Patents

Literature

2827results about "Shaping safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

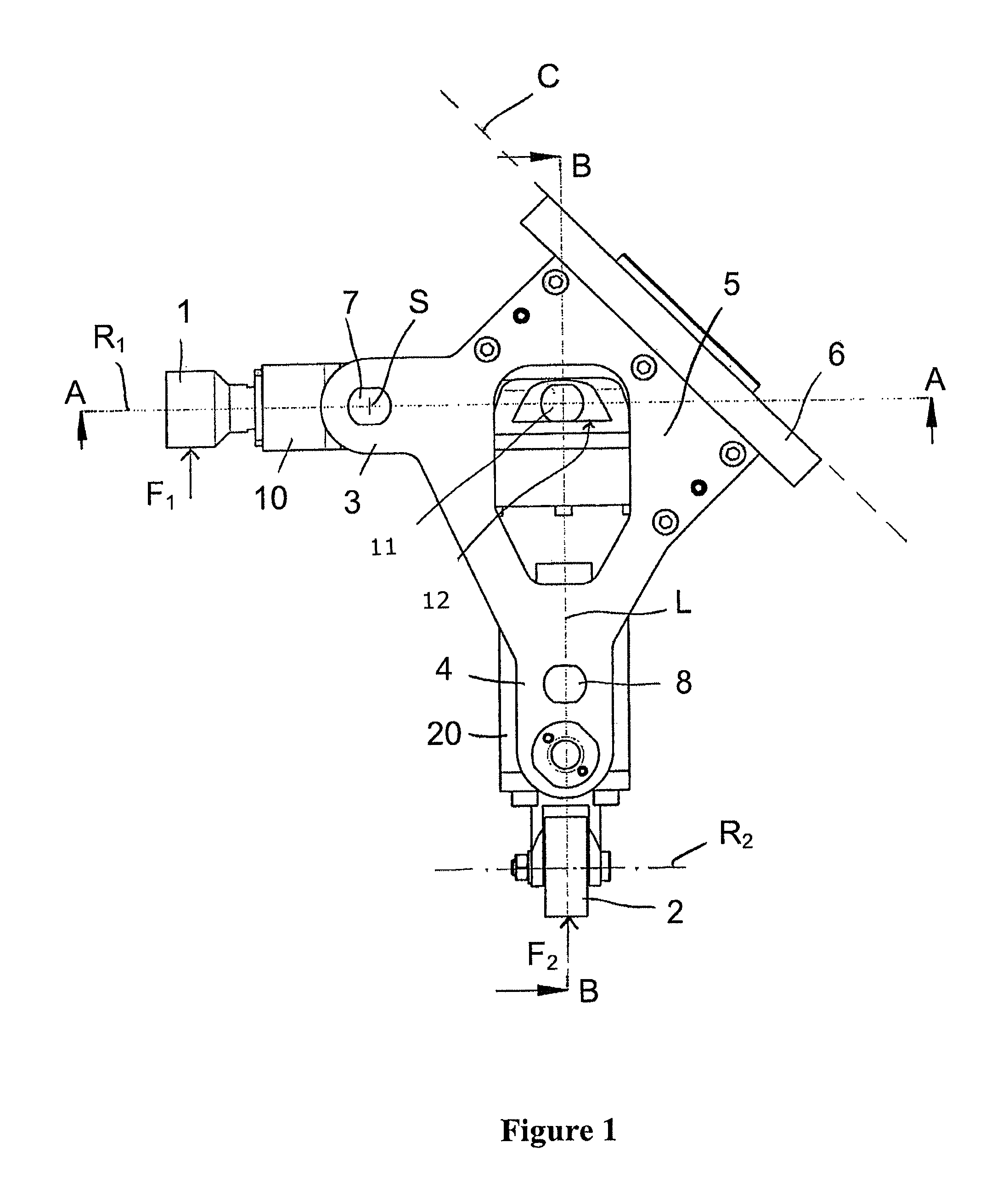

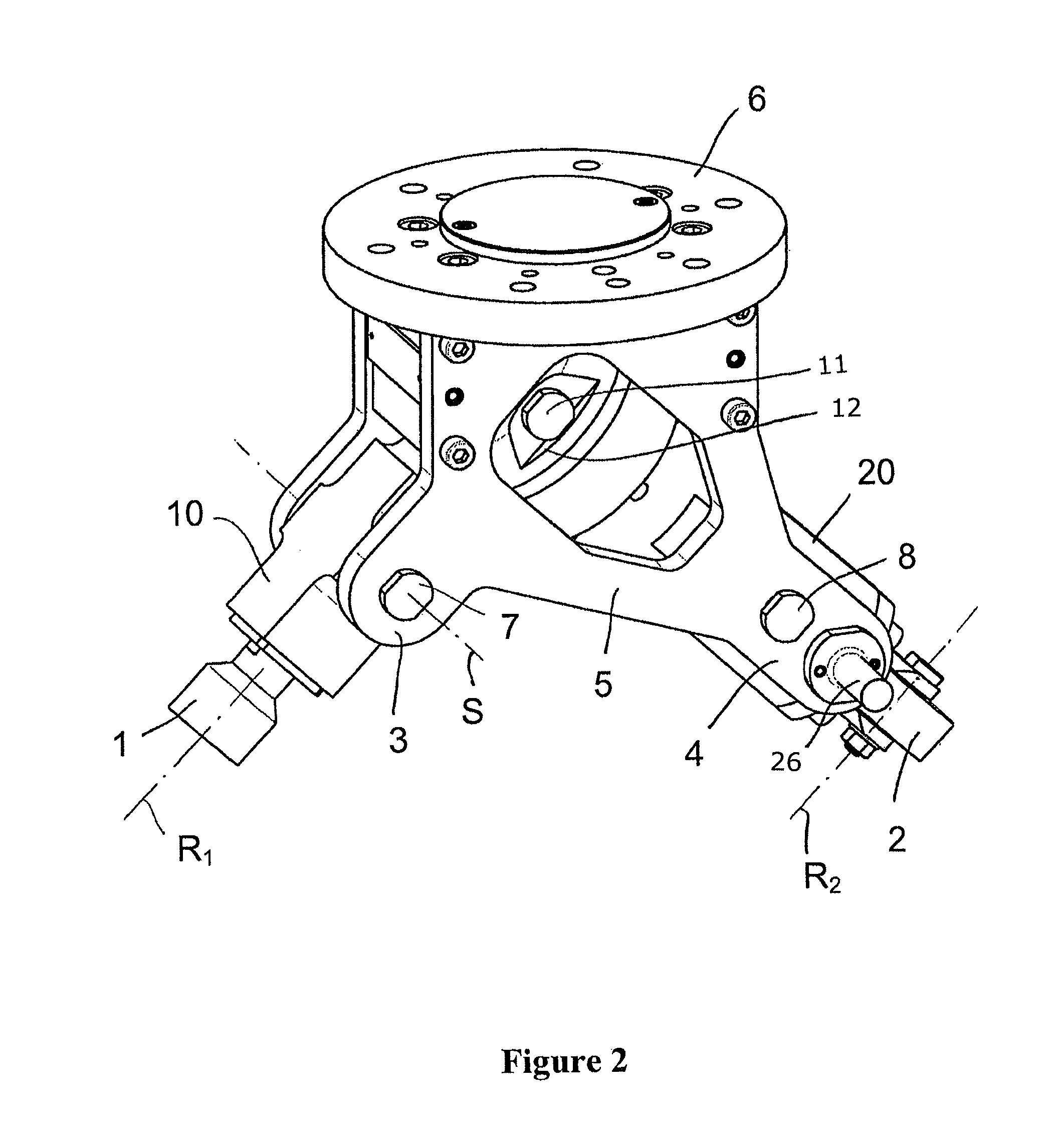

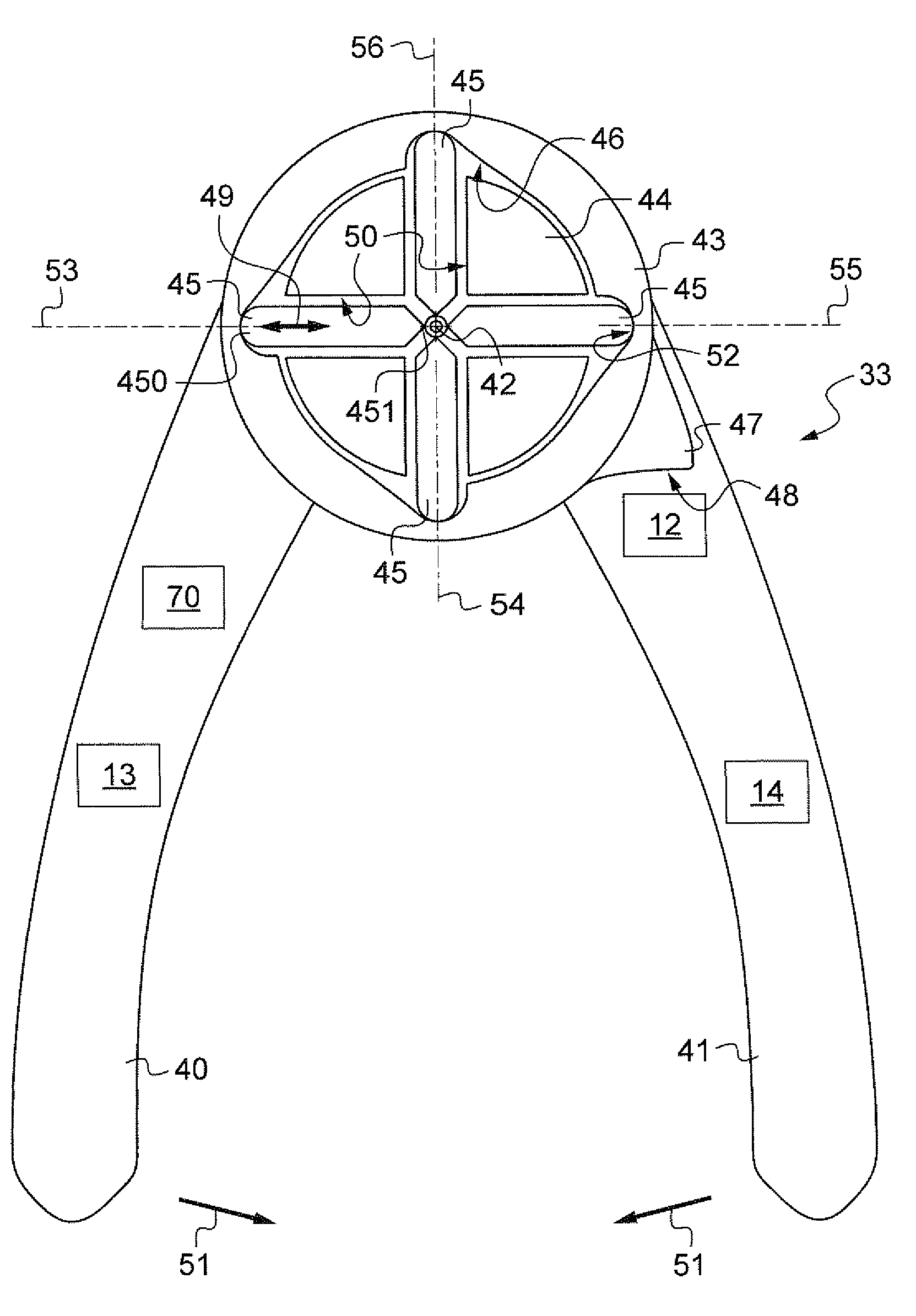

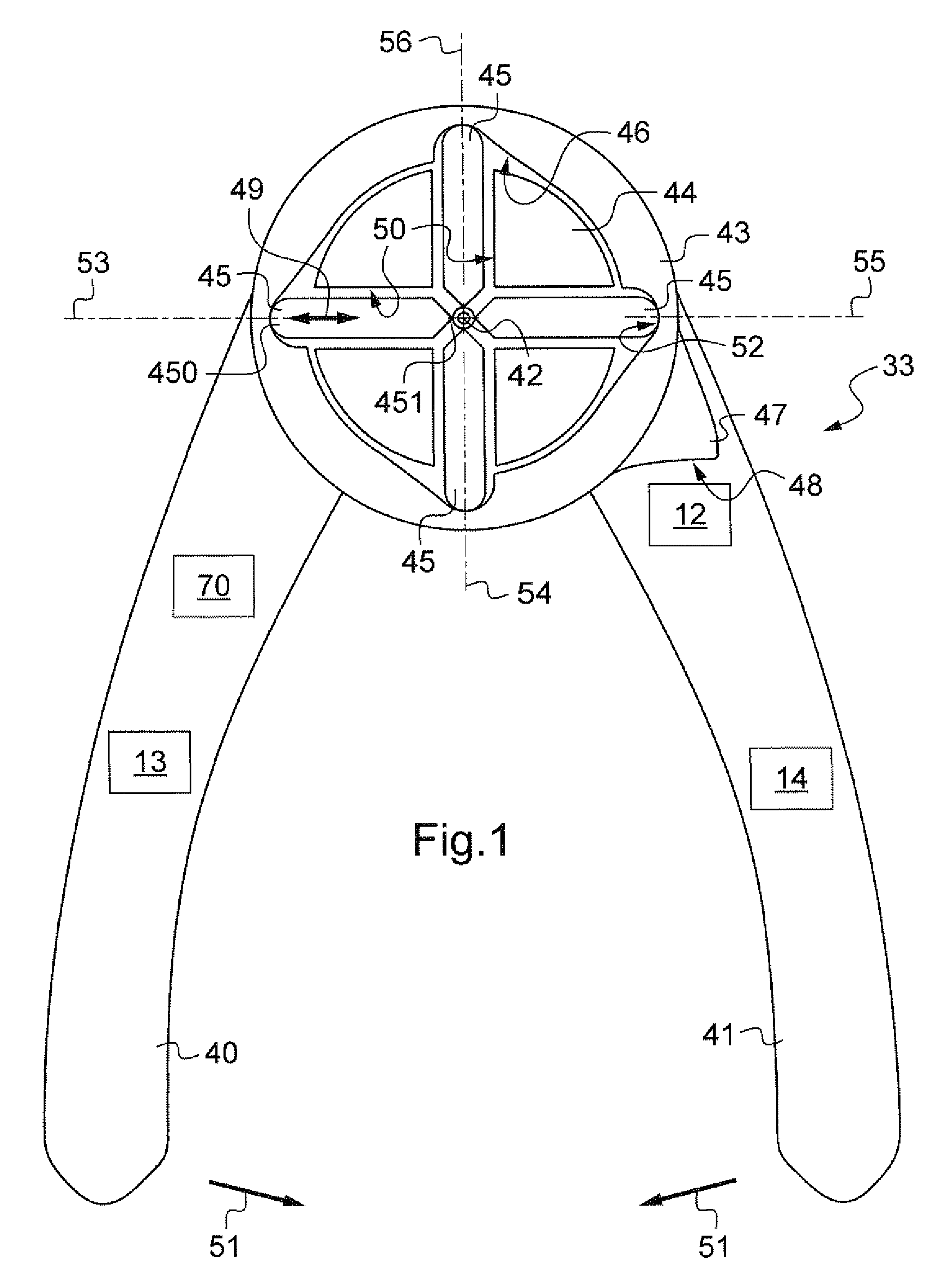

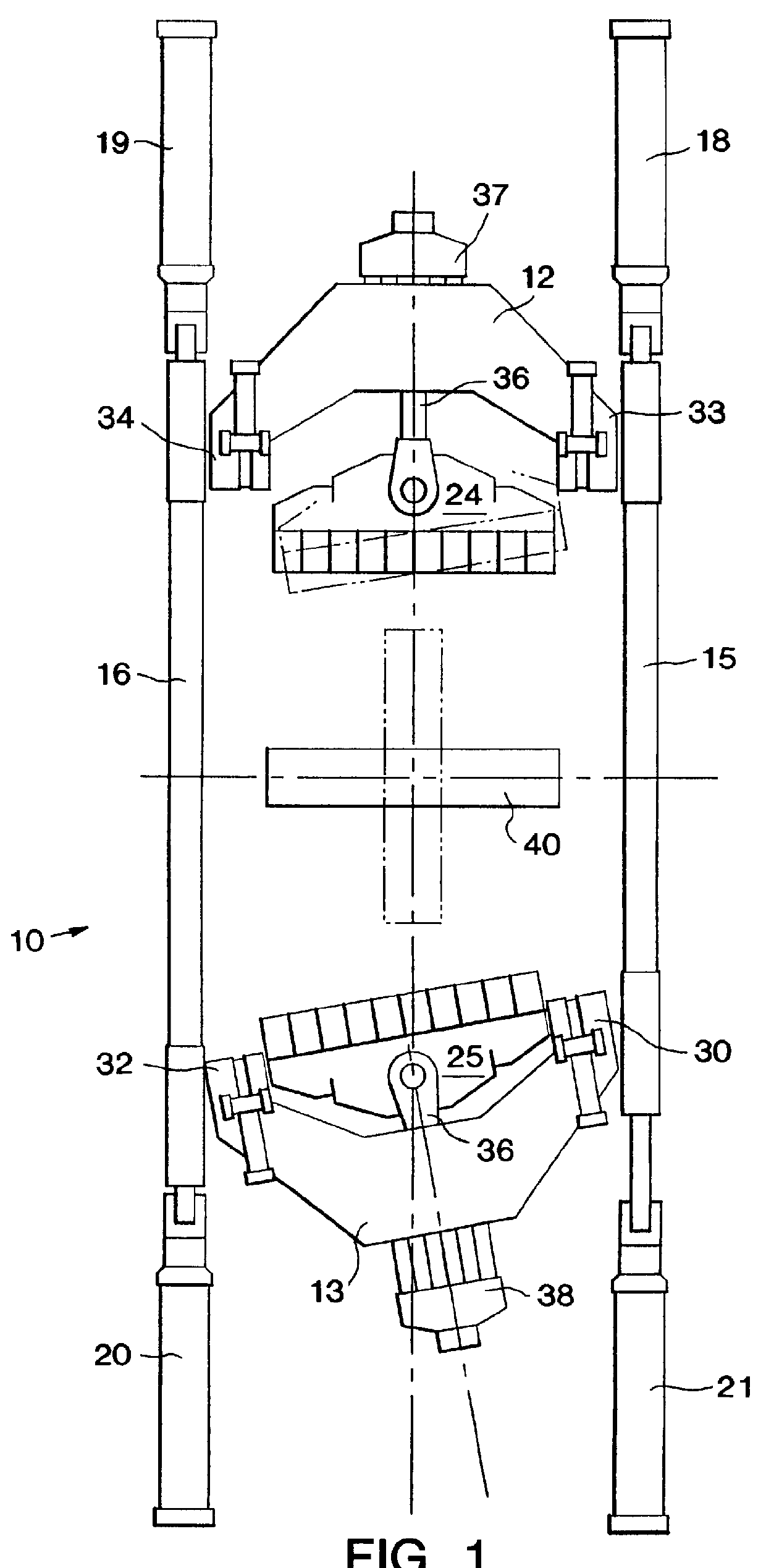

Edge curling tool

A roll-flanging tool, including a bearing structure having a connector, by which the tool can be connected via a connection plane to an actuator which can be moved spatially. A first arm and a second arm are spread apart from each other and connected to each other in a connection portion which includes the connector. A first flanging roller is mounted on an end of the first arm which faces away from the connection plane, such that it can be rotated about a first rotational axis which extends along the first arm and pierces the connection plane. A second flanging roller is mounted on an end of the second arm which faces away from the connection plane, such that it can be rotated about a second rotational axis. The first rotational axis intersects or crosses a perpendicular dropped onto the second rotational axis, in or on the roll-flanging tool.

Owner:FFT PRODIONSSYST

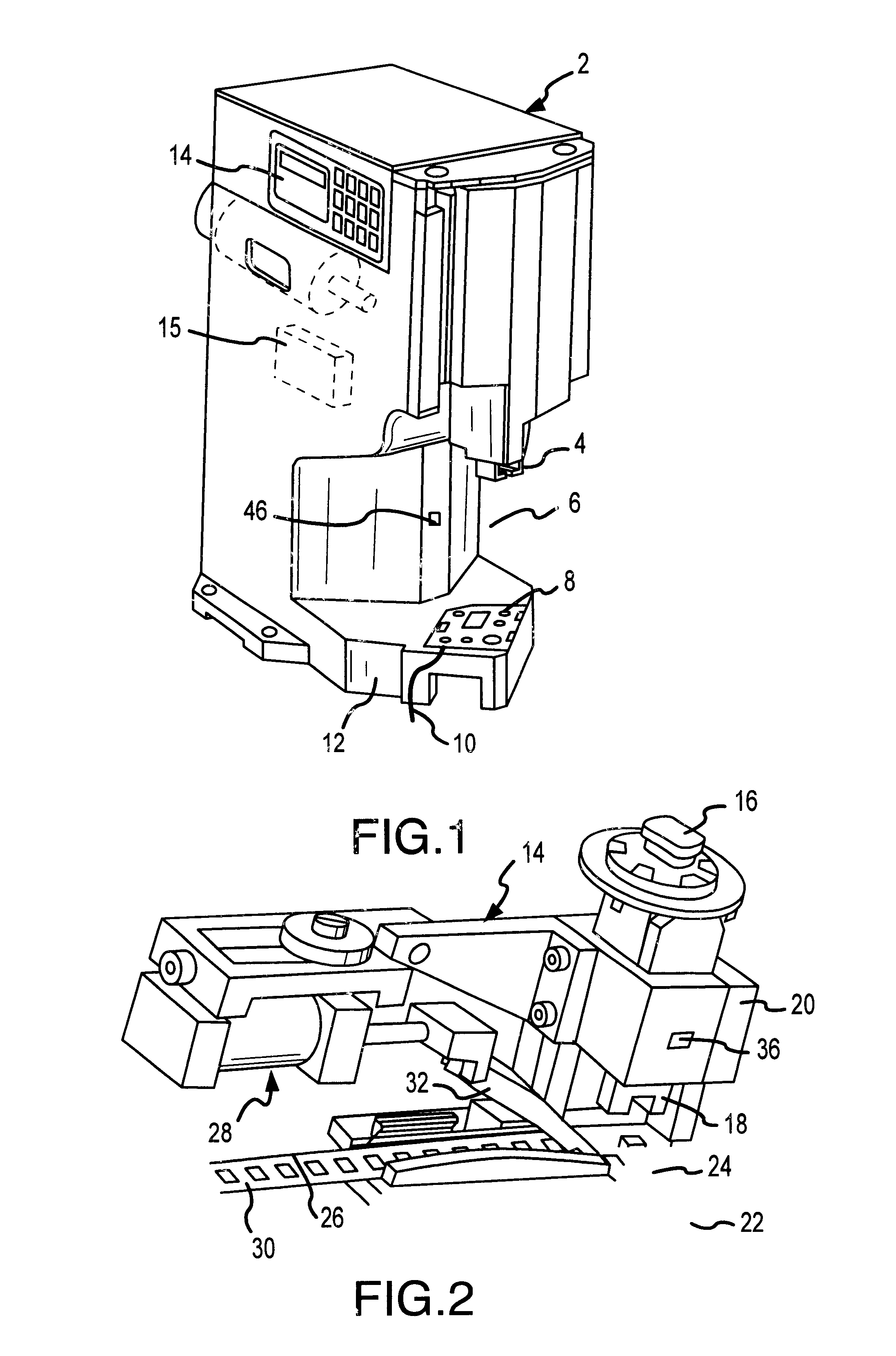

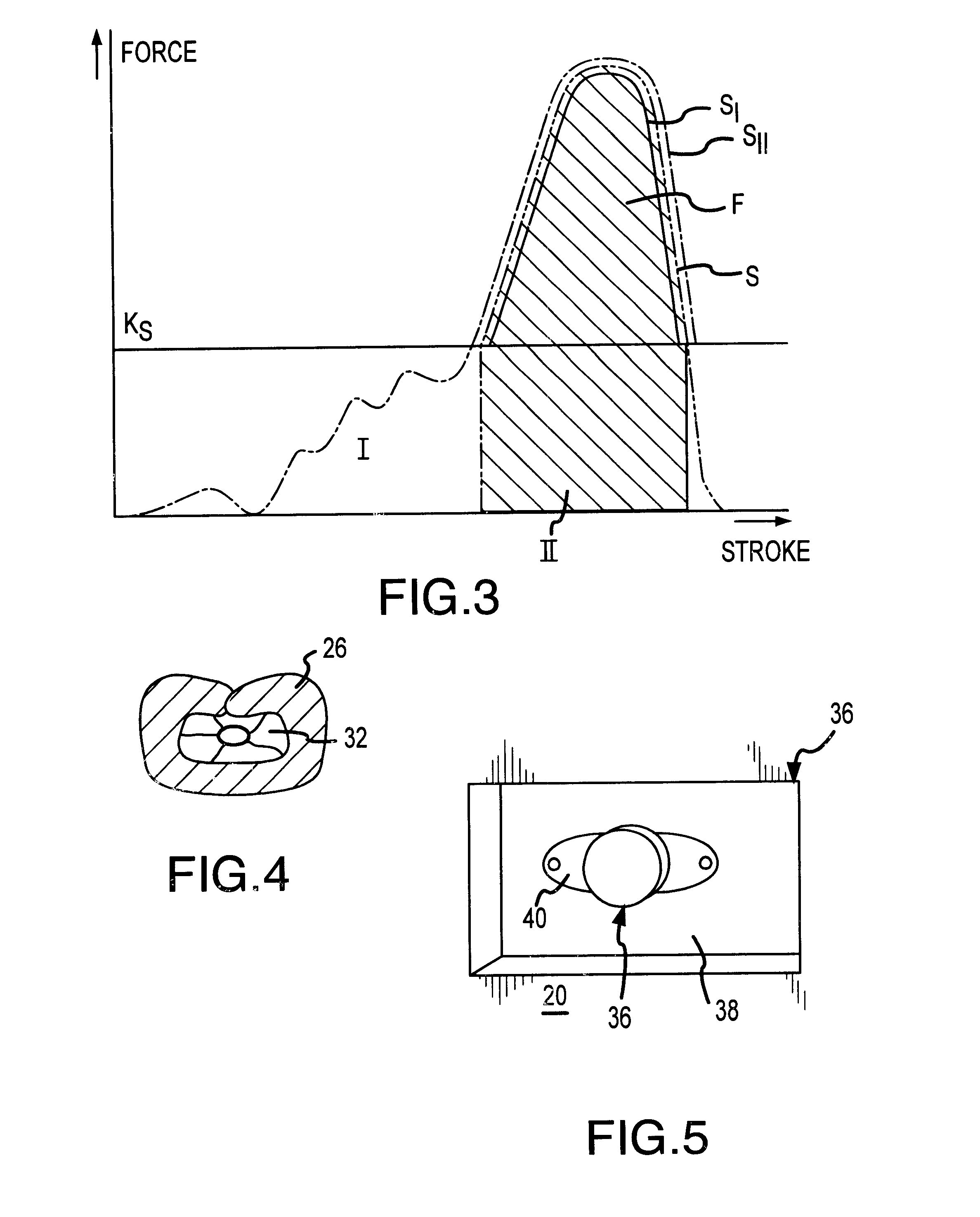

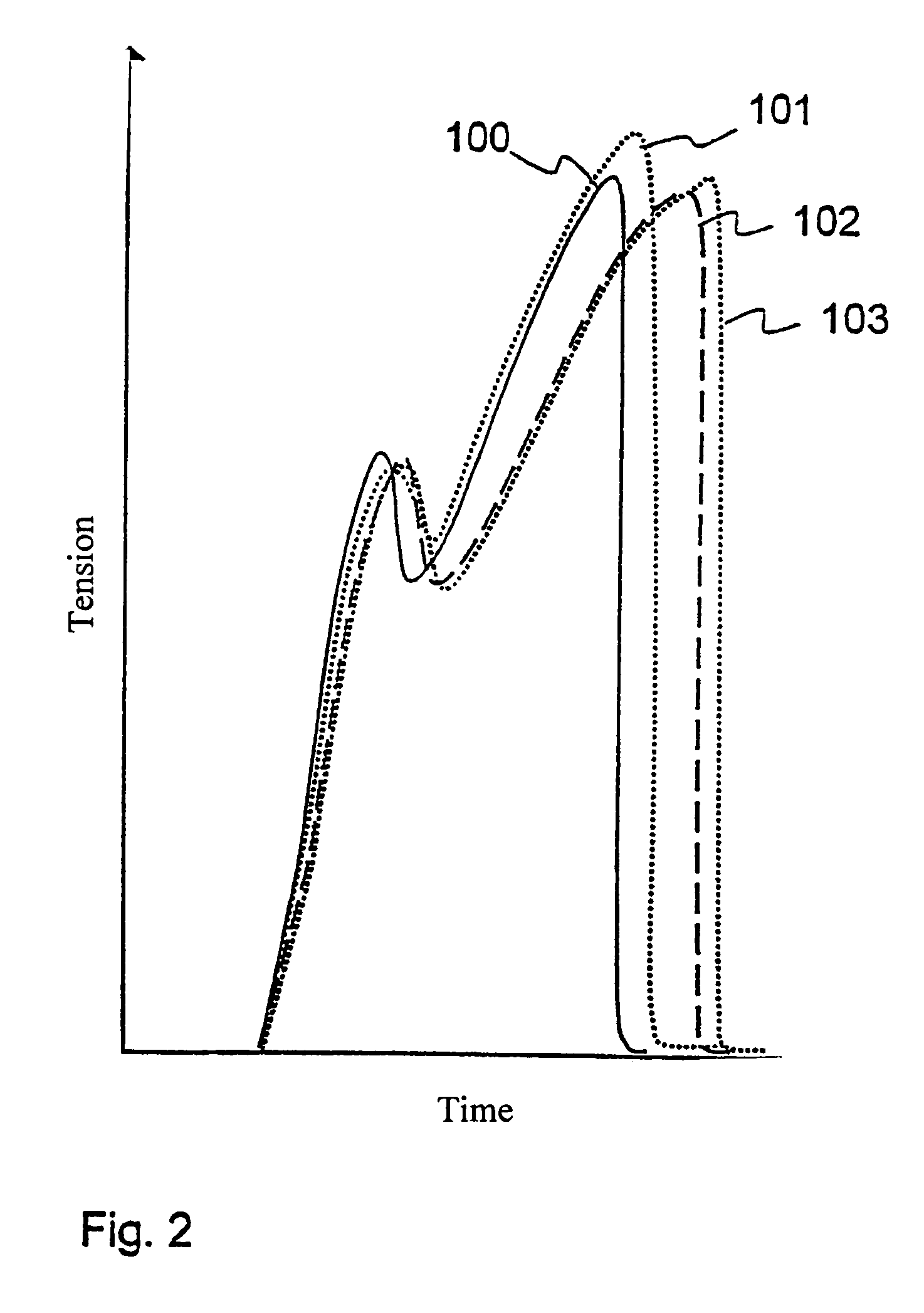

Method for quality assurance of crimp connections produced by a crimping device and crimping tool and crimping device therefor

InactiveUS6418769B1Automatic control devicesShaping safety devicesQuality assuranceMechanical engineering

The method for quality assurance of crimping connections made by a crimping device having an exchangeable tool with two tool parts uses a tool that is provided with an electronic data storage device. The electronic data storage device stores tool-specific nominal data derived from a nominal force-stroke characteristic line of a nominal crimping action of the tool. A crimp connector is fastened to the end of an electrical cable by placing the end of the electrical cable and the crimp connector between the two tool parts and moving the two tool parts relative to one another for carrying out the crimping action. The force-stroke characteristic line of the two tool parts is measured during the crimping action. The measured force-stroke characteristic line is compared to the stored nominal data.

Owner:SLE TECH GMBH

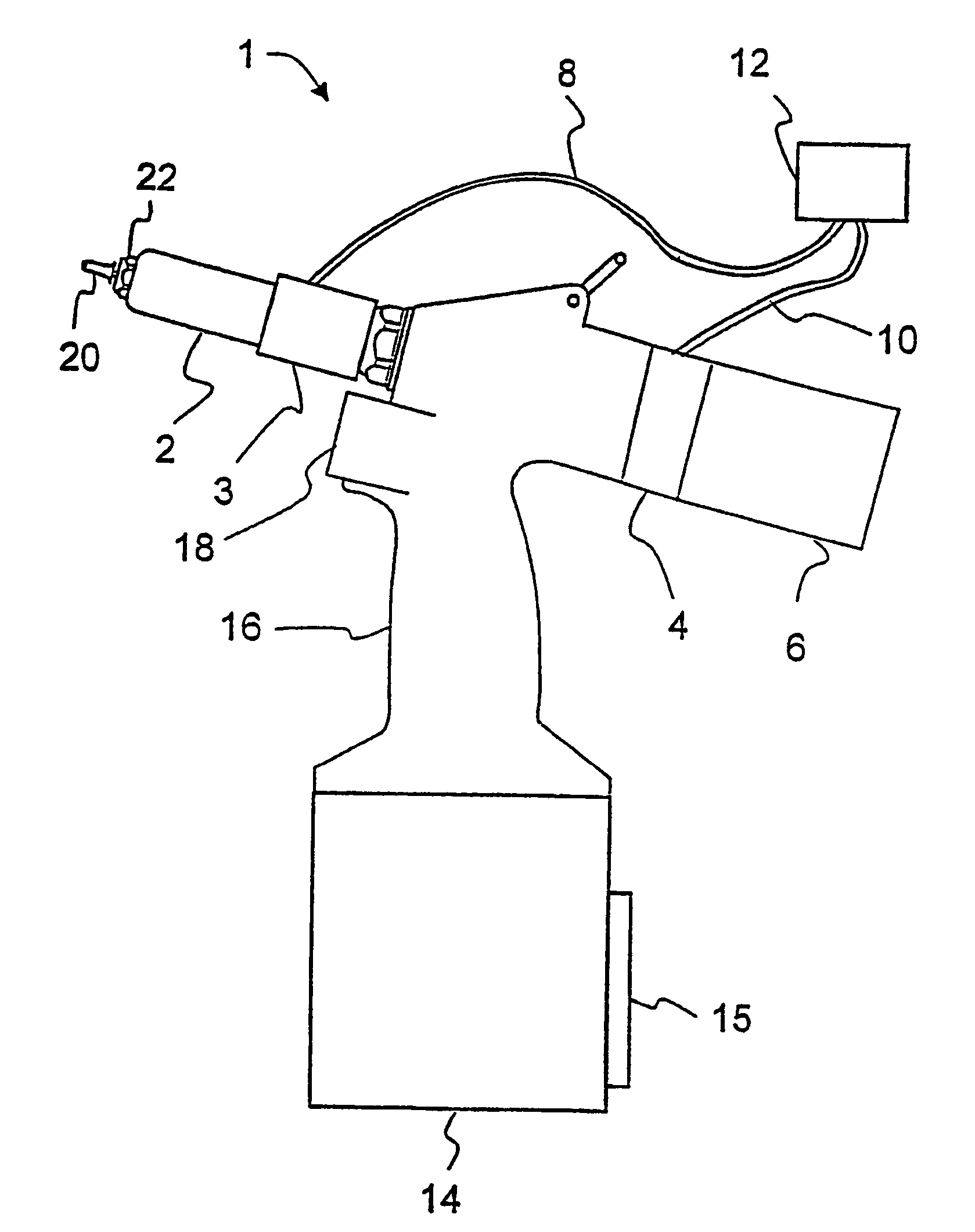

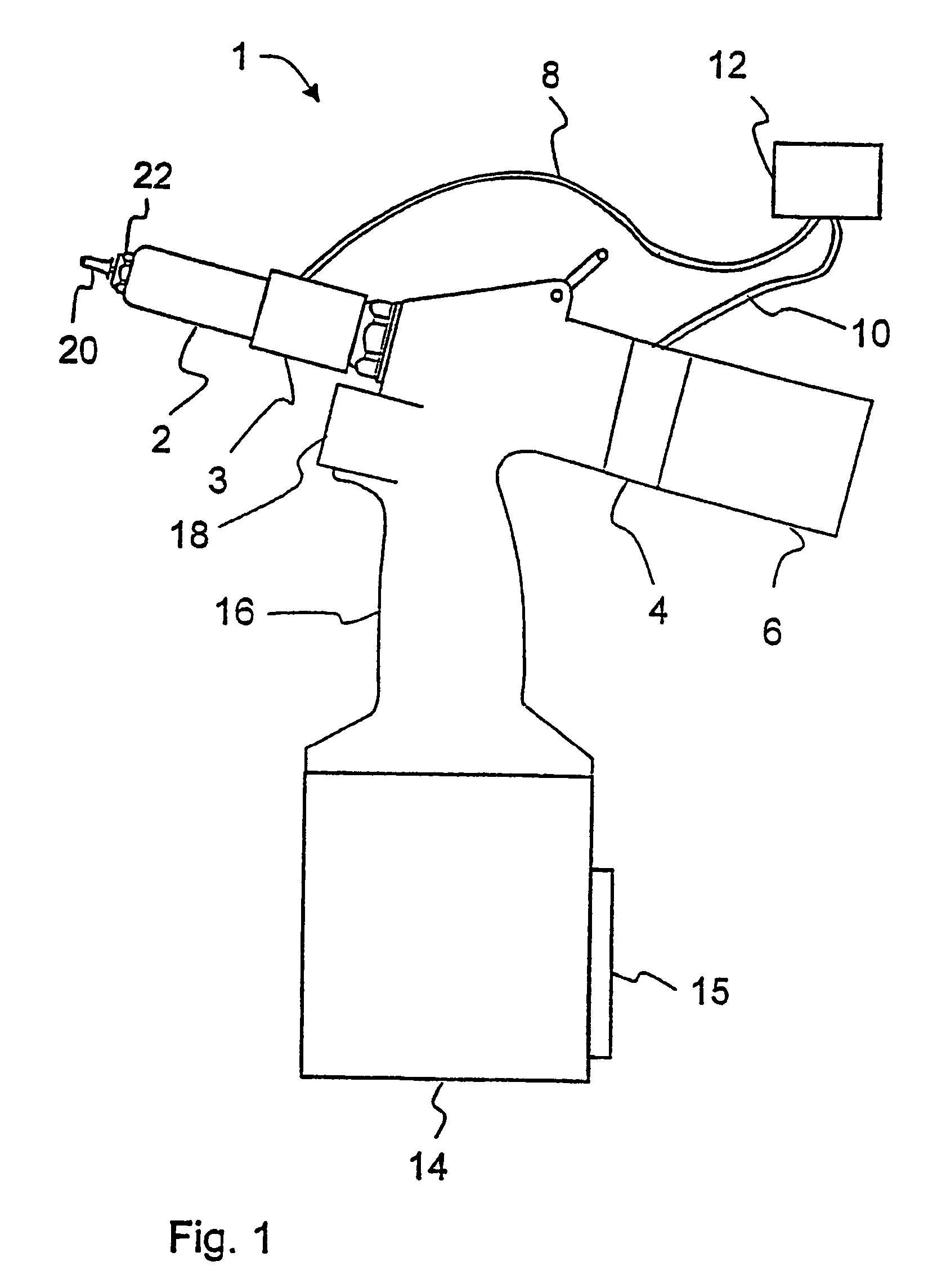

Placing tool with means for controlling placing processes

A rivet setting tool is provided to provide improved monitoring of riveted connections during rivet setting. The rivet setting tool includes a head piece for holding a rivet, a device for gripping a rivet pin, a pulling apparatus connected to the device for gripping a rivet pin, and a device for measuring the tension of the pulling apparatus. Using the setting implement according to the invention, a cause of a fault can be determined by means of a comparison between measured values and stored values.

Owner:MS GERATEBAU

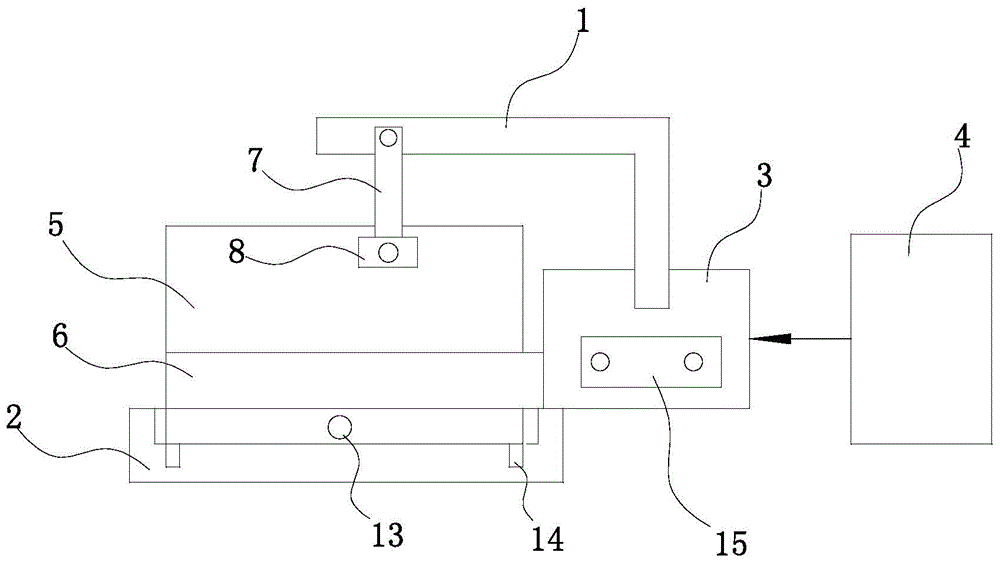

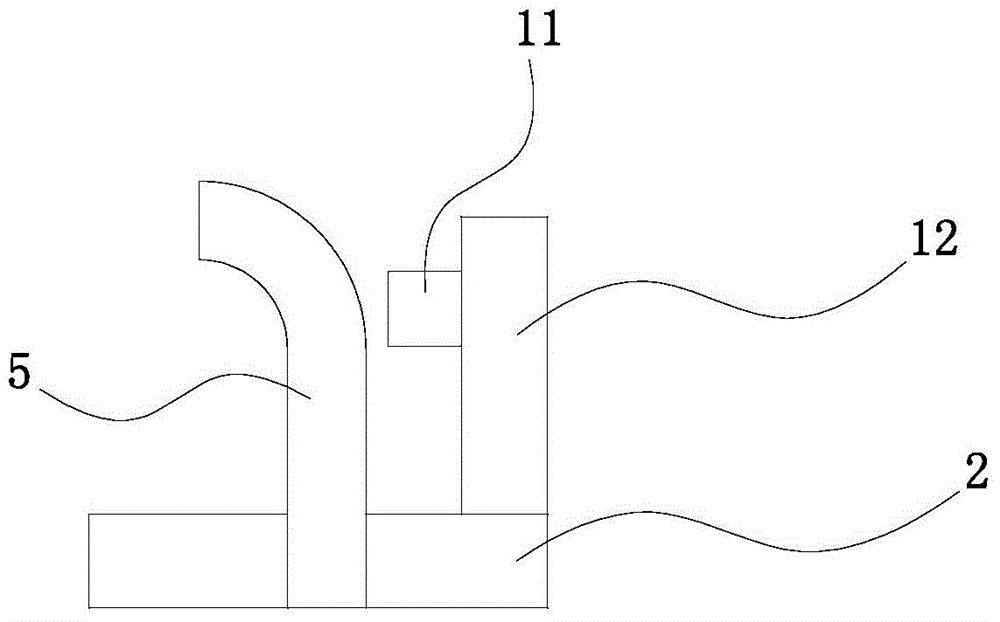

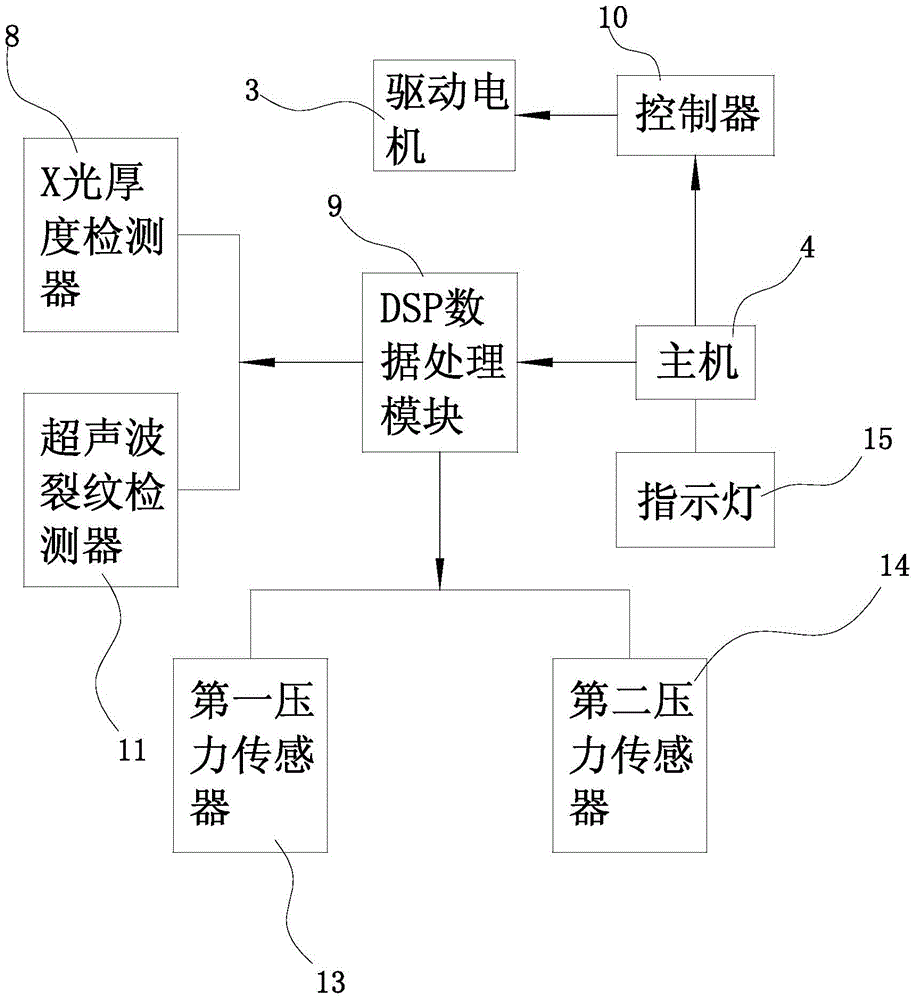

X-ray thickness detection and bending speed adjusting bending machine based on PLC

ActiveCN104624726AAvoid bendingAvoid empty foldsMetal-working feeding devicesShaping safety devicesX-rayDrive motor

The invention relates to an X-ray thickness detection and bending speed adjusting bending machine based on a PLC. The X-ray thickness detection and bending speed adjusting bending machine comprises a driving motor, a clamping fixing base, a main machine as well as an X-ray thickness detector, a first pressure sensor, a second pressure sensor and a detection feedback device, wherein the driving motor is arranged on a rack; the main machine is used for controlling the driving motor; a bending shaft is mounted on a motor shaft of the driving motor; a processed workpiece is arranged on the clamping fixing base; the X-ray thickness detector is mounted on the rack through a first bracket; the first pressure sensor and the second pressure sensor are arranged on the clamping fixing base; the detection feedback device comprises an ultrasonic crack detector which is arranged on the clamping fixing base through a second bracket. The invention further provides a bending processing method adopting the bending machine. Due to PLC controlled sectional processing and positioning detection, the phenomenon of bending deviation or bending omission can be avoided, and the processing reliability can be improved; the processed workpiece can be bent according to most appropriate torque, so that the processed workpiece is prevented from being affected by too large or too small torque, bending cracks can be reduced, and the processing quality can be improved.

Owner:南京比泰数控机械设备有限公司

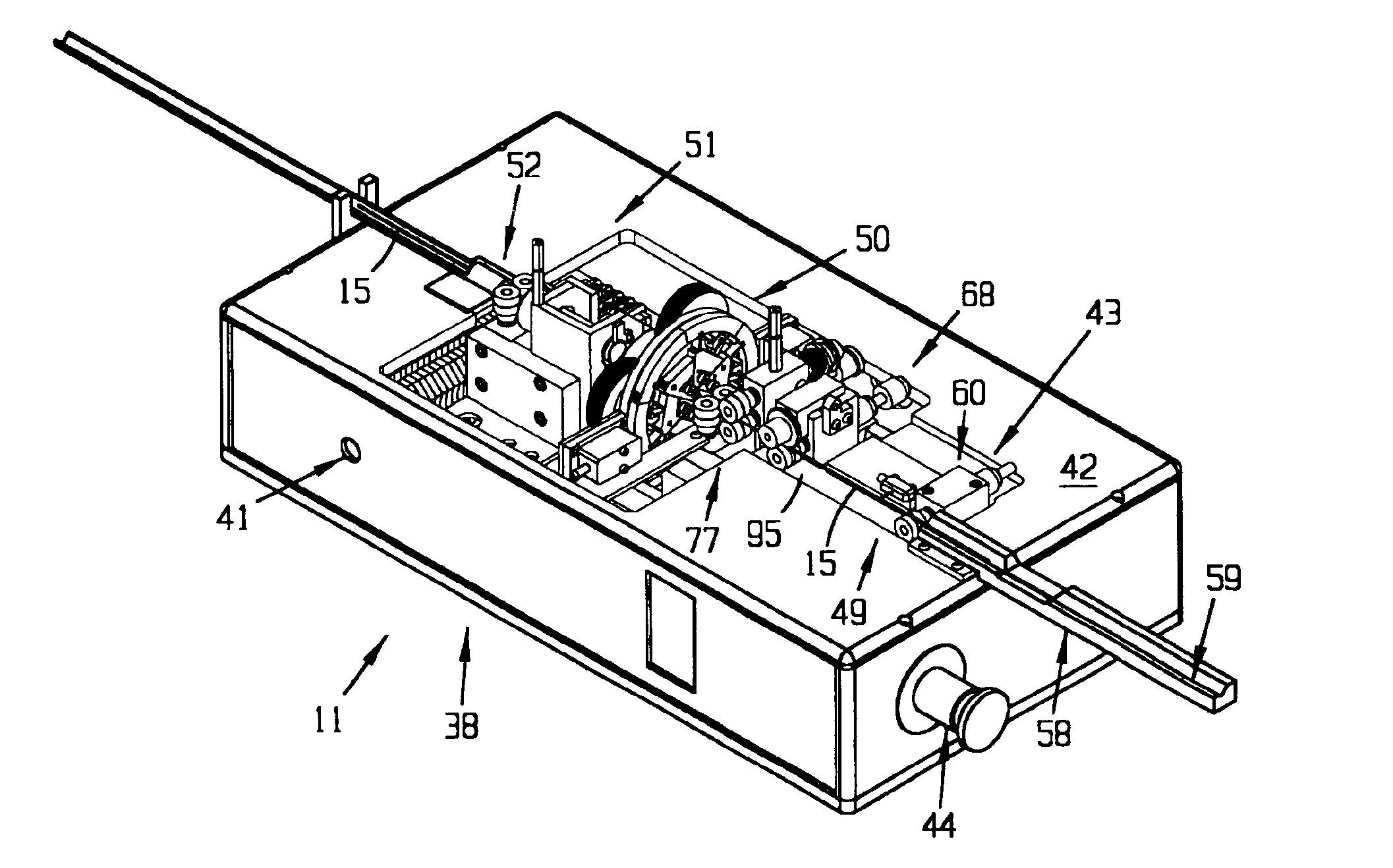

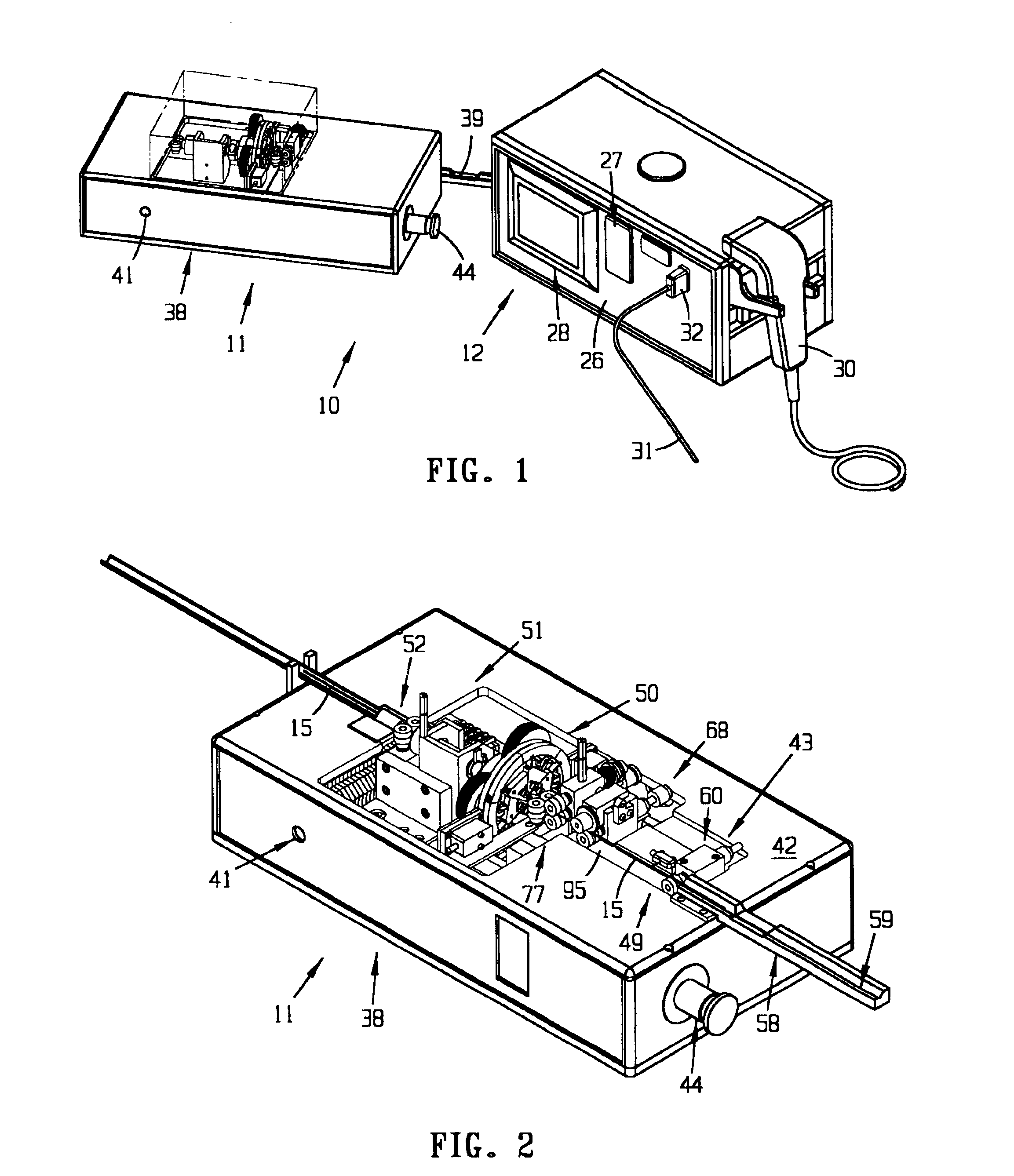

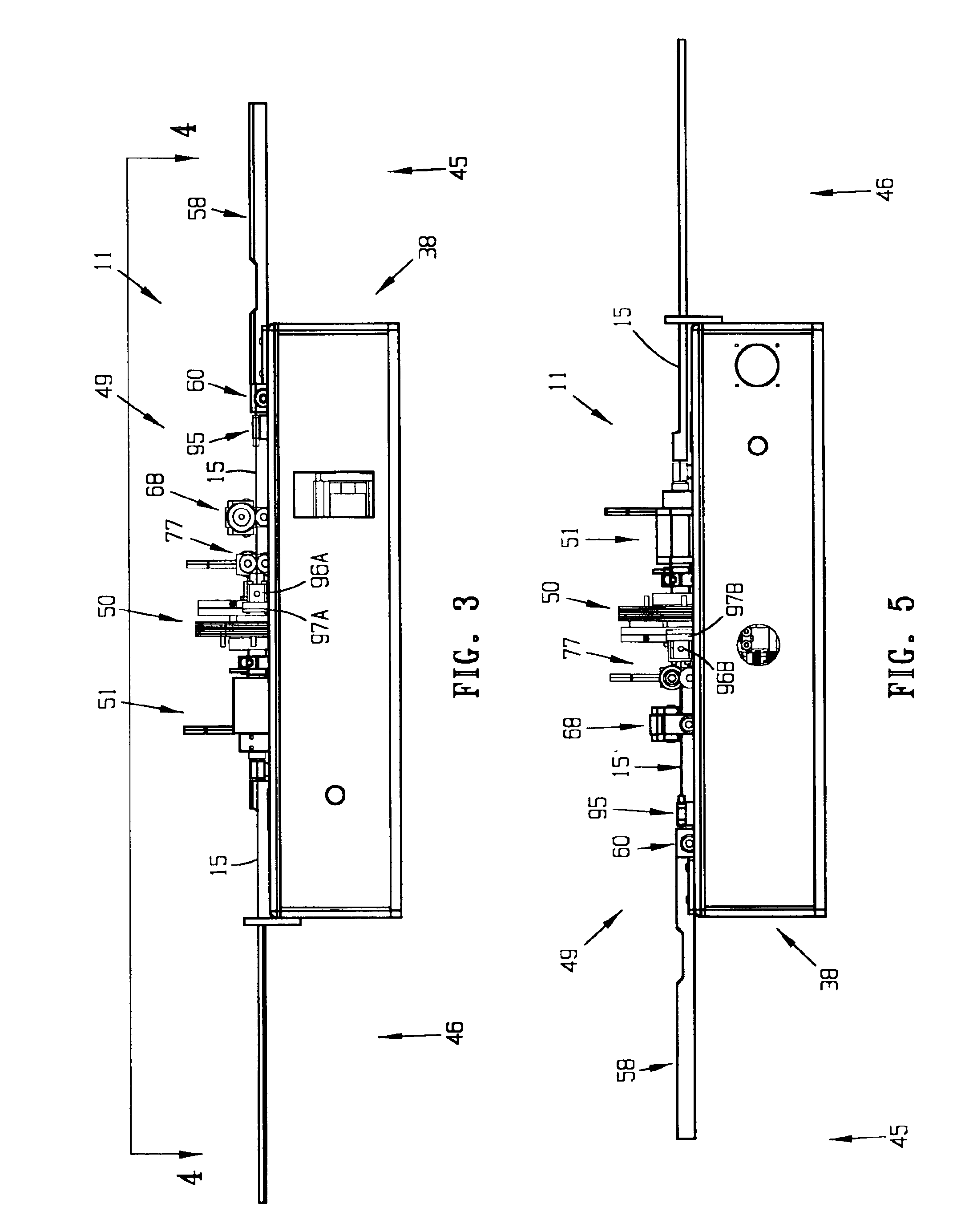

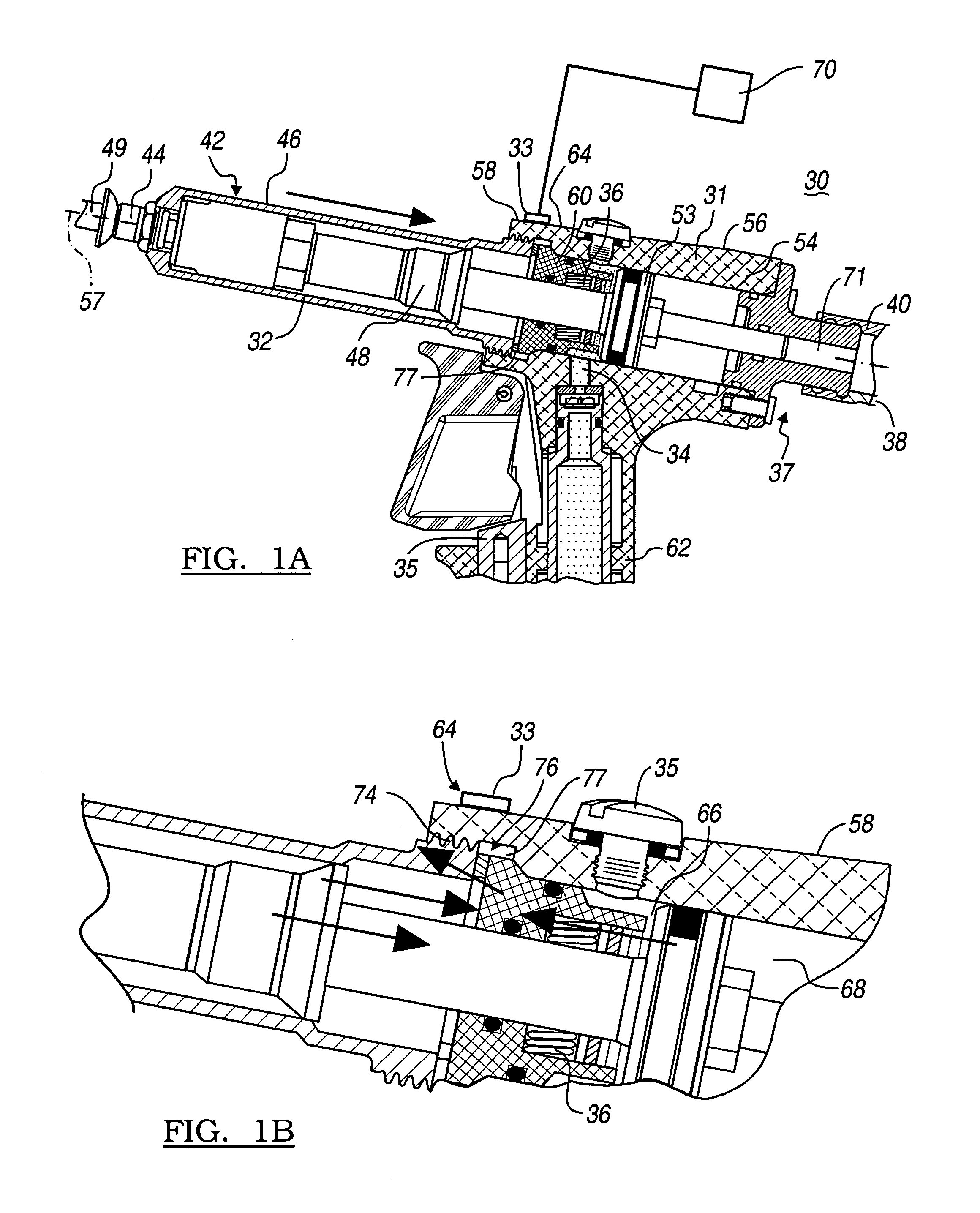

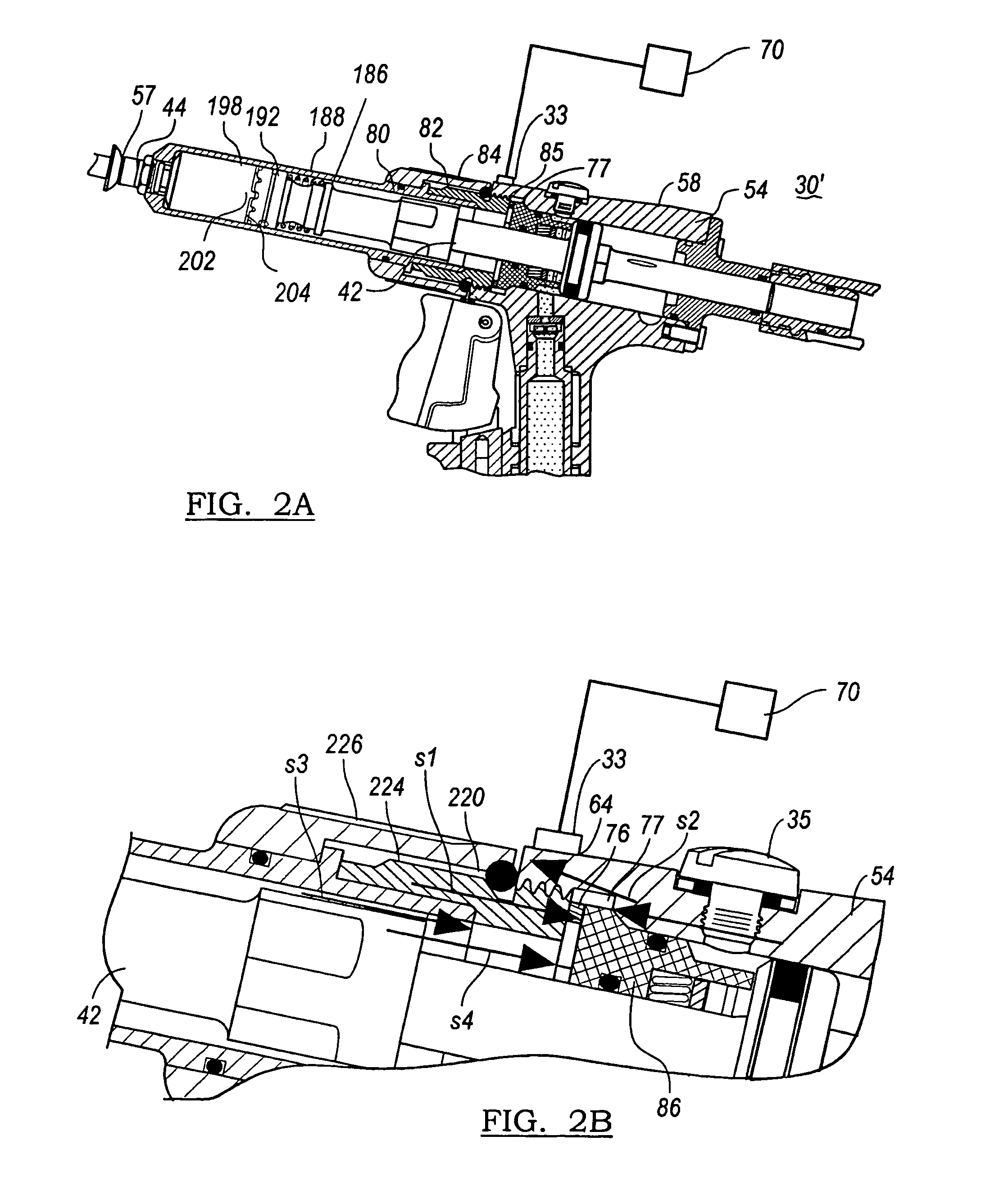

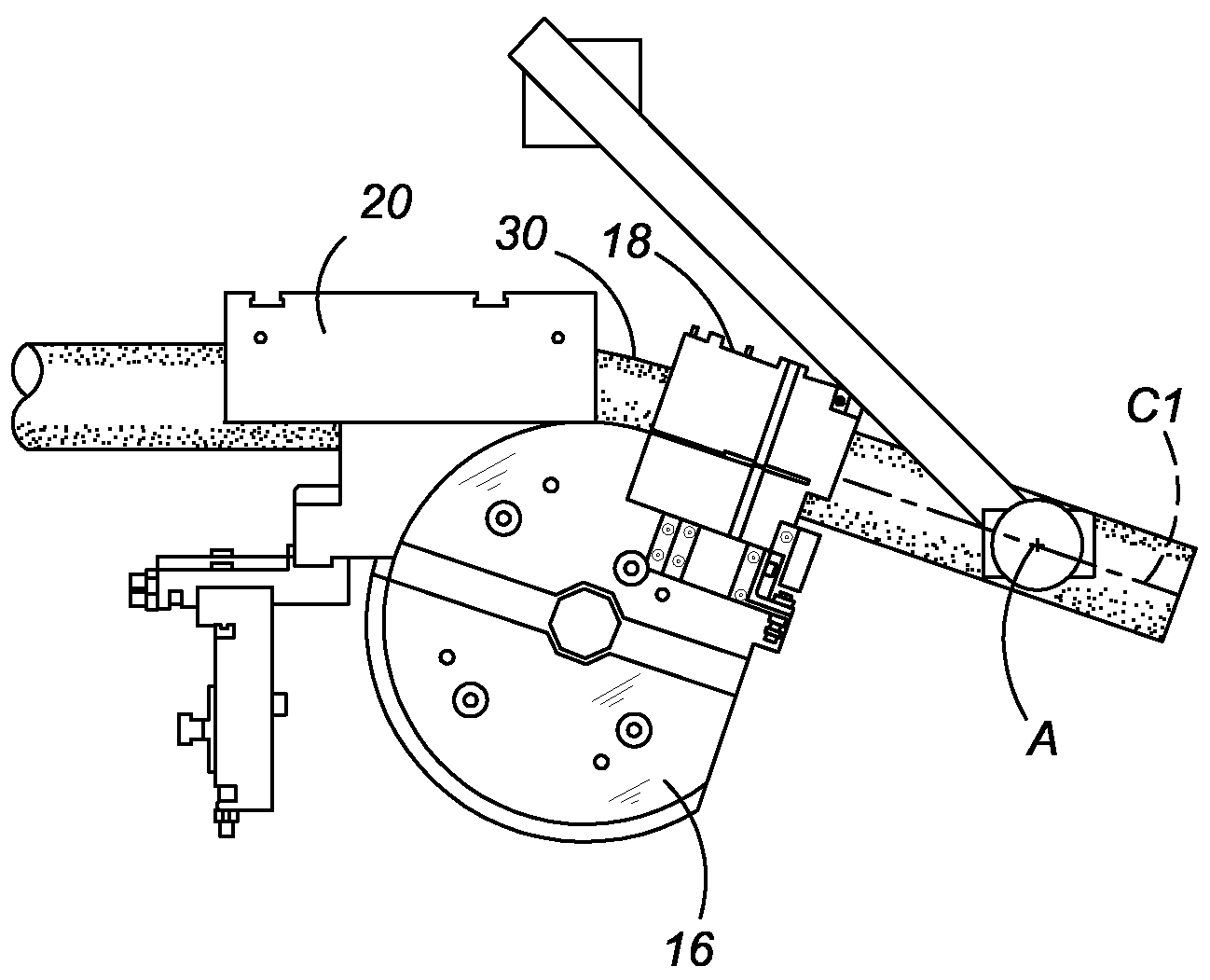

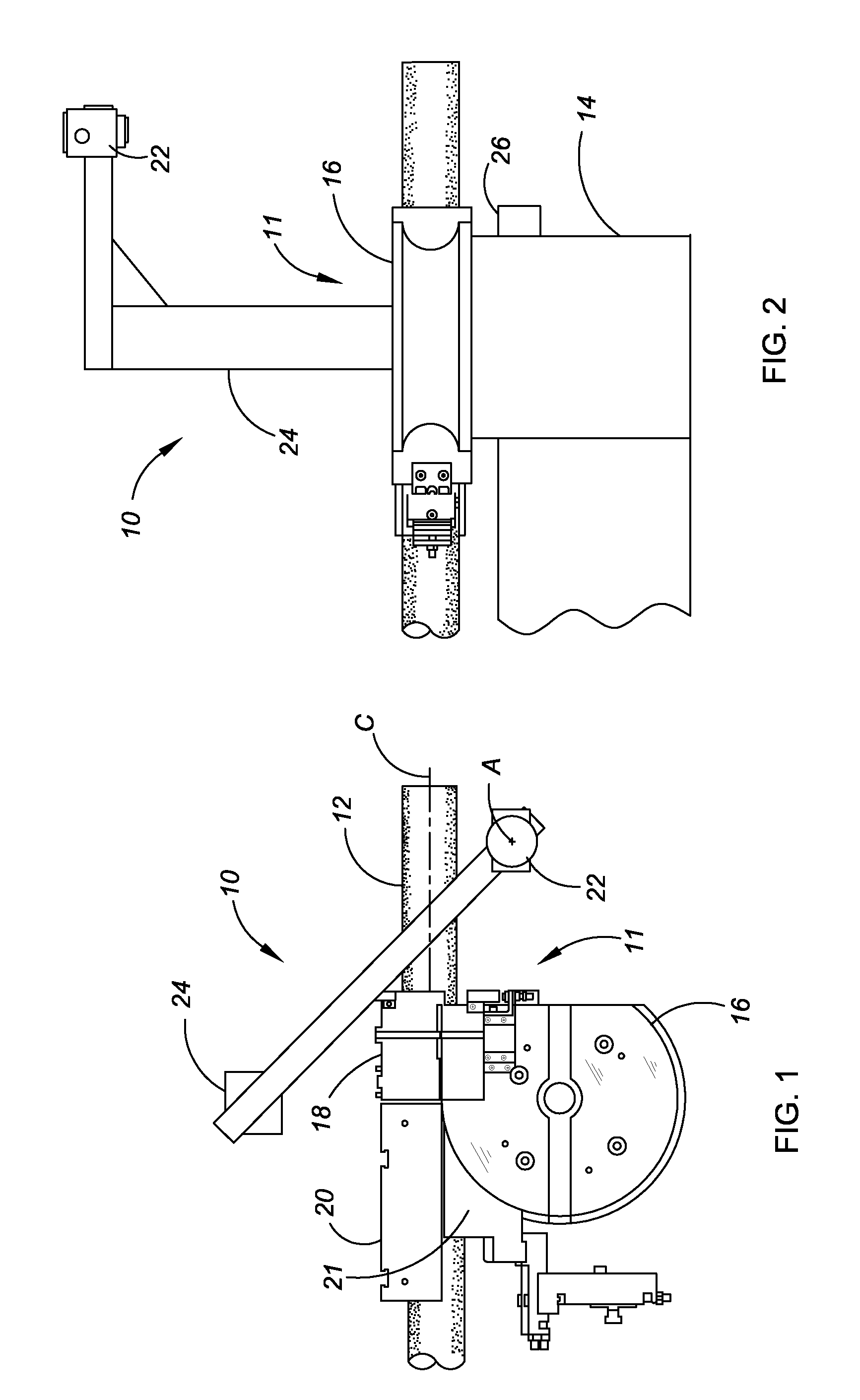

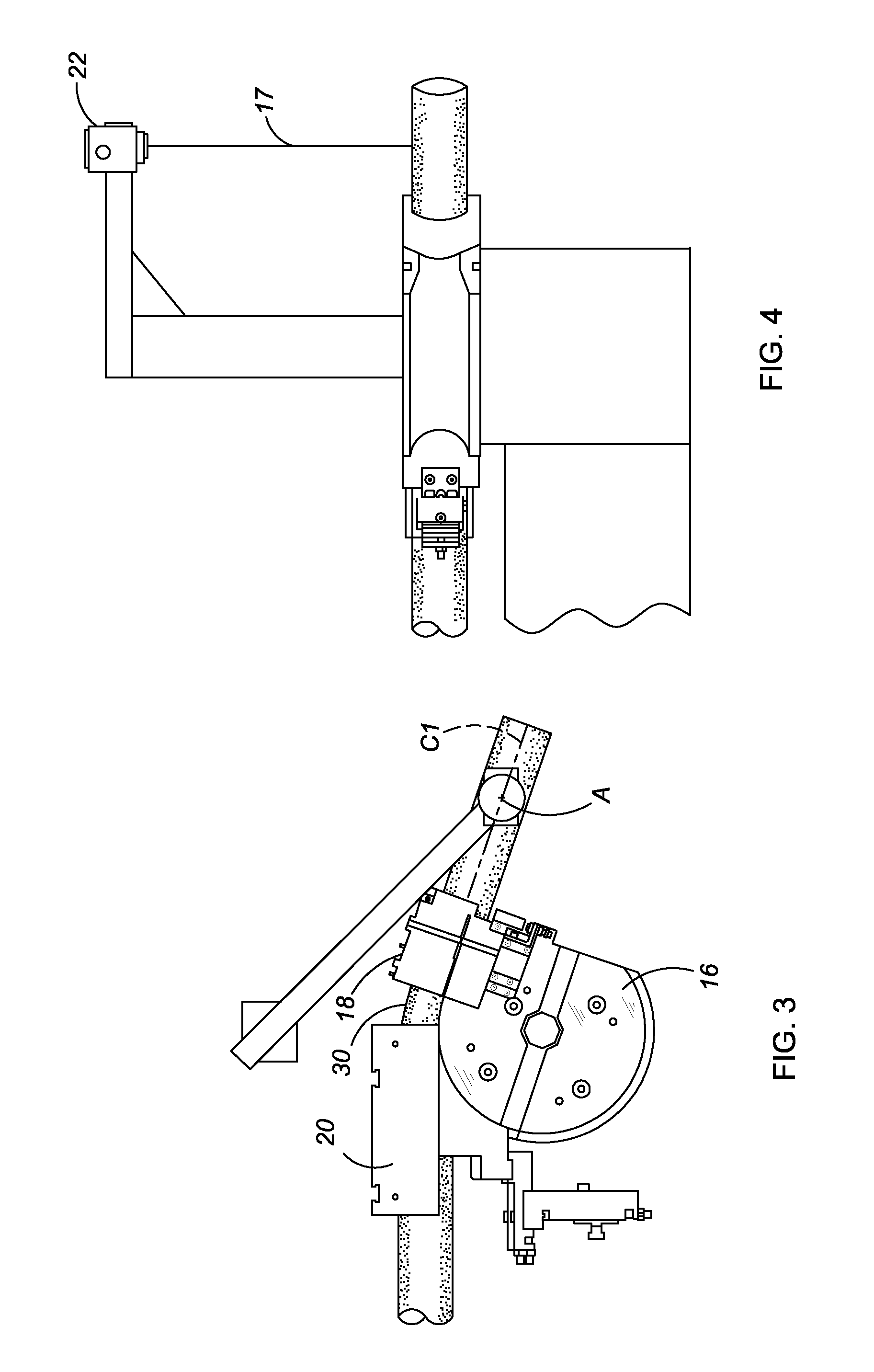

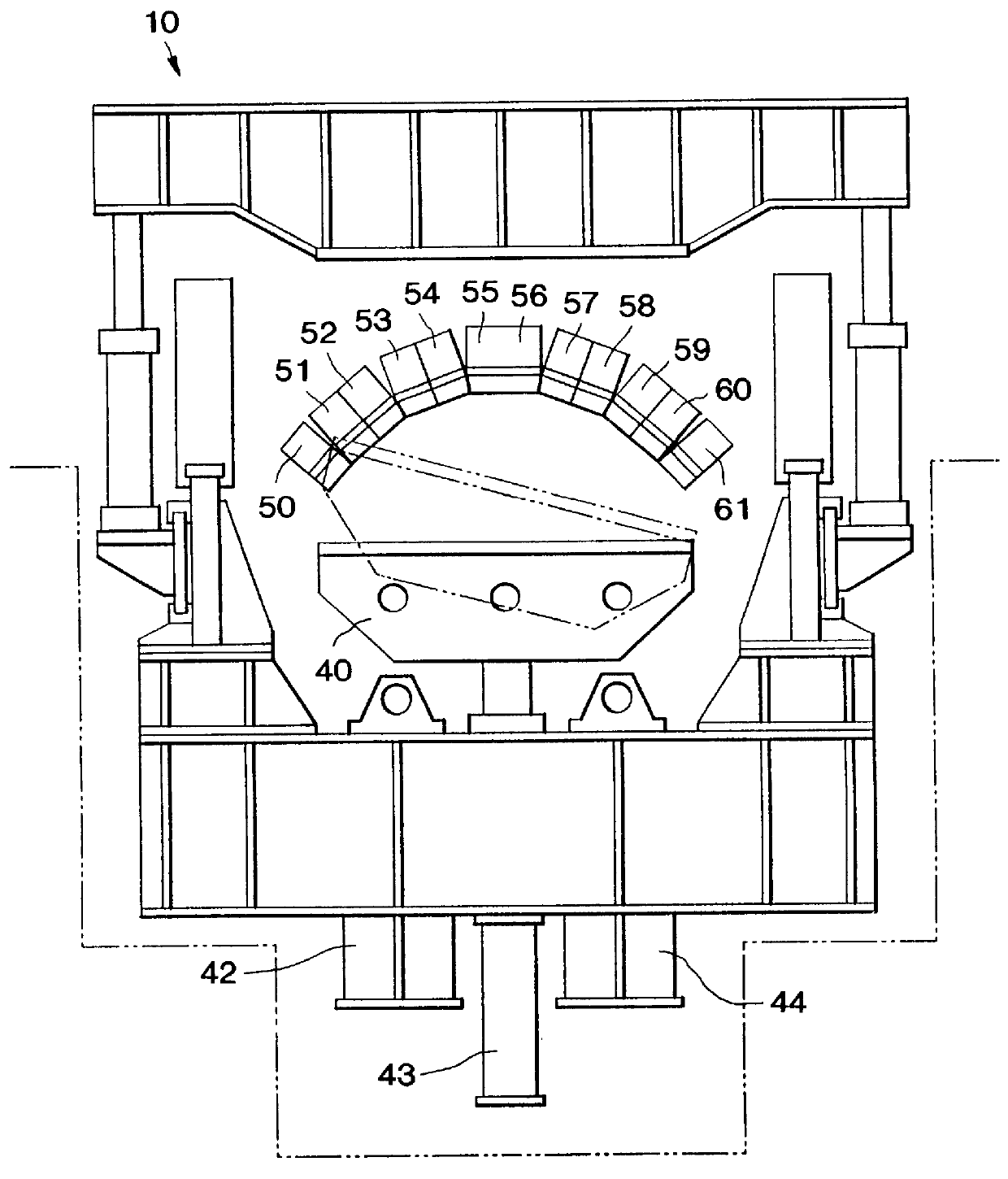

Swaging technology

InactiveUS6931899B2Practical and reliable and accurate and efficientForging hammersShaping safety devicesEngineeringCatheter

A swager for swaging marker bands to a medical catheter, comprises an article input mechanism, the article input mechanism having a first input roller assembly for receiving and conveying an article, a first sensor for detecting a predetermined aspect of the article, a second input roller assembly for receiving and conveying the article, a positioning roller assembly for precisely aligning the article with respect to the swaging head, and a second sensor all constructed and arranged in a streamwise orientation. The swager also has a radial compression swaging head with a central swaging aperture, the swaging head being aligned and communicatively coupled with the input mechanism to receive an input article from the article input mechanism and to swage the article, the swaging head being rotatable and including (i.) a unitary die plate including a plurality of die segments movably coupled to each other to provide a radial compressive force to the article disposed in the central swaging aperture; and (ii.) a closing plate pivotally coupled with respect to each other. The swager also has an output mechanism aligned and communicatively coupled with the swaging head to receive the swaged article. A swaging head and die are also disclosed.

Owner:MACHINE SOLUTIONS

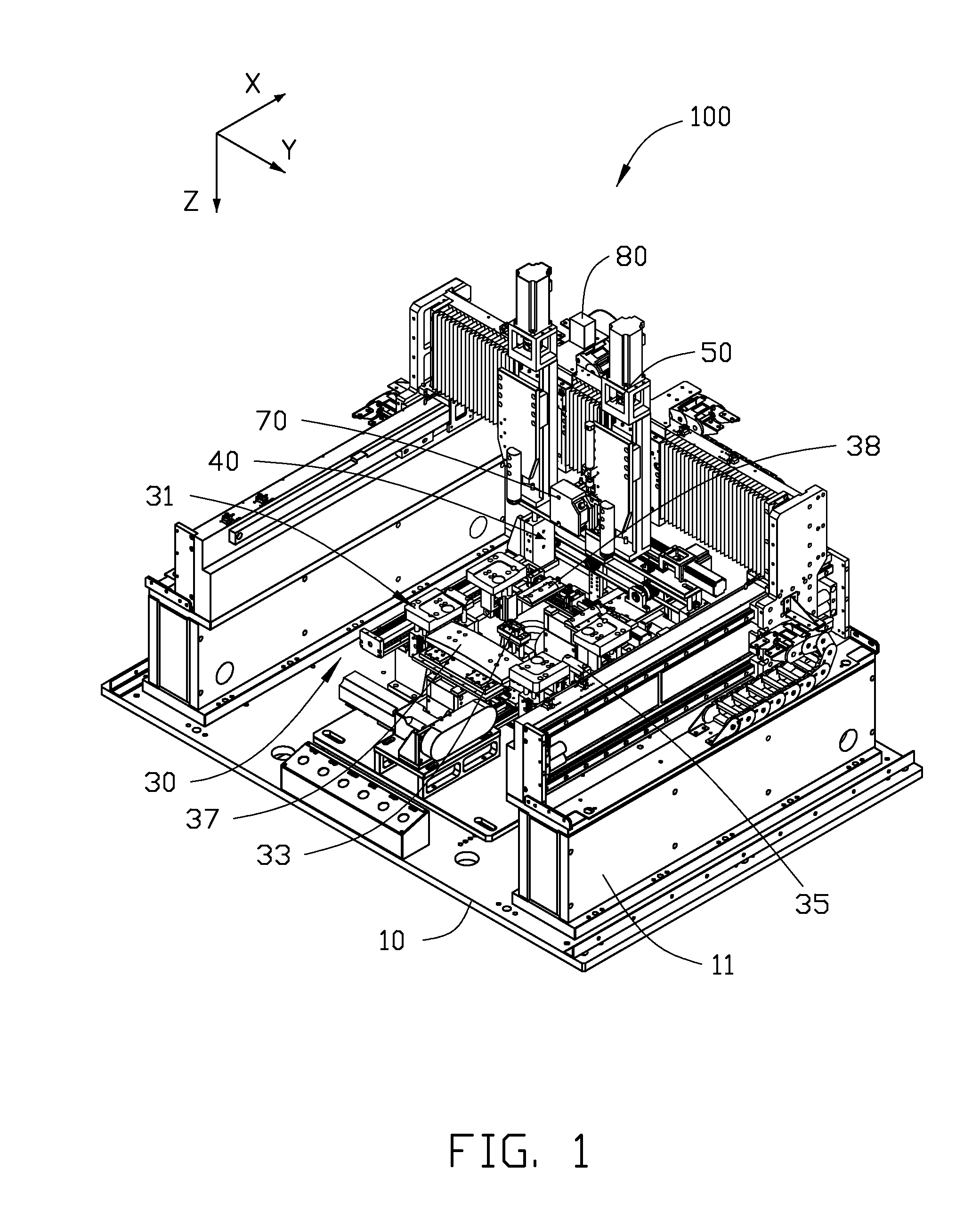

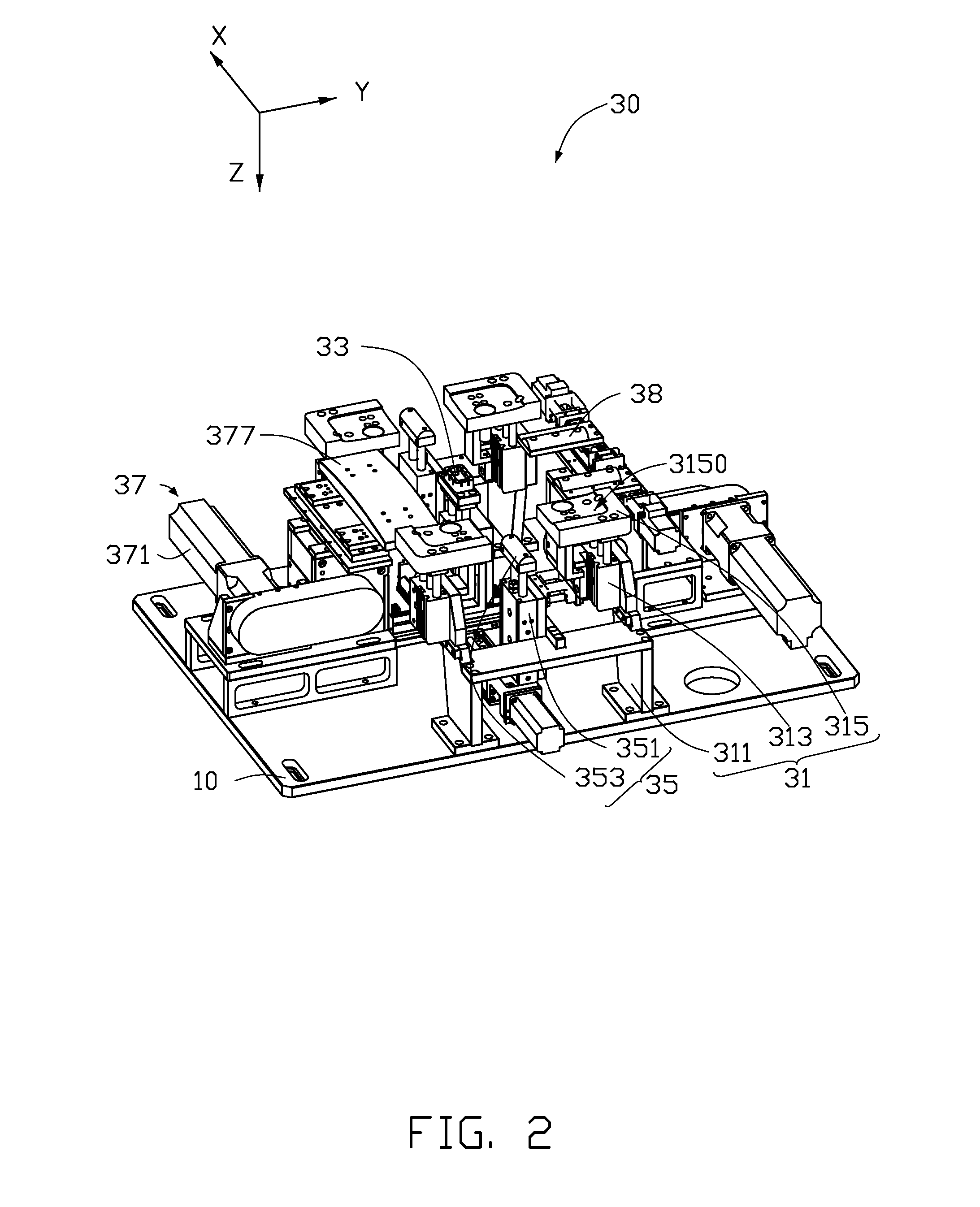

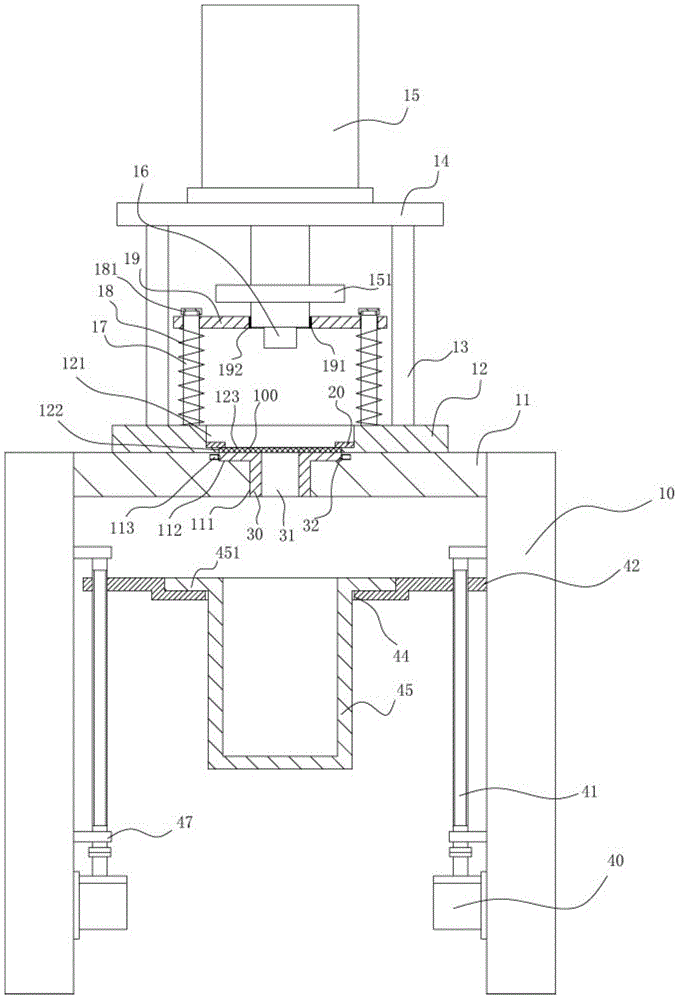

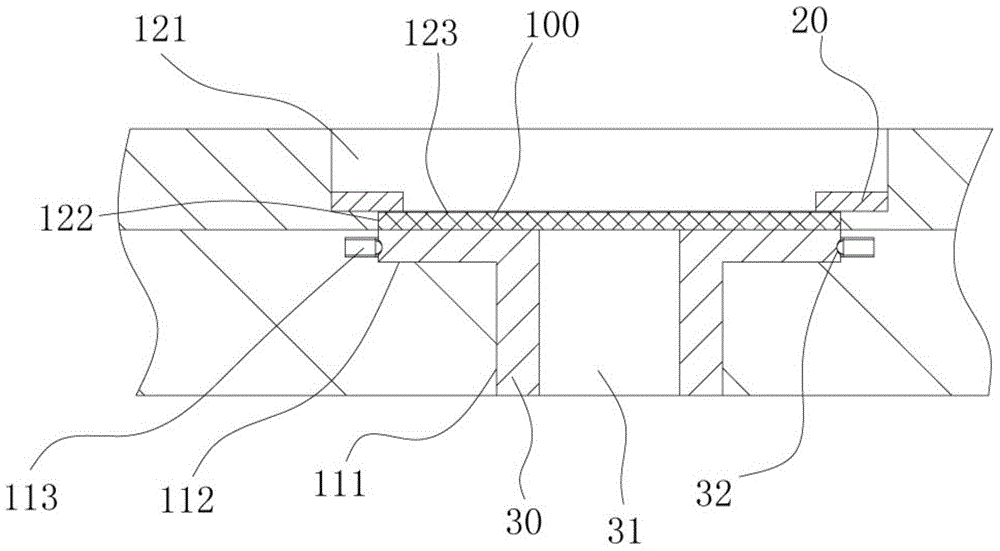

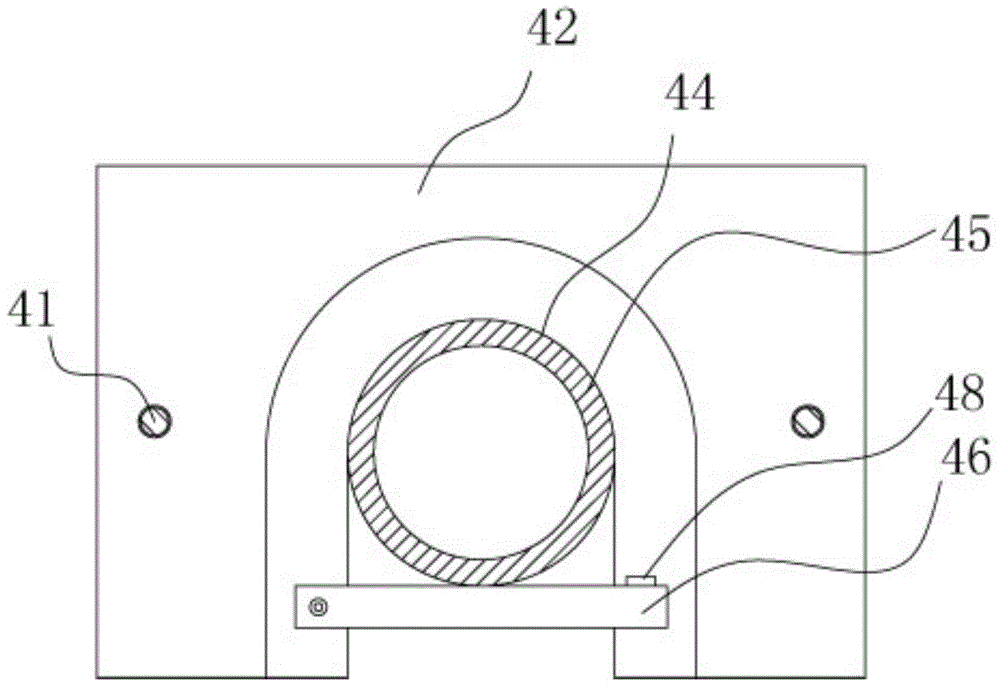

Reshaping device and positioning assembly thereof

InactiveUS20140250964A1Metal-working feeding devicesShaping safety devicesEngineeringElectrical and Electronics engineering

A reshaping device for reshaping a workpiece, includes a worktable, a reshaping assembly, a measuring unit, a positioning assembly, and a controller electrically connected to the reshaping assembly, the measuring unit, and the positioning assembly. The positioning assembly includes a pair of positioning subassemblies and a movable supporting subassembly. Each positioning subassembly comprises a supporting bracket and two positioning members, the two supporting brackets are distributed on the worktable, spaced from each other, for holding the workpiece. The movable supporting subassembly comprises two transmission members and two driving members. The two transmission members are laminated together and disposed on the worktable. The two driving members are respectively assembled to the two transmission members and drive the two transmission members to slide along different directions, thereby supporting the workpiece. The present disclosure further discloses a positioning assembly.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +1

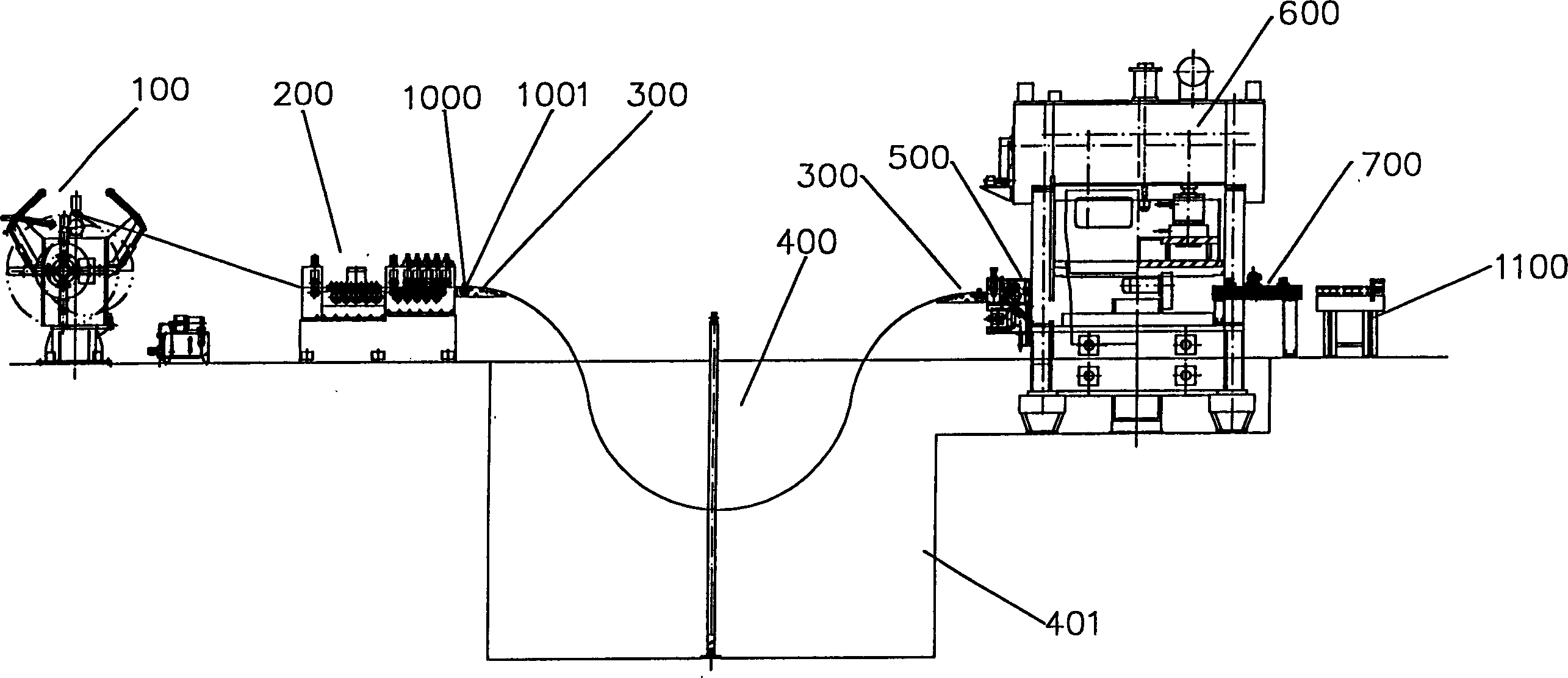

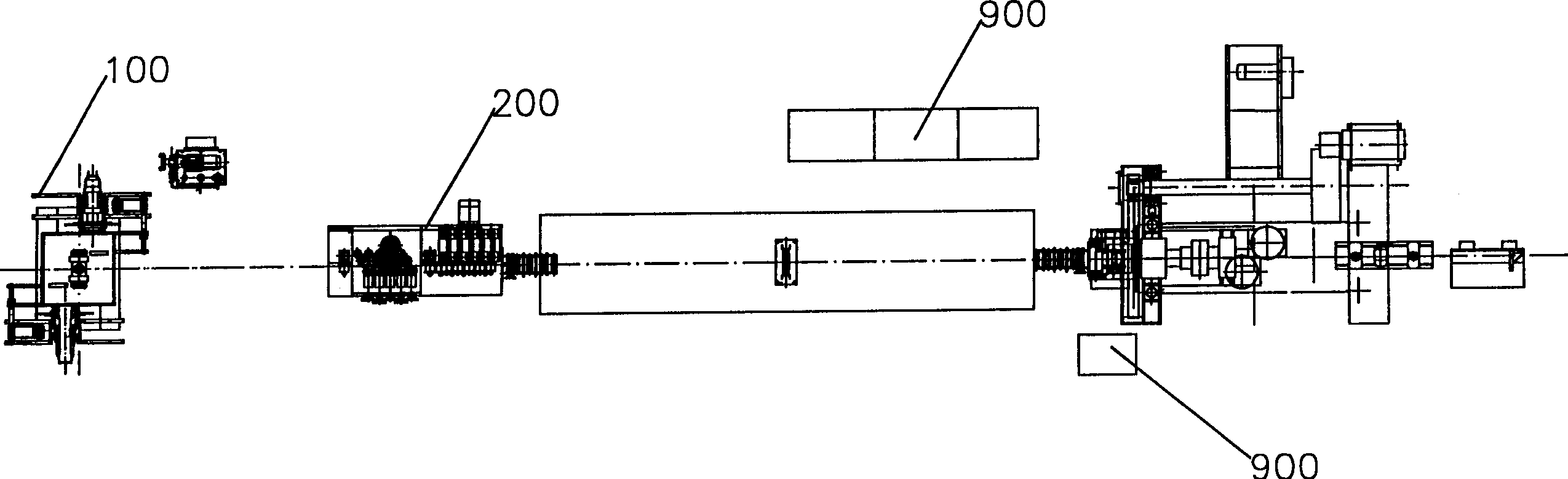

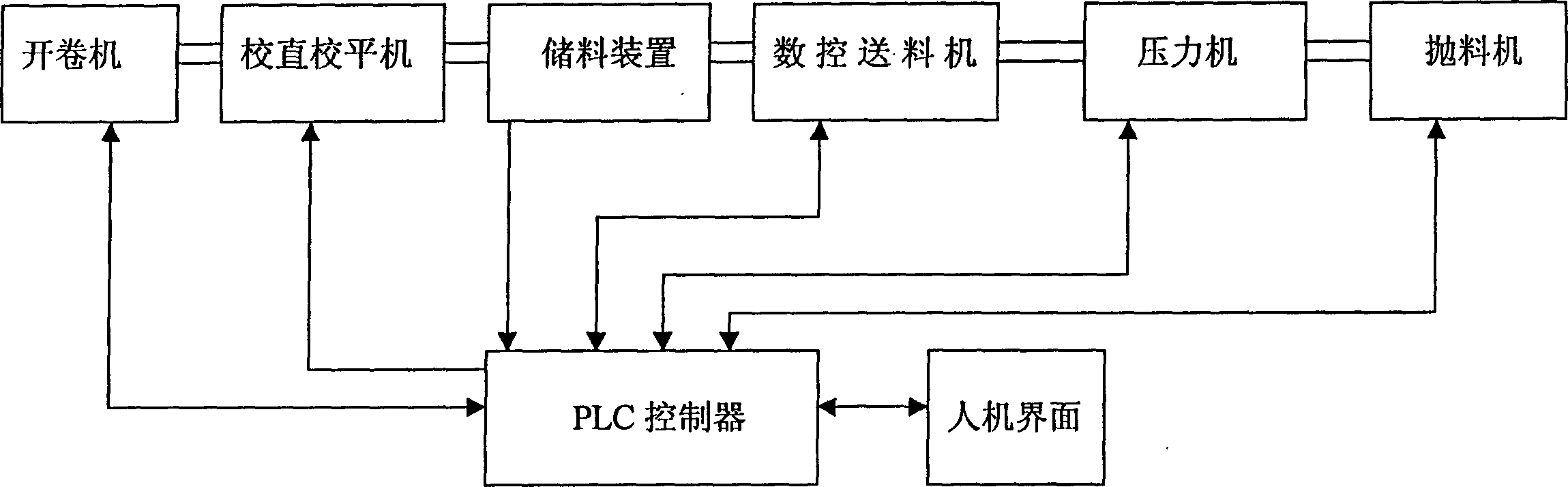

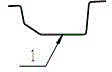

Continuous steel belt punching production line

InactiveCN1416974AImprove machining accuracyIncrease productivityMetal-working feeding devicesShaping safety devicesProduction linePunching

The continuous steel belt punching production line incldues steel belt unwinding machine, straightening machine, material storage in the back of the straightening machine, numerically controlled feeding mechanism connected to the material storage, pressing machine, material thrower, laser ranger, two regulating trays in the tail and the feeding end of the numerically controlled feeding mechanism separately and electric controller unit. By means of the PLC program controller in the electric controller unit, the production line can punch continuously and automatically in high production efficiency and high product precision.

Owner:BEI JING NEW BUILDING MATERIALGRP

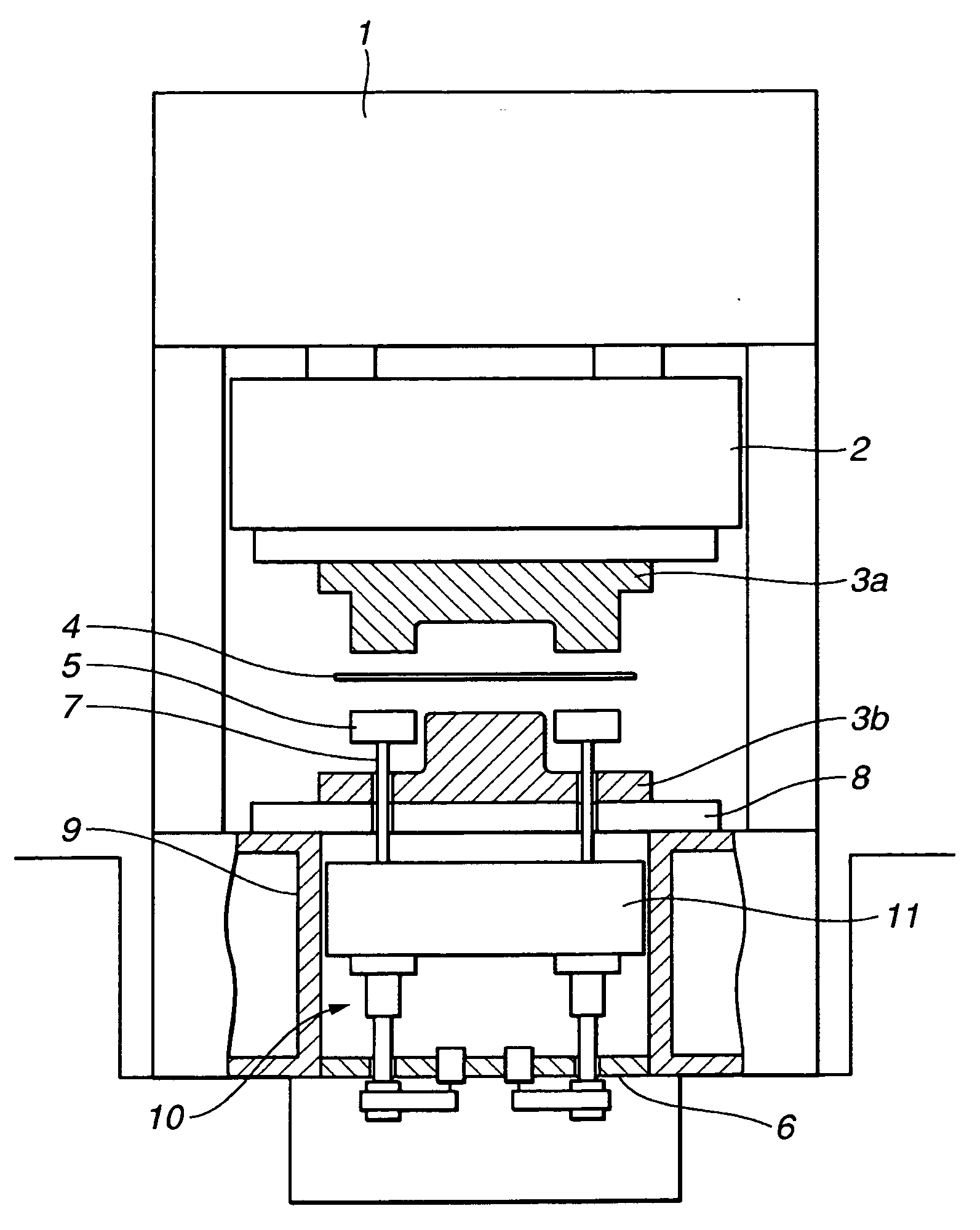

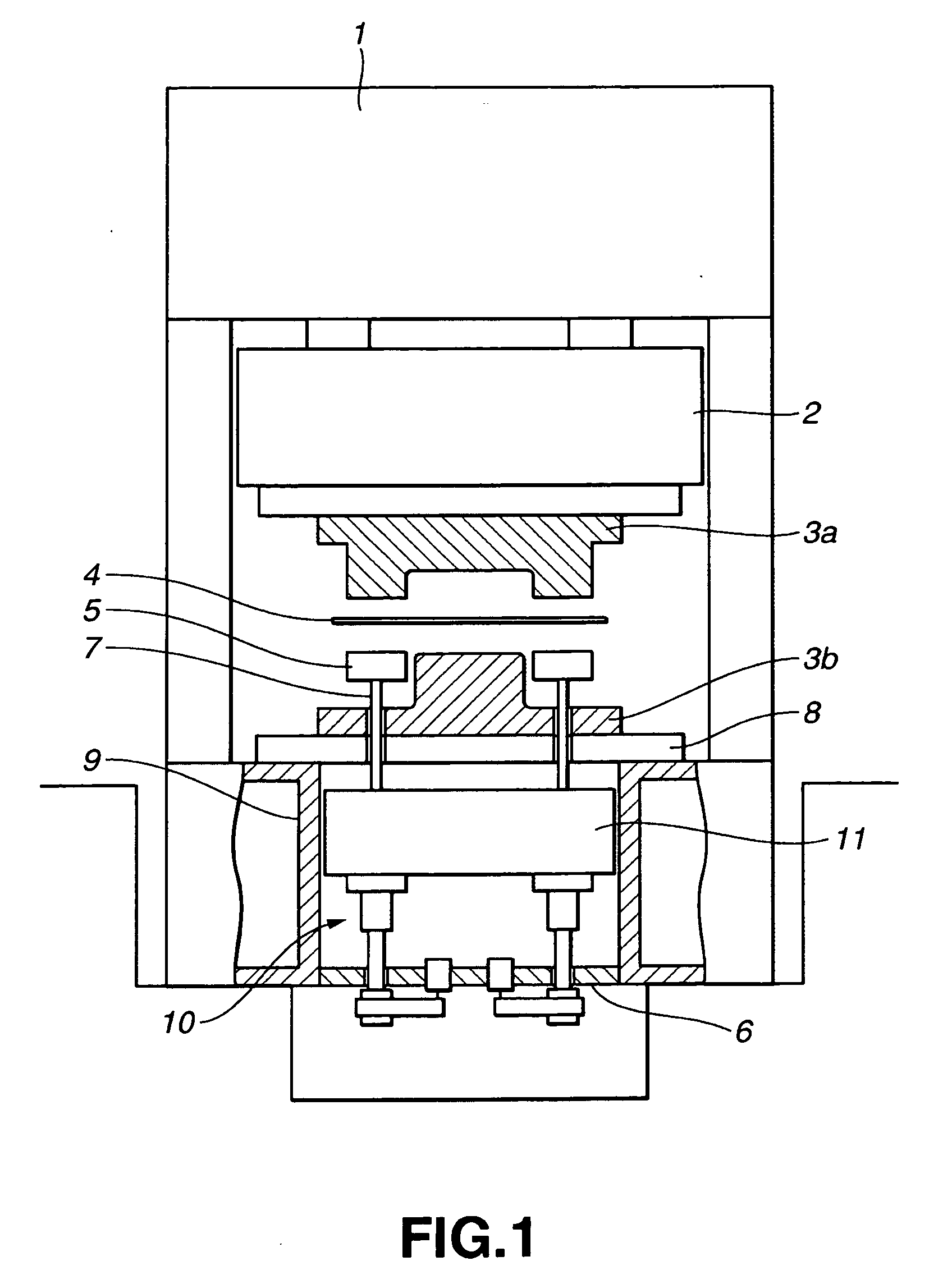

Die cushion controlling apparatus and die cushion controlling method

ActiveUS20050274243A1Cushion pressure of cushion can be controlledImprove accuracyShaping safety devicesForging press detailsEngineeringCushion

A die cushion controlling apparatus for controlling an operation of a cushion pad, which comprises a pad drive mechanism for driving to raise or lower the cushion pad while applying an upward energizing force, a load measuring unit for measuring a load generated in the cushion pad, a time detecting unit for detecting a generating time and a vanishing time of the load, and a control unit for controlling the pad drive mechanism so that a load measured value measured by the load measuring unit follows a preset load pattern during a period from when the time detecting unit detects the generating time of the load until when the time detecting unit detects the vanishing time of the load.

Owner:KOMATSU LTD +1

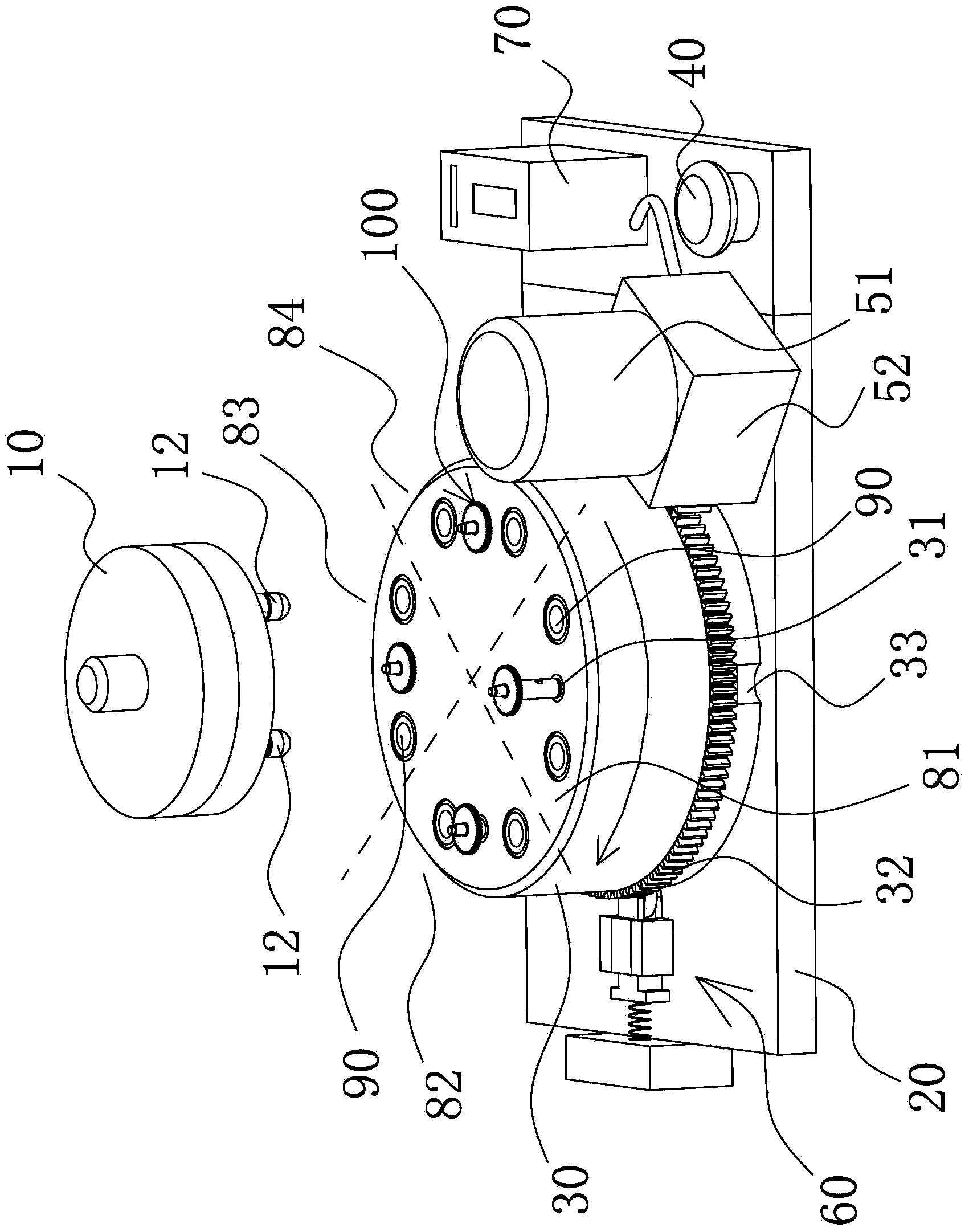

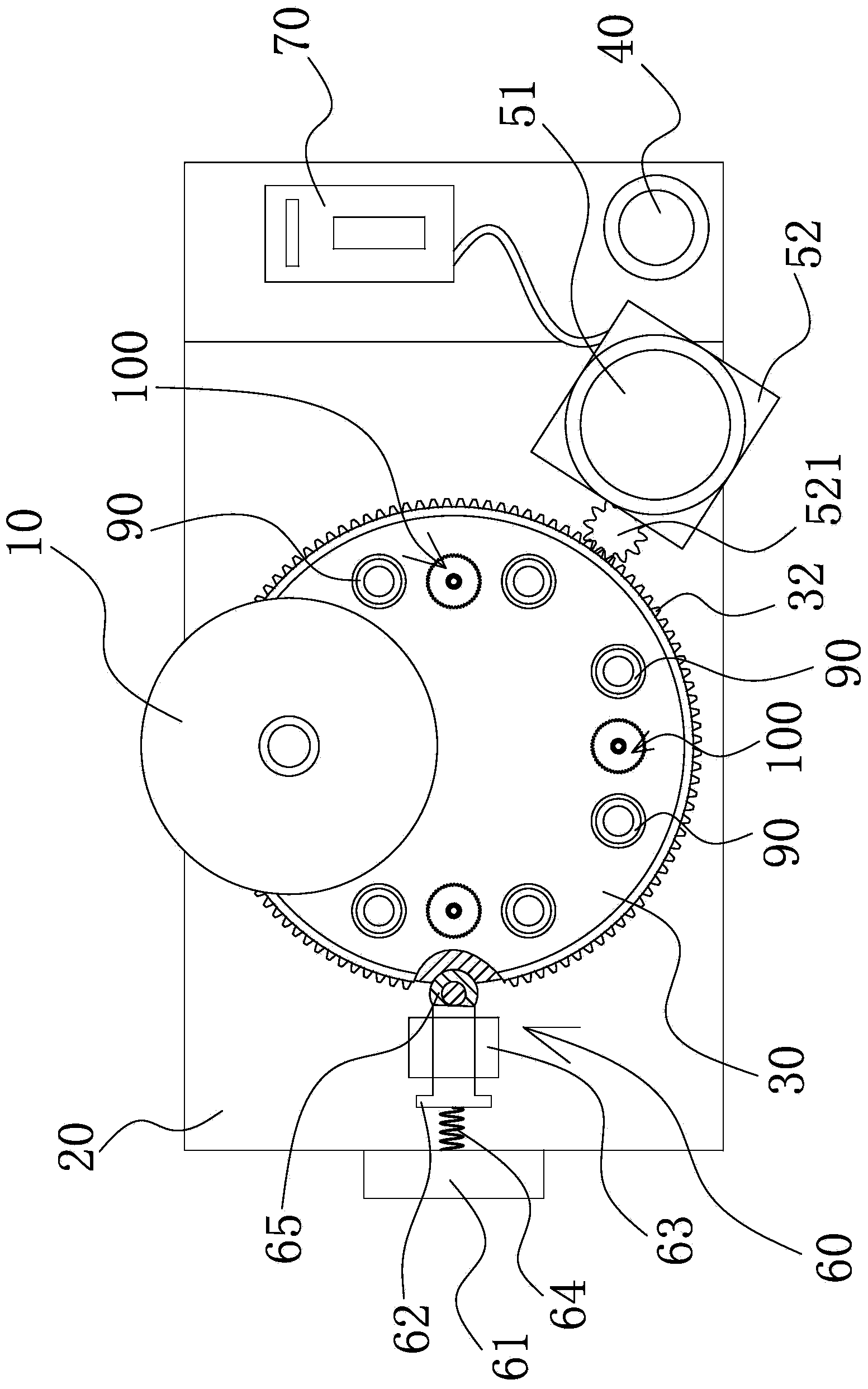

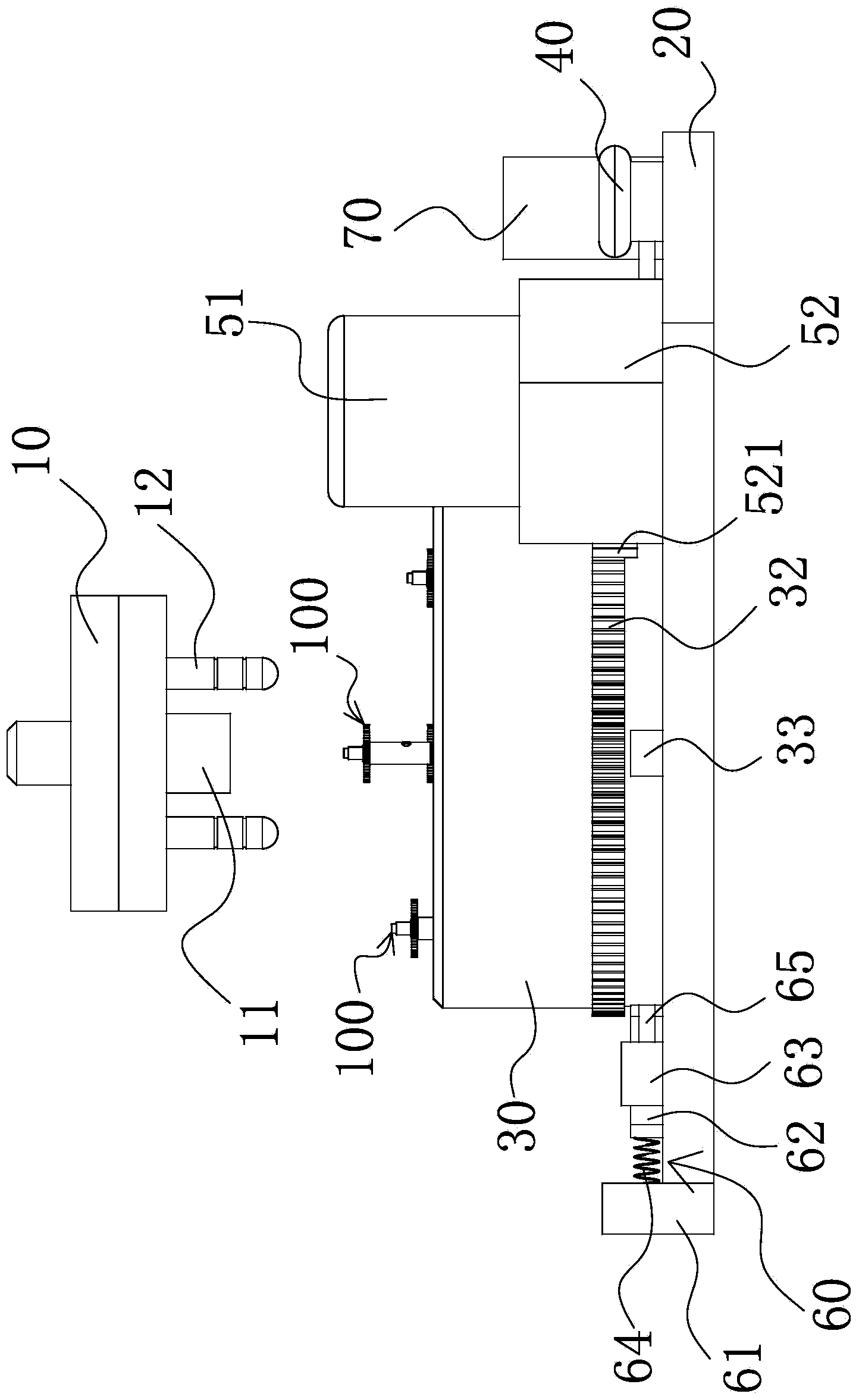

Multi-station punching device

ActiveCN104070098AWork process safetyImprove work efficiencyShaping toolsShaping safety devicesPunchingEngineering

The invention provides a multi-station punching device and belongs to the field of mechanical technology. The multi-station punching device comprises an upper die and a lower die holder arranged under the upper die. The middle of the end surface of the upper die, which faces towards the lower die holder, is provided with a punch; the lower die holder is rotatably provided with a turntable matched with the punch; the end surface of the turntable, which faces towards the upper die, is provided with at least two die holes for placing products; the lower die holder is provided with a control switch and a driving unit for driving the turntable to rotate. When the turntable rotates, one of the die holes is positioned under the lower die and is coaxial with the punch, the other die holes are disposed on the circumference of the upper die, and the control switch, the driving unit and the upper die are electrically connected to form a closed circuit. The multi-station punching device has the advantages of being high in working efficiency, safe and reliable.

Owner:NINGBO NEW GUANLIAN MOTOR ELECTRONICS

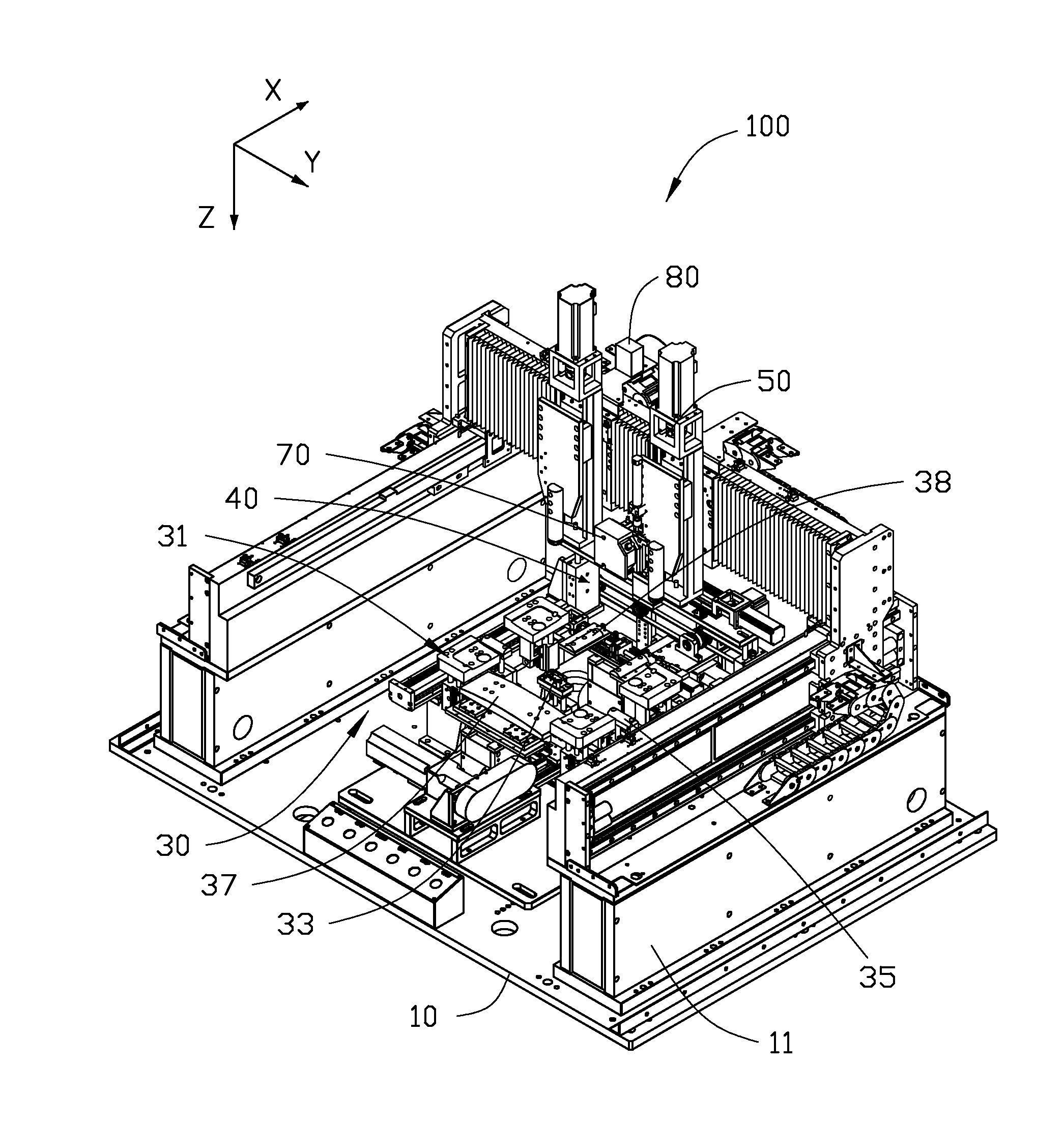

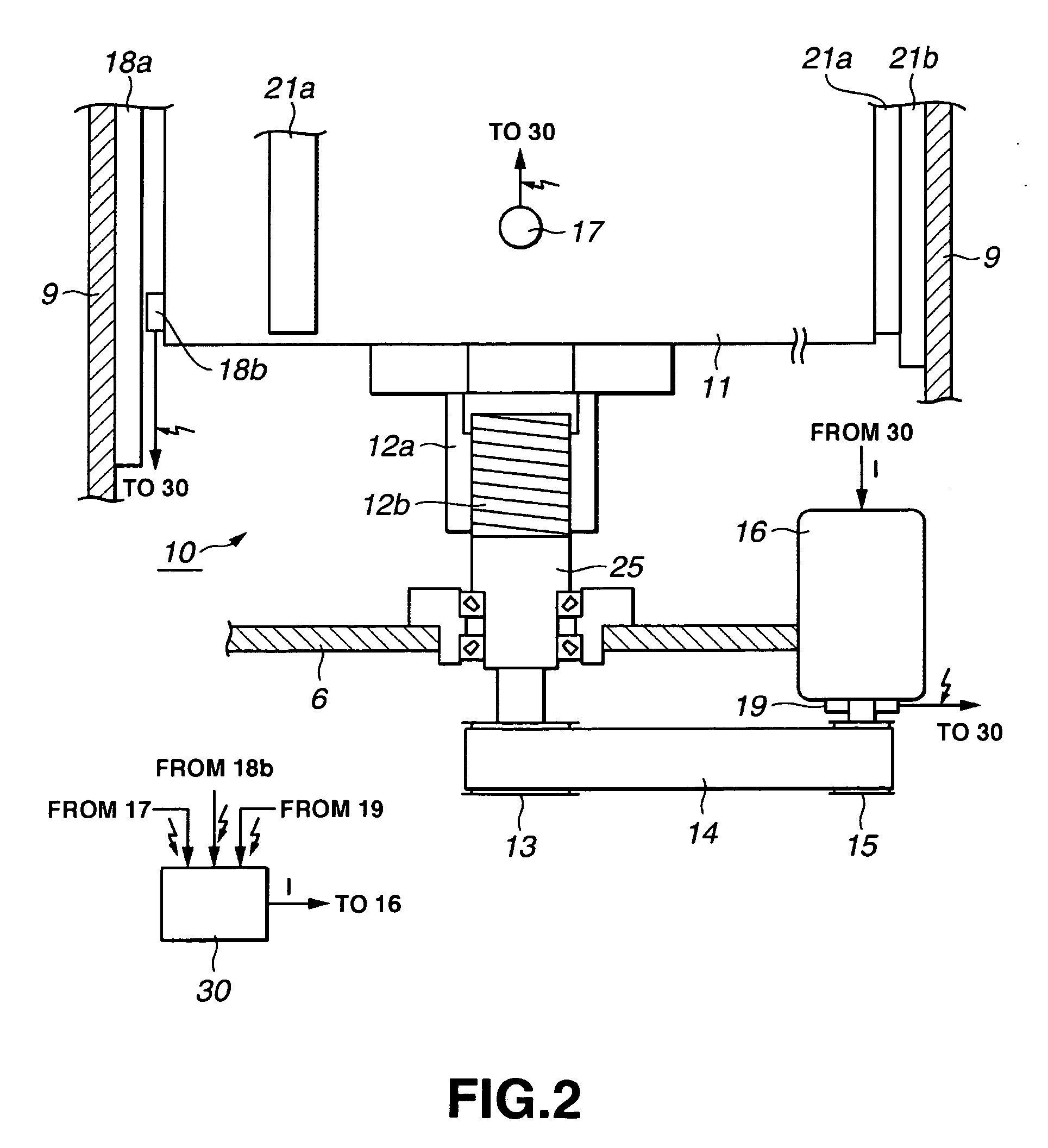

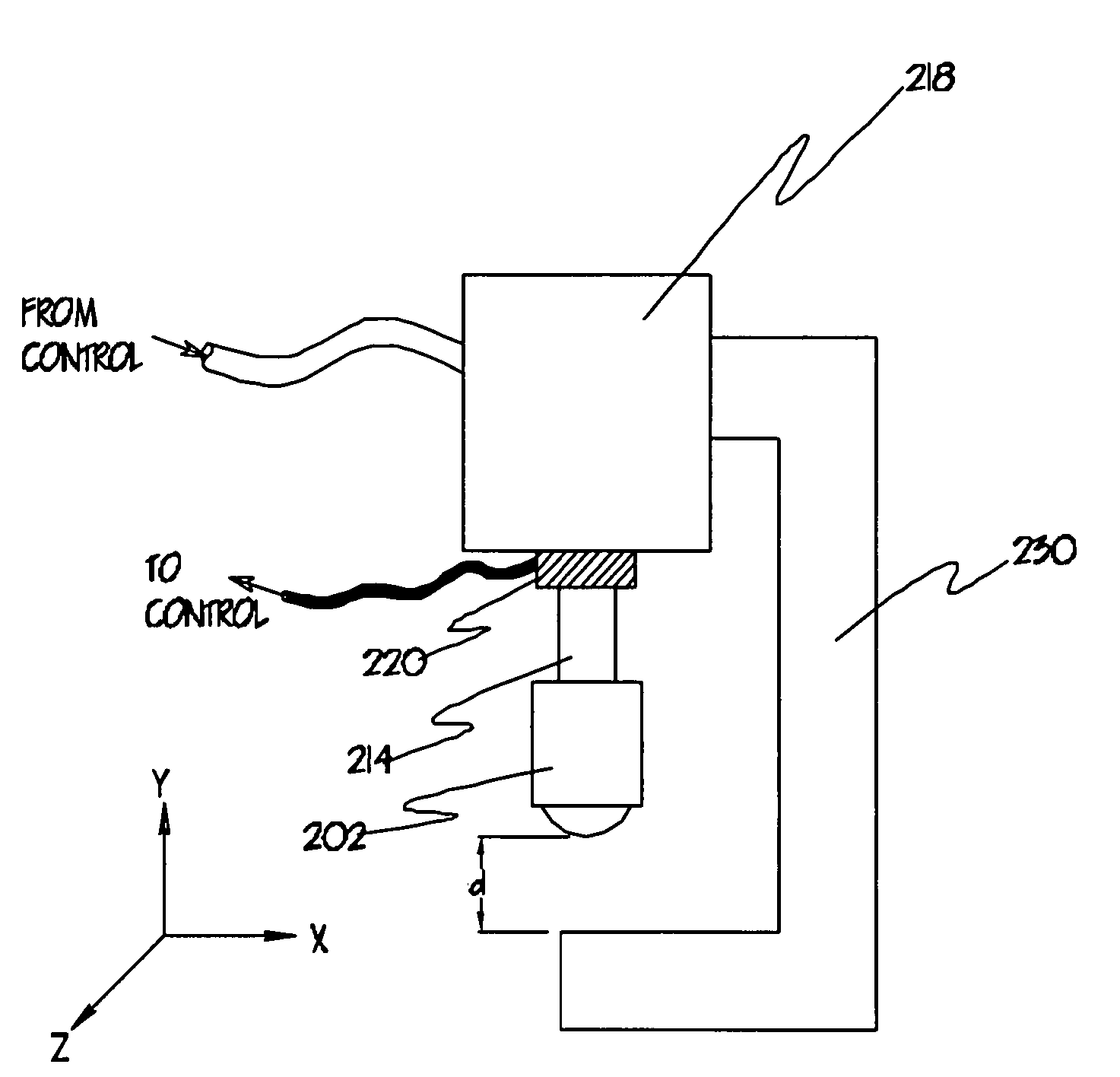

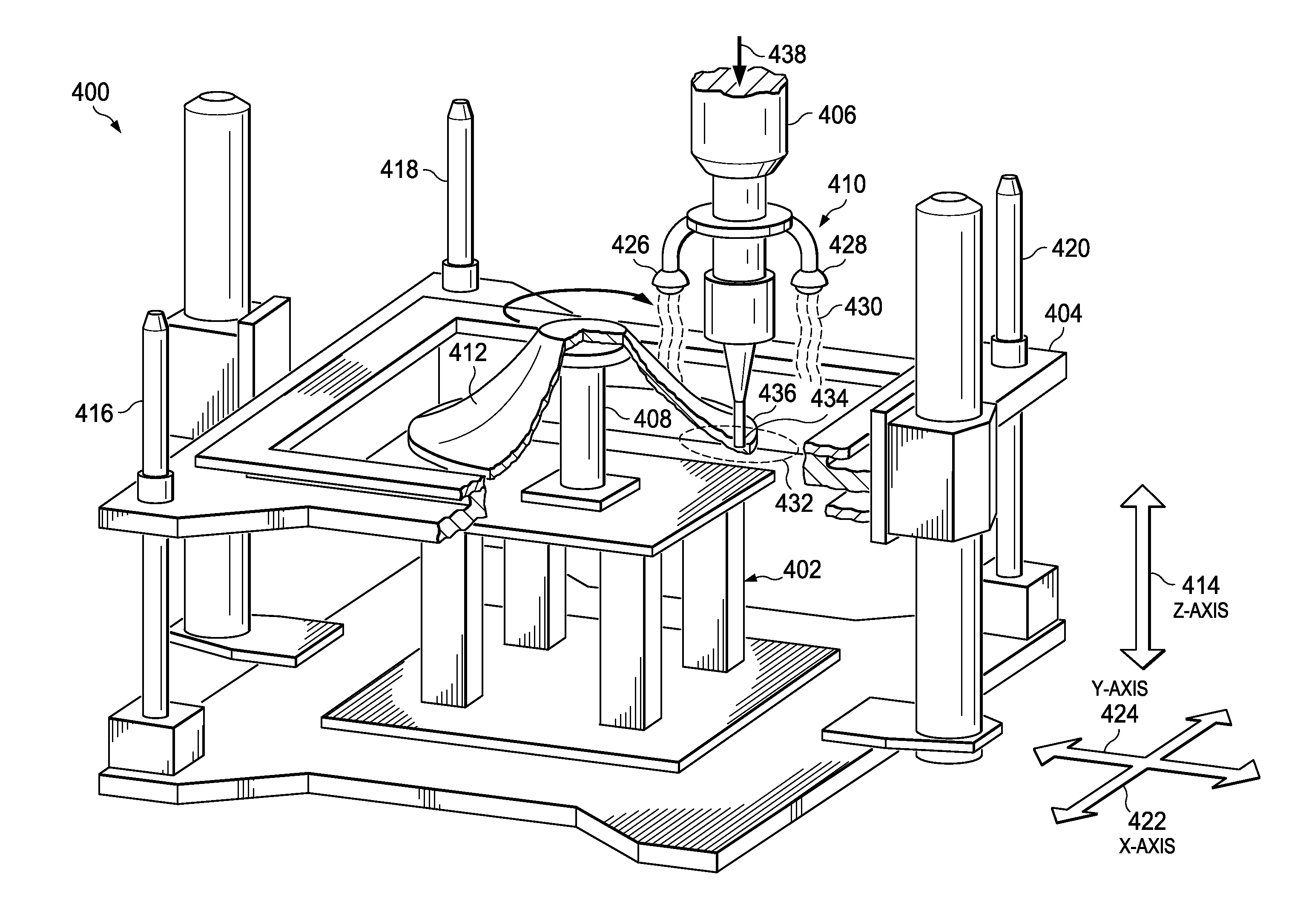

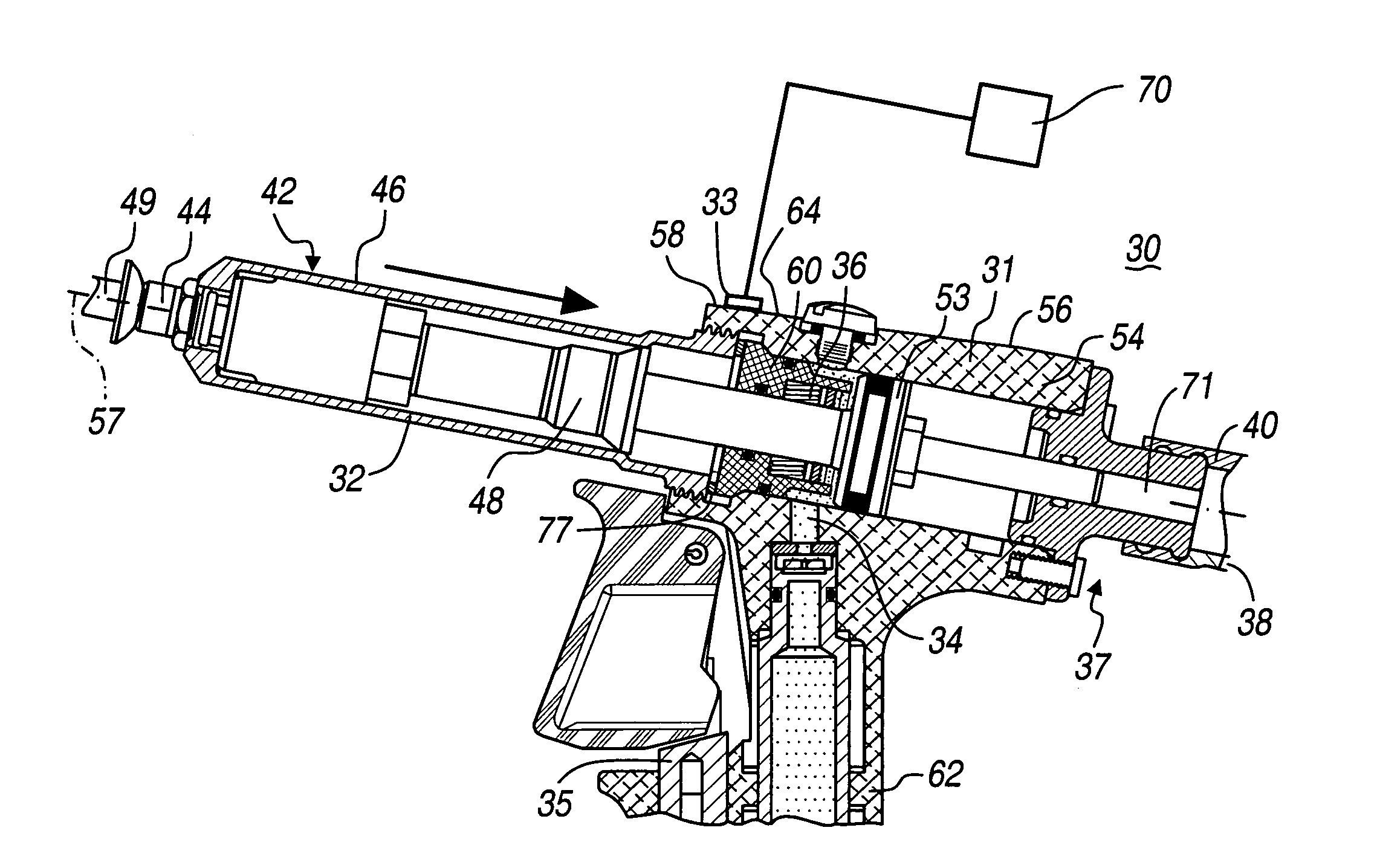

Surface treatment apparatus and method

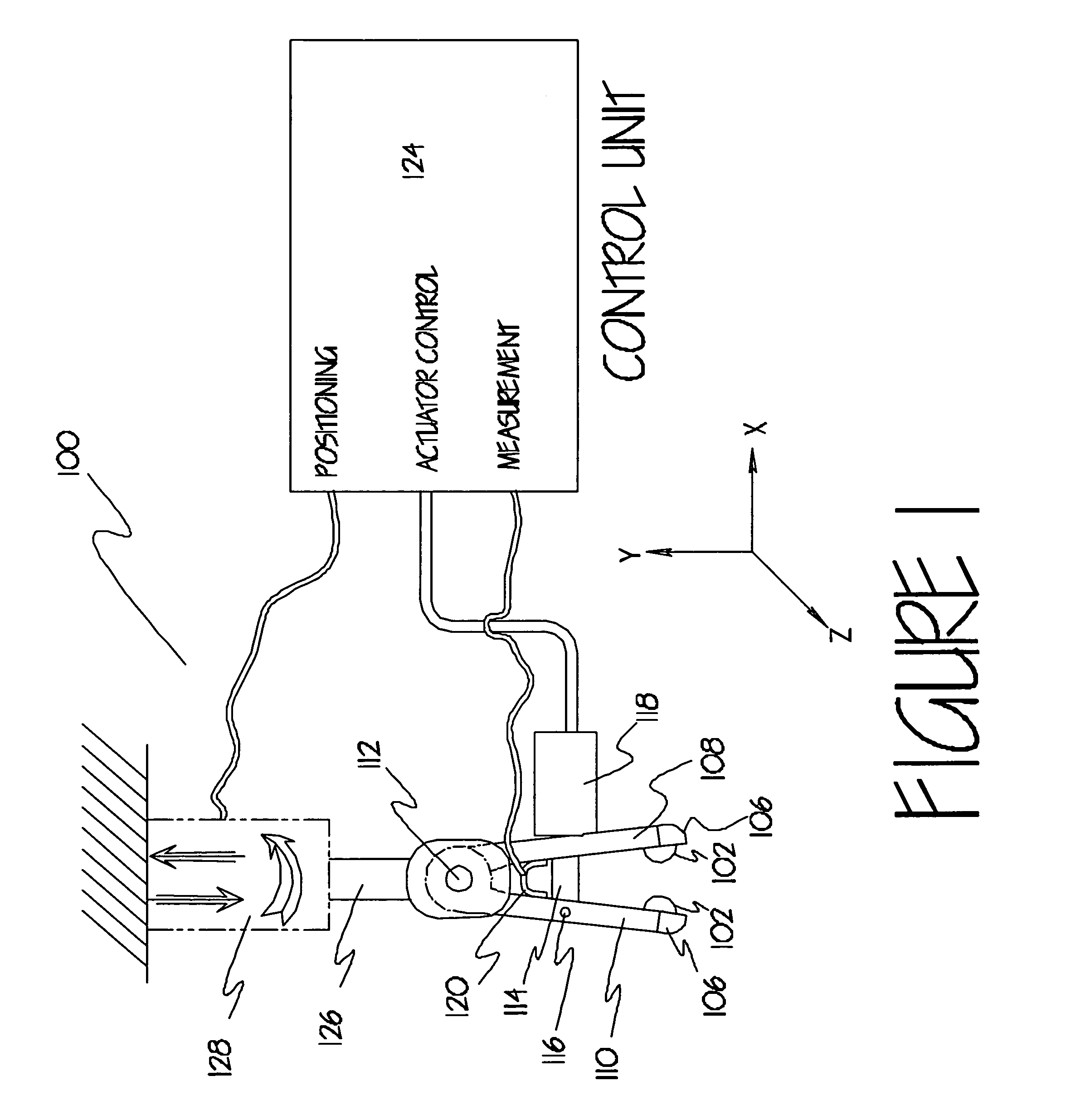

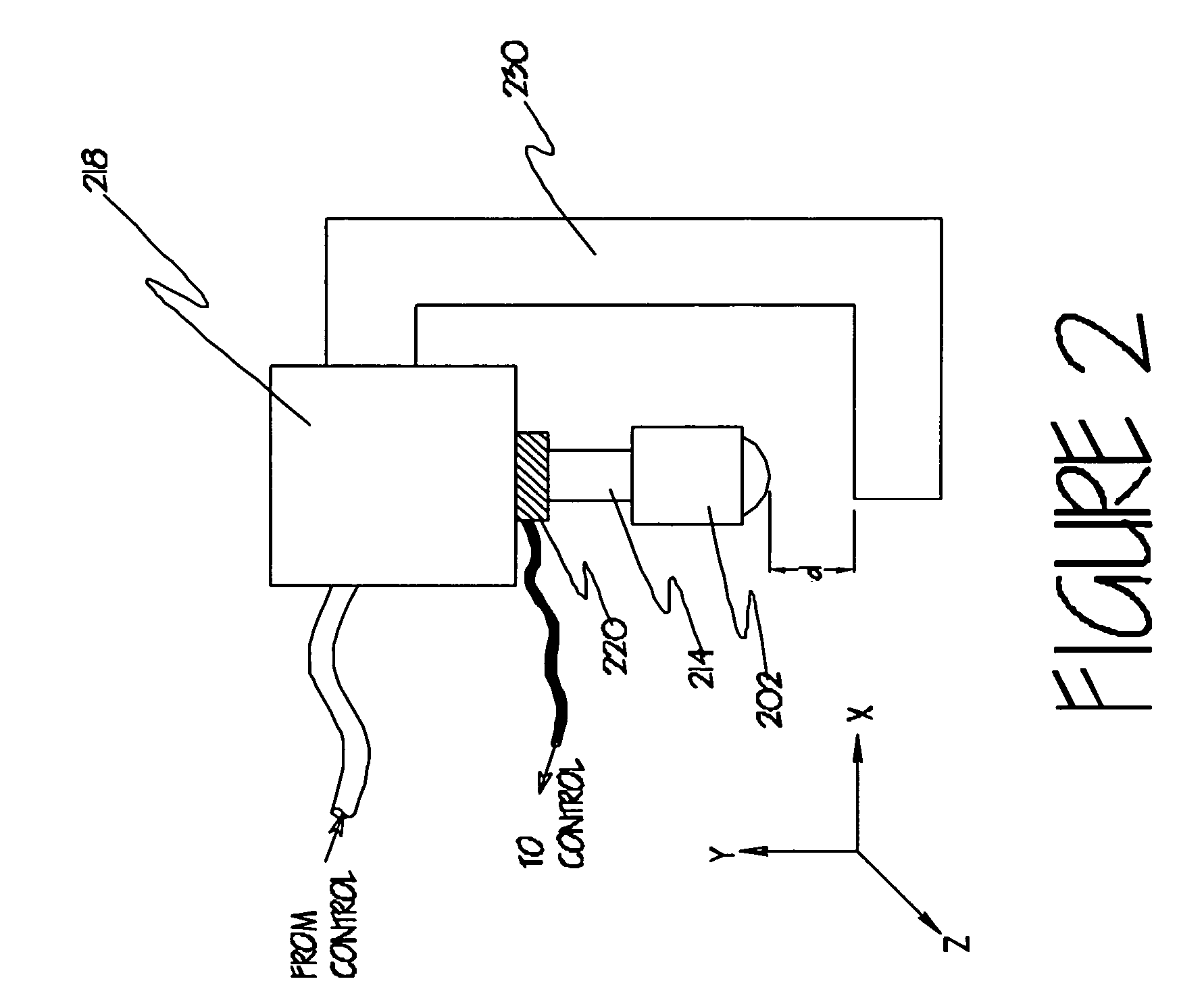

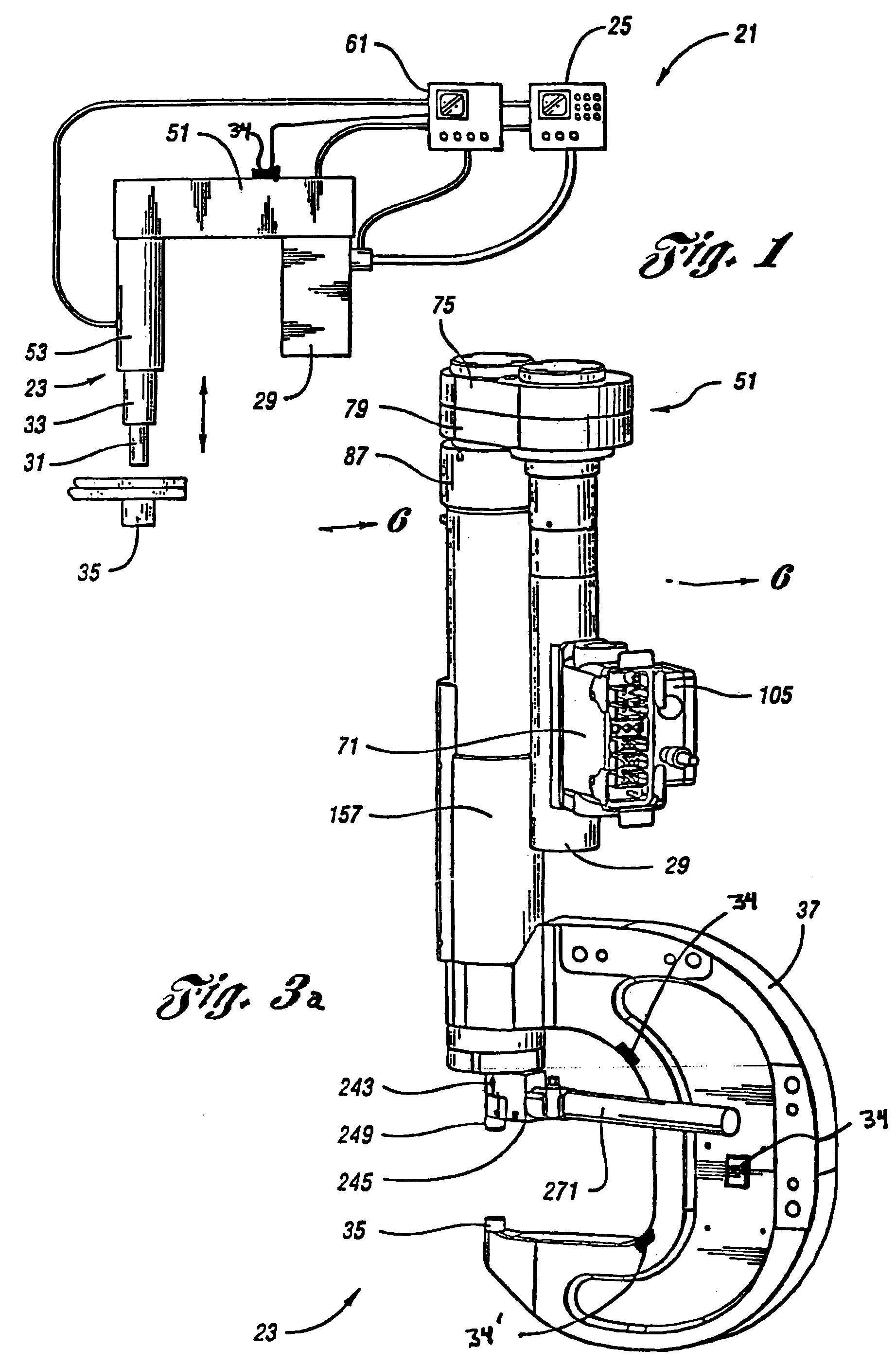

ActiveUS7600404B2Reduce processing timeEliminate needShaping toolsShaping safety devicesActuatorCalipers

The present invention relates to a surface treatment apparatus and method for inducing compressive residual stress in the surface of a workpiece with dimensional variations. The method comprises the acts of measuring the dimensions of the workpiece during a surface treatment operation and adjusting the surface treatment process parameters to account for the measured dimensions. In one embodiment, the apparatus comprises two surface treatment elements oriented in opposition to one another in a caliper configuration. The surface treatment elements are positioned and impinged against the surface of a workpiece by an actuator controlled by a computer control unit. The depth to which the surface treatment elements are impinged is precisely controlled to achieve the desired magnitude and depth of compressive residual stress. A sensor operatively connected to the apparatus senses and relays the dimensions of the workpiece to a computer control unit that adjusts the operating parameters accordingly.

Owner:SURFACE TECH HLDG

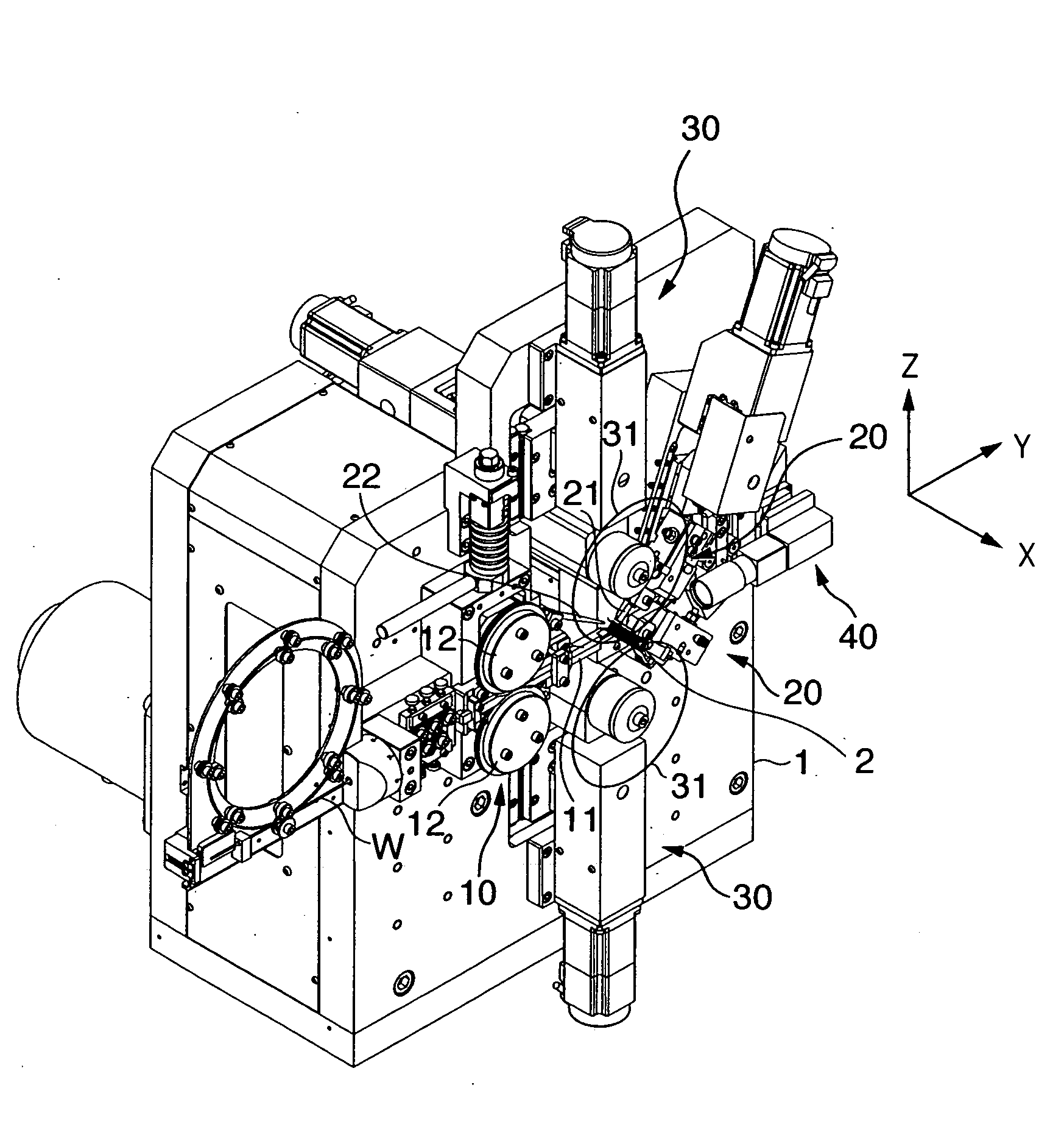

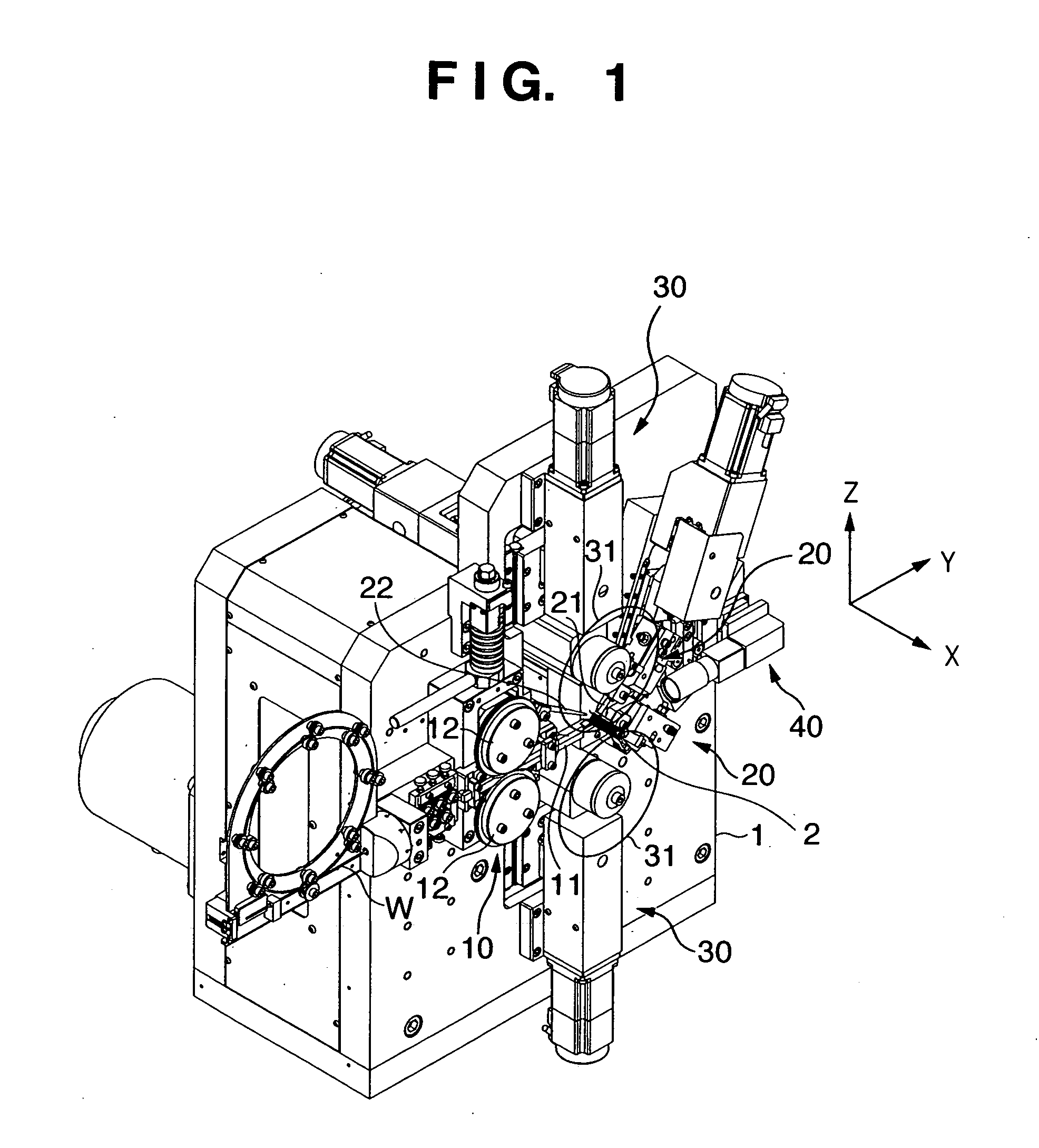

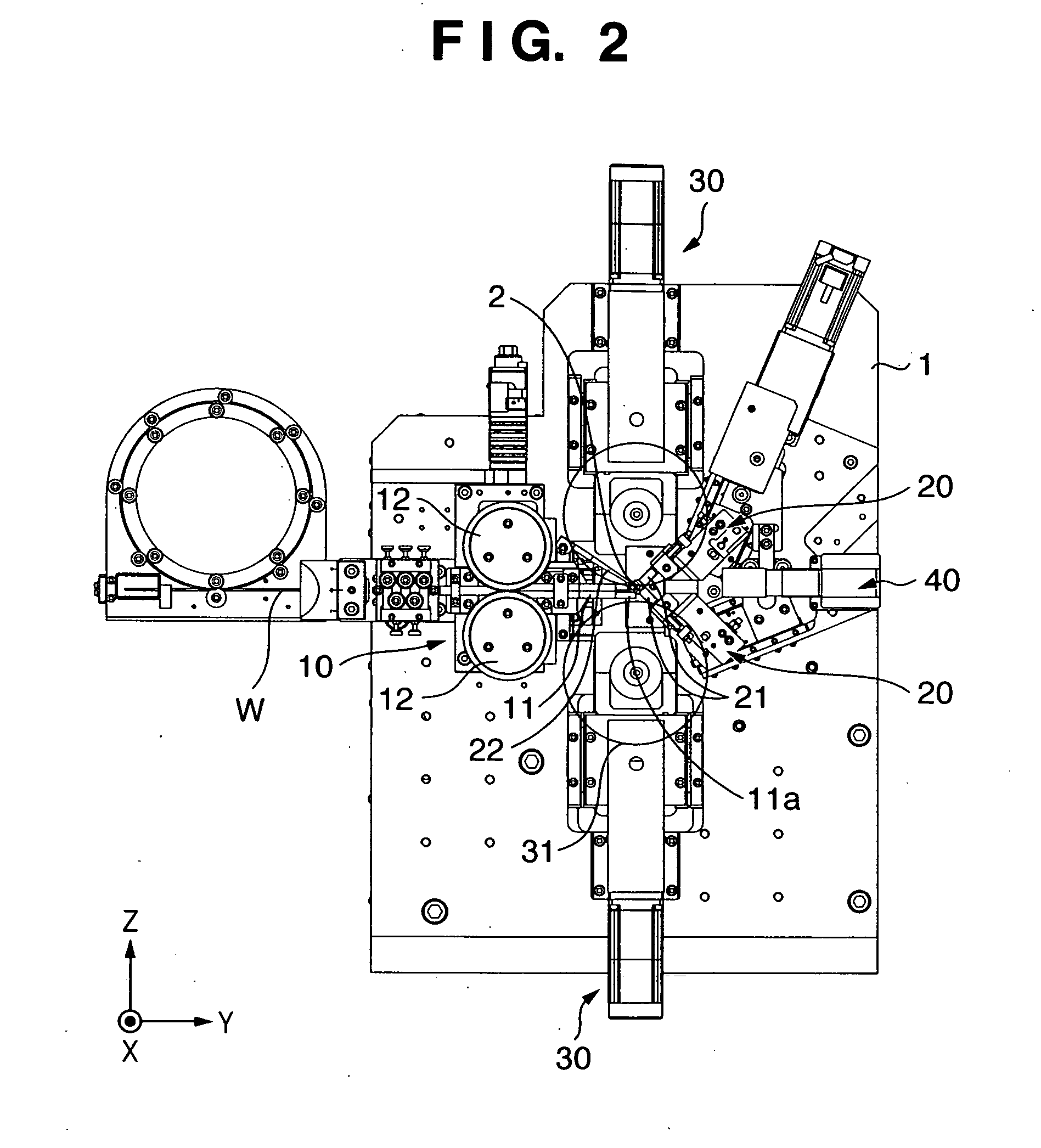

Helical part manufacturing apparatus and control method thereof

InactiveUS20080302156A1Easy to processIncrease productivityShaping safety devicesGrinding feed controlManufactured apparatusEngineering

This invention provides an apparatus for manufacturing a helical part by feeding a wire W toward a pointing tool 21 and pushing the wire W against the pointing tool 21 to forcibly wind the wire. The apparatus comprises: a feed roller 12 for feeding the wire W toward the pointing tool 21; a wire feeding motor 111 for rotatably driving the feed roller; a grindstone tool unit 30, which holds a discoid grindstone 31 rotatable and movable, for cutting the wire W by the rotating discoid-grindstone 31; and a CPU 100 for controlling the wire feeding motor 111 and grindstone tool unit 30 to move the discoid grindstone 31 on a plane which is substantially perpendicular to a coil growing direction of the helical part and to cut the wire W in a direction which is substantially perpendicular to the coil growing direction.

Owner:ITAYA SEISAKUSHO

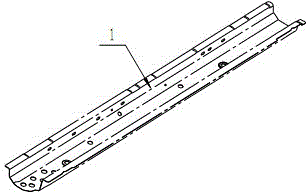

Punching device for electric wire threading slot punching

ActiveCN104889231AMeet punching requirementsRealize up and down adjustmentShaping toolsPerforating toolsPunchingEngineering

The invention discloses a punching device for electric wire threading slot punching. The punching device for electric wire threading slot punching comprises a rack, wherein an oil cylinder connecting bottom plate is fixedly arranged on the bedplate of the rack, a connecting strut is fixedly arranged on the top surface of the oil cylinder connecting bottom plate, an upper connecting plate is fixedly arranged at the upper end of the connecting strut, and a punching oil cylinder is fixedly arranged on the upper connecting plate; waste box adjusting motors are respectively fixedly arranged and vertical adjusting screws are hinged on the two sides plates of the rack, a waste box supporting plate is in threaded connection in the two vertical adjusting screws, the waste box supporting plate is provided with a stepped through hole, a waste box is inserted into the stepped through hole, the outer wall of the top portion of the waste box is provided with a radially extending supporting edge, and the radially extending supporting edge is inserted into the insertion section of the upper portion of the stepped through hole. The punching device for electric wire threading slot punching has the advantages that a wire threading slot plate can be automatically punched, the upward and downward adjustment of the waste box can be realized through the waste box adjusting motors, the waste can be collected in a unified manner and automatically falls down to the ground, and the waste box does not need to be manually lifted for discharging.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

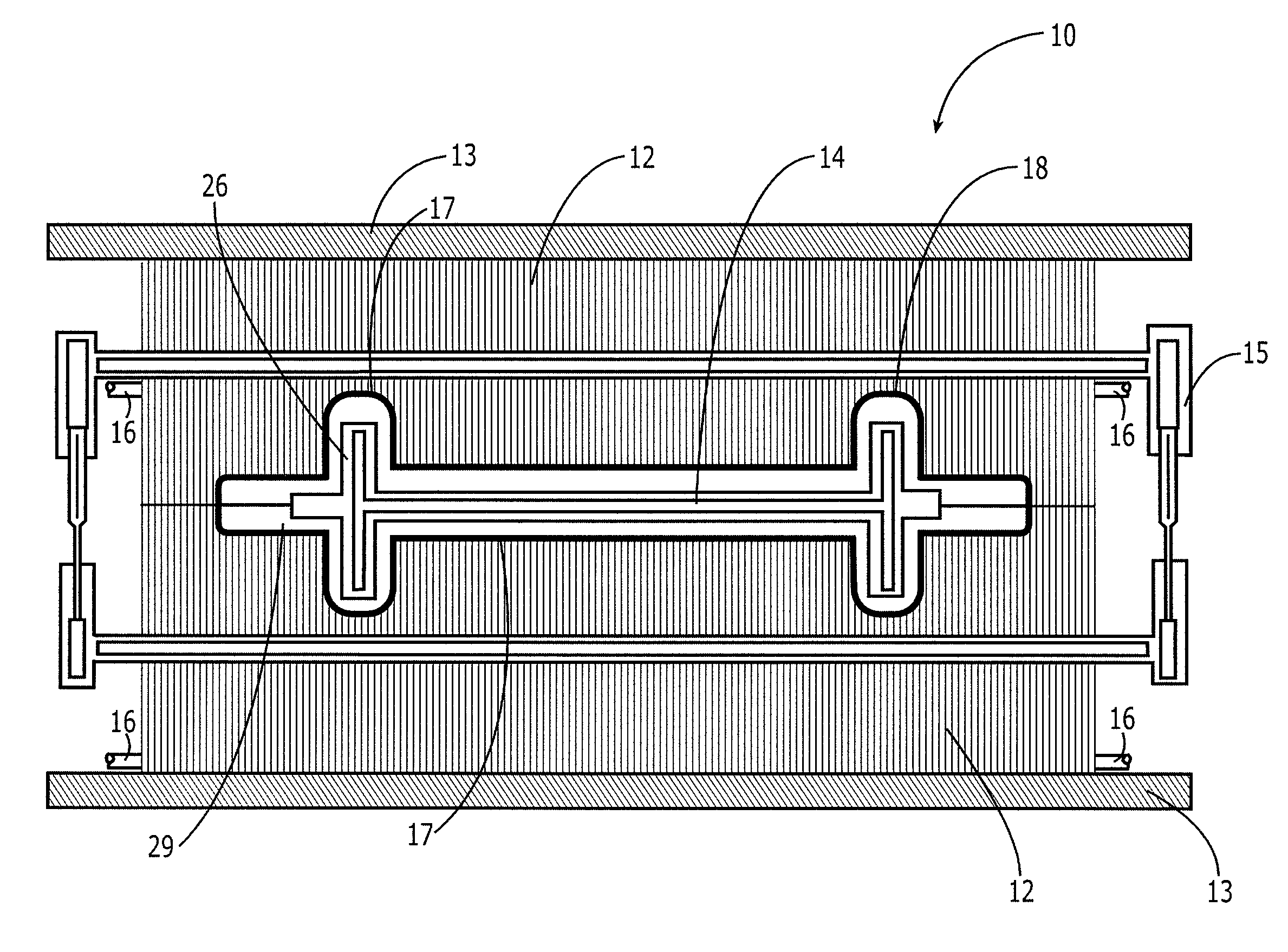

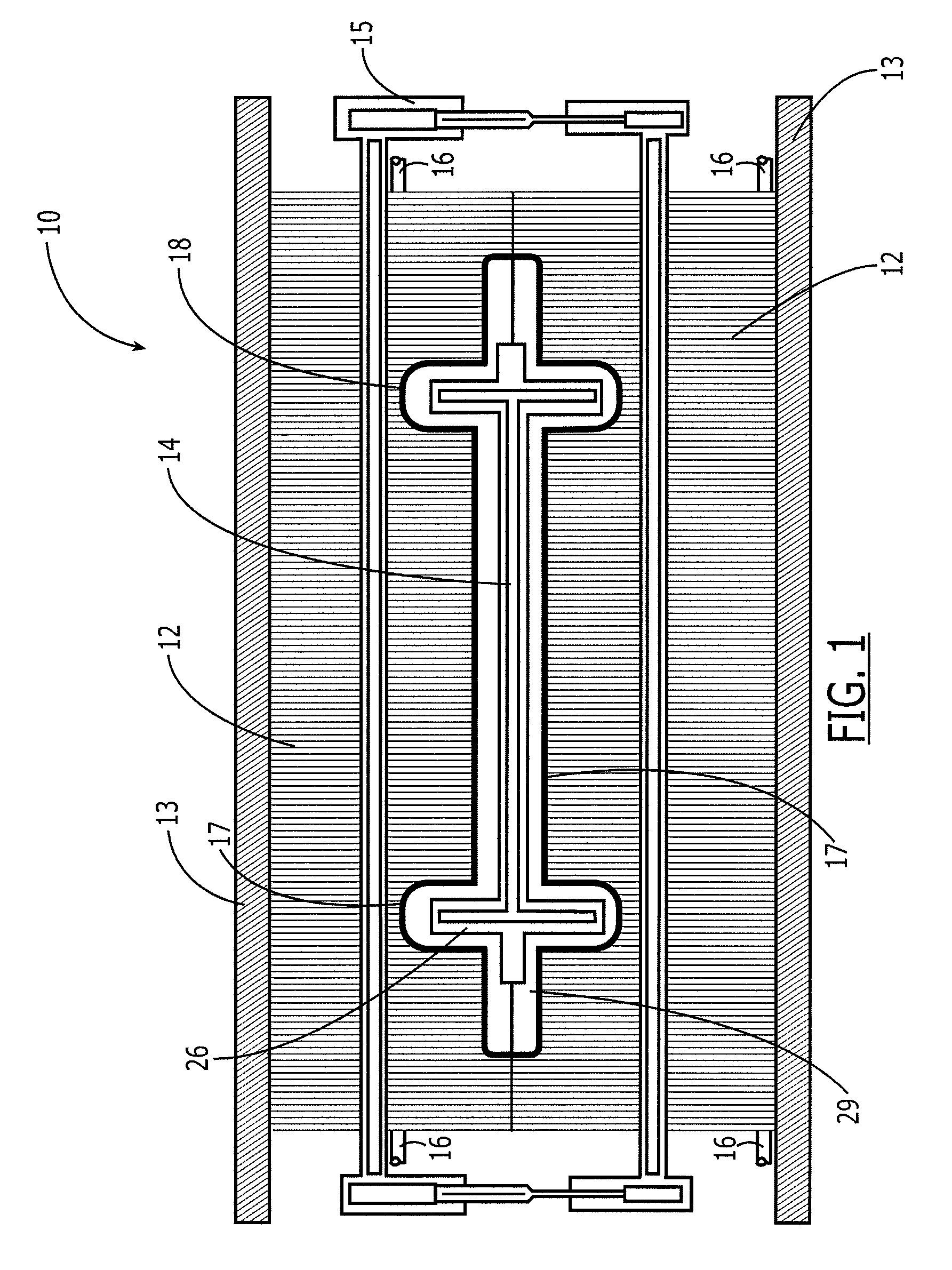

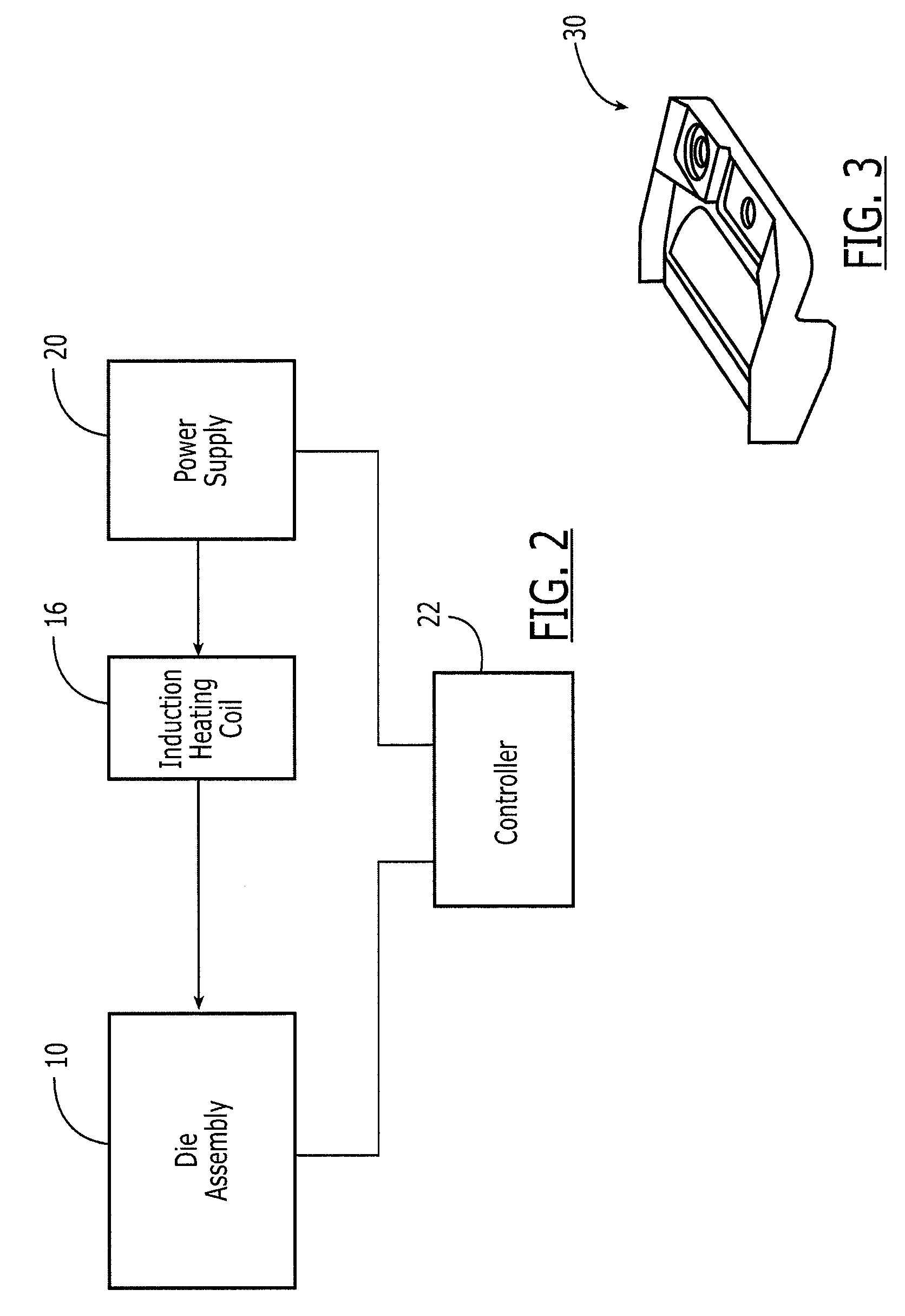

Forming Method And Apparatus And An Associated Preform Having A Hydrostatic Pressing Medium

ActiveUS20100018271A1Stable pressureReduce complexityShaping toolsShaping safety devicesEngineeringViscosity

Owner:THE BOEING CO

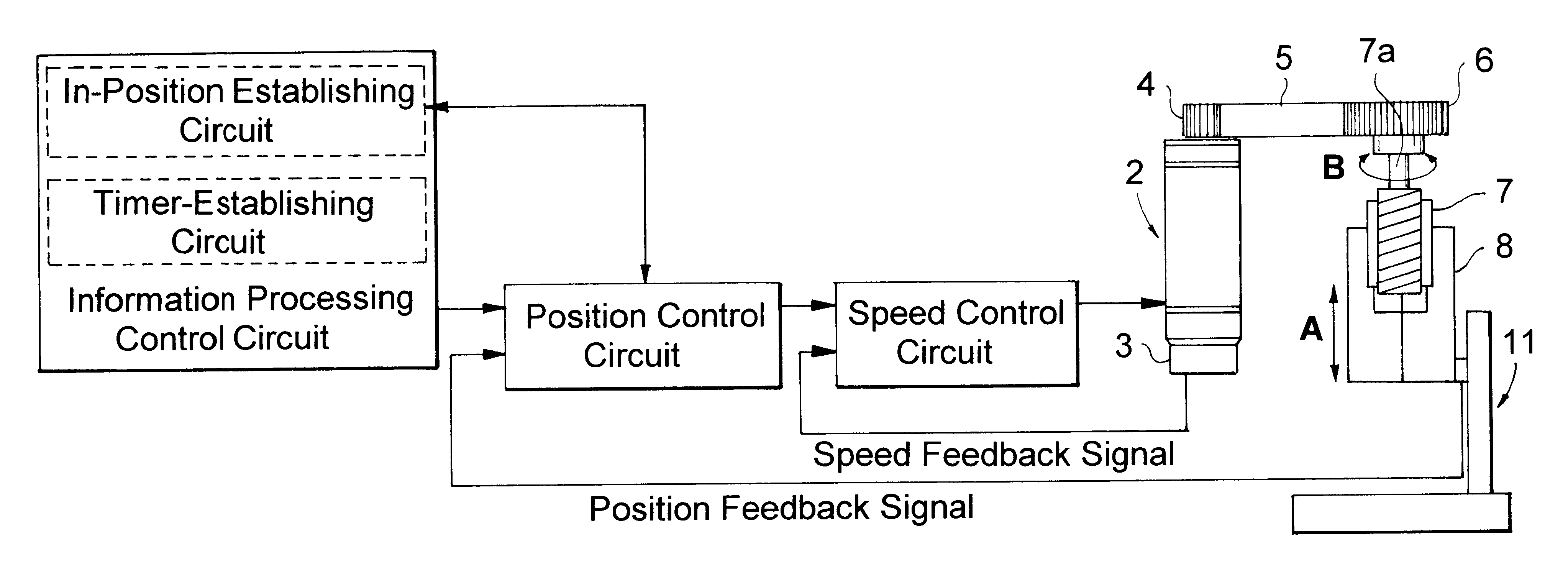

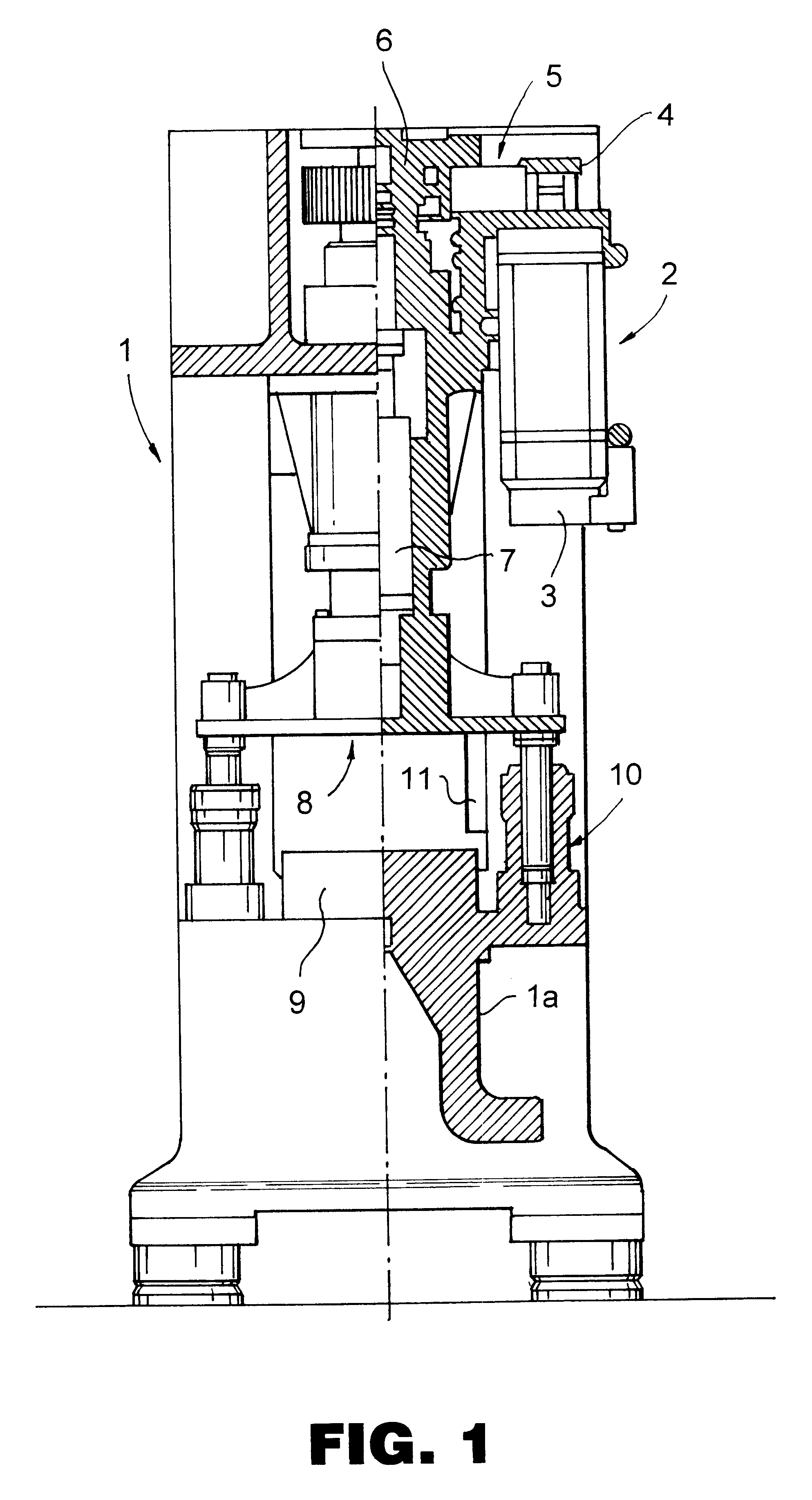

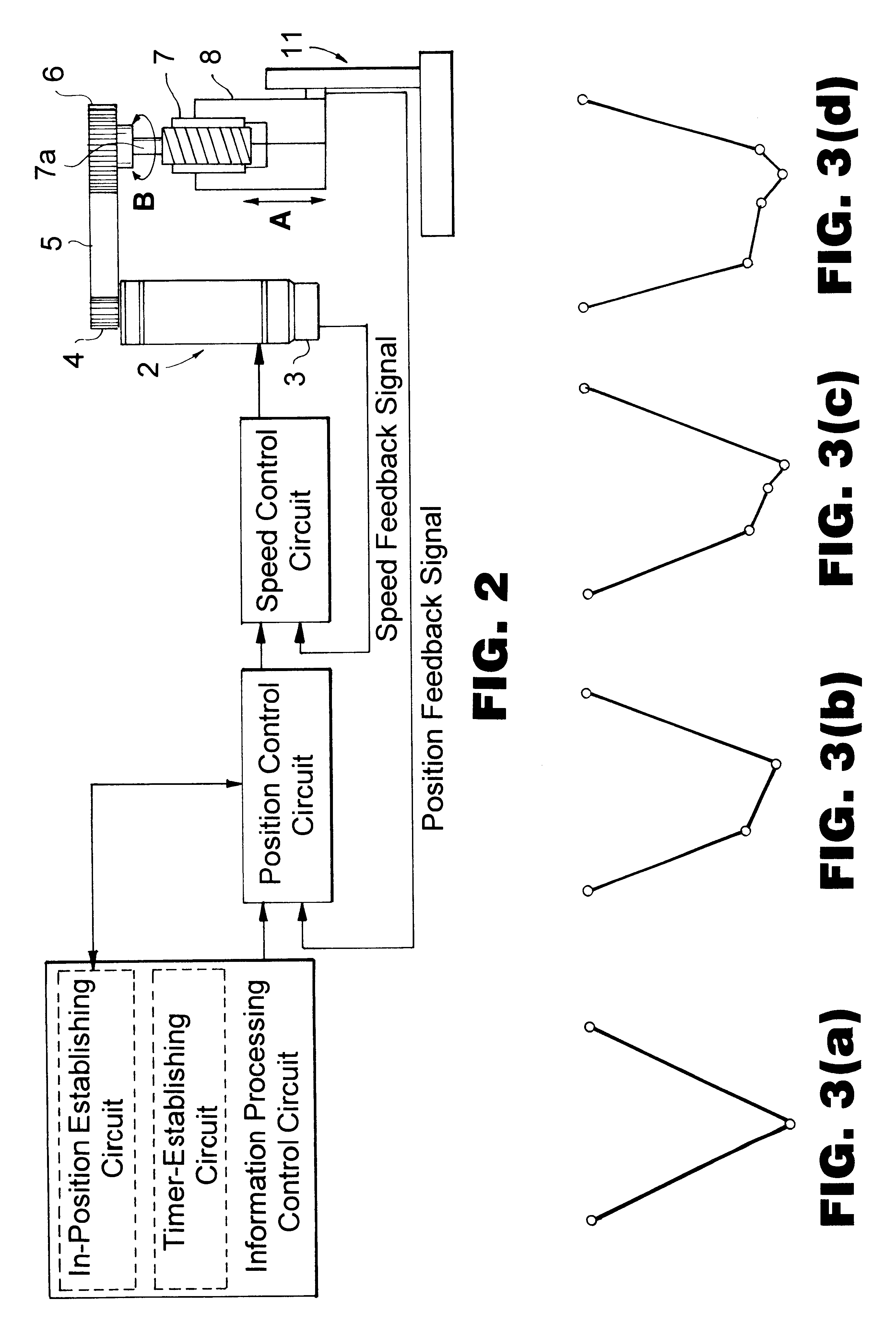

Screw press

InactiveUS6520077B1Precise positioningShaping safety devicesForging press detailsReduction driveControl theory

A screw press which can ensure the positional precision of the ram when the rotation amount of the press motor does not directly translate into the position of the ram because there is other machinery, such as a decelerator and the like, present between the motor (servo motor) and the screw mechanism, has a construction in which a position detection sensor, which detects the position of the ram, is provided, and the position of the ram is controlled by the output from this sensor.

Owner:AIDA ENG LTD

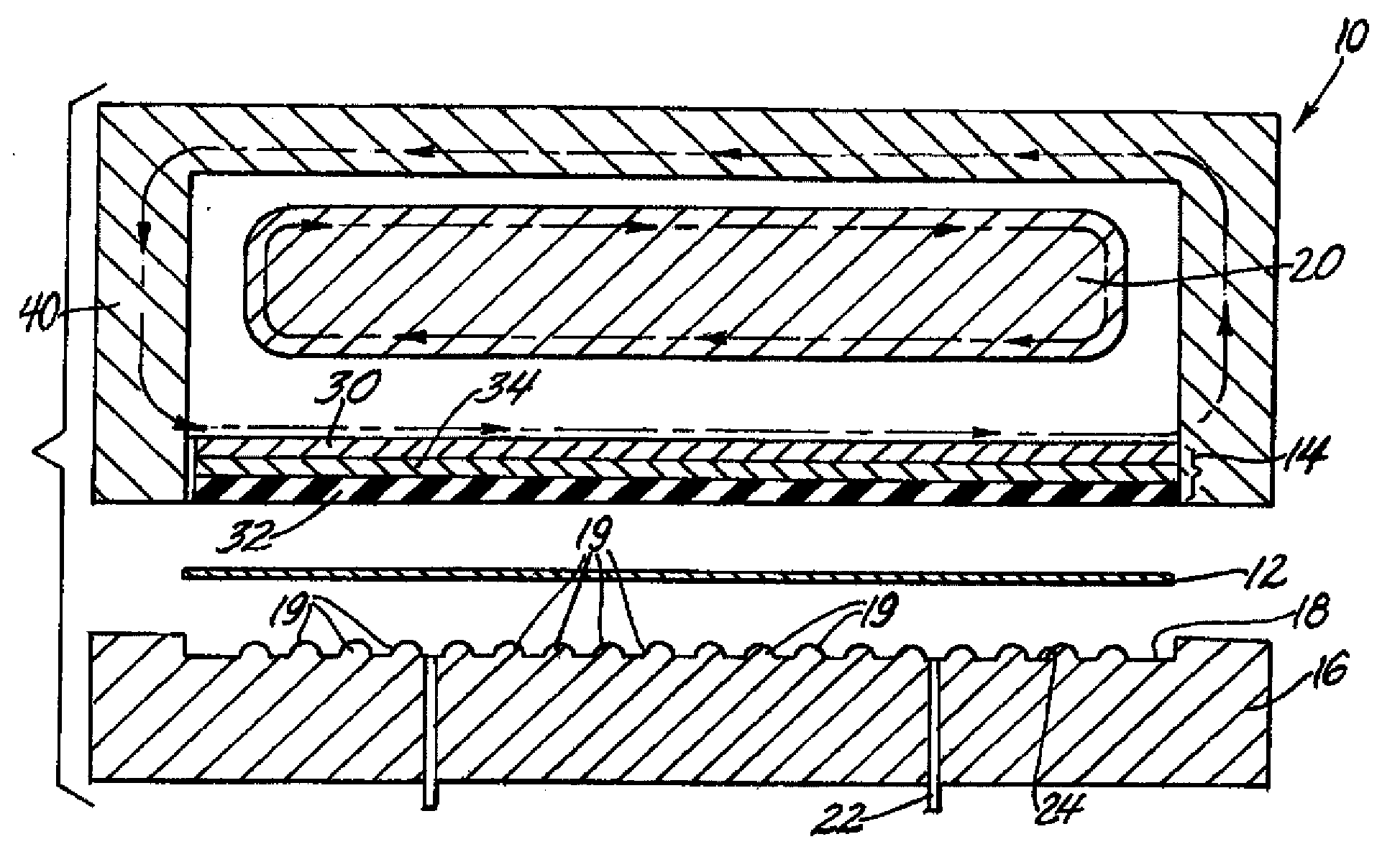

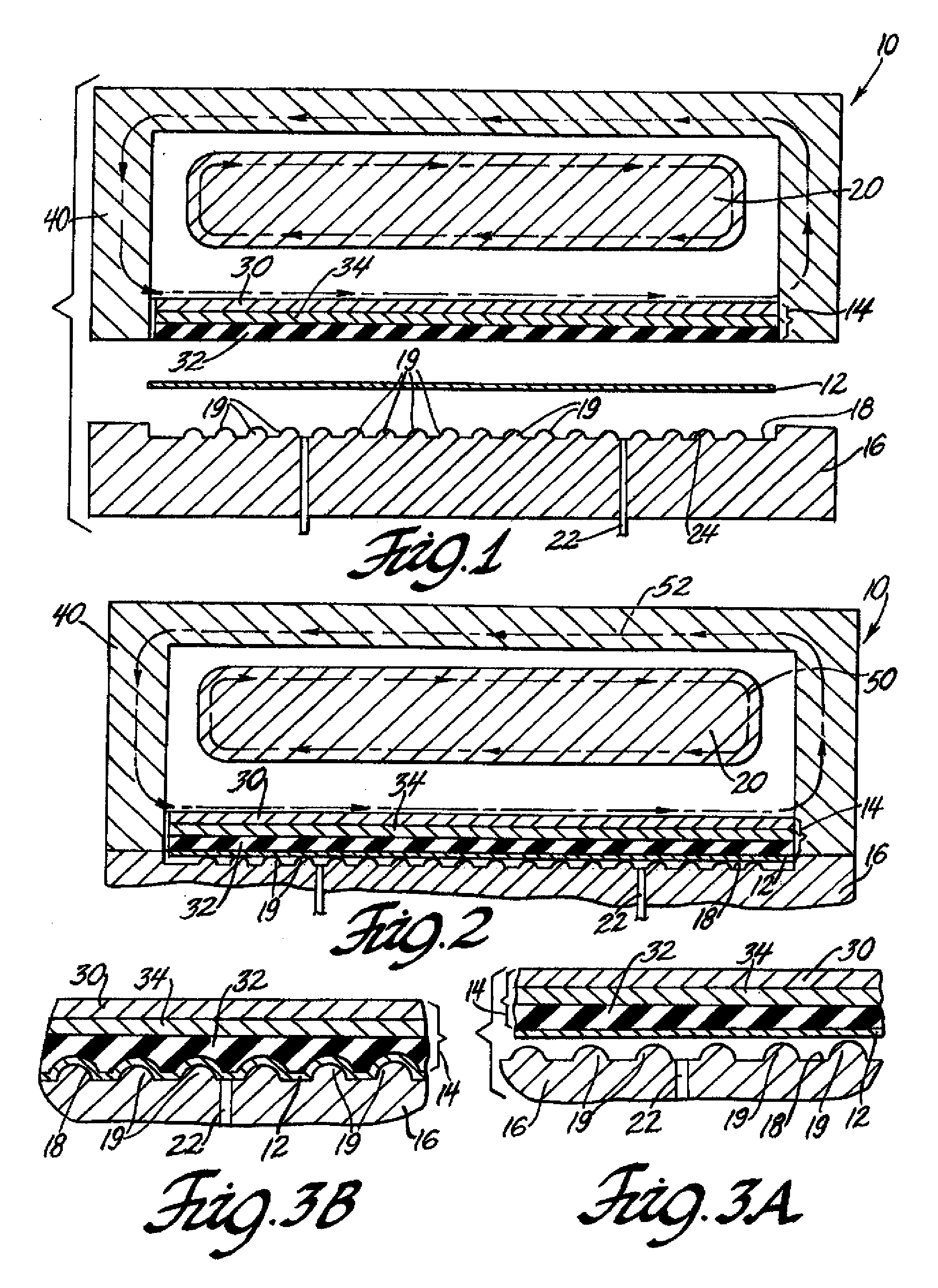

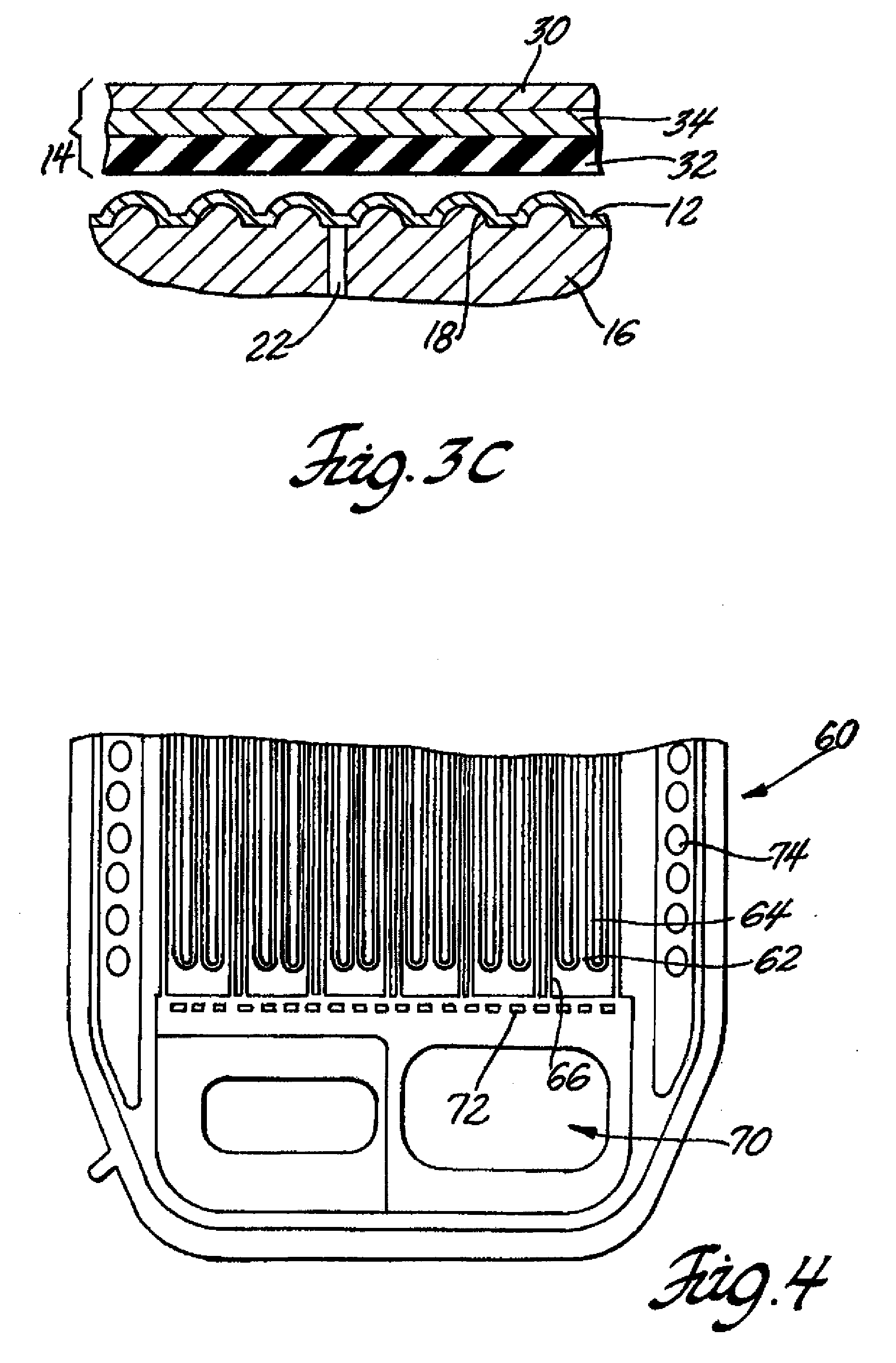

Driver plate for electromagnetic forming of sheet metal

ActiveUS20090090162A1Repeat usageRelieve pressureShaping safety devicesMetal working apparatusMetal formingEngineering

A multi-layer driver plate is disclosed for use in electromagnetic sheet metal forming operations. In one embodiment, the driver plate comprises a first layer characterized by low electrical resistivity and thickness for inducement and application of a suitable electromagnetic forming force, a second layer comprising an elastomeric material for compressing a sheet metal workpiece against a die surface and then regaining its original pre-forming structure, and a third layer interposed between the first layer and the second layer to protect the EMF force providing layer and to provide overall strength and durability to the EMF driver plate.

Owner:THE OHIO STATE UNIV RES FOUND +1

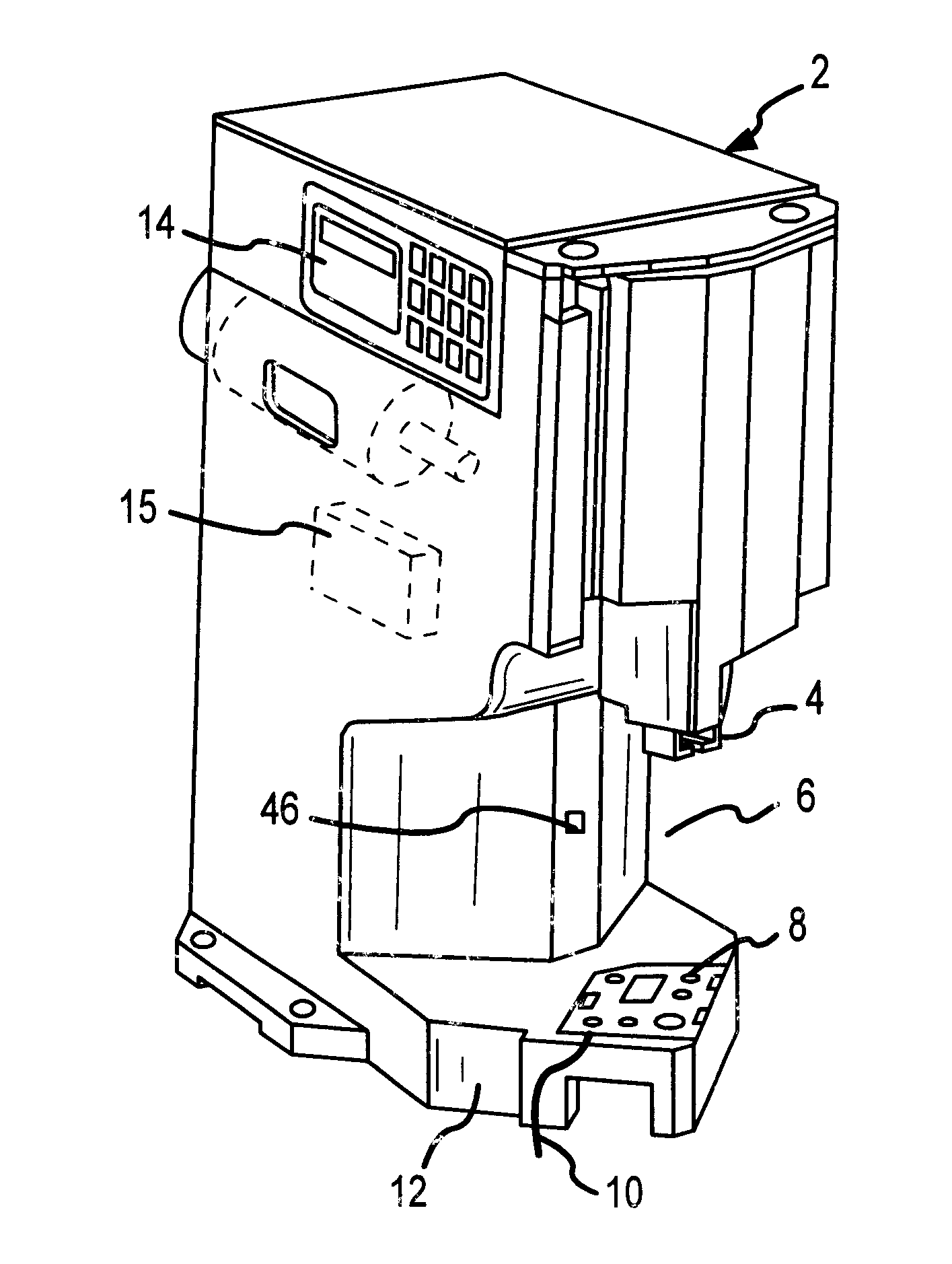

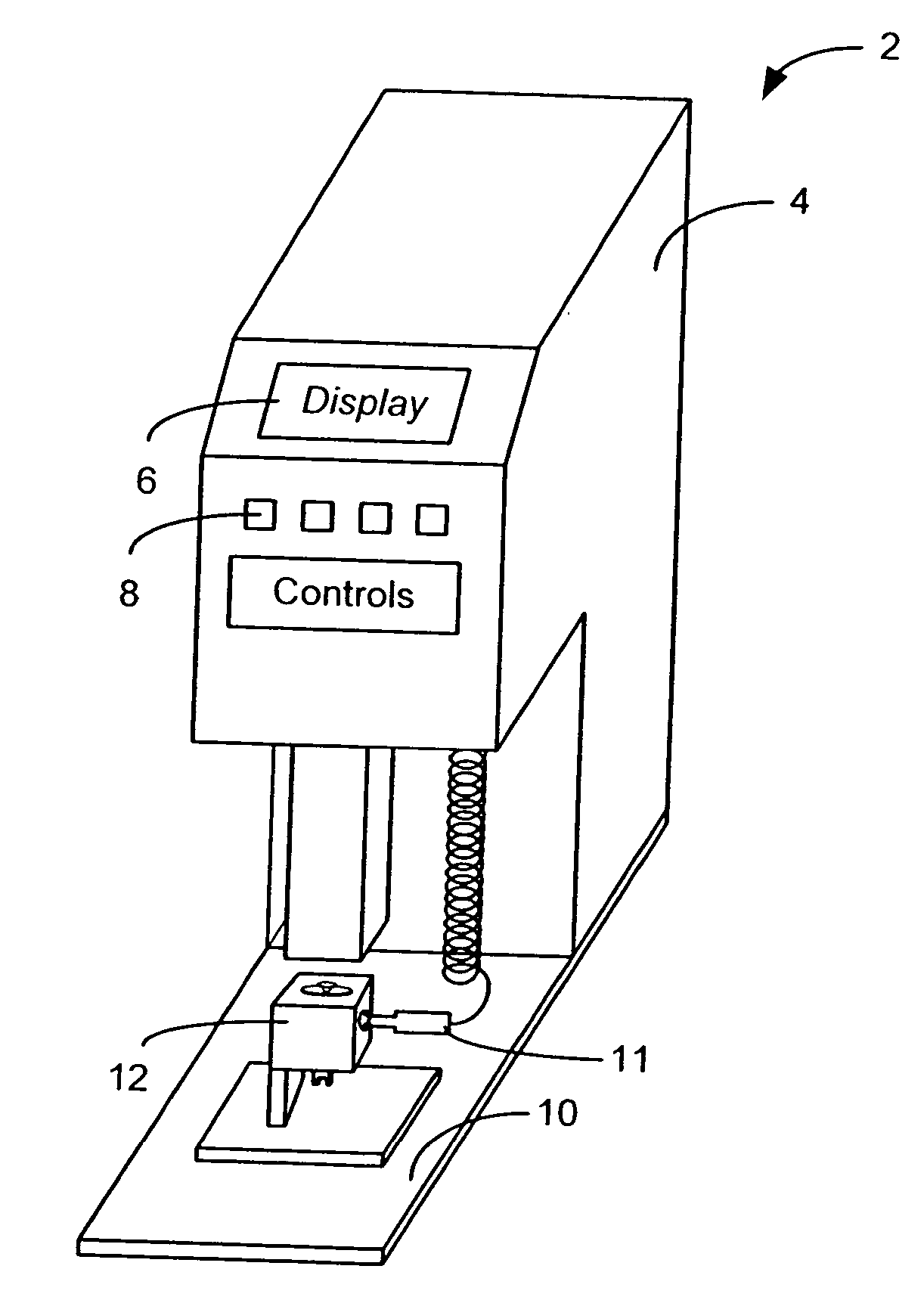

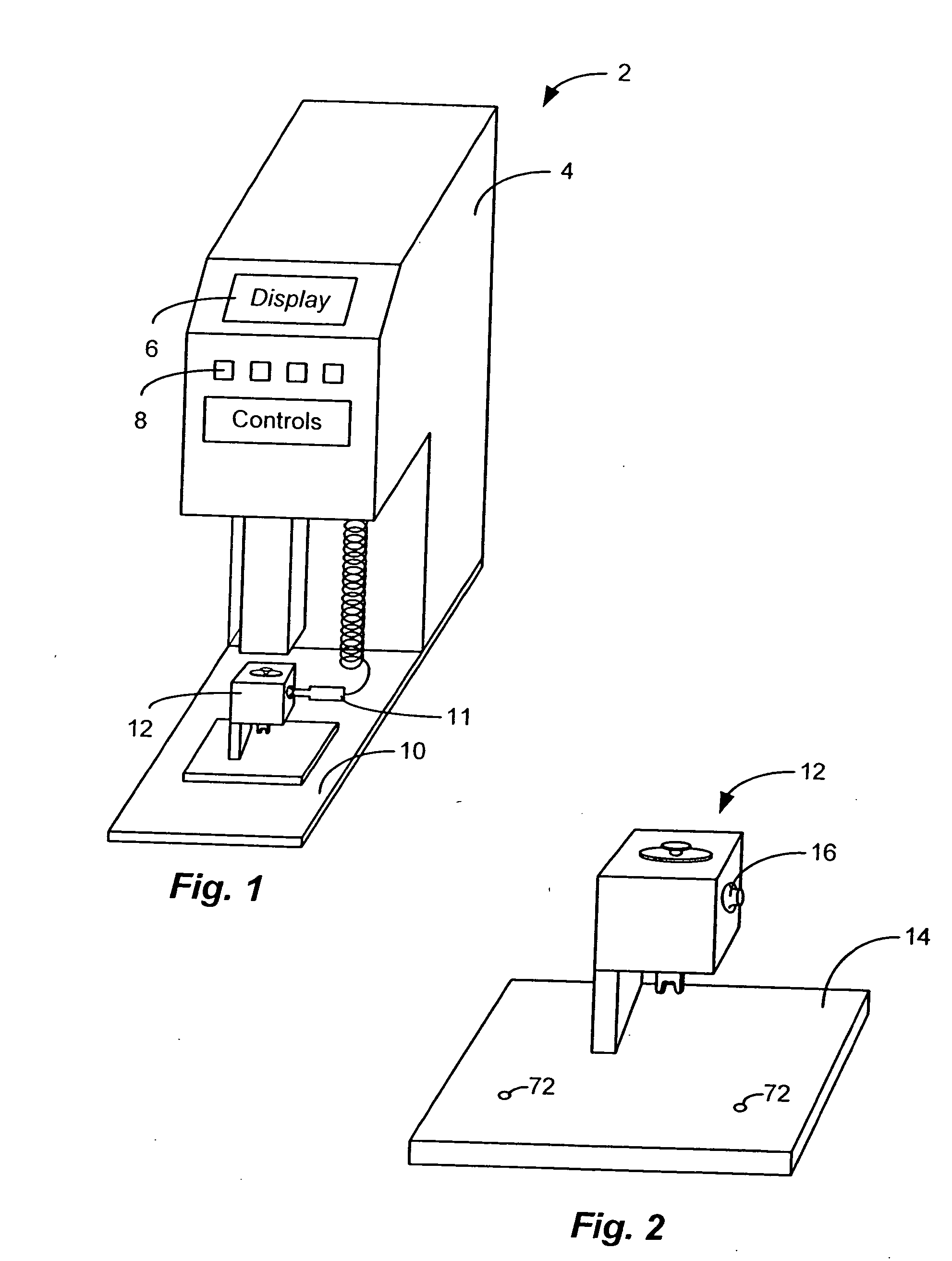

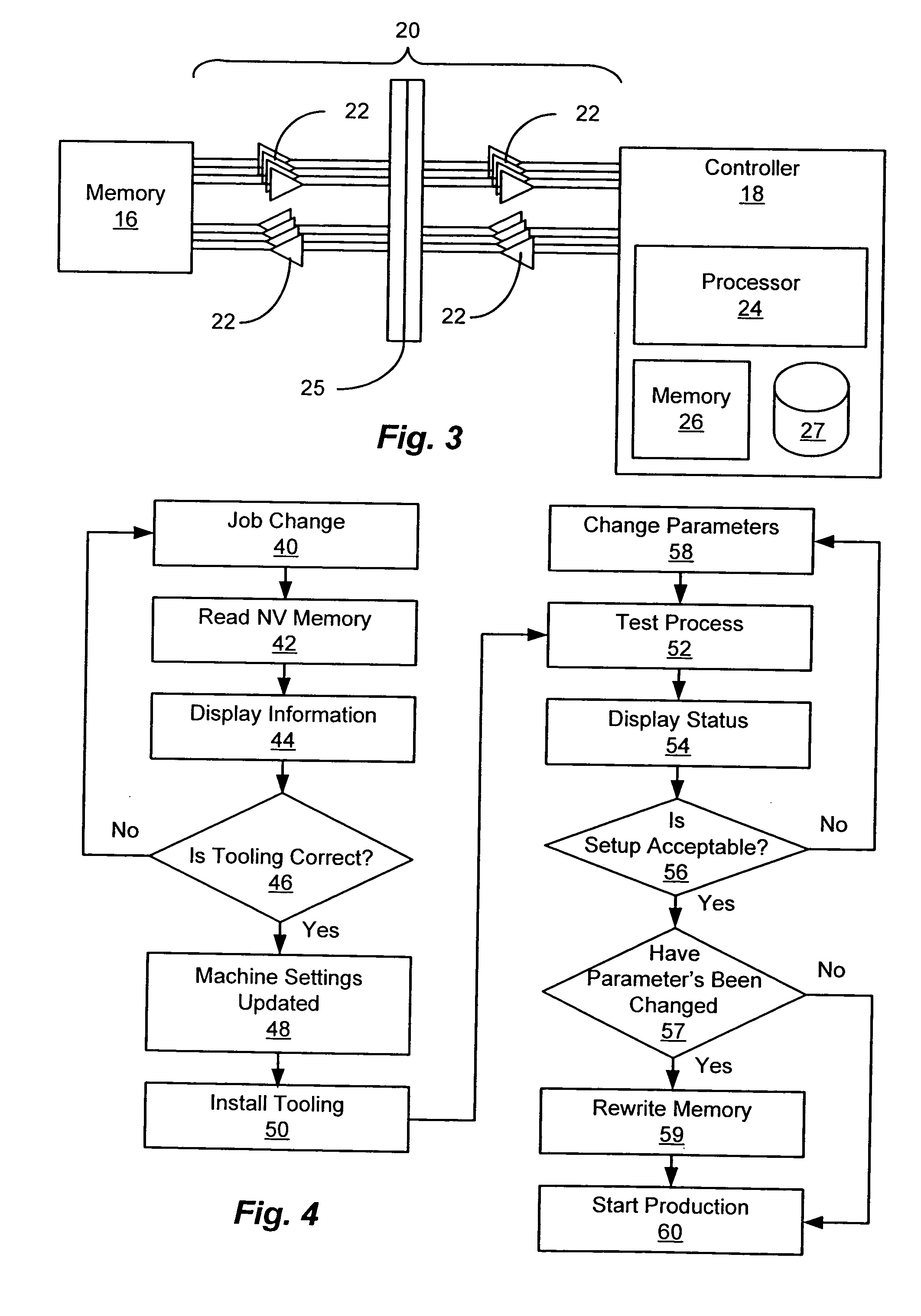

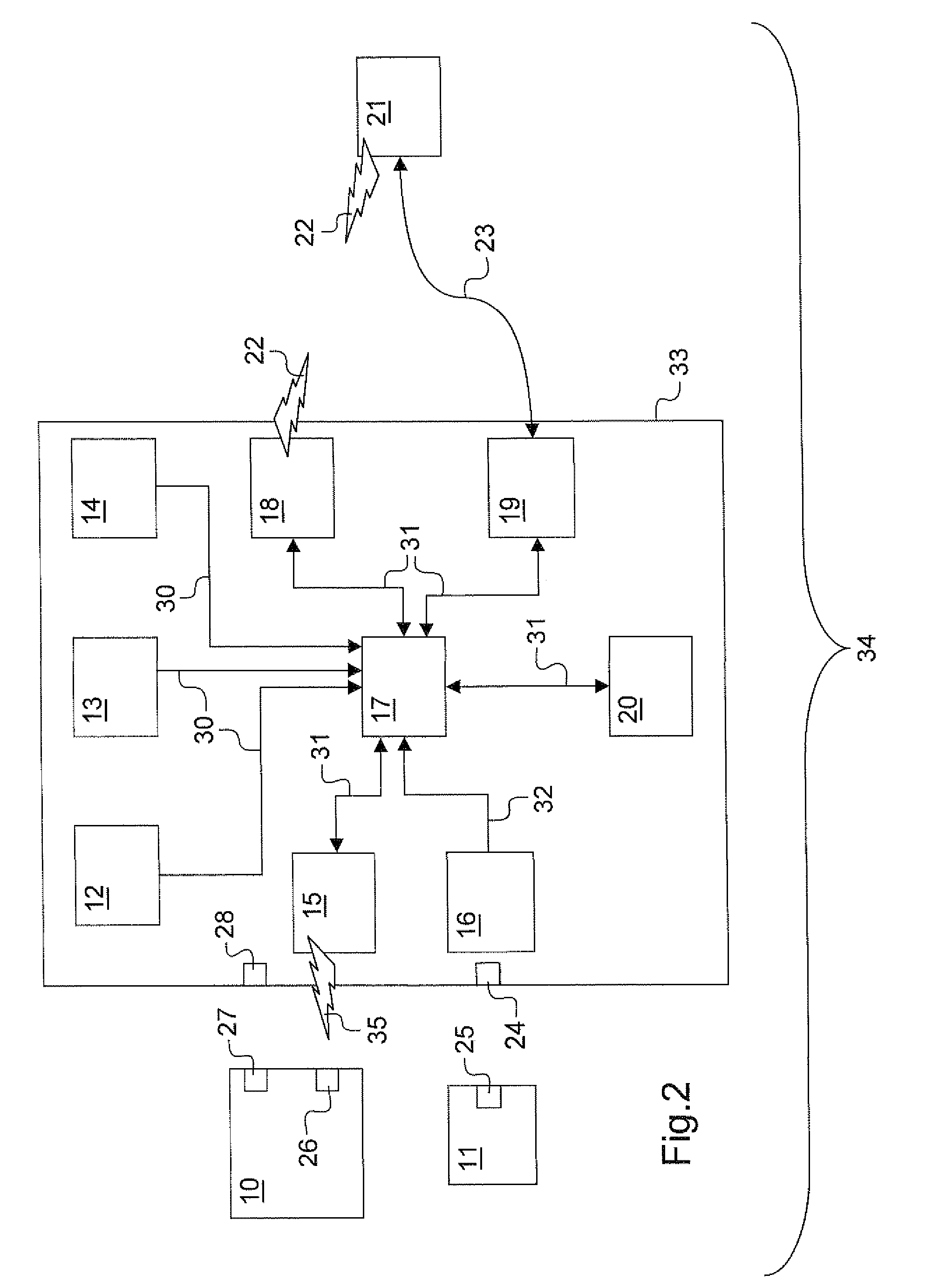

Automated machine setup with modular tooling

Apparatus and a method for establishing setup parameters for use in a machine. In one embodiment a tooling component is removably mountable to a host machine. The tooling component includes a memory that contains information defining setup parameters for the host machine for use with the tooling component. A controller associated with the host machine reads the information from the memory and configures the host machine based on the information read from the memory. In another embodiment, an information carrying tag, is associated with the tooling component. The information carrying tag is read and the identifying information obtained from the tag is used by a controller to select a set of setup parameters from one or more sets of setup parameters stored in a storage device accessible by the controller. A mechanism is provided to precisely position the adapter on the base plate for the host machine to minimize variations in production using the setup parameters derived from the stored information.

Owner:ZUSI CHRISTOPHER J

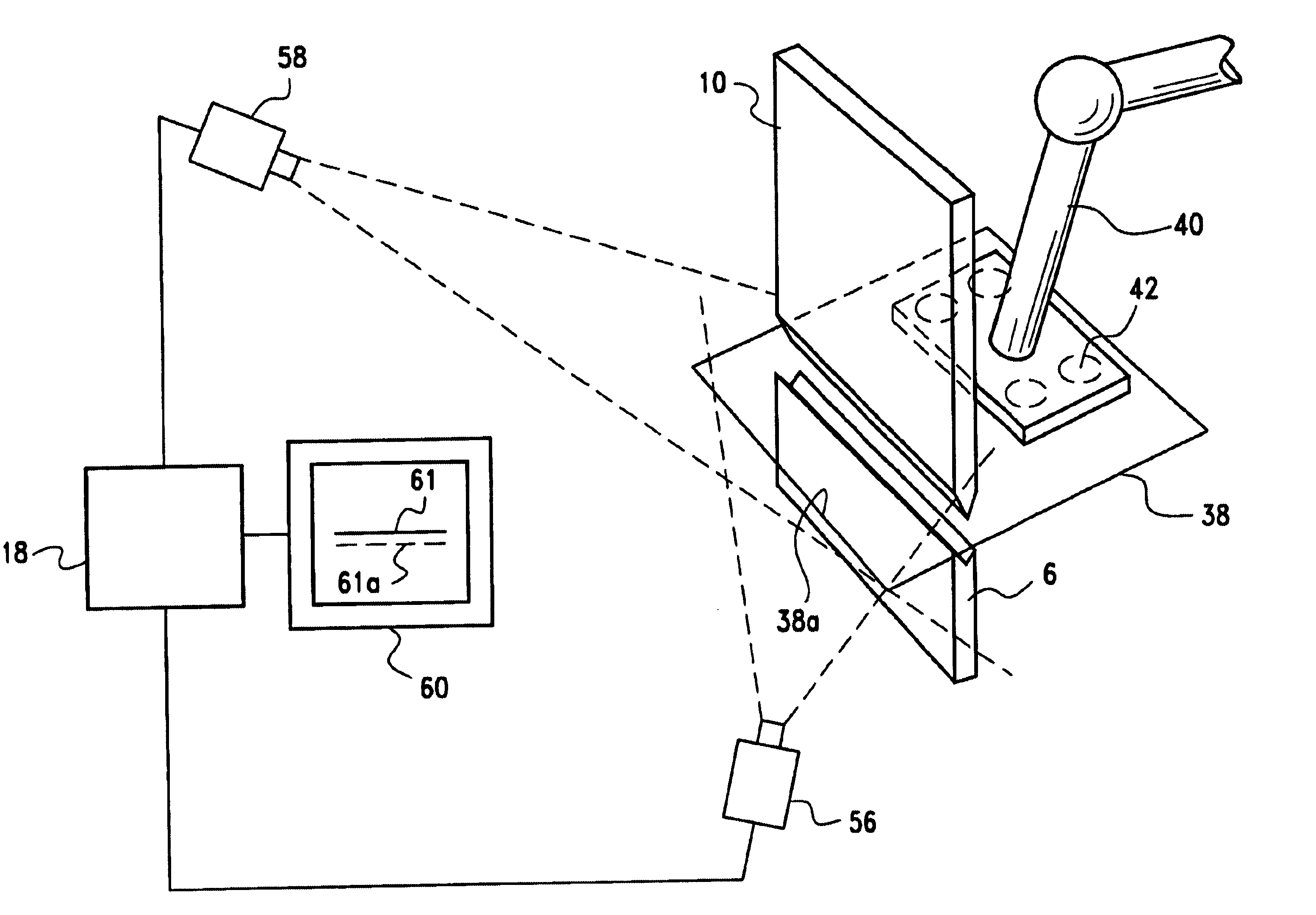

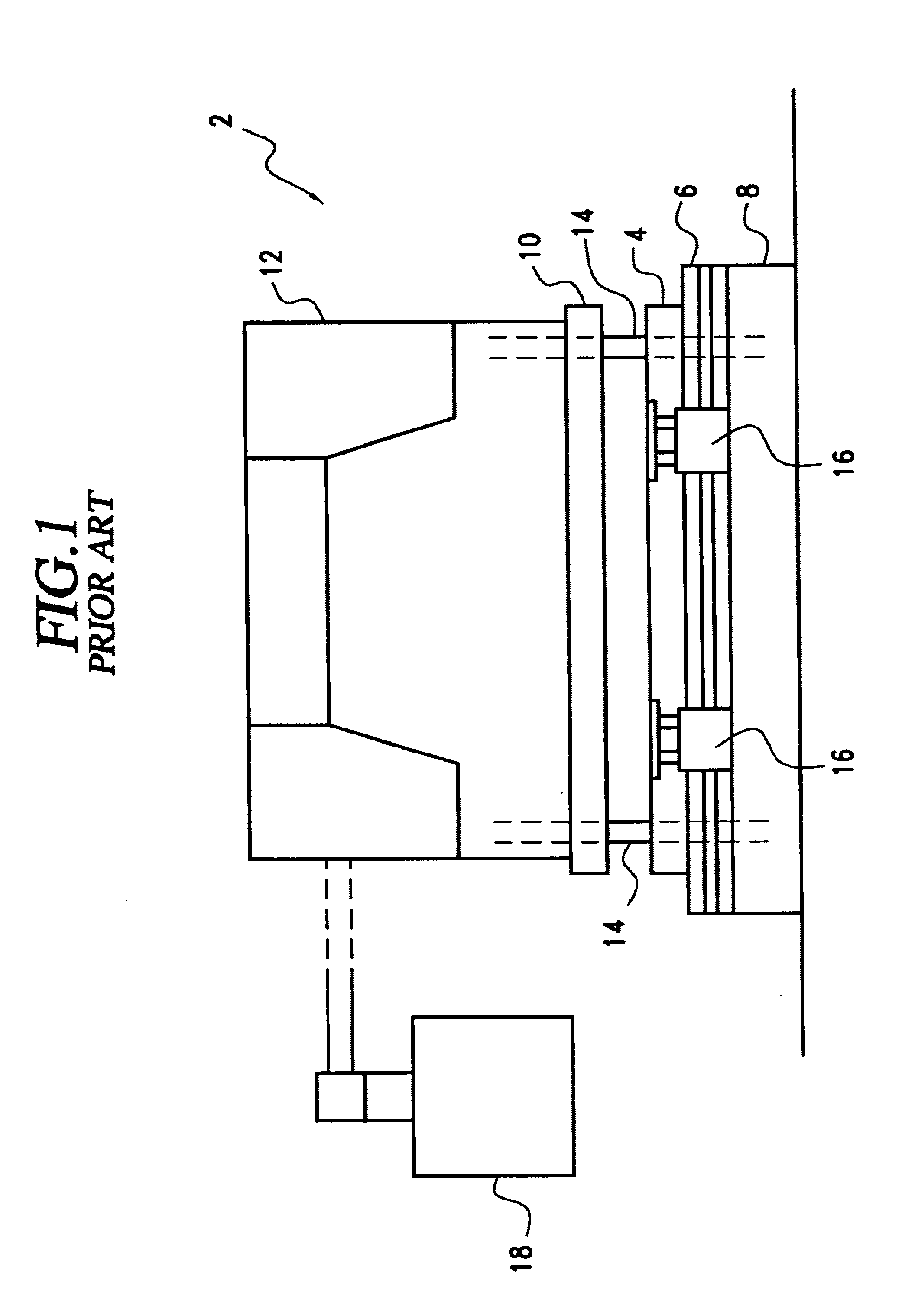

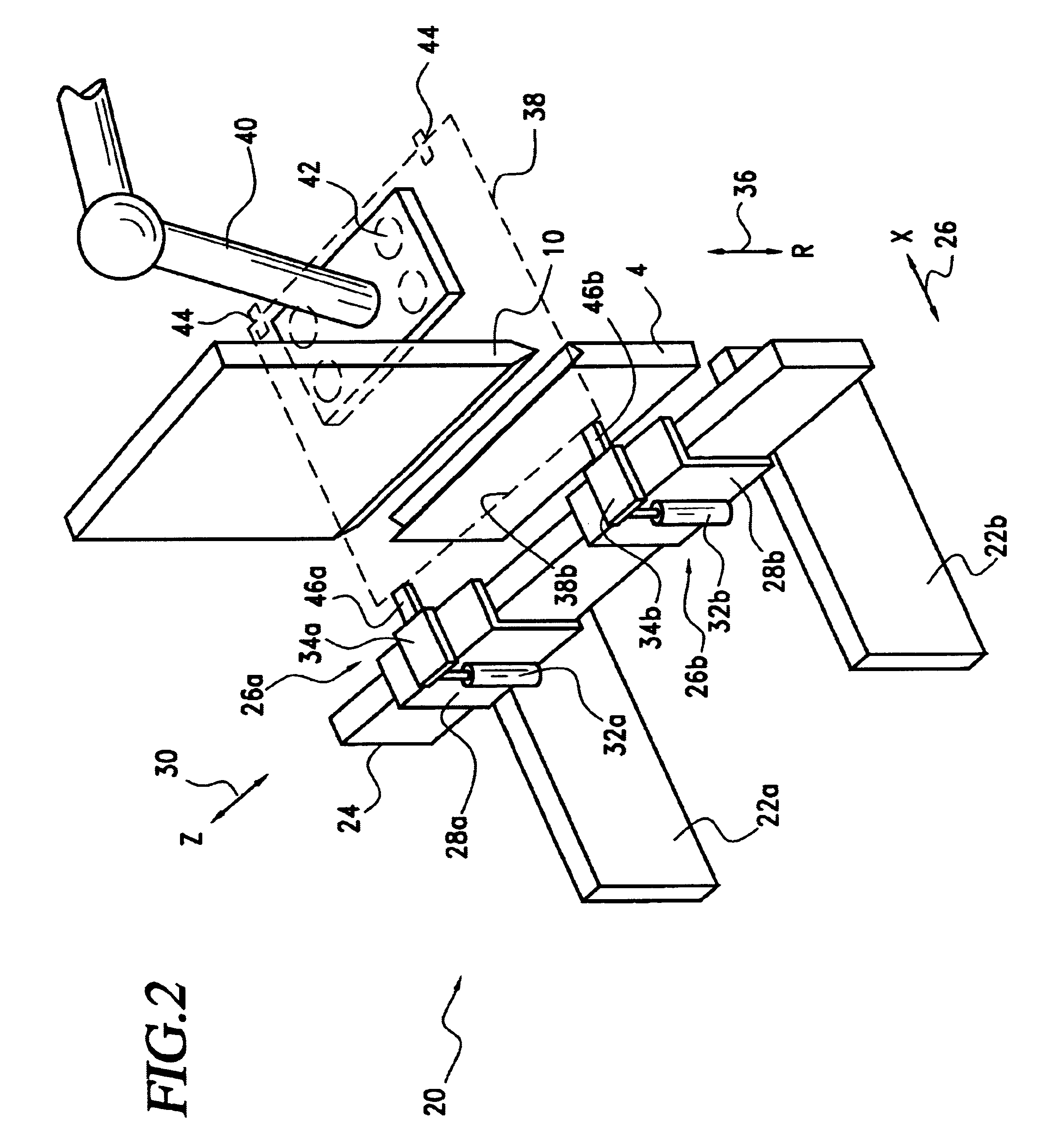

Press brake worksheet positioning system

InactiveUS6644080B2Precise positioningCompensation deviationMetal-working feeding devicesShaping safety devicesPositioning systemPress brake

To improve the speed with which a worksheet is positioned in a press brake, and to further eliminate the need for conventional moving back gauge systems, the present invention replaces the conventional back gauge mechanical system with sensors that non-contactedly determine the positioning of the worksheet, with reference to the bending tools. The thus sensed worksheet position is compared with the desired worksheet location preprogrammed into the CNC controller. Any deviation between the sensed, or the actual worksheet position, with the desired worksheet position for each bend of the worksheet is compensated by further moving the worksheet, until there no longer is any discrepancy between the actual and the preprogrammed desired locations.

Owner:FINN POWER INT

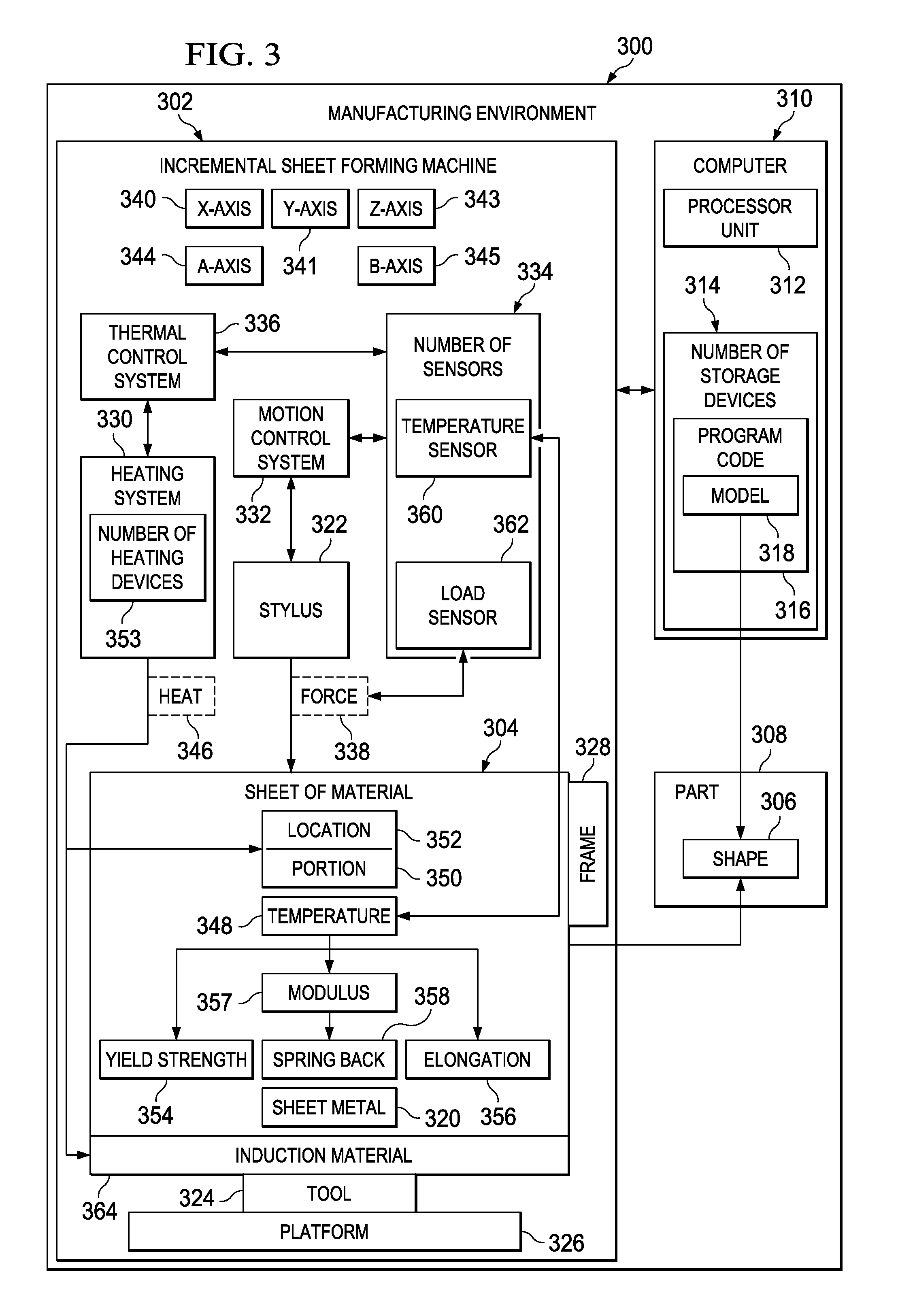

Method and Apparatus for Reducing Force Needed to Form a Shape from a Sheet Metal

ActiveUS20100257909A1Reduction in yield strengthHigh elongationShaping toolsRoll force/gap control deviceHeating systemSheet material

An apparatus comprises a platform, a stylus, and a heating system. The platform is capable of holding a sheet of material. The stylus is capable of impinging the sheet of the material to incrementally form a shape for a part. The heating system is capable of heating at least a portion of the sheet of material in a location on the sheet of material prior to the stylus impinging the location.

Owner:THE BOEING CO

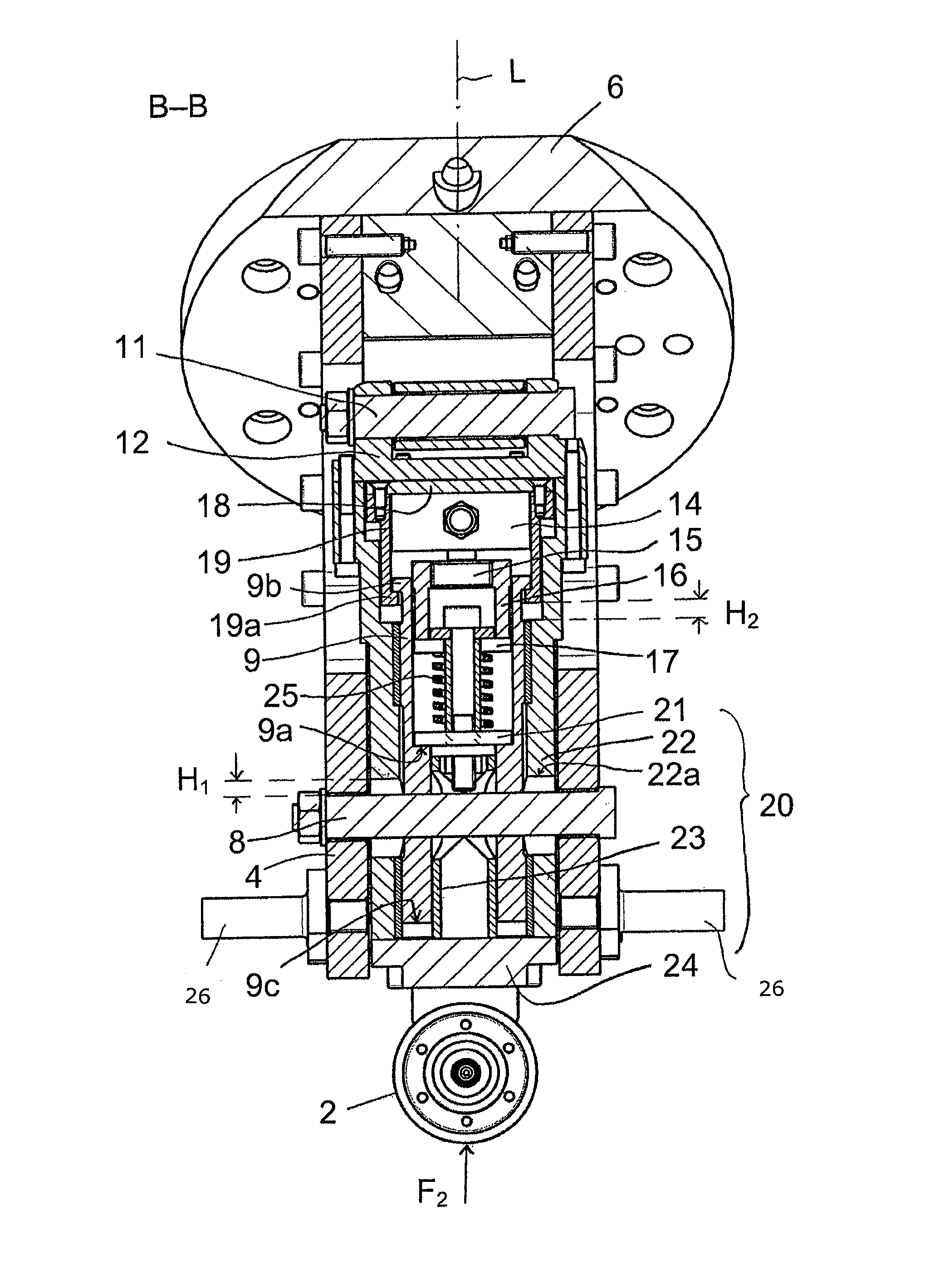

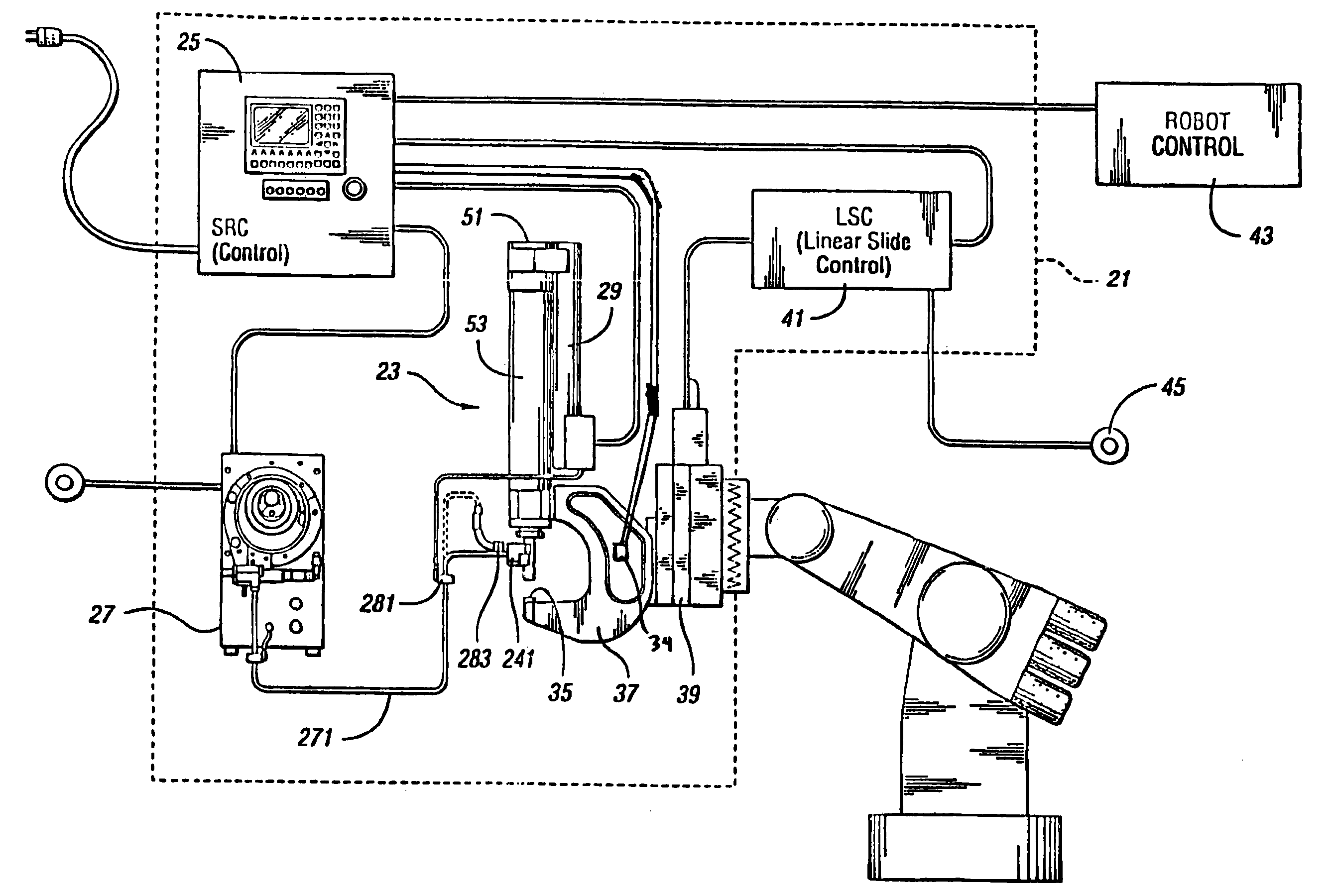

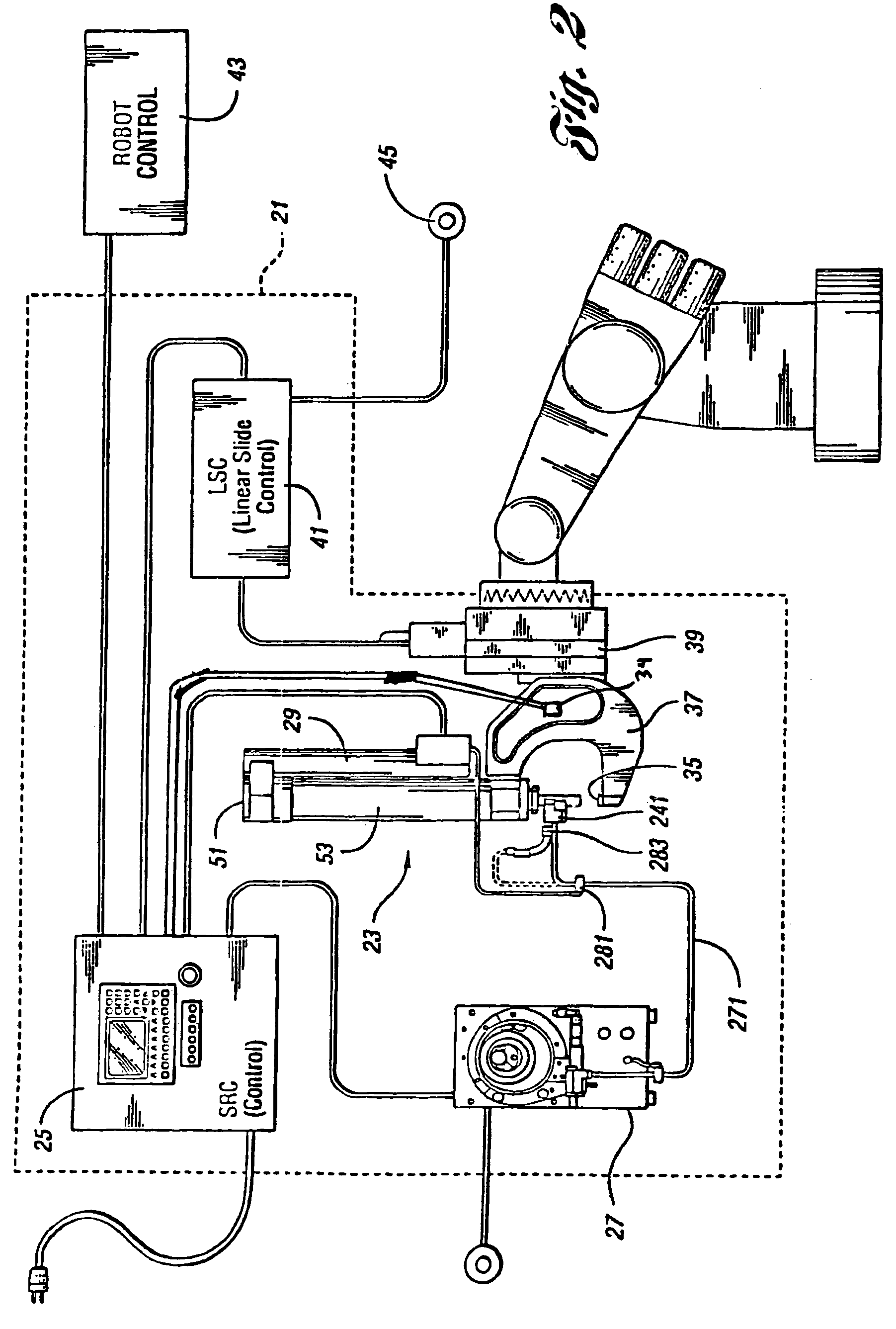

To crimping system with integrated monitoring

InactiveUS20080276678A1Easy to guaranteeEnsure quality controlLine/current collector detailsPliersIntegrated monitoringEngineering

A crimping tool including a punch carrier, a plurality of punches movable in translation in radial housings of the punch carrier, a thrust member having an inside face co-operating with the outer ends of the punches, the thrust member being pivotally mounted relative to the punch carrier, such that pivoting of the thrust member causes a contact to be crimped, a tool body having two pivotal handles for causing the thrust member and the punch carrier to pivot mutually, and a member for adjusting the stroke of the punches, a sensor sensitive to the position of the member for adjusting the stroke of the punches, a sensor sensitive to an identity signal from a contact positioning tool, and a memory associated with the position sensor and with the identity sensor and arranged to record the data delivered by the sensors and / or to deliver the data to a data processor unit.

Owner:EUROCOPTER

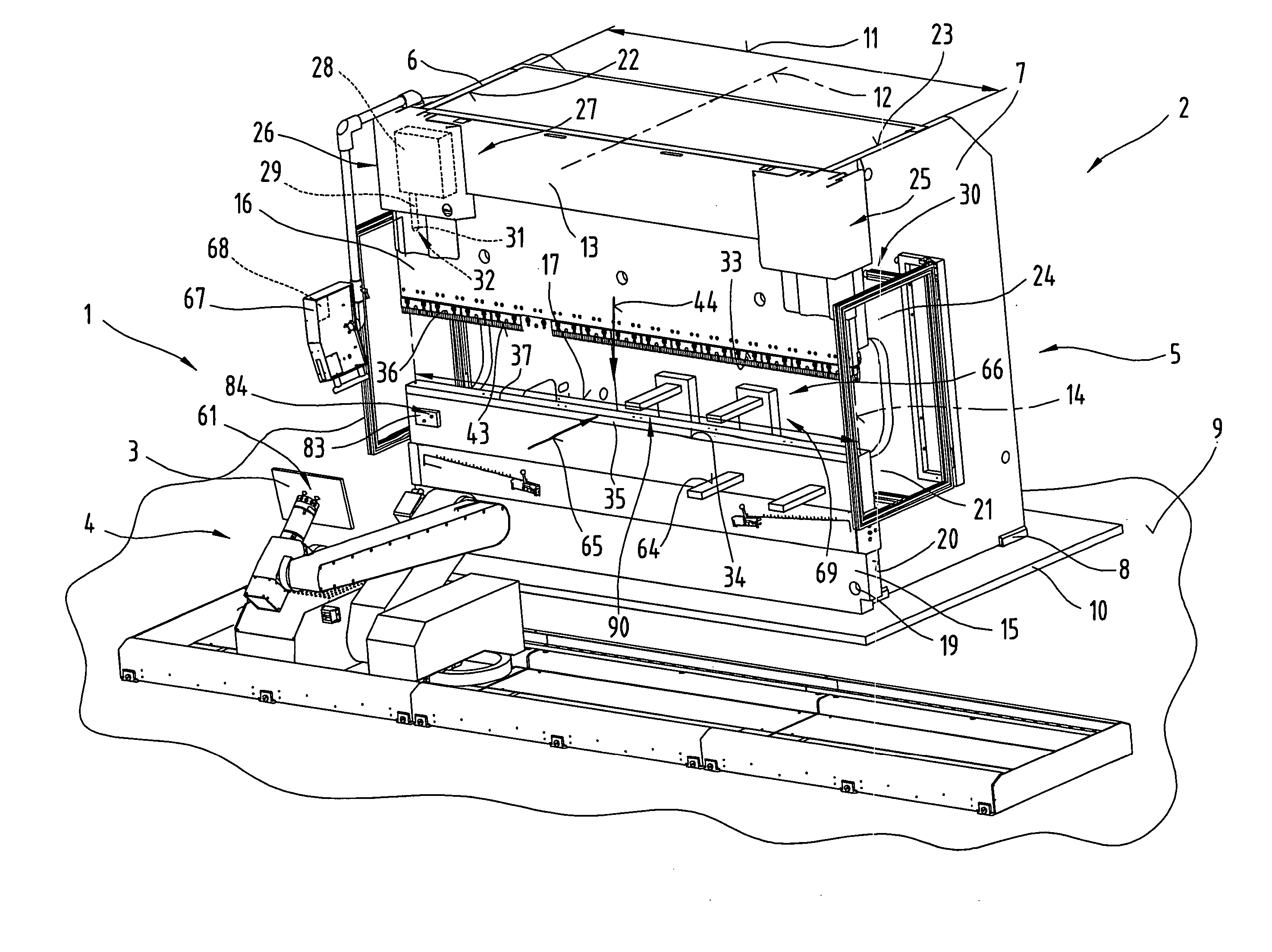

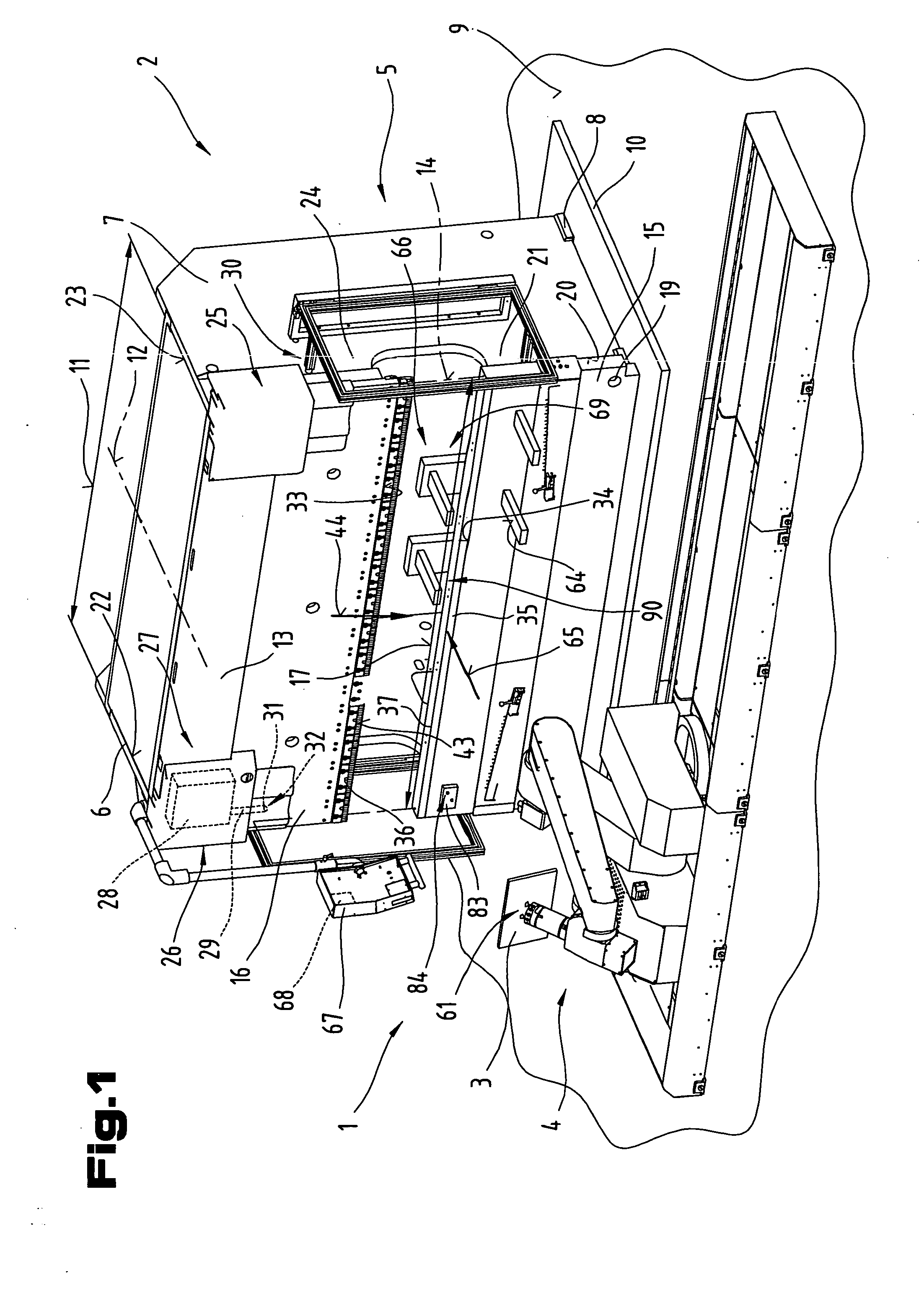

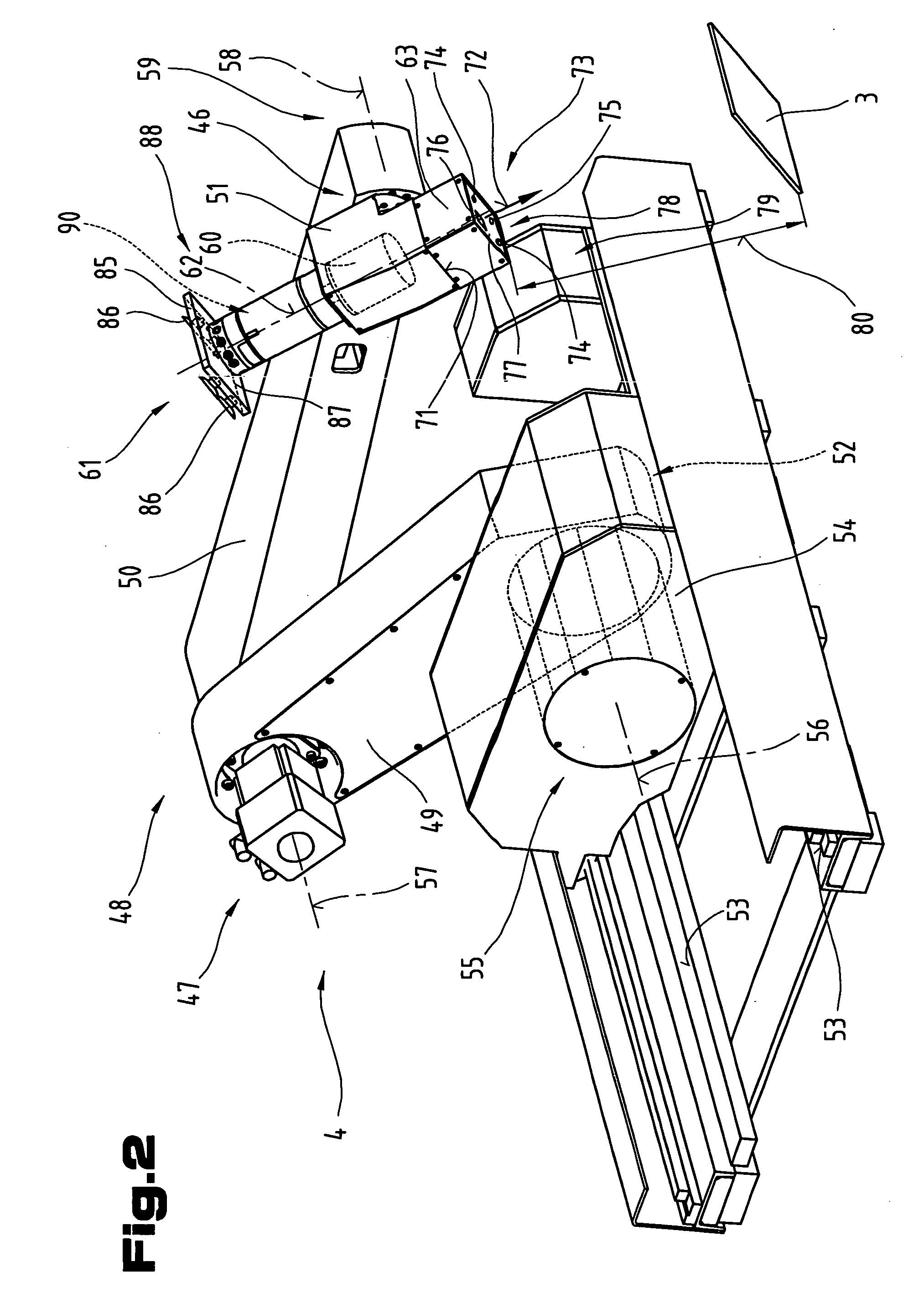

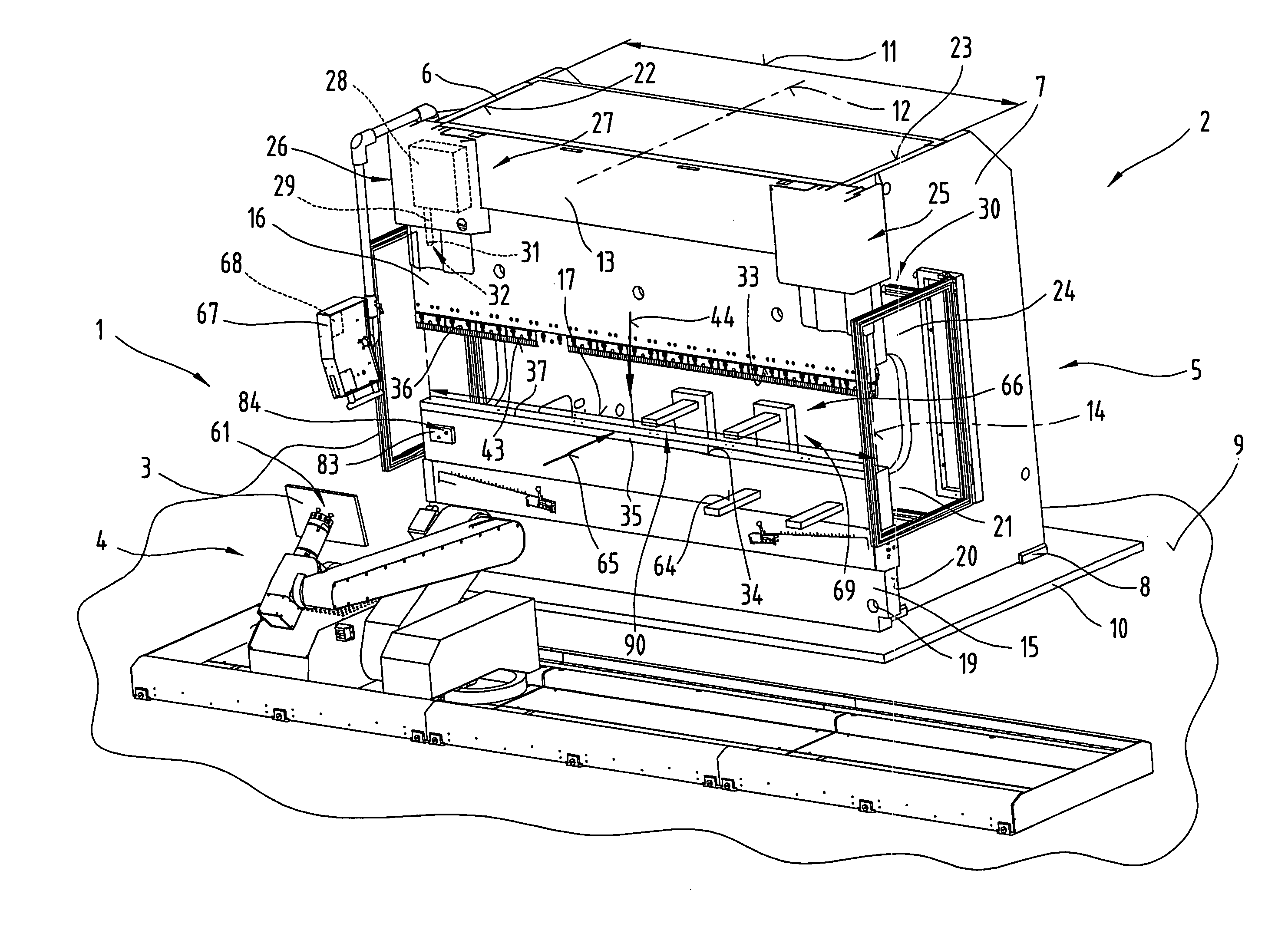

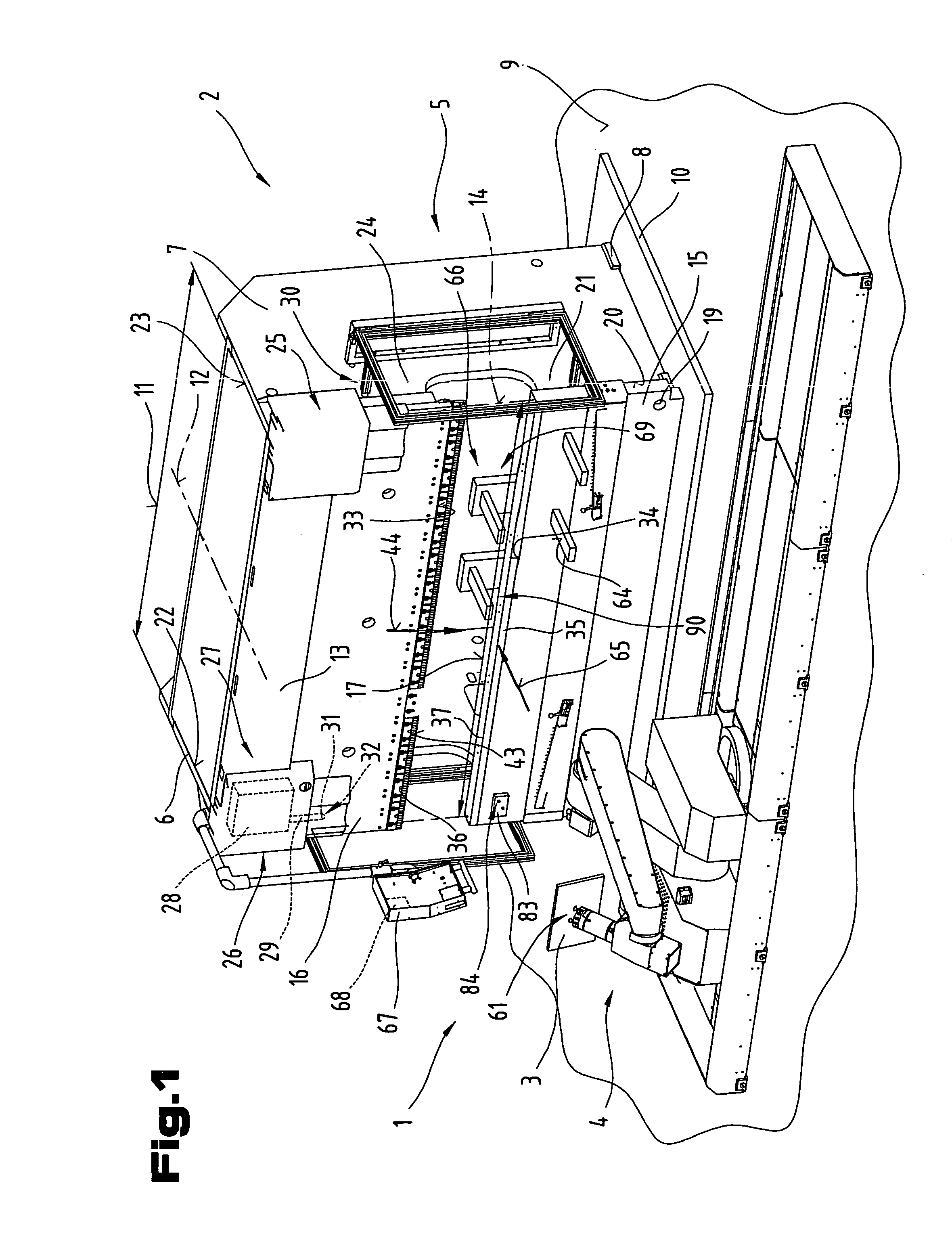

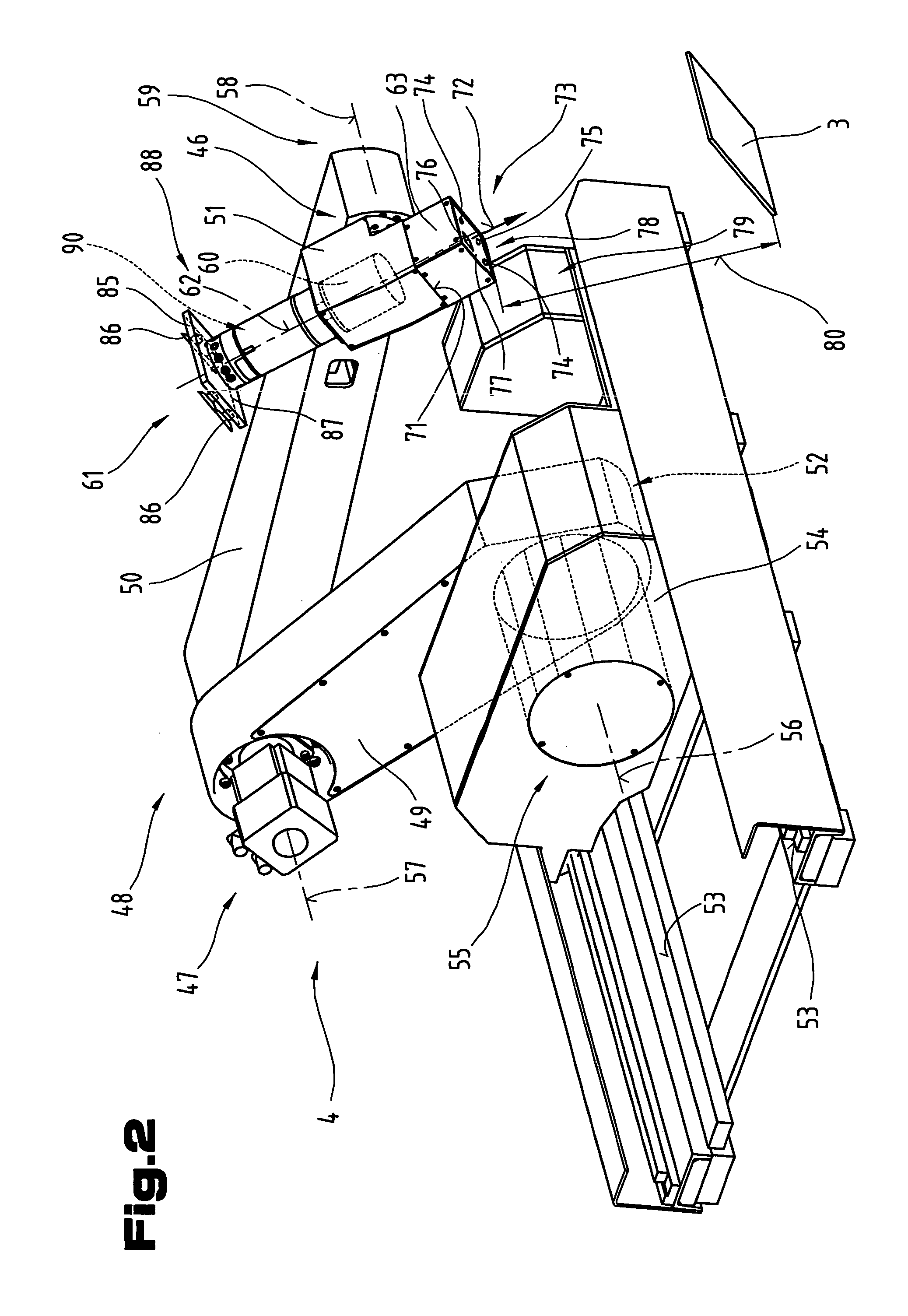

Production device, especially a bending press, and method for operating said production device

InactiveUS20050097940A1Minimize cycle timeMinimize timeProgramme controlMetal-working feeding devicesRotational axisEngineering

A manufacturing system for folding sheet bars, particularly sheet metal bars, comprising a folding press with two press beams, which are adjustable in relation to each other and provided with folding dies, whereby the folding press is fed by means of an automated manipulating system. The manipulating system has three hinged arms connected via pivoting devices to form an arrangement of hinged arms. A first hinged arm is swivel-mounted on a swivel axle extending in a swivel device parallel to a guide track of a linearly displaceable chassis. A second and a third swivel axles supporting the hinged arms are arranged extending parallel to the swivel axle of the swivel device. A gripping system and a seizing device for picking up the sheet bars are arranged in another end area of the hinged-arm arrangement. A positioning device assures that the sheet bar is correctly positioned for the folding process.

Owner:TRUMPF MASCHEN AUSTRIA

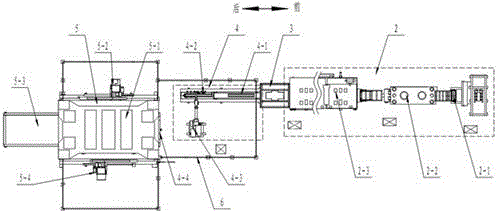

Automatic production device for threshold member of electric vehicle

ActiveCN103949562AAccurate captureAchieve crawlingMetal-working feeding devicesShaping safety devicesRoll formingEngineering

The invention discloses an automatic production device for a threshold member of an electric vehicle. The automatic production device comprises a rolling and forming machine, a cutting-off mechanism, a workpiece conveying unit, a stamping unit and a guard railing, wherein the cutting-off device is arranged between the rolling and forming unit and the workpiece conveying unit; the workpiece conveying unit consists of a transitional receiving belt machine, a quick moving and positioning mechanism, a handling manipulator and a stamping unit feeding worktable; one end of the transitional receiving belt machine is abutted against the discharging end of the cutting-off mechanism; the other end of the transitional receiving belt machine is abutted against the quick moving and positioning mechanism; the handling manipulator is arranged between the quick moving and positioning mechanism and the stamping unit feeding worktable; the stamping unit feeding worktable is matched with the stamping unit; the guard railing is arranged at the peripheral areas of the workpiece conveying unit and the stamping unit. According to the automatic production device disclosed by the invention, the production efficiency can be increased, the quality of products can be improved, the waste of labor force resources and production space can be reduced and the manufacturing cost of the products is reduced.

Owner:LINGYUN INDAL CORP +1

Rivet monitoring system

A rivet monitoring system is provided which has a micro-strain or micro fluid pressure sensor that measures strains or pressures within a tool component. These measured signals are compared to a number of tolerance bands formed about median strain or pressure versus time curve. Various techniques are provided to analyze the measured data with respect to the tolerance bands to determine if a particular rivet set is acceptable.

Owner:NEWFREY

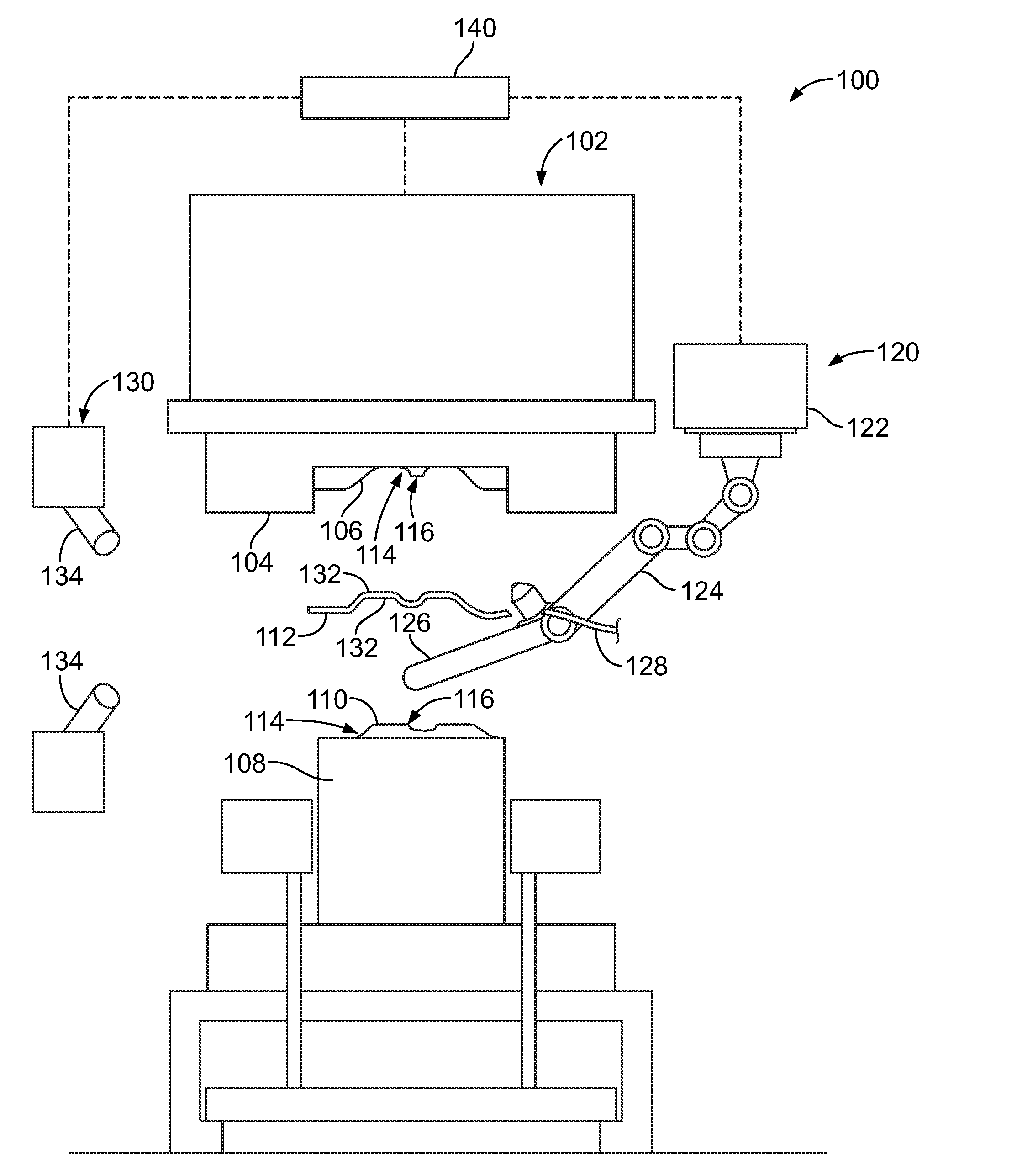

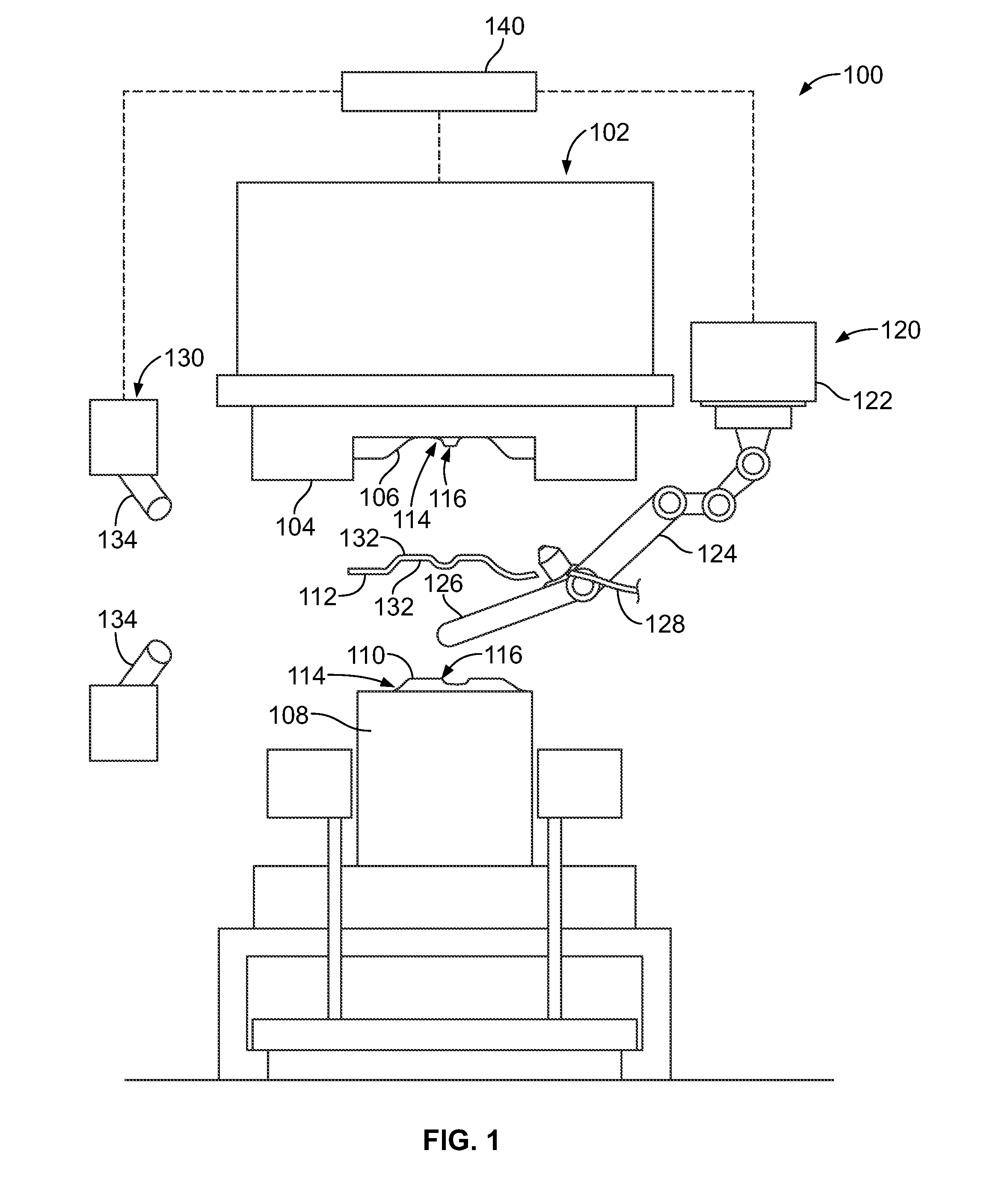

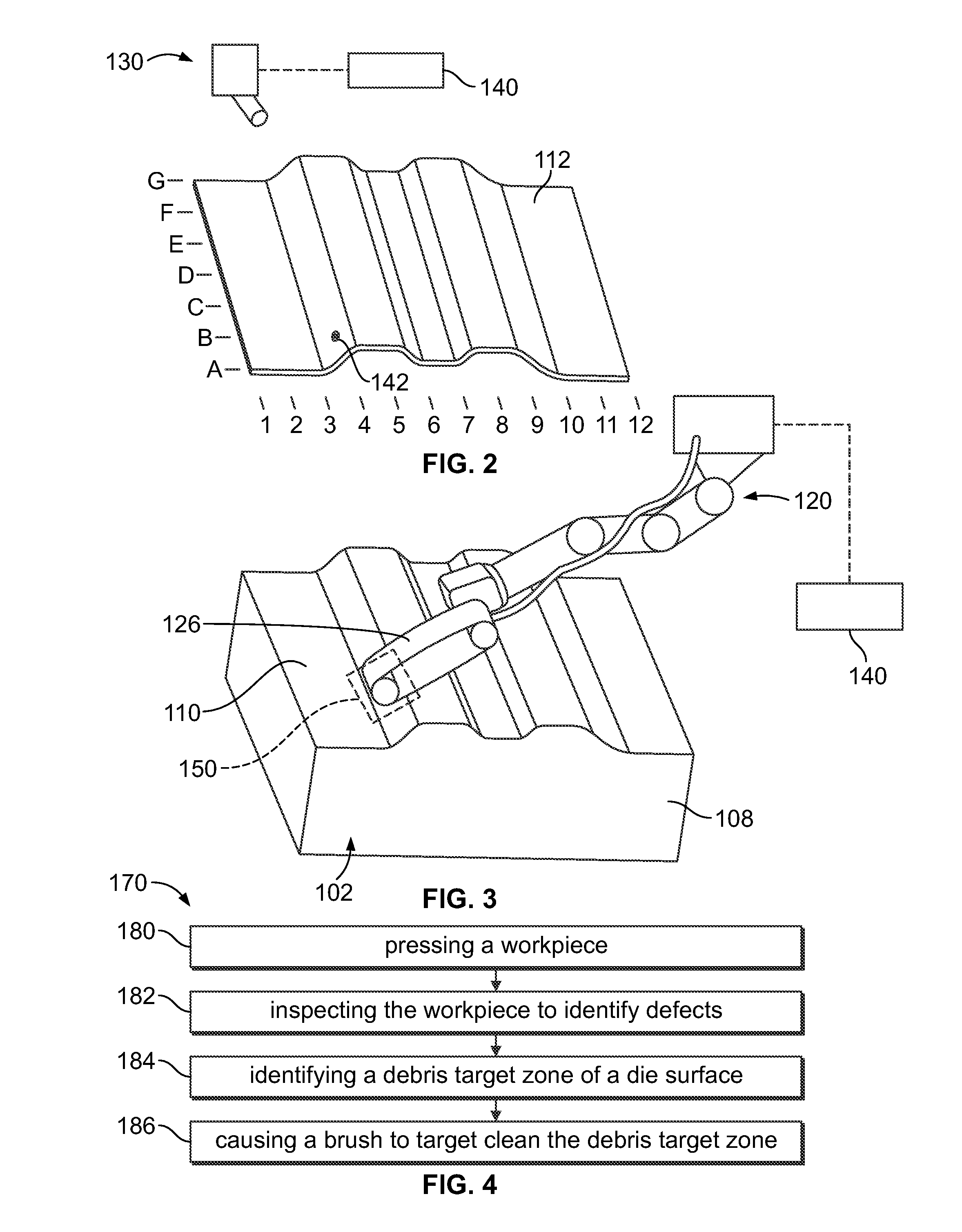

Methods and systems for target cleaning die surfaces of a die of a press machine

ActiveUS20160114380A1Programme-controlled manipulatorShaping safety devicesScrub brushesIndustrial engineering

A stamping system includes a press machine having installed an upper die with an upper die surface and a lower die with a lower die surface. The upper die surface and the lower die surface each have a non-planar geometry. The press machine presses a workpiece between the upper die surface and the lower die surface during a pressing operation. A die cleaning machine is provided having a brush configured to remove foreign debris from at least one of the upper die surface and the lower die surface during a cleaning operation, wherein the die cleaning machine is configured to maneuver the brush in various orientations relative to the press machine to clean the non-planar upper die surface or the non-planar lower die surface.

Owner:HONDA MOTOR CO LTD

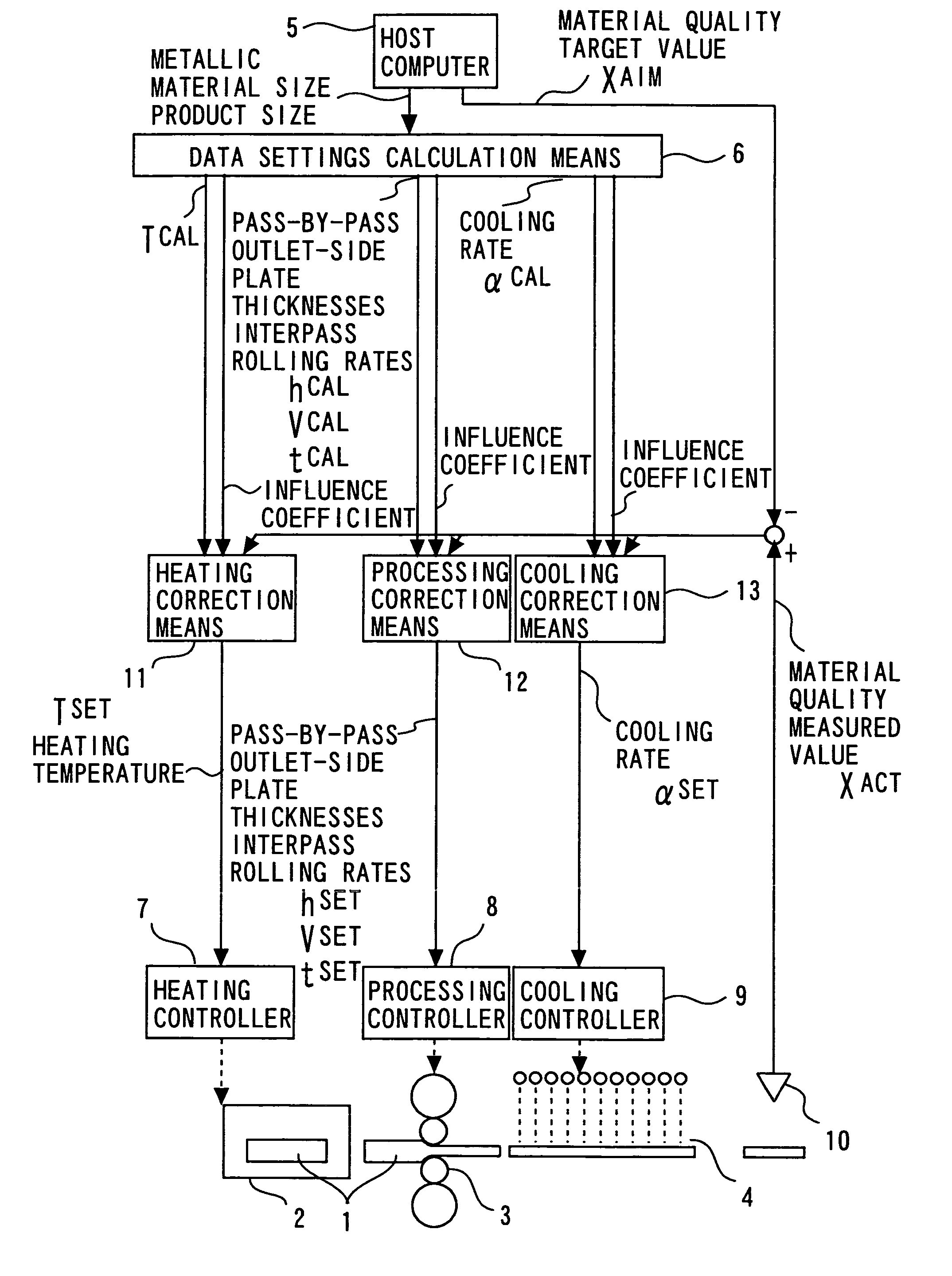

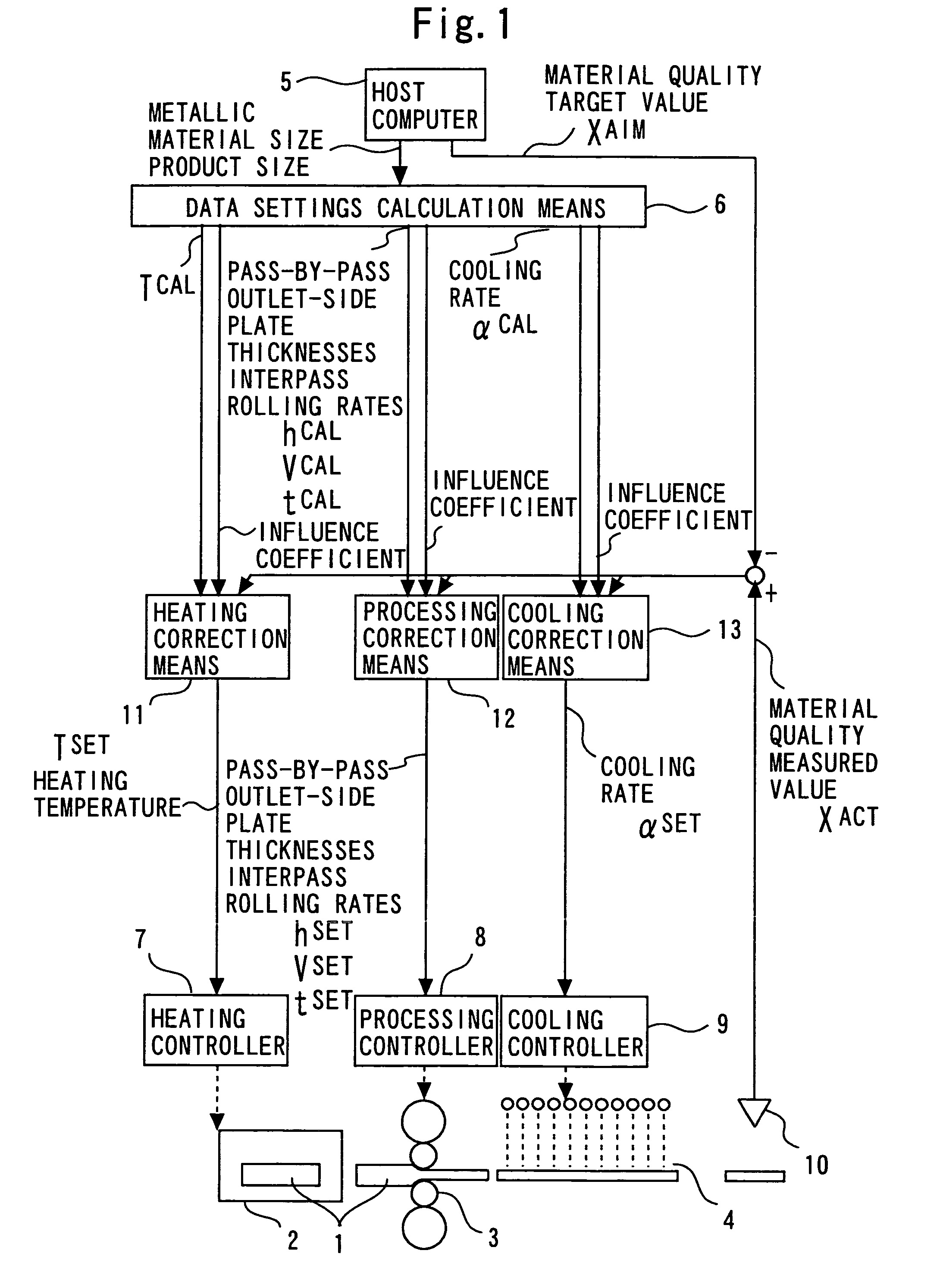

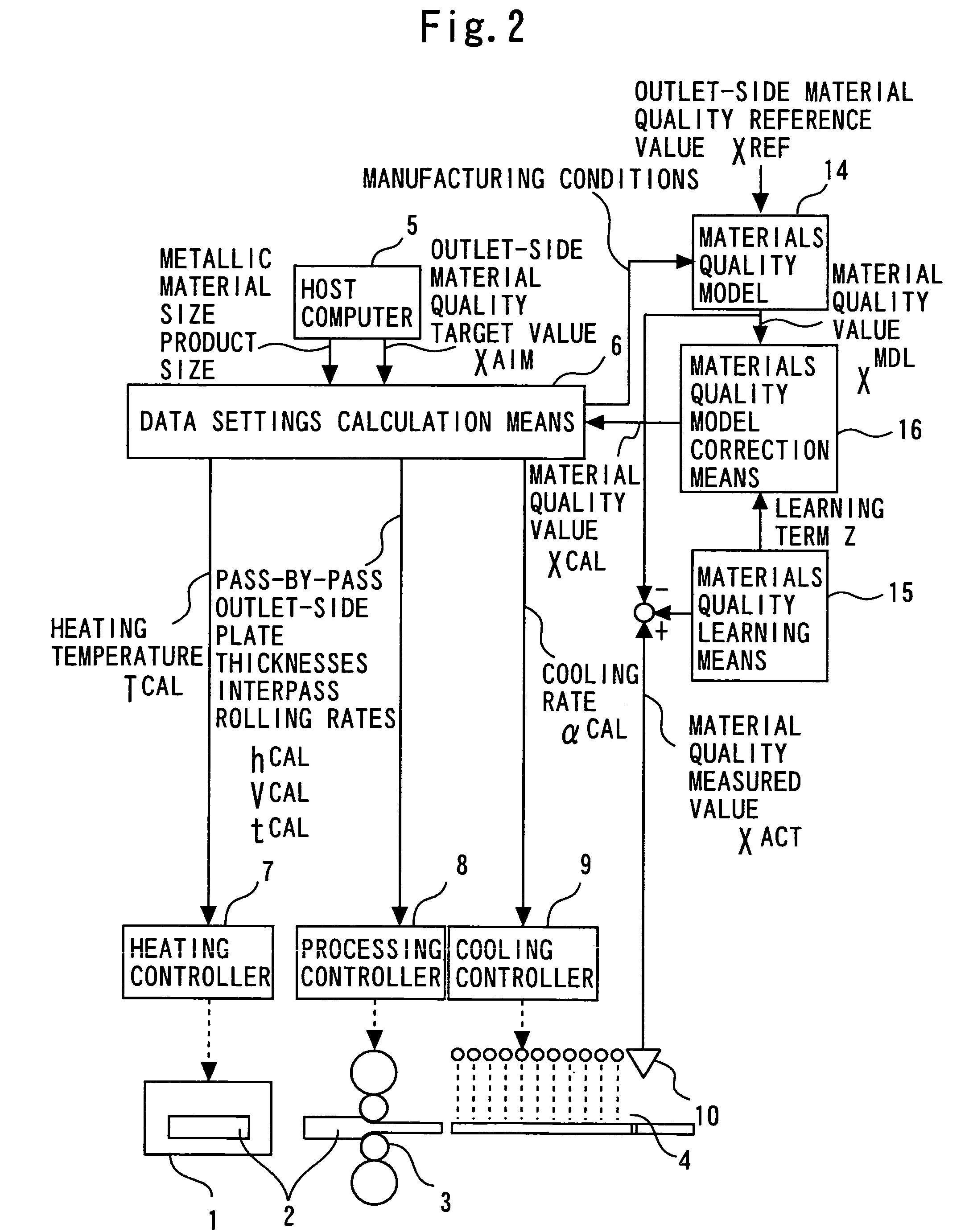

Method and apparatus for controlling materials quality in rolling, forging, or leveling process

ActiveUS20070151635A1Avoid it happening againConstant material qualityShaping toolsEnvelopes/bags making machineryManufacturing lineMaterial quality

The invention matches the material quality of a product to target data, even when a materials quality model is insufficient in prediction accuracy. Heating a metallic material, rolling, forging, or leveling the metallic material, and cooling the metallic material are each conducted at least once. Prior to manufacture of a metallic product of a desired size and shape, qualitative data of the metallic material are measured at a position by materials, quality sensor in a manufacturing line, and modifications based on measured data are made to heating, processing, or cooling conditions in at least one of the steps, upstream of the materials measured data sensor so that the quality of the metallic material at the measuring position agrees with target data.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Bending apparatus and method of bending a metal object

ActiveUS20090178453A1Reduce in quantityShaping safety devicesMetal working apparatusMeasurement deviceClosed loop feedback

A method of bending a metal object, such as a tube, is provided that uses real time, closed-loop feedback of the actual springback of the object in order to modify the applied bending force or preprogrammed bending coordinates so that the final desired bend geometry is achieved. The variability of springback from object to object is thus accounted for and the number of objects that must be scrapped due to incorrect bends (over bend or under bend) is reduced. The method is carried out using an apparatus such as a rotary draw bender with a measuring device operable to measure actual bend coordinates of metal objects bent by the bender. A controller is operatively connected to the bender and the measuring device and is configured to control the bender to bend the metal objects at least partly based on measured bend coordinates provided by the measuring device.

Owner:GM GLOBAL TECH OPERATIONS LLC

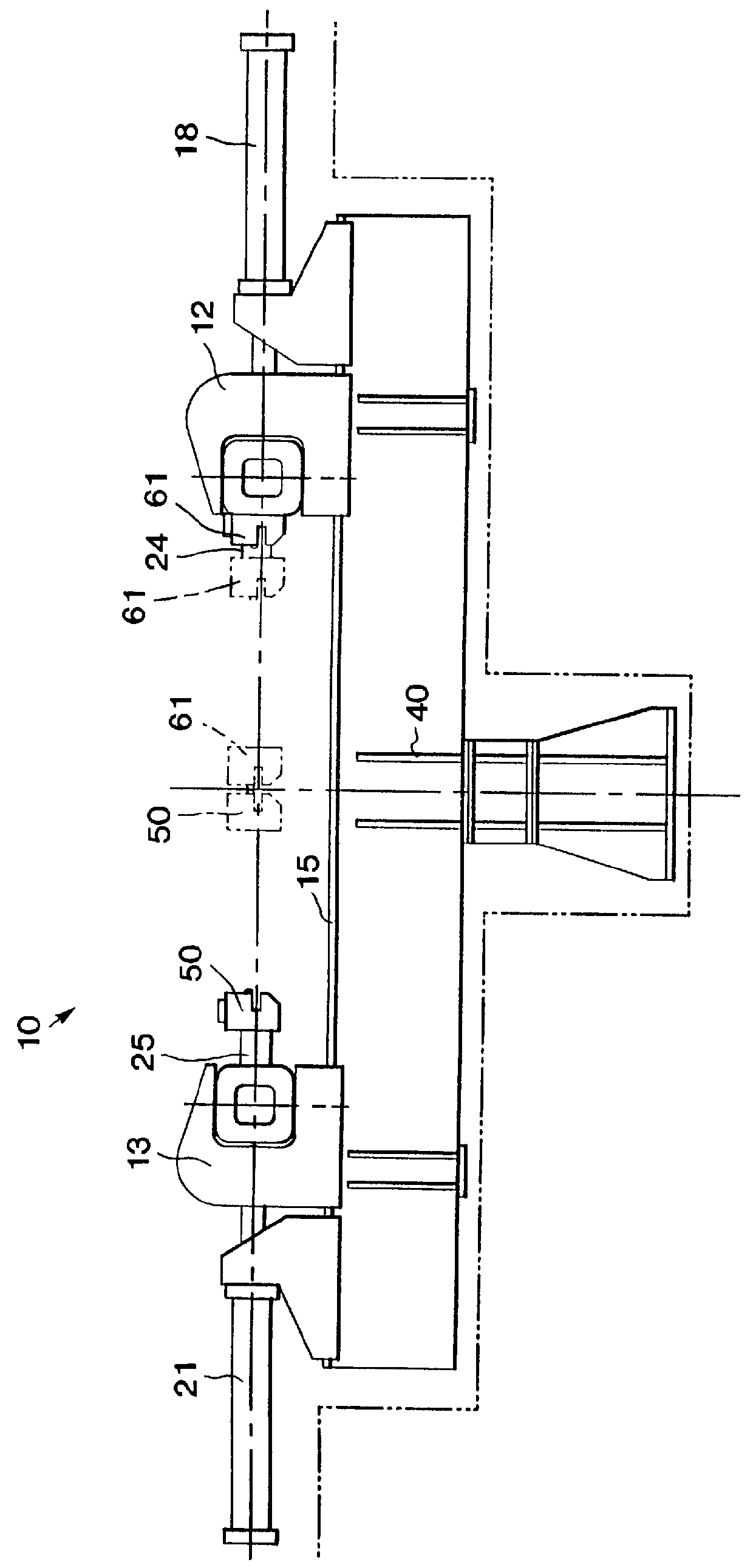

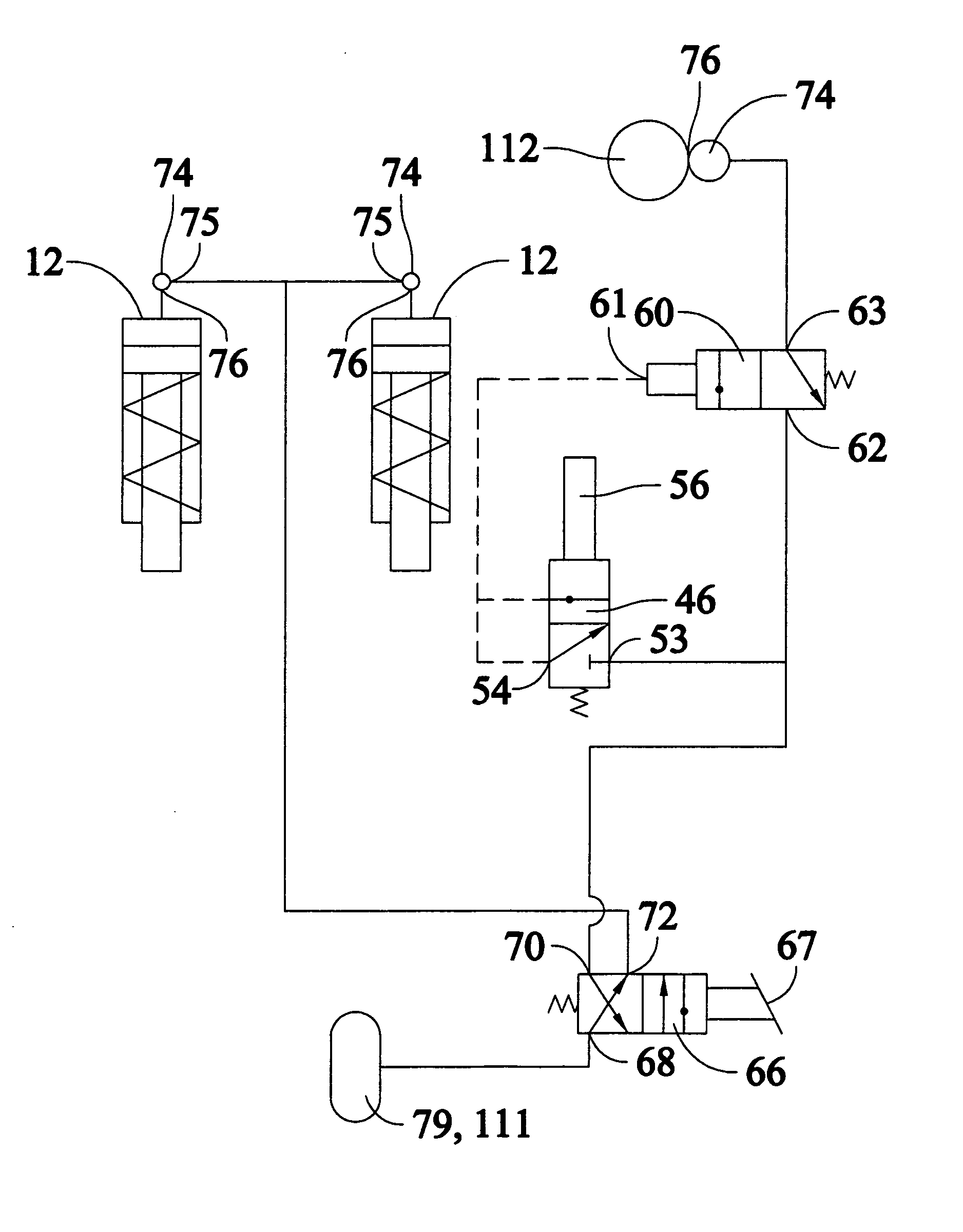

Stretch-forming machine with servo-controlled curving jaws

InactiveUS6018970AQuicker and precise machine set-upSafe working environmentMetal-working feeding devicesShaping safety devicesHydraulic cylinderClosed loop

A stretch-forming machine of the type wherein a pair of opposed curving jaws grips opposing ends of a metal sheet to be stretch-formed in a curved configuration. Each of the jaws are formed of an array of adjacent grippers movable relative to each other by respective hydraulic cylinders to define a part of the curve of the jaw. The improvement to the stretch-forming machine which is the subject of this application comprises a closed-loop servo-control means for moving each one of the grippers into a predetermined position relative to each other. Each of the servo-control means comprises a hydraulic cylinder position controller carried by the hydraulic cylinder of the one gripper for controlling hydraulic fluid flow to the hydraulic cylinder responsive to stored data representing the desired predetermined position of one of the grippers. A motor is provided for actuating the position controller in response to the data received by the position controller to move the hydraulic cylinder. Hydraulic cylinder position feedback means is positioned on the hydraulic cylinder for sensing the position of the hydraulic cylinder and communicating a signal representing the position of the hydraulic cylinder to the position controller.

Owner:CYRIL BATH

Riveting system

InactiveUS7559133B2Improve accuracyLess spilled fluid messStapling toolsTesting/calibration apparatusActuatorControl theory

A riveting system is operable to join two or more workplaces with a rivet. In another aspect of the present invention, a self-piercing rivet is employed. Still another aspect of the present invention employs an electronic control unit and one or more sensors to determine a riveting characteristic and / or an actuator characteristic.

Owner:NEWFREY

Production device, especially a bending press, and method for operating said production device

InactiveUS6938454B2Minimize timeSimplify control sequenceProgramme controlComputer controlRotational axisMetal sheet

A manufacturing system for folding sheet bars, particularly sheet metal bars, comprising a folding press with two press beams, which are adjustable in relation to each other and provided with folding dies, whereby the folding press is fed by means of an automated manipulating system. The manipulating system has three hinged arms connected via pivoting devices to form an arrangement of hinged arms. A first hinged arm is swivel-mounted on a swivel axle extending in a swivel device parallel to a guide track of a linearly displaceable chassis. A second and a third swivel axles supporting the hinged arms are arranged extending parallel to the swivel axle of the swivel device. A gripping system and a seizing device for picking up the sheet bars are arranged in another end area of the hinged-arm arrangement. A positioning device assures that the sheet bar is correctly positioned for the folding process.

Owner:TRUMPF MASCHEN AUSTRIA

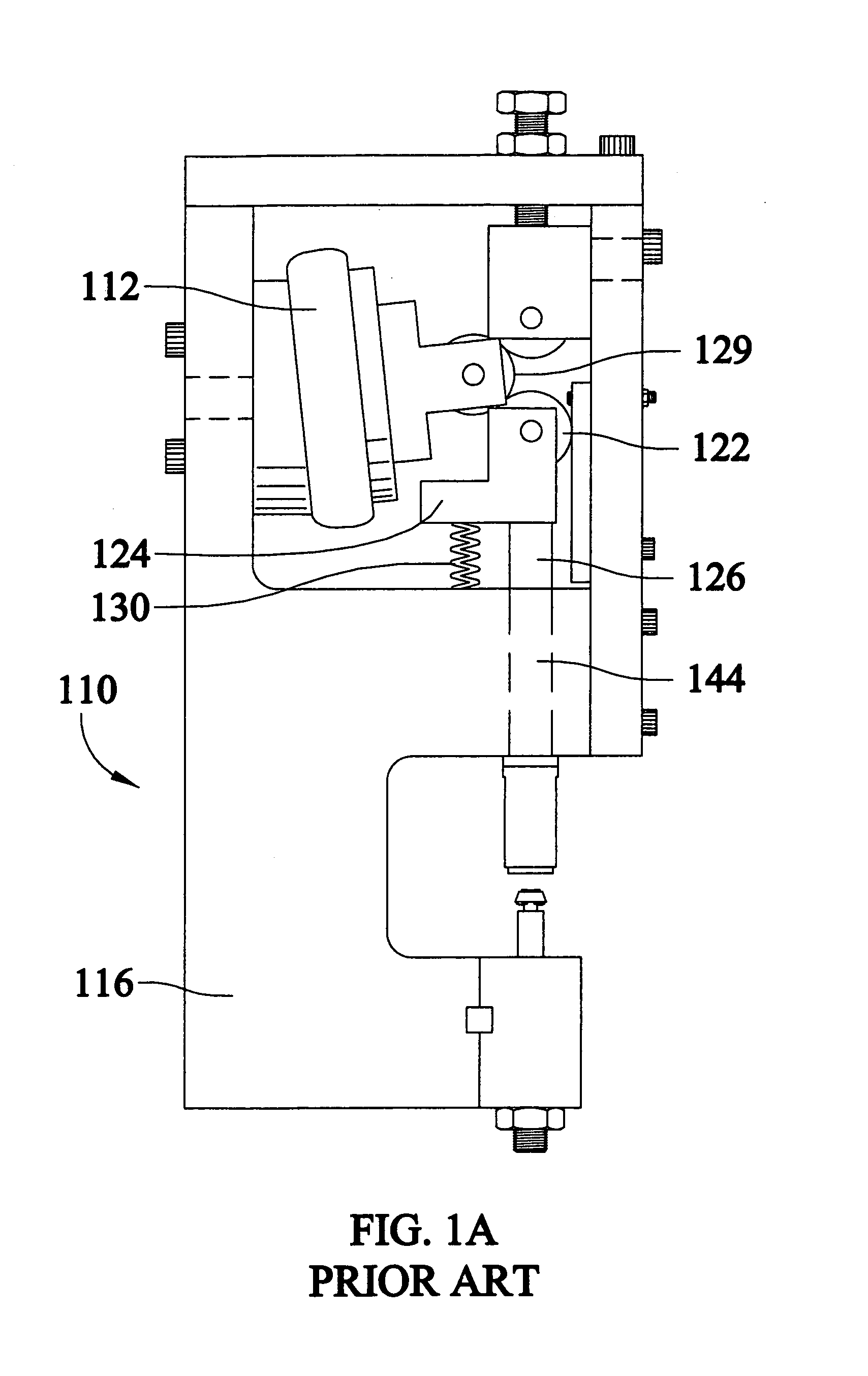

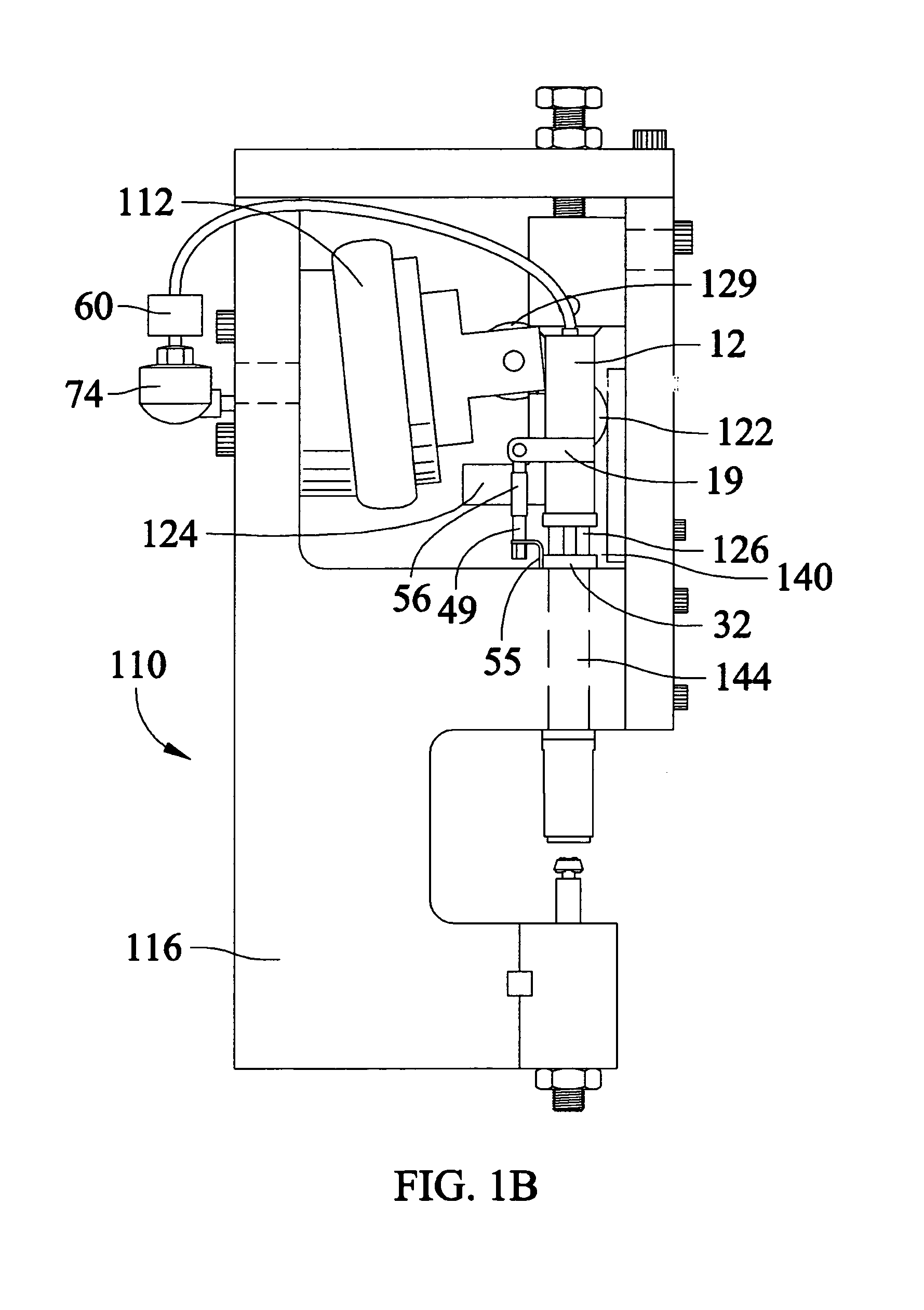

Safety interlock and retraction mechanism for clinching, crimping, and punching presses

A safety interlock and retraction mechanism for all types of presses comprising a sensing or activating valve which does not apply full force to a press ram until the ram displaces to the expected work material thickness and a pneumatically operated retraction mechanism which eliminates the need for a return spring. The art differentiates between the thickness of an operator's finger relative to a work material thickness in order to promote safety. The art further provides an increased press ram force by eliminating the return spring force subtracting from the ram force.

Owner:MUELLER THOMAS L TOD BEVERLY H MUELLER & JOSEPH E MUELLER

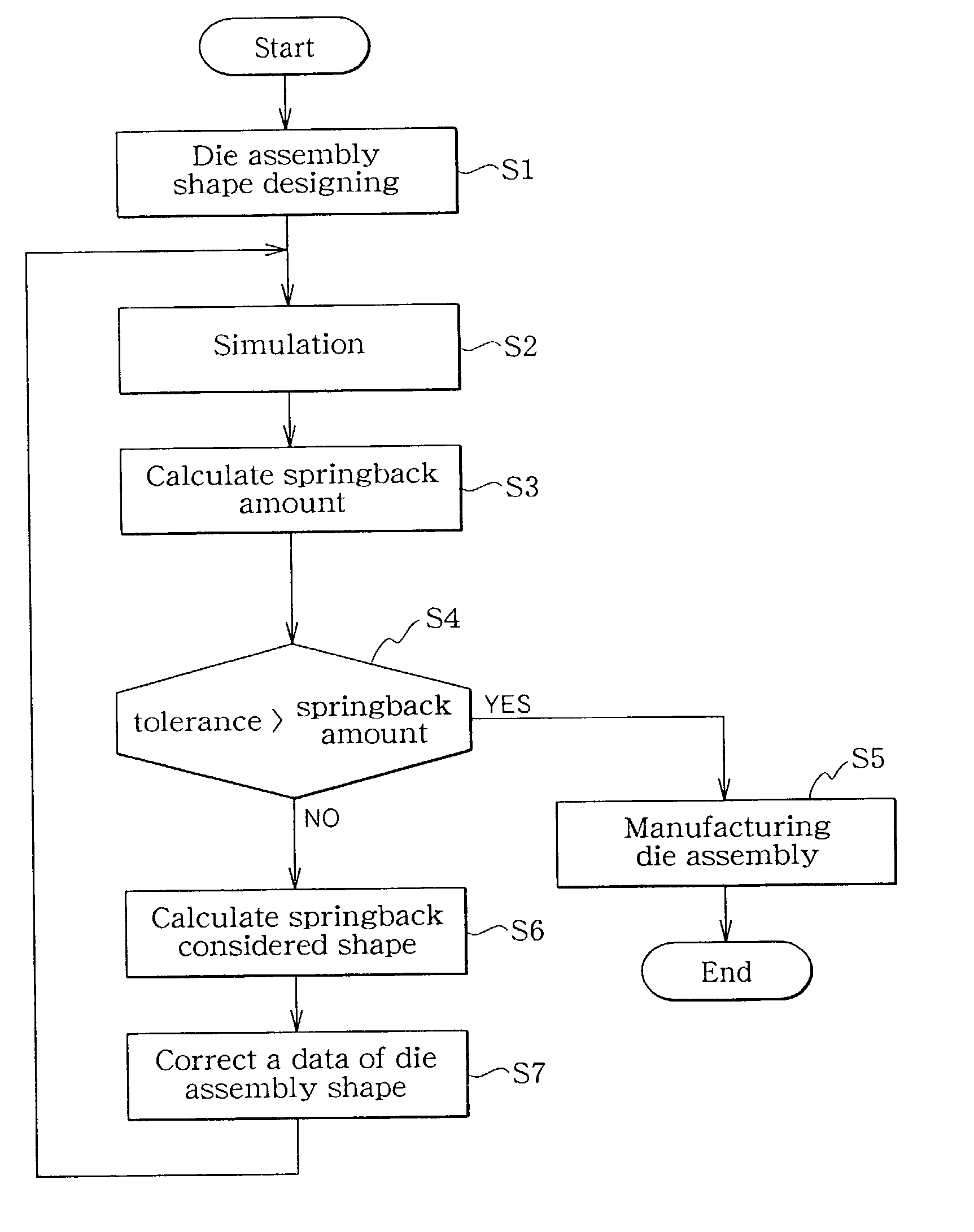

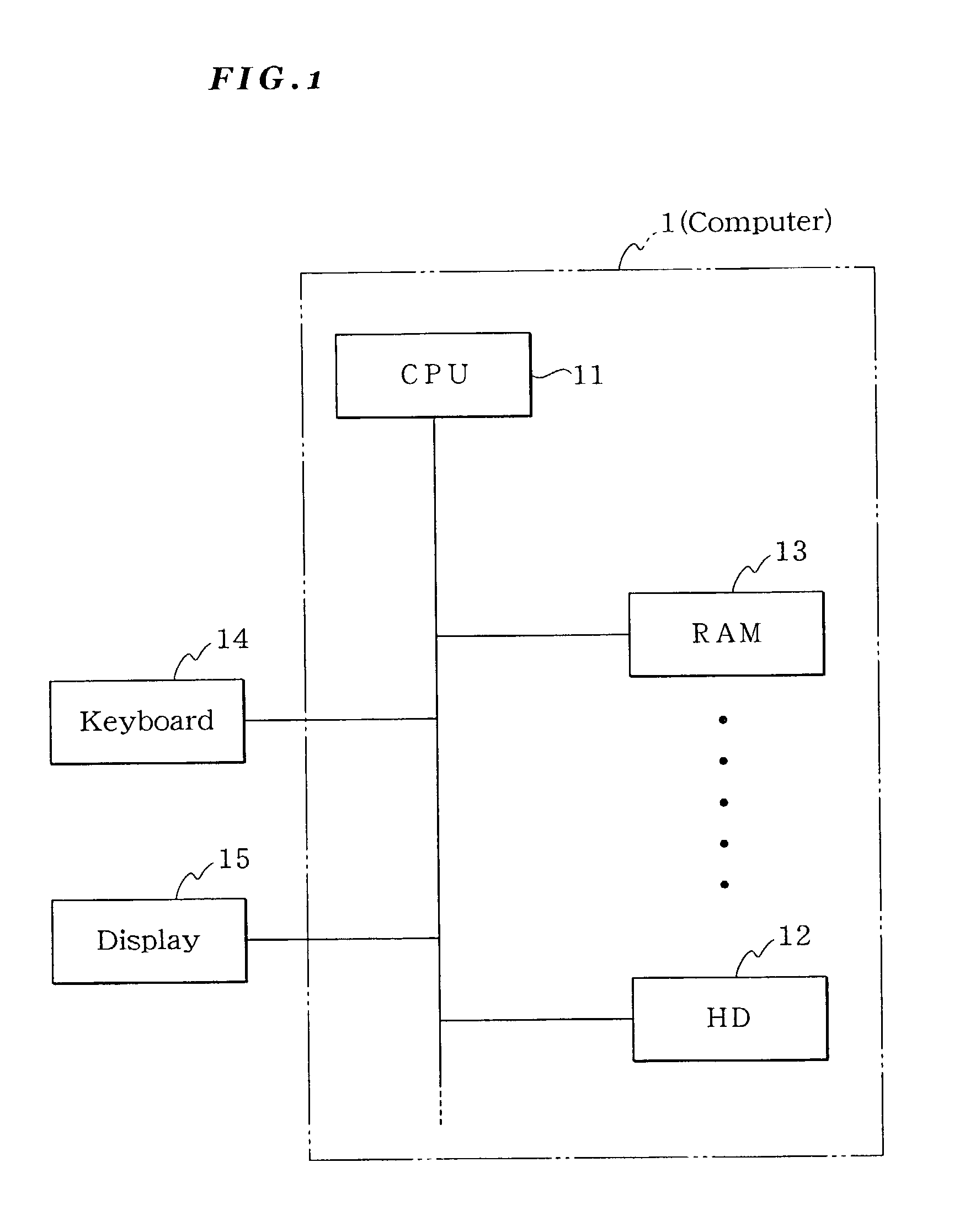

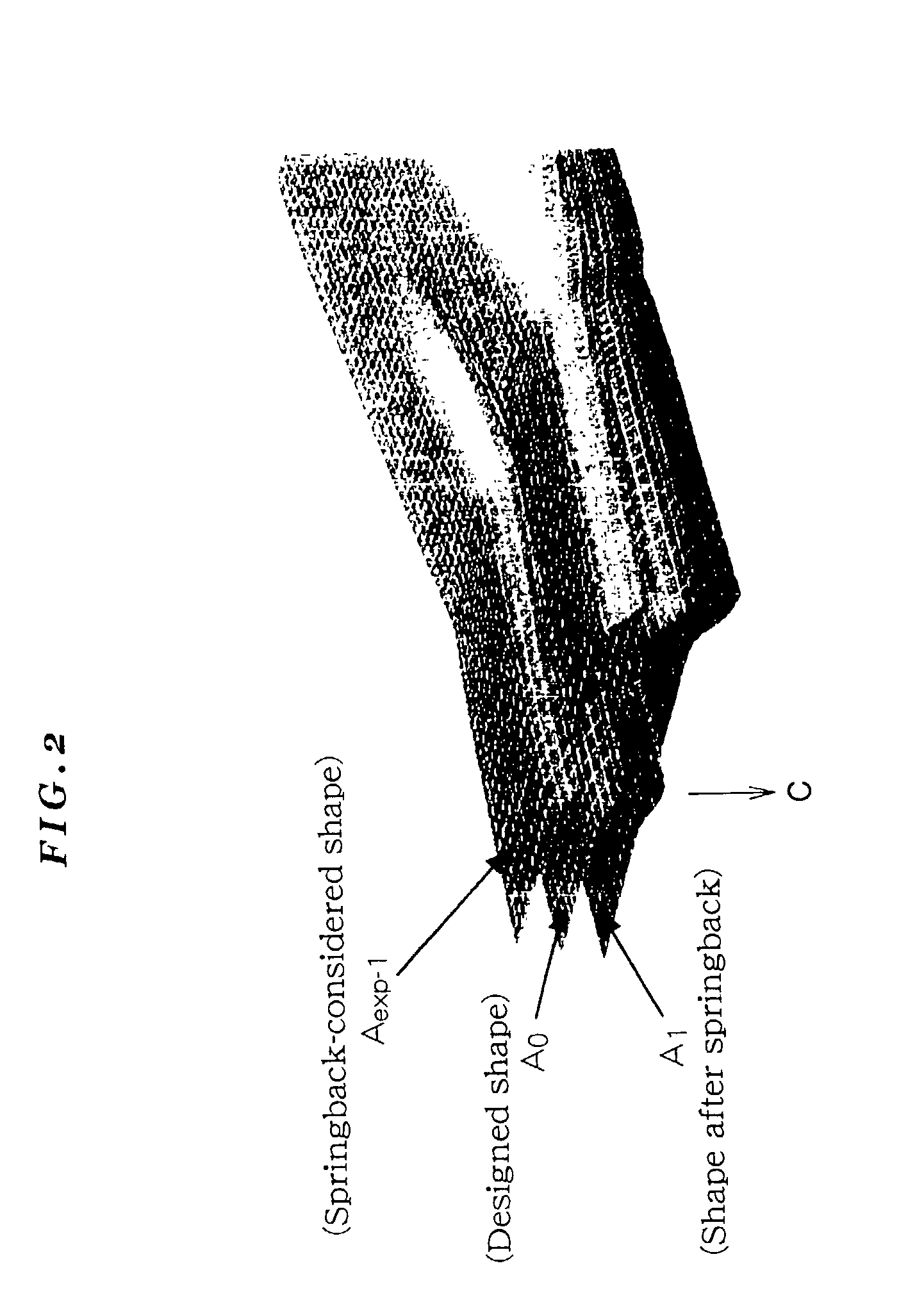

System, method, and computer program product for aiding optimization of die assembly shape for plasticity manufacturing

InactiveUS20030050765A1Shaping safety devicesDigital computer detailsMechanical engineeringTime duration

In order to realize improving dimensional accuracy of a plastic workpiece and realize reducing a production cost and shortening time duration of manufacture, a computer comprises an initial die assembly shape calculating function to calculate a die assembly shape for the plastic workpiece according to a predetermined designed shape of said plastic workpiece; a workpiece shape calculating function to calculate the shape of the plastic workpiece to be manufactured with the initial die assembly shape considering a manufacturing condition of the plastic workpiece; a shape comparing function to compare the calculated shape of the plastic workpiece and the designed shape of the plastic workpiece; a workpiece-redesigning function to calculate a new designed shape of the plastic workpiece according to a result of the comparison; and a die assembly reshaping function to calculate a new die assembly shape according to the new designed shape of the plastic workpiece.

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com