Cold press for glue-laminated bamboo member

A technology of cold presses and components, applied in the field of cold presses, which can solve the problems affecting the overall mechanical properties of structural components, the inability to process molding at one time, and the fixed size of cold presses, etc., so as to facilitate flexible layout, improve processing quality and mechanical properties , the effect of strong applicability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

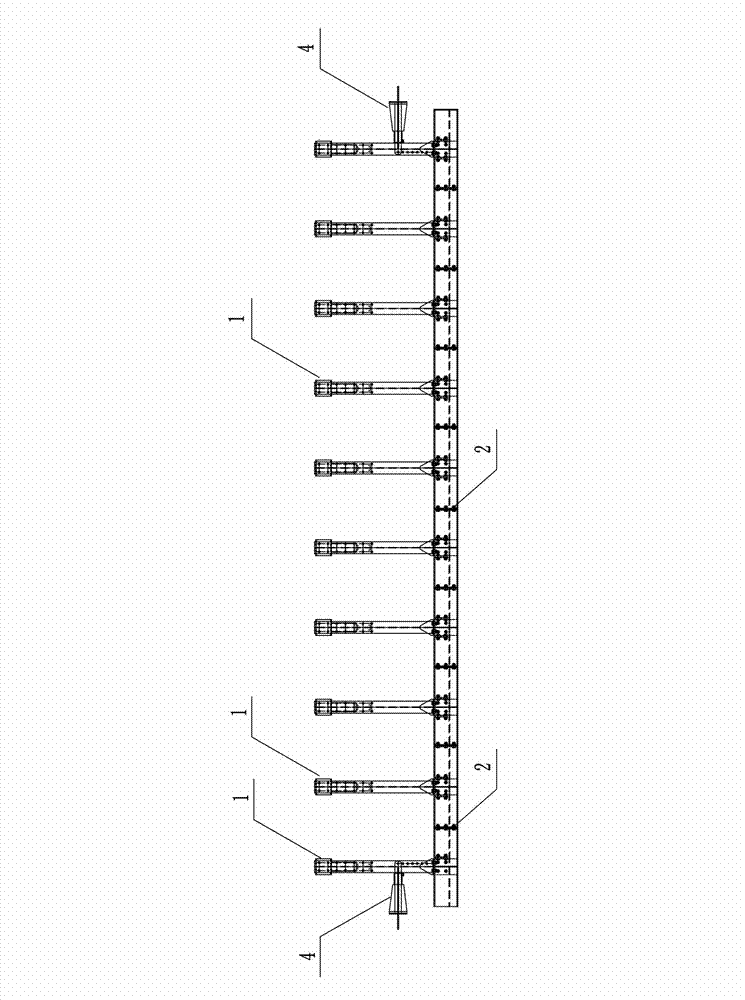

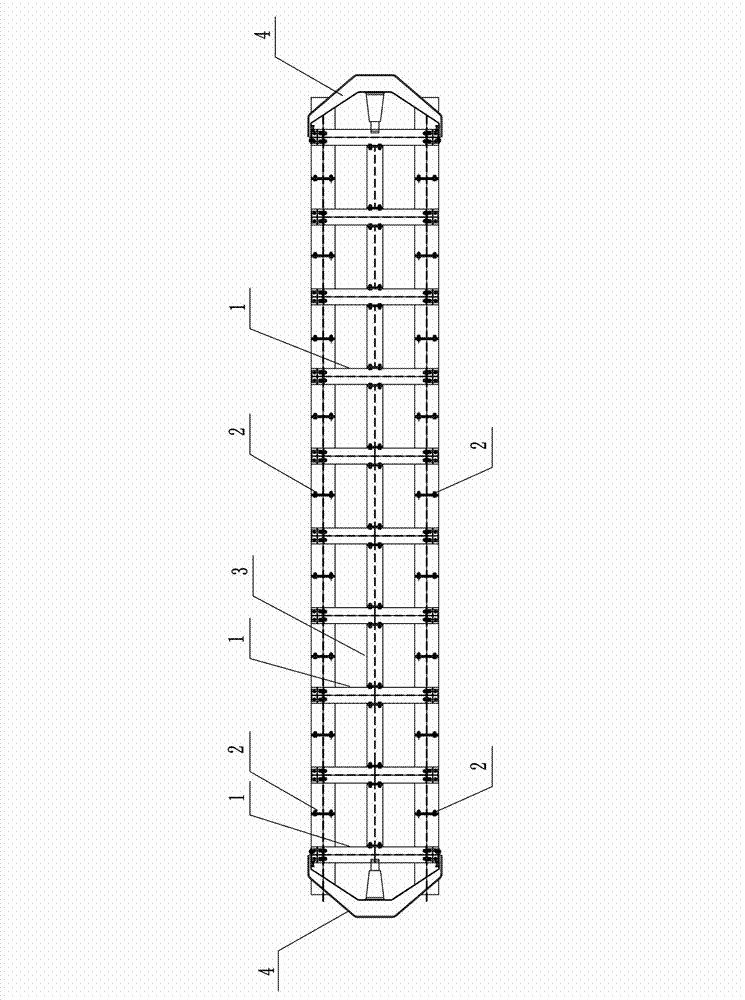

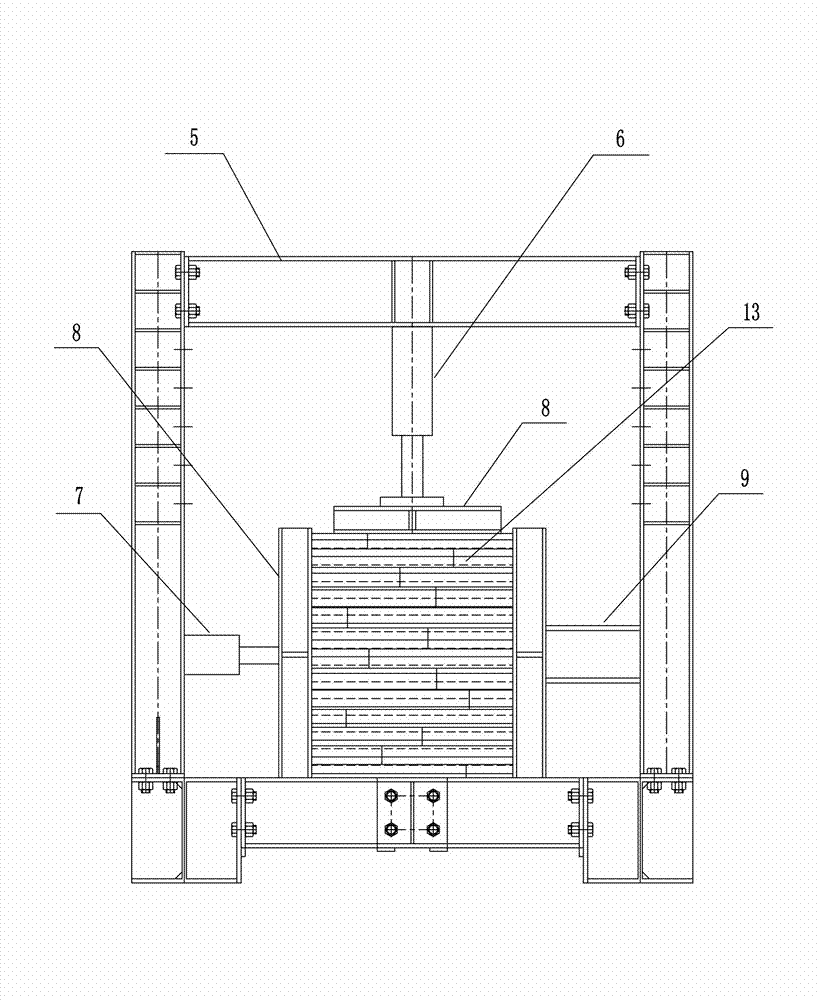

[0025] like Figure 1 ~ Figure 4 As shown, the cold press used for gluing bamboo and wood components according to the present invention includes a longitudinal pressing assembly 4, more than one rack unit 1 arranged in sequence, a control assembly (not shown in the figure) and a machine set on the rack unit 1 The lateral pressure member 7 and the vertical pressure component 6. According to the size requirements (length dimension) of the glued bamboo and wood member 13 to be pressed, one or more rack units 1 are assembled along the longitudinal direction (that is, the length direction of the glued bamboo and wood member 13) through the first bolt 2 and the connecting beam 3 , forming the whole unit of the cold compressor. In the present invention, a longitudinal press assembly 4 is installed on the frame unit 1 located at the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com