Wire electrode for electric discharge cutting processes

A technology of electrode wire and electric spark, which is applied in the field of electrode wire, can solve the problems of reduced cutting performance, unfavorable economic production, coating formability or machinability limitations, etc., to achieve improved cutting performance, reduced idle time, high durability corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

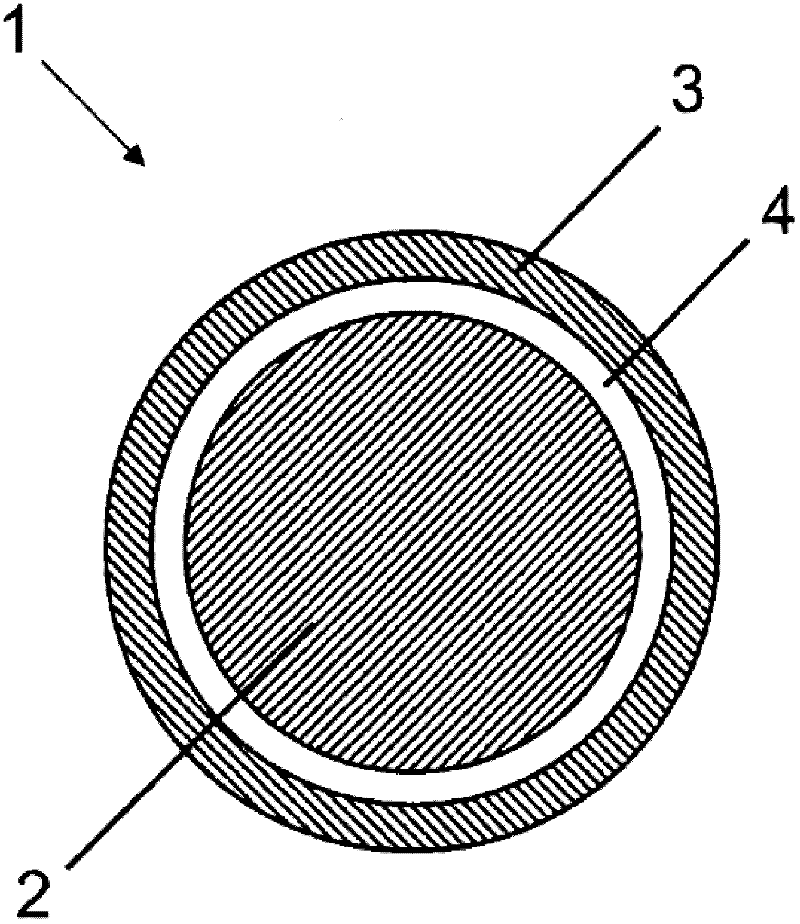

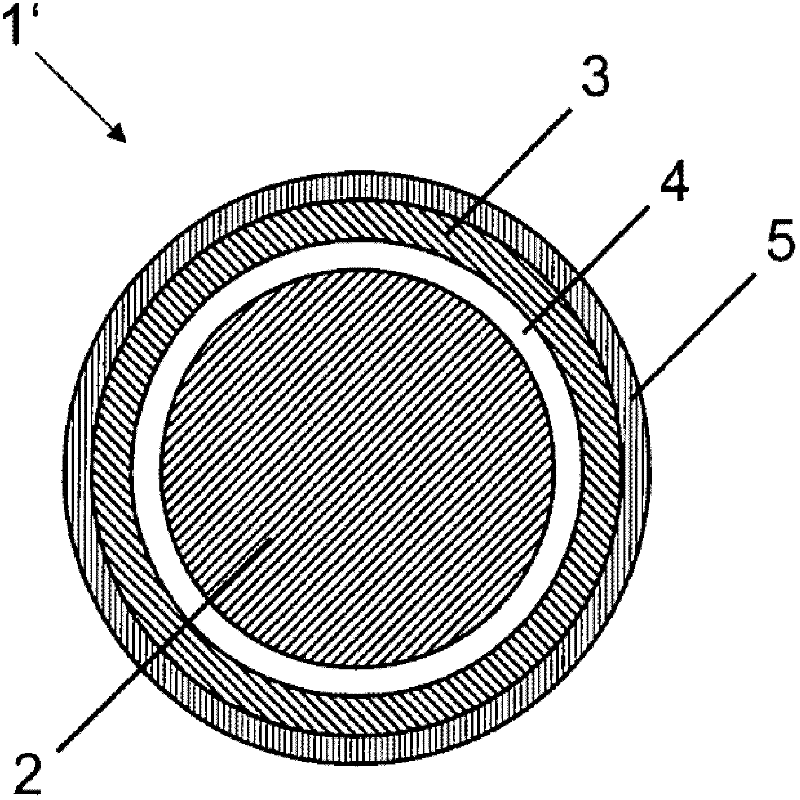

[0042] figure 1 The wire electrode 1 shown in cross section comprises a core wire 2 which is completely surrounded or surrounded by sheaths 3 , 4 which form the outer part of the wire electrode 1 . In the exemplary embodiment shown, the wire core 2 consists entirely or substantially of copper or a homogeneous copper-zinc alloy with a zinc content of 2-40% by weight. The sheaths 3, 4 consist of two laminated parts, namely cladding layers 3 and 4, which are arranged on top of each other and each consist of brass with a percentage of not more than 50% by weight, preferably completely or substantially respectively of such Brass composition. Under certain circumstances, the electrode wire 1 can generally be formed in such a way that the structure of the wire core 2 and / or of the sheath and / or of the individual coating layers differs in the radial direction. In the case of the foreskin, this can be achieved not only in a multi-layer structure, but also in a continuously changing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com