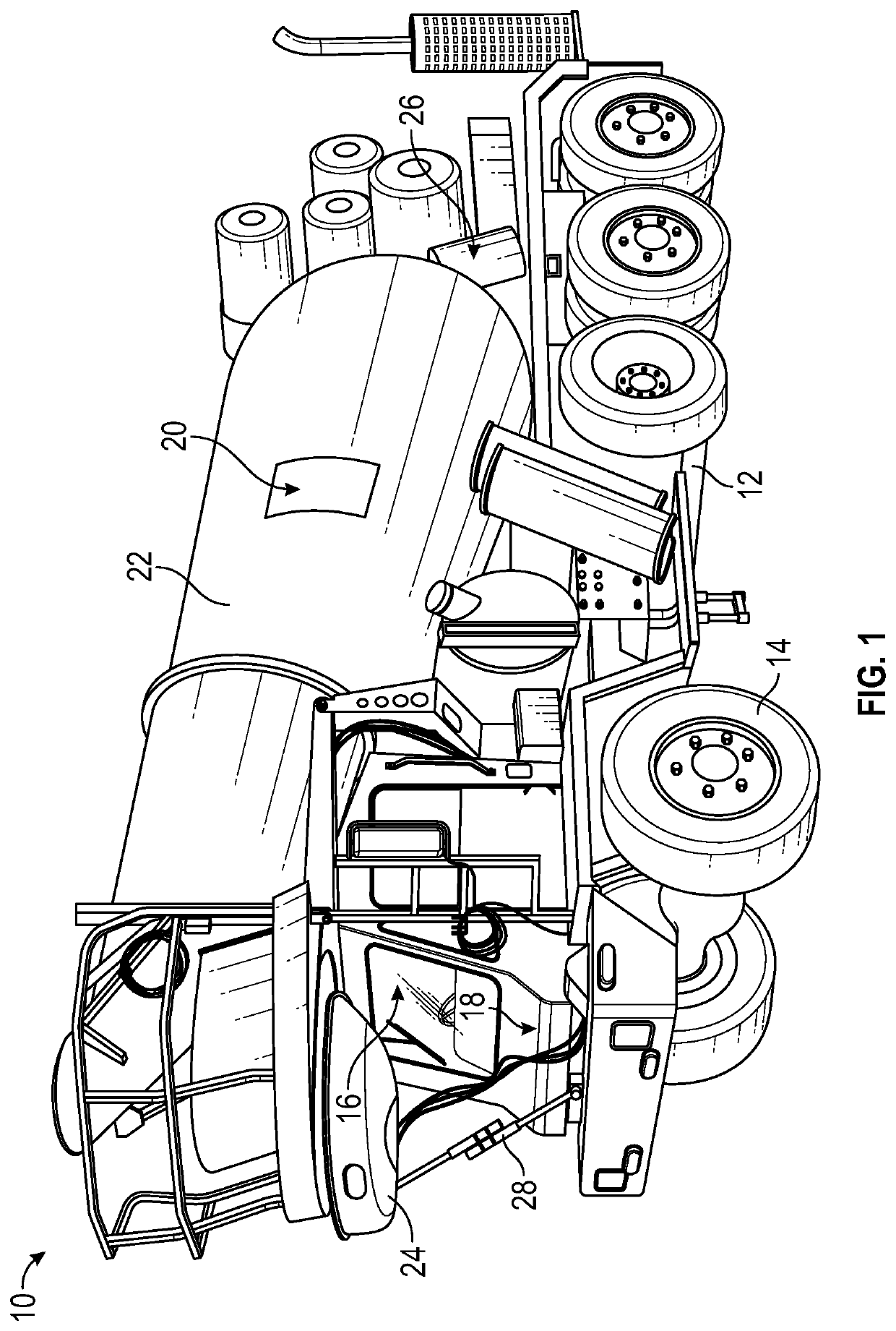

A vehicle includes a rolling chassis structure and a working component coupled to the rolling chassis structure. The rolling chassis structure includes a chassis, a non-working component, and a control interface. The non-working component is coupled to the chassis and is configured to facilitate transit operations for the rolling chassis structure. The control interface is disposed in a cab area of the chassis. The control interface is communicably coupled to the non-working component and is configured to control operation of the non-working component. The working component is configured to move relative to the chassis and is communicably coupled to the control interface. The control interface is configured to control movement of the working component.

Owner:OSHKOSH CORPORATION

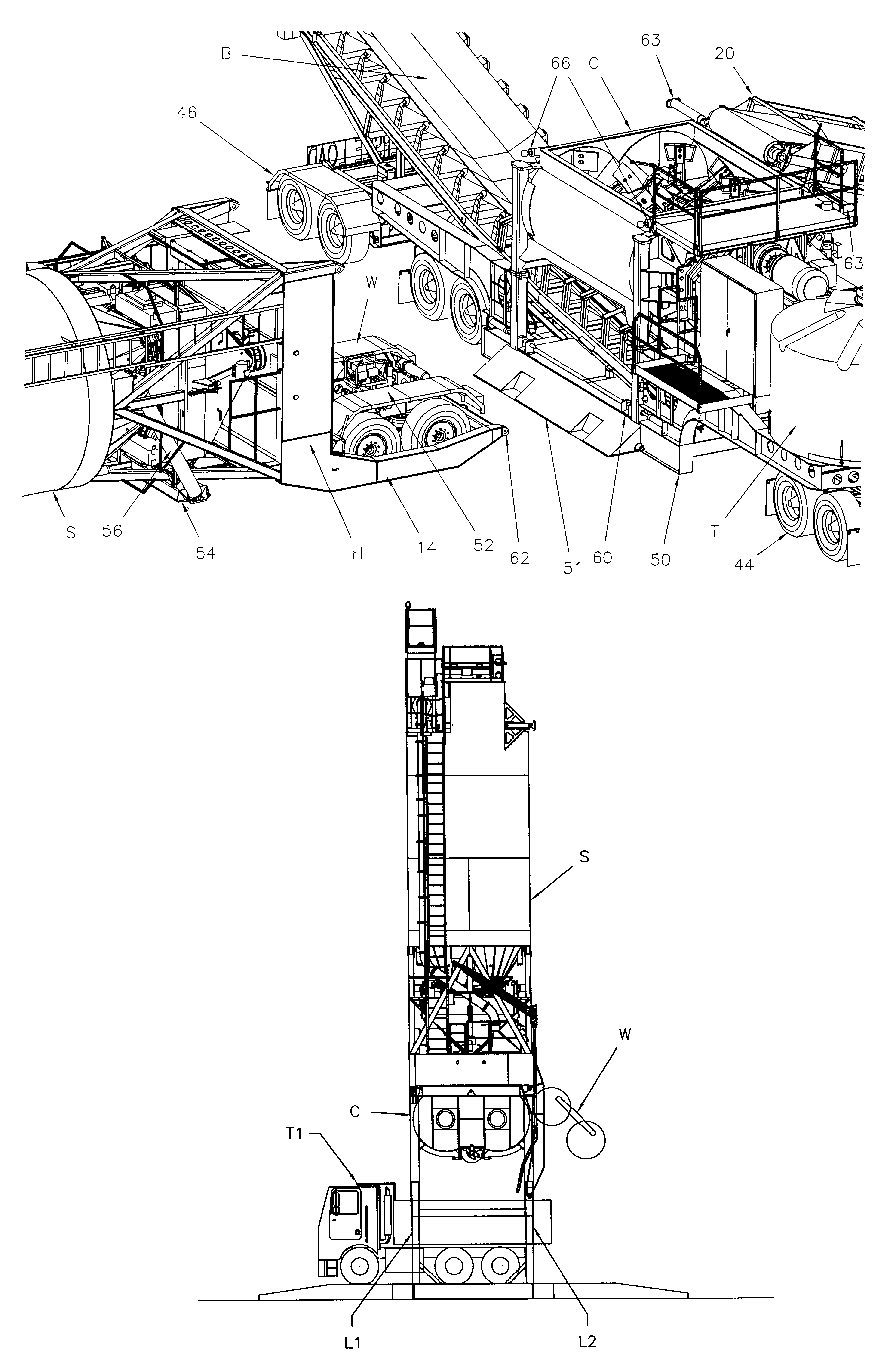

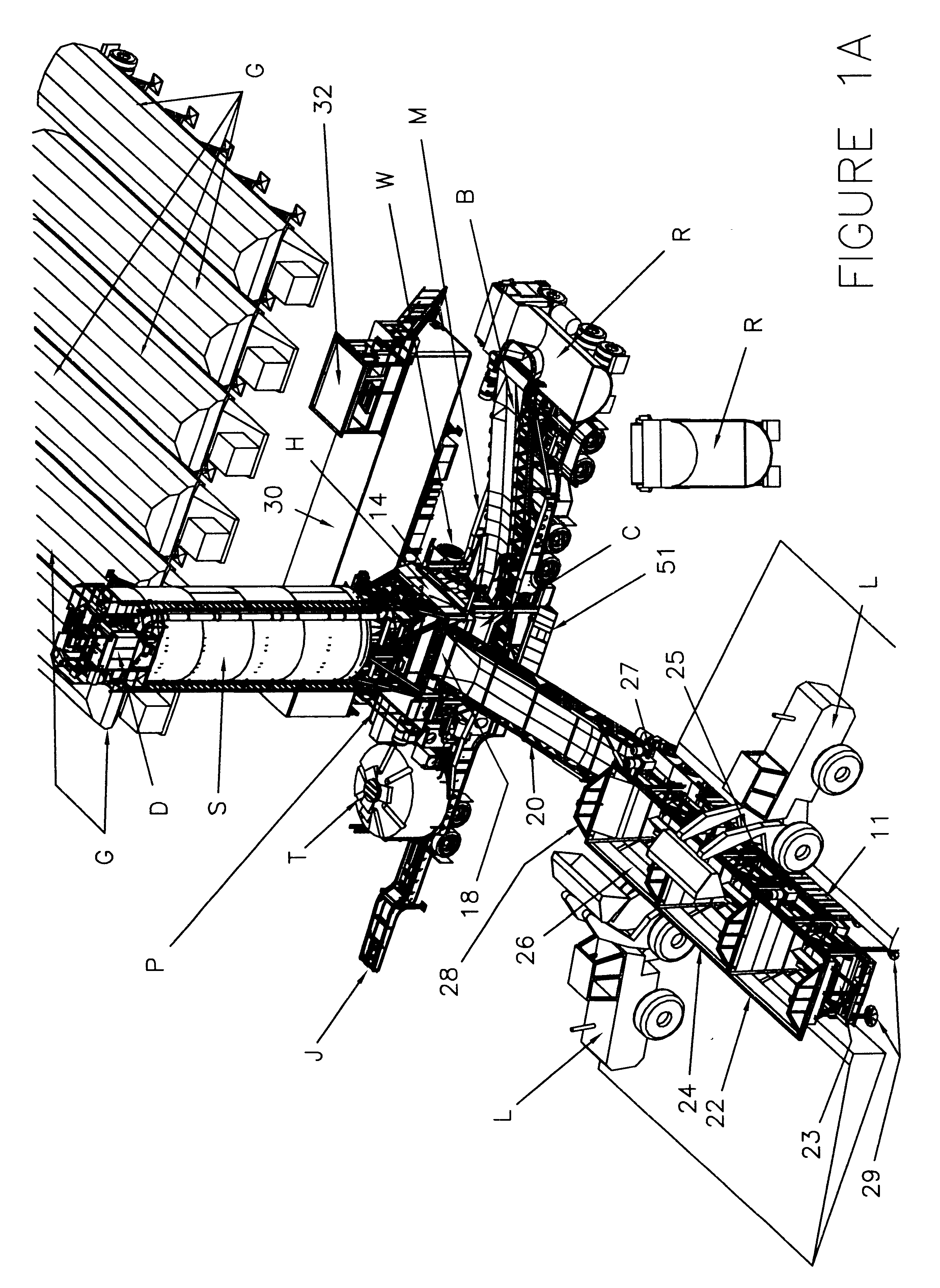

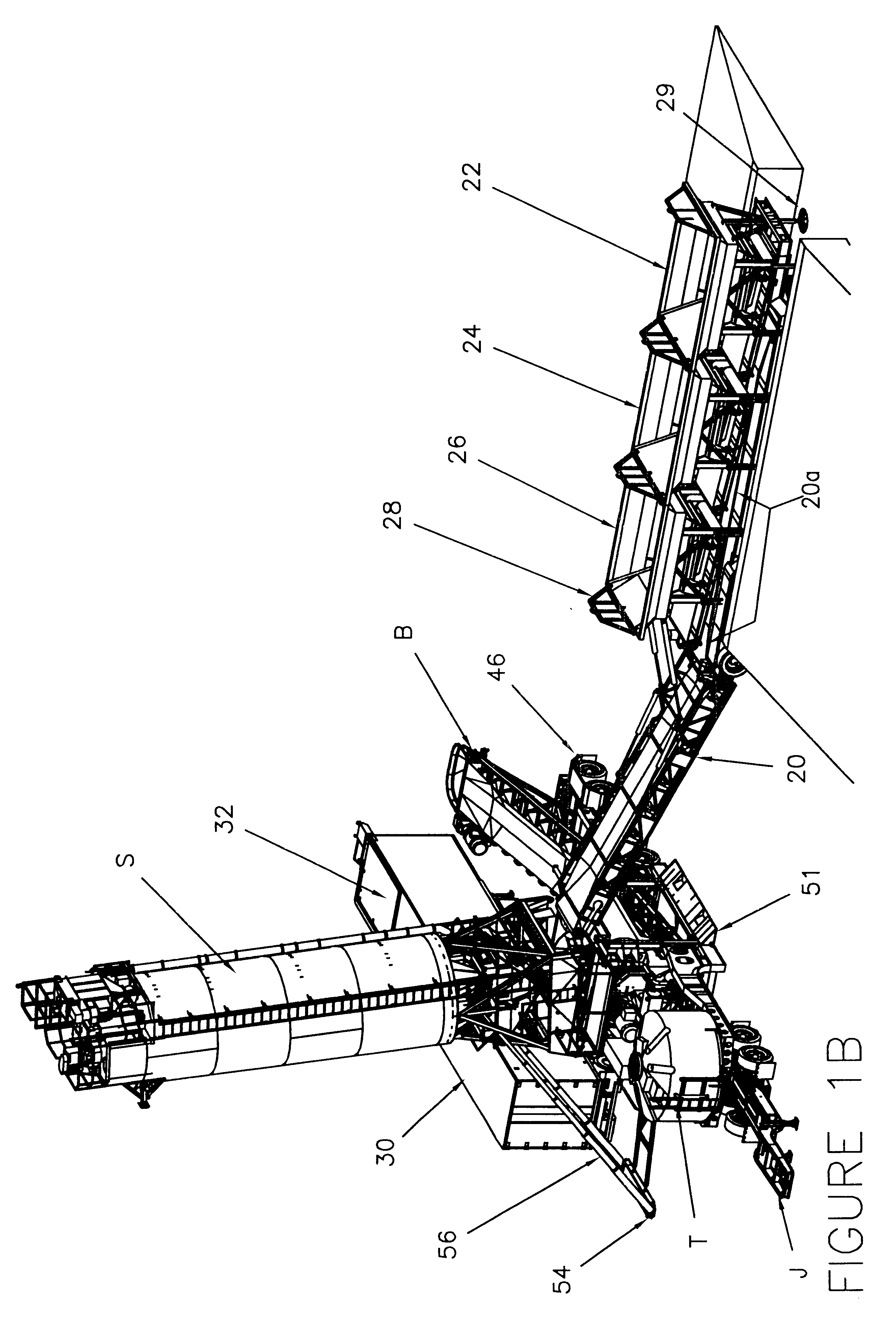

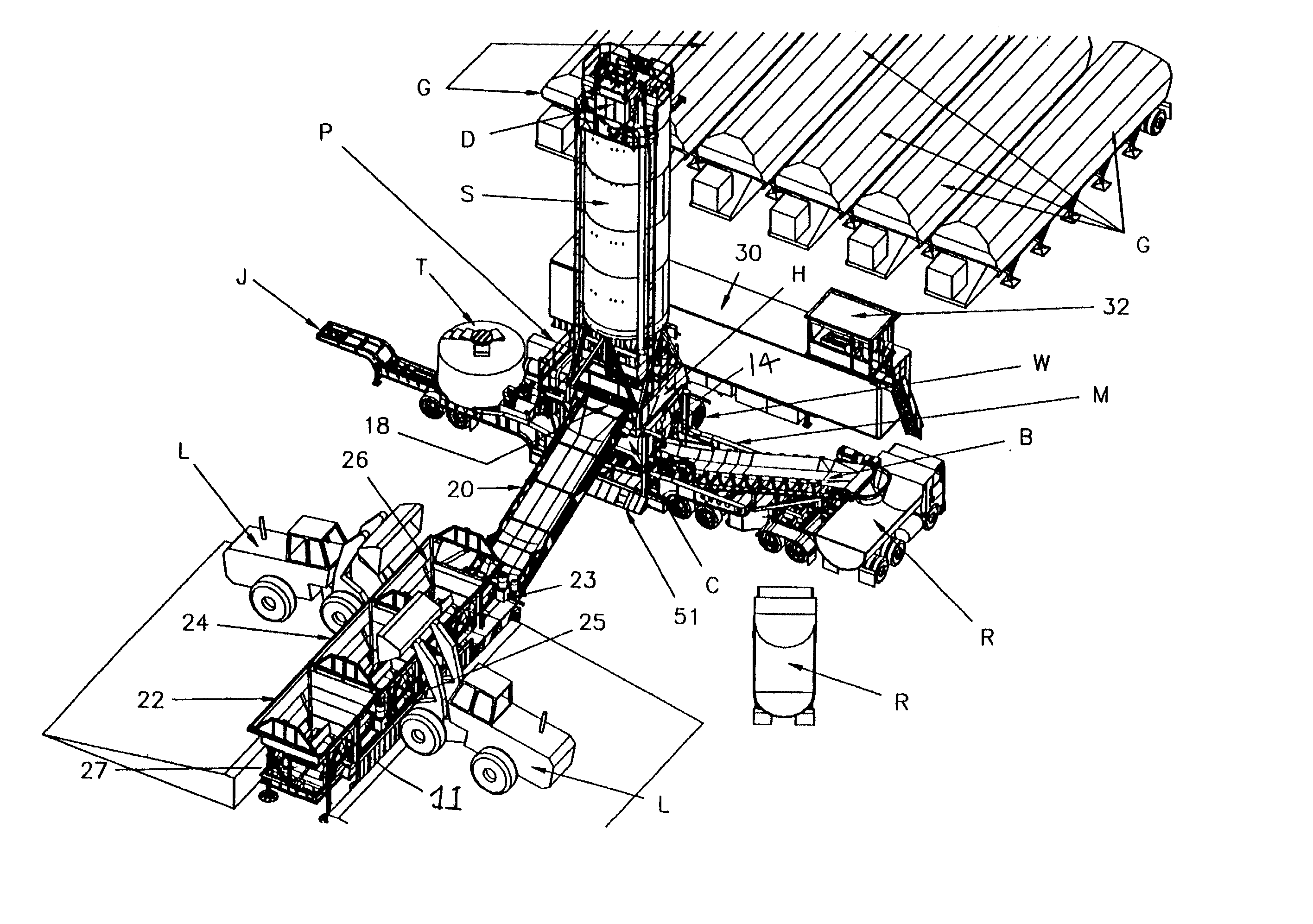

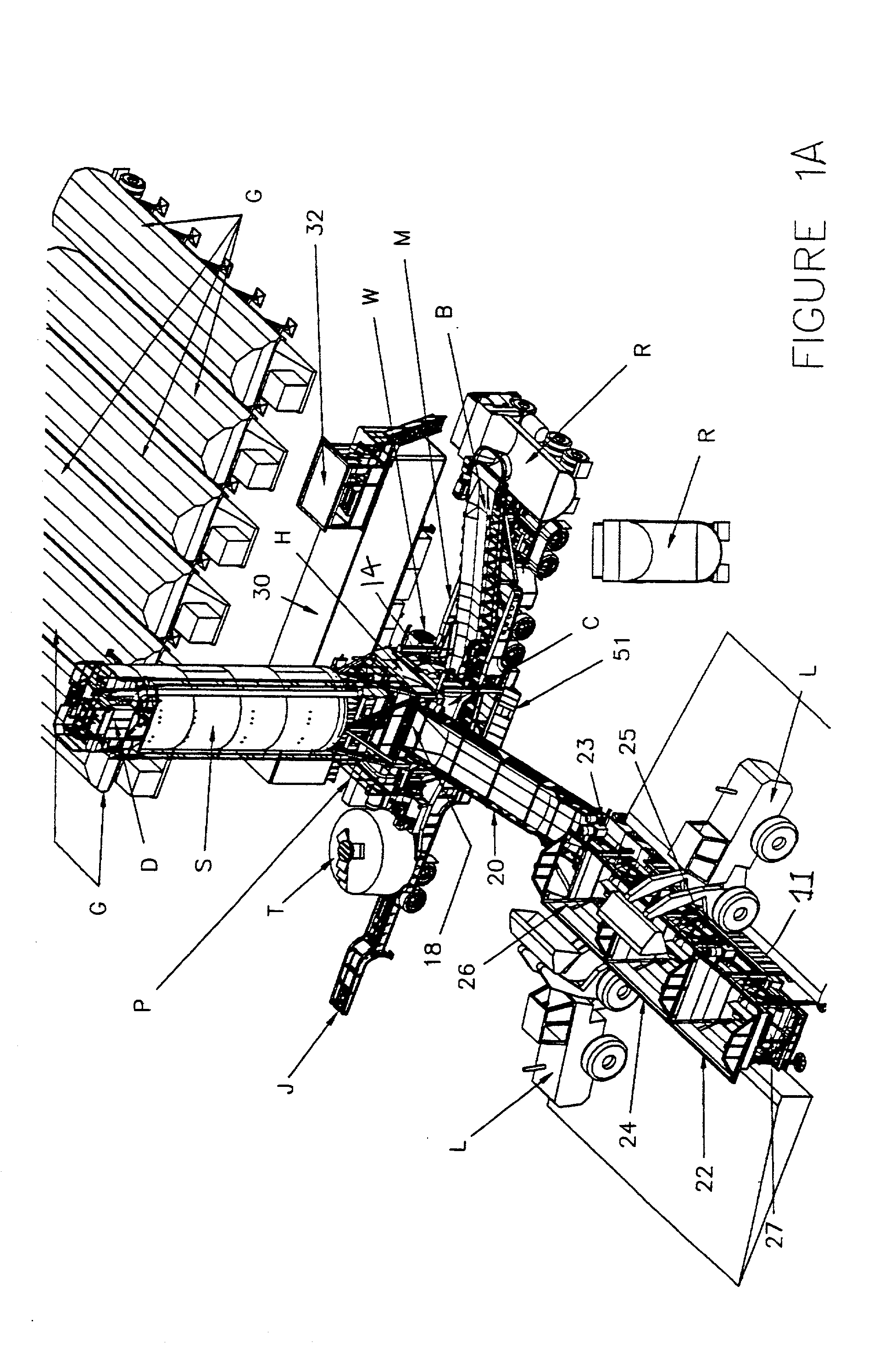

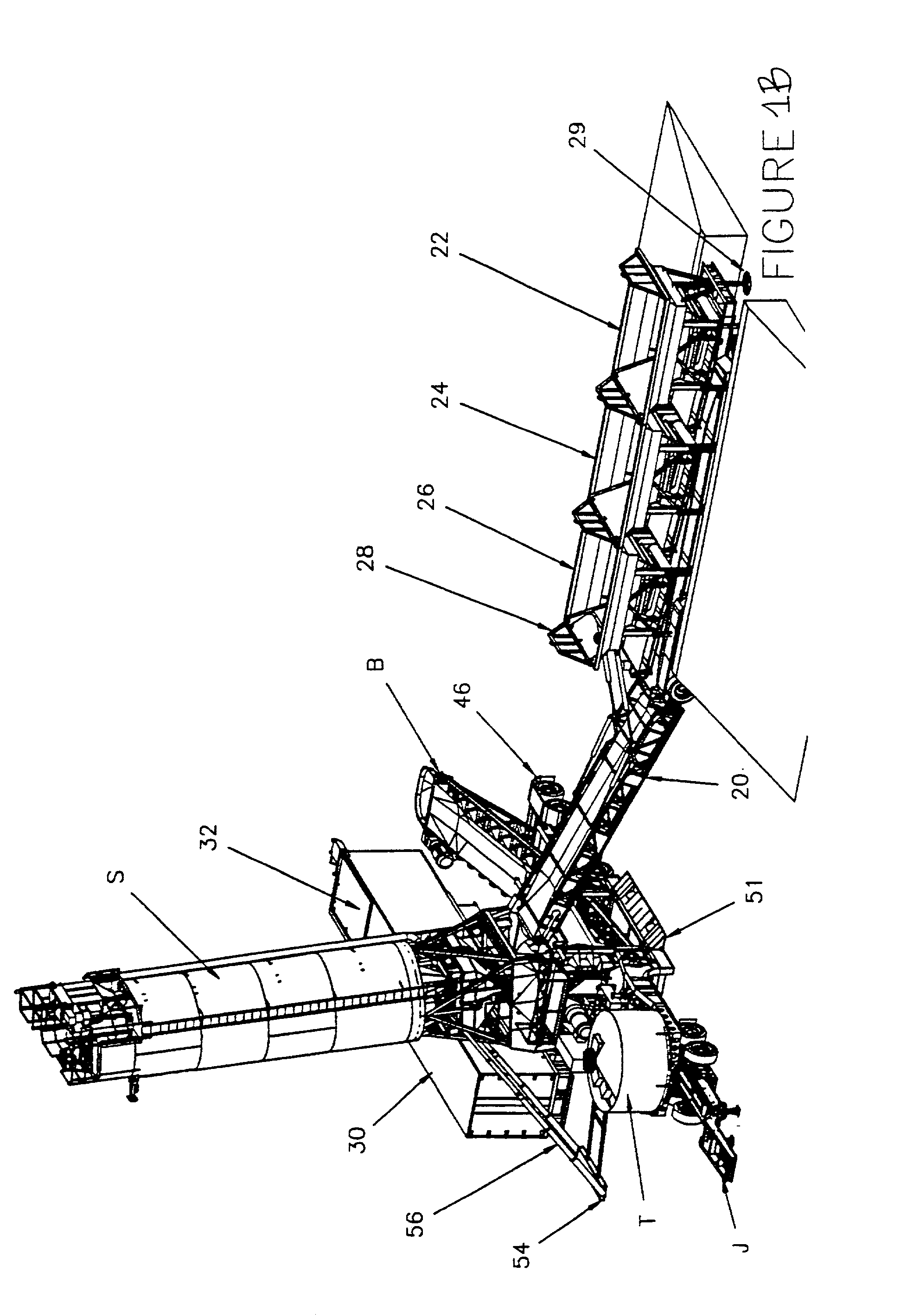

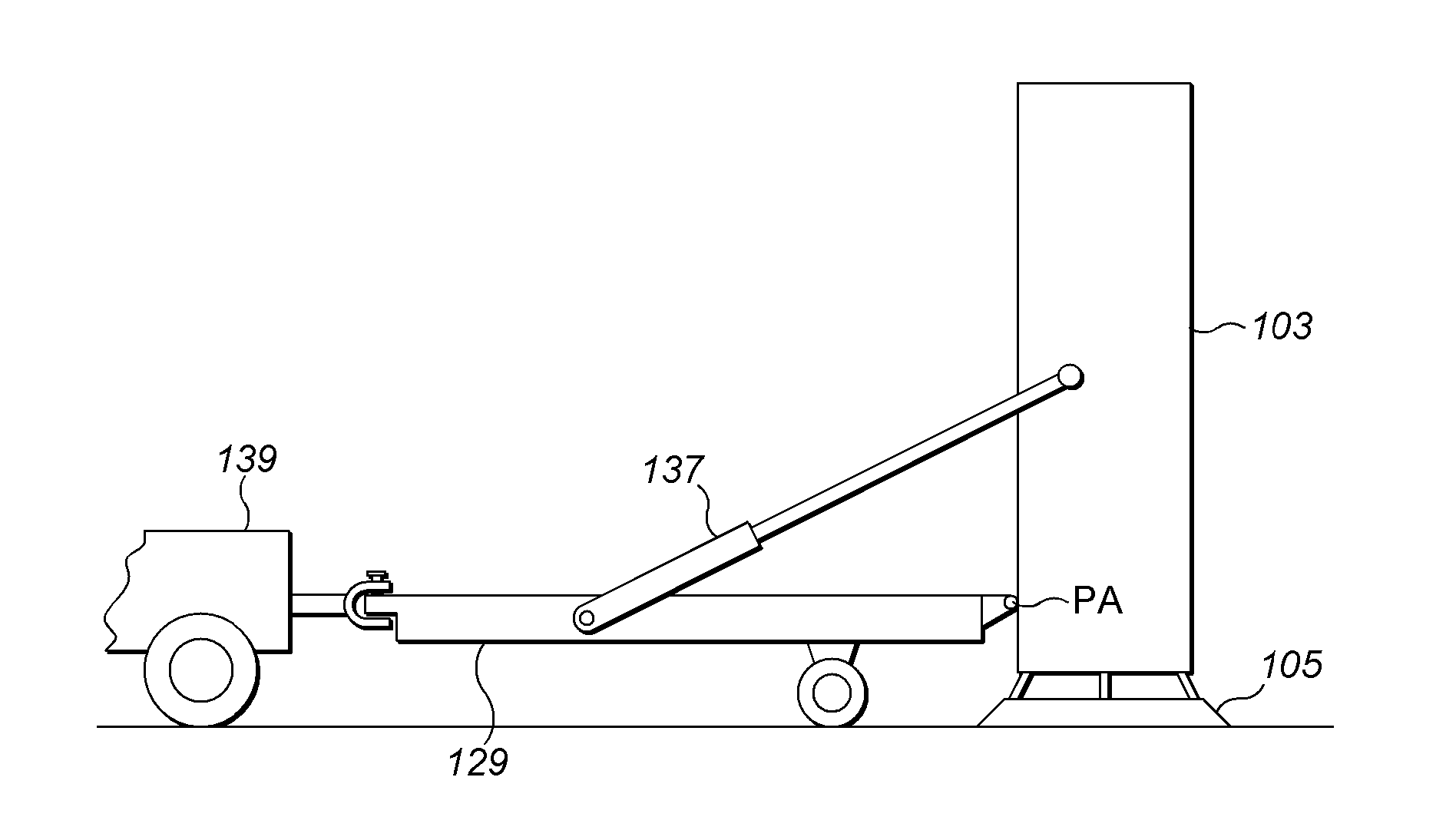

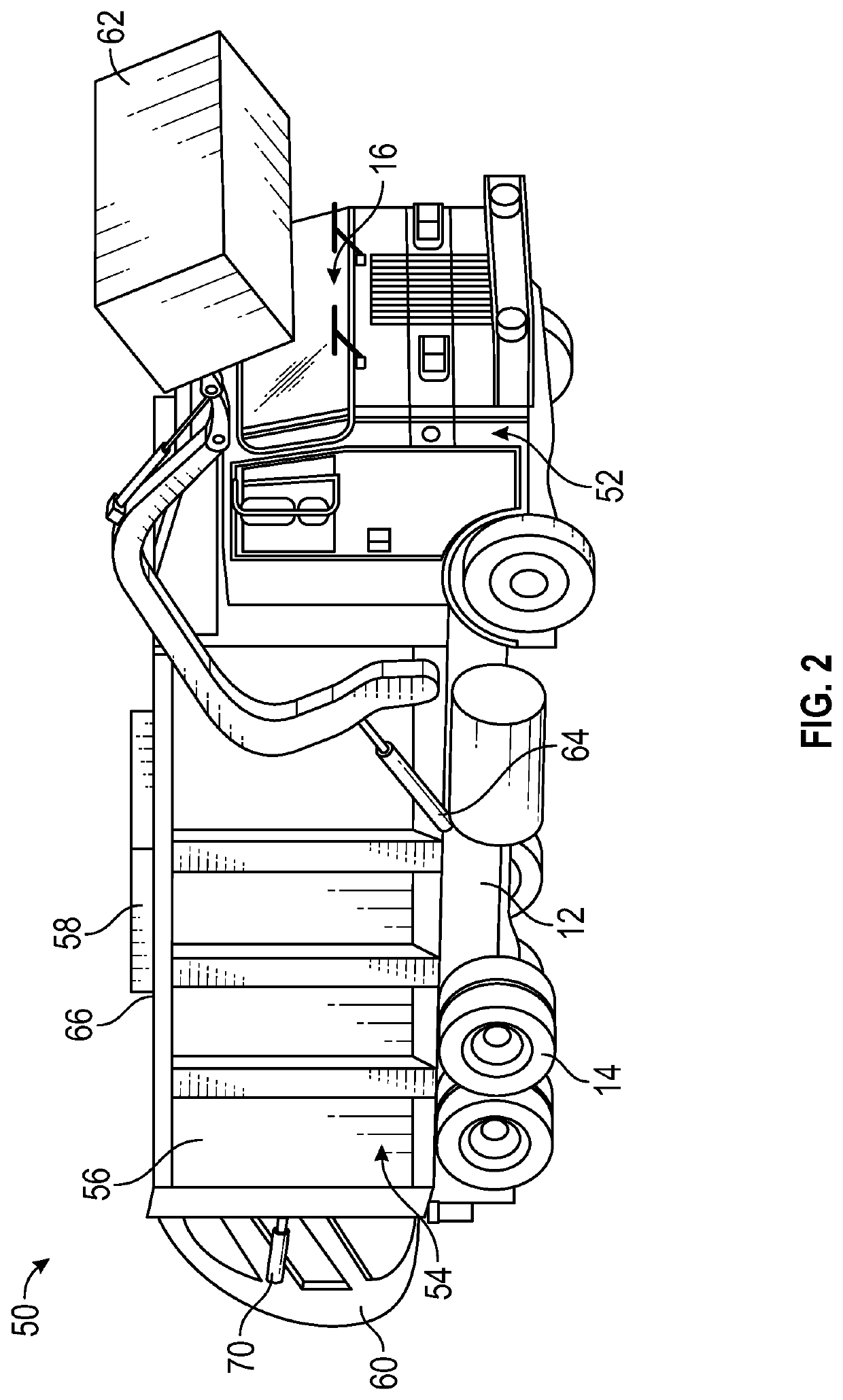

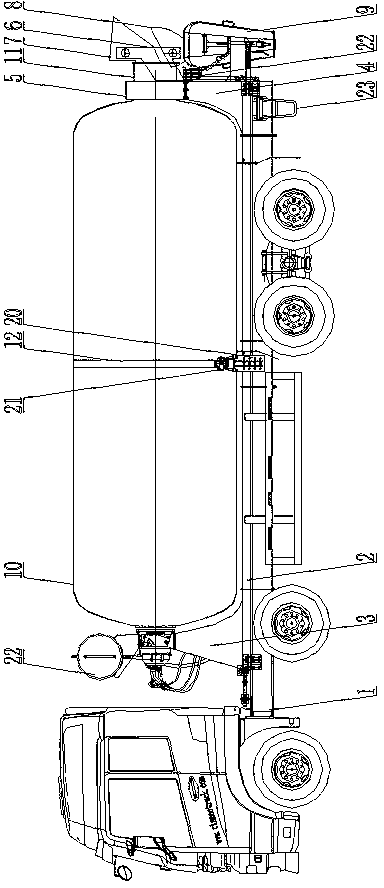

High volume portable concrete batching and mixing plant having compulsory mixer with overlying supported silo

A first mixer trailer forms the plant frame foundation around a twelve-yard compulsory mixer. The compulsory mixer is mounted for elevation relative to plant frame foundation by hydraulic lifting columns. In system erection, a cement silo trailer is first mounted to the top of the compulsory mixer when the compulsory mixer is at ground level. Thereafter, both the mounted silo and the compulsory mixer are raised and pinned in place by the hydraulic lifting columns so that gravitational discharge of mixed concrete can occur directly from the compulsory mixer to an underlying transporting apparatus, usually a truck.

Owner:GUNTERT & ZIMMERMAN CONSTR DIV

High volume portable concrete batching and mixing plant having compulsory mixer with overlying supported silo

A first mixer trailer forms the plant frame foundation around a twelve-yard compulsory mixer. The compulsory mixer is mounted for elevation relative to plant frame foundation by hydraulic lifting columns. In system erection, a cement silo trailer is first mounted to the top of the compulsory mixer when the compulsory mixer is at ground level. Thereafter, both the mounted silo and the compulsory mixer are raised and pinned in place by the hydraulic lifting columns so that gravitational discharge of mixed concrete can occur directly from the compulsory mixer to an underlying transporting apparatus, usually a truck.

Owner:GUNTERT & ZIMMERMAN CONSTR DIV

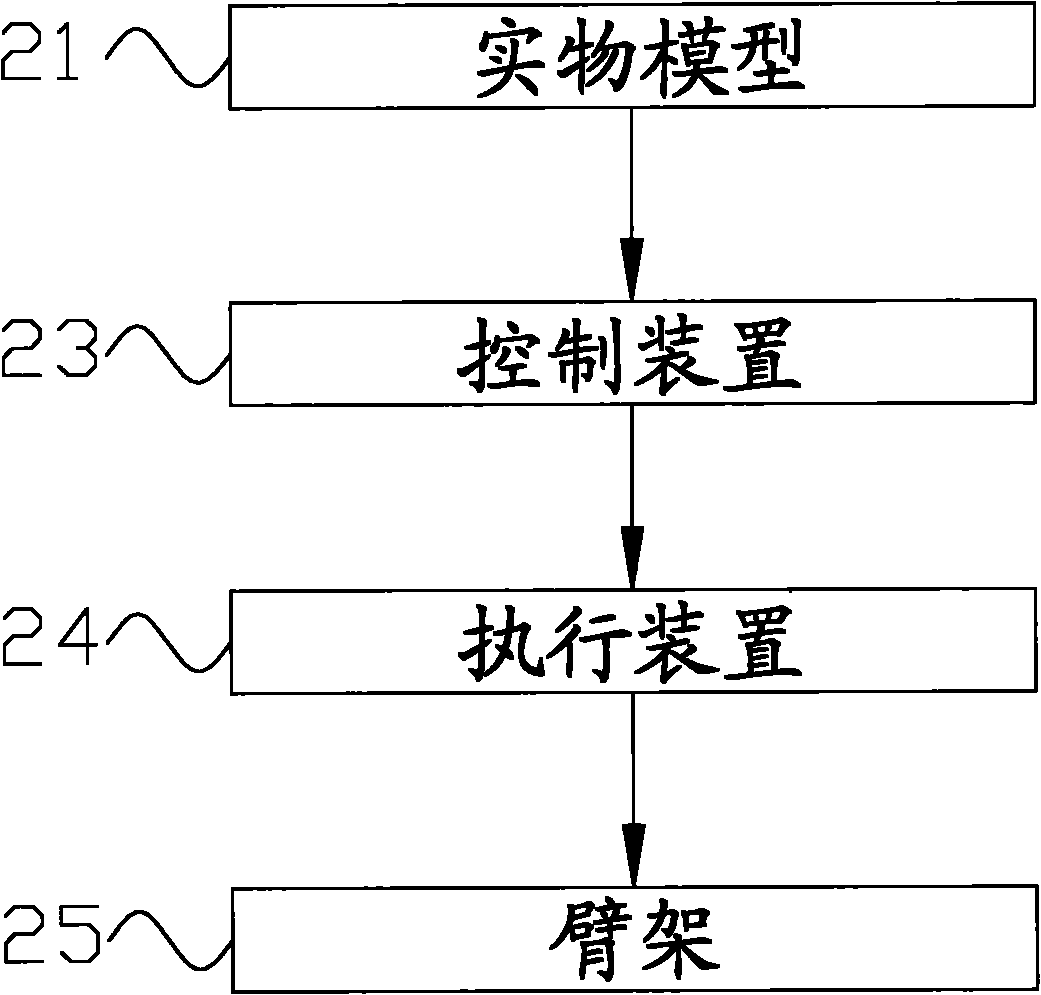

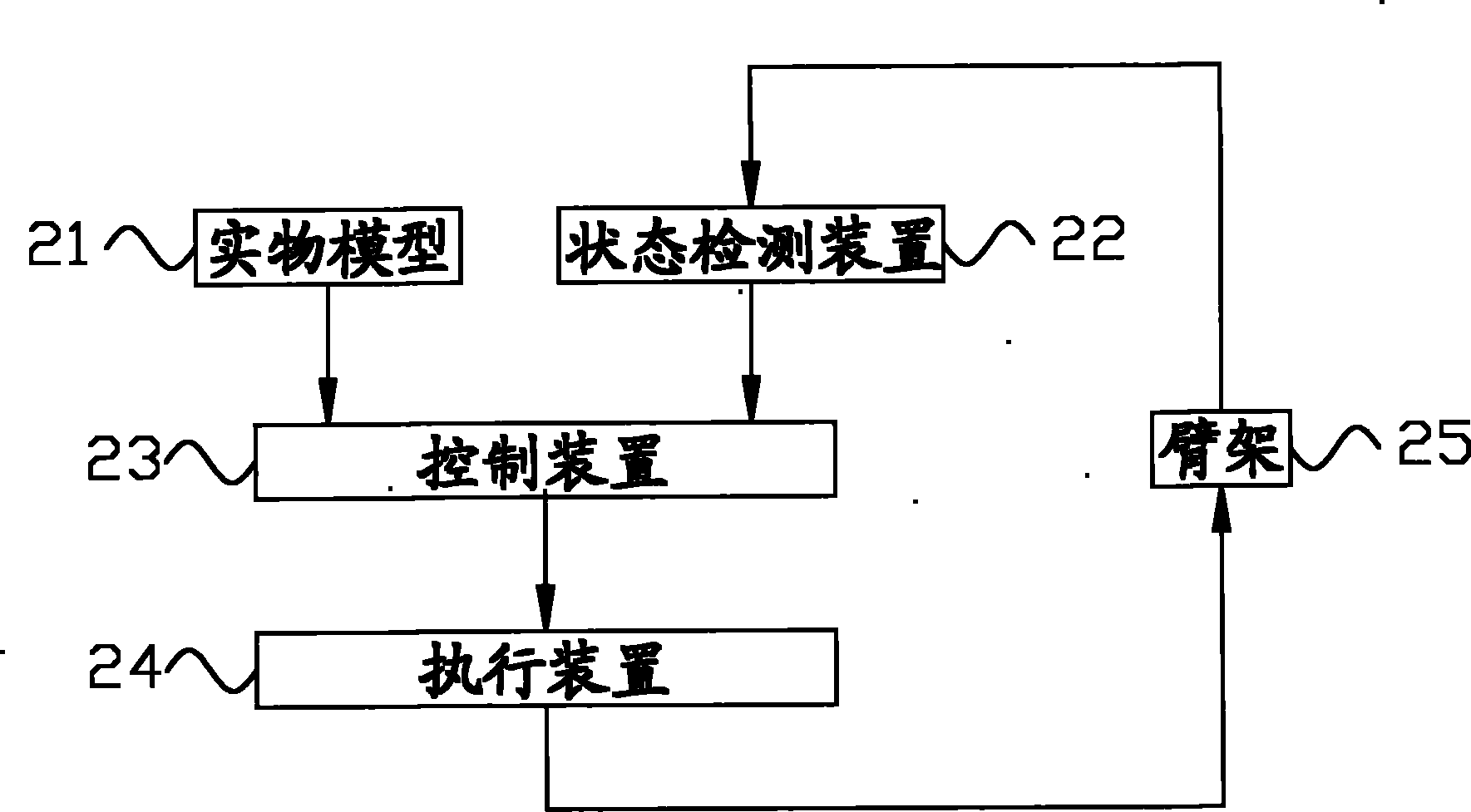

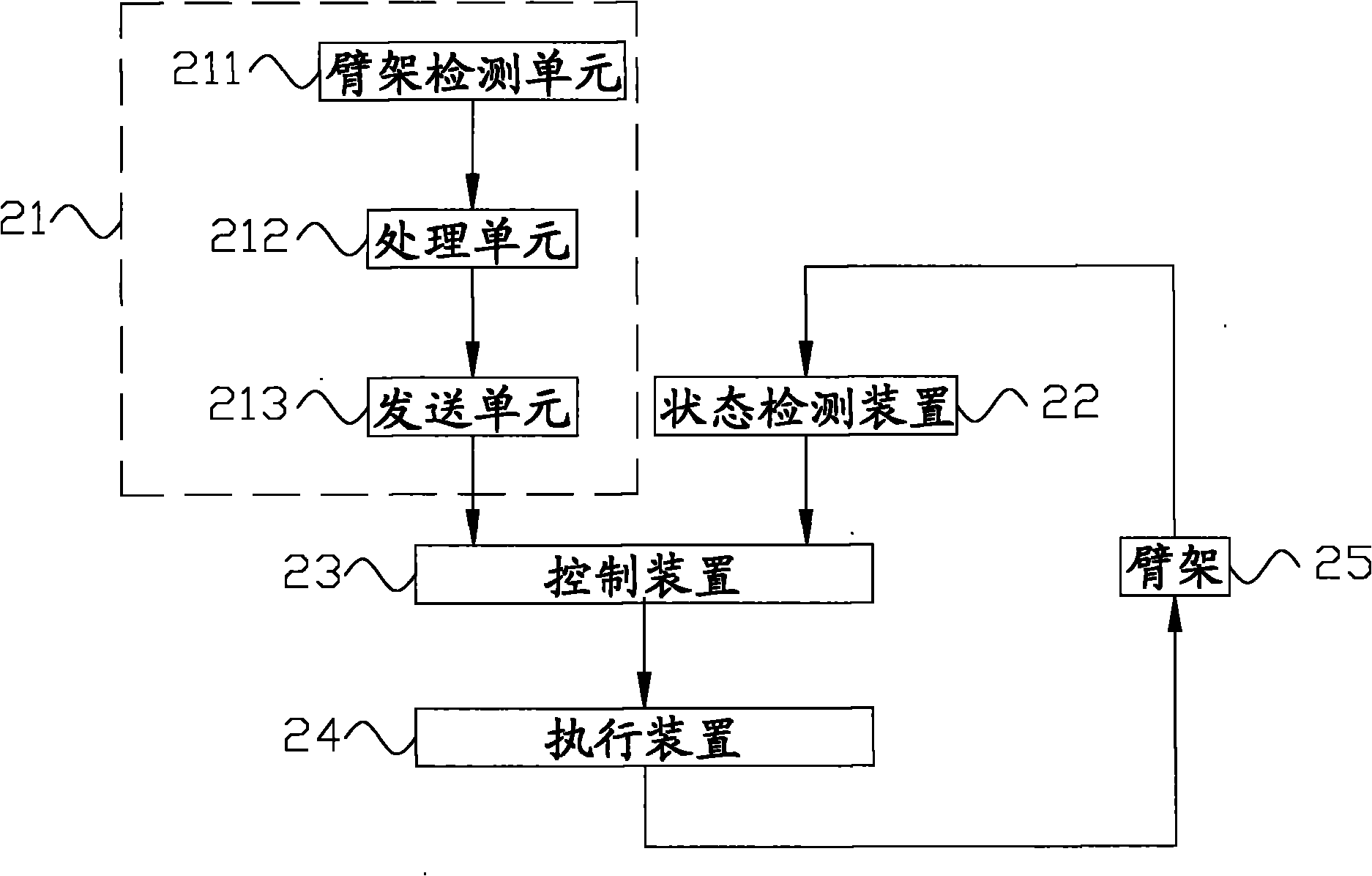

Engineering plant and arm support control system thereof

The invention discloses an arm support control system, which comprises a material object model (21), a control device (23) and an execution device (24), wherein the material object model (21) has a structure the same as that of an engineering plant, and is used for inputting a target position signal of an arm support (25) of the engineering plant by setting the model arm support state of the material object model (21); the control device (23) is used for receiving the target position signal, obtaining a movement path of the arm support (25) according to a preset control strategy and transmitting a control instruction; and the execution device (24) is used for controlling the arm support (25) to move according to the control instruction until the arm support (25) reaches a target position. The system provided by the invention improves the accuracy of control over the movement of the arm support of the engineering plant, increases an arm support state regulation speed, and prolongs the service life of the engineering plant. The invention also discloses the engineering plant and an arm support control method.

Owner:SANY HEAVY IND CO LTD (CN)

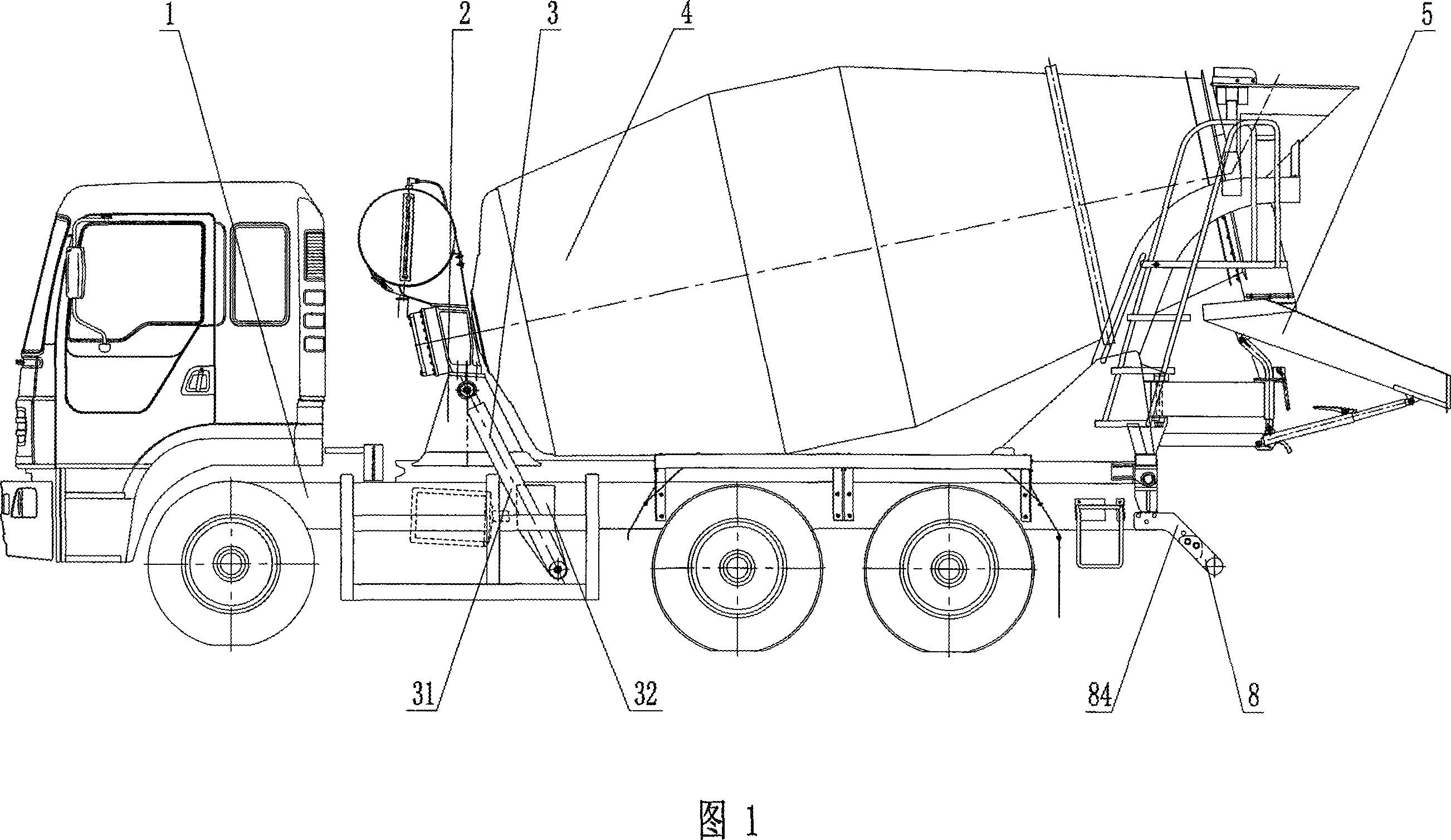

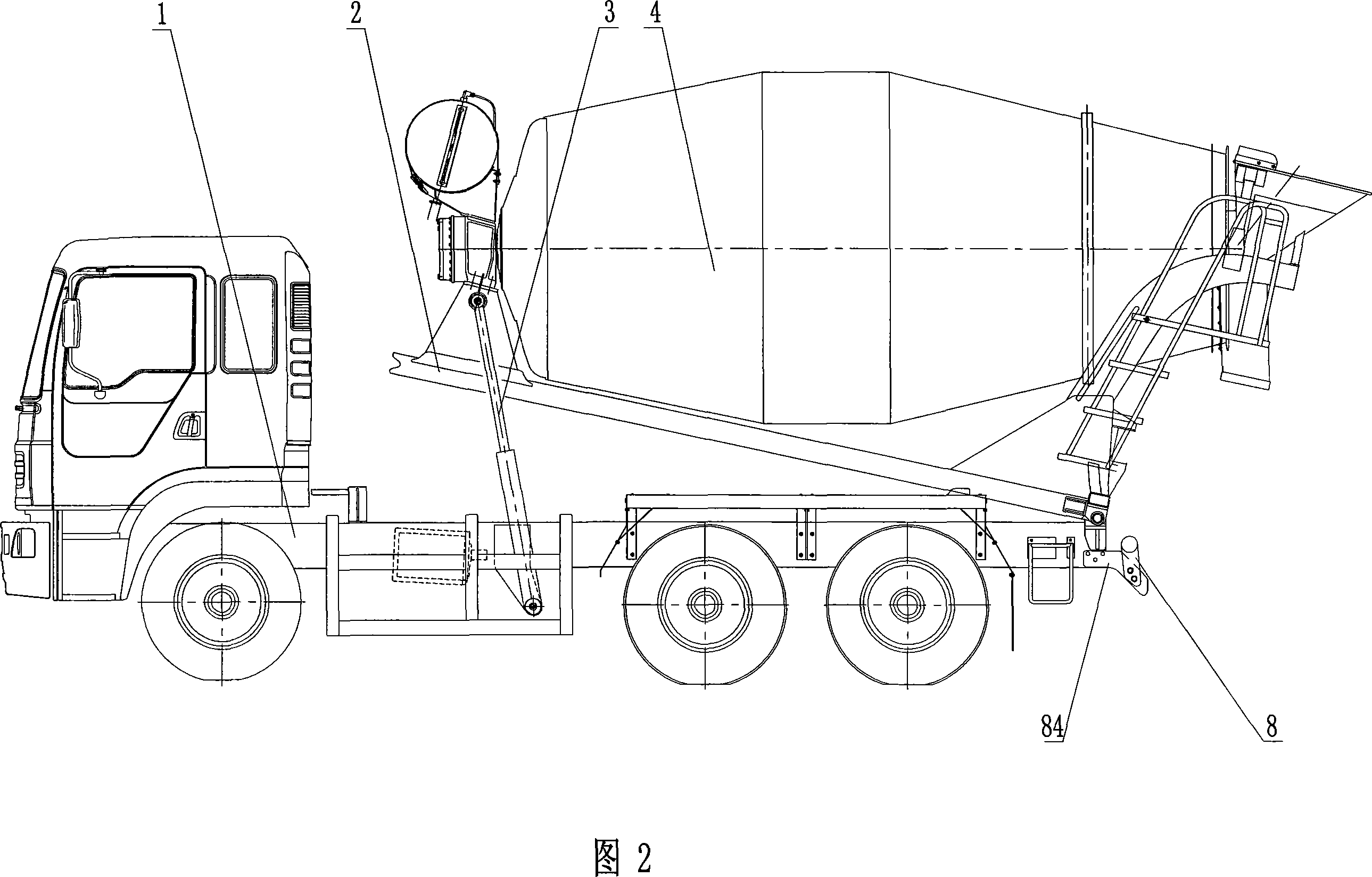

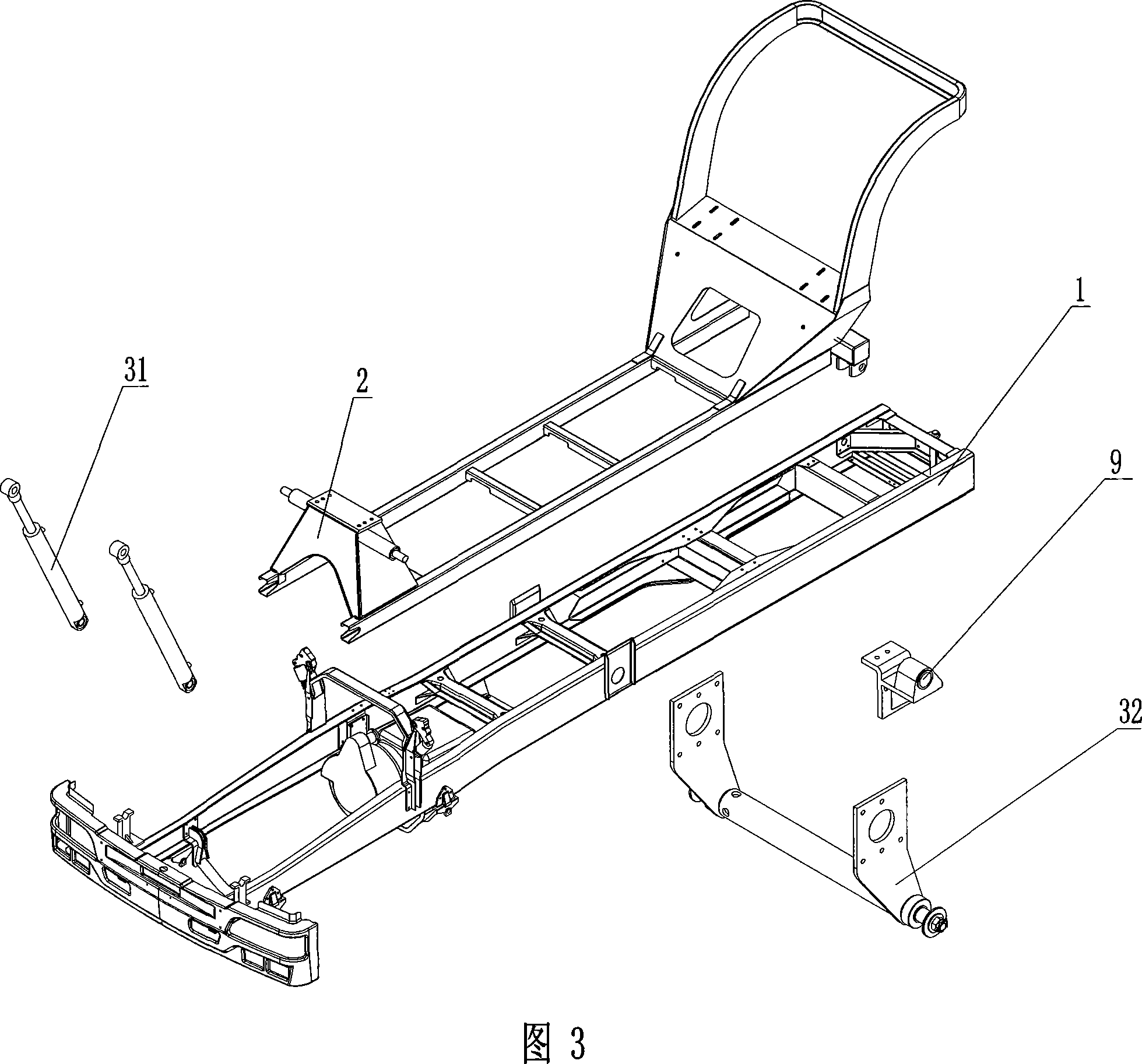

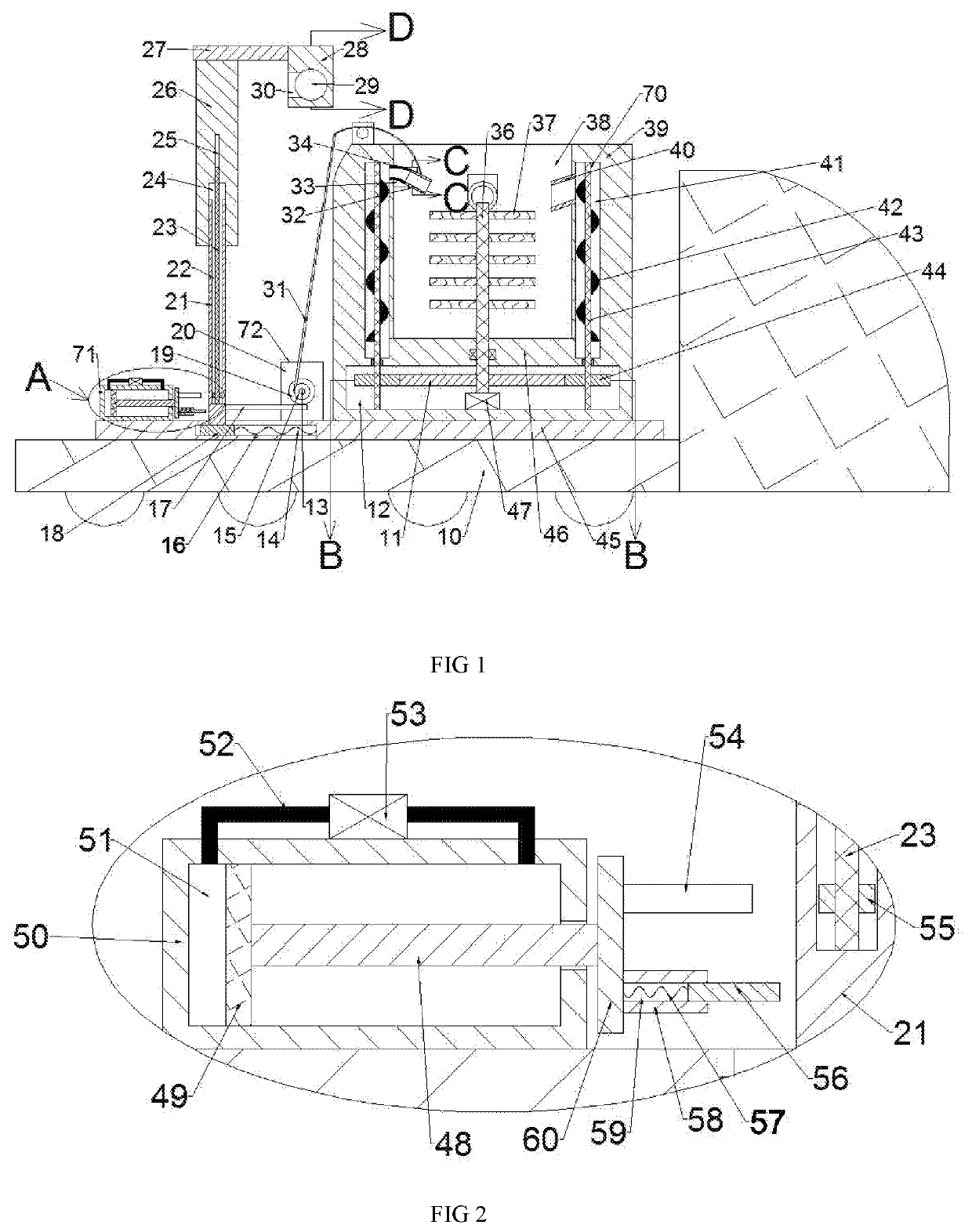

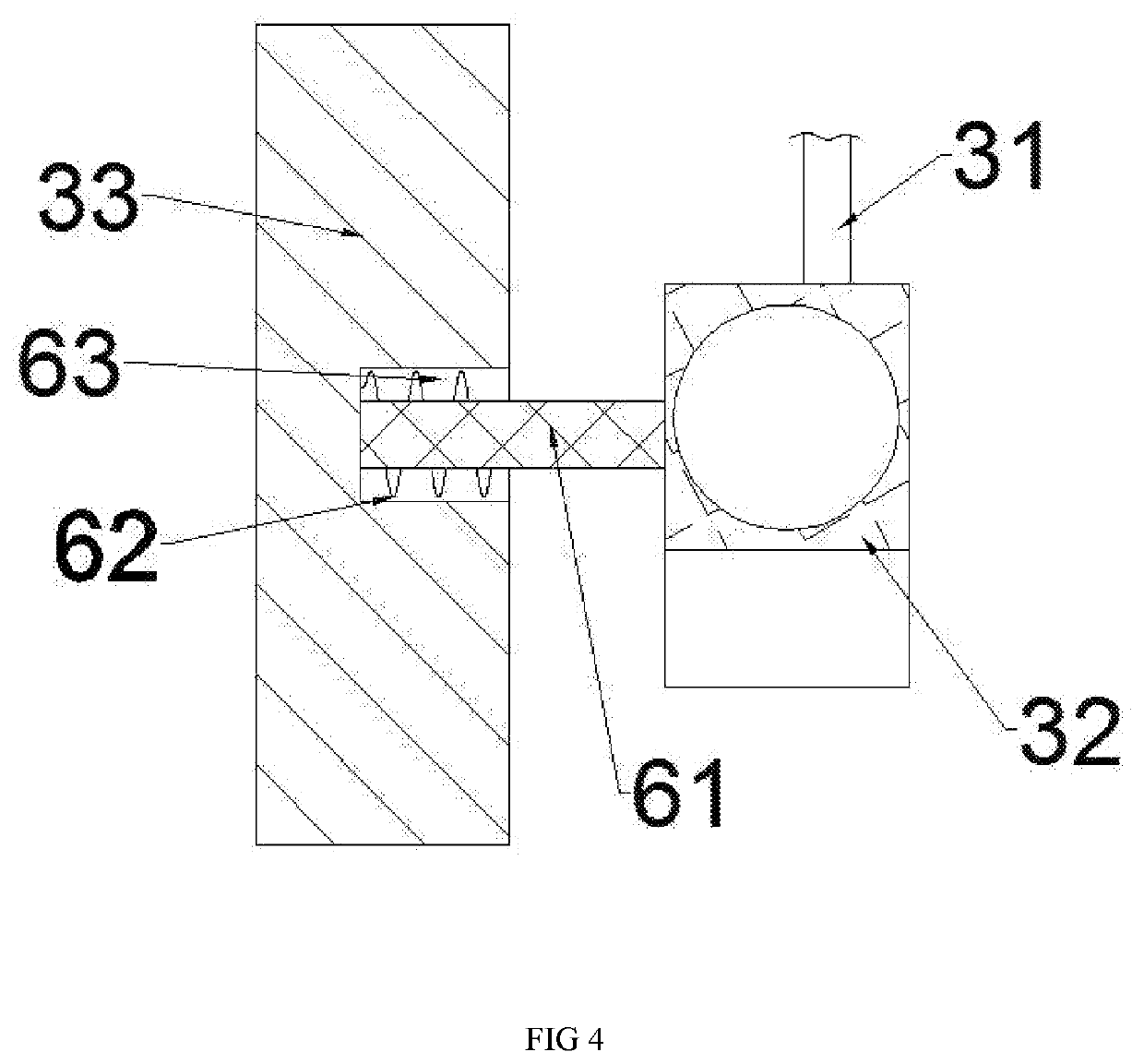

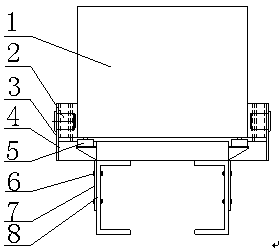

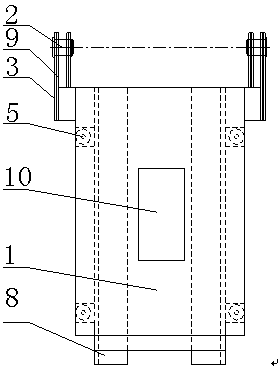

Concrete mixing truck with lifting device

ActiveCN101053980AIncrease the output speedHigh degree of mechanizationConcrete transportationDischarging apparatusVehicle frameSlope angle

The present invention relates to a concrete agitator truck with a lift system and a long life, which is capable of realizing unloading at different slope angles, preventing the agitator drum and subframe from jumping during the running process of the vehicle, and being used for a plurality of operating conditions. The concrete agitator truck with a lift system comprises a chassis, a subframe and a agitator drum supported on the subframe, wherein the tail part of the subframe is hinged with the tail part of the chassis, the front end of the subframe is provided with the lift system which comprises a lift oil cylinder and an oil cylinder support which is arranged on the chassis, the lift oil cylinder is hinged with the oil cylinder support at one end and is hinged with the subframe at the other end.

Owner:SANY HEAVY IND CO LTD (CN)

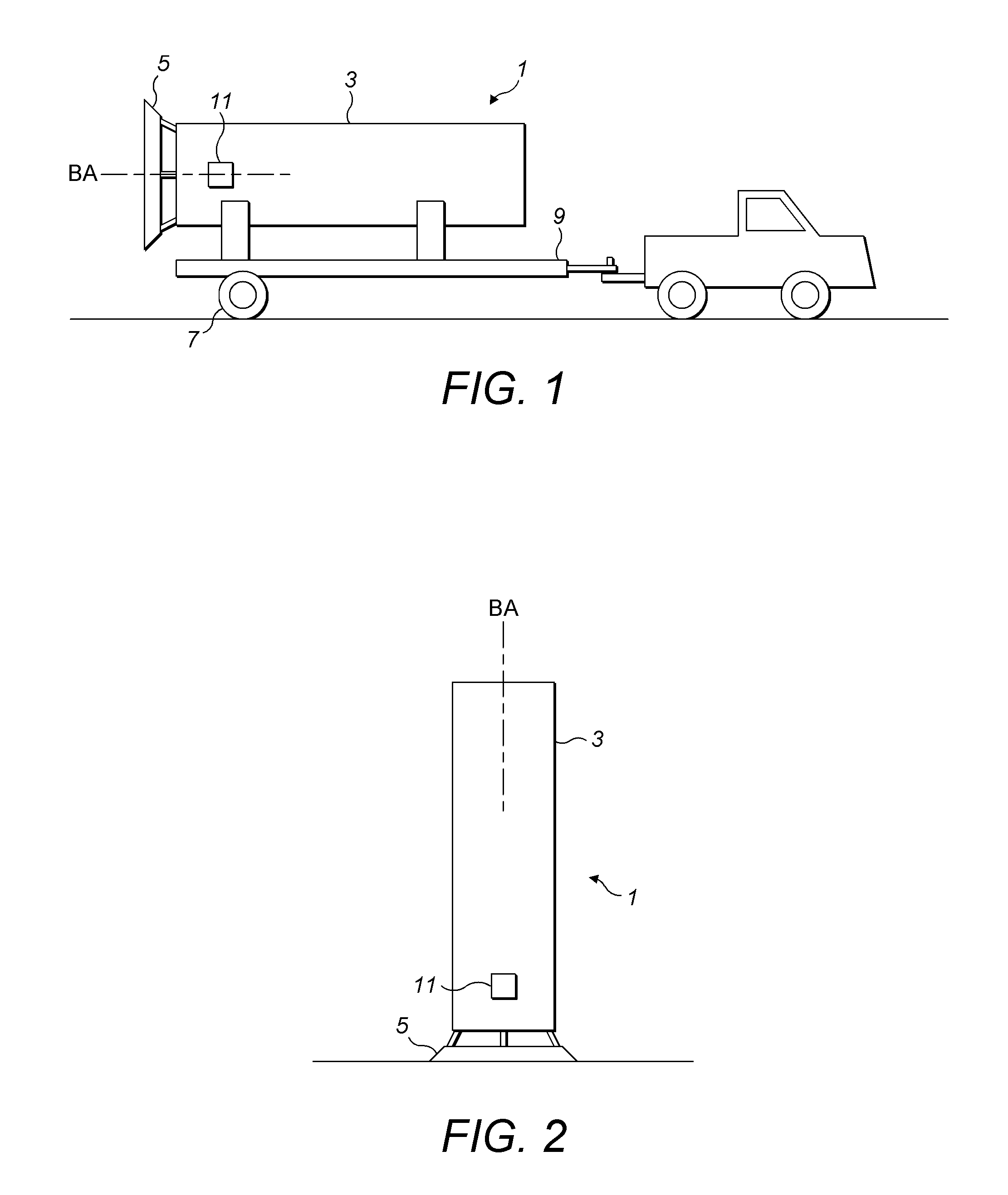

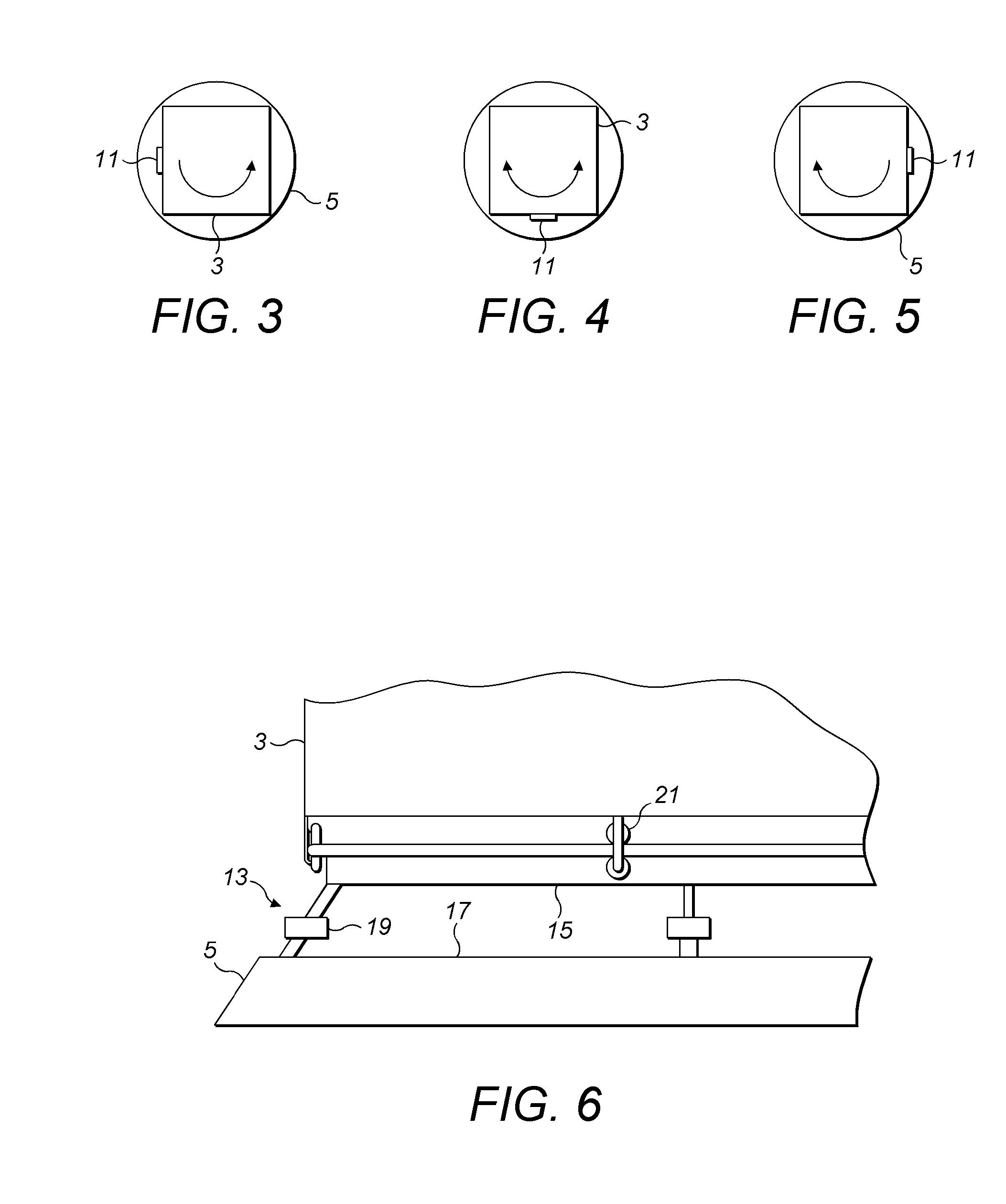

Rotatable Bin or Like Object

ActiveUS20120024738A1Considerable versatilityFast spinConcrete transportationTank vehiclesEngineeringHorizontal orientation

A transportable apparatus has a main body configured to be transported in a horizontal orientation, and then raised to a vertical orientation in a working position. A base is mounted on the bottom end of the main body such that the main body rests on the base in the working position, and such that the base is carried at a rear end of the main body when the main body is in a horizontal transport position supported on. The base is rotatable about a vertical base axis such that the main body can be rotated with respect to the base about the base axis. A frame and wheels can be pivotally attached to the main body to transport the main body and then be stored in a vertical orientation along a wall of the man body in the working position.

Owner:HALLIBURTON ENERGY SERVICES INC

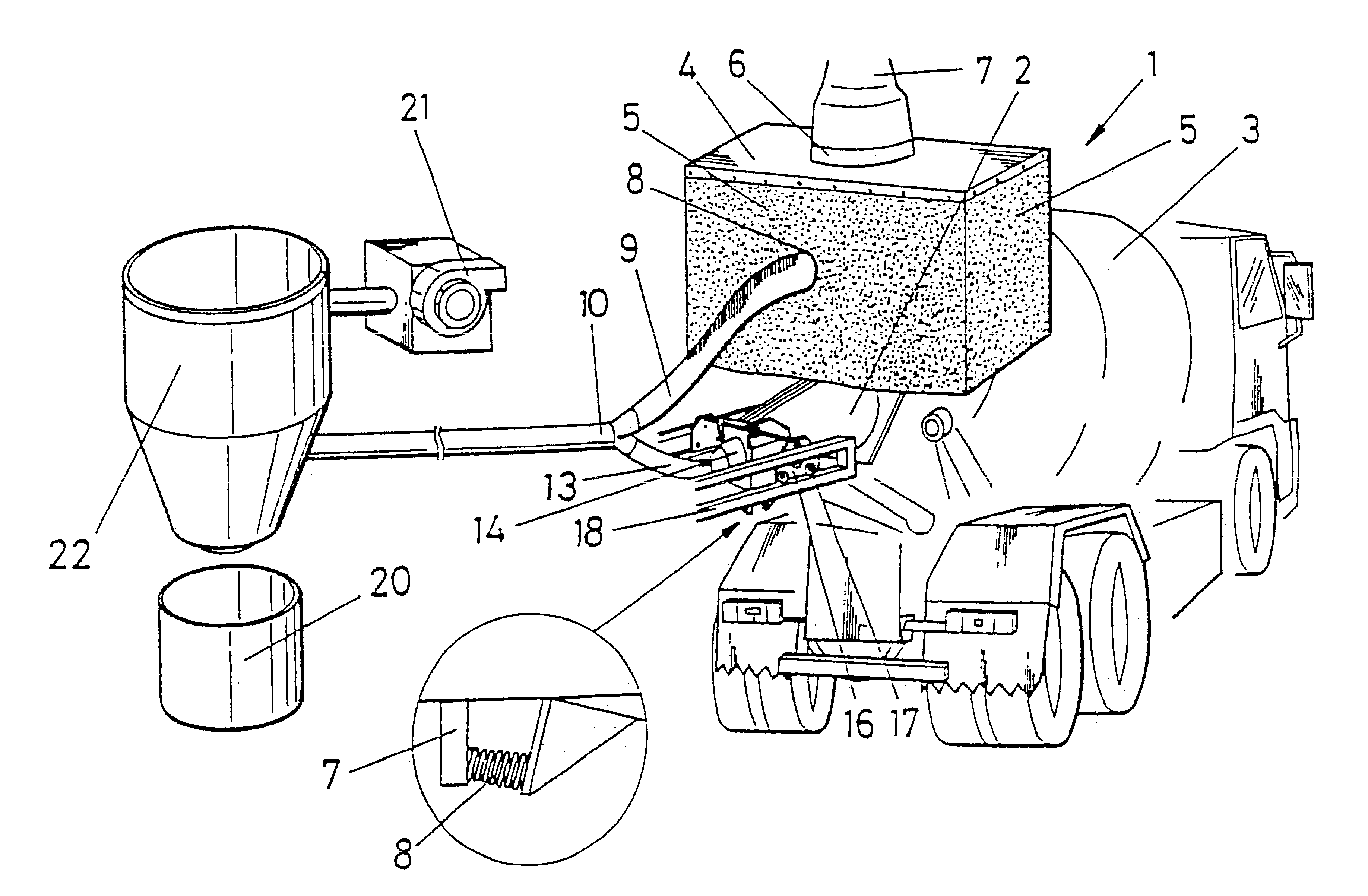

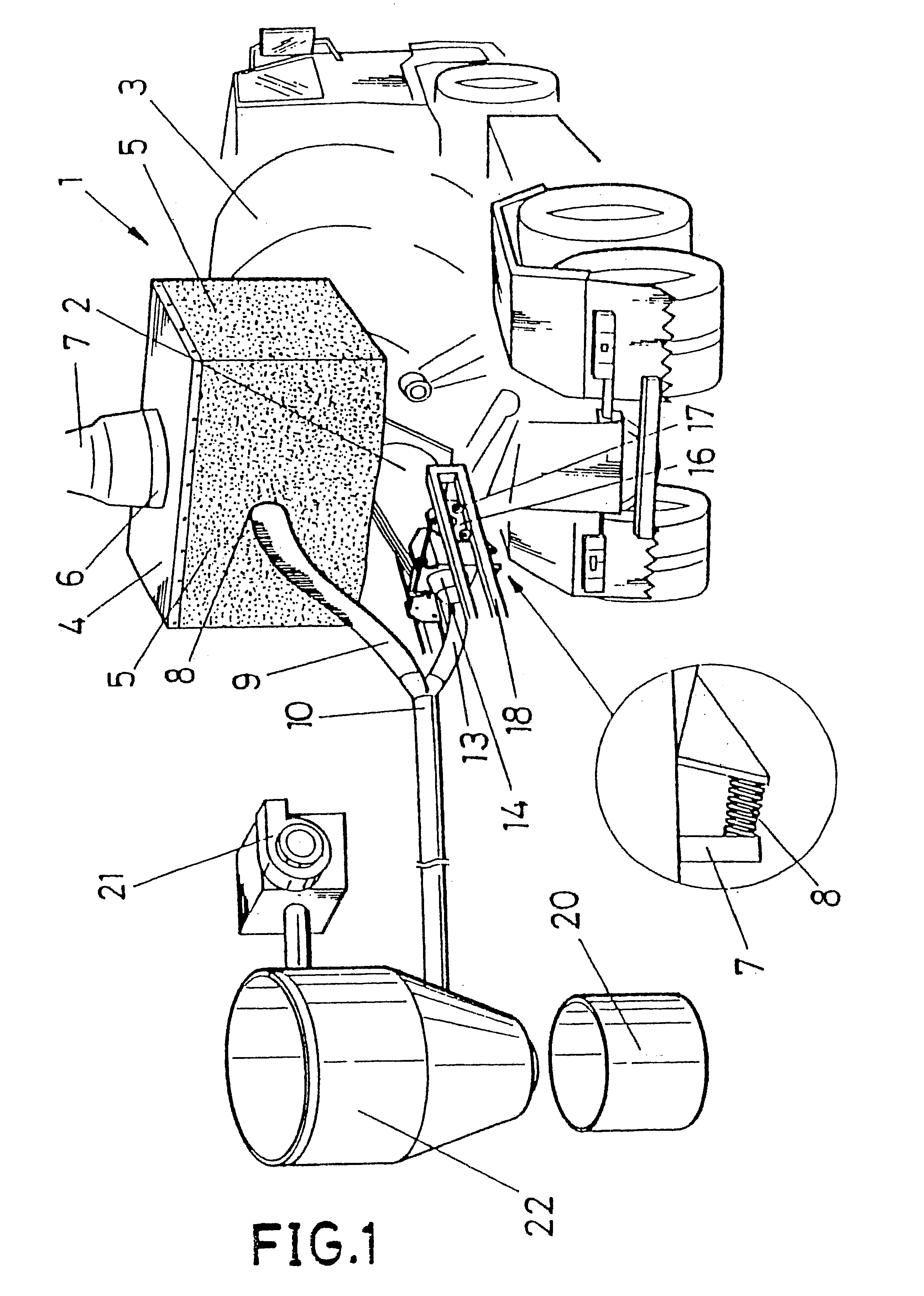

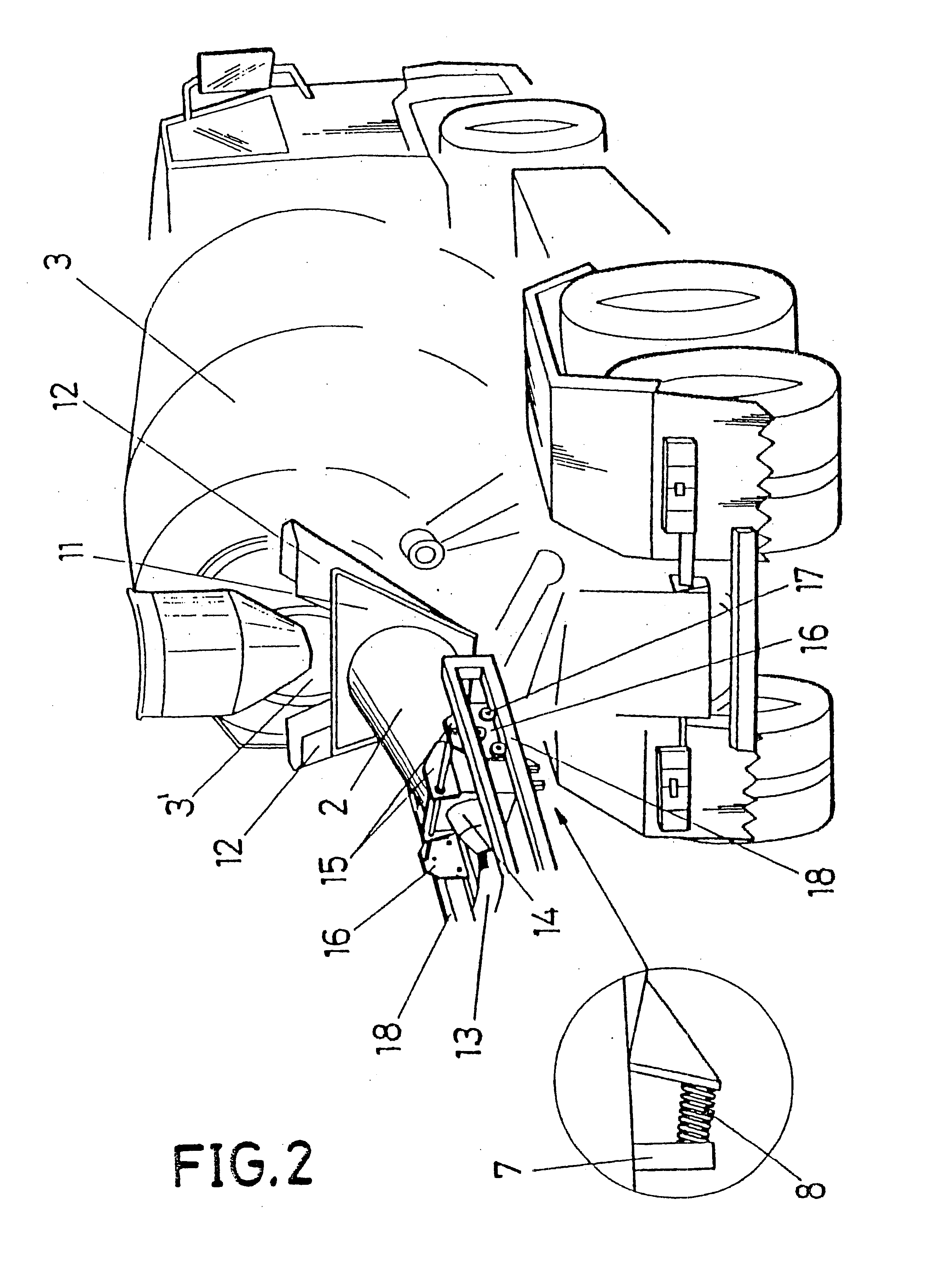

Device for capturing dust in the loading of concrete mixer trucks

The device comprises a container (1) with a mouth (4') to which the end of the conduit through which cement falls into the drum (3) of a concrete mixer truck is coupled, said container being fixed and having a trap door (6) for adapting the back part of said drum (3) so that the dust originating from the fall of the cement remains inside sad container (1). Part of the dust goes out through the conduit (9) to a common collector (10) while the other part is suctioned in through a suctioning head (2) formed by a truncated cone-shaped body, the biggest base thereof being coupled to the mouth (3') for loading the drum (3) and the smallest base leading to a conduit (13) that ends in the common collector (10). The dust is suctioned in from said collector and passed through a container or hopper (22) with filters with the purpose of cleaning and final reception in a tank or common collector (20).

Owner:ESPINA FRUTOS JUAN JOSE

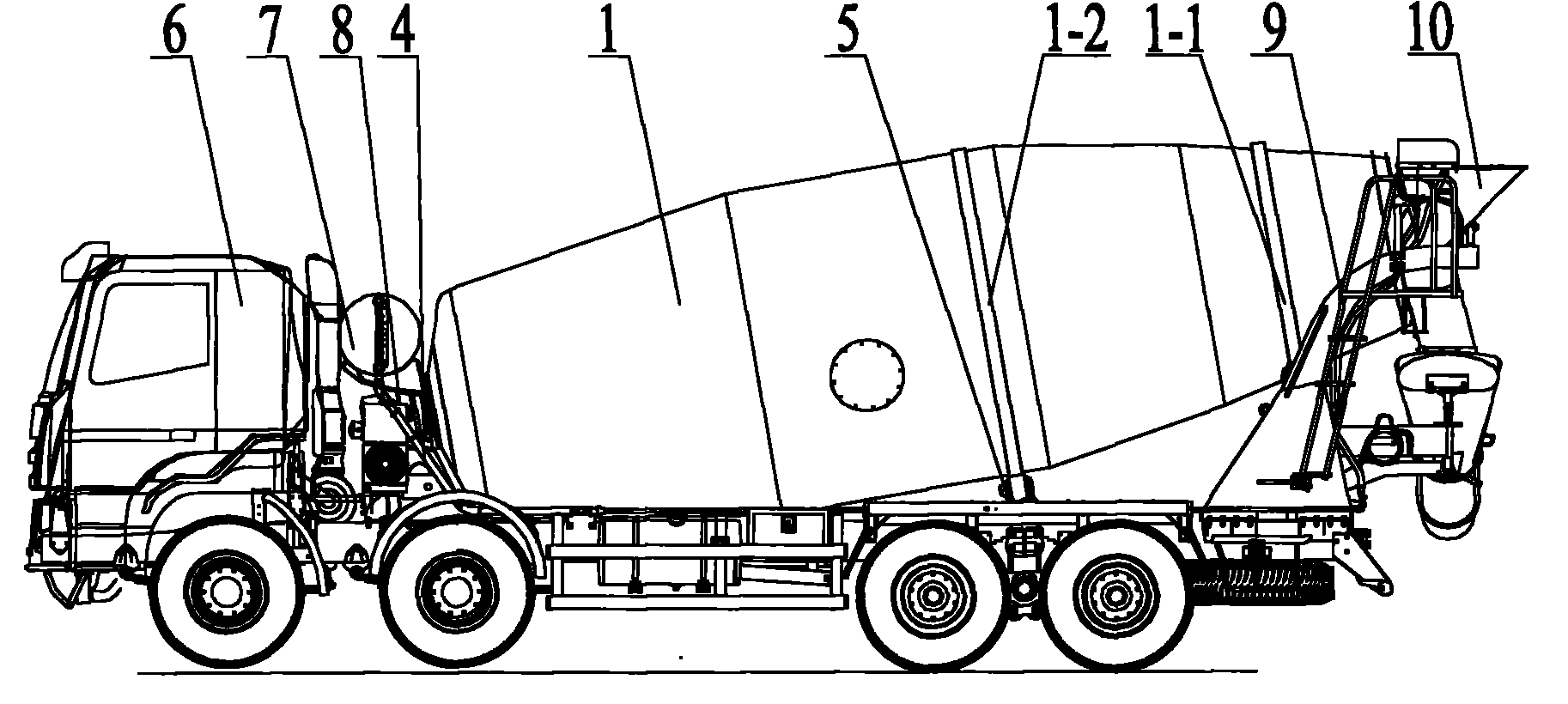

Agitating lorry

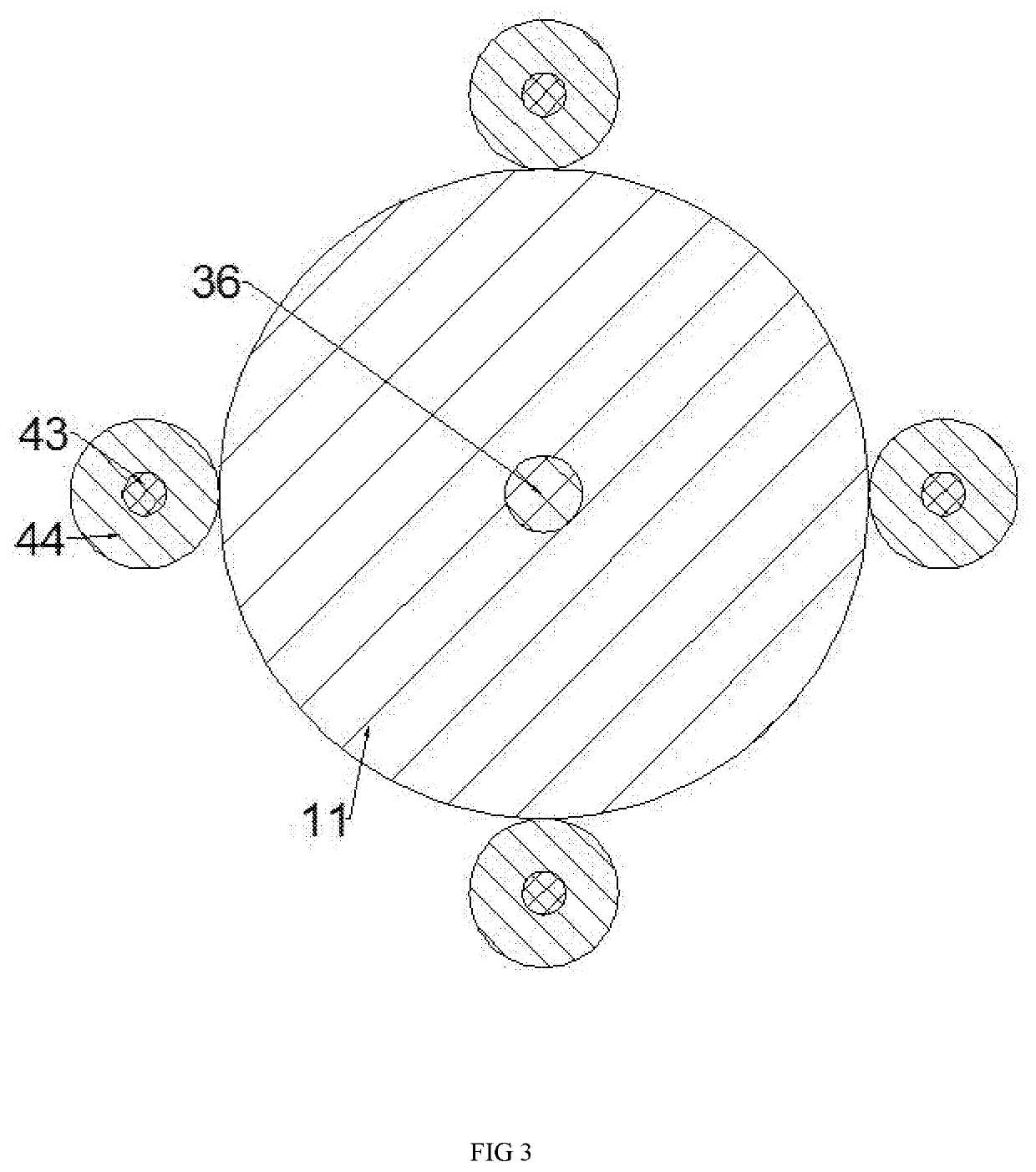

The invention relates to the technical field of agitating lorries, and discloses an agitating lorry. The agitating lorry comprises an agitating barrel (1), a front stand (4) and a rear stand (2); the front end of the agitating barrel (1) is supported by the front stand (4), a rear conical roller way (1-1) of the agitating barrel (1) is supported by a rear conical supporting wheel (3) fixed on the rear stand (2); the barrel body of the agitating barrel (1) is also provided with a middle roller way (1-2); and the corresponding position of a frame of the agitating lorry is provided with a middle supporting wheel (5) for supporting the middle roller way (1-2). The agitating lorry with the structure is characterized in that the middle supporting wheel (5) bears partial load of the agitating barrel (1), so the bearing capacities of the front stand (4) and the rear stand (2) are lightened, the frame is stressed uniformly, the plastic deformation and the borne bending stress of the frame are reduced, and the frame and the agitating barrel (1) do not produce interference.

Owner:SANY AUTOMOBILE MFG CO LTD

Automatic processing irrigation truck for concrete pier for bridge pier

InactiveUS20200114542A1Extend concrete transportation timeStable outputConcrete transportationServomotor componentsDrive shaftArchitectural engineering

The invention discloses an automatic processing irrigation truck for concrete pier for bridge pier, and includes a body plate, a bottom plate is fixed on the end surface of the body plate, and a storage block is fixed on the right side of the end surface of the bottom plate. A processing mechanism is provided in the storage block, and the processing mechanism includes a stirring cavity with an opening facing upward. The agitating chamber is used for containing concrete. The agitating chamber is provided with a rotatable drive shaft. Ten ten agitating rods are evenly fixed on the drive shaft. The device can be used for bridge pier during transportation. The processing of concrete, by means of stirring and spiral circulation, can not only make the processing fully, but also prevent the subsequent layering of the concrete, ensure the quality of the concrete, and use spiral transportation when needed.

Owner:ZHANG HUANGEN

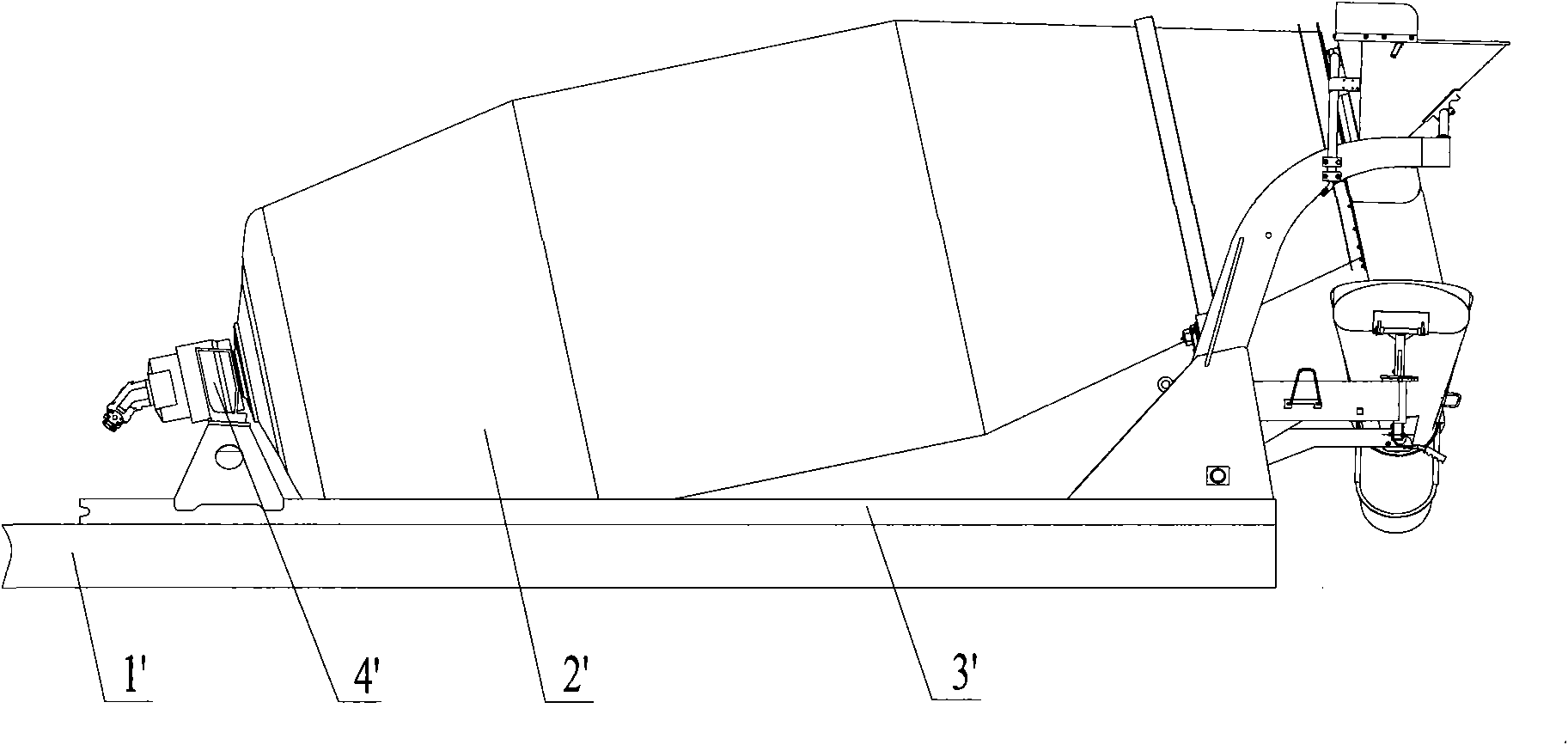

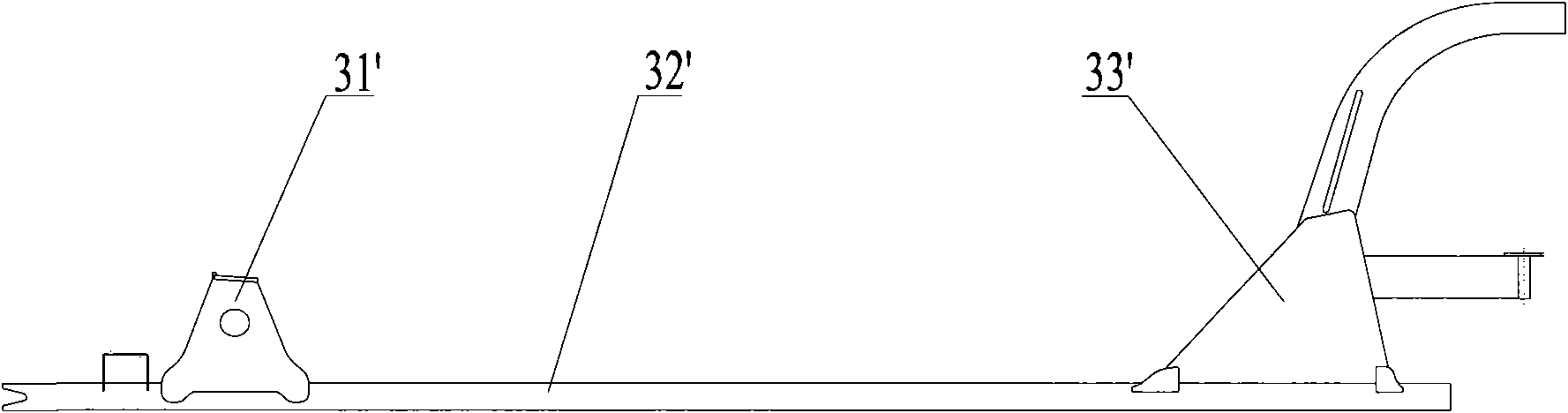

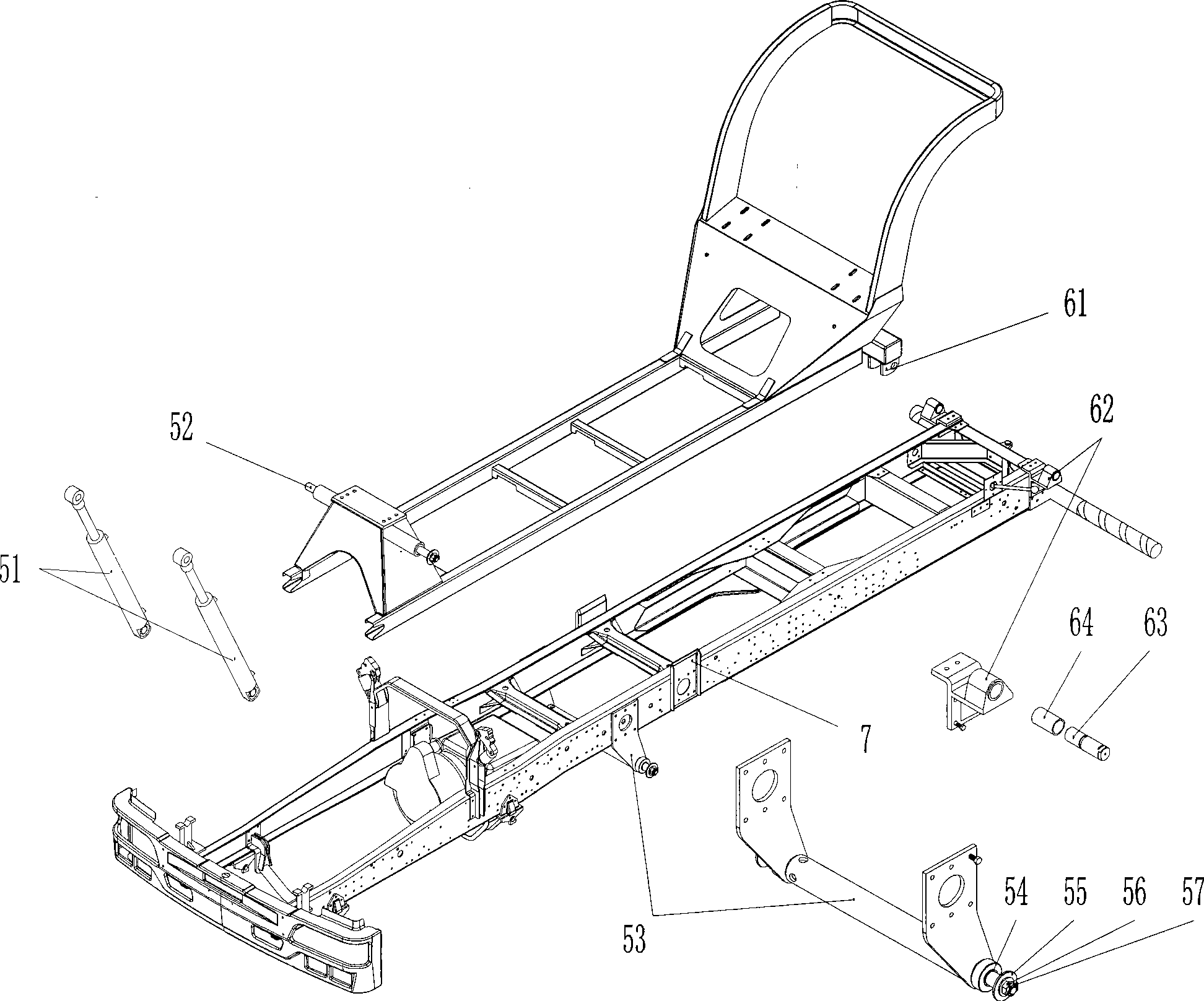

Concrete stirring truck with lift device and steady rest

ActiveCN101474976AHigh degree of mechanizationImprove work efficiencyConcrete transportationUnderstructuresVehicle frameControl theory

The invention discloses a concrete mixing transportation truck with a lifting device and stabilizing frames, which comprises a chassis, an auxiliary frame, a stirring drum and the lifting device, wherein one end of the auxiliary frame is hinged to the chassis, the stirring drum is supported on the auxiliary frame, the lifting device is arranged between the auxiliary frame and the chassis, and more than one stabilizing frame is arranged between the auxiliary frame and the chassis. The invention is the concrete mixing transportation truck which has the advantages of simple and compact structure, low cost and good stability, can improve the service life of the whole truck, and is provided with the lifting device and the stabilizing frames.

Owner:SANY AUTOMOBILE MFG CO LTD

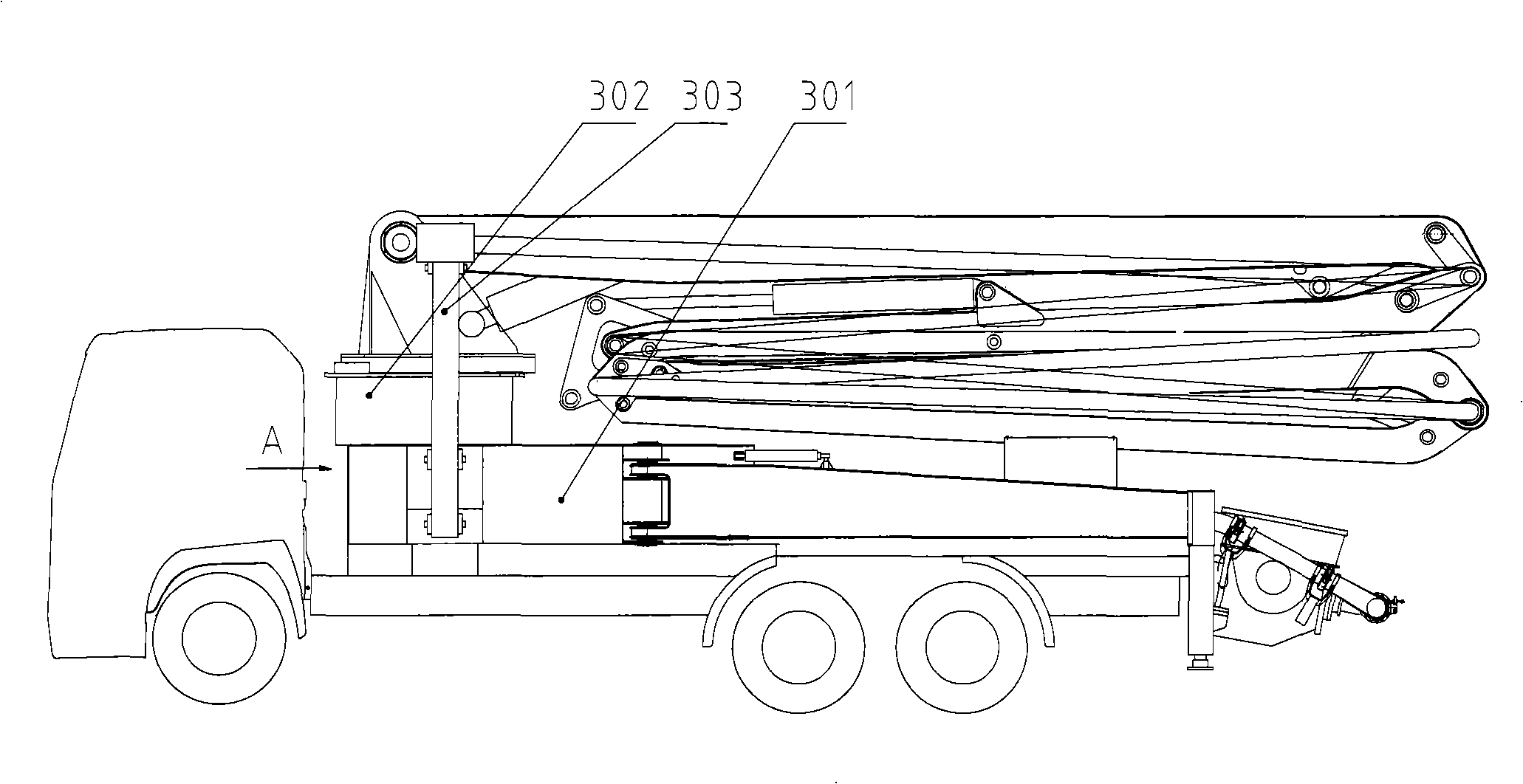

Carbon fiber composite arm rest, method for manufacturing same and concrete pump truck including same

ActiveCN102729488ACompact structureLow costConcrete transportationBuilding material handlingFiberAirbag

The invention discloses a carbon fiber composite arm rest, a method for manufacturing the same and a concrete pump truck including the same. The method for manufacturing the carbon fiber composite arm rest comprises the following steps of: filling air into a contractible airbag to form the airbag with a first status, laying carbon fiber prepreg on the outer surface of the airbag to obtain a firsttransitional component; placing the first transitional component inside a box mold, filling air into the inside of the airbag with the first status, and compressing and shaping the carbon fiber prepreg to obtain a second transitional component; warming and solidifying the second transitional component, and afterwards cooling and demoulding the second transitional component to obtain the carbon fiber arm rest. The method for manufacturing the carbon fiber composite arm rest provided by the invention goes through many times of shaping, so that the carbon fiber prepreg is more compact in structure, which helps to prepare the carbon fiber composite arm rest with excellent performance. Only simple equipments are utilized in the method for manufacturing the carbon fiber arm rest, no autoclave is utilized, so that the equipment cost and production cost are reduced.

Owner:ZOOMLION HEAVY IND CO LTD

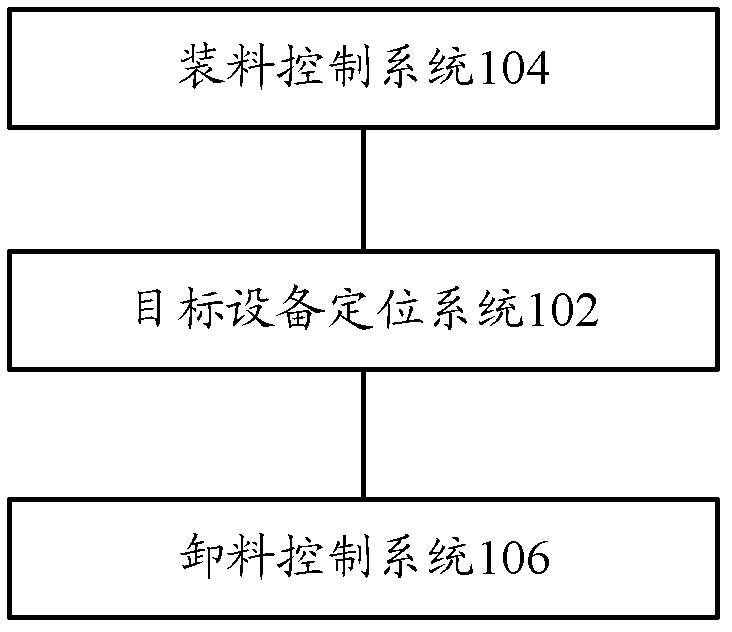

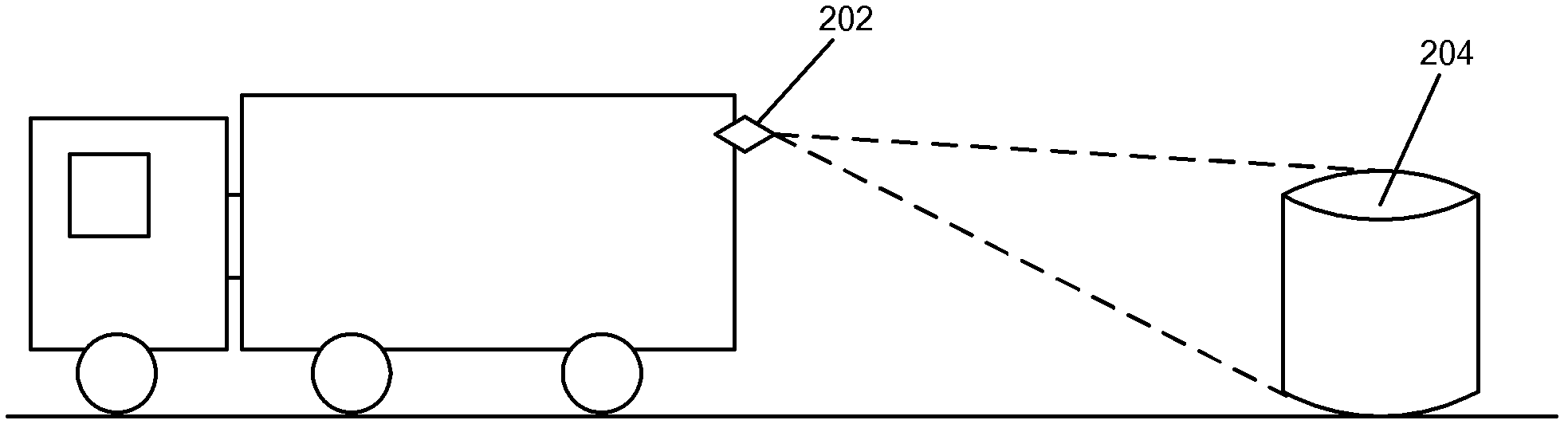

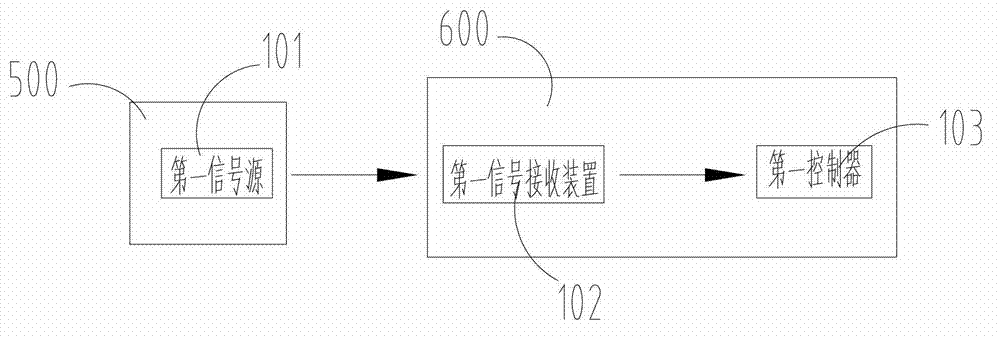

Concrete transporting equipment, loading system, unloading system and automatic loading and unloading method

InactiveCN102602318AReduce operating efficiencyConcrete transportationLoading/unloading vehicle arrangmentControl signalControl system

The invention provides concrete transporting equipment, which comprises a target equipment positioning system, a loading control system and an unloading control system, wherein the target equipment positioning system is used for determining a position and a type of target equipment which refers to concrete mixing equipment or a concrete pump; the loading control system is used for sending out a loading control signal to the concrete mixing equipment when the concrete transporting equipment arrives at the loading position of the concrete mixing equipment, so as to control the concrete mixing equipment to load the concrete transporting equipment; and the unloading control system is used for controlling the concrete transporting equipment to unload to the concrete pump when the concrete transporting equipment arrives at the unloading position of the concrete pump. Correspondingly, the invention further provides a loading system, an unloading system and an automatic loading and unloading method. By the aid of the technical scheme of the concrete transporting equipment, during loading and unloading of concrete, automatic loading / unloading is performed when the concrete transporting equipment arrives at the target positions, so that the number of construction staff is decreased, and work efficiency is improved.

Owner:SANY HEAVY IND CO LTD (CN)

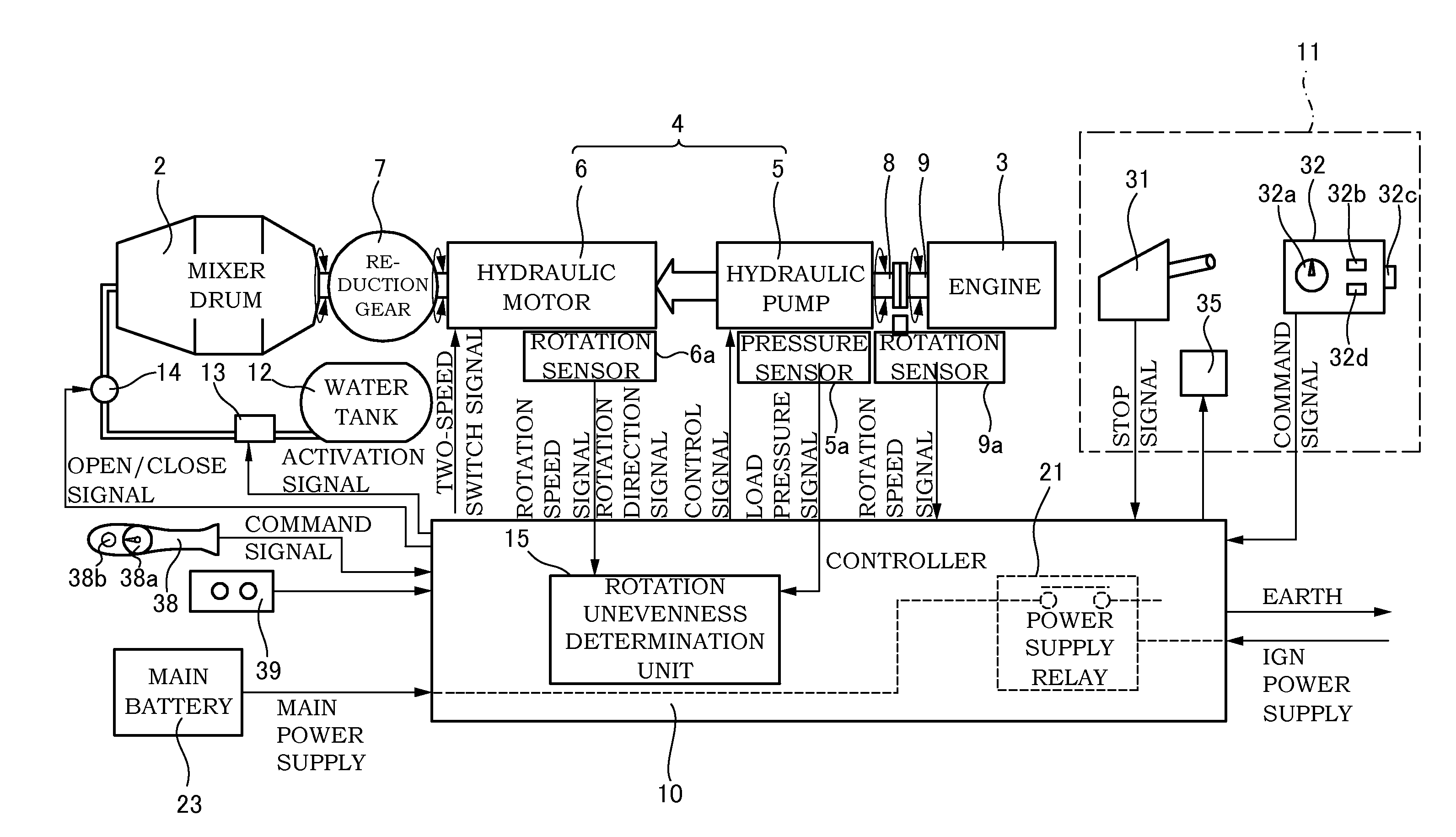

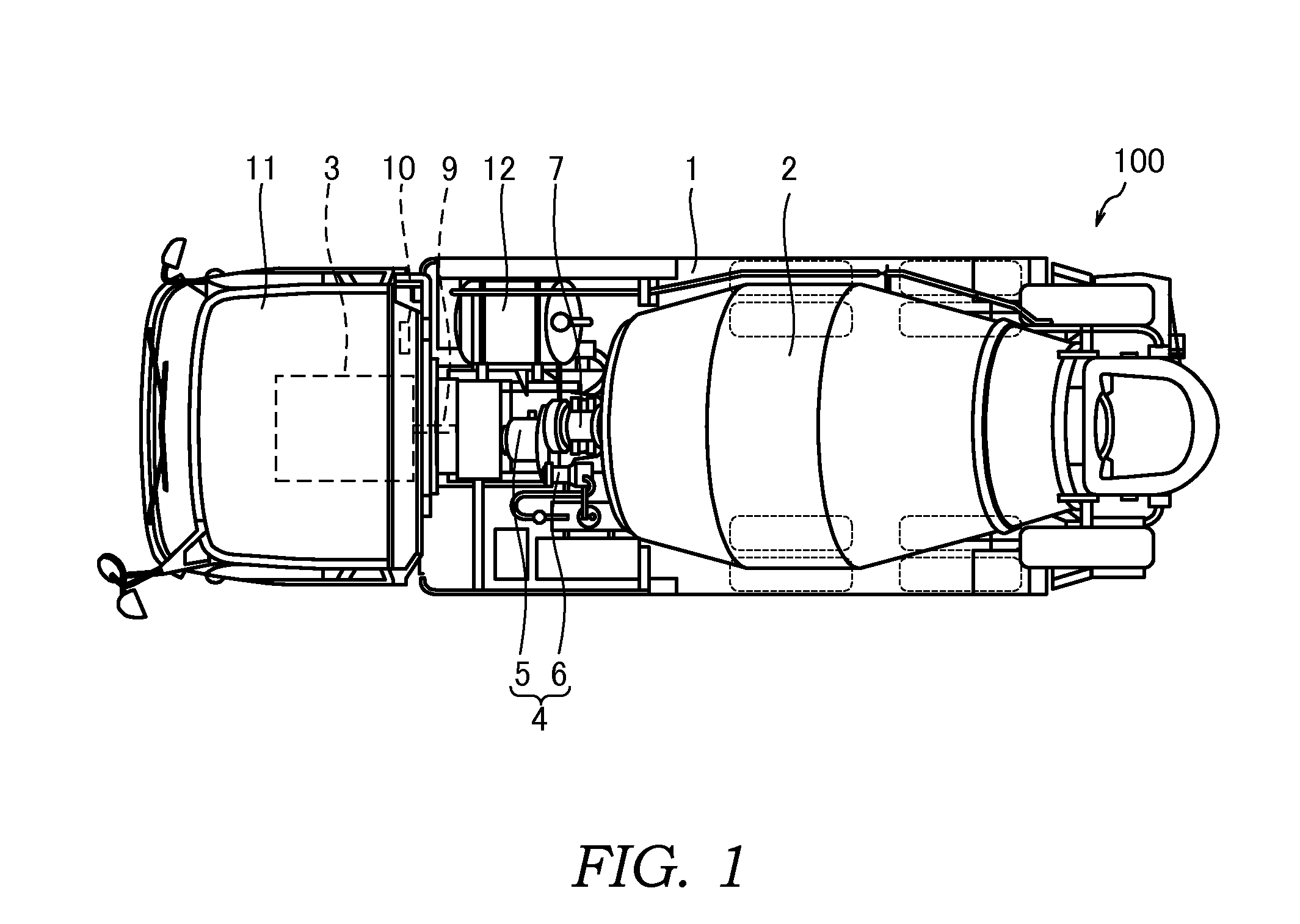

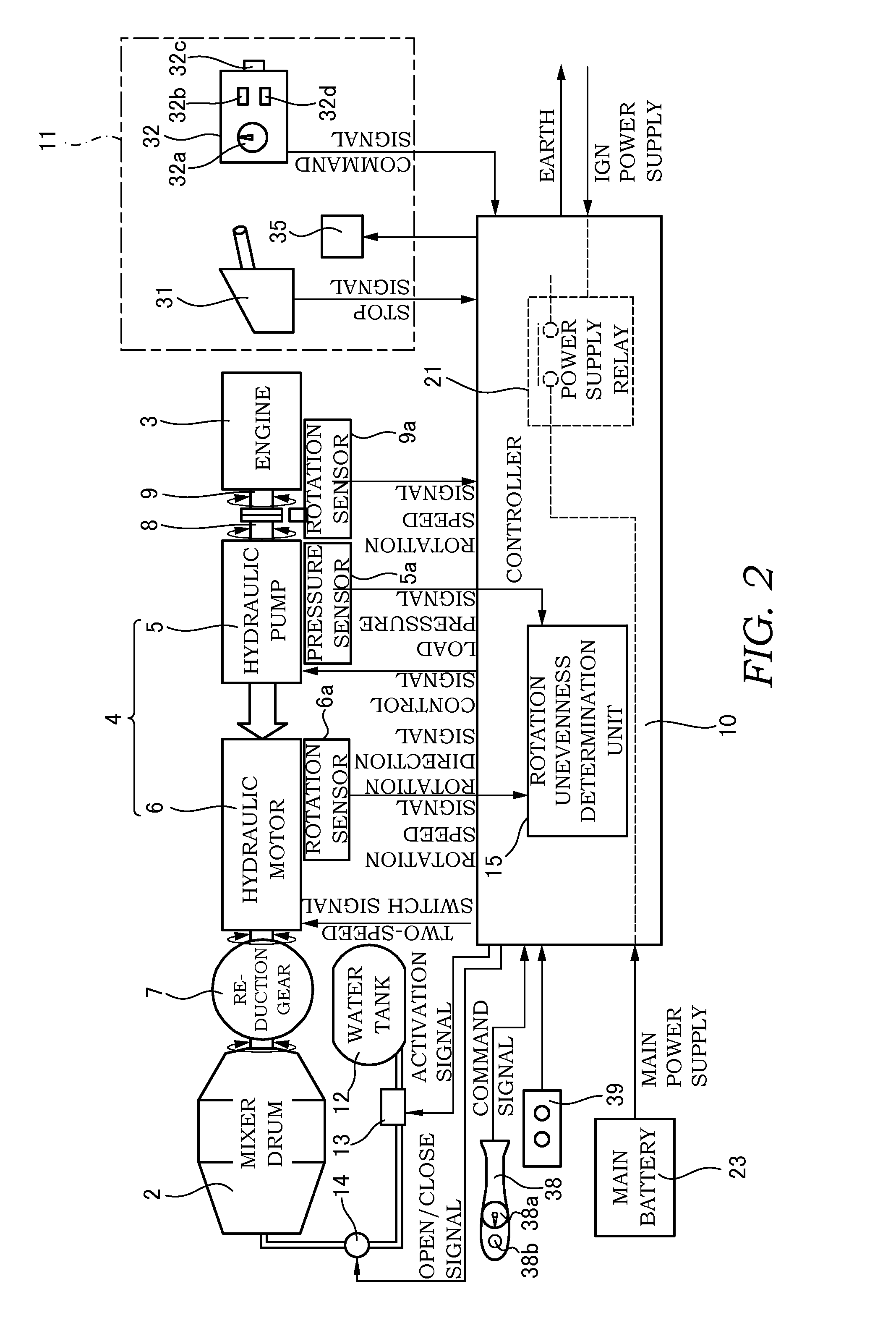

Mixer truck

InactiveUS20140198599A1Concrete transportationCement mixing apparatusDriver/operatorReady mixed concrete

A mixer truck includes: a mixer drum capable of carrying ready-mixed concrete; a driving device that drives the mixer drum to rotate using an oil pressure of a working oil; a pressure sensor that detects a driving condition of the mixer drum driven by the driving device; a controller that determines a magnitude of rotation unevenness in the mixer drum by comparing a magnitude of variation in the driving condition detected by the pressure sensor with a predetermined set value after the ready-mixed concrete in the mixer drum has been discharged; and a notifying device that notifies a driver that the magnitude of the rotation unevenness in the mixer drum has reached an allowable value when the controller determines that the magnitude of the variation in the driving condition detected by the pressure sensor has reached the set value.

Owner:KYB CORP

Integrated operator centric controls

ActiveUS20200398772A1Mechanical power/torque controlConcrete transportationControl theoryMechanical engineering

A vehicle includes a rolling chassis structure and a working component coupled to the rolling chassis structure. The rolling chassis structure includes a chassis, a non-working component, and a control interface. The non-working component is coupled to the chassis and is configured to facilitate transit operations for the rolling chassis structure. The control interface is disposed in a cab area of the chassis. The control interface is communicably coupled to the non-working component and is configured to control operation of the non-working component. The working component is configured to move relative to the chassis and is communicably coupled to the control interface. The control interface is configured to control movement of the working component.

Owner:OSHKOSH CORPORATION

Integrated operator centric controls

ActiveUS11059436B2Mechanical power/torque controlConcrete transportationControl theoryRolling chassis

A vehicle includes a rolling chassis structure and a working component coupled to the rolling chassis structure. The rolling chassis structure includes a chassis, a non-working component, and a control interface. The non-working component is coupled to the chassis and is configured to facilitate transit operations for the rolling chassis structure. The control interface is disposed in a cab area of the chassis. The control interface is communicably coupled to the non-working component and is configured to control operation of the non-working component. The working component is configured to move relative to the chassis and is communicably coupled to the control interface. The control interface is configured to control movement of the working component.

Owner:OSHKOSH CORPORATION

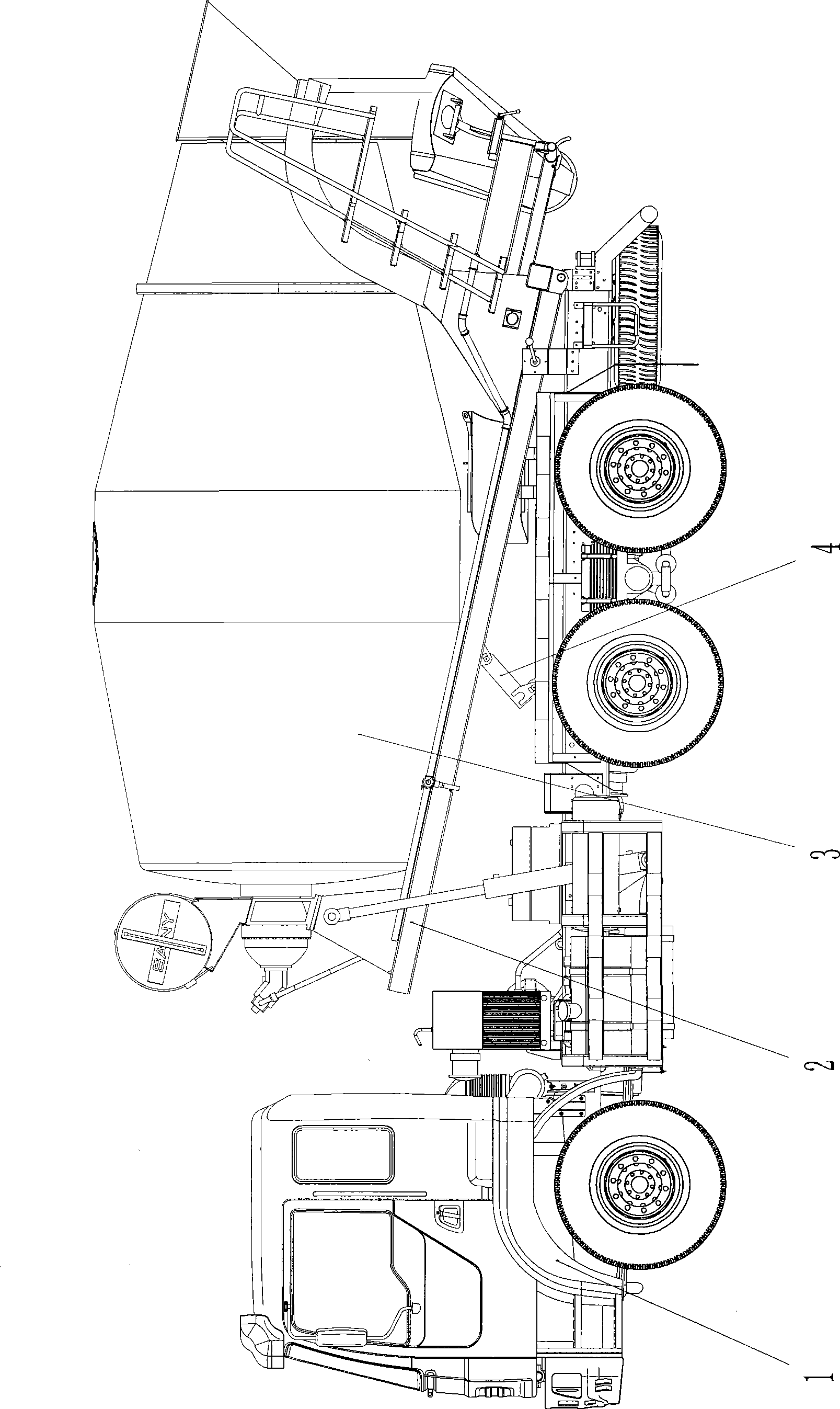

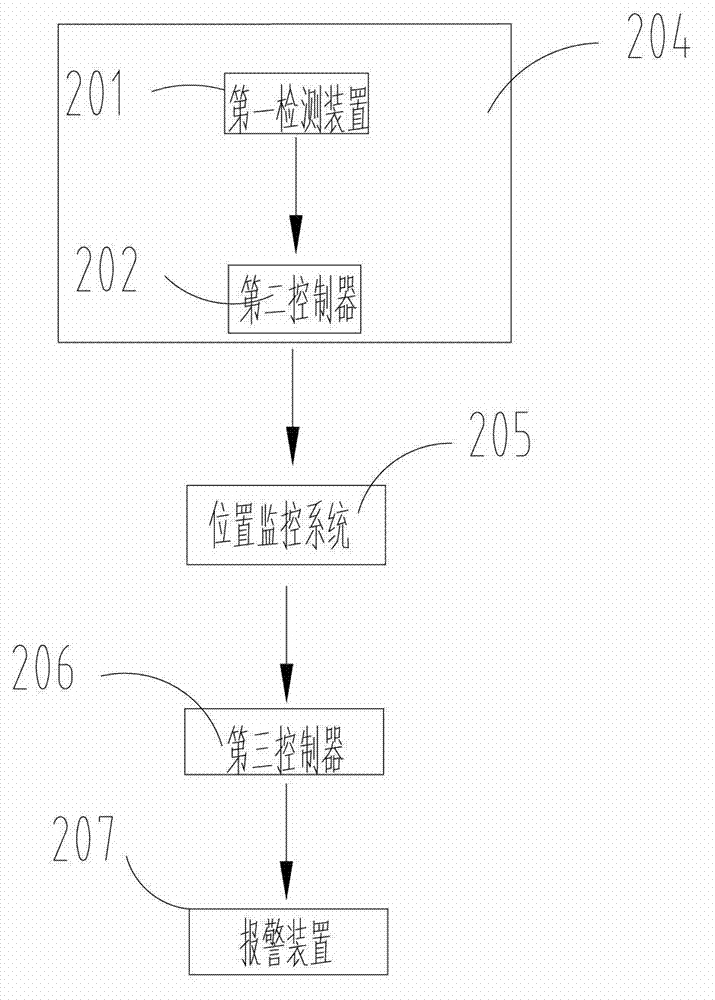

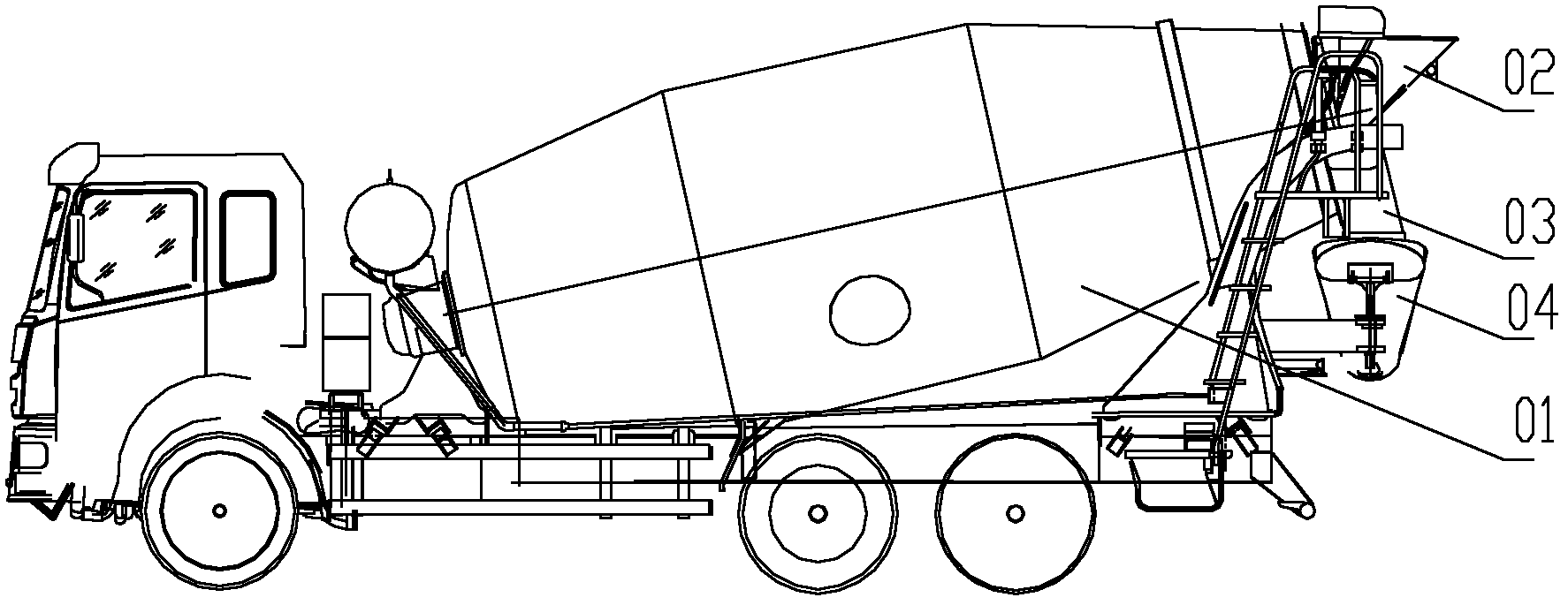

Concrete mixer truck and operation method and system by matching concrete mixer truck with concrete pumping equipment

ActiveCN102773921AImprove matching efficiencyAvoid vacuumingConcrete transportationDischarging apparatusMonitoring systemEngineering

The invention discloses an operation method of by matching a concrete mixer truck with a concrete pumping equipment, The method comprises a discharging step and a truck moving step. In the discharging step, the concrete mixer truck discharges materials to the concrete pumping equipment, and monitors whether the discharging of the materials of the concrete mixer truck is completed. In the truck moving step, after the materials are discharged by the concrete mixer truck, the concrete mixer truck is moved away. The invention also discloses a matching operation system which realizes the matching operation method. The matching operation system comprises a discharging monitoring system used for monitoring whether the materials are discharged by the concrete mixer truck, so that the concrete mixer truck is moved away in time. The invention also discloses a concrete mixer truck using the matching operation system. As whether the materials are discharged can be monitored by the matching operation method and system provided by the invention, after the materials are discharged, the concrete mixer truck can be moved away in time for changing into a new concrete mixer truck, so that the matching operation efficiency can be effectively improved, and the pumping equipment is effectively prevented from sucking the air.

Owner:ZOOMLION HEAVY IND CO LTD

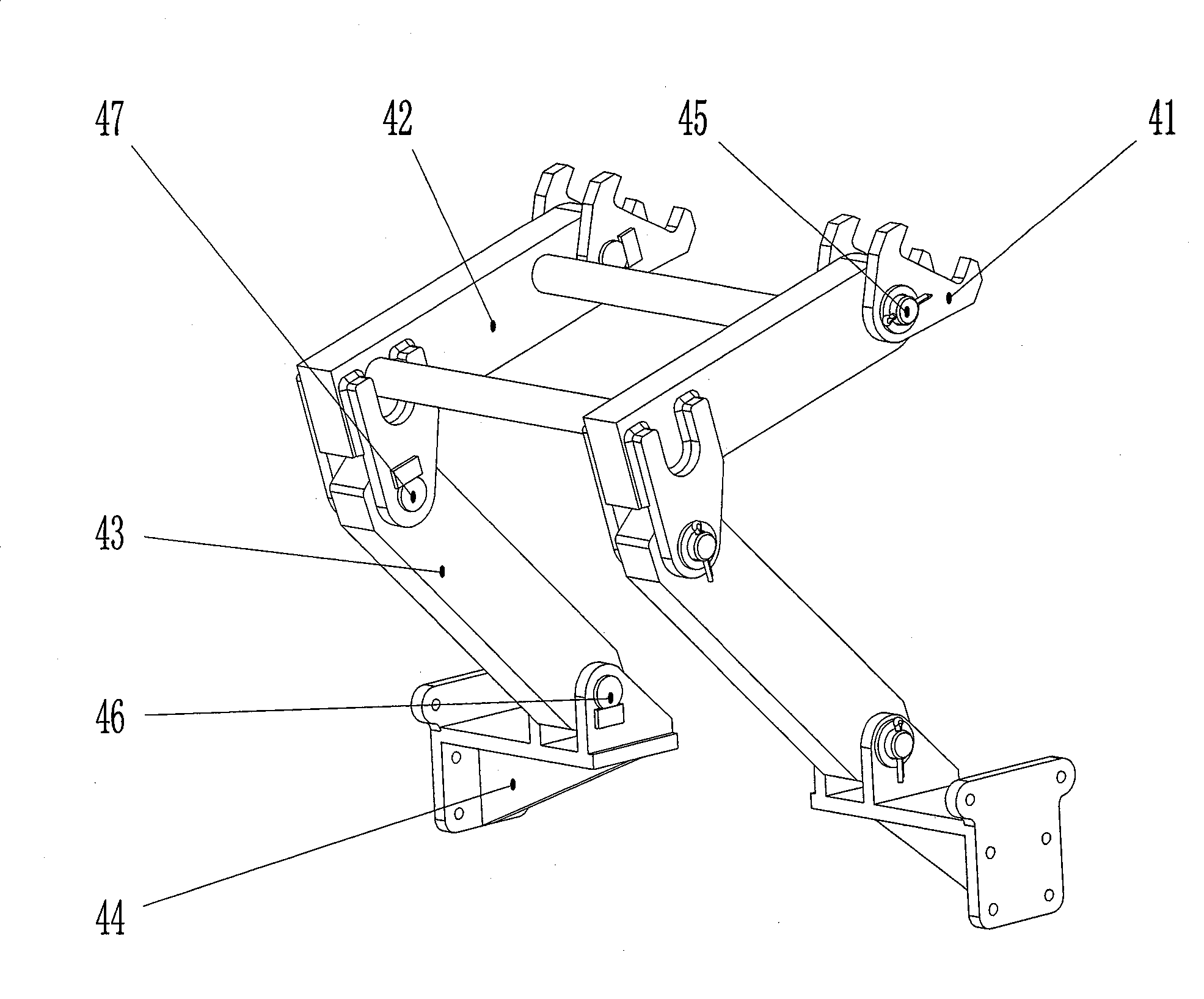

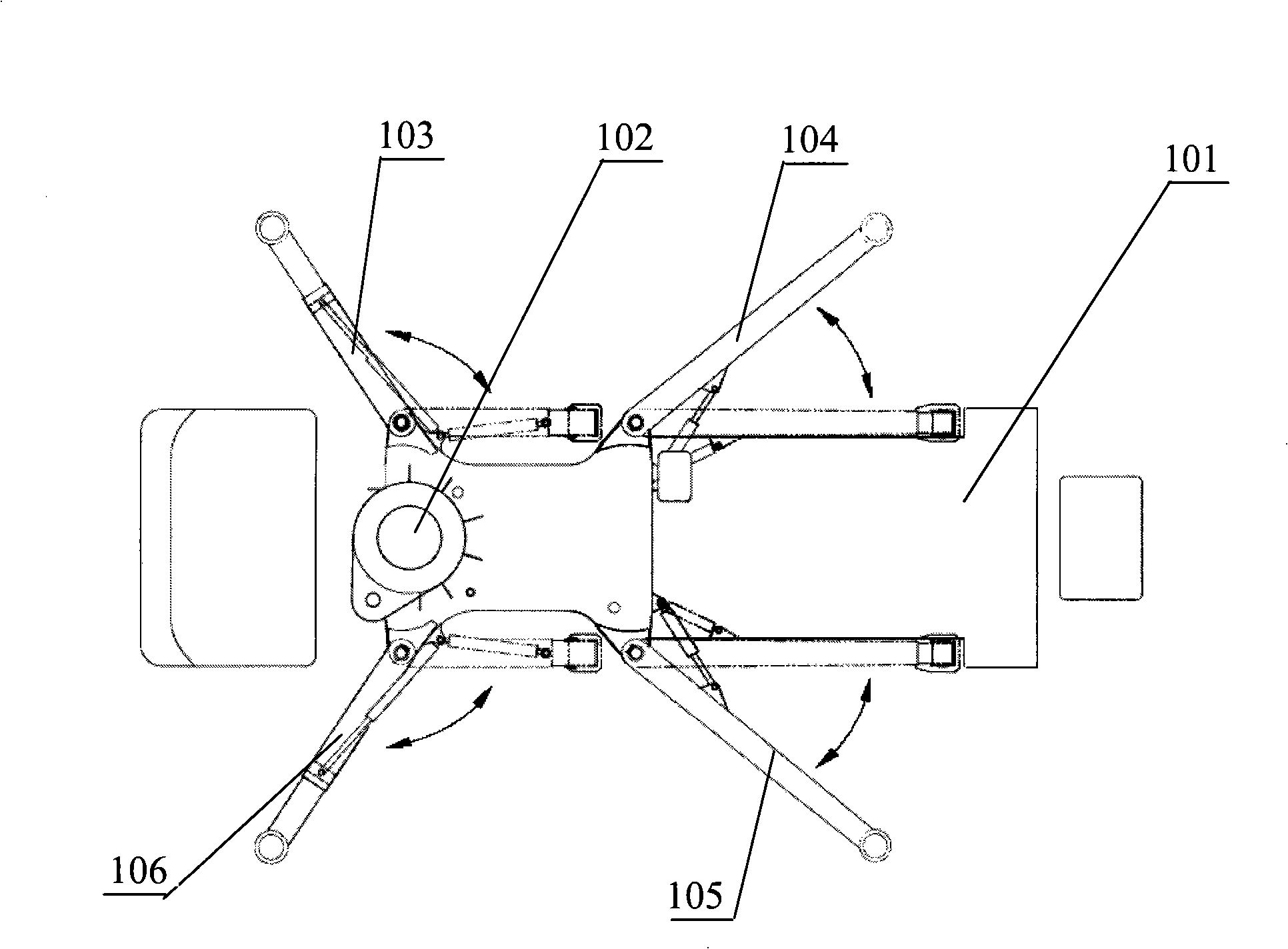

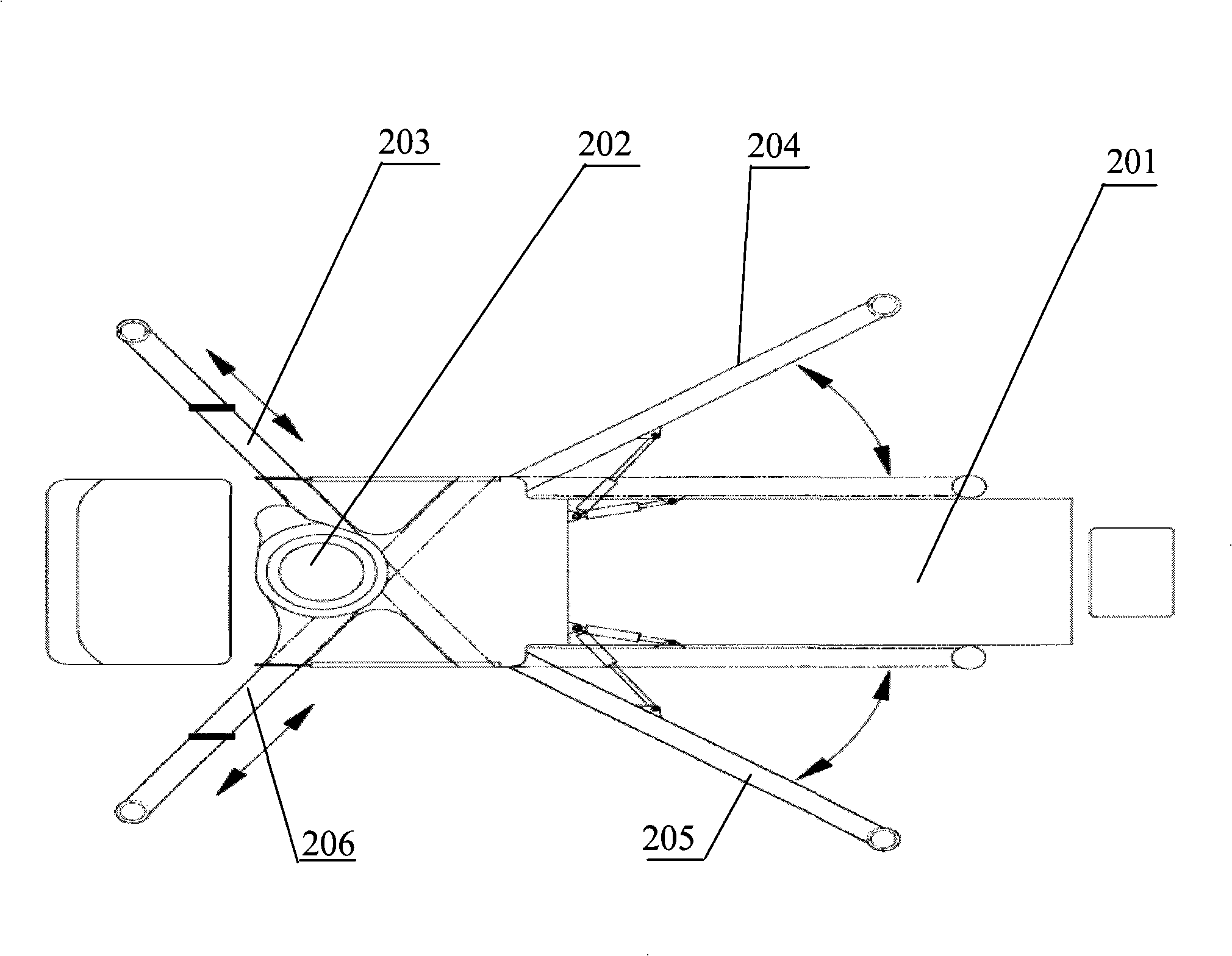

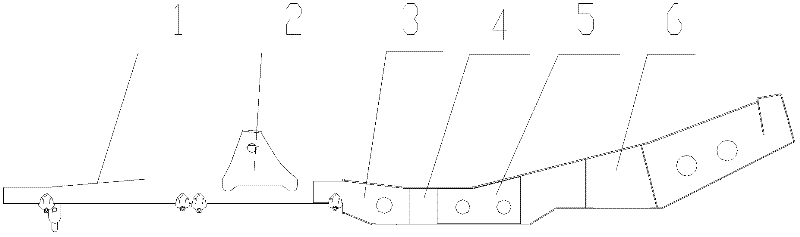

Concrete pump vehicle supporting leg and concrete pump vehicle therewith

ActiveCN101301869AOptimize layoutEasy to expand flexiblyConcrete transportationVehicle fittings for liftingEngineeringLeg moving

The invention discloses a landing leg of a concrete pump truck; the supporting end of the basic arm of the landing leg is hinged on the body of the concrete pump truck by a rotating shaft arranged with an angle less than 45 degrees with a horizontal plane; when being folded from a supporting position, the landing leg rotates towards the inner side surrounding the rotating shaft; besides, when the landing leg finally reaches a folding position, the angle between the basic arm of the landing leg and the vertical line of the horizontal plane is less than 80 degrees. In the preferable scheme of the invention, the landing leg can adopt the forms of a single-section landing leg or a multi-section landing leg. The folding position of the landing leg is arranged above the body of the truck; and the landing leg can be arranged by utilizing the upper part space of the body of the truck by proper arrangement. When the landing leg moves from the folding position to the supporting position, the landing leg moves in a plane vertical to the horizontal plane and can not be baffled by a barrier on the horizontal plane; besides, the restriction to the concrete pump truck in a construction field comes from barriers on the horizontal plane; therefore, compared with the swing type landing leg of the prior art, the landing leg of the invention is more flexible for being unfolded. The invention simultaneously provides a concrete pump truck which uses the landing leg.

Owner:SANY AUTOMOBILE MFG CO LTD

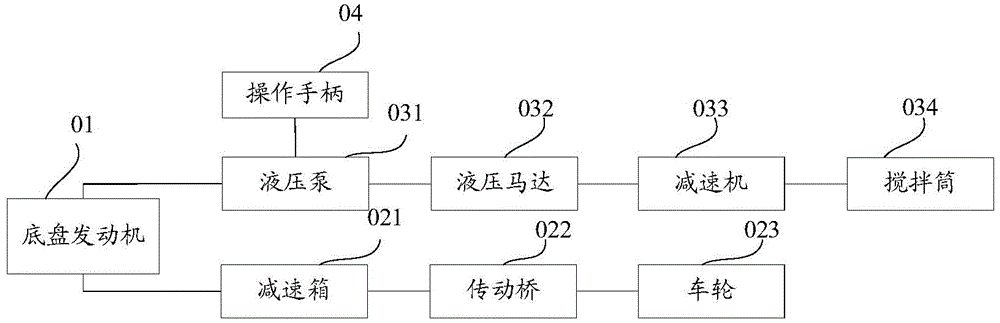

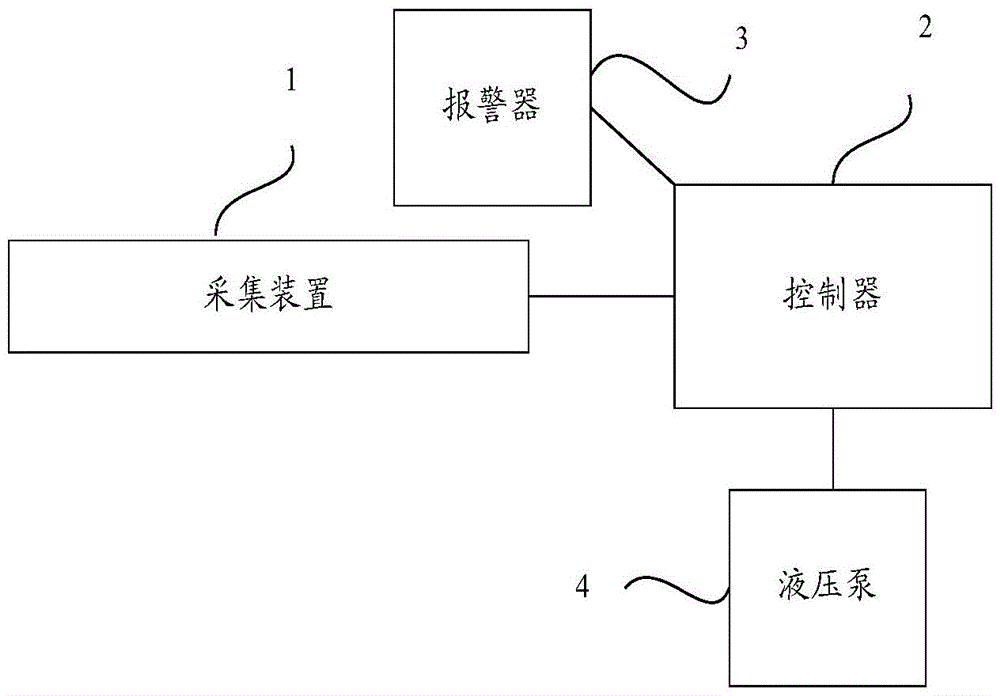

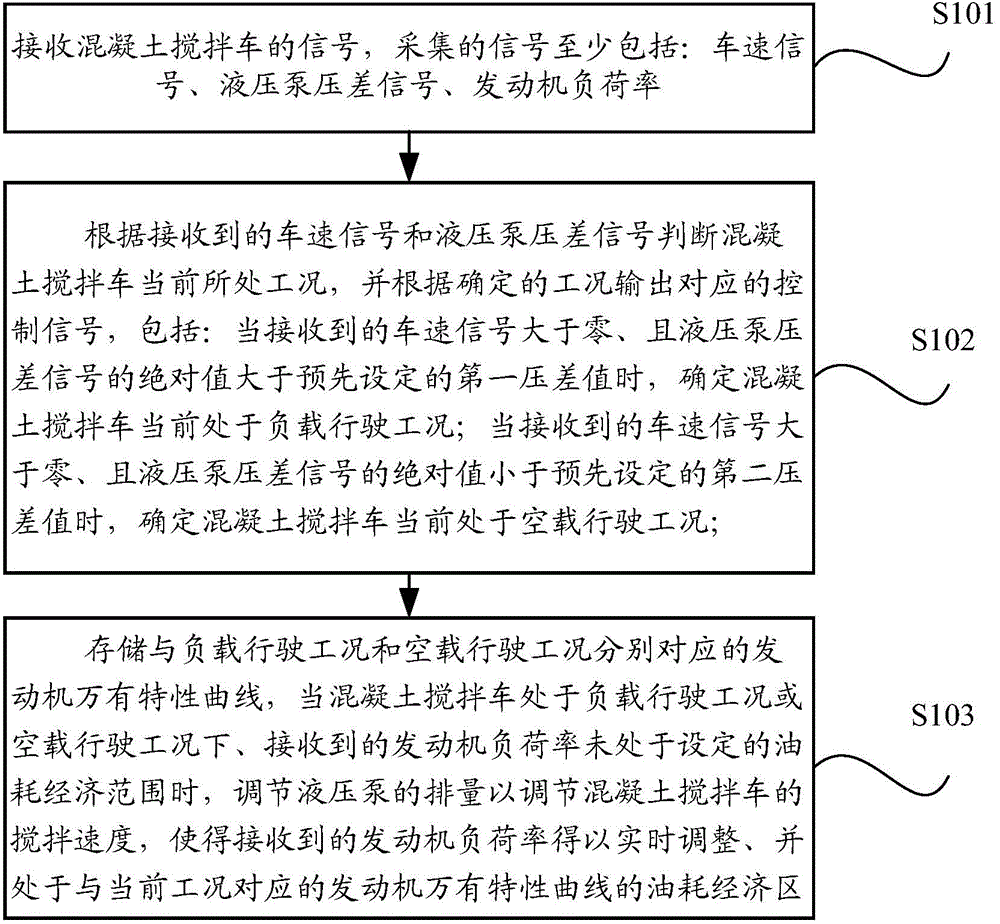

Control system, method and device of concrete mixer as well as concrete mixer

ActiveCN105480141AReduce idle speedConcrete transportationSignalling/lighting devicesEconomic regionControl system

The invention discloses a control system, method and device of a concrete mixer as well as the concrete mixer. The control system, method and device are used for improving the energy-saving performance of the concrete mixer. The control system comprises a plurality of acquisition devices and a controller, wherein the acquisition devices are used for acquiring signals of the concrete mixer; and the controller is used for judging the current working condition of the concrete mixer according to a received speed signal and a received hydraulic pump pressure difference signal and outputting a corresponding control signal according to the determined working condition, and is also used for storing engine universal characteristic curves respectively corresponding to a load running working condition and a no-load running working condition. When the concrete mixer is in the load running working condition or the no-load running working condition and the received engine load rate is not in the set oil consumption economic limit, the displacement of a hydraulic pump is adjusted so as to adjust the stirring rate of the concrete mixer, so that the received engine load rate can be adjusted in real time so as to be in an oil consumption economic region of the engine universal characteristic curve corresponding to the current working condition.

Owner:ZOOMLION HEAVY IND CO LTD

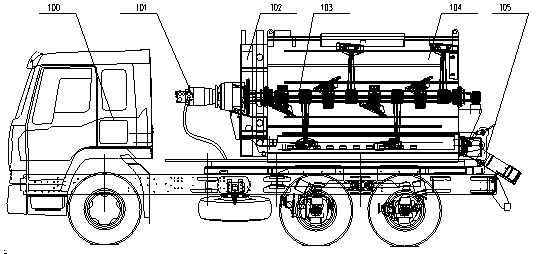

Asphalt concrete regenerative heating and heat-preservation mixing carrier vehicle

ActiveCN103911935AReduce maintenance costsAvoid storageConcrete transportationRoads maintainenceRoad surfaceAsphalt pavement

The invention discloses an asphalt concrete regenerative heating and heat-preservation mixing carrier vehicle which comprises a vehicle body, an asphalt regenerative heating device and an emulsified asphalt spraying device, wherein the asphalt regenerative heating device and the emulsified asphalt spraying device are arranged on a chassis of the vehicle body; the asphalt regenerative heating device comprises a hydraulic power system, a rotary tillage stirring system, a heating heat-preservation system, an asphalt pumping system, a material metering device and a smoke dust removal system. The processing and transporting amount can be 6m<3>, the mixing carrier vehicle is suitable for large-scale asphalt pavement construction so as to guarantee the pavement paving quality, the field construction operation is promoted, and the problems of regenerative utilization, transport, storage and environmental pollution of asphalt pavement milling wastes and maintenance and repair of the asphalt pavement in winter are comprehensively solved. Meanwhile, the problem that heat of asphalt is dissipated during ultra-long distance transport and super-long time construction is solved, and the asphalt pavement maintenance cost is greatly saved.

Owner:瑞天(日照)智能装备有限公司

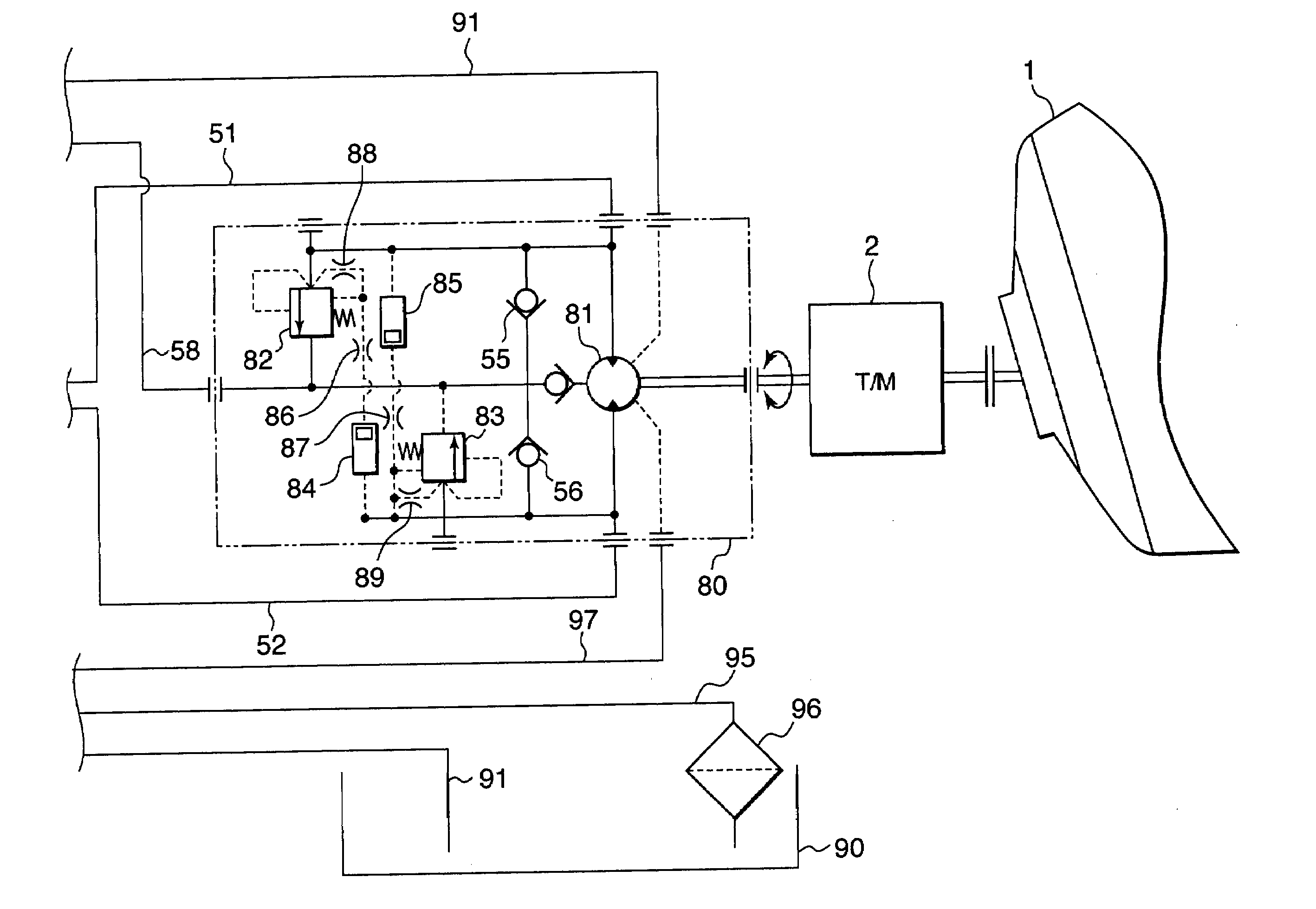

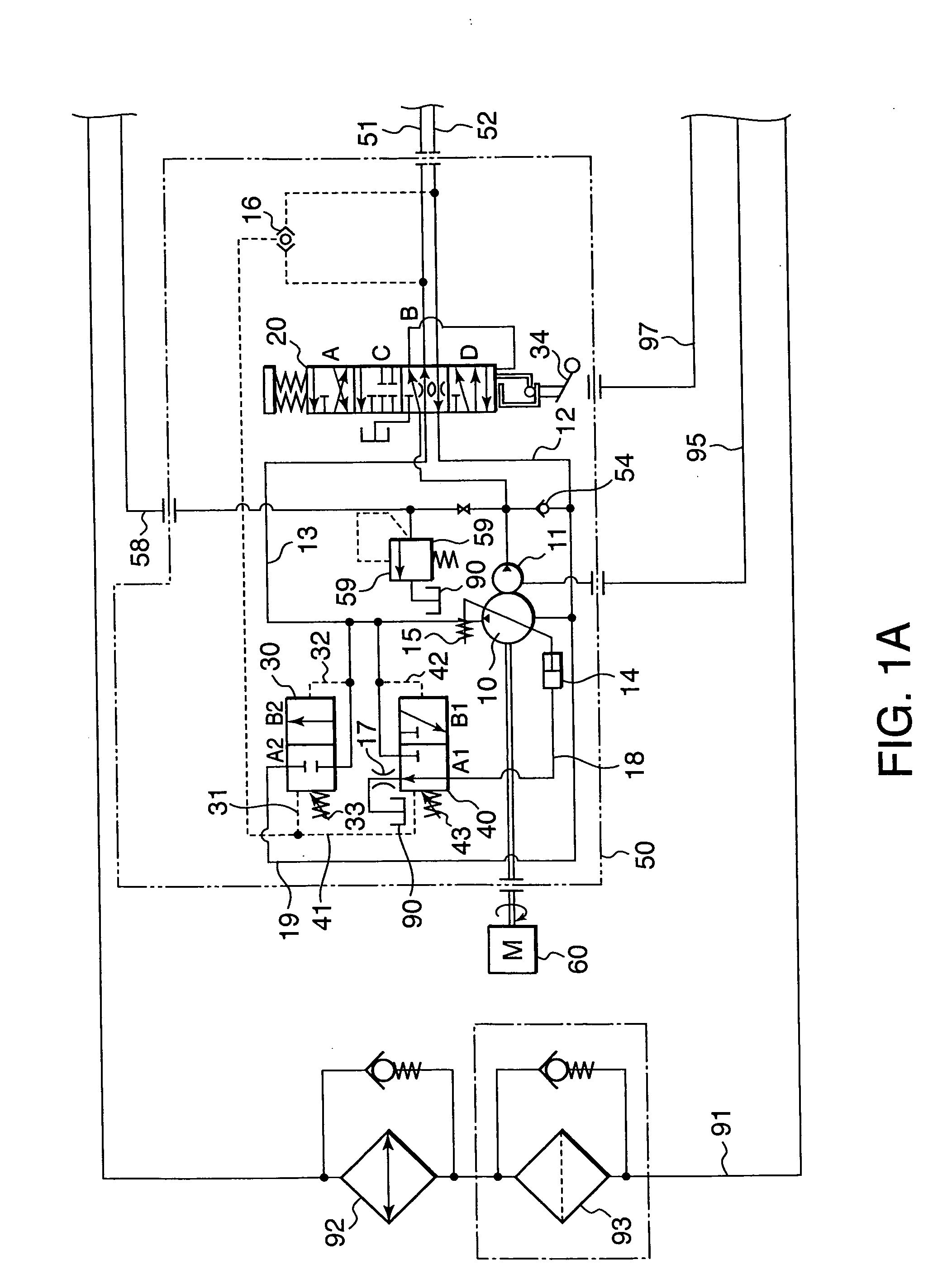

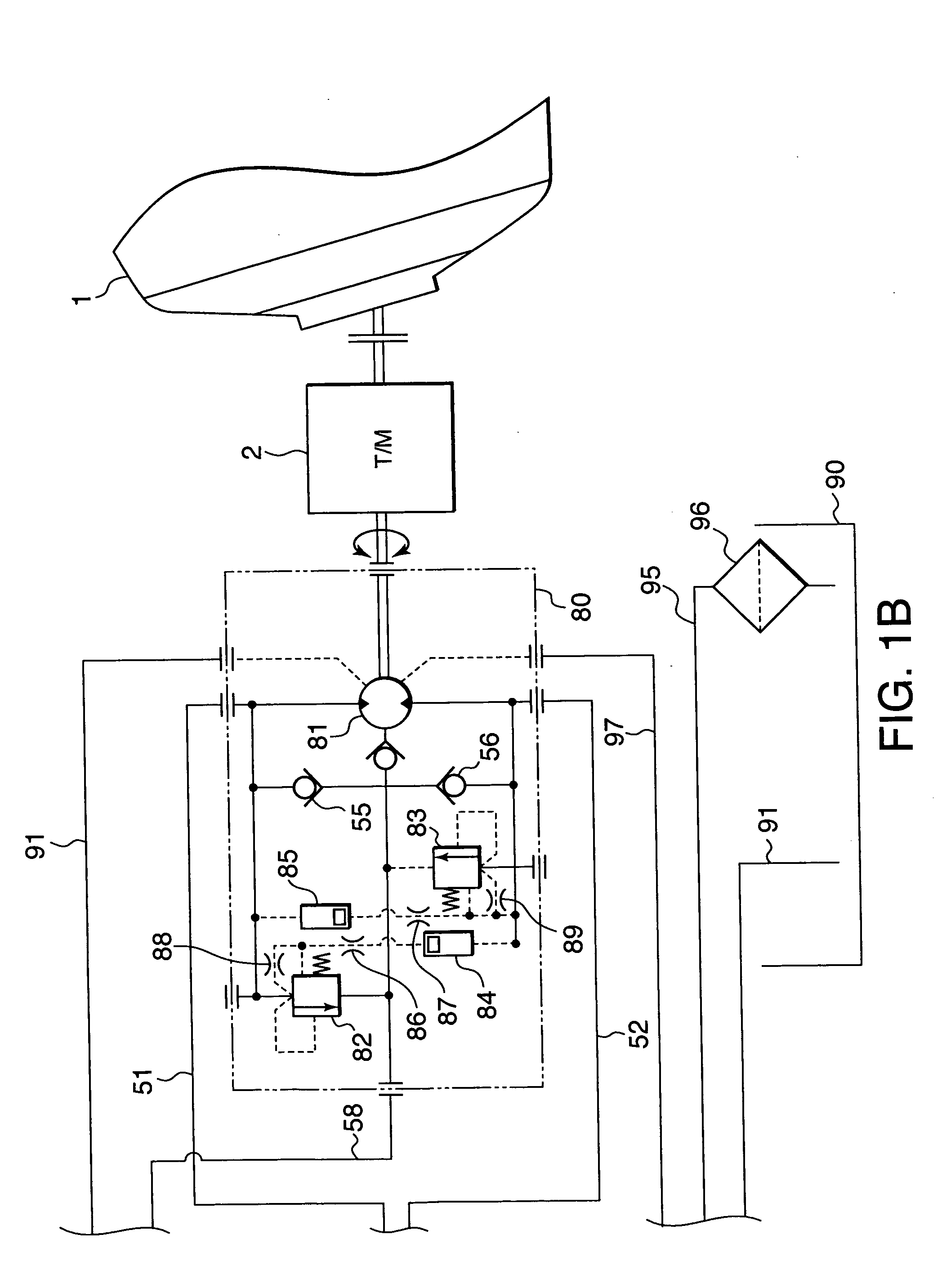

Concrete agitating drum driving device

InactiveUS20090282824A1Increase fuel consumptionReduce fuel consumptionFluid couplingsConcrete transportationHydraulic motorCombustion

A concrete agitating drum (1) is driven by a hydraulic motor (81). A connection switch-over valve (20) is arranged to have a function to regulate a flow cross-sectional area of pressurized working oil supplied to the hydraulic motor (81) from a variable capacity hydraulic pump (10). The variable capacity hydraulic pump (10) is driven by a combustion engine (60) together with a charge pump (11). When a discharge pressure of the charge pump (11) is low, the connection switch-over valve (20) maintains a small flow cross-sectional area to rotate the agitating drum (1) at a low rotation speed so that fuel consumption of the combustion engine (60) is suppressed to be small. When the discharge pressure of the charge pump (11) becomes high, the connection switch-over valve (20) enlarges the flow cross-sectional area, thereby realizing a rated rotation speed of the agitating drum (1).

Owner:KYB CORP

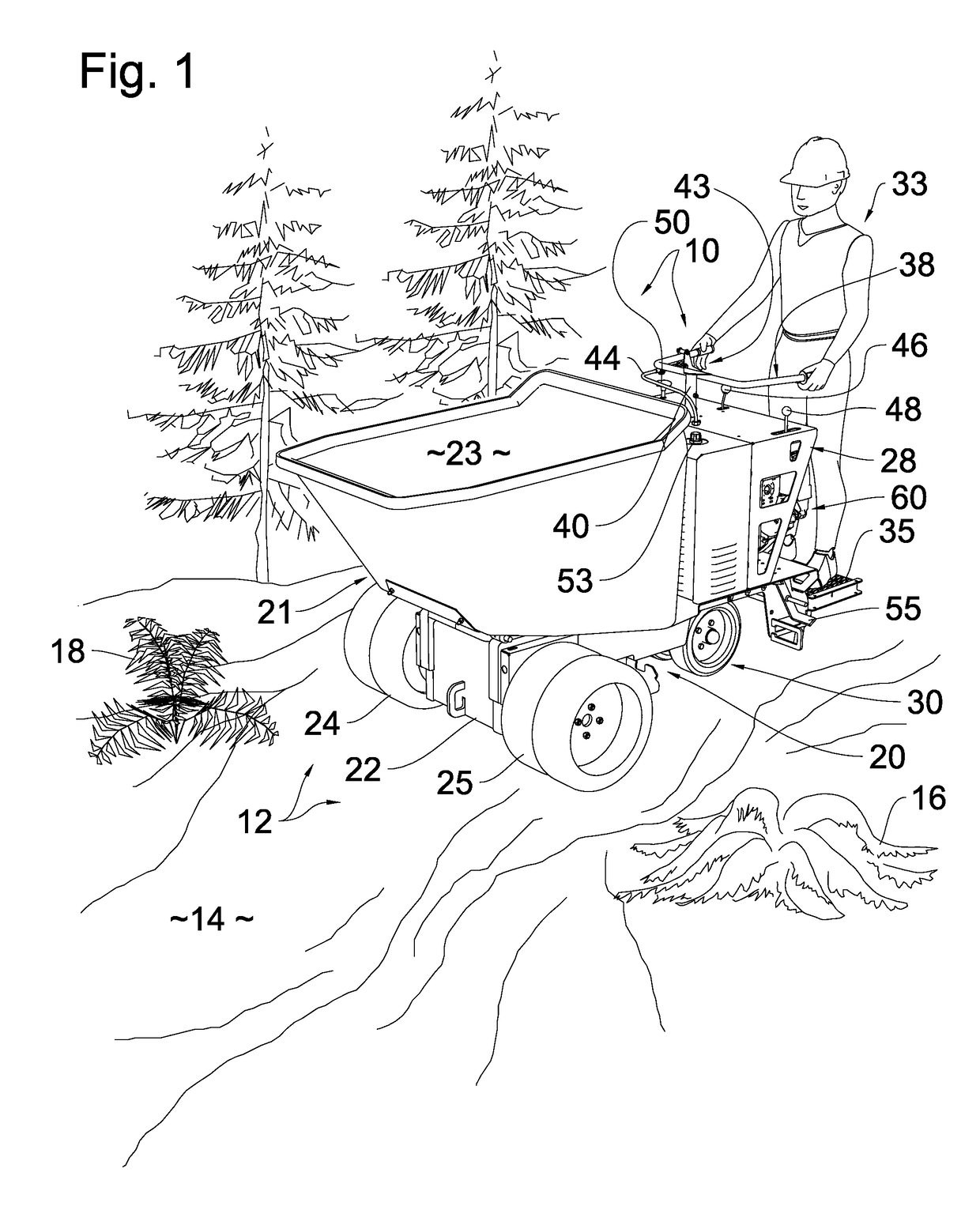

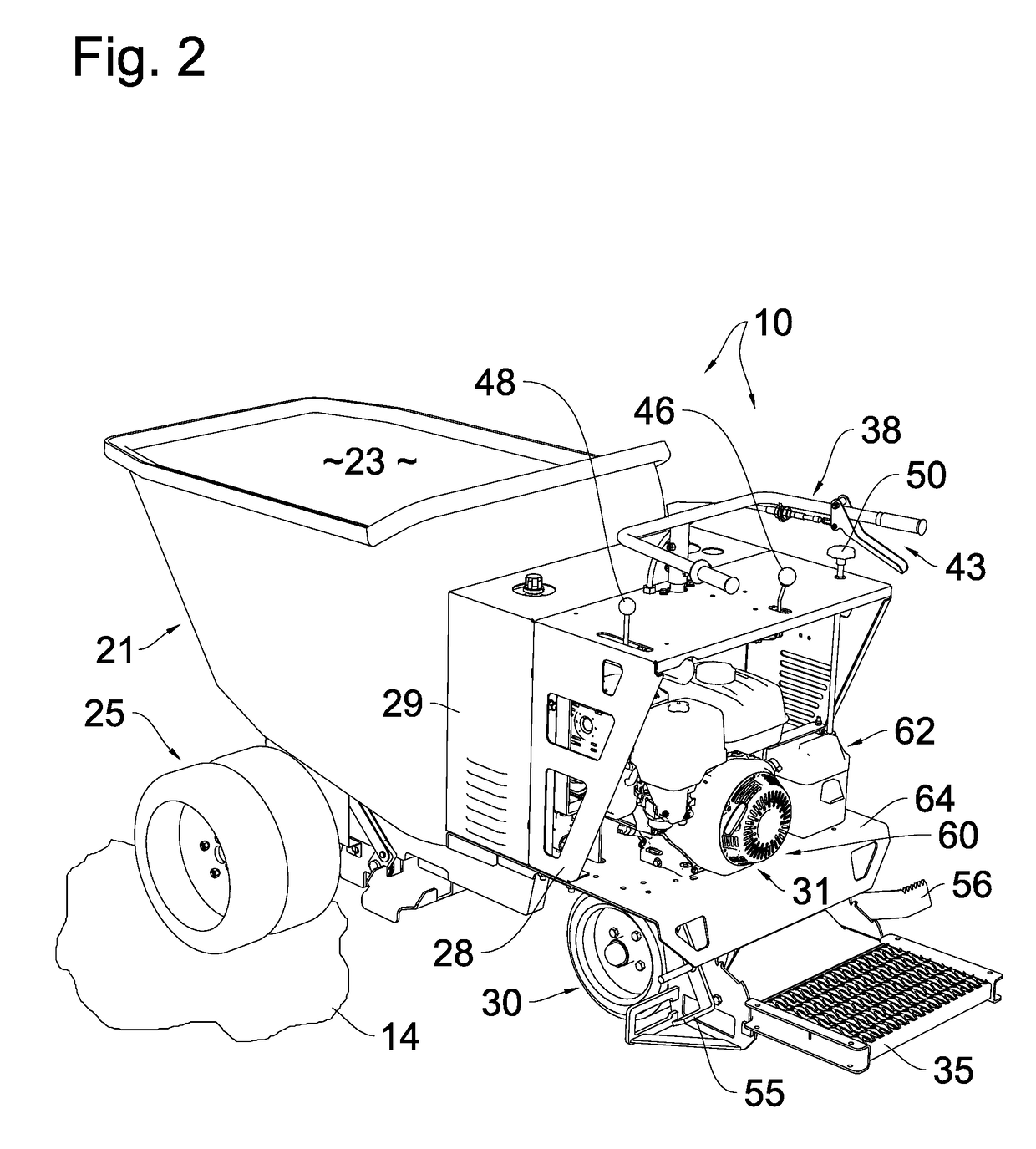

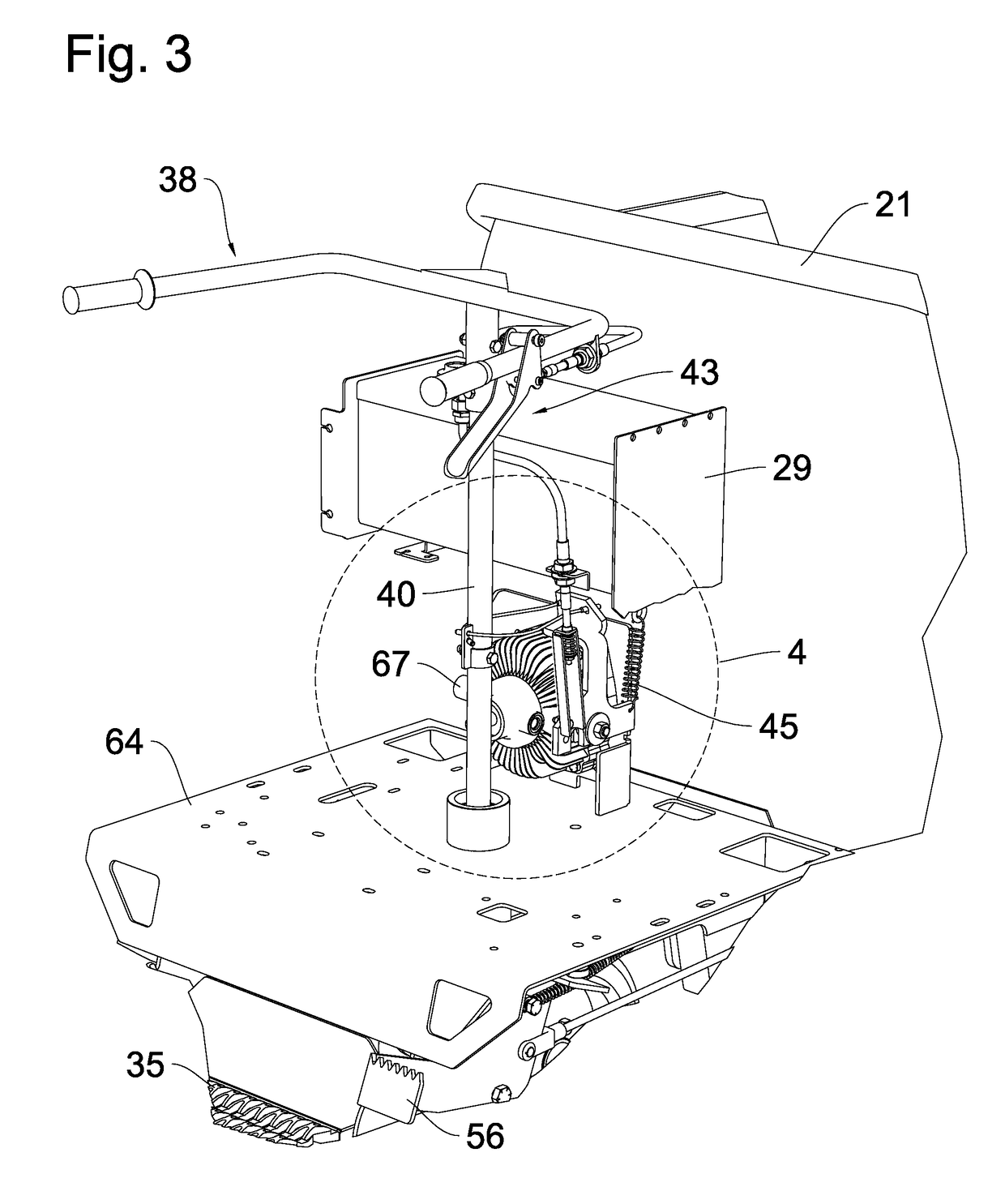

Steering Responsive Speed-Controlled Buggy

ActiveUS20180346007A1Safely maneuverStable and safe heavily loadedConcrete transportationElectric propulsion mountingTerrainDrive wheel

A steerable, self-propelled cart for safely delivering heavy loads, such as concrete, within job sites with unlevel, irregular, or sloped terrain. A cargo bucket is tiltable over front drive wheels for transporting and dumping cargo. Hydraulic drive motors driven by a hydraulic pump propel rear wheels at a selectable speed. Steering handlebars rotate a steering column that turns the rear wheels. A throttle cable extending from the handlebars controls the throttle setting by pivoting a throttle lever mounted on the hydraulic pump. Limiting linkages extend from flanges on an anchor bracket secured to the steering column to a bridge on the throttle lever. As the steering column rotates, the limit linkages are wound partially about it, pivoting the throttle lever by pulling on the bridge, reducing pump speed. Heavy steering displacements will retract the throttle lever to reduce cart speed notwithstanding the previous speed setting chosen by the operator via the cable.

Owner:ALLEN ENG

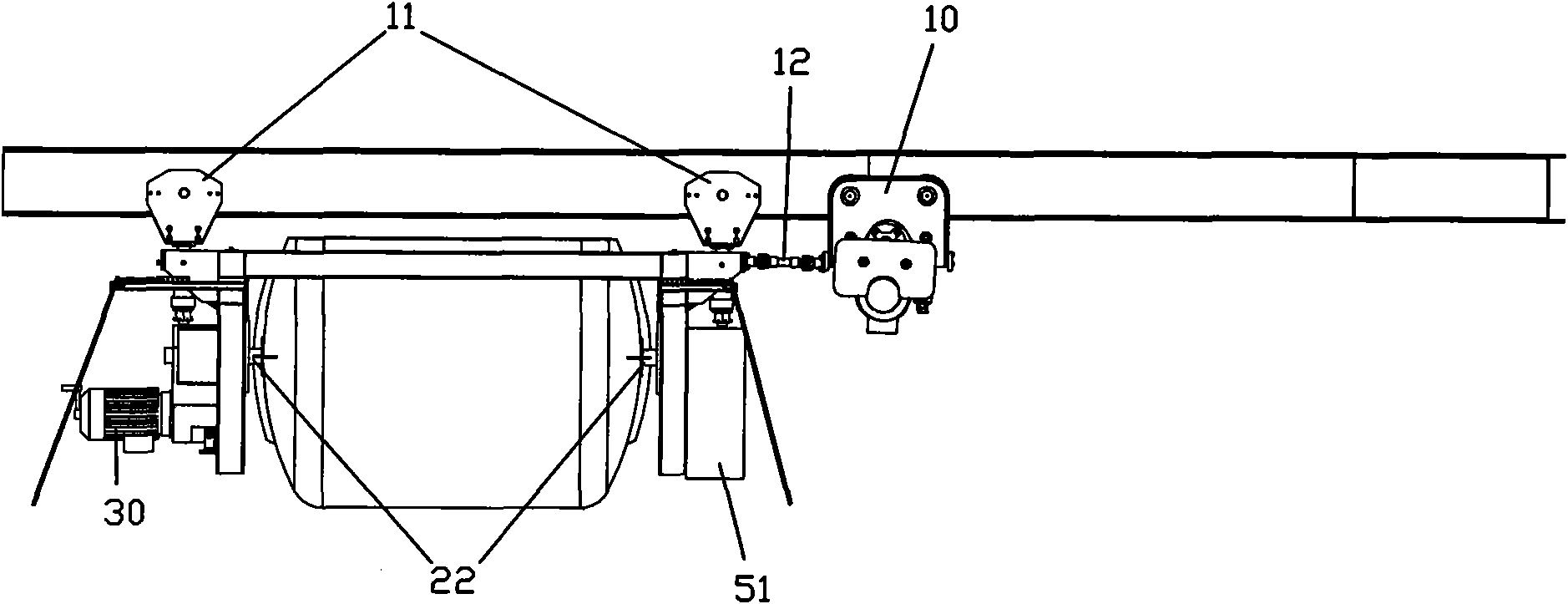

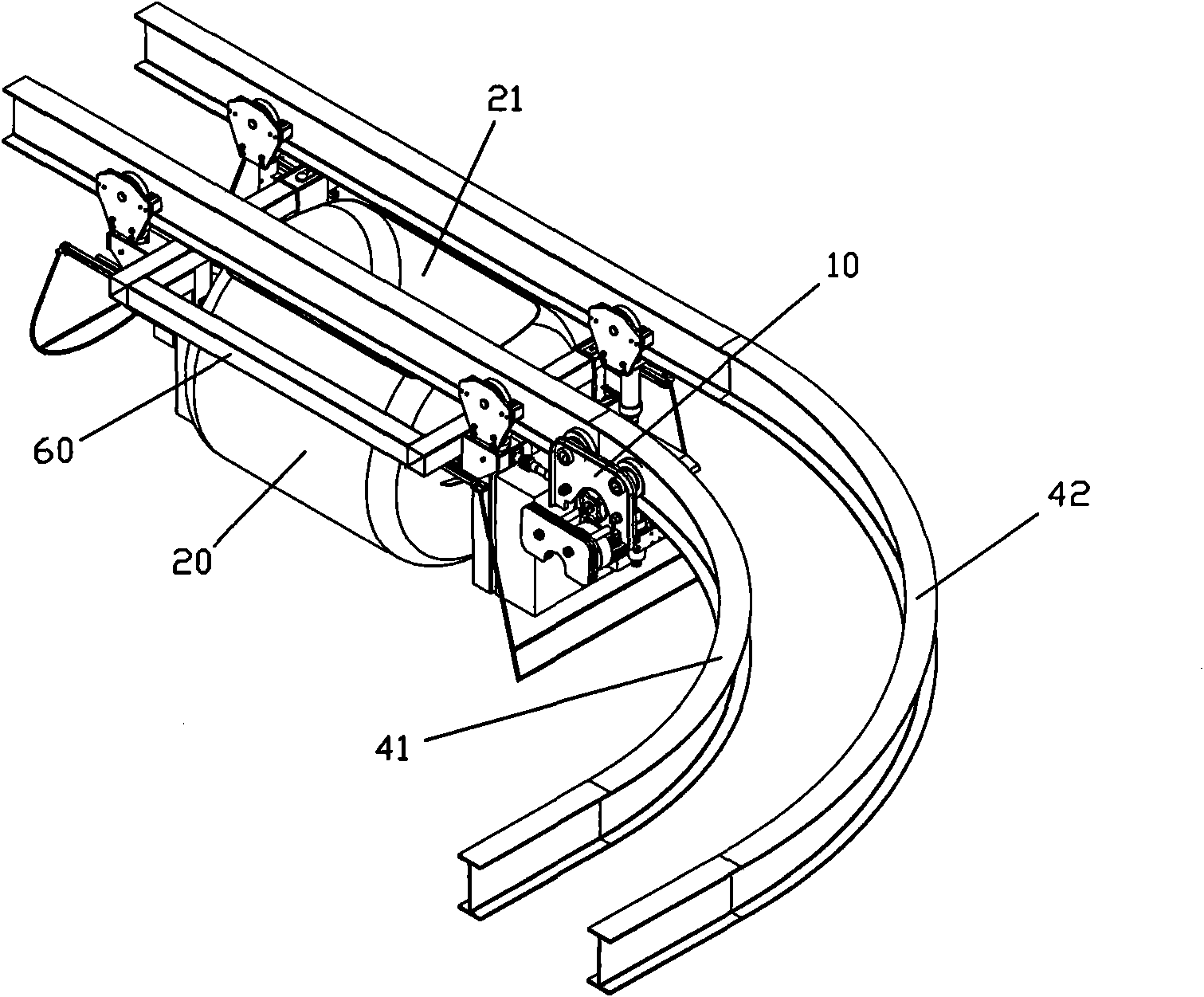

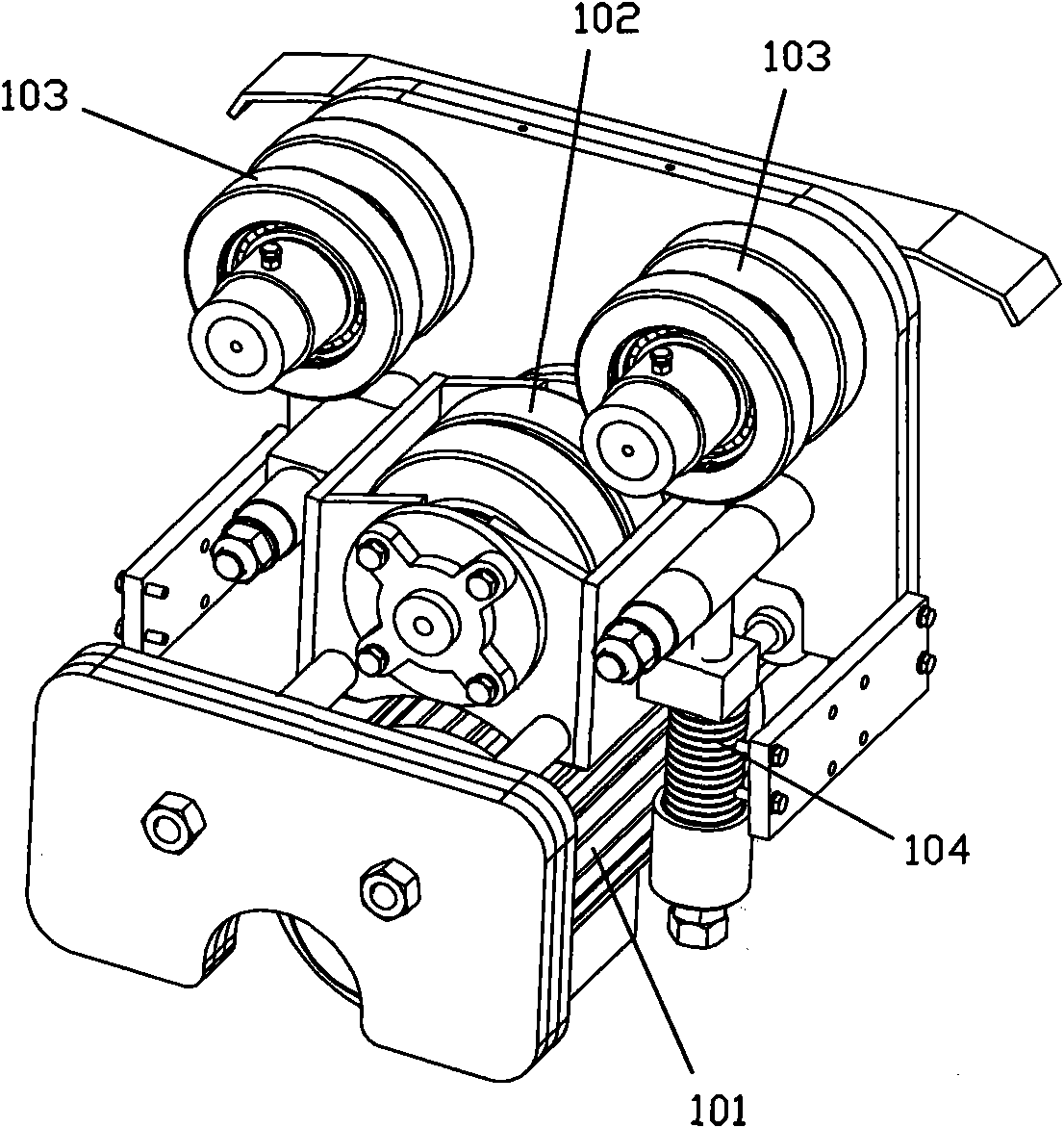

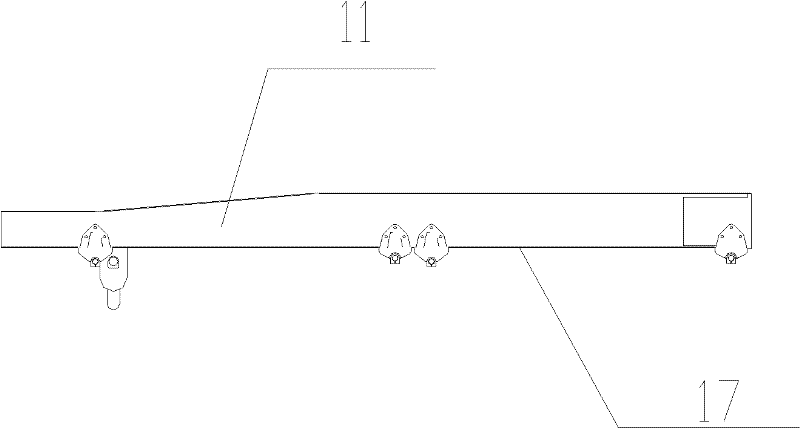

Precast concrete carrier vehicle

ActiveCN102211540ASimple structureEasy to operateConcrete transportationBuilding material handlingDrive wheelElectrical control

The invention relates to a precast concrete carrier vehicle which comprises a travelling mechanism, a storage bin mechanism, a storage bin dumping actuating mechanism, a rail mechanism, an electric control mechanism and a bracket mechanism. When the precast concrete carrier vehicle is used, a bucket driven wheel unit travels on the rail mechanism under the driving of a dragging vehicle, and then the bucket driven wheel unit drives the storage bin mechanism, the storage bin dumping actuating mechanism, a travelling control cabinet and the bracket mechanism to travel following the bucket drivenwheel unit, so as to transport the precast concrete stored in a cylinder from a stirring host machine to a pouring station. After the precast concrete is transported to the pouring station, the storage bin dumping actuating mechanism supplies a power to turn over the cylinder and unload the precast concrete. Compared with the prior art, the precast concrete carrier vehicle provided by the invention has the advantages that the structure and the operation are simple, the use is safe and reliable, the automatic operation of transporting the precast concrete is realized, the labor intensity is relieved, and the labor cost is lowered.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

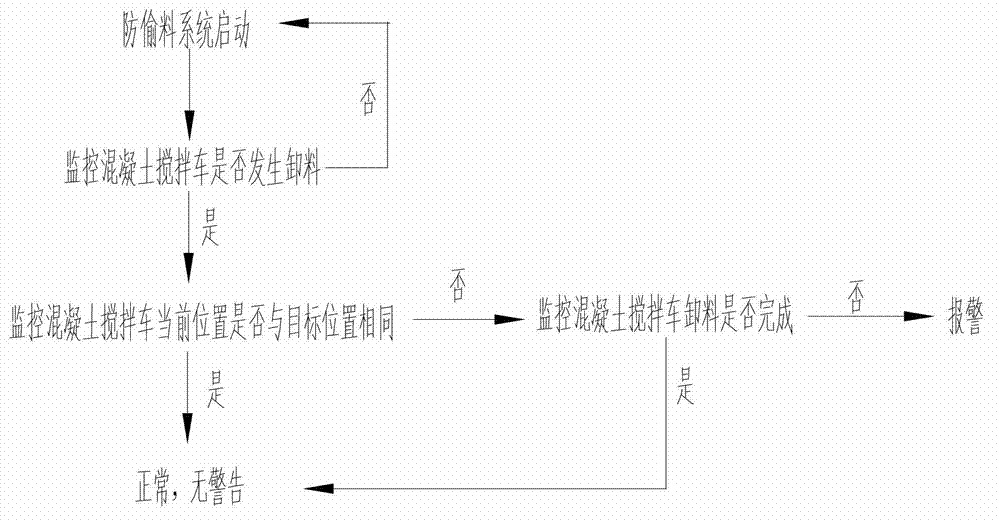

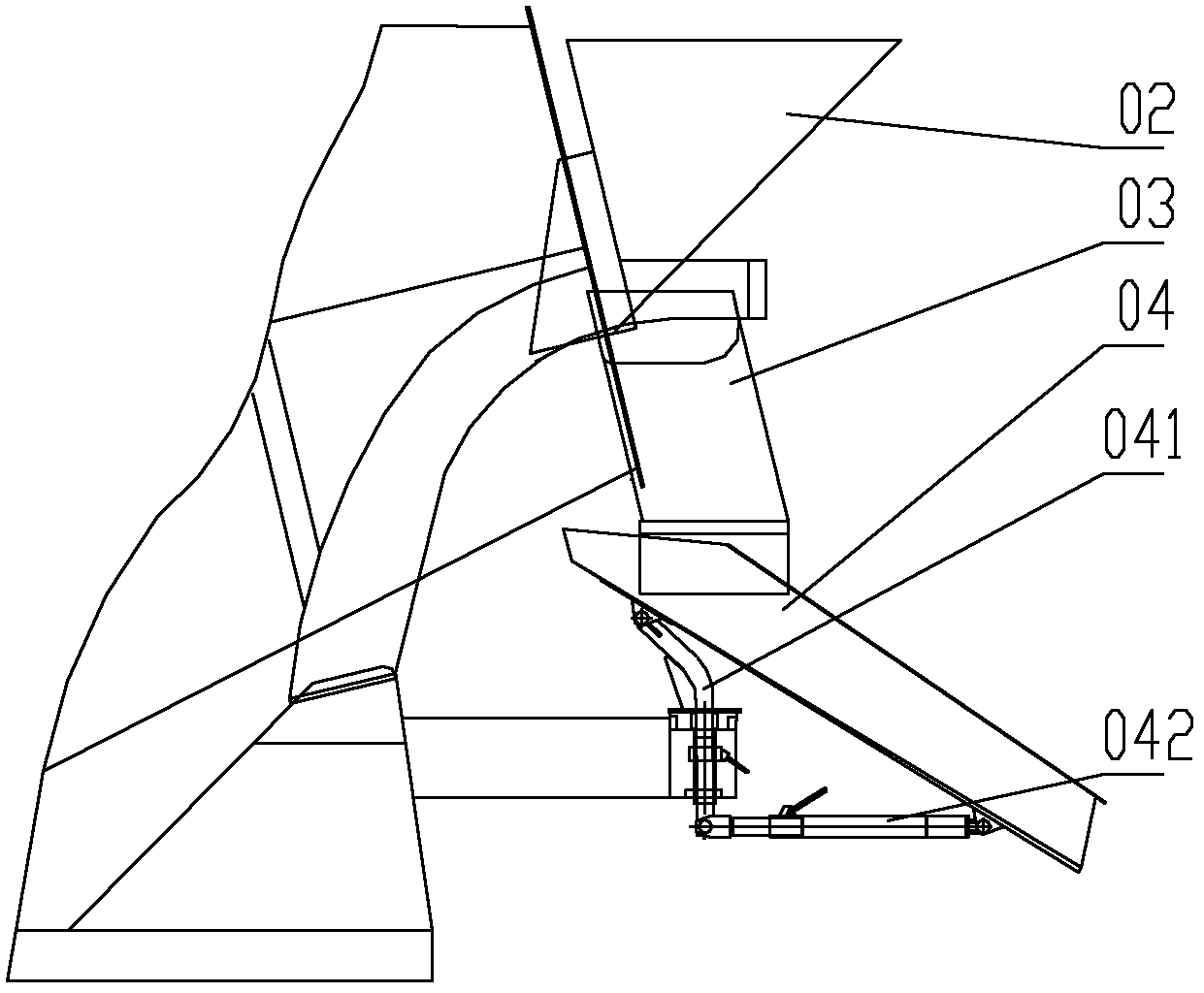

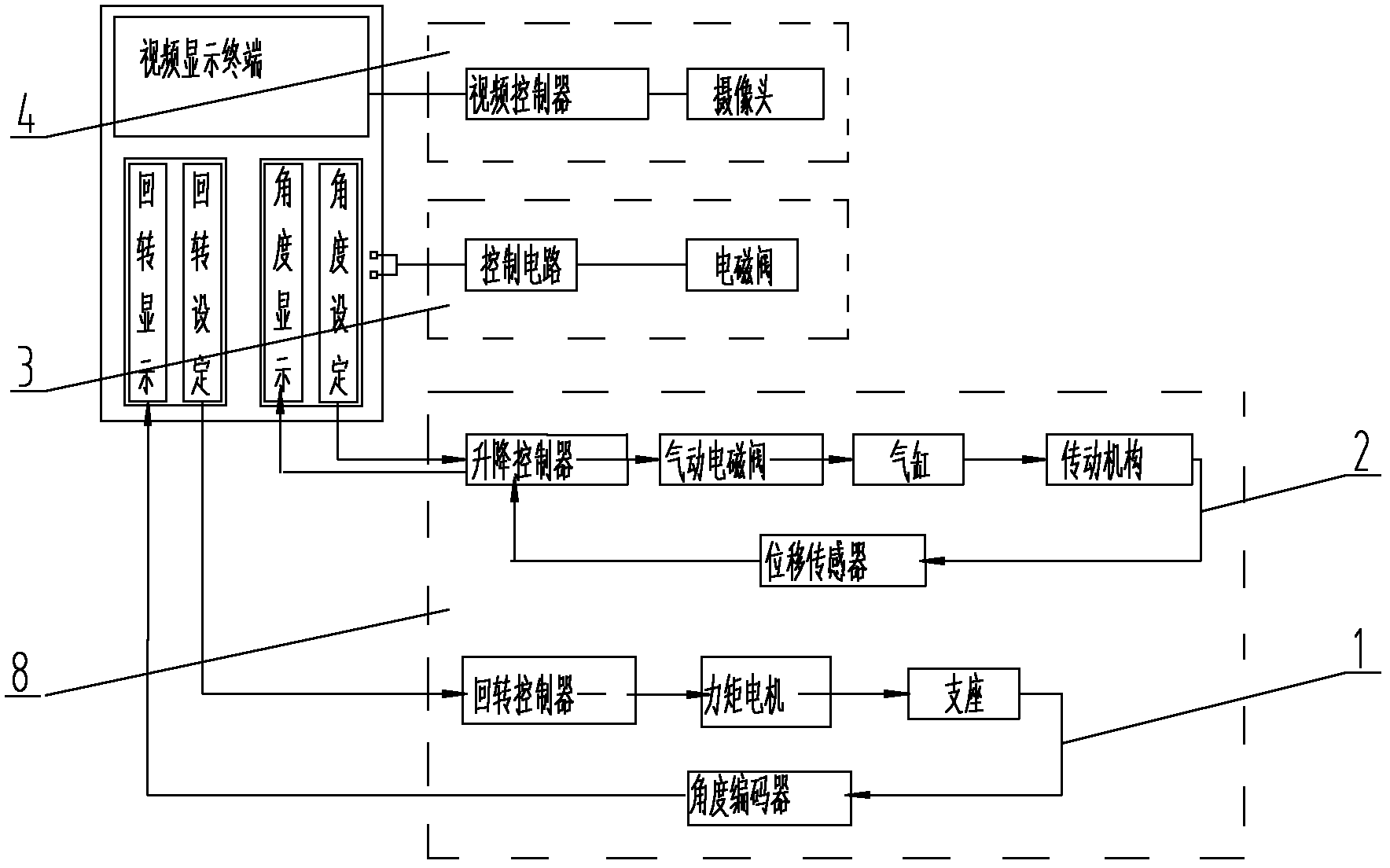

Automatic discharge system and concrete mixing vehicle

ActiveCN102529784ASpeed up the unloading processEasy to adjustConcrete transportationCement mixing apparatusEngineeringPosition control

The invention discloses an automatic discharge system which is used for discharge of a concrete mixing vehicle. The automatic discharge system comprises a driving and positioning control device of a discharge groove and a locking device, wherein the driving and positioning control device of the discharge groove comprises a revolution driving device and a lifting device, the discharge groove can achieve a predetermined revolution angle through the revolution driving device and achieve a predetermined inclination angle through the lifting device; and the locking device is mounted at the rear part of the concrete mixing vehicle and can lock the discharge groove in a non-working state. The driving and positioning control device of the discharge groove can control the discharge groove to fast and accurately achieve the predetermined revolution angle and the predetermined inclination angle, and when the discharge groove achieves the predetermined working position, and repeated adjustment is not required, so that the discharge process of the concrete mixing vehicle is further accelerated. The invention further discloses a concrete mixing vehicle comprising the automatic discharge system.

Owner:SANY AUTOMOBILE MFG CO LTD

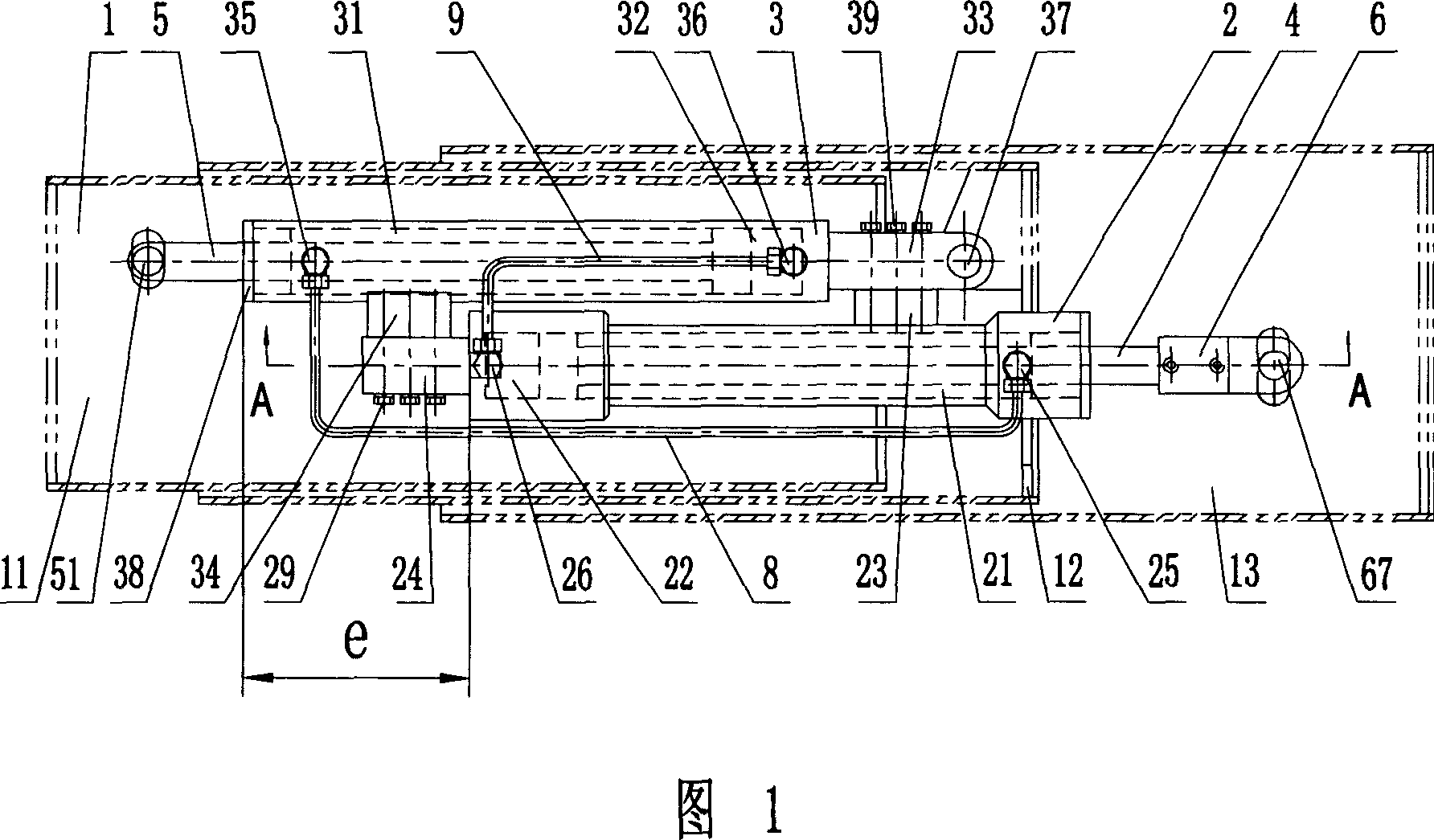

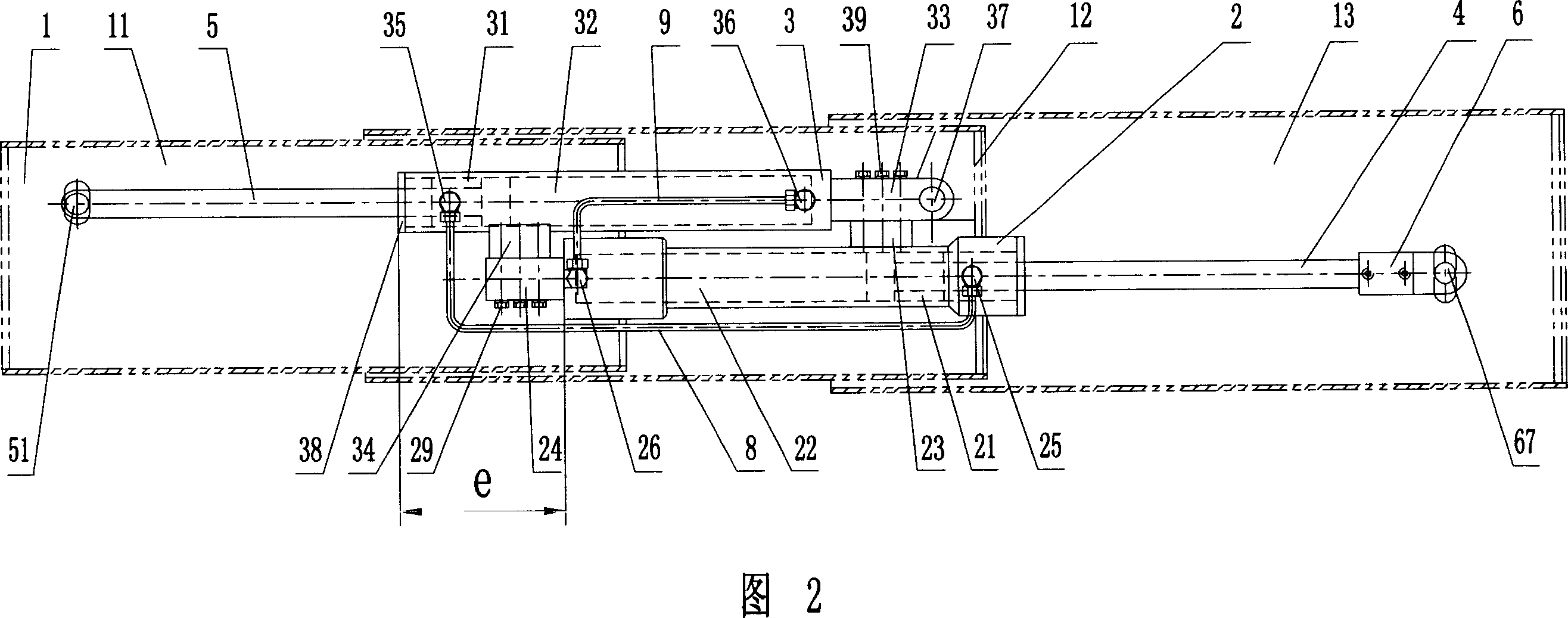

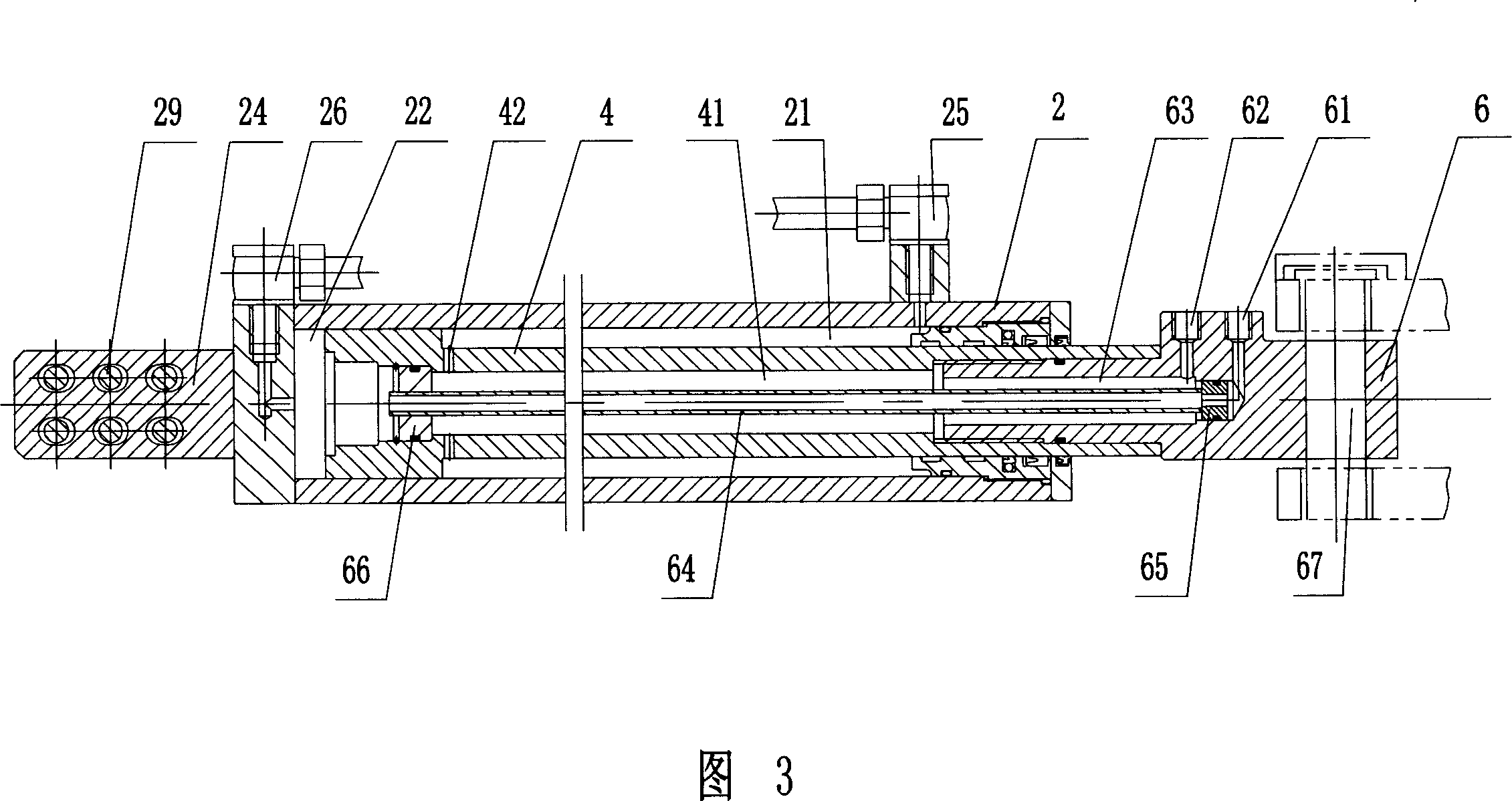

Cylinder set for use in retraction mechanism

ActiveCN1963239AOvercoming the Difficulty of PipingImprove structural strengthConcrete transportationFluid-pressure actuatorsEngineeringMechanical engineering

Owner:SANY HEAVY IND CO LTD (CN)

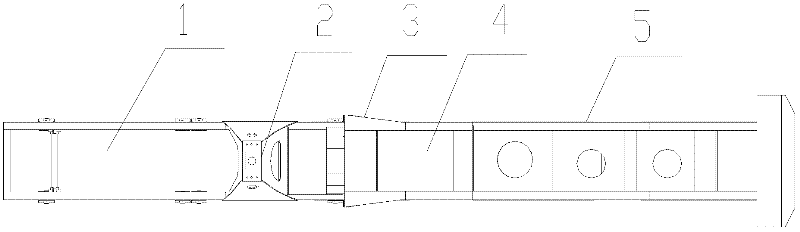

Concrete mixer truck

ActiveCN102328615ASave background materialLow costConcrete transportationUnderstructuresVehicle frameEngineering

The invention provides a concrete mixer truck. The concrete mixer truck comprises a driving cab, a main truck frame, a mixing drum, a foreground assembly and a supporting wheel assembly, wherein the main truck frame comprises two longitudinal beams; the driving cab is fixedly arranged at one end of a longitudinal beam; one end, far away from the driving cab, of the longitudinal beam is inclined upwards relative to the horizontal plane; and the supporting wheel assembly is directly arranged at one end, far away from the driving cab, of the longitudinal beam. In the concrete mixer truck, one end, far away from the driving cab, of the longitudinal beam is provided with the supporting wheel assembly directly by upwards inclination, so background materials are saved, and arrangement space for other accessories is remained and the cost is low.

Owner:SANY AUTOMOBILE MFG CO LTD

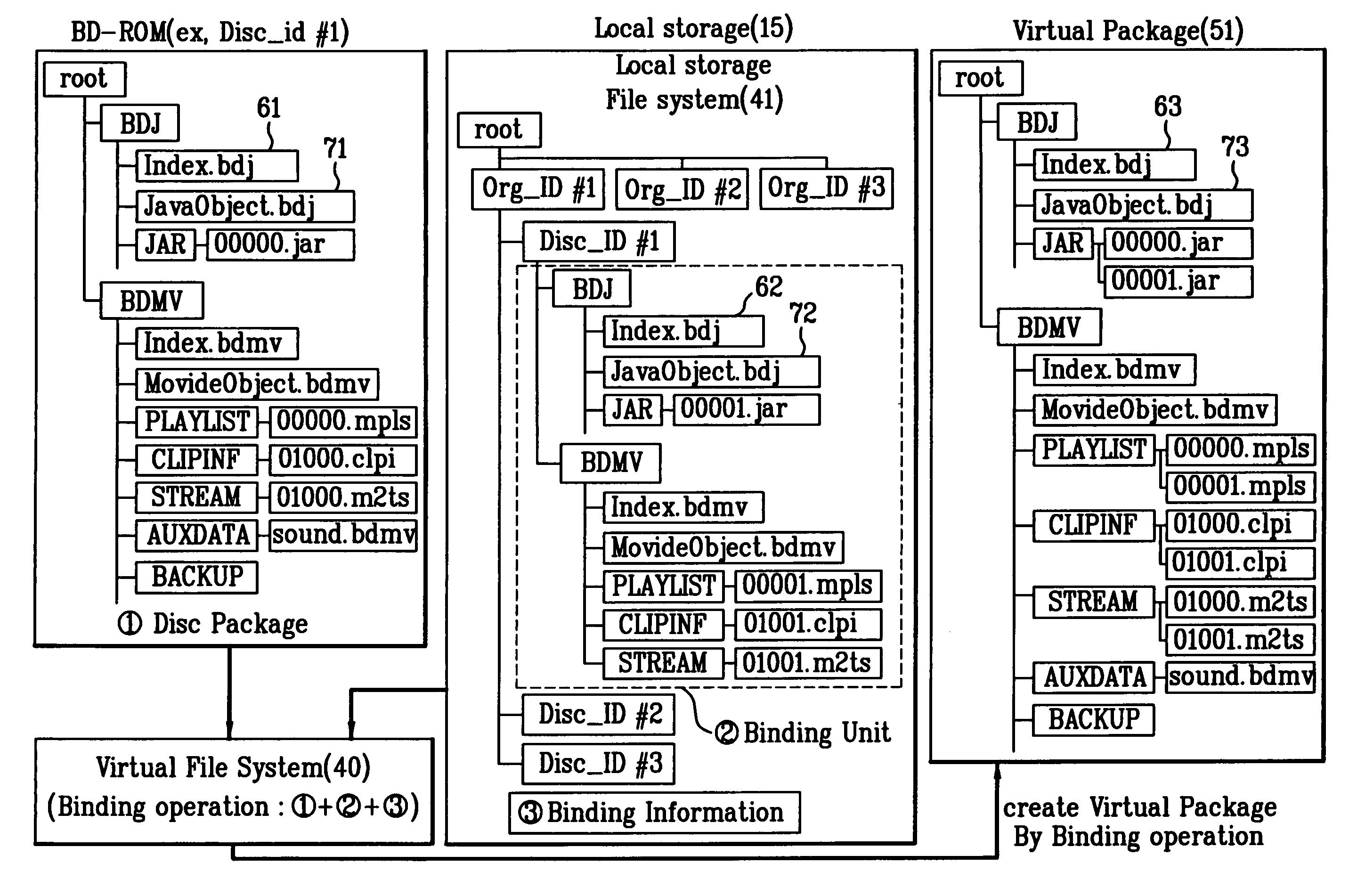

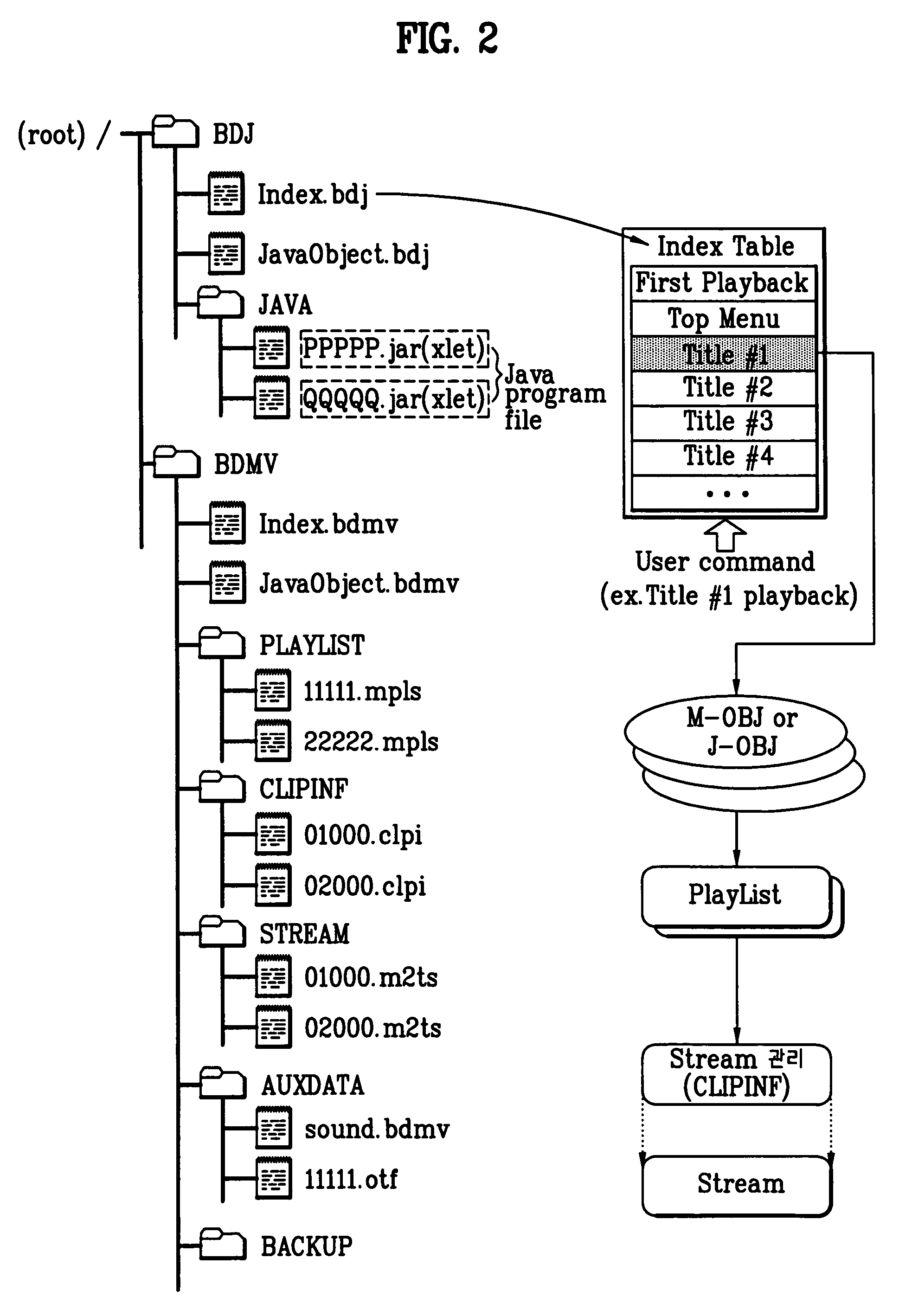

Recording medium, and method and apparatus for reproducing data from the recording medium

A recording medium, and a method and apparatus for reproducing data from the recording medium are disclosed. A disc package for effectively reproducing data having different attributes recorded in the recording medium, and a method and apparatus for reproducing data of the recording medium and data downloaded from a content provider (CP) are disclosed. A first case in which the CP transmits an updated management file, and a second case in which a disc player forms an updated management file are disclosed.

Owner:LG ELECTRONICS INC

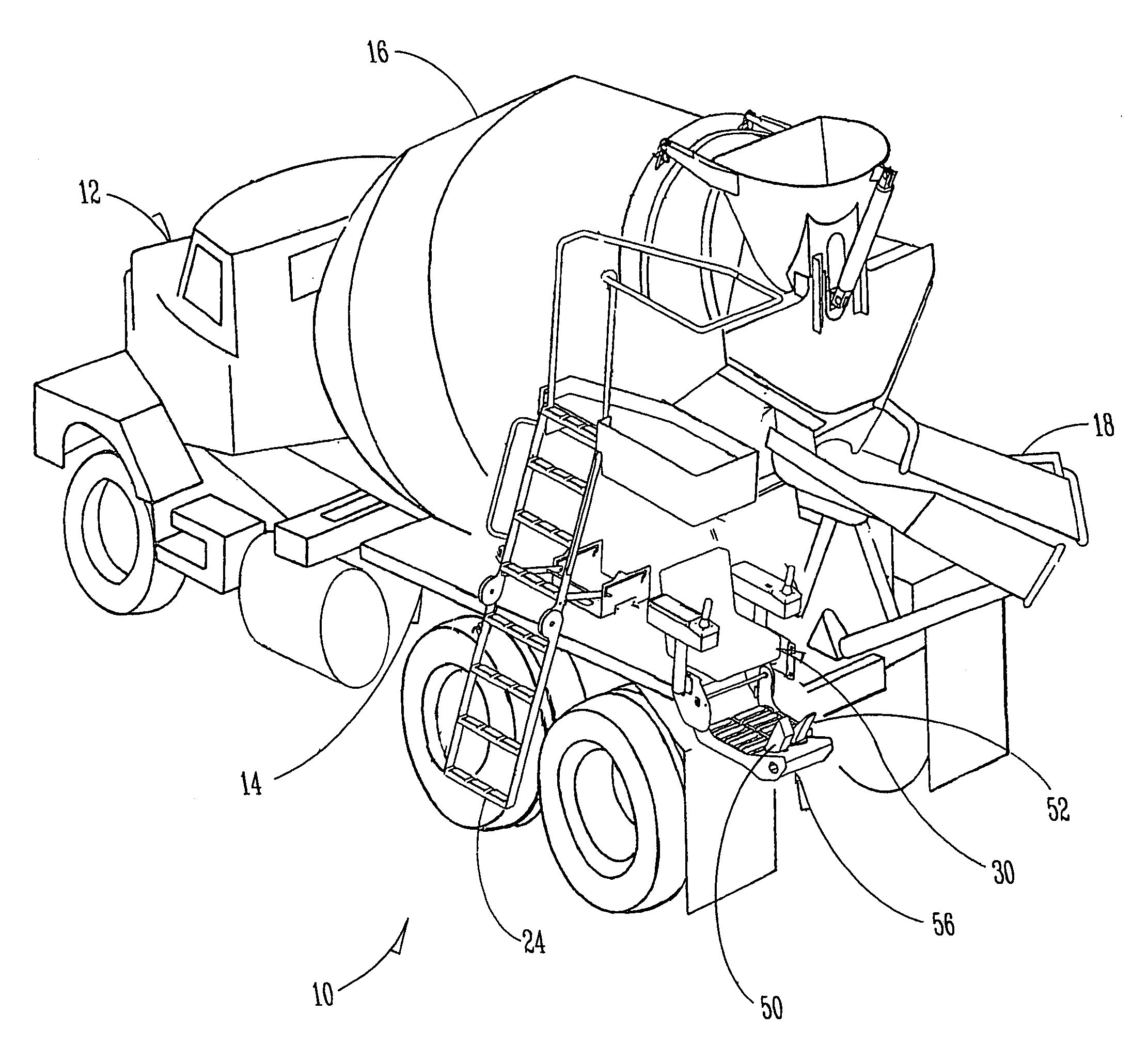

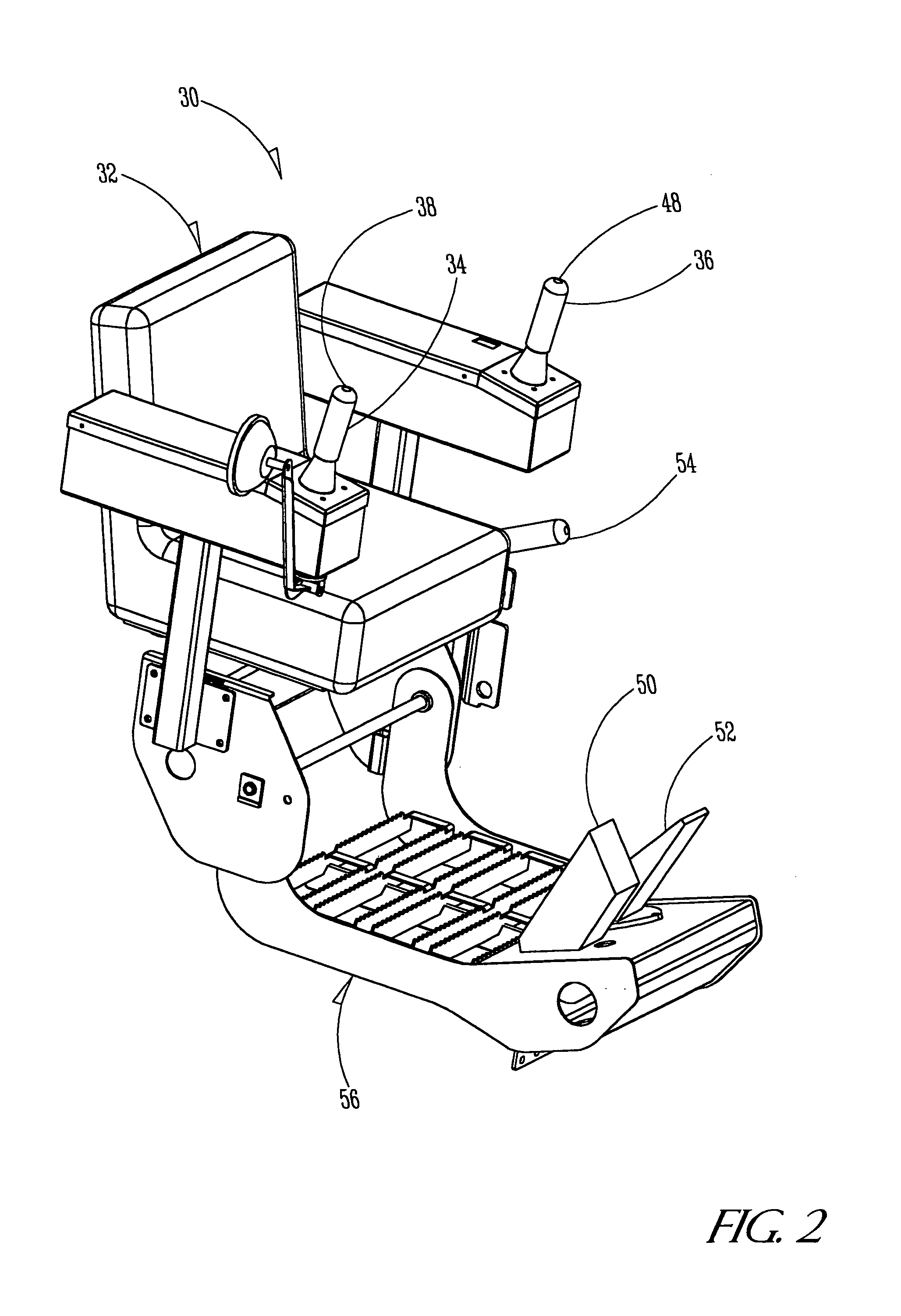

Auxiliary control station for a rear dispensing concrete mixing vehicle

InactiveUS7188991B1The process is simple and convenientEasy to appreciateConcrete transportationAlternative steering controlEngineeringTruck

An auxiliary control station for a rear dispensing concrete truck that controls the truck's steering, braking, and throttle. A seat with controls accessible from the seat may be positioned outside of the cab, such as to allow control of the truck from a position with an unobstructed view of the rear of the truck. The concrete dispensing chute may be modified so as to allow mechanical control of the left and right swing of the chute. The auxiliary control station also controls the drum and positioning of the chute.

Owner:FIVE STAR INDS

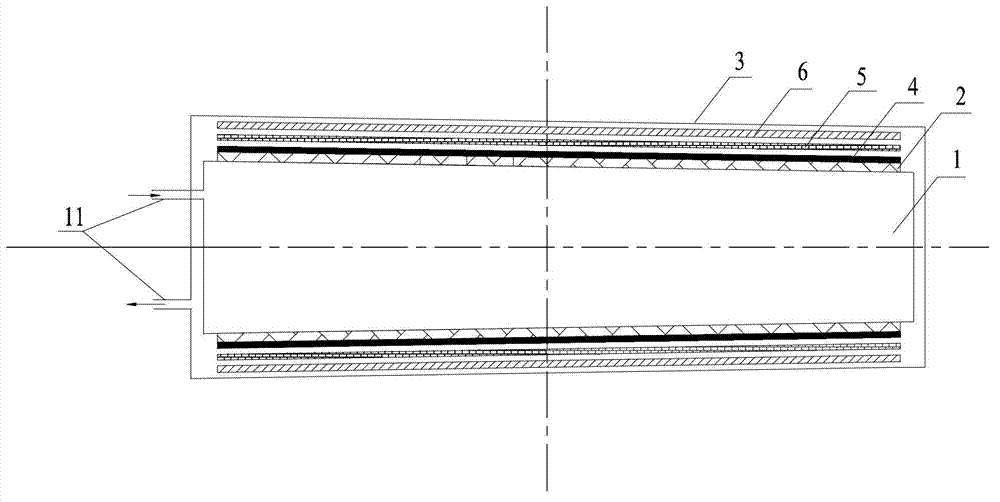

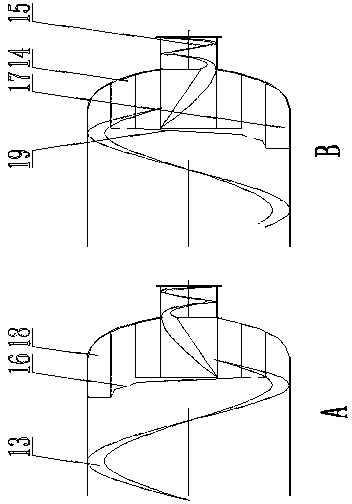

Horizontally-arranged self-sealed stirring and transporting vehicle

InactiveCN103223894AImprove driving stabilityImprove driving safetyConcrete transportationCement mixing apparatusVehicle frameFlange

The invention discloses a horizontally-arranged self-sealed stirring and transporting vehicle. A tank body is horizontally arranged on an auxiliary vehicle frame of an automobile chassis. The horizontally-arranged self-sealed stirring and transporting vehicle has the following innovations: a rotary disc bearing connecting flange I is arranged at the combined part of an inlet-outlet material guide pipe; a rotary disc bearing is connected between the rotary disc bearing connecting flange I and a rotary disc bearing foundation; the rotary disc bearing base is then fixed on a rear support; the rotary disc bearing firmly controls the tank body and rotates flexibly; materials are added in or output by utilizing the synchronous running and cooperation of three stirring cages; the liquid level of fluid is lifted by adopting a disc-type spiral lifting stirring cage, so that the loading liquid level exceeds the inlet-outlet material guide pipe and does not leak; the fluid does not overflow in ascending and bumping, and the disc-type spiral lifting stirring cage is insulated and sealed automatically; and the raceway nest support adopts a mode of supporting in the tank body, the tank body supporting intensity is improved, and the total height is not increased. The general design concept provided by the invention focuses on the driving stability, the safety performance, the market survival capability and loading and transportation capability of the stirring and transporting vehicle.

Owner:SHIYAN DAY SPECIAL PURPOSE VEHICLE TECH DEV

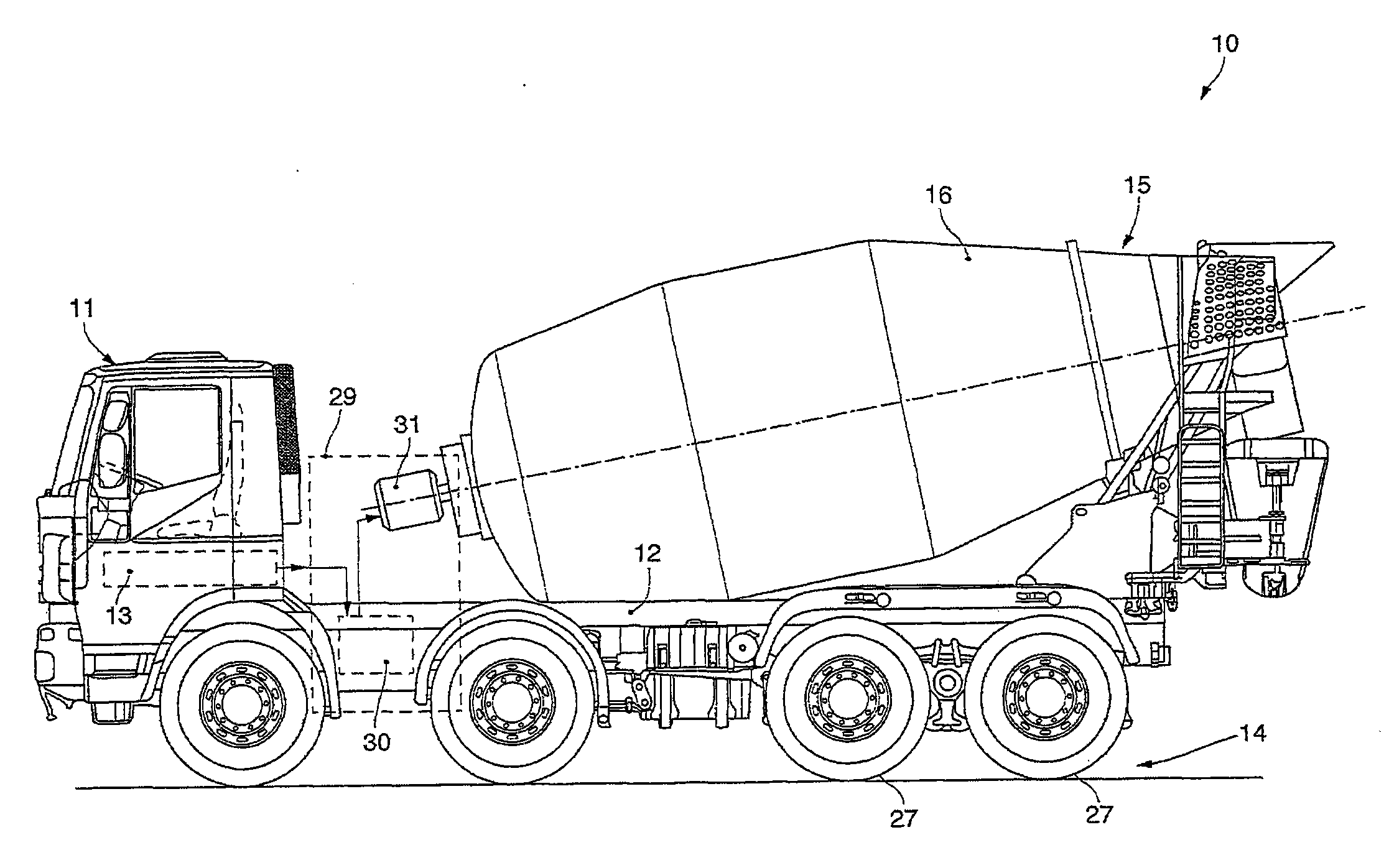

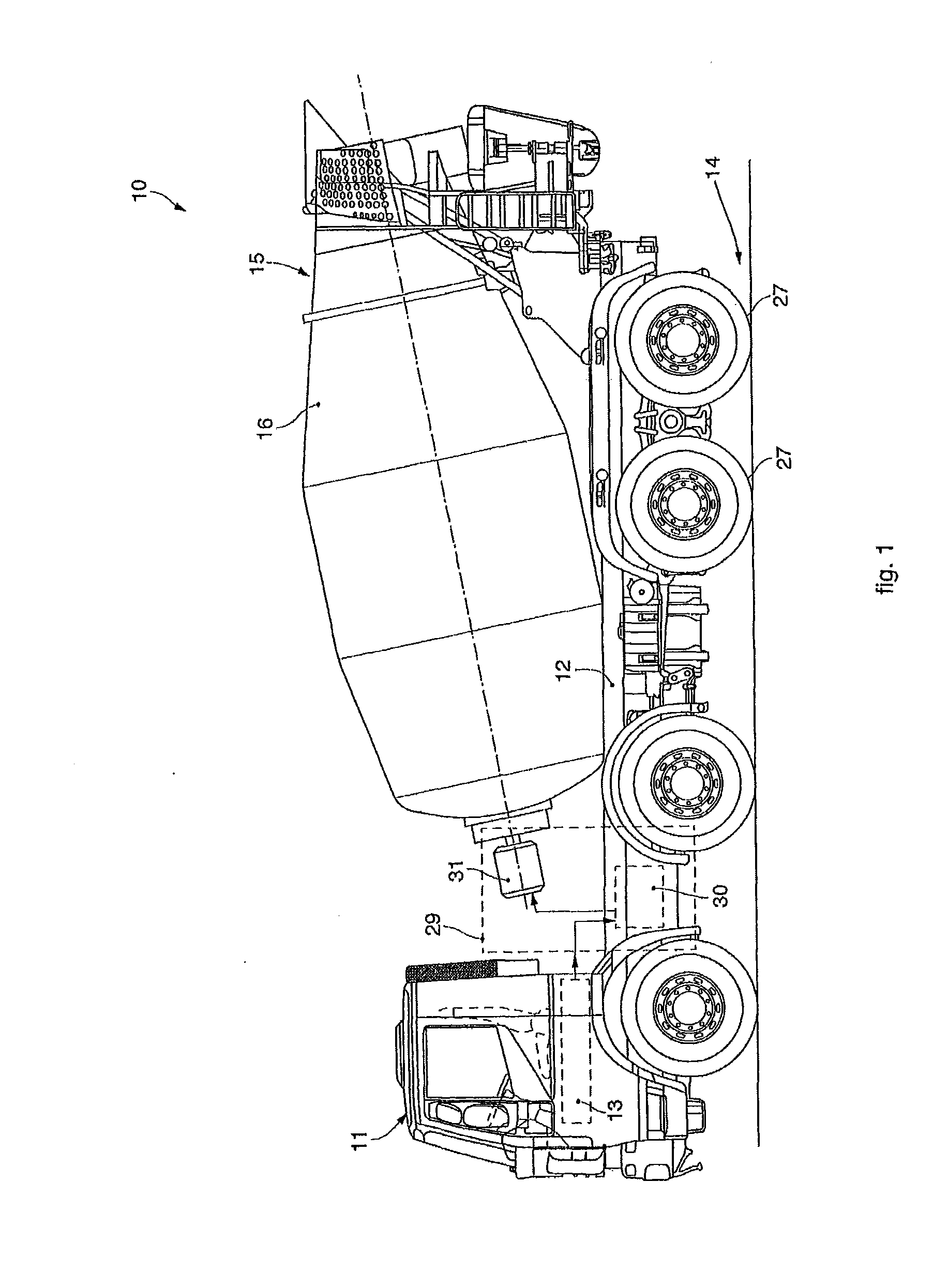

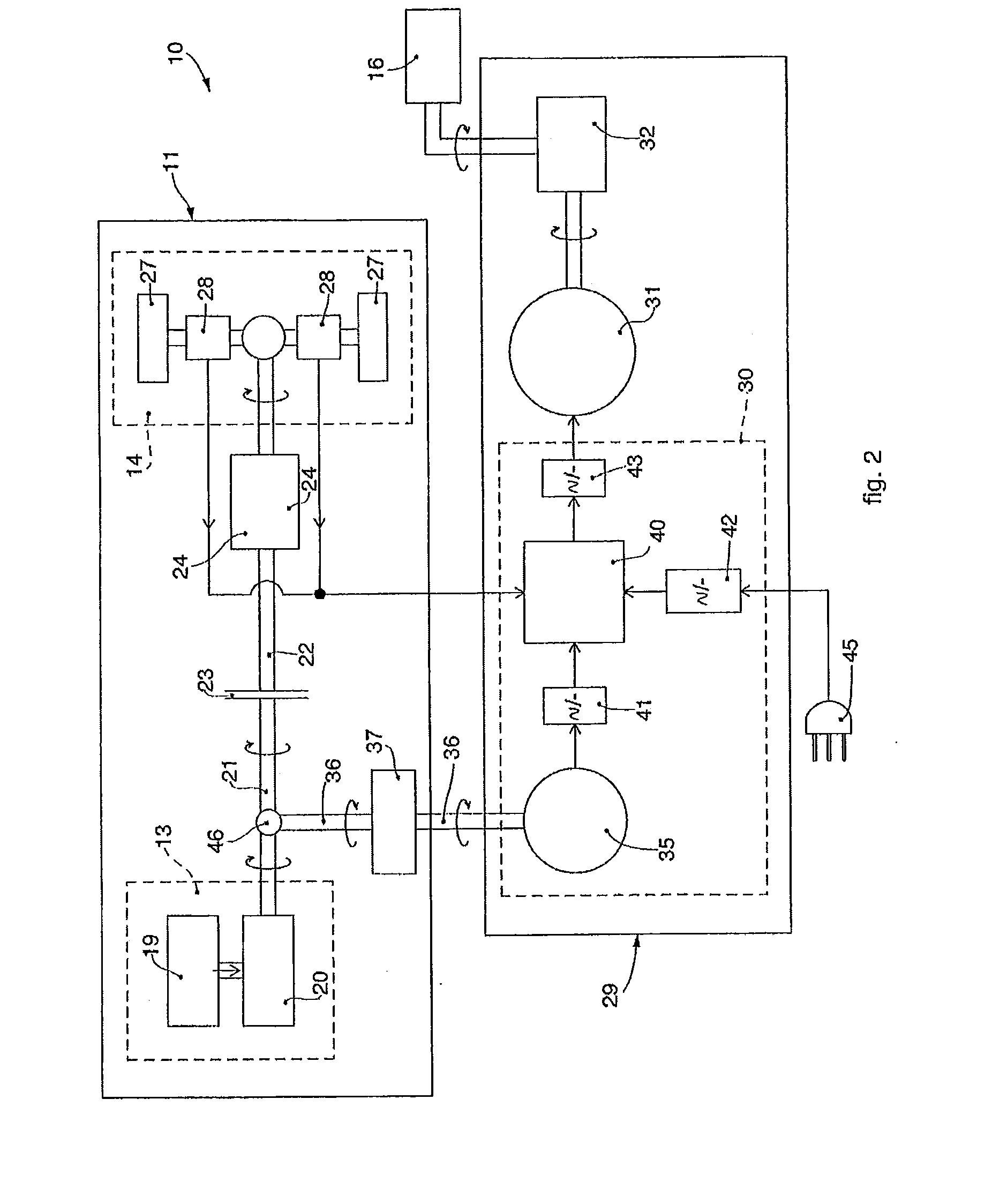

Concrete mixer with perfected auxiliary device

ActiveUS20160199999A1Emission reductionReduce noiseHybrid vehiclesAuxillary drivesDrive wheelMechanical energy

A concrete mixer truck comprises a vehicle provided with a heat engine and a concrete mixer having a rotating drum and an auxiliary device provided with a unit for generating electric energy that selectively feeds an electric motor connected to the rotating drum. The electric energy generating unit comprises at least an alternator selectively connectable to the heat engine and to a movement unit of the vehicle by means of a gearbox and a power take-off positioned between the clutch of the vehicle and the gearbox. The alternator is configured to convert mechanical energy into alternate electric energy and vice versa. The electric energy generating unit also comprises at least one accumulator and reversible conversion means of electric energy, connected to the accumulator and to the alternator in order to selectively take continuous electric energy from the former and supply alternate electric energy to the latter, to move the drive wheels of said movement unit, or to convert the alternate electric energy produced by the alternator into continuous electric energy to be transferred to the accumulator.

Owner:CIFA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com