Patents

Literature

587results about "Ingredients proportioning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

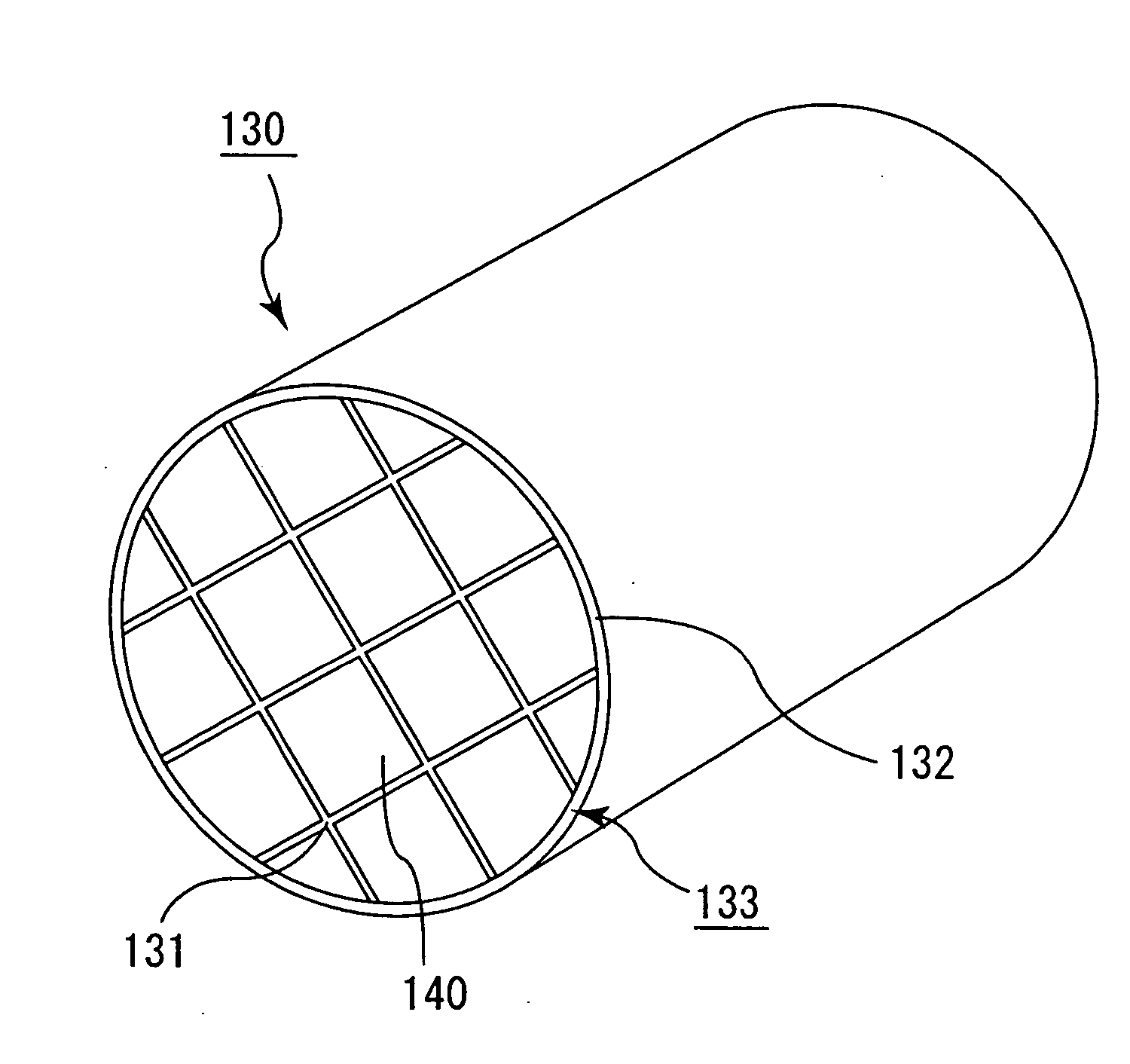

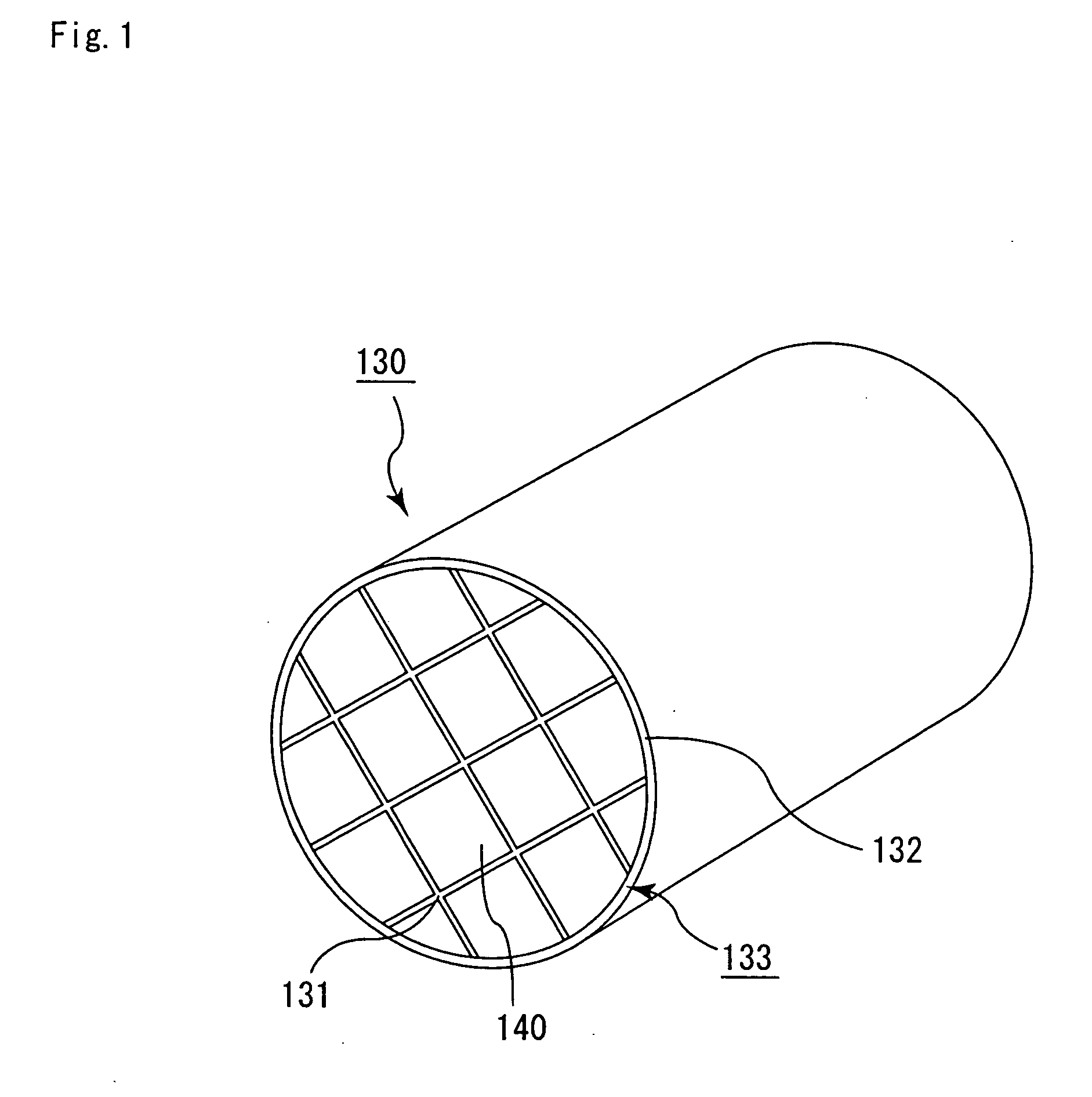

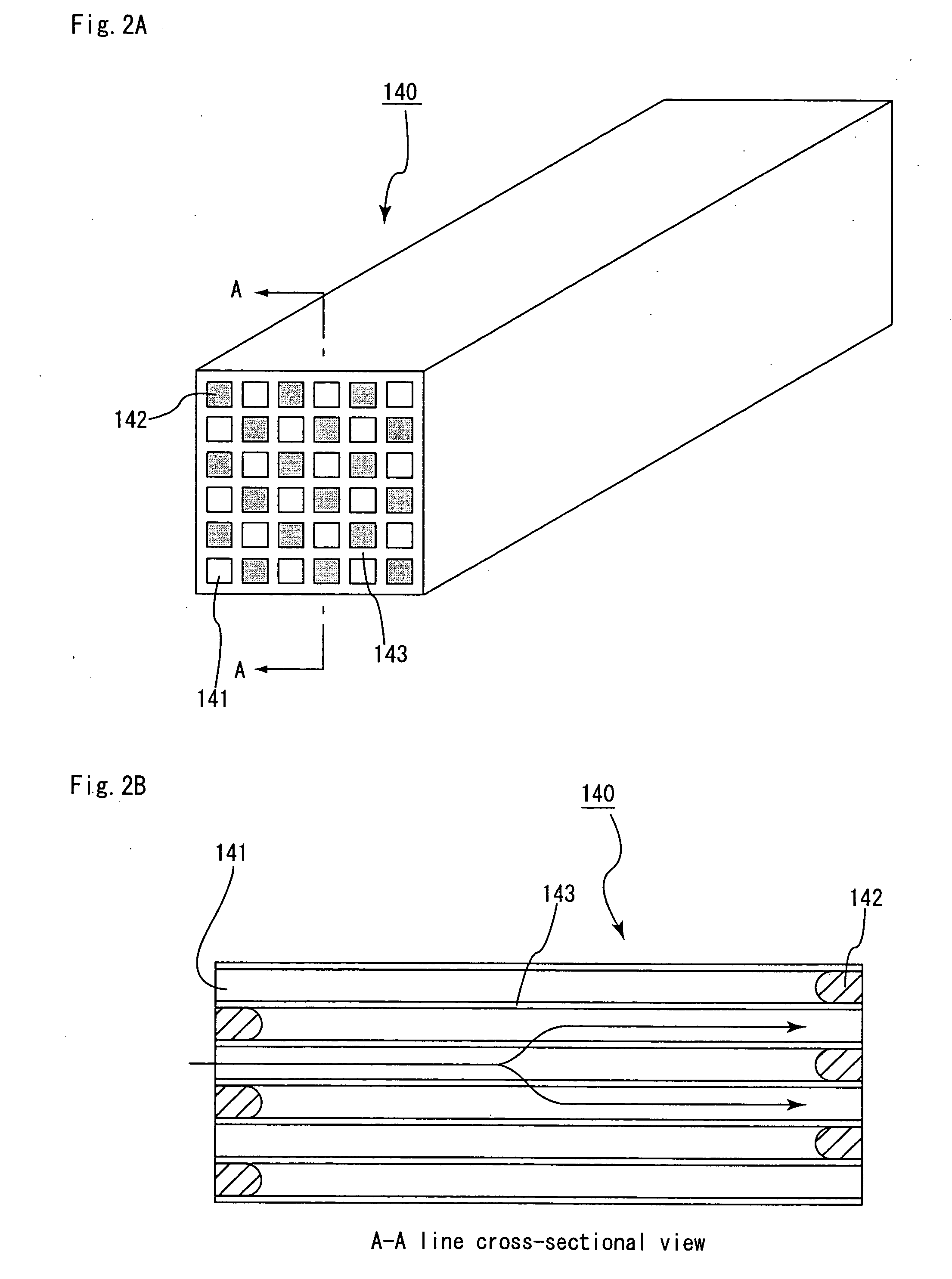

Method for mixing powder, agitation apparatus, and method for manufacturing honeycomb structured body

InactiveUS20070187651A1High hardnessRotary stirring mixersTransportation and packagingHardnessHoneycomb structure

A method for mixing powder according to the present invention is a method for mixing powder by conducting mixing and transporting of at least one kind of powder, comprising: charging said at least one kind of powder into an agitation apparatus; and translating said at least one kind of powder while mixing the powder by rotating an agitation shaft of said agitation apparatus, said agitation apparatus comprising: a screw comprised of the agitation shaft and an agitating blade, said screw configured to rotate along with the said agitation shaft as the center; and, a casing surrounding said screw, wherein either the entire body of said agitating blade is formed of a high hardness member, or, a high hardness coat layer is formed onto at least a portion of said agitating blade.

Owner:IBIDEN CO LTD

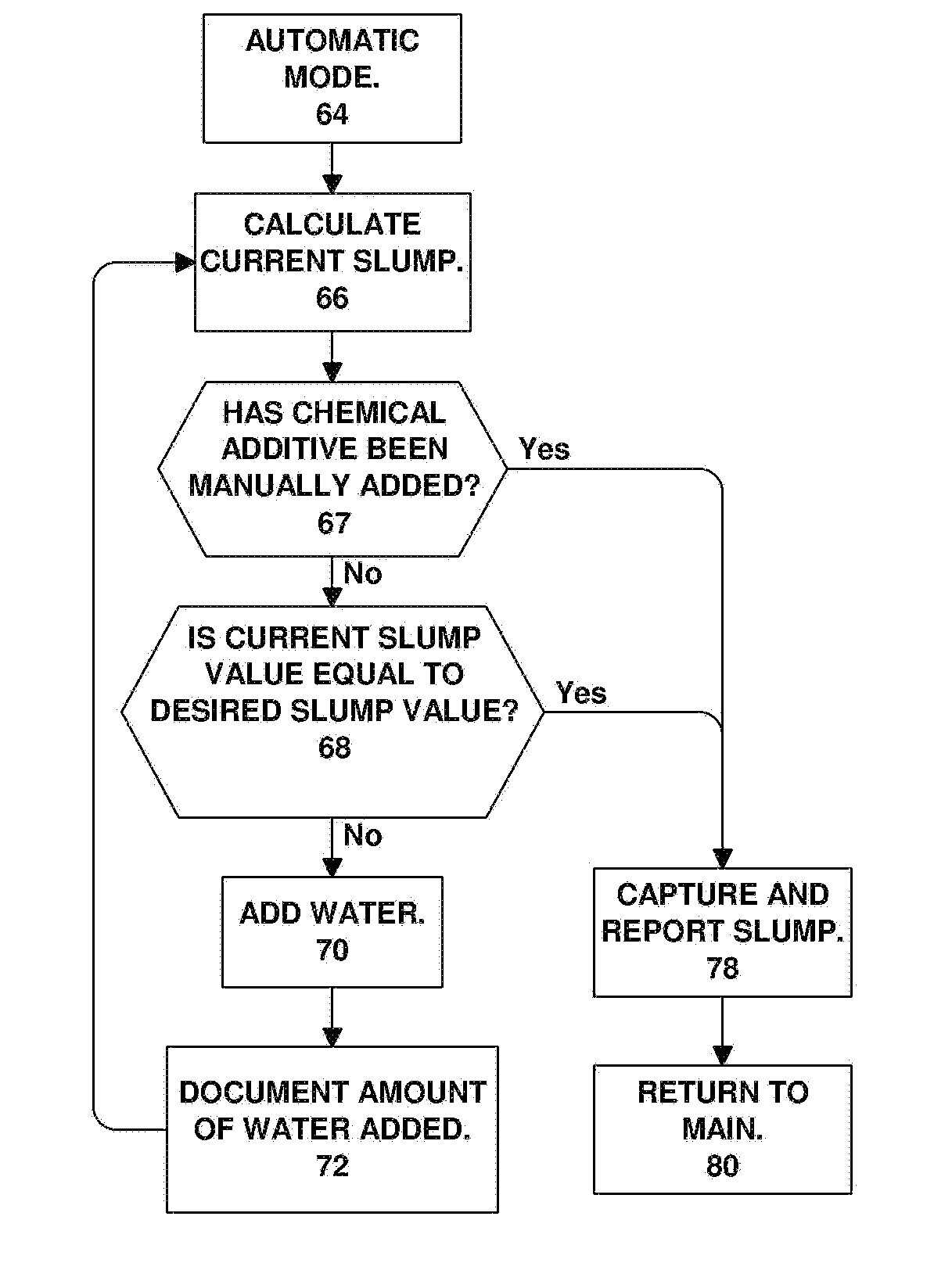

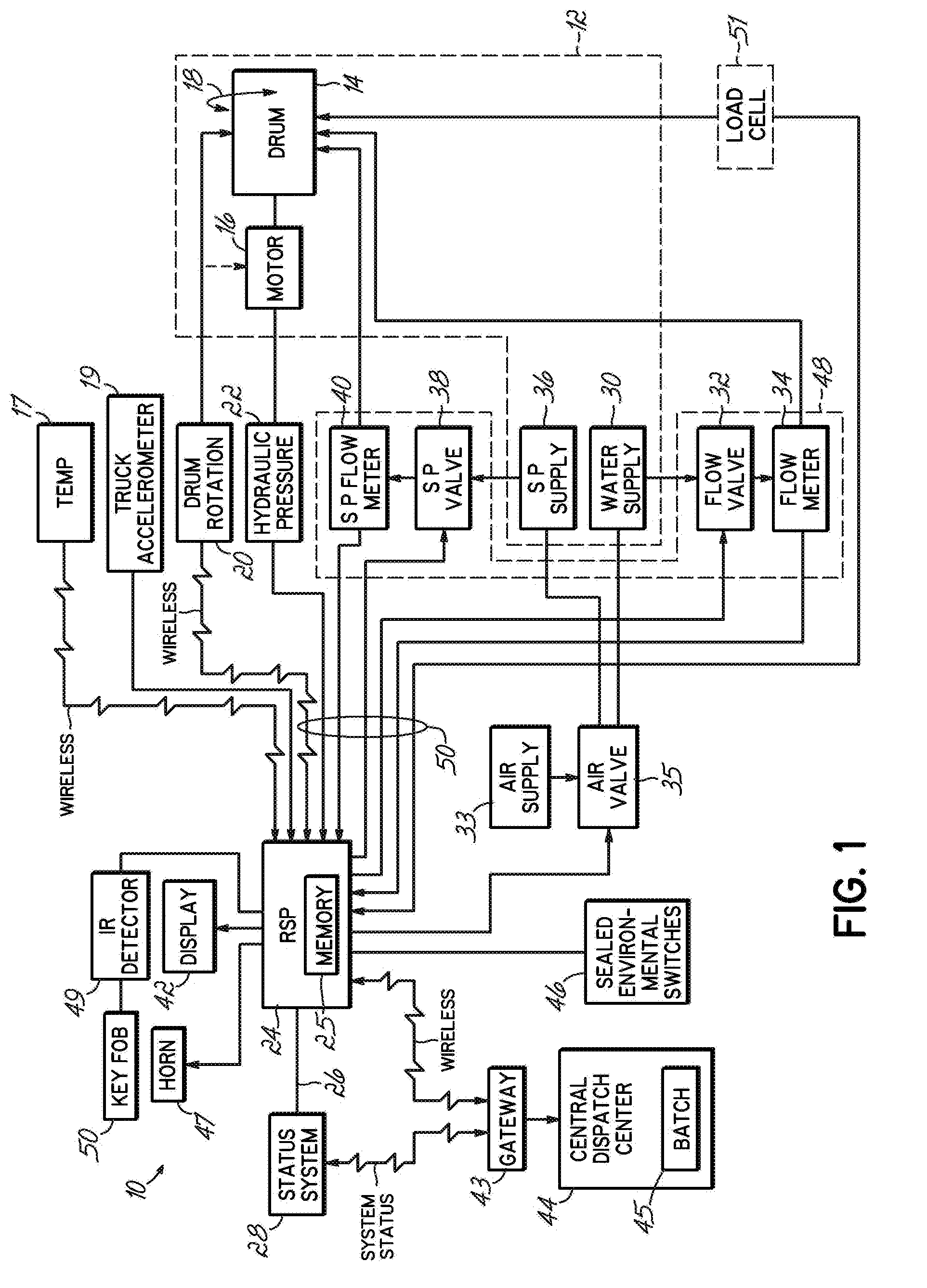

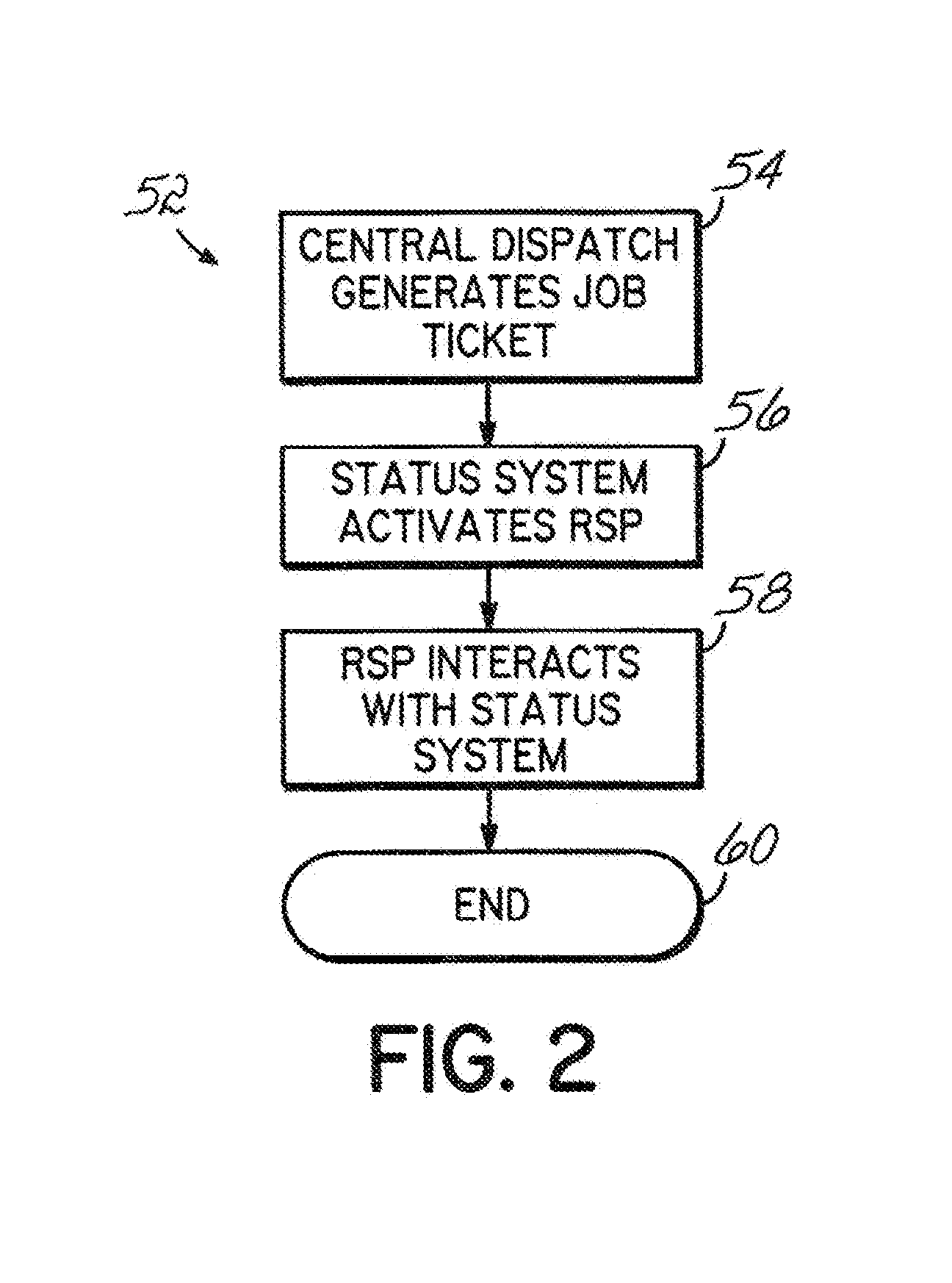

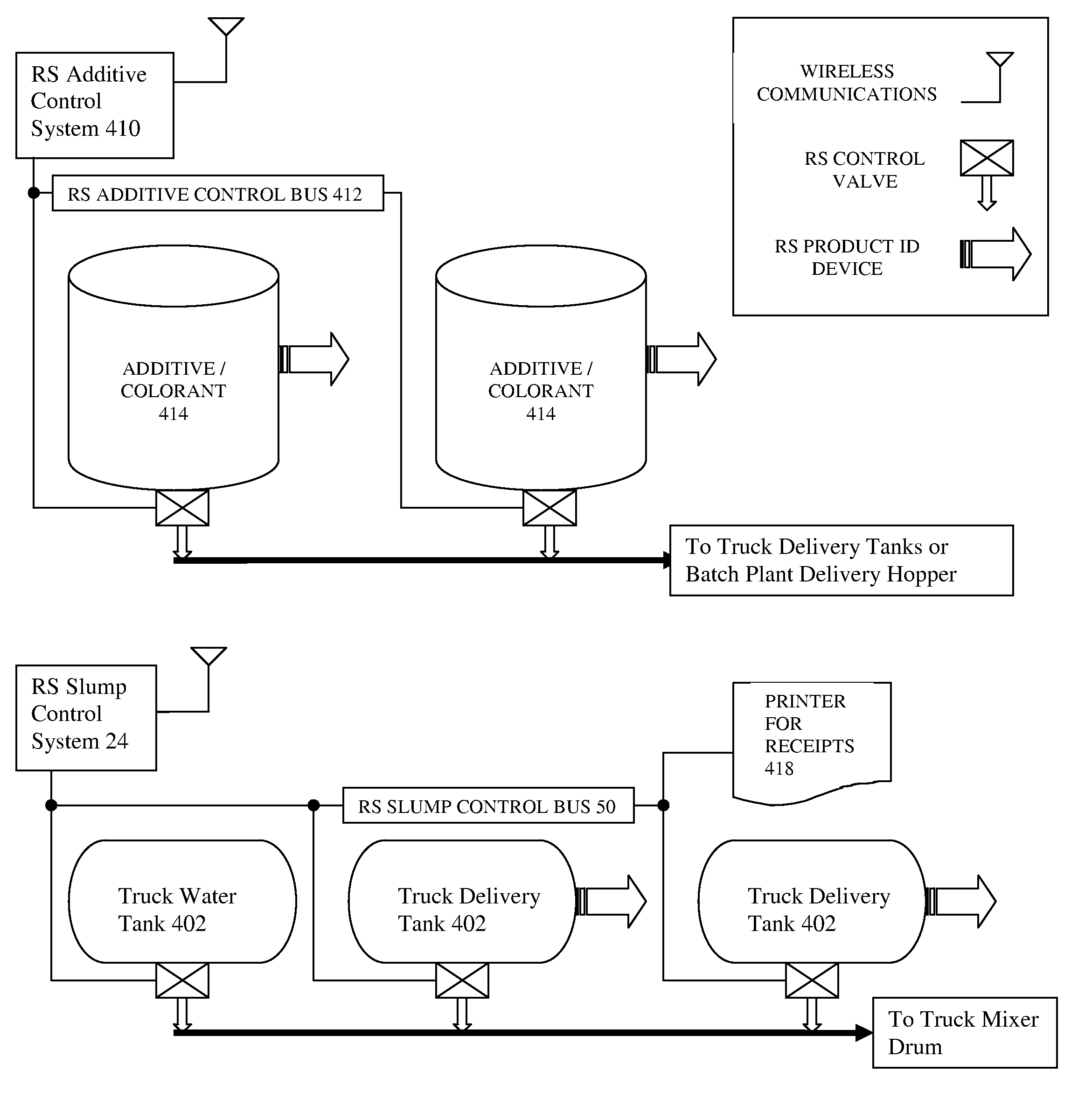

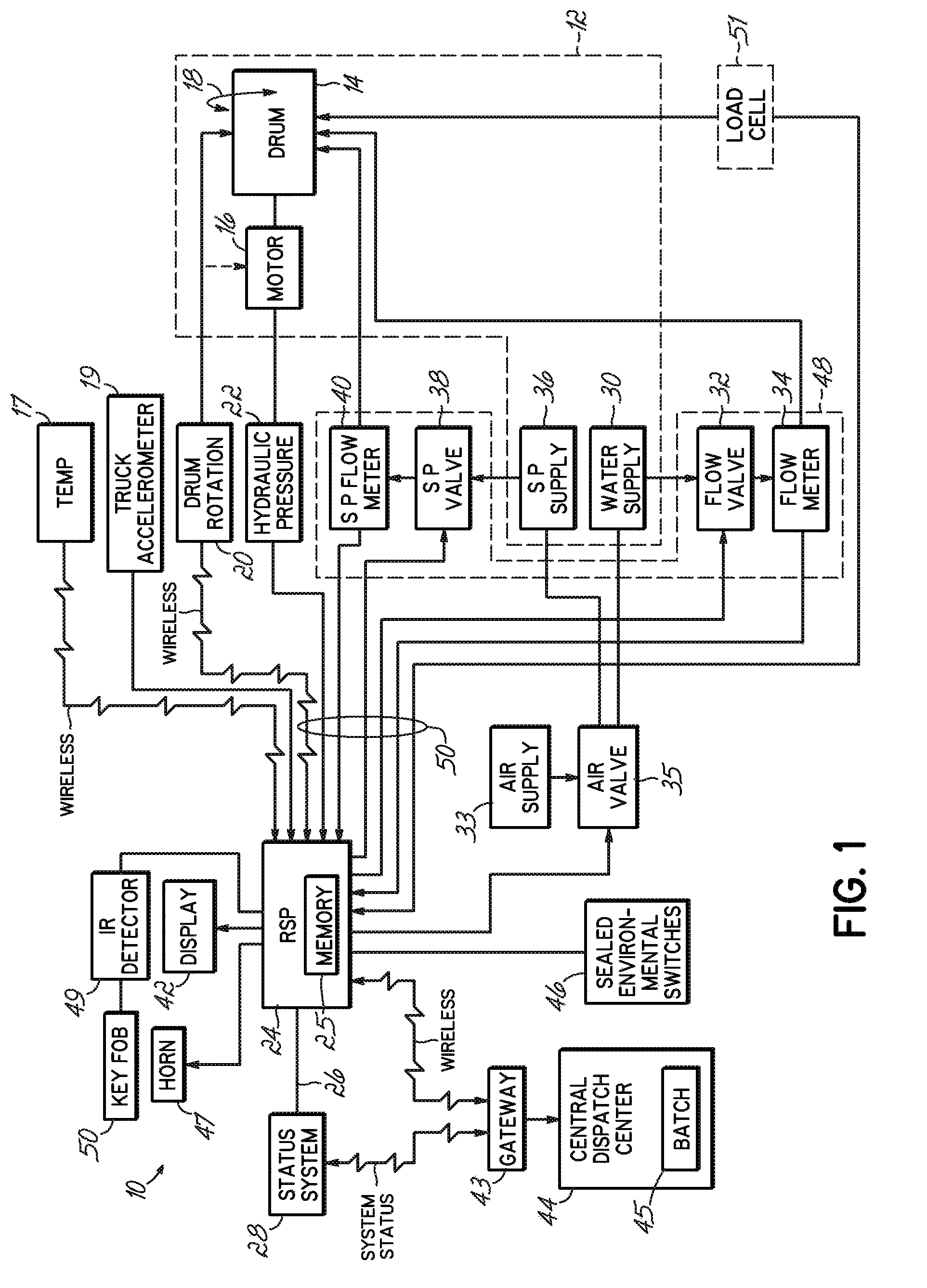

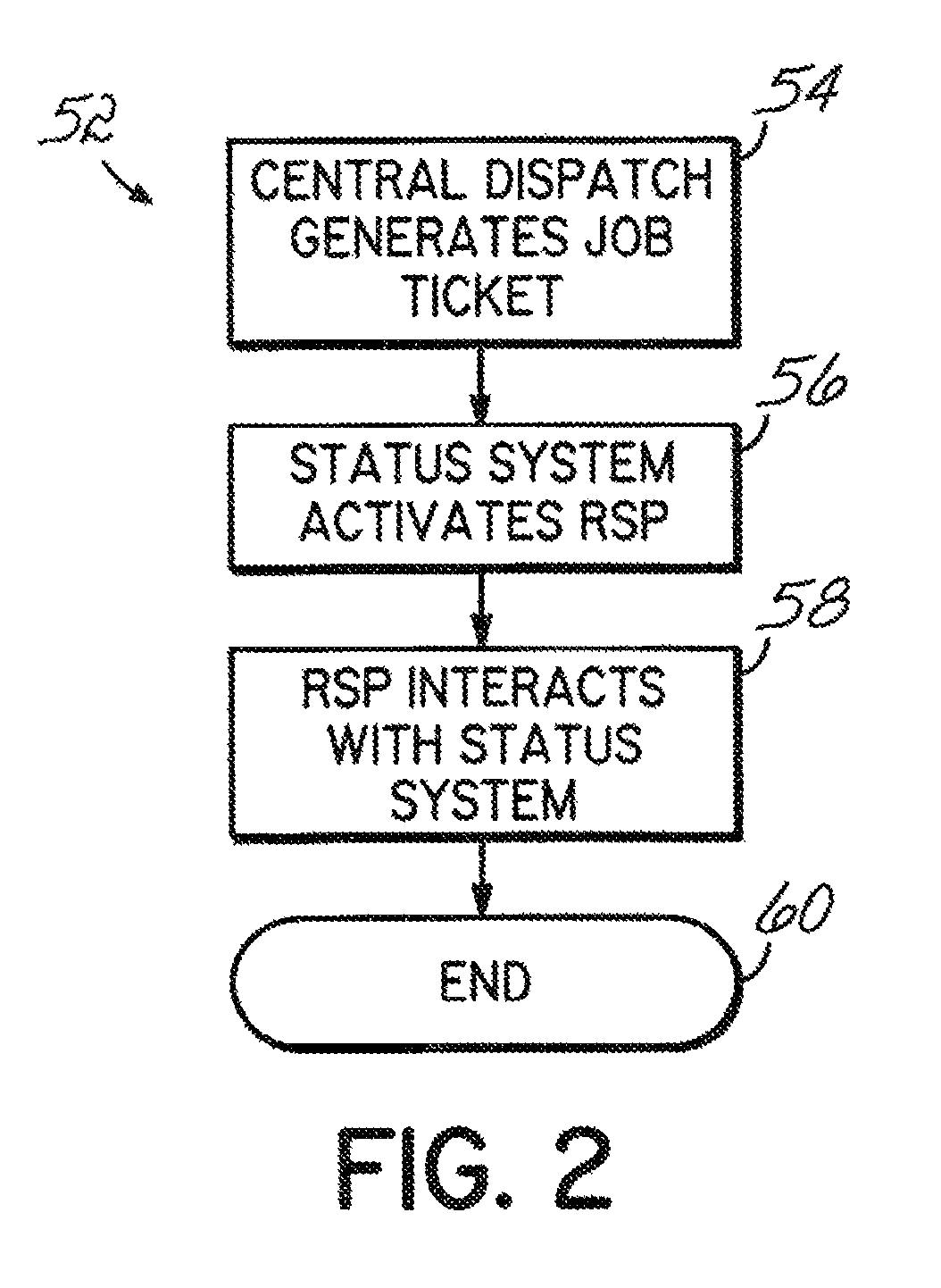

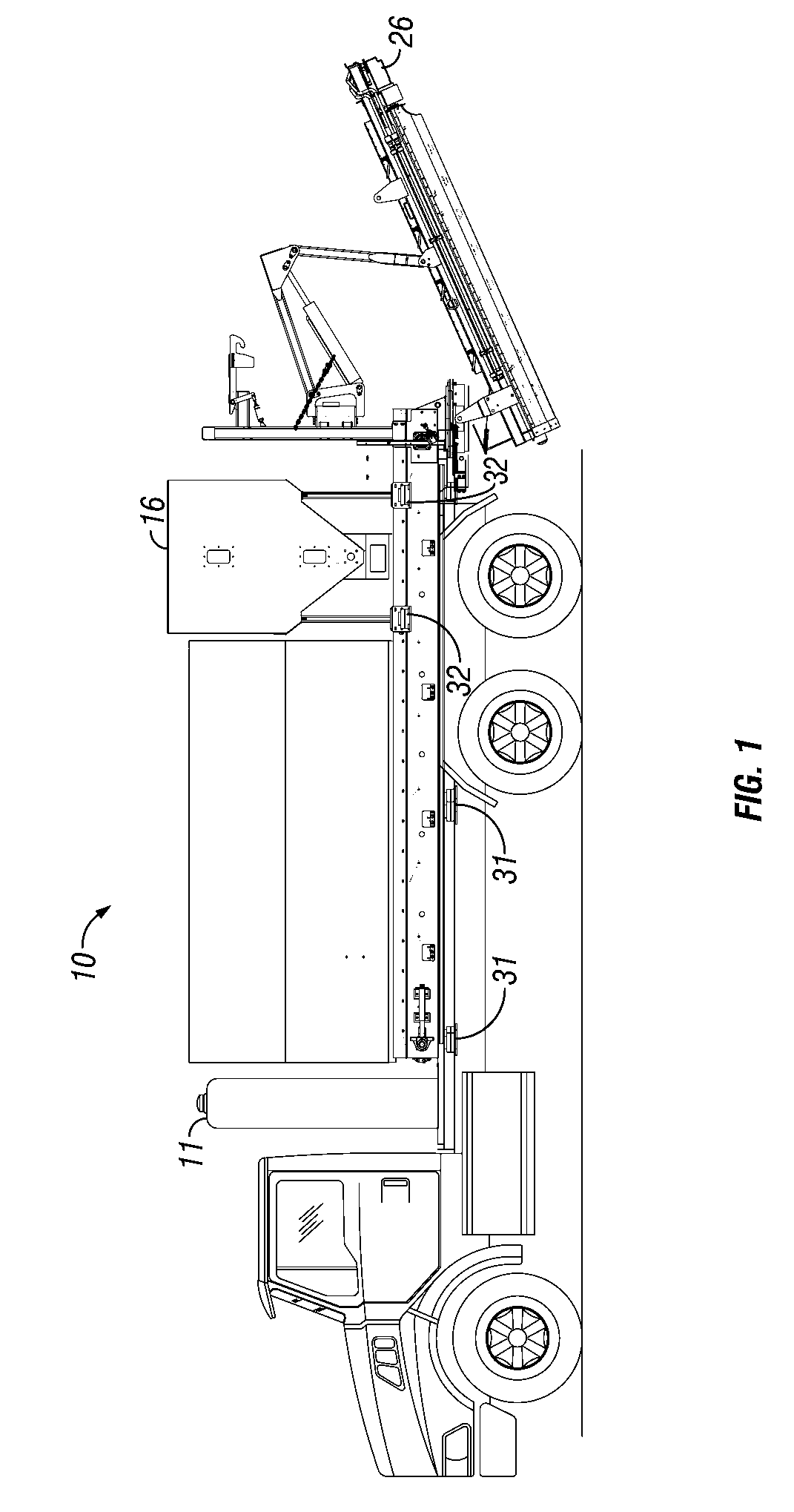

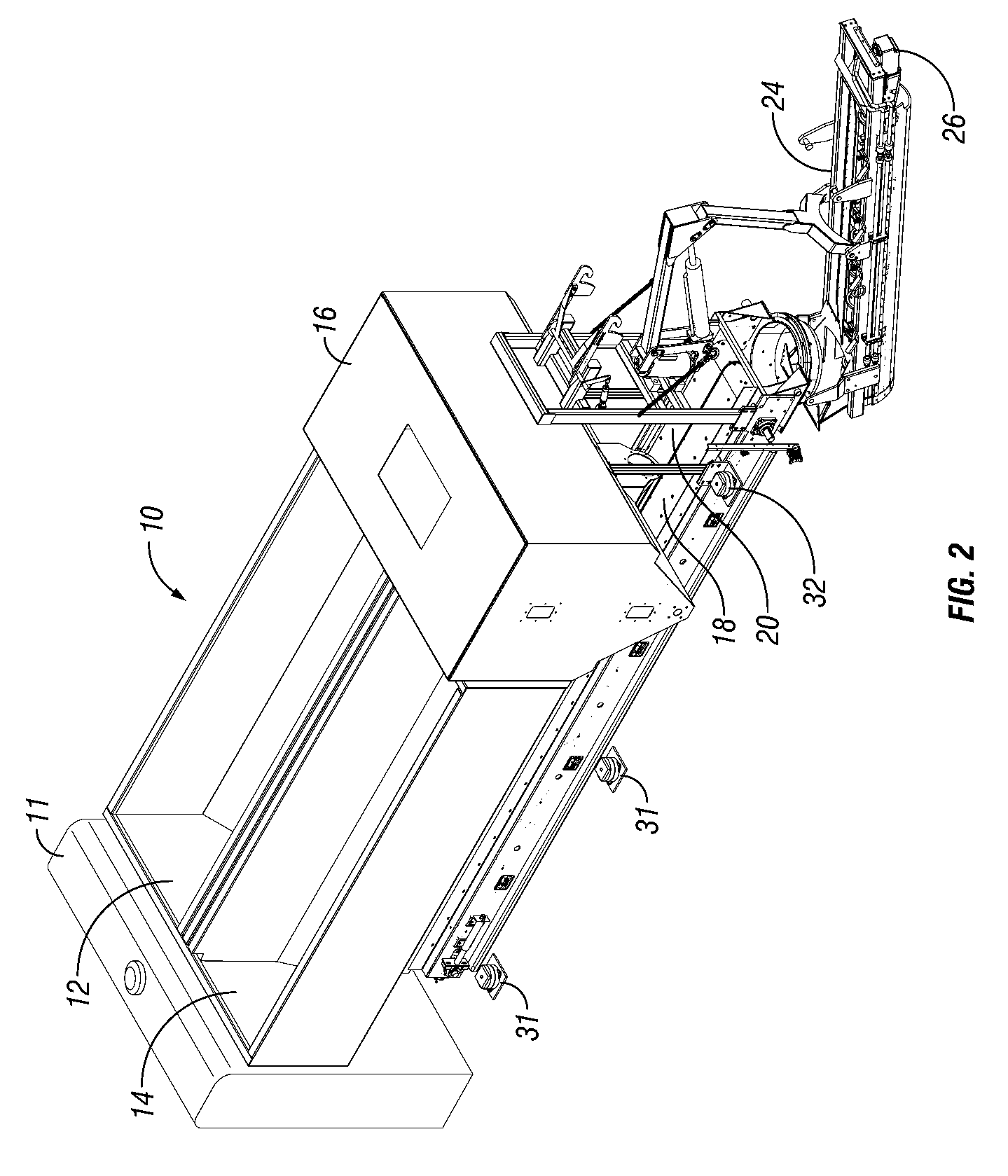

Method and System for Calculating and Reporting Slump in Delivery Vehicles

ActiveUS20090037026A1Easy to useThermometer detailsSampled-variable control systemsDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI

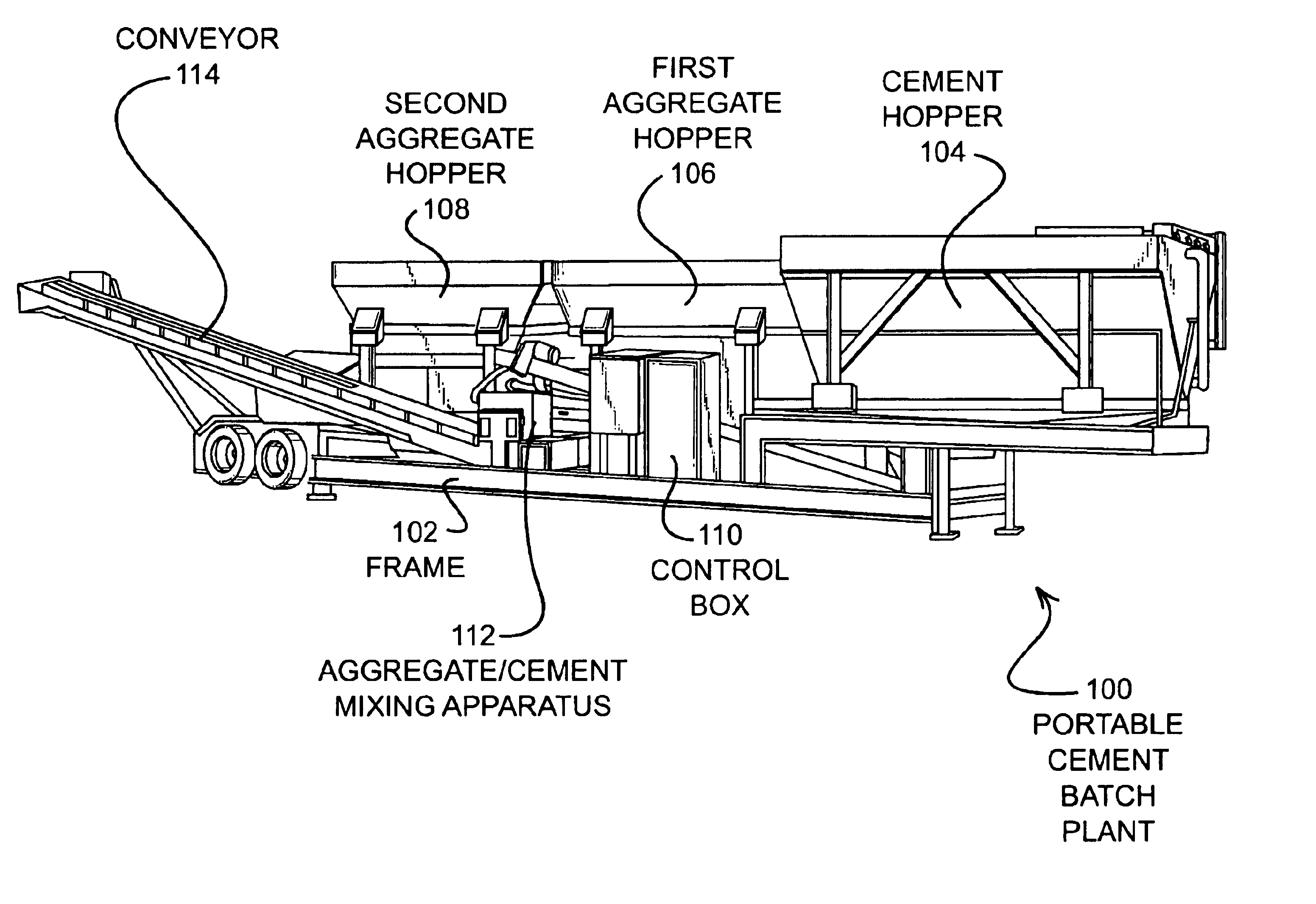

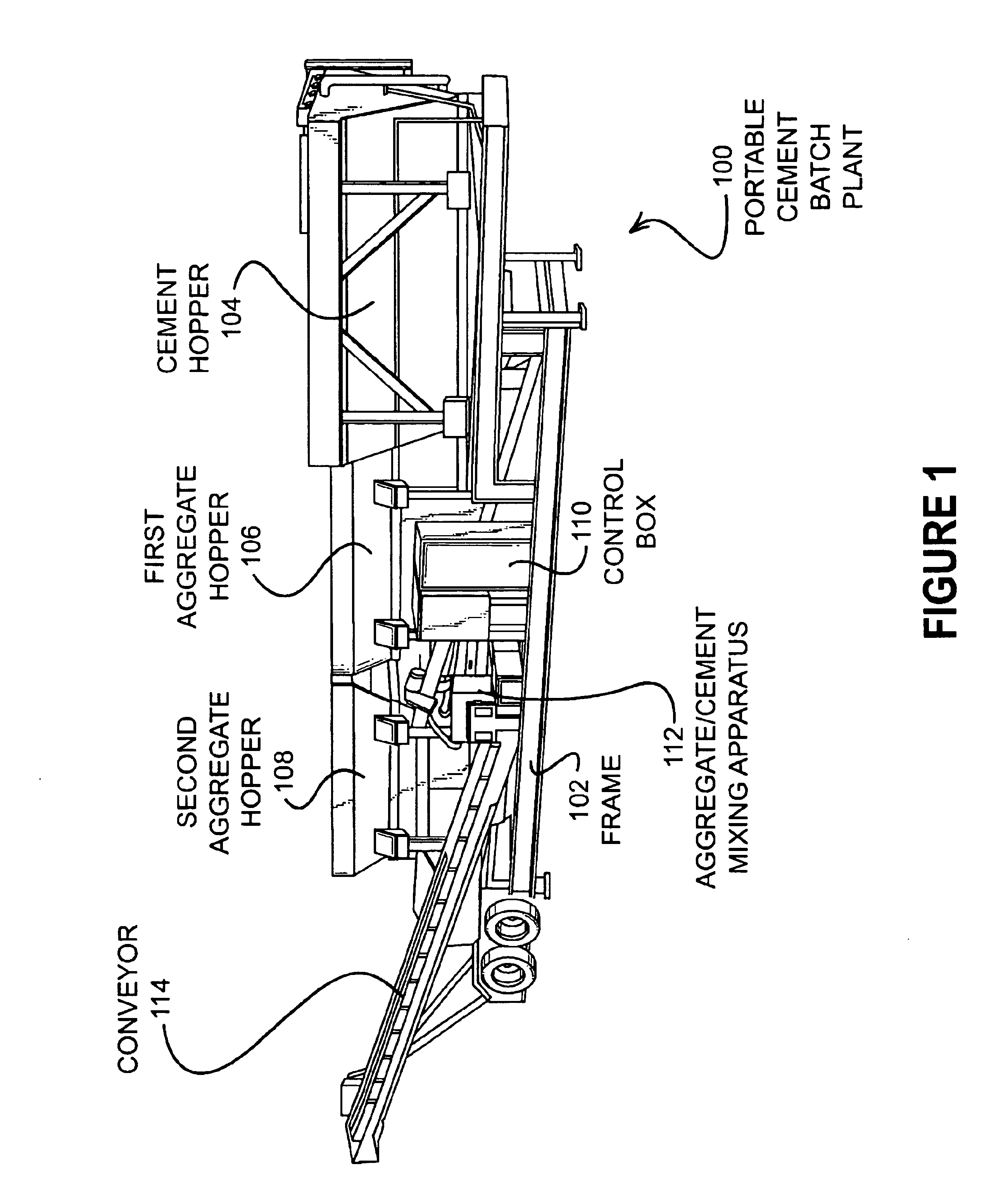

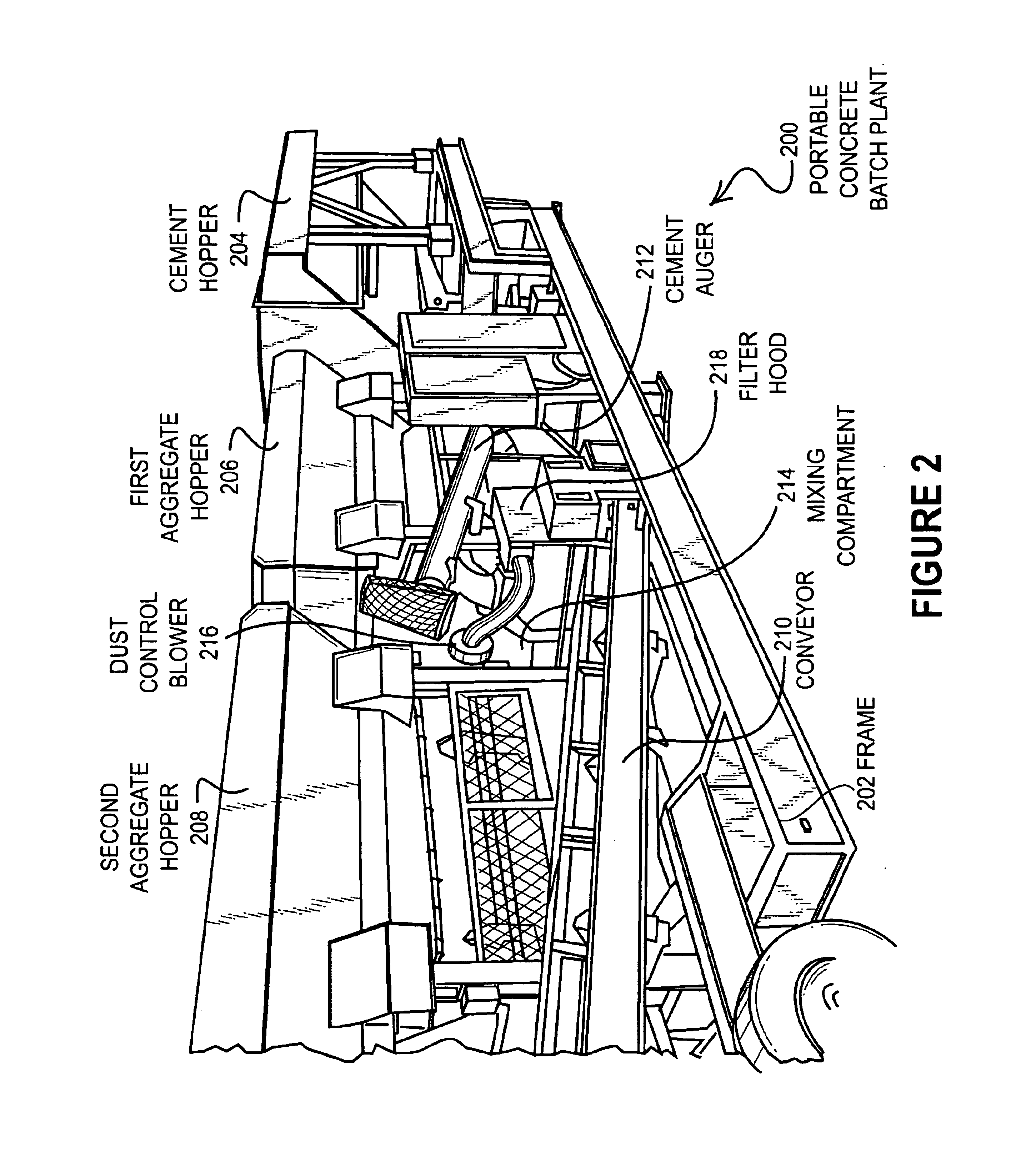

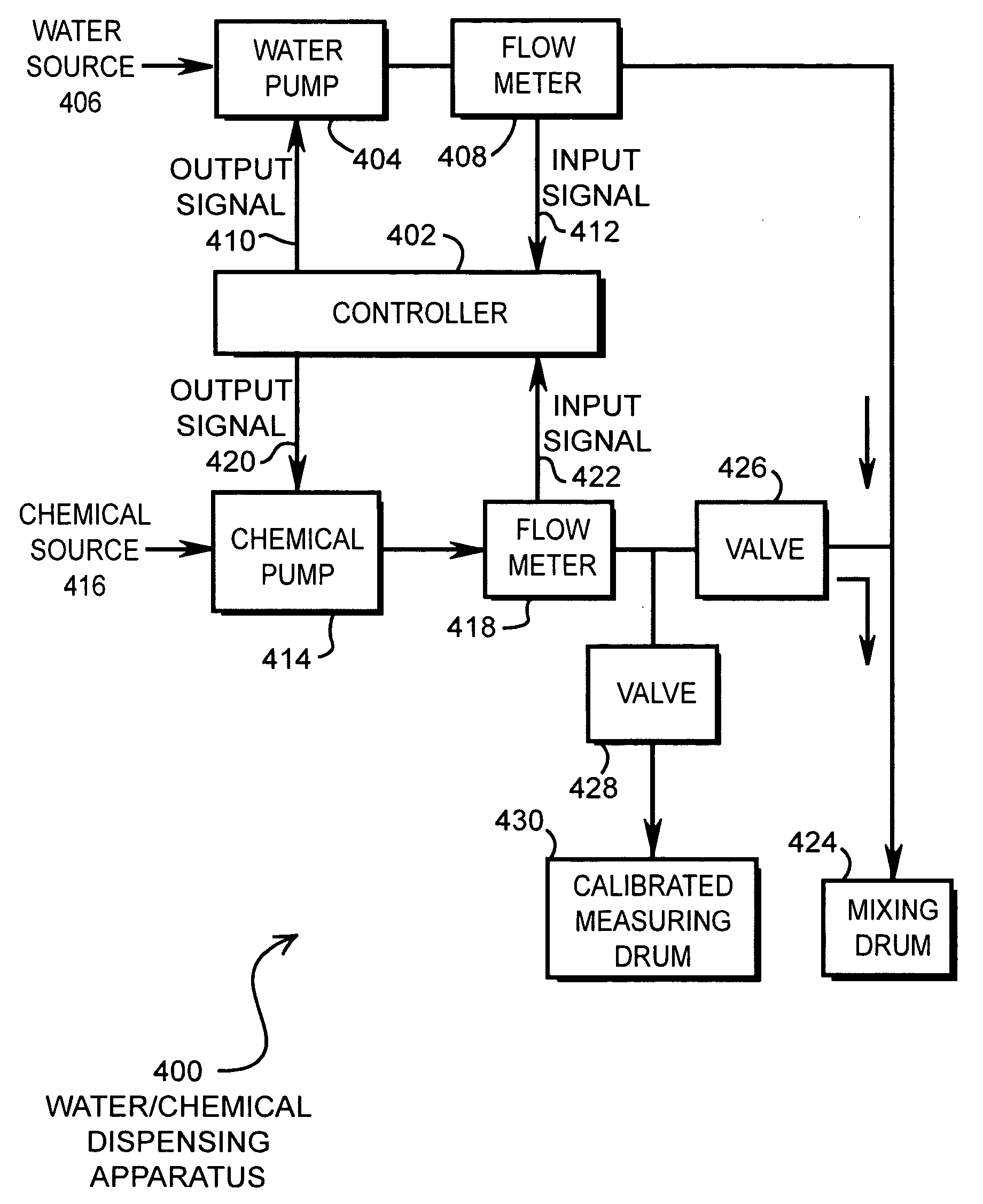

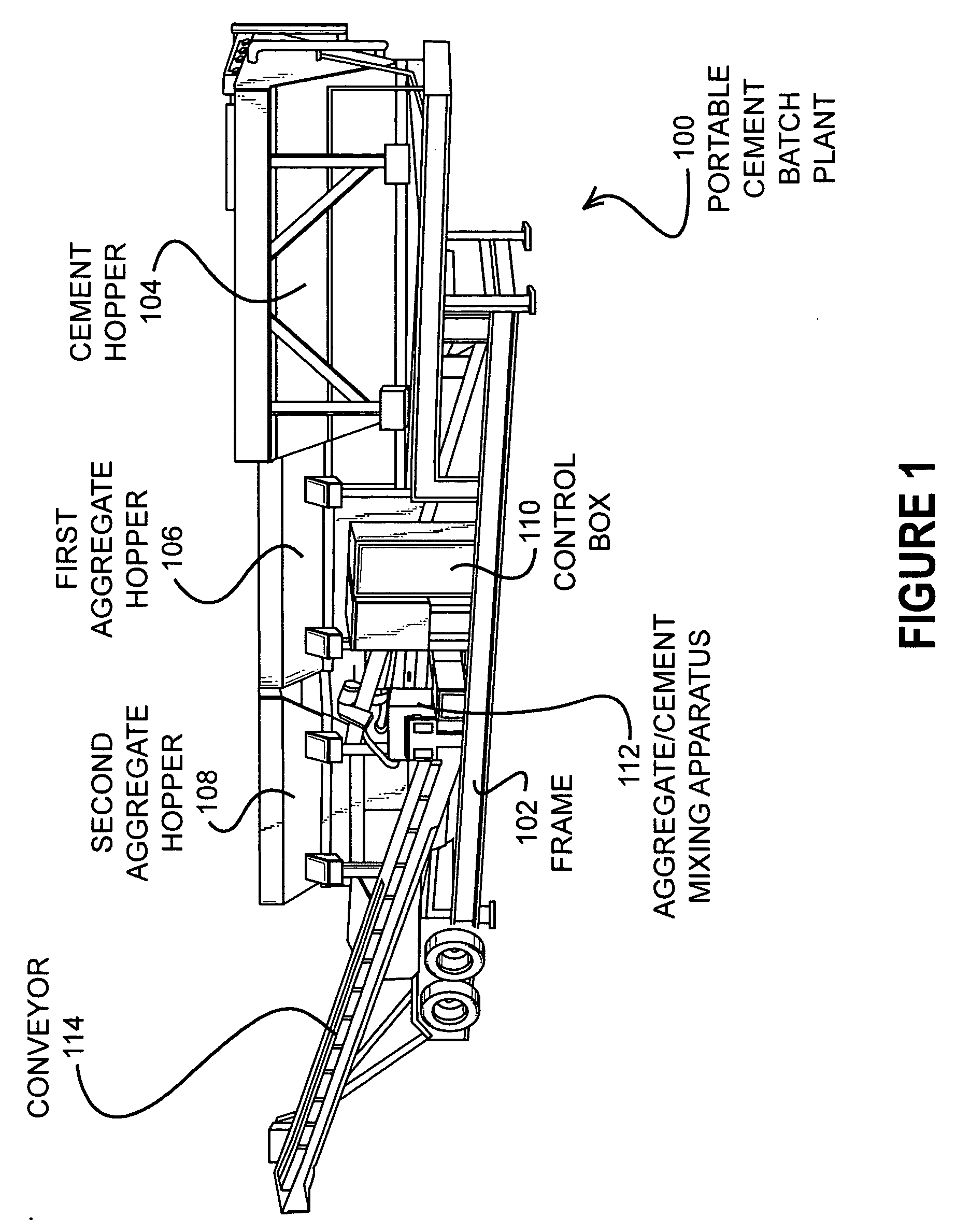

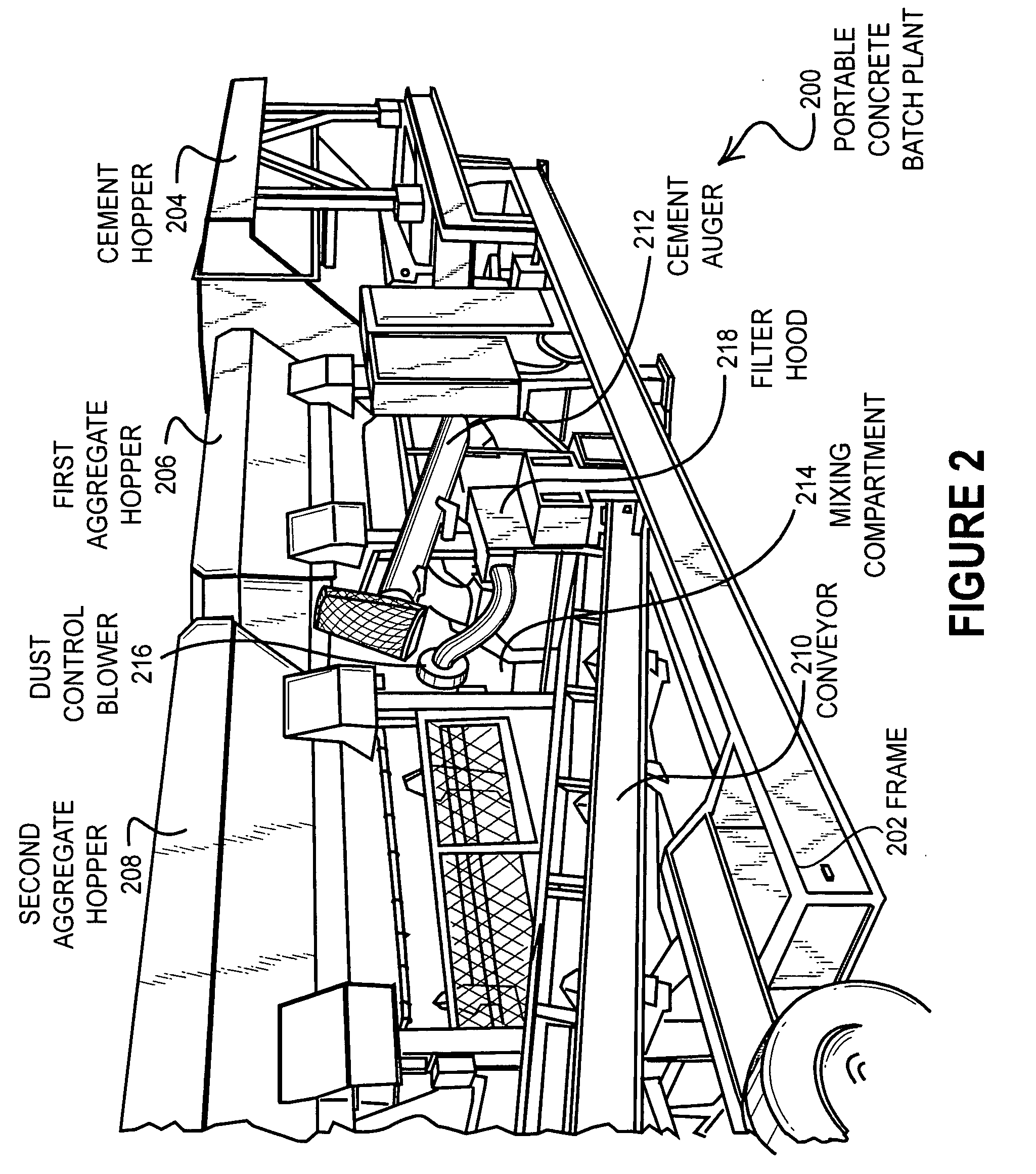

Portable concrete plant dispensing system

ActiveUS6876904B2Dispensed more accuratelyGood repeatabilitySampled-variable control systemsDischarging apparatusDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

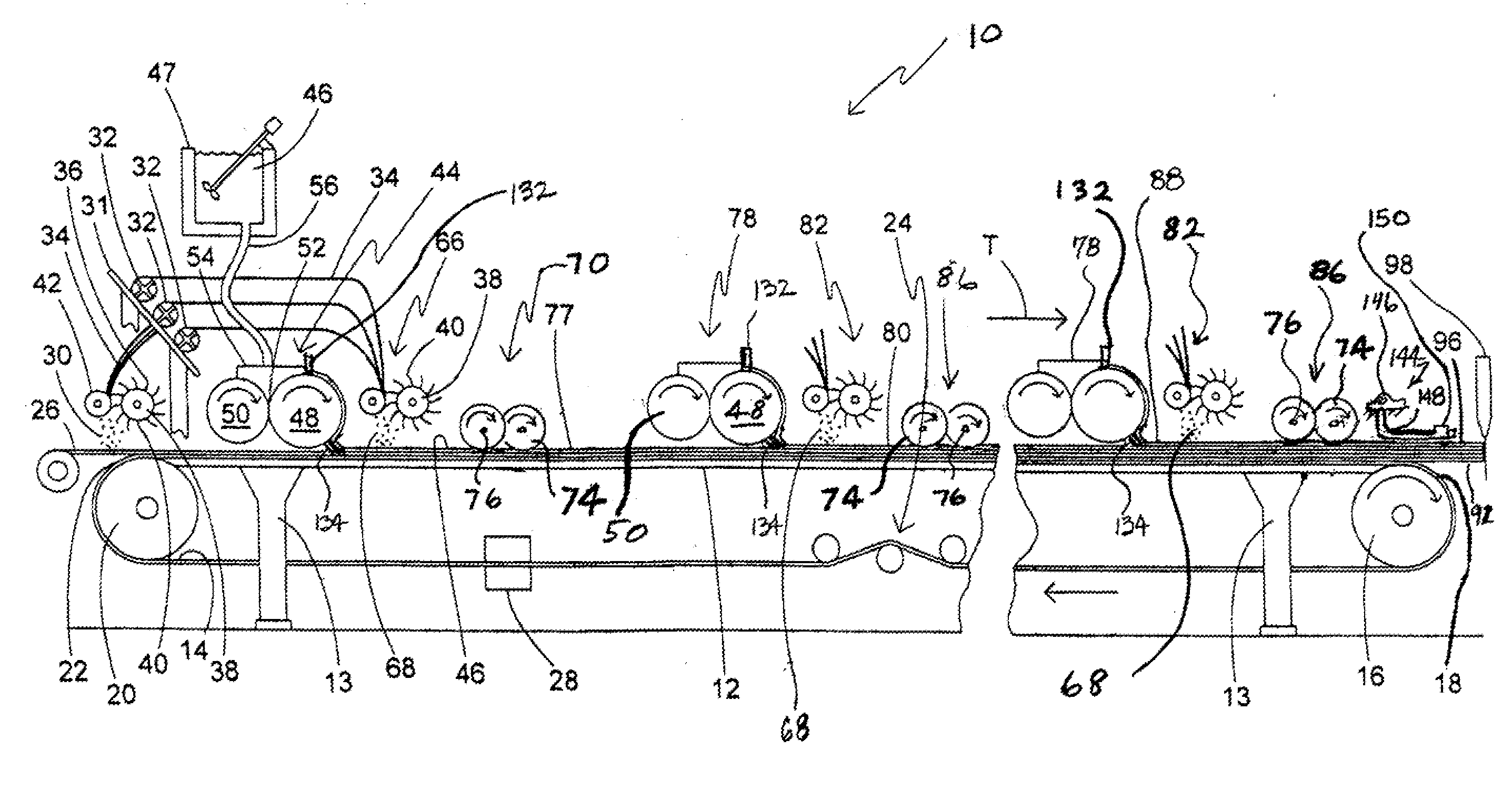

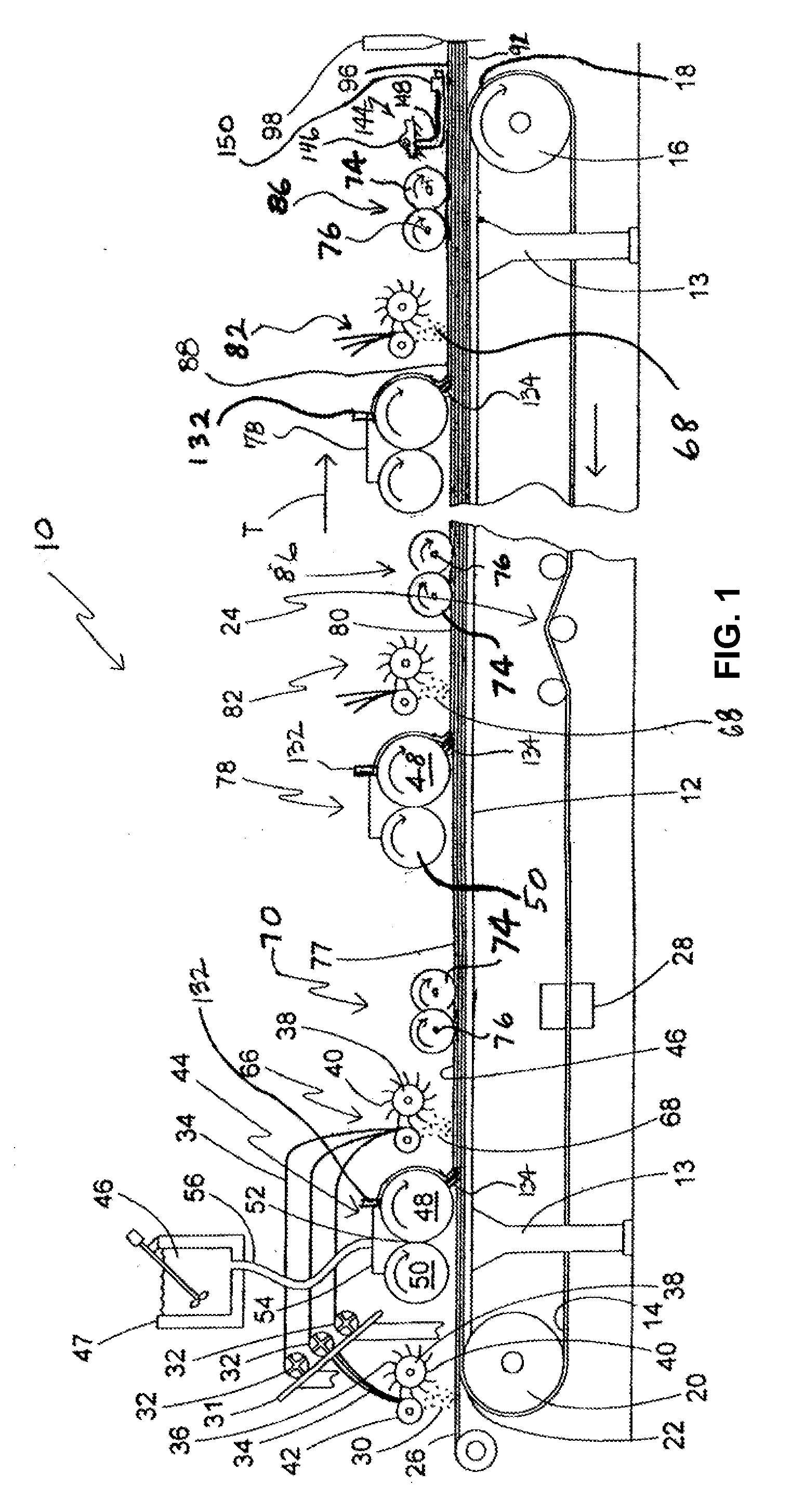

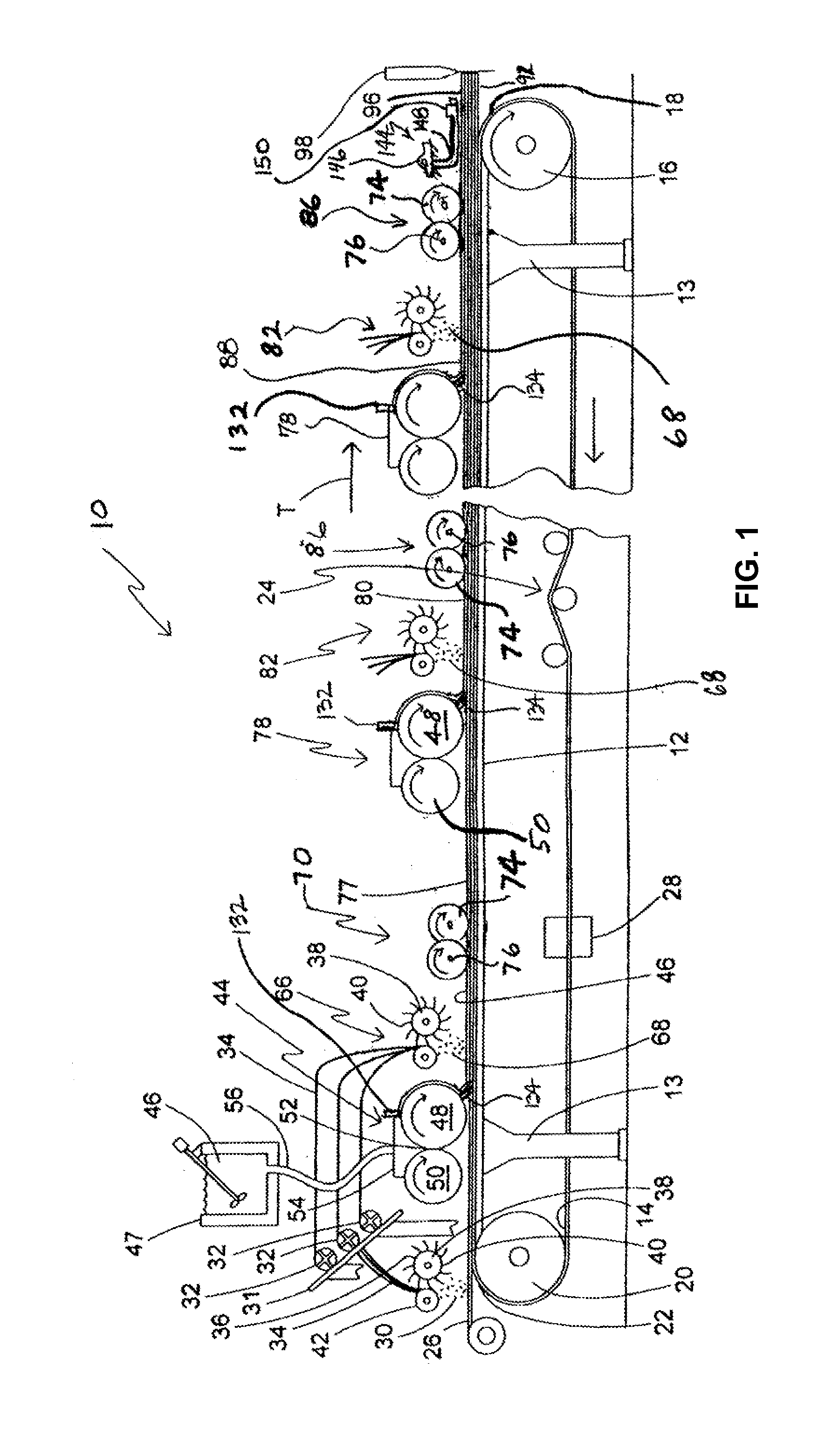

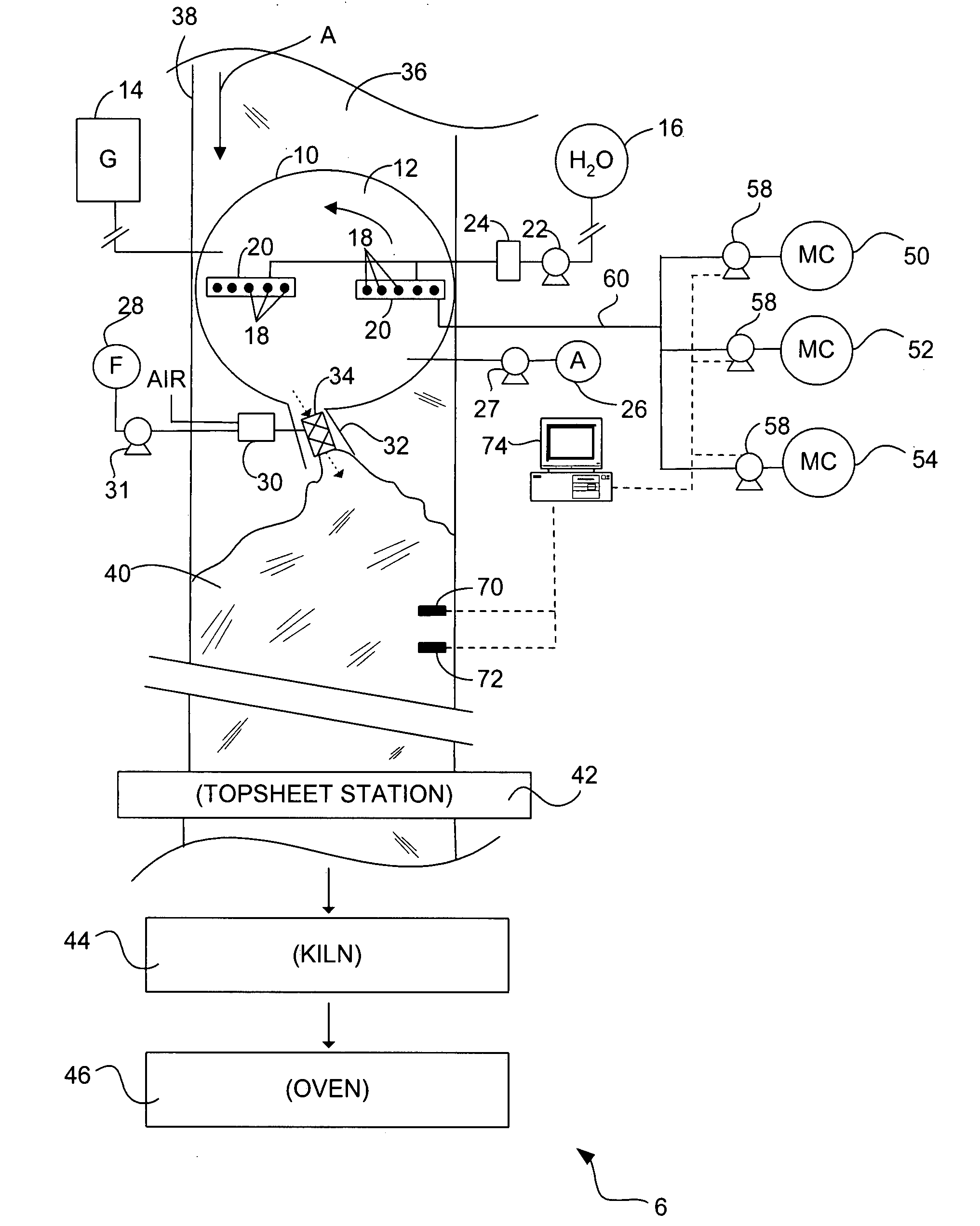

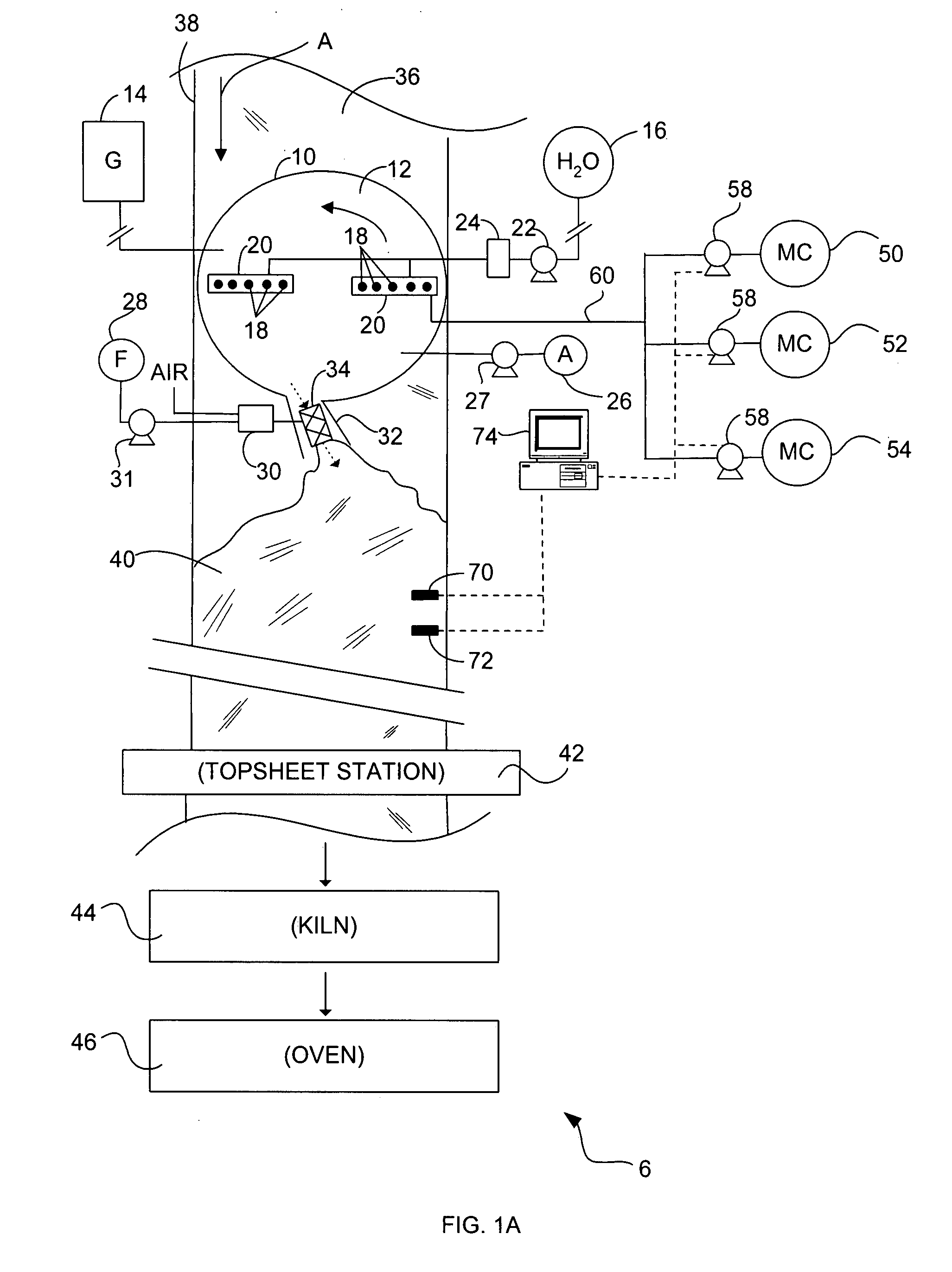

Panel smoothing process and apparatus for forming a smooth continuous surface on fiber-reinforced structural cement panels

InactiveUS20080099133A1Remove pock marks or groovesA large amountSolid waste managementTransportation and packagingProduction lineSurface layer

A vibrating flexible smoothing sheet or shroud disposed transversely of a direction of travel of a formed fiber panel including gypsum-cementitious slurry and embedded chopped fibers. The sheet is used to smooth the surface of the panel as it exits a fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to reduce the need for costly finishing after the panels are cured and cut to size. The flexible sheet is designed to float over the surface of the formed panel without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the panel. The vibrating sheet is pivotally mounted on the side dams of the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

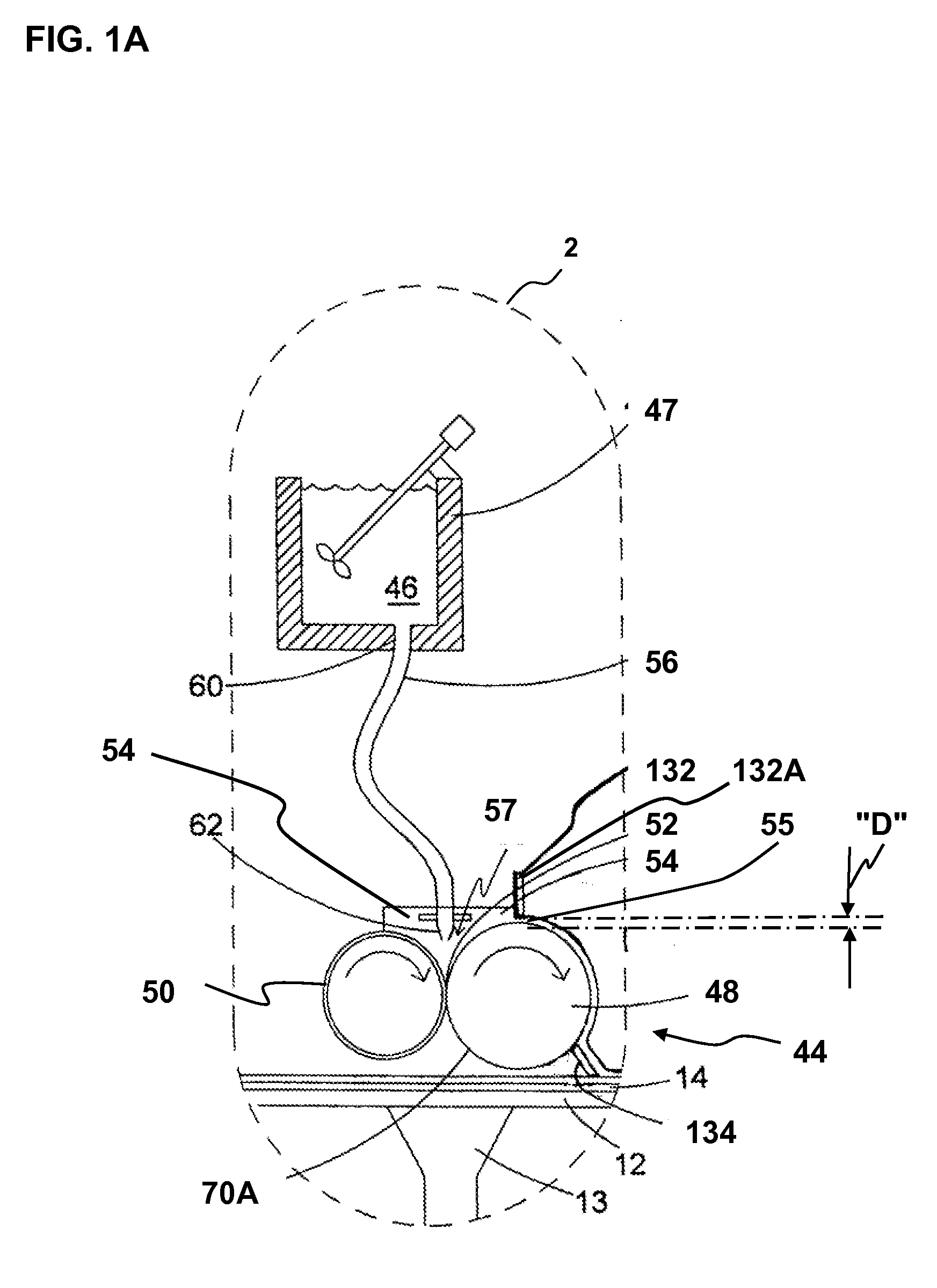

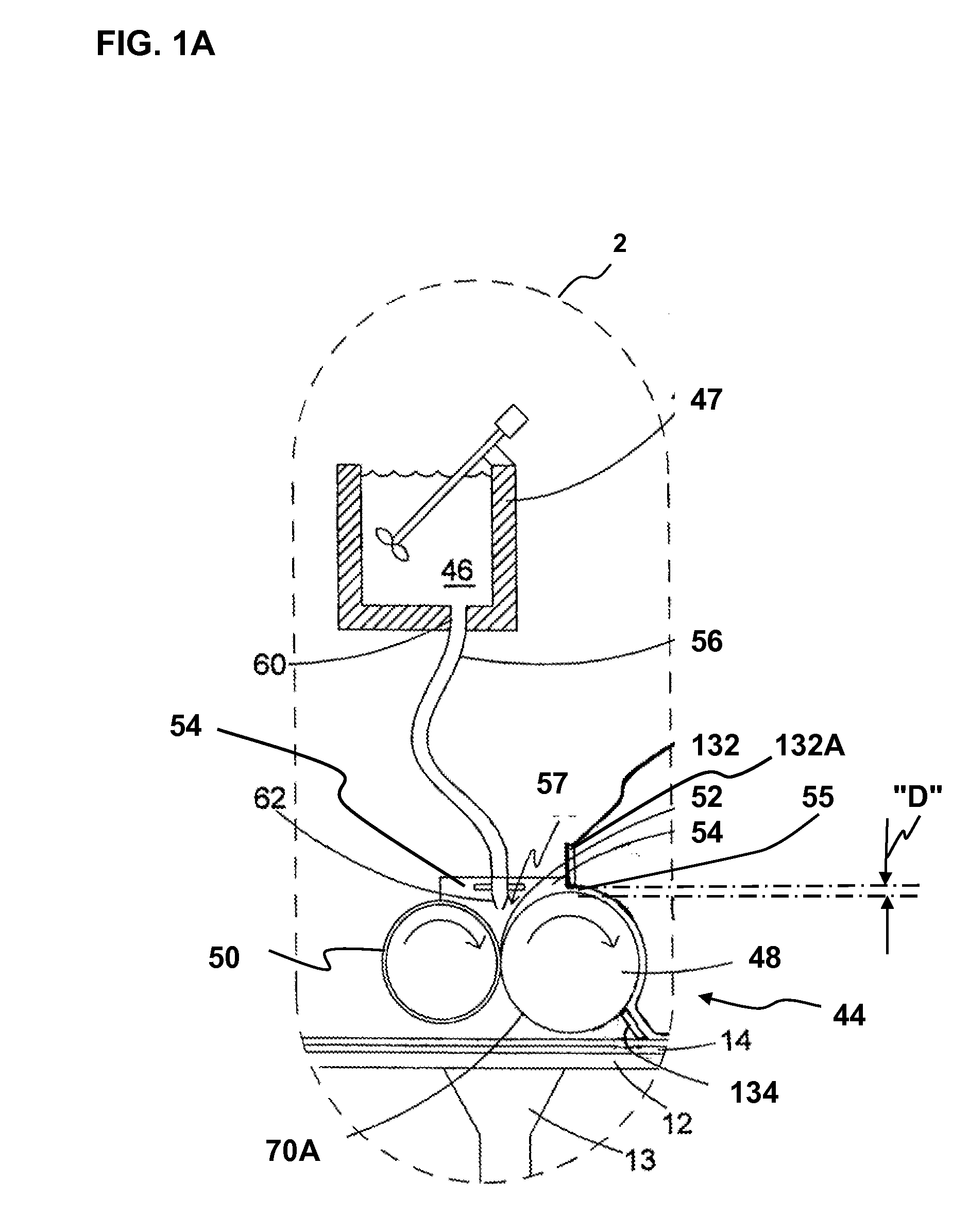

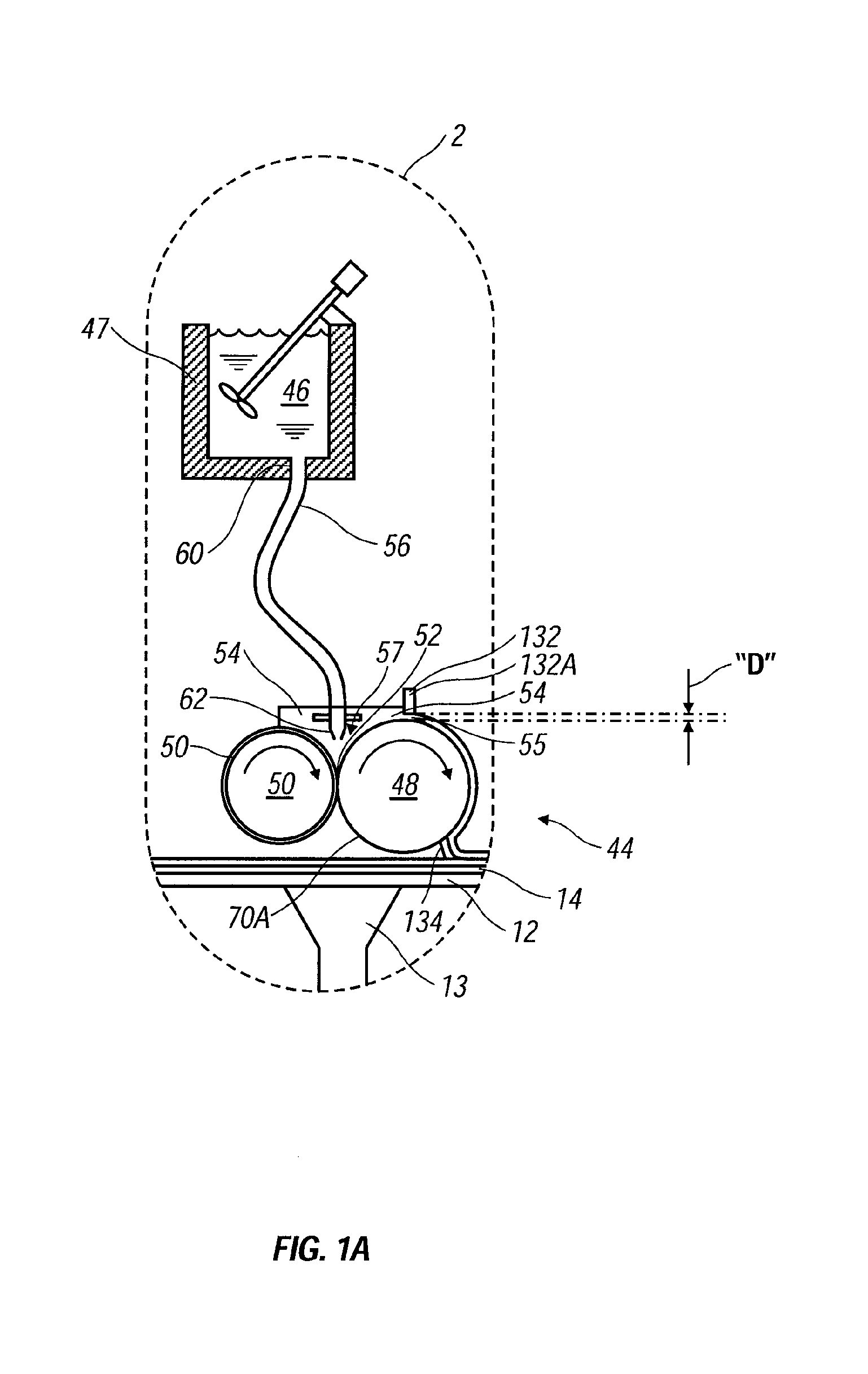

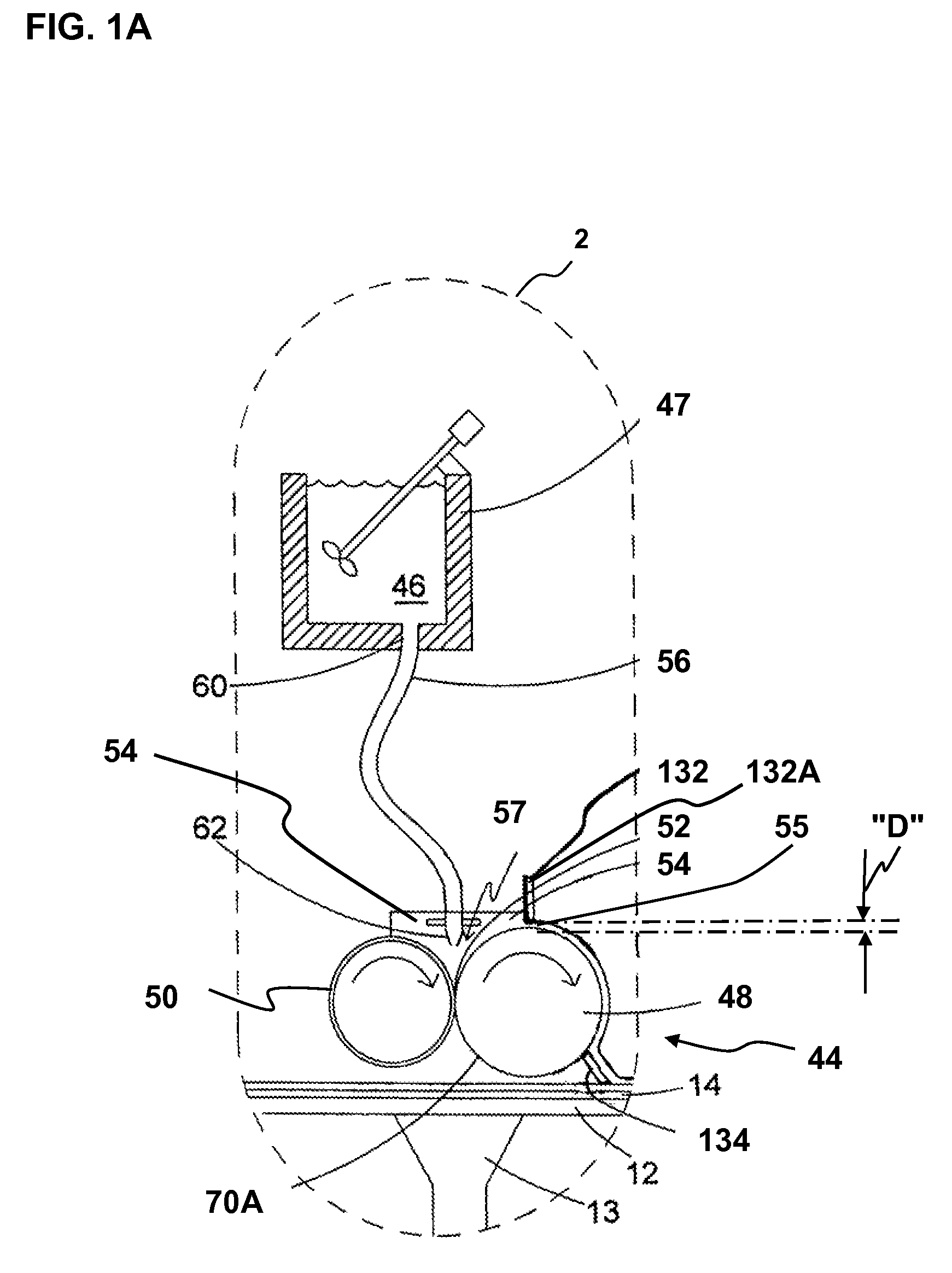

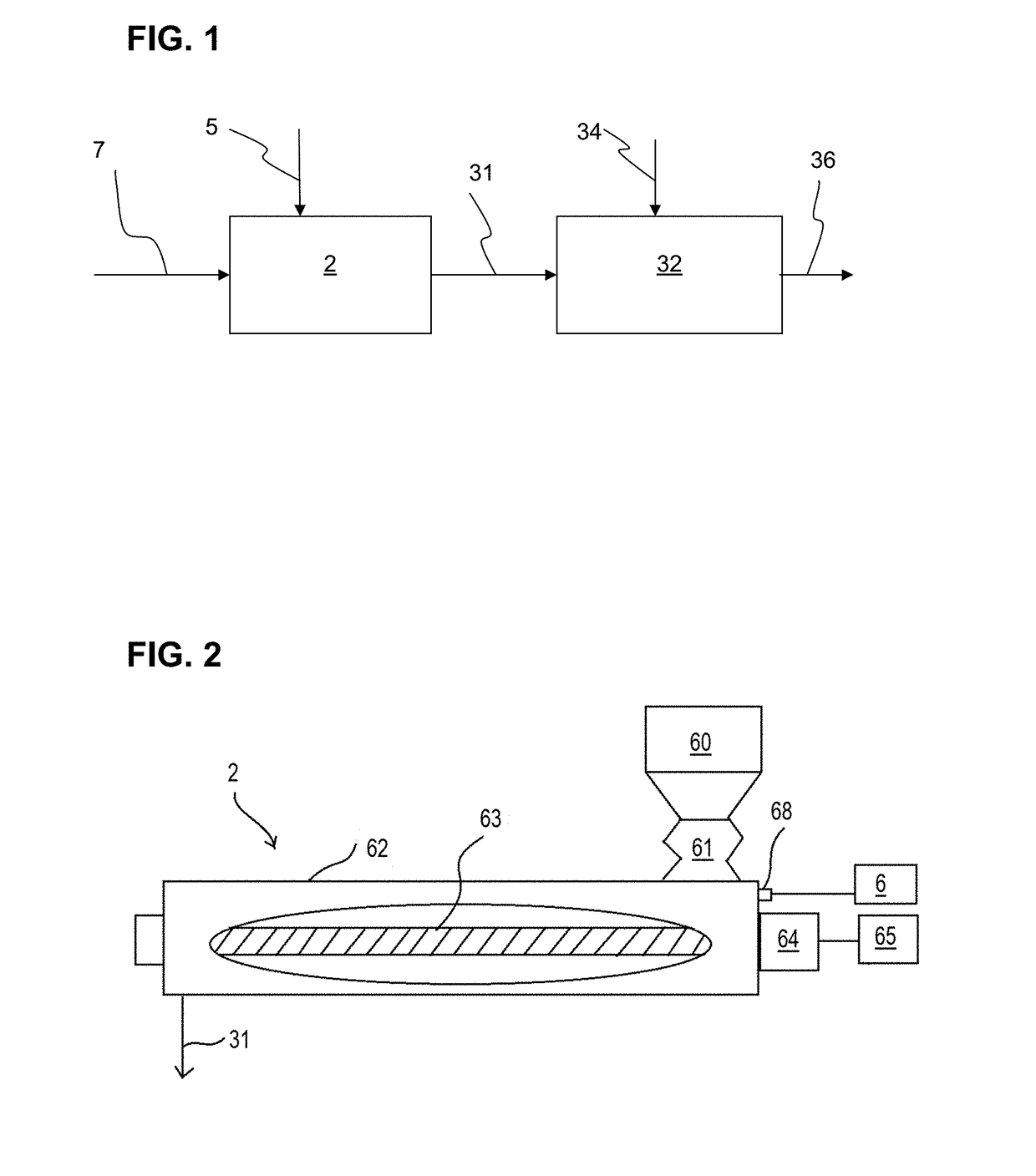

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS20080101150A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed means for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS8989905B2Easy to useThermometer detailsTransportation and packagingDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

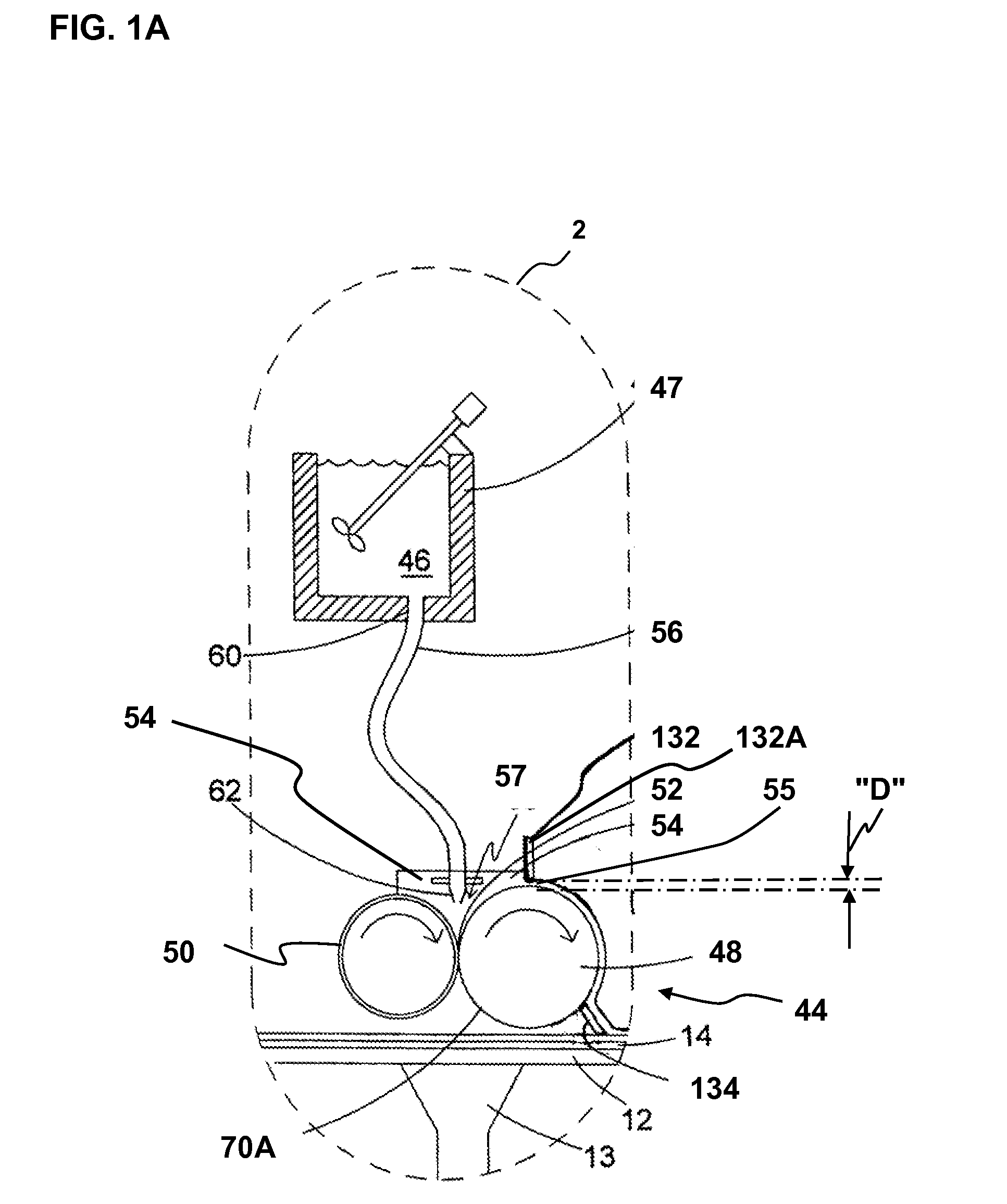

Apparatus and method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080101151A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

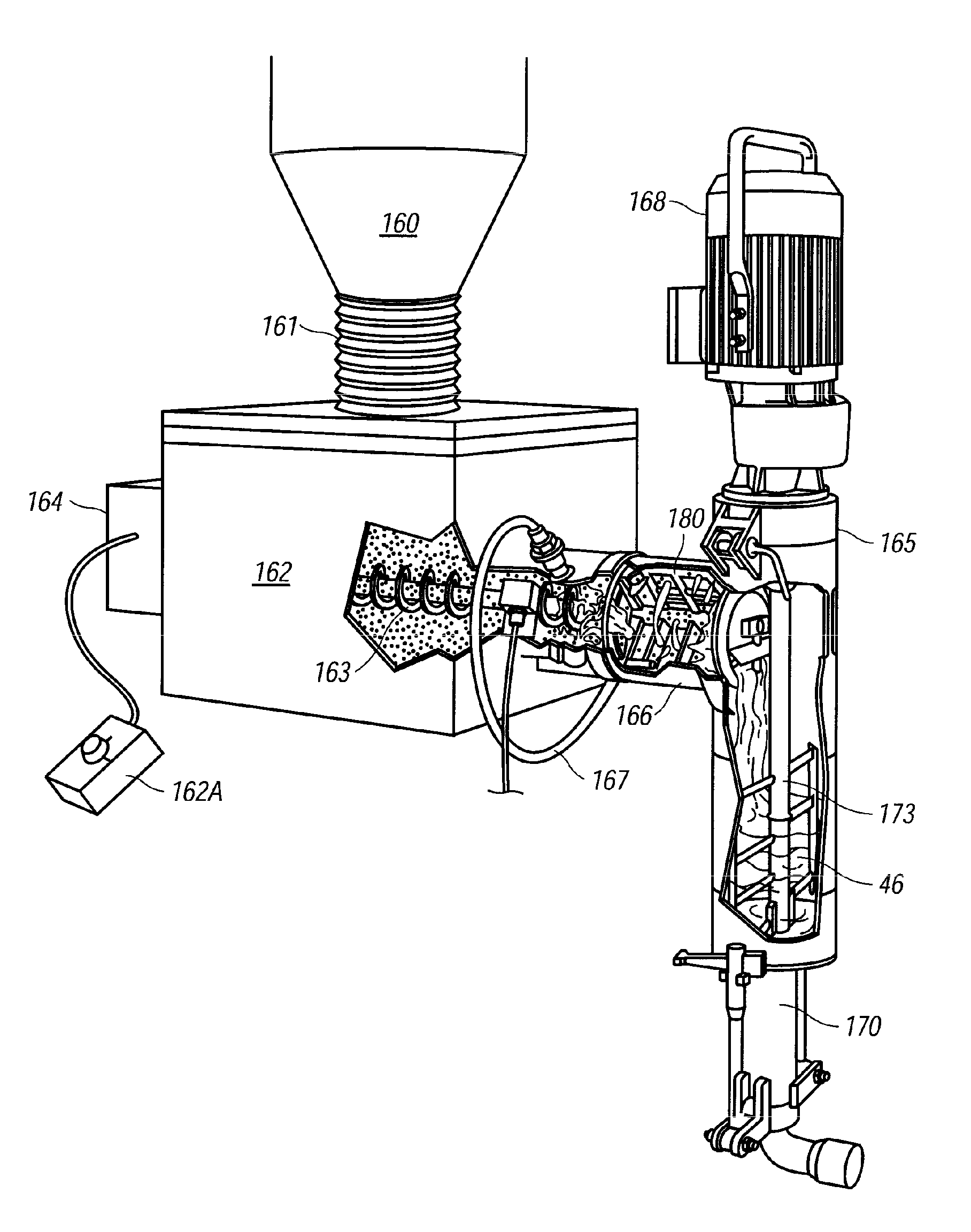

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

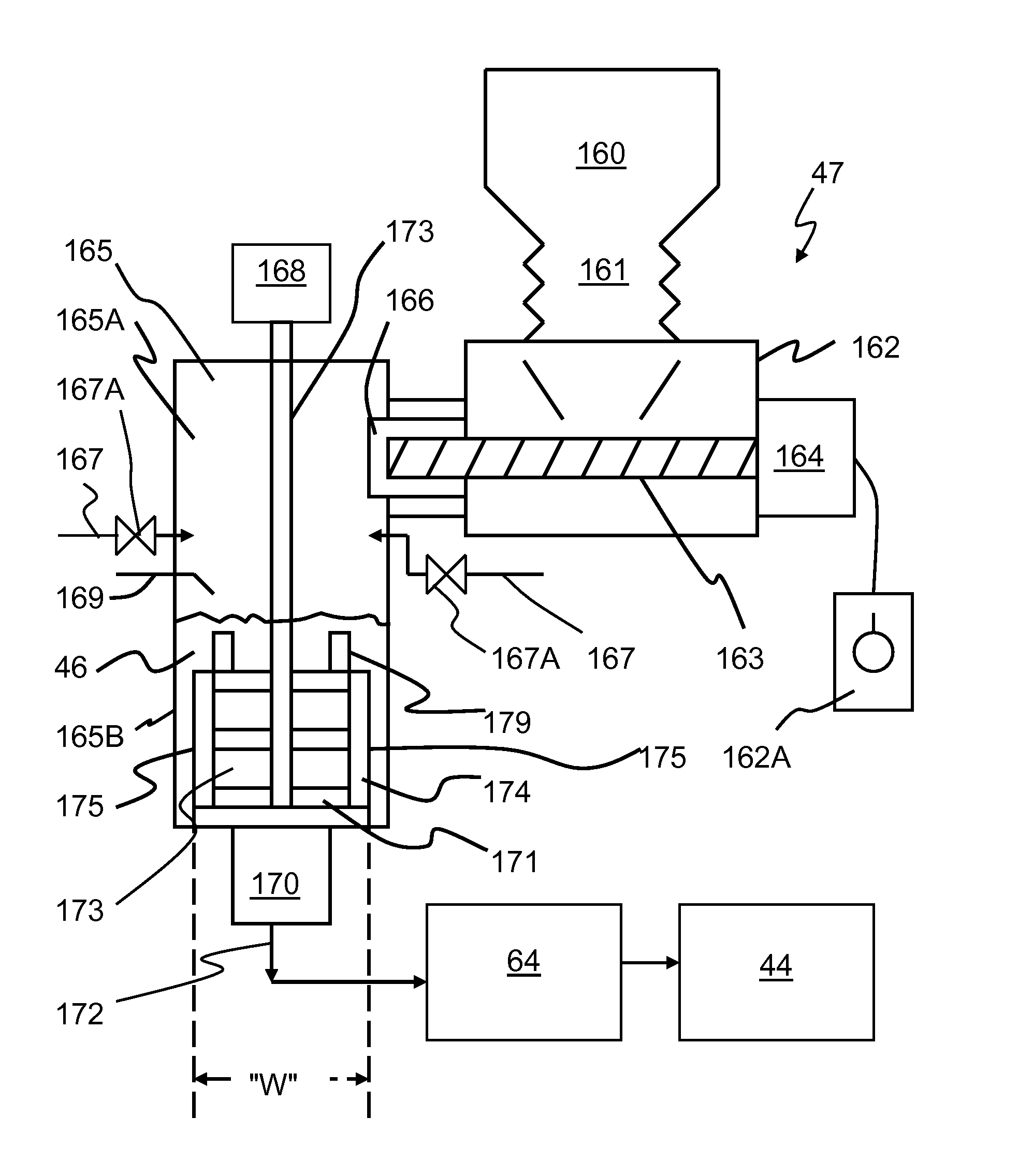

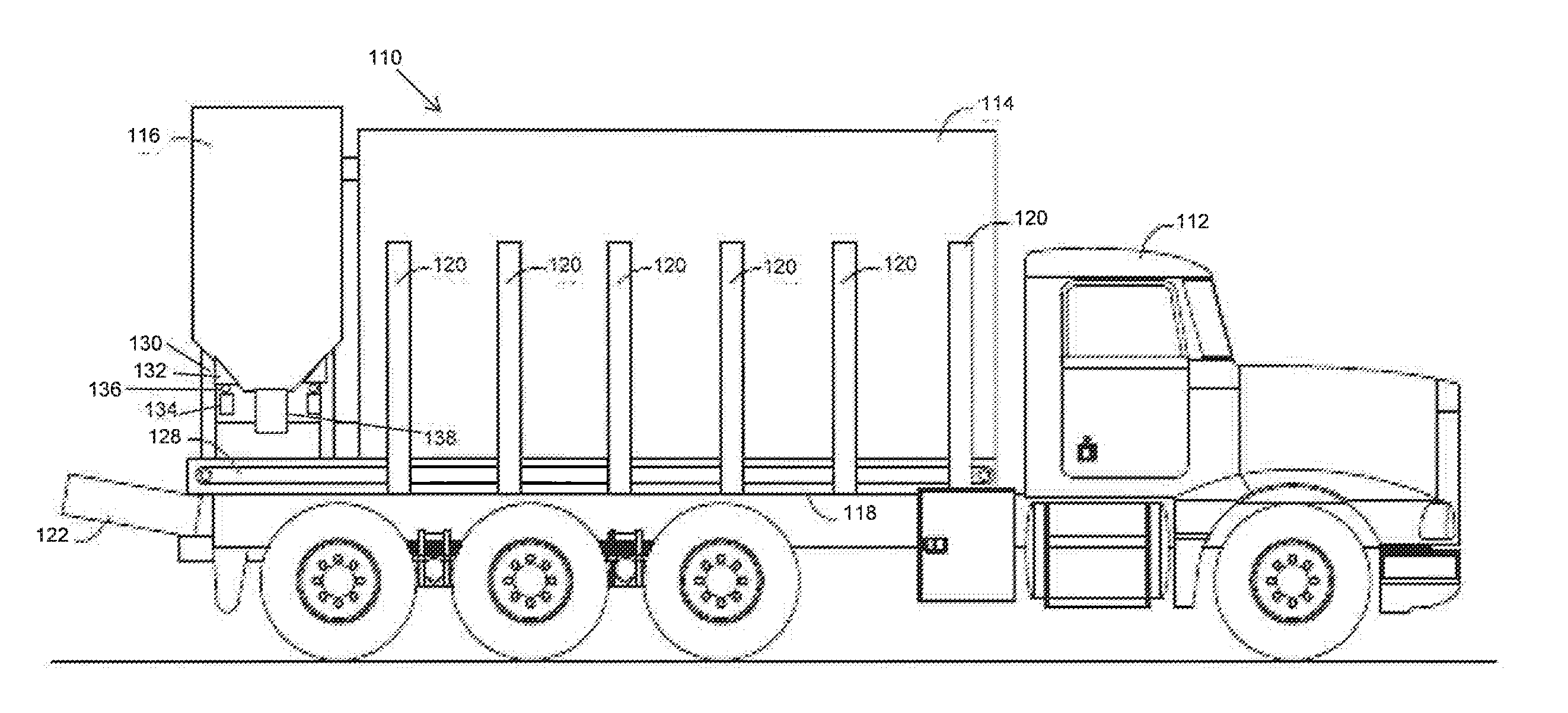

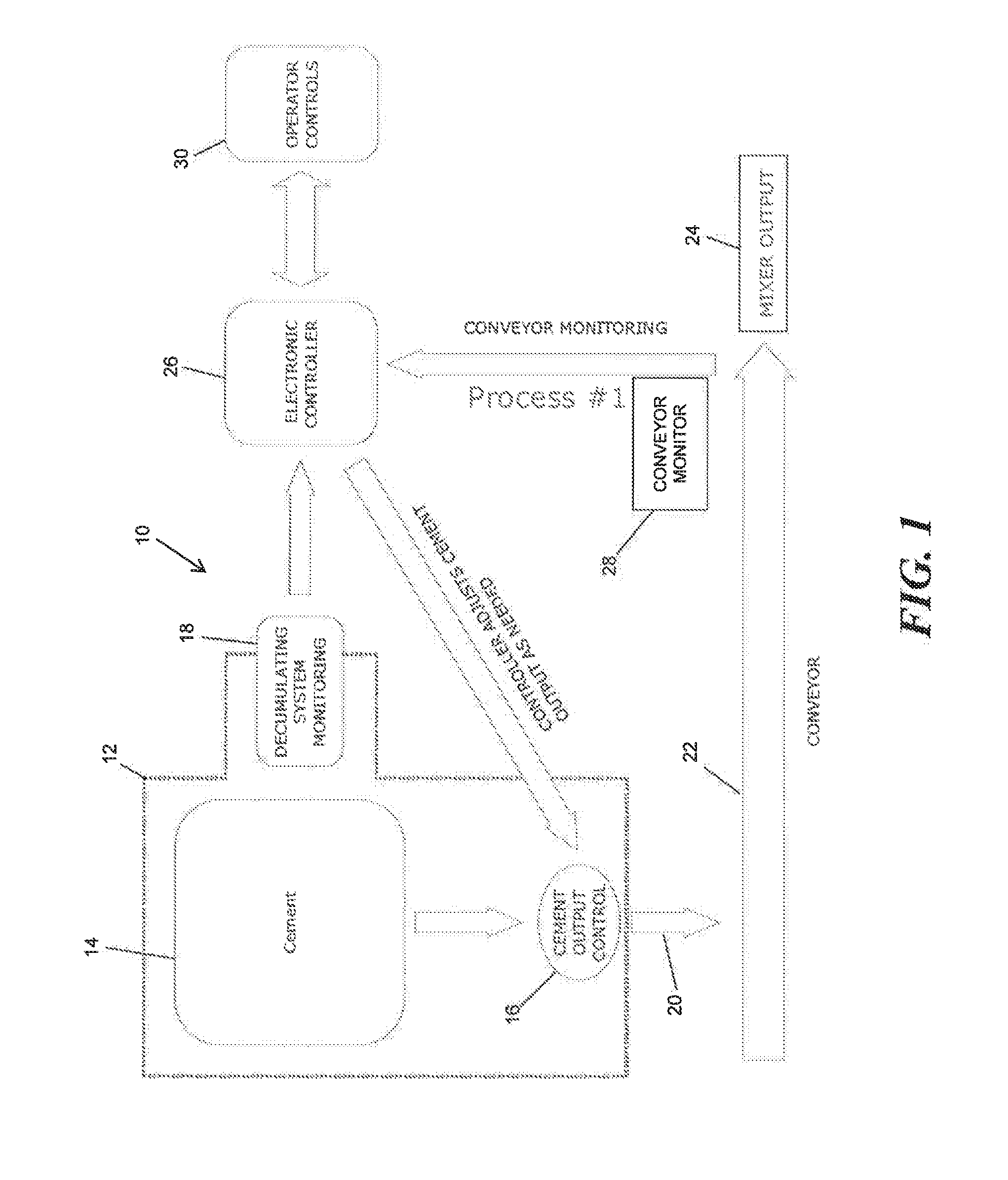

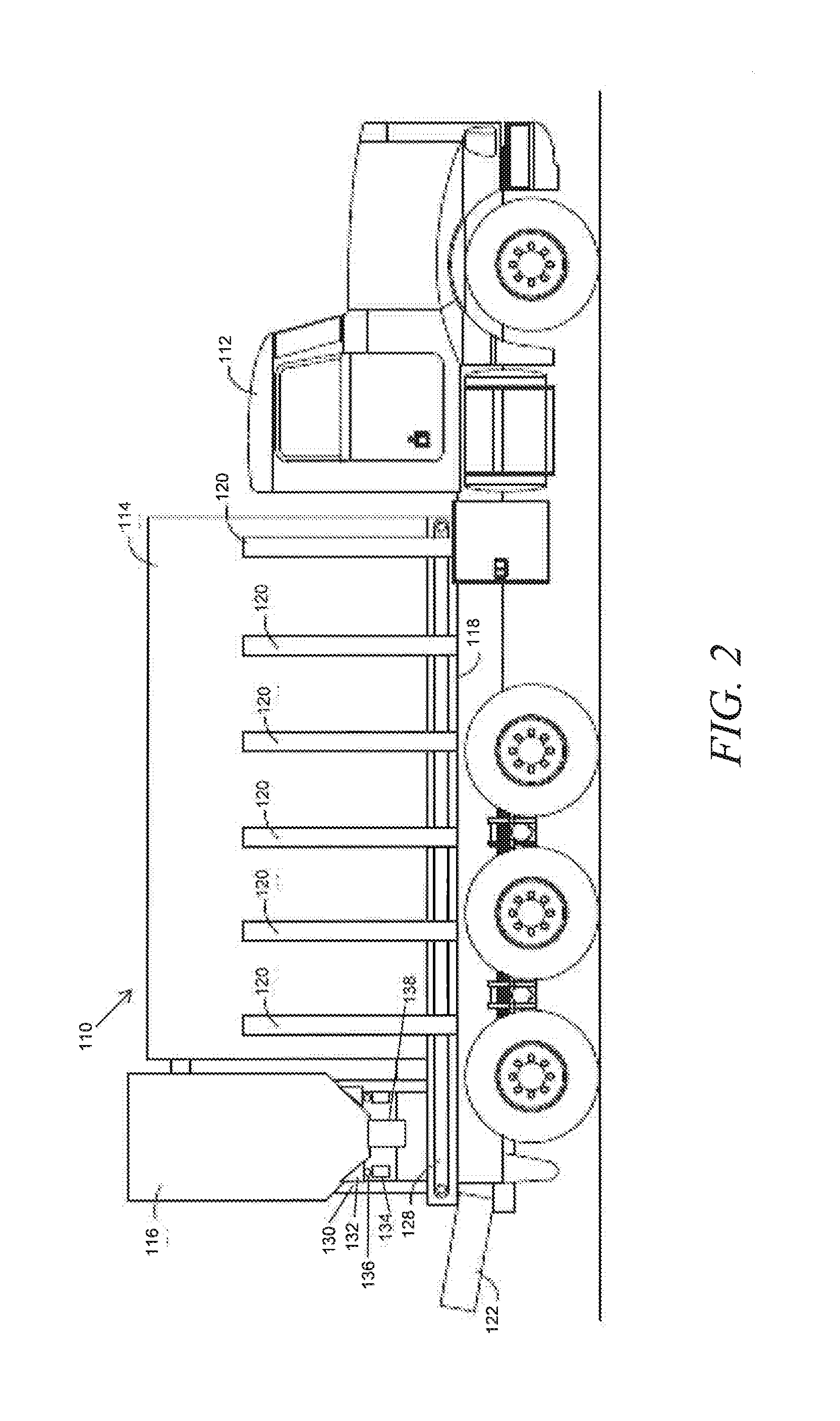

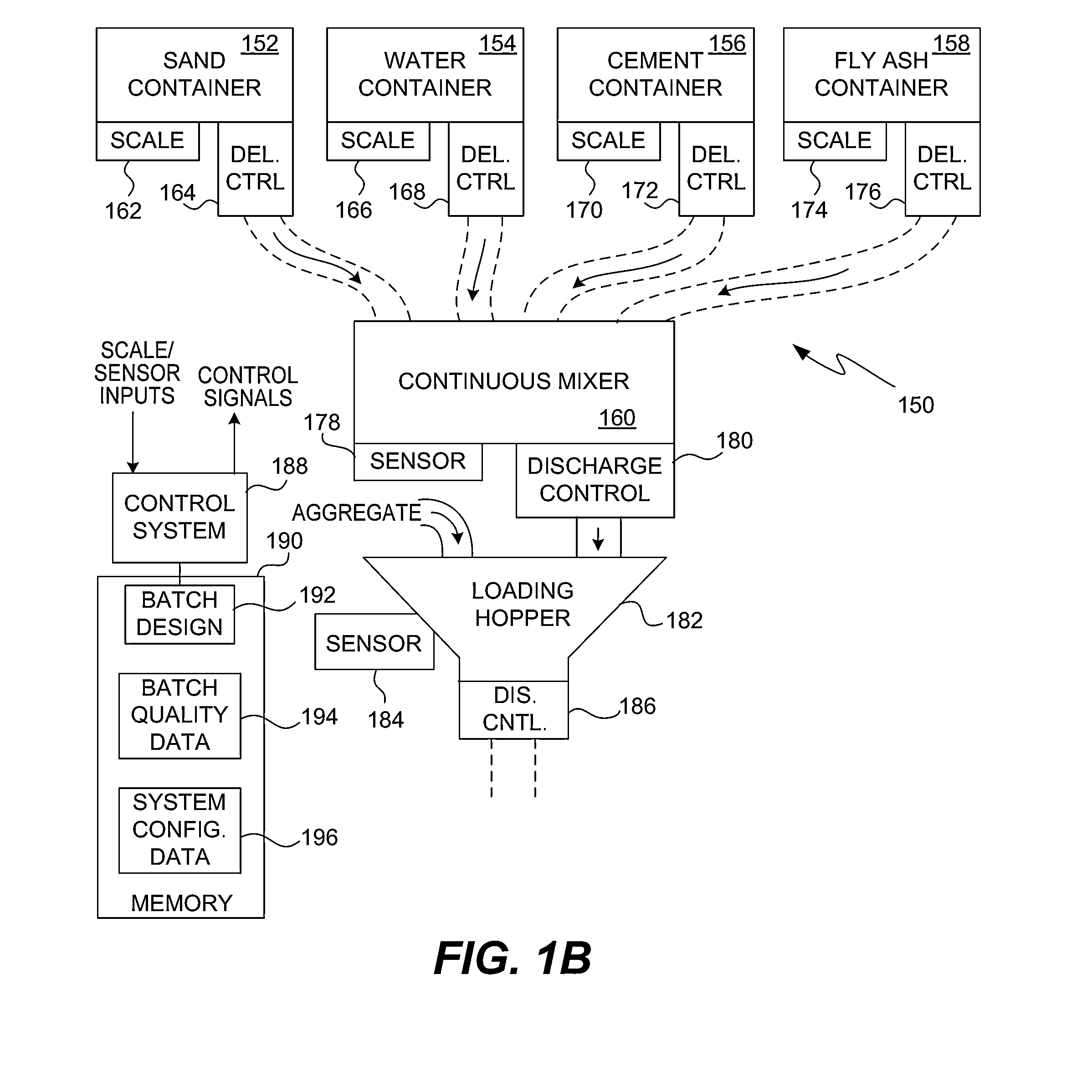

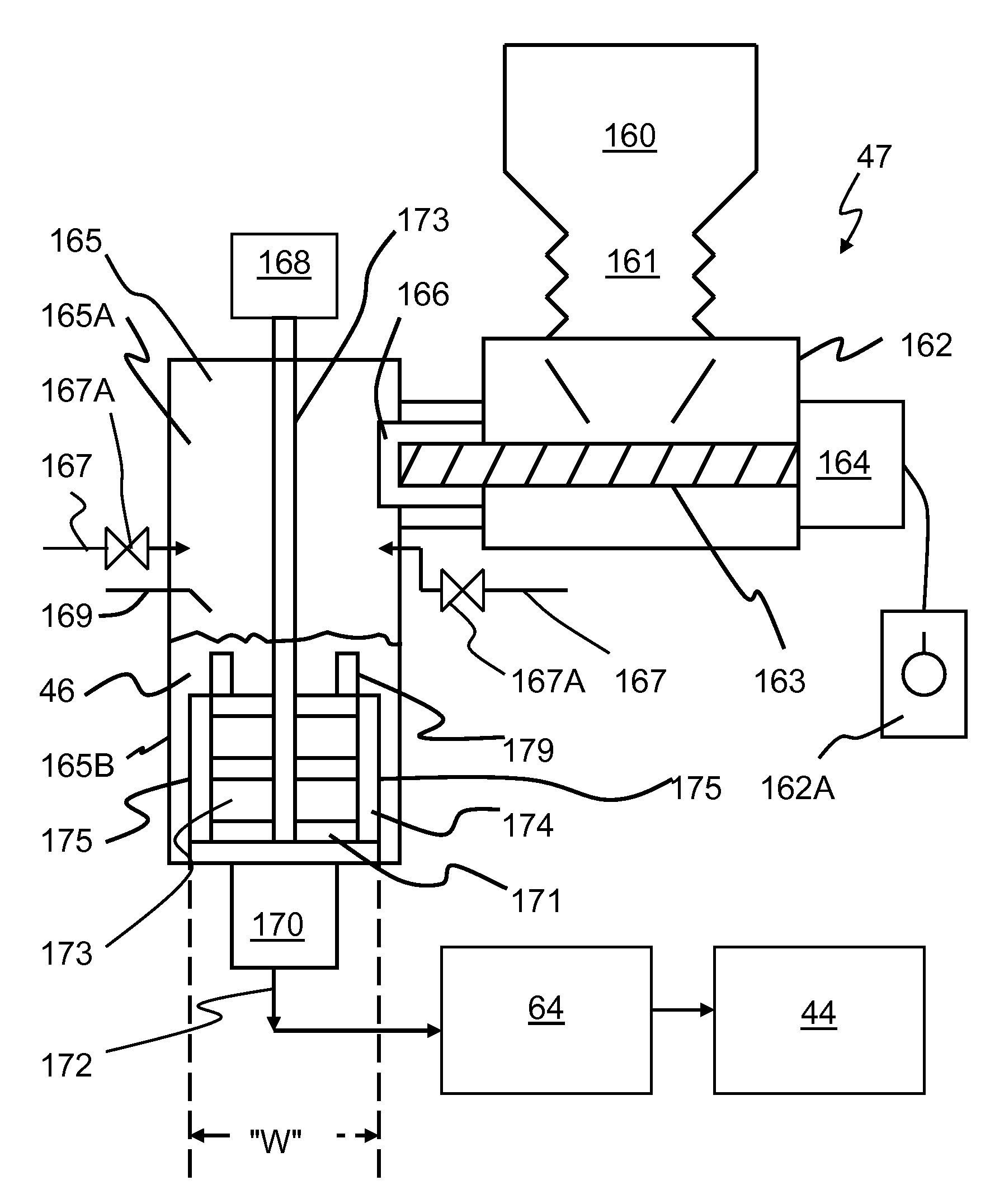

Volumetric mixer with monitoring system and control system

InactiveUS20160221220A1Uniform ratioEasy to controlIngredients proportioning apparatusCement mixing apparatusControl systemMonitoring system

A volumetric concrete mixer includes a monitoring and control system that assures a uniform amount of cement per unit of aggregate. A processor is in communication to receive an input of a weight of a cement bin from a cement bin load cell and in communication to receive an input of a number of rotations of a conveyor from an aggregate sensor. The processor is adapted to determine a rate of change of weight of the cement bin over a set number of rotations of the conveyor, and to instruct the cement dispenser to adjust the cement dispenser speed to maintain a constant rate of cement being dispensed from the dispenser bin to the mixing area per the set number of rotations of the conveyor.

Owner:OMEGA CM DELTA LLC

Dry Mix Cement Composition, Methods and Systems Involving Same

InactiveUS20090071374A1Modifies strengthEnhances polymerisationSolid waste managementAlkali metal silicate coatingsMulti phaseMaterials science

A dry mix cement composition including an alkaline multi-phase aluminosilicate material, wherein the alkaline multi-phase aluminosilicate material provides a source of alkaline and soluble silicate to the cement composition.

Owner:ZEOBOND RES

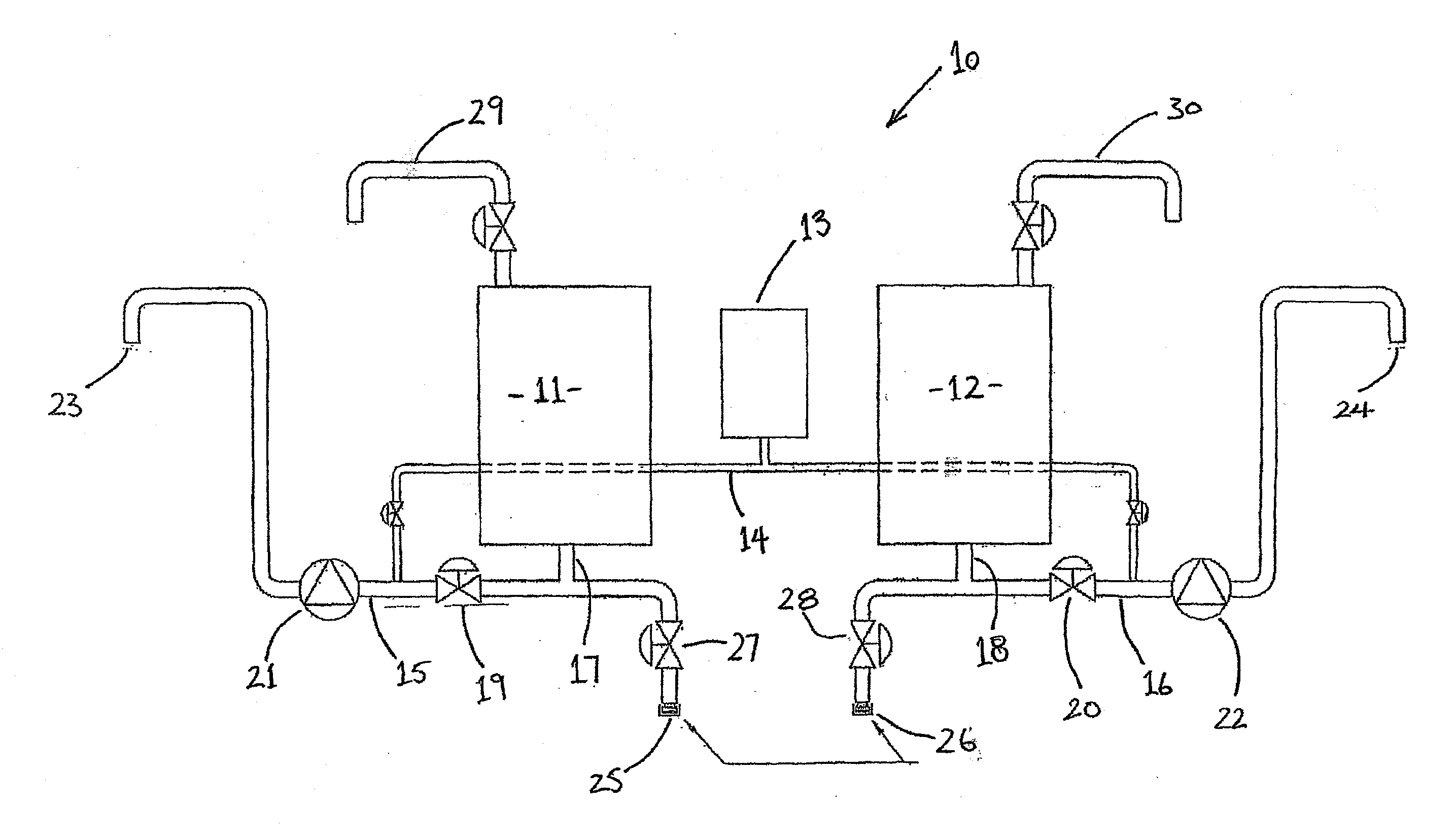

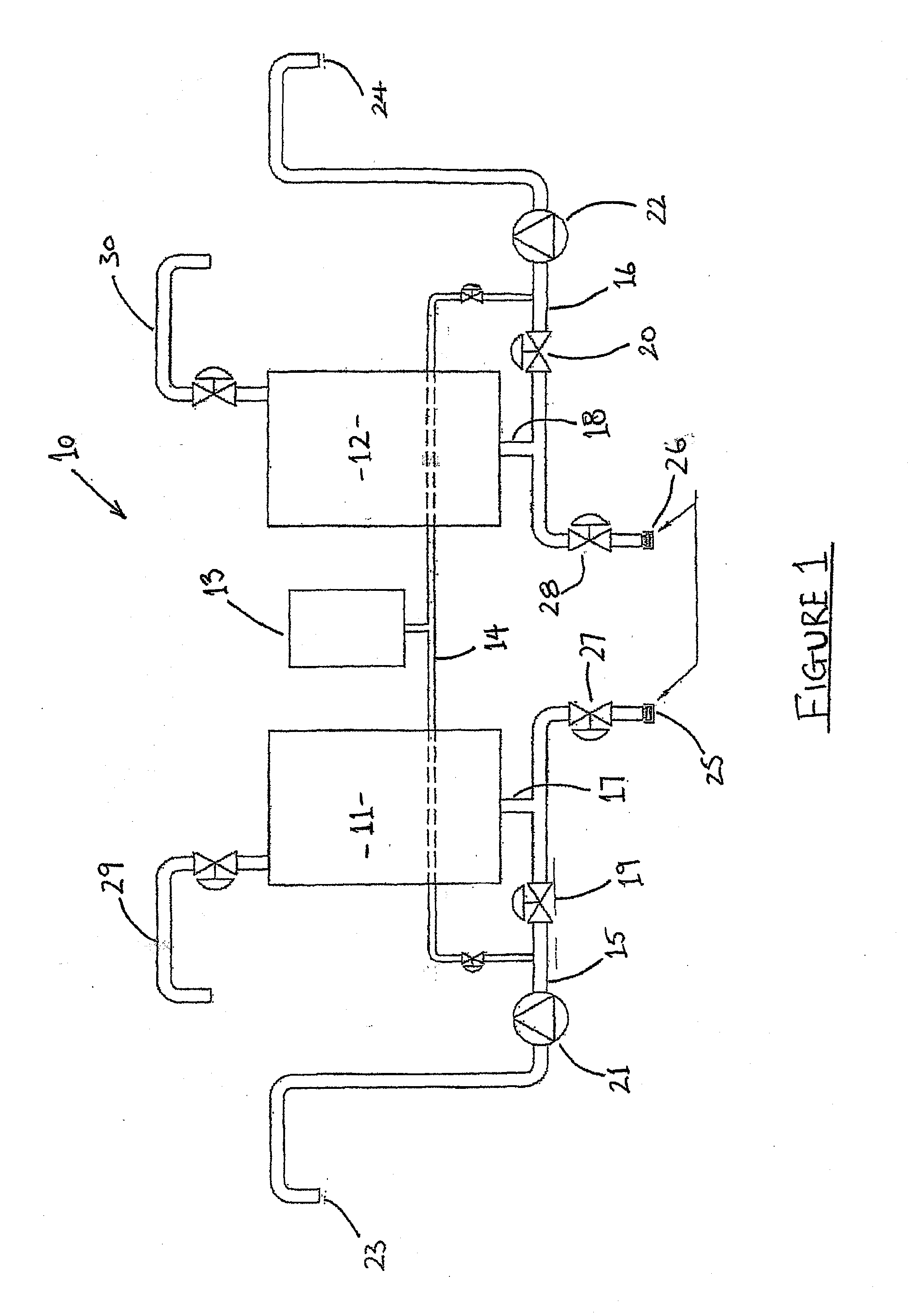

Methods and systems for addition of cellulose ether to gypsum slurry

An example system for making a gypsum board product comprises a container for containing a gypsum slurry, a moving receiver in communication with the container, wherein the container substantially continuously deposits the gypsum slurry on the moving receiver. A first and at least a second cellulose ether supply containing a first cellulose ether communicate with the container. The first and second supplies contain cellulose ethers having different physical or chemical properties. A controller is configured to change the amount of the first and second cellulose ethers delivered to the container in response to a change in at least one slurry physical property.

Owner:UNITED STATES GYPSUM CO

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

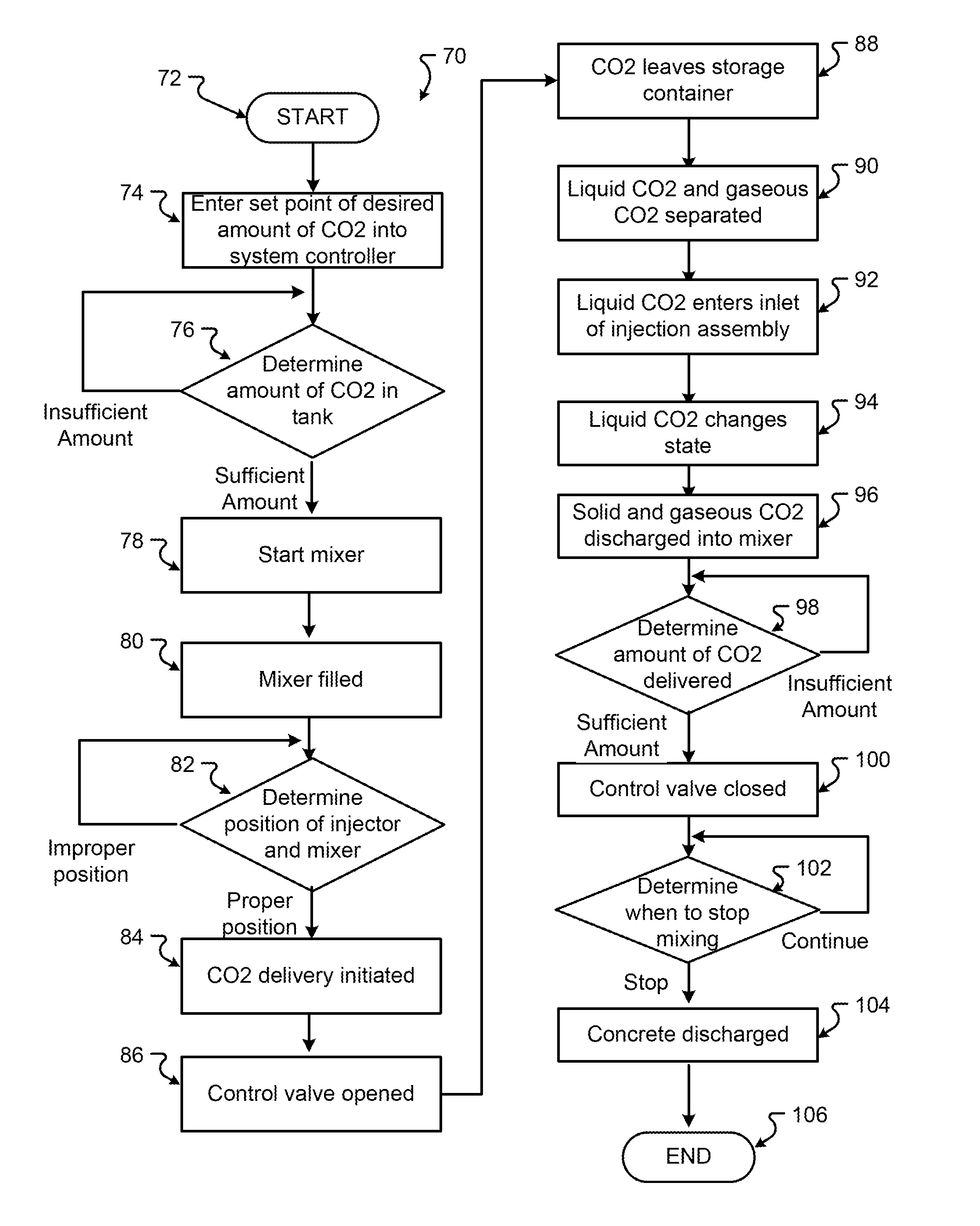

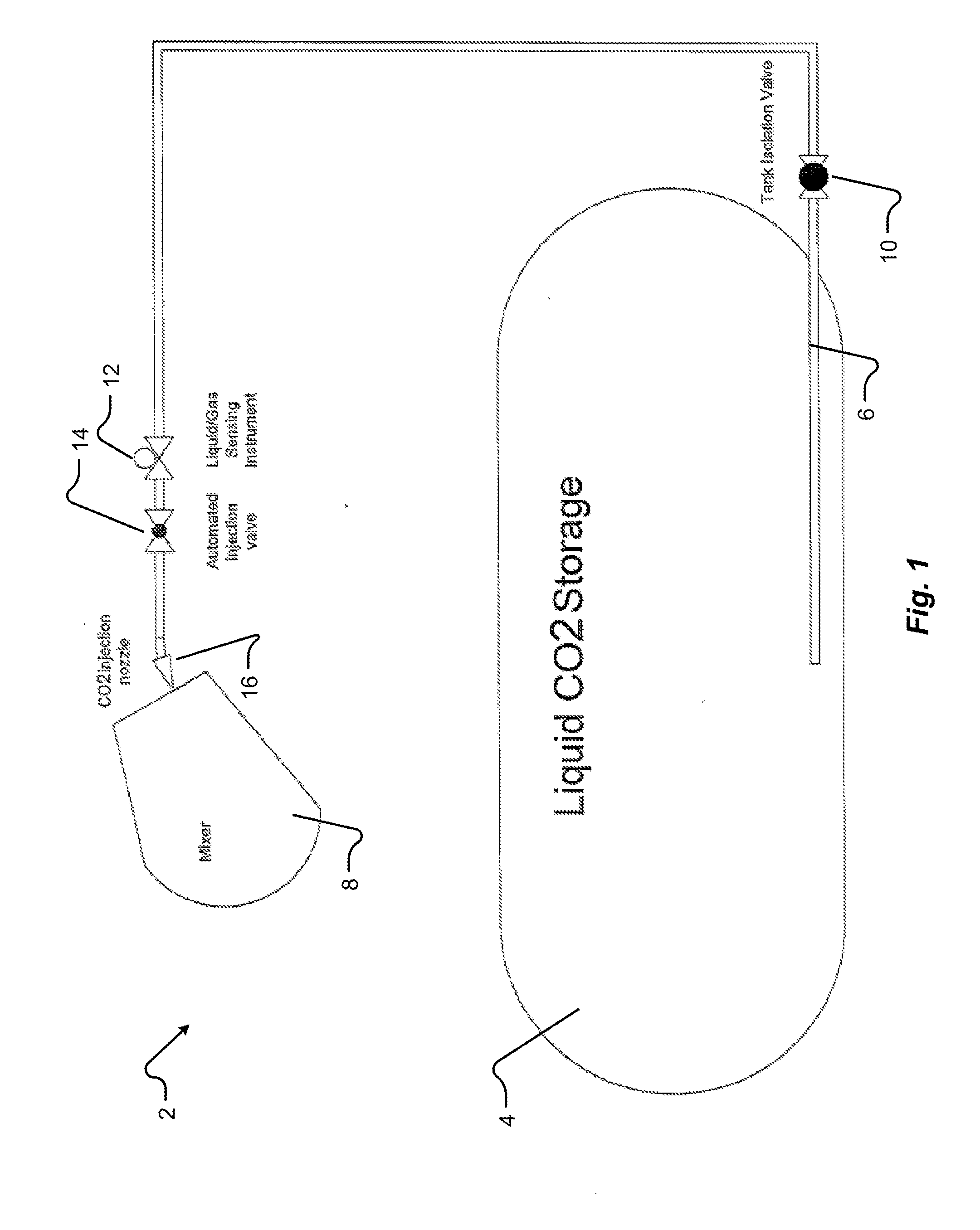

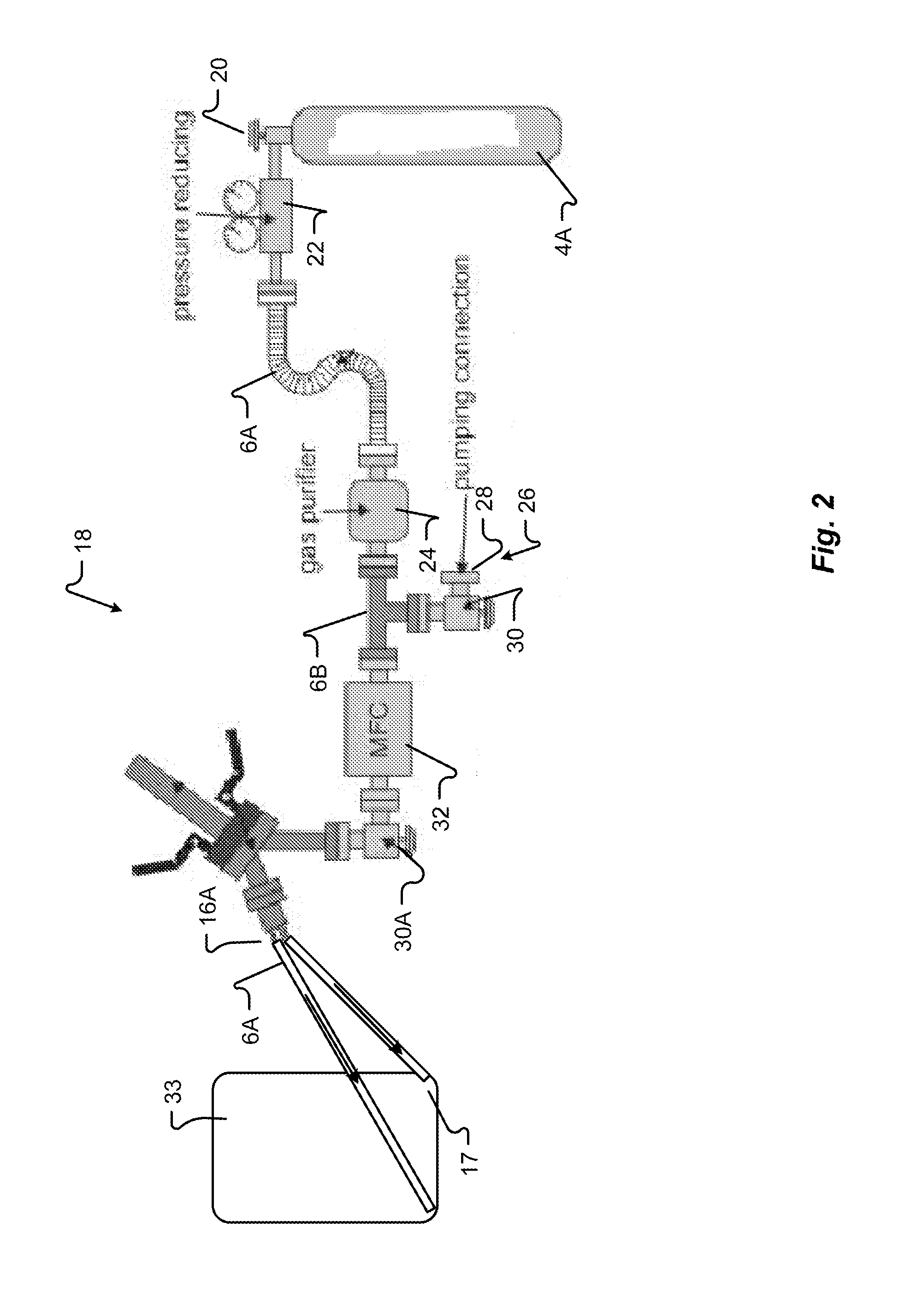

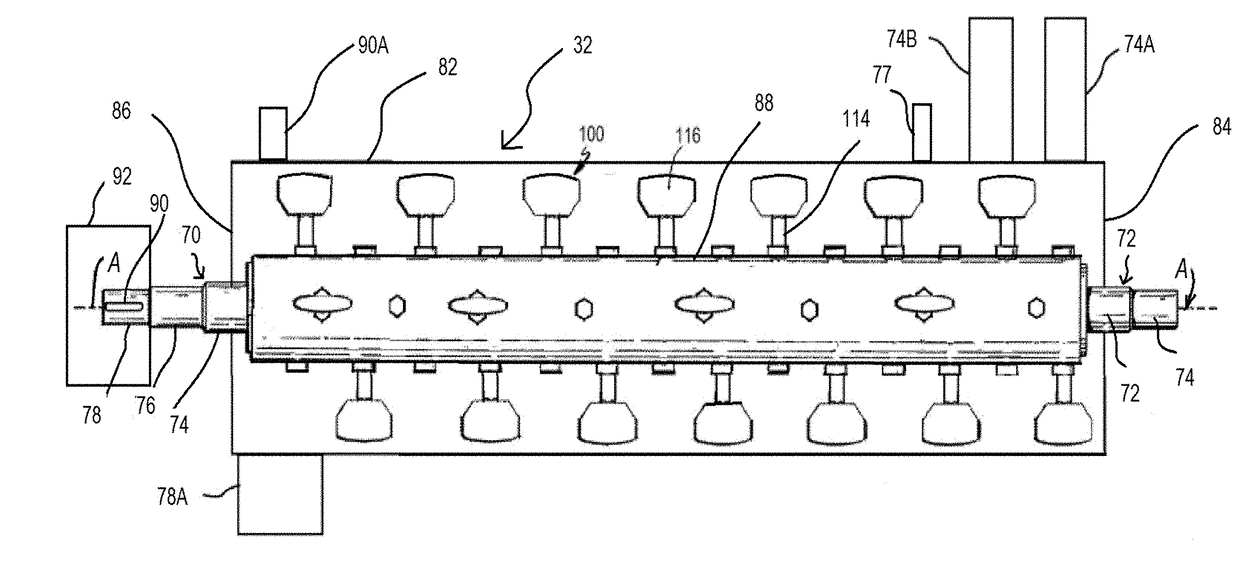

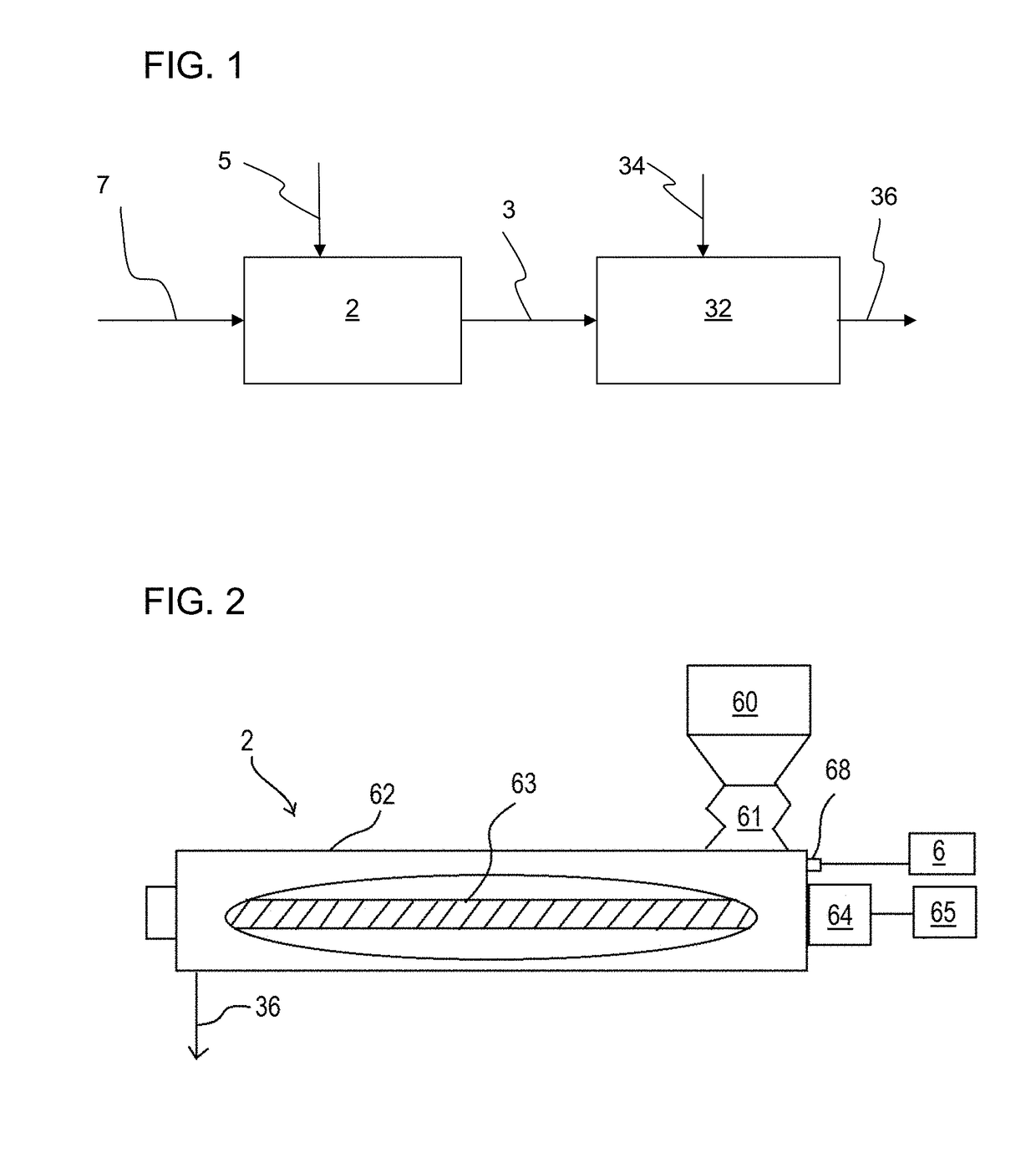

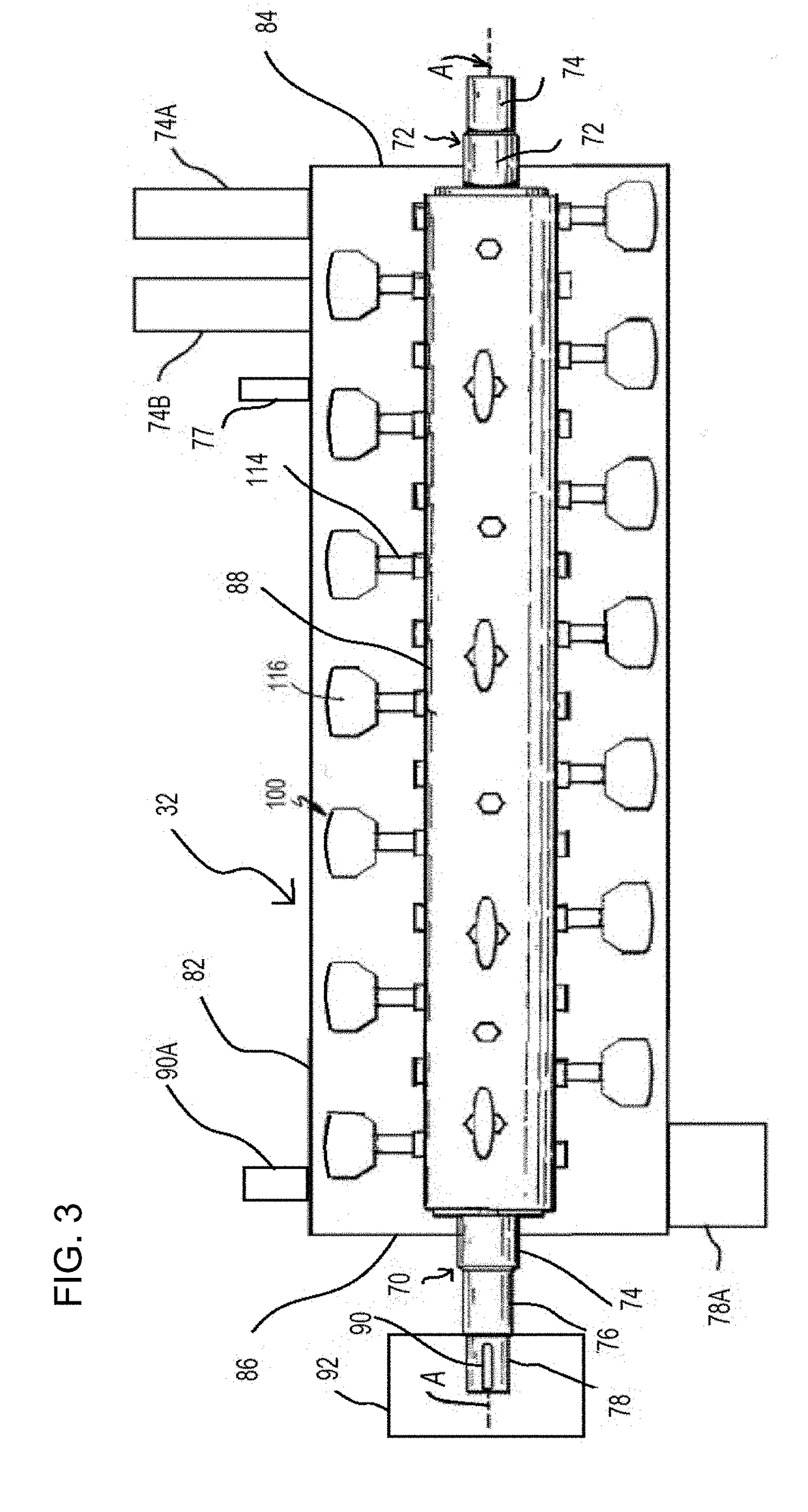

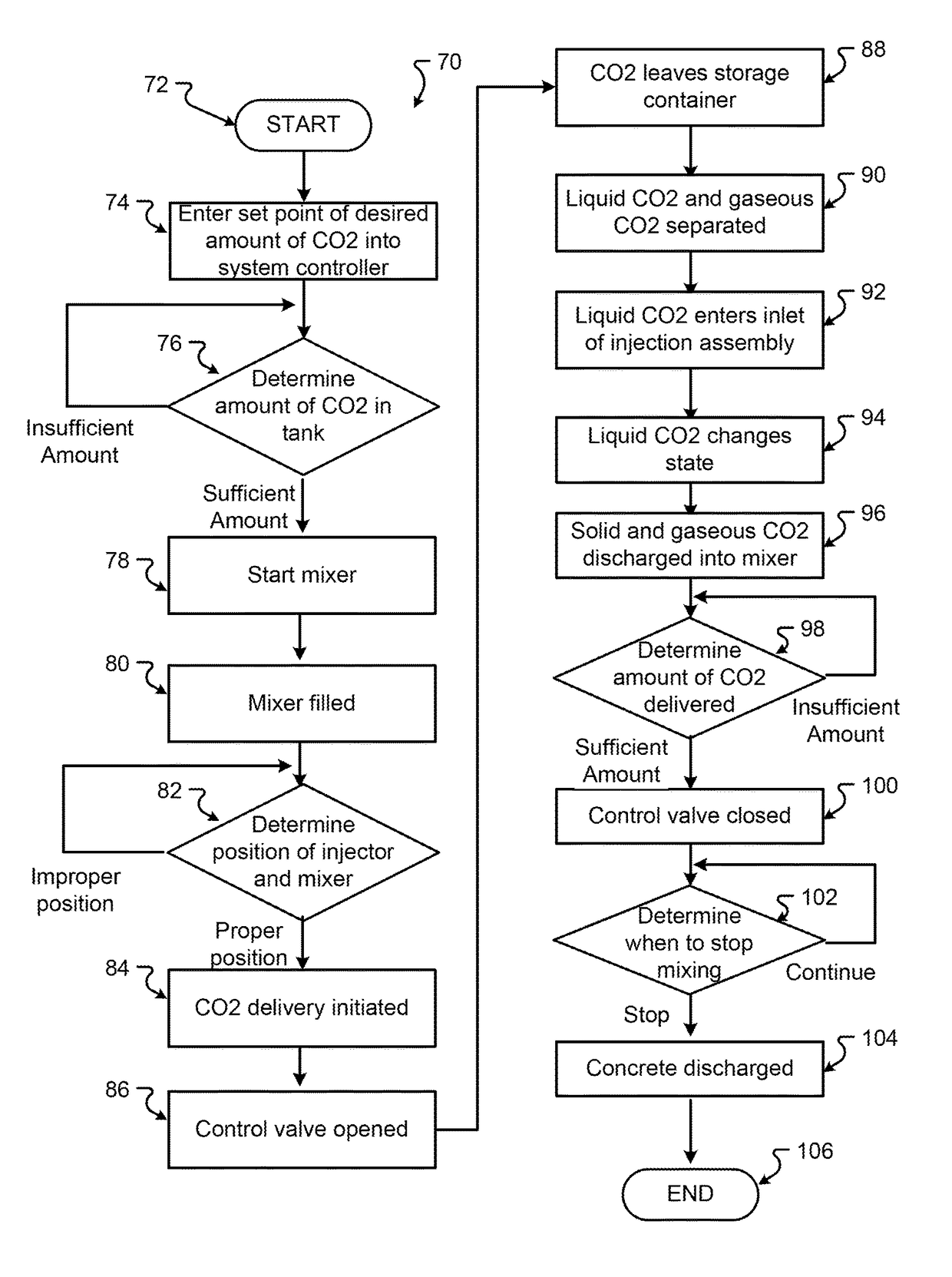

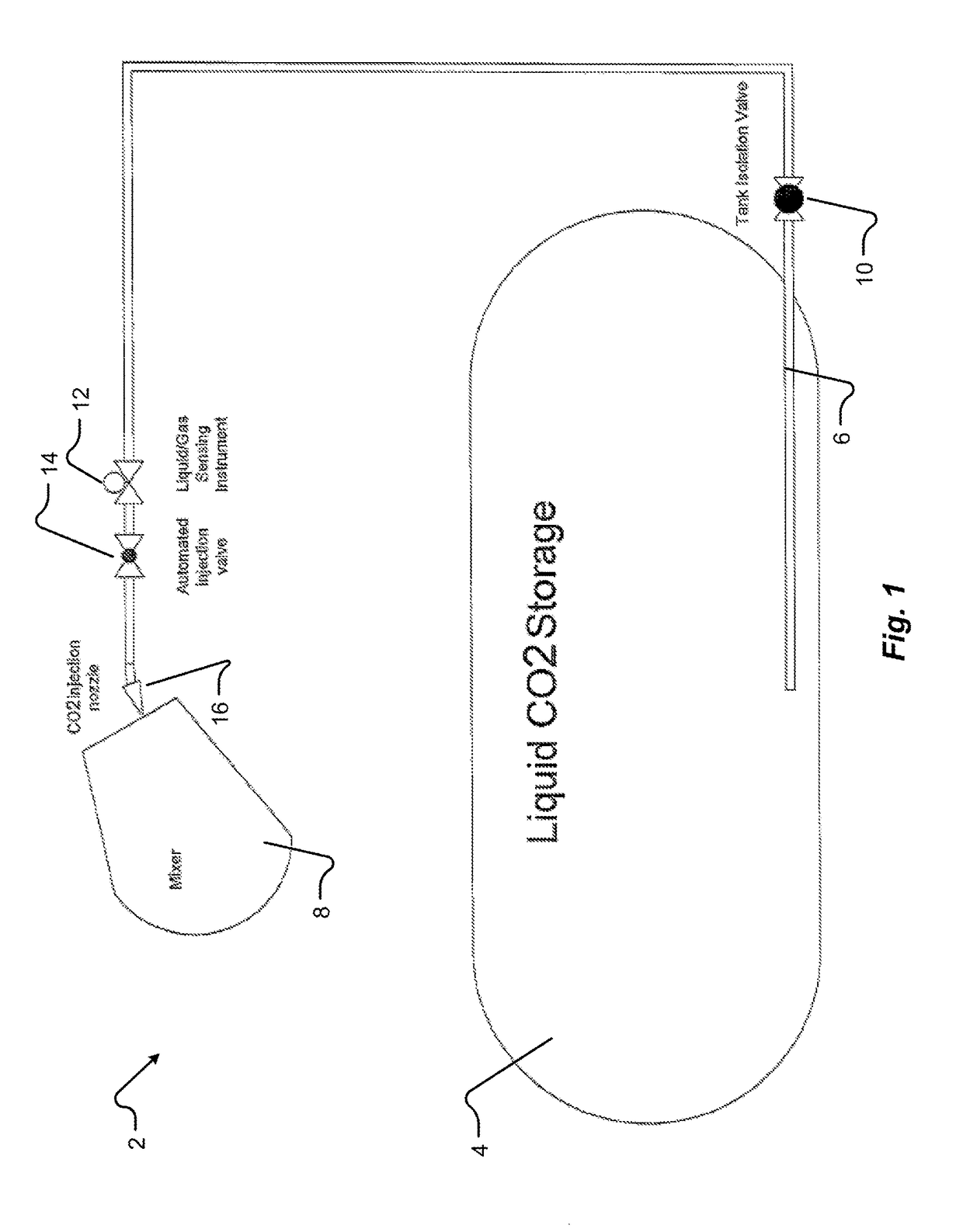

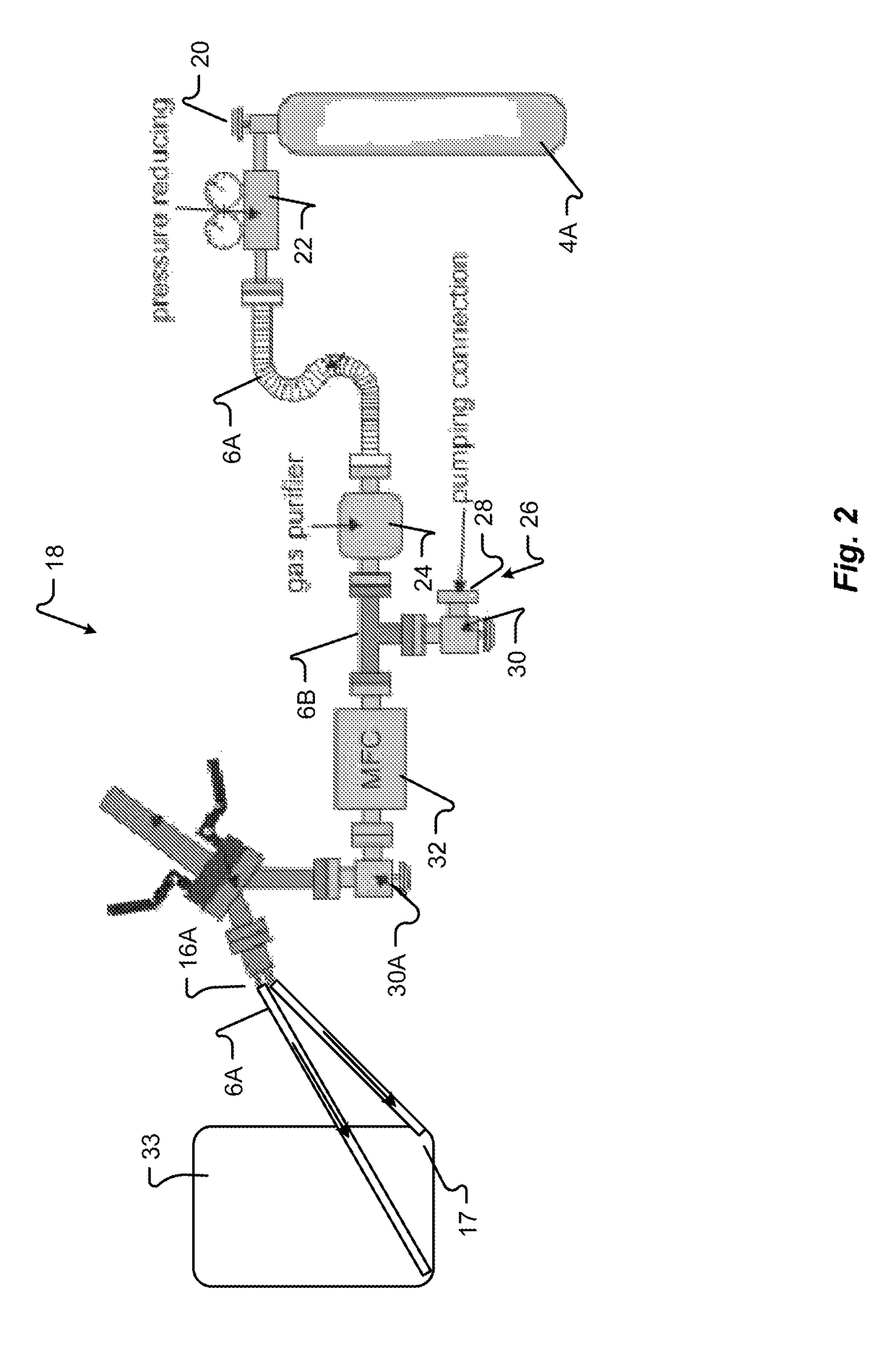

System and method of applying carbon dioxide during the production of concrete

InactiveUS20140216303A1Low costReduce energy consumptionFlow mixersTransportation and packagingMulti materialProcess engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

Portable cement mixing apparatus

InactiveUS20090177313A1Sampled-variable control systemsDigital data processing detailsAdditive ingredientEngineering

A portable cement mixing system uses ingredients such as cement, water and sand in predetermined quantities. A digital controller coordinates all of the operating elements of the apparatus for the entire mixing process and stores mixing programs relative to the mixing process for a variety of cements which includes the various ingredient quantities. Separate storage containers each coupled to a conveyors from the container extend to a mixer to transfer that quantity to the mixer for each cement ingredient. The conveyors are operated in sequence by the controller to load the mixer with a predetermined quantity of each of the required ingredients prior to mixing. The mixer and its contents are weighed before and during the transfer of each ingredient to precisely determine and transfer the required amount of each ingredient. After the mixer is loaded with all of the ingredients, the mixer is operated for a predetermined length of time.

Owner:SMART BATCH SYST

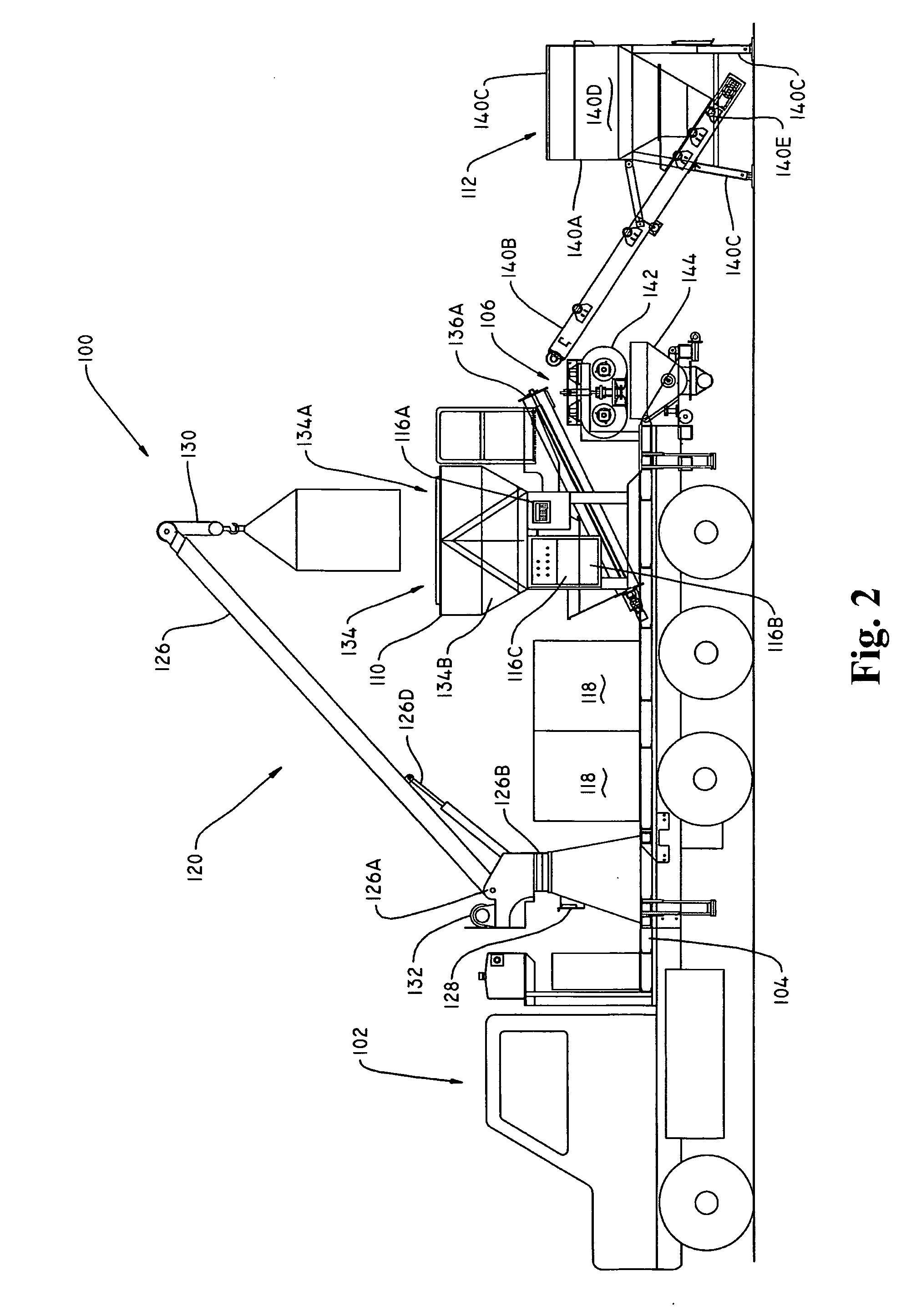

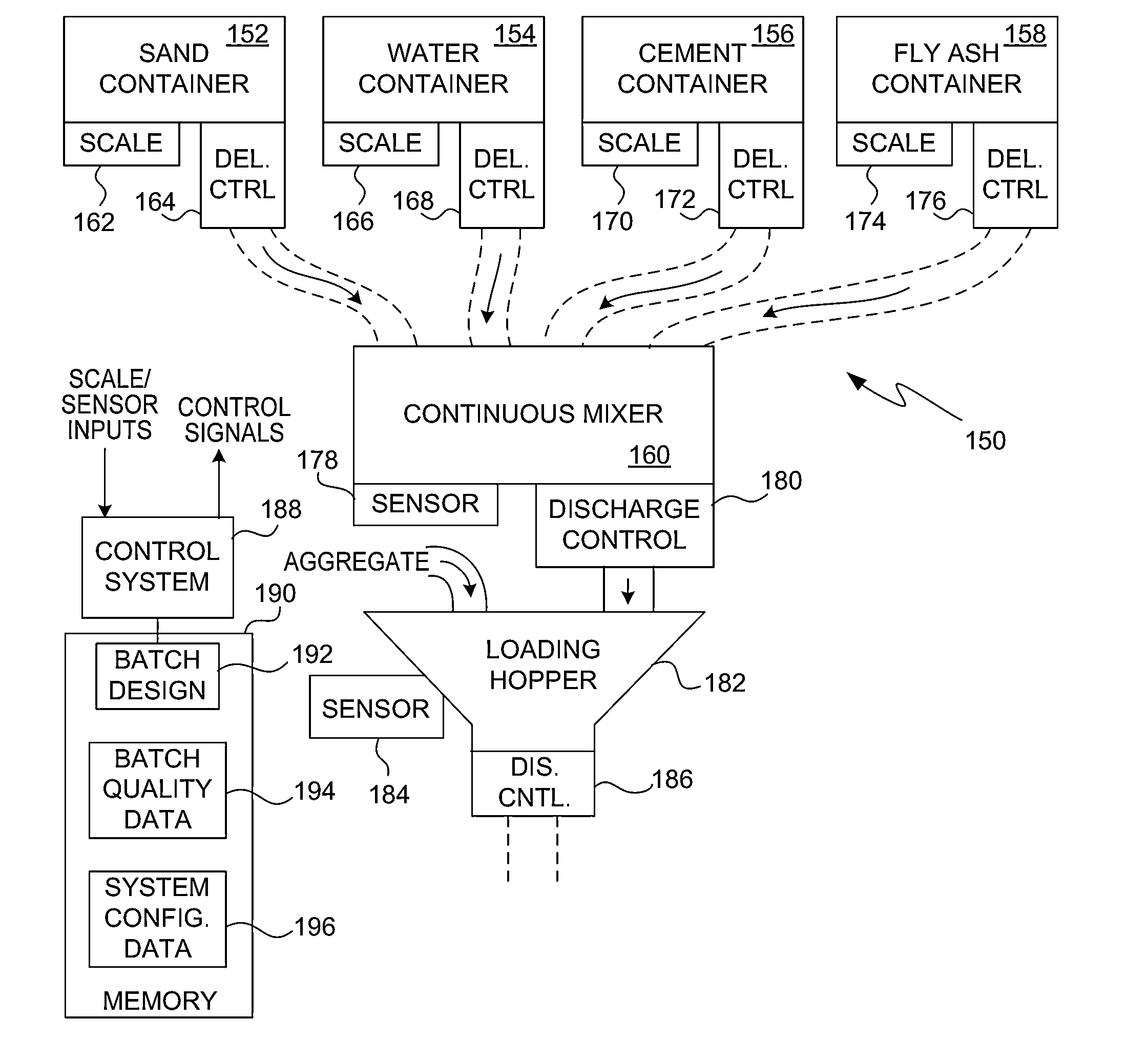

Feedback Controlled Concrete Production

ActiveUS20140355372A1Easy loadingEfficient productionRotary stirring mixersMixing operation control apparatusControl systemStructural engineering

Techniques or processes for efficiently producing concrete using dynamic feedback are disclosed. A concrete plant can use a control system to manage concrete production based on the dynamic feedback. The dynamic feedback can control mixing of concrete ingredients so as to yield uniform particle distribution for the concrete ingredients. The dynamic feedback can also avoid overflow situations as well as yield improved loading of the resulting concrete into a concrete transport vehicle (e.g., concrete truck).

Owner:BLACK MELVIN L +1

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7513963B2Increase volumeSmall sizeSolid waste managementTransportation and packagingProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

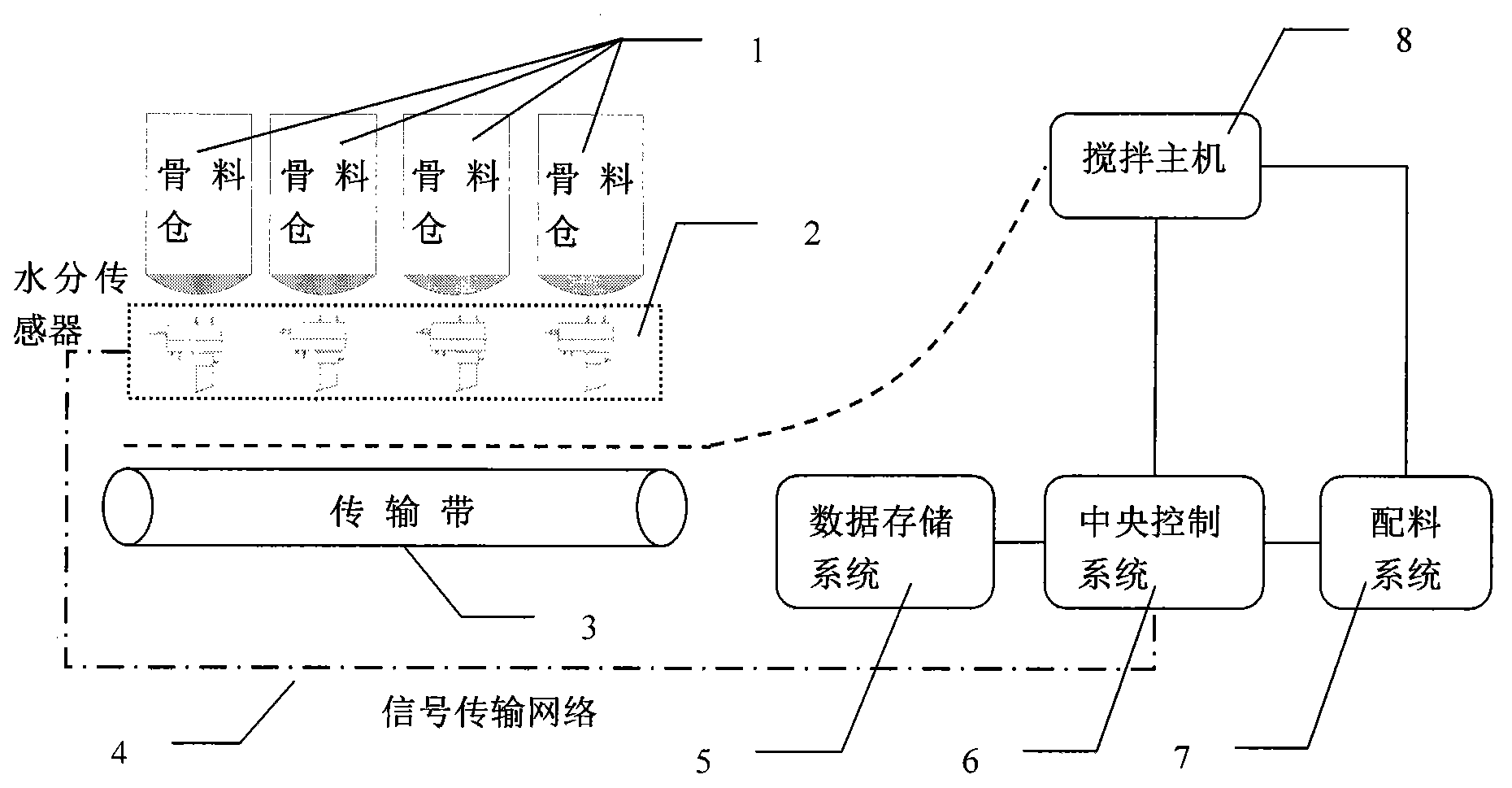

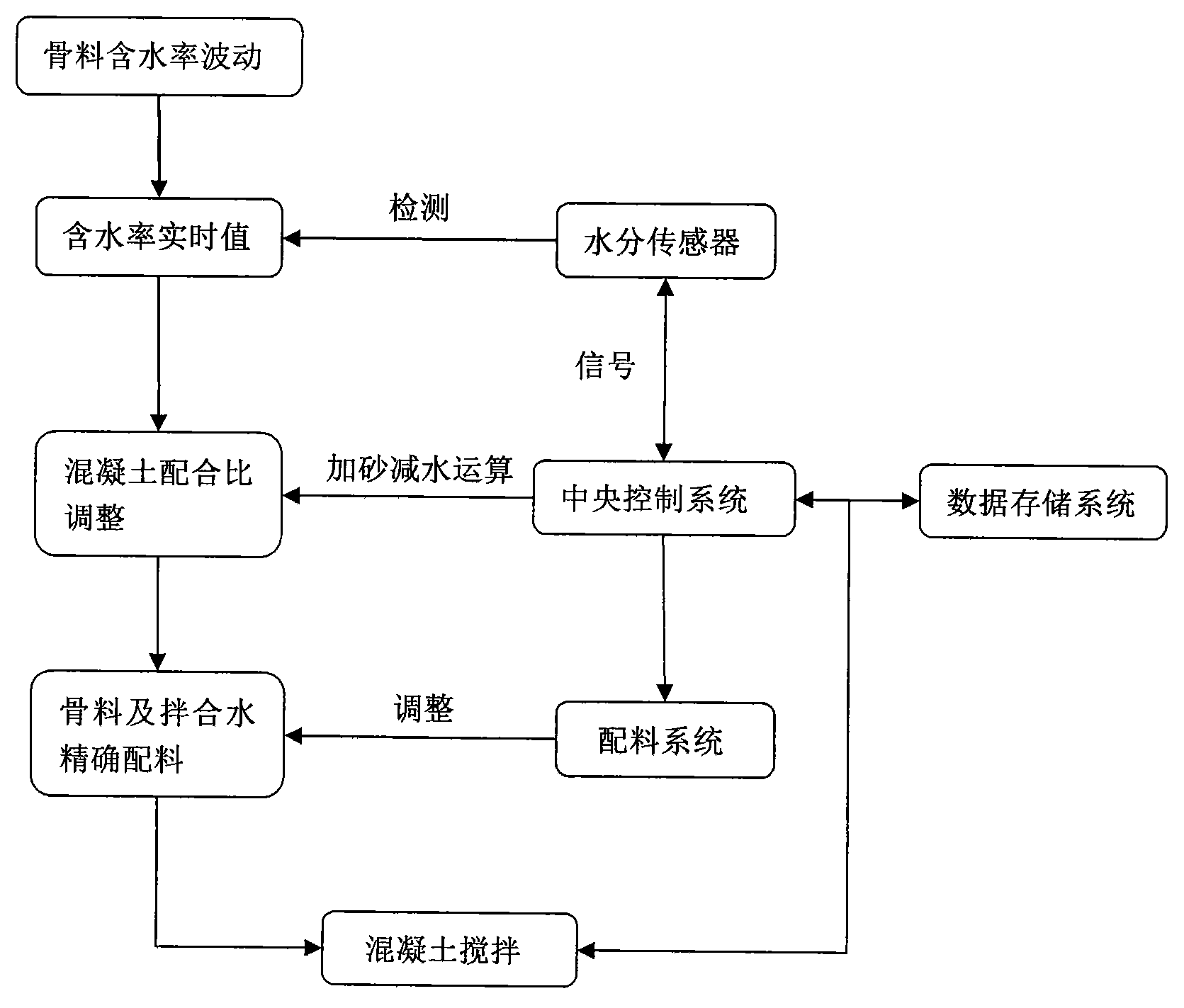

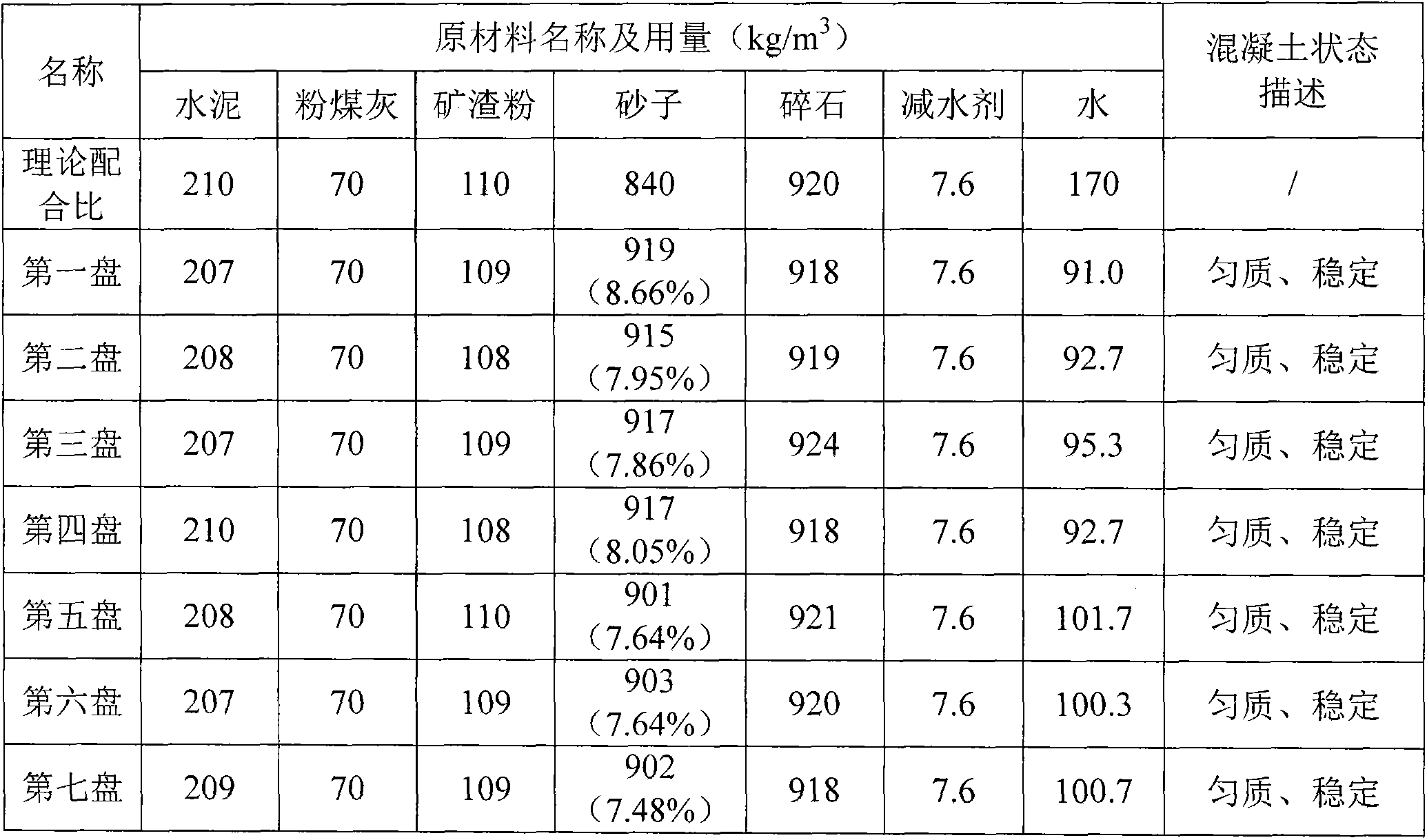

Dynamic regulating system of mix proportion of concrete mixing plant

ActiveCN104175401AReduce Human Intervention FactorsImprove product qualityMixing operation control apparatusIngredients proportioning apparatusControl systemConcrete plant

The invention provides a dynamic regulating system of the mix proportion of a concrete mixing plant. The dynamic regulating system comprises a sensor measurement system, a signal transmitting system, a central control system and a data storage system. The system is used for detecting the aggregate water content on line via a water content sensor installed on the inner wall of a stock bin or below a material outlet, and transmitting the water content information collected automatically to the central control system of the concrete mixing plant in real time; concrete mix proportion parameters can be amended automatically by the system according to the operational rule of increasing the aggregate and reducing mixing water, and the amount of concrete aggregate blended materials and the amount of mixing water blended materials can be regulated simultaneously so as to guarantee the uniformity and stability of concrete quality; the whole dynamic regulation process can be completed within seconds without affecting the production efficiency, so that the system can be widely applied to the concrete mixing plant in the field of civil engineering, not only can improve the automation degree of the mixing plant and improve the production quality of concrete, but also can reduce the working intensity of operators and reduce the personnel configuration, thereby lowering the cost greatly.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

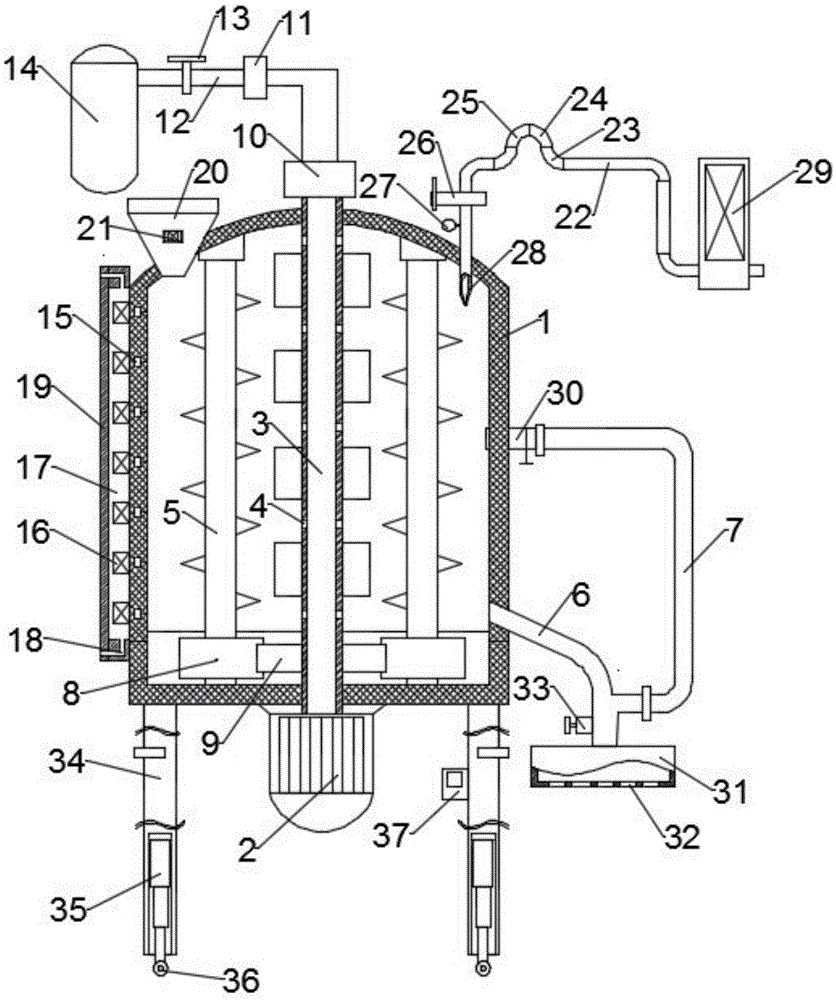

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

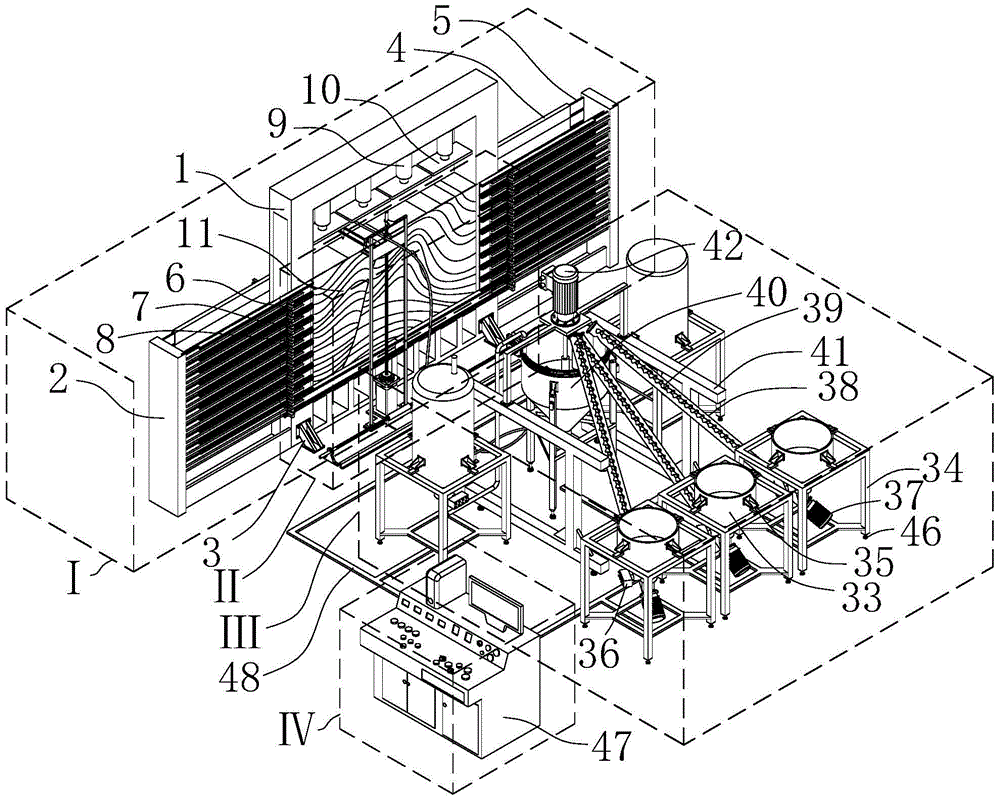

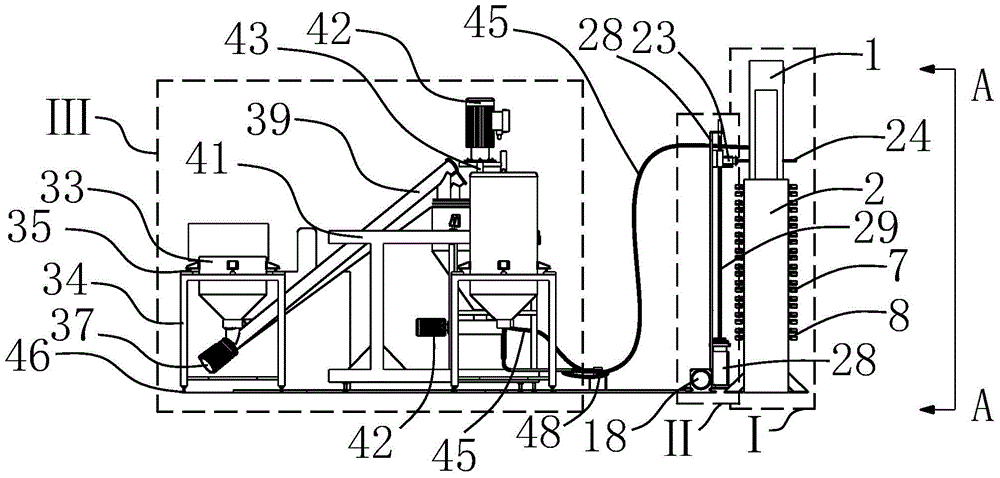

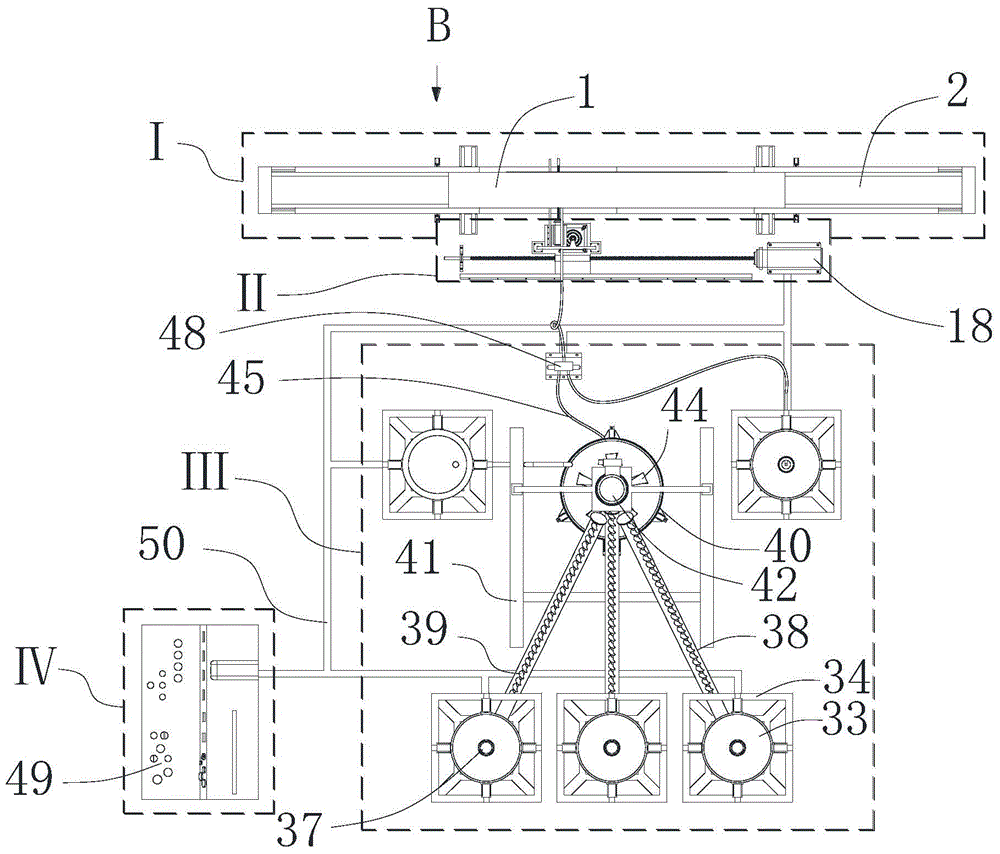

Analog simulation experiment system and method based on 3D printing rapid prototyping technology

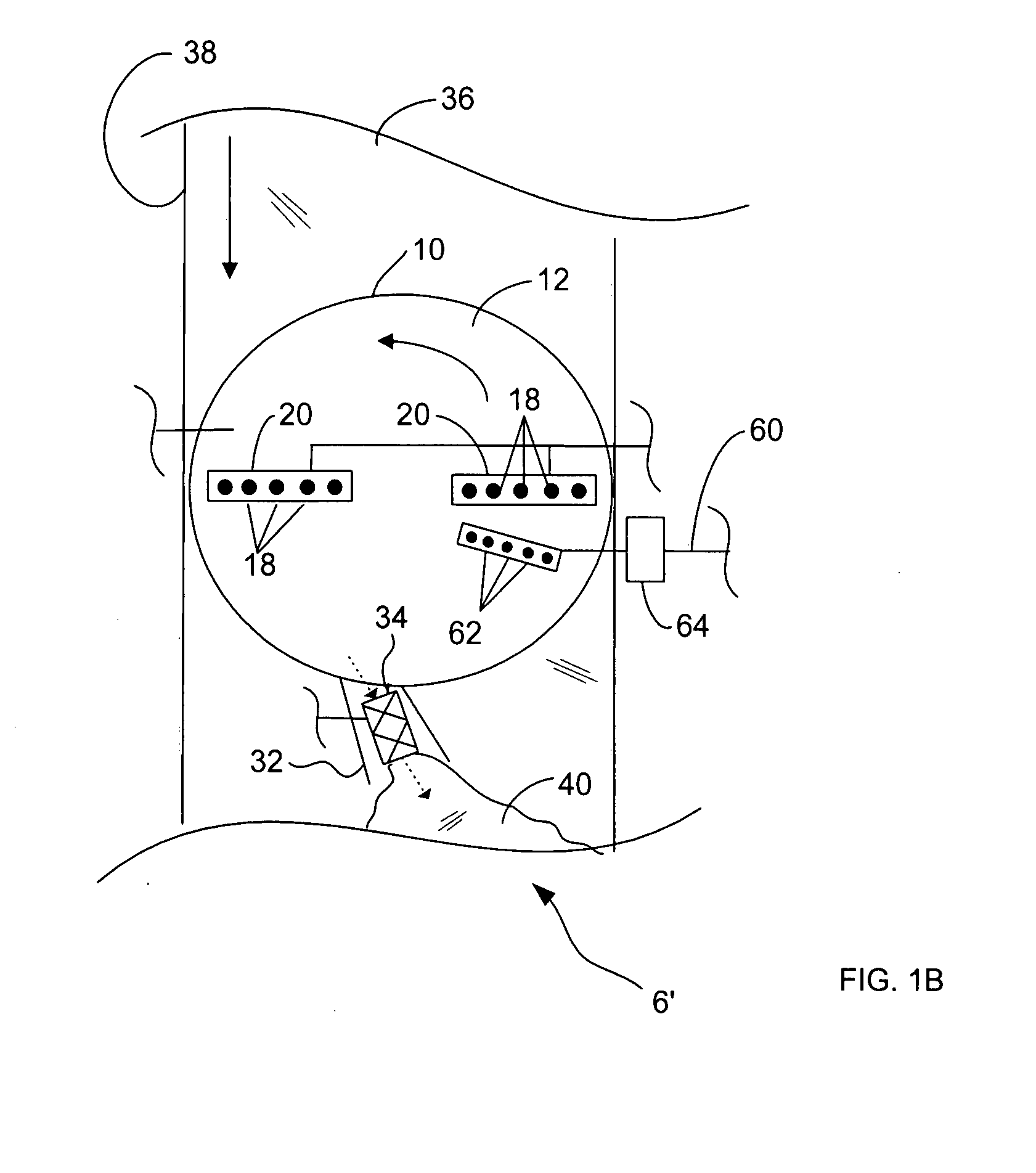

InactiveCN105034139A3D printing rapid prototypingHigh precisionMixing operation control apparatusEarth material testingRock engineeringEngineering

The invention discloses an analog simulation experiment system and method based on a 3D printing rapid prototyping technology. A blending module is connected with an experiment module through a printing material laying module. A control module is connected with and controls the blending module, the printing material laying module and the experiment module. The control module is used for forming a 3D digital model of an analog simulation experiment. The control module controls the experiment module to be adjusted to a state suitable for printing the 3D digital model, controls the blending ratio of the blending module through electromagnetic valves and controls the printing material laying module to carry out 3D material laying at the experiment module through a direction control mechanism and reversing valves. The analog simulation experiment system and method can be used for laying rock models on complex geological structures, where the models cannot be laid through traditional measures, such as fold, faults and collapse columns, the model size precision is high, and therefore the system and method can be better used for observation and study of complex rock engineering such as the working seam overlaying strata movement rule, the roof caving regularity, and the relation between the roof moving features and forms and stability time after working face mining.

Owner:SHANDONG UNIV OF SCI & TECH

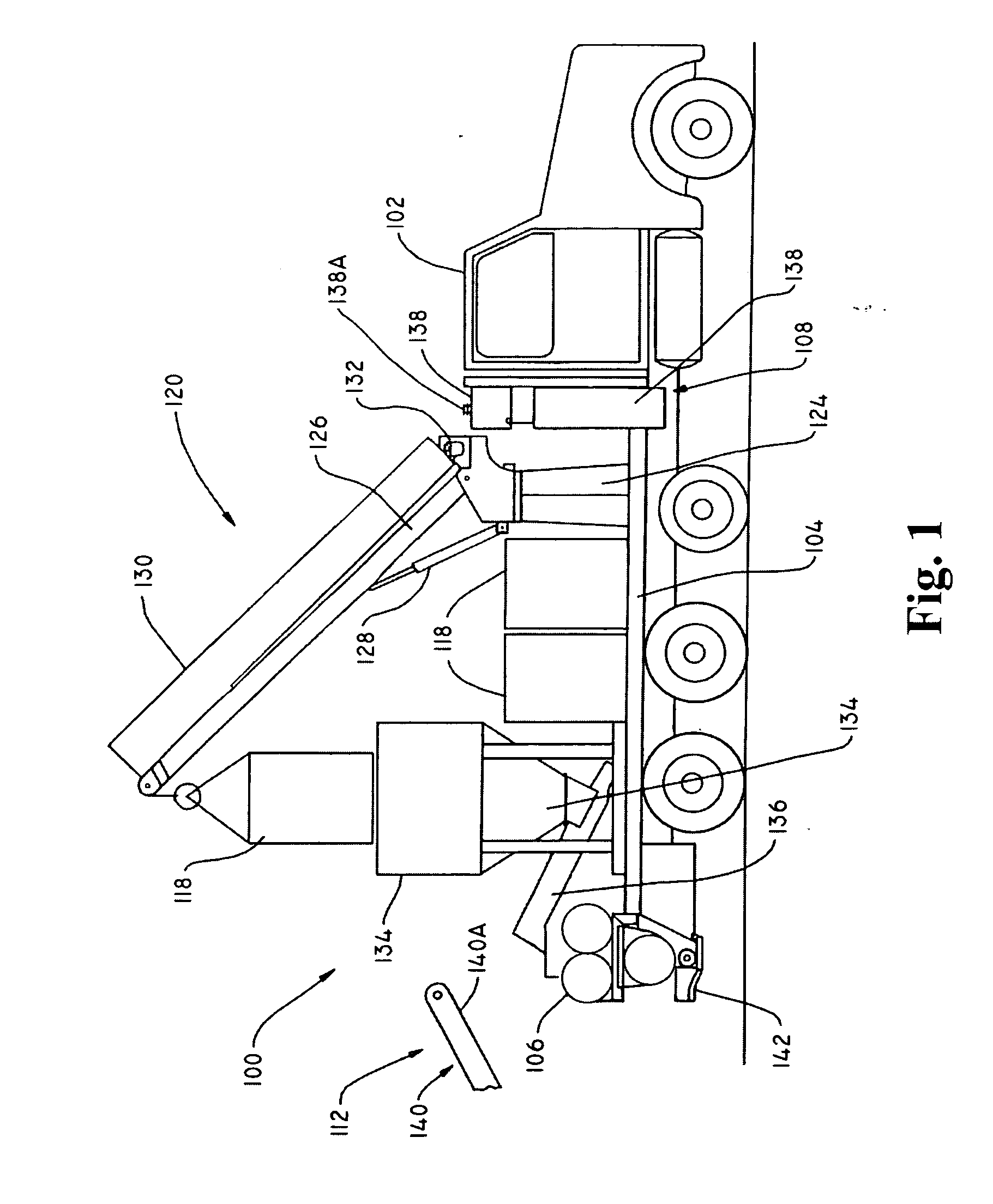

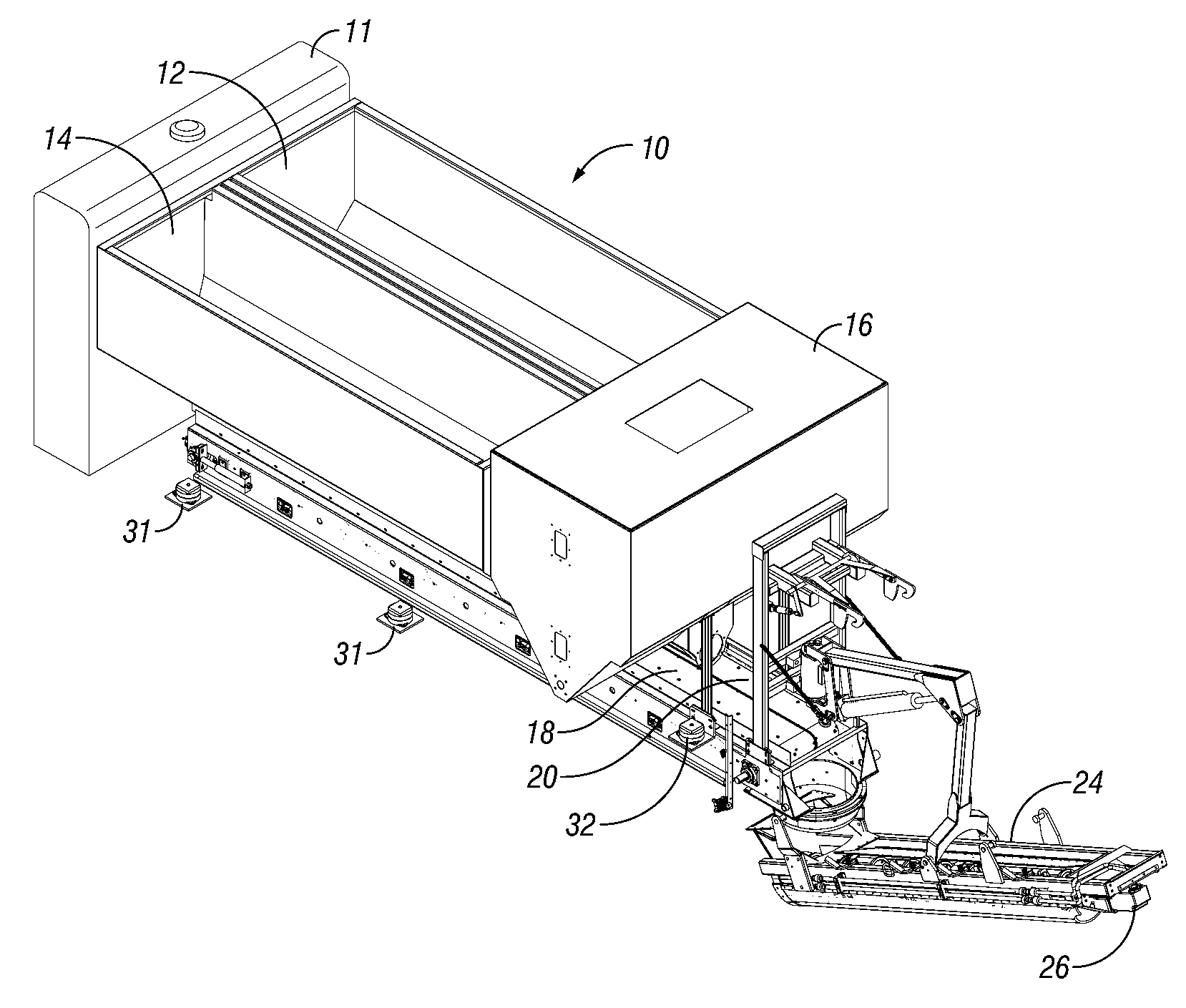

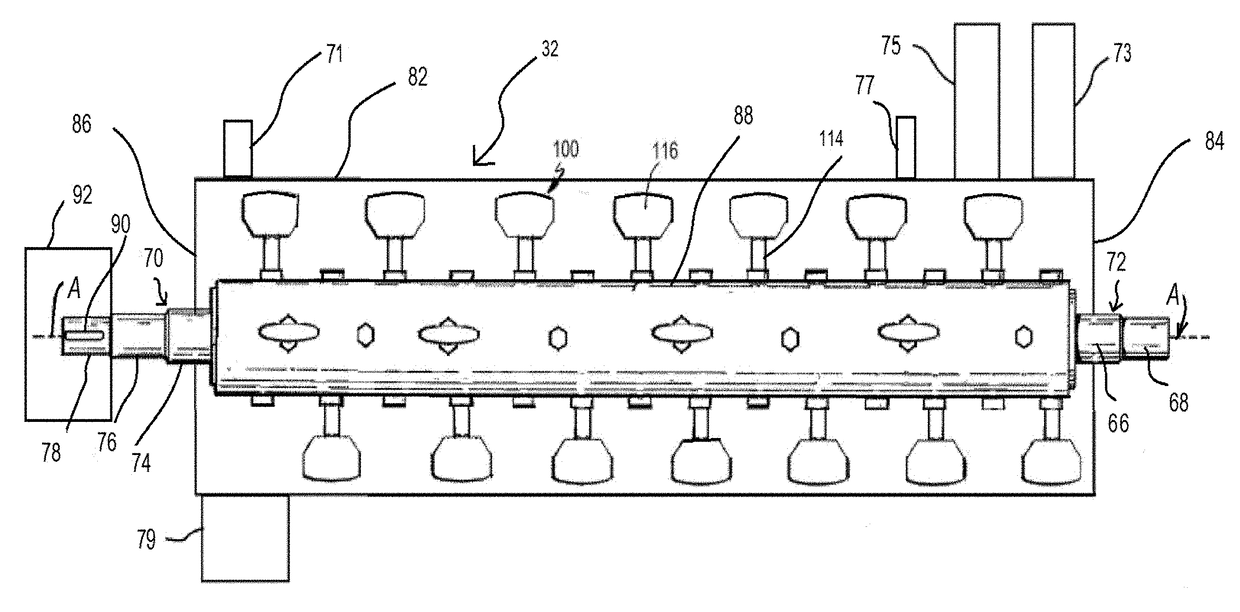

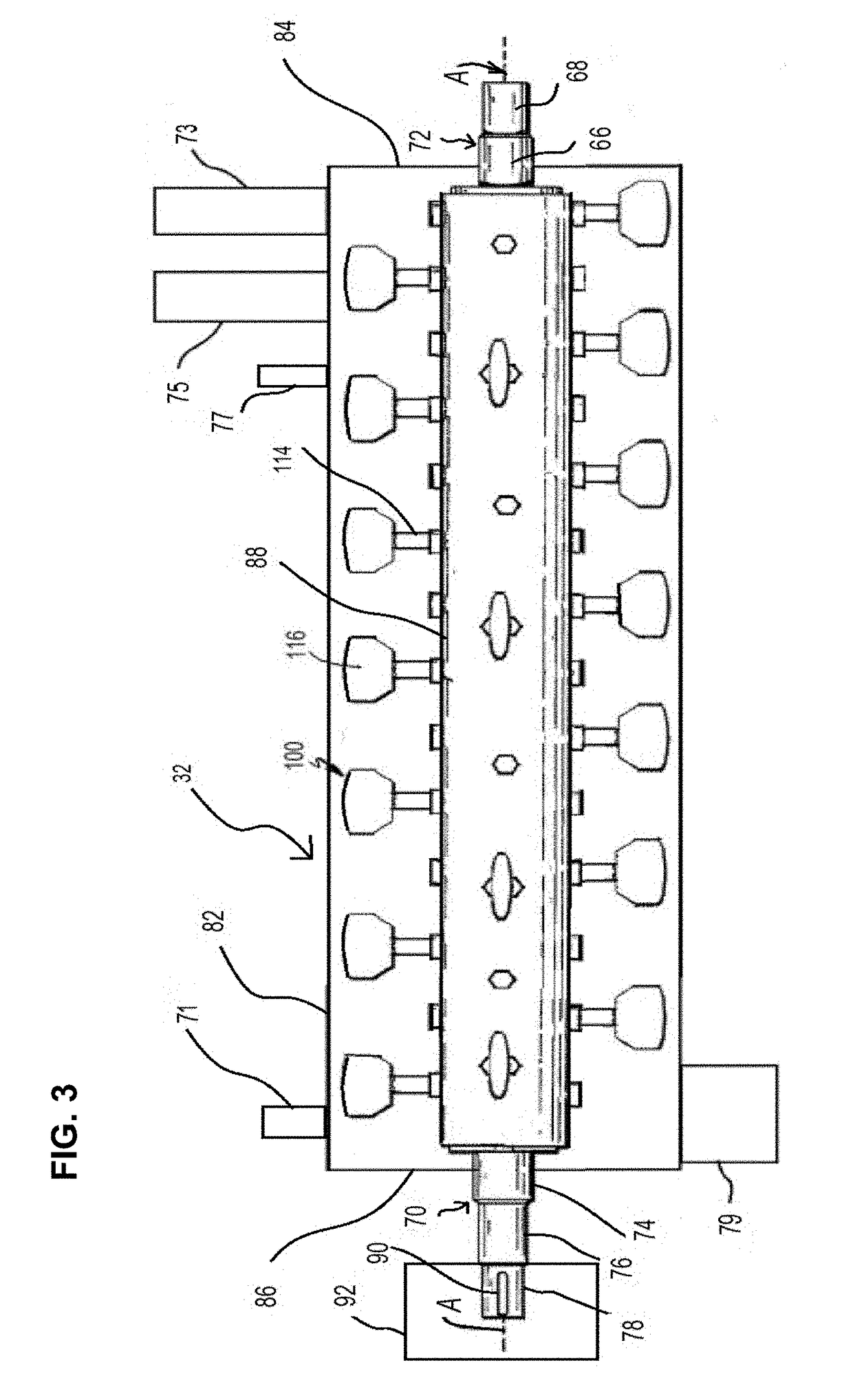

Volumetric concrete mixing method and apparatus

ActiveUS20090180348A1Mixing operation control apparatusIngredients proportioning apparatusAdditive ingredientControl theory

An improved volumetric concrete mixing system and method of the present invention utilizes load cells for measuring weight loss from the aggregate and cement bins. Load cells may also be used for measuring weight loss from the water tank. The load cells provide input data corresponding to the weight loss of each container to a controller which automatically adjusts the delivery of ingredients to a mixing boot so as to achieve a desired concrete mix ratio.

Owner:CEMEN TECH

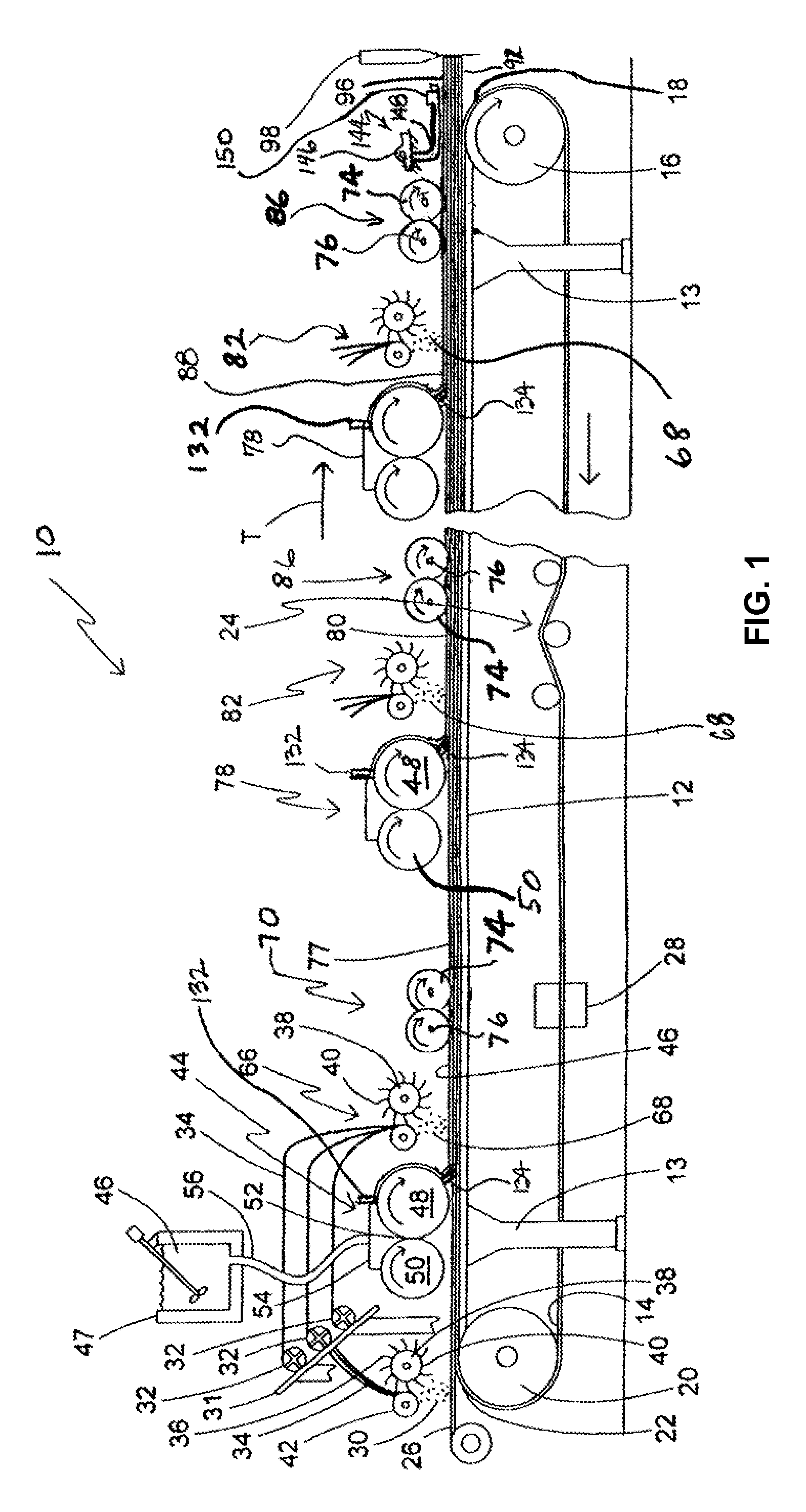

Continuous mixer and method of mixing reinforcing fibers with cementitious materials

ActiveUS20180036911A1Shorten mixing timeNot to damageLiquid surface applicatorsRotary stirring mixersFiberSlurry

A method in which a stream of dry cementitious powder passes through a first conduit and aqueous medium stream passes through a second conduit to feed a slurry mixer to make cementitious slurry. The cementitious slurry passes through a third conduit and a reinforcement fiber stream passes through a fourth conduit to feed a fiber-slurry mixer which mixes the slurry and discrete fibers to make a stream of fiber-slurry mixture. An apparatus for performing the method is also disclosed.

Owner:UNITED STATES GYPSUM CO

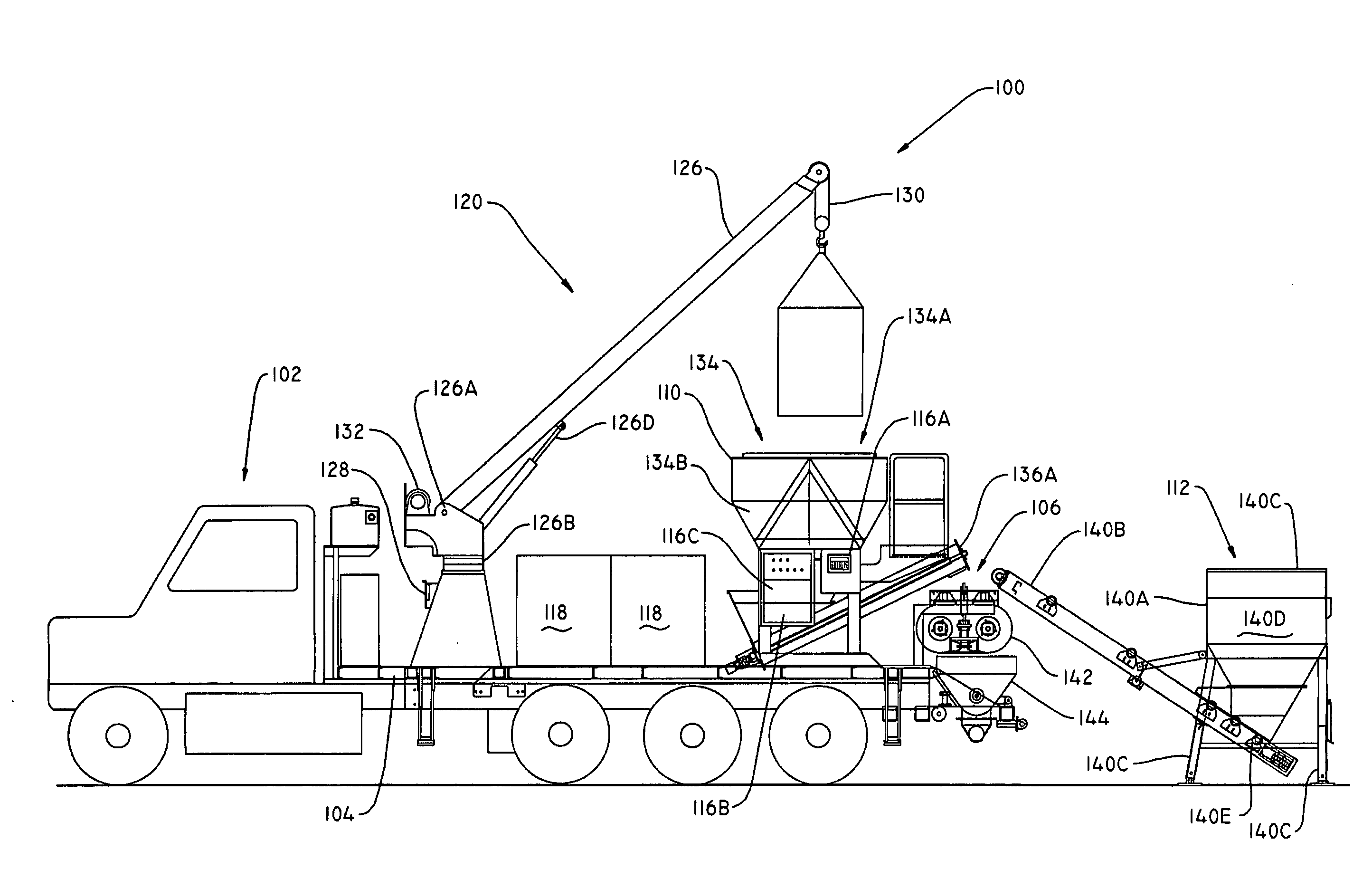

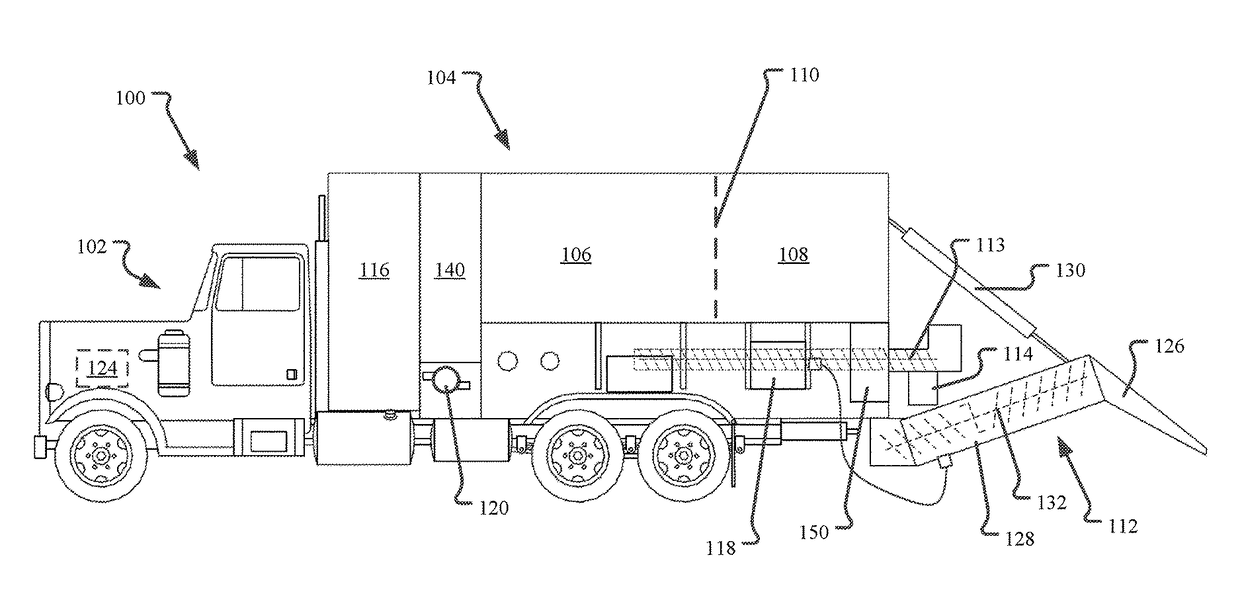

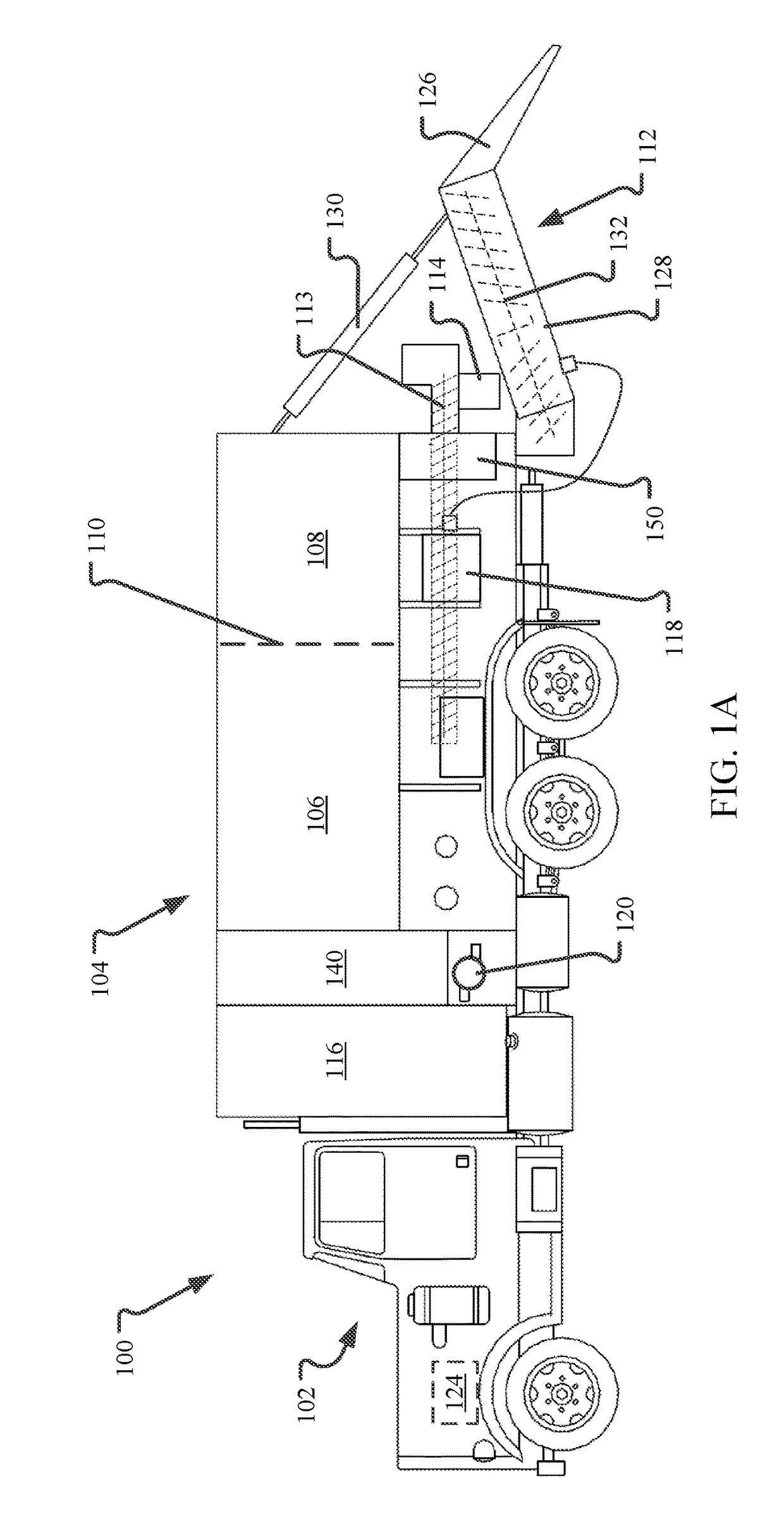

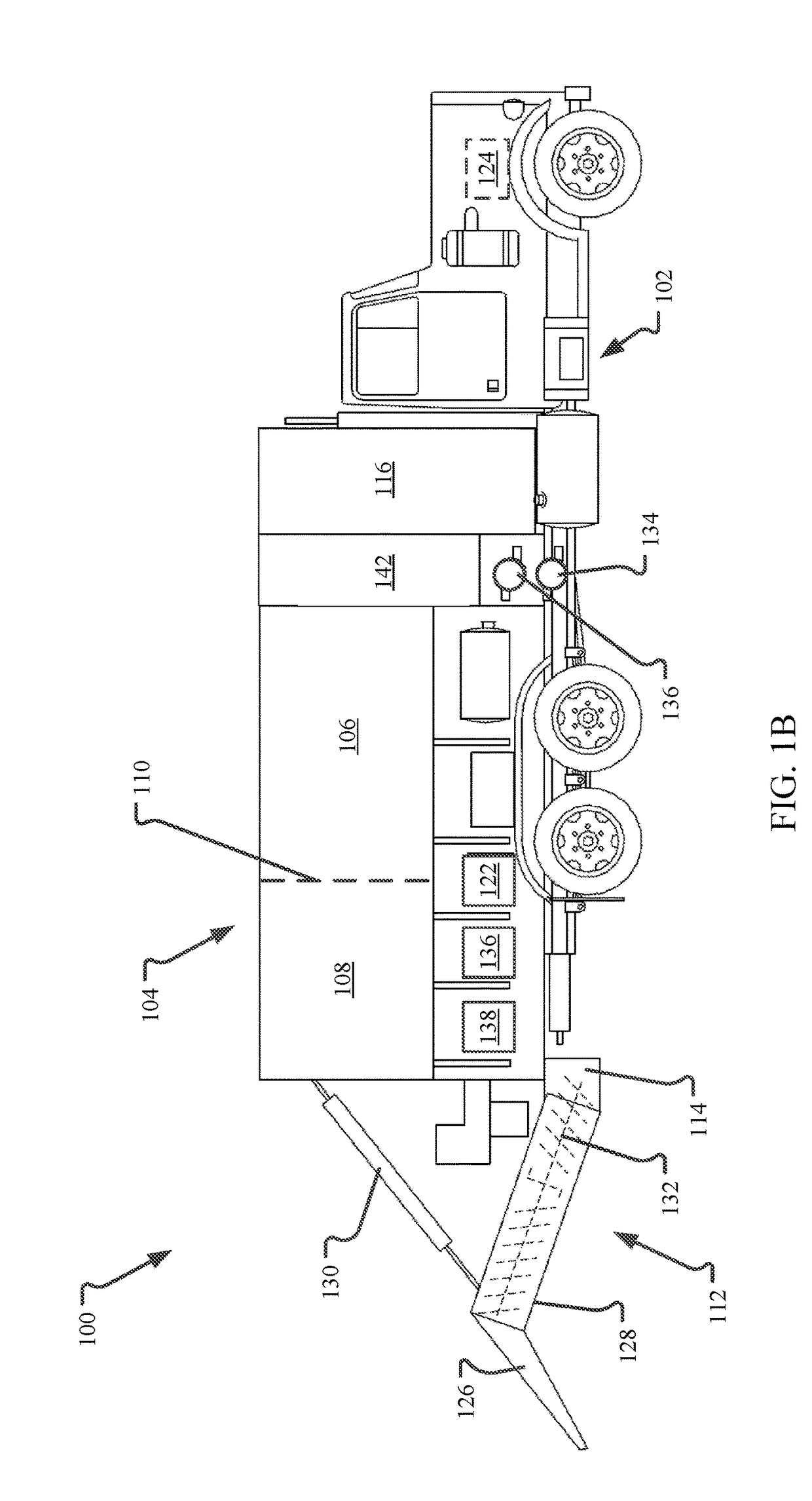

Volumetric mobile powder mixer

ActiveUS20170080601A1Transportation and packagingMixing operation control apparatusSolid componentEngineering

This disclosure describes volumetric mobile powder mixer (VMPM) systems and methods for VMPM operation and use. The VMPM is providing with a number of storage compartments (or bins) for liquid or solid ingredients including at least one powder storage bin, a powder transport system, a dust handling system, a solid / liquid mixing system, a cellular foam generator, a product delivery system, and a controller capable of monitoring the delivery and mixing of each of the ingredients, as well as the discharge of the final product. The controller determines if the proper mixture is being discharged by the VMPM and, if not, alerts the VMPM operator. In an automated embodiment, the VMPM controller is also configured to independently control the delivery and mixing of each of the ingredients, as well as the delivery of the final product.

Owner:EAGLE STRONG INVESTMENTS LLC

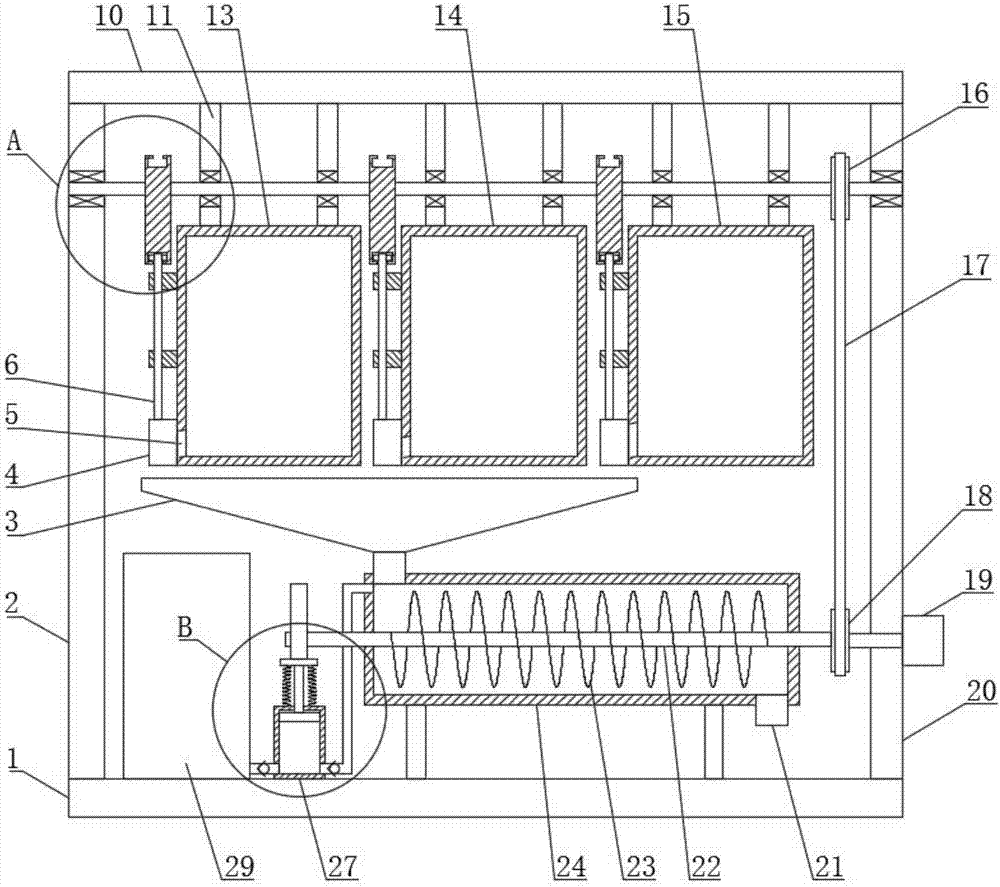

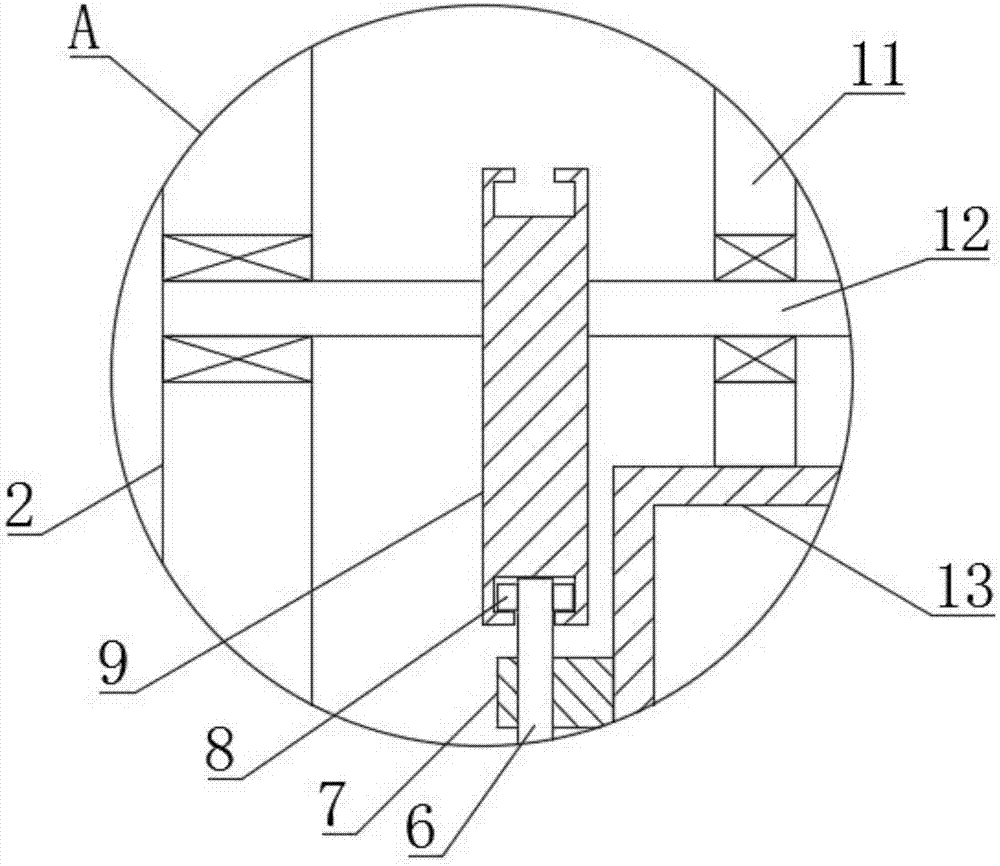

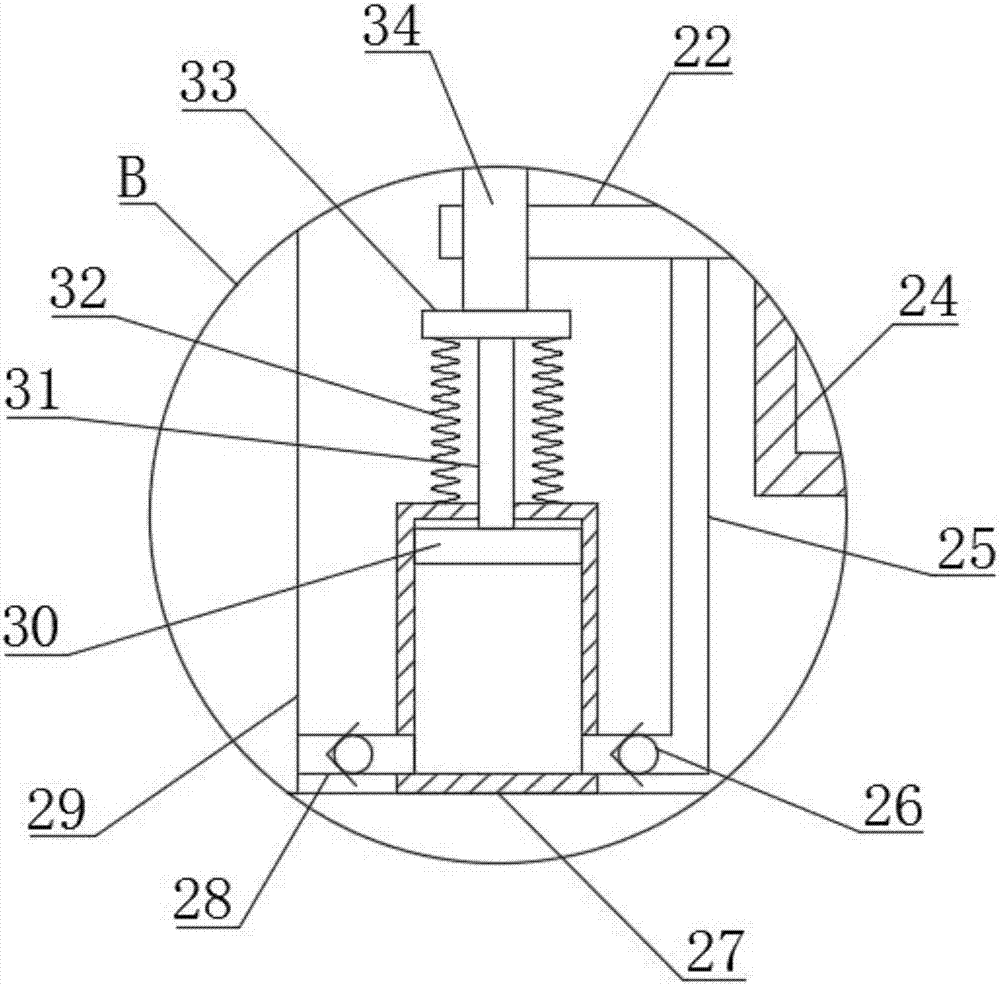

Quantitative mixer for producing ceramics

InactiveCN104924461AImprove practicalityIncrease productivityMixing operation control apparatusIngredients proportioning apparatusHydraulic cylinderEngineering

The invention discloses a quantitative mixer for producing ceramics. The quantitative mixer comprises a mixer body, a hydraulic cylinder and a controller, wherein a feeding funnel is connected to the center of the upper side of the mixer body, a first electronic scale is disposed at the bottom end of the feeding funnel, a first electromagnetic valve is disposed at the center of the first electronic scale, a pulverizer is disposed at the left end of the upper side of the mixer body, and the bottom of the pulverizer is connected with the mixer body. The quantitative mixer has the advantages that an upper mixing mechanism and a lower mixing mechanism mix materials, the lower mixing mechanism can move up and down and left and right, mixing effect is guaranteed, mixing efficiency is increased, quantitative feeding and processing can be achieved, two different materials can be fed simultaneously according to proportion, mixer practicality is increased, ceramic producing efficiency is increased, the mixer can be moved freely and conveniently, and high practicality and convenience are achieved.

Owner:陆丽曼

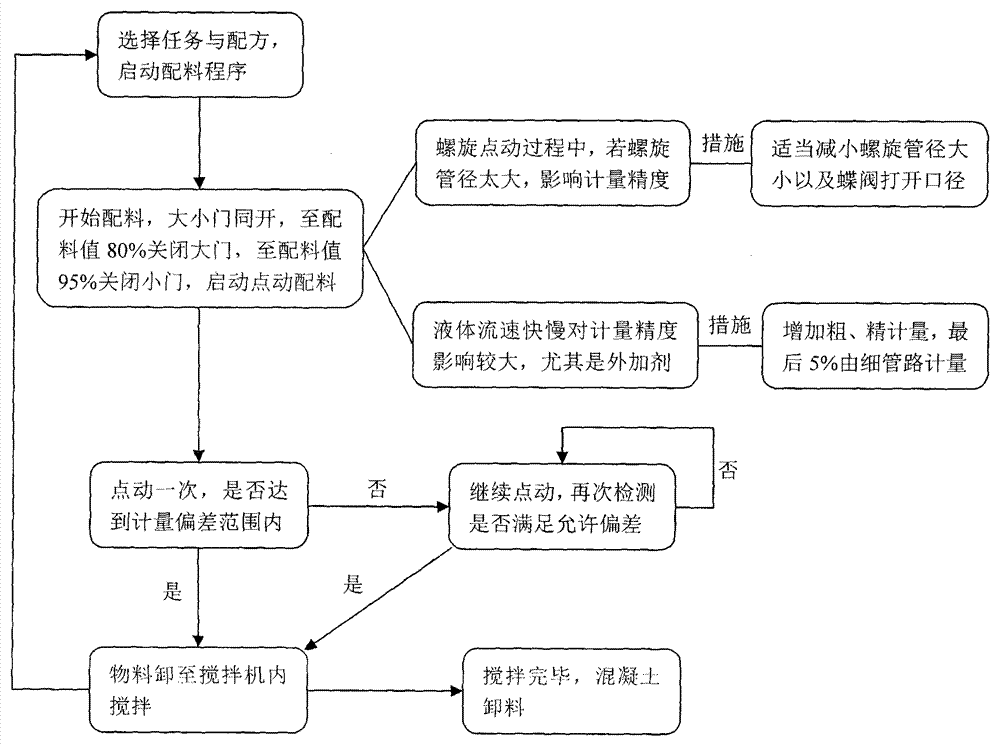

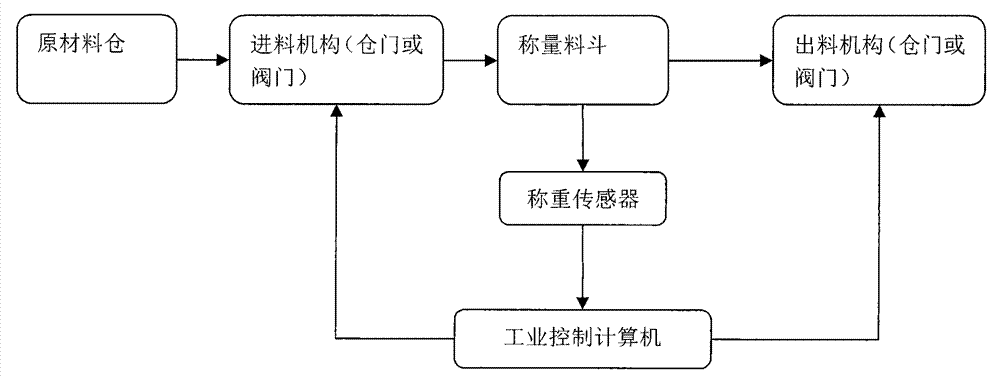

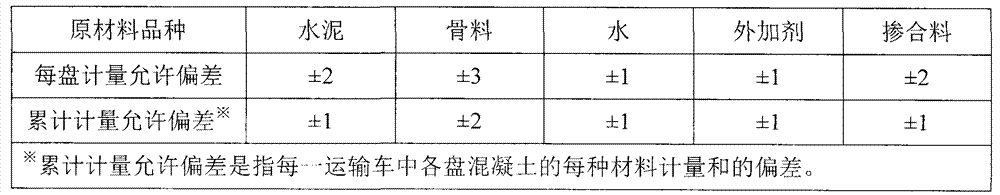

Dynamic control system and method for batching accuracy of concrete mixing plant

ActiveCN104260207AHigh precisionImprove stabilityMixing operation control apparatusIngredients proportioning apparatusAutomatic controlCycle control

The invention belongs to the technical field of concrete engineering and relates to a dynamic control system and method for the batching accuracy of a concrete mixing plant. The dynamic control system comprises a batching device, a weighing sensor, a batching instrument (namely a PLC) and an industrial control computer. According to the control system, dynamic weighing data which is acquired in real time is compared with an expected batching set value (namely a proportioning parameter), the unloading quantity is controlled in a stepped manner by the batching device by virtue of a rough weighing-fine weighing two-stage batching method, and the accurate batching is finished by carrying out inching control and automatically correcting real-time fall by virtue of a cycle control algorithm. The dynamic control system has the outstanding advantages of high batching accuracy and good stability and thus can be applied to concrete and bituminous concrete mixing plants in the field of civil engineering, the real-time automatic control can be realized, the automation degree of the mixing plants can be improved, the batching accuracy and reliability are improved, and the production quality of concrete is guaranteed.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

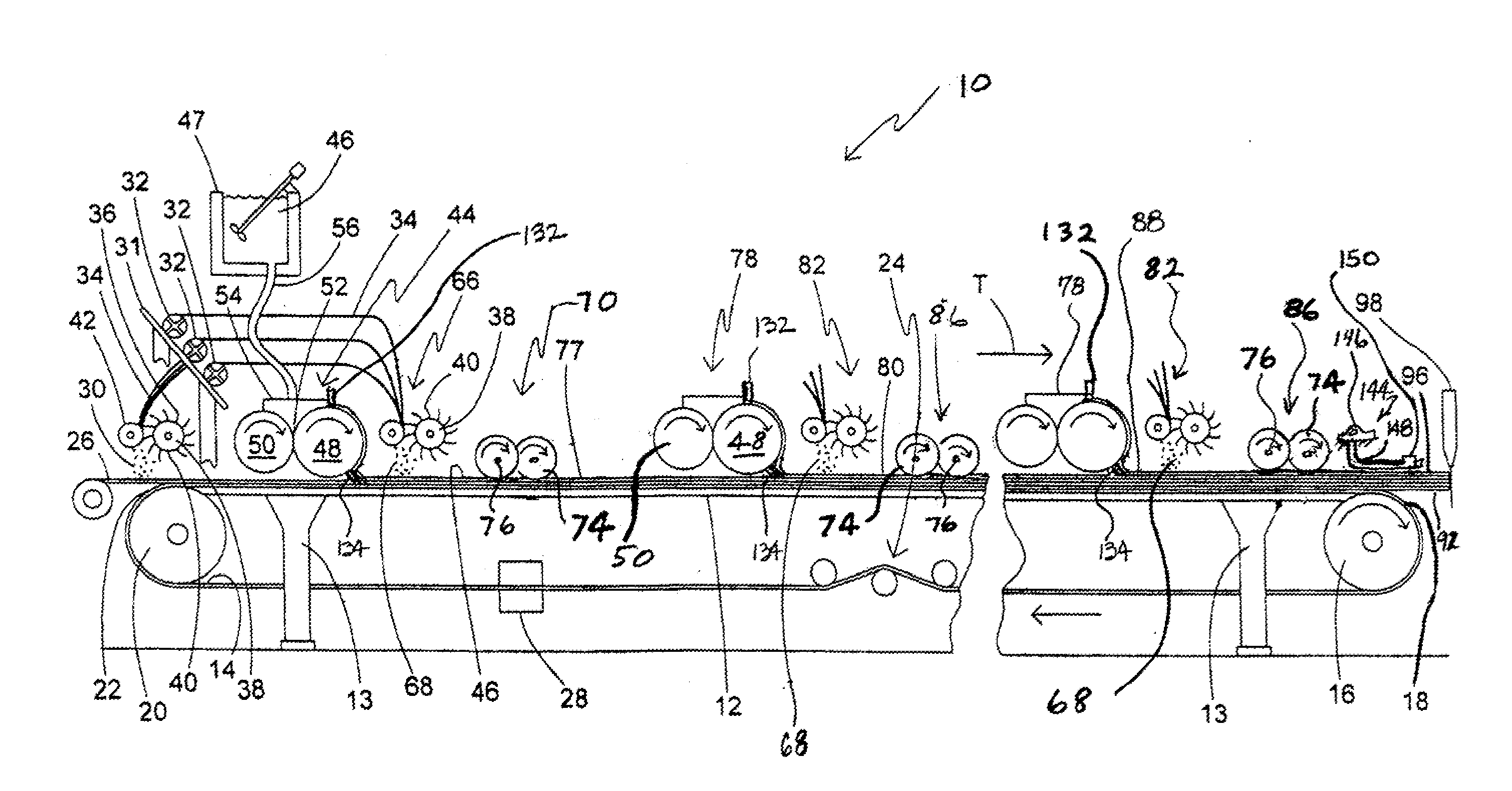

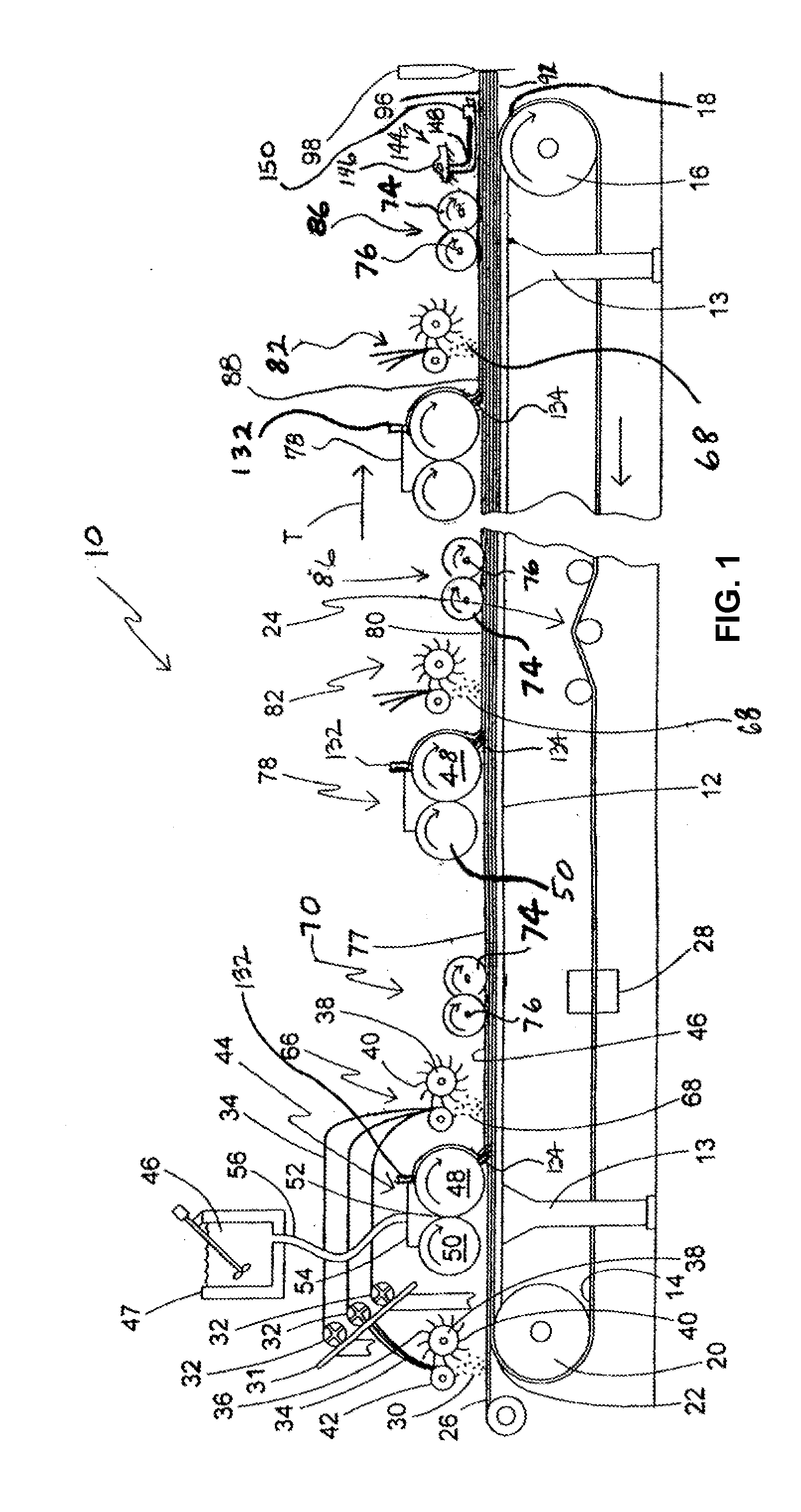

Continuous methods of making fiber reinforced concrete panels

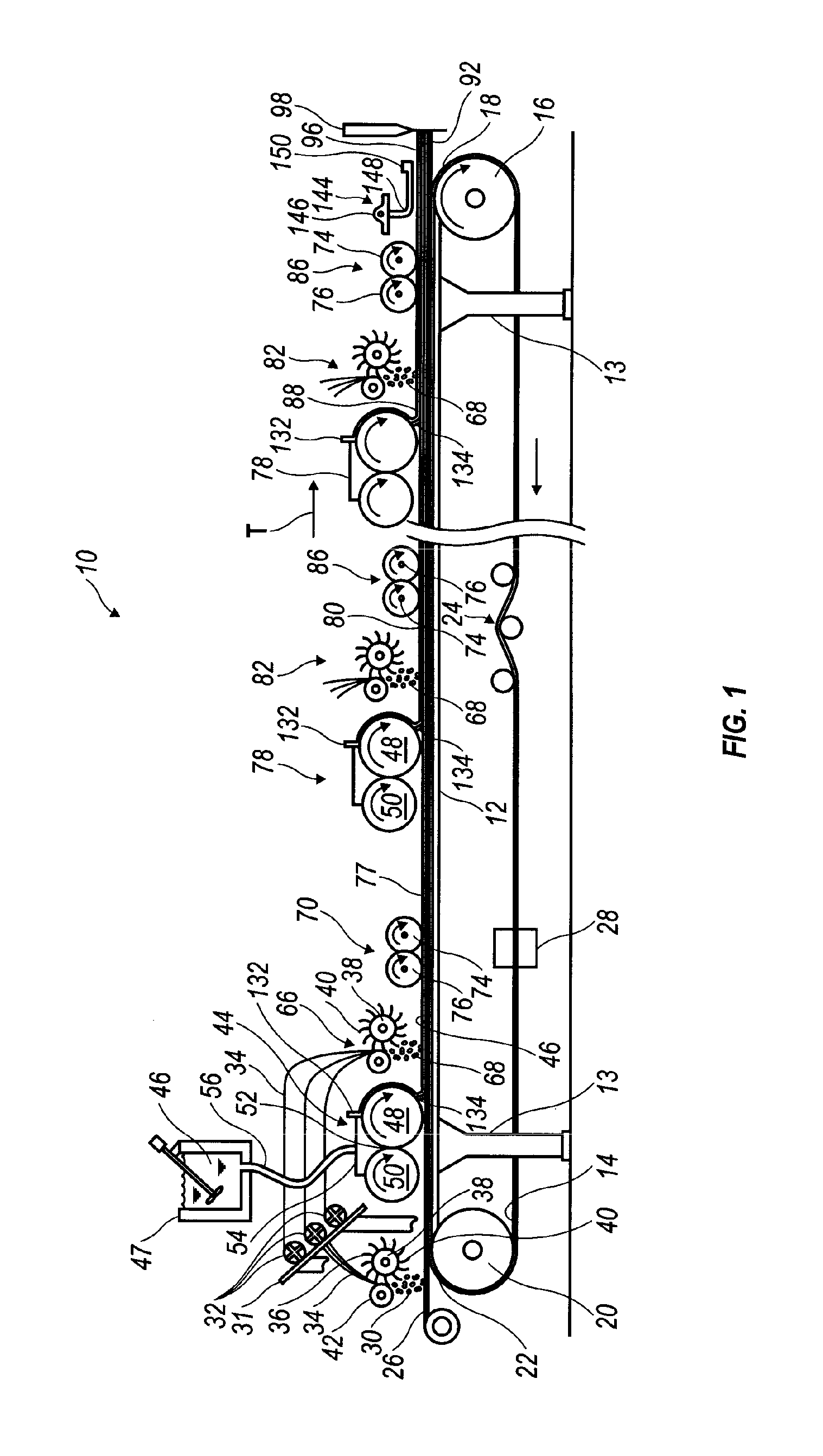

ActiveUS20180036912A1Promote formationEasy to processLiquid surface applicatorsRotary stirring mixersStructural engineeringSlurry

Continuous method including:mixing water and cementitous powder to form slurry;mixing the slurry and reinforcement fibers in a single pass horizontal continuous mixer to form fiber-slurry mixture,the mixer includingan elongated mixing chamber having a reinforcement fiber inlet port, andupstream of the fiber inlet port is an inlet port to introduce water and cementitous powder together as one stream or at least two inlet ports to introduce water and dry cementitous powder separately as separate streams into the chamber,a rotating horizontal shaft / s within the chamber,part of the chamber for mixing the fibers and slurry and moving the fiber-slurry mixture to a mixture outlet;discharging the fiber-slurry mixture from the mixer outlet;forming and setting the fiber-slurry mixture on a moving surface;cutting the set mixture into fiber reinforced concrete panels and removing the panels from the moving surface.

Owner:UNITED STATES GYPSUM CO

System and method of applying carbon dioxide during the production of concrete

ActiveUS9790131B2Reduce energy consumptionLow costFlow mixersTransportation and packagingMulti materialArchitectural engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

Chemical dispensing system for a portable concrete plant

InactiveUS20050159843A1Dispensed more accuratelyGood repeatabilityLevel controlMouldsDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

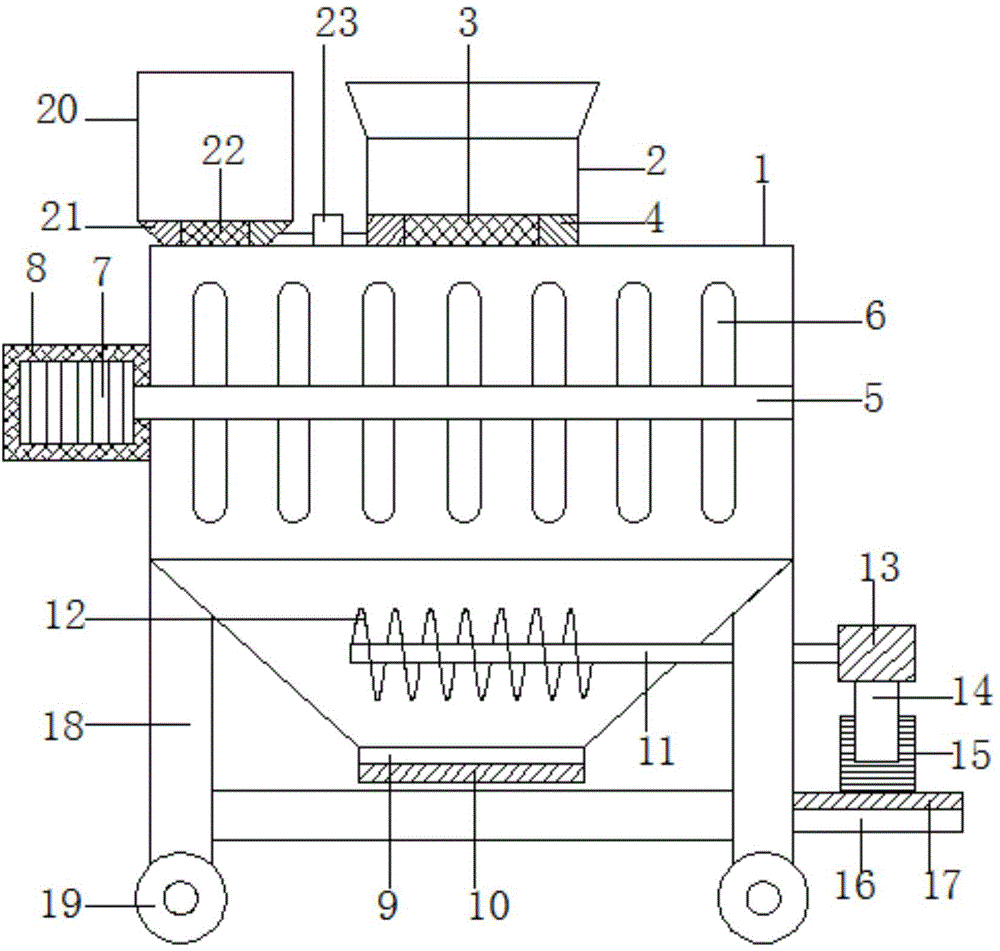

Self-feeding type quantitative matching concrete mixer

InactiveCN107263729AQuality improvementEasy to operateMixing operation control apparatusIngredients proportioning apparatusArchitectural engineeringFeed type

The invention discloses a self-feeding type quantitative proportioning concrete mixer. The boards are respectively fixed with sand boxes, cement boxes and stone boxes, and the sand box, cement box and the bottom of the left side wall of the stone box are all provided with discharge ports; the left support plate and the right support plate are rotatably connected with a first shaft, and the second Three first cams are installed on a rotating shaft, the bottom of the first cam is connected with the first connecting rod through the pin shaft, the bottom of the first connecting rod is connected with a baffle, and the three baffles are respectively matched with the discharge port; Fixed installation with a stirring box. The invention makes the baffle plate move up and down through the rotation of the first cam to control the automatic unloading of sand, gravel and cement; the discharge ports of different sizes are set to automatically proportion the materials, which greatly improves the working efficiency.

Owner:康泽波

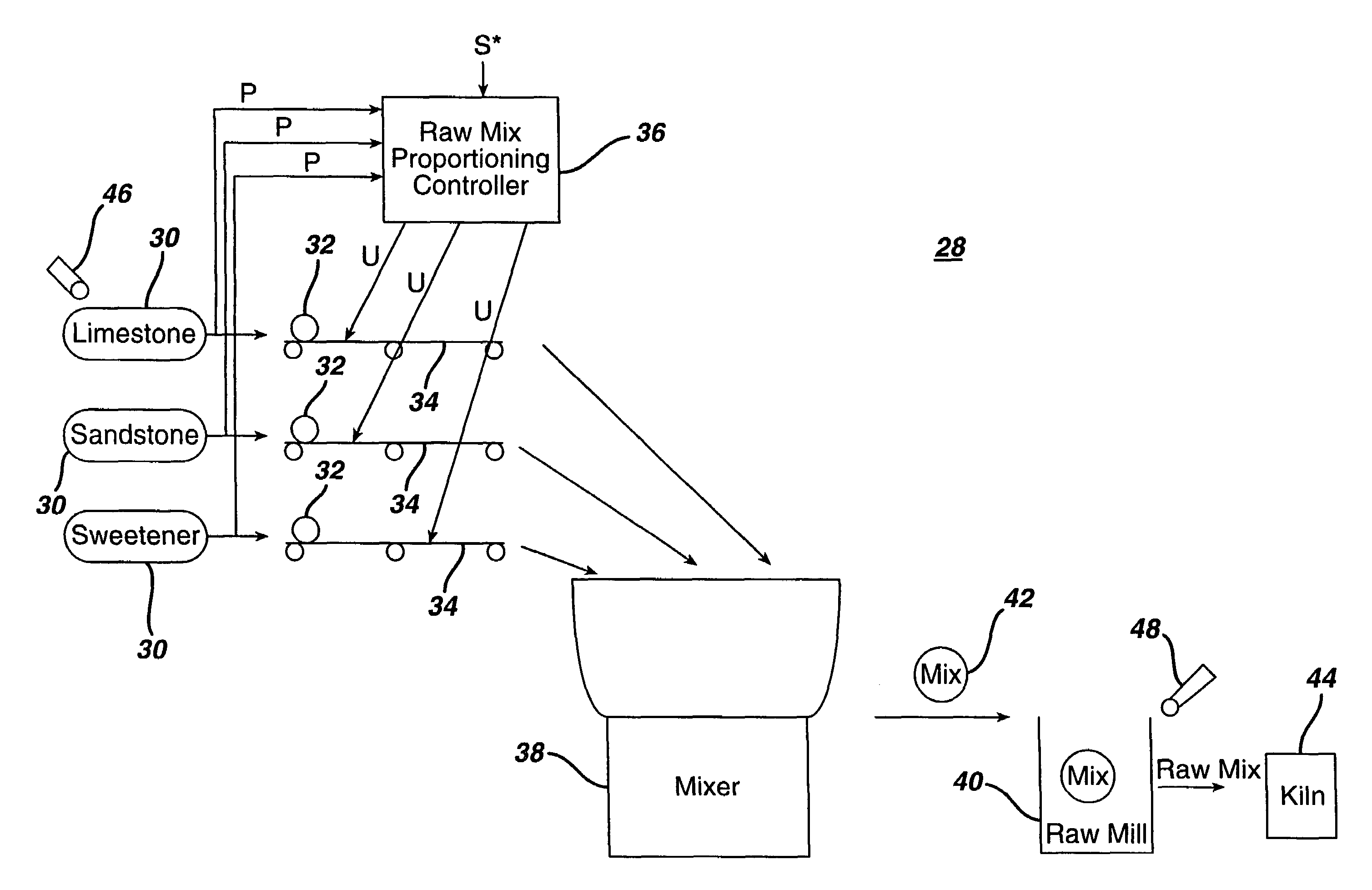

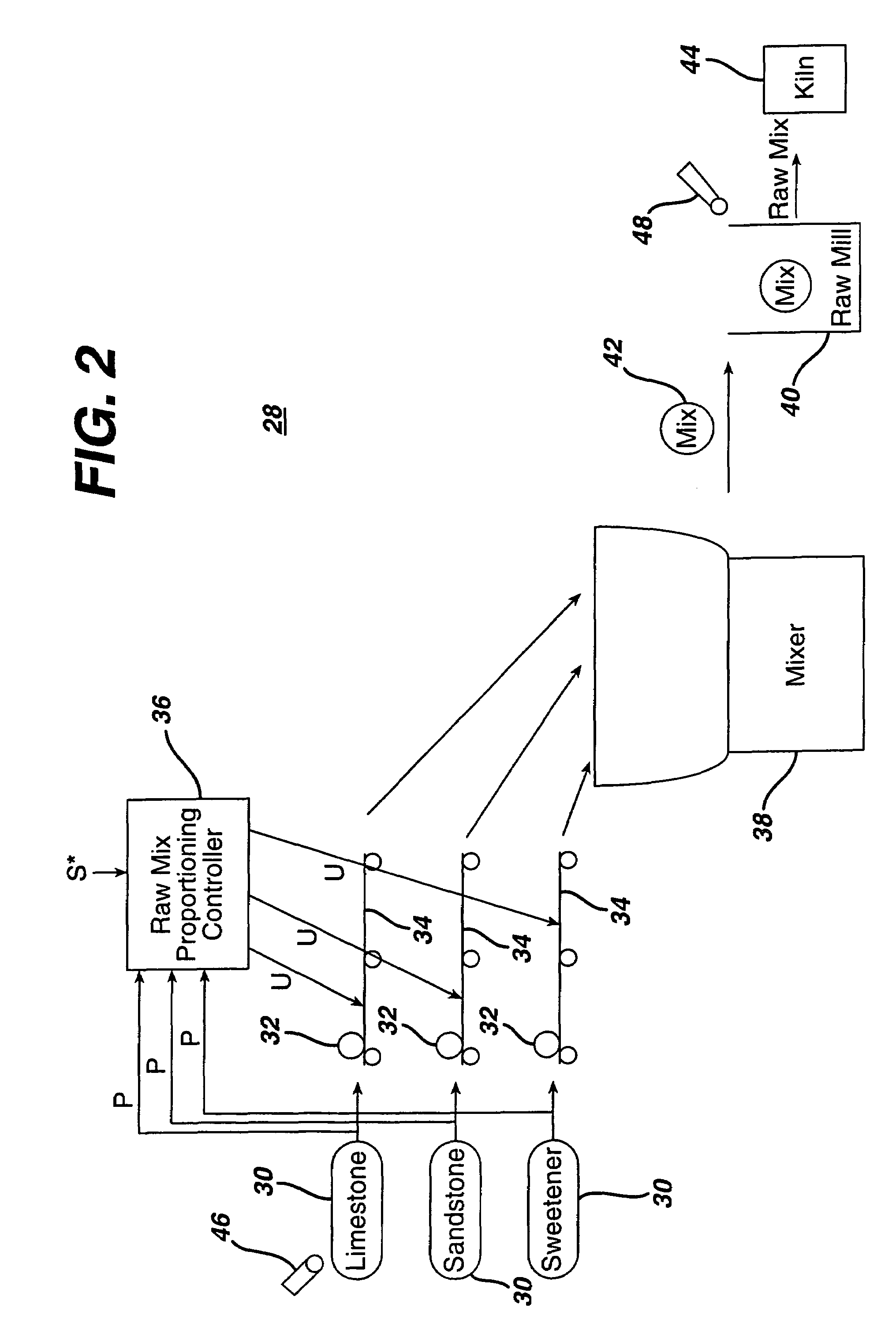

System and method for tuning a raw mix proportioning controller

InactiveUS7308339B2Minimize tracking errorEasy to trackSampled-variable control systemsData processing applicationsGenetics algorithmsEngineering

A system and method for tuning a raw mix proportioning controller used in a cement plant. A fuzzy logic supervisory controller tracks the performance of a cement plant simulator to target set points for attaining a correct mix and composition of raw materials. A genetic algorithm adjusts the fuzzy logic supervisory controller's performance by adjusting its parameters in a sequential order of significance.

Owner:GENERAL ELECTRIC CO

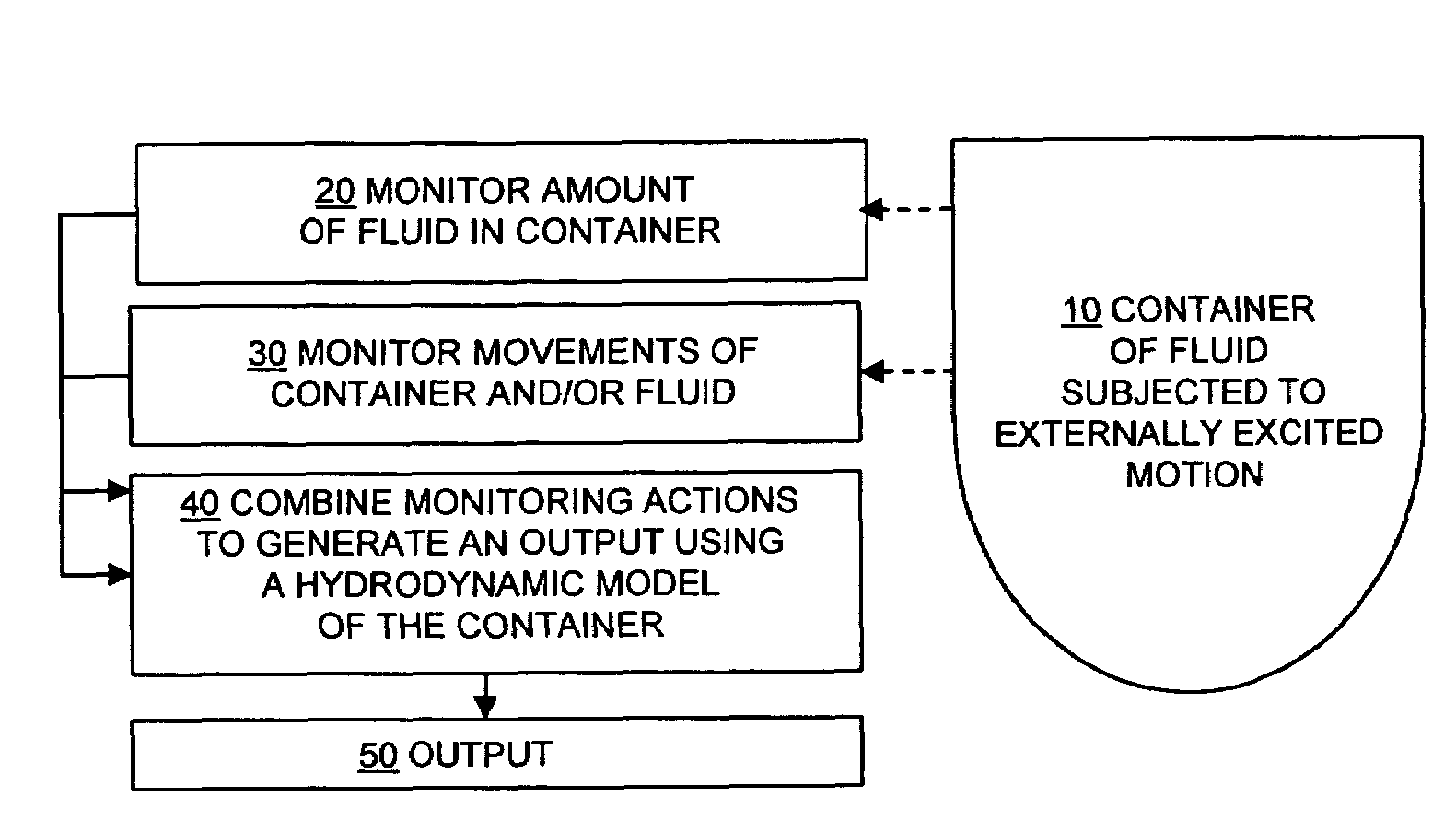

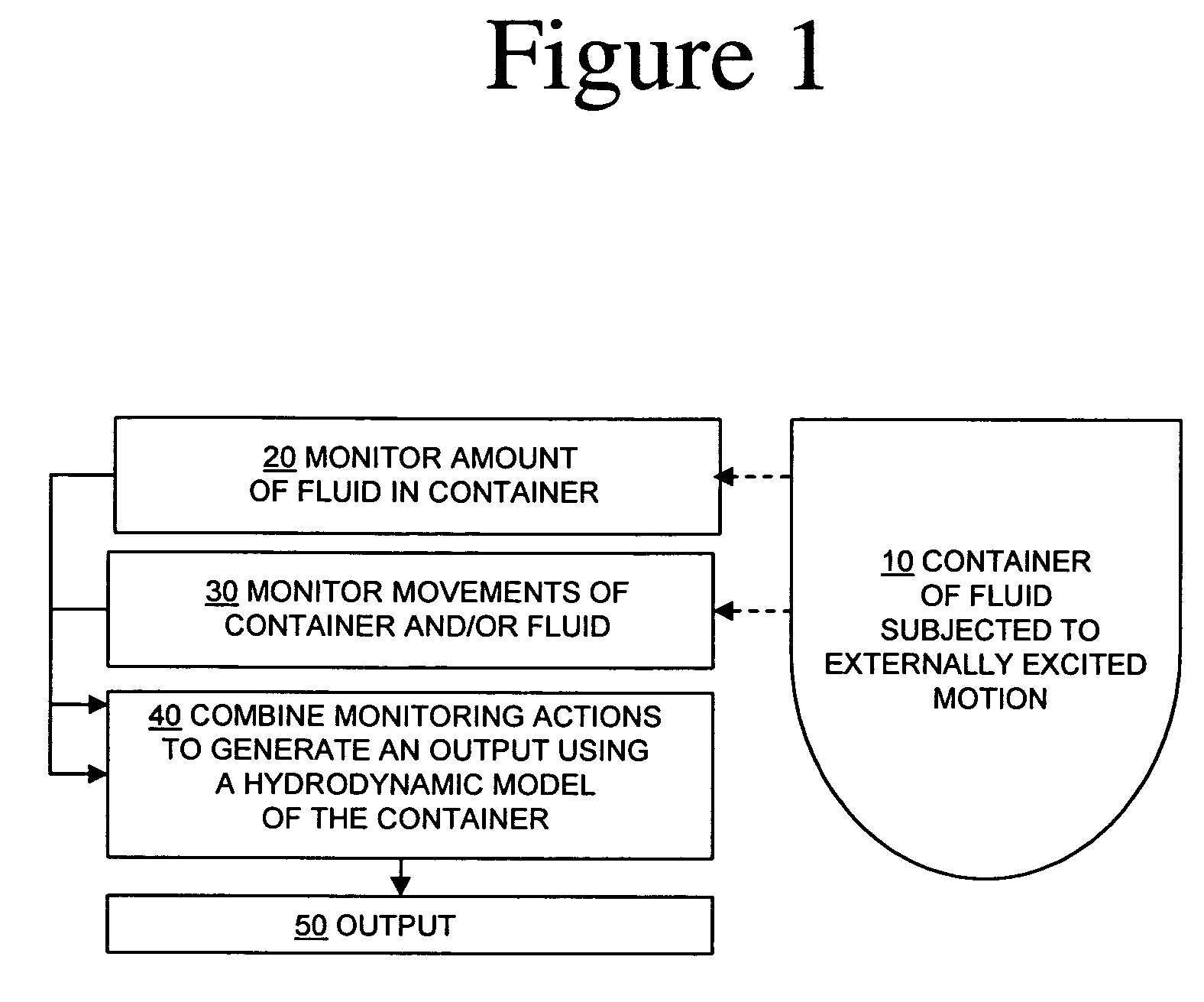

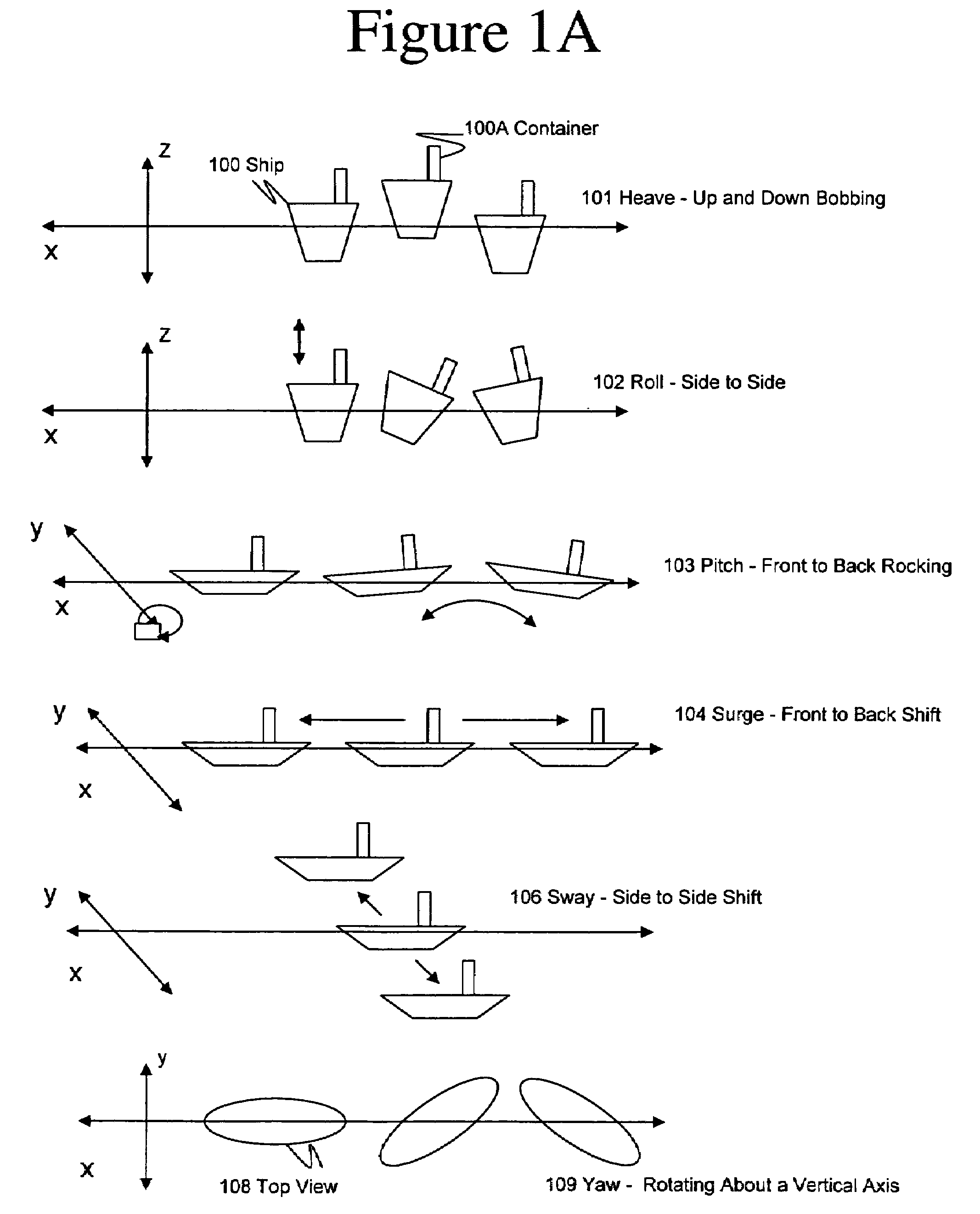

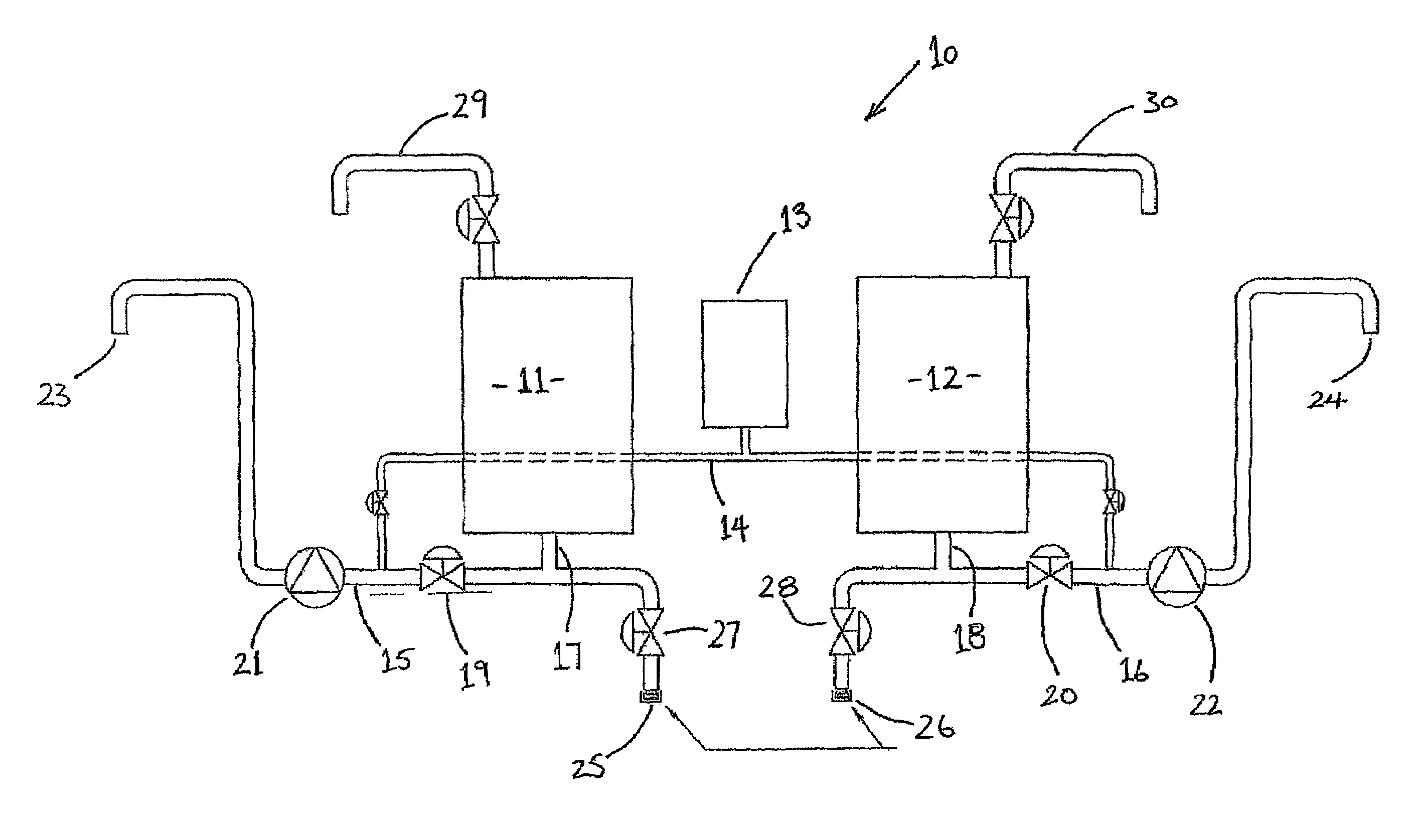

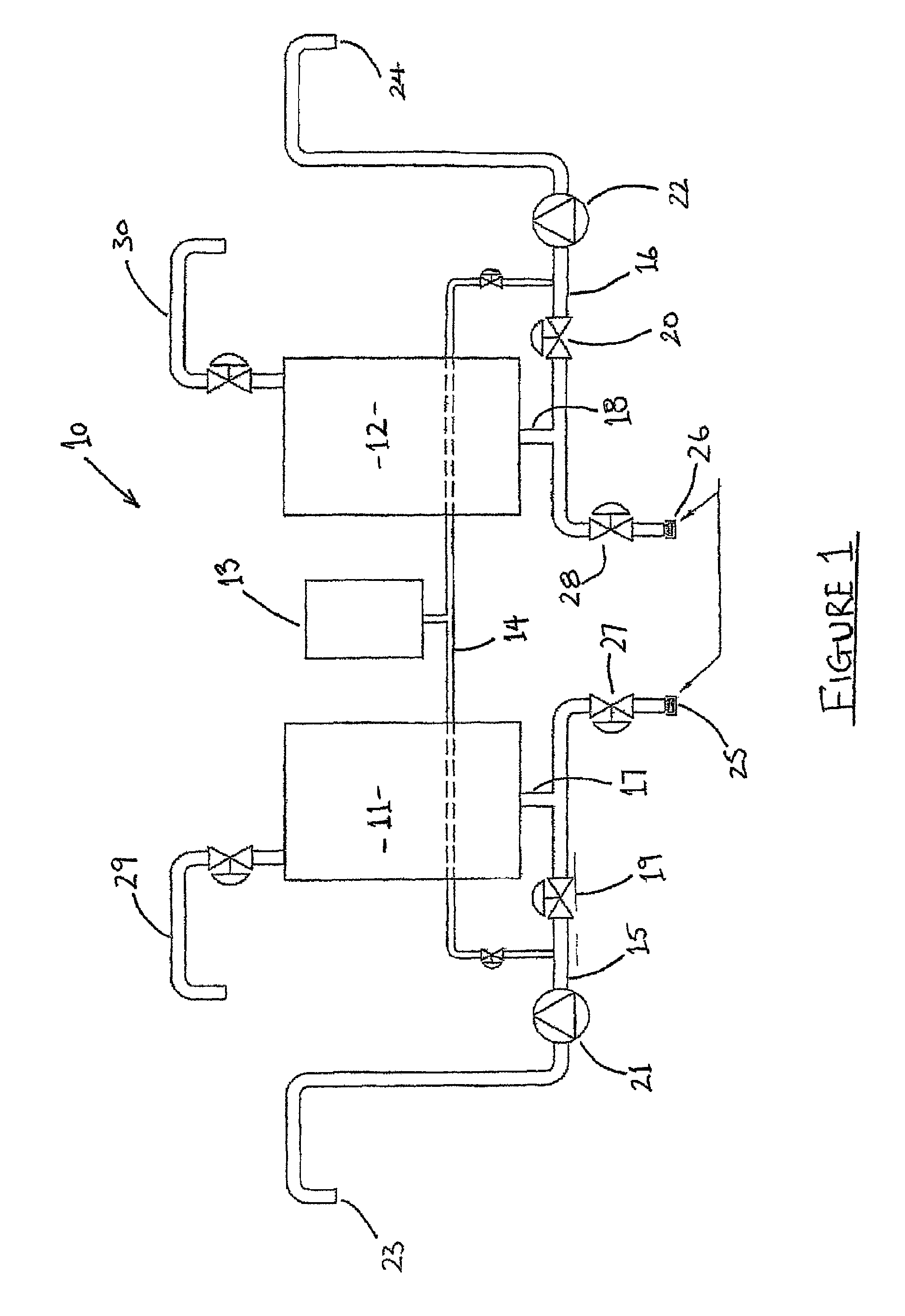

Process control architecture with hydrodynamic correction

Methods and systems for controlling processes related to the amount of fluid in a container subjected to externally-excited motions. Fluid level sensor measurements in processing tanks on-board boats are confused by ocean waves and swells. A hydrodynamic model of a fluid in a tank can be constructed using non-linear dynamic model algorithms with inputs such as multi-axis accelerations, fluid viscosity, and apparent level measurements. The model can be used to filter-out boat motion disturbances to obtain a corrected level of the fluid in the tank. The corrected fluid level signal can be further processed using a dynamic model of the tank and associated input and output flow rates in a closed loop observer. The methods and systems are especially advantageous for offshore equipment such as cementing and fracturing ships.

Owner:HALLIBURTON ENERGY SERVICES INC

Dry mix cement composition, methods and systems involving same

InactiveUS7691198B2Modifies strengthEnhances polymerisationSolid waste managementAlkali metal silicate coatingsMulti phaseMaterials science

A dry mix cement composition including an alkaline multi-phase aluminosilicate material, wherein the alkaline multi-phase aluminosilicate material provides a source of alkaline and soluble silicate to the cement composition.

Owner:ZEOBOND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com