Combined flow startup method of belt conveying system

A belt conveying and combined technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of long idling time and waste of electricity, and achieve reliable operation, save electricity and reduce idling time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

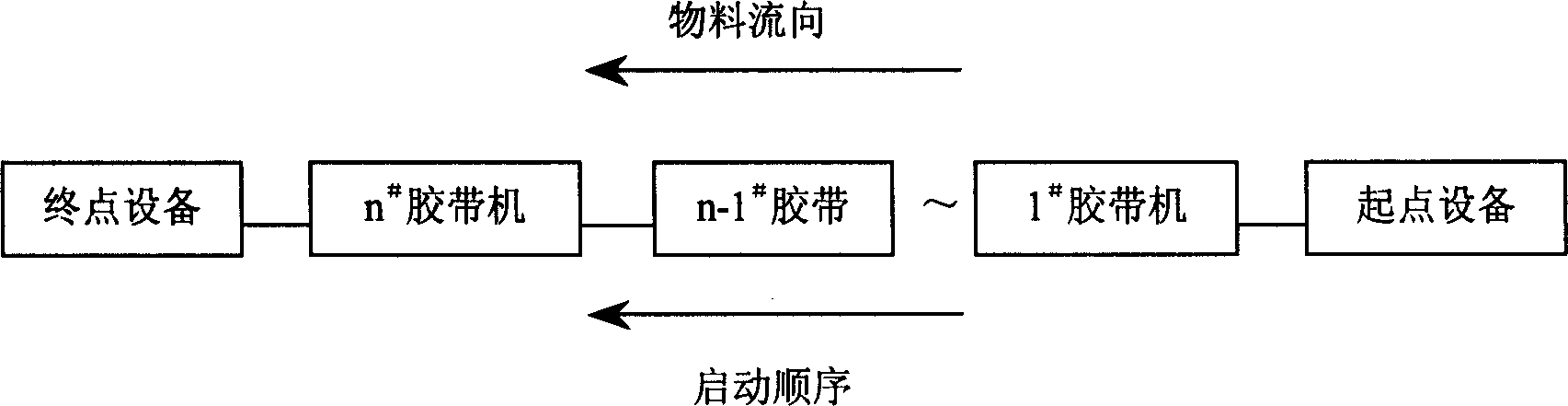

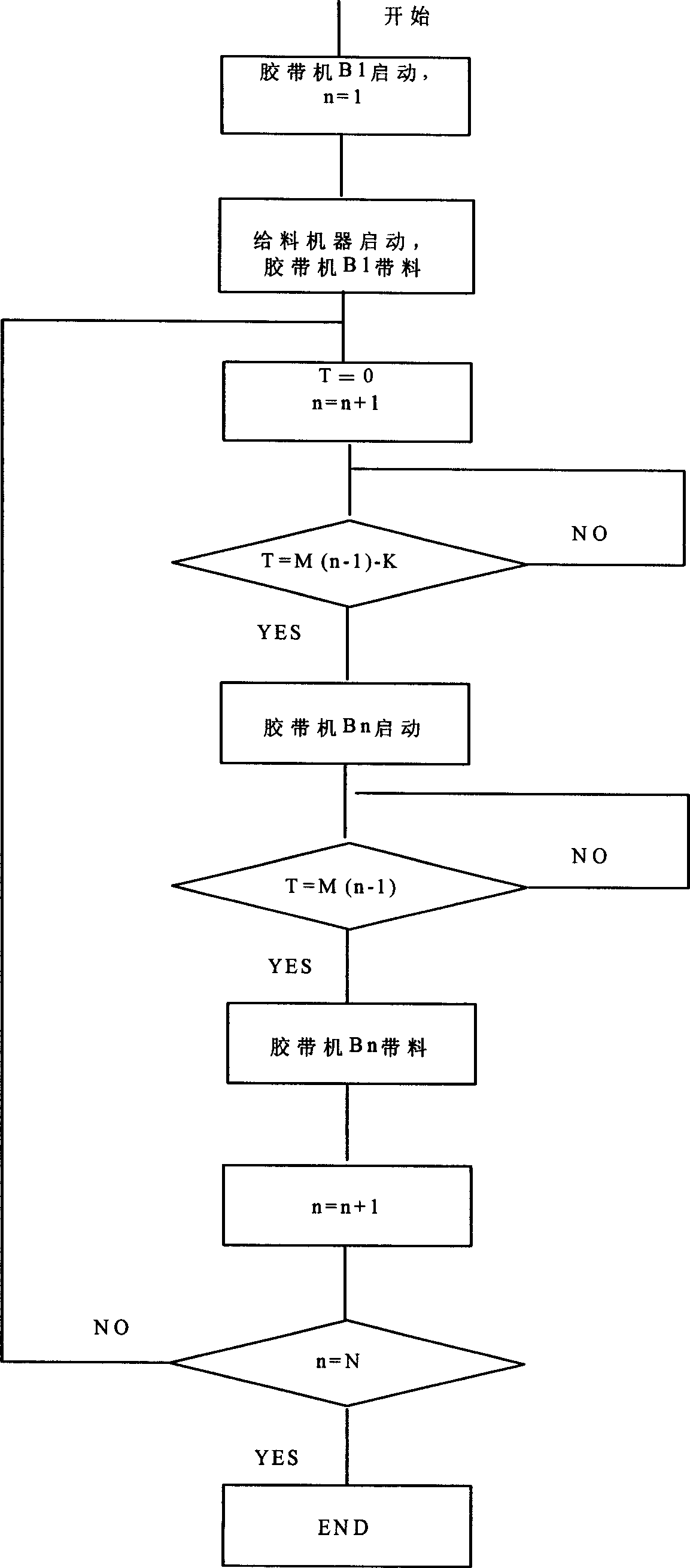

[0014] see figure 2 , image 3 , a combined process start-up method for a tape conveying system, which is to track the materials on the tape machine process, and track the head of the material during the normal material conveying process. The start sequence of the tape machine is consistent with the flow direction of the material, that is, reverse The first start, the start time of the tape machine is started according to the following formula,

[0015] T n =∑M(n-1)-K

[0016] In the formula: M is the full time of the tape machine, which refers to the time required for the material to go from the tail to the head of the tape machine, and K is the early start constant.

[0017] When the feeding equipment stops the feeding operation, the tail of the material is tracked during the material discharge process.

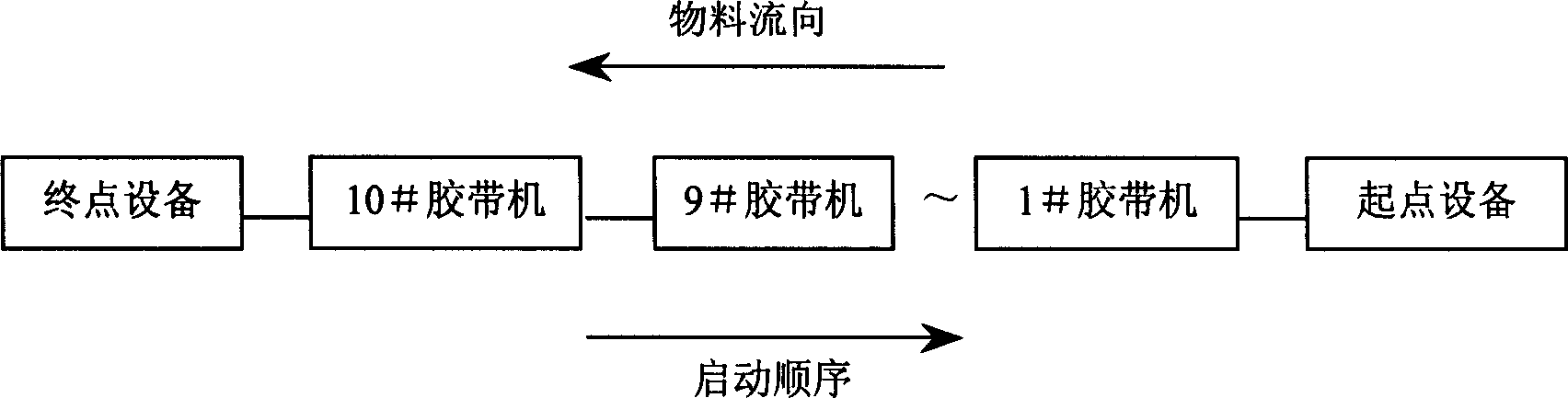

[0018] see figure 1 , Figure 4 , when the tape machine process is restarted after the material is stopped, the start sequence of the tape machine is opposite to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com