Patents

Literature

61results about How to "Strong cavitation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

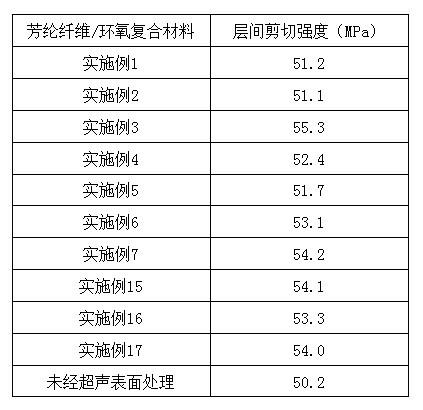

Ultrasonic surface modification treatment method for aramid fibers

InactiveCN102605606AImprove surface conditionQuality improvementFibre typesUltrasonic/sonic fibre treatmentPolymer scienceOrganic solvent

The invention provides an ultrasonic surface modification treatment method for aramid fibers. One or more amidic organic solvents in any proportion are selected as an ultrasonic treatment medium; under an ultrasonic action, fiber surfaces can be etched effectively by the amidic solvents; simultaneously, the sticking points among aramid fiber filaments can be reduced, and the state of the surfaces can be improved, so that the bonding strength between a resin and a fiber is increased; and meanwhile, the online treatment of the fibers is easy to realize by the ultrasonic treatment, and the time for modifying the fiber surfaces is shortened.

Owner:中蓝晨光化工有限公司

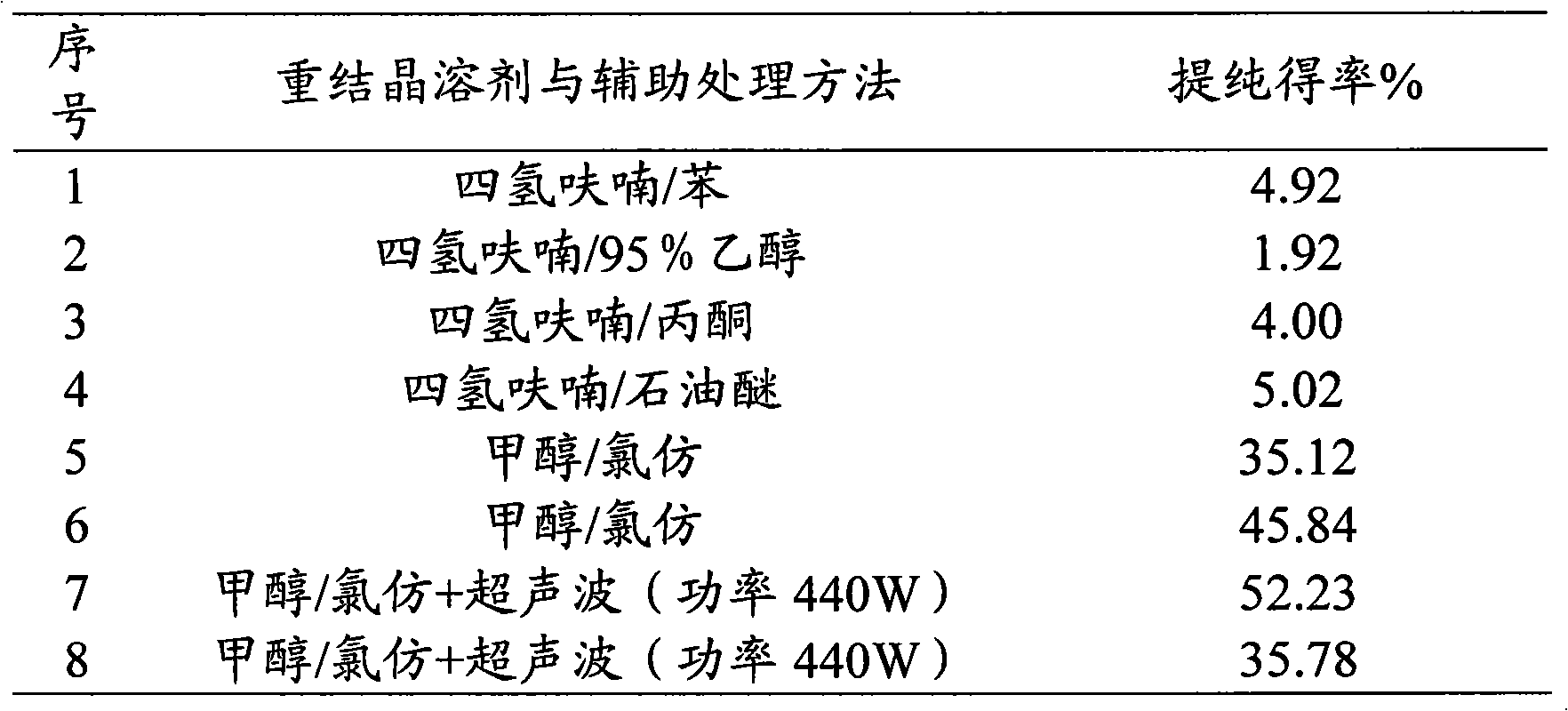

Method for extracting betulin from birch bark

The invention discloses a method for extracting betulin from birch barks, comprising the following steps: firstly, crushed birch barks are added into an ethanol water solution, undergo reflux extraction under auxiliary processing of ultrasonic waves, and then are filtrated for removal of residue, and an extract is obtained; secondly, solid powder is separated out after decompression and concentration of the extract, and then dried to the constant weight so as to obtain betulin coarse products; and thirdly, the betulin coarse products are added into an organic solvent, undergo ultrasonic treatment and then stand, crystals are separated out, and the betulin is obtained after the separated crystals are dried to the constant weight. The method has a simple operation flow, short extraction time, low production cost and high safety, and provides a better method and a better platform for further development and utilization of natural products.

Owner:ZHEJIANG UNIV

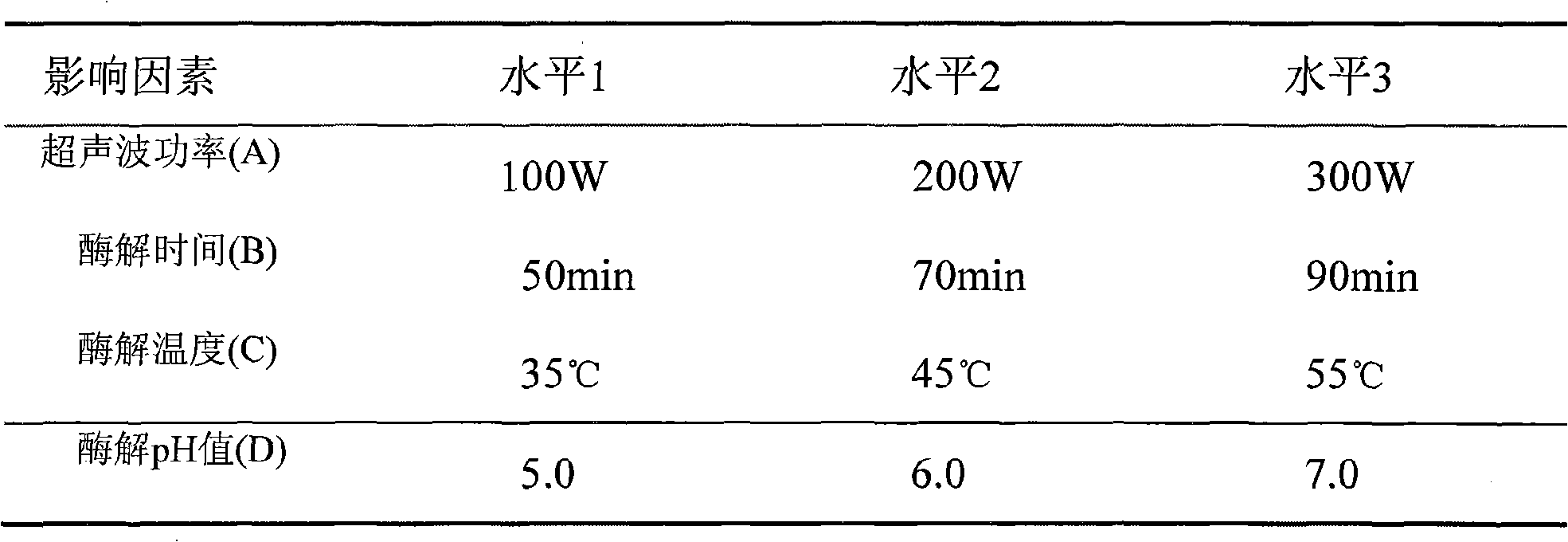

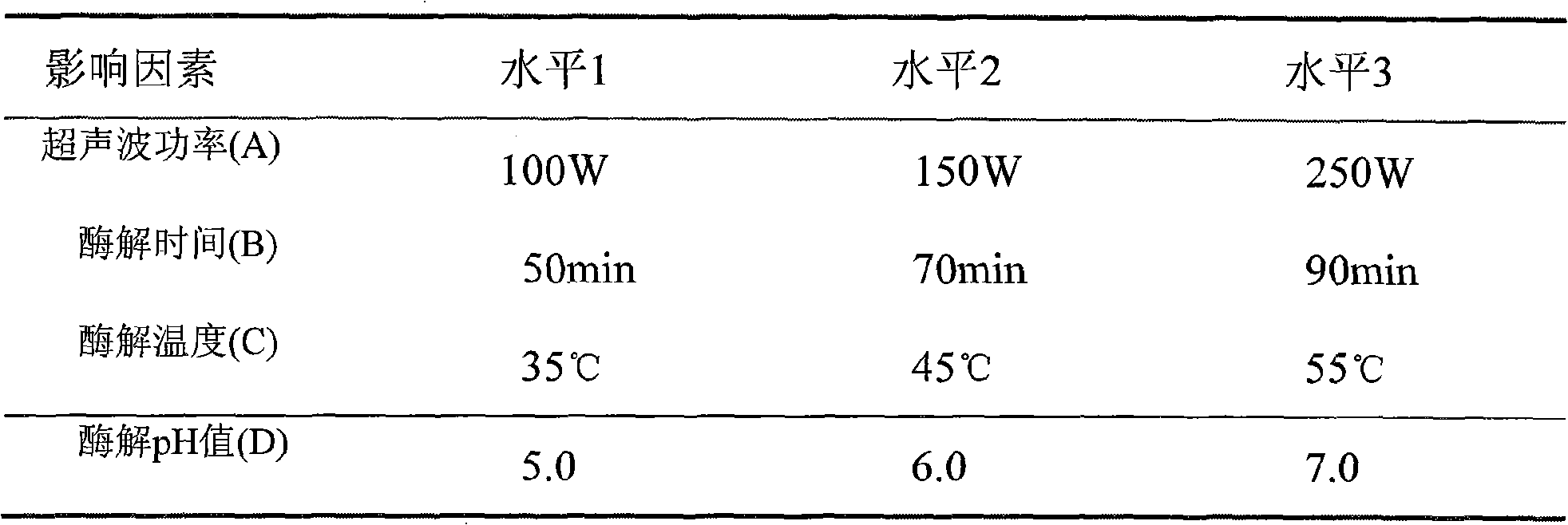

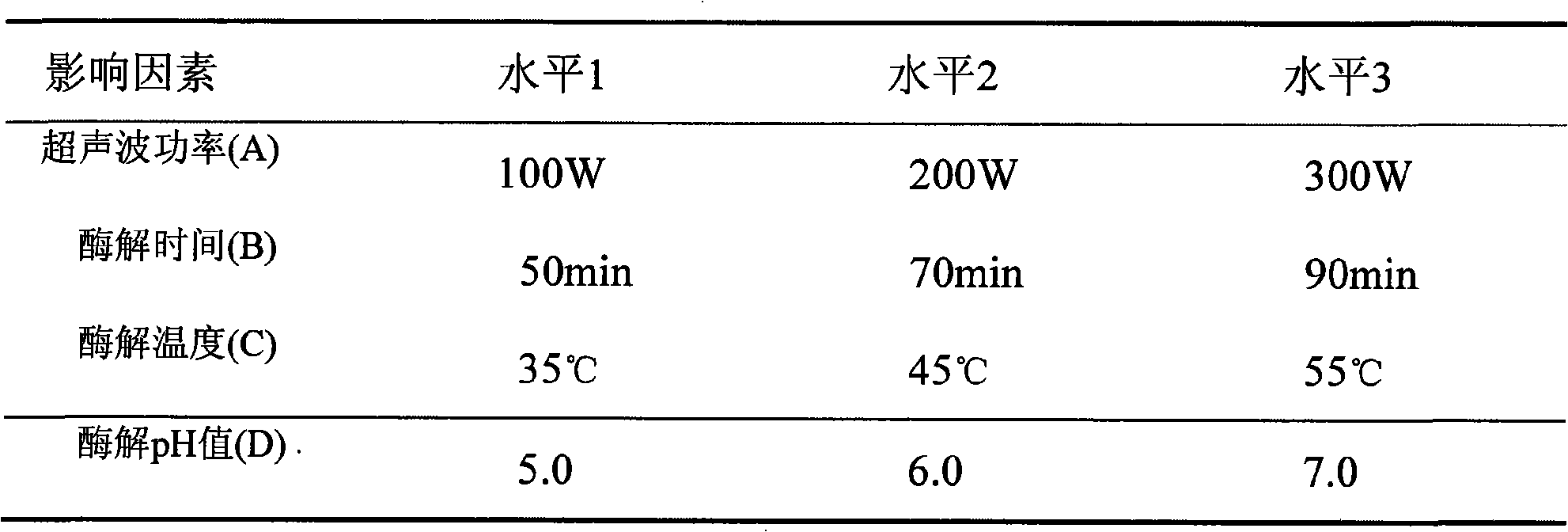

Technique for extracting polysaccharide in glossy ganoderma mycelium cell and method thereof

InactiveCN101560260ASpeed up entryStrong cavitation effectMetabolism disorderAntinoxious agentsLiquid ratioSubmerged fermentation

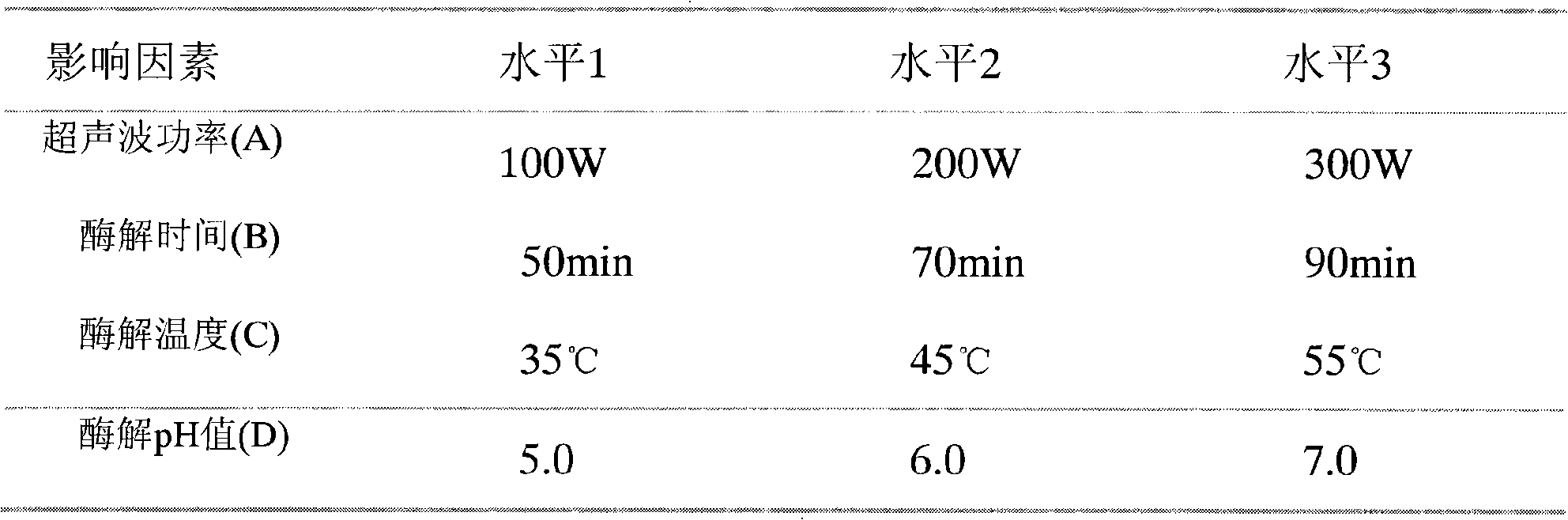

The invention relates to a technique combination for extracting polysaccharide in glossy ganoderma mycelium cell. According to the mass ratio, the solid-liquid ratio is 1:10-1:60, the adding quantity of complex enzyme is 0.5-5.0% of the mass of raw materials, the range of ultrasonic wave power is within 100-500W, the range of enzymolysis time is 40-100min, the range of enzymolysis temperature is 30-60 DEG C, and the pH value range of enzymolysis is 4.0-8.0. The technique for extracting polysaccharide in glossy ganoderma mycelium cell and the method thereof comprise: high quality mycelium is selected for submerged fermentation to obtain mycelium dry powder; the solid-liquid ratio is determined; the adding quantity of the complex enzyme is determined; and the optimum extraction technique combination for extracting the mycelium dry powder polysaccharide by using an ultrasonic wave-composite enzymolysis method is determined.

Owner:ZHEJIANG UNIV

Preparation method and use of ginkgo-leaf extract

The invention discloses a preparation method and an application of a ginkgo leaf extract, wherein the method comprises the following steps of: a) washing and then drying ginkgo leaves; b) crashing and sieving; c) soaking by ethanol; d) oscillating by a ultrasonic cell crasher; e) extracting and filtering; and f) condensing in vacuum and drying. The invention has the advantages of adopting an ultrasonic-assisted extraction method, utilizing the functions of strong vibration, extremely high acceleration, strong cultivation effect, even stirring and the like generated by ultrasonic waves, accelerating the entry of the medicament effective constituents into the solvent, simultaneously avoiding the effect of high temperature on extraction constituents and greatly improving the yield of the extract. In the extract, flavonoids accounts for 36 percent, ginkgo terpene lactones account for over 8 percent while the injurant phenolic acid is less than 3PPM, therefore, the product has high safety. The obtained Ginkgo leaf extract of 4 to 6g is added to each kilogram of feeding stuff, therefore, the animal immune anti-inflammatory action and the production property can be raised by more than 10 percent and 2 to 3 percent respectively.

Owner:曹阳春

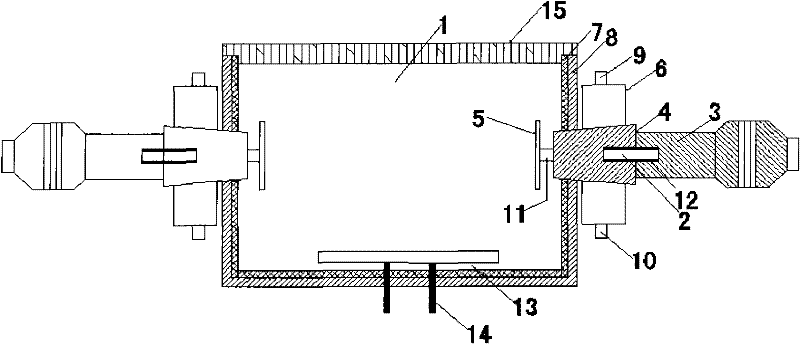

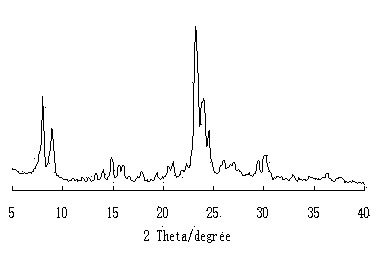

Preparation method of mesopore-micropore zeolite molecular sieve

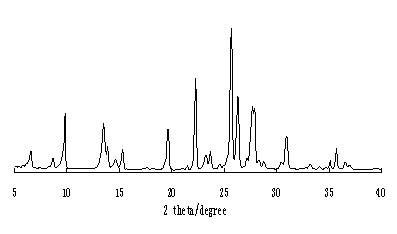

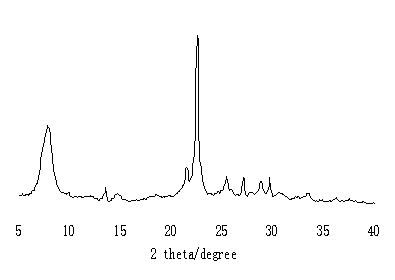

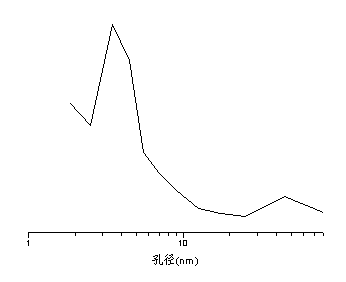

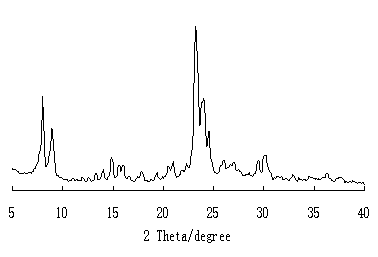

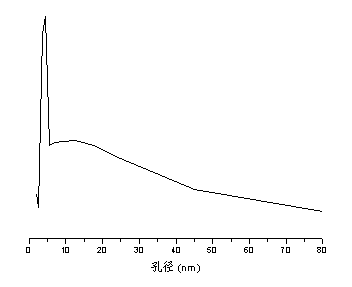

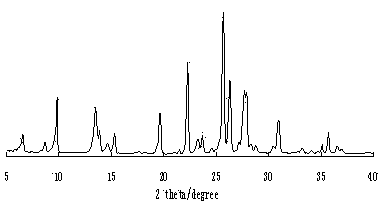

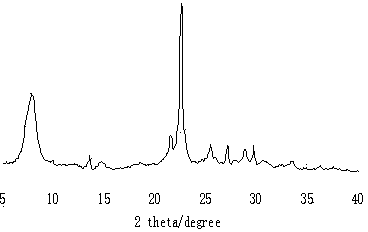

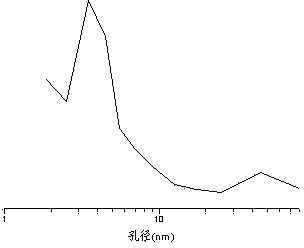

ActiveCN102874829AIncreased BET surface areaMesoporous structure intactCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

The invention discloses a preparation method of a mesopore-micropore zeolite molecular sieve, comprising the following steps of: firstly mixing micropore zeolite and aqueous alkali and carrying out ultrasonic treatment; then carrying out heat treatment on the micropore zeolite in an enclosed system in the presence of an organic solvent; and finally processing the micropore zeolite by the use of an acid solution. According to the method, supersonic wave can generate a cavitation effect so as to activate the micropore zeolite's framework silicon atom; during the alkali treatment, the addition of the organic solvent can promote the generation of a meso-structure so as to more efficiently convert the micropore structure to mesopores and simultaneously stabilize and protect the micropore structure; and acid treatment can reach the purpose of dredging pore canal and increasing total specific surface area. By the adoption of the method, more complete mircopores of the mesopore-micropore zeolite molecular sieve can be retained, more mresopores can be provided, and simultaneously the total BET specific surface area can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process combination for extracting polysaccharide in golden mushroom mycelium cells and determination method thereof

The invention relates to a process combination for extracting polysaccharide in golden mushroom mycelium cells. The solid-liquid ratio according to weight is 1: 10-1: 60, the adding amount of complex enzyme accounts for 0.5 percent to 5.0 percent of the weight of the raw materials, the range of ultrasonic power is 100w to 500w, the range of enzymolysis time is 40min to 100min, the range of enzymolysis temperature is 30 DEG C to 60 DEG C, and the range of enzymolysis pH value is 4.0 to 8.0. The determination method of the process combination for extracting polysaccharide in golden mushroom mycelium cells is as follows: high-quality mycelium is selected to be deeply fermented, thus obtaining mycelium dry powder; the solid-liquid ratio is determined; the adding amount of complex enzyme is determined; and the optimal extracting process combination for extracting mycelium dry powder polysaccharide in an ultrasonic-complex enzyme method is determined.

Owner:蒋海军

Efficient anti-oxidative acne-removing handmade soap

InactiveCN107937176ADestructiveImprove antioxidant capacitySurface-active non-soap compounds and soap mixture detergentsDetergent compounding agentsBULK ACTIVE INGREDIENTSOAP

The invention relates to a high-efficiency anti-oxidation and anti-acne handmade soap, which is characterized in that: calculated according to the weight fraction, it includes the following components: 10-15 parts of Chinese medicine extract, 5-10 parts of Phyllostachys pubescens leaf extract, 1-10 parts of Pyracantha fruit extract 3 parts, 1-3 parts of indigo fruit extract, 1-2 parts of mangosteen husk extract, 1-2 parts of Italian Buglossia extract, 2-4 parts of lychee leaf extract, 2-4 parts of bayberry leaf extract, Perilla leaf extract 1‑2 parts, mugwort extract 1‑2 parts, nicotinamide 6‑10 parts, tea saponin 0.3‑1 part, seabuckthorn seed oil 70‑100 parts, natural soap base 250‑350 parts. The handmade soap raw material extract of the present invention is extracted by ultrasonic extraction. This process has high extraction efficiency, and the utilization rate of active ingredients in plant and fruit medicines is extremely high, because the biological transdermal accelerator is derived from plant extracts and has good biophase Capacitive, and will not cause damage to the skin, with safety.

Owner:宁波秋日小城智能科技有限公司

Process combination for extracting polysaccharide in hericium erinaceus mycelium cells and determination method thereof

The invention relates to a process combination for extracting polysaccharide in hericium erinaceus mycelium cells. The solid-liquid ratio according to weight is 1: 10-1: 60, the adding amount of complex enzyme accounts for 0.5 percent to 5.0 percent of the weight of the raw materials, the range of ultrasonic power is 100w to 500w, the range of enzymolysis time is 40min to 100min, and the range of enzymolysis temperature is 30 DEG C to 60 DEG C, and the range of enzymolysis pH value is 4.0 to 8.0. The determination method of the process combination for extracting polysaccharide in hericium erinaceus mycelium cells is as follows: high-quality mycelium is selected to be deeply fermented, thus obtaining mycelium dry powder; the solid-liquid ratio is determined; the adding amount of complex enzyme is determined; and the optimal extracting process combination for extracting mycelium dry powder polysaccharide in an ultrasonic-complex enzyme method is determined.

Owner:ZHEJIANG UNIV

Modification treatment method of ZSM-5 zeolite

ActiveCN102874840AMesoporous specific surface area is highMesoporous structure intactPentasil aluminosilicate zeoliteCavitationOrganic solvent

The invention discloses a modification treatment method of ZSM-5 zeolite. The method comprises the following steps of: adding a certain proportion of aqueous alkali and a low molecular weight organic solvent into ZSM-5 zeolite, performing ultrasonic treatment on the system, transferring to an enclosed system for alkali treatment, and finally separating and drying to obtain the modified ZSM-5 zeolite. The supersonic wave can generate a super strong cavitation effect so as to activate the ZSM-5 zeolite's framework silicon atom and help the next alkali treatment. During the alkali treatment process, aqueous alkali selectively removes part of silicon element in the ZSM-5 crystals such that structural rearrangement is generated in micropores so as to form mesopores. The addition of the low molecular weight organic solvent can promote the generation of the meso-structure so as to make the micropore structure more efficiently to be converted to mesopores and simultaneously stabilize and protect the micropore structure. By the adoption of the method, more complete micropores can be retained, more mesopores can be provided, and total BET specific surface area also can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

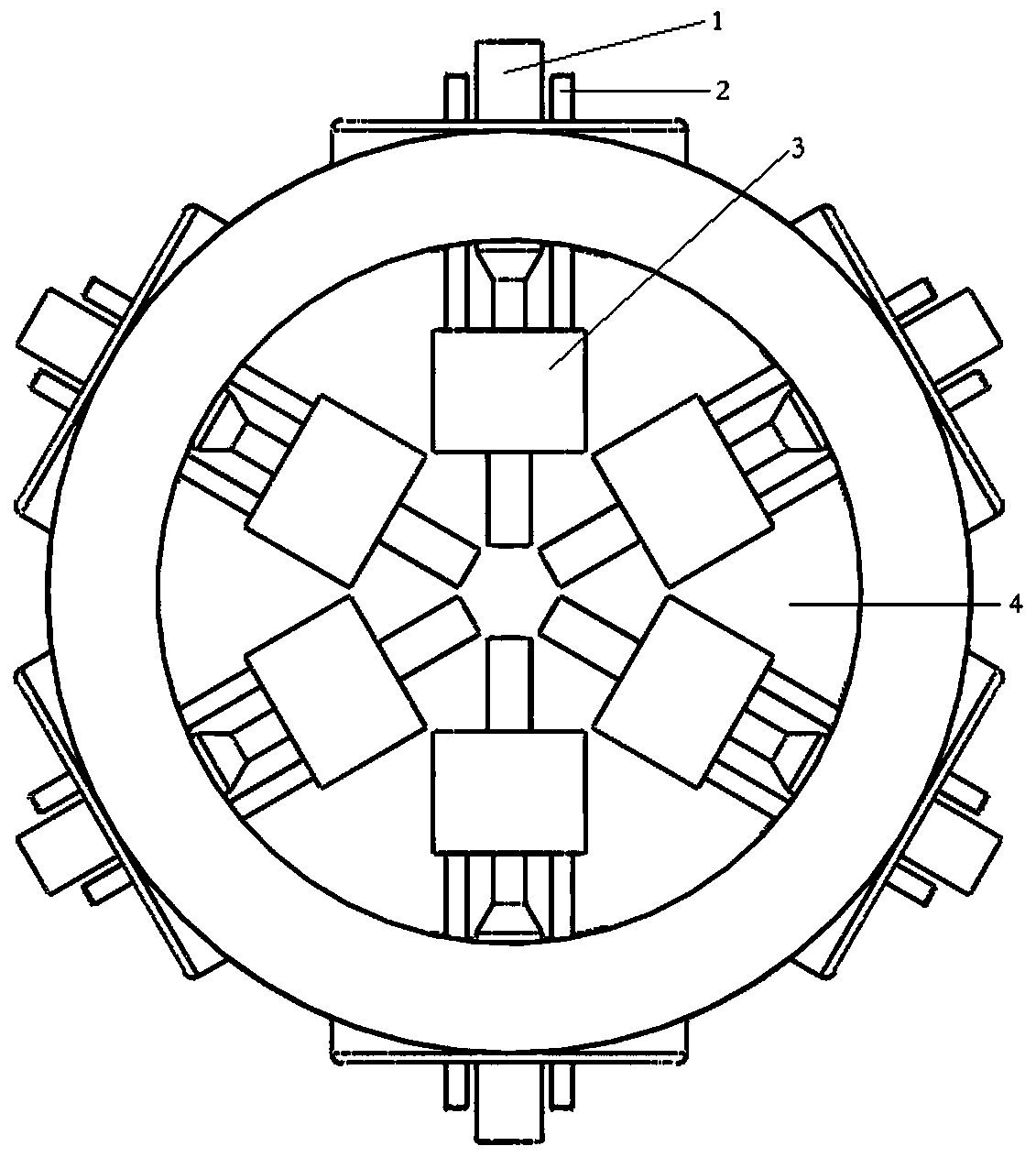

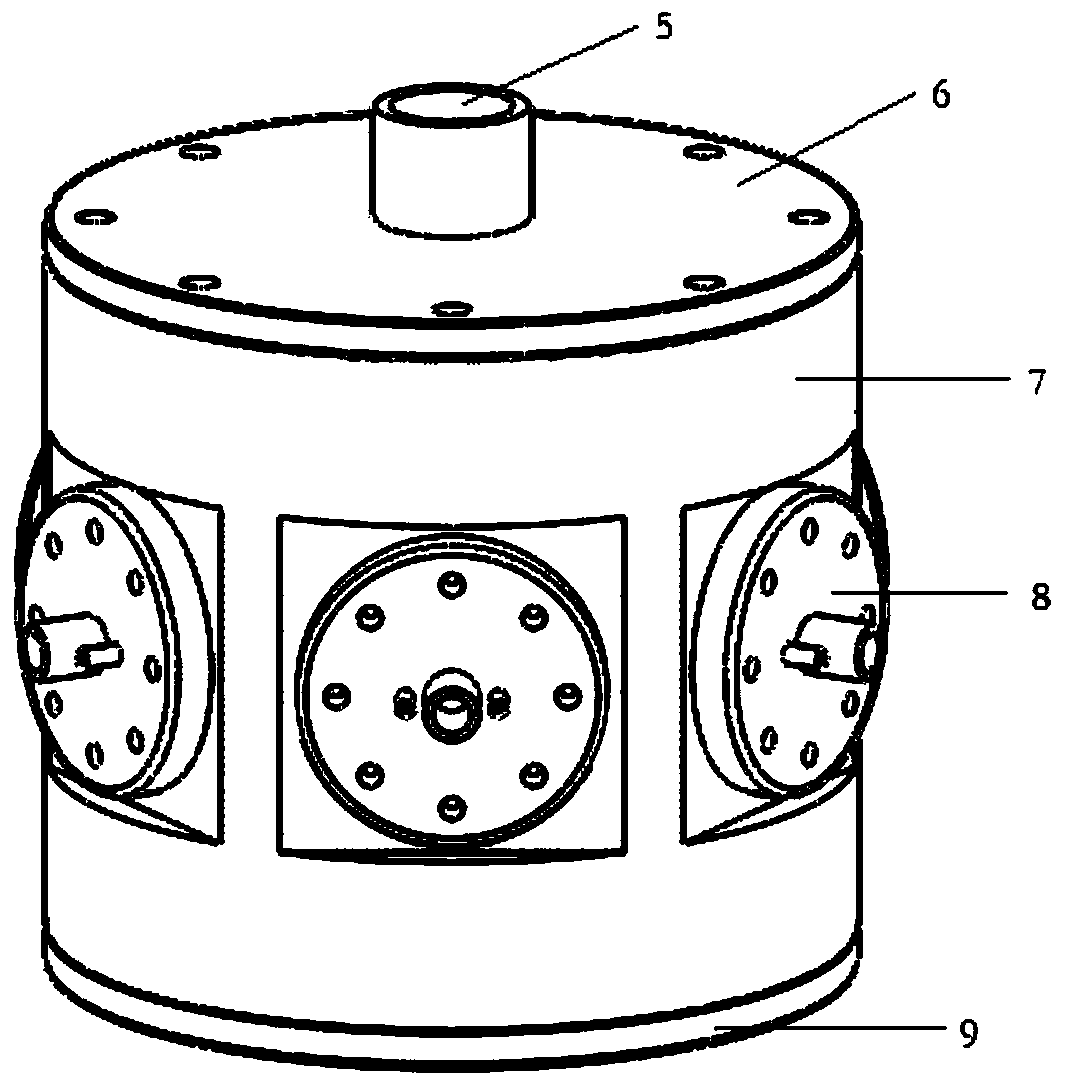

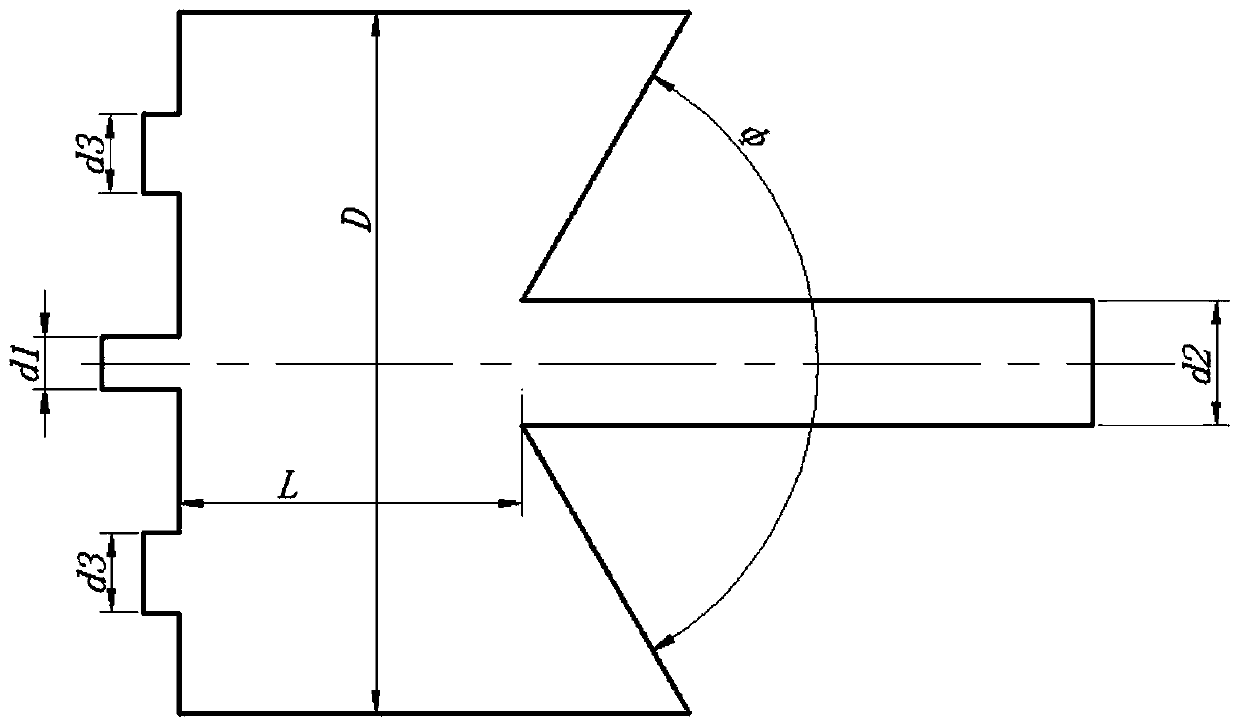

Self-excited oscillation cavitation impinging stream reactor

PendingCN110921770AStrong cavitation effectImprove cavitation performanceWater/sewage treatment by irradiationWater treatment compoundsLiquid jetCavitation (process)

The invention discloses a self-excited oscillation cavitation impinging stream reactor which comprises a liquid inlet pipe, a gas inlet pipe, a cavitator, an impact cavity and a liquid outlet pipe. Apipe connector is mounted on an upper cover plate and used for being connected with the liquid outlet pipe and allowing a liquid to flow out; a water inlet pipe and a flange plate are connected through threads, and the distance between outlets of the self-excited oscillation cavitator can be changed by adjusting the screwing length of the threads. The water inlet pipe is in threaded connection with a self-excited oscillator. The self-excited oscillation cavitator is located in the impact cavity, liquid enters the self-excited oscillation cavitator through the liquid inlet pipe, cavitation is generated, cavitation jet flow is formed, multiple strands of liquid jet flows collide with one another at a high speed in the center of the impact cavity, and cavitation is effectively enhanced; meanwhile, plasma can be introduced into the cavitation process, and the generation efficiency of hydroxyl radicals is improved. The reaction process can be strengthened, the hydrodynamic cavitation strength is improved, and the degradation efficiency of organic wastewater is improved.

Owner:BEIJING UNIV OF TECH

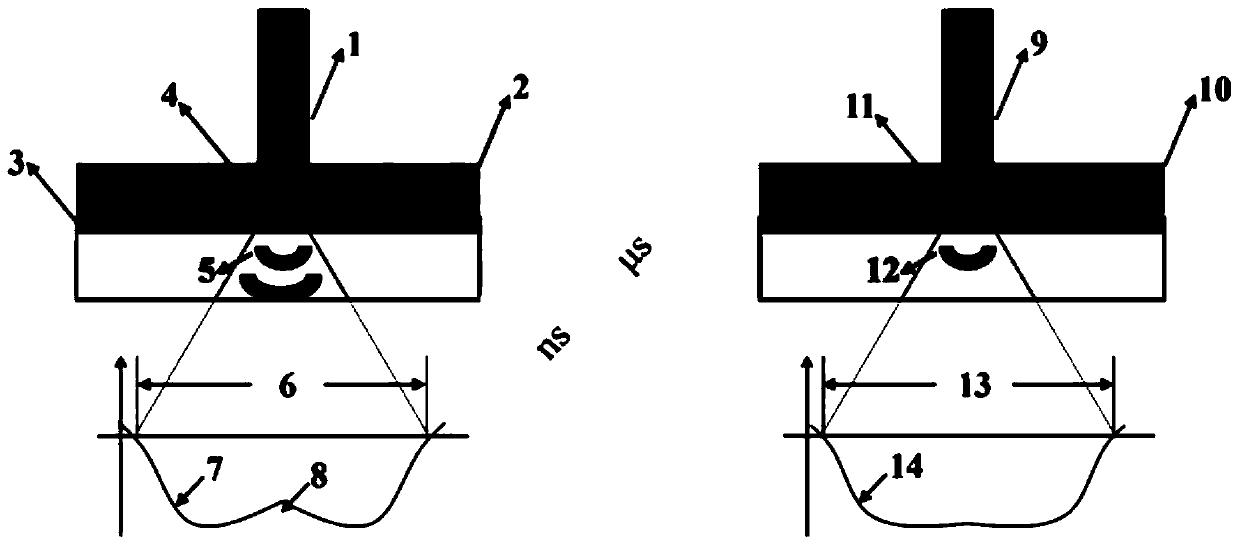

Uniform surface strengthening method based on laser shock wave

ActiveCN111074061AEliminate residual stress holesUniform distribution of residual stressShock waveKtp laser

The invention relates to a uniform surface strengthening method based on a laser shock wave. The uniform surface strengthening method based on the laser shock wave comprises the specific steps that anabsorption layer and a constraining layer are arranged on the surface of a workpiece sequentially in a clamped mode, a laser generator is arranged at a position opposite to the workpiece, the laser generator is located on the side close to the constraining layer of the workpiece, the workpiece is subjected to laser shock, the constraining layer is deionized water, and the thickness of a deionizedwater layer is 2-5 mm. The energy of the laser is 3-7J, the pulse width is 15-20ns, and the spot diameter is 1-4mm. The laser-induced "cavitation" effect is used for performing secondary strengthening on the workpiece to suppress or eliminate "residual stress holes" caused by the laser plasma shock wave on the surface of the workpiece, so that the residual stress is distributed on the surface ofthe workpiece uniformly.

Owner:SHANDONG UNIV

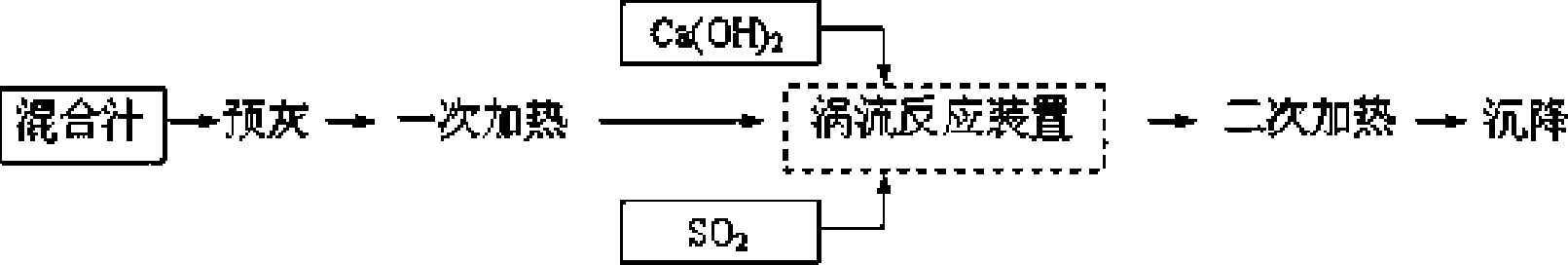

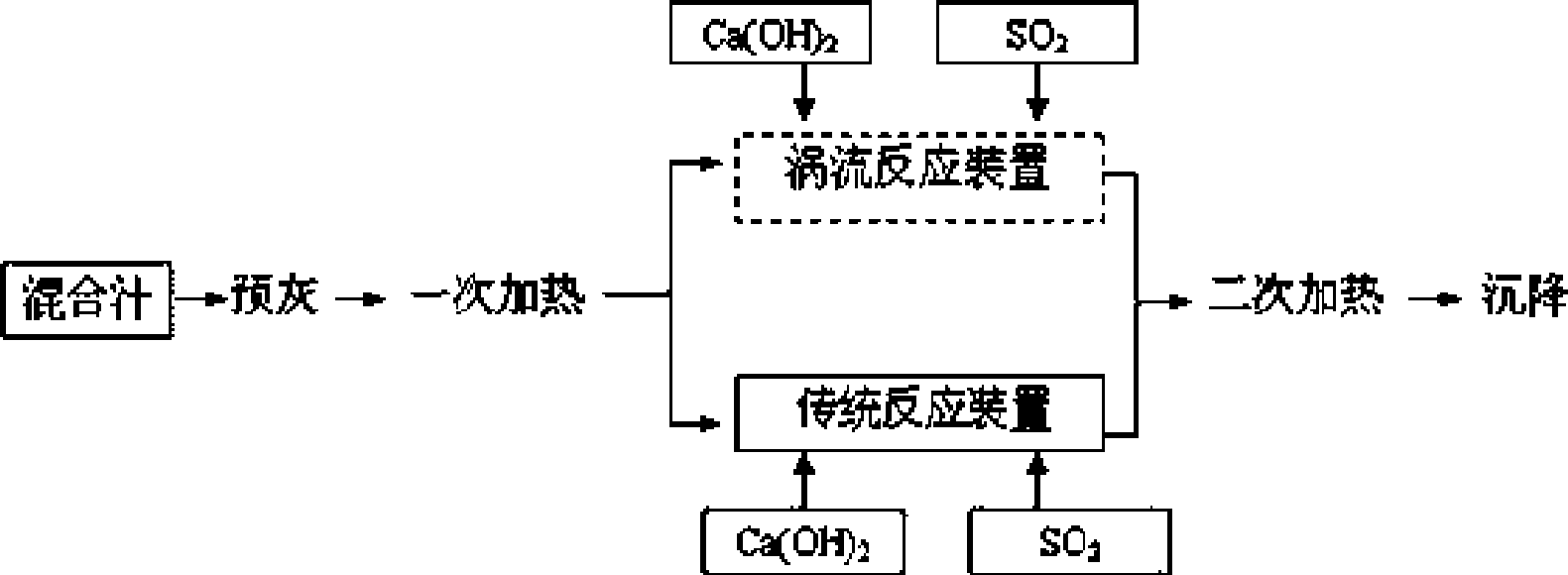

Sugarcane juice clarification method with intensified sulfitation-neutralization reaction

InactiveCN101485409AReduce contentSulfur dioxide content requirements are reducedFood preparationJuice clarificationReaction speed

The invention provides a cane juice clarification method for a reinforced sulfur fumigation neutralization reaction, which relates to a clarification process method for sugar processing. The method adopts the sulfurous method clarification process which comprises preliming, first heating, sulfur fumigation neutralization, secondary heating and settlement procedures; the sulfur fumigation neutralization procedure comprises a reinforced sulfur fumigation neutralization reaction step in which the cane juice is filled in a vortex reaction device for reaction; and at the reinforced sulfur fumigation neutralization reaction step, the full or partial mixing of the cane juice is performed by the combination of the sulfur fumigation neutralization procedure, namely the mixed cane juice after the preliming and the first heating is fully or partially filled in the vortex reaction device, lime milk and SO2 are simultaneously added to the vortex reaction device, so that the reinforced sulfur fumigation neutralization reaction is carried out in the vortex reaction device, or in the prior sulfurous method clarification process; and the cane juice after the sulfur fumigation neutralization is fully or partially filled in the vortex reaction device to reinforce the sulfur fumigation neutralization reaction. The method has the advantages of improving the reaction speed and the reaction extent of the sulfur fumigation neutralization reaction, improving the decolorization effect, and reducing the residual sulfur content in white granulated sugar.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

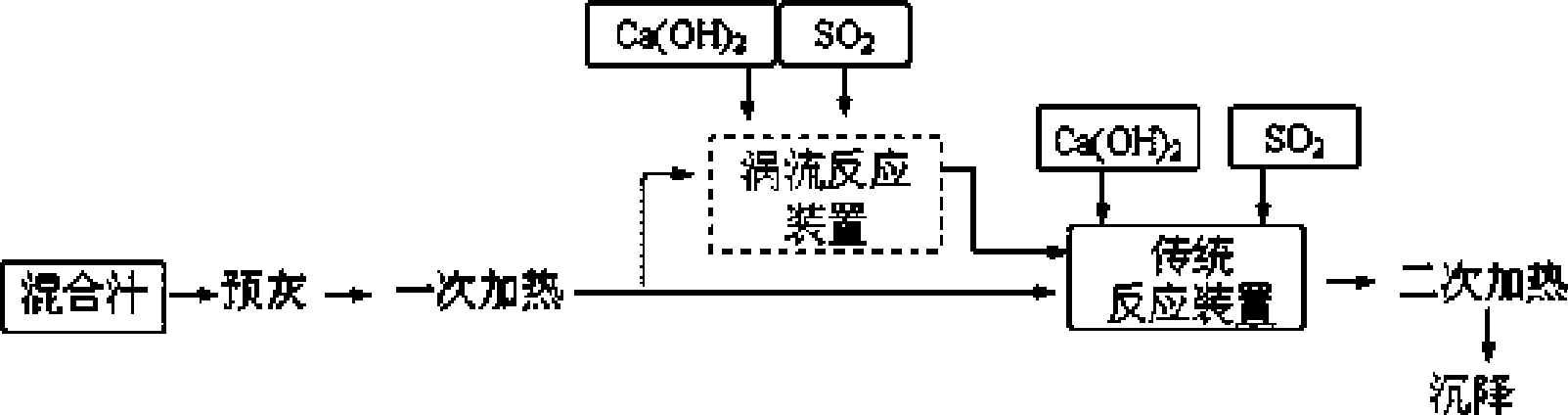

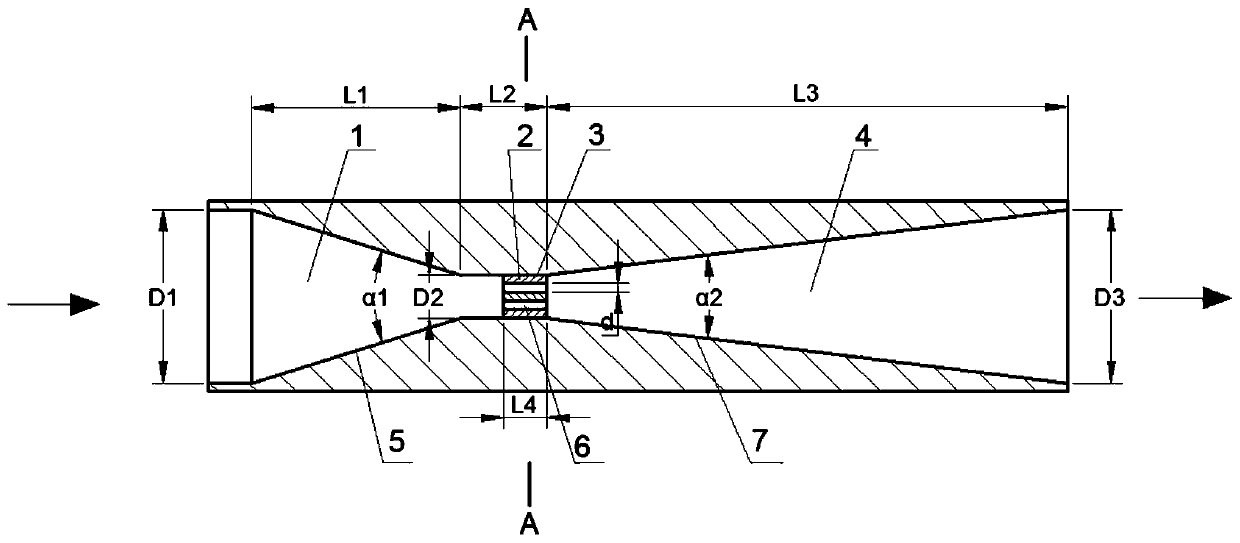

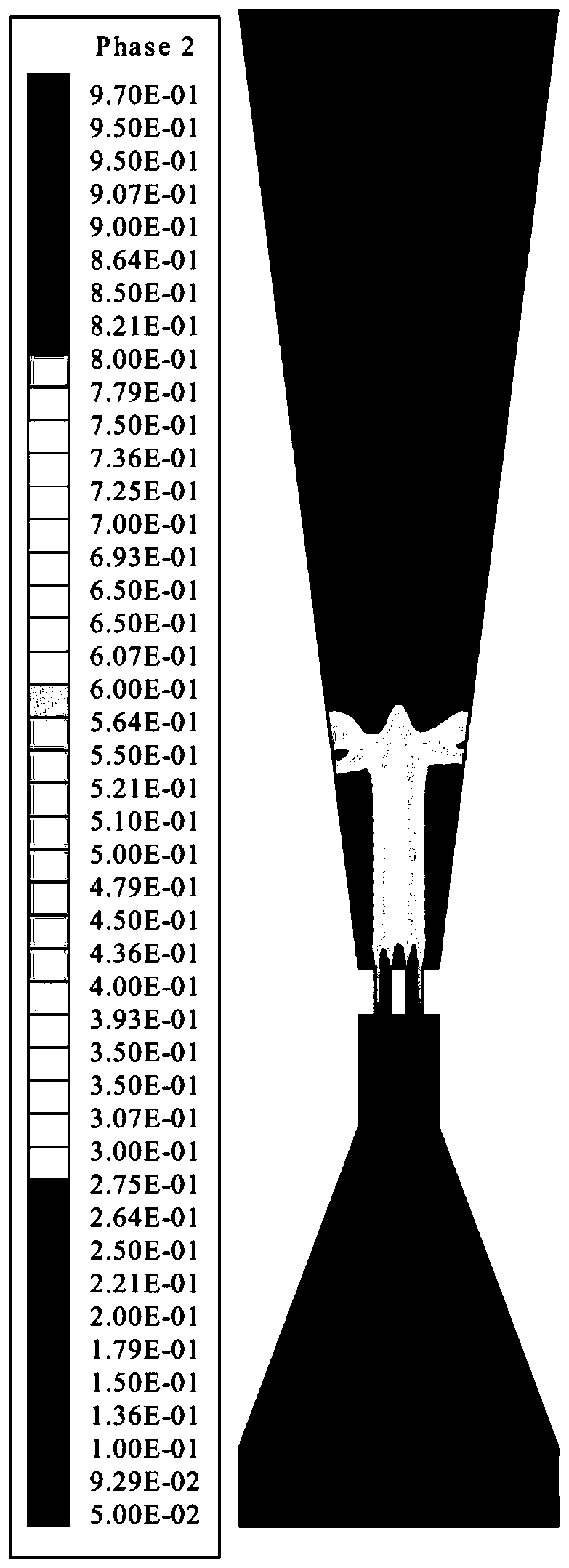

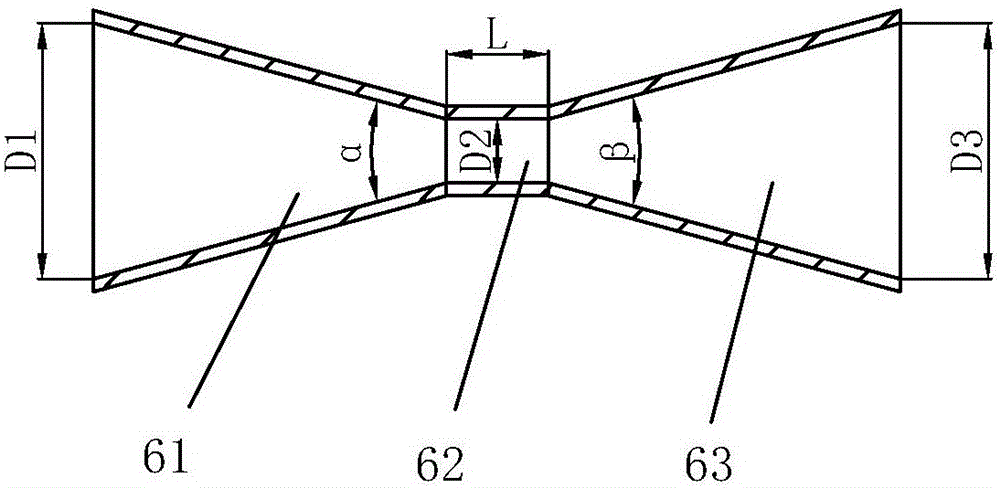

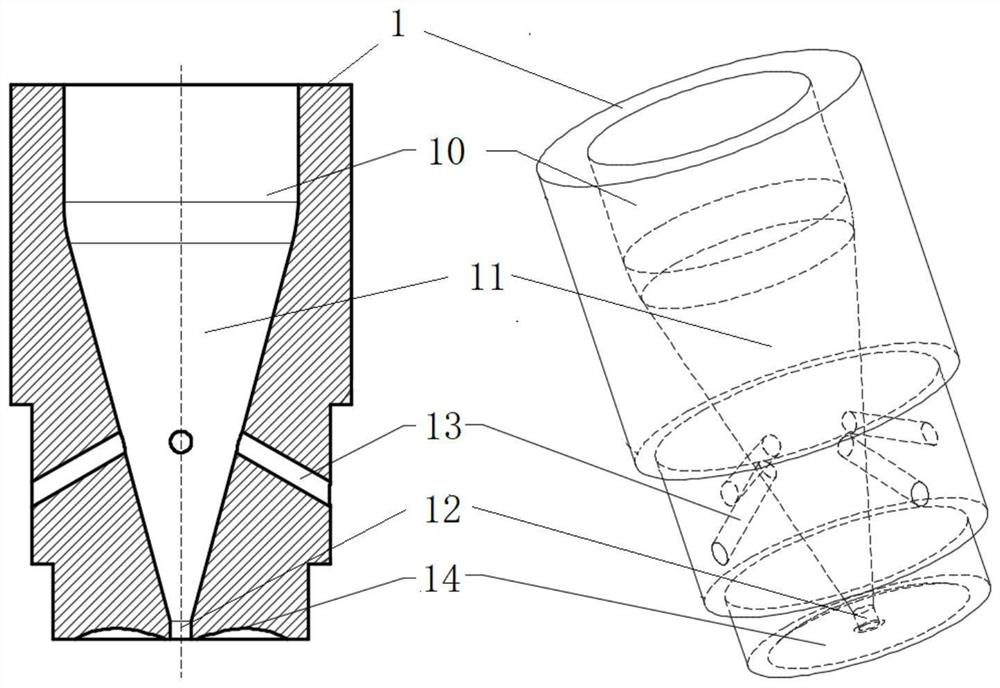

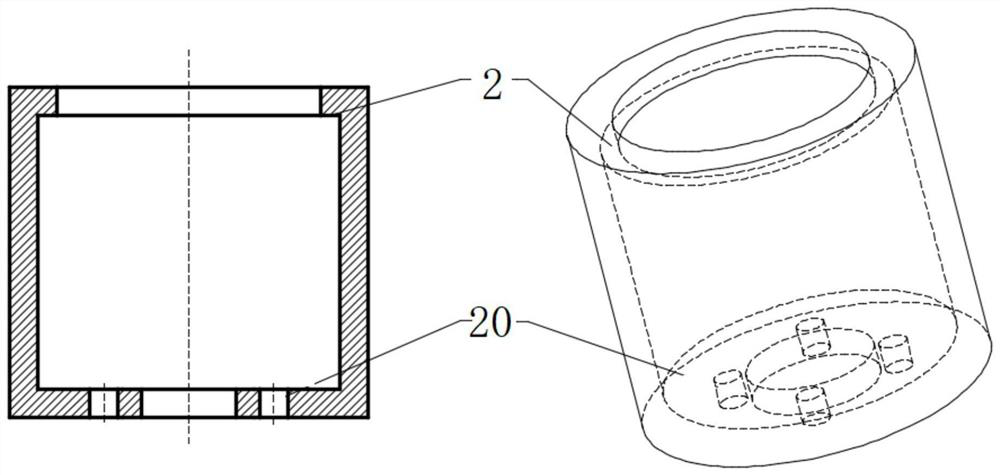

Two-stage cavitation generator with composite structure

PendingCN109956520ALarge range of turbulent kinetic energy variationLarge cavitation areaWater/sewage treatment with mechanical oscillationsVena contracta diameterCavitation

The invention discloses a two-stage cavitation generator with a composite structure. The two-stage cavitation generator comprises a Venturi tube and an orifice plate. The exterior of the Venturi tubeis tubular, and the Venturi tube is successively composed of an inlet end, a gradual contraction section, a throat section, a gradual enlargement section and an outlet end. The orifice plate is provided with several pore channels, which are arranged in the throat section. The two-stage cavitation generator is an integrated two-stage cavitation generator with the orifice plate and the Venturi tubenested. Through simulation verification, the two-stage cavitation generator can complete two cavitation processes when boundary conditions are certain, has higher cavitation efficiency than a traditional single-stage cavitation generator, and has a better cavitation effect and larger cavitation area to release more energy in comparison with a combined cavitation generator formed by direct connection of an orifice plate and a Venturi tube. By combining advantages of a traditional single-stage cavitation generator and optimizing the structure of the combined cavitation generator, the optimum structure value relation is brought forward. The two-stage cavitation generator has engineering development value and anapplication prospect.

Owner:JIANGSU UNIV OF SCI & TECH

Extraction process of ursolic acid in dogwood kernels

The invention discloses an extraction process of ursolic acid in dogwood kernels. In the extraction process, the dogwood kernels are adopted as raw materials, and a qualified product of ursolic acid is obtained by the steps of raw material pretreatment, baking, primary grinding, freezing, secondary grinding, soaking, ultrasonic treatment, distillation, low-temperature evaporation and third grinding. The production period of the process is short, the yield of ursolic acid is high, the product purity is high, the purity of the obtained ursolic acid product can reach 91.37-93.03%, and the recovery rate of ursolic acid reaches 90.73-91.87%, so that a new means is provided for preparing ursolic acid and developing dogwood kernel resources.

Owner:江学忠

Aramid fiber surface treatment process

InactiveCN103321037AFully infiltratedImprove surface conditionPhysical treatmentCooking & bakingUltrasound - action

The invention discloses an aramid fiber surface treatment process. The process is characterized in comprising the steps that: aramid fiber is spun; the aramid fiber is subjected to surface cleaning treatment for 0.5-3min by using a cleaning liquid in ultrasonic waves; when aramid fiber surface cleaning is finished, the aramid fiber is bake-dried in a baking oven, such that surface treatment is finished. The method provided by the invention has the advantages that: ultrasonic waves provide an intense cavitation effect, such that the aramid fiber can be sufficiently impregnated by the cleaning liquid, and aramid fiber surface state can be changed. With the surface cleaning treatment of the aramid fiber, bonding strength between the aramid fiber and resin is improved. Also, a solution prepared by dissolving silane in an organic solvent is adopted as the ultrasonic medium, such that a surface adhesion performance is improved under ultrasonic waves.

Owner:NANTONG HETAI COMM EQUIP +1

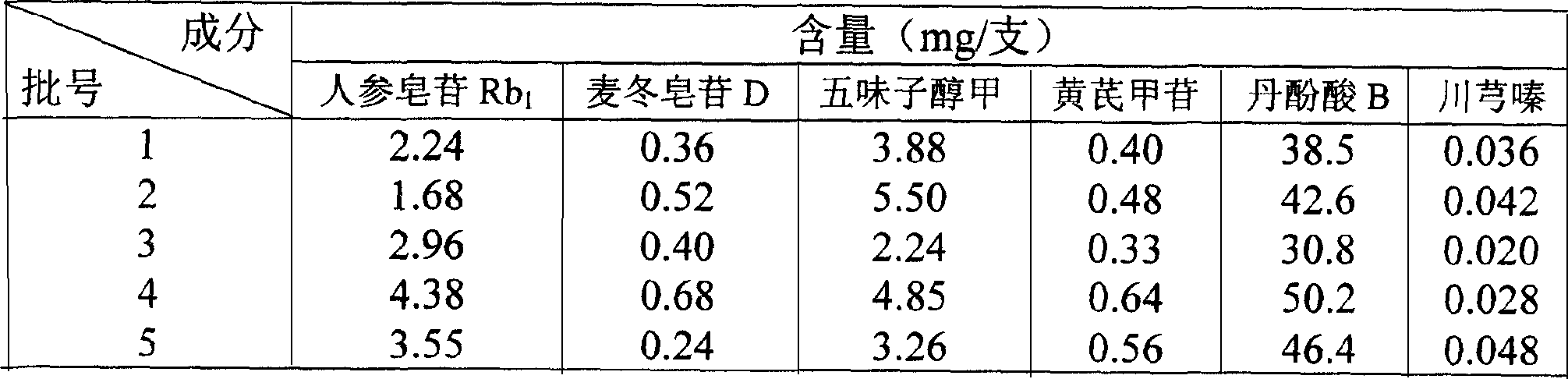

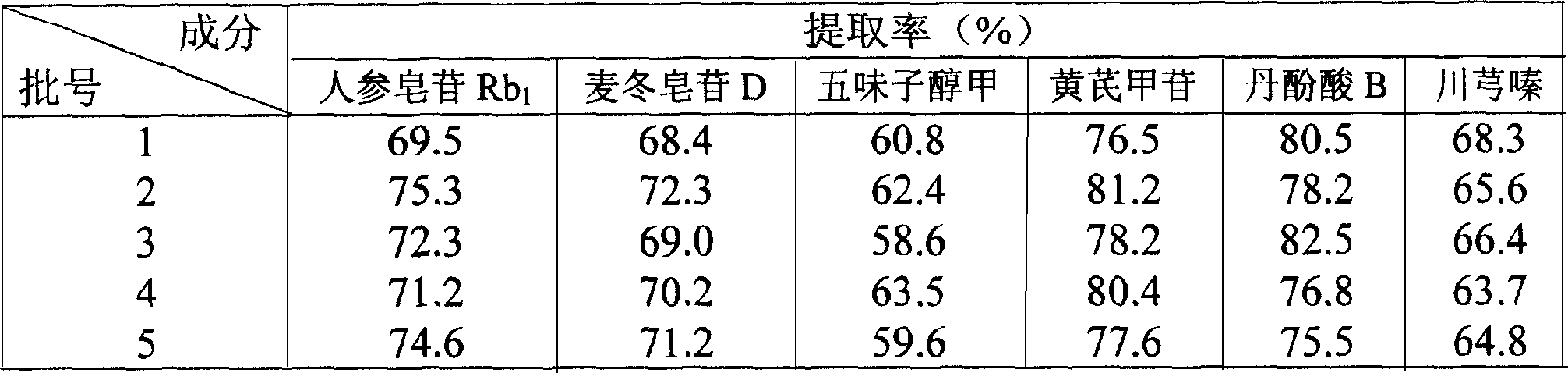

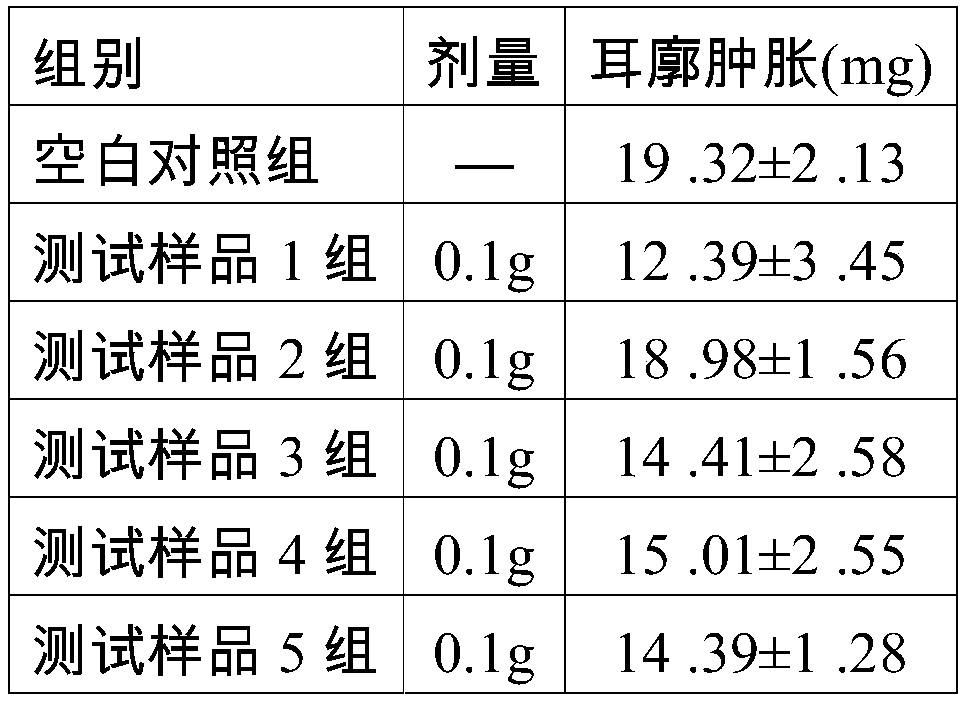

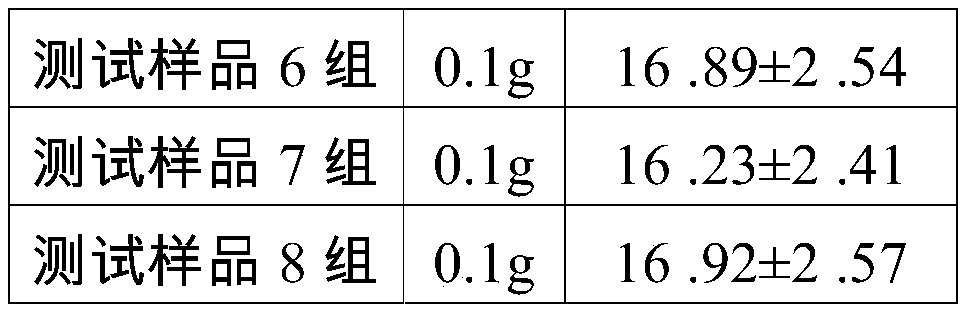

Medicine composition for treating cardiovascular and cerebrovascular diseases and preparation method thereof

InactiveCN1634489AImprove solubilityIncrease the rate of submissionPowder deliveryUnknown materialsDiseaseAdjuvant

Disclosed is a pharmaceutical composition for treating cardiovascular and cerebrovascular diseases, which is prepared fromacanthopanax root extract, gen-seng extract and medicinal adjuvant for water-soluble injection, and has the functions of benefiting vital energy, promoting blood circulation. The invention also discloses the process for preparing the pharmaceutical composition. Pharmacological experiment has shown that the medicinal composition has good actions for preventing and treating cardiovascular and cerebrovascular diseases.

Owner:张平

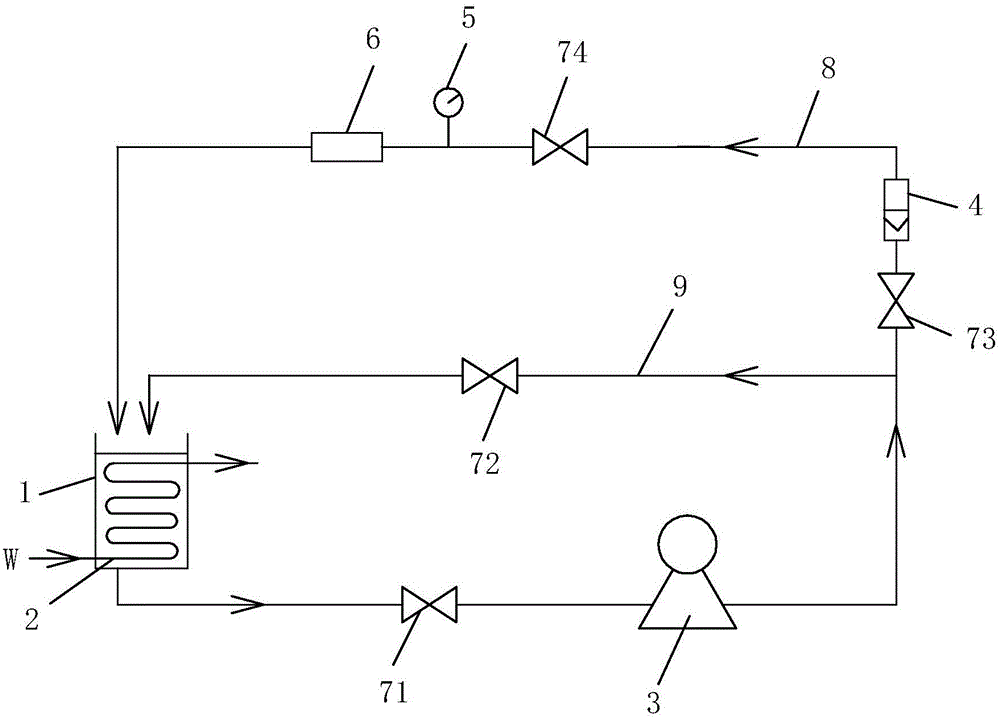

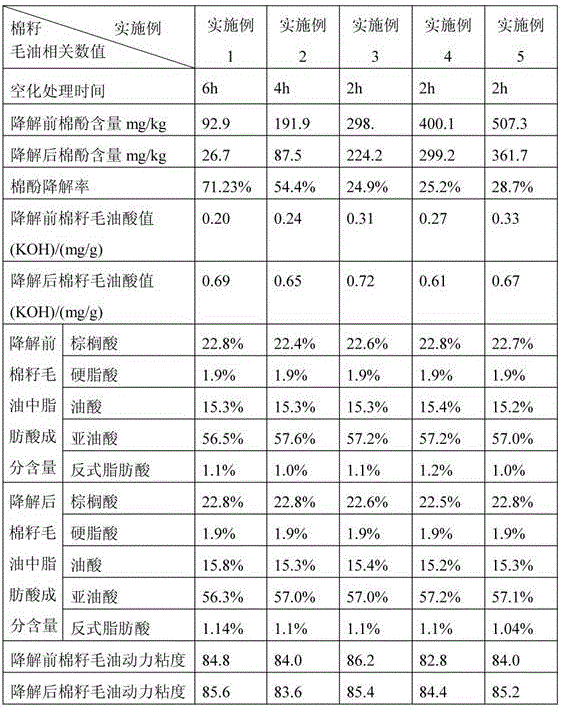

Method for degrading gossypol in cottonseed oil

ActiveCN105695091ANo effect on fatty acid compositionNo effect on viscosityFatty-oils/fats refiningCavitationFood safety

The invention relates to a method for degrading gossypol in cottonseed oil. The method comprises the following steps: putting cottonseed crude oil which contains the gossypol in a hydraulic cavitation device; carrying out hydraulic cavitation processing on the cottonseed crude oil through circulation, wherein the hydraulic cavitation device comprises a cavitator, and process conditions for carrying out cavitation degradation on the cottonseed crude oil are as follows: inlet pressure is 0.1-0.3MPa, the processing temperature of the cottonseed crude oil is 25-35DEG C, processing time is 2-6h, and flow is controlled to 15-60L / min. The hydraulic cavitation technology is used for degrading the gossypol in the cottonseed oil, and the gossypol can be effectively degraded in the cottonseed oil through the cavitation processing. The method has the advantages of low processing cost and simpleness in operation, does not affect the nutrition ingredients of the cottonseed oil and can guarantee food safety. The highest degradation rate of the gossypol in the cottonseed oil can be 71.2%.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Heart-benefiting pulse-invigorating injection and its preparation process

InactiveCN1698806AIncrease the rate of submissionImprove solubilityPharmaceutical delivery mechanismUnknown materials

The invention relates to a heart-benefiting pulse-invigorating injection which is prepared from the raw materials of chuanxiong rhizome, schisandra chinensis volatile oil, HP-beta-CD, sun-dried ginseng, lilyturf root, astragalus root, salvia miltiorrhizae and water-soluble medicinal auxiliary materials for injection. The invention also discloses the process for preparing the injection.

Owner:张海峰

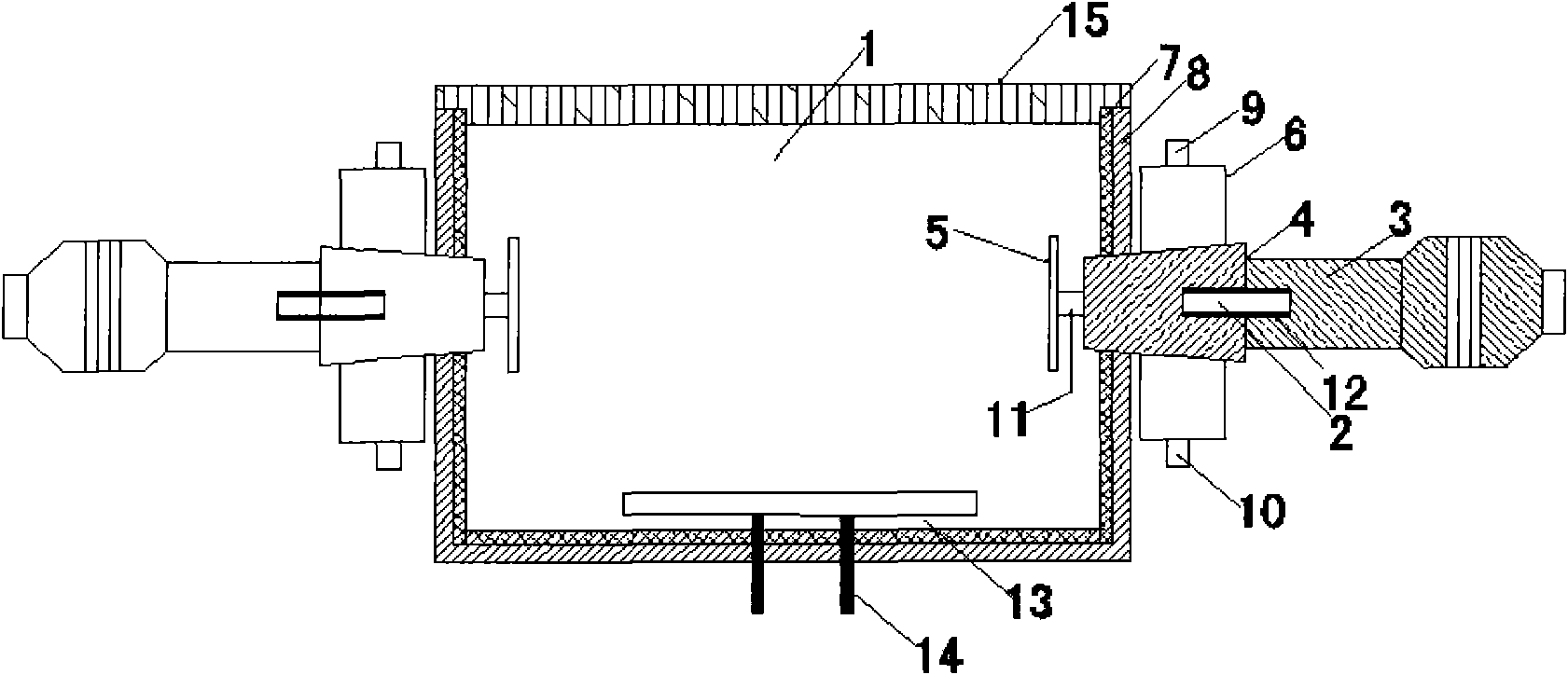

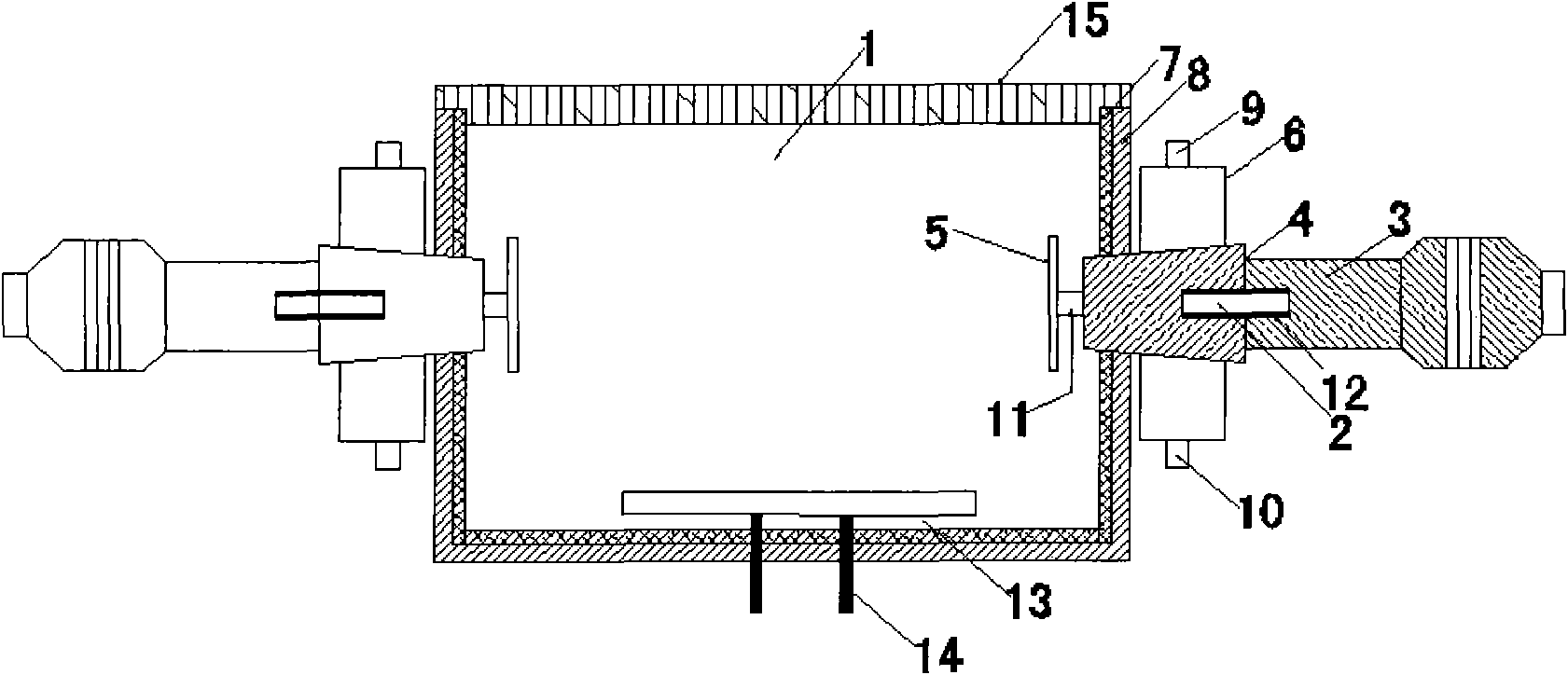

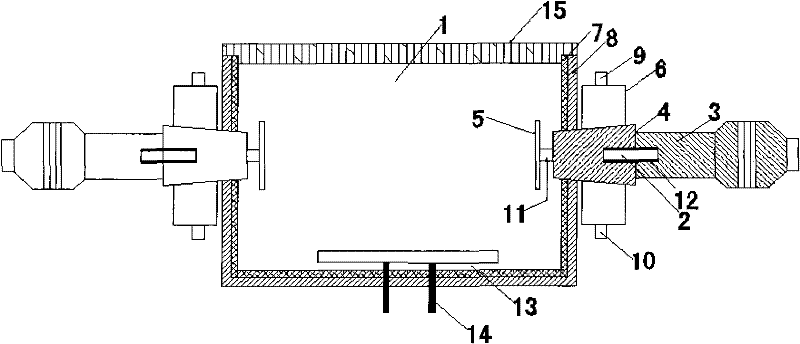

Piezoelectric ultrasonic salt-bath heating nitriding device

InactiveCN101812661AImprove diffusion abilityReduce energy lossSolid state diffusion coatingUltrasoundMachine building

The invention provides a piezoelectric ultrasonic salt-bath heating nitriding device, which comprises a shell provided with a heat insulation layer, a salt bath tank in the shell, a heating plate, a wiring support column and a top cover, and is characterized in that: two sets of piezoelectric ultrasonic devices are symmetrically arranged on the shell; each one of the piezoelectric ultrasonic device comprises an energy-collecting rod, an oscillating plate, an amplitude transformer, an energy transducer and a cooling box; the oscillating plate and the energy-collecting rod form an integral part; the oscillating plate is arranged in the salt bath tank and is connected with the amplitude transformer through threads; and a wave node of the amplitude transformer is arranged on the shell by welding. The piezoelectric ultrasonic salt-bath heating nitriding device has the advantages of compact and simple structure, improved nitriding rate and efficiency, safe and reliable working, high economical efficiency and the like; and in nitriding process production, the piezoelectric ultrasonic salt-bath heating nitriding device can efficiently perform chemical heat treatment on various metallic materials, and can be widely applied in the field of machine building.

Owner:ZHONGBEI UNIV

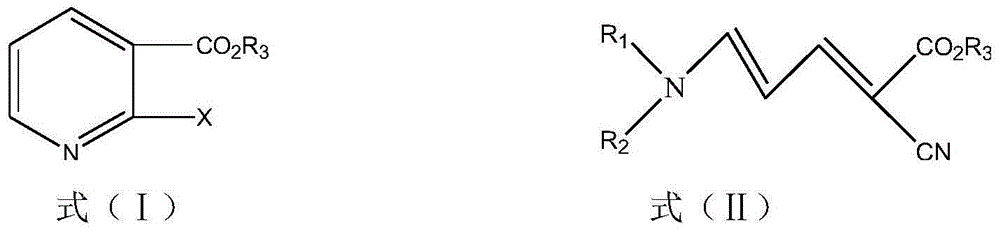

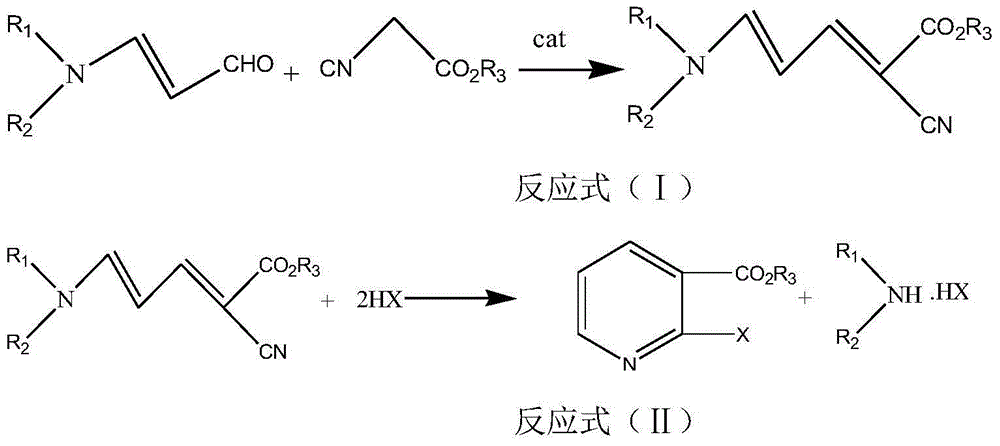

Method for synthesizing 2-halogenated ester nicotinate and 2-halogenated ester nicotinate intermediate according to ultrasonic method

ActiveCN104945317AImprove protectionStrong "cavitation" effectCarboxylic acid nitrile preparationOrganic compound preparationSolventHalogen

The invention discloses a method for synthesizing 2-halogenated ester nicotinate and a 2-halogenated ester nicotinate intermediate according to an ultrasonic method. The method comprises the following steps: adding substituent amino acrolein, a catalyst and cyanacetic ester into a reactor for a reaction under ultrasonic radiation; tracing the reaction till substituent amino acrolein is disappeared, thereby obtaining a reaction solution I containing the 2-halogenated ester nicotinate intermediate; then, adding halogen hydride into the reaction solution I for another reaction to obtain a reaction solution II; tracing and monitoring the reaction till completion; adding a lye into the reaction solution II to adjust the pH value of the reaction solution II to be 5-6; carrying out standing stratification to obtain a water layer and an organic layer; conducting extraction on the water layer by utilizing an organic solvent, and then combining the extraction solution with the organic layer; carrying out refining to obtain 2-halogenated ester nicotinate. Through the adoption of the method, an organic synthesis reaction can be effectively facilitated, the reaction speed and yield can be improved, and the environmental protection can be promoted; the reaction time is short and the operation is simple, that is, the organic synthesis reaction can be finished within 2 hours in general; the product yield and quality are high; specifically, the product yield can reach 90% or higher, and exceed that achieved according to the conventional solvent heating reflux method.

Owner:SHANDONG NORMAL UNIV

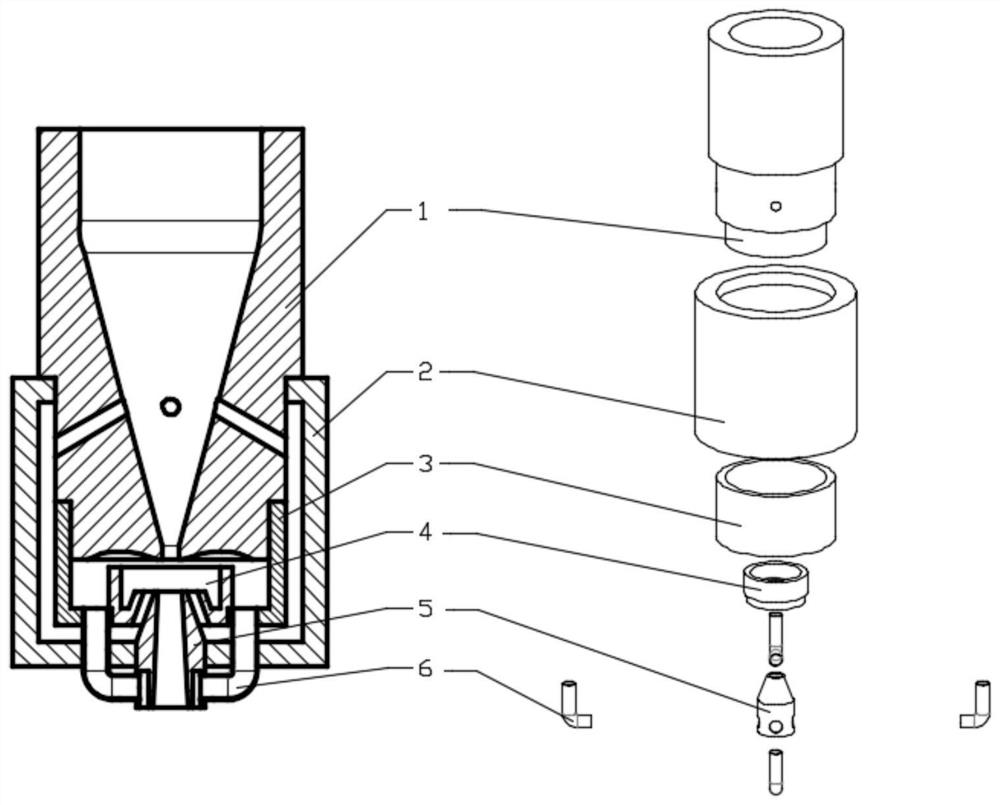

Double-shear type cavitation nozzle

PendingCN113083535ACollapse violentlyImprove cavitation strengthSpray nozzlesCavitation bubbleMechanics

The invention provides a double-shear type cavitation nozzle. The double-shear type cavitation nozzle comprises an upper nozzle, an inner sleeve, an outer sleeve, a mixing cavity, a lower nozzle and a connecting pipe, wherein a first cavity and a first through hole are formed in the upper nozzle along the axial direction; the upper nozzle is sleeved with the inner sleeve, and a second cavity is formed between the inner sleeve and the upper nozzle; the outer sleeve is arranged on the outer wall of the upper nozzle in a sleeving manner and wraps the inner sleeve, and a third cavity is formed between the outer sleeve and the inner sleeve; the mixing cavity is clamped at the outlet of the inner sleeve; the lower nozzle penetrates through the outer sleeve and extends into the mixing cavity, a fifth cavity communicated with the third cavity is formed between the lower nozzle and the mixing cavity, a jet hole is formed in the lower nozzle in the axial direction of the lower nozzle, a second through hole and an annular inner cavity communicated with the second through hole are formed in the side wall of the end side, away from the mixing cavity, of the lower nozzle, and the annular inner cavity is not communicated with the jet hole; and the connecting pipe is used for connecting the second cavity and the second through hole. When a jet flow passes through the nozzle, multiple times of shearing are carried out, lots of cavitation bubbles are generated, and the cavitation effect and the operation efficiency are improved.

Owner:WUHAN UNIV

Nauclea officinalis branch or bark-containing traditional Chinese medicine composition, and preparation method and application thereof

InactiveCN111249197AHeat-clearing and detoxifyingAnti-inflammatory and pain-relievingAntibacterial agentsCosmetic preparationsBiotechnologyOral disease

The invention belongs to the technical field of daily chemical products, particularly relates to a nauclea officinalis branch or bark-containing traditional Chinese medicine composition, and a preparation method and application thereof, and especially relates to an oral care product with functions of clearing away heat and toxic materials, diminishing inflammation, relieving pain and resisting bacteria. The nauclea officinalis branch or bark-containing traditional Chinese medicine composition is prepared from 5-15 parts by weight of nauclea officinalis branches or bark, 10-15 parts by weight of radix notoginseng, 5-15 parts by weight of common aucklandia roots, 1-5 parts by weight of Japanese pagodatree pods, 5-10 parts by weight of Sichuan lovage rhizomes and 1-5 parts by weight of cimicifuga rhizomes, has the effects of clearing away heat and toxic materials, diminishing inflammation, relieving pain and resisting bacteria, can inhibit growth of harmful bacteria in the oral cavity, and effectively prevent oral diseases. The nauclea officinalis branch or bark-containing traditional Chinese medicine composition can be mixed with auxiliary materials to be prepared into various oral care products by a conventional method.

Owner:HAINAN SENQI PHARMA CO LTD

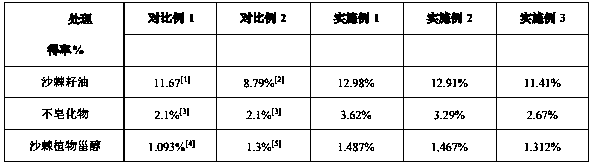

Method for separating and purifying plant sterols from seabuckthorn seeds

PendingCN109054997AStructural influenceActive influenceFatty-oils/fats refiningFatty-oils/fats productionPlant sterolWater baths

The invention relates to the technical field of extracting plant sterols, in particular to a method for separating and purifying plant sterols from seabuckthorn seeds. The method specifically comprises the steps of seabuckthorn seed smashing and drying, ultrasonic-assisted leaching and suction filtration, vacuum concentration, saponification, cooling, extraction, water washing, concentration, water bath reflux, recrystallization, washing, centrifugation and drying. Compared with the prior art, the method for separating and purifying the plant sterols from the seabuckthorn seeds has the advantages of simple operation method, low equipment requirement, low cost of reagents, low energy consumption, and high extraction rate of seabuckthorn seed oil, and the highest extraction rate can reach to12.98%, seabuckthorn sterol has a high purity of up to 1.487%, and the method for separating and purifying the plant sterols from the seabuckthorn seeds is suitable for use in small and medium-sizedproduction and processing enterprises in laboratories or production.

Owner:QINGHAI UNIVERSITY

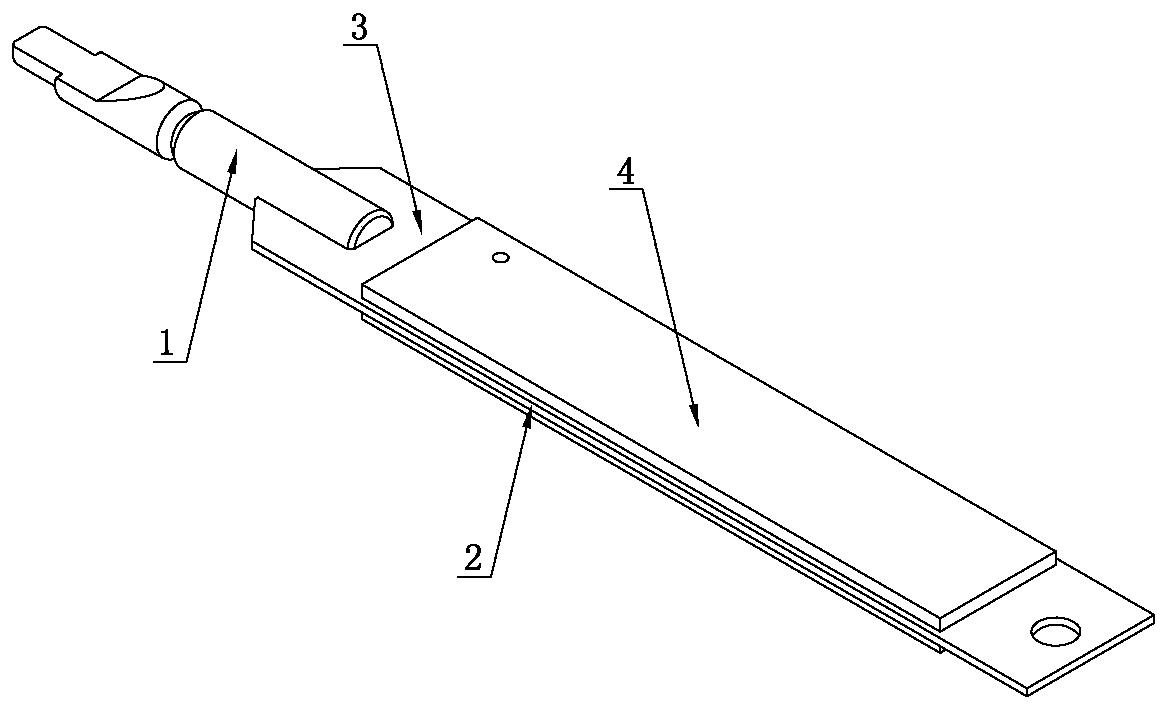

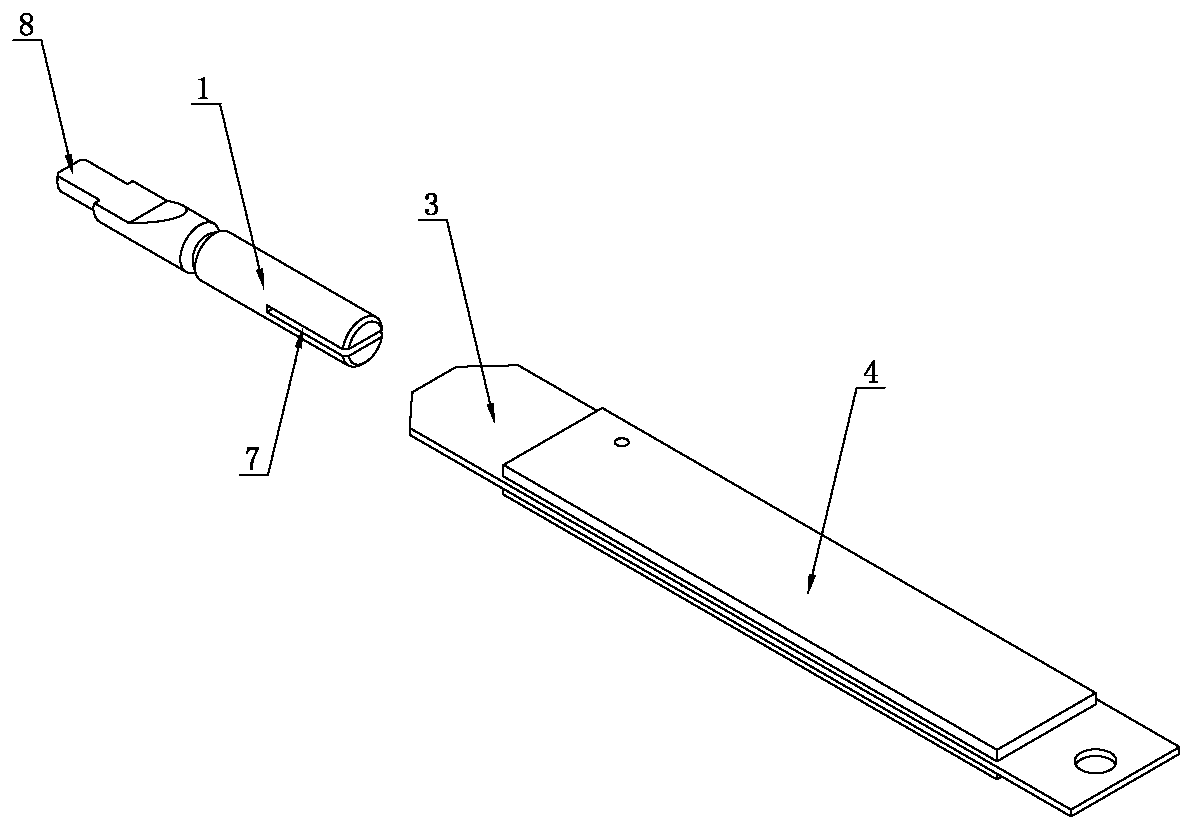

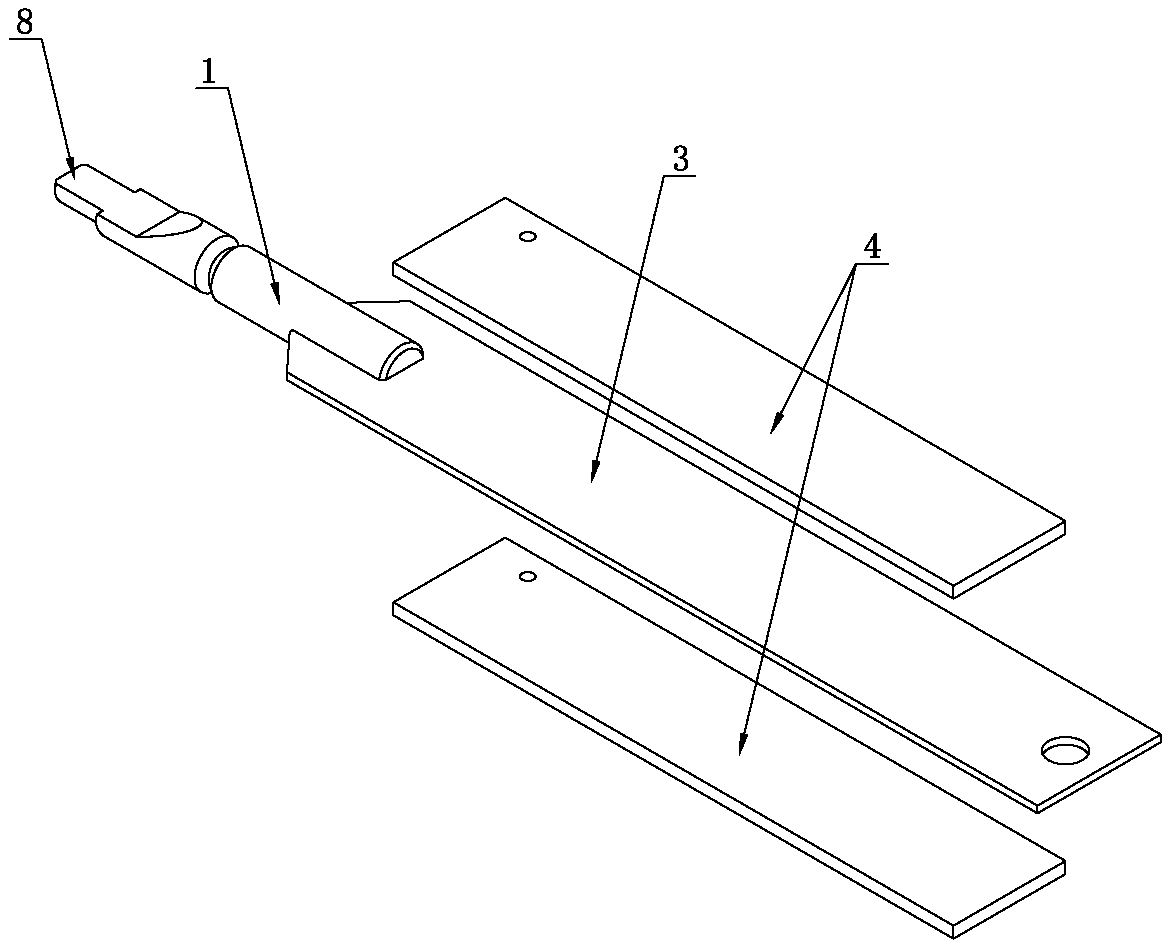

Novel ultrasonic tooth cleaning device

The invention relates to the technical field of oral cleaning devices, and in particular to a novel ultrasonic tooth cleaning device. The device comprises a tool head and an ultrasonic transducer fixedly connected with the tool head; the ultrasonic transducer comprises an intermediate plate; the intermediate plate is provided with at least one piezoelectric ceramic sheet; and the tool head is connected with a detachable toothbrush head or a tooth cleaning head, wherein the vibration frequency range of the ultrasonic transducer is between 10 kilohertz and 100 kilohertz. According to the invention, installation and use of the toothbrush head and the tooth cleaning head can be both considered, and the mature piezoelectric ceramic bimorph structure is used as the ultrasonic transducer, so thatvibration frequency is kept between 10 kilohertz and 100 kilohertz, a good tooth cleaning effect is ensured, and production cost can be greatly reduced.

Owner:DONGGUAN XI ZHE ELECTRONICS CO LTD

Antibacterial, anti-inflammation, acne-removal and repairing facial mask

InactiveCN107951813AEffective reliefWon't hurtCosmetic preparationsToilet preparationsMethacrylateBiocompatibility Testing

The invention relates to an antibacterial, anti-inflammation, acne-removal and repairing facial mask. The facial mask comprises, by weight, 0.3-0.8 part of a detoxifying component, 0.5-1 part of a blood stasis removing and pain alleviating component, 3-5 parts of an anti-inflammation and antiseptic component, 2-4 parts of a skin whitening and repairing component, 1-3 parts of an antibacterial component, 10-25 parts of a moisturizing agent, 0.1-0.3 part of glyceryl polymethacrylate, 0.1-0.2 part of carbomer, 0.1-0.2 part of xanthan gum, 0.1-0.4 part of sodium polyacrylate and 60-88 parts of deionized water. By scientific selection of the components, various pertinent components are combined together to efficiently give play to antibacterial, anti-inflammation, acne-removal and repairing efficacies of the whole facial mask. Since a biological transdermal promoting agent is derived from animal and plant extracts, high biological compatibility is achieved, skin injuries are avoided, and safety is achieved.

Owner:宁波秋日小城智能科技有限公司

Processing method to make jasmine tea by Pu'er process

InactiveCN109123000AHighlight substantive featuresSignificant progressTea substituesCooking & bakingGlucose lowering

The invention relates to the field of tea leaf processing, in particular to a processing method to make jasmine tea by Pu'er process. The raw materials include 100-200 parts of jasmine flower, 5-10 parts of mulberry fruit and 100-200 parts of tea leaf. The processing method includes: picking tea leaf, extracting mulberry extract, withering, fixing, rolling, drying, mixing with Pu'er tea and stacking, fermenting by piling, selecting flowers for maintenance, scenting, baking, packing and the like. The processing method has the advantages of the making process of Pu'er fermented tea; probiotics of the Pu'er fermented tea are absorbed; the jasmine tea made herein has the advantages of body immunity improving, liver tonifying and kidney benefiting, glucose lowering, and good health effect.

Owner:横县南方茶厂

Piezoelectric ultrasonic salt-bath heating nitriding device

InactiveCN101812661BImprove diffusion abilityStrong cavitation effectSolid state diffusion coatingInsulation layerTransformer

Owner:ZHONGBEI UNIV

Modification treatment method of ZSM-5 zeolite

ActiveCN102874840BMesoporous specific surface area is highMesoporous structure intactPentasil aluminosilicate zeoliteOrganic solventCavitation

The invention discloses a modification treatment method of ZSM-5 zeolite. The method comprises the following steps of: adding a certain proportion of aqueous alkali and a low molecular weight organic solvent into ZSM-5 zeolite, performing ultrasonic treatment on the system, transferring to an enclosed system for alkali treatment, and finally separating and drying to obtain the modified ZSM-5 zeolite. The supersonic wave can generate a super strong cavitation effect so as to activate the ZSM-5 zeolite's framework silicon atom and help the next alkali treatment. During the alkali treatment process, aqueous alkali selectively removes part of silicon element in the ZSM-5 crystals such that structural rearrangement is generated in micropores so as to form mesopores. The addition of the low molecular weight organic solvent can promote the generation of the meso-structure so as to make the micropore structure more efficiently to be converted to mesopores and simultaneously stabilize and protect the micropore structure. By the adoption of the method, more complete micropores can be retained, more mesopores can be provided, and total BET specific surface area also can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-efficiency antioxidant acne-removing handmade soap

InactiveCN107805559ADestructiveImprove antioxidant capacitySurface-active non-soap compounds and soap mixture detergentsSkin careWater bathsPyracantha fortuneana fruit extract

The invention relates to a preparation method of a high-efficiency antioxidant acne-removing handmade soap. The preparation method is characterized by comprising the following steps of: (1) heating seabuckthorn seed oil in a water bath to 62 DEG C, and carrying out uniform-speed stirring to obtain A; (2) adding deionized water, nicotinamide, tea saponin and a natural soap base into A, and uniformly stirring the materials to obtain a mixture B; (3) uniformly mixing a traditional Chinese medicine extract, a phyllostachys pubescens leaf extract, a pyracantha fortuneana fruit extract, a lonicera caerulea extract, a mangosteen skin extract, an Italian anchusa italica extract, a litchi leaf extract, a myrica rubra leaf extract, a perilla leaf extract and a mugwort extract in parts by weight, adding the mixture into the mixture B, carrying out stirring for 28min to fully mix the mixture, pouring the mixture into a grinding tool, and curing the mixture for 28h at a constant temperature of 44 DEG C to obtain a semi-finished product; and (4) demoulding the semi-finished product, putting the semi-finished product in a cool and dry place for 12 days, and trimming and packaging the semi-finished product to obtain a finished product of the handmade soap.

Owner:宁波秋日小城智能科技有限公司

Preparation method of mesopore-micropore zeolite molecular sieve

ActiveCN102874829BEfficient transformationImprove protectionCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

The invention discloses a preparation method of a mesopore-micropore zeolite molecular sieve, comprising the following steps of: firstly mixing micropore zeolite and aqueous alkali and carrying out ultrasonic treatment; then carrying out heat treatment on the micropore zeolite in an enclosed system in the presence of an organic solvent; and finally processing the micropore zeolite by the use of an acid solution. According to the method, supersonic wave can generate a cavitation effect so as to activate the micropore zeolite's framework silicon atom; during the alkali treatment, the addition of the organic solvent can promote the generation of a meso-structure so as to more efficiently convert the micropore structure to mesopores and simultaneously stabilize and protect the micropore structure; and acid treatment can reach the purpose of dredging pore canal and increasing total specific surface area. By the adoption of the method, more complete mircopores of the mesopore-micropore zeolite molecular sieve can be retained, more mresopores can be provided, and simultaneously the total BET specific surface area can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com