Classification and detection method of wafer appearance defects

A technology of appearance defects and detection methods, which is applied in the direction of optical testing for defects/defects, can solve problems that affect processing efficiency, affect processing efficiency, reduce processing efficiency, etc., and achieve the effect of improving processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

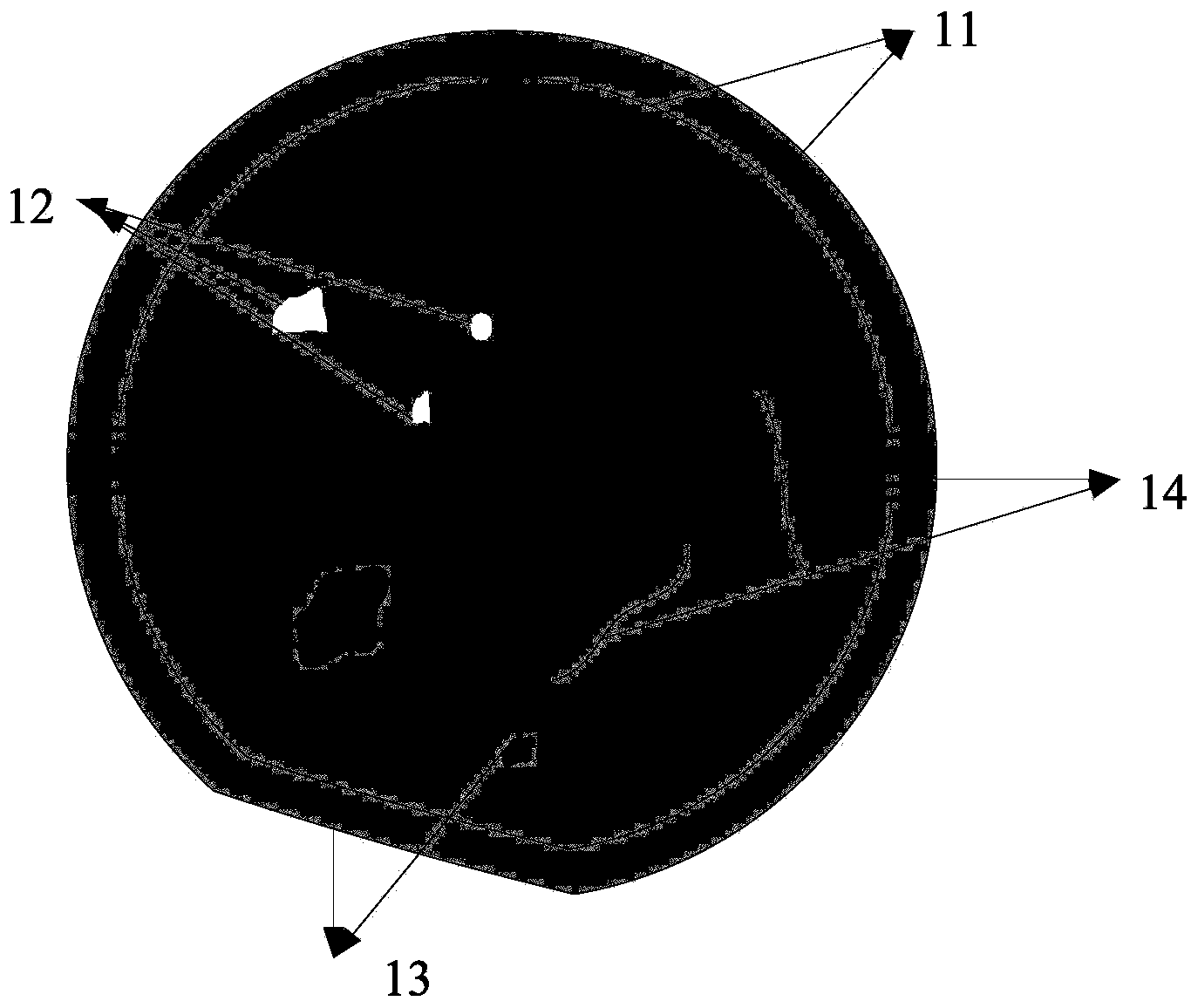

[0027] Such as figure 1 As shown, it is a schematic diagram of the main defects of the appearance of the wafer involved in the present invention. In this embodiment, the wafer is an LED-PSS wafer with a circular structure with cut edges. Among them, the number 11 is the edge of the wafer, and the outer edge is the outer edge, and the inner edge is the inner edge; the number 12 is a white defect; the number 13 is a black defect; and the number 14 is a scratch defect. White defects 12 may specifically include pinholes and image loss. Specifically, the black defect 13 may include large particle contamination and small particle contamination.

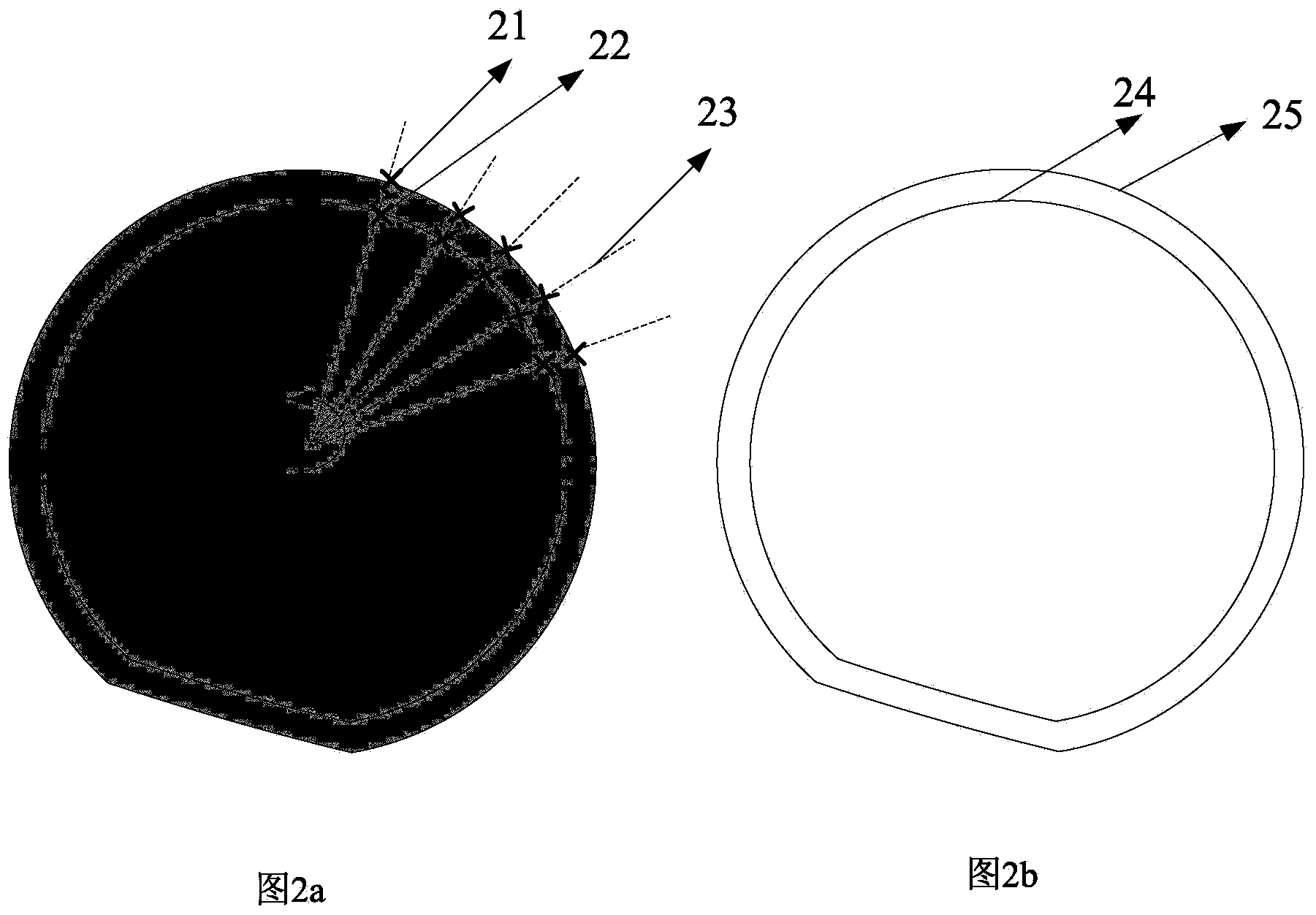

[0028] Such as Figure 2a with Figure 2b As shown, it is a schematic diagram of wafer edge scanning and edge width extraction according to the present invention. in, Figure 2a shows the edge sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com