Patents

Literature

893 results about "Spark discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

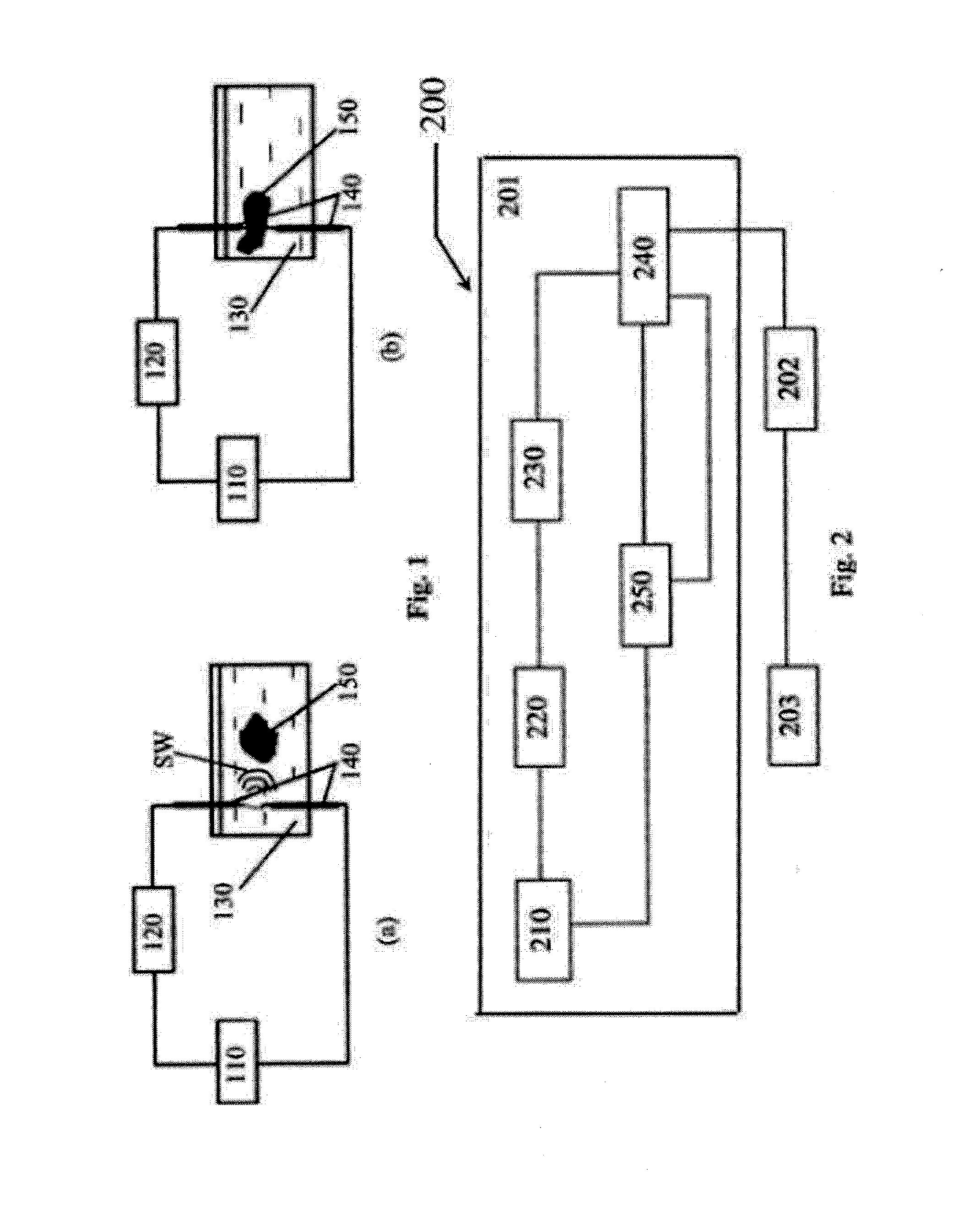

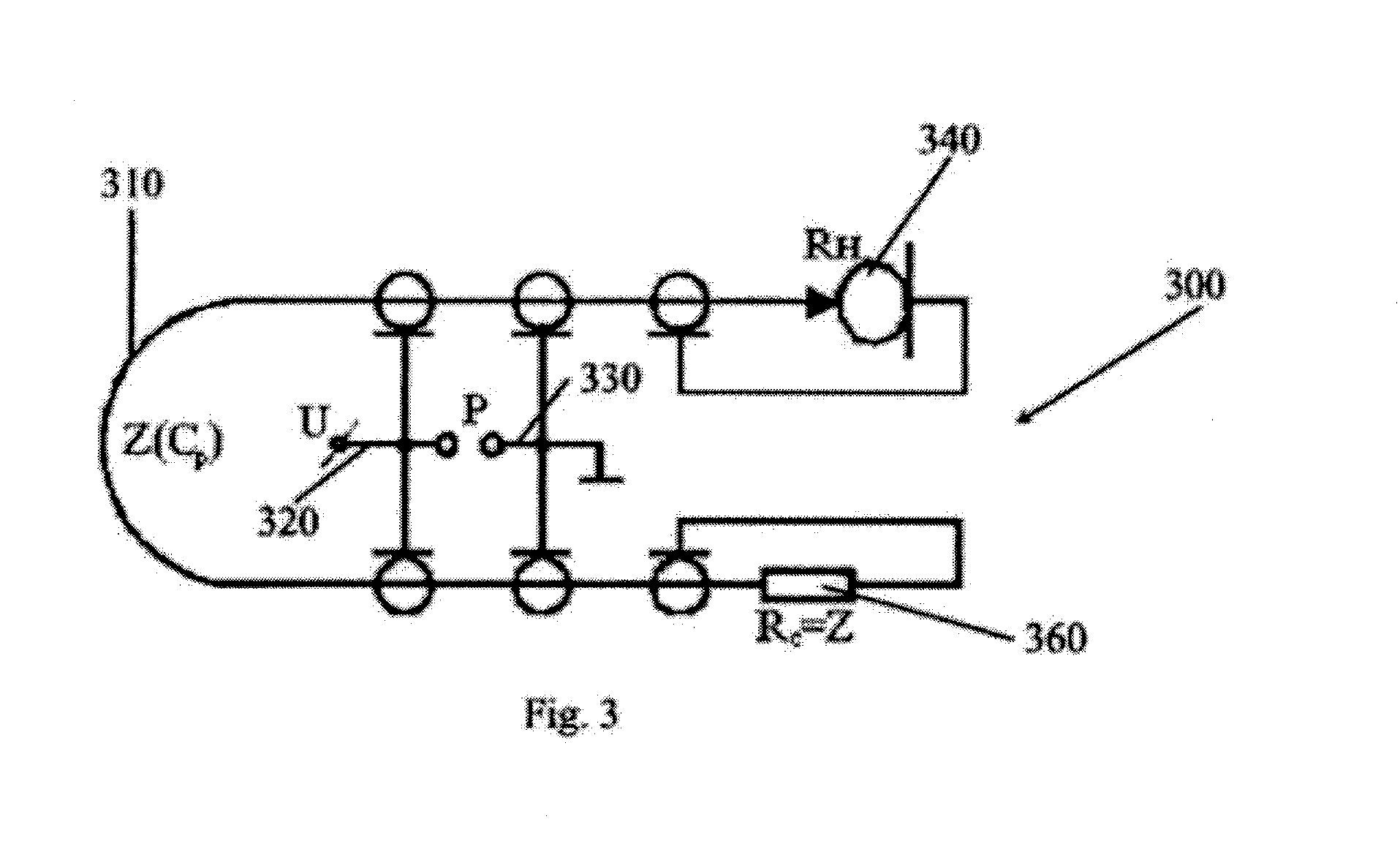

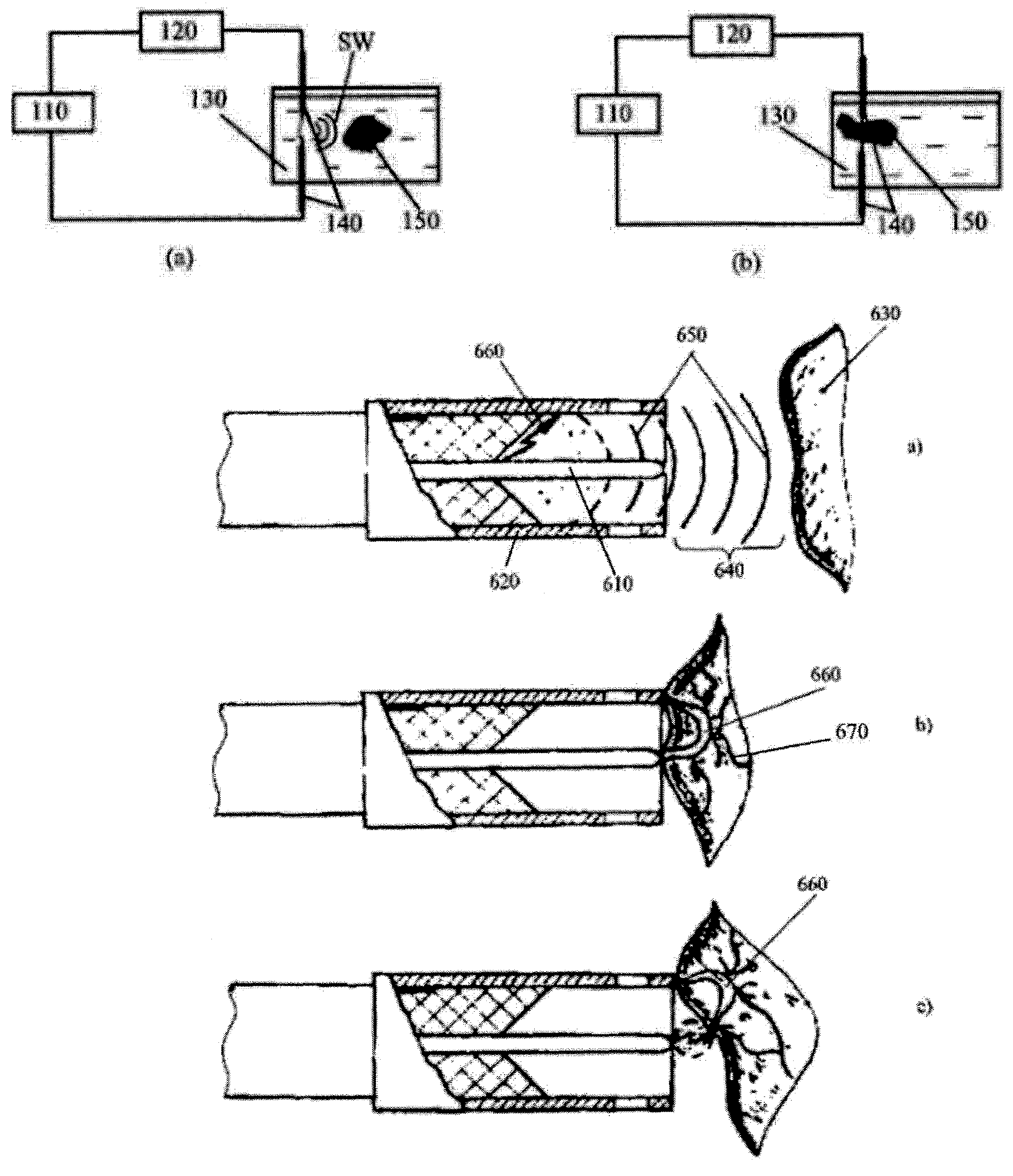

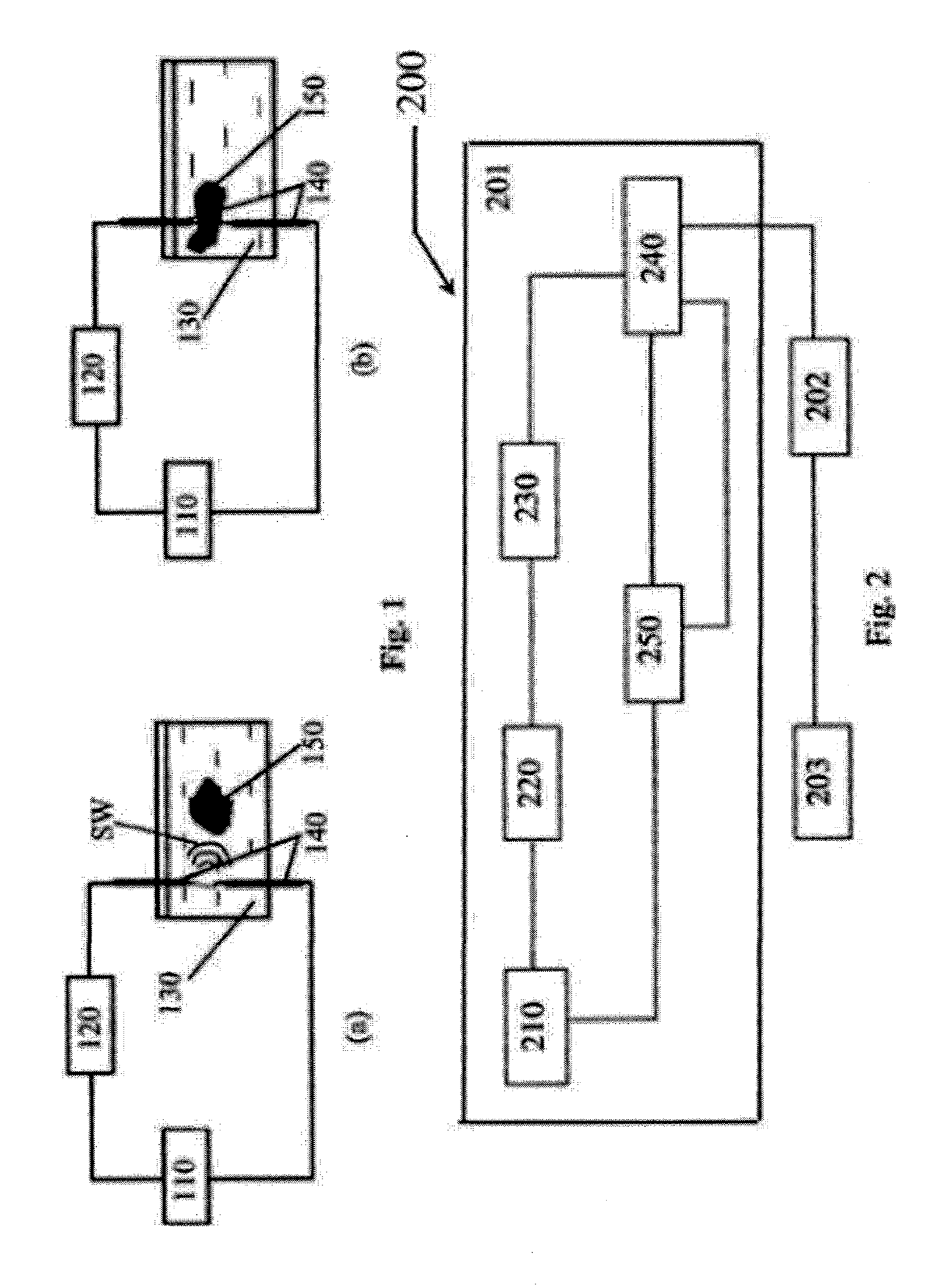

Method for intracorporeal lithotripsy fragmentation and apparatus for its implementation

InactiveUS20030176873A1Reduce probability for traumatizingReliable containmentSurgical instruments for heatingIntracorporeal lithotripsyEngineering

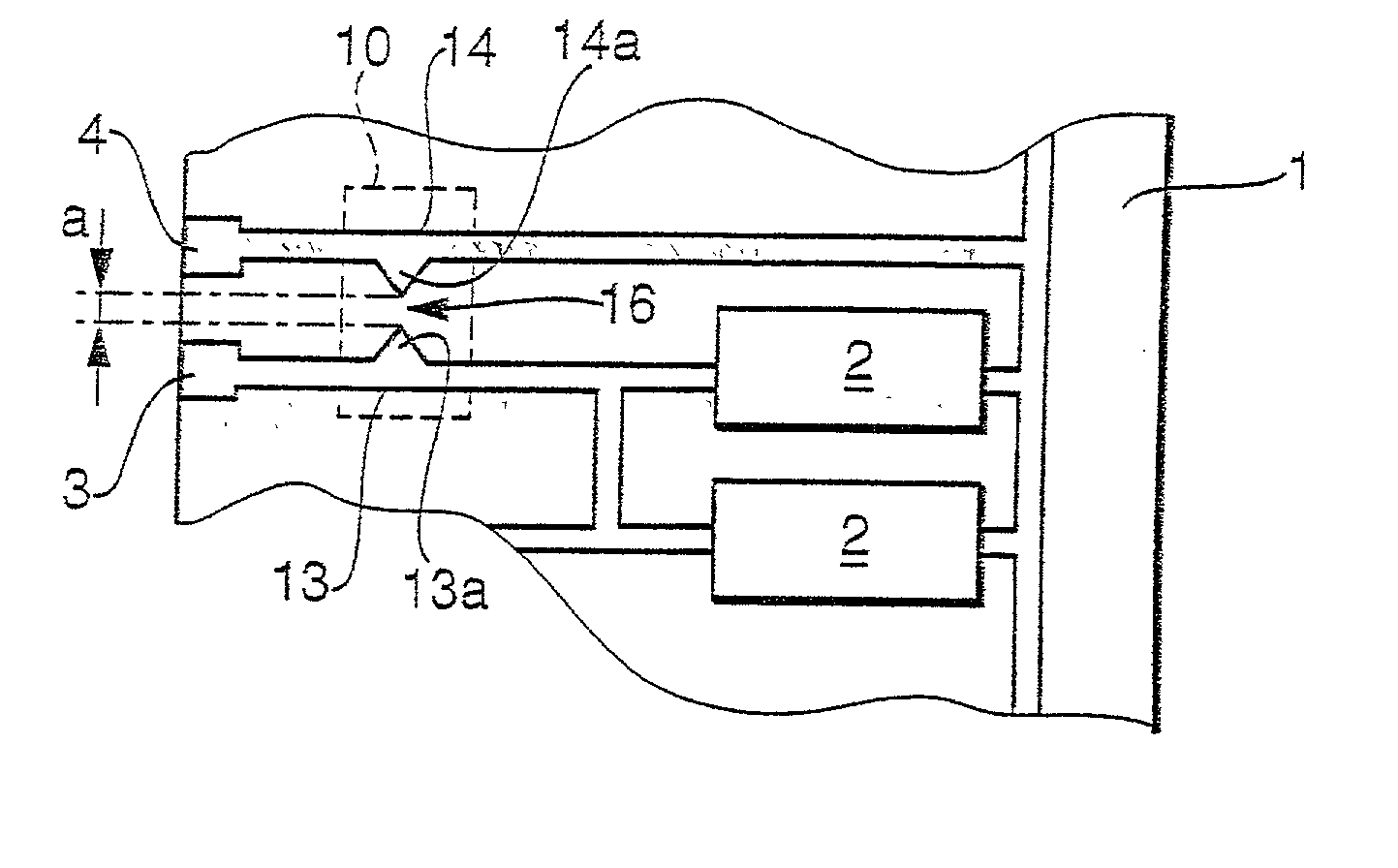

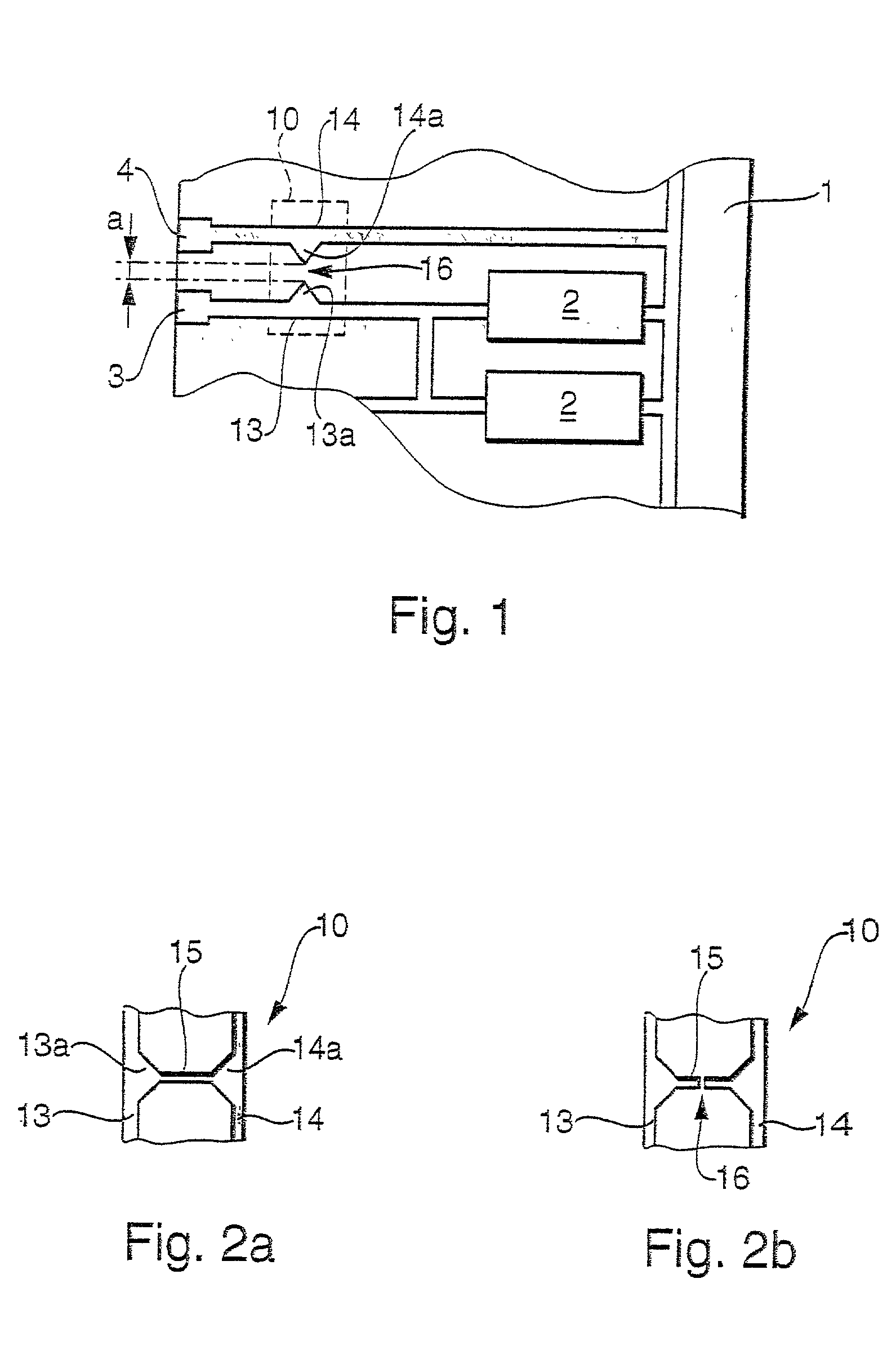

Electro-impulse intracorporeal lithotripsy comprises bringing electrodes of a probe in immediate electrical contact with the calculus and supplying to the electrodes of very short high voltage impulses capable to ignite electrical spark discharge and establish a discharge channel within the bulk of the calculus. The channel goes through the calculus and creates tensile stresses, destroying the calculus.

Owner:LITHOTECH MEDICAL

Method for intracorporeal lithotripsy fragmentation and apparatus for its implementation

InactiveUS7087061B2Reduce probabilityReliably graspSurgical instruments for heatingIntracorporeal lithotripsyEngineering

Electro-impulse intracorporeal lithotripsy comprises bringing electrodes of a probe in immediate electrical contact with the calculus and supplying to the electrodes of very short high voltage impulses capable to ignite electrical spark discharge and establish a discharge channel within the bulk of the calculus. The channel goes through the calculus and creates tensile stresses, destroying the calculus.

Owner:LITHOTECH MEDICAL

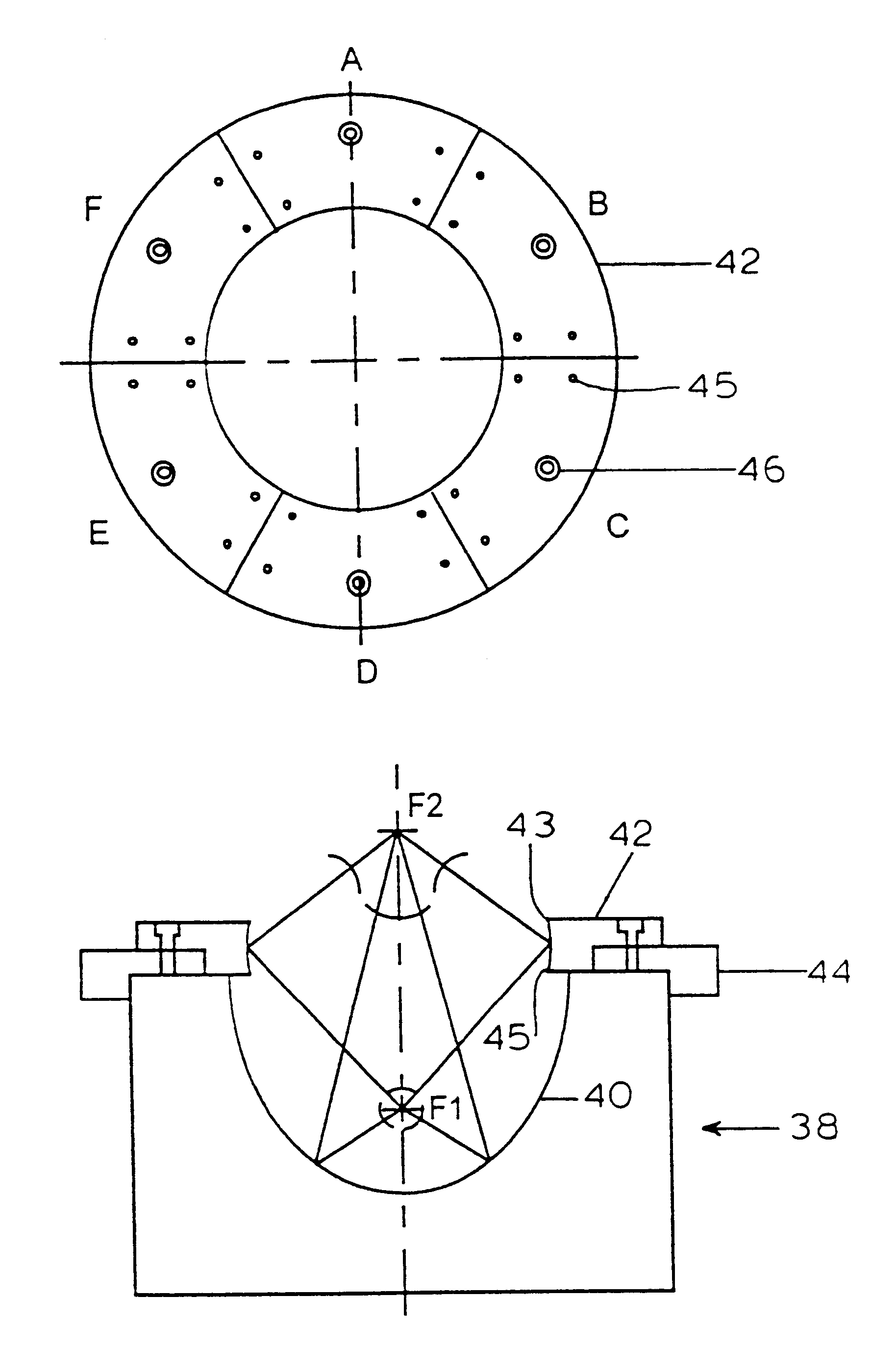

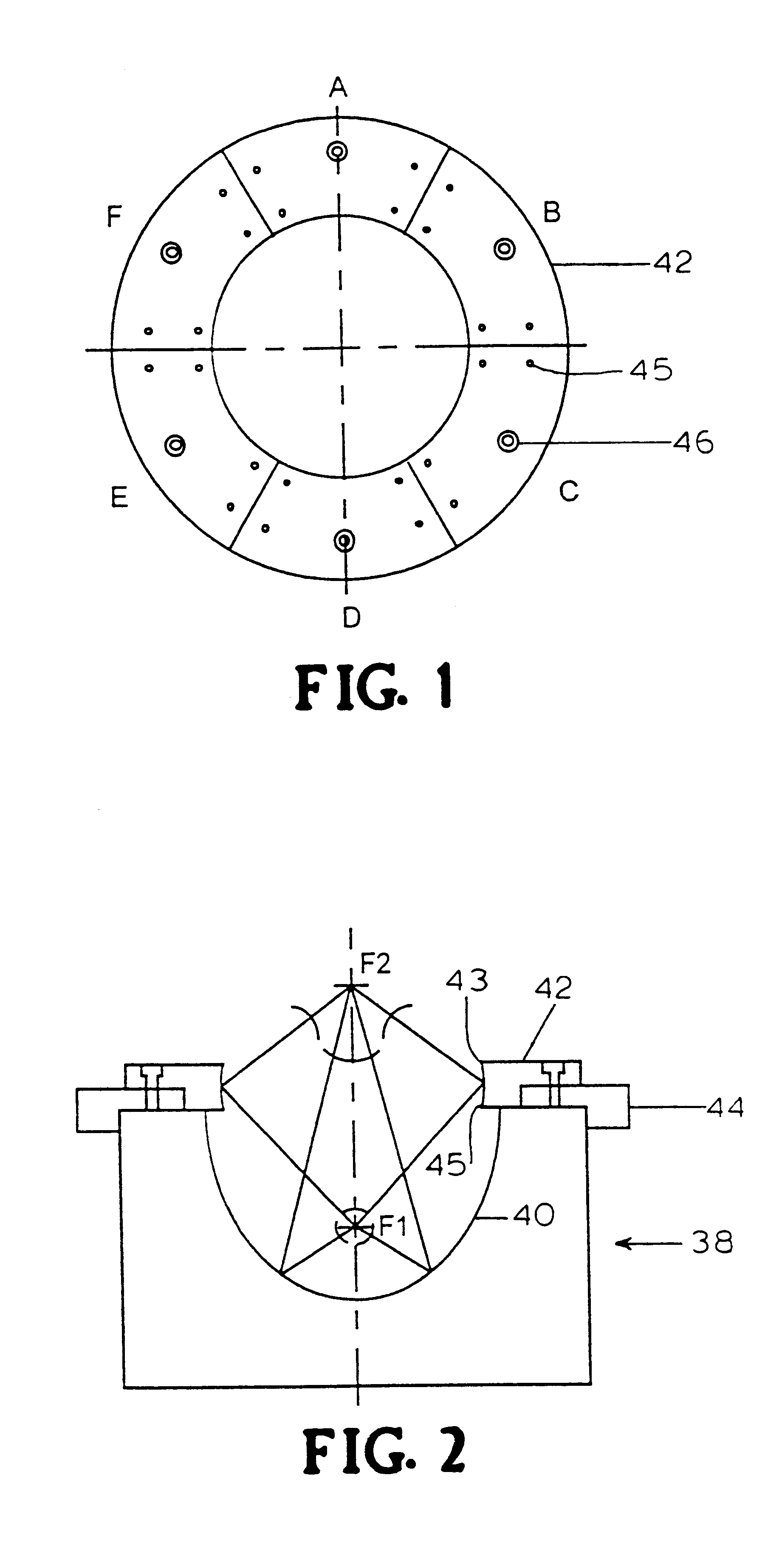

Apparatus and method for macromolecule delivery into living cells

InactiveUS6298264B1Improve efficiencyEasily damagedElectrotherapySurgeryShock waveShock wave lithotripter

This invention discloses an apparatus and method for producing microcavitational activity in aqueous fluids for non-invasive macromolecule delivery into living cells. A standard electrohydraulic shock wave lithotripter is fitted with an adjustable ring reflector that shares the same foci as the standard lithotripter hemi-ellipsoidal reflector. A small portion of the spherical shock wave, generated by the spark discharge at the first focus (F1), is reflected and diffracted by the ring reflector, resulting in a weak preceding shock wave approximately 8.5 mus in front of the lithotripter shock wave reflected and diffracted by the hemi-ellipsoidal reflector. The peak negative pressure of the preceding weak shock wave or pulse at F2 can be adjusted from -0.96 to -1.91 MPa, using an output voltage of 25 kV. Living cells are exposed to the preceding shock wave and the lithotripter shock wave. With optimal pulse combination, the maximum efficiency of shock wave-induced cell membrane permeabilization can be enhanced substantially (up to 91%), by applying to the living cells a low dosage of, for example, 50 shocks. In addition, injury to mouse lymphoid cells is significantly increased at high dosage (up to 50% with shock number >100). The invention thus enables shock wave-inertial microbubble interaction to be used selectively to either enhance the efficiency of shock wave-mediated macromolecule delivery at low dosage or tissue destruction at high dosage.

Owner:DUKE UNIV

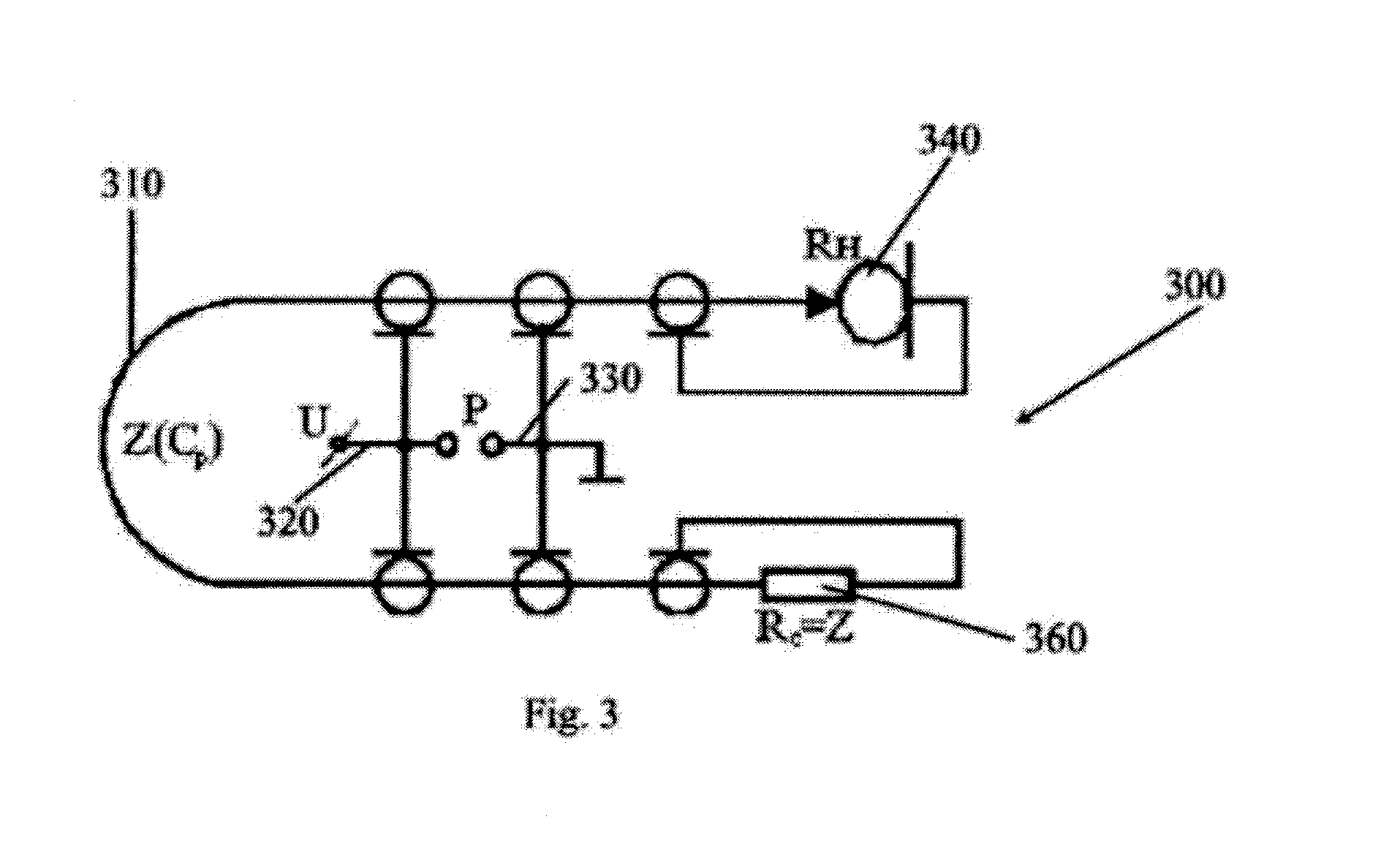

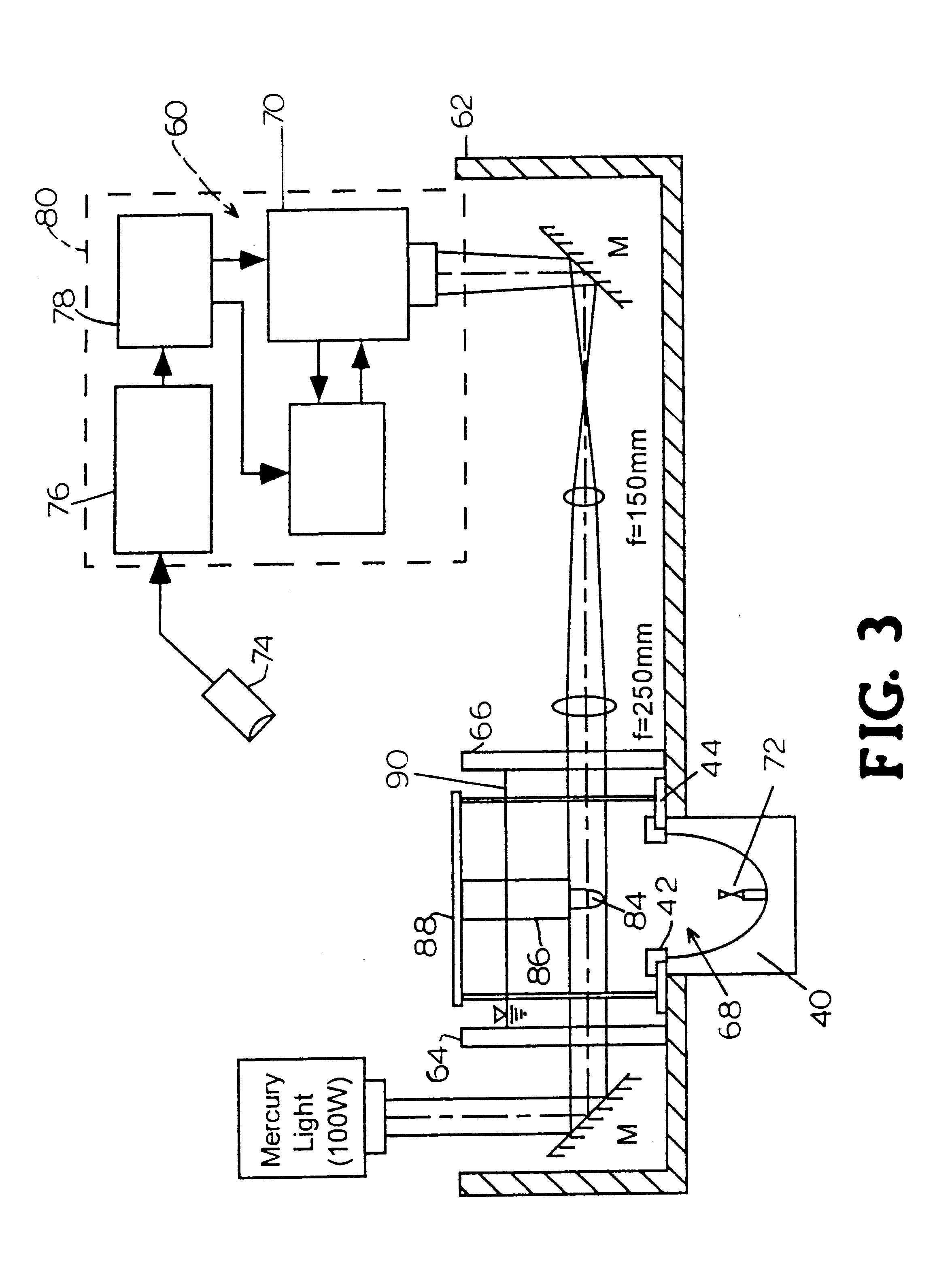

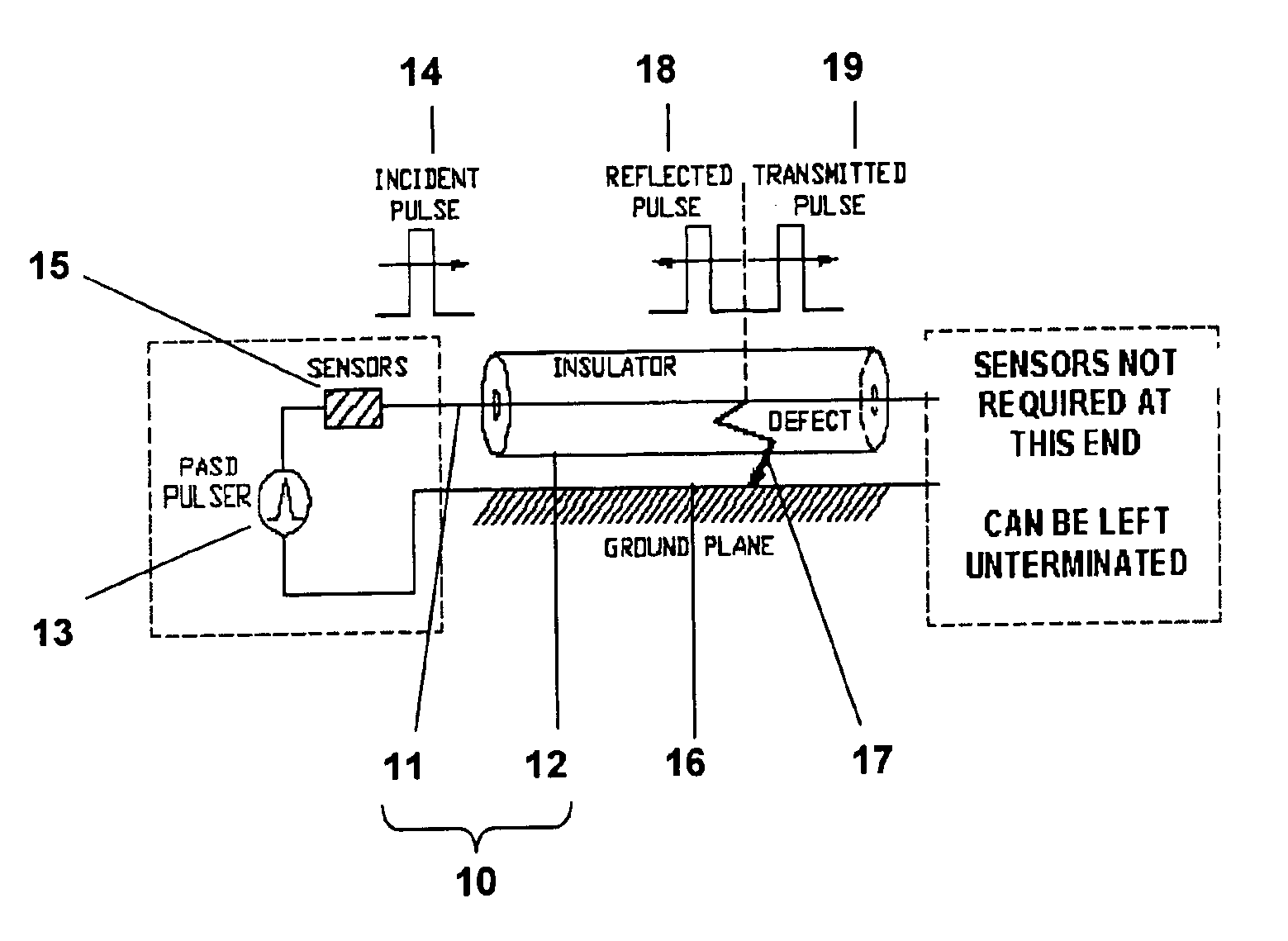

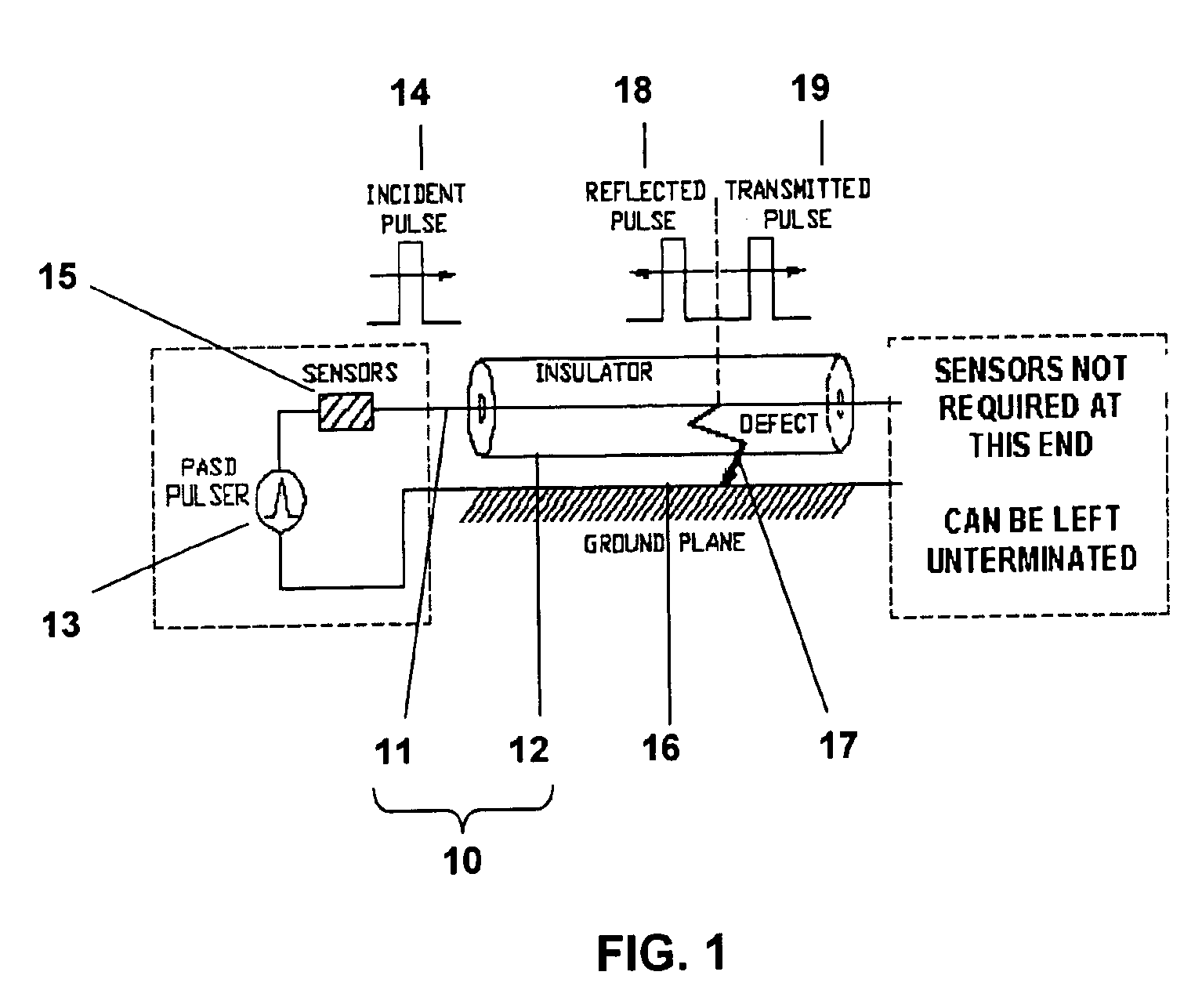

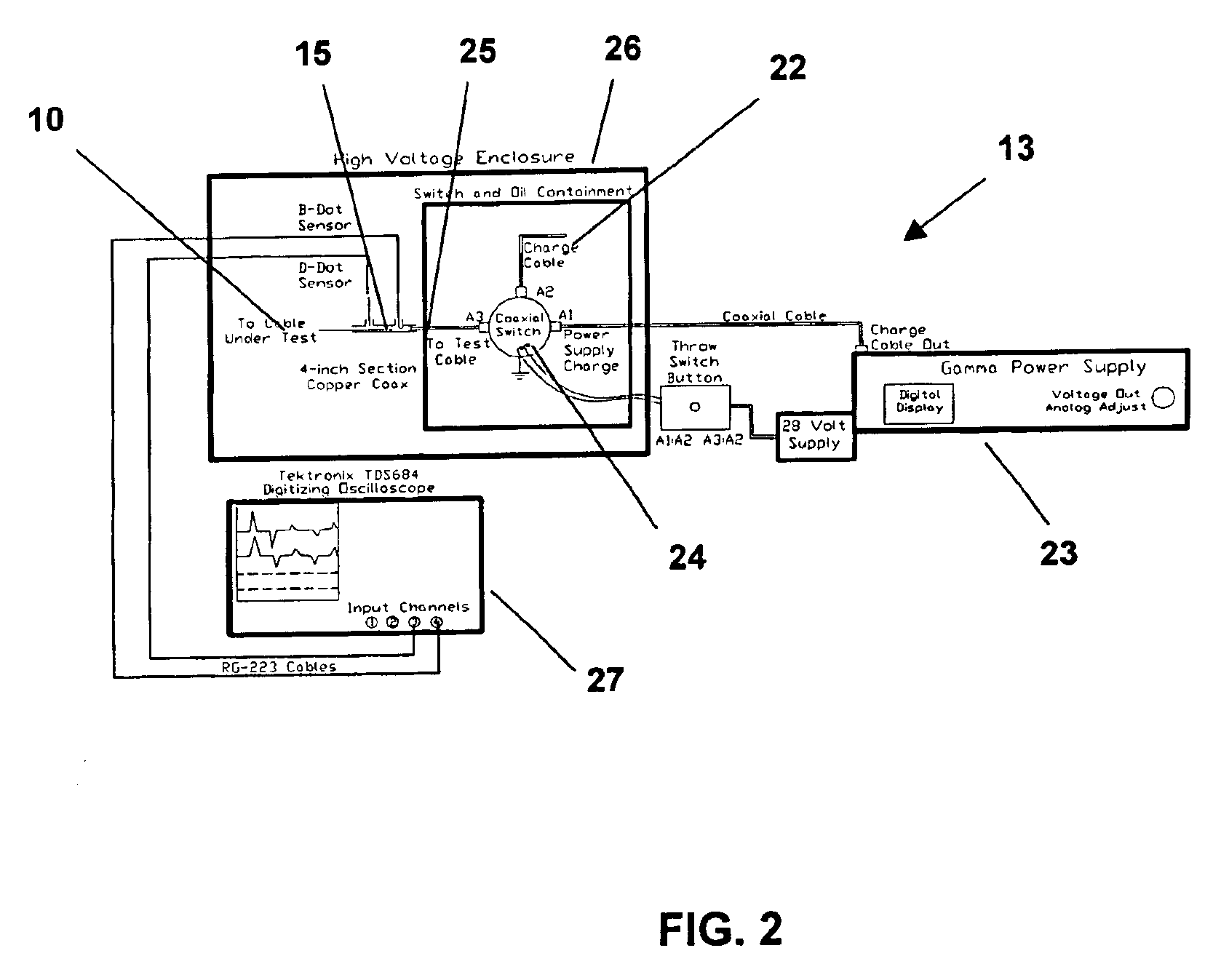

Method and apparatus for electrical cable testing by pulse-arrested spark discharge

InactiveUS6853196B1Enhance and inhibit onsetLower breakdown voltageResistance/reactance/impedenceFault location by pulse reflection methodsElectricityNuclear power

A method for electrical cable testing by Pulse-Arrested Spark Discharge (PASD) uses the cable response to a short-duration high-voltage incident pulse to determine the location of an electrical breakdown that occurs at a defect site in the cable. The apparatus for cable testing by PASD includes a pulser for generating the short-duration high-voltage incident pulse, at least one diagnostic sensor to detect the incident pulse and the breakdown-induced reflected and / or transmitted pulses propagating from the electrical breakdown at the defect site, and a transient recorder to record the cable response. The method and apparatus are particularly useful to determine the location of defect sites in critical but inaccessible electrical cabling systems in aging aircraft, ships, nuclear power plants, and industrial complexes.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

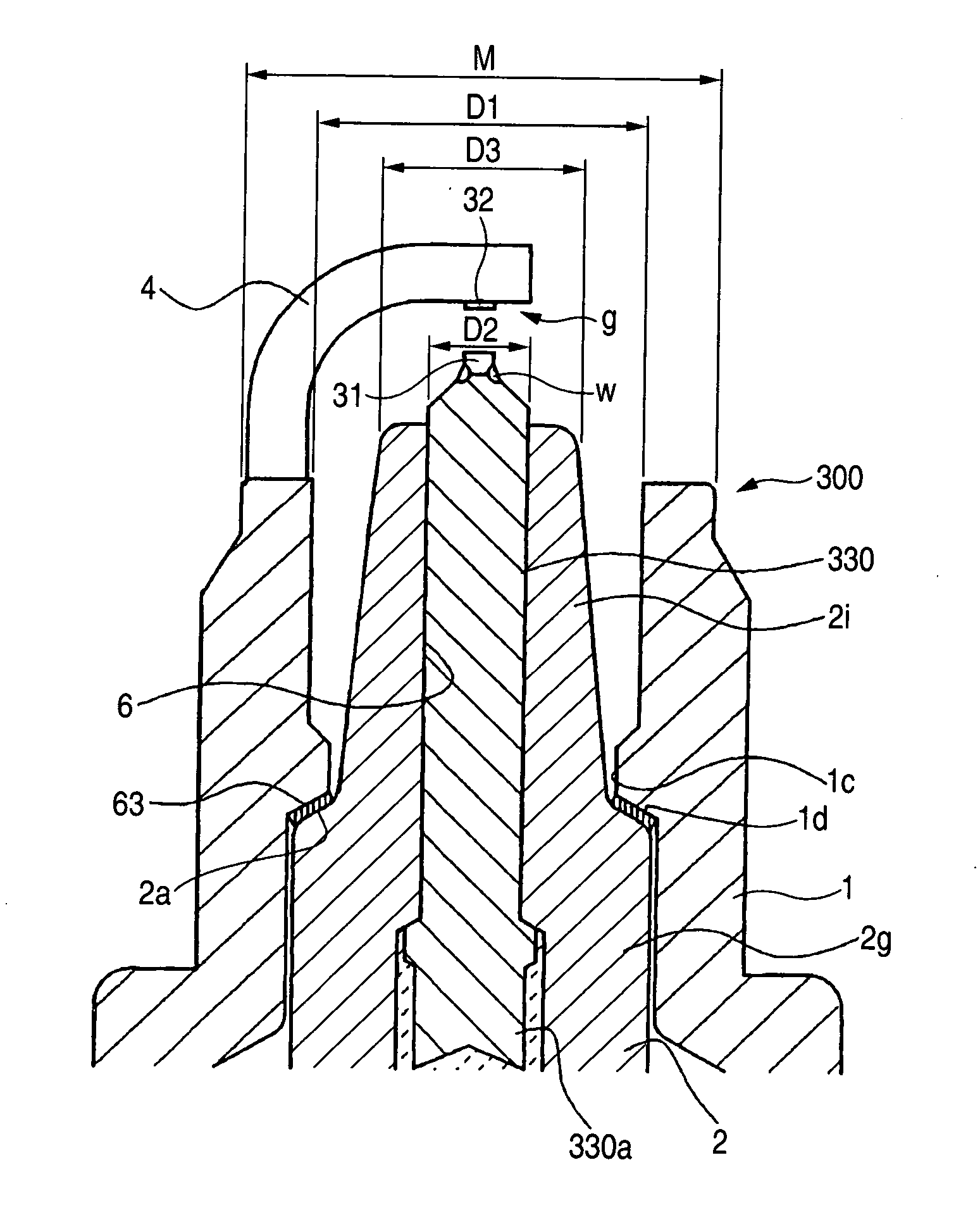

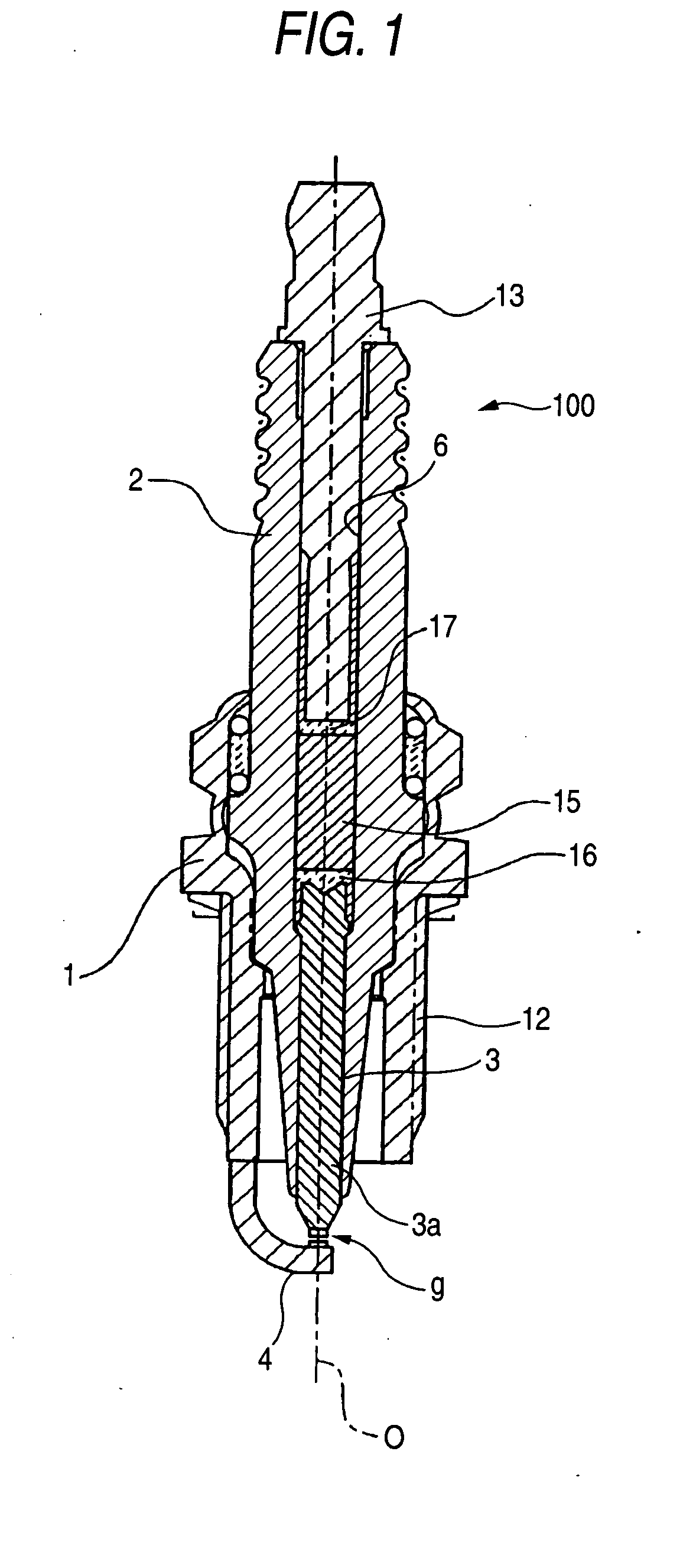

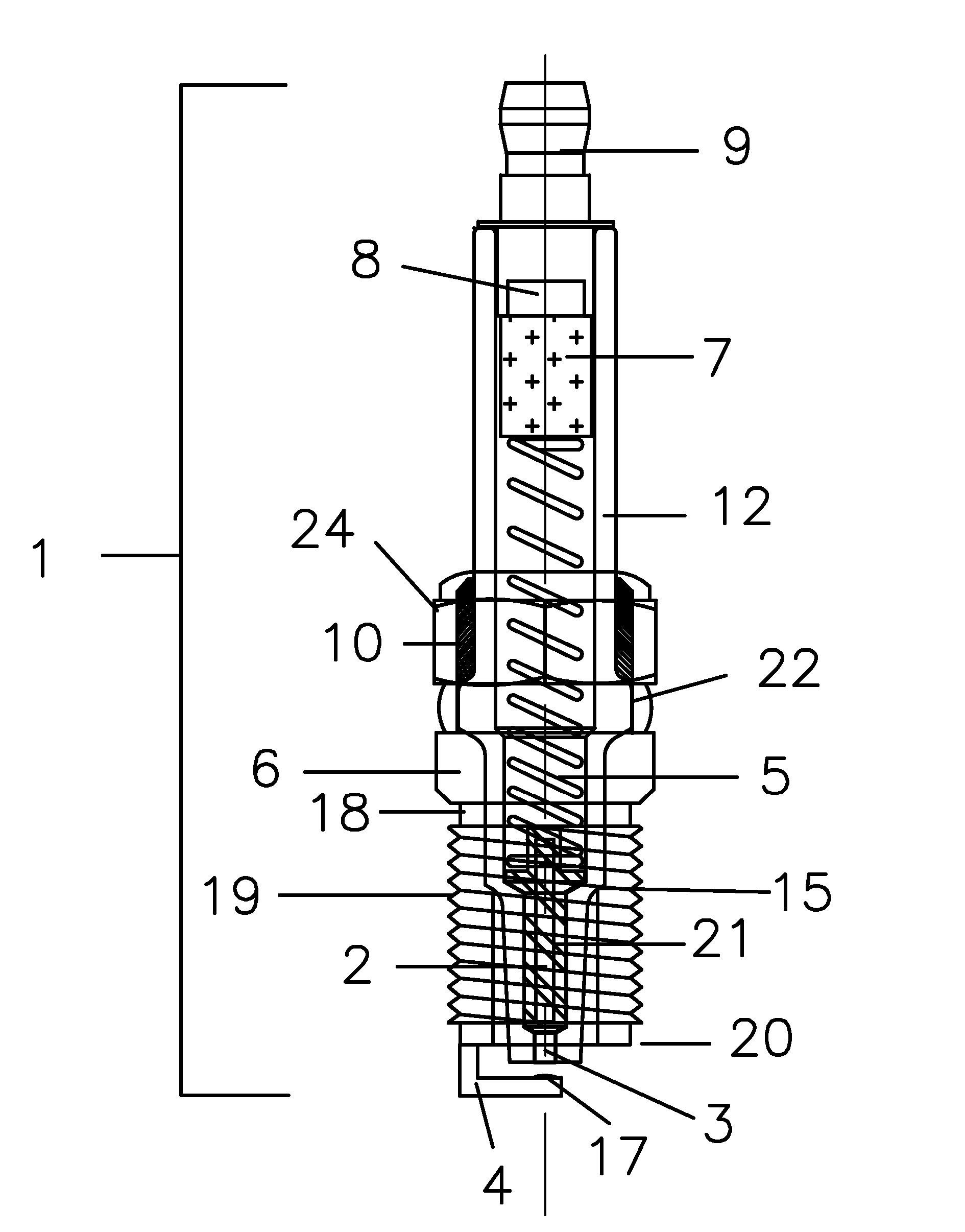

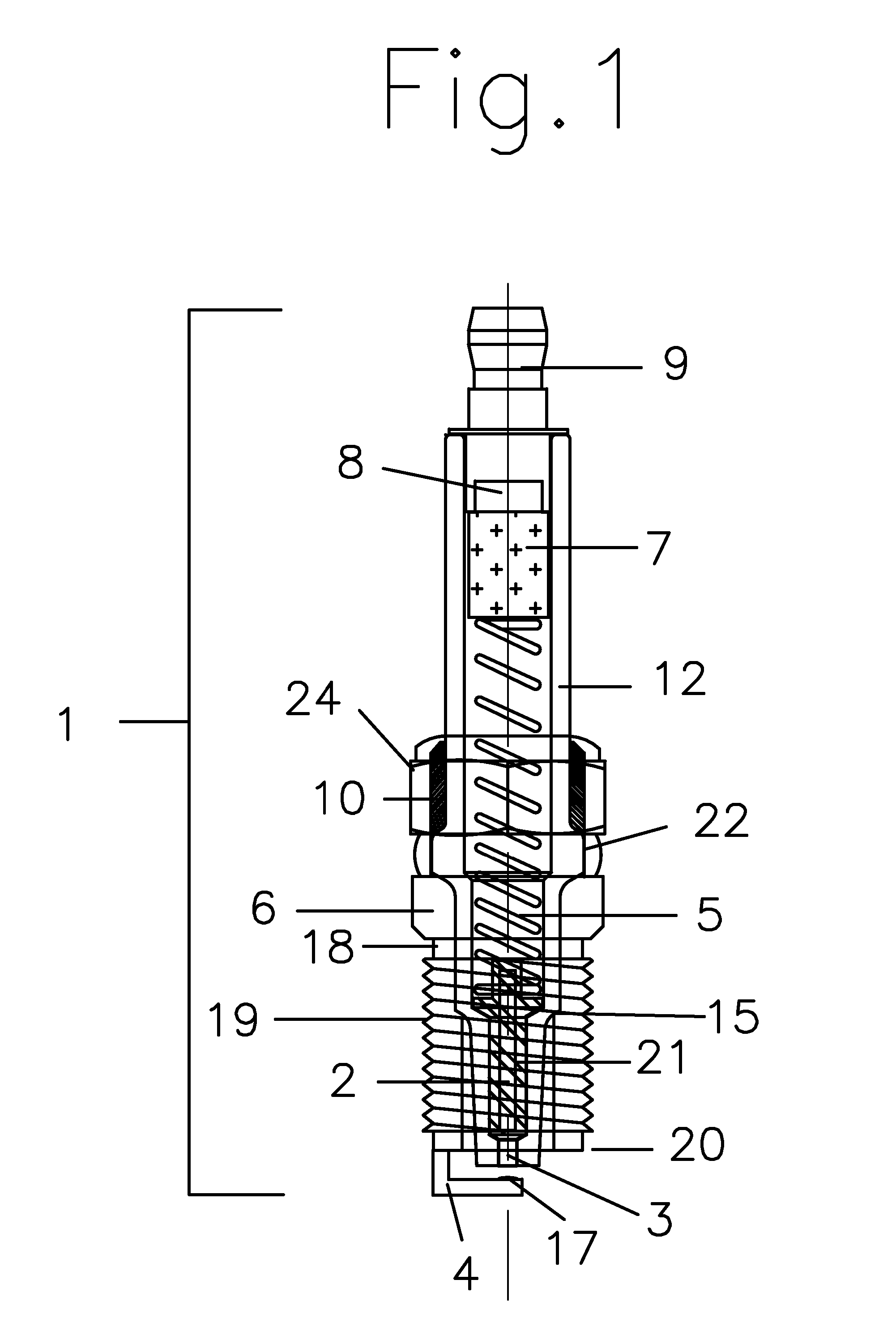

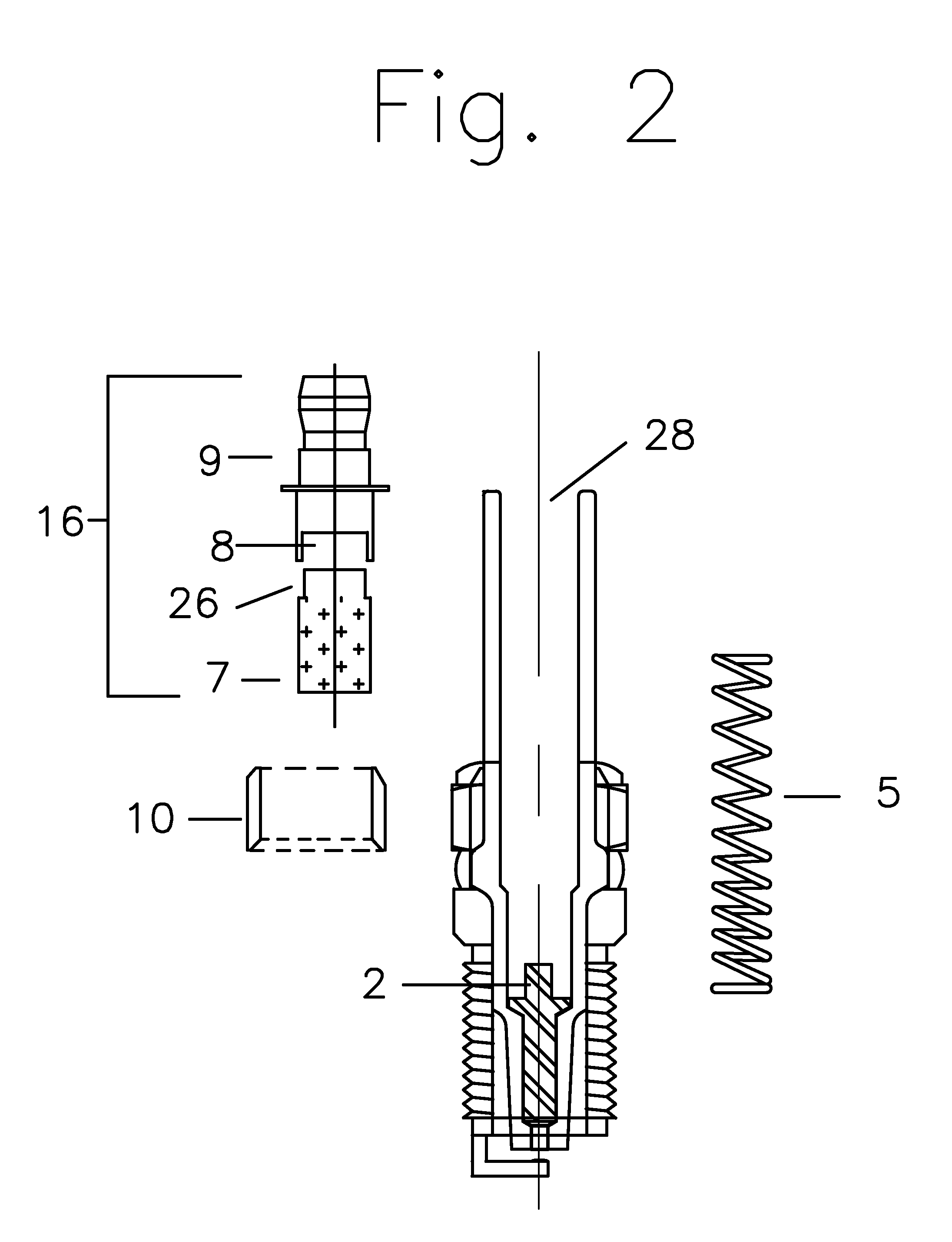

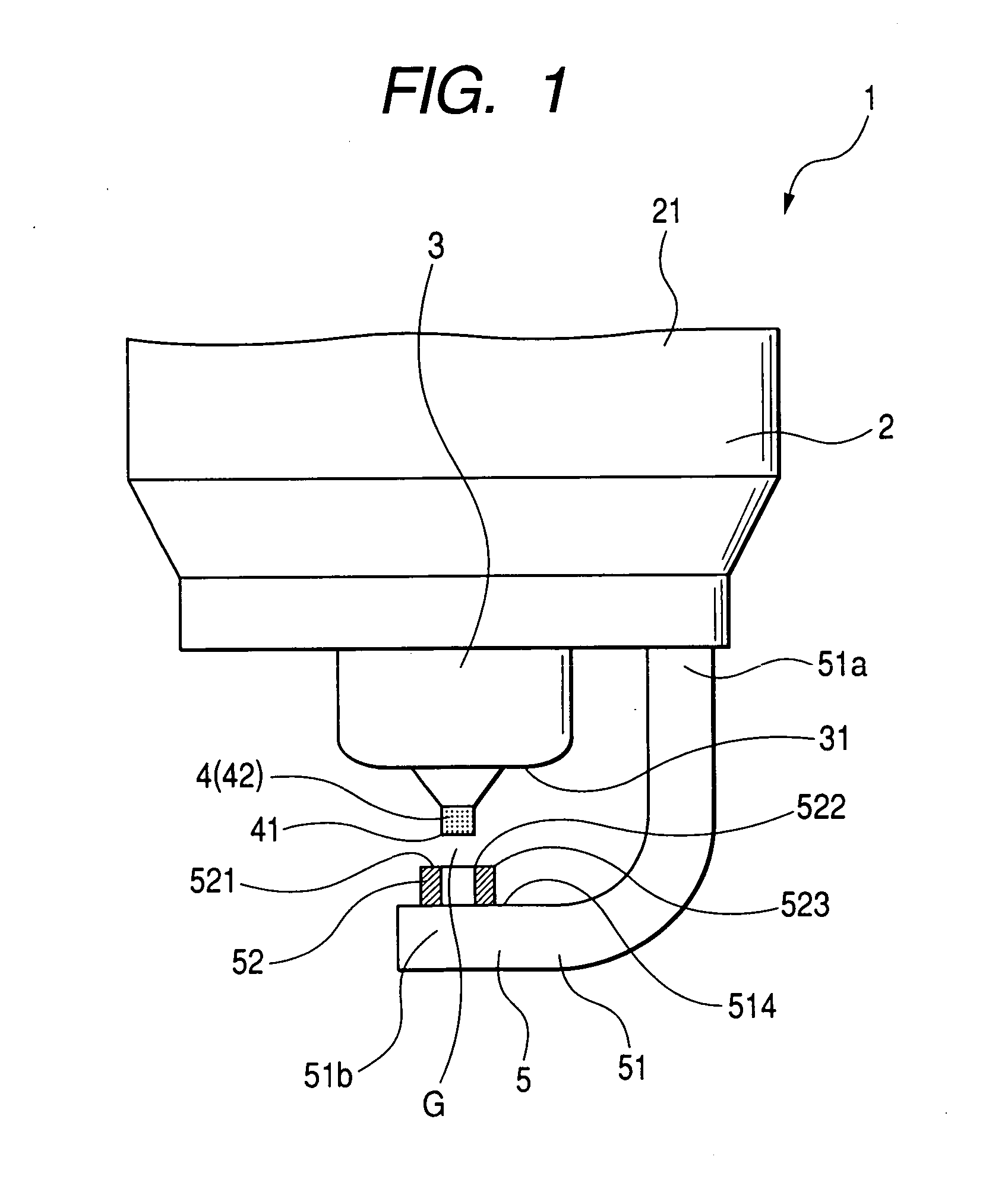

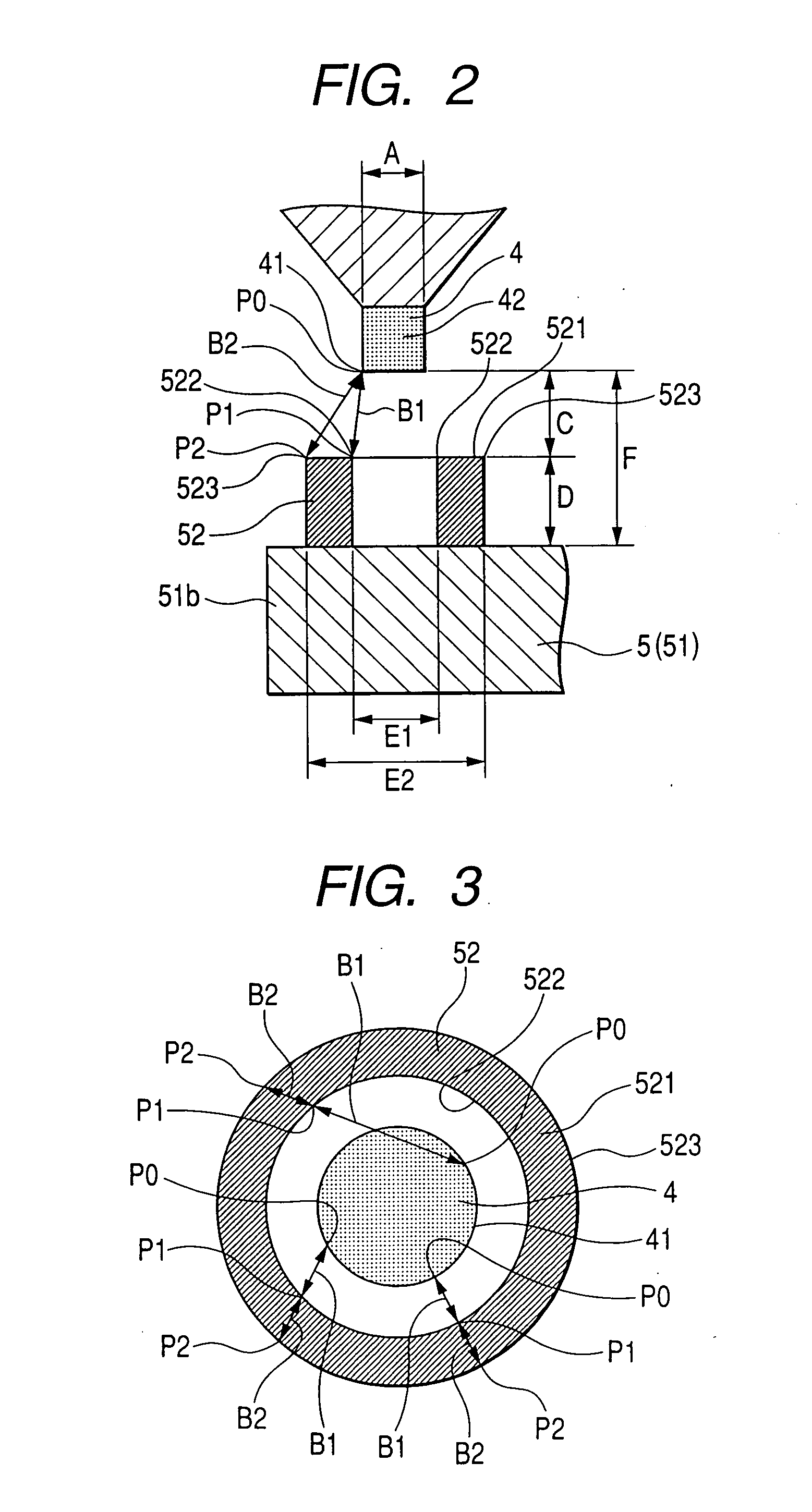

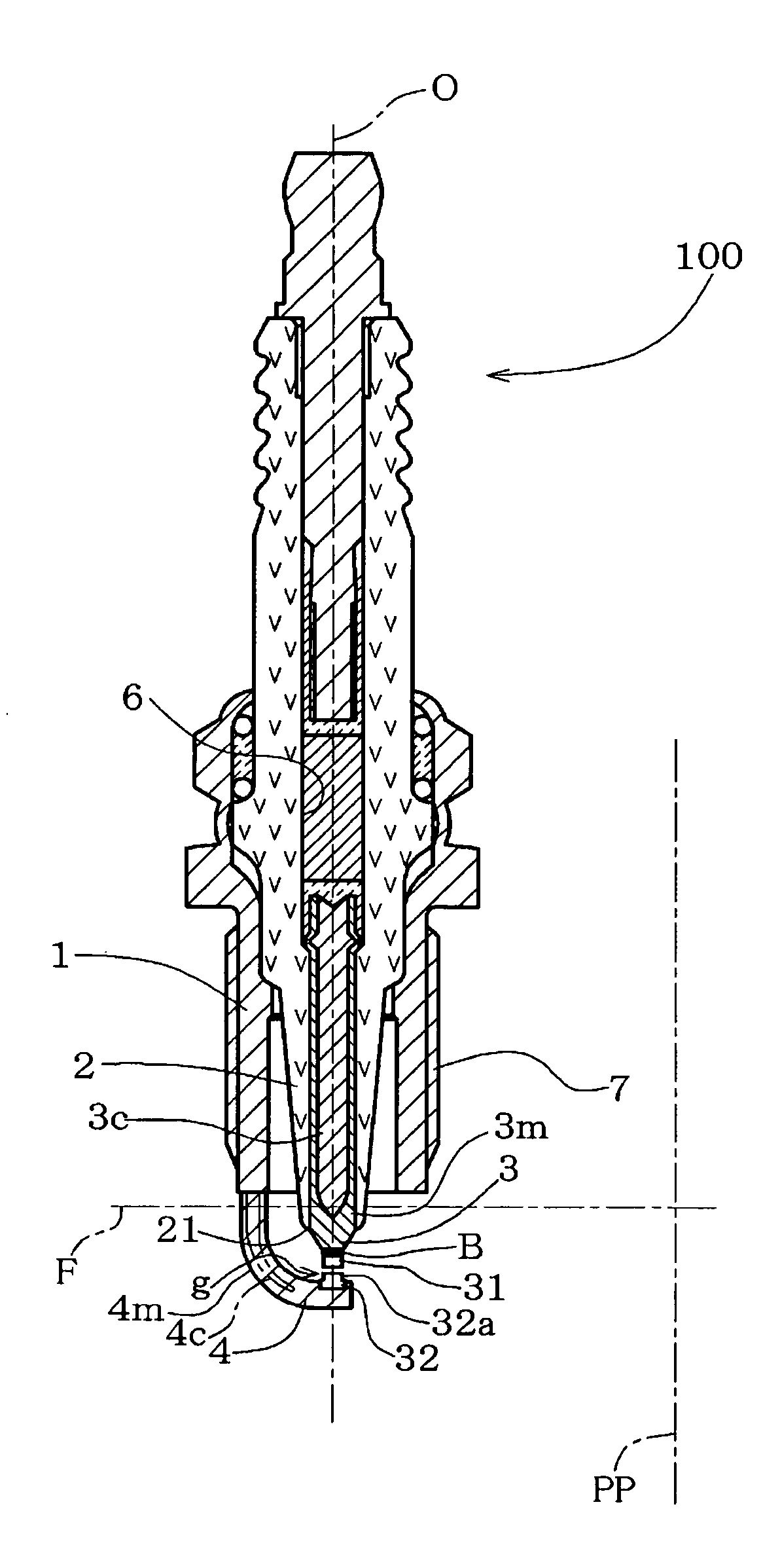

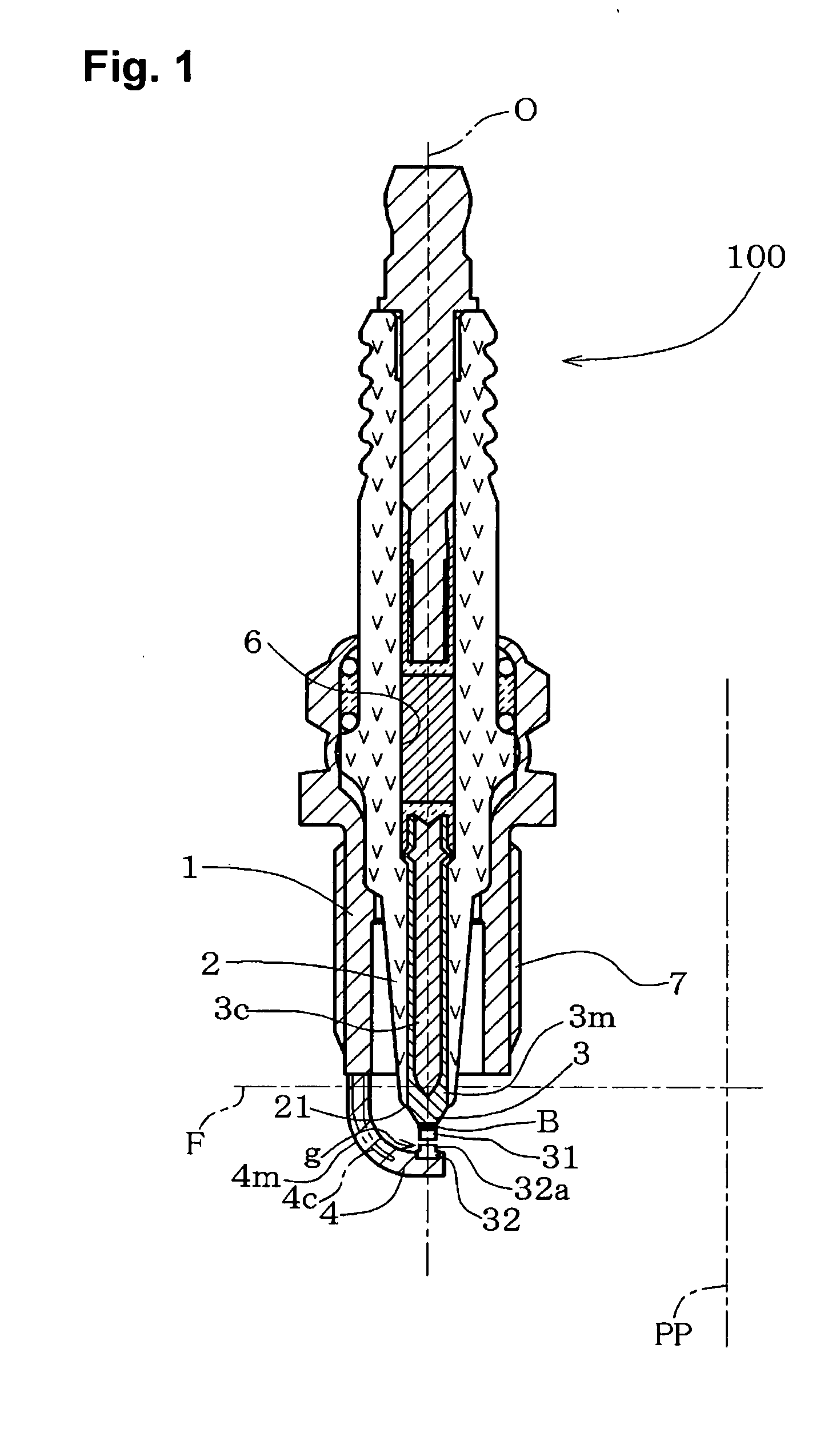

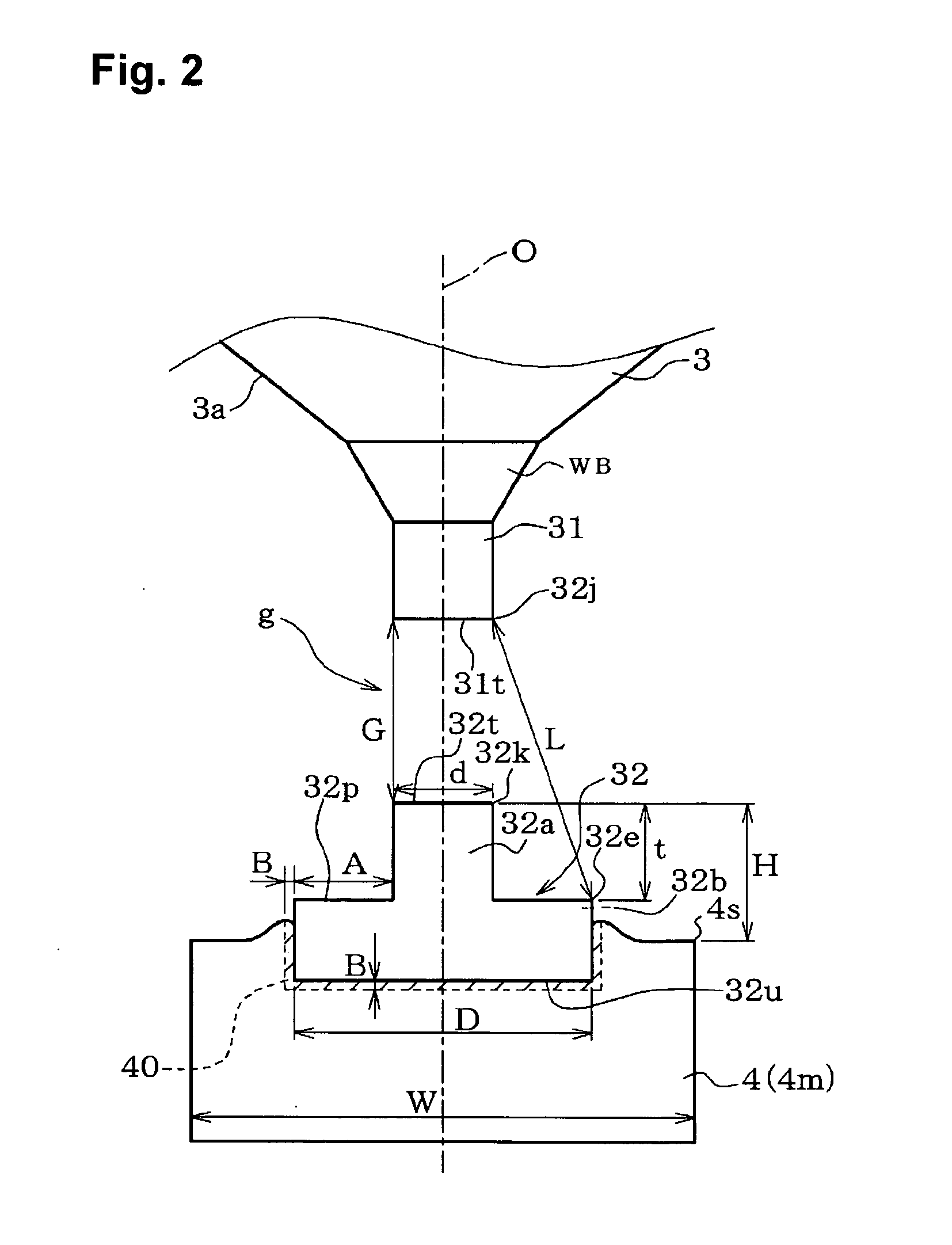

Spark plug and method for manufacturing the spark plug

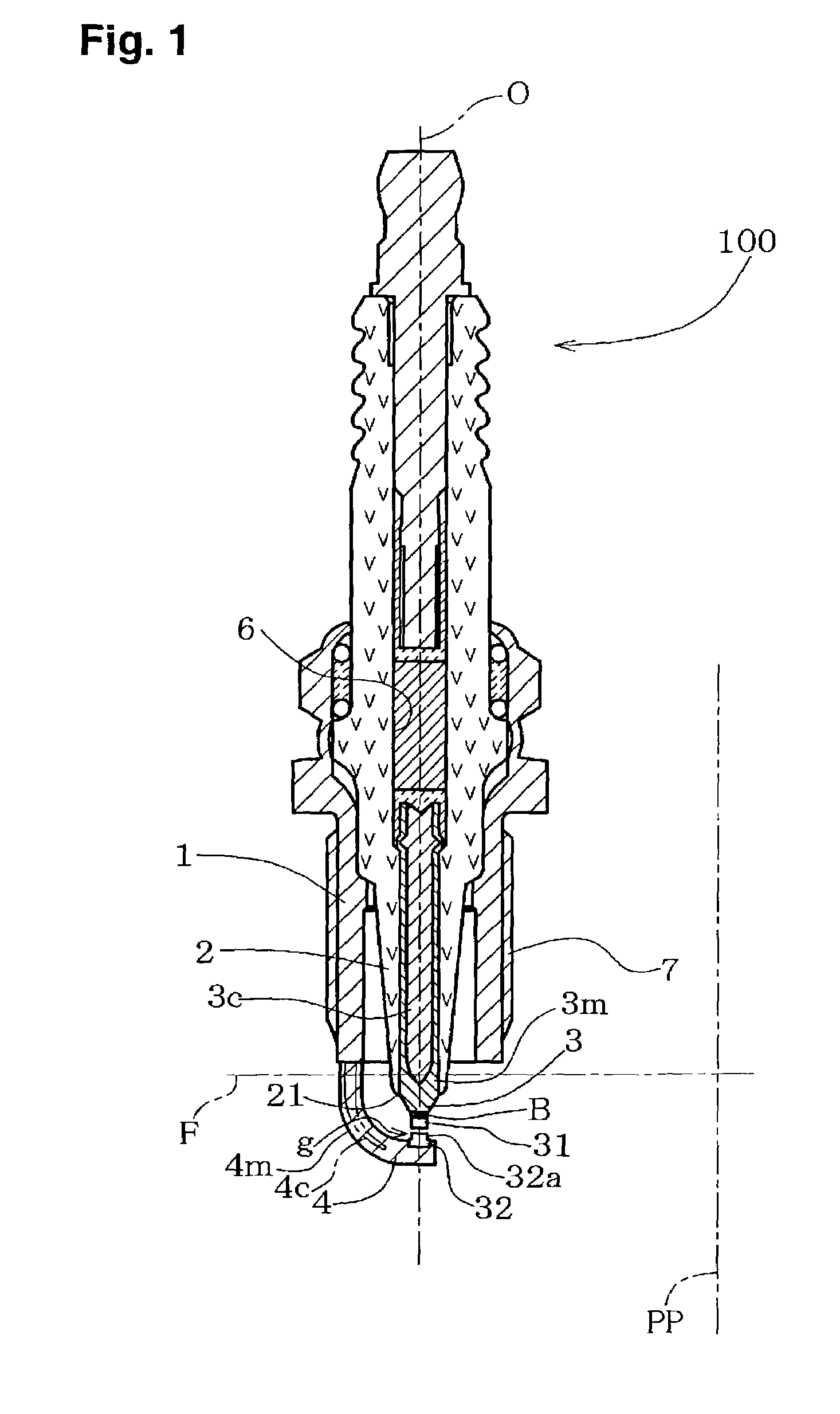

InactiveUS7084558B2OptimizationJoining process can be facilitatedSpark gapsSparking plugs manufactureIn planeAlloy

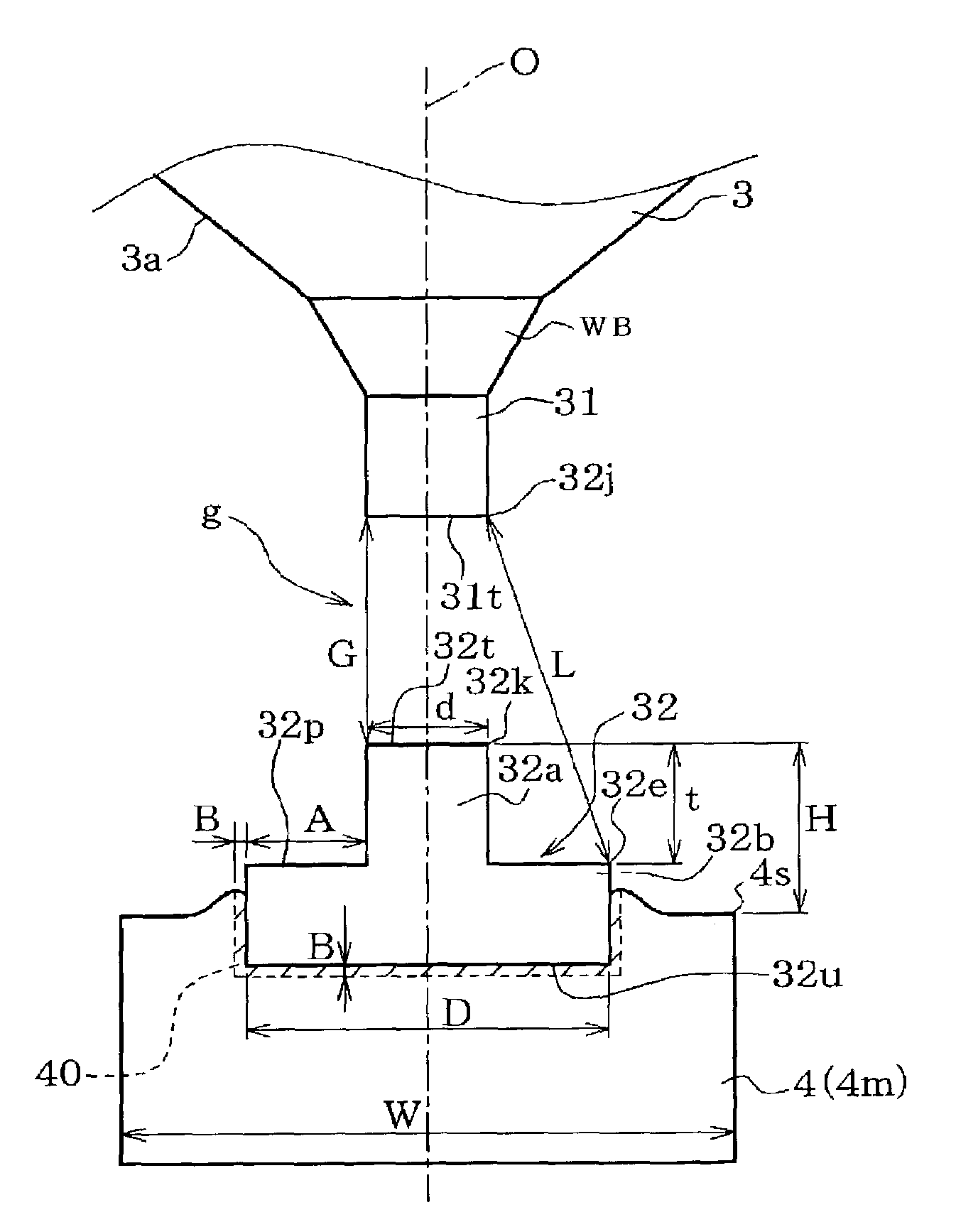

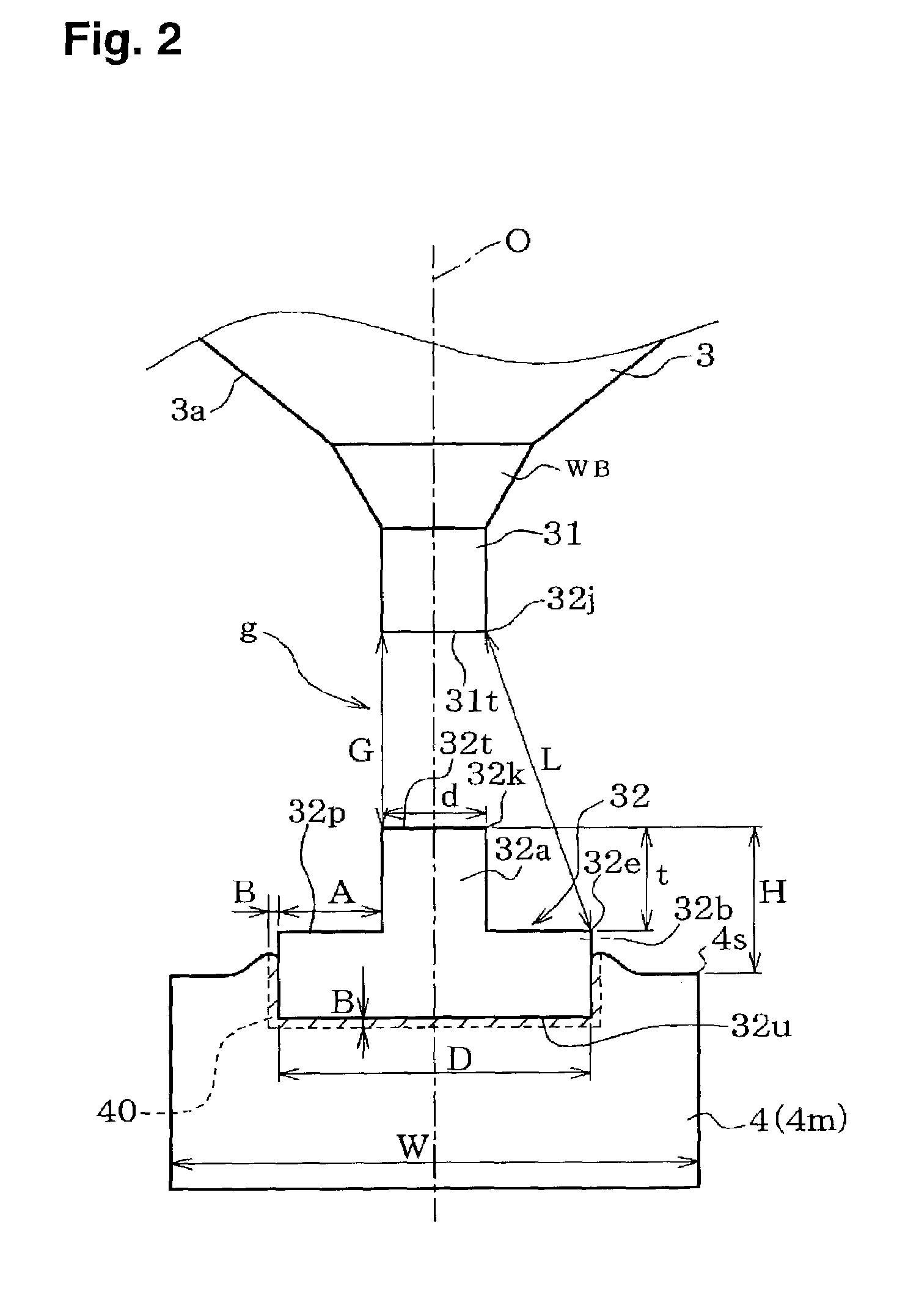

A ground-electrode spark portion 32 is formed from a noble metal which contains Pt as a main component, and is joined to a main metal portion of the ground electrode 4 via an alloy layer which has a thickness ranging from 0.5 μm to 100 μm and in which the noble metal that constitutes the ground-electrode spark portion 32 and the metal that constitutes the main metal portion of the ground electrode 4 are alloyed with each other. The ground-electrode spark portion 32 is configured such that a distal end surface 32t facing a spark discharge gap g is smaller in diameter than a bottom surface 32u joined to the ground electrode 4; and the distal end surface 32t is protrusively located beyond the side surface 4s of the ground electrode 4. When the ground-electrode spark portion 32 is viewed in plane from the distal end surface 32t, a portion of the surface of the ground-electrode spark portion 32 is viewed as a peripheral exposed-region surface 32p which is exposed on the side surface 4s of the ground electrode 4 so as to surround the distal end surface 32t.

Owner:NGK SPARK PLUG CO LTD

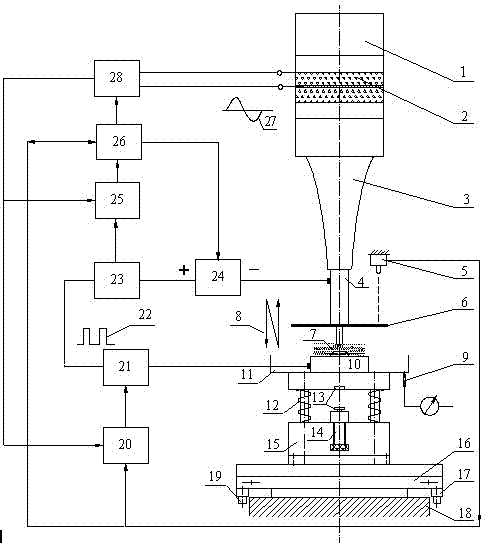

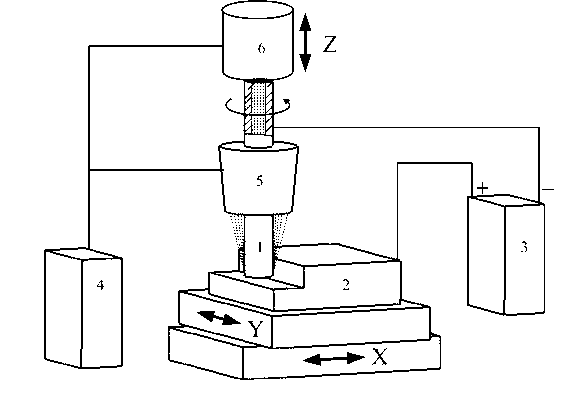

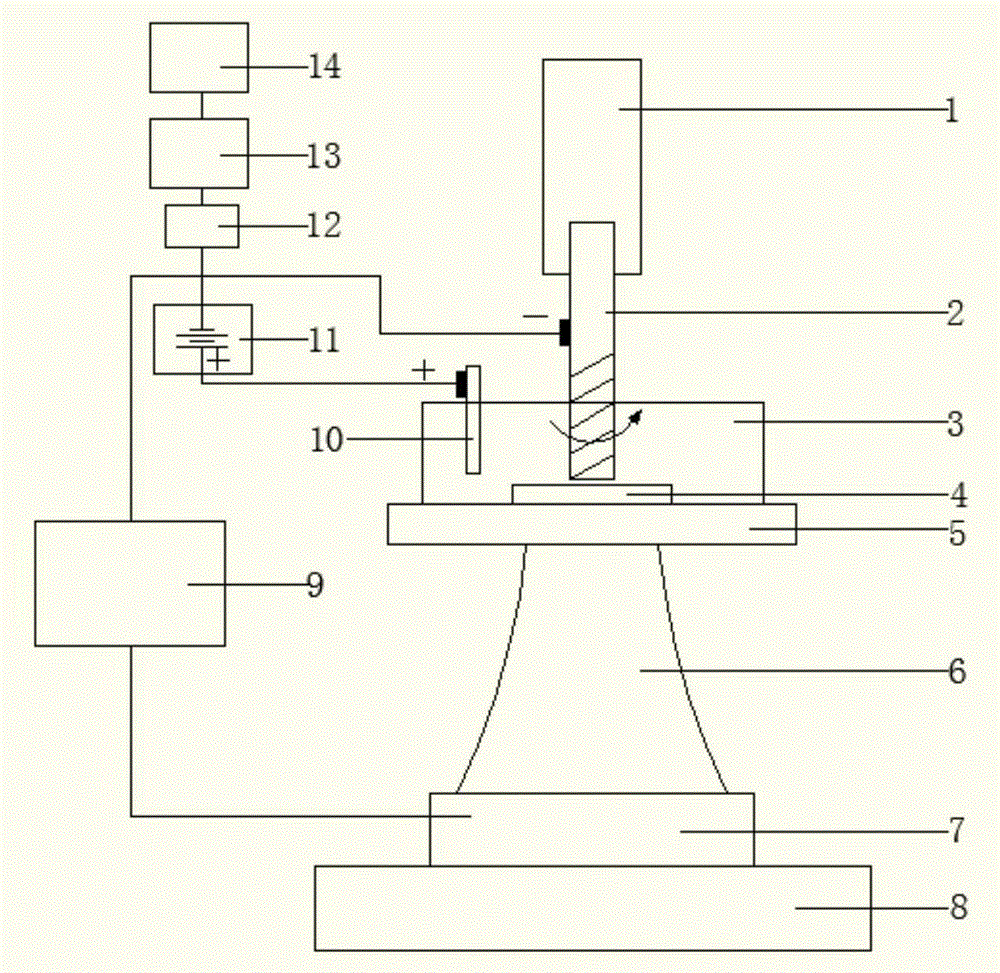

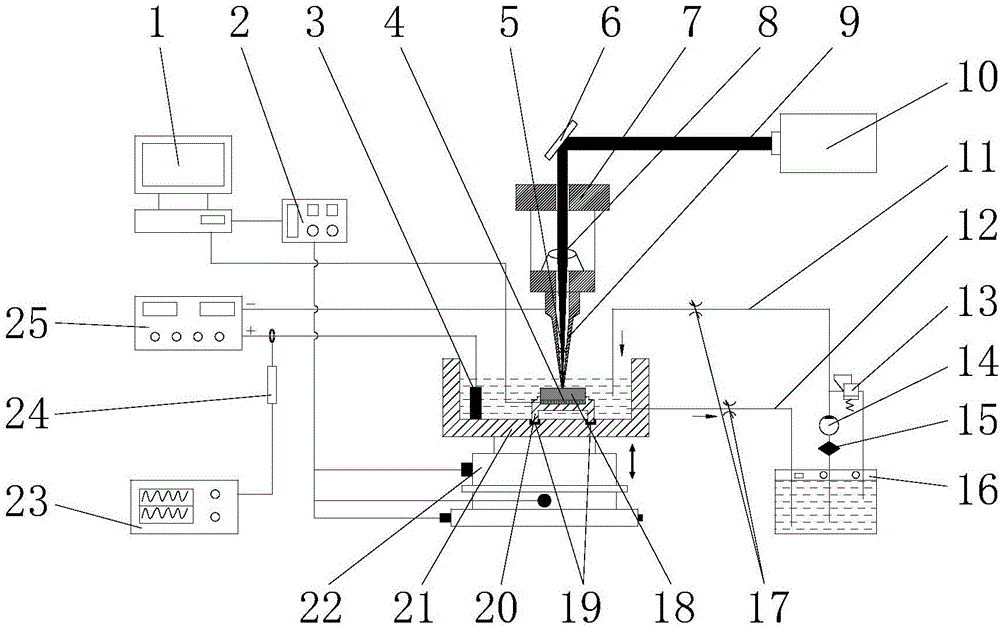

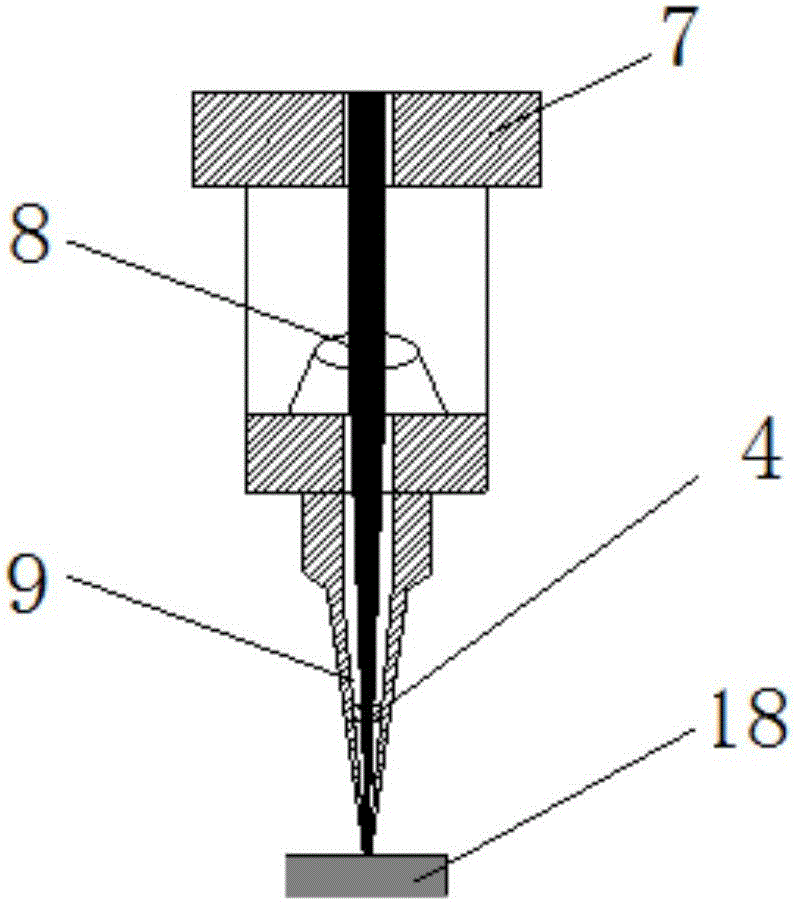

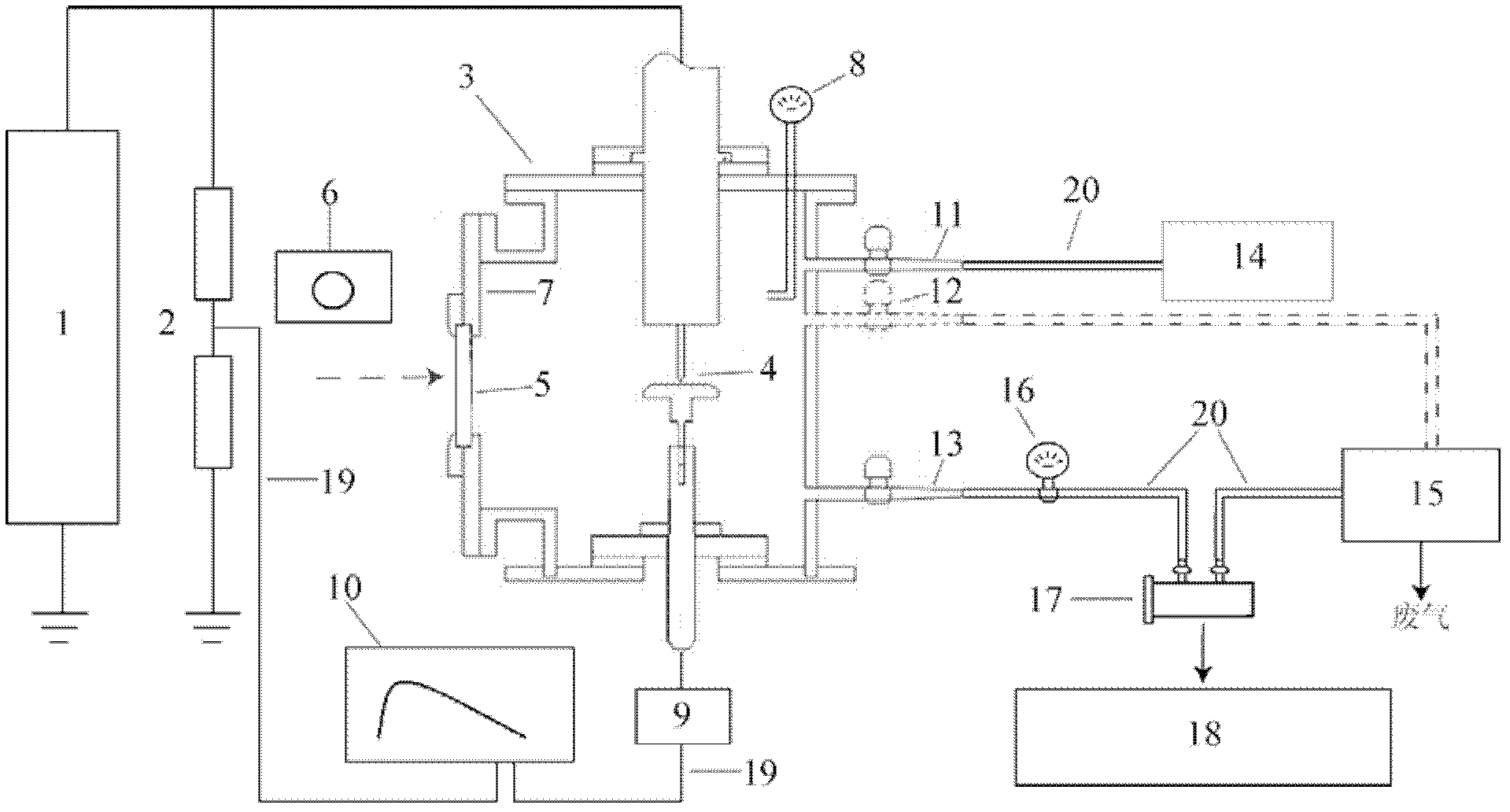

Micro and fine machining method for material difficult to machine and machining system

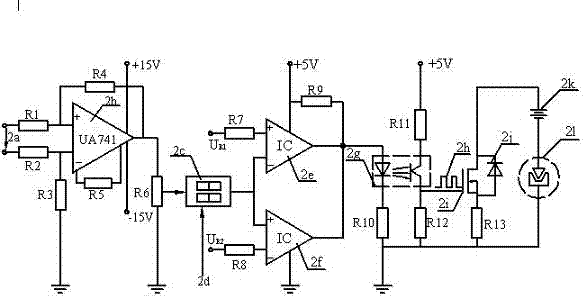

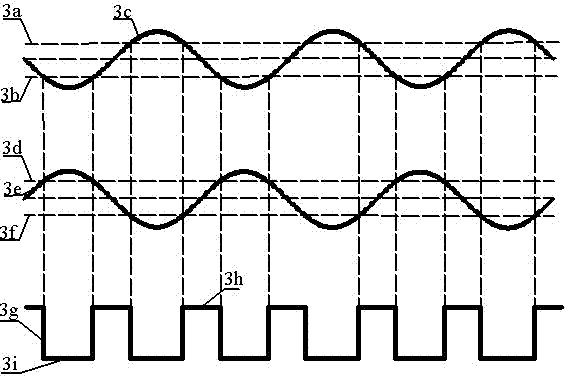

ActiveCN102513622AImprove machining clearance processImprove local processing performanceMechanical vibrations separationElectric circuitsUltrasonic cavitationElectrolysis

The invention relates to a micro and fine machining method for a material difficult to machine and a machining system, belonging to the technical field of composite, precise, micro, fine and special machining. In the method and the machining system for implementing the method disclosed by the invention, ultrasonic modulation, low-voltage discharge and electrolysis are effectively compounded, a micro and fine discharge-electrolysis function is organically combined with ultrasonic frequency vibration identical frequency and synchronization, and discharge of machining products and circular update of a working fluid are realized under the actions of ultrasonic cavitation and spark discharge explosive force, so that a gap machining process is improved effectively, localized machining performance is enhanced, machining accuracy and surface quality can be further enhanced while high machining efficiency is achieved, machining can be realized in a static fluid simultaneously, and complex pressure flow and circular supply of the working fluid to the system is not required; and during processing, contact of the workpiece with an electrode under a certain constant pressure is kept, continuous and stepless micro pressure adjustment can be performed by using a magnetic adjusting mechanism, and a precision stable-speed micro feeding system necessary for electrolytic machining and a servo feeding system necessary for electric spark machining are not required, so that the equipment research cost can be reduced greatly.

Owner:扬州健行电子科技有限公司

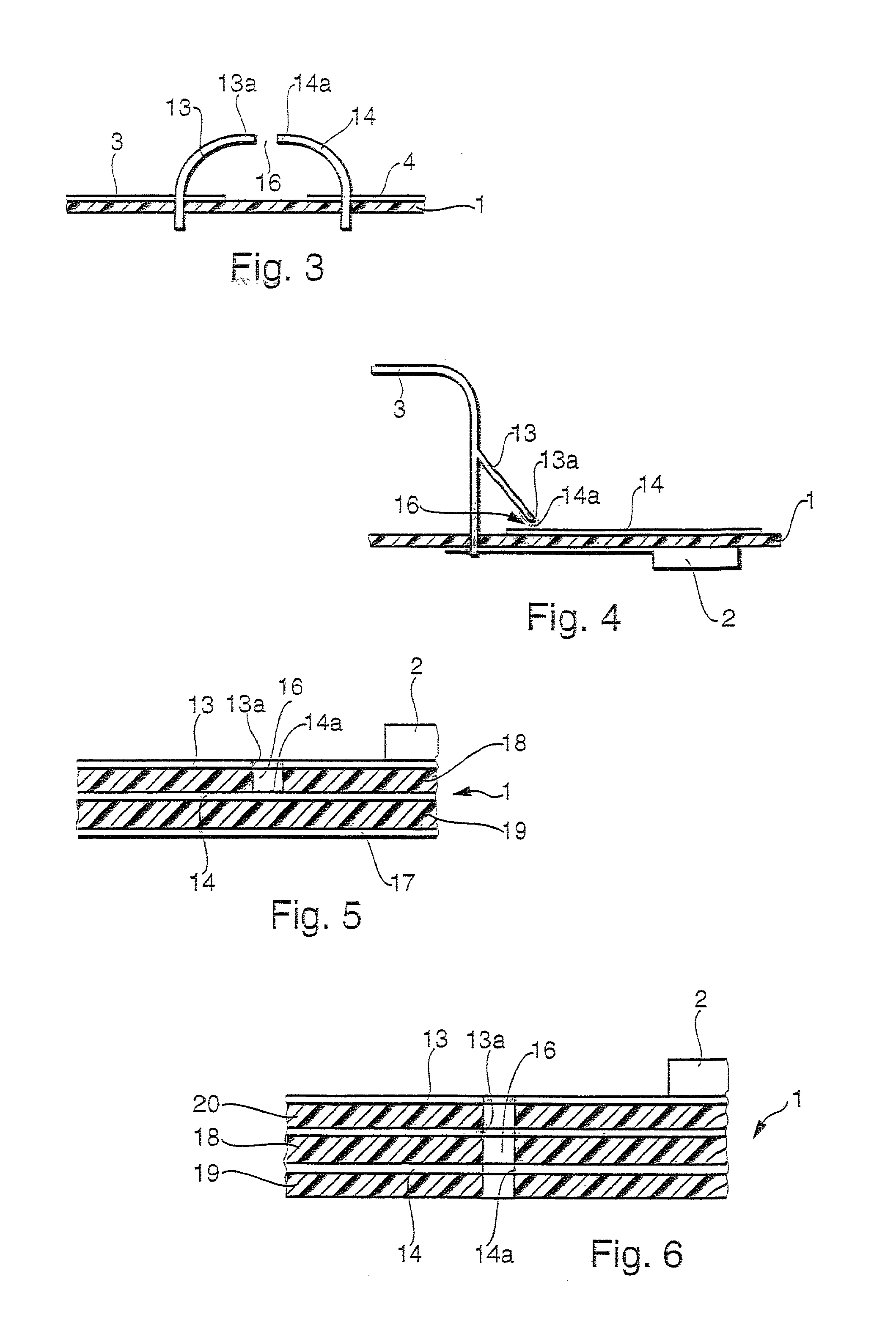

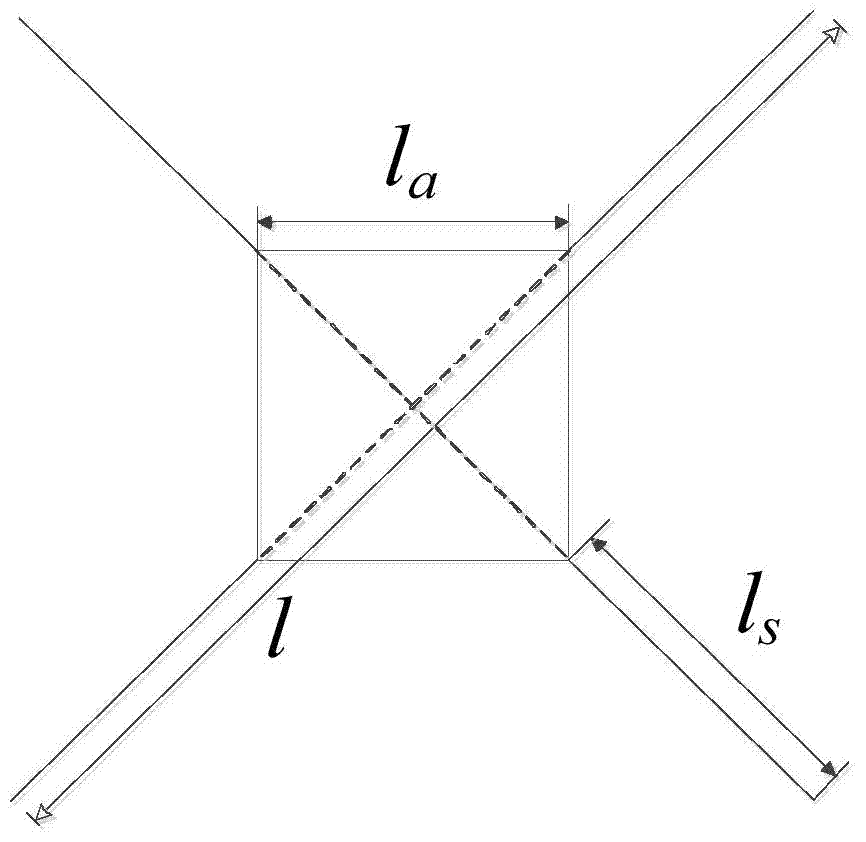

Device for protecting an electric and/or electronic component arranged on a carrier substrate against electrostatic discharges

InactiveUS20020151200A1Low production costReduce discharge voltagePrinted circuit assemblingFinal product manufactureOvervoltageContact element

The proposal relates to a device for protecting an electrical and / or electronic component, arranged on a carrier substrate, from electrostatic discharges, an overvoltage occurring in the case of discharge at a carrier-substrate contact element connected to the component being diverted to a ground connection, bypassing the component. It is proposed that the protective device include a first electroconductive structure conductively connected to the jeopardized contact element, and a second electroconductive structure arranged adjacent to the first structure on the carrier substrate and conductively connected to the ground connection. Mutually facing sections of the electroconductive structures are set apart spatially from one another by a defined gap in such a way that an overvoltage transmitted to the contact element is transferred by a spark discharge in the gap from the section of the first electroconductive structure to the section of the second electroconductive structure, and is diverted to the ground connection.

Owner:ROBERT BOSCH GMBH

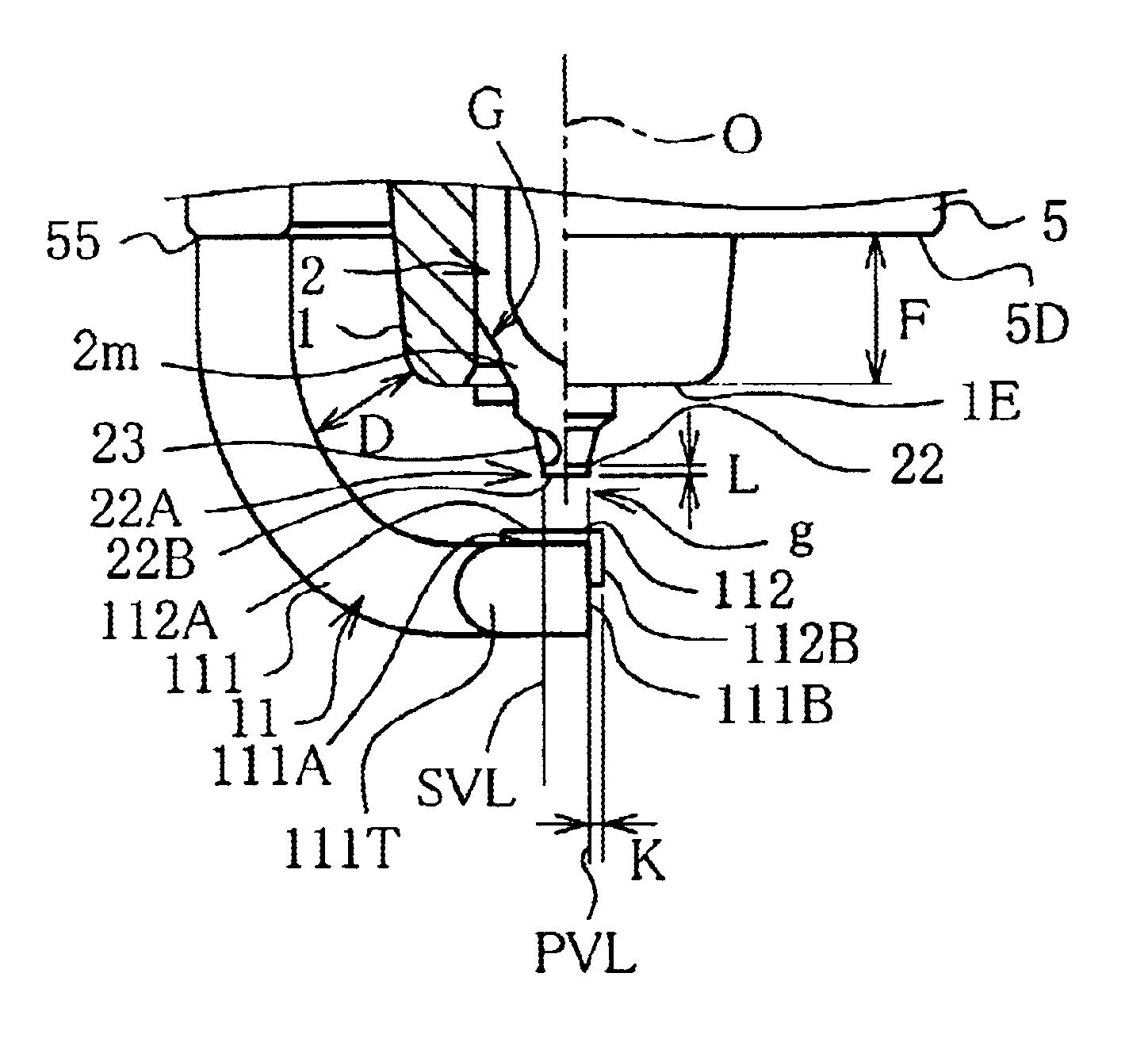

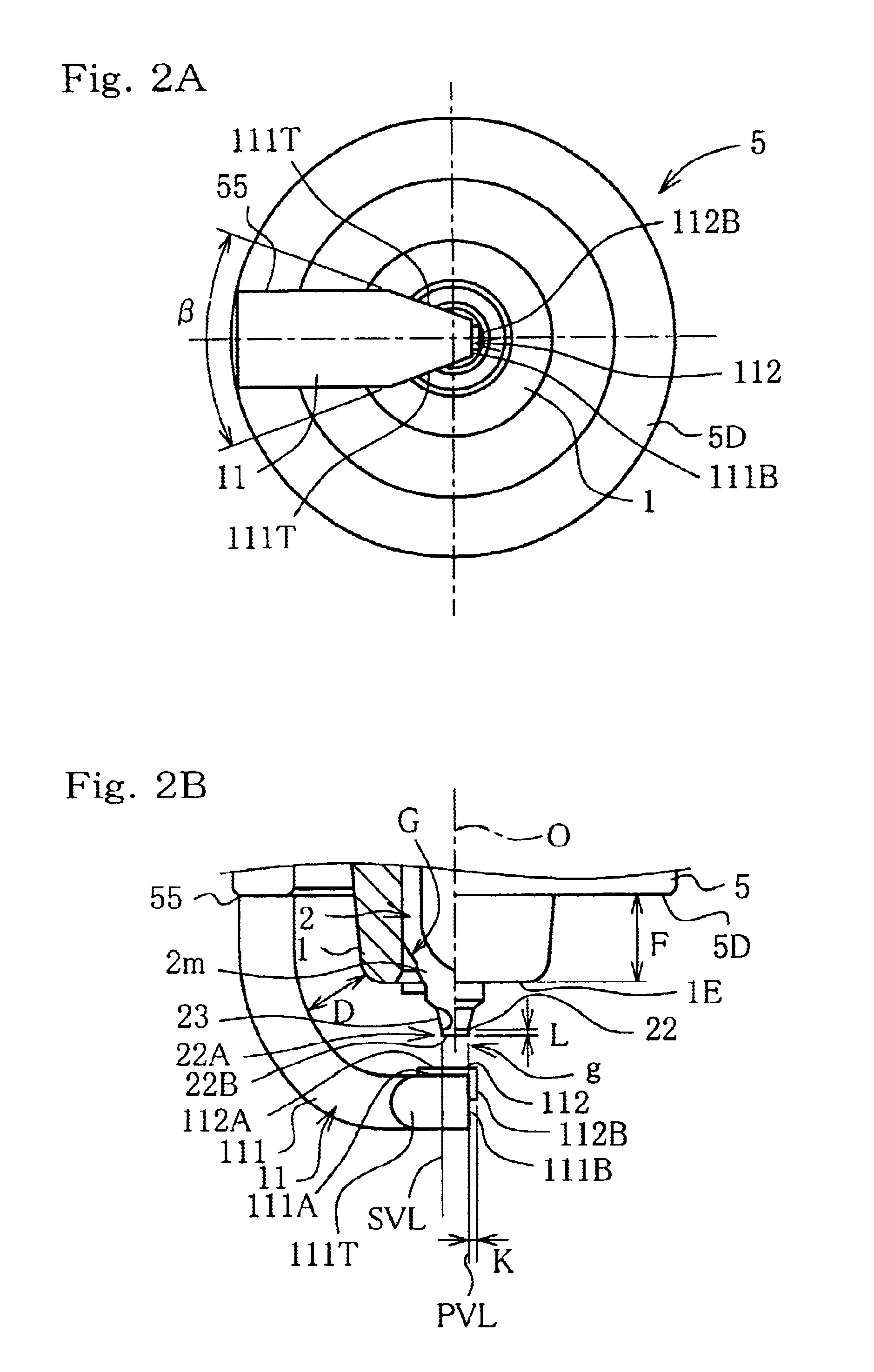

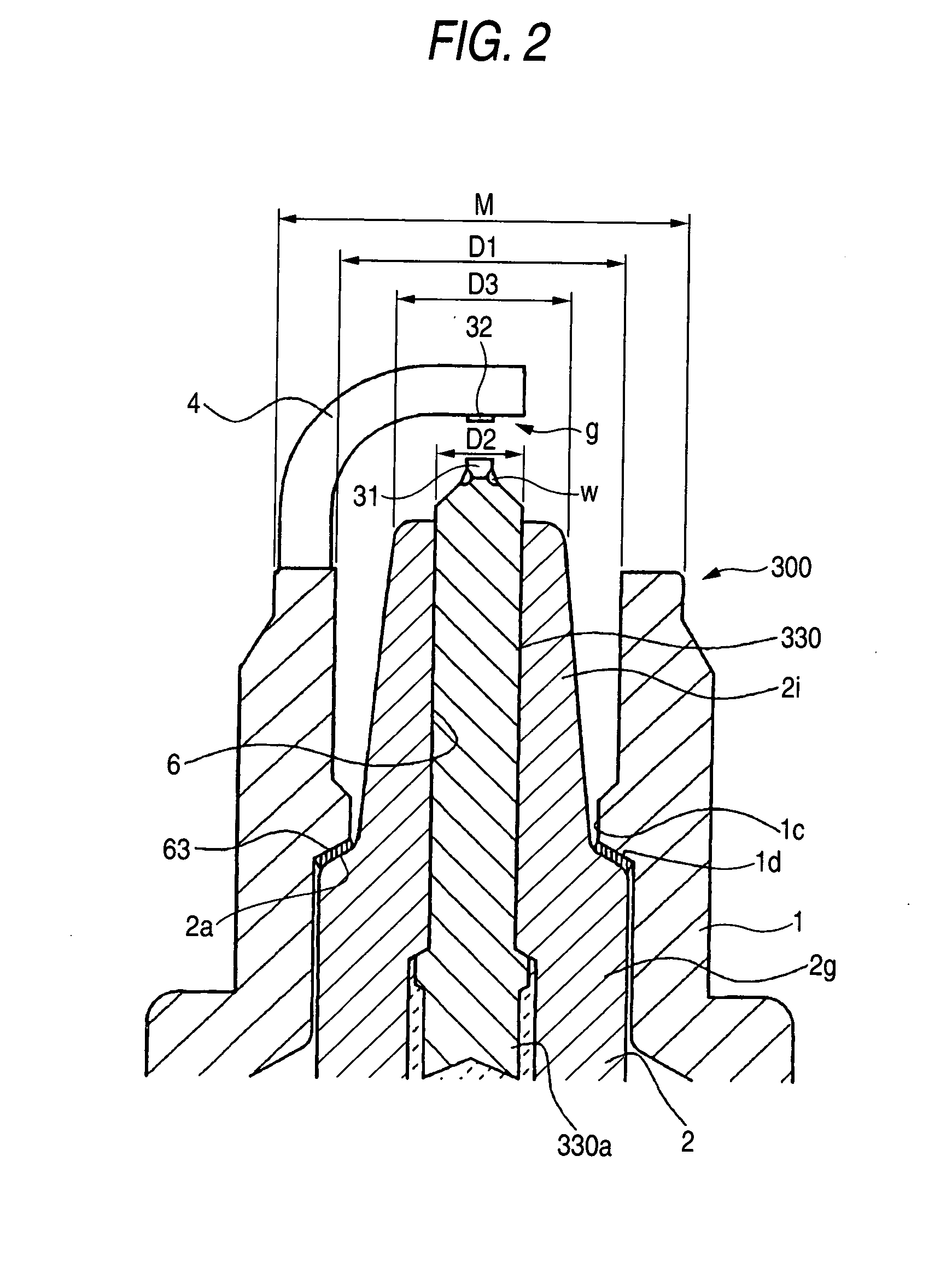

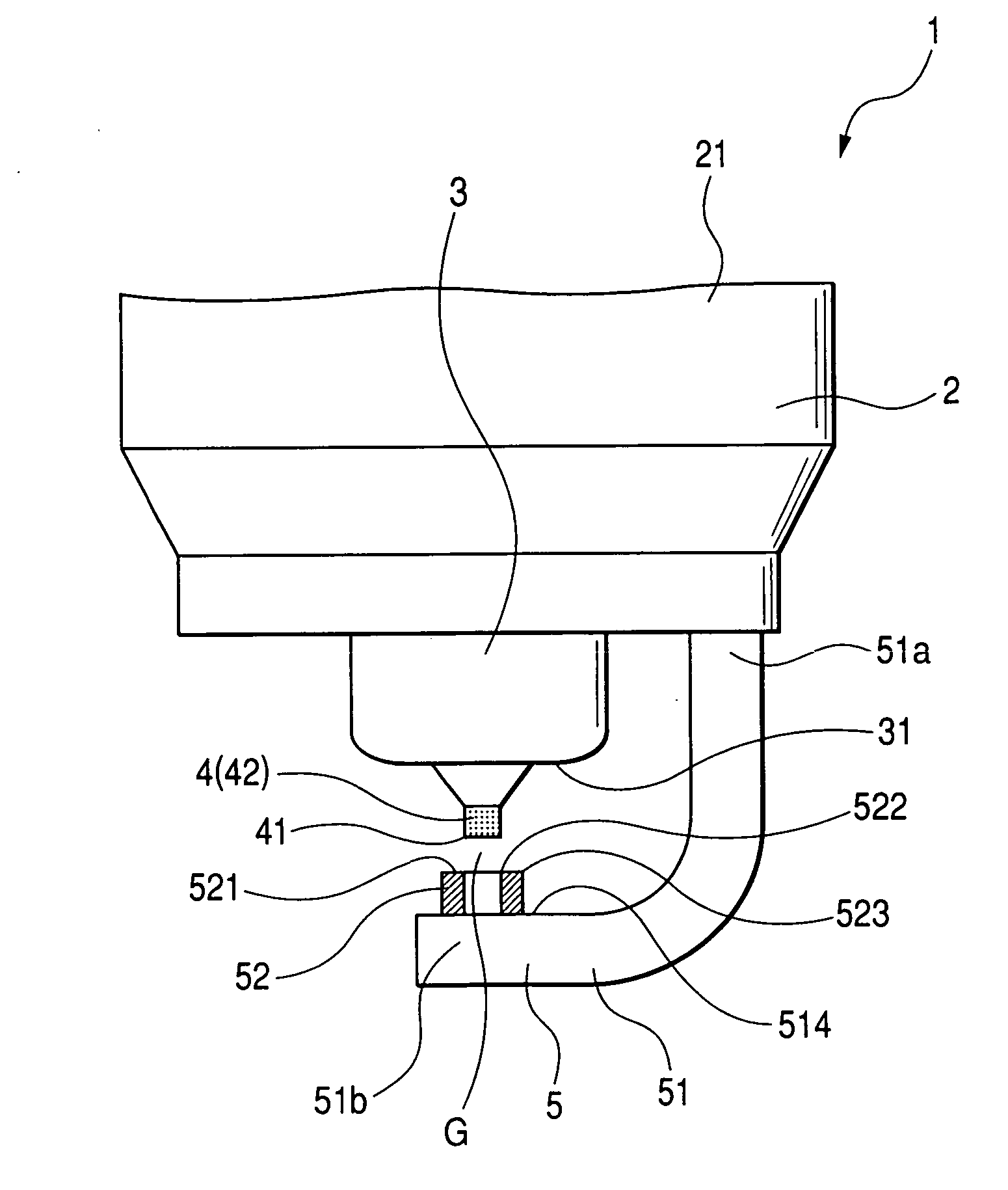

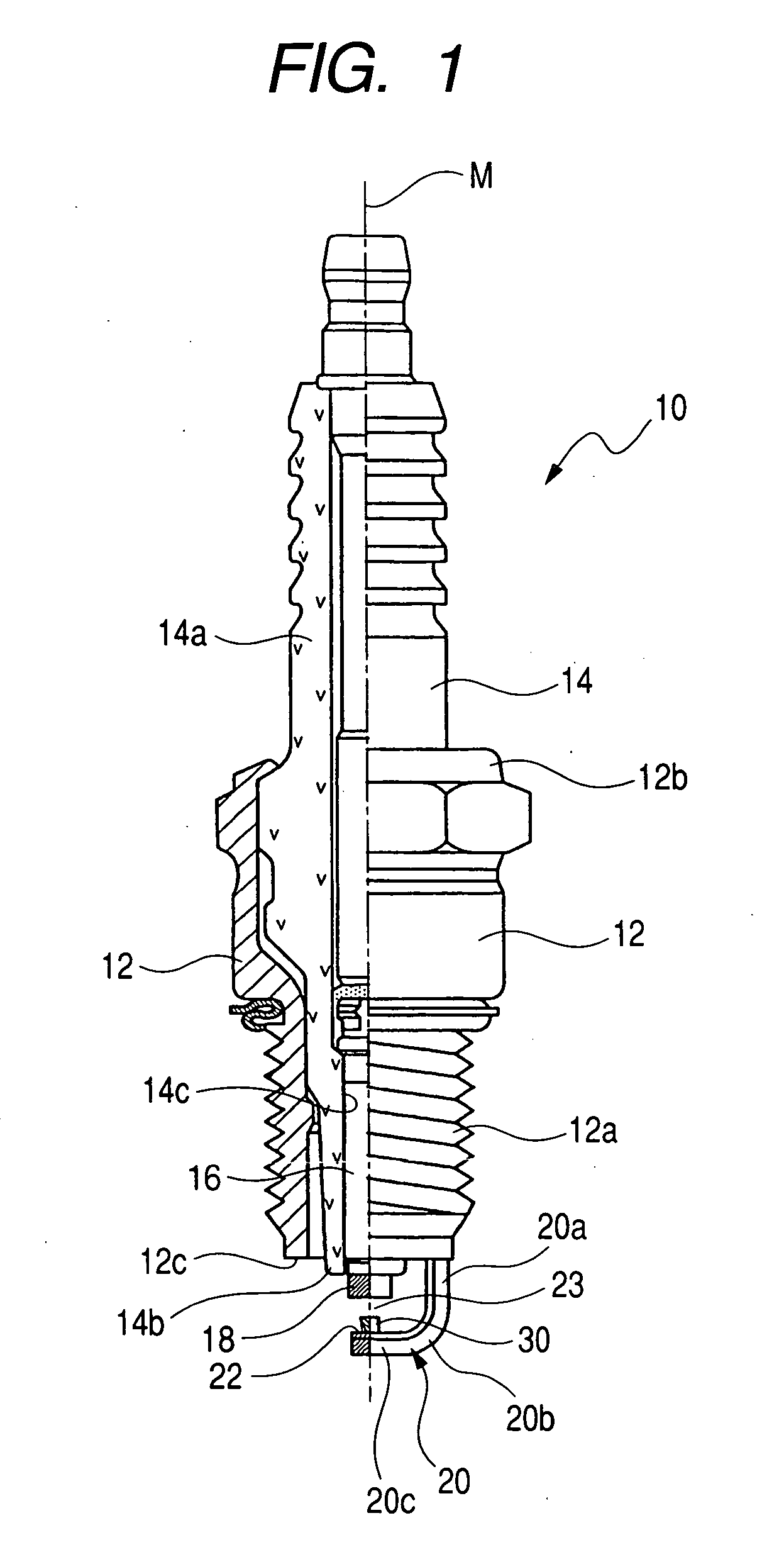

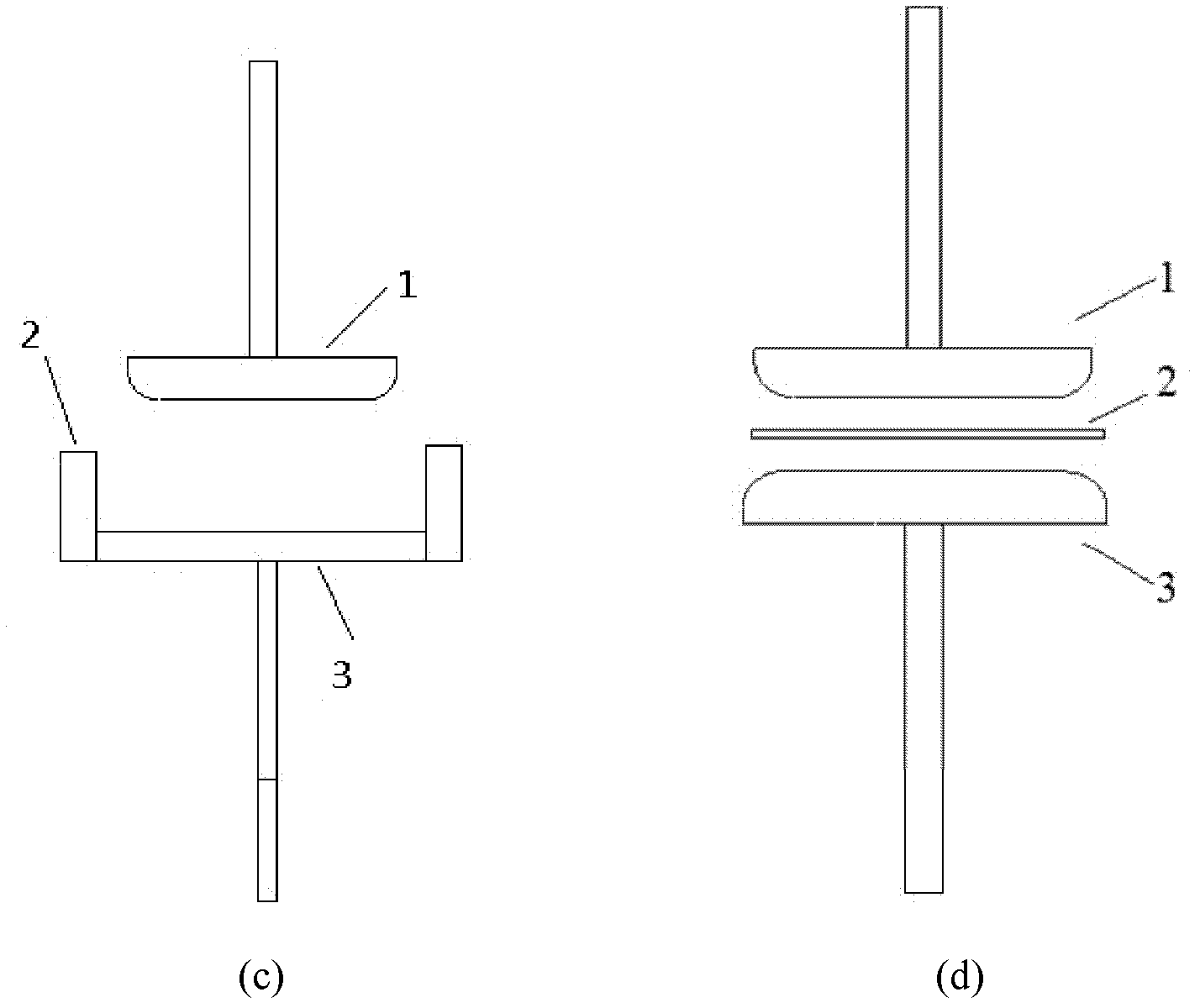

Spark plug

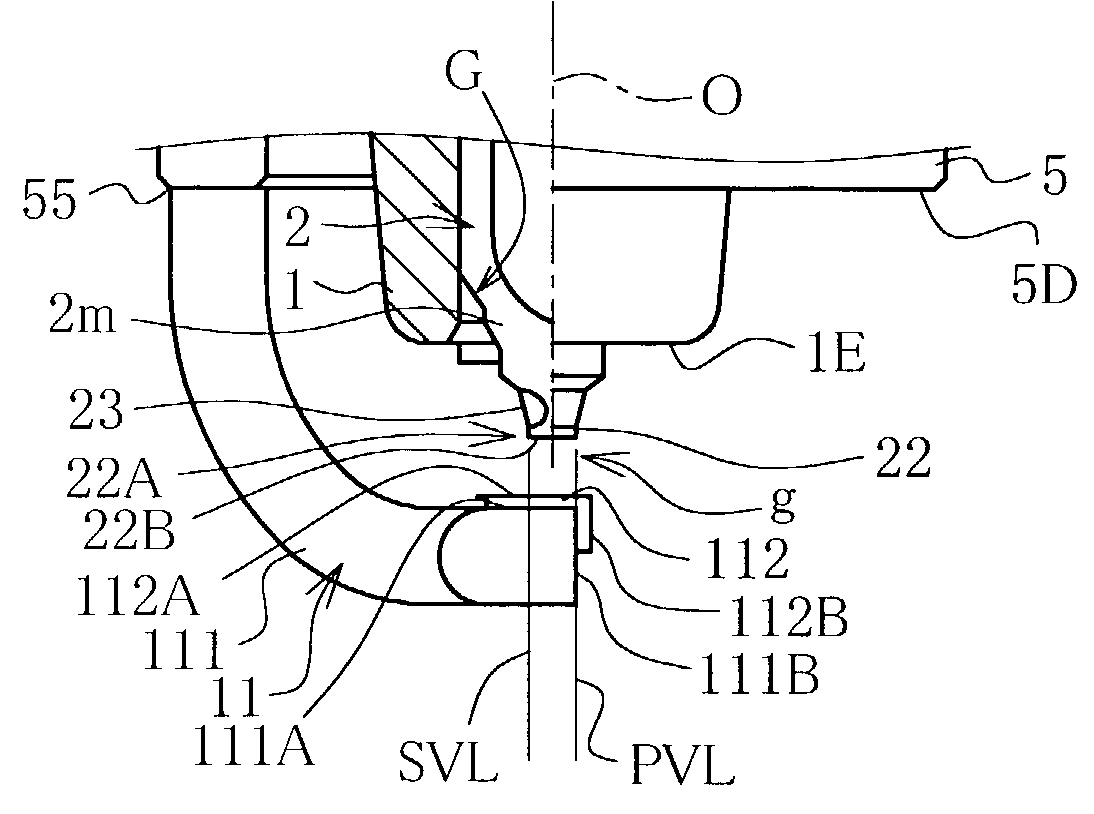

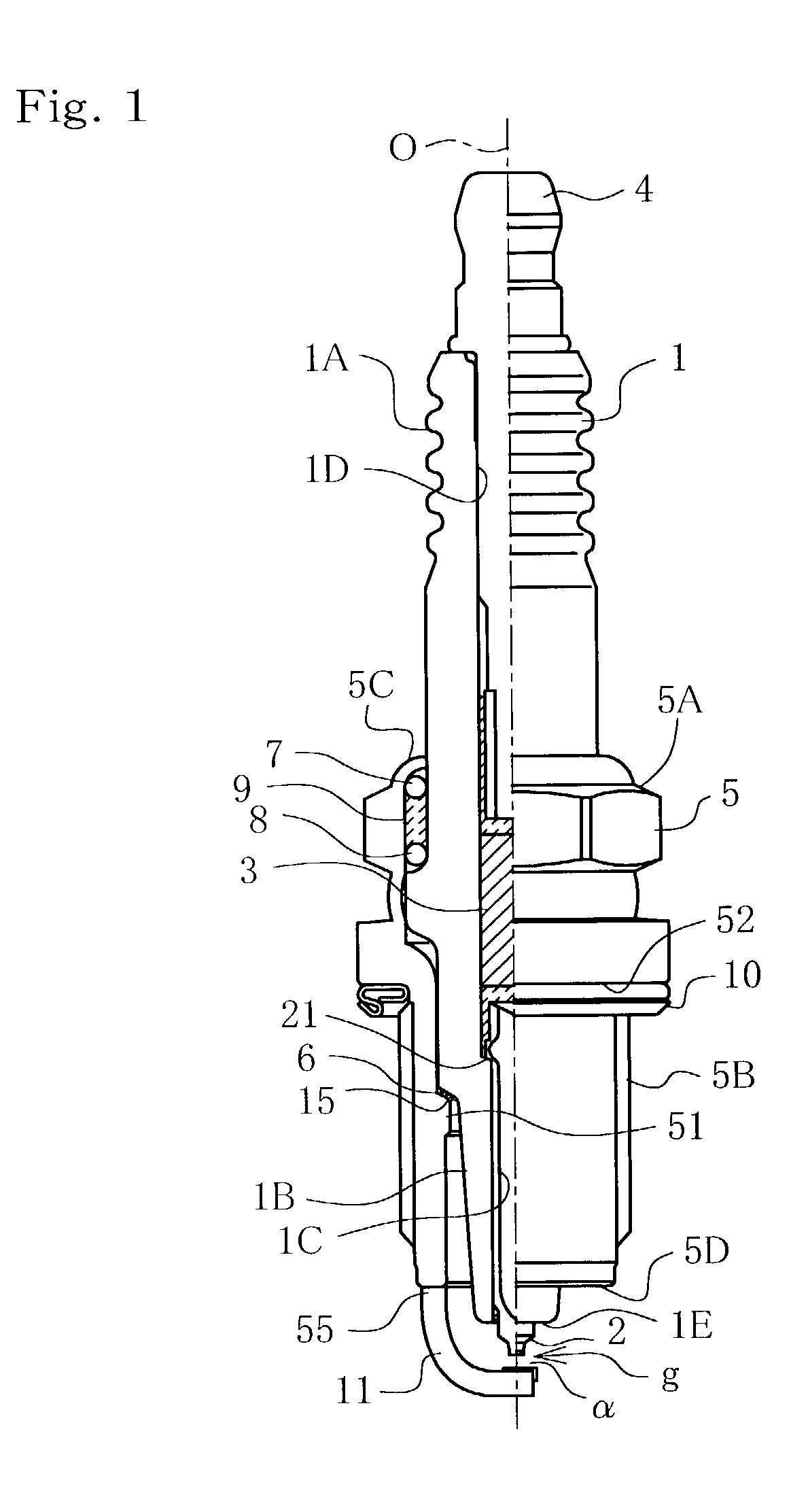

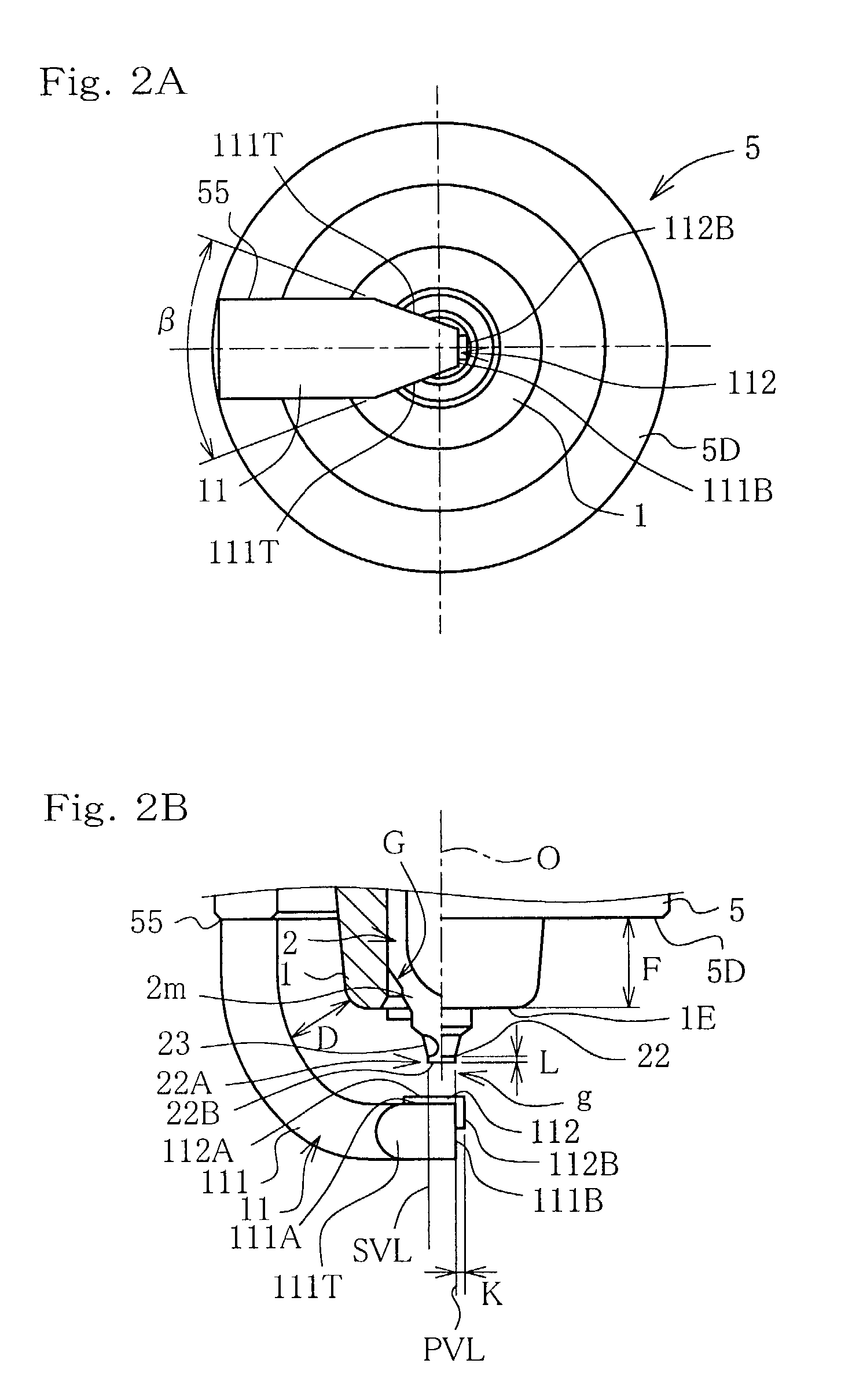

A spark plug is disclosed, in which a center electrode has, at the end thereof which forms a spark discharge gap, a noble metal chip which has a straight rod portion of 1.0 mm or less in diameter and 0.2 mm or more in length; width of coverage K of a ground electrode on which a rectangular noble metal chip is welded satisfies a relation of -d<=K<=0.5 mm (where, d represents the diameter of the end face of the center electrode); and width w of a portion of the discharge plane 111A which falls within a range corresponded to the axial extension of the end face 22B of the noble metal chip 22 provided on the center electrode 2 satisfies a relation of w<2.1-K (in mm), where K is the foregoing width of coverage.

Owner:NGK SPARK PLUG CO LTD

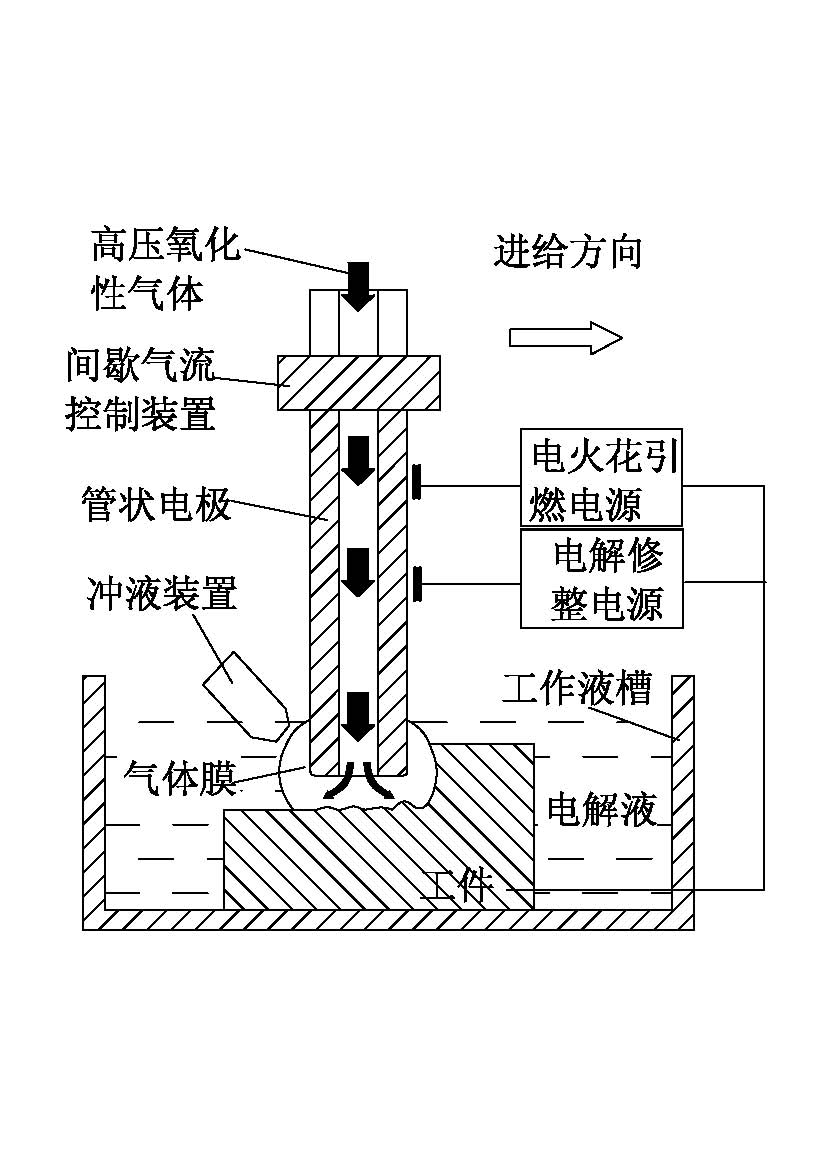

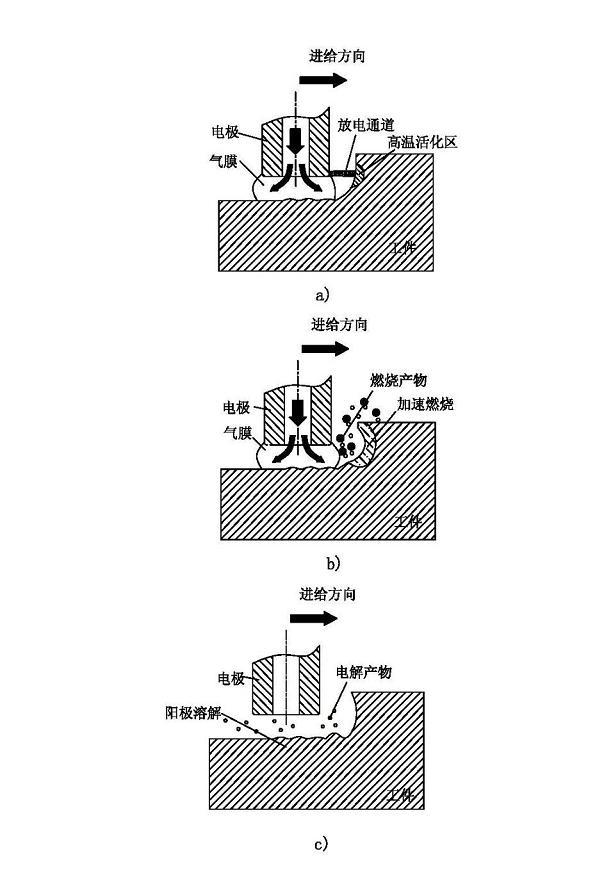

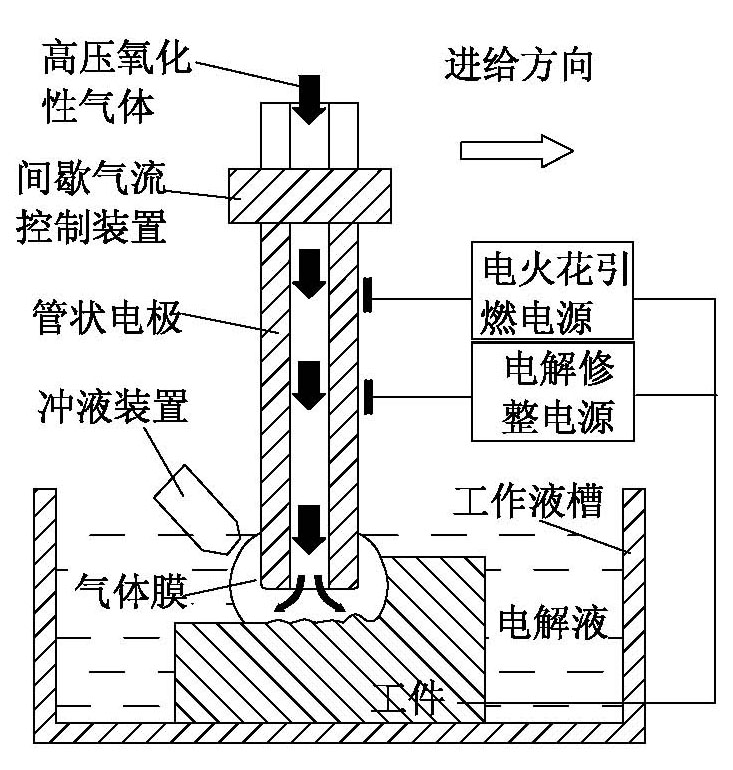

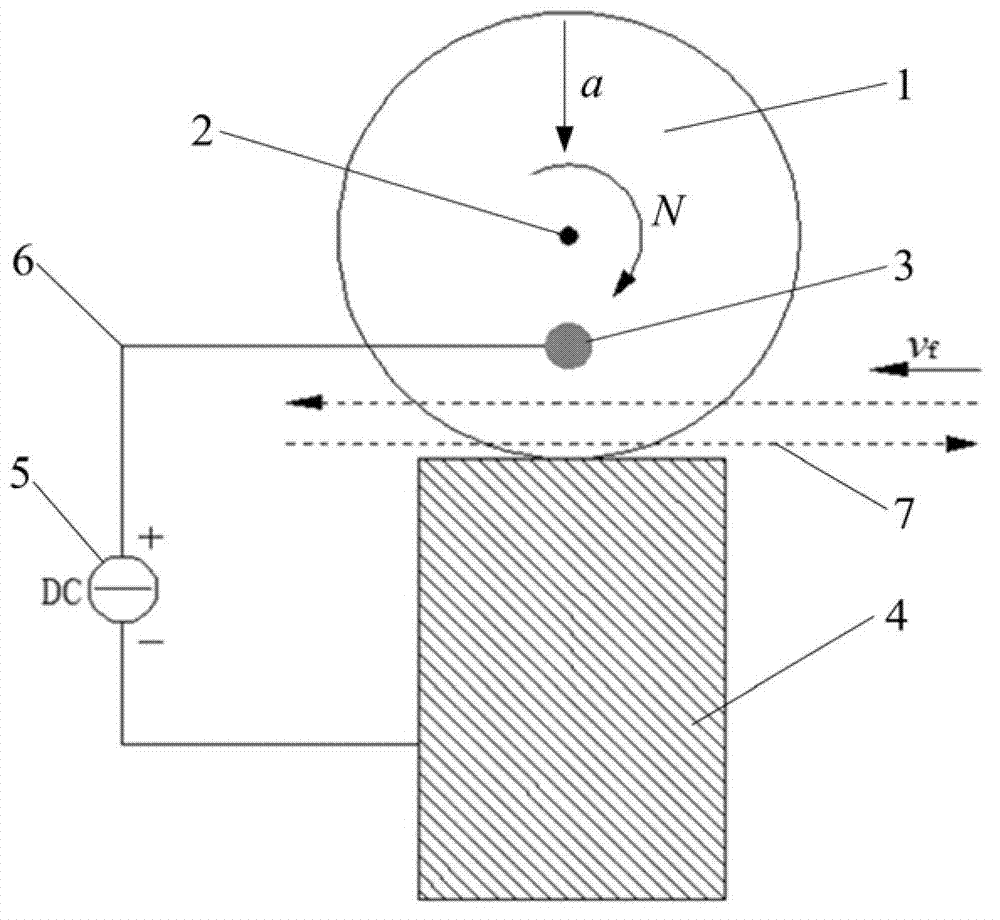

Electric spark induction controllable erosion and electrolysis compound efficient machining method

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

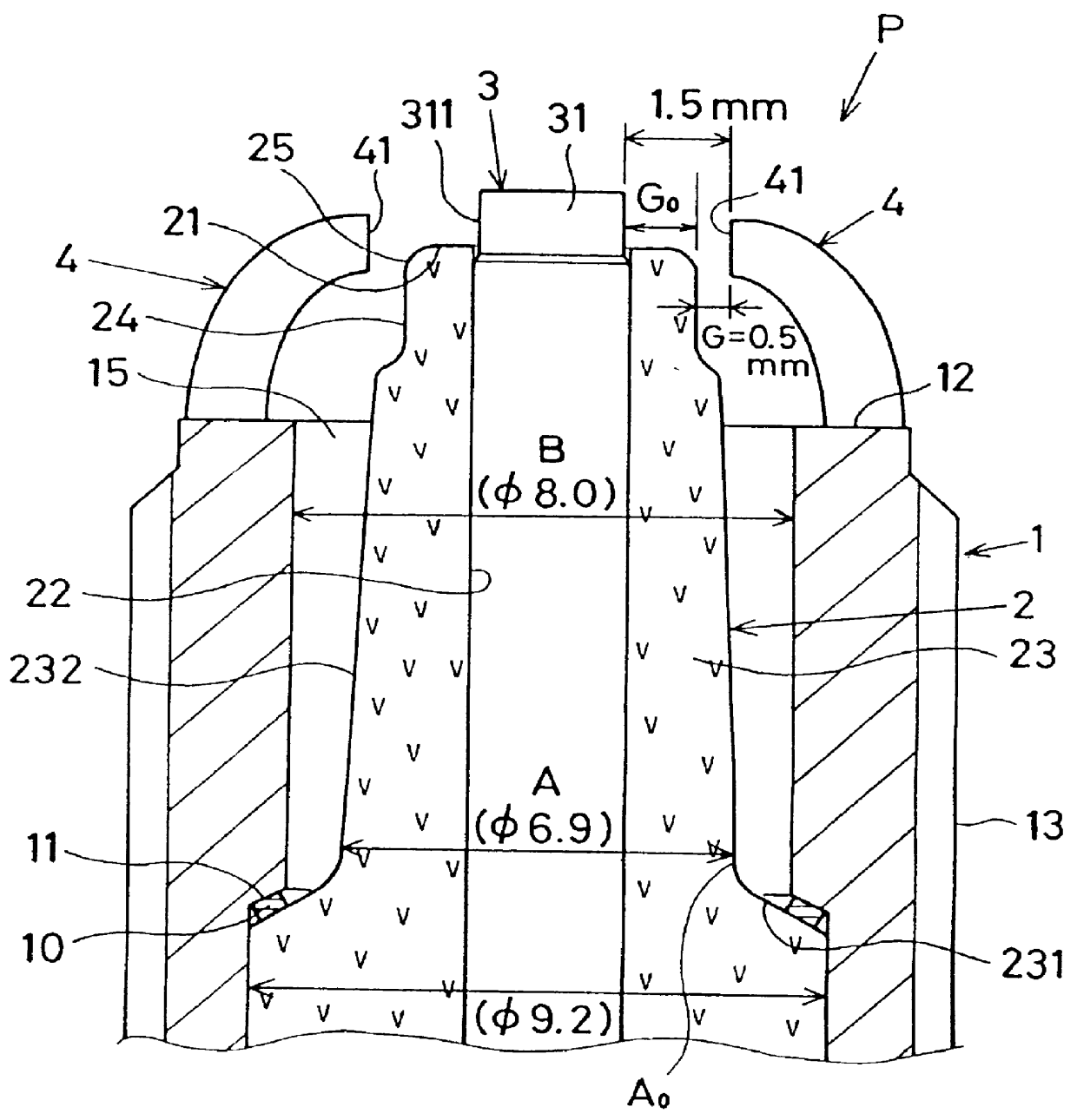

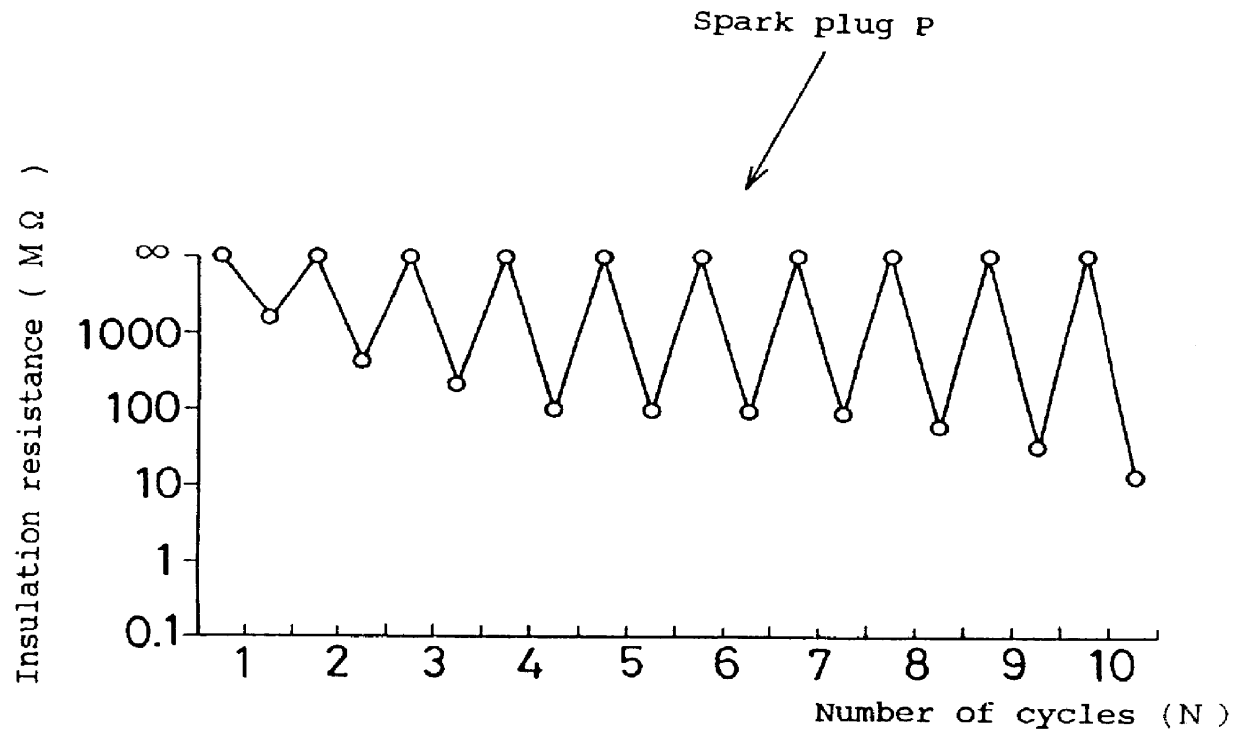

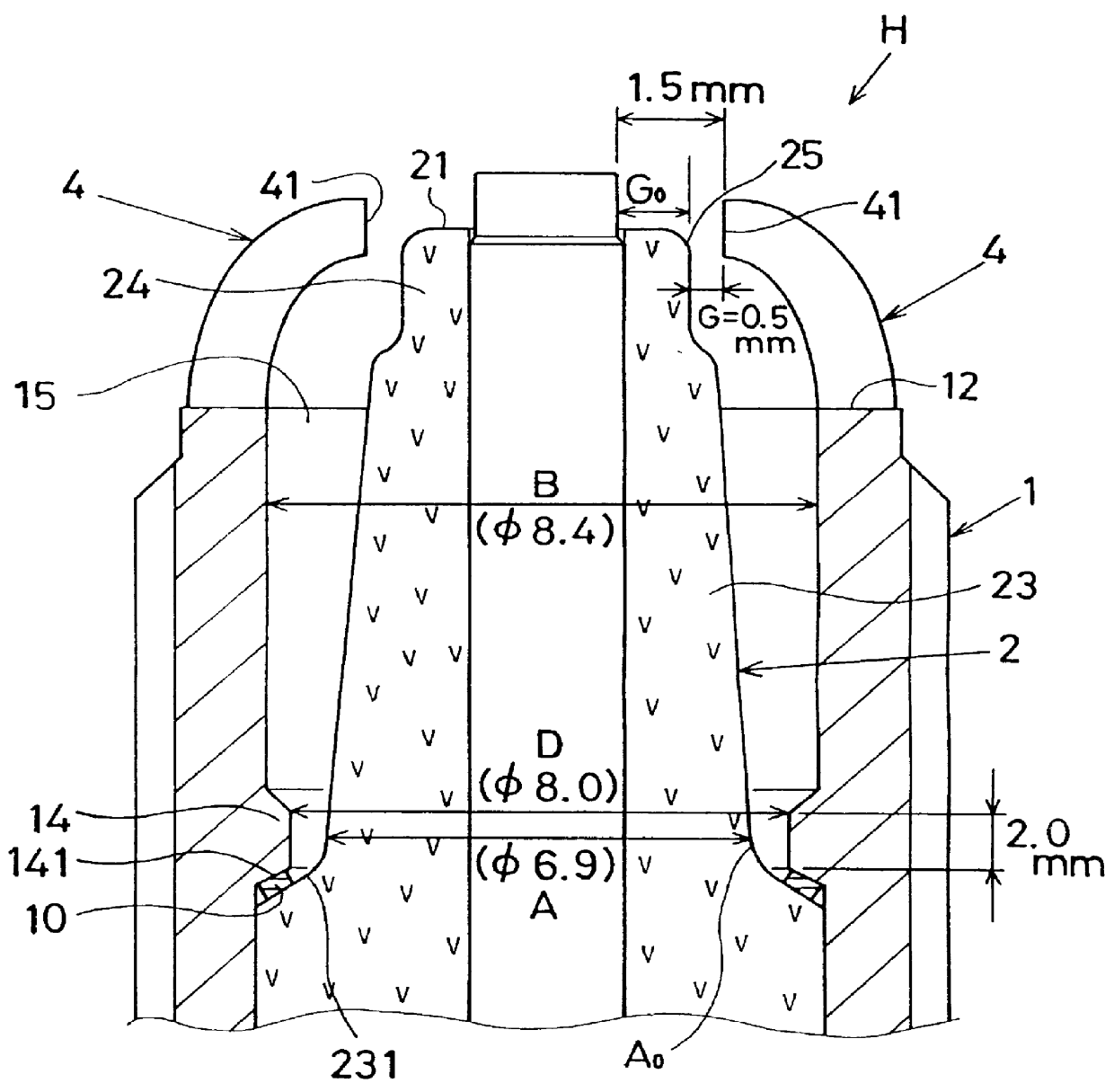

Lateral electrode type spark plug with geometrical relationships with ground electrode

InactiveUS6091185AEffective protectionHigh insulation resistanceSparking plugsFuel injection apparatusNoseEngineering

In a spark plug, a cylindrical metal shell (1) is provided whose inner wall has a rear section and a front section to respectively serve as a diameter-increased section and a diameter-decreased section with a seat portion (1) as a boundary therebetween. An insulator (2) is fixedly placed within the metal shell (1) so that a front end surface (21) of the insulator (2) extends beyond a front end surface (12) of the metal shell (1) with a shoulder portion (231) of an insulator nose (23) engaged against the seat portion (11) of the metal shell (1) by way of a packing (10). A center electrode (3) is fixedly placed within an axial bore (22) of the insulator (2), A ground electrode (4) is connected to the front end surface (12) of the metal shell (1), and bent so that a front end surface (41) of the ground electrode (4) opposes an outer surface (311) of the center electrode (3). The outer surface (311) and a front end surface (31) of the center electrode (3) are provided to respectively serve as a firing portion so as to form a spark discharge gap (Go) with the front end surface (41) of the ground electrode (4), the front end surface (41) of the ground electrode (4) forming an air gap (G) with an outer surface (25) of the insulator (2) so as to release creeping spark discharges along a front end surface (21) of the insulator (2).

Owner:NGK SPARK PLUG CO LTD

High-instantaneous-energy-density electric spark high-speed milling method

InactiveCN103008802AGood removal effectEfficient processingElectrical-based machining electrodesWorking fluidCombined method

The invention relates to a high-instantaneous-energy-density electric spark high-speed milling method, which belongs to the field of machining. The method comprises the following steps of: connecting a rotary rod-like electrode with an inner flushing fluid hole with a negative electrode of a power supply, connecting a to-be-machined workpiece with a positive electrode of the power supply and melting to remove the workpiece material by utilizing high-instantaneous-energy-density spark discharge between the electrodes and the workpiece in a machining process; discharging molten material out of a discharge gap by working fluid which flows at a high speed; and cooling the machined workpiece. According to the method, by utilizing high-instantaneous-energy-density spark discharge and a high-pressure forced inner flushing fluid and low-pressure outer flushing fluid combined method, the stability and the high efficiency of machining are realized, and high-efficiency machining on any conductive material, including conventional difficult-to-machine materials such as engineering ceramic with weak conductivity and high-temperature alloy, can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

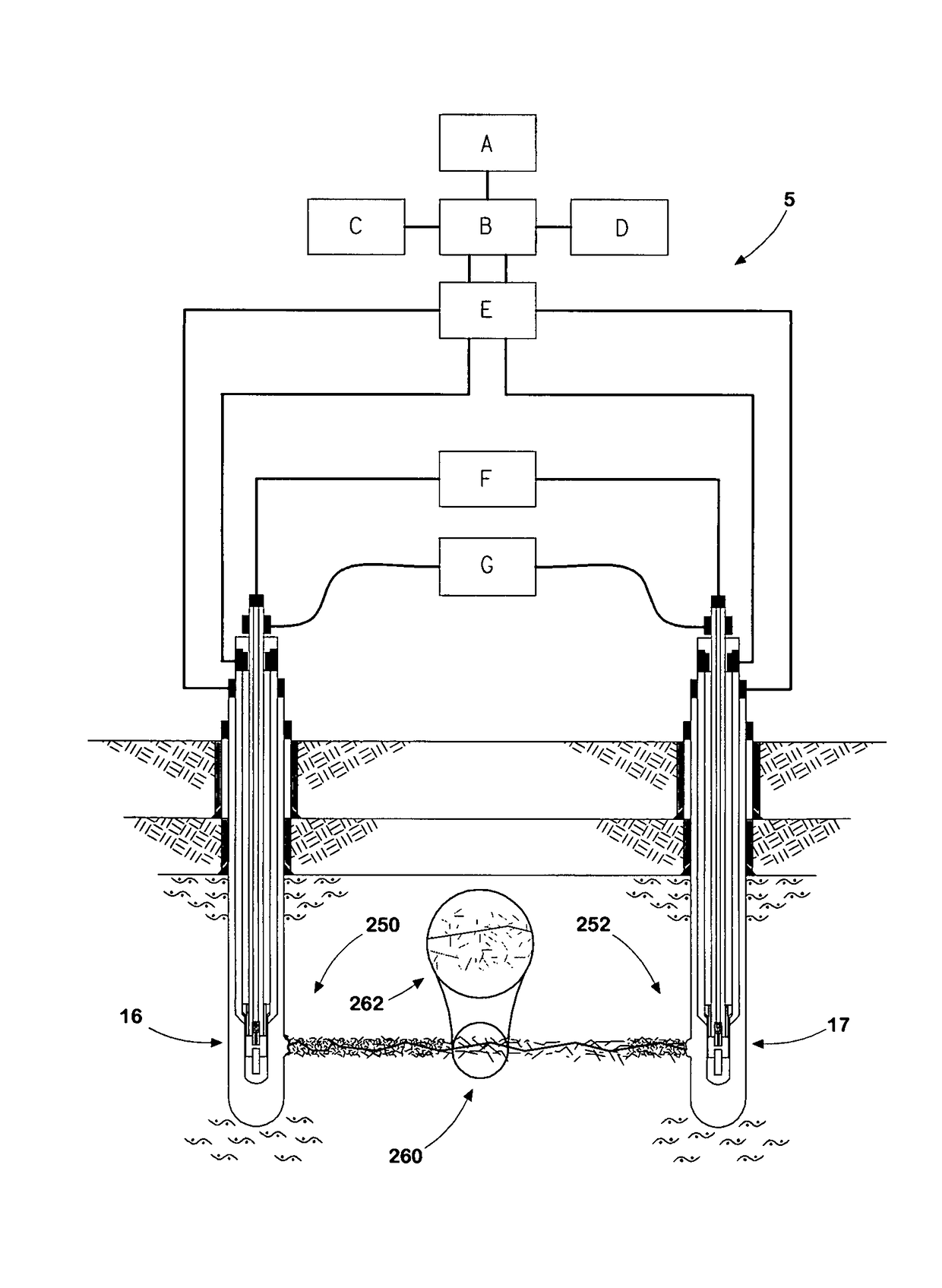

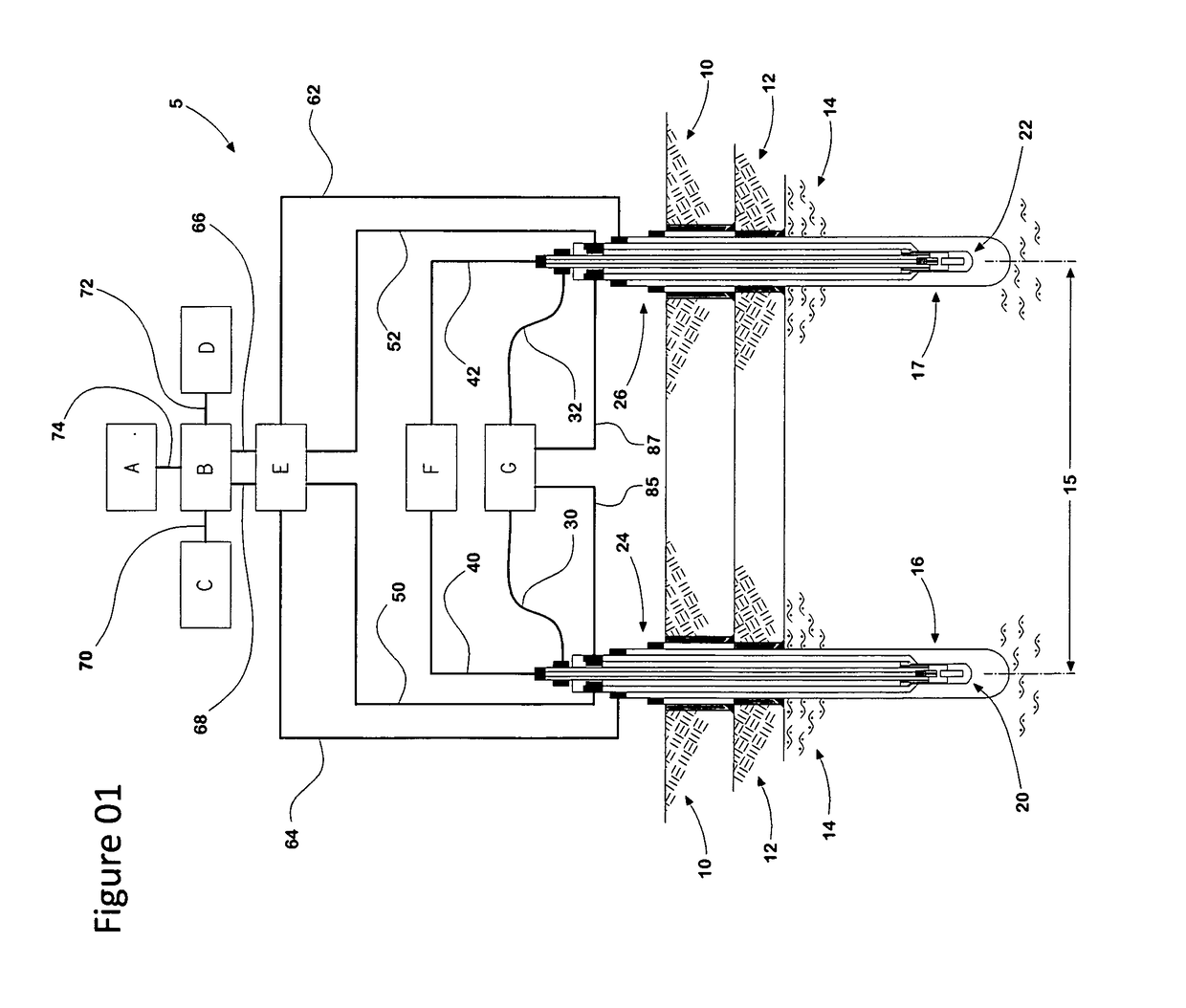

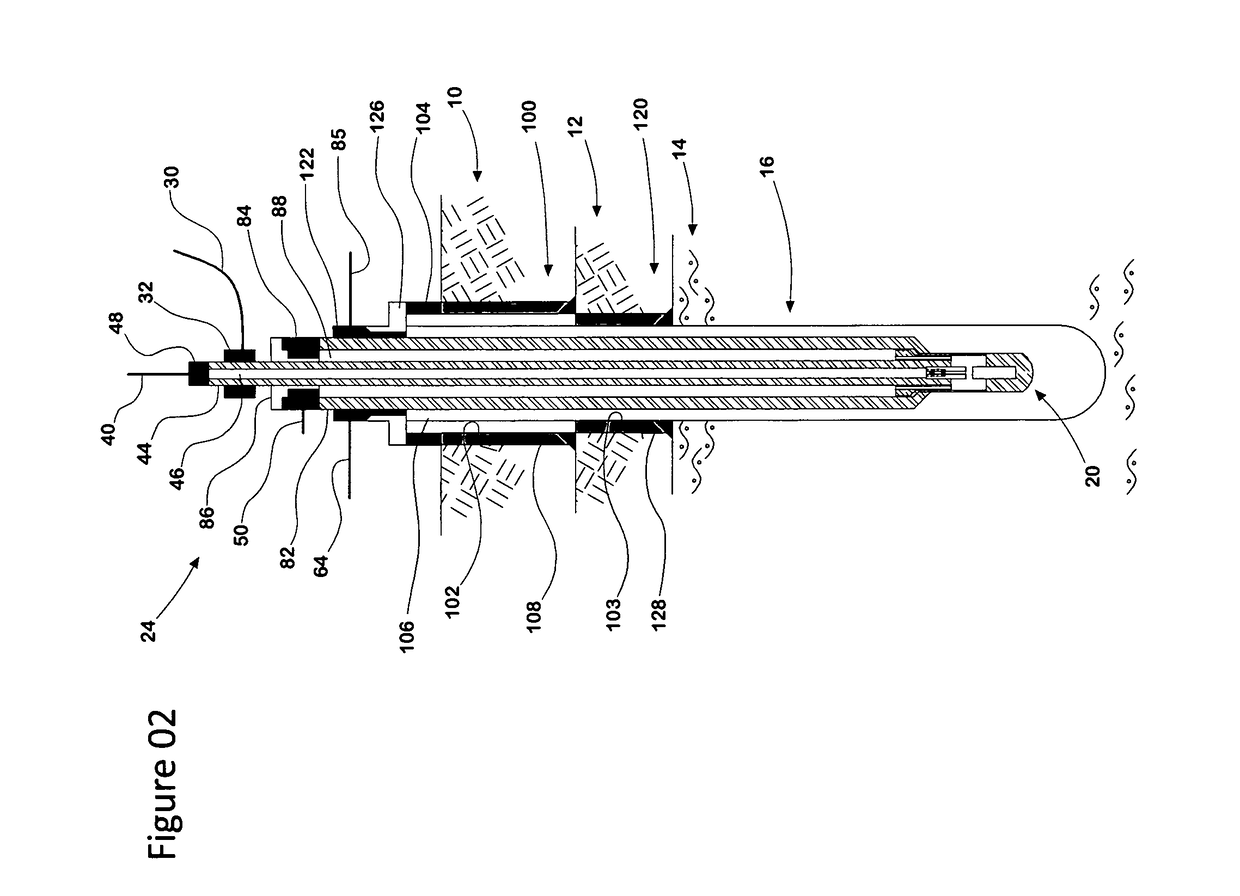

Method and System for Subsurface Resource Production

ActiveUS20170175505A1Improve breathabilityHigh densityGeothermal energy generationFluid removalPower flowMagneto hydrodynamic

A means to generate increasing geological permeability to produce greater volumes of various subsurface geological resources when compared to the current conventional production methods is disclosed. The means include a Pulsed Power Plasma Emitter System capable of substantially increasing the available electrical energy for use in high power compression surge currents that can be discharged and transmitted to power a simplified downhole Plasma Emitter Tool subsystem. The simplified downhole Plasma Emitter Tool sub-system is capable of generating a broad range of precisely controlled magnetohydrodynamic plasma spark discharges that produce a broad range of high power electromagnetic, acoustic and hydrodynamic surge waves. These powerful surge waves are generated at energy and power levels that are necessary to physically modify all types of geological formation permeability and to energize the mobilization of various subsurface fluids and fluidized resources.

Owner:GREEN CHEM ENERGY LLC

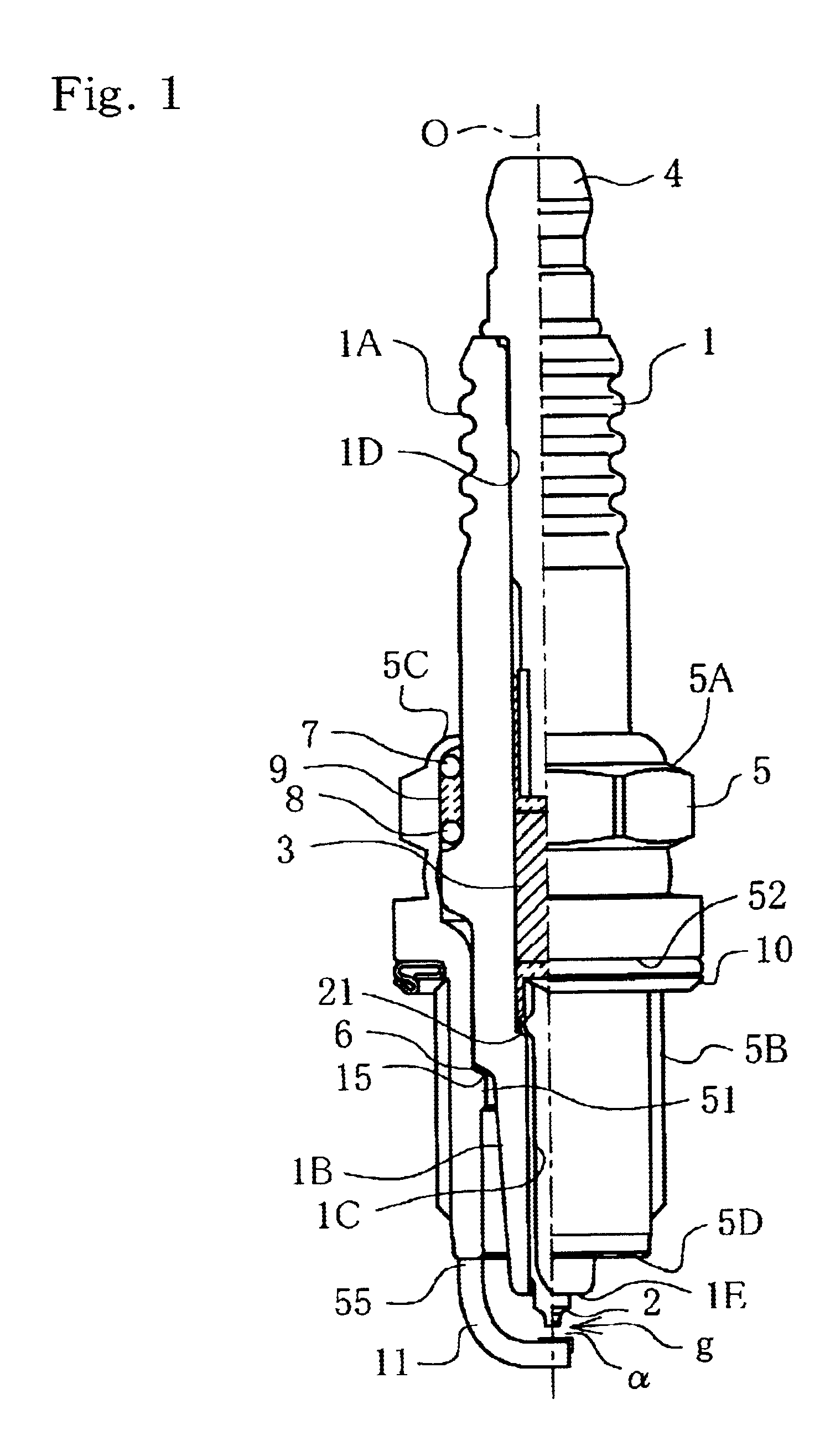

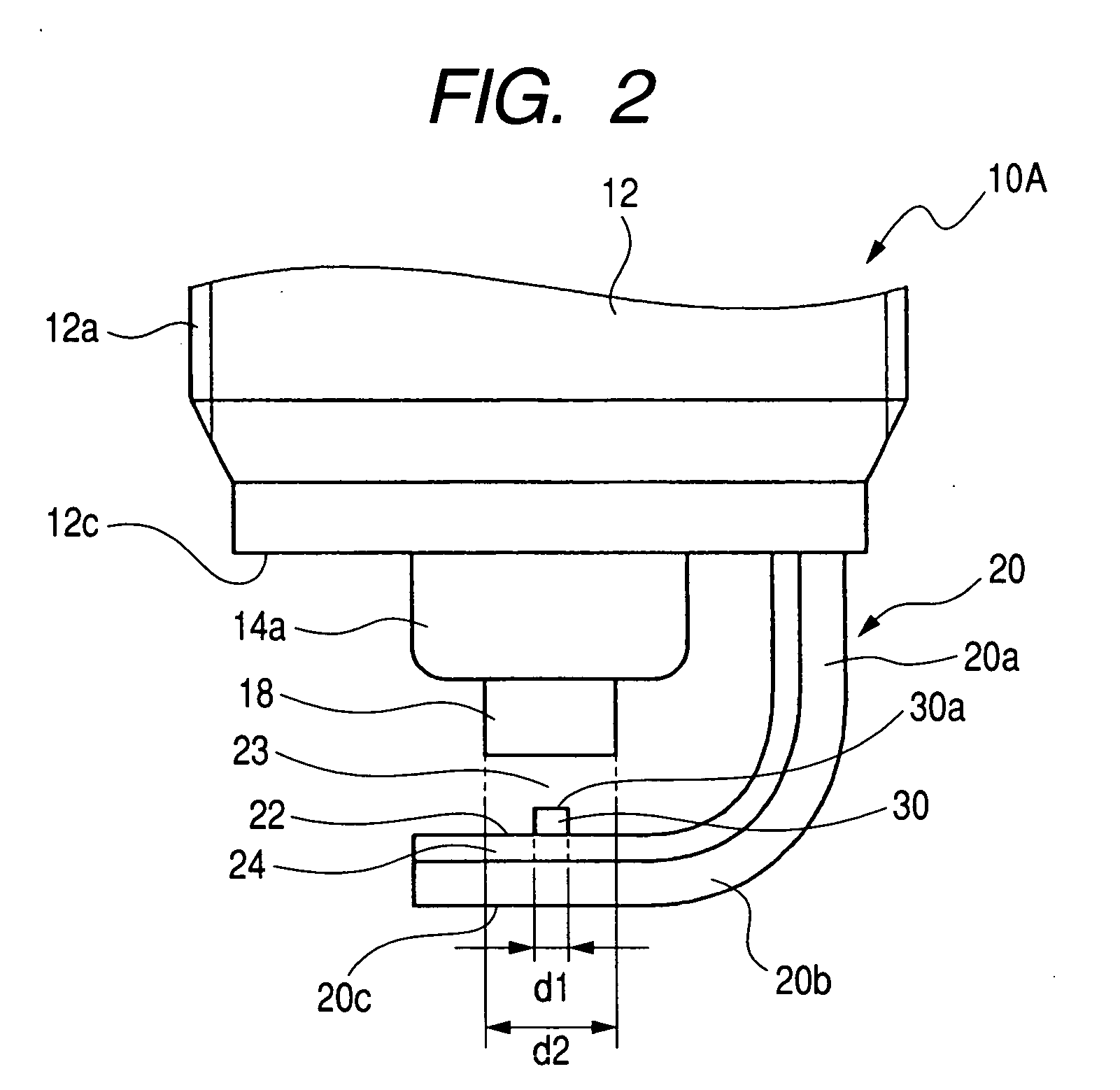

Spark plug

A spark plug including an insulator having an axial hole in an axial direction; and a center electrode disposed in a tip end side of the axial hole of the insulator so as to project a tip end of the center electrode from the tip end side of the insulator. The center electrode includes an electrode base member made of pure Ni or an Ni alloy containing 85 wt % or more of Ni; and a noble metal chip fixed to a tip end of the electrode base. The spark plug further includes a metal shell surrounding the insulator; and a ground electrode in which one end is joined to the metal shell, and another end portion opposes the noble metal chip to form a spark discharge gap between the ground electrode and noble metal chip, wherein M, D1, and D2 as defined herein satisfy M≦10.1 mm, 0.5 mm≦D2<1.4 mm, and D1 / D2≧3.5.

Owner:NGK SPARK PLUG CO LTD

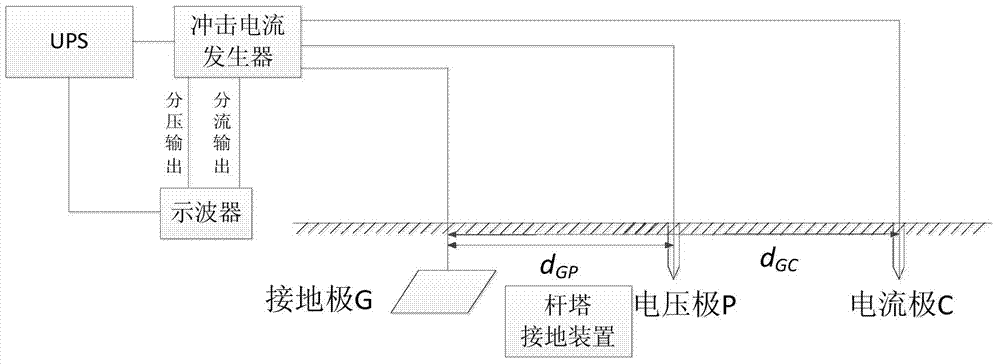

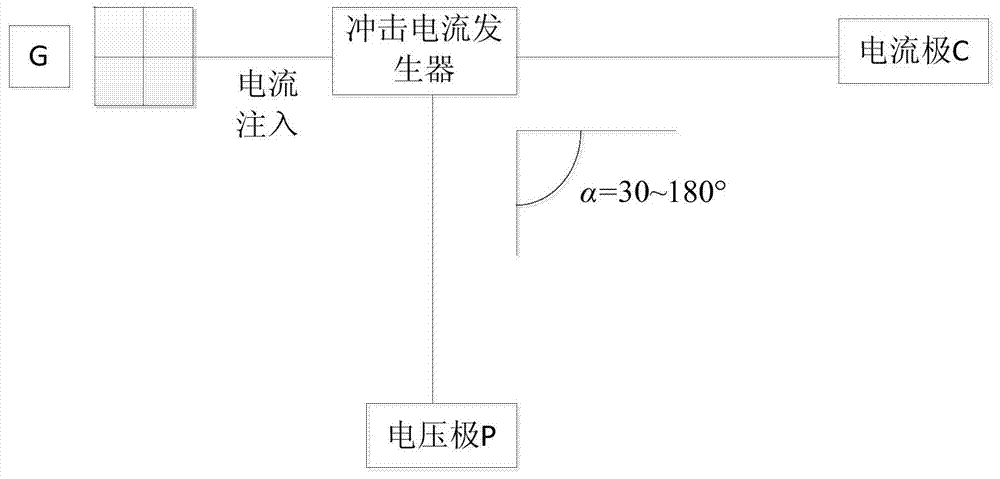

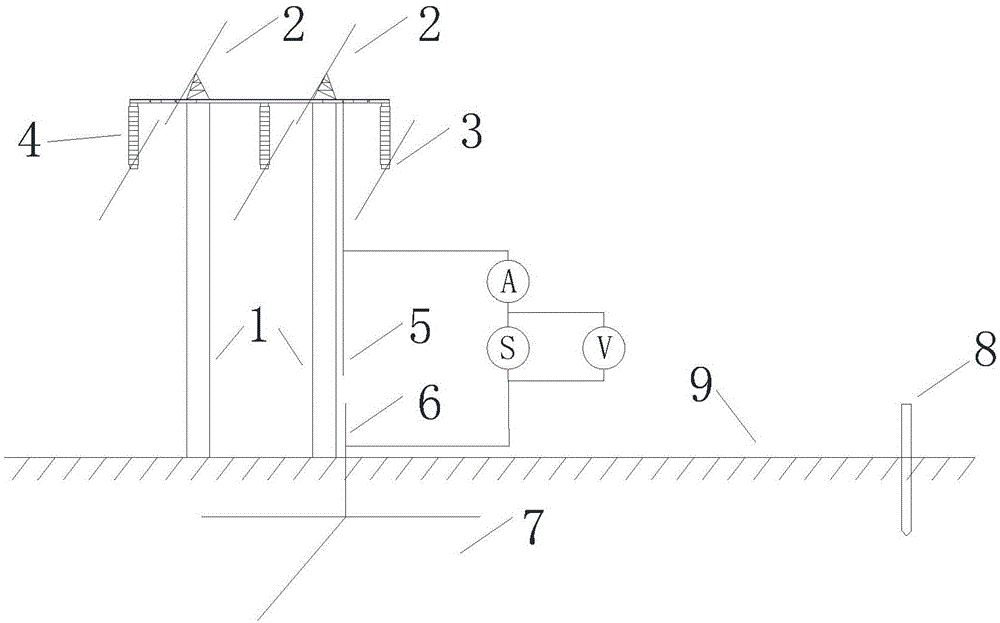

Measuring method using spark coefficient for correcting low-amplitude value impact resistance of tower grounding device

ActiveCN103792433ASolve problems that cannot be measured on siteEarth resistance measurementsThree levelGrounding resistance

Provided is a measuring method using a spark coefficient for correcting low-amplitude value impact resistance of a tower grounding device. A portable impulse current generator is used as a signal output source, a three-level measuring mode is adopted to arrange the grounding device, an UPS is used for supplying power to inject impulse currents from a grounding electrode, a spark coefficient alpha of soil where the grounding device located is calculated, and initial impulse grounding resistance Rc obtained through convolution calculation is corrected according to the spark coefficient alpha obtained through calculation. According to the measuring method using the spark coefficient for correcting the low-amplitude value impact resistance of the tower grounding device, standard impulse grounding resistance under lightning currents is obtained by adopting the convolution calculation and a spark coefficient modification method, the inductive effect of the grounding device and spark discharge of the soil can be taken into consideration effectively, the corrected impulse grounding resistance is more similar to practical situations when electric transmission lines are struck by lightning. The measuring method using the spark coefficient for correcting the low-amplitude value impact resistance of the tower grounding device solves the problems that only power frequency grounding resistance can be adopted to carry out approximate estimation and field measurement cannot be carried out in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +2

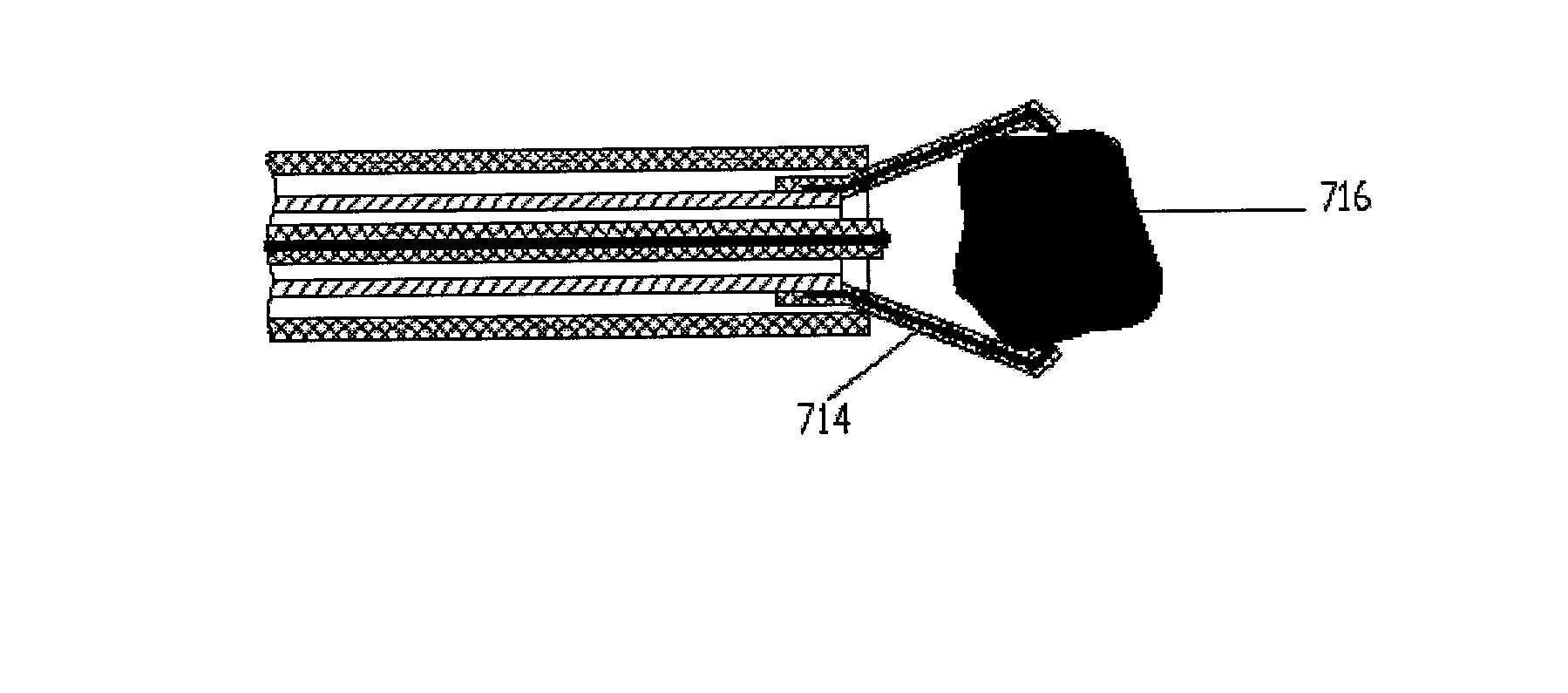

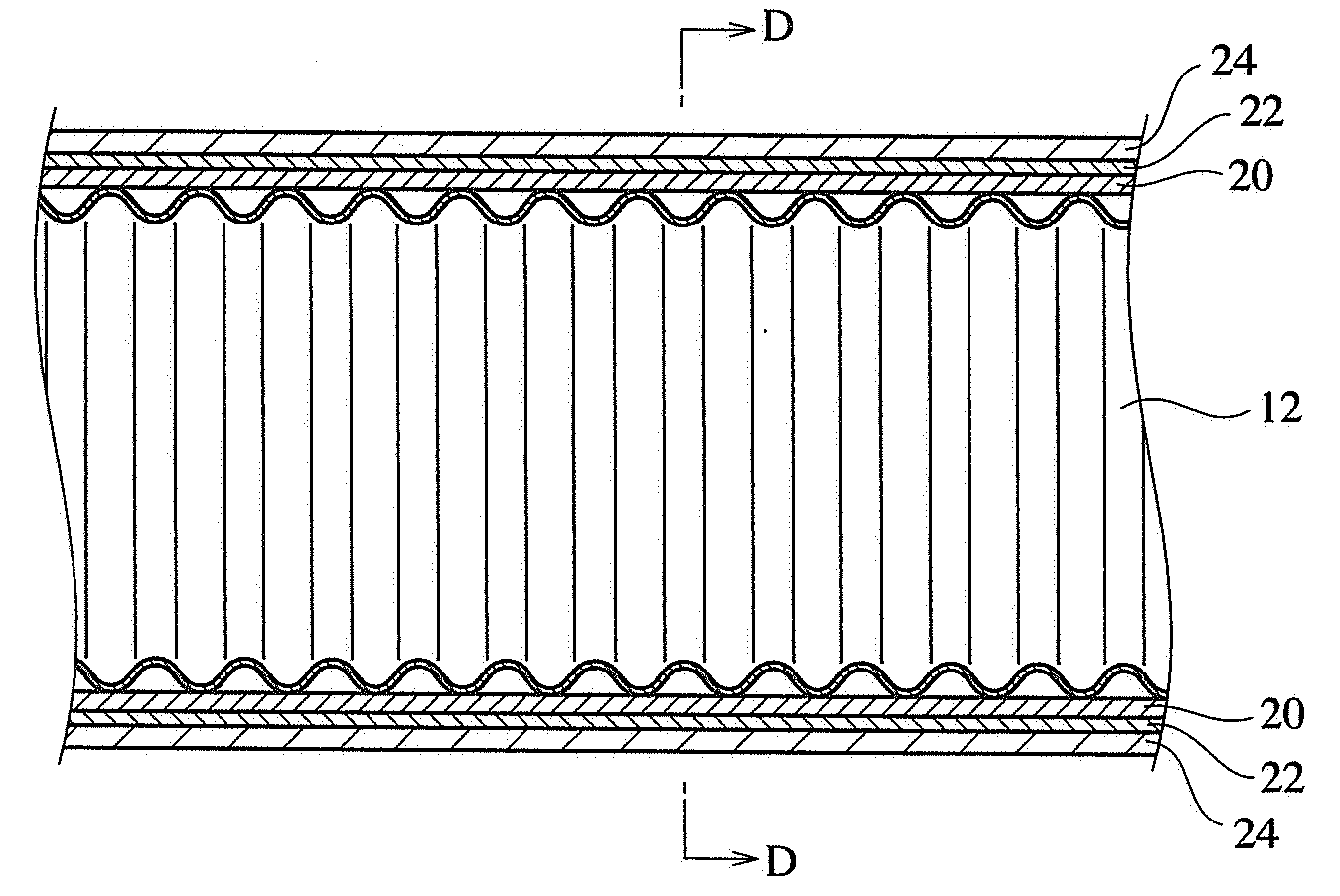

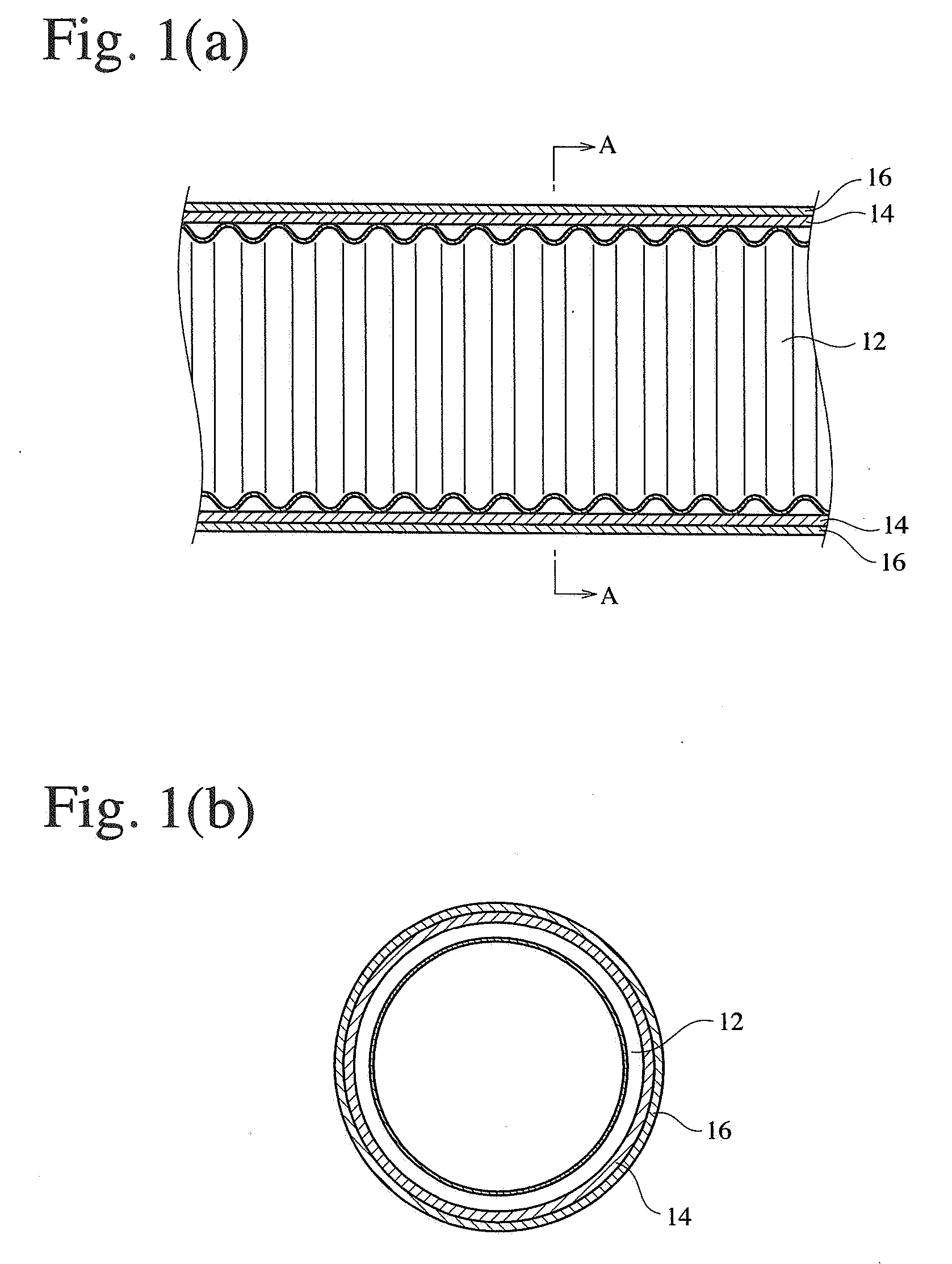

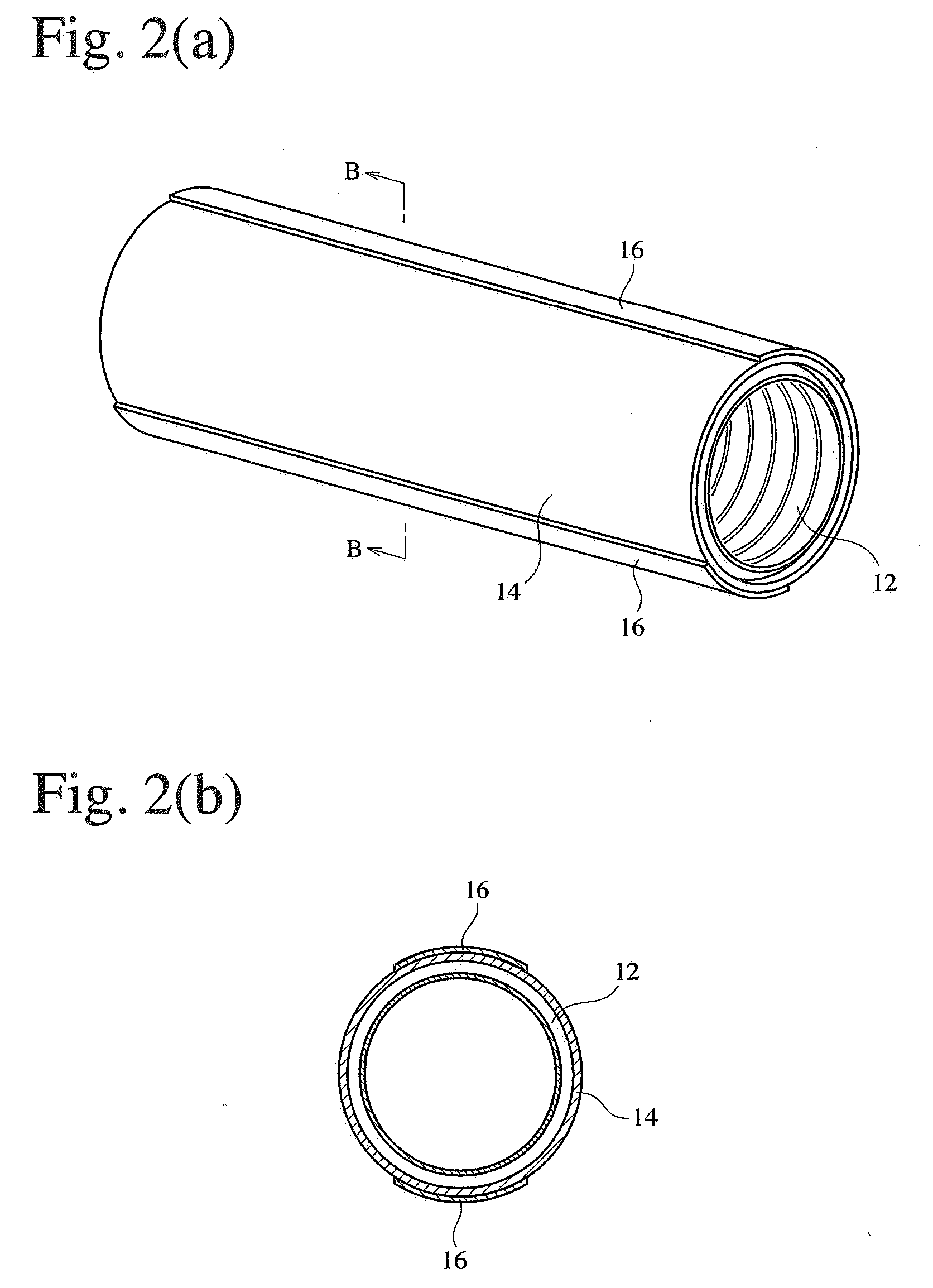

Flexible pipe

ActiveUS20090114304A1Sufficient protectionPrevent gas leakageElectrical apparatusFlexible pipesEngineeringSpark discharge

Owner:HITACHI METALS LTD

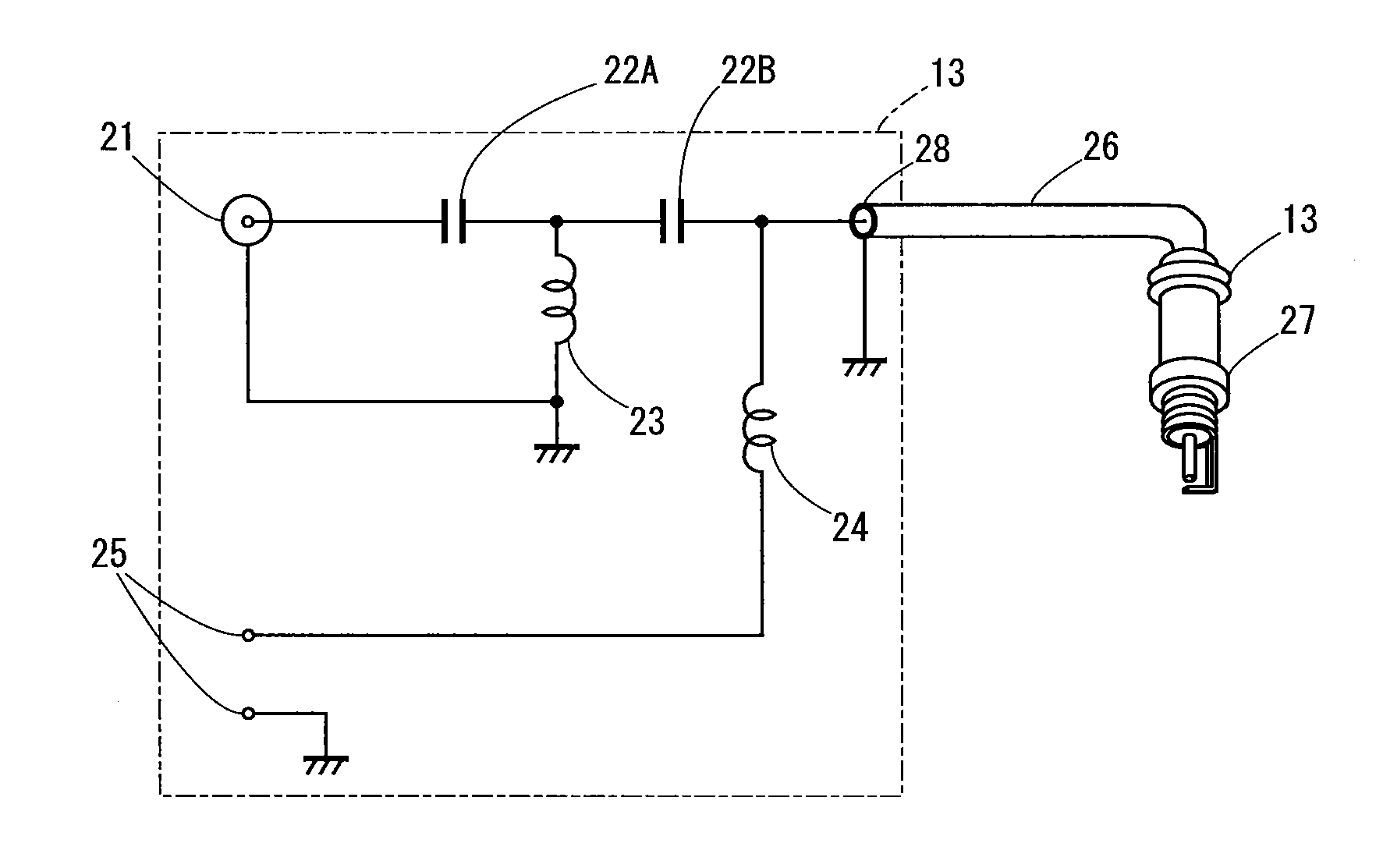

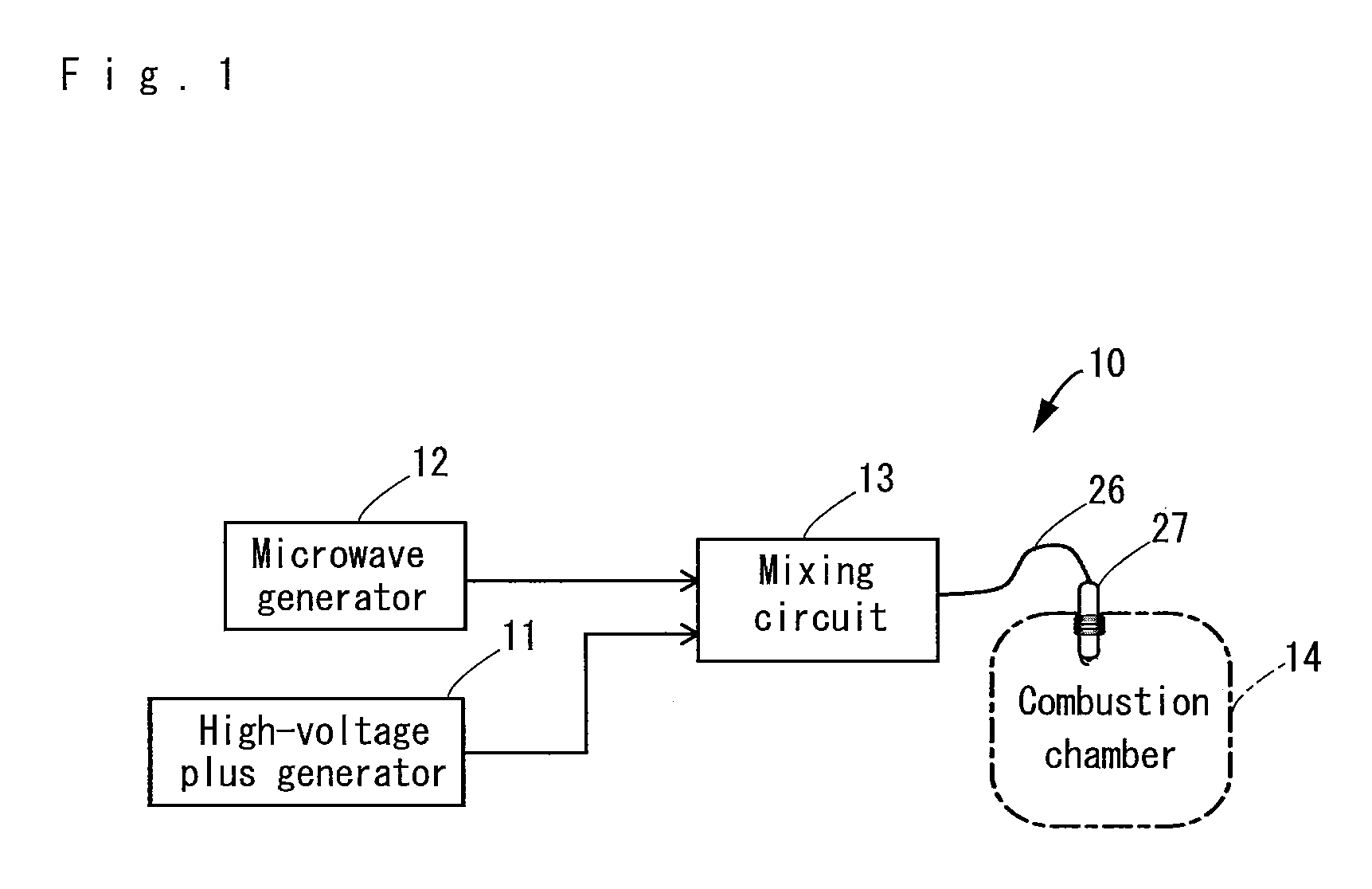

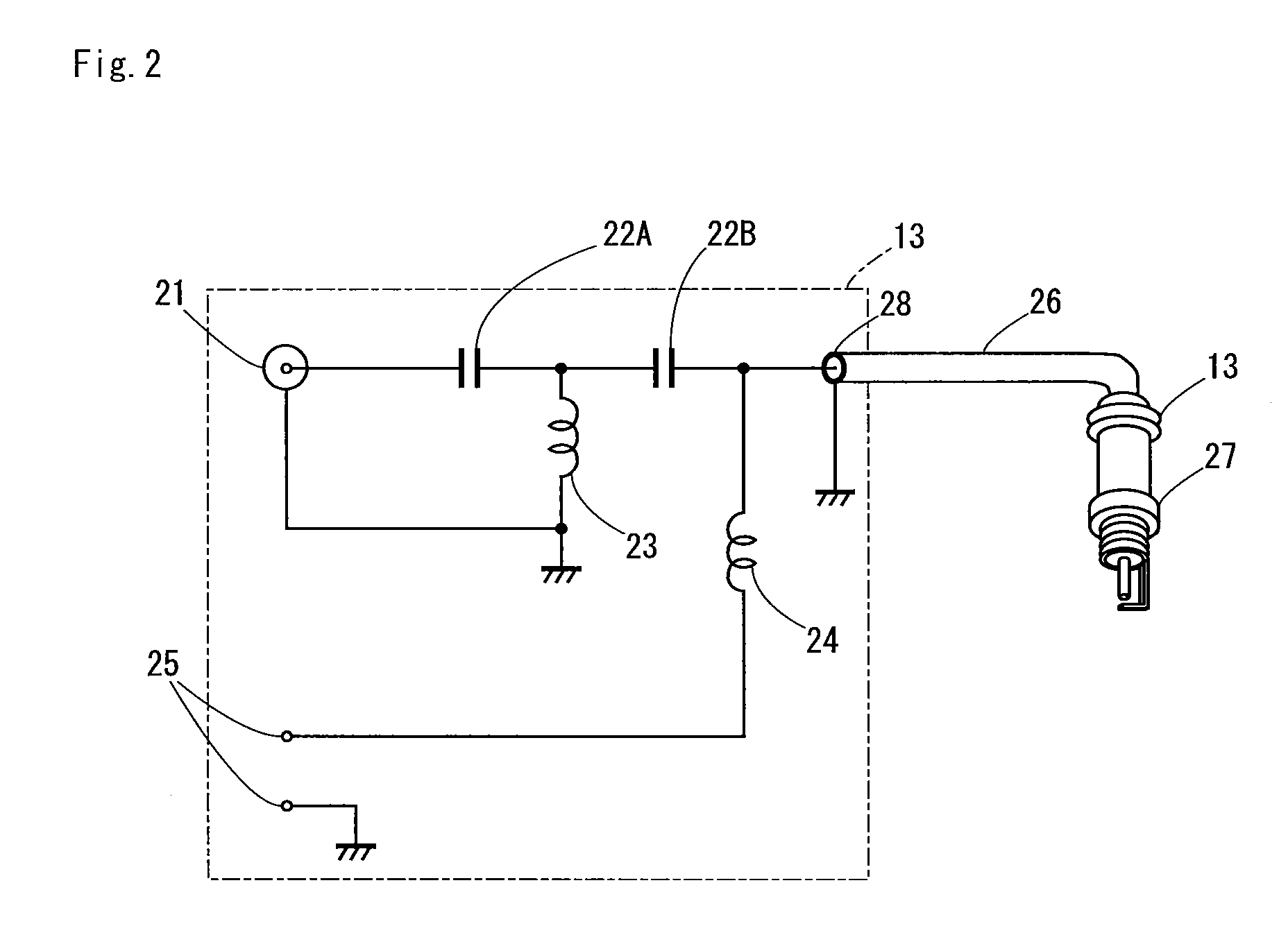

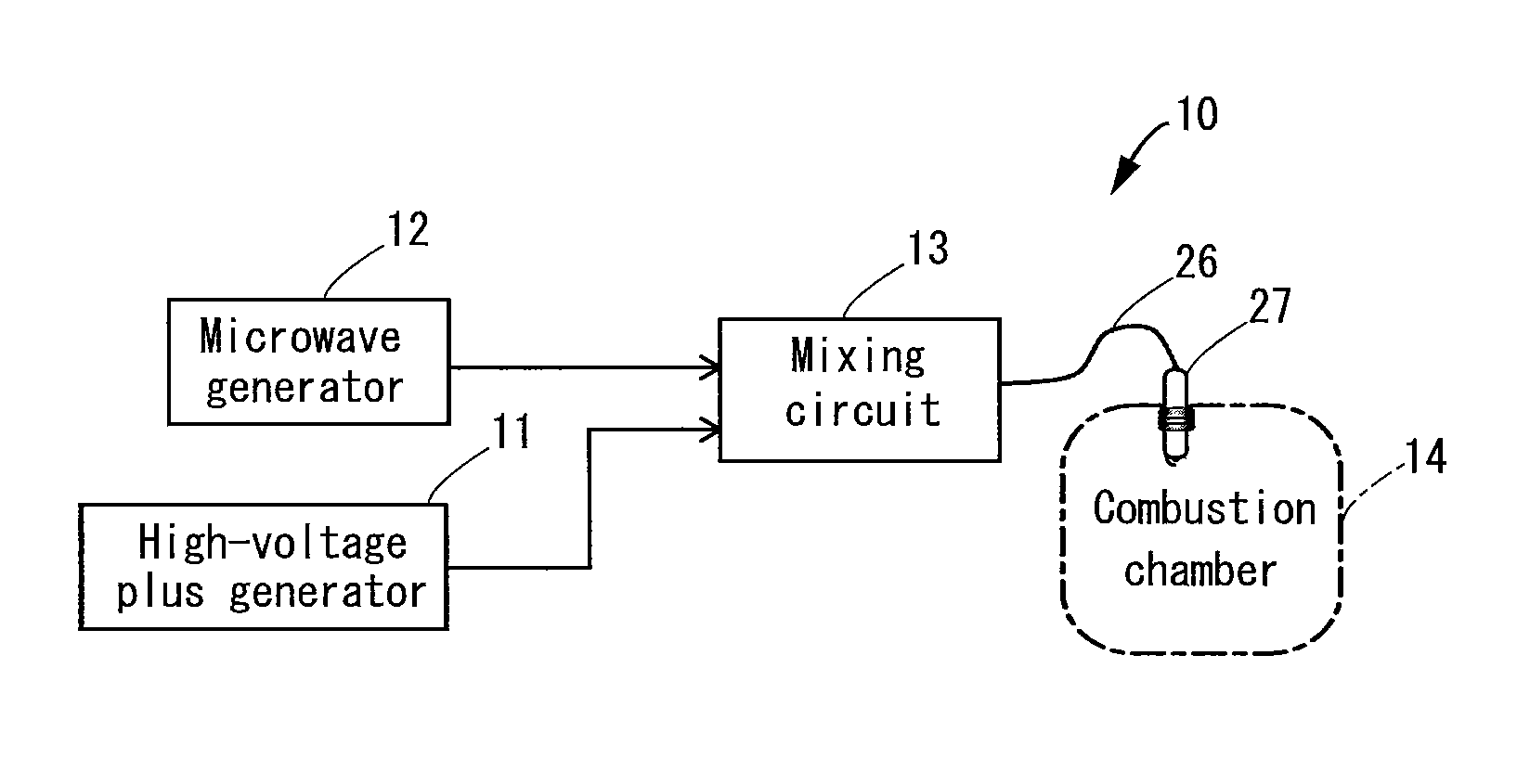

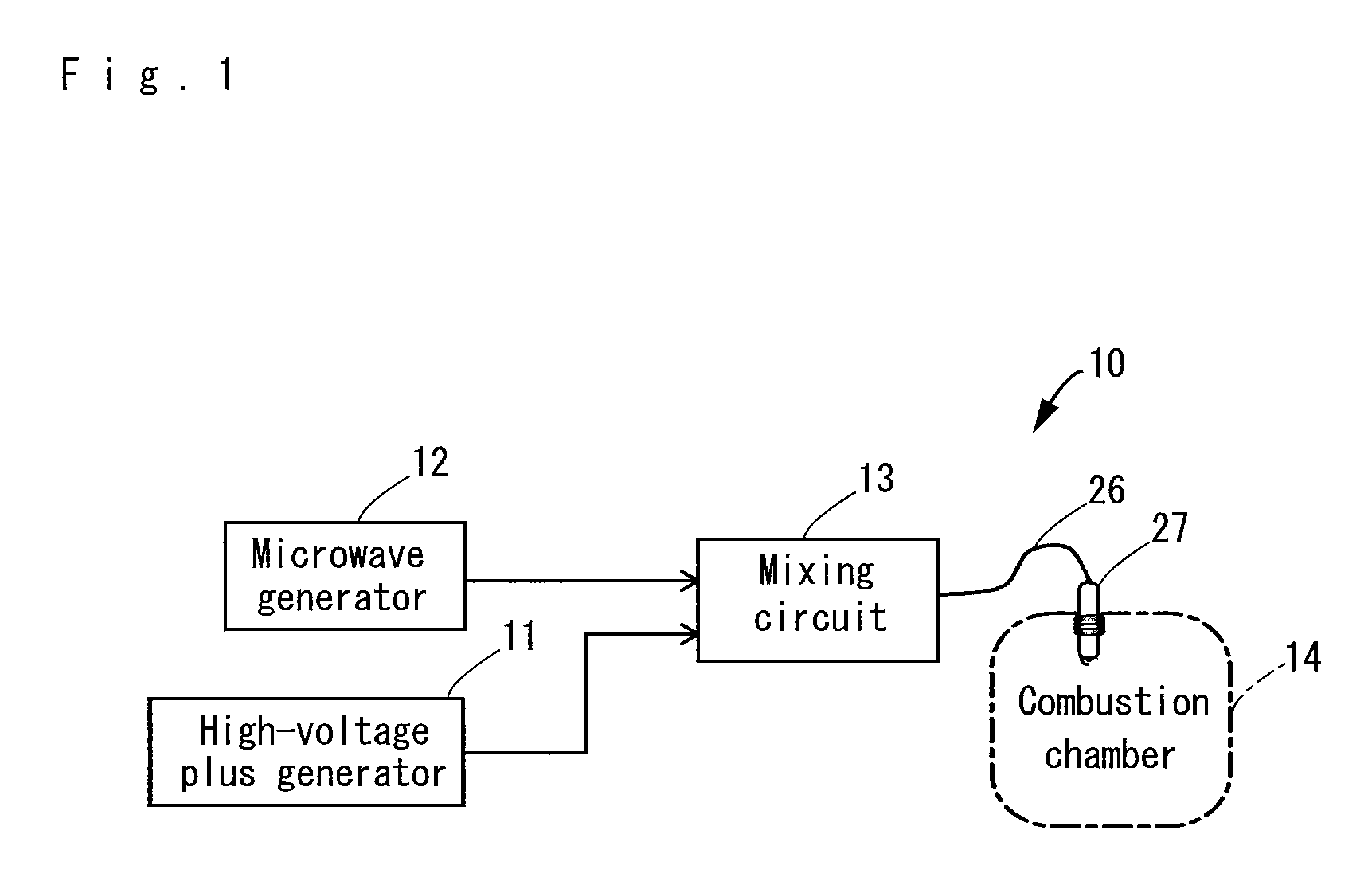

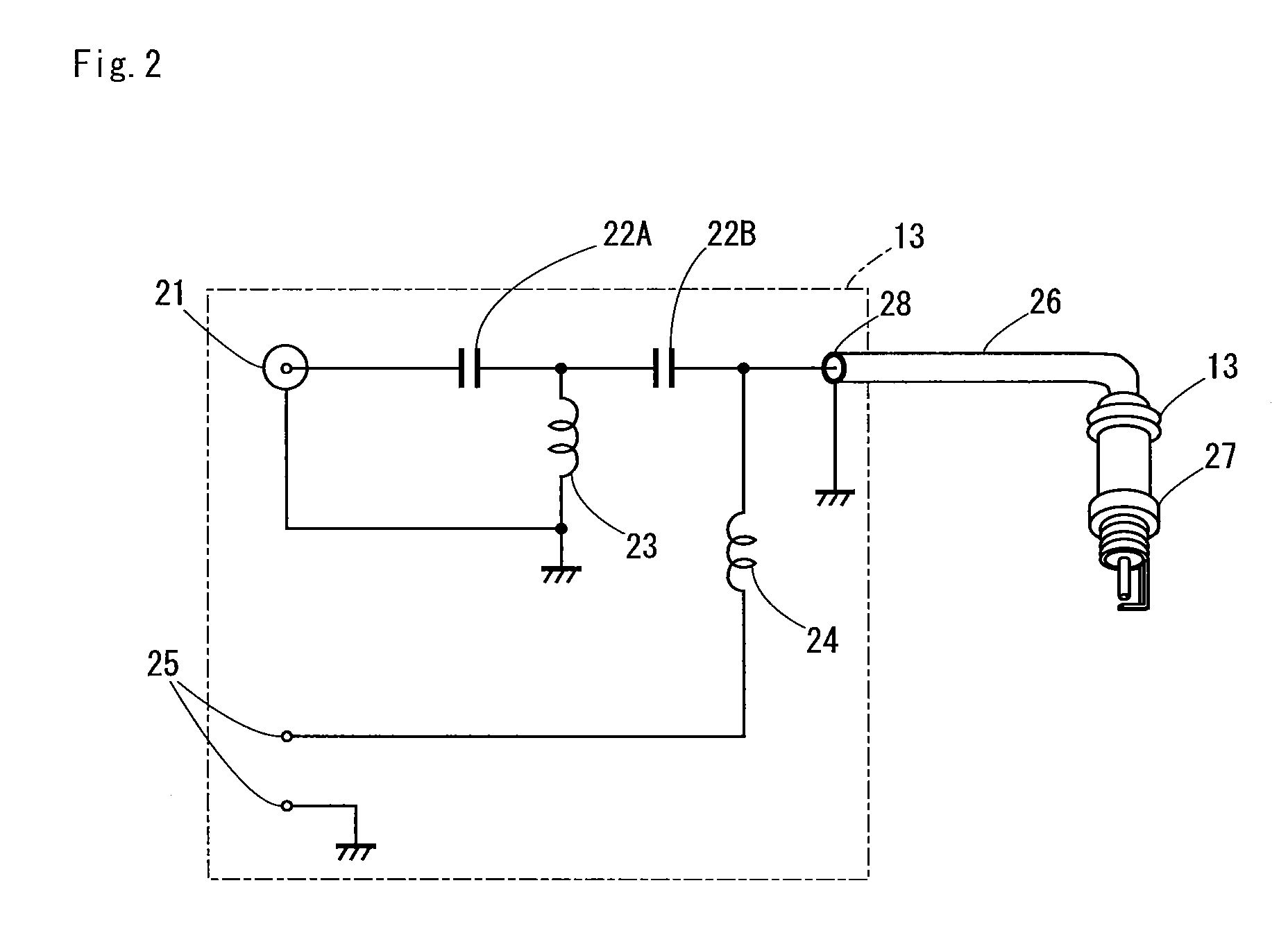

Ignition or plasma generation apparatus

InactiveUS20100196208A1Easy to mass produceEasy wiringSparking plugsMaterial analysis by electric/magnetic meansCombustion chamberMicrowave

There is provided an ignition or plasma generation apparatus that eliminates the need for resonance means in a combustion chamber and simplifies the electrode structure within the combustion chamber in an instance where energy from each of a spark discharge and microwaves is used to ignite an air-fuel mixture gas in an internal combustion engine. The ignition or plasma generation apparatus includes a mixing circuit for mixing a high-voltage pulse from a high-voltage pulse generator and microwave energy from a microwave generator; and an ignition plug into which an output from the mixing circuit is supplied, the plug used for introducing the output into a combustion chamber of an internal combustion engine. The output supplied from the mixing circuit to the ignition plug is supplied in a manner in which the microwave energy and the high-voltage pulse are superimposed on each other on a same transmission line.

Owner:MAGINEERING INC

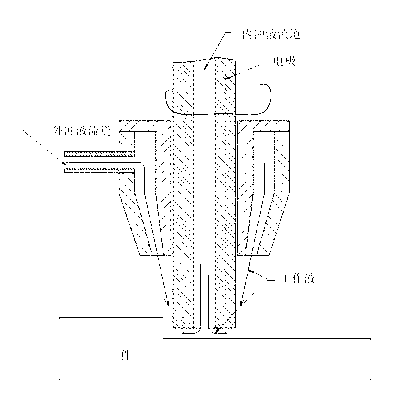

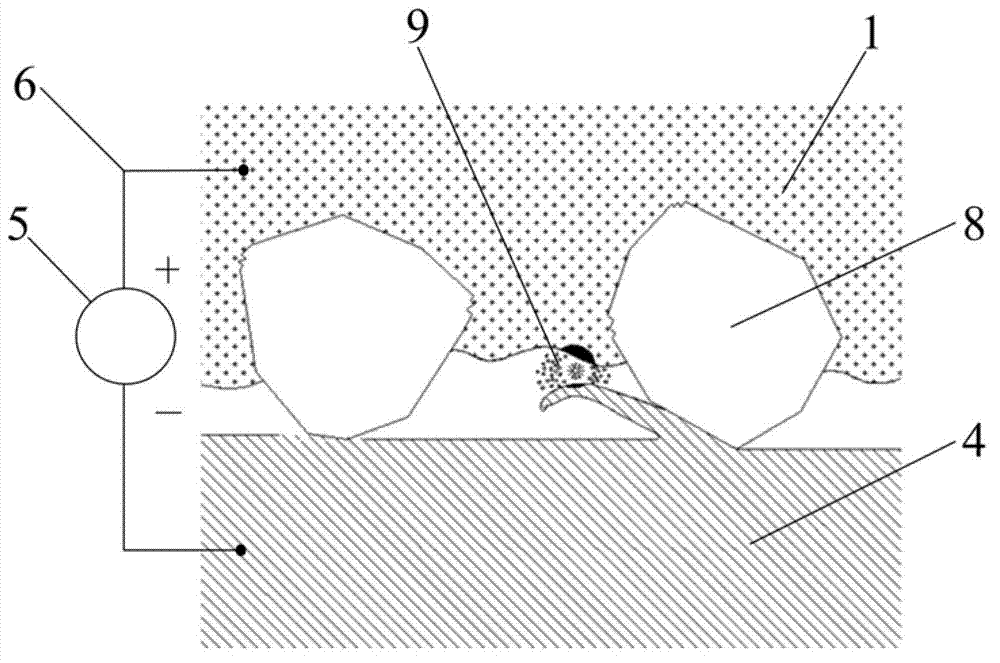

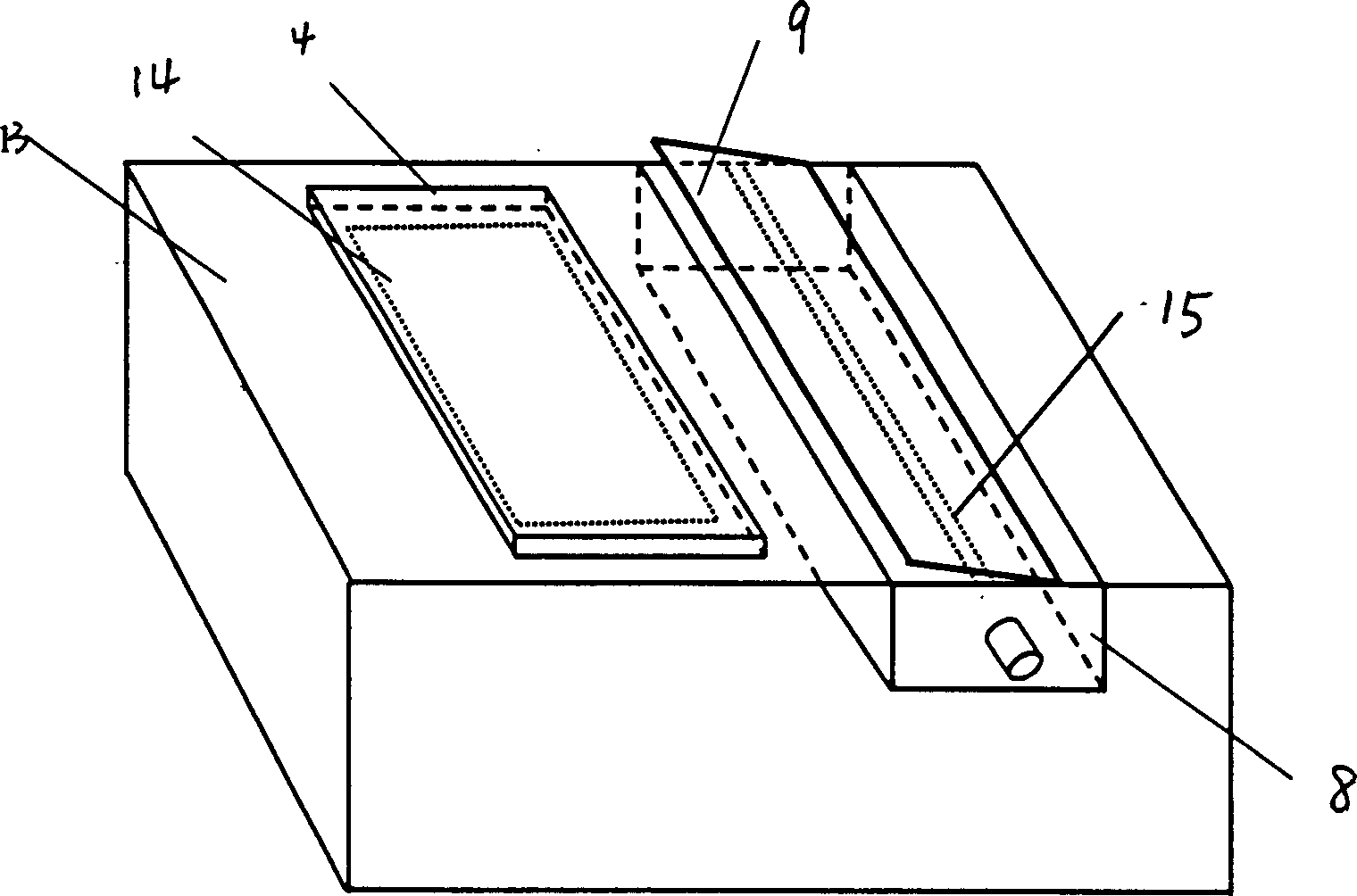

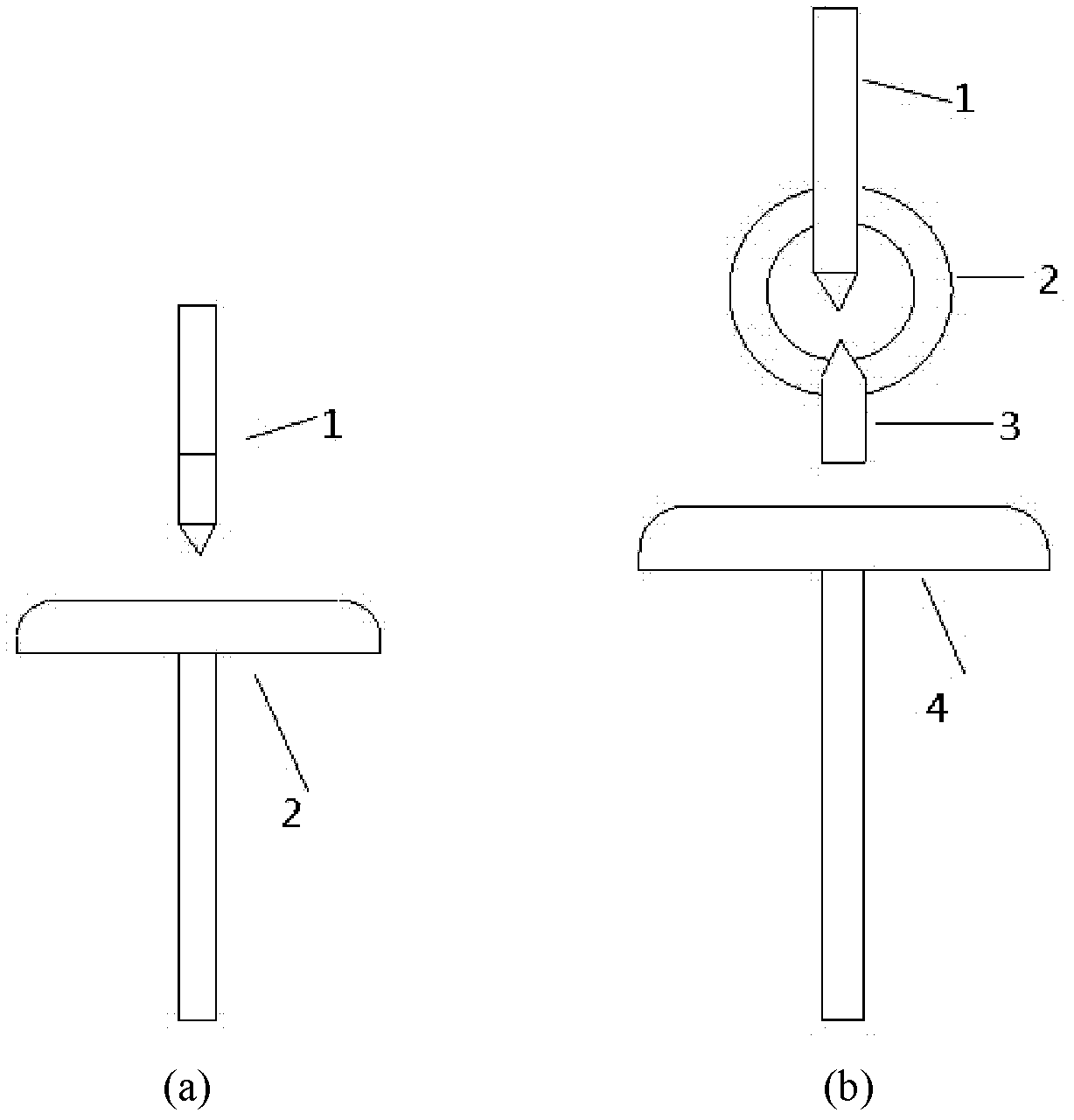

Efficient micro-machining method and device for non-conductive crisp and hard material

InactiveCN105215487AEasy to updateAccelerated exclusionStone-like material working toolsElectrolysisAuxiliary electrode

The invention belongs to the field of combined micro-machining and discloses an efficient micro-machining method and device for a non-conductive crisp and hard material. According to the machining method, ultrasonic vibration, electrolyzing, electric sparks, high-speed drill milling and other machining methods are organically combined to complete machining of non-conductive microstructures. In other words, a workpiece, a tool electrode and an auxiliary electrode are immersed into an electrolyte; the auxiliary electrode and the tool electrode are subjected to an electrolytic reaction; hydrogen evolution happens to the surface of the tool electrode connected with a negative electrode, and an insulation air film is formed; generation and homogenizing of the air film on the surface of the tool electrode are facilitated under the cavatition effect of ultrasonic vibration; and during machining, the tool electrode and the electrolyte on the surface of the workpiece generate spark discharge to puncture the air bubble film, and therefore a high-temperature erosion non-conductive workpiece material is generated. The machining device comprises a machine tool bed, an electrolysis-electrical discharge machining unit, an ultrasonic vibration worktable and a feeding worktable. Due to high-speed rotation of the spiral tool electrode and ultrasonic vibration of the workpiece, a clearance flow field can update the electrolyte efficiently. The efficient micro-machining method and device have the beneficial effects that efficiency and precision are high, and cost is low, and the efficient micro-machining method and device are very suitable for micro-machining of the non-conductive hard and crisp materials.

Owner:SHANDONG UNIV

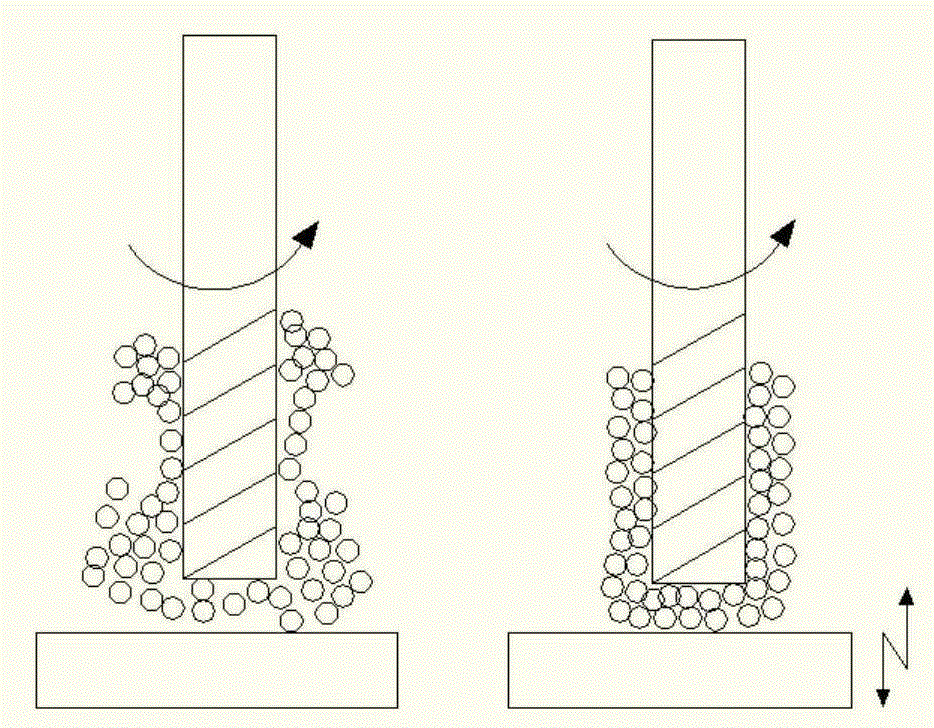

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

High power discharge fuel ignitor

ActiveUS20080018216A1Reduce erosionGreat cross sectionSpark gapsMachines/enginesElectricityCombustion

A spark-ignited, internal combustion engine ignition device to increase electrical transfer efficiency of the ignition by peaking the electrical power of the spark during the streamer phase of spark creation and improving combustion quality, incorporating an electrode design and materials to reduce electrode erosion due to high power discharge, an insulator provided with capacitive plates to peak the electrical current of the spark discharge, and concomitant methods.

Owner:PASSAIC RIVER CO INC

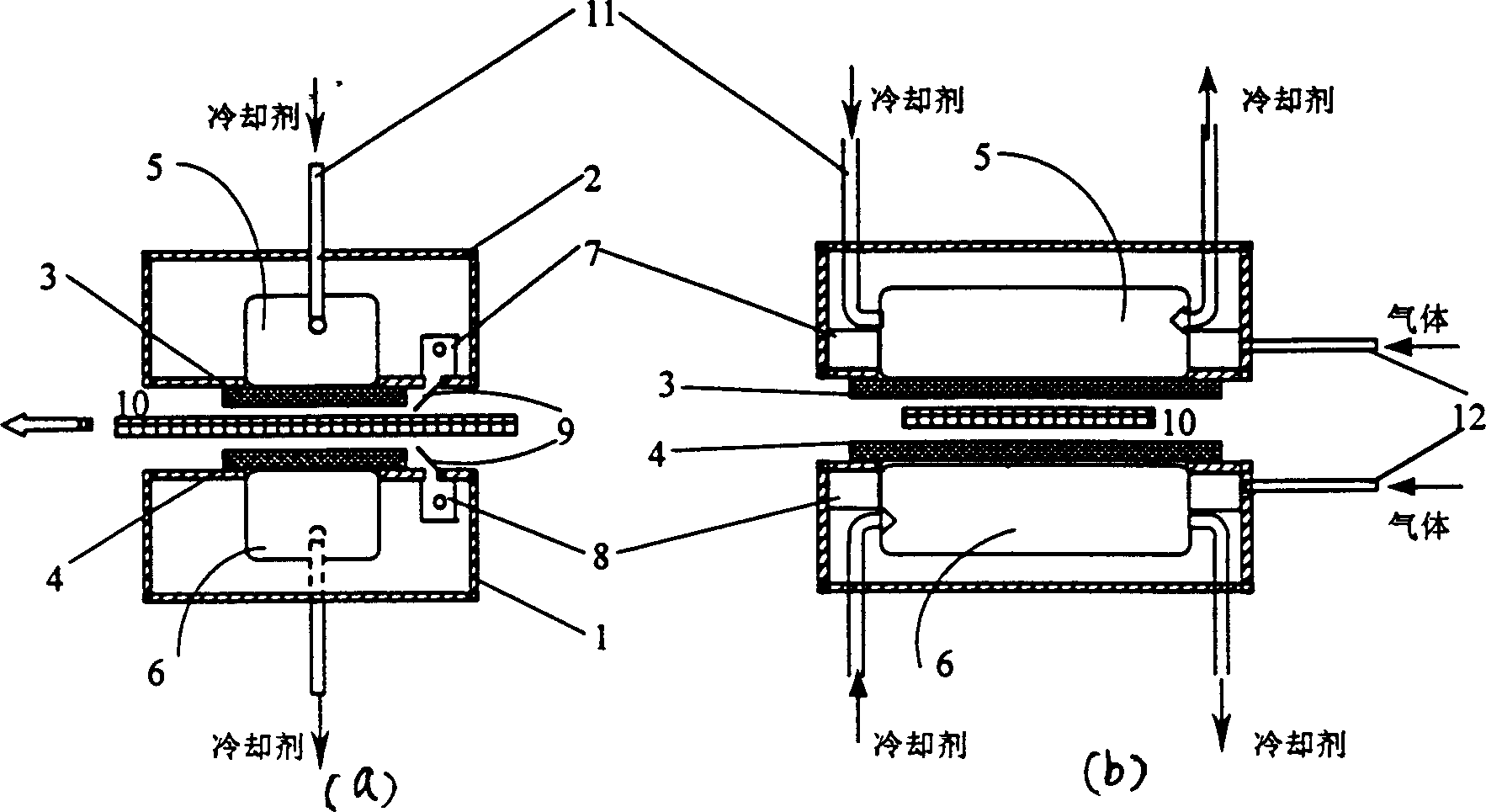

Normal-pressure low-temperature plasma treater for modifying fiber surface

The present invention relates to one kind of medium-blocked discharge treater producing normal pressure low temperature plasma for fiber material modification. The treater consists of four parts including one pair of cooled planar discharge electrodes; two reaction gas ducts and two gas guide plates. The treater produces homogeneous low temperature plasma at atmosphere while avoiding interpolar arc light and spark discharge. Fiber material set in or passing through the discharge area is treated by the normal pressure and low temperature plasma to obtain effective modification. After the said treatment, the surface moistening performance and dyeing performance are improved obviously.

Owner:DONGHUA UNIV

Spark plug

A spark plug is disclosed, in which a center electrode has, at the end thereof which forms a spark discharge gap, a noble metal chip which has a straight rod portion of 1.0 mm or less in diameter and 0.2 mm or more in length; width of coverage K of a ground electrode on which a rectangular noble metal chip is welded satisfies a relation of -d<=K<=0.5 mm (where, d represents the diameter of the end face of the center electrode); and width w of a portion of the discharge plane 111A which falls within a range corresponded to the axial extension of the end face 22B of the noble metal chip 22 provided on the center electrode 2 satisfies a relation of w<2.1-K (in mm), where K is the foregoing width of coverage.

Owner:NGK SPARK PLUG CO LTD

Method and device for coaxial combined machining with tubular electrode discharging and laser irradiation

ActiveCN106424987AImprove processing efficiencyImprove processing localityStress concentrationMaterial defect

The invention provides a method and a device for coaxial combined machining with tubular electrode discharging and laser irradiation, and belongs to the field of non-traditional machining and combined machining. Micro-etching machining is performed on the surface of an insulating high-hardness brittle material by virtue of a coaxial action of cone-shaped tube electrode discharging and laser irradiation, recessive material defects and stress concentration generated by pulsed laser acting on the surface of a workpiece can attract spark discharge to always act on the current area, and meanwhile, the spark discharge changes the surface shape and physico-chemical property of the current area, then nonlinear absorption of the current area on laser energy is improved, a local field enhancement effect is generated, and pulsed laser focused irradiation can accelerate an electrochemical reaction to promote generation of a stable discharge gas film layer on the surface of a hollow tool electrode; and the interactive cooperation of two types of energy achieves fixed-area micro-etching of the insulating high-hardness brittle material, the machining efficiency is significantly improved, and the machining quality is improved.

Owner:JIANGSU UNIV

Ignition or plasma generation apparatus

InactiveUS8226901B2Simple electrode structureEliminate needSparking plugsMaterial analysis by electric/magnetic meansCombustion chamberMicrowave

There is provided an ignition or plasma generation apparatus that eliminates the need for resonance means in a combustion chamber and simplifies the electrode structure within the combustion chamber in an instance where energy from each of a spark discharge and microwaves is used to ignite an air-fuel mixture gas in an internal combustion engine. The ignition or plasma generation apparatus includes a mixing circuit for mixing a high-voltage pulse from a high-voltage pulse generator and microwave energy from a microwave generator; and an ignition plug into which an output from the mixing circuit is supplied, the plug used for introducing the output into a combustion chamber of an internal combustion engine. The output supplied from the mixing circuit to the ignition plug is supplied in a manner in which the microwave energy and the high-voltage pulse are superimposed on each other on a same transmission line.

Owner:MAGINEERING INC

Spark plug having ground electrode protruding member with inner and outer edges

A spark plug includes a metal shell, an insulator, a center electrode, and a ground electrode. The insulator is retained in the metal shell. The center electrode is secured in the insulator and has an end portion that protrudes from the insulator and has an end edge. The ground electrode includes a base member fixed to the metal shell and a protruding member joined to the base member. The protruding member protrudes from a surface of the base member and has a hollow end face that faces the end portion of the center electrode through a spark gap. The end face of the protruding member has an inner edge and an outer edge, both of which face the end edge of the end portion of the center electrode. With the above configuration, the spark plug can induce spark discharges with a low discharge voltage while securing the ignition capability thereof.

Owner:DENSO CORP +1

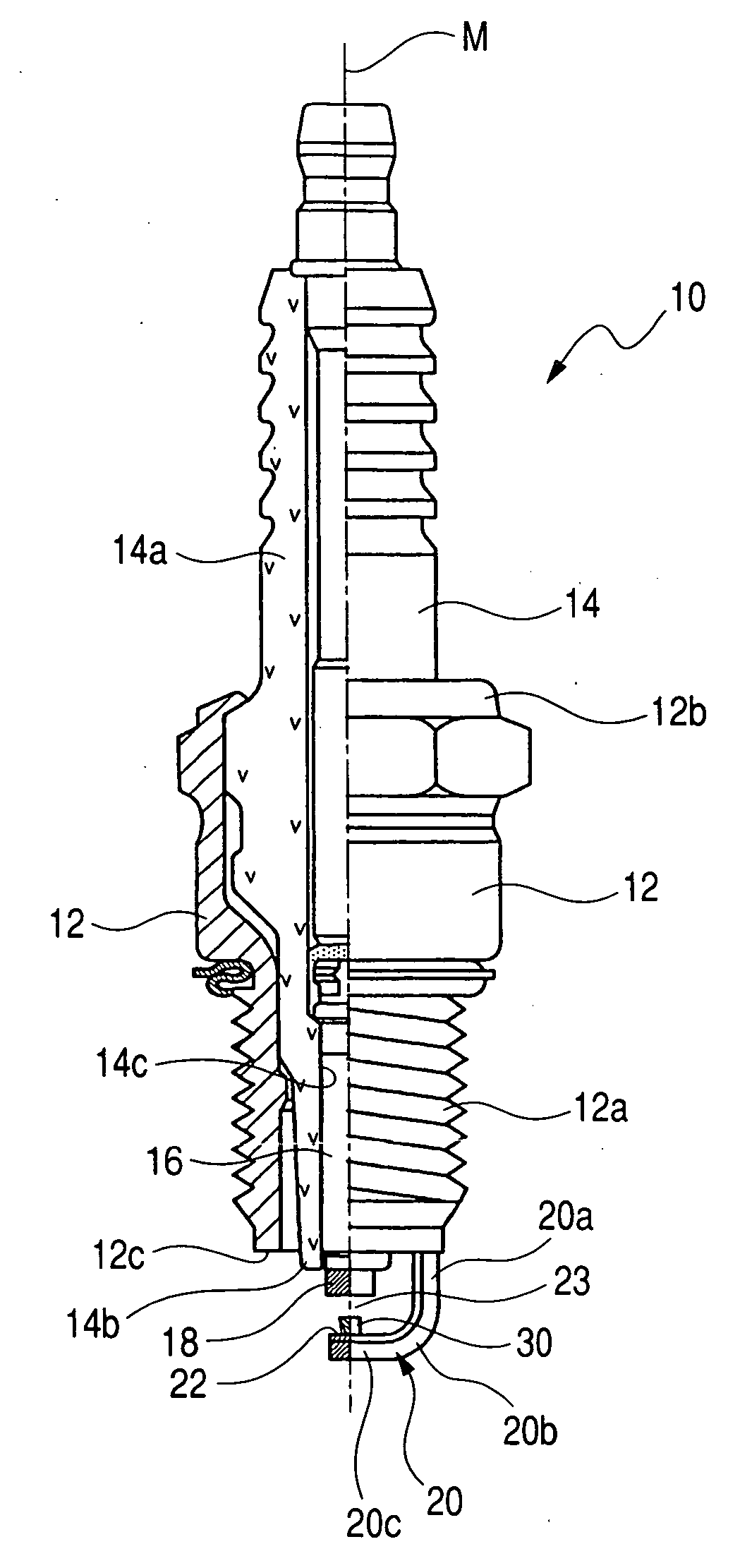

Spark plug for internal combustion engine

InactiveUS20070188065A1Excellent fuel clamping resistance and fuel bridging resistanceInhibitionSparking plugsEngineeringInternal combustion engine

A spark plug for an internal combustion engine is disclosed having a metal shell having an outer periphery formed with a mounting thread, a porcelain insulator fixedly secured to the metal shell on a central axis thereof, a center electrode retained within the porcelain insulator along a central axis thereof with a distal end located outside the porcelain insulator, and a ground electrode joined to the metal shell and having an end associated with the distal end of the center electrode to define therebetween a spark discharge gap. The ground electrode includes a facing surface intersecting the central axis of the center electrode and having a width equal to or less than 1.6 mm.

Owner:DENSO CORP

Tester for testing SF6 gas discharge decomposition product characteristics

The invention discloses a testing system device for testing SF6 gas discharge decomposition product characteristics, which comprises a test transformer, a resistance capacitance divider, a gas discharge device, a single lens reflex, a discharge capacity detecting unit, a gas taking loop and a Fourier infrared spectrometer. Different discharge faults such as pin plate corona discharge, spark discharge, particle discharge and suspension potential discharge can be simulated; the Fourier infrared spectrometer with fast response and high accuracy is utilized to analyze gas decomposition product components and disciplines under different discharge faults; and an optical signal recorded by the single lens reflex and an electric signal recorded by an oscilloscope are combined to extract typical gas and characteristic quantity reflecting the discharge faults, so that a test and theoretical foundation is laid for applying an SF6 gas decomposition product to diagnose the running state of equipment. The testing system device disclosed by the invention has the advantages of simplicity in operation, strictness, practicability, low cost of expansion, accuracy in measurement and large obtained information contents.

Owner:XI AN JIAOTONG UNIV +1

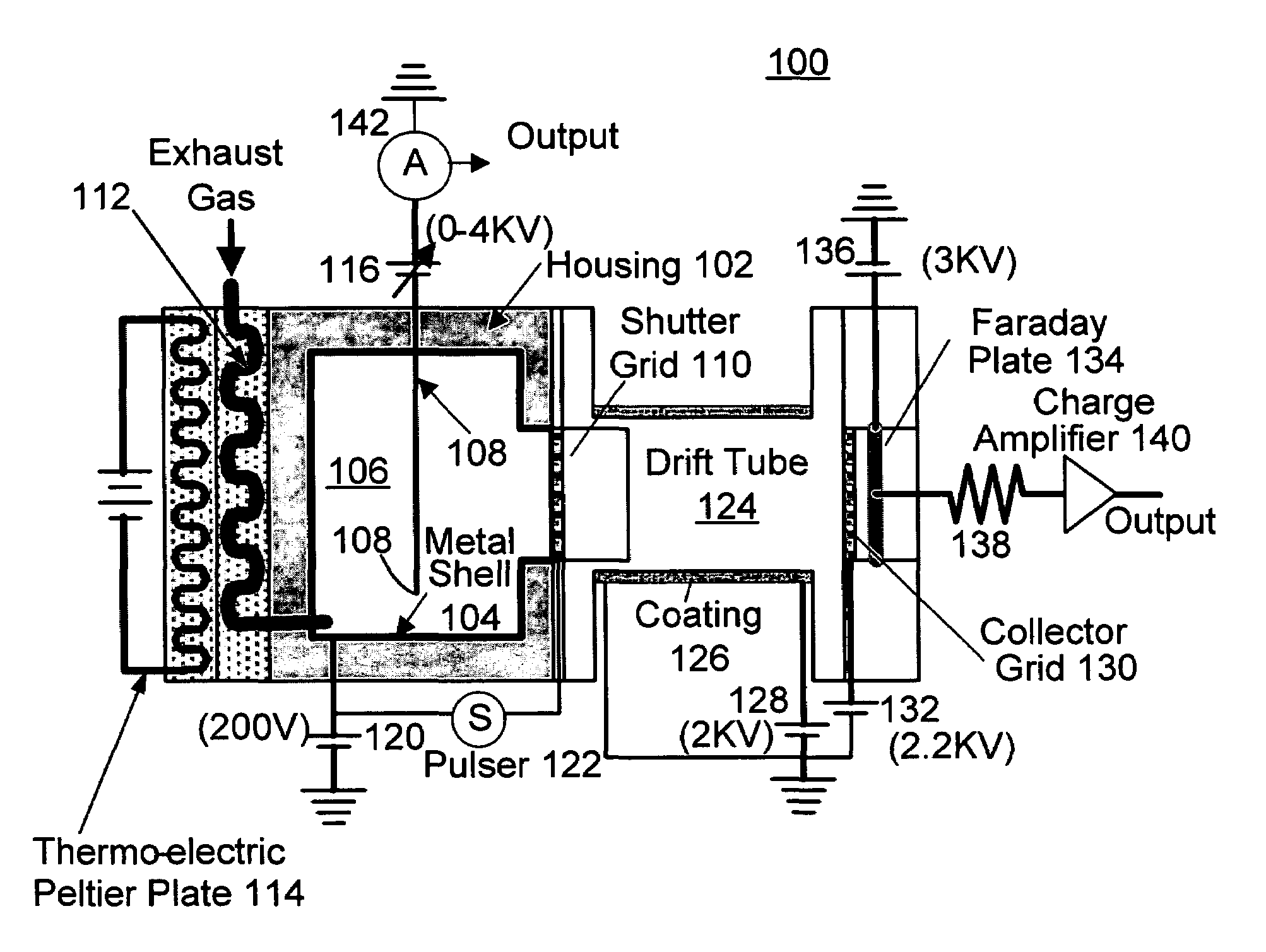

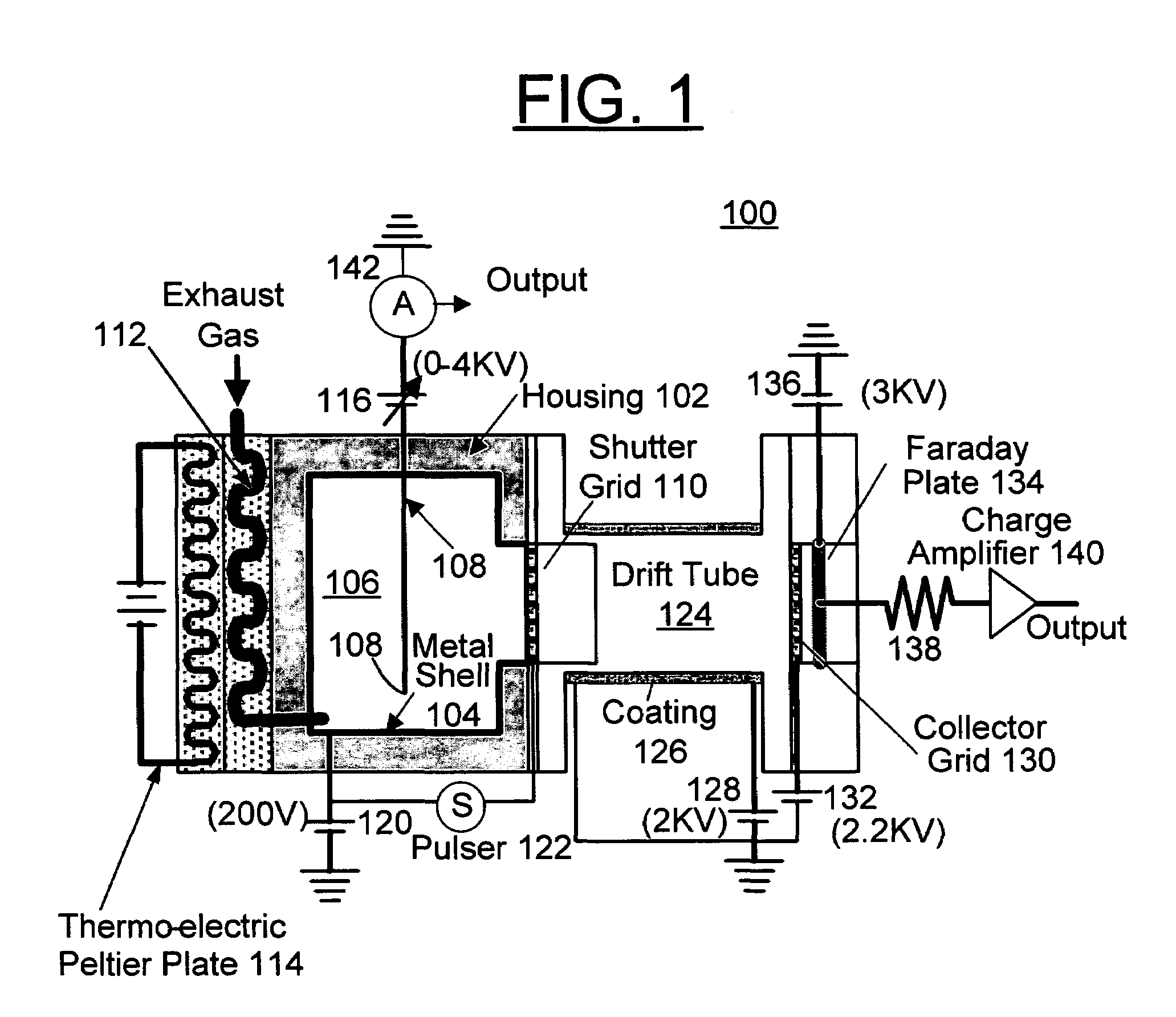

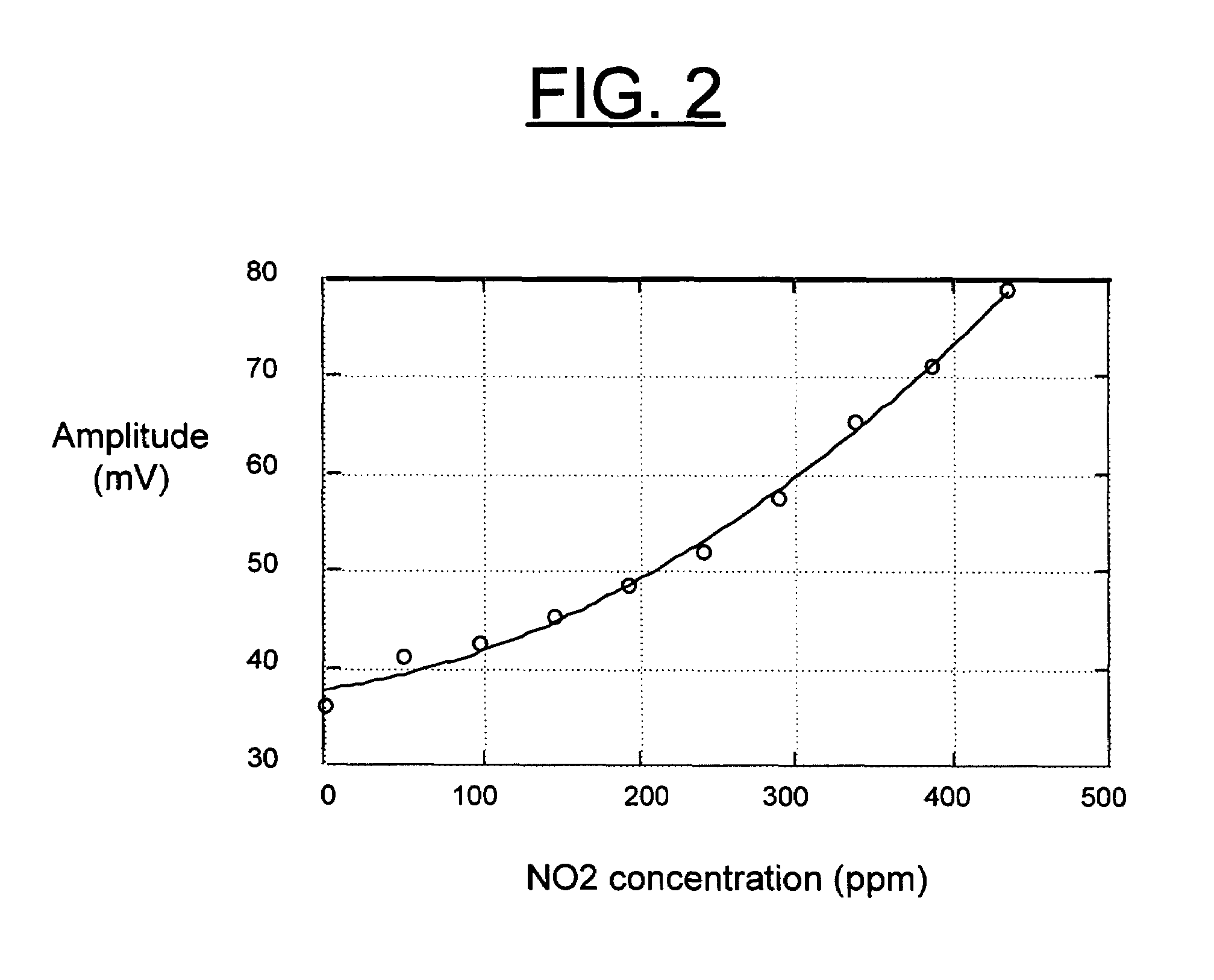

Ion-mobility spectrometry sensor for NOx detection

InactiveUS6969851B1Remove moistureMaterial analysis using wave/particle radiationTime-of-flight spectrometersIonization chamberEngineering

A sensor and detection methods are provided for detecting nitric oxides (NOx) in an exhaust gas based upon ion mobility spectrometry (IMS) technique. An ionization chamber having an interior electrically conductive shell receives exhaust gas. A spark electrode having a needle tip extends into the ionization chamber. A shutter grid is coupled between the ionization chamber and an ion drift tube. A substantially continuous spark discharge is established between the electrically conductive shell and the needle tip of the spark electrode for ionization of the exhaust gas. Negative NO2 ions are kept inside the chamber by biasing the electrically conductive shell and the shutter grid at a negative voltage. Then a positive pulse is applied to the shutter grid to cause the shutter to open for negative NO2 ions to exit into the ion drift tube. The IMS sensor is small-sized, low-cost, robust, and reliable.

Owner:UCHICAGO ARGONNE LLC

Spark plug and method for manufacturing the spark plug

A ground-electrode spark portion 32 is formed from a noble metal which contains Pt as a main component, and is joined to a main metal portion of the ground electrode 4 via an alloy layer which has a thickness ranging from 0.5 μm to 100 μm and in which the noble metal that constitutes the ground-electrode spark portion 32 and the metal that constitutes the main metal portion of the ground electrode 4 are alloyed with each other. The ground-electrode spark portion 32 is configured such that a distal end surface 32t facing a spark discharge gap g is smaller in diameter than a bottom surface 32u joined to the ground electrode 4; and the distal end surface 32t is protrusively located beyond the side surface 4s of the ground electrode 4. When the ground-electrode spark portion 32 is viewed in plane from the distal end surface 32t, a portion of the surface of the ground-electrode spark portion 32 is viewed as a peripheral exposed-region surface 32p which is exposed on the side surface 4s of the ground electrode 4 so as to surround the distal end surface 32t.

Owner:NGK SPARK PLUG CO LTD

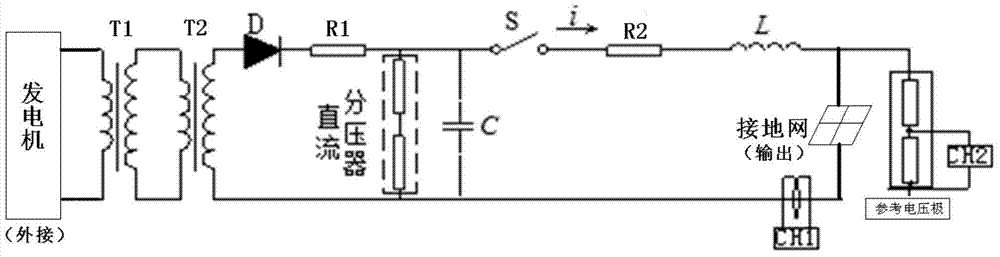

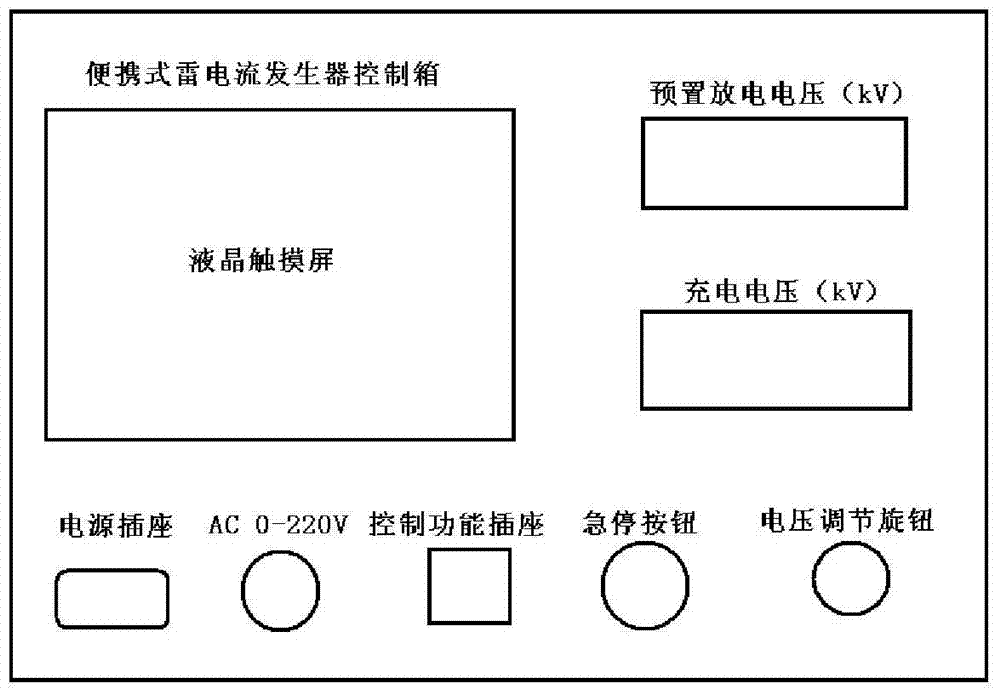

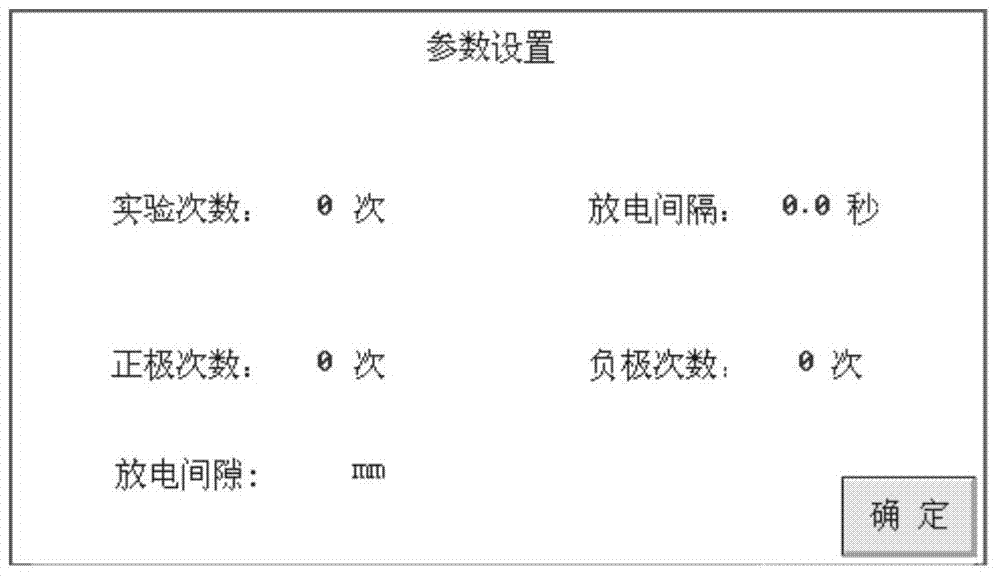

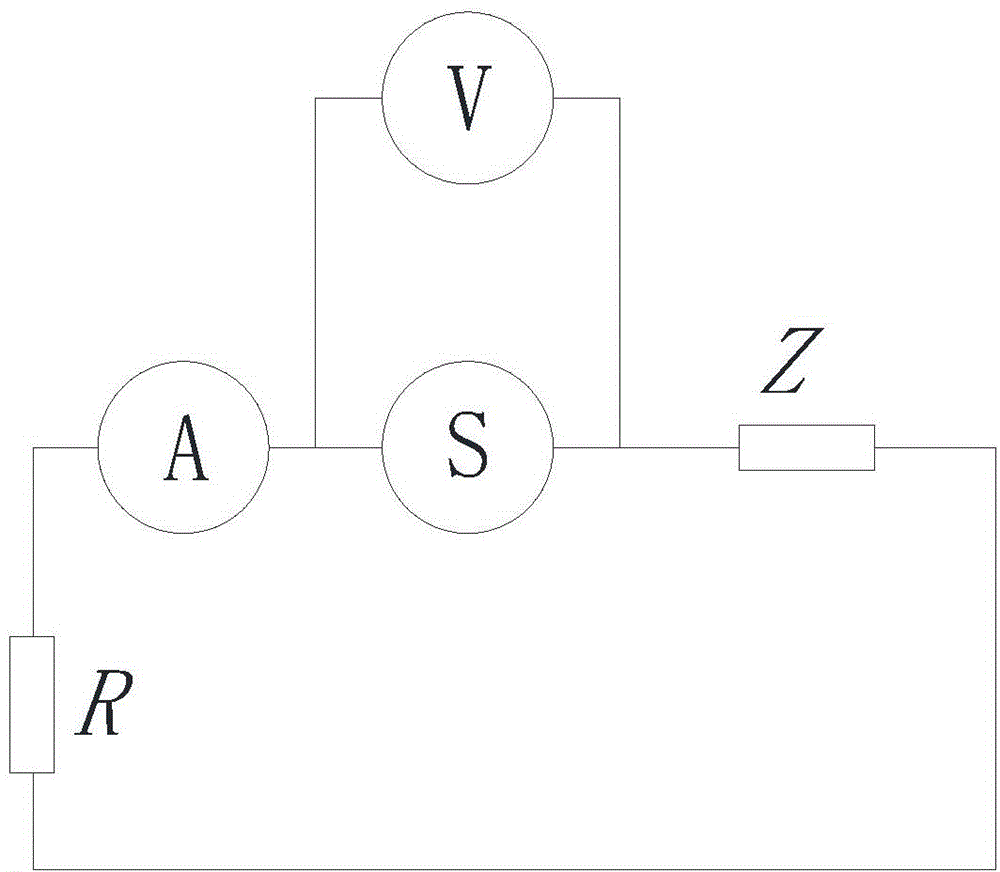

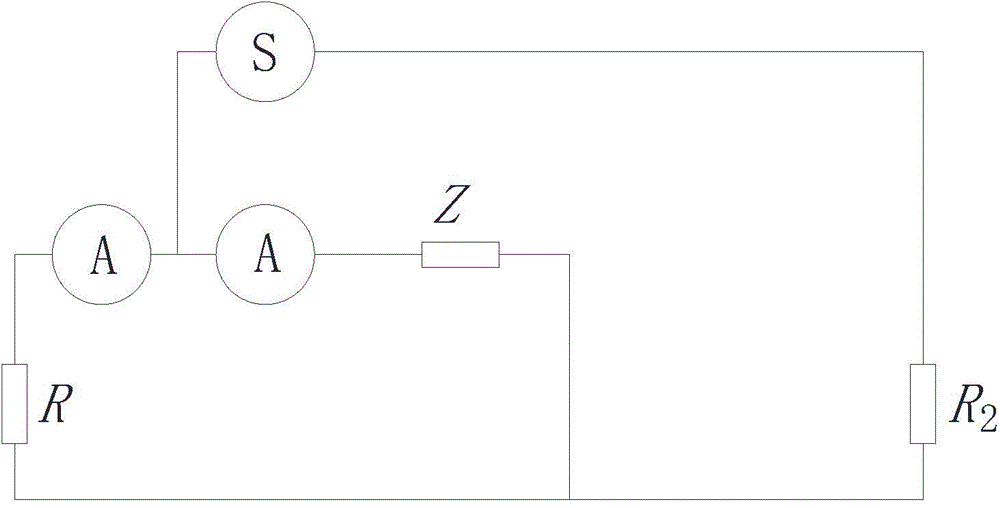

Portable lightning current generating device and method for grounding device impact impedance testing

ActiveCN104714067AImprove work efficiencyEasy to carryTesting dielectric strengthElectrical measurement instrument detailsVoltage referenceEngineering

The invention discloses a portable lightning current generating device and method for grounding device impact impedance testing. The device comprises a power generator and a lightning current generator main loop test box. A rectifying silicon stack D, a charging resistor R1 and a direct-current voltage divider are connected in series to the output end of a boosting transformer T2. An energy-storage capacitor C is connected in parallel to the direct-current voltage divider. One end of a discharging switch S is connected with a positive electrode of the energy-storage capacitor C. The other end of the discharging switch S is connected with an adjustable wave modulated resistor R2. The other end of the adjustable wave modulated resistor R2 is connected with one end of an adjustable wave modulated inductor L. The other end of the adjustable wave modulated inductor L is connected with a grounding grid to be tested through a grounding testing current injection point. A grounding testing reverse current electrode and a reference voltage electrode are arranged on the periphery of the grounding grid to be tested. The ground testing reverse current electrode is connected to a negative electrode of the energy-storage capacitor C of a lightning current generator main loop. The device can simulate inductive effect and soil spark discharging effect really, and impact grounding resistance can be tested really.

Owner:STATE GRID CORP OF CHINA +2

Method for measuring impact earthing impedance of electric transmission overhead line structure earthing device with lightning conductor

The invention provides a method for measuring impact earthing impedance of an electric transmission overhead line structure earthing device with a lightning conductor. According to the method, a lightning conductor or an overhead ground wire of other type are erected on an electric transmission overhead line structure; the earthing device of the overhead line structure is connected with the overhead line structure or the lightning conductor or the overhead ground wire through a downlead; the downlead is connected with the earthing device through bolts; the downlead and the earthing device are electrically connected and can be detached. According to the method, the impact earthing impedance of the electric transmission overhead line structure earthing electrode can be directly measured, errors in measurement caused by uneven soil structure and measuring electrode position deviation are avoided, the wiring manner is simpler and the measurement result is more accurate; through the adoption of the methods such as increasing the amplitude value of the output voltage waveform or the current waveform of the power supply or multiplying spark discharging coefficient, the impact earthing impedance of the electric transmission overhead line structure earthing device after the spark discharge can be further gained.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com