Patents

Literature

144 results about "Feed type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed Types And Preparation. The different categories of feed are cereals, protein feeds, bulk feeds, compound feeds and forages. Cereals. These are energy giving feeds which have been treated to reduce the amount of starch that is present in them and to make them more digestible for the horse.

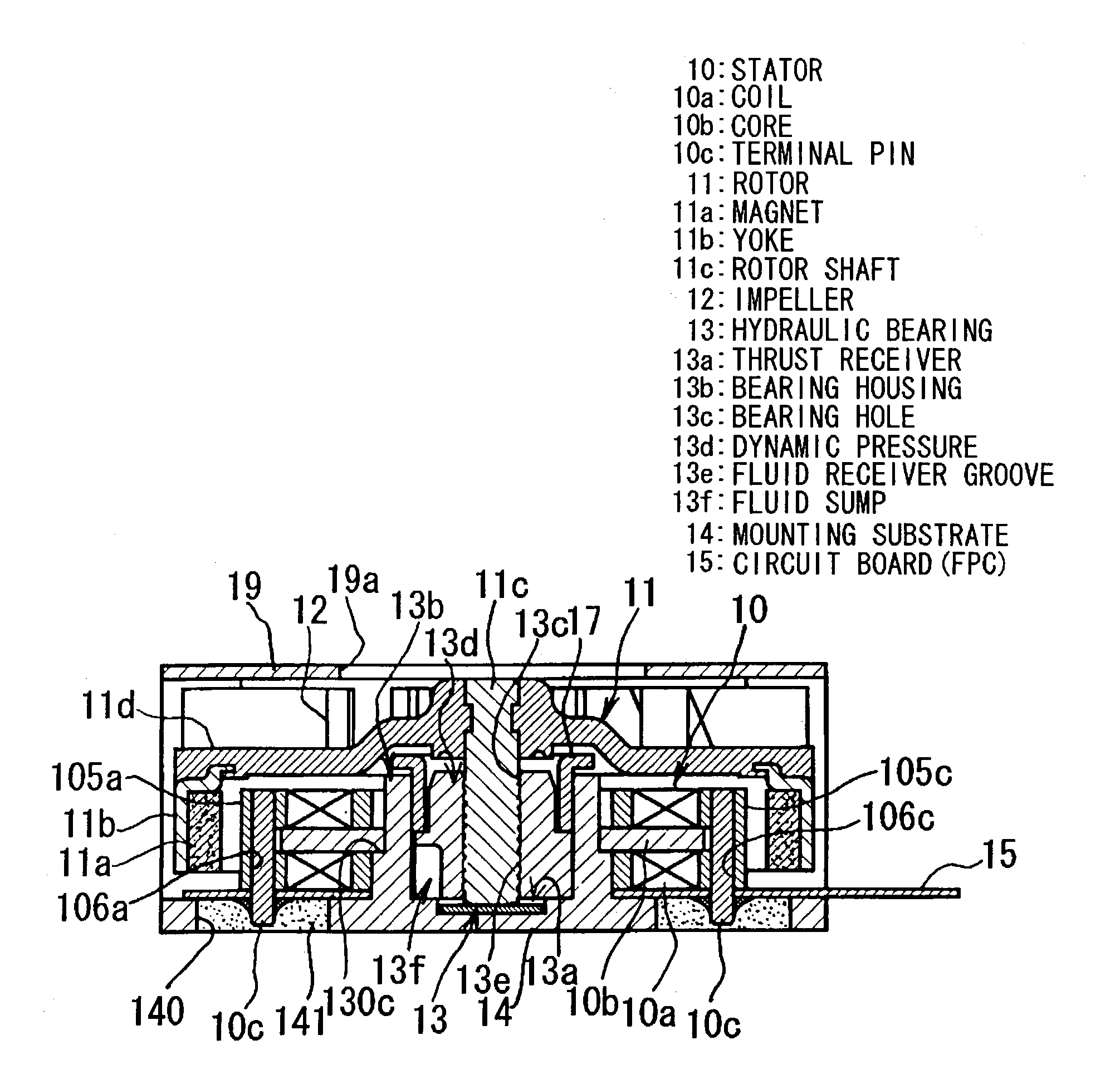

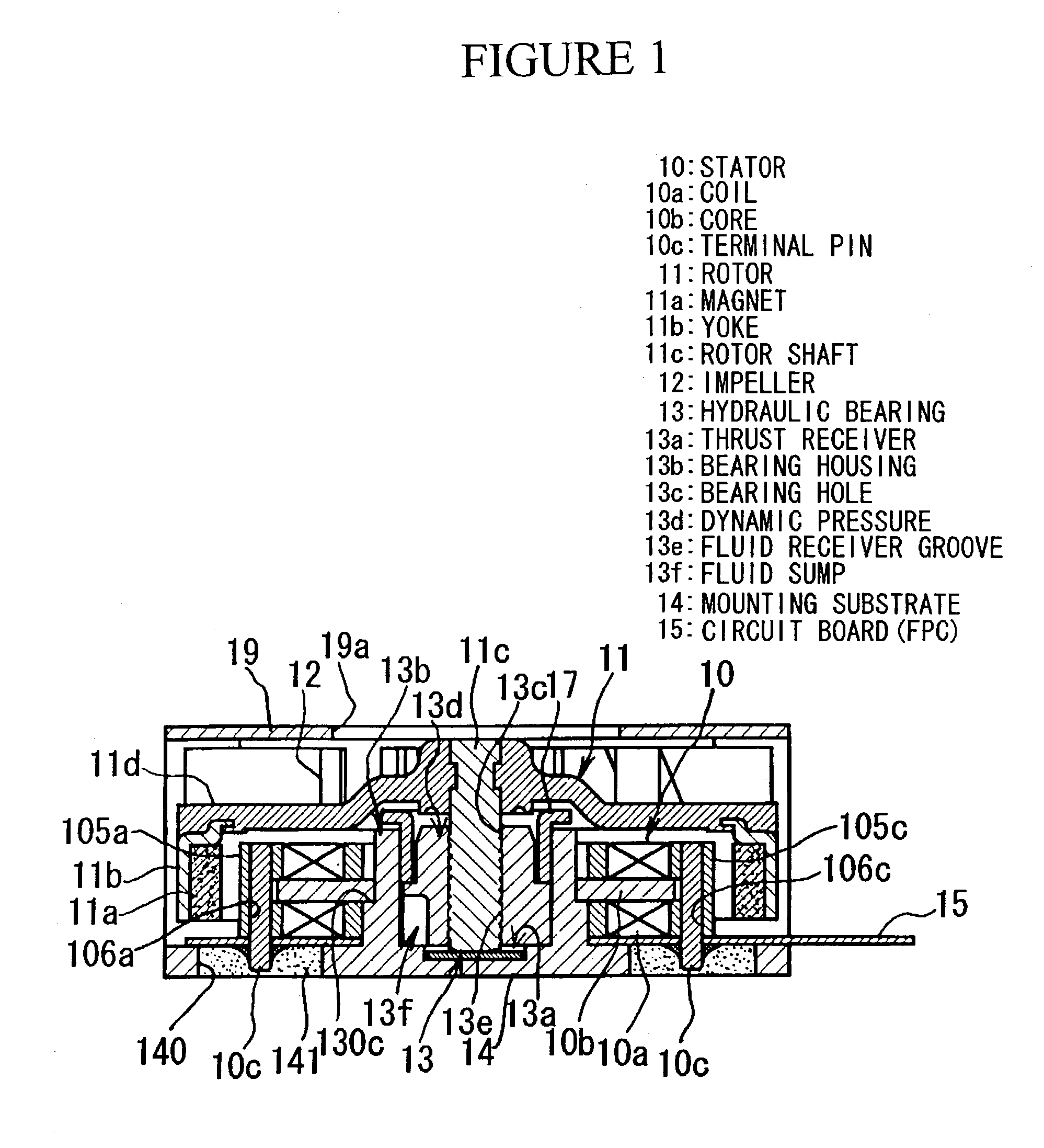

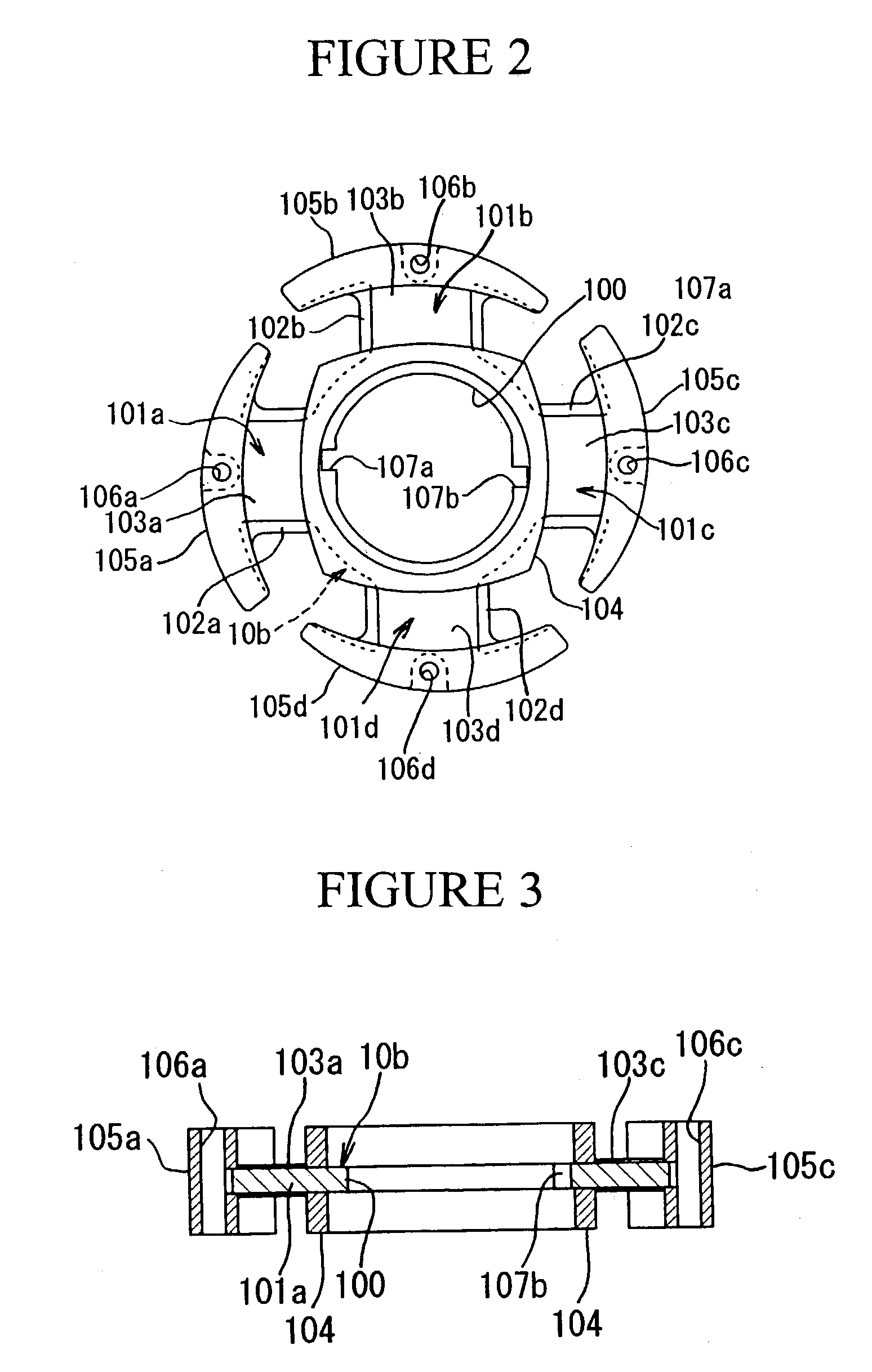

Fluid dynamic pressure bearing for small flat motor, small flat motor, fan motor, and forced air feed type air cell

This invention has a stator 10 having a coil 10a wound on a core 10b, a rotor 11 having a yoke 11b that holds a magnet 11a facing the core 10a, in which an impeller 12 is attached to the rotor 10 that is supported by a hydraulic bearing 13 having a fluid sump 13f that communicates with the thrust receiver 13a of a bearing housing 13b and a fluid receiver groove 13c, and that is formed around the outer periphery of a hydraulic sleeve 13d fitted within the inner cylinder of the bearing housing 13b.

Owner:NAMIKI PRECISION JEWEL CO LTD

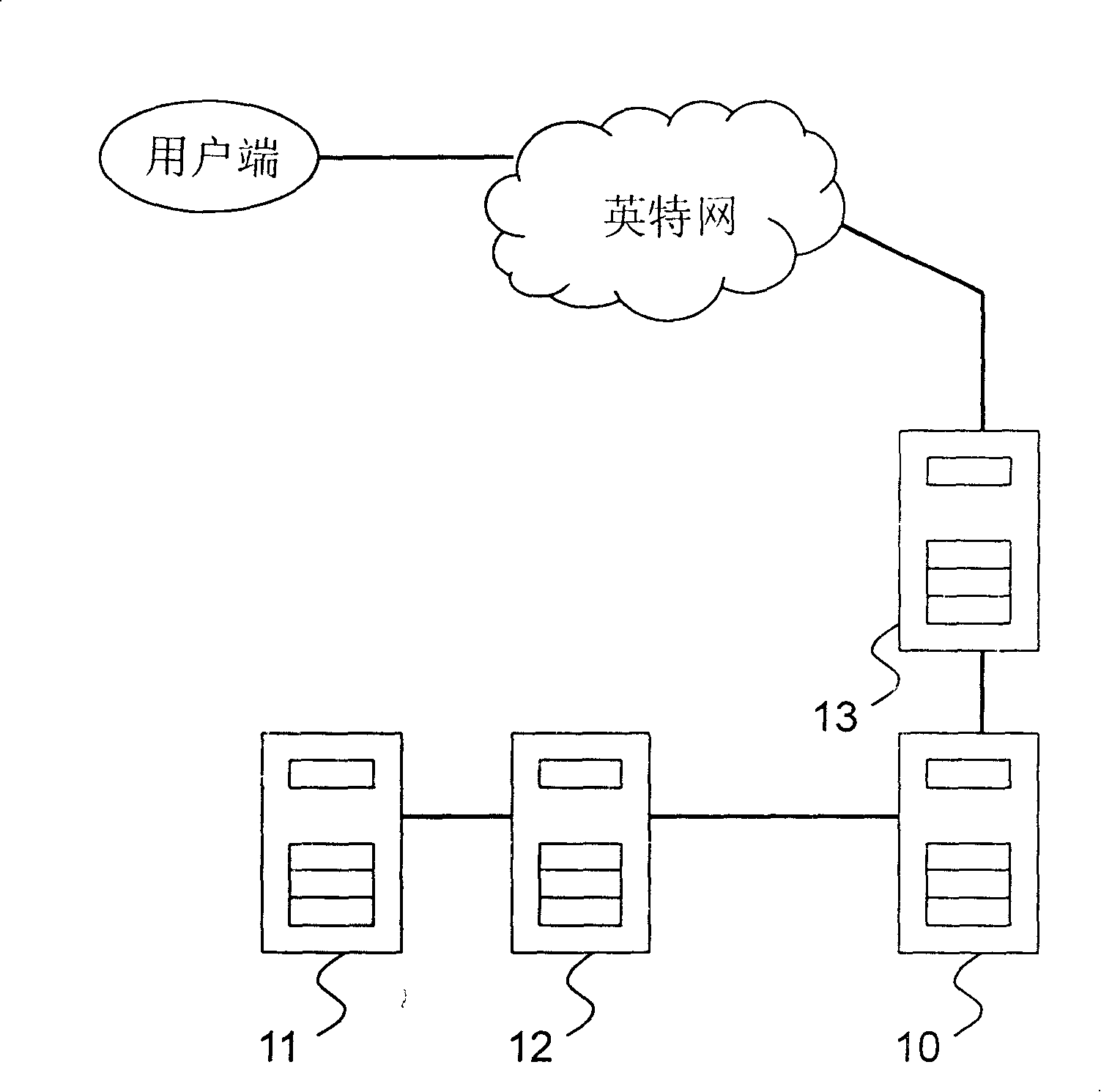

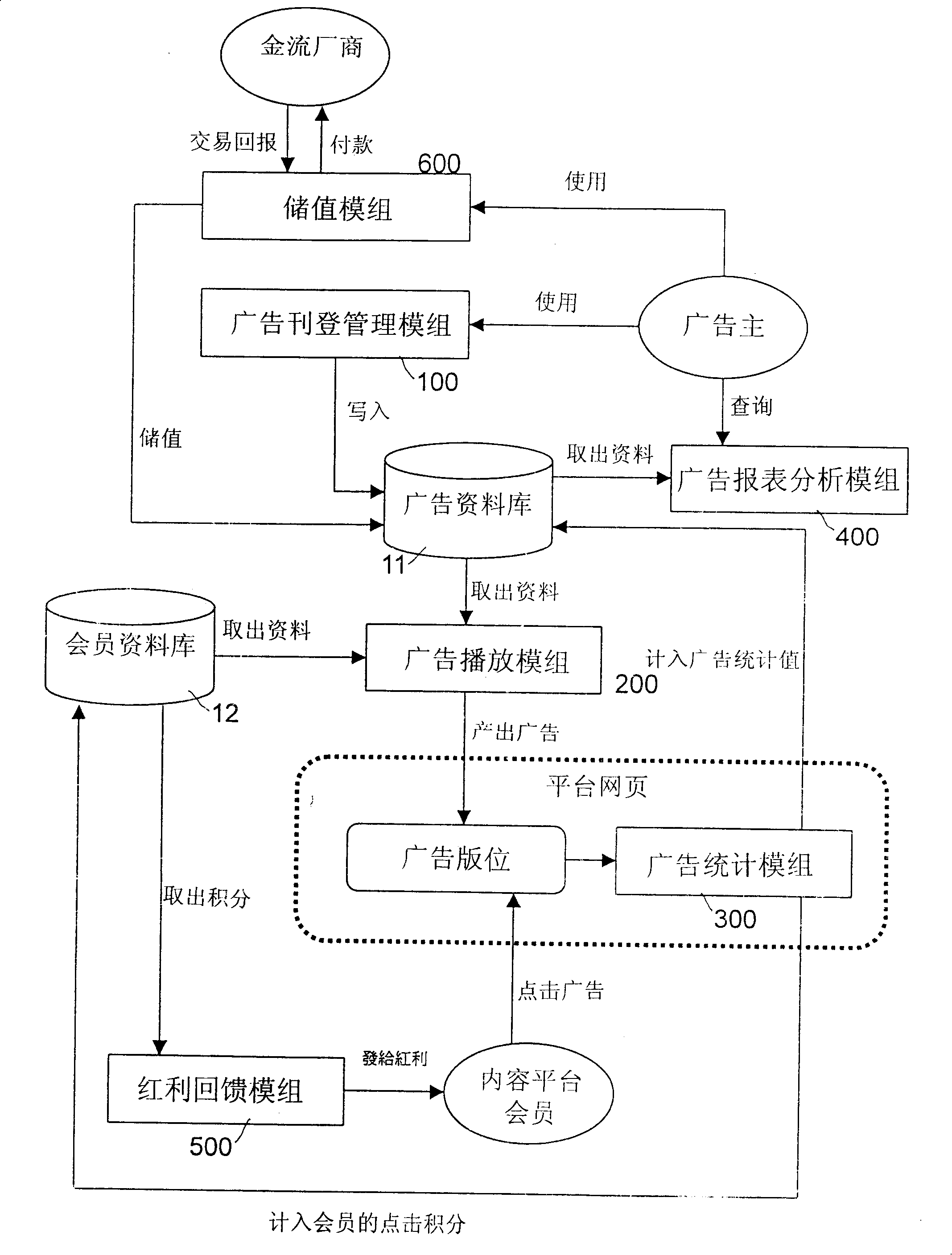

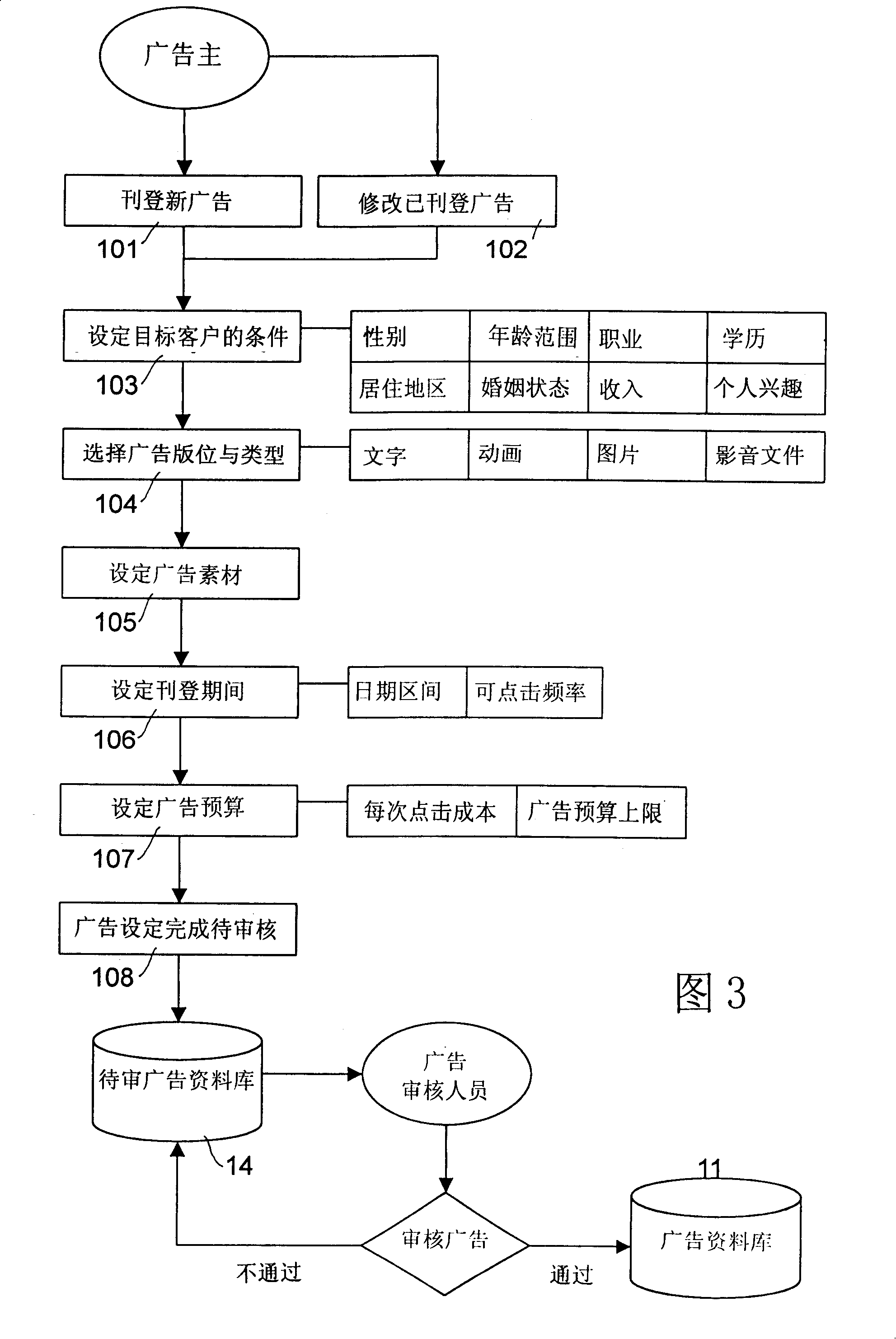

System for management of mutually feeding type website advertisement

InactiveCN101226618AEnsure advertising effectivenessIncrease advertising revenueCommerceCredit cardManagement system

A mutual-fed website advertisement management system comprises an advertisement data base, a member data base, a value storing module, an advertisement publishing module, an advertisement playing module and a bonus back-feeding module, wherein the advertiser can publish advertisement via the advertisement publishing module, remits deposit in the value storing module as the advertising fee, the content of the advertisement is stored in the advertisement data base and can assign member who has specific conditions to play, when the website member plays the advertisement, the bonus back-feeding module sends bonus to the member who plays the advertisement as the feedback, simultaneously, the value storing module deducts the deposit or automatically deducts money by using credit card as the advertisement cost, basing on the method, member has bonus feedback when plays advertisement, which increases the willing of the member to play advertisement, also the advertiser can promote sales and increase playing rate aiming at specific consumer groups. Further, the invention enables the advertiser to design, monitor and control the exposure of the single advertisement to every member or the times of clicking advertisement, thereby reaching mutual benefit.

Owner:SUNFUN INFO

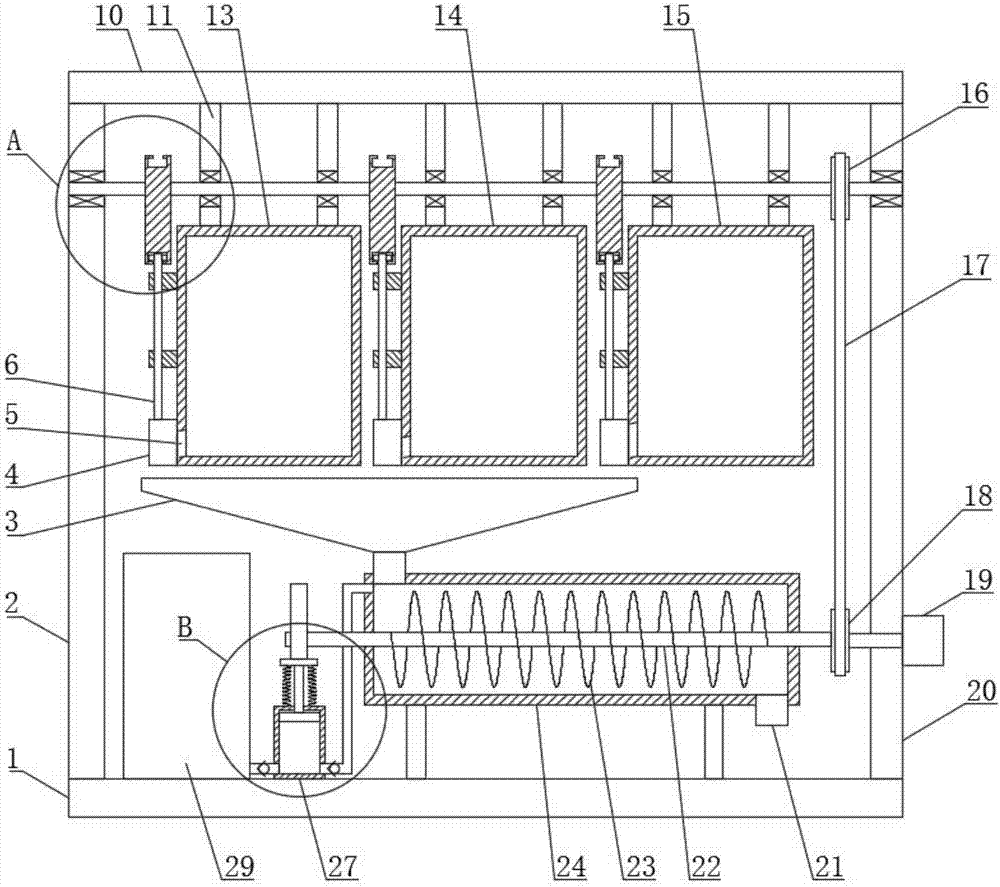

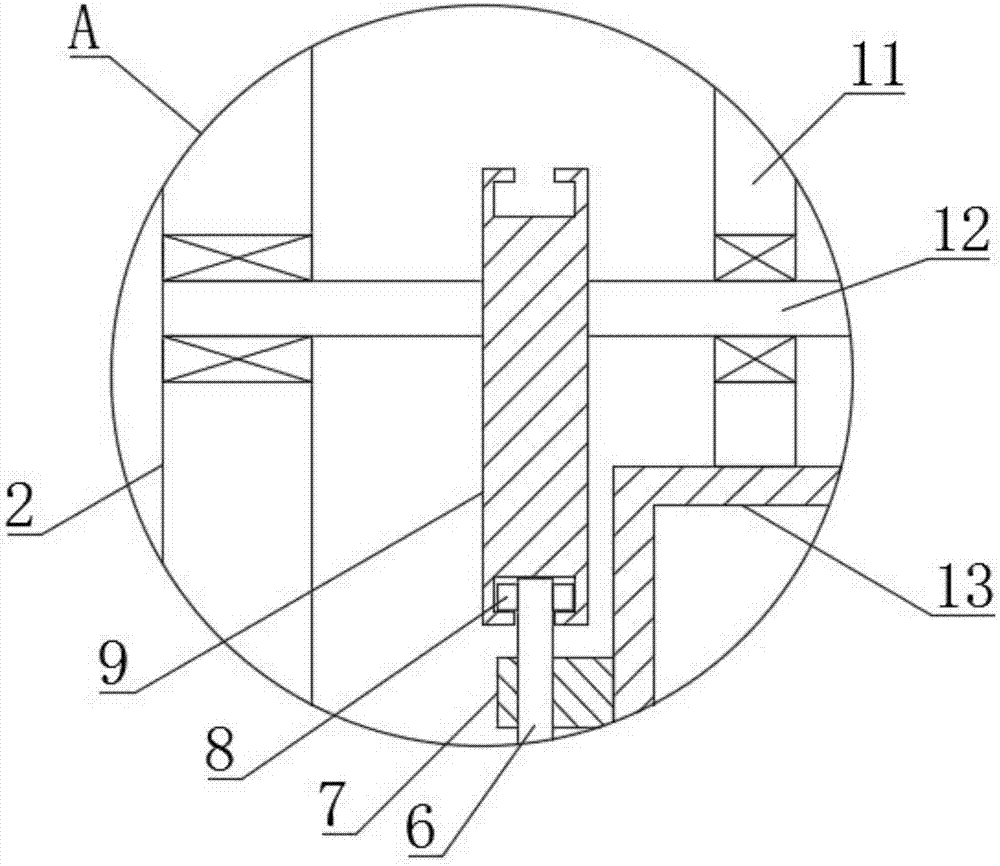

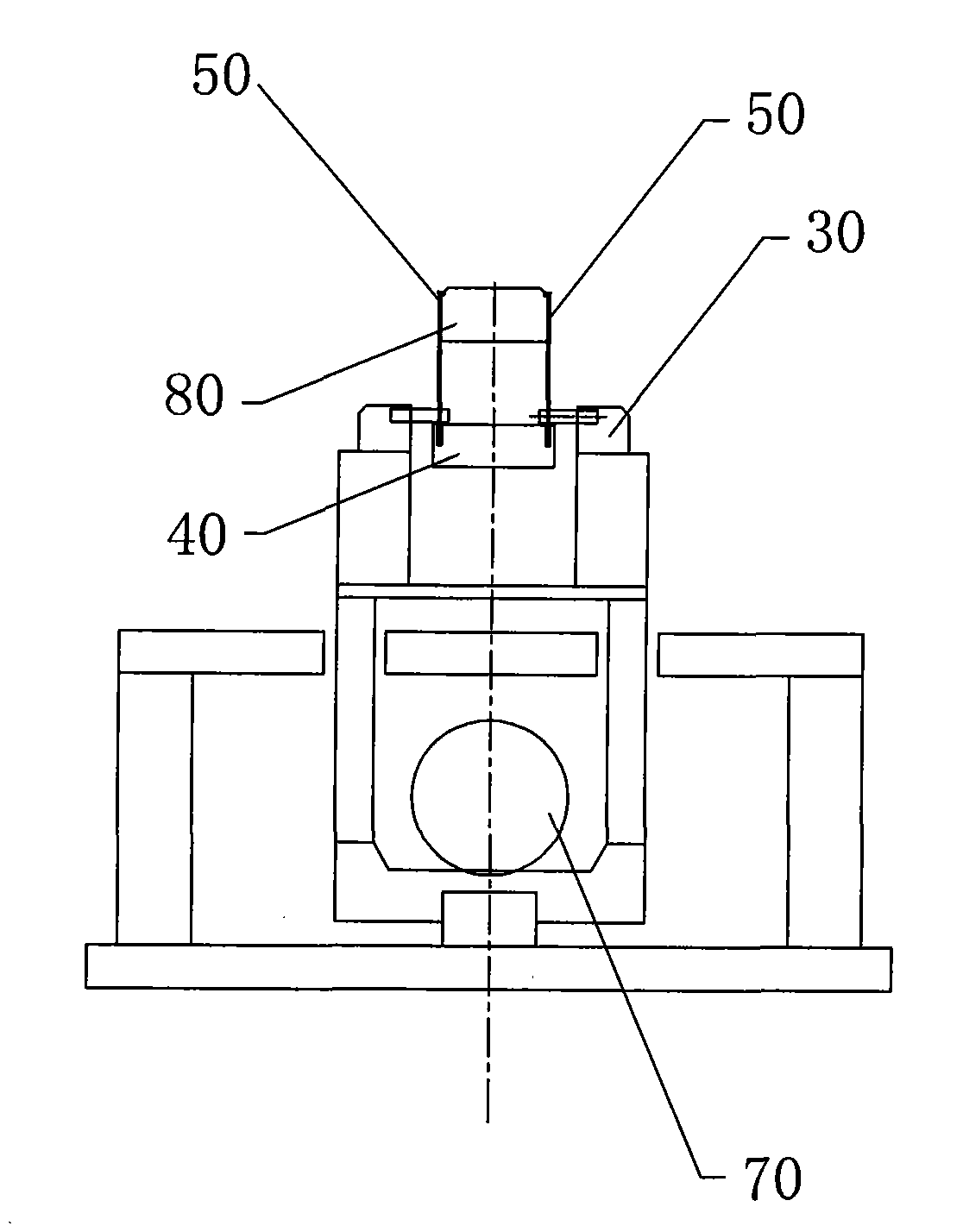

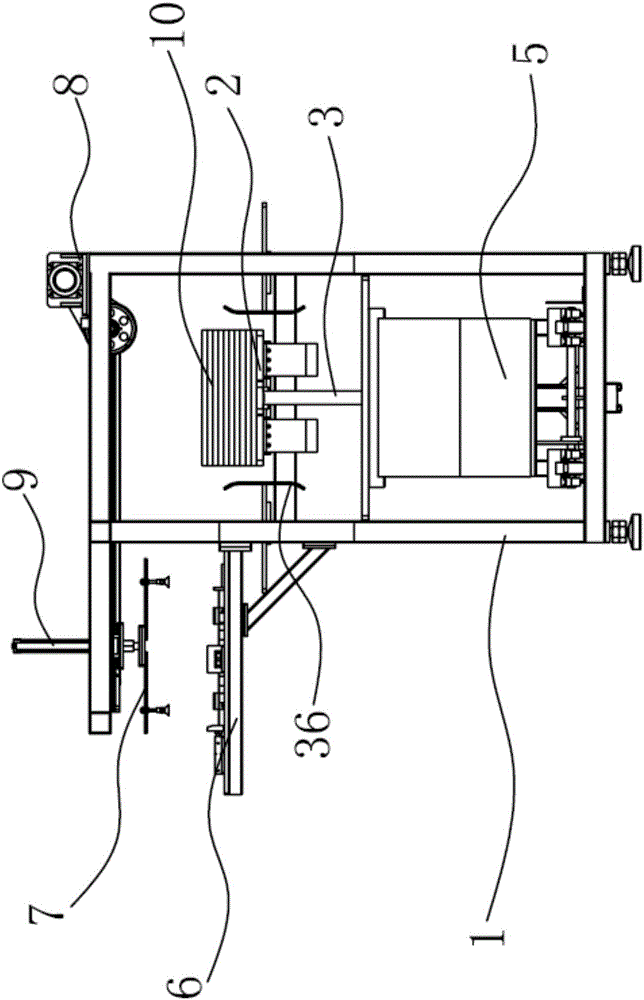

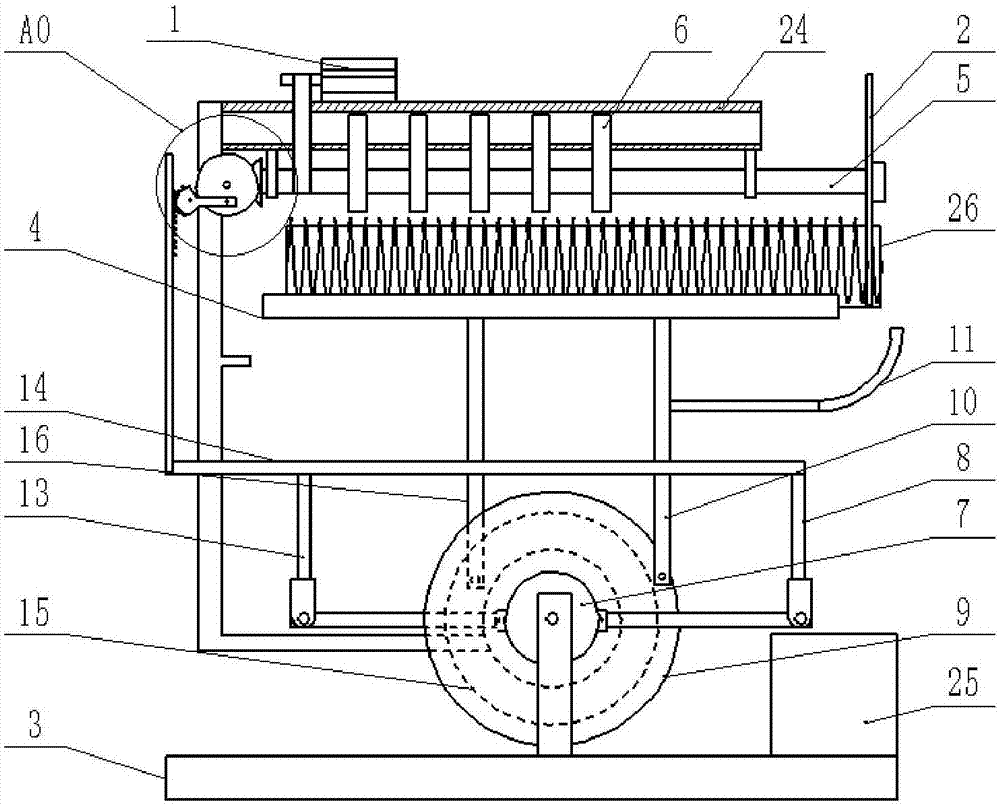

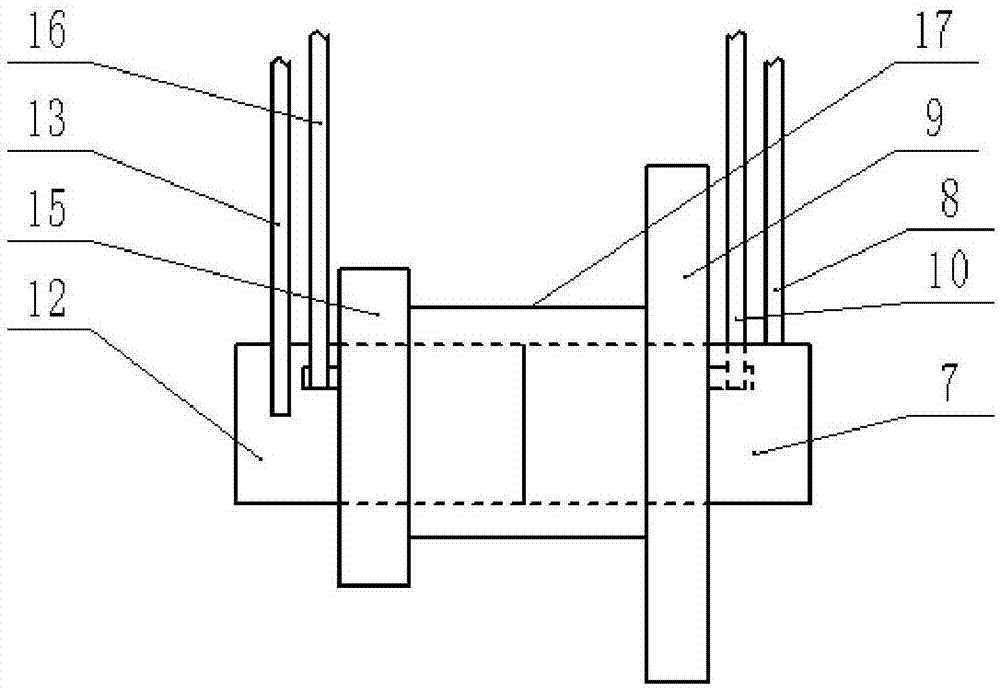

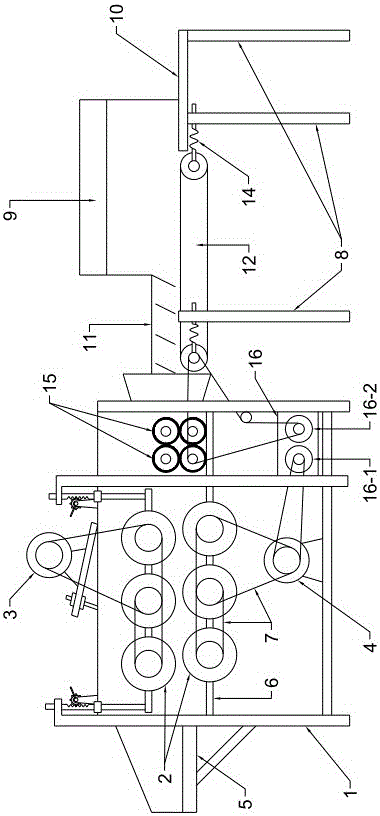

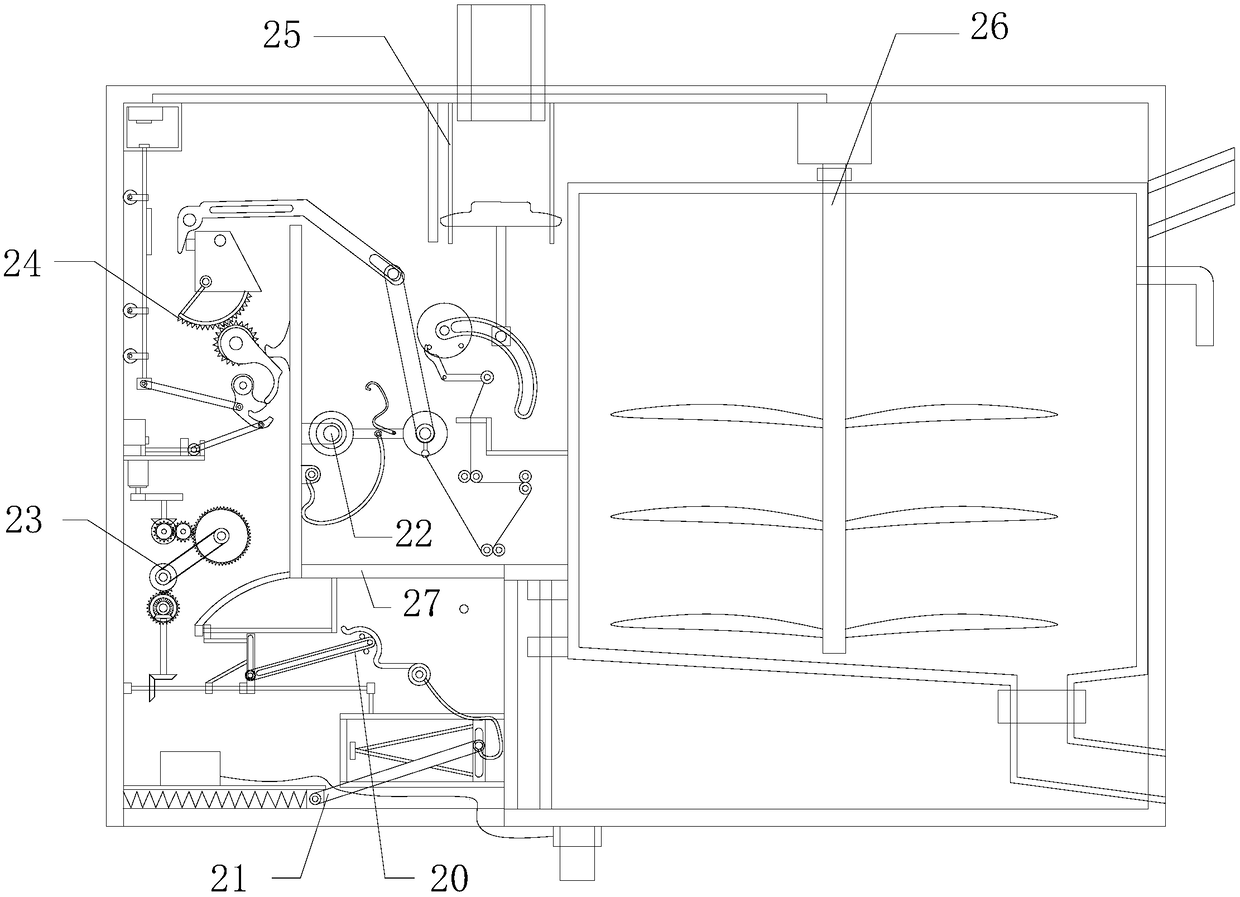

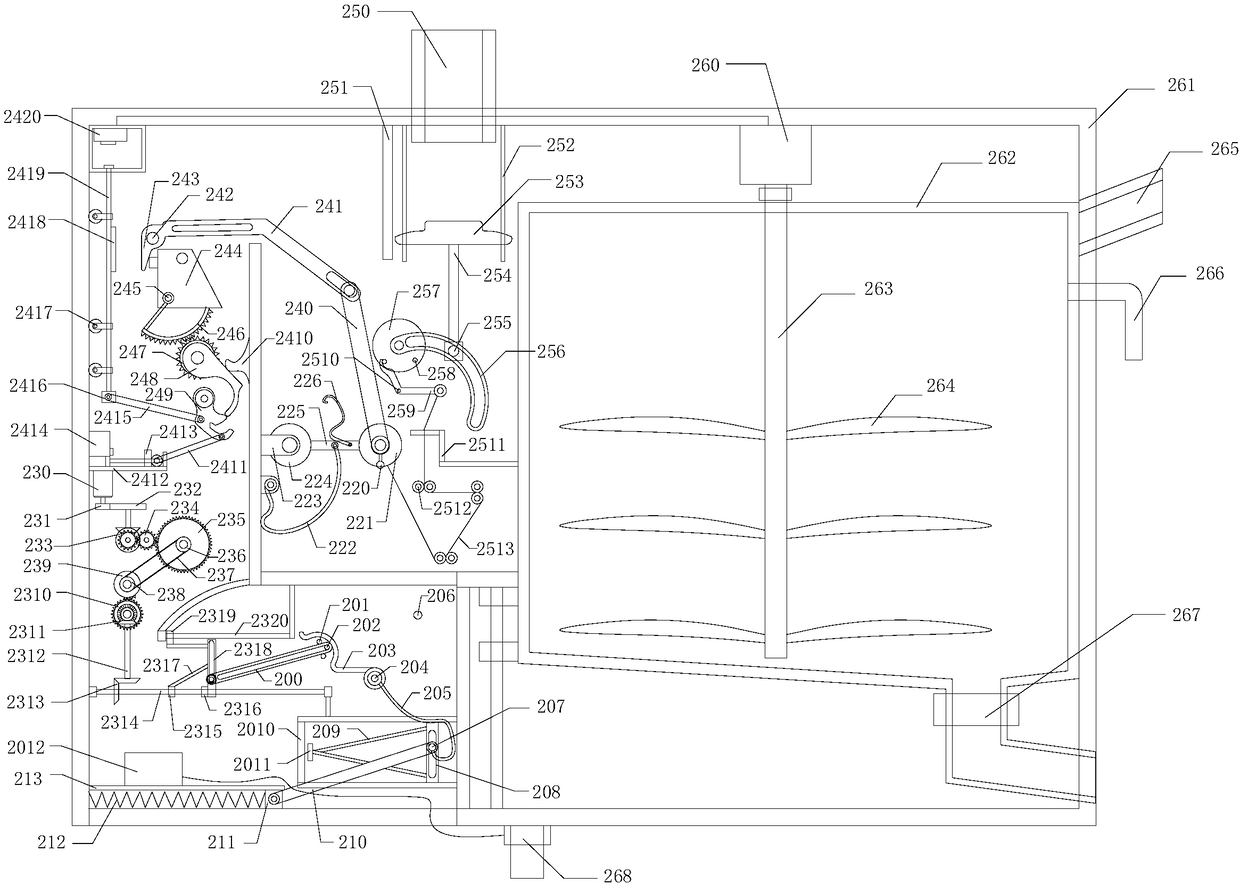

Self-feeding type quantitative matching concrete mixer

InactiveCN107263729AQuality improvementEasy to operateMixing operation control apparatusIngredients proportioning apparatusArchitectural engineeringFeed type

The invention discloses a self-feeding type quantitative proportioning concrete mixer. The boards are respectively fixed with sand boxes, cement boxes and stone boxes, and the sand box, cement box and the bottom of the left side wall of the stone box are all provided with discharge ports; the left support plate and the right support plate are rotatably connected with a first shaft, and the second Three first cams are installed on a rotating shaft, the bottom of the first cam is connected with the first connecting rod through the pin shaft, the bottom of the first connecting rod is connected with a baffle, and the three baffles are respectively matched with the discharge port; Fixed installation with a stirring box. The invention makes the baffle plate move up and down through the rotation of the first cam to control the automatic unloading of sand, gravel and cement; the discharge ports of different sizes are set to automatically proportion the materials, which greatly improves the working efficiency.

Owner:康泽波

Formulation and method of manufacturing an almond leaf fodder

An improved animal feed or fodder formulation for grazing animal is provided. The animal feed is formulated such that a significant portion of the nutrient is derived from almond leaves or almond leaf by-products. The animal feed formulation may be used on any grazing type of livestock including, cattle, sheep, goats, horses, or pigs. The formulation may also be used in a number of different feed types.

Owner:CHOU CHIN PAO

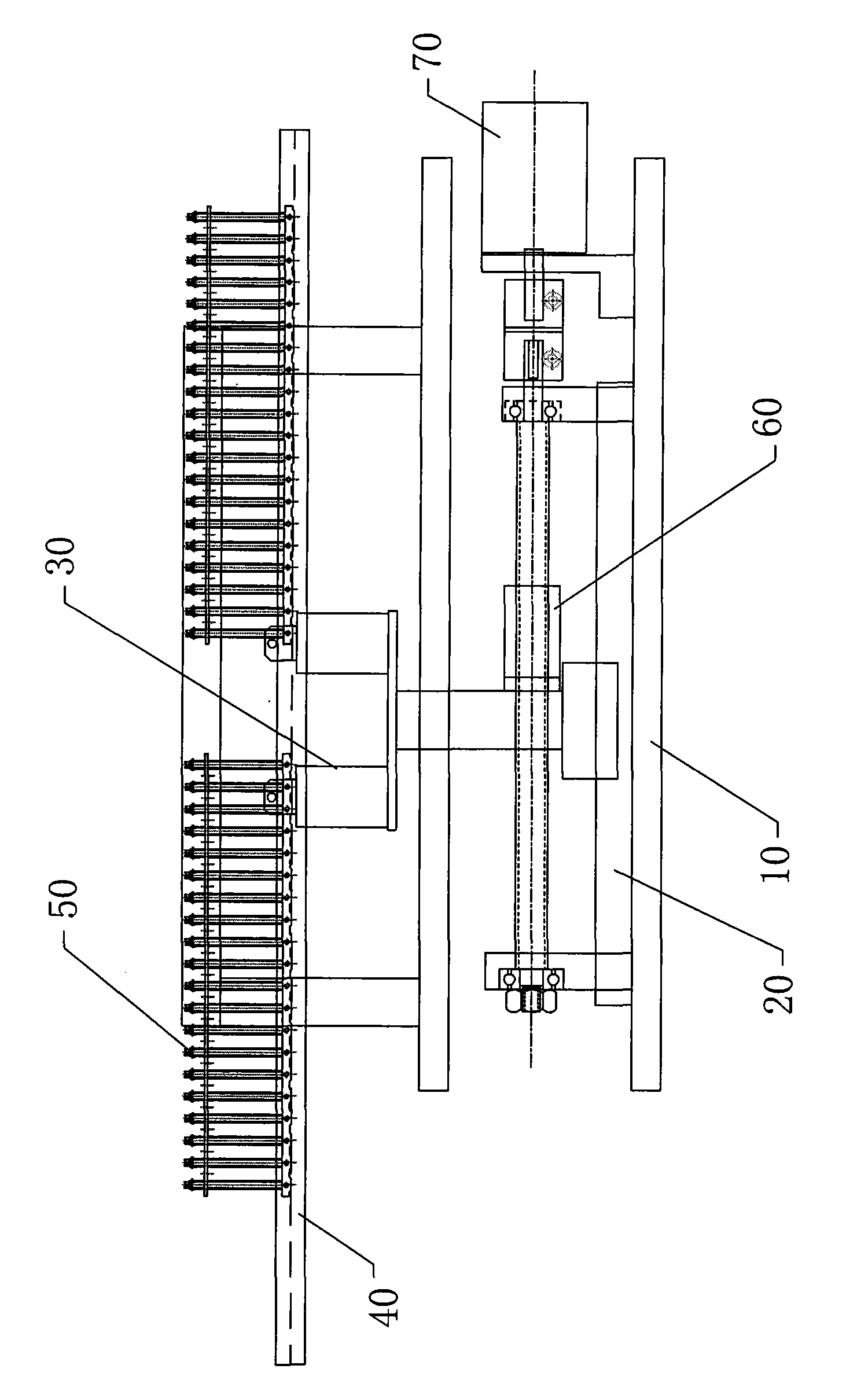

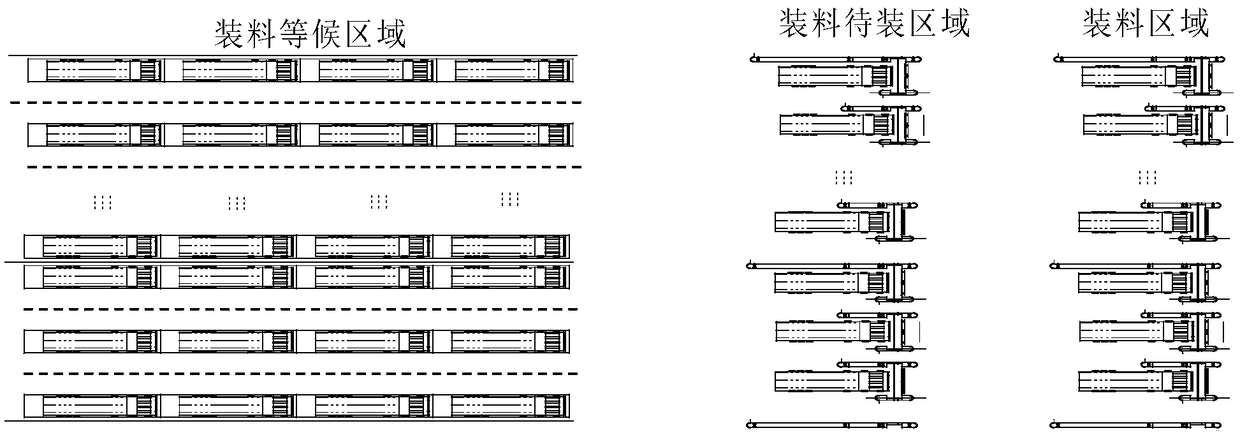

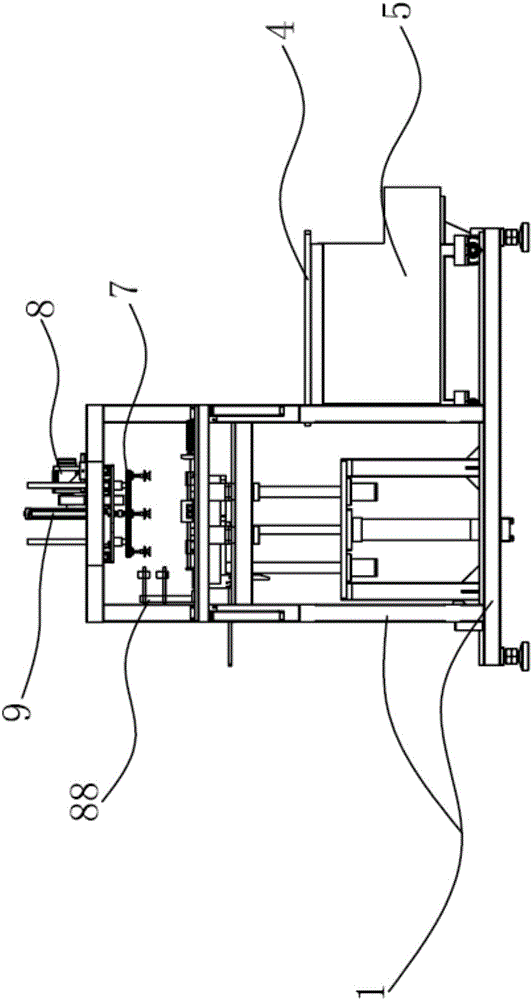

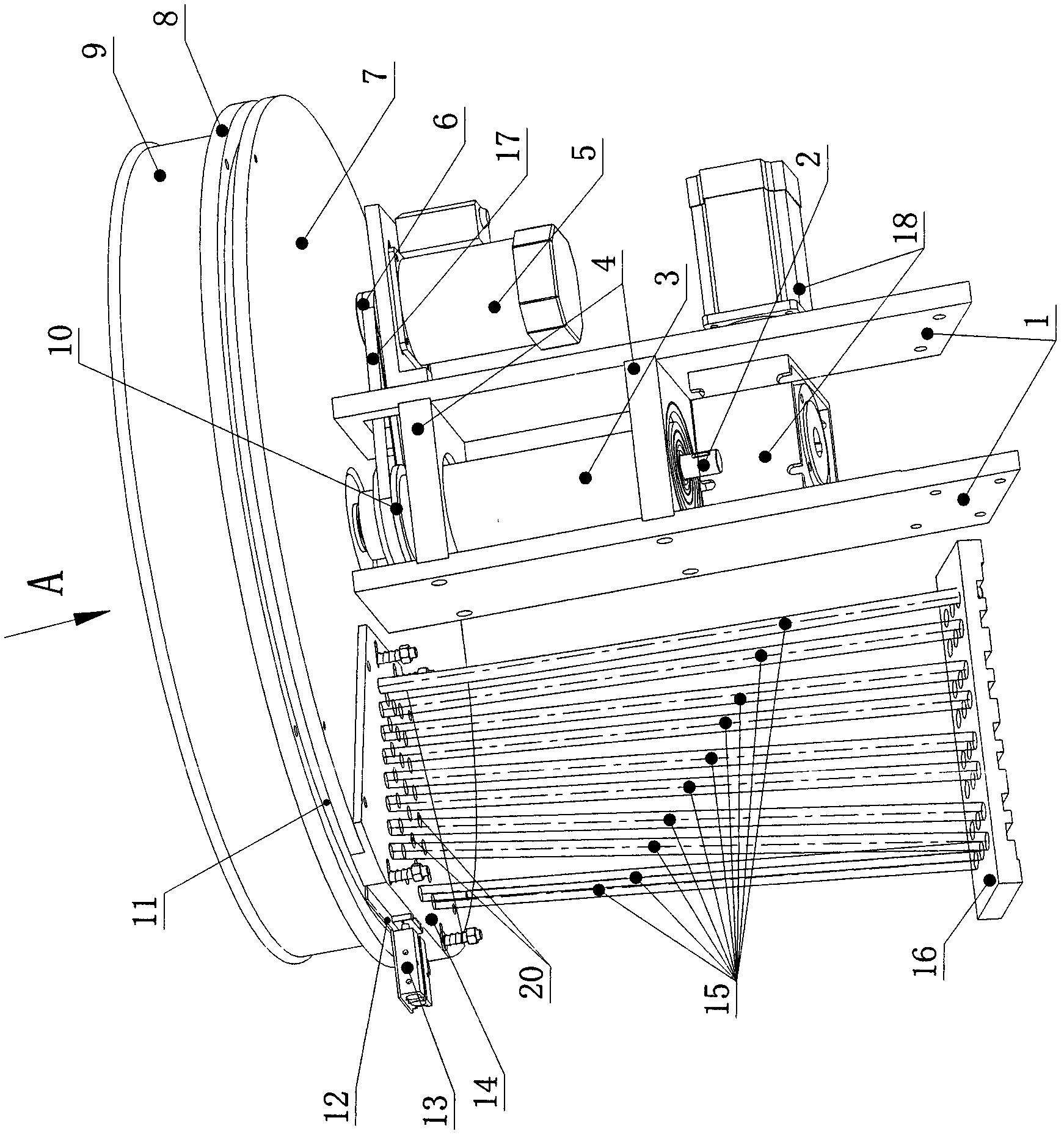

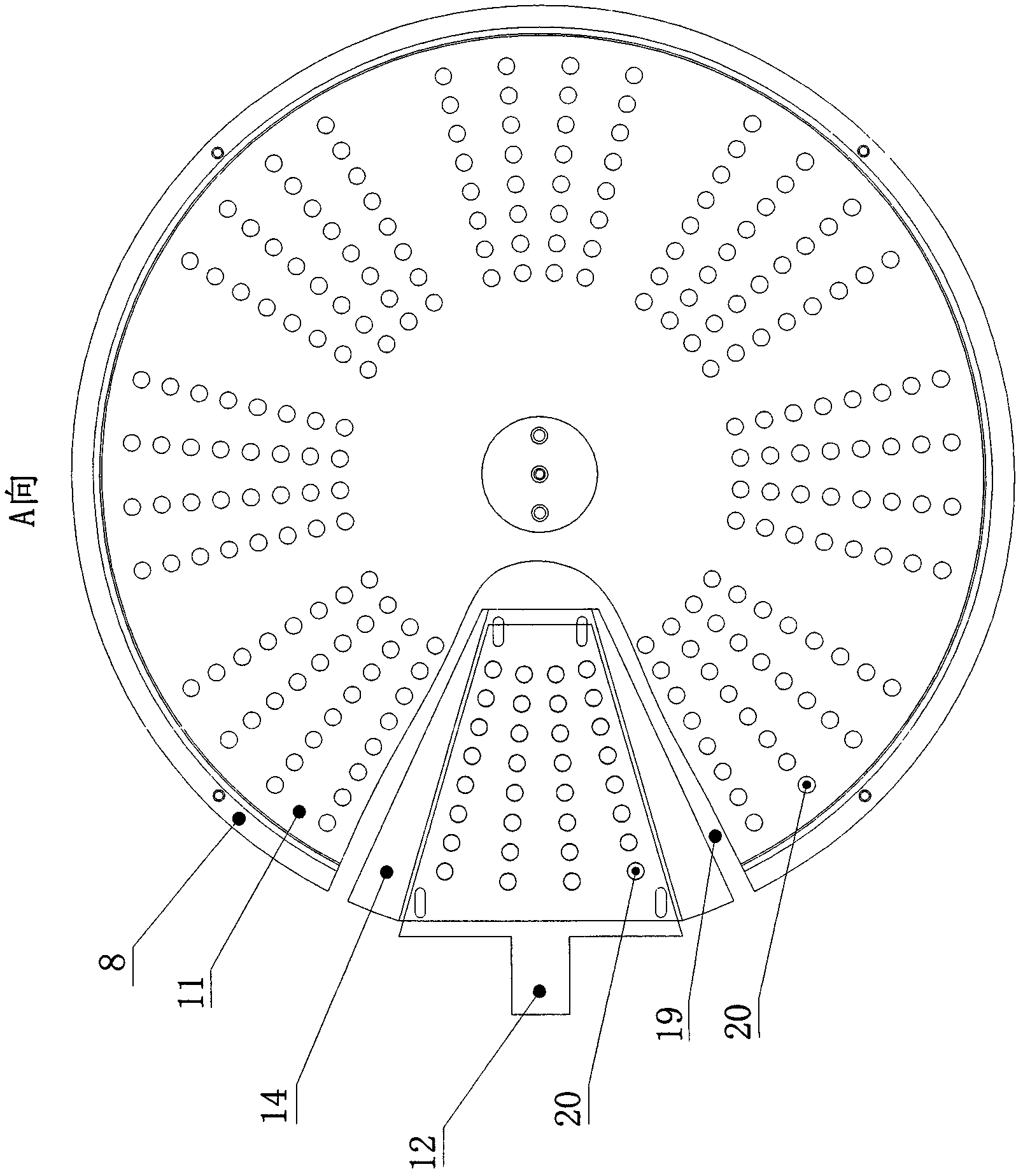

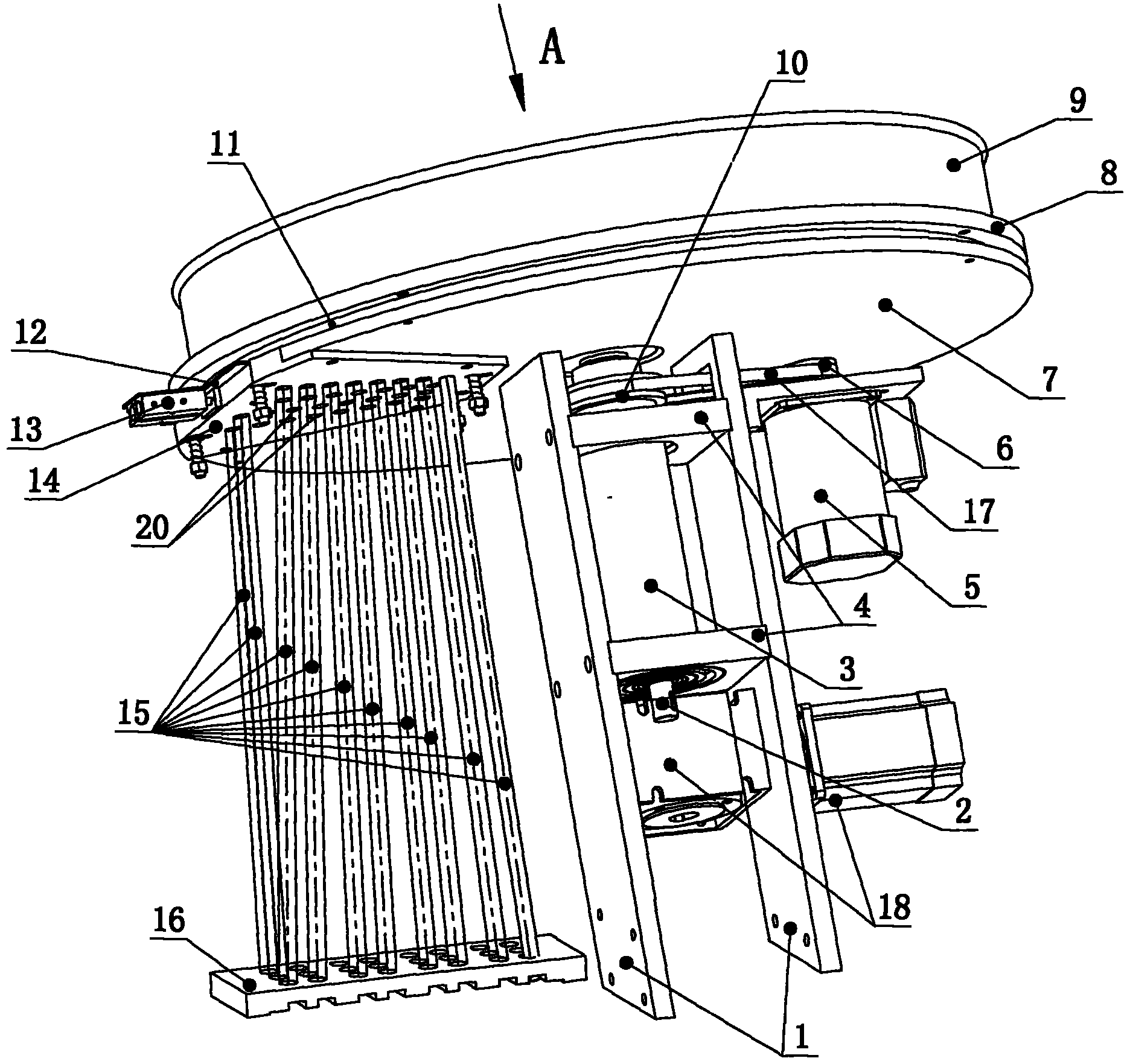

Double-row track feed type system for specific feeding of vertical LED lead frame

The invention relates to a feeding system, in particular to a double-row track feed type system for specific feeding of a vertical LED lead frame, which is applied to a wire bonder. The system comprises a base frame, wherein a sliding block device is arranged at the upper side of the base frame, a support claw is arranged on the sliding block device and can slide on the sliding block device, two rows of delivery tracks are arranged at the upper side of the support claw and used for delivering an LED support to the output position from the input position, the support claw is used for transferring the LED support product to the output position from the input position, a motor device is also arranged on the base frame, a ball screw is connected on a motor output shaft and used for moving theposition of the support claw, and the motor is used for providing the rotating powder for the ball screw. The invention has the beneficial effects that the system utilizes the two rows of the tracks for feeding so that the feeding and the discharging of the materials can be respectively performed; the double-row track feeding system can perform back-forth feeding and is used for supplying materials in parallel for an operating platform; and the system aims at eliminating the feeding time, keeping the normal running of production and improving the production efficiency.

Owner:英展有限公司

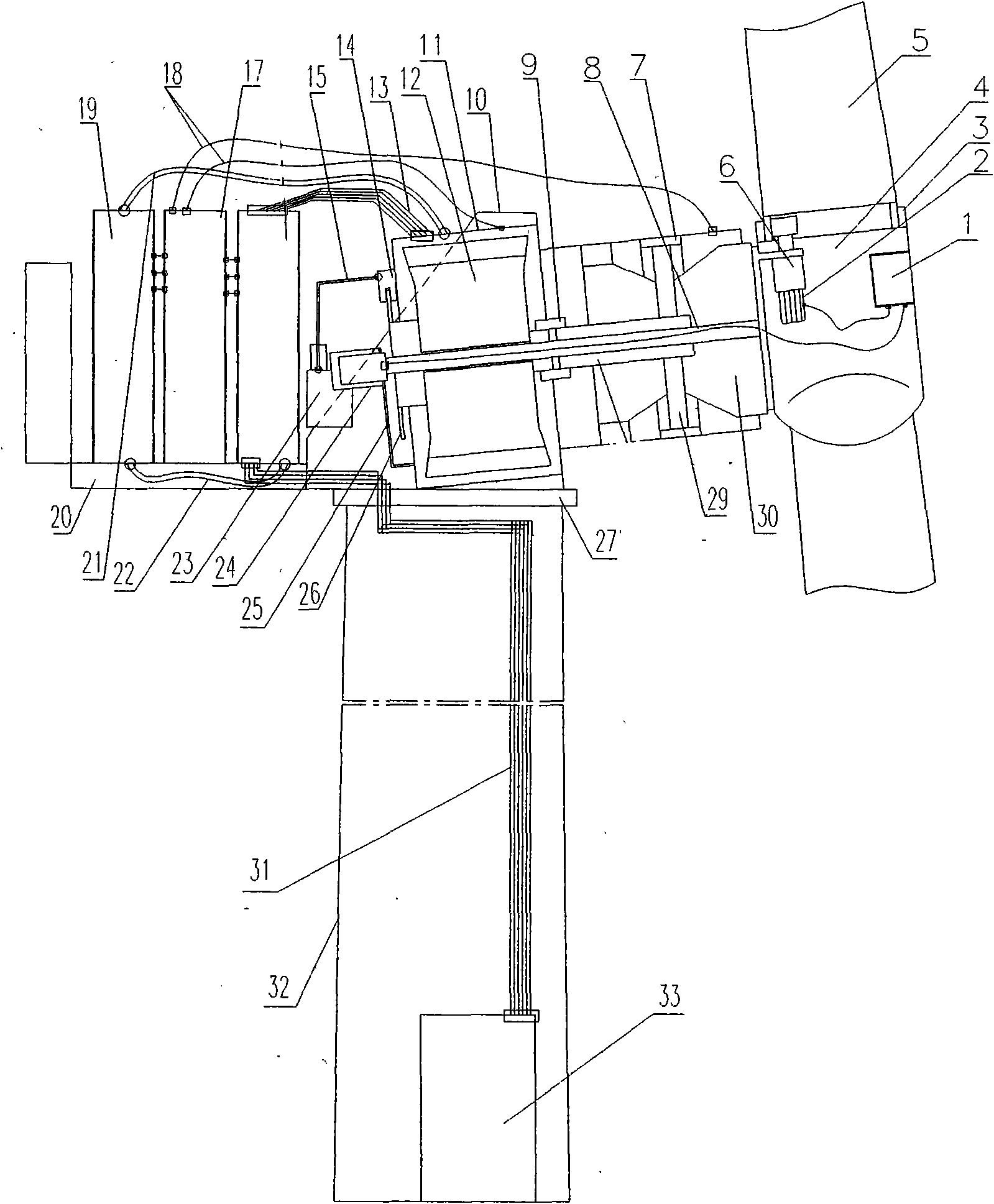

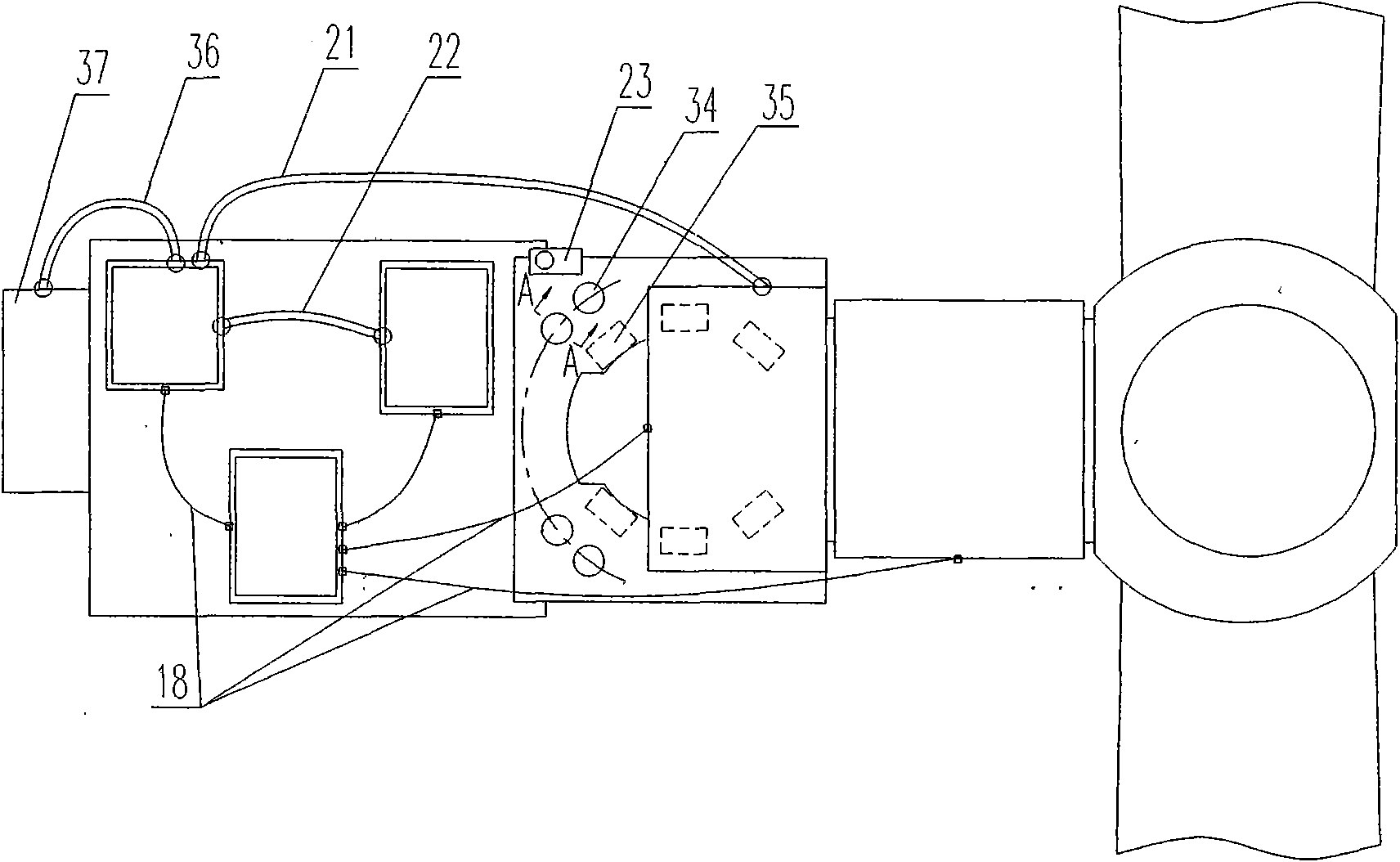

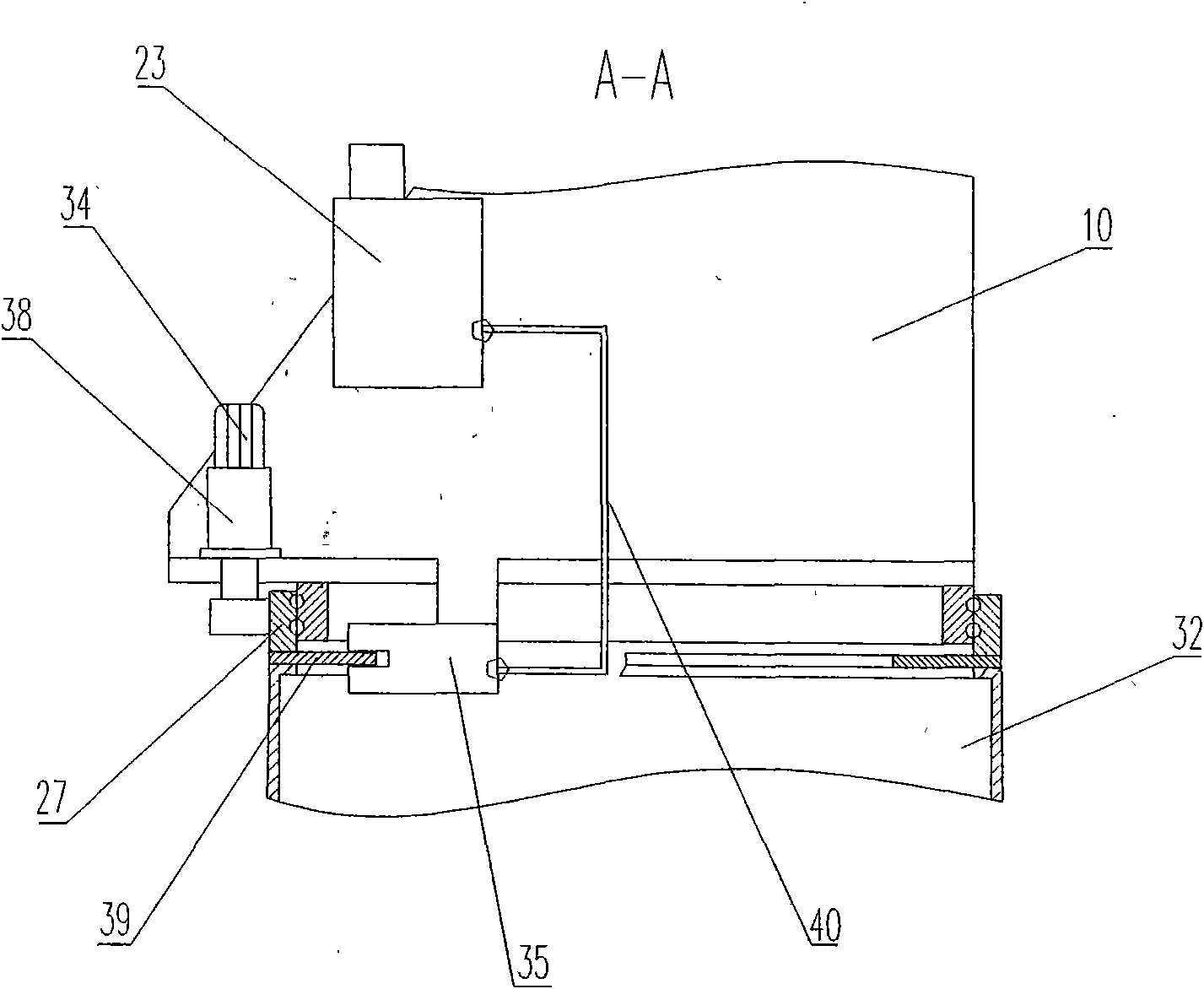

Grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set

InactiveCN101660499AReduce maintenance costsImprove reliabilityWind motor controlMachines/enginesConstant frequencyLow speed

The invention provides a grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set which is developed against two popular types of direct-driven type anddouble-feed type in China presently. The grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set consists of an impeller system, a transmission system, a support system, a yaw system, a hydraulic system, a temperature control system and an electrical system, wherein the impeller system is directly connected with a flange of a planet carrier of a speed increasing box of the transmission system, and comprises three blades, a wheel hub and a variable-pitch control unit, a casing of a stator of a generator of the transmission system and a casing ofan inner gear ring of the speed increasing box are respectively fixed on a rotary support of a support system by the way of a front flange and a back flange, and the generator is a synchronous permanent magnet generator. The grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set adopts a primary planetary gearbox and the low-speed permanent magnetsynchronous generator, thereby having the advantages of small volume, simple structure, fewer maintenance items of the set, low maintenance cost, no need of special hoisting equipment, sufficient space for meeting the requirements of maintenance and ergonomics, and optimal maintainability of all the parts.

Owner:HARBIN HAFEI IND

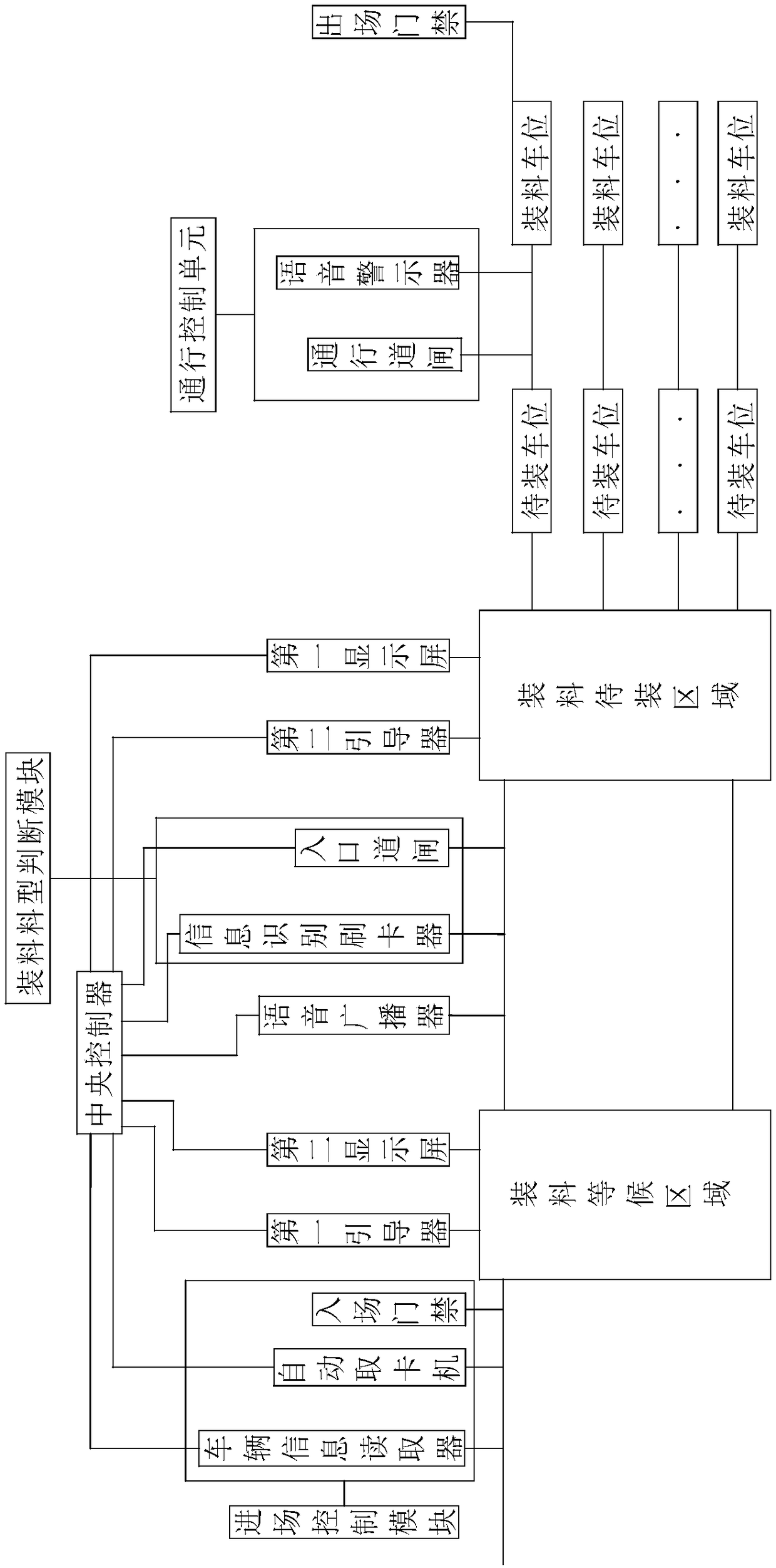

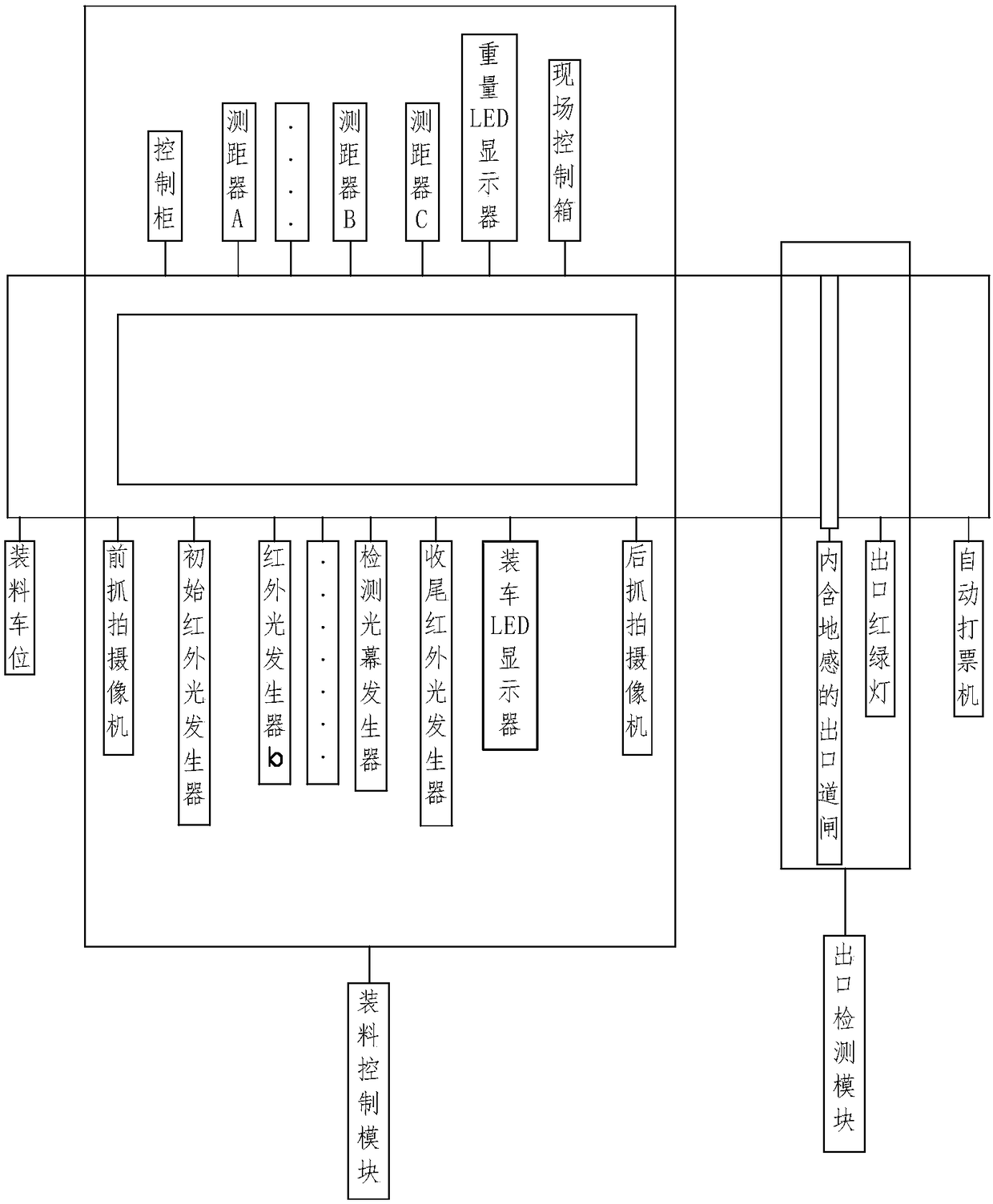

Automatic truck loading management system

PendingCN108922006AImprove intelligent controlImprove loading speedChecking apparatusIndividual entry/exit registersTruckManagement system

The invention discloses an automatic truck loading management system which comprises an entering queuing unit. The entering queuing unit comprises a loading waiting area and a feed to-be-loaded area.The loading waiting area comprises a plurality of different feed type waiting areas, and each feed type waiting area comprises a plurality of queuing truck spaces. First guiding devices are arranged in all the feed type waiting areas correspondingly, and all the first guiding devices are electrically connected with a central controller. The feed to-be-loaded area comprises a plurality of to-be-loaded truck spaces of different feed types, and feed-type judgment modules arranged at inlets of all the to-be-loaded truck spaces. Second guiding devices are arranged on all the to-be-loaded truck spaces correspondingly, and all the second guiding devices are electrically connected with the central controller. The automatic truck loading management system further comprises loading truck spaces formed behind all the to-be-loaded truck spaces correspondingly. Truck loading control units are arranged on all the loading truck spaces correspondingly. Compared with the prior art, feed trucks can be queued orderly, the loading speed is increased, starting and stopping of the trucks are accurately controlled, and the working efficiency is improved.

Owner:重庆欢腾科技有限公司

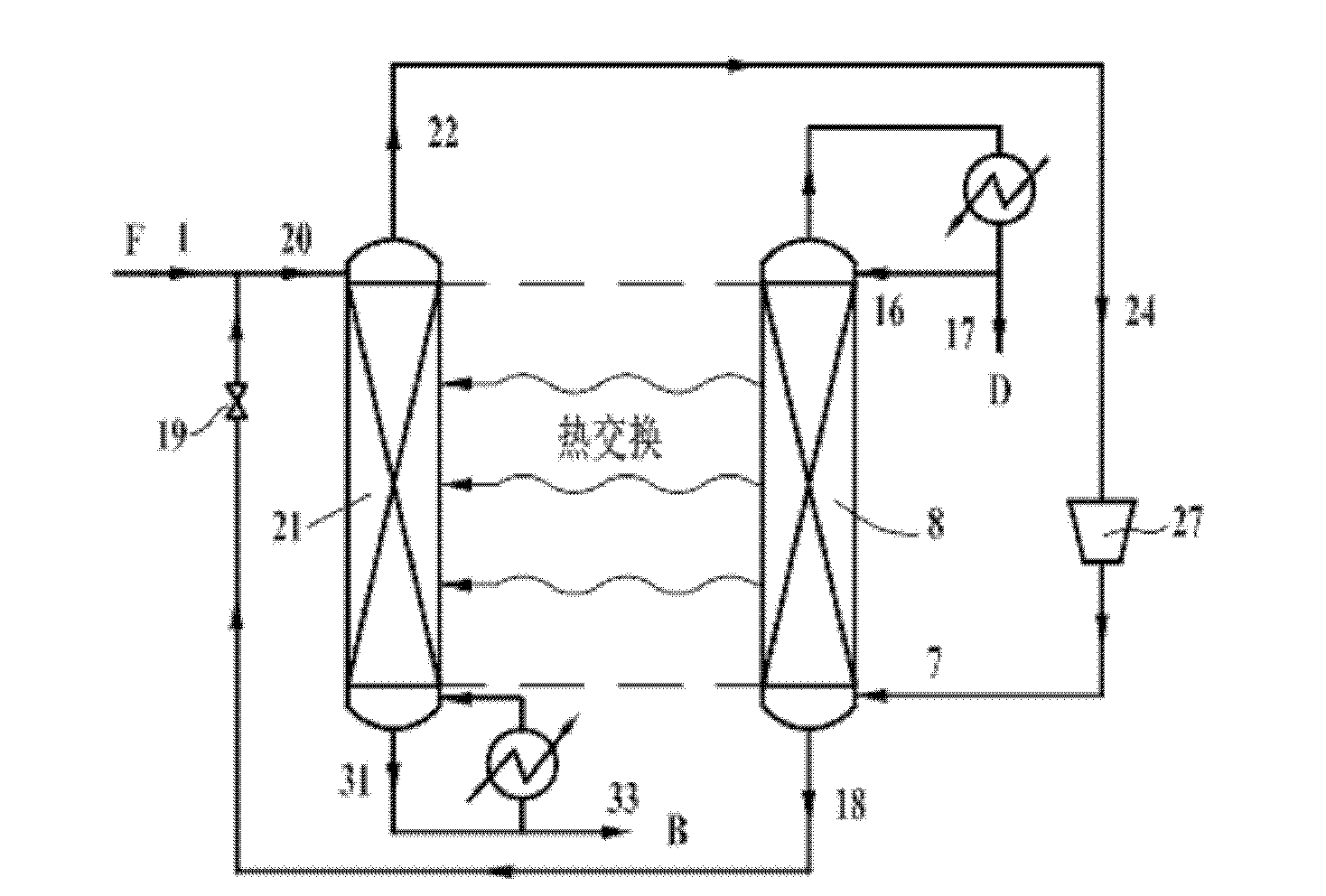

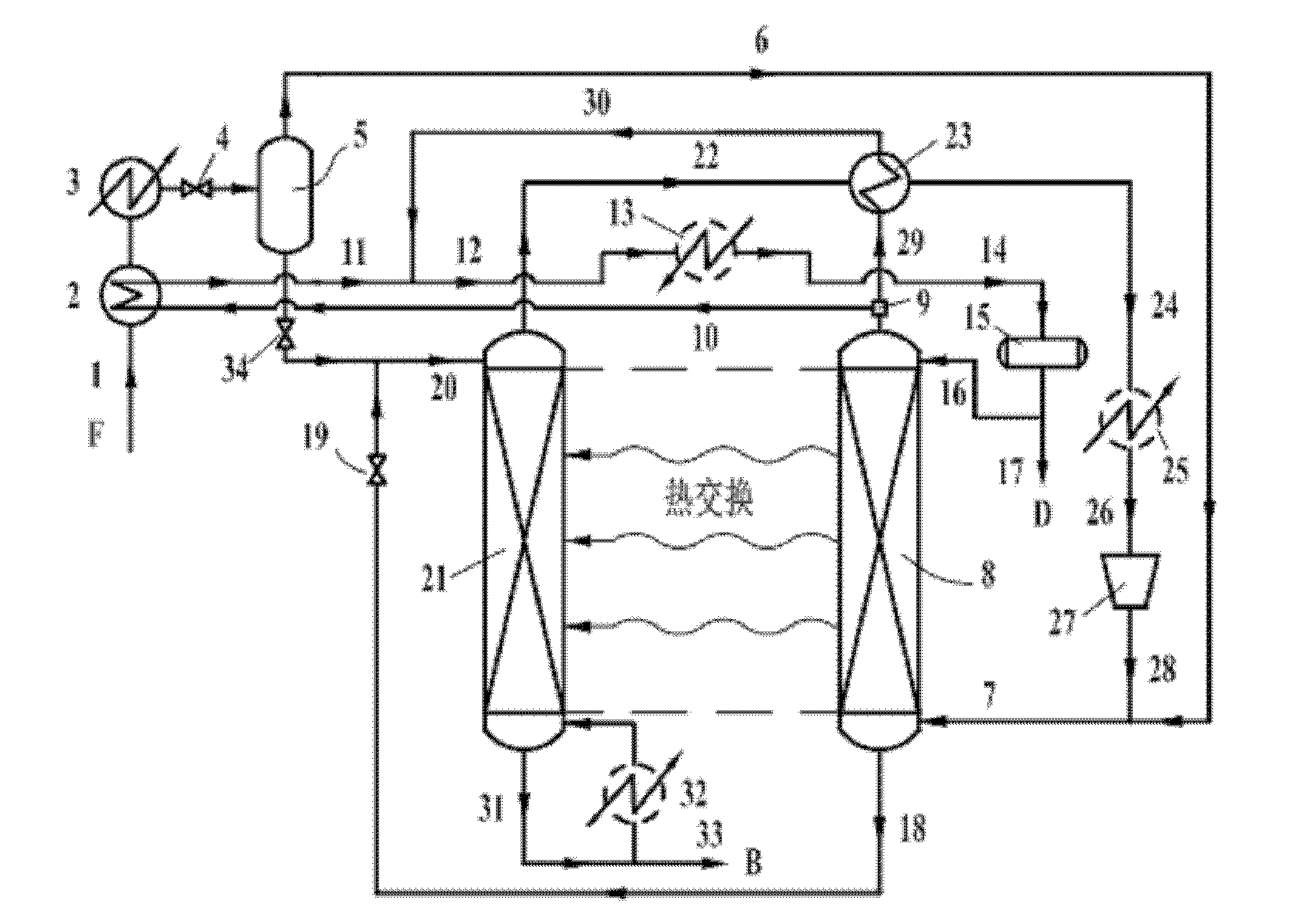

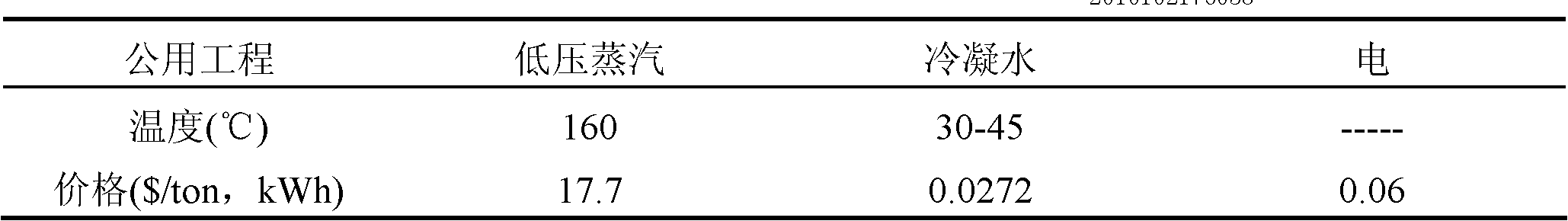

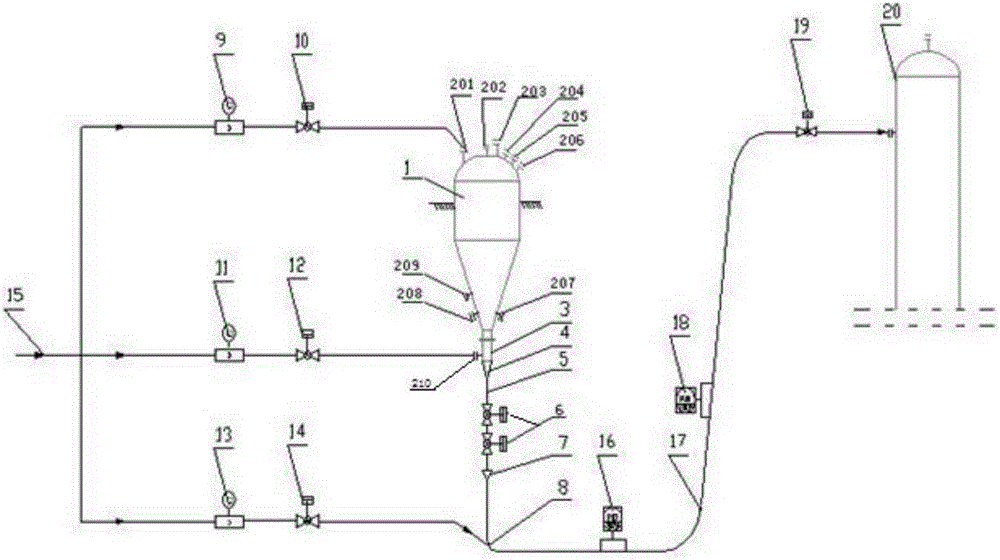

Flash evaporation feed type internal heat integration energy-saving rectifying device and method

InactiveCN101874934AReduce gas volumeReduced Compression Power ConsumptionDistillation regulation/controlFractional distillationVapor–liquid separatorReboiler

The invention relates to a flash evaporation feed type internal heat integration energy-saving rectifying device and a method, and the device comprises a system heat recovery heat exchanger, a feed preheater, a gas-liquid separator, a rectifying section, an auxiliary condenser, a stripping section, a compressor, an auxiliary reboiler and the like. The device is mainly characterized in that the gas-liquid separator is arranged on a feed pipeline; raw material liquid passes through the system heat recovery heat exchanger for heating and the feed preheater for further pre-heating and then enters into the gas-liquid separator; gas separated by the gas-liquid separator directly enters into tower bottom at the rectifying section, and liquid passes through a pressure reducing valve for reducing pressure and then enters into the top part of the stripping section; in addition, one part of saturated steam at tower top at the rectifying section is used for pre-heating fed materials, and the other part of the saturated steam is used for heating a gas overheater at the tower top at the stripping section. Compared with an ordinary internal heat integration rectifying tower, the adoption of the method and the device can greatly reduce the total energy consumption during the rectifying process, save operation cost and further achieve the purposes of energy conservation and synergy.

Owner:TIANJIN UNIV

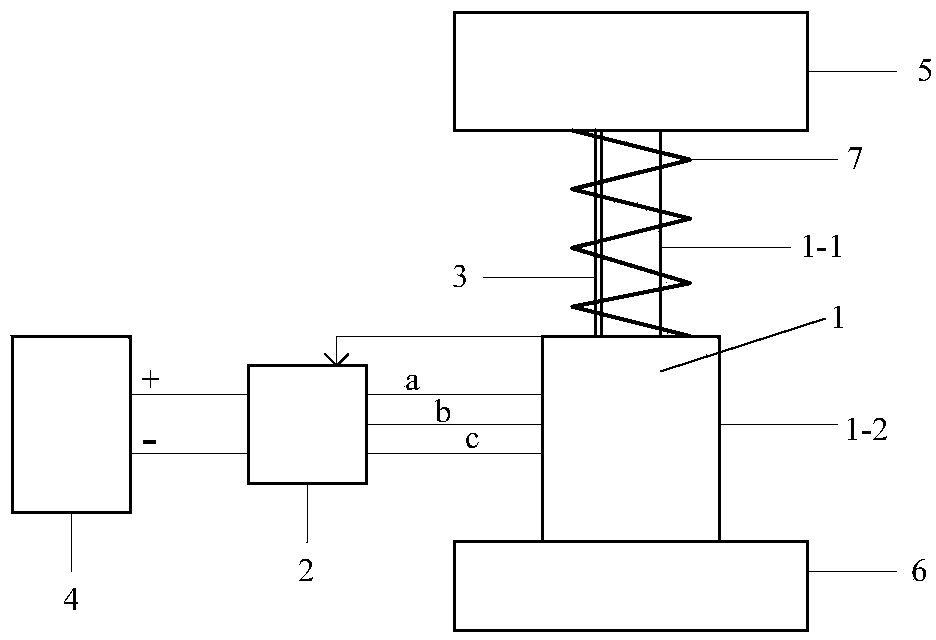

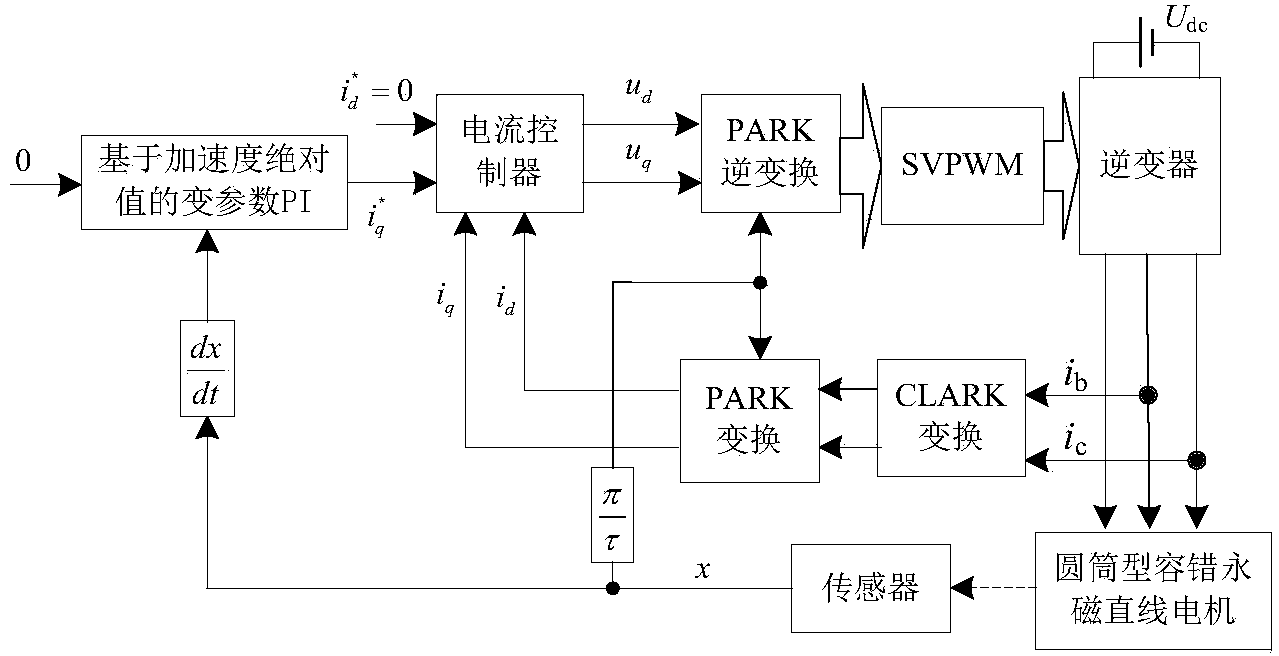

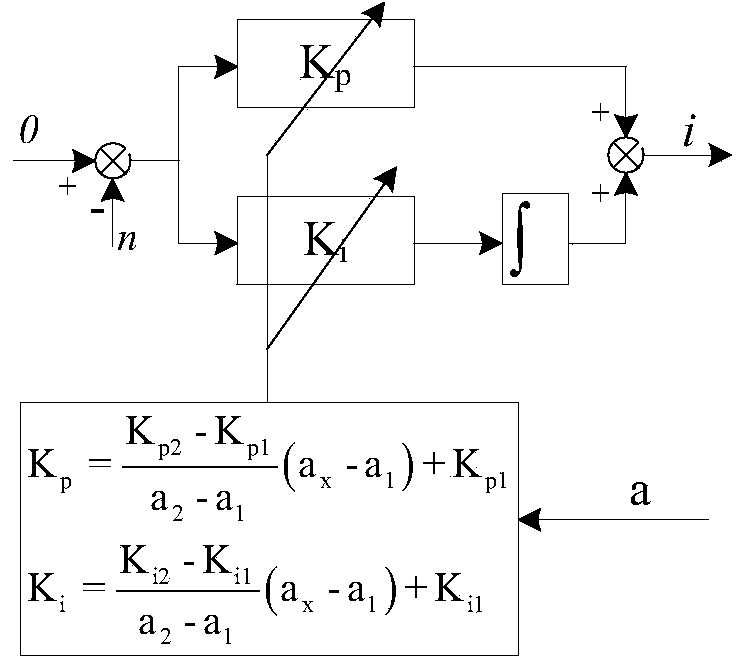

Feed-type electromagnetic damping vibration attenuation control method for vehicle suspension

InactiveCN103770594AWith feed functionImprove reliabilityResilient suspensionsDevice formClosed loop

The invention discloses a feed-type electromagnetic damping vibration attenuation control method for a vehicle suspension. The method is applicable to an electromagnetic damping vibration attenuation device formed by a cylindrical fault-tolerant permanent-magnet linear motor, a motor controller, a speed sensor and a storage battery. Since the motor controller figures out the speed and the acceleration of the cylindrical fault-tolerant permanent-magnet linear motor according to the signal of the speed sensor, calculates the proportionality coefficient Kp and the integral coefficient Ki of a variable parameter PI based on the absolute value of the acceleration in real time and controls the cylindrical fault-tolerant permanent-magnet linear motor to run by adopting a speed closed-loop vector control strategy, the electromagnetic vibration attenuation function is realized, the vibration energy is recovered, the electromagnetic damping coefficient can be adjusted in real time according to the actual situation, the vibration attenuation performance of the suspension and the smoothness of a 'man-vehicle' system are improved and the energy is saved.

Owner:JIANGSU UNIV

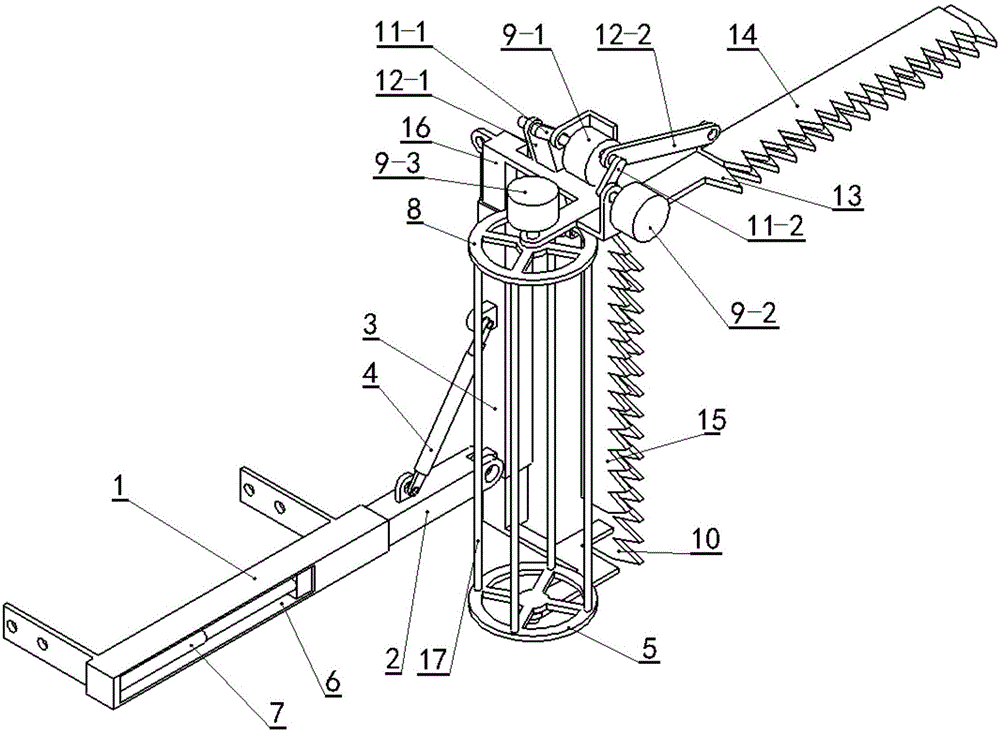

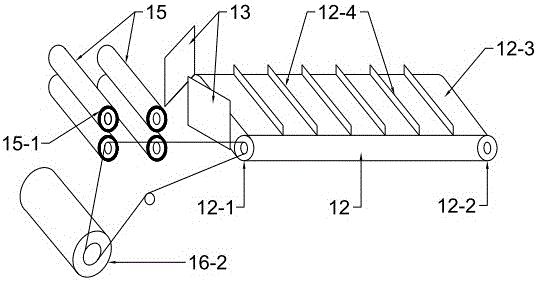

Feed type high-effect grape branch shearing machine

ActiveCN105052575AImprove resection rateImprove clippingCuttersMotor driven pruning sawsAgricultural engineeringKnife blades

The invention discloses a feed type high-effect grape branch shearing machine. The feed type high-effect grape branch shearing machine comprises a bearing support, a first telescopic device, a transversely-moving supporting arm, a second telescopic device, a swing frame, a vertical movable support, a third telescopic device, a torque output device, a feeder, a first crank, a first connecting rod, a vertical fixed blade and a vertical movable blade. The feed type high-effect grape branch shearing machine is more reasonable in structure and higher in shearing effect, and the grape branch shearing rate is greatly increased.

Owner:URUMQI YOUNIKE BIOLOGICAL SCI & TECH CO LTD

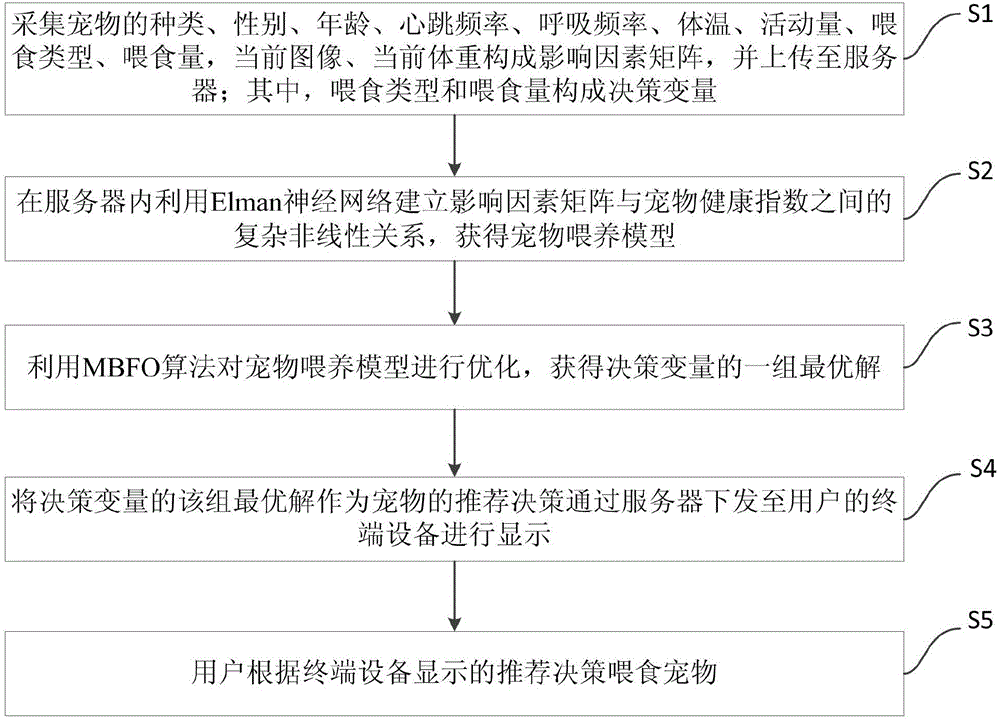

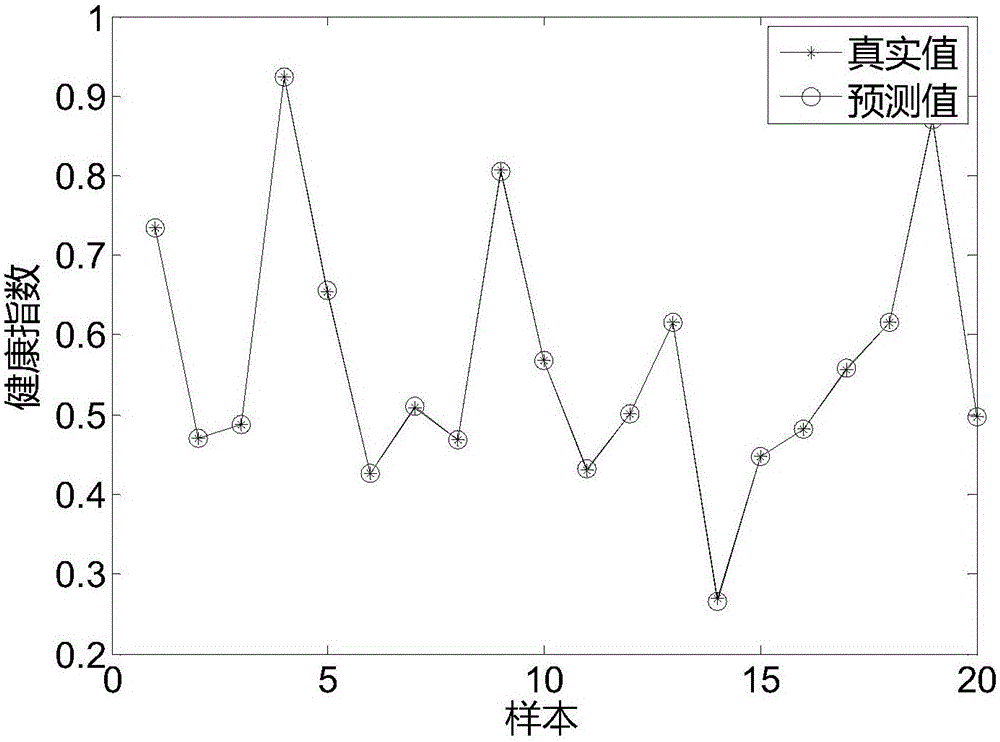

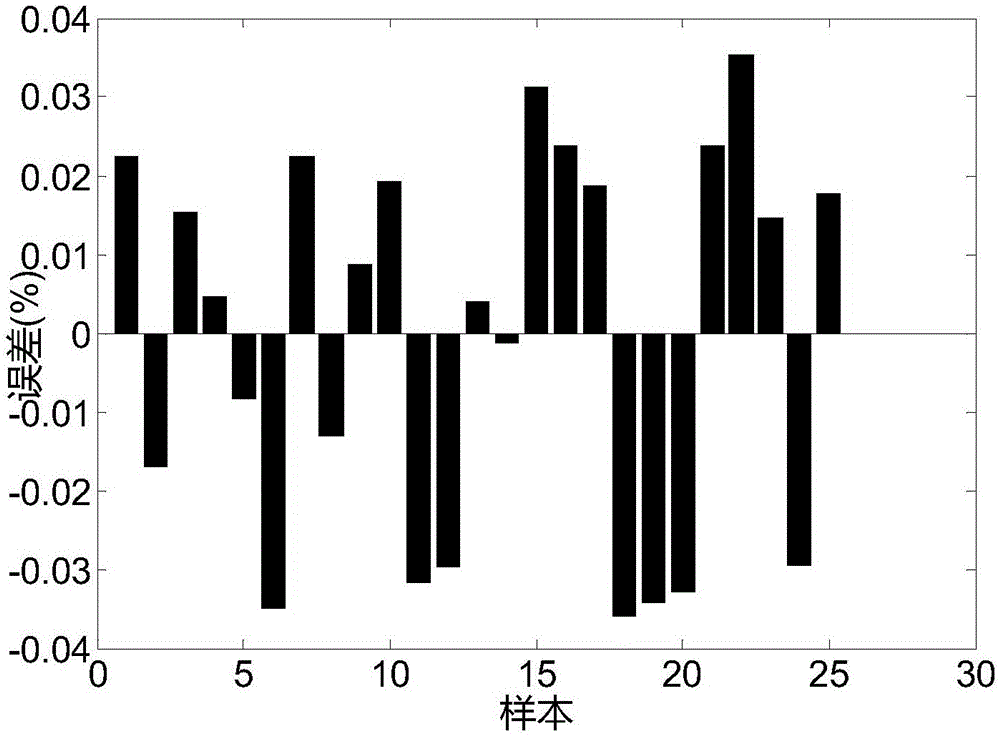

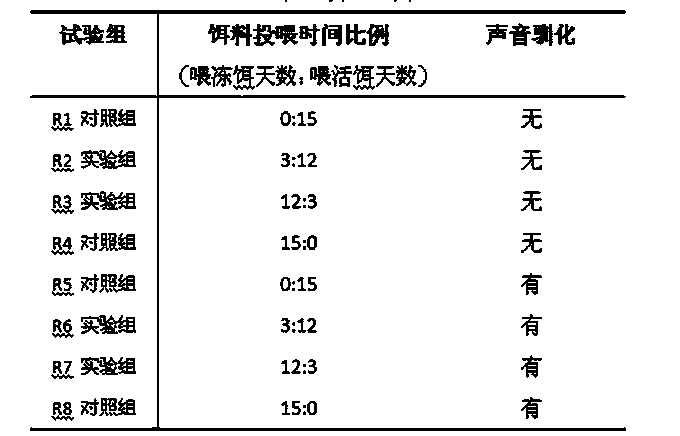

Recommendation method and recommendation system of pet feeding based on cloud data

InactiveCN106407711AImprove the living environmentComputer-assisted diets prescription/deliverySpecial data processing applicationsHealth indexLinear relationship

The invention provides a recommendation method and a recommendation system of pet feeding based on cloud data. The method comprises the steps of acquiring the kind, sex, age, heartbeat rate, respiratory rate, body temperature, activity level, feeding type and feeding quantity of a pet, forming an influencing factor matrix X with the current image and the current weight, uploading the influencing factor matrix X to a server, forming decision variables with the feeding type and the feeding quantity, establishing a complicated nonlinear relation between the influencing factor matrix X and a pet health index in the server by utilizing an Elman neural network to obtain a pet feeding model, optimizing the pet feeding model by utilizing an MBFO algorithm to obtain optimal solutions of the decision variables, allowing the server to send the optimal solutions of the decision variables as a recommendation decision X* of the pet to terminal equipment of a user for displaying, and allowing the user to feed the pet according to the recommendation decision X* displayed by the terminal equipment. With the adoption of the method and the system, an optimal pet feeding scheme can be determined, and a good living environment is built for the pet.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

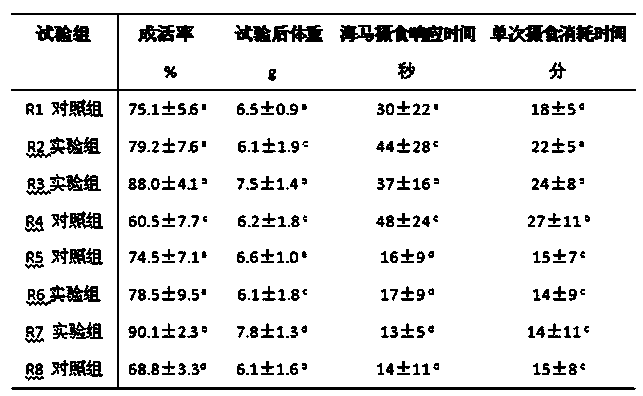

Optimized feeding method for adult stage of sea horses

ActiveCN103430880AMeet the nutritional needs of rapid growthReinforcement feeding behaviorClimate change adaptationPisciculture and aquariaFisheryZoology

The invention discloses an optimized feeding method for the adult stage (2 to 6 months old) of sea horses, which includes the reasonable arrangement and optimization of a sea horse culture environment, feed types, feeding time, feeding amount, a feeding method and a feed processing method. When the feeding method is adopted, the survival rate and growing rate of sea horses at the growing stage are remarkably increased, meanwhile, the feed coefficient is decreased, the overall sea horse culture efficiency can be increased ultimately, and the degree of ecological pollution can be decreased.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

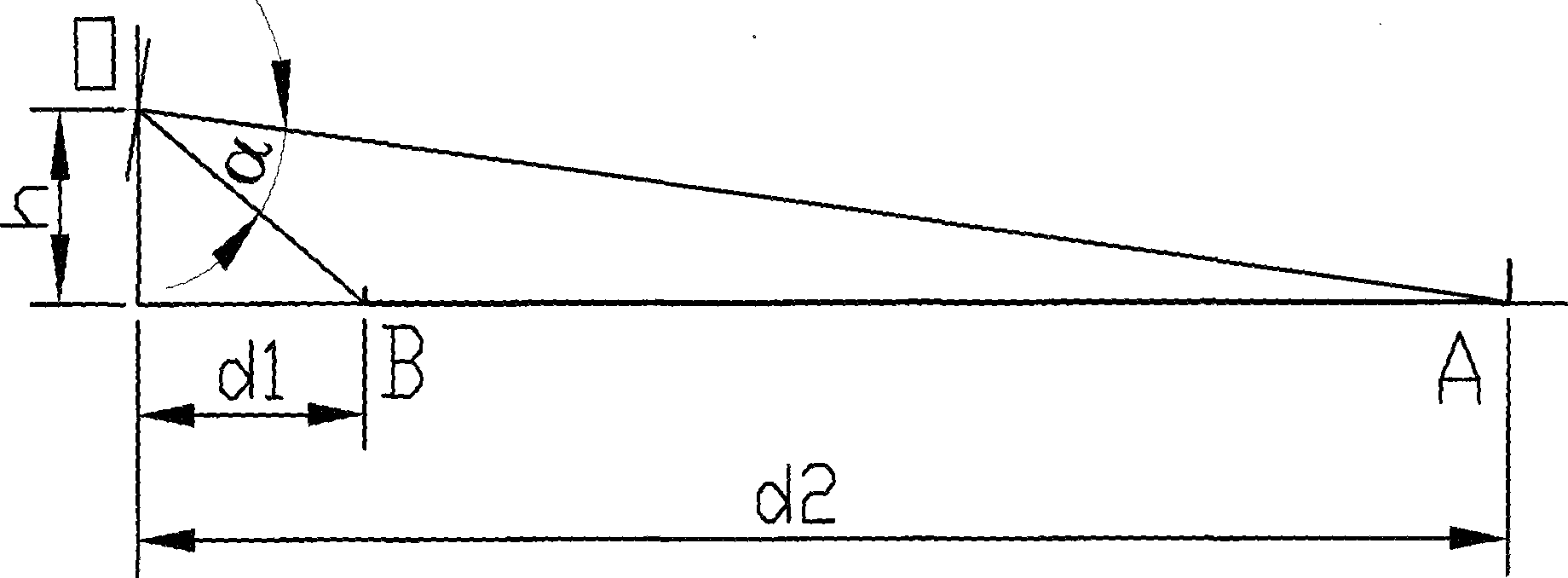

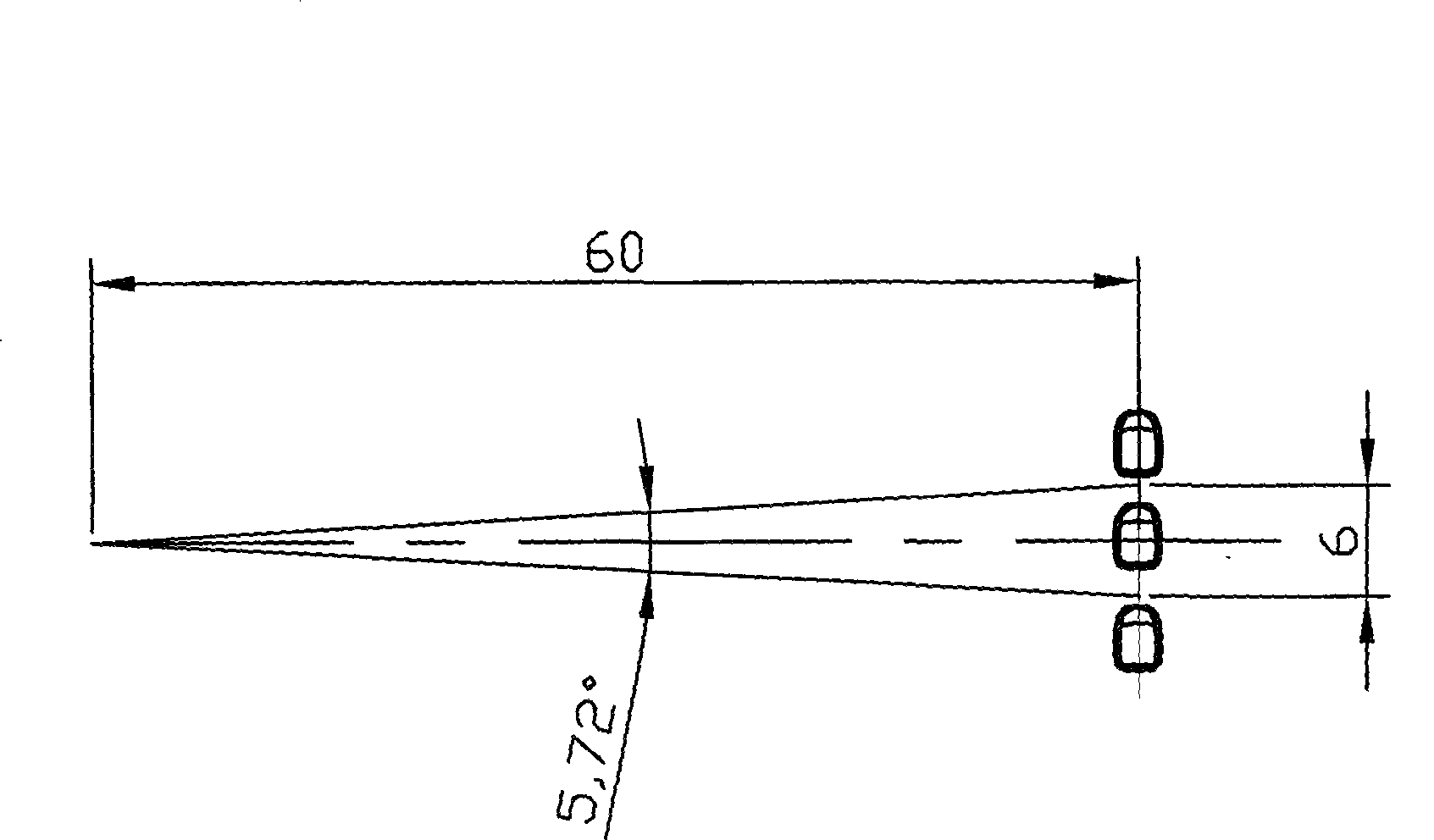

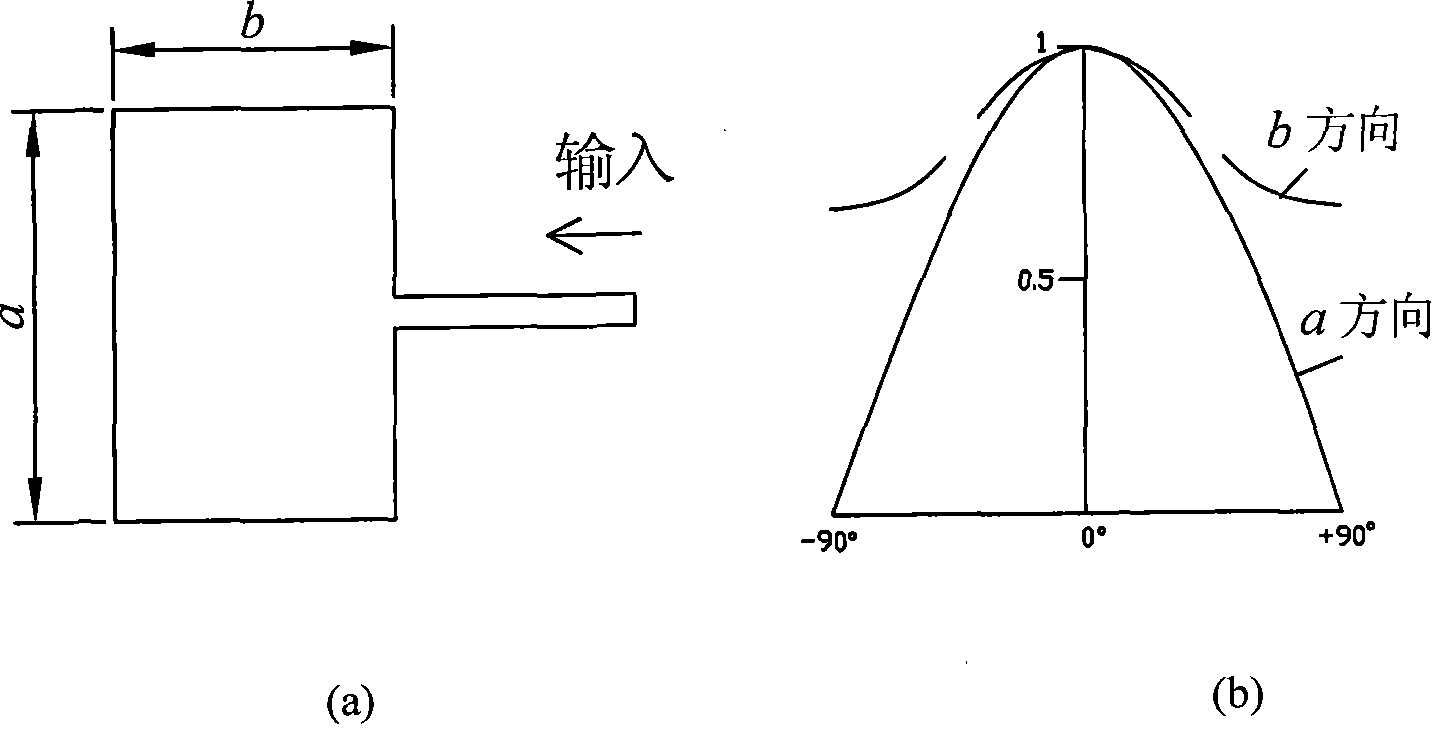

Design method for traffic flow detection radar antenna

InactiveCN101383093AHigh azimuth resolutionImprove economyDetection of traffic movementRadio wave reradiation/reflectionAntenna designMicrostrip array antenna

The invention relates to a method for designing a detection radar antenna of road traffic vehicle flow, which is concretely embodied by a design embodiment. The invention uses an optimized demonstration method to determine the requirements for the indexes of the detection radar antenna of the road traffic vehicle flow, points out the defects of designed antennae in the prior similar radar products, and provides a basic microstrip array antenna of a shunt feed type. Accordingly, a design scheme and a method of two microstrip array antennae of a shunt feed type are provided, and a concrete design result is provided. The method provided by the invention is proved to be capable of generating the antennae more suitable for the need of a detection radar of the vehicle flow and achieving the comprehensive aim of high performance, low price and small size.

Owner:邹谋炎

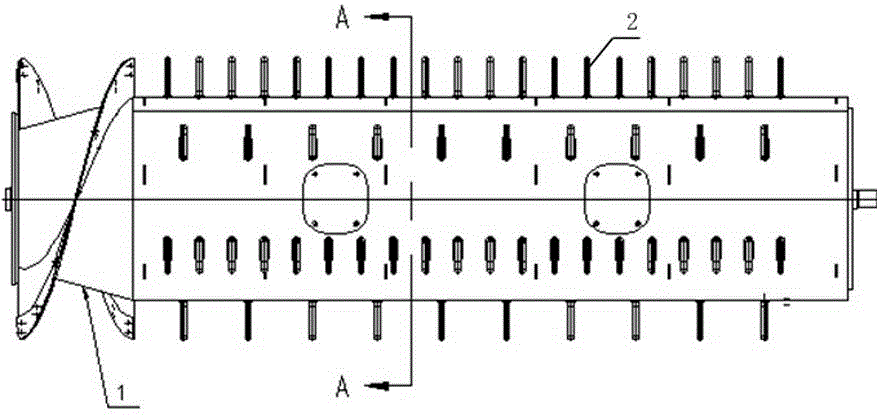

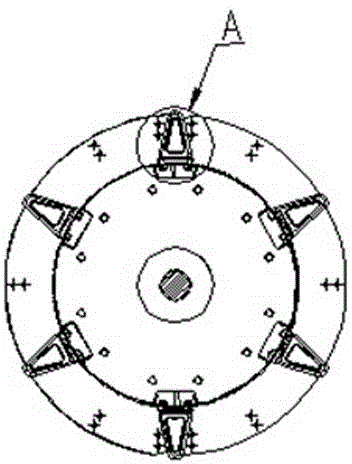

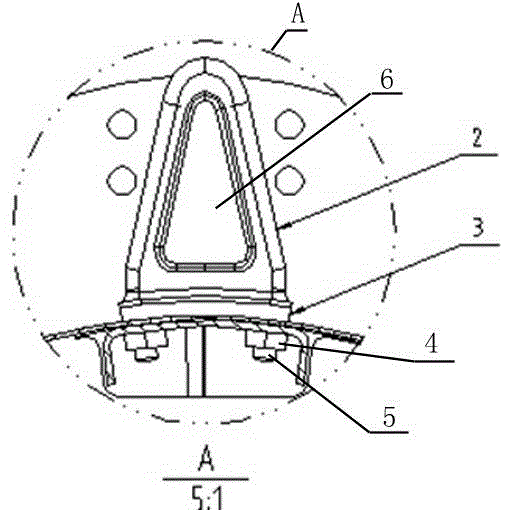

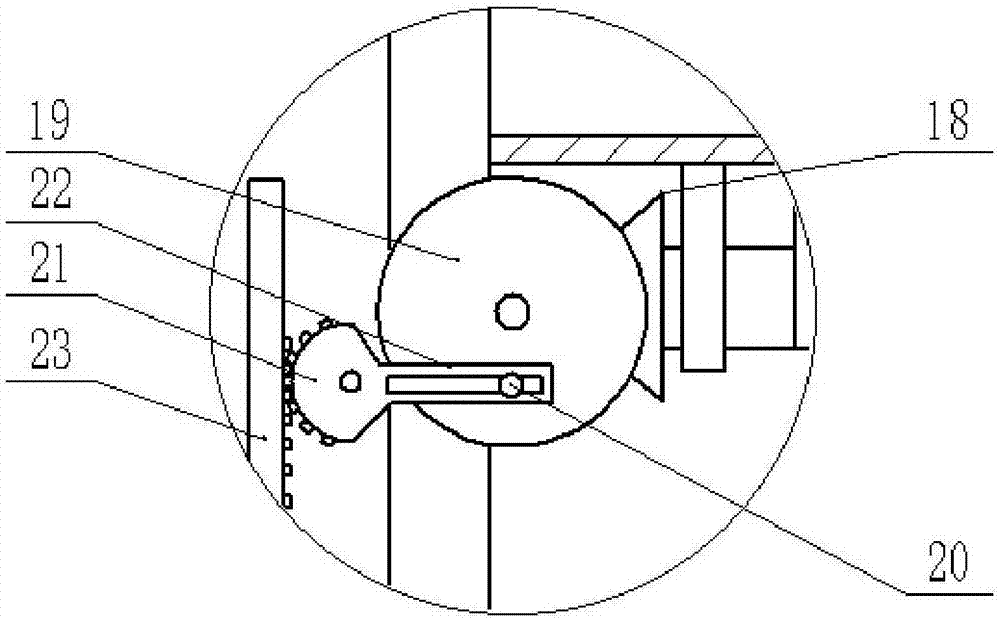

Full-feed type combine-harvester threshing cylinder

InactiveCN105684634AHigh strengthEasy maintenanceMowersThreshersAgricultural engineeringStructural engineering

The invention provides a full-feed type combine-harvester threshing cylinder. A plurality of independent cylinder teeth are evenly arranged on the circumferential surface of a cylinder body. Lengthened screw rods are arranged at the root of each cylinder tooth and are fixedly mounted by screwing nuts from the inside of the cylinder body. The cylinder teeth are formed by forging of 45# materials and are integrated with anti-twining pieces therein, and gaps are not formed between the anti-twining pieces and the cylinder teeth. The center of each cylinder tooth is tapered, the raised top end of each cylinder tooth is in the shape of a circular arc, and two sides of each cylinder tooth form a symmetrical shape structure. Adjustment cushion blocks are arranged between the roots of the cylinder teeth and the cylinder body. Every six cylinder teeth are evenly distrusted on the circumferential surface of the cylinder body circumferentially, and rows are formed by vertical arrayed cylinder teeth. The full-feed type combine-harvester threshing cylinder has the advantages that the cylinder teeth are independent teeth, the cylinder teeth are formed by forging of 45# materials, the lengthened screw rods are arranged at the roots of the teeth, the teeth can be mounted and demounted individually, and maintenance is facilitated; the integrally forged structure is adopted, production cost is lower, the overall strength of the cylinder teeth is higher, and the anti-twining pieces and the external teeth are integrated to prevent grass twining at the gaps among the cylinder teeth.

Owner:湖北双兴智能装备有限公司

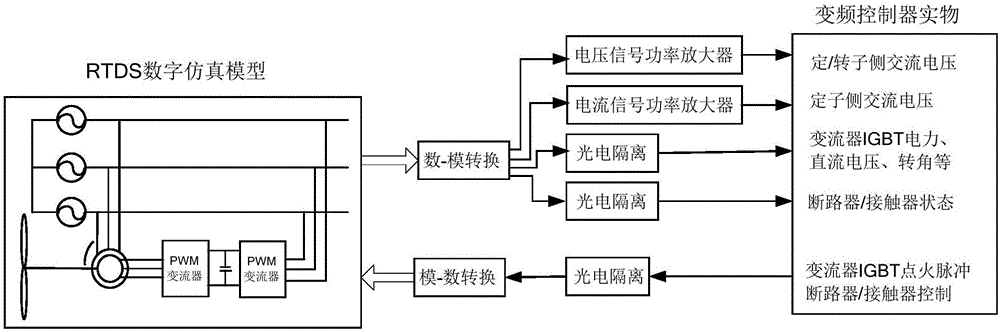

Performance test simulation platform of doubly-fed type wind turbine generator system frequency conversion controller

ActiveCN105134506AThe test result is accurateEfficient test resultsWind motor controlMachines/enginesClosed loopAudio power amplifier

The invention discloses a performance test simulation platform of a doubly-fed type wind turbine generator system frequency conversion controller. The performance test simulation platform comprises an RTDS (real time digital simulator), multiple voltage signal power amplifiers, multiple current signal power amplifiers and multiple photoelectric isolation devices. The RTDS is provided with an analog quantity output interface plate and a digital quantity input interface plate. A power grid digital simulation model with a doubly-fed type wind turbine generator system is established by the RTDS, the RTDS and a tested doubly-fed type wind turbine generator system frequency conversion controller entity are in signal connection through the voltage signal power amplifiers, the current signal power amplifiers and the photoelectric isolation devices, a digital-physical dynamic real-time closed-loop semi-entity wind turbine system is formed, and then the network entry performance of the tested doubly-fed type wind turbine generator system frequency conversion controller entity can be tested through the power grid digital simulation model of the RTDS. The performance test simulation platform has the beneficial effects that the test result is accurate, and high efficiency is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

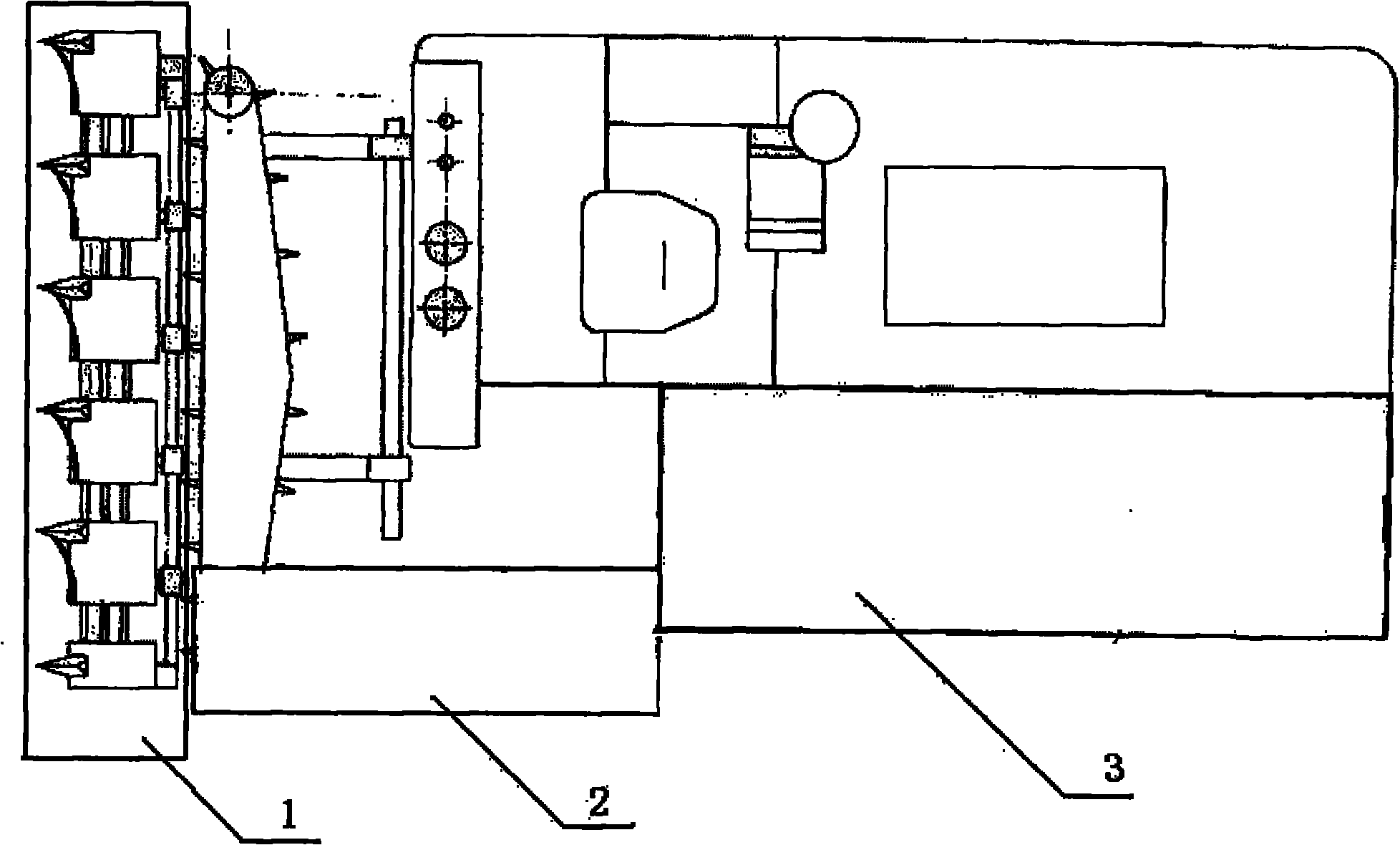

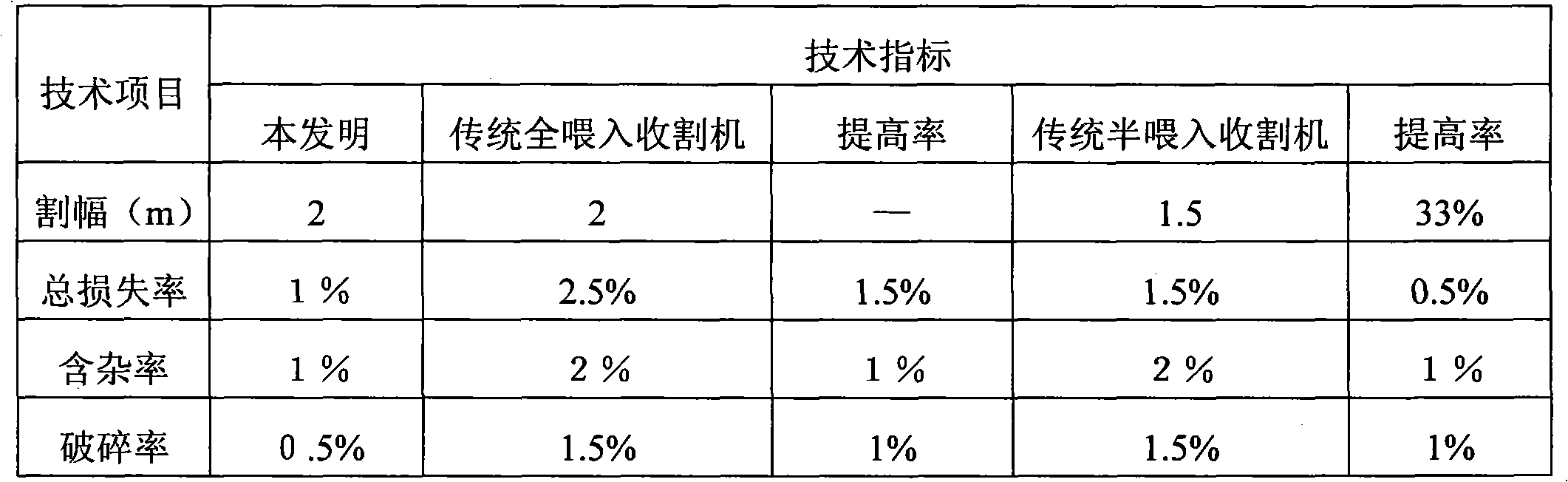

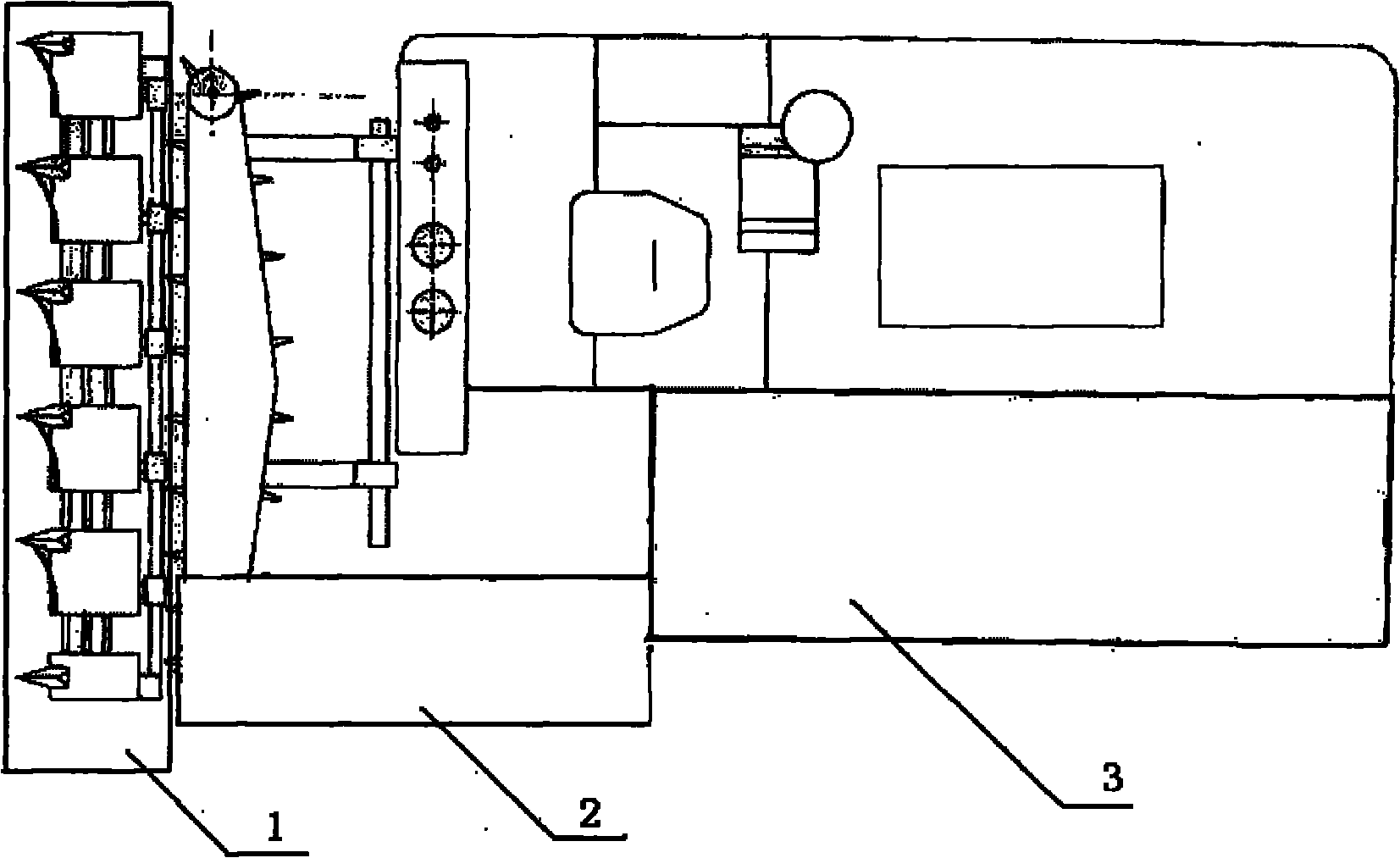

Whole-feed type combine harvester with vertical reaper

The invention provides a whole-feed type combine harvester with a vertical reaper. The invention is characterized in that the vertical reaper is wider than the reaper of a half feeding type combine harvester; a compulsory clamp turning conveyor is arranged on an ear feeding device which is formed by respectively adding a double teeth clamp chain between the two rows of conveying chains and at a turning; press steel wires are arranged between the upper and lower tooth of the double teeth clamp chain, and the height thereof is lower than the prong height of the double teeth clamp chain; a driving wheel for driving the double teeth clamp chain and a driven wheel of the conveying chains are coaxial. A threshing device uses a design of a longitudinal axial-flow type threshing cylinder, the threshing tooth of the threshing cylinder are in a spiral belt shape revolving a shaft and are fixed on the surface of the cylinder; and the angle of the threshing tooth and the cylinder shaft can be regulated. The invention derives advantages of the whole-feed type harvester and the half feeding type harvester, thereby solving the problem that the traditional whole-feed type combine harvester is hard to harvest lodging rice, has more threshing constraints and the threshing is unclean; and the invention has the advantages of clean threshing, complete separation, low broken rate and less trash content.

Owner:GUANGXI GUIGANG COMBINE HARVESTER

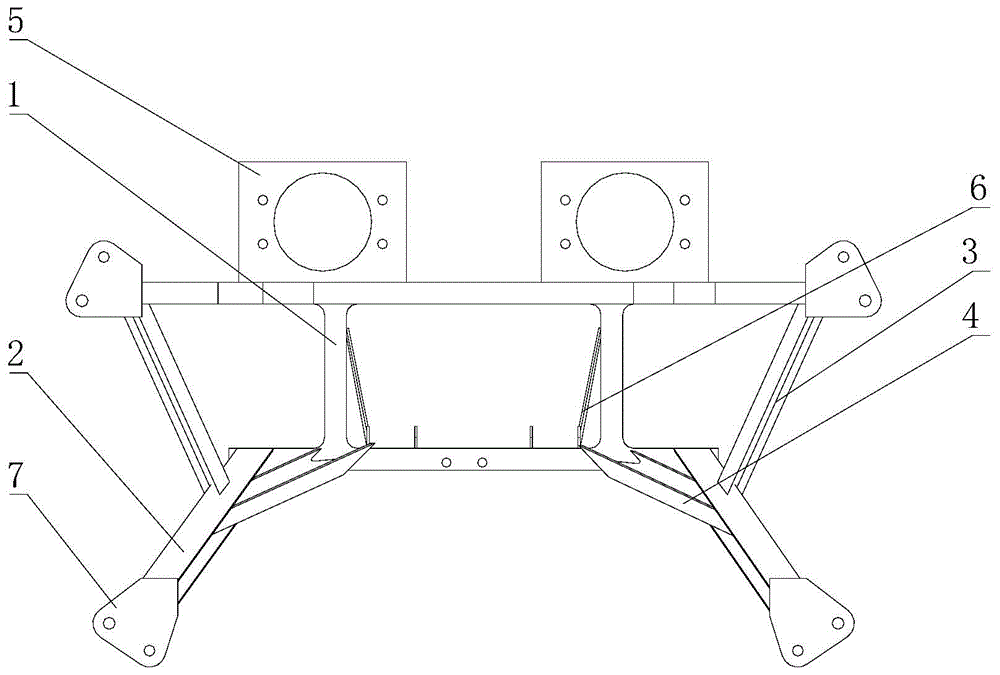

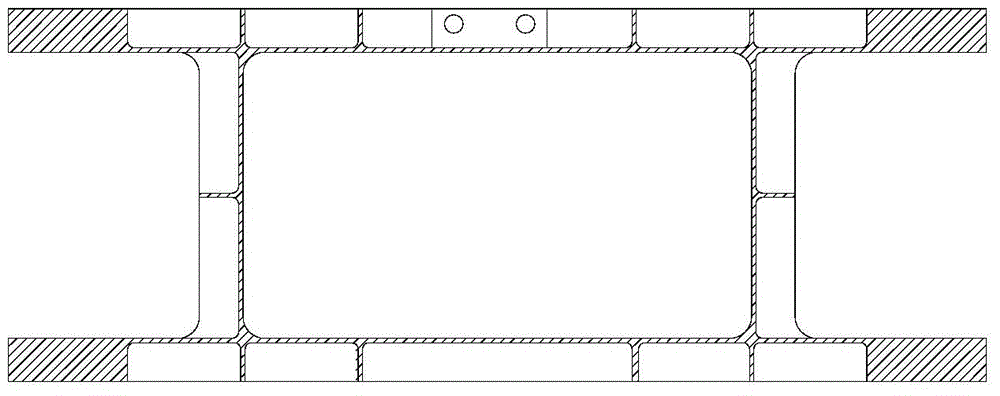

Wide-range variable thrust two-generator parallel pump-fed type engine frame and preparation method thereof

ActiveCN104859867ALightweight structureLarge strength marginCosmonautic propulsion system apparatusTurbopumpFeed type

The invention relates to a wide-range variable thrust two-generator parallel pump-fed type engine frame and a preparation method thereof. The wide-range variable thrust two-generator parallel pump-fed type engine frame comprises a portal-type frame body with symmetric openings, and bearing rods respectively arranged at the lower ends of four end corners of the frame body; a butted lug is arranged at the end of each bearing rod; an inclined supporting rod is arranged between each bearing rod and the frame body; each bearing rod, the frame body and the corresponding inclined supporting rod jointly form a triangular supporting structure; supporting rods are respectively arranged between the bearing rods on the left side of the frame body and between the bearing rods on the right side of the frame body; turbine pump mounting supporting seats for mounting of engine turbine pumps are symmetrically arranged at the upper end of the front part of the frame body; adjuster mounting supporting seats for mounting of adjusters and main valves are symmetrically arranged at the upper end of the rear part of the frame body. The wide-range variable thrust two-generator parallel pump-fed type engine frame obtained according to the preparation method is light in structural weight, large in strength margin, and good in open performance.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Fattening cattle feed and preparation method thereof

ActiveCN106962623AHigh nutritional valueLess crude fiberFood processingAnimal feeding stuffTrace element compositionFodder

The invention discloses fattening cattle feed and a preparation method thereof. The fattening cattle feed consists of whole plants of feed type green corns, whole plants of fresh Chinese herbal medicines, wheat bran, earthworm powder, earthworm feces, table salt, baking soda, a straw decomposing and fermenting agent and a nano organic chelating trace element. The preparation method comprises the following steps: harvesting the whole plants of 90 percent of mature feed type corns planted in a farmland together with corn cobs and straws, and kneading into a filament shape by using a straw filament kneading machine or cutting into 2 to 3 cm long; when the Chinese herbal medicines planted in the farmland are just mature, harvesting whole plants together with stems and leaves, and kneading into a filament shape by using the straw filament kneading machine or cutting into 2 to 3 cm long; putting all the components into a dry and wet feed stirring machine, adding the straw decomposing and fermenting agent after expanding propagation, regulating the total moisture into 40-60 percent, uniformly stirring, packing and fermenting. The fattening cattle feed and the preparation method thereof disclosed by the invention have the benefits that the utilization rate of the fattening cattle feed and the medicine effect of the Chinese herbal medicines can be greatly improved, the growth speed of fattening cattle is accelerated, the period of the fattening cattle is shortened, and the fattening cattle do not get sick in the growth process.

Owner:莫力达瓦达斡尔族自治旗兴军农业生态发展有限公司

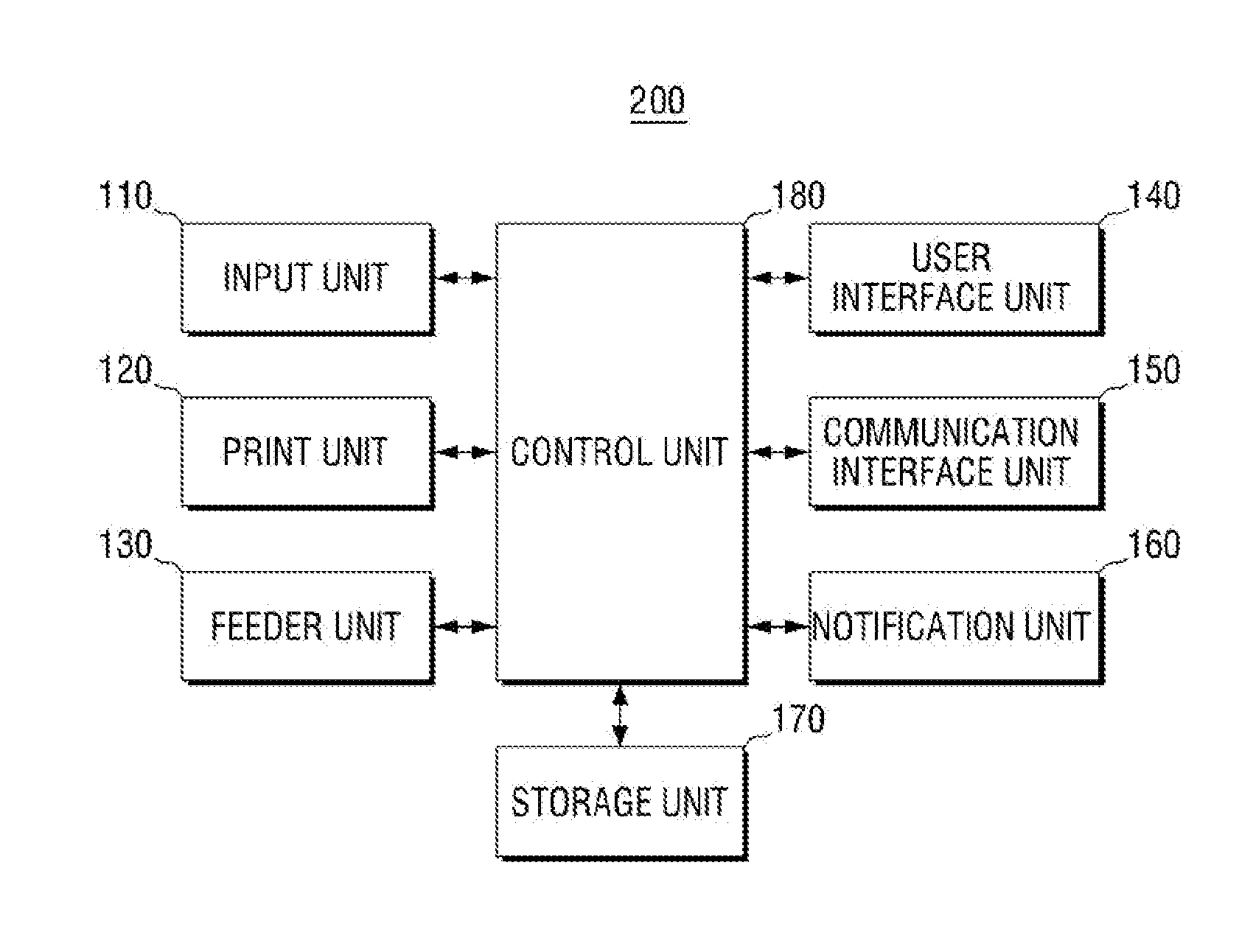

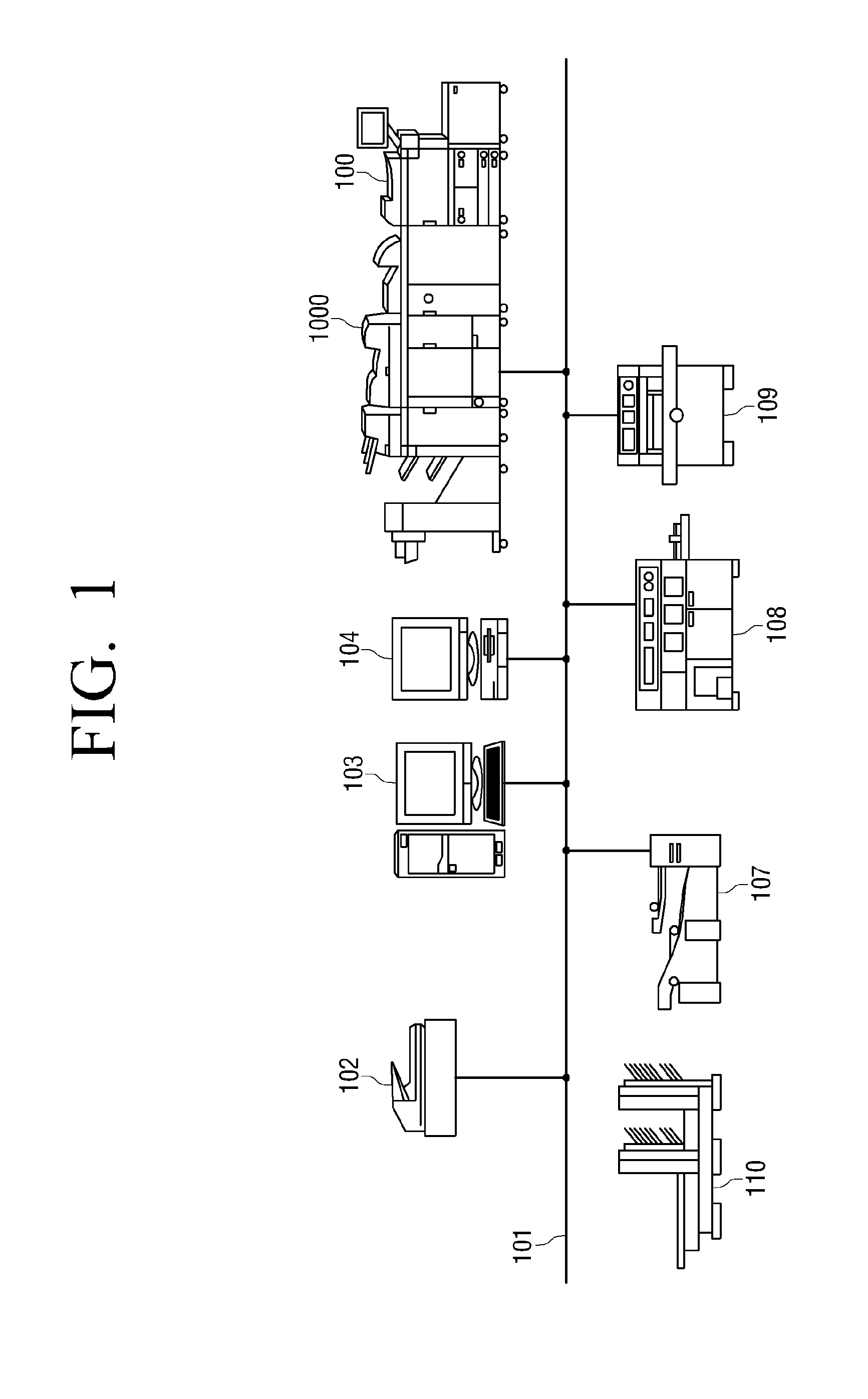

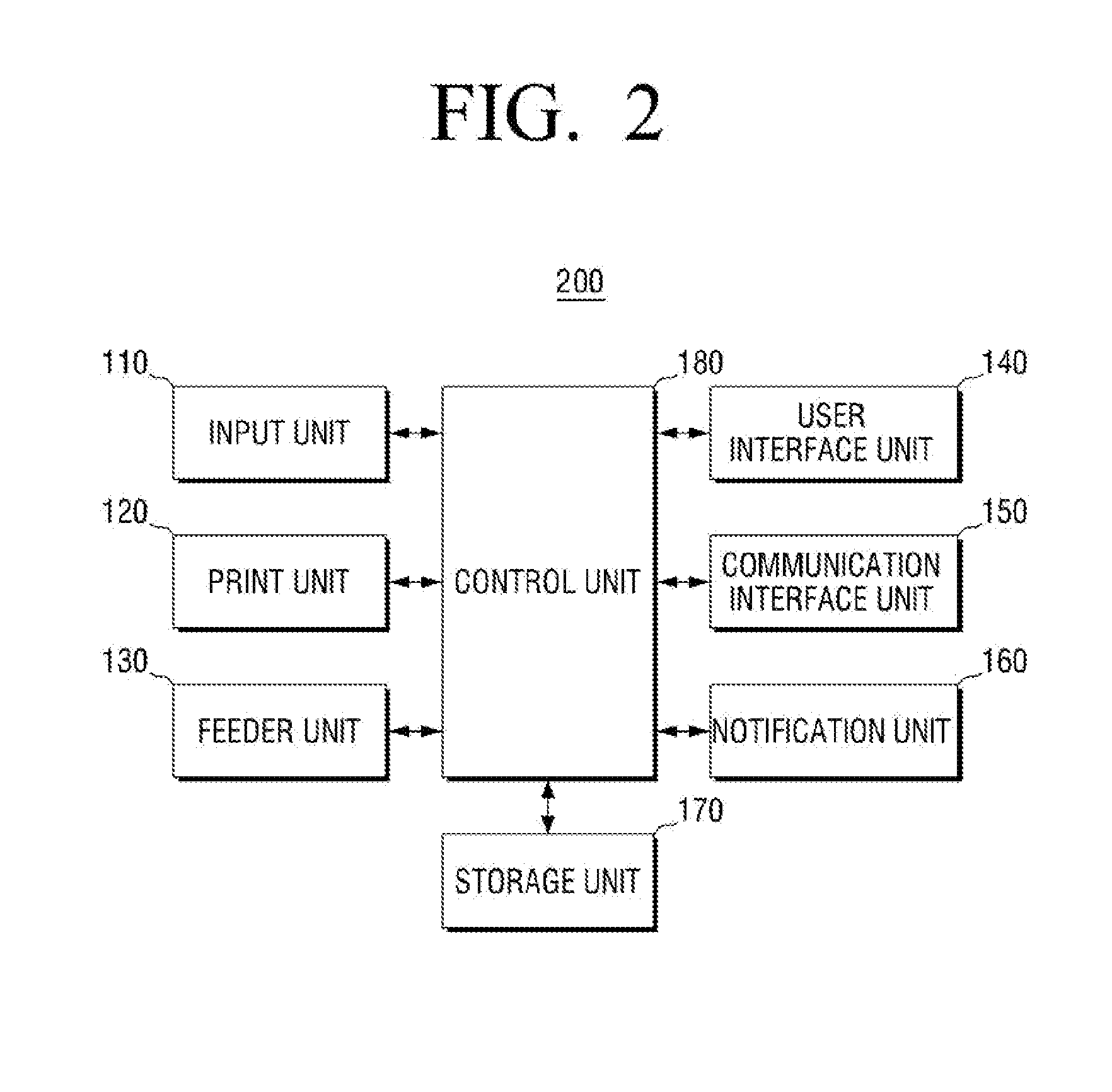

Image forming apparatus controlling feeding of long-edge and short edge printing paper and method for controlling the same

InactiveUS20140169854A1Improve printing effectTypewritersElectrographic process apparatusImage resolutionImage formation

An image forming apparatus and method are provided. The apparatus includes a control unit controlling a feeder unit to feed a printing paper in a long-edge feed type or a short-edge feed type in accordance with a print mode set for print data. The control unit controls the feeder unit to feed the printing paper in the long-edge feed type upon a high resolution print mode being set and in the short-edge feed type upon a low resolution print mode being set.

Owner:S PRINTING SOLUTION CO LTD

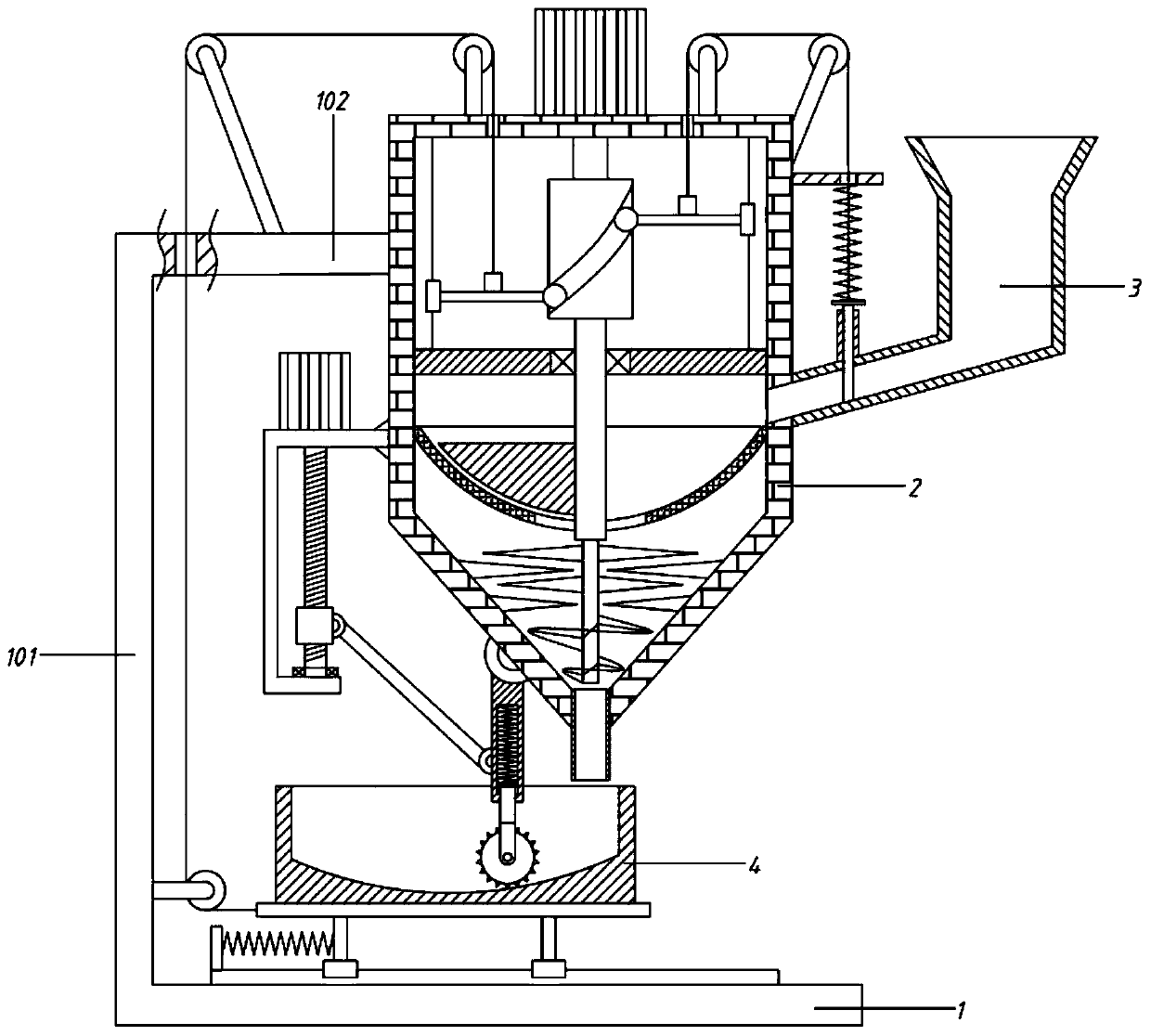

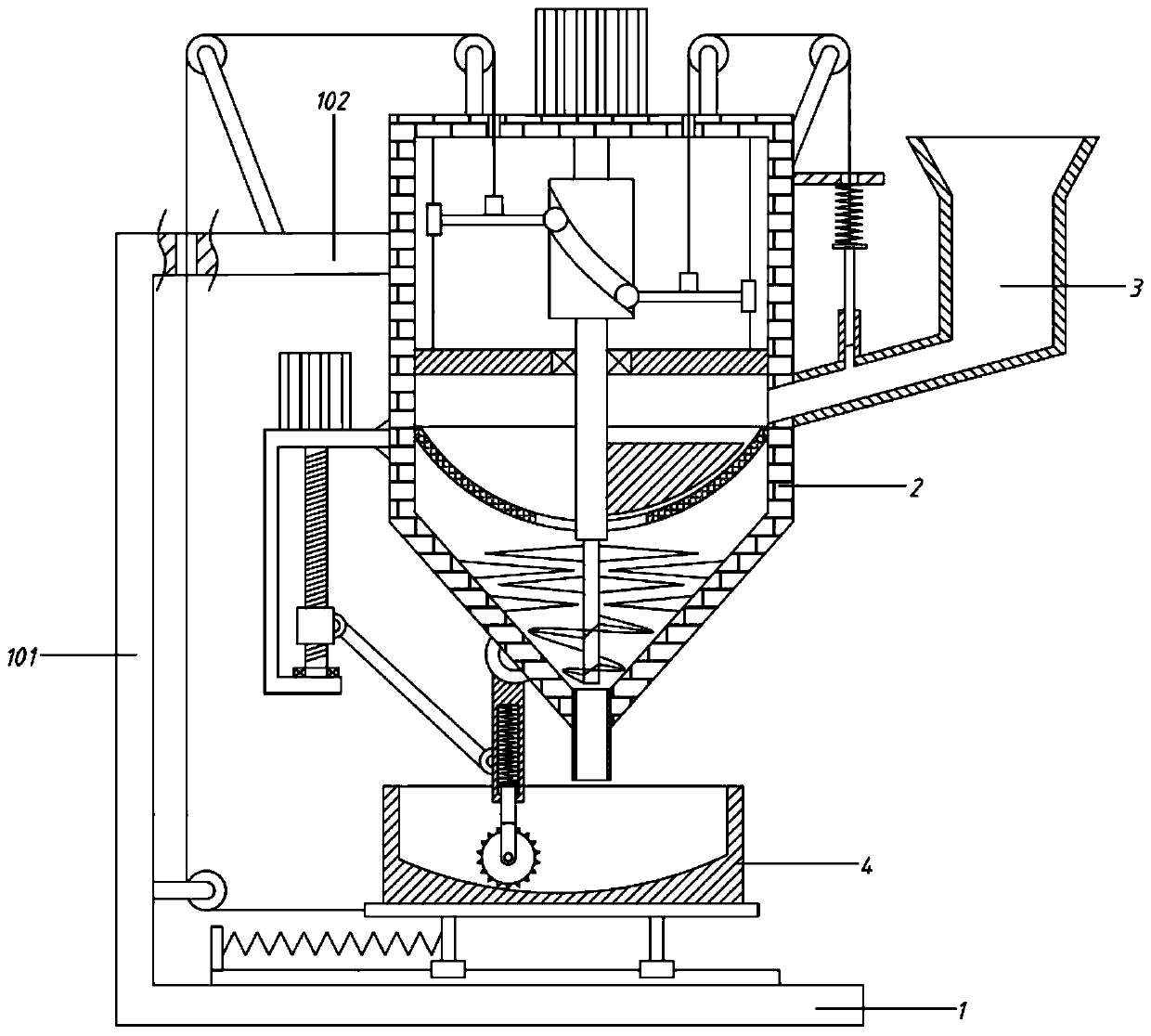

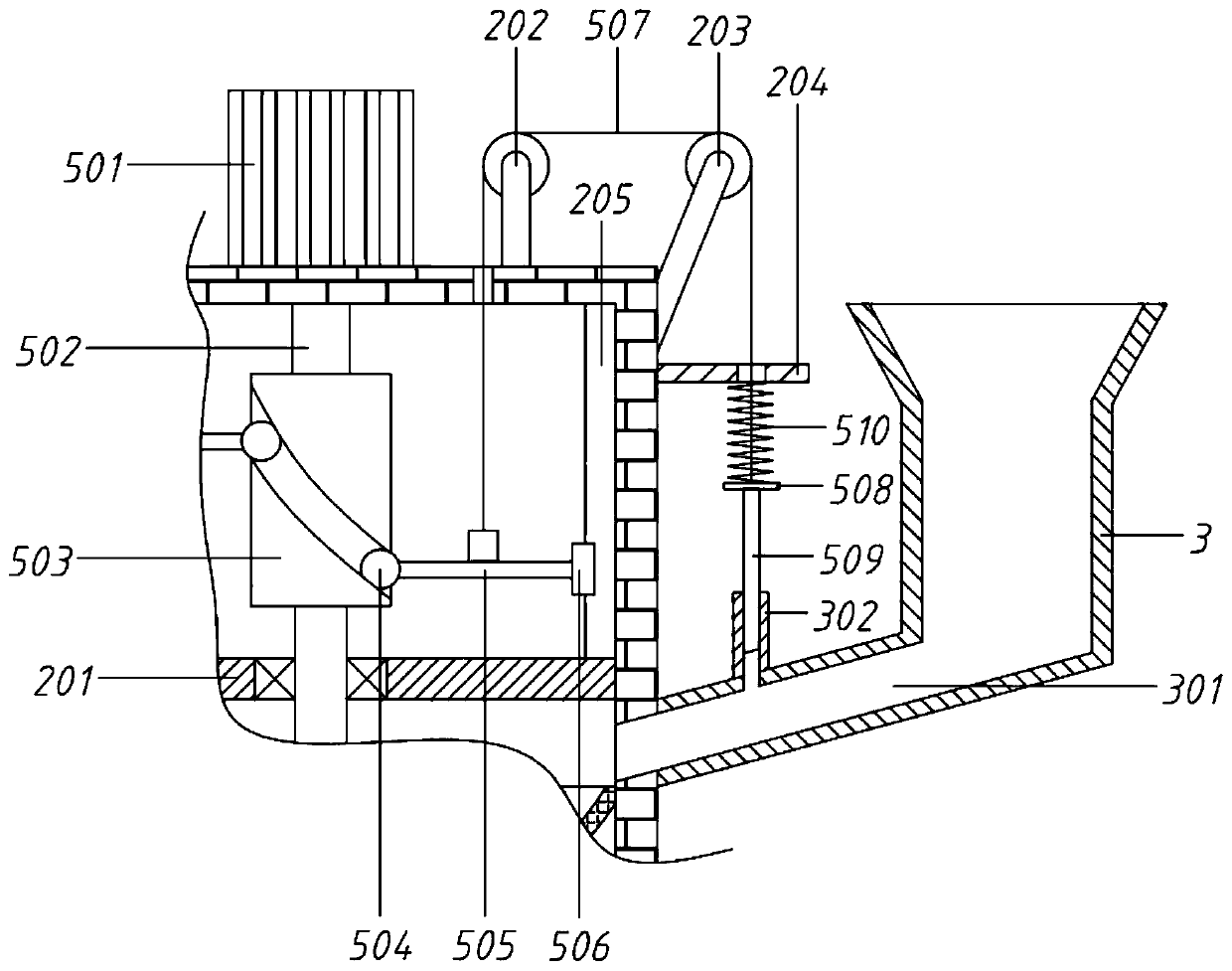

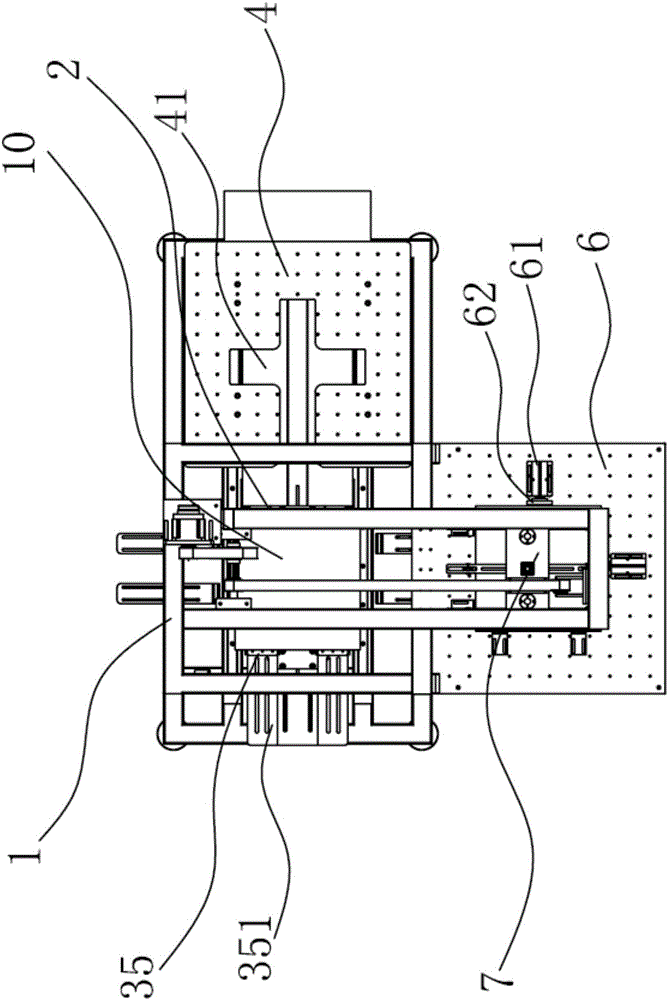

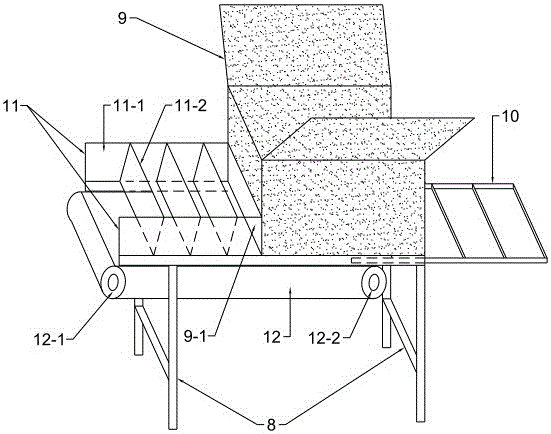

Intermittent feeding type feed mixing and crushing device for organic agriculture

InactiveCN110975731AGuaranteed production efficiencyEasy to removeFeeding-stuffRotary stirring mixersAgricultural scienceOrganic farming

The invention relates to the technical field of organic feed mixing and crushing equipment, and in particular, relates to an intermittent feeding type feed mixing and crushing device for organic agriculture. Based on the design of a cylindrical cam, a first servo motor drives a first rotating shaft to rotate, the cylindrical cam rotates along with the first rotating shaft, a first roller drives afirst connecting rod to move up and down to pull a first pull rope up and down, then a baffle is driven to get in and out of a material guide pipe, the material guide pipe is blocked or opened, and thus automatic intermittent feeding is achieved, and the production efficiency is guaranteed. A material receiving pot body is arranged at the upper part of a crushing cavity, and a material guide plateis arranged on the first rotating shaft, so that raw materials entering the crushing cavity from the right side are spread under the action of the material guide plate, the raw materials flow to a blanking opening from multiple directions and fall into a crushing knife area, and crushing knives interact along with the rotation of the first rotating shaft to mix and crush the raw materials; and then crushed particles are discharged from a blanking pipe after being guided by a spiral packing auger and subjected to secondary mixing.

Owner:安徽顺超知识产权集团有限公司

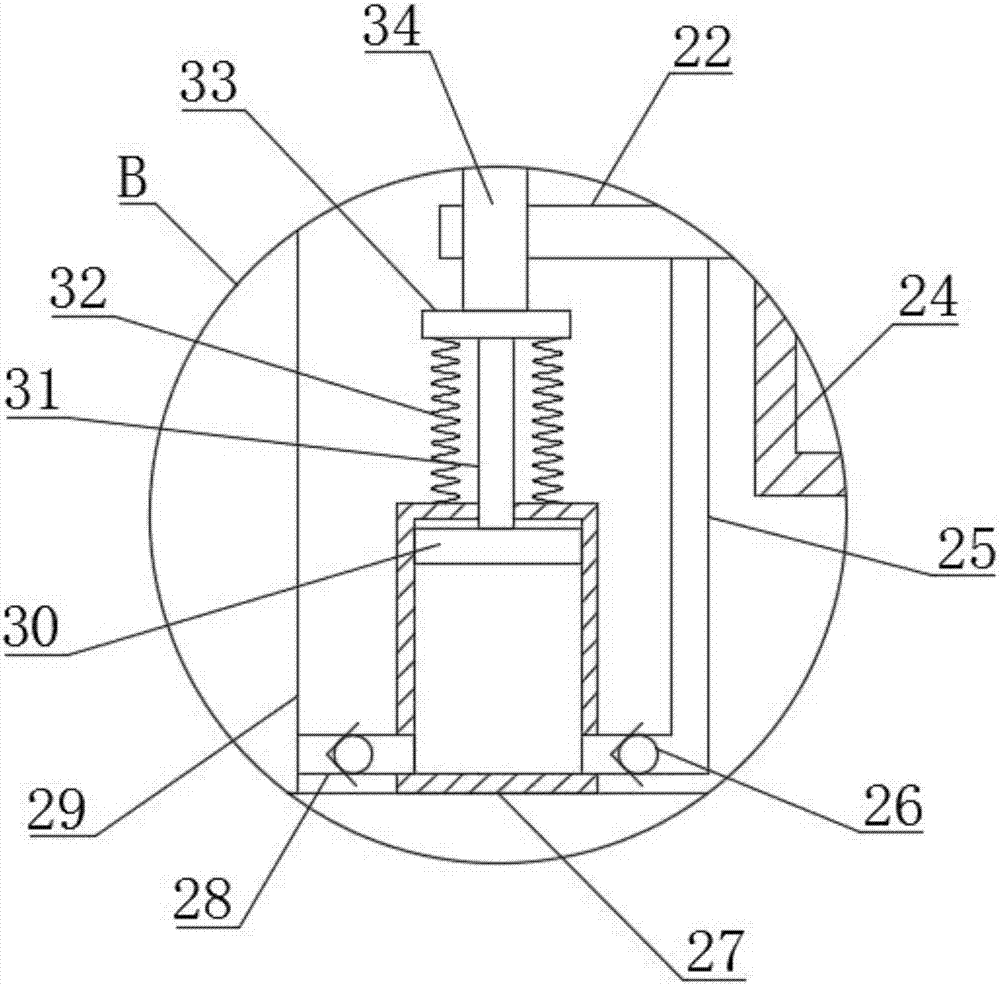

Feeding type single-station feeding material rack

InactiveCN105109960AFast and precise retrieving actionRealize the feeding functionConveyor partsRack unitMaterial supply

The invention discloses a feeding type single-station feeding material rack which comprises a machine base, a material rack unit, a conveying unit, a material supplying unit and a material taking unit. The material rack unit is driven by a first driving unit to move back and forth in the vertical direction. The conveying unit is arranged on one side of the material rack unit and is driven by a second driving unit to move back and forth in the horizontal direction, and products are ejected from bottom to top and horizontally moved to the material rack unit from the conveying unit. The material supplying unit is fixedly arranged on the machine base and located on the other side of the material rack unit. The material taking unit is fixedly arranged above the material rack unit and the material supplying unit and is driven by a third driving unit to move back and forth between the material rack unit and the material supplying unit in the horizontal direction. Meanwhile, the material taking unit is driven by a fourth driving unit to move back and forth in the vertical direction. According to the feeding type single-station feeding material rack, the products can be accurately located and fast taken through a mechanical arm, and under the conditions that the material taking success rate is guaranteed and the products are not damaged, the production efficiency of the whole material rack and a production line can be improved.

Owner:YIHE PRECISION IND SUZHOU

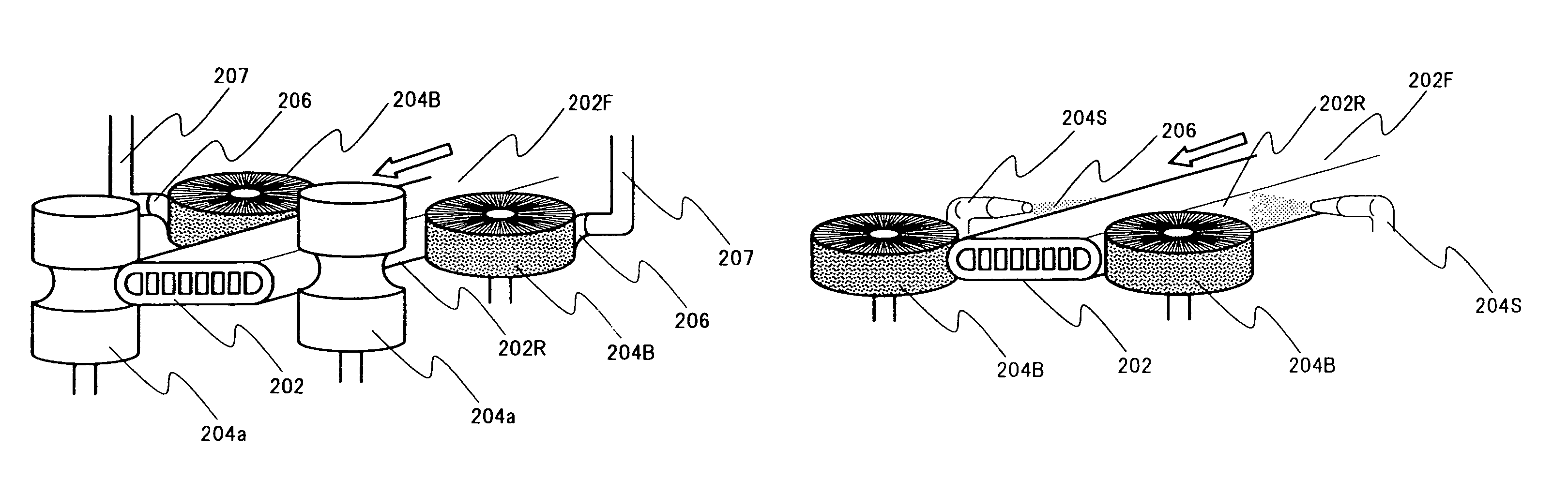

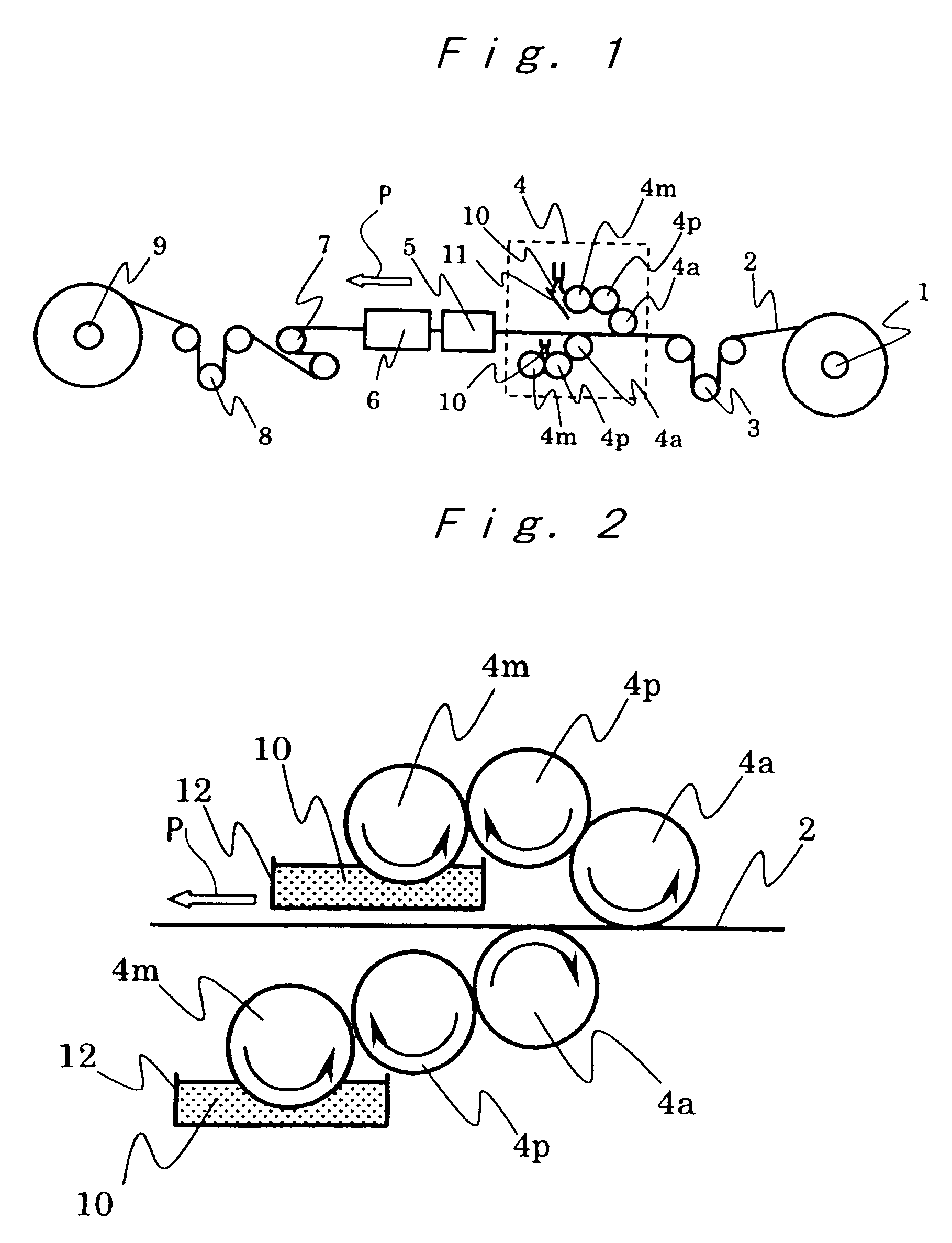

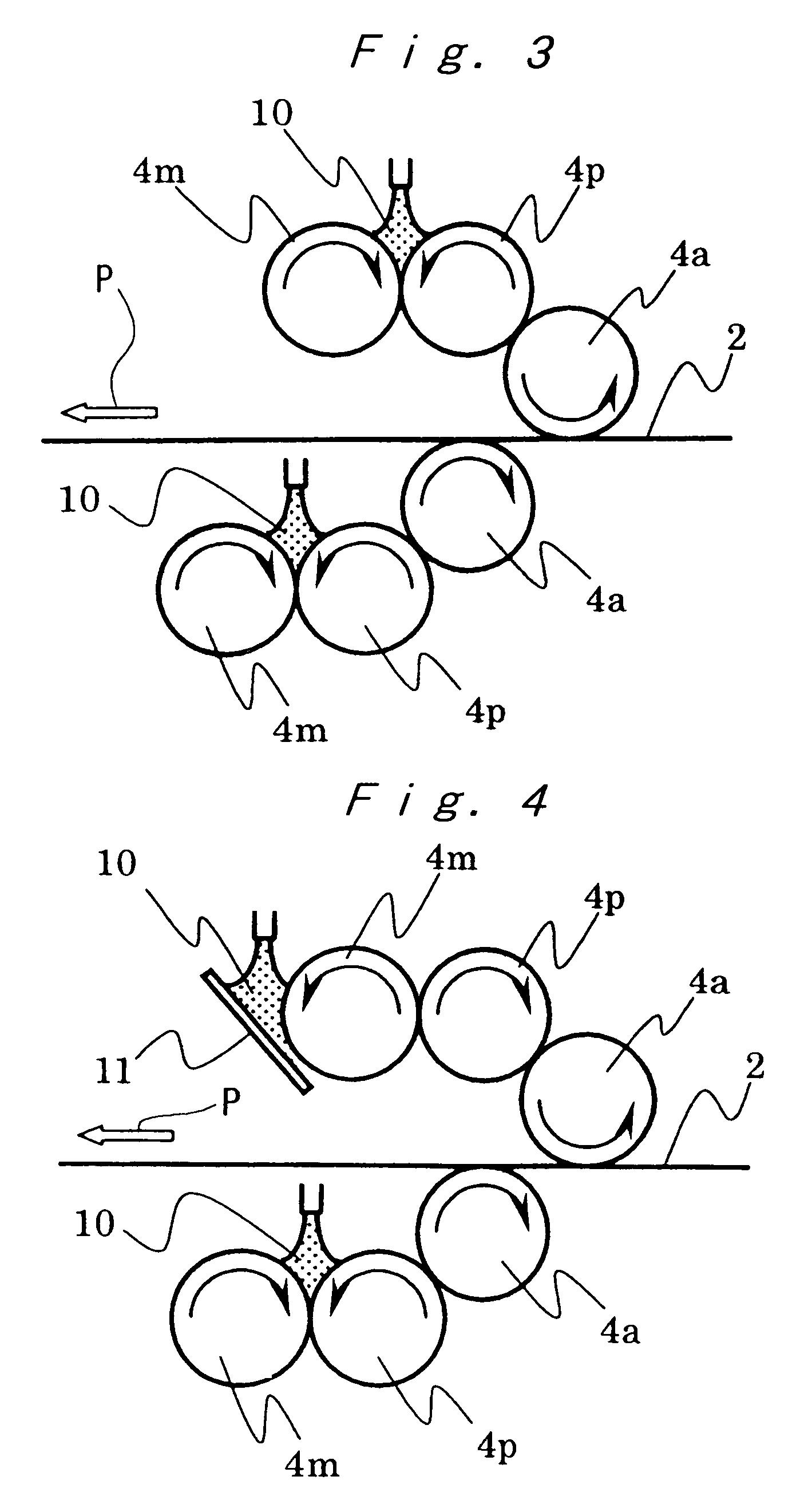

Coating apparatus for an aluminum alloy heat exchanger member, method of producing a heat exchanger member, and aluminum alloy heat exchanger member

InactiveUS7722922B2Hot-dipping/immersion processesTransportation and packagingPowder mixtureTransfer system

An coating apparatus, wherein the apparatus applies a coating, onto a surface of an aluminum alloy member for a heat exchanger to be assembled by brazing, with a top-feed-type roll transfer system having at least three rolls, the coating being obtained by mixing into an organic binder a metal powder, a flux powder, a powder mixture thereof, or a compound containing a metal component and a flux component, wherein rotation directions of transfer rolls of the apparatus arranged above a surface to be coated of an aluminum alloy extruded member that moves in a horizontal direction, satisfy a relationship in which a rotation direction of a coated-metal roll for coating, which rotates in a direction opposite to a moving direction of the extruded member, and a rotation direction of a metal roll for adjusting an adhesion amount of the coating by contacting with the above roll, are opposite to each other; and a method of producing an aluminum alloy heat exchanger member using the apparatus; and an aluminum alloy heat exchanger member.

Owner:FURUKAWA SKY ALUMINUM CORP

Self-feeding type plastic corrugated pipe cutting machine

The invention relates to the technical field of pipe cutting and discloses a self-feeding type plastic corrugated pipe cutting machine. The self-feeding type plastic corrugated pipe cutting machine comprises a machining table; a motor and a blade are arranged on the machining table; the machining table comprises a rack and a bottom board; the upper portion of the bottom board is rotationally connected with a rotary shaft; the rotary shaft is fixedly connected with a plurality of cams; the two ends of the rotary shaft are connected with the motor and the blade; the lower portion of the rack isrotationally connected with a first shaft; a first support rod is hinged to the first shaft; the first shaft is fixedly connected with a large rotary wheel; a first supporting arm is hinged to the large rotary wheel; the first shaft is movably connected with a second shaft; a second support rod is hinged to the second shaft; a connection rod is fixedly connected between the second support rod andthe first support rod; the connection rod is connected with a drive mechanism; the second shaft is fixedly connected with a small rotary wheel; a second supporting arm is hinged to the small rotary wheel; and the second supporting arm and the first supporting arm are hinged to the bottom board. By means of the self-feeding type plastic corrugated pipe cutting machine, automatic feeding of corrugated pipes is achieved, and the machining efficiency of the corrugated pipes is improved.

Owner:SHANDONG WANSHIDA SPECIAL PURPOSE VEHICLE MFG

Pressure feed type high-pressure dense-phase pneumatic conveying device and pneumatic conveying method

The invention discloses a pressure feed type high-pressure dense-phase pneumatic conveying device and a pneumatic conveying method. Pressure feed type high-pressure dense-phase pneumatic conveying is adopted for providing a device and a method for supplying an ultra-concentrated-phase and high-stable-mass-flow-rate powder material; the structures of a conveying system and a material sending tank are greatly simplified; the shortcomings that a fluidization tank is complicated in form and structure, control requirements of fluidization wind in the tank are relatively high, a conveying tube is unfavorable to fluidization and overall flowing of powder in the tank and the like are avoided; investment is saved; meanwhile, the conveying device needs no power running member, so the safety of the high-pressure conveying device is guaranteed better. According to the conveying device disclosed by the invention, the gas-solid flow velocity is small; the gas-solid impact wear is greatly reduced; the wear resistance of the device is greatly improved; the service life of the device is greatly prolonged; the conveying device is stable, reliable and relatively good in regulation function, has the effect of avoiding the influences caused by unstable conveying to subsequent processes and especially has a more remarkable effect on a technique which requires high stability of subsequent processes of a pneumatic conveying terminal and ultrahigh concentration of coal dust.

Owner:SOUTHEAST UNIV

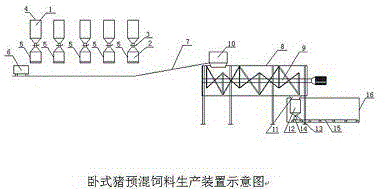

Horizontal type premix pig feed production process and device

InactiveCN104938795AImprove space utilizationLow running costFeeding-stuffAnimal feeding stuffRegular ProductionEffective volume

Current premix pig feed is produced by adopting a vertical feed type mixer with a vertical paddle, and the technological process is as follows: all the raw materials pass through bins, the feeding amount of all the raw materials is controlled through quantitative weighing in the bins, the raw materials enter the mixer via a vertical pipe under the action of gravity, and the mixing operations are completed quickly under the fast stirring of a blender with a vertical paddle. For a mixer with an effective volume of 250 kg, the required space height is about 8 m, and the larger the effective volume is, the higher the required space is. For a common workshop, the technological process is not suitable for being applied, and application of the process is greatly restricted. In order to solve the problem, the invention develops a horizontal type premix pig feed production process and device, wherein the process adopts closed bins for automatic weighing, an automatic rail trolley for material lifting, and a ribbon-type mixer for quick mixing; compared with the vertical type process, the process provided by the invention occupies smaller space, the required space height is decreased by 50% or above, and the production requirements of common workshops are met. Therefore, the production process provided by the invention is duplicable and can be popularized.

Owner:AOWEI TIANJIN ENVIRONMENTAL PROTECTION TECH +2

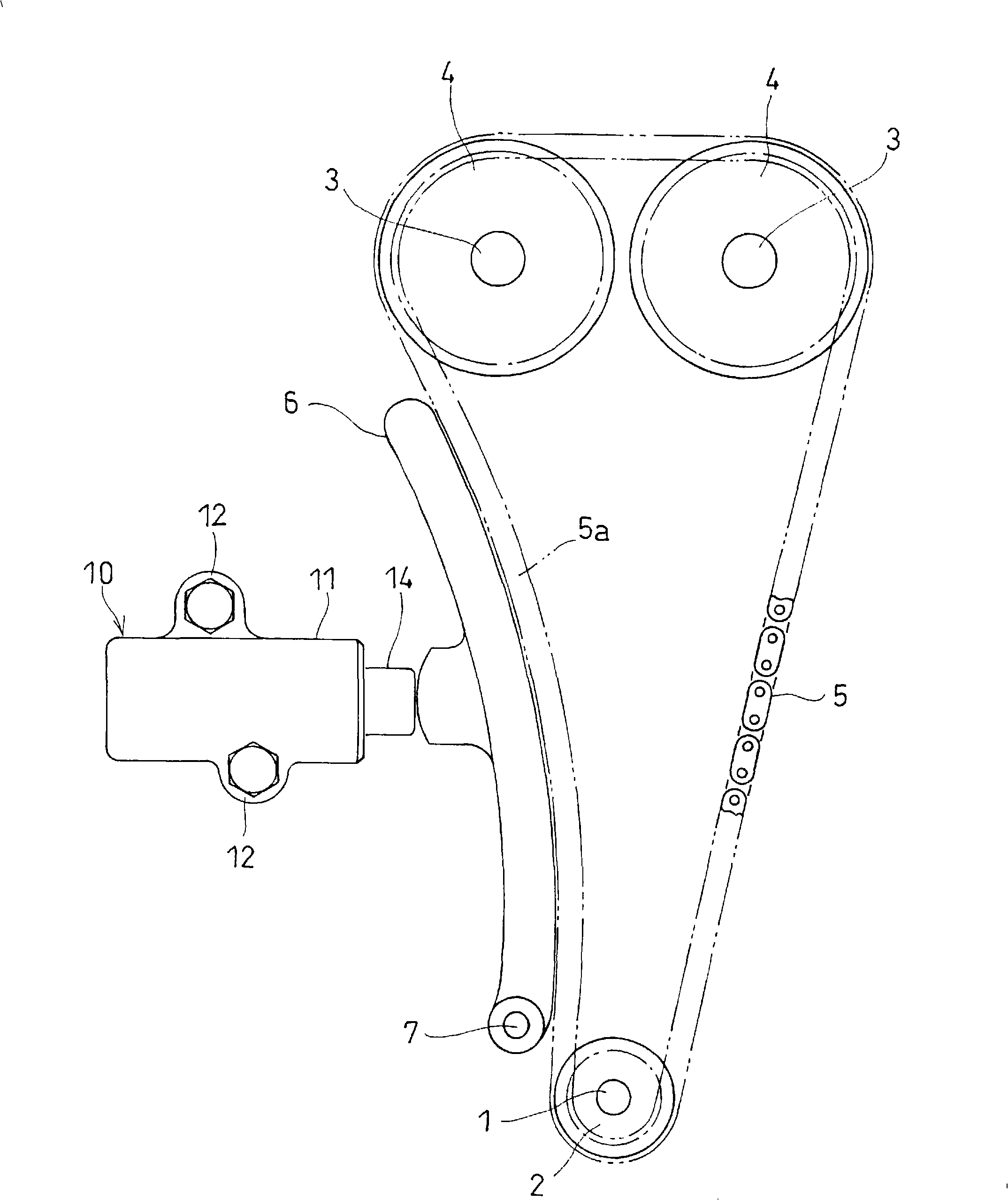

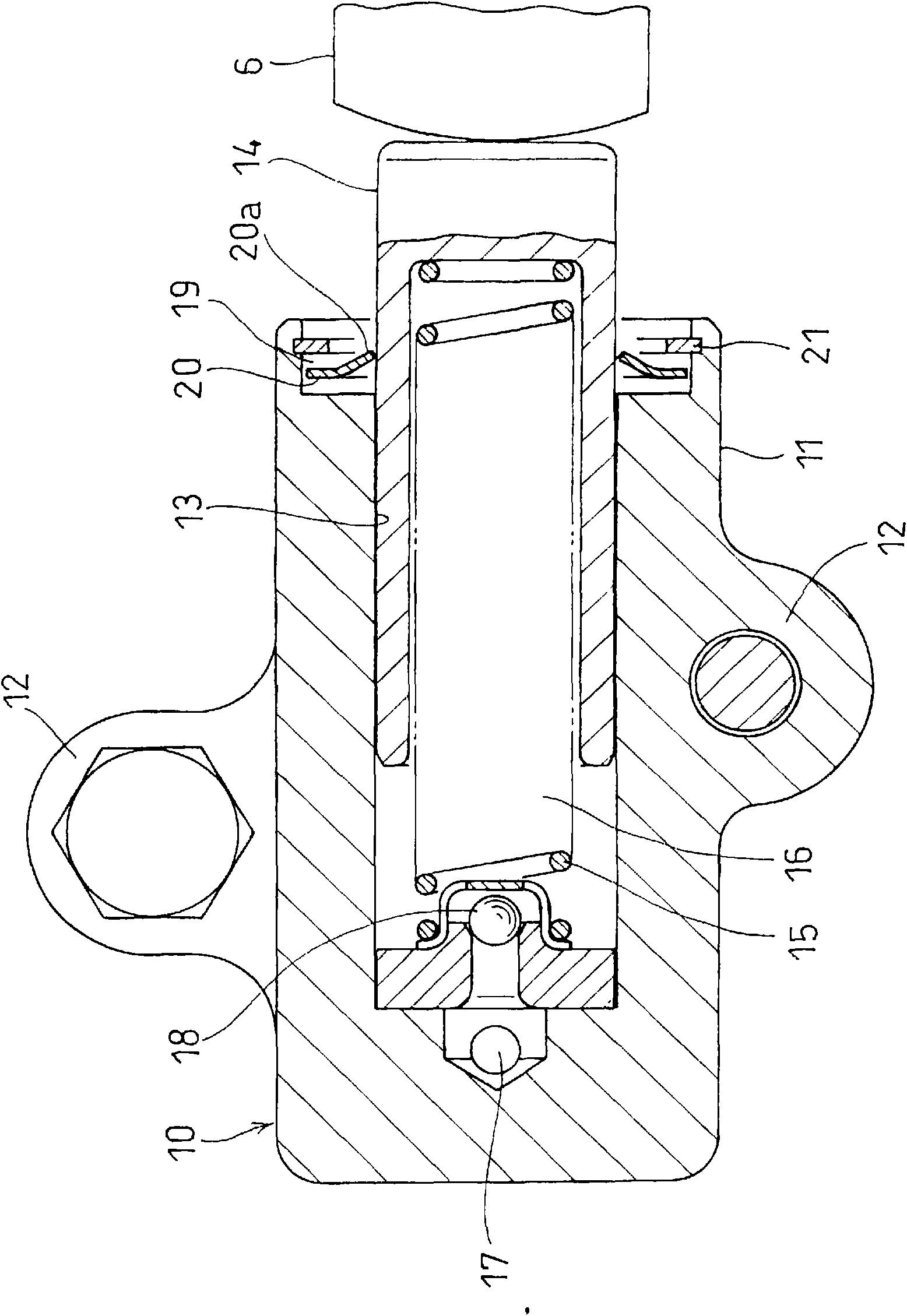

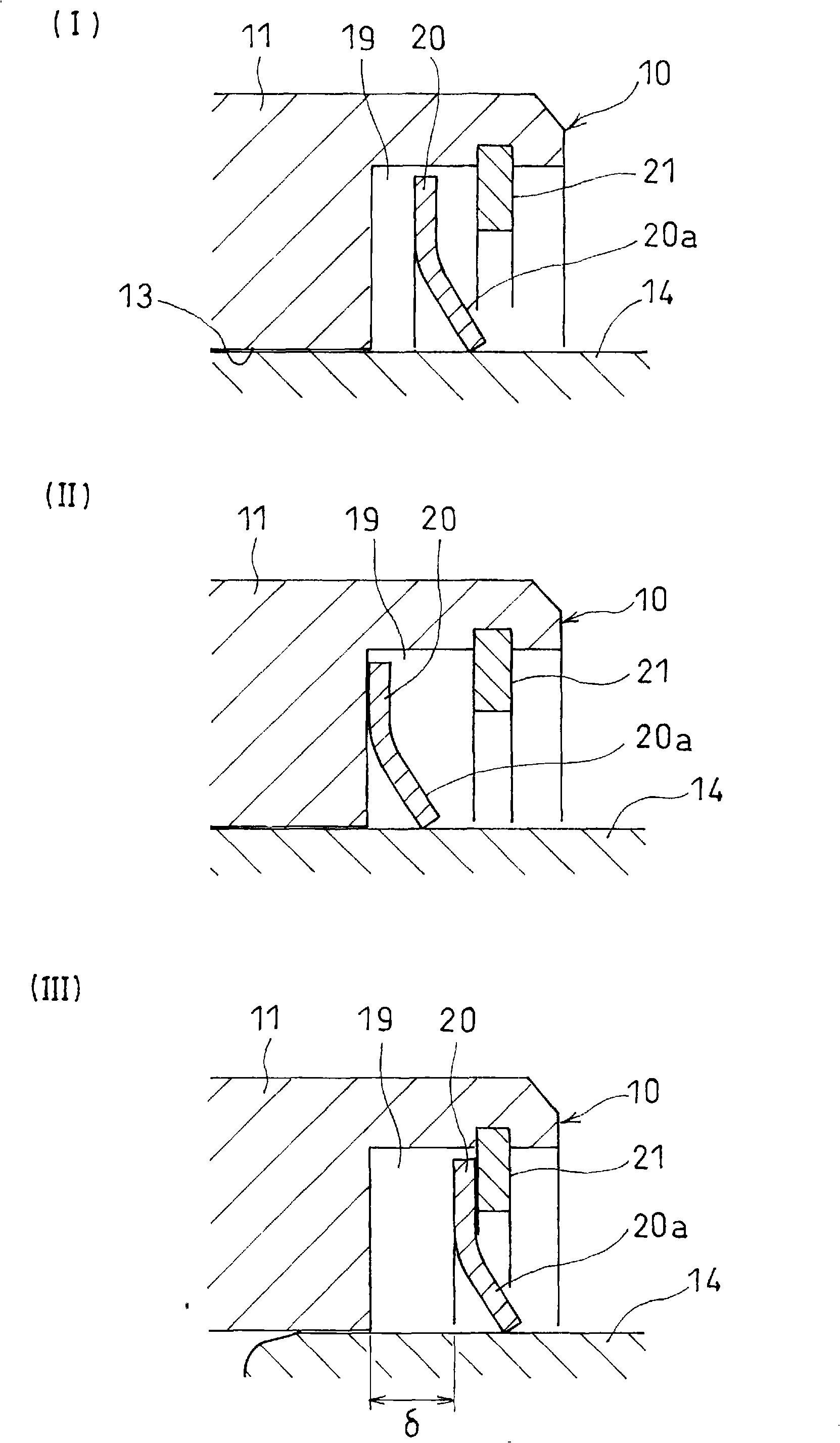

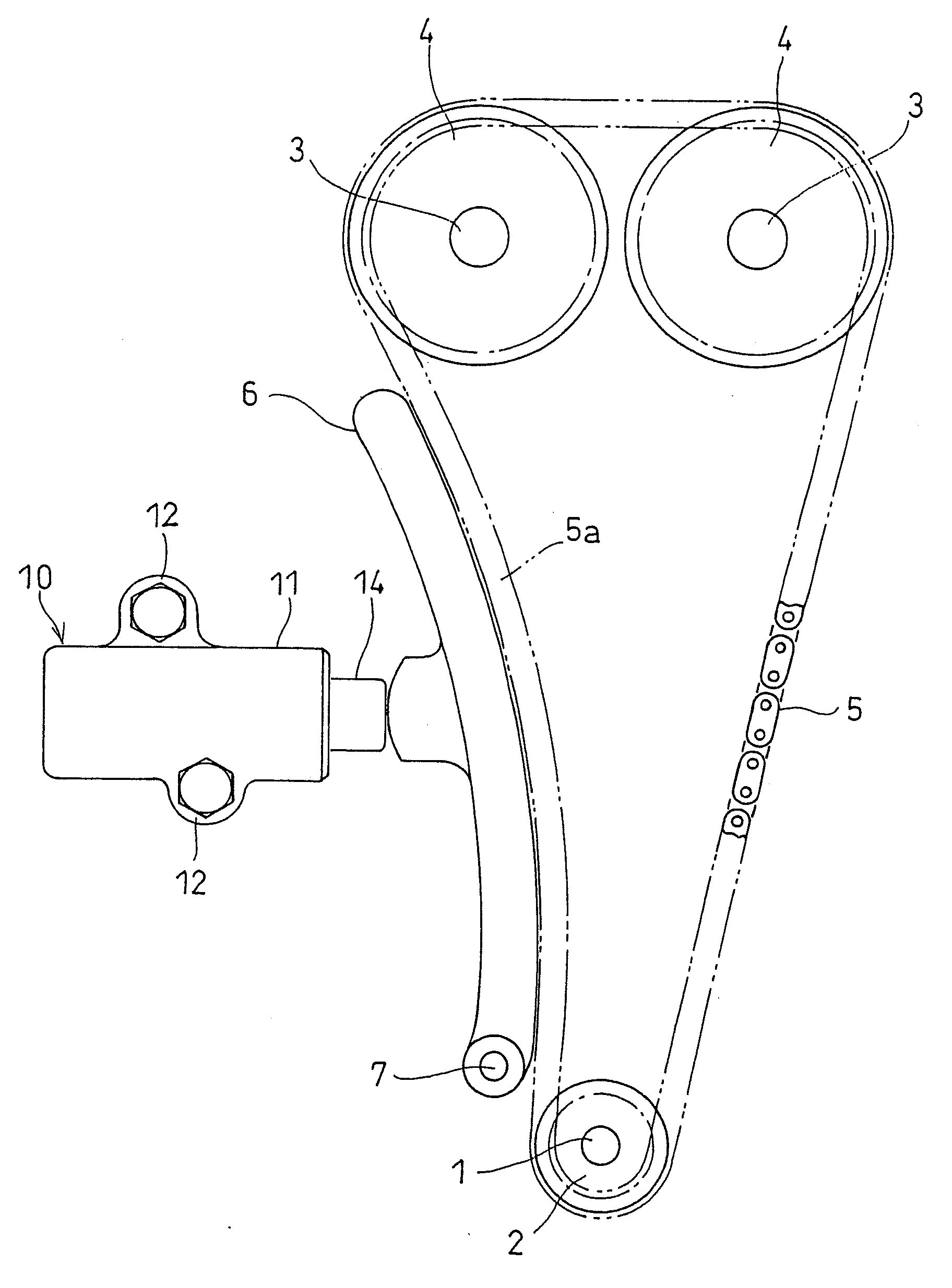

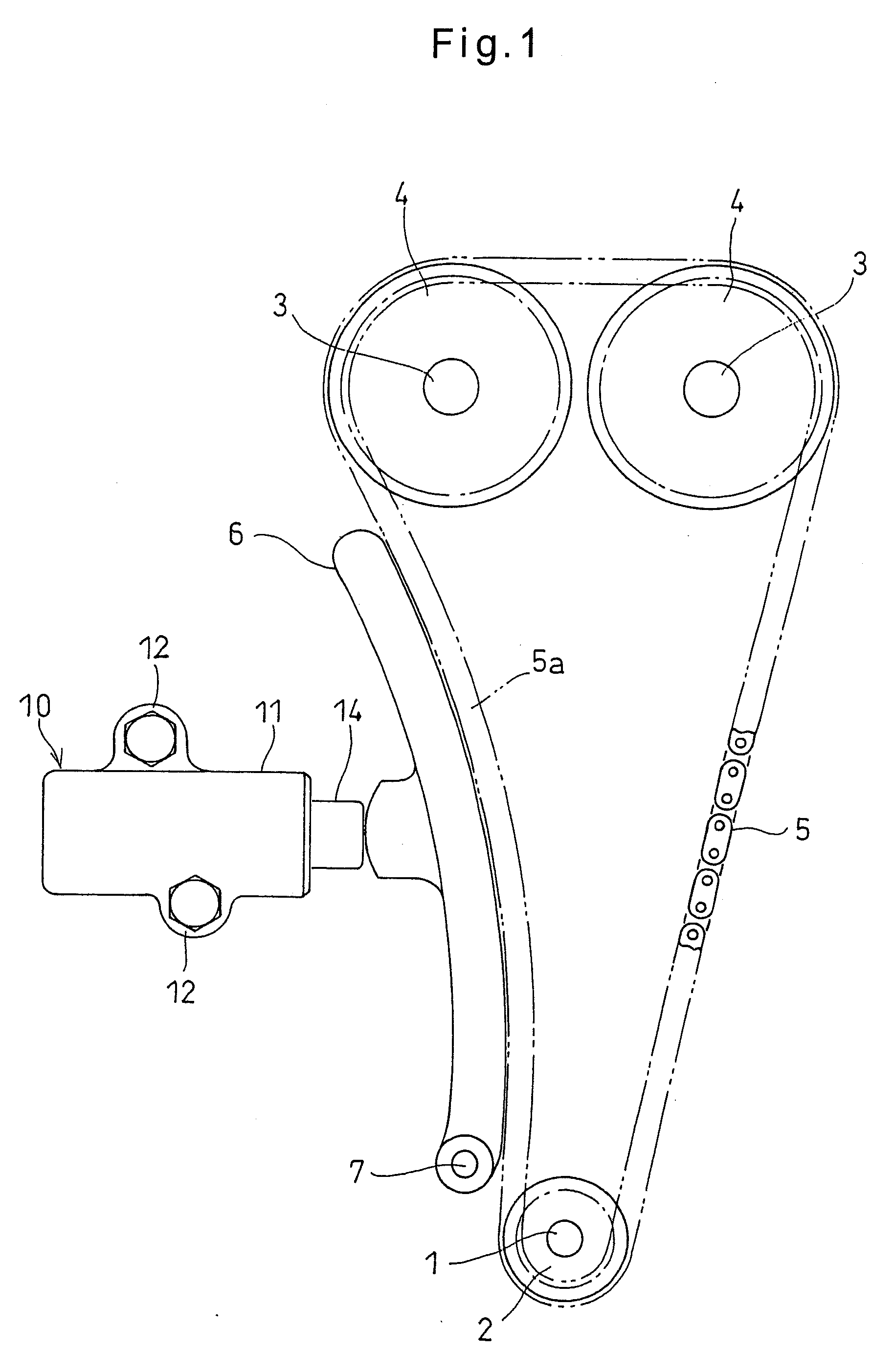

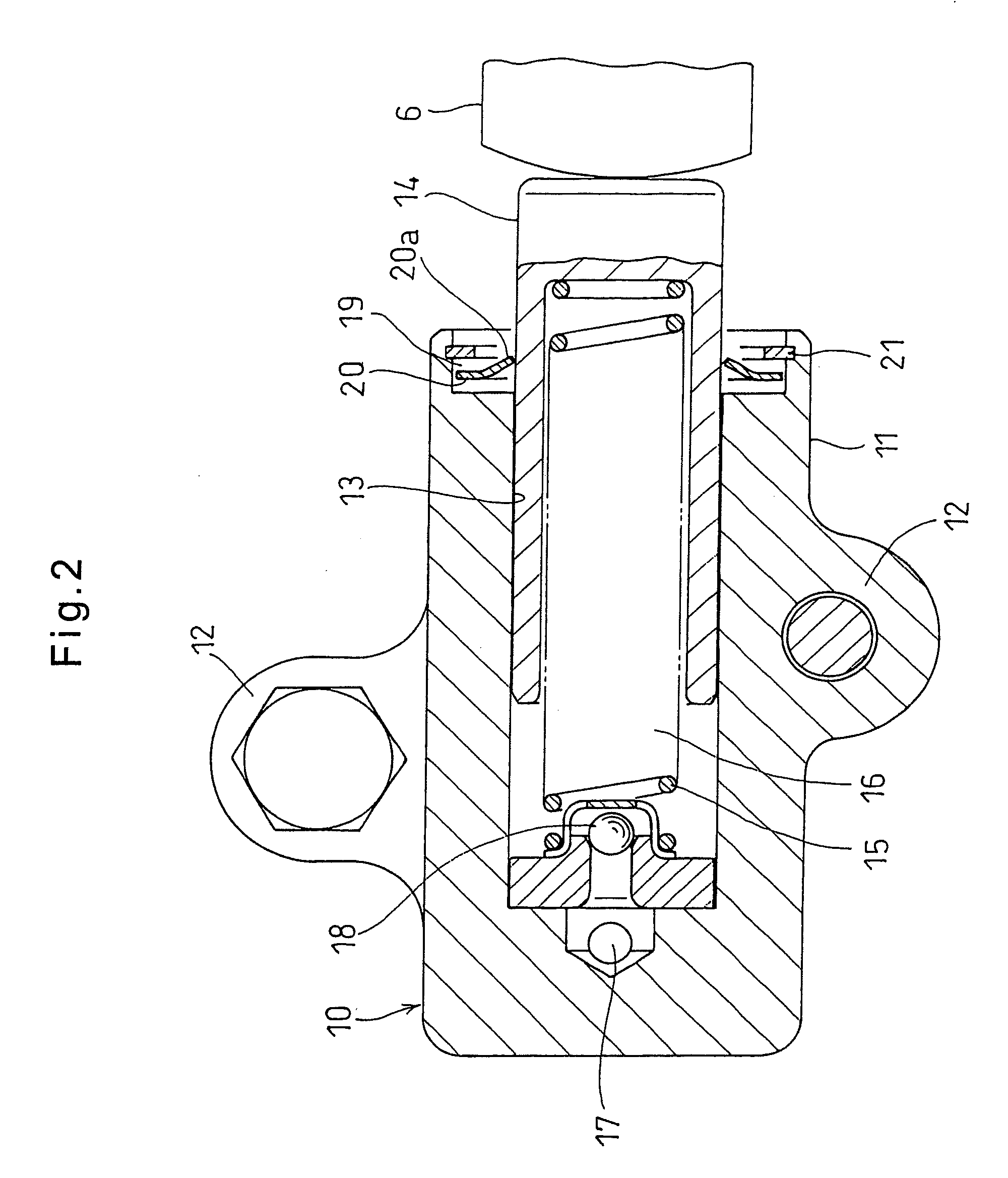

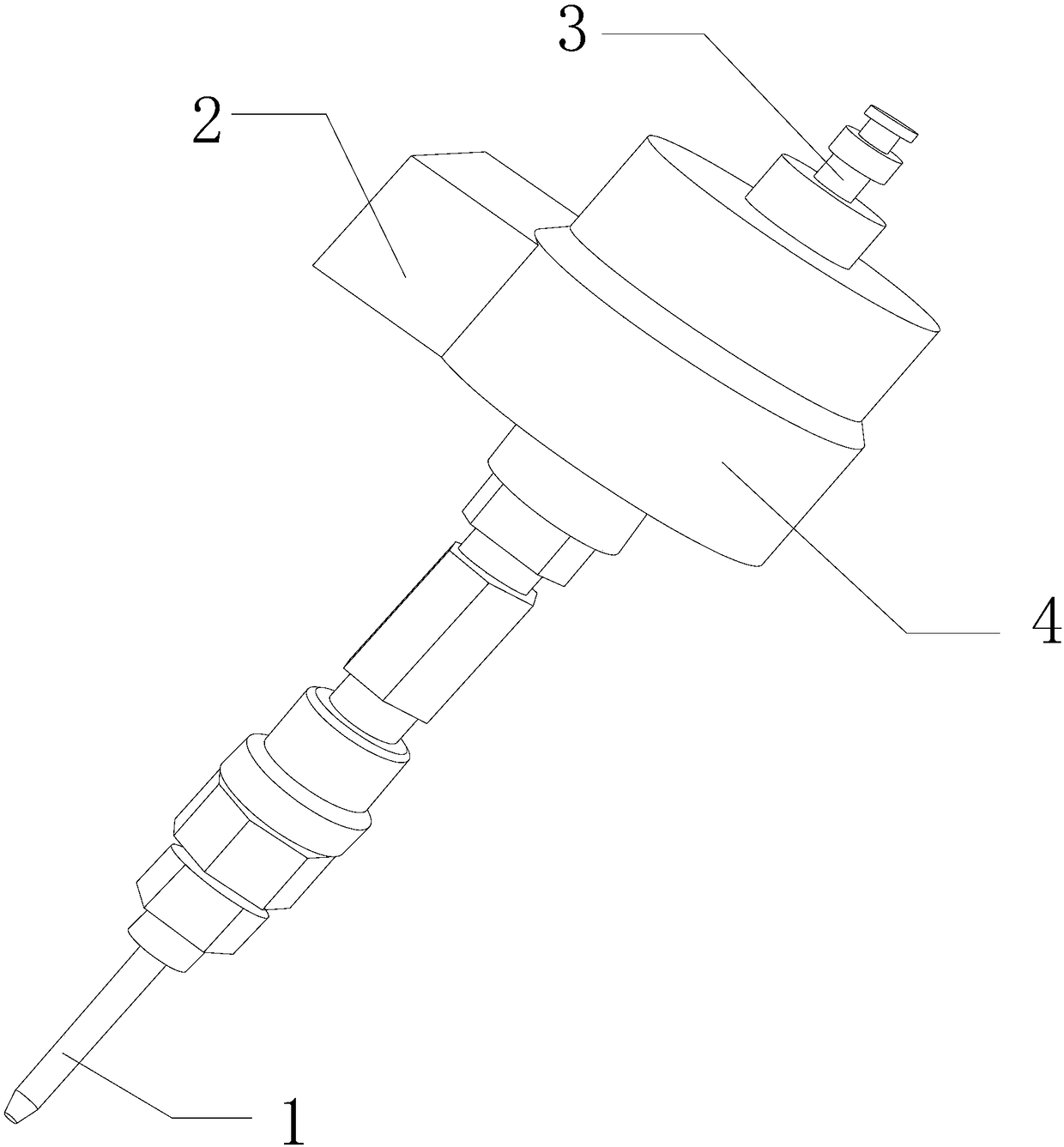

Oil feeding type auto-tensioner

Provided is an oil feeding type auto-tensioner, which is enabled to prevent the working oil in a pressure chamber reliably from being aerated. In a cylinder chamber (13) formed in a housing (11), there are assembled a slidable plunger (14) and a return spring (15) for protruding the plunger (14) outward. In the housing (11), there is formed an oil feeding passage (17), which communicates with a pressure chamber (16) formed in the back of the plunger (14). A check valve (18) is disposed in the working oil exit portion of the oil feeding passage (17). A diametrically large hole portion (19) is formed in the open end portion of the cylinder chamber (13). A braking stop ring (20) is made movable in that diametrically large hole portion (19), and is equipped on its inner circumference with a plurality of engaging members (20a), which are inclined in the projecting direction of the plunger (14) and which engage at their leading internal diameter edges with the outer circumference of the plunger thereby to prevent the backward movement of the plunger. When the plunger (14) is loaded with a pushing force by the chain at an engine stopping time, the braking stop ring (20) is held in the stopped state by the abutment against the closed end face of the diametrically large hole portion (19). By the engagements between the leading end radially inner edges of the engaging members (20a) formed on the inner circumference of the braking stop ring (20) and the outer circumference of the plunger (14), the backward movement of the plunger (14) is blocked to hold the chain in a predetermined tensile state thereby to prevent the plunger (14) from moving largely outward at the restarting time of the engine.

Owner:NTN CORP

Feed-type vibratory feeding method and feed-type vibratory feeding mechanism

Owner:WENZHOU XIAOJIANG MACHINERY TECH

Oil feed type auto-tensioner

An object is to provide an oil feed type auto-tensioner which can reliably prevent air from mixing into hydraulic oil in the pressure chamber.This tensioner includes a housing (11) defining a cylinder chamber (13), a plunger (14) slidably mounted in the cylinder chamber (13), a return spring (15) mounted in the cylinder chamber (13) and biasing the plunger (14) outwardly of the cylinder chamber (13), the housing (11) being formed with an oil supply passage (17) communicating with a pressure chamber (16) defined in the cylinder chamber behind the plunger (14), and a check valve (18) provided at a hydraulic oil outlet of the oil supply passage (17). The cylinder chamber (13) includes a large-diameter hole portion (19) provided at an open end thereof, in which a snap ring (20) for braking is received so as to be movable therein. The snap ring (20) includes a plurality of engaging pieces (20a) provided at a radially inner portion thereof and inclined in a direction in which the plunger (14) protrudes from the housing. The engaging pieces (20a) have radially inner edges that are in engagement with the outer periphery of the plunger, thereby restraining retraction of the plunger. When a pushing force is applied to the plunger (14) from the chain while the engine is at a stop, the snap ring (20) for braking abuts the closed end face of the large-diameter hole portion (19) and is stopped. In this state, because the radially inner edges of the engaging pieces (20a) formed on the radially inner portion of the snap ring (20) are in engagement with the outer periphery of the plunger (14), the plunger (14) is prevented from retracting, thus keeping the tension of the chain within a predetermined range. This prevents the plunger (14) from markedly moving outwardly when the engine is subsequently restarted.

Owner:NTN CORP

Automatic-feed-type reed peeling machine

ActiveCN107433663AProtect your healthExtended service lifeConveyorsOsier rod peelingReducerEngineering

The invention relates to the technical field of the automatic mechanical equipment and in particular to an automatic-feed-type reed peeling machine. The automatic-feed-type reed peeling machine comprises a peeling mechanism and an automatic feed mechanism. The peeling mechanism is formed by three pairs of upper and lower steel wire rollers, a first motor, a second motor, a reducer, a roller distance regulating device, a discharging port and a peeling machine frame. The automatic feed mechanism is formed by a feed machine frame, an active material bracket, a gliding-type hopper, a feeding machine, a one-way guiding channel, a belt conveyor, and a feeding port. The belt conveyor is formed by a main belt wheel, a driven belt wheel, a conveying belt, a tooth-shaped scraper blade and a conveyor tensioning device. The structure and design of the automatic-feed-type reed peeling machine are rational, a worker does not need to execute the feeding continuously beside the machine, the feeding process is automatically completed by the machine, the labor force is greatly saved, the body health of the worker is protected, the feeding process is rapid, uniform and stable, the working efficiency is greatly improved, the problem of non-uniform wearing of a wire brush can be overcome, and the service life is prolonged.

Owner:崔吉华

High-pressure abrasive feeding type wood cutting gun

InactiveCN108422326AReduce dust contentReduce procurement costsBlast gunsAbrasive feedersSpray nozzleAgricultural engineering

The invention discloses a high-pressure abrasive feeding type wood cutting gun. The high-pressure abrasive feeding type wood cutting gun structurally comprises a jet nozzle, an abrasive pretreating device, a high-pressure water pipe and a mixing cavity; the jet nozzle is connected to the bottom of the mixing cavity, the high-pressure water pipe is arranged in the mixing cavity, and the side face of the mixing cavity is connected with the abrasive pretreating device; and the abrasive pretreating device is composed of a link mechanism, a reset mechanism, a liquid level transmission mechanism, atiming transmission device, a linkage mechanism, a liquid level switch, a cleaning device and a partition plate, the partition plate is installed in the cleaning device, and the cleaning device is electrically connected with the linkage mechanism. According to the high-pressure abrasive feeding type wood cutting gun, abrasives can be cleaned, water feeding can be automatically stopped and stirringand timing can be started when water is fed to a certain water level, automatic water draining can be conducted after stirring is conducted for a period of time through the timing transmission device, the dust content of the abrasives can be greatly decreased, it is guaranteed that cutting is smoothly conducted, and the purchase cost is reduced.

Owner:陈志煌

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com