Patents

Literature

65 results about "Ready mixed concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ready-mixed concrete with phosphorus slag powder

InactiveCN101798207AImprove impermeabilityReduce heat of hydrationSolid waste managementSolid waste disposalTensile strainReady mixed concrete

The invention relates to a ready-mixed concrete with phosphorus slag powder, which is characterized in that the composition ratio and the weight ratio comprise the following parts: 120-150 parts of cement, 100-250 parts of phosphorus slag powder, 0-120 part(s) of fly ash, 0.5-20 part(s) of water reducing agent, 0-0.5 part of air entraining agent, 0-0.02 part of water retention agent, 50-17000 parts of coarse aggregate, 20-9000 parts of fine aggregate and 100-300 parts of water. The invention takes the industrial waste residue i.e. the phosphorus slag powder as the admixture part of the concrete to replace the cement to dope in the ready-mixed concrete, thereby reducing the use amount of the cement, uses the retarding characteristic of the phosphorus slag to reduce the gelled material cost of the concrete and the manufacture cost the of concrete pumping aid, simultaneously gives full play to the characteristic of the phosphorus slag so as to reduce the hydration heat and the adiabatic temperature rise of the concrete, decreases the elasticity modulus and improves the ultimate tensile strain capacity of the concrete, the strength growth rate is high, and the durability is significantly improved; and the invention can changes the waste into the valuable and turns the harmful into the beneficial.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing aliphatic high efficiency water reducing agent by using industrial by-product and application thereof

InactiveCN101186459AImprove protectionPromote sustainable developmentSolid waste managementSuperplasticizerP-Cresol

The invention relates to a preparation method of an aliphatic high range water reducer applying industry byproduct and the application thereof, which belongs to the field of concrete water reducer. The invention uses the industry byproduct in production of sulfonation-process phenol or the byproduct (Na2SO3 content is 60-85percent) in production of p-cresol and sodium hydrosulfite to produce the aliphatic high range water reducer and takes acetone, formaldehyde, industry byproduct, sulphite or sodium pyrosulfite as raw materials and then sulfonation and condensation reactions are carried out in aqueous medium, the reactant weight ratio is acetone: formaldehyde: sulphite plus industry byproduct: water is equal to 1:2.5-4.5:1.5-2.6:4.0-6.0, the mass concentration of the condensation compound obtained is 30-42 percent, and the viscosity thereof is 20-100m.Pa.S. The product performance of the invention is similar to the common product, but the cost is reduced by 10-20 percent. The invention has environmental protection and waste utilization, can be applied to preparation of various concrete members and production of ready mixed concrete and has good industrialization prospect.

Owner:BEIJING UNIV OF TECH

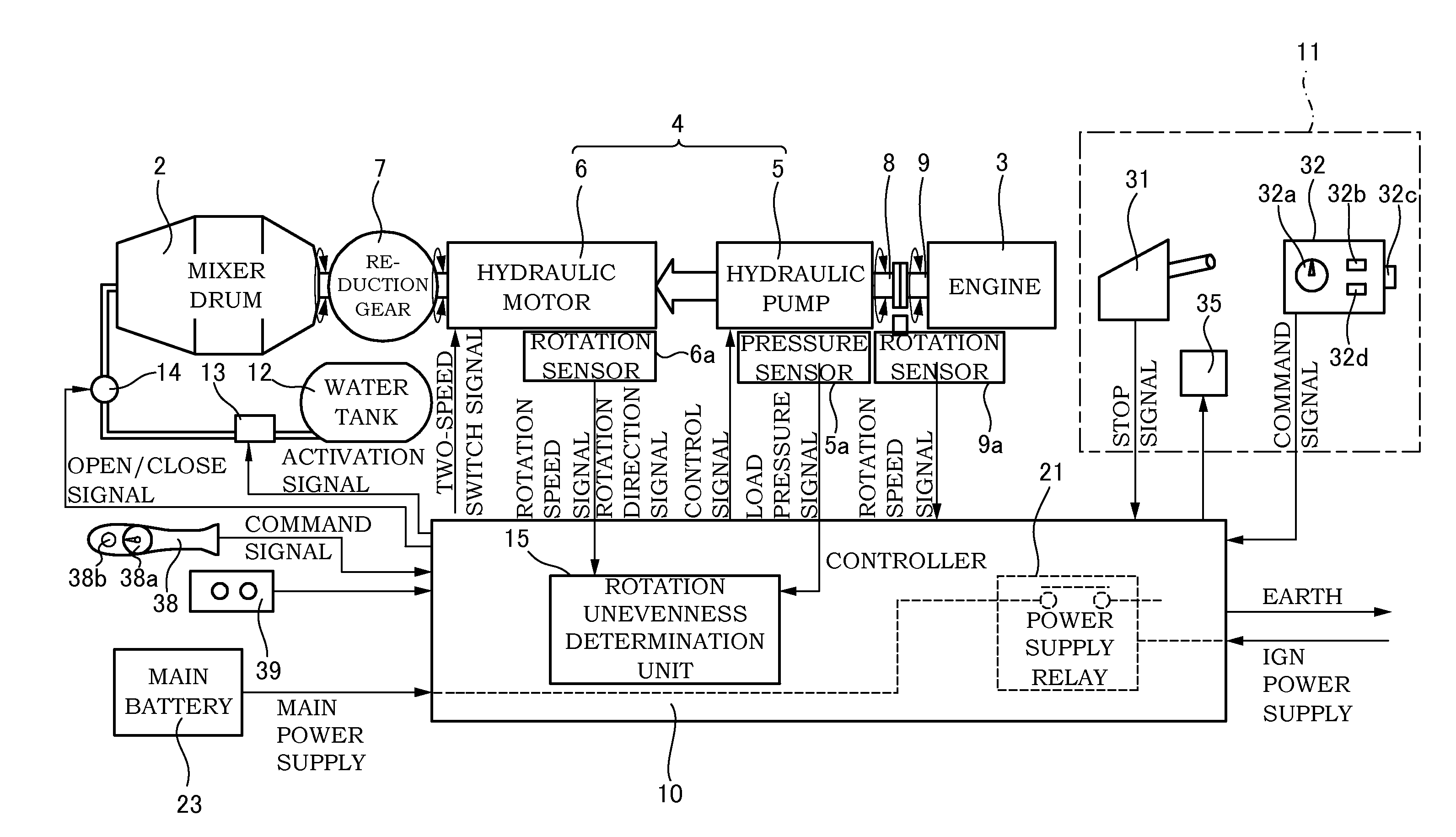

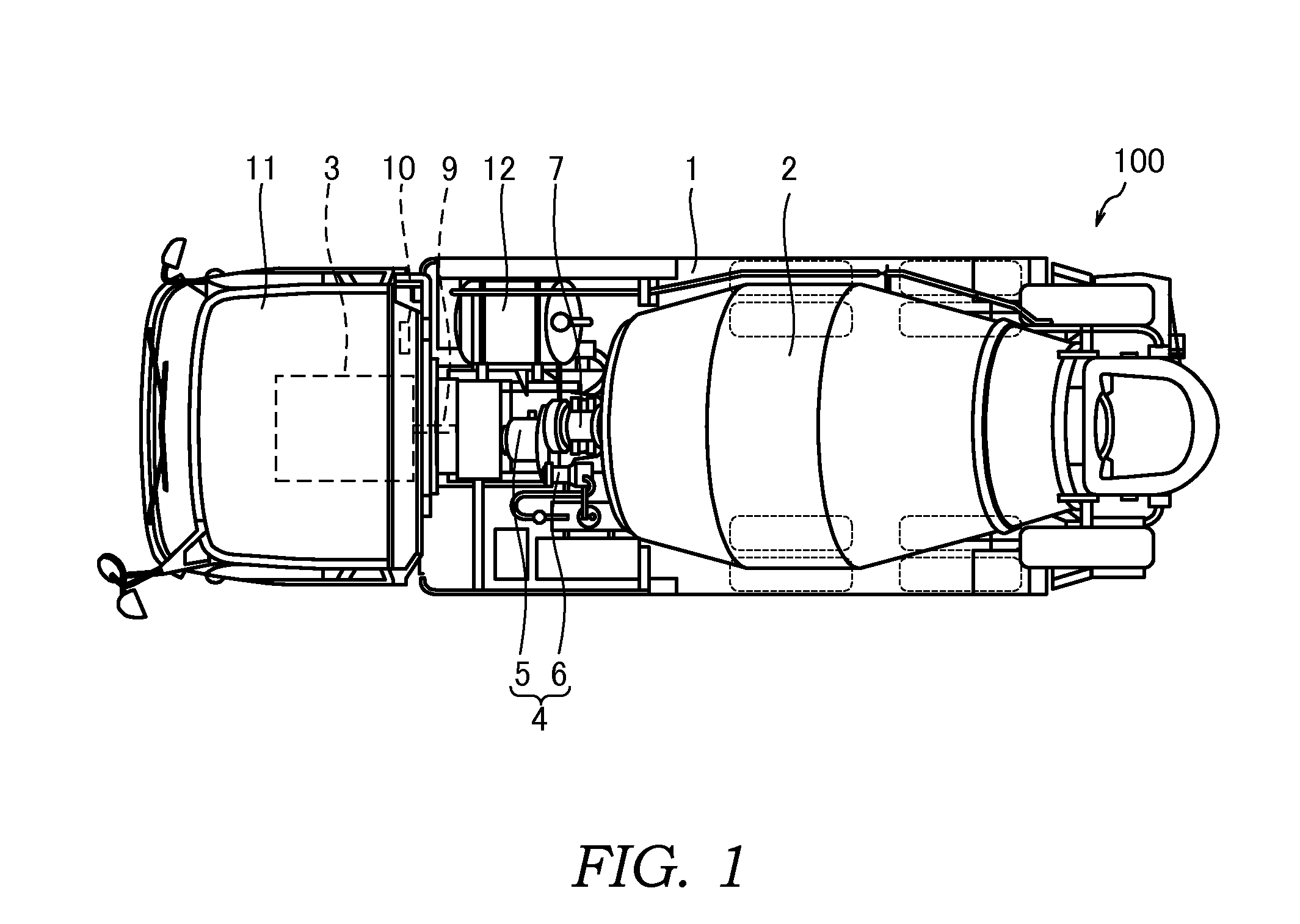

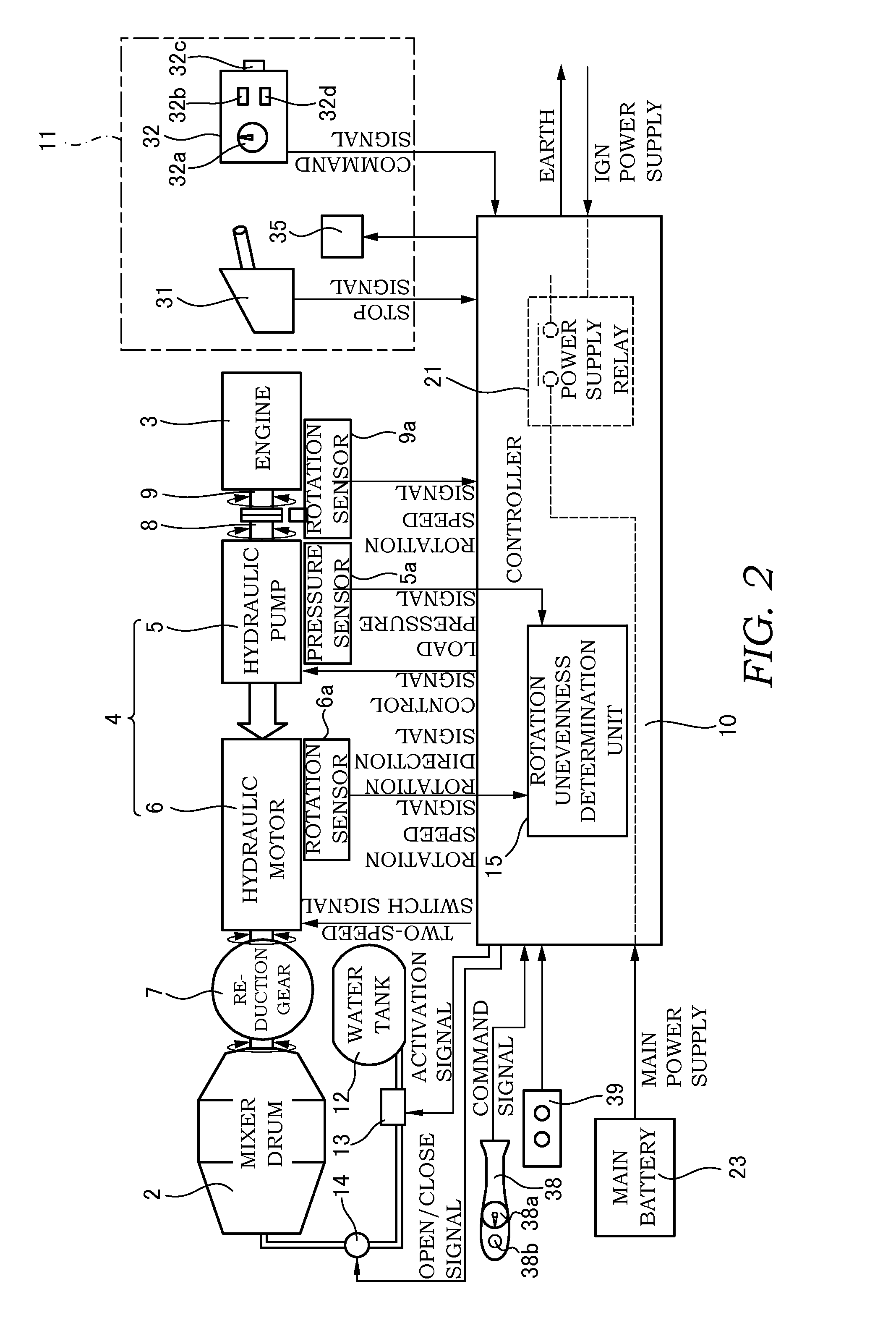

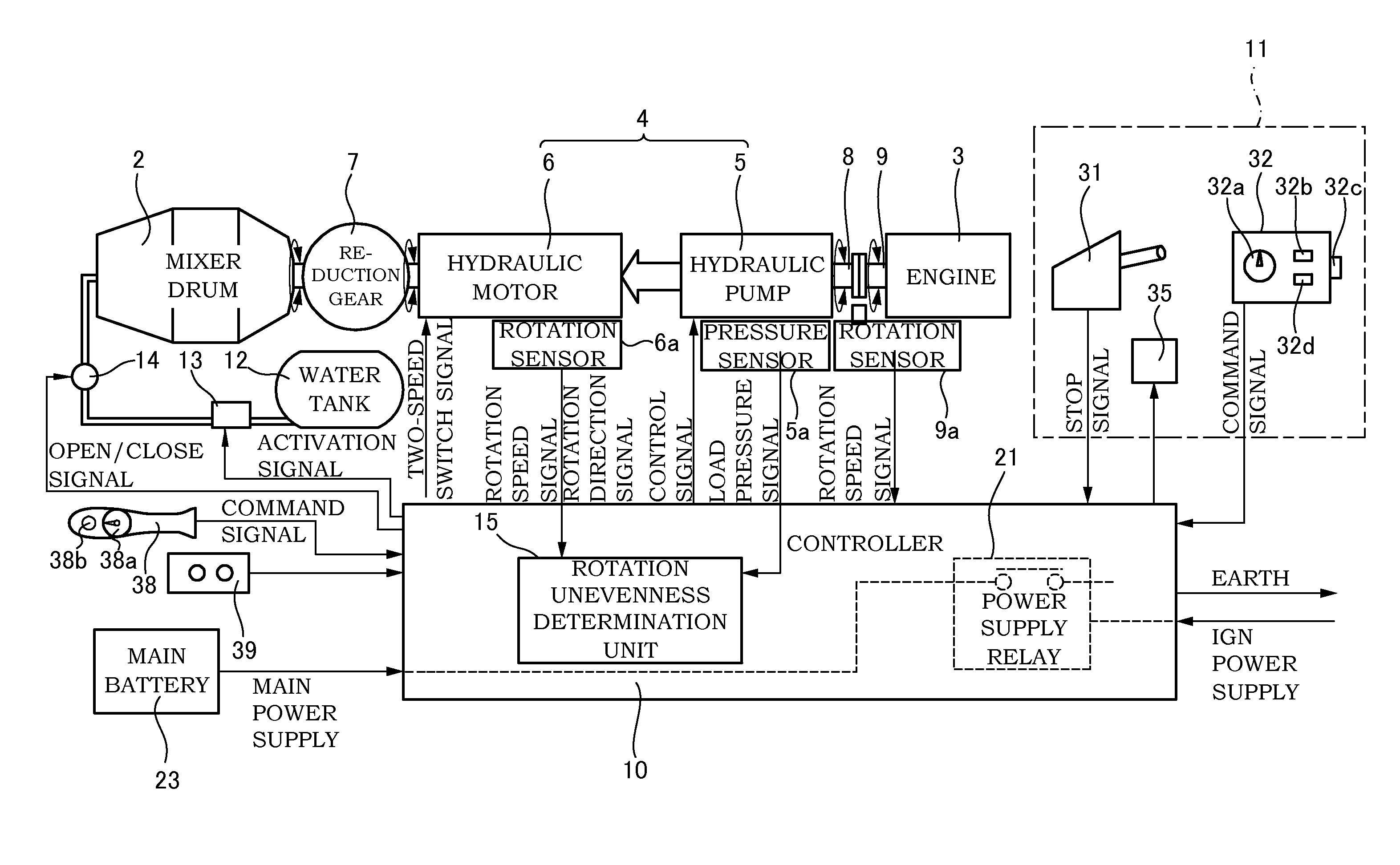

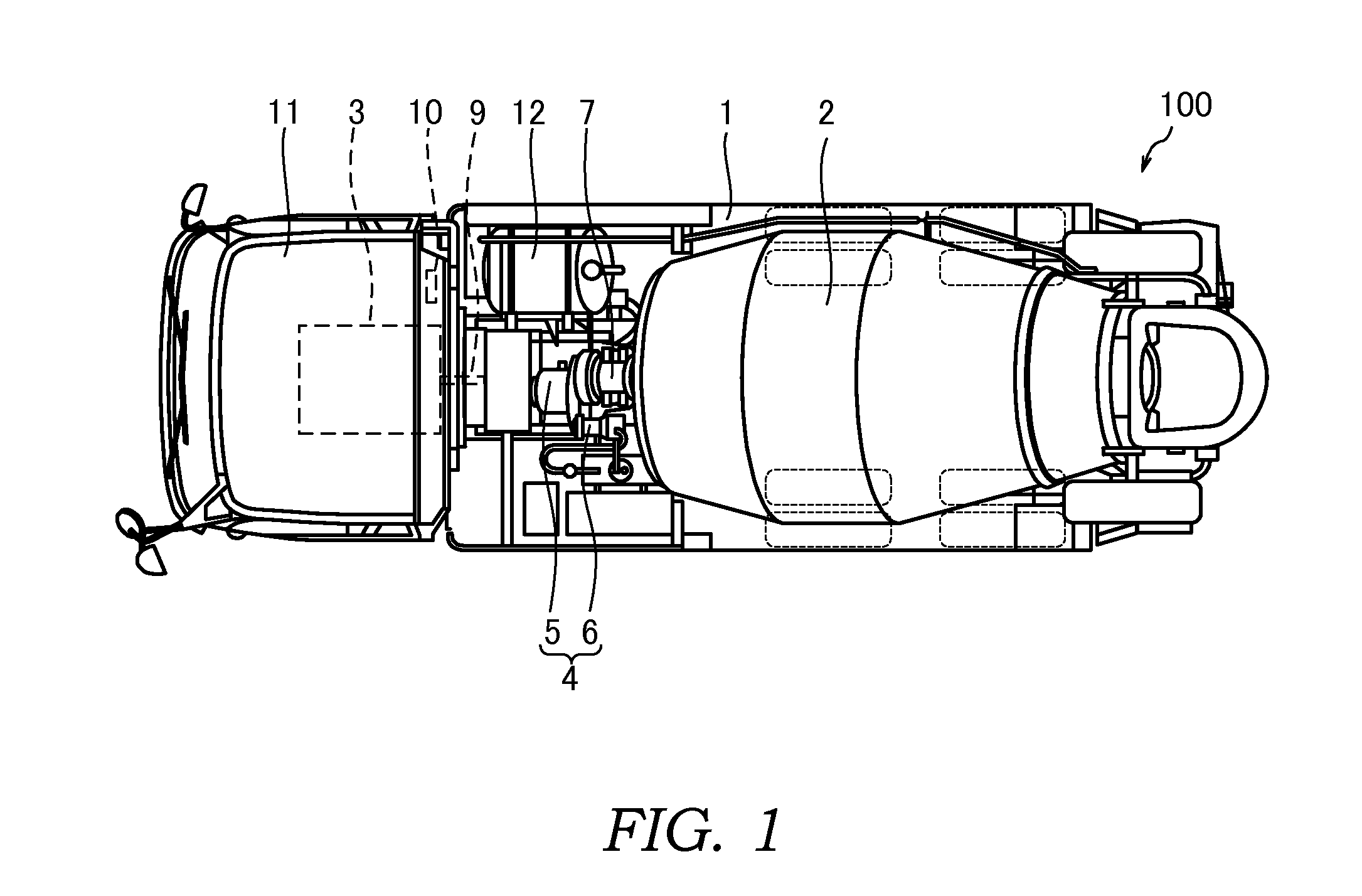

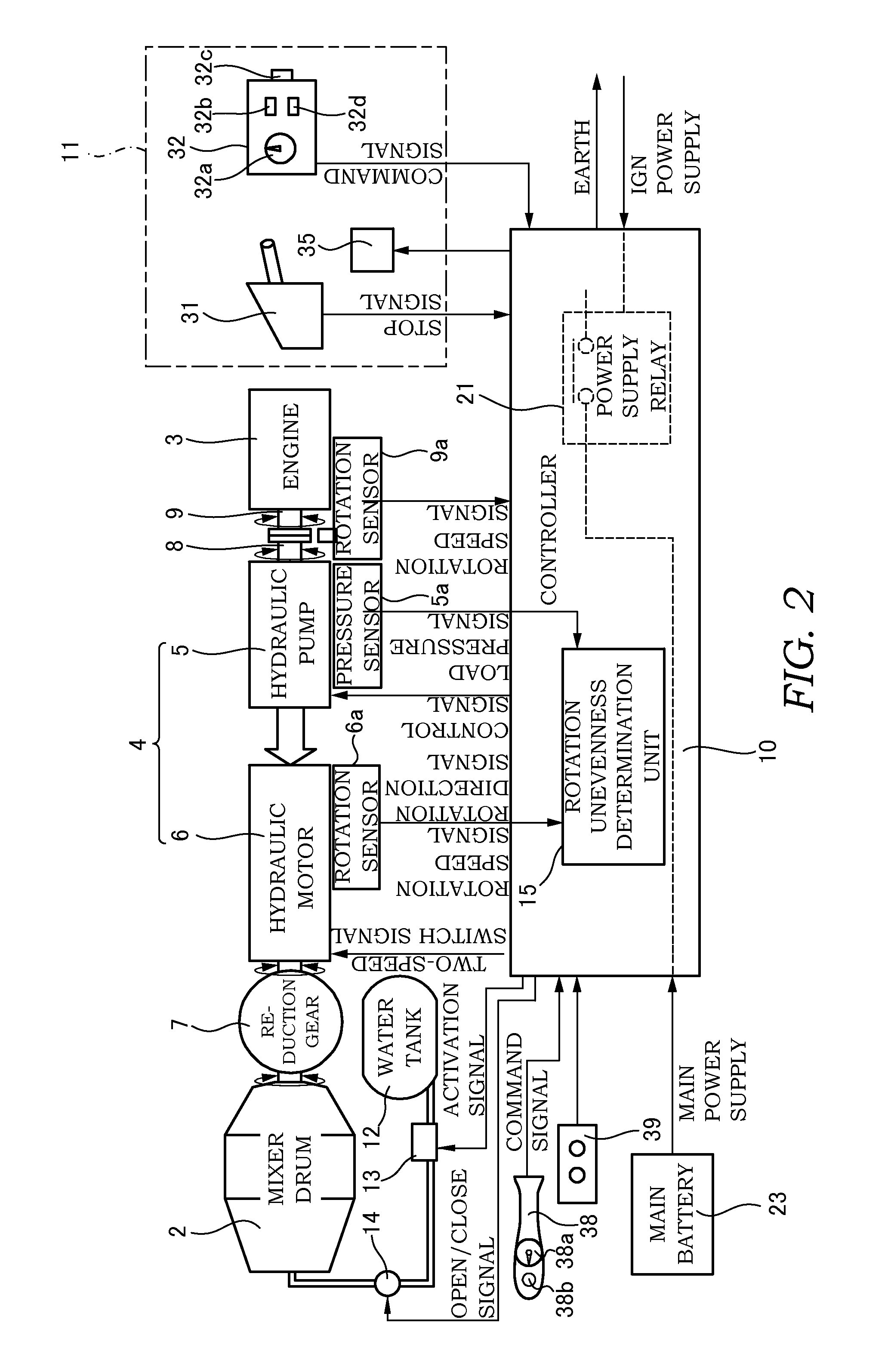

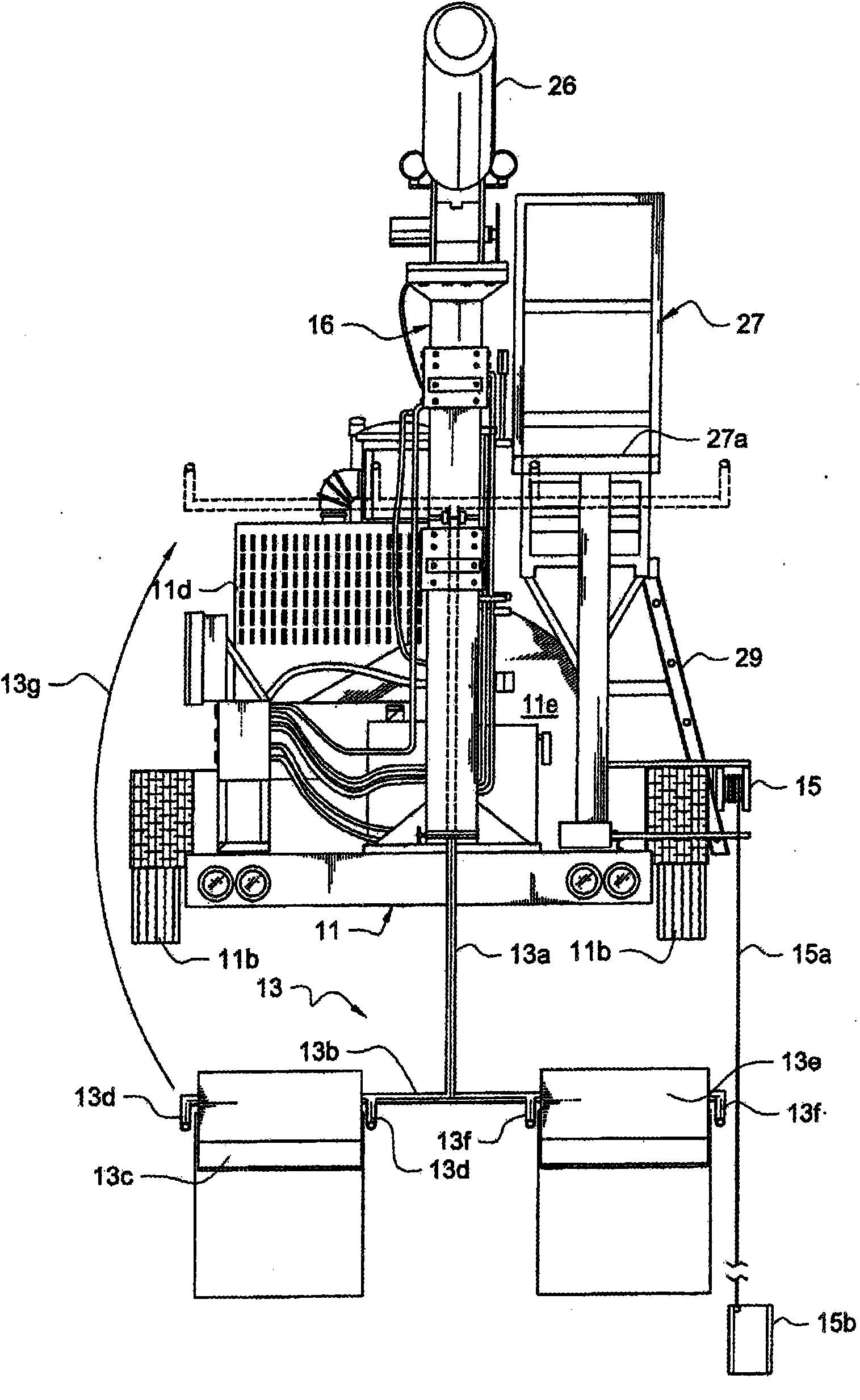

Mixer truck

InactiveUS20140198599A1Concrete transportationCement mixing apparatusDriver/operatorReady mixed concrete

A mixer truck includes: a mixer drum capable of carrying ready-mixed concrete; a driving device that drives the mixer drum to rotate using an oil pressure of a working oil; a pressure sensor that detects a driving condition of the mixer drum driven by the driving device; a controller that determines a magnitude of rotation unevenness in the mixer drum by comparing a magnitude of variation in the driving condition detected by the pressure sensor with a predetermined set value after the ready-mixed concrete in the mixer drum has been discharged; and a notifying device that notifies a driver that the magnitude of the rotation unevenness in the mixer drum has reached an allowable value when the controller determines that the magnitude of the variation in the driving condition detected by the pressure sensor has reached the set value.

Owner:KYB CORP

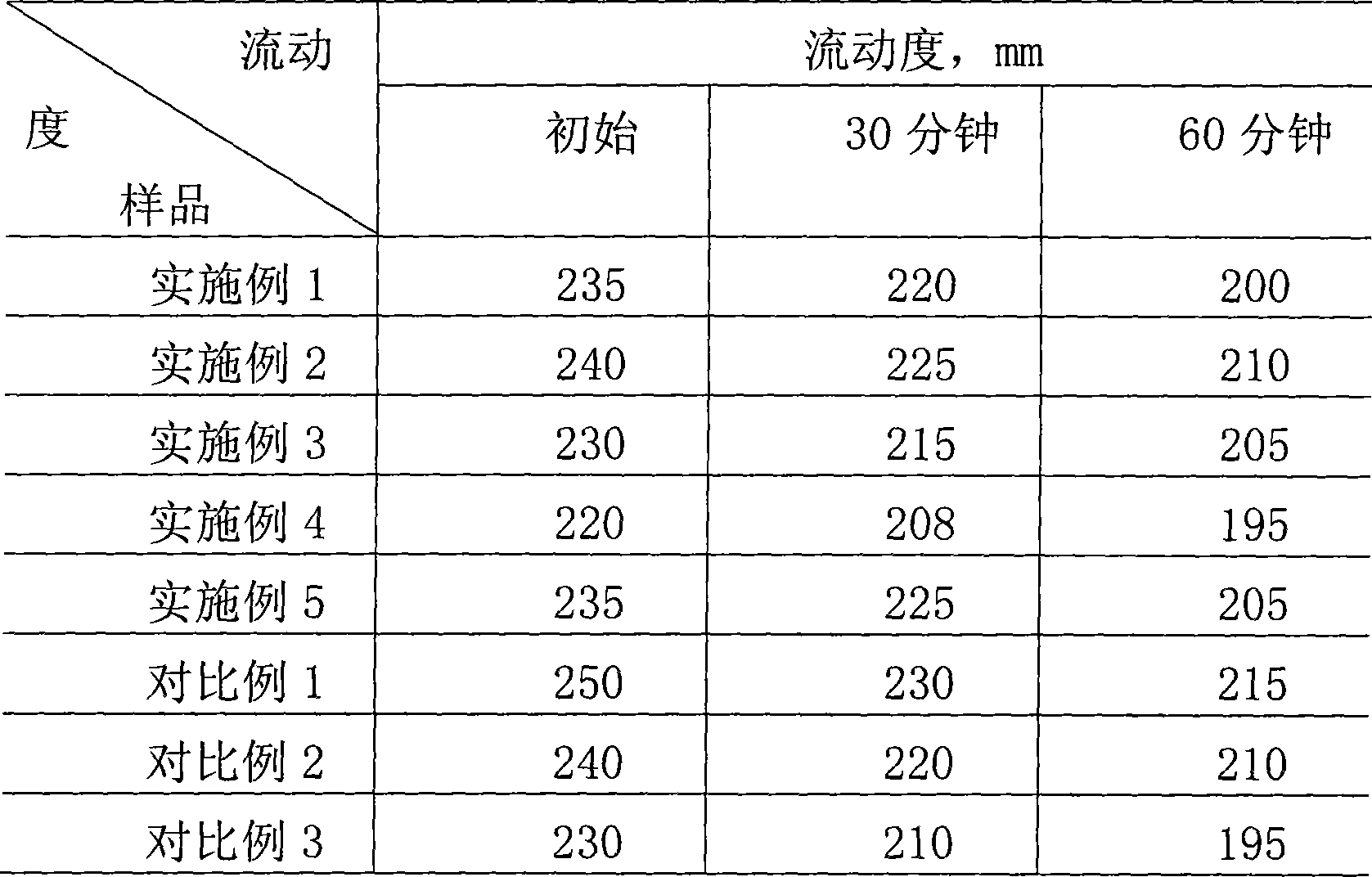

Ultra high strength fiber-reinforced cement composition, ultra high strength fiber-reinforced mortar or concrete and ultra high strength cement additives

InactiveUS20090071378A1Improve liquidityImprove machinabilitySolid waste managementGeneral purposeMass ratio

Therefore, the problem to be solved by the present invention is to provide highly general purpose ultra high strength fiber-reinforced mortar or concrete that shows a higher fluidity (workability) at the fresh state, a higher bending strength with a less content of metal fiber by enhancing both the absolute value of the compressive strength of mortar -matrix excluding metal fiber and the ratio of the bending strength relative to the compressive strength simultaneously at the hardened state, and acceptability of fine aggregate being used in ordinary ready-mixed concrete. An ultra high strength fiber-reinforced cement composition is characterized in that it contains cement, silica fume, coal gasification fly ash, gypsum and metal fiber and that the mass ratio of silica fume : coal gasification fly ash is 95 through 50 portions: 5 through 50 portions. Ultra high strength fiber-reinforced mortar or concrete contains such a cement composition and fine aggregate. An ultra high strength cement additives is characterized in that it contains silica fume, coal gasification fly ash and gypsum as principal ingredients and the mass ratio of silica fume: coal gasification fly ash is 95 through 50 portions: 5 through 50 portions.

Owner:DENKA CO LTD +1

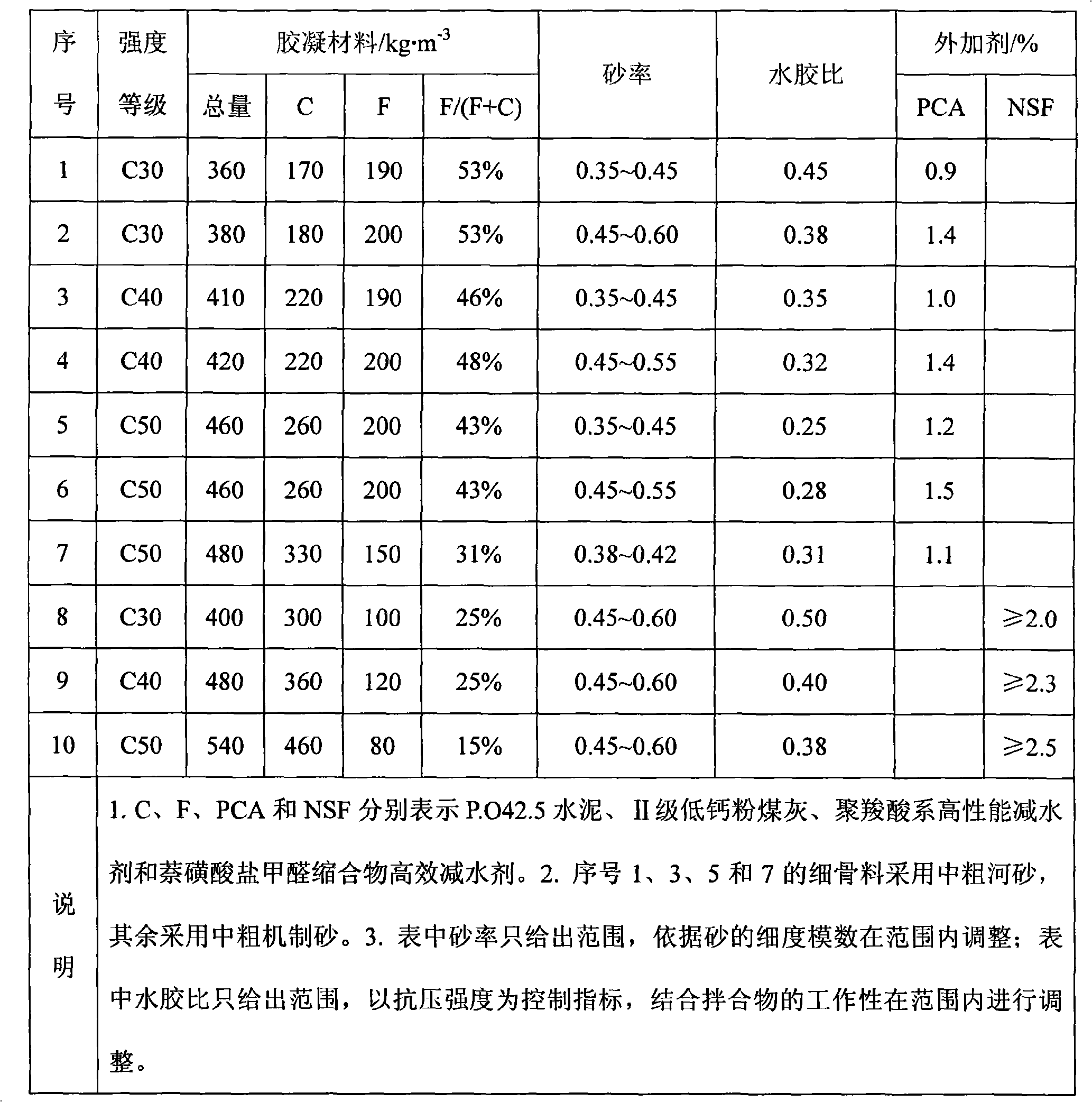

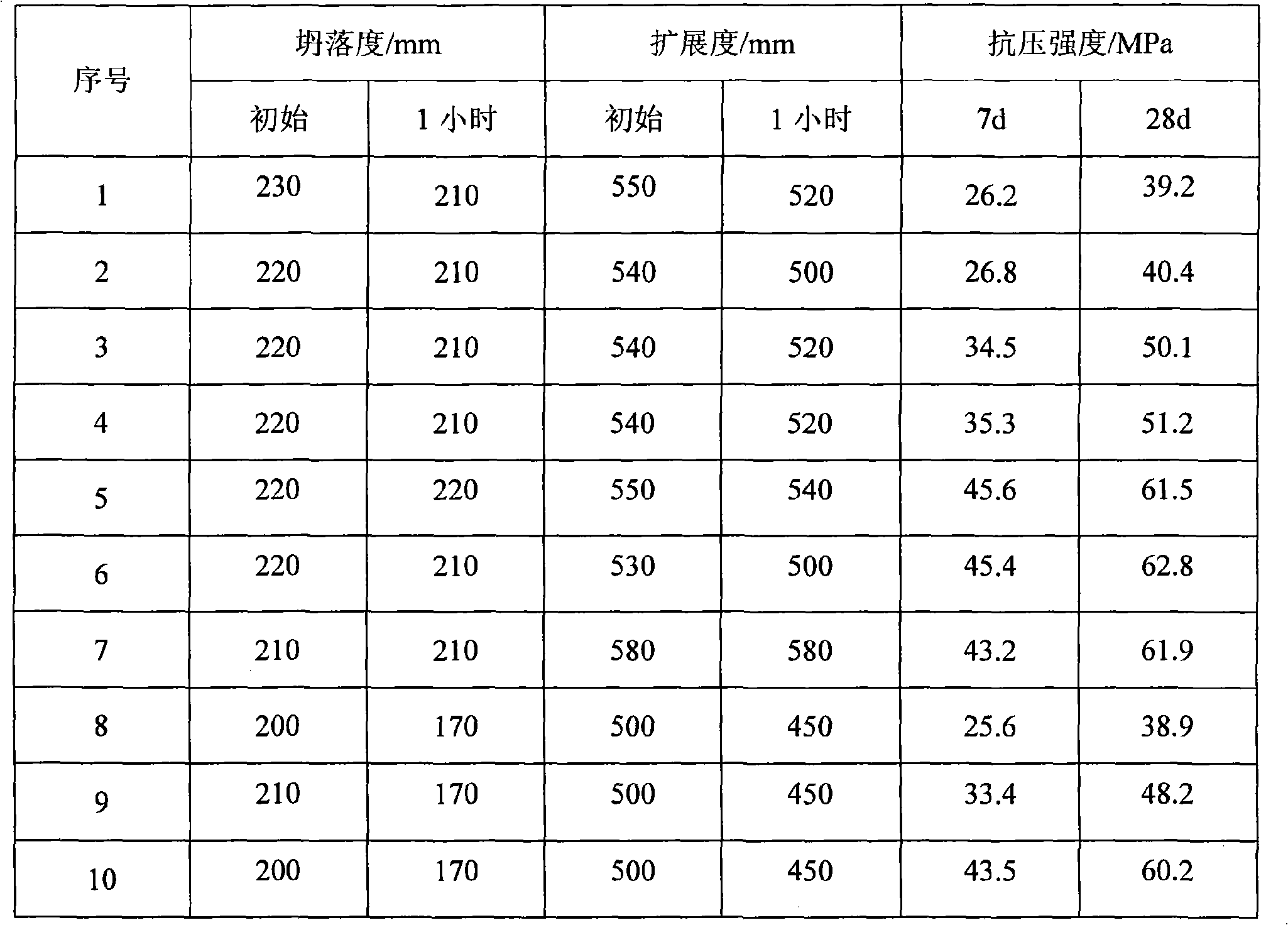

High fly ash commercial concrete or ready-mixed concrete

InactiveCN101525223AHigh water reduction rateImprove work performanceSolid waste managementChemical admixtureFrost

The invention relates to high fly ash commercial concrete or ready-mixed concrete or a preparation method thereof. The high fly ash commercial concrete or ready-mixed concrete is made from gelled material, aggregate, chemical additive and water; wherein, the gelled material comprises cement and fly ash; the aggregate comprises fine aggregate and coarse aggregate; and the chemical additive is polycarboxylate-based high performance water reducer. The usage of the gelled material is 360-480kg / m<3>concrete; wherein, the concrete is 47%-69wt% of the total gelled material; and the fly ash is 31%-53wt% of the total gelled material. The concrete has good workability, suitable strength and strength development, lower hydration temperature rising, higher volume stabilization, higher cracking resistance, impermeability, frost resistance, corrosion stability, resistance to carbonizing, alkali-resistant-aggregate reaction and chloride-resistant diffusibility.

Owner:WUHAN UNIV

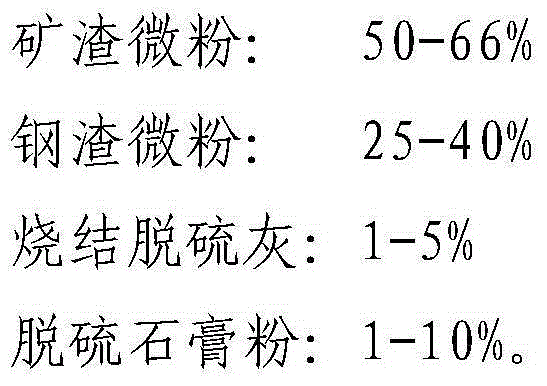

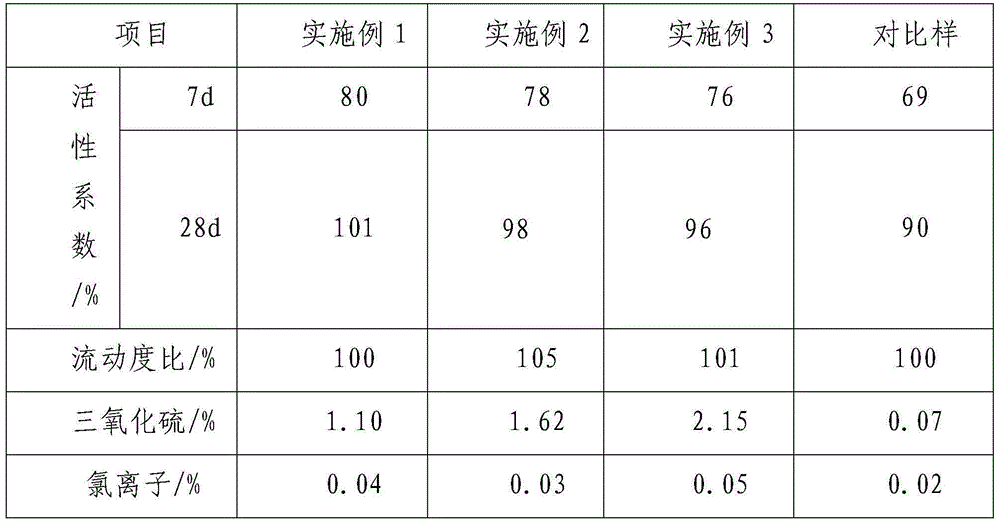

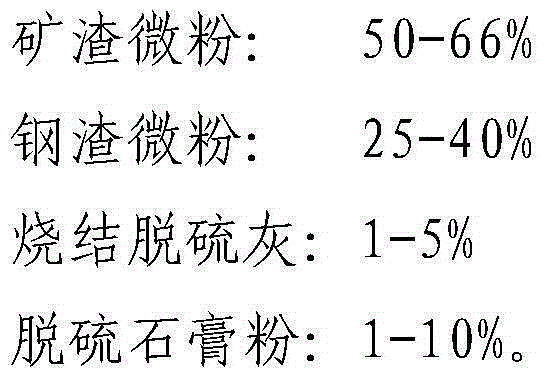

Compound mineral admixture

InactiveCN106277881AHigh activityReduce consumptionSolid waste managementActivity indexReady mixed concrete

The invention relates to the technical field of building materials, in particular to a compound mineral admixture with high activity. The compound mineral admixture comprises raw materials in percentage by weight as follows: 50%-66% of slag micropowder, 25%-40% of steel slag micropowder, 1%-5% of sintering desulfurization ash and 1%-10% of desulfurization gypsum powder. The sintering desulfurization ash and the desulfurization gypsum powder are taken as activators, the exited activity is good, the 7-day activity index is increased by 10%-15% on year-on-year basis, the 28-day activity index is increased by 7%-12% on year-on-year basis, and the production cost is low. The compound mineral admixture prepared with the formula system has good early strength, the long-age strength can be increased continuously, and can effectively improve the working performance of concrete and reduce loss at the slump time and is easy to vibrate when applied as ready-mixed concrete; technical indexes of heat of hydration, flexural strength, permeability resistance, wear resistance, dry shrinkage resistance and the like of the concrete can be improved.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

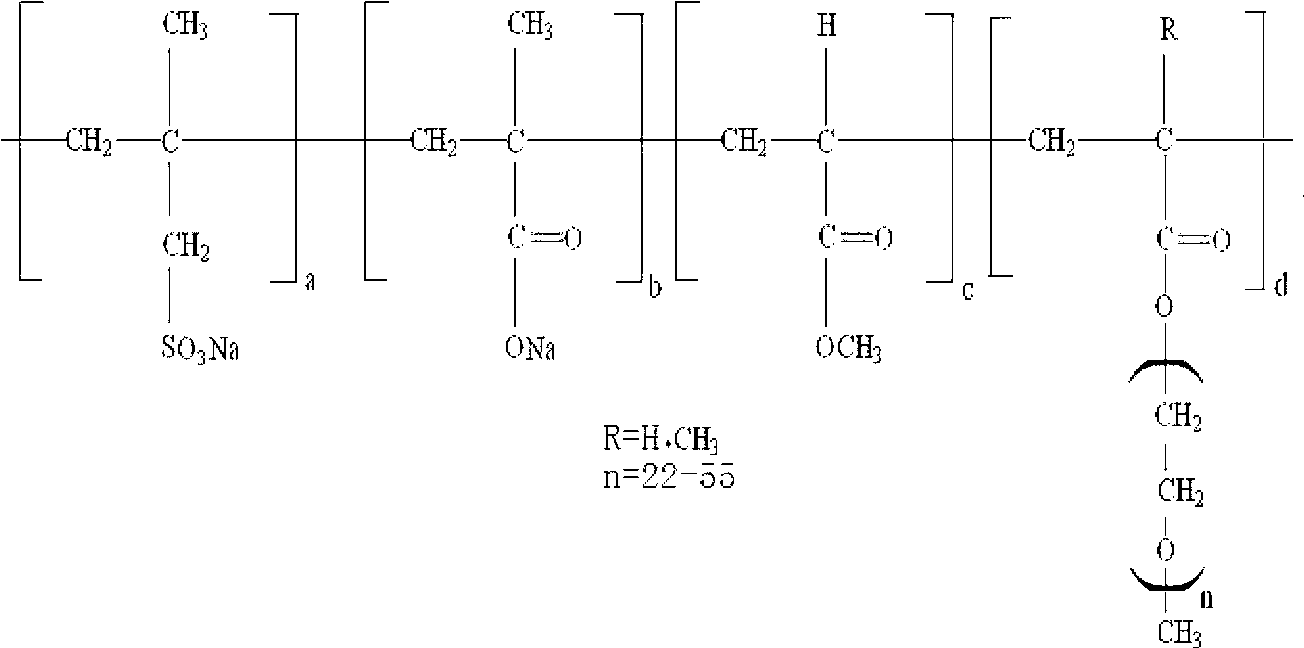

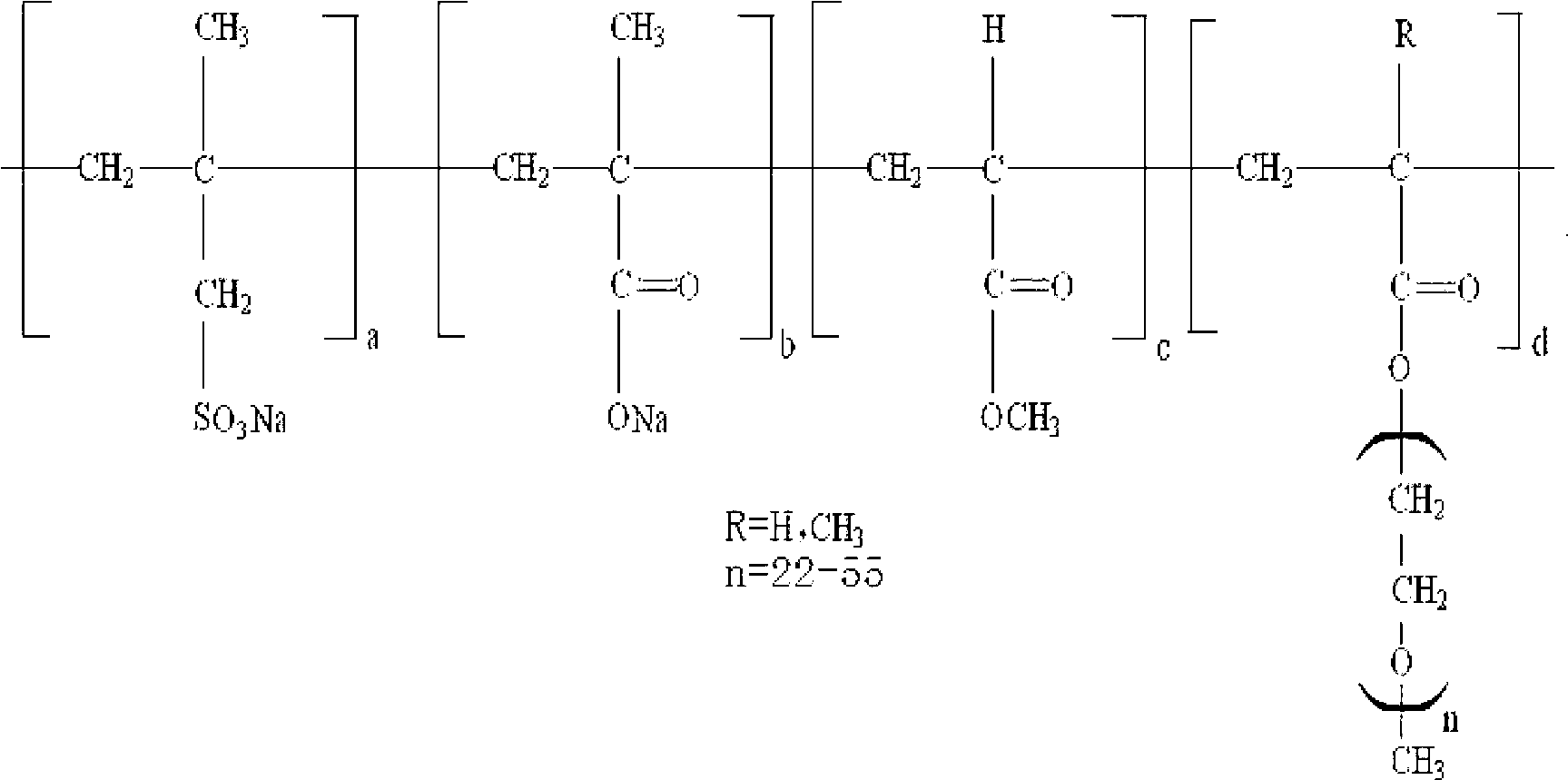

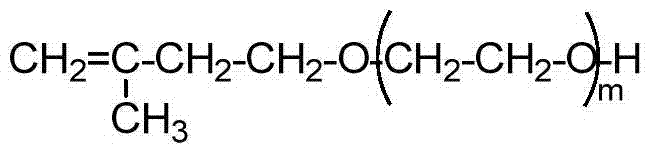

Universal polycarboxylic acid water reducing agent and preparation method thereof

ActiveCN102992682AConstant reaction temperatureThe feeding procedure is simpleSide chainMethyl group

The invention relates to a universal polycarboxylic acid water reducing agent and a preparation method thereof. The universal polycarboxylic acid water reducing agent is of a liquid state and has the solid content of 40%. The universal polycarboxylic acid water reducing agent is the water reducing agent which is prepared from monomers such as allyl polyether, and maleic anhydride, (meth)acrylic acid or itaconic acid, methyl acrylate and sodium methallyl sulfonate through polymerization under the effects of a molecular weight chain initiator and a chain transfer agent and neutralization; and the water reducing agent contains carboxyl, sulfonic group and an allyl polyether side chain. The universal polycarboxylic acid water reducing agent disclosed by the invention is low in alkali content, high in water-reducing rate, labor-saving in concrete operation, simple in production process, easy in reaction condition control and free of environmental pollution; the cement mixture has high mobility and slump keeping property, and good peaceability; and the universal polycarboxylic acid water reducing agent disclosed by the invention can be used as an important component of high-performance concrete, and can be widely applied to stirred and cast-in-place concrete and ready-mixed concrete for various industrial and civil buildings.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

Mixer truck with drum rotation unevenness determination

A mixer truck includes: a mixer drum capable of carrying ready-mixed concrete; a driving device that drives the mixer drum to rotate using an oil pressure of a working oil; a pressure sensor that detects a driving condition of the mixer drum driven by the driving device; a controller that determines a magnitude of rotation unevenness in the mixer drum by comparing a magnitude of variation in the driving condition detected by the pressure sensor with a predetermined set value after the ready-mixed concrete in the mixer drum has been discharged; and a notifying device that notifies a driver that the magnitude of the rotation unevenness in the mixer drum has reached an allowable value when the controller determines that the magnitude of the variation in the driving condition detected by the pressure sensor has reached the set value.

Owner:KYB CORP

Composite clay substituting natural sand and premixed concrete adopting composite clay as raw material

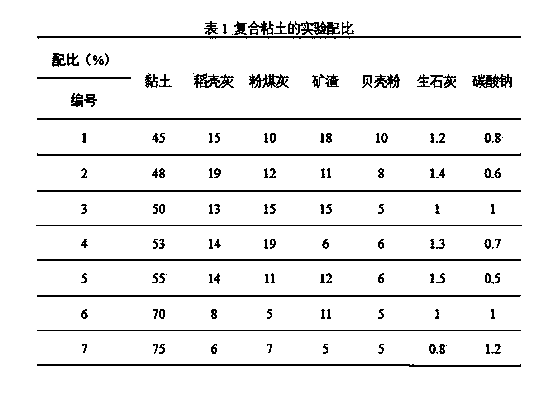

InactiveCN104072002AImprove compactnessHigh bulk densitySolid waste managementSlagUltimate tensile strength

The invention belongs to the field of a building material, and discloses composite clay substituting the natural sand and premixed concrete adopting the composite clay as a raw material. The composite clay comprises the following raw materials by weight percent: 45 to 75 percent of clay, 3 to 10 percent of shell powder, 5 to 20 percent of coal ash, 5 to 20 percent of slag, 5 to 20 percent of rice hull ash, 0.5 to 2 percent of quick lime and 0.5 to 1.5 percent of sodium carbonate. All components are added into water to be premixed, stirred, ground and rolled, and the obtained mixture is dried, granulated, screened and graded at the temperature of 200 to 300 DEG C to obtain a raw material for stirring the concrete. The composite clay is composited with cement, stones, mineral powder, a water reducing agent and water according to a given ratio to obtain the premixed concrete with excellent slump and tensile strength. The composite clay is adopted to substitute the natural sand to be used as fine aggregates in the premixed concrete, so that the corrosion resistance and durability of the concrete can be improved; moreover, the resources such as rice shell and shells are adequately utilized, the waste is converted into treasure, the market popularization value is high, and the application prospect is wide.

Owner:广西经正科技开发有限责任公司

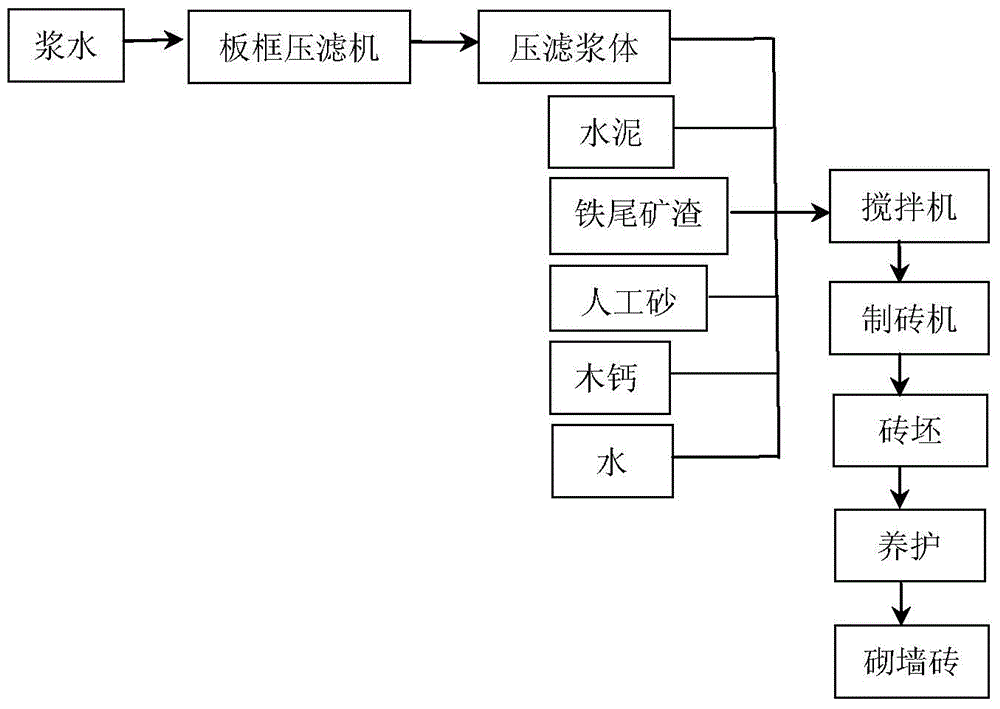

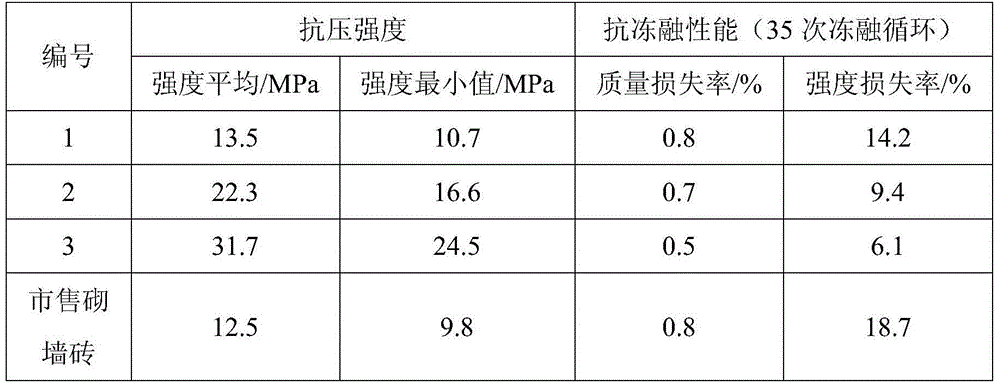

Wall brick prepared by virtue of ready-mixed concrete waste slurry

InactiveCN104446211AHigh compressive strengthImprove freeze-thaw resistanceSolid waste managementEnvironmental resistanceFreeze thawing

The invention provides a wall brick prepared by virtue of ready-mixed concrete waste slurry. The wall brick prepared by virtue of ready-mixed concrete waste slurry is mainly prepared from the following components in parts by weight: 600-800 parts of pressure-filtered slurry, 40-140 parts of cement, 1-1.4 parts of calcium lignosulphonate, 25-125 parts of water, 800-950 parts of artificial sand and 400-550 parts of iron tail slag, wherein the components are measured in parts by weight. The wall brick utilizes the slurry generated by ready-mixed concrete enterprises and the waste liquid generated during paper-making, and is low in cost, green and environment-friendly, and high in economic benefits; the prepared wall brick is high in compressive strength and good in freezing-thawing resistance.

Owner:JINAN CHANGXING CONSTR GRP

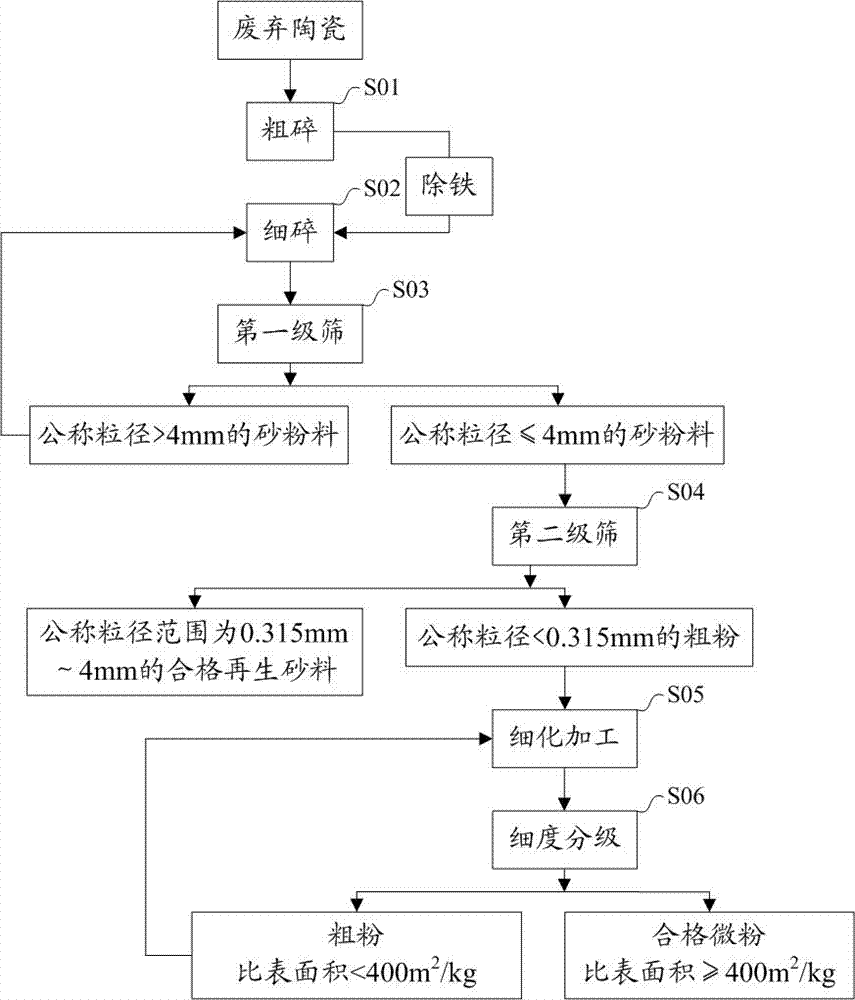

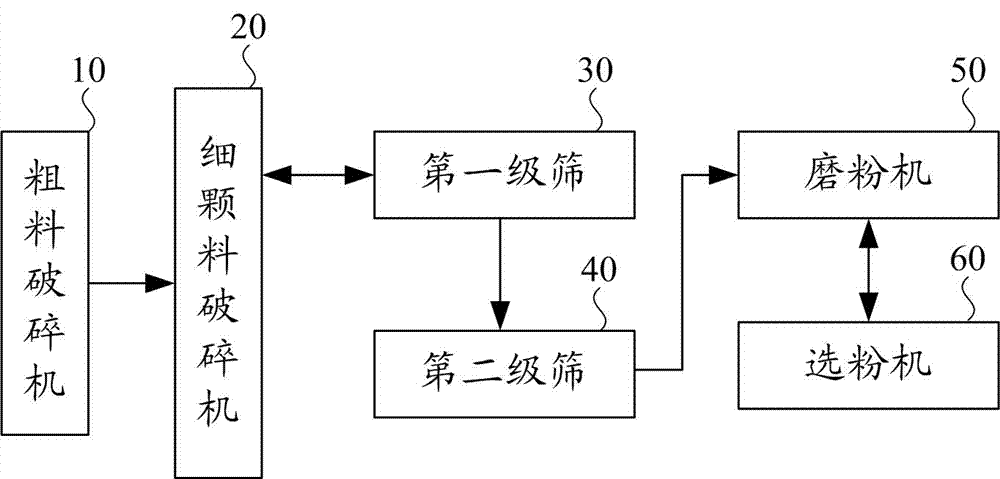

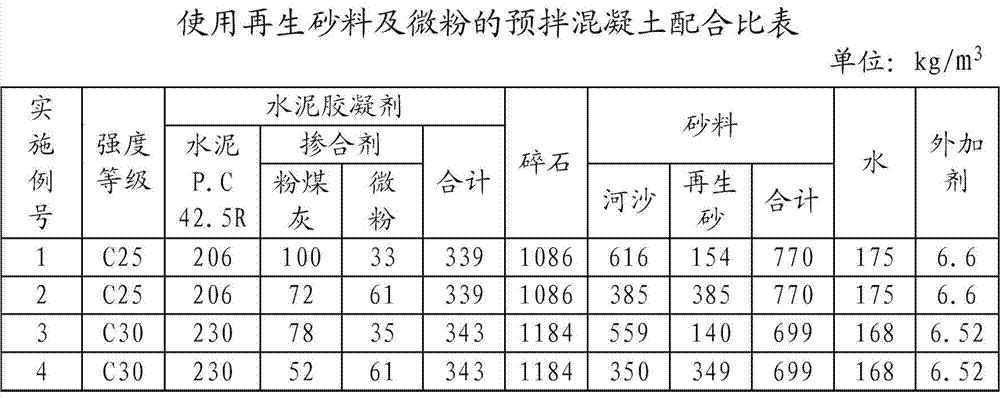

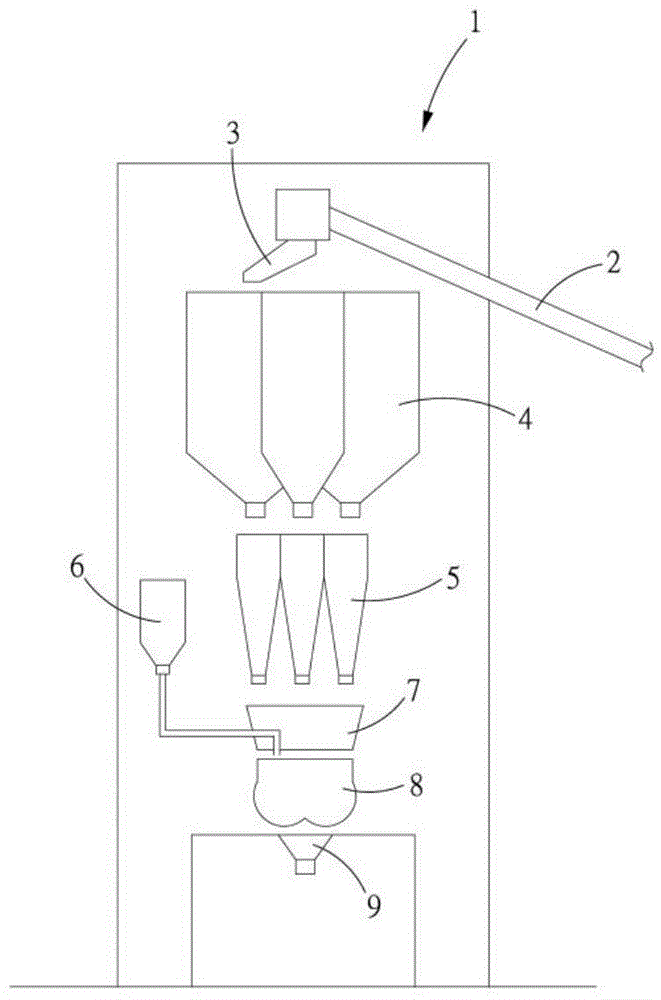

Recycling and treatment process and device for waste ceramic by crushing and grinding and pre-mixed concrete

The embodiment of the invention discloses a recycling and treatment process for waste ceramic by crushing and grinding. The recycling and treatment process comprises the following steps: inputting the waste ceramic into a rough-crushing crusher to be roughly crushed; further finely crushing the obtained roughly-crushed waste ceramic by a fine grain crusher; carrying out first-grade sieving on the obtained finely-crushed waste ceramic to obtain sand powder with a nominal grain diameter which is less than or equal to 4mm; finely crushing the finely-crushed waste ceramic which are remained on a sieve; carrying out second-grade sieving on the sand powder to obtain qualified regenerated sand; and grinding the powder with the nominal grain diameter which is less than 0.315mm by a powder grinder to obtain micro-powder with the specific surface area which is more than or equal to 400m<2> / kg. The embodiment of the invention further discloses a recycling and treatment device for the waste ceramic by crushing and grinding and pre-mixed concrete prepared by using the regenerated material. According to the recycling and treatment process for the waste ceramic by crushing and grinding, the waste ceramic is processed into the regenerated sand and the micro-powder and the regenerated sand and the micro-powder are used for replacing one part of natural sand and a cement gelatinizing agent to prepare the pre-mixed concrete; the strength meets the requirements of technical specifications; a sintering link for producing the ceramic in an existing recycling method is avoided and fuel is not used; carbon emission at a sintering phase is not proceeded so that the recycling and treatment process is low-carbon and environment-friendly, and the regeneration and reutilization of resources are promoted.

Owner:GUANGDONG DONGBAO GRP

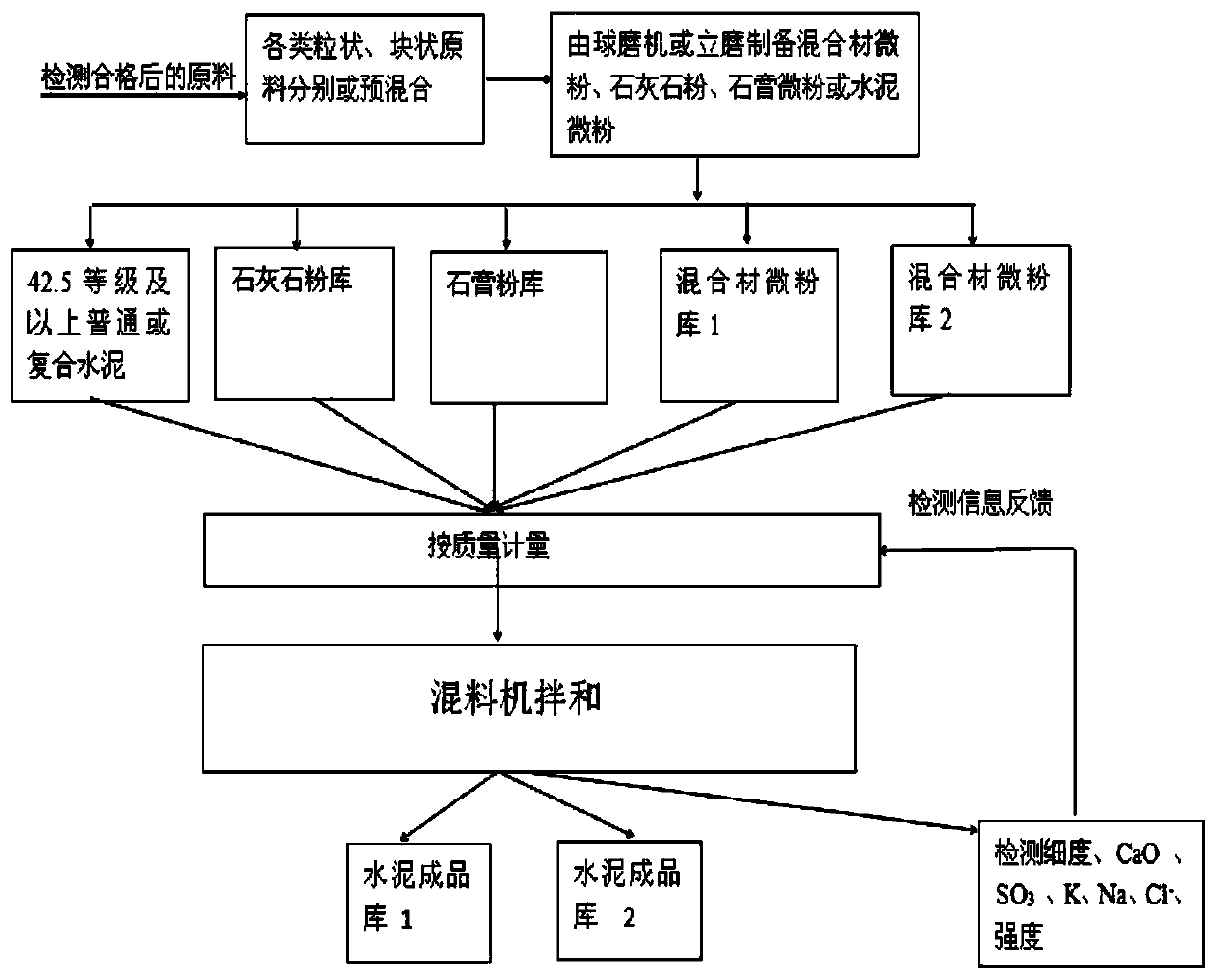

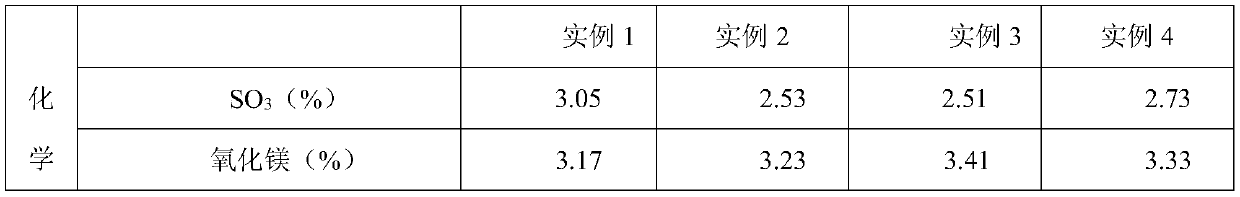

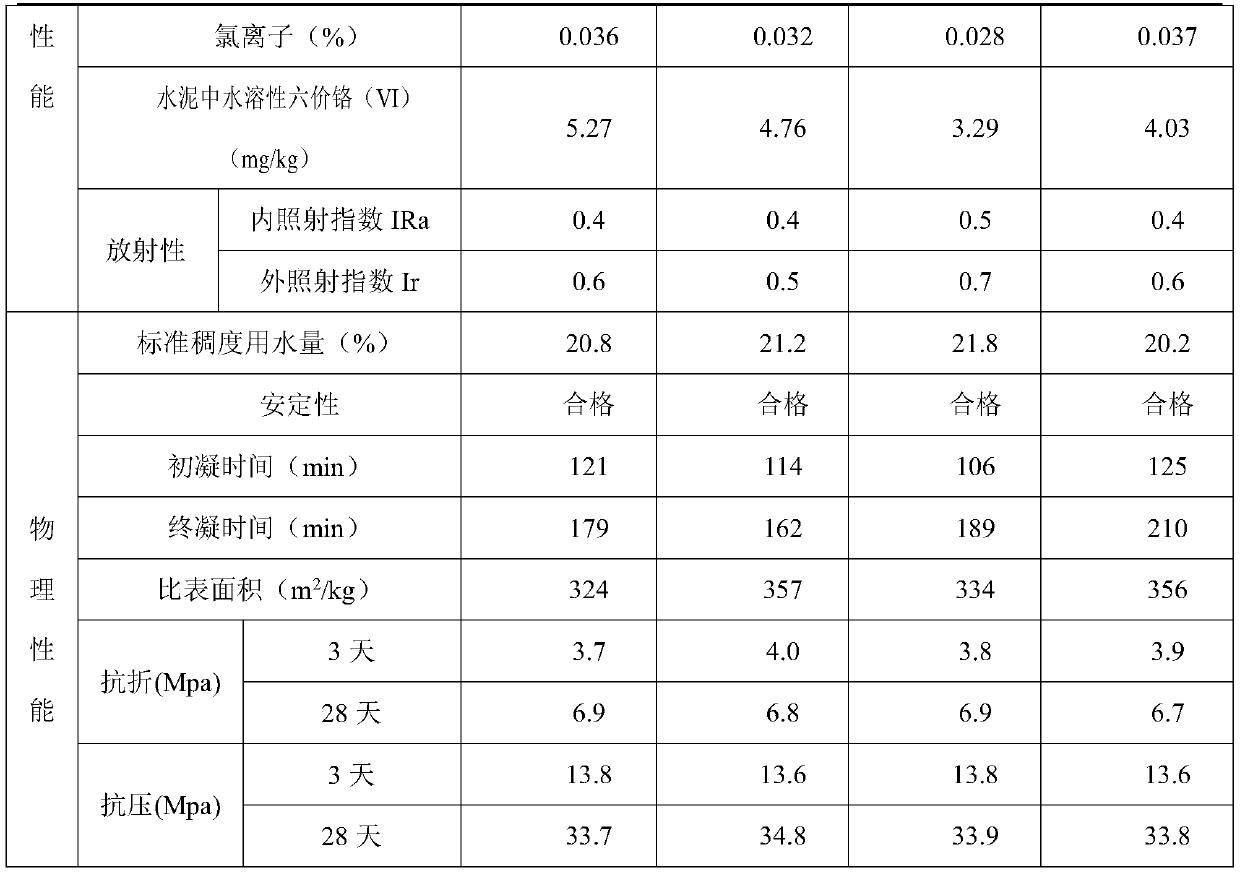

Special mixed cement for on-site preparation of concrete as well as preparation method and application

The invention relates to the field of cement and concrete. The invention discloses special mixed cement for on-site preparation of concrete as well as a preparation method and application. Except formixing and grinding cement clinker and other raw materials, the mixed cement is prepared from the following components in percentage by mass: 60%-80% of general Portland cement of the 42.5 grade or above, 3.0%-6.0% of gypsum, 5%-15% of limestone, 2%-29% of an admixture and 0.5%-3.0% of a functional additive. The general Portland cement with the grade of 42.5 or above meets the requirements of GB175, and parameters of the general Portland cement are controlled such that the mass ratio of the micro powder less than or equal to 3 [mu]m is less than or equal to 10%, the one-day compressive strength is less than or equal to 12 MPa, the 3-day compressive strength is more than or equal to 20 MPa, the 28-day compressive strength is more than or equal to 45 MPa, the water consumption of the standard consistency of the cement paste is less than or equal to 28%, the alkali content is less than 0.6% in terms of 0.658 K2O + Na2O, and the chloride ion content is less than 0.06%. The raw materials are wide in source, the mixed cement can be directly used for preparing or premixing concrete on site, no admixture or functional additive needs to be added again, crack resistance, workability and themechanical property of the concrete are improved, and construction operation is simplified.

Owner:程菲 +1

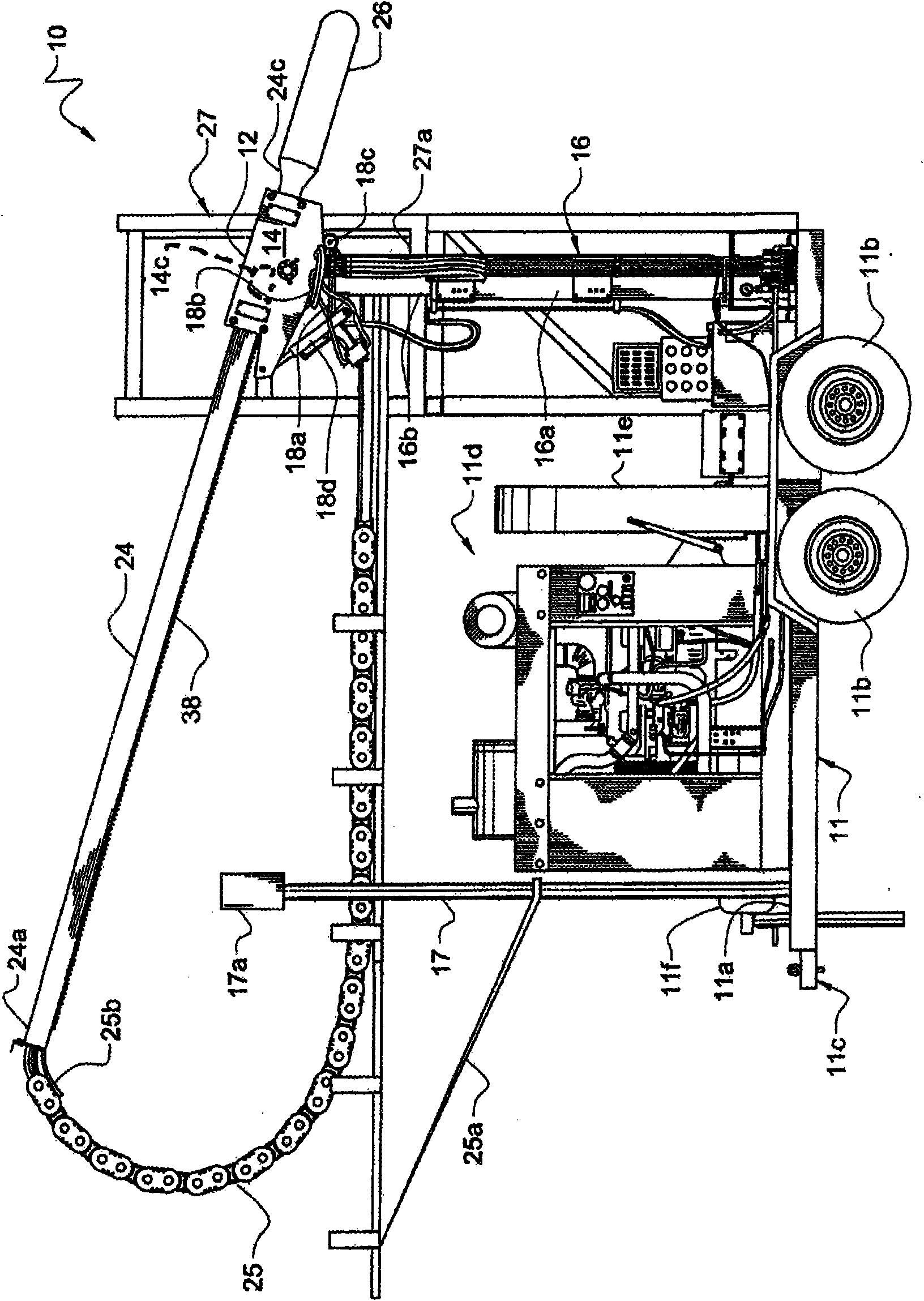

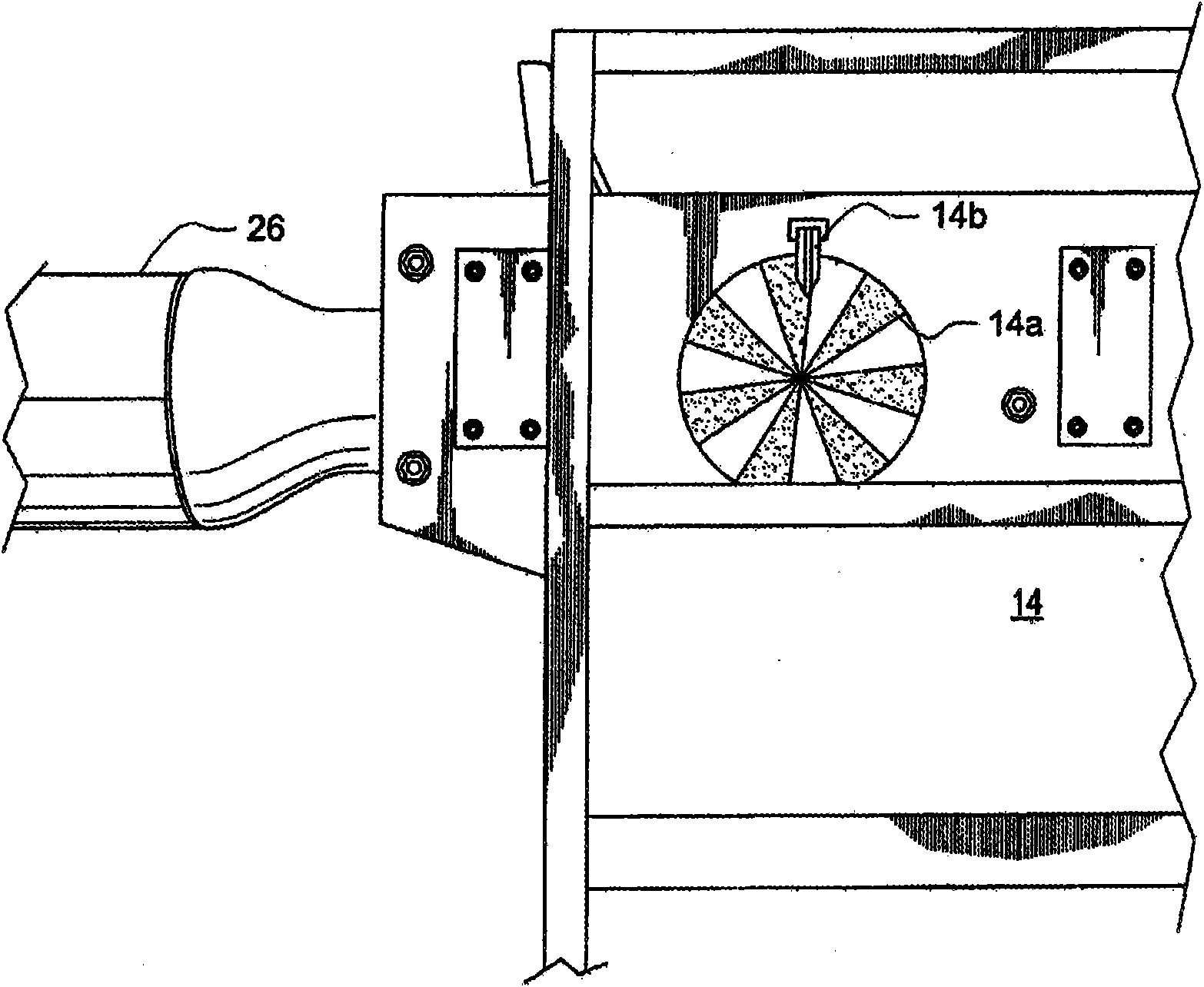

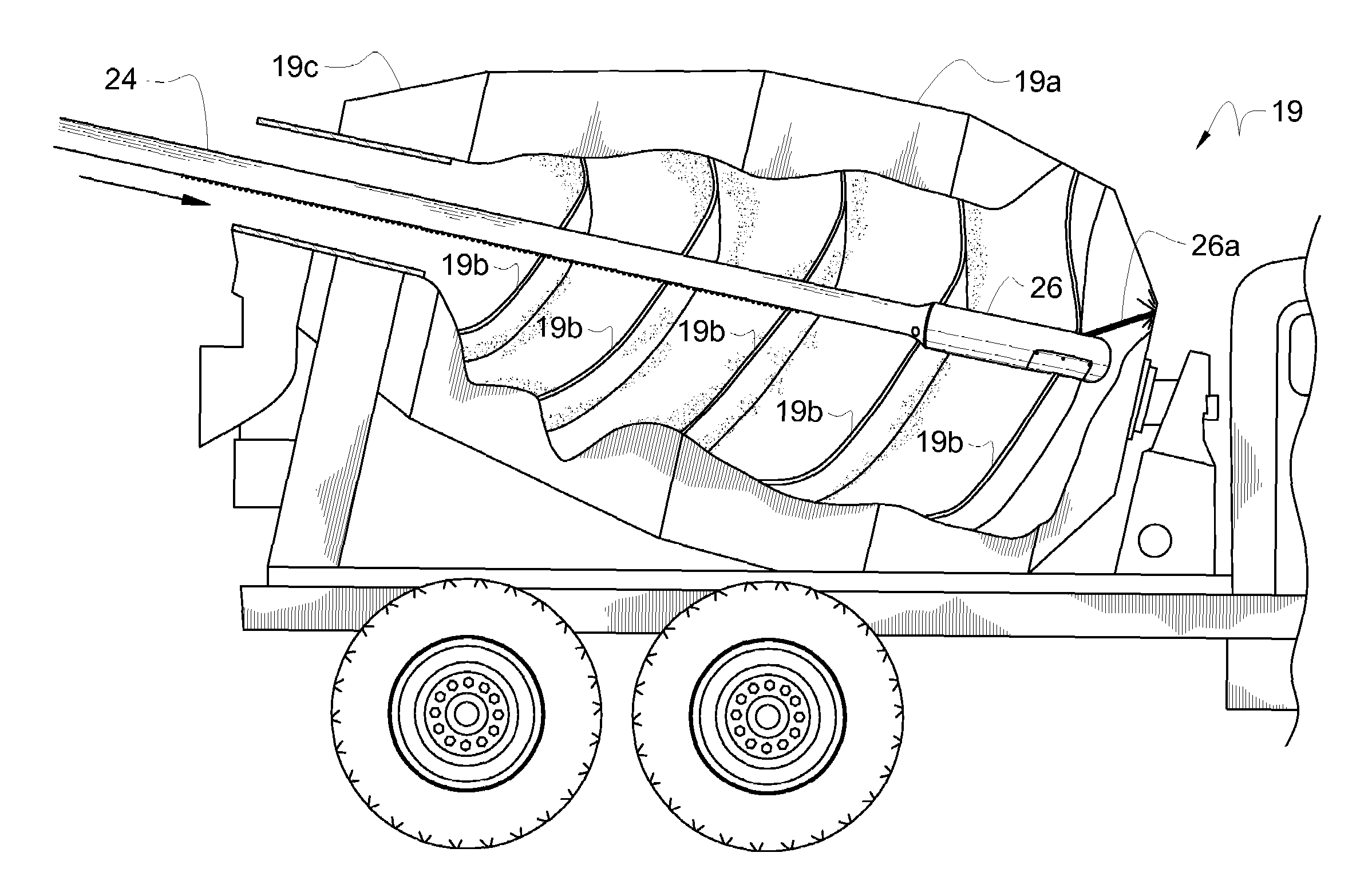

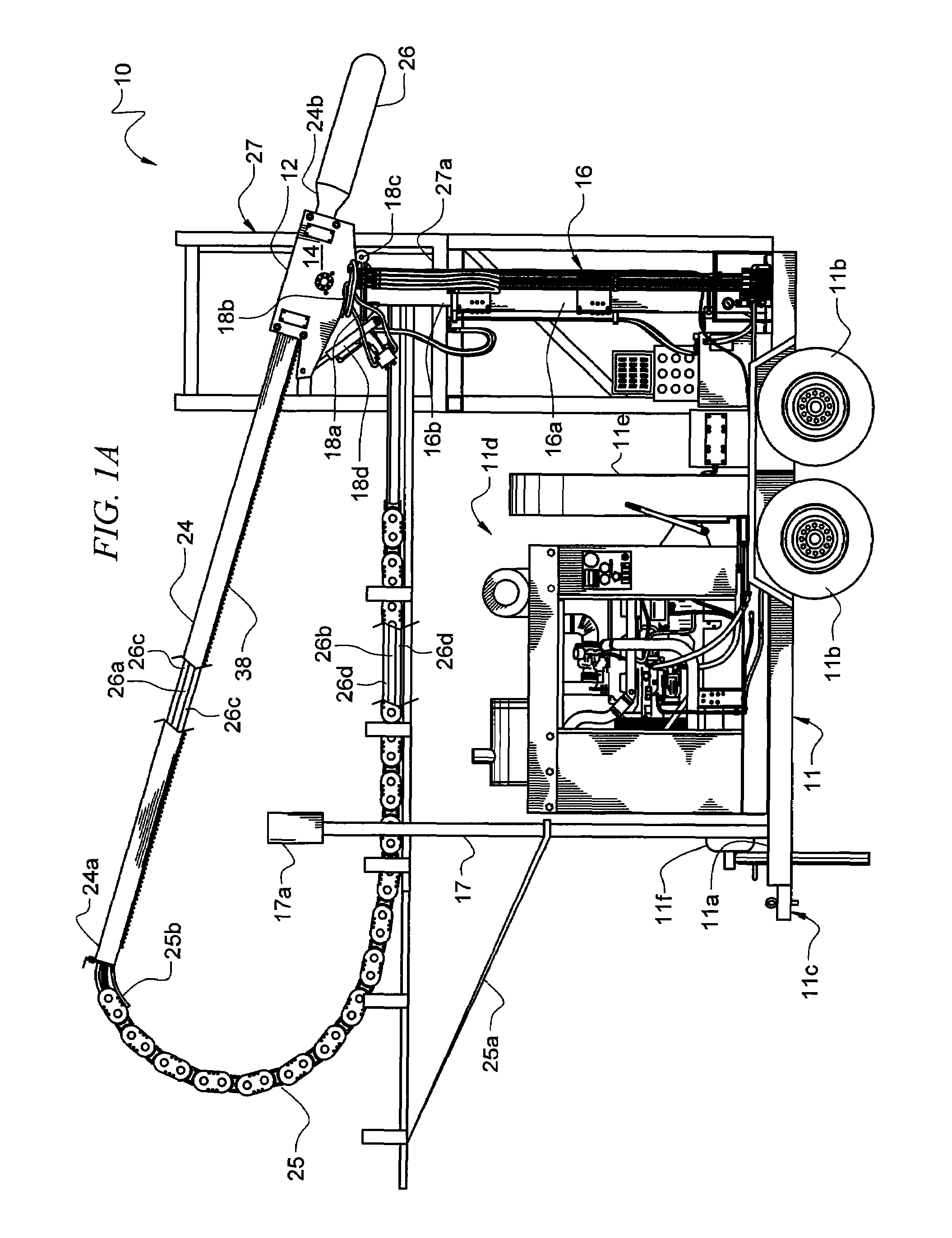

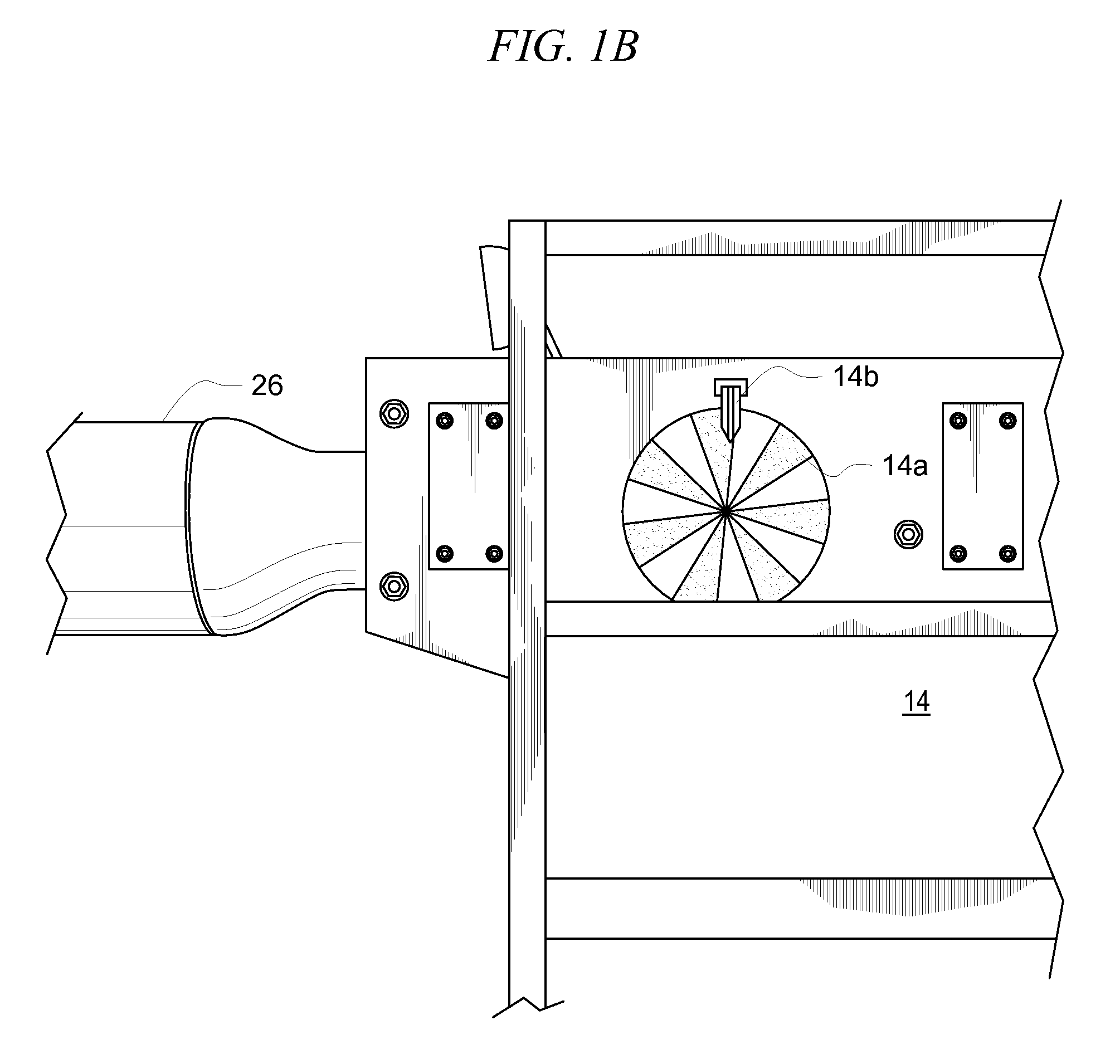

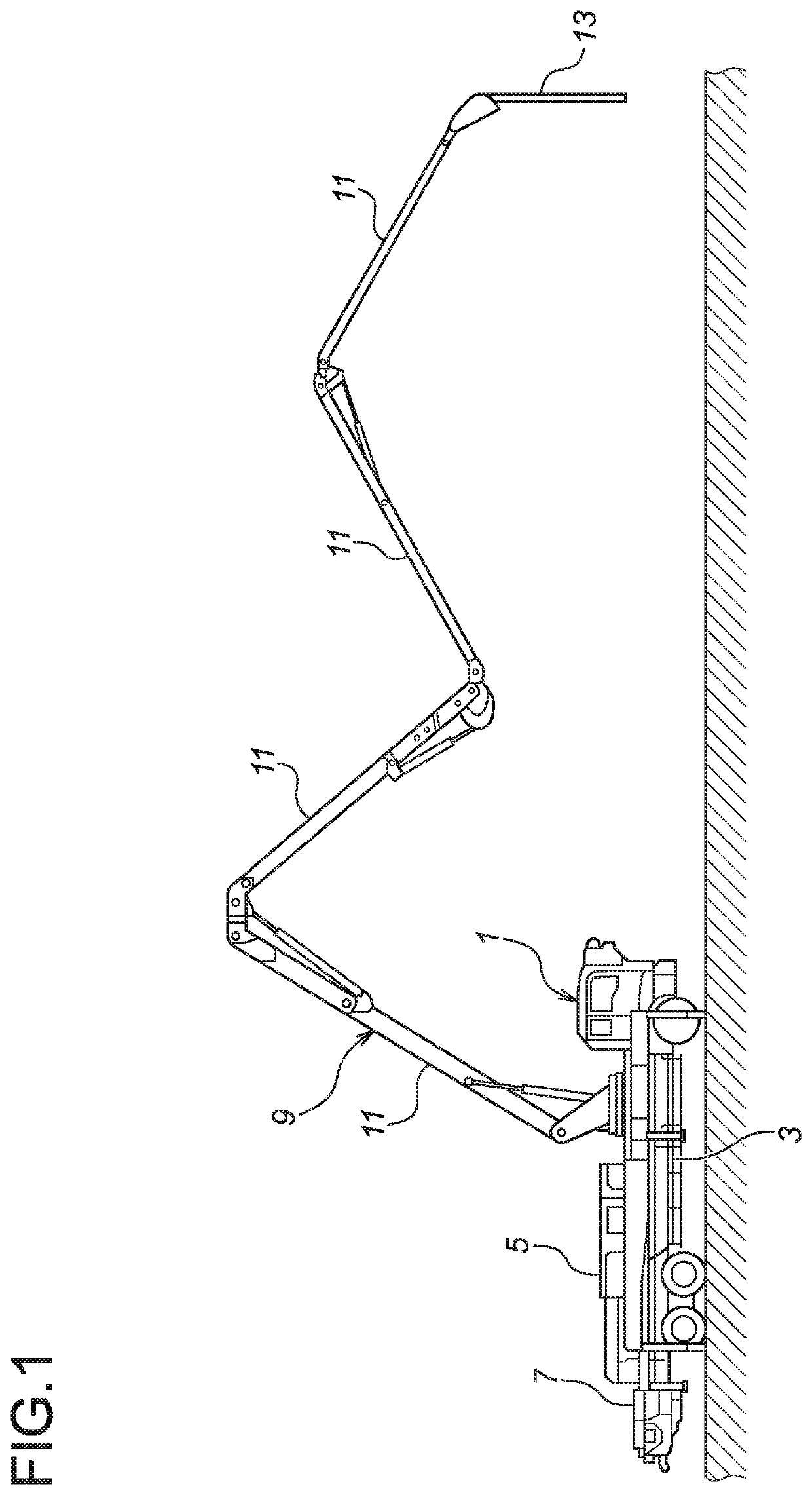

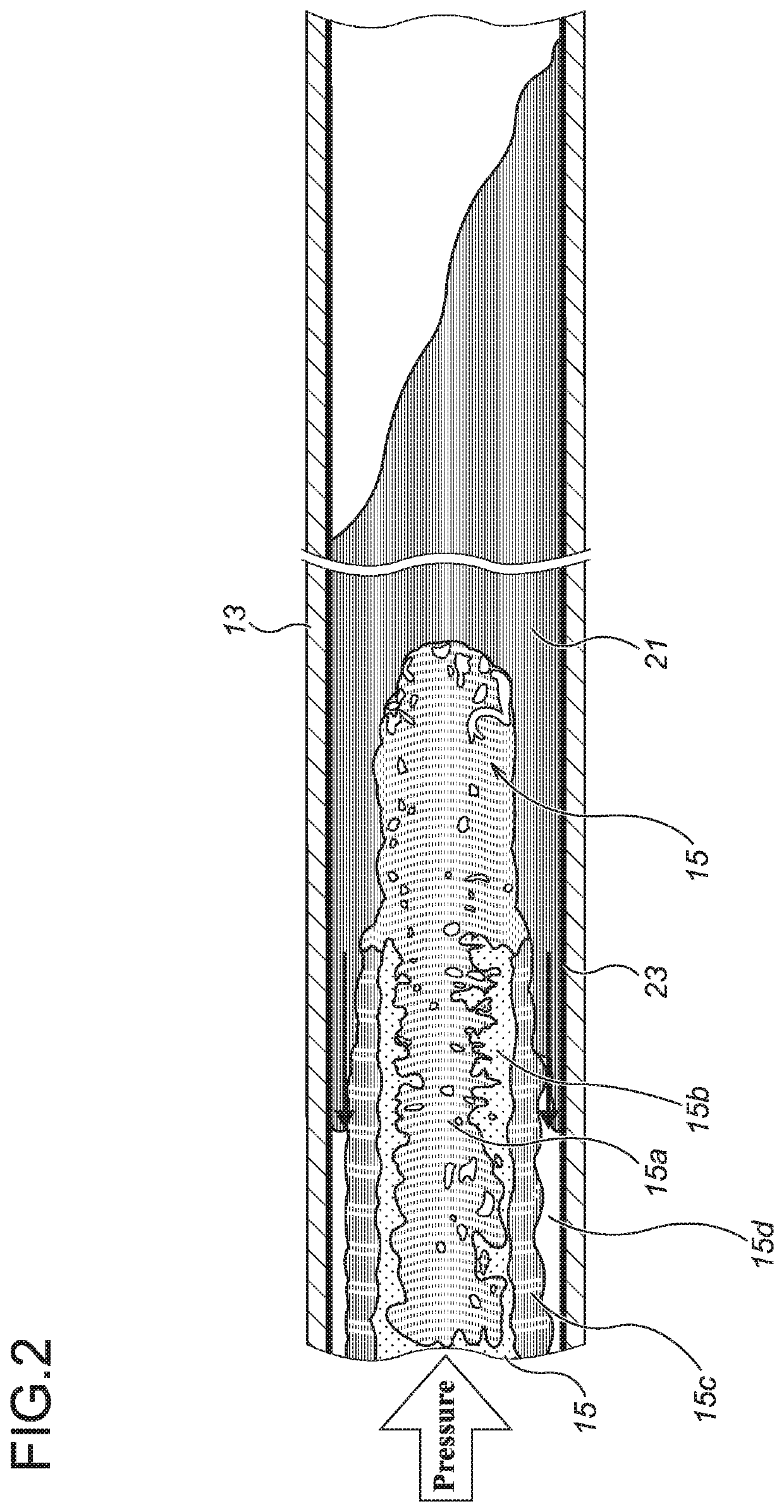

Removal of residual concrete from ready mixed concrete drums

ActiveCN101868305AEfficient removalIdeal pitchHollow article cleaningCement mixing apparatusReady mixed concreteEngineering

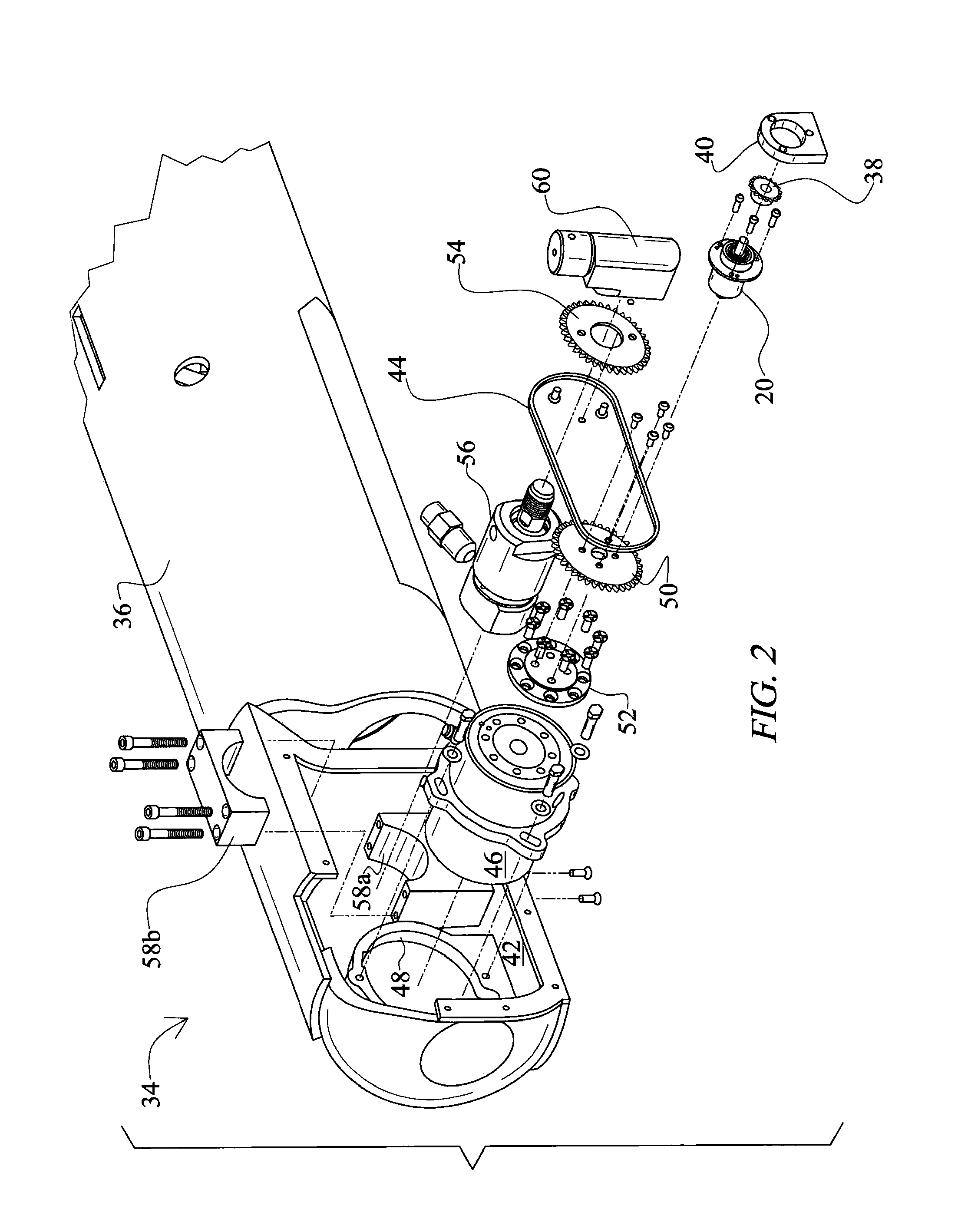

Residual concrete in the drum of a ready mixed concrete truck is removed by high-pressure water. A nozzle is mounted on the leading end of a torpedo-shaped nozzle housing that is hingedly mounted to an elongate boom. The boom enters the mouth of the drum at an angle that matches the angle of the drum. The hinge allows the nozzle housing to pivot with respect to the elongate boom so that the nozzle is close to the residual concrete. The boom is retracted toward the mouth with the drum rotating in the mix direction and the nozzle oscillating so that it cuts through a swath of concrete. As the boom retracts, the torpedo-shaped nozzle housing maintains the nozzle close to the residual concrete on the drum and both sides of the helical fins. The nozzle sweeps an arc from about eighty to one hundred twenty degrees as it oscillates.

Owner:BLASTERS

Special reinforcing agent for ready-mixed pervious concrete and preparation method thereof

The invention provides a special reinforcing agent for ready-mixed pervious concrete and a preparation method thereof. The special reinforcing agent for the ready-mixed pervious concrete includes thefollowing raw materials by mass: 40-45% of anti-cracking component, 20-25% of flexural component, 2%-4% of thickening component, 19-24% of adhesive component and 10-15% of water reduction component. The dosage of the special reinforcing agent in the pervious concrete is 2-3% of the mass of a cementing material. The reinforcing agent can not only effectively prevent the late shrinkage of the pervious concrete and reduce the stress cracking, but also significantly improve the flexural resistance and the frost resistance of the pervious concrete, ensures the mechanical property and the durabilityof pervious concrete pavements, and enhances the water retention and the slump retention of the previous concrete to meet the construction requirements of the ready-mixed concrete. The reinforcing agent is beneficial to prepare the premixed medium and high strength pervious concrete.

Owner:武汉源锦建材科技有限公司

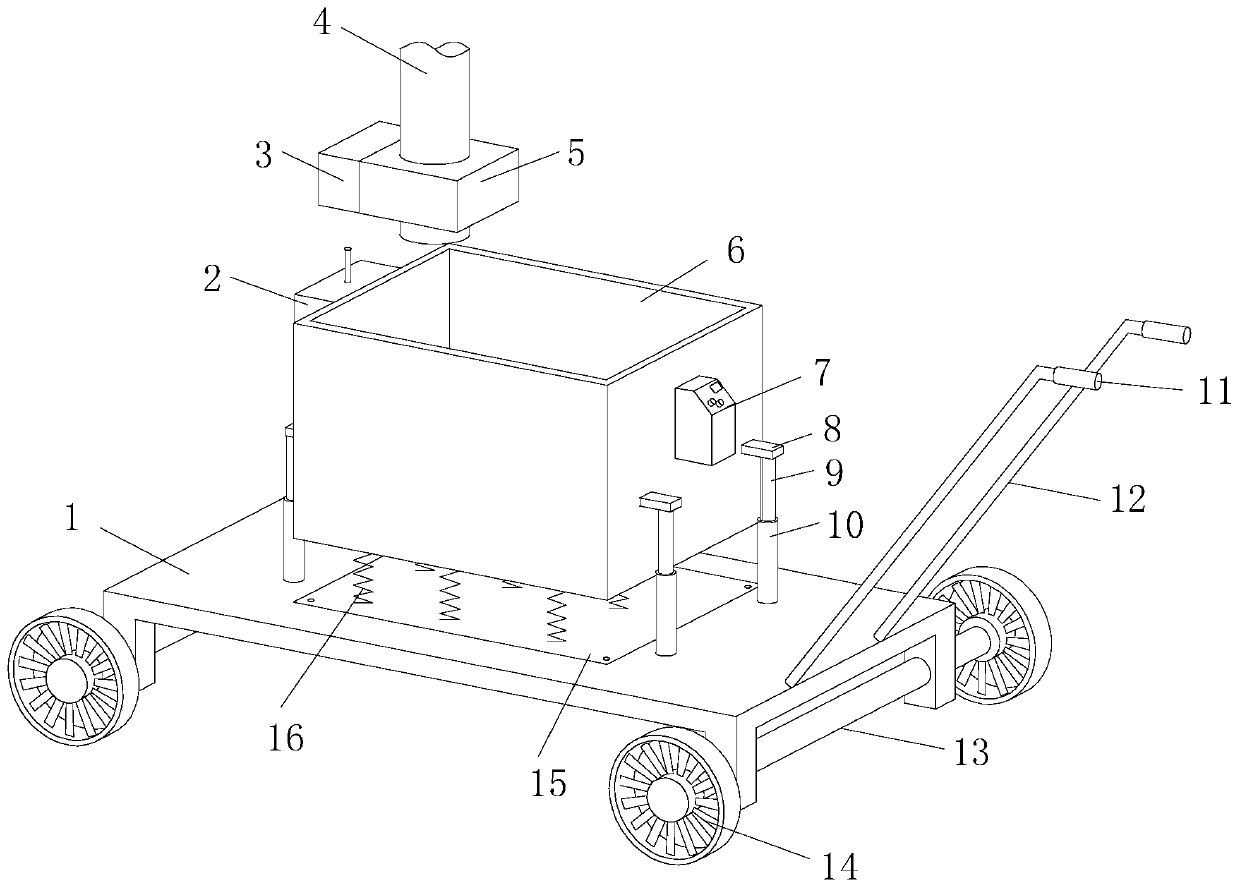

A sampling device for ready-mixed concrete mixture

ActiveCN107803933BHigh degree of automationEnsure balanceWithdrawing sample devicesCement mixing apparatusReady mixed concreteSolenoid valve

The invention discloses a sampling device for a premixed concrete mixture. The sampling device structurally comprises a movable base, a jacking device, a travel switch, an unloading pipe, a solenoid valve, a hopper, a stirring controller, supporting plates, guide columns, four guide sleeves, a handle, a pushing handle, two wheel shafts, travelling wheels, a base plate and compression springs. Thetwo wheel shafts are arranged at the bottom of the movable base and are in parallel with each other. The two wheel shafts are mounted on the two sides of the bottom of the movable base correspondingly, and the two ends of the wheel shafts are connected with the traveling wheels. The top of the movable base is attached to the base plate through bolts, and the cylindrical compression springs are vertically placed on the base plate. The tops of the compression springs are connected with the top of the hopper, and the supporting plates are arranged on the two sides of the hopper. The four guide sleeves are distributed on the two sides of the hopper in pairs. According to the sampling device for the premixed concrete mixture, transmission can be conducted through the weight of concrete, the solenoid valve is closed to automatically stop unloading, the structure is reasonable, and the automation degree is high.

Owner:NANTONG KEDA BUILDING MATERIALS

A variety of colored pavement concrete ready-mixed mortar

The invention relates to multi-color pavement concrete ready-mixed mortar. Pigments in different colors are respectively mixed with other raw materials to form mortar in at least two kinds of colors. The pavement concrete ready-mixed mortar comprises the following raw materials in percentage by weight: 20 percent to 25 percent of cement, 70 percent to 75 percent of sand, 1 percent to 3 percent of powder smelting dust, 2 percent to 5 percent of pigments, 1 percent to 3 percent of rubber powder, 0.01 percent to 0.02 percent of cellulose ether, 0.2 to 0.3 percent of hydrophobing agents, 0.5 percent to 0.8 percent of water reducing agents, 0.5 percent to 0.8 percent of anti-shrinking agents, 0.5 percent to 0.8 percent of fluidizing agents and 0.3 to 0.5 percent of fiber. The mortar in different colors is used for paving a pavement for distinguishing left and right roads, so the visual fatigue of drivers can be relieved; the toughness and the frictional property of the pavement are better, so the braking distance can be shortened, and the traffic accident rate is reduced; the attractive degree of the roads is improved; the goal can be achieved only through paving the mortar and adding steel bar bands on an existing asphalt or cement pavement; the service life of the original pavement is prolonged; the road repair cost is reduced; the peculiar smell of the asphalt pavement is avoided; and the air pollution is relieved.

Owner:HEBEI HUANXING BUILDING MATERIAL

Removal of hardened concrete from ready mixed drum interiors using upwardly directed high pressure water

ActiveUS7546843B2Easy to cleanMinimizing overall energy requiredServomotor componentsHollow article cleaningReady mixed concreteHigh pressure water

Residual concrete in the drum of a ready mixed concrete truck is removed by high-pressure water. A nozzle is mounted on the leading end of a torpedo-shaped nozzle housing that is hingedly mounted to an elongate boom. The boom enters the mouth of the drum at an angle that matches the angle of the drum. The hinge allows the nozzle housing to pivot with respect to the elongate boom so that the nozzle is close to the residual concrete. The boom is retracted toward the mouth with the drum rotating in the mix direction and the nozzle oscillating so that it cuts through a swath of concrete. As the boom retracts, the torpedo-shaped nozzle housing maintains the nozzle close to the residual concrete on the drum and both sides of the helical fins. The nozzle sweeps an arc from about eighty to one hundred twenty degrees as it oscillates.

Owner:BLASTERS

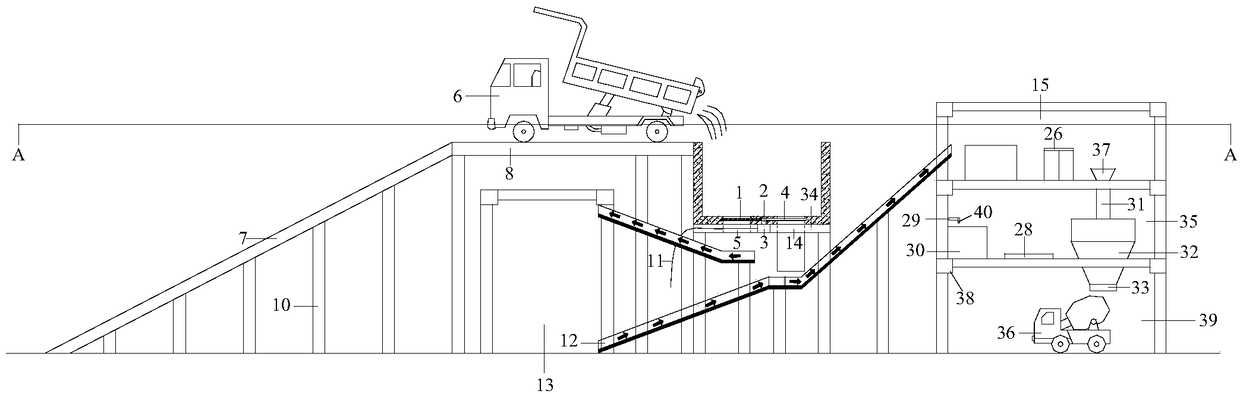

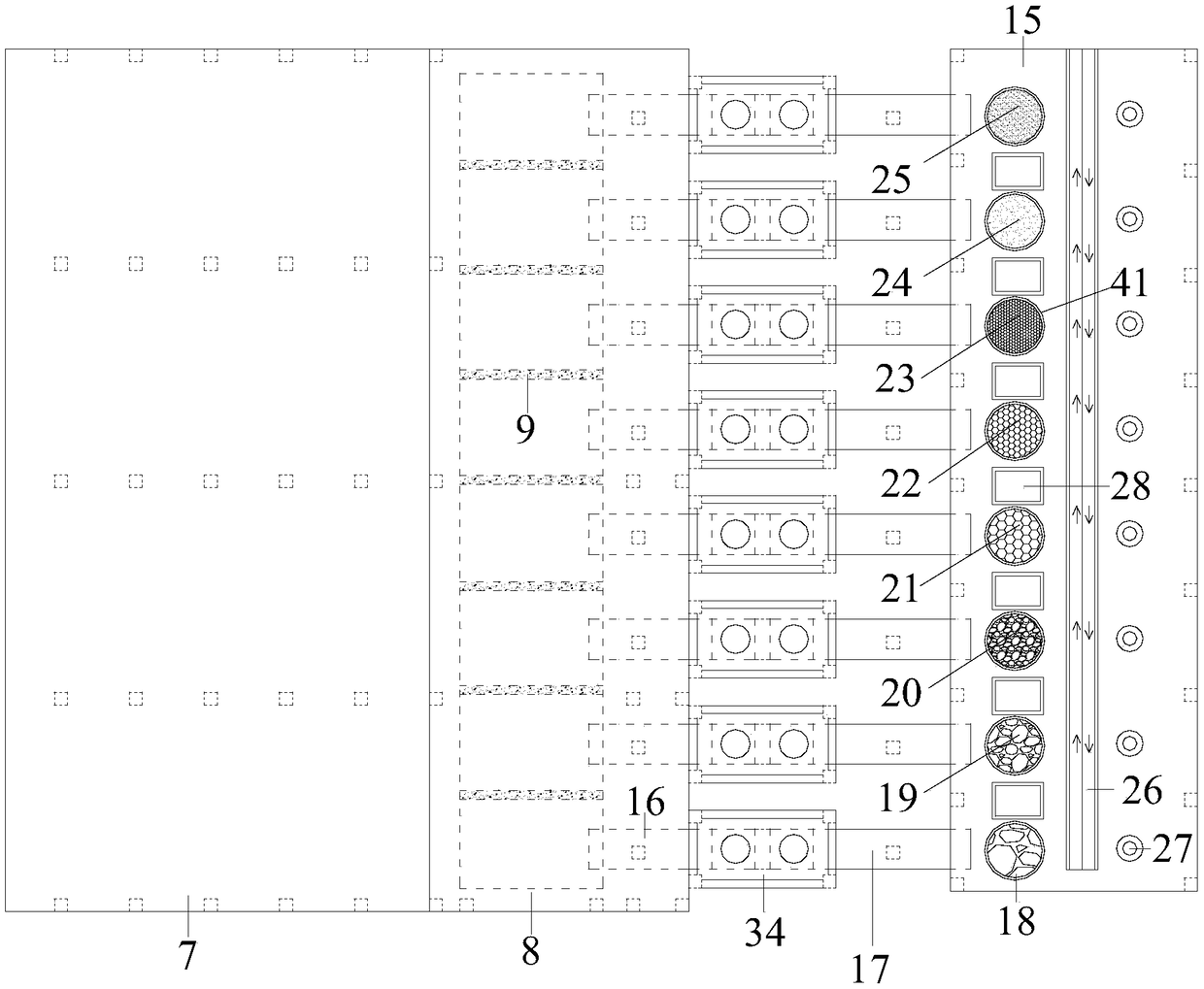

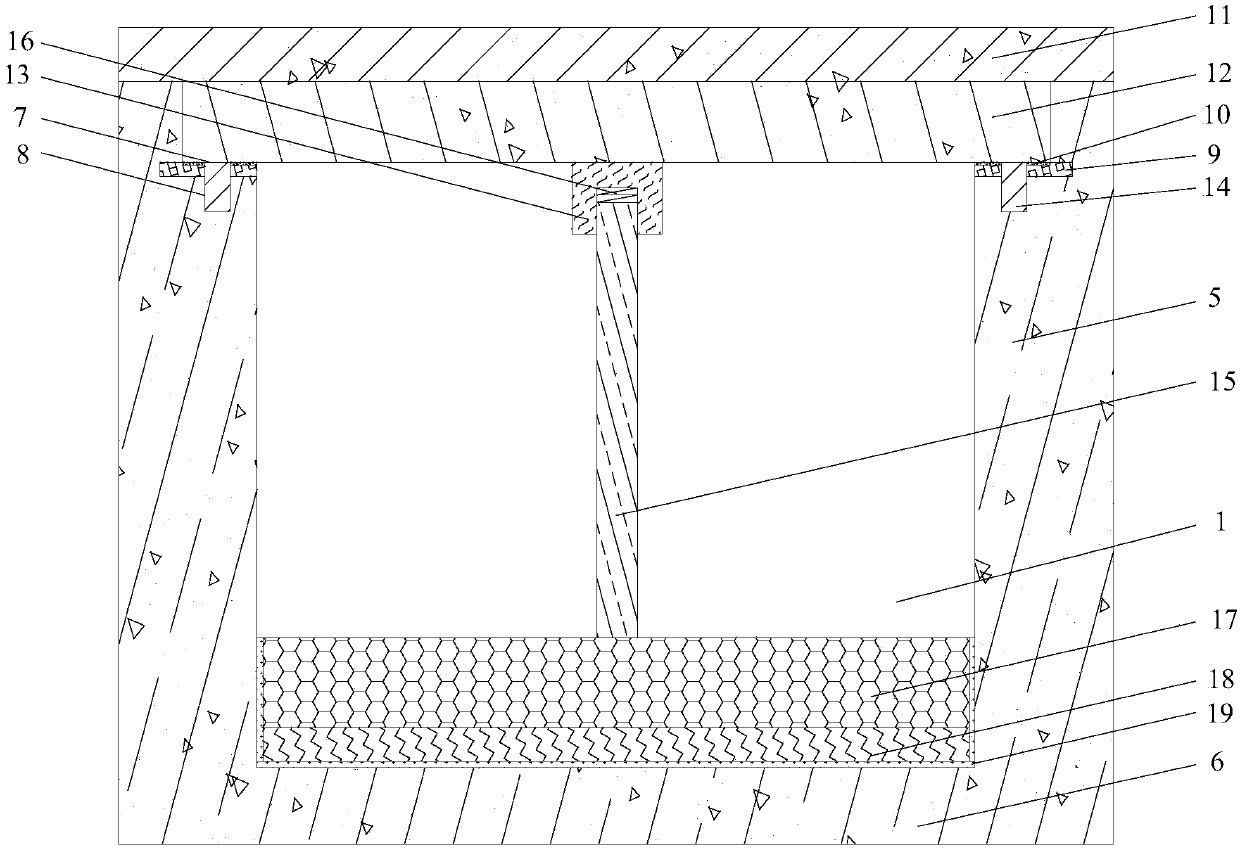

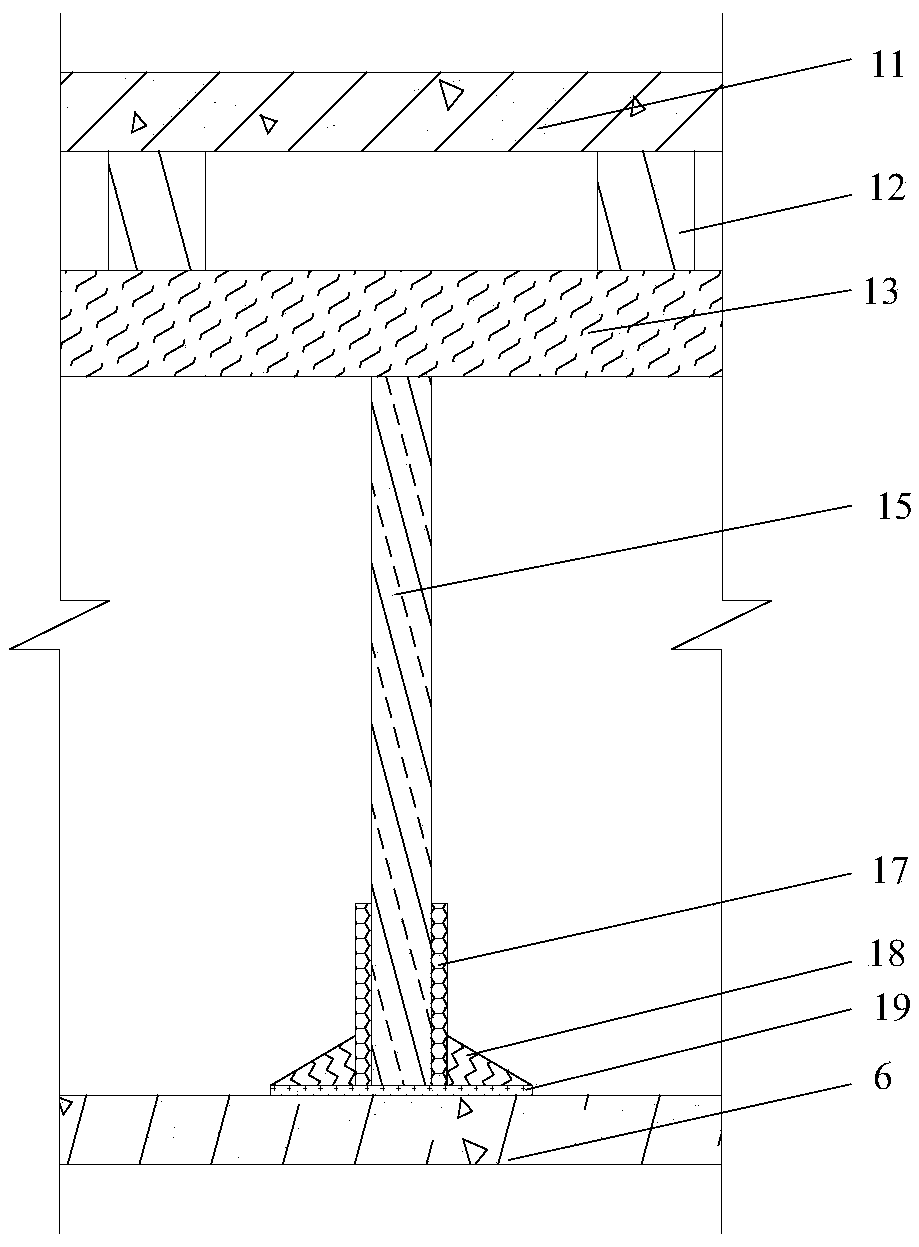

Fully-enclosed automatic ready-mixed concrete feeding system and operation method

InactiveCN109333829AImprove shipping efficiencyEasy to operateMixing operation control apparatusIngredients proportioning apparatusReady mixed concreteEngineering

The invention relates to a fully-enclosed automatic ready-mixed concrete feeding system. The fully-enclosed automatic ready-mixed concrete feeding system comprises a concrete discharging system and aconcrete feeding system. The concrete discharging system comprises a gentle slope, a discharge transition groove, a dumping platform, a reserve material field, first conveyor belts, second conveyor belts, a third conveyor belt and a high-position batching bin. A bottom plate of the discharge transition groove is provided with a rotating closing plate, a rotating shaft, an electric motor, a preformed groove, a first discharge hole, a second discharge hole and a wire. The concrete feeding system includes the high-position batching bin, a stirring bin and a discharging bin which are arranged fromtop to bottom in sequence. The fully-enclosed automatic ready-mixed concrete feeding system has the beneficial effects that a two-way conveyor belt is placed in the high-position batching bin, staffputs weighed materials on the two-way conveyor belt, the staff can pour the materials on the two-way conveyor belt into feed holes beside the feed holes, and in the process, the staff can complete thesupply of various materials of concrete without reciprocating walking.

Owner:HANGZHOU JIANGRUN TECH LIMITED

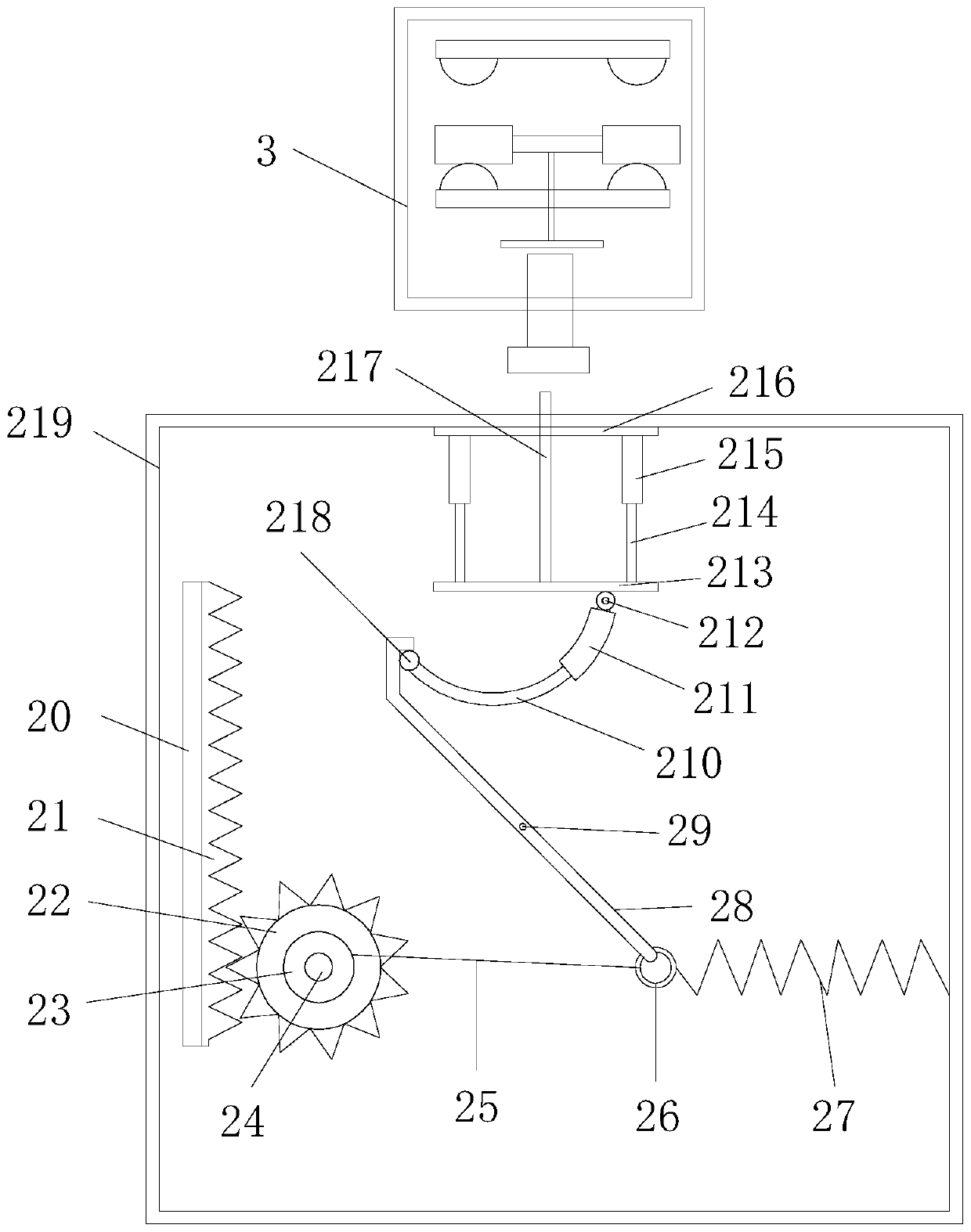

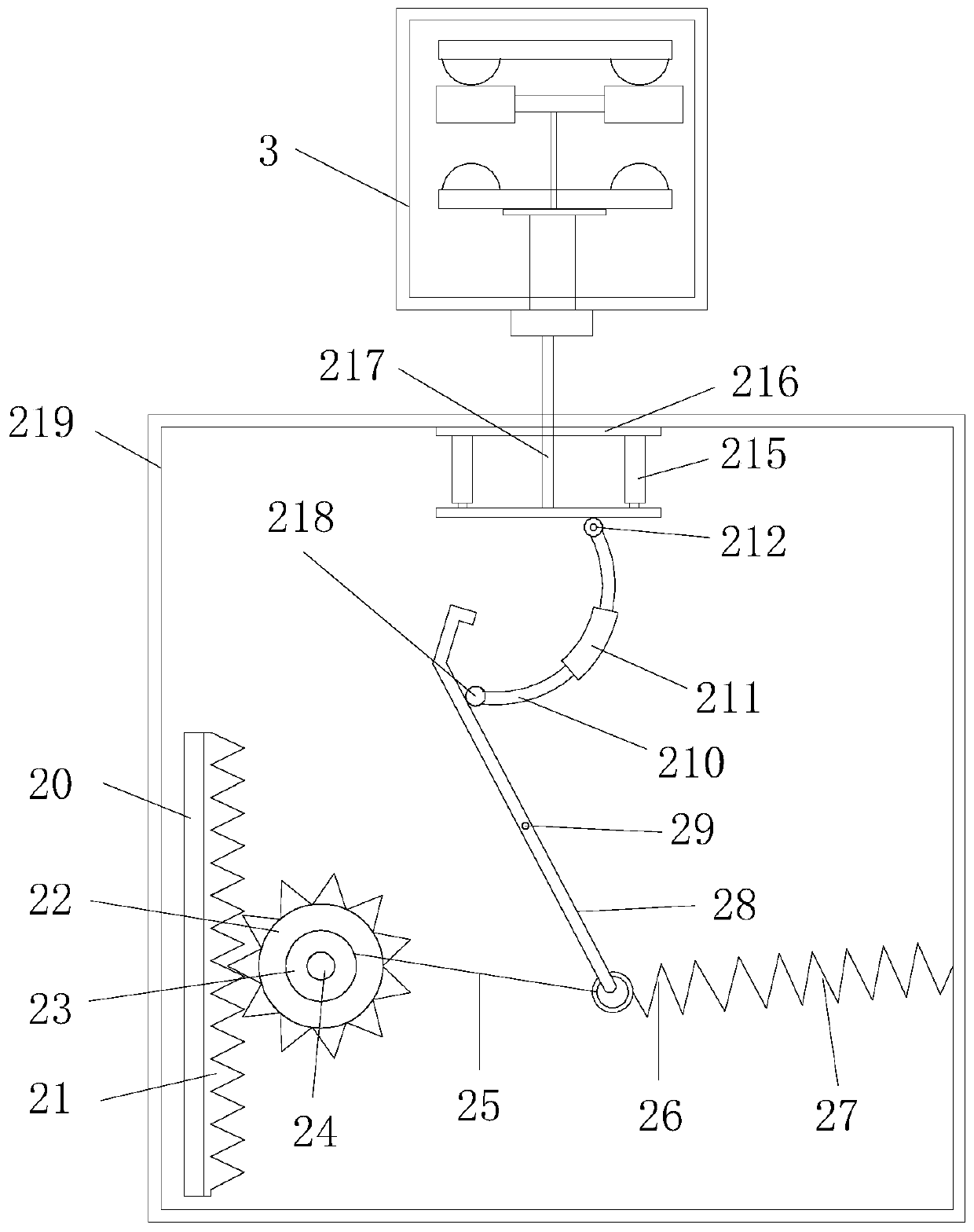

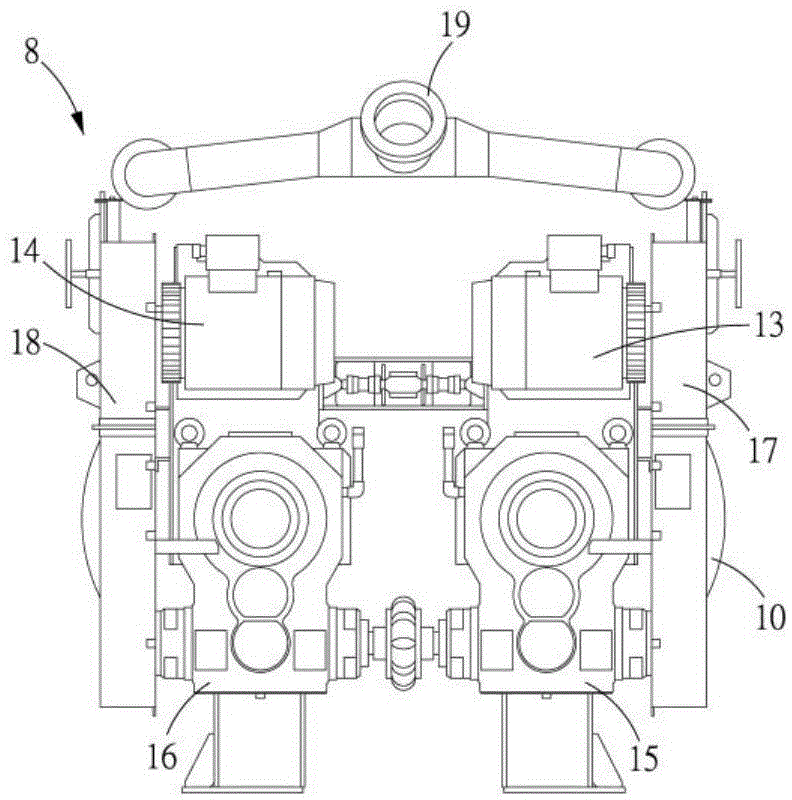

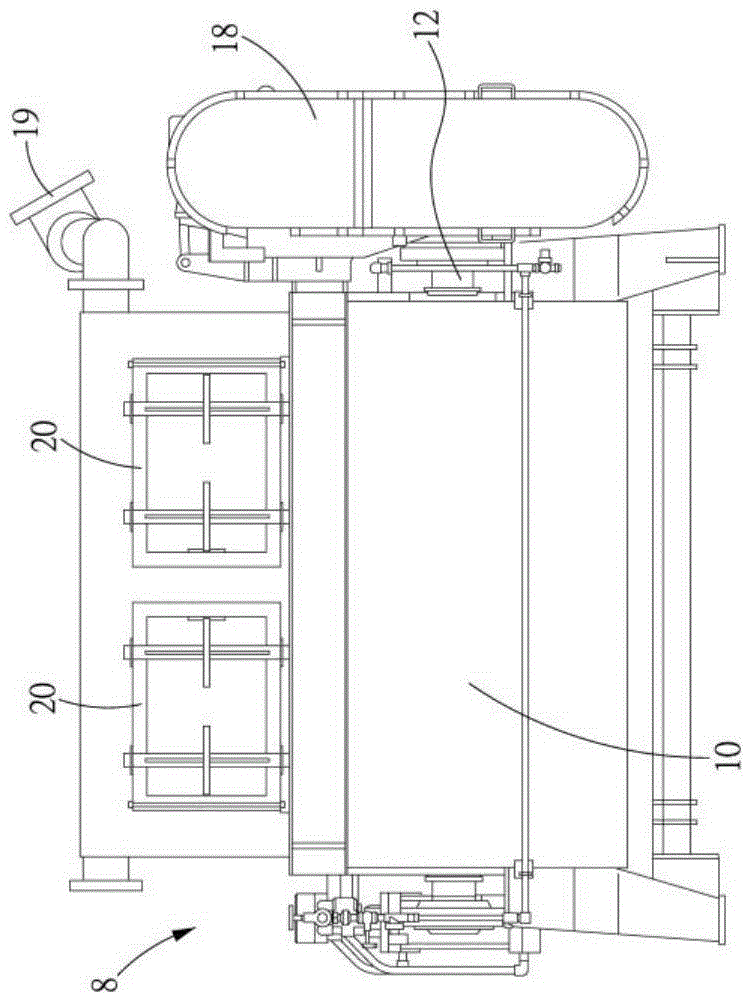

Concrete mixer and ready-mixed concrete producing apparatus using same

ActiveCN105082355AEnhance stirringImprove clipping effectMixing operation control apparatusCement mixing apparatusReady mixed concreteEngineering

The invention discloses a concrete mixer capable of improving shearing effect for mulling objects and having high mulling efficiency. The concrete mixer comprises a mixer body accommodating raw material for pre-mixed concrete, a first mulling shaft rotationally arranged on the mixer body and a plurality of stirring paddles, wherein each stirring paddle is formed by an arm body connected to the first mulling shaft and a first plate body arranged on a tip end of the arm body; material can be stirred by the stirring paddle; each first plate body is in a spiral shape, so each first plate body can wind the first mulling shaft and has a concave part in an adjacent part of the plurality of first plate bodies; space near the concave part changes with rotation of the stirring paddles in an irregular way; material flows in an irregular way due to the space changes; and therefore, stirring efficiency and shearing effect can be improved and material can be mulled with high efficiency.

Owner:KYC MACHINE IND

High performance concrete pumping agent controlling falling degree loss type and its usage method

The invention belongs to the technical field of building materials, and in particular relates to a high-performance concrete pumping agent for controlling slump loss. It is composed of naphthalenesulfonic acid formaldehyde condensation product water reducer, polyvinyl alcohol, sodium 12 alkyl sulfate, citric acid, sodium gluconate and water. Using this invention can greatly improve the fluidity of concrete, and make the concrete slump between 2- There is basically no loss within 4 hours, and it reduces bleeding, increases strength, and improves concrete durability. The invention is applicable to structures (structures) such as commercial ready-mixed concrete, mass concrete, reinforced concrete, light aggregate concrete, bridges, buildings, hydraulic engineering and road surfaces.

Owner:TONGJI UNIV

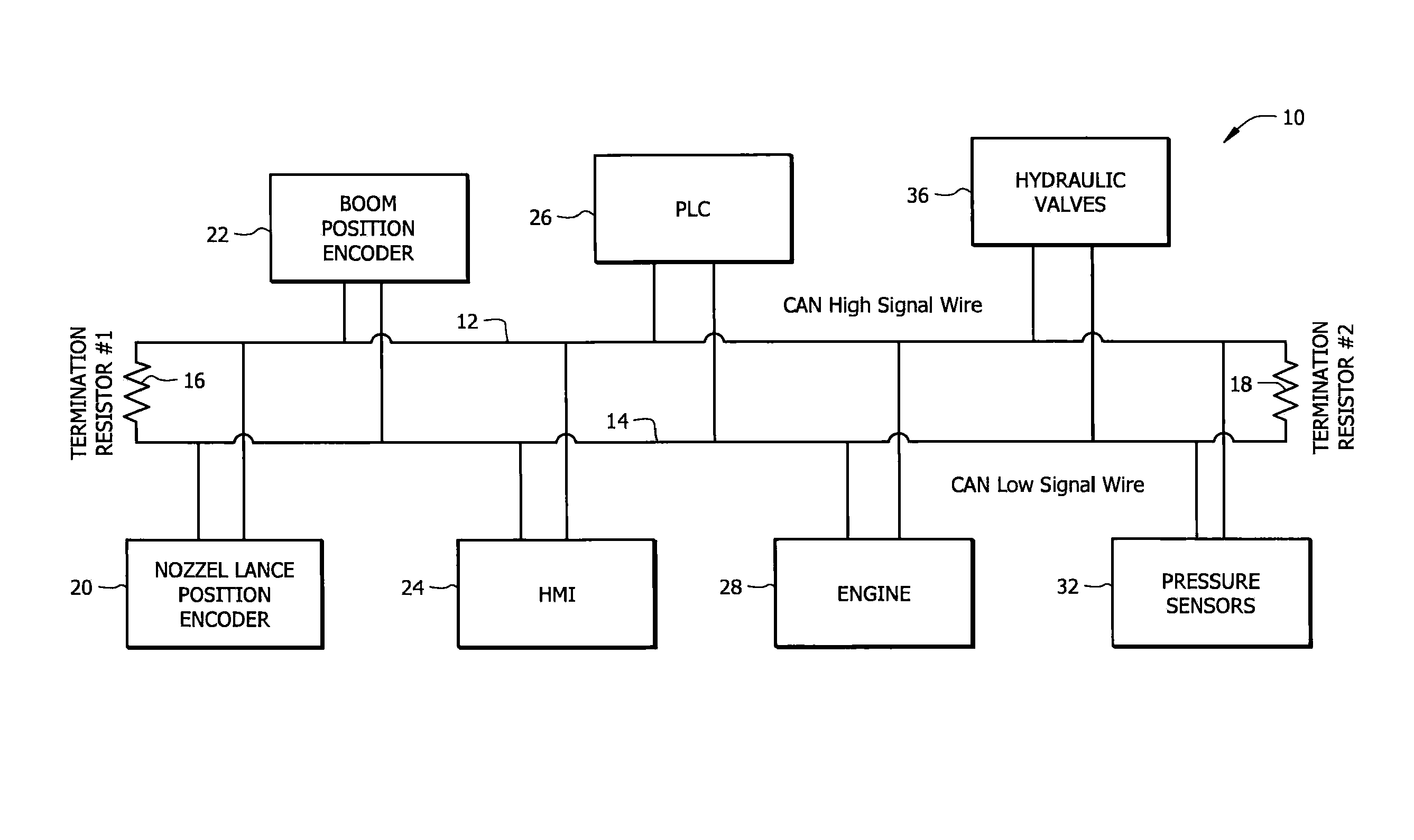

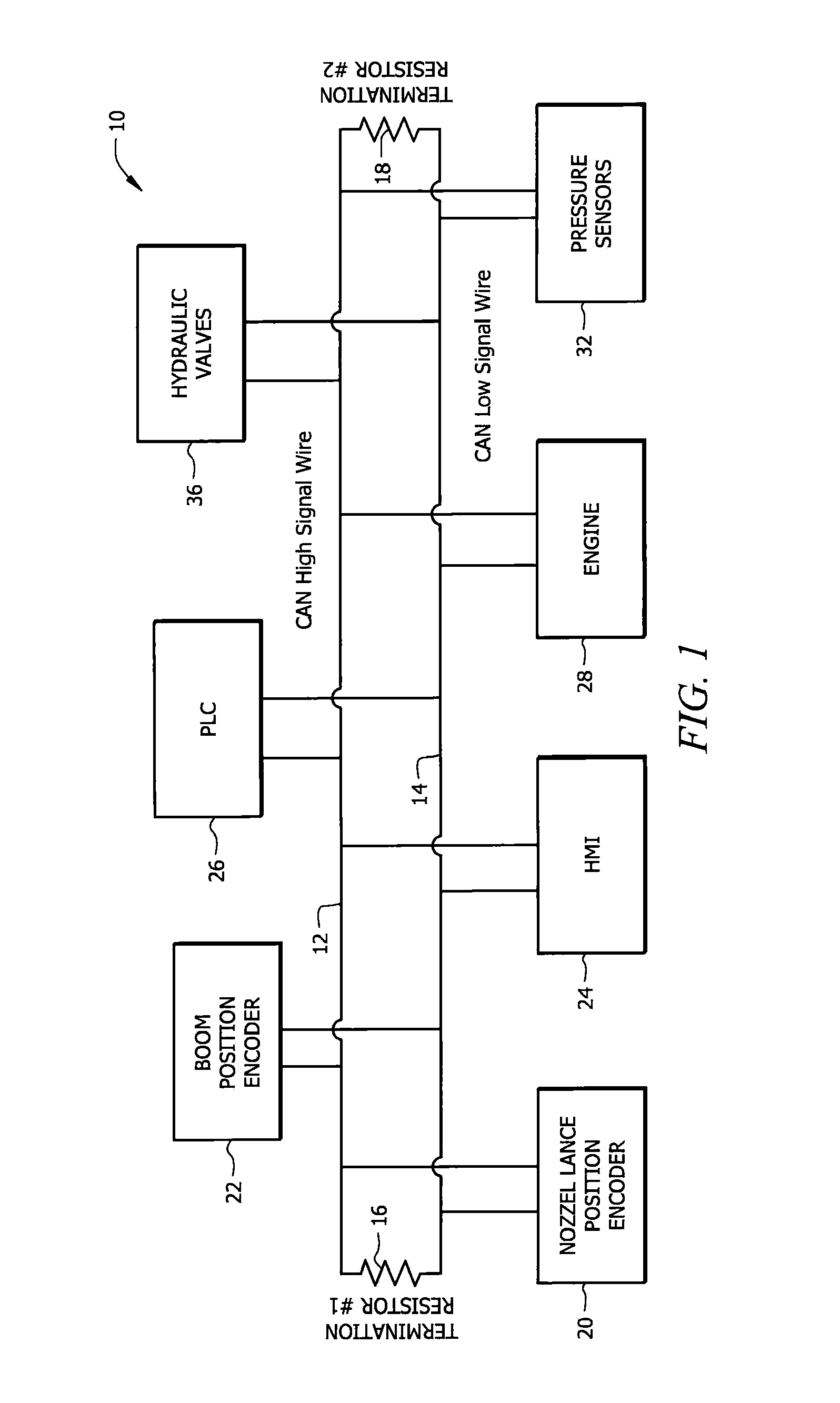

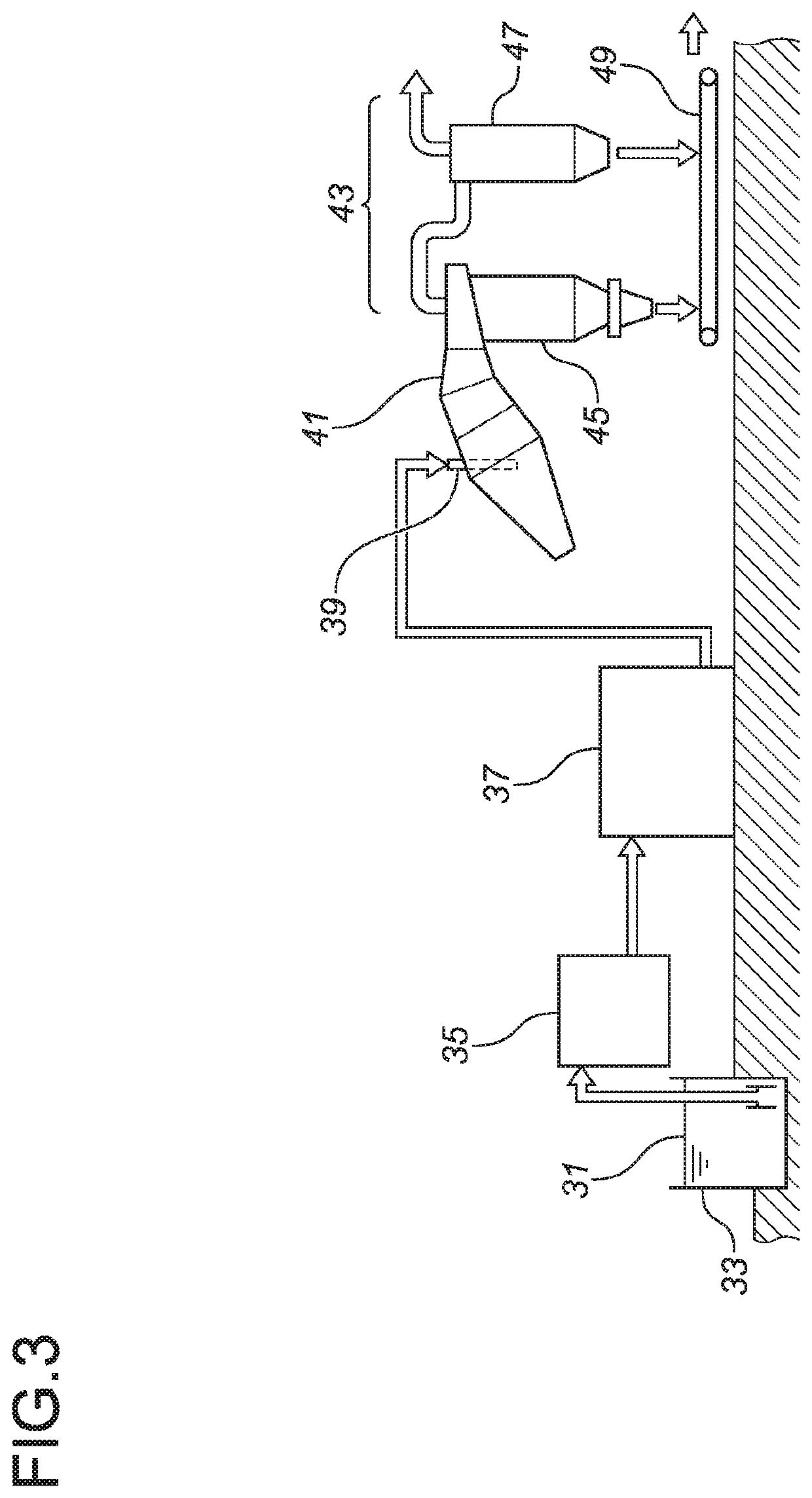

Control system for machine that cleans drums of ready mixed concrete trucks

ActiveUS8301306B1Easy to controlSampled-variable control systemsComputer controlHuman–machine interfaceReady mixed concrete

A control apparatus for an apparatus that cleans the drum of a ready mixed concrete truck includes a CAN-bus control system that includes a nozzle lance position encoder, a boom position encoder, a human-machine interface, a programmable logic controller, and monitors for an engine, hydraulic valves, and pressure sensors. The nozzle lance position encoder includes a rotary encoder, a bi-directional motor, a nozzle lance including a nozzle adapted to discharge water under high pressure, and a swivel assembly to which the nozzle lance is mounted for reciprocating motion. The programmable logic controller enables an operator to control the range of oscillation of the nozzle lance by inputting a desired range of oscillation into the programmable logic controller. An operator can also control extension and retraction of an elongate boom by inputting a desired rate of extension and retraction into the programmable logic controller.

Owner:BLASTERS

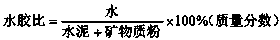

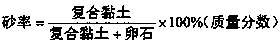

How to make anti-corrosion concrete

ActiveCN104230217BImprove corrosion resistanceReduce manufacturing costReady mixed concreteSuperplasticizer

The invention provides a method for making anti-corrosion concrete. The technical plan is: the material formula for making anti-corrosion concrete is: special cement for commercial concrete + fine aggregate + coarse aggregate + water + special high-efficiency water reducing agent, and the material formula ratio is: concrete per cubic meter: special for commercial concrete Binder 300-500kg, fine aggregate 700-1000kg, coarse aggregate 800-1100kg, water consumption 180kg, special high-efficiency water reducer is 1.7-2.2% of the weight of the special cement for commercial concrete. Concrete bulk density: 2350-2450kg / m³, water-binder ratio: 0.35-0.45, sand rate: 0.38-0.53. It improves the corrosion resistance of concrete, solves the problem of poor concrete durability in the saline-alkali area around the Bohai Sea for many years, reduces the manufacturing cost of commercial concrete, improves the quality of commercial concrete, and is suitable for general promotion and use.

Owner:SLOF YINGHAI IND GRP

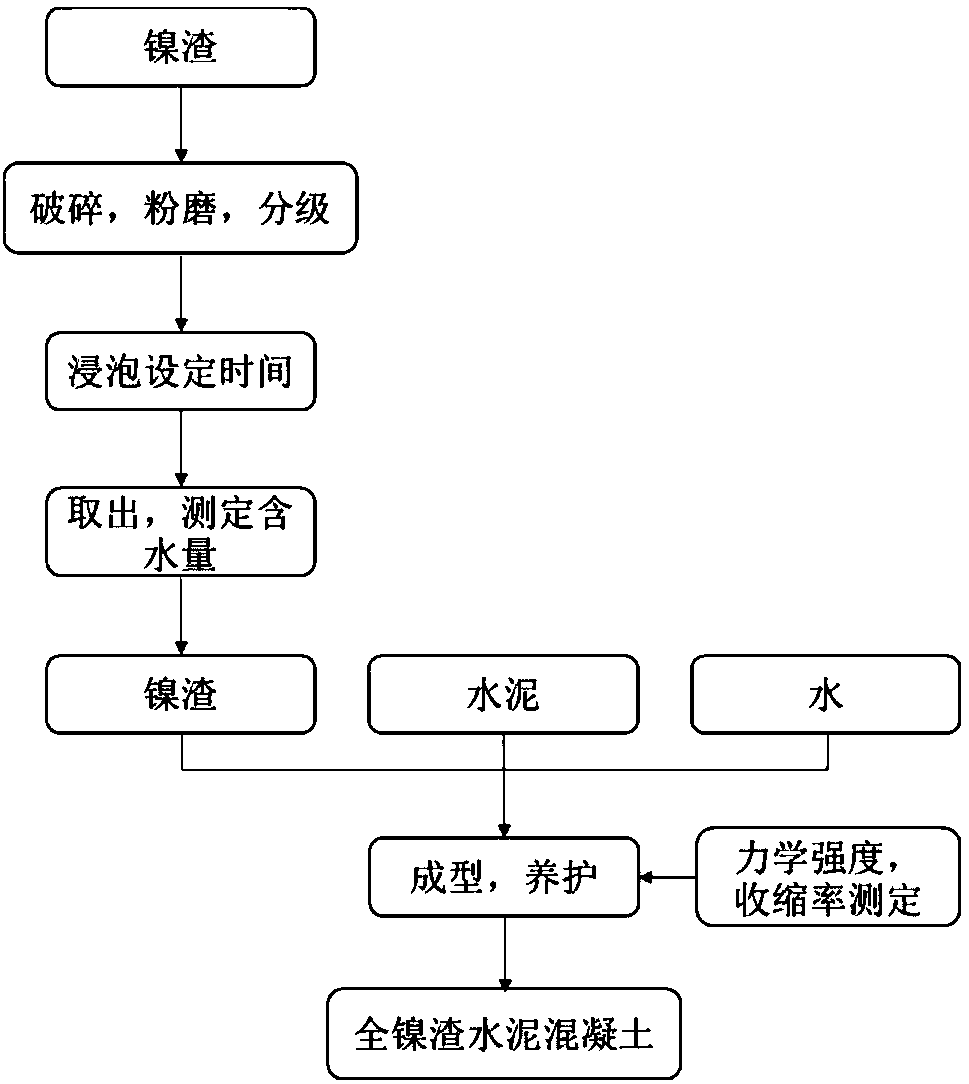

A kind of preparation method of fully mixed nickel slag ready-mixed concrete

The invention relates to a preparation method of premixed concrete fully doped with nickel slag. The method comprises the following steps: (1) carrying out pretreatment on the nickel slag: pouring thenickel slag into a crusher for crushing; then, classifying the crushed nickel slag according to particle sizes, and grinding fine powder again to obtain nickel slag powder; (2) respectively dipping the nickel slag powder, relatively coarse nickel slag and coarse nickel slag into saturated limewater for 1-6 days, fishing out and drying for later use; (3) mixing: mixing the following raw materialsin parts by weight: 190-210 parts of cement, 170-180 parts of water, 150-170 parts of the nickel slag powder, 800 parts of the relatively coarse nickel slag and 1050 parts of the coarse nickel slag. According to the preparation method, the nickel slag is prepared into admixture, fine aggregate and coarse aggregate of the concrete, and the conventional admixture, fine aggregate and coarse aggregatein the concrete are completely replaced with the admixture, the fine aggregate and the coarse aggregate which are prepared from the nickel slag, so that the raw material cost of the concrete is significantly reduced. A certain amount of Mg(OH)2 is generated in a hydration process by using magnesium oxide mineral existing in the nickel slag, so that a certain volume is increased, and a concrete product which has good shrinkage property and even does not shrink can be prepared.

Owner:YANCHENG GUOTAI CONCRETE +1

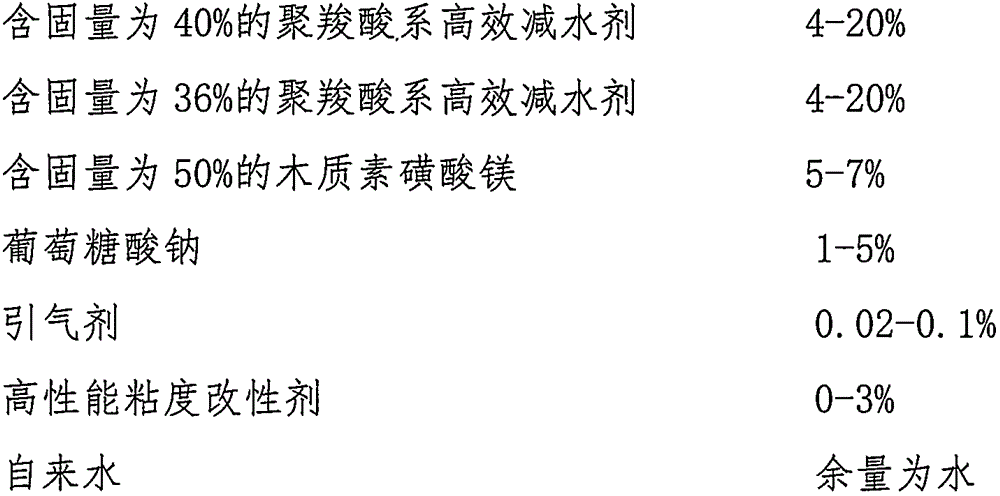

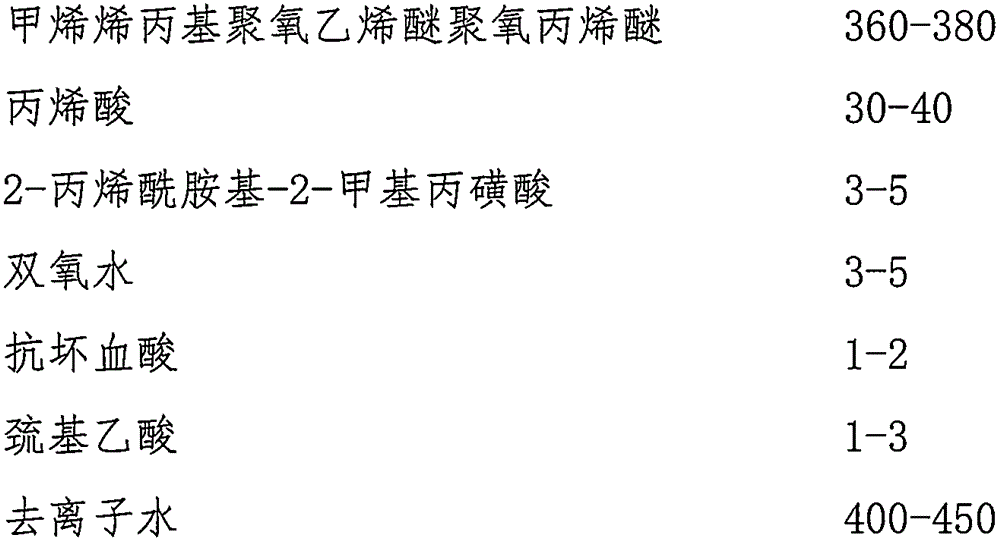

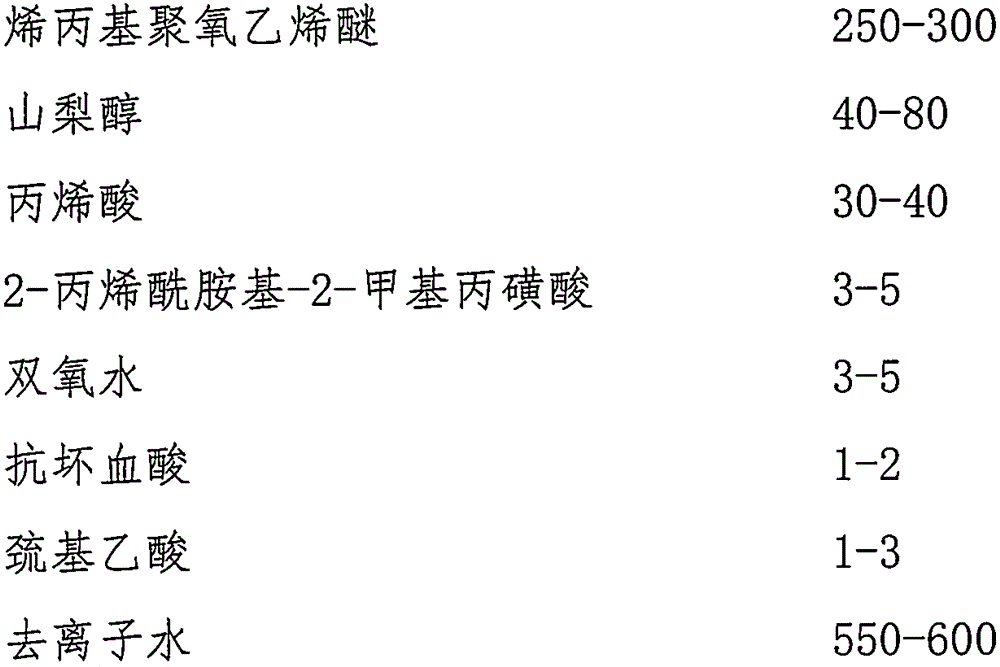

Polycarboxylate medium-efficiency pumping agent for ready-mixed commodity pumping concrete

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

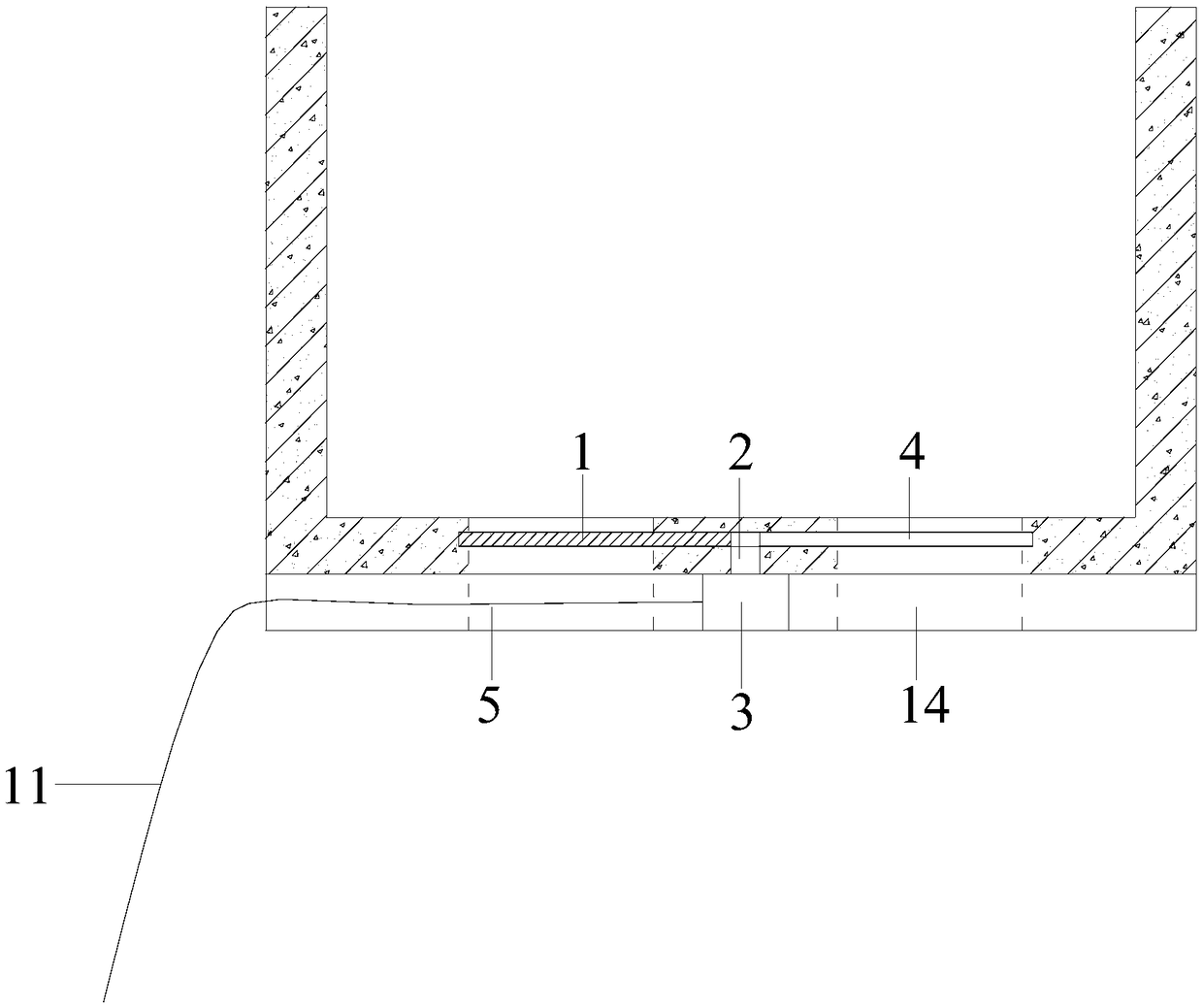

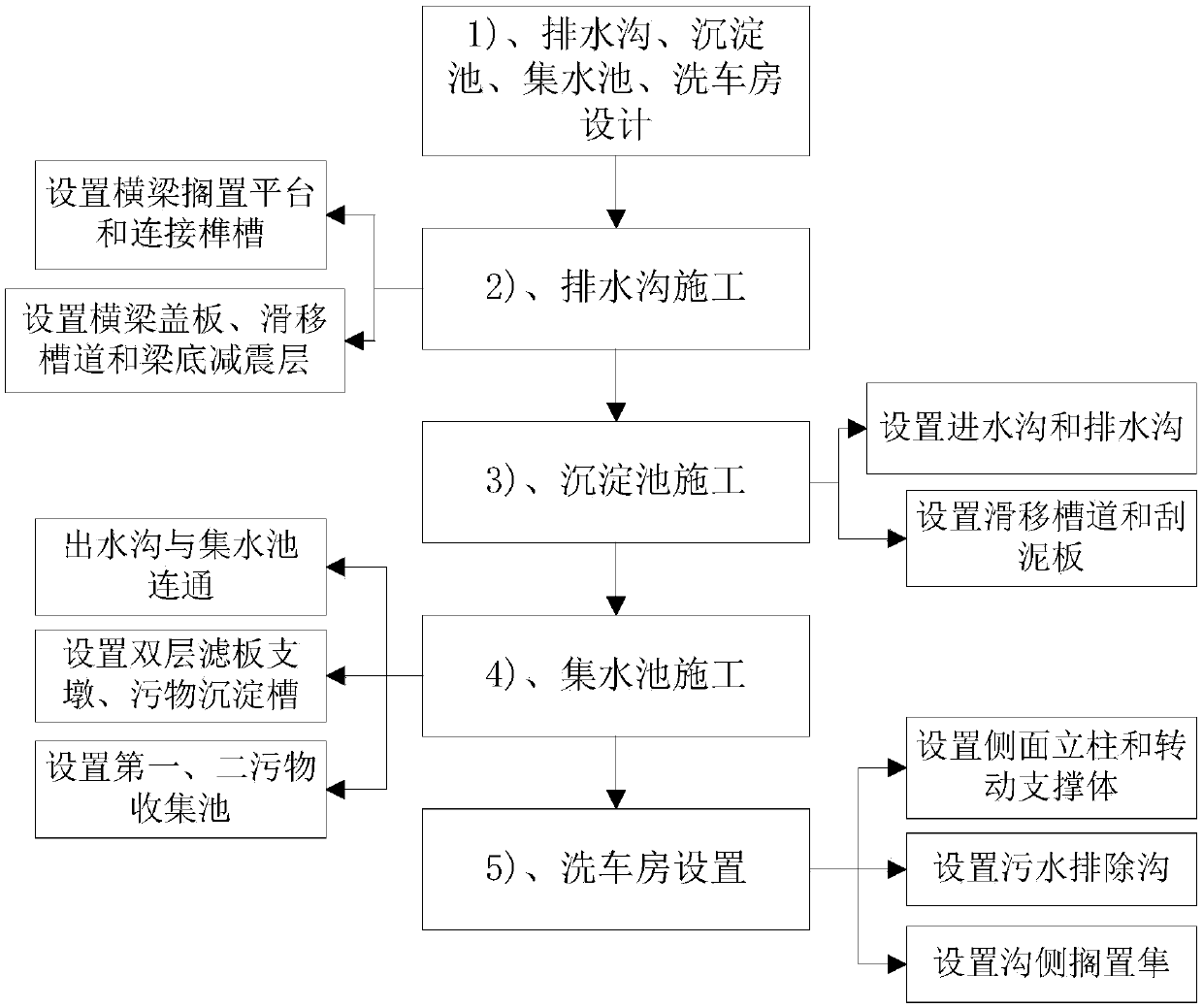

Construction method of rain and sewage purification treatment system in ready-mixed concrete production plant area

ActiveCN109577698AImprove carrying capacityQuality improvementFatty/oily/floating substances removal devicesSewerage structuresReady mixed concreteSewage

The invention relates to a construction method of a rain and sewage purification treatment system in a ready-mixed concrete production plant area. The method includes the following steps: (1) designing a drainage ditch, a sedimentation tank, a water collecting tank and a car washing room; (2) preforming drainage ditch construction; (3) preforming sedimentation tank construction; (4) preforming water collecting tank construction; (5) arranging the car washing room. The method has the advantages that a ditch top cover plate of the drainage ditch is connected with a cover plate cross beam, so that the bearing capacity of the ditch top cover plate can be effectively improved; through the arrangement of a shock absorption layer at the bottom of the beam, the anti-seismic performance of the structure can be improved; an elastic connector is arranged between a sliding groove channel and a sliding pull rod, so that the quality of dirt removal in the drainage ditch can be effectively improved;the sliding groove channel is formed in the bottom of the sedimentation tank, and the sliding groove channel is connected with a sliding limiting plate, so that the efficiency of removing dirt insidethe sedimentation tank can be effectively improved; and the water collecting tank is communicated with a dirt collecting tank, so that the layered filtering effect is good, dirt is respectively liftedand taken out in the dirt collecting tank through a lifting ring, and the on-site construction efficiency is high.

Owner:四川兴城港瑞建材有限公司

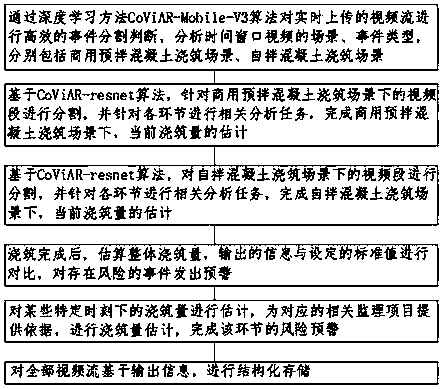

Concrete pouring amount estimation method based on artificial intelligence video analysis

ActiveCN111582191AImprove human efficiencyEasy retrievalNeural architecturesNeural learning methodsAlgorithmReady mixed concrete

The invention provides a concrete pouring amount estimation method based on artificial intelligence video analysis. The method includes: carrying out efficient event segmentation judgment on a video stream uploaded in real time through a deep learning method CoViAR-Mobile-V3 algorithm; analyzing a scene and an event type of the time window video; respectively finishing pouring of commercial premixed concrete and pouring of self-mixed concrete; after the current pouring amount is estimated and pouring is completed, estimating the overall pouring amount, comparing output information with a set standard value, giving out an early warning for events with risks, estimating the pouring amount at some specific moments, providing a basis for corresponding related supervision projects, carrying outnecessary pouring amount estimation, and completing risk early warning of the link. According to the invention, full-flow intelligent side station supervision is adopted, potential risks caused by human factors of a supervisor are avoided, online real-time risk early warning is realized, only a small number of supervision experts are needed, the risk of system early warning is remotely analyzed and judged, and the human efficiency of side station supervision and management is improved.

Owner:广东创成建设监理咨询有限公司

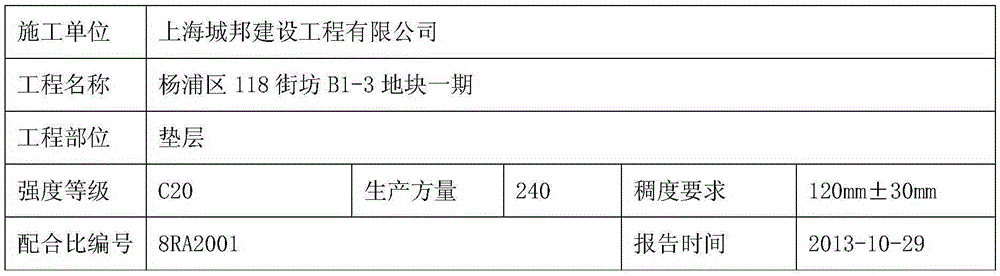

A kind of ready-mixed recycled concrete and preparation method thereof

The invention discloses premixed recycled concrete which is characterized in that the premixed concrete per cube is prepared from the following raw materials by weight: 133-162 kg of 42.5# cement, 300-327 kg of first yellow sand, 571-608 kg of second yellow sand, 387-404 kg of natural pebbles, 527-547 kg of recycled coarse aggregate, 71-80 kg of coal ash, 2.66-3.20 kg of additive, 129-160 kg of mineral powder and 122-126 kg of water; the slump of the premixed concrete is 120+ / -30 mm. A preparation method of the premixed concrete comprises the following steps: firstly, adding the first yellow sand, the second yellow sand, the mineral powder, the 42.5# cement and the coal ash according to a feeding sequence and stirring for 20 seconds; then adding the natural pebbles and the recycled coarse aggregate and stirring for 20 seconds; finally adding water and the additive and stirring for 60 seconds; discharging out of a stirrer. According to the premixed recycled concrete, the mixing amount of the recycled coarse aggregate in the premixed concrete having the strength grade of C30 can reach 100% and the mixing amount of the recycled coarse aggregate in the premixed concrete having the strength grade of C40 can reach 50%.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

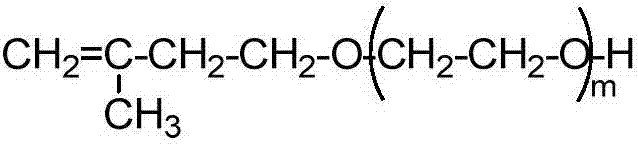

A mud-resistant polycarboxylate water reducer, its preparation method and use method

The invention discloses a mud-resistant polycarboxylate water reducer, a preparation method and a use method thereof. The anti-mud type polycarboxylate water reducer is made of the following raw materials: 100 parts of isopentenol polyoxyethylene ether, 9 to 13 parts of monomer A, 0 to 6 parts of monomer B, 0 parts of monomer C ~4 parts, 0~2 parts of amino trimethylene phosphonic acid, 1~3 parts of maleic anhydride, 1~2 parts of monomer D, 1~2 parts of initiator, 0~1 part of sodium hypophosphite, 0.4 parts of chain transfer agent ~1.6 parts, 3~7 parts of pH regulator and 140~160 parts of water. The anti-mud type polycarboxylate water reducer prepared by the preparation method of the present invention can be used when the aggregate mud content is high, avoiding the adverse effect of the aggregate mud content on the polycarboxylate water reducer in ready-mixed concrete. Impact; raw material cost is low, performance is good; at the same time, the preparation method and use method of the anti-mud type polycarboxylate superplasticizer of the present invention, the process is simple, the operation is convenient, and the application range is wide.

Owner:SHANGHAI DONGDA CHEM

Preceding material for pumping

PendingUS20200339474A1Increase distanceEffectively wastedSolid waste managementDischarging apparatusCelluloseReady mixed concrete

The purpose of the present invention is to provide a preceding material for pumping, a feeding of a very small amount thereof being capable of extending the pumping distance. The preceding material for pumping includes an added cellulose nanofiber and having calcium carbonate as a main component. The present invention enables a thin lubricant layer of a uniform thickness to be formed inside a pipe even when the pipe has a slightly roughened inner surface due to, for example, residues of solidified cement paste or the like, allowing the pumping distance to be extended. Thus, the present invention is suitable, for example, for casting ready-mixed concrete at various construction sites.

Owner:TAKE CITE CO LTD

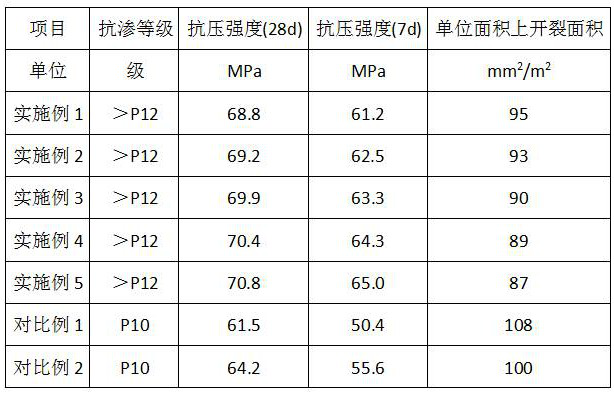

A kind of anti-cracking and anti-seepage ready-mixed concrete and preparation process thereof

The invention discloses an anti-cracking and anti-seepage ready-mixed concrete, comprising the following components in parts by weight: 100-150 parts of cement, 1,000-1,100 parts of crushed stone, 650-750 parts of sand, and 50- parts of slag powder. 60 parts, 3-5 parts of corn grits meal, 7-fluoro-5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a] Quinoline-4-carboxylic acid / methacrylate group-modified N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer 5-8 parts, waste Kevlar fiber 8-13 parts , 8-15 parts of UEA expansion agent, 10-15 parts of wollastonite fiber, 3-5 parts of water-soluble hyperbranched polyamide, 1-2 parts of hyperbranched polysulfide polyamine, 2-4 parts of nano borosilicate, Water 60‑100 parts. The invention also discloses a preparation process of the anti-cracking and anti-seepage ready-mixed concrete. The anti-cracking and anti-seepage ready-mixed concrete disclosed by the invention has obvious anti-cracking and anti-seepage effects, good integrity, stability, safety and durability, and long service life.

Owner:宁波龙峰混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com