Patents

Literature

364 results about "Rack unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rack unit (abbreviated U or RU) is a unit of measure defined as 1 ³⁄₄ inches (44.45 mm). It is most frequently used as a measurement of the overall height of 19-inch and 23-inch rack frames, as well as the height of equipment that mounts in these frames, whereby the height of the frame or equipment is expressed as multiples of rack units. For example, a typical full-size rack cage is 42U high, while equipment is typically 1U, 2U, 3U, or 4U high.

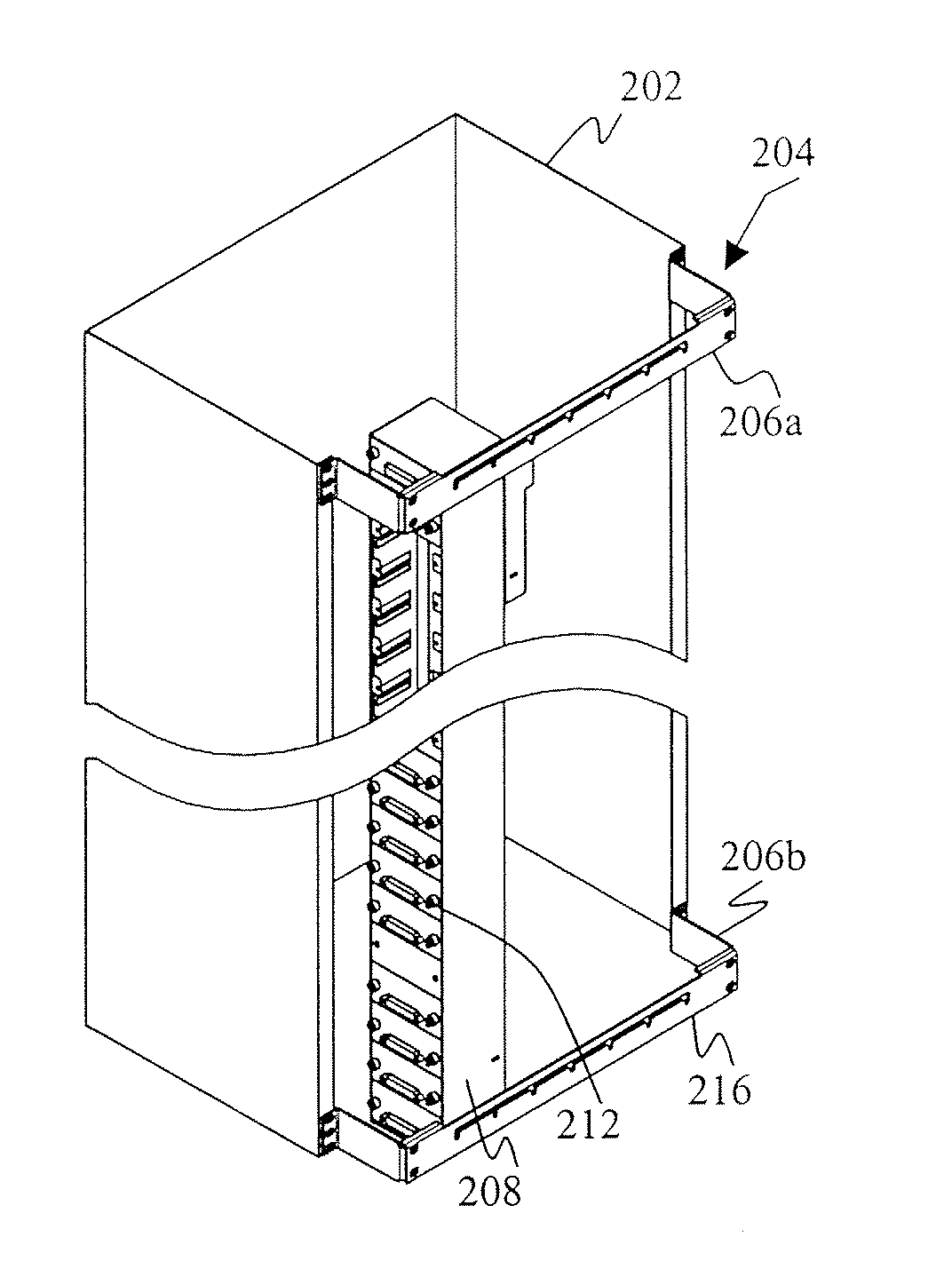

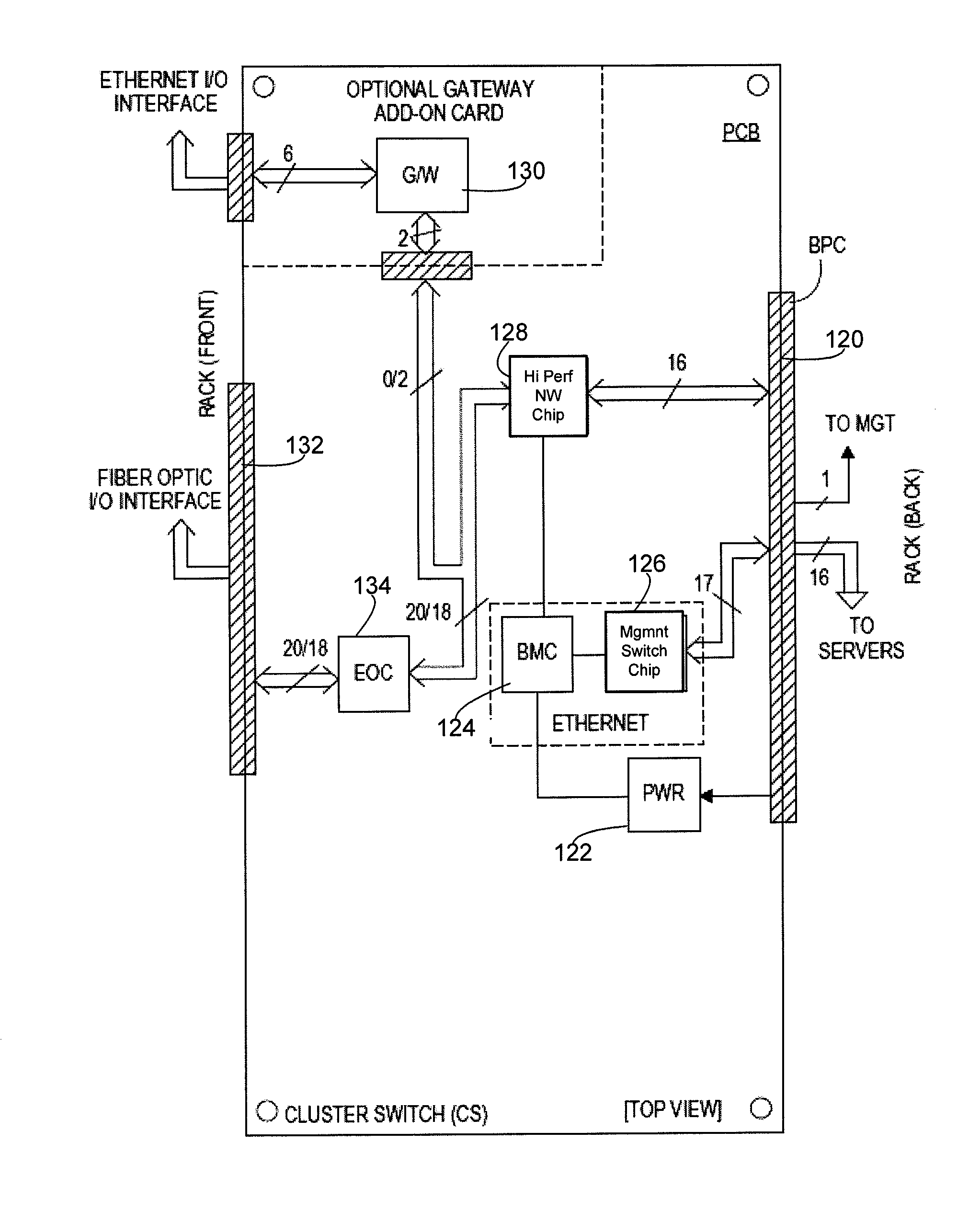

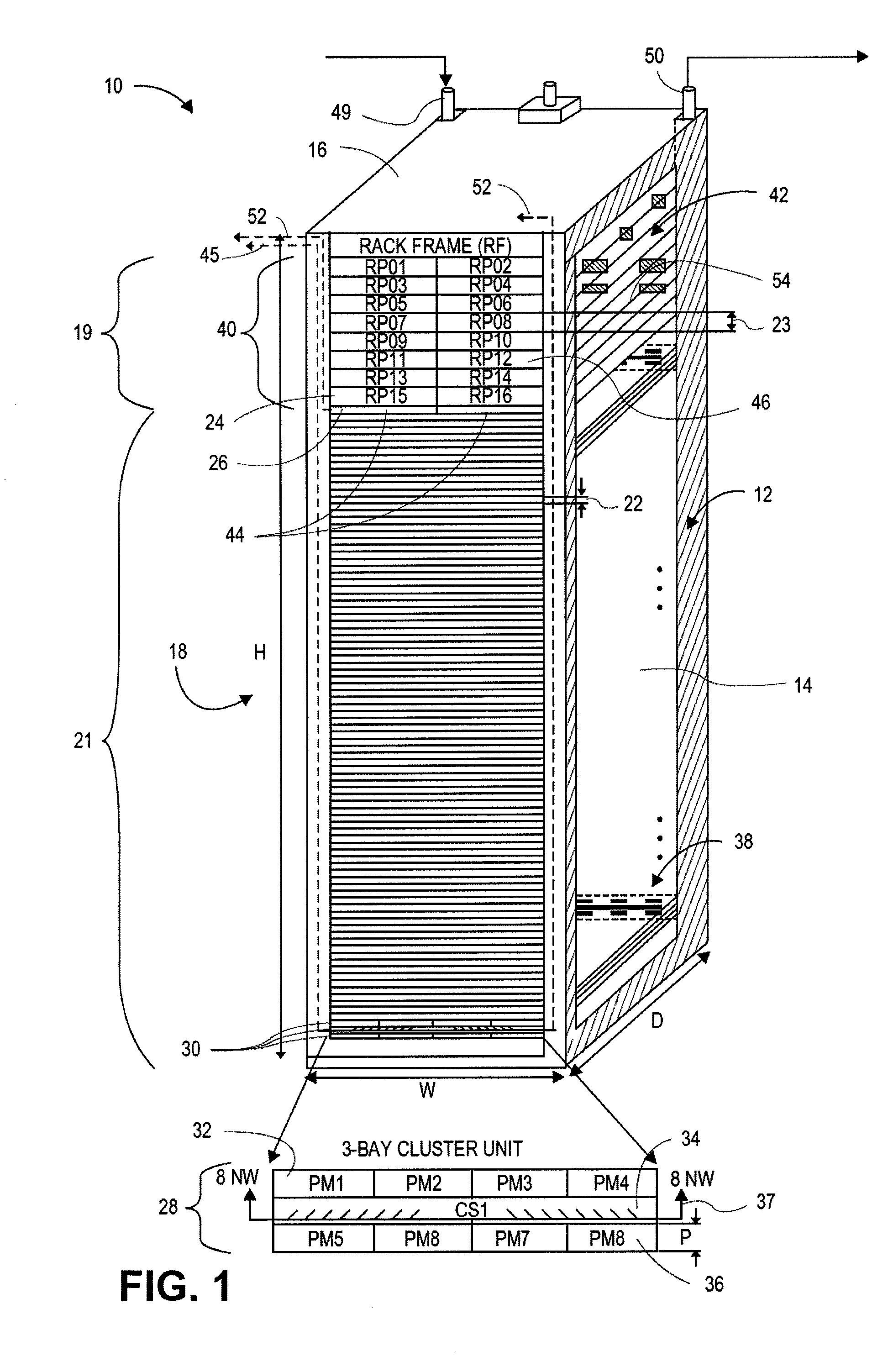

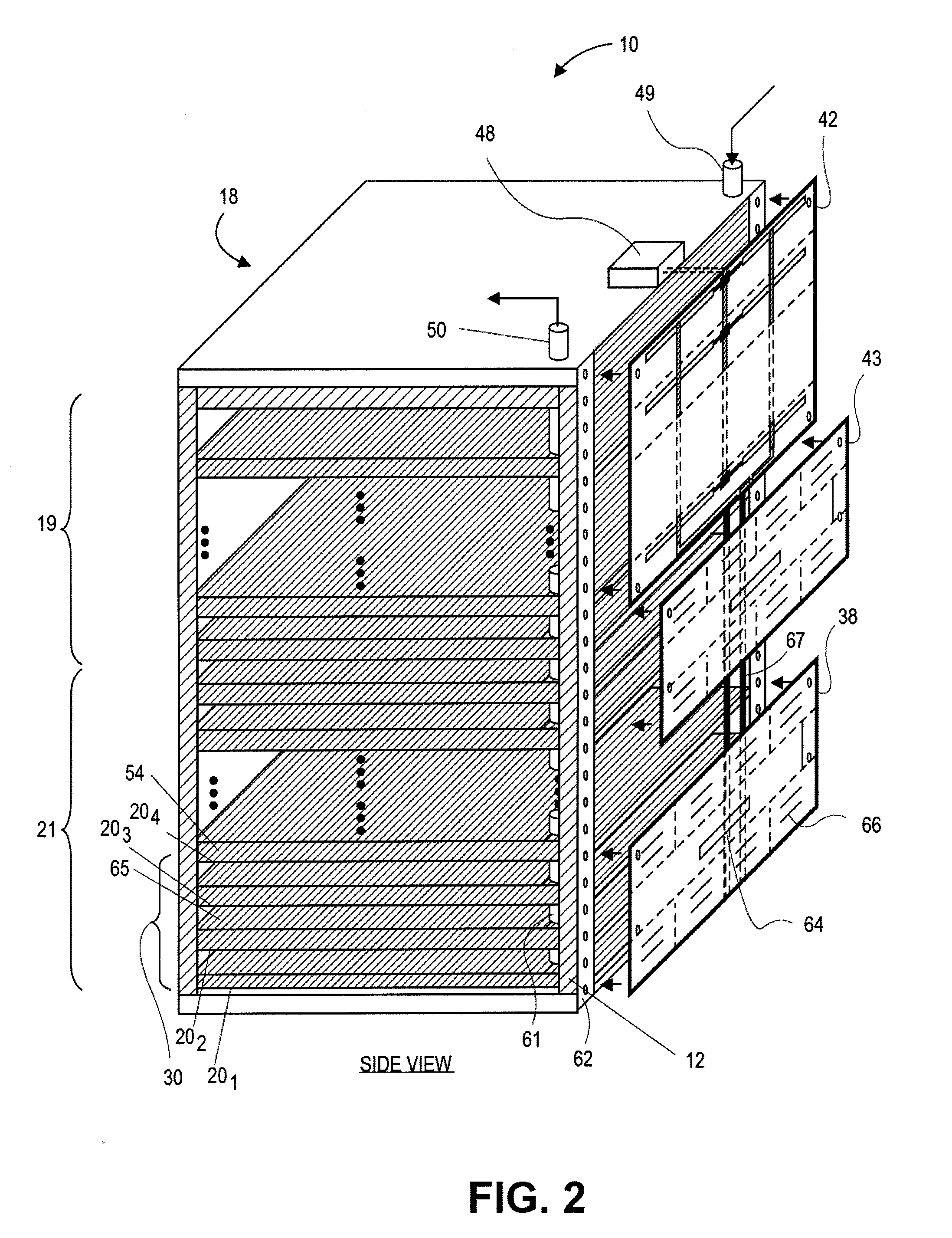

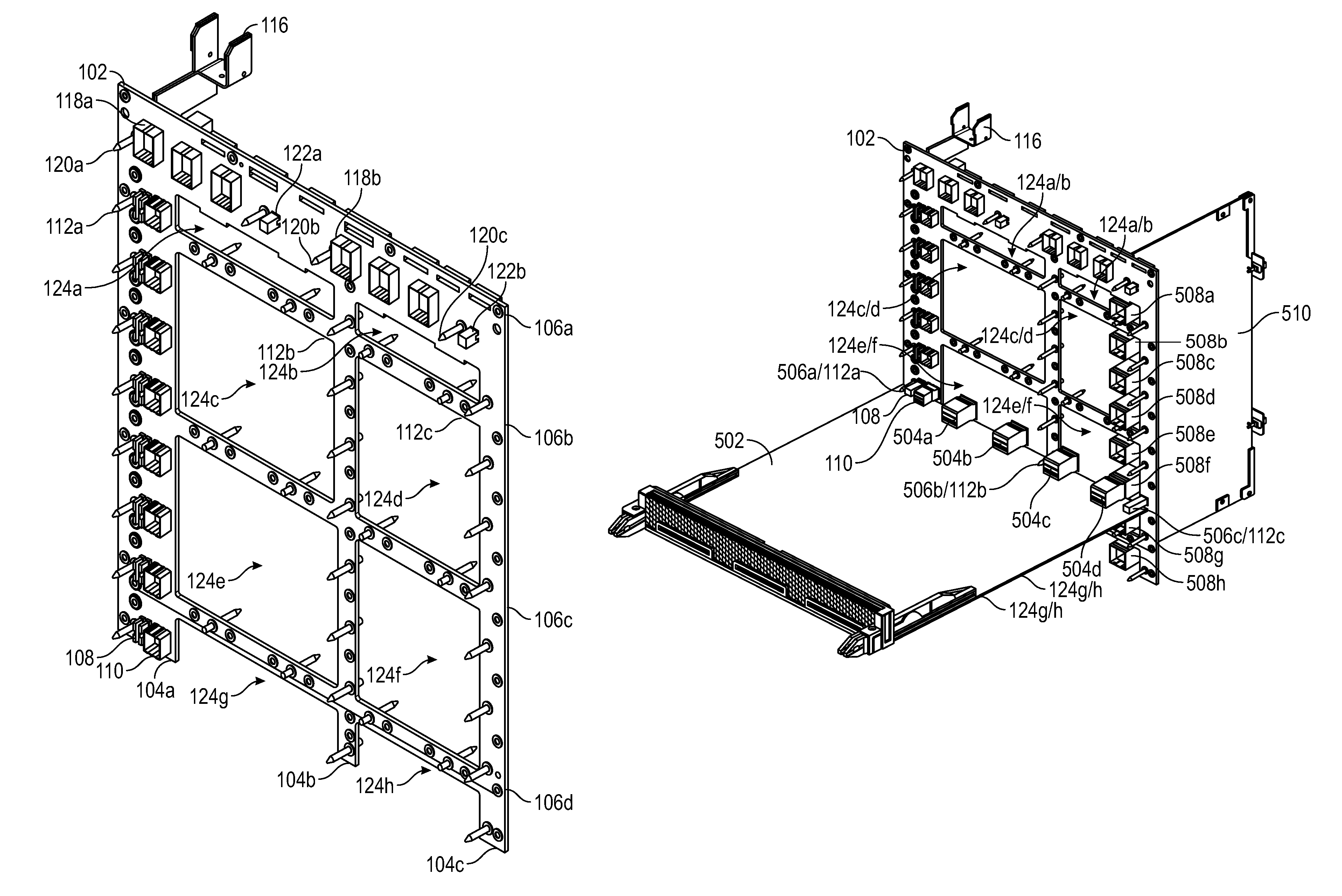

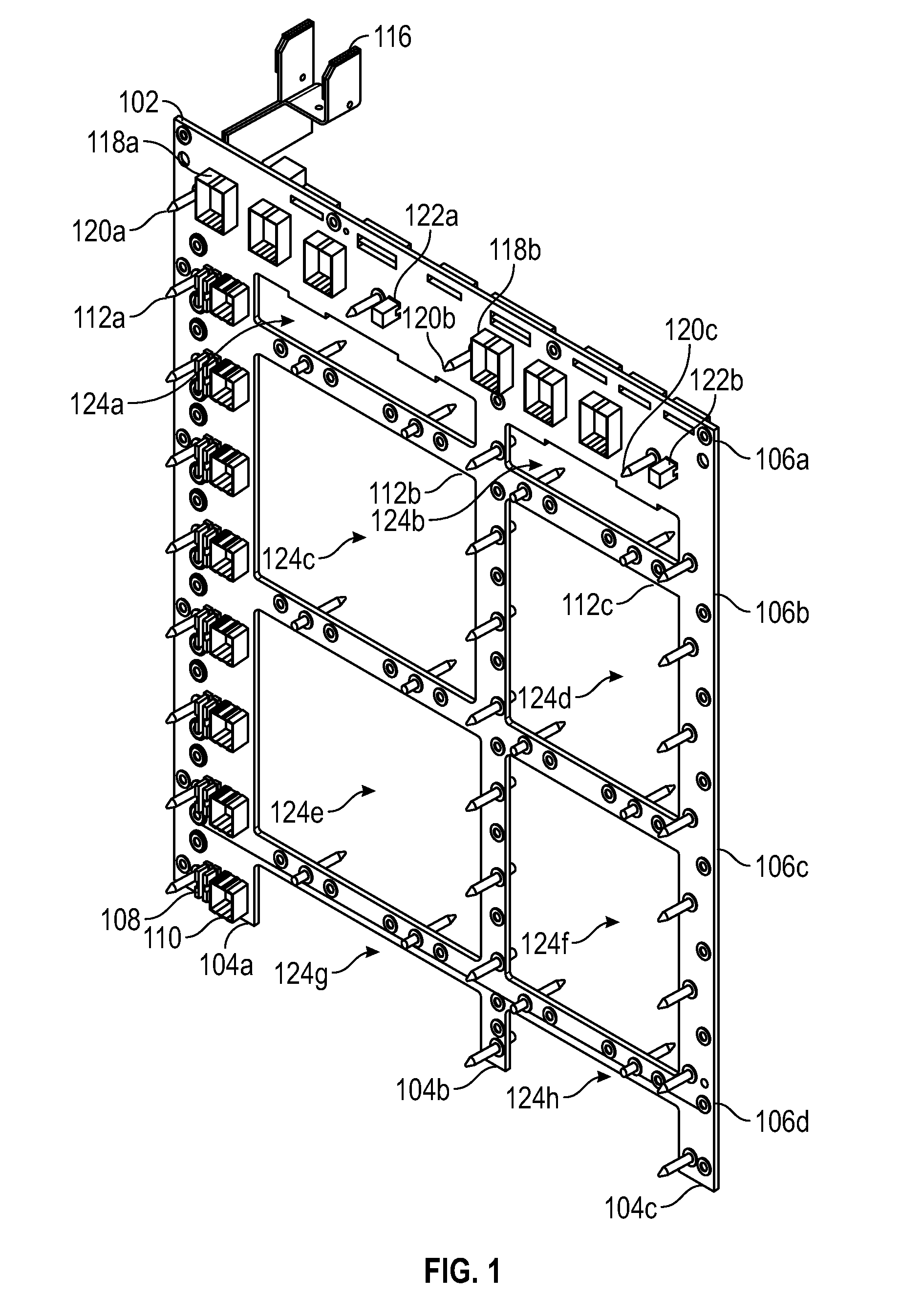

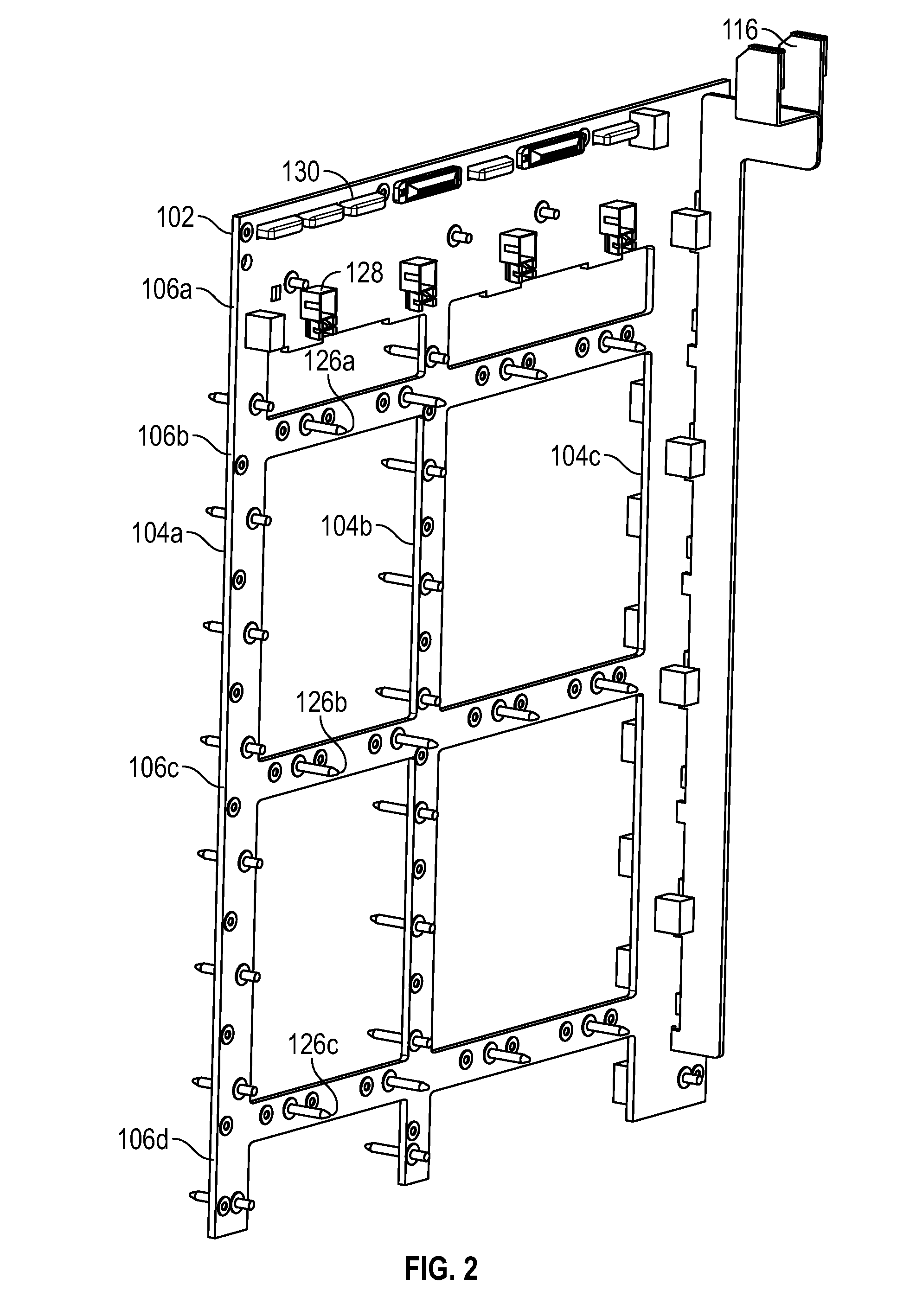

Rack architecture and management system

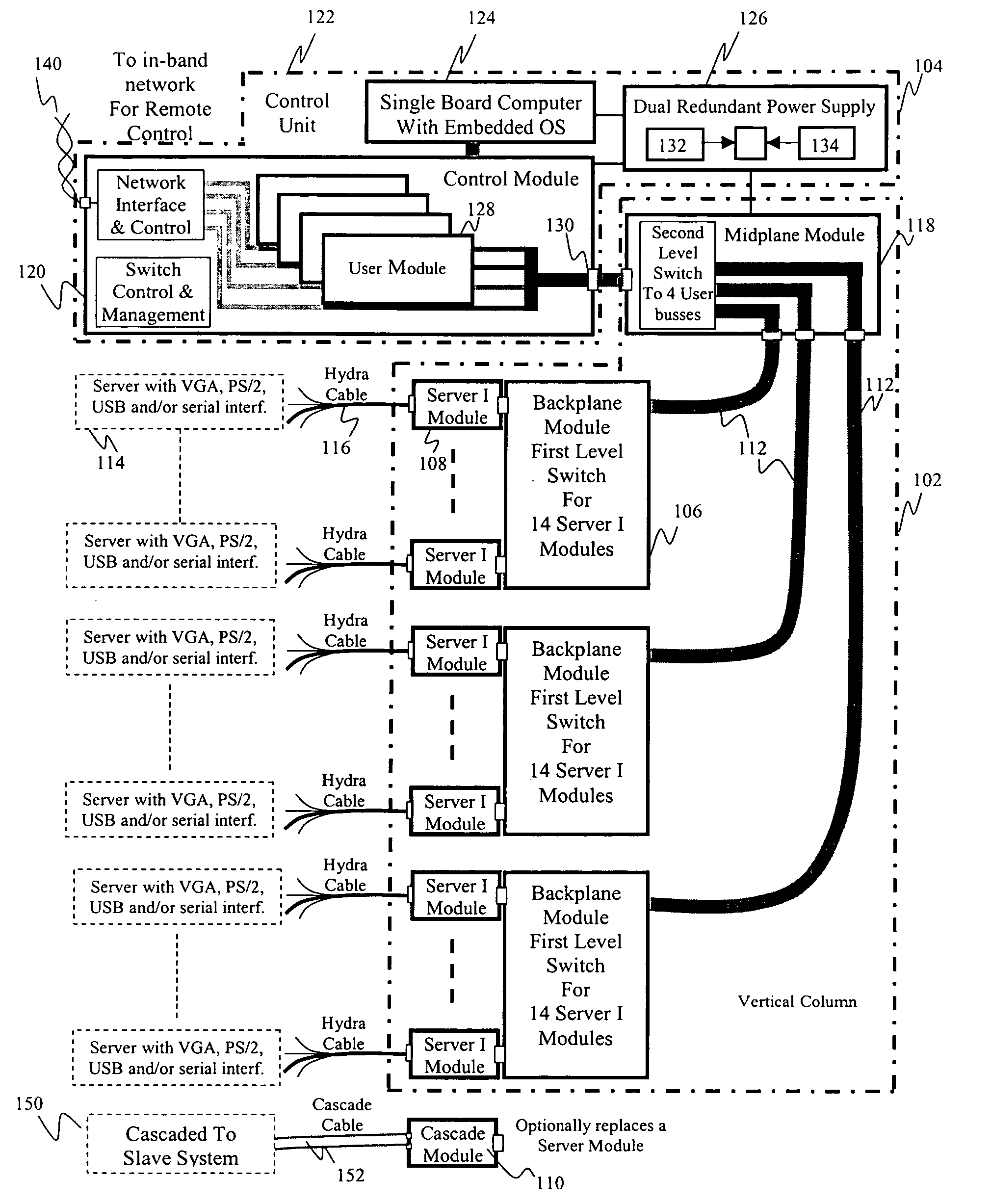

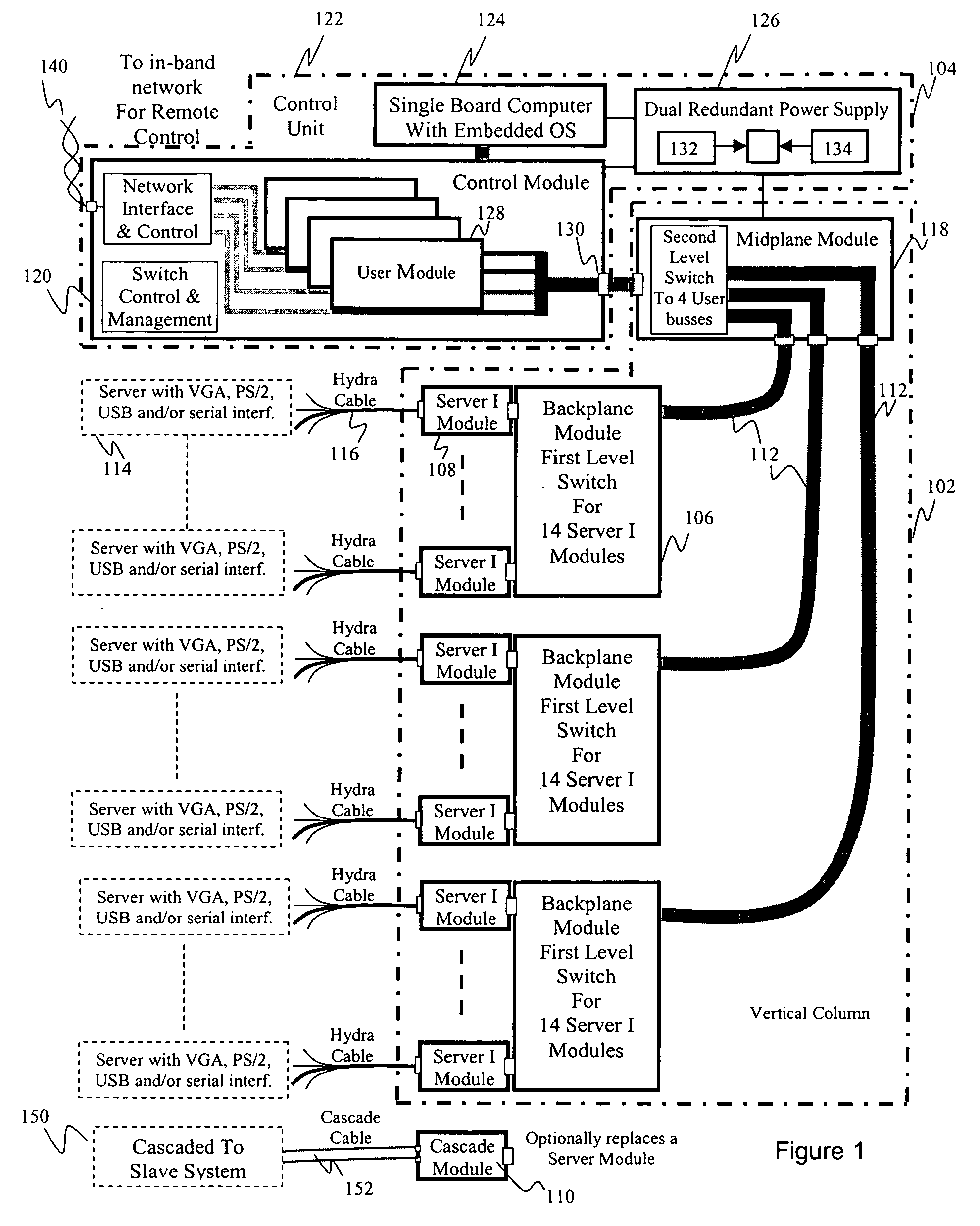

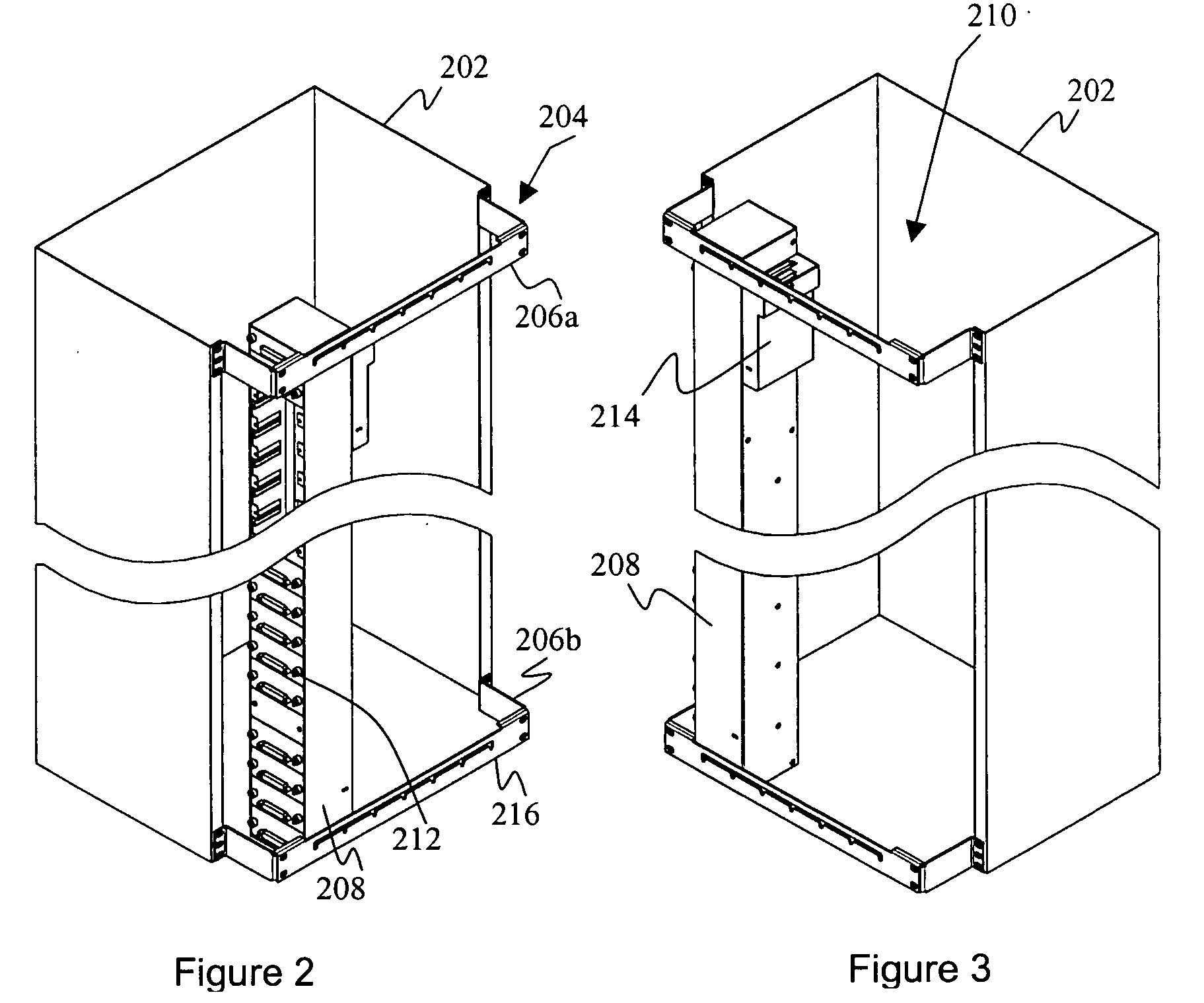

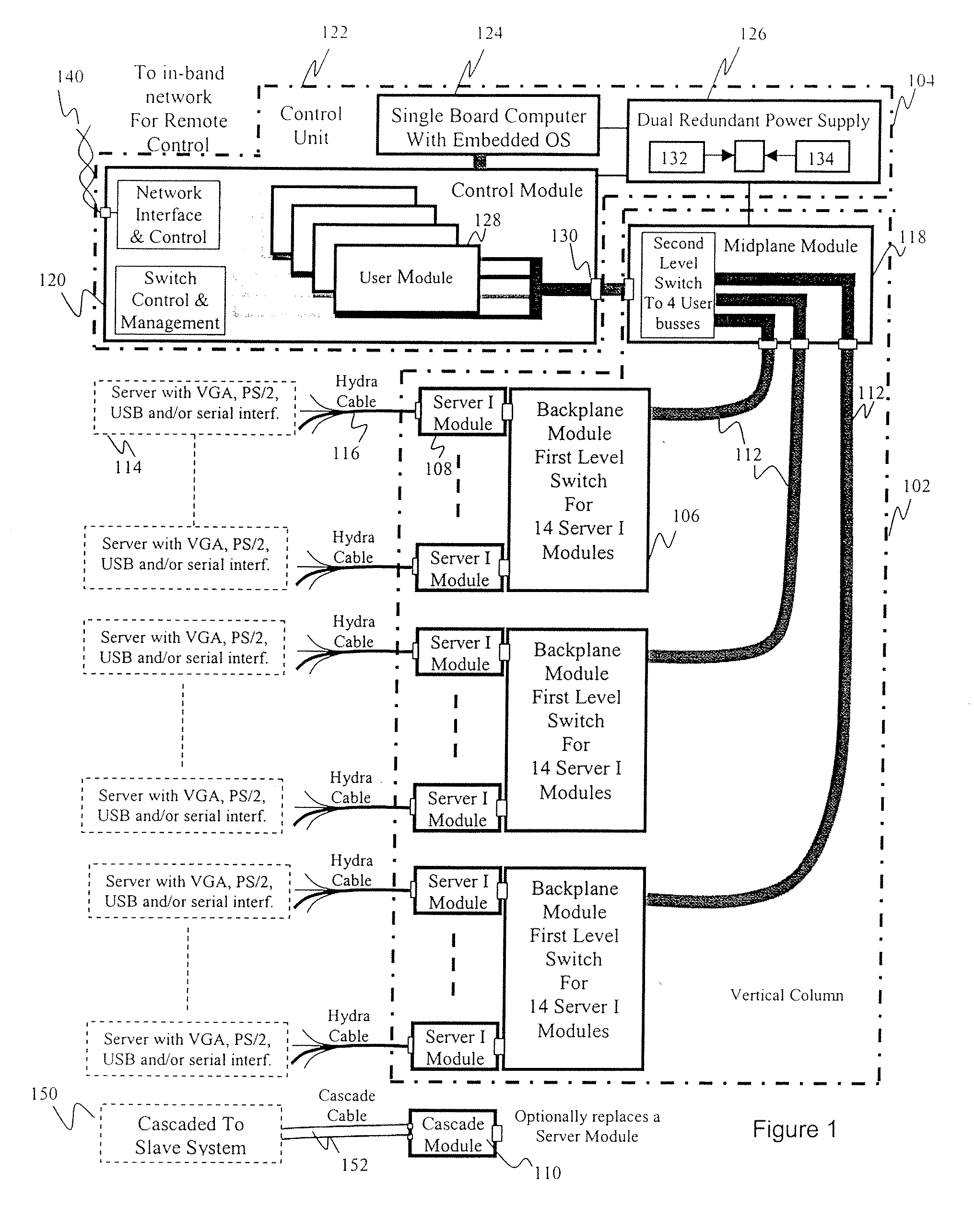

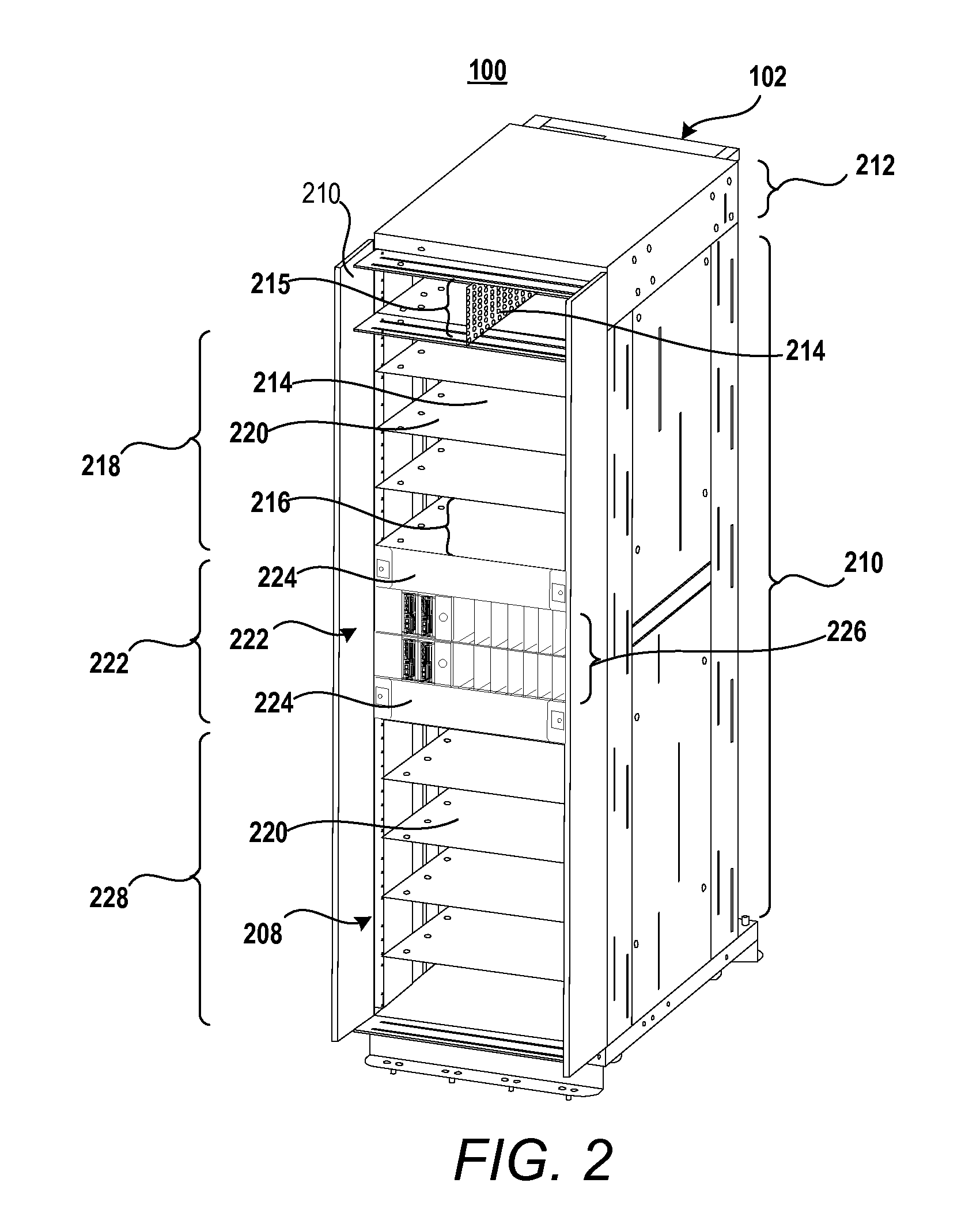

ActiveUS20050050272A1Eliminating vertical runFacilitates hot-swappable user card slotBus-bar/wiring layoutsServersRack unitEmbedded system

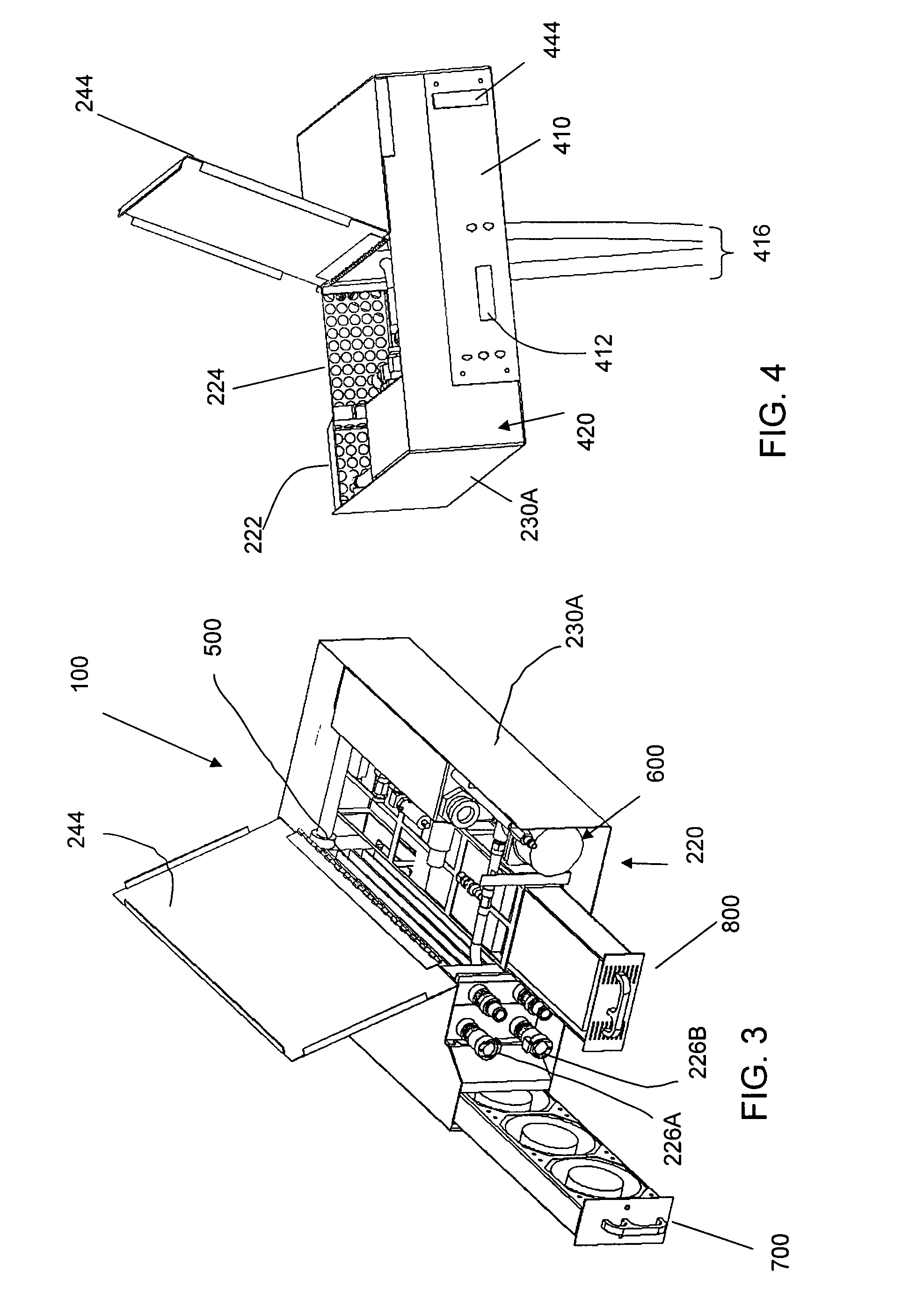

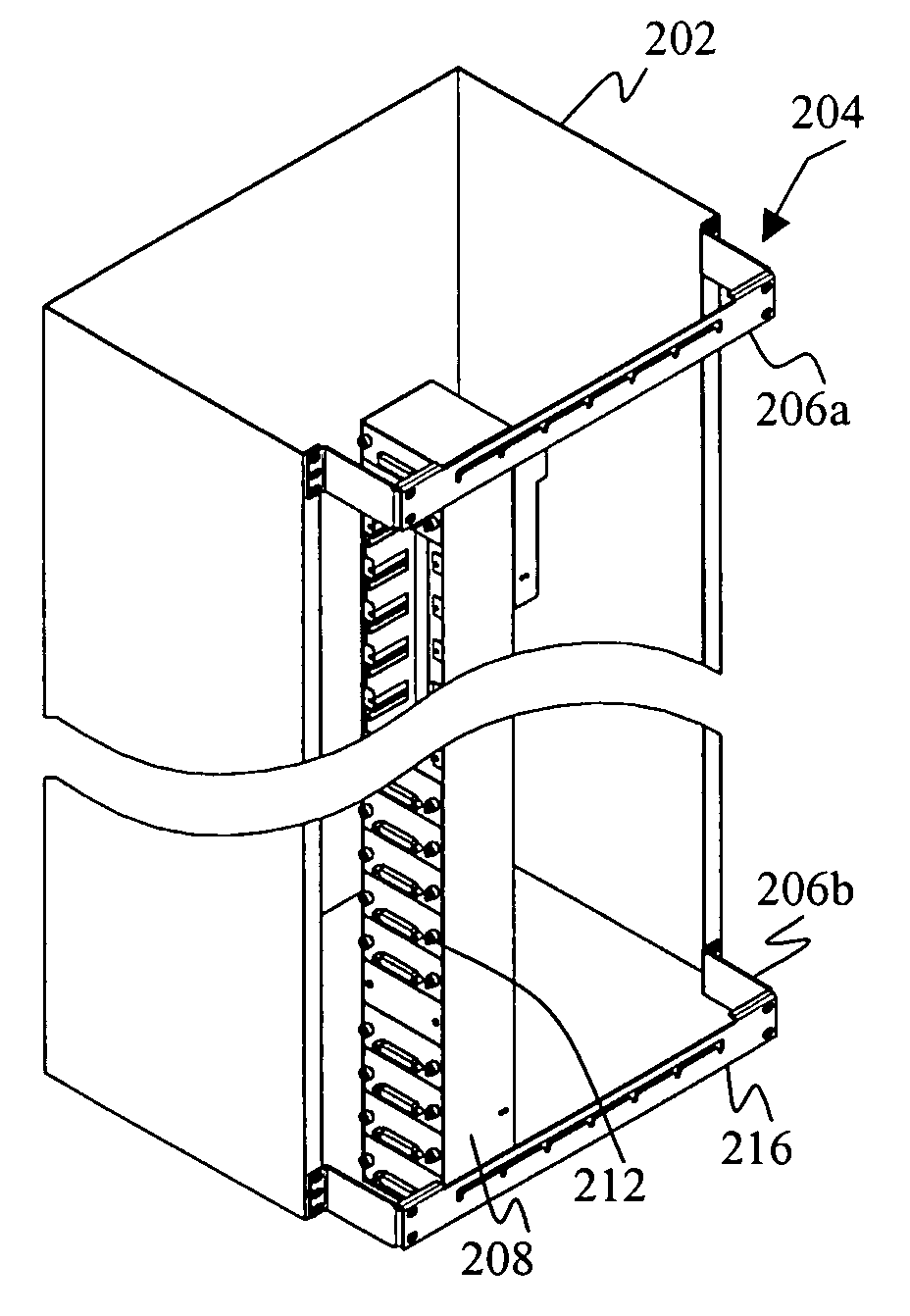

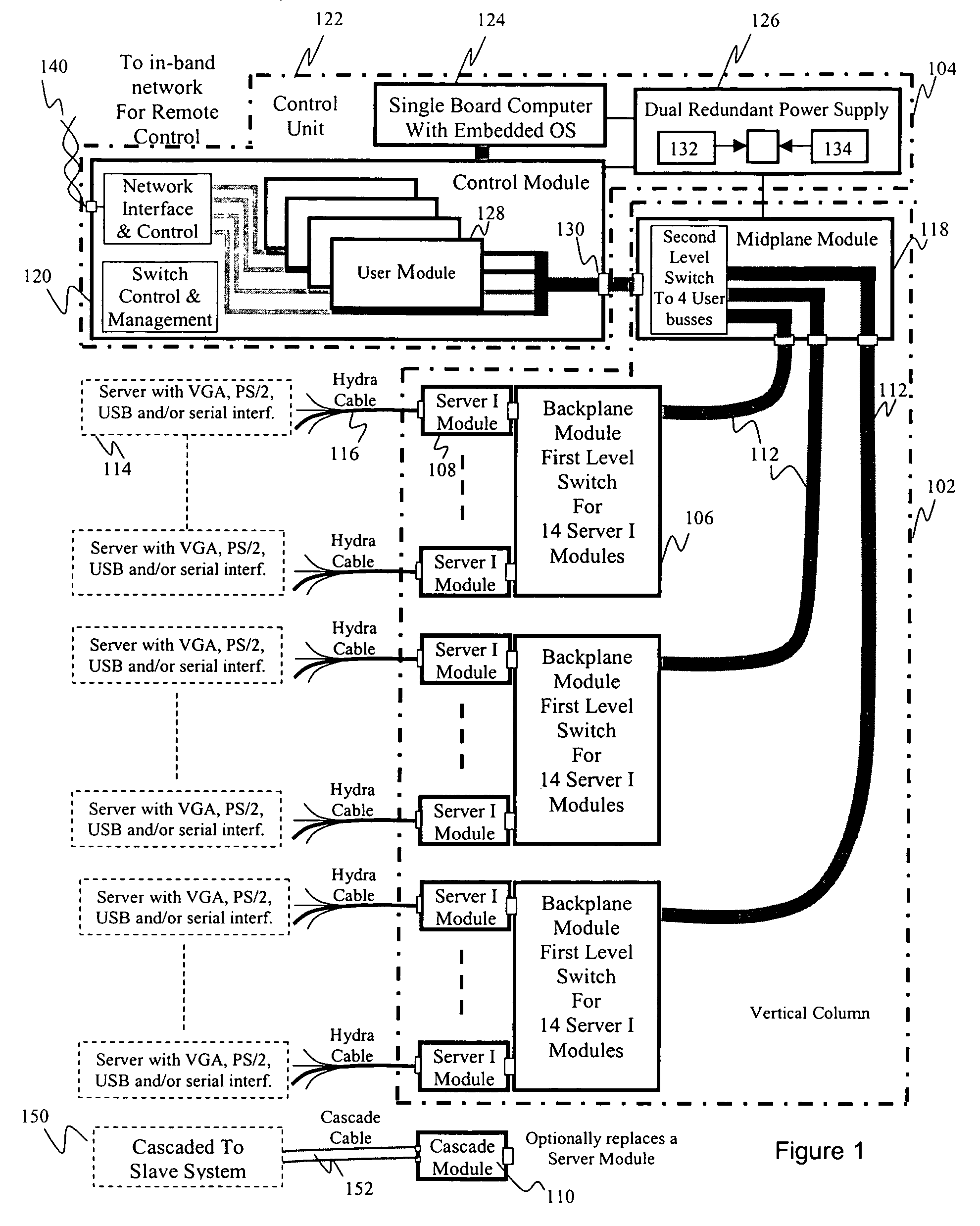

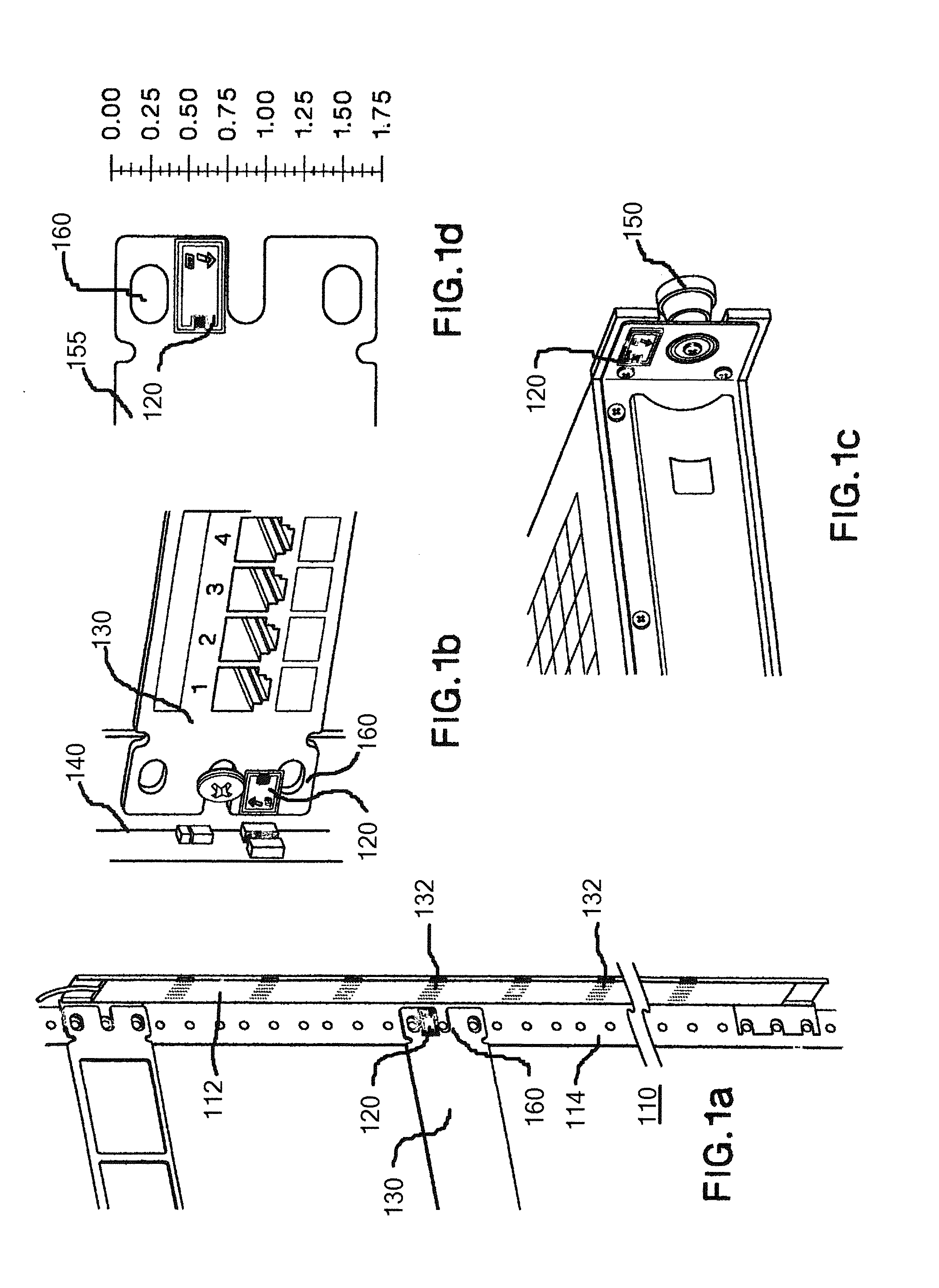

One embodiment of the invention provides a fully distributed, scaleable and modular rack architecture and management system. One feature of the invention provides device management throughout the rack system with a vertical interface column integrated into the rack cabinet. Within each rack unit (U) of the vertical interface column, the vertical interface column may deliver connectivity to a device housed within the rack cabinet thereby eliminating runs of cable typically necessary for management of such devices. The vertical interface column can be expanded as necessary to provide connectivity to more devices using hot-swappable interface modules. A rack management system allows both local and remote management access to all devices mounted in the rack cabinet and coupled to the vertical interface column. The rack management system may also access to devices mounted in other rack cabinets.

Owner:CHATSWORTH PROD INC

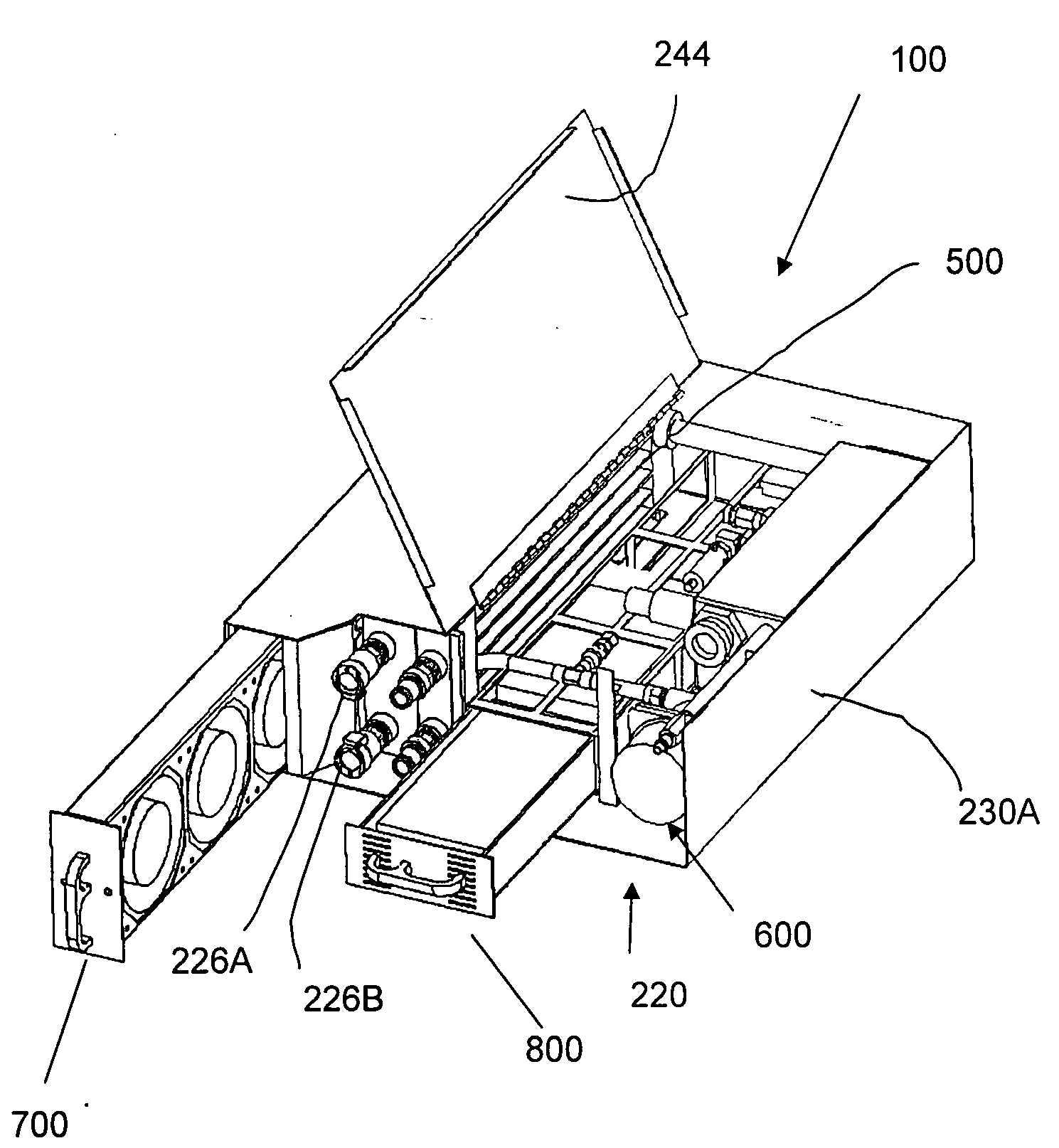

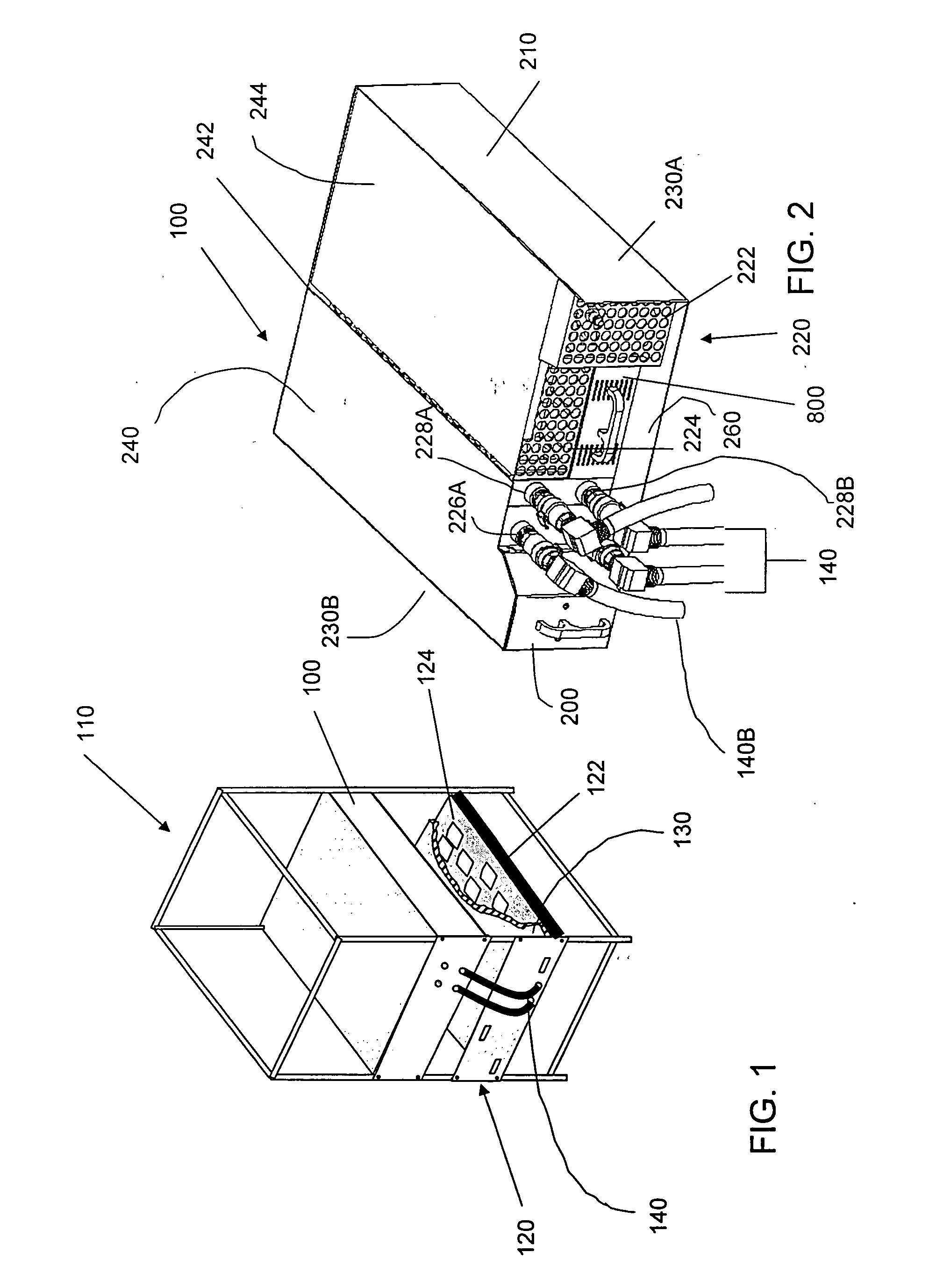

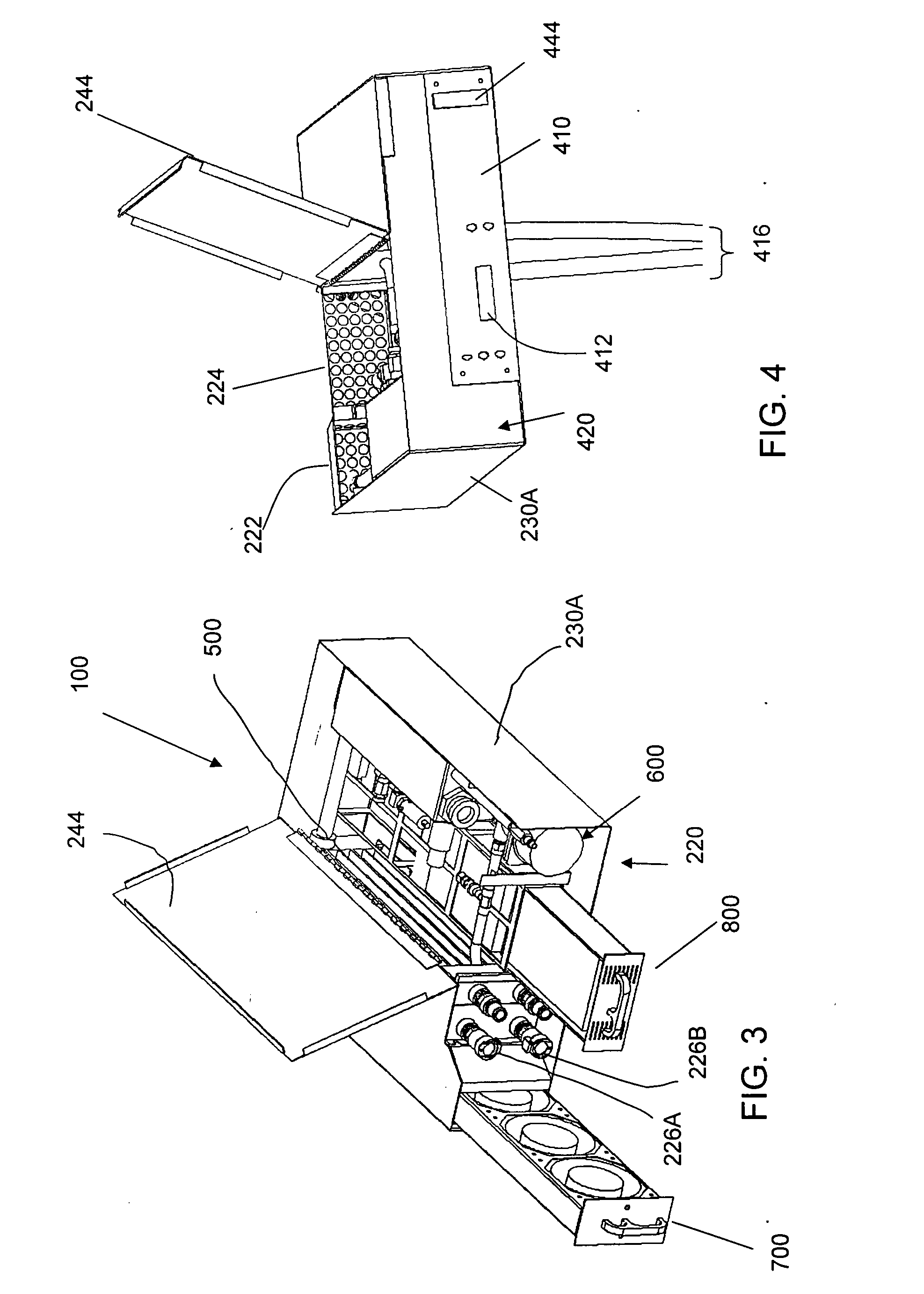

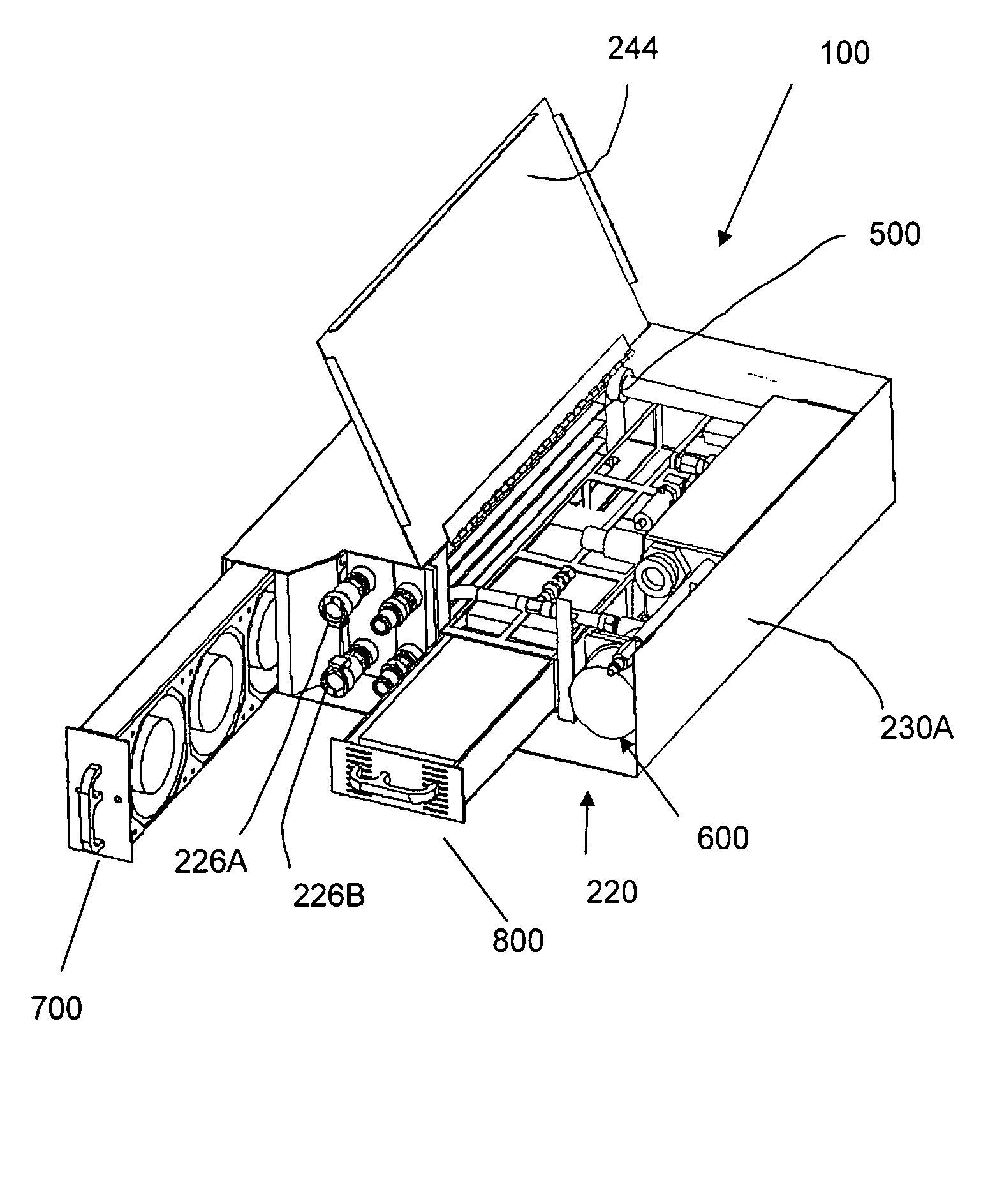

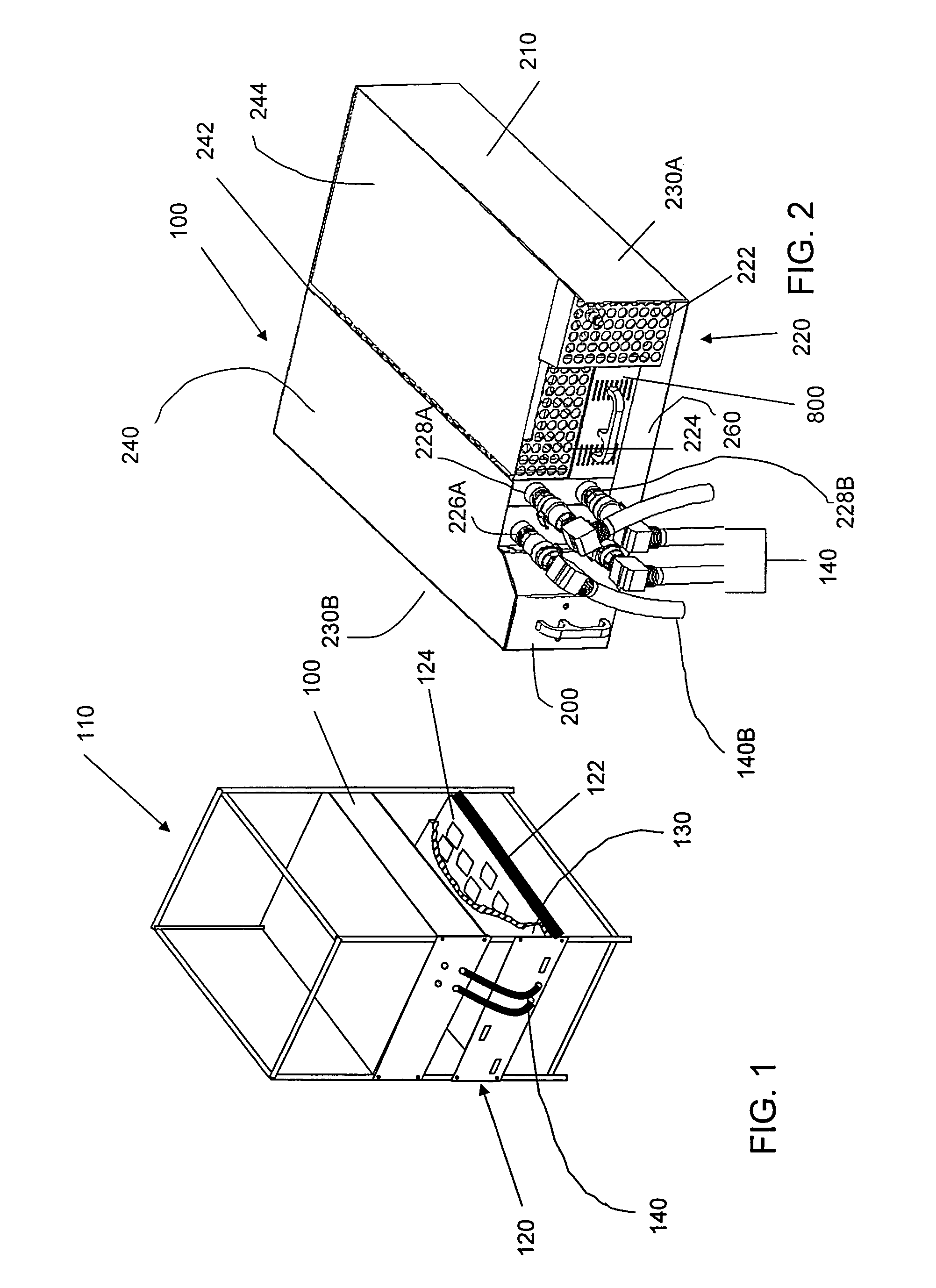

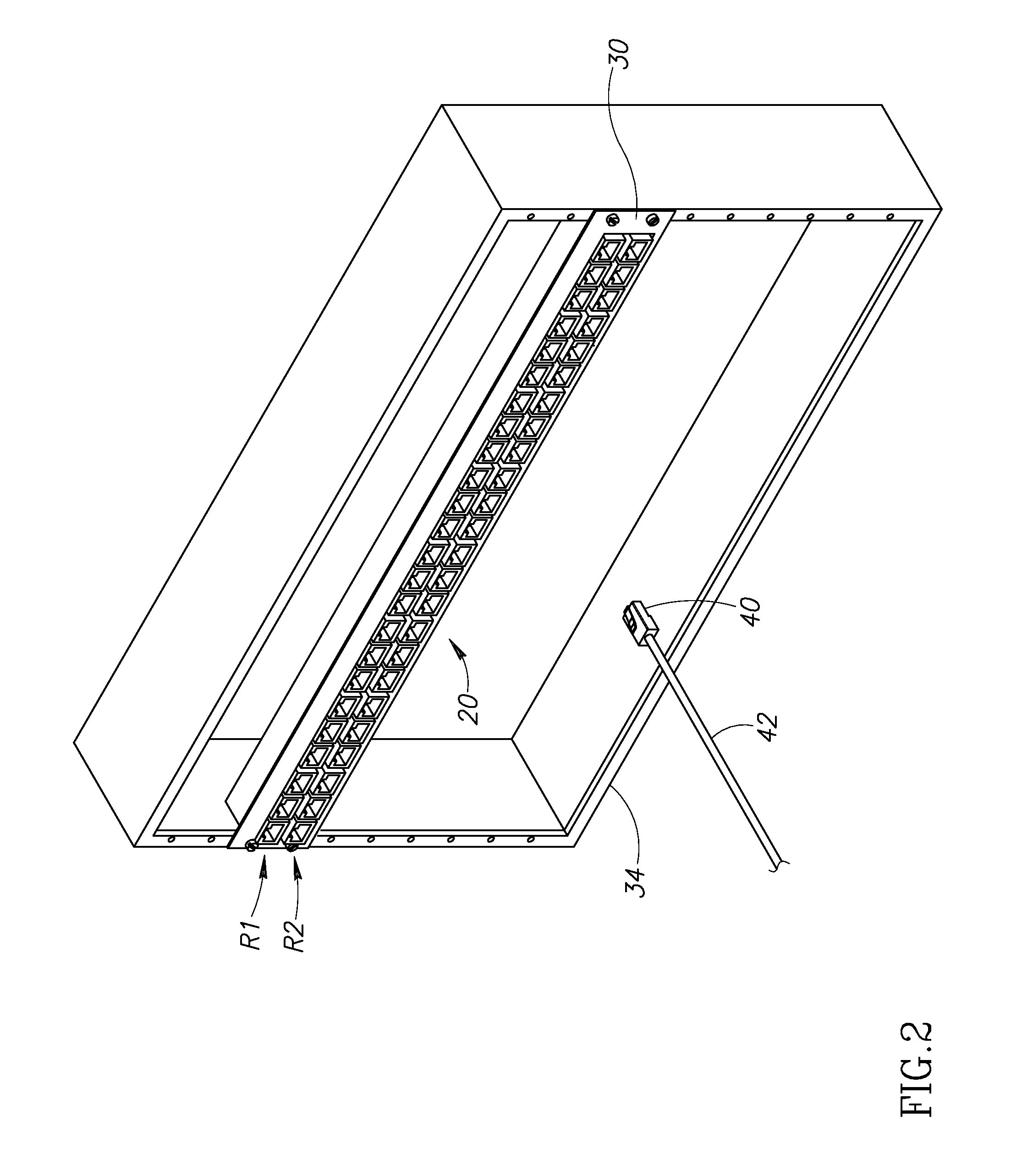

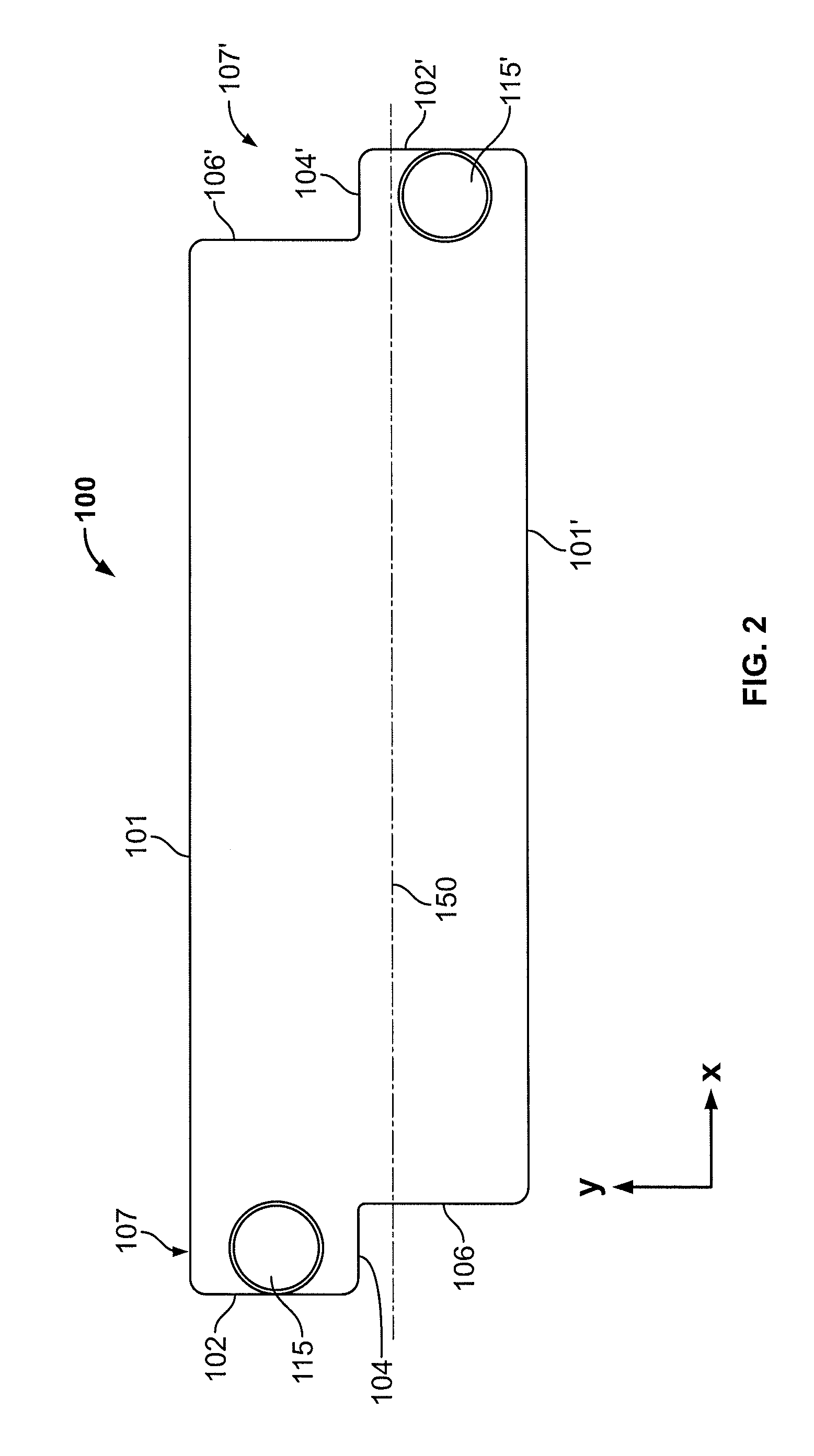

Modular rackmount chiller

InactiveUS20050133214A1Easy accessEasy to removeDigital data processing detailsStationary conduit assembliesRack unitModularity

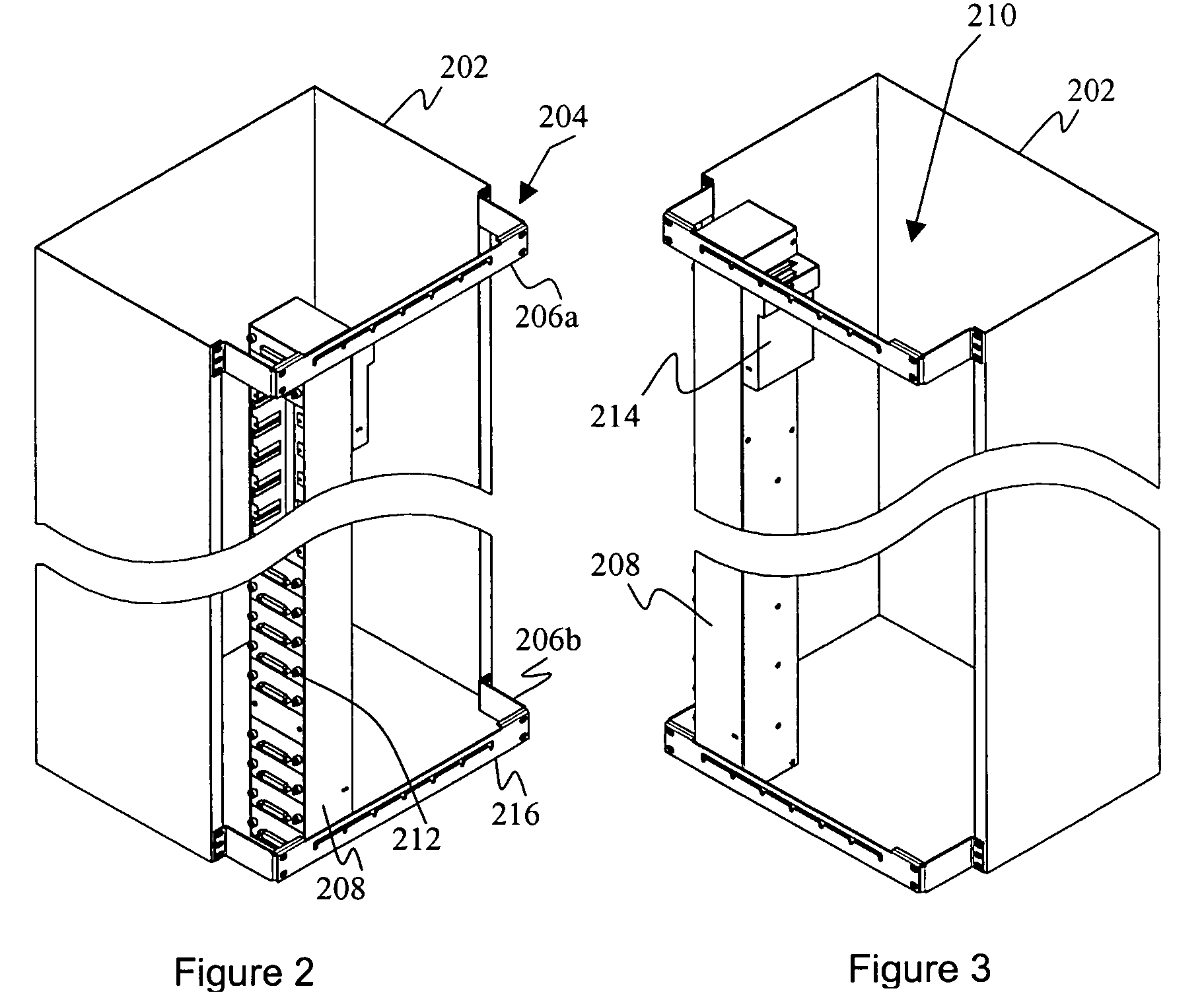

A chiller assembly shaped for use in a standard electronics rack. The chiller has a low profile, and is capable of being made to occupy less than 5 rack units. The chiller is modular, with subassemblies positioned to allow easy removal for maintenance. The fan and power supply are made as replaceable subassemblies that can be inserted or removed from the front of the unit without any special tools. The pump is made with a magnetically coupled motor, allowing the motor to be easily removed for service or replacement. The motor is also accessible from the front panel of the assembly.

Owner:AMPHENOL CORP

Modular rackmount chiller

InactiveUS7484552B2Easy accessEasy to removeDigital data processing detailsStationary conduit assembliesRack unitModularity

A chiller assembly shaped for use in a standard electronics rack. The chiller has a low profile, and is capable of being made to occupy less than 5 rack units. The chiller is modular, with subassemblies positioned to allow easy removal for maintenance. The fan and power supply are made as replaceable subassemblies that can be inserted or removed from the front of the unit without any special tools. The pump is made with a magnetically coupled motor, allowing the motor to be easily removed for service or replacement. The motor is also accessible from the front panel of the assembly.

Owner:AMPHENOL CORP

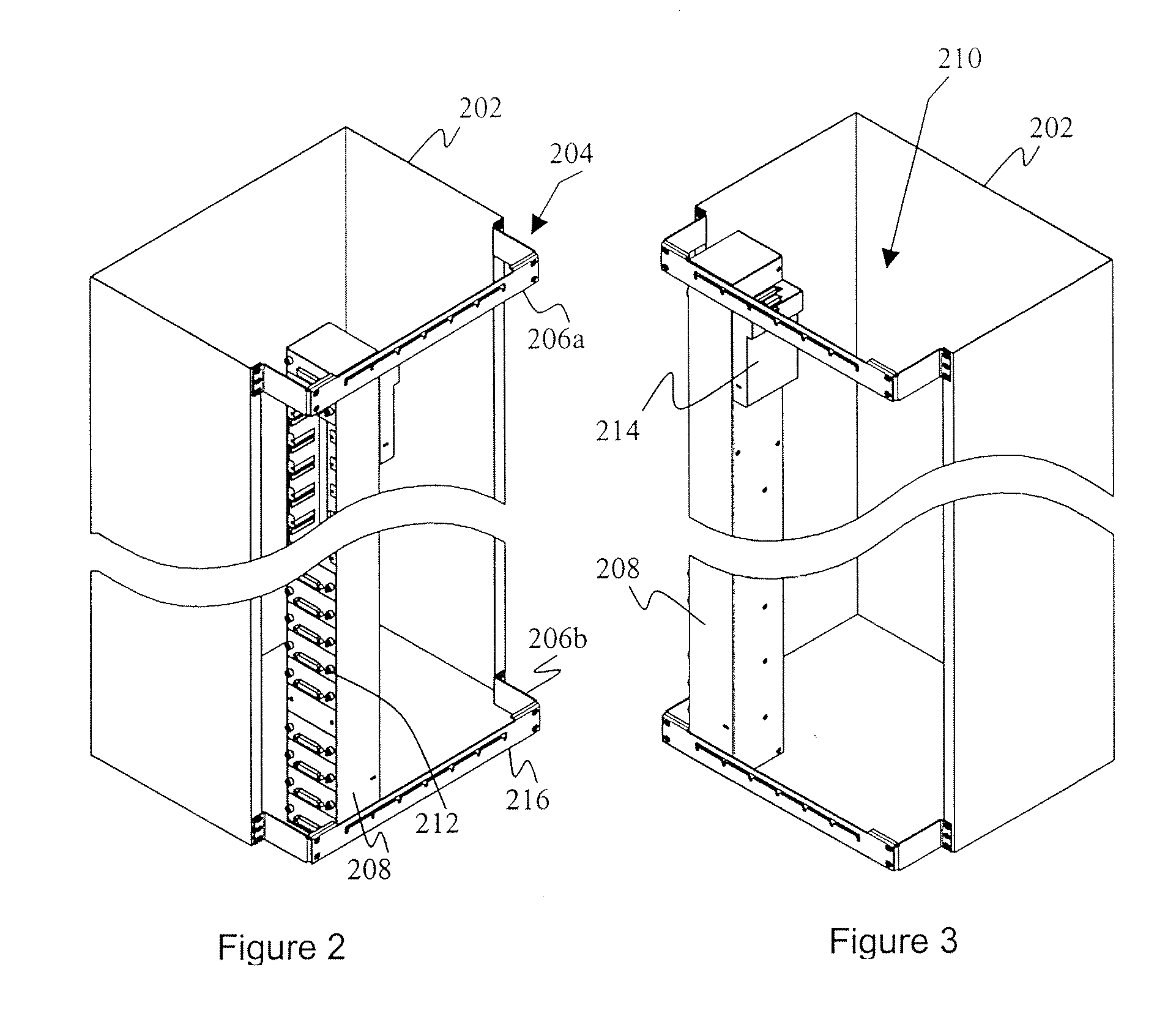

Rack architecture and management system

ActiveUS7289334B2Eliminating vertical runFacilitates hot-swappable user card slotBus-bar/wiring layoutsServersRack unitComputer module

One embodiment of the invention provides a fully distributed, scaleable and modular rack architecture and management system. One feature of the invention provides device management throughout the rack system with a vertical interface column integrated into the rack cabinet. Within each rack unit (U) of the vertical interface column, the vertical interface column may deliver connectivity to a device housed within the rack cabinet thereby eliminating runs of cable typically necessary for management of such devices. The vertical interface column can be expanded as necessary to provide connectivity to more devices using hot-swappable interface modules. A rack management system allows both local and remote management access to all devices mounted in the rack cabinet and coupled to the vertical interface column. The rack management system may also access to devices mounted in other rack cabinets.

Owner:CHATSWORTH PROD INC

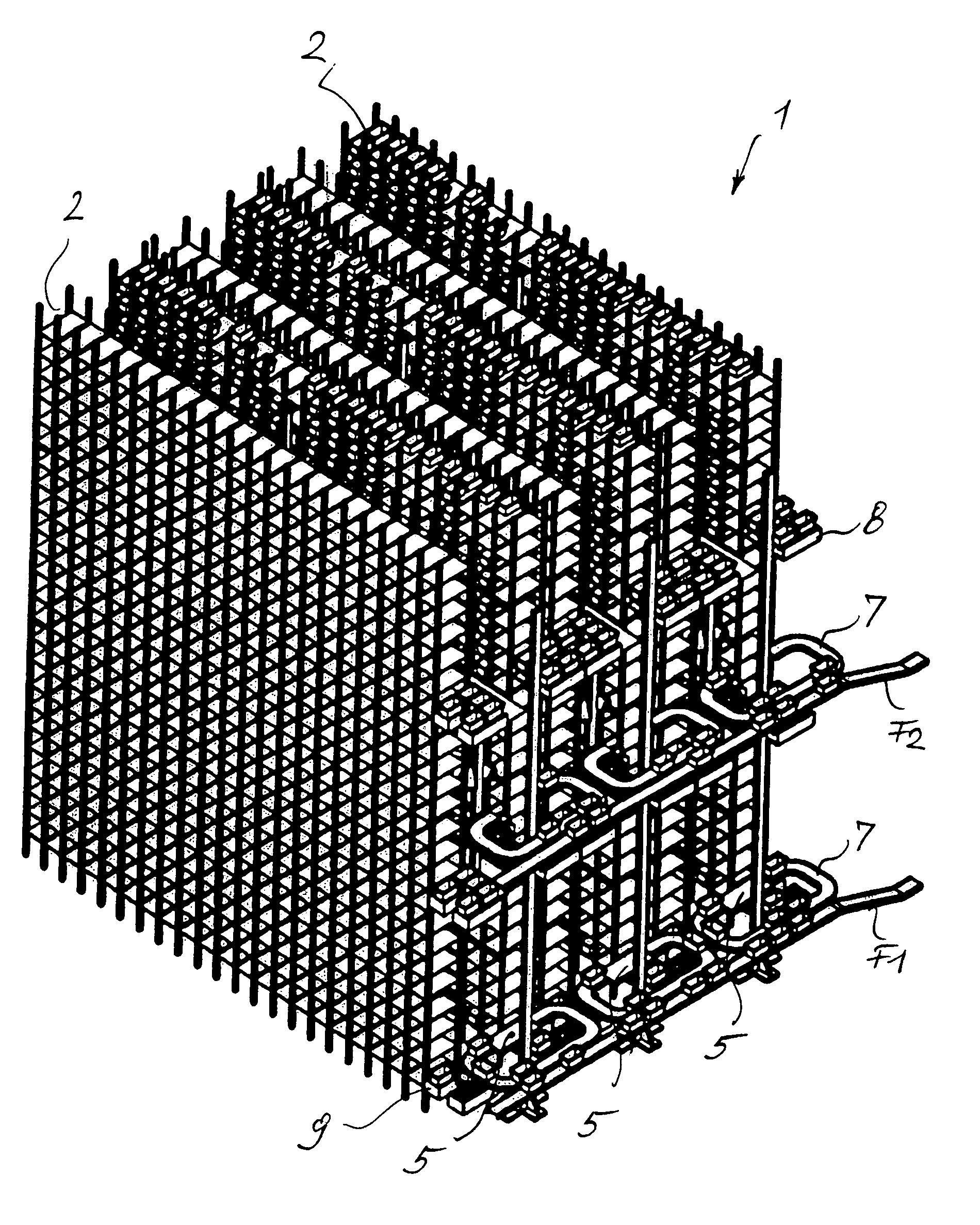

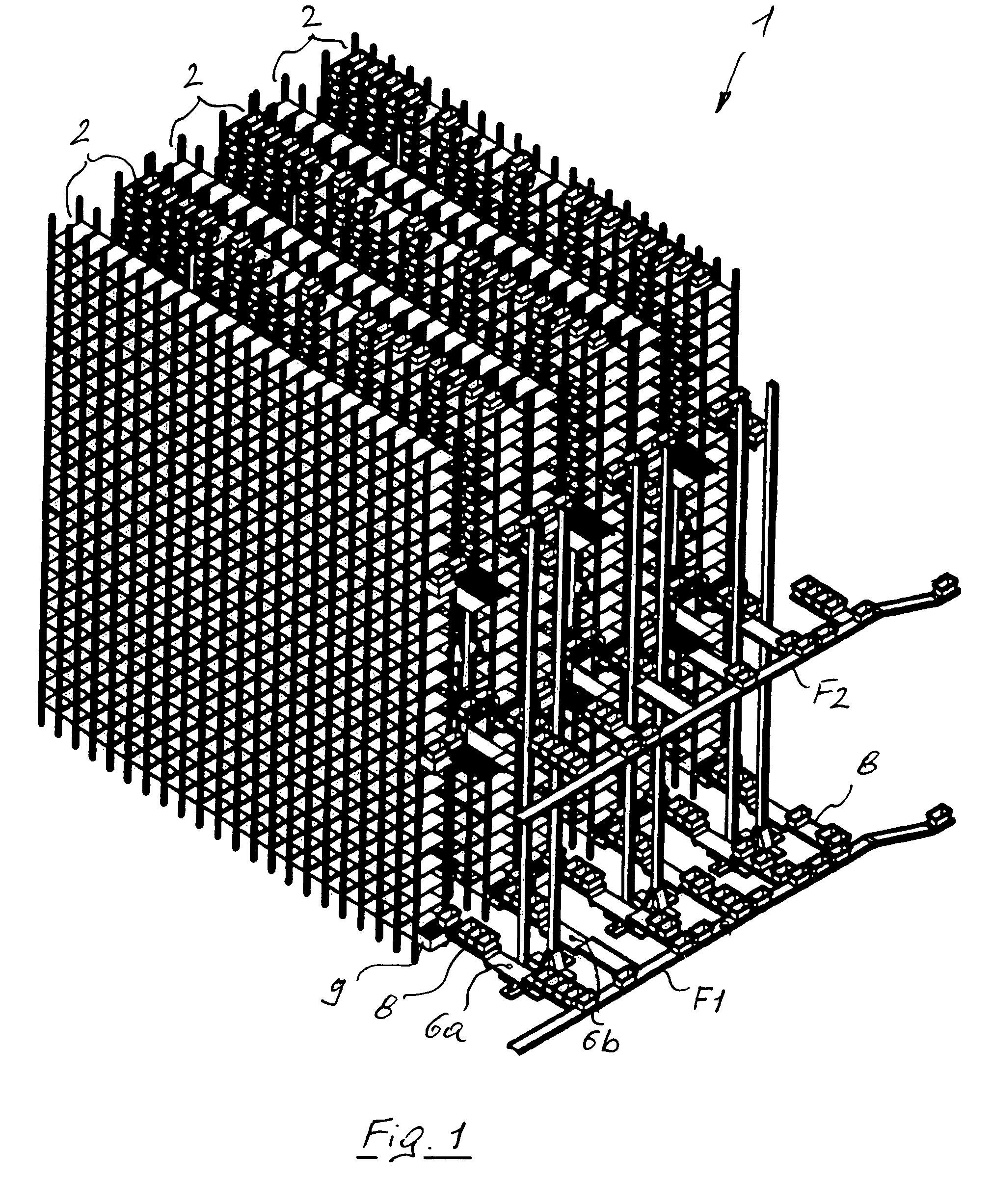

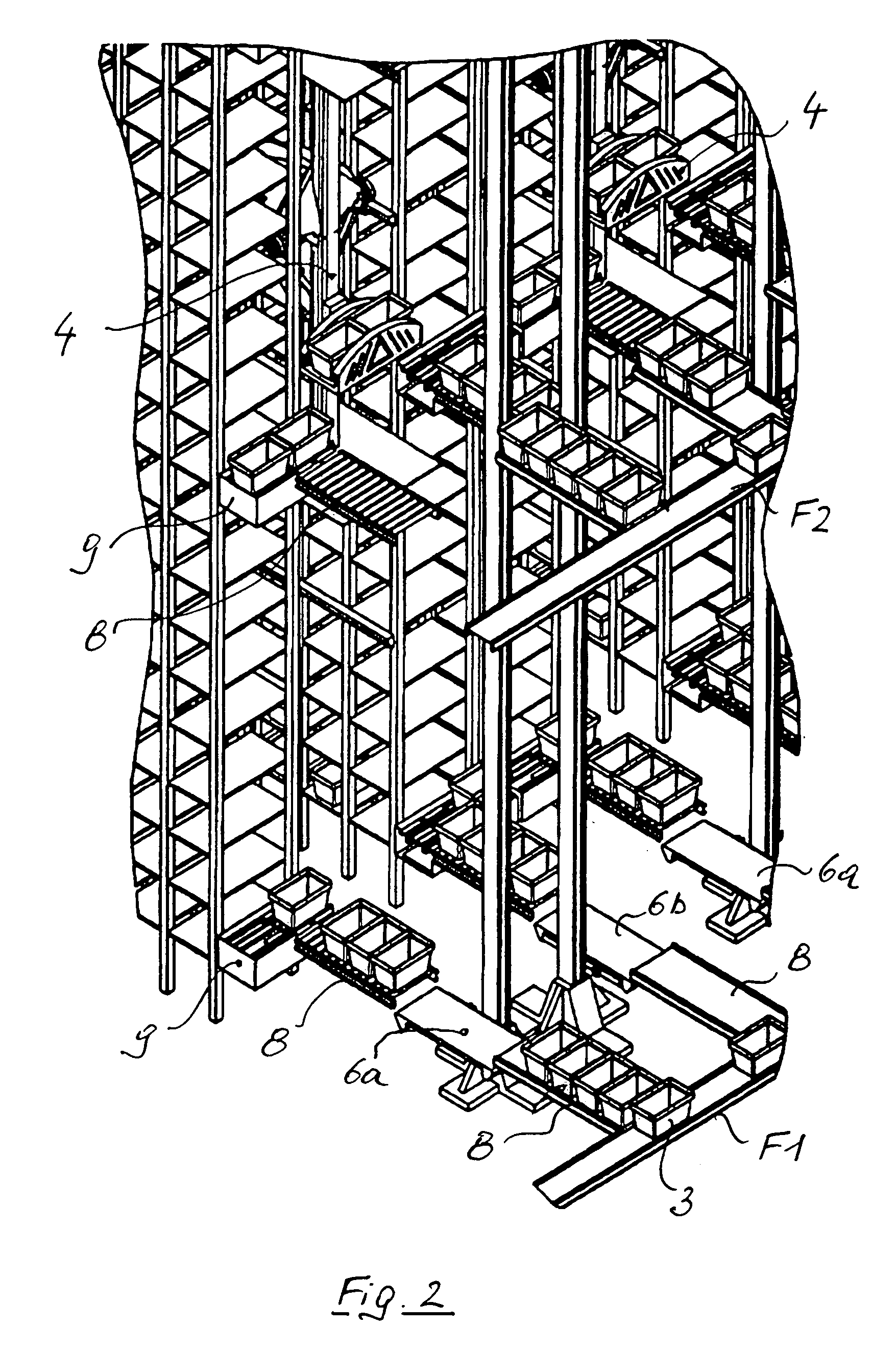

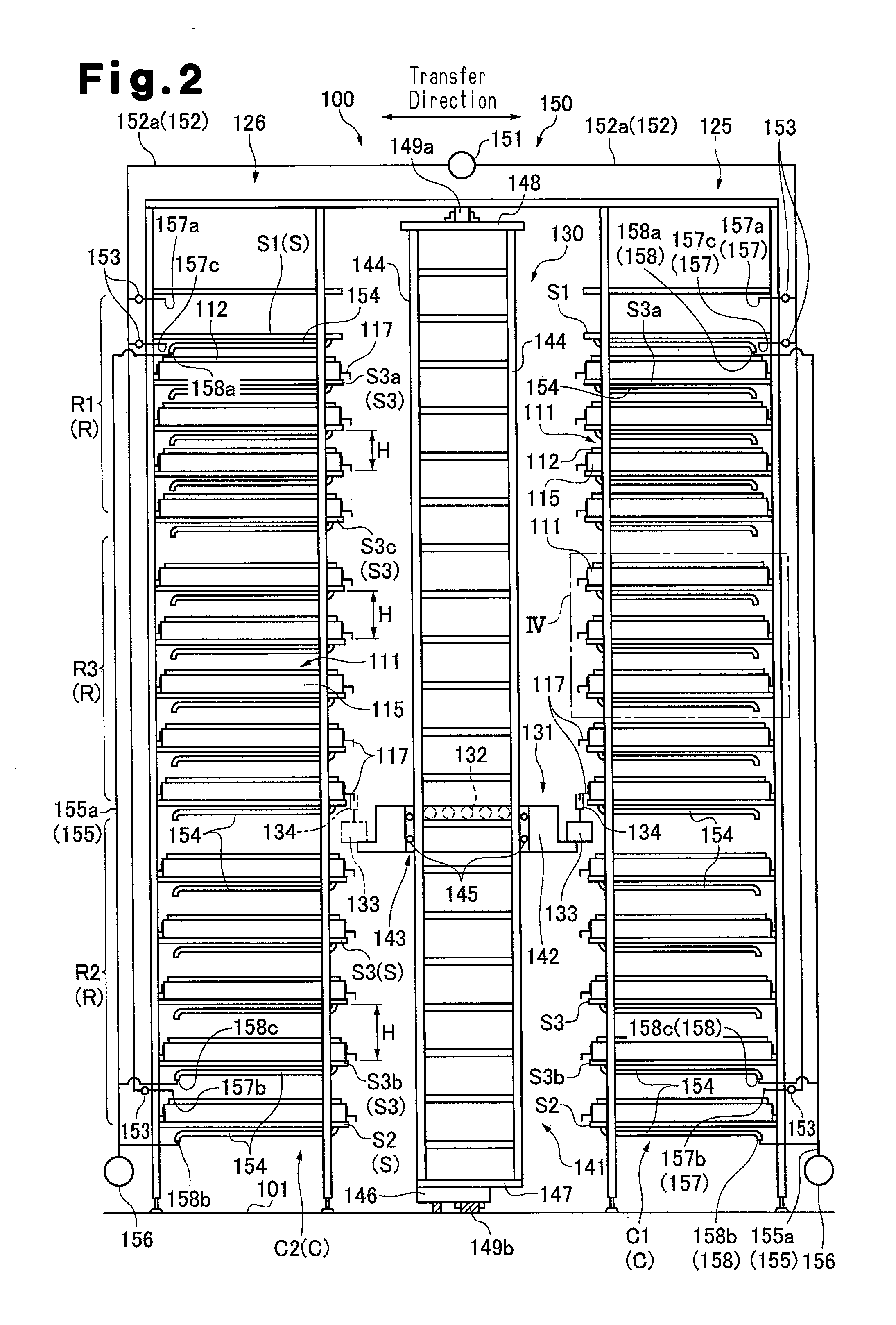

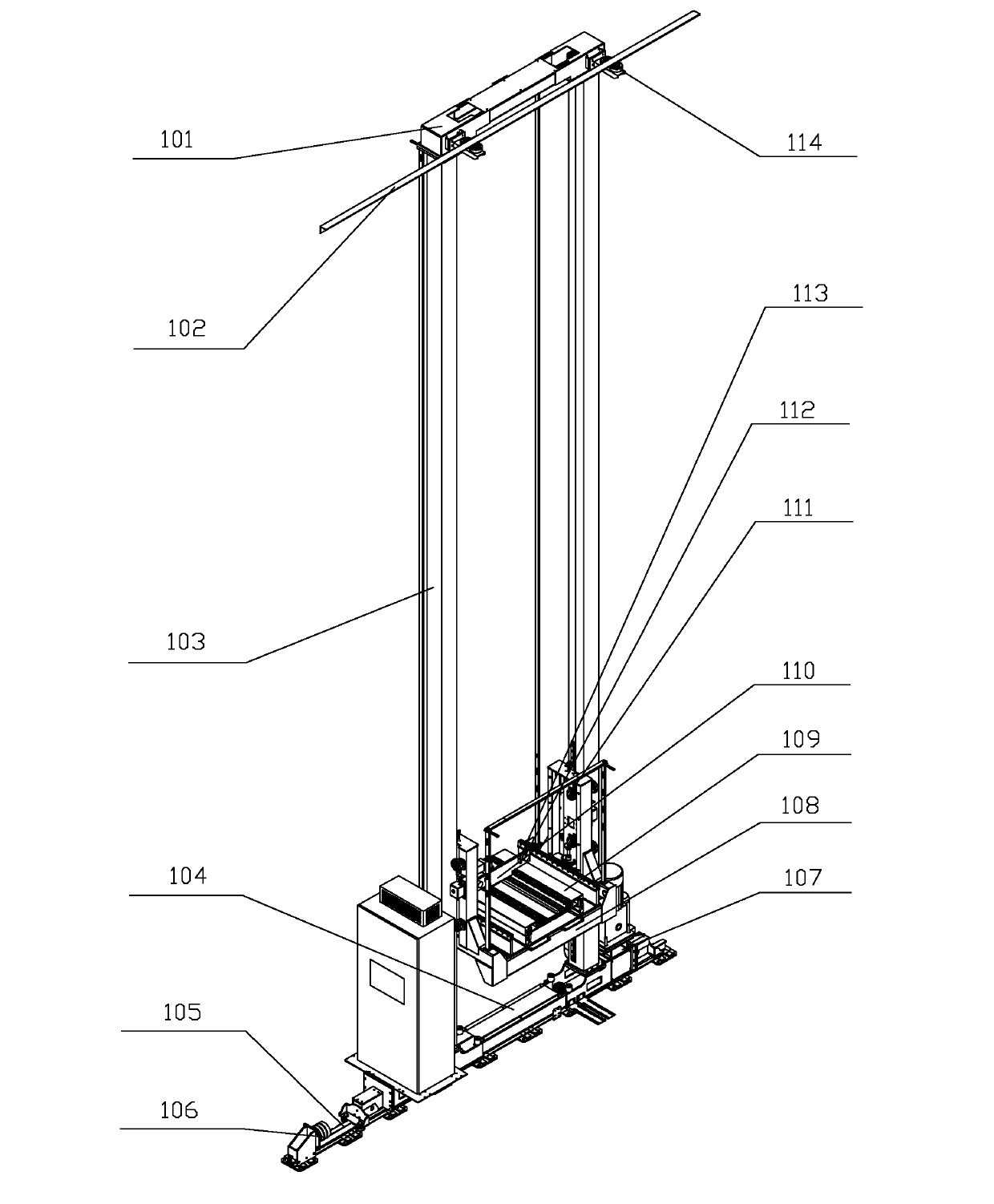

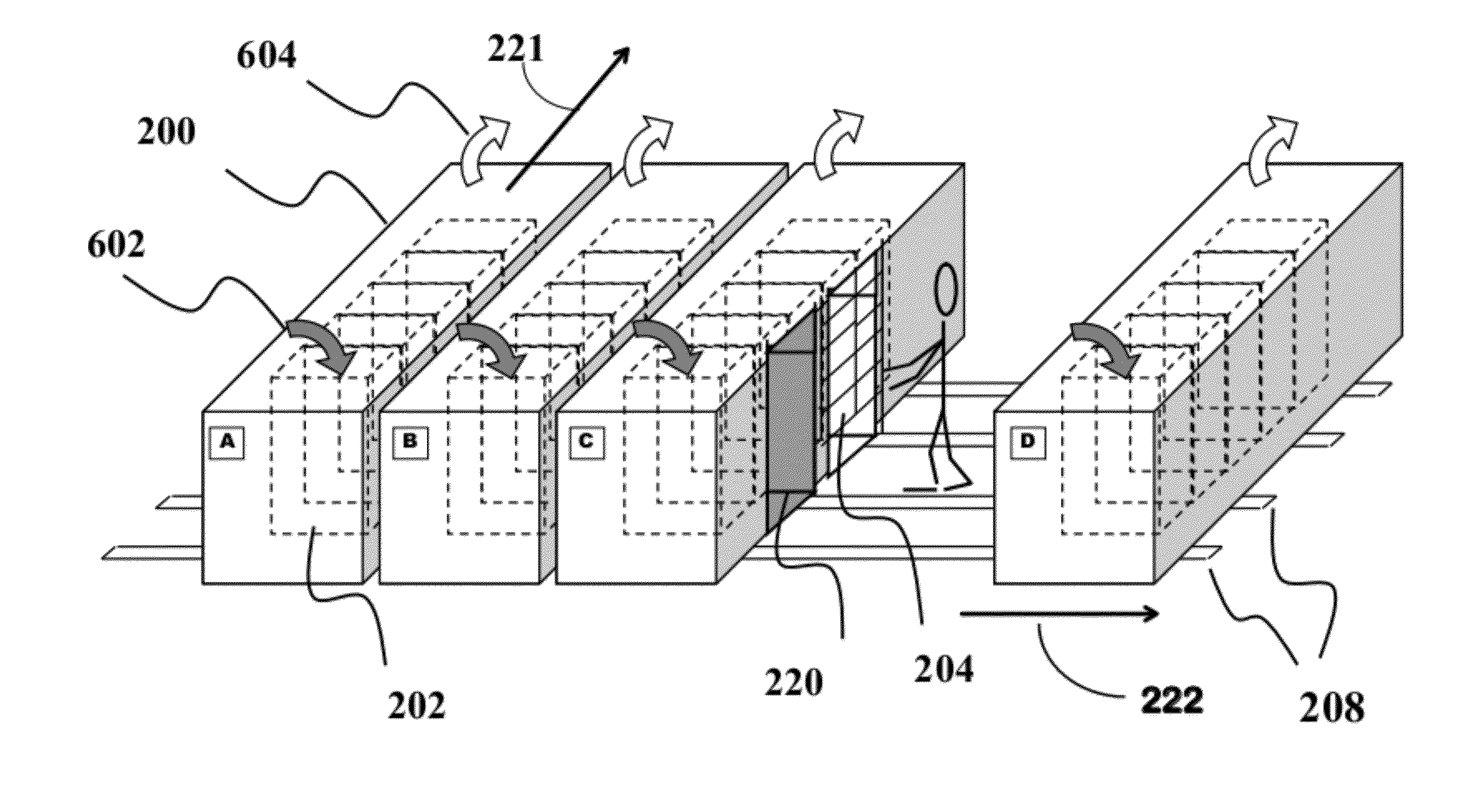

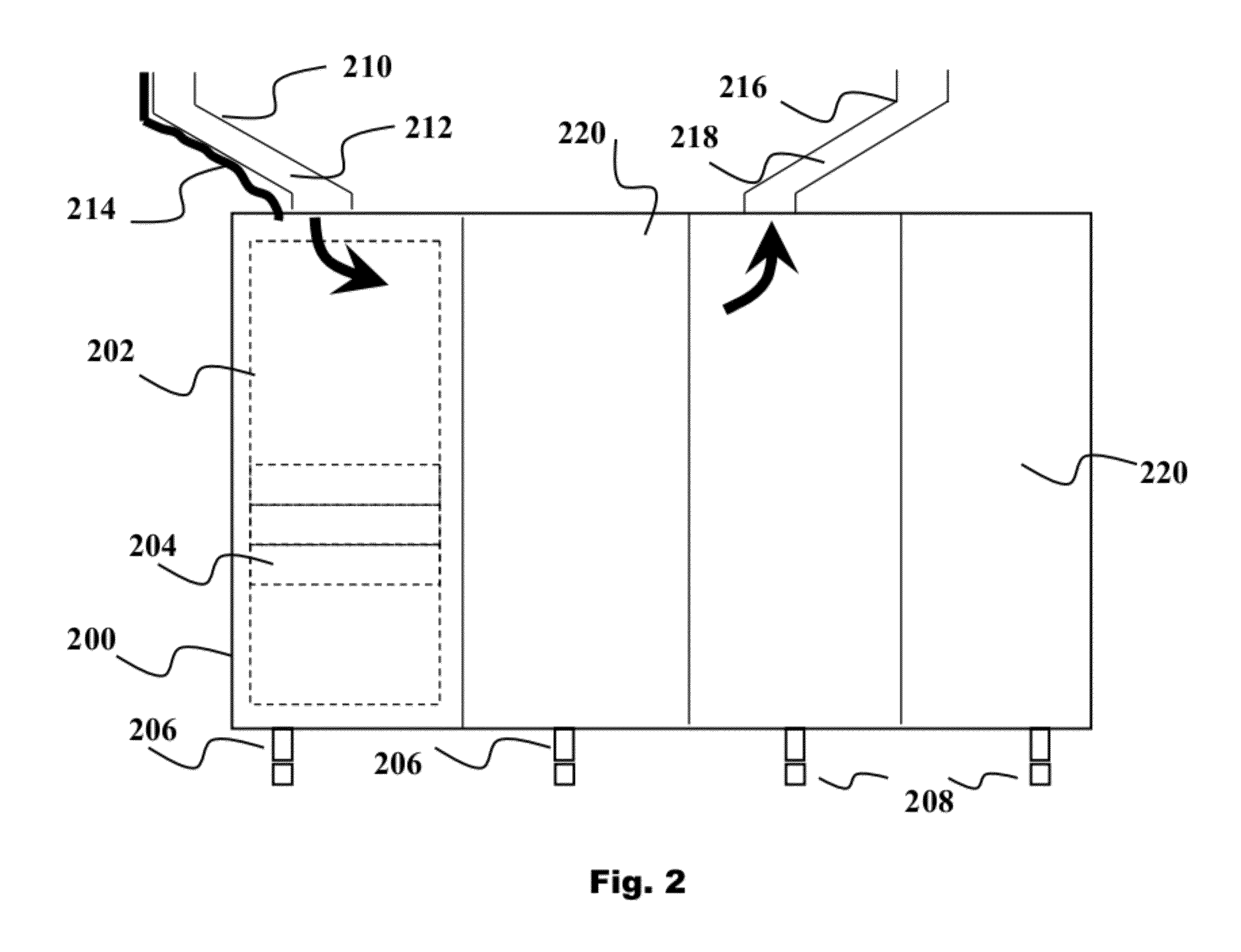

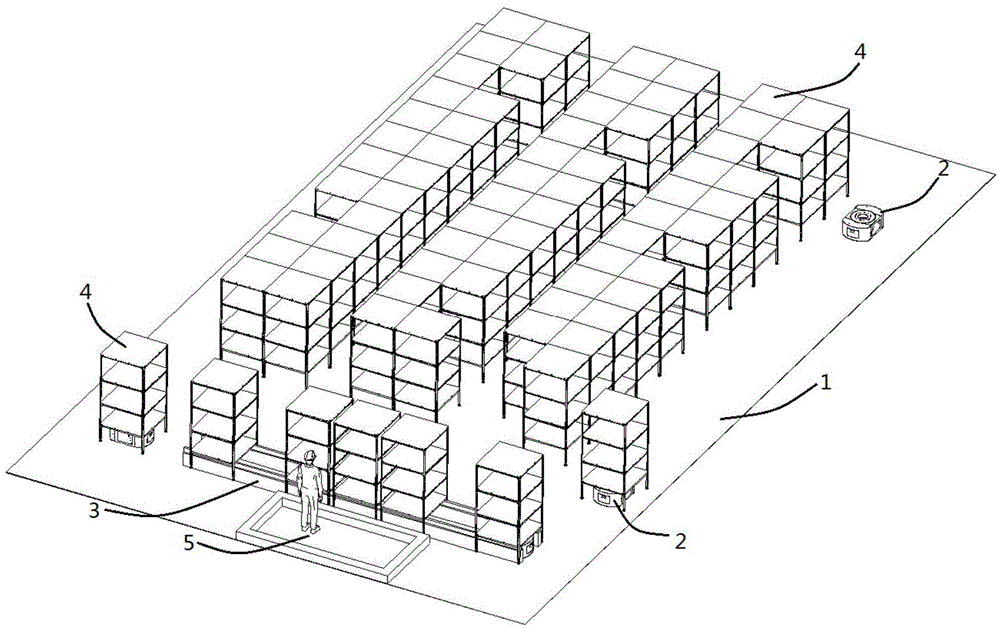

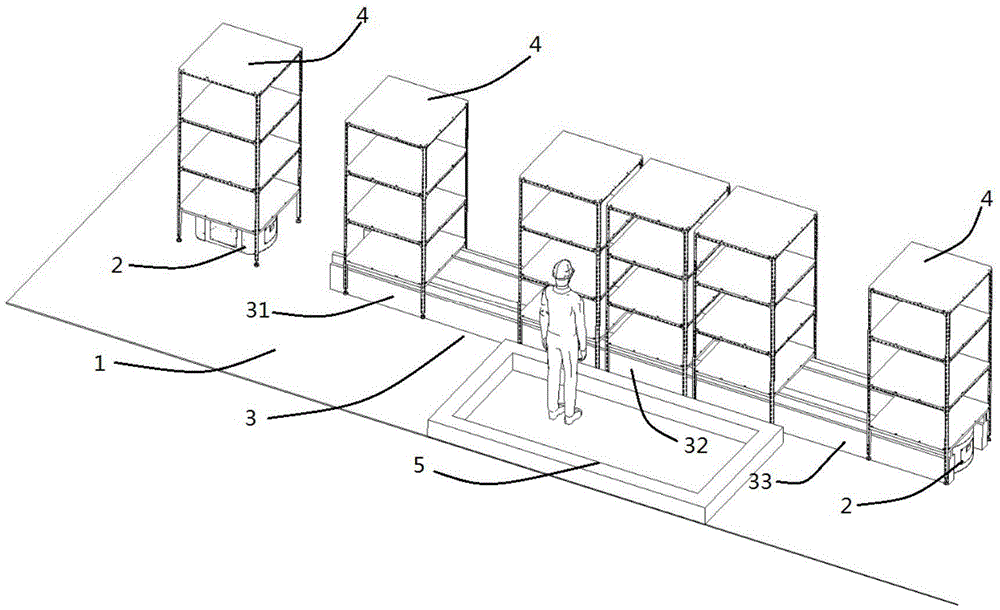

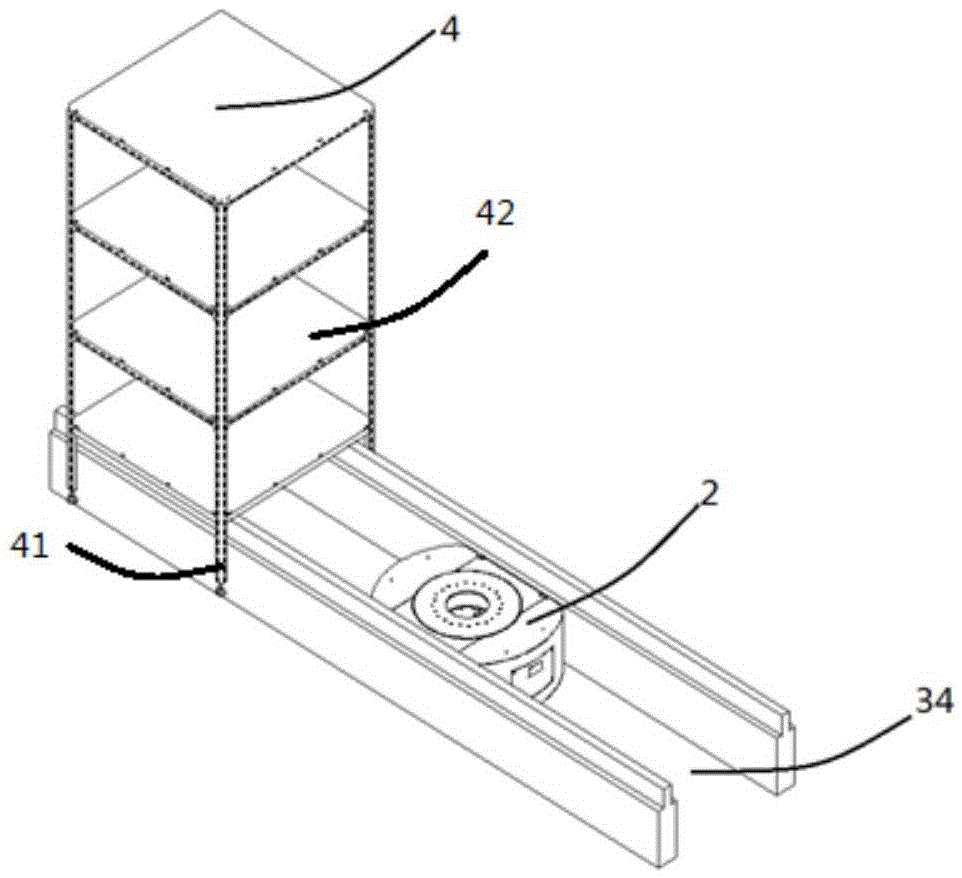

Method and system for operating a racking system preferably in a dispatch unit

A method for operating a rack system preferably in a dispatch unit (1), with a rack (2) and an associated rack serving device for the storage and retrieval of containers (3), trays or the like to or from the rack. A rack region of the rack (2) has a plurality of rack planes (13) arranged one above the other and is served by a dedicated, mechanically coupled, height and length-adjustable rack serving device (4). In each track region embodied as an independent, closed rack unit (A, B, C), containers (3), trays or the like undergo interim storage in a buffer zone (P1, P2, P3) on the same level, are transferred for storage or retrieval and transported by an elevator (5; 6a, 6b) and / or a preferably horizontal transport connection (F1, F2) arranged in the region of the rack unit (A, B, C) at the same level, from or to a transport system or workplace outside the rack system.

Owner:KNAPP AG

Rack architecture and management system

ActiveUS20070097659A1Eliminating vertical runFacilitates hot-swappable user card slotBus-bar/wiring layoutsServersRack unitEmbedded system

Owner:CHATSWORTH PROD INC

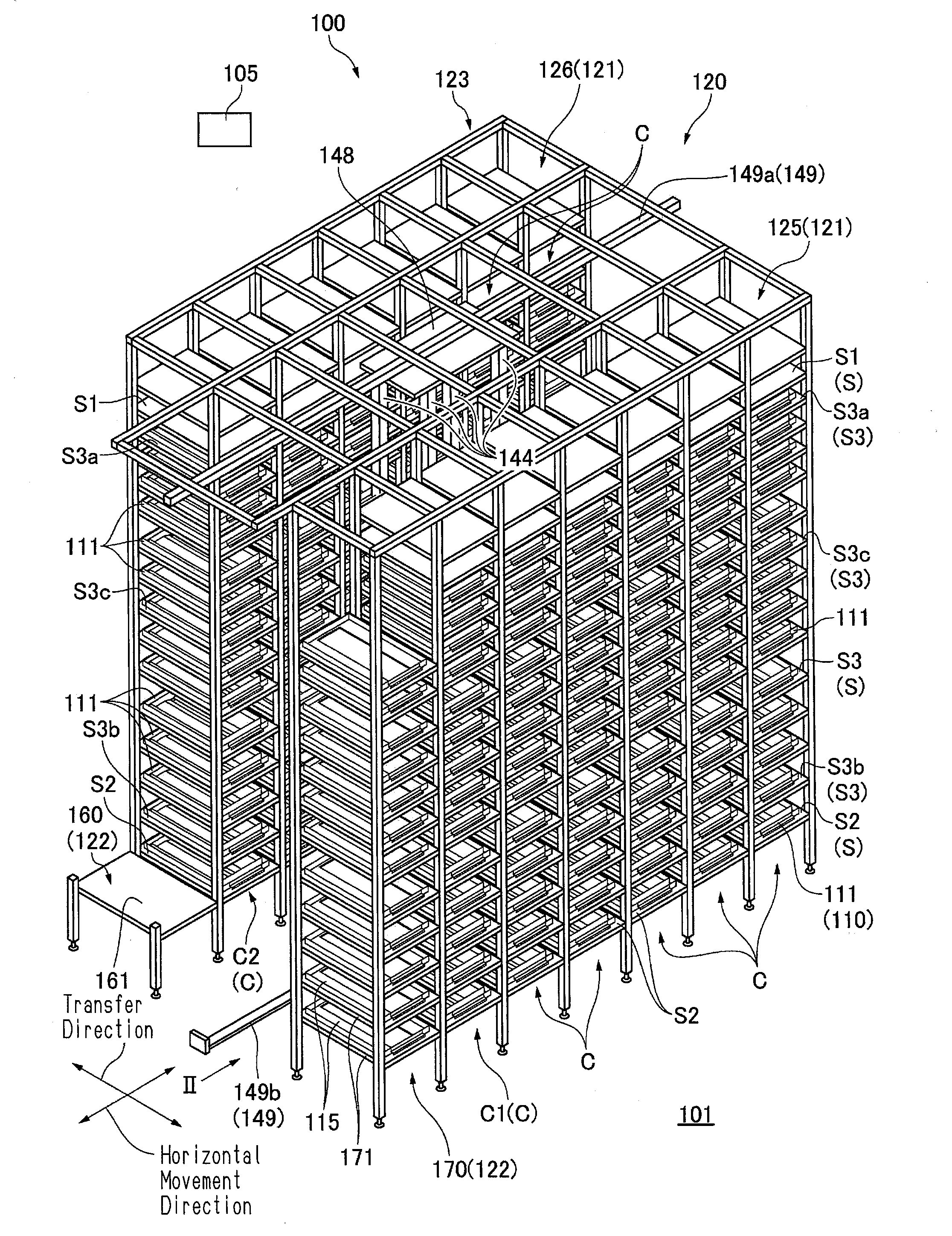

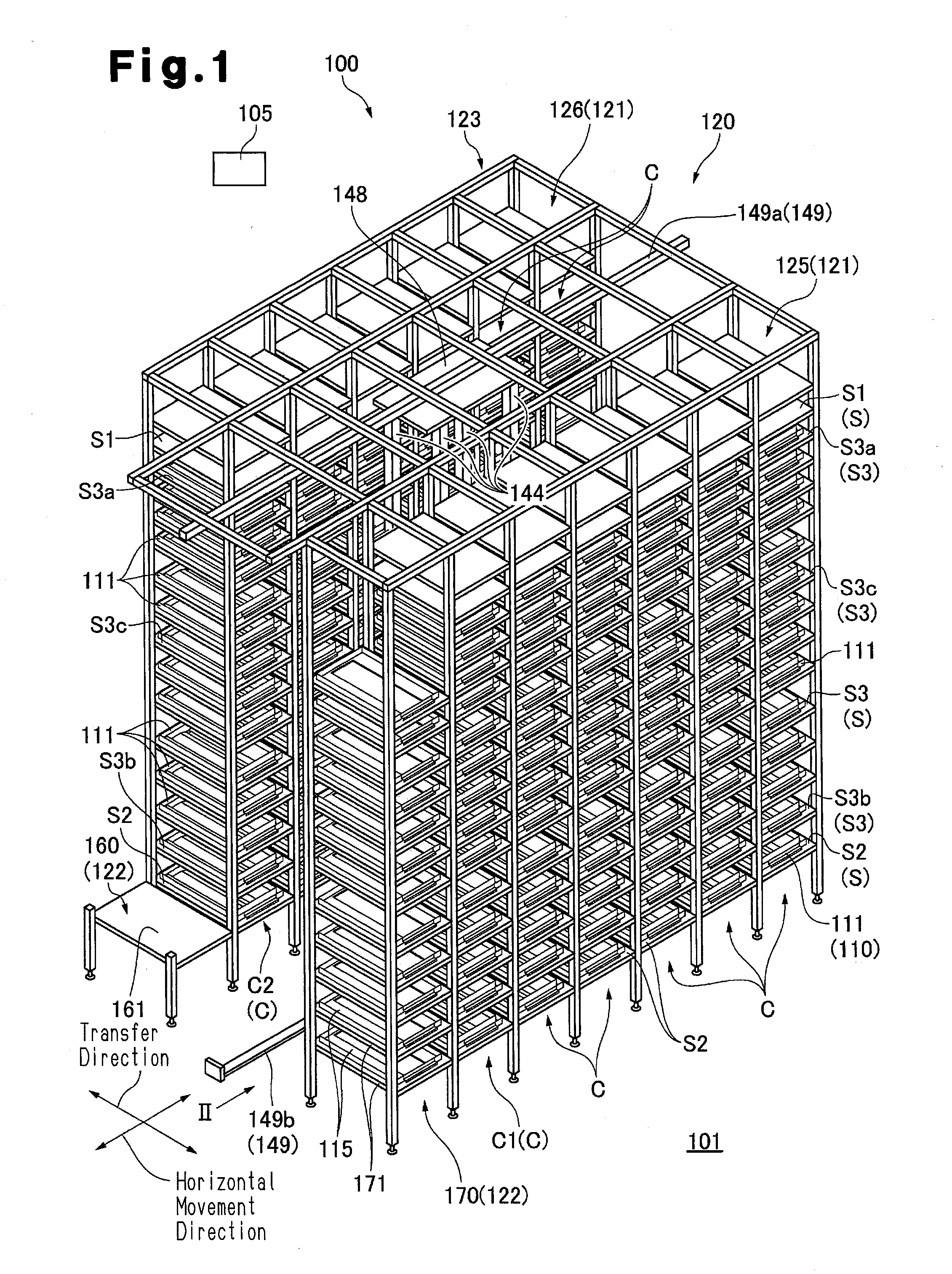

Plant cultivation device

InactiveUS20140017043A1Improve cultivation efficiencyConvenience to workSelf-acting watering devicesClimate change adaptationRack unitUsability

Provided is a plant cultivation device that improves cultivation efficiency and usability. A plant cultivation device comprises: a rack unit provided with cultivation racks on which cultivation units accommodating plants are stored as culture medium units; and a conveying device which moves along a horizontal movement path defined by a guide rail, and performs transport of the culture medium units and loading / unloading of the culture medium units to / from the cultivation racks. Multiple cultivation racks constitute a cultivation rack row, in which the cultivation racks are arranged at multiple levels in an up-down direction. The rack unit comprises: a cultivation storage constituted of multiple cultivation rack rows; and a loading / unloading station having a stock rack row, in which the holding frames of cultivation units not accommodating plants are stored as empty units. The transport device performs loading / unloading of the holding frames to / from the stock rack row.

Owner:TSUBAKIMOTO CHAIN CO

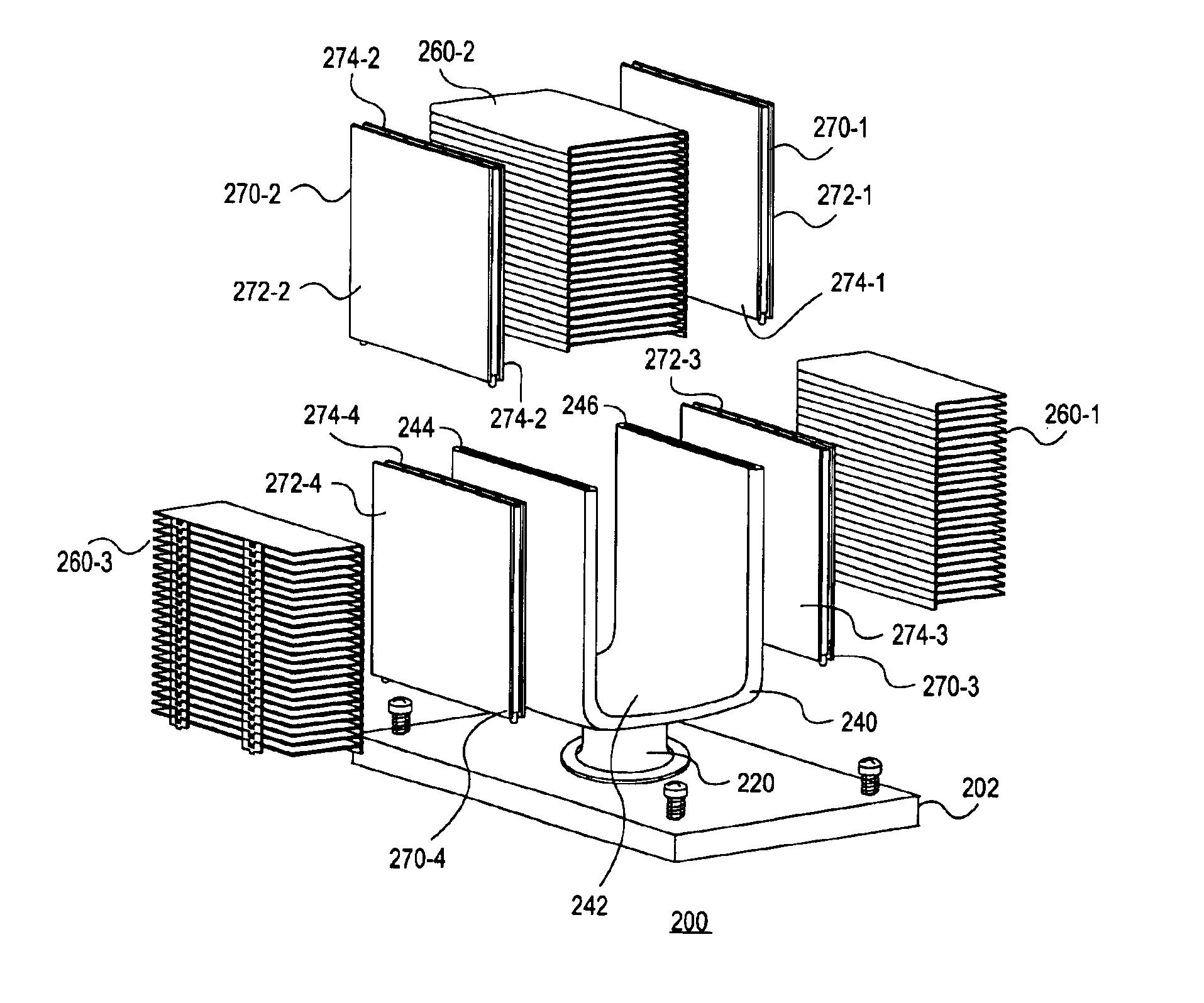

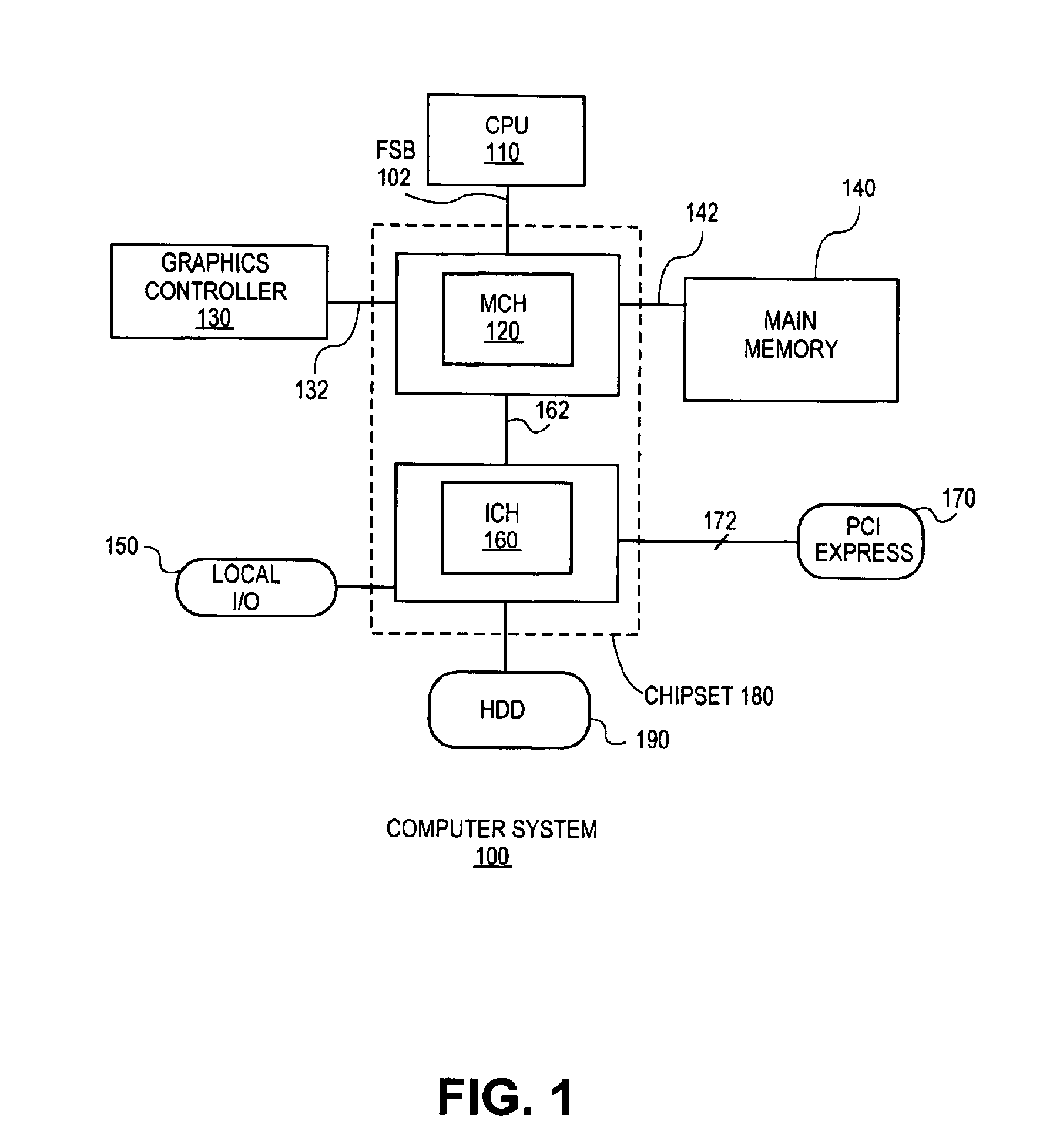

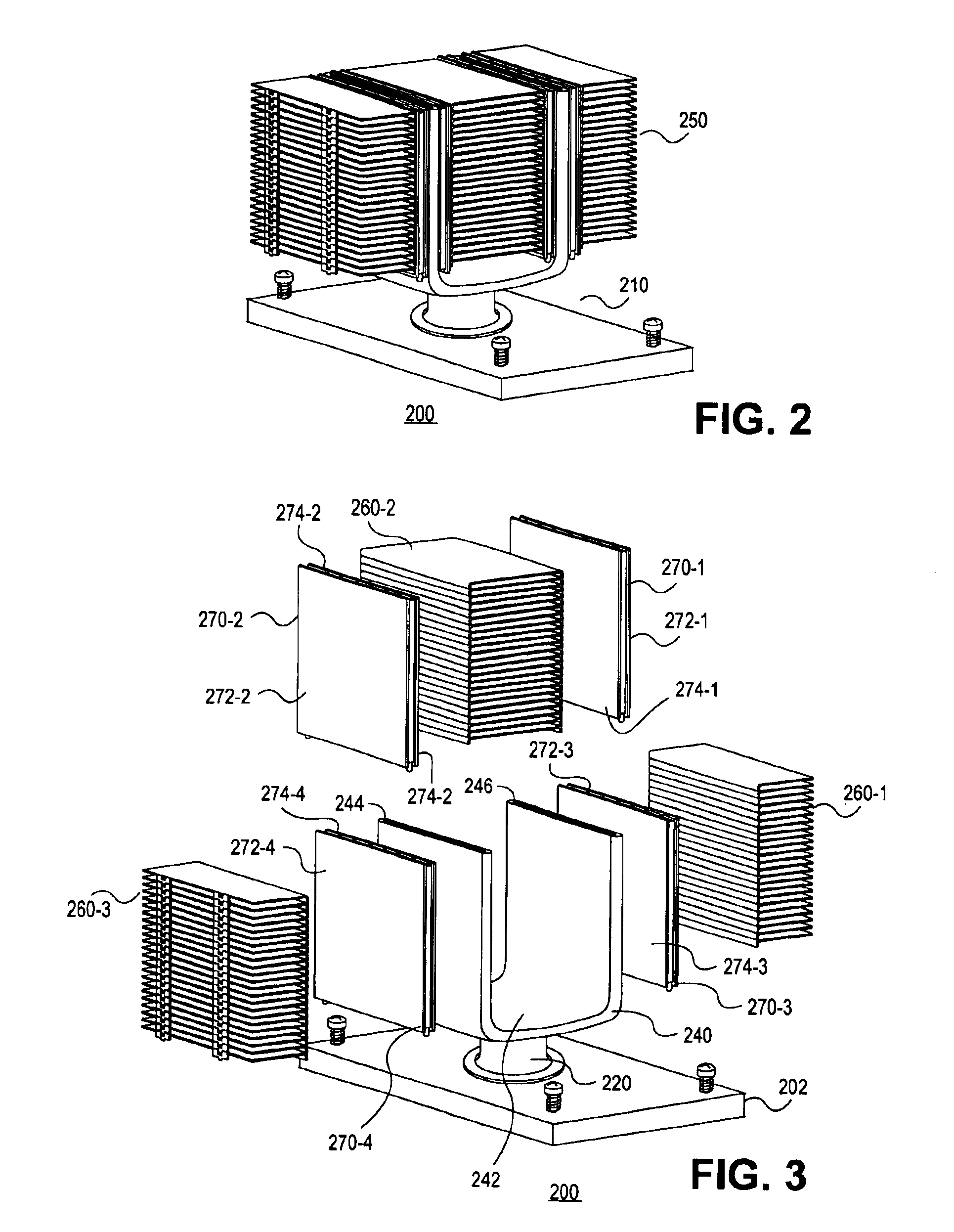

Apparatus and method for cooling integrated circuit devices

ActiveUS6917522B1Domestic cooling apparatusSemiconductor/solid-state device detailsRack unitEngineering

Some embodiments of a method and apparatus for cooling integrated circuit devices are described. In one embodiment, the apparatus includes a thermosiphon having an evaporator portion coupled to a first surface of a heat source and a condenser portion coupled to the evaporator portion distal from the first surface of the heat source. A remote heat exchanger is coupled to the condenser of the thermosiphon. In addition, one or more thermoelectric elements are coupled between the heat exchanger and the condenser of the thermosiphon. In one embodiment, the remote heat exchanger, the thermoelectric elements and the condenser portion of the thermosiphon are located outside a chassis of a one rack unit (1U) server computer.

Owner:INTEL CORP

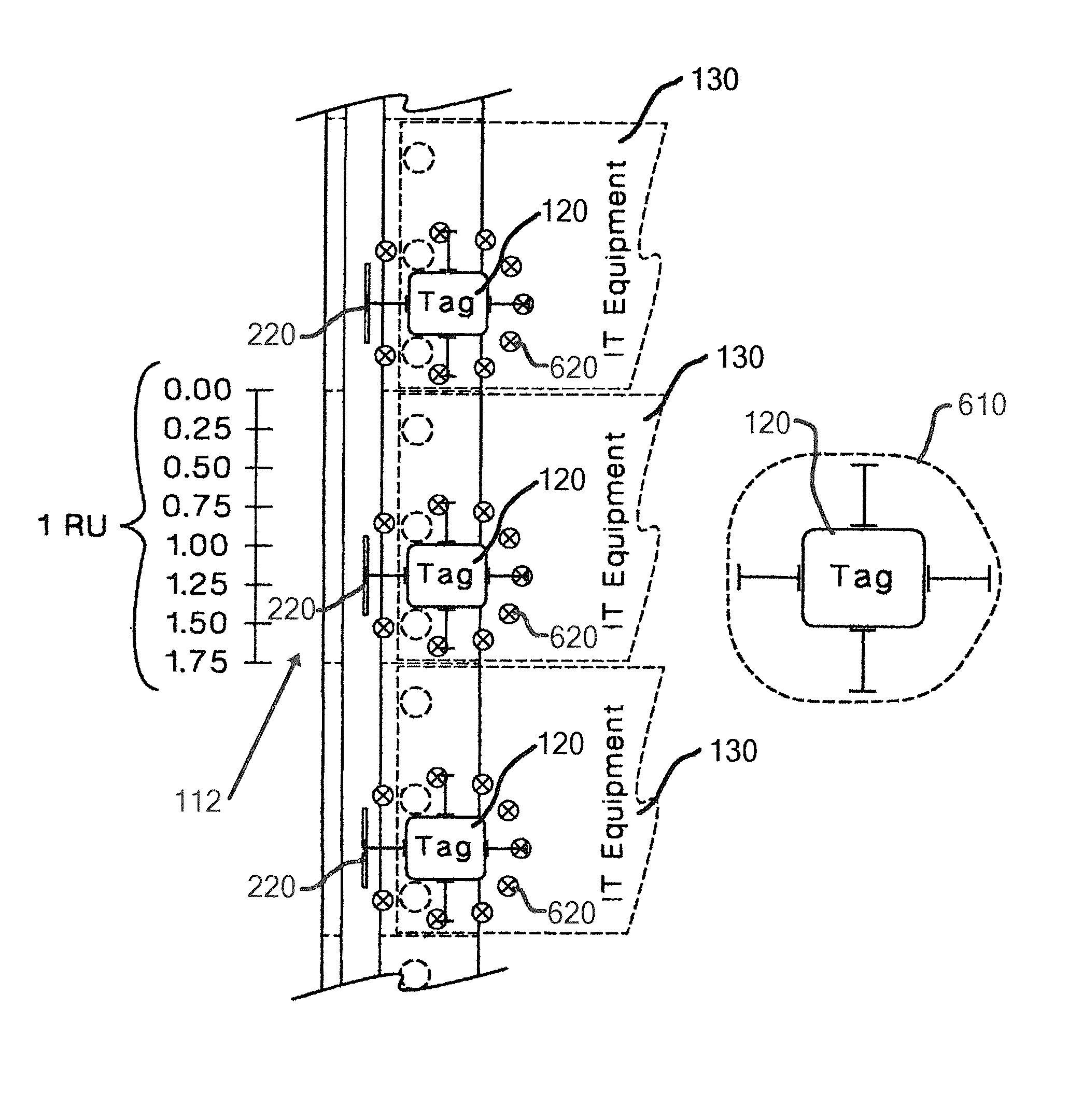

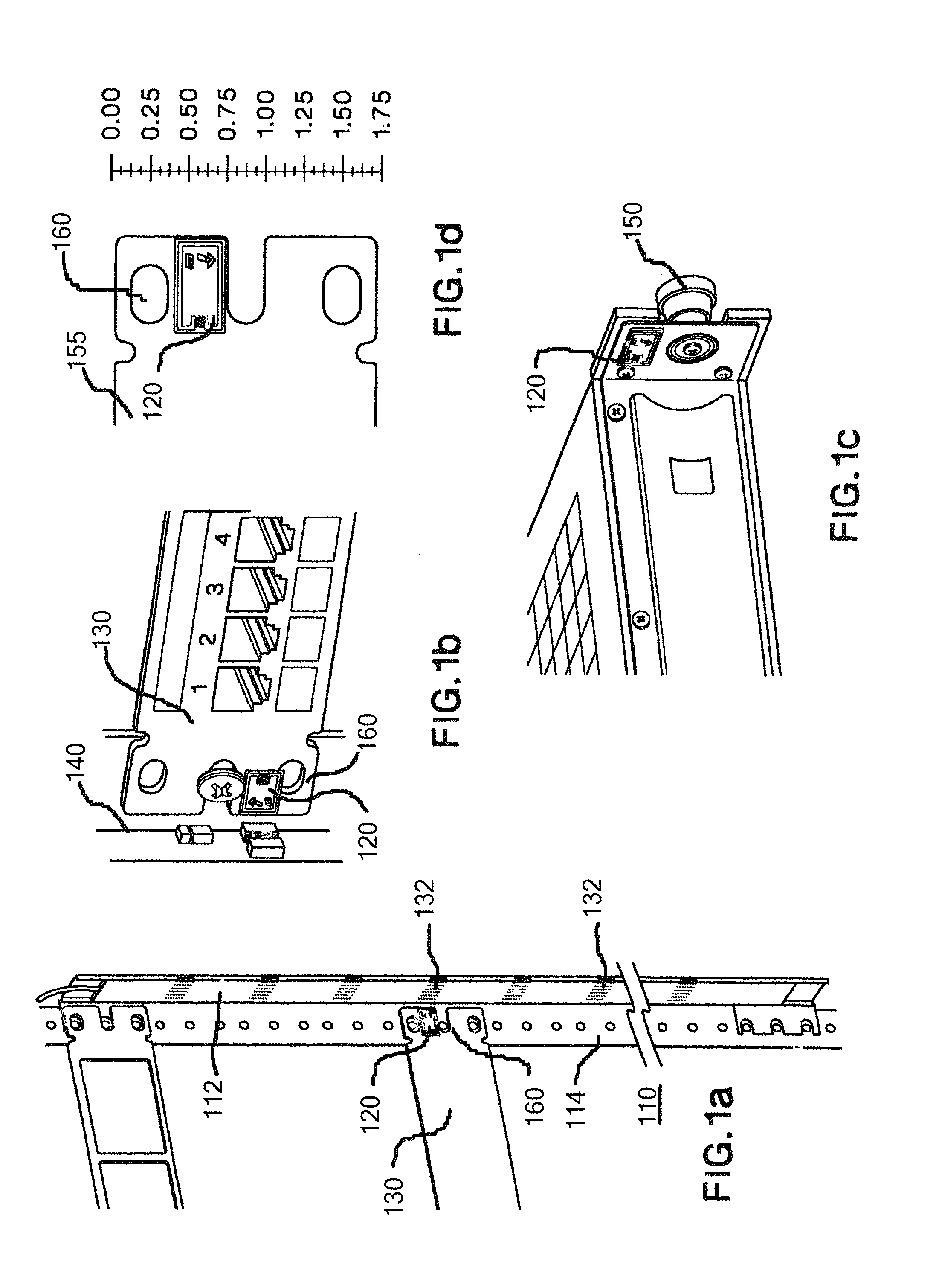

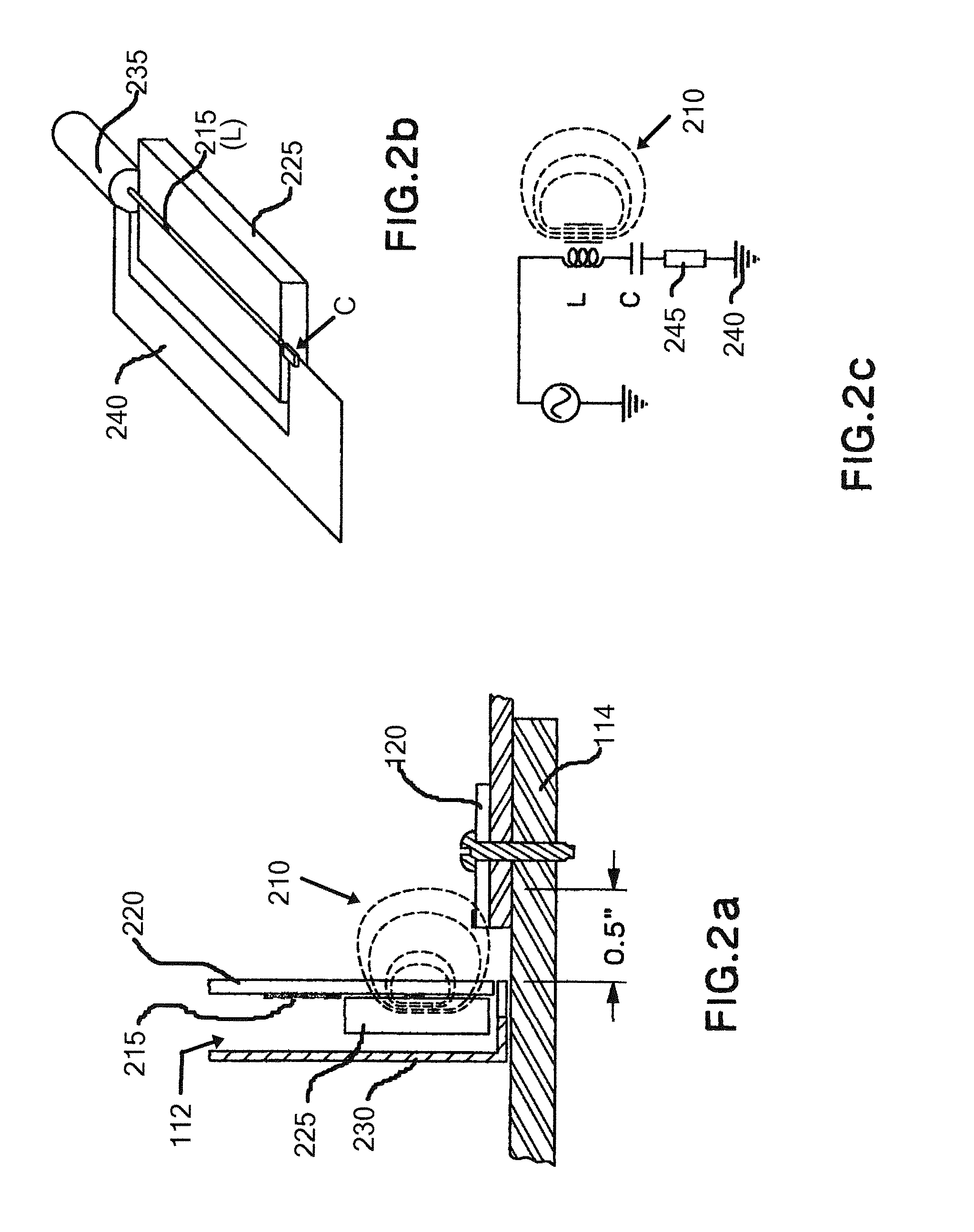

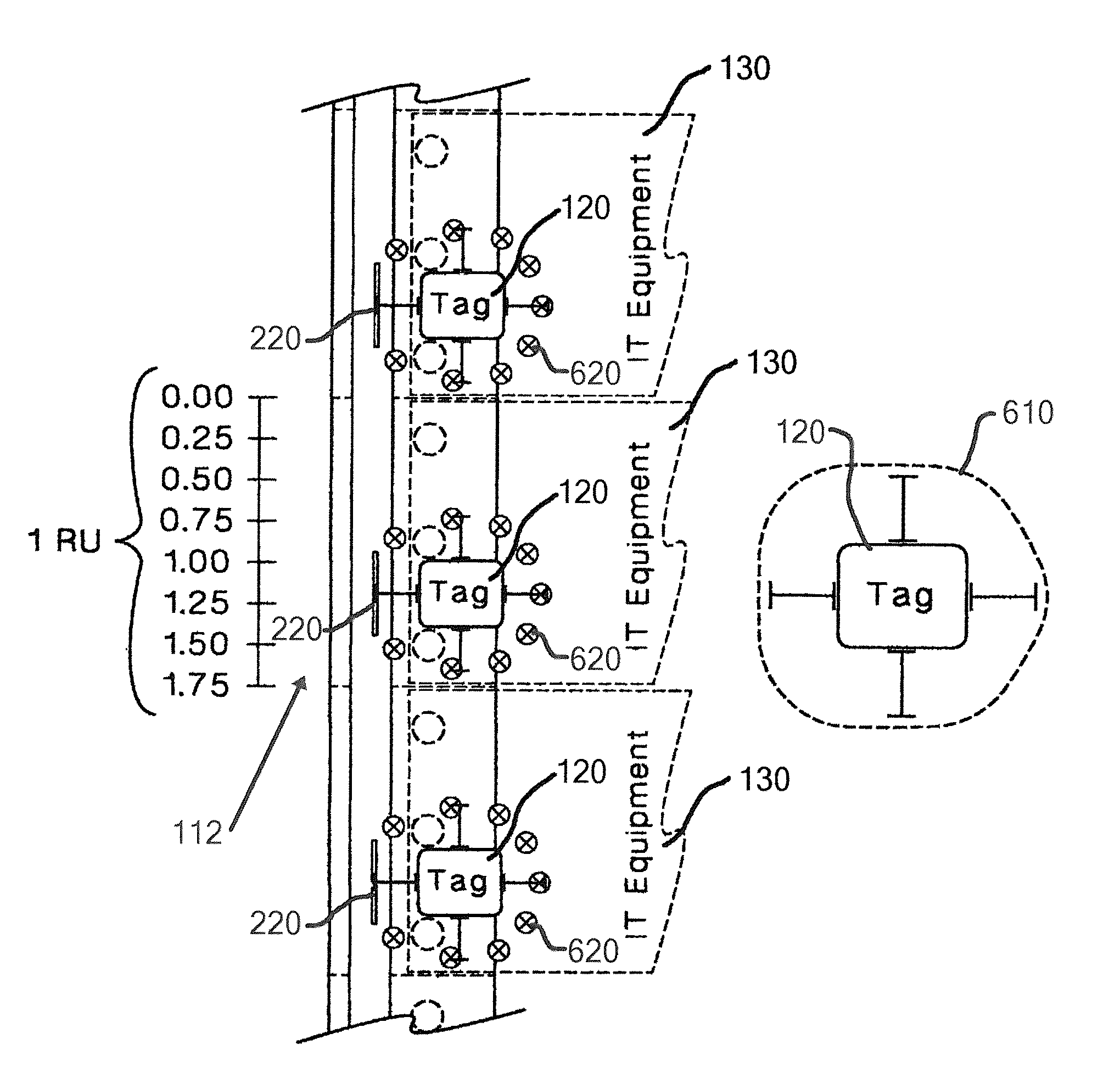

RFID system

ActiveUS8816857B2Memory record carrier reading problemsCo-operative working arrangementsRack unitRadio frequency

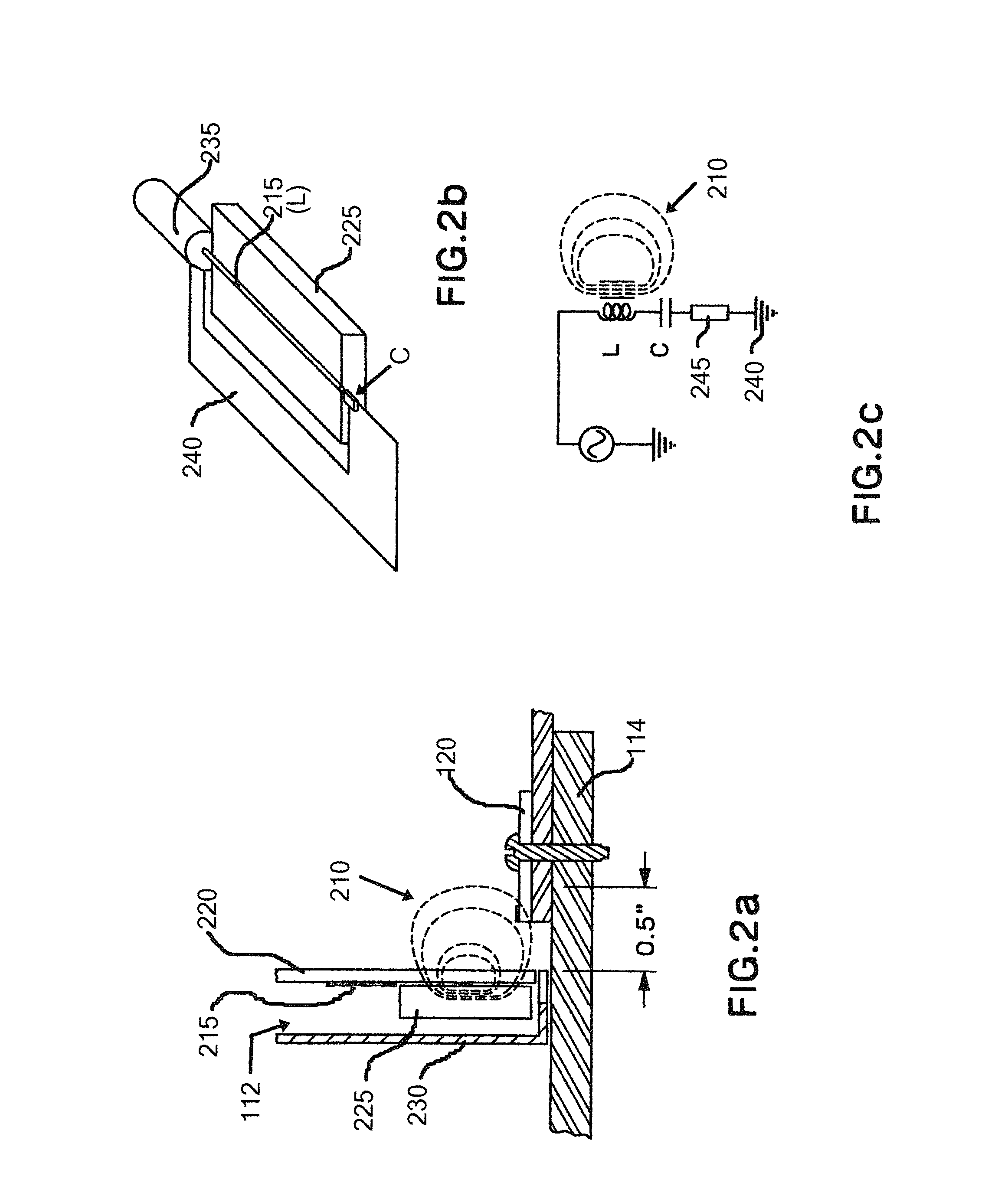

The present invention provides an automated system for asset tracking and management and utilizes near field Radio Frequency IDentification (RFID) technology. RFID tags are attached to the assets, and RFID antennas (and corresponding readers) are strategically located in close proximity to read the tags. As applied to a rack or cabinet, near-field antennas are mounted along one of the mounting posts at each rack unit location such that when a piece of equipment (rack mounted or rail mounted) is installed at a particular rack unit space, the tag will be read and registered in an RFID management system. A magnetic field shaping arrangement ensures that crosstalk between adjacent rack positions is prevented. Ferrite elements are used to control the magnetic field.

Owner:PANDUIT

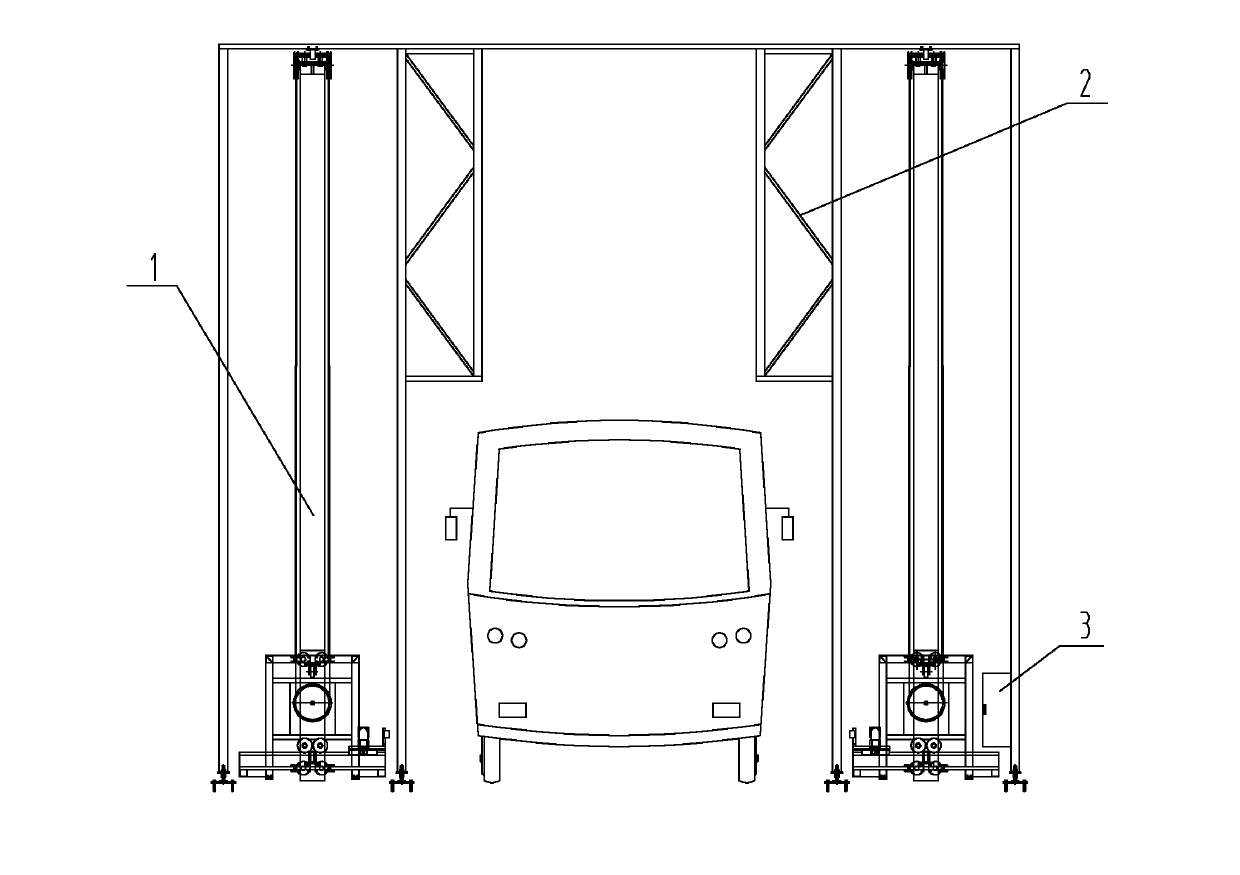

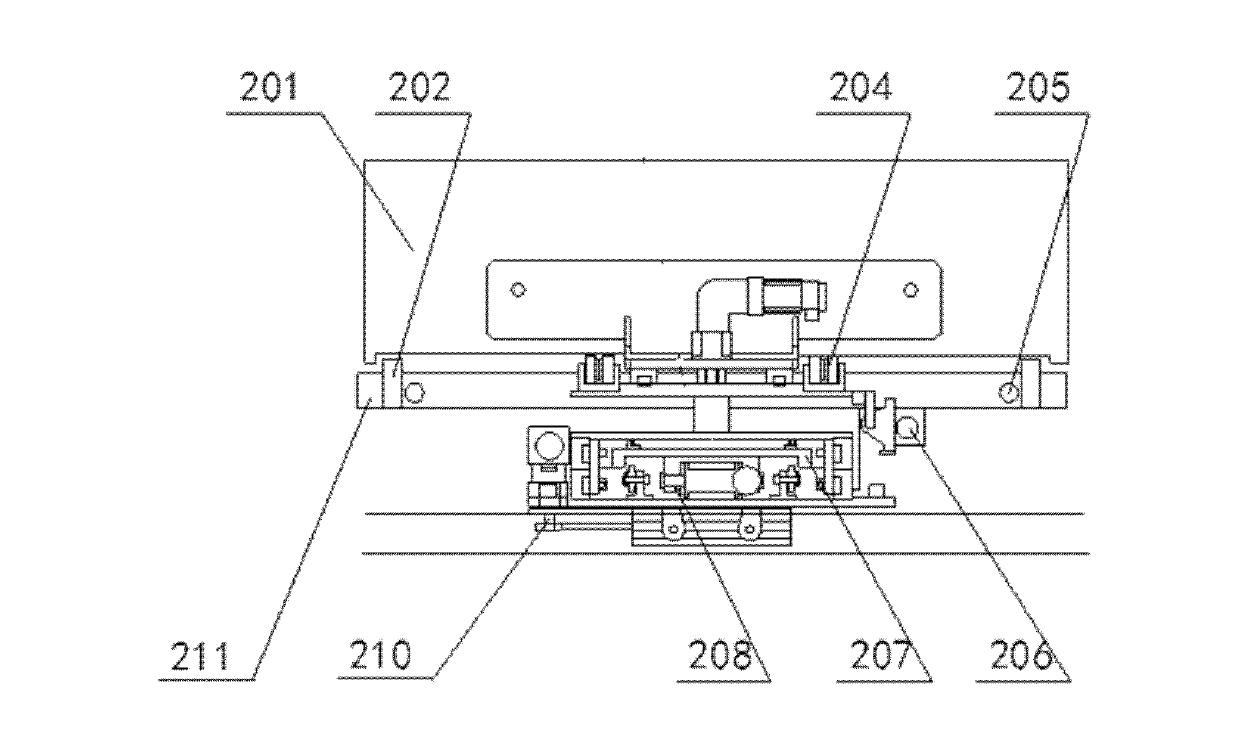

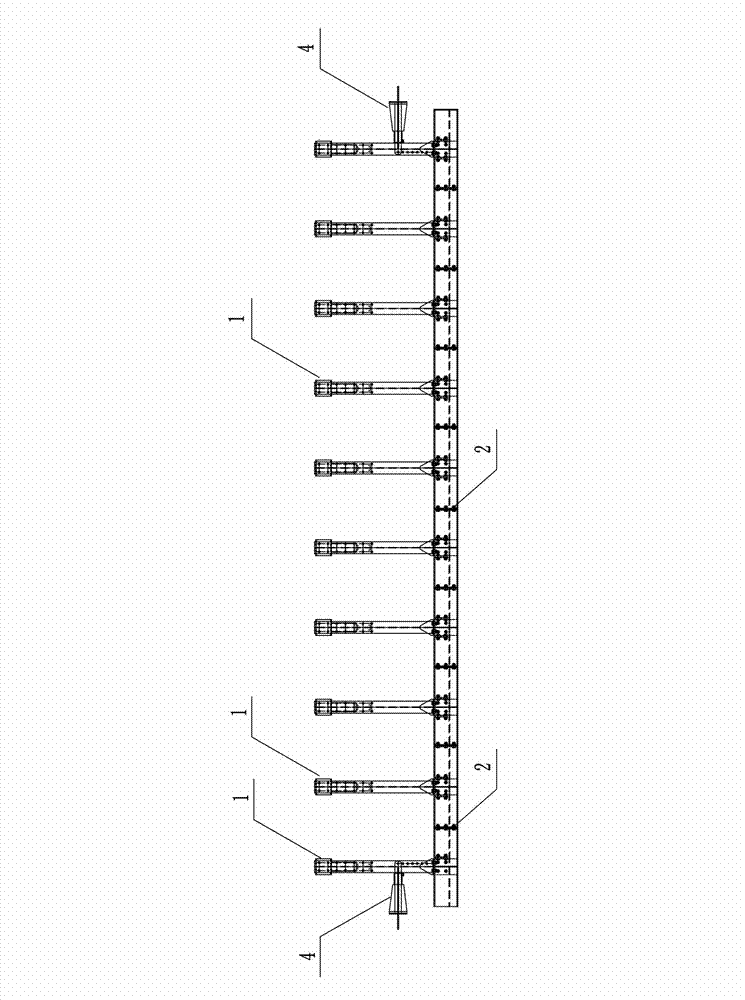

System and method for quickly replacing electric bus batteries

ActiveCN102602372AAvoid cumbersome actionsReduce space occupancyElectric propulsion mountingElectric/fluid circuitElectricityElectrical battery

The invention discloses a system and a method for quickly replacing electric bus batteries. The batteries are arranged above battery replacing robots instead of being arranged at an original position, so that the robots can acquire the charged batteries from above without turning around, and then the batteries can be replaced by the battery replacing robot on the sides as same as those of the battery replacing robot, so that occupied space of the batteries is saved, a turning mechanism of the battery replacing robot is omitted, equipment structure is simplified, and reliability and replacing efficiency of equipment are further improved. The system comprises charging storage rack units with the charged batteries thereon, at least one lifting battery replacing robot on the side as same as that of the corresponding charging storage rack unit is arranged and matched with the corresponding charging storage rack unit, each lifting battery replacing robot moves along the length direction of the corresponding charging storage rack unit, and is used for taking the batteries needing to be replaced down from an electric bus, lifting the batteries needing to be replaced to a battery storage position on the corresponding charging storage rack, taking the charged batteries and descending to a battery replacing position to complete battery replacement of the electric bus.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

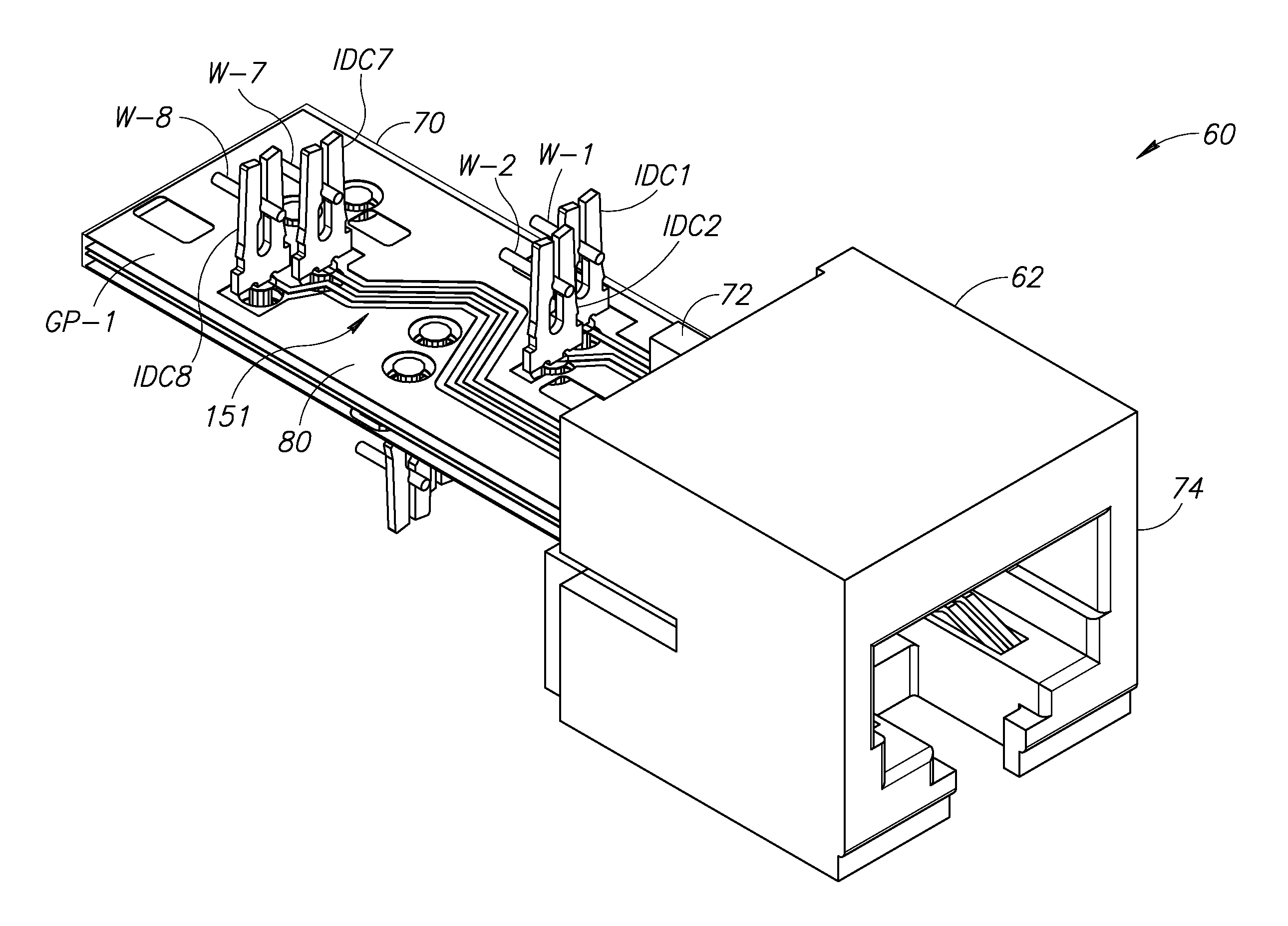

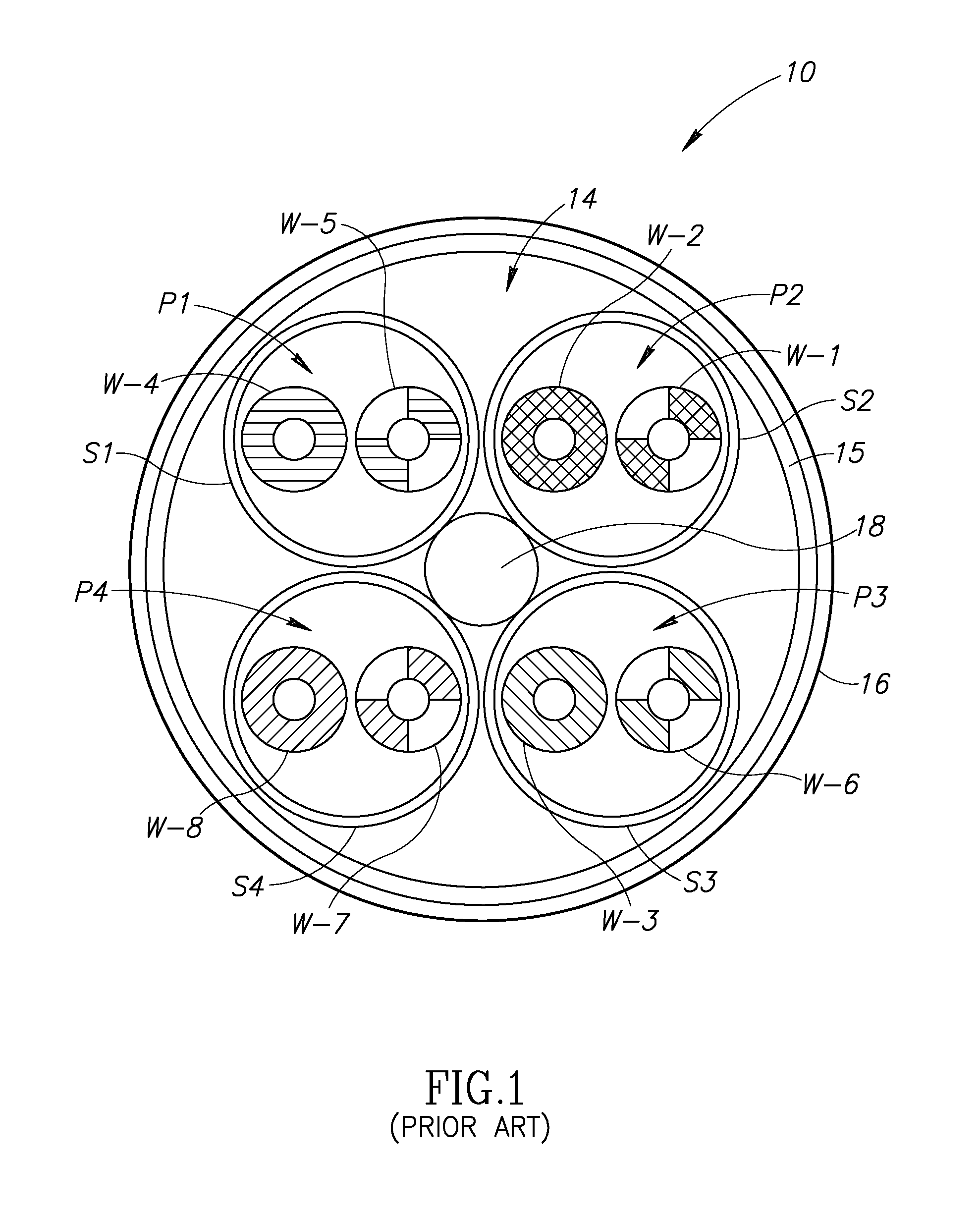

High density high speed data communications connector

An outlet that includes first and second substrates, and a plurality of electrical contacts. The first substrate includes an electrical circuit adjacent to and spaced apart from a first ground plane. Each of the electrical contacts is connected to the circuit. The second substrate includes a second ground plane electrically connected to the first ground plane. The circuit is spaced apart from the second ground plane. The electrical contacts are positioned adjacent to the first and second substrates. Together the first and second ground planes may form a localized, electrically floating, isolated ground plane. The outlet may be connected to a cable and / or configured to be mounted to a panel for use with a rack. The outlet may be implemented as a Category 7A and / or Next Generation type outlet having an overall height that allows two rows of twenty-four like outlets to be mounted within one rack unit (“1RU”).

Owner:LEVITON MFG

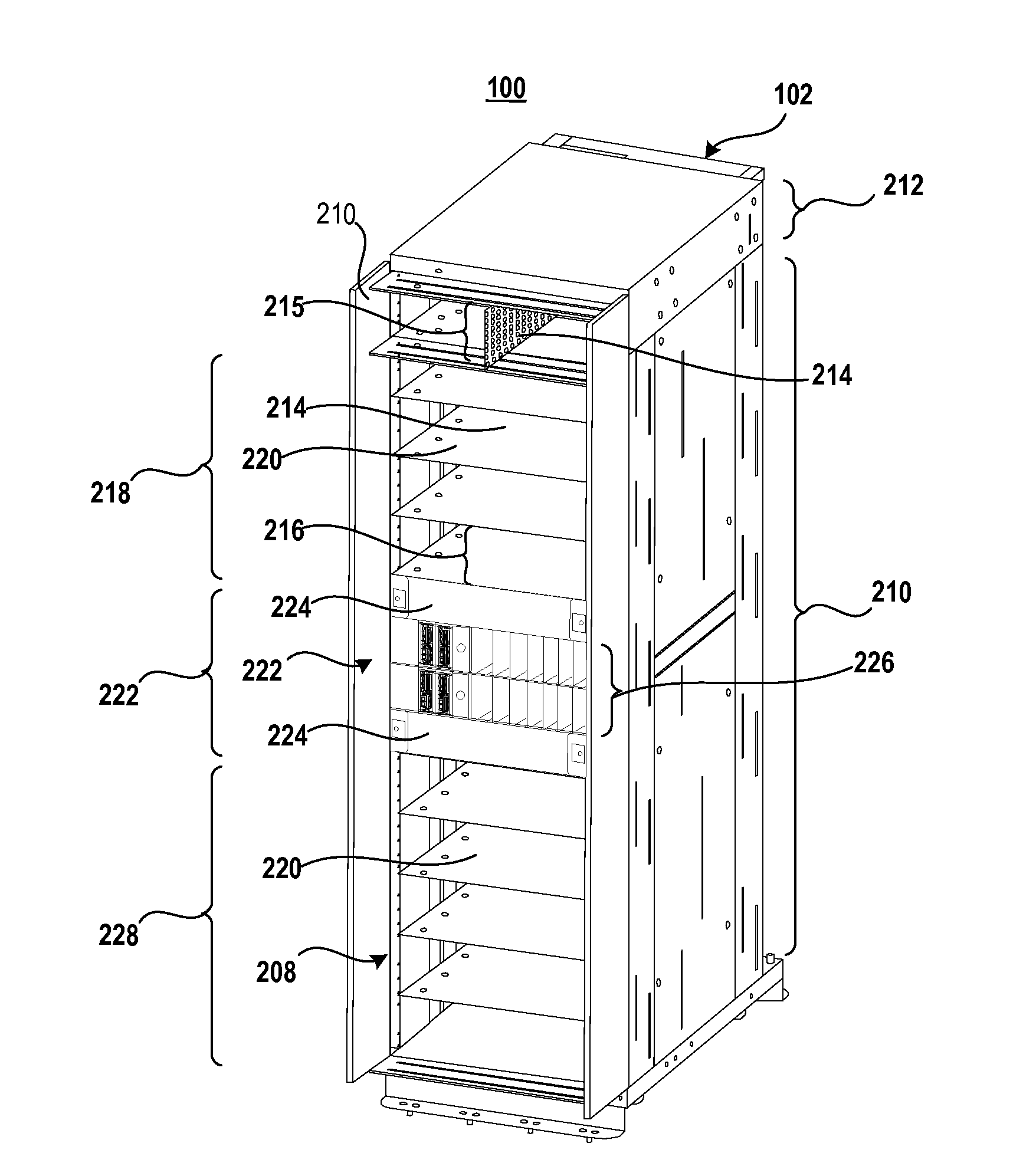

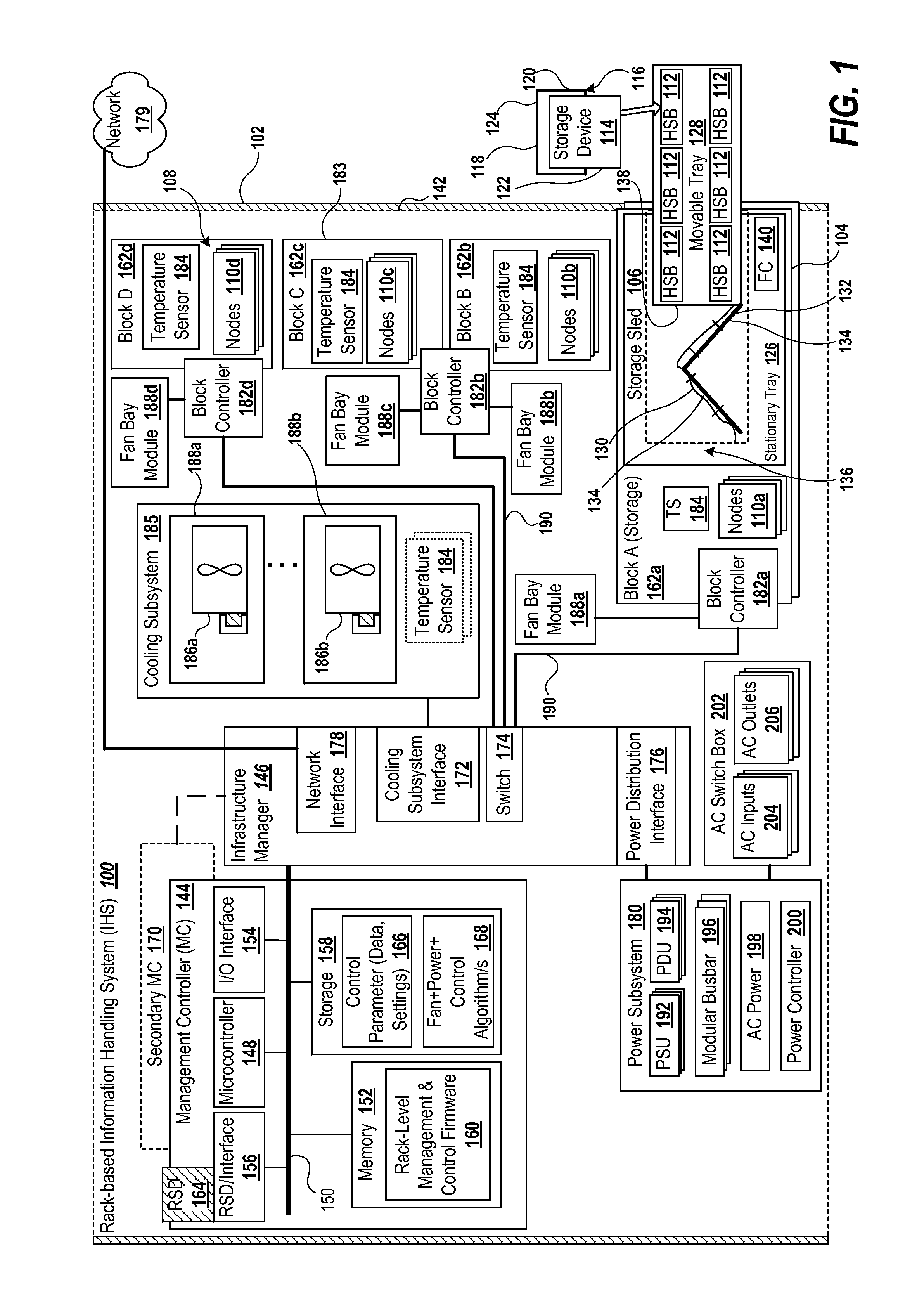

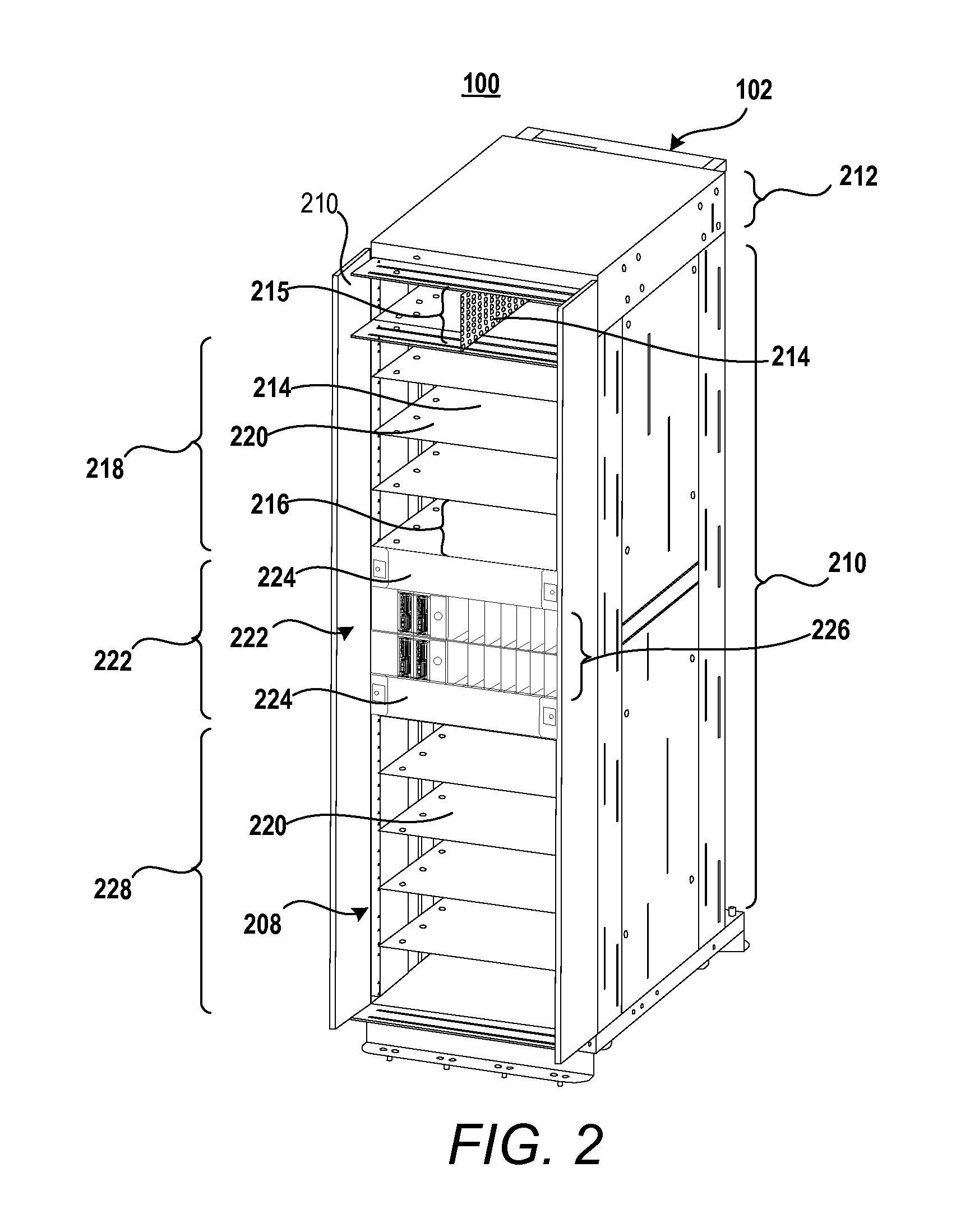

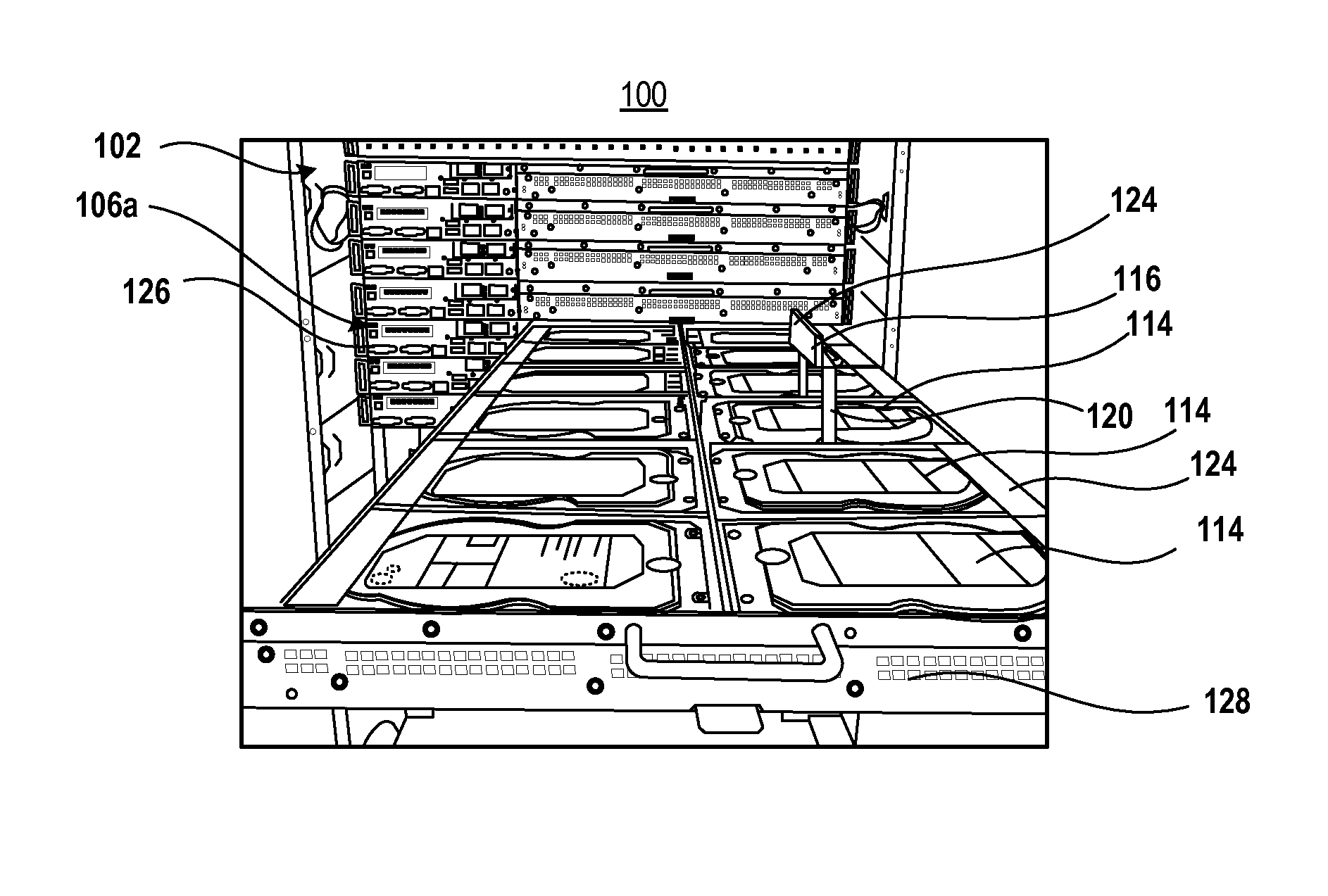

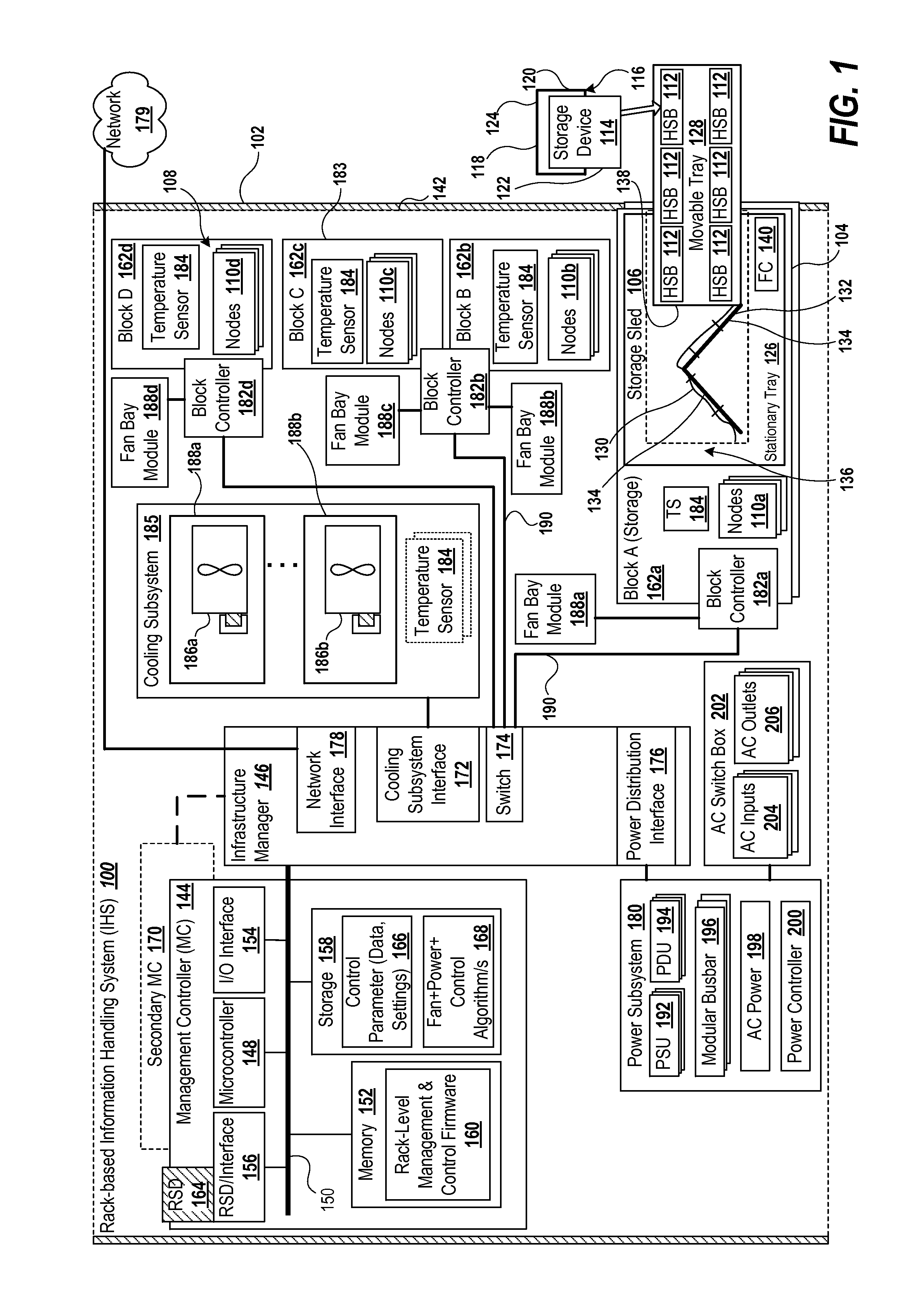

Single unit height storage sled with lateral storage device assembly supporting hot-removal of storage devices and slidable insertion and extraction from an information handling system rack

A rack-based information handling system (IHS) includes a rack containing at least one chassis having a plurality of bays open to laterally receive sleds that contain a plurality of information technology (IT) components that, when operational, enable the rack to function as an IHS. A storage sled including a stationary tray received in the chassis and a moveable trace received in the stationary tray. One or more hot swap bays that are horizontally arrayed in the storage sled in less than one (1) Server System Infrastructure (SSI) rack unit of height, wherein the moveable tray is extendable from the rack to a service position to expose all of its hot swap bays. Storage devices are insertable into a respective one of the hot swap bays of the storage sled. Each storage device may include a latching handle to lift and downward position the storage device in the corresponding hot swap bay.

Owner:DELL PROD LP

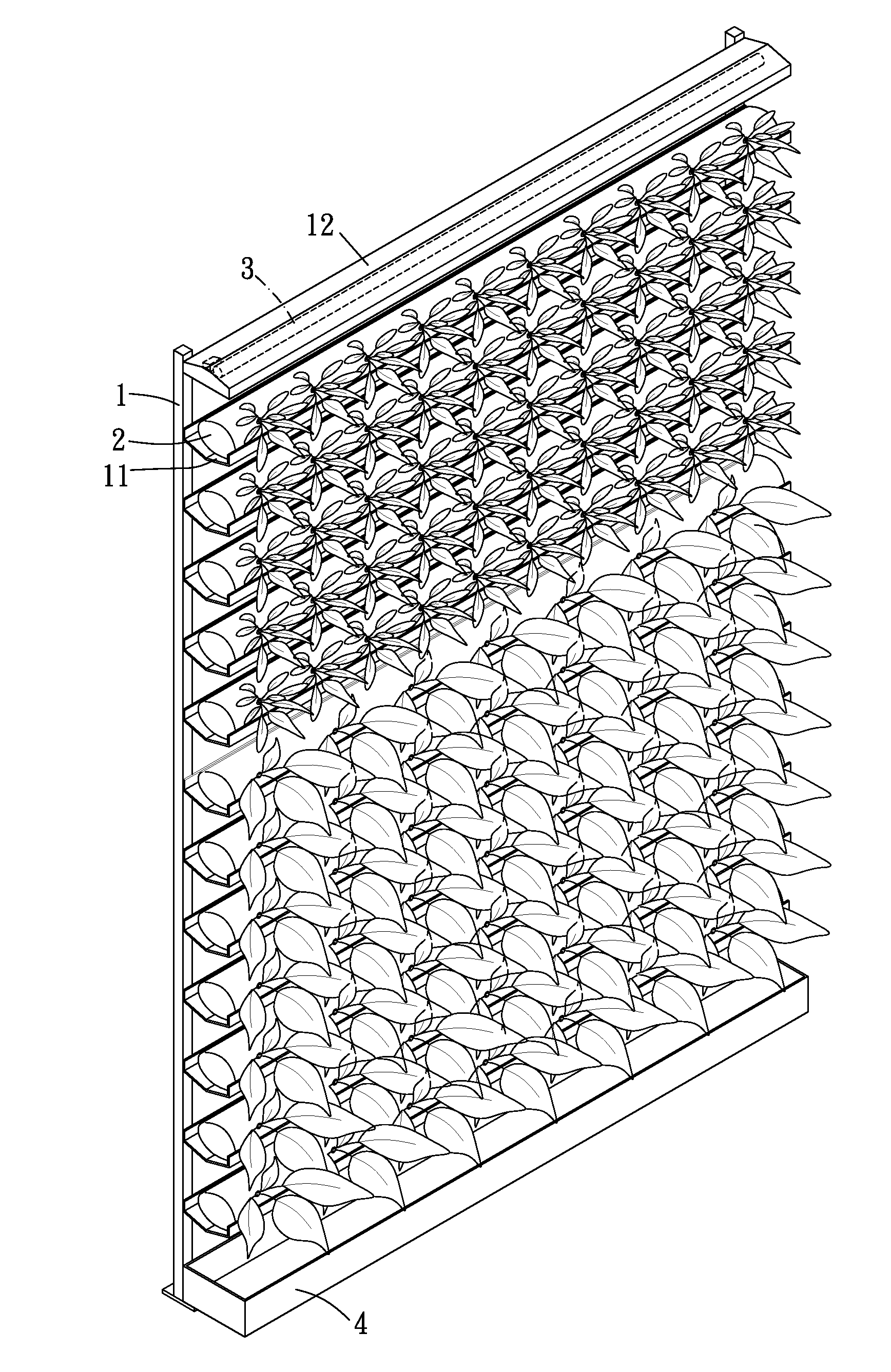

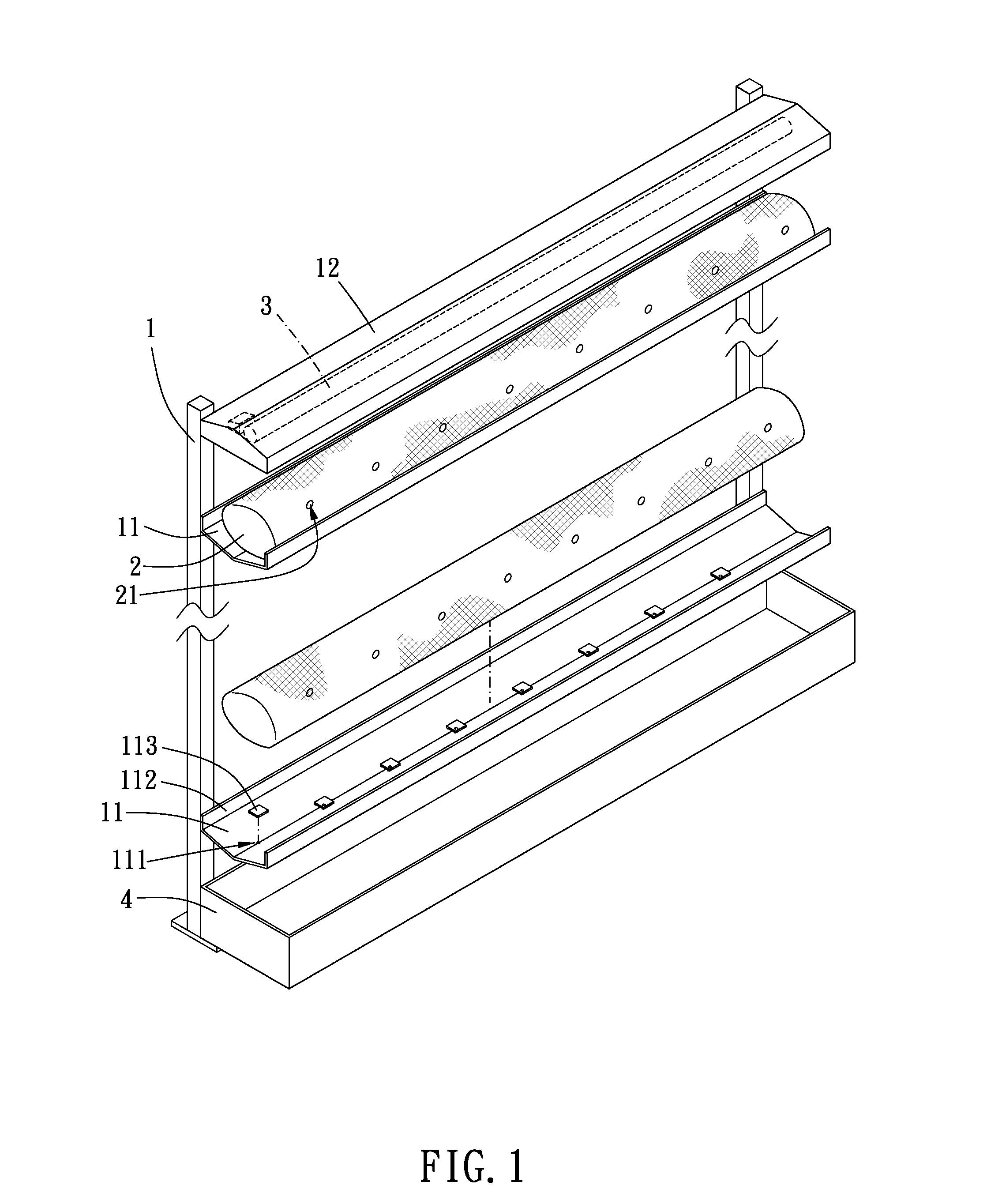

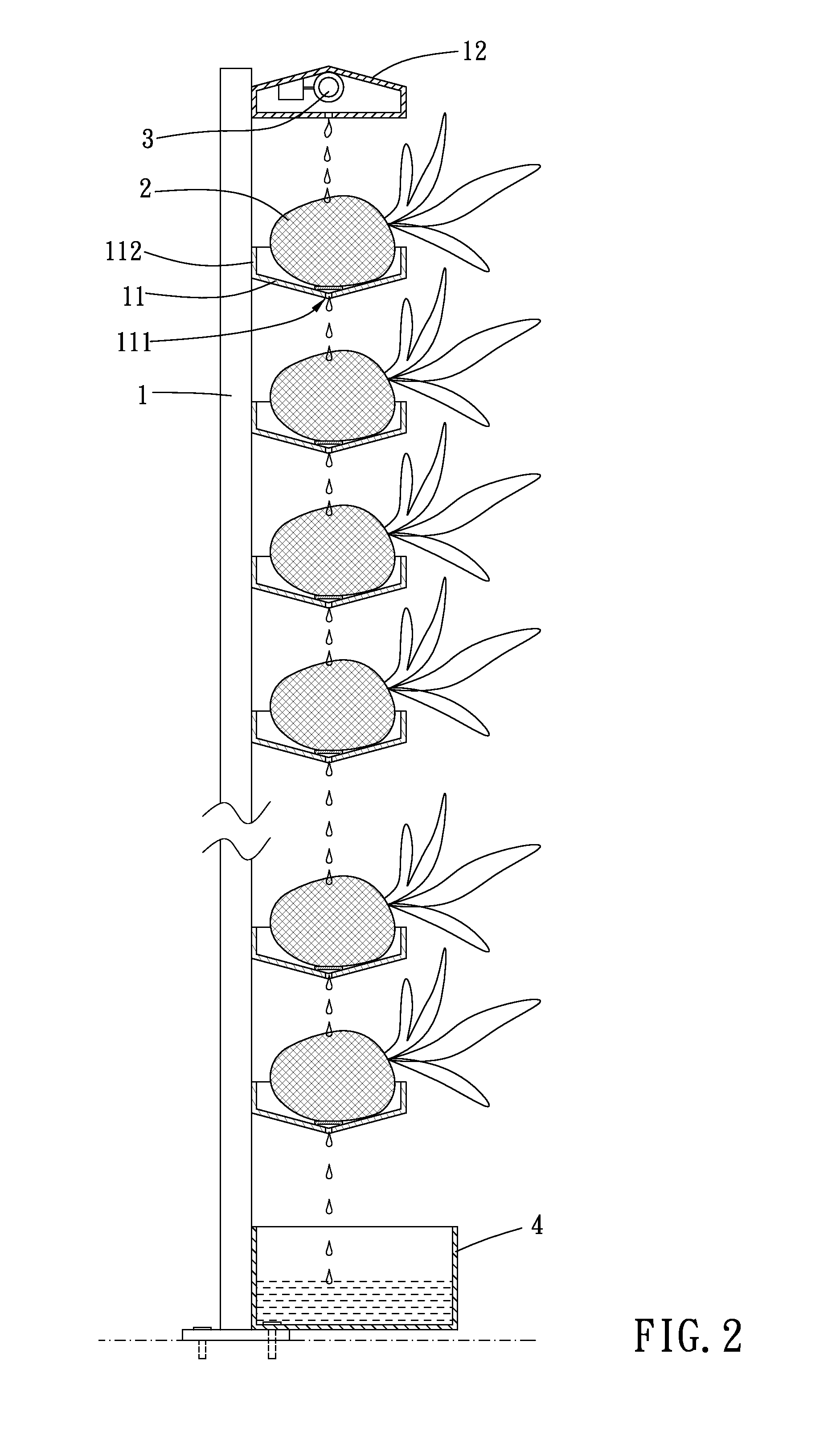

Plant develop rack

InactiveUS20130340337A1Improve water efficiencyWatering devicesCultivating equipmentsRack unitAgricultural engineering

A plant develop rack includes a base, plural soil packages, a water supply device, and a water collecting tank. Plural rack units are disposed on the base and are arranged vertically. Each soil package encloses growth medium and plant and forms plural openings for the plant to extend outward. The water supply device is located above the rack units. Thereby, when the water supply provides water to the most upper rack unit, water may enter the soil package on that rack unit to nourish the plant. Thereafter, excess water may flow downward via draining holes of the rack unit to reach lower rack units. Thus, the soil packages on all rack units can acquire sufficient water for growing the plant.

Owner:ELE GARDEN LANDSCAPE CONSTR

RFID System

ActiveUS20120098664A1Memory record carrier reading problemsRecord carriers used with machinesRack unitRadio frequency

The present invention provides an automated system for asset tracking and management and utilizes near field Radio Frequency IDentification (RFID) technology. RFID tags are attached to the assets, and RFID antennas (and corresponding readers) are strategically located in close proximity to read the tags. As applied to a rack or cabinet, near-field antennas are mounted along one of the mounting posts at each rack unit location such that when a piece of equipment (rack mounted or rail mounted) is installed at a particular rack unit space, the tag will be read and registered in an RFID management system. A magnetic field shaping arrangement ensures that crosstalk between adjacent rack positions is prevented. Ferrite elements are used to control the magnetic field.

Owner:PANDUIT

System to increase server's density in datacenter

A system and a method for forming the system. The system includes a cooling conduit and rack containers stacked in a first direction parallel to a floor. Each rack unit includes at least one heat generating device configured to generate heat while in operation. Each rack container is equipped with wheels positioned on a supporting structure to enable the wheels to move along the supporting structure in a second direction which enables adjacent rack containers to move closer to or further from each other. The second direction is parallel to the floor and perpendicular to the first direction. The supporting structure is on the floor and oriented in the second direction. The cooling conduit is secured on a top surface of each rack container to allow a cooling fluid to flow into each rack container and be heated by absorbing heat from the at least one heat generating device.

Owner:KYNDRYL INC

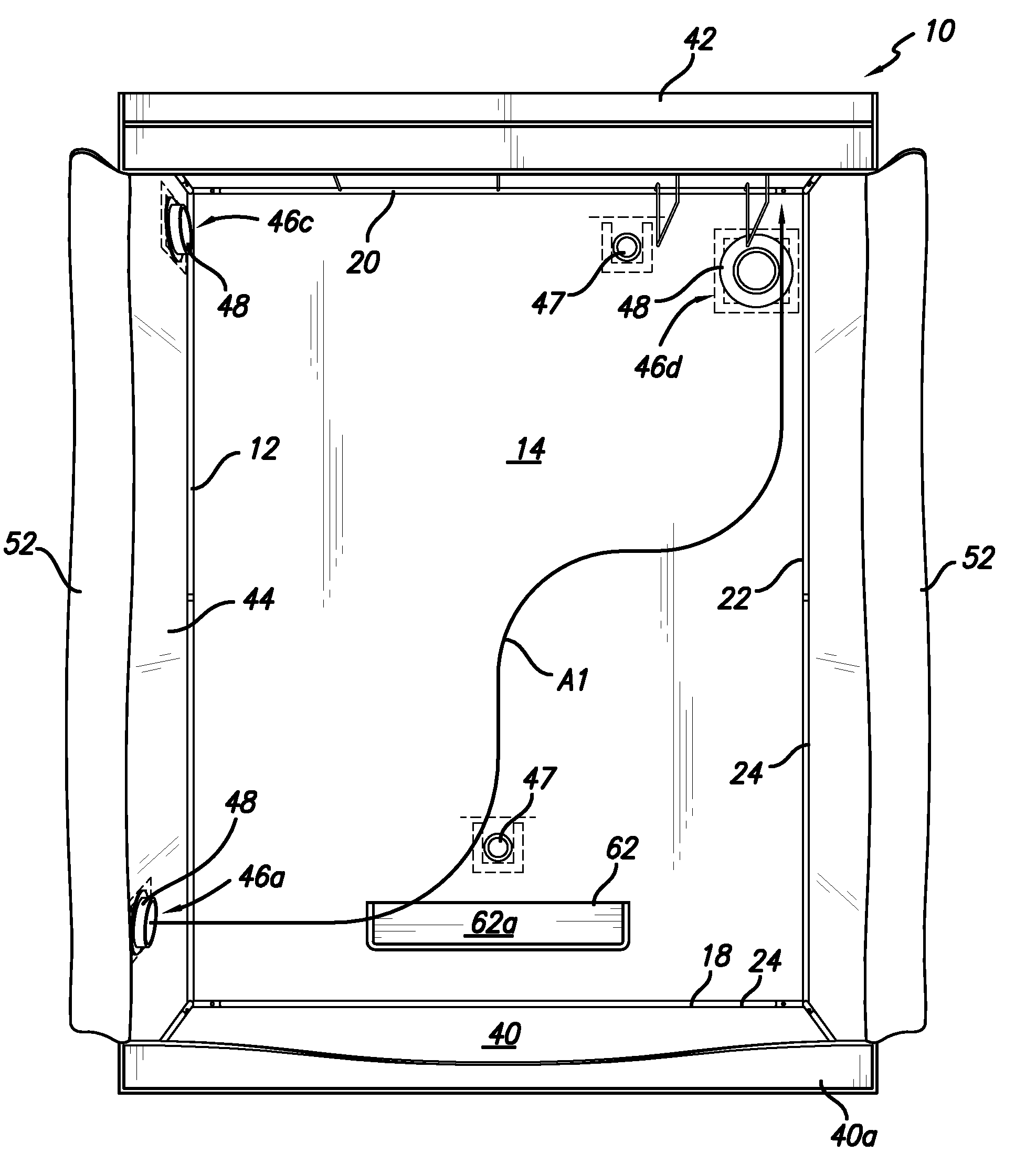

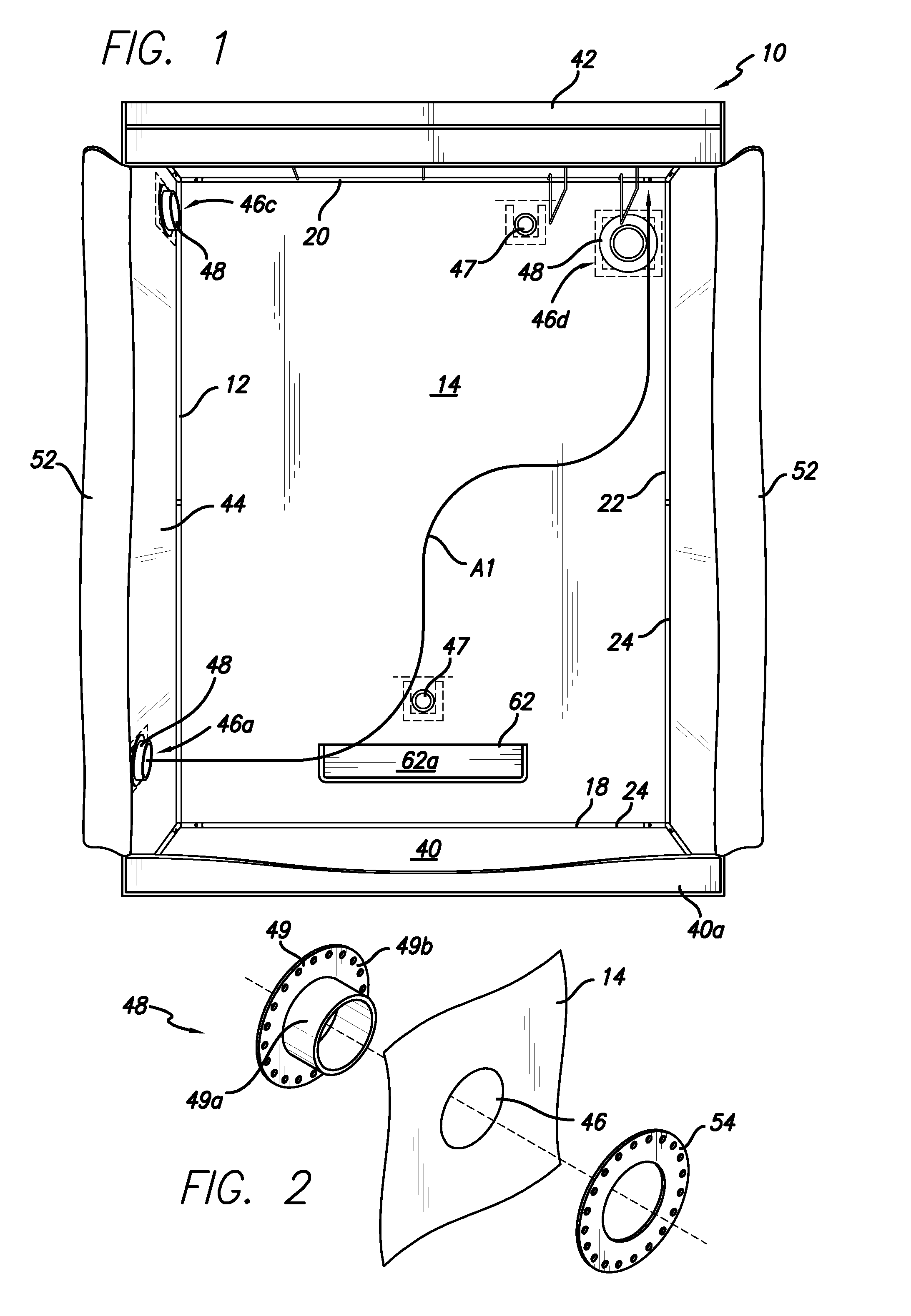

Indoor greenhouse

Described herein is an indoor greenhouse that includes a rack unit, an outer layer that surrounds the rack unit and defines a greenhouse interior, at least one light surrounded by a light enclosure, a cooling system, and a ventilation system all disposed in the greenhouse interior. The ventilation system includes a fan, a filter and at least one duct that cooperate to exhaust air out of the exhaust vent opening. The rack unit includes a top, a bottom, and an intermediate portion extending therebetween. The outer layer includes a top, a bottom, and an intermediate portion extending therebetween that correspond to the similar portions of the rack unit. The outer layer also has intake and exhaust vent and light cooling openings defined therein. The cooling system includes at least one duct that cooperates with the light enclosure to define an air path between the intake and exhaust light cooling openings.

Owner:INT GROWERS SUPPLY

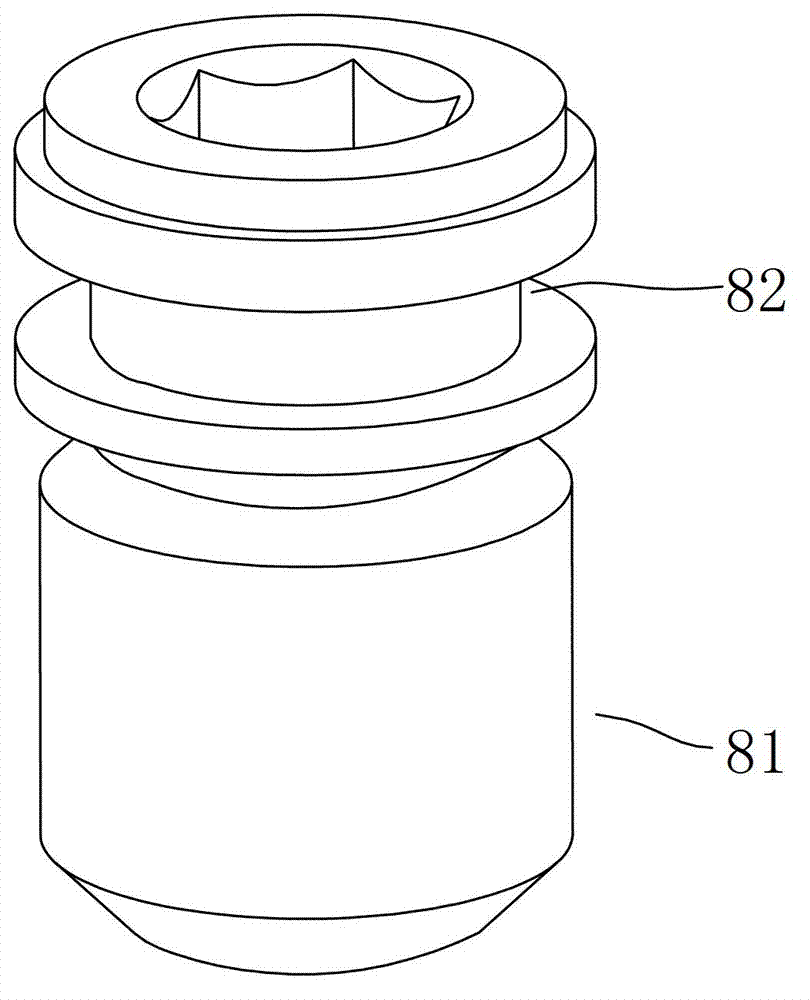

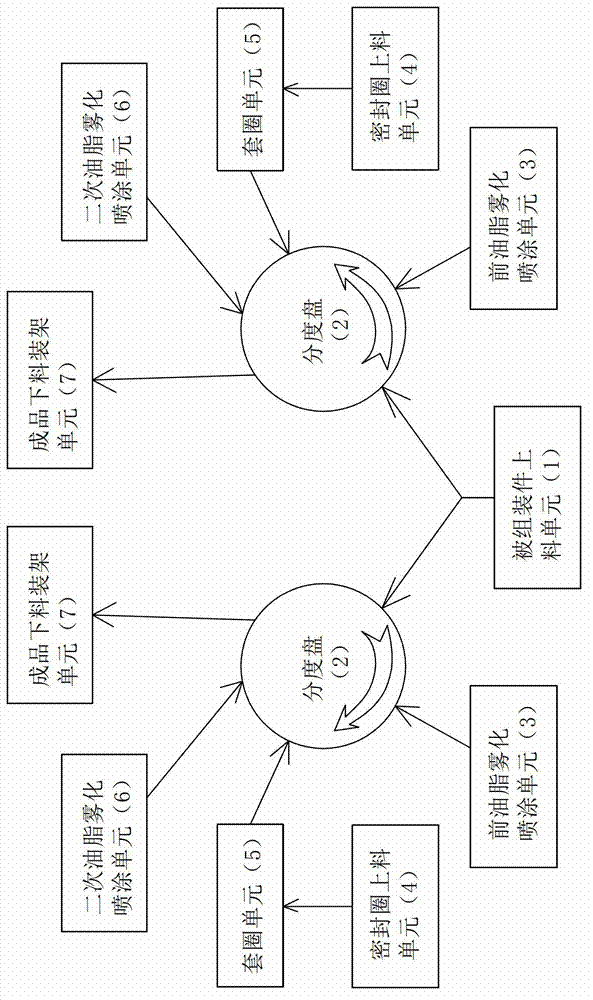

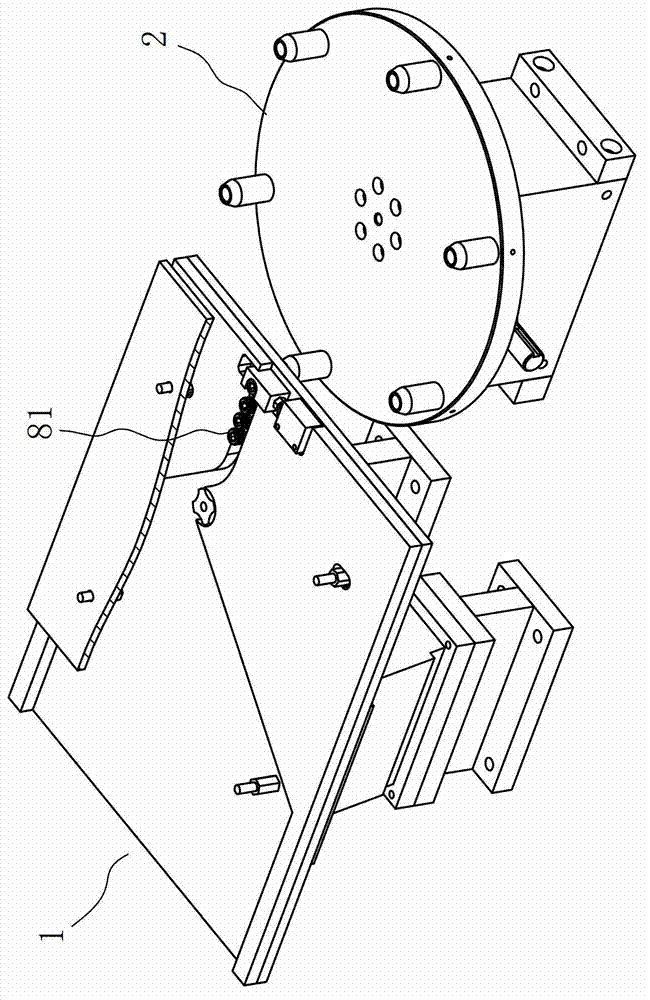

Sealing ring component full-automatic assembly machine

InactiveCN103170831AIncrease productivityImprove controllabilityMetal working apparatusEngine lubricationRack unitEngineering

The invention discloses a sealing ring component full-automatic assembly machine which comprises an assembled part feeding unit, an assembled part transfer channel, an indexing disc, a sealing ring feeding unit, a front grease atomization spray unit, a ring-knotting unit, a secondary grease atomization spray unit and a finished product baiting racking unit, wherein an assembled part can vibrate and advance on the assembled part feeding unit and transported on the indexing disc along the assembled part transfer channel, then the front grease atomization spray unit conducts first oil injection, the ring-knotting unit selects a sealing ring from the sealing ring feeding unit to conduct assembling of the sealing ring to the assembled part, the secondary grease atomization spray unit conducts secondary grease spray on the assembled part, and finally the assembled part is output from the finished product baiting racking unit. Each unit performs a function by self and is organically integrated. Feeding, inner grease spray, ring-knotting, outer grease spray and baiting and racking are fully and automatically completed, so that production efficiency is greatly improved, and controllability is high. The sealing ring component full-automatic assembly machine can be used in a workpiece assembling procedure of the sealing ring.

Owner:深圳南方精益科技有限公司

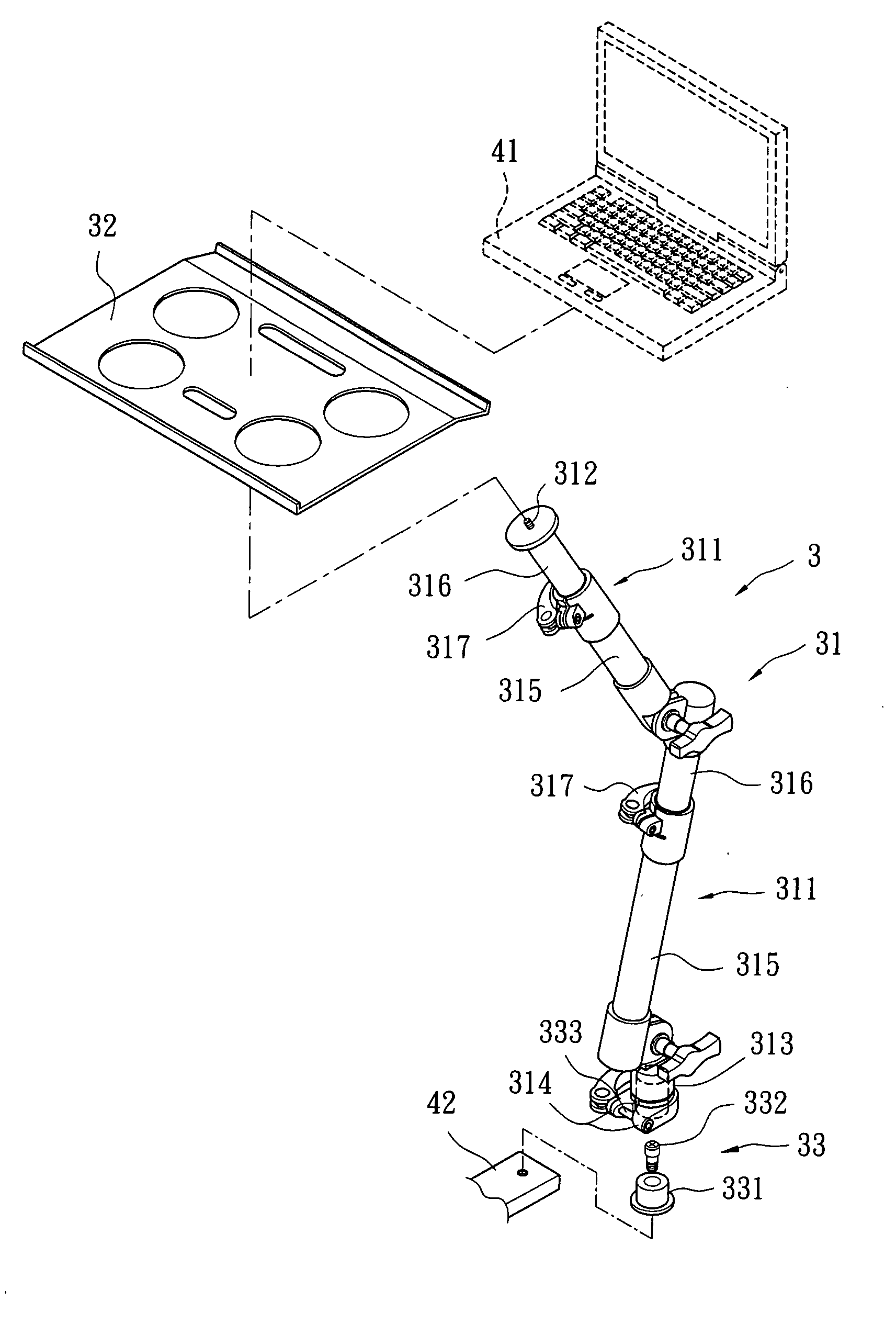

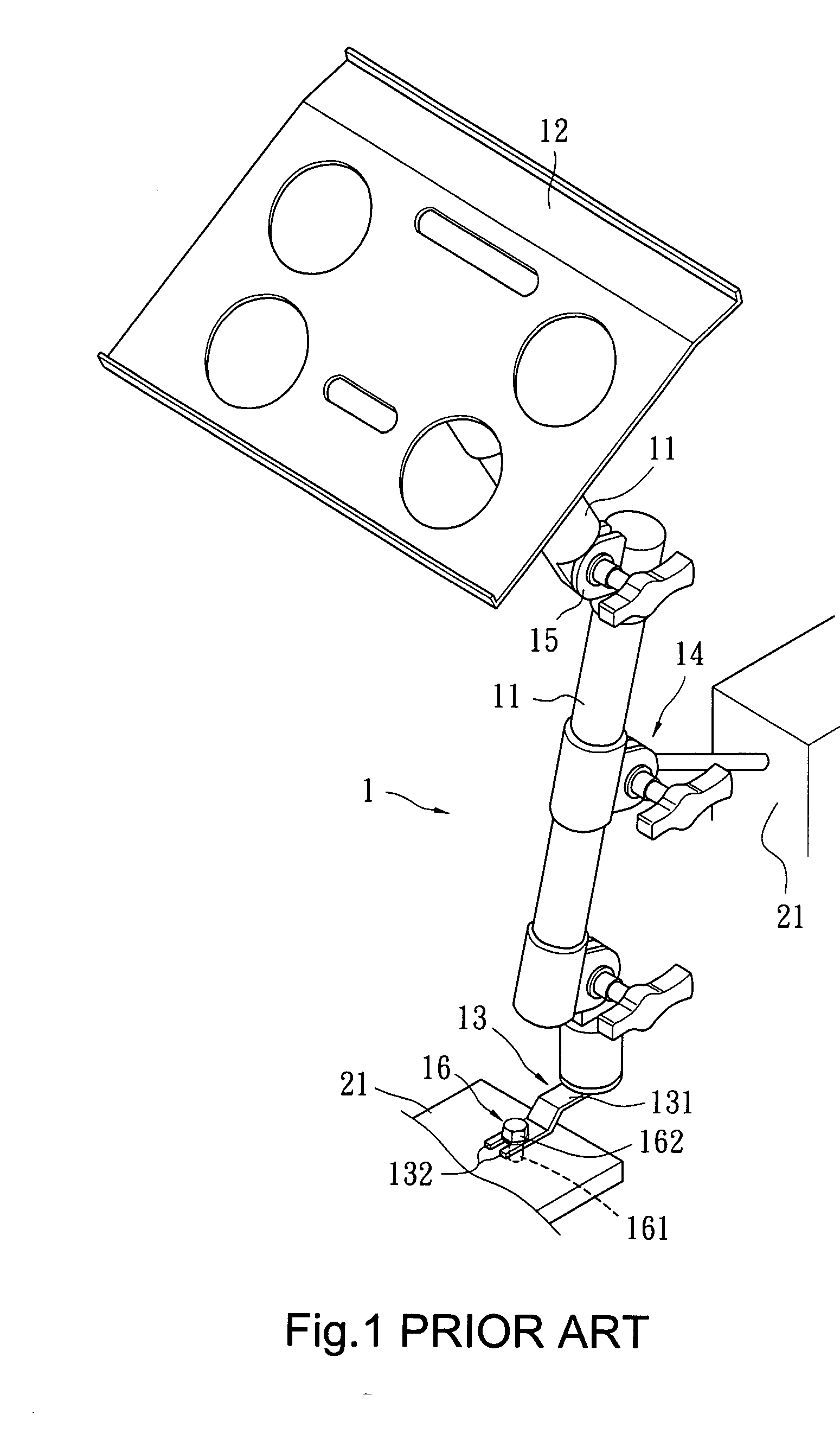

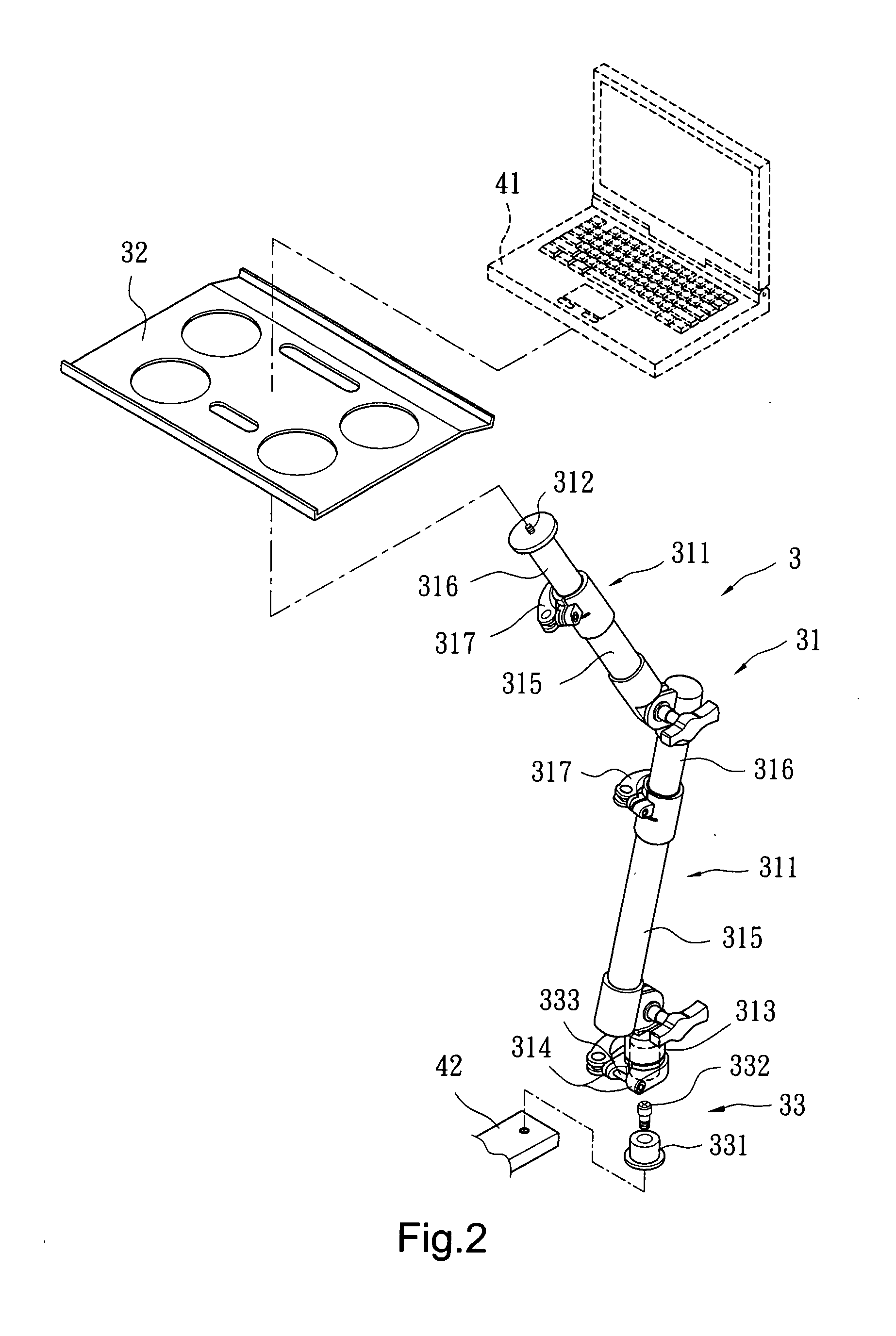

Multi-function supporting rack

InactiveUS20070295679A1Easy to assembleEasy to installStands/trestlesKitchen equipmentRack unitEngineering

A multi-function supporting rack includes a rack unit, a holding unit and a coupling unit. The rack unit has a fastening member at the top end and a hollow housing portion at the bottom end thereof. The holding unit is located on the fastening member to hold an article. The coupling unit has a latch member located in the housing portion and a connection member to couple the latch member and an equipment together. Such a design forms a greater supporting contact area between the latch member and the housing portion to provide an improved supporting effect. Moreover, once the latch member and the connection member are fastened to the equipment, the housing portion is coupled on the latch member. The finished assembly of the invention takes less space and installation is easier.

Owner:PIN ZUEN

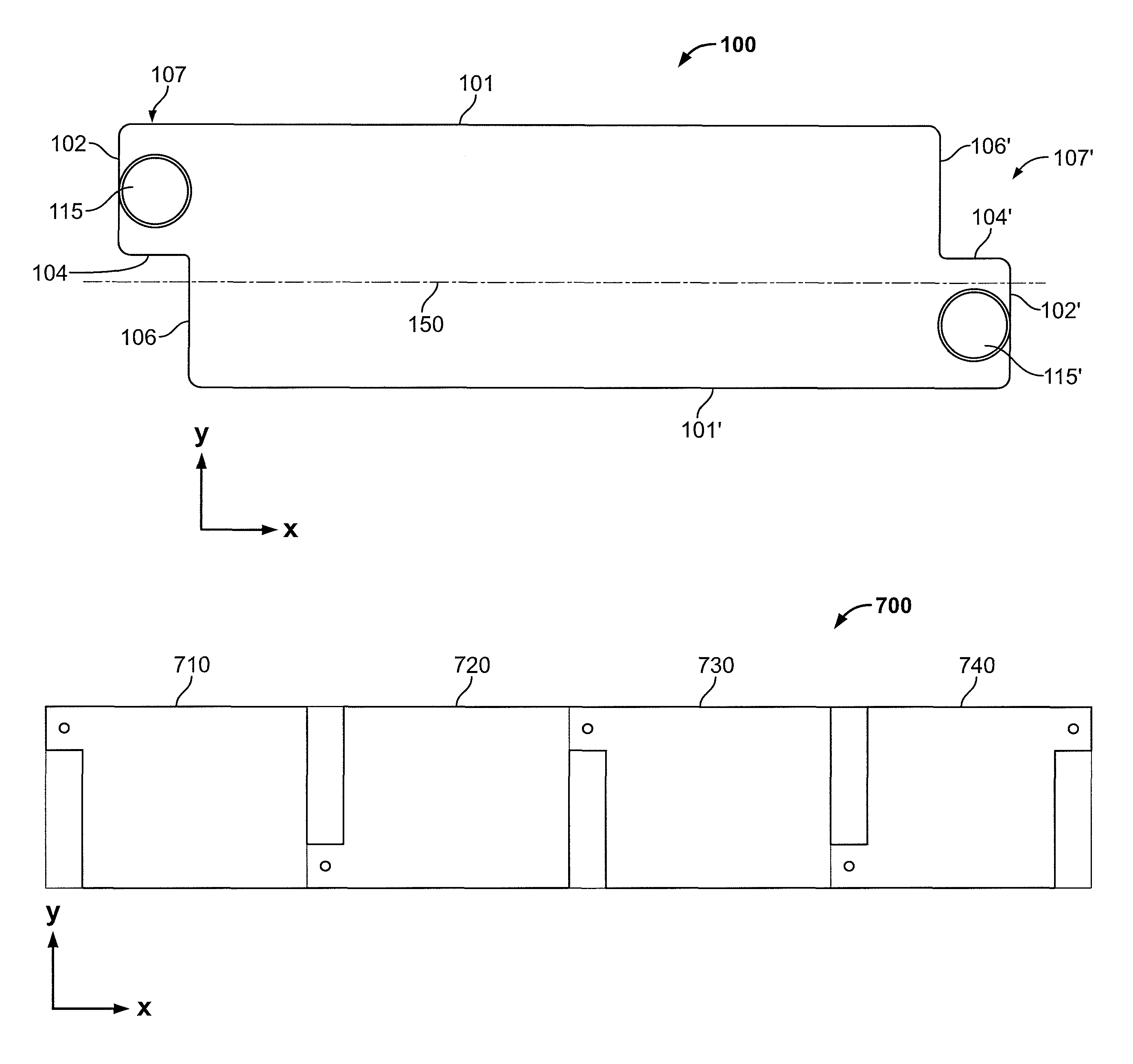

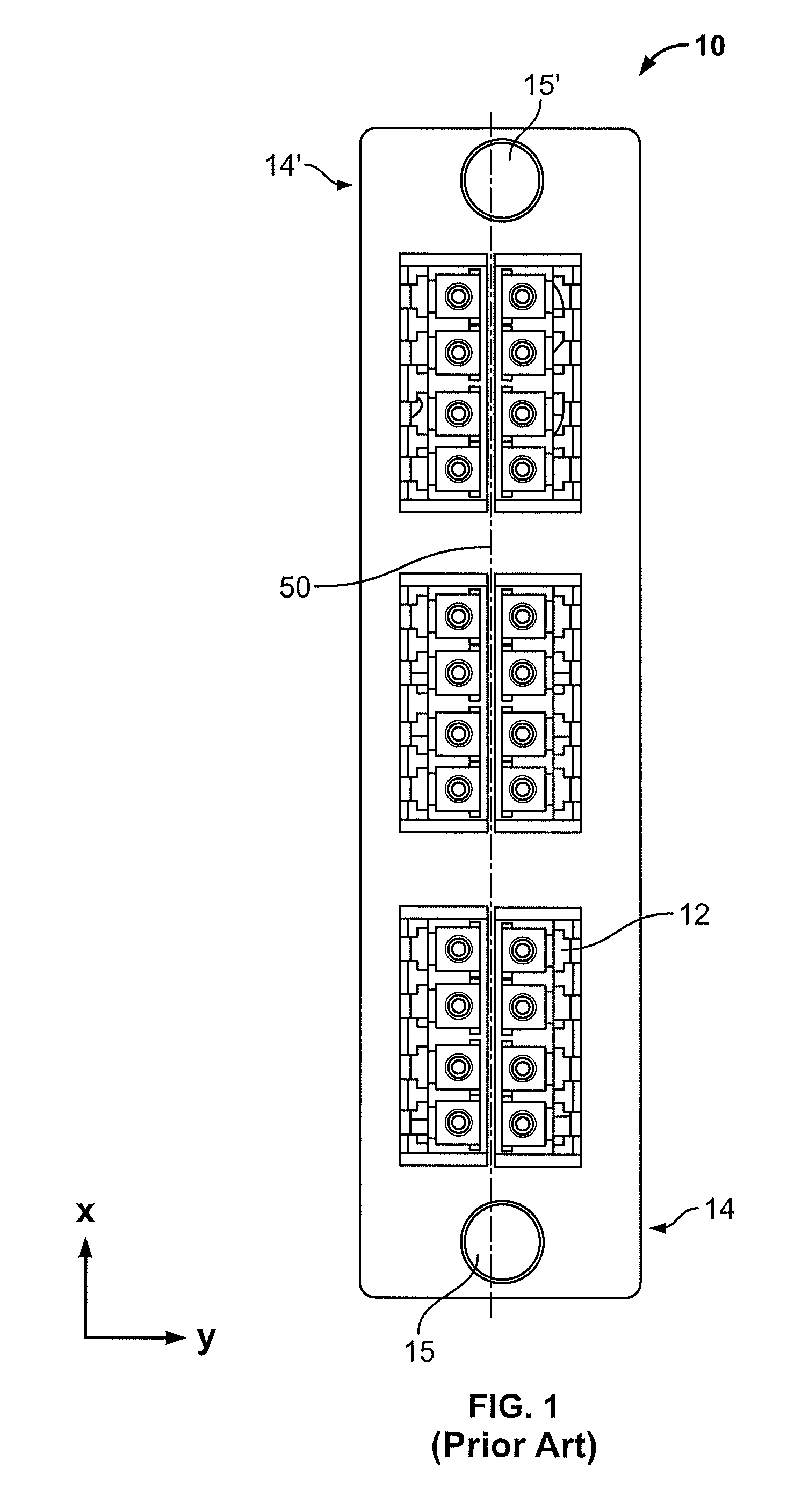

Mounting panel, system and method for high density fiber optic applications

A mounting plate having at least two L-shaped mounting flanges alternatively offset from a centerline defined to bisect the mounting flanges. A mounting system including a plurality of mounting plates with interlocking mounting flanges positioned horizontally on a mounting frame of one standard rack unit (1.75 inches) height. A mounting system including a plurality of mounting footprints with overlapping fastener flanges positioned horizontally on a mounting frame of one standard rack unit width. A method of mounting plates configured and dimensioned to receive a fiber optic coupler or adapter including a mounting a plurality of plates having at least two L-shaped mounting flanges into a mounting frame such that the mounting flanges of adjacent plates are configured to interlock or overlap.

Owner:CORNING OPTICAL COMM LLC +1

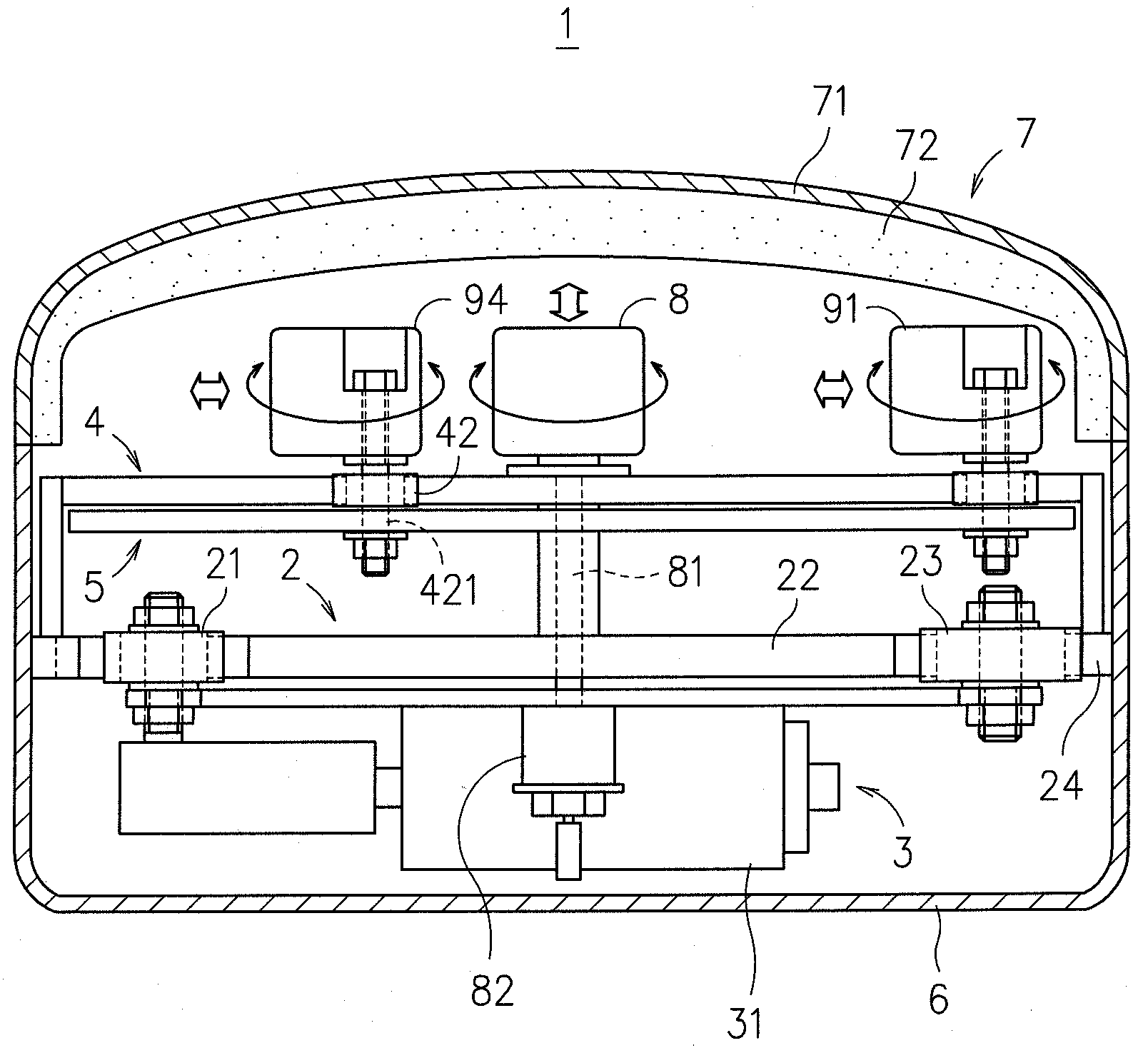

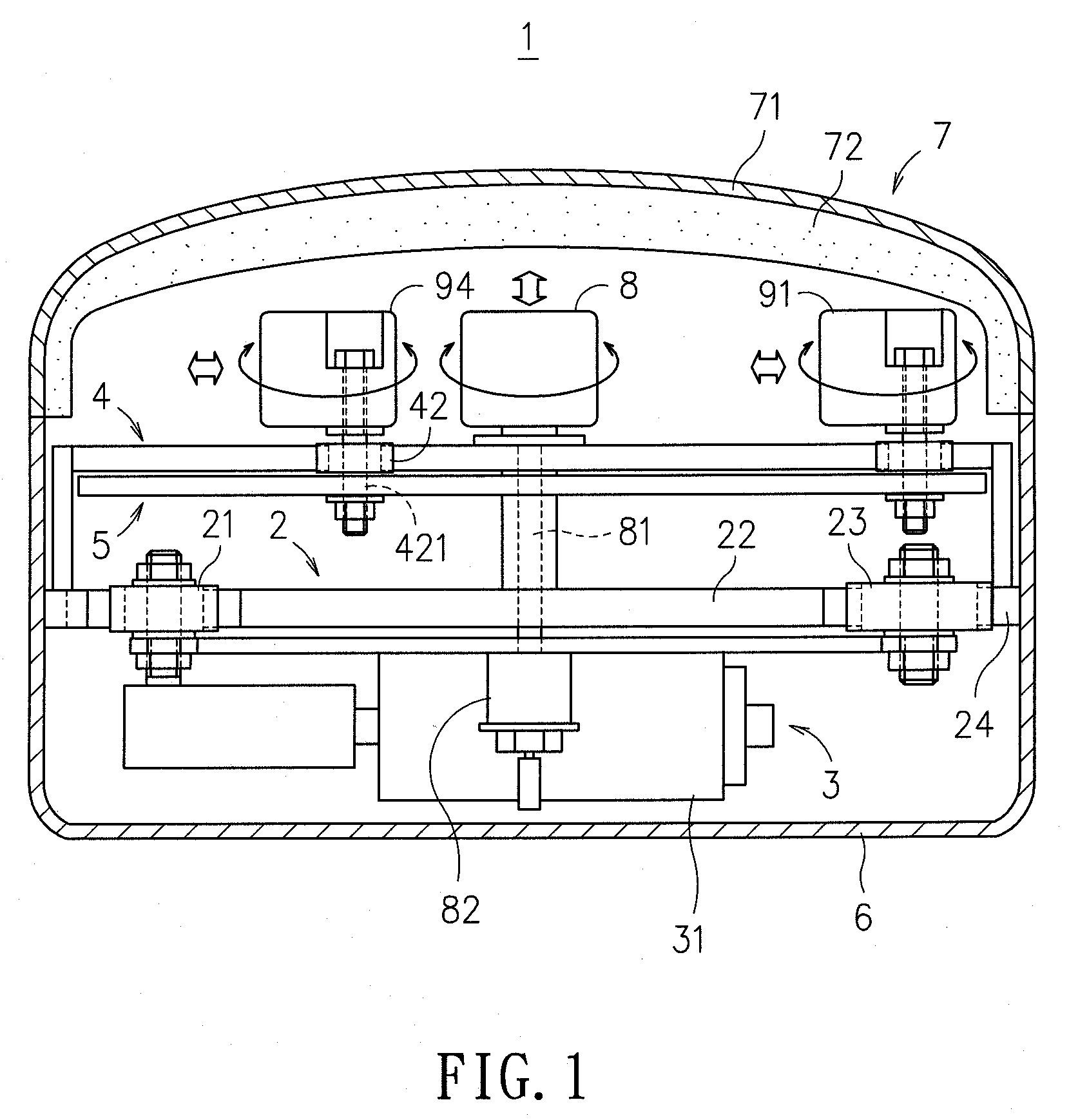

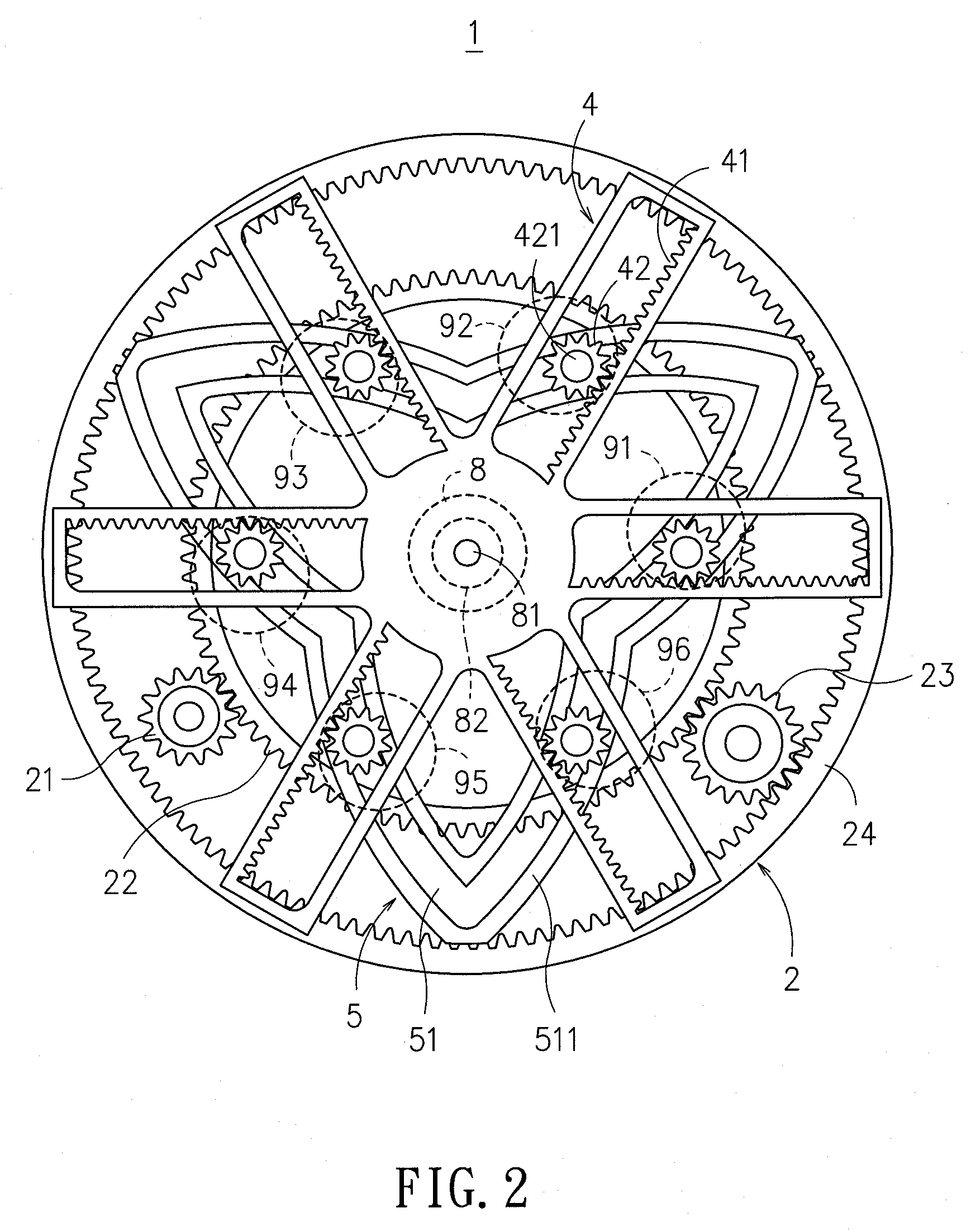

Abdomen Massaging Apparatus

An abdomen massaging apparatus includes a gear unit, a drive motor unit, a toothed rack unit, and a sliding track unit. The toothed rack unit includes a plurality of elongated toothed racks which are arranged in a radiating manner, a plurality of roller gears each meshing with a respective one of the toothed racks and each having a central mandrel, and a plurality of rolls each mounted on the central mandrel of a respective one of the roller gears. The sliding track unit includes a successive channel to allow passage of the central mandrel of each of the roller gears. Thus, the rolls are movable along the toothed racks of the toothed rack unit reciprocally and simultaneously so as to provide a massaging effect to a user.

Owner:WU RUEI SHAN

Automatic circulation system for storage

ActiveCN105540125ASimplify the queuing processIncrease costStorage devicesMechanical conveyorsRack unitButt joint

The invention discloses a conveying mechanism used for storage picking and an automatic circulation system for storage. The conveying mechanism comprises a first conveying station, a third conveying station and a travelling channel. On the first conveying station, the conveying mechanism and driving units are in butt joint, and goods rack units are conveyed to the third conveying station. On the third conveying station, the conveying mechanism and the driving units are in butt joint, and the goods rack units break away from the conveying mechanism; the driving units move to the third conveying station from the first conveying station along the travelling channel. The automatic circulation system for storage comprises the conveying mechanism, a plurality of driving units and a plurality of goods rack units. The goods rack units and the driving units are in butt joint so that a target goods rack unit can be carried by the corresponding driving unit to move to the first conveying station of the conveying mechanism. The conveying mechanism is used for assistant queuing and can be in seamless butt joint with robot carrying, the whole queuing process is simplified, a robot only needs to pay attention to the carrying process where value is most shown, and therefore running efficiency of the system can be substantially improved, and cost of an overall scheme can be substantially reduced.

Owner:HANGZHOU JIAZHI TECH CO LTD

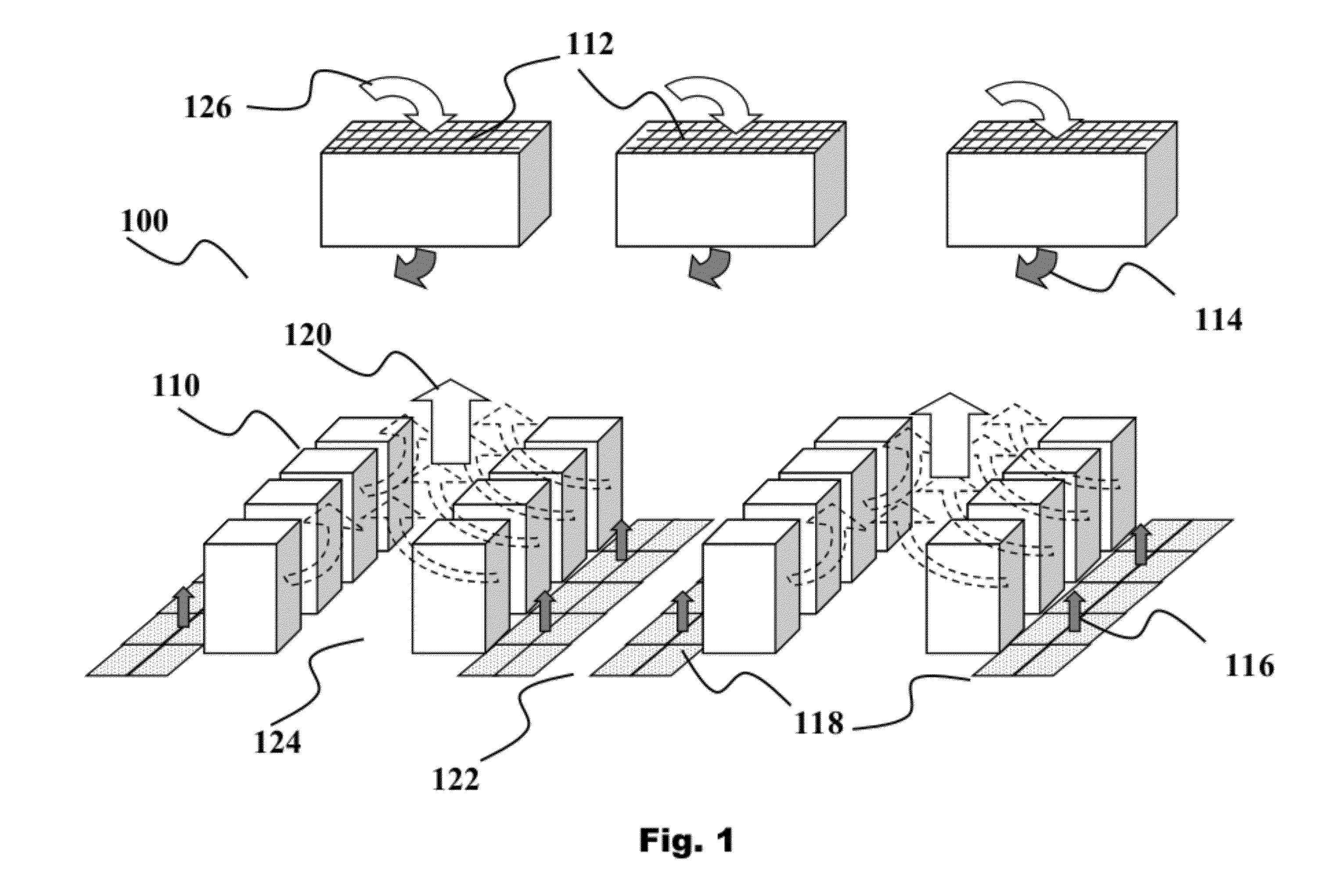

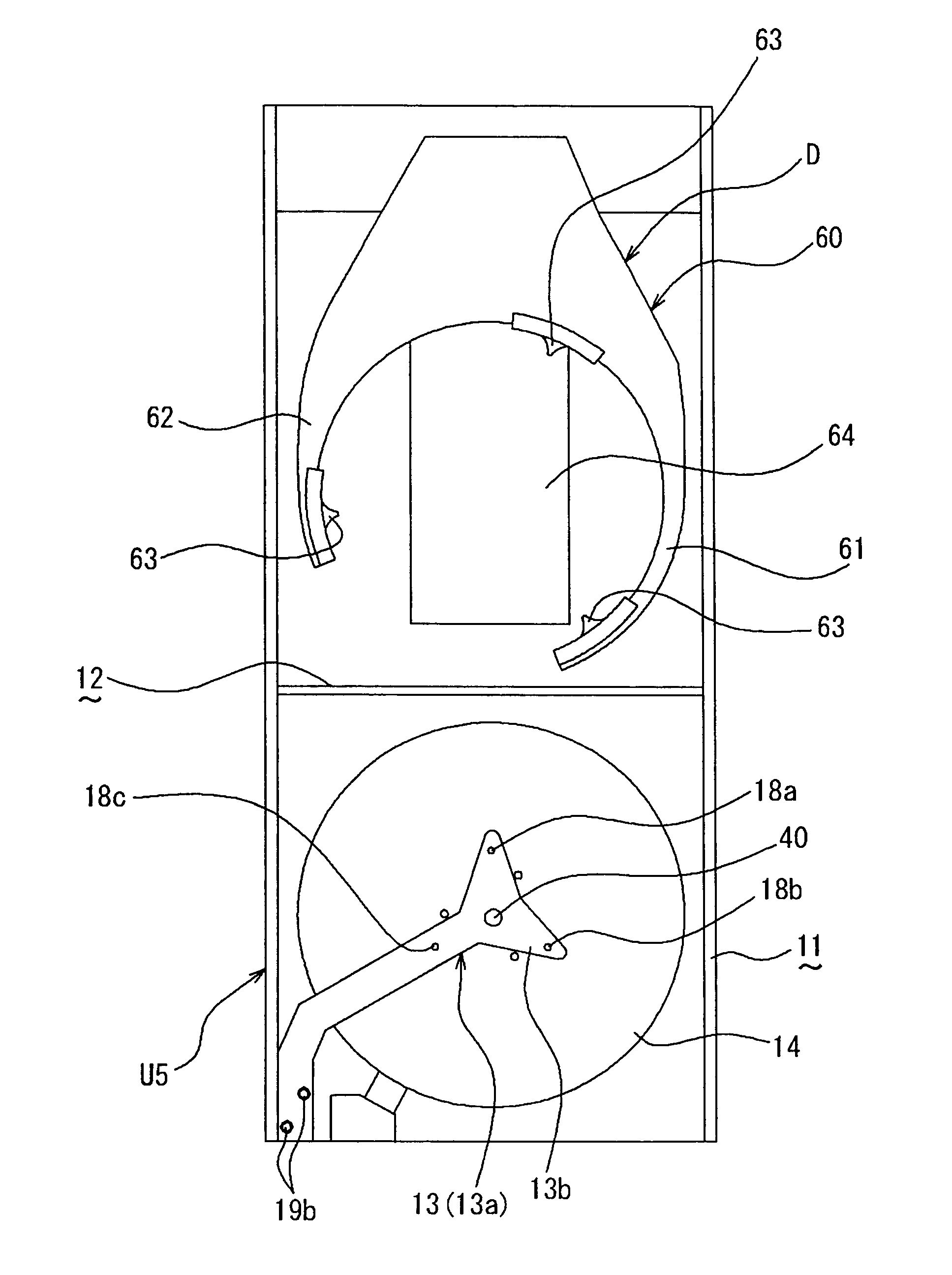

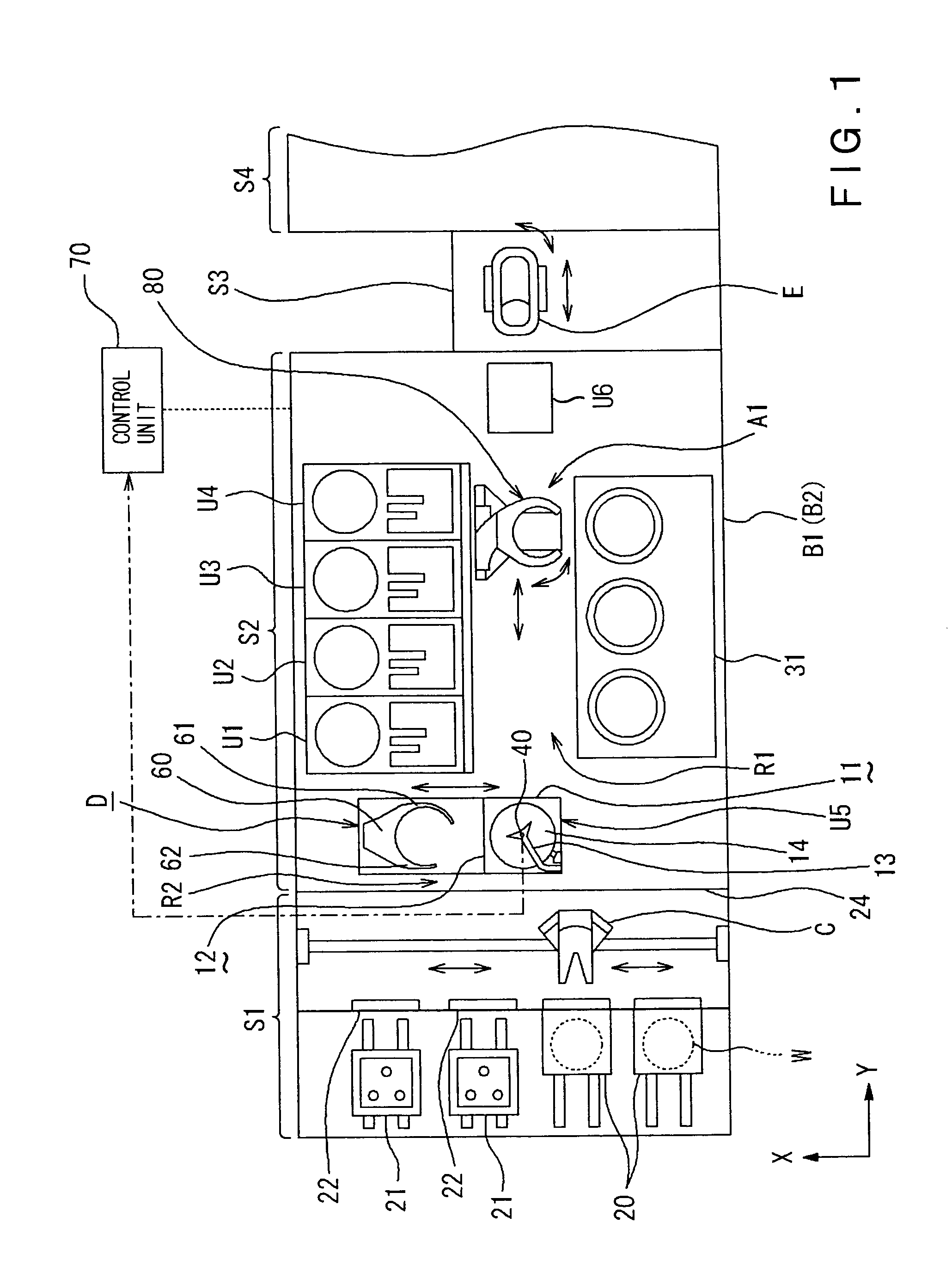

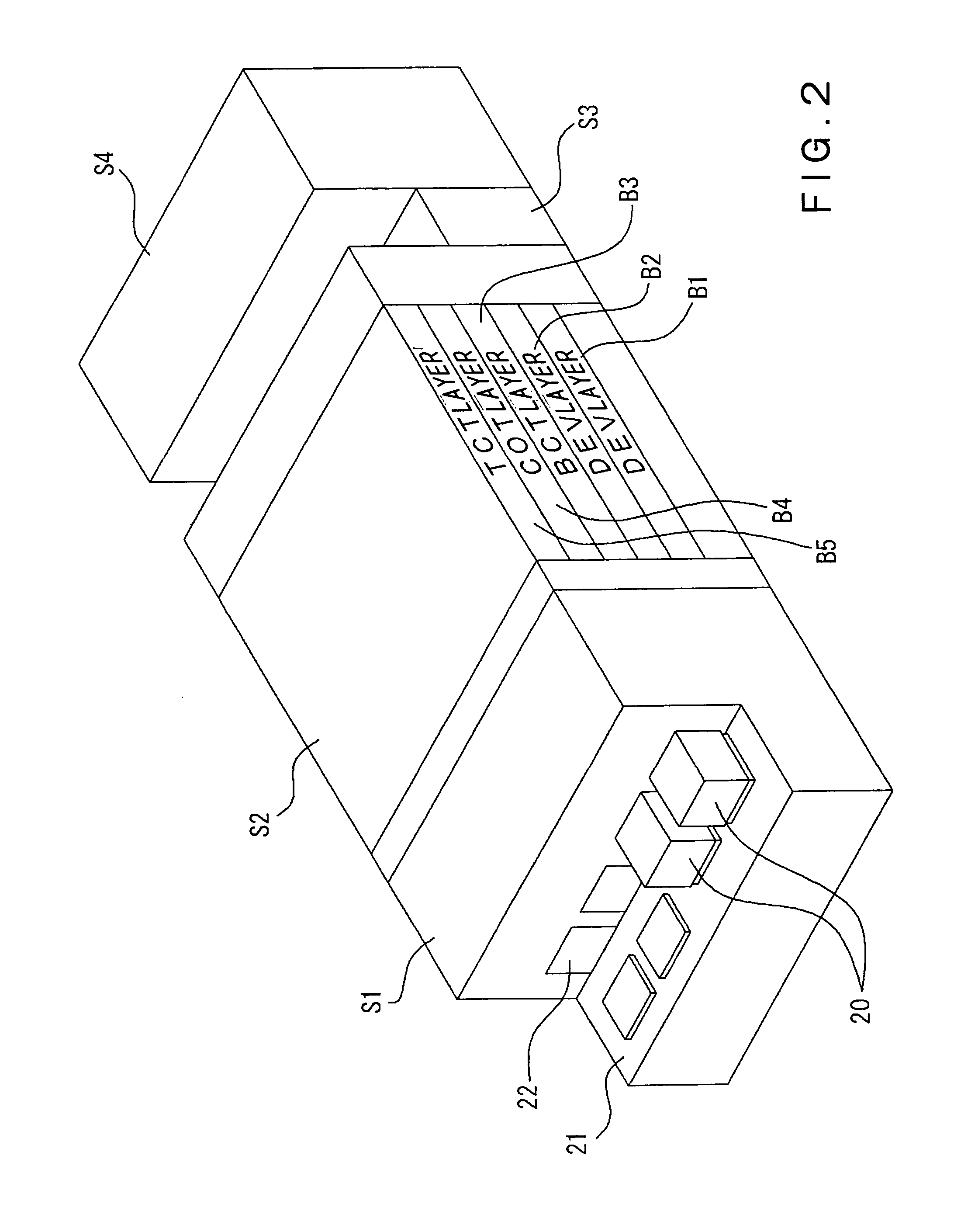

Substrate carrying and processing apparatus

ActiveUS7836845B2Largely downsizedIncrease the number ofLiquid surface applicatorsVacuum evaporation coatingRack unitEngineering

The present invention provides a substrate carrying and processing apparatus which is intended to reduce the size of the space for storing substrates in each substrate storing section as much as possible so as to downsize the apparatus and increase the number of substrates to be stored therein as well as to enhance the throughput. The substrate carrying and processing apparatus comprises a carrier block S1 which is adapted to position carriers 20 each receiving wafers W therein, a processing block S2 including processing units U1 to U4, 31 used for processing each wafer, a main arms A1 adapted to transfer each wafer to each processing unit, a rack unit U5 which is disposed between the carrier block and the processing block and able to store wafers to be processed, and a transfer arm D adapted to transfer each wafer to the rack unit. The rack unit has openings 11, 12 to which the main arm and the transfer arm can transfer each substrate along two directions crossing to each other, and includes a plurality of placing shelves with a space therebetween and adapted to support a wafer. The main arms and transfer arms are configured such that they can be advanced into and retracted from the substrate storing section and such that they can be overlapped to the corresponding placing shelf in the vertical direction, when viewed in the horizontal direction.

Owner:TOKYO ELECTRON LTD

Single unit height storage sled with lateral storage device assembly supporting hot-removal of storage devices and slidable insertion and extraction from an information handling system rack

A rack-based information handling system (IHS) includes a rack containing at least one chassis having a plurality of bays open to laterally receive sleds that contain a plurality of information technology (IT) components that, when operational, enable the rack to function as an IHS. A storage sled including a stationary tray received in the chassis and a moveable trace received in the stationary tray. One or more hot swap bays that are horizontally arrayed in the storage sled in less than one (1) Server System Infrastructure (SSI) rack unit of height, wherein the moveable tray is extendable from the rack to a service position to expose all of its hot swap bays. Storage devices are insertable into a respective one of the hot swap bays of the storage sled. Each storage device may include a latching handle to lift and downward position the storage device in the corresponding hot swap bay.

Owner:DELL PROD LP

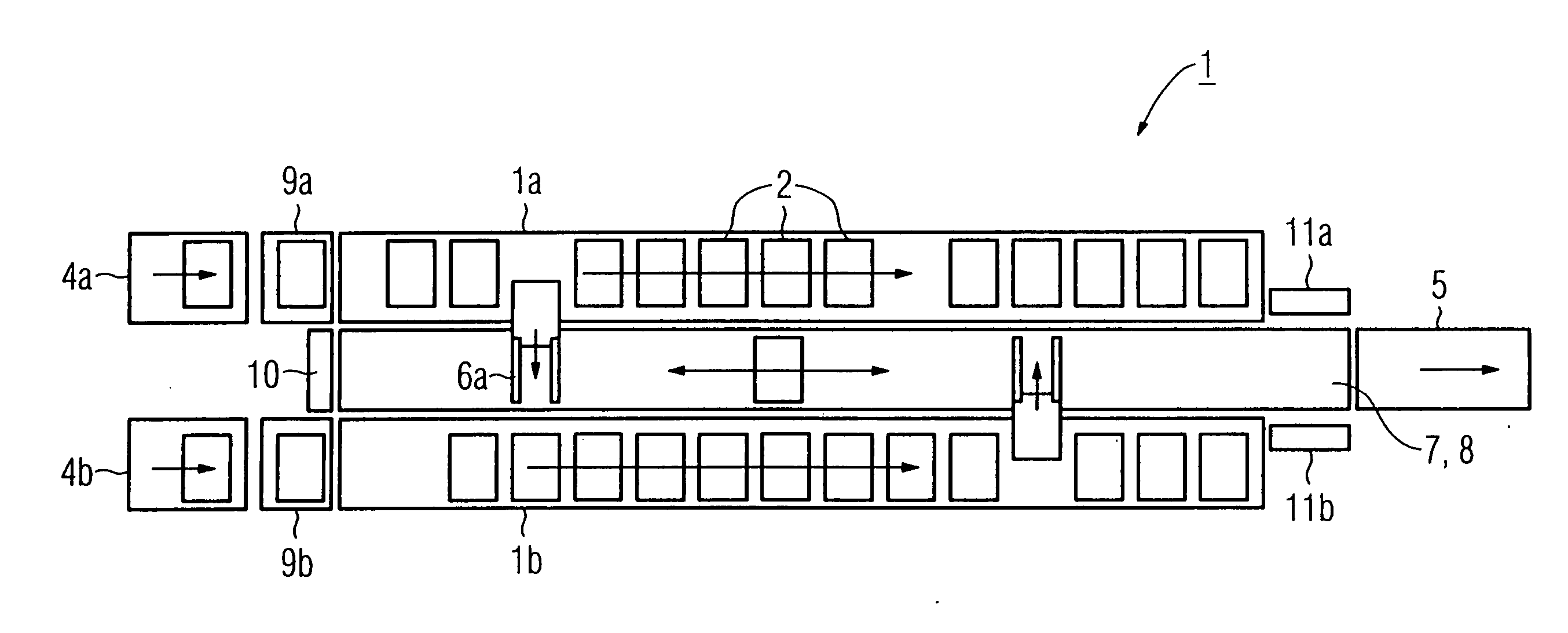

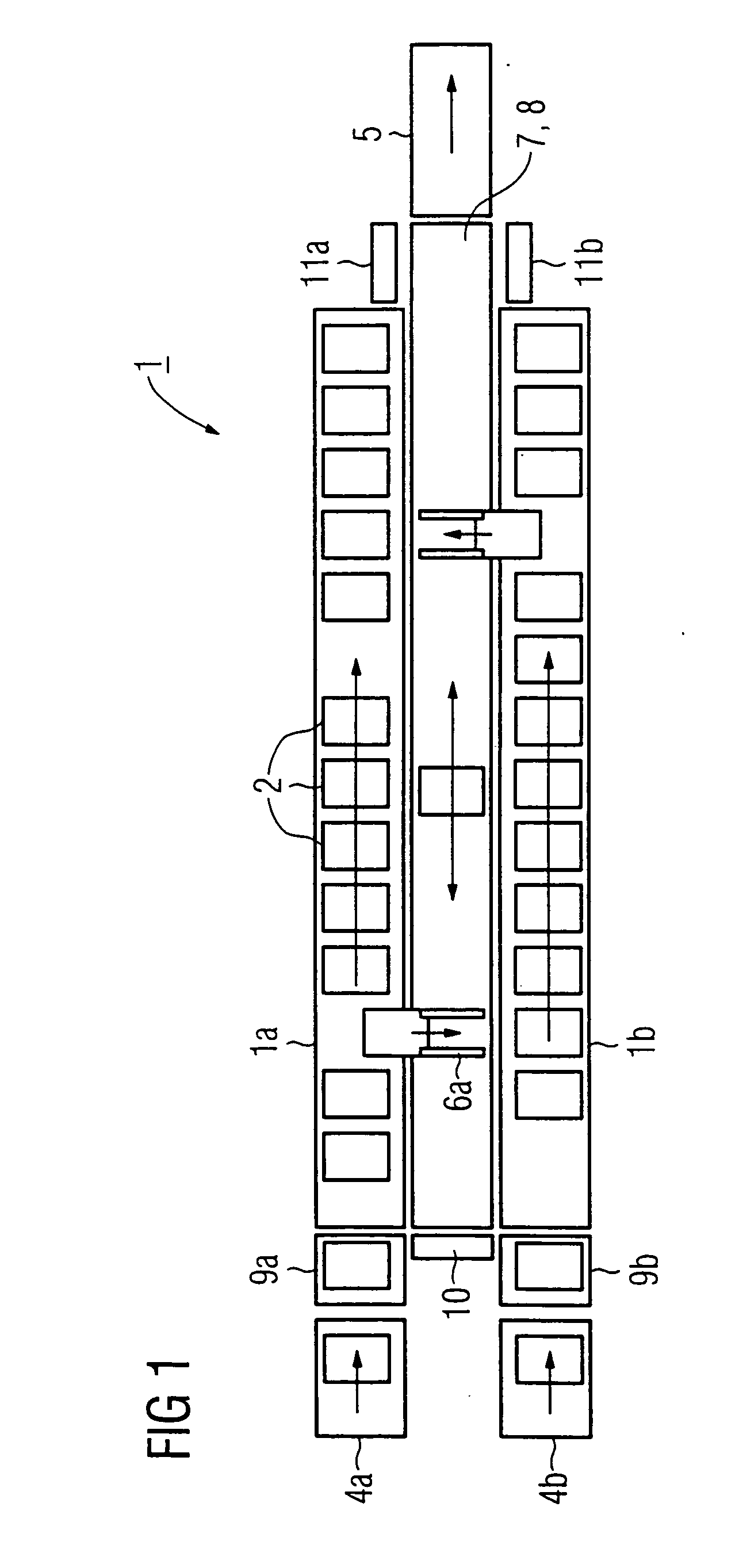

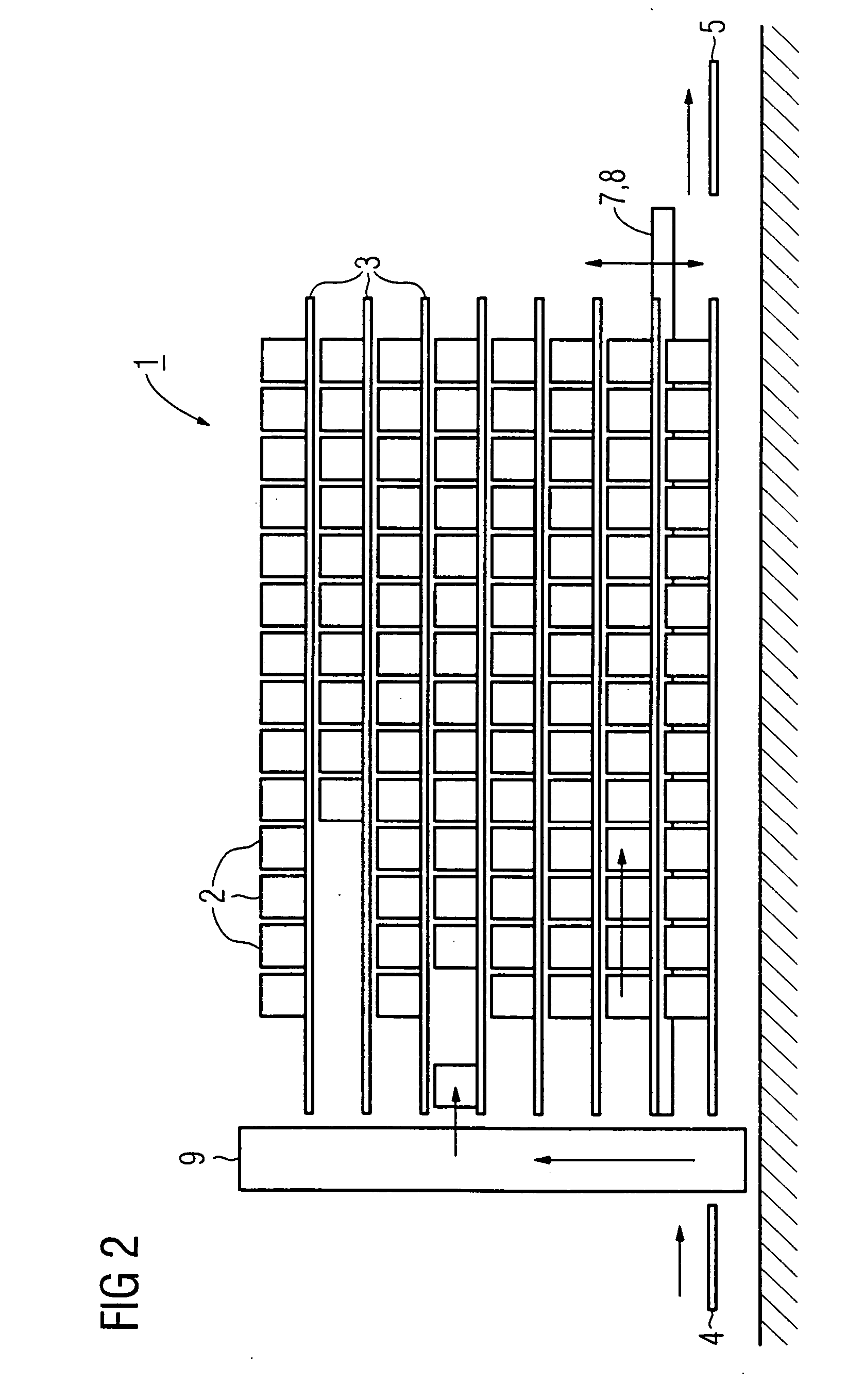

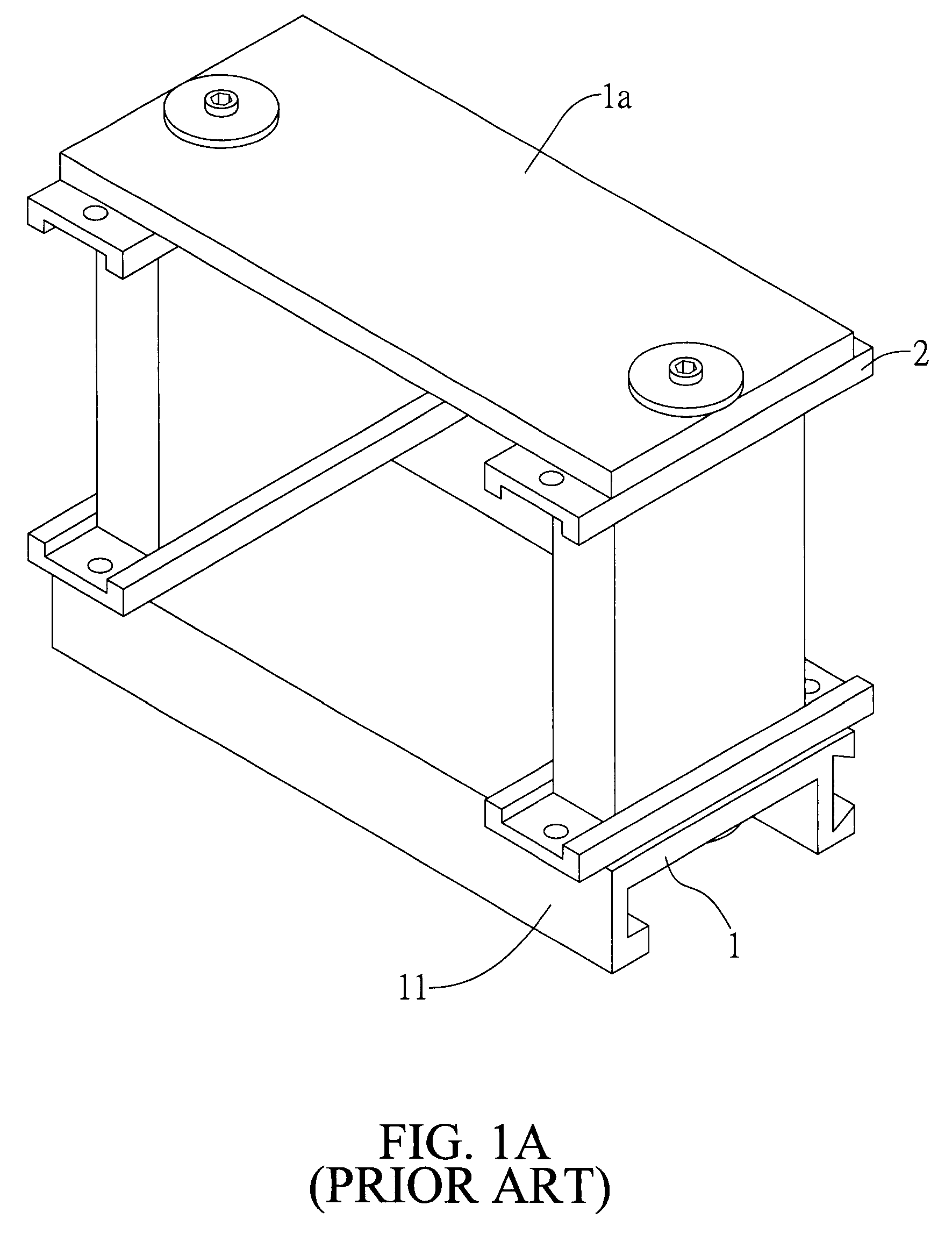

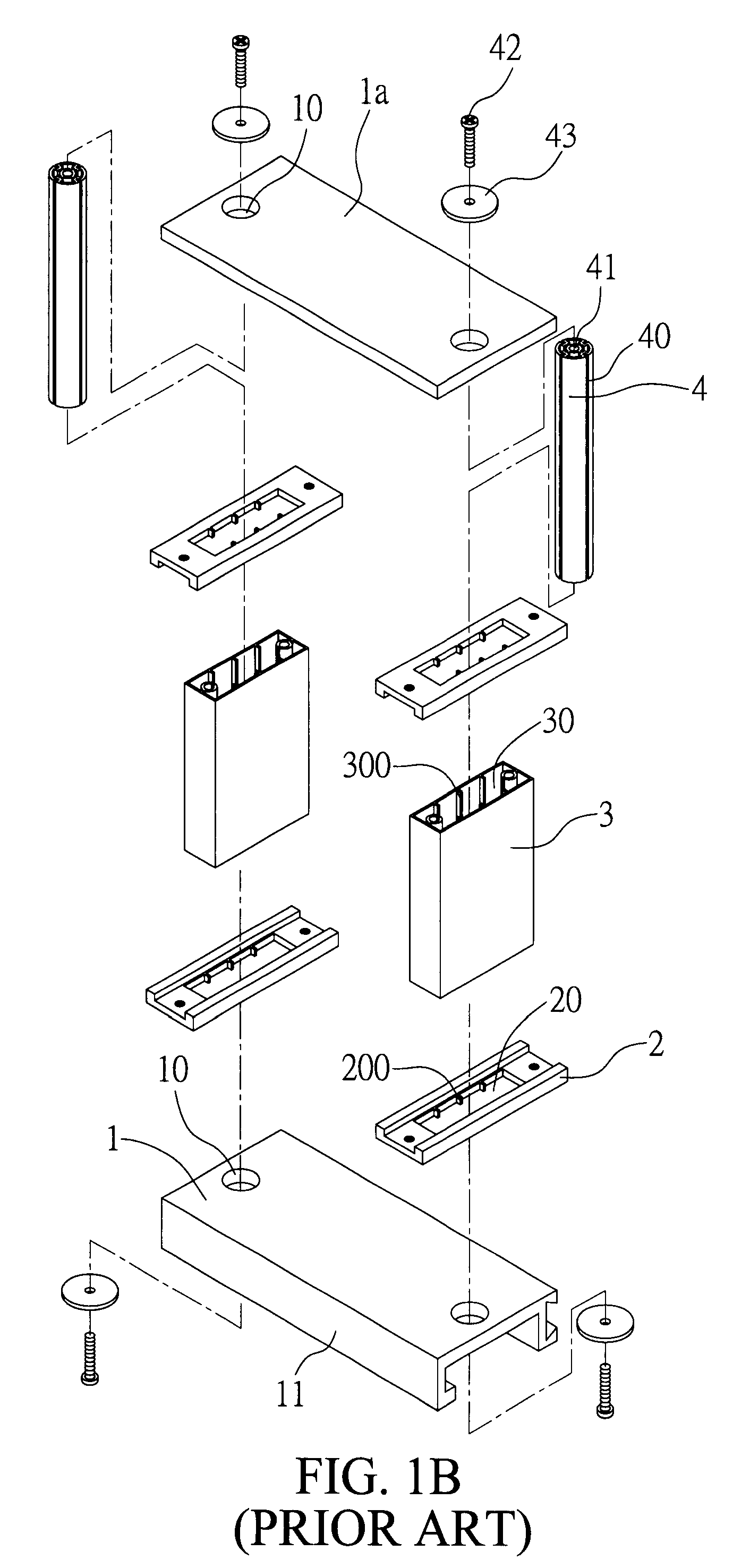

Apparatus for forming a sequence of load carriers by means of a temporary store, and method for temporary storage

InactiveUS20060245858A1Improve throughputReduce investment expenditureLoading/unloadingStorage devicesRack unitOrder form

In order to permit a temporary storage with a simultaneously high number of storage places and high throughput capacity, a rack (1) which may include mutually opposite rack units (1a, 1b), in the rack aisle of which a vertically movable lifting bar (7) is arranged. Two load suspension means (6a, 6b) may be provided for removing the load carriers (2) and are movable horizontally at the lifting bar (7). Removed load carriers (2) are deposited in the respectively desired sequence on a conveyor (8), which is connected fixedly to the lifting bar (7) and the conveying direction of which can be reversed, and may then be delivered batchwise onto a removal device (5) for further transportation. The rack levels (3) of the rack (1) may be accumulating conveyors, with it being possible for the load carriers (2) to be placed into the store from the end side of the rack (1) via a lifting device (9a, 9b) without using the load suspension means (6a, 6b). The method and apparatus may be used, by way of example, to facilitate the packing of goods order picked on load carriers (2), the load carriers (2) belonging to an order are first of all collected in a temporary store and are then conveyed for dispatch in a predetermined sequence favorable for packing.

Owner:SIEMENS AG

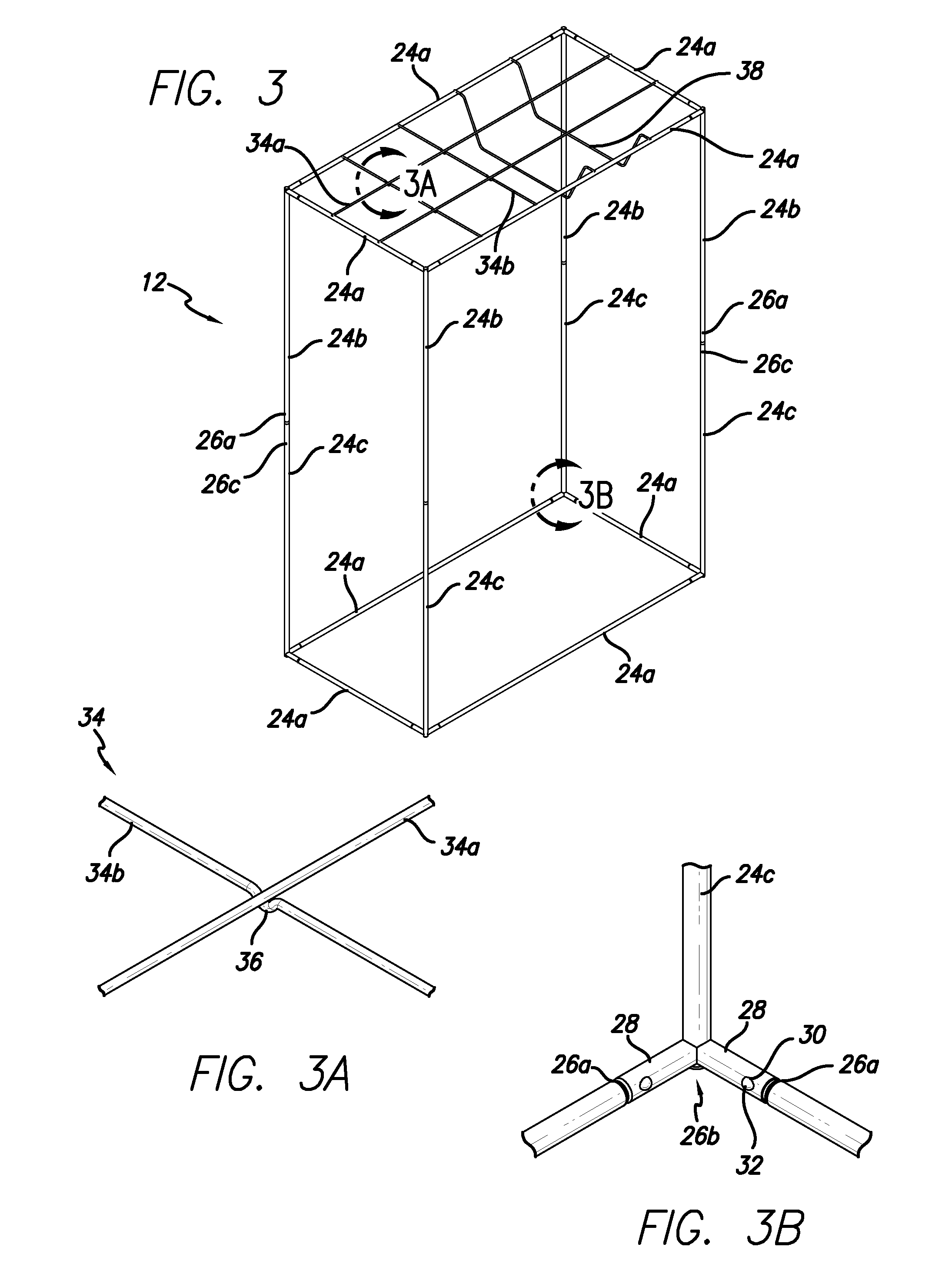

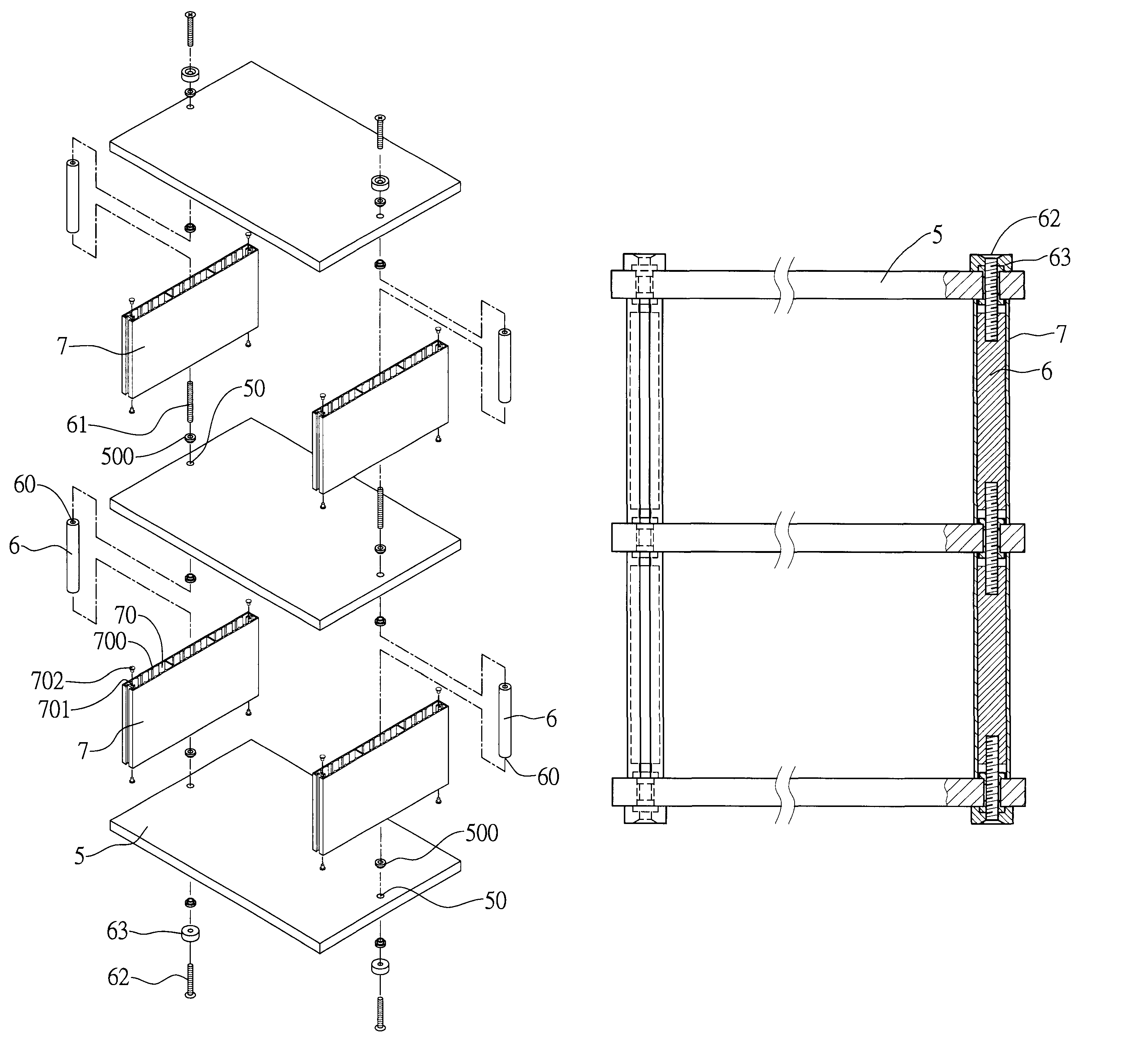

Interlocking component assembly for an expandable rack assembly

InactiveUS7765942B2Easy to assembleImprove structural rigidity and strengthFolding cabinetsSectional furnitureJoint componentRack unit

An interlocking component assembly of an expandable rack assembly is proposed, including a plurality of horizontally-deposed panels each formed with a first opening, a plurality of vertically-deposed panels each disposed between two horizontally-deposed panels, a plurality of middle joint components each disposed in vertically-deposed panels, and a plurality of interlocking components each adapted for interconnecting two middle joint components to interconnect and fasten the horizontally-deposed panel to the vertically-deposed panel, wherein the height of the vertically-deposed panel is greater than the length of the middle joint component, such that the vertically-deposed panel can be coupled to the interlocking component to securely engage the horizontally-deposed panel with the vertically-deposed panel, thereby enabling the rack assembly to be free from limitations of assembling locations or dimensional specifications while the structural rigidity and strength of the assembled rack unit is enhanced.

Owner:CHOI YING KIT

Architecture for a robust computing system

InactiveUS20120020349A1Data switching by path configurationMultiple digital computer combinationsRack unitComputer module

A computer system may include N rack unit switches and 6N processing rack units, where N is a positive integer. Each rack unit switch may include four switching units and each switching unit may include at least M2 / 2 ports. Each processing rack unit may include at least 27*4N ports originating from a plurality of processing modules of each respective processing rack unit. The ports of the N rack unit switches may be coupled to the ports of the 6N processing rack systems to create a network architecture.

Owner:BIRCHBRIDGE

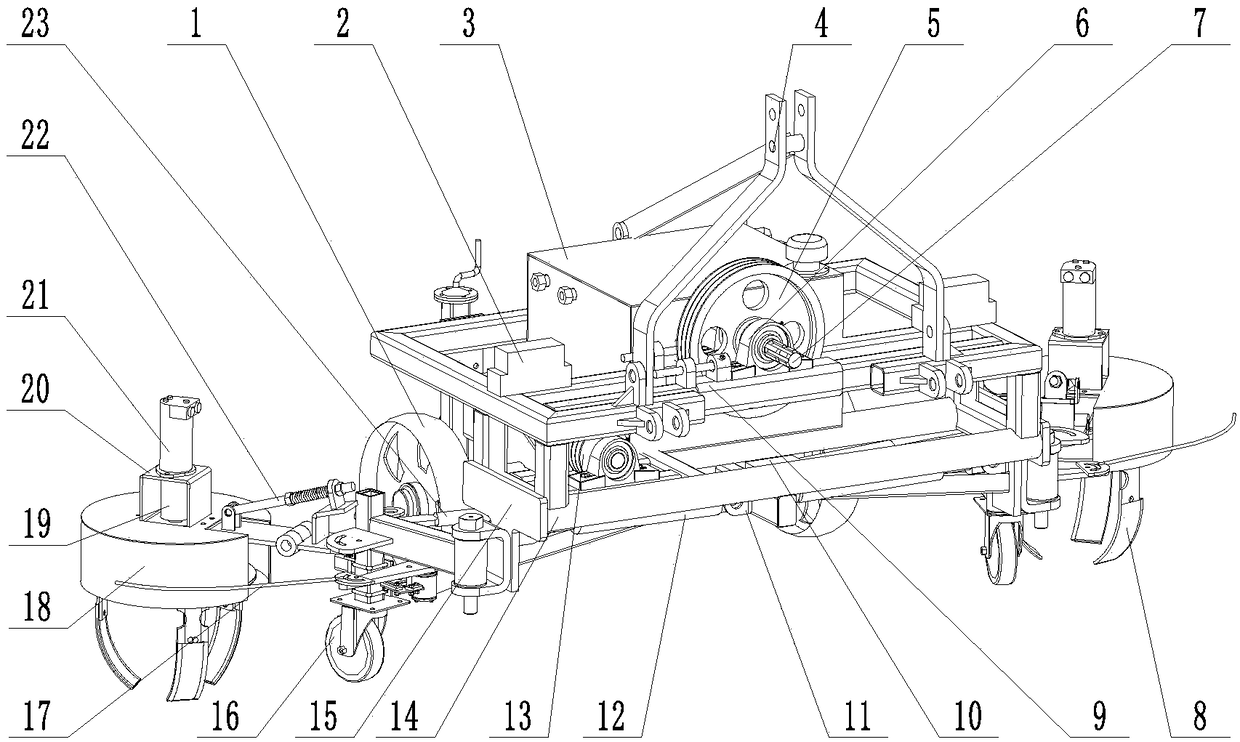

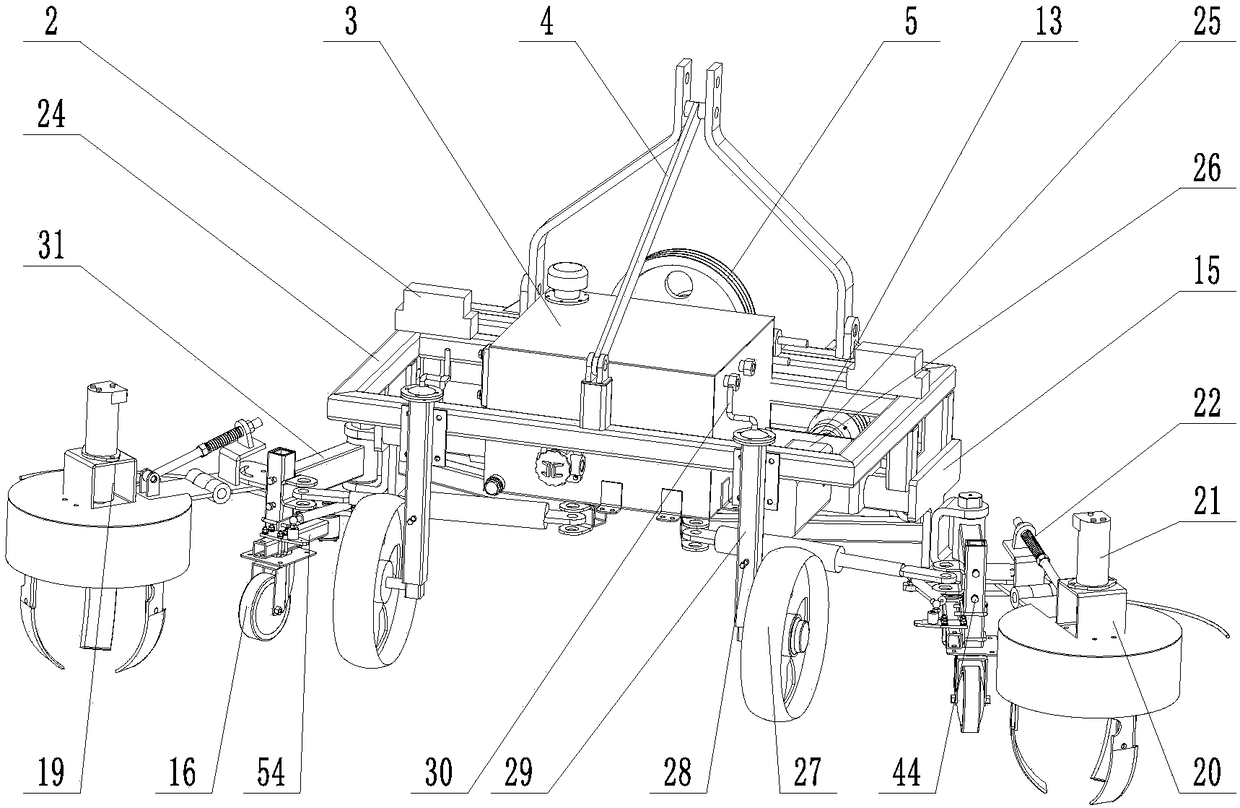

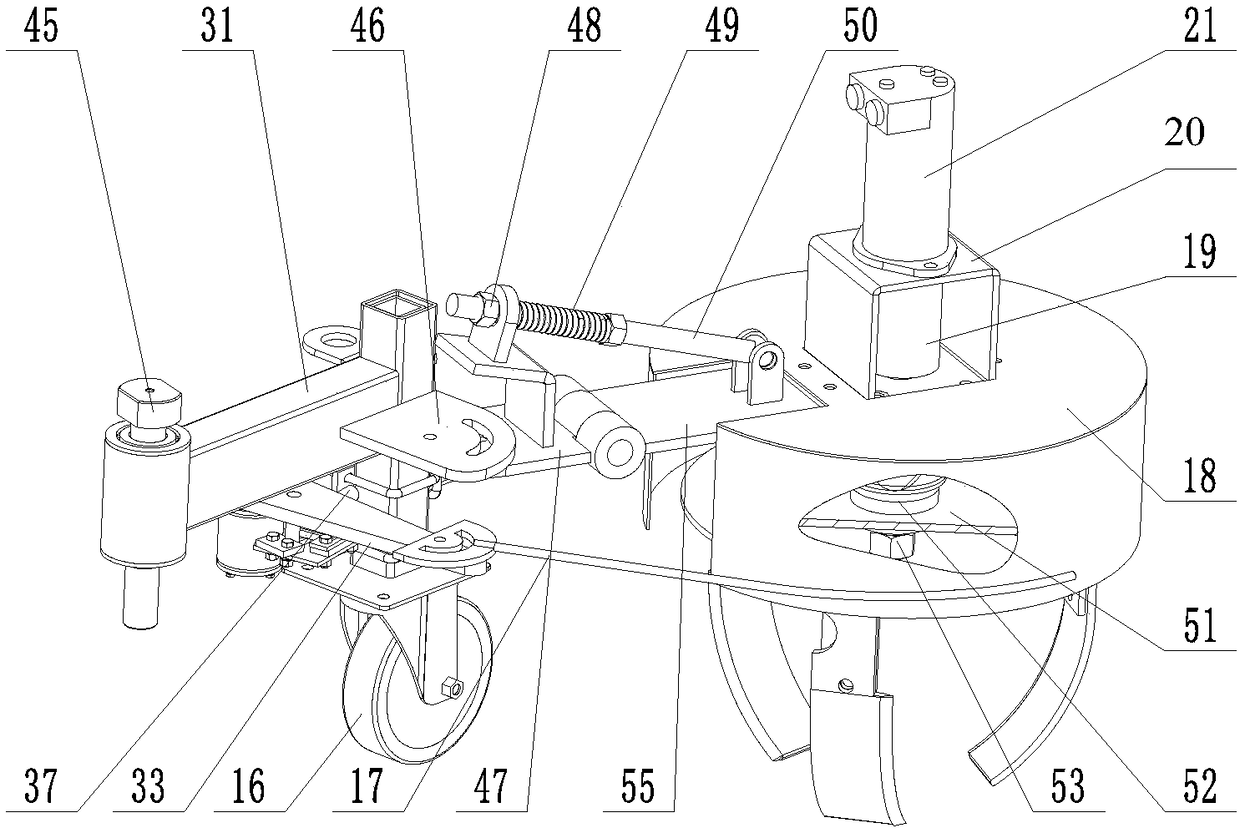

Bilateral and vertical inter-plant weeding machine capable of automatically avoiding obstacles

PendingCN108551775AImprove work efficiencyLow costSoil-working equipmentsPosition/course control in two dimensionsHydraulic motorHydraulic cylinder

The invention relates to a bilateral and vertical inter-plant weeding machine capable of automatically avoiding obstacles. The bilateral and vertical weeding machine comprises a rack unit, a power transmission unit, a row width adjusting unit, two automatic obstacle avoidance units, a bilateral hydraulic control unit and two weeding units. The rack unit is a mounting carrier of all other units, and the power transmission unit transmits power to the weeding machine from a tractor PTO; the row width adjusting unit can change the working row width according to actual needs; the automatic obstacleavoidance units can make the weeding units automatically avoid crop stalks, and triggering rod mechanisms are important parts for the automatic obstacle avoidance units to collect signals; the bilateral hydraulic control unit provides power for a hydraulic motor and a hydraulic cylinder; the weeding units are used for shallow ploughing and weeding for inter-row weeds of crops, and a profiling mechanism can guarantee that the weeding depth on an uneven ground is the same as that on a smooth ground. According to the bilateral and vertical inter-plant weeding machine capable of automatically avoiding the obstacles, bilateral work can be achieved, the obstacles can be automatically avoided, the working efficiency is improved, and the weeding working effect is improved.

Owner:CHINA AGRI UNIV

Midplane for orthogonal direct connection

ActiveUS9116660B1Facilitates mechanical registrationEasy alignmentDigital data processing detailsElectrical connection printed elementsRack unitCell space

A novel midplane is shaped with voids through which a dataplane connection is made between components on one side of the midplane and components on the opposite side of the midplane. The voids in the novel midplane offer numerous advantages in the design of network devices, including improved cooling performance, minimizing rack unit space and maximizing interface density, improved signal integrity allowing greater bandwidth through elimination of midplane signaling connections, improved upgradability of orthogonal direct connectors with little or no impact on the midplane or chassis, and proper alignment between the components of the dataplane.

Owner:EXTREME NETWORKS INC

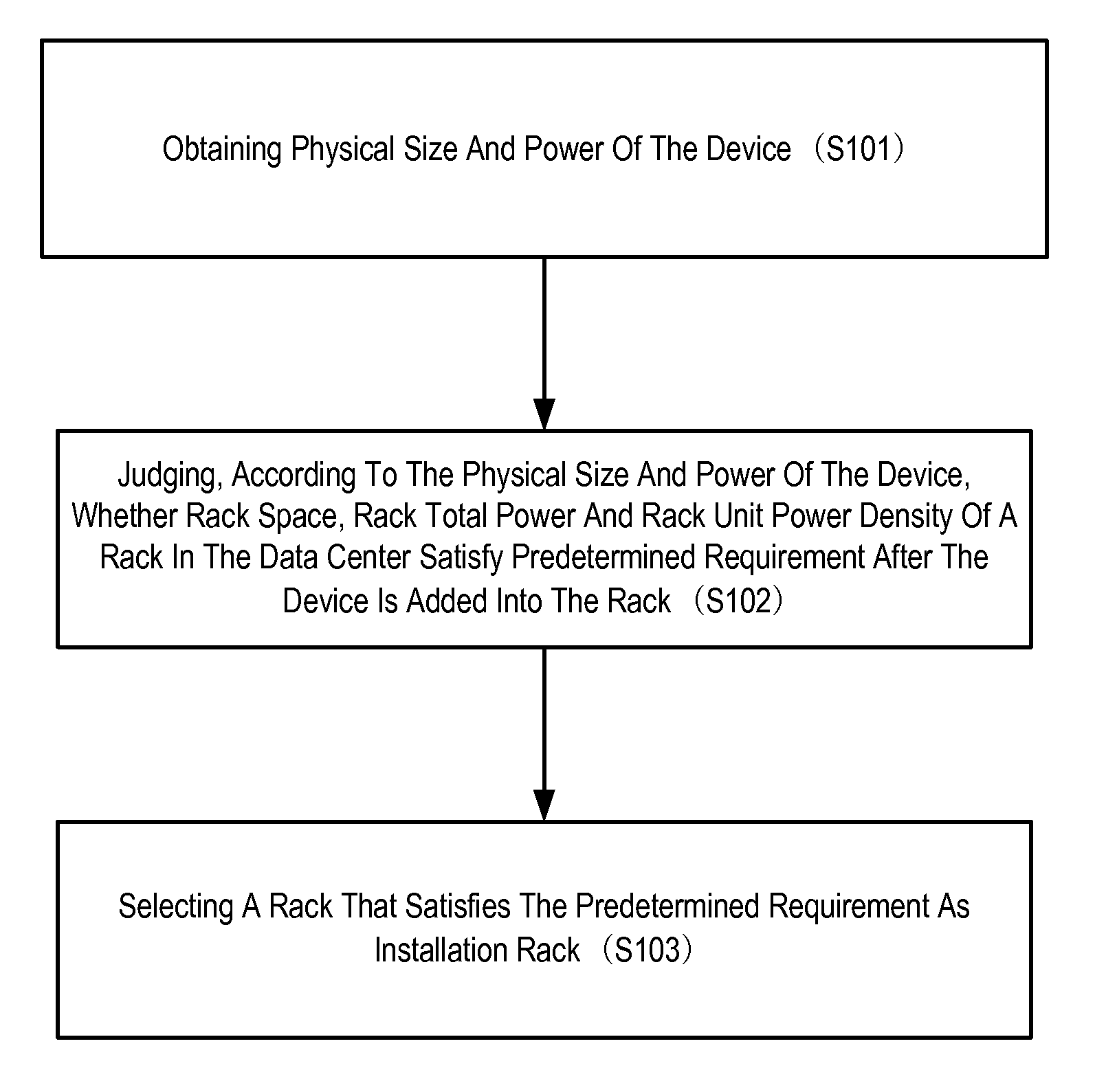

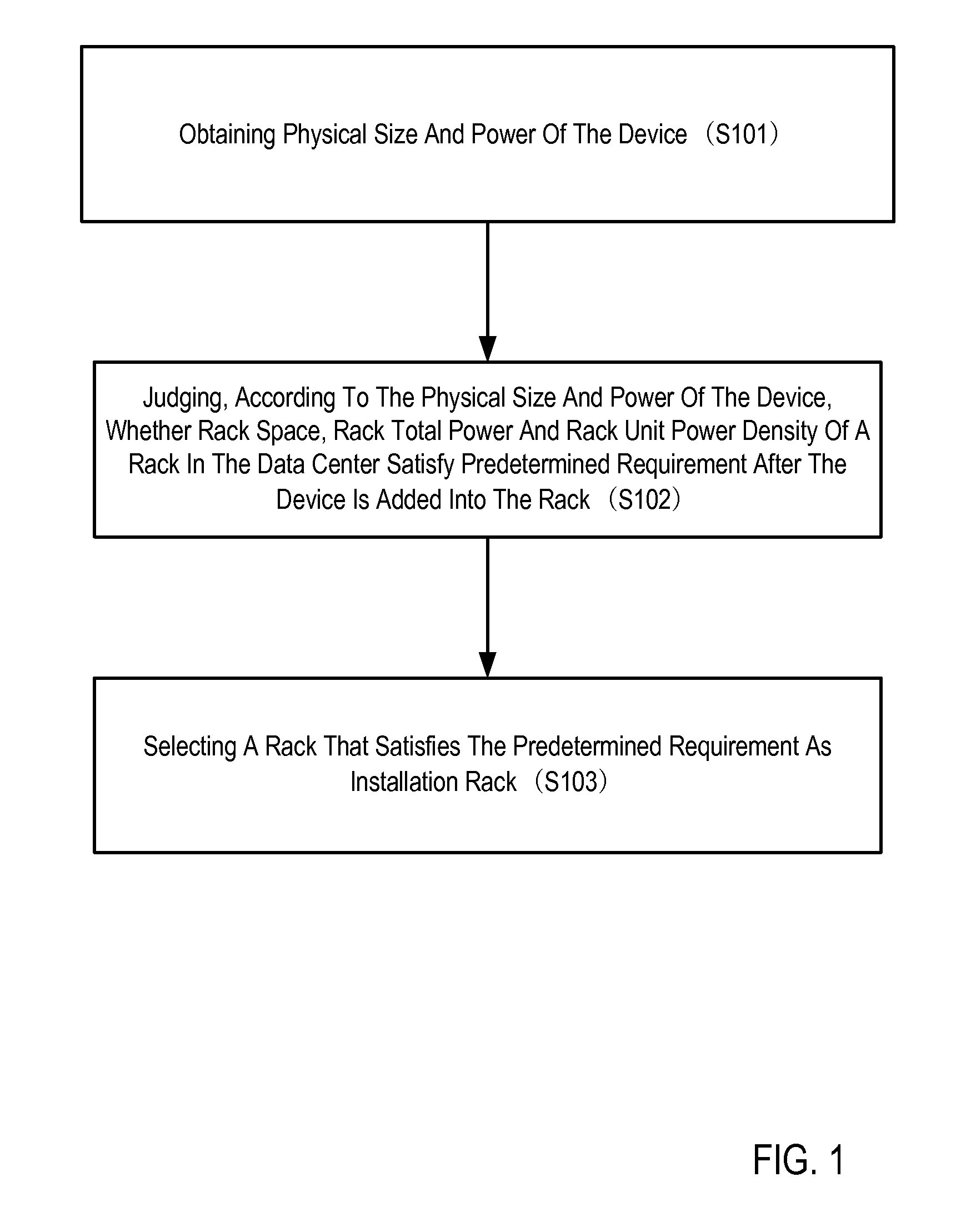

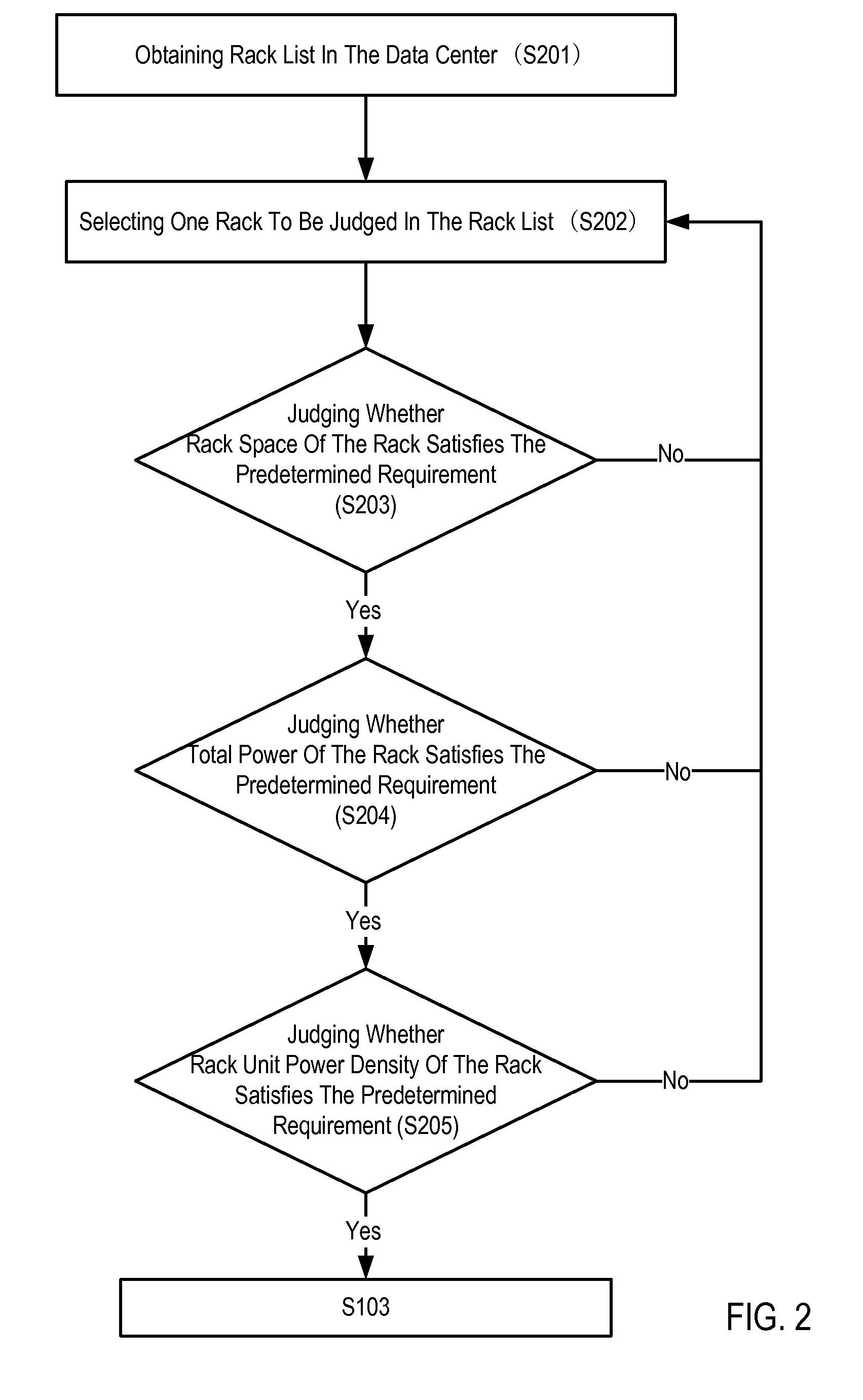

Selecting An Installation Rack For A Device In A Data Center

InactiveUS20110213735A1Improve space utilizationImprove rack space utilizationServersData processing applicationsData centerRack unit

Selecting an installation rack for a device in a data center including obtaining physical size and power of the device; judging, according to the physical size and power of the device, whether rack space, rack total power, and rack unit power density of a rack in the data center satisfy predetermined requirement after the device is added into the rack; and selecting a rack that satisfies the predetermined requirement as an installation rack.

Owner:LENOVO ENTERPRISE SOLUTIONS SINGAPORE

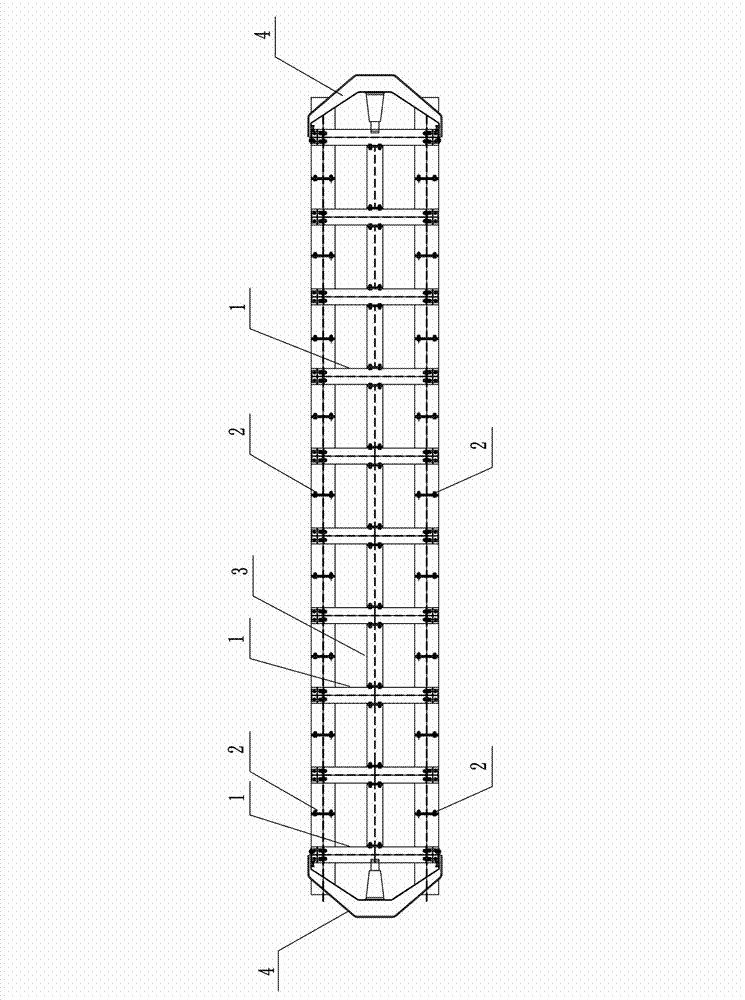

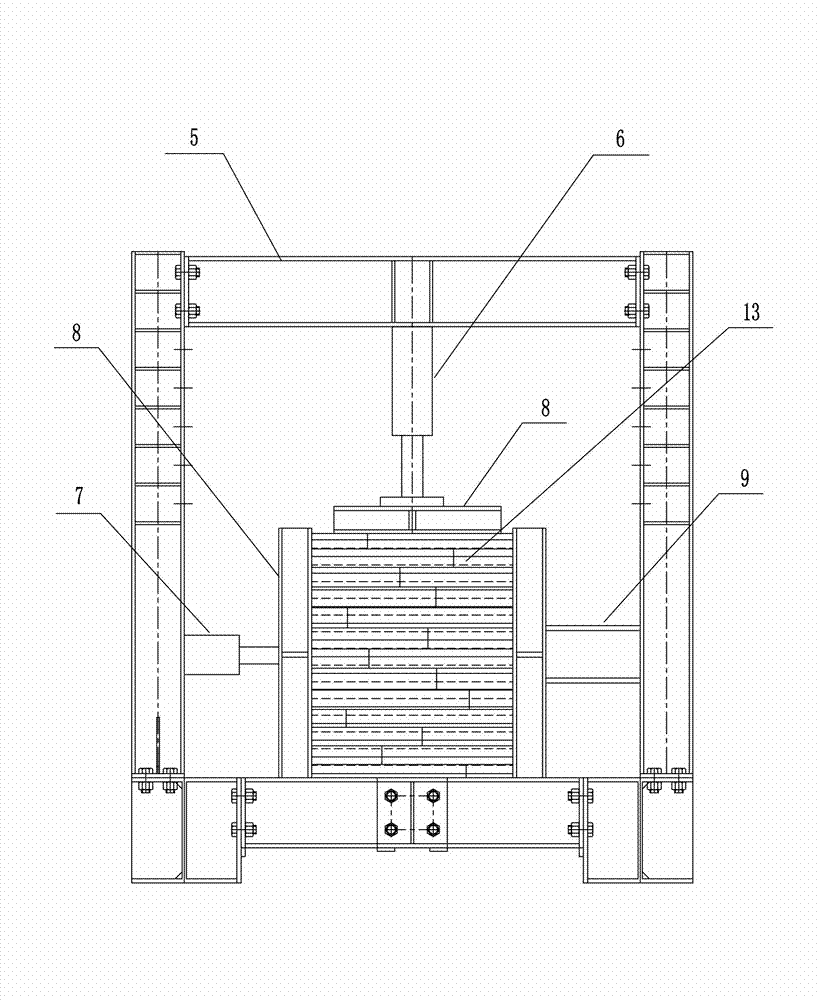

Cold press for glue-laminated bamboo member

ActiveCN102862196AImprove processing qualityImprove mechanical propertiesPlywood pressesVeneer pressesRack unitEngineering

The invention discloses a cold press for a glue-laminated bamboo member, comprising longitudinal pressurizing assemblies, a cold press integral set composed of more than one rack unit which is sequentially arrayed, as well as a lateral pressurizing element and a vertical pressurizing assembly which are arranged on the rack unit, wherein the longitudinal pressurizing assemblies are installed on the rack units which are located on the two end parts in the cold press integral set, and the force-applying ends of the longitudinal pressurizing assemblies generate a pressure along the longitudinal direction of the glue-laminated bamboo member. The cold press disclosed by the invention has the advantages of being simple and convenient in operation, wide in application range, capable of applying multidirectional pressures, capable of improving machining capacity and machining efficiency, and the like.

Owner:湖南博世安新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com