Patents

Literature

46results about How to "Improve cavitation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

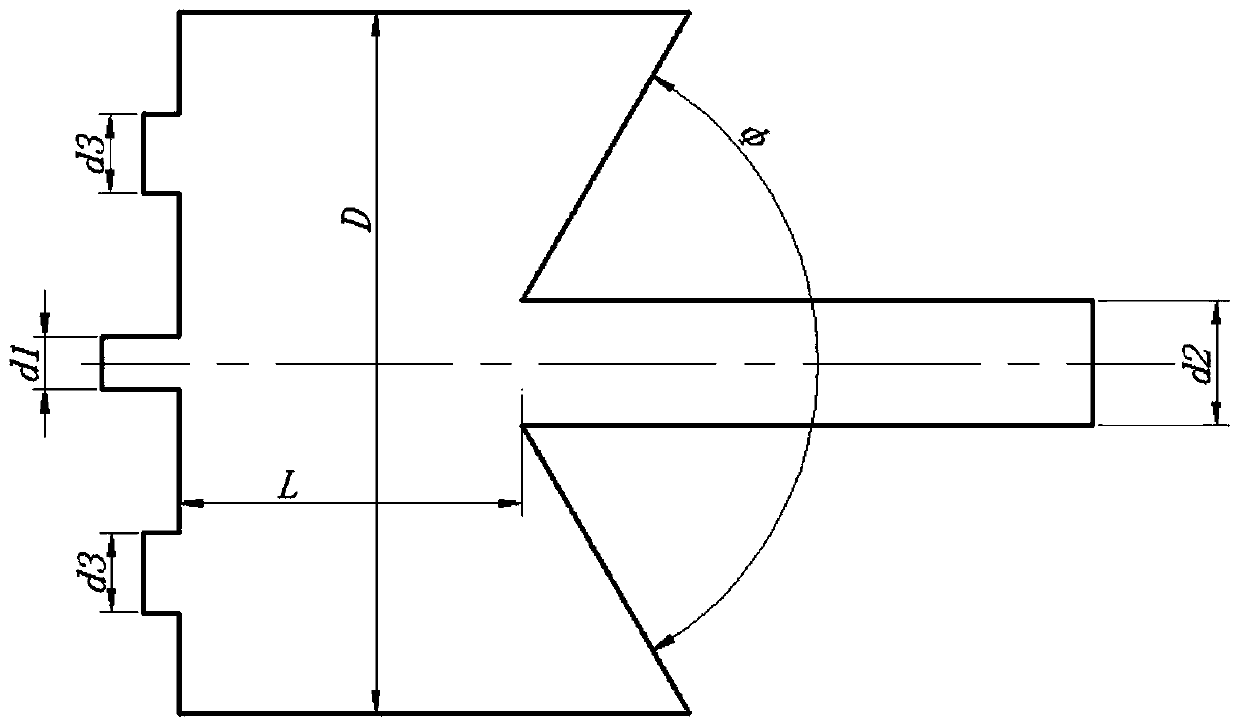

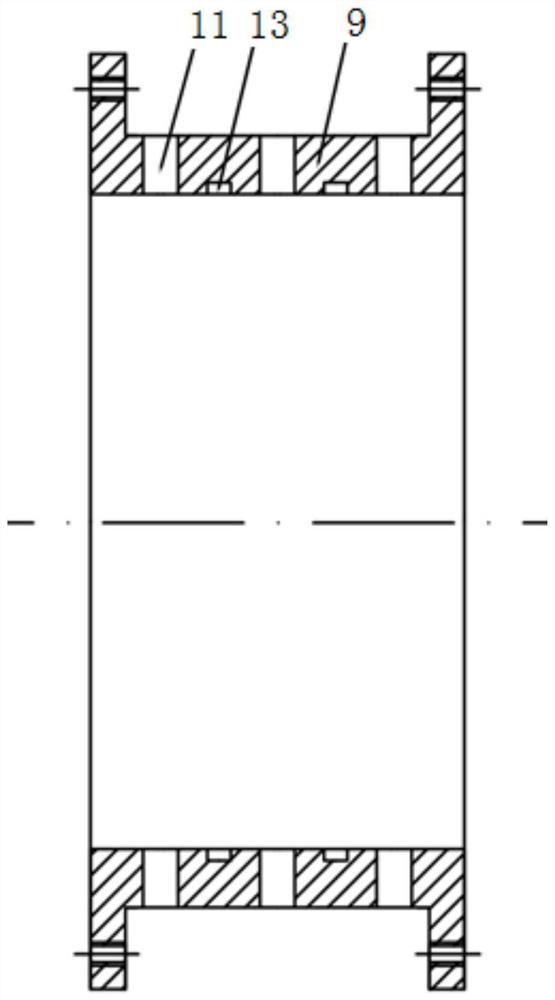

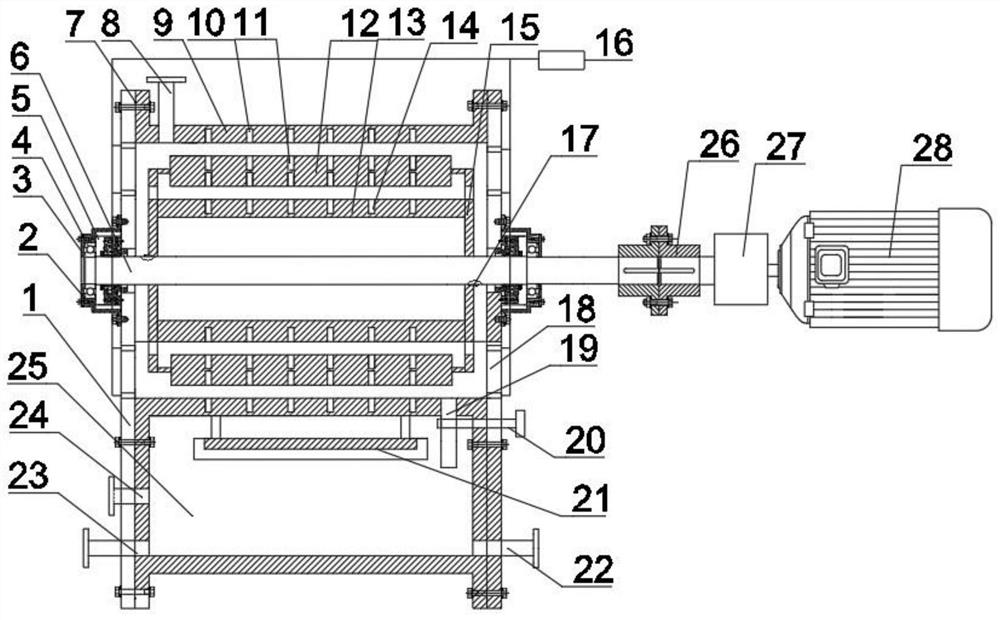

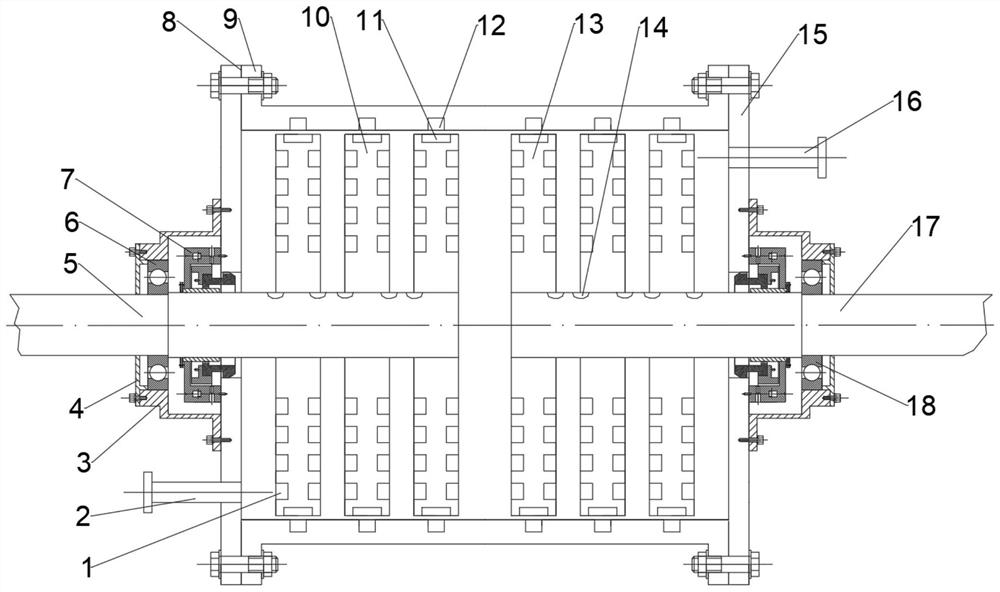

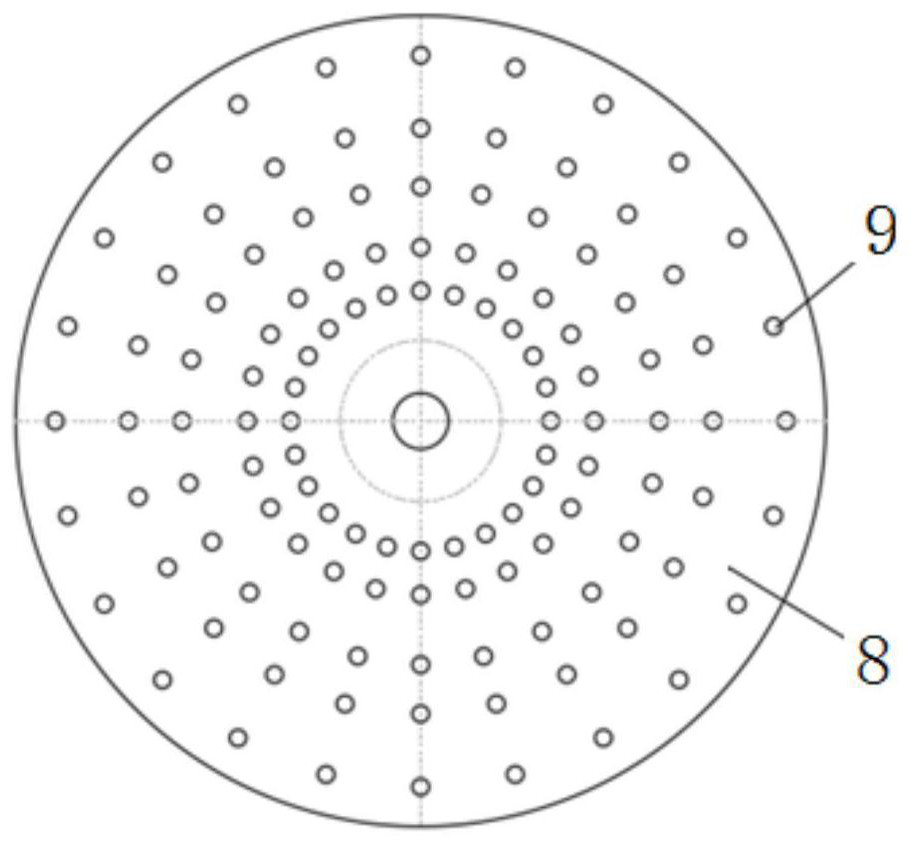

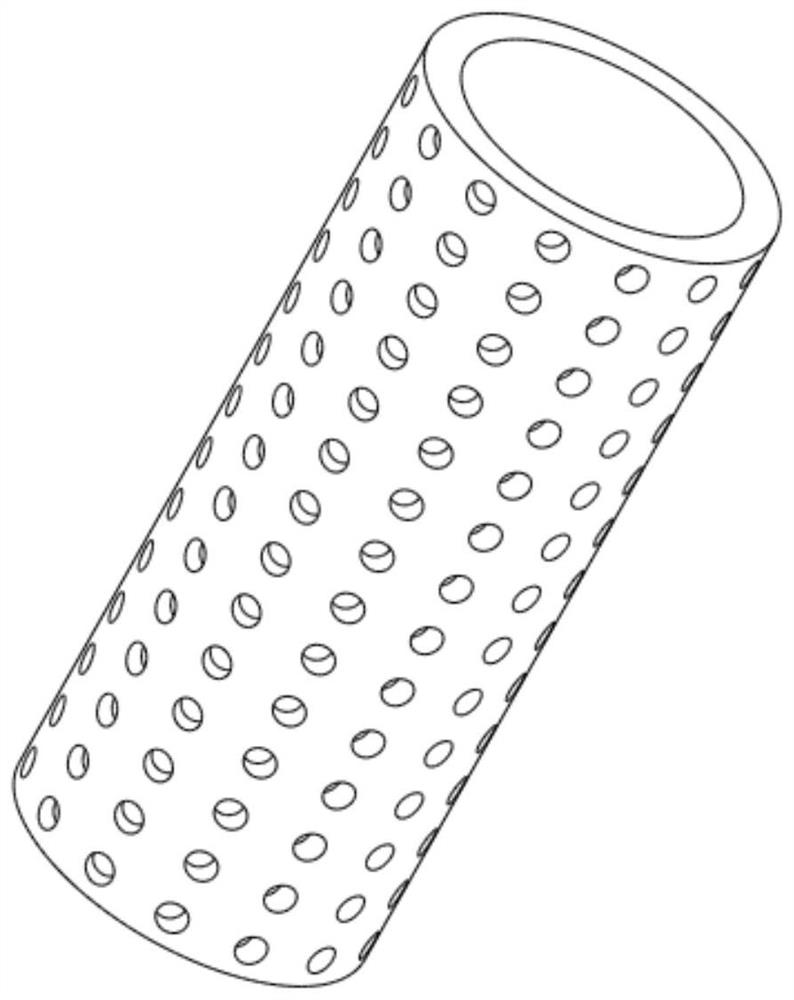

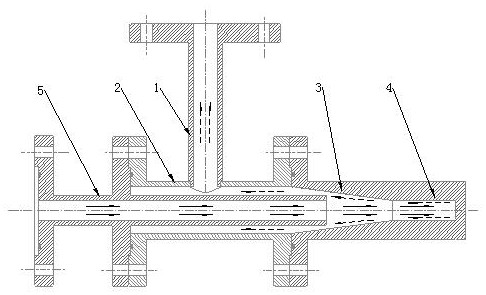

Cavitation reactor

InactiveCN104857904AImprove cavitation performanceImprove cavitation strengthChemical/physical/physico-chemical processesShock waveWater velocity

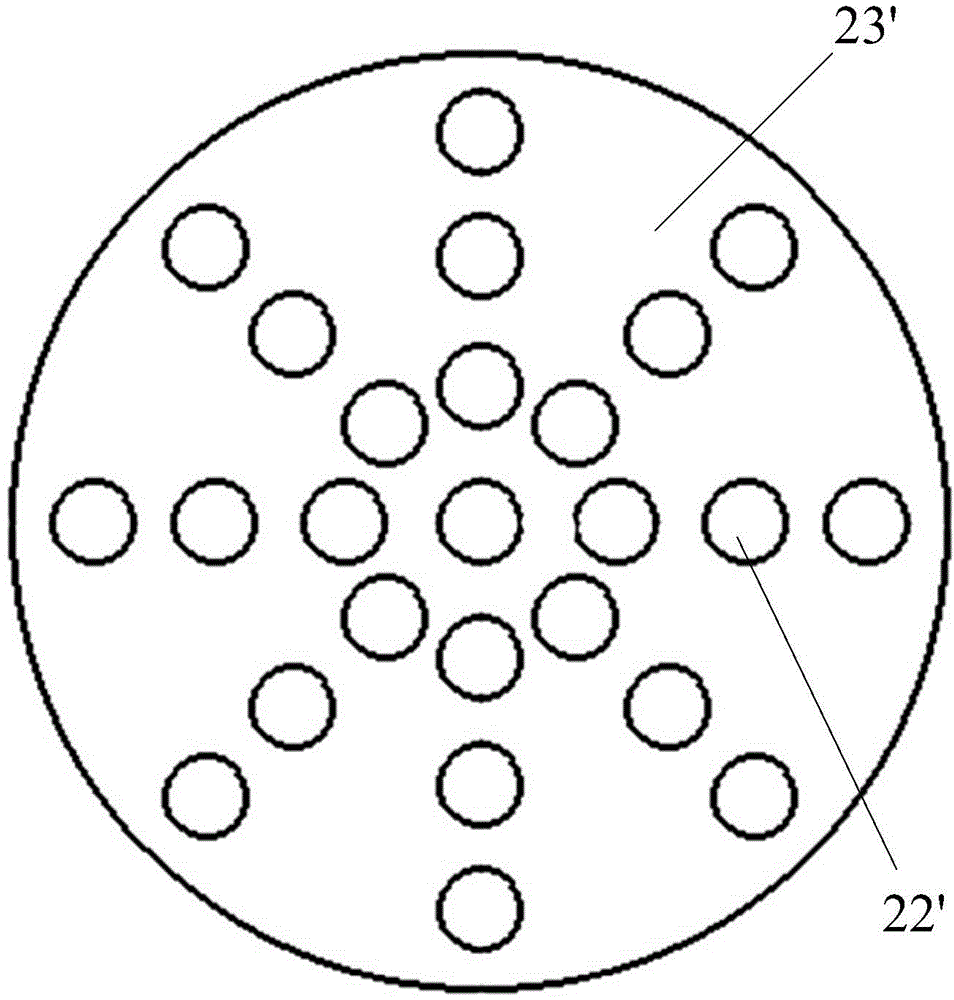

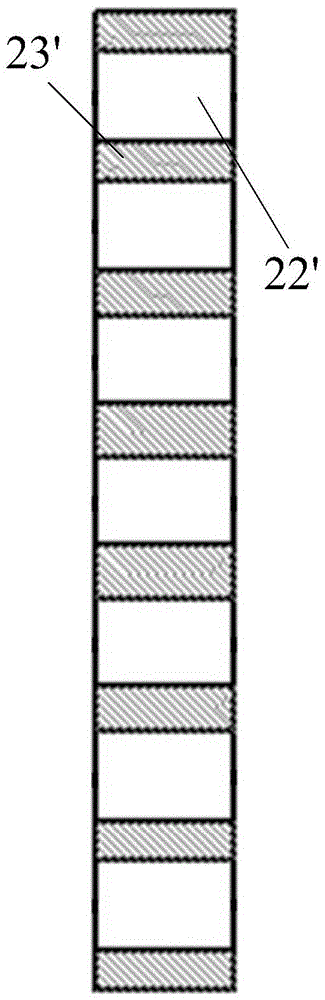

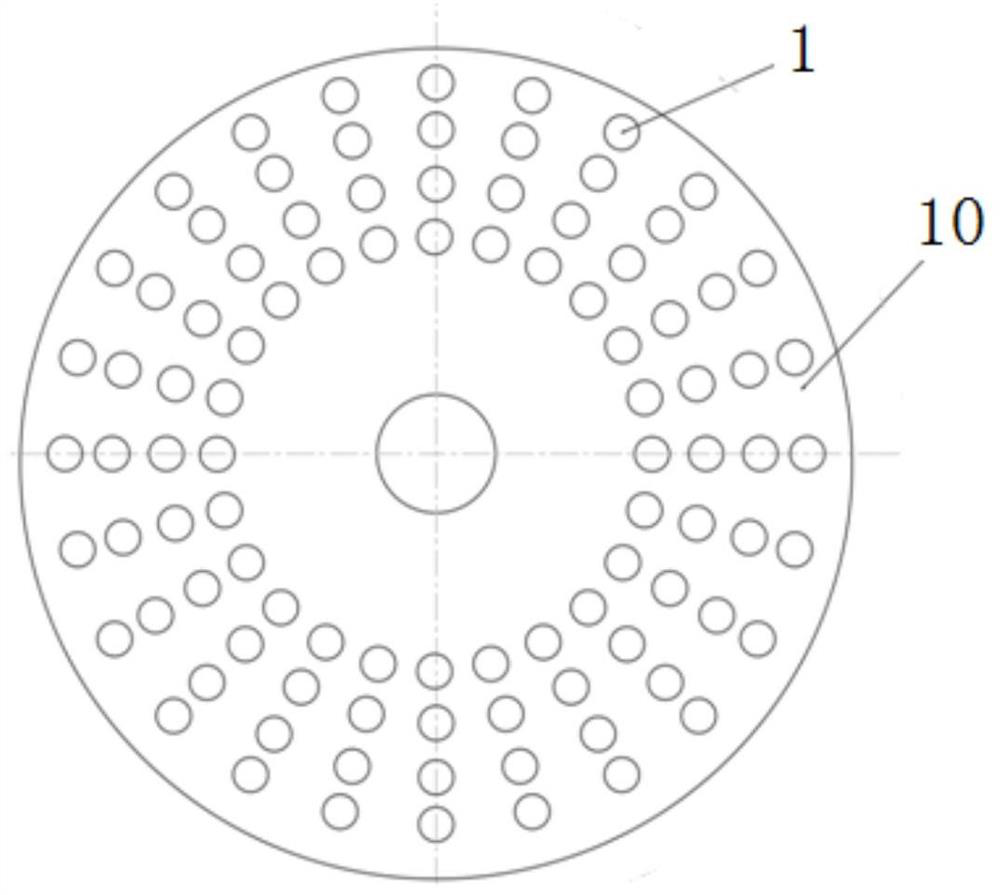

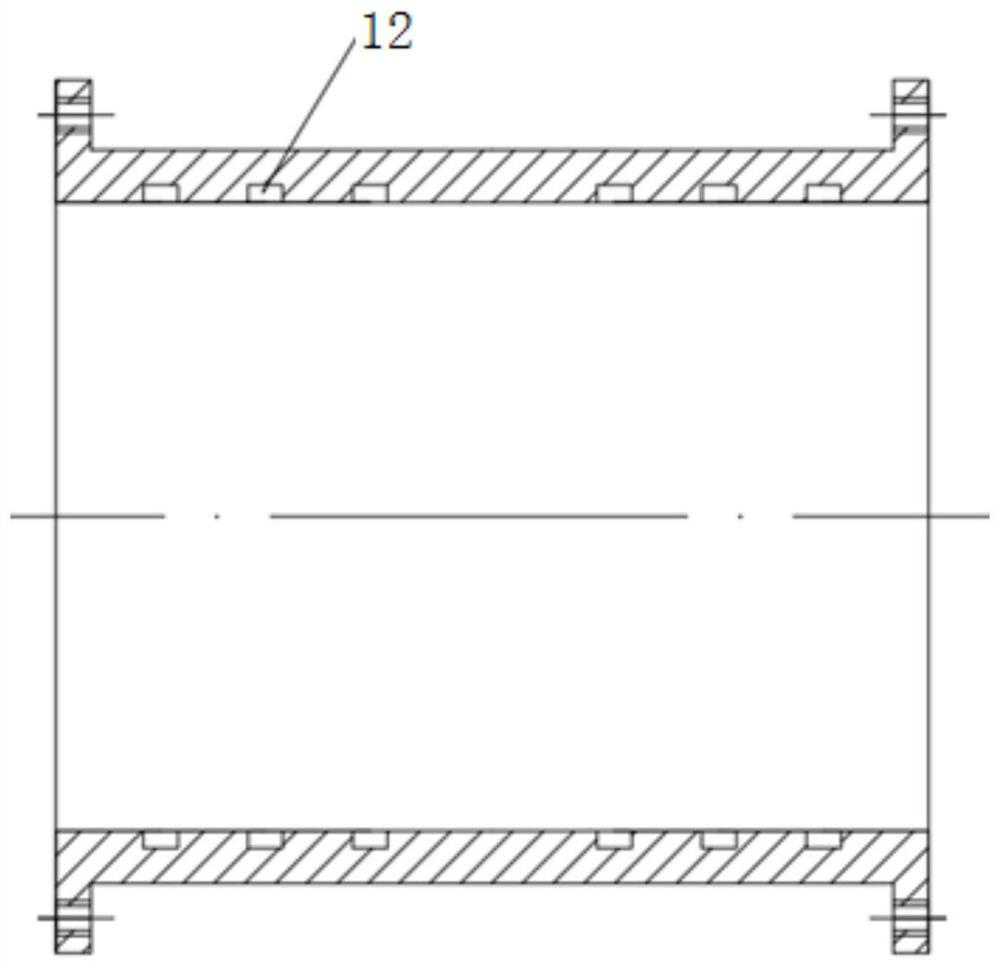

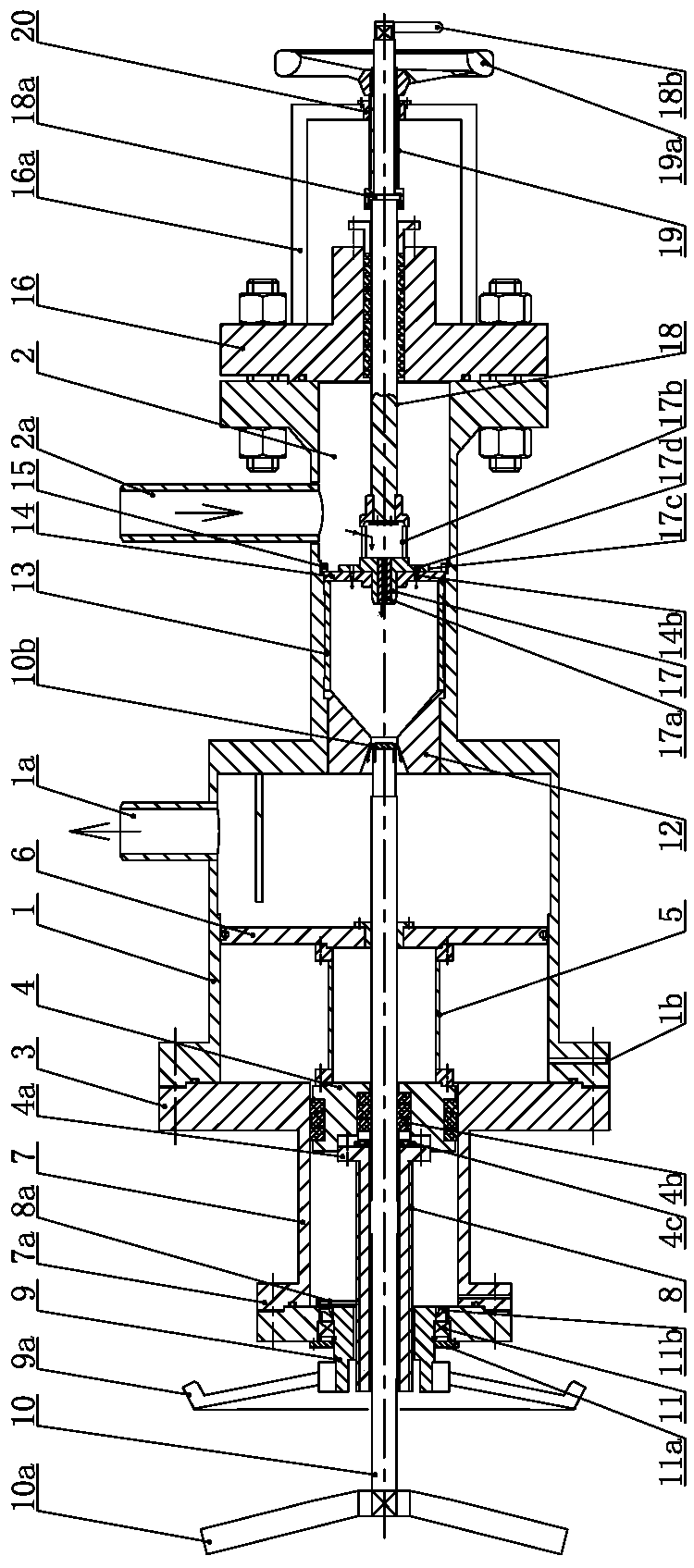

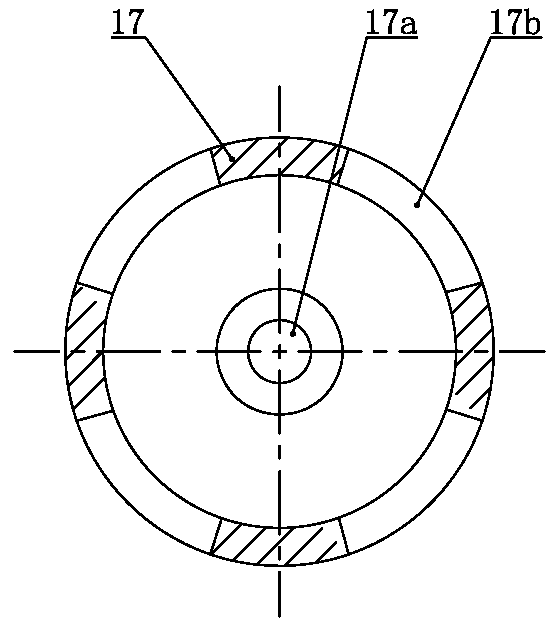

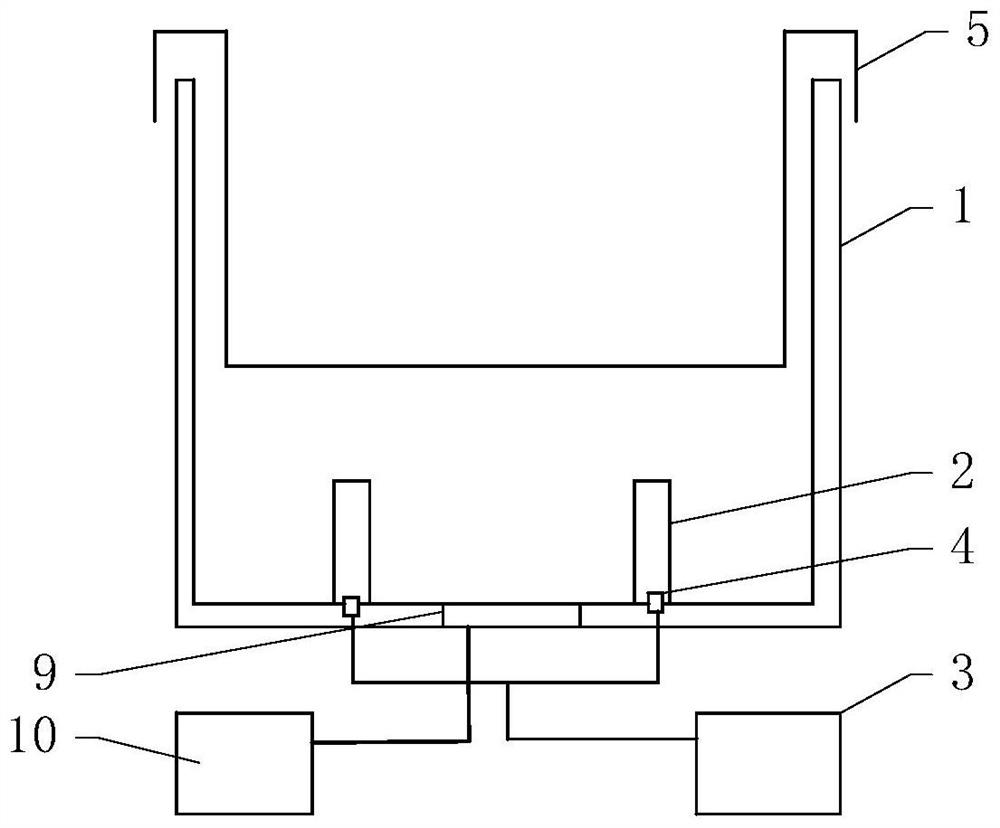

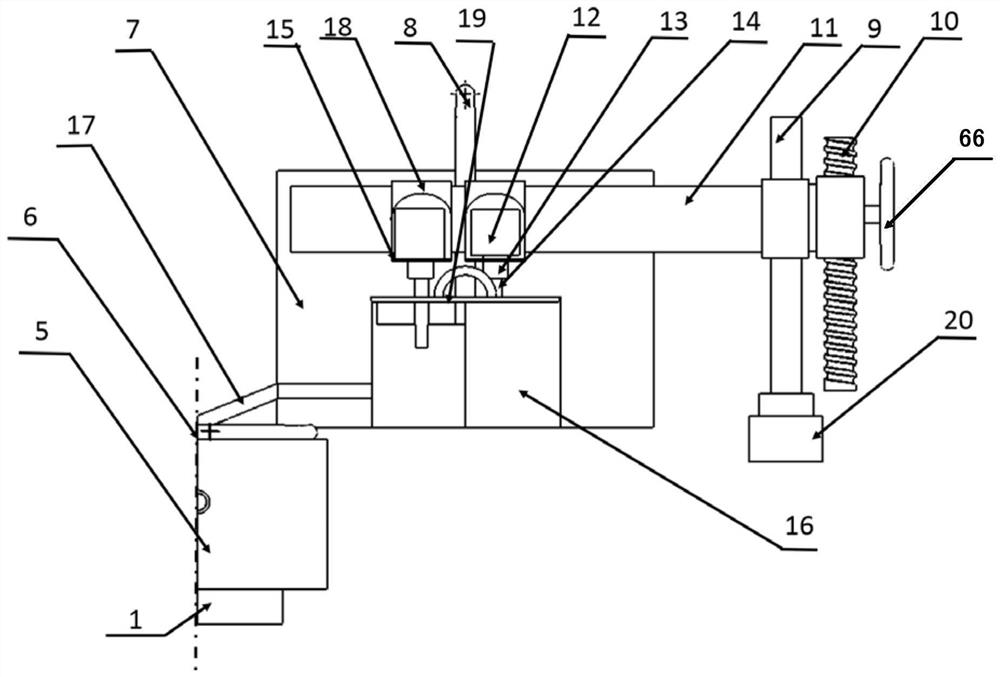

The invention relates to the technical field of hydrodynamic cavitation, in particular to a cavitation reactor. The cavitation reactor comprises a power device, a hydrodynamic cavitator and a water tank, wherein a plurality of Venturi type through holes are formed in each cavitation plate on the hydrodynamic cavitator, that is, hole reaming structures are arranged at two ends of each through hole, accordingly, the sectional area of each flow channel becomes small when water flows into the through holes in the cavitation plates from cavitation pipes, the water velocity is increased, and the water flow pressure is reduced; when the water flow pressure is decreased under the saturated vapor pressure of water, cavitation happens, cavitation bubbles are formed, then, the cavitation bubbles flow out of the cavitation plates with the water flow, the water pressure rises, the cavitation bubbles break, shock wave and microjet are formed at the moment the cavitation bubbles break, and high temperature and high pressure are generated. Compared with an existing straight-hole cavitation plate, the cavitation effect is better, and the cavitation efficiency is higher; a plurality of cavitation plates are connected together stage by stage and uniformly distributed in the cavitation pipes, the multi-stage cavitation reactor is formed, the energy utilization rate is greatly increased, and the cavitation effect is improved.

Owner:ICM INT CAVITENERGY MACHINES BEIJING

Modified zeolite adsorbent for removing ammonia nitrogen and phosphate in water, and preparation and regeneration method thereof

InactiveCN105381782AImprove the ability to adsorb ammonia nitrogenImprove performanceAluminium silicatesCombustible gas purificationAmmoniacal nitrogenPhosphate

The invention belongs to the technical field of water treatment, and specifically relates to a modified zeolite adsorbent capable of removing ammonia nitrogen and phosphate in water at the same time, and a preparation and regeneration method thereof. Cheap natural zeolite is modified by a sodium chloride solution, the contents of calcium and magnesium in zeolite are reduced, the ion exchange performance of zeolite on ammonia nitrogen is improved at the same time; then zirconium is loaded on the zeolite through a precipitation method, and zirconium has a specific adsorbing performance on phosphor, so the adsorption performance of zeolite on phosphate is improved. Cheap zeolite is adopted and modified through a simple modification method to prepare a bifunctional adsorbent capable of adsorbing ammonia nitrogen and phosphate at the same time. Moreover, through a provided regeneration liquid, the used modified zeolite adsorbent can be regenerated, the zeolite adsorbent can be effectively used repeatedly, and the adsorbent has a good application prospect.

Owner:FUDAN UNIV

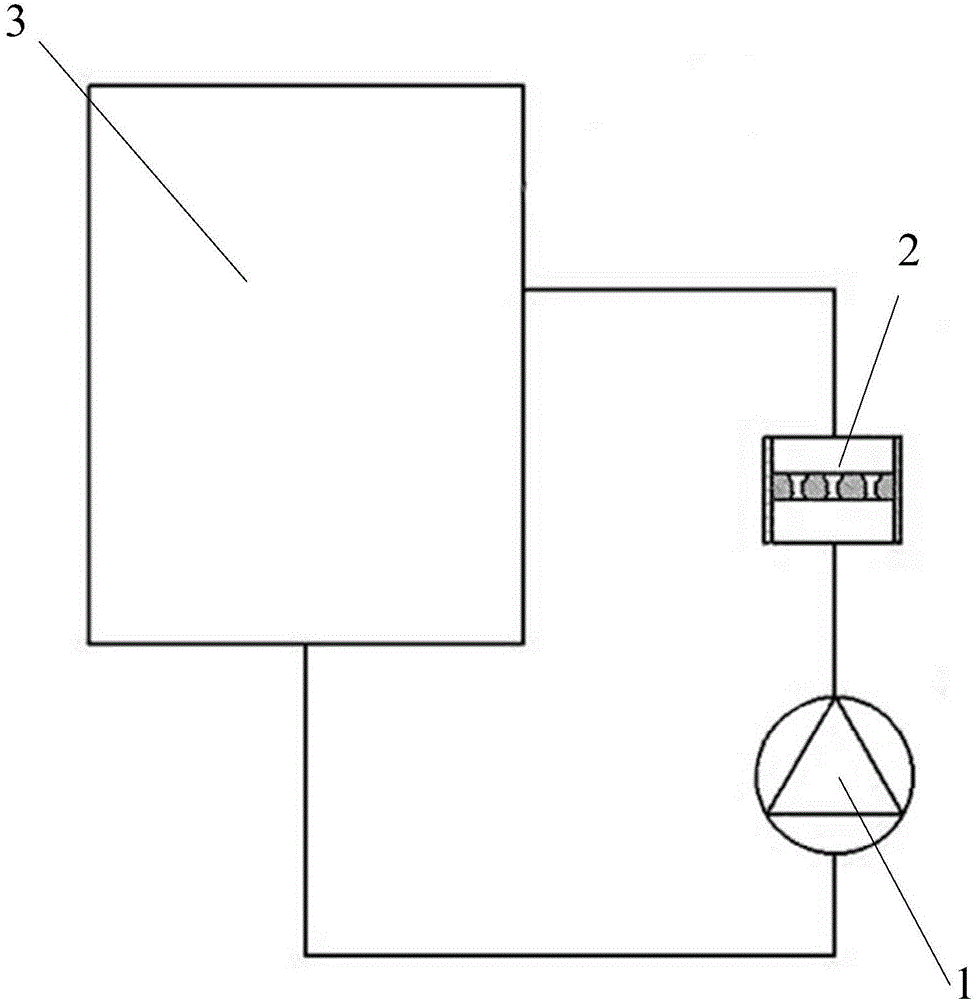

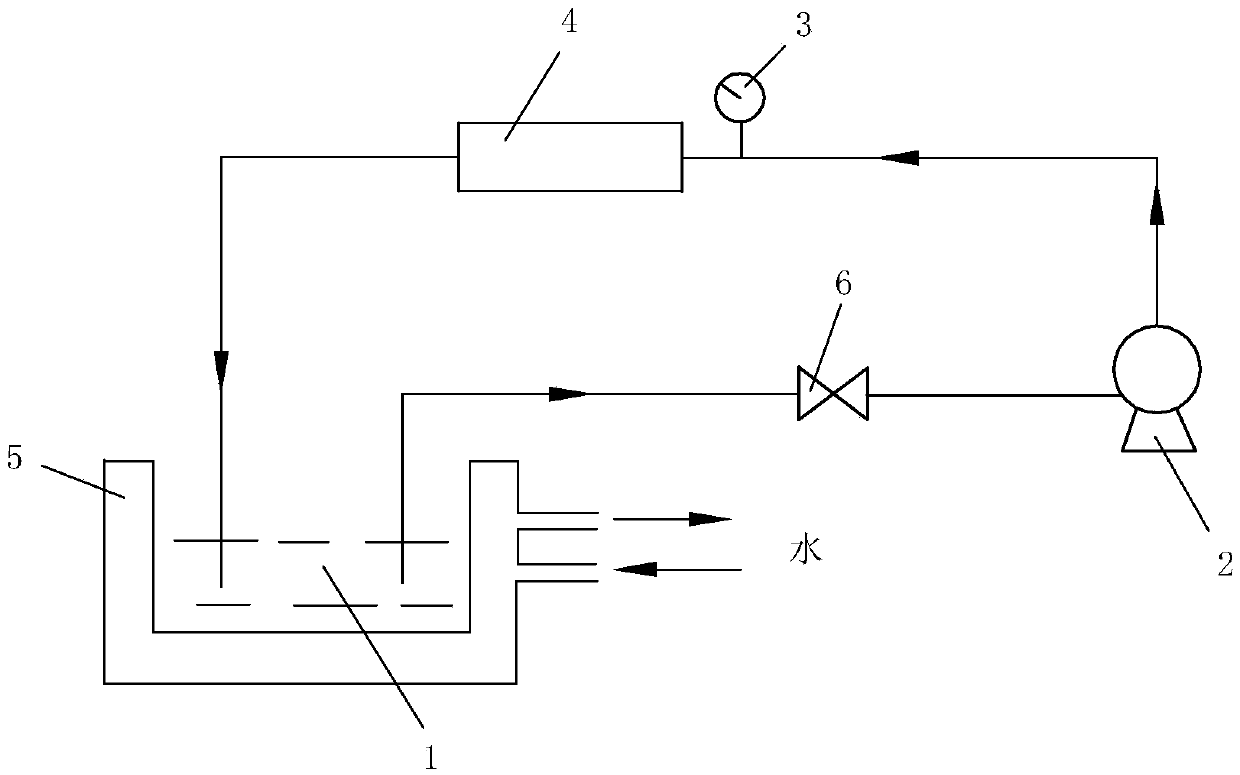

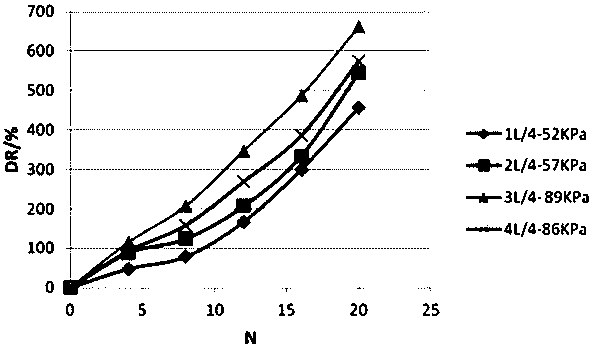

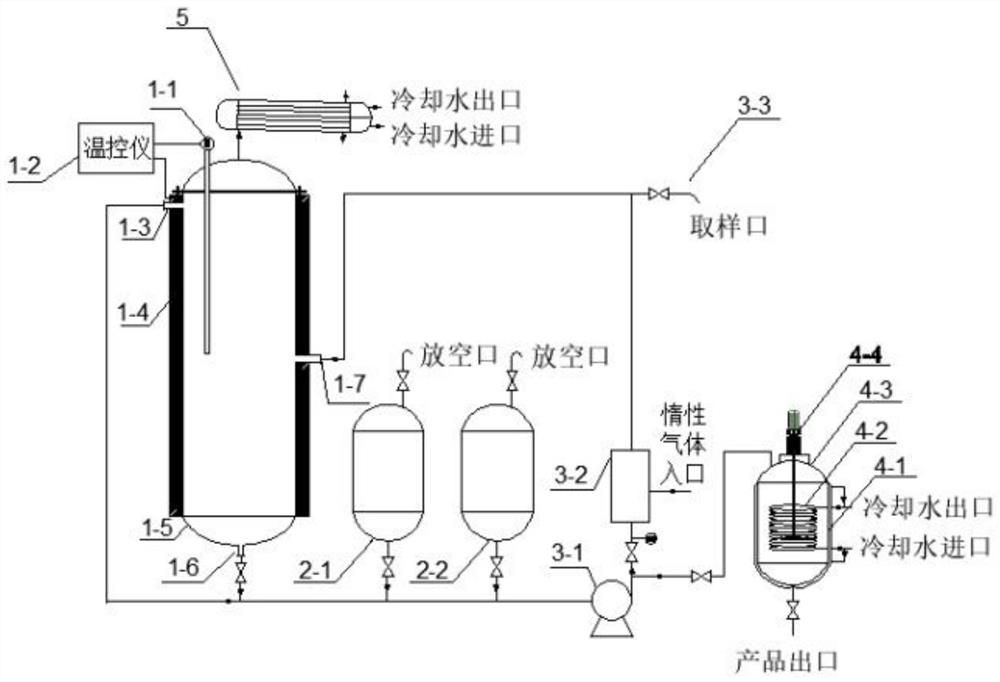

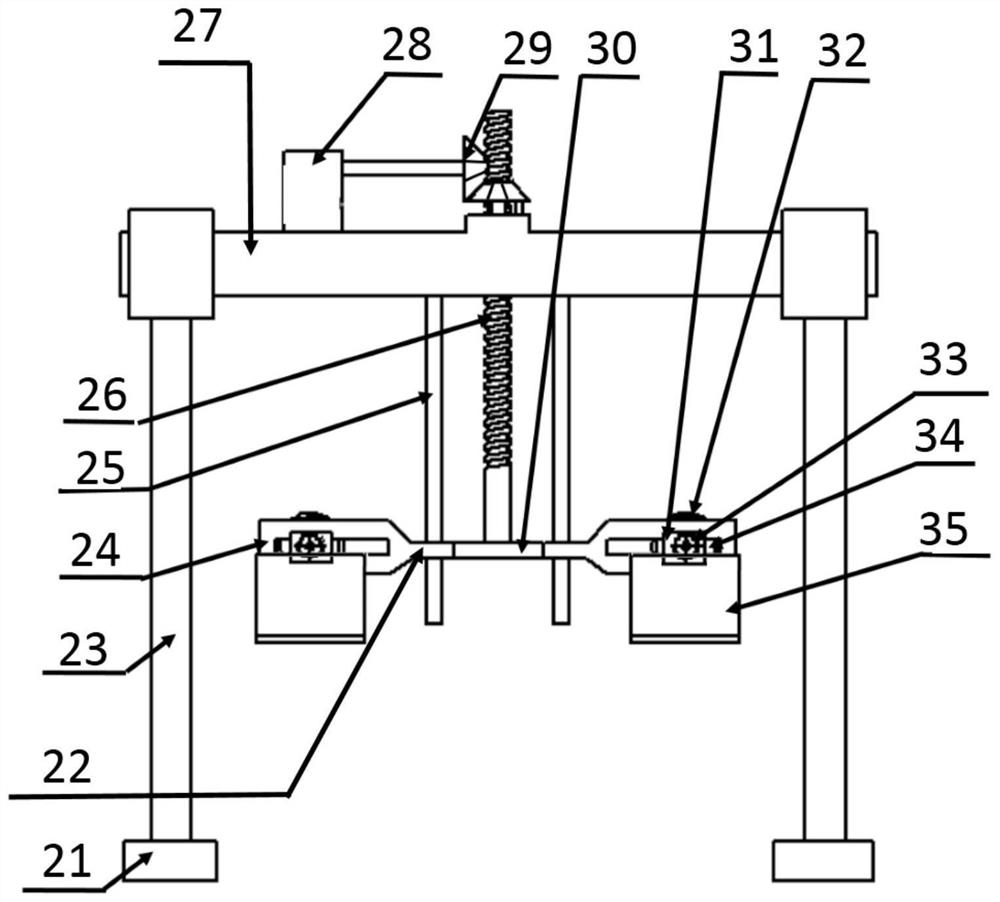

Method for preparing chitosan oligosaccharide by utilizing ultrasonic-hydraulic collaborative cavitation

The invention relates to a method for preparing chitosan oligosaccharide by utlizing ultrasonic-hydraulic collaborative cavitation. The method is characterized by performing ultrasonic-hydraulic cavitation degrading treatment on a chitosan solution in an ultrasonic-hydraulic cavitation device by adopting ultrasonic-hydraulic collaborative cavitation degrading, wherein the ultrasonic-hydraulic cavitation device comprises a constant-temperature water bath circulating water tank, a storage tank, a pump, an ultrasonic-hydraulic cavitator, a pipeline for conveying the chitosan solution, a pressure gauge and a valve. The technological process comprises the following steps: putting the chitosan solution into the storage tank, stabilizing the temperature through the circulating water tank, conveying the chitosan solution to the ultrasonic-hydraulic cavitator through the pump for cavitation degrading, adjusting the inlet pressure through the valve, and monitoring the pressure through the pressure gauge, wherein the chitosan solution subjected to cavitation degrading flows back into the storage tank. Compared with the degrading rate of the existing hydraulic cavitation device (a Venturi tube) for preparing the chitosan oligosaccharide, the degrading rate of the method disclosed by the invention is improved by at least 70 percent; the method has the characteristics of simplicity, convenience, feasibility, low energy consumption, high efficiency and the like, and has the advantage of large-scale industrial application.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

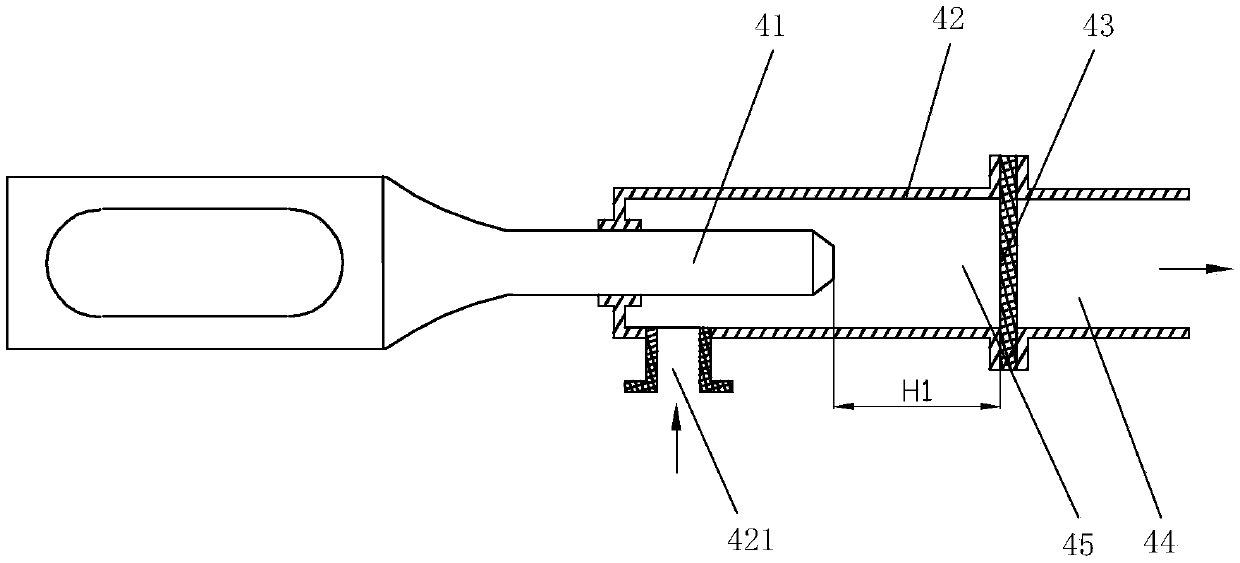

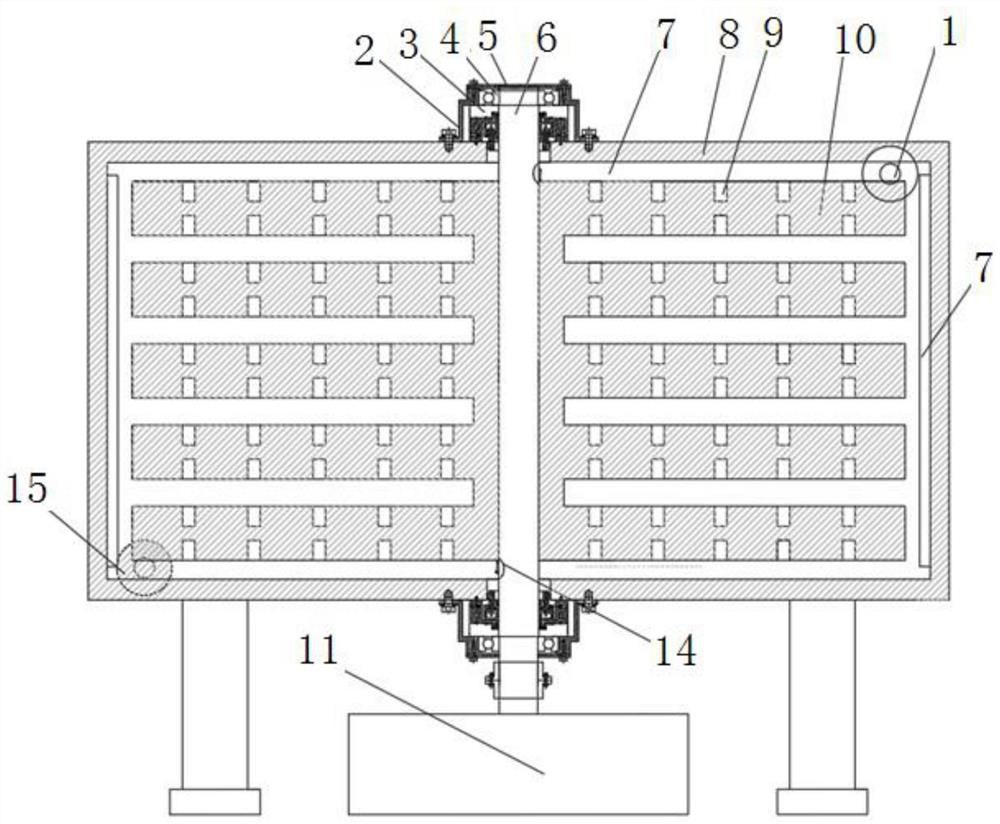

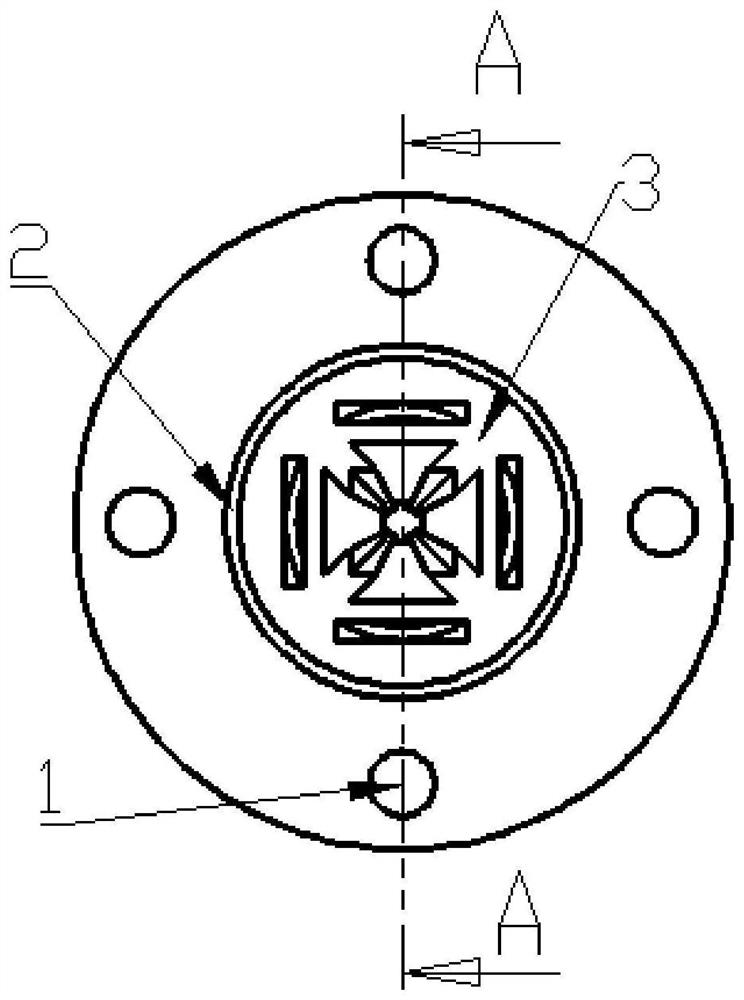

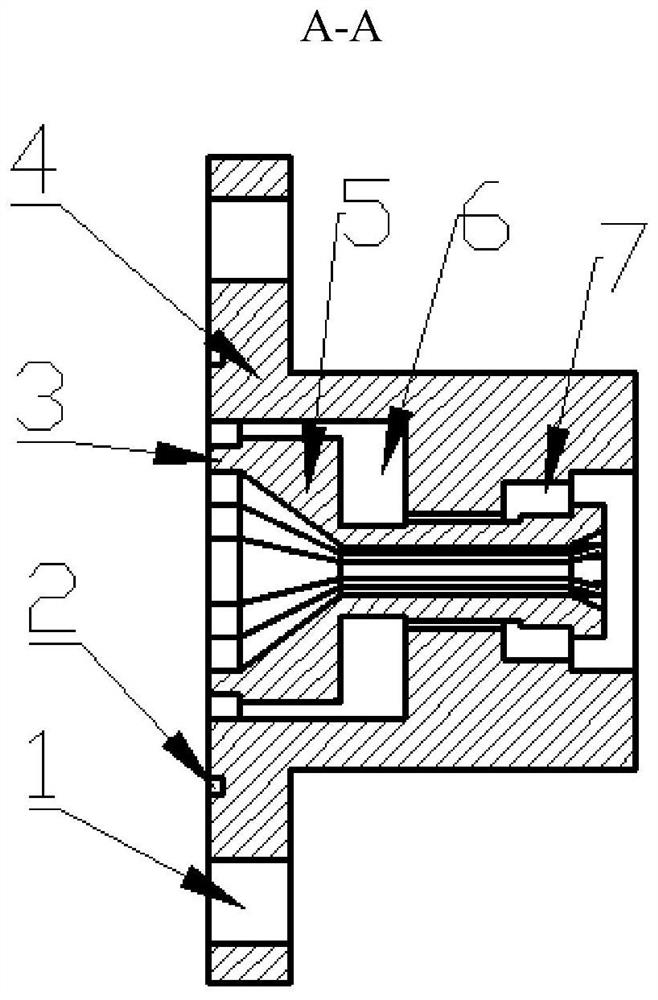

Self-excited oscillation cavitation impinging stream reactor

PendingCN110921770AStrong cavitation effectImprove cavitation performanceWater/sewage treatment by irradiationWater treatment compoundsLiquid jetCavitation (process)

The invention discloses a self-excited oscillation cavitation impinging stream reactor which comprises a liquid inlet pipe, a gas inlet pipe, a cavitator, an impact cavity and a liquid outlet pipe. Apipe connector is mounted on an upper cover plate and used for being connected with the liquid outlet pipe and allowing a liquid to flow out; a water inlet pipe and a flange plate are connected through threads, and the distance between outlets of the self-excited oscillation cavitator can be changed by adjusting the screwing length of the threads. The water inlet pipe is in threaded connection with a self-excited oscillator. The self-excited oscillation cavitator is located in the impact cavity, liquid enters the self-excited oscillation cavitator through the liquid inlet pipe, cavitation is generated, cavitation jet flow is formed, multiple strands of liquid jet flows collide with one another at a high speed in the center of the impact cavity, and cavitation is effectively enhanced; meanwhile, plasma can be introduced into the cavitation process, and the generation efficiency of hydroxyl radicals is improved. The reaction process can be strengthened, the hydrodynamic cavitation strength is improved, and the degradation efficiency of organic wastewater is improved.

Owner:BEIJING UNIV OF TECH

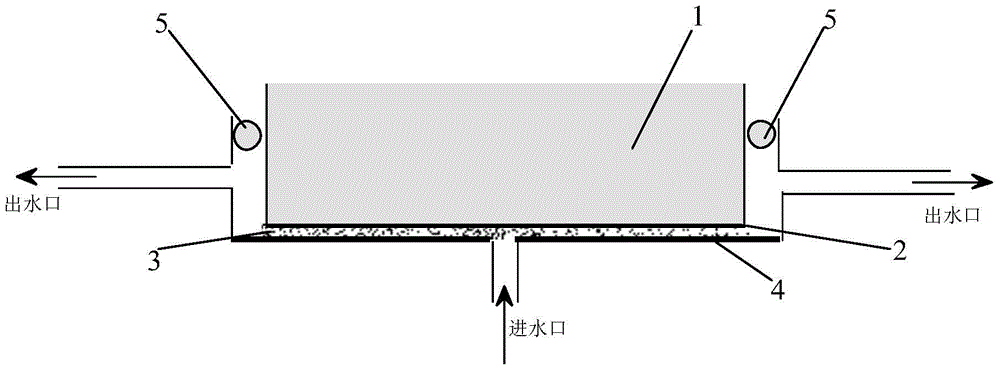

Water treatment device and system and water treatment method

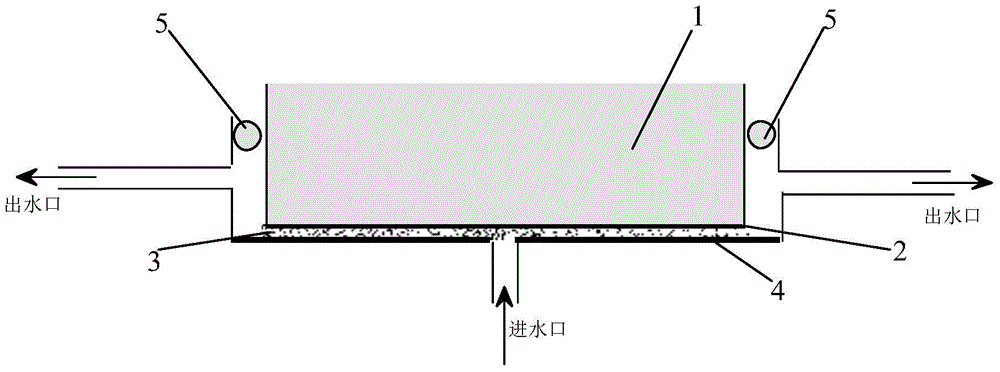

ActiveCN107986388AMeet processing needsEasy to handleWater/sewage treatment with mechanical oscillationsUltrasonic cavitationCoupling

The invention relates to a water treatment device and system and a water treatment method. The device comprises an ultrasonic transducer and a thin-layer treatment chamber, wherein the thin-layer treatment chamber is provided with a first cover plate, a second cover plate and a tapered and gradually-enlarged flow channel; the tapered and gradually-enlarged flow channel is provided with one or morevalves; liquid is remained between the first cover plate and the second cover plate; a radiation surface of the ultrasonic transducer is fixed on the first cover plate; the ultrasonic transducer is used for emitting ultrasonic waves; the thin-layer treatment chamber is used for receiving the ultrasonic waves and generating ultrasonic cavitation; the tapered and gradually-enlarged flow channel isused for generating hydraulic cavitation; the hydraulic cavitation and the ultrasonic cavitation are coupled to grenade coupling cavitation; the coupling cavitation is used for treating water. According to the water treatment device provided by the invention, the washing groove type ultrasonic transducer is adopted and the diameter of the radiation surface is greater than that of a piezoelectric sheet, so that the device has the advantages of low price, stability in working and strong adaptability; a large radiation area covers a coupling region and an external region with an independent ultrasonic effect, so that wastes of ultrasonic energy are avoided.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

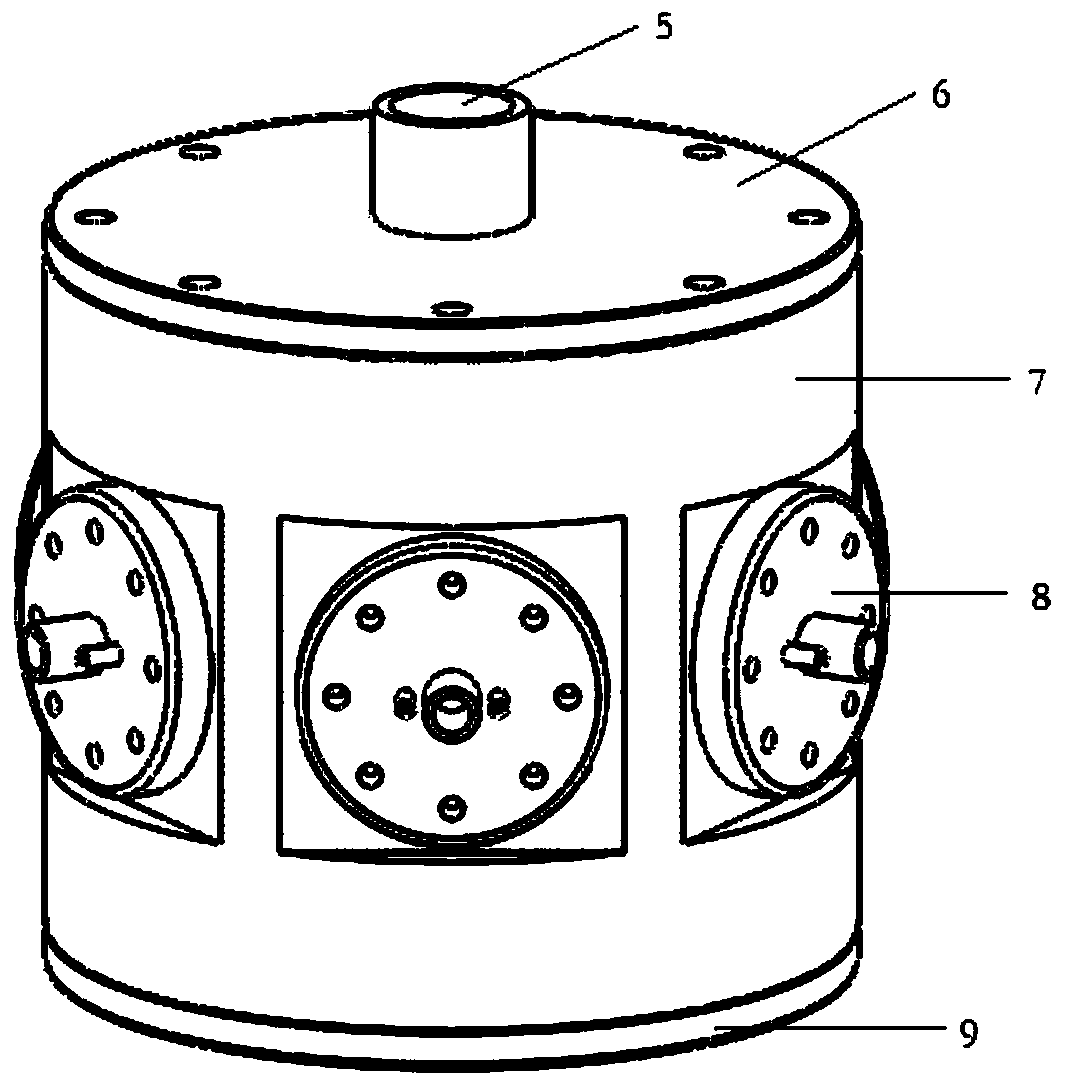

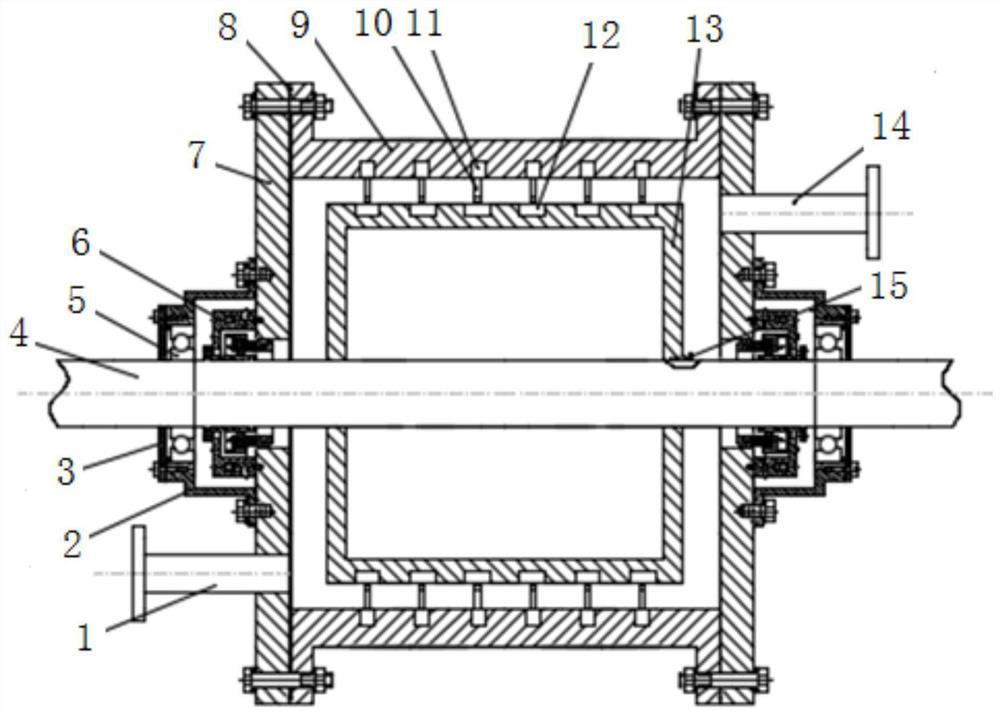

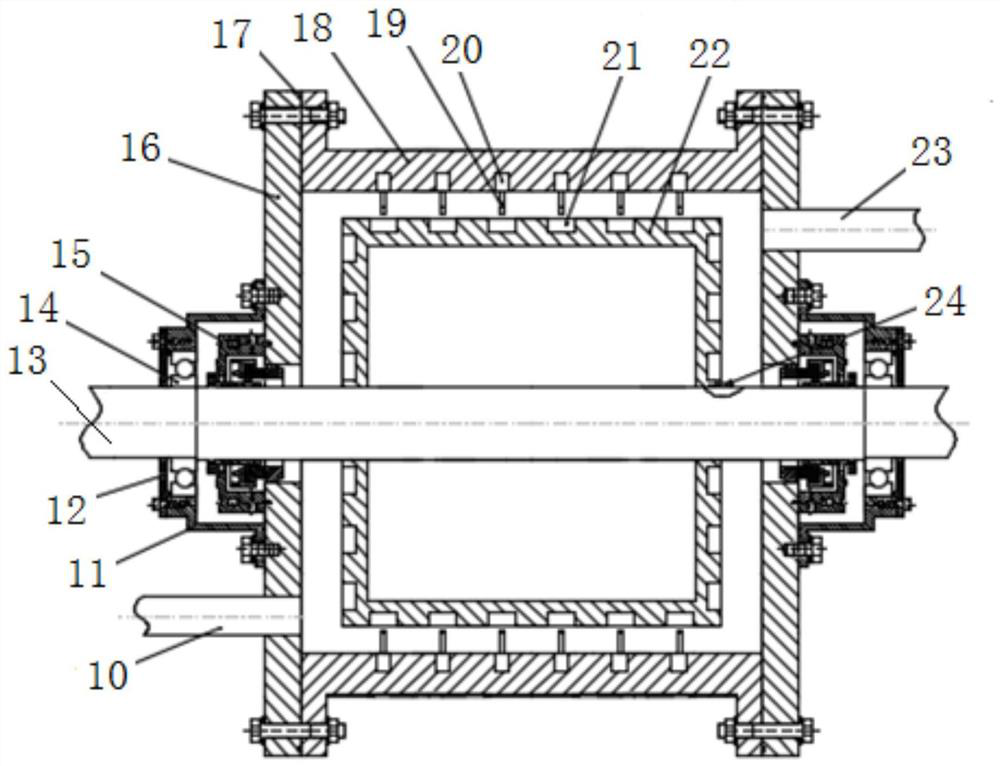

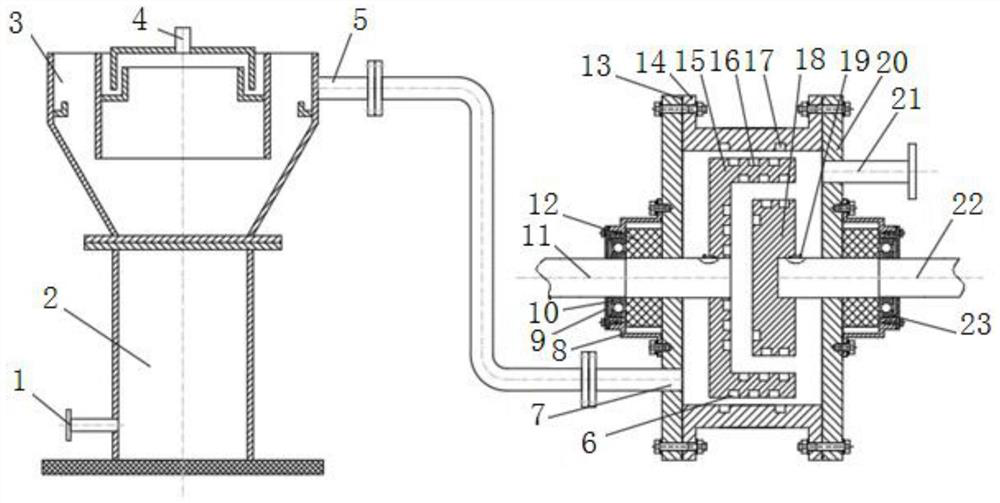

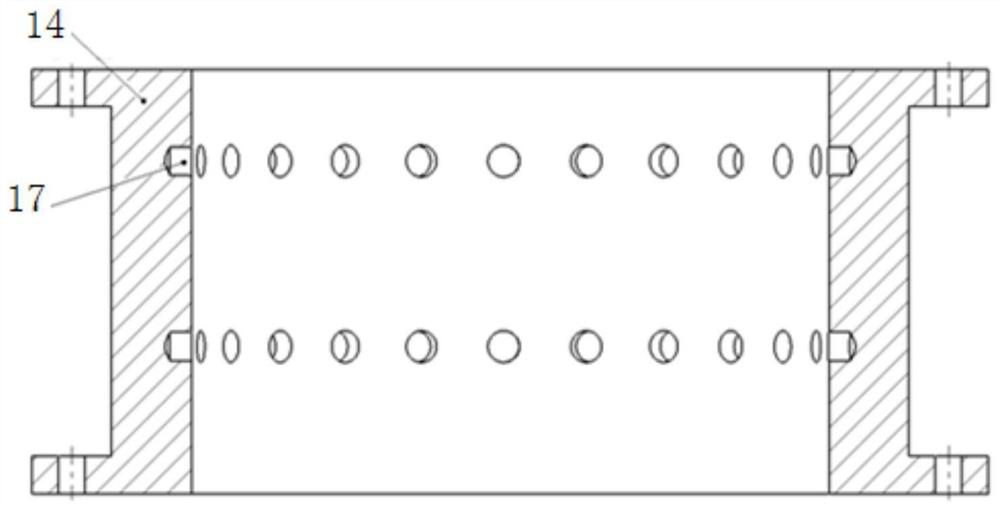

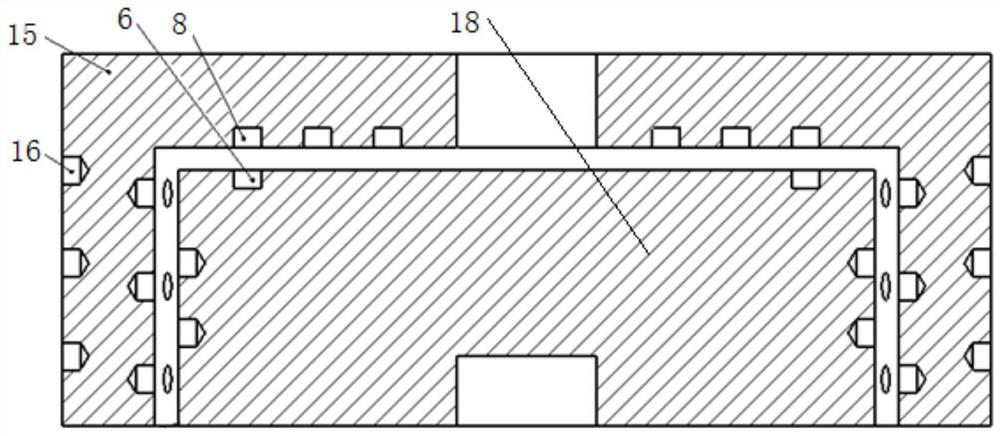

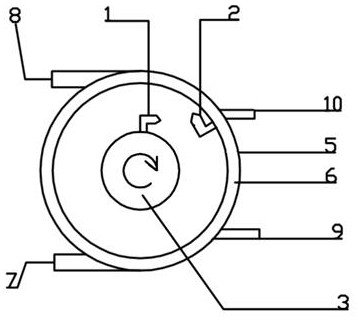

Antibiotic wastewater degradation device coupled with hydraulic, ultrasonic cavitation and oxidation processes

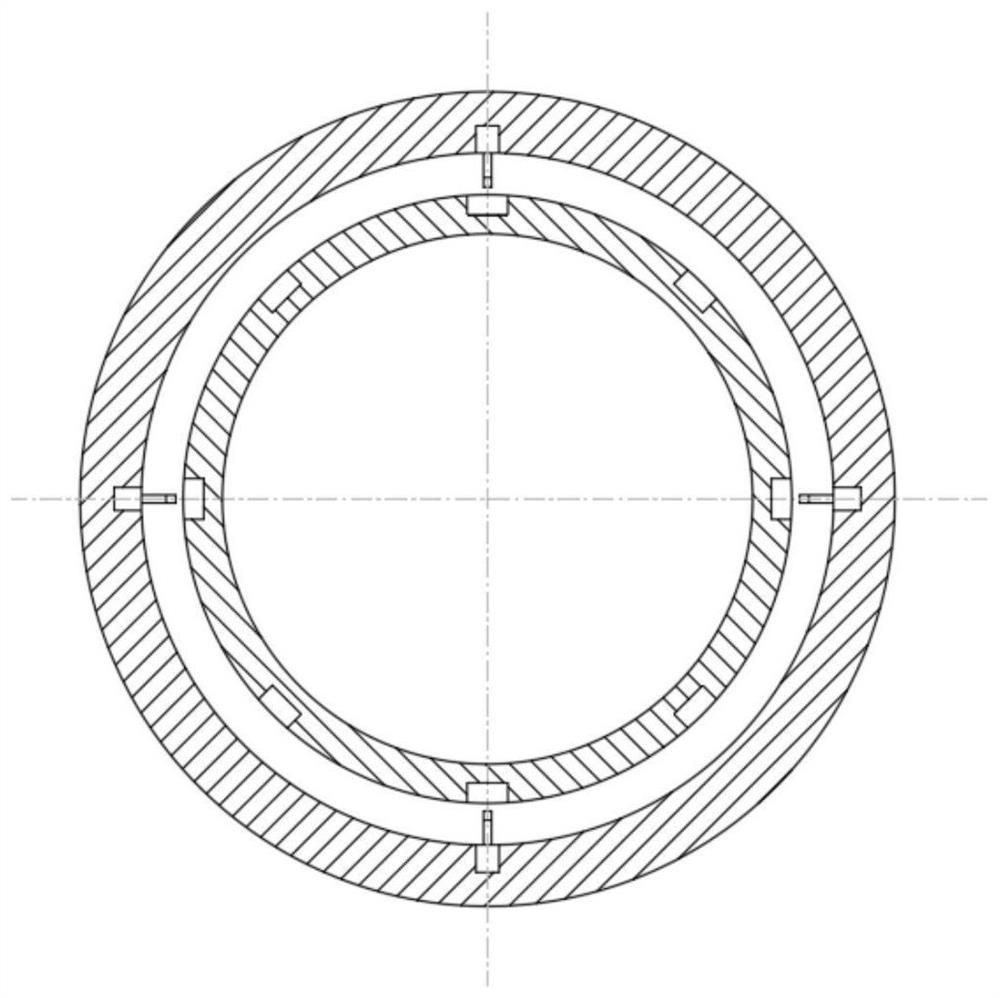

InactiveCN111807459ASame depthUniform cavitation intensityWater treatment compoundsWater contaminantsUltrasonic cavitationMechanical engineering

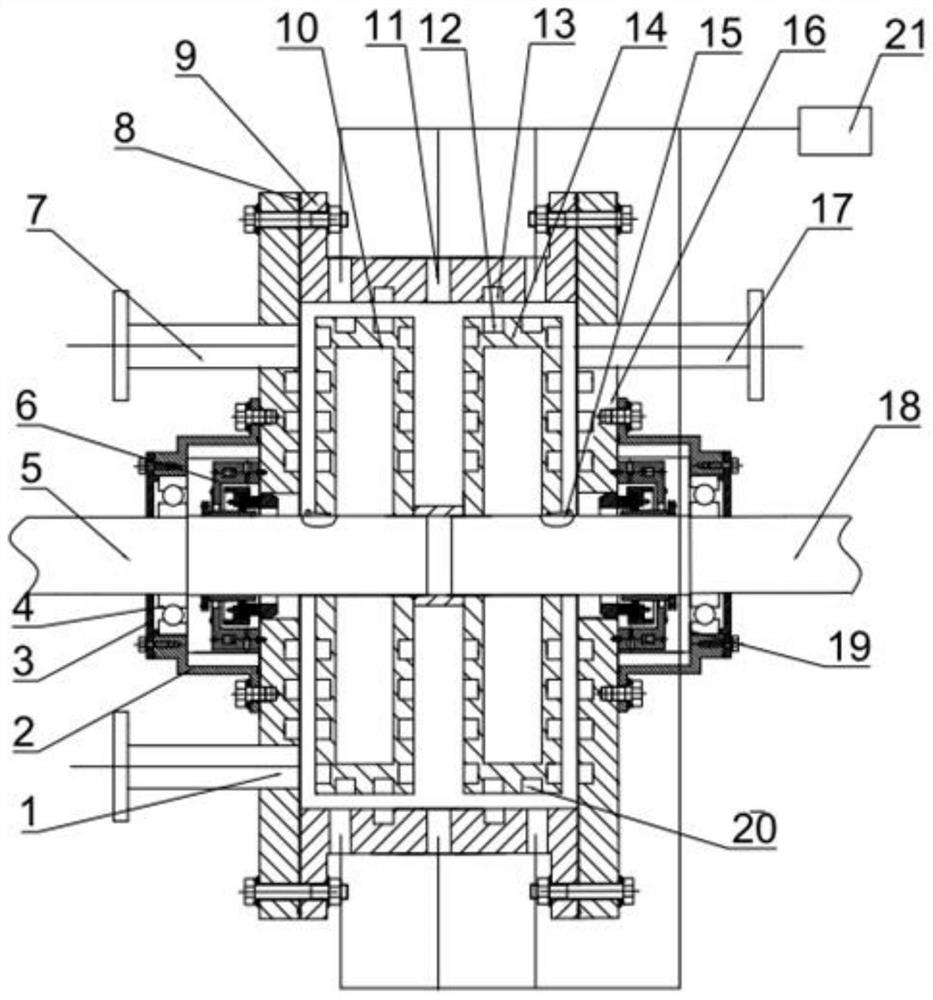

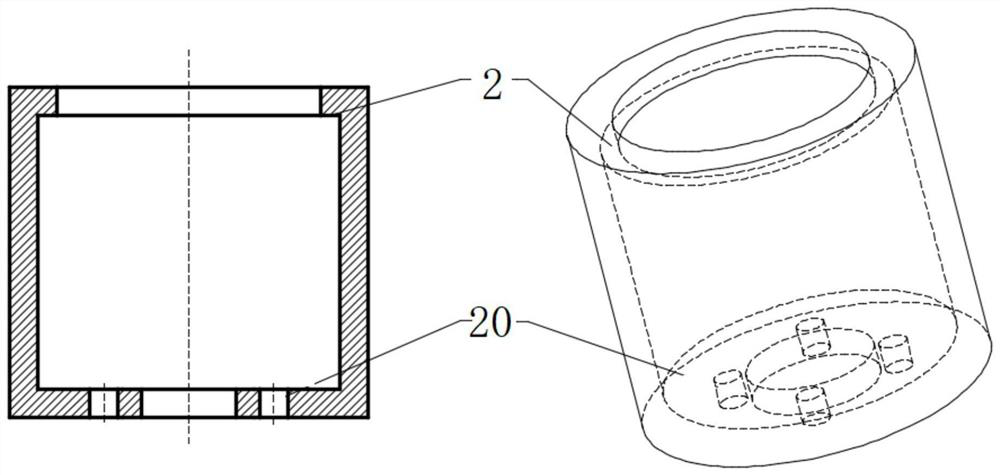

The invention provides an antibiotic wastewater degradation device coupled with hydraulic, ultrasonic cavitation and oxidation processes. The device comprises a stator, a rotor, an ultrasonic generator and an ultrasonic transducer. The stator is a hollow sealed cylinder, and the ultrasonic transducer extending into an inner cavity of the stator is arranged on the outer wall of the stator; stator cavitation holes are distributed in the inner wall of the stator. Two wheel discs are arranged in the stator, and each wheel disc is fixedly connected to one rotating shaft; the two rotating shafts aresymmetrically installed at the two ends in the stator respectively. Wheel disc cavitation holes are distributed in the circumferential direction and the end face of each wheel disc. One end of the stator is provided with a wastewater inlet pipe and an oxidant pipe, and the other end is provided with a liquid outlet pipe. According to the device, the antibiotic wastewater is degraded by coupling hydraulic power, ultrasonic cavitation and an oxidizing agent, the cavitation energy density is enhanced, the effect of the oxidizing agent is improved, the antibiotic wastewater is degraded efficiently and synergistically, the effect is good, the amplification performance is good, the treatment capacity is large, continuous operation can be achieved, the cost is low, secondary pollution is avoided, and the device has wide application prospects in the field of wastewater degradation.

Owner:SHANDONG UNIV

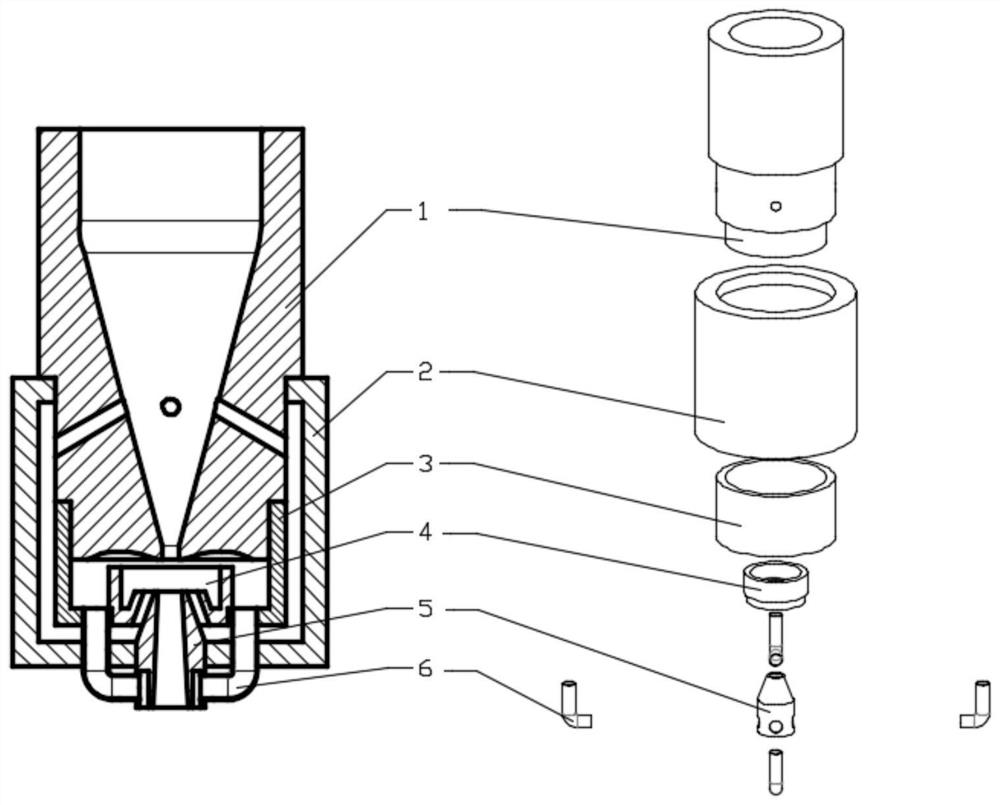

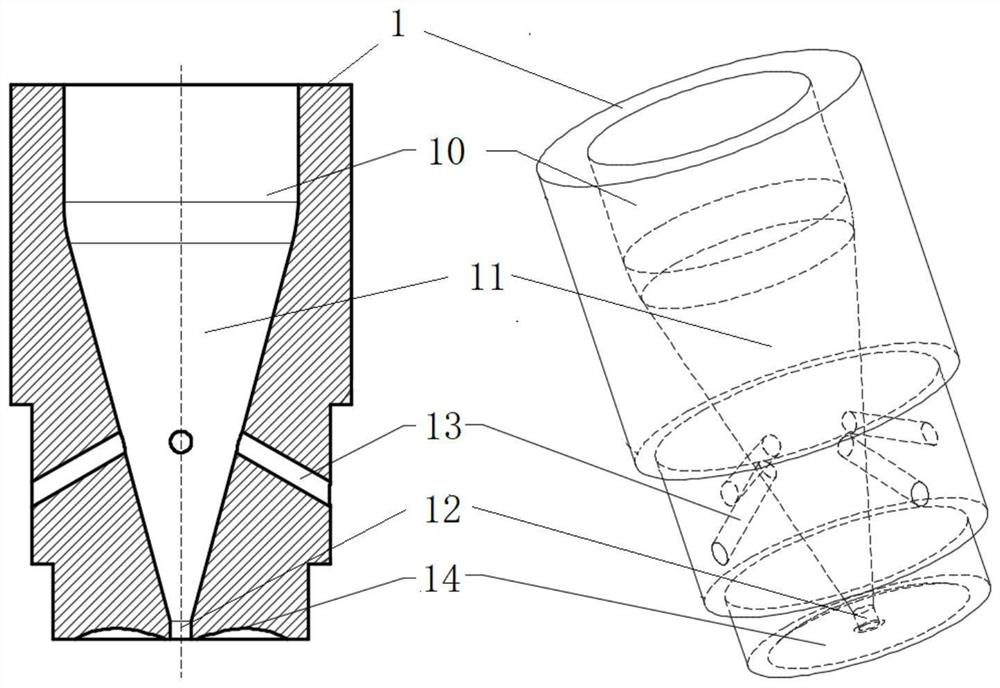

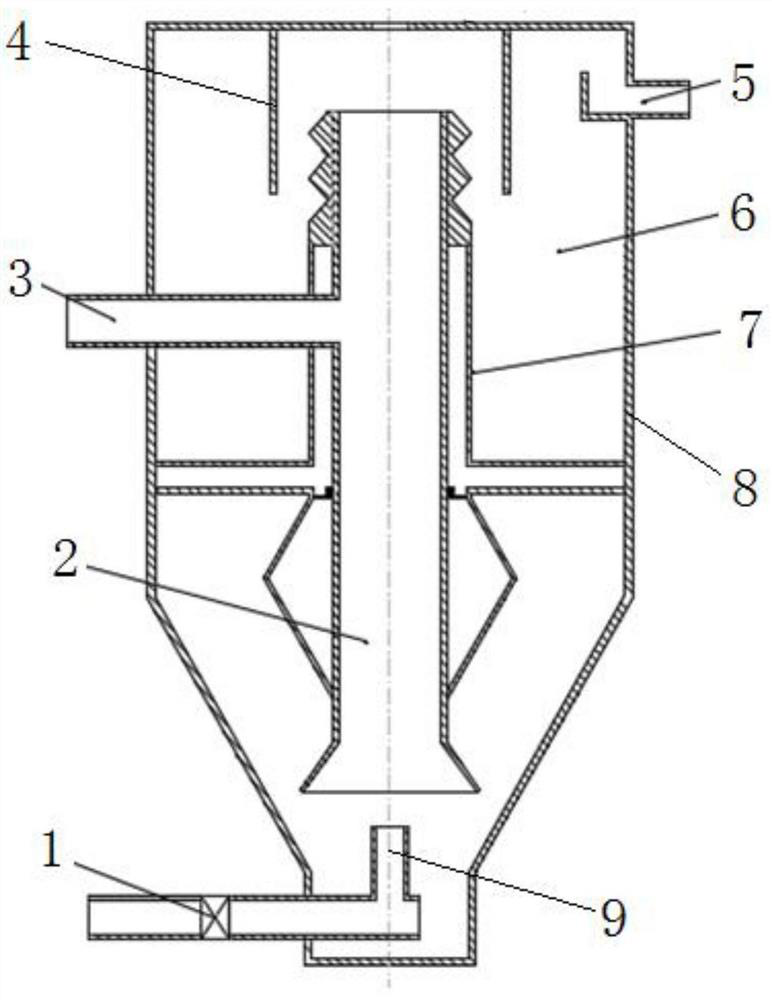

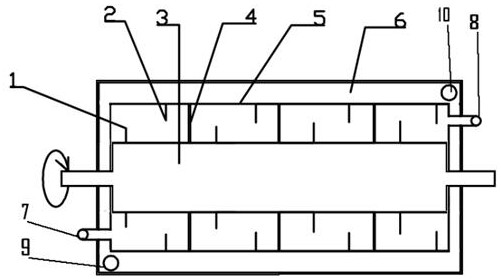

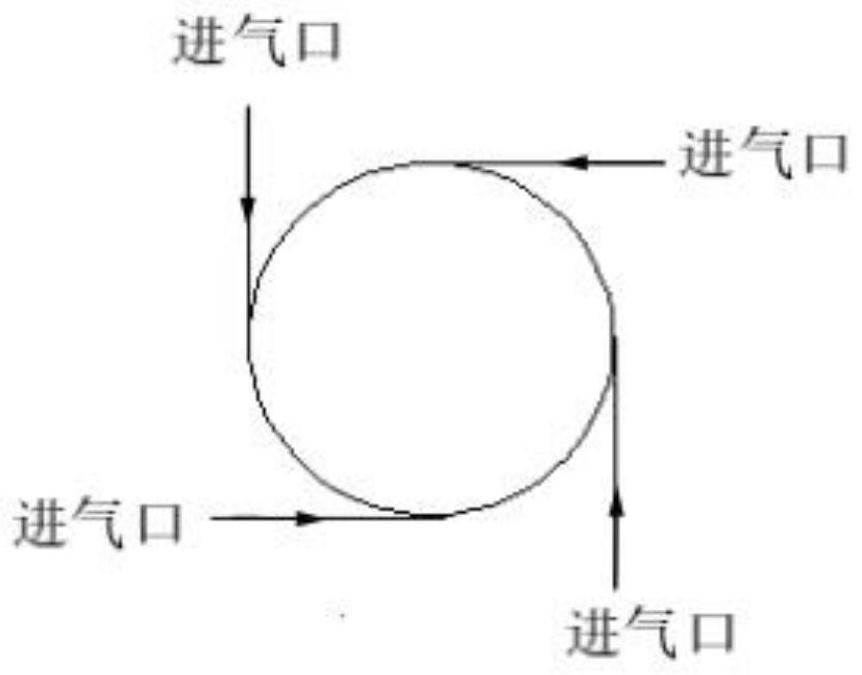

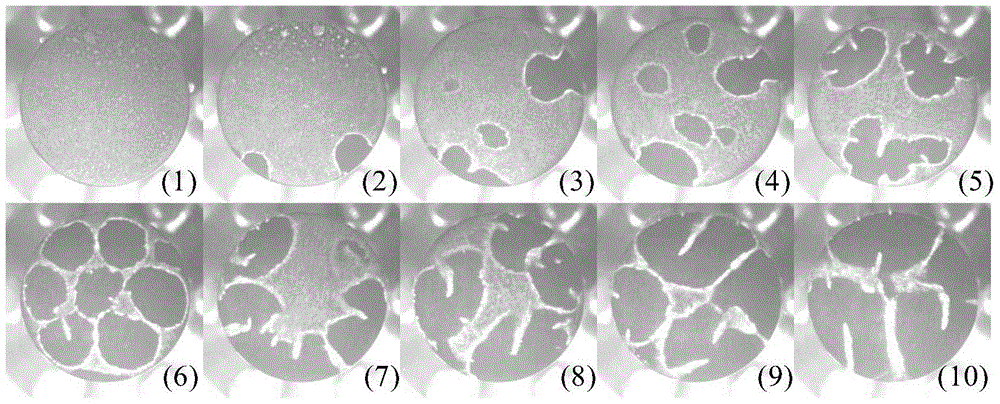

Spiral-flow type jammed cavitation device for breaking excess sludge

ActiveCN105668973ASimple structureEffective collapseSludge treatment by oxidationWater/sewage treatment apparatusSludgeCollapsed cavity

The invention relates to a hydrodynamic cavitation sludge breaking device. A spiral-flow type jammed cavitation device for breaking excess sludge is characterized by comprising a spiral-flow body, a spiral-flow core, a jammed body and a backpressure cover. The spiral-flow body and the spiral-flow core are matched to form a spiral-flow nozzle. A through hole in the jammed body forms a jammed pipe. The jammed body and the backpressure cover are matched to form a collapse cavity. A backpressure hole is formed in the backpressure cover in the radial direction. After fluid enters the spiral-flow nozzle through the spiral-flow body, flows along a spiral channel to possess the tangential speed and the radial speed, and forms rotating jet flow when being ejected through an outlet end, the rotating jet flow is induced on the upstream of the jammed pipe to generate a large number of cavitation bubbles and an acute shear effect, cavitation bubbles carried by the fluid collapse when the fluid passes through the jammed section on the downstream of the jammed pipe to form jammed cavitation, and when the cavitation bubbles collapse, the mechanical effect of formed micro jet and the like effectively promotes breaking of the excess sludge. Compared with the prior art, the spiral-flow type jammed cavitation device is simple in structure, high in cavitaion strength, strong in mechanical shear force action, high in excess sludge breaking rate and the like.

Owner:安徽明亮面业股份有限公司

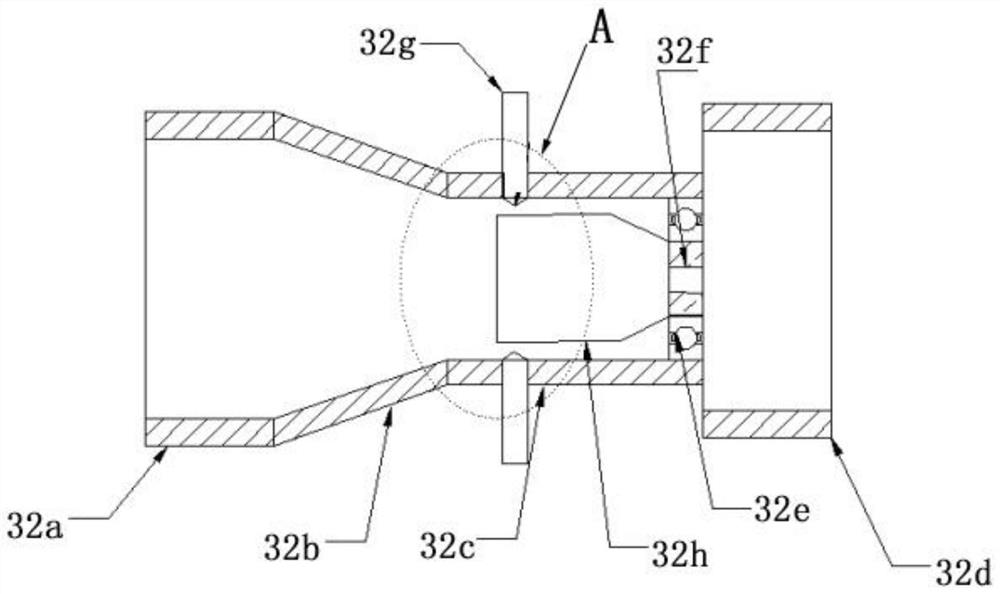

Double-shear type cavitation nozzle

PendingCN113083535ACollapse violentlyImprove cavitation strengthSpray nozzlesCavitation bubbleMechanics

The invention provides a double-shear type cavitation nozzle. The double-shear type cavitation nozzle comprises an upper nozzle, an inner sleeve, an outer sleeve, a mixing cavity, a lower nozzle and a connecting pipe, wherein a first cavity and a first through hole are formed in the upper nozzle along the axial direction; the upper nozzle is sleeved with the inner sleeve, and a second cavity is formed between the inner sleeve and the upper nozzle; the outer sleeve is arranged on the outer wall of the upper nozzle in a sleeving manner and wraps the inner sleeve, and a third cavity is formed between the outer sleeve and the inner sleeve; the mixing cavity is clamped at the outlet of the inner sleeve; the lower nozzle penetrates through the outer sleeve and extends into the mixing cavity, a fifth cavity communicated with the third cavity is formed between the lower nozzle and the mixing cavity, a jet hole is formed in the lower nozzle in the axial direction of the lower nozzle, a second through hole and an annular inner cavity communicated with the second through hole are formed in the side wall of the end side, away from the mixing cavity, of the lower nozzle, and the annular inner cavity is not communicated with the jet hole; and the connecting pipe is used for connecting the second cavity and the second through hole. When a jet flow passes through the nozzle, multiple times of shearing are carried out, lots of cavitation bubbles are generated, and the cavitation effect and the operation efficiency are improved.

Owner:WUHAN UNIV

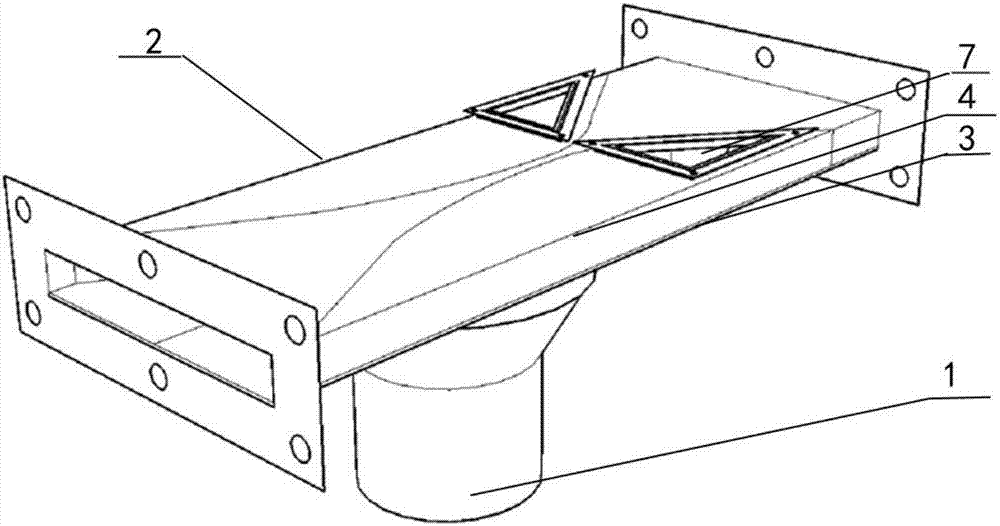

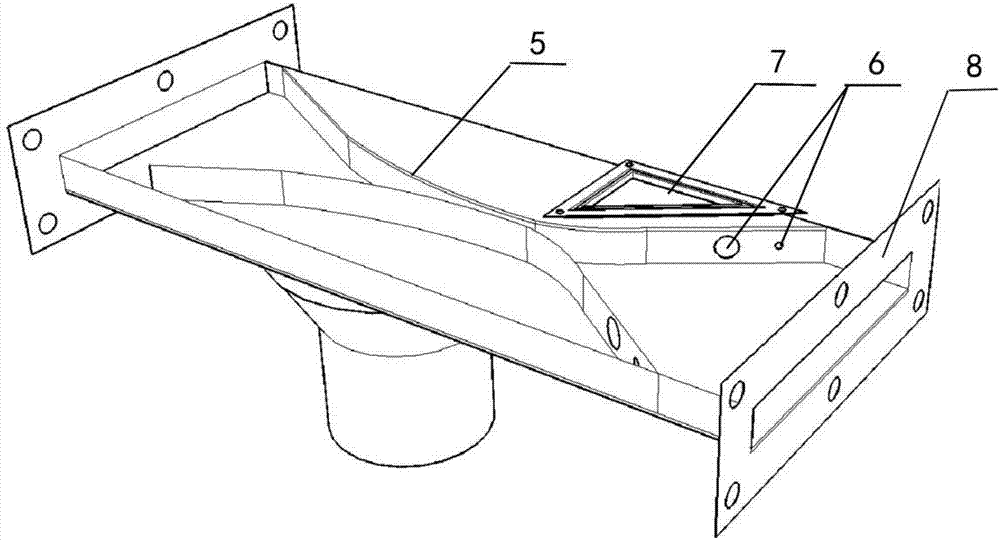

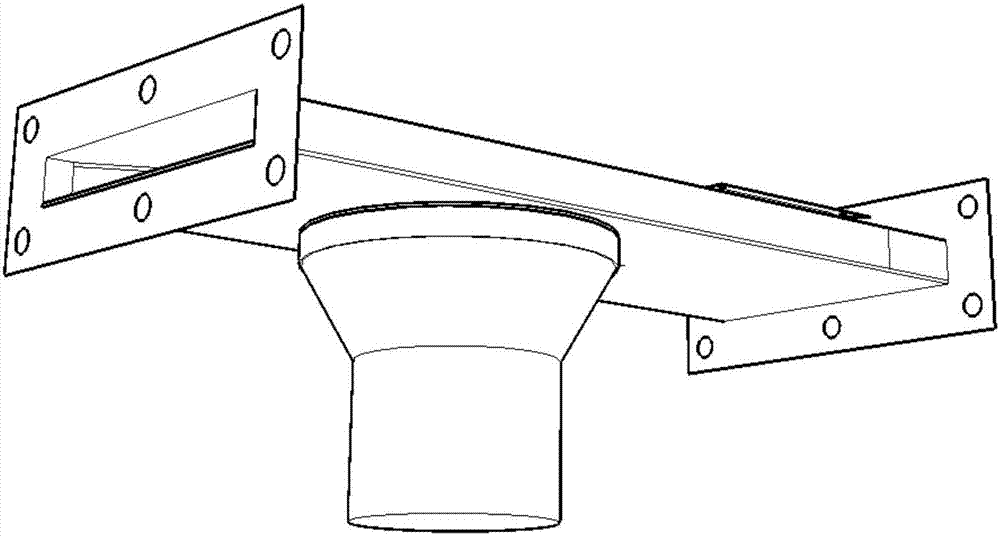

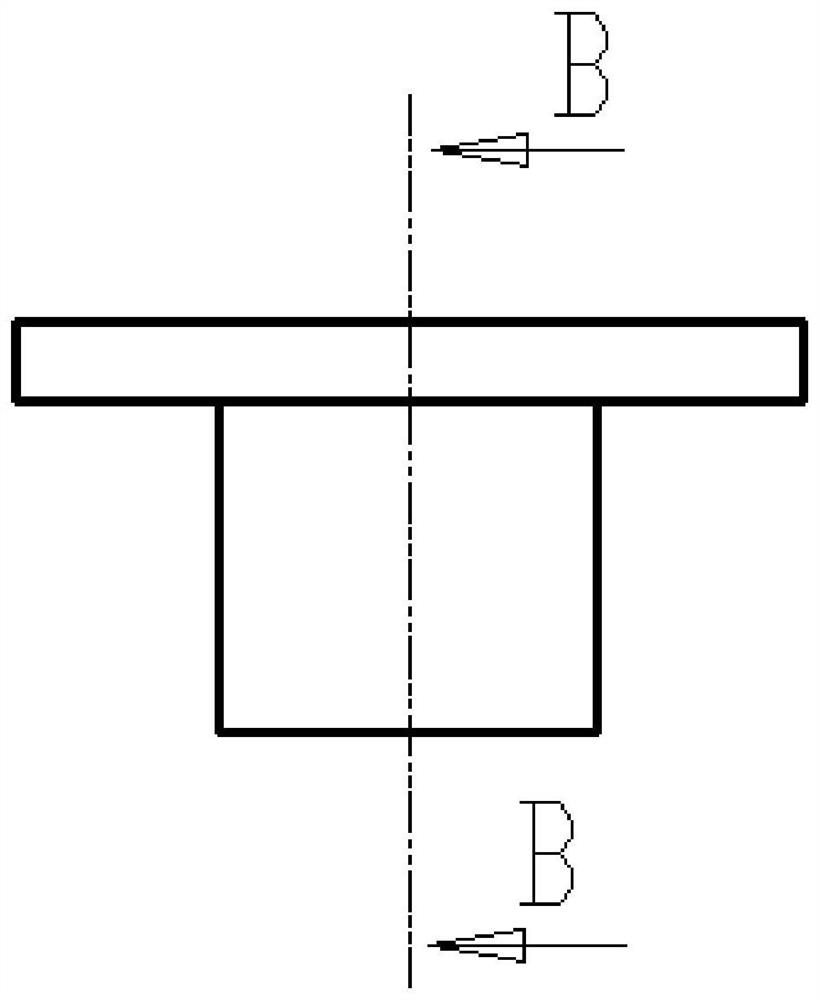

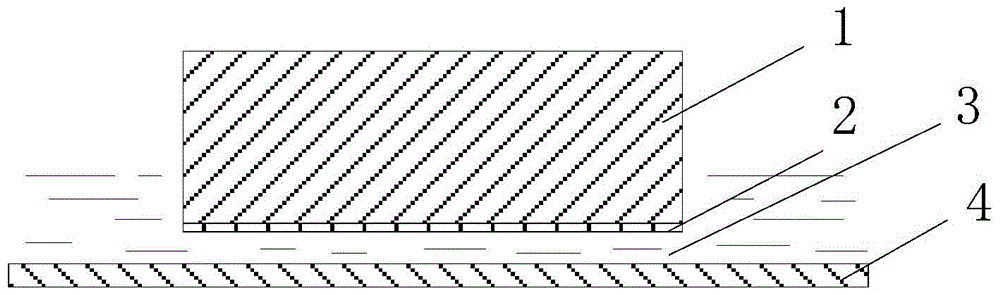

Ultrasonic cavitation device

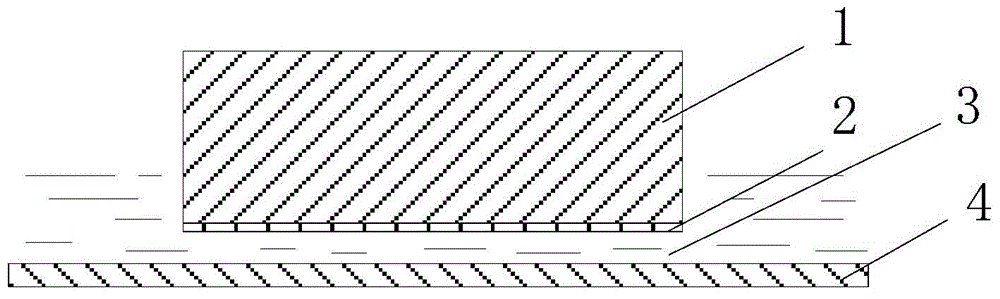

ActiveCN104138736AHigh space to volume ratioImprove cavitation strengthEnergy based chemical/physical/physico-chemical processesLiquid layerUltrasonic cavitation

The invention relates to an ultrasonic cavitation device, which comprises an oscillator and a reflector, wherein a radiation surface is arranged at one end of the oscillator; a thin liquid layer is formed between the radiation surface and the reflector; the oscillator generates ultrasonic waves, which enters the thin liquid layer through the radiation surface; a sound field is formed in the thin liquid layer; the reflector reflects the ultrasonic waves radiated by the radiation surface; the sound field in the thin liquid layer is strengthened through multiple reflection and superposition of the ultrasonic waves by the reflector and the radiation surface, and therefore, the large-area cavitation cloud transversely spread along the thin liquid layer is formed. According to the ultrasonic cavitation device provided by the invention, a reflection surface is arranged on the opposite side of the radiation surface of an energy converter, and therefore, the sound field in the thin liquid layer is strengthened, so that the transversely spread large-area cavitation cloud is formed under low input power.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

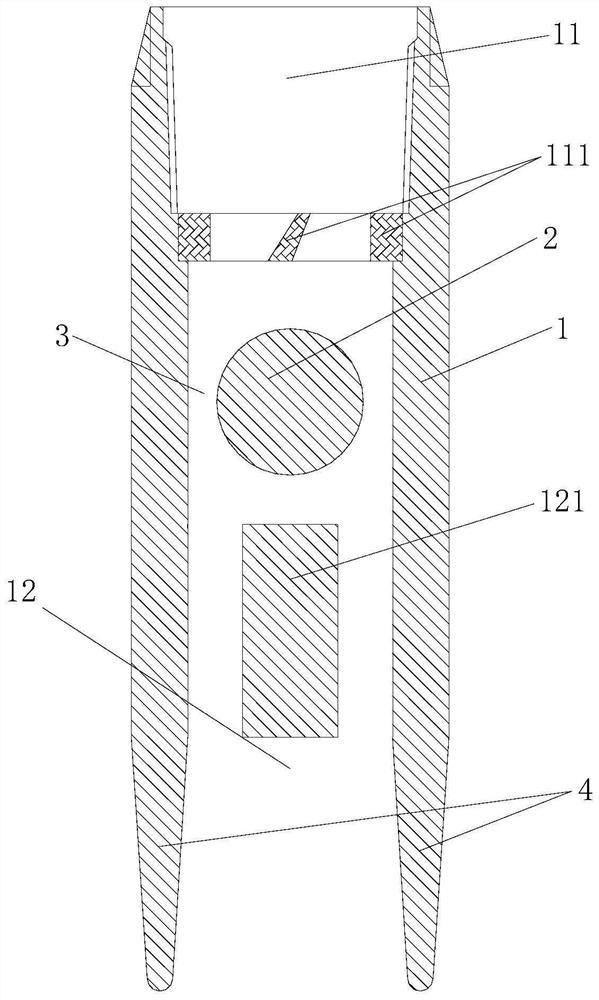

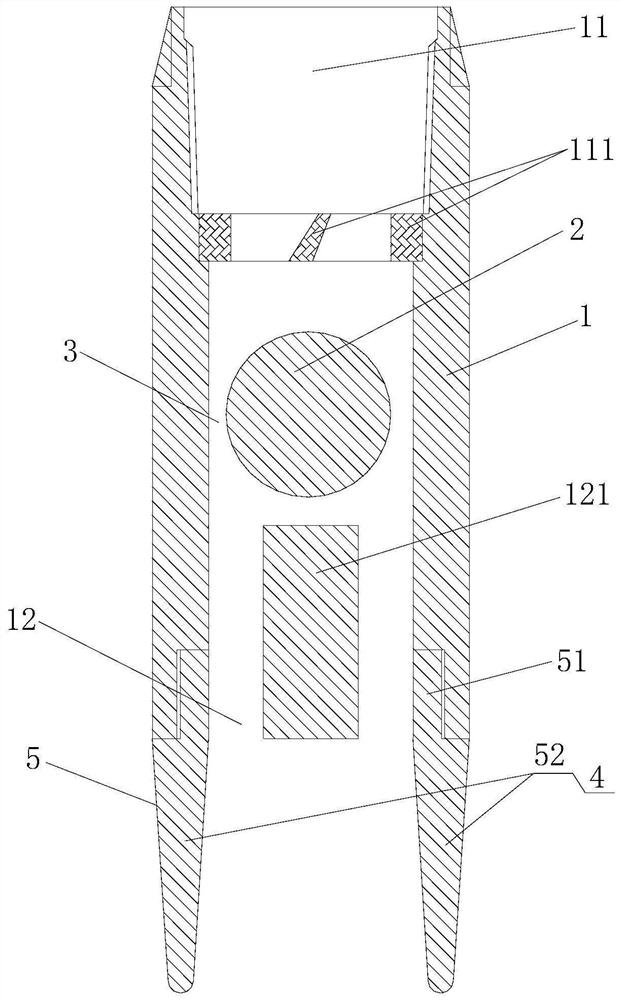

Liquid flow cavitation device

PendingCN112282715AImprove the transformation effectEnhanced effect on cavitationFluid removalVibration devicesCavitationEngineering

The invention discloses a liquid flow cavitation device. The liquid flow cavitation device comprises a shell and a working medium, wherein the shell is provided with a top opening and a bottom opening, the working medium is limited in an inner cavity of the shell and can move freely, and a flow channel for liquid flow to flow through is formed between the working medium and the cavity wall of theinner cavity of the shell; and the cavitation device further comprises a resonance empennage which is located on the shell and extends out of the end face of the bottom opening of the shell in the axial direction of the cavitation device. According to the liquid flow cavitation device, the cavitation effect of a cavitator can be further enhanced, the transformation effect on an underground rock stratum is improved, and the seepage capacity and the recovery ratio of a reservoir are improved.

Owner:刘杰

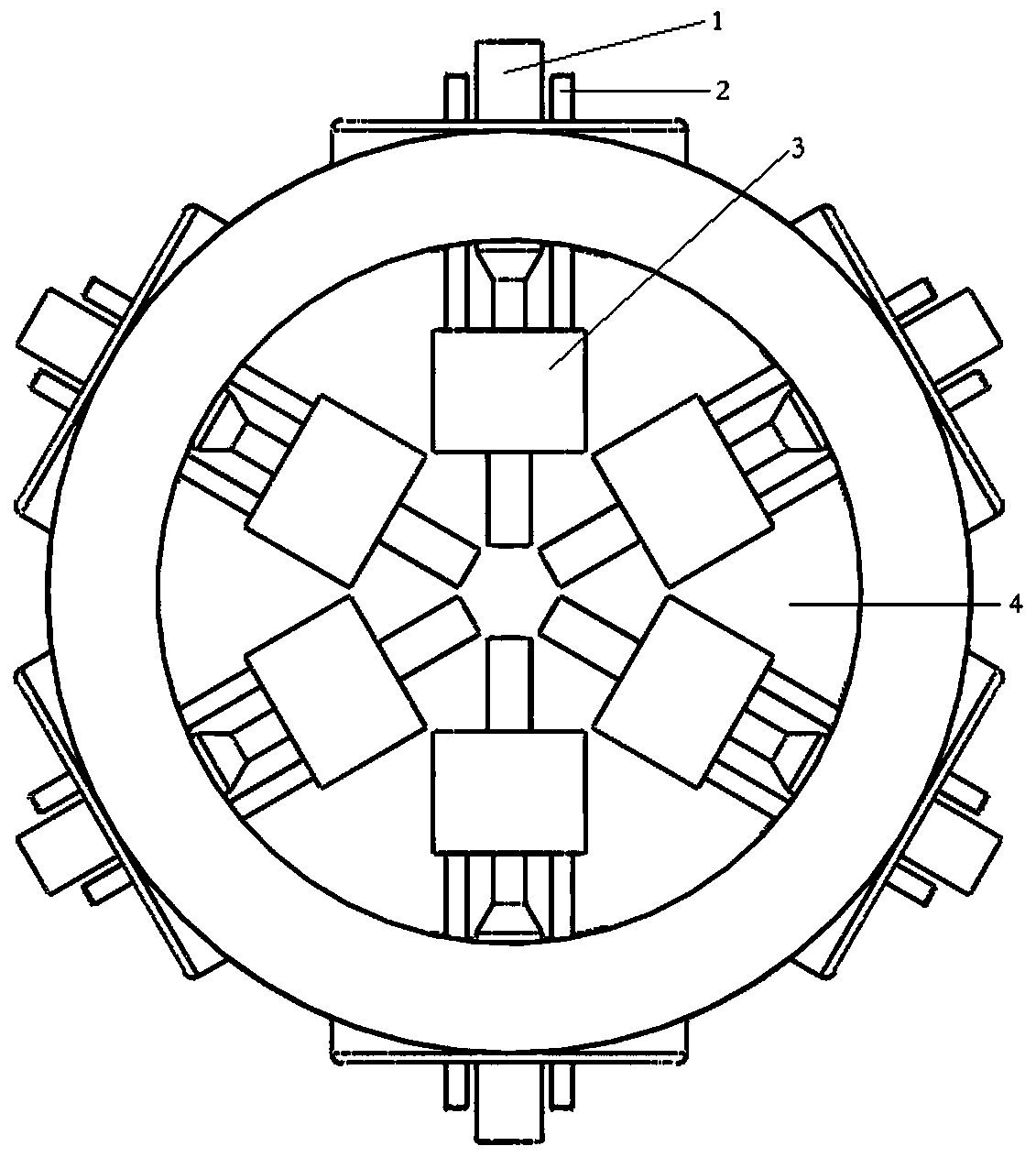

Device for degrading antibiotics by combining hydrodynamic cavitation with ultrasonic cavitation and photolysis technology

ActiveCN111807595AImprove efficiencyEfficientWater/sewage treatment by irradiationWater treatment compoundsCentral cylinderEngineering

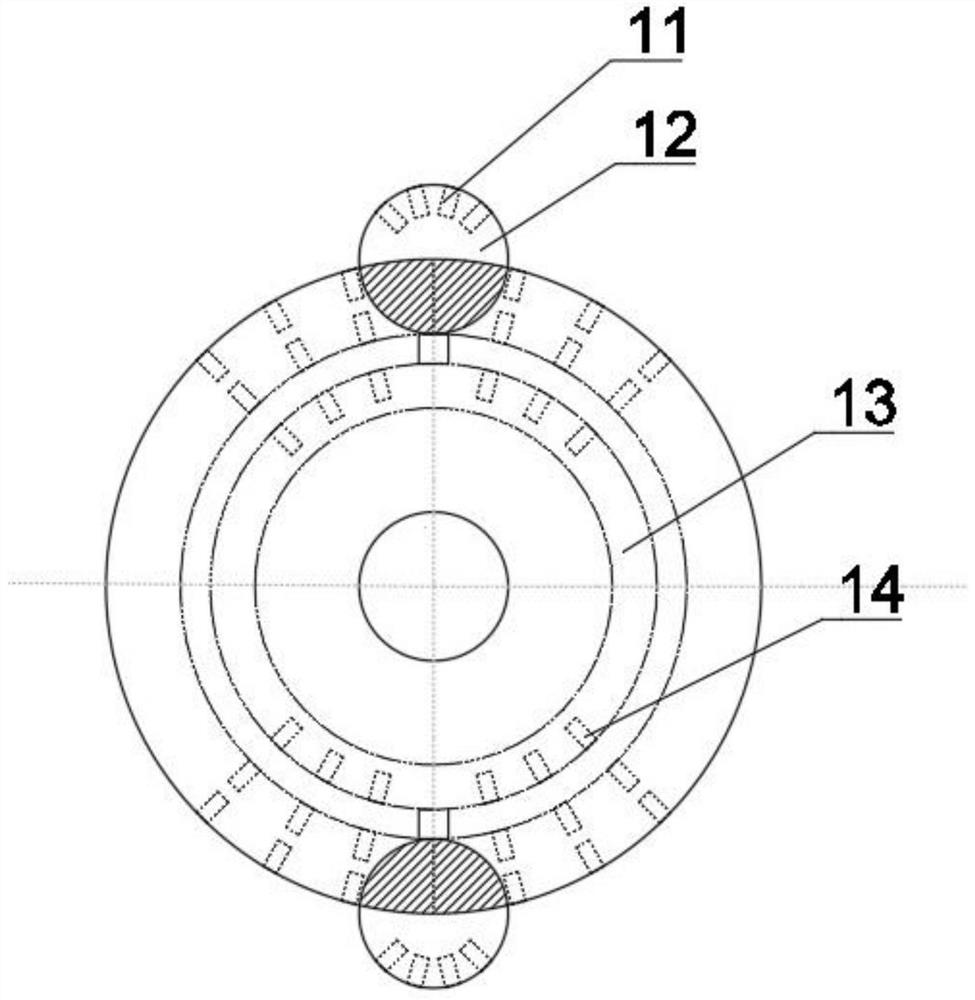

A device for degrading antibiotics by combining hydrodynamic cavitation with ultrasonic cavitation and photolysis technology comprises a hydrodynamic cavitation and ultrasonic cavitation combined reaction chamber and a photolysis reaction chamber, and the two reaction chambers are connected by a connecting pipe with a control valve; a rotor is arranged in the hydrodynamic cavitation and ultrasoniccavitation combined reaction chamber; the rotor comprises a central cylinder and a satellite body; the satellite bodies are distributed on the periphery of the center cylinder and connected to the center cylinder. The central cylinder body is fixed on the rotating shaft; cavitation holes are uniformly distributed in the inner wall of the hydrodynamic cavitation and ultrasonic cavitation combinedreaction chamber and the outer surfaces of the central cylinder and the satellite body; an ultrasonic generation device is arranged on the inner wall of the hydrodynamic cavitation and ultrasonic cavitation combined reaction chamber, a water inlet pipe is arranged at the upper part of the hydrodynamic cavitation and ultrasonic cavitation combined reaction chamber, and an ultraviolet lamp is arranged in the photolysis reaction chamber. The device adopts hydrodynamic cavitation and ultrasonic cavitation to degrade the antibiotic wastewater, can realize repeated cyclic treatment, has a good treatment effect, does not generate secondary pollution, and ensures the optimal cavitation effect.

Owner:SHANDONG UNIV

Integrated antibiotic wastewater degradation device based on hydraulic power and ultrasonic cavitation

InactiveCN111807460AMeet emission standardsLarge amount of processingWater treatment compoundsWater contaminantsUltrasonic cavitationEngineering

The invention discloses an integrated antibiotic wastewater degradation device based on hydraulic power and ultrasonic cavitation. The device comprises a stator, a rotor, a wireless ultrasonic transducer, an ultrasonic probe and a rotating shaft, wherein the stator and the rotor are sealed cylinders, the two ends of the stator are respectively provided with a waste water inlet and a water outlet,the inner wall of the stator is provided with an ultrasonic probe, the rotor is arranged in the stator, a rotating shaft is arranged in the stator and penetrates through the stator and the rotor, therotor is fixedly connected to the rotating shaft, and cavitation blind holes are distributed in the outer side wall of the rotor; according to the method, the antibiotic wastewater is degraded by adopting a method of combining hydrodynamic cavitation and ultrasonic cavitation, the efficiency and quality are far higher than those of single hydrodynamic cavitation or ultrasonic cavitation, and the method has high efficiency and large water treatment capacity and can be used for continuous operation; the device is not influenced by the external environment, has high flexibility and can be startedand stopped at any time as required; the device is simple in structure, high in adaptability, convenient to operate, safe, reliable and convenient to maintain.

Owner:SHANDONG UNIV

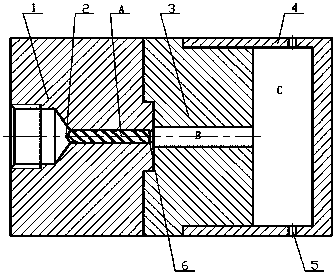

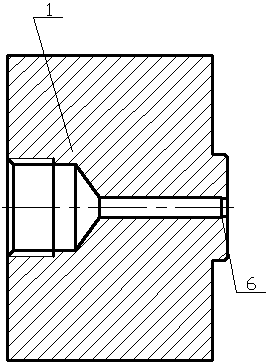

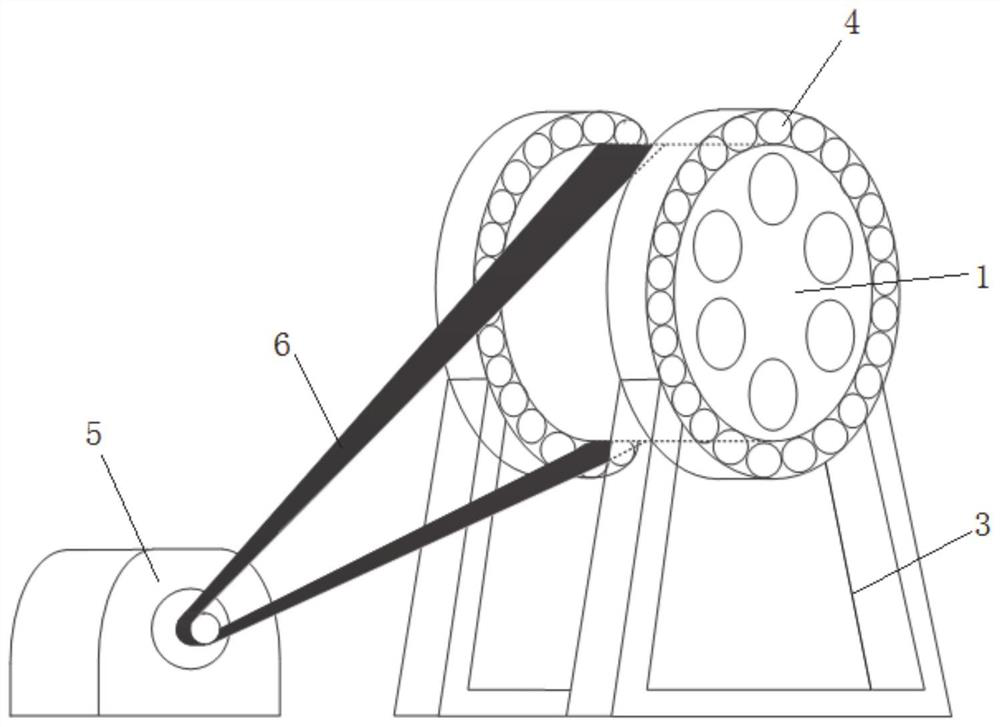

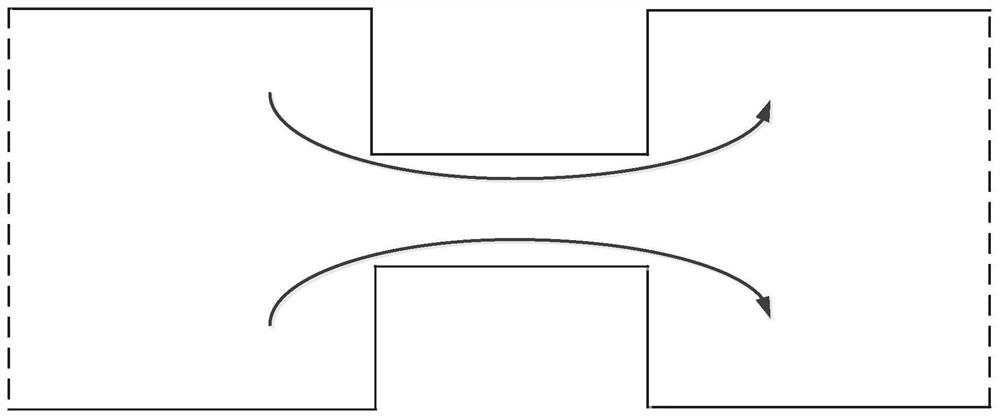

Hydrodynamic cavitation generation device and method

ActiveCN113120990AUnsteady CavitationImprove cavitation strengthWater/sewage treatment with mechanical oscillationsFlow mixersEngineeringMechanical engineering

The invention relates to a hydrodynamic cavitation generation device and method. The device comprises a wheel disc which is provided with a plurality of flow channels, the flow channels being internally provided with pore plates, and the pore plates being provided with throat holes; a driving mechanism connected with the wheel disc and used for driving the wheel disc to rotate; and a water inlet pipe fixedly arranged and attached to the end face of one side of the wheel disc. Water can be injected into the flow channel when the water inlet pipe is aligned with the flow channel, and the hydrodynamic cavitation generation device is good in cavitation effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

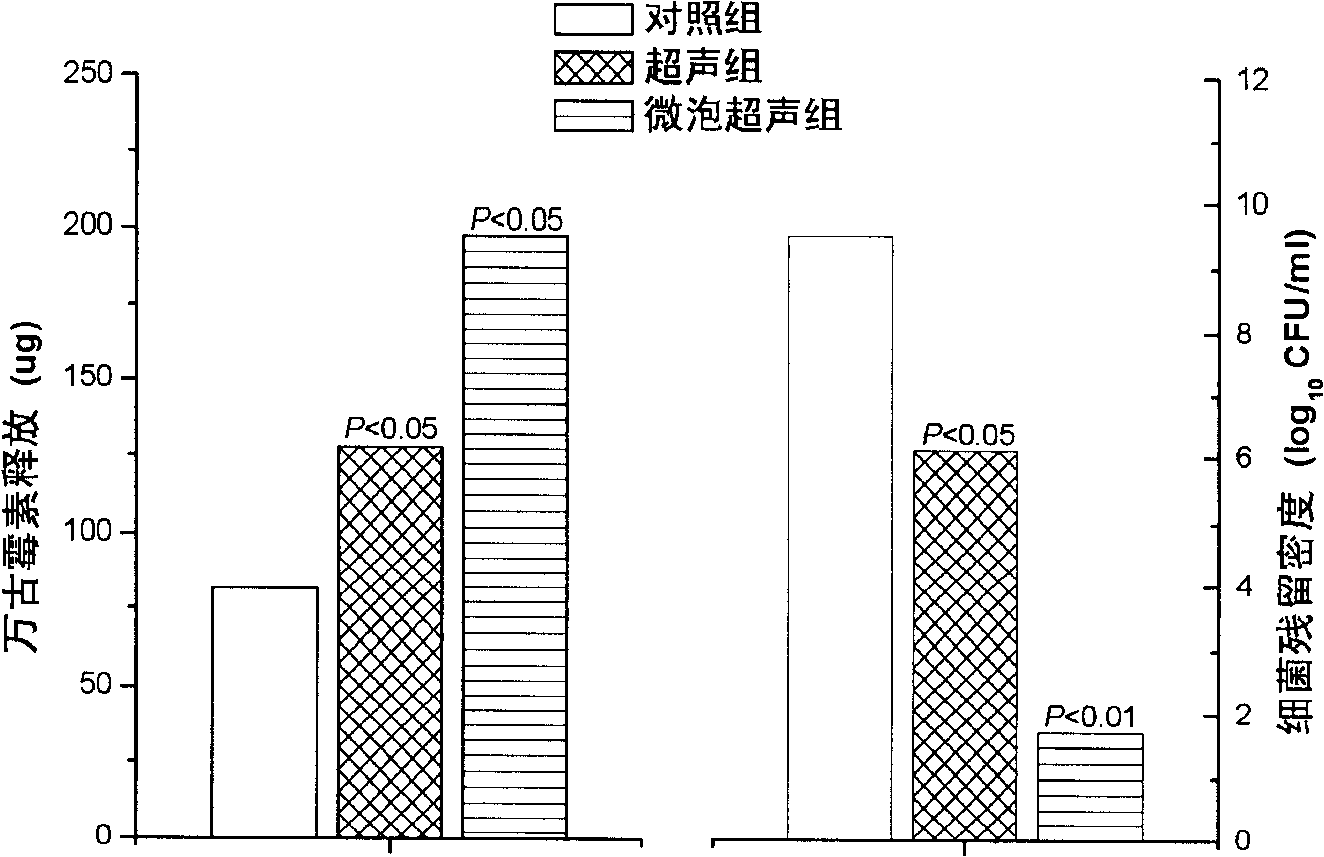

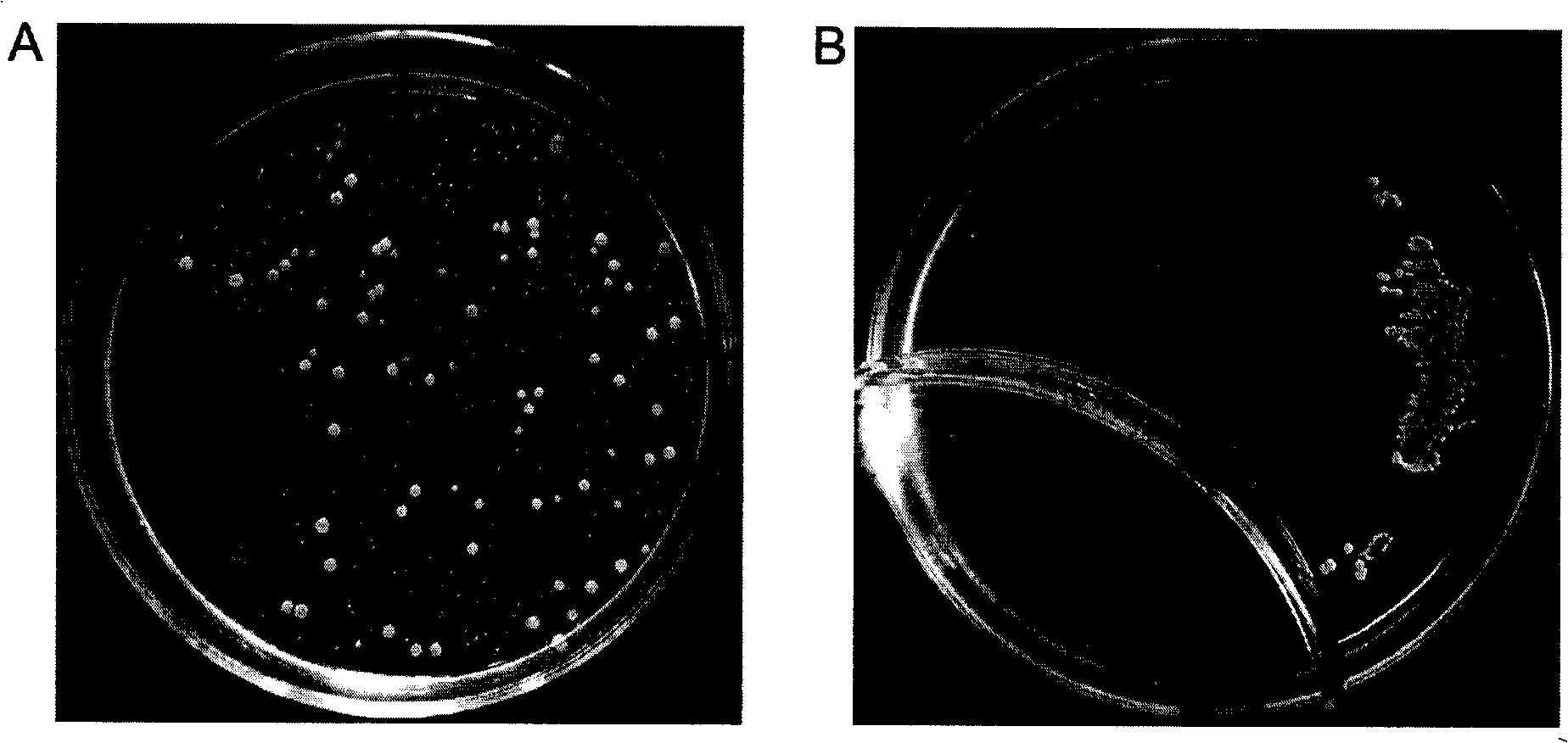

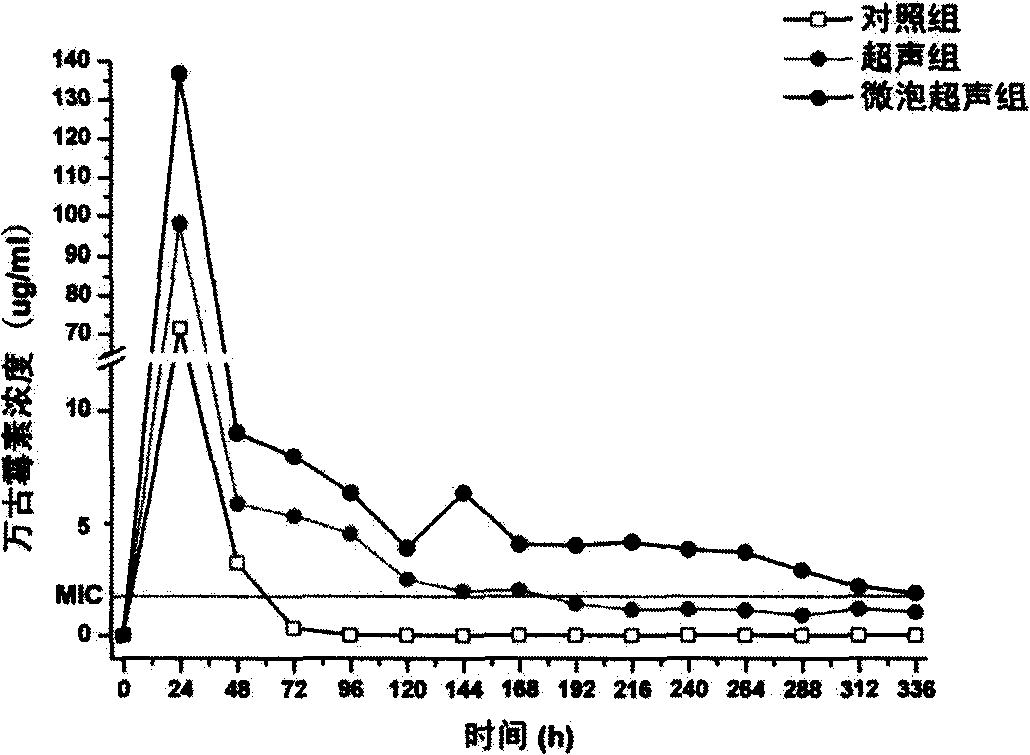

Method for promoting topical drug release on bone cement carried with antibiotics

InactiveCN101288781BGive full play to the antibacterial effectHigh speedProsthesisMicro bubbleAntibiotic Y

The present invention provides a releasing method for promoting antibiotics loading bone cement local drug. The acrylic acid bone cement of loading antibiotics is put in a volume bottle containing phosphate buffer liquid. Micro bubble agent is injected. An ultrasonic probe is arranged at the bottom of the volume bottle. An ultrasonic generation device is started. The ultrasonic frequency is 20-100 KHz, and the space average time strength is 20mW / cm<2>-3W / cm<2>. The model includes a continuous type and a pulse type. The duty cycle is 20 to 100 percent. The modulation pulse frequency is 1Hz-10 KHz. The method can promote the releasing speed and the total amount of the antibiotics loading bone cement drug and maintain for a certain time, can effectively prevent the formation of pellicle, can enhance the sensitivity of bacteria to the antibiotics, can effectively prevent the adhesion of the bacteria and secrete the pellicle, thereby improving the antibacterial effect of the antibiotics loading bone cement and expanding the application range of the antibiotics loading bone cement.

Owner:ZHEJIANG UNIV

Antibiotic wastewater deep degradation device based on hydrodynamic cavitation

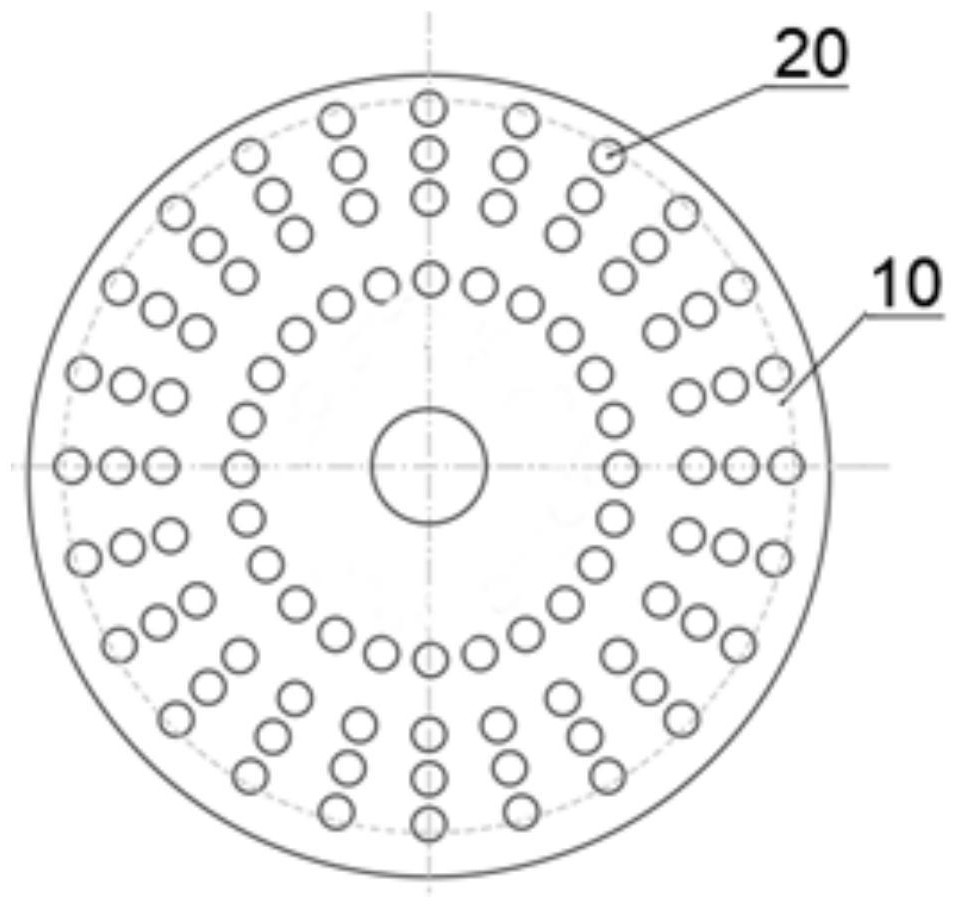

InactiveCN111807497AAchieve degradationBalance axial forceWater treatment compoundsWater contaminantsEnvironmental engineeringOrganic matter

The invention provides an antibiotic wastewater deep degradation device based on hydrodynamic cavitation. The device comprises a stator and rotors, the stator is a hollow sealed cylinder, and rotatingshafts are installed at the two ends of the interior of the stator; a plurality of rotors are mounted on each rotating shaft and are of wheel disc structures; the two rotating shafts rotate oppositely in opposite directions; blind holes are distributed in the end surface of the rotors and the inner wall of the stator; cavitation grooves are formed in the circumferential direction of the rotors; amicro gap formed by the blind holes, the cavitation grooves, the rotor wall surface and the stator wall surface forms a current limiting structure so that a current limiting effect is achieved, and the cavitation phenomenon is enhanced; one end of the stator is provided with a feeding pipe, and the other end is provided with a discharging pipe. The two rotors rotate at a relatively high speed sothat cavitation holes in the rotors move relative to the antibiotic wastewater, and the cavitation phenomenon is caused. The method adopts hydrodynamic cavitation to degrade organic matters in the antibiotic wastewater, has the advantages of high efficiency, good magnification, large treatment capacity, continuous operation, low cost and no secondary pollution, and has wide application prospects in the field of wastewater degradation.

Owner:SHANDONG UNIV

Variable and controllable cavitator

PendingCN110538626AReduce the effective volumeFavorable collapseChemical/physical/physico-chemical stationary reactorsWatercraft hull designCavitationSlide plate

The invention relates to a variable and controllable cavitator, which comprises a large jar body and a small jar body, wherein the small jar body is located on the right side of the large jar body, and is communicated to the large jar body, the left port of the large jar body is covered with a large jar end cover, the right port of the small jar body is covered with a right end cover, the right end of the small jar body is connected to a fluid inlet, the right end of the large jar body is connected to a fluid outlet, the left port of the small jar body is provided with a flow intercepting cone, a flow passing throat port is arranged along the axis of the flow intercepting cone, a sliding plate capable of axially sliding along the inner wall of the large jar body is arranged on the middle section of the inner cavity of the large jar body, the left side of the large jar end cover is connected to an end cover box, a piston is arranged in the center hole of the large jar end cover, is driven by a screw rod sleeve, and is connected to the sliding plate through a connecting cylinder, a screw rod shaft is screwed in the screw rod sleeve, a jet cone is fixed on the right end head of the screw rod shaft, and is inserted into the flow passing throat port of the flow intercepting cone, and a fixed pore plate is arranged on the right end of the flow intercepting cone, and is provided withan adjustable center hole and peripheral holes. According to the present invention, the cavitator can achieve multiple cavitation modes, and has characteristics of high raw material adaptability and good cavitation effect.

Owner:MYANDE GRP CO LTD

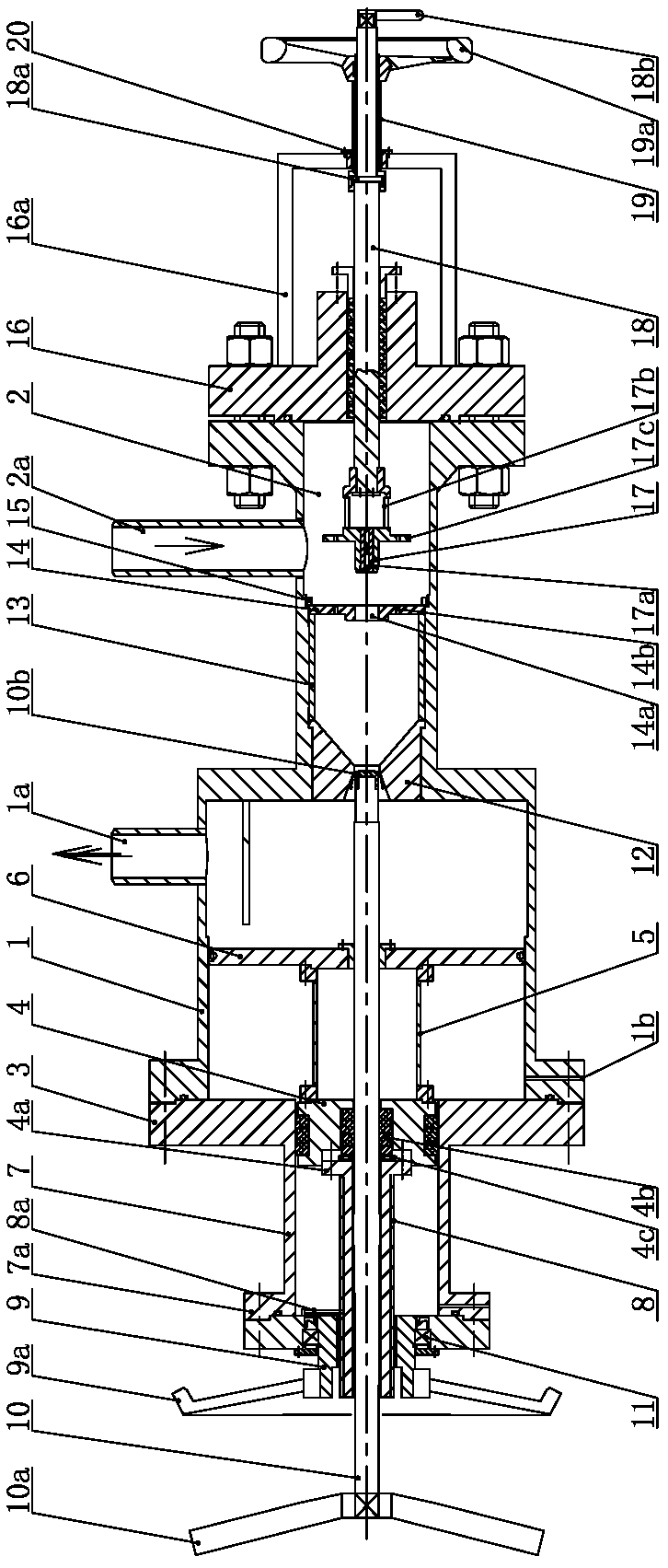

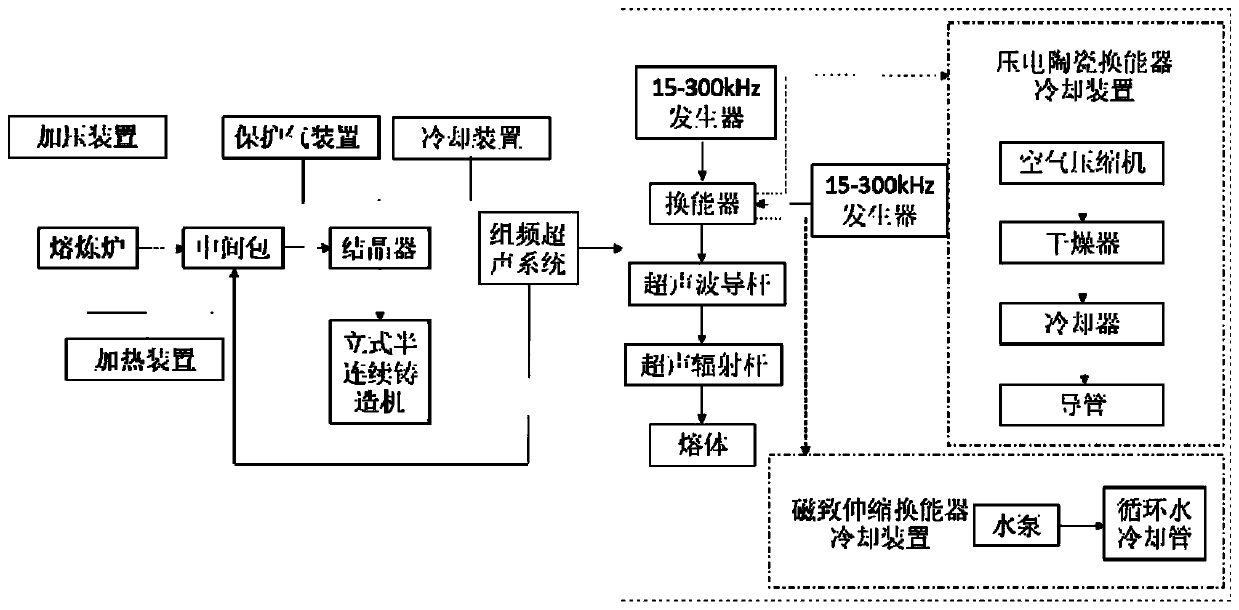

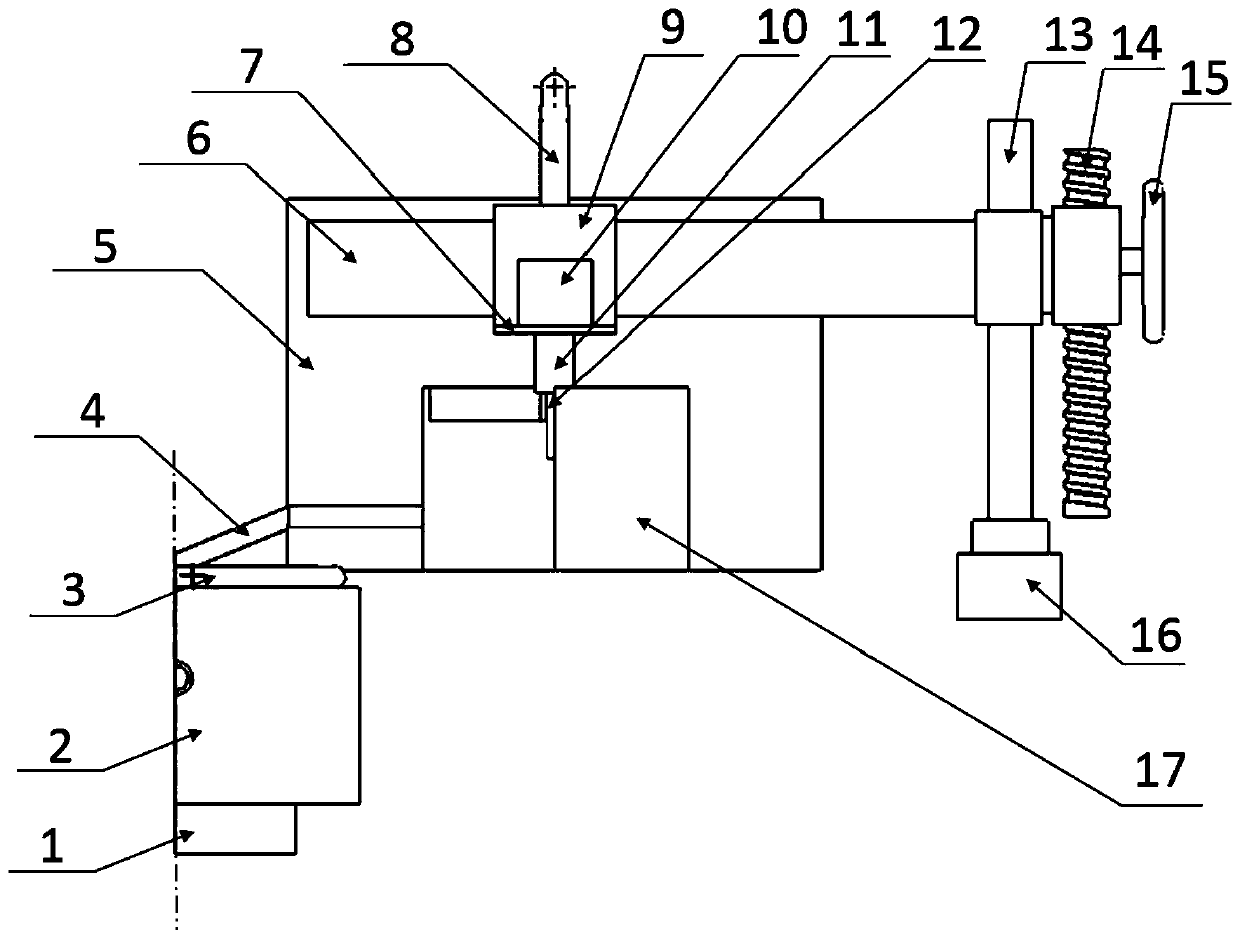

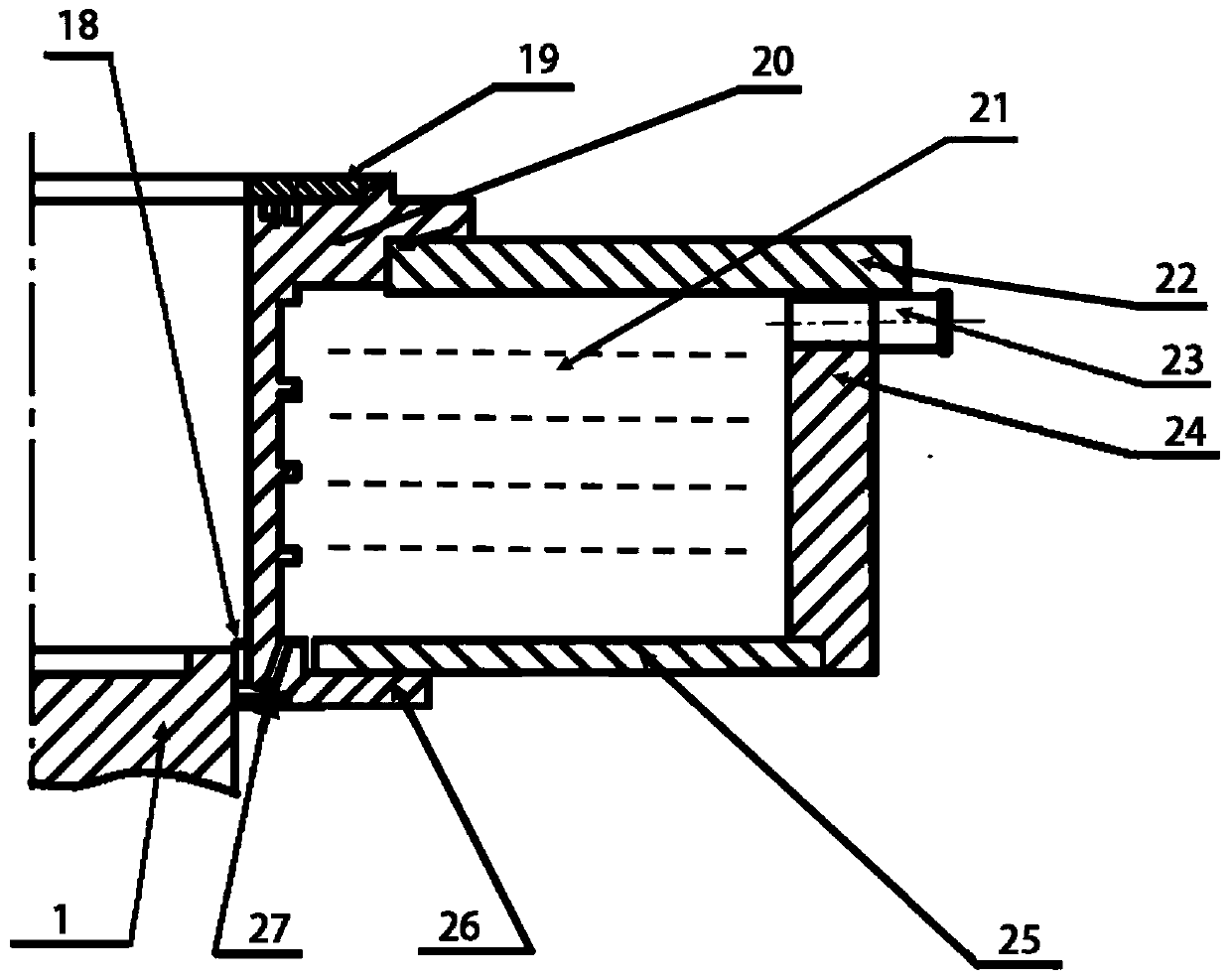

Device and method for applying group frequency ultrasounds to conduct magnesium alloy semi-continuous casting

ActiveCN110216251AReduce lossImplement nonlinear superpositionMelt-holding vesselsUltrasound attenuationCavitation

The invention discloses a device and method for applying group frequency ultrasounds to conduct magnesium alloy semi-continuous casting. The device comprises a tundish, a first ultrasonic generation device is fixed to the side wall or a bottom plate of the tundish, a second ultrasonic generation device is arranged in the tundish, and the front end faces of ultrasonic radiation rods of the two ultrasonic generation devices are located in the tundish. The method includes the steps that firstly, magnesium alloy melt is smelted; secondly, the tundish, a liquid moving pipe and the two ultrasonic radiation rods are preheated; thirdly, the refined magnesium alloy melt is conveyed to the tundish, two ultrasonic generators are started, ultrasonic waves are transmitted through the two ultrasonic radiation rods, and group frequency ultrasonic waves are formed and are applied to the magnesium alloy melt; fourthly, a crystallizer is started; and fifthly, after the group frequency ultrasonic waves are applied, a flow control valve is opened, and the magnesium alloy melt enters the crystallizer to conduct semi-continuous casting. By means of the device and the method, nonlinear overlapping of sound waves in the melt is achieved, the limitation brought by the problems of frequency drifting, sound pressure attenuation and the like are overcome, the cavitation acting range is enlarged, and the cavitation strength is improved.

Owner:NORTHEASTERN UNIV

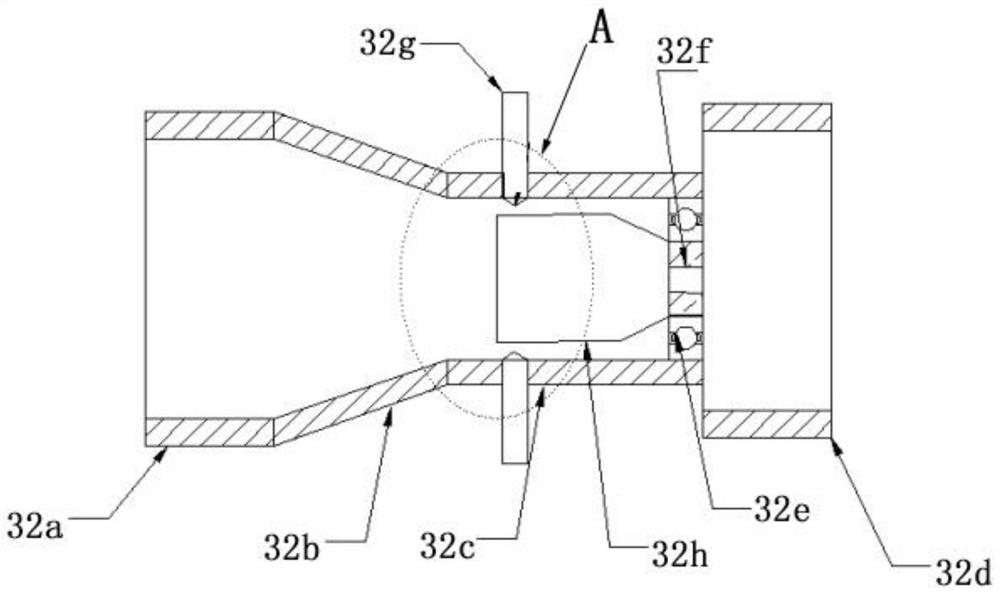

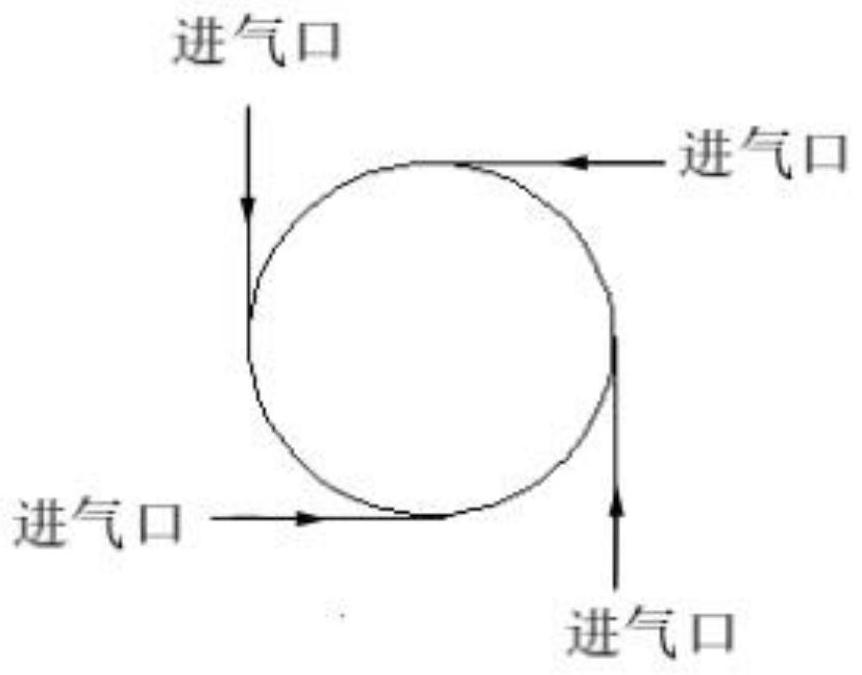

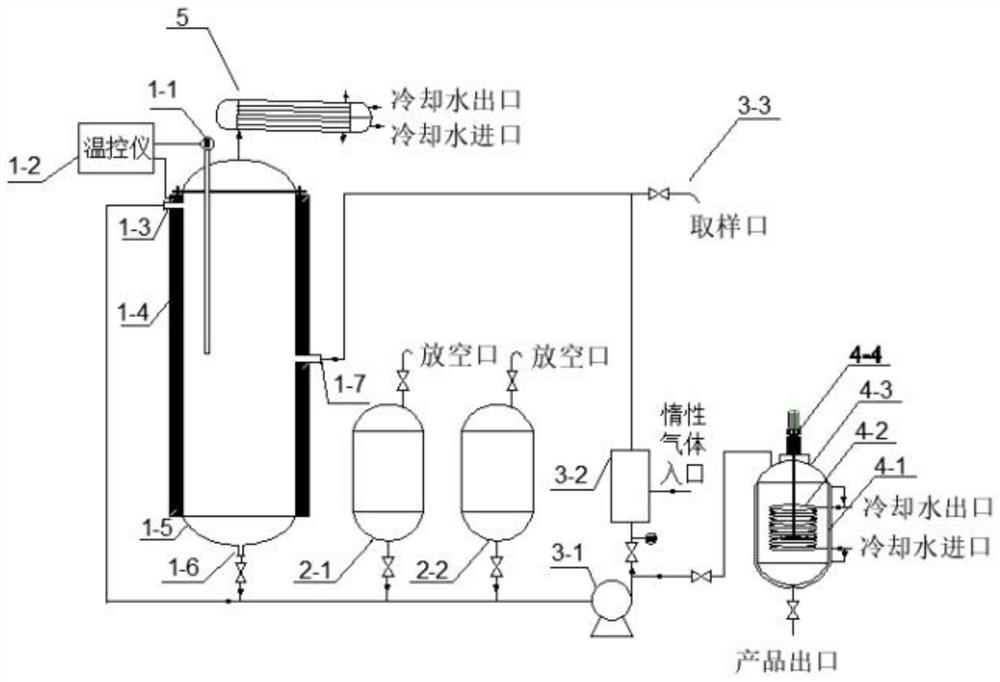

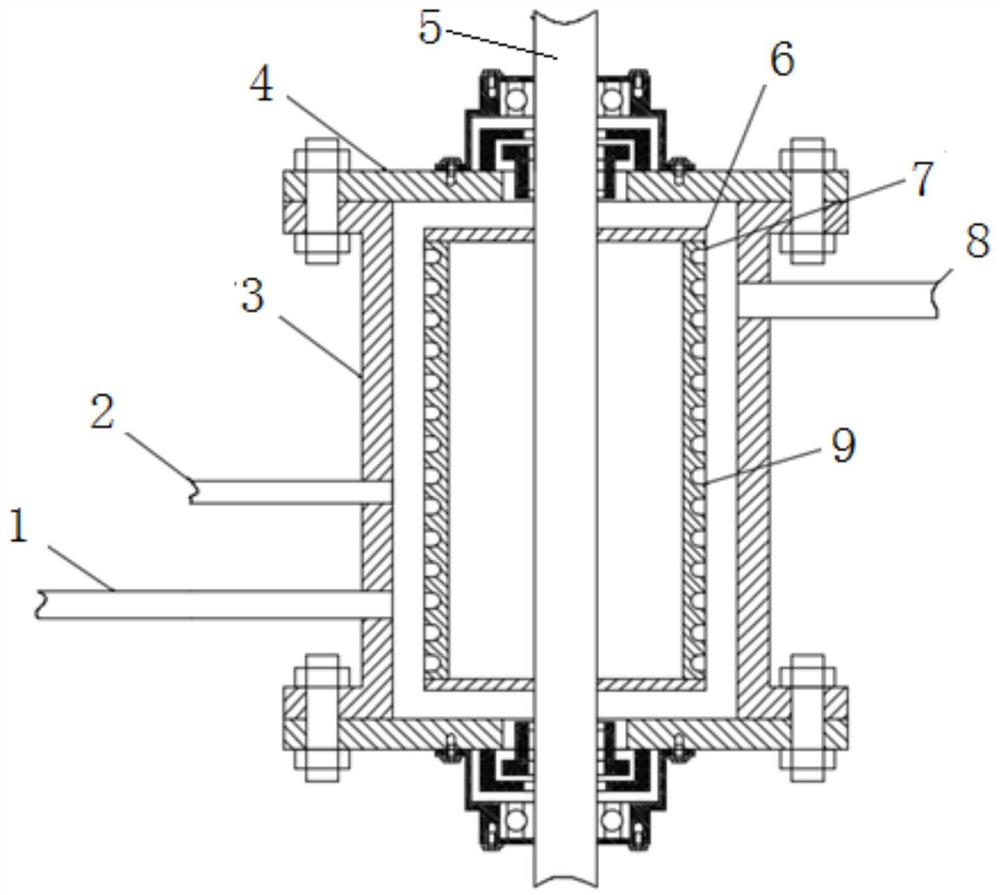

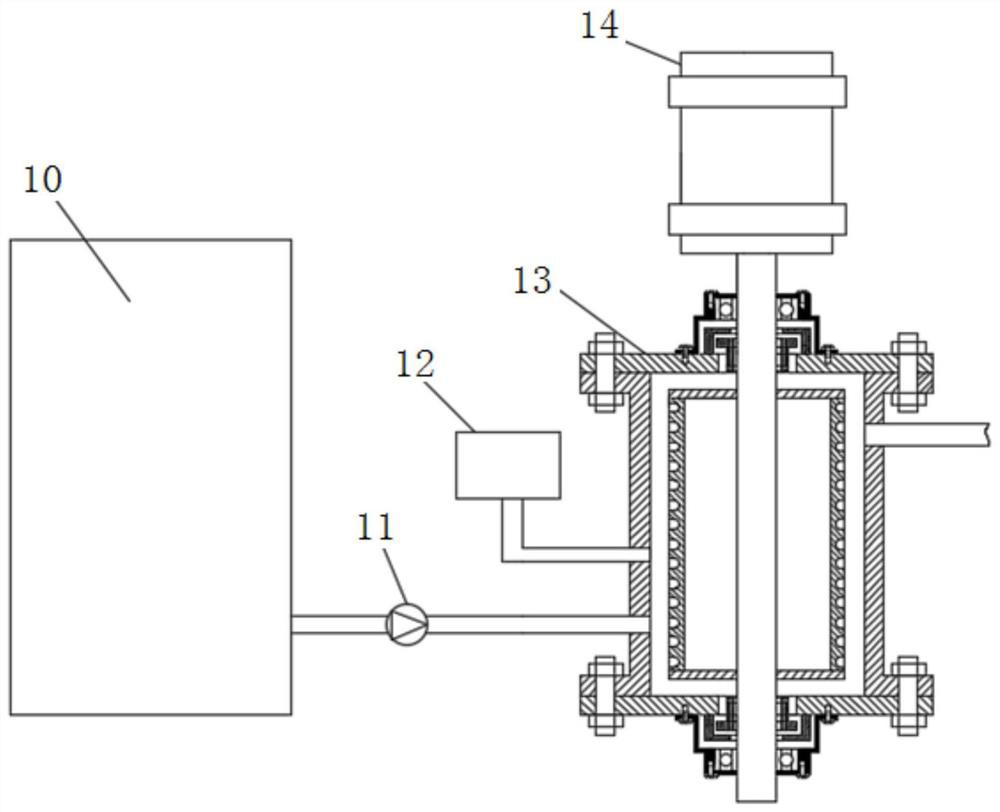

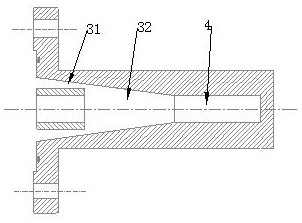

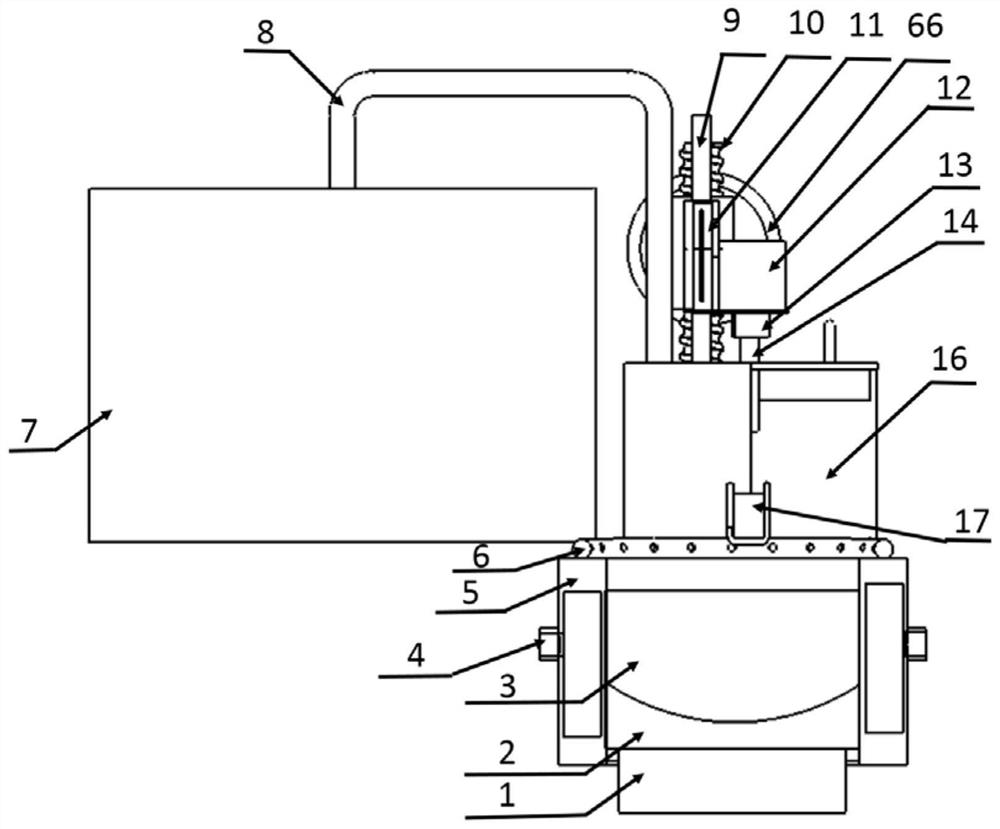

Method and device for preparing monoglyceride based on hydrodynamic cavitation intensification,

ActiveCN111992157AFree from high temperature oxidationImprove cavitation strengthFatty acid esterificationFlow mixersPhysicsMonoglyceride

The invention discloses a method and device for preparing monoglyceride based on hydrodynamic cavitation intensification. The device comprises a reaction kettle, a cavitation pump and a cavitator; a liquid outlet of the reaction kettle is connected with a liquid inlet of the reaction kettle by a pipeline through the cavitation pump and the cavitator in sequence to form a circulation loop; the cavitator is a composite device comprising a venturi tube, a rotary porous cavitation plate and a rotary blade; the rotary porous cavitation plate is installed at the position, close to the outlet, of theinner wall of the throat of the venturi tube, and a plurality of open holes are formed in the rotary porous cavitation plate; the rotary blade is arranged on the side, facing an inlet of the venturitube throat, of the rotary porous cavitation plate; and a plurality of air inlet pipes are evenly arranged on the outer wall, close to the inlet end, of the venturi tube throat at intervals. Accordingto the cavitator disclosed by the invention, the cavitation, mixing and reaction effects can be further improved by introducing inert gas, and the activation energy of the reaction is reduced, so that the reaction temperature is reduced, the catalyst consumption is reduced, and the reaction time is shortened.

Owner:ZHEJIANG UNIV OF TECH

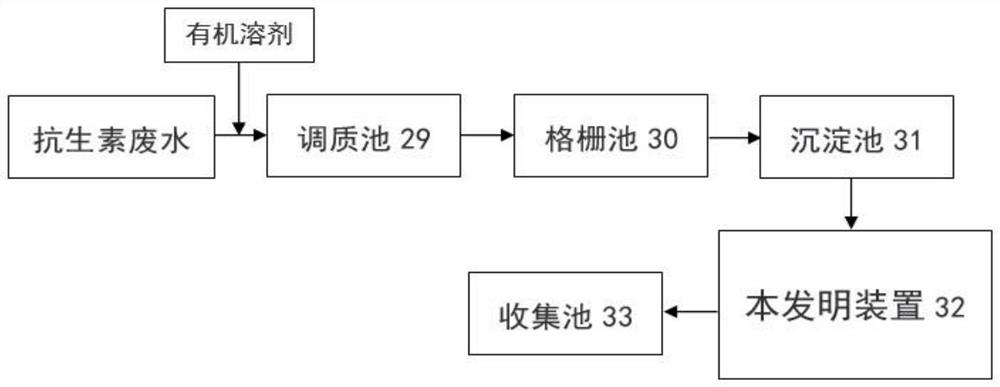

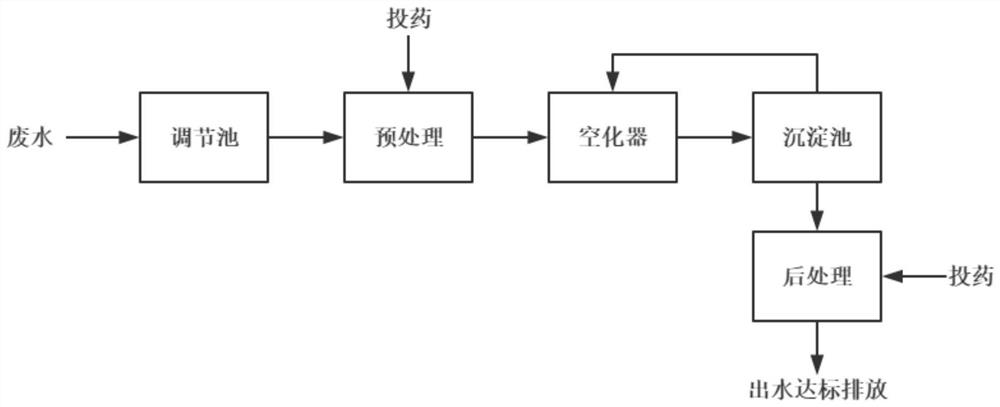

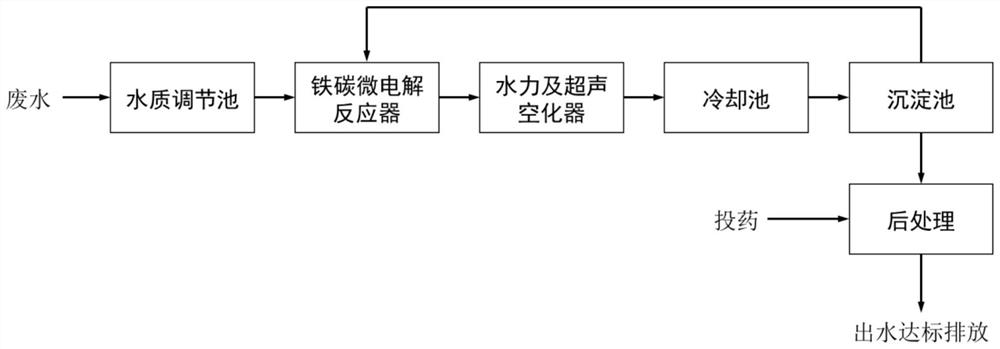

Antibiotic wastewater degradation method and device based on combined action of electrolysis and cavitation

InactiveCN111807583APromote degradationImprove efficiencyWater treatment compoundsWater contaminantsUltrasonic cavitationElectrolysis

The invention discloses an antibiotic wastewater degradation method and device based on the combined action of electrolysis and cavitation. The method comprises the following steps: (1) wastewater homogenization treatment; (2) carrying out iron-carbon micro-electrolysis reaction, and carrying out catalytic pretreatment on the antibiotic wastewater; (3) carrying out hydraulic and ultrasonic cavitation degradation to degrade antibiotics; (4) cooling and precipitating; (5) post-treatment; the device comprises an iron-carbon micro-electrolysis reactor and a hydraulic and ultrasonic cavitator, wherein a water outlet of the iron-carbon micro-electrolysis reactor is connected with a wastewater inlet of the hydraulic and ultrasonic cavitator. According to the method, the antibiotic wastewater is degraded by utilizing a method of combining iron-carbon micro-electrolysis pretreatment and hydraulic power and ultrasonic cavitation; compared with a single method, a better degradation effect and higher degradation efficiency can be obtained, secondary pollution caused by adding chemicals is avoided, the whole degradation process of the antibiotic wastewater is simplified, the structure is simple, maintenance is convenient, the energy utilization rate is greatly increased, and industrialization is easy to achieve.

Owner:SHANDONG UNIV

Hydrodynamic cavitation and electrocatalysis integrated antibiotic wastewater degradation device

InactiveCN111807499AEffectiveZero dischargeWater treatment compoundsWater contaminantsEngineeringMechanical engineering

The invention provides a hydrodynamic cavitation and electrocatalysis integrated antibiotic wastewater degradation device which comprises a rotor and a stator, the stator is a hollow sealed cylinder,and an electrode is arranged on the inner wall of the stator; the rotor is arranged in the stator and is of a multi-layer cylinder structure, and annular cutting grooves are distributed in the surfaceof the rotor. The rotor is fixedly connected to the rotating shaft, the rotating shaft penetrates through the stator and the rotor in the stator, and the stator and the rotating shaft rotate synchronously. Cavitation holes are formed in the end faces of all layers of the rotor; and a water outlet pipe is arranged at the other end of the stator. According to the device, an annular-like multilayerreaction cavity is formed through the annular cutting grooves; the space is fully utilized to obtain higher cavitation intensity; an electrocatalysis process is coupled to form an integrated rotary hydrodynamic cavitation reactor, and hydrodynamic cavitation is combined with electrocatalysis to degrade antibiotics so that the number of required electrodes is reduced, cavitation and electrocatalysis are ensured to effectively act on antibiotic wastewater, the treatment effect is good, the treatment capacity is large, continuous operation can be realized, and secondary pollution is avoided.

Owner:SHANDONG UNIV

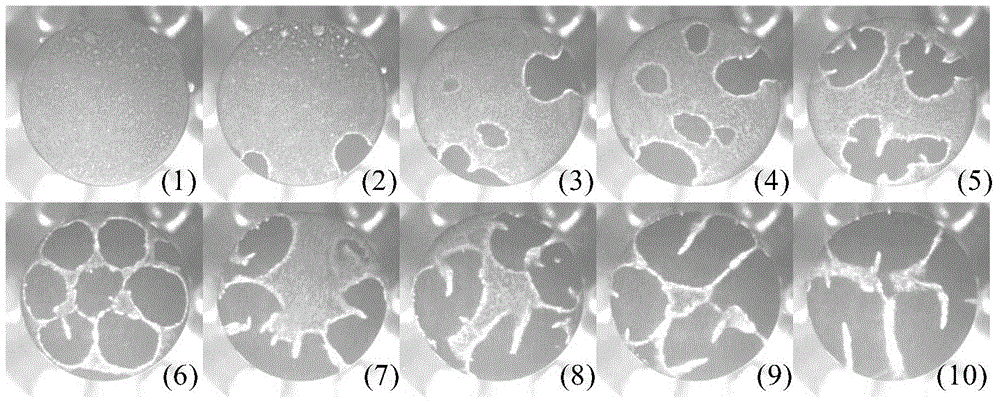

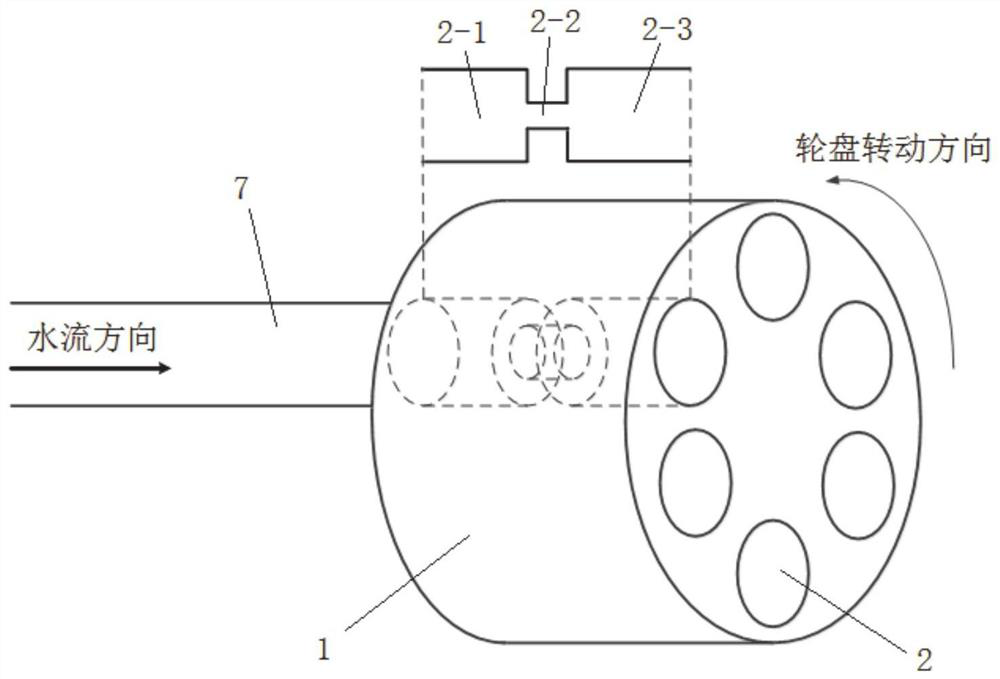

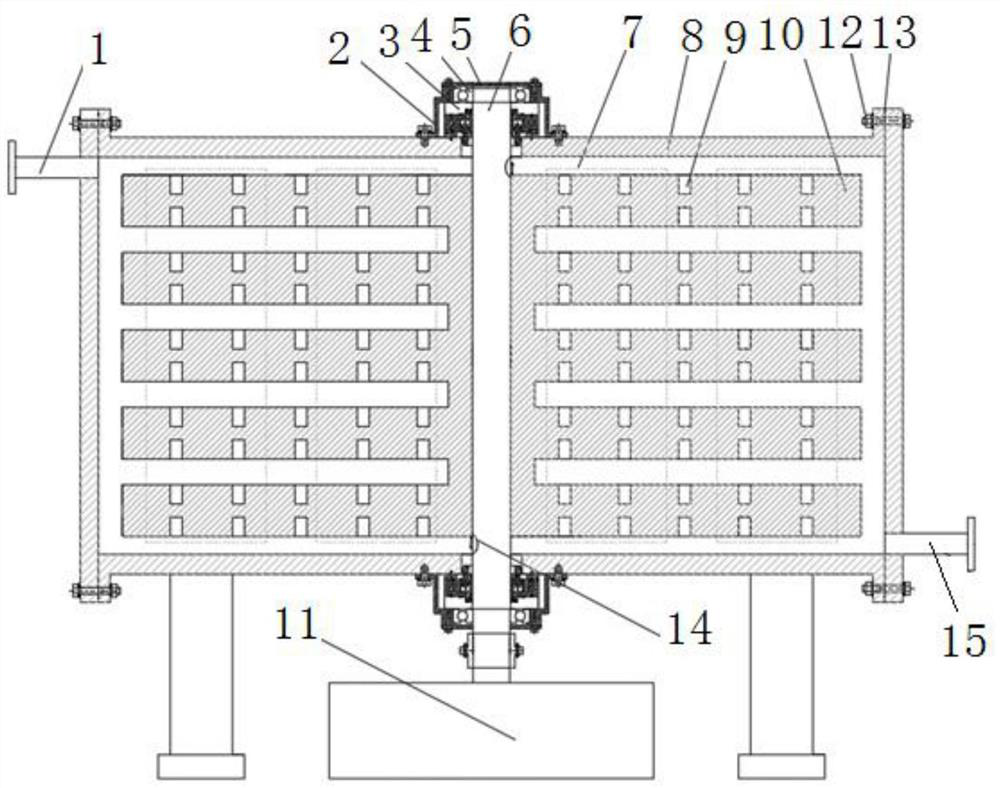

Antibiotic wastewater degradation device combining hydrodynamic cavitation and biological method

InactiveCN111807644ALarge amount of processingImprove efficiencyWater treatment compoundsWater contaminantsEnvironmental engineeringBiology

An antibiotic wastewater degradation device combining hydrodynamic cavitation and a biological method is disclosed and comprises a UASB reactor and a hydrodynamic cavitator, a water outlet of the UASBreactor is connected with a wastewater inlet pipe of the hydrodynamic cavitator, the hydrodynamic cavitator comprises two wheel discs and a stator, the stator is a sealed cylinder, the two wheel discs are both arranged in the stator, each wheel disc is fixedly connected to a rotating shaft, the two rotating shafts are installed at the two ends of the stator respectively and extend out of the stator, and the rotating directions of the two wheel discs are opposite. Wheel disc cavitation holes are distributed in the outer wall of the wheel disc, and stator cavitation holes are distributed in theinner wall of the stator. One end of the stator is provided with a wastewater inlet pipe, and the other end is provided with a liquid outlet pipe, and the cavitation holes form a current limiting structure under a tiny gap between the stator and the rotor, so that the cavitation phenomenon is enhanced. The device degrades antibiotic wastewater by coupling hydraulic power and a biological method,and is efficient, good in magnification, large in treatment capacity, capable of continuously operating, low in cost and free of secondary pollution.

Owner:SHANDONG UNIV

A New Type of Rotating Liquid Whistle Cavitation Generator

ActiveCN109399755BEnhanced ultrasonic cavitation effectRealize temperature controlShaking/oscillating/vibrating mixersTransportation and packagingUltrasonic cavitationEngineering

The invention discloses a novel rotating liquid whistle cavitation generator, which comprises a coaxially arranged rotor and a casing, the rotor is arranged in the casing through a rotating shaft, one end of the casing is provided with a feed liquid inlet, and the other end of the casing is provided with a There is a feed liquid outlet, and a heat exchange interlayer is arranged outside the shell; several rows of primary reeds are arranged at intervals along the axial direction on the outer wall of the rotor, each row of primary reeds is arranged at intervals on the radially outer side of the rotor, and several Rows of secondary reeds, each row of secondary reeds are arranged at intervals on the radial inner side of the housing, primary reeds and secondary reeds are arranged alternately in the housing, under the action of the rotor and the primary reeds, The material liquid of primary ultrasonic cavitation flowing around the rotor hits the secondary reed, and secondary ultrasonic cavitation occurs. Through the two-stage reed structure of the present invention, the improvement of cavitation efficiency and cavitation intensity is realized, and the uniform temperature control of the liquid inside the casing is realized by providing a heat exchange interlayer outside the casing.

Owner:ZHEJIANG UNIV OF TECH

A method and device for preparing monoglyceride based on hydrodynamic cavitation enhancement

ActiveCN111992157BFree from high temperature oxidationImprove cavitation strengthFatty acid esterificationFlow mixersMonoglyceridePtru catalyst

The application discloses a method and device for preparing monoglyceride based on hydraulic cavitation enhancement. The device of the application includes a reactor, a cavitation pump and a cavitator, and the liquid outlet of the reactor passes through the cavitation pump and cavitation The liquid inlet of the reactor and the reactor is connected by a pipeline to form a circulation loop; the cavitator is a composite device including a Venturi tube, a rotating porous cavitation plate and a rotating blade, and the inner wall of the venturi throat is installed near the outlet to rotate The porous cavitation plate, the rotating porous cavitation plate is provided with a number of openings; the rotating blades are arranged on the side of the rotating porous cavitation plate facing the inlet of the throat of the Venturi tube, and the outer wall of the throat of the Venturi tube near the inlet end is evenly spaced There are several intake pipes. The cavitator of the present application can further improve cavitation, mixing and reaction effects through the introduction of inert gas, and reduce the activation energy of the reaction, thereby reducing the reaction temperature, reducing the amount of catalyst, and shortening the reaction time.

Owner:ZHEJIANG UNIV OF TECH

Device for treating antibiotic wastewater by combining hydrodynamic cavitation with oxidation

InactiveCN111825202ADeep degradation and high efficiencyNo pollution in the processWater treatment compoundsWater contaminantsProcess engineeringEnvironmental engineering

A device for treating antibiotic wastewater by combination of hydrodynamic cavitation and oxidation comprises a rotor, a stator and a center shaft; the stator is a closed cylinder, the rotor is a hollow cylinder, the rotor is arranged in the stator, and ball-column-shaped blind holes are distributed in the outer wall of the rotor; the center shaft is vertically mounted in the stator, penetrates through the stator and the rotor and is fixedly connected with the rotor, a wastewater inlet pipe is arranged at the upper part of the stator, and a wastewater outlet pipe is arranged at the bottom; andan oxidant adding pipe is arranged at the wastewater inlet pipe. Hydrogen peroxide is added into the antibiotic wastewater, the rotor rotates to cavitate the antibiotic wastewater, and the oxidant can degrade part of antibiotics, so that the removal efficiency is improved. The antibiotic wastewater is treated through combination of hydrodynamic cavitation and oxidation, the antibiotic removal rate is high, the effect is good, and secondary pollution is avoided.

Owner:SHANDONG UNIV

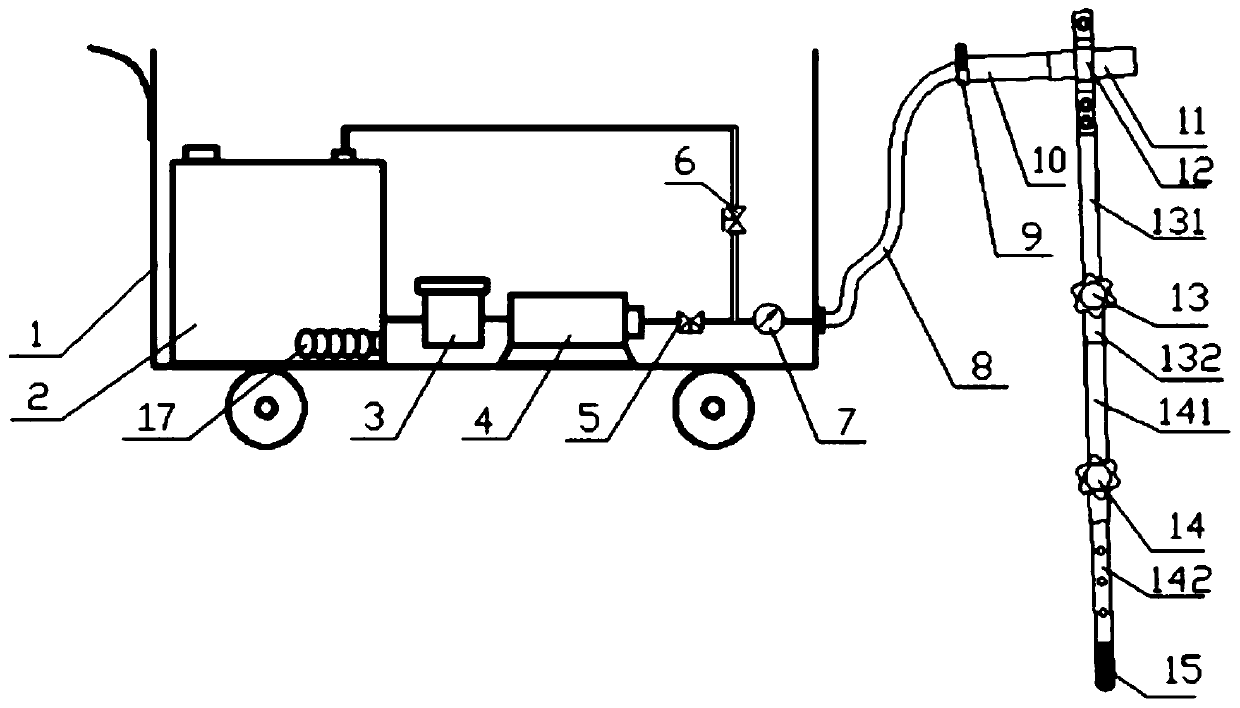

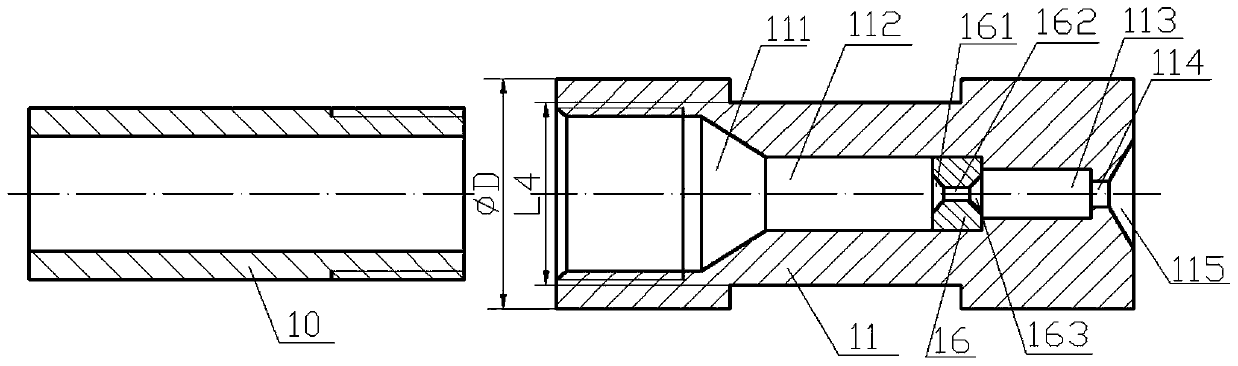

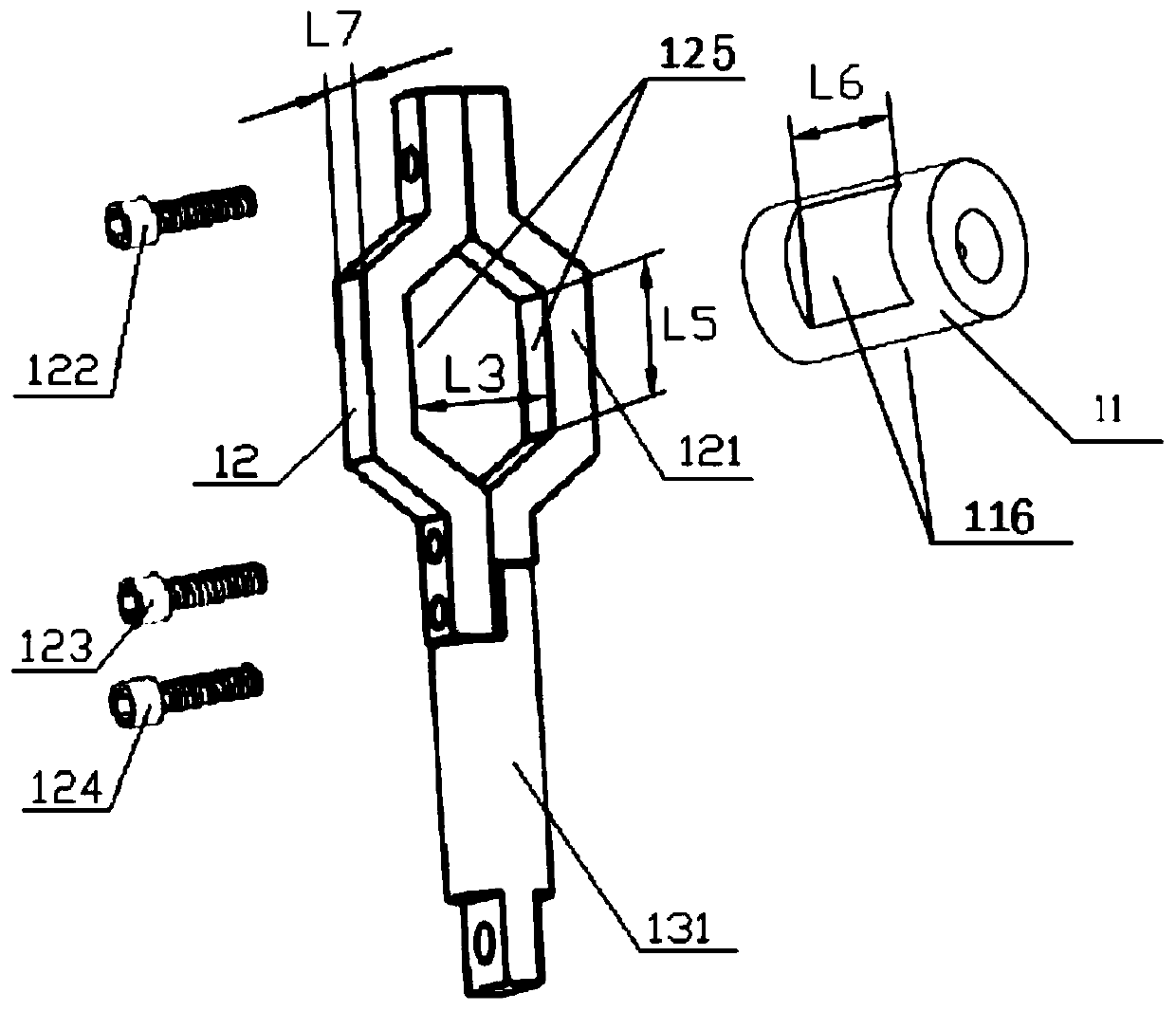

A domestic cavitation cleaner for high-altitude outdoor glass

Owner:JIANGSU UNIV

A Strong Shear Annular Jet Cavitation Generator

ActiveCN106669584BCollapse violentlyImprove cavitation strengthChemical/physical/physico-chemical nozzle-type rreactorsWorking fluidJet flow

The invention discloses a strong-shear annular jet cavitation generator, which comprises a high-pressure water supply pipe, a rectifier pipe, a tubular constriction section, a back pressure chamber and an outlet pipe, wherein the tubular constriction section can be further divided into an annular nozzle and a cavitation nozzle. room in two parts. The working fluid enters the rectifier pipe through the high-pressure water supply pipe, and then flows through the annular nozzle. After the pressure energy is converted into kinetic energy, it is ejected at a high speed at the outlet of the annular nozzle and injected into the cavitation chamber. Due to the diffusion of the jet and the hindrance of the back pressure chamber, The backflow of the working fluid occurs, and the backflow meets the high-speed jet in the cavitation chamber to generate a strong shearing effect, which induces severe cavitation. Then the cavitation flow flows through the cavitation chamber and the outlet pipe, the flow velocity decreases, the pressure increases, and the cavitation bubbles collapse under the action of higher pressure, resulting in local high temperature and high pressure, and the formation of shock waves and micro jets. The invention can realize strong shearing action, so that the cavitation intensity is higher and the cavitation effect is better. The invention has no moving parts, simple structure, easy processing and can be used on a large scale.

Owner:WUHAN UNIV

A kind of cavitation generator with special-shaped flow channel

ActiveCN111974237BIncreased turbulence intensityImprove cavitation strengthFlow mixersTransportation and packagingEngineeringMechanics

The invention discloses a cavitation generator with a special-shaped flow channel, which comprises an outer pipe, an inner pipe and a connecting block, the space between the outer pipe and the inner pipe is an annular flow passage, and the center of the inner pipe is a central flow passage; The outer tube and the inner tube form a whole double flow channel through a connecting block, and the whole double flow channel is printed by 3D printing technology; the central flow channel is composed of an inlet section, a tapering section, a holding section and a diverging section Composition, the cross-section of the central channel is an irregular polygon; the annular channel is a stepped channel along the axial direction and consists of two stages of deceleration chambers. The special-shaped flow channel adopted in the present invention can greatly enhance the turbulent flow intensity in the tapered section and the tapered section through exploration. In the tapered section, the fluid will squeeze from the dovetail-shaped part of the flow channel to the square part. Diffuse from the square part of the flow channel to the dovetail part, forming strong turbulence and eddies. The cavitation intensity is significantly enhanced, the required water supply pressure is significantly reduced, and it is more efficient and energy-saving.

Owner:DALIAN MARITIME UNIVERSITY

Ultrasonic extraction traditional Chinese medicine decocting machine

PendingCN114288184AImprove cavitation strengthIncrease solvent penetration and solvencyPharmaceutical product form changeSolid solvent extractionMedicinal herbsUltrasonic generator

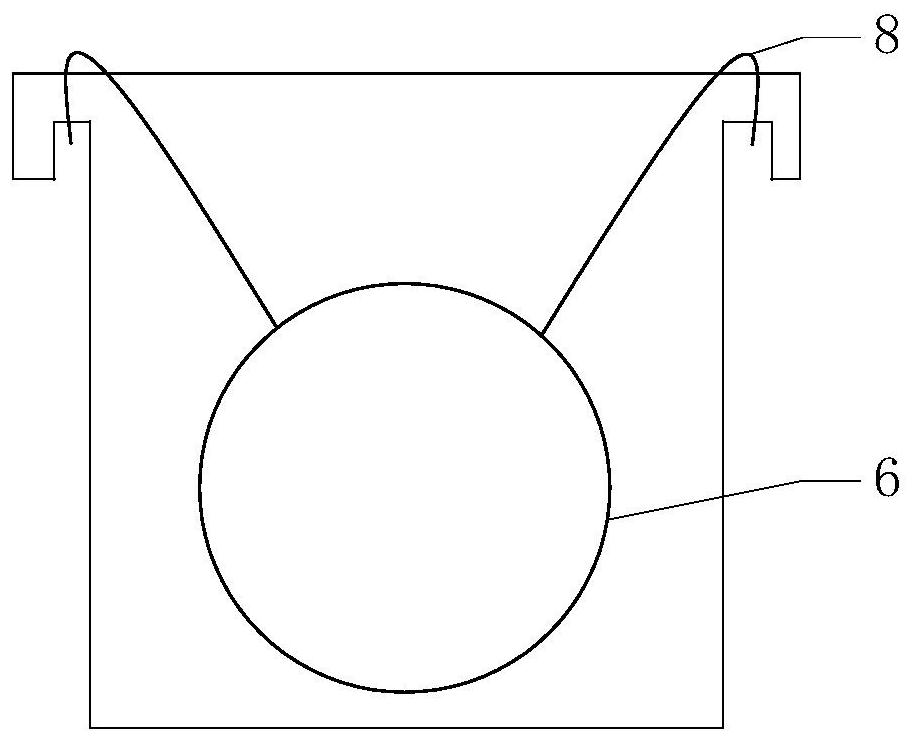

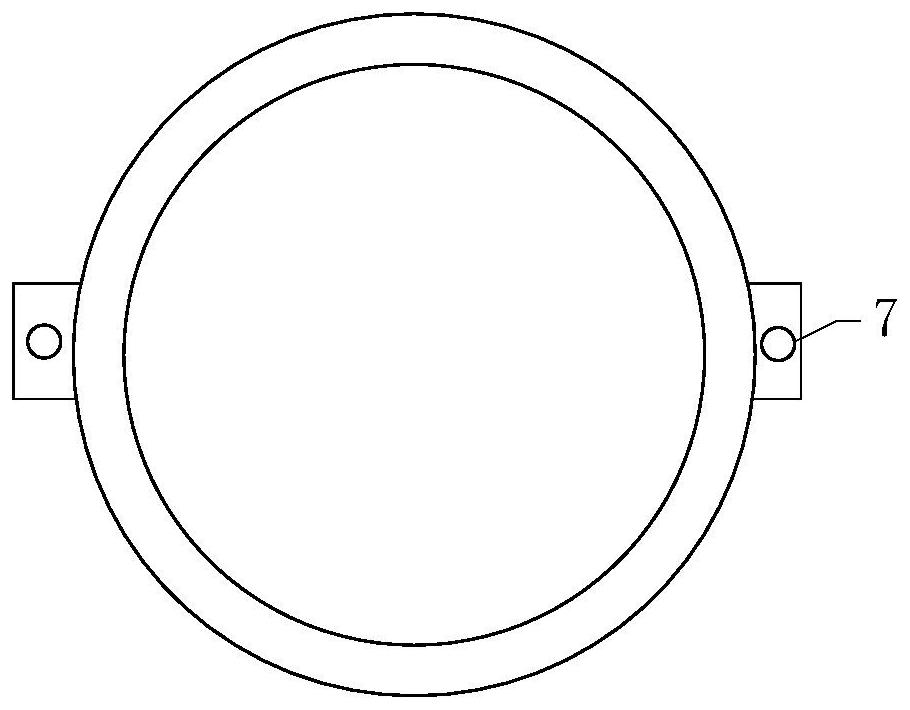

The invention discloses an ultrasonic extraction traditional Chinese medicine decocting machine which comprises a decocting barrel, a resonant cavity is formed in the bottom of the decocting barrel, and an ultrasonic vibrator connected with an ultrasonic generator is arranged below the resonant cavity; a split type medicine decocting ball is arranged in a medicine containing basket of the medicine decocting barrel, hooks correspondingly connected with through holes in hanging lugs on the two sides of the medicine containing basket are arranged on the two sides of the medicine decocting ball, and the hole diameter of the medicine containing basket is smaller than that of the medicine decocting ball. According to the ultrasonic extraction traditional Chinese medicine decocting machine, the ultrasonic extraction principle is applied, the resonant cavity is adopted, the cavitation intensity of ultrasonic waves is further enhanced, then the component analysis of medicinal materials is increased, the decocting time is shortened, and the efficacy of the medicinal materials is effectively improved.

Owner:苏增民

A semi-continuous casting device and method for group frequency ultrasonic magnesium alloy

ActiveCN110216250BGuaranteed temperatureImplement nonlinear superpositionMelt-holding vesselsMetallurgyUltrasonic radiation

A group-frequency ultrasonic magnesium alloy semi-continuous casting device and method, the device includes a tundish, and two ultrasonic generating devices are arranged in the tundish, and the front end surface of the ultrasonic radiation rod of the ultrasonic generating device is located in the tundish; the transducer and the supporting device Assembled together; the support device is a lifting support device or a variable angle support device; the method is: (1) smelting the magnesium alloy melt; (2) preheating the tundish, pipette and two ultrasonic radiation rods; inserting the ultrasonic radiation rod Tundish, or insert into the tundish after adjusting the angle; (3) The magnesium alloy melt is transported to the tundish; the ultrasonic generator is turned on, and the two ultrasonic radiation rods emit ultrasonic waves, which are combined to form a group frequency ultrasonic wave; (4) The crystallizer is turned on; (5) After applying group-frequency ultrasonic waves, the magnesium alloy melt in the tundish is transported to the crystallizer for semi-continuous casting. The device and method of the invention can enhance the nonlinear coupling of sound waves, improve the cavitation range and cavitation intensity of the melt, and obtain large-scale magnesium alloy ingots with uniform structure and excellent performance.

Owner:NORTHEASTERN UNIV LIAONING

An ultrasonic cavitation device

ActiveCN104138736BHigh space to volume ratioImprove cavitation strengthEnergy based chemical/physical/physico-chemical processesLiquid layerUltrasonic cavitation

The invention relates to an ultrasonic cavitation device, which comprises: a vibration body and a reflector, wherein a radiation surface is arranged at one end of the vibration body, and a liquid thin layer is formed between the radiation surface and the reflection body; the vibration body generates ultrasonic waves and enters through the radiation surface into the liquid thin layer, and form a sound field in the liquid thin layer; the reflector reflects the ultrasonic radiation radiated by the radiation surface, and the sound field in the liquid thin layer is strengthened through multiple reflections and superpositions of the reflector and the radiation surface ultrasonic waves, thereby A large cavitation cloud is formed that spreads laterally along a thin layer of liquid. In the ultrasonic cavitation device provided by the present invention, a reflective surface is arranged on the side of the transducer radiation surface, so that under a small input power, the sound field in the liquid thin layer is strengthened to form a large-area laterally spread cavitation cloud.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com