Patents

Literature

528 results about "High acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

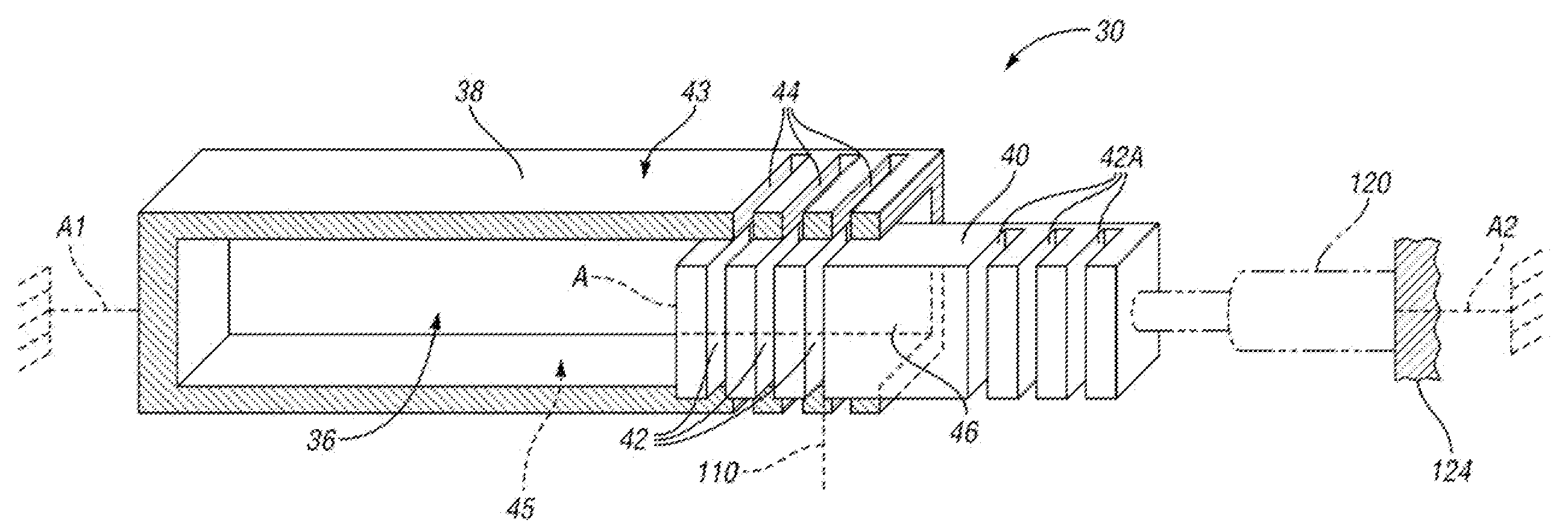

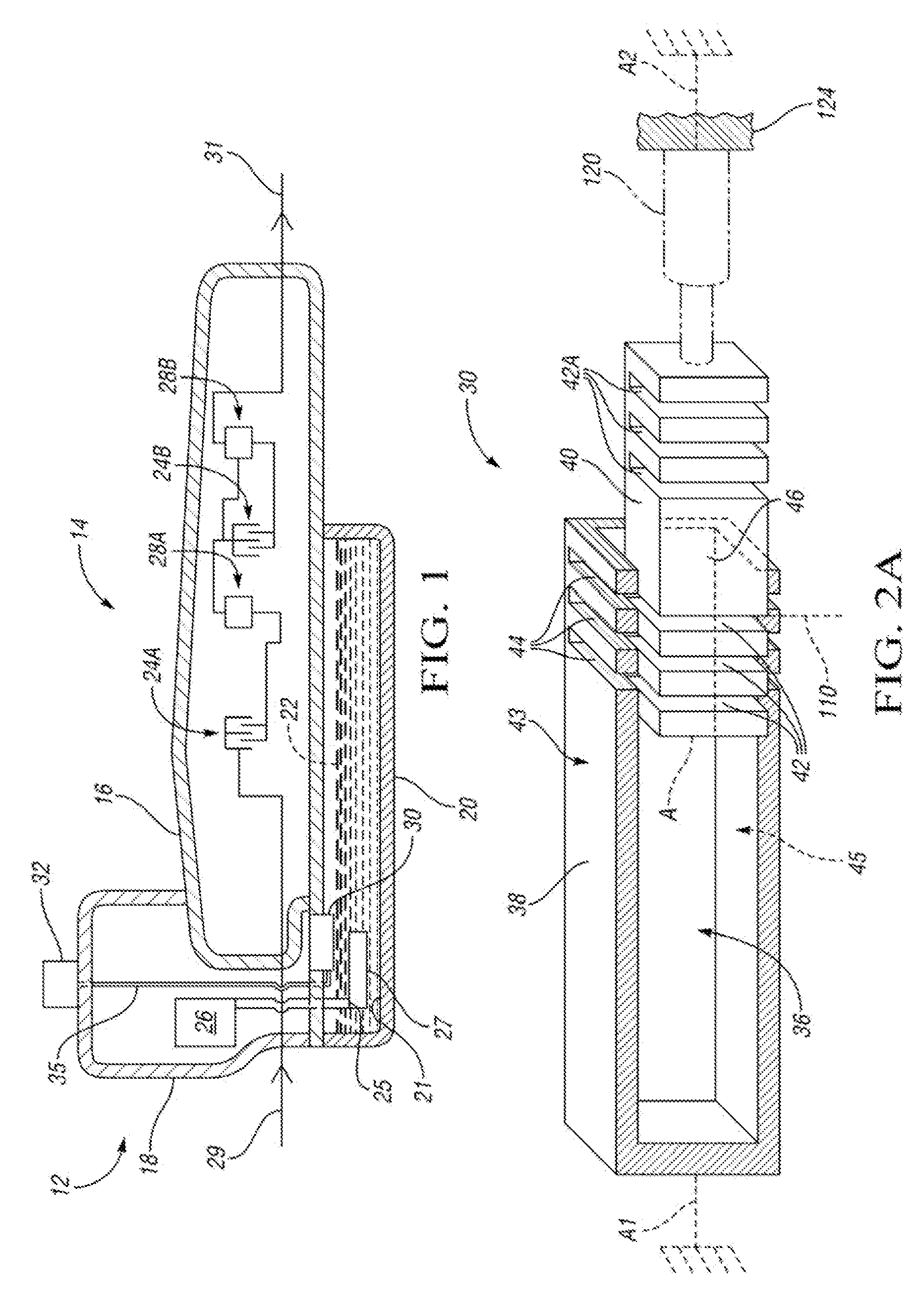

Bone treatment systems and methods

ActiveUS20060122625A1Inhibit migrationInternal osteosythesisJoint implantsHigh accelerationVertebra compression fracture

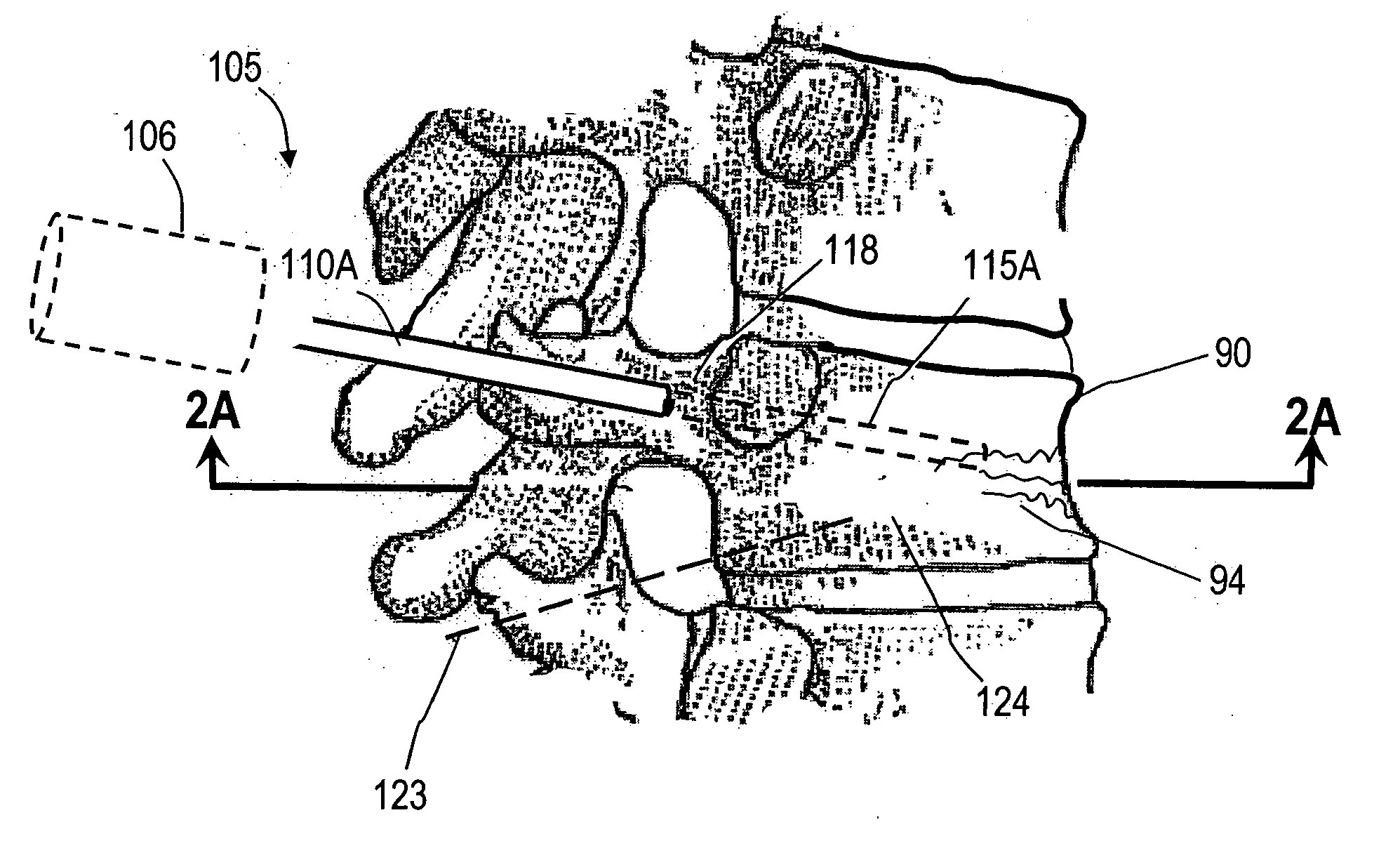

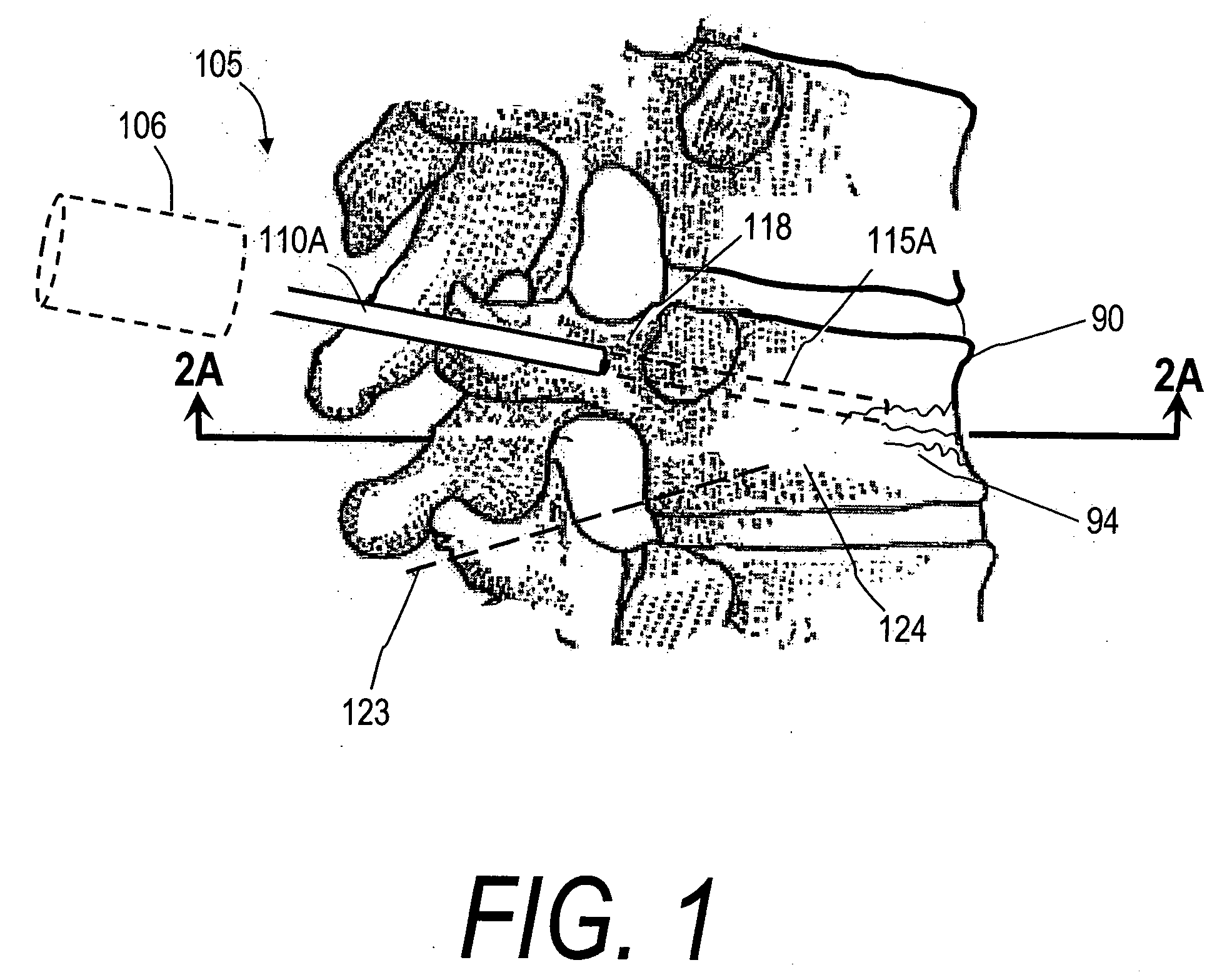

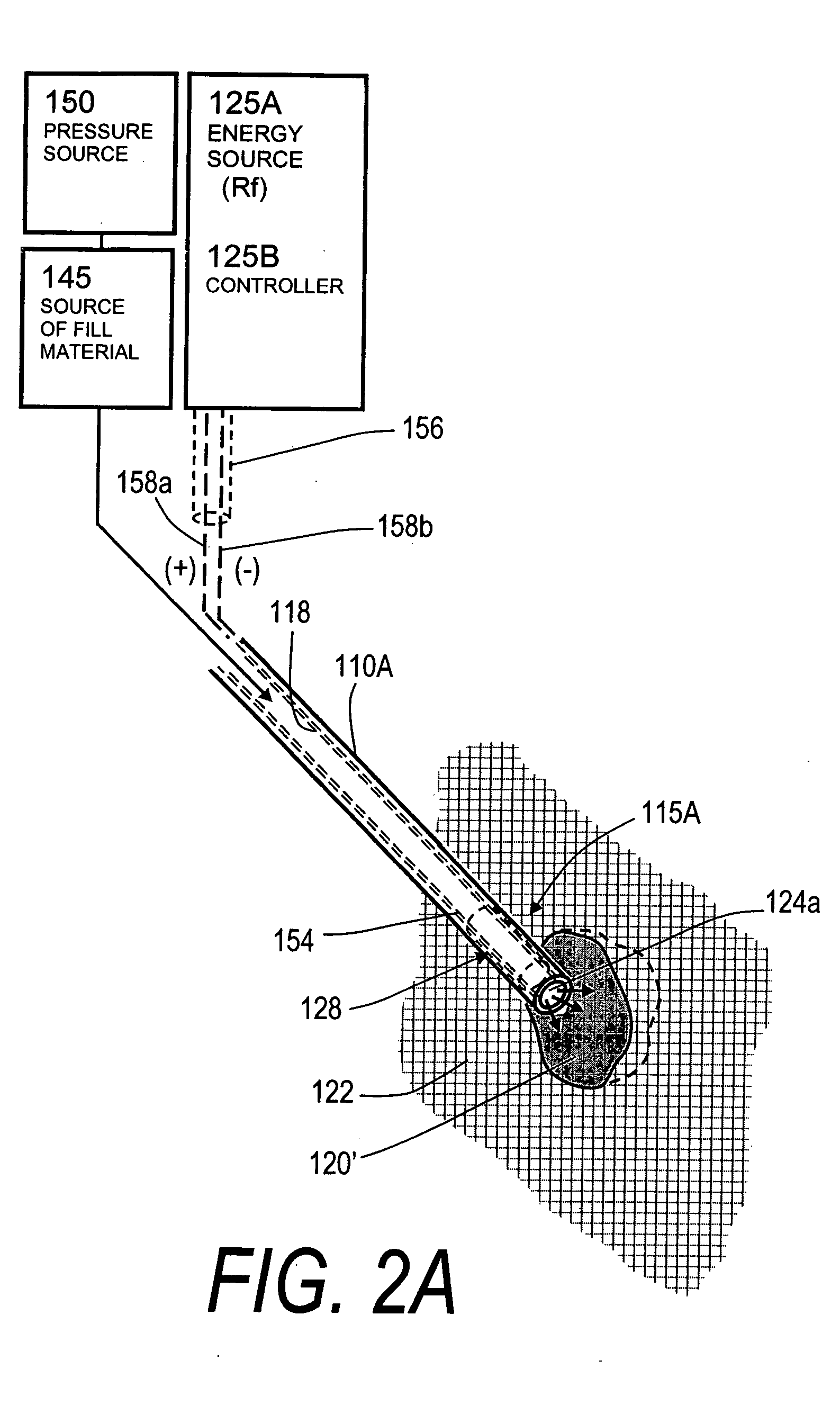

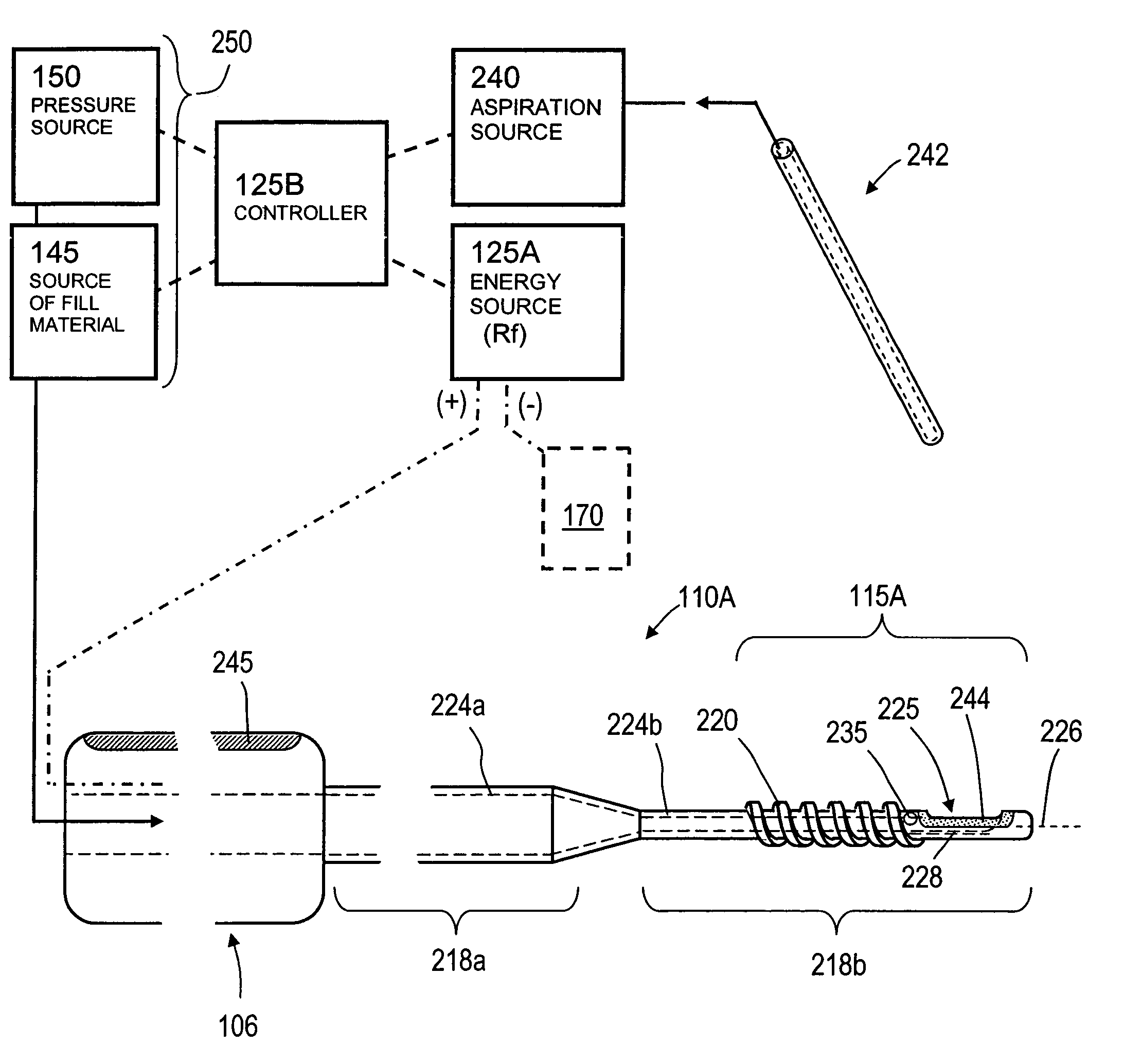

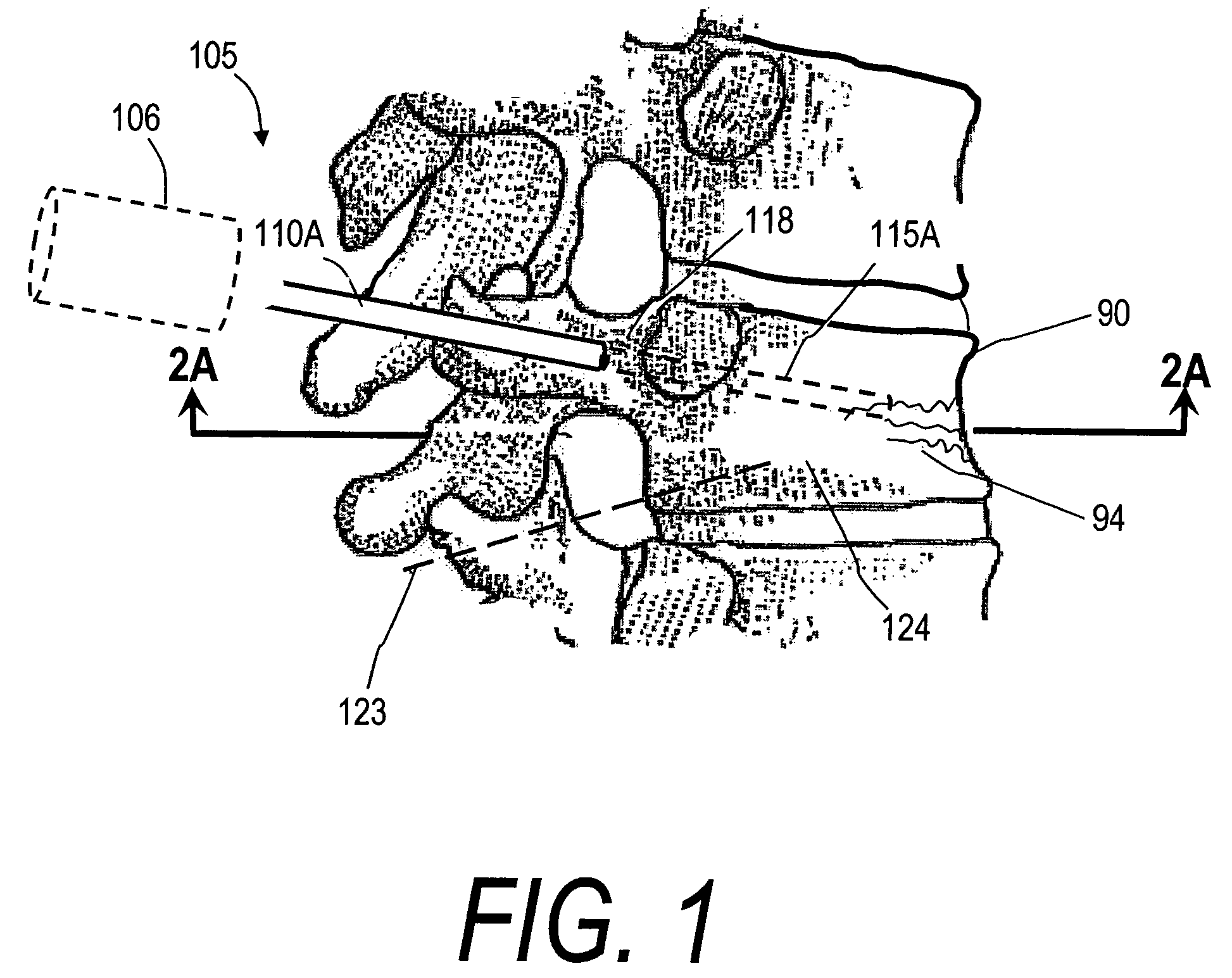

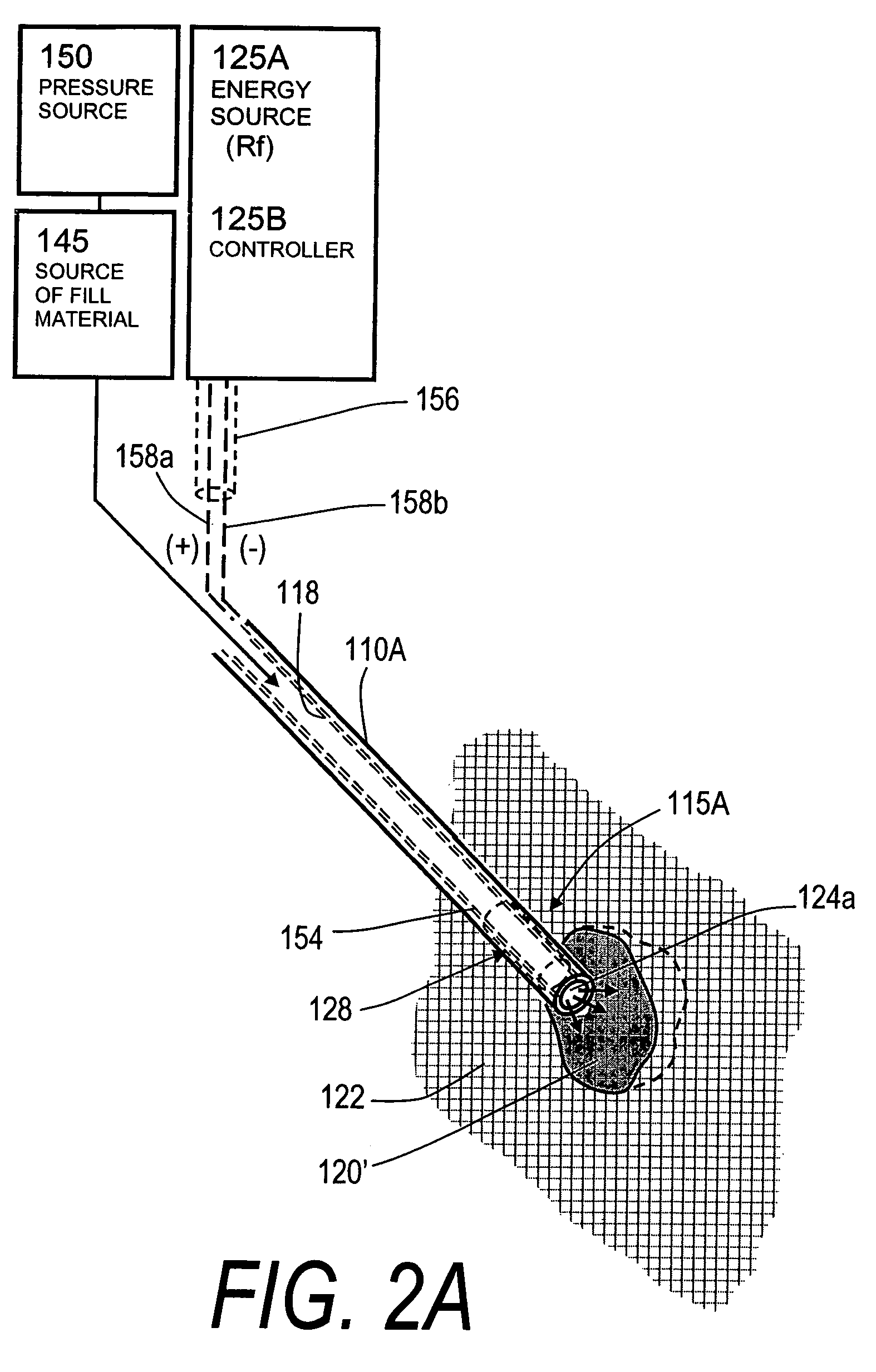

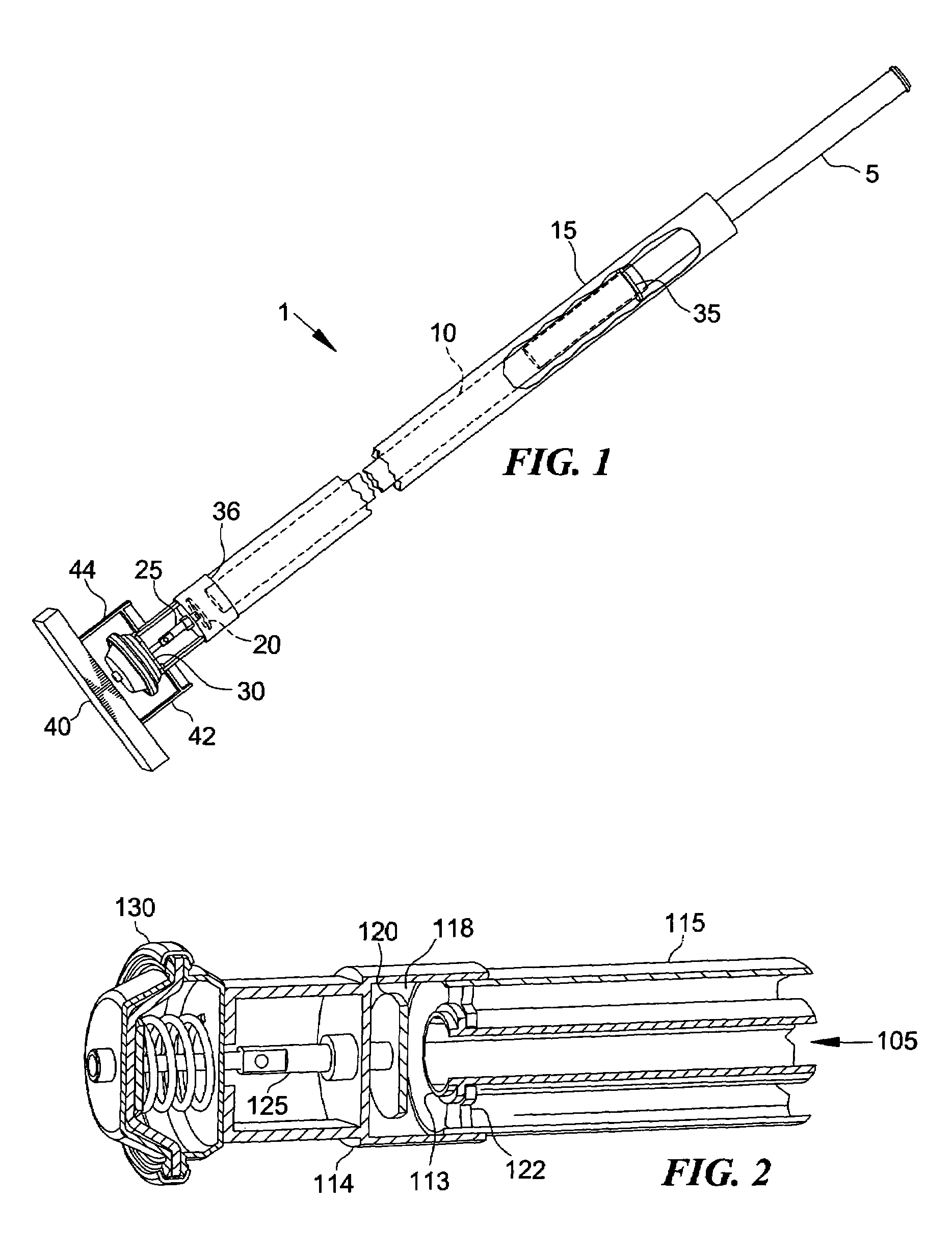

The present invention relates in certain embodiments to medical devices for treating vertebral compression fractures. More particularly, embodiments of the invention relate to instruments and methods for controllably restoring vertebral body height by controlling the flow of bone cement into the interior of a vertebra and the application of forces causes by the cement flow. An exemplary system utilizes Rf energy in combination a conductive bone cement for selectively polymerizing the inflow plume to increase the viscosity of the cement. In one aspect of the invention, the system utilizes a controller to control bone cement flow parameters to either allow or disallow cement interdigitation into cancellous bone. A method of the invention includes pulsing the flows of bone cement wherein high acceleration of the flow pulses can apply expansion forces across the surface of the cement plume to reduce a vertebral fracture.

Owner:DFINE INC

Bone treatment systems and methods

Owner:DFINE INC

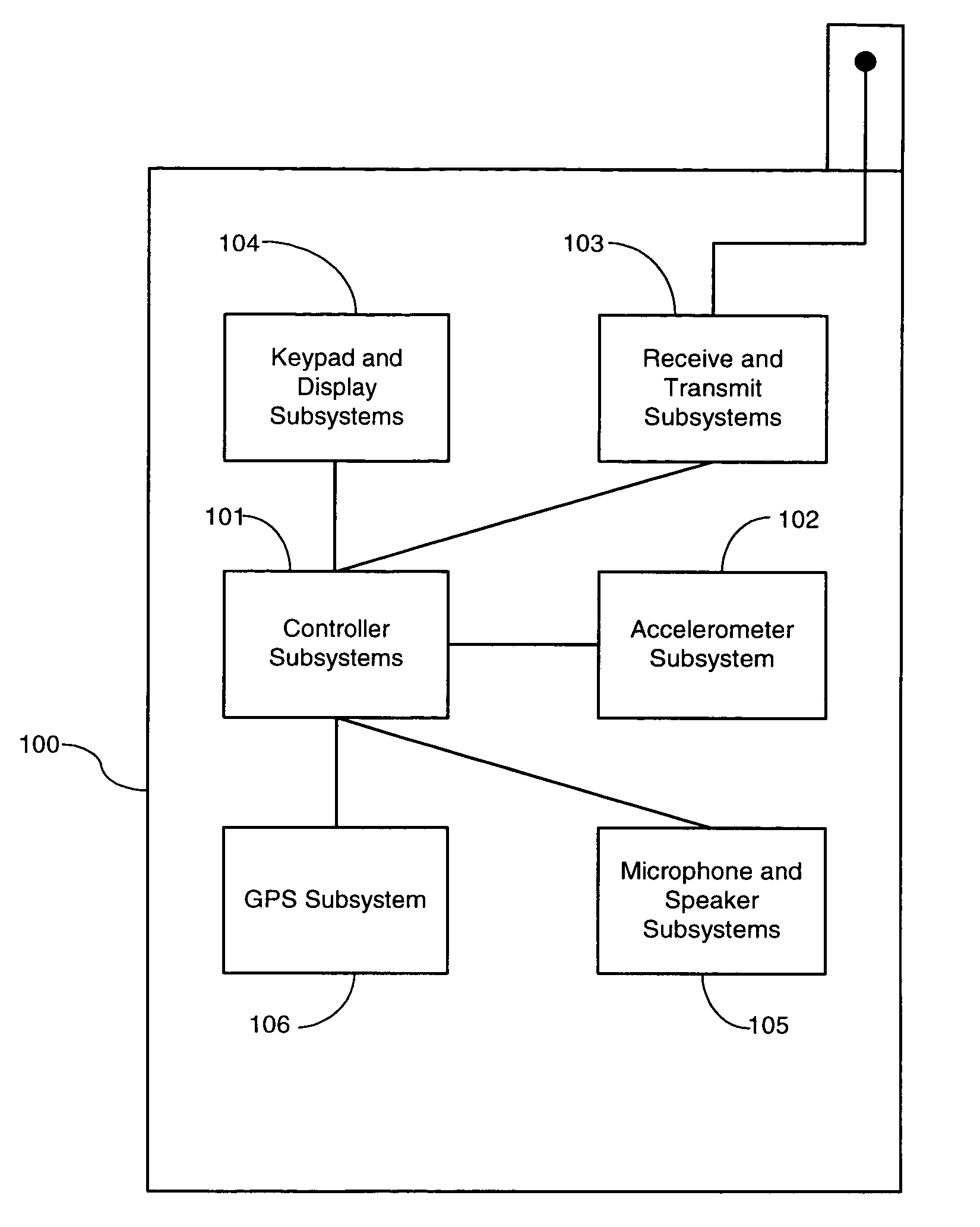

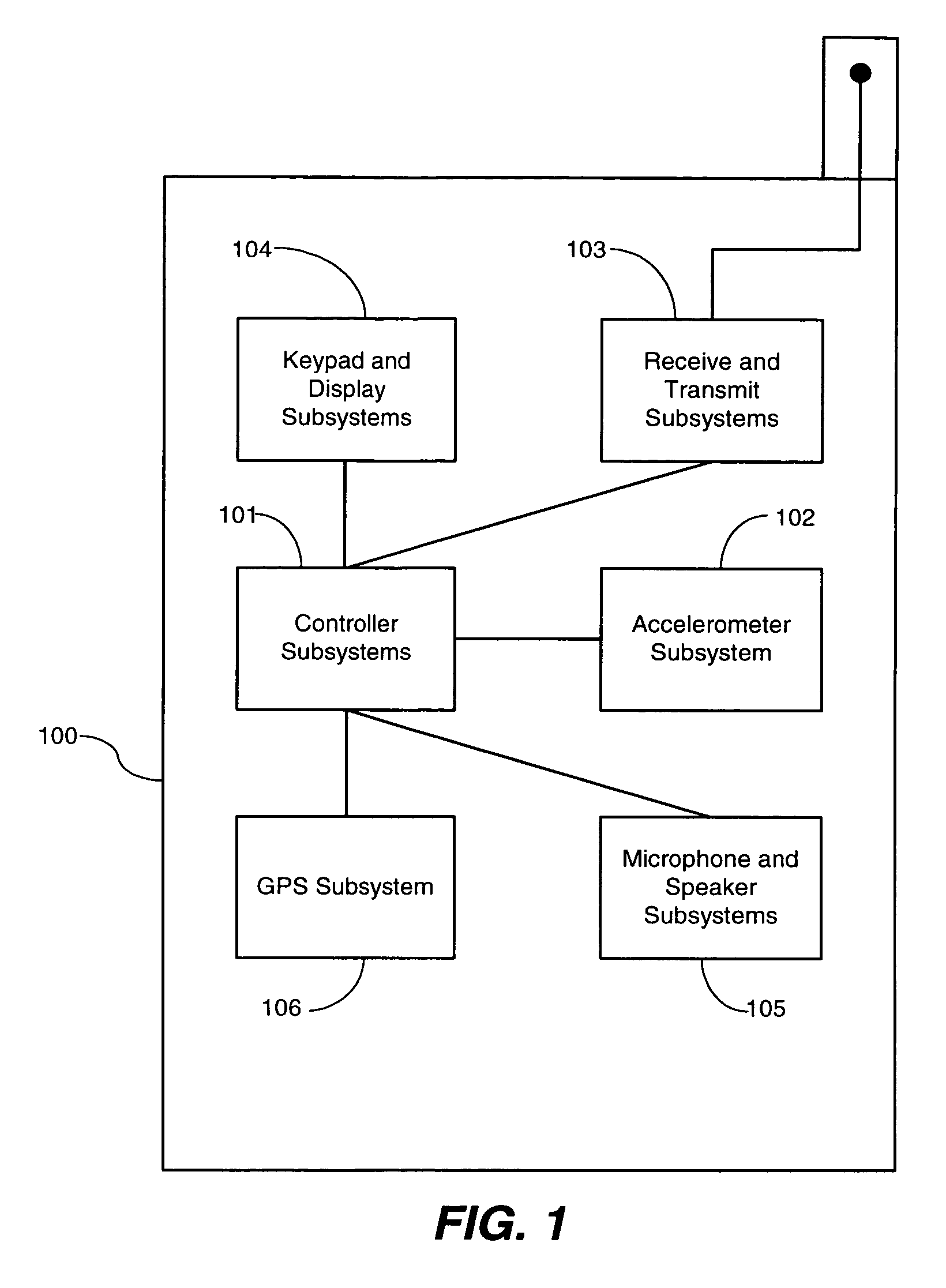

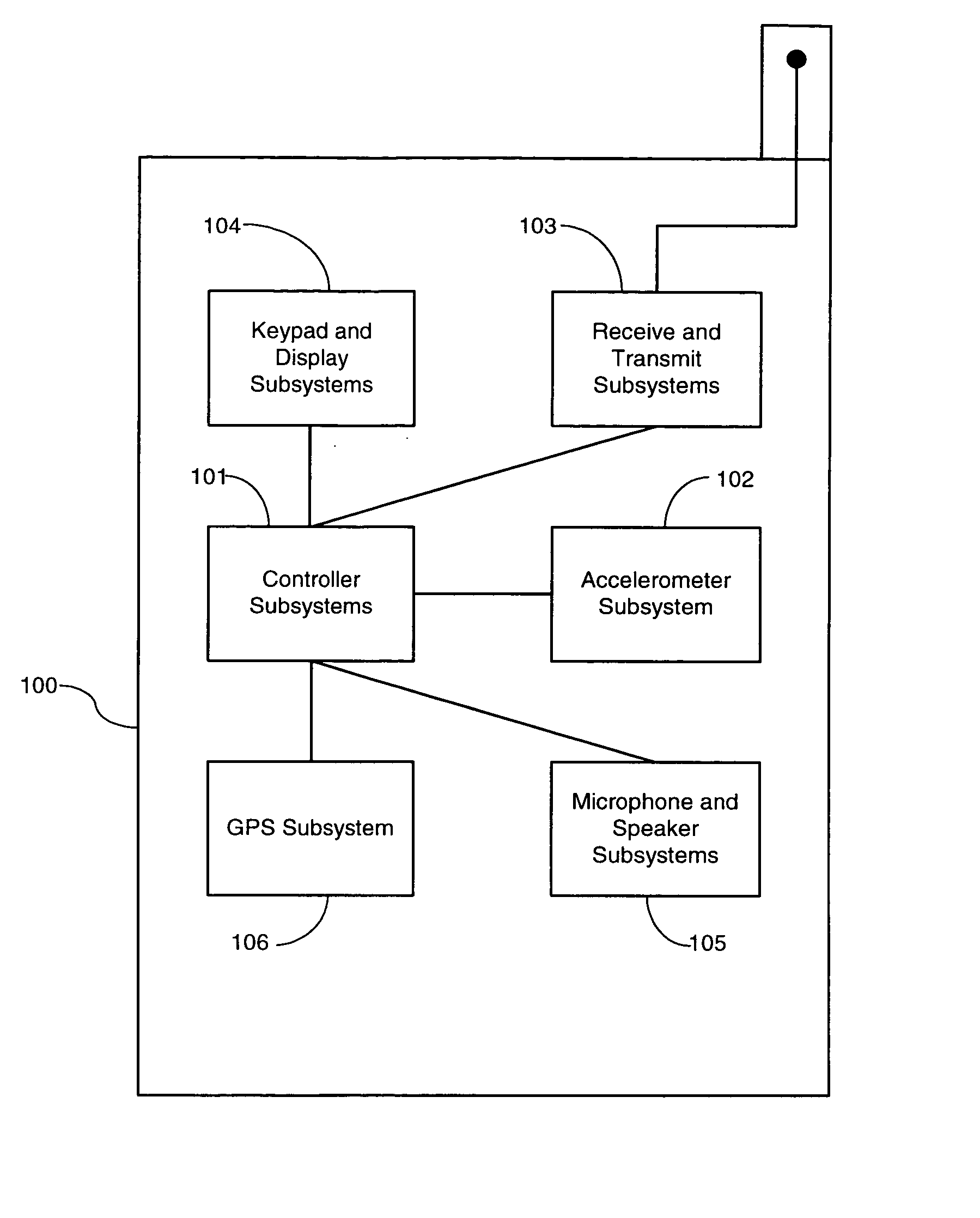

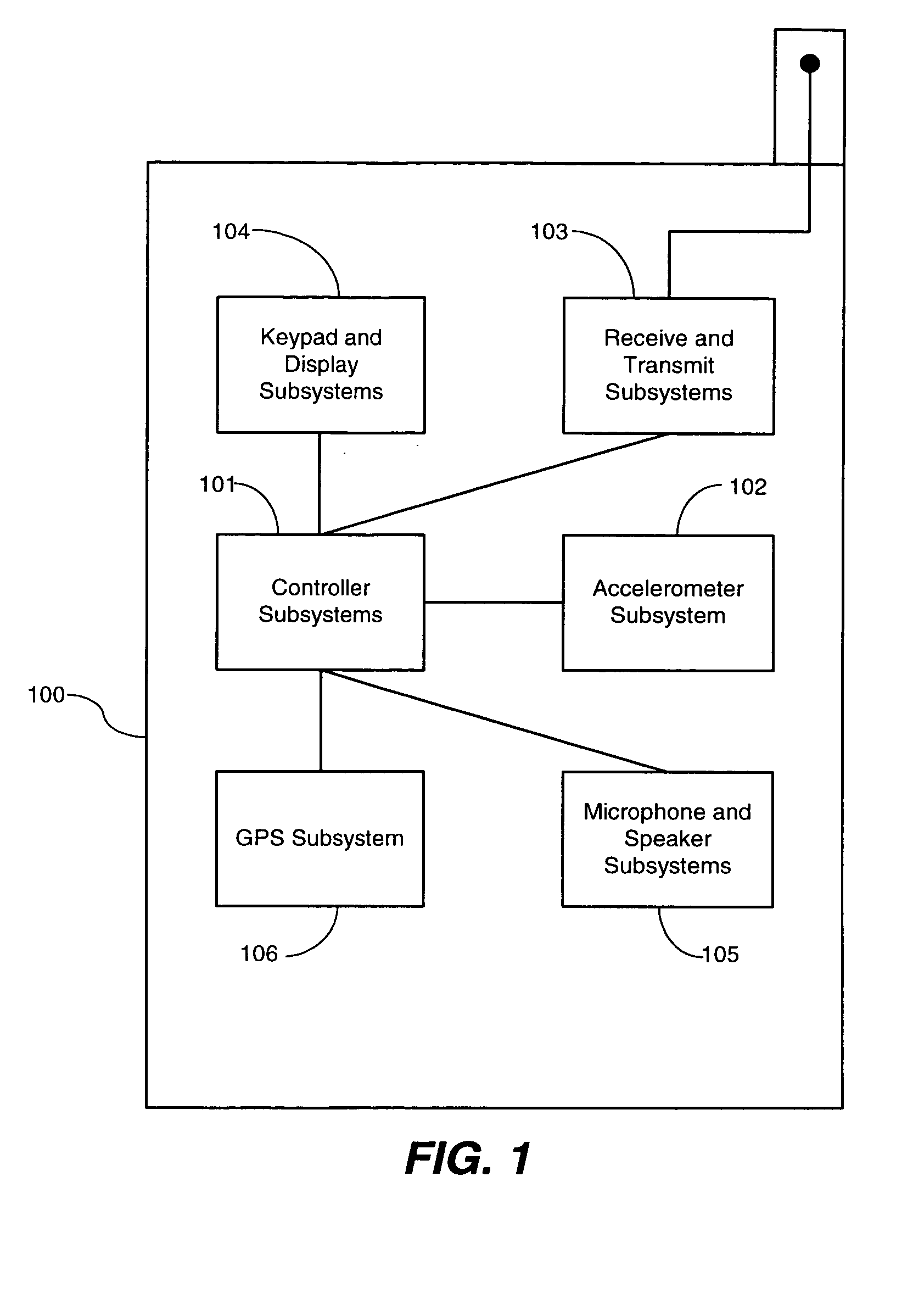

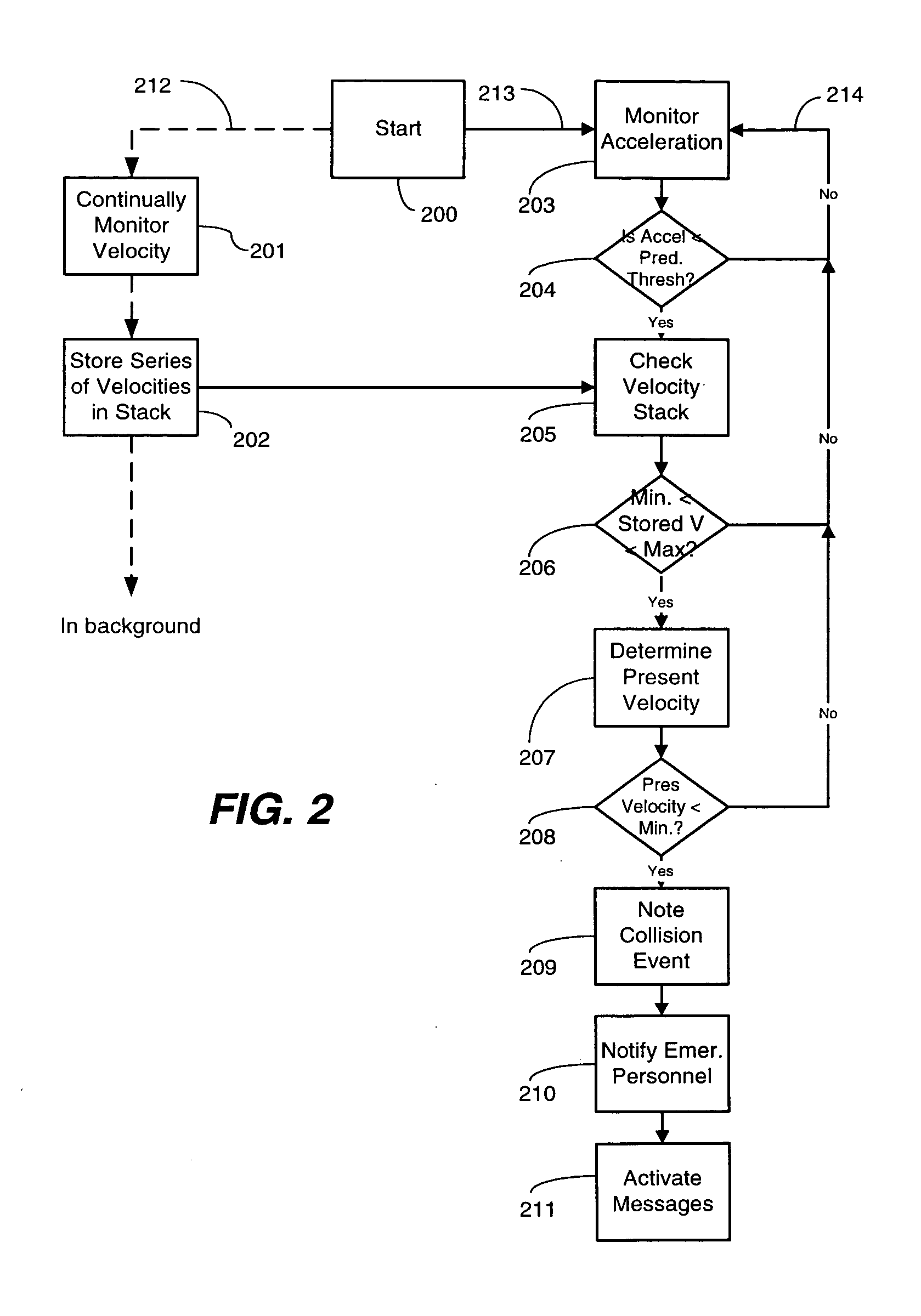

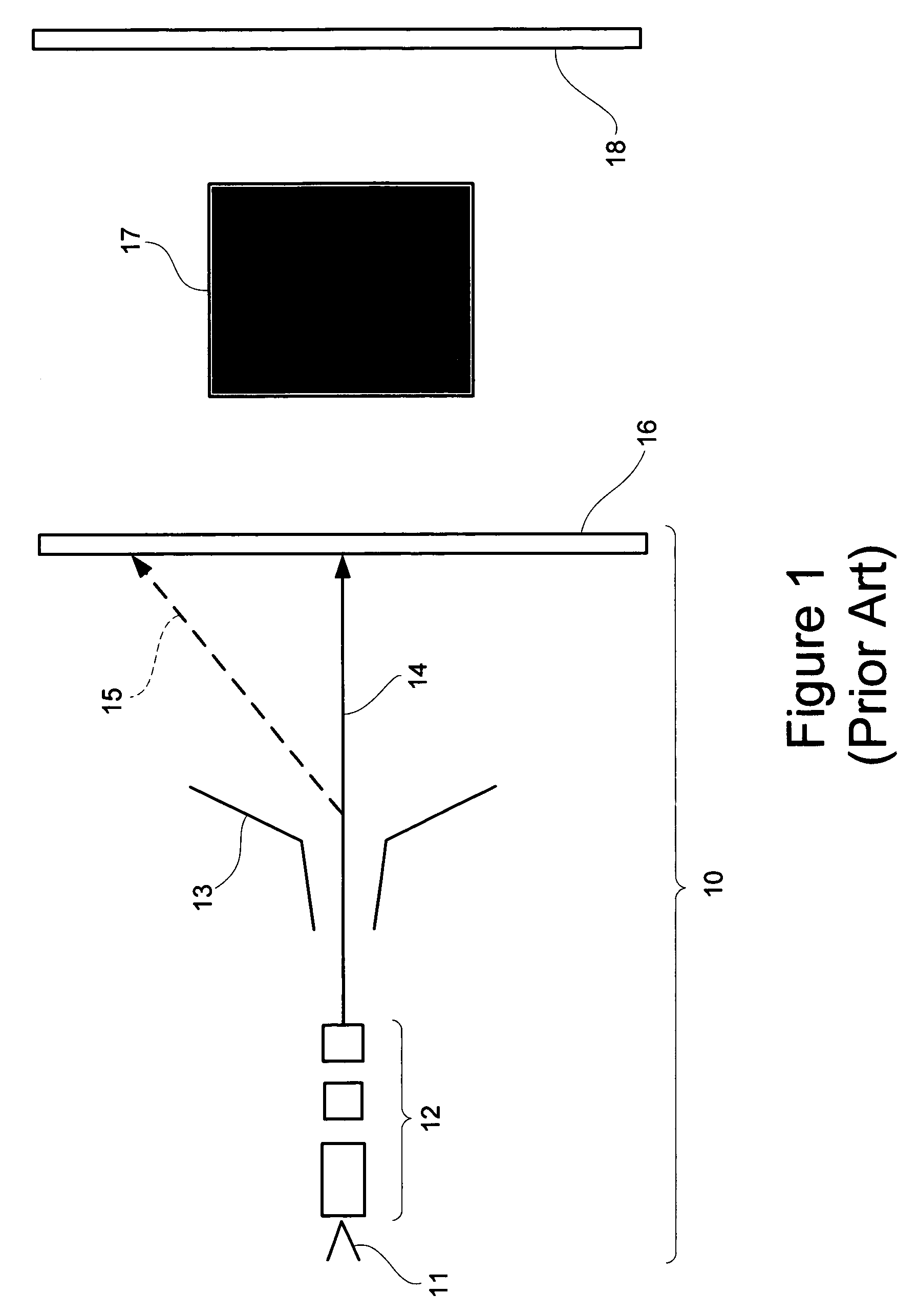

Method and apparatus for detecting vehicular collisions

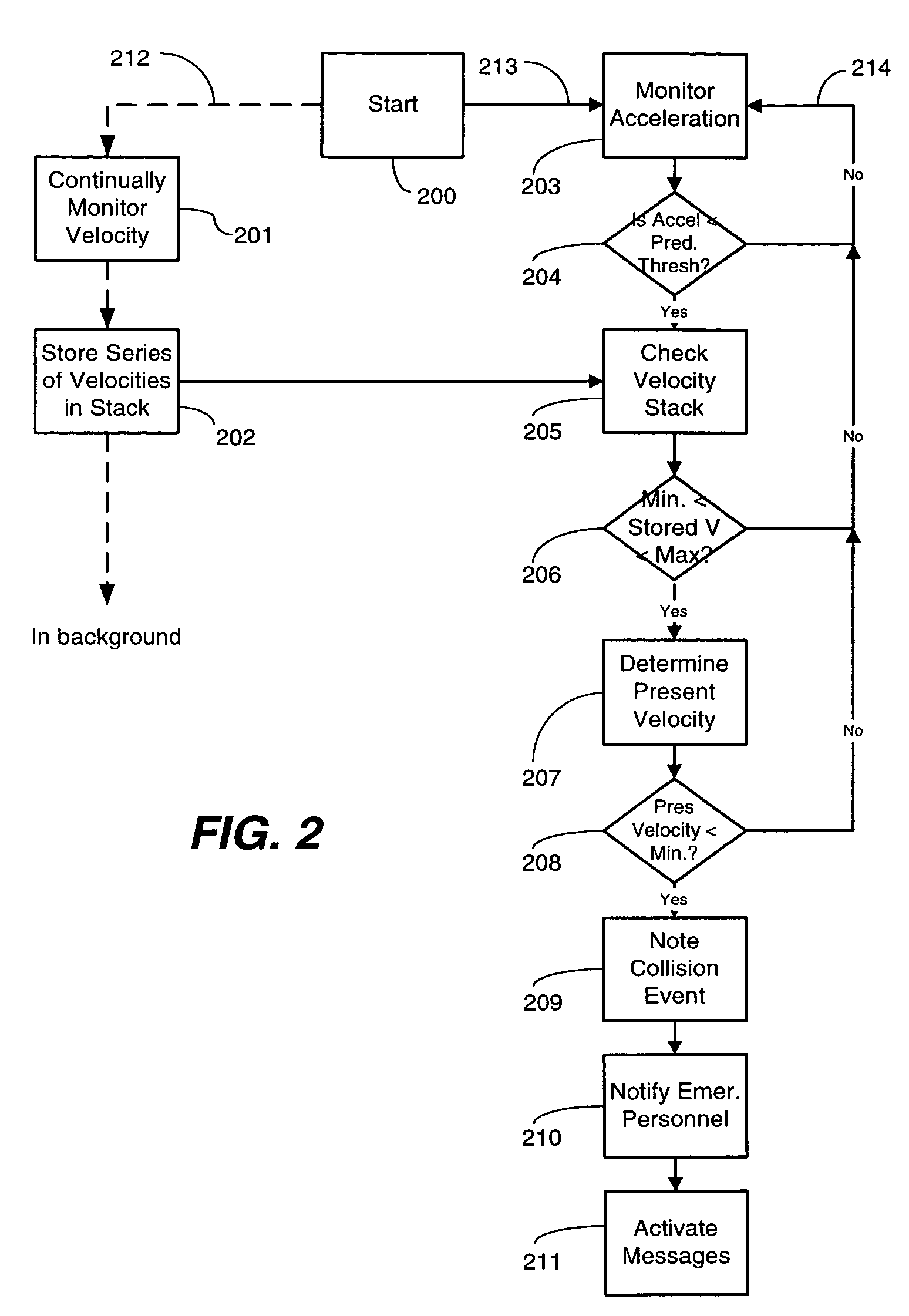

A portable electronic device, like a cellular telephone is capable of detecting collisions between vehicles and notifying the proper authorities. The device includes a microprocessor and memory, in addition to an accelerometer and global positioning systems receiver. The memory includes at least one filter for screening out false positives, which are false collision detections. In one embodiment, the device determines its velocity. It then checks to see if its velocity falls within a range associated with moving vehicles. If so, the device monitors the accelerometer. When acceleration values in excess of a predetermined threshold are detected, the device pauses and again checks its velocity. If the velocity has fallen from the range associated with moving vehicles to a range associated with a vehicle that has sustained a collision, the device notifies emergency personnel that a collision has occurred. Another filter includes an operability check of the keypad, coupled with a notification message that the authorities will be called if the keypad has not been actuated within a predetermined time. Another embodiment includes a detector capable of detecting a vehicular cradle, such that the notification only occurs when high acceleration values are detected in a vehicle.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

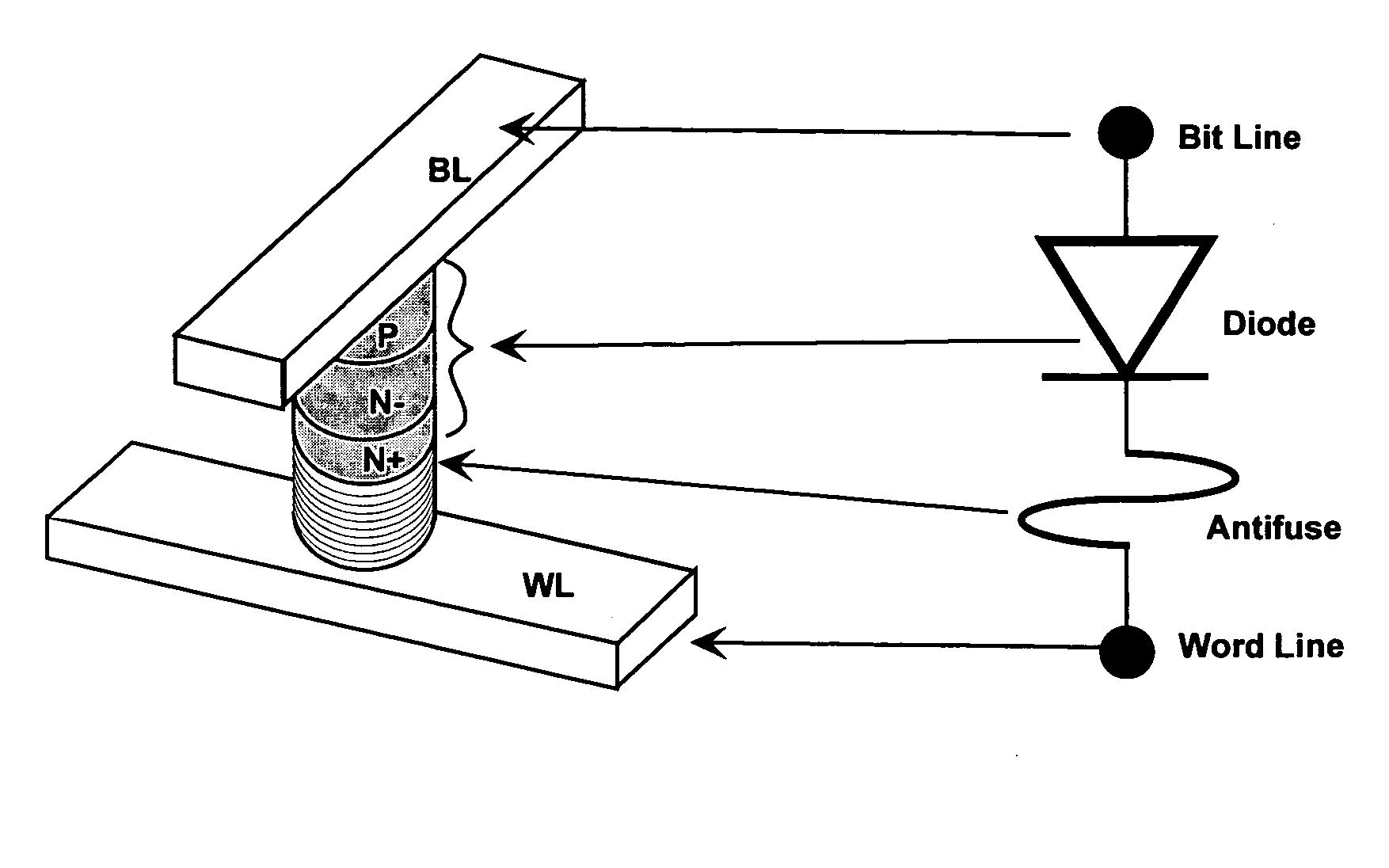

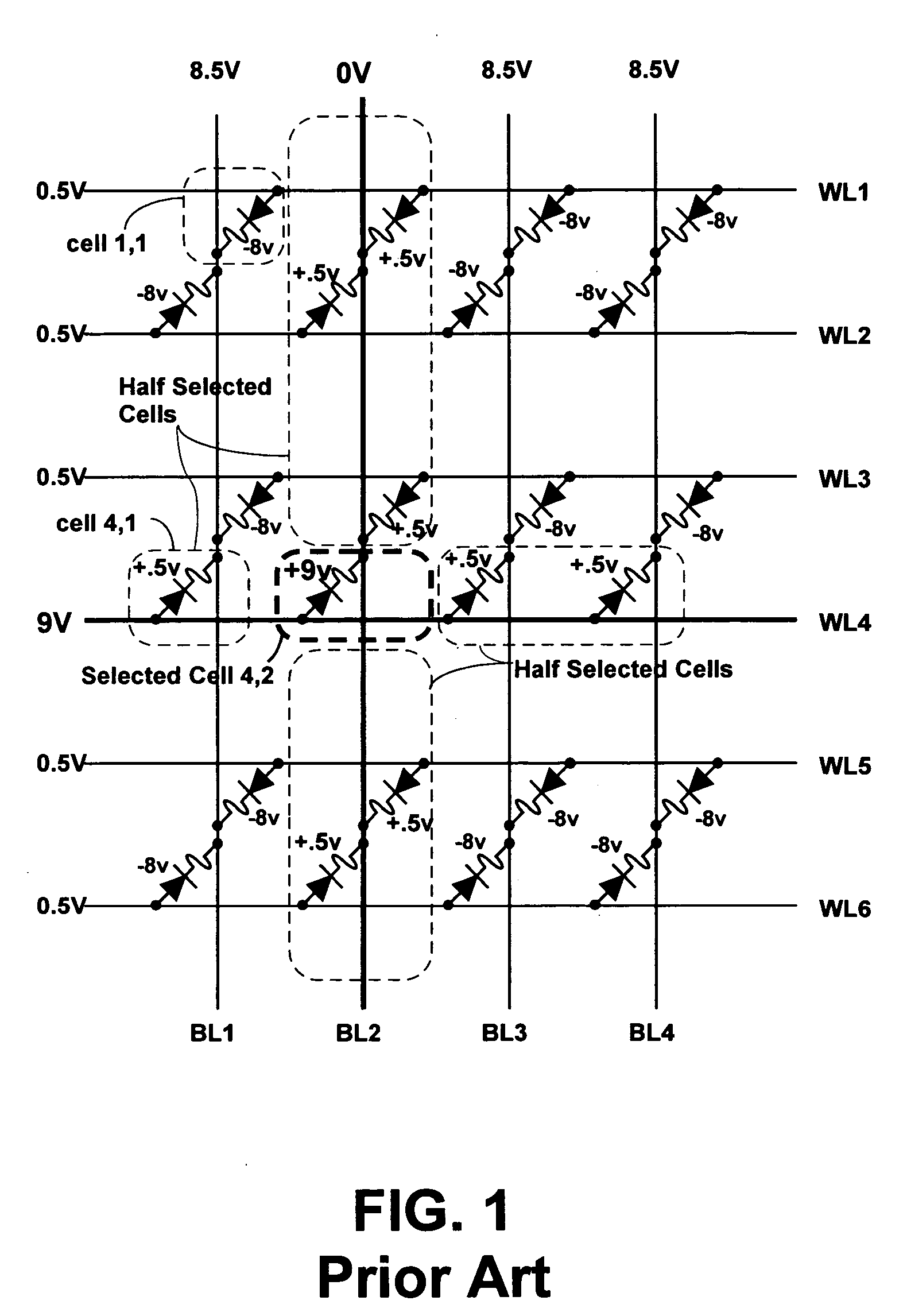

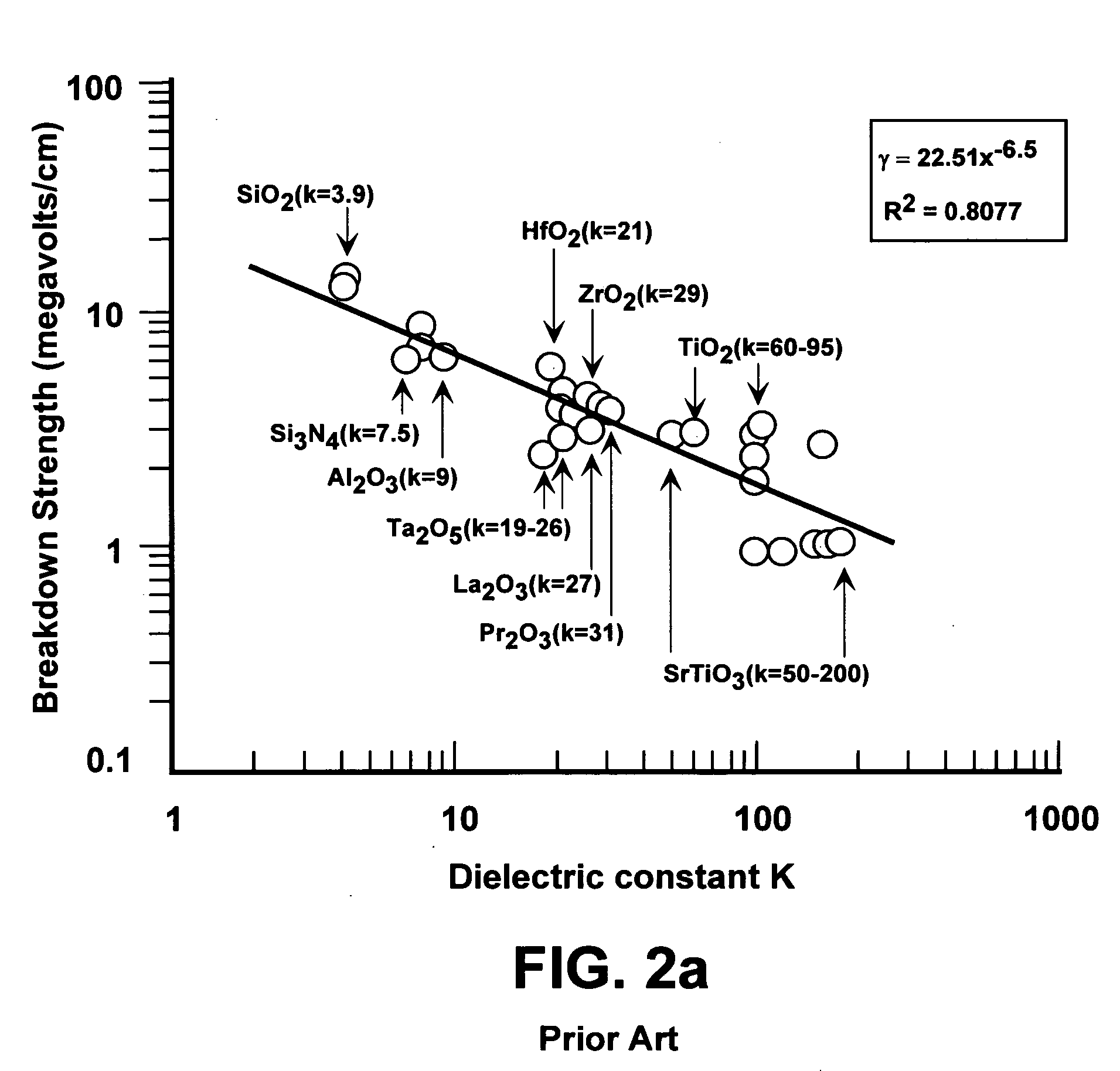

Memory with high dielectric constant antifuses and method for using at low voltage

InactiveUS20070069241A1Reliable readWrite reliablySemiconductor/solid-state device detailsSolid-state devicesLow voltageAlloy

A memory array having memory cells comprising a diode and an antifuse can be made smaller and programmed at lower voltage by using antifuse materials having higher dielectric constant and higher acceleration factor than silicon dioxide, and by using diodes having lower band gaps than silicon. Such memory arrays can be made to have long operating lifetimes by using the high acceleration factor and lower band gap materials. Antifuse materials having dielectric constants between 5 and 27, for example hafnium silicon oxynitride or hafnium silicon oxide are particularly effective. Diode materials with band gaps lower than silicon, such as germanium or a silicon-germanium alloy are particularly effective.

Owner:SANDISK TECH LLC

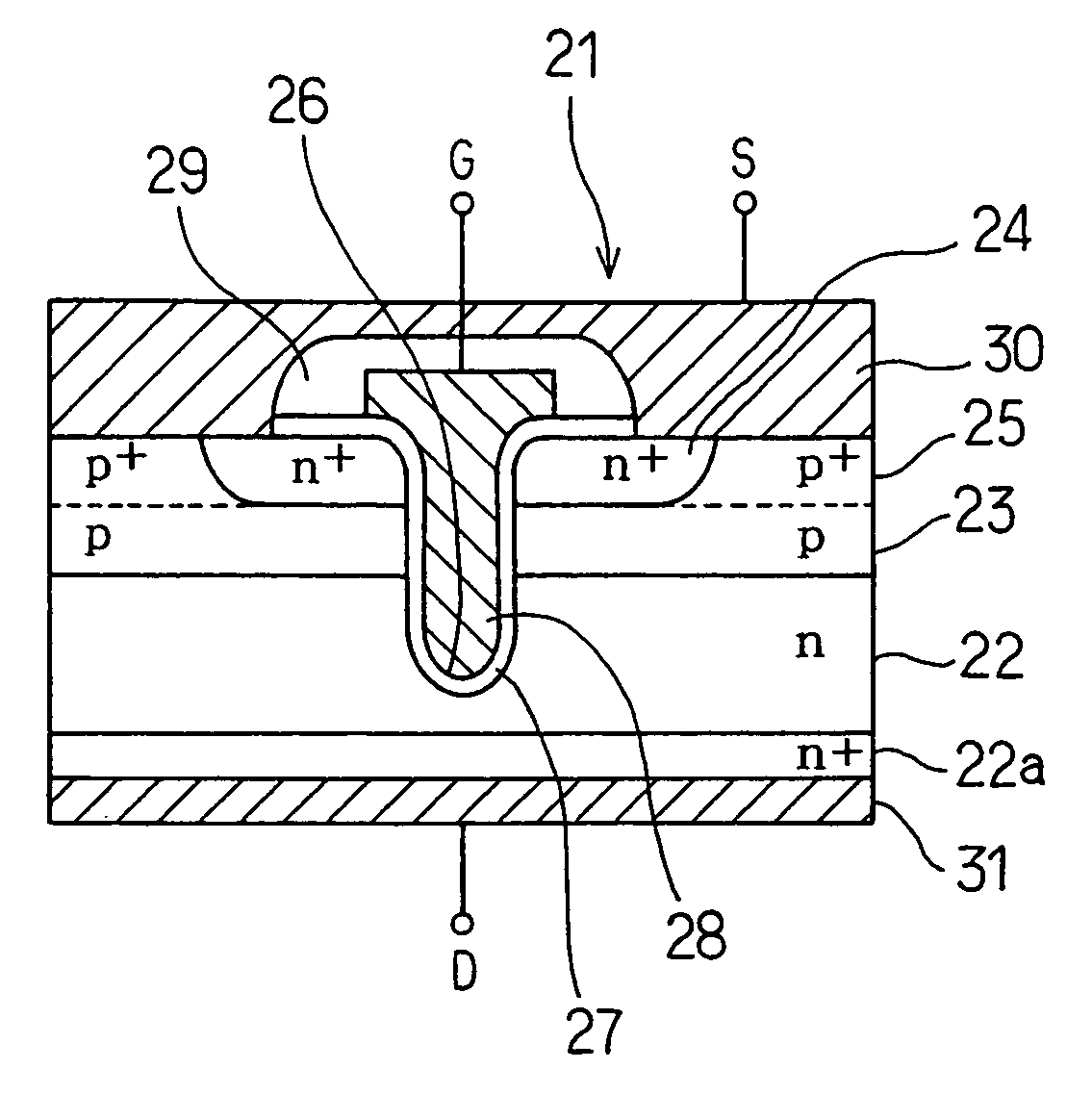

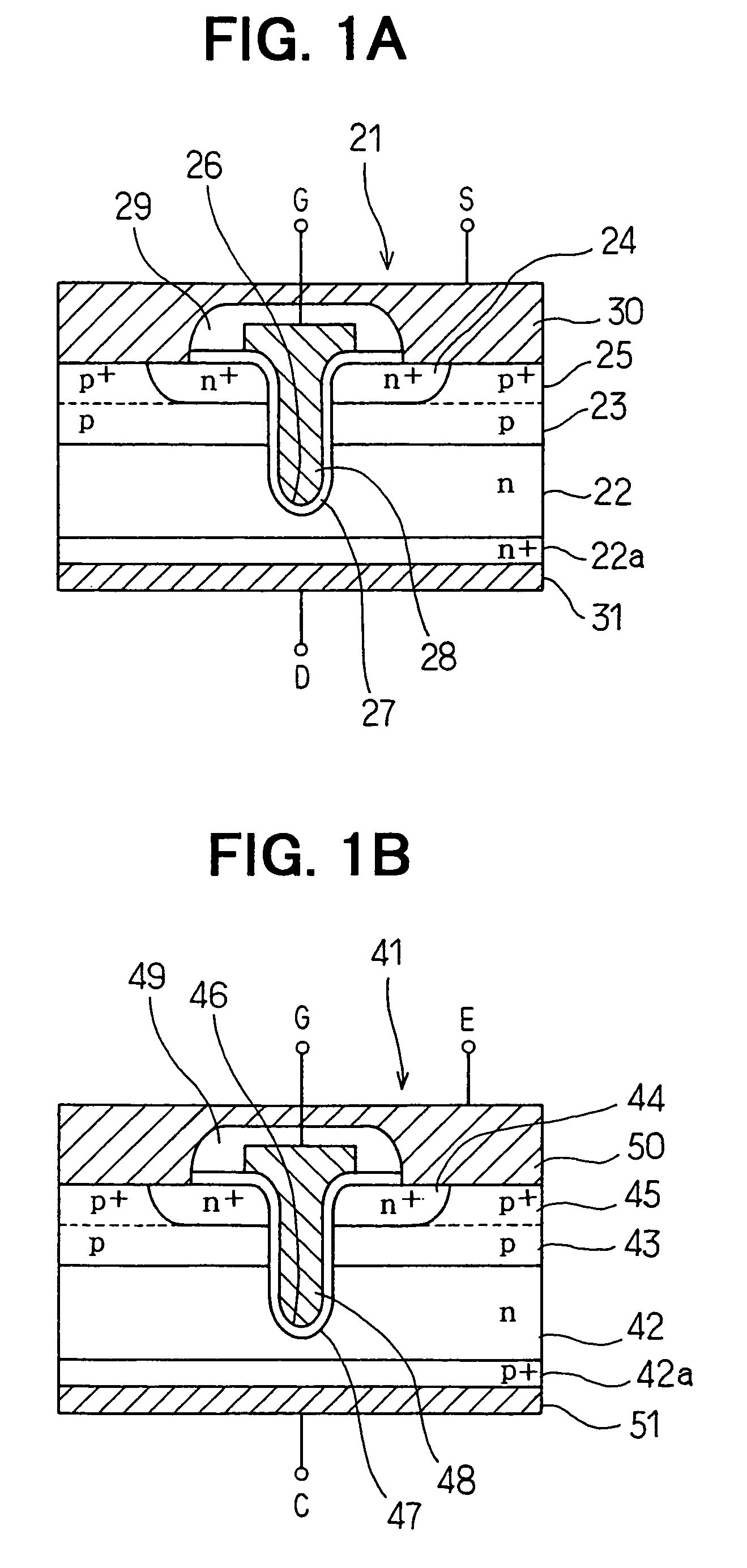

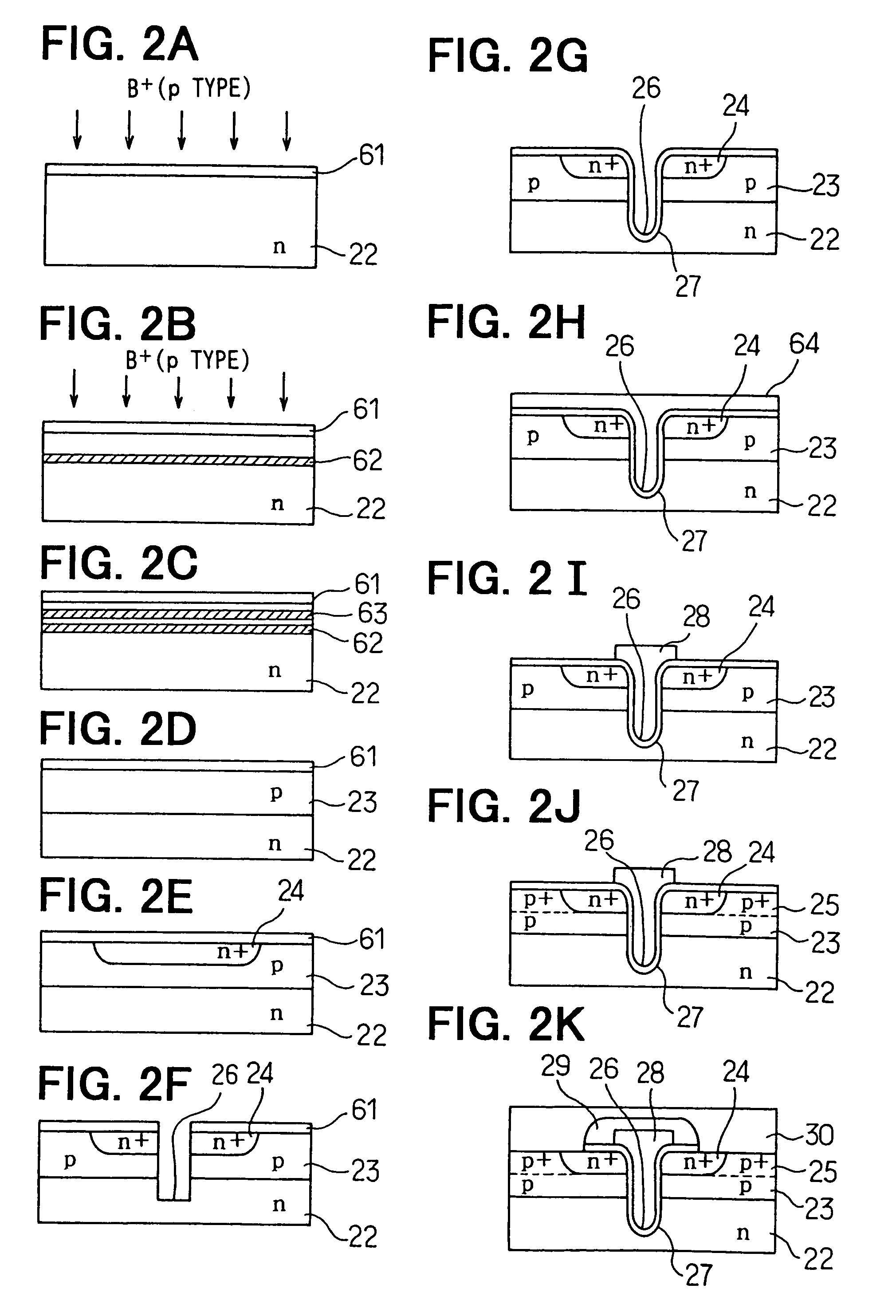

Manufacturing method of semiconductor device

InactiveUS7037788B2Suppress mutationDeterioration of characteristicSemiconductor/solid-state device manufacturingSemiconductor devicesSub thresholdHigh acceleration

By improving profile of impurity concentration in a channel portion of an FET or an IGBT of a trench gate type, variation of threshold value is lessened, and a destruction caused by current concentration is prevented while suppressing deterioration of cut-off characteristics. An island of a base region of p-type is formed in a semiconductor substrate of n-type by carrying out high acceleration ion implantation twice followed by annealing, so that the impurity concentration profile in a channel portion changes gradually in a depth direction. Accordingly, it is possible to lessen variation of the threshold value and to reduce pinch resistance while at the same time improving sub-threshold voltage coefficient and conductance characteristics.

Owner:DENSO CORP

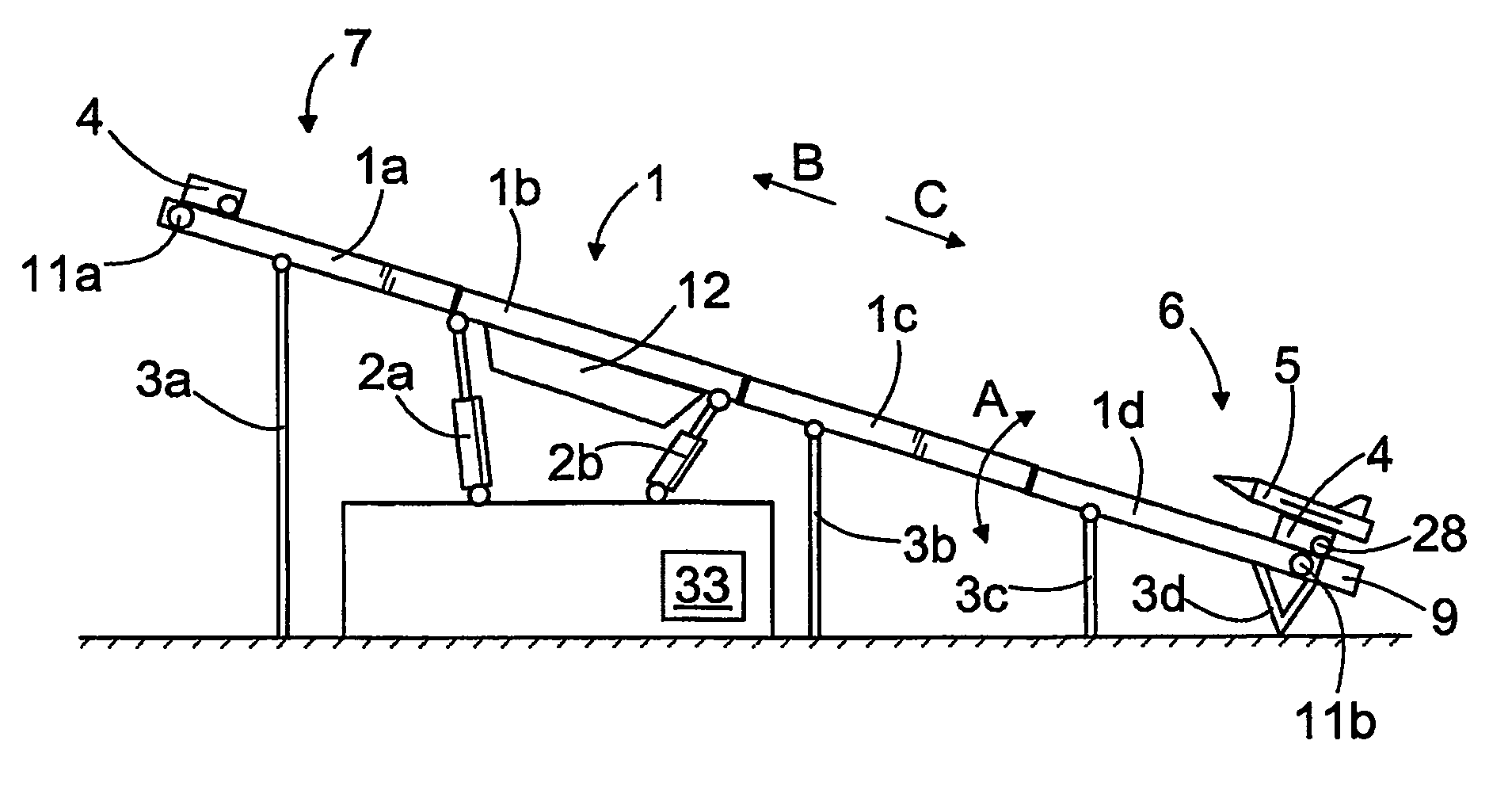

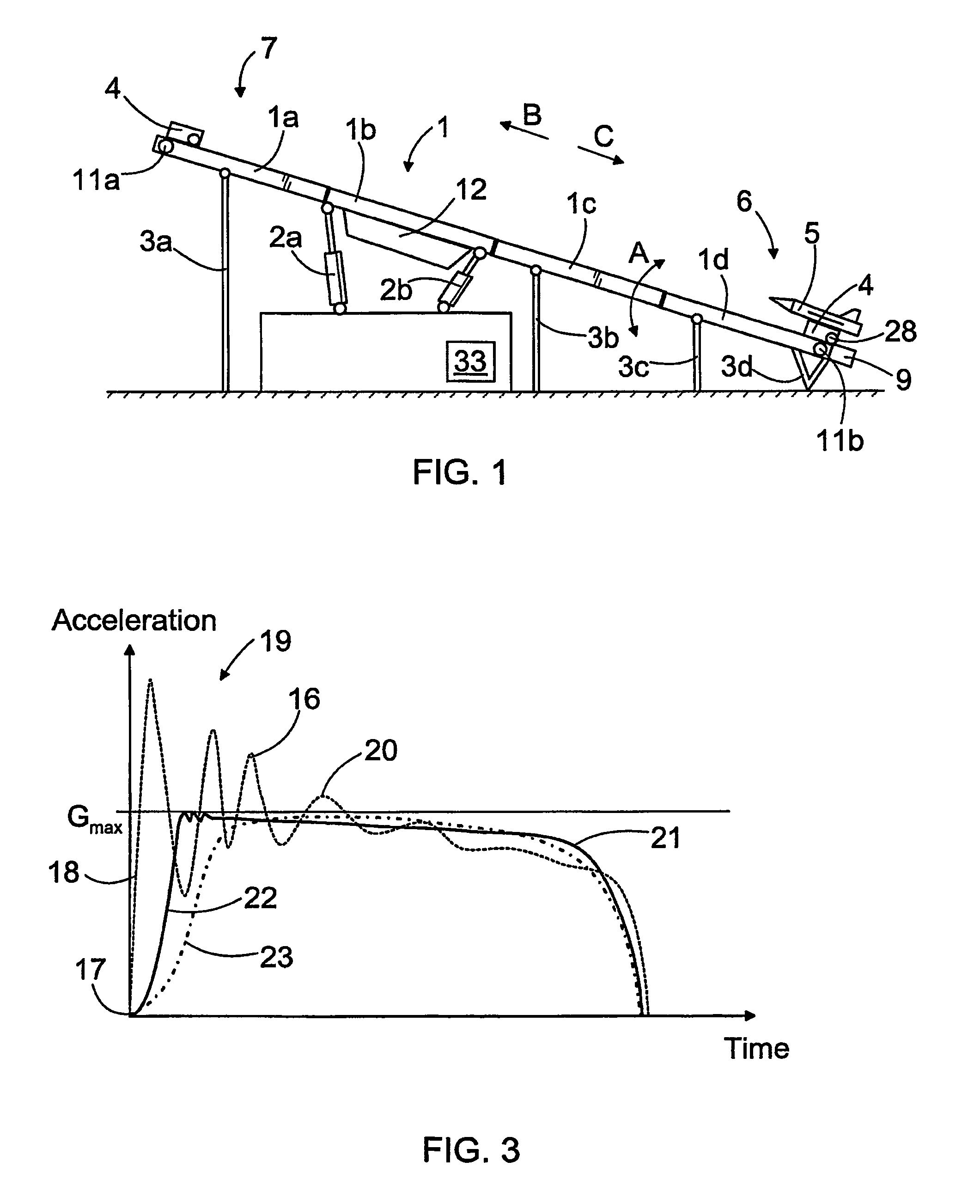

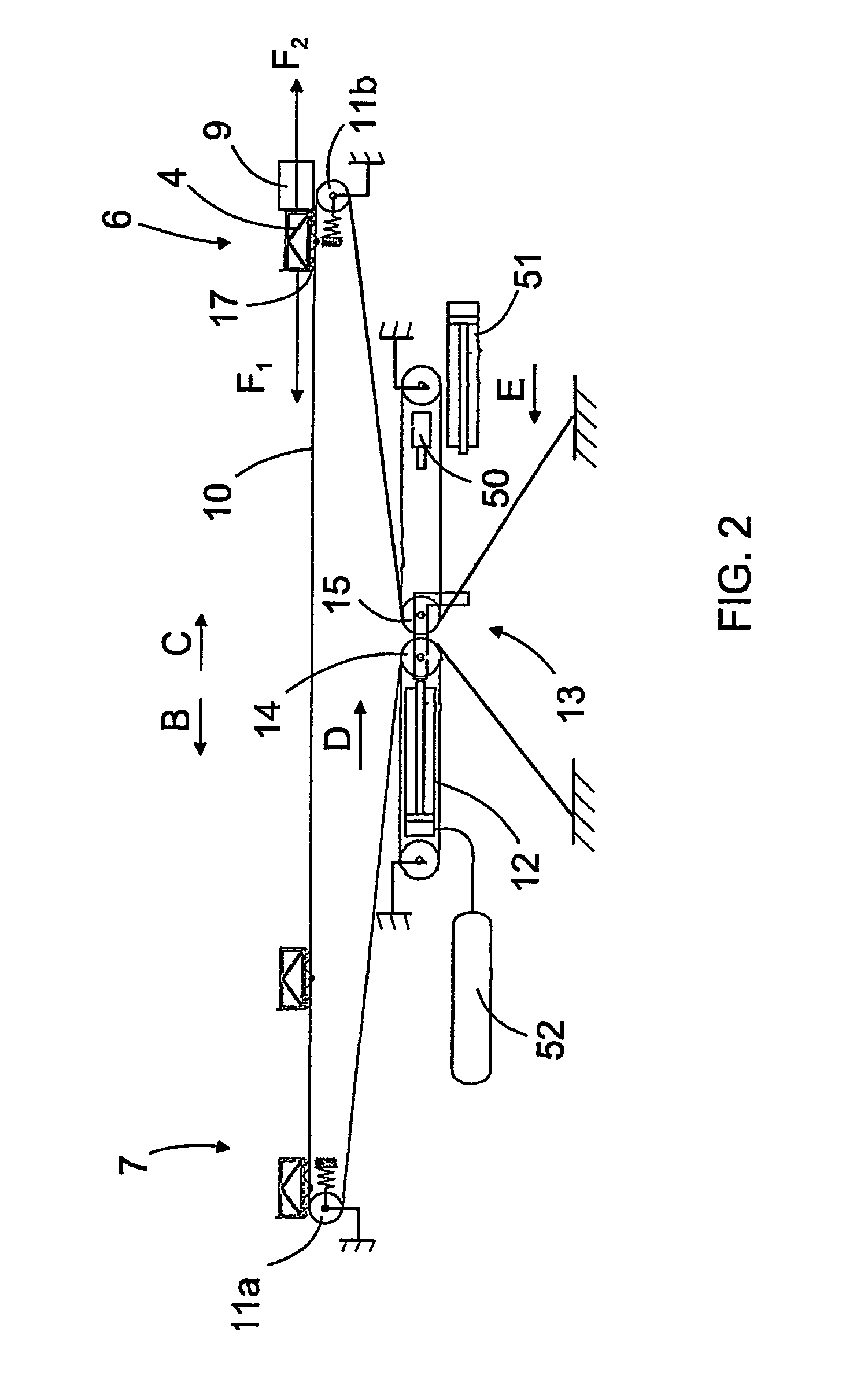

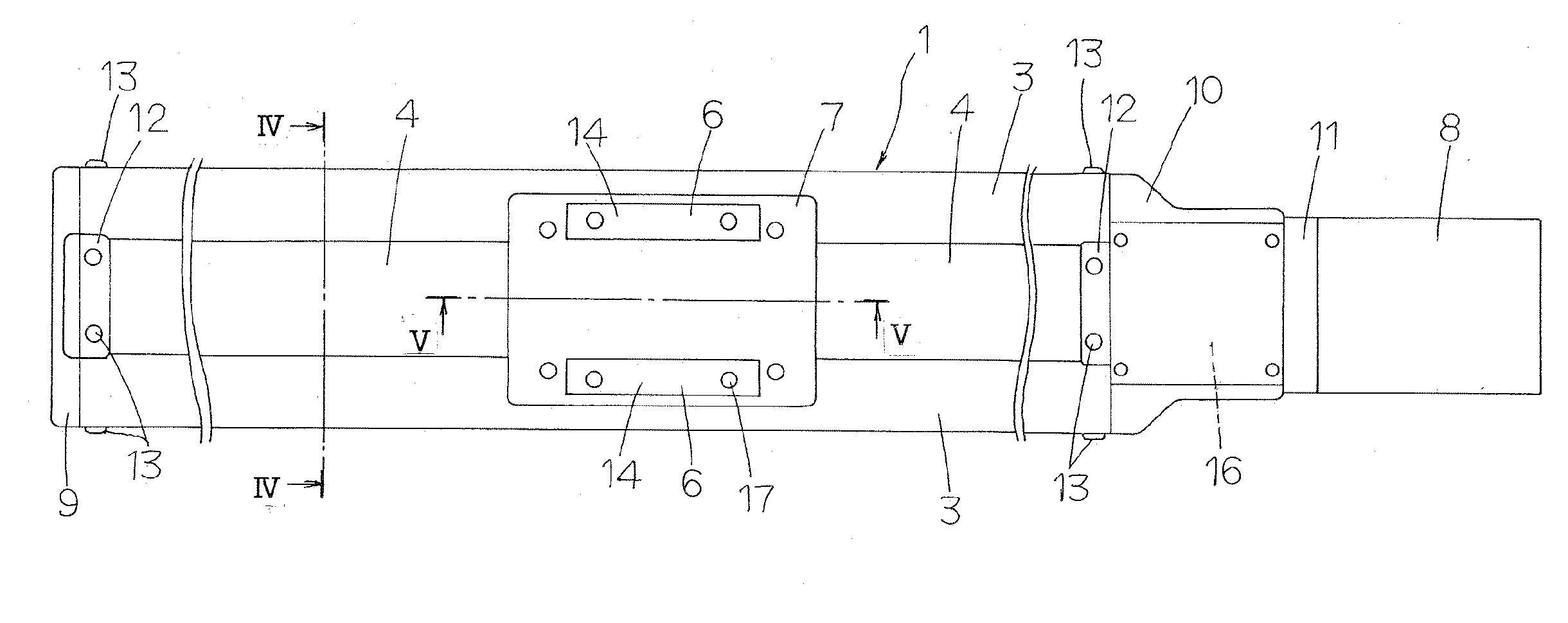

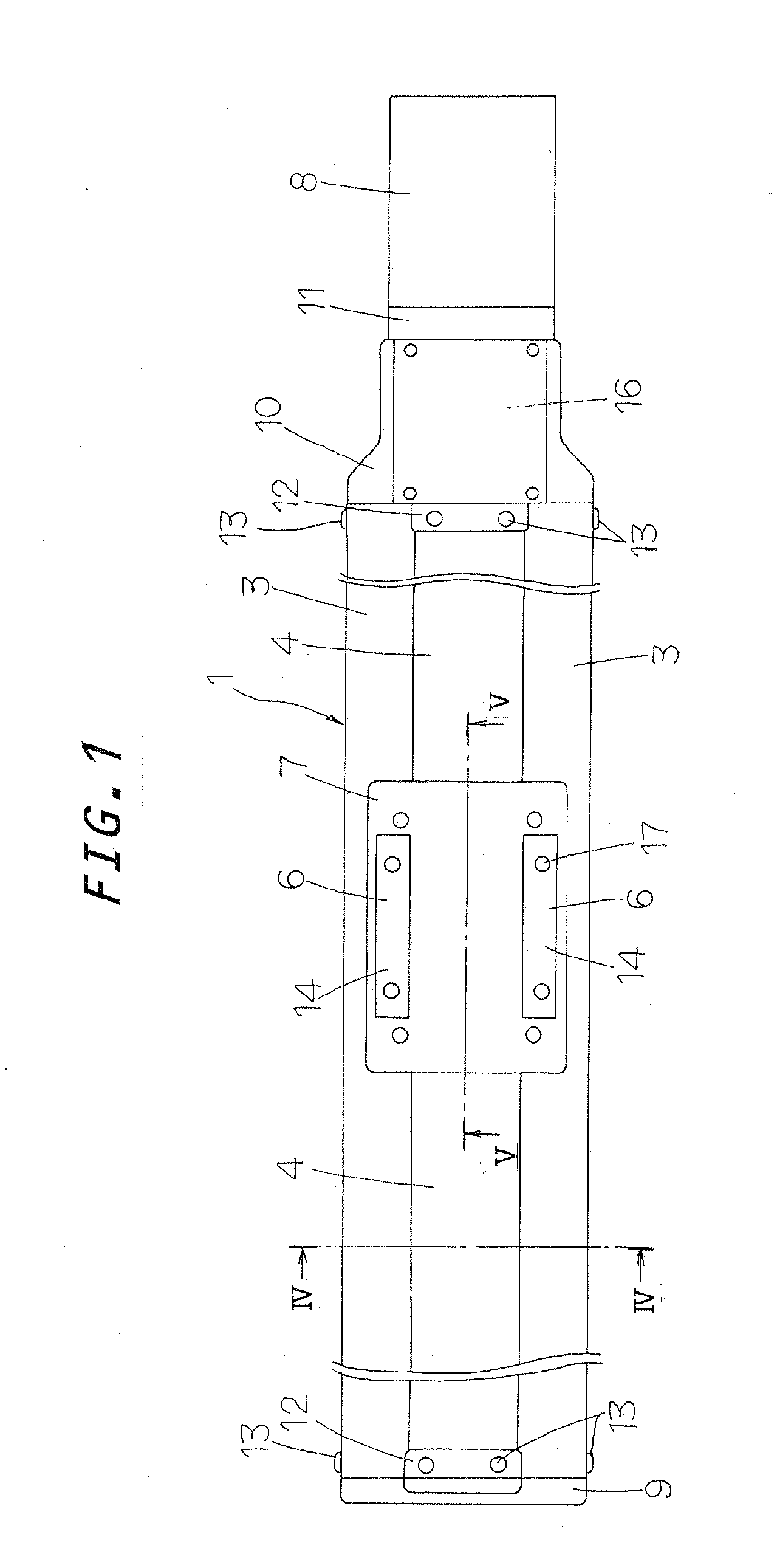

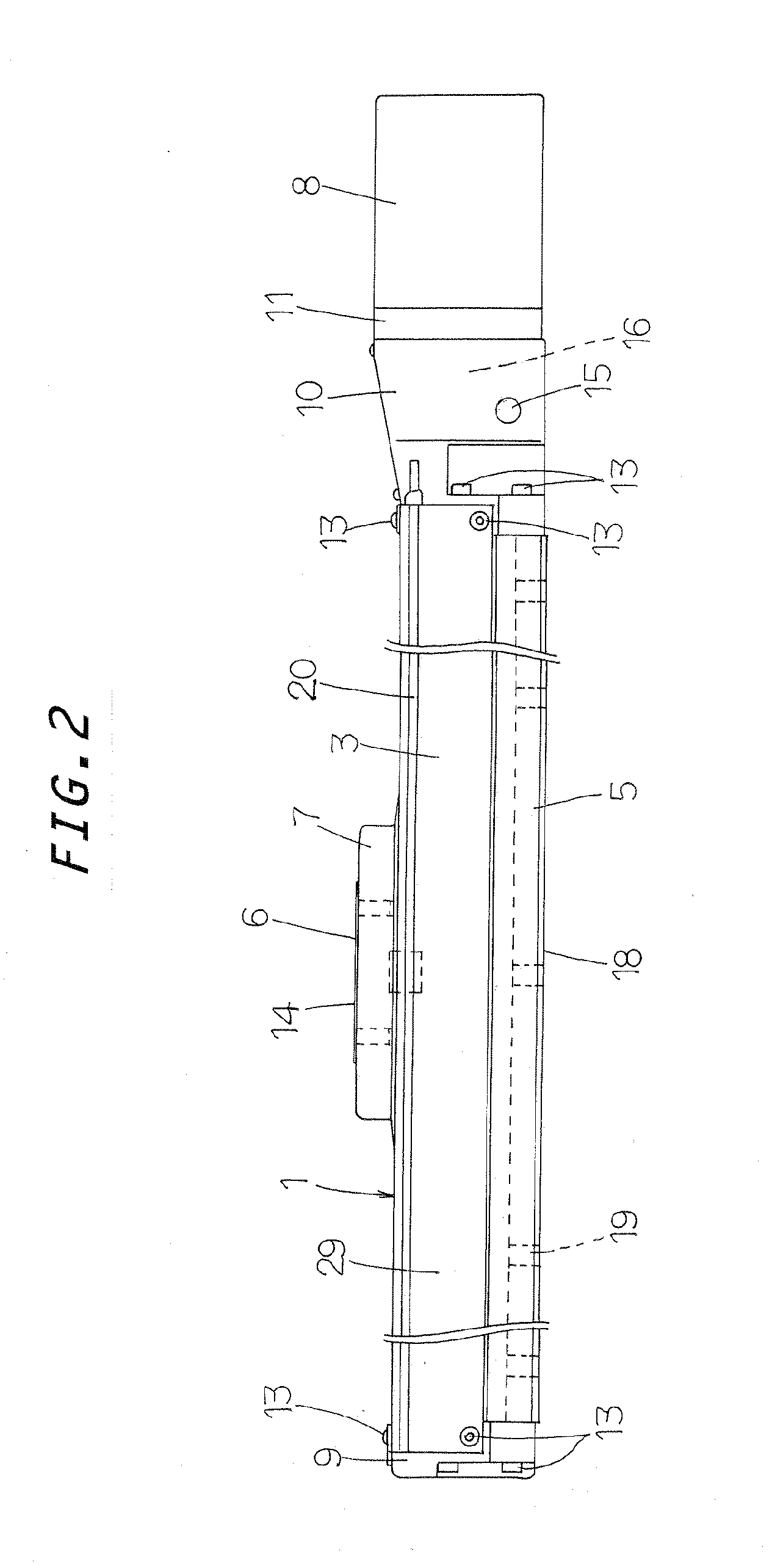

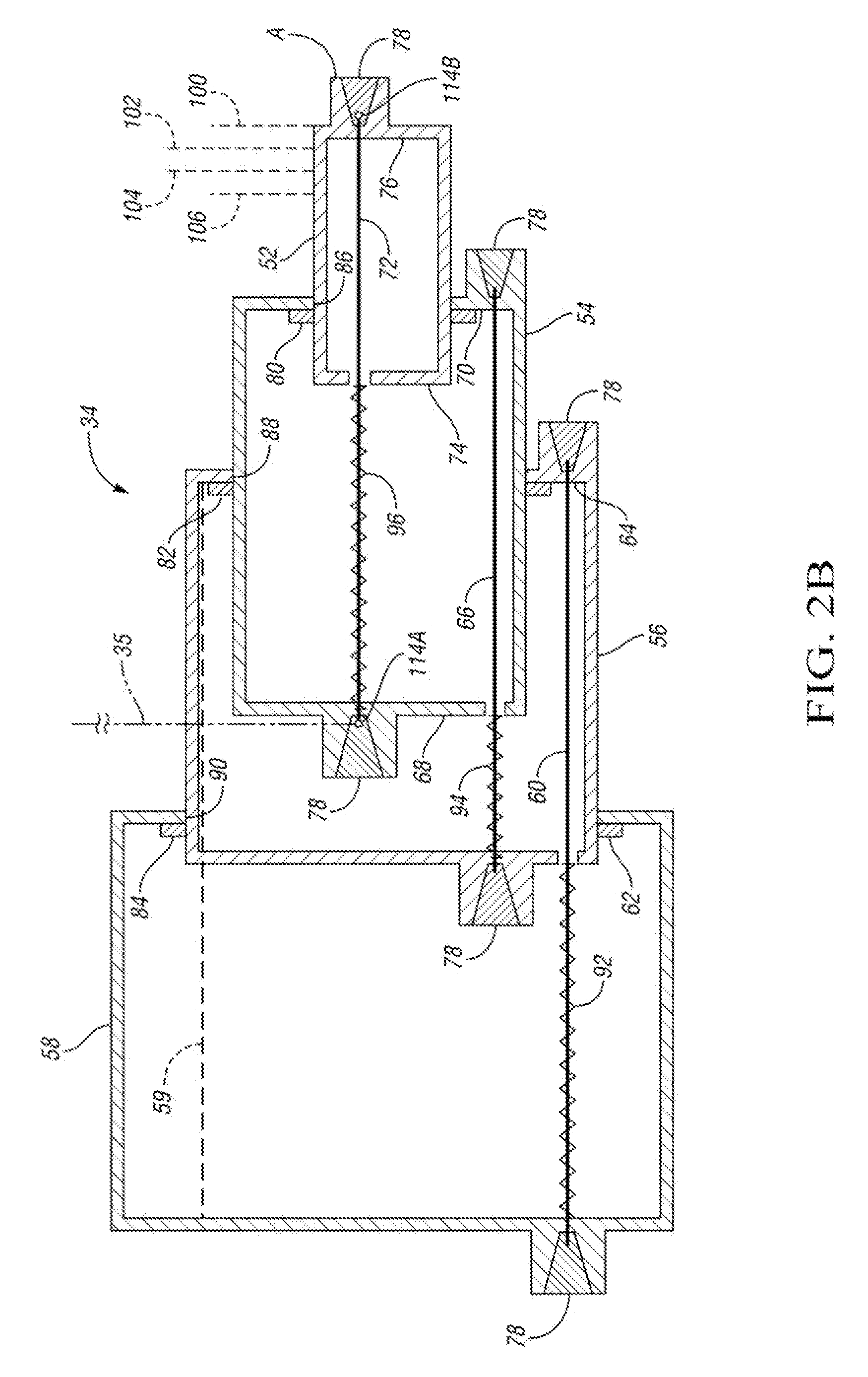

Method of launching a catapult, catapult, and locking device

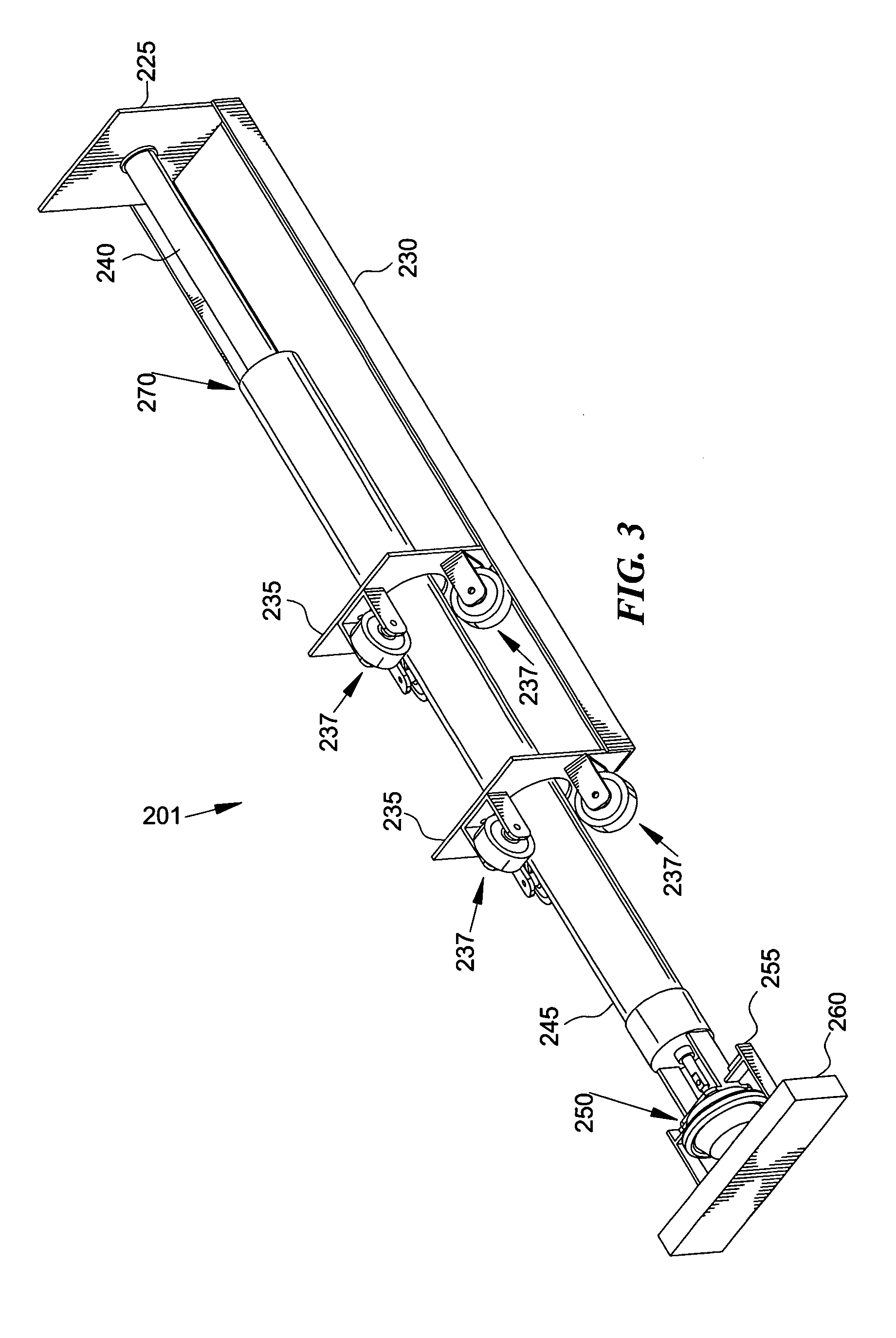

ActiveUS7562843B2Reduce damping forceAvoid creatingRocket launchersLaunching/towing gearHigh accelerationCatapult

A method of launching a catapult, a catapult and a locking device for a catapult. The catapult comprises a carriage (4) for fastening an aircraft (5). The carriage (4) can be provided with a high acceleration by directing a launching force (F1) generated by a launching device thereto. The carriage (4) can be held at a launching position (6) by means of the locking device (9). The catapult further comprises a takeoff damper (34) that generates a damping force (F2) having a direction opposite relative to the launching force. Accordingly, the takeoff damper (34) restricts the acceleration of the carriage (4) at the initial launching moments.

Owner:ROBONIC

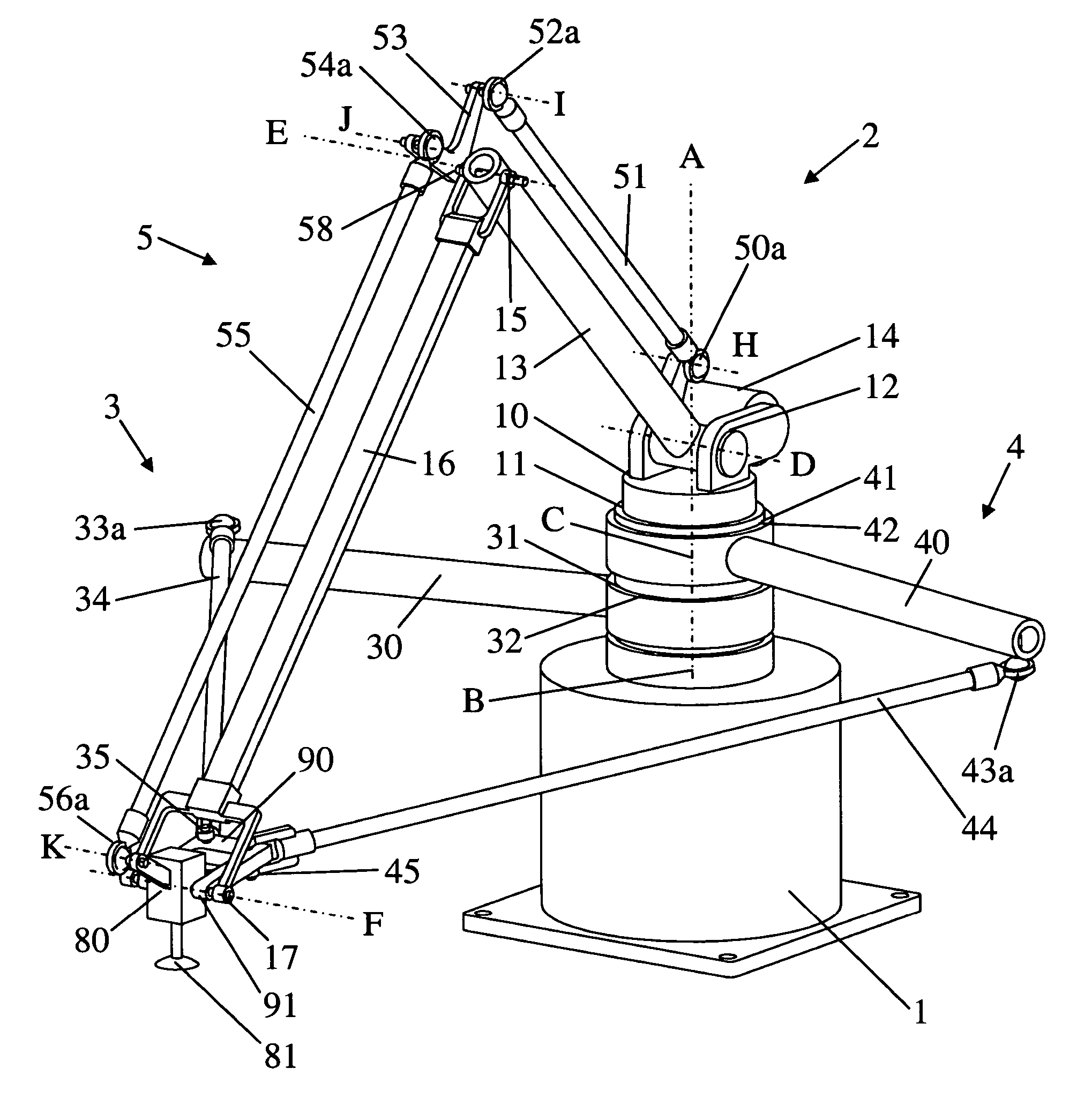

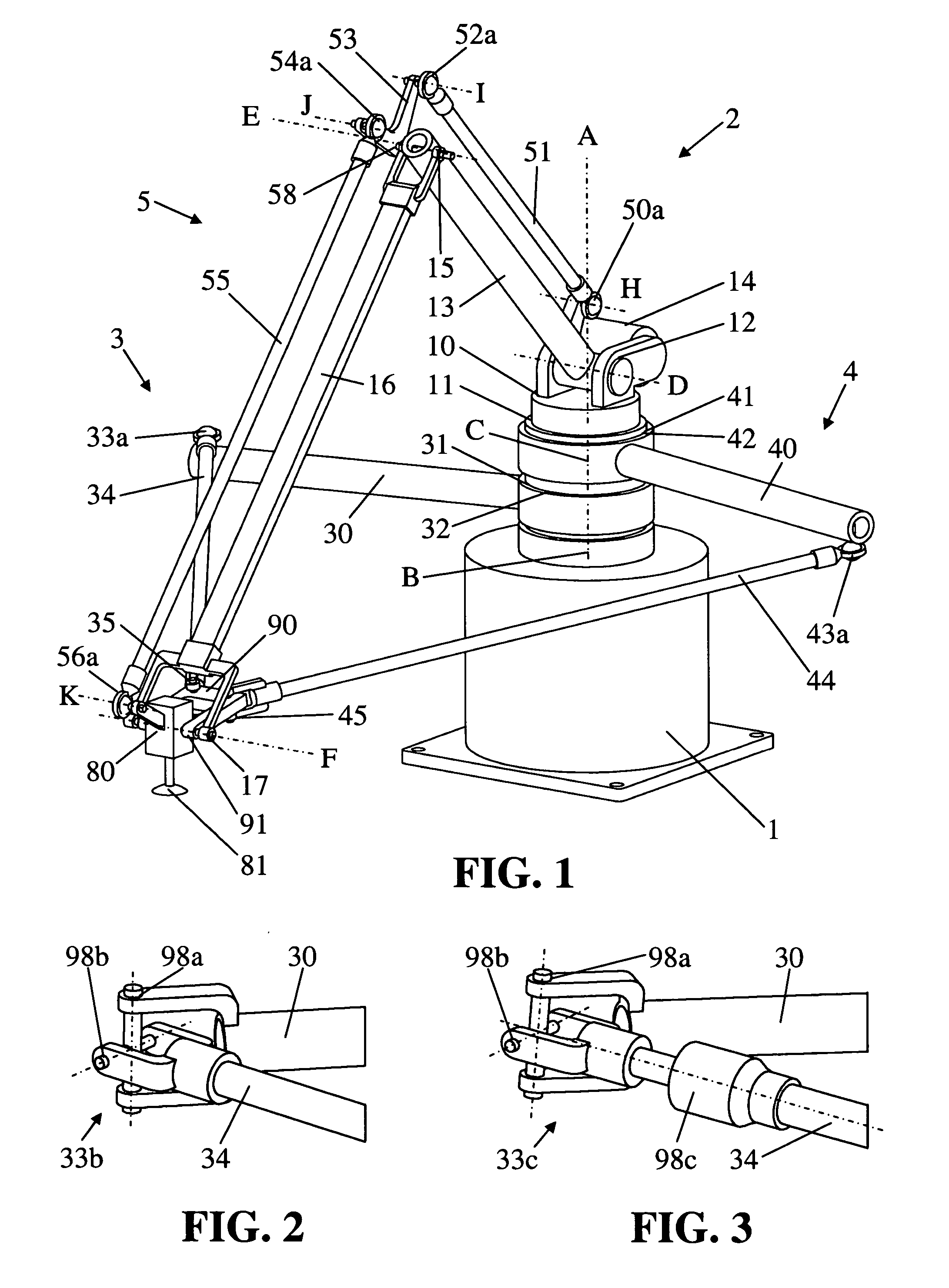

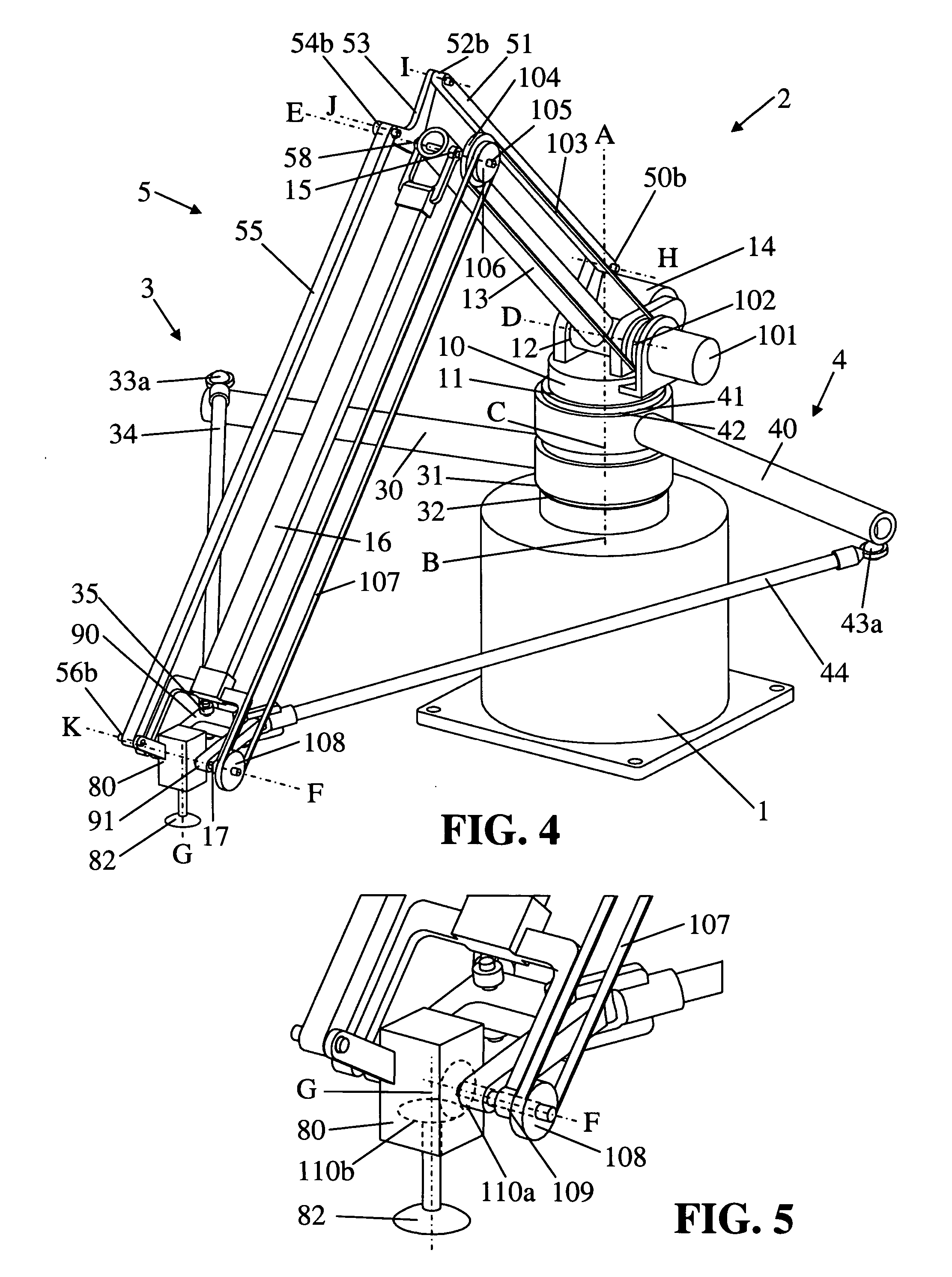

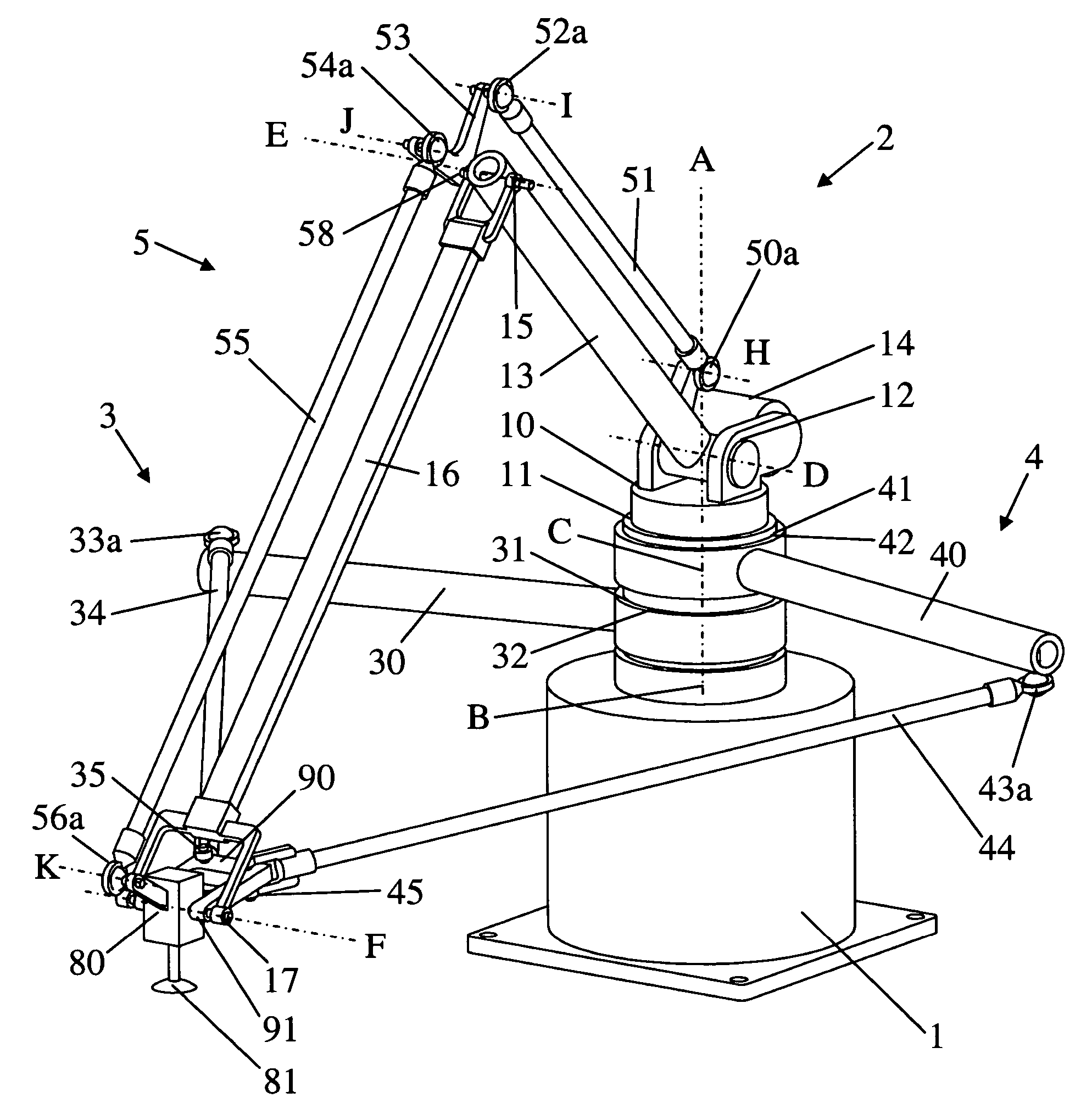

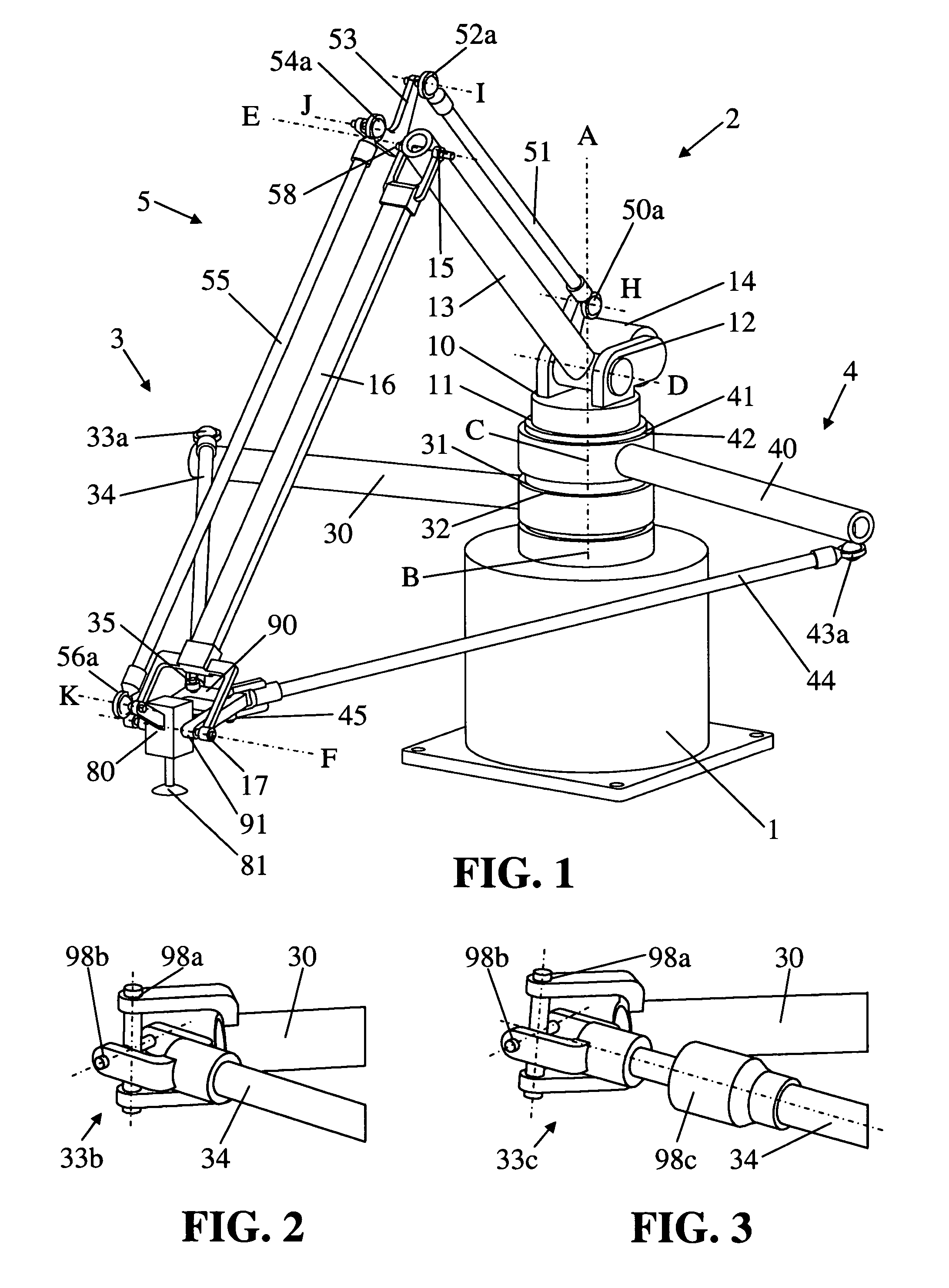

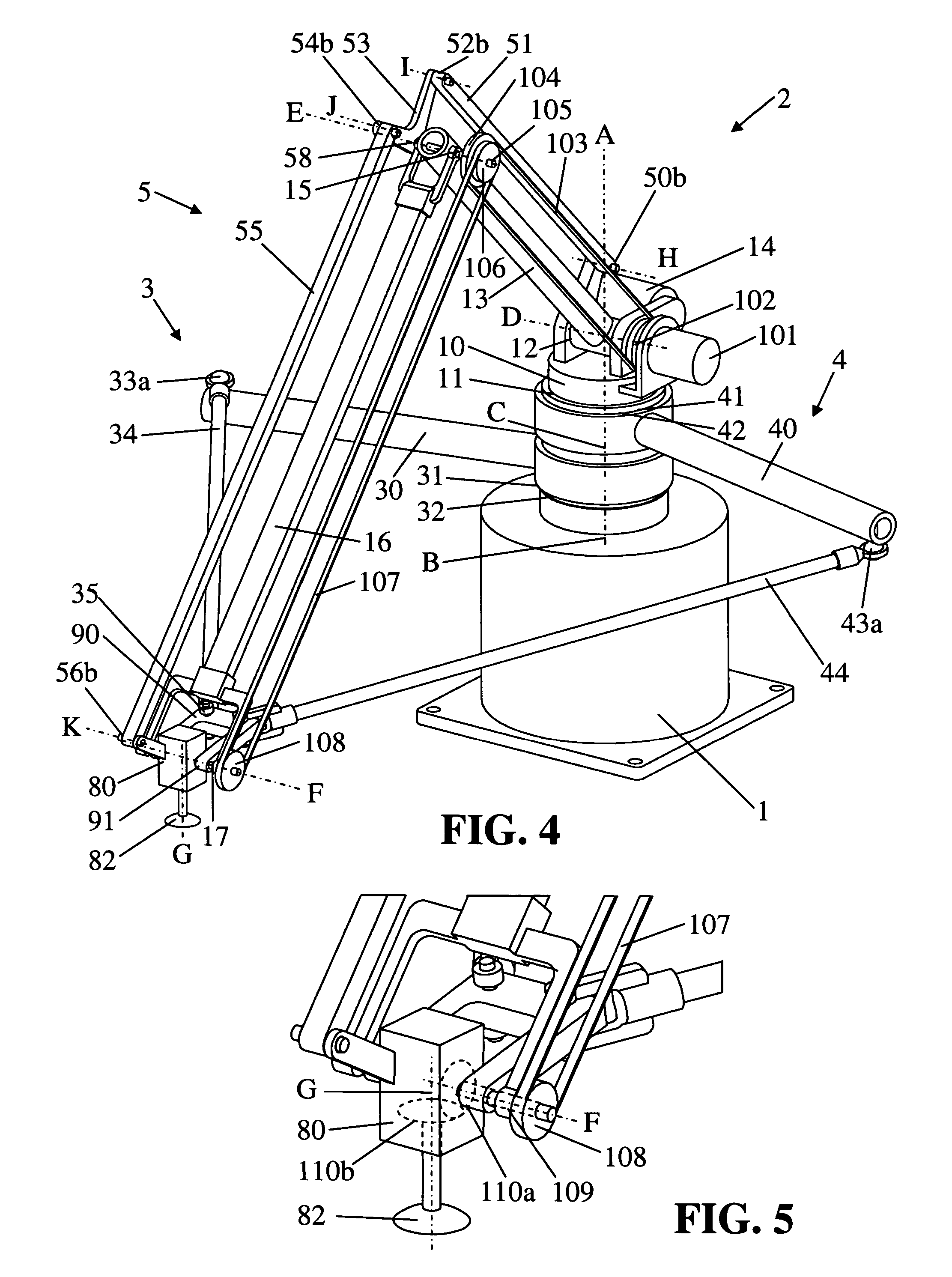

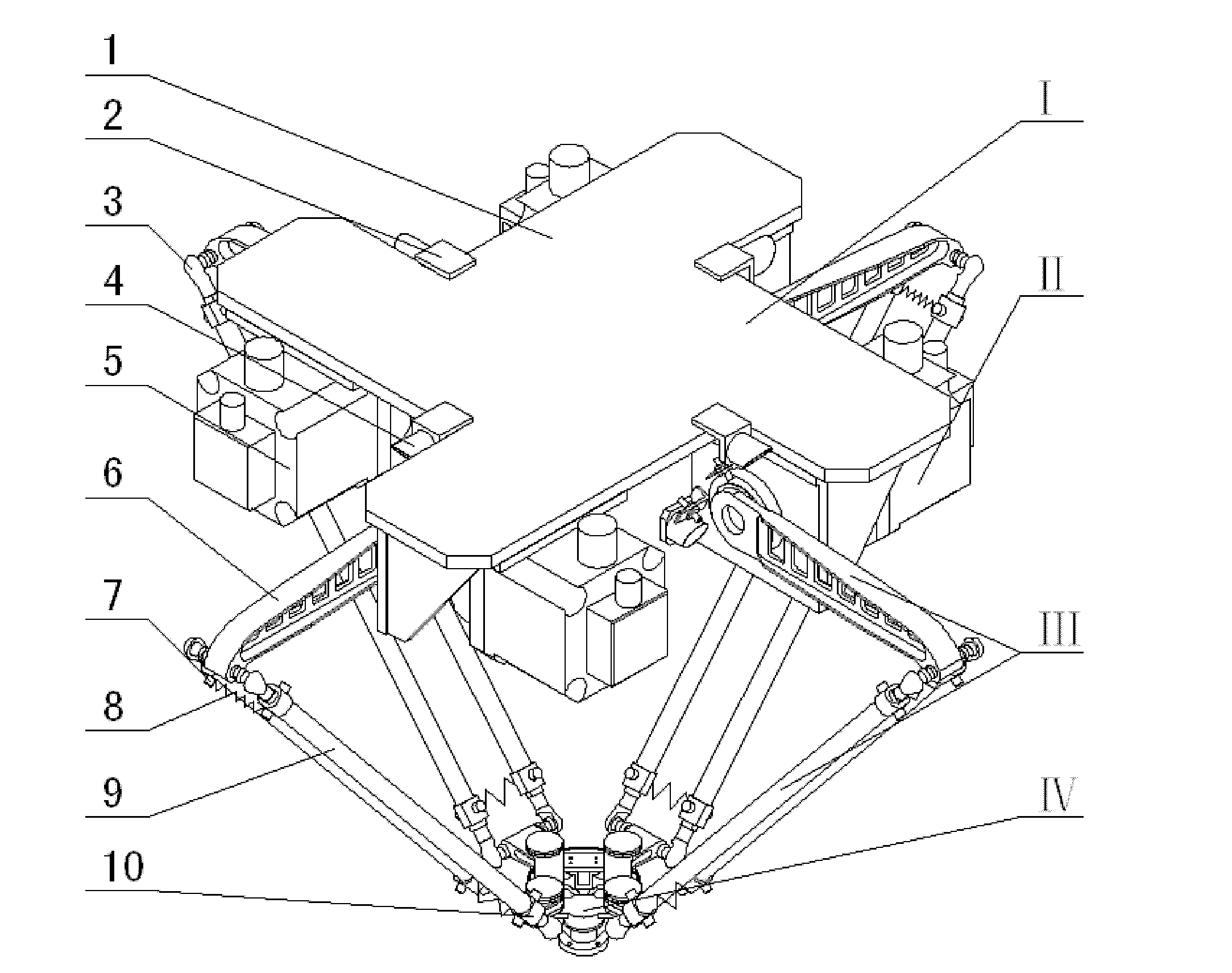

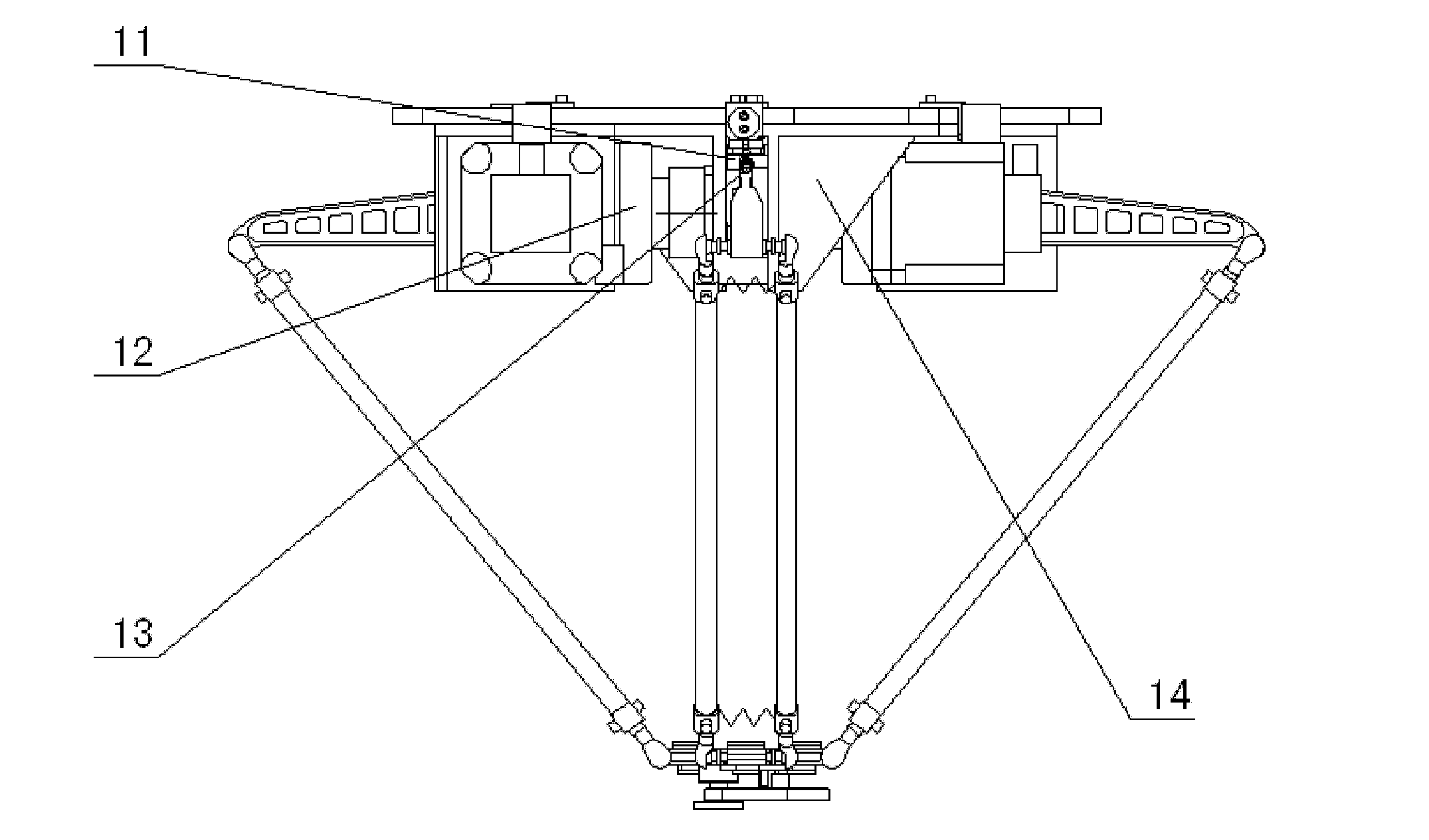

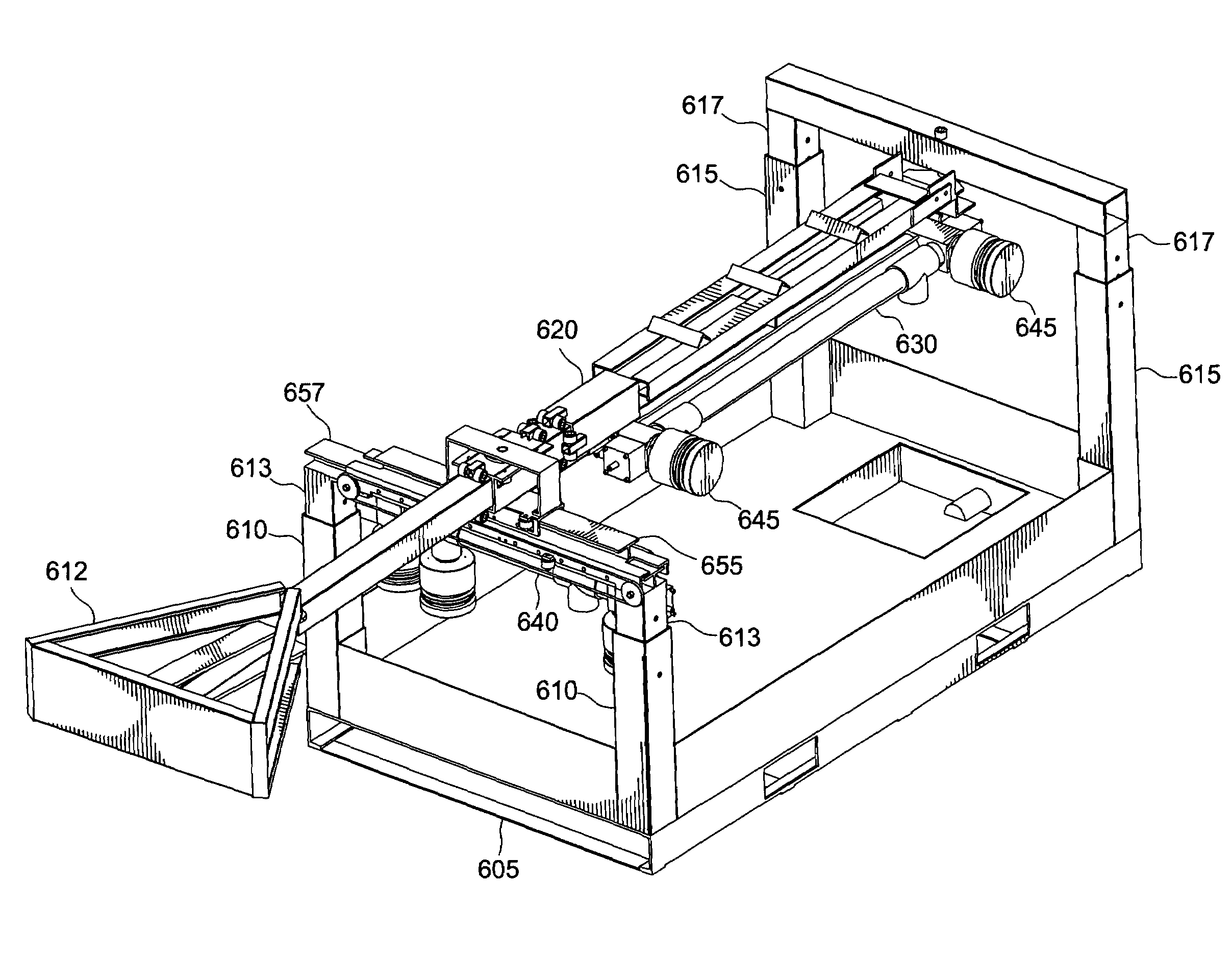

Parallel robot

ActiveUS20060245894A1Large workspace-to-footprint ratioSimple designProgramme-controlled manipulatorMechanical apparatusThree degrees of freedomParallel kinematics

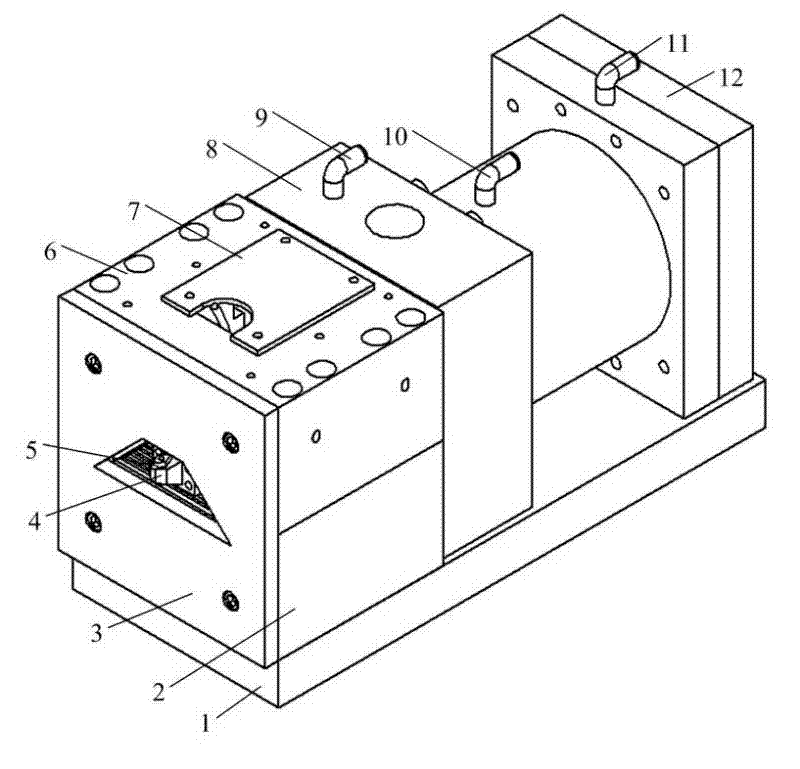

A parallel robot or parallel kinematics mechanism is provided for uses such as robotics or machining. The mechanism comprises a fixed base, a main arm, and a first and second support arm to position and orient an object in a cylindrical space with at least three degrees of freedom and retained inclination. The main arm includes an end component for supporting the object and linkage means to retain the inclination of the end component with respect to the base for all positions and orientations of the end component. The mechanism advantageously provides a large cylindrical workspace and a small footprint and is capable of moving an object at high accelerations and speeds. The mechanism can be equipped with an additional motor to orient an object, thereby providing the mobility of a SCARA robot. Alternatively, it can be equipped with passive transmission means that allow for an object to be displaced in parallel to itself.

Owner:MERZ PHARMA GMBH & CO KGAA +1

Parallel robot

ActiveUS7331750B2Large workspace-to-footprint ratioSimple designProgramme-controlled manipulatorMechanical apparatusRoboticsThree degrees of freedom

A parallel robot or parallel kinematics mechanism is provided for uses such as robotics or machining. The mechanism comprises a fixed base, a main arm, and a first and second support arm to position and orient an object in a cylindrical space with at least three degrees of freedom and retained inclination. The main arm includes an end component for supporting the object and linkage means to retain the inclination of the end component with respect to the base for all positions and orientations of the end component. The mechanism advantageously provides a large cylindrical workspace and a small footprint and is capable of moving an object at high accelerations and speeds. The mechanism can be equipped with an additional motor to orient an object, thereby providing the mobility of a SCARA robot. Alternatively, it can be equipped with passive transmission means that allow for an object to be displaced in parallel to itself.

Owner:MERZ PHARMA GMBH & CO KGAA +1

Method and apparatus for detecting vehicular collisions

A portable electronic device, like a cellular telephone is capable of detecting collisions between vehicles and notifying the proper authorities. The device includes a microprocessor and memory, in addition to an accelerometer and global positioning systems receiver. The memory includes at least one filter for screening out false positives, which are false collision detections. In one embodiment, the device determines its velocity. It then checks to see if its velocity falls within a range associated with moving vehicles. If so, the device monitors the accelerometer. When acceleration values in excess of a predetermined threshold are detected, the device pauses and again checks its velocity. If the velocity has fallen from the range associated with moving vehicles to a range associated with a vehicle that has sustained a collision, the device notifies emergency personnel that a collision has occurred. Another filter includes an operability check of the keypad, coupled with a notification message that the authorities will be called if the keypad has not been actuated within a predetermined time. Another embodiment includes a detector capable of detecting a vehicular cradle, such that the notification only occurs when high acceleration values are detected in a vehicle.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

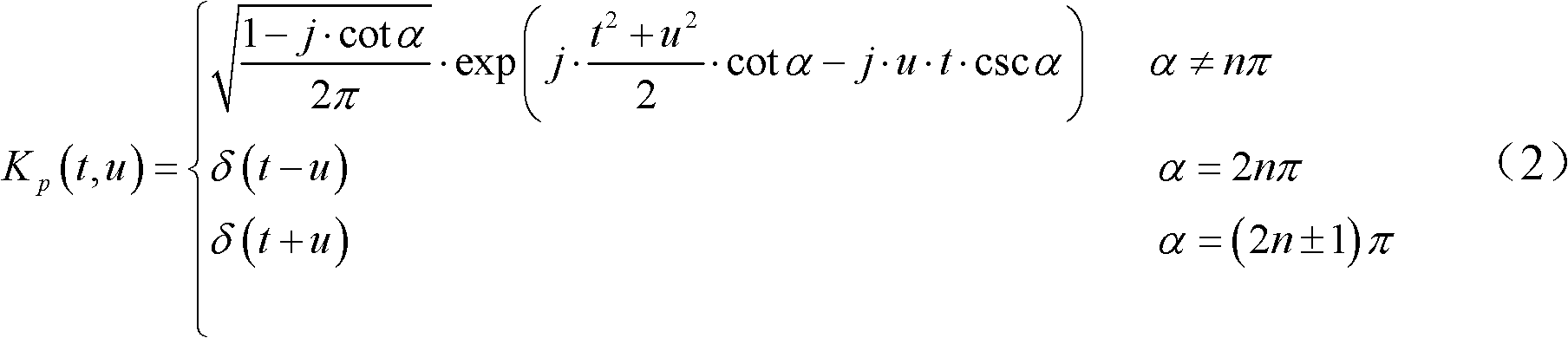

High-dynamic weak-signal rapid capture method for direct sequence spread spectrum system

InactiveCN102098074AImprove detection signal-to-noise ratioImprove detection rateTransmissionFast algorithmCarrier signal

The invention discloses a high-dynamic weak-signal rapid capture method for a direct sequence spread spectrum system, belonging to the field of radio communication. Because a spread spectrum carrier has a chirp signal characteristic under the condition of high-dynamic motion (high-speed and high-acceleration), the high-dynamic weak-signal rapid capture method comprises the steps of: firstly, carrying out carrier Doppler frequency compensation by using a time frequency focusing characteristic of fractional order Fourier transform; secondly, carrying out incoherent accumulation on a spread frequency signal by using an order resolving capacity of the fractional order Fourier transform; and finally, carrying out capture judgment on the signal in an order Fourier domain by using a constant false alarm rate detection technology. According to the invention, the difficulty of incapability of long-time coherent accumulation under the high-dynamic condition in the traditional Fourier transform based rapid capture method is solved; and under the condition of high dynamicity and low signal to noise ratio, the signal to noise ratio is effectively increased and the signal capture time is shortened. In addition, a rapid algorithm exists in the invention and is easy to realize on the engineering in real time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

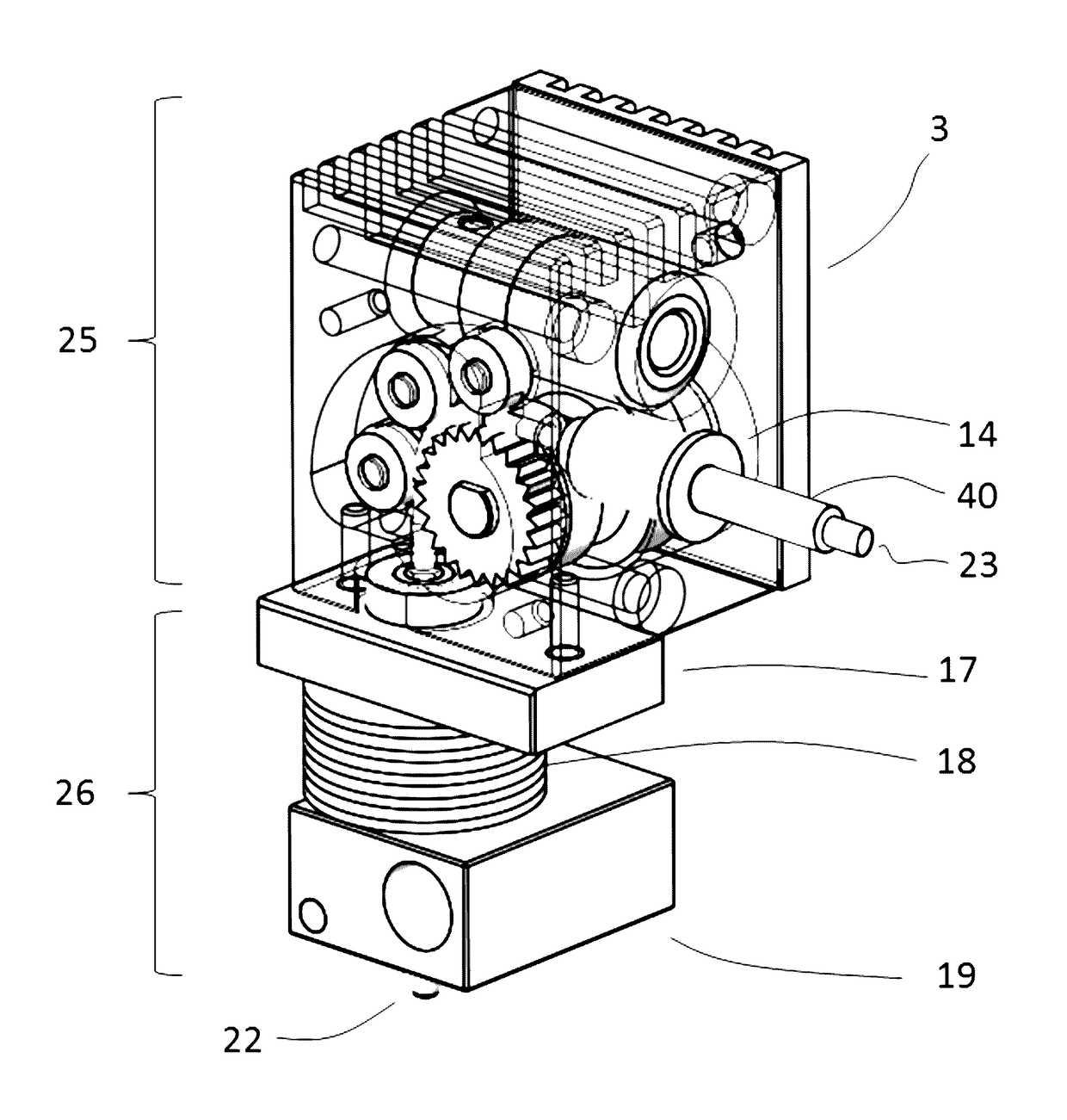

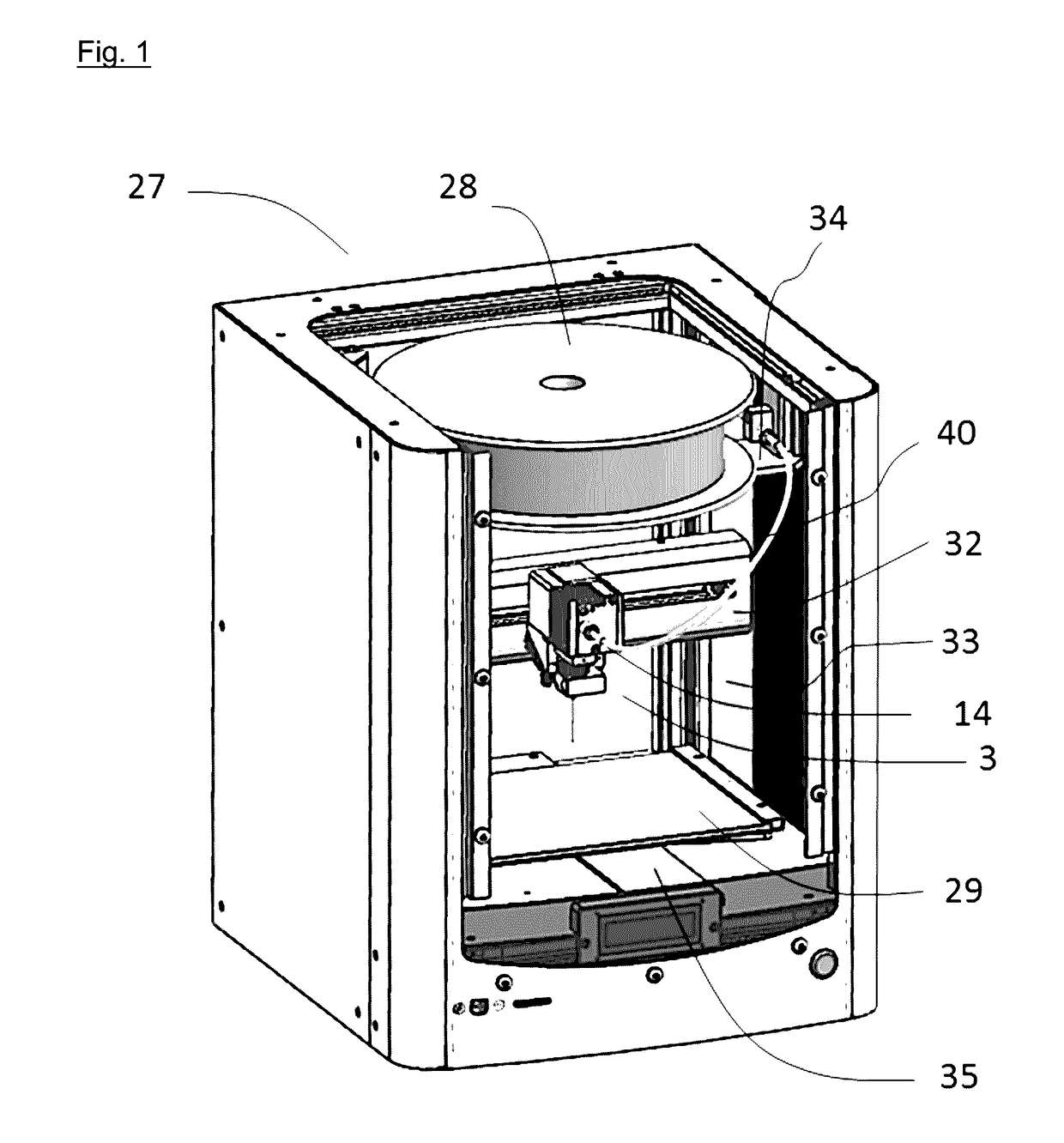

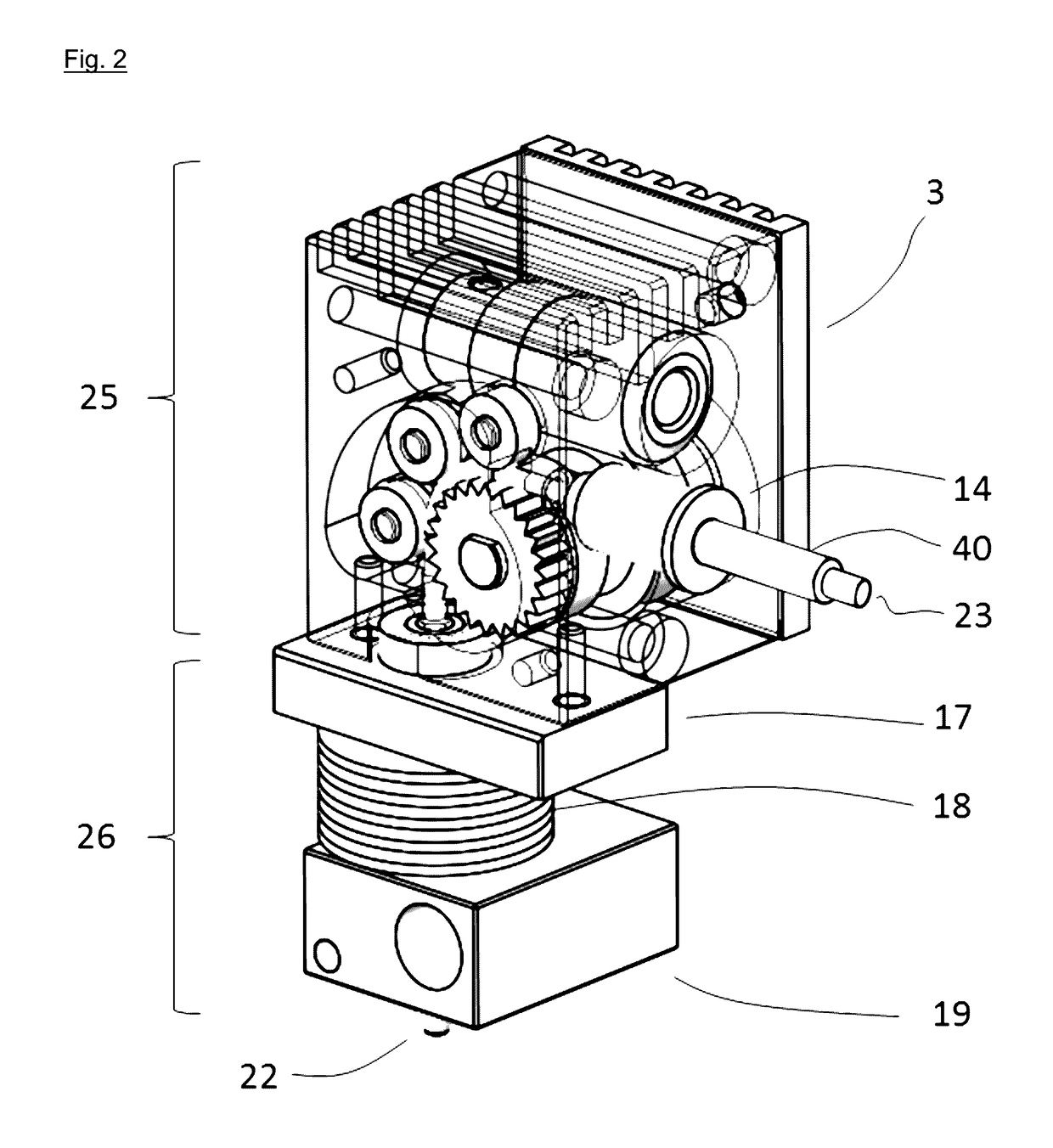

Extruder for fused filament fabrication 3D printer

InactiveUS20170157826A1Increase extrusion speedIncrease feed rateAdditive manufacturing with liquids3D object support structuresFused filament fabricationHigh acceleration

Disclosed is an improved extruder head for a fused filament fabrication 3D printer. It would be beneficial with a thinner nozzle diameter and higher extrusion speed without slippage in the feeding mechanism. The proposed improved extruder head enables extrusion of thinner extruded material at a higher extrusion speed without any slippage in filament feeding mechanism, thereby allowing higher overall building speed of the 3D printer with high quality build. Higher feed-rate of the filament material is achieved by increased usable friction between pinch wheel and filament by increasing the grippable area of the filament. This is done by feeding the filament into the feeding mechanism at an angle different to the outlet angle and routing it around the pinch wheel, back supported by a plurality of support rollers, so that the filament is in frictional contact with the pinch wheel along a greater part of its circumference, thereby increasing the surface contact area between the pinch wheel and the filament. Owing to non-slippage of the filament feeder, nominal volume of extruded material is exactly the same as desired volume with high filament feeding rate. Due to compact feeding mechanism, total mass of extruder kept small enough to enable higher acceleration of the printing nozzle resulting higher printing speed. Owing to horizontal loading of the filament material, feed roll can be mounted just above the extruder for smooth filament supply and compact size of 3D printer.

Owner:RHOMBUS INT TECH

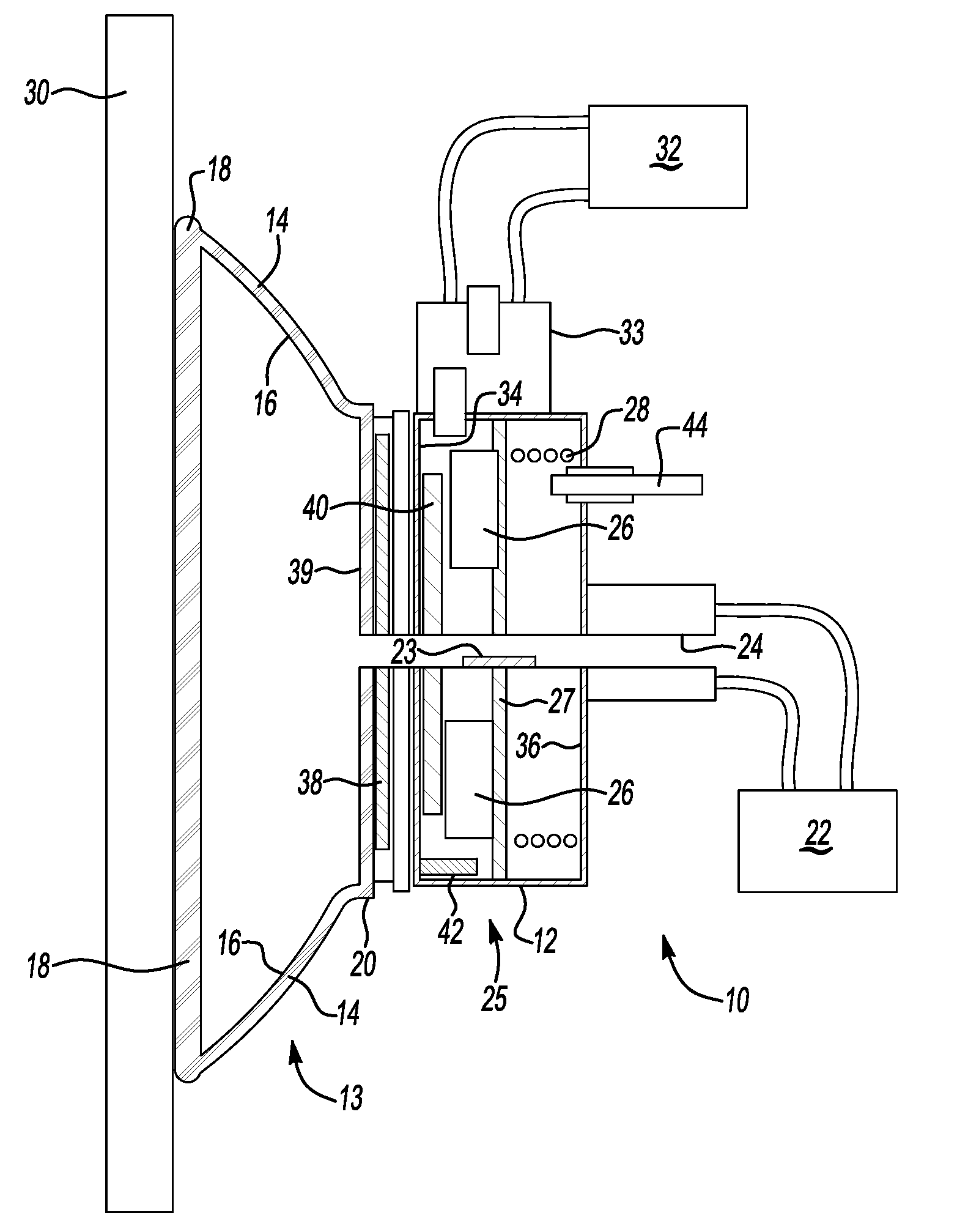

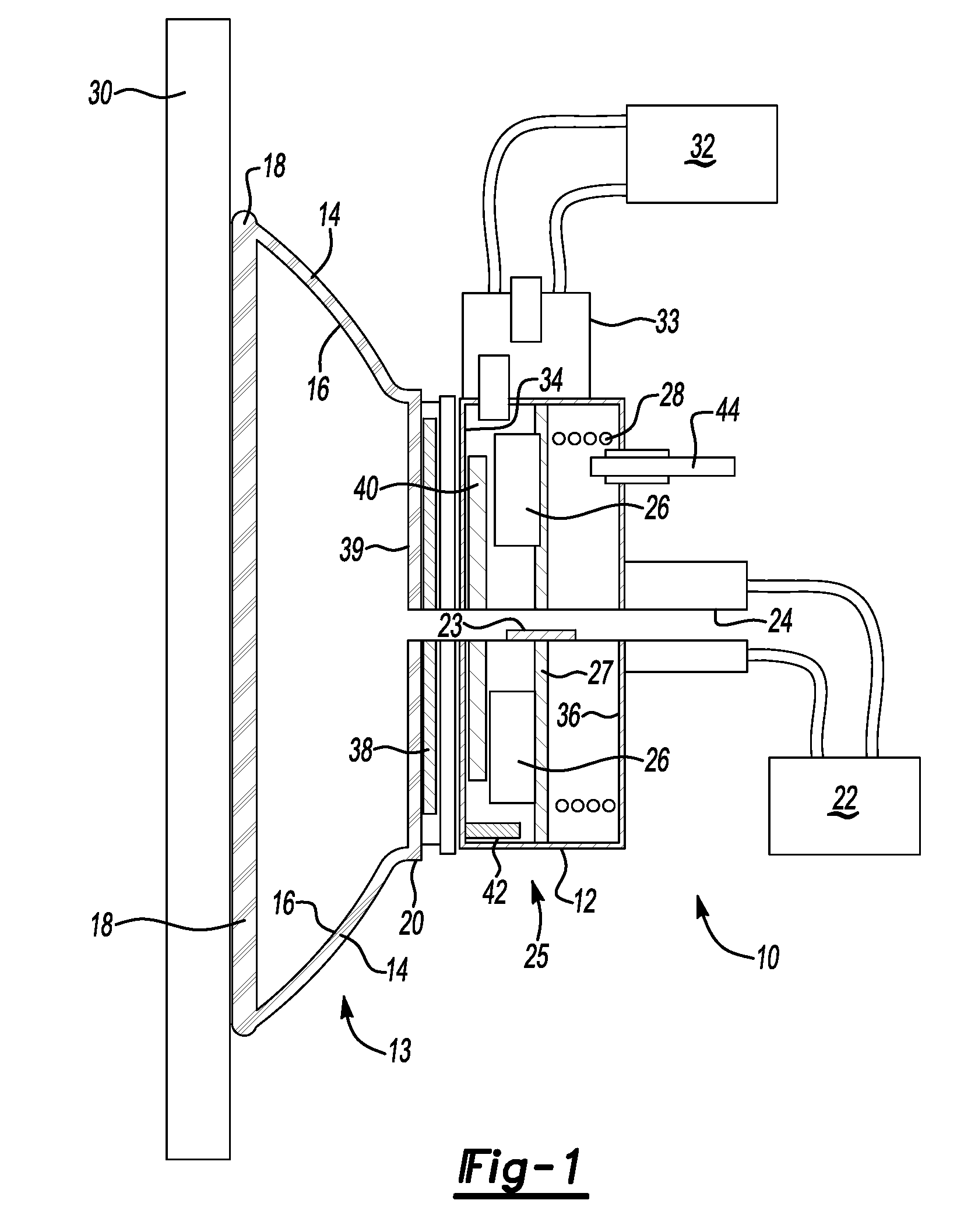

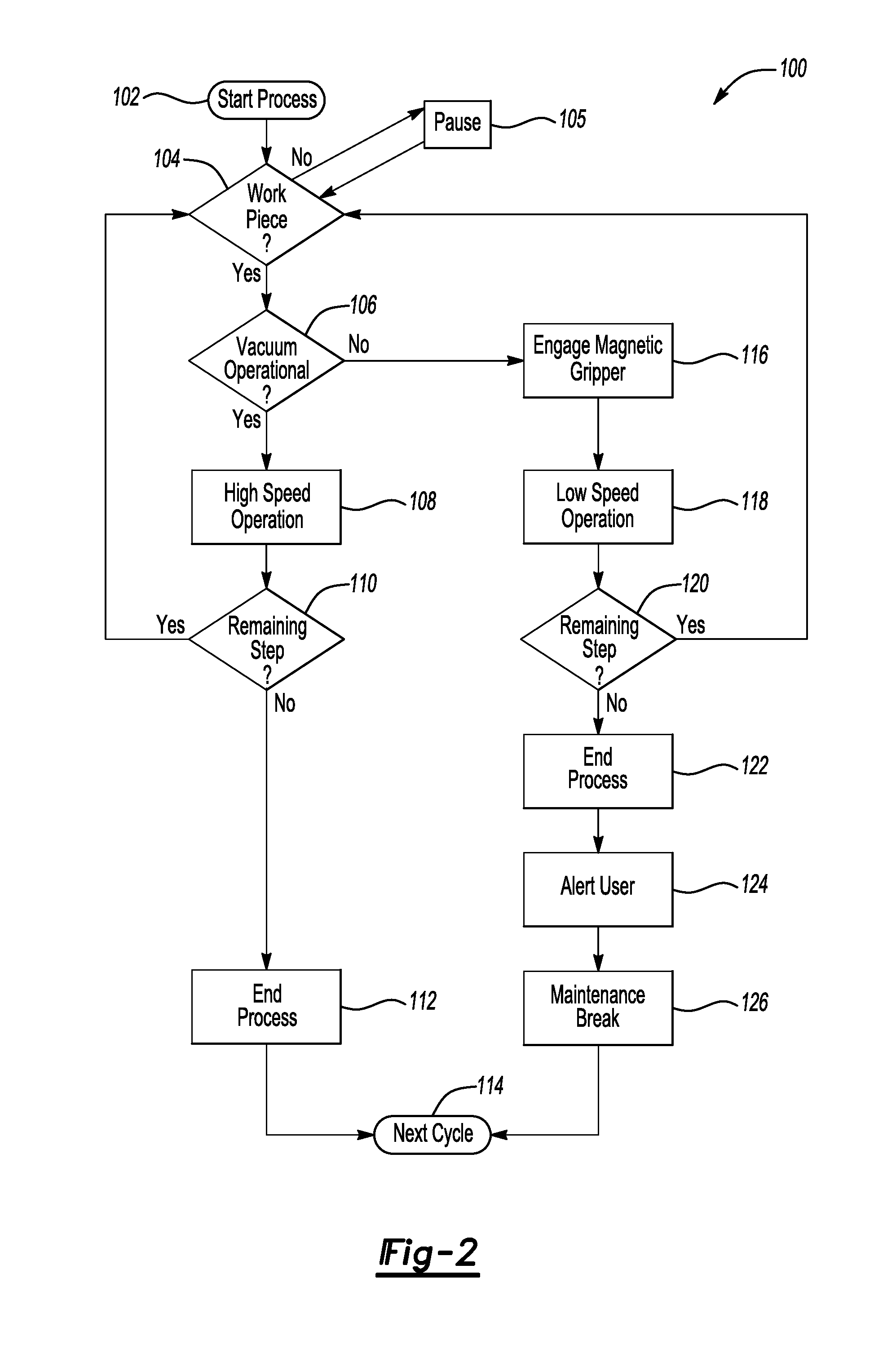

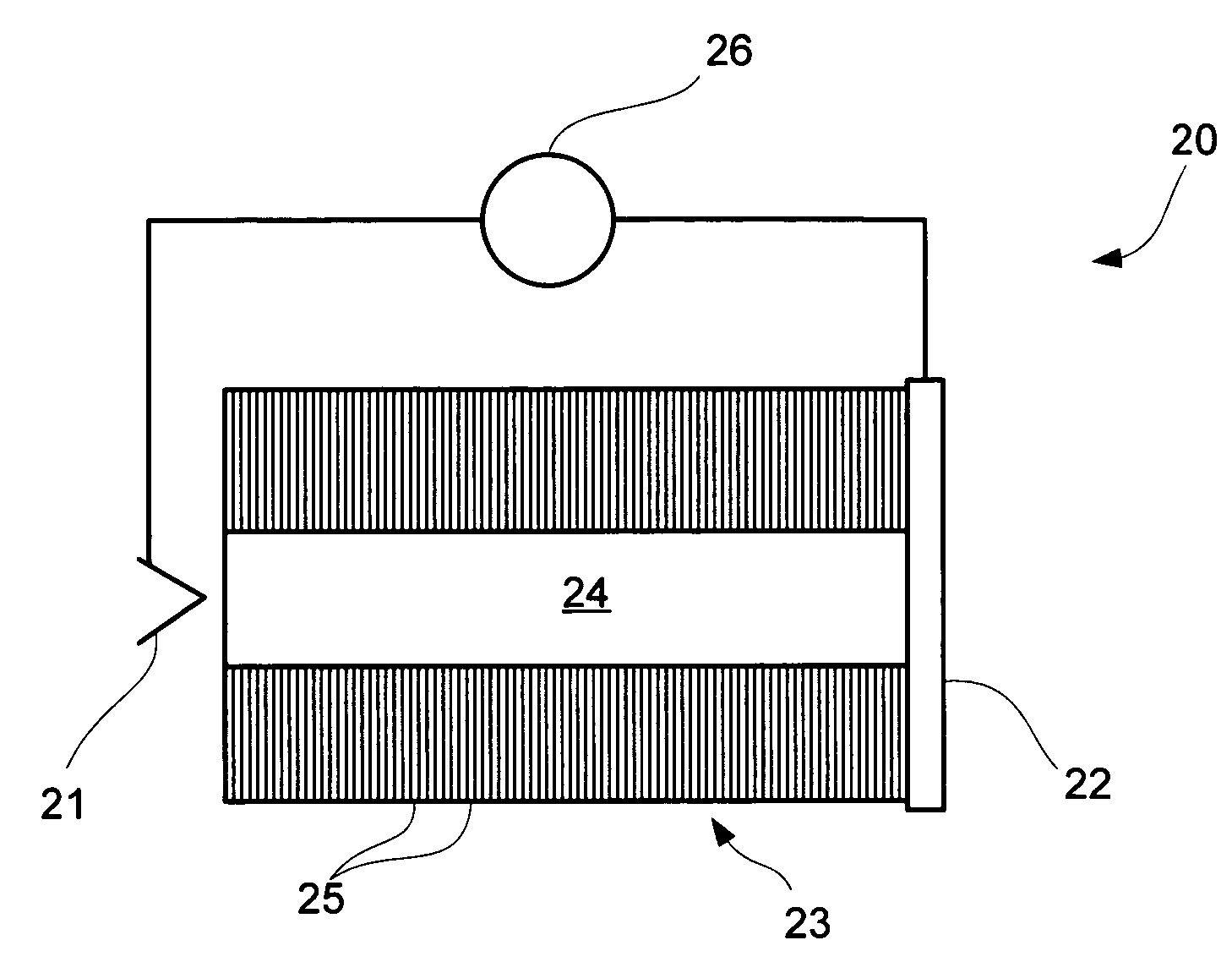

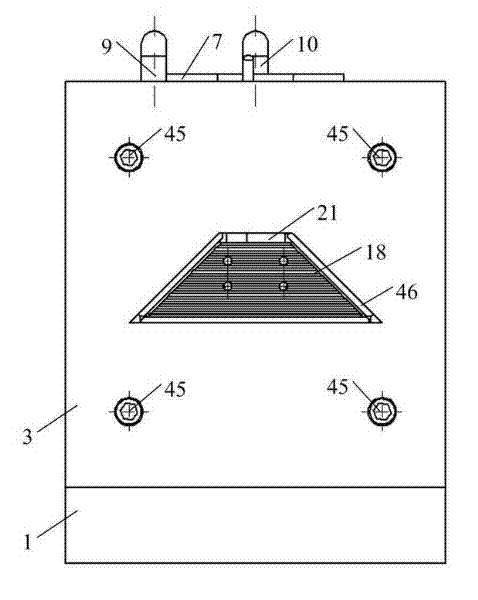

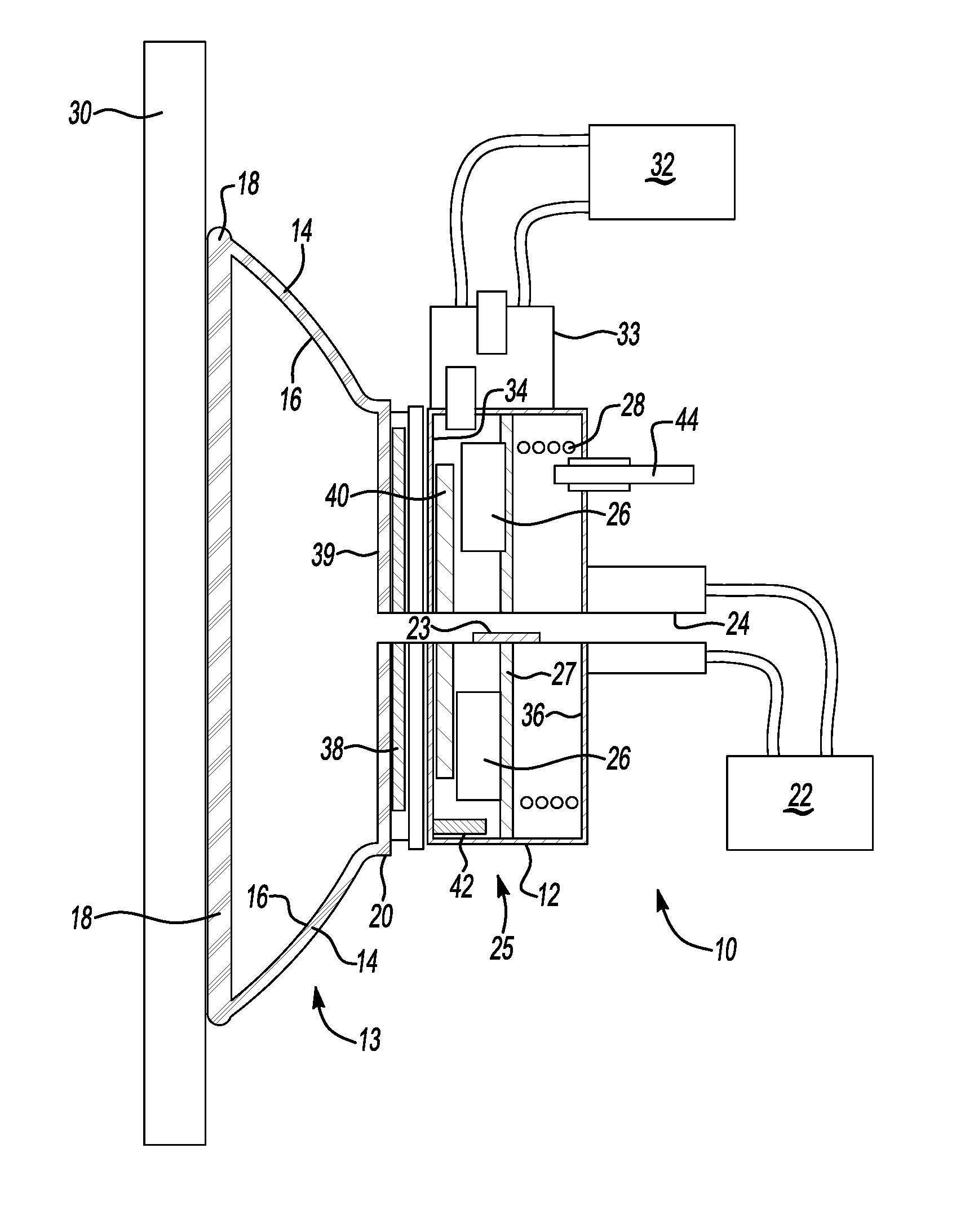

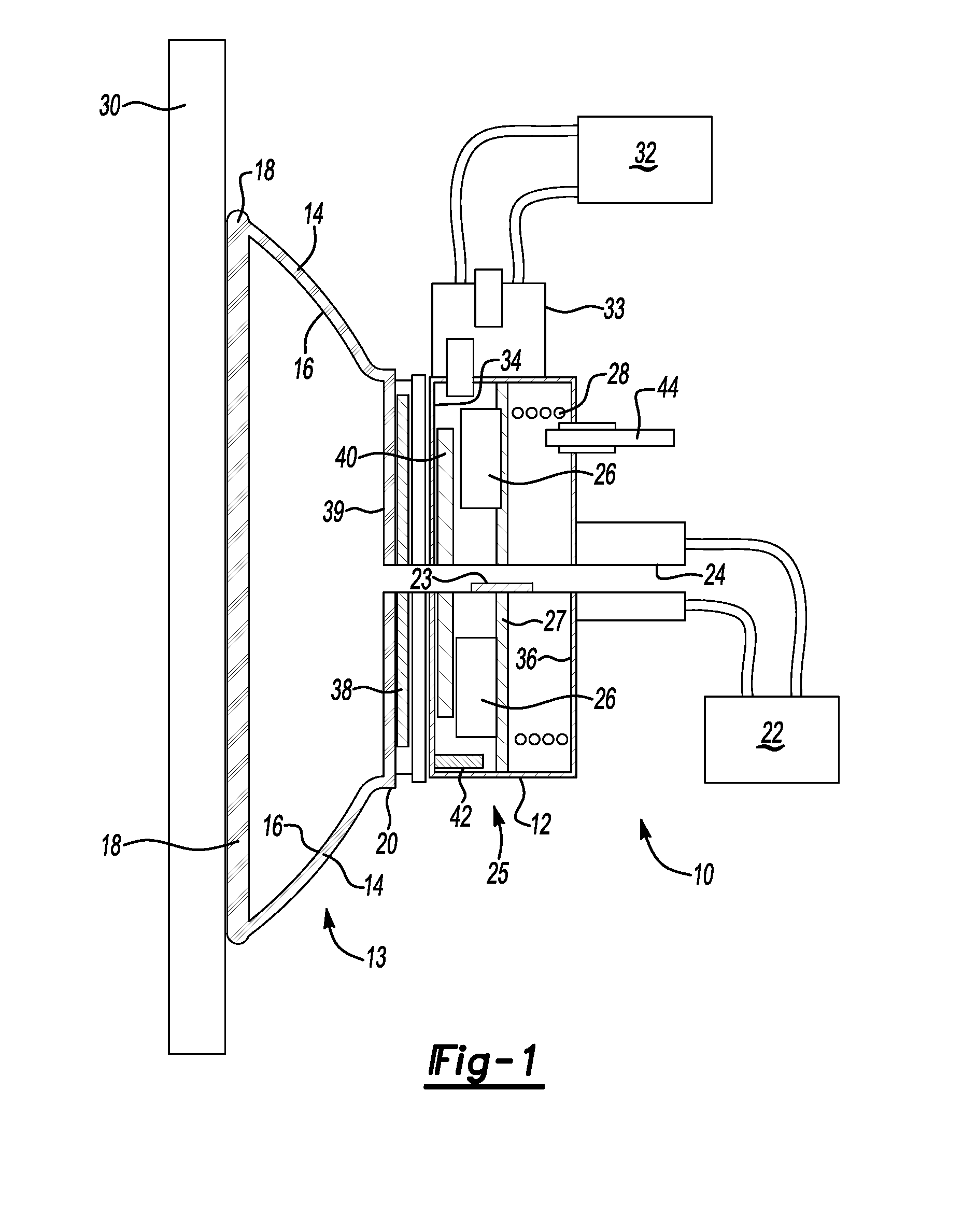

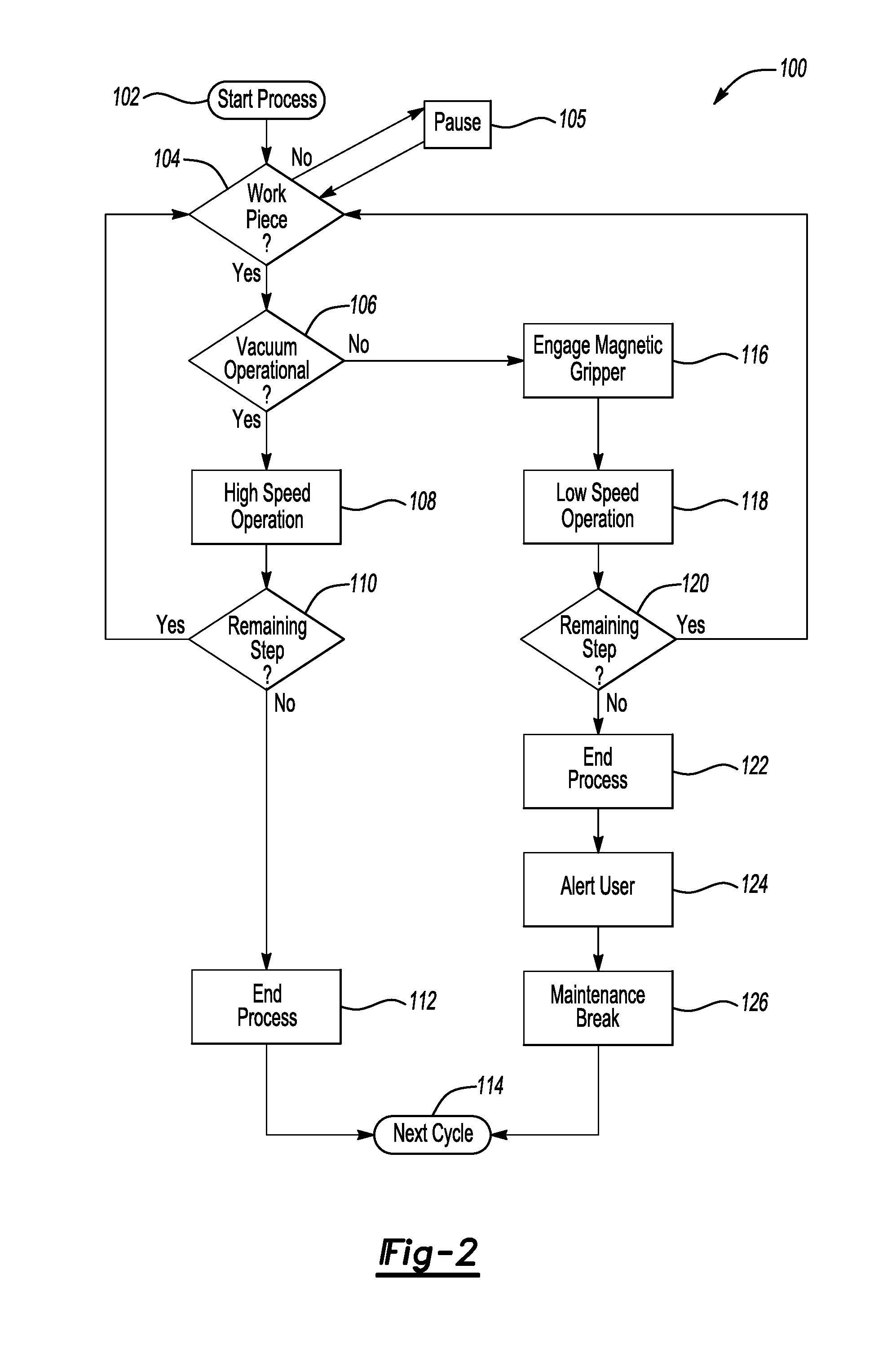

Integrated vacuum gripper with internal releasable magnet and method of using same

InactiveUS7963578B2Increase flexibilityLow investment costPliersGripping headsHigh accelerationEngineering

An integrated vacuum and magnetic gripper includes a rigid housing defining an internal chamber, and a flexible vacuum cup operatively connected thereto. A vacuum cavity is defined by the vacuum cup and a vacuum source is configured to reduce pressure in the vacuum cavity. A permanent magnet is disposed within the rigid housing, and a magnet release mechanism is configured to selectively render the magnet incapable of exerting sufficient force to hold the work piece. A pole plate may be interposed between the internal chamber and vacuum cavity, such that the pole plate forms a portion of the internal chamber and may act to provide friction on the work piece. A method of using the gripped includes operating at high acceleration while the vacuum gripper is monitored as fully operational and operating only at lower acceleration while the vacuum gripper is not fully operational.

Owner:GM GLOBAL TECH OPERATIONS LLC

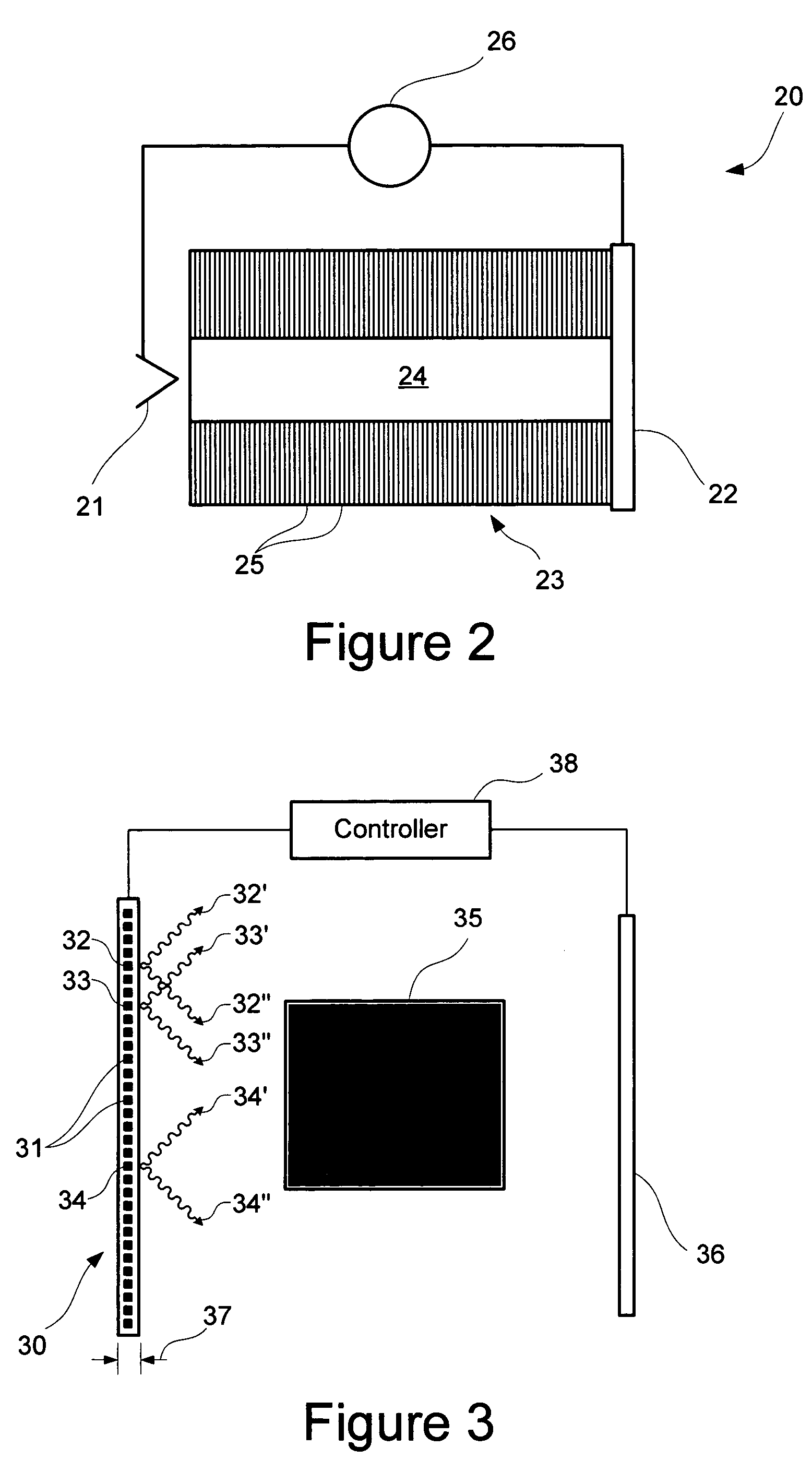

Compact x-ray source and panel

ActiveUS7330533B2Short drift distance/spacingSignificant differenceCathode ray concentrating/focusing/directingX-ray tube with very high currentSoft x rayElectrical conductor

A compact, self-contained x-ray source, and a compact x-ray source panel having a plurality of such x-ray sources arranged in a preferably broad-area pixelized array. Each x-ray source includes an electron source for producing an electron beam, an x-ray conversion target, and a multilayer insulator separating the electron source and the x-ray conversion target from each other. The multi-layer insulator preferably has a cylindrical configuration with a plurality of alternating insulator and conductor layers surrounding an acceleration channel leading from the electron source to the x-ray conversion target. A power source is connected to each x-ray source of the array to produce an accelerating gradient between the electron source and x-ray conversion target in any one or more of the x-ray sources independent of other x-ray sources in the array, so as to accelerate an electron beam towards the x-ray conversion target. The multilayer insulator enables relatively short separation distances between the electron source and the x-ray conversion target so that a thin panel is possible for compactness. This is due to the ability of the plurality of alternating insulator and conductor layers of the multilayer insulators to resist surface flashover when sufficiently high acceleration energies necessary for x-ray generation are supplied by the power source to the x-ray sources.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

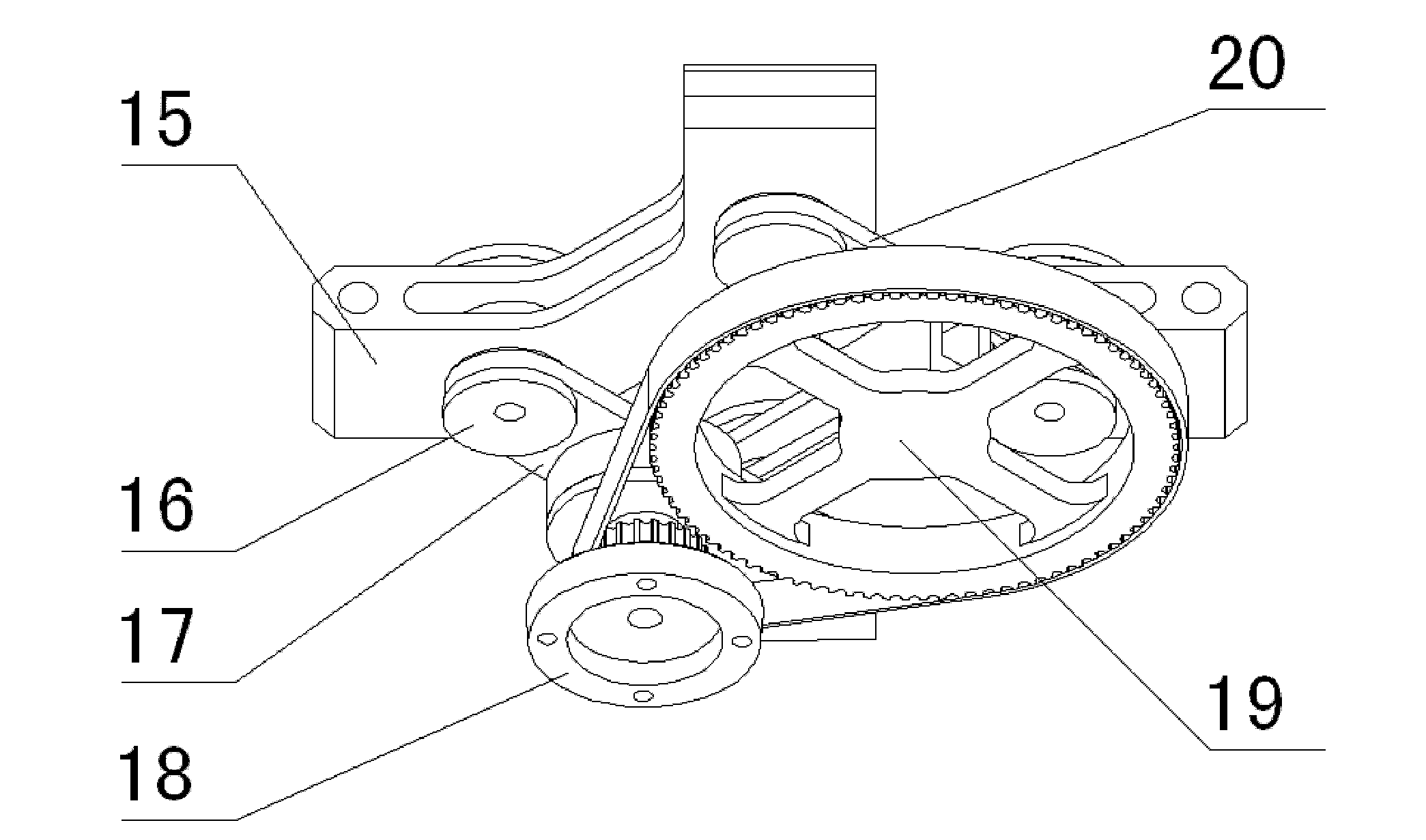

Three-dimensional-translation and one-dimensional-rotation high-speed parallel robot

ActiveCN102601797AImprove work performanceImprove rigidityProgramme-controlled manipulatorControl systemSimulation

The invention discloses a three-dimensional-translation and one-dimensional-rotation high-speed parallel robot, which belongs to the technical field of industrial robots and comprises a robot mechanical body structure, a control system and a vision system. The control system and the vision system are combined to control the robot mechanical body structure to complete required movement. The robot has four degrees of freedom of three-dimensional translation and one-dimensional rotation, high-speed automatic picking and grading placement of products can be realized, and the robot has high-speed and high-acceleration moving capacity and further has advantages of high rigidity, uniformity in stress, high positioning precision and the like.

Owner:大连创奇科技有限公司

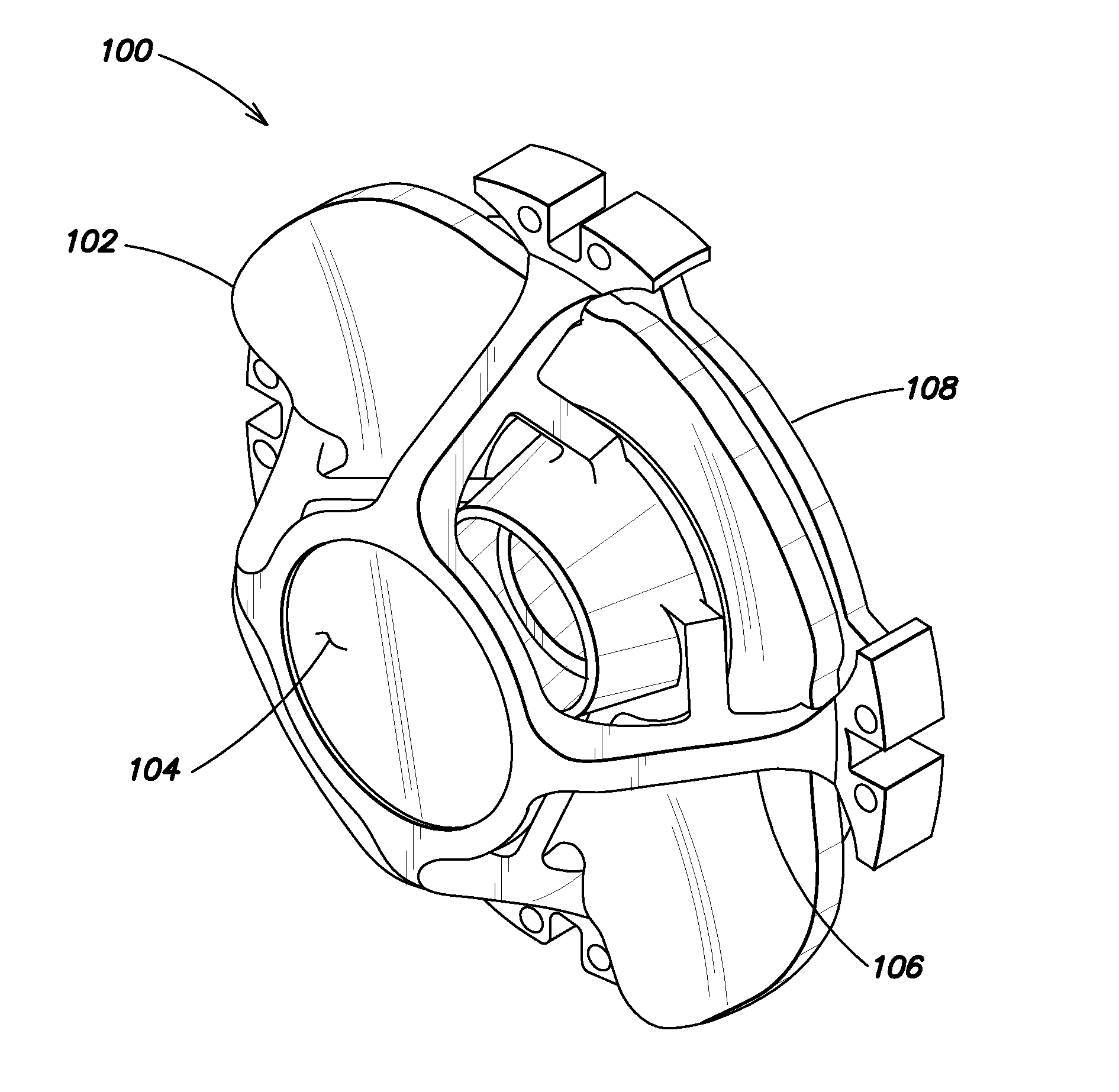

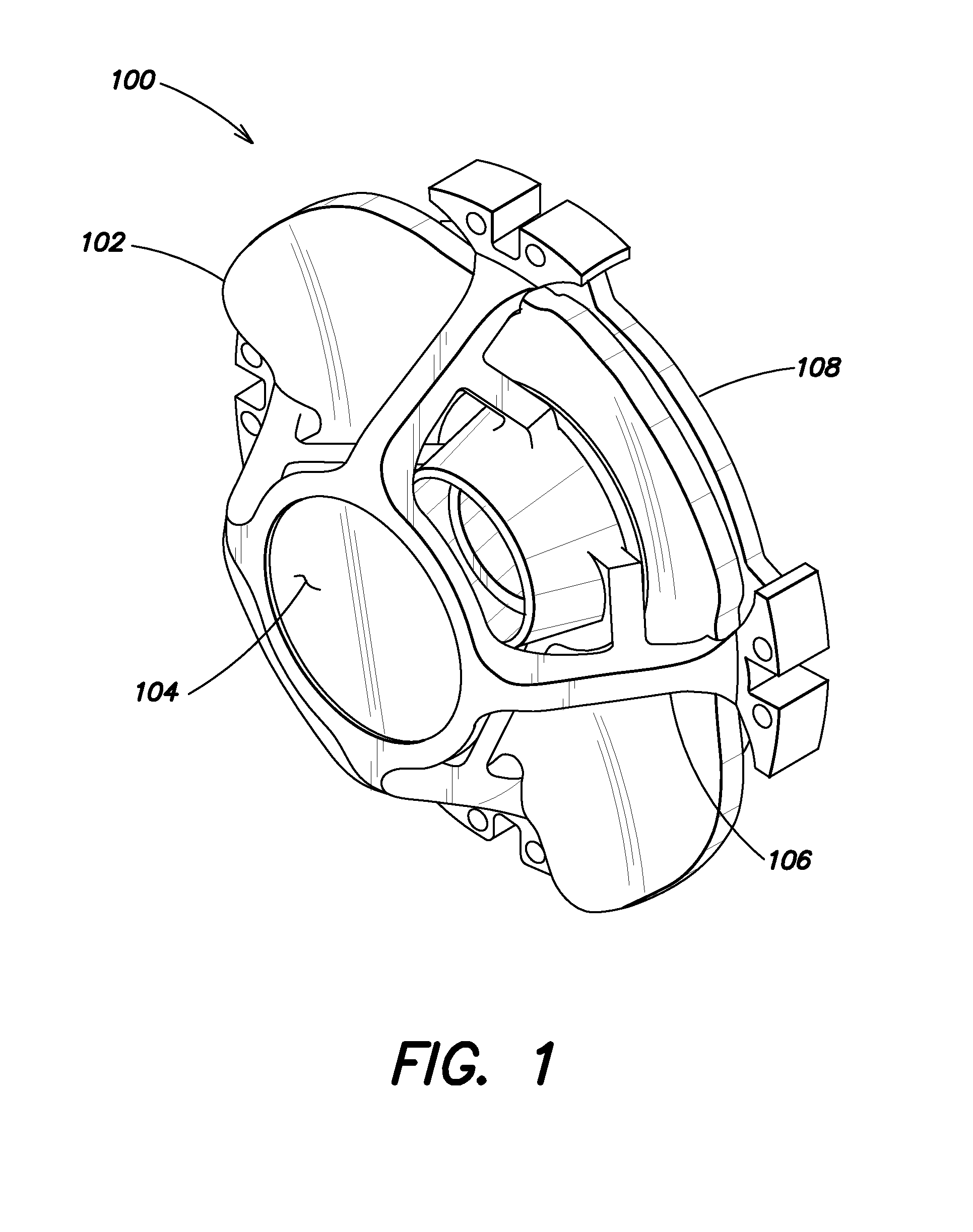

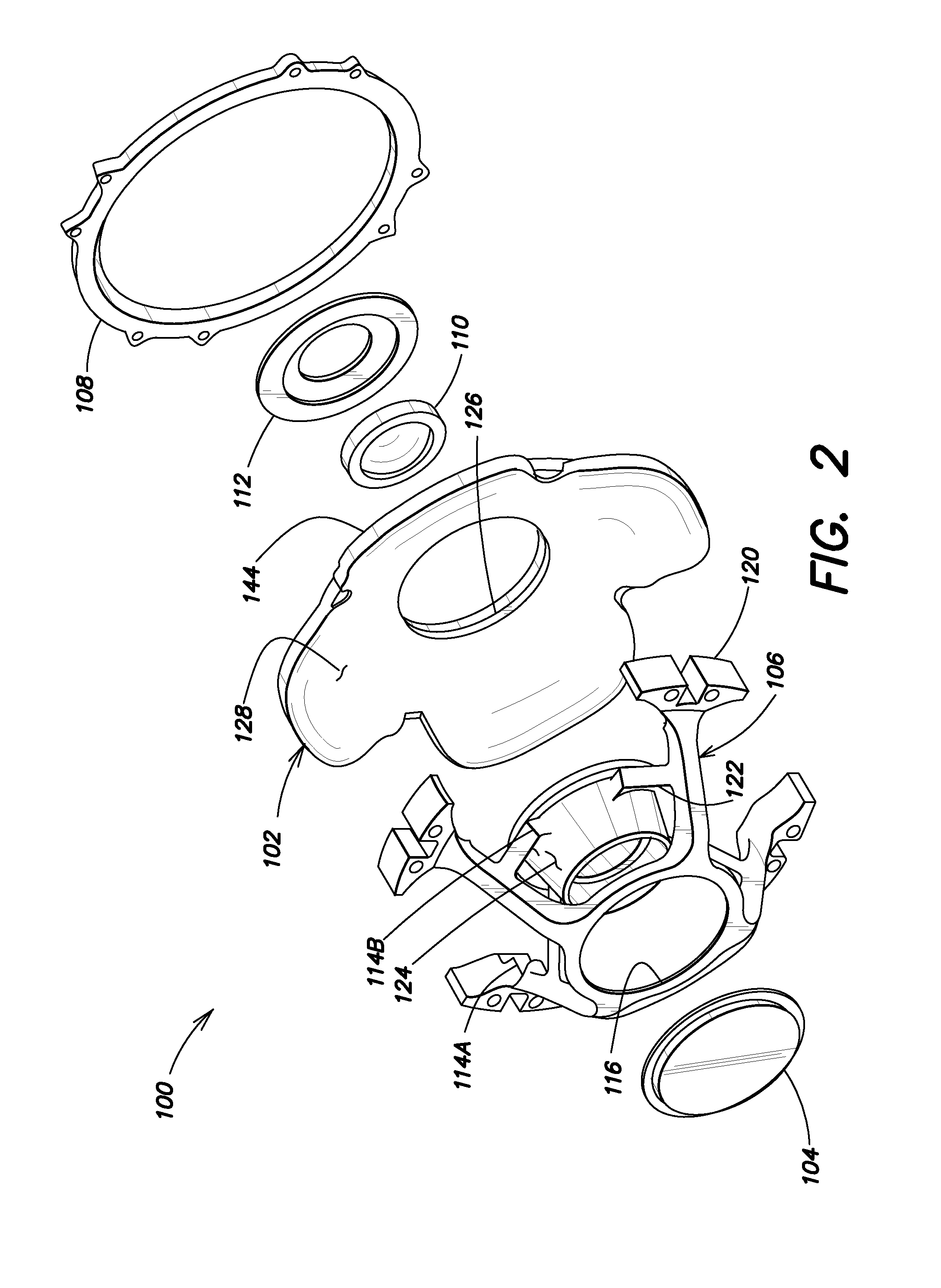

Bi-polymer infrared optics for high-g applications

ActiveUS20130208367A1Low costSacrificing optical qualityMirrorsDirection controllersCamera lensHigh acceleration

Optical systems configured to withstand operation in high acceleration and varying temperature environments, and methods of assembling the same. In one example, an imaging optical apparatus includes a primary minor made of an unreinforced polymer, a secondary mirror made of the unreinforced polymer and optically coupled to the primary minor, a field lens optically coupled to the secondary minor, and a strut having a plurality of cross-struts and mounting features configured to mount the primary minor, the secondary mirror and the field lens. In some examples, the imaging optical apparatus further includes an outer retainer disposed behind the primary minor and coupled to the strut, and an inner retainer disposed behind the field lens and coupled to the strut, the outer and inner retainers configured to structurally support the primary minor and the field lens and to accommodate deflections of the primary minor.

Owner:RAYTHEON CO

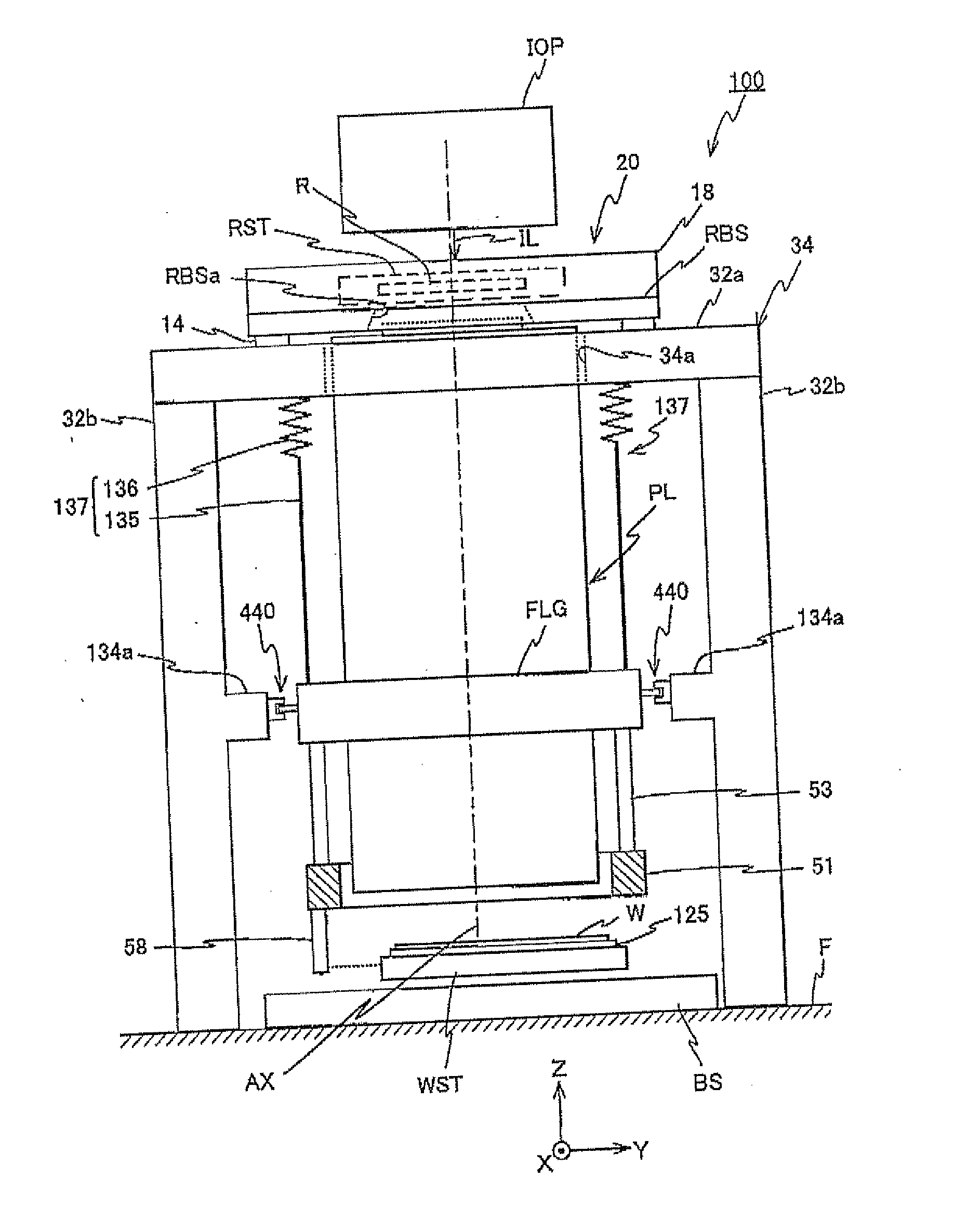

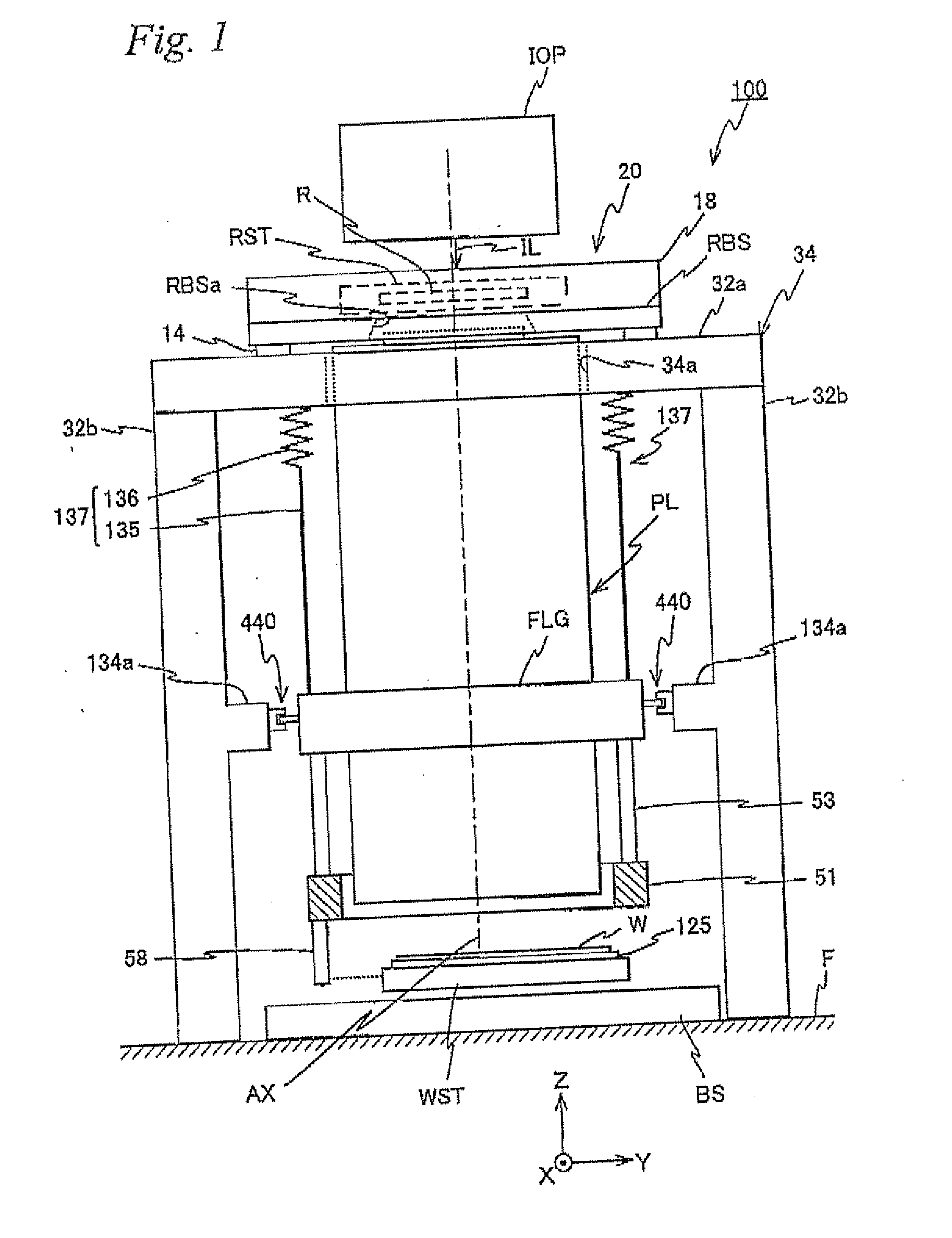

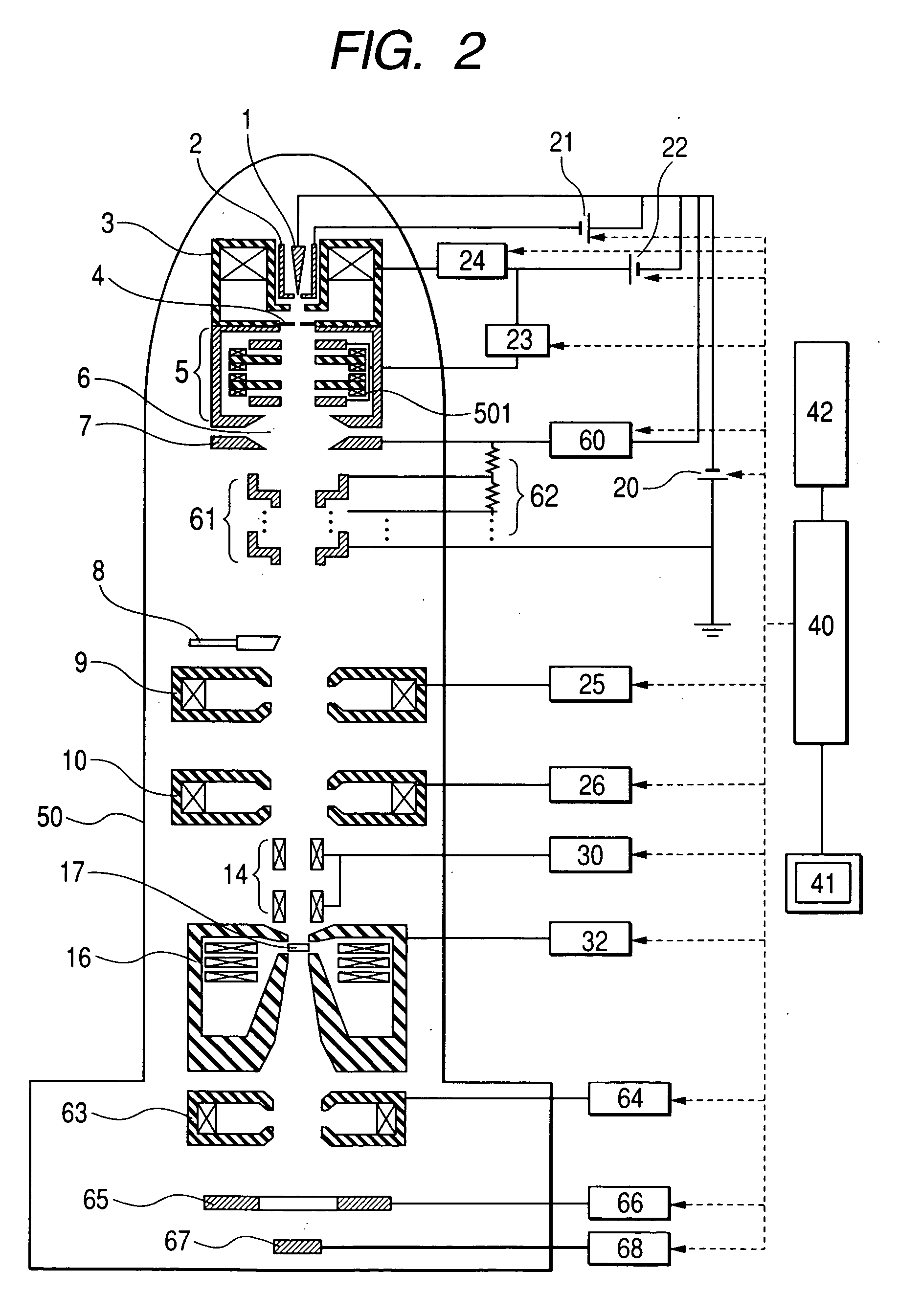

Movable body apparatus, exposure apparatus, exposure method, and device manufacturing method

ActiveUS20110032496A1Increase productionReduce weightMechanical apparatusPhotomechanical apparatusHigh accelerationEngineering

One pair each of a Y linear motor (a total of four) on the +X side and the −X side that drive a reticle stage include one pair each of a stator section (a total of four) and three each of a mover section (a total of six) on the +X side and the −X side. In this case, the three each of the mover sections on the +X side and the −X side configure one each of a mover. The mover section located in the center in the Z-axis direction of each of the movers is used in common by each pair of the Y linear motors. Therefore, the weight of the mover section (reticle stage) of the reticle stage device is reduced, which allows a higher acceleration. Further, the mover section located in the center in the Z-axis direction of each of the movers coincides with a neutral plane of the reticle stage.

Owner:NIKON CORP

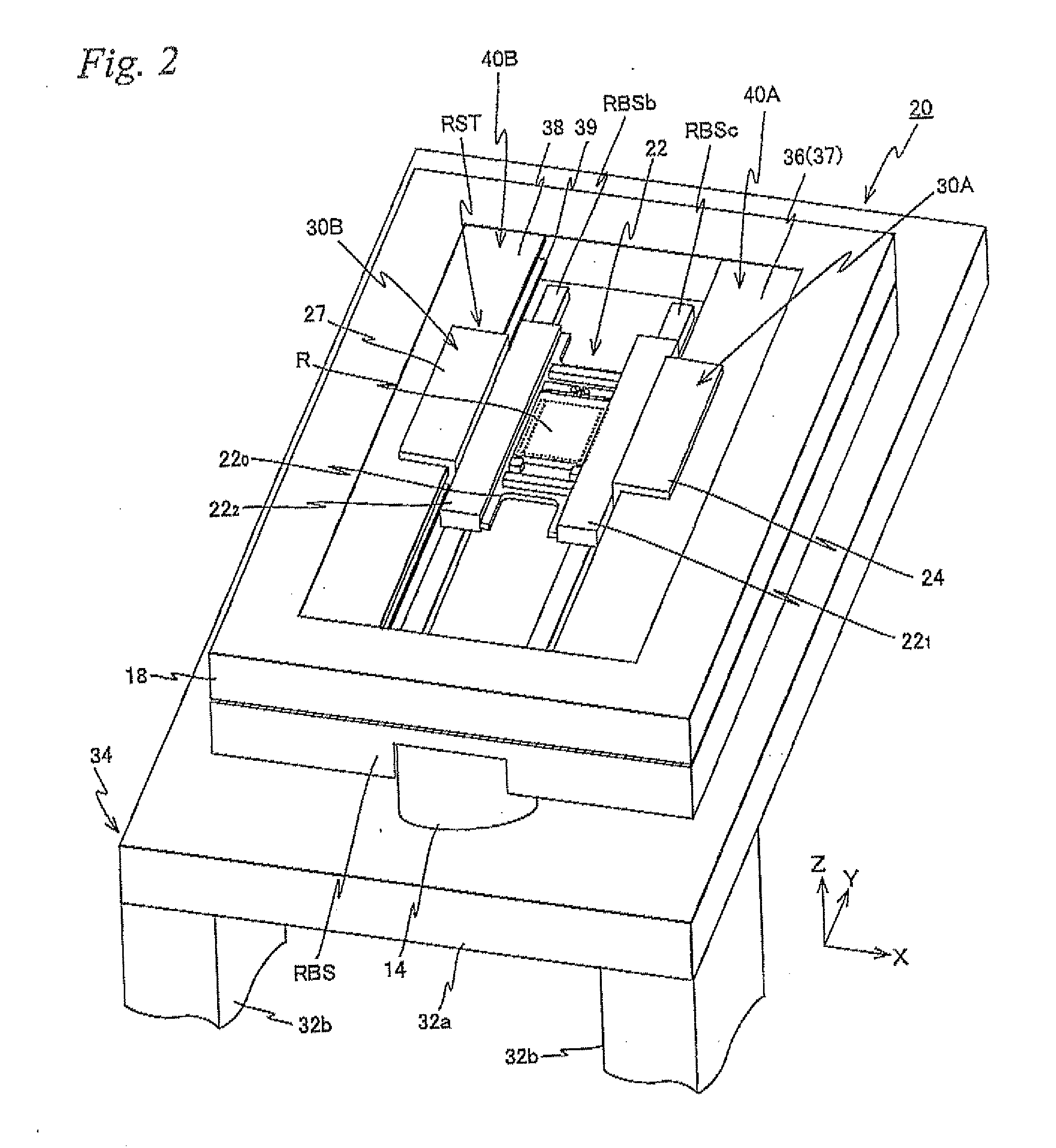

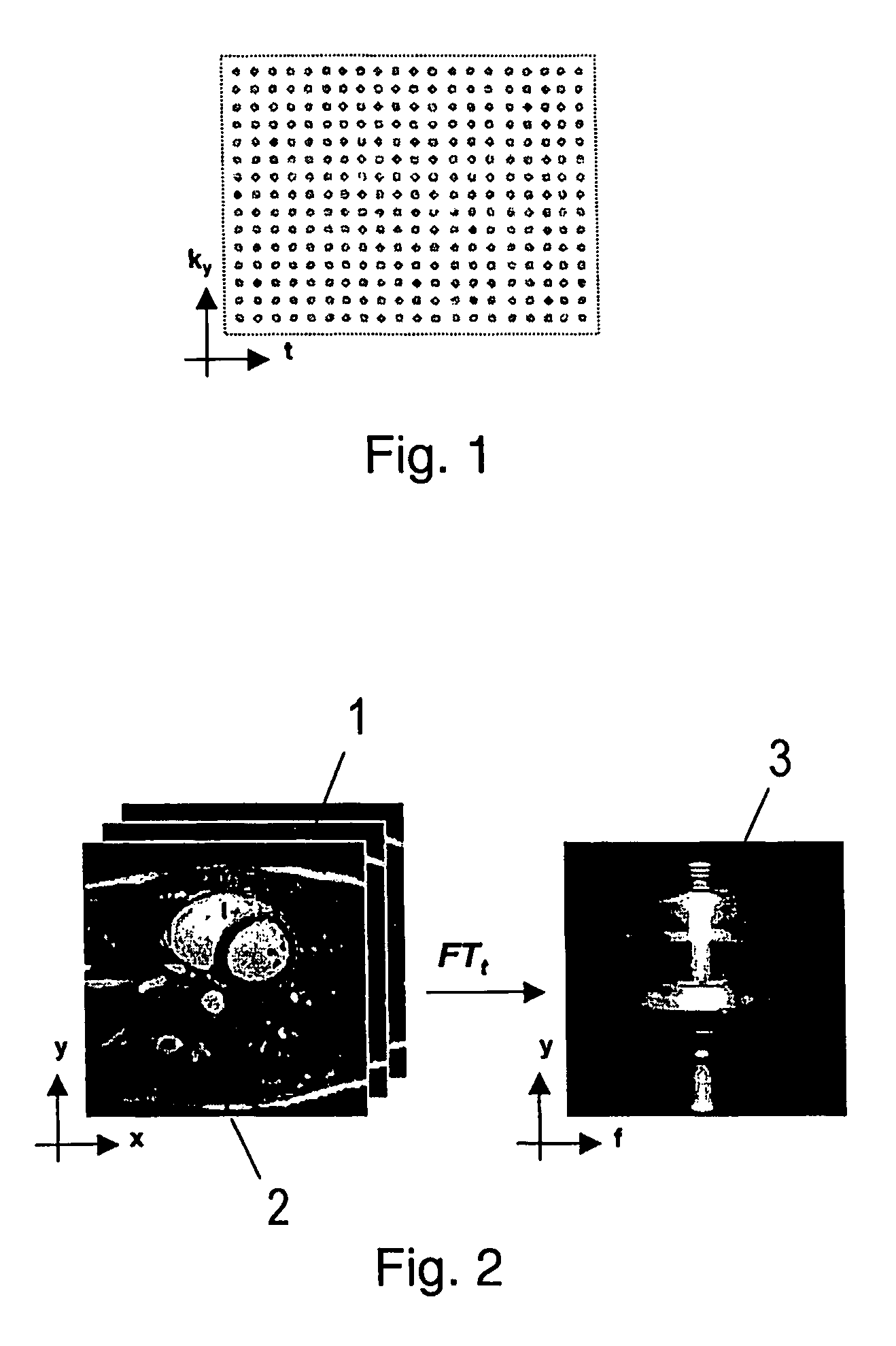

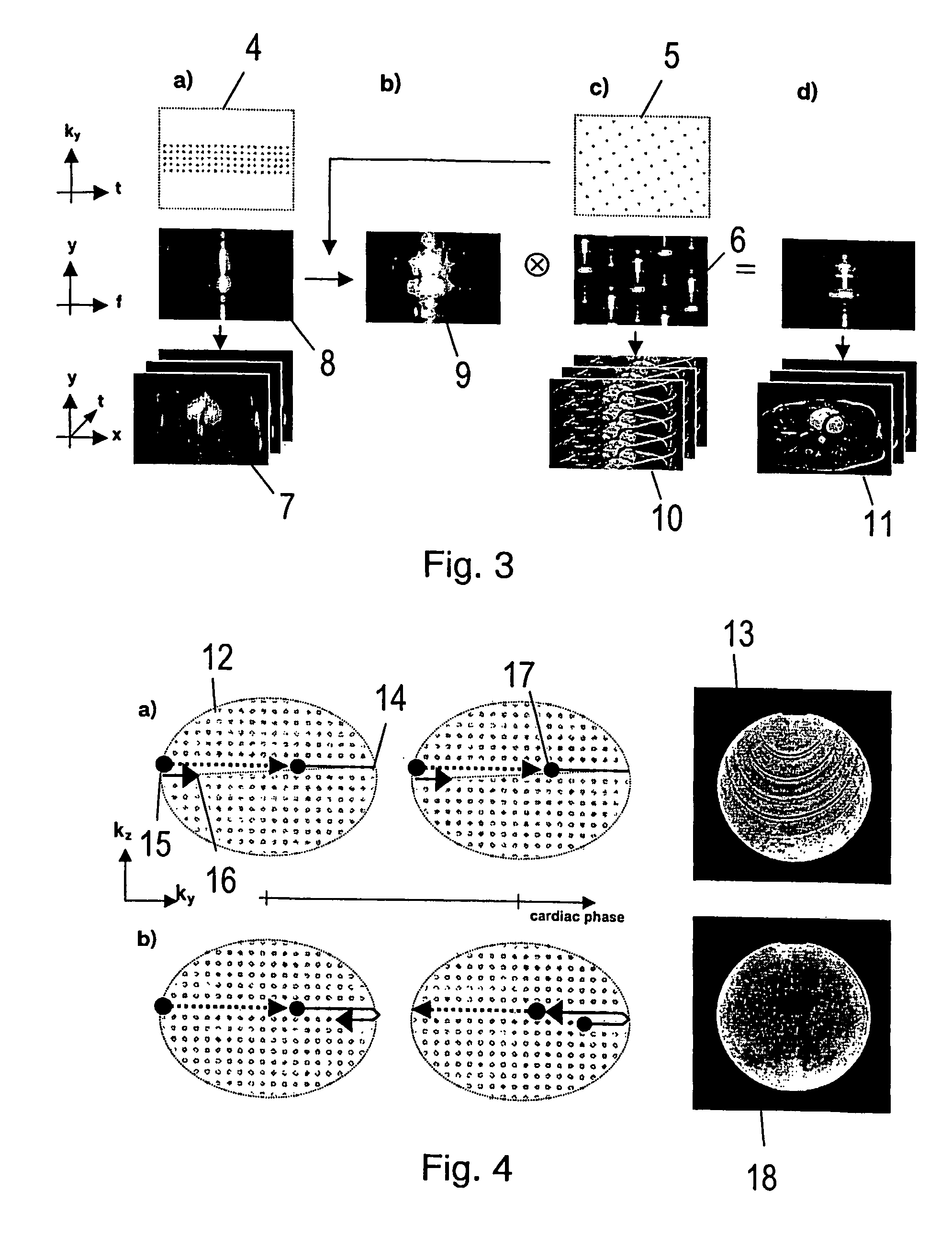

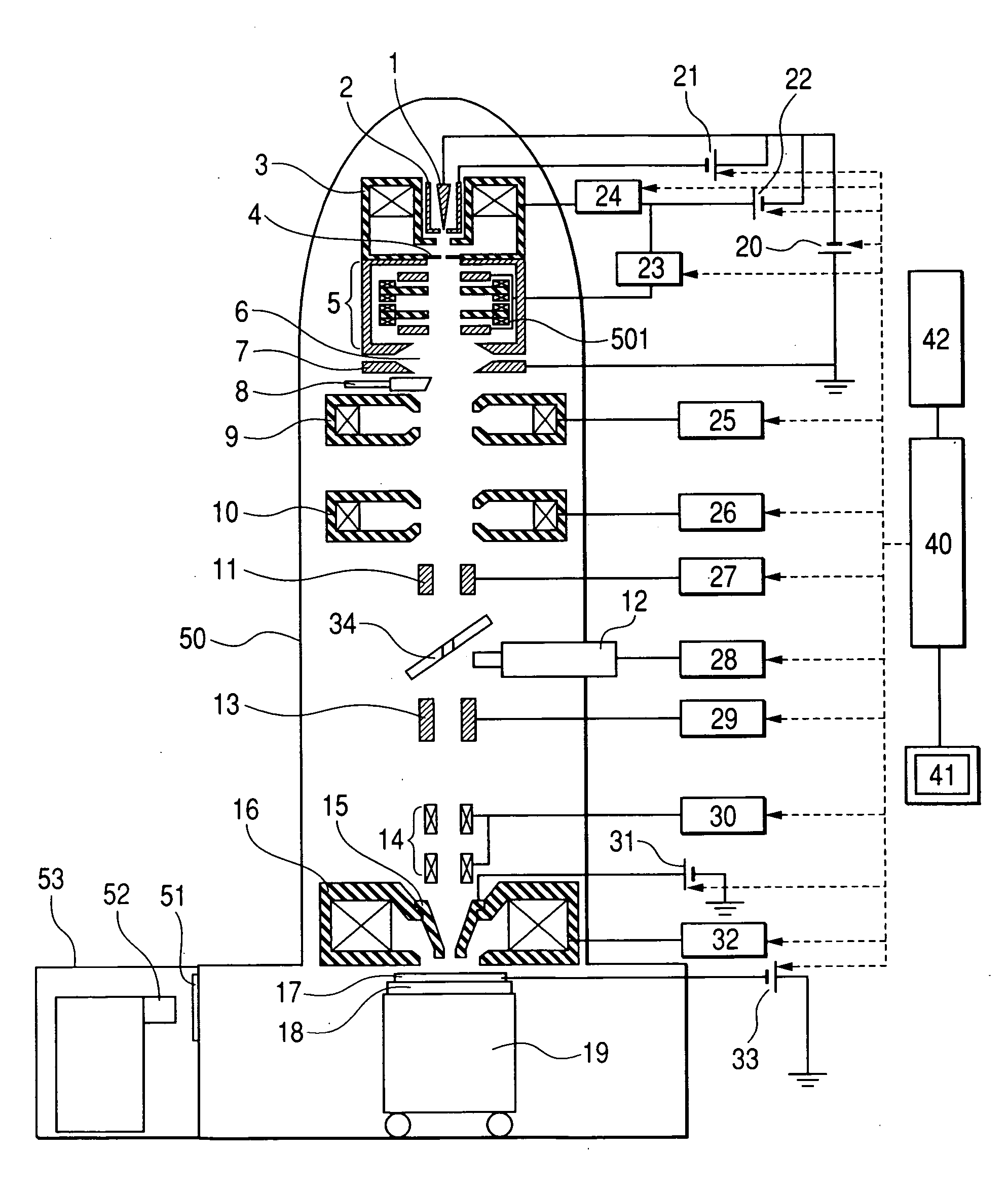

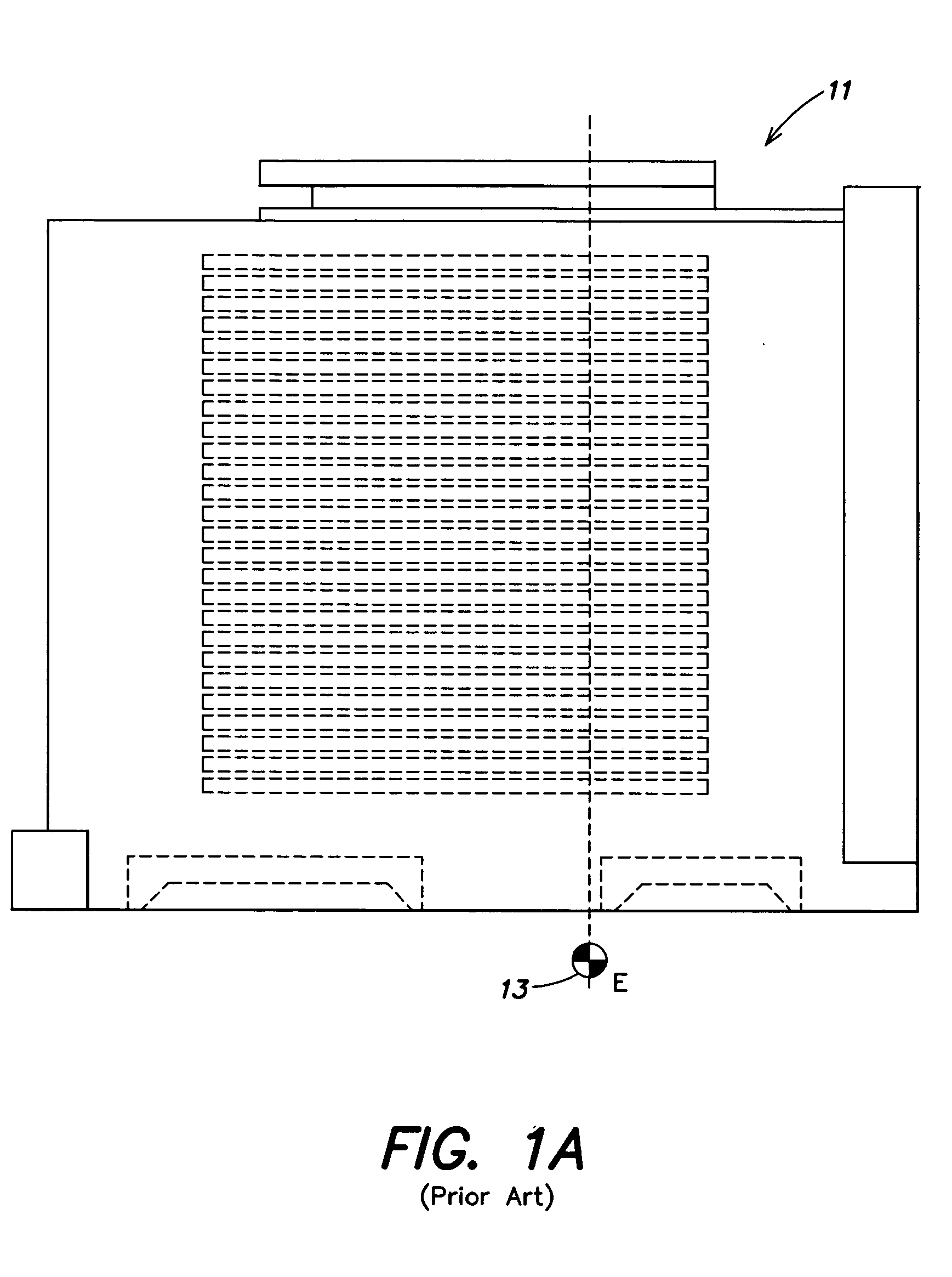

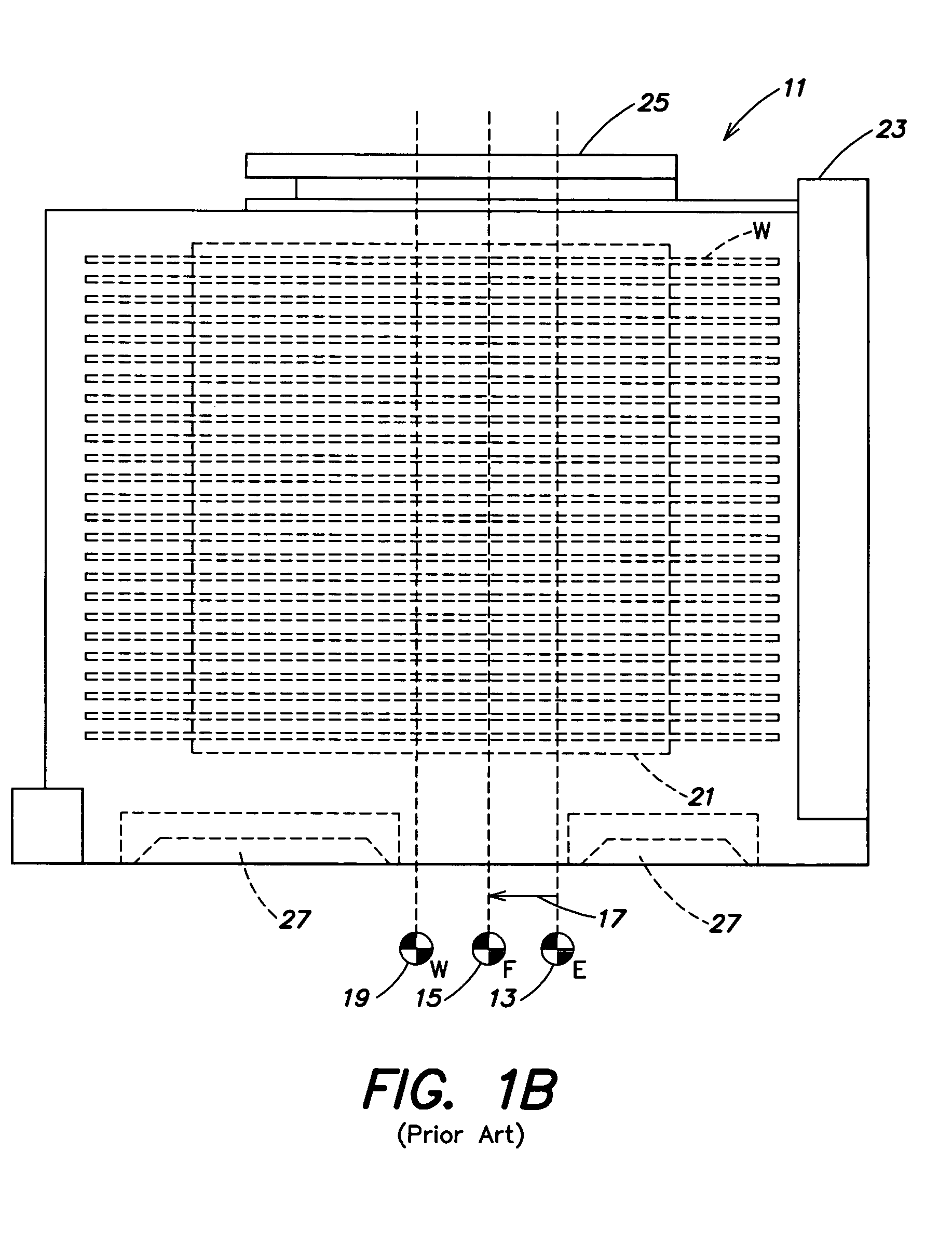

System and method of magnetic resonance imaging for producing successive magnetic resonance images

InactiveUS7330027B2Speed up SSFP dynamic imagingReduce dataMagnetic measurementsElectric/magnetic detectionTemporal resolutionData acquisition

This invention describes the combination of SSFP, a method for accelerating data acquisition, and an eddy current compensation method. This synergistic combination allows acquisition of images with high signal-to-noise ratio, high image contrast, high spatial and temporal resolutions, and good immunity against system instabilities. k-t BLAST and k-t SENSE are the preferred method for accelerating data acquisition, since they allow high acceleration factors, but other methods such as parallel imaging and reduced field-of-view imaging are also applicable. Typical applications of this invention include cine 3D cardiac imaging, and 2D real-time cardiac imaging.

Owner:UNIV ZURICH +1

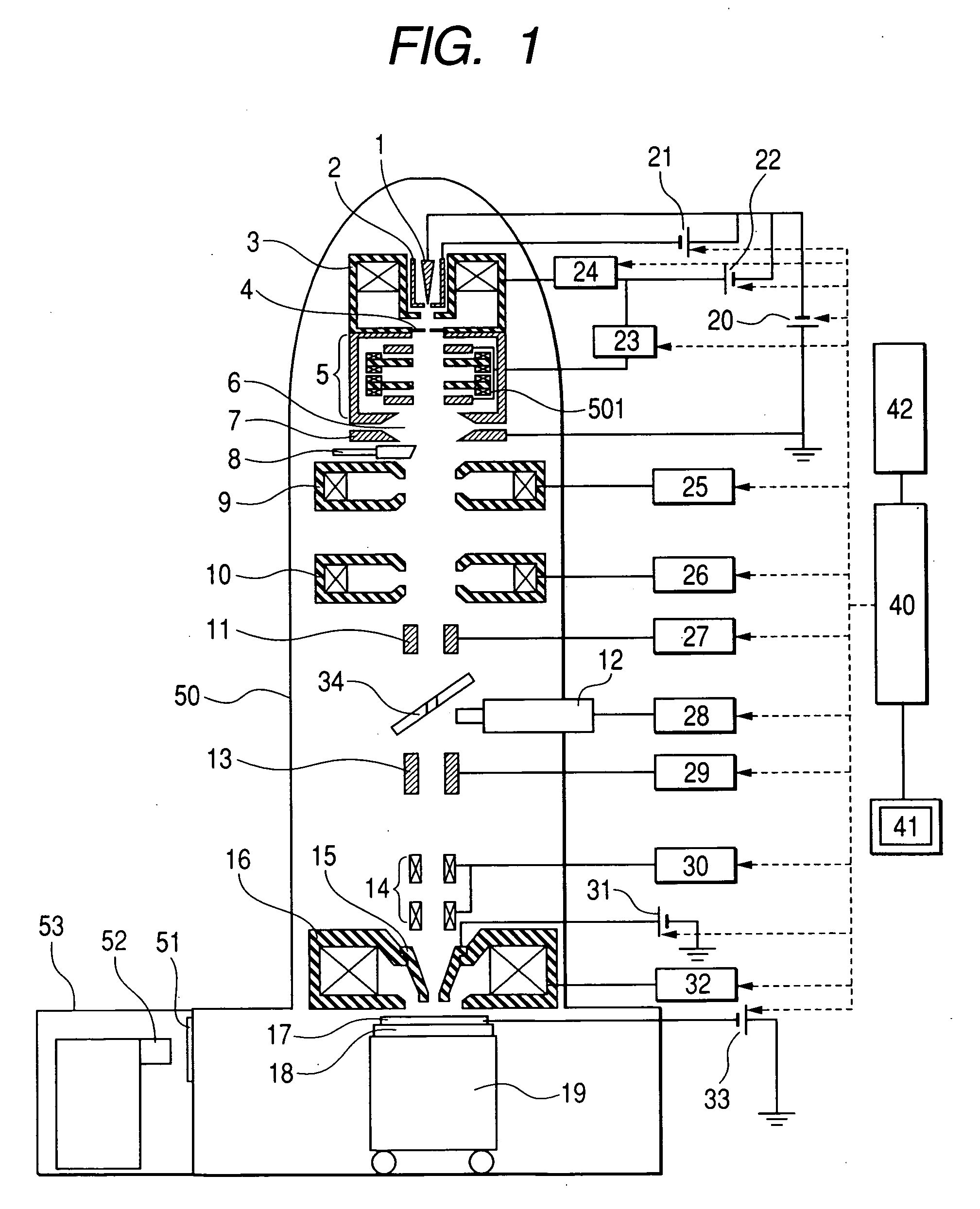

Charged particle beam apparatus

InactiveUS20060175548A1Weaken energyStability-of-path spectrometersMaterial analysis using wave/particle radiationLight beamHigh acceleration

A charged particle beam apparatus having an aberration correction capability at high acceleration voltages. The charged particle beam apparatus comprises a charged particle beam source; an extraction electrode to extract charged particles from the charged particle beam source; a charged particle beam gun including a means for converging a charged particle beam; an acceleration means for accelerating a charged particle beam emitted from the charged particle beam gun; and an aberration correction means disposed between the charged particle beam gun and the acceleration means, in which an aberration enough to cancel out an aberration of a charged particle beam on the specimen surface is provided to an extraction electrical potential or an equivalent beam at the initial acceleration stage.

Owner:HITACHI HIGH-TECH CORP

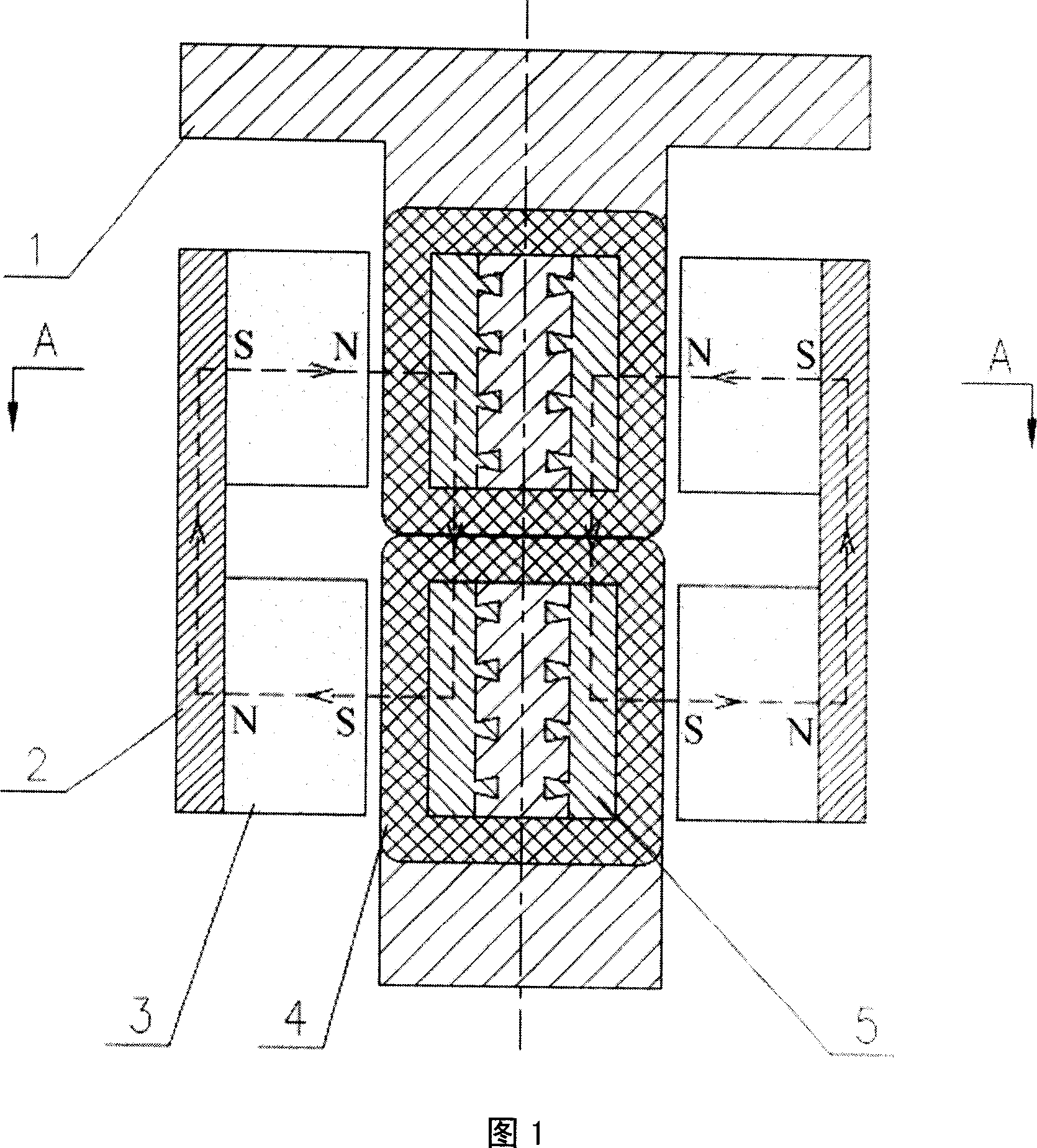

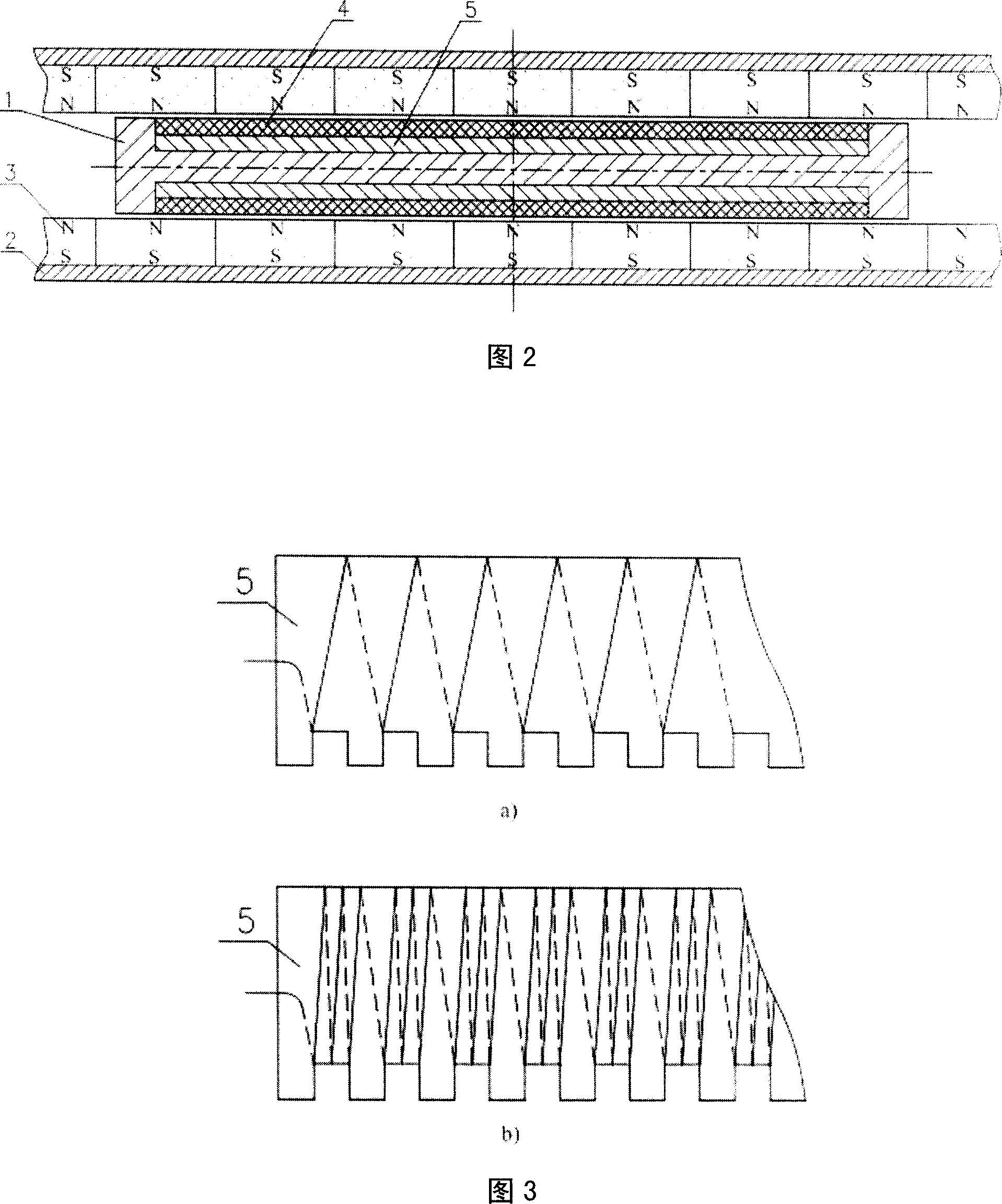

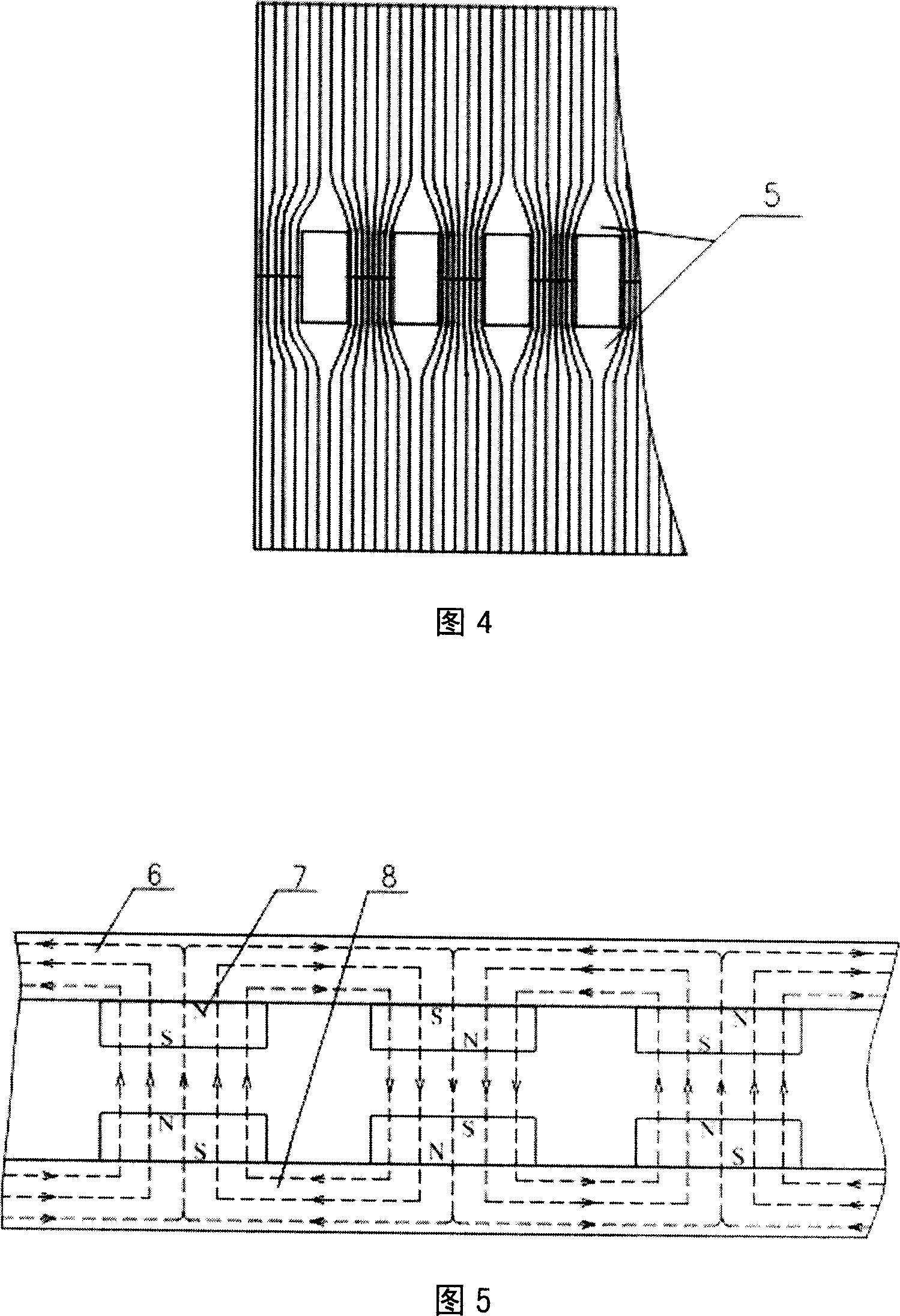

Long range big-push force permanent-magnet brushless linear DC motor

InactiveCN101009455AGood magnetic conductivityHigh resistivityAC motor controlMagnetic circuit rotating partsNumerical controlSpeed control system

A long journey big thrust permasyn brushless beeline direct electromotor that includes stator part, rotor part and position and speed controlling system of the electromotor. The stator part composes permanent-magnet (3) and magnetic yoke (2), magnetizer (5) is connected with rack (1) via coattail groove structure, and two windings (4) with different direction current circle the magnetizer to form rotor part. The invention adopts the two-sized stator structure to eliminate the single sized magnetic pull, and the thrust is big, journey is long, the weight of rotor is light, without contact running and cost is low, it is fit for common numerical control machine tool feeding system, special numerical control machine tool feeding system which adopts gas floating or magnet floating guiding track and other high speed and high acceleration direct feeding systems.

Owner:DALIAN JIAOTONG UNIVERSITY

Actuator available in controlled environment

ActiveUS20120285278A1Easy to controlLose weightLinear bearingsToothed gearingsHigh accelerationEngineering

A clean environmental actuator is less in weight, height in transverse section and compact in construction, even with ensuring accurate position control and conformable to high speed operation and high acceleration / deceleration. Both a bed and a slider are stowed in an enclosure and packings are in T-slots in side walls of the bed to seal clearances between the bed and the enclosure. The enclosure is composed of an end bracket to cover one end of the bed, a motor bracket to cover another end of the bed, a pair of side coverings to enclose the side surfaces and tops of the side walls of the bed, a sealing panel to cover an upward opening between the side coverings, and a table covering to overlay an area of the sealing panel lying on the slider and side areas of the table bulging out from side edges of the sealing panel.

Owner:NIPPON THOMPSON

Exercise apparatus based on a variable mode hydraulic cylinder and method for same

ActiveUS7762934B1Security challengeDistance minimizationMuscle exercising devicesWater sourceEngineering

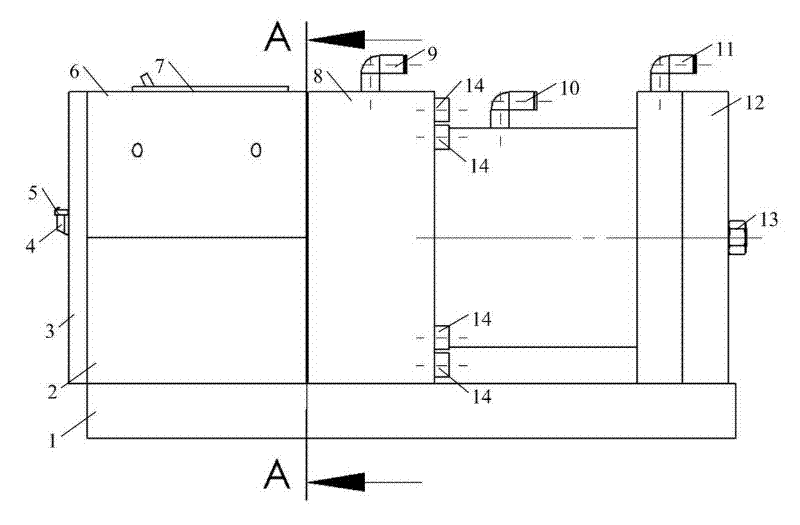

The invention is a hydraulic cylinder for use in exercise machines to deliver a controllable fast acting force. The invention uses a hydraulic cylinder with features that allow high acceleration rates, rapid changes of force level and direction, and positive force limitation. In the preferred embodiment, the hydraulic cylinder is composed of a rodless, hydraulic cylinder coupled to a cable and pulley system. A water source delivers water to generate a force against an inner bi-directionally moving piston to generate a regulated movement and force.The ends of the rodless hydraulic cylinder are sealed by both a water control spool valve and a controllable poppet style pressure relief valve. The water control spool valves adjustably permits water to enter and exit the hydraulic cylinder to regulate the direction and speed of movement of the piston. The pressure relief valve controls the desired maximum pressure and corresponding forces exerted on cylinder. Thus, both the internal speed and force of movement of the piston can be controlled. The invention can deliver high acceleration / speed, high force resistance; high acceleration / speed, low force resistance; low acceleration / speed, high force resistance; or low acceleration / speed, low force resistance exercise forces and movements depending on the water flow, internal pressure, and resulting generated forces.

Owner:FOI GRP

Long-stroke high-frequency-response quick cutter servo device

InactiveCN102554633ANo noiseNo vibrationFeeding apparatusLarge fixed membersHigh accelerationControl theory

The invention discloses a long-stroke high-frequency-response quick cutter servo device, which comprises a driving component and a cutter saddle moving component. The driving component is mounted on a mounting component, the cutter saddle moving component is connected with the driving component and consists of a floatation guide track supported by a floatation support component, one end of the floatation guide track is connected with the driving component, and the other end of the floatation guide track is connected with a cutter saddle provided with a cutter. The long-stroke high-frequency-response quick cutter servo device has the advantages of high processing precision, long stroke, high speed of the cutter, high acceleration and the like.

Owner:NAT UNIV OF DEFENSE TECH

Integrated Vacuum Gripper with Internal Releasable Magnet and Method of Using Same

InactiveUS20090297316A1Increase flexibilityLow investment costPliersGripping headsHigh accelerationEngineering

An integrated vacuum and magnetic gripper includes a rigid housing defining an internal chamber, and a flexible vacuum cup operatively connected thereto. A vacuum cavity is defined by the vacuum cup and a vacuum source is configured to reduce pressure in the vacuum cavity. A permanent magnet is disposed within the rigid housing, and a magnet release mechanism is configured to selectively render the magnet incapable of exerting sufficient force to hold the work piece. A pole plate may be interposed between the internal chamber and vacuum cavity, such that the pole plate forms a portion of the internal chamber and may act to provide friction on the work piece. A method of using the gripped includes operating at high acceleration while the vacuum gripper is monitored as fully operational and operating only at lower acceleration while the vacuum gripper is not fully operational.

Owner:GM GLOBAL TECH OPERATIONS LLC

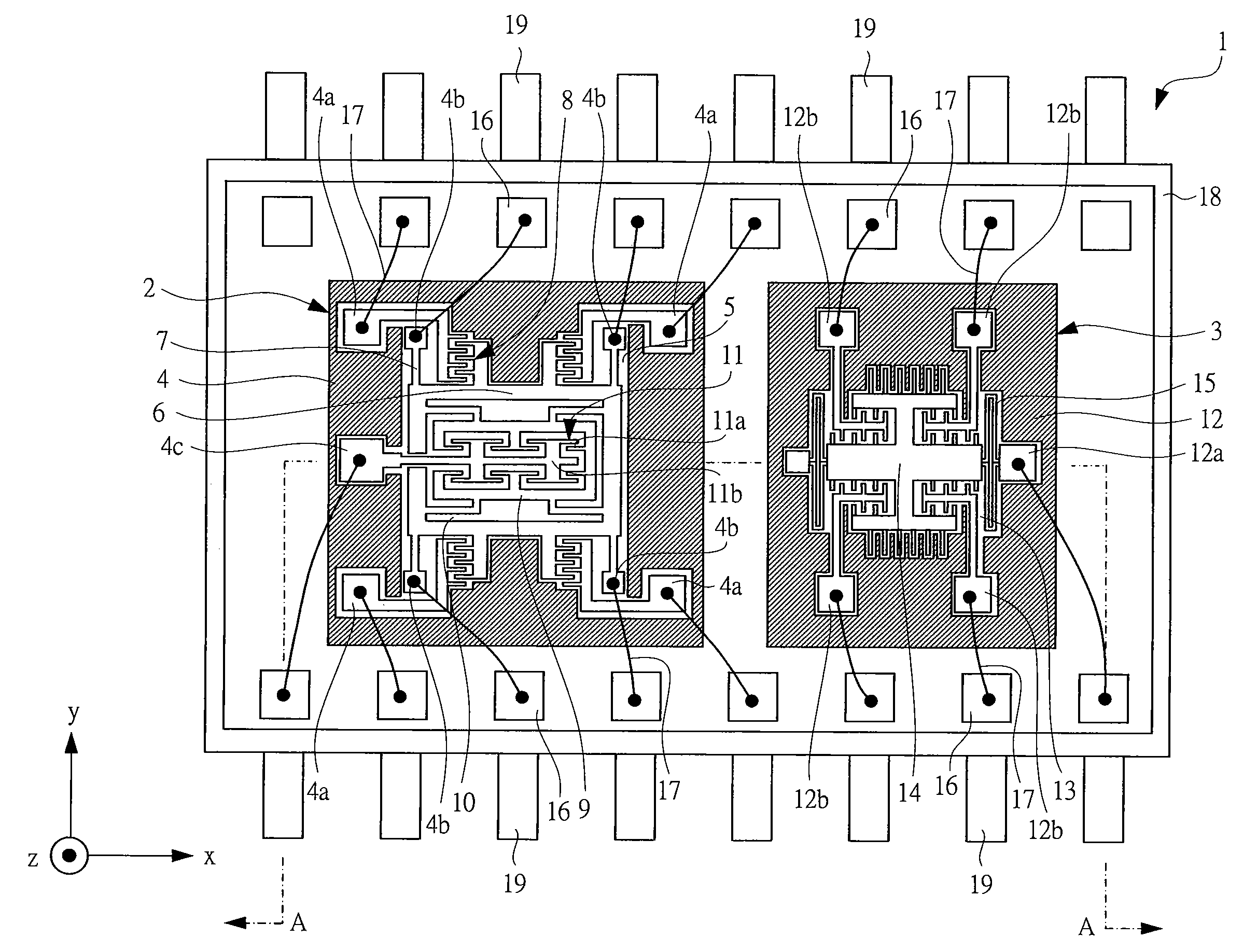

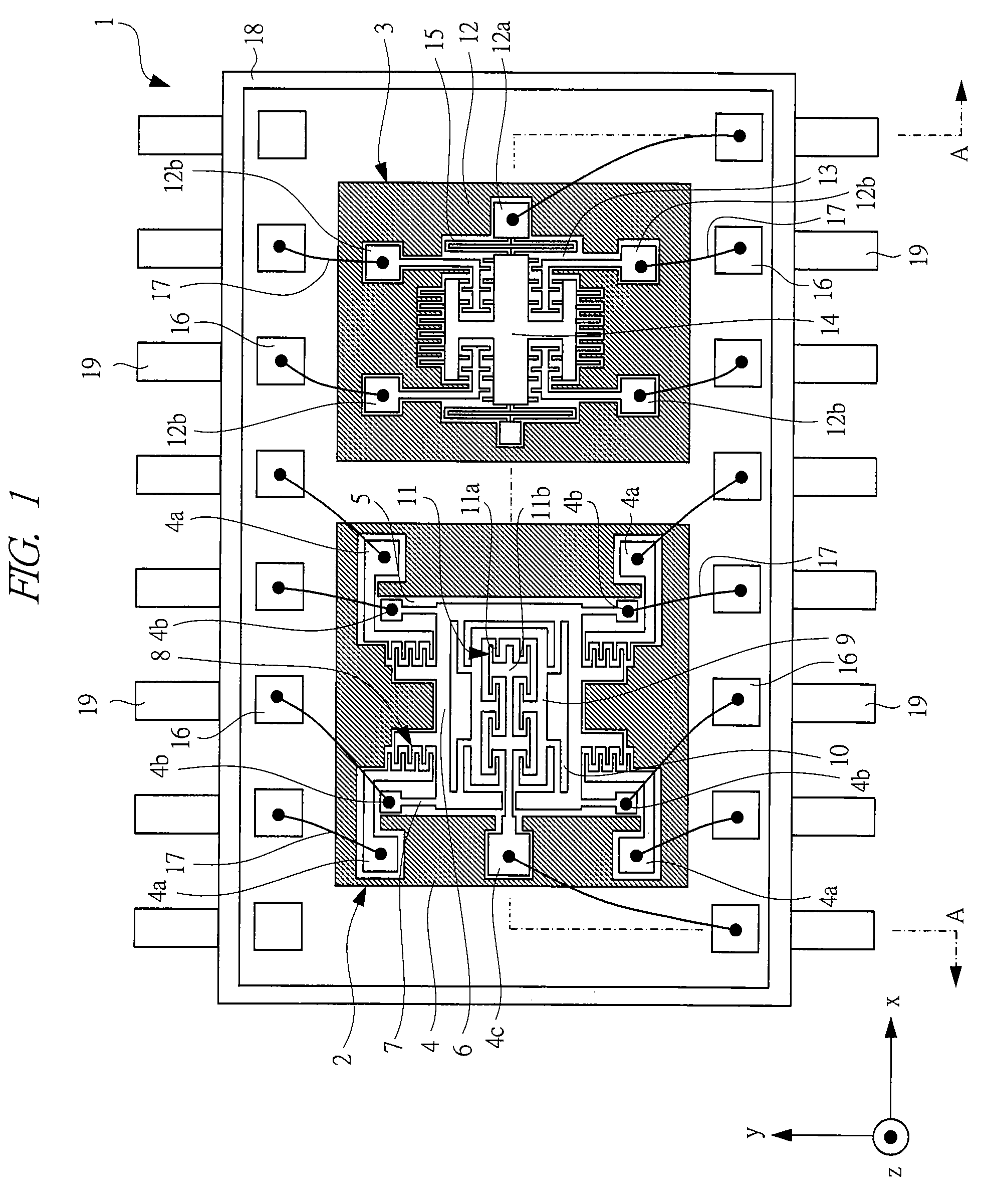

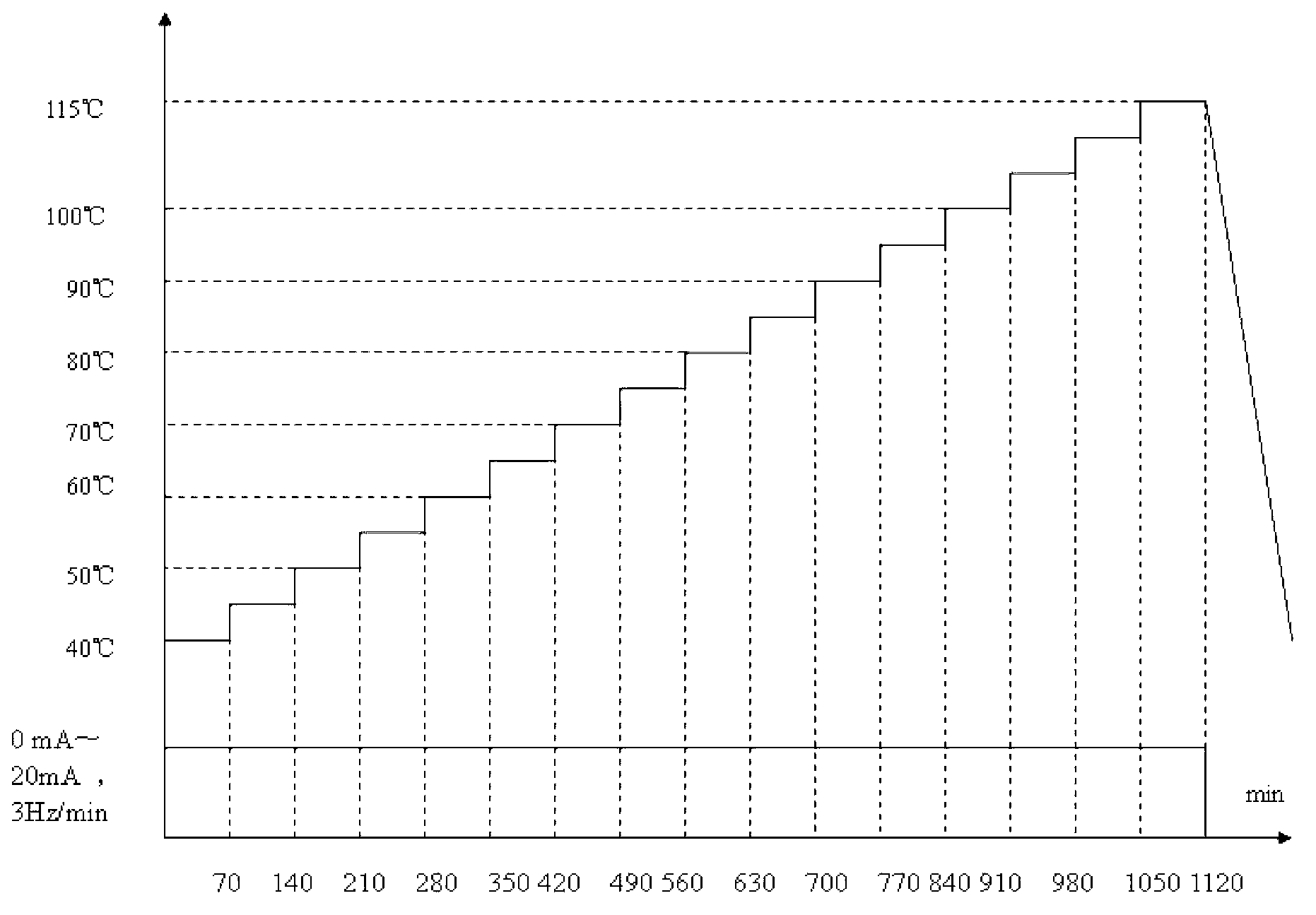

Inertial sensor

ActiveUS20090183568A1High detection sensitivityAvoid displacementAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorHigh acceleration

An angular rate sensor and an acceleration sensor are sealed at the same sealing pressure. The sealing pressure at this time is put into a reduced pressure state below the atmospheric pressure in view of improving a detection sensitivity of the angular rate sensor. Even in the reduced pressure atmosphere, to improve the detection sensitivity of the acceleration sensor, a shift suppressing portion (damper) for suppressing shifts of a movable body of the acceleration sensor is provided. This shift suppressing portion includes a plurality of protruding portions integrally formed with the movable body and a plurality of protruding portions integrally formed with a peripheral portion, and the protruding portions are alternately disposed separately at equal intervals.

Owner:HITACHI LTD

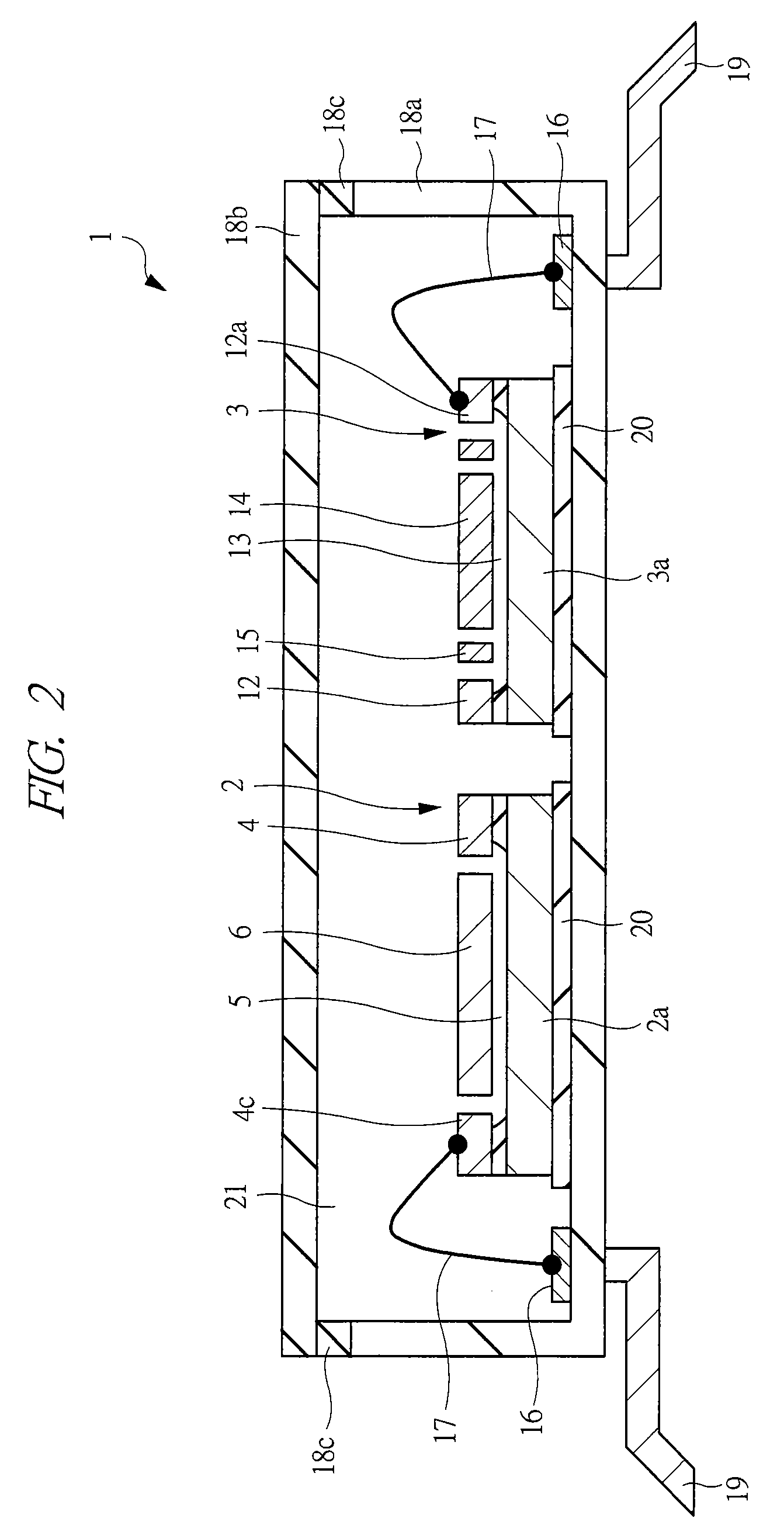

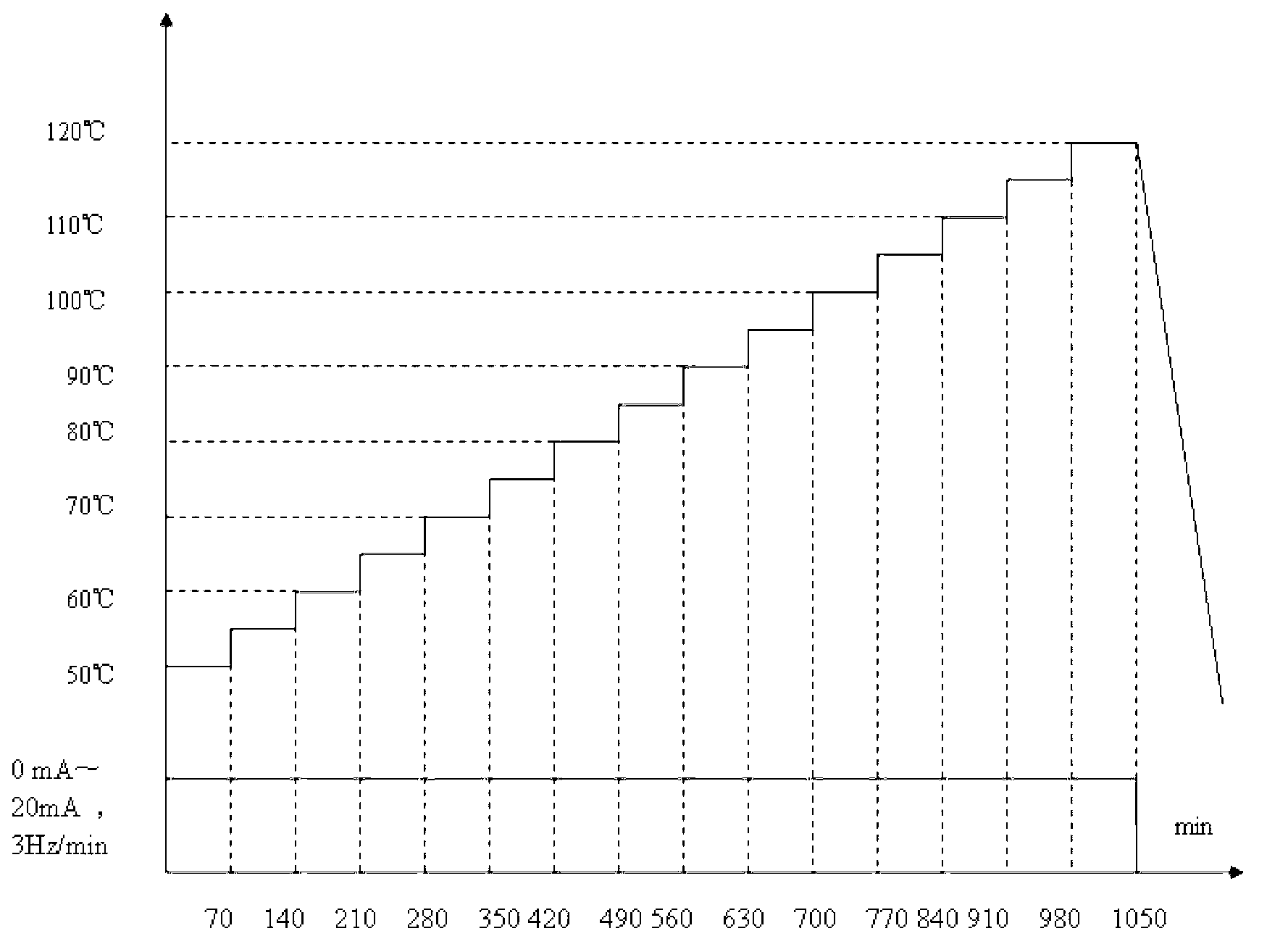

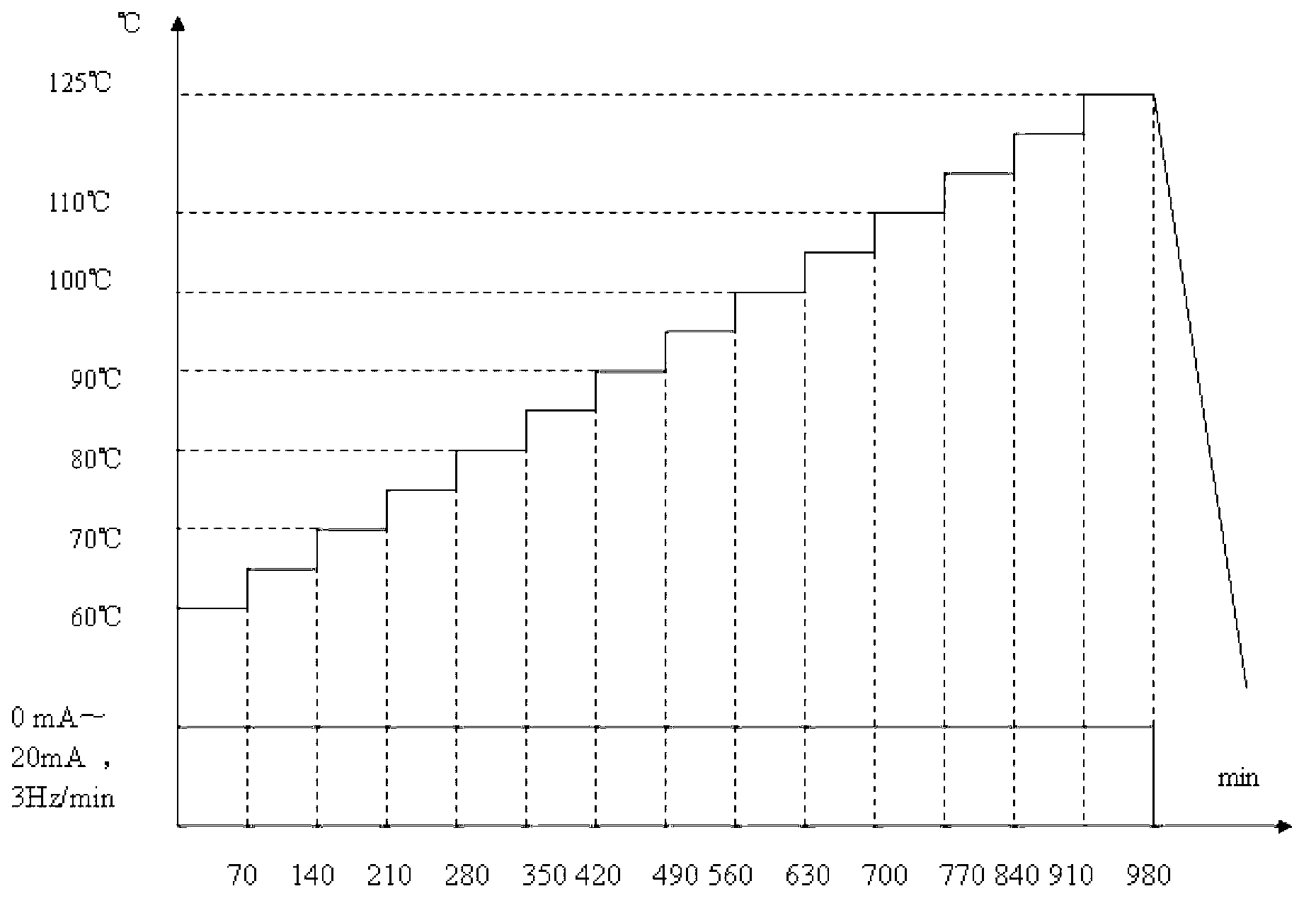

Method for testing high-temperature breaking limit of antiskid brake control box

InactiveCN103294050AReduce consumptionShorten test timeElectric testing/monitoringHigh accelerationTemperature resistance

Disclosed is a method for testing a high-temperature breaking limit of an antiskid brake control box. Three comprehensive testing devices are used for conducting a test, under a high-temperature stepping condition, antiskid brake working currents are applied, whether the performance of the antiskid brake control box is qualified or not is tested, if not qualified, improvement suggestions are put forward so that the high-temperature resistance of the antiskid brake control box can be improved, and if qualified, the test continues until required high-temperature resistance is achieved. A high-temperature stepping test belongs to accelerated life tests, test data of the high-temperature breaking limit are used as one of the bases for formulating the profile of a high-acceleration stress screening test. According to the method for testing the high-temperature breaking limit of the antiskid brake control box, the method with the high-temperature stepping test and the applied working currents integrated is used for stimulating high-temperature fault potential risks of the antiskid brake control box, the improvement suggestions directing at the fault potential risks are put forward and carried out, and the high-temperature breaking limit needed by the accelerated life tests and the high-acceleration stress screening profile is determined.

Owner:XIAN AVIATION BRAKE TECH

Flow-regulating valve and oil level control system using same

InactiveUS20080185541A1Open or close more quicklyOperating means/releasing devices for valvesMultiple way valvesControl signalActuator

A flow-regulating valve has at least one active material component that may be passively activated (e.g., in response to changes in surrounding temperature) to control fluid flow through the valve. Additionally, an actuator, which may be of any type, such as a solenoid or even another active material component, actuates due to active activation, such as resistive heating in response to a sensor / control signal, which could be due to external conditions (such as existence of high acceleration) or internal conditions (such as change in fluid temperature) to provide an active level of control of fluid flow through the valve. The flow-regulating valve may be used in an oil level control system of a transmission to ensure adequate oil availability during various operating conditions while minimizing the adverse effects such as spin and windage losses. Similar applications can be made in other fluid flow or fluid level control systems.

Owner:GM GLOBAL TECH OPERATIONS LLC

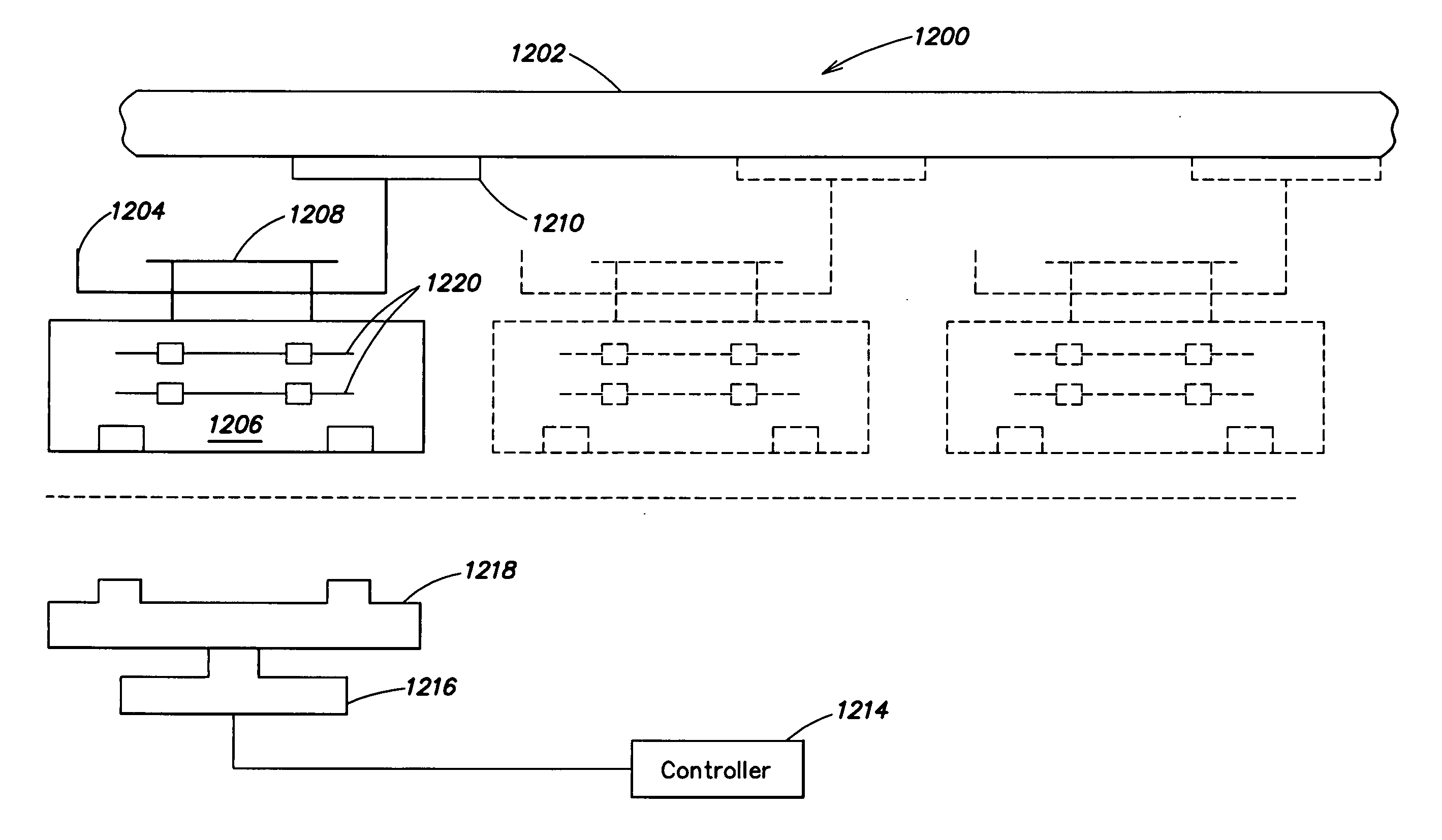

Methods and apparatus for carriers suitable for use in high-speed/high-acceleration transport systems

InactiveUS20050105997A1Semiconductor/solid-state device manufacturingCharge manipulationTransport systemHigh acceleration

A substrate carrier is counterbalanced so that the center of gravity of the carrier is aligned with the center of gravity of any substrates that the carrier may hold. In some embodiments, substrate supports disposed within the carrier are adapted to hold substrates such that the center of gravity of the substrates are aligned with the center of gravity of the carrier. A flange may be coupled to the carrier so as to provide a means to apply a net lifting or support force to the carrier that is aligned with the center of gravity of the carrier.

Owner:APPLIED MATERIALS INC

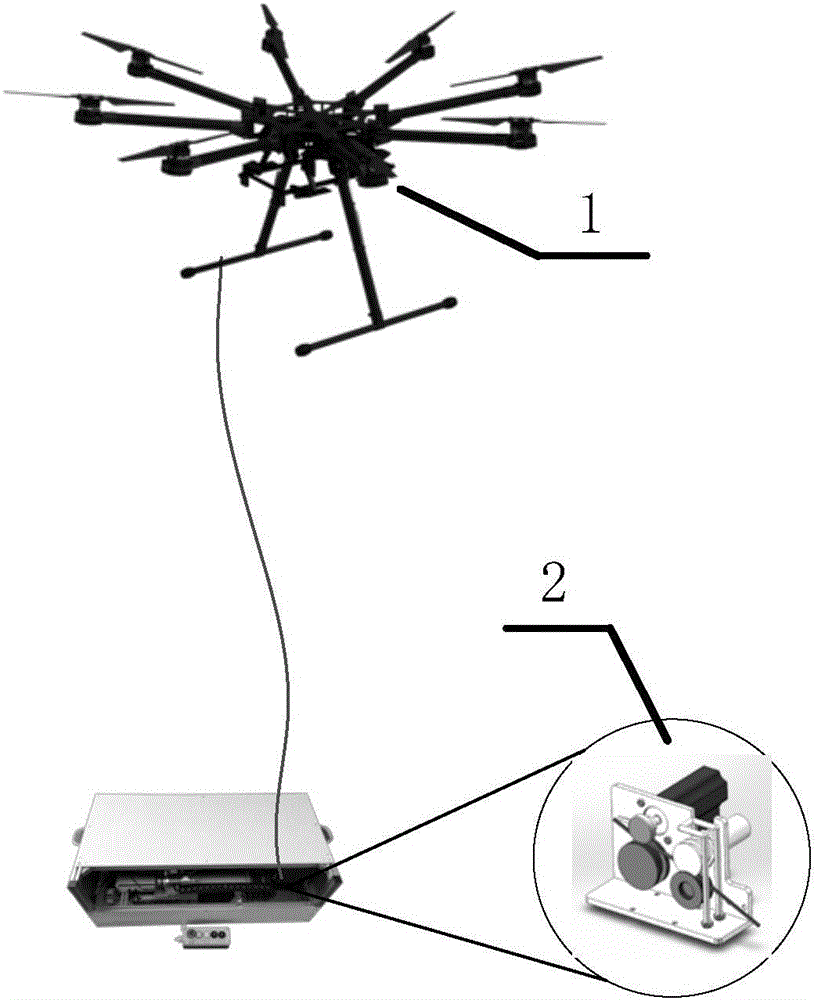

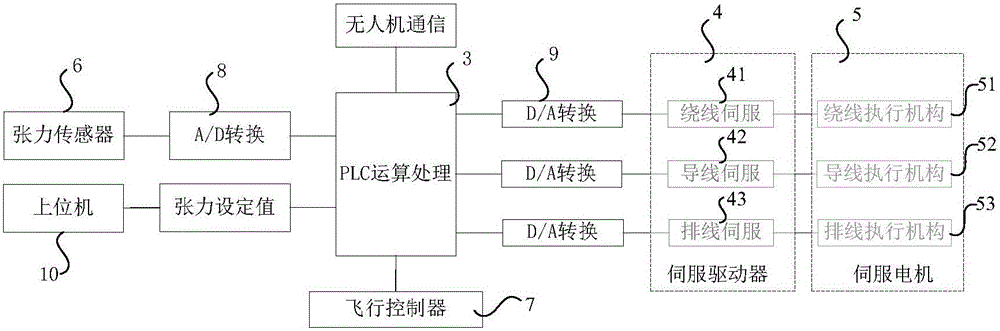

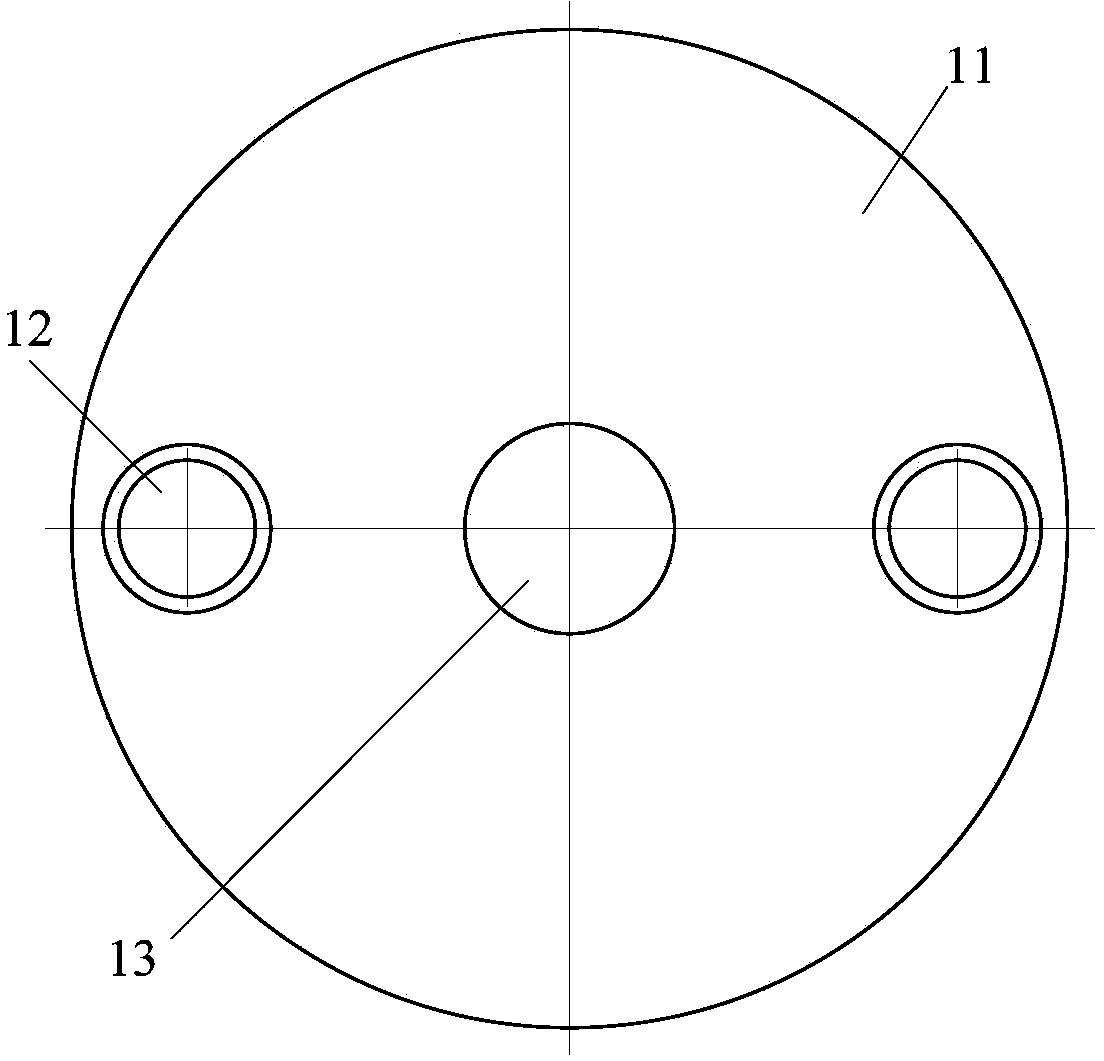

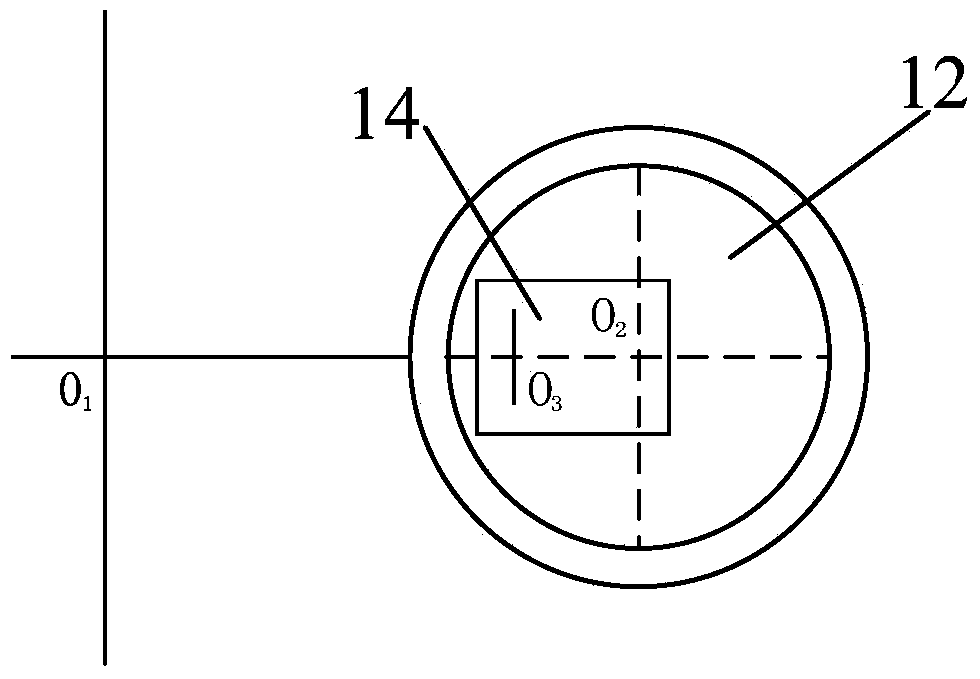

Automatic take-up and payoff control system for mooring unmanned plane

ActiveCN105752337AFully automatedRealize intelligenceTethered aircraftRemote controlled aircraftInterference resistanceControl system

The invention discloses an automatic take-up and payoff control system for a mooring unmanned plane. The automatic take-up and payoff control system comprises a PLC, a server driver, a servo motor, a tension sensor and a flying controller, wherein the servo motor is used for controlling a cable of the mooring unmanned plane to do actions; the servo driver is used for controlling the servo motor; the tension sensor is used for sensing the size of a tension value of the cable; the flying controller is used for controlling a flying state of the mooring unmanned plane; the PLC is used for controlling the servo driver according to information of the tension sensor and the flying controller. According to the automatic take-up and payoff control system for the mooring unmanned plane, the problems of rapid response of an automatic take-up and payoff device and interference resistance of the automatic take-up and payoff device under external interferences such as wind blowing during acceleration and deceleration of the existing mooring unmanned plane at a higher acceleration are solved.

Owner:BEIJING INST OF COMP TECH & APPL

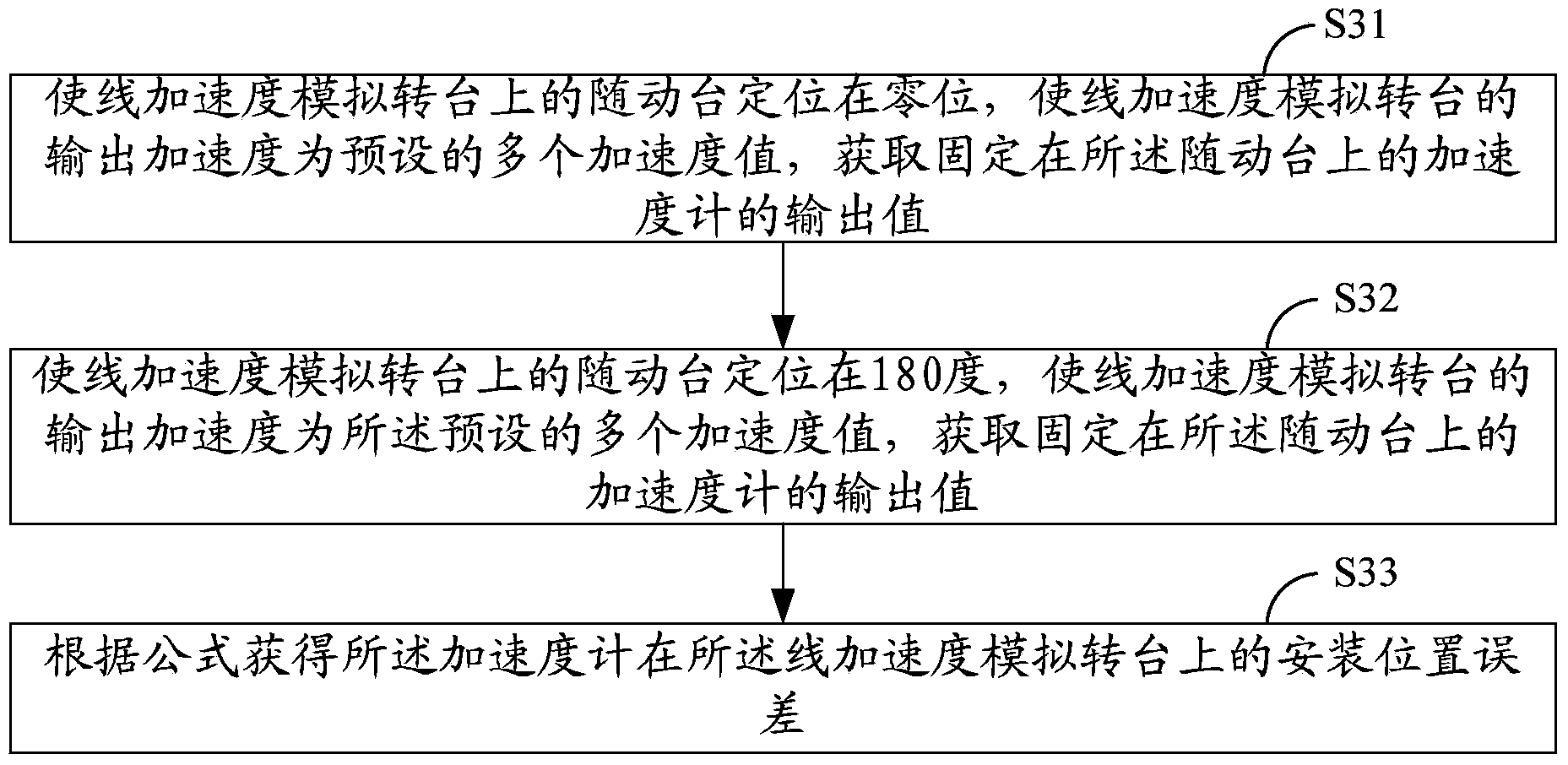

Method and device for improving accelerometer calibration accuracy

ActiveCN103884870ALow installation requirementsImprove calibration accuracyTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerHigh acceleration

The invention provides a method for improving accelerometer calibration accuracy. The method comprises the steps that a servo table on a linear acceleration simulation rotary table is positioned at the zero position, the output accelerated speed of the linear acceleration simulation rotary table is made to have a plurality of preset acceleration values, and the output value of an accelerometer fixed to the servo table is obtained; the servo table on the linear acceleration simulation rotary table is positioned at 180 degrees, the output accelerated speed of the linear acceleration simulation rotary table is made to have a plurality of preset acceleration values, and the output value of the accelerometer fixed to the servo table is obtained; according to the formula, the error of the installation positions of the accelerometer on the linear acceleration simulation rotary table is obtained. The invention further provides a device for improving accelerometer calibration accuracy. Working radius error influences of the accelerometer can be eliminated, and calibration accuracy can be improved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

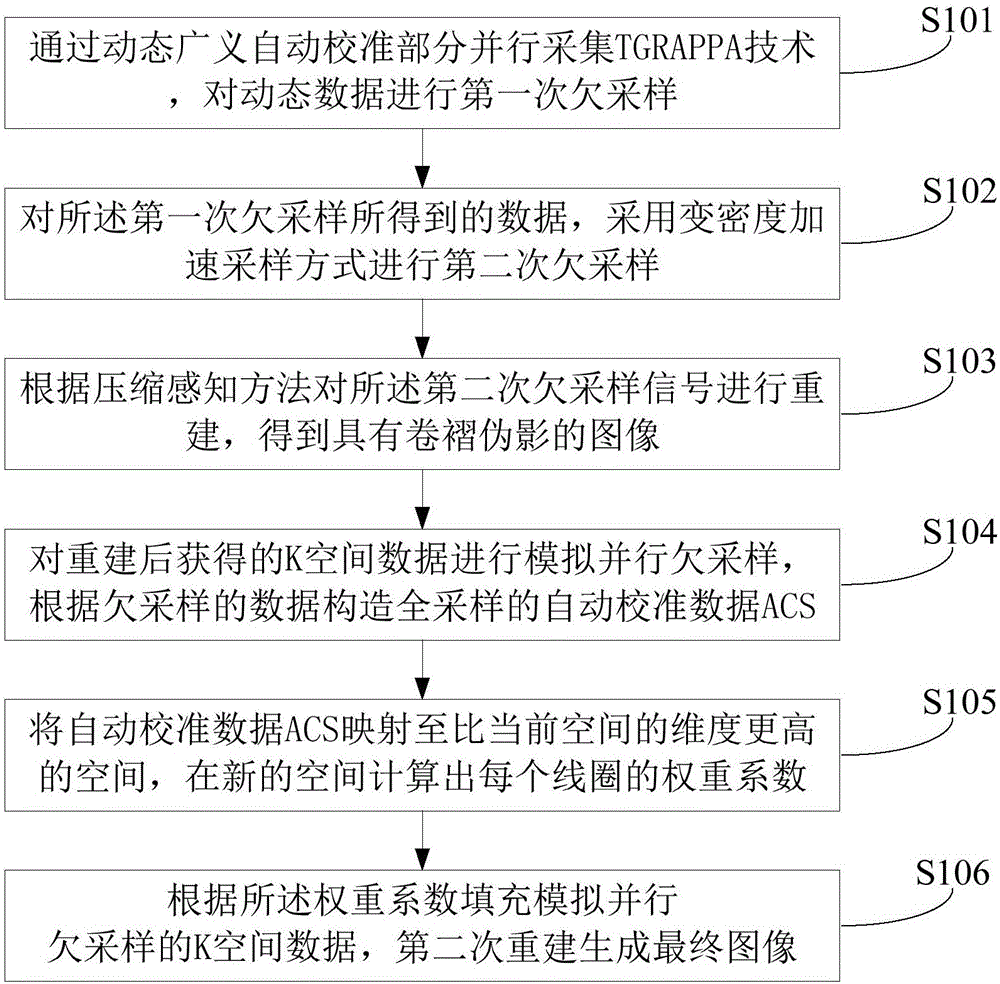

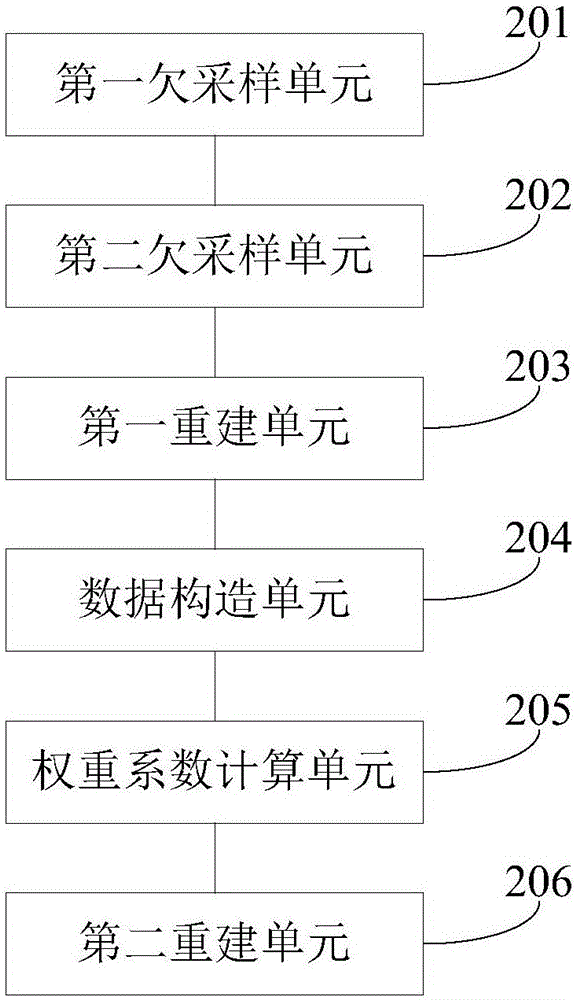

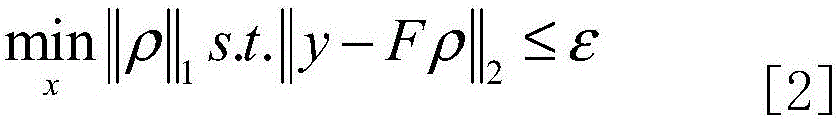

Magnetic resonance based dynamic imaging method and device

ActiveCN106491131AImprove signal-to-noise ratioSuppression of noise amplificationDiagnostic recording/measuringSensorsWeight coefficientParallel imaging

A magnetic resonance based dynamic imaging method comprises the steps that dynamic data is under-sampled by adopting TGRAPPA technology; the data obtained through under-sampling, and second under-sampling is performed by adopting a variable-density sampling acceleration mode; a second-time under-sampling signal is reconstructed; simulation parallel under-sampling is conducted on K space data obtained after reconstruction in the TGRAPPA mode, a full-sampling automatic calibration data ACS is established according to the under-sampled data; the full-sampling automatic calibration data ACS is mapped to a space higher than a current space in dimension, and the weight coefficient of each coil is calculated in a novel space; the K space data undergoing the simulation parallel under-sampling is filled according to the weight coefficient, and second time of reconstruction is perform to generate a final image. The magnetic resonance based dynamic imaging method does not need additional acquisition of automatic calibration signals from a K space center, noise amplification caused by acceleration time increase in parallel imaging can be well inhibited under high acceleration times, and images high in signal to noise ratio can be obtained.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com