Patents

Literature

378results about How to "Increase extrusion speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

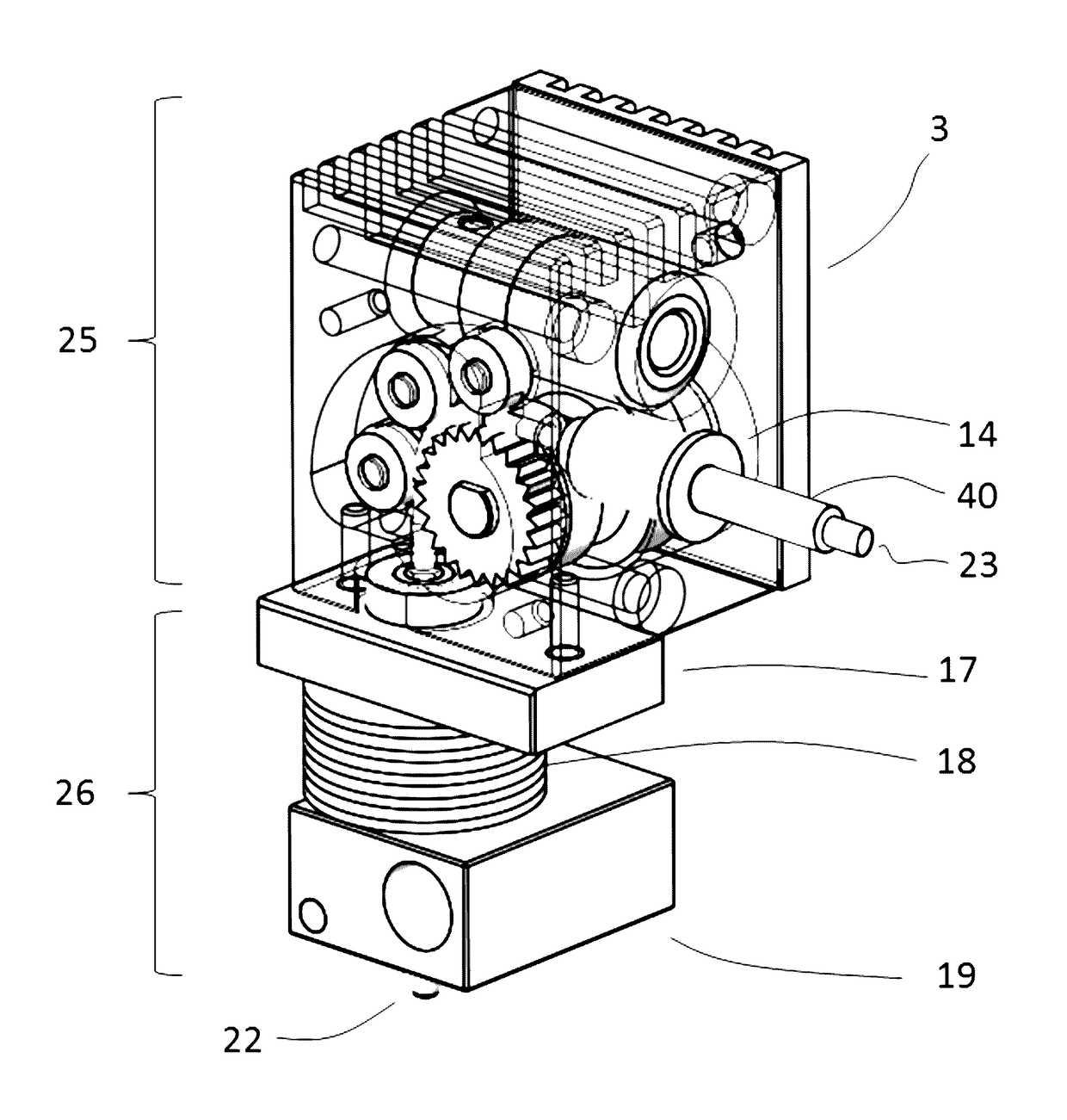

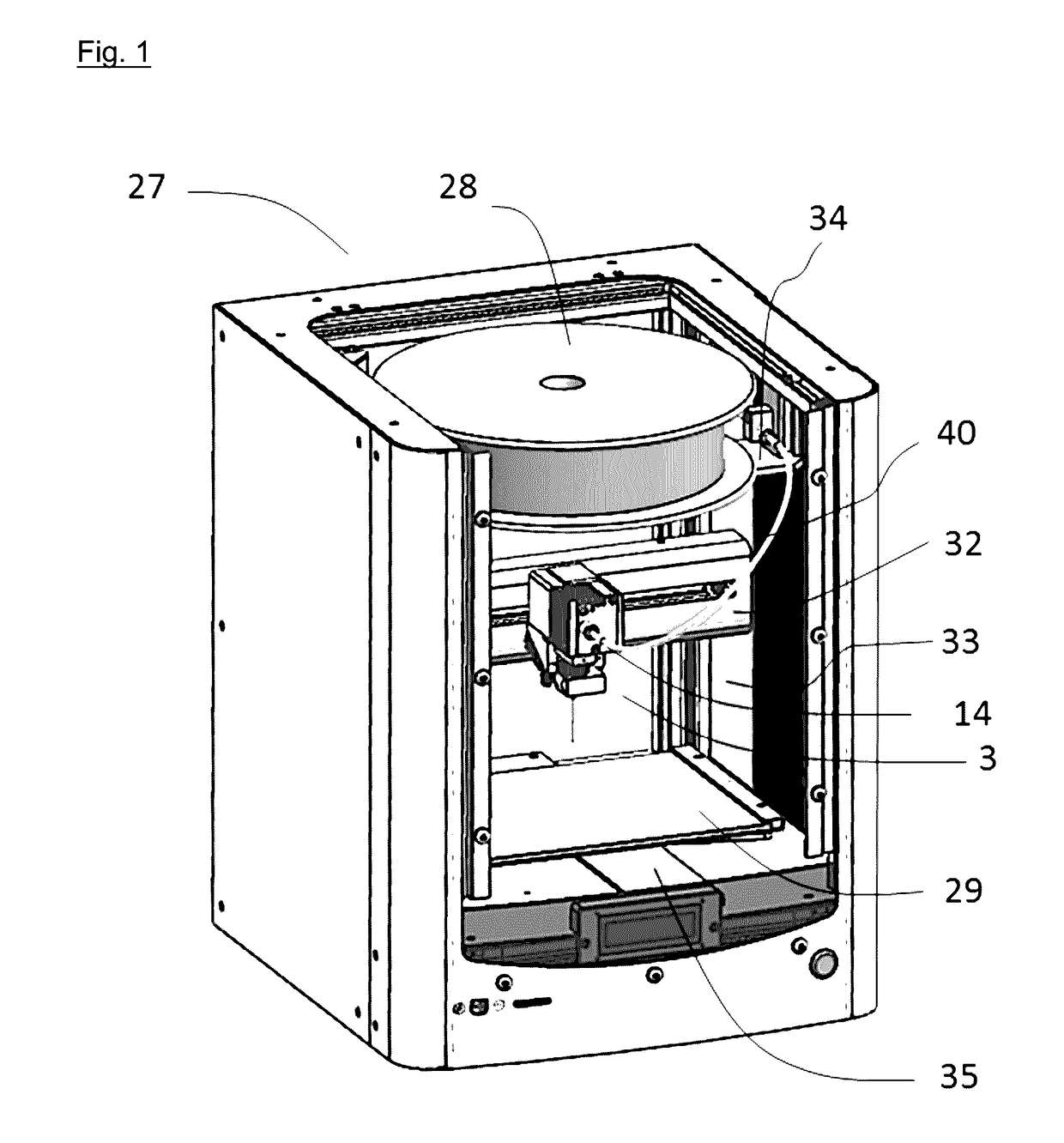

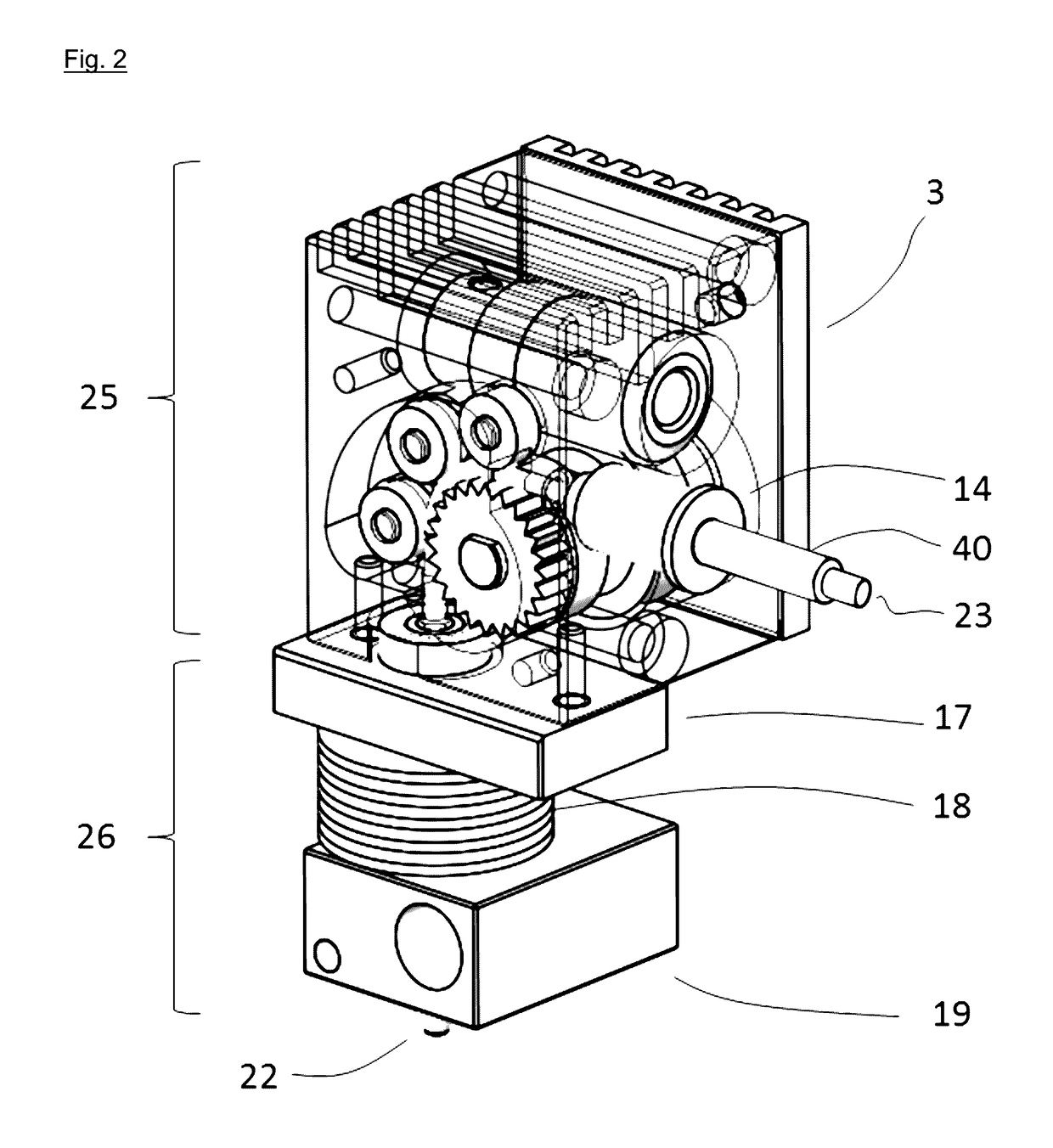

Extruder for fused filament fabrication 3D printer

InactiveUS20170157826A1Increase extrusion speedIncrease feed rateAdditive manufacturing with liquids3D object support structuresFused filament fabricationHigh acceleration

Disclosed is an improved extruder head for a fused filament fabrication 3D printer. It would be beneficial with a thinner nozzle diameter and higher extrusion speed without slippage in the feeding mechanism. The proposed improved extruder head enables extrusion of thinner extruded material at a higher extrusion speed without any slippage in filament feeding mechanism, thereby allowing higher overall building speed of the 3D printer with high quality build. Higher feed-rate of the filament material is achieved by increased usable friction between pinch wheel and filament by increasing the grippable area of the filament. This is done by feeding the filament into the feeding mechanism at an angle different to the outlet angle and routing it around the pinch wheel, back supported by a plurality of support rollers, so that the filament is in frictional contact with the pinch wheel along a greater part of its circumference, thereby increasing the surface contact area between the pinch wheel and the filament. Owing to non-slippage of the filament feeder, nominal volume of extruded material is exactly the same as desired volume with high filament feeding rate. Due to compact feeding mechanism, total mass of extruder kept small enough to enable higher acceleration of the printing nozzle resulting higher printing speed. Owing to horizontal loading of the filament material, feed roll can be mounted just above the extruder for smooth filament supply and compact size of 3D printer.

Owner:RHOMBUS INT TECH

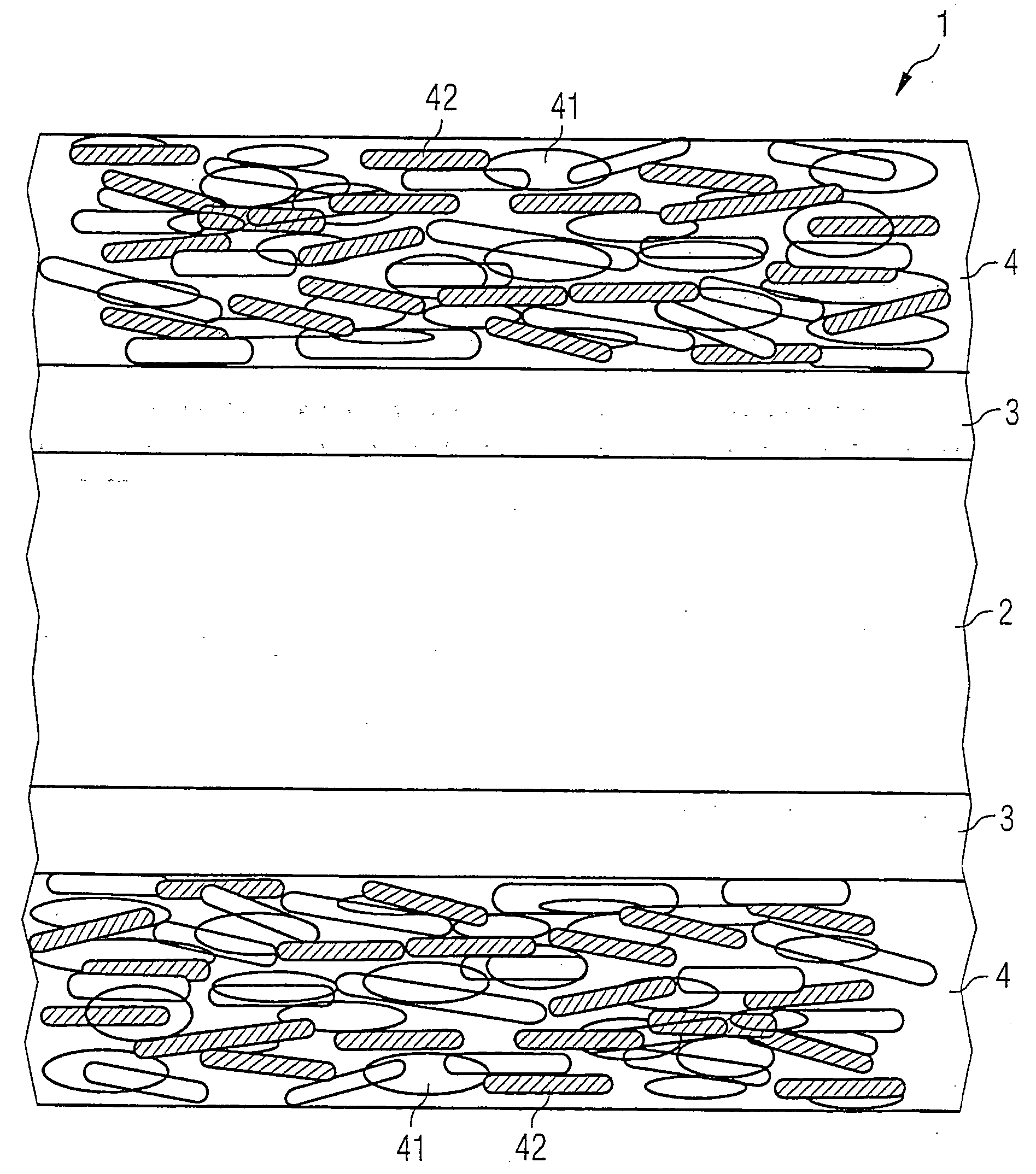

Solid core optic fiber and method for the production thereof

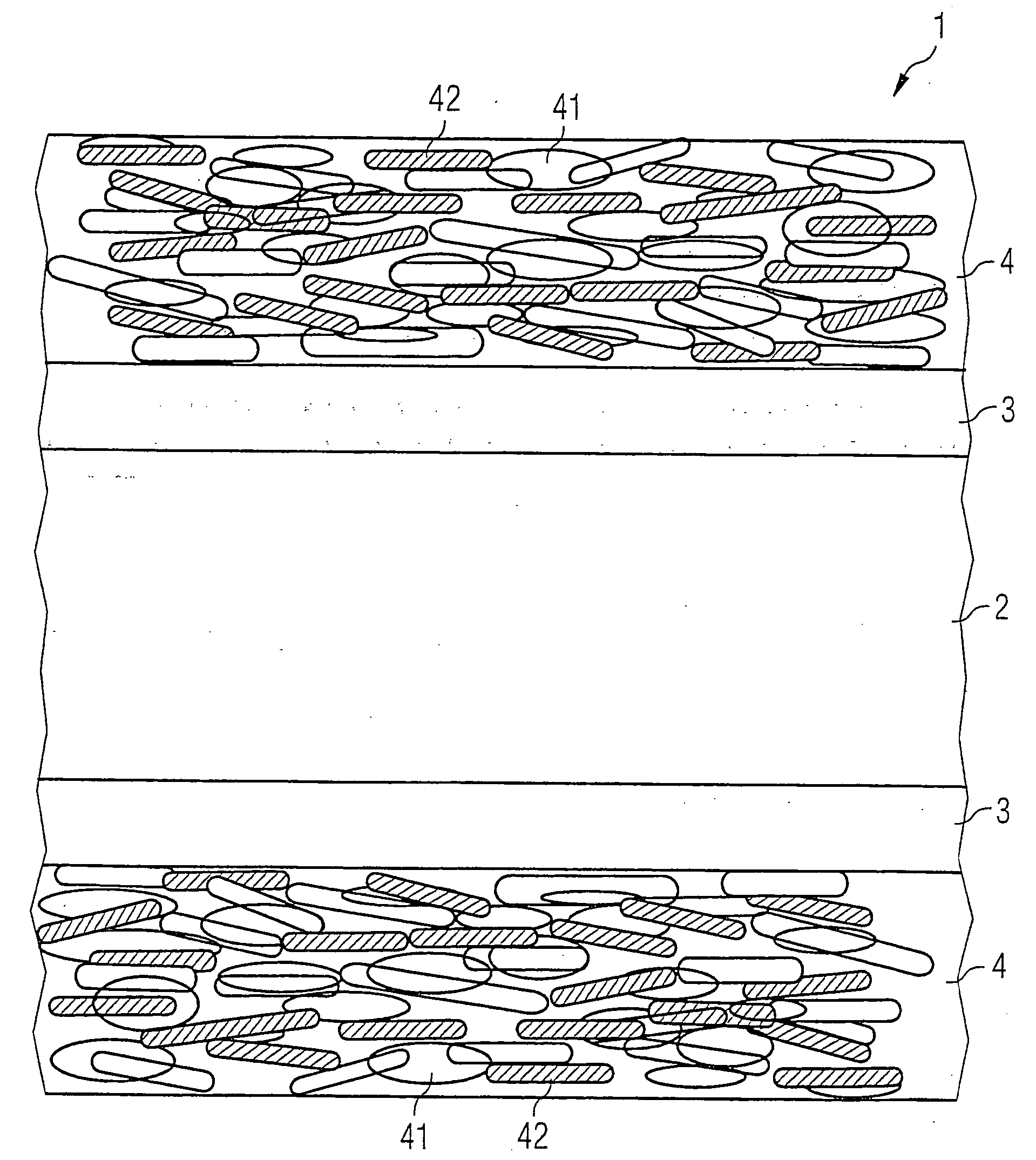

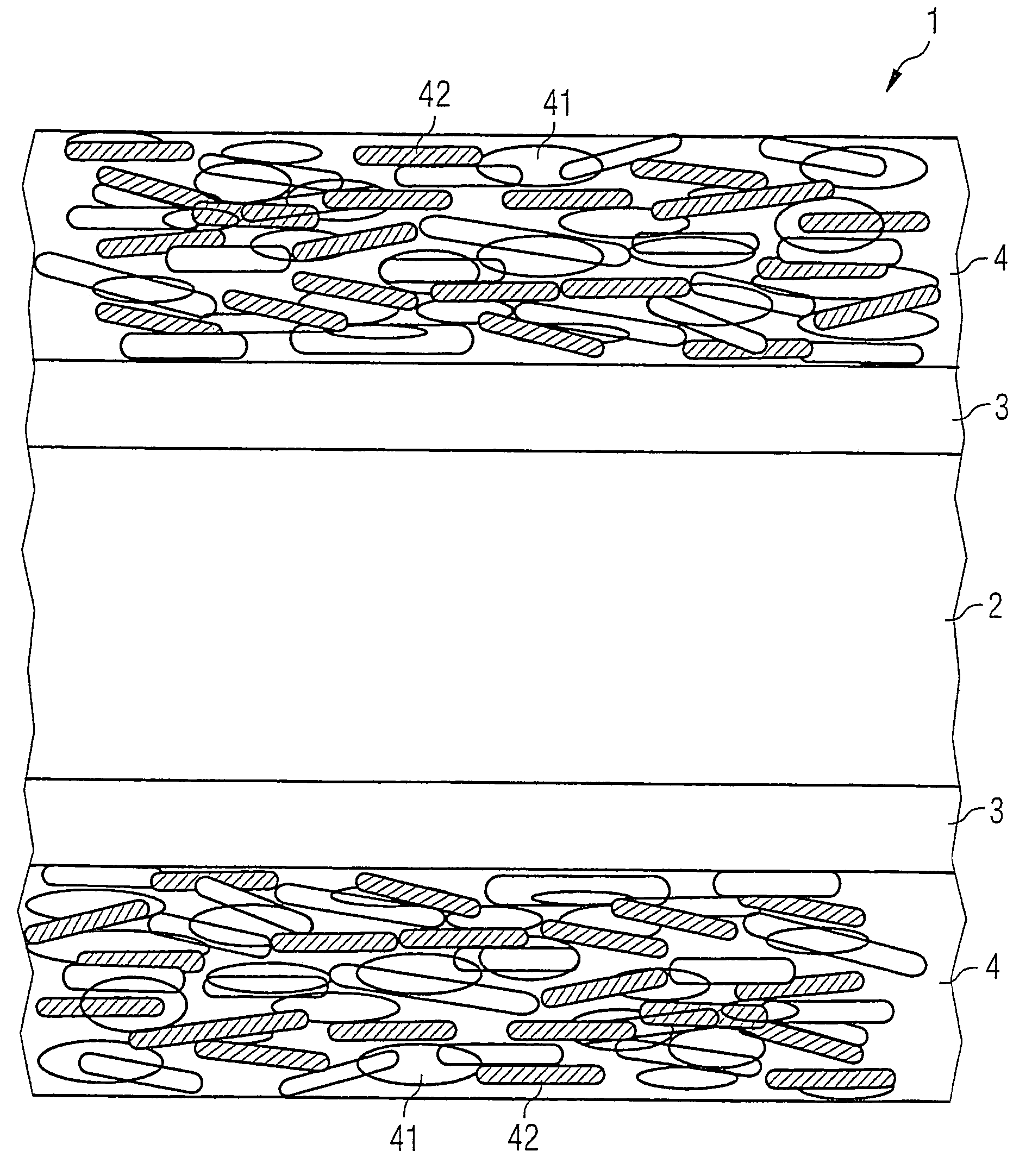

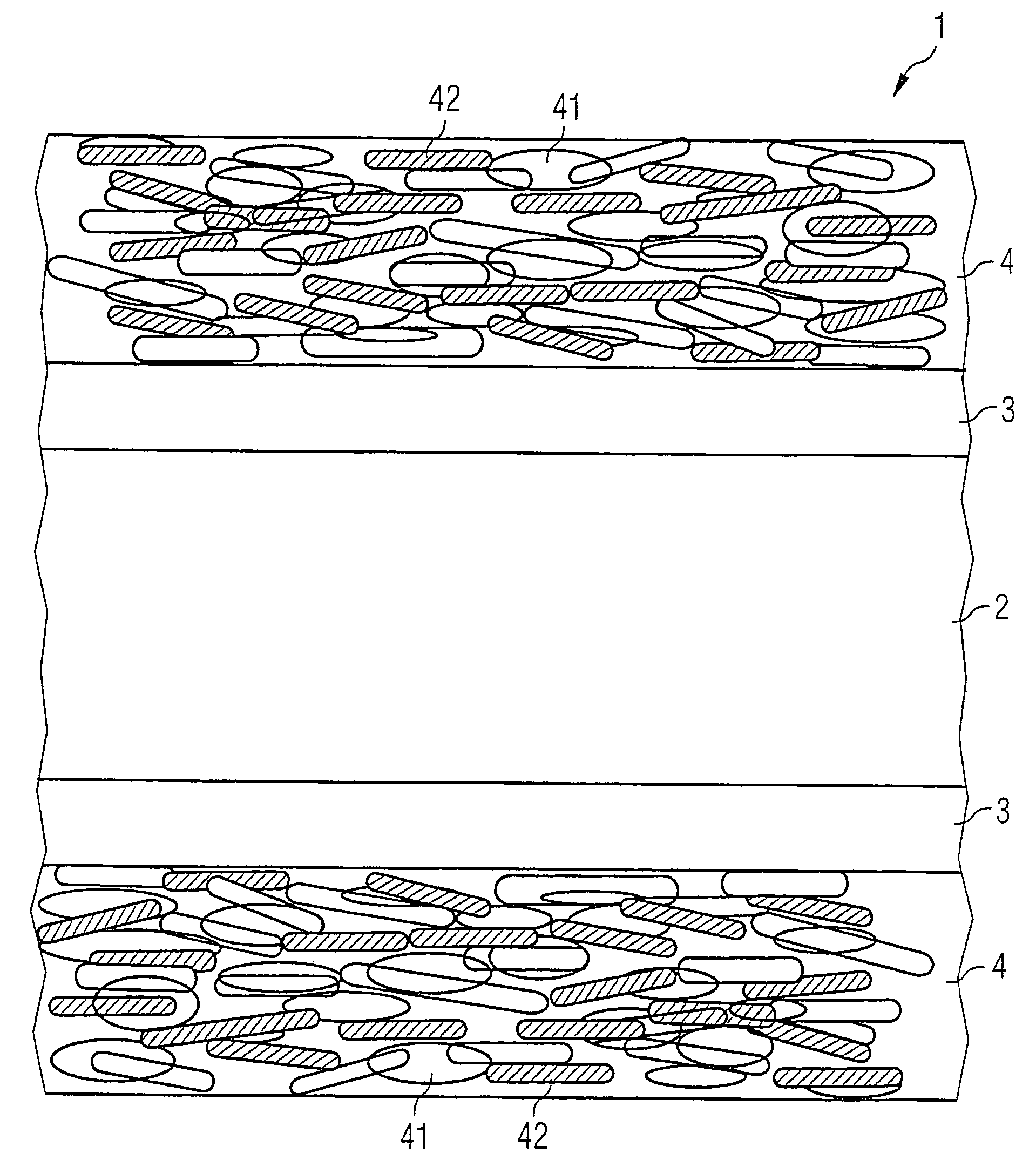

InactiveUS20050036753A1Easy to disassembleAvoid disadvantagesOptical fibre with multilayer core/claddingOptical articlesFiberSolid component

An optical insulated core with a coated optical fiber (2) shows a core jacket (4) with a core jacket material containing polyvinylchloride (41) which is applied to the coating of the optical fiber. It contains a solid component (42) distributed within the core jacket material, which produces a mechanical separation effect against the coating of the optical fiber. The solid component (42) is mixed and distributed into the core jacket material during a compounding process. Thus the core jacket can be removed from the coating of the optical fiber in a simple way.

Owner:CCS TECH INC

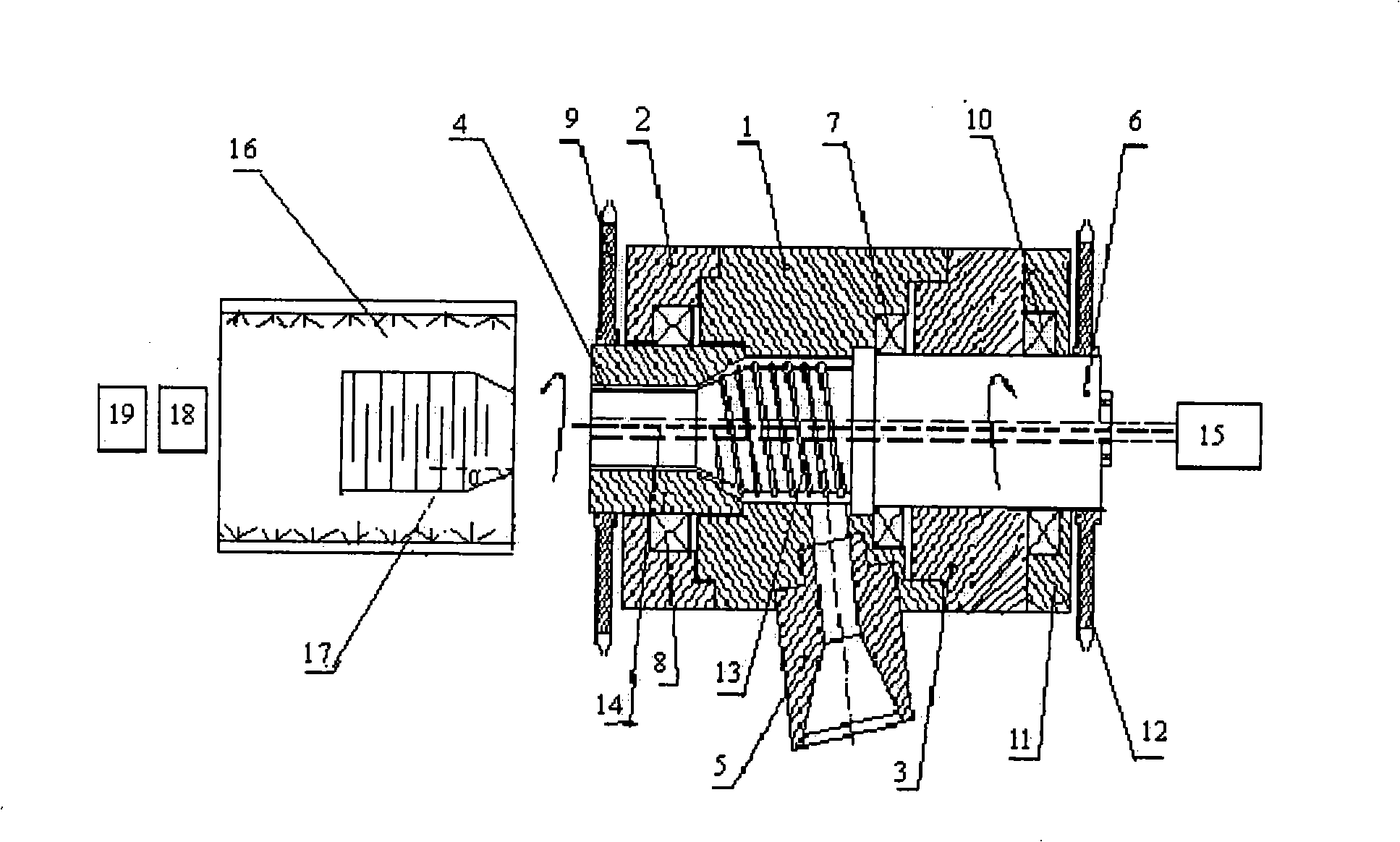

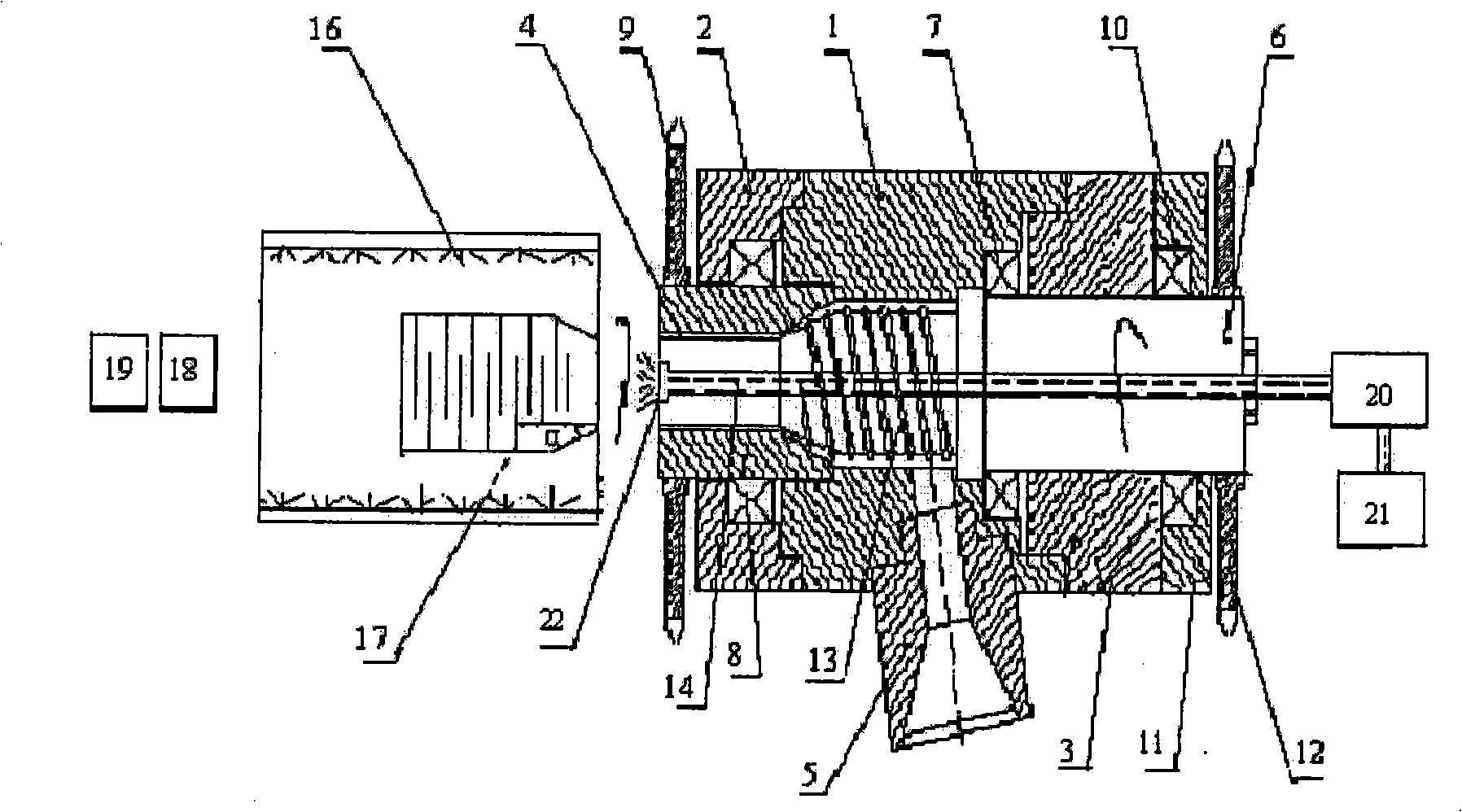

Preparation method and device of high performance polymers pipes

The invention discloses a method for preparing a high-performance polymer pipe. The method adopts the steps that during the extrusion molding process of the pipe, the crystallization, the orientation or the dispersed phase morphological structure of the polymer pipe can be adjusted, controlled and fixed through the shearing action generated by the rotation of a core rod in a machine head relative to an orifice die, or the rotation of the orifice die in the machine head relative to the core rod, or the rotation of the core rod and the orifice die in the identical or opposite direction simultaneously, and by cooling and shaping the inner wall and the outer wall of the extruded pipe simultaneously, and adjusting and controlling the temperature field, the cooling rate and the temperature gradient during the extrusion molding process of the pipe. The invention further discloses a device designed according to the method. The method has the advantages that the macromolecular orientation, the crystallization or the dispersed phase morphological structure which are generated through induction can be retained in the plastic pipe, so that deorientation can be avoided, the internal stress of the pipe can be reduced, and the performance of the pipe is improved.

Owner:SICHUAN UNIV

Novel 6063 aluminum alloy material and its production technology

The invention discloses a novel 6063 aluminum alloy material. Rare earth elements are added into the original 6063 aluminum alloy. The novel 6063 aluminum alloy material comprises, based on the weight percentage,0.36%- 0.4% of Si, 0.48% - 0.52% of Mg, 0 -0.35% of Fe, 0 -0.1% of Cu, 0 - 0.05% of Mn, 0 - 0.05% of Cr, 0 - 0.05% of Zn, 0 - 0.05% of Ti, 0.18%-0.22% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. According to the invention, the content of Mg and Si is controlled within a narrow range. At the same time, cerium-based mixed rare earth elements and alloying element boron are added, which keeps alloy material high strength and high electrical and thermal conductivity; improves machining property and plastic extrusion; and improves production efficiency.

Owner:CHENGDU SUNSHINE ALUMINUM

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

Flame retardant thermoplastic elastomers

ActiveUS20120037396A1No negative effect on elasticityGood mechanical propertyRubber insulatorsAntifouling/underwater paintsEtherInsulation layer

A flame-retardant thermoplastic elastomer compound is disclosed having polyphenylene ether, a hydrogenated styrene block copolymer, at least one solid non-halogenated phosphorus containing flame retardant, and a nucleated olefinic polymer. The compound has a before-aging tensile elongation of >200% and an after-aging tensile elongation residual of at least 75%, according to the UL 62 test, which makes it useful as an insulation layer, a jacketing layer, or both for protected electrical lines such as alternating current wire and cable products, accessory cables, and variety of injection molded electrical or electronic parts.

Owner:AVIENT CORP

Silane cross-linked polyethylene insulating material and production method thereof

InactiveCN102532664AEvenly dispersedIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsSilanesAntioxidant

The invention provides a silane cross-linked polyethylene insulating material composition, which comprises a material A and a material B, wherein the material A is composed of the following components in parts by weight: 100 parts of polyethylene, 0.01-1 parts of initiator, 0.2-5 parts of silane cross-linking agent, and 0.1-0.5 parts of antioxidant; the material B is composed of the following components in parts by weight: 100 parts of polyethylene, 0.5-5 parts of catalyst, 0.01-5 parts of processing aid, and 0.1-0.5 parts of antioxidant; and the material A is mixed and extruded by a reciprocating single-screw extruder.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Noodle processing machine

InactiveCN103518792AReduce volumeSuitable for home useMixing/kneading with horizontally-mounted toolsDough extruding machinesEngineeringMechanical engineering

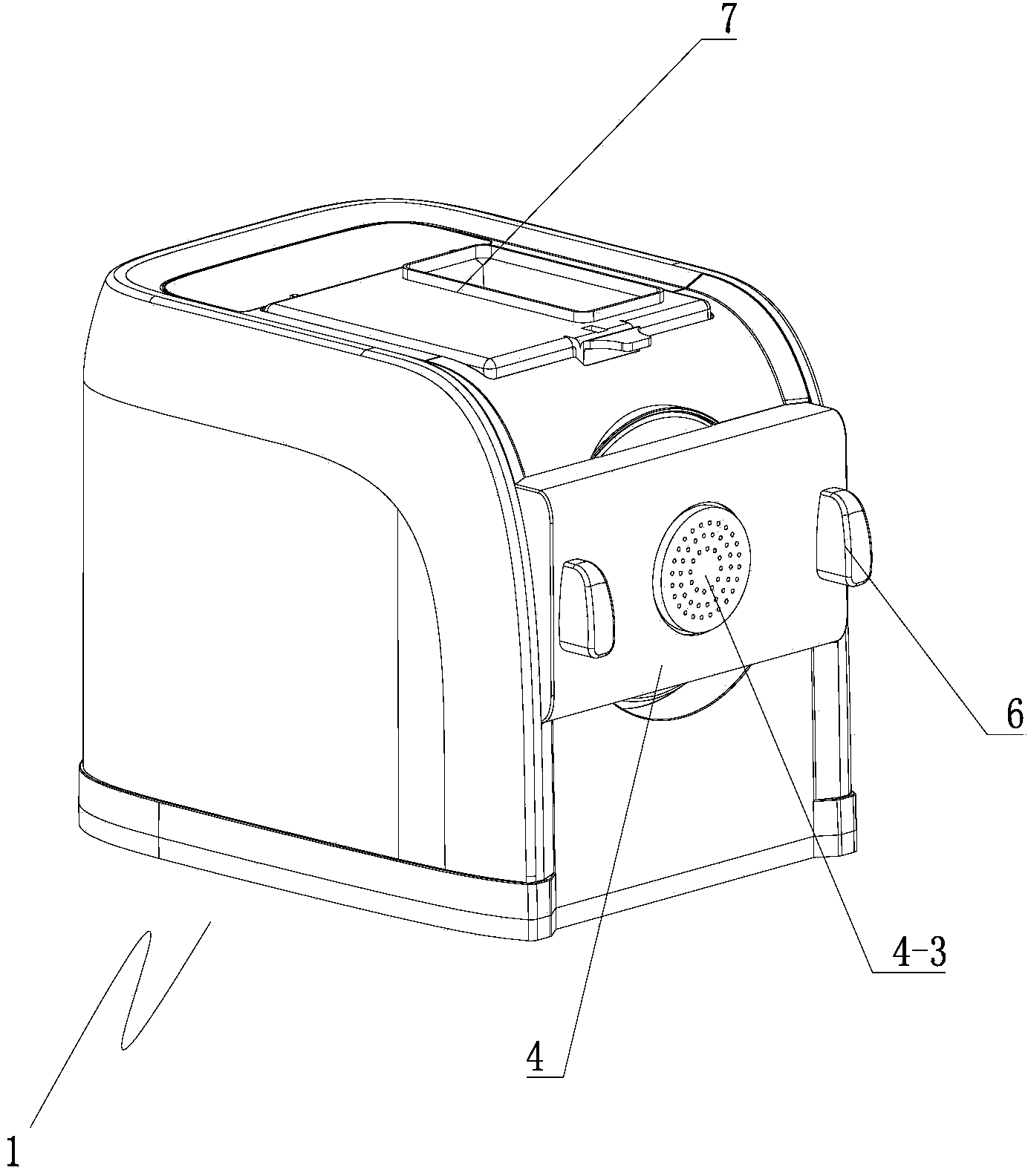

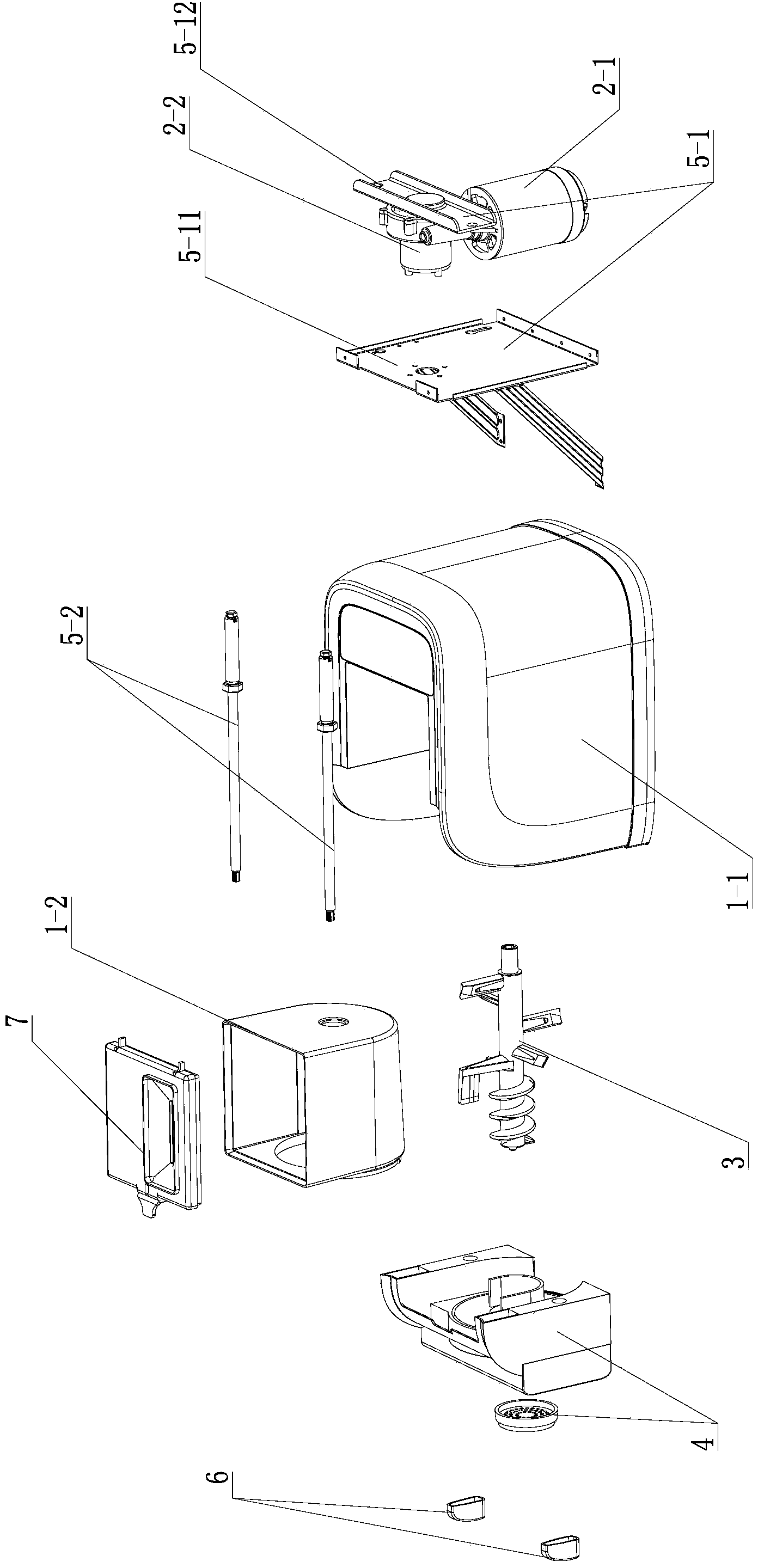

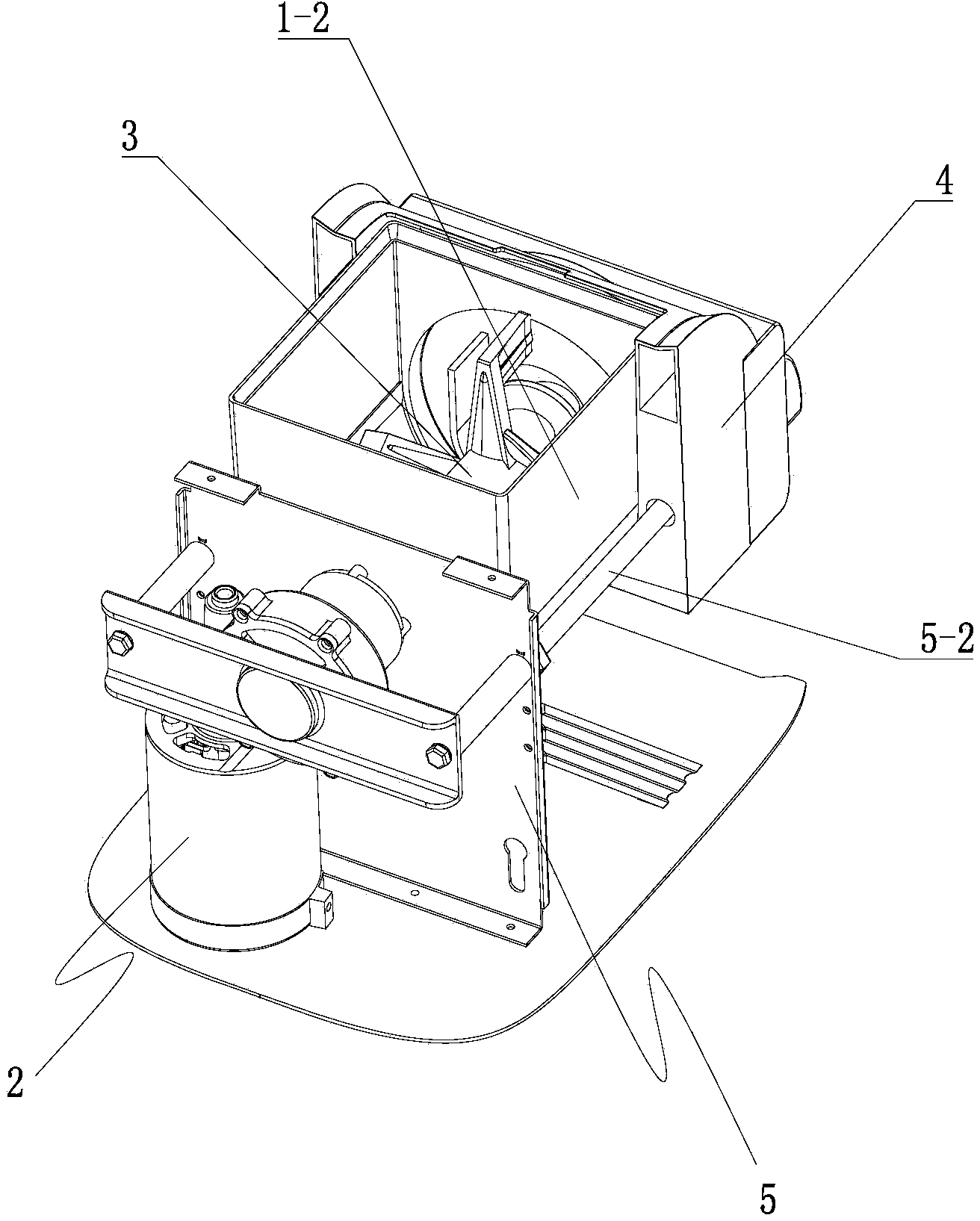

The invention discloses a noodle processing machine. The noodle processing machine comprises a shell (1), wherein a driving device (2) capable of rotating forward and reversely is arranged in the shell (1); the shell (1) comprises an outer shell (1-1) in which the driving device (2) is arranged and a stirring chamber (1-2) for mixing noodles; a stirring and extruding device (3) which is connected with the driving device (2) and used for stirring the mixed noodles and extruding the mixed paste is arranged in the stirring chamber (1-2); a blade assembly (4) is arranged at the front end of the stirring chamber (1-2); a holder (5) is arranged in the outer shell (1-1) and at one end of the outer shell (1-1), opposite to the blade assembly (4), and comprises a fixing plate (5-1) for fixing the driving device (2); a group of tensioning bolts (5-2) are arranged between the fixing plate (5-1) and the blade assembly (4).

Owner:王玉霞

Solid core optic fiber and method for the production thereof

InactiveUS7158707B2Easy to disassembleReduce manufacturing costOptical fibre with multilayer core/claddingOptical articlesFiberSolid component

An optical insulated core with a coated optical fiber (2) shows a core jacket (4) with a core jacket material containing polyvinylchloride (41) which is applied to the coating of the optical fiber. It contains a solid component (42) distributed within the core jacket material, which produces a mechanical separation effect against the coating of the optical fiber. The solid component (42) is mixed and distributed into the core jacket material during a compounding process. Thus the core jacket can be removed from the coating of the optical fiber in a simple way.

Owner:CCS TECH INC

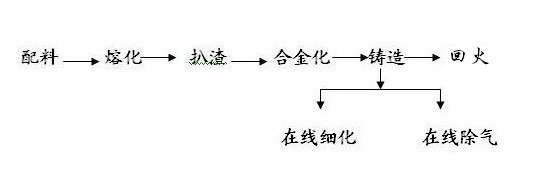

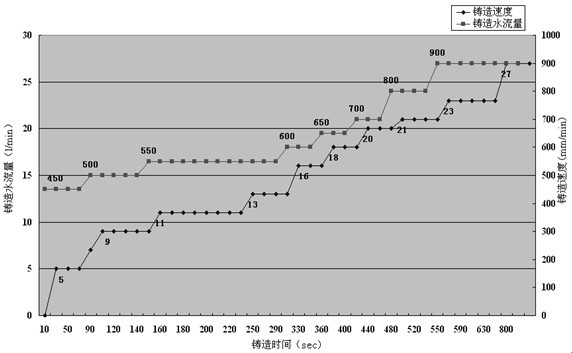

Hot-top casting process of 7075 aluminium alloy round rod with diameter of phi582 mm

ActiveCN102328065AImprove bottom plasticityReasonable control of impurity contentRound bar7075 aluminium alloy

The invention discloses a hot-top casting process for casting a large-diameter hard aluminium alloy round rod by using a wiping disc. The process comprises the following steps of: a, batching; b, melting; and c, casting, wherein the casting step is a key process. The process protected by the invention is a casting process of a largest-diameter hard aluminium alloy which is put into operation in the country currently. Namely, the process comprises: hot-top casting equipment is used; the wiping disc is configured at the same time; step type casting process parameters are adopted; the suspension height of the wiping disc and the three casting process parameters are searched; and finally, the best casting process of the 7075 aluminium alloy round rod with a diameter of phi582 mm is established. According to the process disclosed by the invention, the crack tendency in the process of casting the large-diameter hard aluminium alloy can be greatly reduced without the bottoming process; the cast round bar has good grain size, thin coarse grain layer and good surface quality; and the turning quantity on the cast rod before extruding is reduced, therefore, the production cost is reduced, and the yield is increased.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

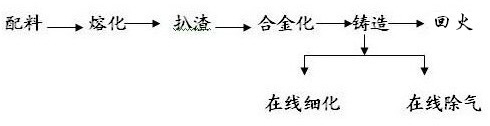

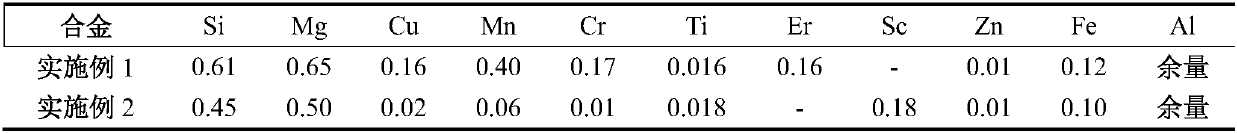

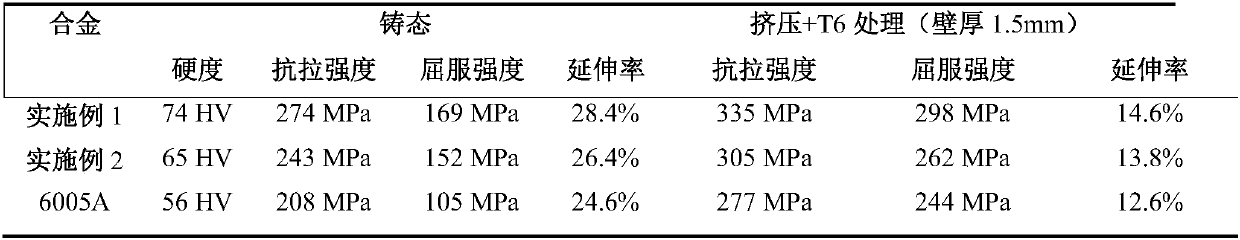

High performance Al-Mg-Si aluminum alloy extrusion material and preparation method thereof

ActiveCN110669964AImprove performanceStrong precipitation strengtheningRare-earth elementSingle element

The invention belongs to the technical field of aluminum alloy materials, and relates to a high performance Al-Mg-Si aluminum alloy extrusion material and a preparation method thereof. The high performance Al-Mg-Si aluminum alloy extrusion material is prepared from the following element components in percent by weight: 0.4-0.7% of Si, 0.5-0.7% of Mg, 0.01-0.2% of Cu, 0.05-0.45% of Mn, 0.01-0.3% ofCr, 0.01-0.02% of Ti, 0.05-0.30% of rare earth elements, less than or equal to 0.1% of Zn, less than or equal to 0.15% of Fe and the balance Al, wherein the content of single elements is less than orequal to 0.05%, the total content of impurities is less than or equal to 0.15%, and any one or two of the rare earth elements Er and Sc are mixed. The preparation method can optimize the alloy components obviously, balance and refine crystal grains, purify and clean a melt, reduce the casting flaws and improve the quality of a cast ingot greatly. In addition, the surface quality of an extruded profile can be better improved, and the extrusion speed and the thermal treatment comprehensive mechanical property of the extruded profile product are improved.

Owner:CHINA ZHONGWANG

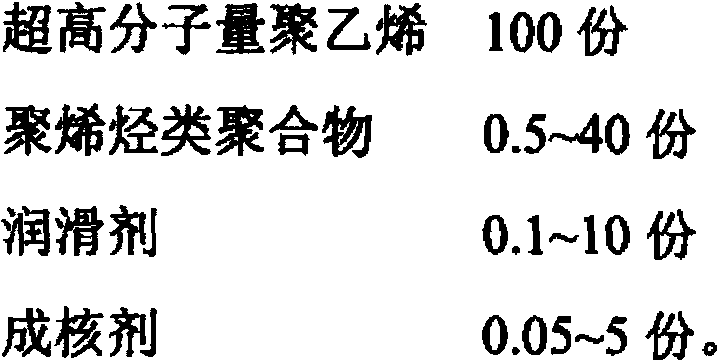

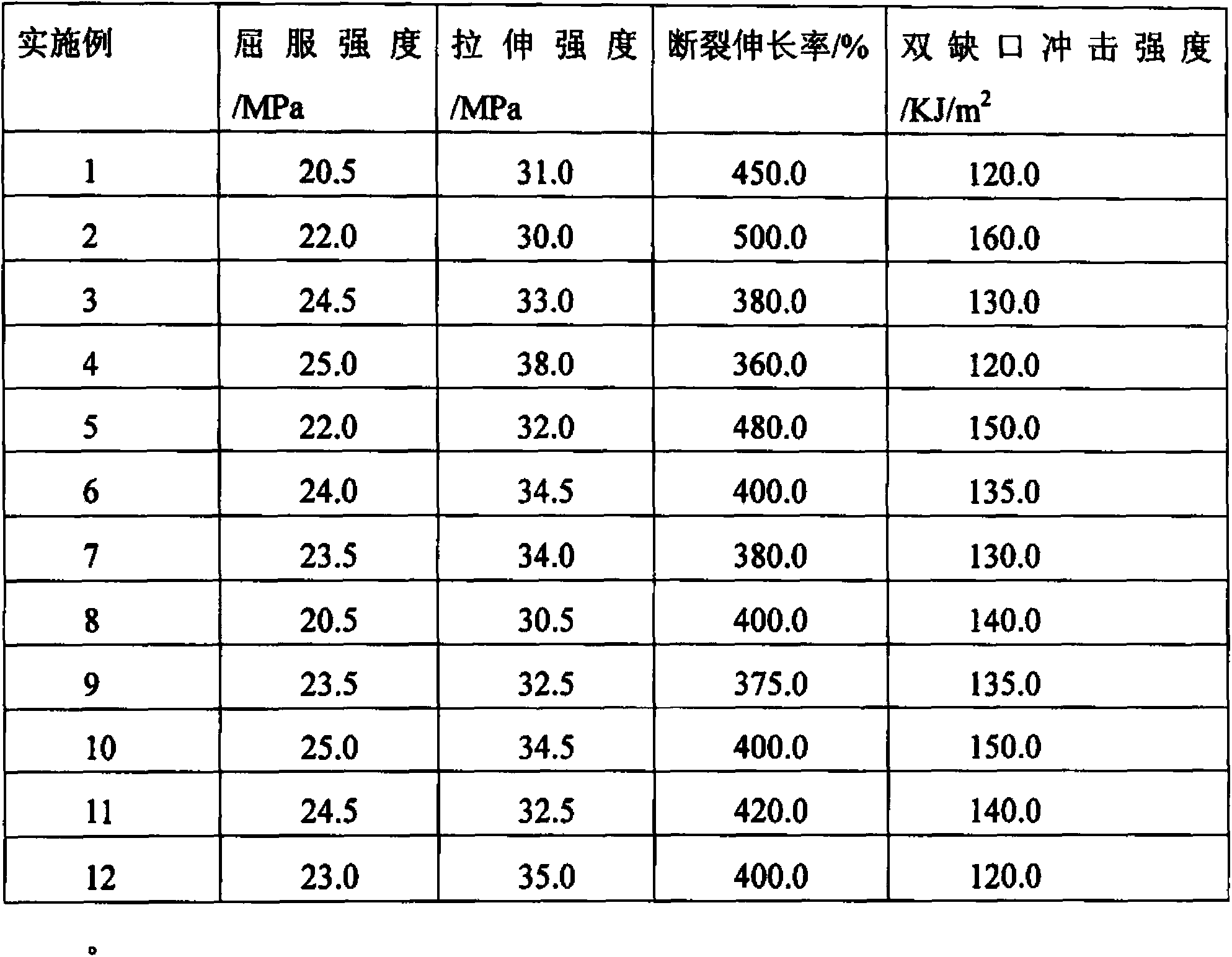

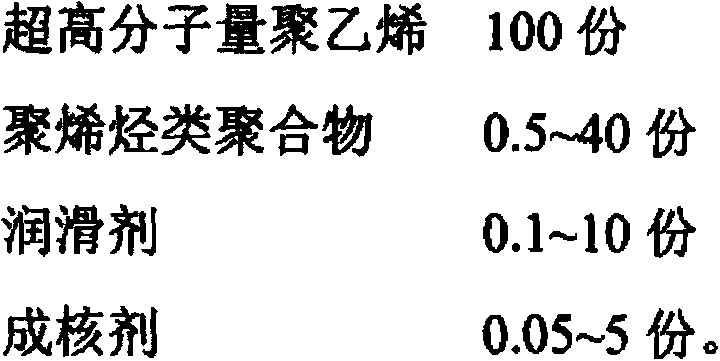

Material special for ultrahigh-molecular-weight polyethylene tube, and preparation and application thereof

ActiveCN104031305ACooling and crystallization rate is fastImprove mechanical propertiesPolymer scienceMechanical property

The invention relates to a material special for an ultrahigh-molecular-weight polyethylene tube subjected to rapid extrusion molding, and preparation and application of the material, and the material is specially used for the extrusion-molded tube. The extrusion-molded tube has the following characteristics: (1) the extrusion speed of the tube is 2.5 m / h-6.0 m / h; (2) the external diameter of the tube is 10 mm-1200 mm; (3) the wall thickness of the tube is 2 mm-100 mm; (4) the extrusion melt temperature of the tube is 150 DEG C-280 DEG C; and (5) the viscosity average molecular weight of the tube is 1.5 millions-7 millions. Compared with the prior art, the production efficiency of the ultrahigh-molecular-weight polyethylene tube is improved by 0.5-3 times, and also the tube possesses excellent mechanical properties.

Owner:SHANGHAI RES INST OF CHEM IND

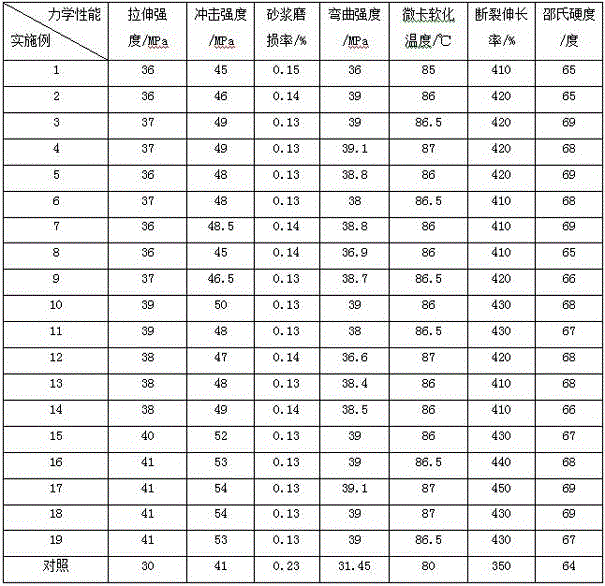

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

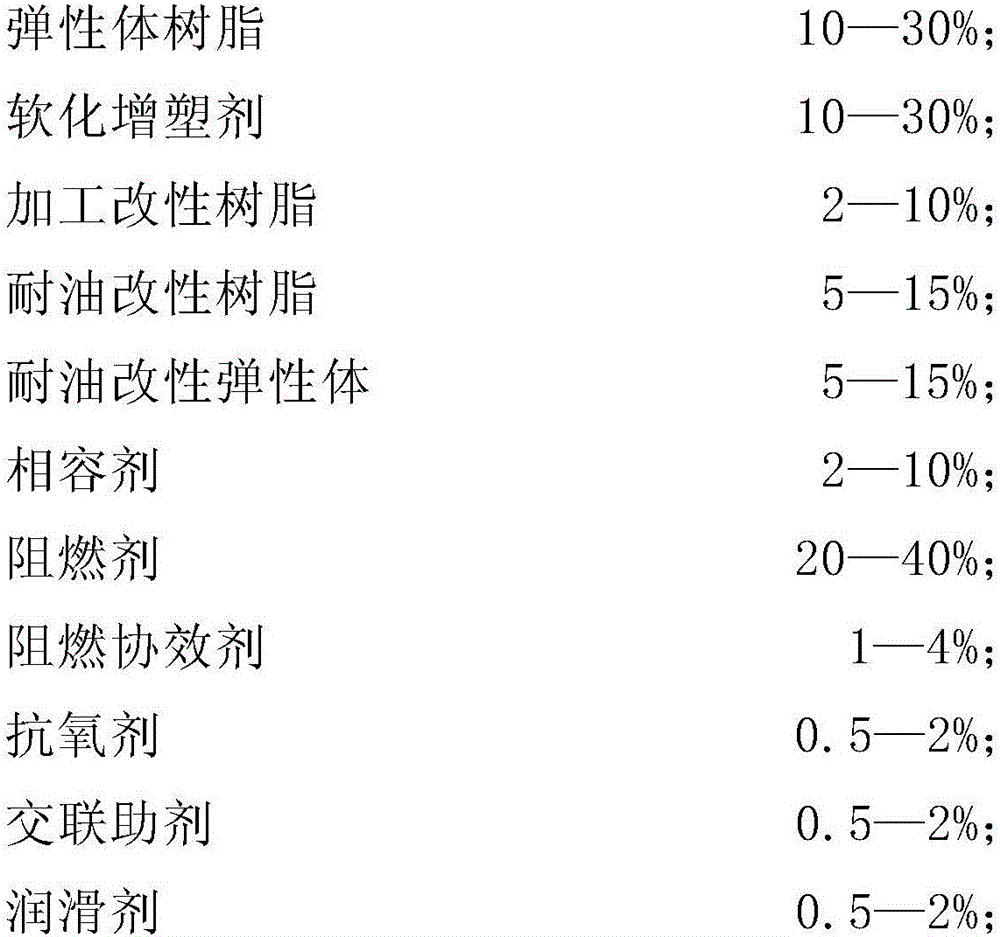

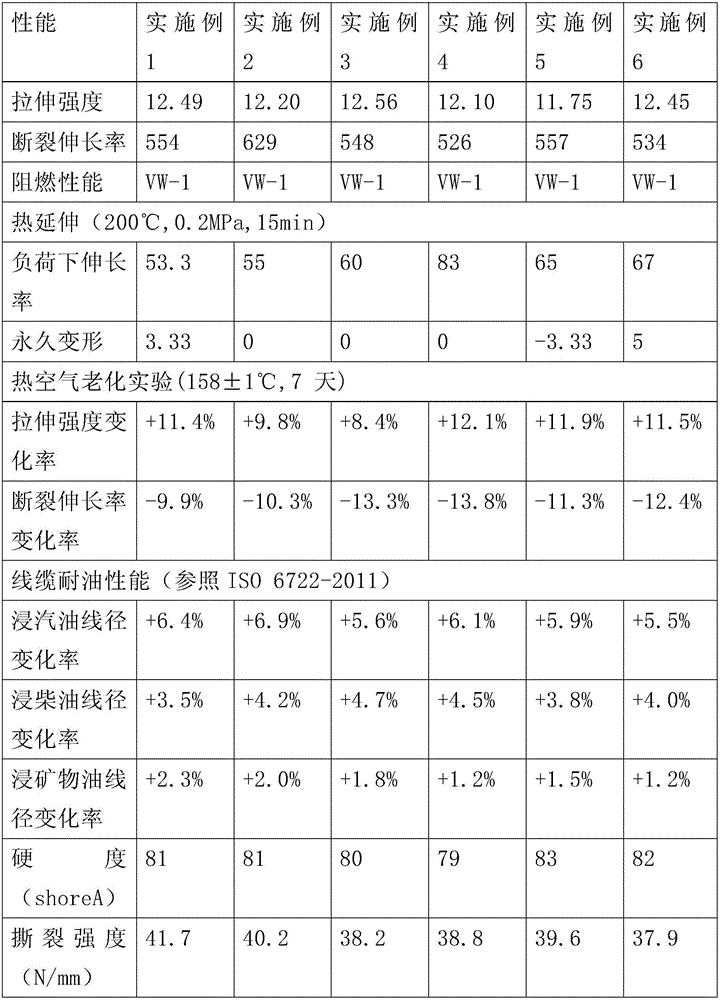

125-degree irradiation-crosslinked elastomer cable material used for new energy automobile high-voltage cable and manufacture method of elastomer cable material

InactiveCN106380869AExcellent performanceGood aging resistancePlastic/resin/waxes insulatorsPlasticizerNew energy

The invention discloses a 125-degree irradiation-crosslinked elastomer cable material used for a new energy automobile high-voltage cable. The elastomer cable material is manufactured from an elastomer resin, a softening plasticizer, a processing modified resin, an oil-resistant modified resin, oil-resistant modified elastomer, a compatilizer, a fire retardant, a flame-retardant synergistic agent, an anti-oxidant, a crosslinking auxiliary agent and a lubricant. The invention further discloses a manufacture method of the elastomer cable material. After irradiation crosslinking, an electric wire and cable product made from the cable material is good in physical and mechanical properties, electrical insulation property, flame resistance and thermal resistance and can meet the oil resistance requirement in the ISO6722 Standard. The elastomer cable material is high in production efficiency and can be widely applied to the new energy field of a high-voltage connection cable used in an electric automobile.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

Al-Mg-Si-Cu alloy and preparation method thereof

The invention discloses Al-Mg-Si-Cu alloy and a preparation method thereof. The alloy consists of the following components in percentage by mass: 0.4 to 0.6 percent of Mg, 0.45 to 0.6 percent of Si, 0.3 to 0.8 percent of Cu, 0.1 to 0.2 percent of Mn, 0.1 to 0.7 percent of Zn, 0 to 0.1 percent of Cr, 0.01 to 0.02 percent of Ti, not more than 0.3 percent of Fe, not more than 0.1 percent of other impurities (total content), and the balance of Al. The alloy has the characteristics of the reduction of deformation resistance, improves extrusion speed and production efficiency, and can improve the yield under the condition of constant productivity. In addition, the alloy does not need an extra water quenching process, and can reduce investment cost of equipment by on-line air quenching after hot extrusion.

Owner:CENT SOUTH UNIV

High-quality 6-series aluminum alloy extrusion casting blank and preparation method thereof

ActiveCN110735073AReduce hardnessImprove extrusion deformationFurnace typesHeat treatment furnacesIngotUltimate tensile strength

The invention discloses a high-quality 6-series aluminum alloy extrusion casting blank and a preparation method thereof. The preparation method comprises the following steps of performing primary cooling treatment, bath treatment and subsequent cooling treatment on a 6-series aluminum alloy ingot subjected to homogenization heat treatment in sequence. Compared with a traditional uniform casting blank in actual production, the prepared casting blank has the advantages that a large number of dispersed micron-sized precipitated phases are distributed in a matrix, the structure can not only effectively reduce the extrusion deformation resistance of a cast ingot, improve the surface quality of an extruded product, but also improve the online quenching solid solubility of the extruded product, so that a good tissue basis is provided for later aging treatment. Finally, the high-quality extrusion casting blank capable of improving the extrusion performance and improving the final aging strength is finally obtained.

Owner:SUZHOU UNIV +1

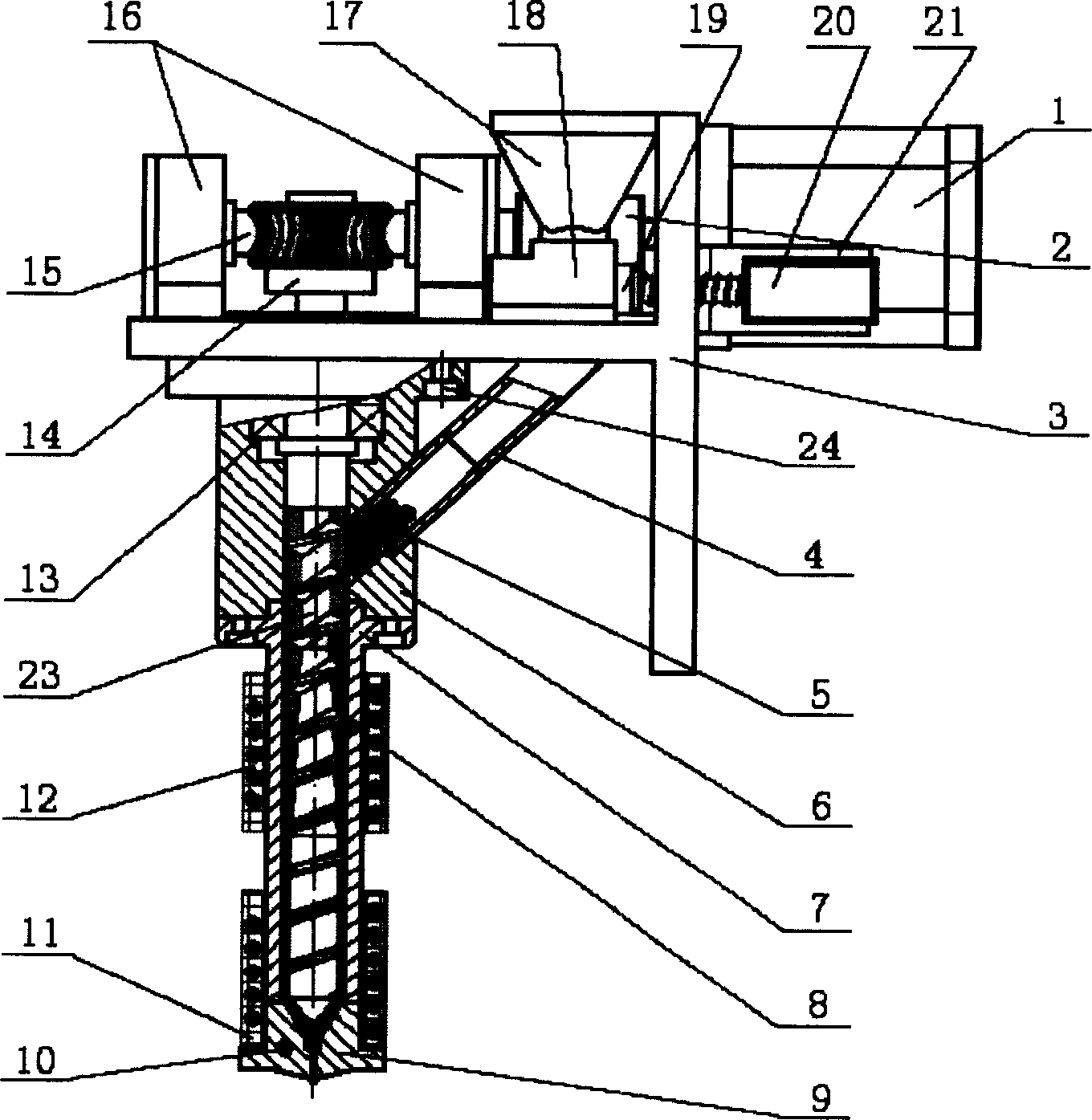

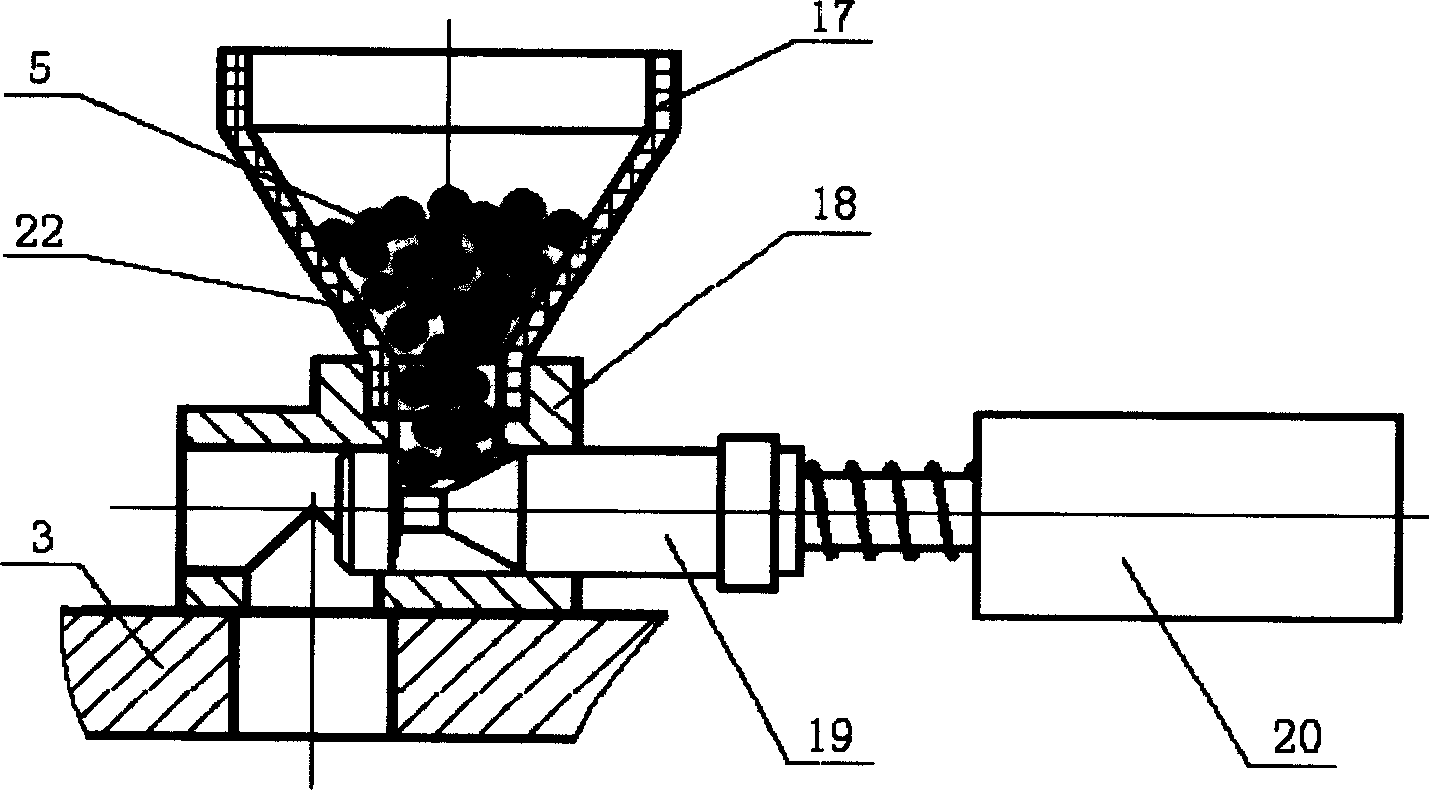

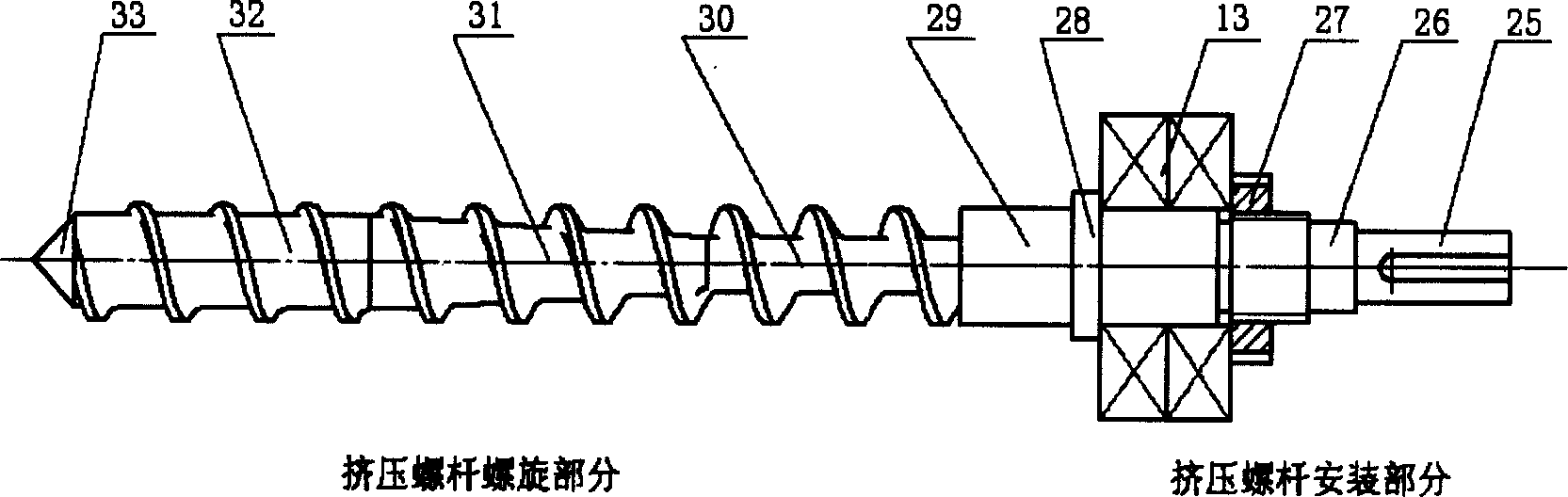

Quick forming screw extruding jet device for thermoplastic particle material

The quick forming and screw extruding jet device for thermoplastic particle material belongs to the field of fast forming and smelting extrusion stacking technology in mechanical processing. The device includes push rod feeding mechanism, reducing worm gear transmission mechanism, micro extruding screw jet mechanism and temperature controlling heating mechanism. The push rod feeding mechanism consists of electromagnet, push rod and switching joint, and realizes the intermittent feeding of particle material via the reciprocation of the push rod notch between the material bin and material barrel. The present invention is a ideal smelting, extruding, stacking and forming jet device with effectively lowered cost, raised processing speed and less flow casting.

Owner:SHANGHAI JIAO TONG UNIV

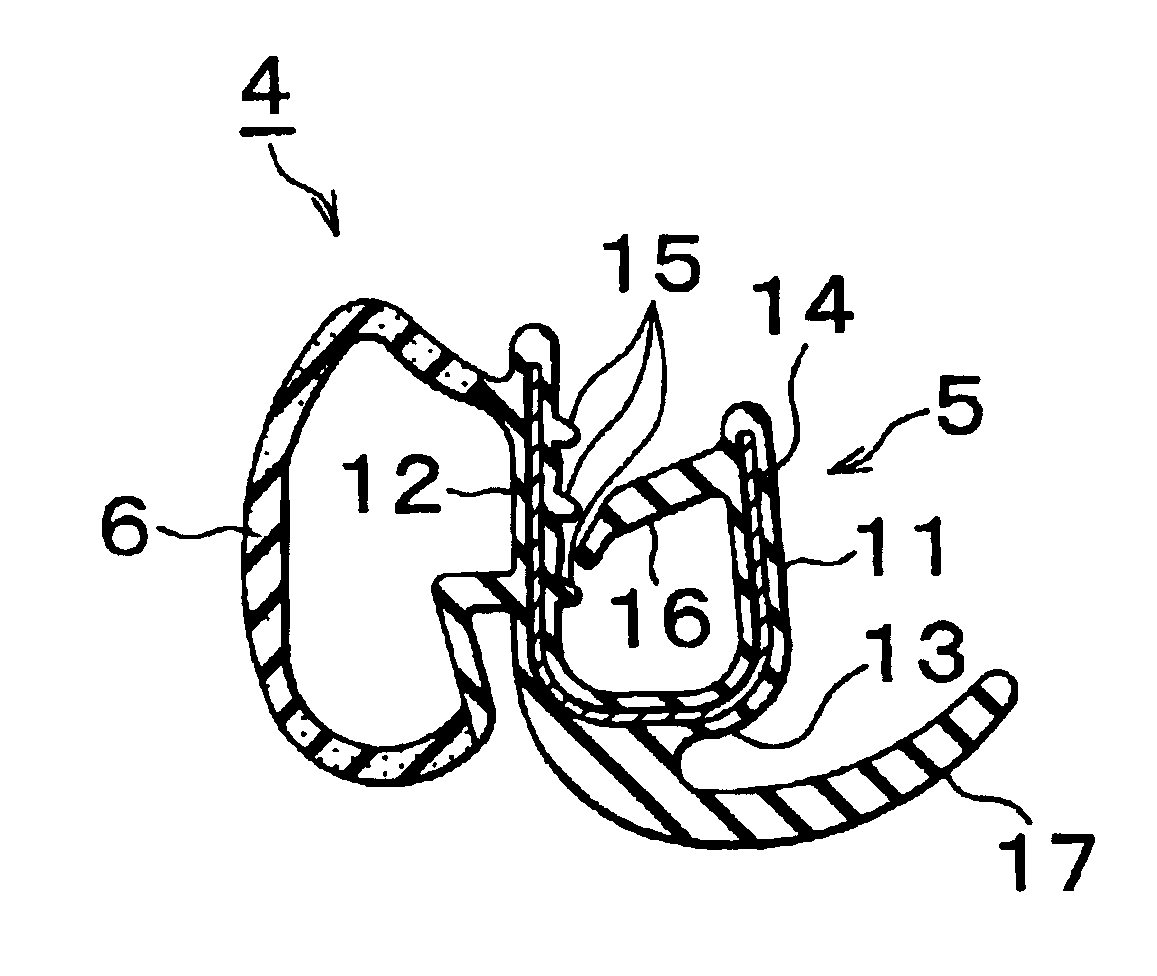

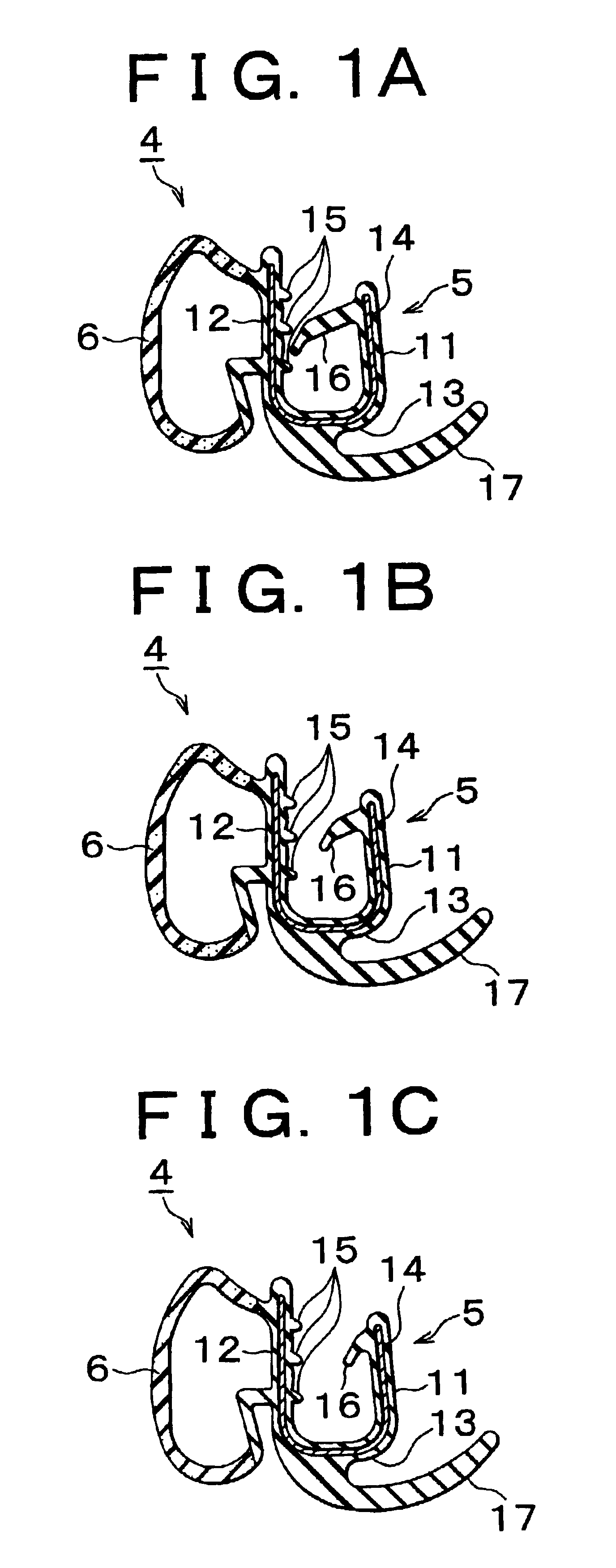

Weather strip having variable length holding lip

InactiveUS6935072B2Reduce loadReduce stressEngine sealsVehicle sealing arrangementsEngineeringFlange

A weather strip includes a trim body having a generally U-shaped cross section, a hollow seal portion that protrudes from an outside surface of the trim body, and a holding lip formed on the trim body so as to extend from an inside surface of the trim body toward the inside of the trim body. The weather strip is mounted on the vehicle body such that the trim body is held by a flange provided at a periphery of a door opening of a motor vehicle. The weather strip is formed by extrusion molding such that the length of the holding lip is changed in a stepped manner in accordance with the thickness of the flange.

Owner:TOYODA GOSEI CO LTD

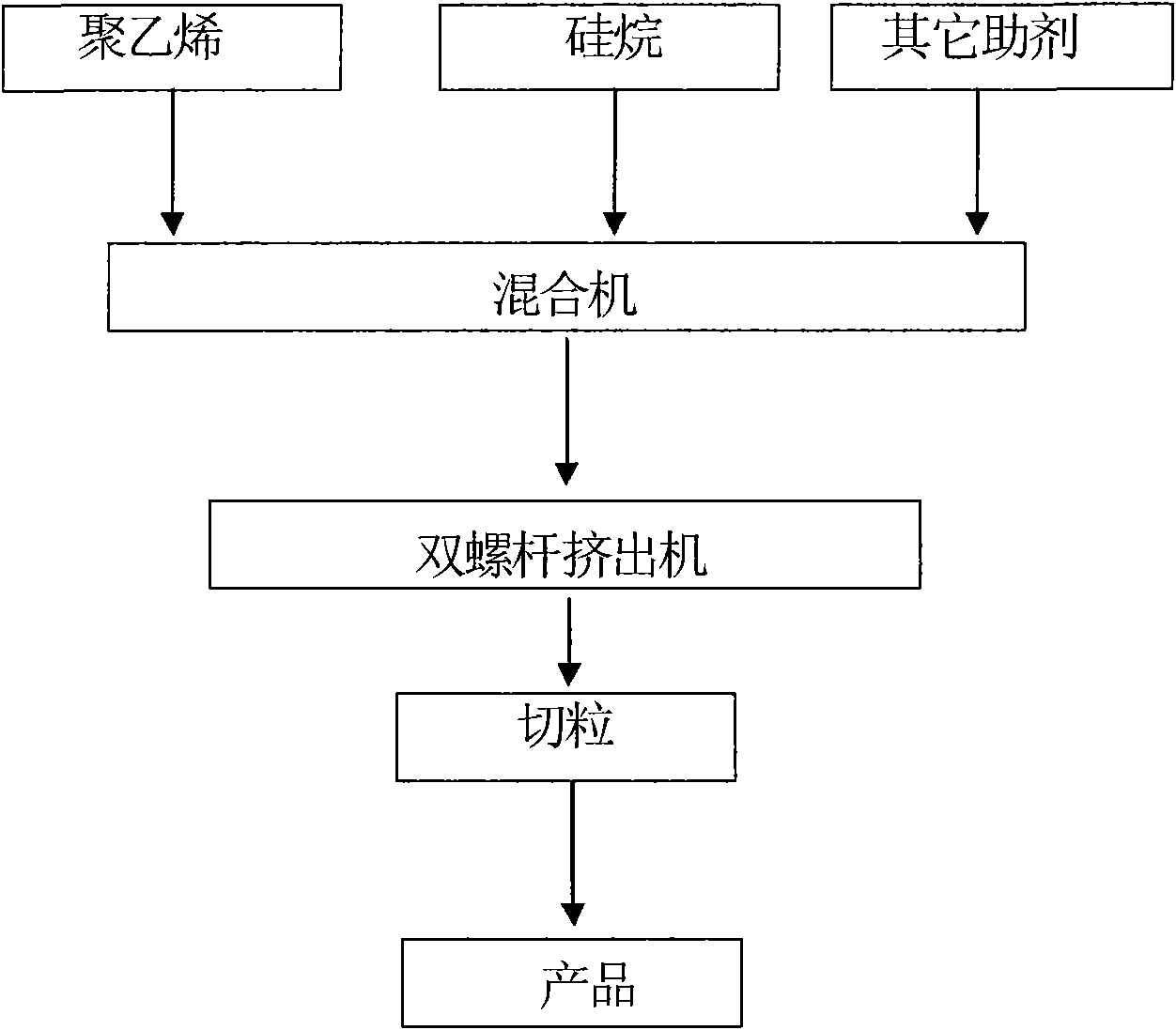

Composition of single-component silane natural cross-linking polyethylene materials and processing process thereof

ActiveCN101838410ANo pre-crosslinking phenomenonEasy to usePlastic/resin/waxes insulatorsCross-linkPolymer science

The invention relates to the field of application of silane natural cross-linking polyethylene materials, in particular to a composition of single-component silane natural cross-linking polyethylene materials and a processing process thereof. The composition comprises polyethylene resin, silane cross-linking agents, antioxidizers, initiators and catalyst mixtures. The processing process comprises the following steps: using the polyethylene resin as base materials; adding the silane cross-linking agents, and adding proper antioxidizers, initiators and catalyst mixtures to be mixed and stirred; and adopting a double-screw extruding machine for fused plasticized mixed filtering granulation for preparing the silane natural cross-linking polyethylene materials. The invention adopts a one-step method granulation process, the polyethylene rein is made into products through the fused plasticized mixed filtering granulation via the screw extruding machine under the effect of the silane cross-linking agents, antioxidizers, initiators and catalyst mixtures, the products are single-component materials, and materials A and materials B are not needed to be distinguished. The materials have good flowability, high extrusion speed and long storage time, no pre-cross-linking phenomenon occurs in the technical processing process, the technical temperature range is wide, the use is convenient, and the invention is applicable to industries such as electric wires and cables, plastic products and the like.

Owner:上海永进电缆(集团)有限公司

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

Halogen free flame-proof composite material of polythene and preparation method thereof

InactiveCN101429302AImprove flame retardant performanceImprove mechanical propertiesPolymer scienceNanometre

The invention provides a halogen-free flame retardant polyethylene composite material, which is characterized by consisting of the following raw materials in weight portion: 74.3 to 41.5 portions of polyethylene; 0.2 to 1.5 portions of heat stabilizer; 0.3 to 1 portion of light stabilizer; 0.2 to 1 portion of processing aid; 23 to 50 portions of halogen-free flame retardant; and 2 to 5 portions of nanometer addition agent. The invention also provides a method for preparing the composite material. Compared with the prior halogen-free flame retardant polyethylene, the composite material greatly improves the flame retardant performance of polyethylene due to the addition of the nanometer addition agent, and reduces the usage of the halogen-free flame retardant; besides, the obtained polyethylene has better mechanical properties, smoother surface and faster extrusion.

Owner:SHANGHAI KINGFA SCI & TECH +1

High-strength, high-ductility rare earth aluminum alloy material and method of producing the same

The invention relates to a rare earth aluminium alloy material with high strength and high toughness and the preparation method thereof, belonging to the technical field of metal alloy and the preparation thereof. The invention is characterized in that the invention comprises Mg, Si, Fe, a rare earth compound additive and Al, with the weight percentages as follows: Mg: 0.50-0.60%; Si: 0.35-0.45%; Fe less than or equal to 0.35%; rare earth additive less than or equal to 0.065-0.2%; the margin being Al. The preparation method comprises charging and melting down the 6063 aluminum alloy furnace materials in accordance with the conventional methods, adjusting the furnace temperature, deairing, refining and purifying the melt and then adding Al-RE, Al-Sr and Al-Zr master alloys at the temperature between 720 DEG C and 760 DEG C and preserving heat for 30min-7h, then carrying out homogenization treatment on electromagnetic stirring components and detection, pouring and casting, finally carrying out homogenization treatment and subsequent quick cooling treatment, rapid heating before extrusion, extrusion and on-line quenching treatment as well as artificial aging treatment. The product section obtained from the invention has rapid extrusion and high mechanical property of the section and can improve the apparent mass of the section and increase the modification of oxide film density.

Owner:BAOTOU JI TAI RARE EARTH ALUMINUM CO LTD +1

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

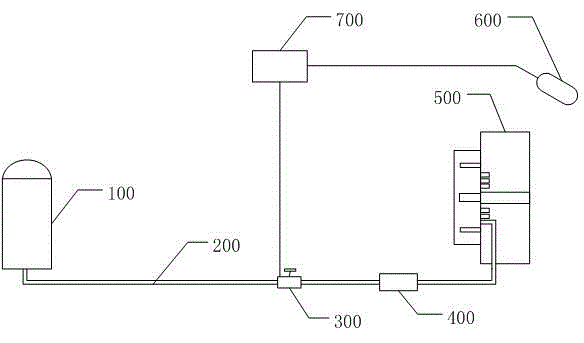

Method and device for liquid nitrogen cooling of aluminum profile extrusion die

The invention discloses a method and a device for liquid nitrogen cooling of an aluminum profile extrusion die. According to the method and the device, a channel is opened on an extrusion die cushion according to the shape of the cross section of the die cushion, liquid nitrogen is input into the channel during the extrusion process of profiles, the liquid nitrogen cooling process is controlled by a closed ring control system, and the temperature of an extrusion die is controlled at 440-480 DEG C. With the method and the device for liquid nitrogen cooling of an aluminum profile extrusion die, the problems that the product quality is lowered and the extrusion efficiency is low caused by overhigh temperature during extrusion of aluminum alloy profiles are avoided, the extrusion speed of the die is improved by 10-50 percent, the service life of the die is prolonged, and meanwhile, the product quality is improved, the dimension precision of aluminum profiles machined is higher, the surface smoothness is better, and the rejection rate is reduced.

Owner:佛山市三水凤铝铝业有限公司 +1

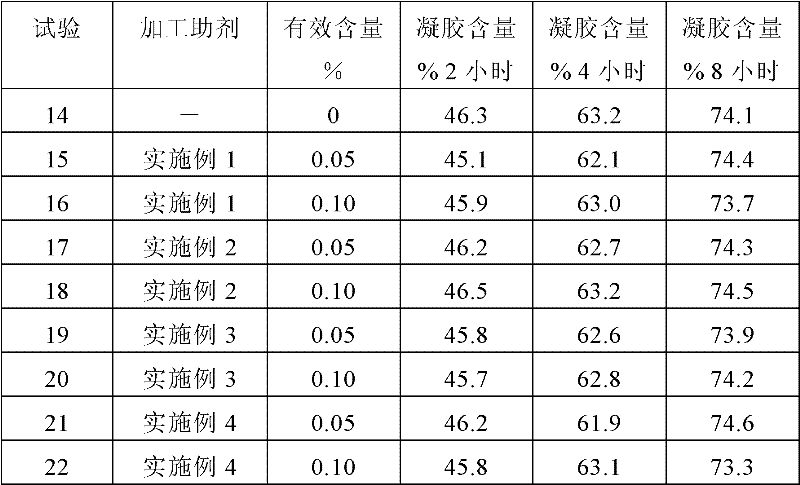

Fluoropolymer processing aid, silane-crosslinked polyethylene composition containing same and application thereof

ActiveCN102286157AInhibition of pre-crosslinkingIncrease extrusion speedCoatingsSurface finishProcedure Agents

The invention provides a fluoropolymer processing aid. The fluoropolymer processing aid is particles which are formed by a core part and a shell part and have average particle diameter of 0.2 to 1 micron, wherein the core part is made of fluorocarbon polymer, the shell part is made of MQ silicon resin, the ratio of M to Q is 0.5 to 0.9, and the weight ratio of the core part to the shell part is 20:80-45:55. The invention also provides a silane cross-linked polyethylene composition containing the processing aid and application of the fluoropolymer processing aid in silane cross-linked polyethylene extrusion molding. Not only the silane cross-linked polyethylene added with the fluoropolymer processing aid has high extrusion velocity, but also the extruded product has high surface finishment.

Owner:上海鲁聚聚合物技术有限公司

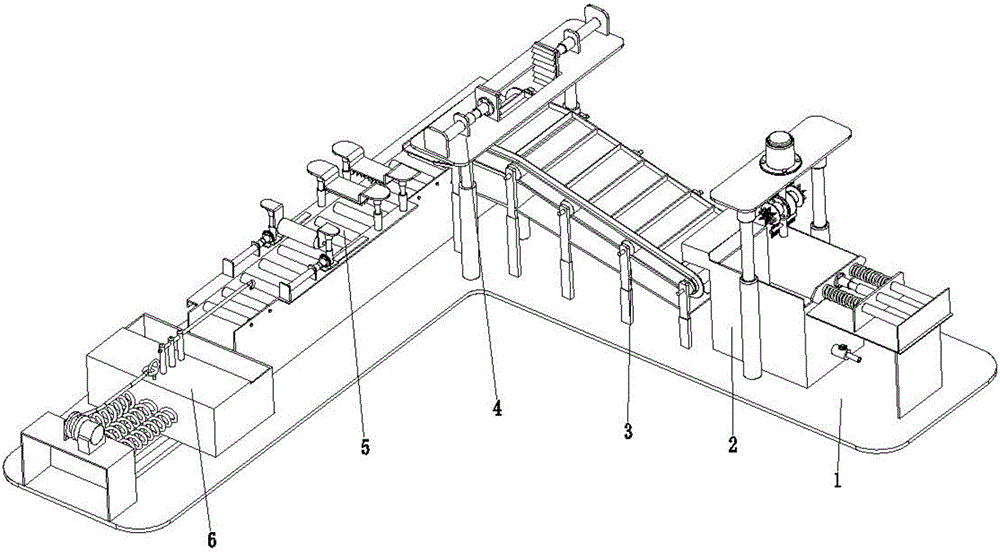

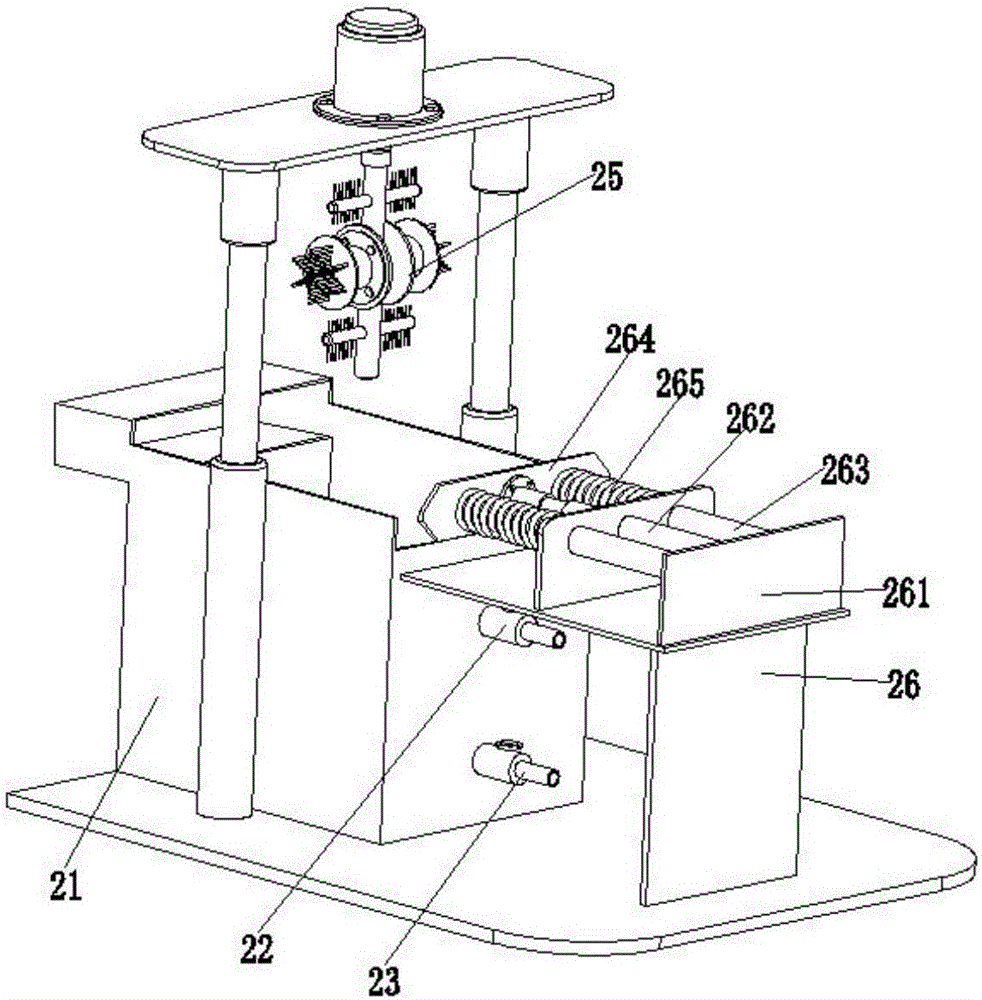

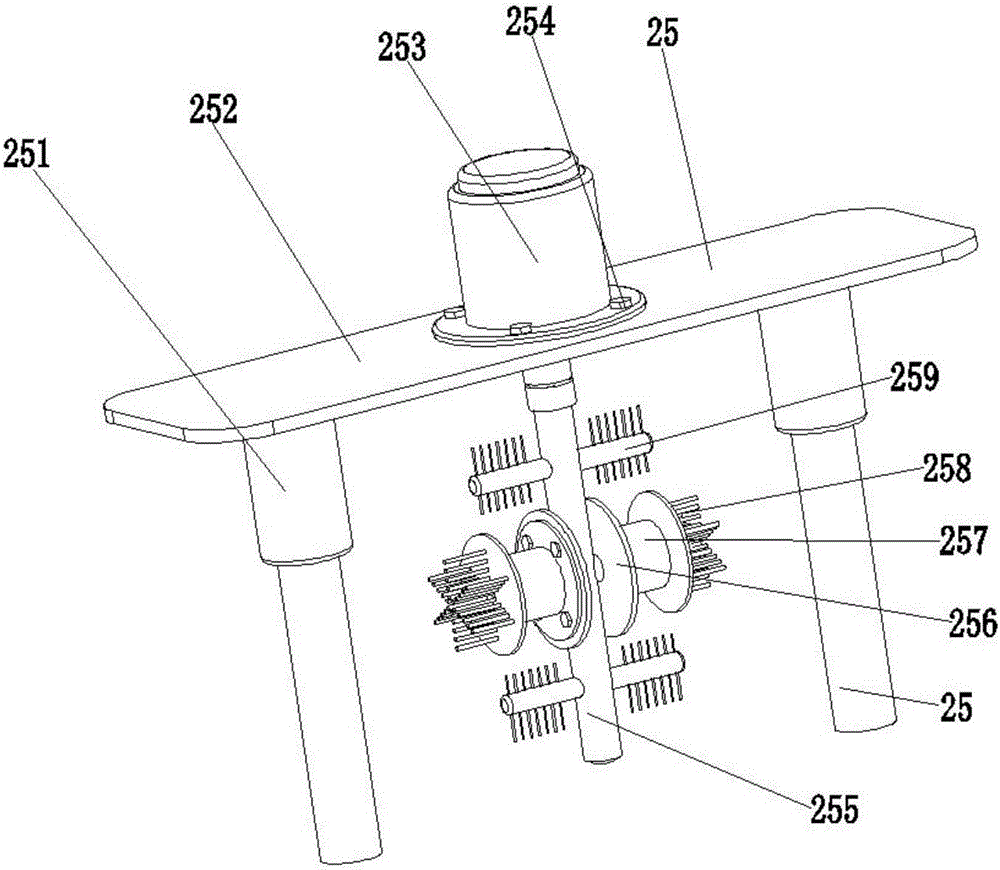

Environment-friendly recycling treatment system for waste plastic bottles

ActiveCN106608004AAvoid pollutionProtect the ecologyPlastic recyclingMechanical material recoveryPollutionMechanization

The invention relates to an environment-friendly recycling treatment system for waste plastic bottles. The environment-friendly recycling treatment system comprises a base plate, a cleaning and feeding device, a conveying device, a squeezing device, a crushing device and a storage device. The base plate is of an L-shaped structure. The cleaning and feeding device is located at the front side end of the base plate. The conveying device is located right on the rear portion of the cleaning and feeding device, and the conveying device and the cleaning and feeding device are located on the same straight line. The squeezing device is located at an outlet in the rear side of the conveying device. The crushing device and the conveying device are vertically arranged, and the crushing device is fixedly connected with the base plate. The storage device is installed at the left side of the crushing device. By means of the environment-friendly recycling treatment system, the waste plastic bottles can be cleaned, pushed, fed, conveyed, squeezed, crushed and stored, and the whole recycling treatment of the waste plastic bottles is realized; moreover, the treatment process is high in degree of mechanization, a large number of labor force is saved, and treatment efficiency is improved; and meanwhile, pollution to the environment by the waste plastic bottles is avoided, and the environment and ecology are protected.

Owner:同信生态环境科技有限公司

Radiation crosslinked polyethylene pipe and its preparation method

ActiveCN1282699CImproved chemical purityAvoid cross-linking reactionsTubular articlesPolymer scienceCross linker

The invention relates to a radiation crosslinked polyethylene pipe, which has a three-dimensional network crosslinked molecular structure, and the pipe is made of a certain proportion of mixed polyethylene resin, antioxidant and stearate lubricant. The raw material is extruded into a tube by a tube extruder at a temperature below 235°C, and then irradiated by electron rays; the ratio of each component in the raw material is: polyethylene resin 98.5-99.0%wt, antioxidant 0.1 ~0.6%wt, stearate lubricant 0.5~1.0%wt; molecular crosslinking degree inside the pipe ≥60%. The invention provides a radiation cross-linked polyethylene pipe material which does not need to add a cross-linking agent, has low raw material cost, high extrusion production efficiency and high chemical purity of the product.

Owner:FSPG HI TECH

Rare earth aluminum alloy and preparation method thereof

The invention provides a rare earth aluminum alloy and a preparation method of the rare earth aluminum alloy. The rare earth aluminum alloy comprises the following compositions in percentage by weight: 0.7-1.3 wt percent of Si, 0.4-1.0 wt percent of Mn, 0.6-1.2 wt percent of Mg, 0.1-0.2 wt percent of Re, Fe larger than 0 wt percent and no more than 0.5 wt percent, Cr larger than 0 wt percent and no more than 0.25 wt percent, Zn larger than 0 wt percent and no more than 0.2 wt percent, Ti larger than 0 wt percent and no more than 0.1 wt percent, Cu larger than 0 wt percent and no more than 0.1 wt percent and the balance of aluminum. According to the rare earth aluminum alloy provided by the invention, because a small number of rare earth elements are added in an aluminum alloy and can have stronger affinity with gas and many nonmetals, and a compound with high melting point is produced, the rare earth aluminum alloy has the certain actions of dehydrogenation, refining and purification; and meanwhile, the rare earth elements can also be selectively adsorbed to an interface of a grown crystal grain to block the growth of the crystal grain and enable the crystal grain to be refined, thus strengthening the strength of the aluminum alloy and improving the processing performance of the aluminum alloy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com