Efficient micro-machining method and device for non-conductive crisp and hard material

A technology of hard and brittle materials and processing methods, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve the problems of easy generation of micro-cracks and thermal stress, difficult to achieve micro-processing of parts, and macro-cutting forces. Achieve the effect of improving machining accuracy and surface quality, optimizing the gap electric field, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

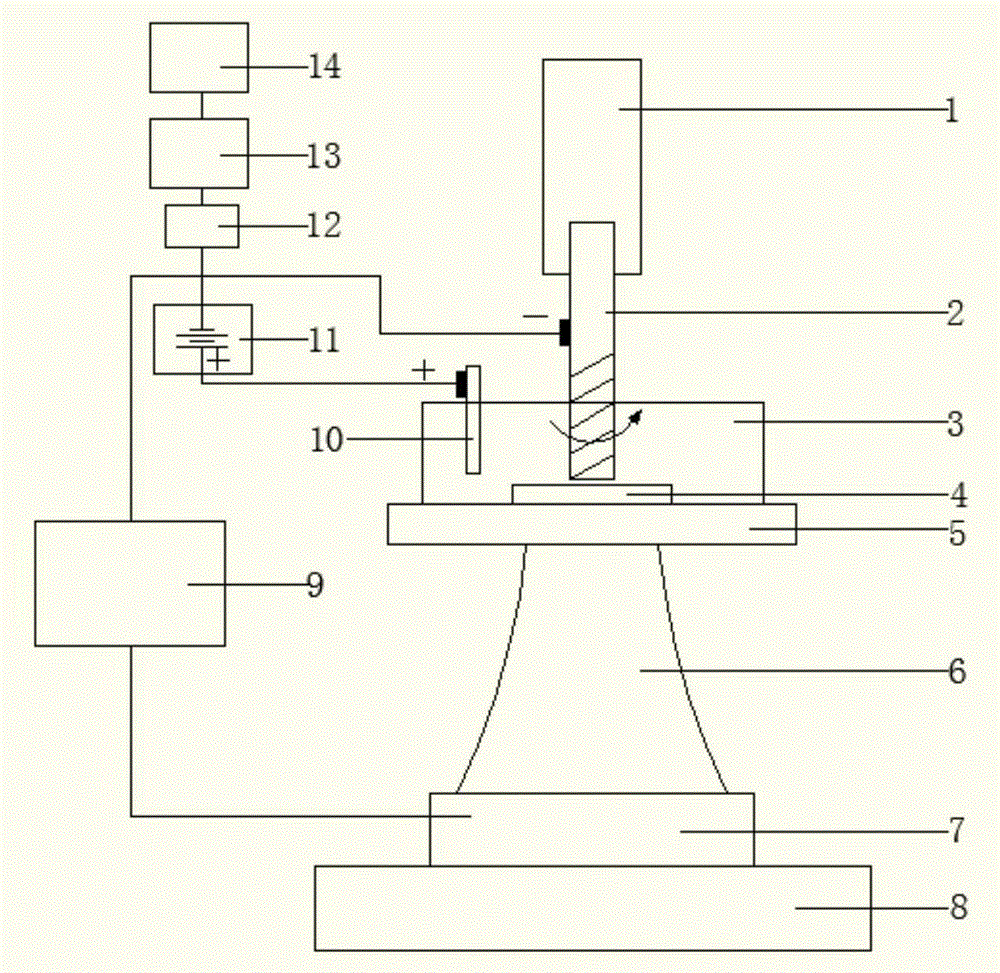

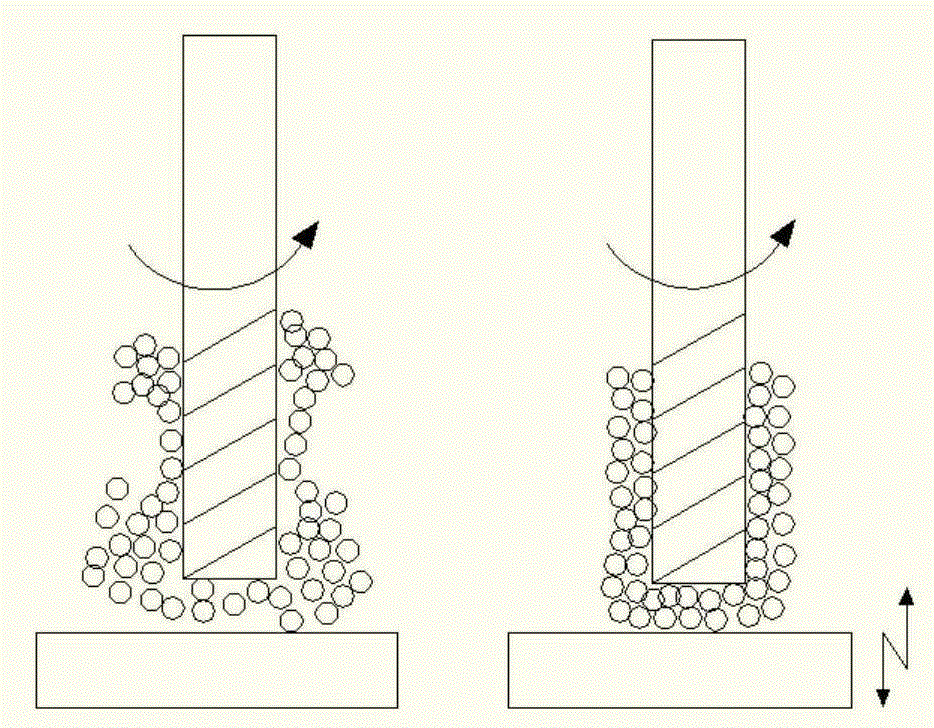

[0017] A micro-high-efficiency machining method for non-conductive hard and brittle materials—ultrasonic electrolysis-EDM micromachining, using micro-electrolysis-EDM to process workpieces with ultrasonic excitation; the power supply of the electrolysis-EDM unit adopts DC high-frequency pulse power supply ; The tool electrode is helical and rotates at high speed during machining.

[0018] Ultrasonic electrolysis-EDM micromachining device, including electrolysis-EDM unit, ultrasonic vibration table and feed table, etc. The electrolysis-EDM unit is composed of spindle 1, tool electrode 2, electrolyte 3, workpiece 4, feed table 8, auxiliary electrode 10 and electrolysis-EDM power supply 11; the tool electrode 2, auxiliary electrode 10 and workpiece 4 are submerged In the electrolyte 3; the tool electrode 2 is connected to the negative pole of the power supply, and the auxiliary electrode 10 is connected to the positive pole of the power supply; the main shaft 1 has a displacement...

Embodiment 2

[0021] The electrolysis-spark power supply 11 adopts a DC pulse power supply, the electrolyte solution 3 adopts a sodium hydroxide solution, and others are as in Example 1.

Embodiment 3

[0023] The tool electrode 2 is made of a steel needle, and the horn 6 and the vibrating disc 5, and the vibrating disc 5 and the workpiece 4 are fixedly connected by bonding, and others are as in Example 1.

[0024] The method of the present invention has the advantages of high precision of low-voltage discharge, and can also obtain good surface quality; the method of the present invention makes the workpiece perform ultrasonic vibration, making the processing process more stable, and the ultrasonic vibration of the workpiece and the high-speed rotation of the spiral electrode greatly improve the Processing efficiency; the method of the present invention is easy to realize fine, precise and high-efficiency processing in terms of processing mechanism, and the production cost is low; the method of the present invention is especially suitable for the micro-processing of non-conductive hard and brittle materials, which is conducive to improving processing accuracy and surface qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com