Patents

Literature

785 results about "Ultrasonic cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic wound debrider probe and method of use

ActiveUS7931611B2Shorten the timeImprove surgical efficiencyUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic cavitationMedical treatment

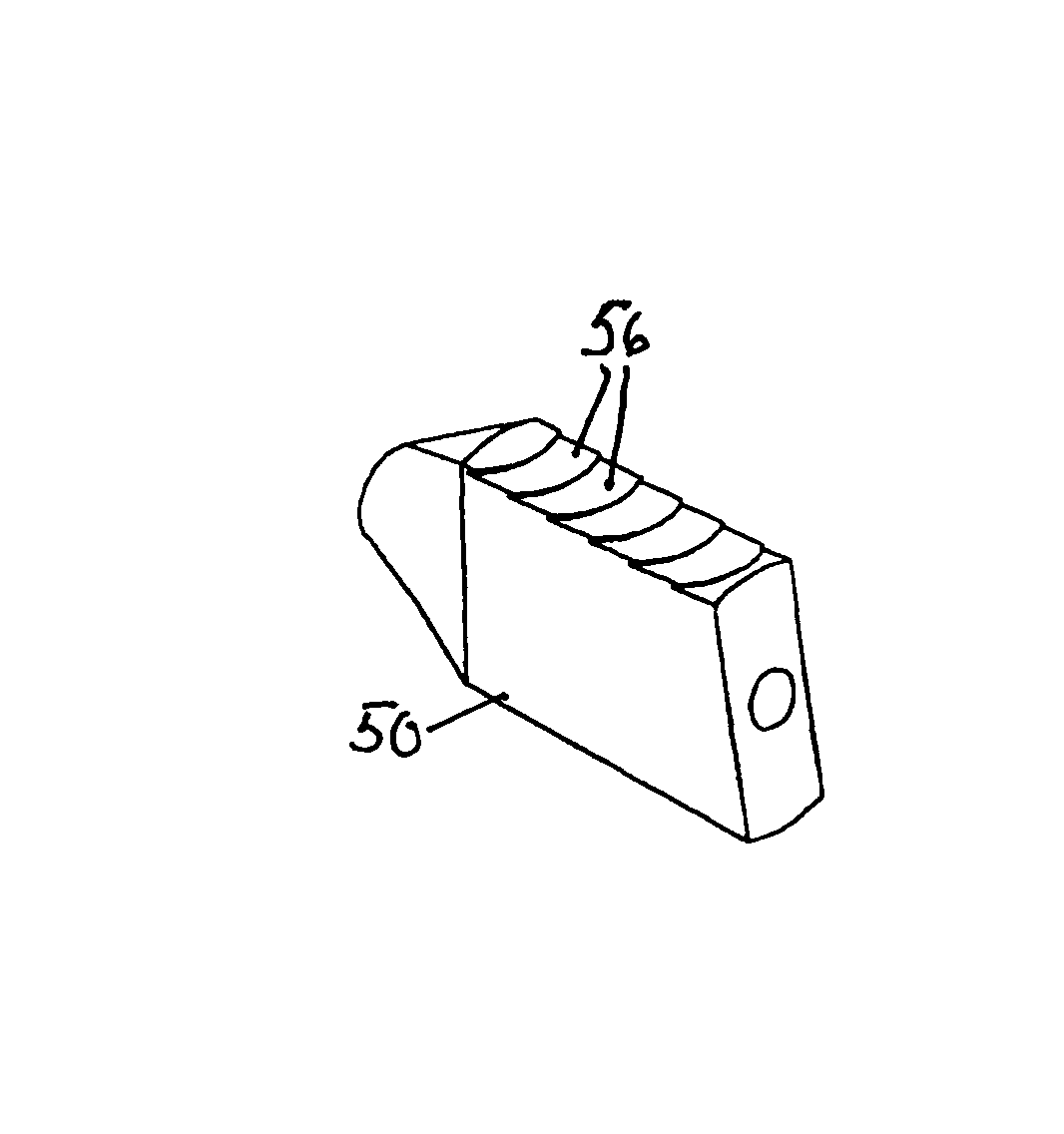

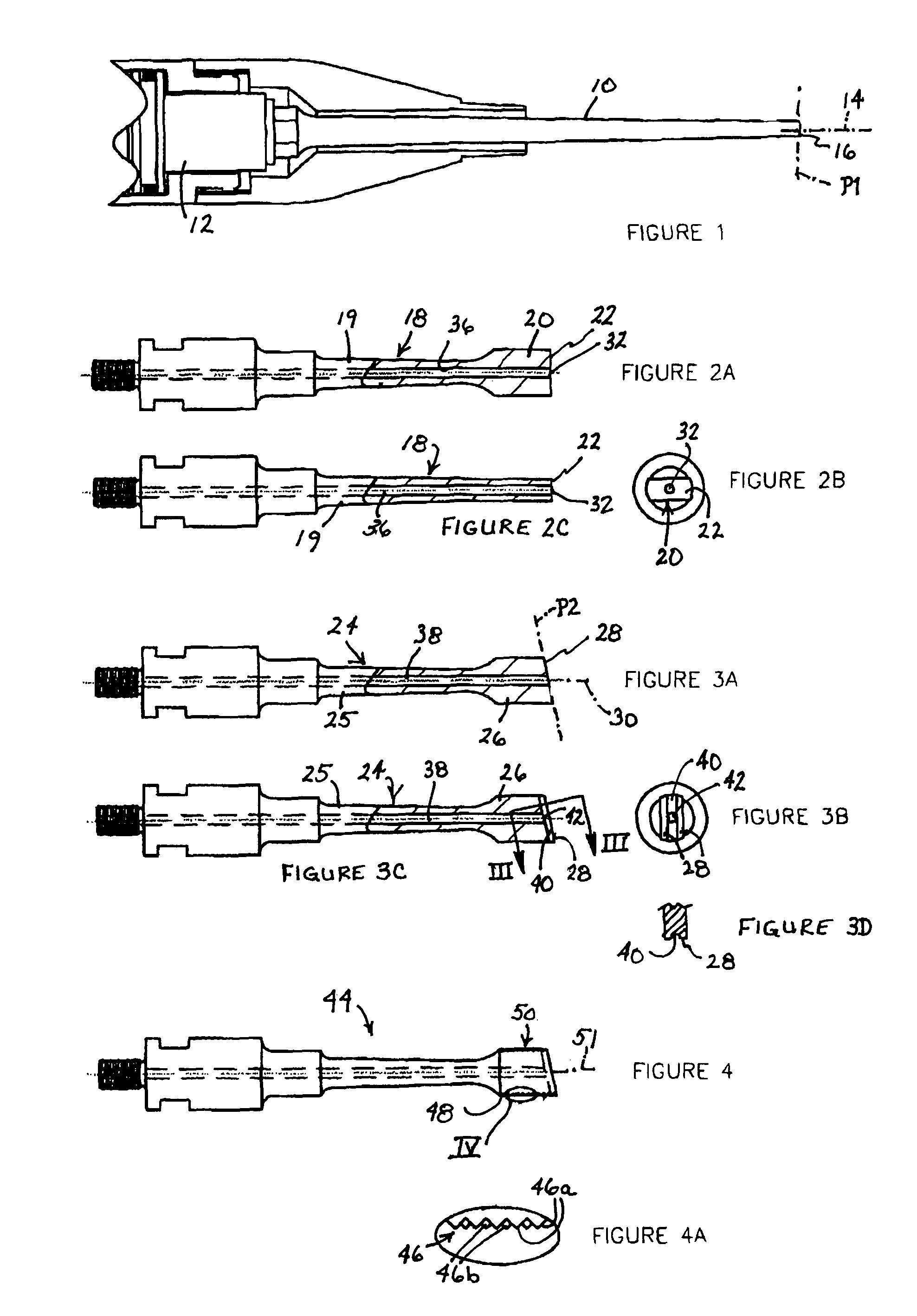

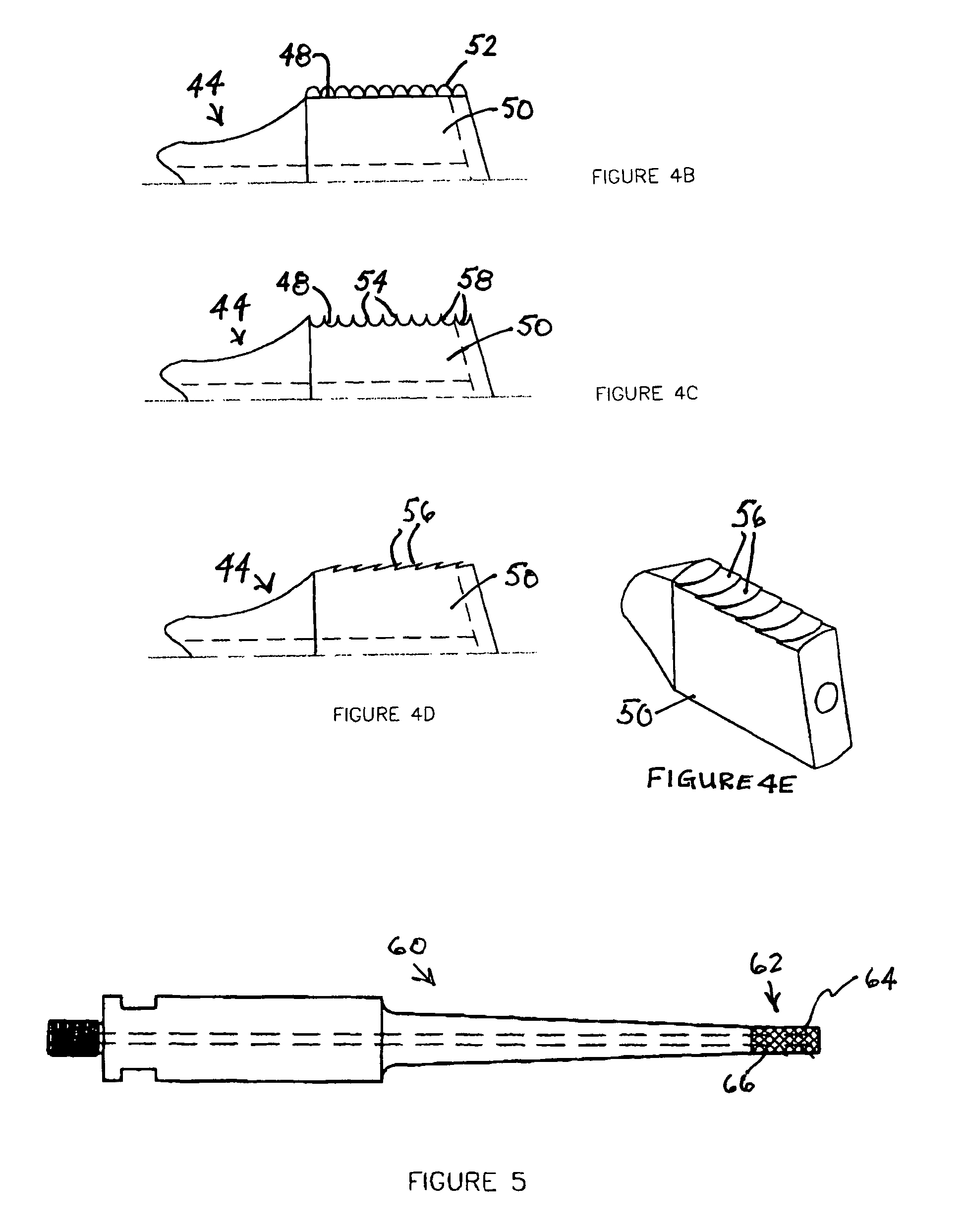

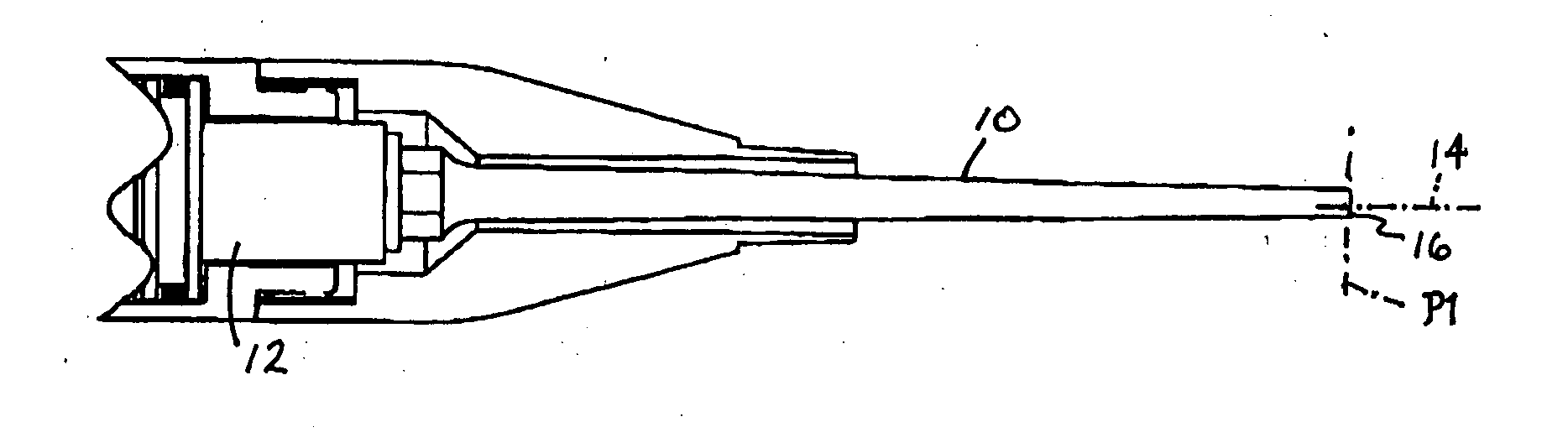

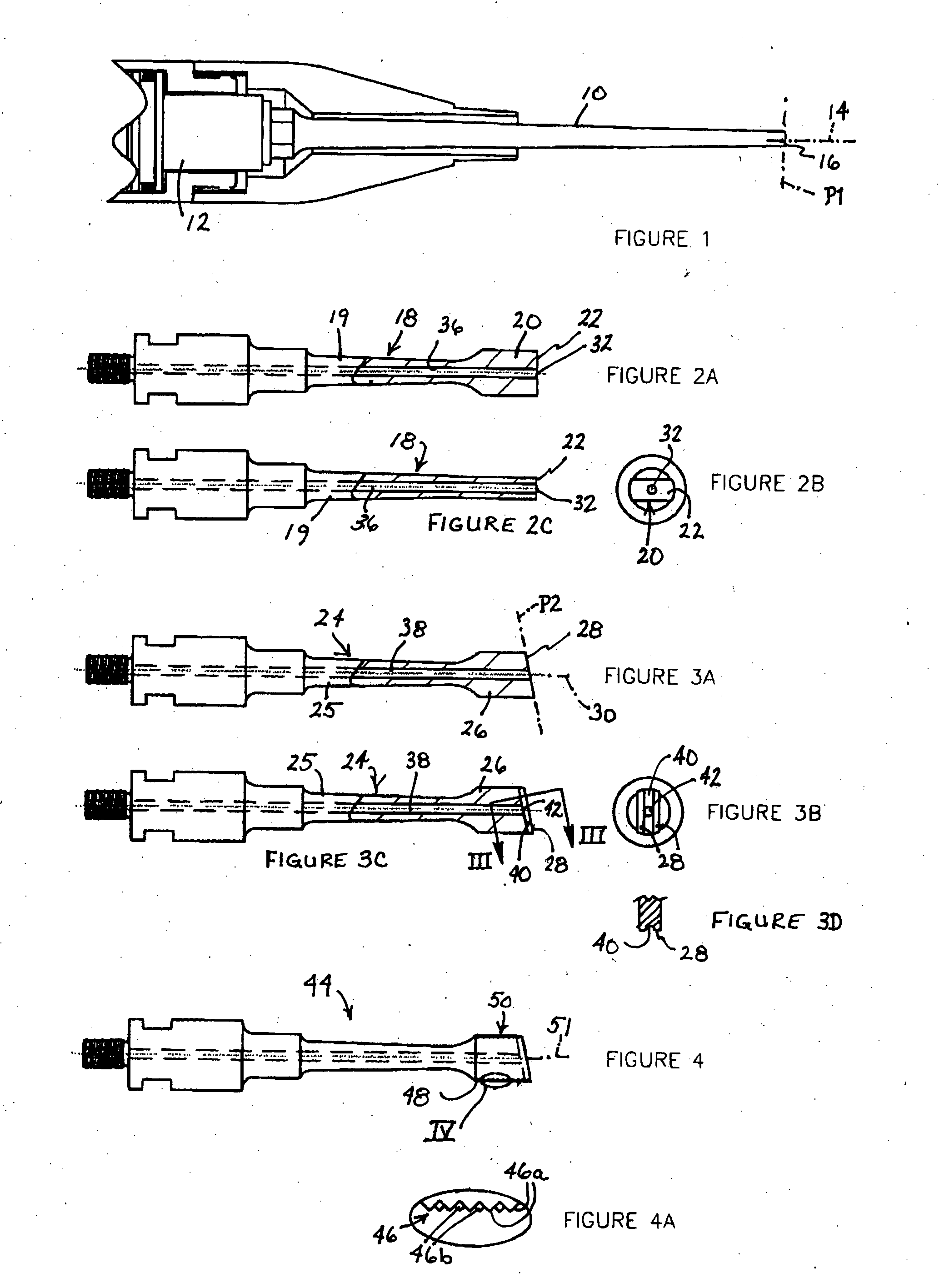

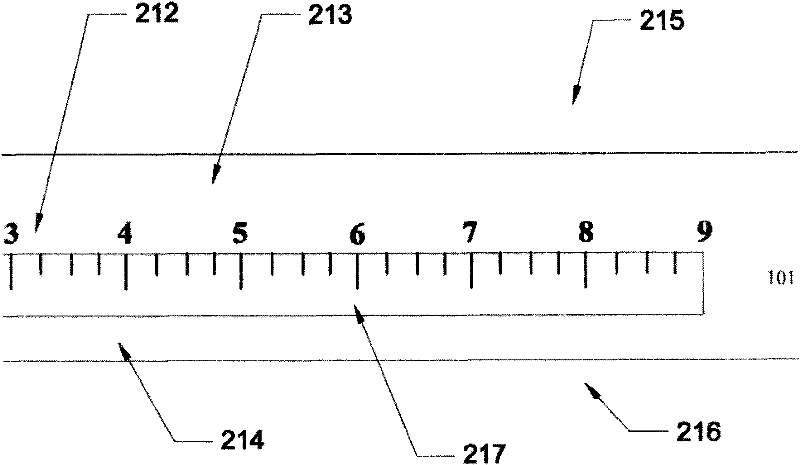

An ultrasonic medical probe comprises an elongate shaft formed integrally with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The shaft is provided with an internal longitudinal channel or bore extending to the end face. The end face is formed with an indentation communicating with the channel or bore at a distal end thereof, whereby liquid is guided over an extended surface of the end face relative to the channel or bore. The head portion also has a lateral surface extending substantially parallel to the longitudinal axis of the probe. The lateral surface is provided with at least one outwardly or radially extending projection. The projection enables the application of ultrasonic cavitation energy to a tissue surface that is in contact with the lateral or side surface of the probe head.

Owner:MISONIX INC

Ultrasonic wound debrider probe and method of use

ActiveUS20060241470A1Improve efficiencyAccelerate liquid flowUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic cavitationMedical treatment

An ultrasonic medical probe comprises an elongate shaft formed integrally with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The shaft is provided with an internal longitudinal channel or bore extending to the end face. The end face is formed with an indentation communicating with the channel or bore at a distal end thereof, whereby liquid is guided over an extended surface of the end face relative to the channel or bore. The head portion also has a lateral surface extending substantially parallel to the longitudinal axis of the probe. The lateral surface is provided with at least one outwardly or radially extending projection. The projection enables the application of ultrasonic cavitation energy to a tissue surface that is in contact with the lateral or side surface of the probe head.

Owner:MISONIX INC

Process method for treating hardly-biodegradable organic wastewater

ActiveCN101786756AReduce dosageReduce generationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsElectrochemical responseUltrasonic cavitation

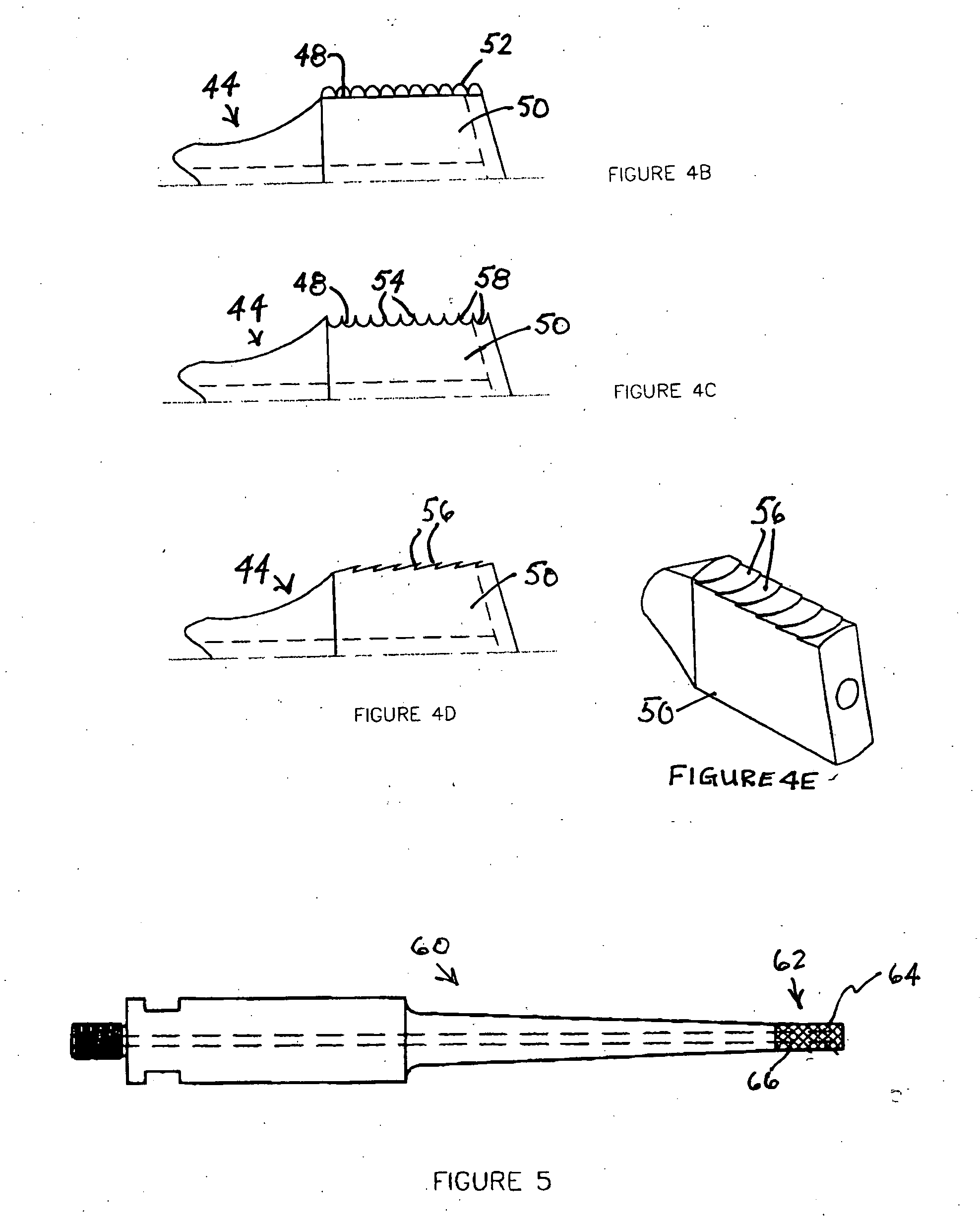

The invention relates to a process method for treating hardly-biodegradable organic wastewater, and the method comprises the following steps: mainly utilizing the combination of ultraviolet light, electrochemistry, ultrasonic waves and oxidation-reduction chemical reaction for treating the hardly-biodegradable organic wastewater, and treating the wastewater by three reaction units of an ultrasonic cavitation zone, an electrochemical reaction zone and an ultraviolet light catalytic reaction zone, thereby realizing the high-efficient multi-stage deep wastewater oxidation reaction which combines the ultrasonic wastewater treatment method, the ultrasonic light and the collaborative Fenton reagent oxidation wastewater treatment, as well as the electrochemistry and the collaborative Fenton reagent oxidation wastewater treatment, effectively treating a variety of types of hardly-biodegradable organic wastewater and leading the COD removal rate of the wastewater after the treatment to be more than 90%.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Preparation method of hydro-treatment catalyst

ActiveCN103769125AModerate decrease in viscosityImprove permeabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystUltrasonic cavitation

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

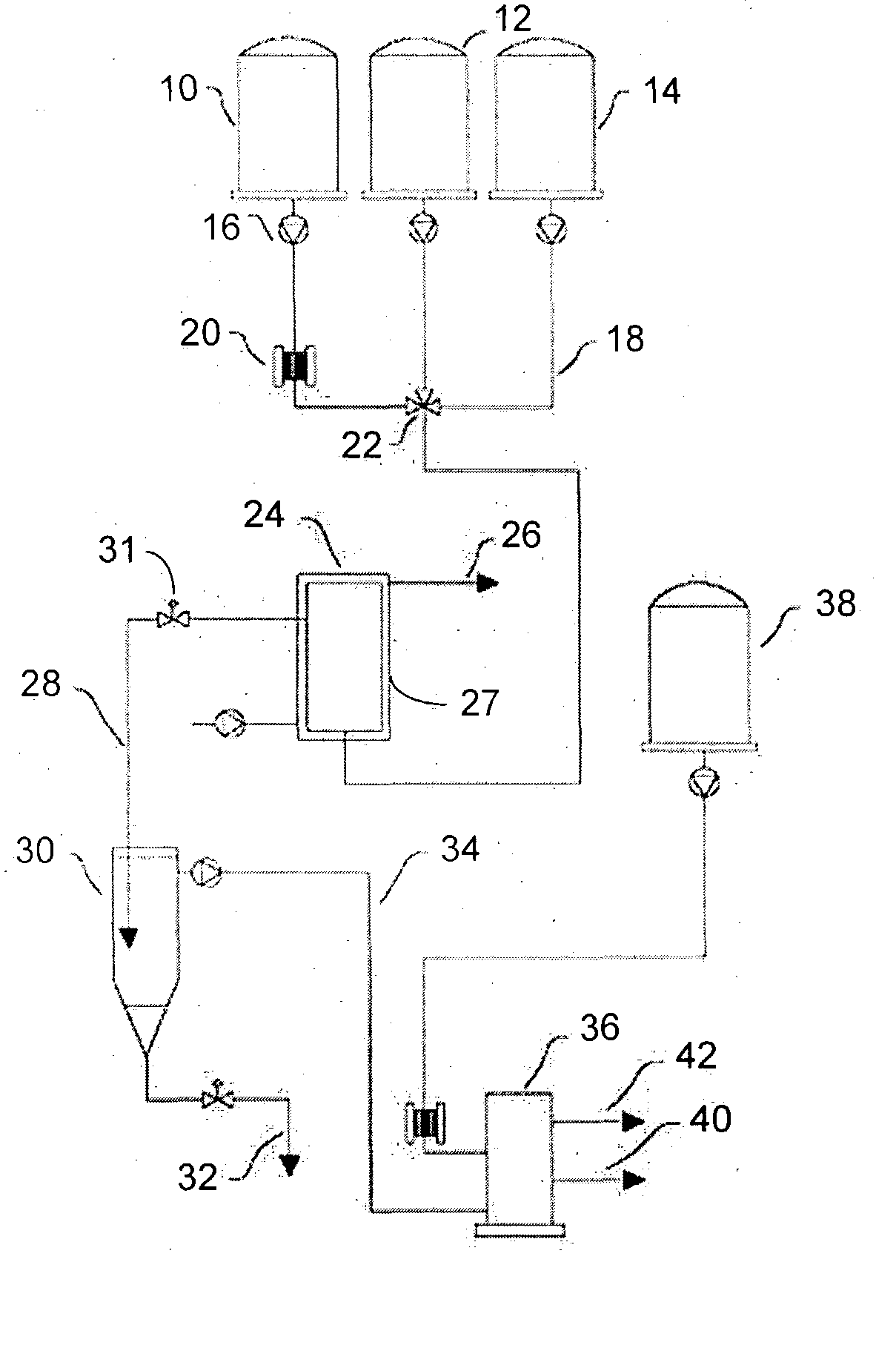

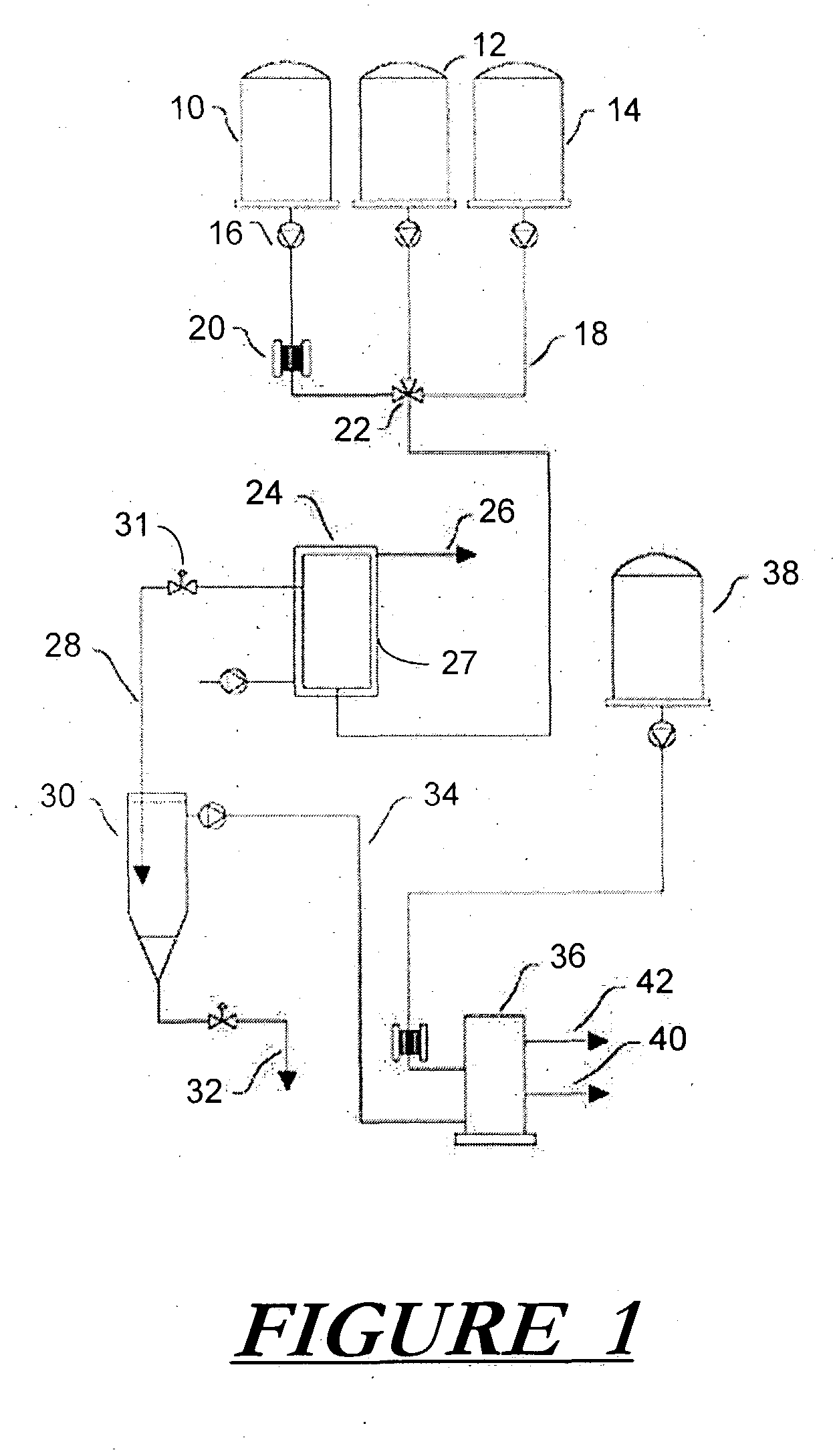

Apparatus and method for the production of fatty acid alkyl ester

InactiveUS20050027137A1Eliminate operationShort possible reaction timeFatty oils/acids recovery from wasteAnalysis using chemical indicatorsAlcoholVegetable oil

An apparatus and method for producing fatty acid alkyl esters from fatty acids derived from vegetable oils and animal fats with an alkaline solution dissolved in stoichiometric or near stoichiometric levels of a monoalkyl alcohol to form a mixture. The method further comprises emulsifying the mixture as a means to reach a completed chemical reaction state in a reactor section, wherein the oils or fats are transesterified into fatty acid alkyl esters. The transesterification occurs when the natural boundary surfaces of the immiscible mixture are enlarged by ultrasonic cavitation in the reaction section and the transesterification is performed at, or near atmospheric pressure. The method finally includes, after reaching the chemical reaction state, separating residues from the fatty acid alkyl ester in a gravitational phase separation section.

Owner:HOOKER JEFFREY D

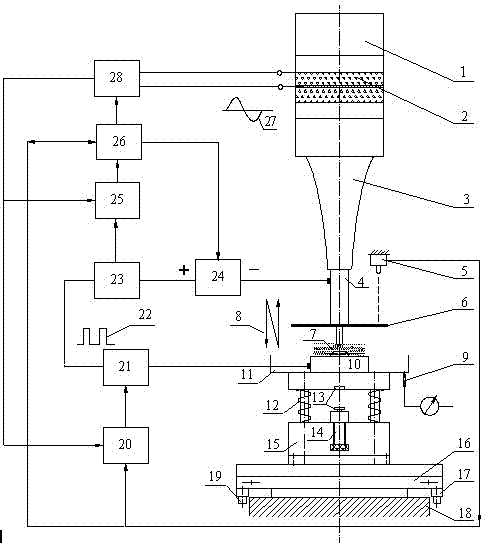

Micro and fine machining method for material difficult to machine and machining system

ActiveCN102513622AImprove machining clearance processImprove local processing performanceMechanical vibrations separationElectric circuitsUltrasonic cavitationElectrolysis

The invention relates to a micro and fine machining method for a material difficult to machine and a machining system, belonging to the technical field of composite, precise, micro, fine and special machining. In the method and the machining system for implementing the method disclosed by the invention, ultrasonic modulation, low-voltage discharge and electrolysis are effectively compounded, a micro and fine discharge-electrolysis function is organically combined with ultrasonic frequency vibration identical frequency and synchronization, and discharge of machining products and circular update of a working fluid are realized under the actions of ultrasonic cavitation and spark discharge explosive force, so that a gap machining process is improved effectively, localized machining performance is enhanced, machining accuracy and surface quality can be further enhanced while high machining efficiency is achieved, machining can be realized in a static fluid simultaneously, and complex pressure flow and circular supply of the working fluid to the system is not required; and during processing, contact of the workpiece with an electrode under a certain constant pressure is kept, continuous and stepless micro pressure adjustment can be performed by using a magnetic adjusting mechanism, and a precision stable-speed micro feeding system necessary for electrolytic machining and a servo feeding system necessary for electric spark machining are not required, so that the equipment research cost can be reduced greatly.

Owner:扬州健行电子科技有限公司

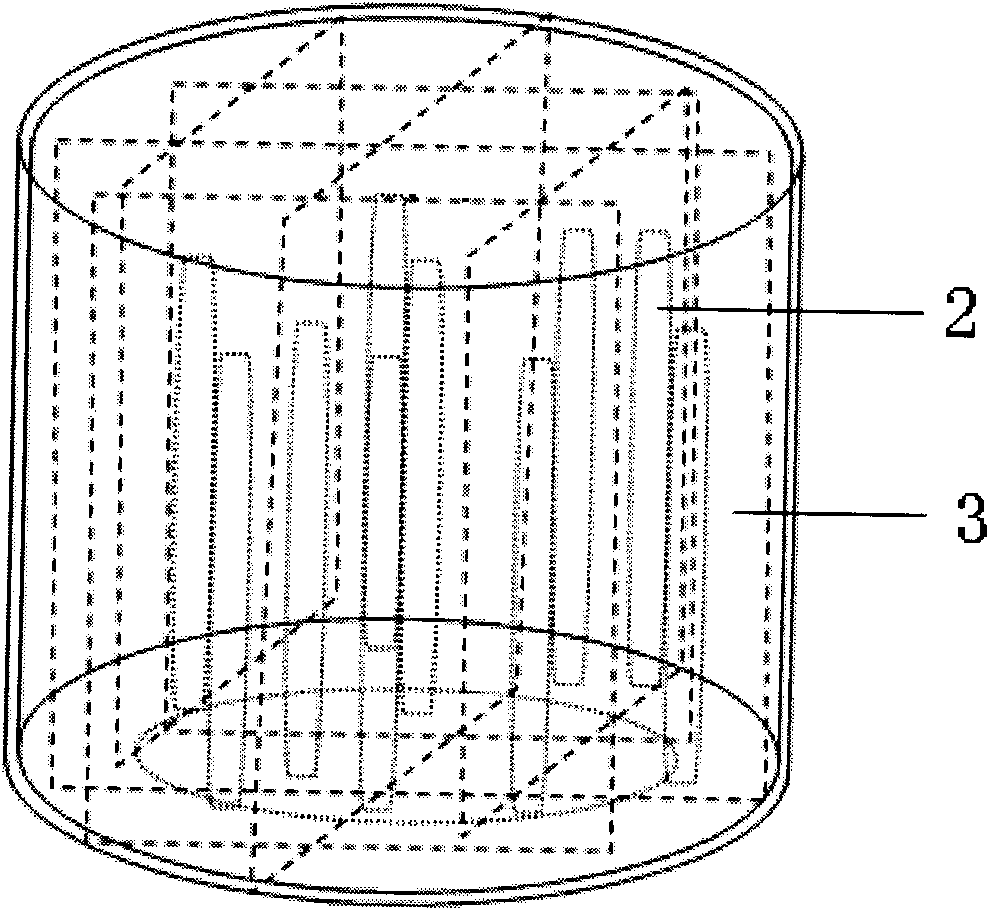

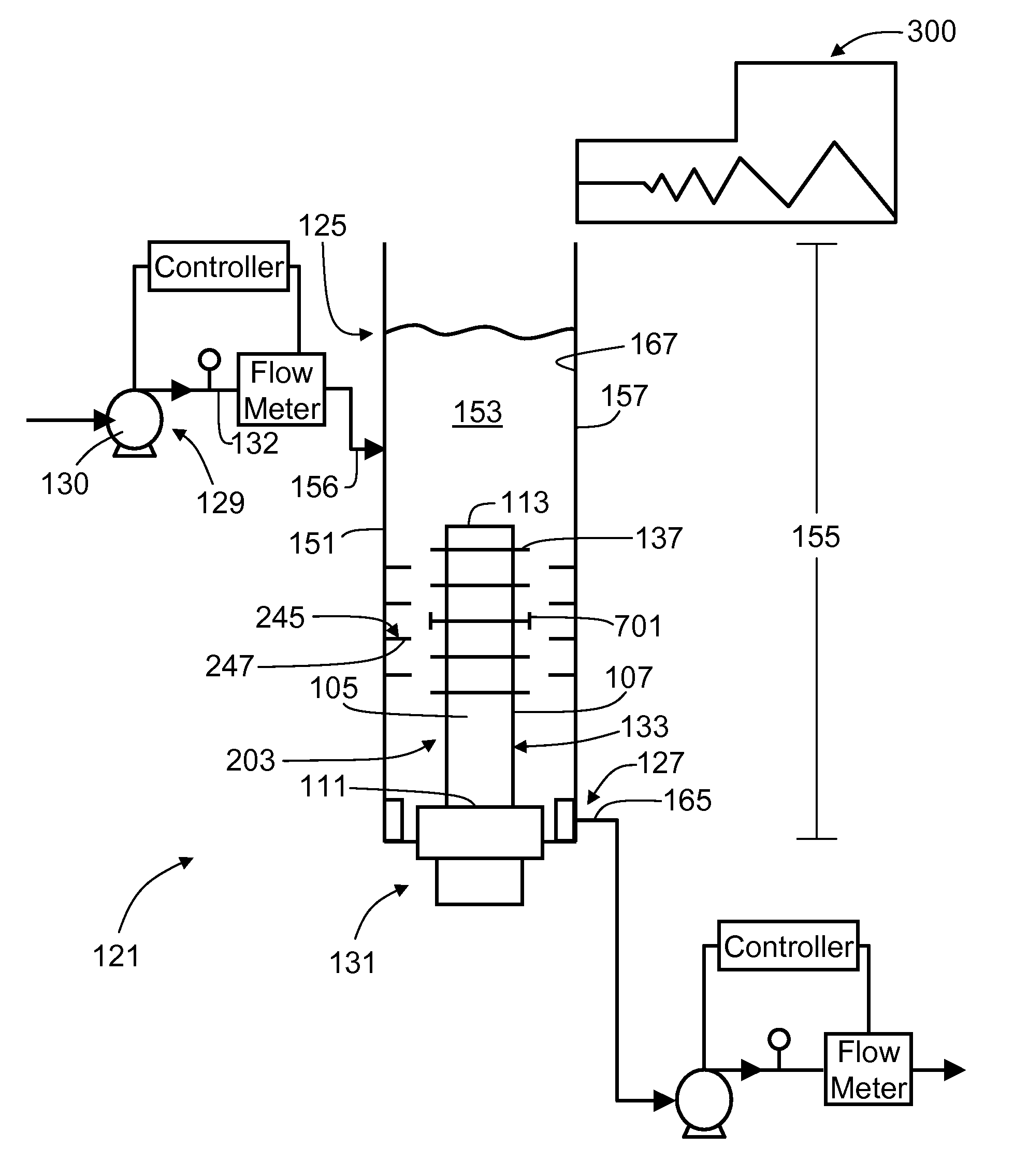

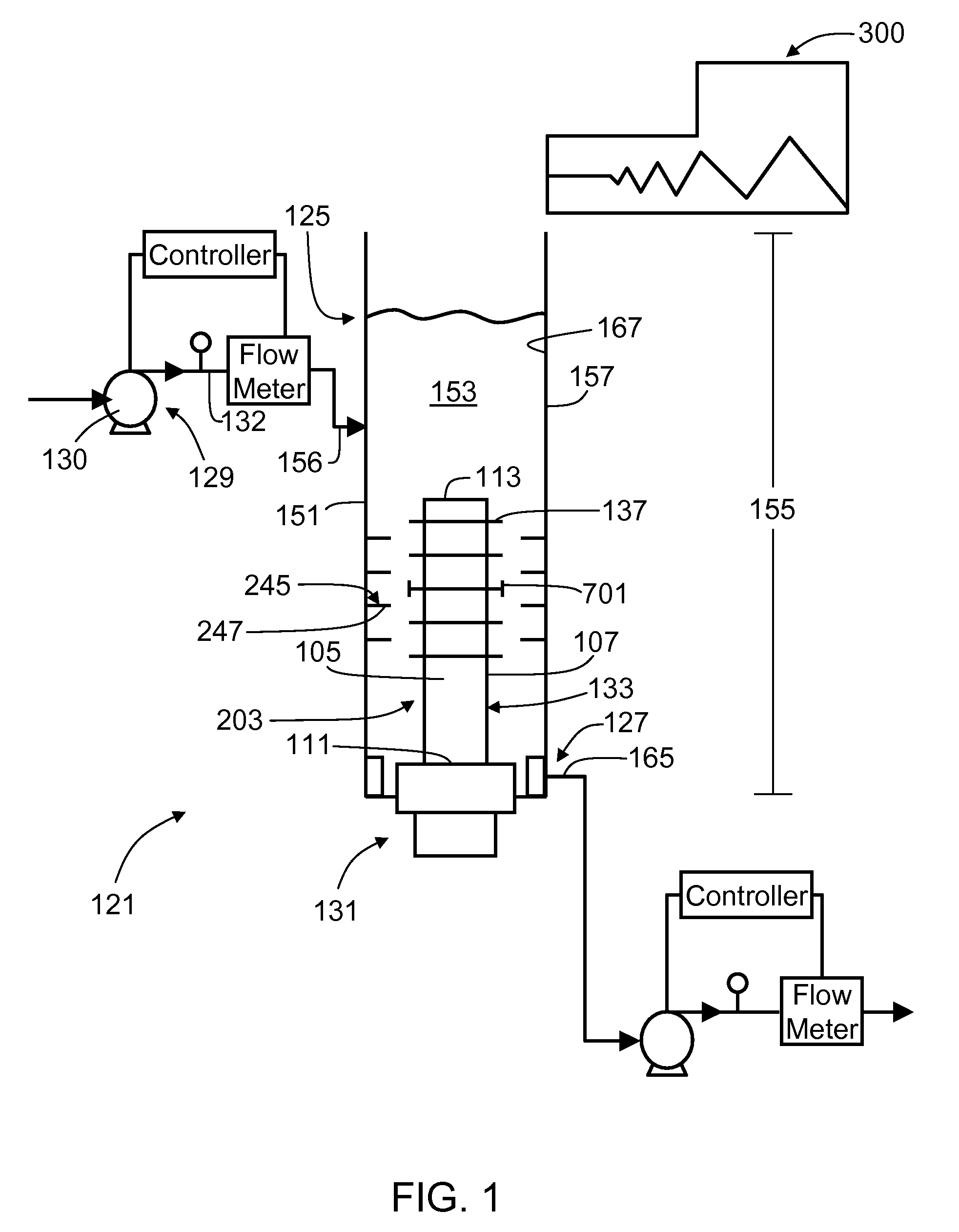

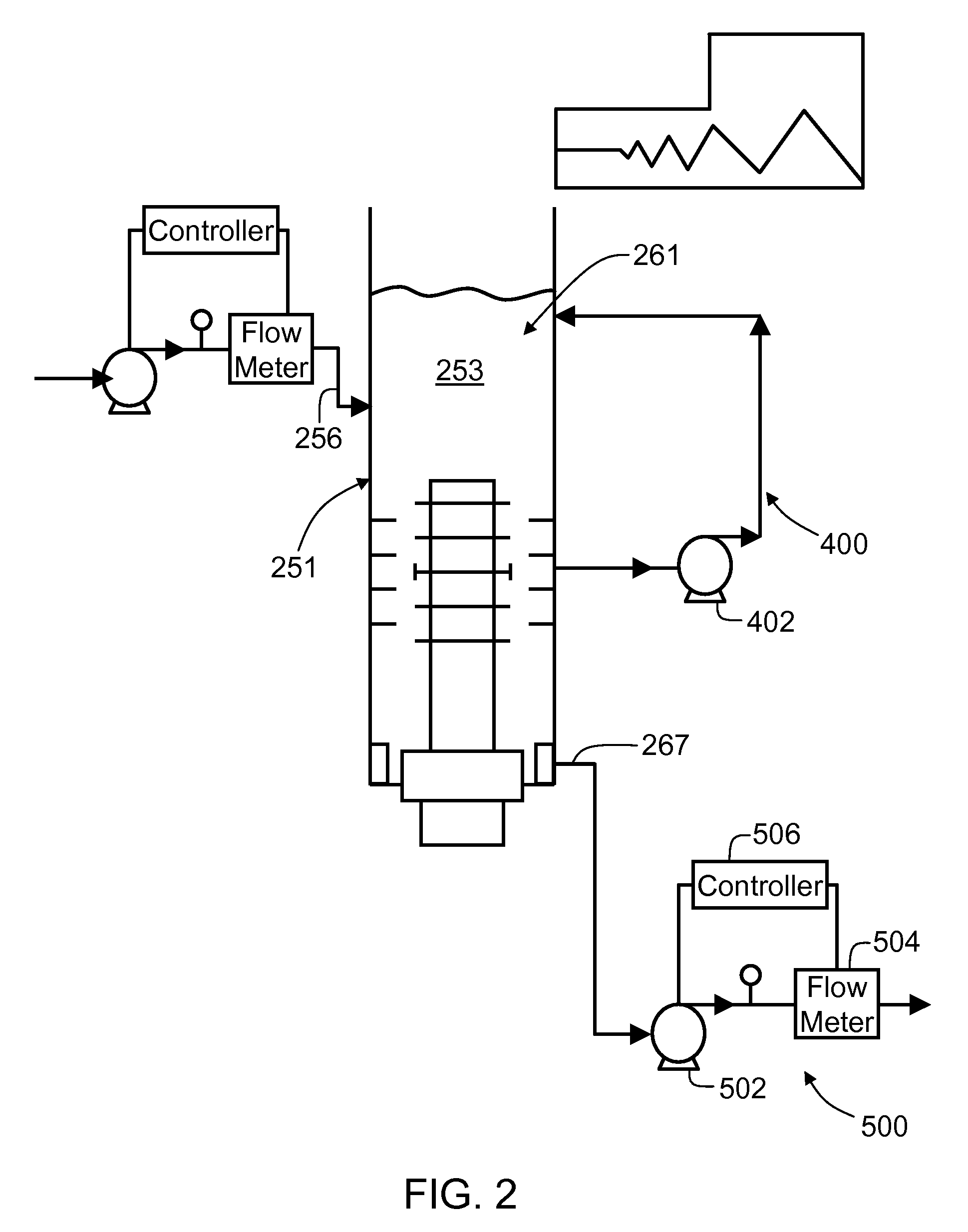

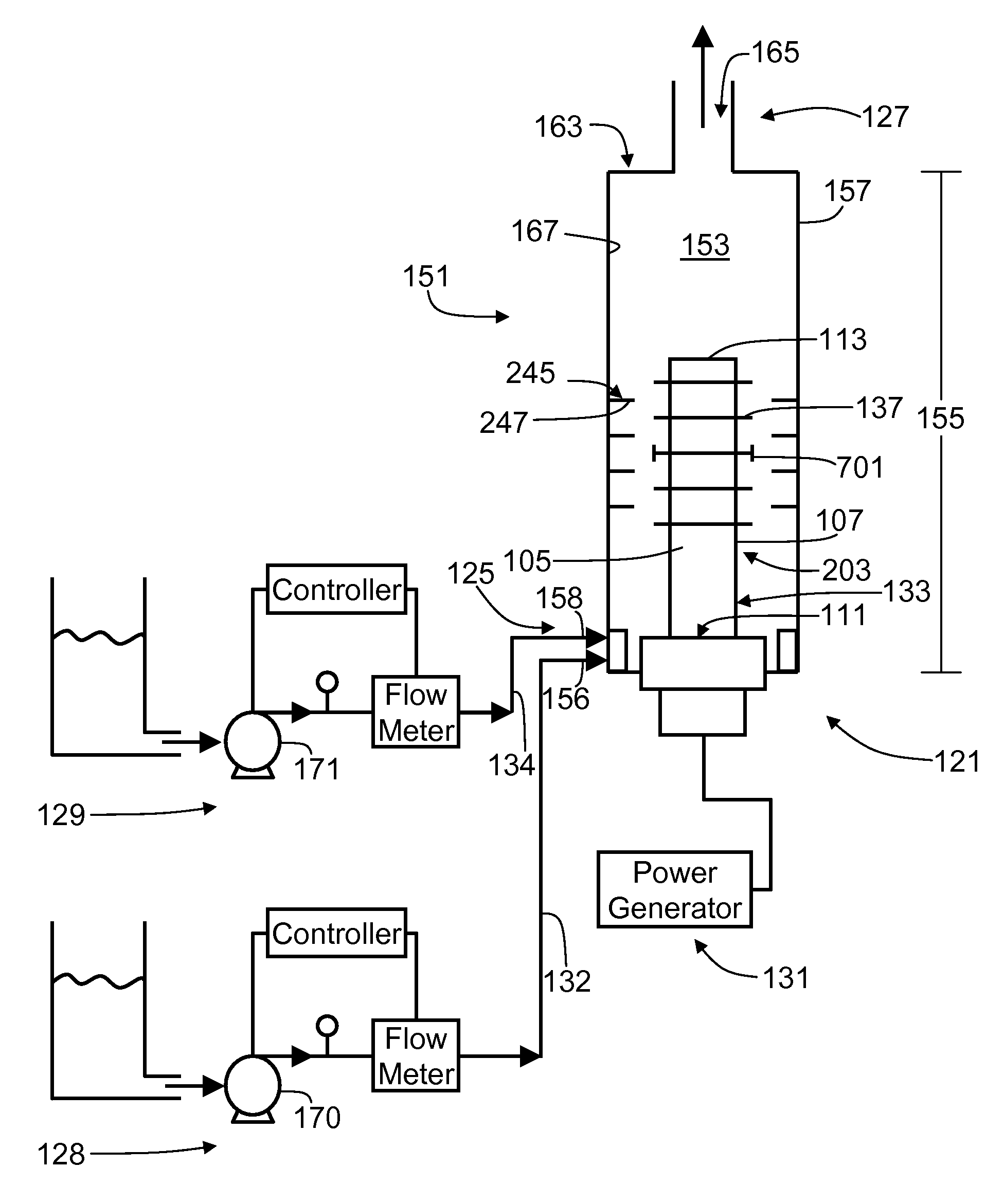

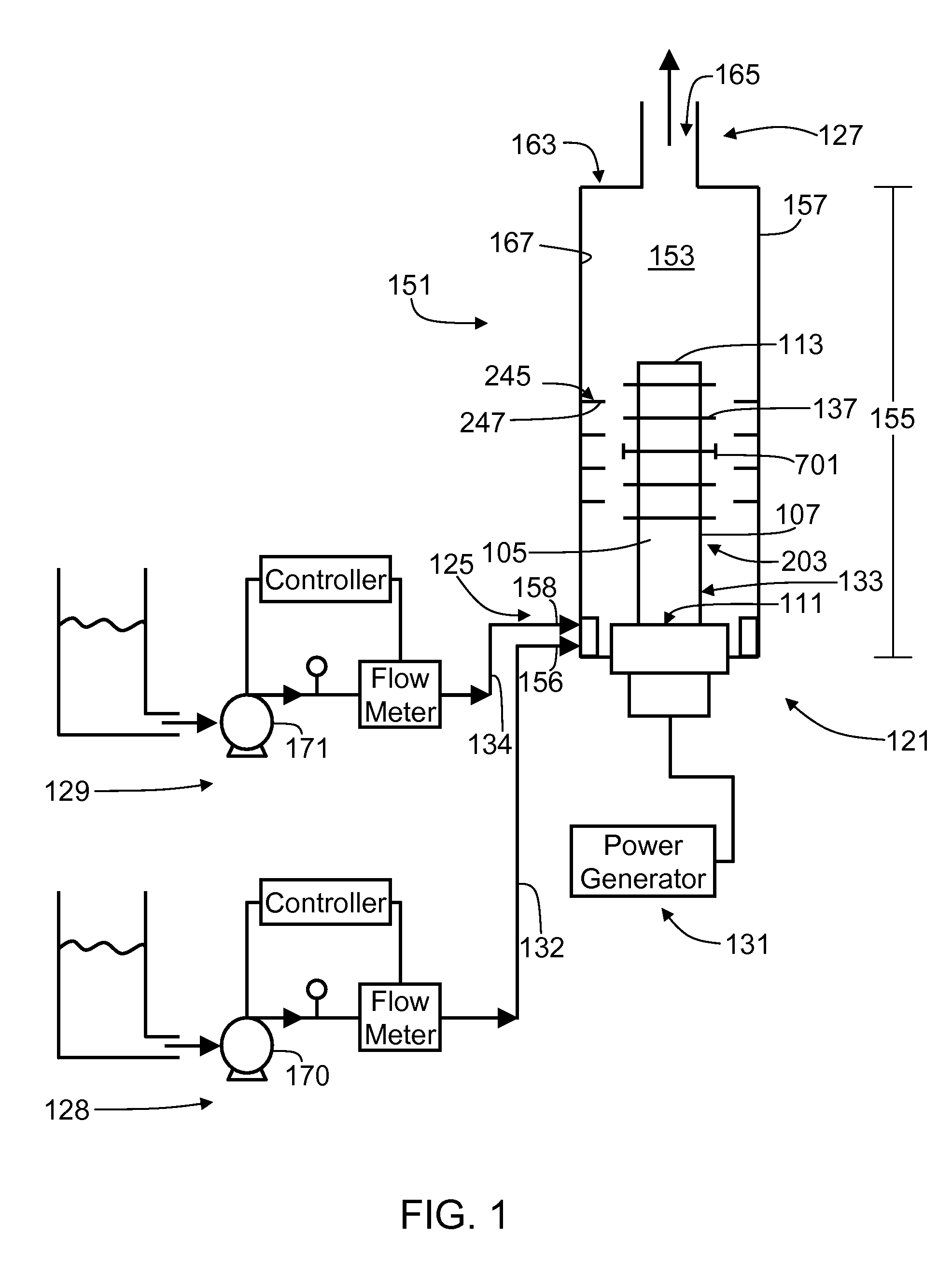

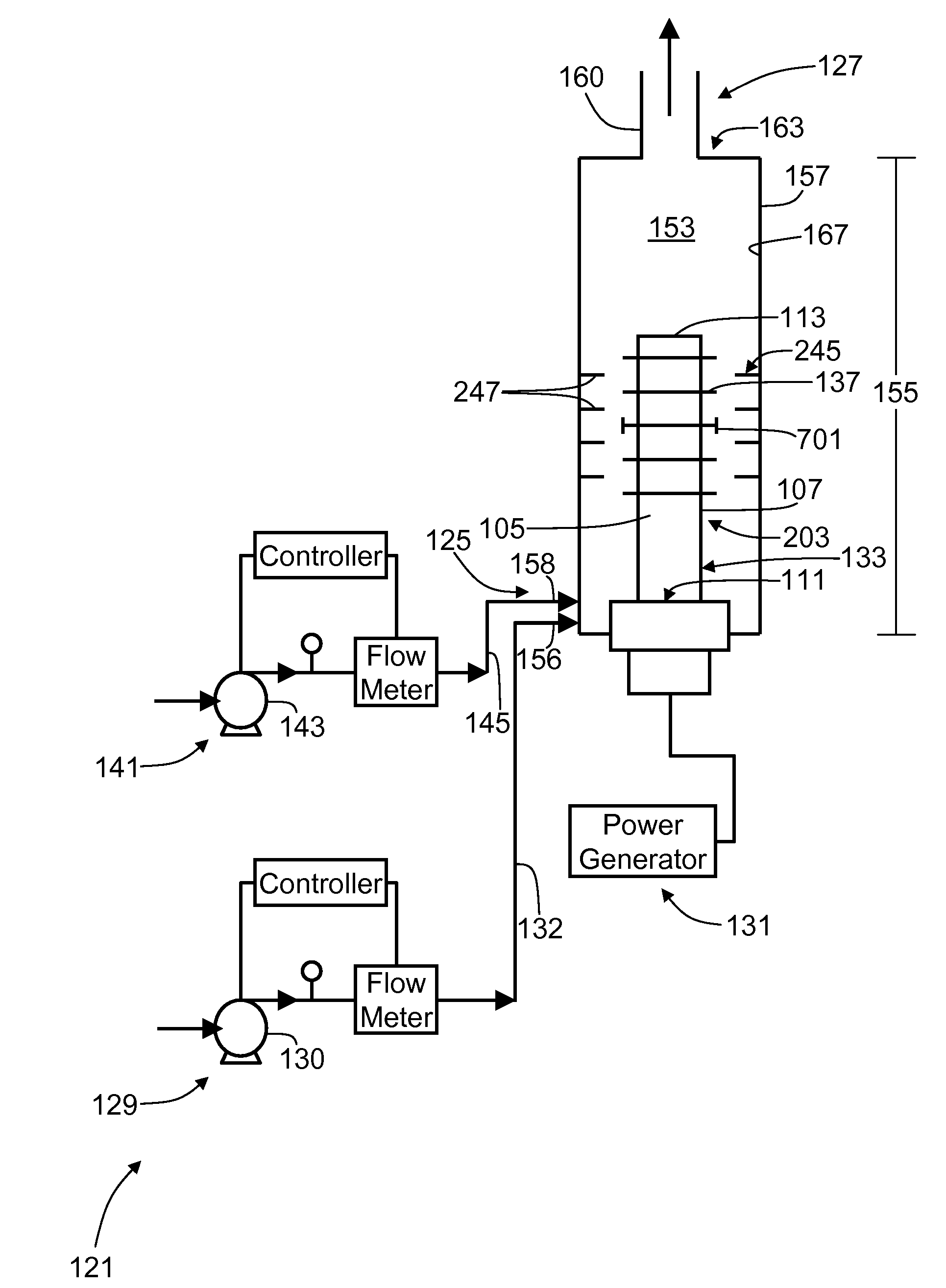

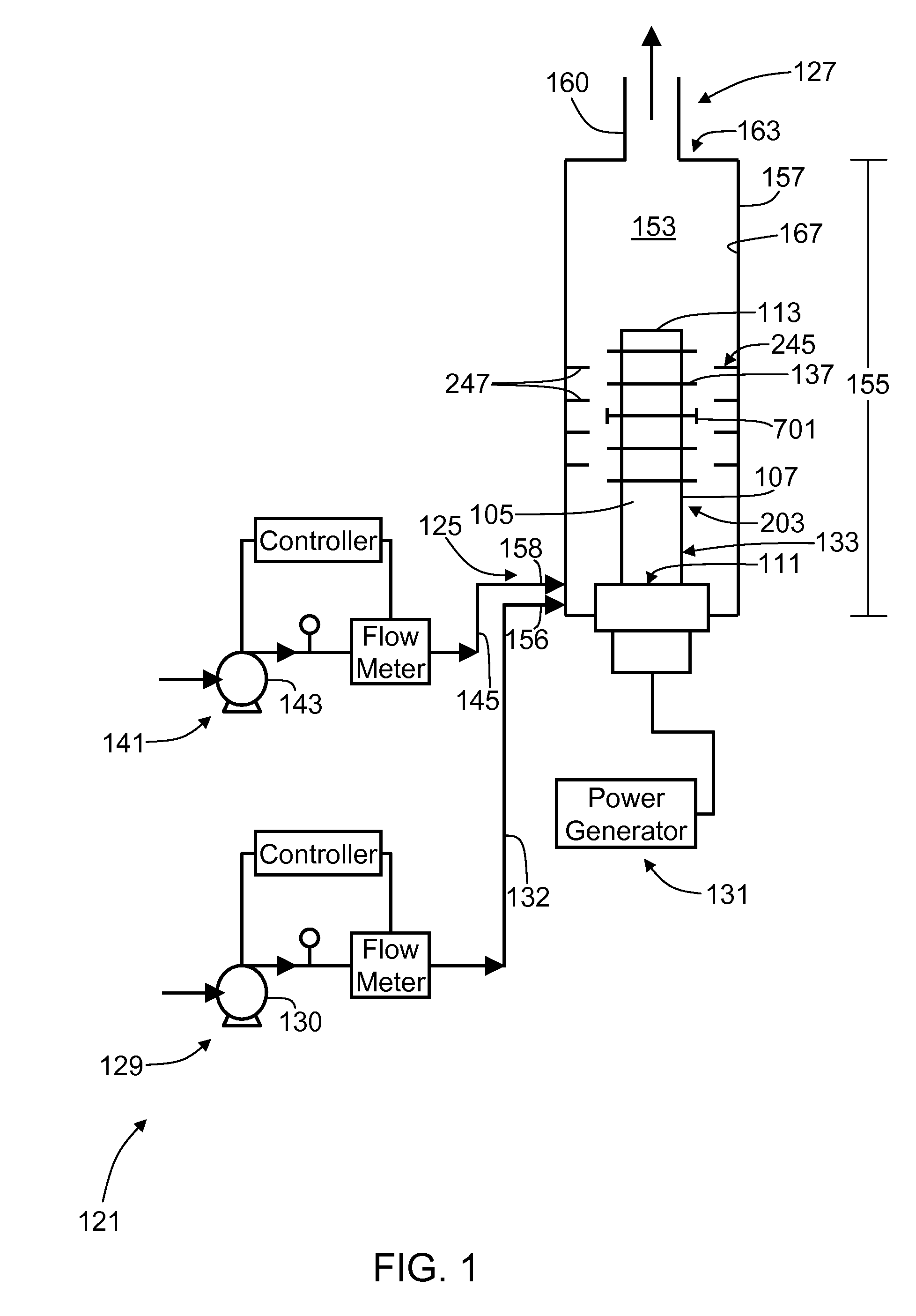

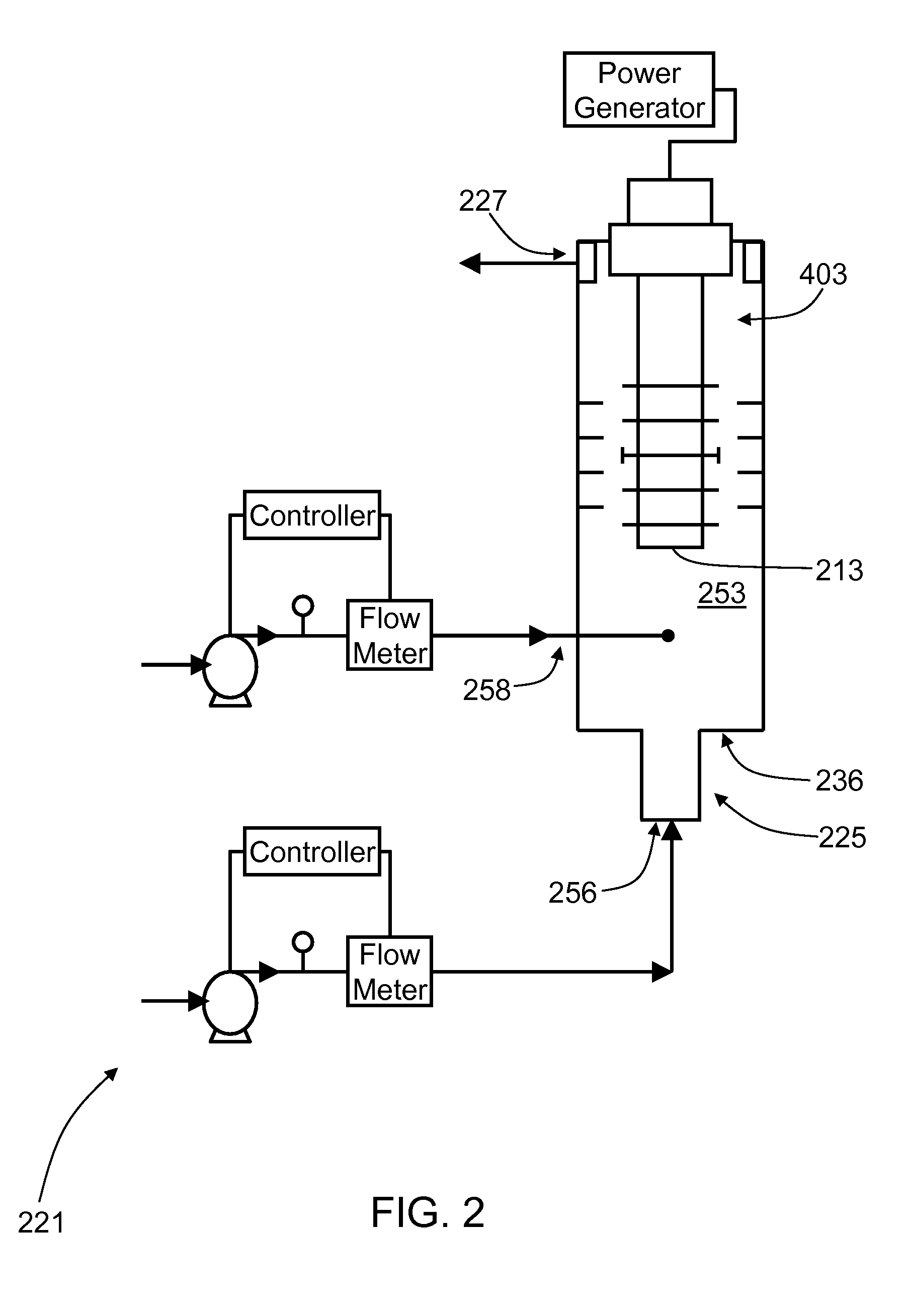

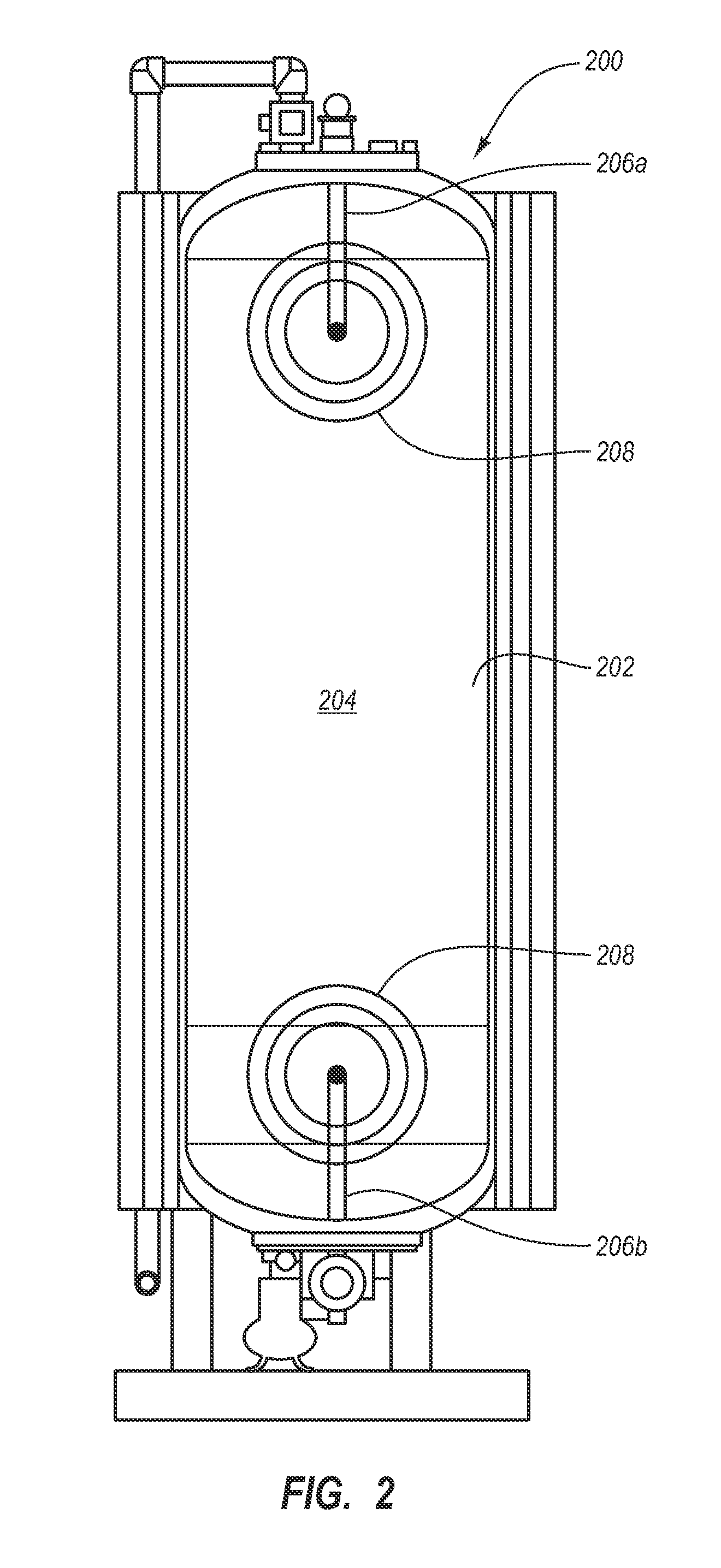

High capacity ultrasonic reactor system

ActiveUS8651230B2Increases the total amount of acoustic energy radiatedImprove availabilityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLiquid mediumReactor system

An ultrasonic reactor system with an appropriately designed reactor chamber used in conjunction with a compatible ultrasonic Barbell Horn or its derivative that provides a significant efficiency increase and an intensification of sonochemical and sonomechanical processes is disclosed. These enhancements arise from the ability of the reactor chamber to direct all treated liquid media through the highly active ultrasonic cavitation region located near the surface of the horn, as well as from several improvements in the Barbell Horn design that significantly increase its longevity and in its output surface area, thereby increasing the total size of the active cavitation region.

Owner:INDAL SONOMECHANICS

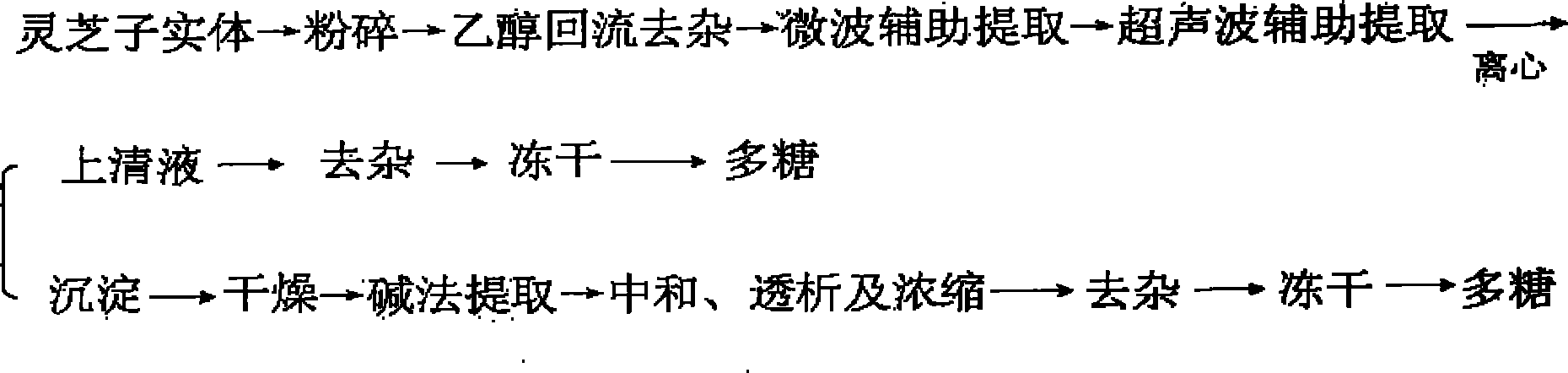

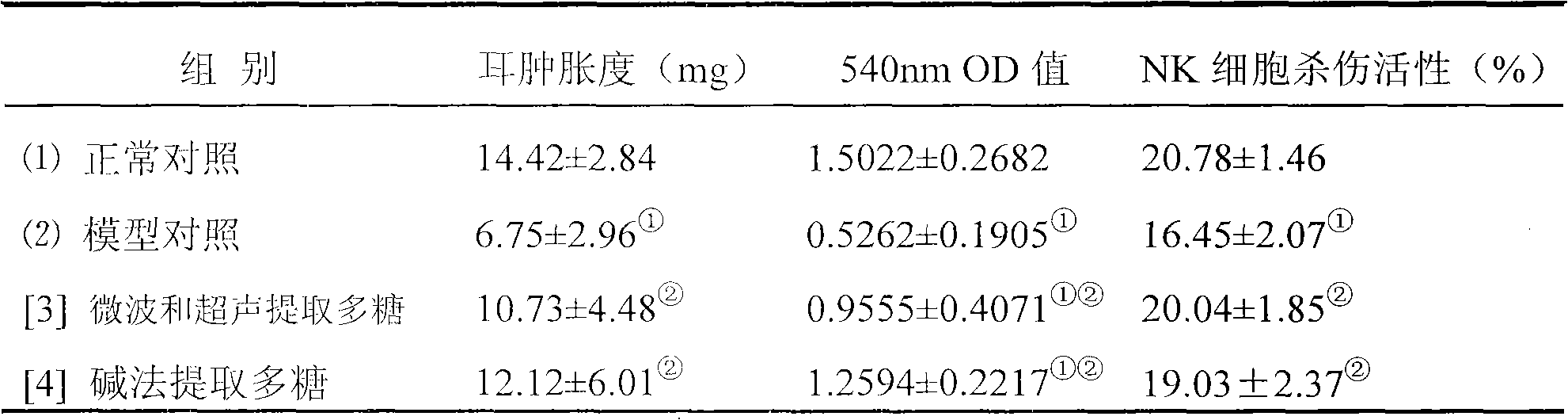

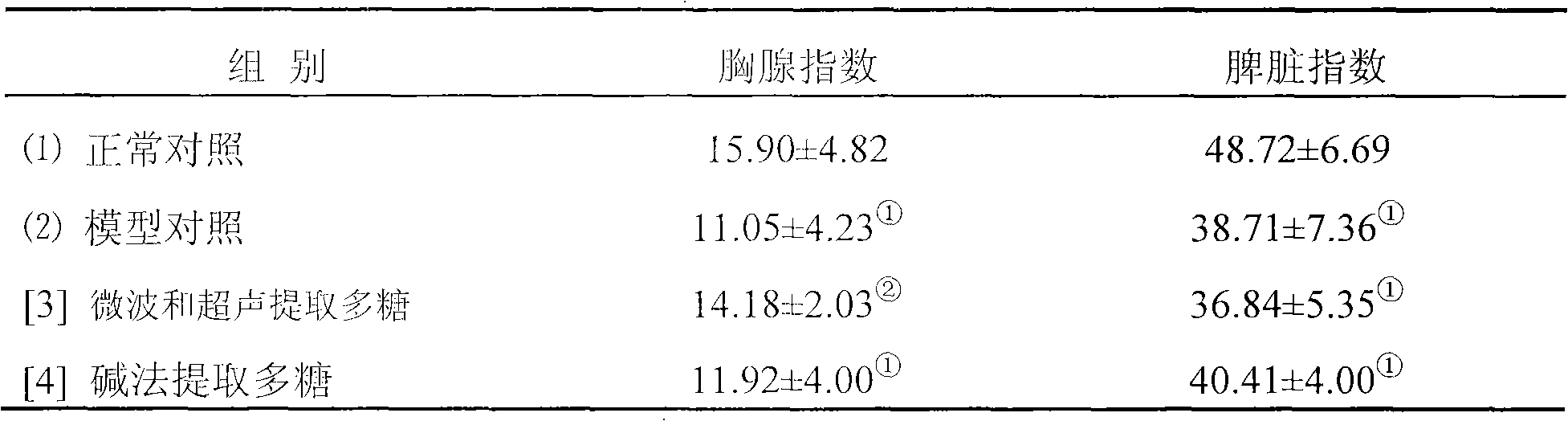

Preparation method of ganoderma lucidum polysaccharide with high yield

The invention discloses a preparation method of ganoderma lucidum polysaccharide with high yield, which comprises the following steps: firstly, crushing ganoderma lucidum fruiting bodies into ganoderma lucidum powder, then sequentially extracting the ganoderma lucidum powder by adopting a microwave-assisted hot water extraction method and an ultrasonic-assisted hot water extraction method, and carrying out concentration, impurity removal, concentration, alcohol precipitation and drying on the obtained extracting solution to obtain water-soluble ganoderma lucidum polysaccharide; and extracting the ganoderma lucidum residues by adopting an alkali extraction method, and carrying out neutralization, dialysis, concentration, impurity removal, alcohol precipitation and drying on the obtained extracting solution to obtain alkali-soluble ganoderma lucidum polysaccharide. The method is used for extracting the ganoderma lucidum polysaccharide by combining microwave heating action and ultrasonic cavitation and extracting the alkali-soluble polysaccharide in the ganoderma lucidum by utilizing the alkali extraction method, thereby reducing the loss of the ganoderma lucidum polysaccharide; and the prepared ganoderma lucidum polysaccharide has the characteristics of high production yield, strong immunological activity and the like.

Owner:INFINITUS (CHINA) CO LTD

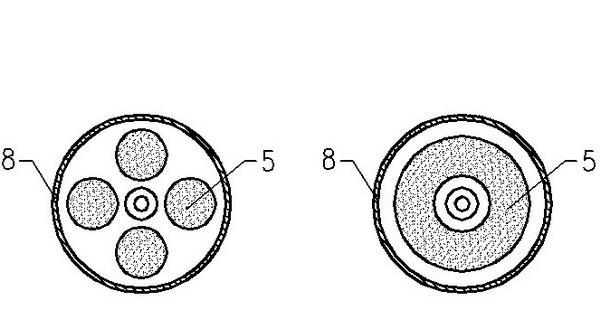

Ultrasonic treatment chamber for particle dispersion into formulations

ActiveUS20090168591A1Shaking/oscillating/vibrating mixersFlow mixersUltrasonic cavitationDynamic motion

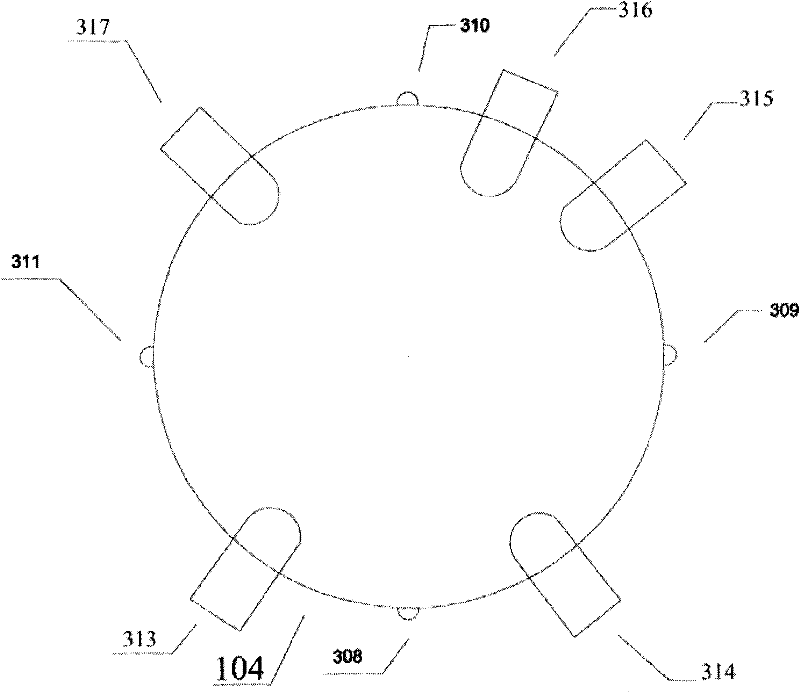

An ultrasonic mixing system having a particulate dispensing system to dispense particulates into a treatment chamber and the treatment chamber in which particulates can be mixed with one or more formulations is disclosed. Specifically, the treatment chamber has an elongate housing through which a formulation and particulates flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the formulation and particulates within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the formulation and particulates being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

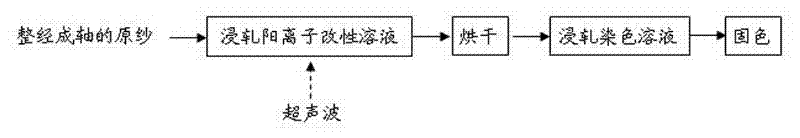

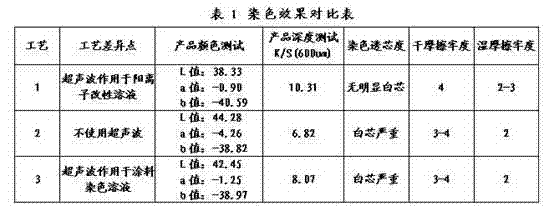

Dyeing method of cotton yarns

ActiveCN102127870AImprove adsorption capacityImprove diffusion abilityDyeing processVegetal fibresYarnUltrasonic cavitation

The invention relates to a dyeing method of cotton yarns. The dyeing method comprises a cation modified solution padding process, a drying process, a dyeing solution padding process and a color fixing process, which are carried out in sequence, wherein in the cation modified solution padding process, base yarns are padded in a cation modified solution subjected to ultrasonic cavitation treatment. With the method, the problems of color fastness, core penetration degree and color depth of a cotton yarn continuous pad dyeing technology are solved, a scouring or pretreatment process with a scouring effect before and during a dyeing process can be omitted, and energy consumption and pollution emission during the scouring or in a pretreatment process with the scouring effect are eliminated from the sources.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

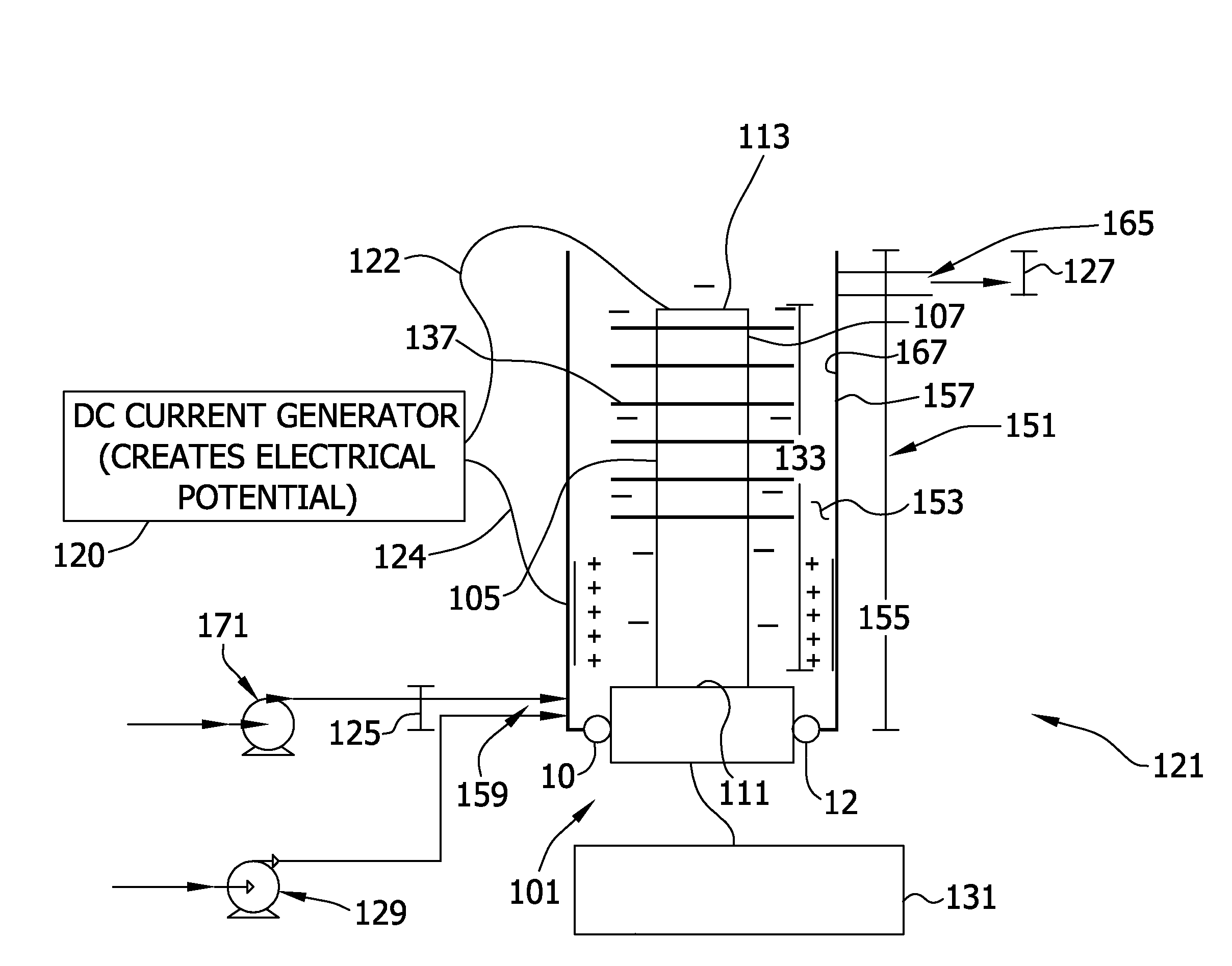

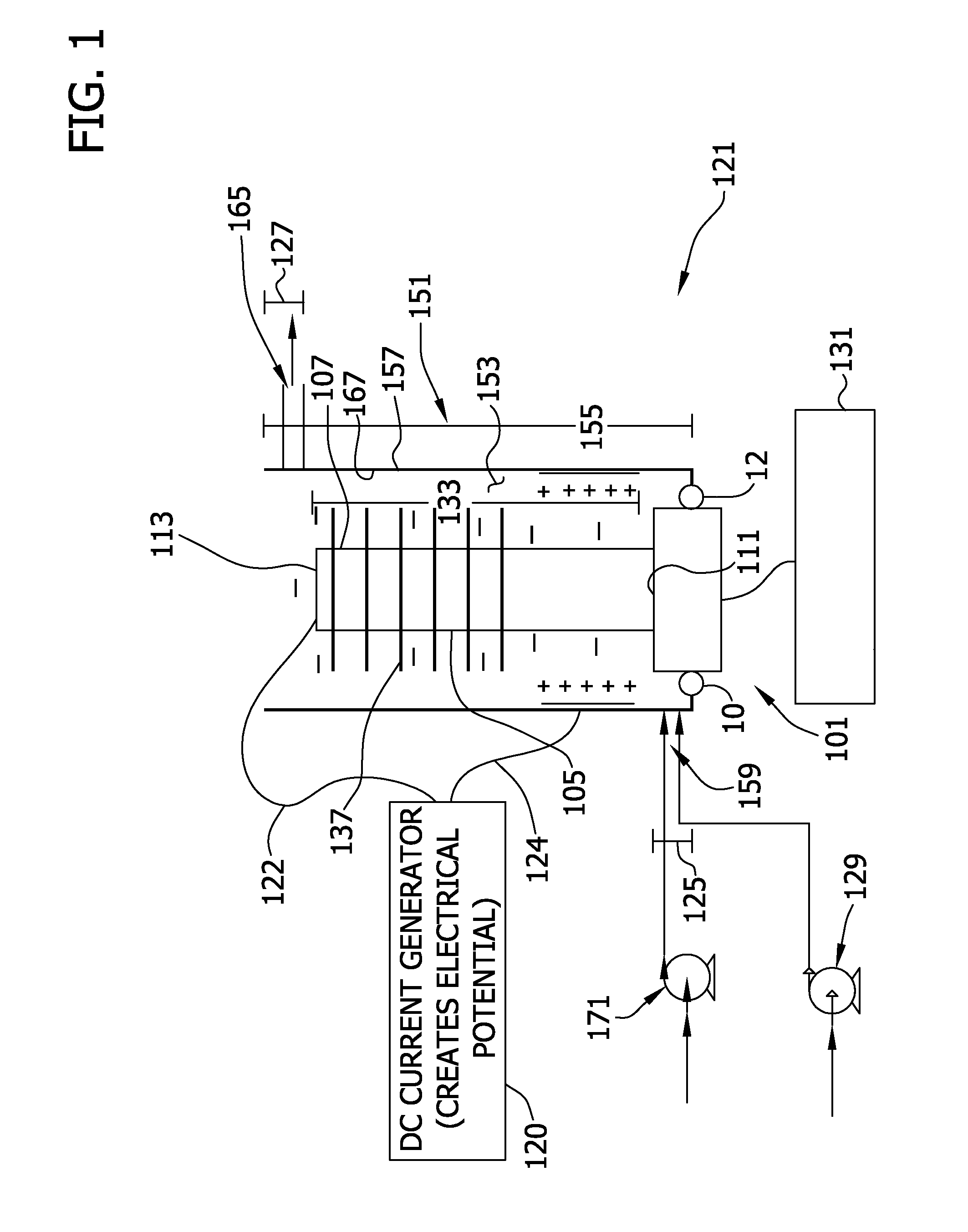

Ultrasonic treatment chamber having electrode properties

InactiveUS20090014377A1Electrolysis componentsSpecific water treatment objectivesElectrode potentialElectrolysis

A liquid treatment chamber having an elongate housing through which liquid flows longitudinally from an inlet port to an outlet port thereof is disclosed. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrode potential to ultrasonically energize and electrolyze liquid within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the liquid being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

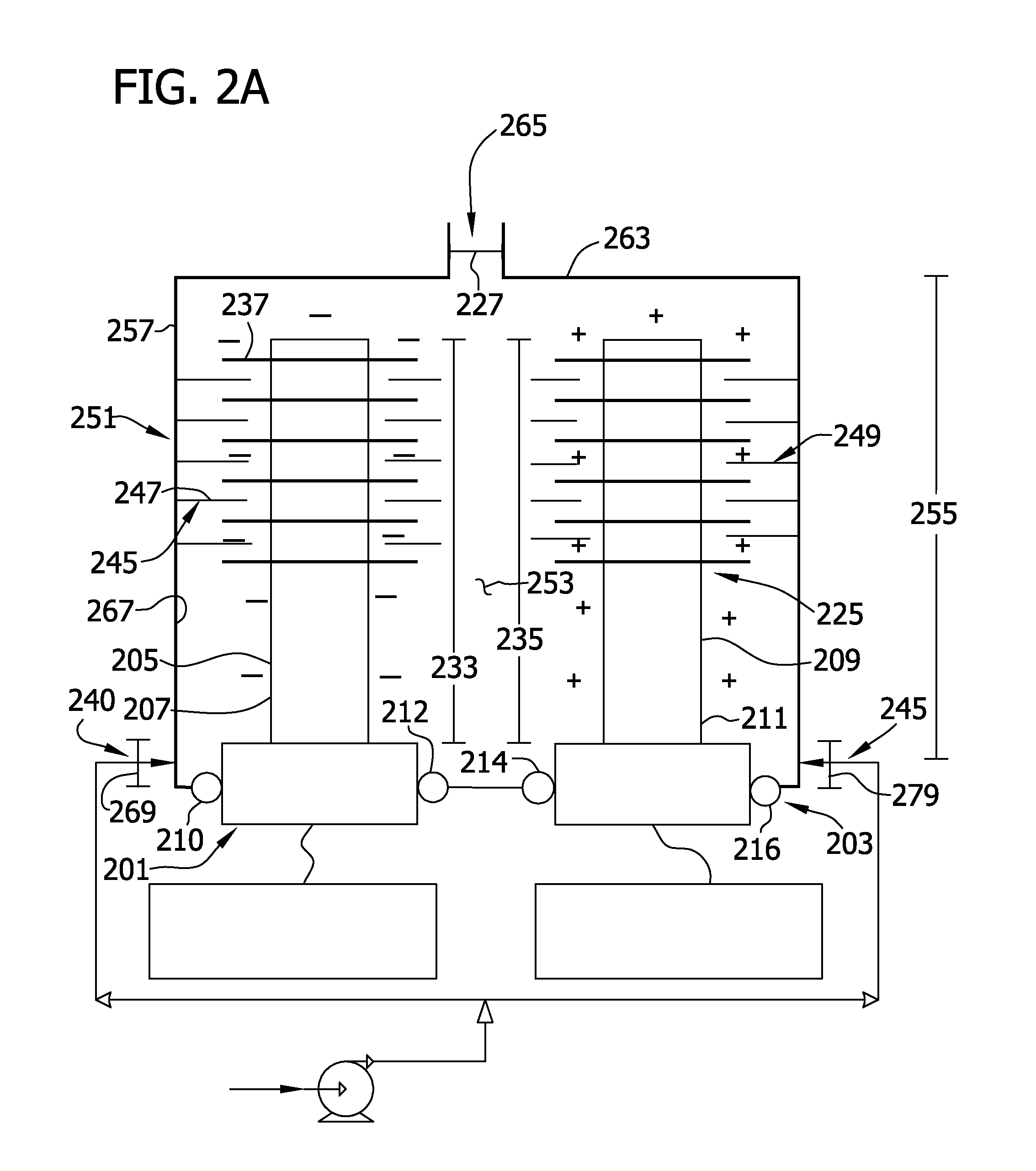

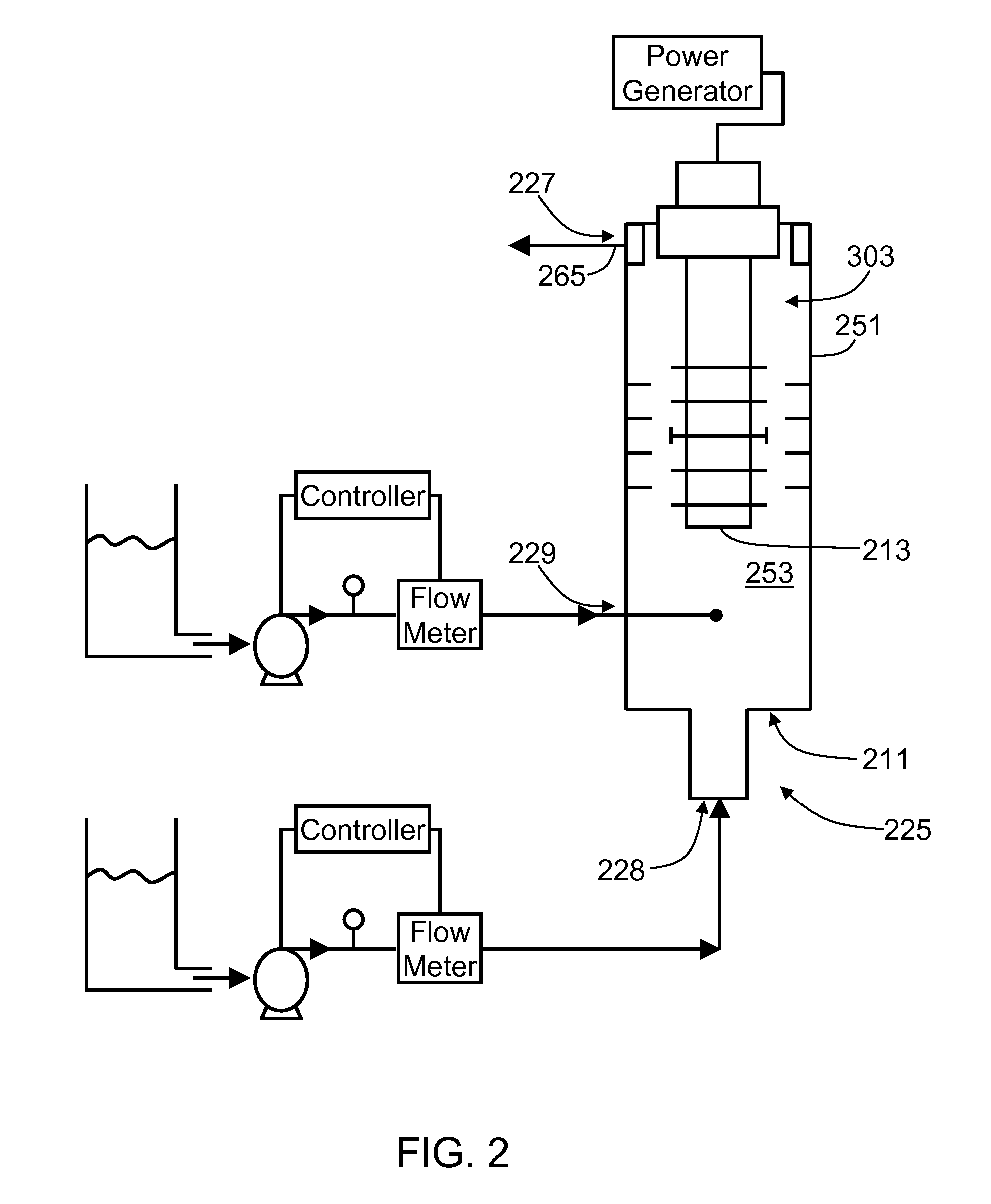

Ultrasonic treatment chamber for preparing emulsions

InactiveUS20090166177A1Shaking/oscillating/vibrating mixersCircuit elementsUltrasonic cavitationEmulsion

An ultrasonic mixing system having a treatment chamber in which at least two separate phases can be mixed to prepare an emulsion is disclosed. Specifically, at least one phase is a dispersed phase and one phase in a continuous phase. The treatment chamber has an elongate housing through which the phases flow longitudinally from a first inlet port and a second inlet port, respectively, to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the phases within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the phases being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

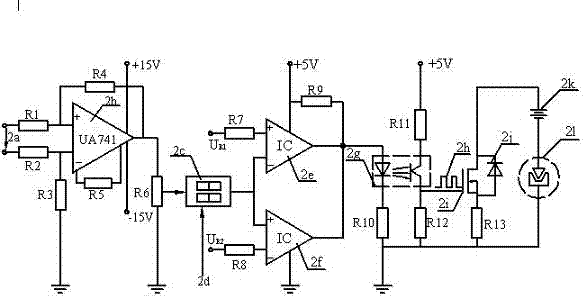

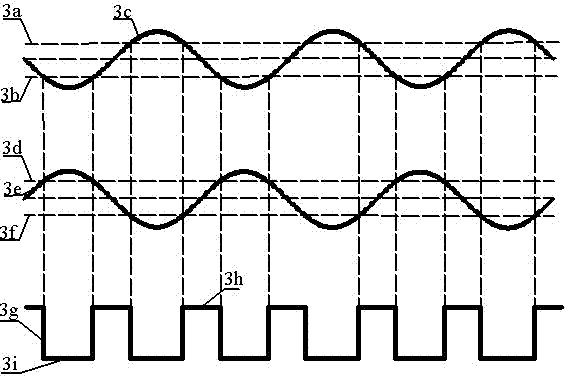

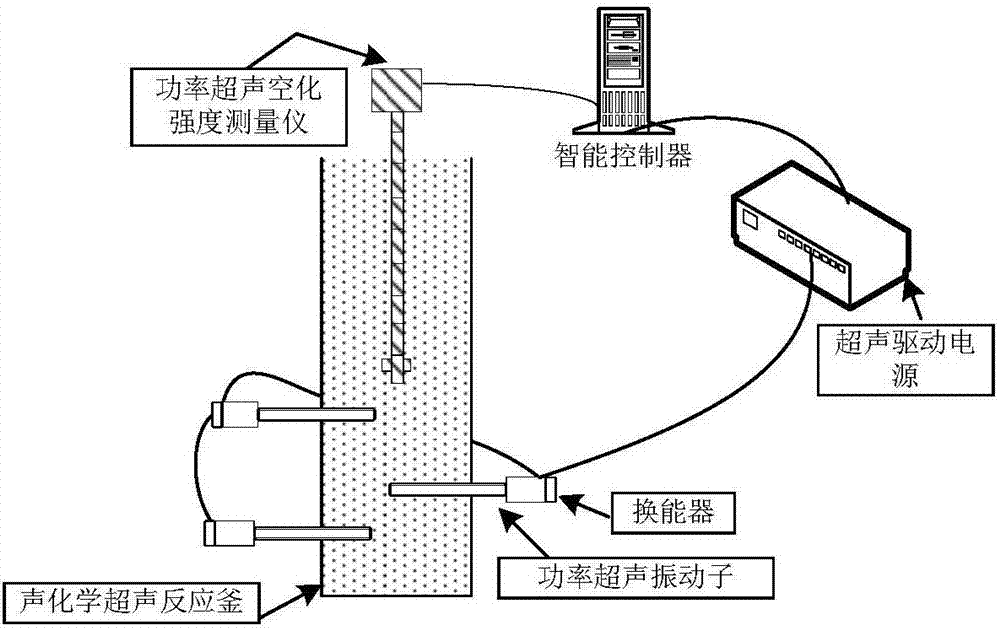

Ultrasonic dispersion control device using cavitation intensity feedback and ultrasonic dispersion control method thereof

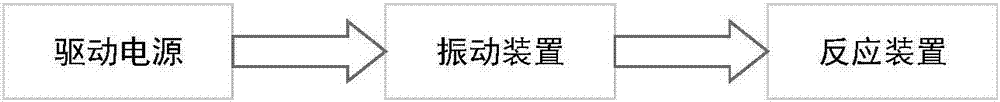

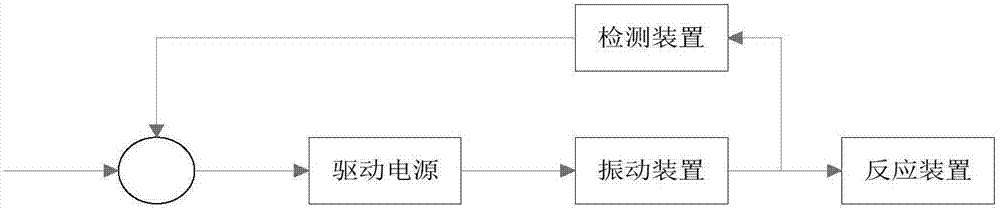

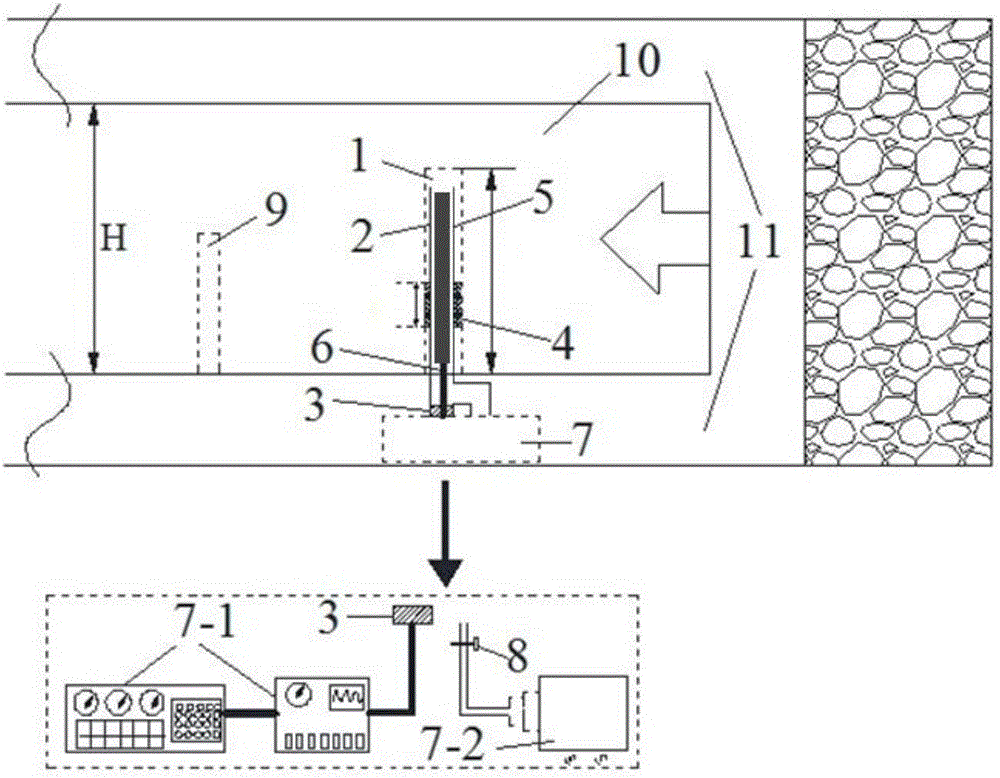

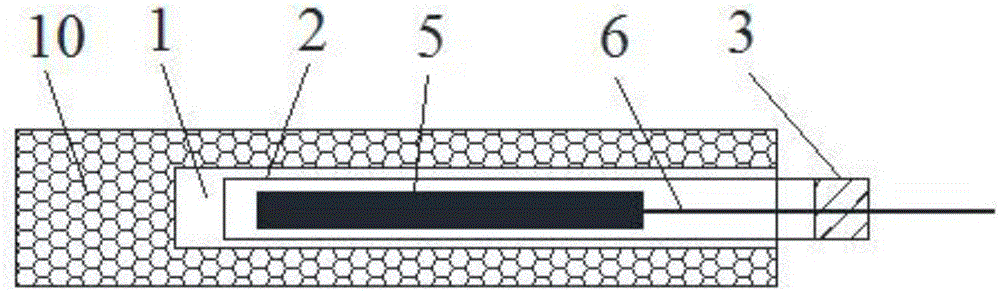

ActiveCN106950832AMuch interferenceImprove control effectMechanical vibrations separationEnergy based chemical/physical/physico-chemical processesUltrasonic cavitationMeasuring instrument

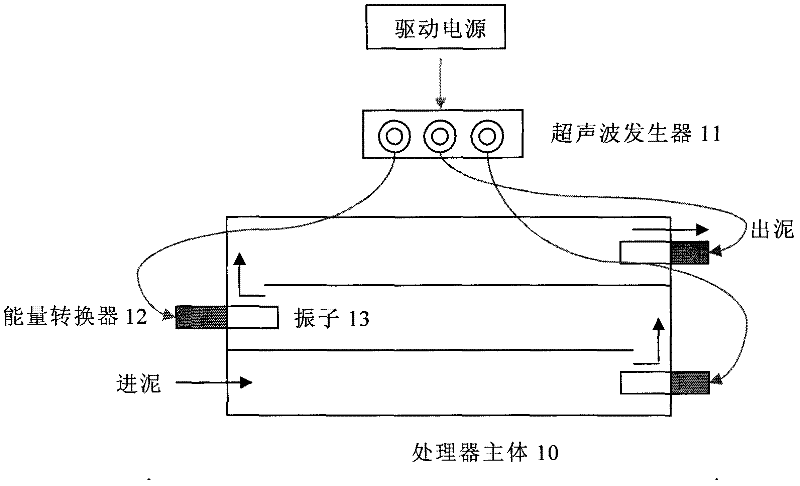

The invention discloses an ultrasonic dispersion control device using cavitation intensity feedback and an ultrasonic dispersion control method thereof. The device part comprises a controller, an ultrasonic power supply, an ultrasonic cavitation intensity measuring instrument, energy transducers and an ultrasonic oscillator. The control signal end of the controller is connected with the control signal input end of the ultrasonic power supply. The power supply output end of the ultrasonic power supply is connected with the power supply input end of each energy transducer. The signal output end of each energy transducer is connected with the ultrasonic oscillator. The ultrasonic oscillator is inserted in a chemical ultrasonic reaction kettle. The ultrasonic cavitation intensity measuring instrument is arranged in the chemical ultrasonic reaction kettle. The signal output end of the chemical ultrasonic reaction kettle is connected with the signal input end of the controller. The ultrasonic dispersion control device has the characteristics of being more suitable for large load change and multiple interferences of the industrial field and has the advantages of great control effect and stable output production. Meanwhile, the ultrasonic dispersion control device has the advantages of being reasonable in design, easy to operate, high in reliability and high in efficiency.

Owner:CONPROFE MACHINE TOOLS CO LTD

Ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method

ActiveCN105971660ASave construction timeGreat practicabilityFluid removalGas removalUltrasonic cavitationHydraulic fracturing

The invention discloses an ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method. A main drill hole and a monitoring drill hole are constructed in an air inlet way or an air return way of the working face at first, a steel pipe of a built-in ultrasonic transducer is sent into the main drill hole after a drill bit in the main drill hole reaches a coalbed preset target position, the main drill hole is subjected to high-pressure-resistant hole sealing through a conventional grouting method, and an ultrasonic generator is turned on to continuously emit low-frequency ultrasonic waves with the frequency being 20-25 kHz to the coalbed after hole sealing is completed; hydrofracture equipment is started in 1-2 h to conduct hydrofracture operation on the main drill hole; the power of the ultrasonic waves is kept unchanged while coalbed hydrofracture is conducted, and the frequency of the ultrasonic waves is adjusted to 30-35 kHz; and hydrofracture is stopped when water flows out of the monitoring drill hole or pressure of a water injection pump decreases suddenly, the frequency and power of the ultrasonic waves are kept unchanged at the time, ultrasonic waves are emitted to the coalbed continuously, and the ultrasonic generator is turned off in 30 min. The coalbed permeability-increase method is free of pollution, low in cost and good in effect.

Owner:CHINA UNIV OF MINING & TECH

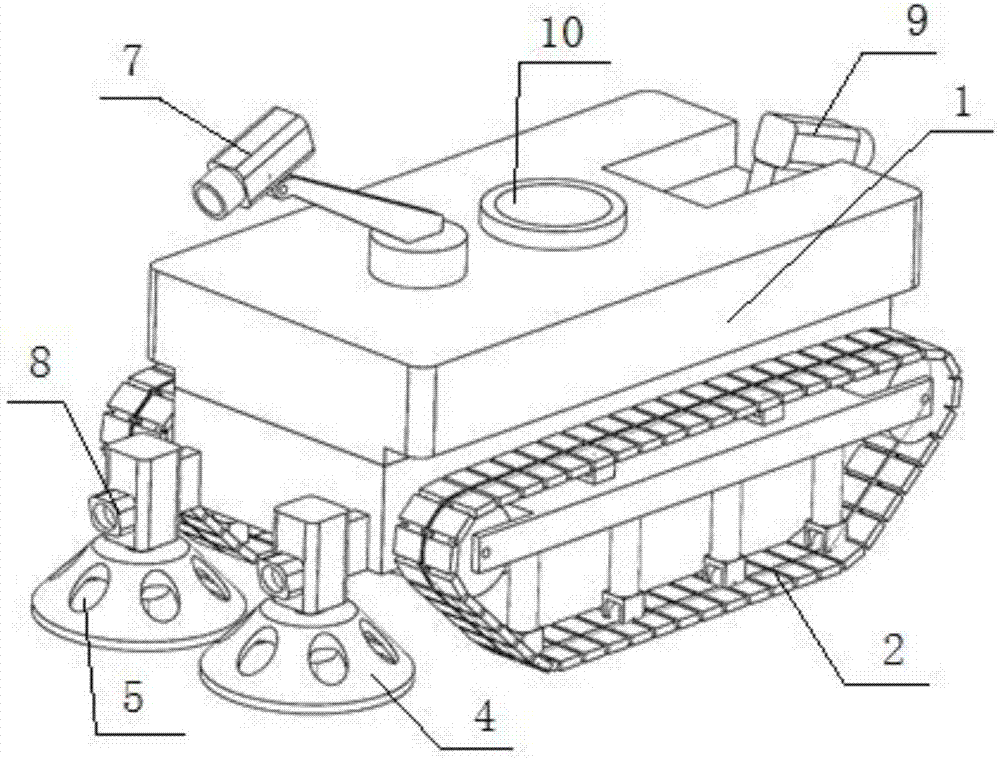

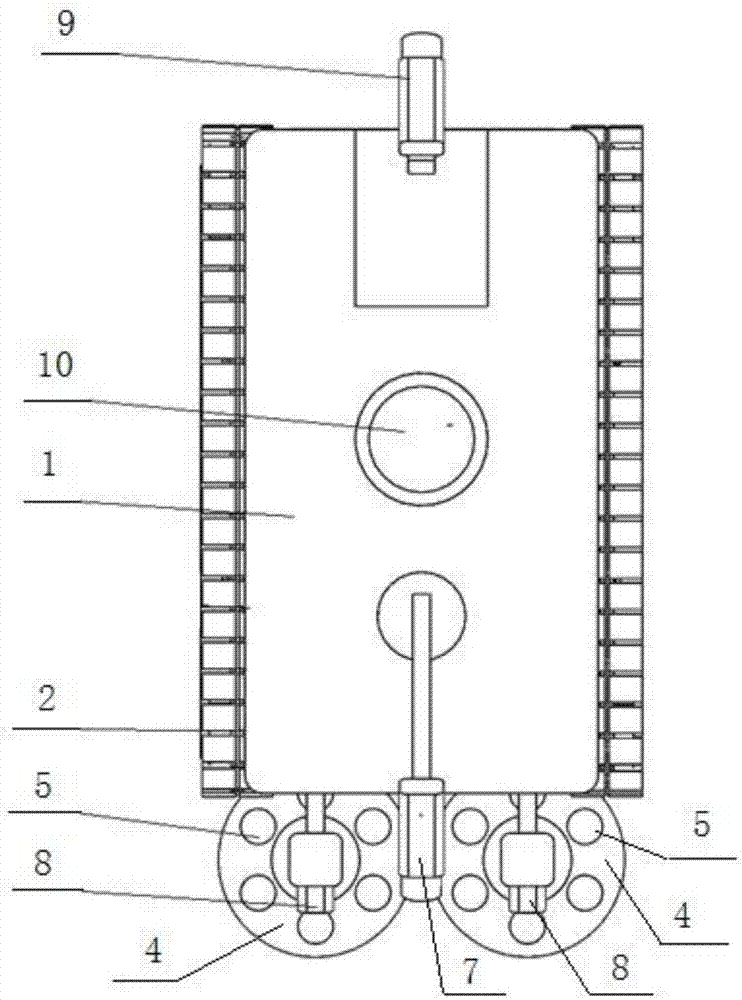

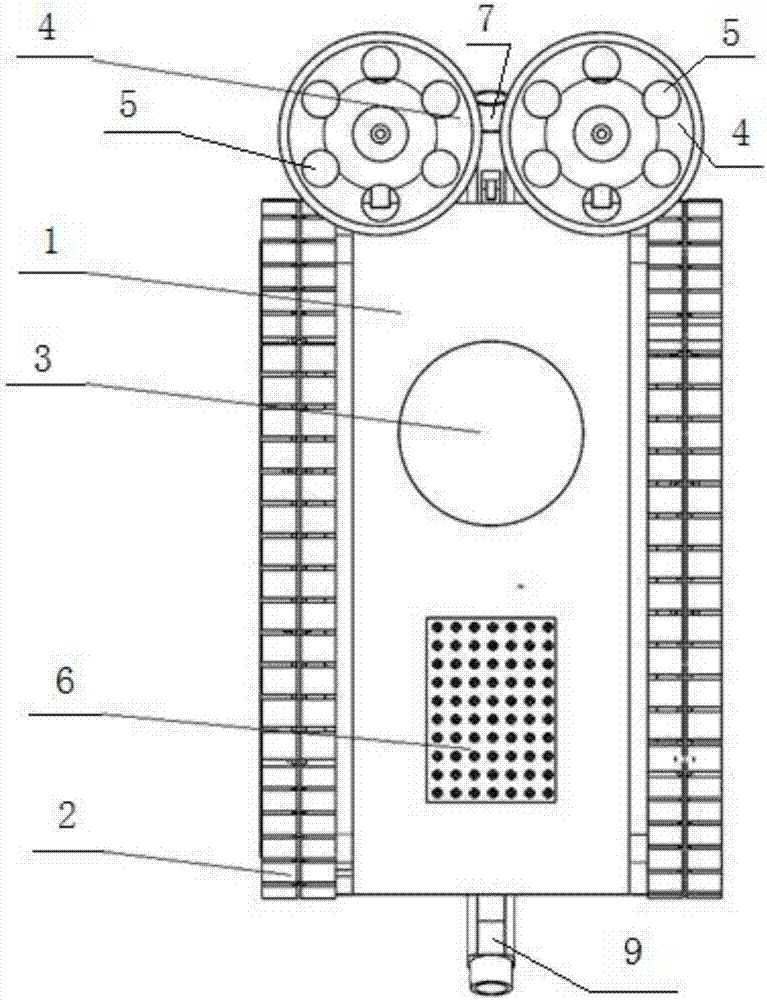

Ship fouling monitoring and removal device based on cavitation technology

InactiveCN107226180AGuaranteed flight dateReduce cleanup costsVessel cleaningHullsUltrasonic cavitationTransducer

The invention discloses a ship fouling monitoring and removal device based on cavitation technology. The device comprises a controller and a remote-operated vehicle module, wherein a cleaning module and a monitoring module are arranged on the remote-operated vehicle module; the controller controls the remote-operated vehicle module, the cleaning module and the monitoring module to work; the remote-operated vehicle module comprises a remote-operated vehicle, a crawler walking mechanism positioned on the remote-operated vehicle, an electromagnetic adsorption mechanism located on the remote-operated vehicle, and a permanent magnet located on the crawler walking mechanism; the cleaning module comprises a cavitation jet cleaning mechanism and an ultrasonic cavitation jet cleaning mechanism, the cavitation jet cleaning mechanism comprises a water supply tank, a high pressure water pump and a cavitation jet cleaning disc, and the cavitation jet cleaning disc is provided with a rotatable cavitation jet nozzle; and the ultrasonic cavitation cleaning mechanism comprises an ultrasonic generator and a transducer connected to the ultrasonic generator. The monitoring and removal device can remove attachments at the bottom of a ship under the condition that the ship does not need to dock, and does not affect the sailing schedule of the ship, and the fouling cleaning cost is low.

Owner:WUHAN UNIV OF TECH

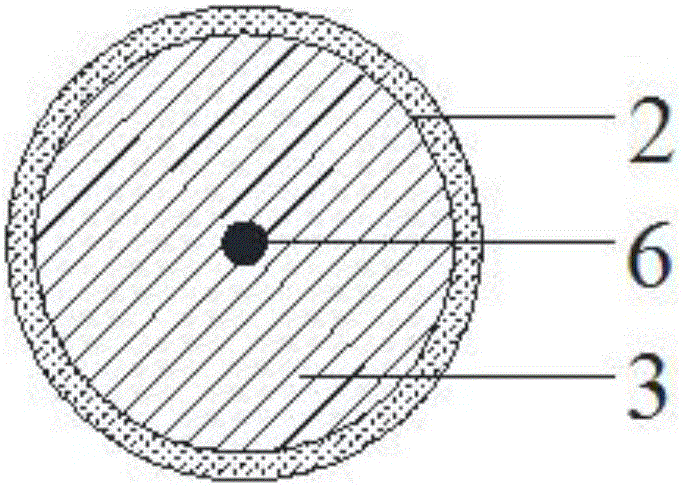

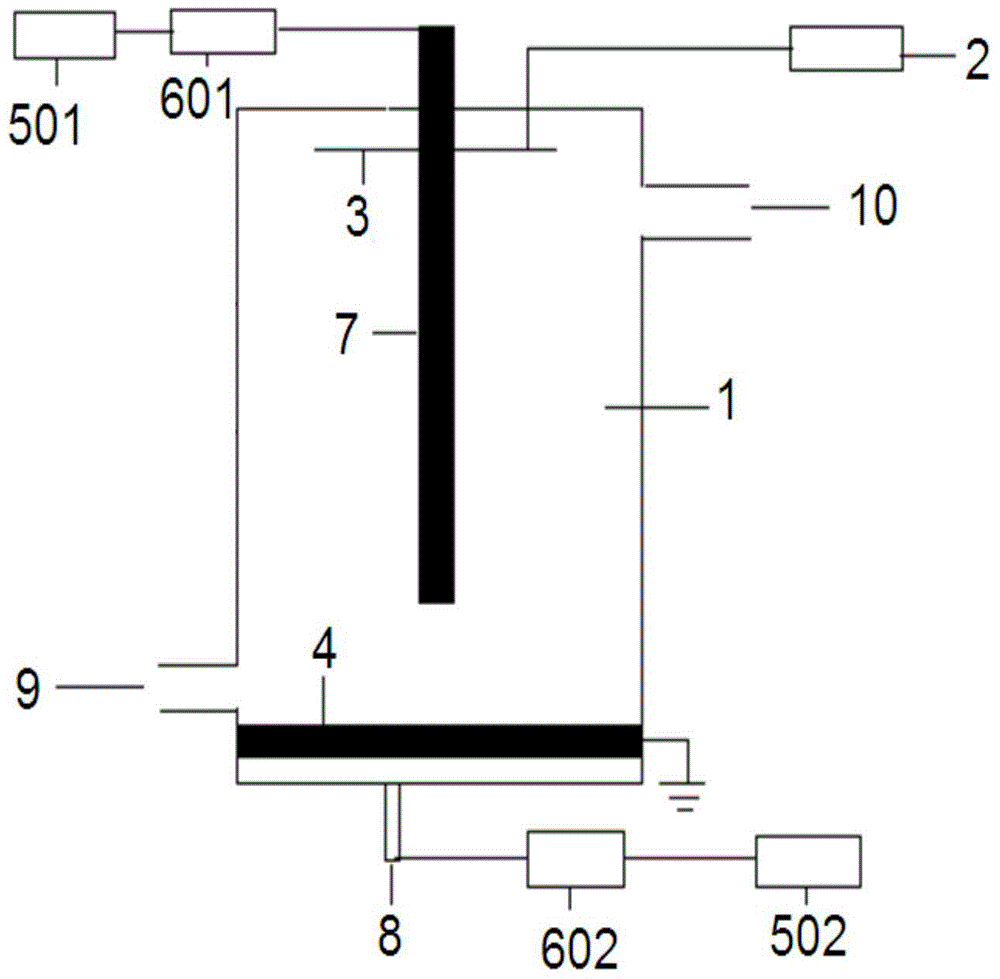

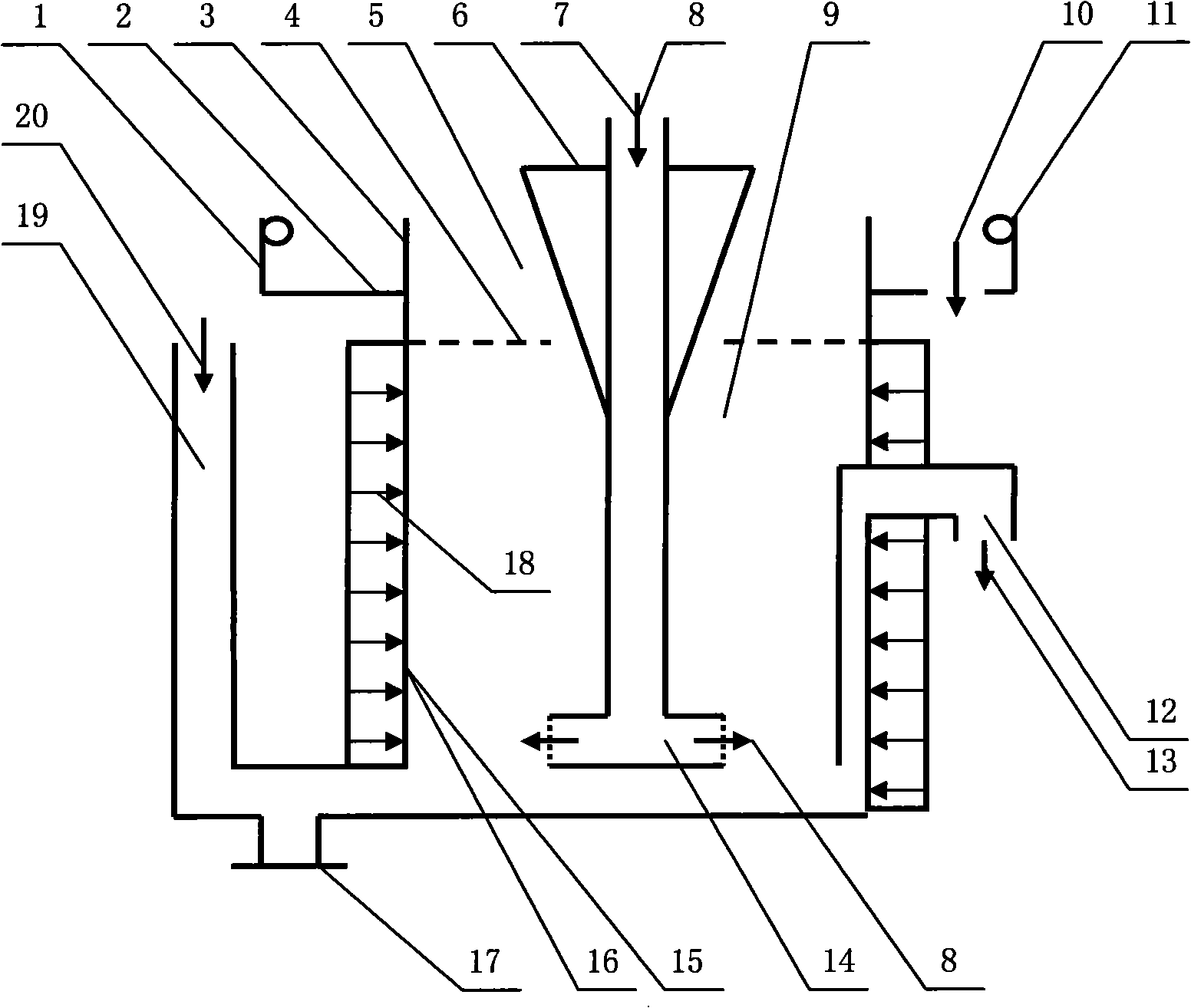

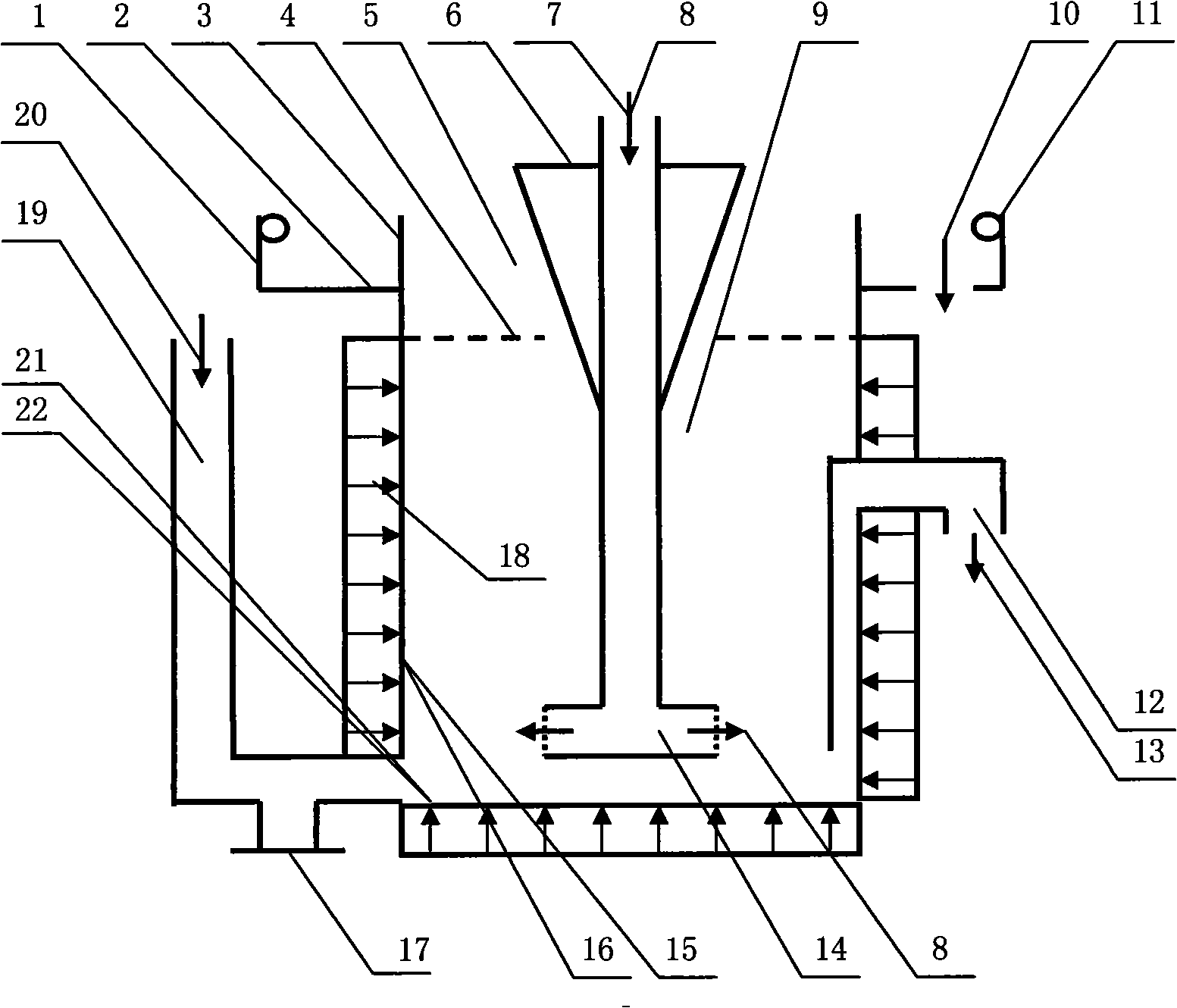

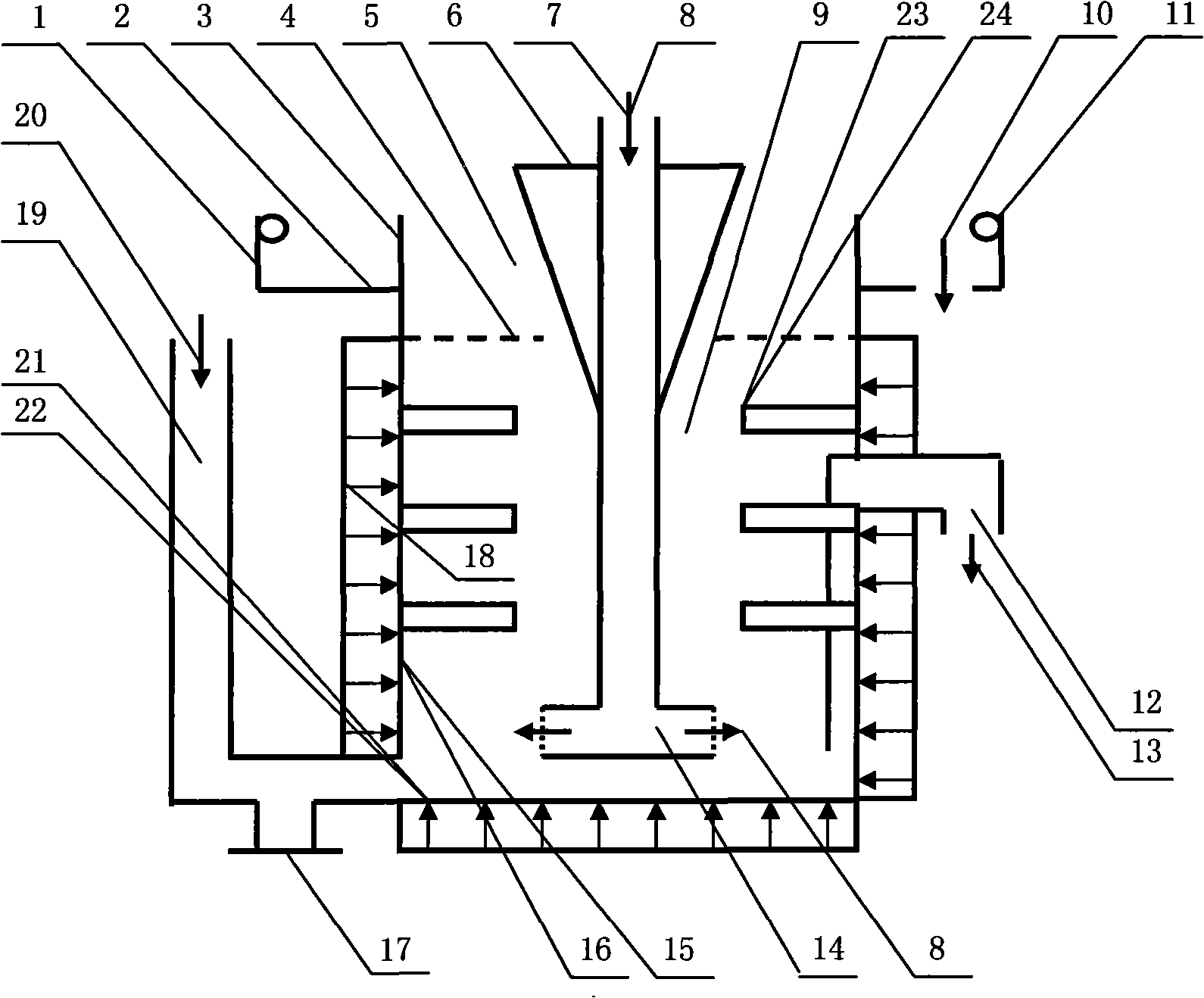

Plasma synergistic ultrasonic cavitation effect waste water treatment reactor

InactiveCN104129833ANo secondary pollutionLarge capacityWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsUltrasonic cavitationWave field

The invention discloses a plasma synergistic ultrasonic cavitation effect waste water treatment reactor. The plasma synergistic ultrasonic cavitation effect waste water treatment reactor comprises a line-plate gas-liquid two-phase discharge reactor (1), a high-voltage pulse power supply (2), a line electrode (3), a plate electrode (4), ultrasonic generators (501, 502) and piezoelectric transducers (601, 602), wherein the high-voltage pulse power supply (2) is connected with the line electrode (3); the line electrode (3) is arranged on the top inside the line-plate gas-liquid two-phase discharge reactor (1); the plate electrode (4) is arranged at the bottom of the line-plate gas-liquid two-phase discharge reactor (1); the plate electrode (4) is connected with the ground; the two ultrasonic generators (501, 502) are connected with the two piezoelectric transducers (601, 602); and the two piezoelectric transducers (601, 602) are connected with an amplitude-change pole (7) and a connecting rod (8) respectively. Ultrasonic wave fields generated by the two sets of ultrasonic generators (501, 502) are vertical too each other, and a generated high-frequency sound field contributes to the improvements on the mechanical and cavitation effects of a low-frequency sound field.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

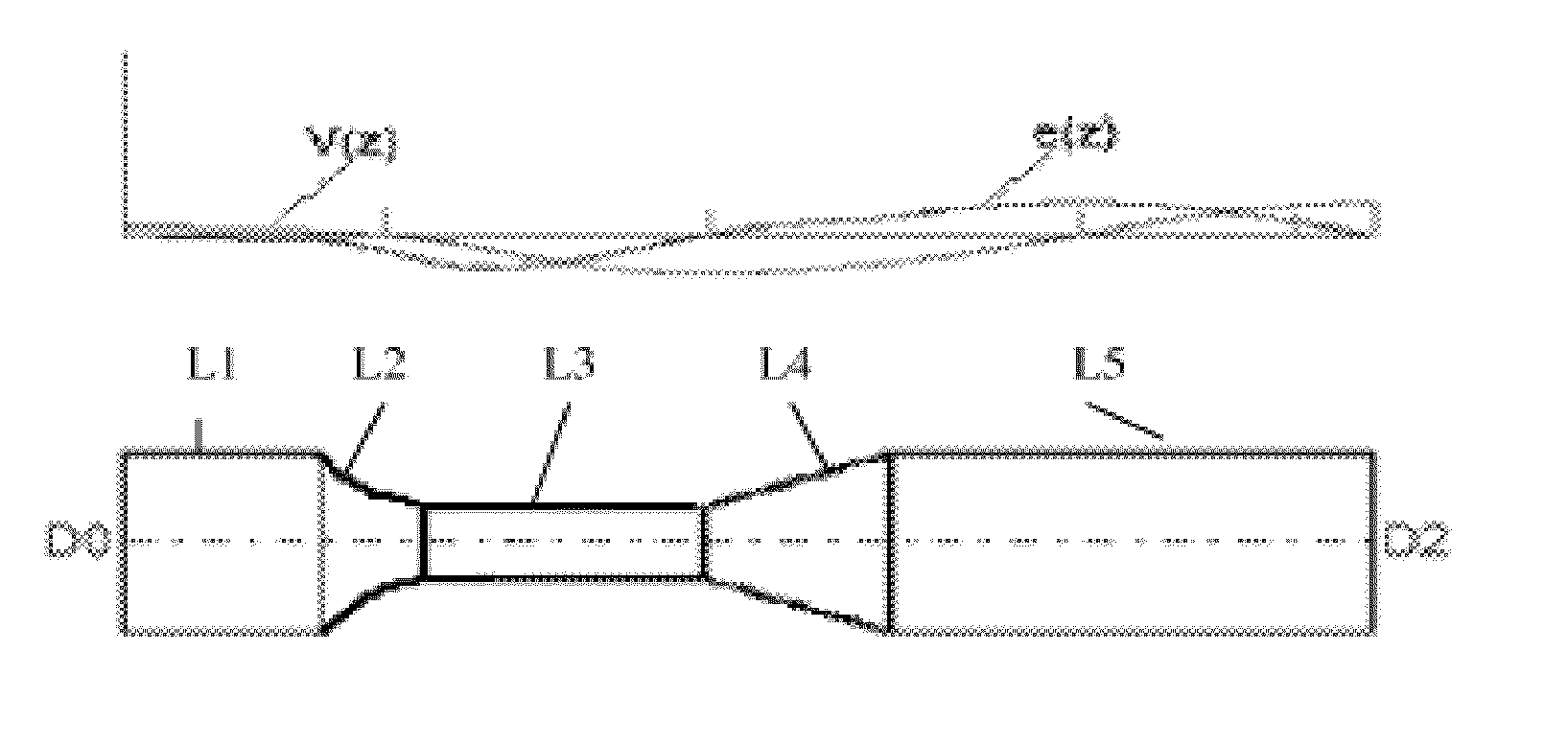

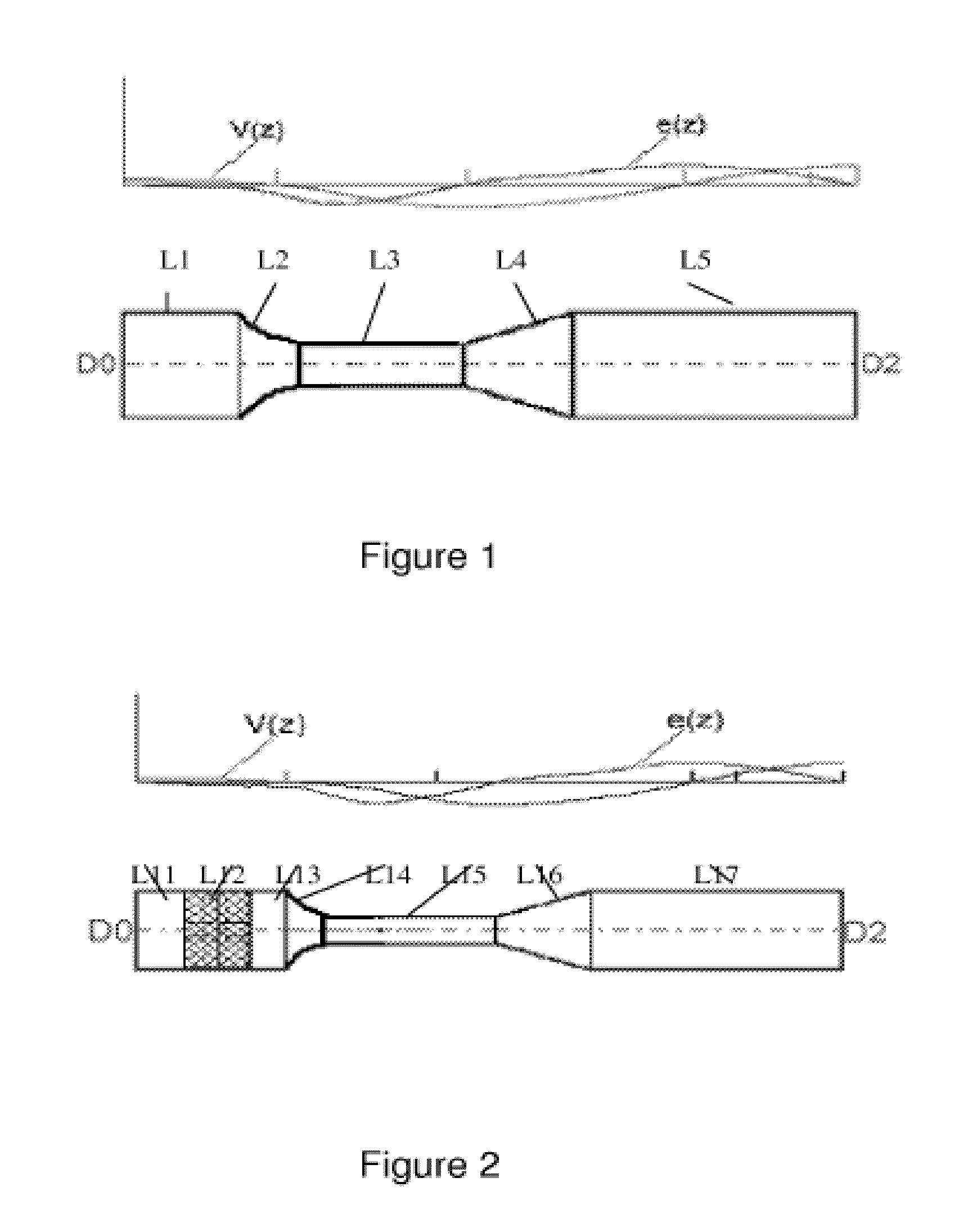

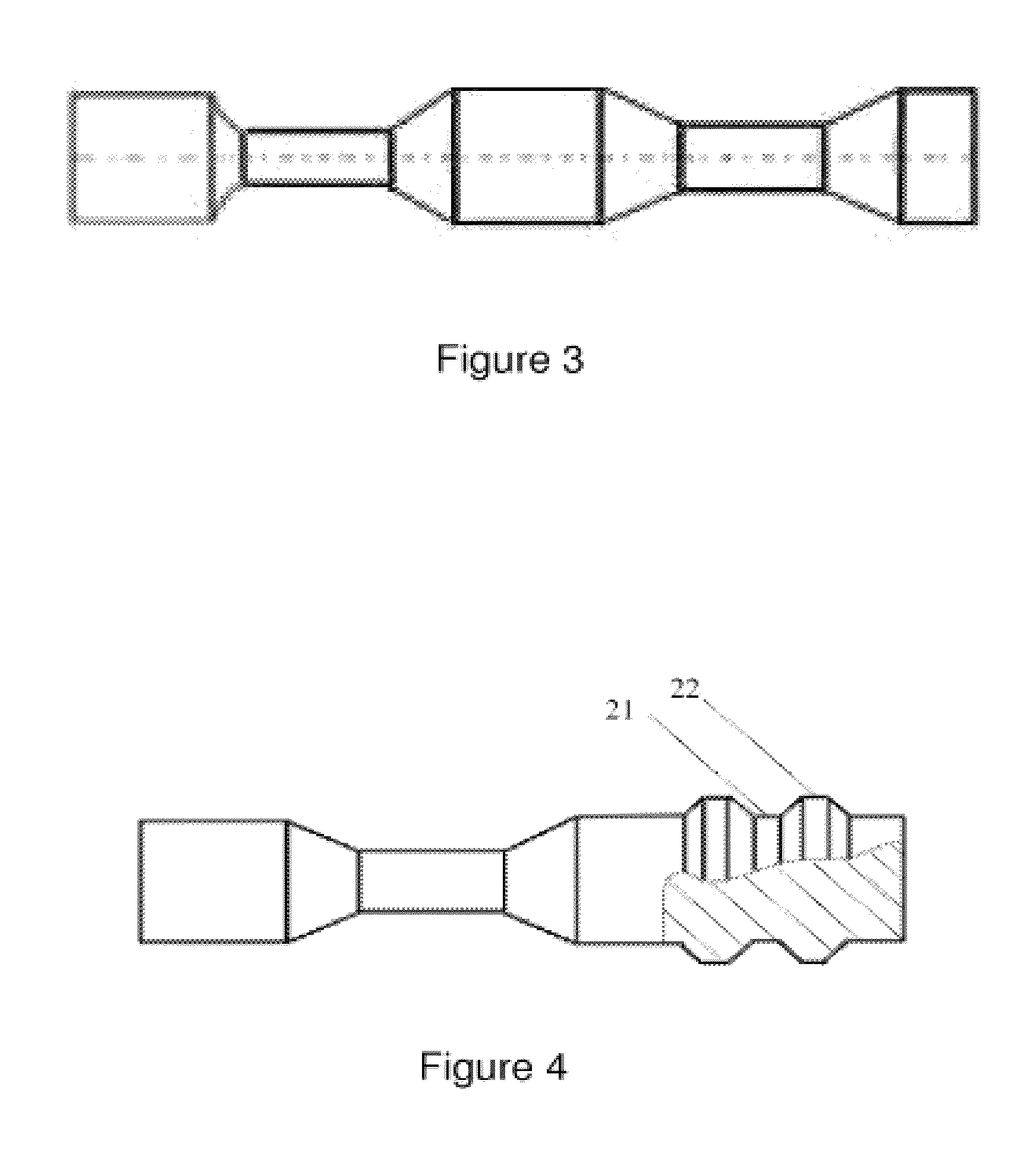

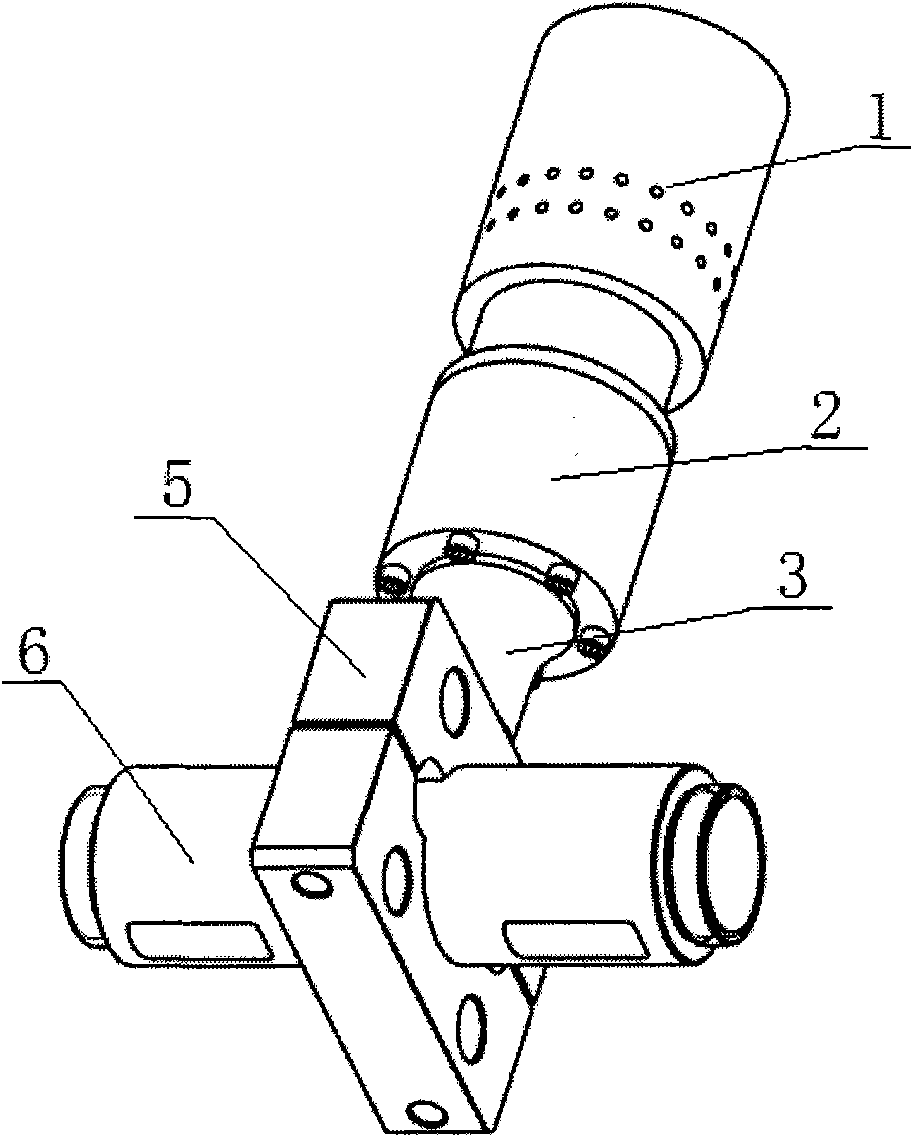

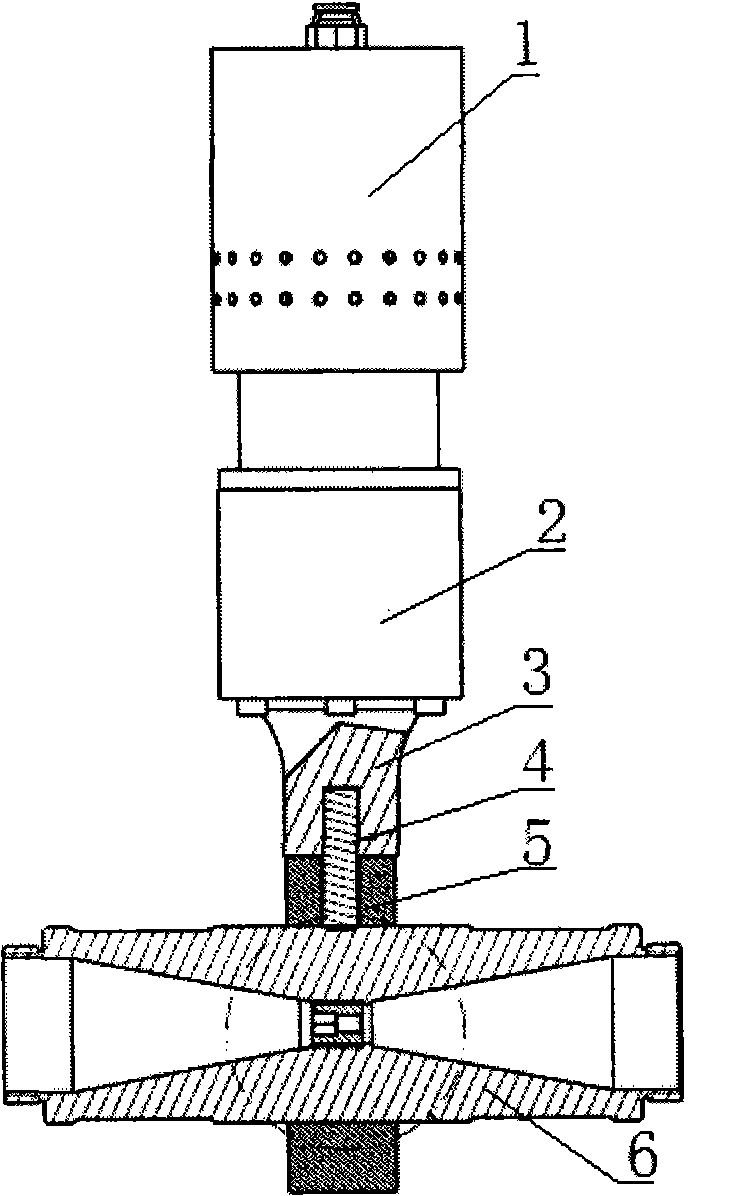

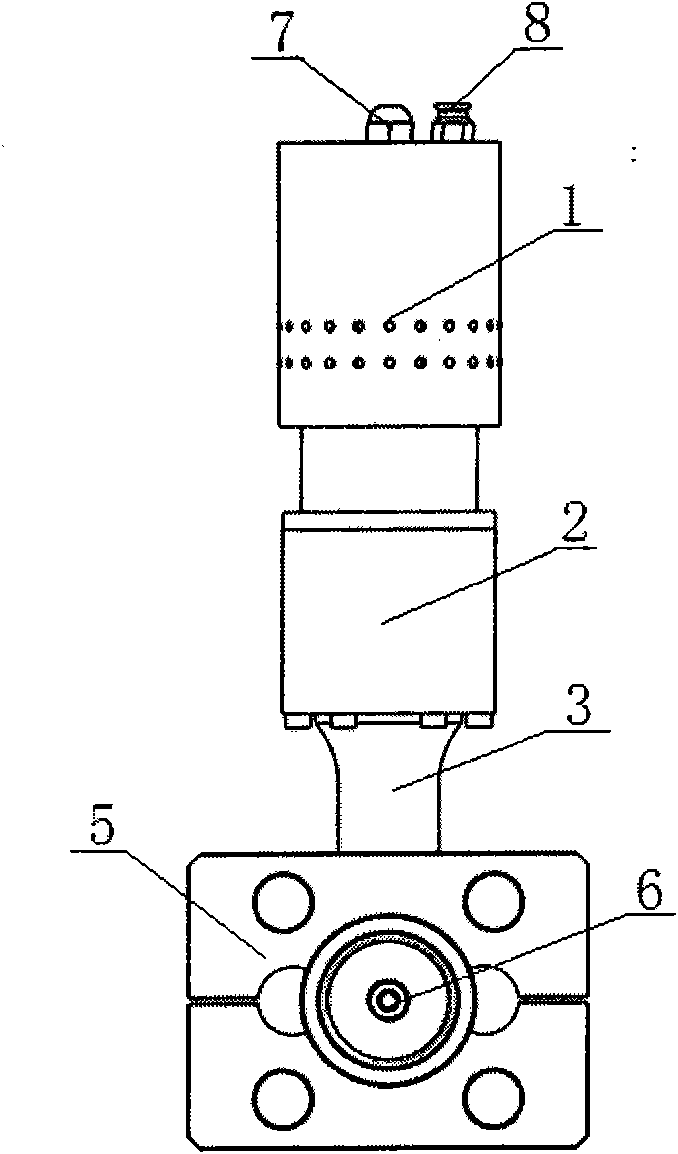

Hydraulic/ultrasonic coupling cavitation device

ActiveCN102059070AImprove cavitation strengthIncreased cavitation energyShaking/oscillating/vibrating mixersFlow mixersUltrasonic cavitationTransformer

The invention discloses a hydraulic / ultrasonic coupling cavitation device which comprises a hydraulic cavitation mechanism and an ultrasonic functional mechanism, wherein the ultrasonic functional mechanism is arranged on the hydraulic cavitation mechanism; the ultrasonic functional mechanism comprises an ultrasonic transducer, a connecting flange, an amplitude transformer and a functional fixture, wherein the ultrasonic transducer is connected with the amplitude transformer through the connecting flange, the amplitude transformer is connected with the functional fixture, and the hydraulic cavitation mechanism is arranged in the functional fixture and can be a Venturi tube, a pore plate or a liquid nozzle. The invention has the advantages that: an electric ultrasonic cavitation device is combined with the hydraulic cavitation device, and the coupling synergistic effect of the ultrasonic cavitation and the hydraulic cavitation can greatly enhance the cavitation effect to ensure that cavitation energy, sound pressure, sound intensity and efficiency are greatly improved. The hydraulic / ultrasonic coupling cavitation device can be effectively used in industrial production processes of sewage degradation treatment, oil water demulsification treatment, liquid inactivation treatment, Chinese medicine extraction, induced crystallization, wine ageing treatment, material uniform dispersing treatment, and the like.

Owner:GUANGZHOU NEWPOWER ULTRASONIC ELECTRONICS EQUIP +1

Double-frequency ultrasonic multi-dimensional focused cerebrovascular thrombolytic system

InactiveCN102232856AImprove solubilityNot brokenUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyFocus ultrasoundUltrasonic cavitation

The invention discloses a double-frequency ultrasonic multi-dimensional focused noninvasive cerebrovascular thrombolytic system, which is characterized in that: a craniocerebral vertical positioning ring is worn for image detection and acquisition of positioning image data; the position and treatment position of a focus can be determined by using a medical image three-dimensional reconstruction technique; a multi-dimensional low-power low-frequency ultrasonic transducer is placed on the same cut face of a focus of cerebral embolism to form a stable ultrasonic cavitation effect is formed in the thrombus or the focus of the cerebral embolism; a medium-frequency and / or high-frequency focused ultrasound transducer is used to radiate the thrombus by a focused ultrasonic focal point from a position on the same cut face of body surface which is most close to the focus, the focused ultrasonic waves are focused with high power, high sound intensity and high accuracy and are intermittently emitted in a pulse modulation ultrasonic wave mode in a short time to form an instant unstable ultrasonic cavitation effect in the thrombus to induce blasting in the thrombus, so that the thrombus is disintegrated and dissolved quickly; and while the thrombus is quickly and effectively dissolved, the inner wall of the blood vessel and surrounding normal brain tissues are not damaged, so in-vitro noninvasive thrombolytic effect is achieved.

Owner:高春平

System and method for obtaining carbon source by utilizing ultrasonic enhanced sludge hydrolysis

InactiveCN102229463AImprove efficiencyIncrease speedBiological sludge treatmentBiological water/sewage treatmentPropanoic acidUltrasonic cavitation

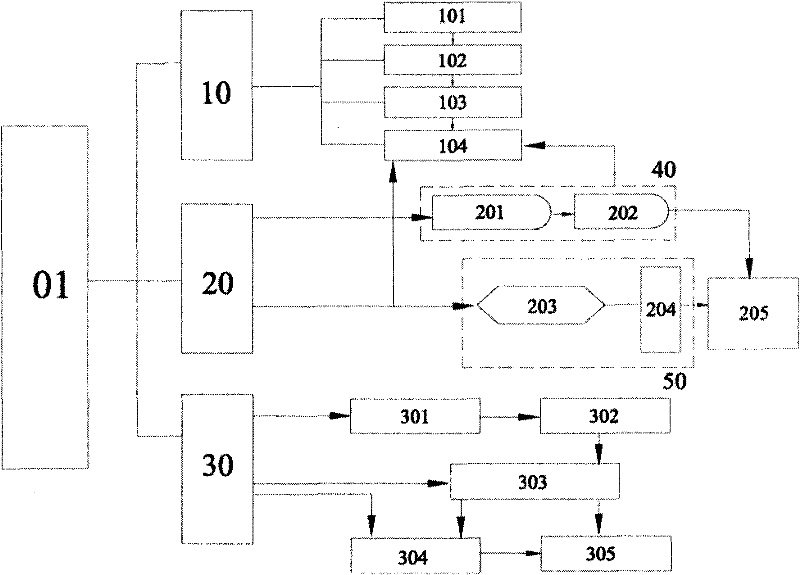

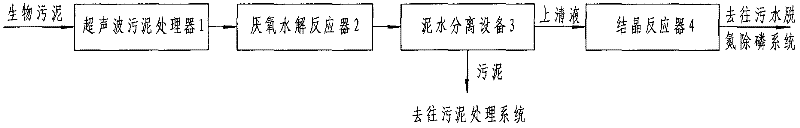

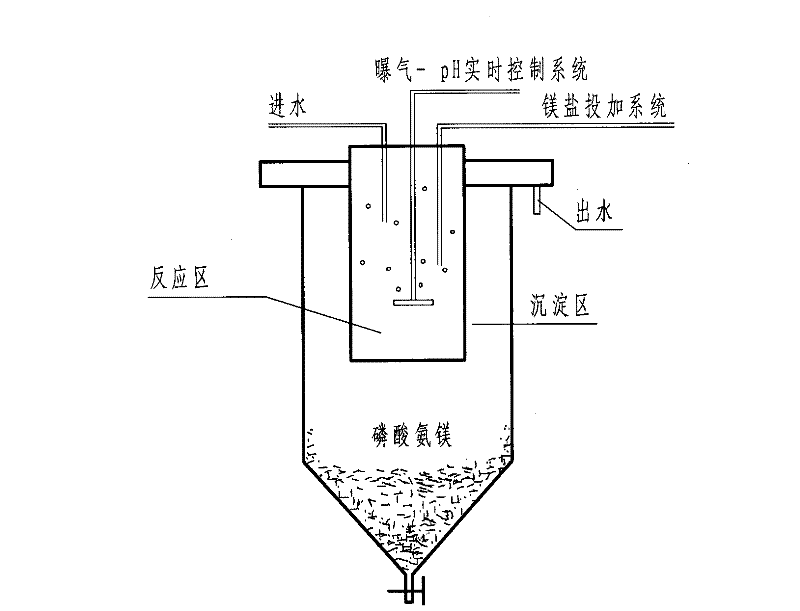

The invention relates to a system and method for obtaining a carbon source by utilizing ultrasonic enhanced sludge hydrolysis. The biological sludge in a municipal sewage plant is used as a raw material; the flocculation structure and cell wall of the sludge are firstly damaged by utilizing a waterpower shear force generated by an ultrasonic cavitation effect; the sludge after ultrasonic preprocessing is added to an anaerobic hydrolysis reactor; and under anaerobic conditions, macromolecular solid organic matters are finally converted into volatile fatty acids (VFAs) such as acetic acid, propionic acid, butyric acid and the like through a series of biological hydrolytic action. In the invention, the efficiency and velocity for a sludge to release a carbon source are improved by utilizing the coupling of ultrasonic processing and anaerobic hydrolysis processes, and the N (nitrogen) and P (phosphorus) which are released by hydrolysis are effectively eliminated and recovered by utilizing a crystallization method. The invention can solve the problem of carbon source insufficiency of the existing denitrification and dephosphorization process and realizes the stabilization and resource of the sludge to some extent. Simultaneously, because the hydrolysis velocity of the sludge is enhanced, the hydrolysis time of the sludge is greatly shortened and the investment and operating cost of engineering are lowered.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

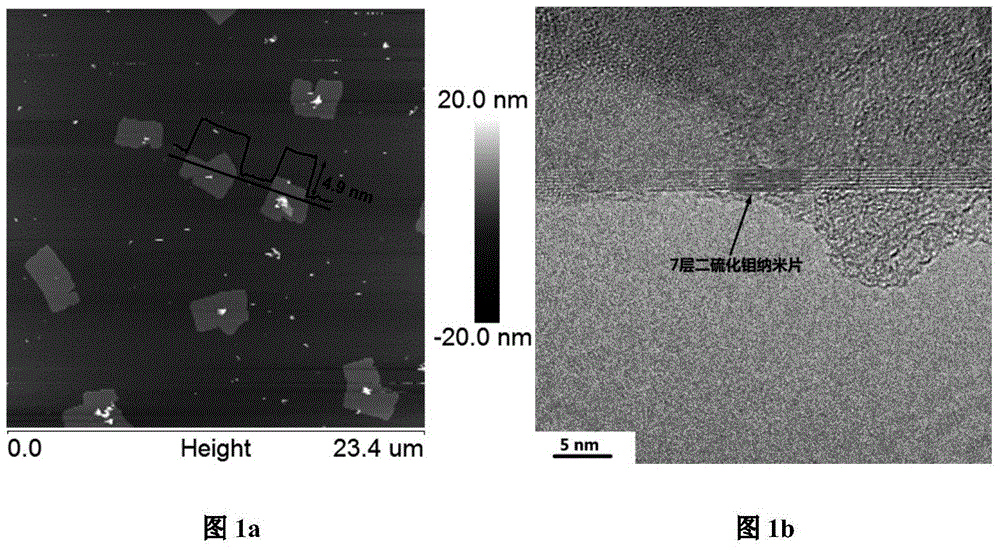

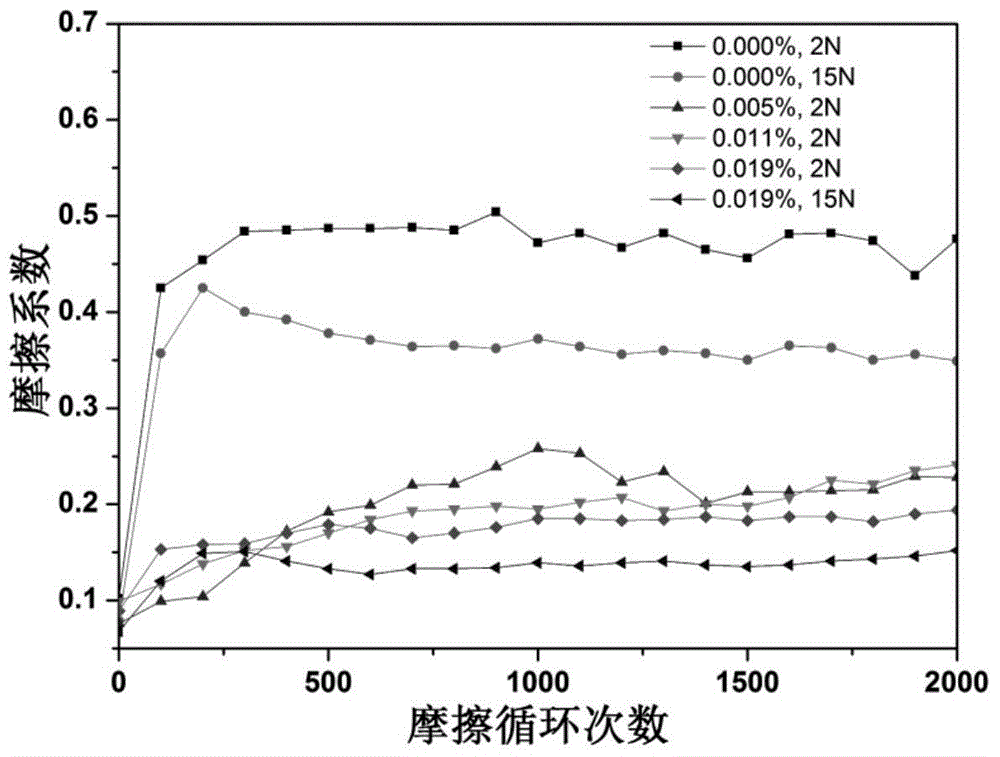

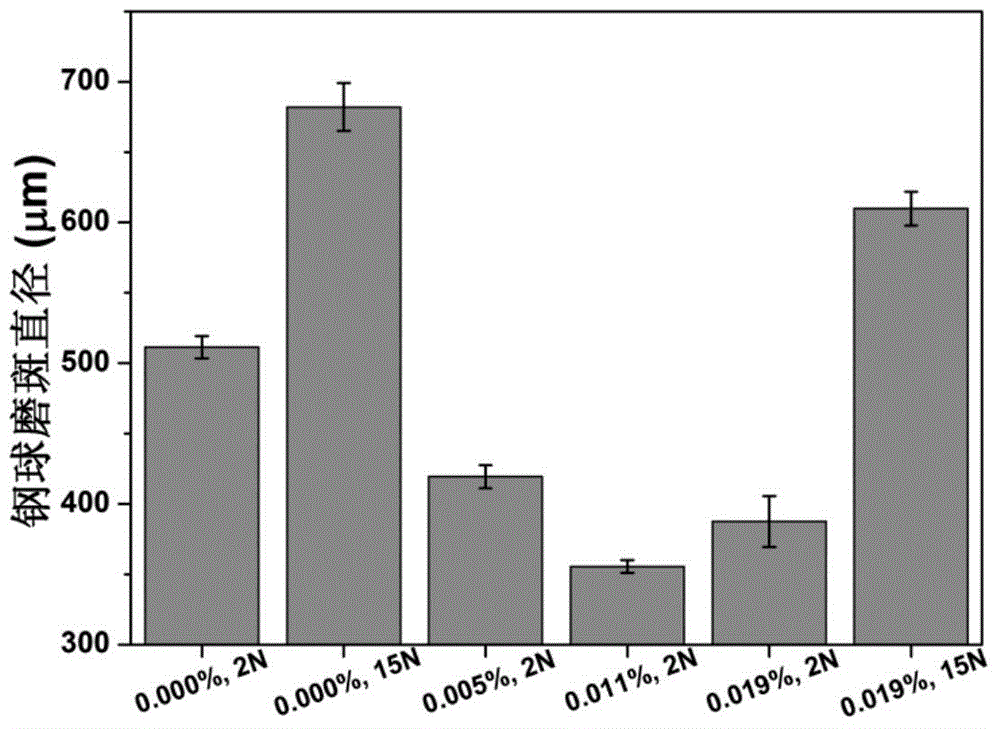

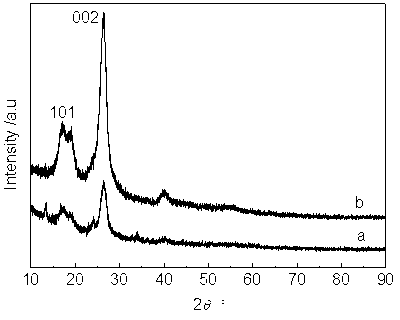

In-situ preparation method of water-based lubricant containing molybdenum disulfide nanosheet

An in-situ preparation method of a water-based lubricant containing a molybdenum disulfide nanosheet comprises six steps as follows: (1), a surface active agent is dissolved in deionized water in a proportion to obtain a solution; (2), molybdenum disulfide powder is uniformly dispersed into the solution; (3), a molybdenum disulfide dispersion liquid is subjected to ultrasonic cavitation processing; (4), the solution is left to stand for a certain period of time, and a supernatant liquid of the solution is taken; (5), the obtained solution is subjected to centrifugal separation processing; (6) the supernatant liquid of the centrifugal solution is collected, and the water-based lubricant containing the in-situ prepared molybdenum disulfide nanosheet is obtained. The method is easy, convenient and feasible, and the dispersion stability of the molybdenum disulfide nanosheet is good. A friction experiment result indicates that the wear-resistant and anti-friction performance of the lubricant can be greatly improved by adding a small quantity of the molybdenum disulfide nanosheet on the premise that the original excellent characteristics of good cooling performance and processability and the like of the water-based lubricant are not influenced, and the addition quantity of the molybdenum disulfide nanosheet ranges from 0.001% to 1%.

Owner:BEIHANG UNIV

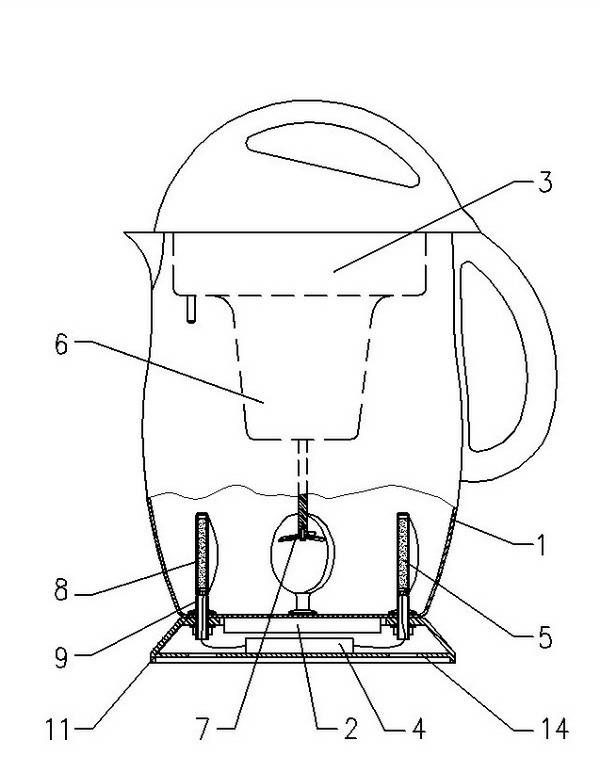

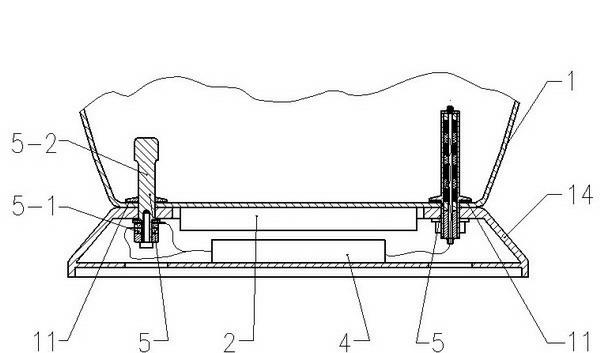

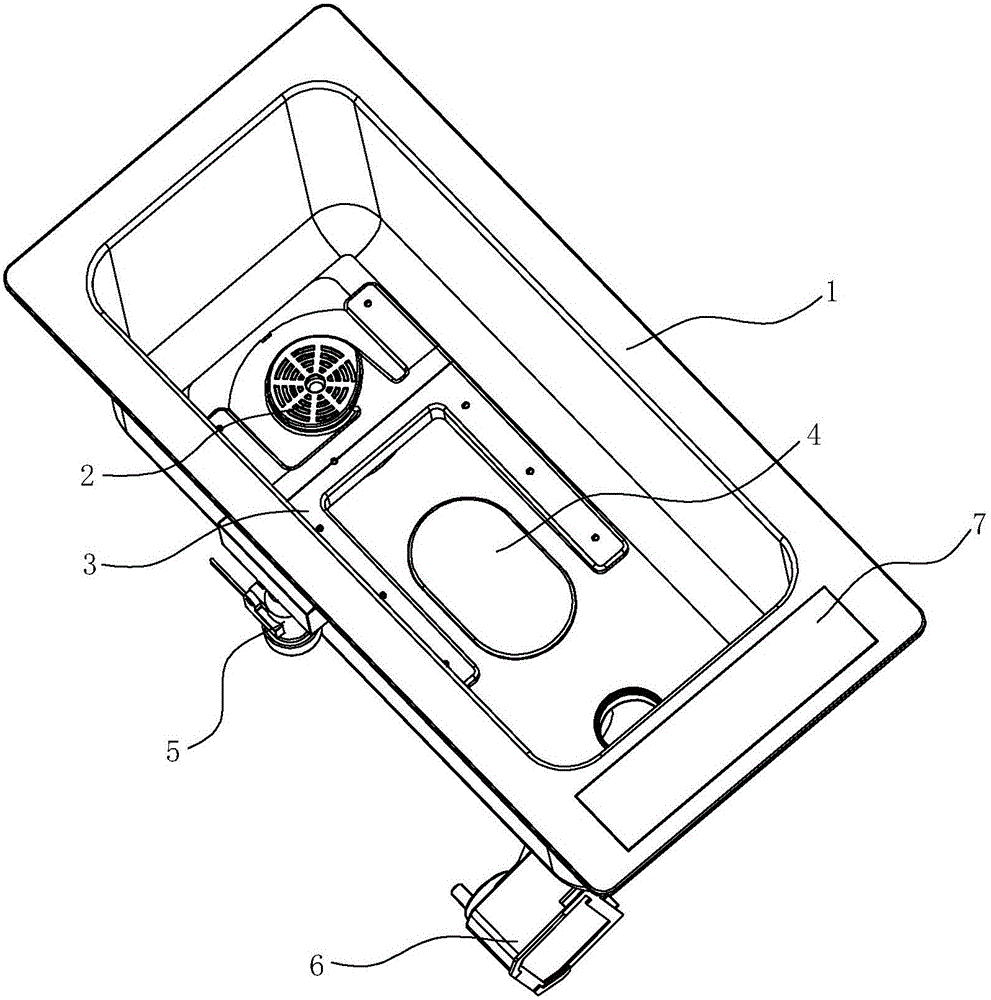

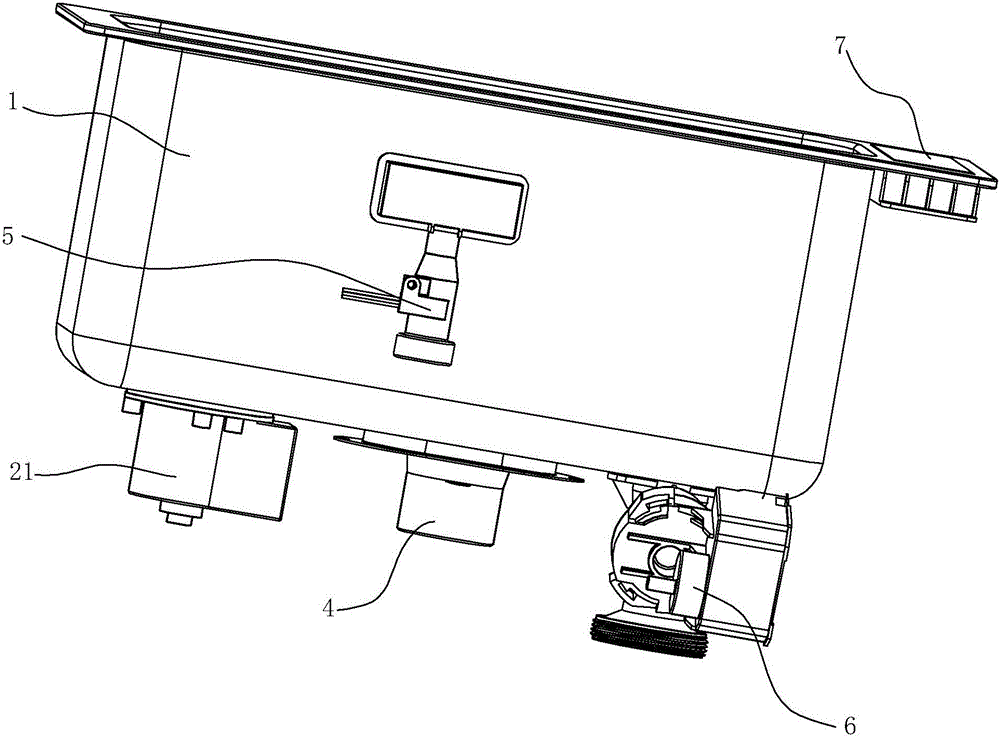

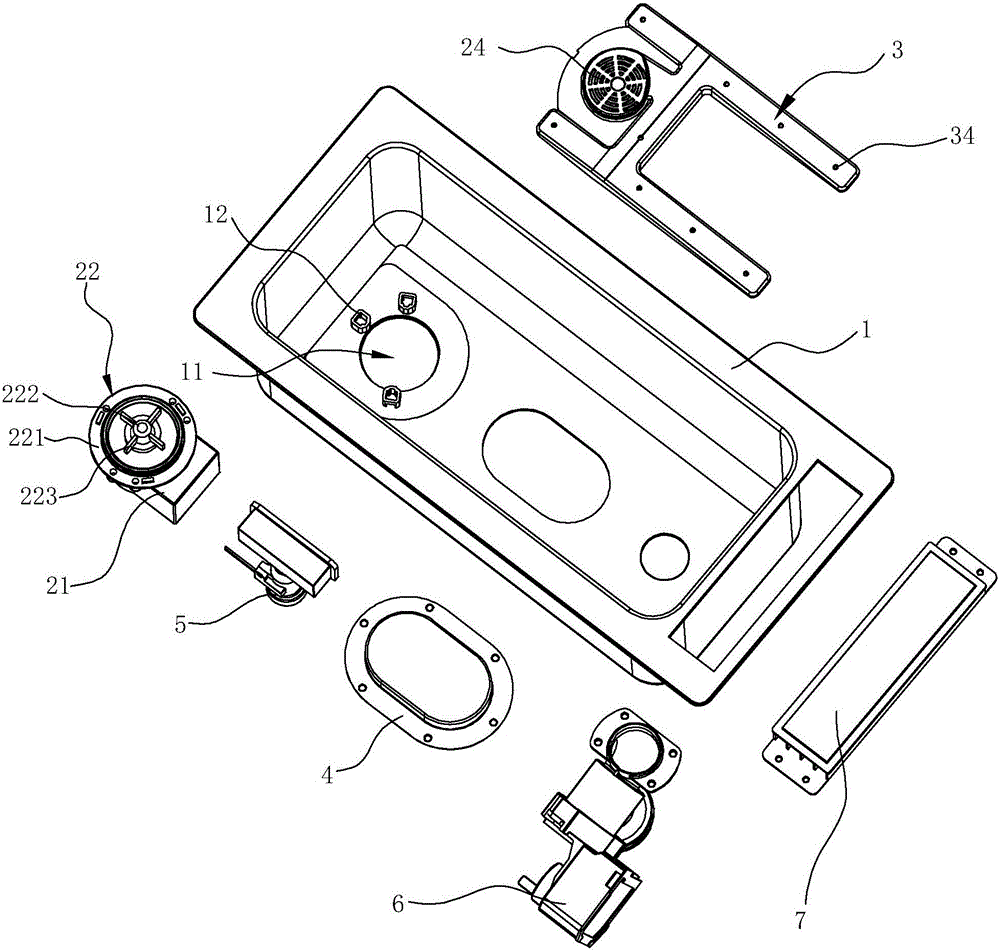

Soymilk grinder with ultrasonic wave device

InactiveCN102119832AWith self-cleaning functionEasy to clean automaticallyBeverage vesselsMilk substitutesUltrasonic cavitationMegasonic cleaning

The invention provides a soymilk grinder with an ultrasonic wave device. An ultrasonic transducer extends into a cup body from the machine head (or cup cover) or the outside of a cup body to convert a high-frequency electrical signal generated by an ultrasonic wave generator into high-frequency mechanical oscillation to generate an 'ultrasonic cavitation' effect in water, so that the soybean residual and attached materials in the cup body and on parts of the machine head are cleaned. The soymilk grinder has a self-cleaning function, so a user can conveniently allow the soymilk grinder to clean automatically. Thus, the difficult soymilk grinder cleaning problem that troubles people for a long time is solved radically, and a particular effect can be produced in a soybean milk cooking process by using the properties of ultrasonic waves.

Owner:阮泽明

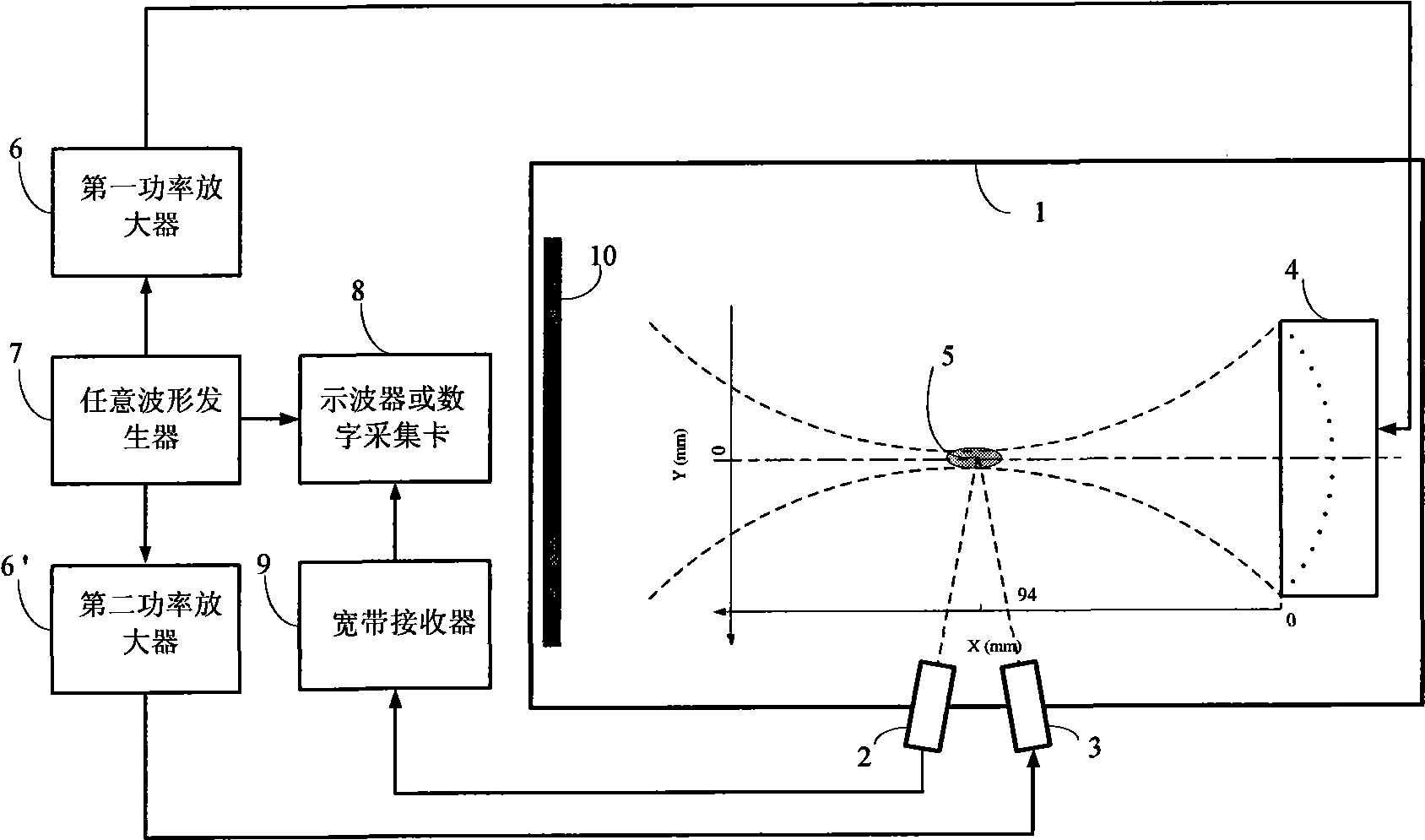

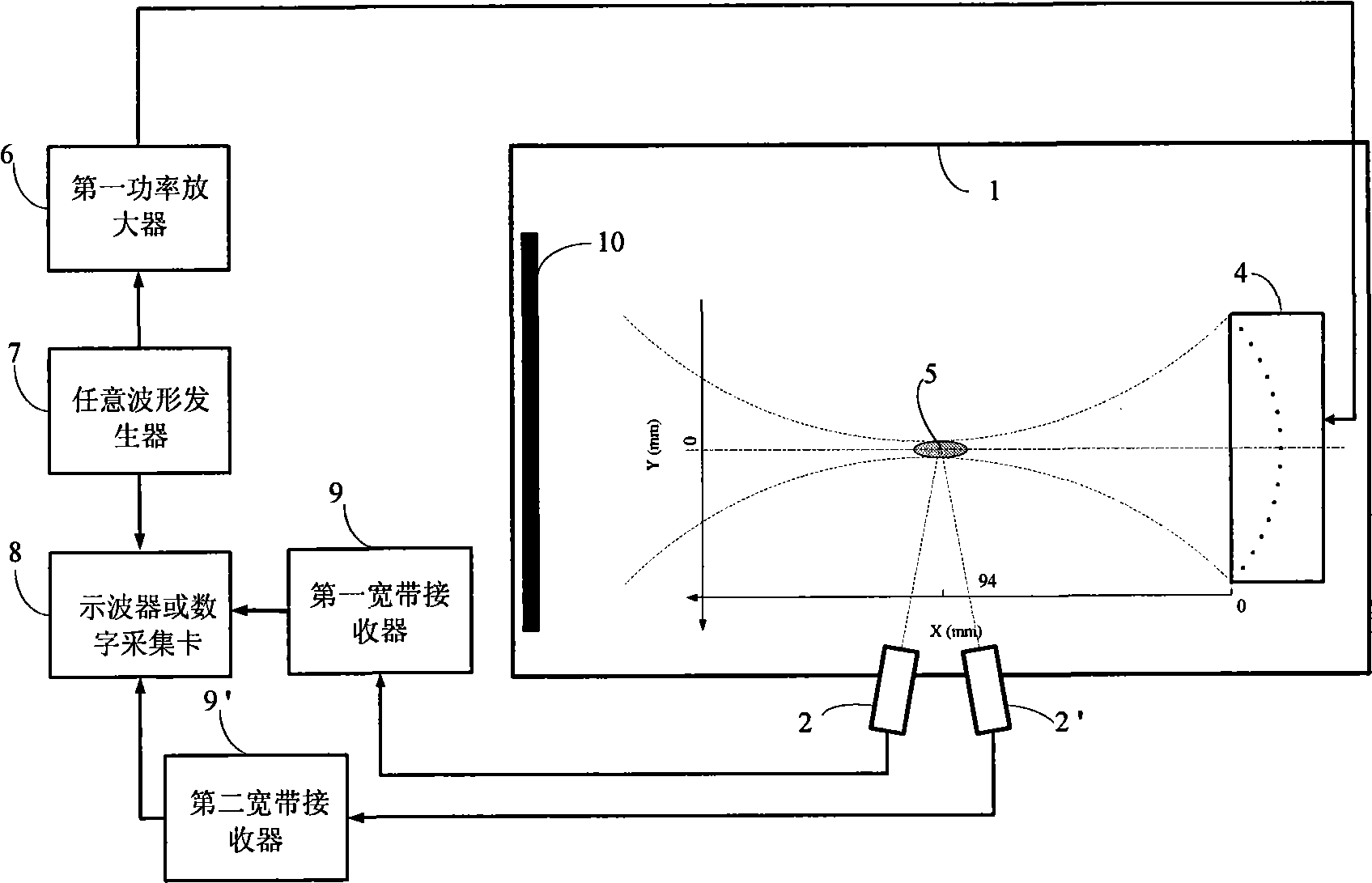

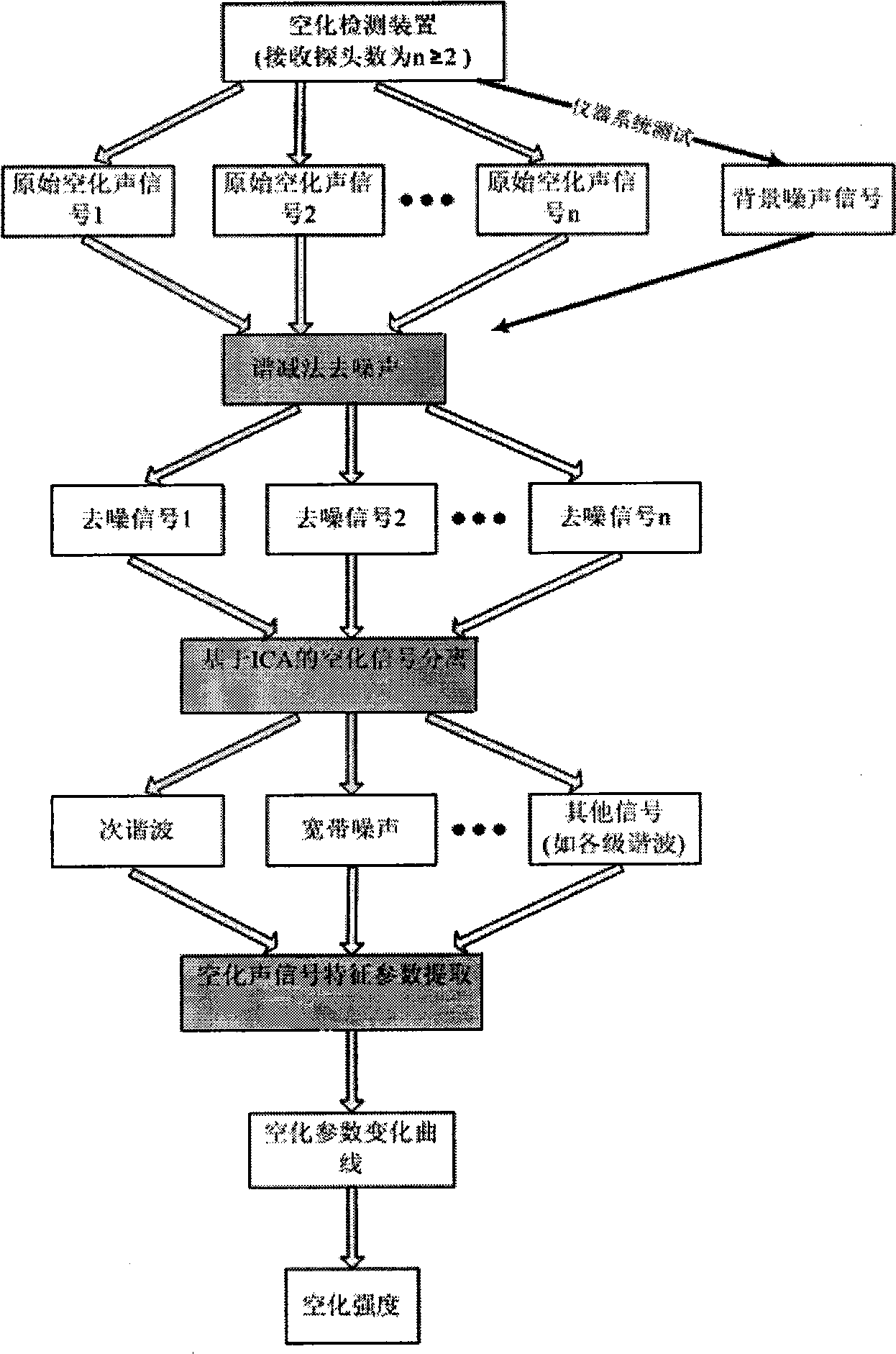

Real-time extracting device and detection method for focused ultrasonic cavitation and microbubbles thereof

InactiveCN101530320AAchieving real-time identification detectionHas inhibitory effectDiagnostic recording/measuringSensorsBroadband noiseUltrasonic cavitation

The invention belongs to the technical field of ultrasonic cavitation detection and signal analysis, and relates to a method and a device for separating and detecting focused ultrasonic cavitation signals. An ultrasonic transducer of a device emits cavitation detecting signals in a pulse-inversion mode, and another ultrasonic transducer receives acoustic signals diffused by ultrasonic cavitation and movement of microbubbles; a transducer of another device generates cavitation signals in the pulse-inversion mode; for each cavitation detecting experiment, the detection method extracts background signals when the cavitation does not happen, respectively calculates power spectrums of the acquired cavitation acoustic signals and the background signals, calculates the subtracted power spectrum estimation and phase position estimation, and converts the power spectrum estimation and the phase position estimation into time domain signals to filter noise of a system; and an ICA method separates target signals such as broadband noise component, subharmonic and the like in cavitation acoustic signals from other signal components and extracts characteristic parameters of the cavitation acoustic signals. The detection method has high sensitivity and can perform quantitative analysis.

Owner:XI AN JIAOTONG UNIV

Ultrasonic treatment chamber for preparing antimicrobial formulations

InactiveUS20090168590A1Shaking/oscillating/vibrating mixersTransportation and packagingUltrasonic cavitationMedicine

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves

The invention discloses a method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves, belonging to the field of biomass nano materials. According to the nano material, liquid acid is taken as a catalyst, and the high-efficiency hydrolysis at the amorphous area of cellulose is promoted due to the simultaneous assistance of the ultrasonic waves and microwaves, so that the nano cellulose is rapidly prepared by plant fiber raw materials. The preparation method comprises the steps of acid hydrolysis of plant cellulose, centrifugal recovery of liquid acid and centrifugal separation of nano cellulose. According to the method, the mechanical dispersion action and ultrasonic cavitation effect of the ultrasonic waves, microwave uniform heating effect, catalytic action of the liquid acid and the synergistic effect of the ultrasonic waves and microwaves are utilized sufficiently, and the hydrolytic process of cellulose is enhanced, so that the high-efficiency and rapid preparation of the nano cellulose can be realized. The prepared nano cellulose material can be used for food additives, drug excipients, engineering material additives, specialty paper additives and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

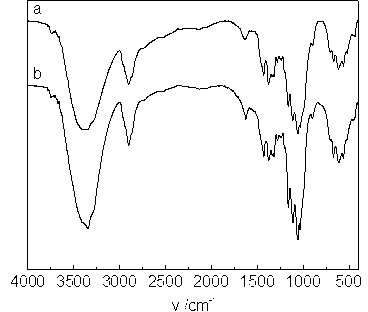

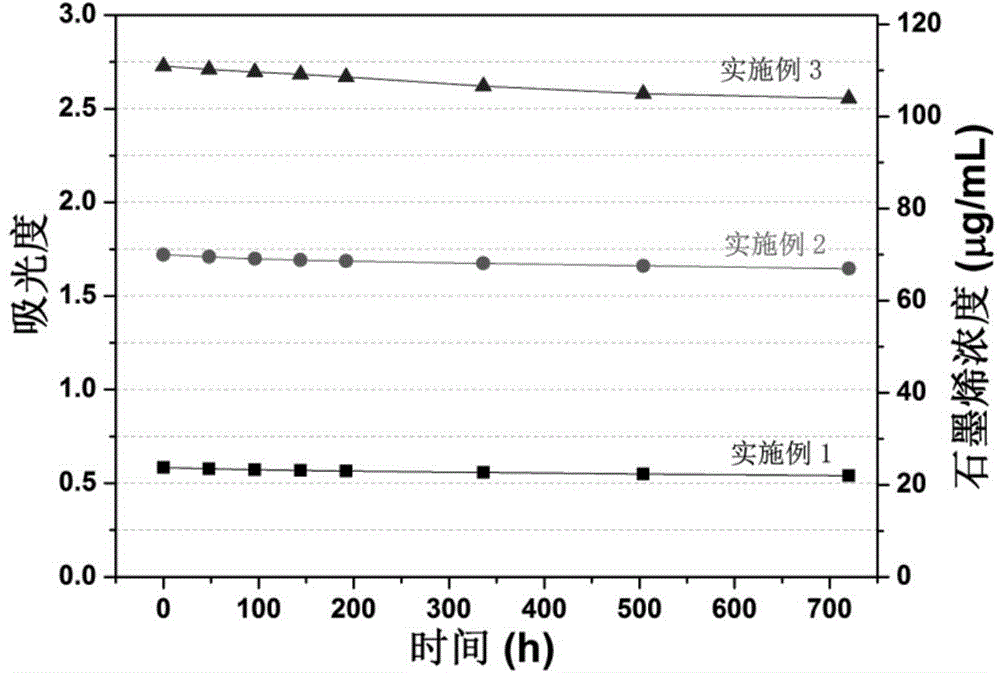

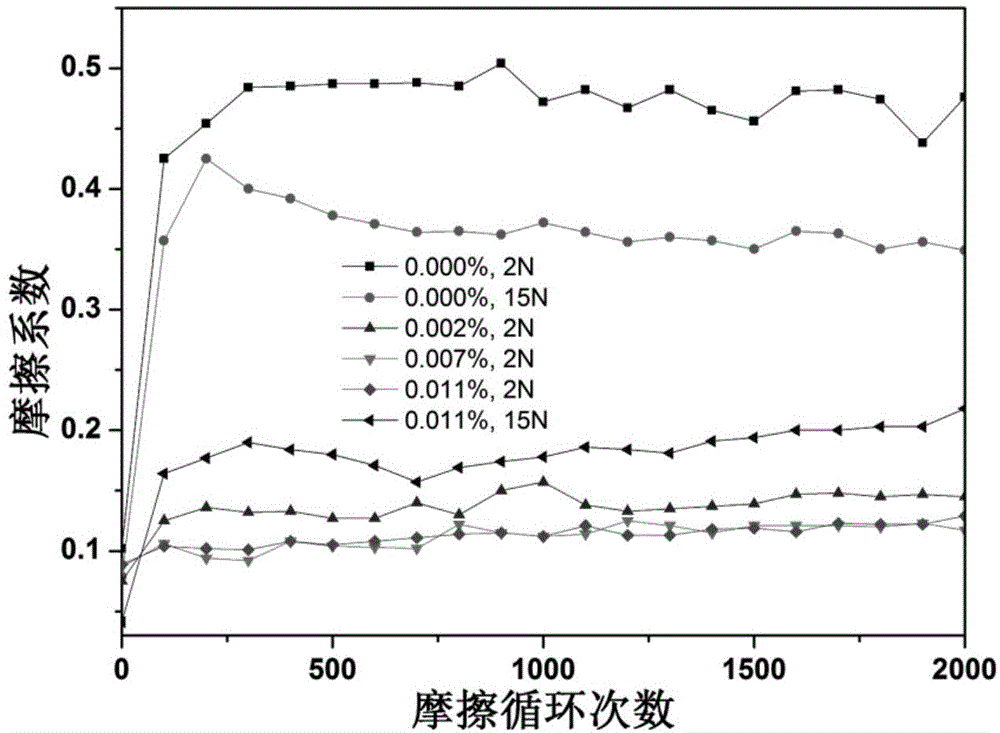

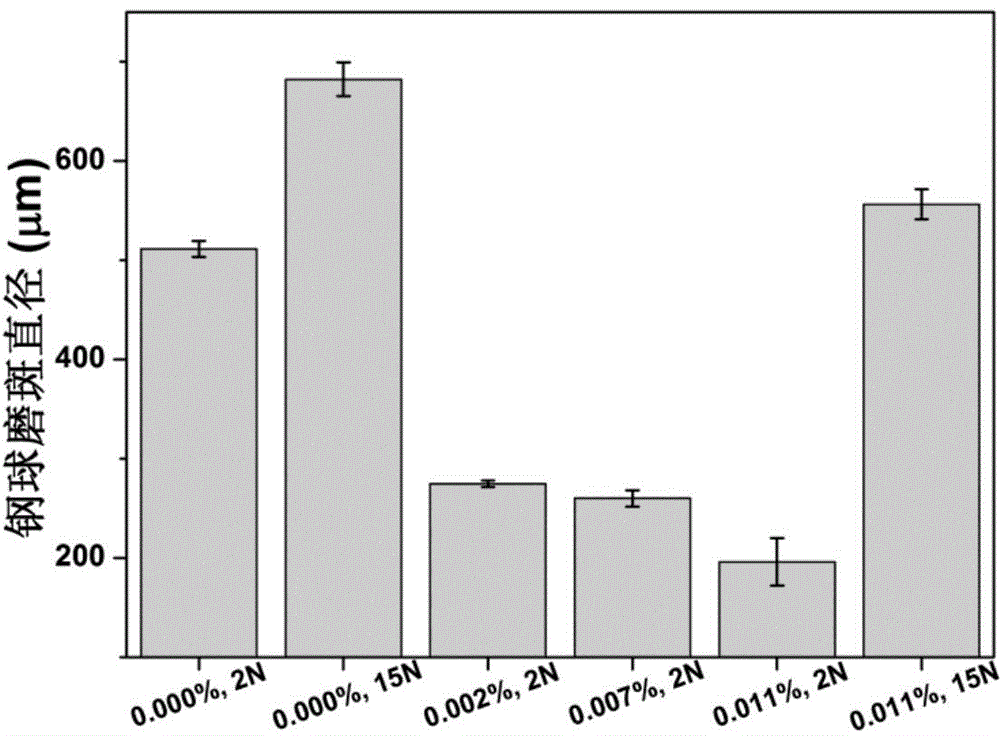

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

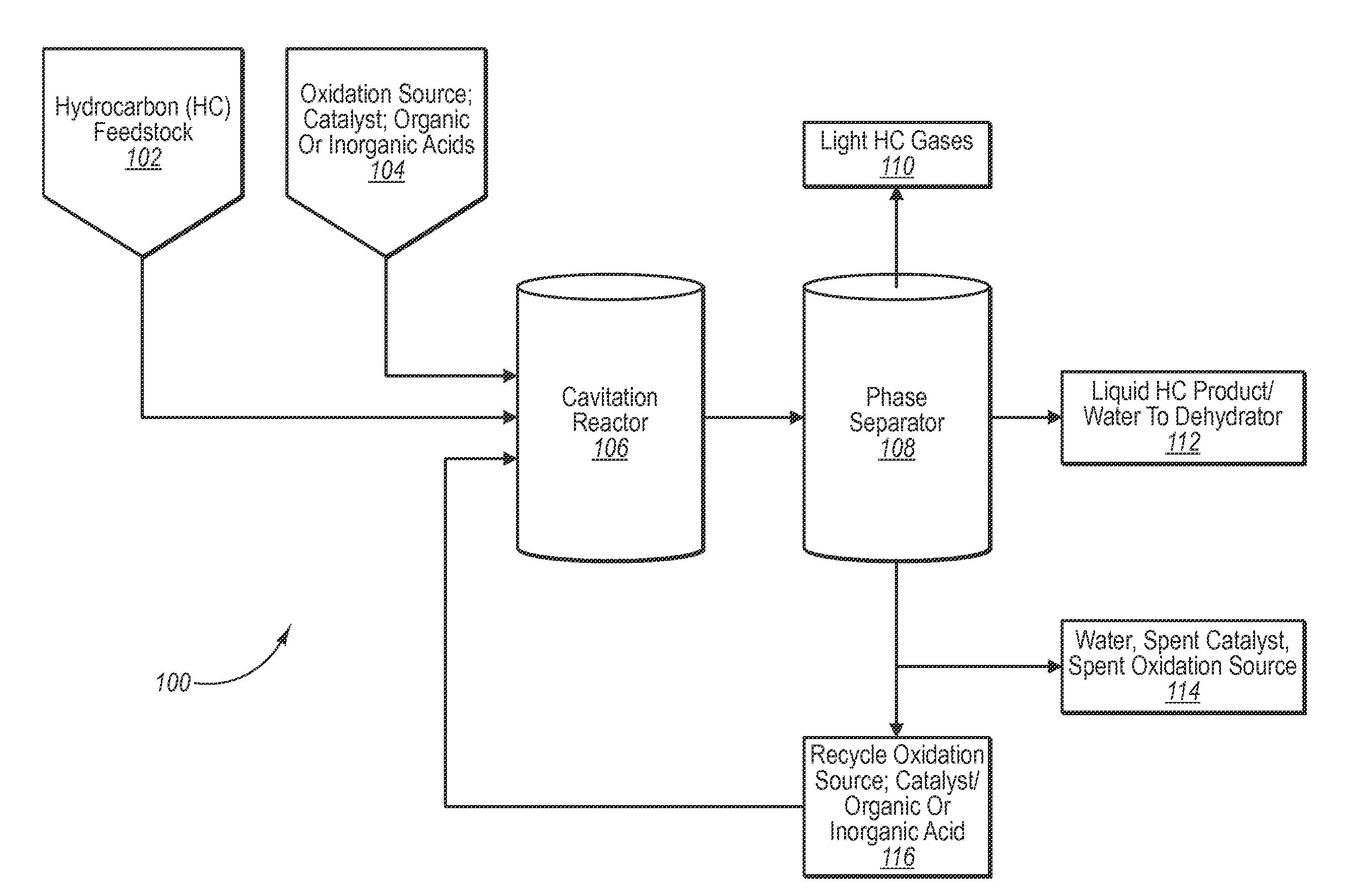

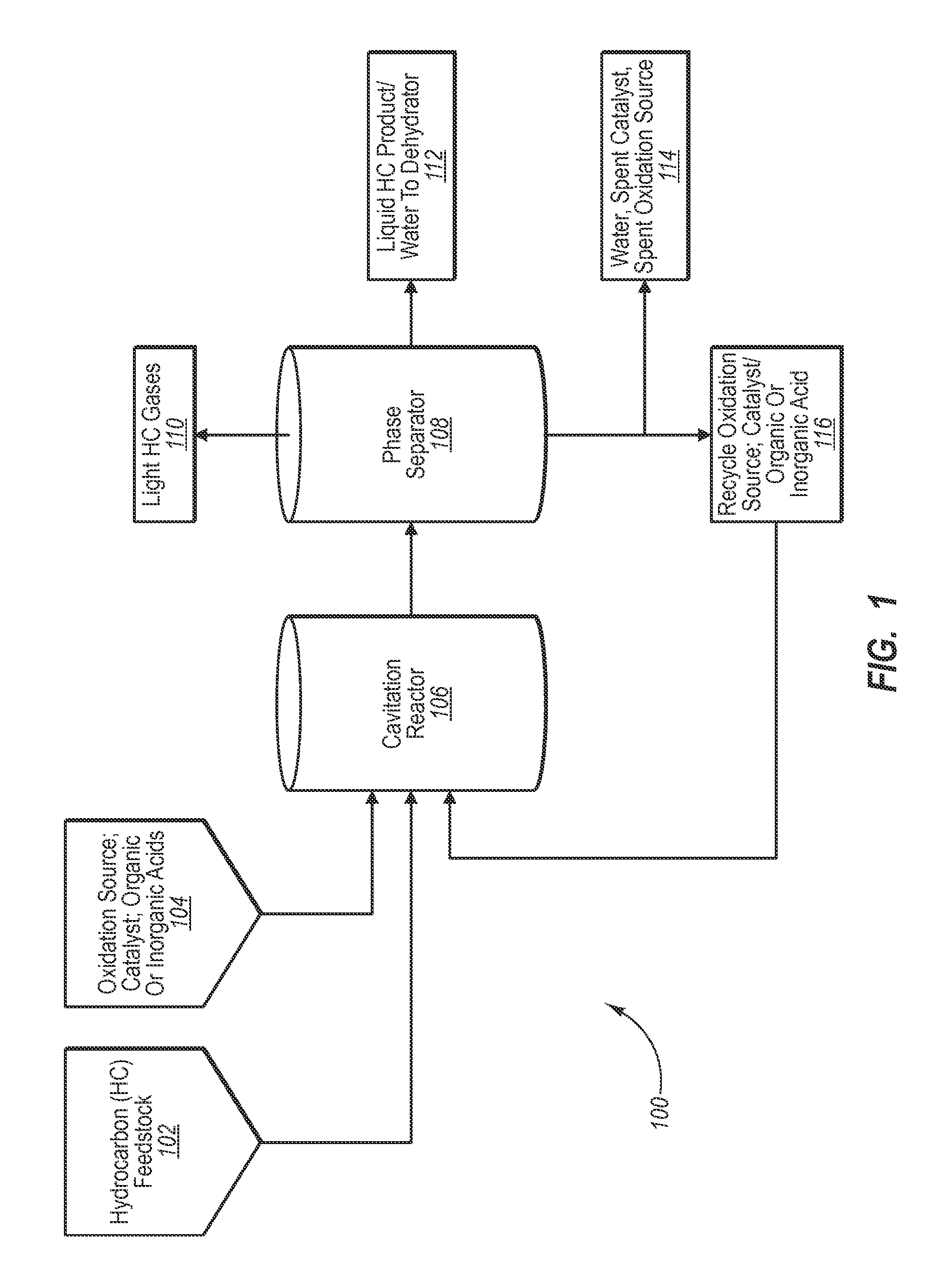

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

InactiveUS20110065969A1Increase heightIntense release of energyRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

High energy (e.g., ultrasonic) mixing of a liquid hydrocarbon feedstock and reactants comprised of an oxidation source, catalyst and acid yields a diesel fuel product or additive having substantially increased cetane number. Ultrasonic mixing creates cavitation, which involves the formation and violent collapse of micron-sized bubbles, which greatly increases the reactivity of the reactants. This, in turn, substantially increases the cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. Alternatively, an aqueous mixture comprising water and acid can be pretreated with an oxidation source such as ozone and subjected to ultrasonic cavitation prior to reacting the pretreated mixture with a liquid hydrocarbon feedstock.

Owner:CETAMAX VENTURES

Ultrasonic flotation method and device and application thereof

The invention relates to an ultrasonic flotation method and a device and application thereof, which comprise the following steps: arranging an ultrasonic device in or outside a floatation tank body, starting the ultrasonic device when the floatation device carries out the mineral floatation, using ultrasonic waves to irradiate floatation pulp, providing a high-energy elastic mechanical wave to the pulp, initiating an ultrasonic cavitation effect, generating a large number of cavitation bubble particle flows which flow at high speed, and effectively washing the surfaces of the ore particles in the pulp to enable target ore particles to expose the fresh surfaces; at the same time, using ultrasonic energy to improve the activity of medicament in the pulp, quickening adsorption process of the medicament and the surfaces of the target ore particles to further improve the effects of breaking, restructuring and floating of mineralized bubbles in a pulp system, and thus realizing the optimization of flotation process.

Owner:佛山市兴民科技有限公司

Washing method of water tank type cleaning machine

ActiveCN105662301AEasy to cleanSave energyTableware washing/rinsing machine detailsKitchen equipmentUltrasonic cavitationWater flow

The invention discloses a washing method of water tank type cleaning machine. The water tank type cleaning machine comprises a water tank body, a spraying arm, a water pump and an ultrasonic generator. The washing method includes the following steps that 1, a certain quantity of water is injected into the water tank body, then the ultrasonic generator is started, and ultrasonic cavitation is conducted on matter to be washed in the water tank body for certain time; the method is characterized by further comprising the steps that 2, the water pump is started, water flows are sprayed out through spraying holes of the spraying arm, the sprayed water and other water flows in the water tank body jointly form turbulent flows different in flow velocity and direction, and after washing is conducted with the turbulent flows for certain time, water is discharged through the water tank body; 3, water is injected into the water tank body again, then the water pump is started, water flows are sprayed out through the spraying holes of the spraying arm, then the matter to be washed is rinsed, and washing is completed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for ultrasonic extraction of steviosides

InactiveCN101798329AReduce extraction timeHigh extraction rateSugar derivativesSugar derivatives preparationUltrasonic cavitationSolvent

The invention discloses a method for the ultrasonic extraction of steviosides. Smashed dry leaves of stevia rebaudiana serve as raw material; based on the characteristic that an ultrasonic cavitation can reinforce the extraction of active ingredients in plants, the solvent and the smashed raw materials flow in opposite directions, and the extract of the stevia rebaudiana is prepared by immersed extraction and ultrasonic extraction; white powder of the stevia rebaudiana is prepared by flocculating, filtering, absorbing, decolorizing, exchanging, concentrating, spray drying and the like; the stevioside content of the products is 85 to 98 percent. In the invention, the extraction time is only 10 to 60 minutes; the extraction rate can reach 95 to 99.9 percent; the temperature of the extraction solvent is only 10 to 40 DEG C; and the mass-to-volume ratio of the dry leaves to the solvent is only 1: 10-40 (kg: L). The method has the advantages of short extraction time, high extraction rate, low consumption of solvent, clean and sanitary production process and large scale and industrial continuous production; and the produced stevioside products have high purity and good quality.

Owner:GANZHOU JULONG HIGH TECH INDAL

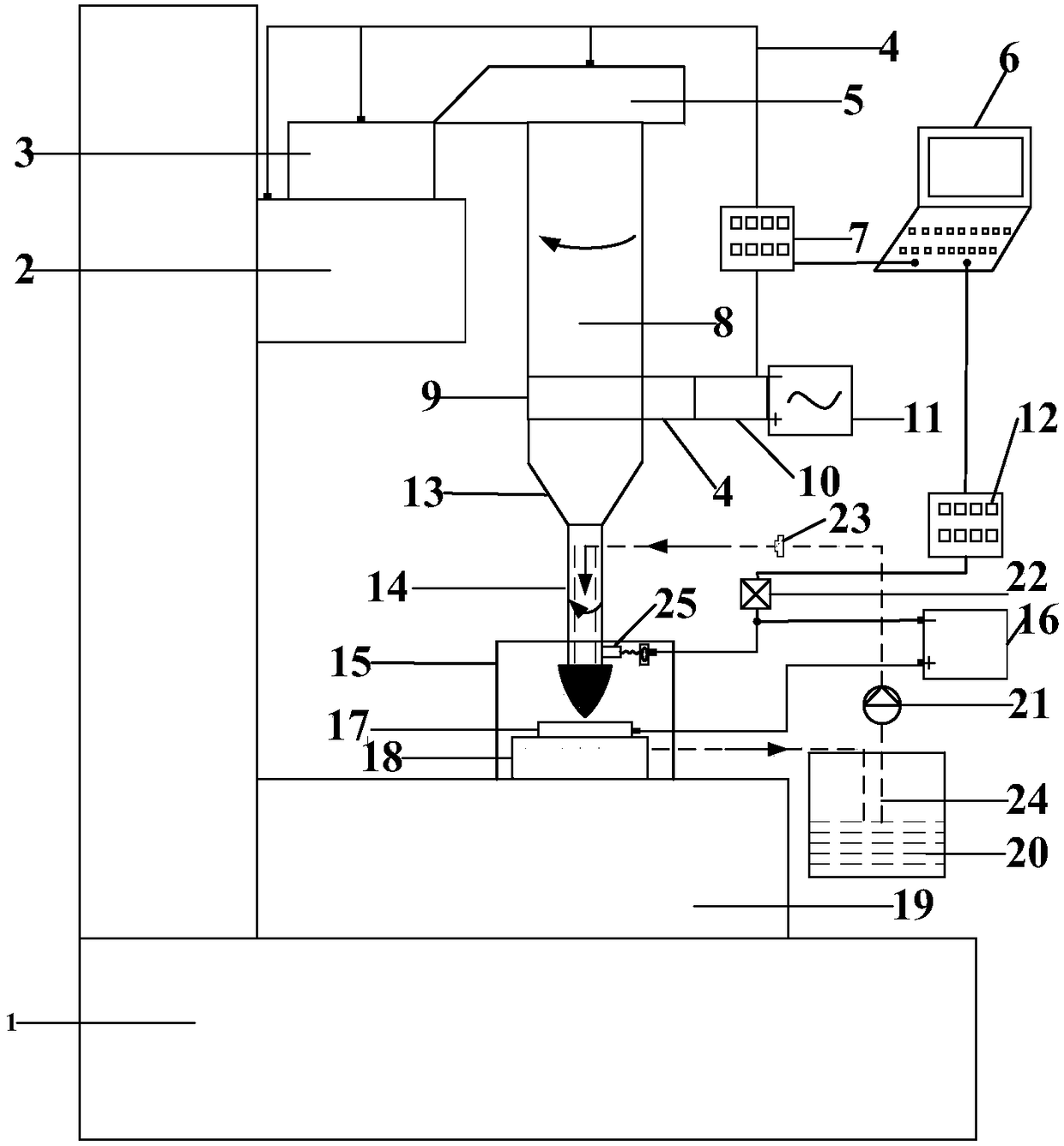

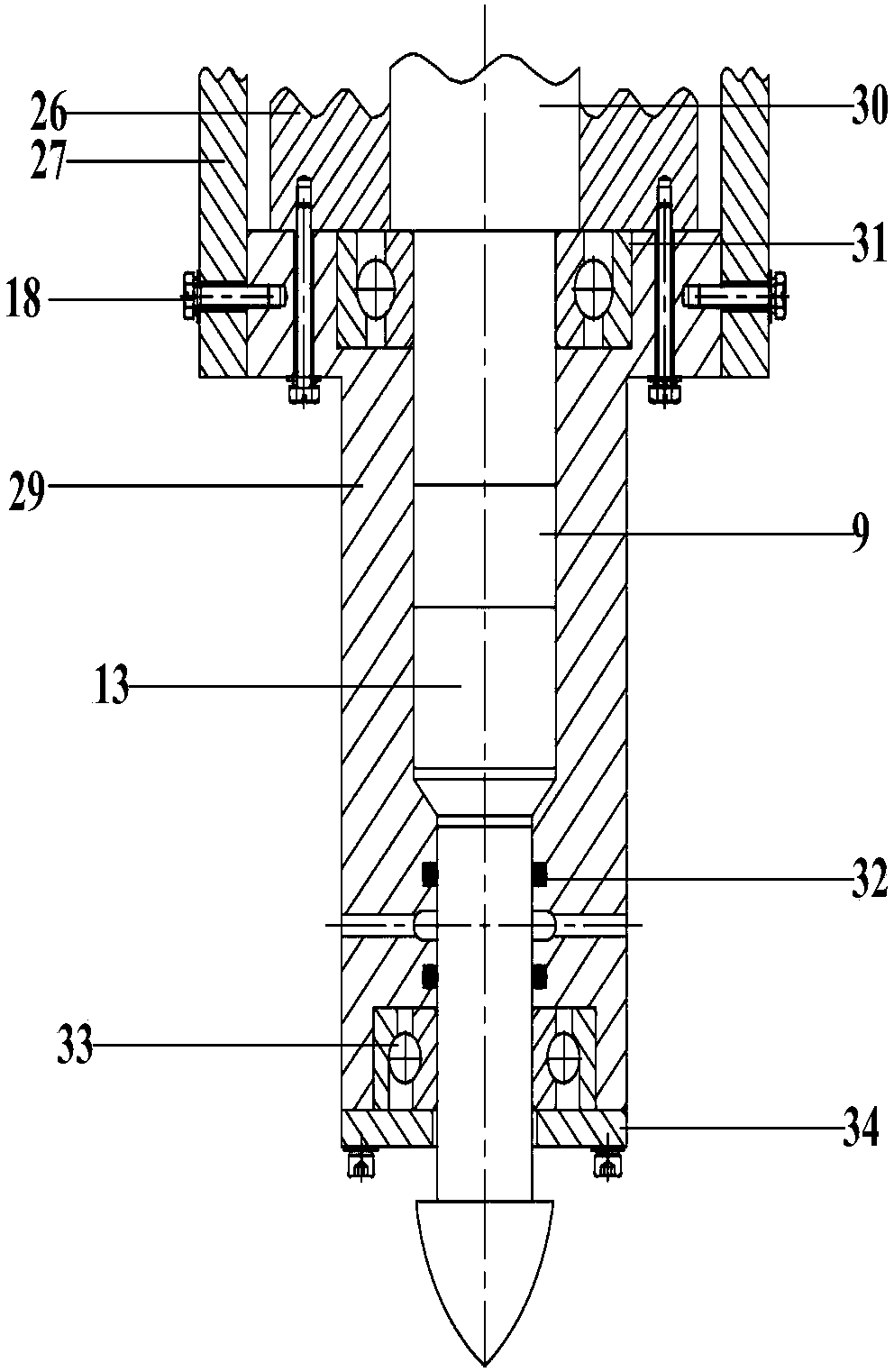

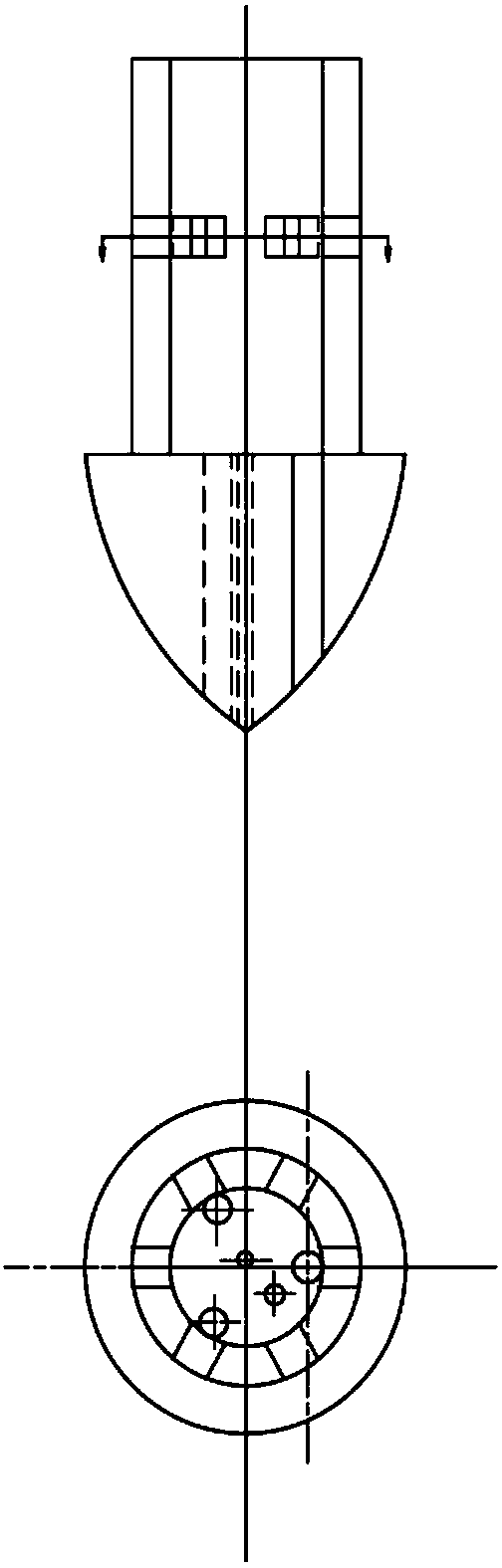

Internal channel ultrasonic vibration auxiliary internal spraying type electrolytic grinding system and method

The invention discloses an internal channel ultrasonic vibration auxiliary internal spraying type electrolytic grinding system and method. The system and method solves the problem that the machining efficiency of a deep hole, a cavity and an inner channel is low at present, and the system and method can improve the machining efficiency and reduce the roughness of the machining surface. The systemmainly comprises a motion control device, a current detection control device, an electrolyte circulating device, an ultrasonic vibration device and an inner spraying type tubular conductive grinding head, wherein the motion control device is used for controlling the high-speed rotation and feeding stability of a main shaft, the current detection control device is used for detecting the current size and controlling the generation of sudden change current in the machining process in real time, the electrolyte circulating device is used for realizing supply, filtering and recycling of the electrolyte, the ultrasonic wave vibration device is used for realizing the effects that the conductive grinding head rapidly removes a passivation film on the surface of a workpiece under the ultrasonic cavitation effect of the electrolyte and the electrochemical reaction is enhanced, and the inner spraying type tubular conductive grinding head avoids the turbulence effect between the grinding head andthe workpiece in the machining process, and maintains the stability of an electrolyte flow field.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com