Method for extracting betulin from birch bark

A technology of betulin and birch bark, which is applied in the fields of phytochemistry and food chemistry, can solve the problems of multiple reflux extractions, cumbersome extraction steps, complicated purification operations, etc., and achieve shortened extraction time, high biological activity of products, and efficient extraction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

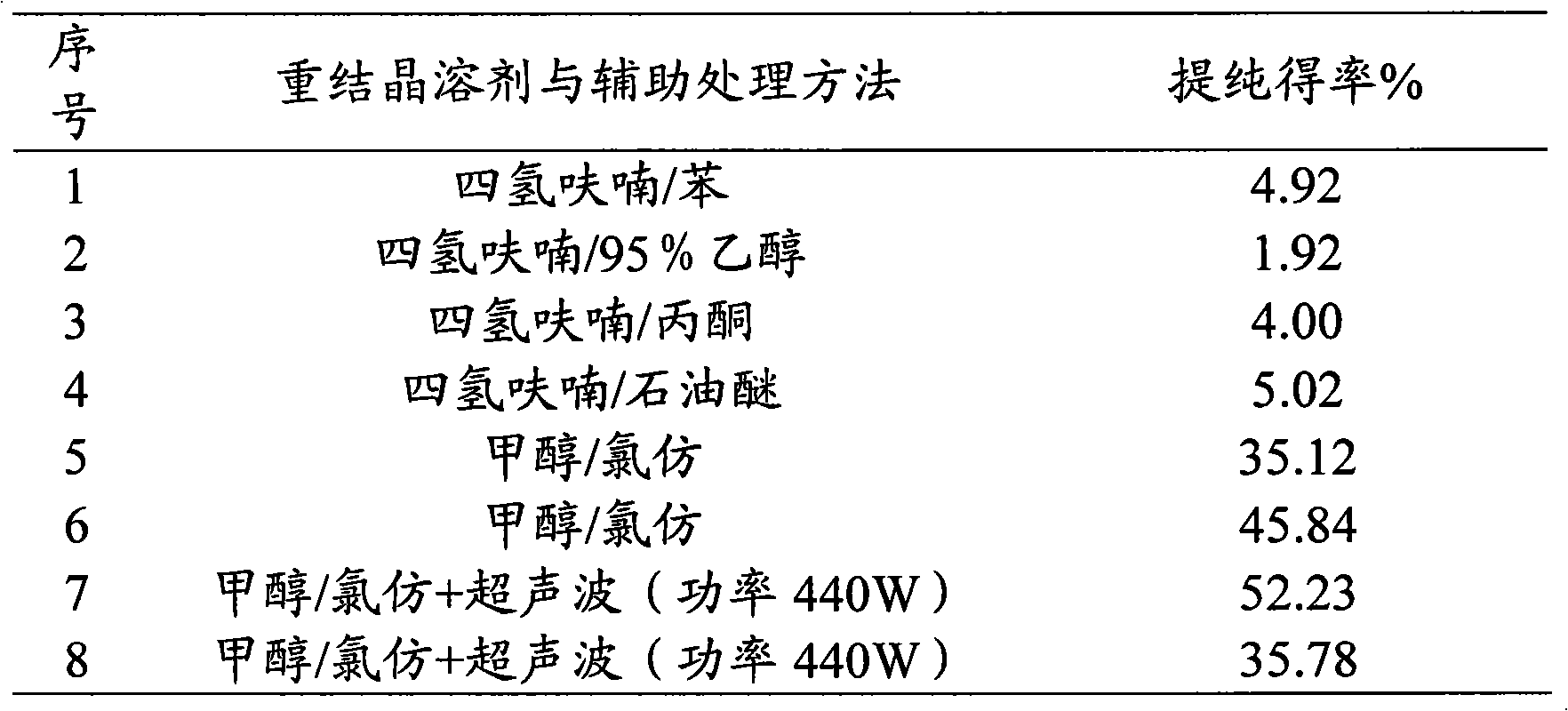

Method used

Image

Examples

Embodiment 1

[0028] Grind the dried birch bark with a pulverizer, weigh 2.0g of the bark powder and place it in a 250ml round-bottomed flask; add 50ml of 80% ethanol solution, ultrasonically reflux for 3 hours, the ultrasonic temperature is 60°C, and the ultrasonic power is 550W; reflux extraction After the end, the residue was removed by filtration and separation to obtain a brown-yellow extract; the filtrate was distilled under reduced pressure on a rotary evaporator, and a yellow solid powder was precipitated; dried at 60°C to a constant weight to obtain 0.596 g of a crude product of betulin, which was obtained by reverse-phase high-efficiency Liquid chromatography (RP-HPLC) analysis showed that the purity of the crude product of betulin was 81.101%, and the extraction yield was 24.160%.

Embodiment 2

[0030] Grind the dried birch bark with a pulverizer, weigh 2.0g of the bark powder and place it in a 250ml round bottom flask; add 80ml of 62% ethanol solution, ultrasonically reflux for 1 hour, ultrasonic temperature is 40°C, ultrasonic power is 220W; reflux extraction After the end, filter and separate to remove the residue to obtain a brown-yellow extract; distill the filtrate under reduced pressure on a rotary evaporator to precipitate a yellow solid powder; dry at 60°C to a constant weight to obtain 0.300 g of the crude product of betulin, which was obtained by reverse-phase high-efficiency Liquid chromatography (RP-HPLC) analysis showed that the purity of the crude product of betulin was 63.831%, and the extraction yield was 9.57%.

Embodiment 3

[0032] Grind the dried birch bark with a pulverizer, weigh 2.0g of the bark powder and place it in a 250ml round bottom flask; add 50ml of 99.74% ethanol solution, ultrasonically reflux for 6 hours, ultrasonic temperature is 60°C, ultrasonic power is 550W; reflux extraction After the end, filter and separate to remove the residue to obtain a brown-yellow extract; distill the filtrate under reduced pressure on a rotary evaporator to precipitate a yellow solid powder; dry at 60°C to a constant weight to obtain 0.700 g of the crude product of betulin, which was obtained by reverse-phase high-efficiency Liquid chromatography (RP-HPLC) analysis showed that the purity of the crude product of betulin was 73.132%, and the extraction yield was 25.596%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com