Patents

Literature

564 results about "Belt machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer engineering and in programming language implementations, a belt machine is a real or emulated computer that uses a FIFO queue rather than individual machine registers to evaluate each sub-expression in the program. A belt computer is programmed with an instruction set that specifies arguments explicitly but results implicitly. The common alternative to belt machines are register machines, in which each instruction explicitly names the specific registers to use for operand argument and result locations. Belt machines are related to stack machines, which specify both arguments and results implicitly using a pushdown stack. A belt machine implements temporary storage with a fixed-length FIFO queue, or "belt" by analogy to a conveyor belt. The operands of the arithmetic logic units and other functional units may be taken from any position on the belt, and the result from the computation is "dropped" in the front position of the belt, advancing the belt to make room.

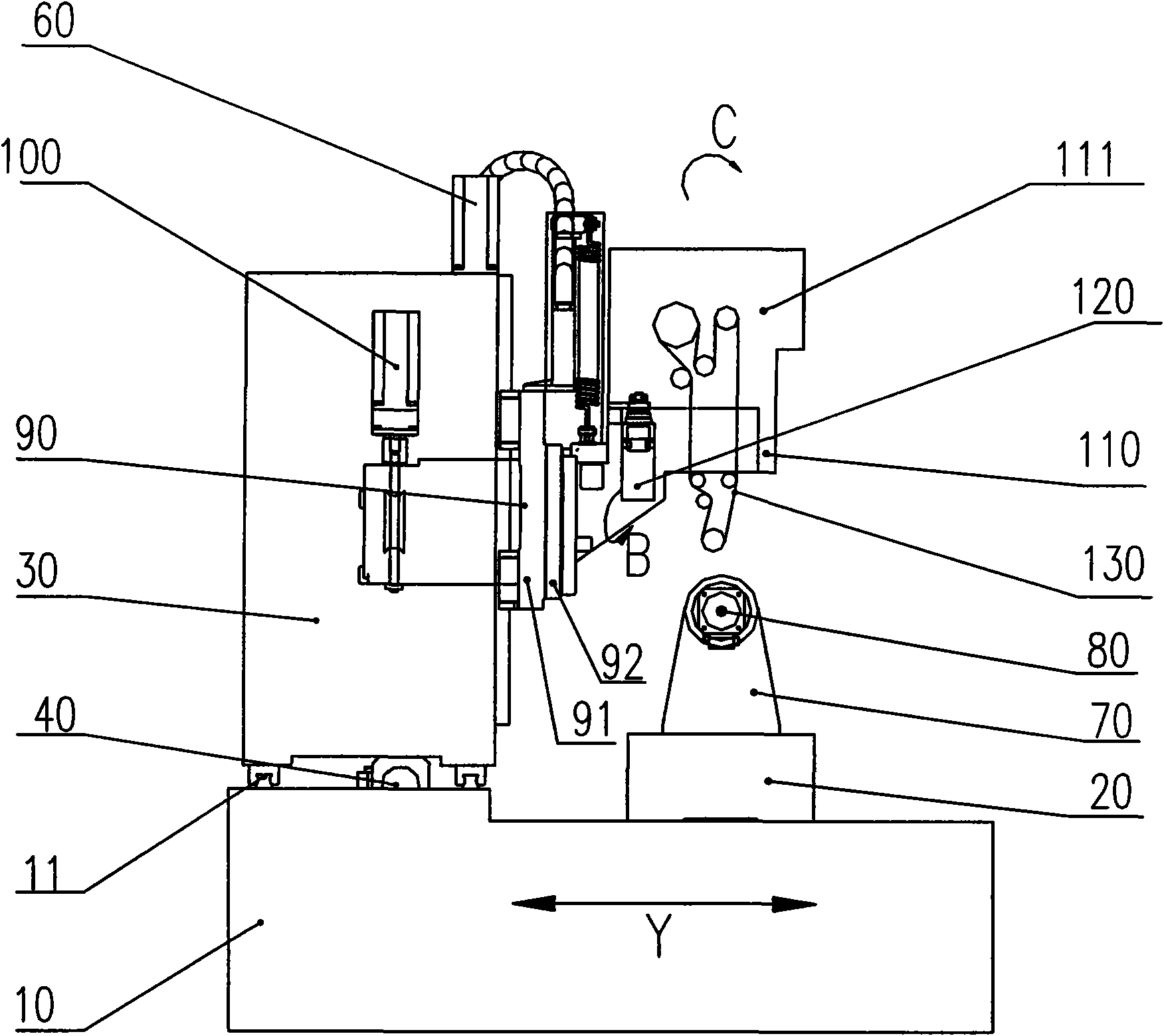

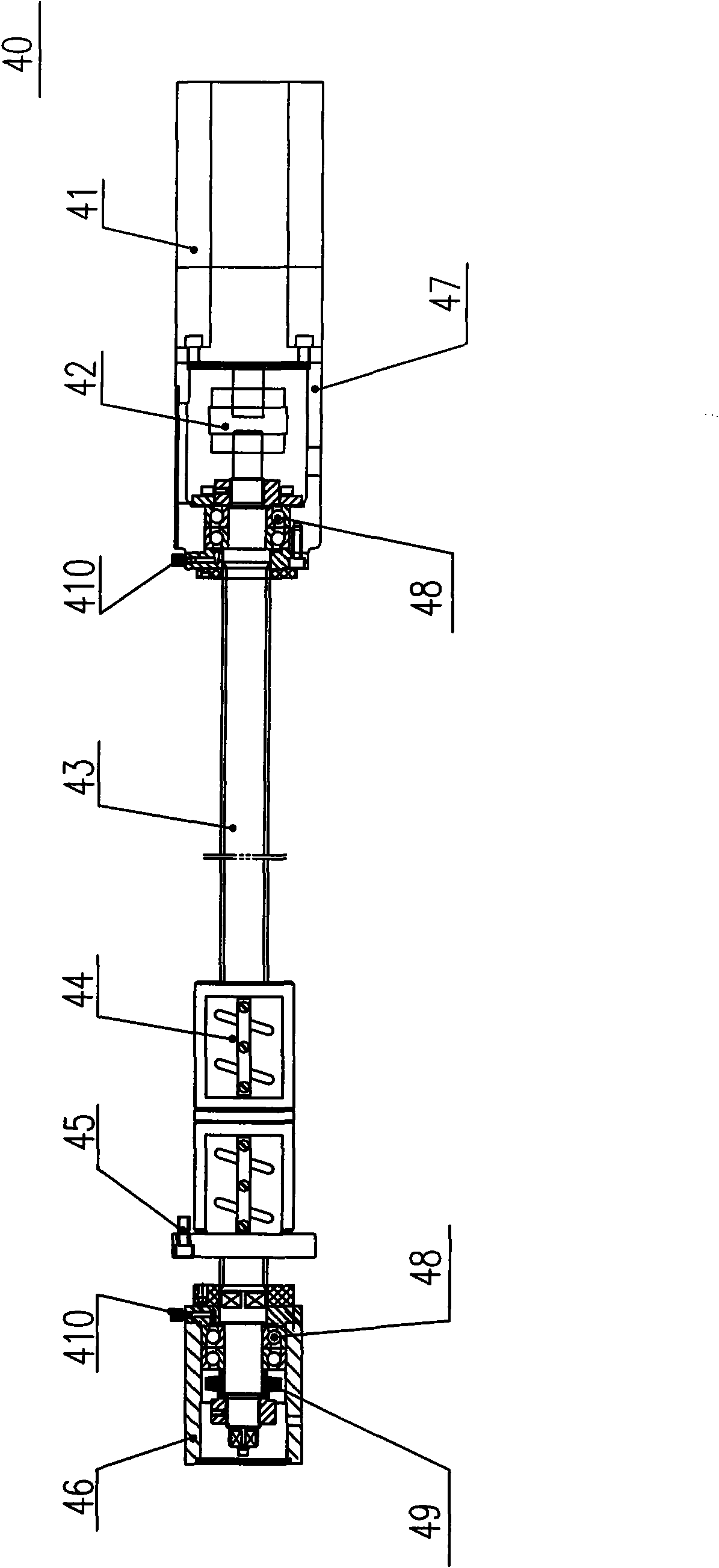

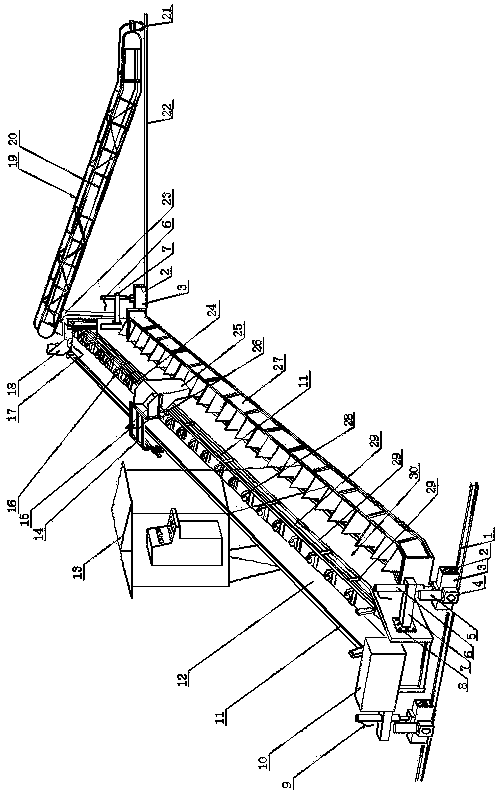

Numerical control abrasive belt grinding machine with six-axis linkage

ActiveCN101559574AImprove processing efficiencyHigh dimensional accuracyGrinding carriagesBelt grinding machinesMachine controlForm liner

The invention discloses a numerical control abrasive belt grinding machine with six-axis linkage. An upright post component and a worktable are arranged on the grinding machine body in a sliding way, and the relative sliding between the two of the upright post component and the worktable and the grinding machine body respectively forms liner motion of X-axis direction and Y-axis direction; an A-axis component is arranged above the worktable and used for clamping a workpiece to rotate around the axial line thereof so as to form rotary motion of the A-axis; a cantilever on the upright post component is provided with a grinding seat which is connected with the upright post component through a box body in a sliding way so as to form liner motion of Z-axis direction; a turntable is arranged on the box body in a rotating way, and the relative rotation between the turntable and the box body forms rotary motion of B-axis direction; an abrasive belt machine is arranged inside the grinding seat, and the relative rotation between the abrasive belt machine and the grinding seat forms swivel motion of C-axis direction; and the grinding machine controls the motion of each axis direction by a numerical control system. The numerical control abrasive belt grinding machine can greatly enhance grinding efficiency, and can effectively improve the grinding precision and surface quality of the workpiece.

Owner:北京胜为弘技数控装备有限公司

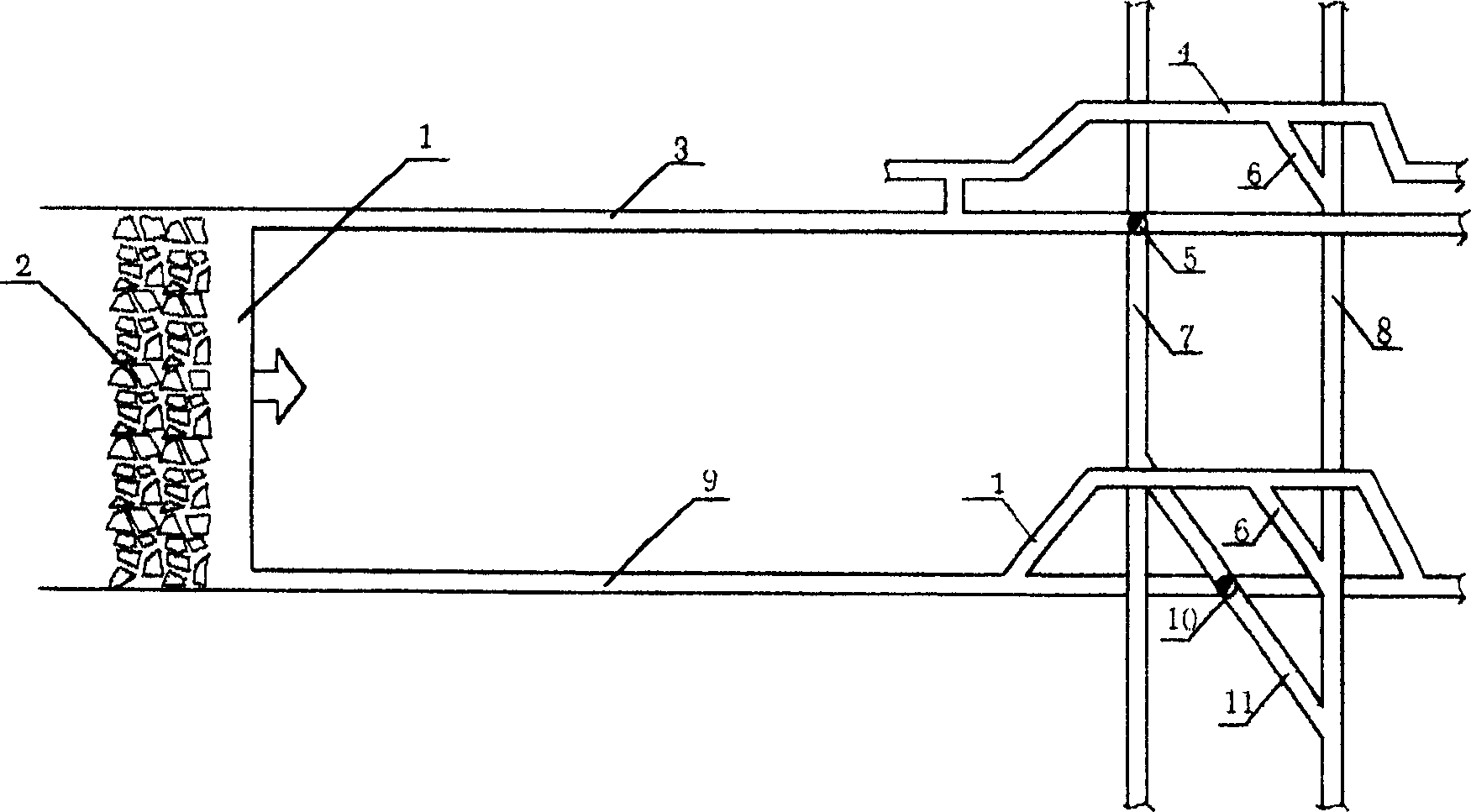

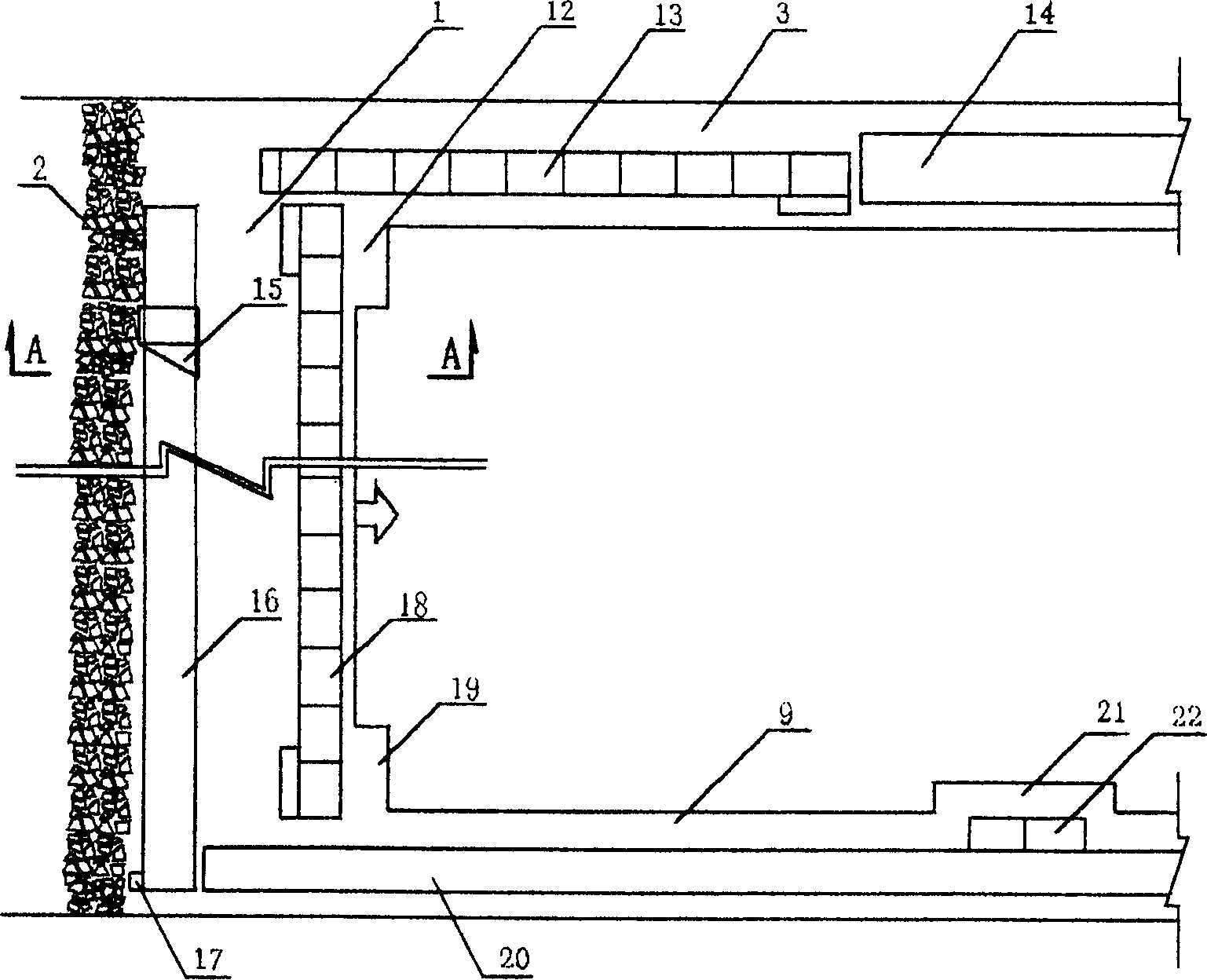

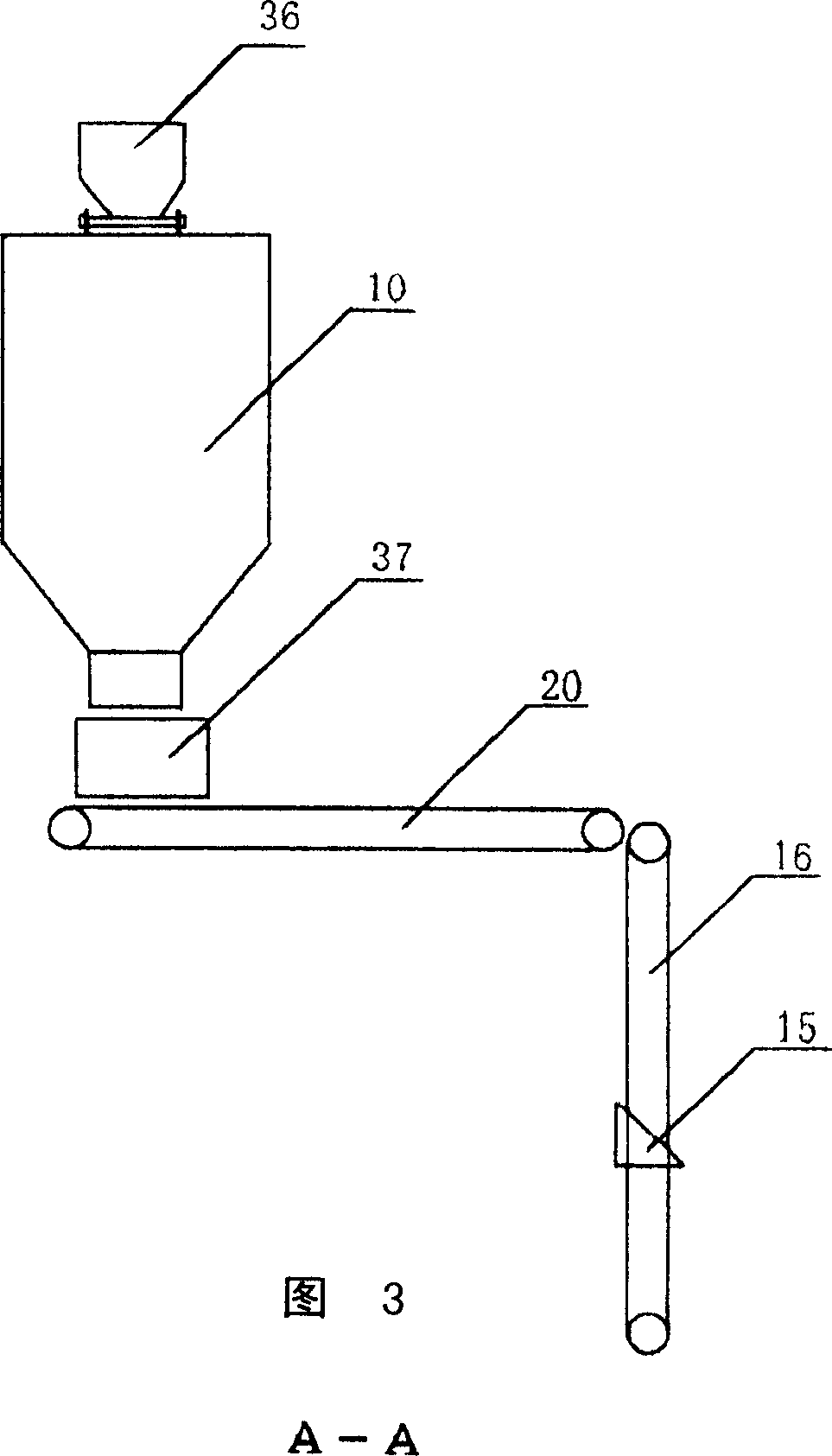

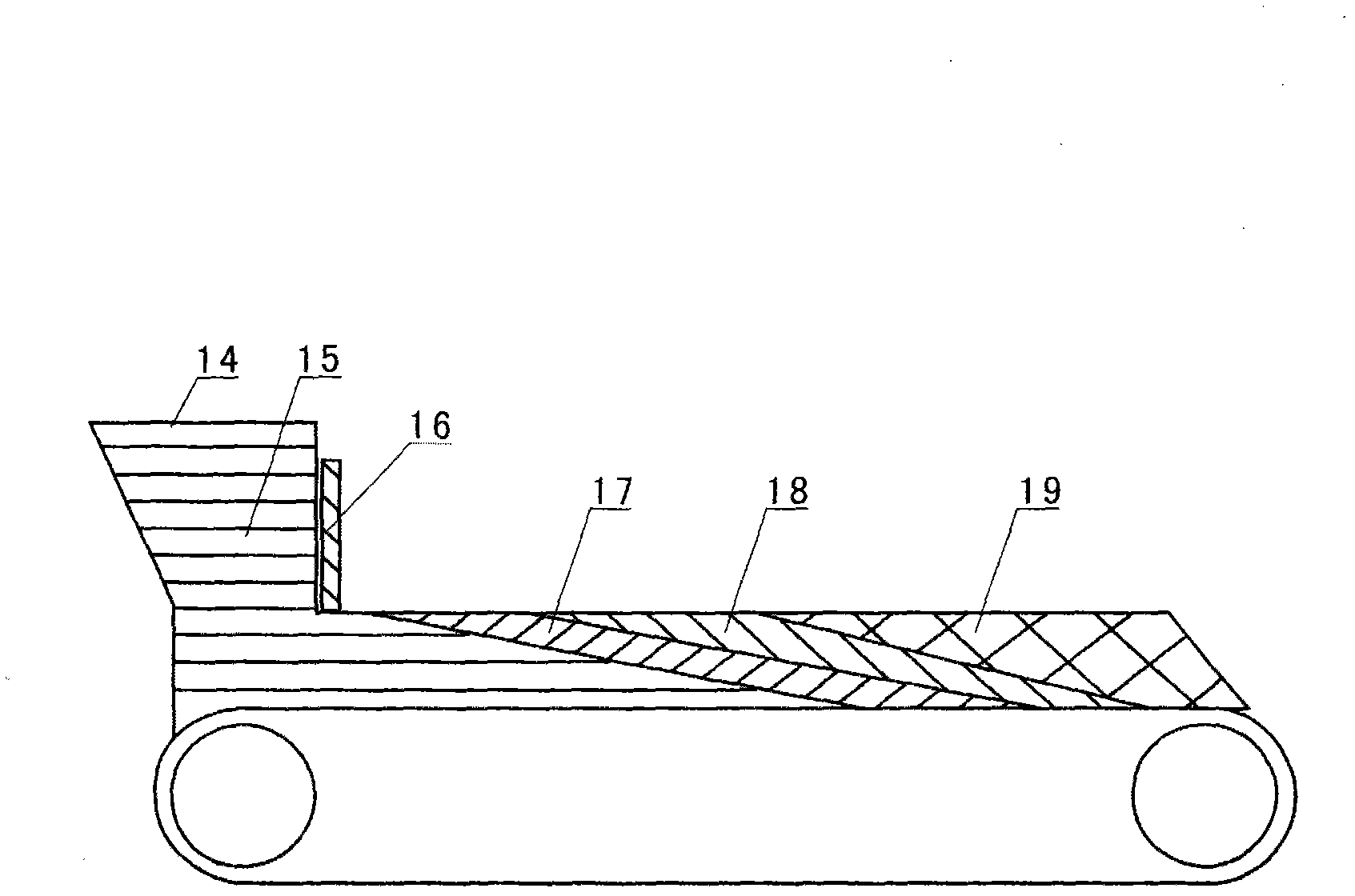

Method for filling goaf by gangue

The invention relates to a method for using stone to fill the worked-out section under the coal well, which arranges a stone bin (10) outside the working surface to transfer the under-well stone or the ground stone to the stone bin (10) to be broken by the breaker; and using the stone belt machine (20) on the producing surface to transfer them to the upper end of producing surface (1); the producing surface (1) is supported by the filling brackets or the brackets whose back have extending beams; when the bracket is self-motion type, suspending a small belt device (16) on the extending beam and moving ahead with the bracket; when the bracket is not self-motion type, the small belt device (15) is arranged at the bottom plate under the extending beam and using slide device to move ahead; the small belt device (16) is mounted with a self-motion stone unload cart (15); transferring the small belt device (16) to the upper end of producing surface to unload the stone to the worked-out section. The invention can reduce the earth sink, effectively treat the stone, and reduce the accommodation area of stone and the pollution, with simple device and lower cost.

Owner:新汶矿业集团汶南煤矿有限责任公司

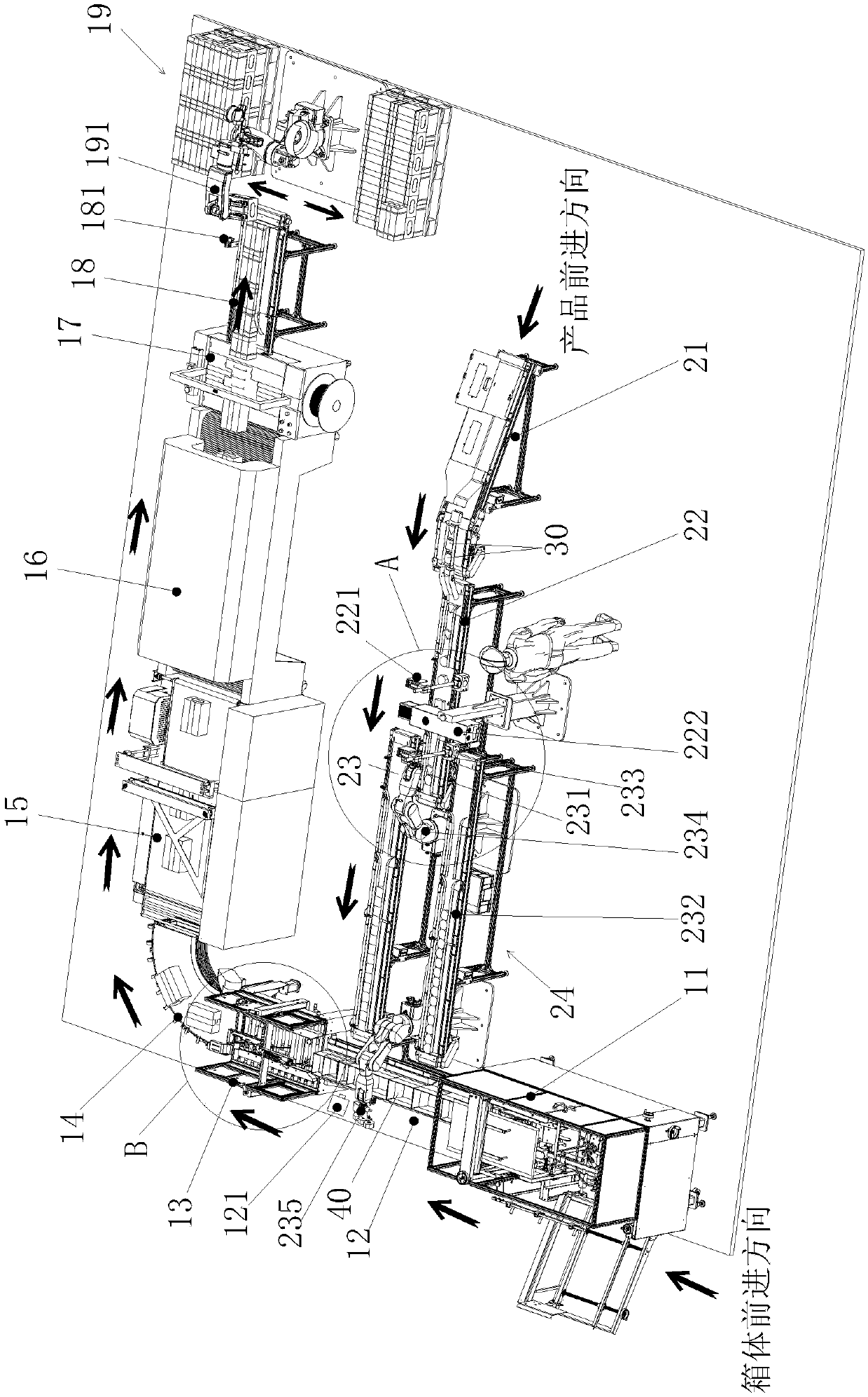

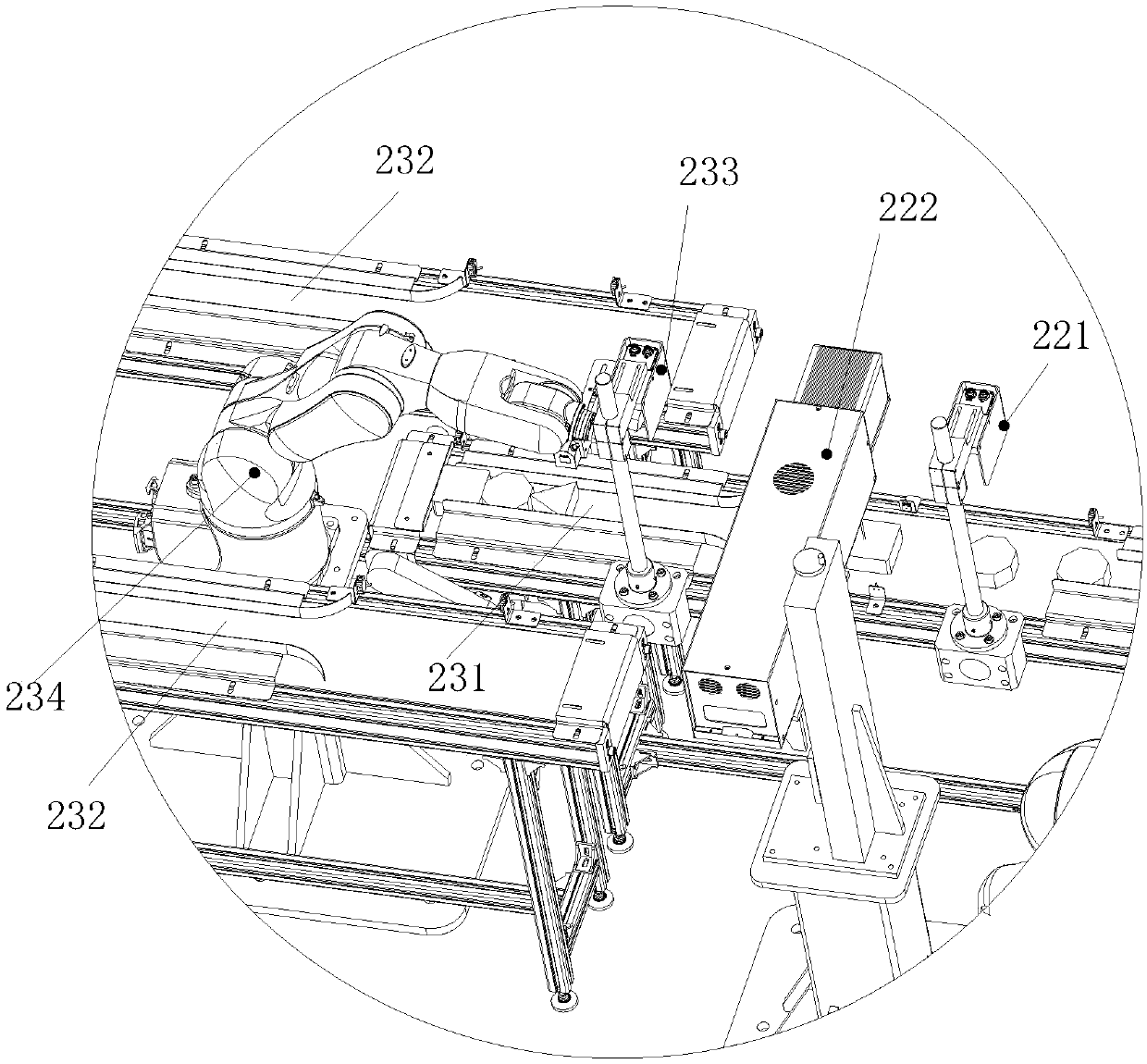

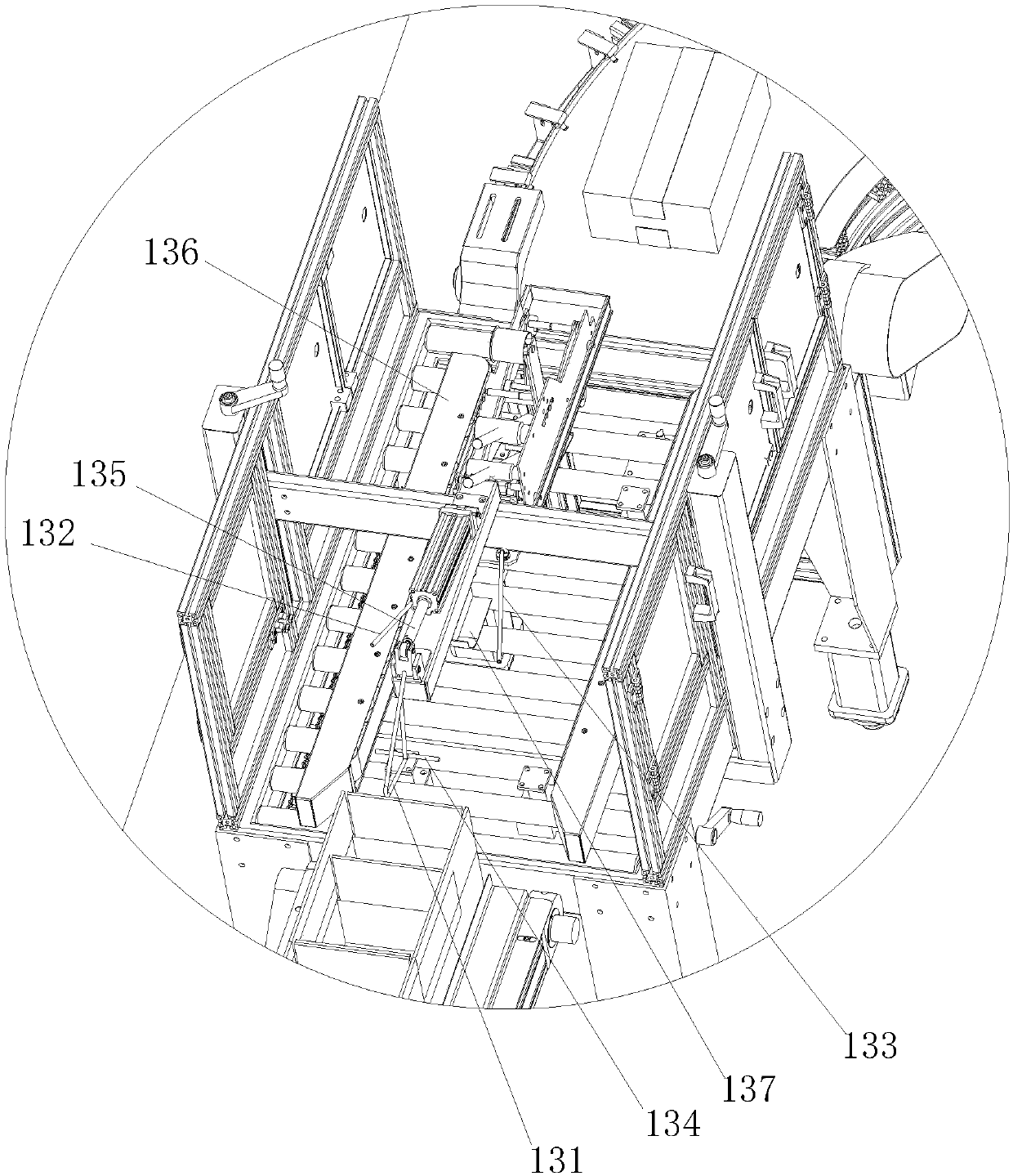

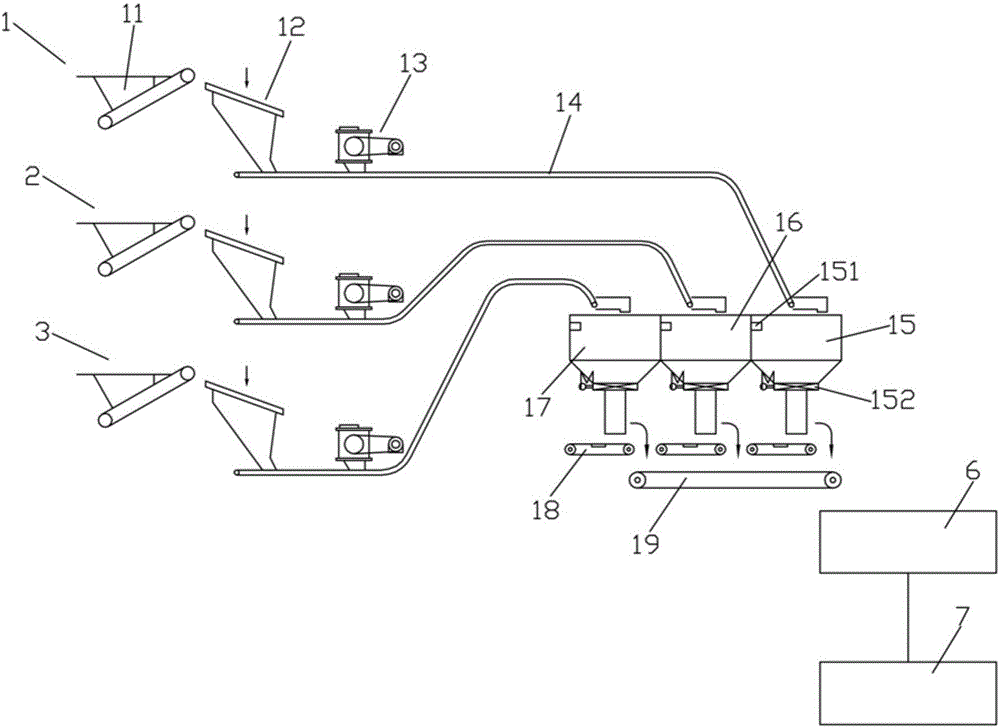

Automatic packaging line for simultaneous production in diversified mode

The invention discloses an automatic packaging line for simultaneous production in a diversified mode. The automatic packaging line comprises a packaging box conveying unit and a product conveying unit. The packaging box conveying unit comprises an automatic box opening machine, a packaging box conveyor, an automatic box sealing machine, a 90-degree turning machine, an automatic film laminating machine, an automatic thermo-plastic machine, an automatic packaging belt machine, a finished product conveyor and an automatic classifying and stacking machine. The product conveying unit comprises anautomatic feeder, a marking conveyor, a product sorting machine and a classified product conveyor. The automatic feeder can convey one or at least two products simultaneously. A first product visual identification system and a product laser coding machine are installed on the marking conveyor. The product sorting machine is provided with at least two single product conveyors and a mixed product conveyor in butt joint with the automatic feeder; the input end of the product sorting machine is provided with a second product visual identification system and a first manipulator. According to the automatic packaging line, two or more products with different specifications can be simultaneously packaged in one production line.

Owner:青岛普力捷自动化科技有限公司

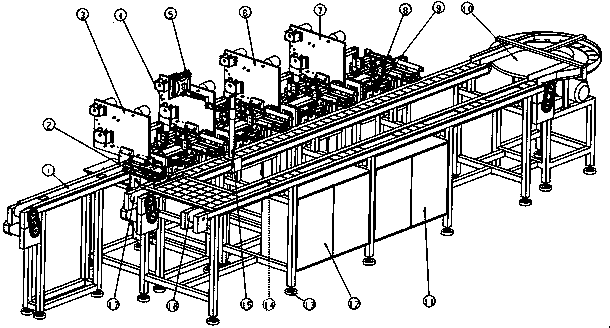

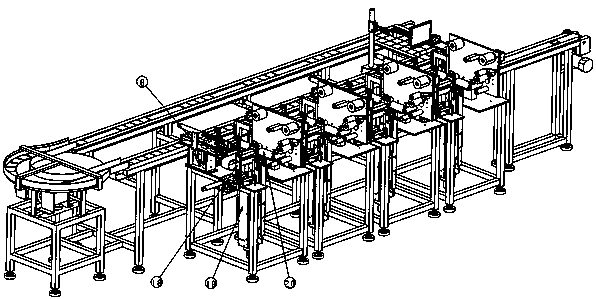

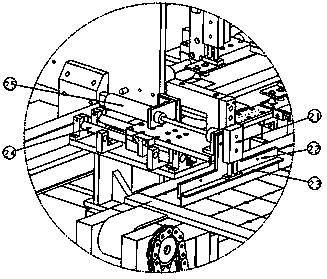

LCD (liquid crystal display) automatic paster production line and LCD automatic paster production method thereof

The invention discloses an LCD (liquid crystal display) automatic paster production line and an LCD automatic paster production method of the LCD automatic paster production line, and belongs to the field of production technology equipment of electronic, electrical as well as electromechanical products. The LCD automatic paster production line is provided with a material charge conveying belt, a material discharge conveying belt and four plaster machine heads; the material charge conveying belt is provided with a net belt machine, a belt machine, a cleaning manipulator and a rotary disc which are installed on a rack; the net belt machine, the belt machine and the rotary disc are provided with glass molds driven by a driving device so as to form a complete operation cycle, so that glass base plates are automatically conveyed; the paster machine heads are arranged at one side of a net belt, and each paster machine head comprises a glass platform, a membrane sheet material groove, a membrane sheet platform, a material charge and discharge manipulator, a membrane sheet manipulator and the like which complete the paster operation independently. The LCD automatic paster production line and the LCD automatic paster production method of the LCD automatic paster production line provided by the invention have the characteristics that the structure is compact; the design is ingenious; the four machine heads operate synchronously, and the LCD paster production process automation is realized through a PLC (programmable logic controller) control technique, and does not rely on manual operation too much; the production efficiency is high; and the paster quality is good.

Owner:许翔

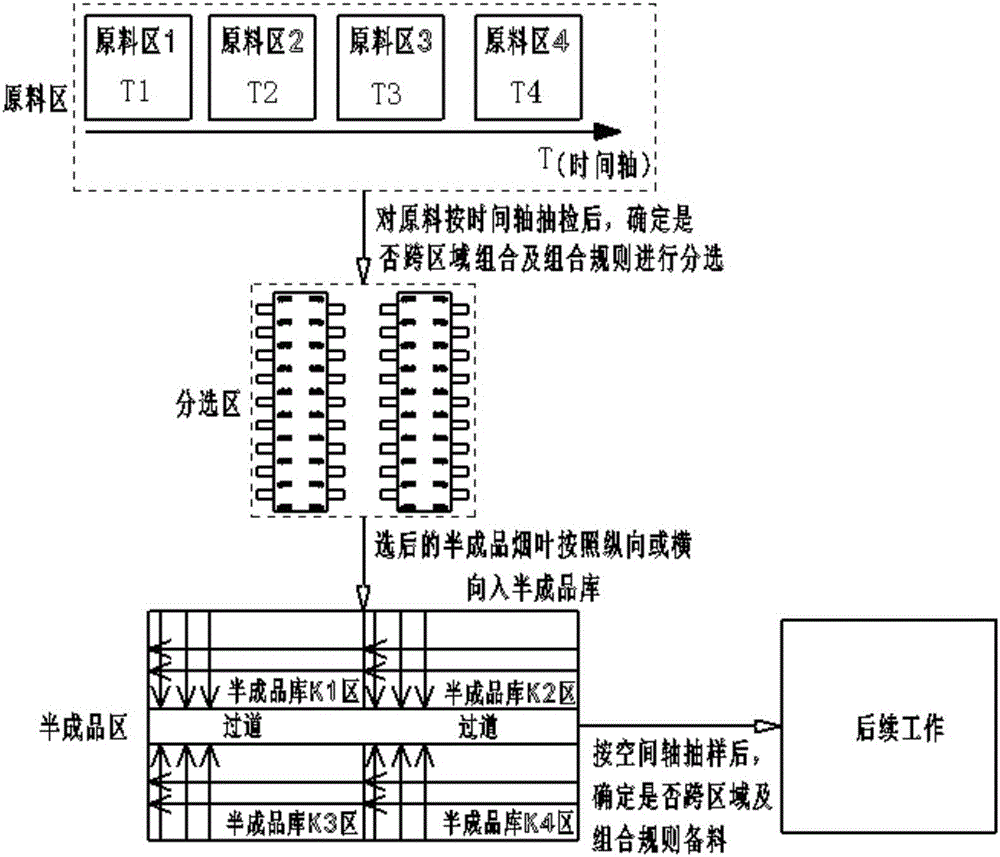

Time-and-space-area sampling tobacco-re-drying homogenization processing method

ActiveCN105686045AIncrease the lengthSolve the detection speed is slowTobacco preparationMaterial analysis by optical meansWork in processCoefficient of variation

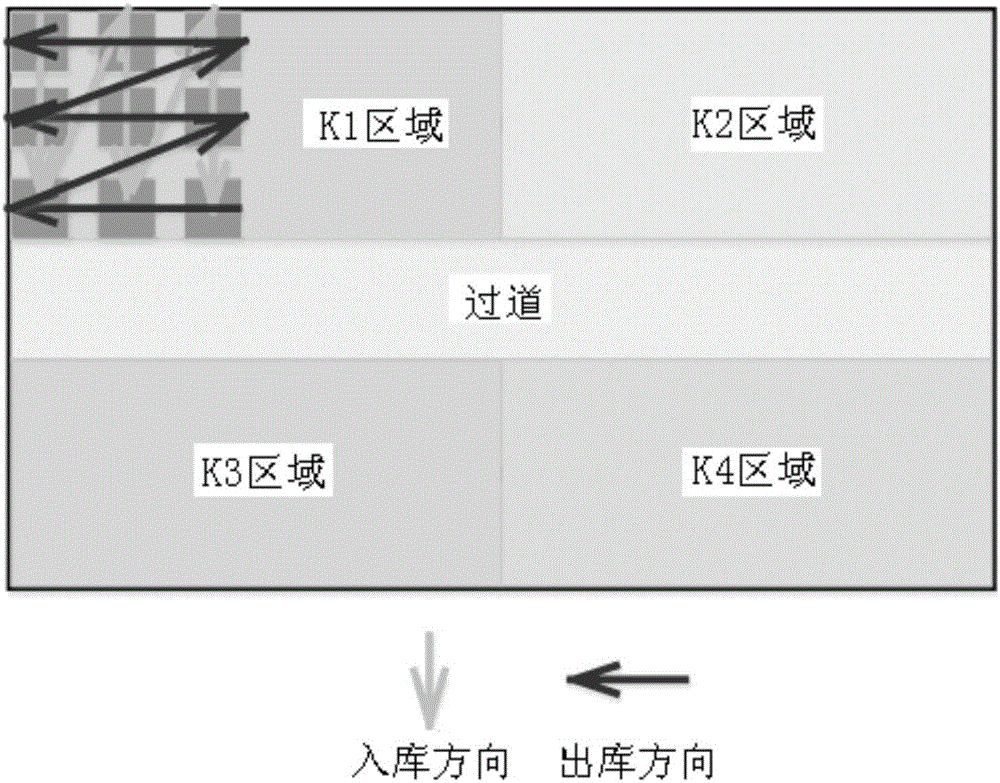

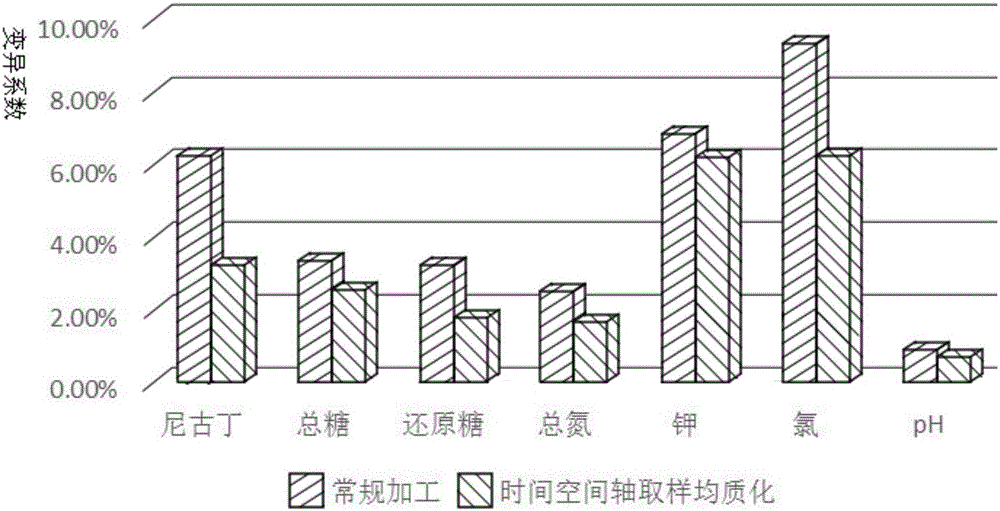

The invention discloses a time-and-space-area sampling tobacco-re-drying homogenization processing method. The processing method includes the following steps that in the step 1 and the step 2, all-grade raw tobaccos are divided into 4-6 time areas according to the time sequence of warehousing respectively; raw tobacco samples in all the time areas are detected, whether combination is carried out in a cross-time-area mode or not is determined according to the combinational rule, the tobaccos are put into labor separation fields to be separated, and the separated tobacco leaves are manually put into a belt machine in a bundle mode, mixed and framed; in the step 3 and the step 4, a warehouse is divided into 4-6 space areas; semi-finished product tobacco leaves in all the space areas are sampled to be detected, matching is carried out in the space areas according to the nicotine value, materials are put into a defoliation re-drying workshop for the leaf laying and bundle untying working procedure, and labor placing bundle processing is carried out according to the set leaf laying rule. According to the time-and-space-area sampling tobacco-re-drying homogenization processing method, due to multiple times of effective mixing, the variable coefficient of nicotine of the tobacco leaves is greatly reduced; the process cycle is short, labor cost is low, changes of the original technology are small, and input cost is low.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING

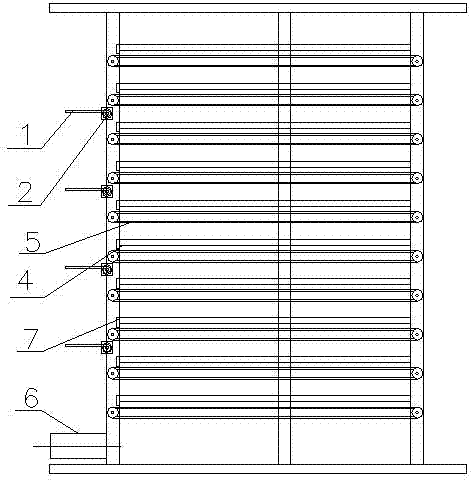

Conveying belt type article storage and delivery device

InactiveCN102344029ARealize automatic loading and unloadingImprove space utilizationStorage devicesMachine partsEngineering

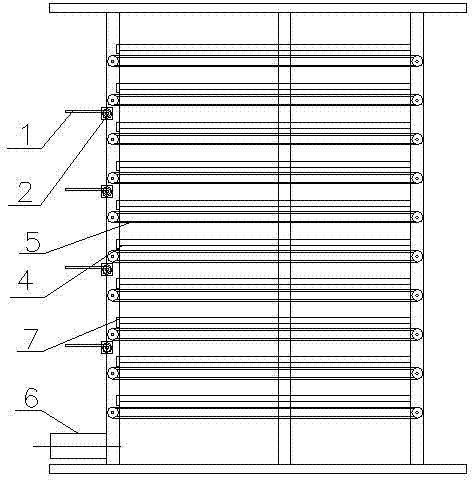

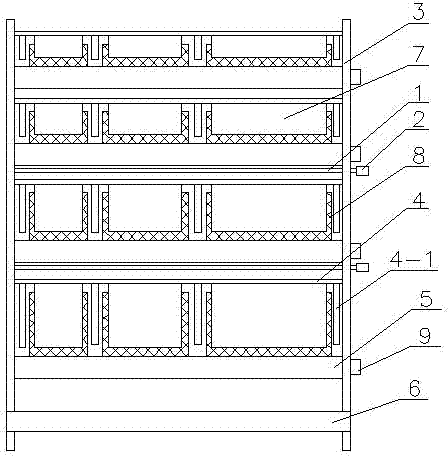

The invention discloses a conveying belt type article storage and delivery device. Conveying belts are arranged on a frame body of an article storage frame from upside to downside in sequence; the two adjacent conveying belts are parallel to each other; each conveying belt is driven by a corresponding conveying belt power device to operate; a partition board is arranged above each conveying belt; the conveying belt is divided into a plurality of independent article storage channels by the partition boards according to the article storage size; each article storage channel is parallel to the advancing direction of the conveying belt; a delivery controller capable of being opened is arranged at the output end of each article storage channel; a turnover plate is arranged at the outlet end of the conveying belt and driven by a corresponding turnover plate power device to turn over; a belt machine is arranged at the bottom of the article storage frame and positioned below the lowest turnover plate. The conveying belt type article storage and delivery device disclosed by the invention can be widely used for automatically storing drugs, foods, daily necessities, chemicals, mechanical parts, electronic components and other materials.

Owner:JIANGSU XUNJIE HARNESS TECH

Self-portable belt conveyer

InactiveCN101537925AHighlight substantiveGuaranteed uptimeConveyorsControl devices for conveyorsTransportation technologyCoal

The invention provides a self-portable belt conveyer, which comprises a belt conveying machine head, a hydraulic belt tightener, a belt conveyer middle part, a belt conveyer tail and a belt and is characterized in that the belt conveyer also comprises the belt conveying machine head and a dragging device connected with the hydraulic belt tightener; the machine head of the belt conveyer is the self-portable belt machine head, has the functions of free-installation and dismantling, easy maintenance, constructor reduction, labor intensity of constructor reduction, increasing working performance, creating safe operating environment, self moving a hydraulic dram tightening belt, free drag of tightening system and the like, and has the advantages of good explosion prevention and safe performance, high flexibility and the like. The self-portable belt conveyer increases the transportation technology of coal mine underground coal and rock, provides unitized technical equipment for coal mine coal and rock transportation system, and creates the fundamental conditions for realizing the safe production of big, medium and small-size coal mines.

Owner:闫振东

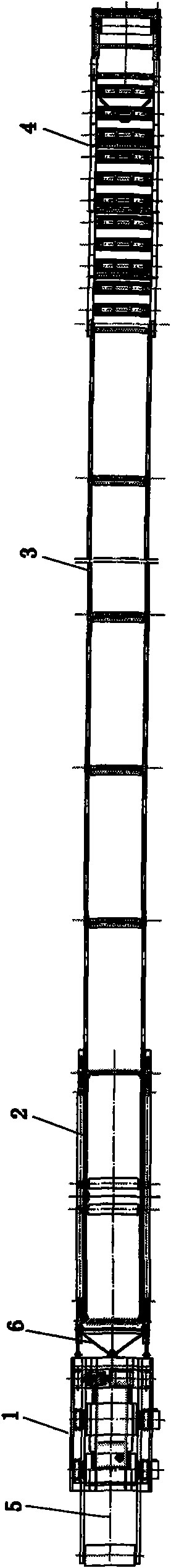

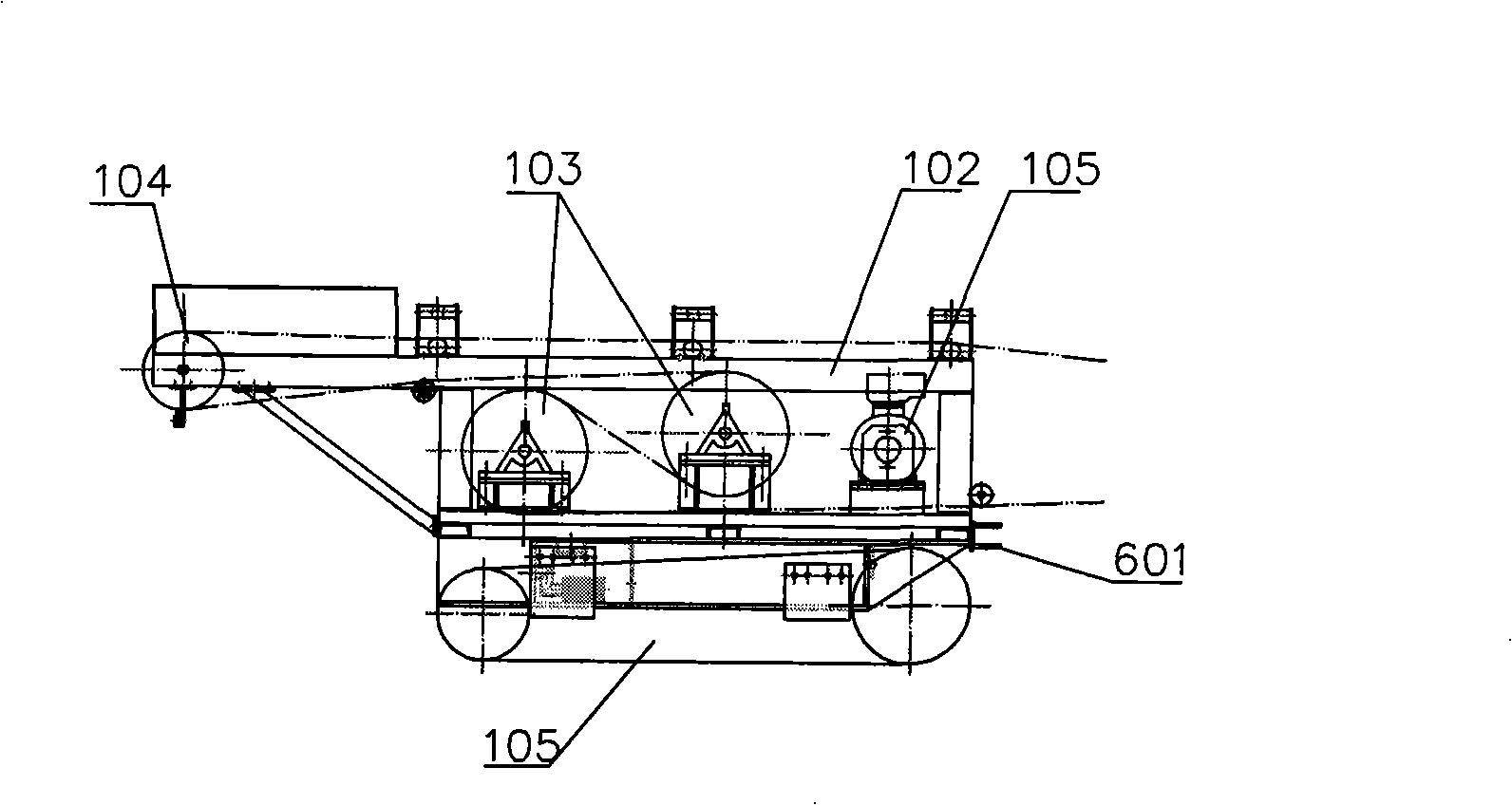

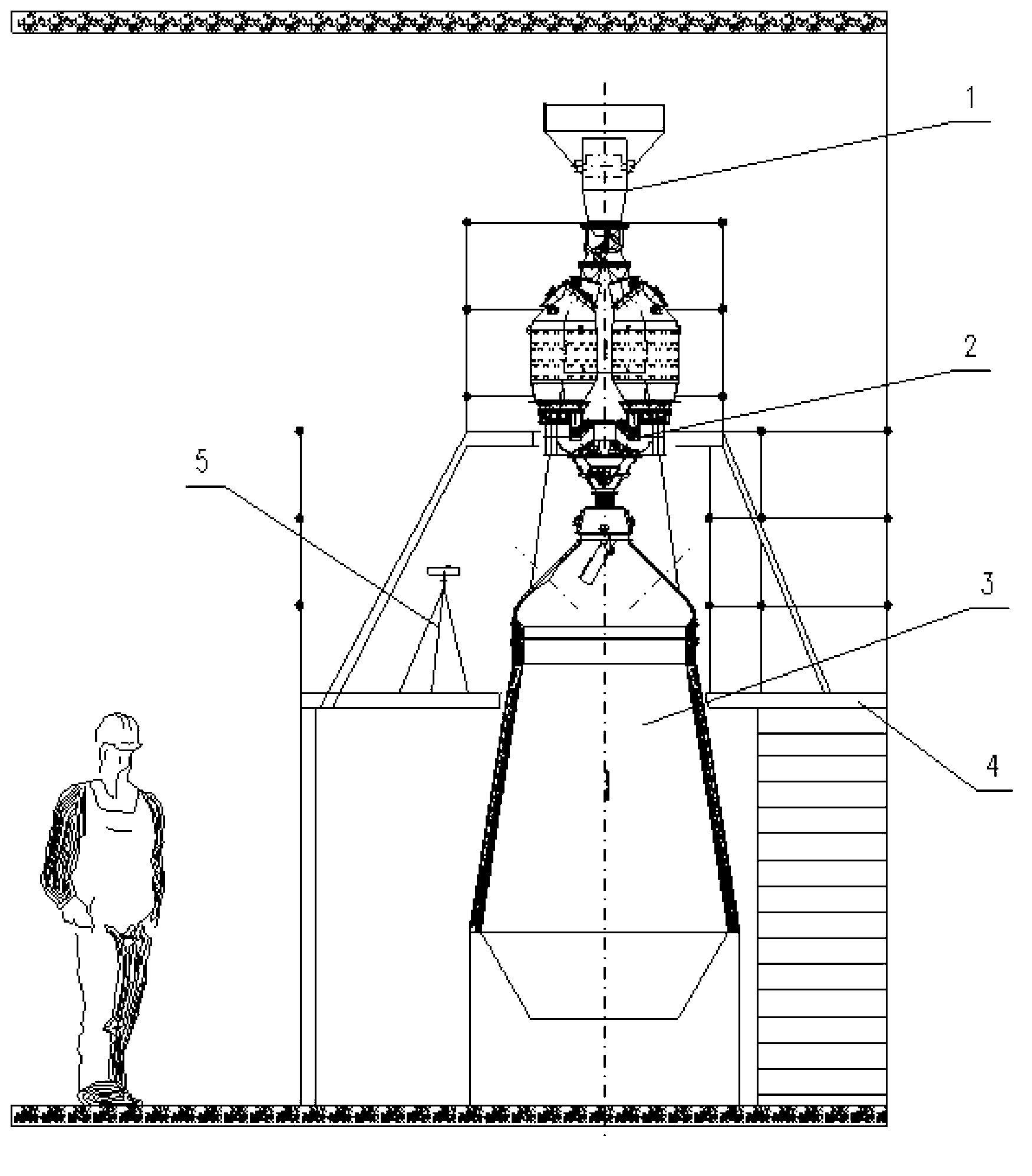

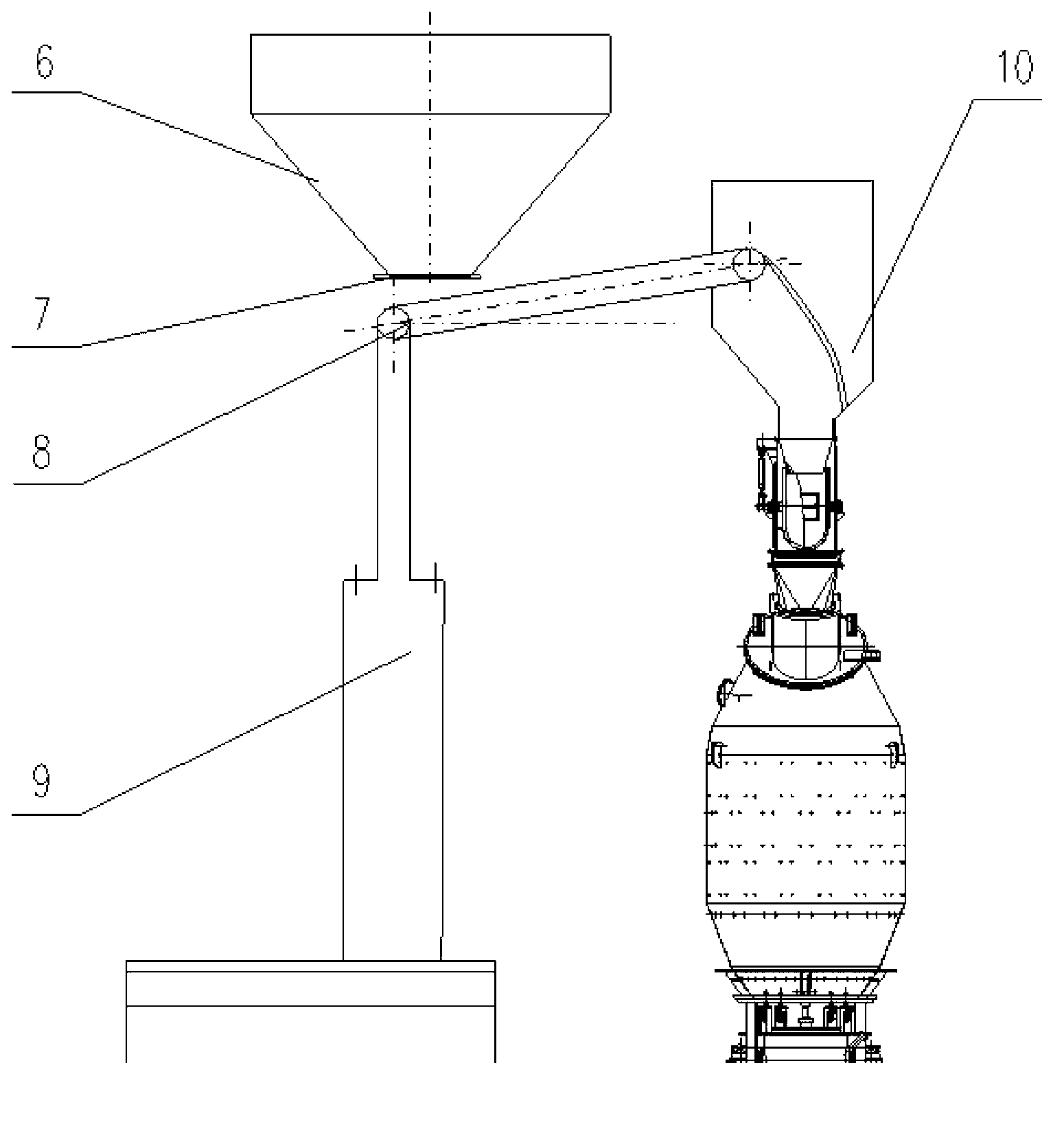

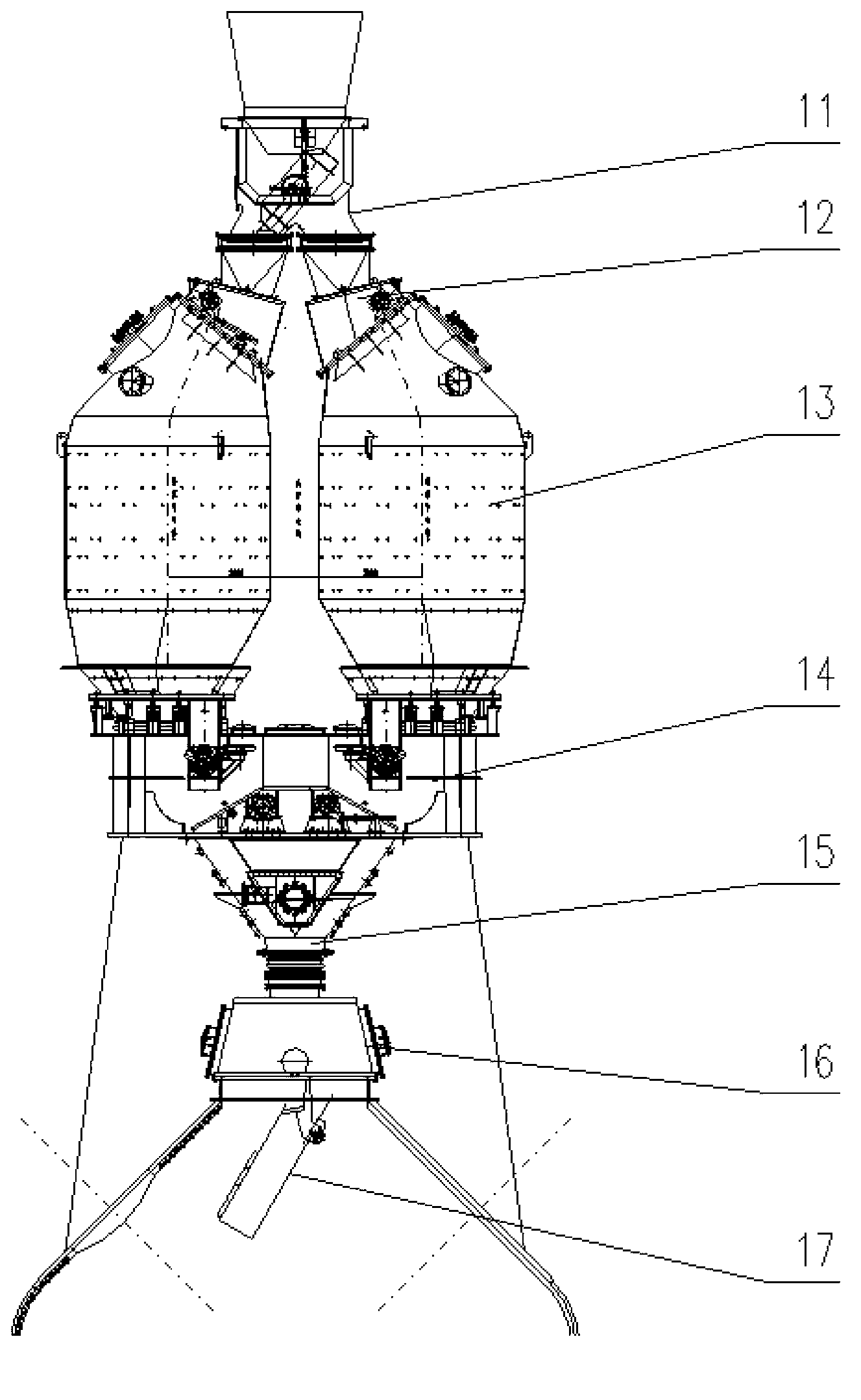

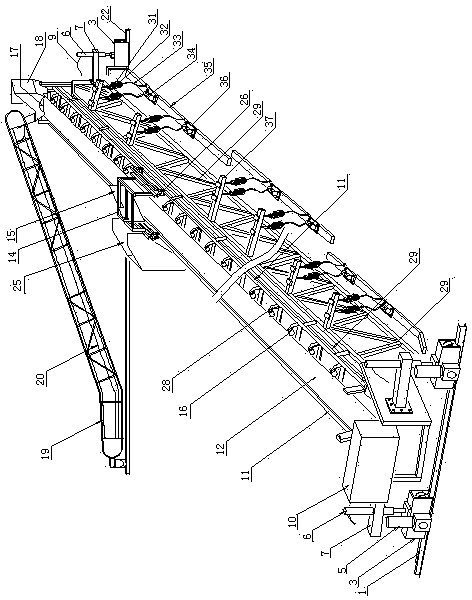

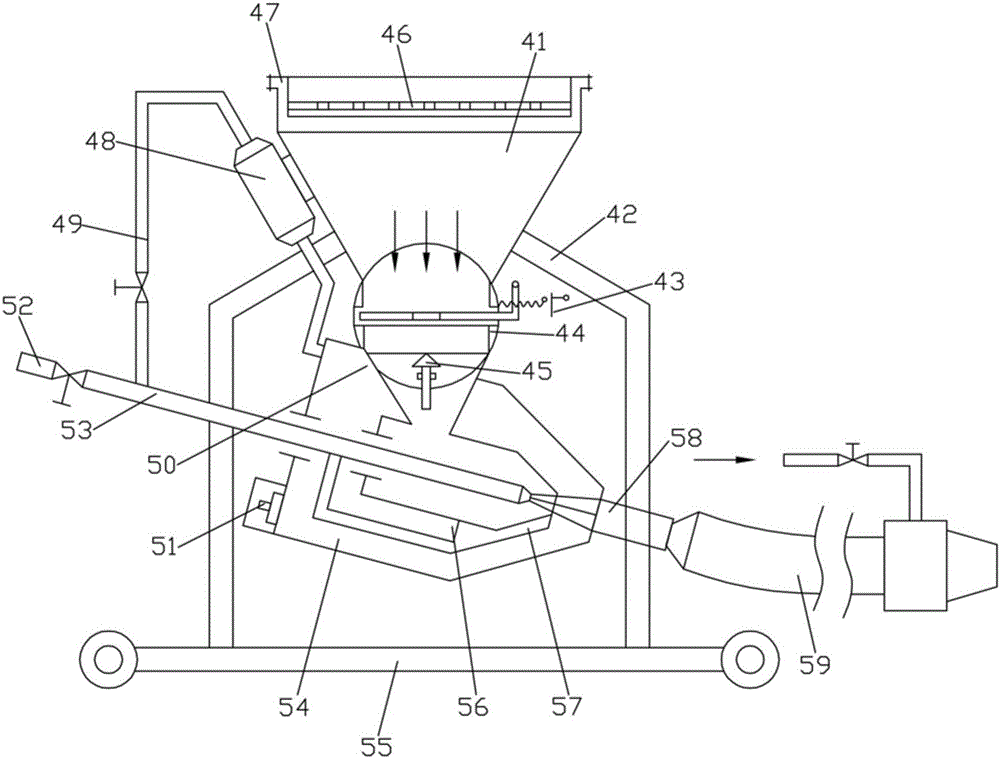

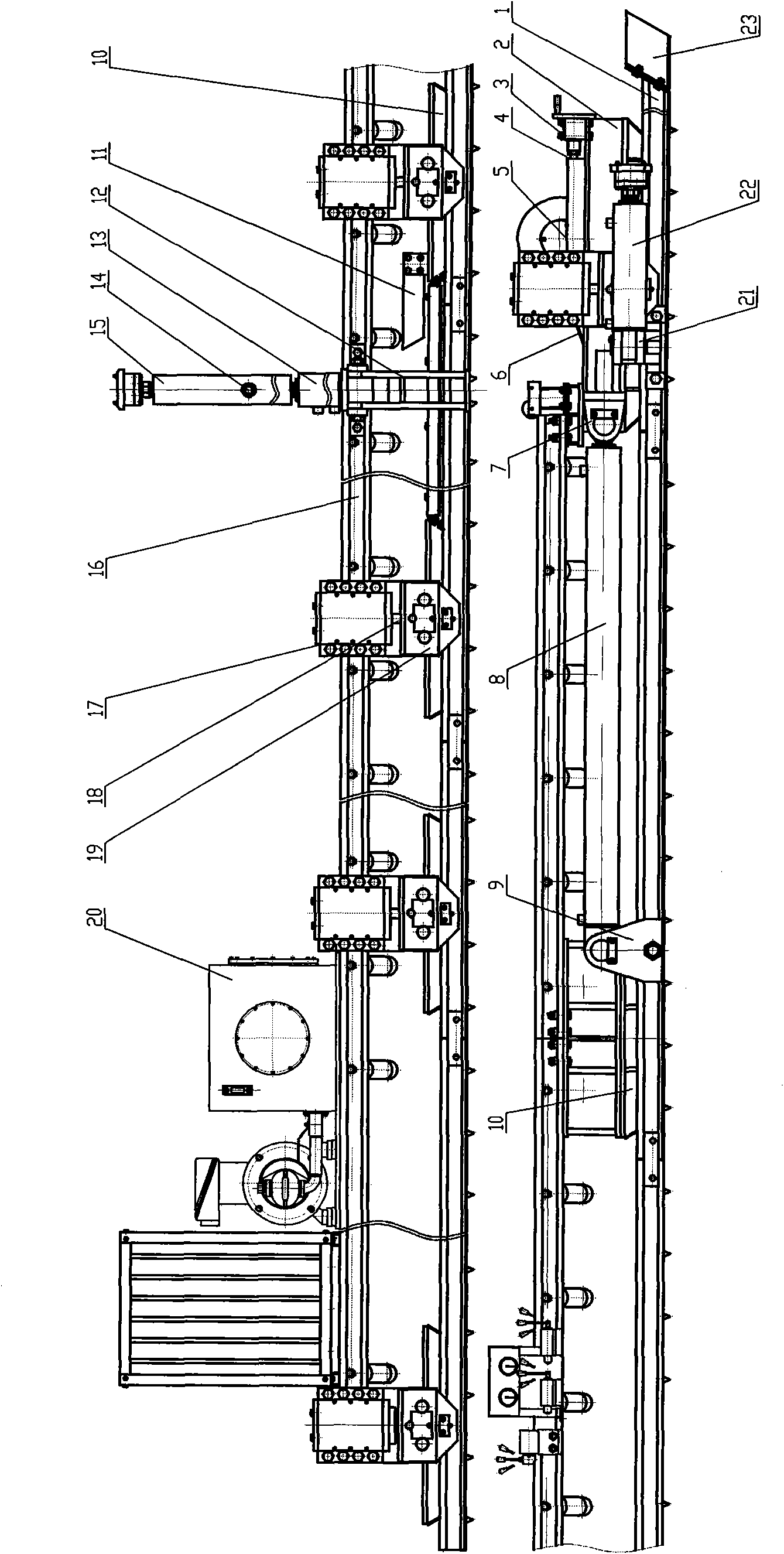

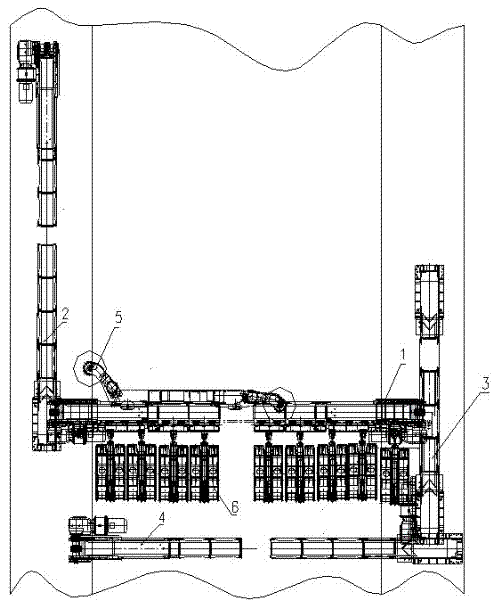

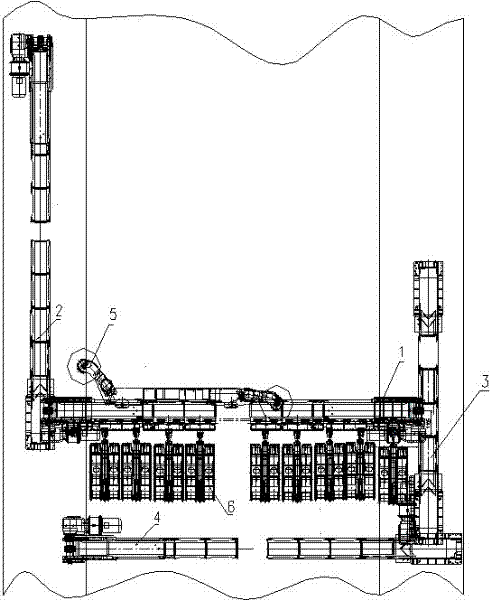

System for researching material distribution rule of furnace top equipment

ActiveCN103194555ASimplified protocolReliable resultsBell-and-hopper arrangementEducational modelsResearch modelTest platform

The invention relates to a system for researching a material distribution rule of furnace top equipment and belongs to the technical field of smelting. The system comprises a fully-emulational belt machine loading system, a fully-transparent furnace top material distribution equipment whole model, a fully-transparent furnace body partition research model, an enterprise-level high-speed camera shooting and analysis system and a test platform, wherein the fully-emulational belt machine loading system (1) is arranged at the top end of the whole set of system and is connected with a second layer of platform of the test platform (4) through a moveable bracket; a lower opening of the fully-emulational belt machine loading system (1) is connected with the fully-transparent furnace top material distribution equipment whole model (2); the lower end of the fully-transparent furnace top material distribution equipment whole model (2) is mounted on the fully-transparent furnace body partition research model (3); and a shooting terminal of the enterprise-level high-speed camera shooting and analysis system (5) is generally placed on a first layer of platform of the test platform (4). The invention has the advantages that the research system is comprehensive, complete, intuitive and accurate; and the test scheme is simple and practical, reliable in result and is a new breakthrough in the field of research on a blast furnace material distribution rule.

Owner:BEIJING SHOUGANG INT ENG TECH

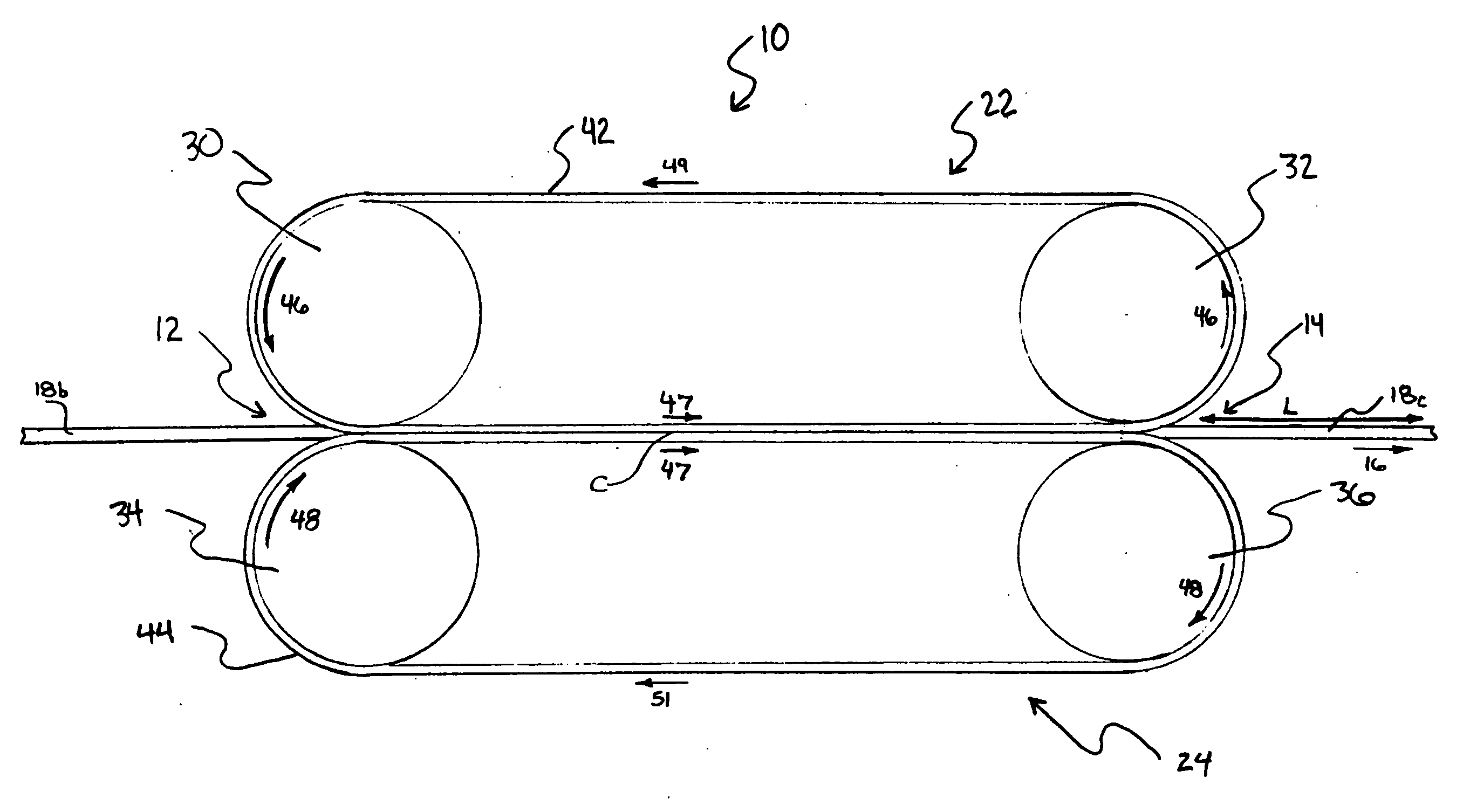

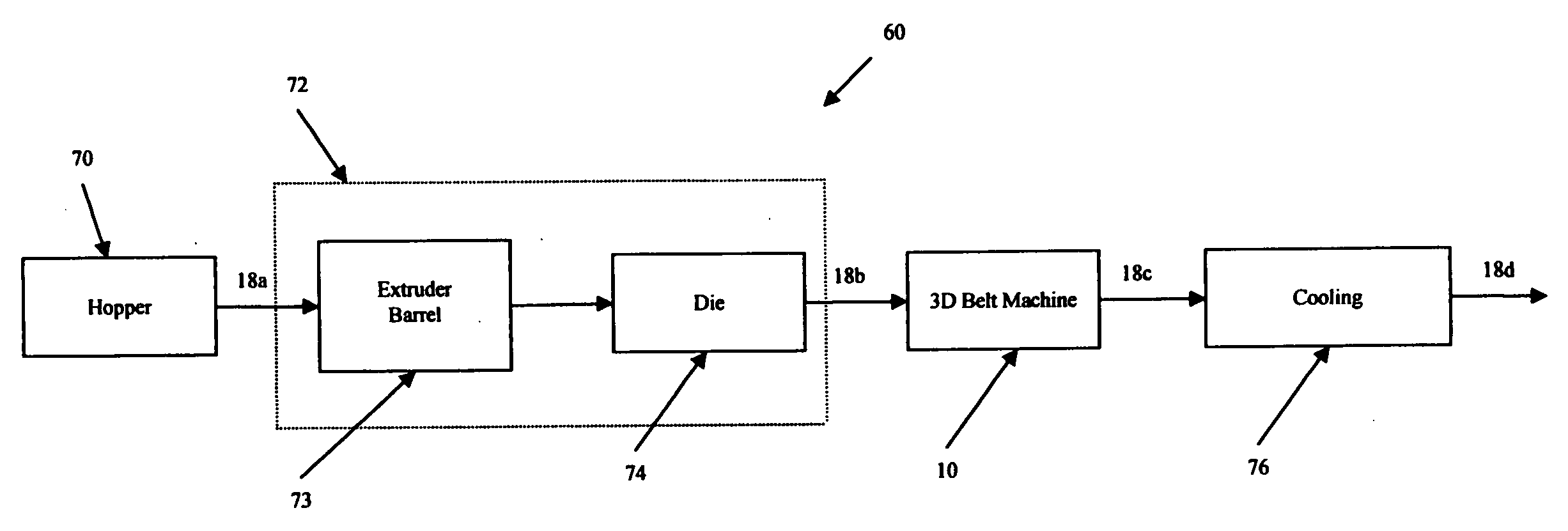

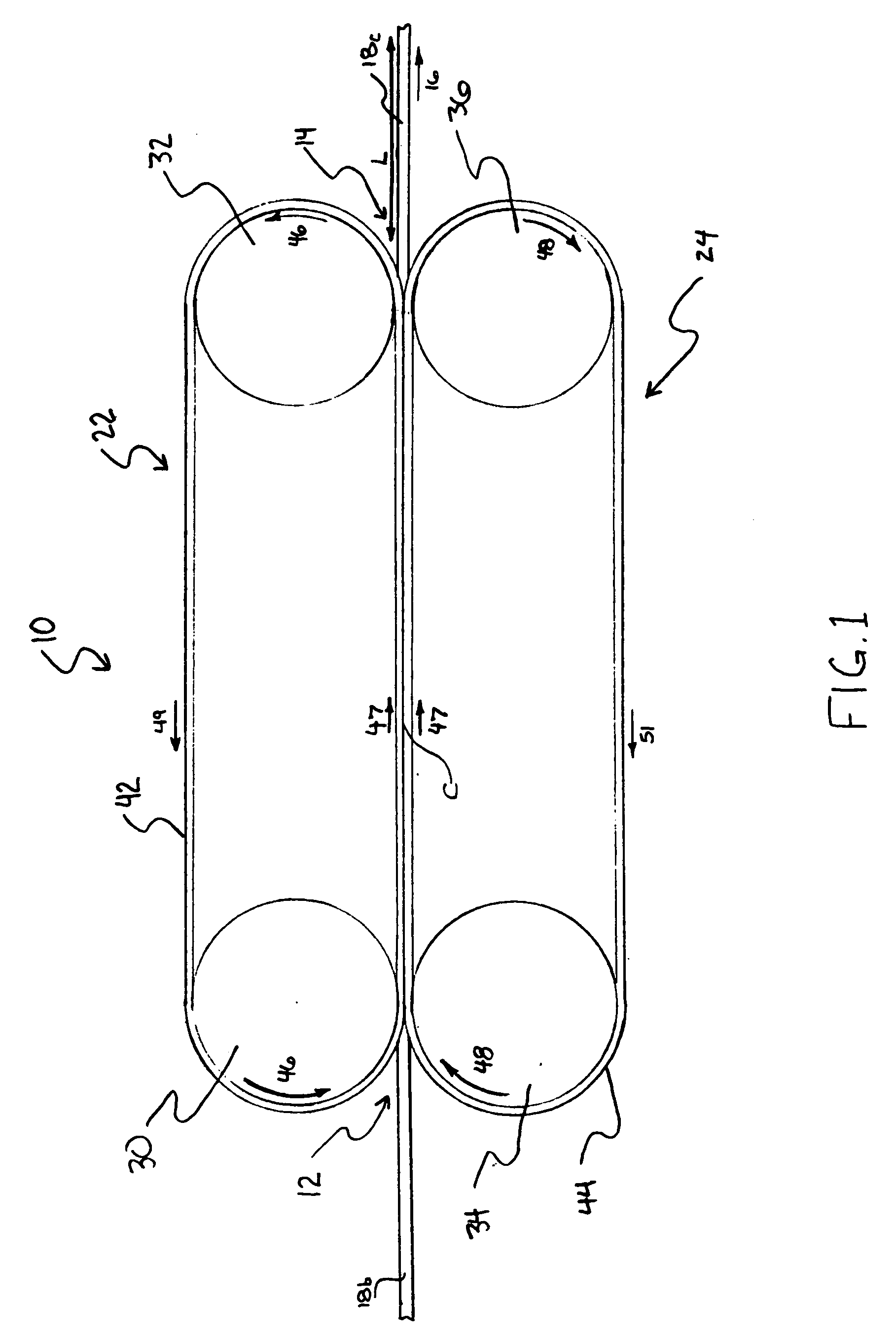

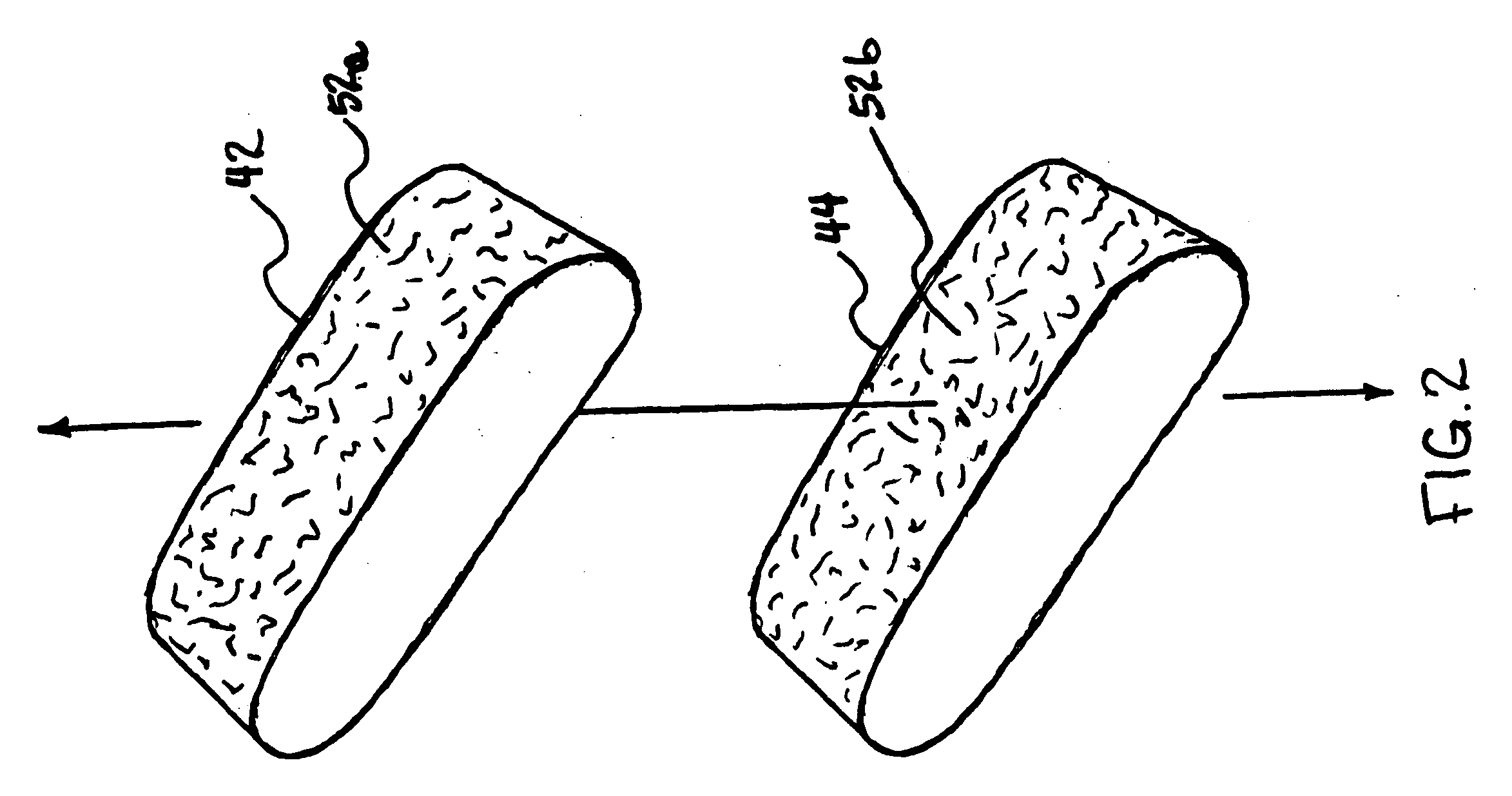

Integrated belt puller and three-dimensional forming machine

InactiveUS20060068053A1Improve cooling effectOvercomes shortcomingDough-sheeters/rolling-machines/rolling-pinsConfectioneryPlastic materialsMolding machine

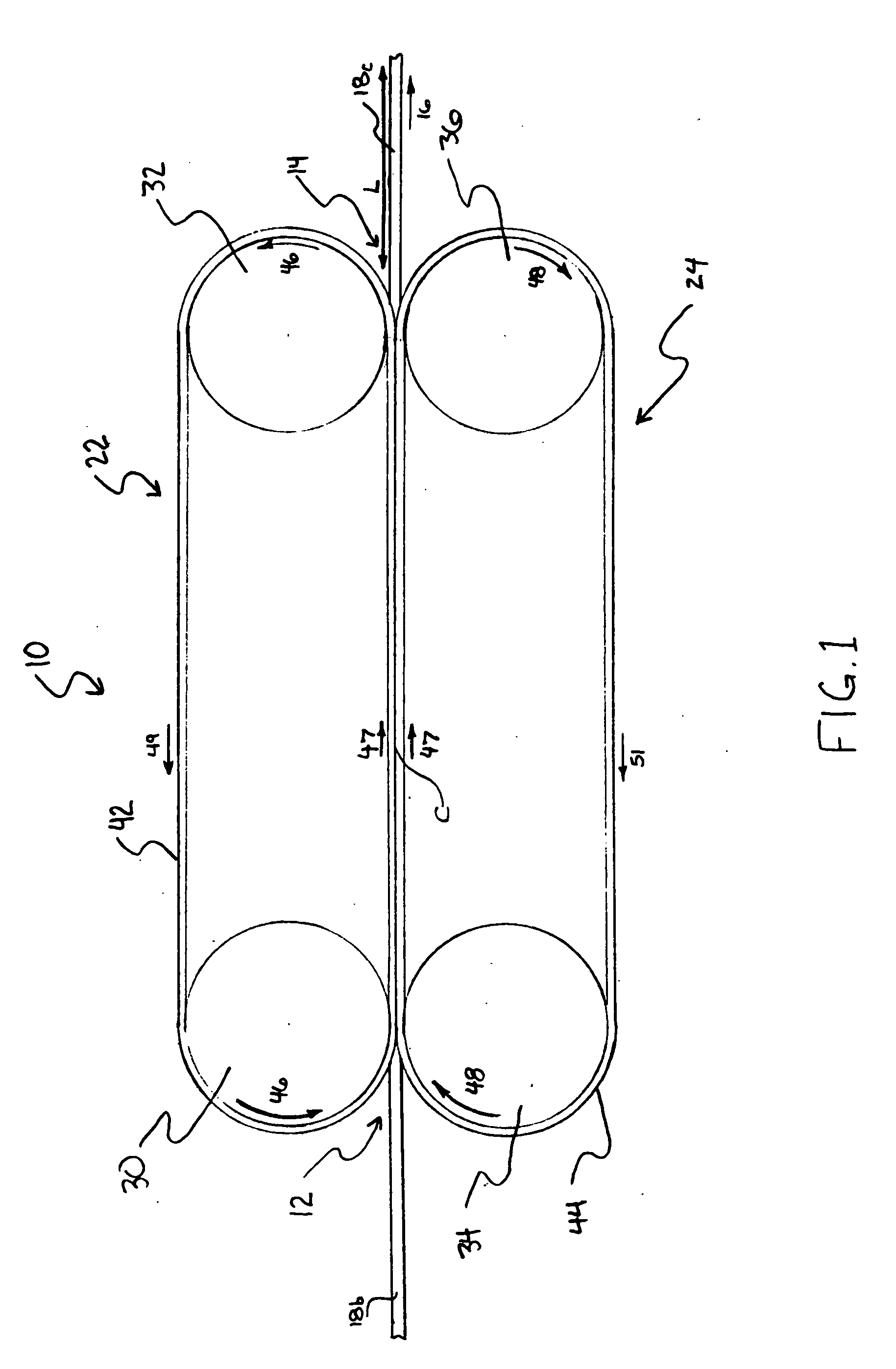

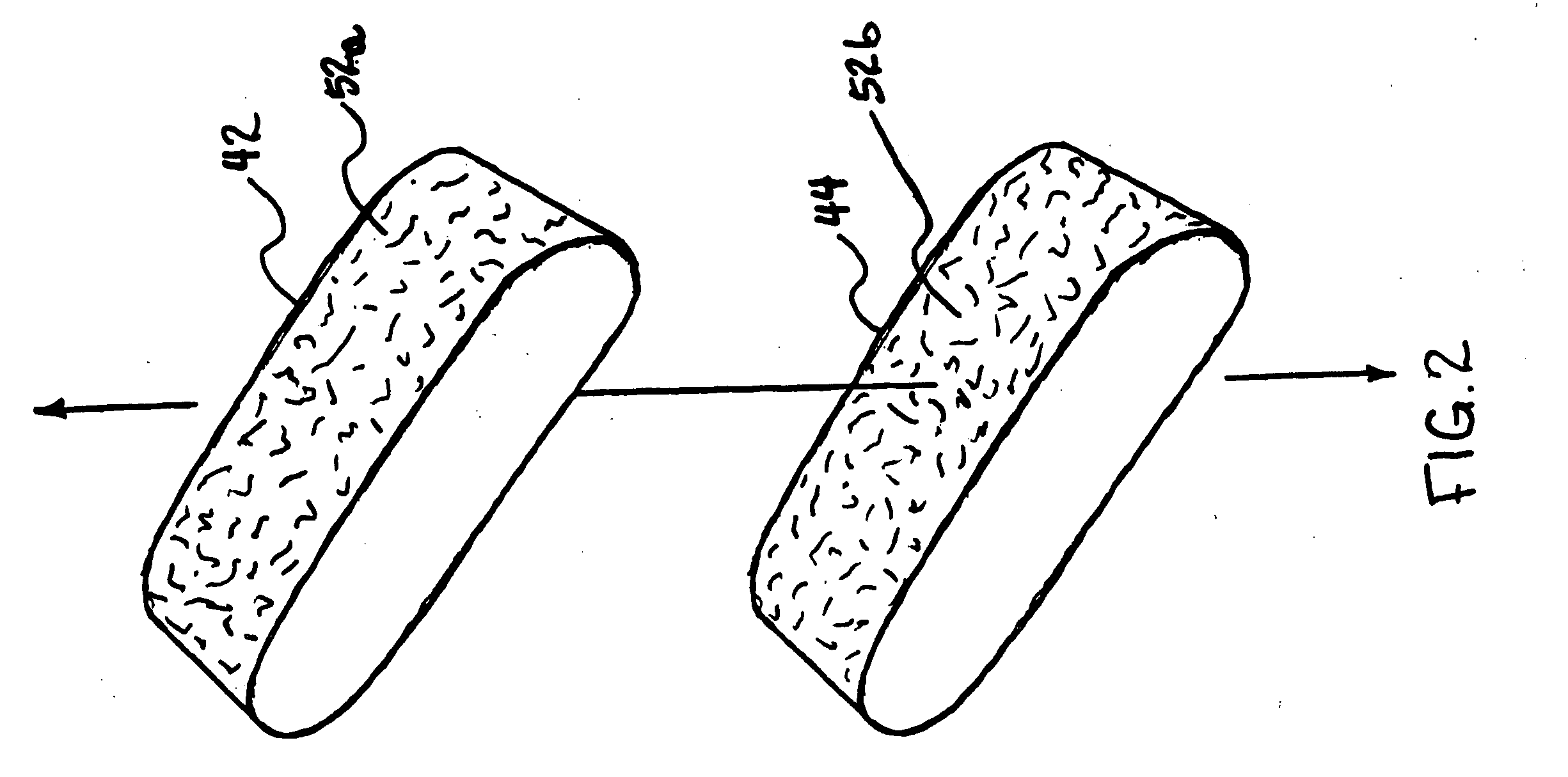

The present invention relates generally to an integrated belt machine. More particularly, the present invention is directed to an integrated belt puller and 3D forming machine for continuously forming 3D products from plastic materials.

Owner:CRANE PLASTICS PARTNERSHIP

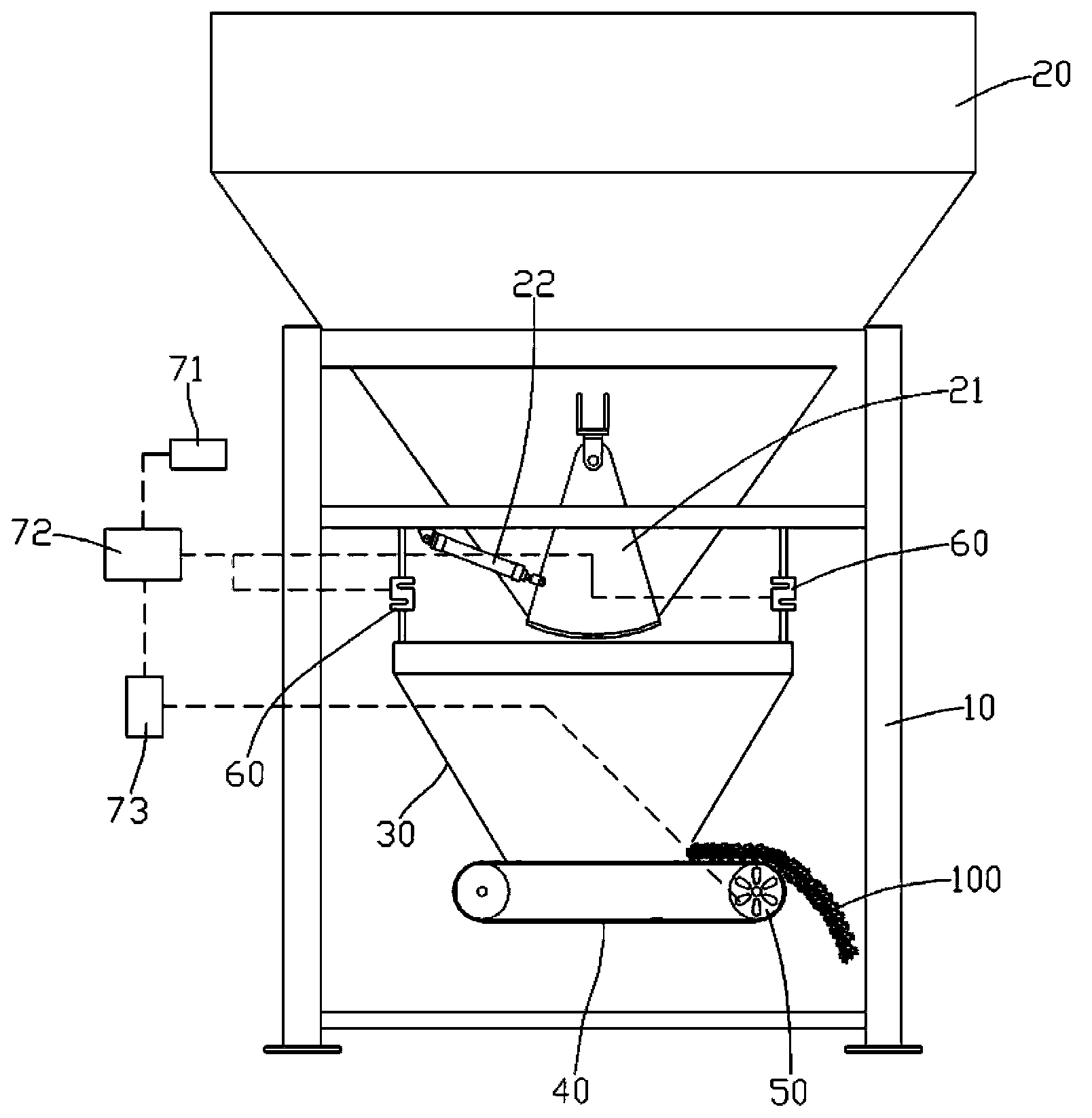

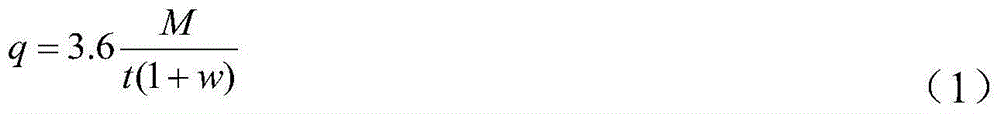

Material continuous dynamic metering device

InactiveCN103449148ARealize continuous dynamic meteringConveyor partsLoad cellVariable frequency control

The invention discloses a material continuous dynamic metering device comprising a frame, a material storing hopper, a metering hopper and a conveying belt machine. The material storing hopper is located above the metering hopper, the lower portion of the material storing hopper is provided with a material gate, the material storing hopper is integrated with the conveying belt machine driven by a variable frequency motor and is hung on the frame through a plurality of weighting sensors, the weighting sensors are connected with a weighting controller, and the weighting controller is connected with a solenoid directional valve which is used for controlling the material gate to open and close and a variable frequency controller which is used for regulating rotating speed of the variable frequency motor. The material continuous dynamic metering device has the advantages of reasonable design, stable and reliable operation and accurate metering.

Owner:杨林江

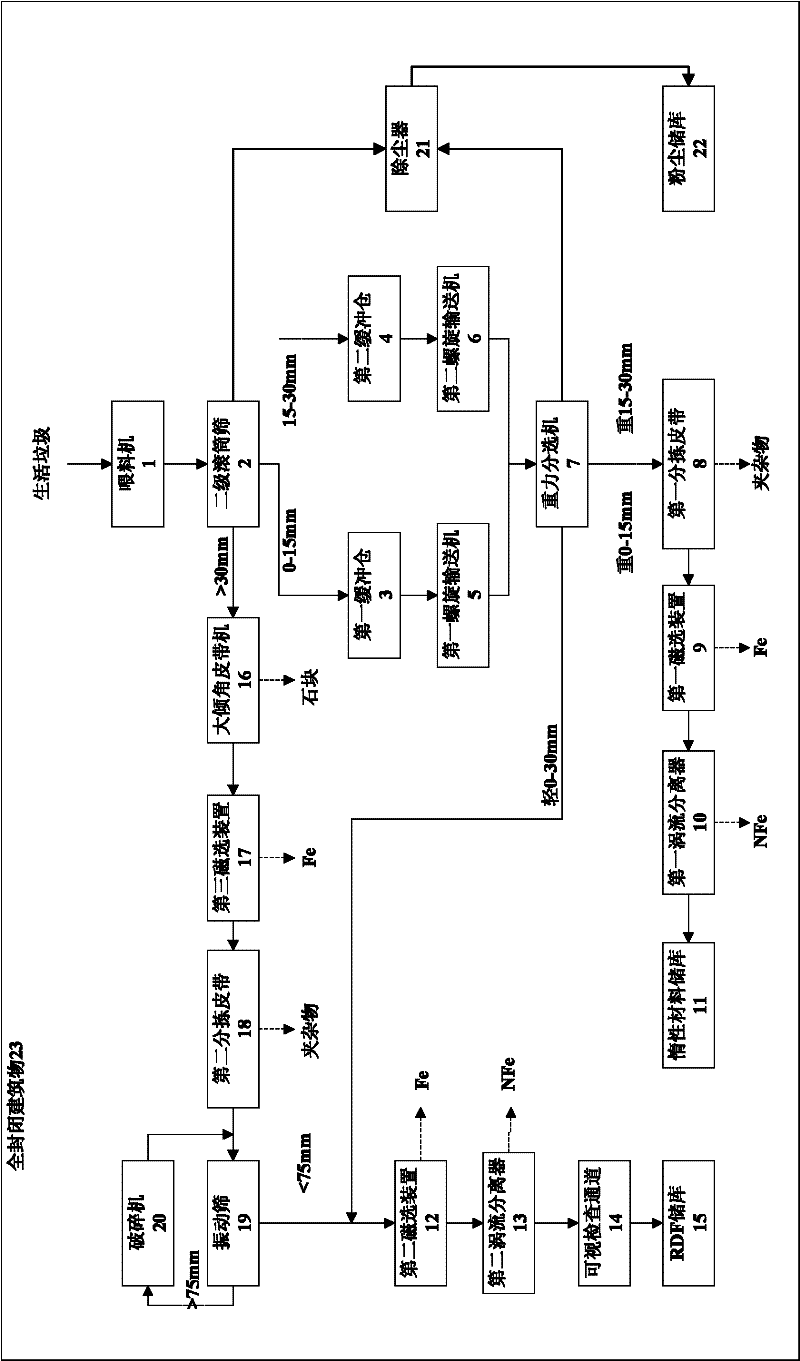

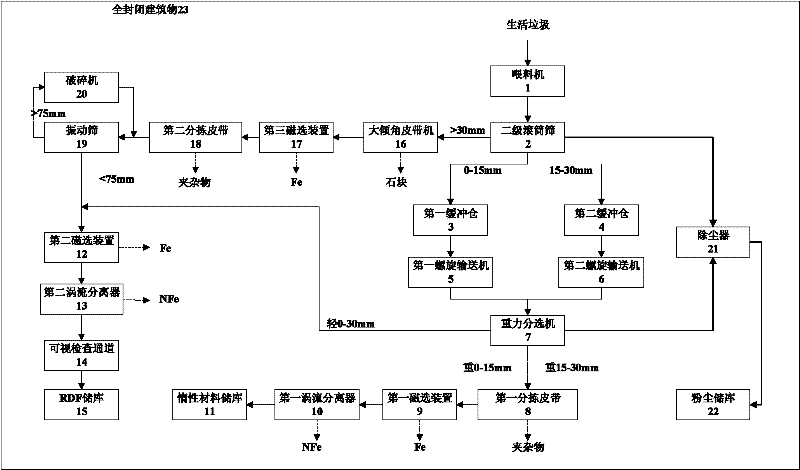

Municipal waste separation system

ActiveCN102189094AEfficient separationImprove working environmentSolid waste disposalSolid separationHazardous substanceEngineering

The invention relates to a municipal waste separation system. The municipal waste separation system is characterized by comprising a feeding machine, a secondary rotary screen, a first buffer bin, a second buffer bin, a first spiral conveyer, a second spiral conveyer, a gravity separator, a first sorting belt, a second sorting belt, a first magnetic separation device, a second magnetic separationdevice, a third magnetic separation device, a first vortex separation device, a second vortex separation device, an inert material storage hall, a resource description framework (RDF) storage hall, alarge-inclination-angle belt machine, a vibrating screen and a crushing machine. The separation system has high sorting efficiency, and can effectively separate combustible substances, insert components, ferrous metal / non-ferrous metal, and harmful substances in the pre-crushed and dried municipal waste to facilitate subsequent comprehensive utilization. The separation process is totally closed,remote operation and control is performed by using a computer, waste is not required to be directly contacted, the working environment of workers is improved, mechanization and automation are realized, and efficiency is improved.

Owner:华新环境工程有限公司

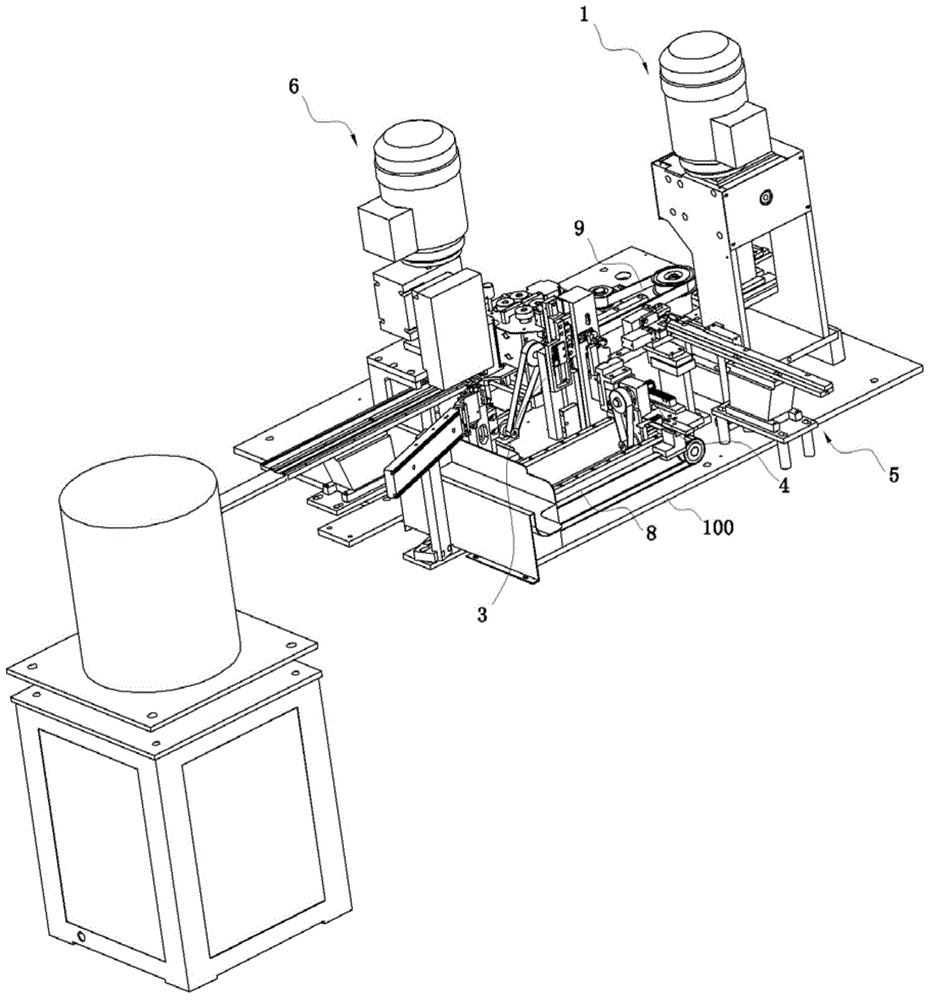

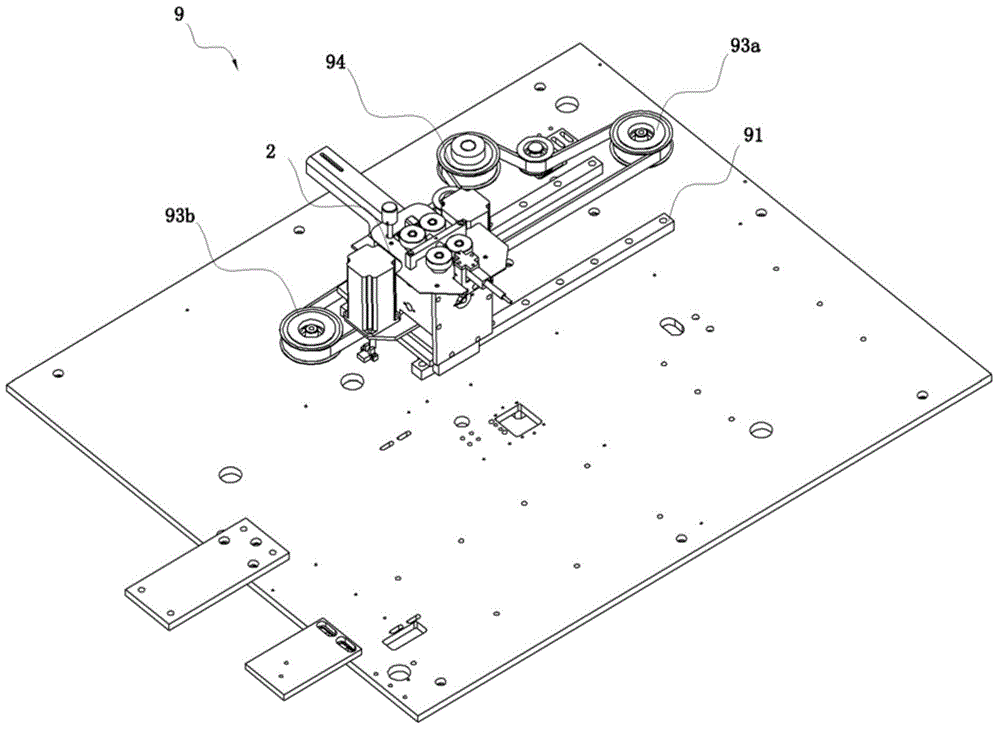

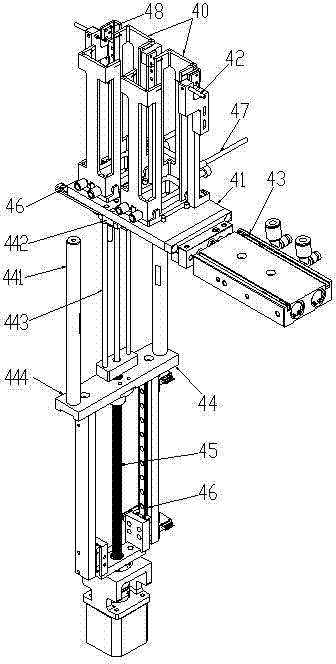

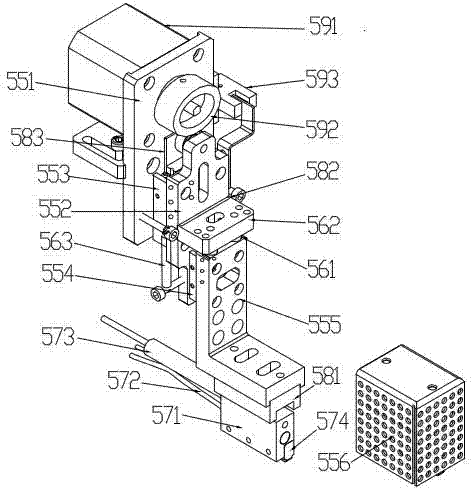

Full-automatic copper belt machine, terminal machine and method for feeding sheaths by pressing copper belt riveting terminals

ActiveCN104917028ASimple structureHigh degree of automationConnection formation by deformationCable/conductor manufactureEngineeringCopper

The invention relates to a full-automatic copper belt machine, a terminal machine and a method for feeding sheaths by pressing copper belt riveting terminals. The terminal machine is provided with a working platform as well as a wire feeding mechanism, an electric wire cutting peeling device, a sheath feeding device, a first terminal pressing device, a clamping device, a first belt conveying mechanism and the full-automatic copper belt machine which are mounted on the working platform. The method comprises the following steps: peeling the insulating skin of the first end of an electric wire; inserting the first end of the electric wire in a sheath provided by the sheath feeding device; performing terminal riveting on the first end of the electric wire; enabling the sheath to tightly overlap the terminal riveted to the first end of the electric wire; and cutting the electric wire to form a second end through the electric wire cutting peeling device, wherein the second end is riveted with an electric component through the full-automatic copper belt machine. The full-automatic copper belt machine, the terminal machine and the method for feeding sheaths by pressing copper belt riveting terminals disclosed by the invention have the advantages that the structure is simpler and the degree of automation is high.

Owner:东莞市雄州机械设备有限公司

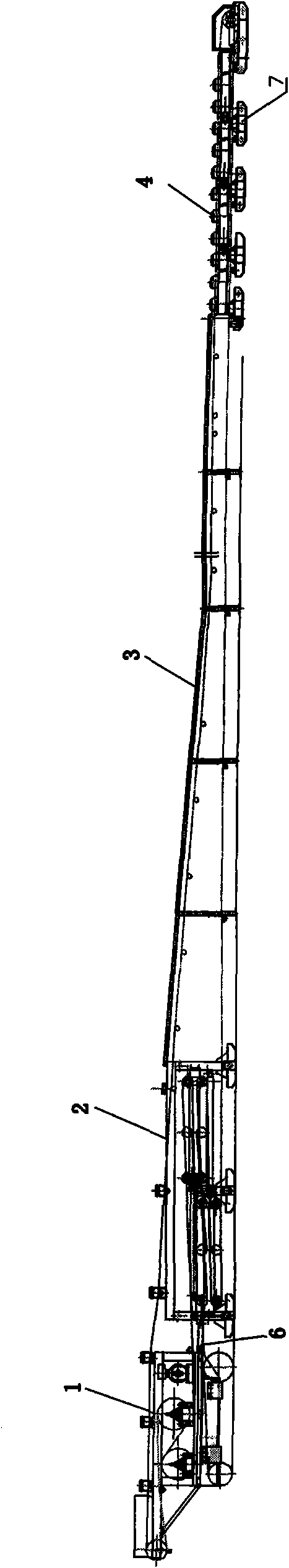

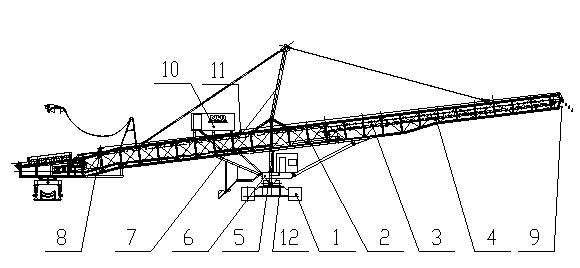

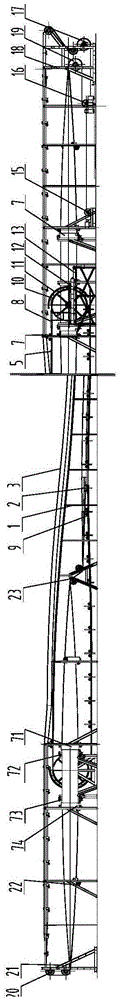

Simple earth dumping machine

The invention relates to a simple earth dumping machine applied to the fields of open mine earth dumping sites or other bulk material stacking sites, comprising a crawler unit, an arm support device, a rubber belt machine, a telescopic trolley, a bracket device, a rotating device, a pull rod device, a hoisting device, a walkway guardrail, a cab, a cable wiring system and a centralized lubricating system. The simple earth dumping machine is just provided with one truss type arm support, the discharge rubber belt machine is arranged inside the arm support device, the telescopic trolley is arranged in the arm support device, and the middle position of a discharge arm support of the earth dumping machine is connected with the crawler unit through the bracket device and the rotating device; the pull rod device is positioned at the upper part of the arm support device, and the hoisting device and the control room are arranged at the middle upper part of the arm support device; the walkway guardrail and the cable wiring system are arranged along the length direction of the arm support device; and the centralized lubricating system is arranged at the rear part of the crawler unit. The simple earth dumping machine has the advantages of simple structure, low manufacture cost and short manufacture period.

Owner:NORTHERN HEAVY IND GRP CO LTD

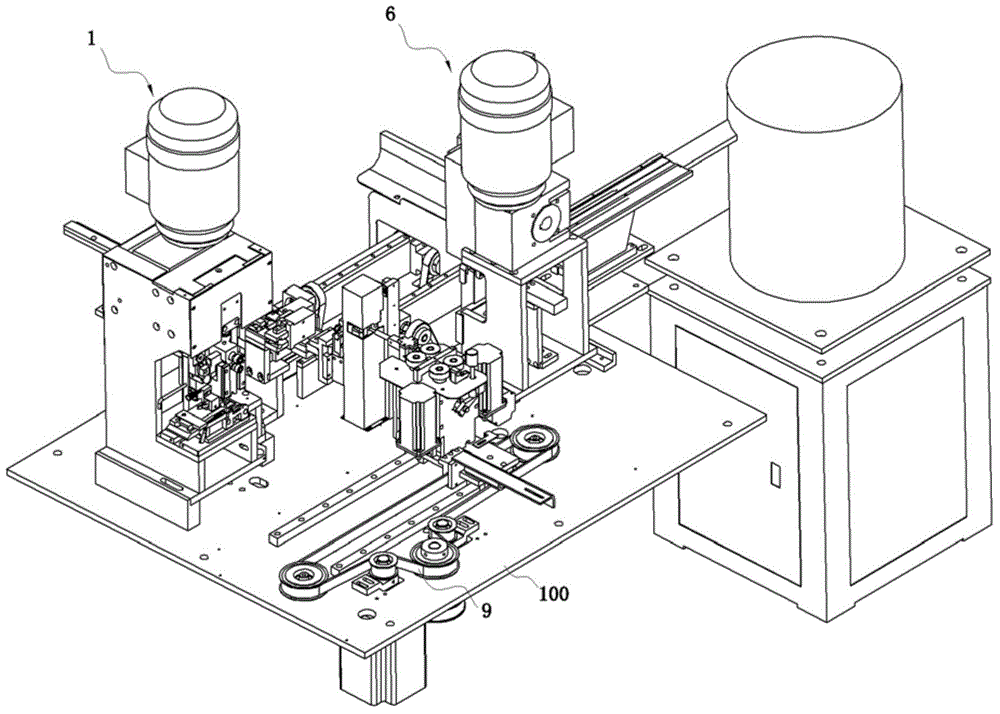

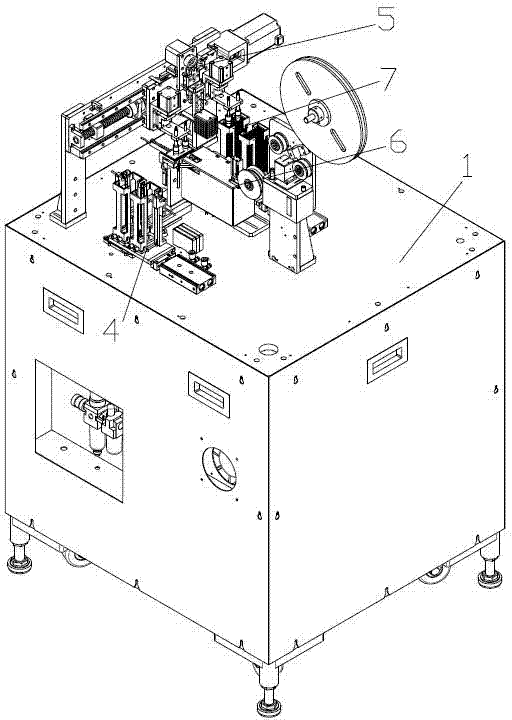

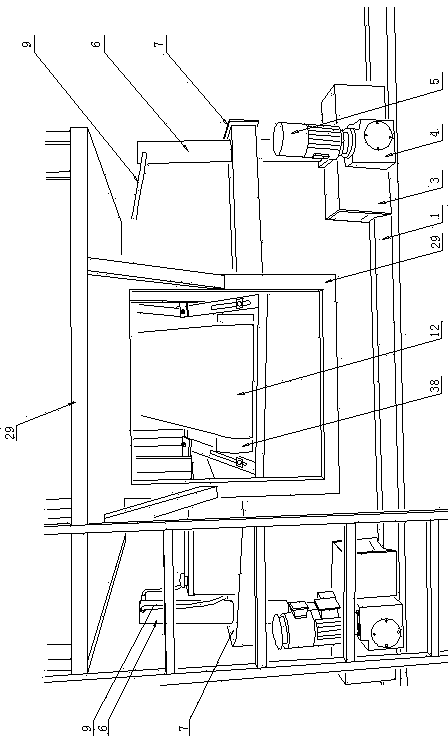

Full-automatic solar battery piece welding belt machine

ActiveCN104741727AQuality assuranceIncrease production capacityFinal product manufactureWelding/cutting auxillary devicesControl systemSolar battery

The invention relates to a solar battery piece welding belt machine, in particular to a full-automatic solar battery piece welding belt machine capable of performing programmable control over automatic conveying of battery pieces and welding belt materials. The full-automatic solar battery piece welding belt machine mainly comprises a welding belt system, a working rack and a control system. The working rack is a metal plate rack composed of a workbench and a work cabinet, a rack outer cover matched with the working rack is arranged, and the control system is a programmable control system. The welding belt system mainly comprises an automatic material piece supplying system, a material piece conveying system, a welding belt conveying system and an automatic material collecting mechanism. The continuous battery piece feeding, welding belt feeding and battery piece welding belt and battery piece colleting work of the welding belt machine can be finished through the automatic material piece supplying system, the material piece conveying system, the welding belt conveying system and the automatic material collecting mechanism which are compact in structure and the programmable control system, the quality of the welded battery pieces is guaranteed while the productivity of enterprises is greatly improved, the situations of sealing off, pseudo soldering and deviation soldering do not exist in the battery pieces, and the product is more standardized.

Owner:DONGGUAN LISU LED MACHINERY TECH

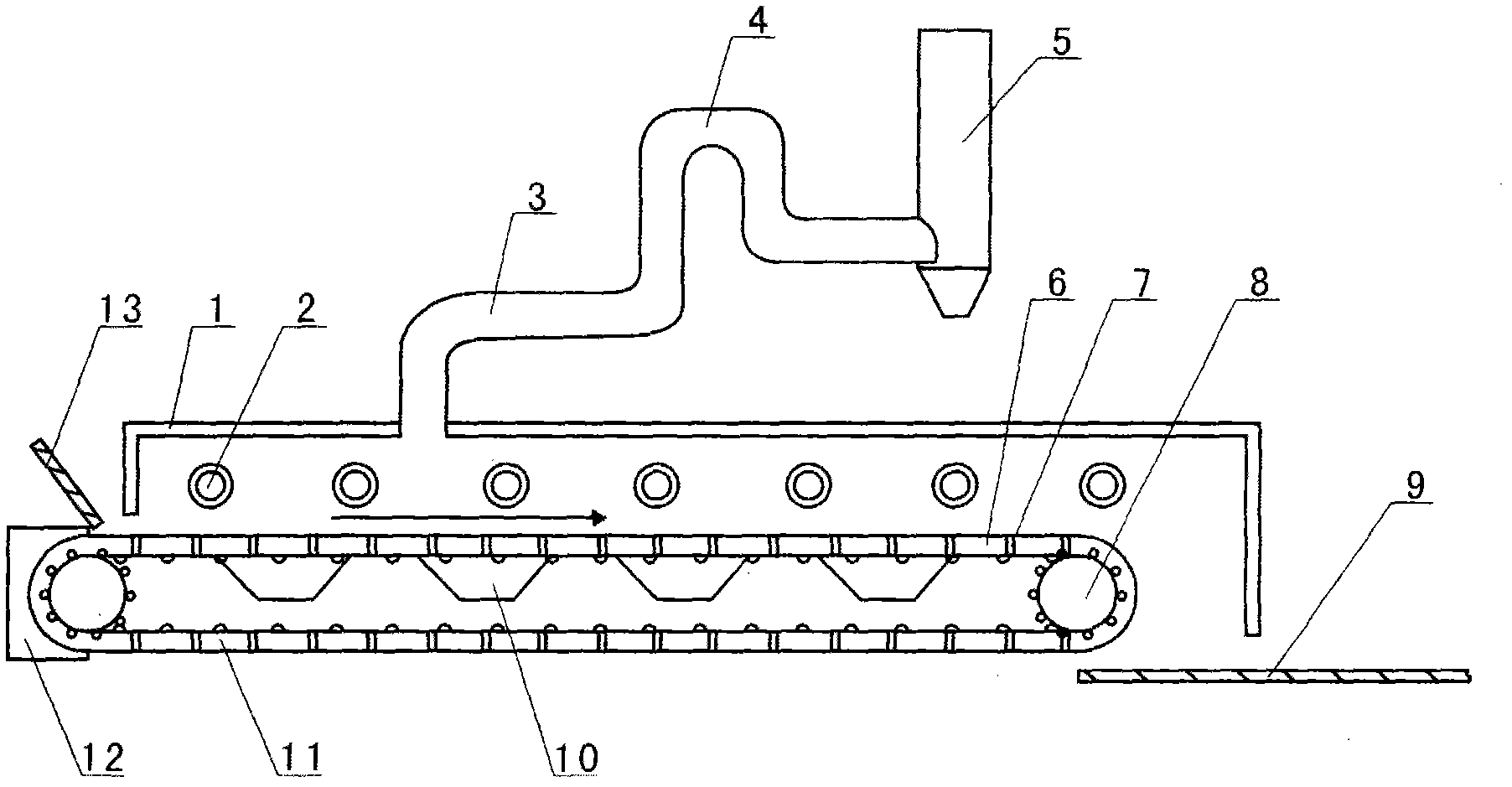

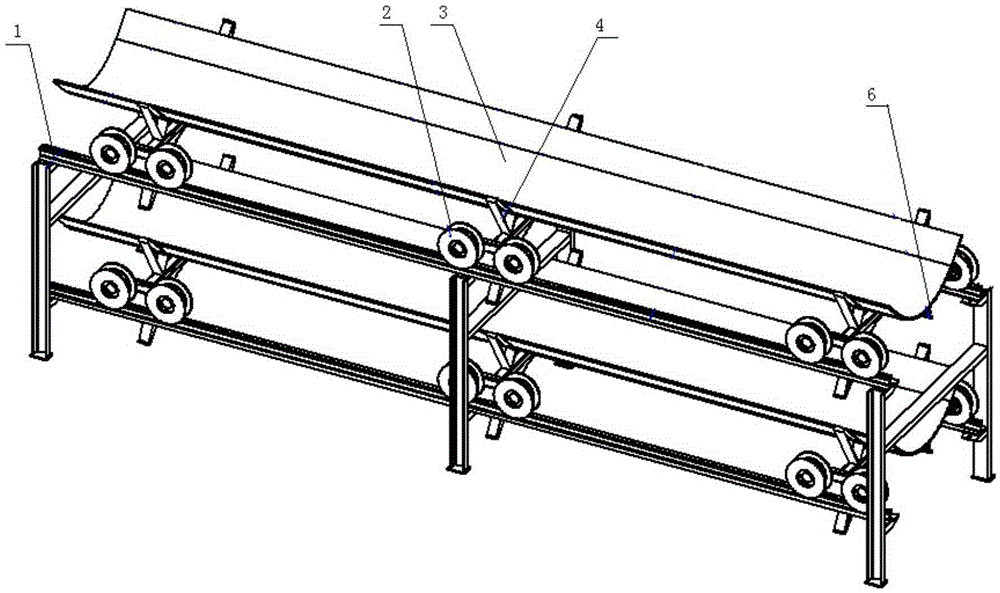

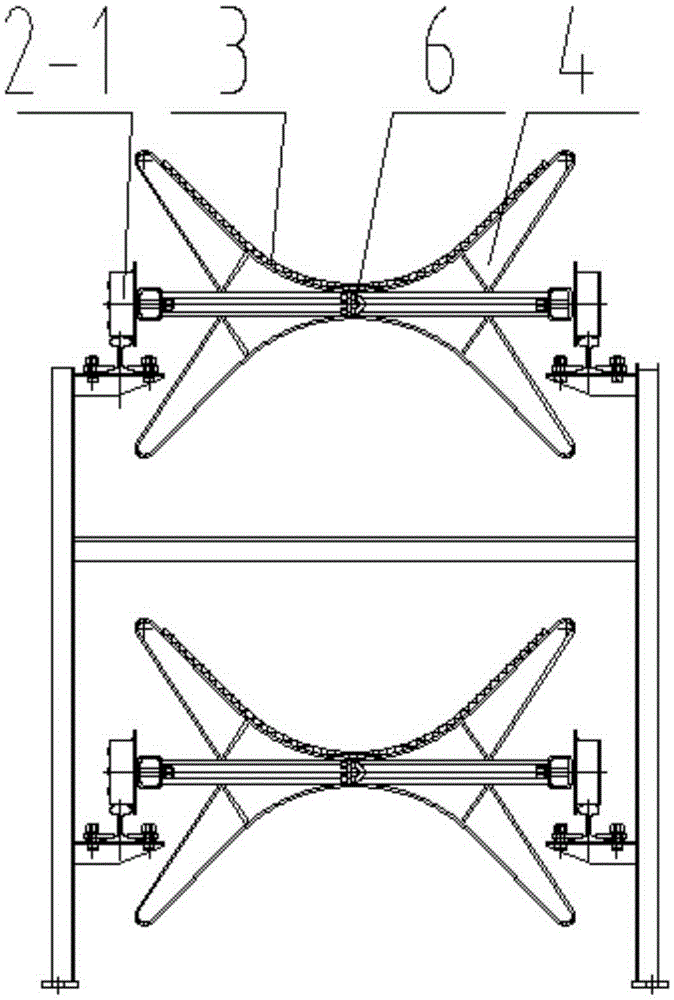

Large channel side slope bed course spreading machine

InactiveCN103469767AHigh degree of mechanizationImprove flatnessArtificial water canalsEngineeringHydraulic fluid

The invention relates to a large channel side slope bed course spreading machine, and belongs to the field of hydraulics. The machine comprises a feeding part, a traveling and lifting part, a distributing part and a vibration forming part, wherein the feeding part consists of a feeding belt machine which is distributed in the running direction of a channel shoulder, the traveling and lifting part consists of guide rails, traveling wheel groups, wheel boxes, transmission gears, motors, hydraulic fluid cylinder piston rods and support beams, the guide rails are paved in the running directions of the channel shoulder and the channel bottom, the traveling wheel groups are arranged on the rails, the wheel boxes are coated outside the wheel groups, the transmission gears are engaged with the wheel groups, the motors are linked with gear shafts, the hydraulic fluid cylinder piston rods are connected with the wheel boxes, the support beams are connected with a cylinder tube, the distributing part consists of a delivery belt machine, a distributing vehicle, an operation room and a material bin, the distributing vehicle and the operation room are arranged on a machine frame, the material bin is connected with one side of the machine frame, the two ends of the machine frame are respectively connected with the support beams, the vibration forming part consists of an inner vibration beam and an outer vibration beam, the inner vibration beam and the outer vibration beam are connected to the interior of the cavity and the outside of the machine frame of the delivery belt machine, the machine frame is sequentially provided with a spring seat, a connecting rope and the vibration beams from top to bottom, and the upper end surfaces of the two vibration beams are respectively provided with a vibration motor. The machine has the advantages that multiple operations, such as feeding, distributing, spreading and leveling, and compaction forming, are integrated, the flatness is higher, and the compactness is good.

Owner:XINJIANG IRTYSH RIVER BASIN DEV ENG CONSTR ADMINISTRATION

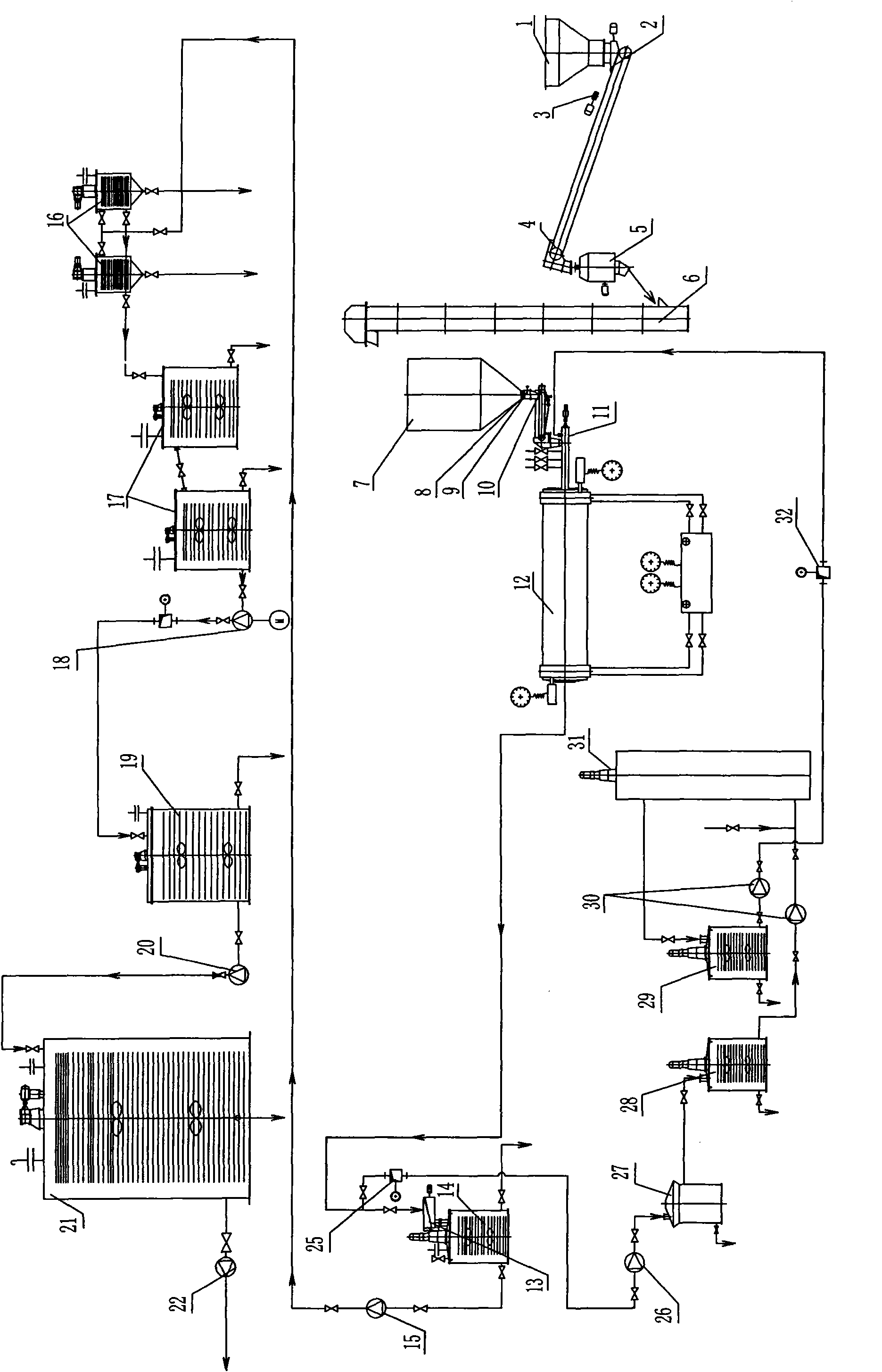

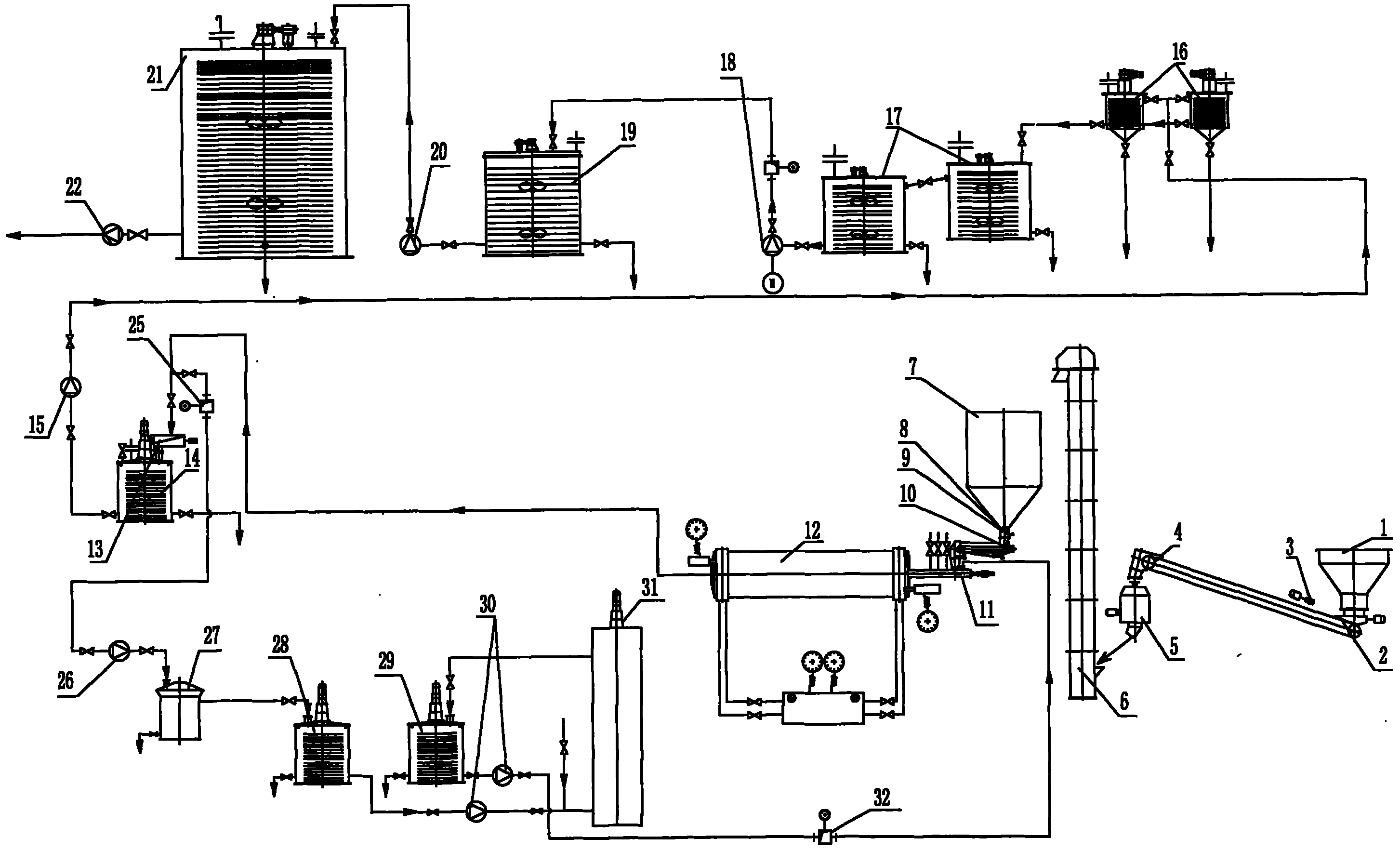

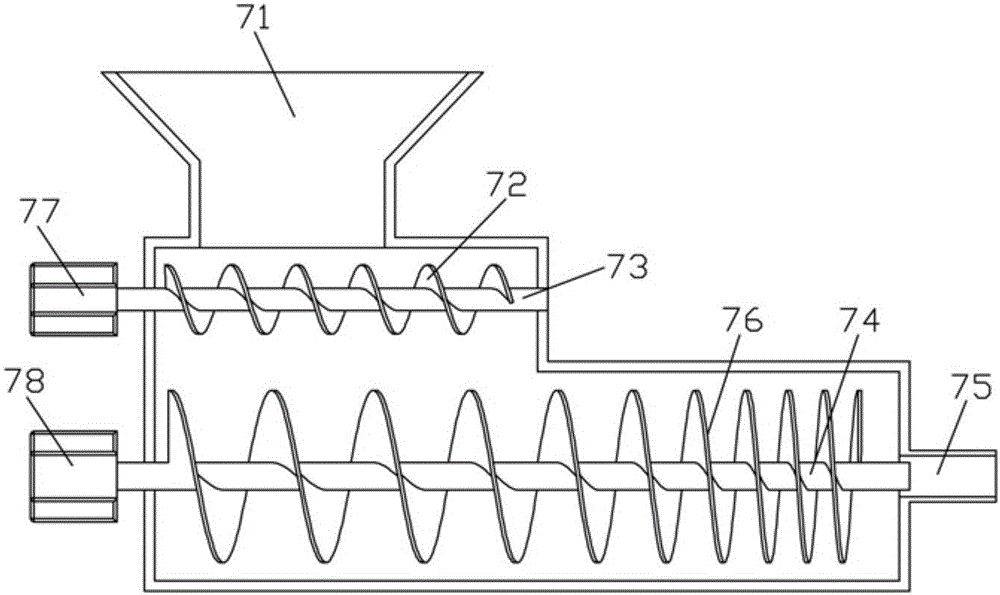

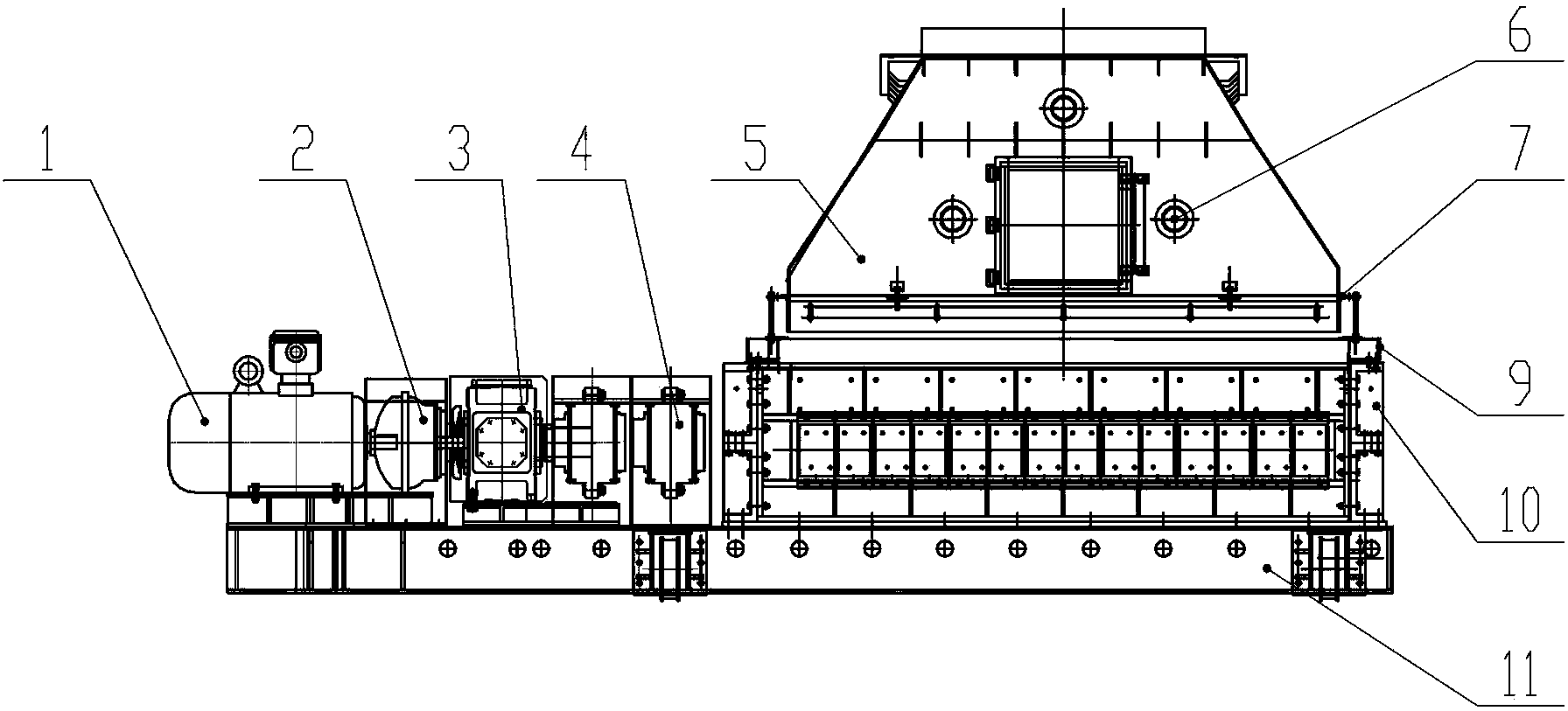

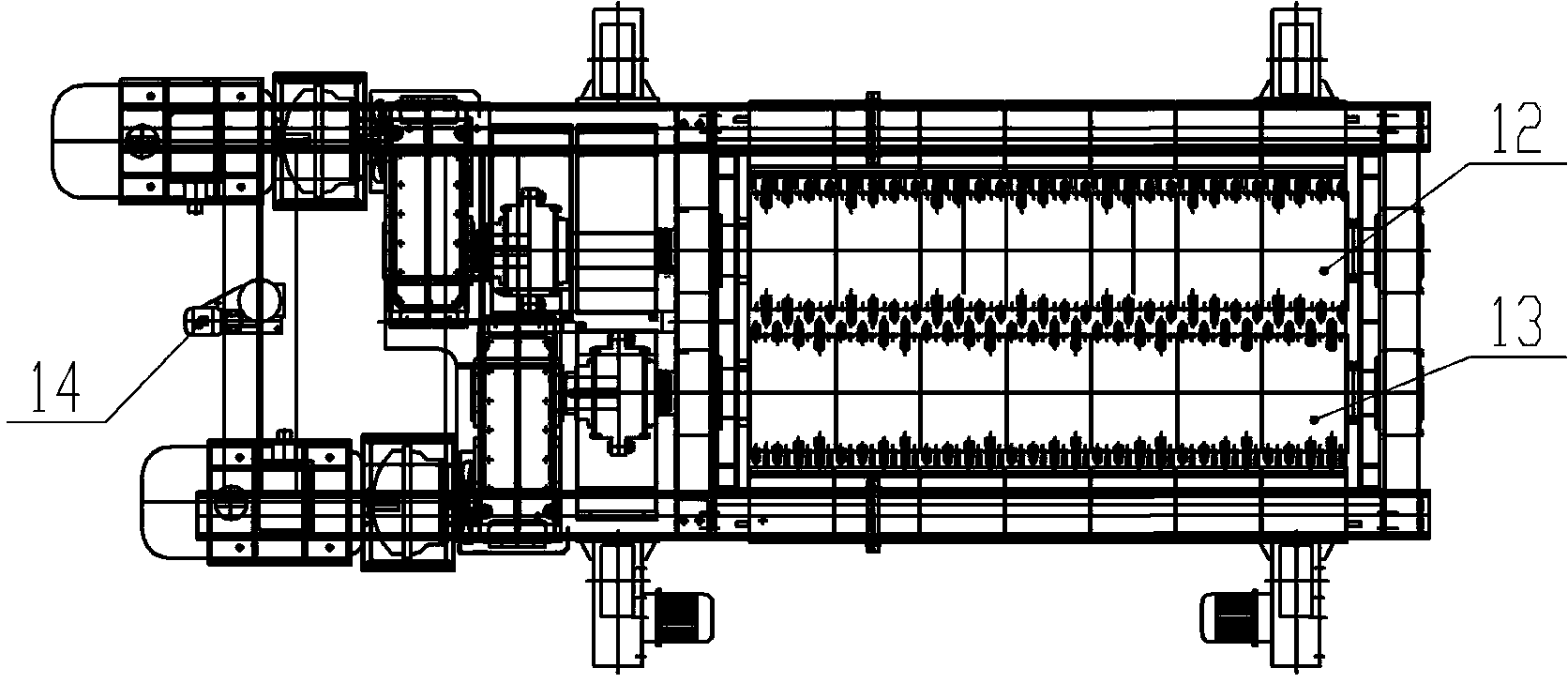

Complete two-stage slurry production equipment of water-coal-slurry and gasified water-coal-slurry by using low-rank coal fuel

ActiveCN101955824AOptimize particle size distributionImprove product qualityLiquid carbonaceous fuelsLump/pulverulent fuel preparationHigh concentrationPower station

The invention relates to complete two-stage slurry production equipment of water-coal-slurry and gasified water-coal-slurry by using low-rank coal fuel, mainly used for fuel for industrial boilers and power station boilers and fuel for gasification furnaces. The complete two-stage slurry production equipment for water-coal-slurry and gasified water-coal-slurry from low-rank coal fuel comprises a low-rank coal raw material warehouse (1), a vibration feeder (2), a type conveyer (4), a crusher (5) of a reversible counterattack hammer type, a hopper lifter (6), a low-rank coal middle warehouse (7), a measuring belt machine (10), a spiral feeder (11), a high-concentration water-coal-slurry ball mill (12), a water-coal-slurry vibration sieve (13), a water-coal-slurry buffer tank (14), a water-coal-slurry filter (16), a stability treatment tank (17), a Homogenizing tank (19) and a slurry storage tank (21), wherein a bypass is divided from a discharge port of the high-concentration water-coal-slurry ball mill (12), is a fine slurry preparation system and comprises a rotary vibration sieve (27), a front inlet tank (28) of a fine grinding machine, a medium-concentration ultrafine vertical mill (31) and a slurry storage tank (29) of the fine grinding machine. The invention can improve the product concentration of the water-coal-slurry.

Owner:JIANGSU QIULIN HEAVY IND

Integrated belt puller and three-dimensional forming machine

The present invention relates generally to an integrated belt machine. More particularly, the present invention is directed to an integrated belt puller and 3D forming machine for continuously forming 3D products from plastic materials.

Owner:CRANE BUILDING PRODS

Concrete integral production system

ActiveCN105922438AStir wellAvoid slump lossDischarging apparatusMixing operation control apparatusMaterial supplyBelt machine

The invention discloses a concrete integral production system. The concrete integral production system comprises a dry material supply device, a concrete stirring device, a spiral extrusion conveying device and a control device; the dry material supply device, the concrete stirring device and the spiral extrusion conveying device are joined in sequence, wherein the dry material supply device includes a cement conveying line, a sand conveying line and a bubble conveying line; and cement, sand and bubble are pneumatically conveyed by the dry material supply device to enter a conveying belt machine, and are conveyed to the concrete stirring device by the conveying belt machine. Raw materials are conveyed by using a remote supply system, and are stirred by adding water in scene, so that dry concrete can be transported remotely or even preserved through sealing, the business scope of a concrete mixing plant is widened, the slump loss of concrete in the transportation process is prevented, and the construction while stirring is realized.

Owner:东莞市交港建材有限公司

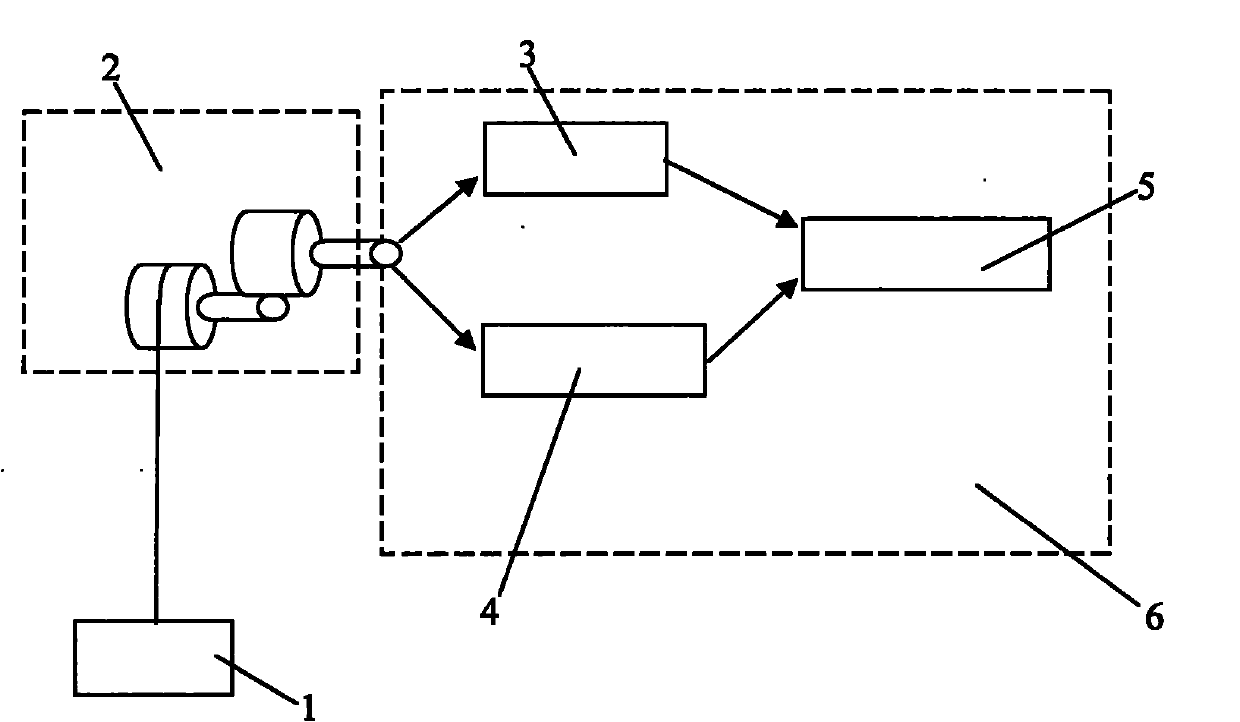

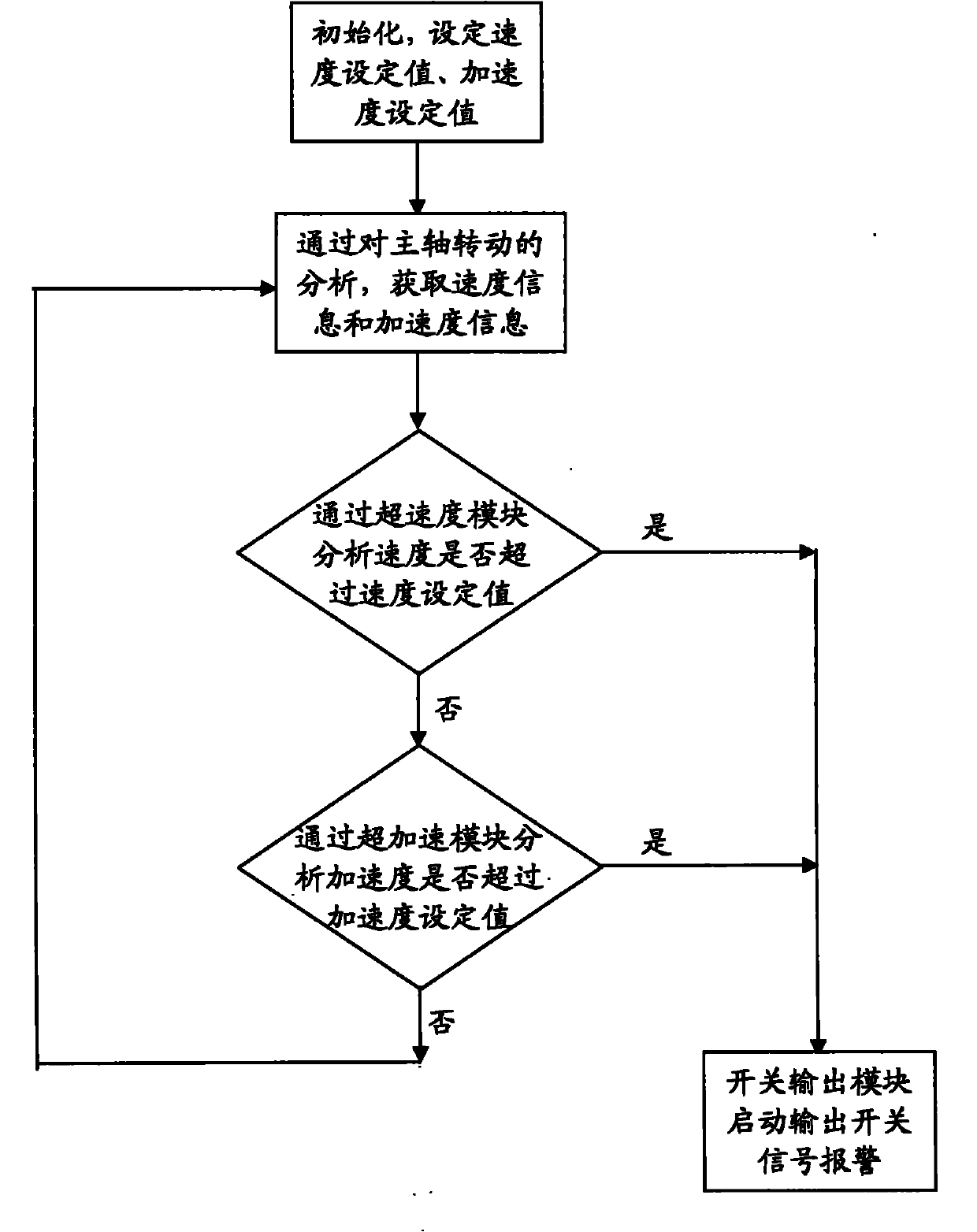

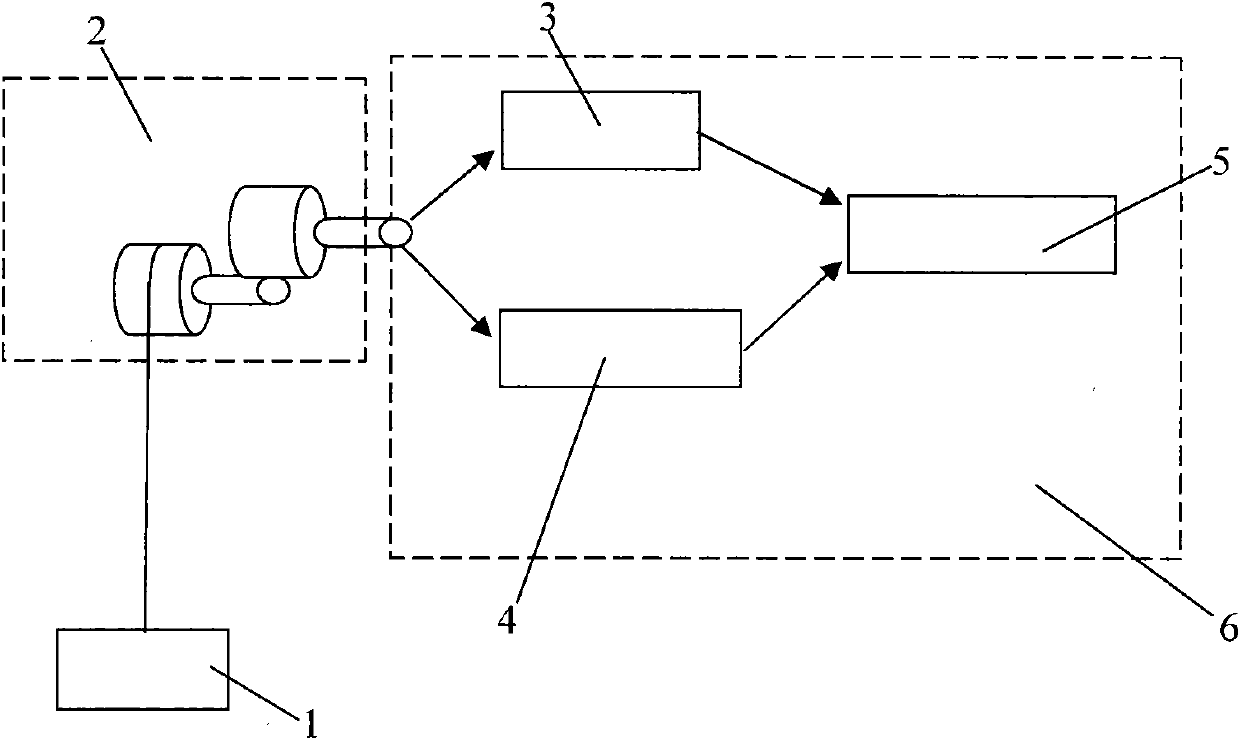

Protection switching device for lost control of crane and related control method

The invention provides a protection switching device for lost control of a crane, which comprises a super-speed module, a super-acceleration module and a switching output module. The super-speed module and the super-acceleration module are connected with the switching output module respectively; the super-speed module is used for measuring the speed of a lifted object and analyzing whether the speed exceeds a preset speed setting value; the super-acceleration module is used for measuring the acceleration of the lifted object and analyzing whether the acceleration exceeds a preset acceleration setting value; and if the speed exceeds the speed setting value and / or the acceleration exceeds the acceleration setting value, the switching output module is started to alarm. The invention also provides a related control method. The protection switching device has the advantages of skilful design, simple structure, low cost, economy and practicability, quick response, safety and reliability, can effectively prevent the lost control of the crane, has the same effect on the potential energy load movement of other crane types such as an obliquely-pulled belt machine and a conveyor, and is suitable for large-scale popularization and application.

Owner:上海能港电气工程科技有限公司

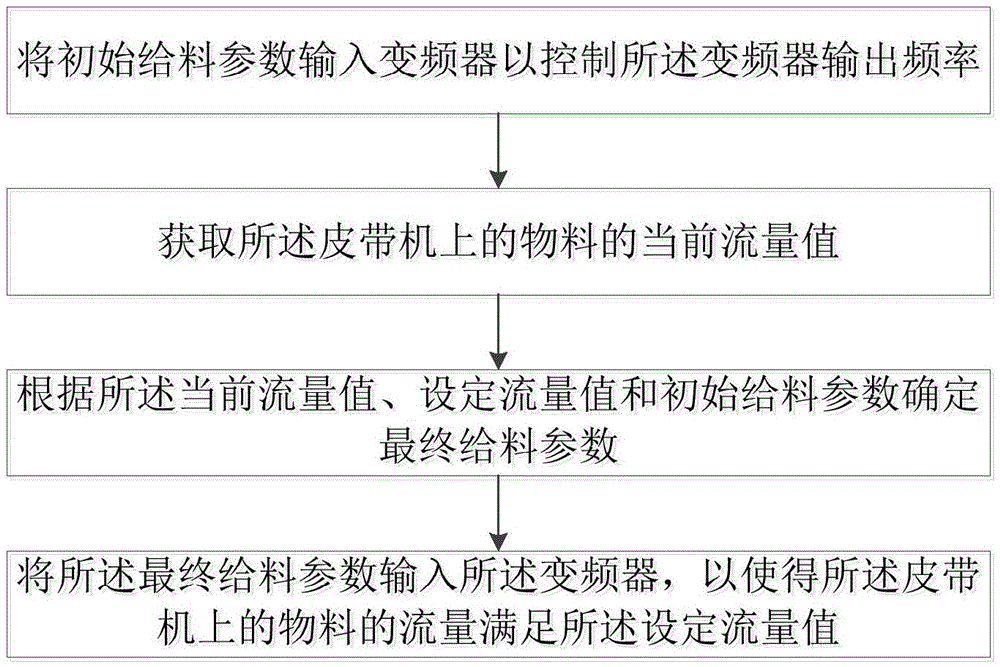

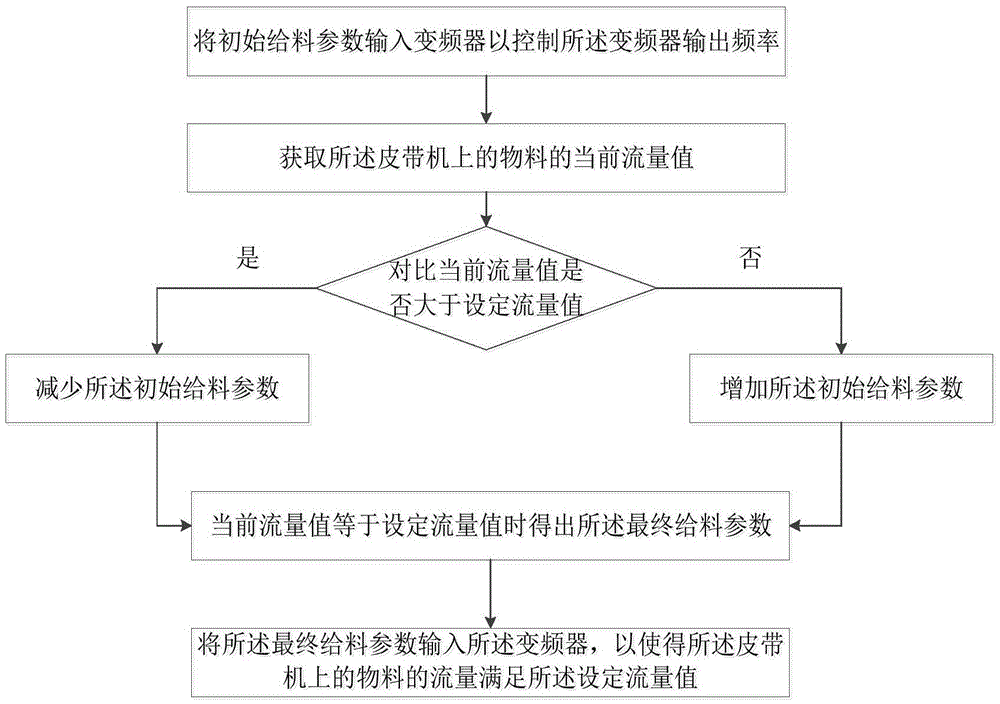

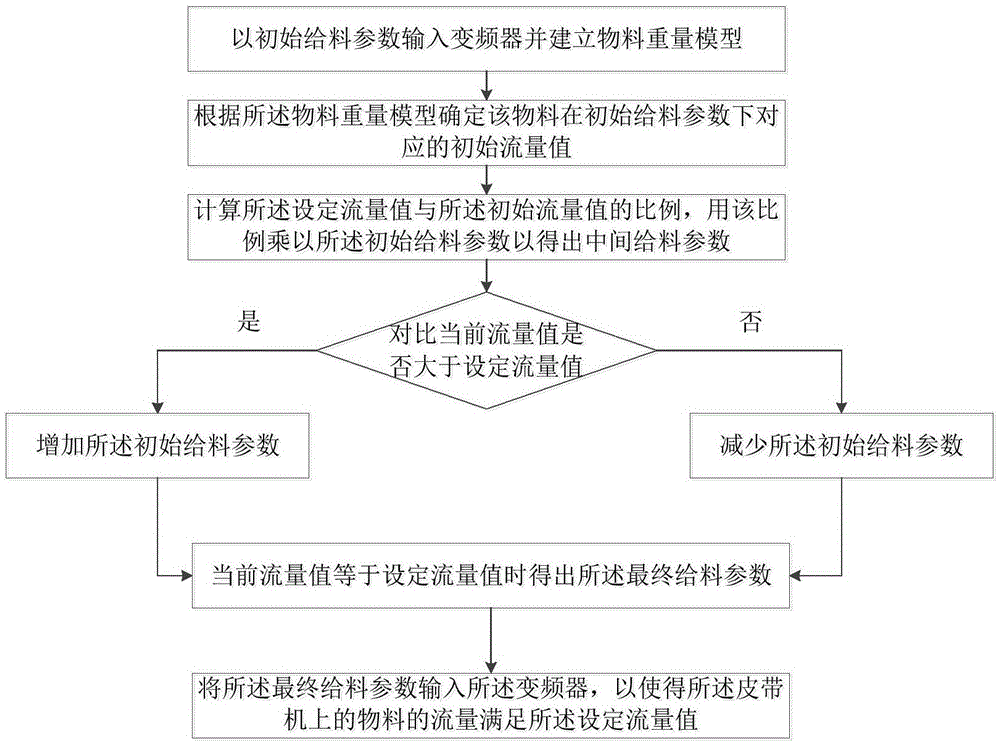

Full-automatic tippler feeding method and system

ActiveCN105523368ARealize fully automatic feeding operationReduce labor intensityConveyor partsFrequency changerElectric machinery

The invention relates to feeding control, and discloses a full-automatic tippler feeding method. The method comprises the following steps: initial feeding parameters are input in a frequency converter to control an output frequency of the frequency converter, wherein the frequency converter is used for driving a motor of a vibration feeder positioned below a funnel to control a vibration frequency of the vibration feeder so as to control the blanking speed from the funnel to a belt machine; a present flow value of a material on the belt machine is obtained; final feeding parameters are determined according to the present flow value, a set flow value and the initial feeding parameters; and the final feeding parameters are input in the frequency converter to enable the flow of the material on the belt machine to satisfy the set flow value. The full-automatic tippler feeding method can realize full-automatic tippler feeding operation, can largely reduce labor intensity of operators, and improves the unloading operation efficiency.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Self-moving belt machine tail part

Owner:SHANXI DONGHUA MACHINERY

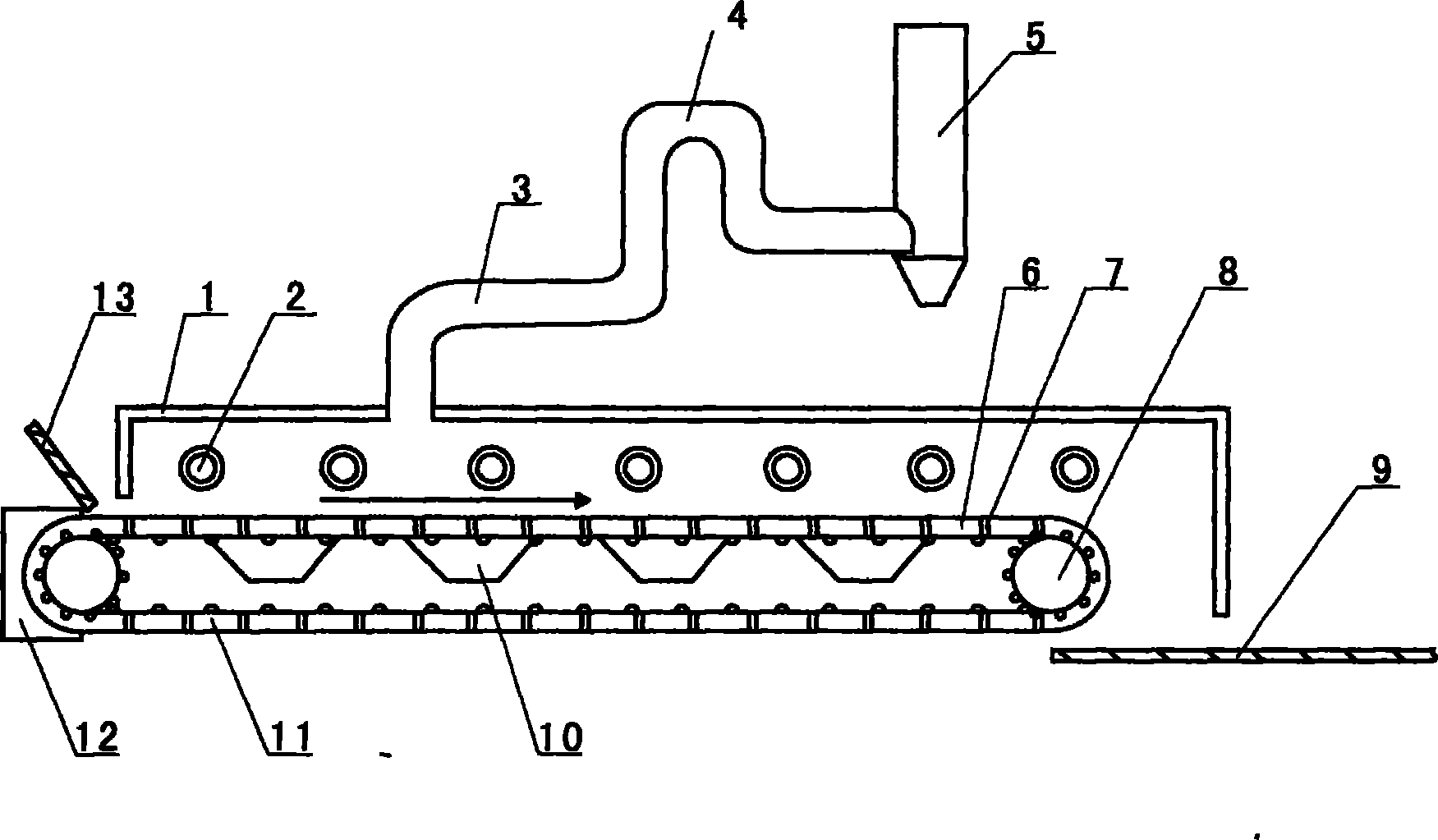

Method for producing metallized pellets by using composite carbon-containing pellets and chain belt type roasting machine

The invention discloses a method for producing metallized pellets by using composite carbon-containing pellets. The method comprises the following steps of: preparing carbon-containing pellets by using a raw material mixed with quantitative carbon and iron; preparing cladding powder containing carbon and volatile matters; preparing the composite carbon-containing pellets; and drying the composite carbon-containing pellets, performing high-temperature reductive roasting in a chain belt type roasting machine, quenching with water, de-cladding, and performing magnetic separation and grading treatment, thus obtaining the metallized pellets. The invention also discloses the chain belt type roasting machine. Two ends of a furnace body of the roasting machine are respectively provided with a feeding hole and a discharge hole; the upper part of the furnace body is provided with a chimney; a chain belt and a blowing chamber of a chain belt machine are positioned in the lower space in the furnace body; a distributor and a discharger are respectively arranged at the feeding hole and discharge hole of the furnace body; and a nozzle is arranged at the inner face of the upper wall of the furnace body. The metal intermediate slag mixed with the carbon and the iron is processed into an iron-making high-quality raw material, namely the metallized pellets, so waste is changed into valuables; and the method is low in processing energy consumption and efficient, and can be implemented in a large scale.

Owner:陈小林 +2

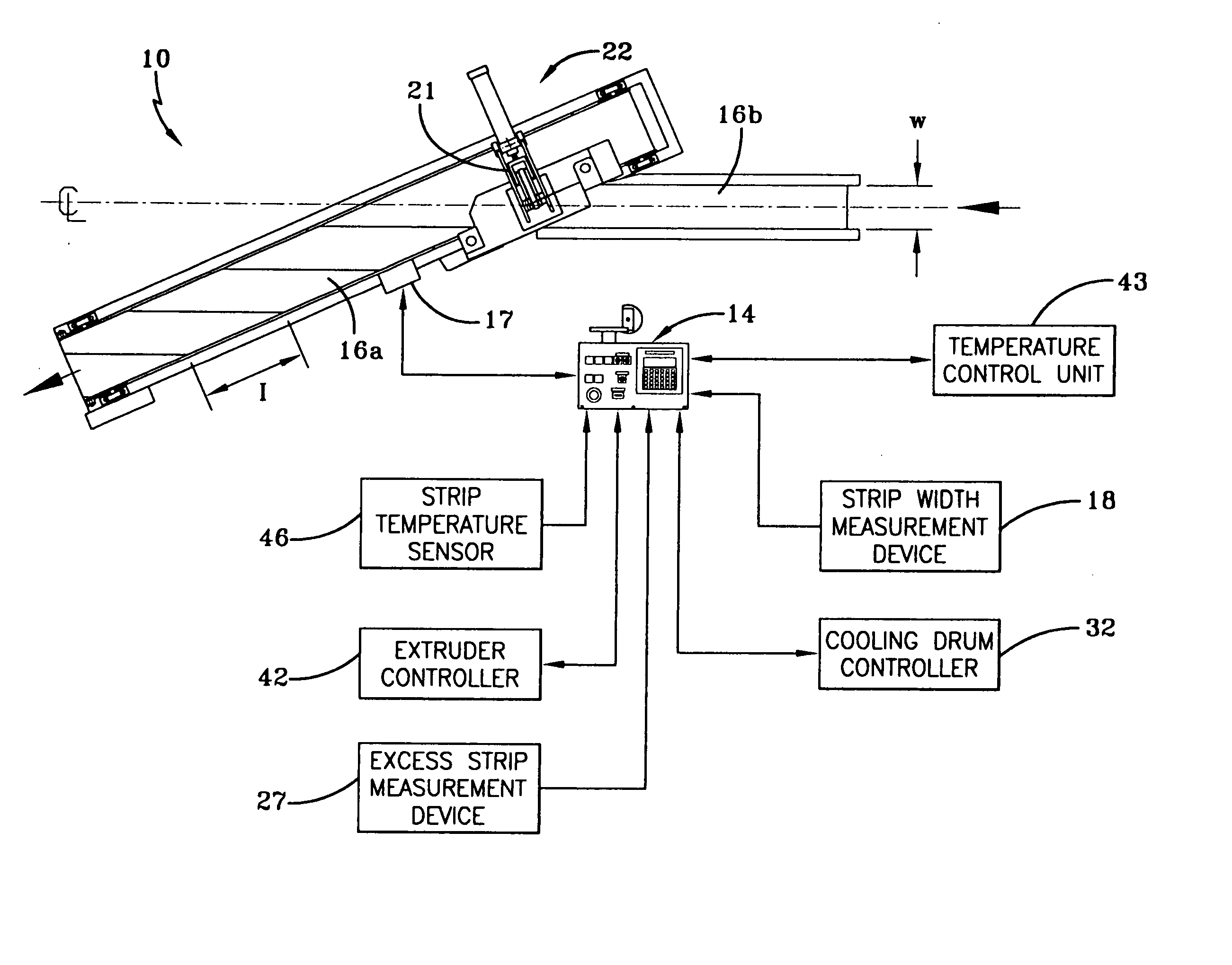

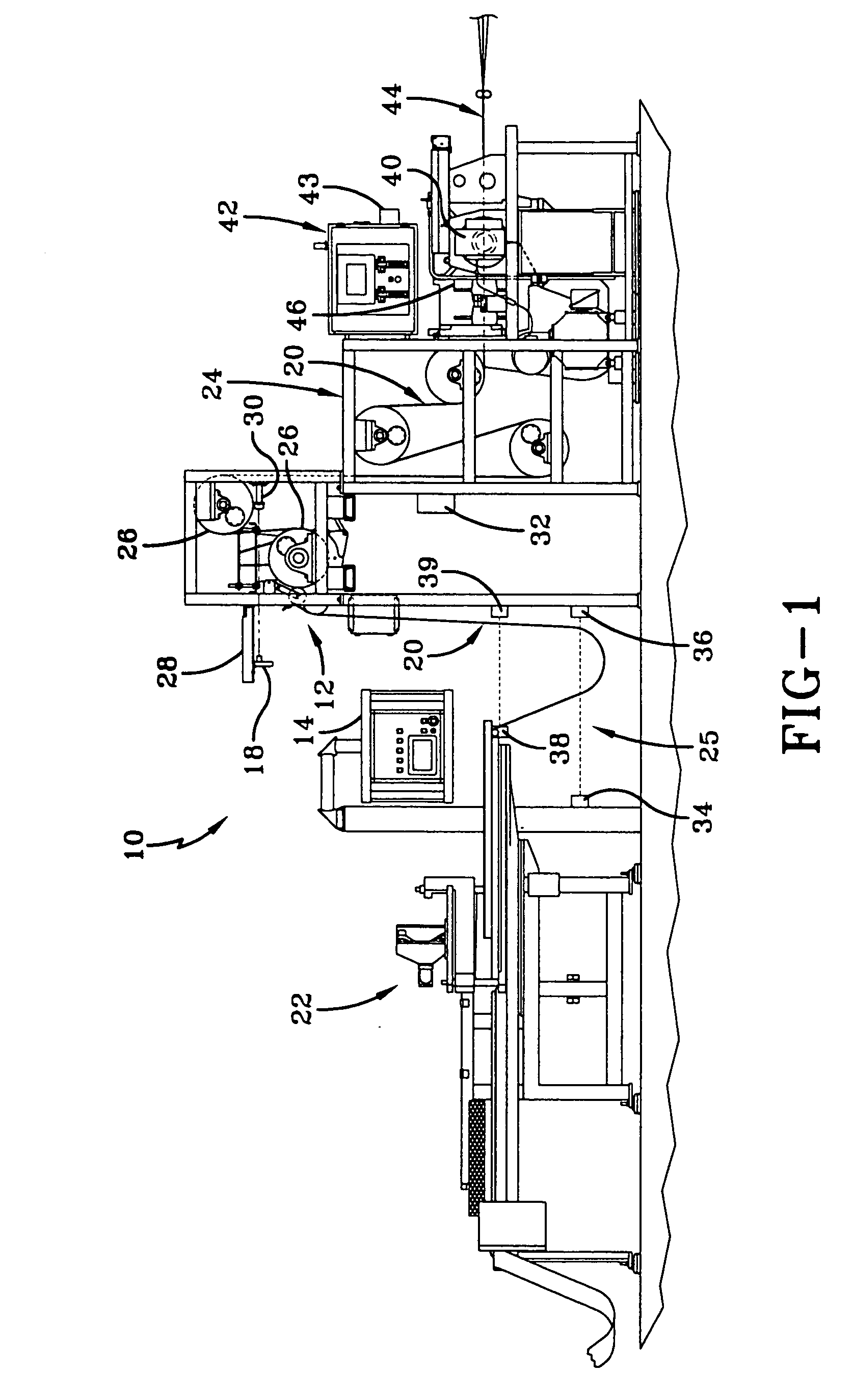

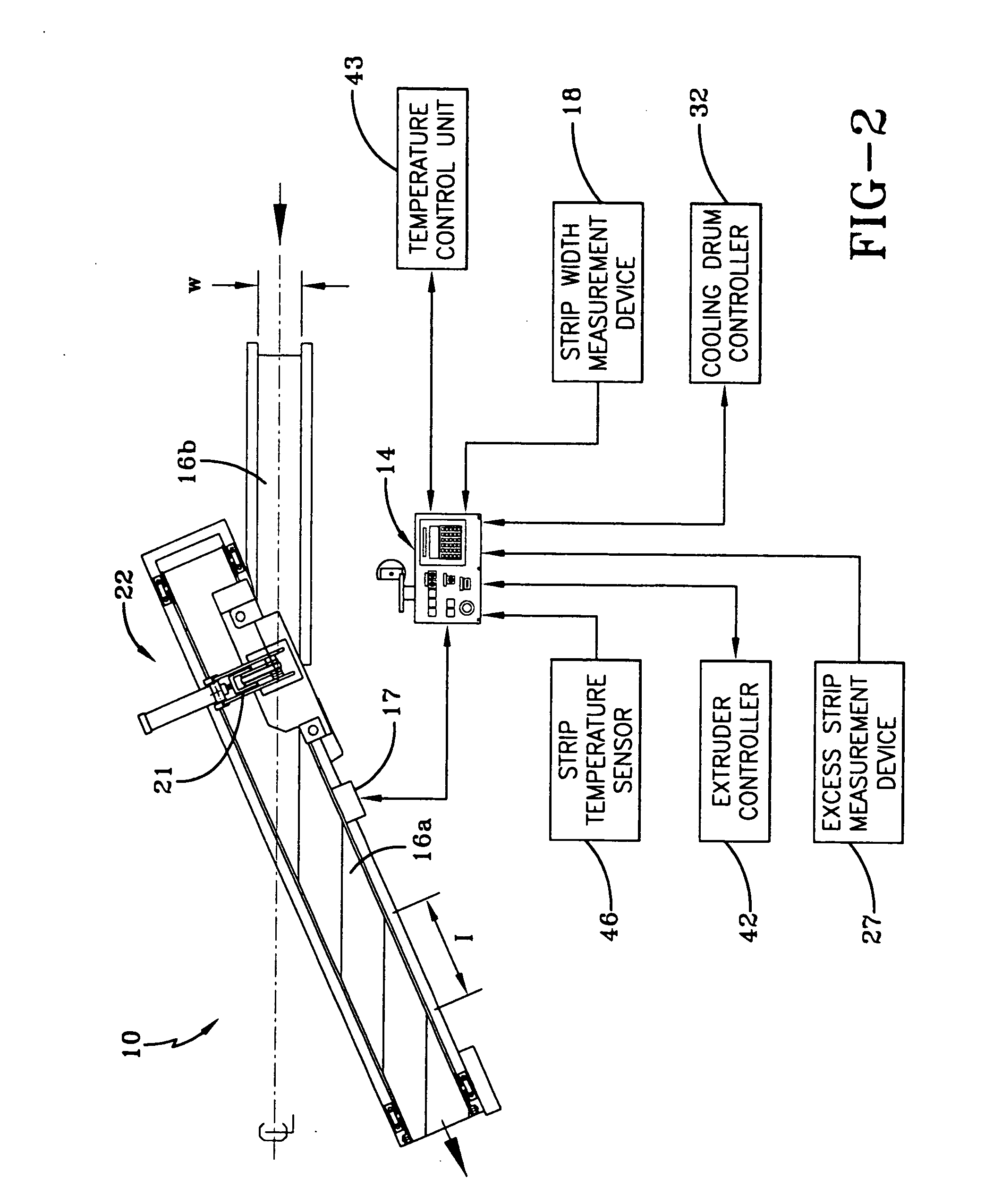

Tire belt machine

A method of controlling a tire belt machine having a cutting station that receives a strip of material cuts it into plural lengths that are spliced together on a belt conveyor, the method including establishing a belt conveyor index distance; receiving signals representing a width of the strip entering a cutting station; and automatically adjusting the belt conveyor index distance based on the strip's width such that uniform splice characteristics are attained.

Owner:STEELASTIC COMPANY L L C THE

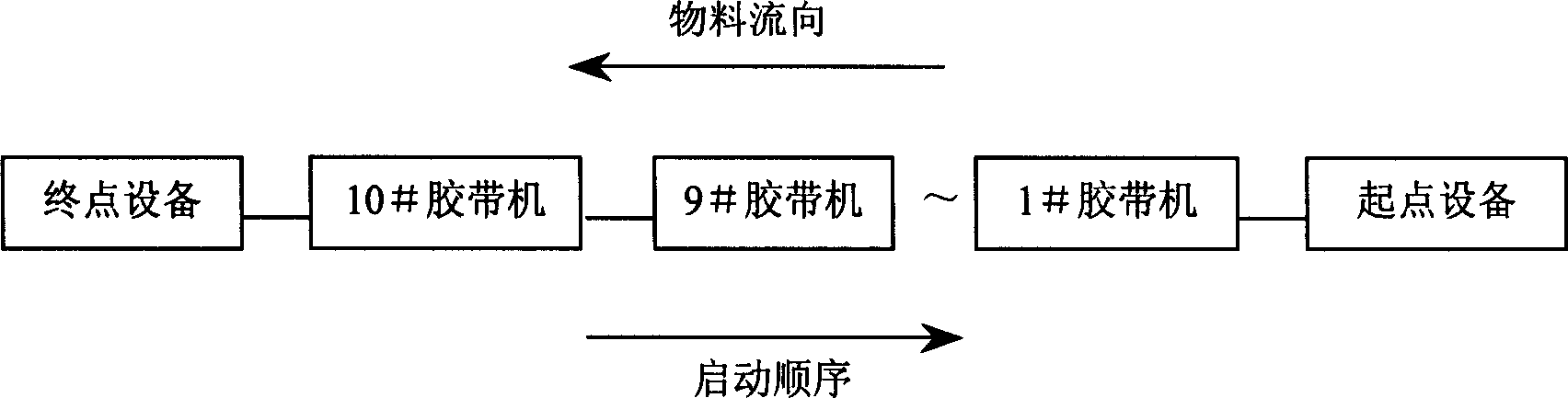

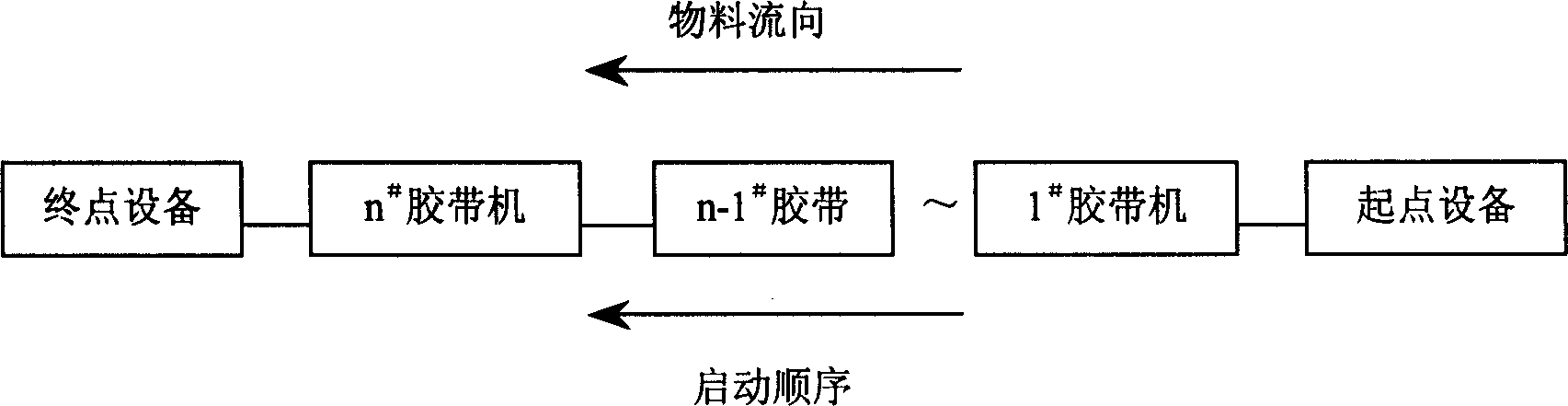

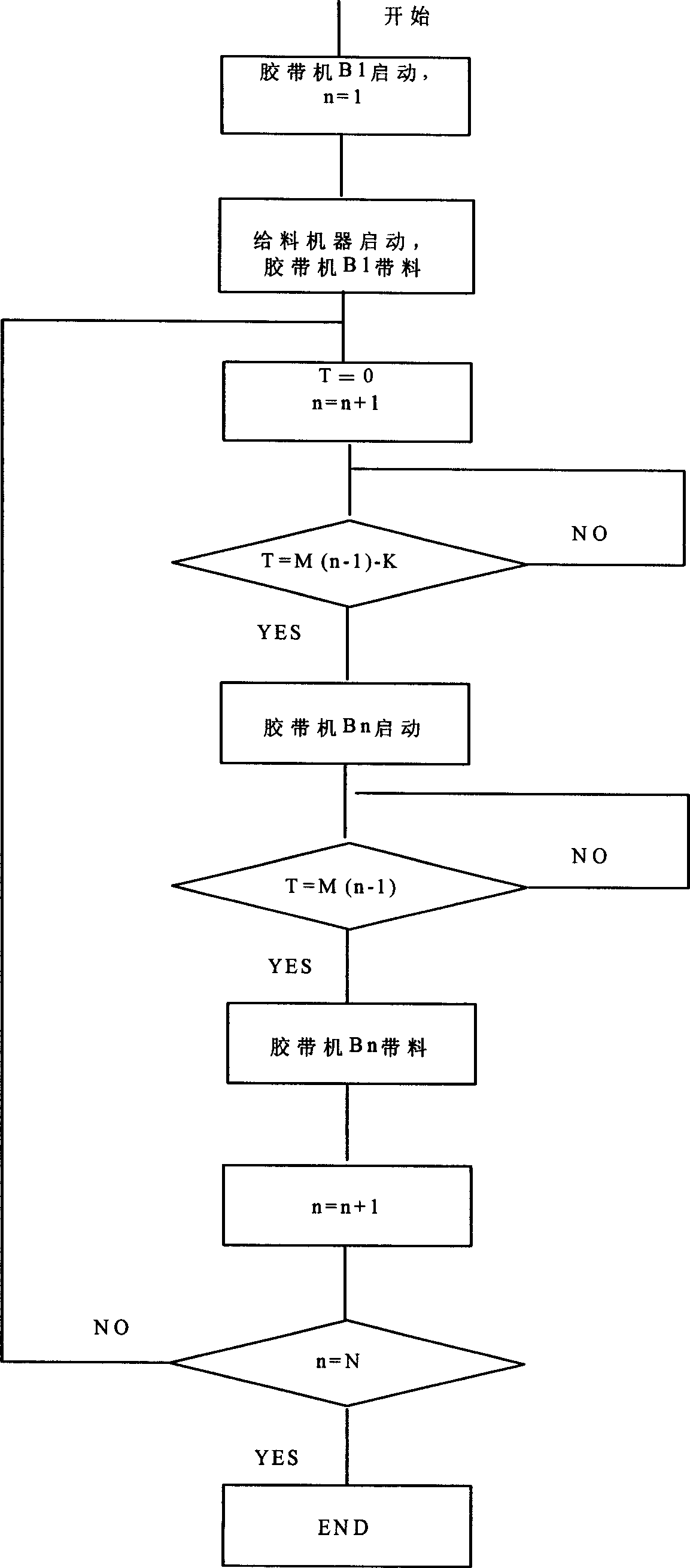

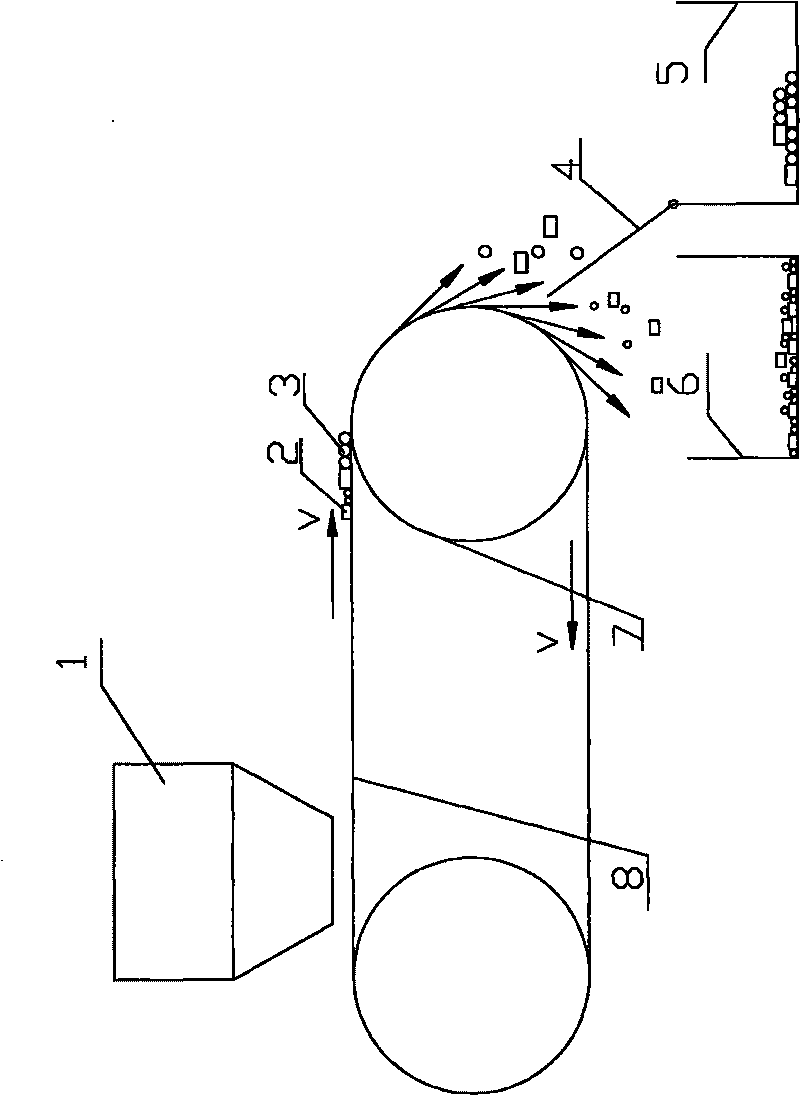

Combined flow startup method of belt conveying system

InactiveCN1803558AReduce idle timeGuaranteed uptimeControl devices for conveyorsEngineeringDelivery system

The invention discloses a combined type flow path starting method of belt transmission system, which comprises the following steps: tracing the head of material on the belt flow path; making the starting sequence consistent with the flow direction of material to start by inversed-sequence; according to Tn=SigmaM(n-1)-K to start the belt machine (M is full-path time of belt machine; K is the advanced starting constant); Tracing the rear of material in the discharging course when the feeding equipment stops running. The invention switches the starting pattern at inversed-sequent and sequent pattern mutually, which improves the equipment utility and saves power.

Owner:BAOSHAN IRON & STEEL CO LTD

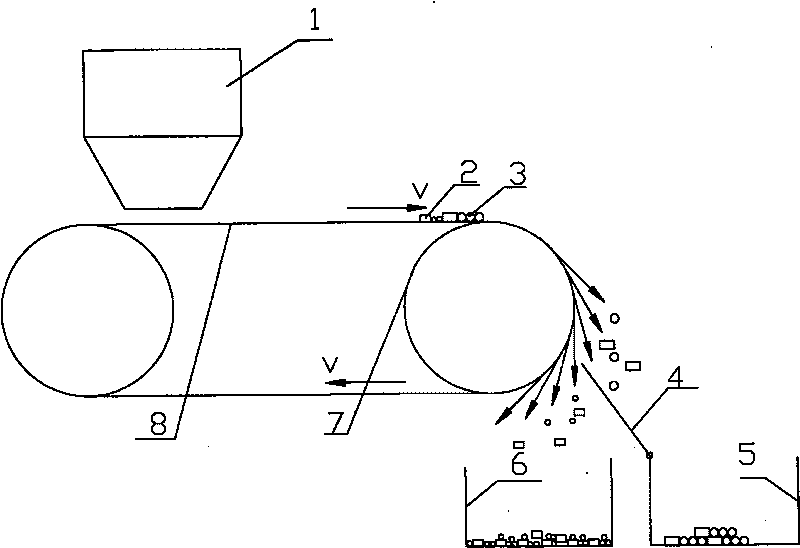

Steel ball and steel segment sorter

InactiveCN101712031ASolve wear and tearSolve the sorting problem after crushingGradingSteel ballEngineering

The invention relates to sorting machinery, in particular to a steel ball and steel segment sorter. The steel ball and steel segment sorter comprises a belt machine; a conveyer belt is sleeved on a roller of the belt machine; a driving roller or a turnabout roller of the belt machine is an electromagnetic roller; a receiving hopper for accommodating steel balls and steel segments to be sorted is arranged above the conveyer belt of the belt machine; the discharging side of the belt machine is provided with a steel ball or steel segment division board along the tangential direction of the electromagnetic roller; and two sides of the steel ball or steel segment division board are provided with containers for collecting the steel balls and the steel segments. Compared with an artificial steel mesh screen, the steel ball and steel segment sorter has the advantages of good sorting effect, high work efficiency, simple structure, convenient operation and the like, can save a large amount of sorting manpower and time by replacing manual operation, and solves the problems of abrasion of a grinding body of a ball mill in the conventional cement and metallurgical mine industry and sorting after breaking.

Owner:JIDONG DEV GROUP

Technology and equipment for separating coal and gangue and refilling gangue

InactiveCN102305069ASolve the backfill problemLow costUnderground miningSurface miningMining engineeringBelt machine

The invention discloses a technology and equipment for separating coal and gangue and refilling the gangue. The technology is characterized by comprising the following steps of: cutting an upper coal layer by using a coal mining machine and conveying the coal to a well by using a scraper conveyor, a transferring loader and a belt machine; cutting a middle gangue layer by using the coal mining machine and reversely running the scraper conveyor to convey the gangue to a gangue back-conveying transferring loader, wherein the gangue back-conveying transferring loader conveys the gangue to a gangue throwing scraper conveyor which is suspended on the rear part of a hydraulic bracket and provided with an open middle slot plate and throws the gangue into a gob; and cutting a lower coal layer by using the coal mining machine and conveying the coal to the well by using the scraper conveyor, the transferring loader and the belt machine. Compared with the prior art, the invention has the advantages that: the coal and the gangue can be separated, and the gangue can be refilled into the gob, so that mixed mining and conveying for the coal and the gangue are avoided; therefore, the cost is savedand the environment is protected.

Owner:SHANDONG XINMEI MASCH EQUIP CO LTD

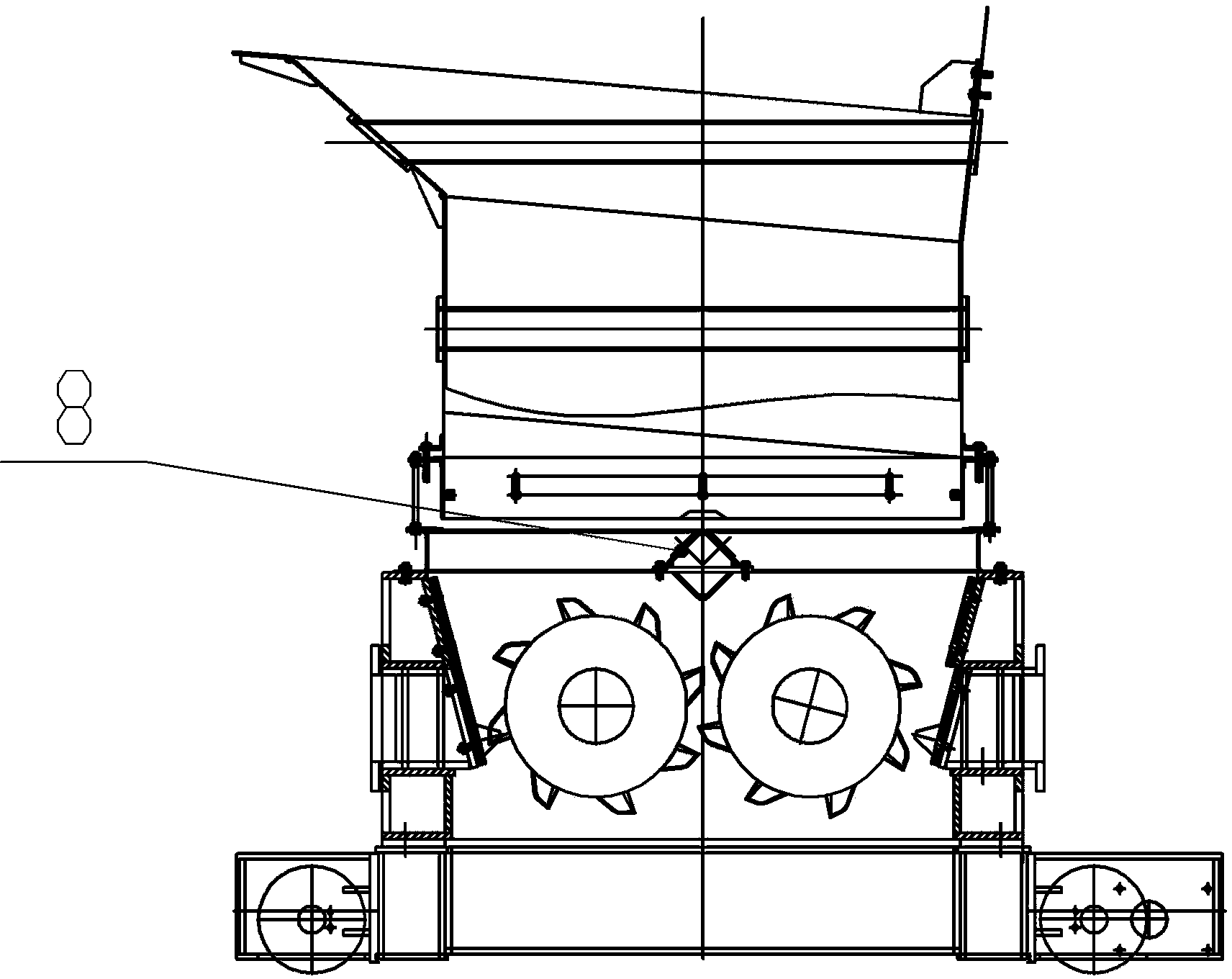

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

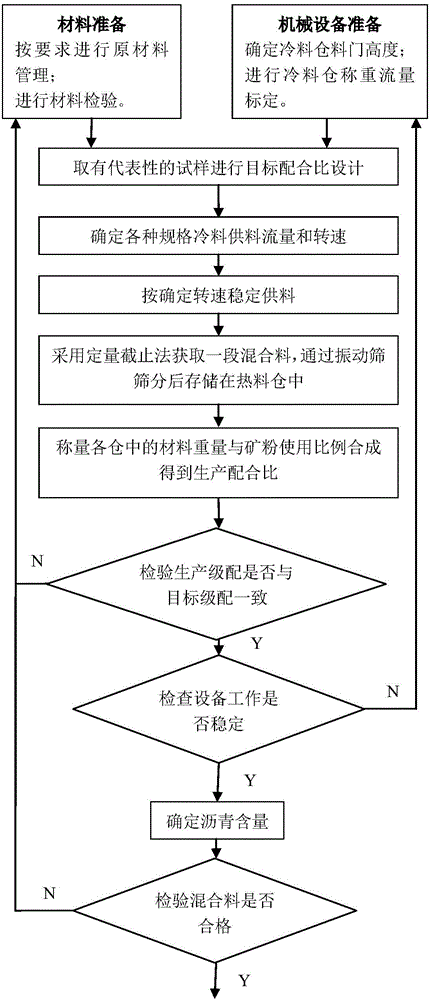

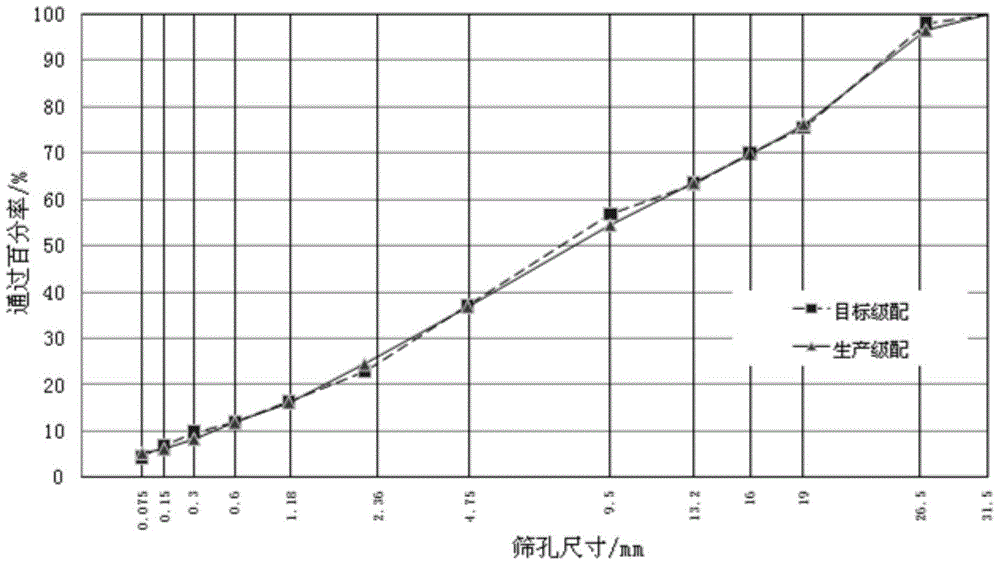

Normalized design method of production mix proportion and target mix proportion of bituminous mixture

InactiveCN104594160AGuaranteed uptimePrecise ingredientsRoads maintainenceEngineeringCalibration curve

The invention relates to a normalized design method of production mix proportion and target mix proportion of a bituminous mixture. The normalized design method comprises the following steps of calibrating a cold stock bin so as to obtain a two-dimensional calibration curve of the rotation speed of a feeding belt machine and the feeding flow rate; determining the feeding rotation speed according to the target mix proportion, intercepting the mixture by adopting a quantitative cut-off experiment method, screening by a vibration screen, and storing into a hot stock bin; weighing materials in the bins so as to obtain the proportion of hot aggregate; combining the proportion of the hot aggregate and the proportion used for mineral powder so as to obtain the production mix proportion; and combining the production grading according to the production mix proportion so as to obtain a production grading curve conforming to the target grading. The design method of the bituminous mixture is named as the normalized design method of the production mix proportion and the target mix proportion.

Owner:CHANGAN UNIV

Rail type belt conveyor

The invention relates to a rail type belt conveyor. The rail type belt conveyor comprises a support, a machine head frame, a machine tail frame, an upper guide rail, a lower guide rail, a towing trolley, a rubber belt, a steel wire rope, closed-loop systems, a driving roller, an elevating supporting roller set, a redirection frame and a triangular frame. The elevating supporting roller set is mounted at the position, close to the machine head frame, of the support, the redirection frame is mounted on the machine tail frame, a redirection drum is arranged on the machine head frame, and a tensioning vehicle is arranged at the position, close to one side of the redirection drum, of the support; and the triangular frame is arranged at the position, between the two closed-loop systems, of the support, and the rubber belt is wound around the elevating supporting roller set, the redirection drum, the tensioning vehicle, a supporting roller on the redirection frame and a supporting roller on the triangular frame. The rail type belt conveyor has the beneficial effects that a traditional rubber belt machine structure is removed, a supporting belt trolley is used for replacing a part of a common supporting roller, the cost and the mounting cost are reduced, and revolutionary innovation is brought to bulk conveying.

Owner:LIBO HEAVY MACHINE TECH

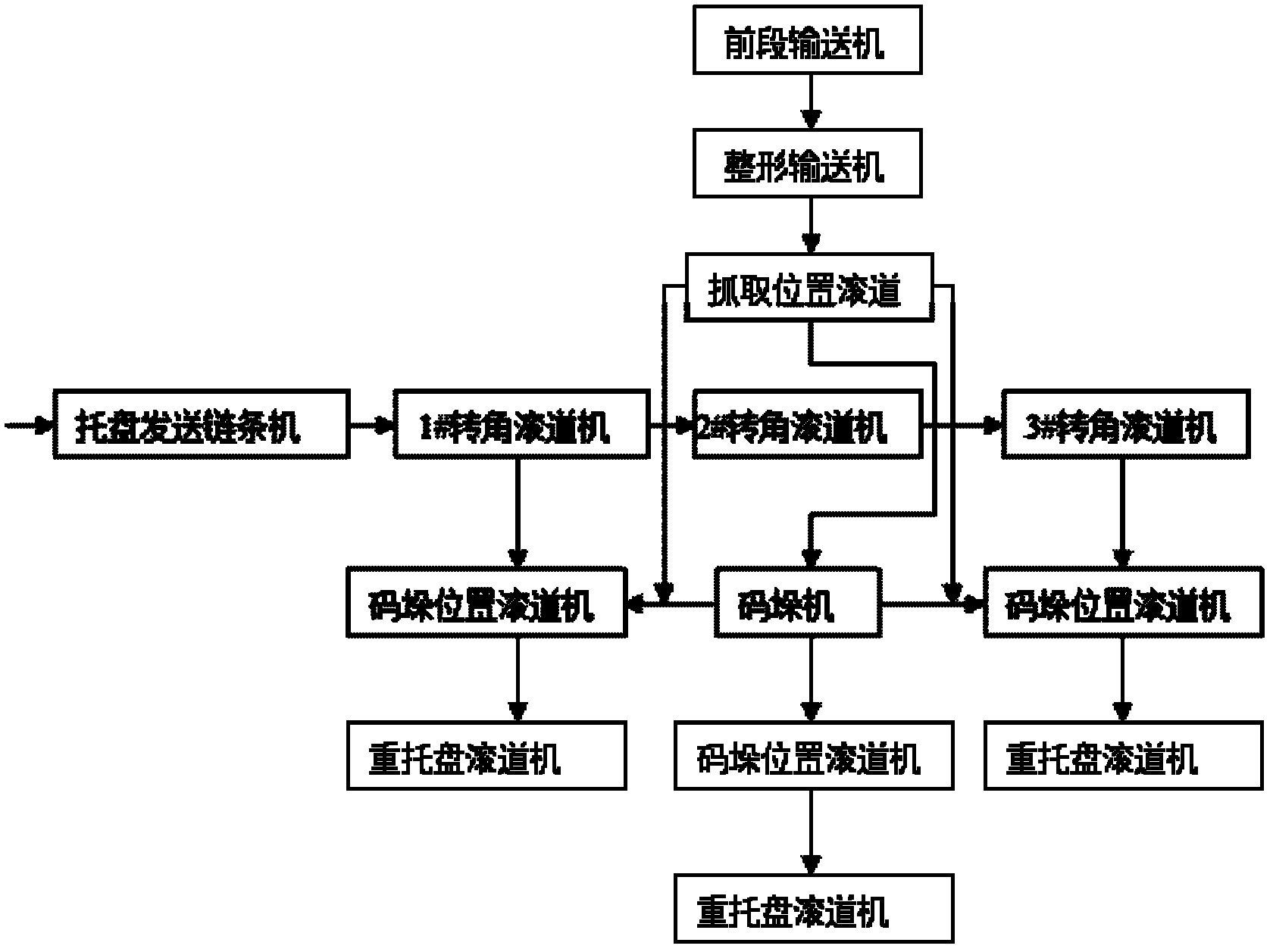

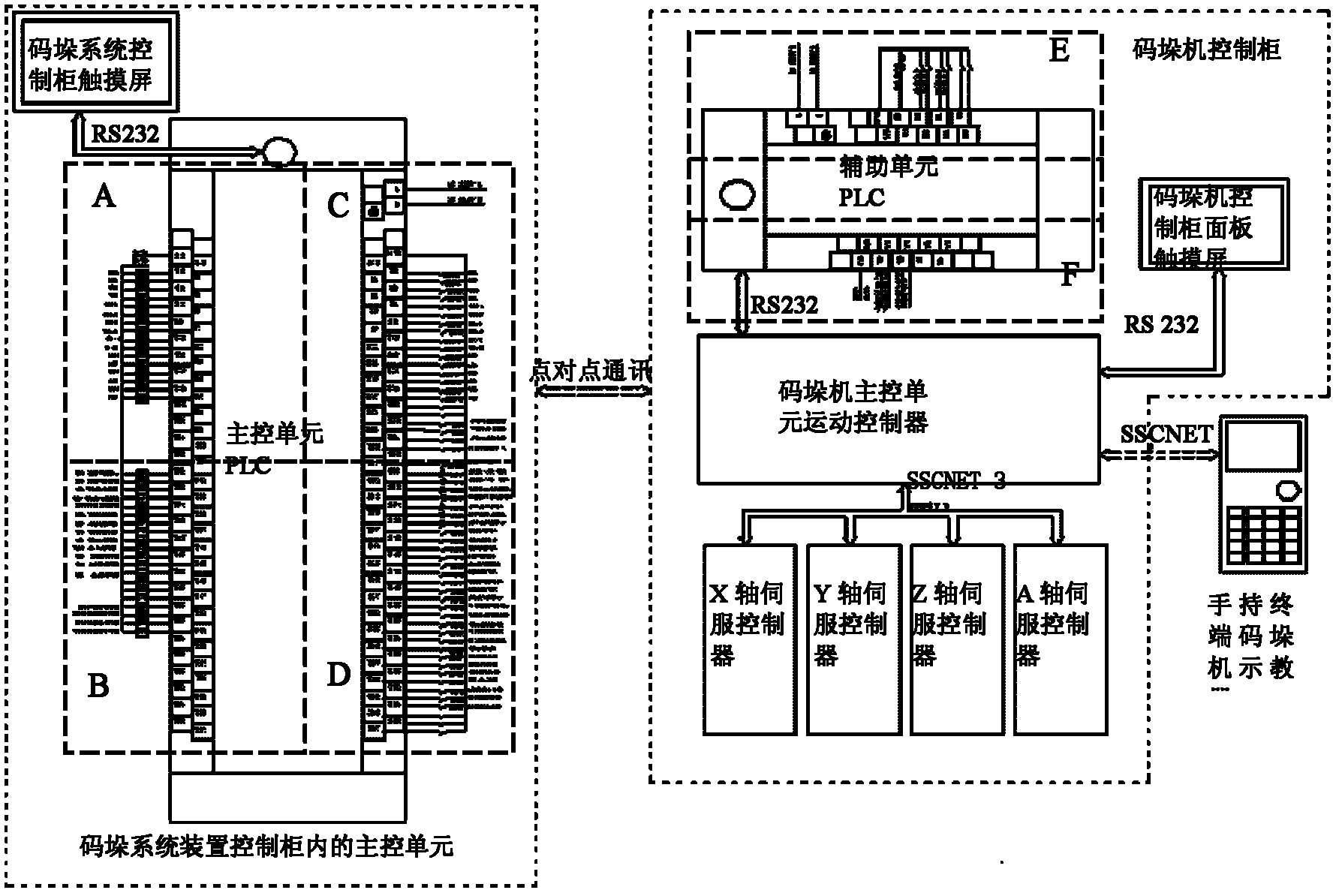

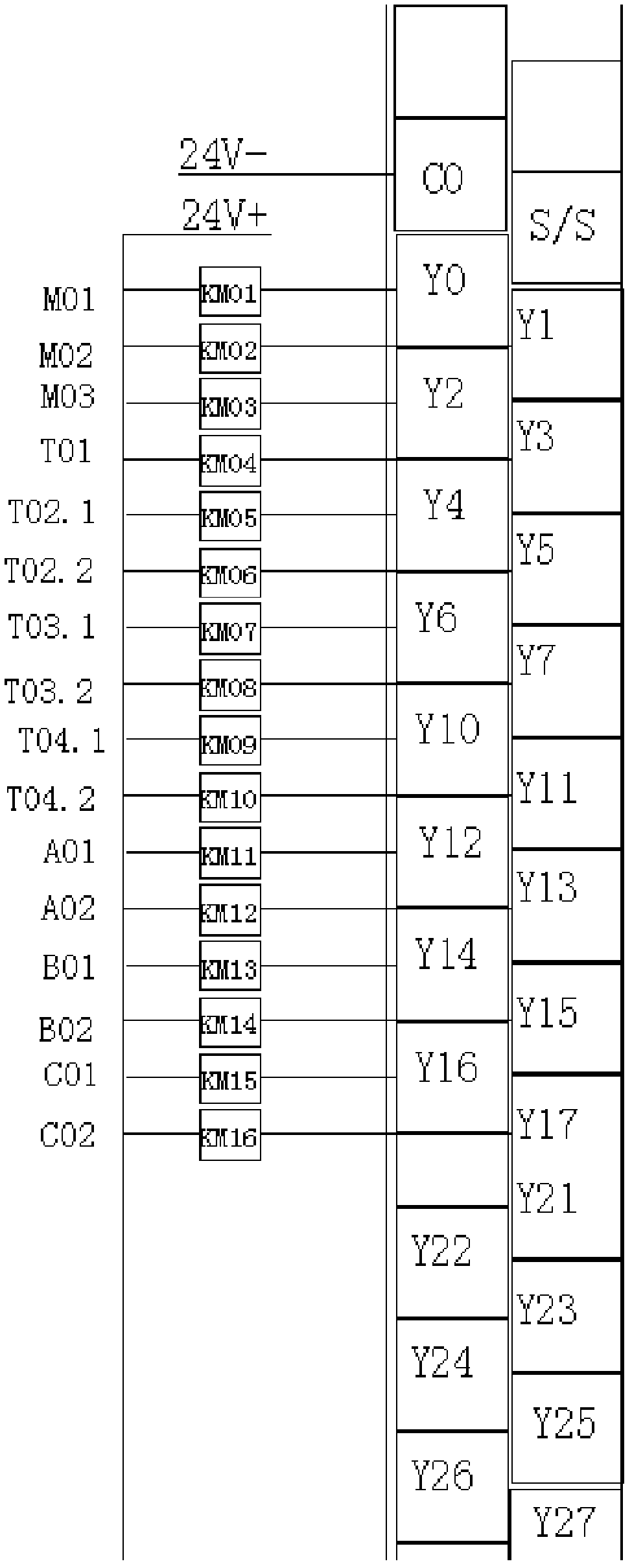

Intelligent joint robot stacking system and control system thereof

InactiveCN102633129ARealize automatic sendingRealize automatic sortingStacking articlesDe-stacking articlesPhysical hard workStack machine

The invention provides an intelligent joint robot stacking system and a control system thereof. The intelligent joint robot stacking system comprises a front-section conveyor, a reshaping conveyor, a fetching position raceway, a stacking position raceway machine, a stacking rear heavy tray raceway machine, a tray sending chain machine positioned on a tray library, a corner raceway machine on a tray library, an intelligent joint robot stacking machine and a device control system, wherein the device control system adopts a PLC (Programmable Logic Controller) control technology; equipment, such as an intelligent stacking machine, the intelligent tray transmitter, a conveying belt machine, a power raceway and the like, is organically combined with various detection elements and pneumatic elements; and under the control of a main control unit, one joint robot stacking machine is adopted to distinguish and automatically stack different products. According to the intelligent joint robot stacking system and the control system thereof, manpower can be saved, heavy manual work is liberated, and various possible errors which possibly appear during manual operation are avoided. The production efficiency is improved, the system can stably and reliably work, the equipment use ratio is improved, the equipment investment is saved, and the energy consumption is lowered.

Owner:WUXI DADONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com