Patents

Literature

584results about How to "Uniform flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

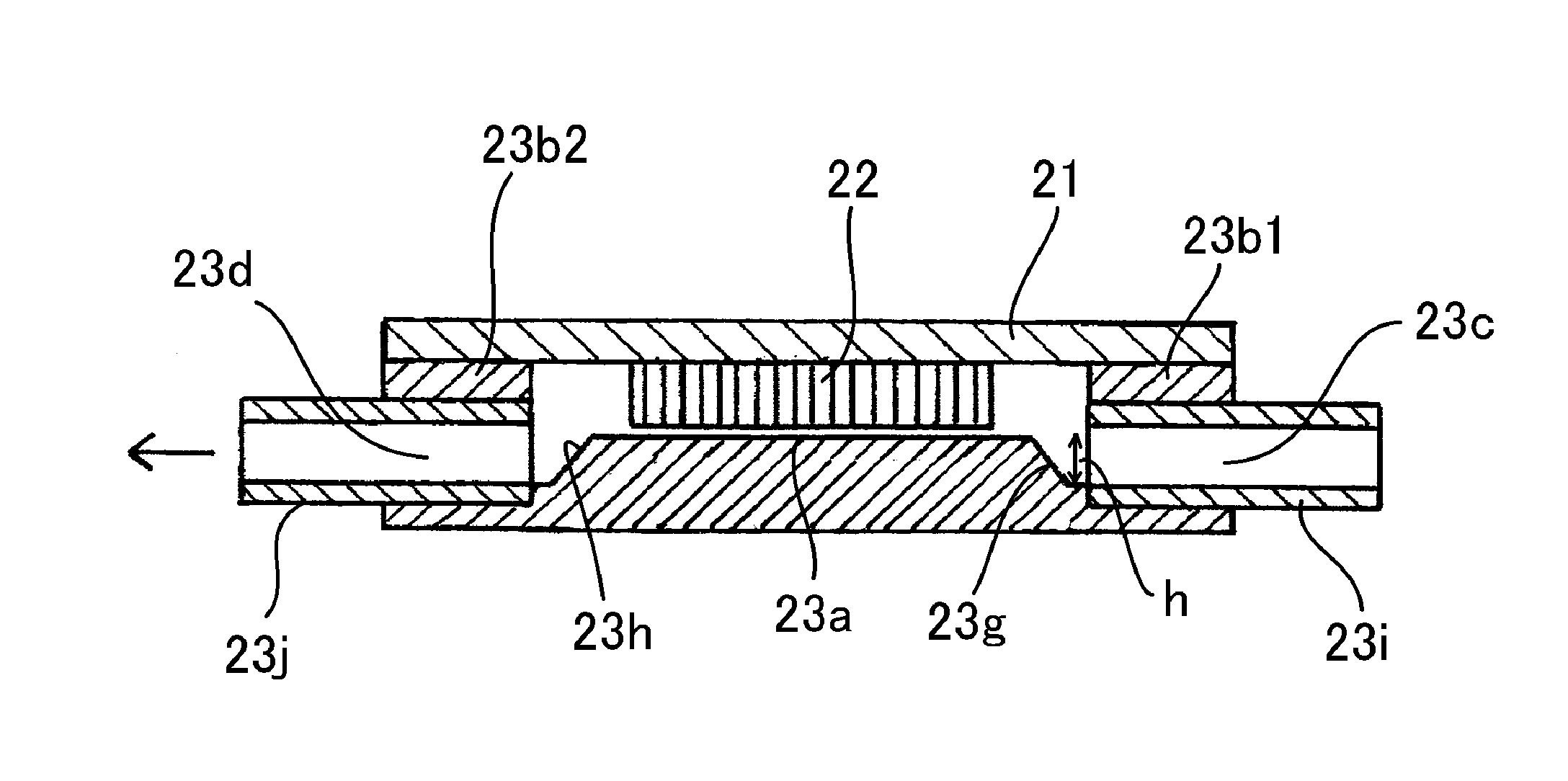

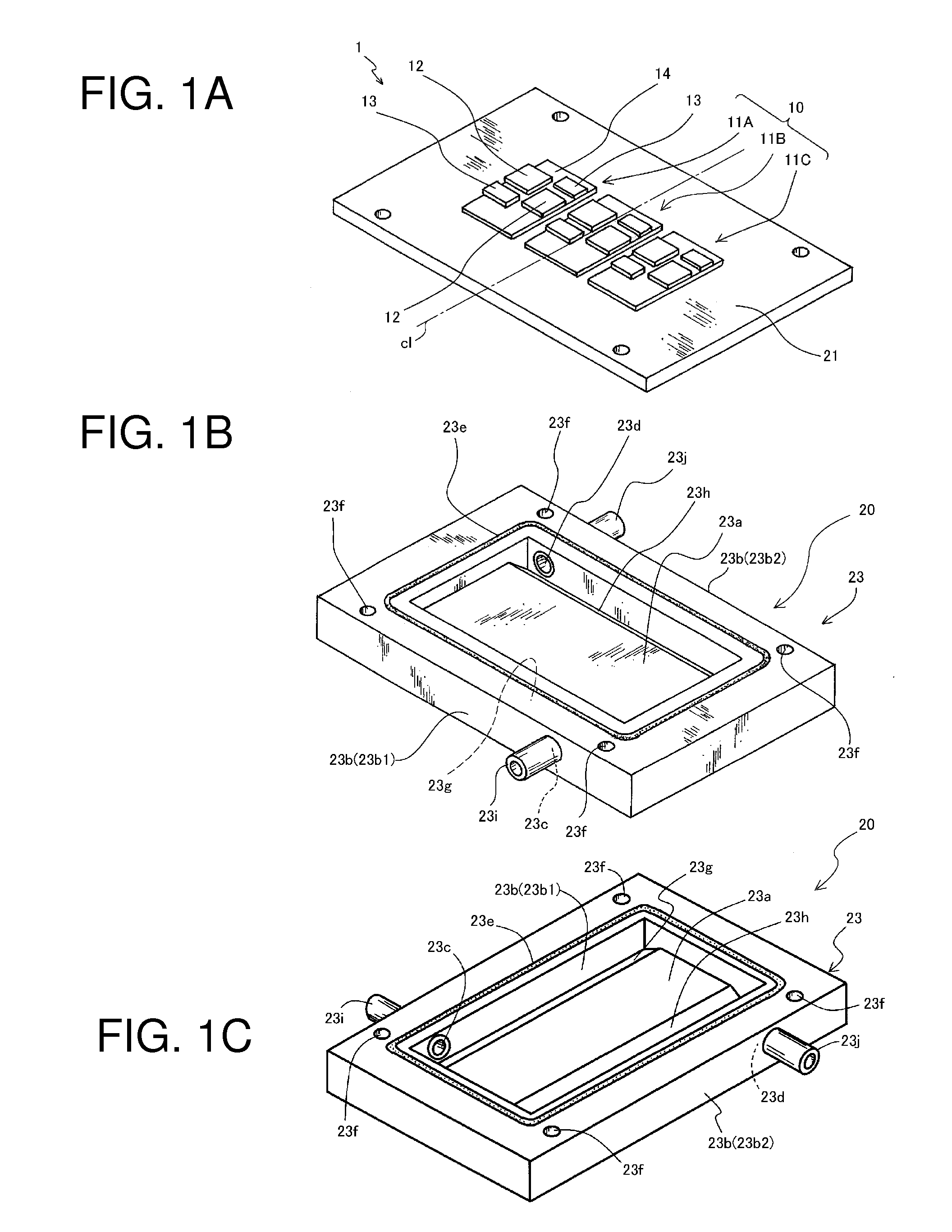

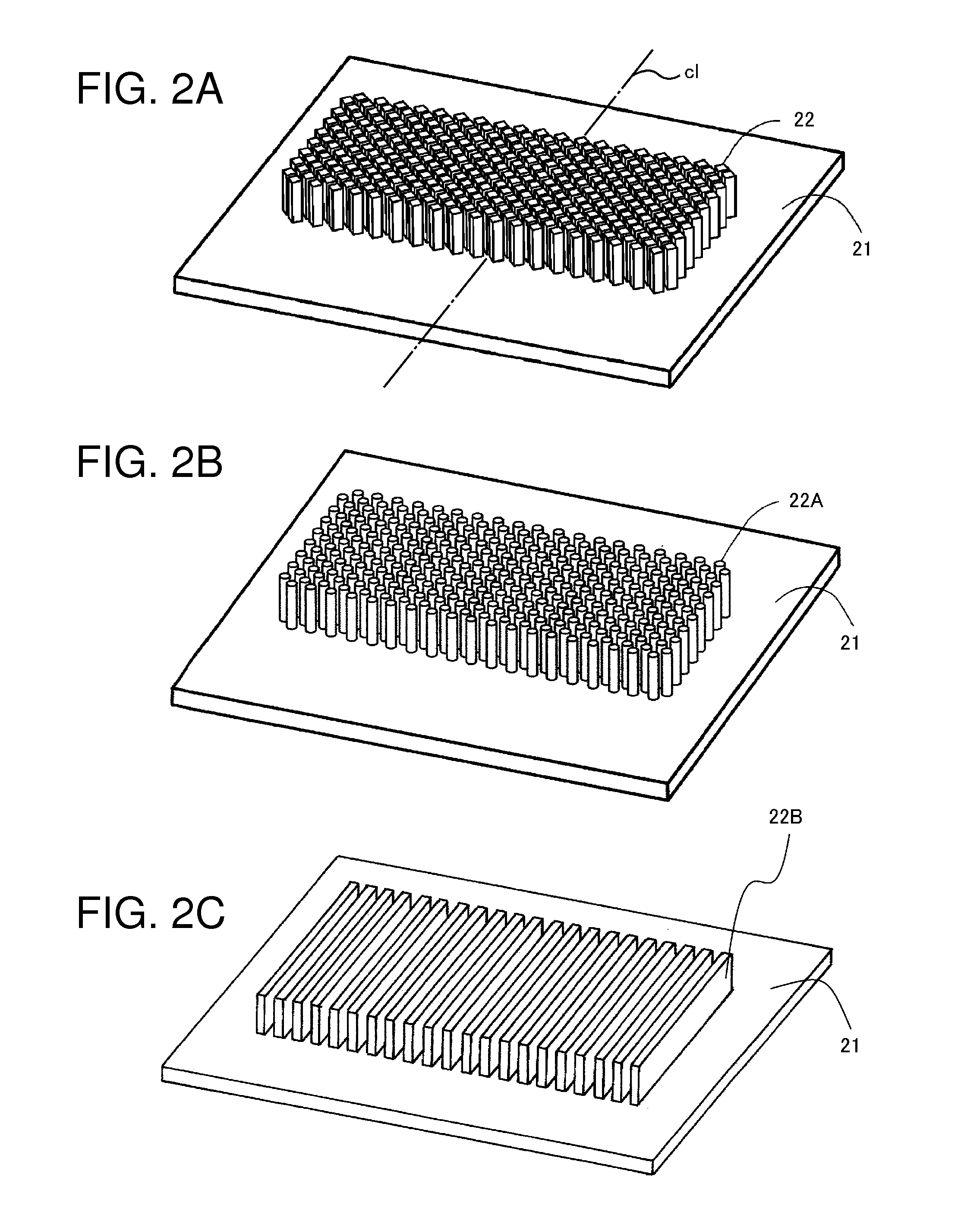

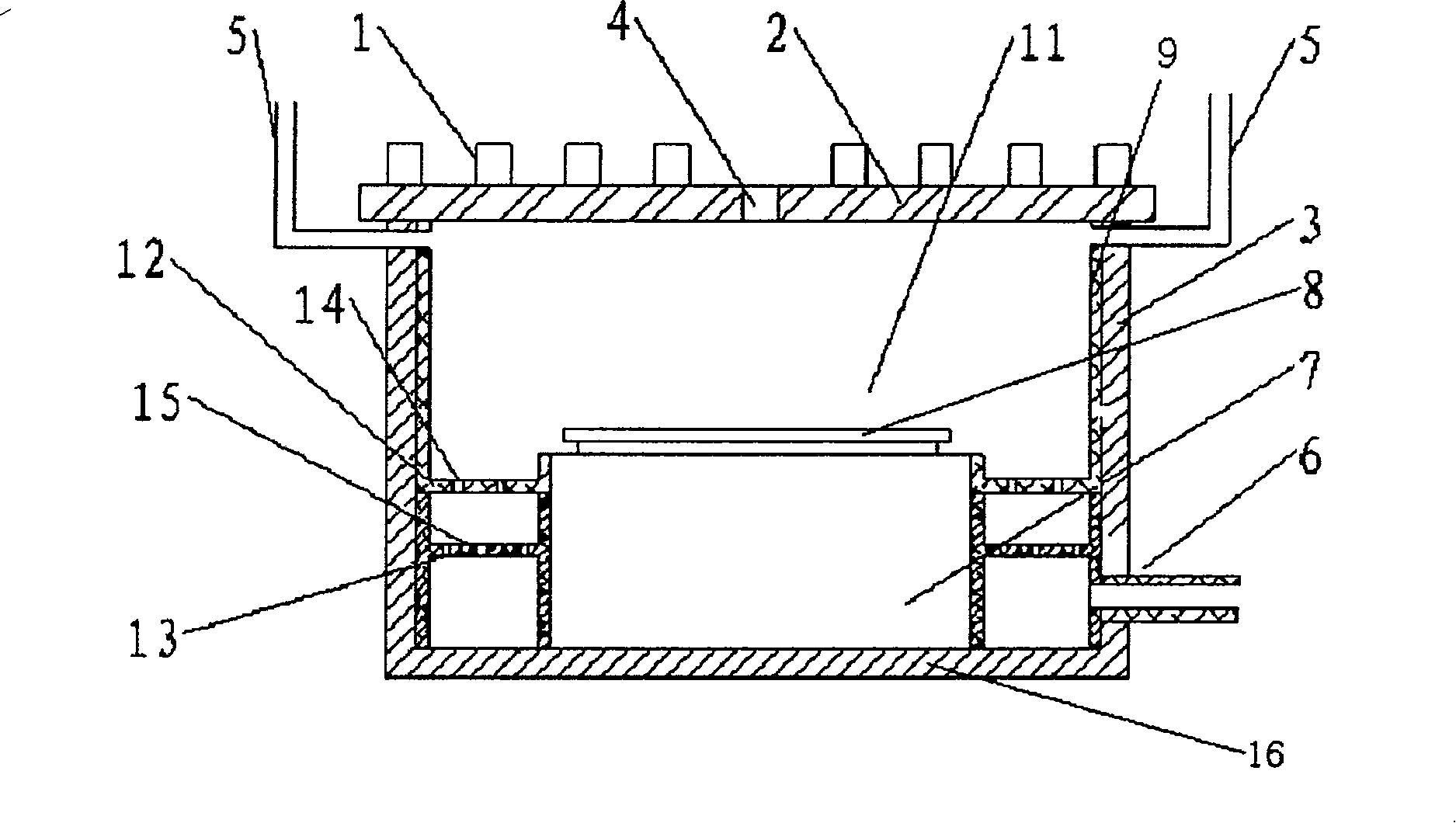

Semiconductor device

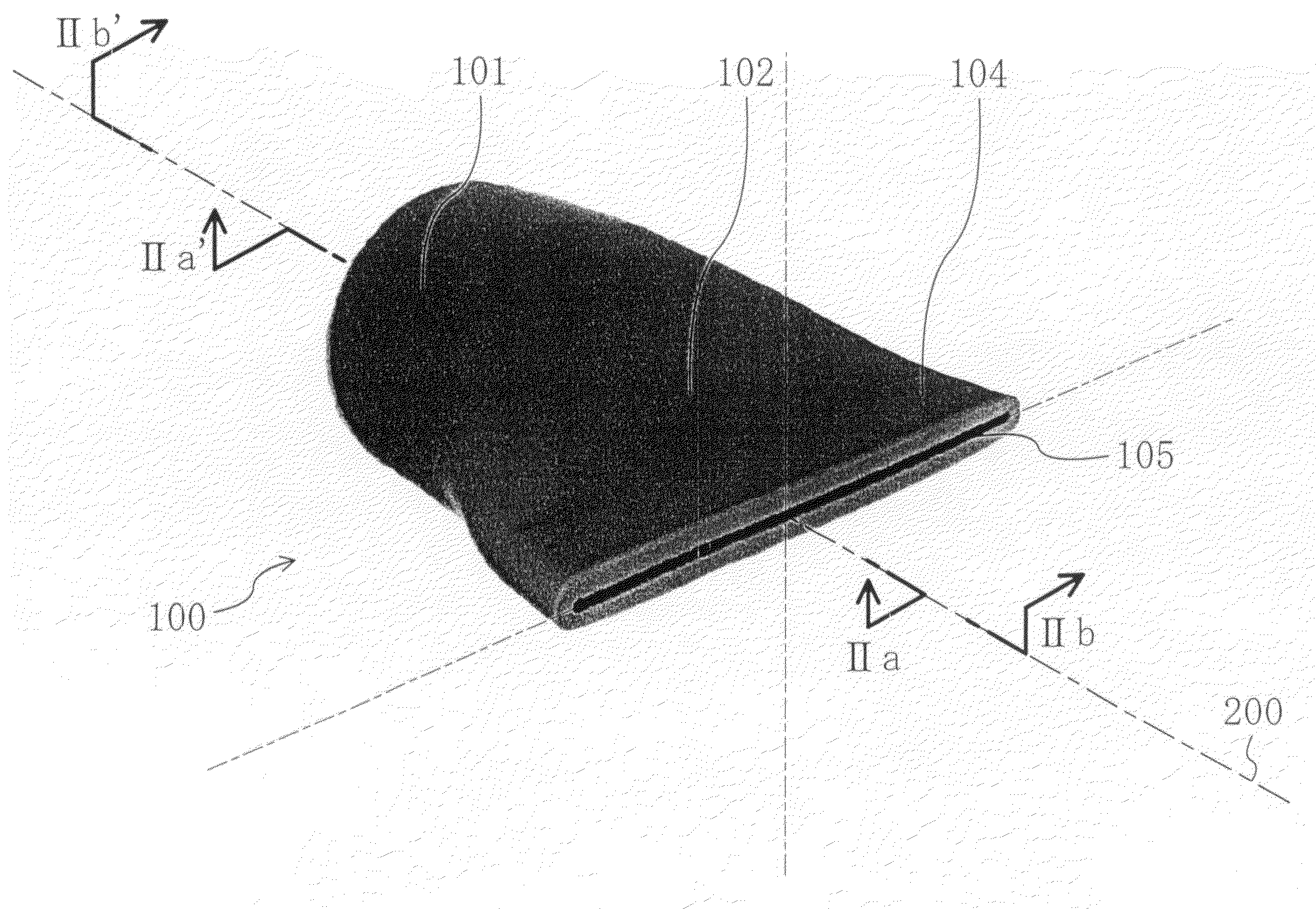

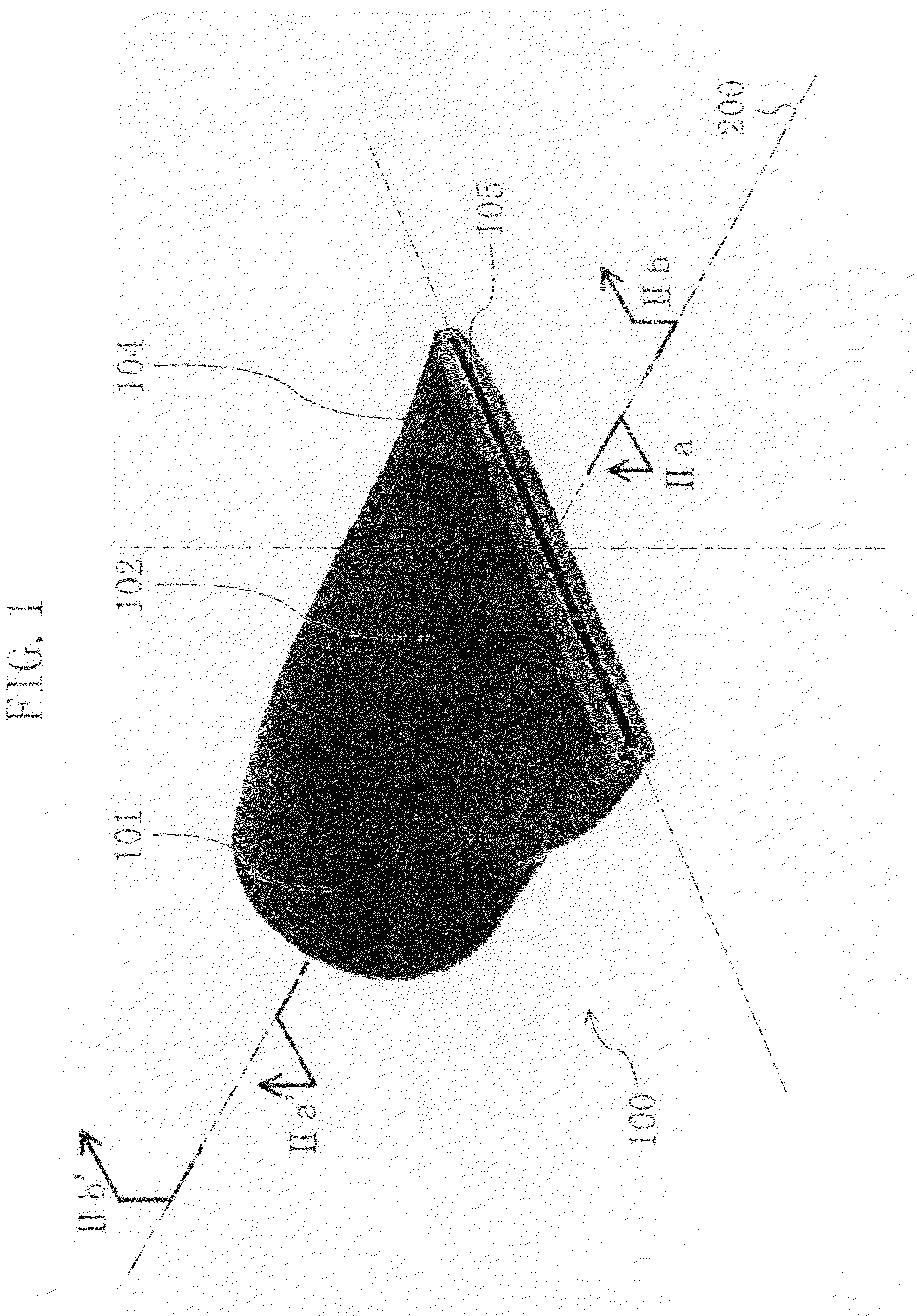

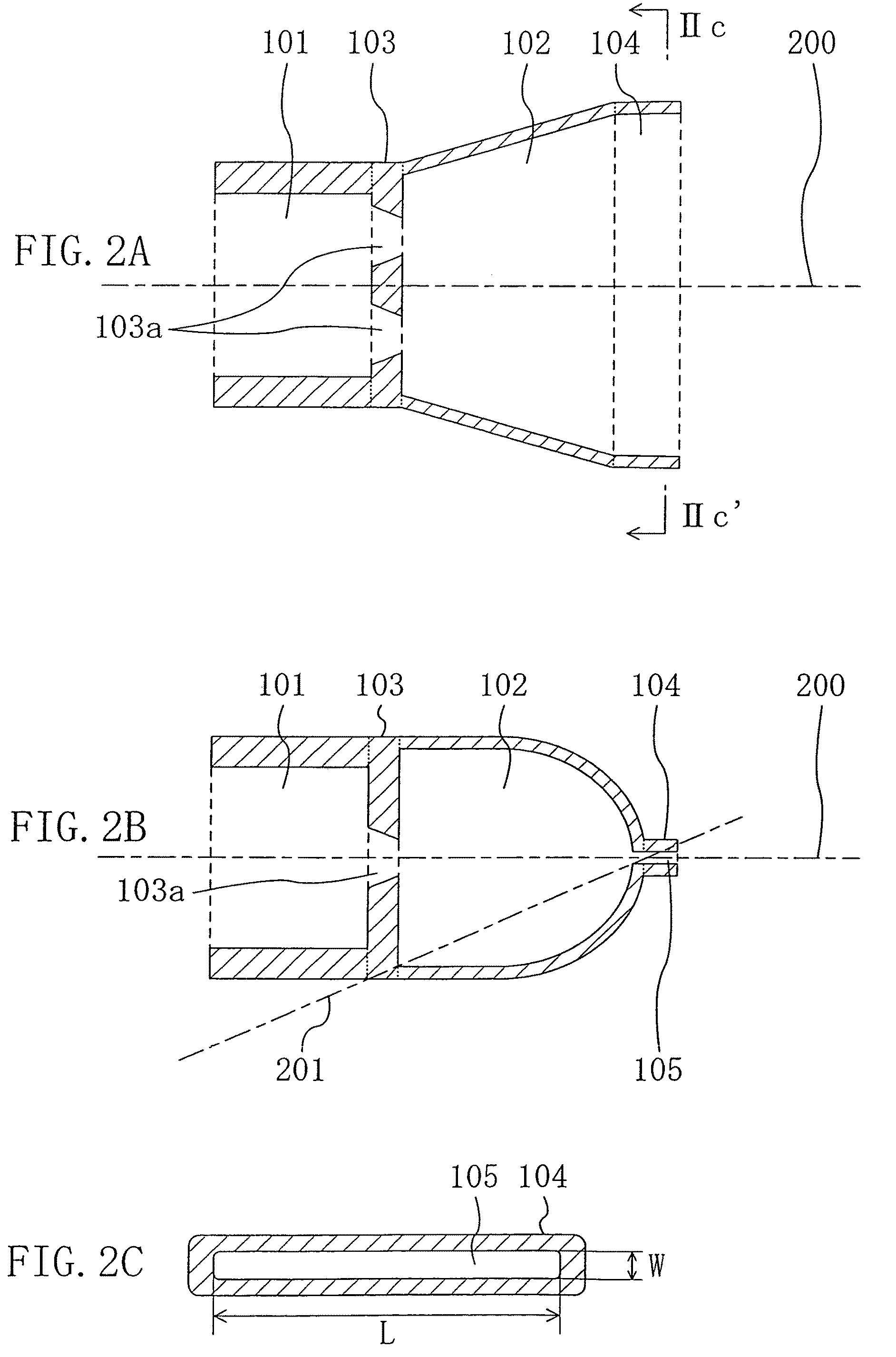

ActiveUS20150021756A1Increase heat radiation abilityUniform flow rateSemiconductor/solid-state device detailsSolid-state devicesHeat sinkEngineering

A semiconductor device includes an insulating substrate, semiconductor elements and a cooling device. The cooling device includes a heat radiation substrate, fins, and a cooling case of a box-like shape that accommodates the fins and has a bottom wall and side walls. An introducing port and a discharge port for a cooling liquid are provided diagonally in a pair of side walls provided along the longitudinal direction of the assembly of the fins, among the side walls of the cooling case. A diffusion wall facing the introducing port is provided inside the cooling case.

Owner:FUJI ELECTRIC CO LTD

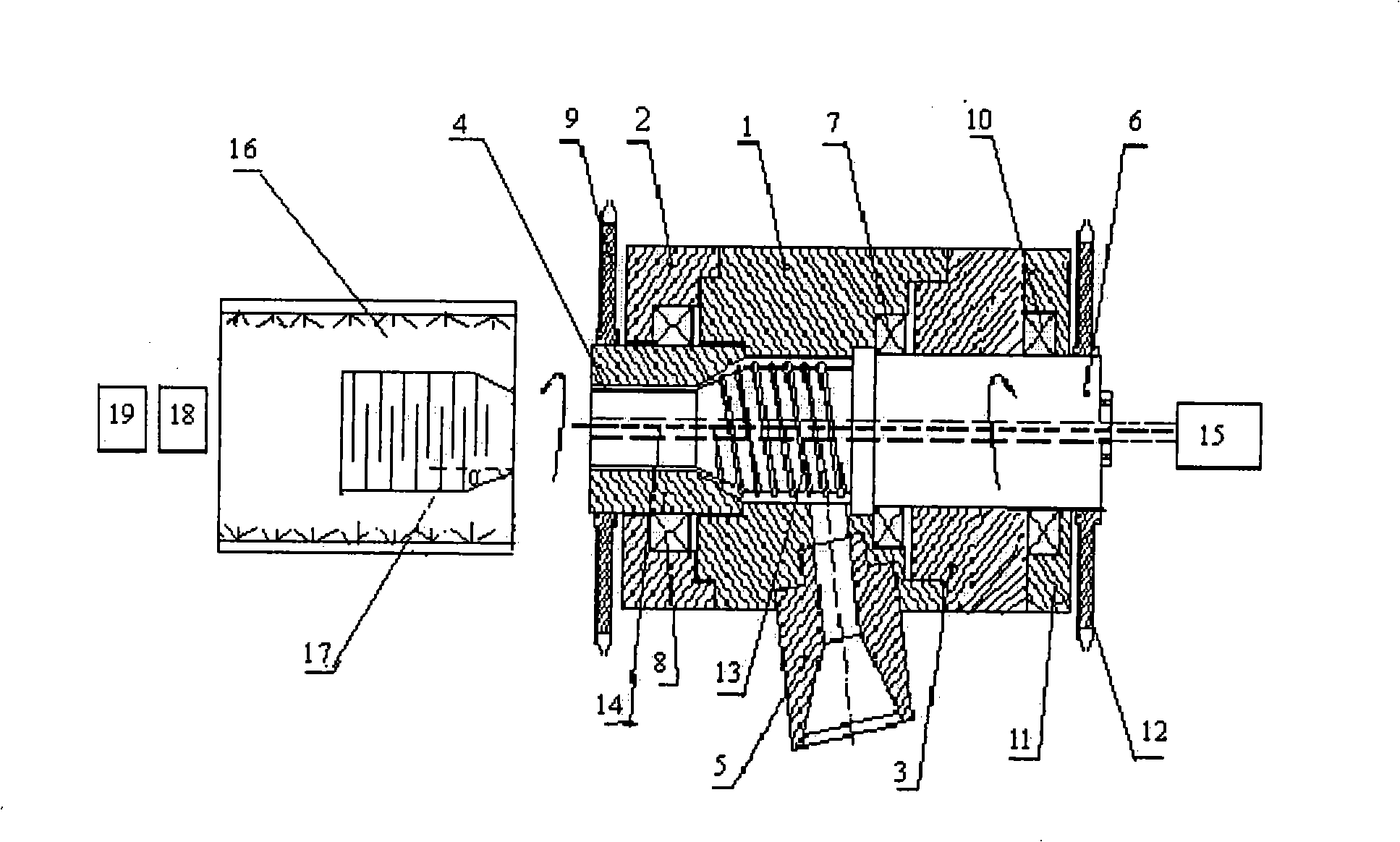

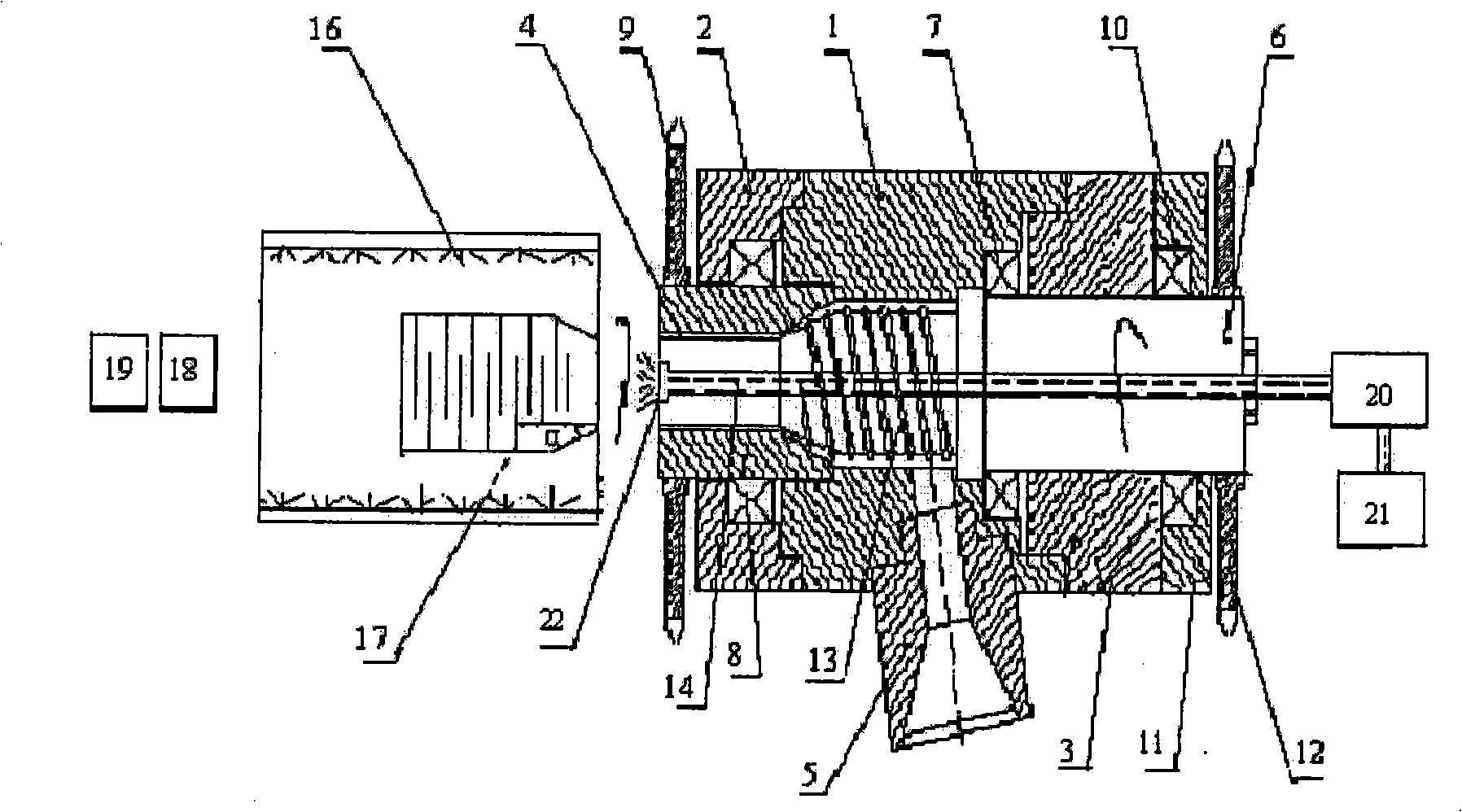

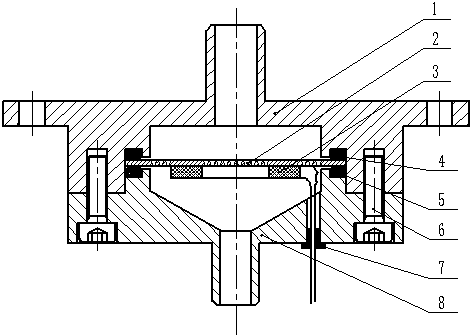

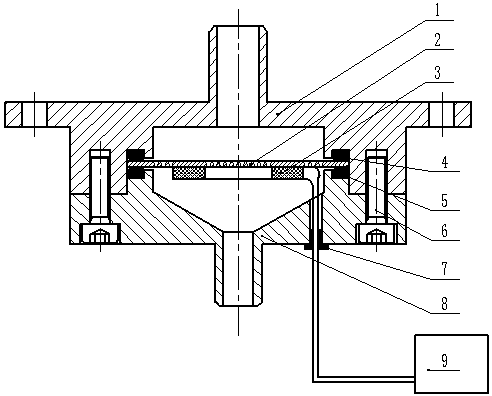

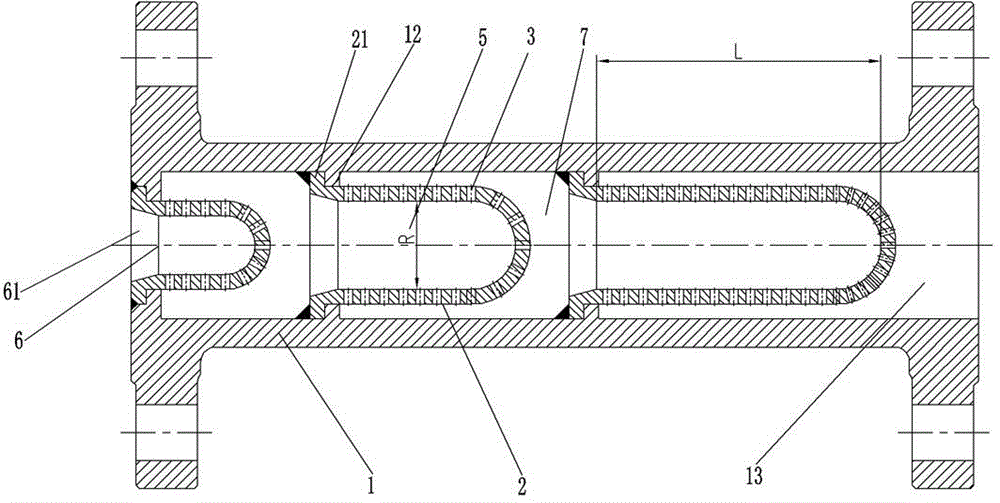

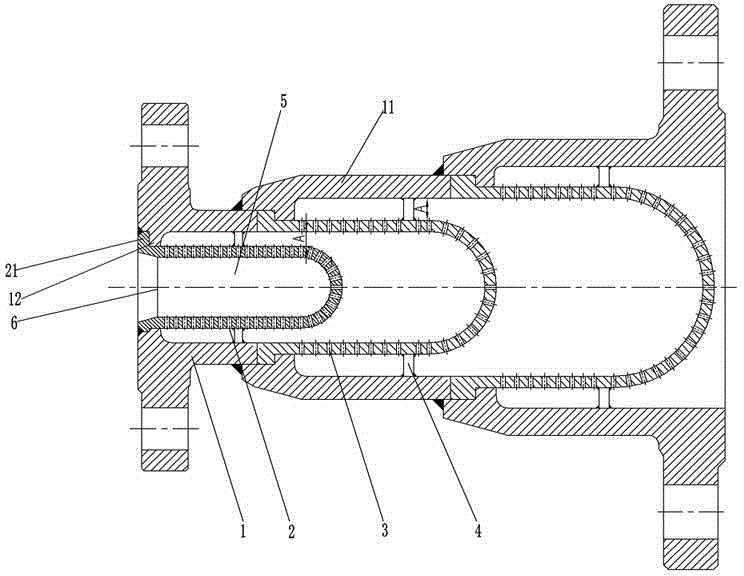

Preparation method and device of high performance polymers pipes

The invention discloses a method for preparing a high-performance polymer pipe. The method adopts the steps that during the extrusion molding process of the pipe, the crystallization, the orientation or the dispersed phase morphological structure of the polymer pipe can be adjusted, controlled and fixed through the shearing action generated by the rotation of a core rod in a machine head relative to an orifice die, or the rotation of the orifice die in the machine head relative to the core rod, or the rotation of the core rod and the orifice die in the identical or opposite direction simultaneously, and by cooling and shaping the inner wall and the outer wall of the extruded pipe simultaneously, and adjusting and controlling the temperature field, the cooling rate and the temperature gradient during the extrusion molding process of the pipe. The invention further discloses a device designed according to the method. The method has the advantages that the macromolecular orientation, the crystallization or the dispersed phase morphological structure which are generated through induction can be retained in the plastic pipe, so that deorientation can be avoided, the internal stress of the pipe can be reduced, and the performance of the pipe is improved.

Owner:SICHUAN UNIV

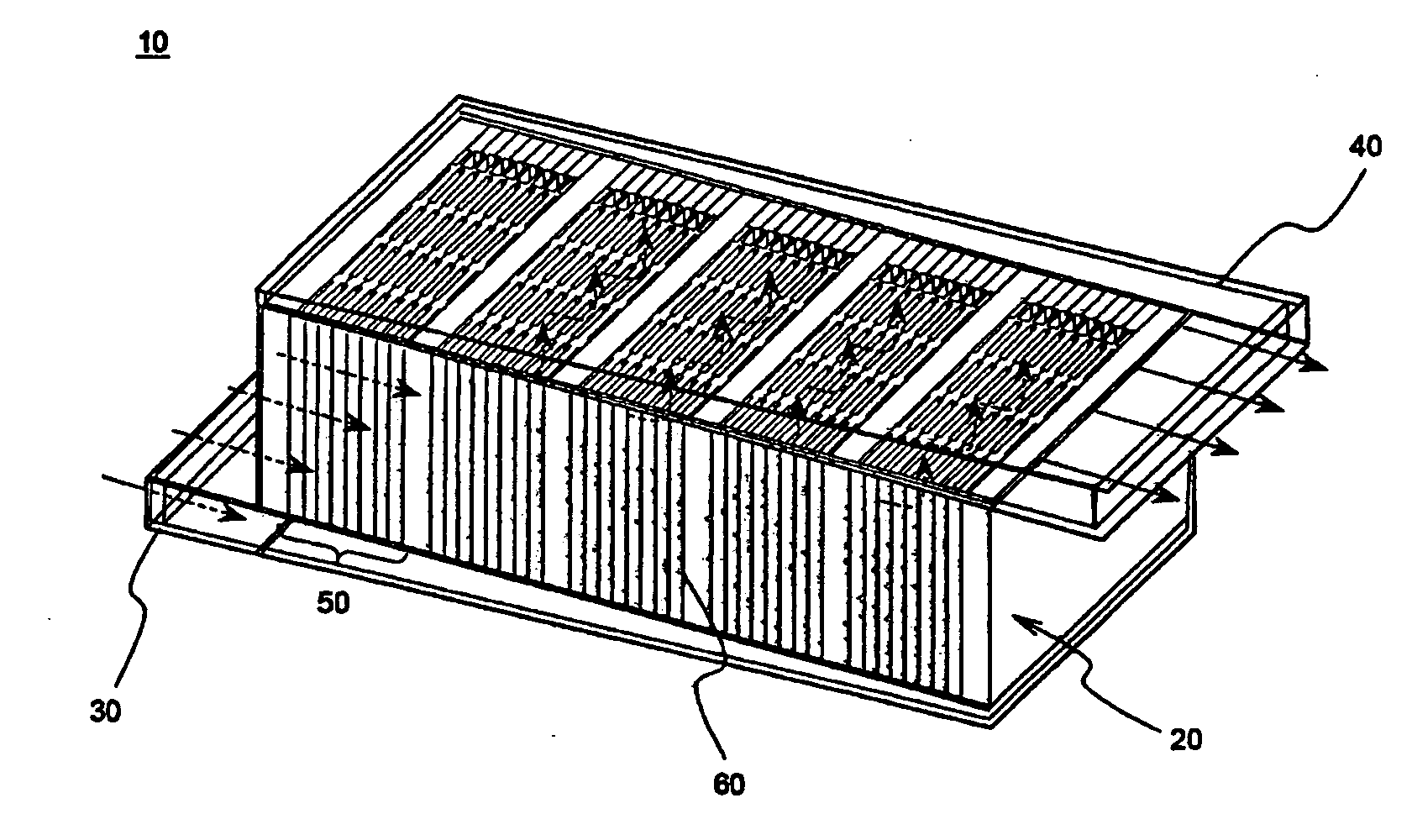

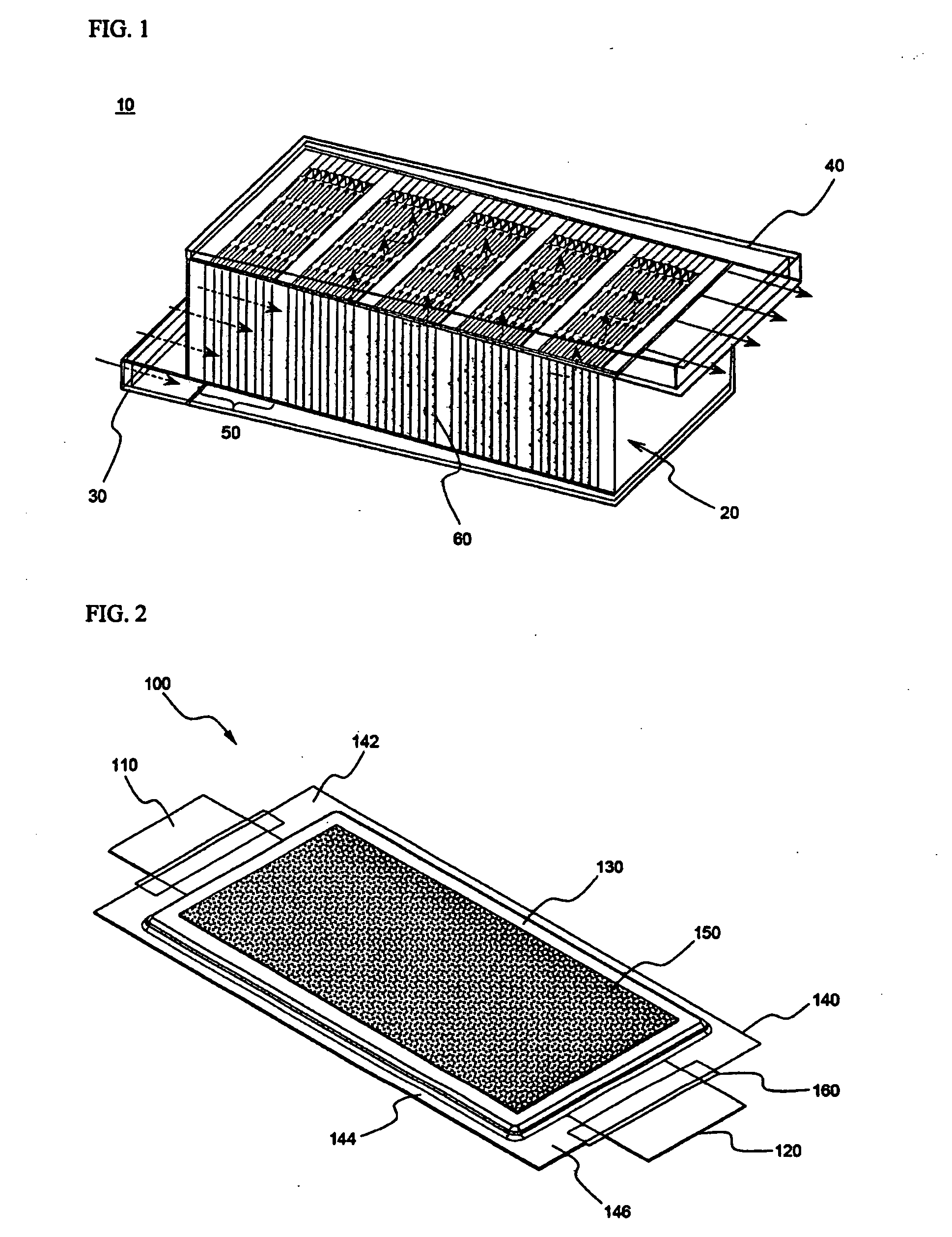

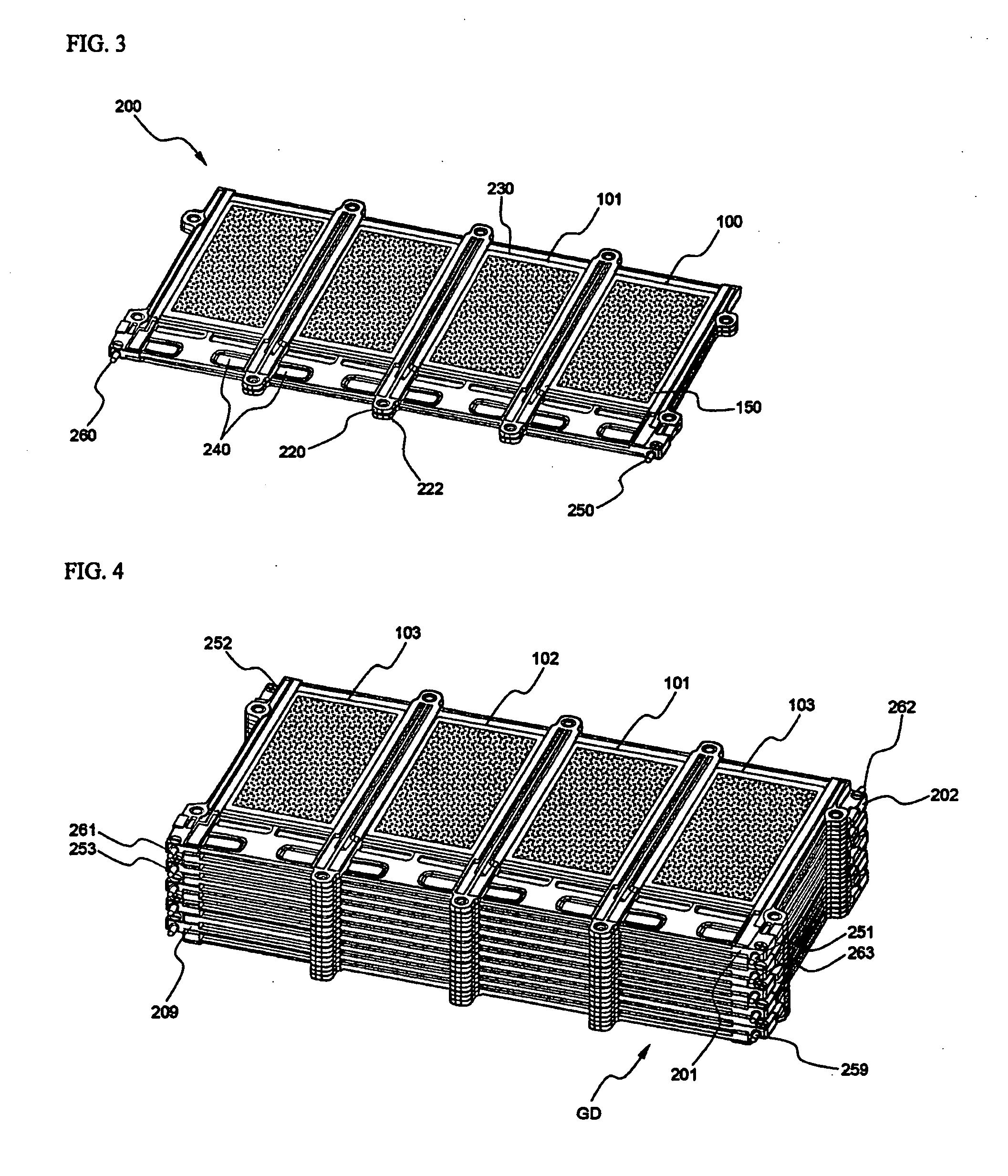

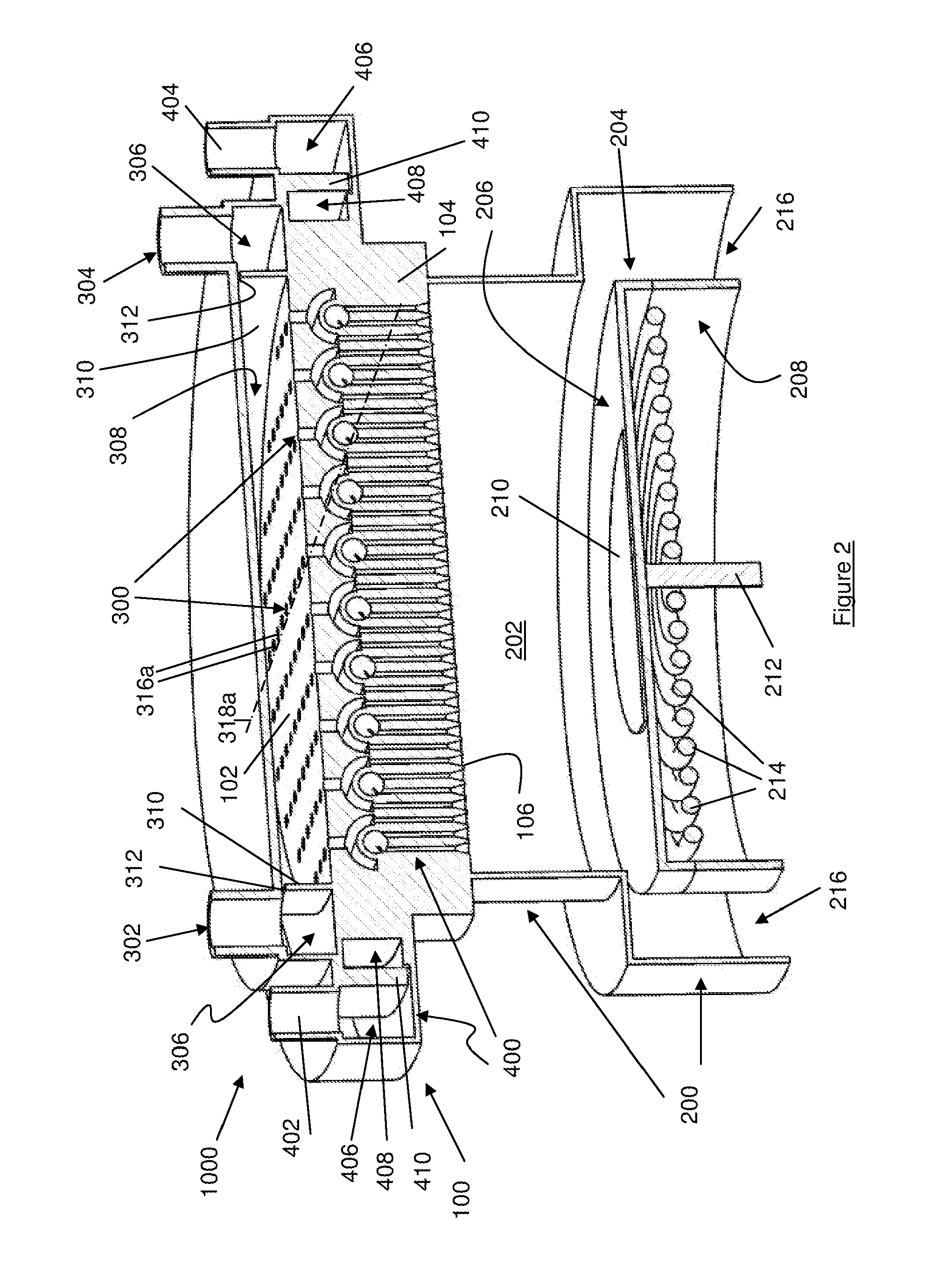

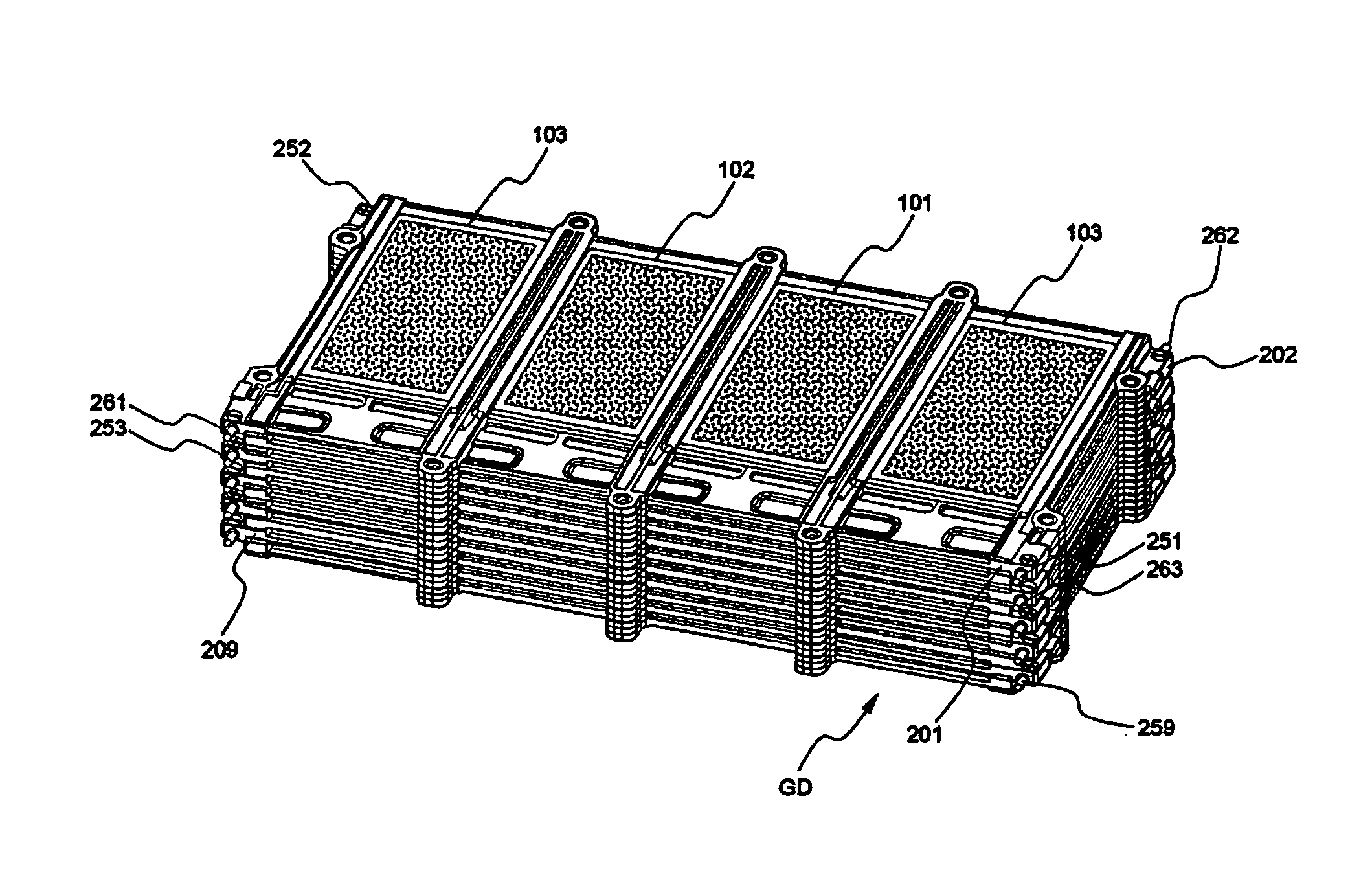

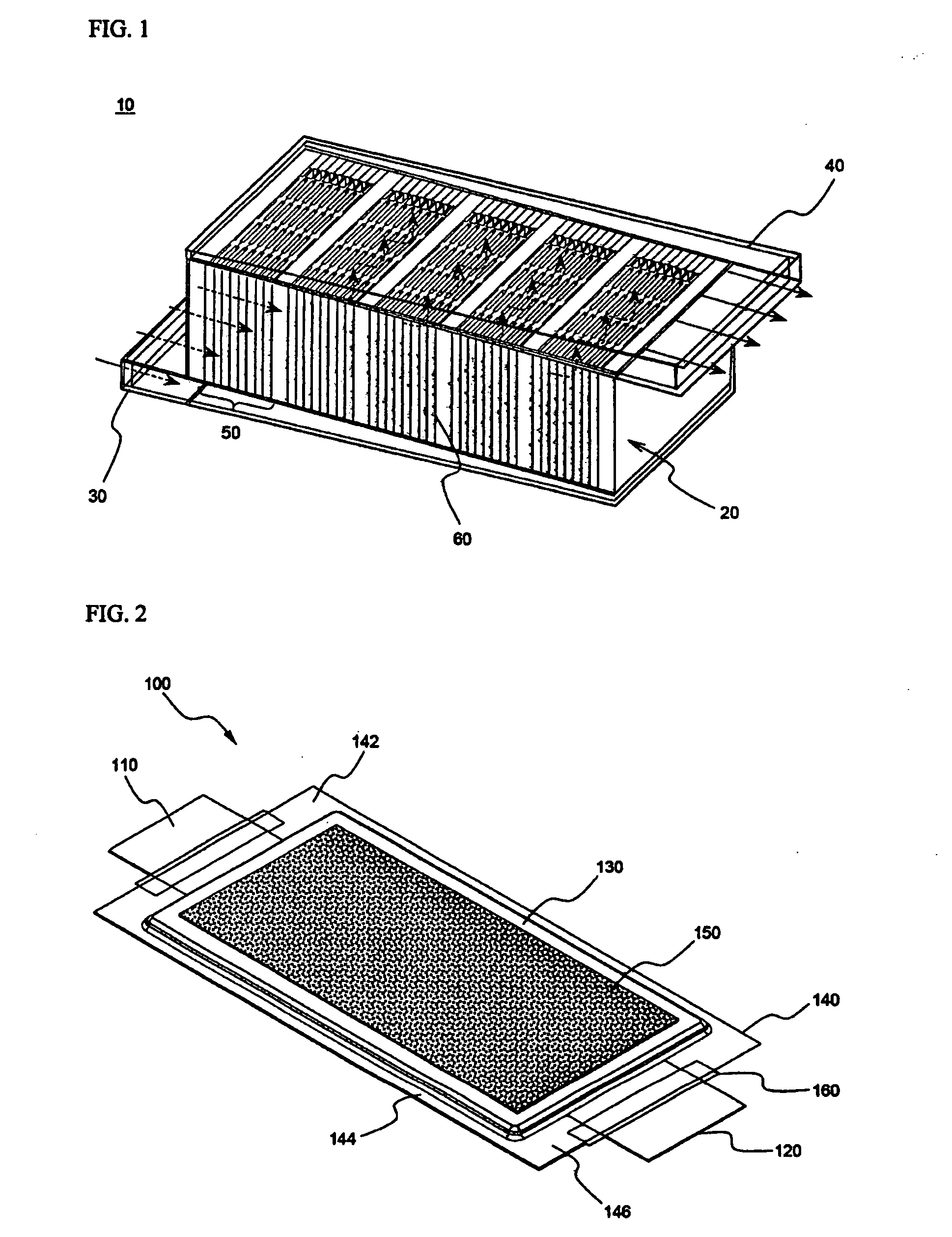

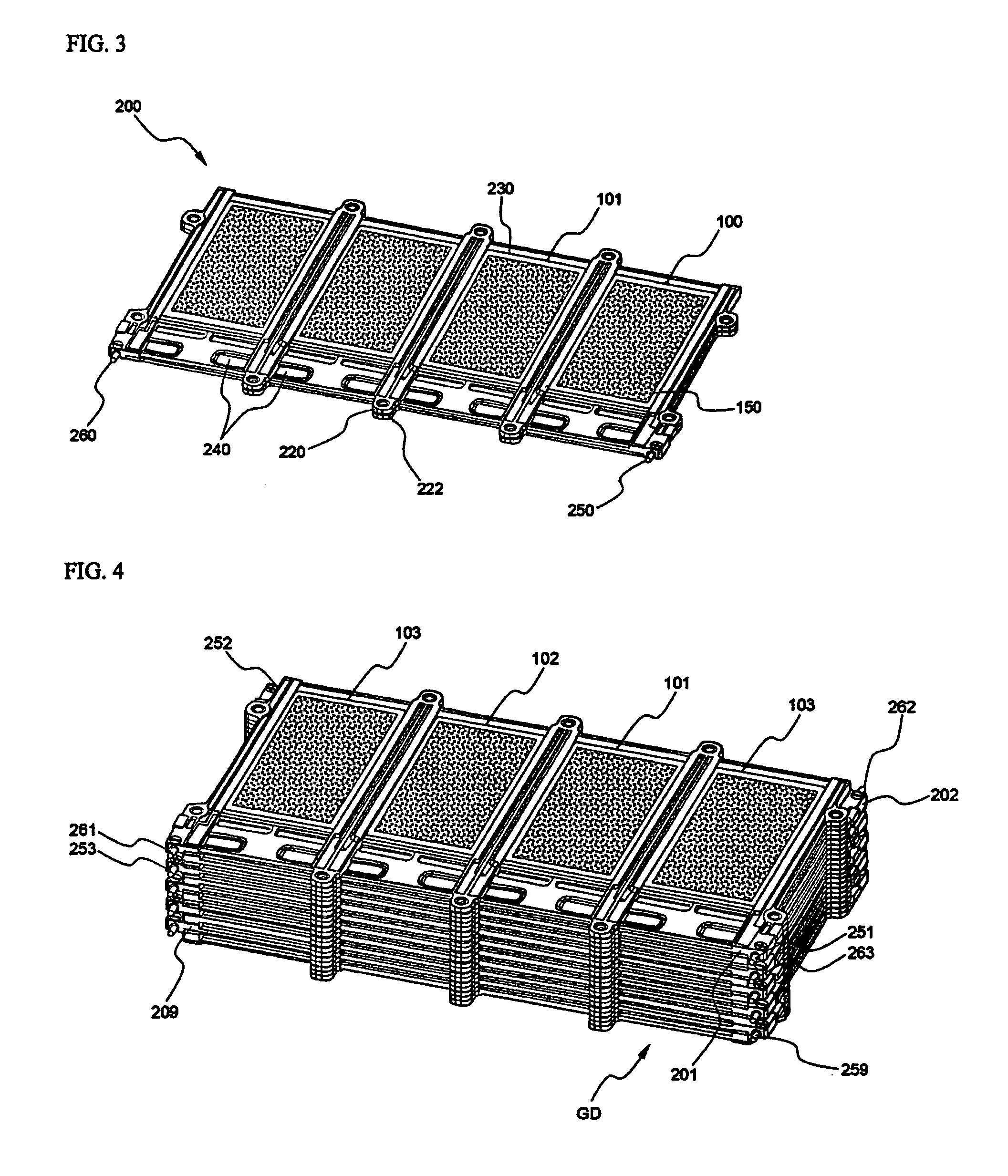

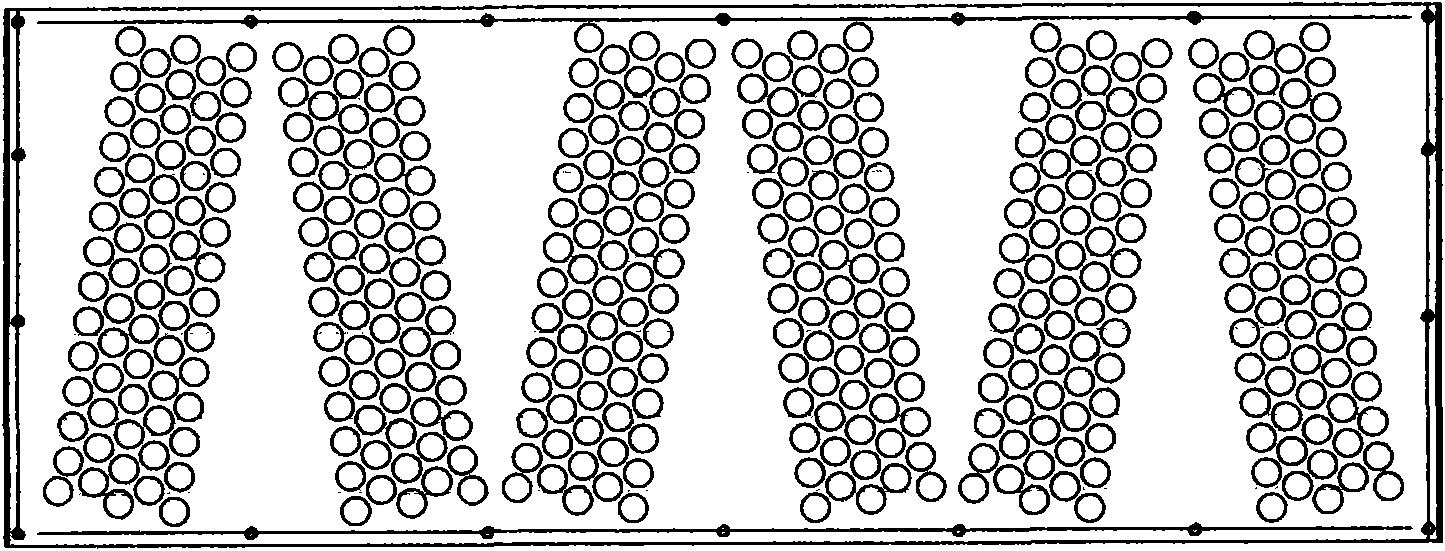

Battery Pack Comprising Combined Temperature-Controlling System

ActiveUS20090305124A1Minimize temperature differenceTemperature controlCell temperature controlBattery isolationForeign matterTemperature control

Disclosed herein is a middle- or large-sized battery pack including a plurality of unit cells electrically connected with each other, wherein the battery pack is constructed in a structure in which a heat transfer medium flows through gaps defined between the unit cells for controlling the overall temperature of the battery pack to be within a predetermined temperature range for the optimum operation of the battery pack, and each unit cell is provided at the outer surface thereof, at which the heat transfer medium is brought into contact with each unit cell, with a layer containing a phase transformation material (‘phase transformation layer’) for minimizing individual temperature difference between the unit cells. The present invention has the effect of controlling the overall temperature of the battery pack and individual controlling the temperatures of unit cells constituting the battery pack. Also, the present invention has the effect of restraining the abrupt change in temperature of the unit cells, when the battery pack is not in operation or when the external environment abruptly changes, thereby preventing the degradation of the unit cells. Furthermore, the present invention has the effect of minimizing damage to the unit cells due to foreign matter when the foreign matter is brought into contact with the unit cells. In addition, the present invention has the effect of reducing the overall temperature difference of the battery pack and manufacturing a middle- or large-sized battery pack having a compact structure.

Owner:LG ENERGY SOLUTION LTD

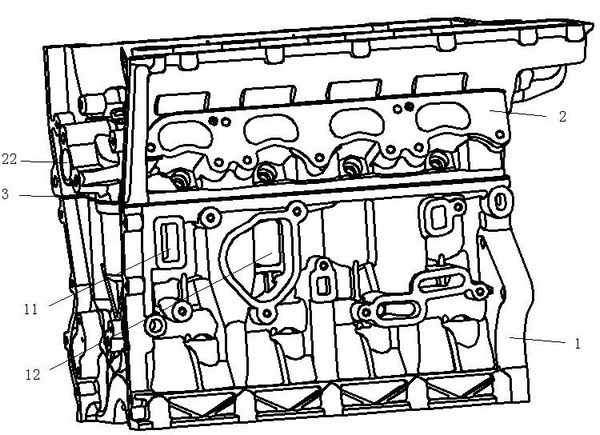

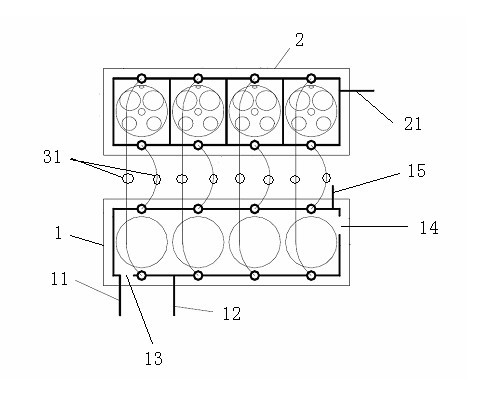

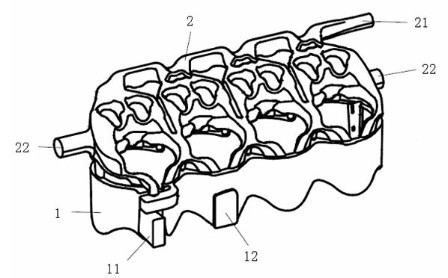

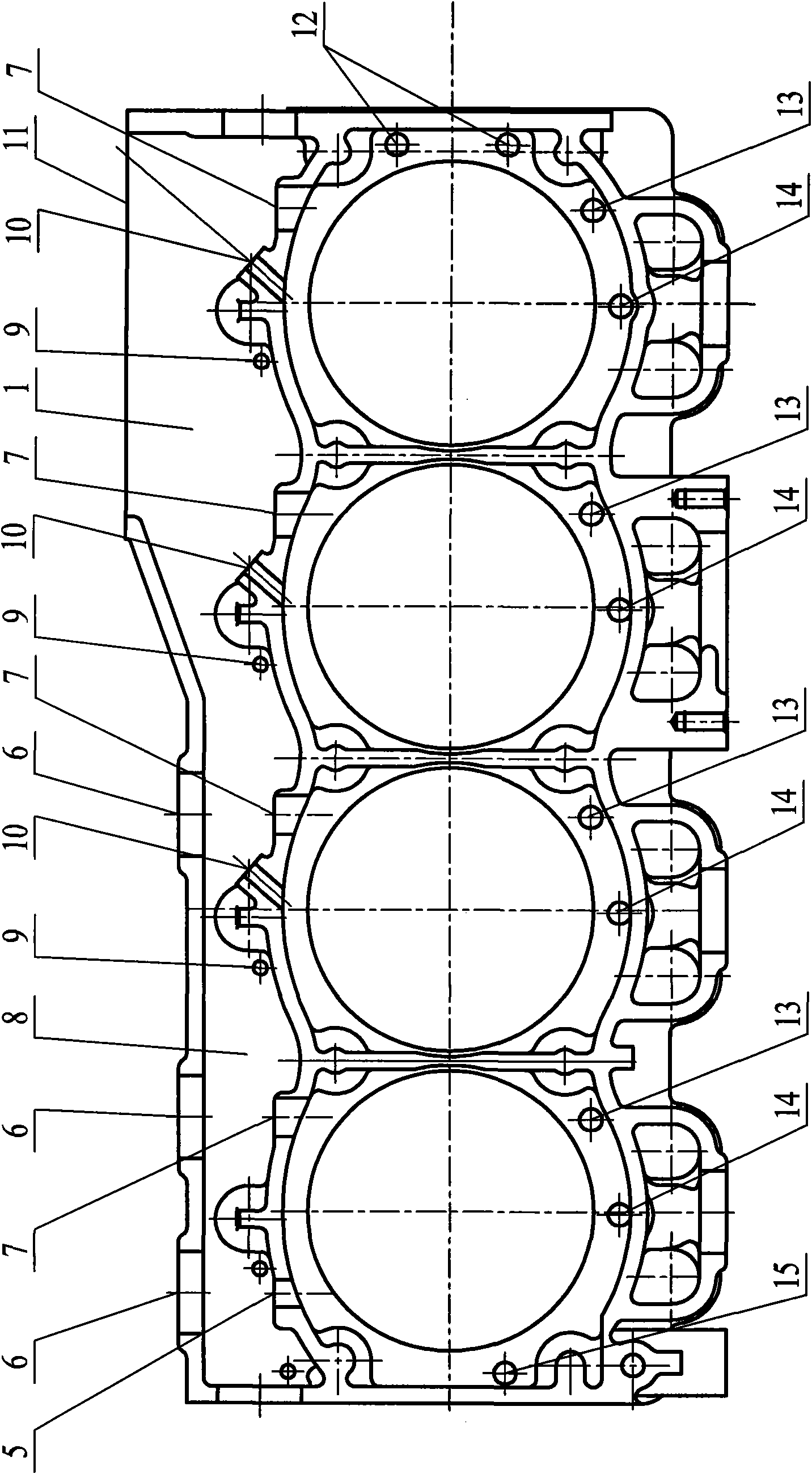

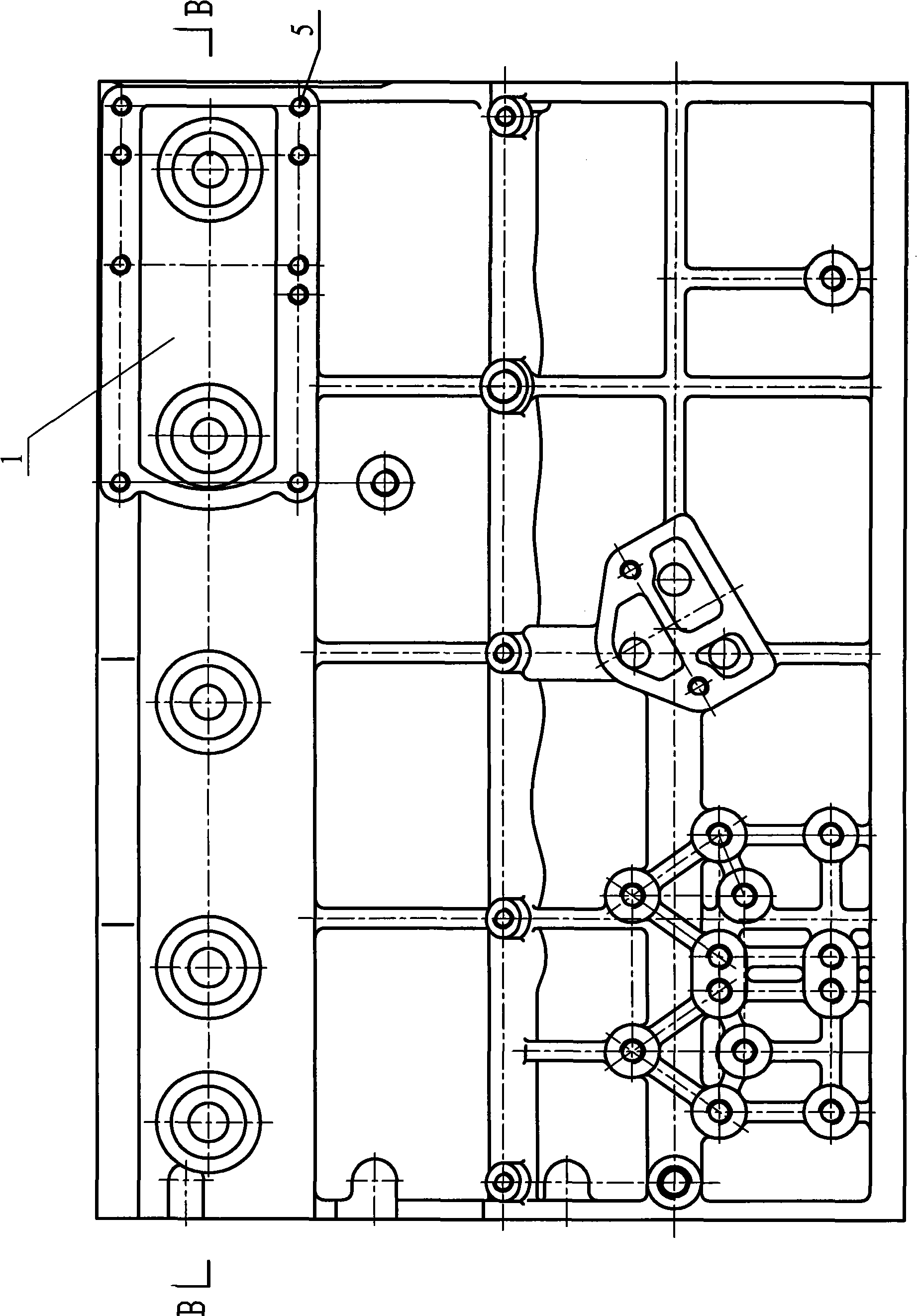

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

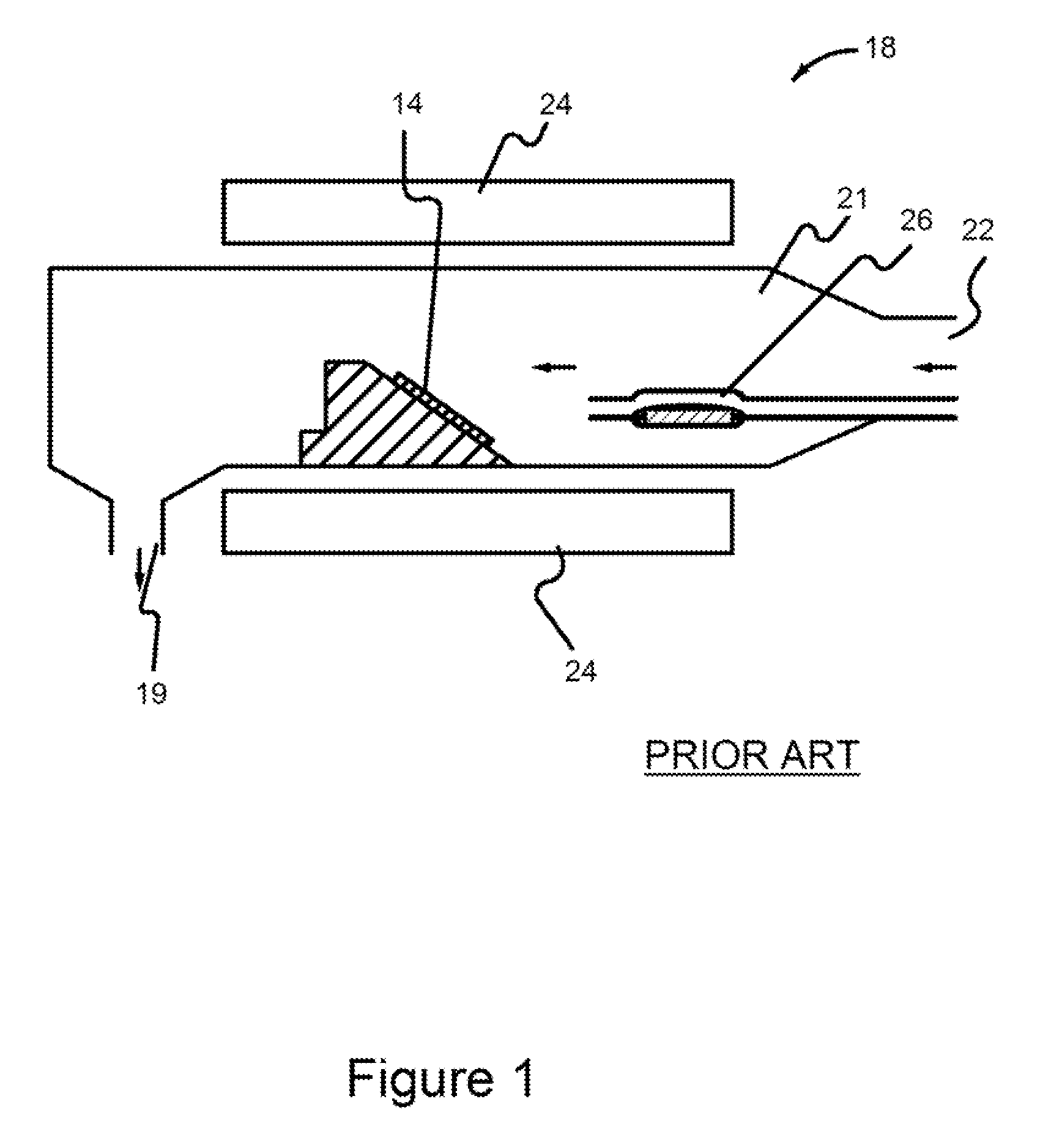

Modern hydride vapor-phase epitaxy system & methods

ActiveUS20110155049A1Uniform flow rateReduce distancePolycrystalline material growthFrom chemically reactive gasesChemical reactionSusceptor

Hydride vapor-phase deposition (HVPE) systems are disclosed. An HVPE hydride vapor-phase deposition system may include a reactant source chamber and a growth chamber containing a susceptor coupled to the reactant source chamber. The reactant source chamber may be configured to create a reactant gas through a chemical reaction between a solid or liquid precursor and a different precursor gas. The reactant source chamber can be configured to operate at a temperature T(M) significantly above room temperature. The reactant gas can be chemically unstable at or near room temperature. The susceptor is configured to receive a substrate and maintain the substrate at a substrate temperature T(S). The growth chamber includes walls can be configured to operate at a temperature T(C) such that T(M), T(S) are greater than T(C).

Owner:CBL TECH

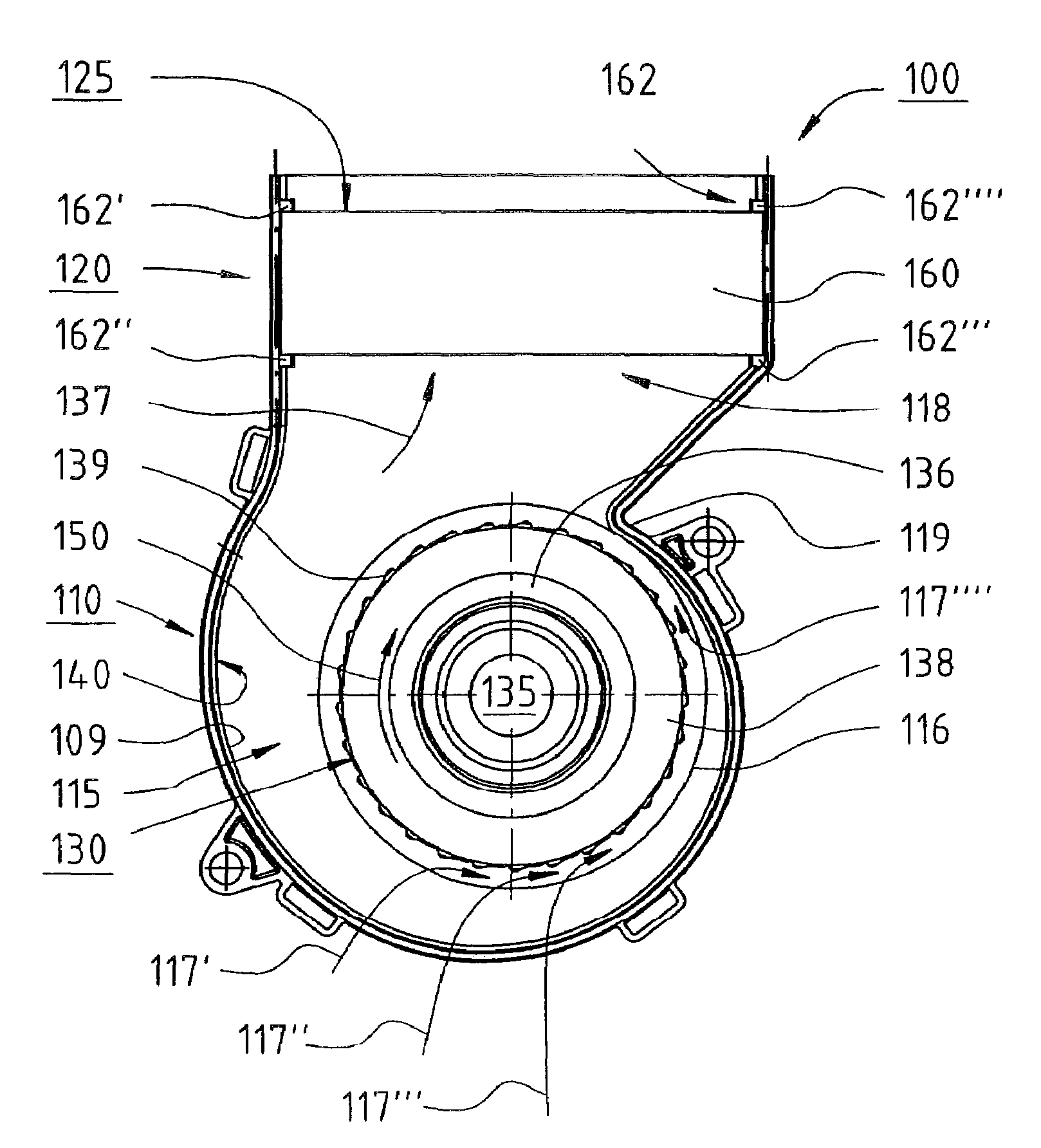

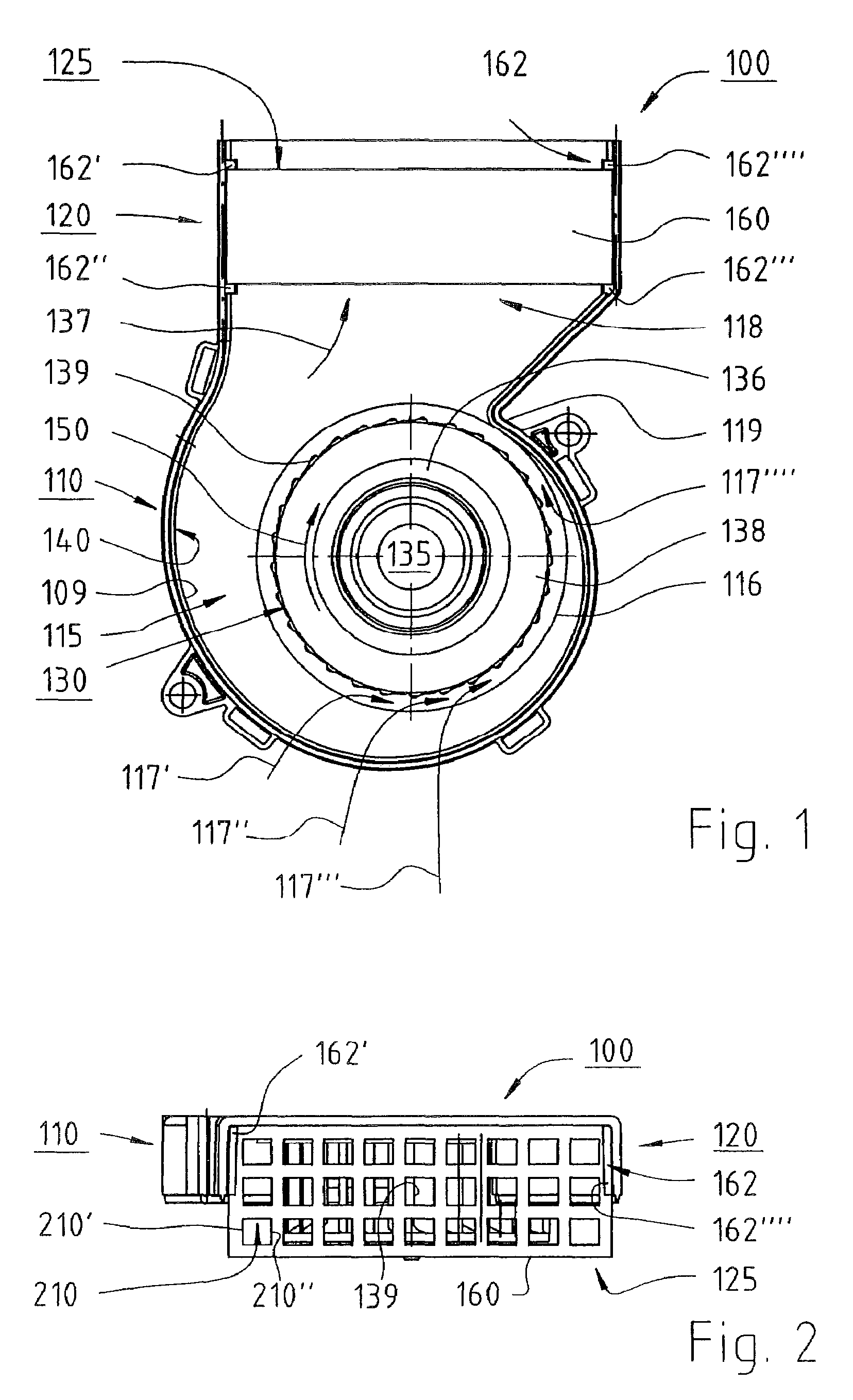

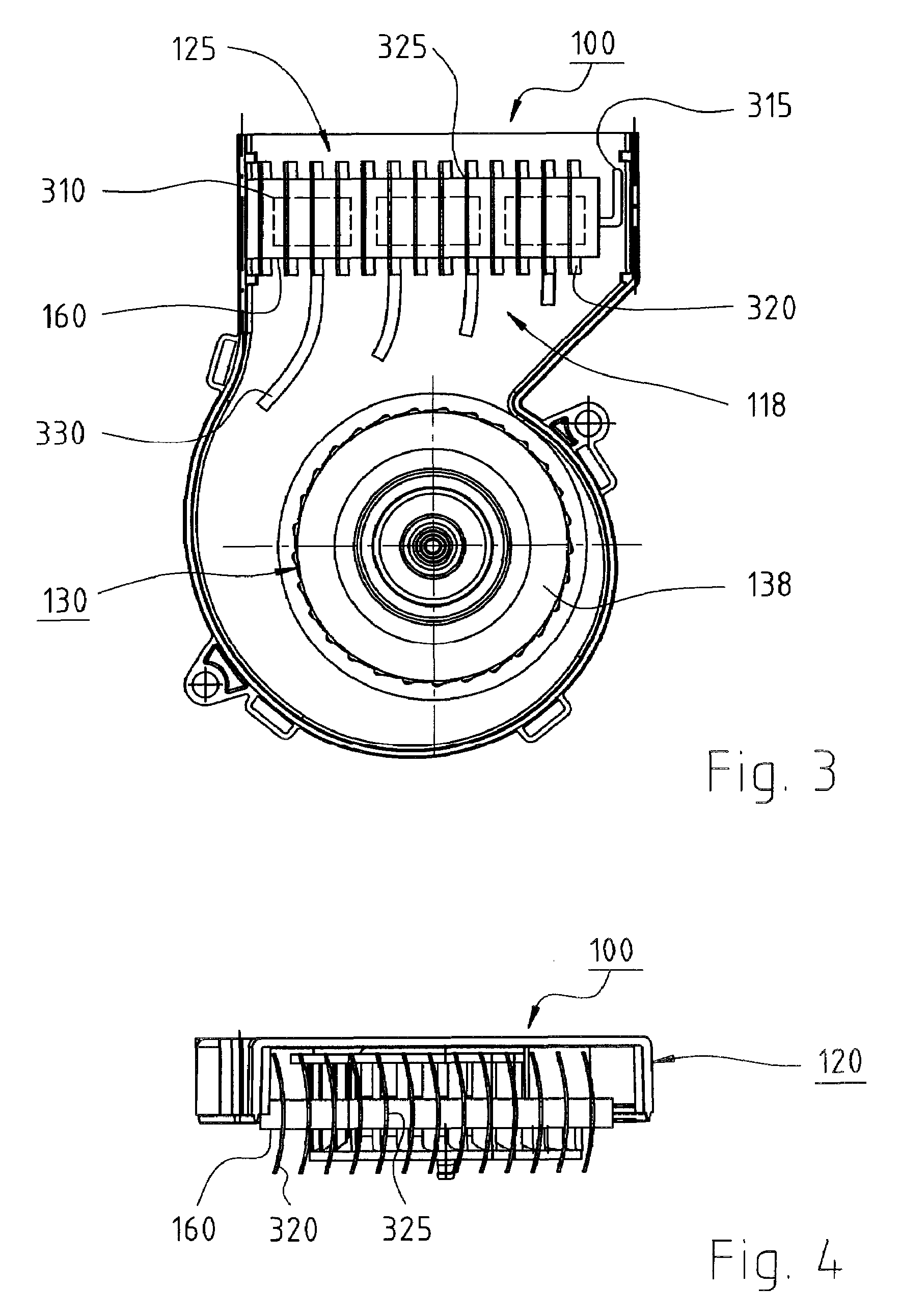

Heating unit

ActiveUS7355146B2Improve uniformityPhysically compactAir-treating devicesRailway heating/coolingImpellerEngineering

A heating unit for a vehicle features a radial fan (100) having a housing (110), which housing has an air inlet (116) and an air exit opening (118). The heating unit has an air-directing device (140) that guides an air flow in a pressure chamber (115) of the housing (110) to the exit opening (118). Arranged in the housing (110) is a radial fan wheel (130) that serves to generate a flow from the air inlet (116) via the pressure chamber (115) to the air exit opening (118). Also provided is an electrical heating element, e.g. a PTC (Positive Temperature Coefficient) heating element (125), that serves to transfer heat to the air flow generated by the fan. Air-directing elements (632, 634, 636, 638) are provided between the exit opening (118) and the heating element (125), in order to generate an air flow having a more uniform (680) velocity distribution.

Owner:EBM PAPST ST GEORGEN & -

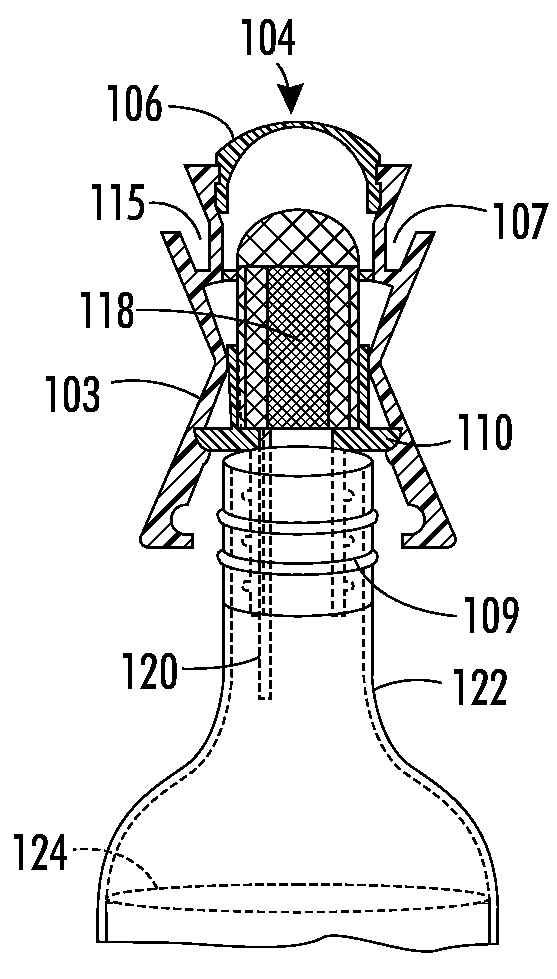

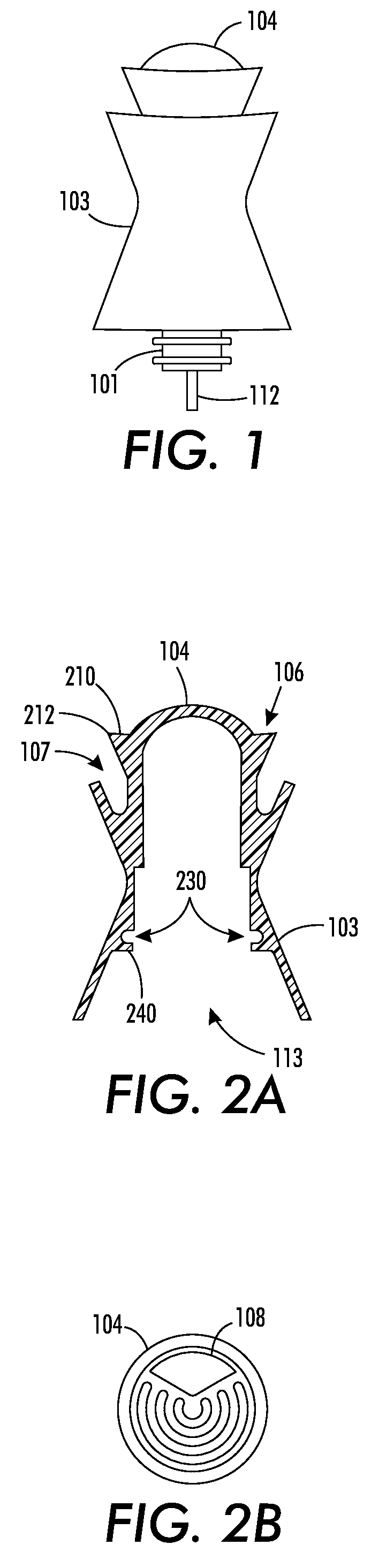

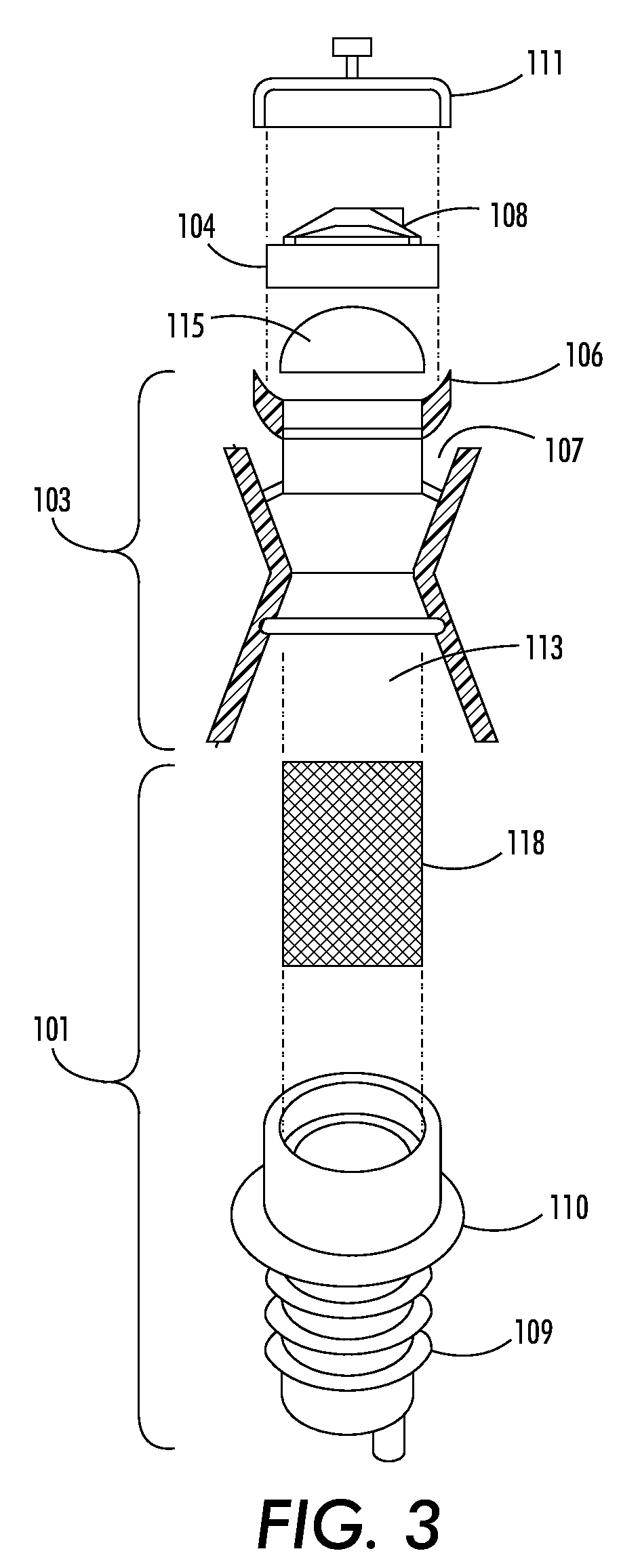

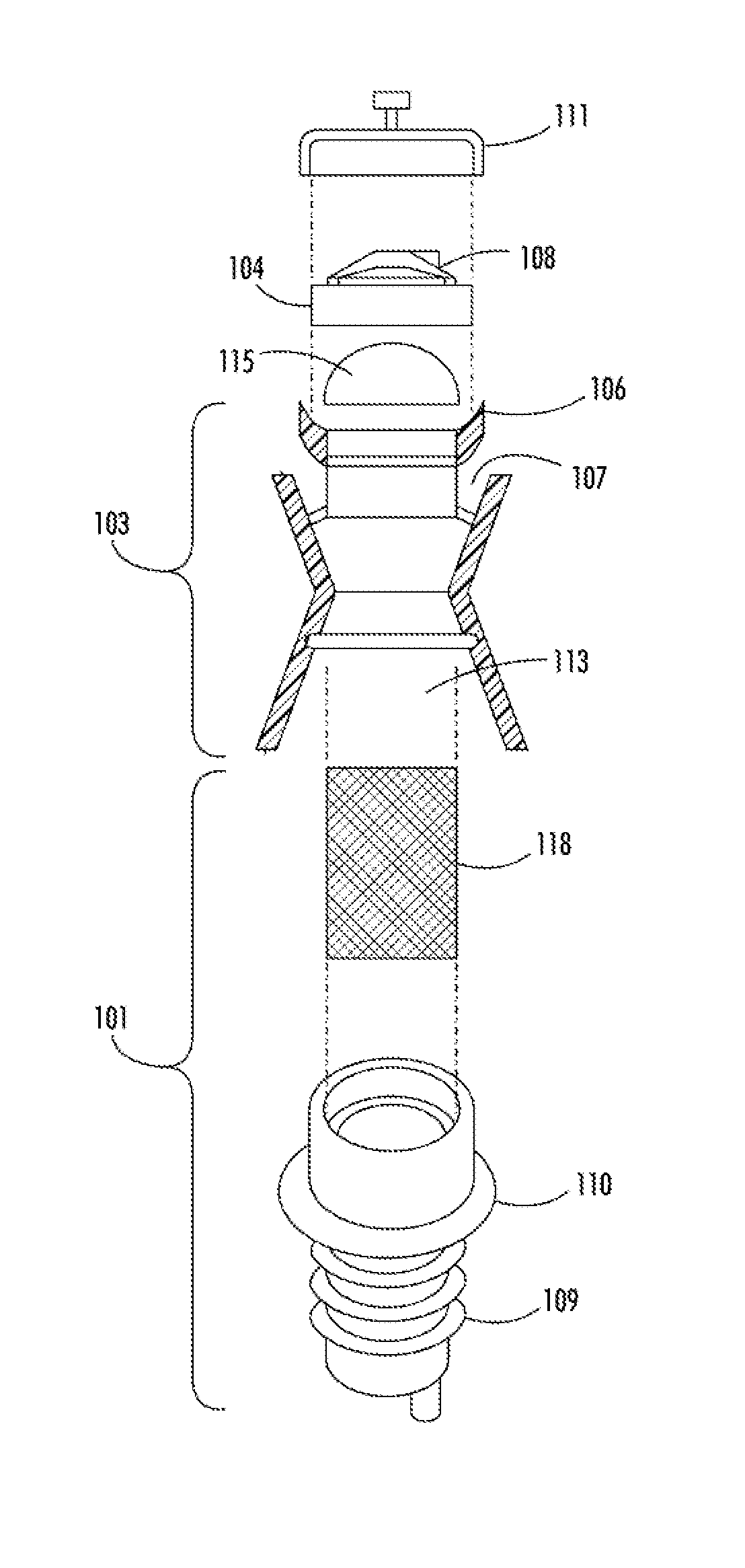

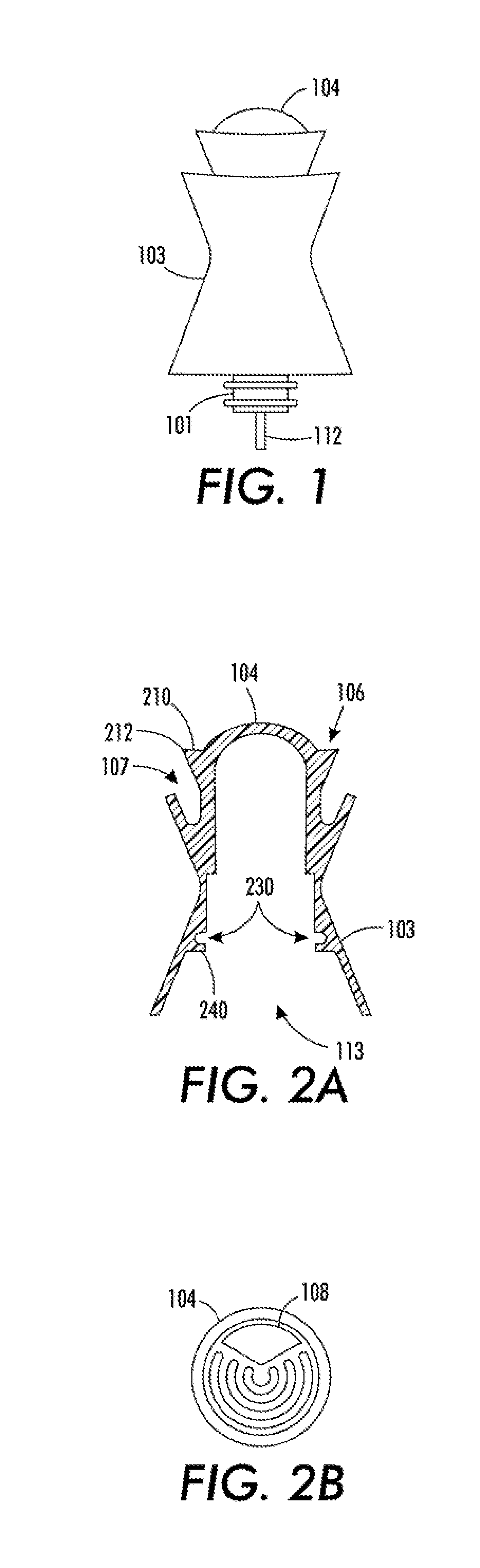

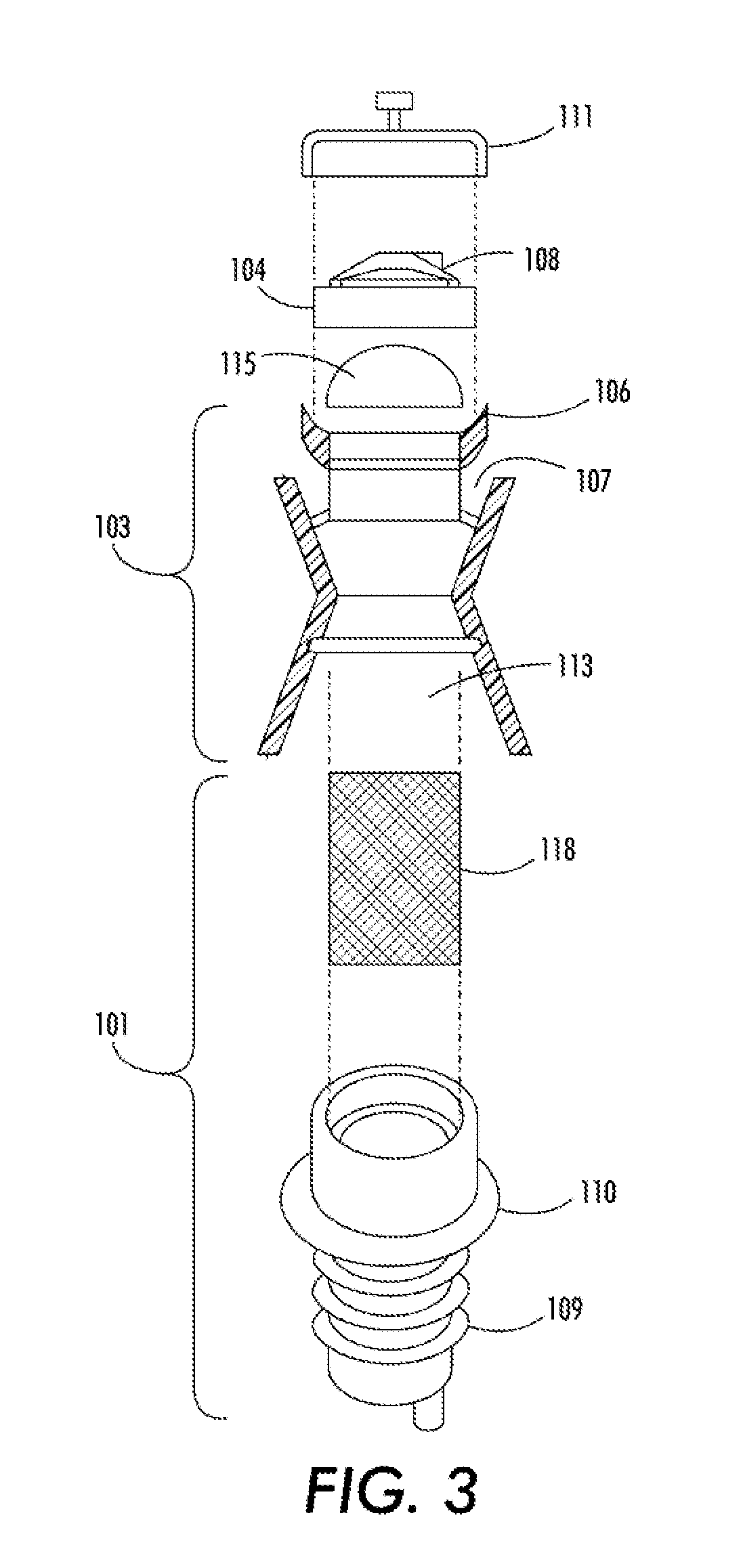

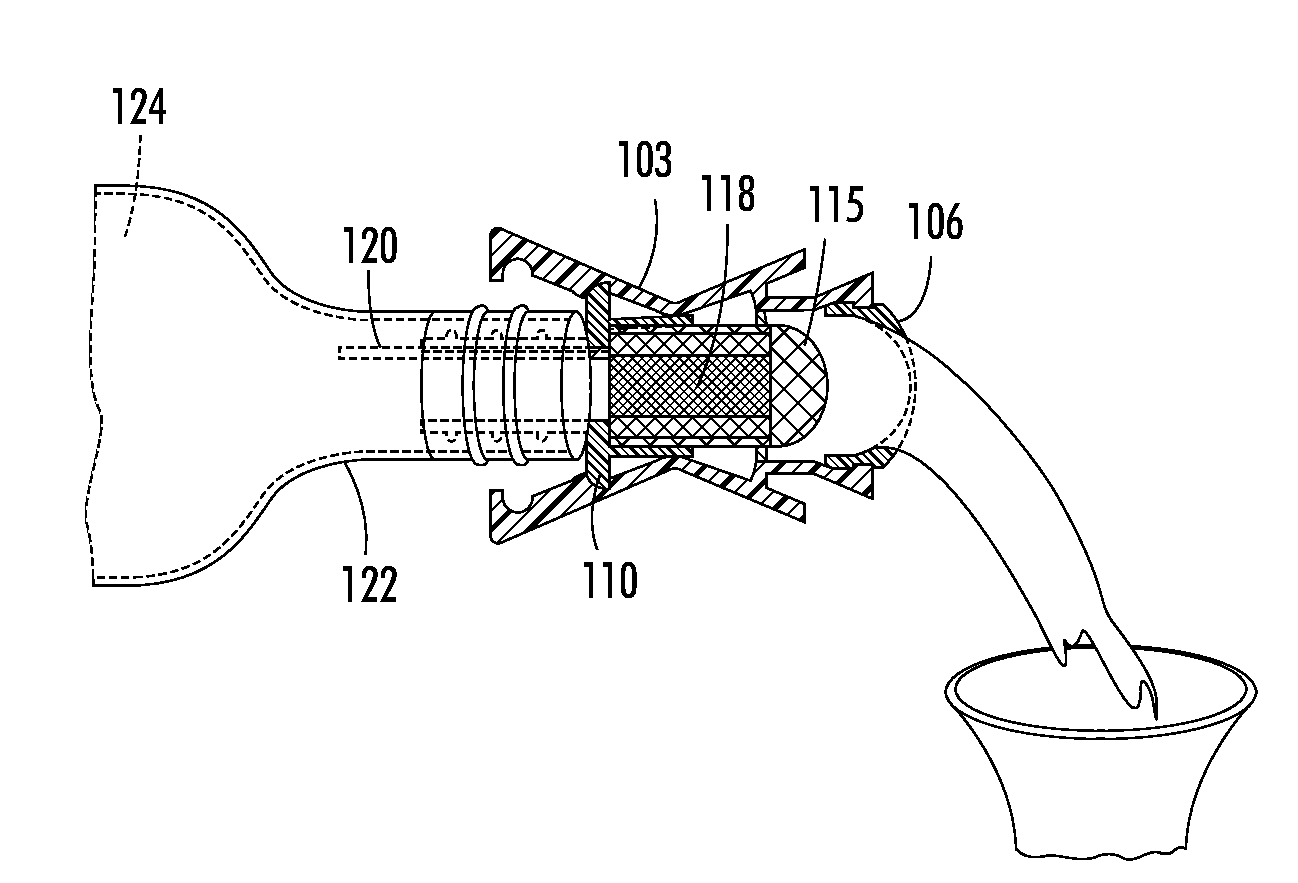

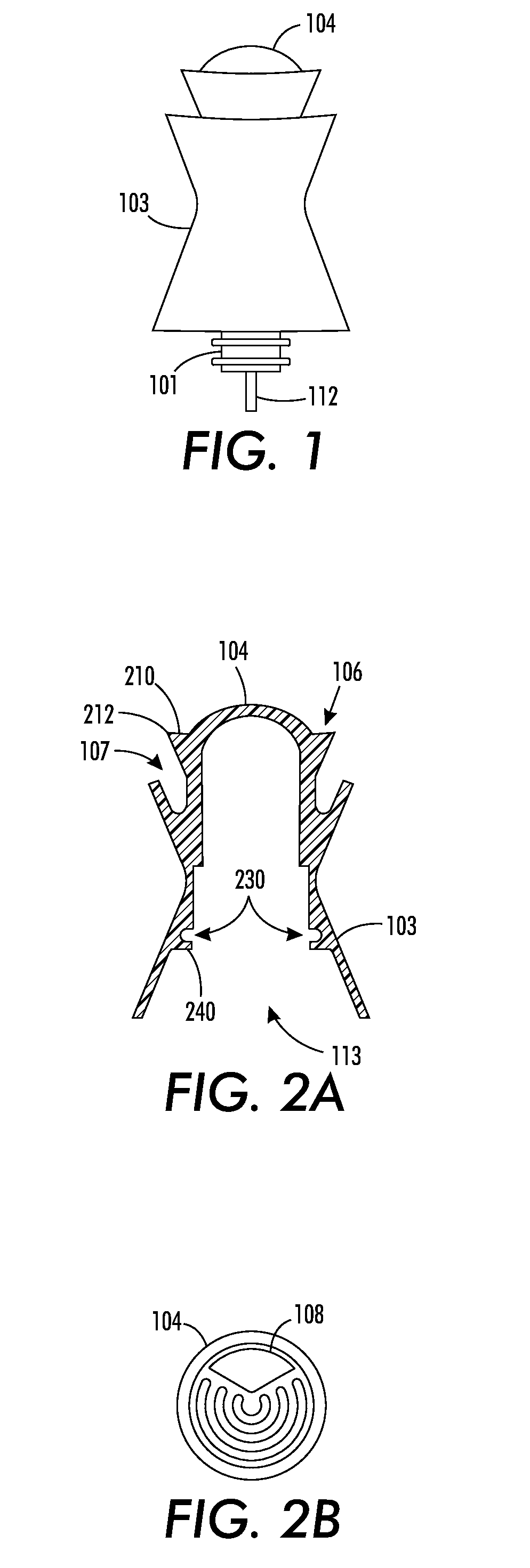

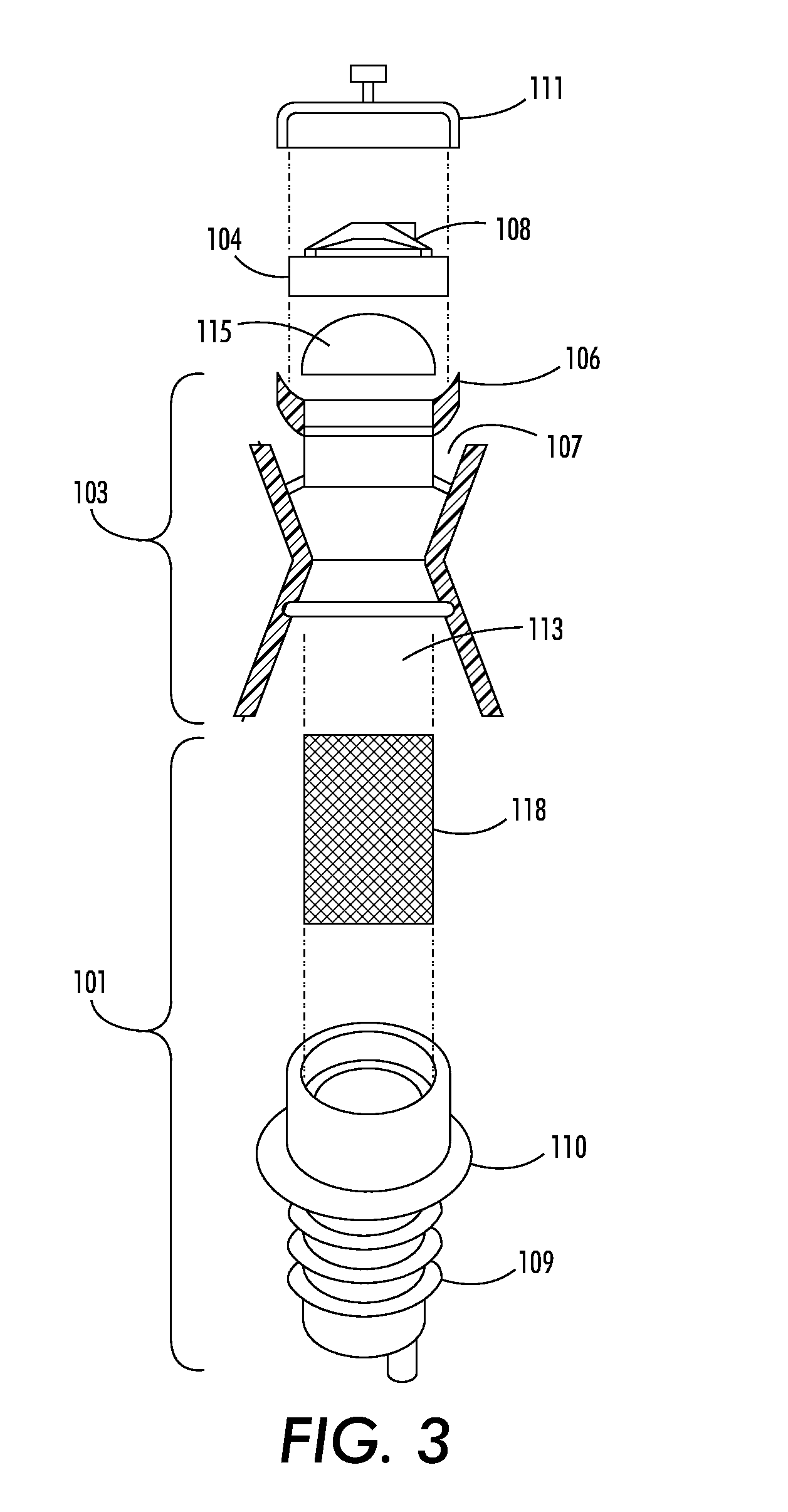

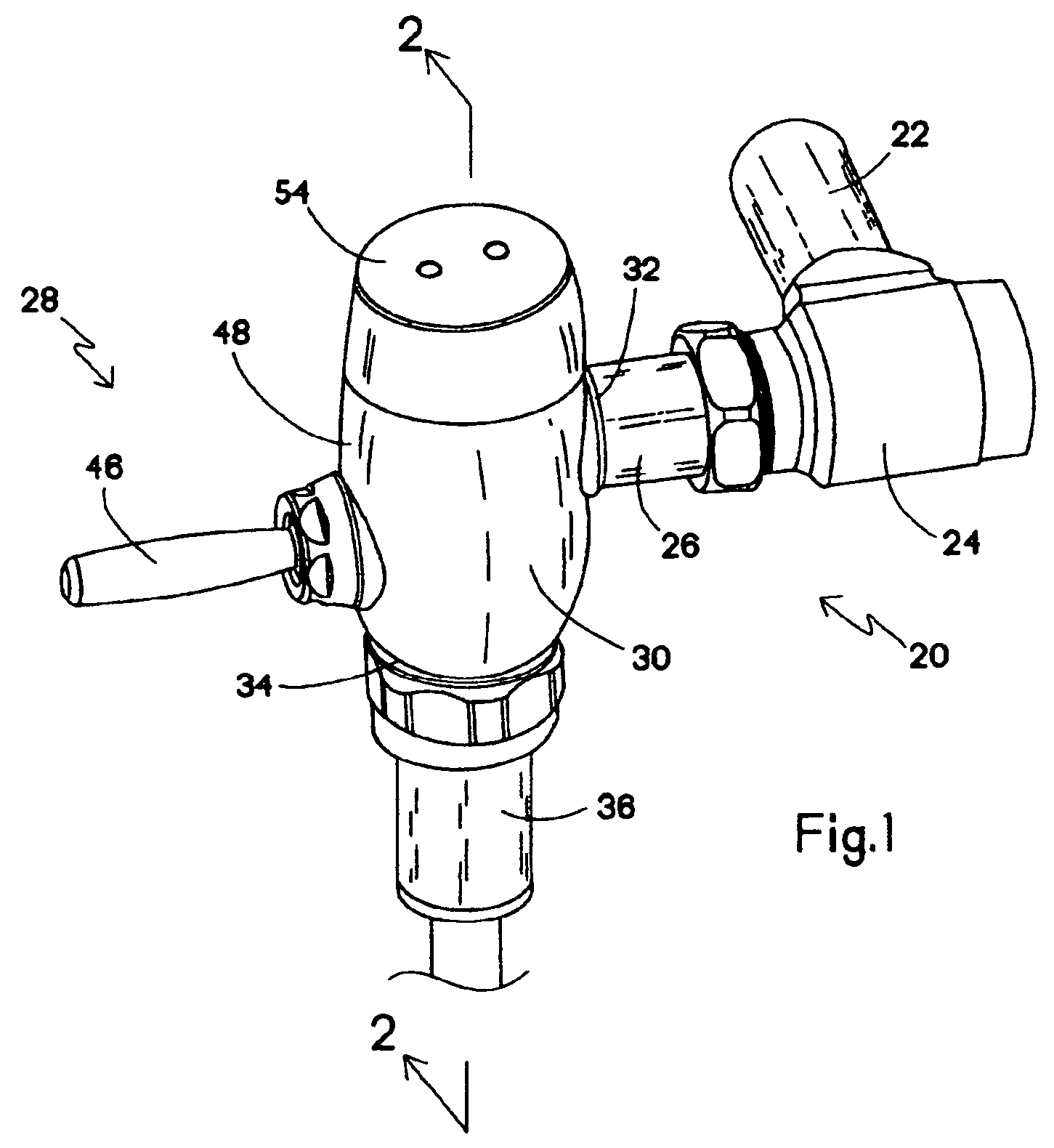

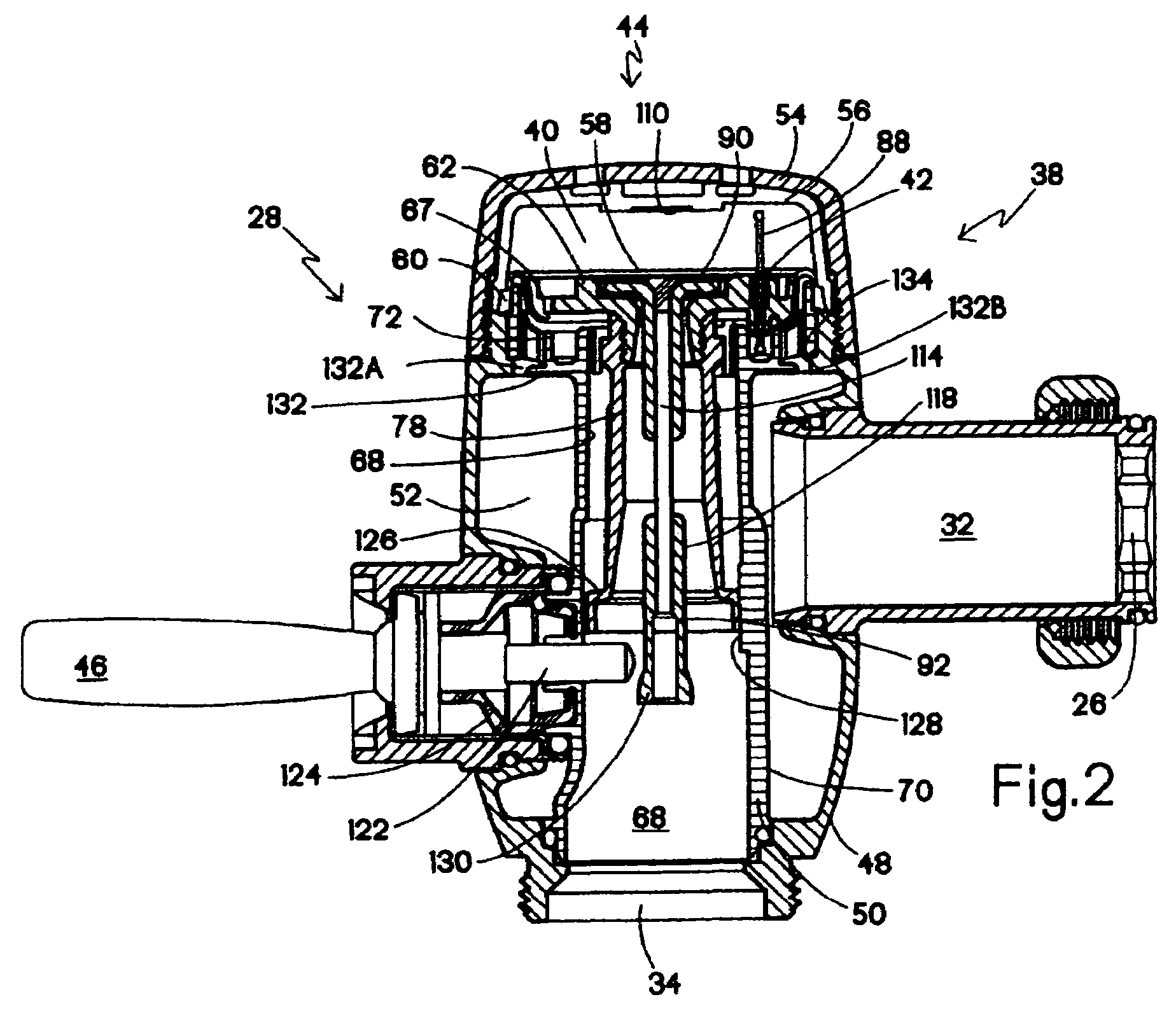

Wine pouring regulator and aerator therein

A bottle top regulator / aerator for controlling the flow from a bottle having a narrow cylindrical opening through which wine or similar liquid may be poured. The dispensing apparatus includes, in combination, an air inductor, a regulating cartridge having a percolation labyrinth, and an anti-drip trough integrated within a housing. The application of this apparatus provides for both the rapid aeration of the wine, as well as a uniform flow rate absent the hazard of post-pouring droplets.

Owner:BARBERIO JANET +1

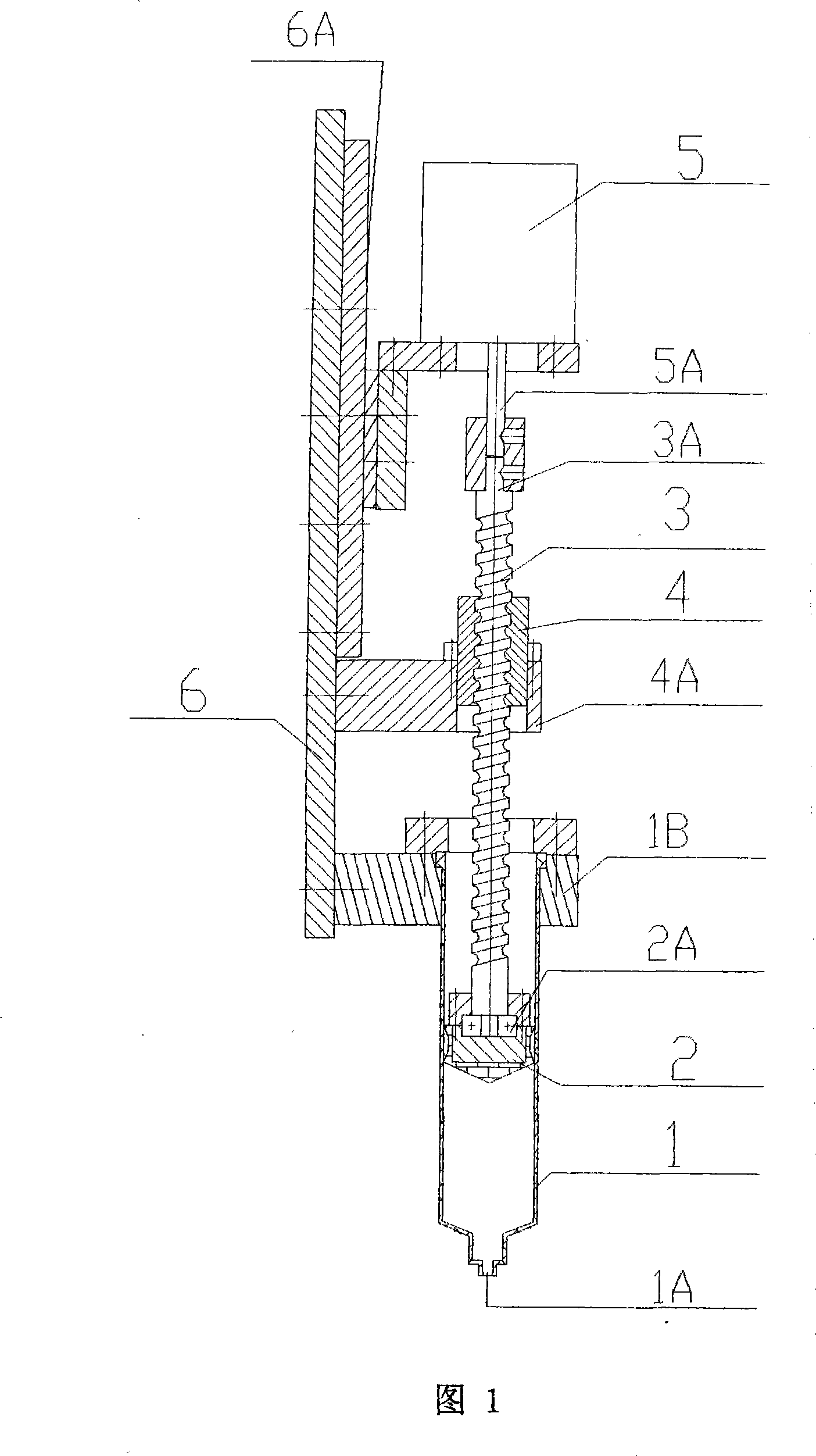

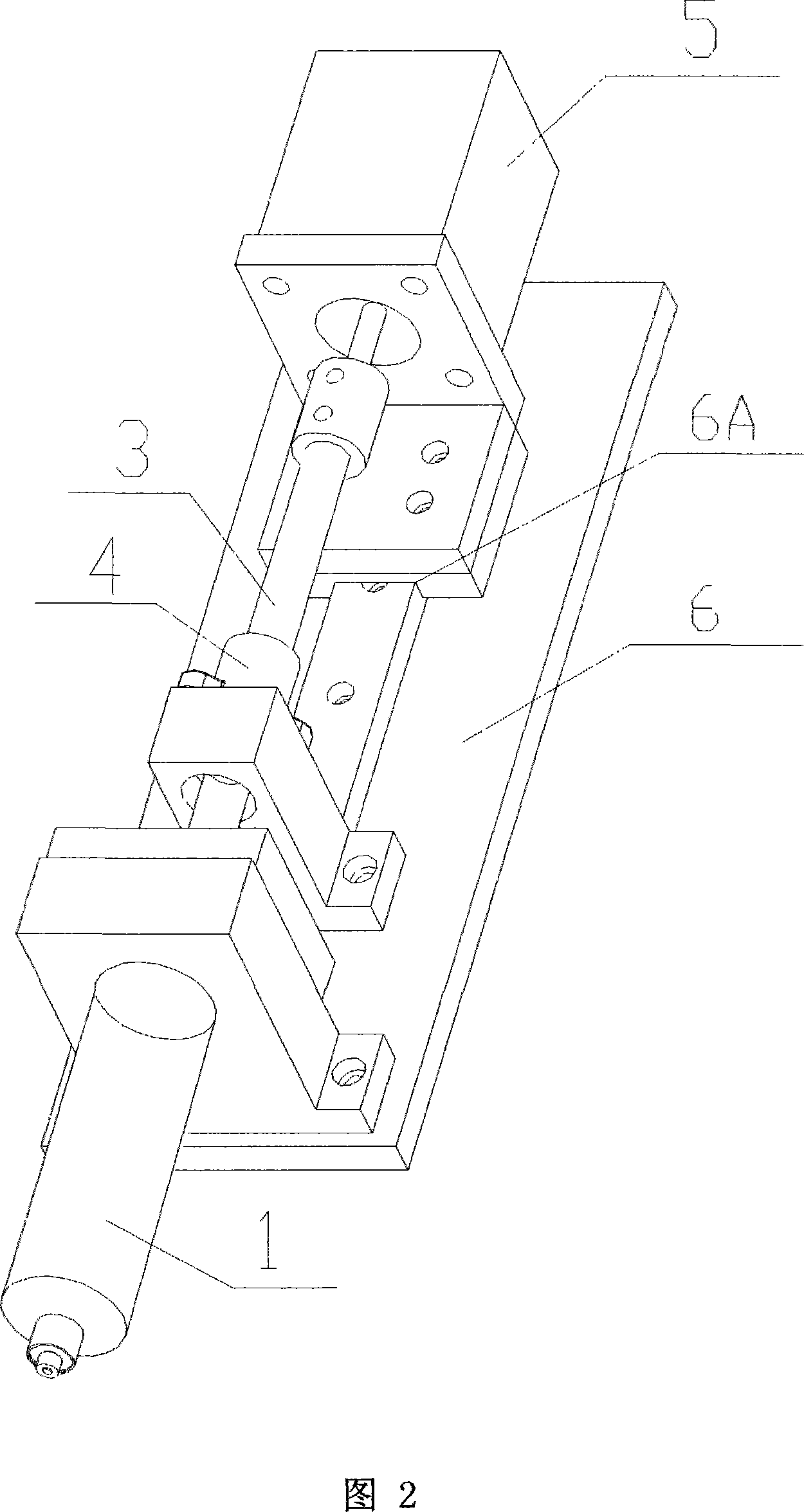

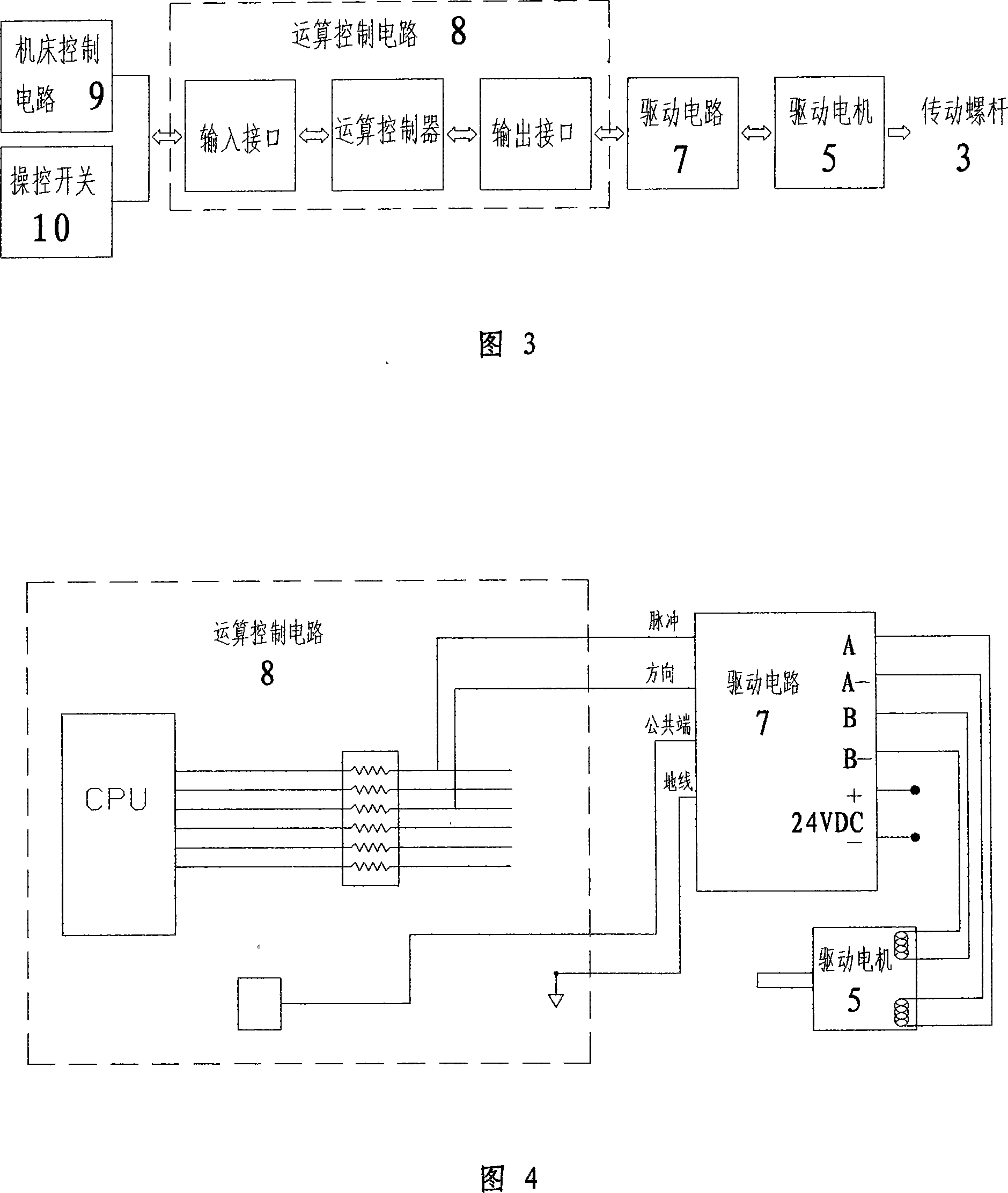

Electric point gum machine and working way thereof

InactiveCN101224454AIncrease forceFast injectionLiquid surface applicatorsCoatingsAxial displacementMotor drive

The invention discloses a motor adhesive injecting device and an operating mode thereof. The device comprises a shooting cylinder which is provided with an outlet at the bottom, a pressure ram arranged inside the shooting cylinder, a drive screw connected with the upper part of the pressure ram, a fixing screw used together with the drive screw and a drive motor arranged on top of the drive screw. The rotation of a motor drives the screw to make the spiral movement inside the nut and drives a piston to have the axial displacement to act on the liquid. The operating mode is that the rotating axle of the motor is controlled to continuously rotate, discontinuously rotate, impulse rotate or reverse the axle to drive the piston to move up and down or vibrate correspondingly to the cylinder. With excellent response, the motor can control the injection rate accurately by the controlling the rotating angle. The motor can satisfy the requirements for accurate and rapid adhesive injecting for the constant running speed and uniform flowing speed of the liquid.

Owner:PRECISION TECH DEV SHENZHEN

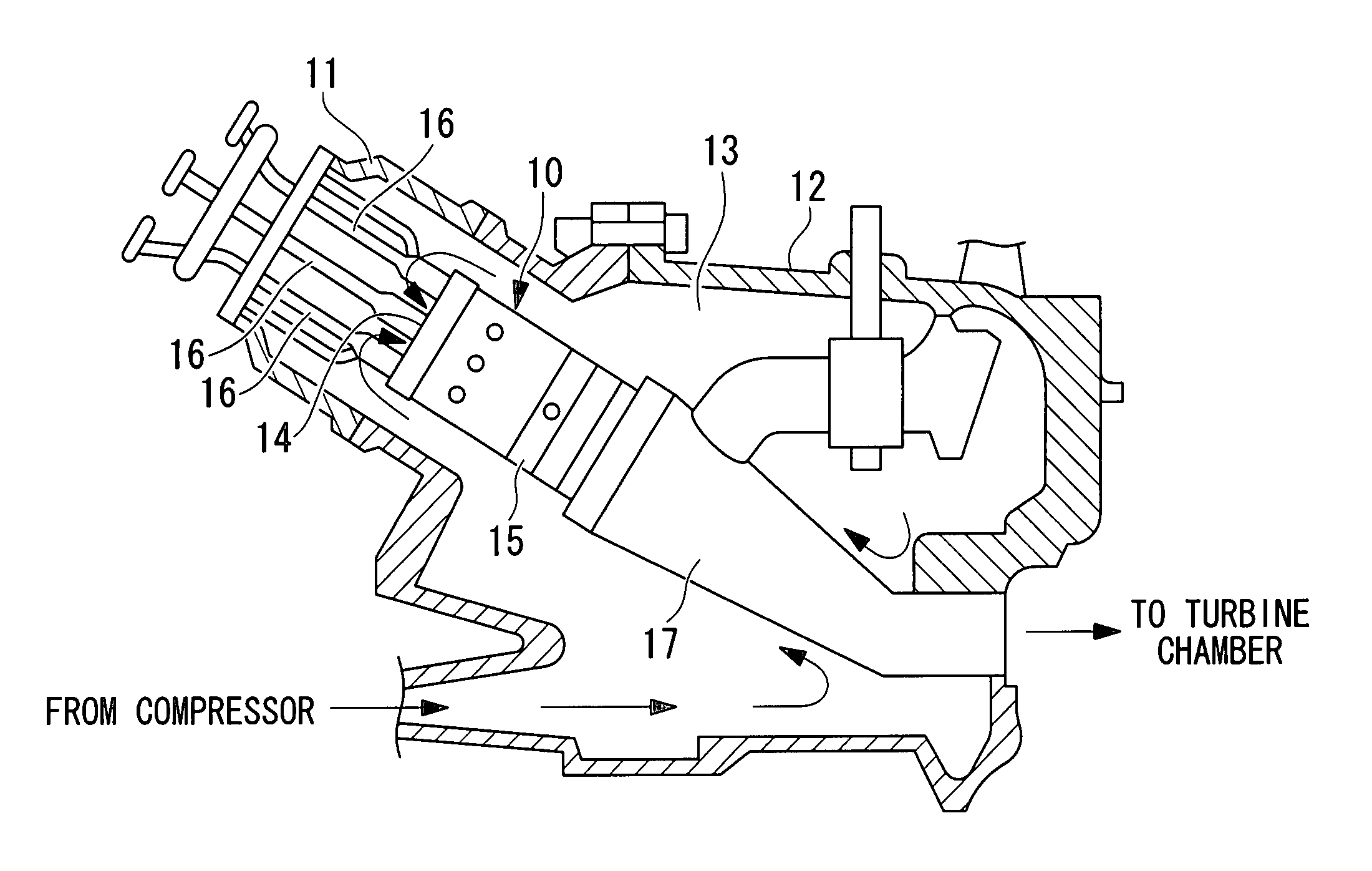

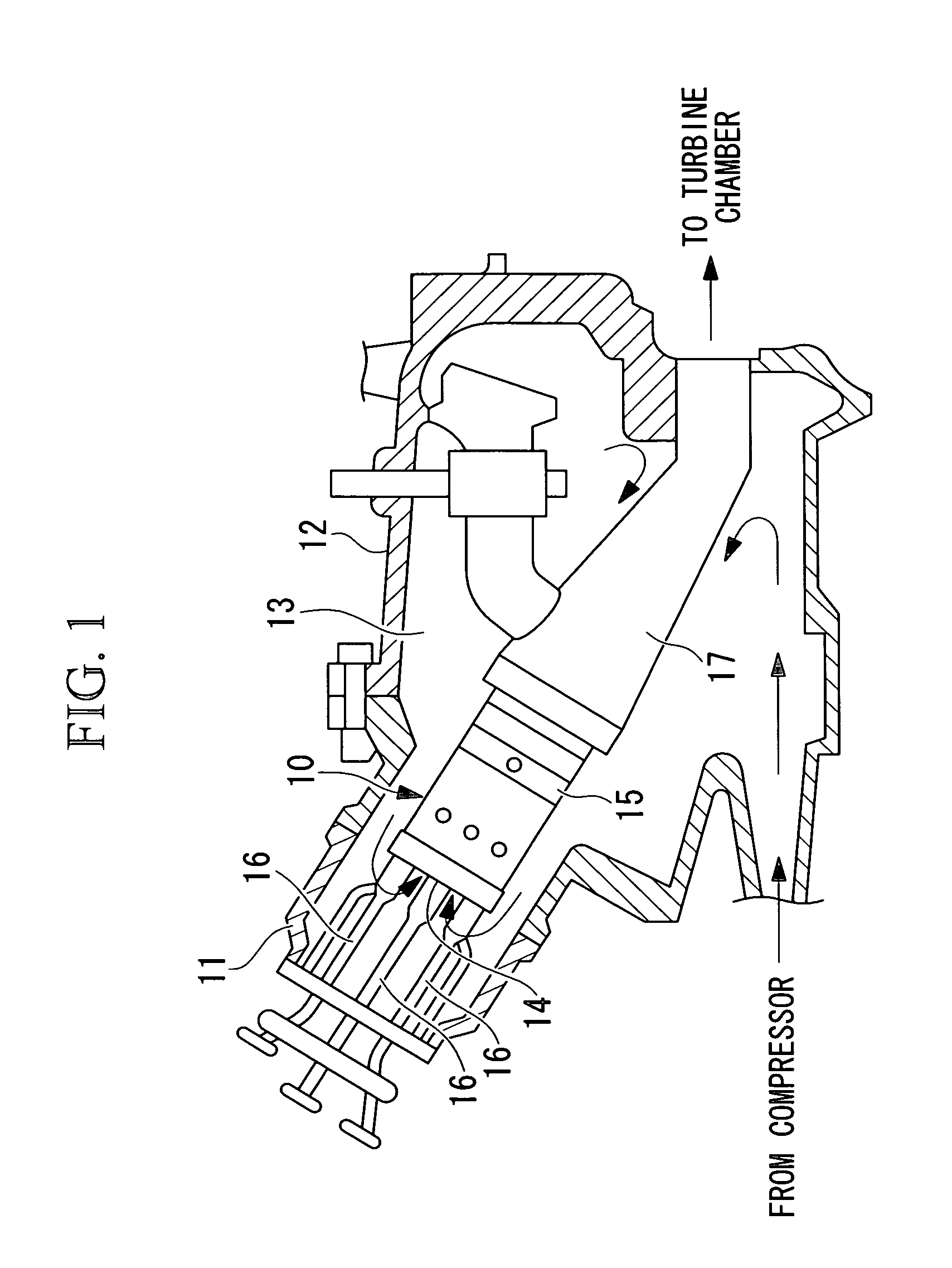

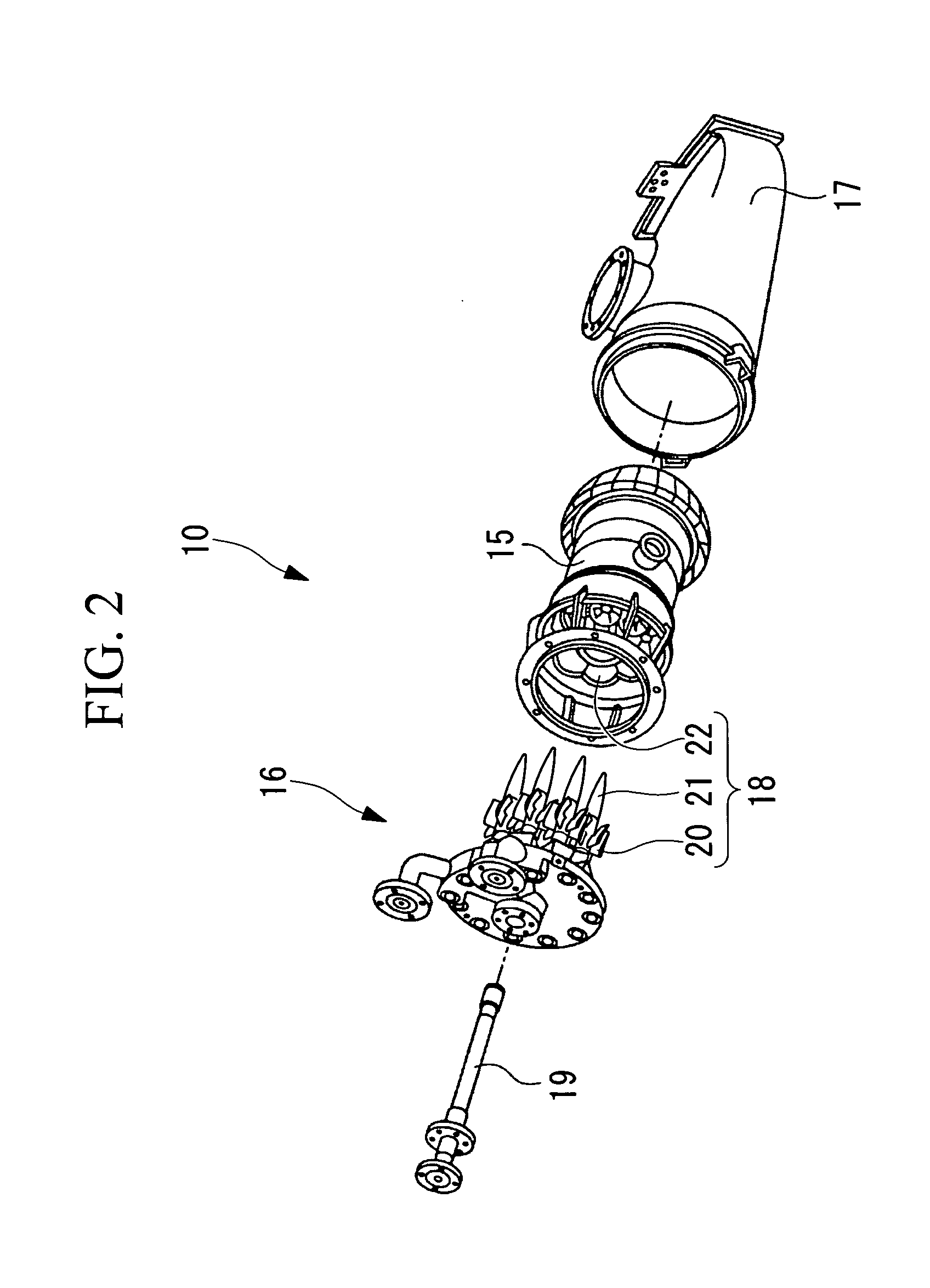

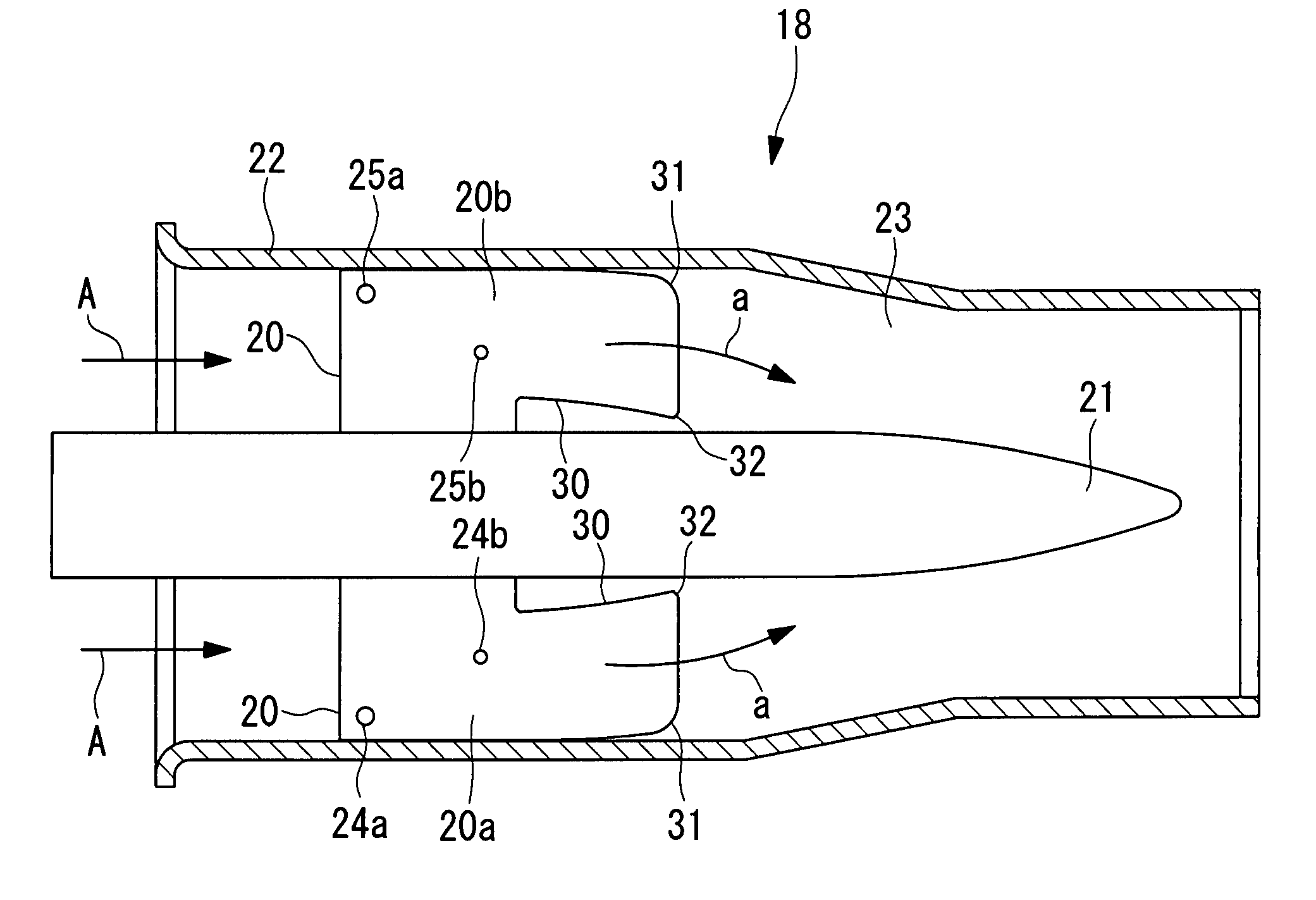

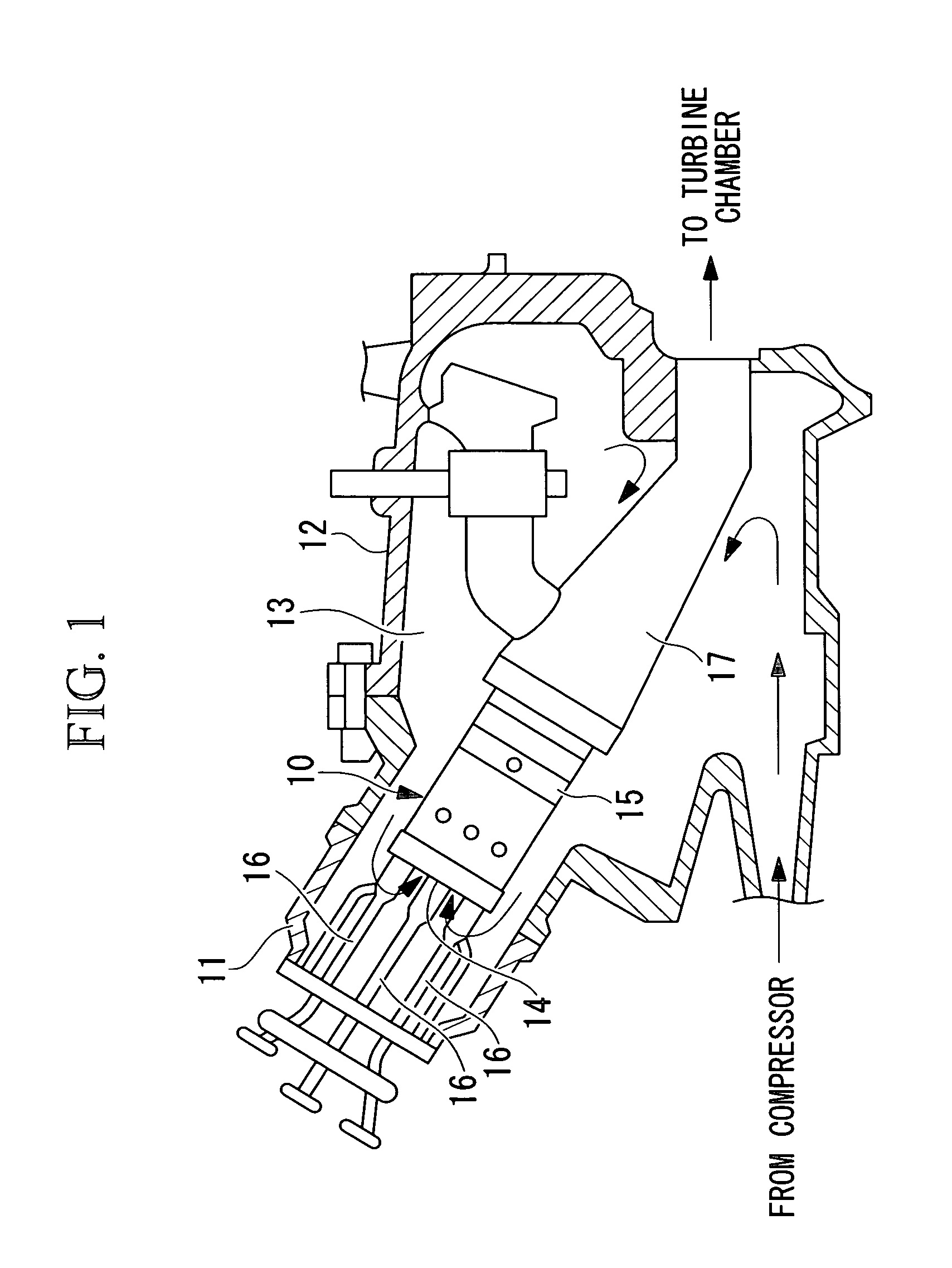

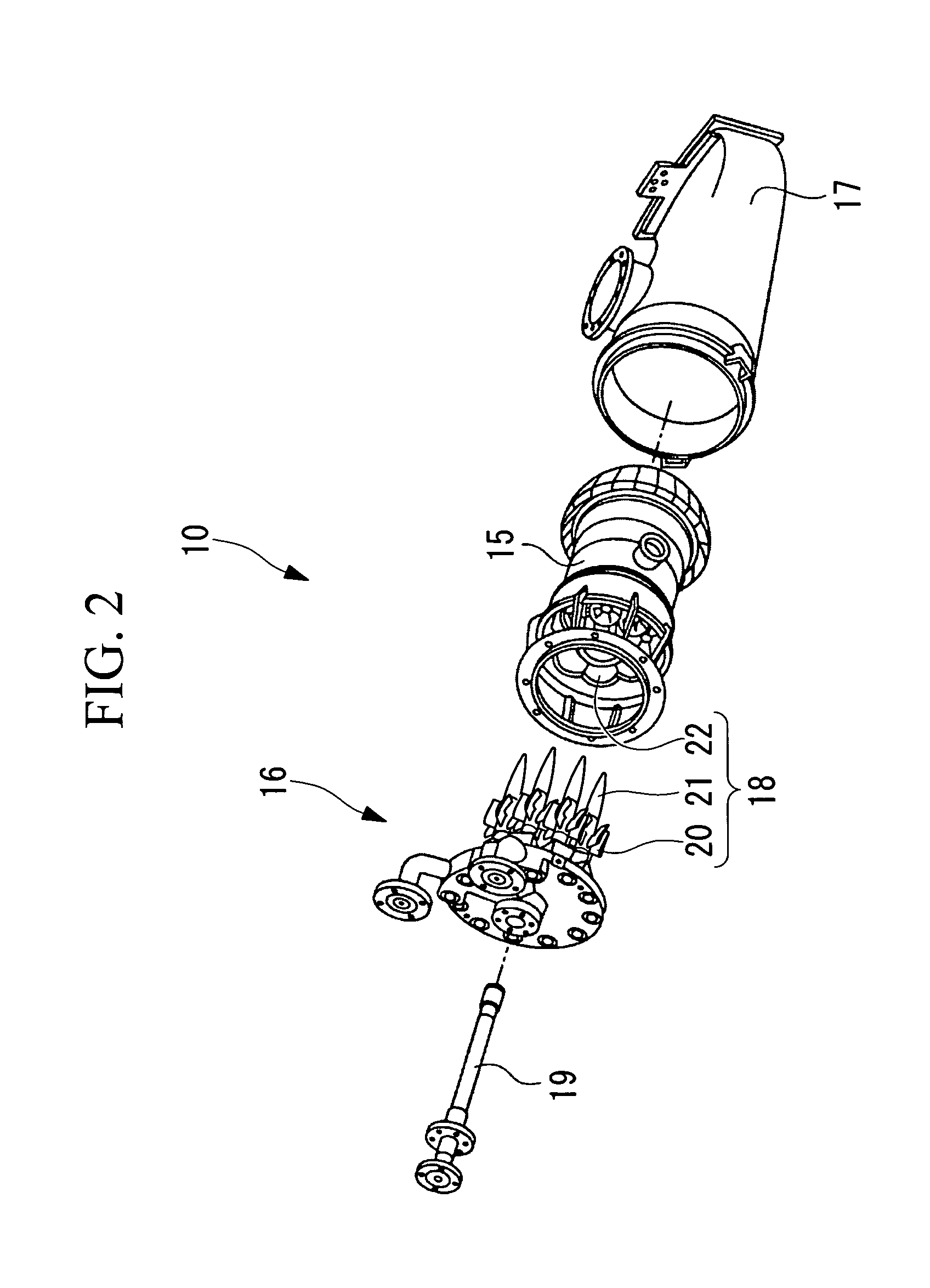

Premixed combustion burner for gas turbine

ActiveUS20100263381A1Uniform concentrationAvoid problemsContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEngineering

A premixed combustion burner for a gas turbine is provided that can efficiently premix fuel and air to produce fuel gas having a uniform concentration, while reliably achieving prevention of flash back by making the flow rate of fuel gas substantially uniform. The premixed combustion burner for a gas turbine has: a fuel nozzle; a burner cylinder arranged so as to surround the fuel nozzle and form an air passageway between itself and the fuel nozzle; and swirler vanes that are arranged along an axial direction of the fuel nozzle in a plurality of positions around the circumferential direction of an outer circumference surface of the fuel nozzle and that gradually curve from an upstream side to a downstream side to spin the air traveling within the air passageway from the upstream side to the downstream side. A cutaway section is provided in a rear edge section on an inner circumference side of the swirler vane.

Owner:MITSUBISHI POWER LTD

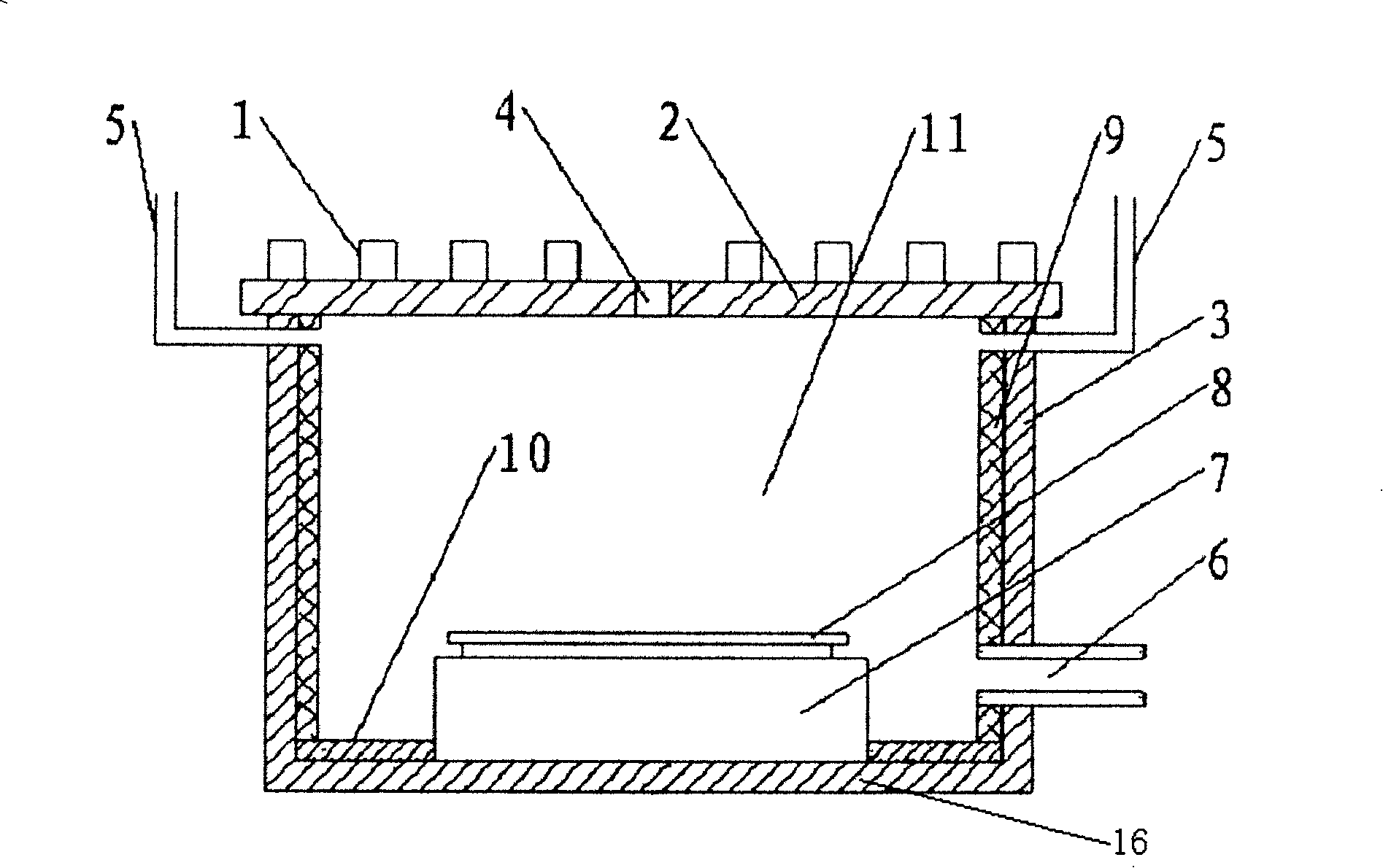

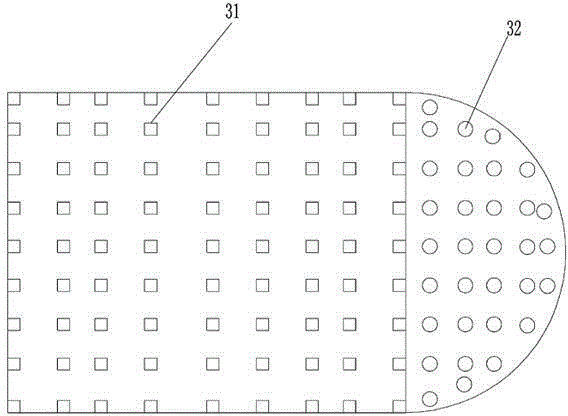

Reaction cavity lining and reaction cavity including the same

ActiveCN101197249AUniform flow rateEvenly distributedElectric discharge tubesSemiconductor/solid-state device manufacturingSemiconductorPhysics

The invention discloses a reaction cavity lining and a reaction cavity including the lining, which comprises a side lining and a bottom lining, wherein, the bottom lining is higher than the lower edge of the side lining and at least one bottom lining is provided. A plurality of lining holes are arranged on the bottom lining. The reaction cavity including the lining is divided into an upper space and a lower space. The upper space is communicated with the lower space through the lining hole. The technics air coming from an air inlet into the reaction cavity can only be pumped from an air outlet by passing the lining hole on the bottom lining. The air flowing speed in the reaction cavity tends to be even, thus protecting the wall of the cavity and allowing uniform distribution of air in the cavity. When the wafer is performed with etching technics in the cavity, the surface of entire wafer can acquire uniform etching speed rate. The invention is mainly applicable to the reaction cavity for the semi-conductor manufacture device, also applicable to other similar cavities.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Premixed combustion burner for gas turbine

ActiveUS8065880B2Avoid problemsUniform flow rateContinuous combustion chamberGas turbine plantsCombustorEngineering

Owner:MITSUBISHI POWER LTD

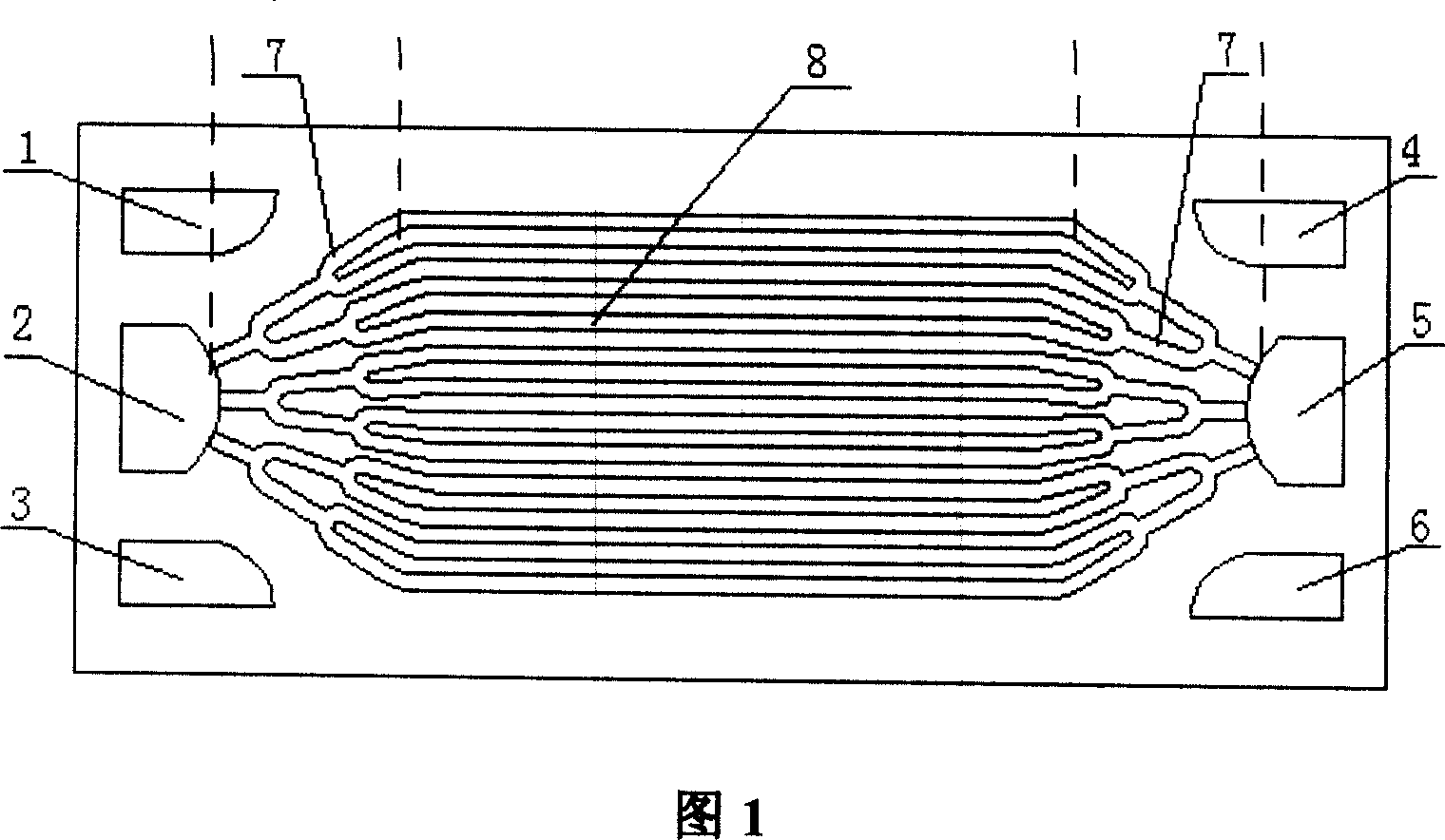

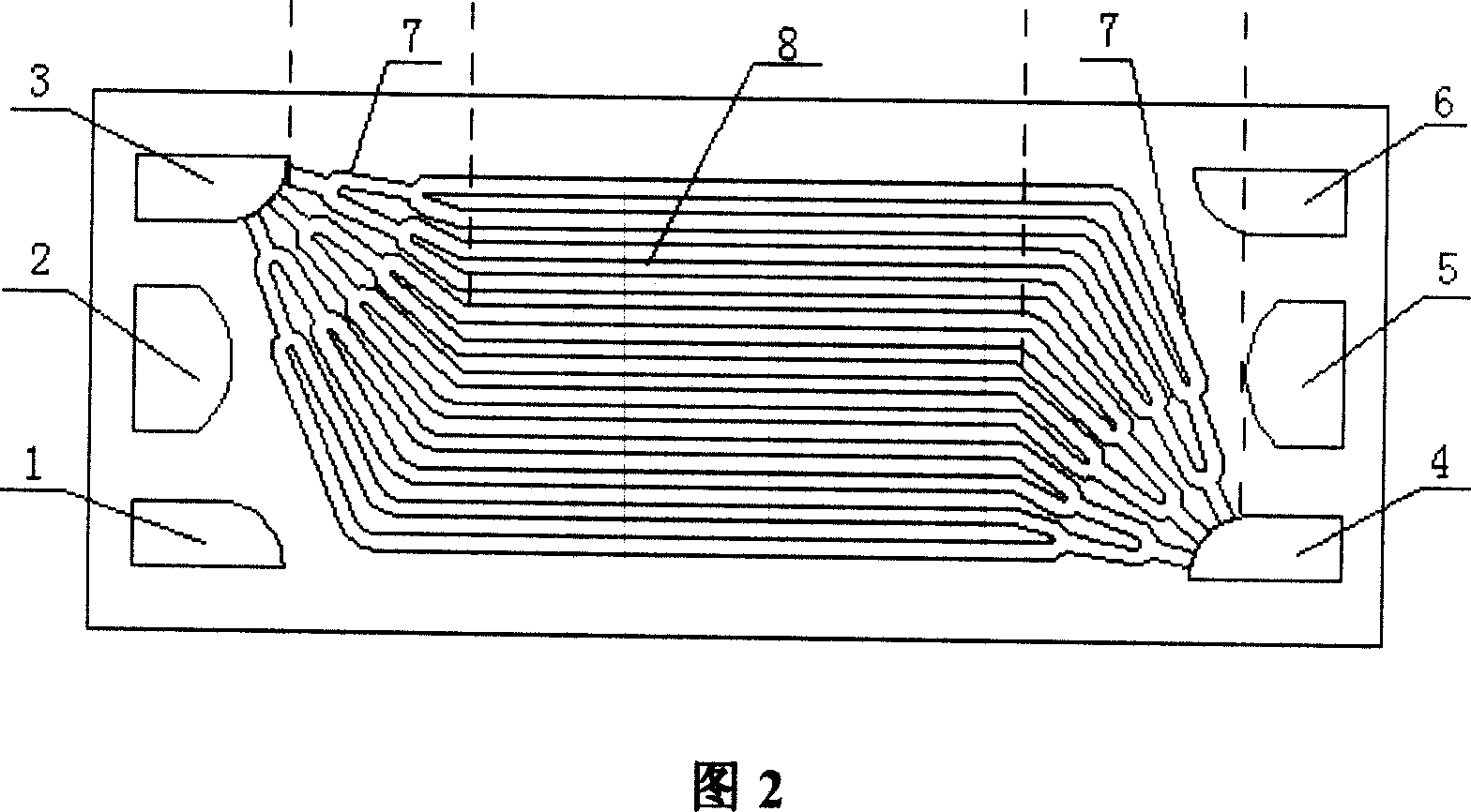

Neutral network fractal runner double-pole plate for proton exchange film fuel cell

InactiveCN1933222AEvenly distributedLimit turbulenceCell electrodesFuel cell detailsNeuron networkFlow resistivity

This invention relates to a neuron network runner dual-pole plate used in PEM fuel batteries, one side of the pole plate is set with a cathode flow field for transmitting oxidizer gas, the other side is set with anode runners for transmitting fuel, inlets and outlets of gas and cooling fluid are set on the pole plate, a flow field transition region and a flow field reaction region set in it and connected with it are placed near the gas inlet / outlet, in which, the runners of the transition region are in the structure of a multi-channel neuron network., the length of runners in the field and the flowing resistance of gas in the runners are almost the same so it is favorable for gas flowing in the field uniformly.

Owner:WUHAN UNIV OF TECH

Chemical vapour deposition injector

InactiveUS20140284404A1Uniform flow rateEasy to manufactureLiquid spraying apparatusChemical vapor deposition coatingCompound (substance)Gas syringe

Disclosed is a chemical vapour deposition injector 100, comprising a gas injector body 104 having a plurality of holes for directing a first gas from a first gas plenum into respective first gas channels of the gas injector body, each first gas channel extending in a first direction and arranged to branch into separate flow paths; a plurality of discrete first conduits, each first conduit being arranged to connect to a respective one of the discrete flow paths for carrying the first gas to a reaction chamber; a second gas channel for directing a second gas from a second gas plenum into the gas injector body, the second gas channel having a longitudinal axis which extends in a second direction transverse to the first direction; and a plurality of discrete second conduits coupled to the second gas channel and arranged to carry the second gas from the second gas channel to the reactor chamber; wherein at least some of the discrete second conduits are arranged between the discrete first conduits.

Owner:ASM TECH SINGAPORE PTE LTD

Wine pouring regulator and aerator therein

InactiveUS20120272831A1Disrupt laminar flowEasy to fillFlow mixersTransportation and packagingInductorBottle

A bottle top regulator / aerator for controlling the flow from a bottle having a narrow cylindrical opening through which wine or similar liquid may be poured. The dispensing apparatus includes, in combination, an air inductor, a regulating cartridge having a percolation labyrinth, and an anti-drip trough integrated within a housing. The application of this apparatus provides for both the rapid aeration of the wine, as well as a uniform flow rate absent the hazard of post-pouring droplets.

Owner:BARBERIO JANET +1

Wine pouring regulator and aerator therein

A bottle top regulator / aerator for controlling the flow from a bottle having a narrow cylindrical opening through which wine or similar liquid may be poured. The dispensing apparatus includes, in combination, an air inductor, a regulating cartridge having a percolation labyrinth, and an anti-drip trough integrated within a housing. The application of this apparatus provides for both the rapid aeration of the wine, as well as a uniform flow rate absent the hazard of post-pouring droplets.

Owner:BARBERIO JANET +1

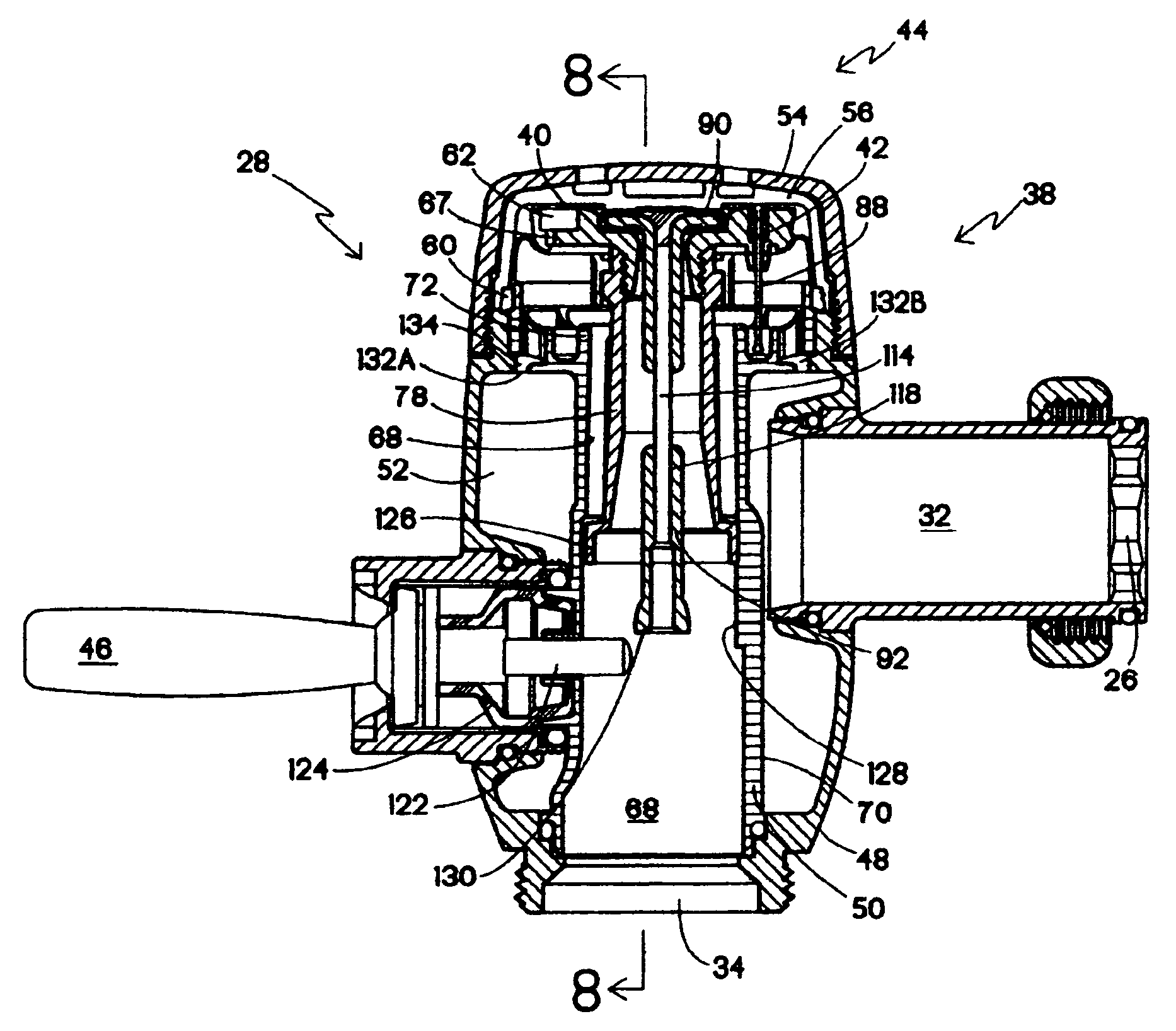

Flush valve

ActiveUS7487950B2Easy to replaceConsistent and reliable operationOperating means/releasing devices for valvesFlushing devicesEngineeringInlet pressure

Tilting of a main valve assembly in unison with the head portion of a pilot valve under high inlet pressure conditions is prevented by supporting the main valve assembly with housing rib engaging a skirt on the main valve guide tube opposed to the handle actuated push rod. A positive, toggle like pilot valve opening results from contact of an enlargement on the pilot valve stem with the push rod as the pilot valve begins its upward movement. An off center baffle in the inlet passage compensates for the non uniform pressure pattern resulting from the side entry inlet. The pilot valve head includes an easily replaceable cup shaped seal having a reentrant rim engaging the pilot valve surface in the main valve member and having an upper central portion engaging an abutment with a valve rotator configuration is the full open position. A secondary throttling structure provided by a skirt on the guide tube cooperating with a shoulder in the outlet passage provides a desirable large flush flow for siphon fixtures.

Owner:SLOAN VALVE COMPANY

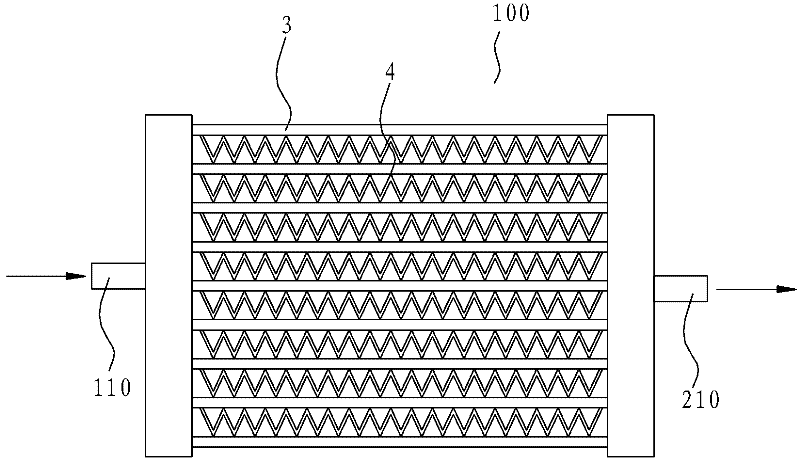

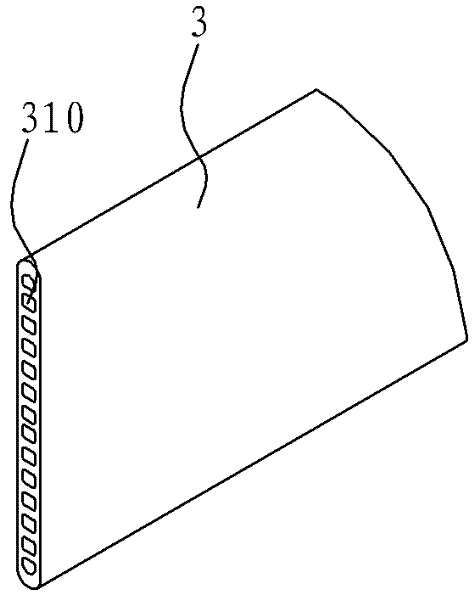

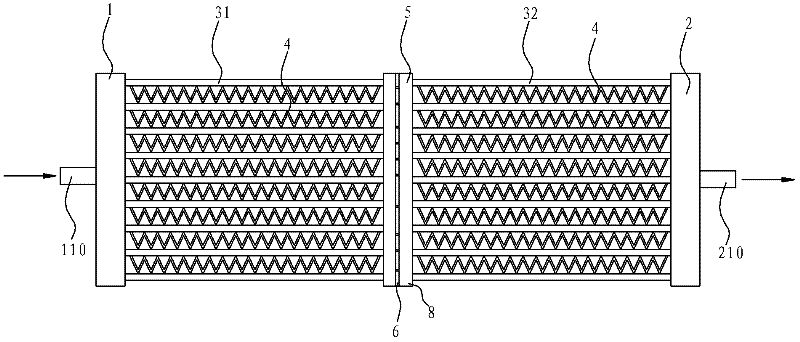

Heat exchanger with improved heat exchange performance

ActiveCN102230692AExert heat exchange capacityUniform flow rateEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

The invention discloses a heat exchanger comprising a first collecting pipe, a second collecting pipe, heat exchange pipes and fins, wherein the second collecting pipe and the first collecting pipe are spaced; a refrigerant path is confined in each heat exchange pipe; two ends of each heat exchange pipe are respectively connected with the first collecting pipe and the second collecting pipe to communicate the first collecting pipe with the second collecting pipe via the refrigerant path; the total cross section area of the refrigerant paths of the heat exchange pipes is changed along the flowing direction of the refrigerant in the heat exchange pipes so as to cause the flowing rate of the refrigerant to be coincident with the flowing direction of the refrigerant; and the fins are arranged between the adjacent heat exchange pipes. According to the heat exchanger disclosed by the embodiment of the invention, the total cross section area of the heat exchange pipes on the inlet side and outlet side of the refrigerant changes along with the state of the refrigerant, so that the refrigerant flows in the heat exchange pipes and maintains relatively even flowing rate, thereby improving the integral efficiency of the heat exchanger so as to better perform the heat exchange capability of the heat exchanger.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

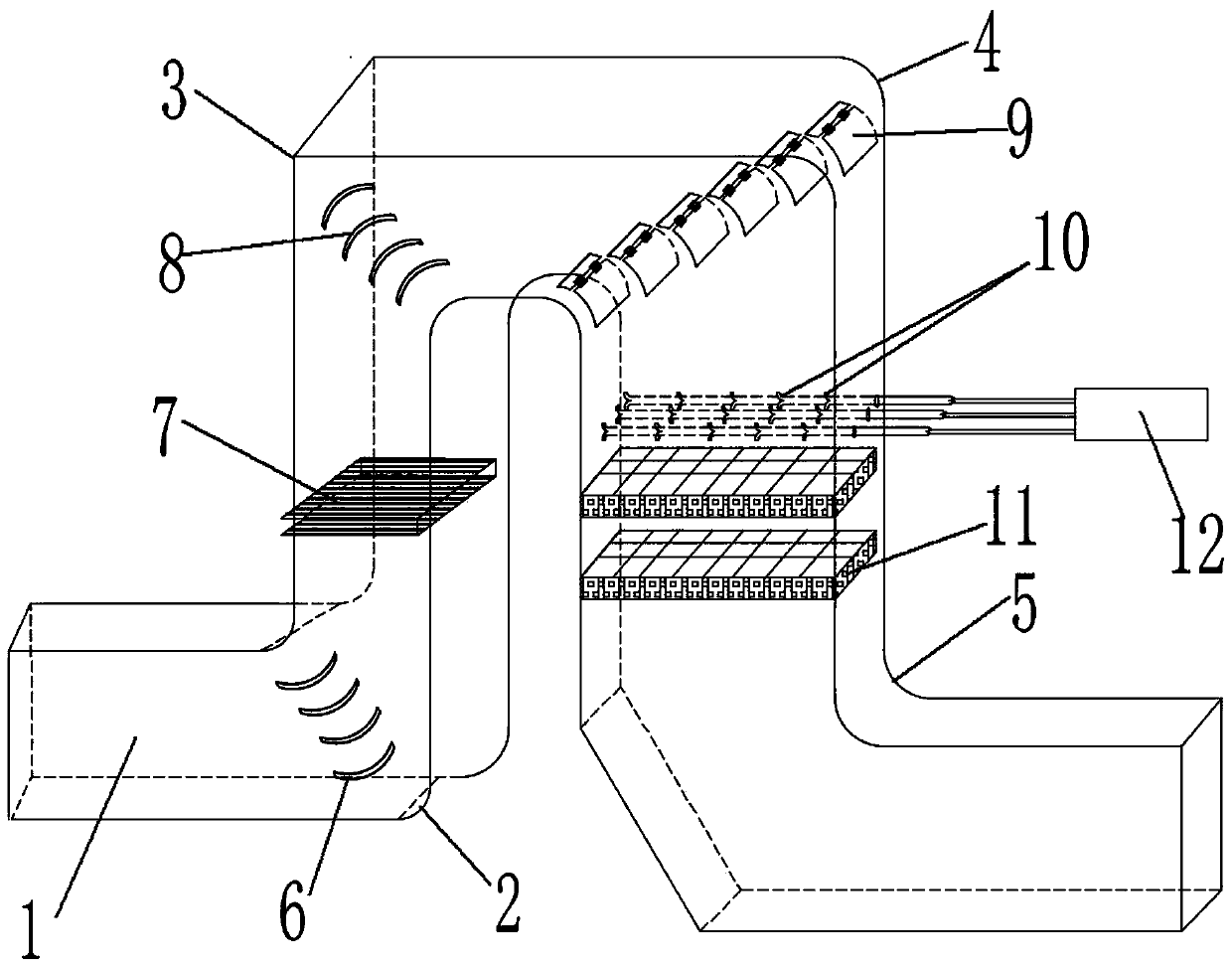

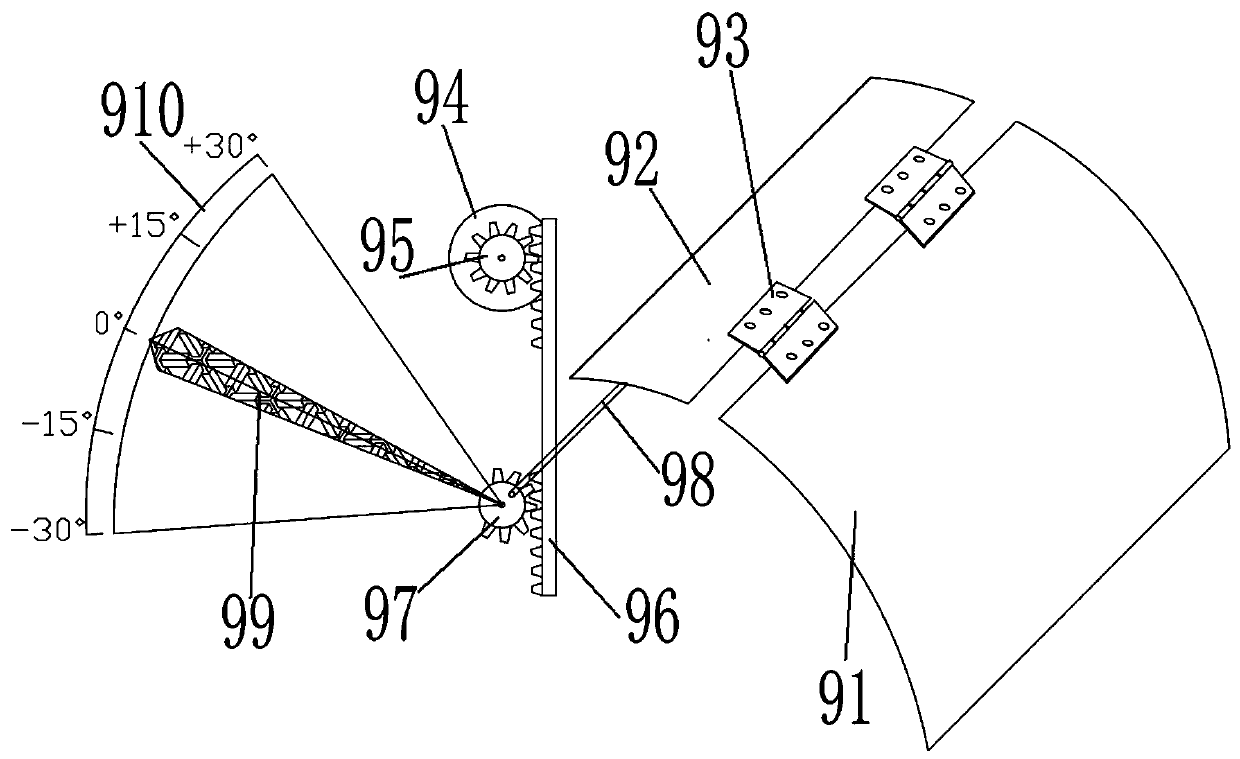

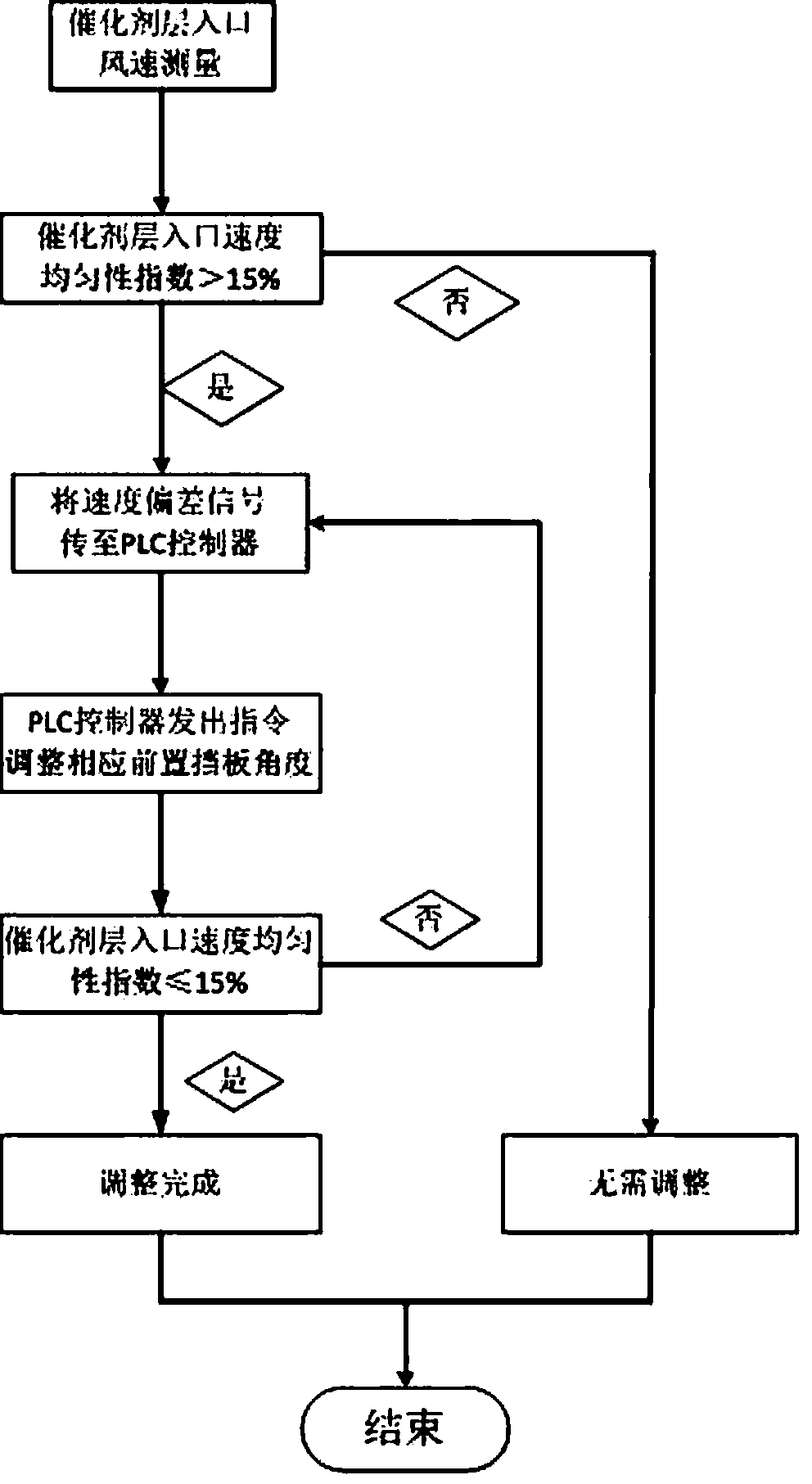

System and method for improving uniformity of selective catalytic reduction (SCR) flow field

ActiveCN107198964AIncrease the circulation areaReduce cloggingGas treatmentDispersed particle separationFlue gasDifferential pressure

The invention relates to a system and a method for improving the uniformity of a selective catalytic reduction (SCR) flow field. The system comprises a flue, a plurality of circular arc-shaped primary guide plates, a plurality of circular arc-shaped secondary guide plates, an ammonia injection grid, N tertiary guide plates, a plurality of catalyst layers, and M sets of differential pressure measurement components which are horizontally arranged along the width direction of the flue and are positioned between the catalyst layers and the tertiary guide plates, wherein each set of differential pressure measurement component is evenly provided with N differential pressure detection devices arranged at intervals along the depth direction of the flue. The system and the method can improve the flue gas flow field in front of the catalyst layers, guarantees the speed uniformity of an SCR system, and effectively reduces the phenomenon that the catalyst layers are blocked or worn.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Fluid supply nozzle, substrate processing apparatus and substrate processing method

InactiveUS7669780B2Increase rotation speedImprove efficiencySelf-acting watering devicesWatering devicesEngineeringFluid supply

A fluid supply nozzle includes a fluid flow-in section into which a fluid flows in, a reservoir section for storing the fluid, a flow velocity control wall provided between the fluid flow-in section and the reservoir section and including an orifice for making the fluid flow in the reservoir section while reducing a flow velocity, and a discharging section including a slit for discharging the fluid with pressure of the fluid applied to the reservoir section. A substrate processing apparatus is formed so as to include the fluid supply nozzle. Moreover, a substrate processing method includes the step of discharging a fluid in a single-layered, continuous film to supply the fluid onto a substrate. Thus, the substrate is processed. To perform this method, the fluid supply nozzle of the present invention can be used.

Owner:PANASONIC CORP

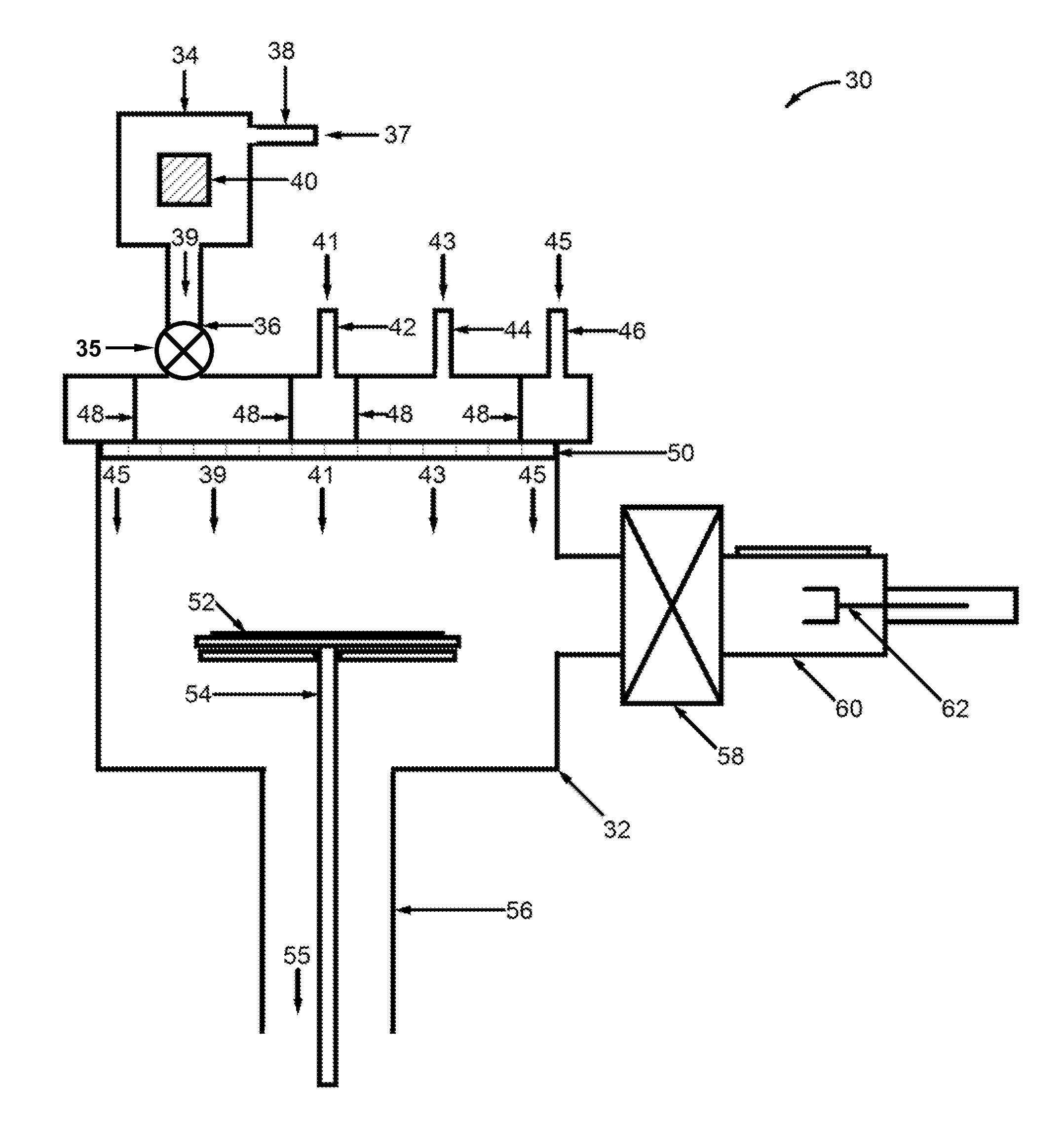

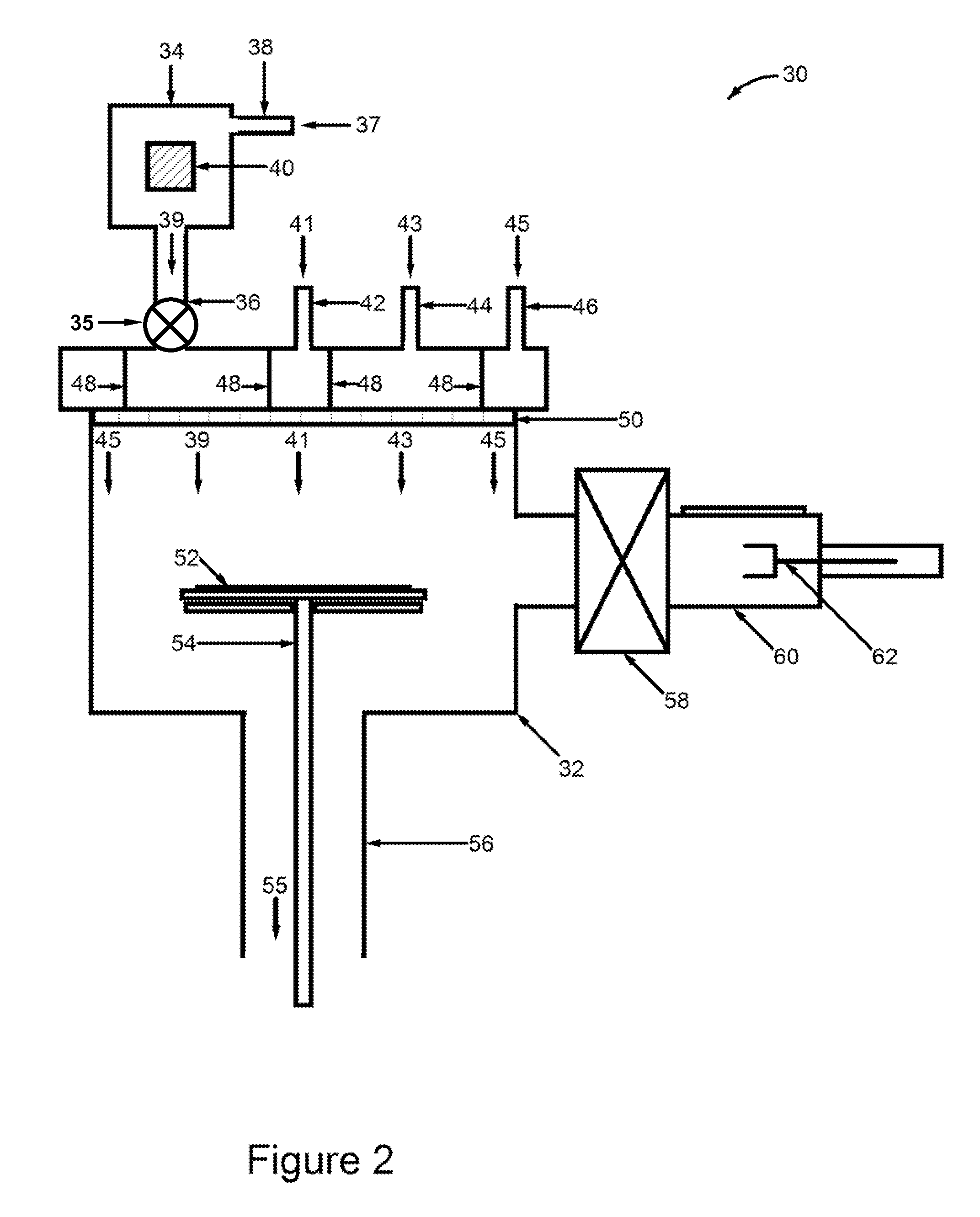

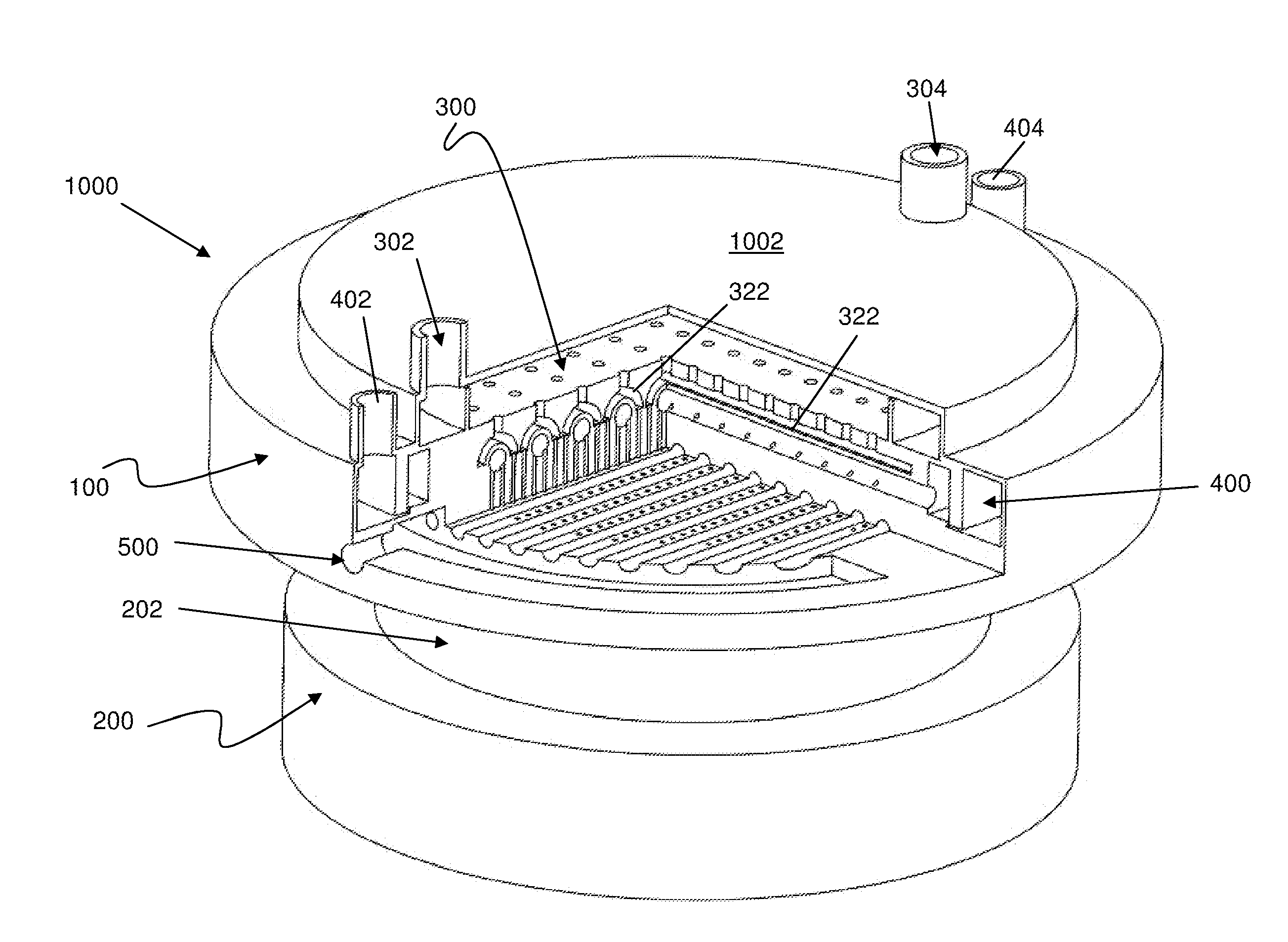

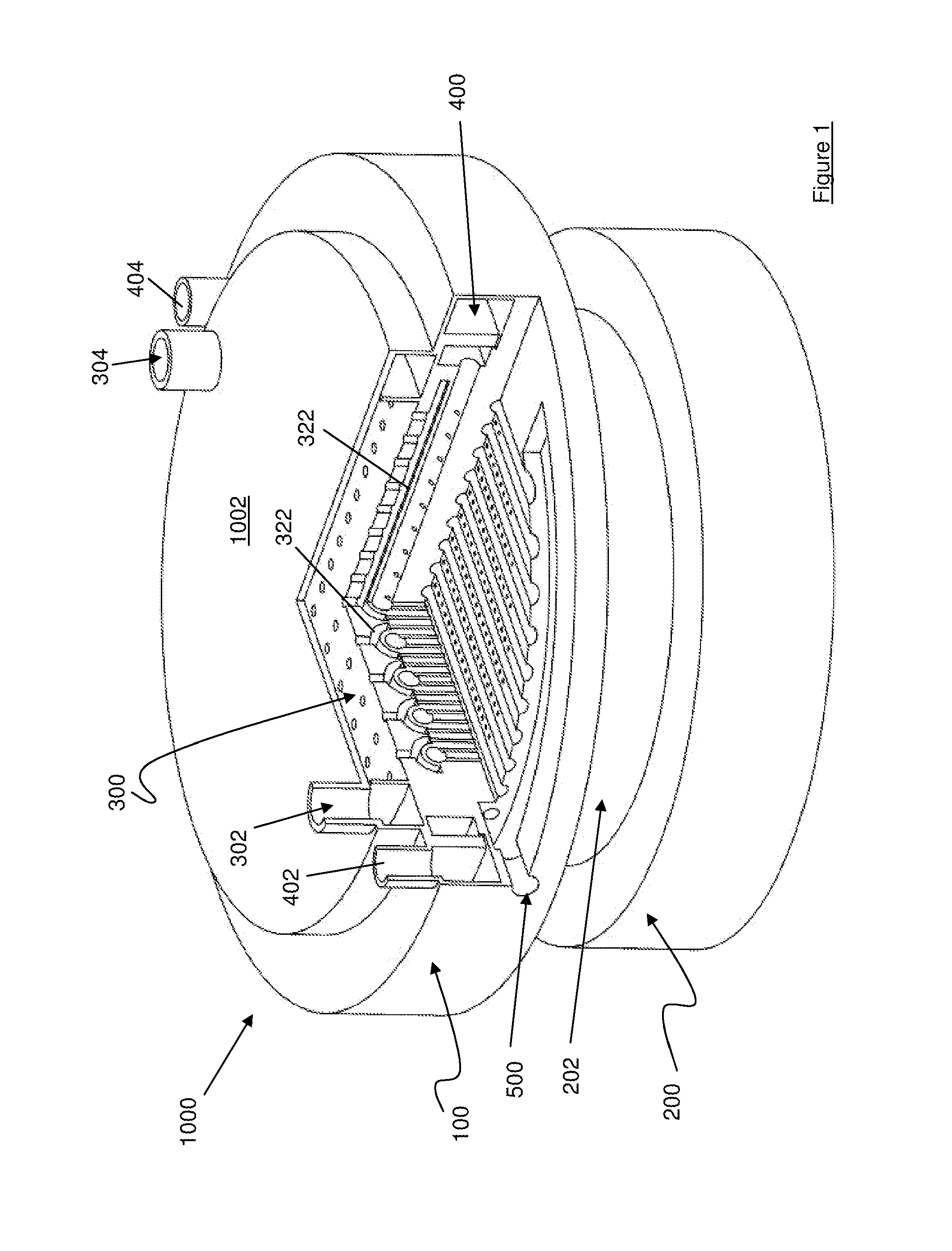

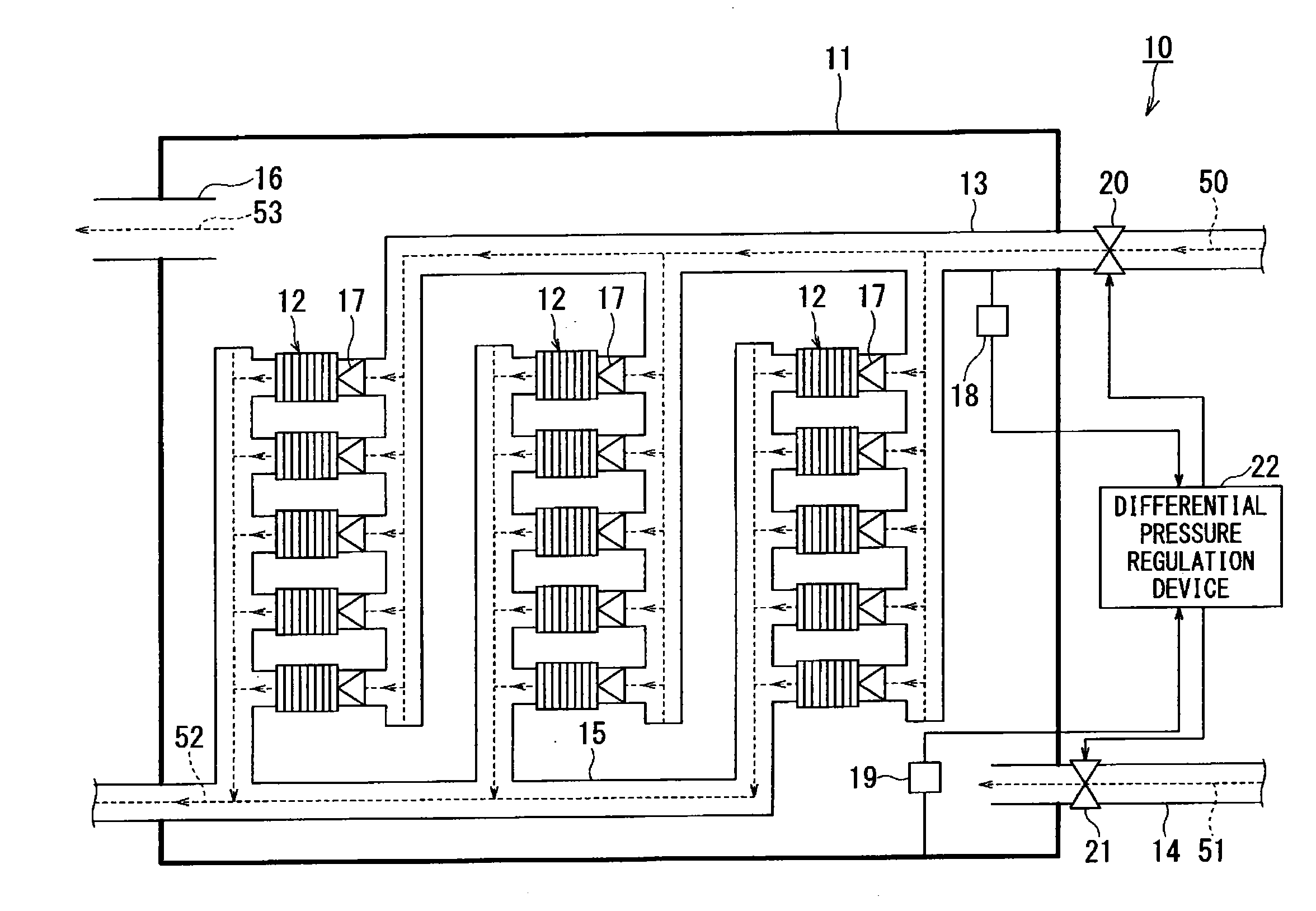

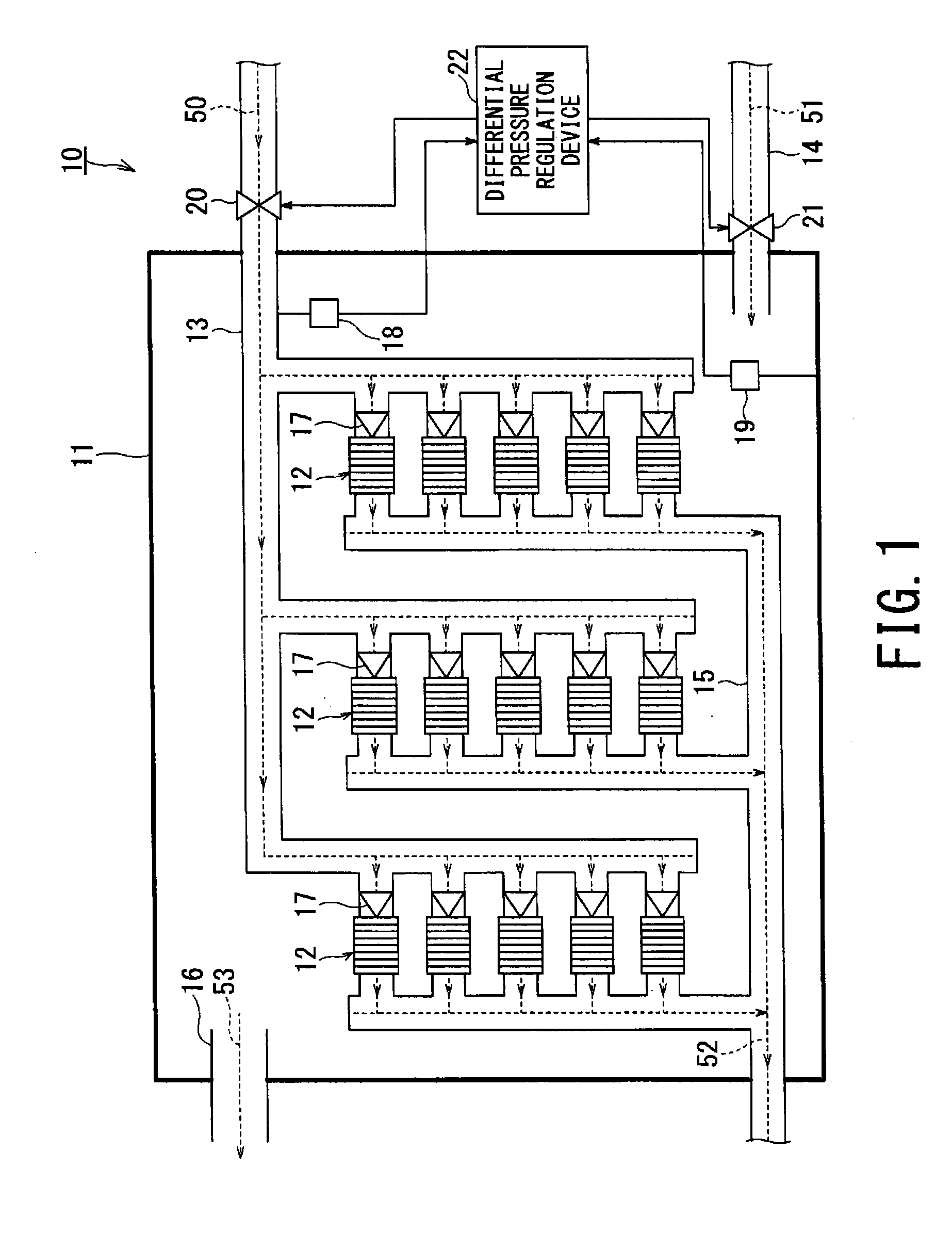

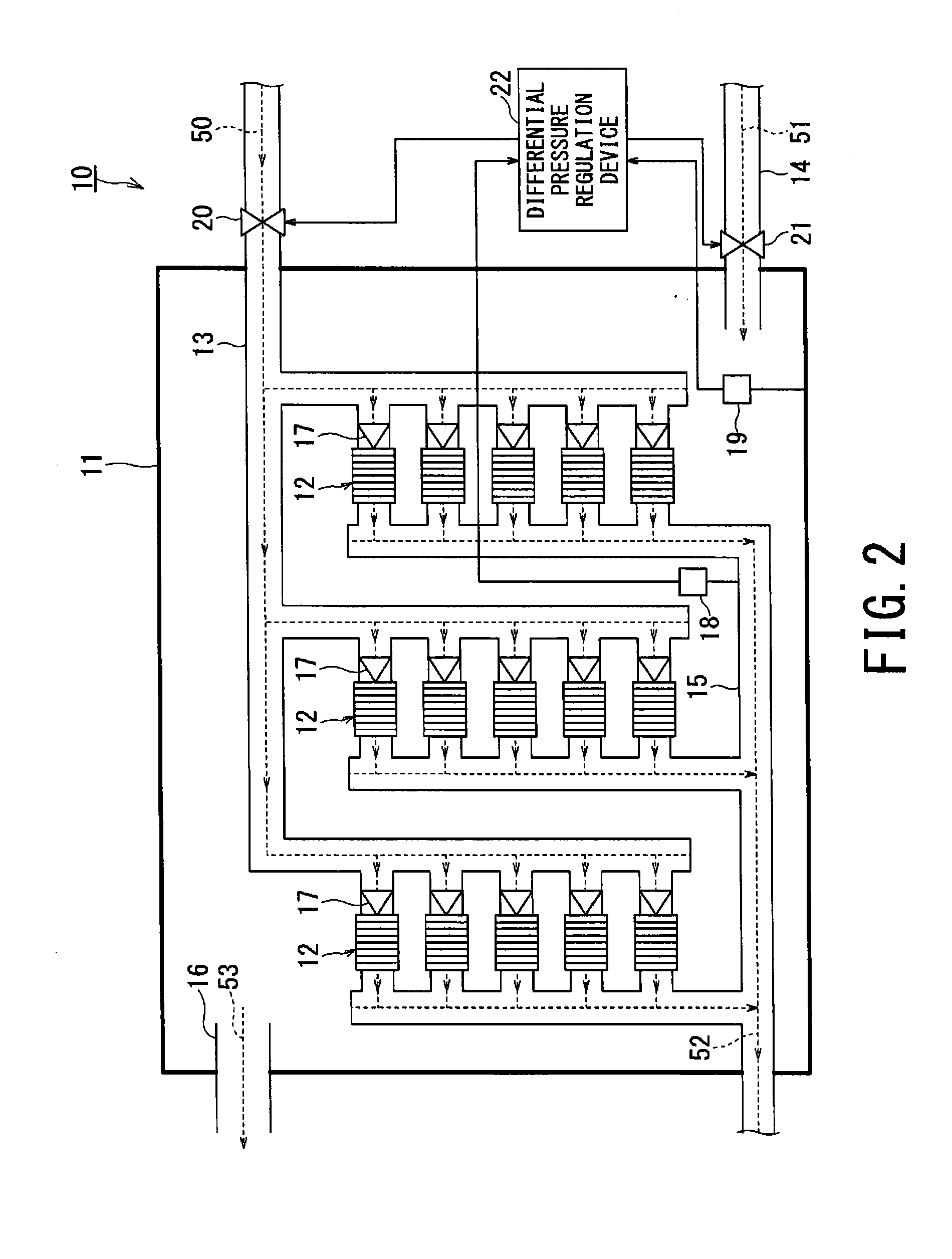

Hydrogen production system and method for producing hydrogen

ActiveUS20160060776A1Efficient hydrogen productionUniform flow rateCellsMachining electric circuitsElectrolysisEngineering

A hydrogen production system that achieves highly-efficient hydrogen production even when hydrogen is produced by using the plurality of cell stacks is provided.A hydrogen production system includes a plurality of cell stacks provided within a reaction containment, the cell stacks generating hydrogen by high temperature steam electrolysis by supplying steam to the plurality of cell stacks, a first flow path guiding the steam to each of the cell stacks, a second flow path causing a carrier gas containing air as a main component to flow into the reaction containment, and a flow regulation device provided at an inlet of the steam in each of the cell stacks, the flow regulation device regulating a flow rate of the steam caused to flow into each of the cell stacks to be uniform.

Owner:KK TOSHIBA

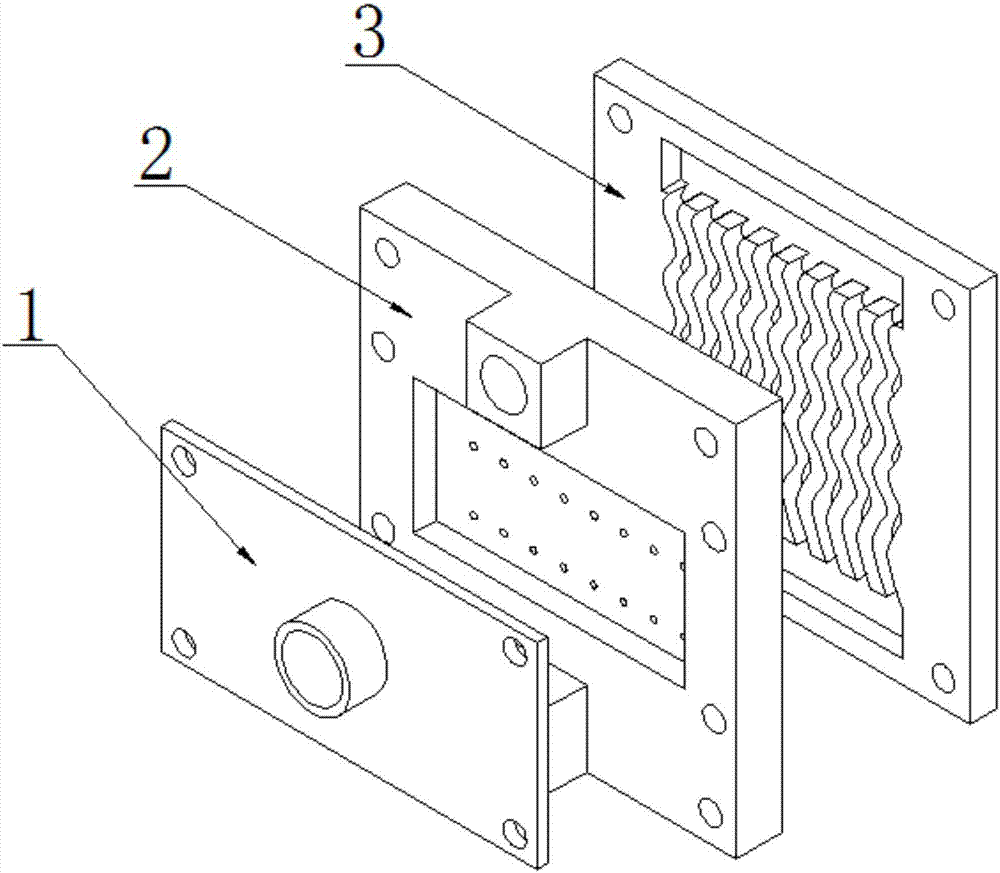

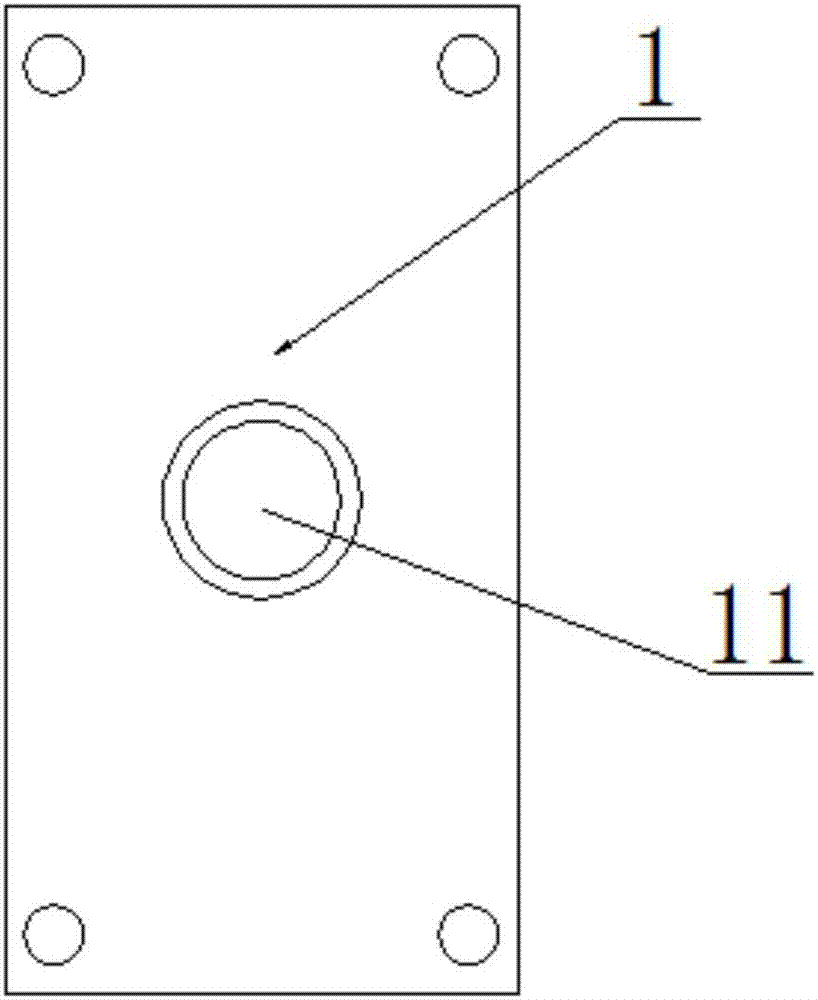

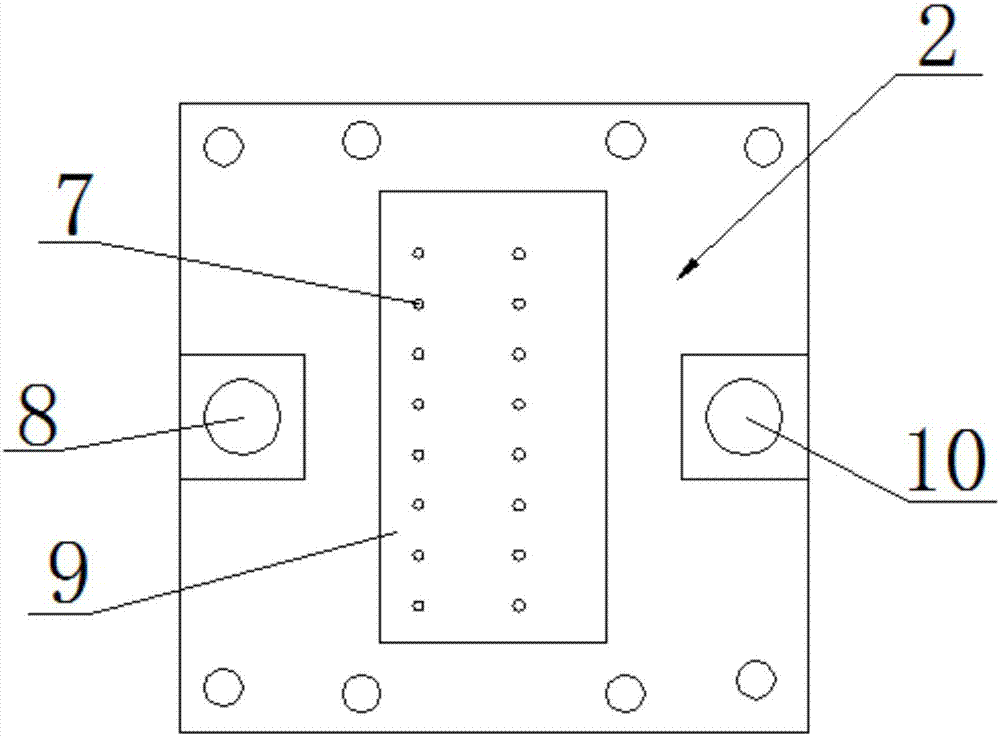

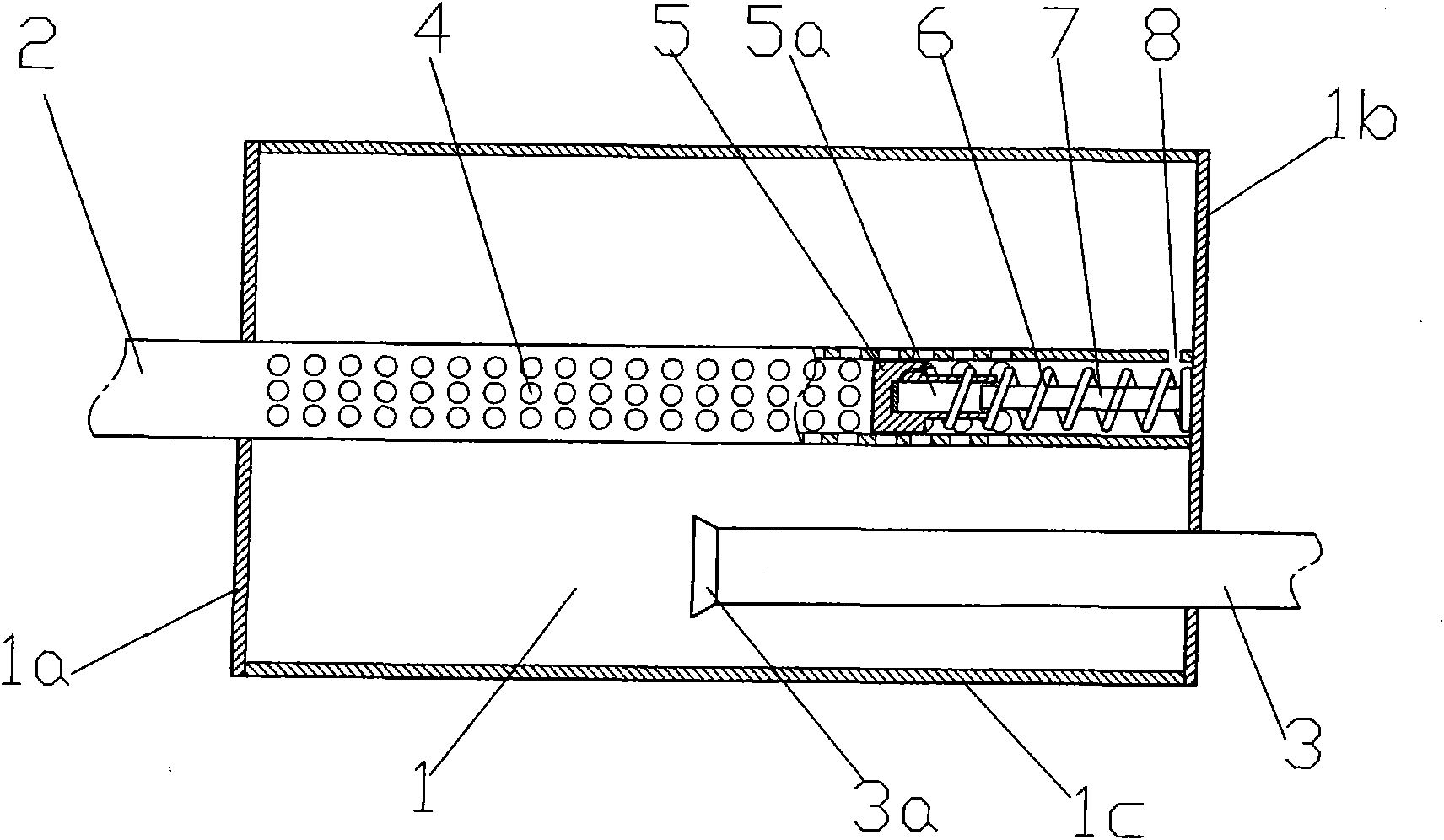

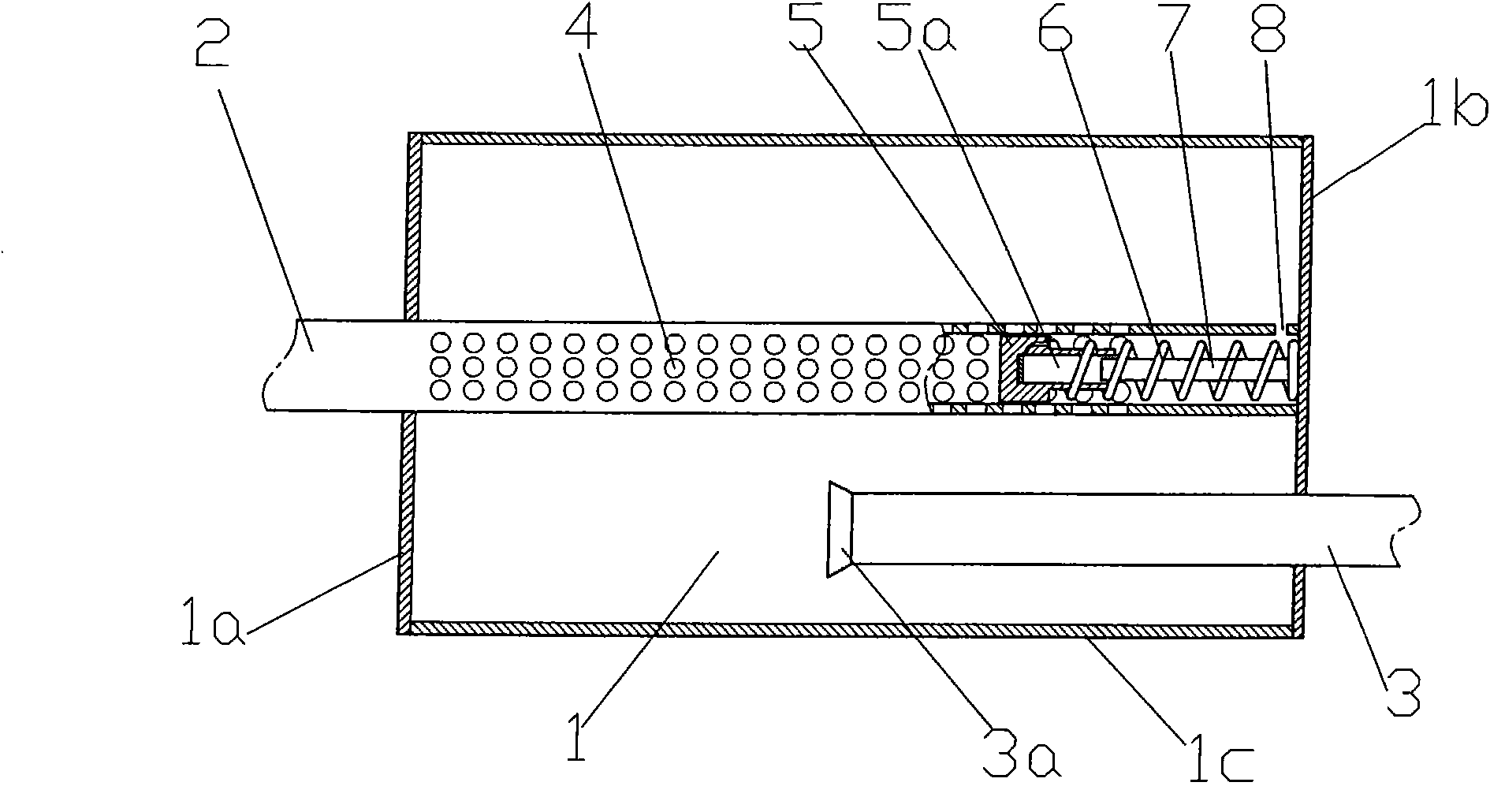

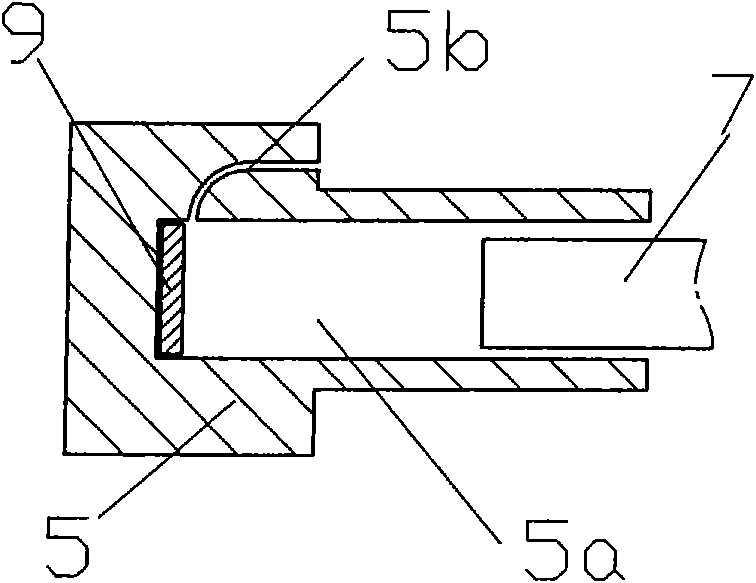

Valveless piezoelectric micro pump

InactiveCN103195694AEasy to controlSimple structureFlexible member pumpsPositive-displacement liquid enginesEngineeringMicro pump

The invention discloses a valveless piezoelectric micro pump comprising a vibrating plate, a pump body (8) and an upper cover plate (1) connected on the pump body (8) through a bolt (6); a cavity is formed between the upper cover plate (1) and the pump body (8); a vibrating plate is arranged between the upper cover plate (1) and the pump body (8); the cavity is divided into a liquid inlet negative pressure cavity and a liquid outlet negative pressure cavity by the vibrating plate; a vibrating diaphragm (2) and an annular piezoelectric ceramic chip (3) are coaxially adhered to form the vibrating plate; cone holes are distributed on the middle circular area and the peripheral annular area where the annular piezoelectric ceramic chip (3), the upper cover plate(1) and the pump body (8) do not contact with in the vibrating diaphragm (2); the bigger ends of the cone holes face towards the liquid inlet negative cavity; and the smaller ends of the cone holes face towards the liquid outlet negative pressure cavity. The valveless piezoelectric micro pump is simple in structure, light in weight, big in power capacity, easy to assemble for whole machine manufacturing and low in production cost.

Owner:SUZHOU UNIV OF SCI & TECH

Battery pack comprising combined temperature-controlling system

ActiveUS8343647B2Temperature controlMinimized in sizeCell temperature controlBattery isolationForeign matterElectricity

Disclosed herein is a middle- or large-sized battery pack including a plurality of unit cells electrically connected with each other, wherein the battery pack is constructed in a structure in which a heat transfer medium flows through gaps defined between the unit cells for controlling the overall temperature of the battery pack to be within a predetermined temperature range for the optimum operation of the battery pack, and each unit cell is provided at the outer surface thereof, at which the heat transfer medium is brought into contact with each unit cell, with a layer containing a phase transformation material (‘phase transformation layer’) for minimizing individual temperature difference between the unit cells. The present invention has the effect of controlling the overall temperature of the battery pack and individual controlling the temperatures of unit cells constituting the battery pack. Also, the present invention has the effect of restraining the abrupt change in temperature of the unit cells, when the battery pack is not in operation or when the external environment abruptly changes, thereby preventing the degradation of the unit cells. Furthermore, the present invention has the effect of minimizing damage to the unit cells due to foreign matter when the foreign matter is brought into contact with the unit cells. In addition, the present invention has the effect of reducing the overall temperature difference of the battery pack and manufacturing a middle- or large-sized battery pack having a compact structure.

Owner:LG ENERGY SOLUTION LTD

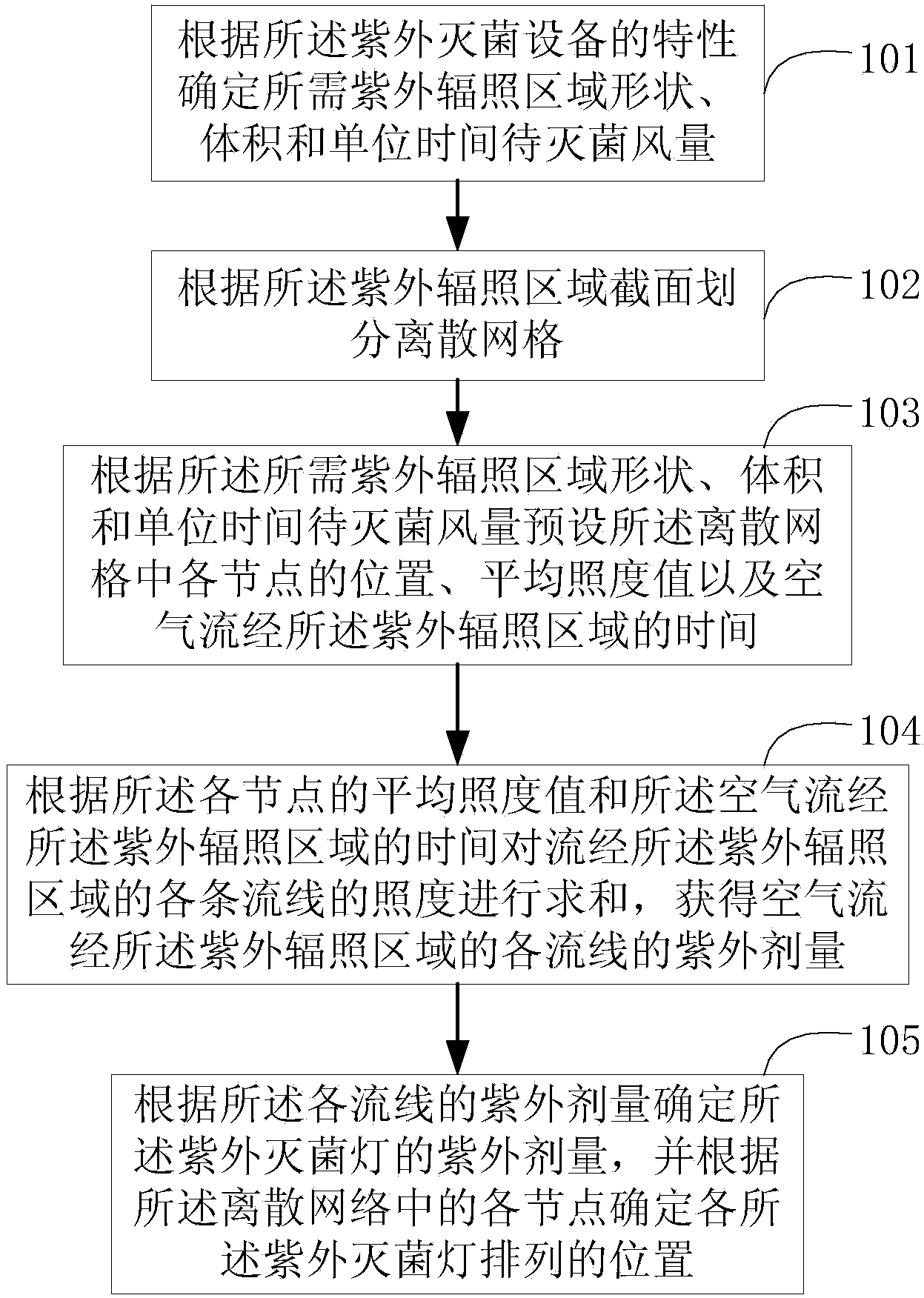

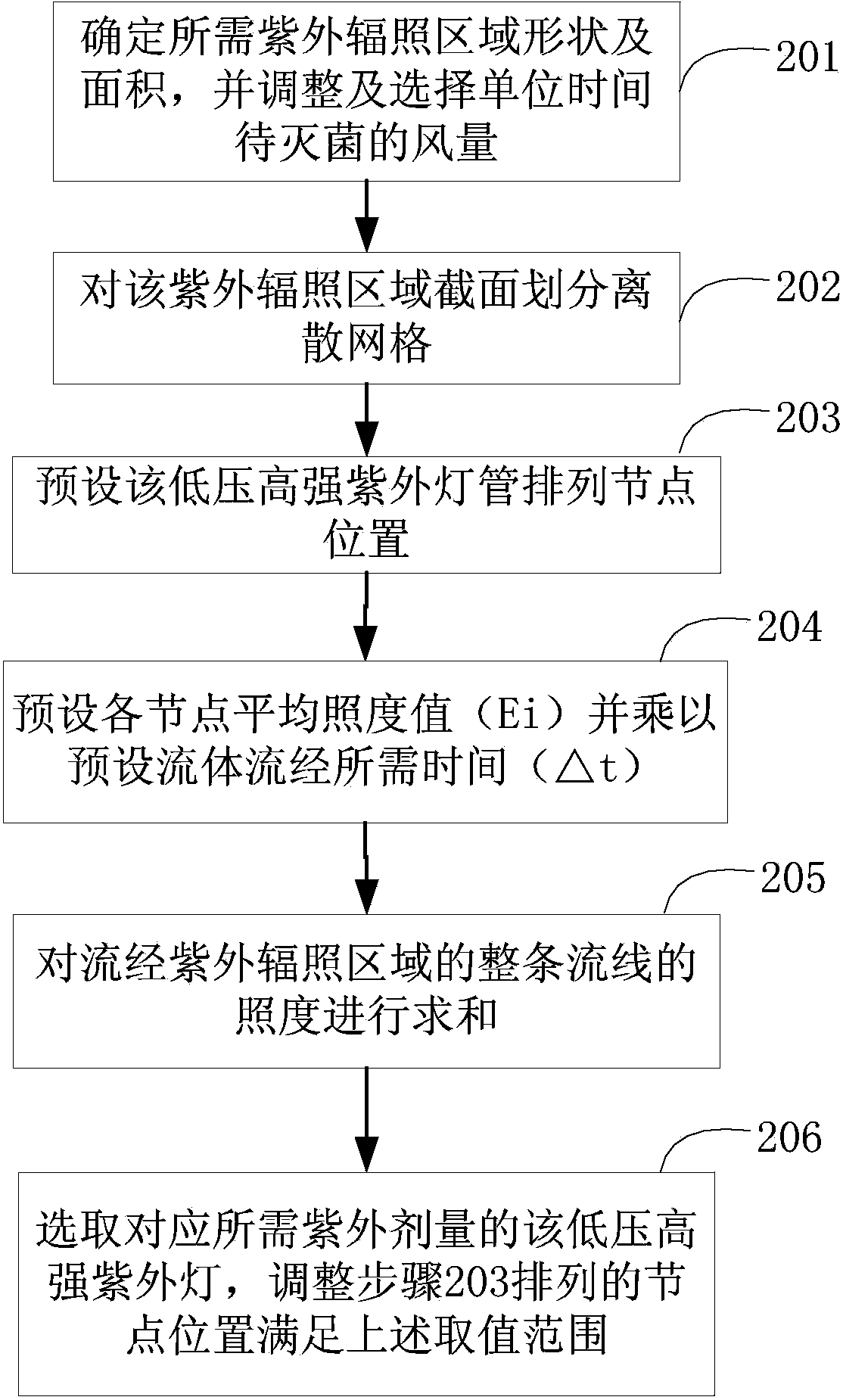

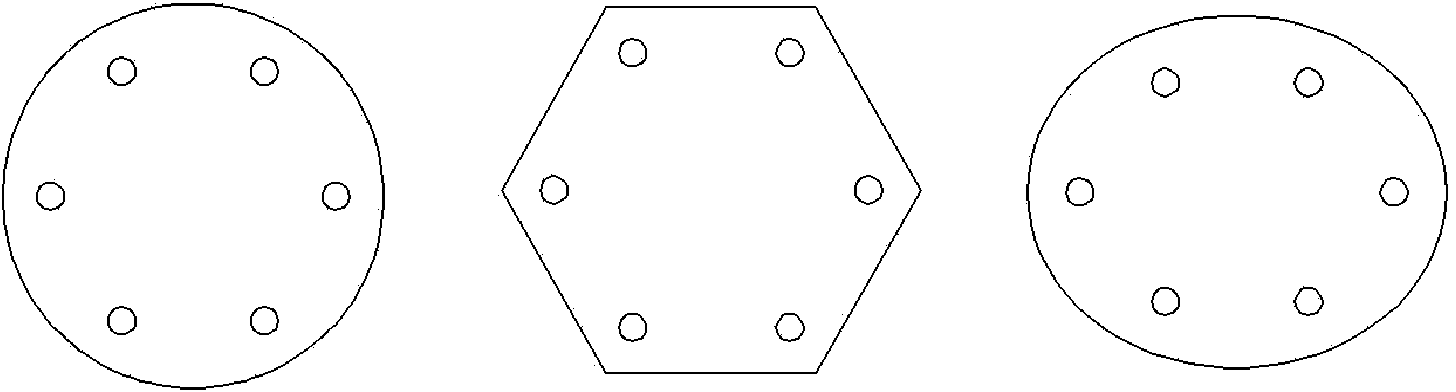

Ultraviolet sterilization disinfection device and setting method thereof

ActiveCN103463666AReasonable illumination settingIncrease UV illuminationLow-pressure discharge lampsSpecial data processing applicationsEngineeringMaterials science

The invention discloses an ultraviolet sterilization disinfection method and an ultraviolet sterilization disinfection device. One or more low-pressure ultraviolet lamps are arranged in the ultraviolet sterilization disinfection device, the inner diameter of each low-pressure ultraviolet lamp is phi 30-36mm, and the tube current density of each low-pressure ultraviolet lamp is 0.250-0.800A / cm<2>; or the inner diameter of each low-pressure ultraviolet lamp is phi 26-30mm, and the tube current density of each low-pressure ultraviolet lamp is 0.280-0.850A / cm<2>; or the inner diameter of each low-pressure ultraviolet lamp is phi 20-26mm, and the tube current density of each low-pressure ultraviolet lamp is 0.300-1.100A / cm<2>; or the inner diameter of each low-pressure ultraviolet lamp is phi 15-20mm, and the tube current density of each low-pressure ultraviolet lamp is 0.340-1.350A / cm<2>. By the adoption of the ultraviolet sterilization disinfection method and the ultraviolet sterilization disinfection device, the ultraviolet dosage of the ultraviolet sterilization disinfection device can be improved, and the sterilization disinfection efficiency is improved.

Owner:FOSHAN COMWIN LIGHT & ELECTRICITY

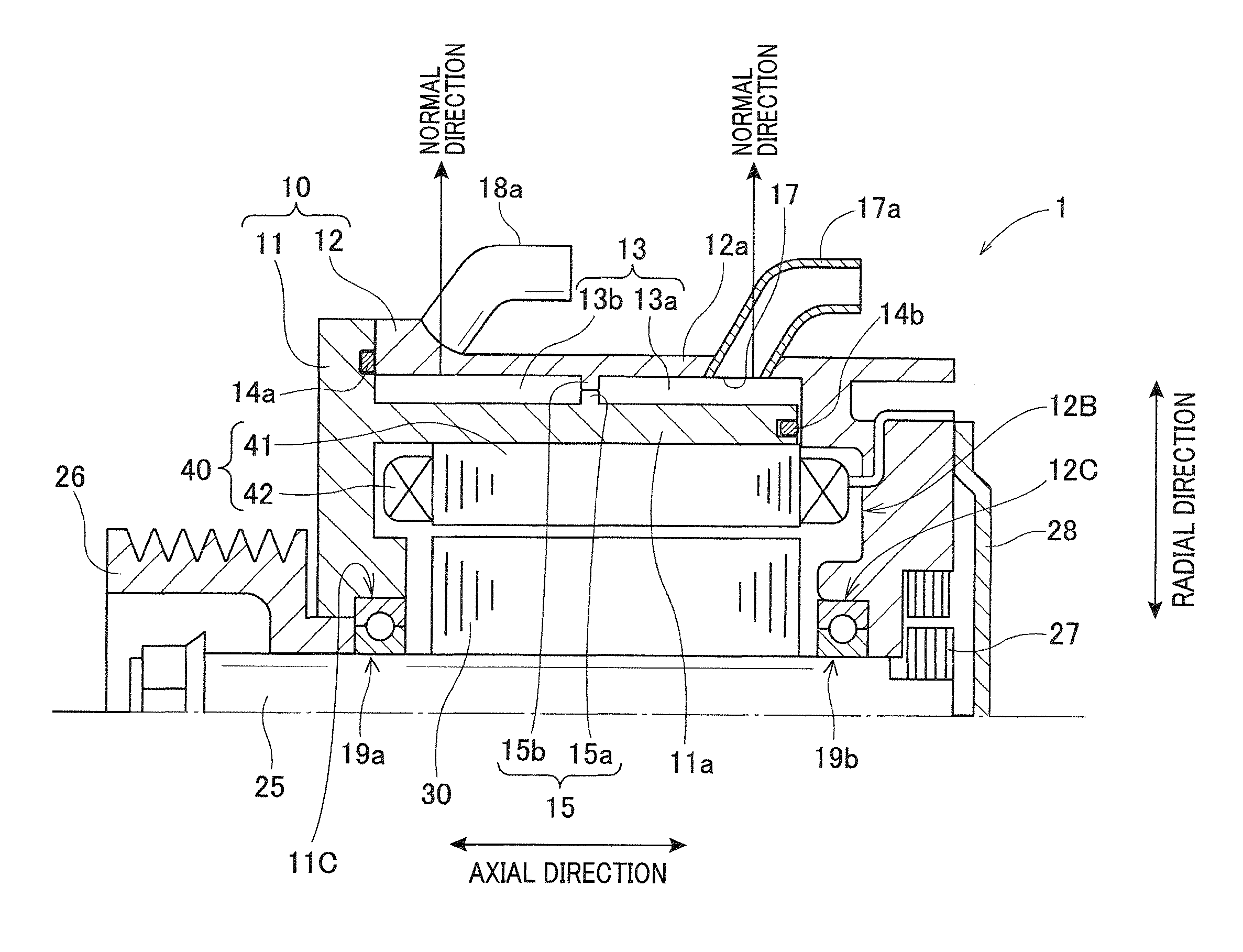

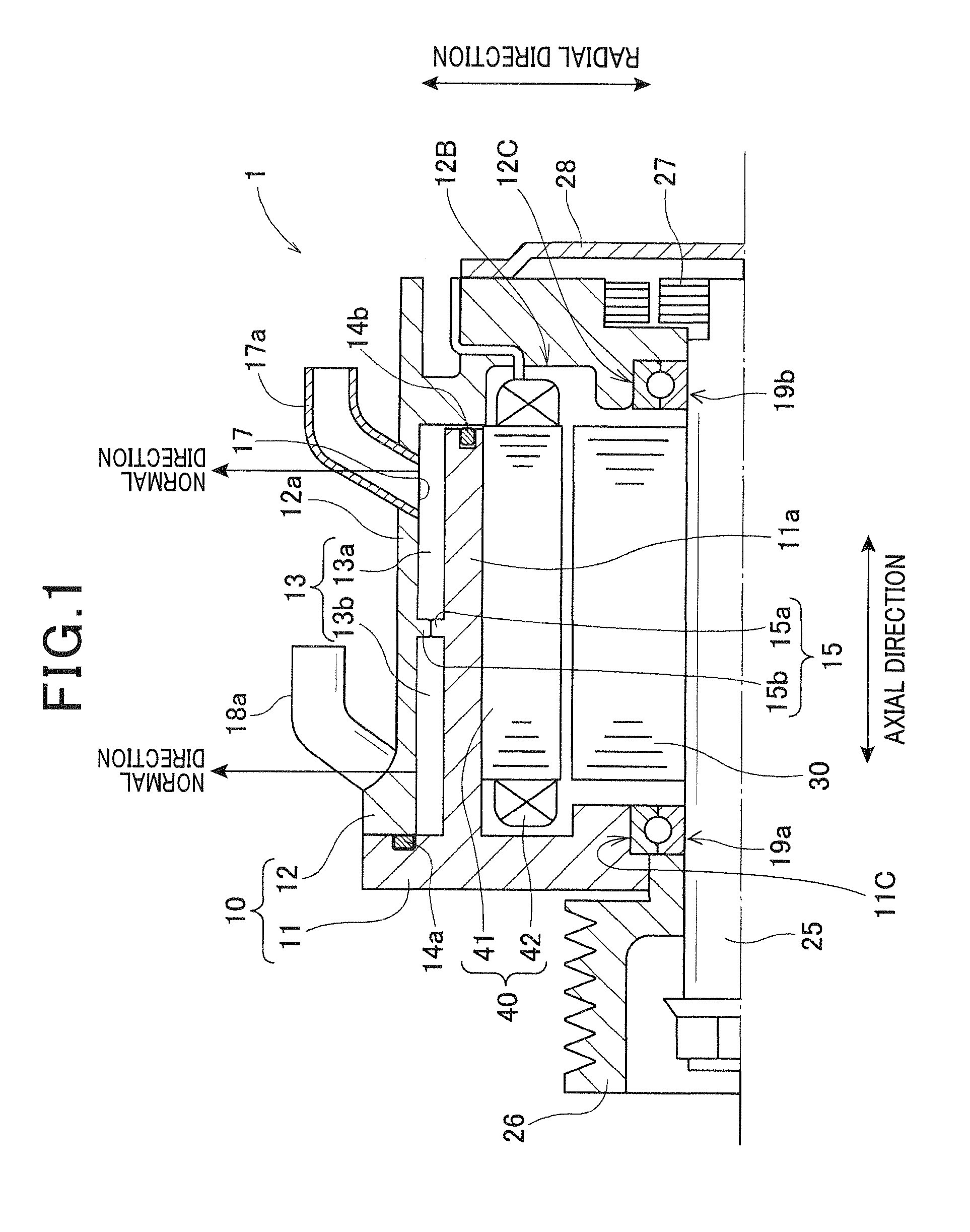

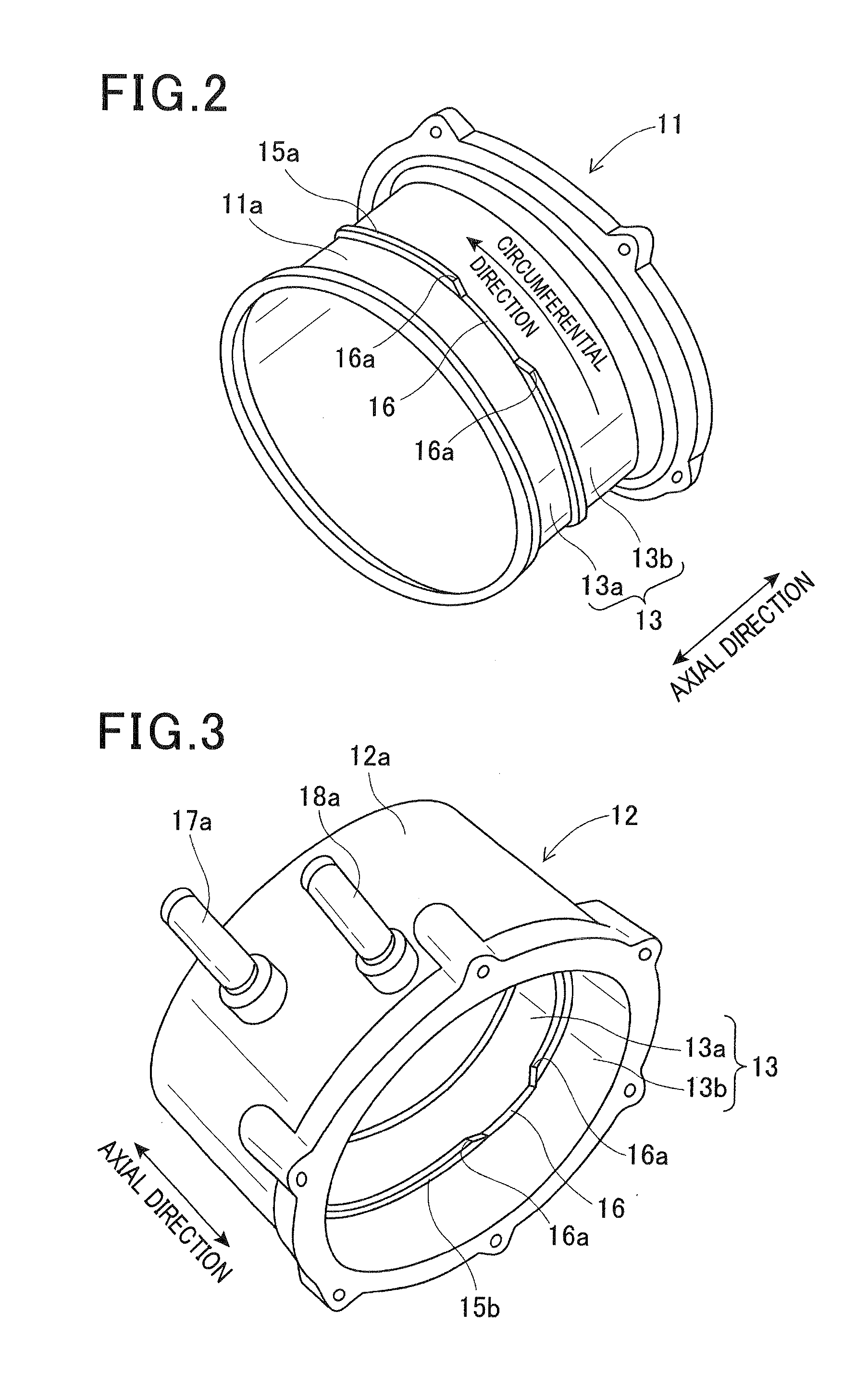

Electric rotary machine

InactiveUS20130169077A1Uniform temperature distributionAvoid output torqueCooling/ventillation arrangementSupports/enclosures/casingsElectric machineCooling fluid

An electric rotary machine has a motor frame having a cooling fluid passage, a rotary shaft rotatably supported by the motor frame, a rotor fixed to the rotary shaft, and a stator. The stator has a core having a ring shape and a stator winding wound around the core. The stator core is arranged to face an outer periphery of the rotor in a radial direction. An inlet section and an outlet section are formed in the motor frame. Cooling fluid is introduced into the cooling fluid passage through the inlet section and discharged from the outlet section. A partition wall section is formed on the motor frame and divides the cooling fluid passage into a cooling fluid inlet passage and a cooling fluid outlet passage. Through an opening formed in the partition wall section, the cooling fluid inlet passage and the cooling fluid outlet passage communicate with each other.

Owner:DENSO CORP

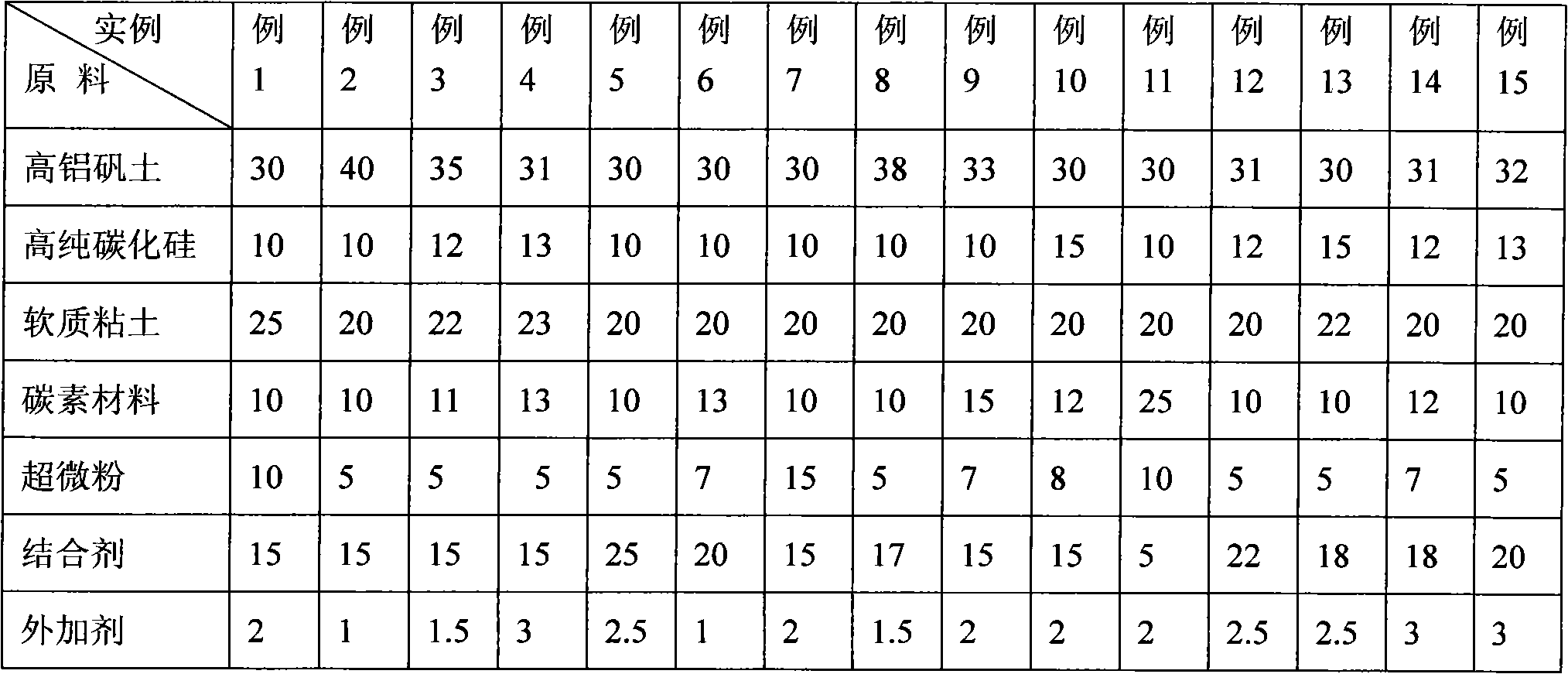

Anhydrous stemming for blast furnace

The invention relates to an anhydrous stemming for a blast furnace. The anhydrous stemming is prepared from the following raw materials in percentages by weight: 30-40 percent of high-alumina bauxite, 10-15 percent of high-purity silicon carbide, 20-25 percent of soft clay, 10-25 percent of carbonaceous material, 5-15 percent of submicron powder, 15-25 percent of binding agent, and additionally silicon metal powder addictives accounting for 1-3 percent of the total weight of the raw materials. The anhydrous stemming has the advantages of favorable high-temperature fire performance, linearity change ratio of lower than 0.3 percent under the condition of 1400 DEG C*2h, breaking strength of more than or equal to 10MPa, high intensity, slag-iron resistant scouring, easy sintering, excellent work performance, less pollution and low production cost, and is beneficial to environment protection as well as popularization and application.

Owner:HENAN HUAXI FURNACE REFRACTORY

Multi-stage denoiser and valve with same

ActiveCN104913148AImprove noise reductionReduce oscillationValve members for absorbing fluid energyPipe elementsVALVE PORTSmall hole

The invention discloses a multi-stage denoiser and a valve with the same. The multi-stage denoiser comprises a hollow denoising cylinder and at least two stages of denoising covers. The denoising covers are arranged in the hollow denoising cylinder in the extension direction of the hollow denoising cylinder. Each stage of denoising cover is provided with a fluid cavity and a fluid inlet formed in the head portion of the fluid cavity. The wall of the fluid cavity of each stage of denoising cover is provided with a plurality of through holes. The fluid inlet of the fluid cavity of the rear stage of denoising cover corresponds to the tail portion of the front stage of denoising cover and forms a buffer cavity together with the tail portion of the front stage of denoising cover. The valve comprises a valve body and an outflow passageway of fluid. The outlet of the outflow passageway is fixedly connected with the denoiser in the axial direction. By arranging the multiple stages of denoising covers, the denoising efficiency is improved, the denoising effect is achieved through the frequency shift effect of small hole spraying, and the fluid flow speed is uniform through the buffer cavity. The vibration caused by fluid impact to the denoiser is reduced in the medium flowing process, and therefore the stability of the product is improved, and the overall service life of the denoiser is prolonged.

Owner:NEWAY VALVE SUZHOU

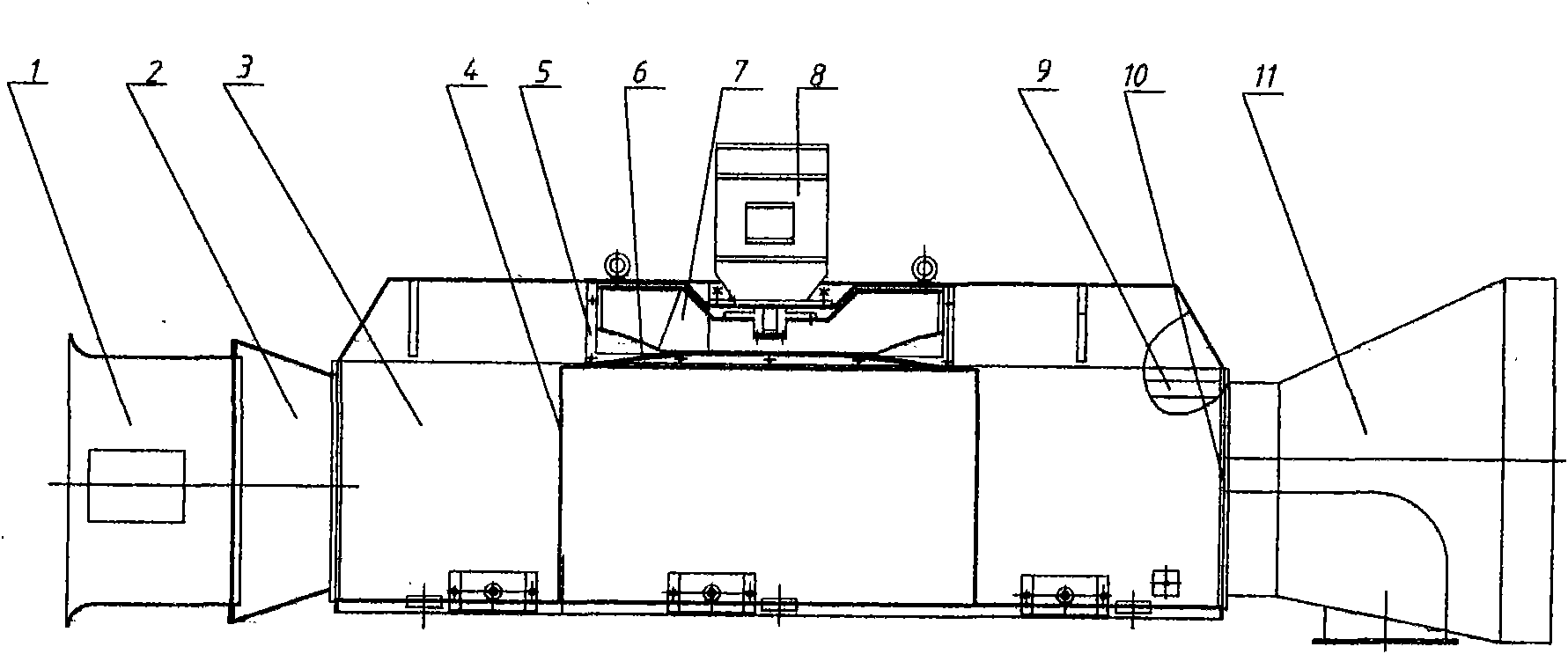

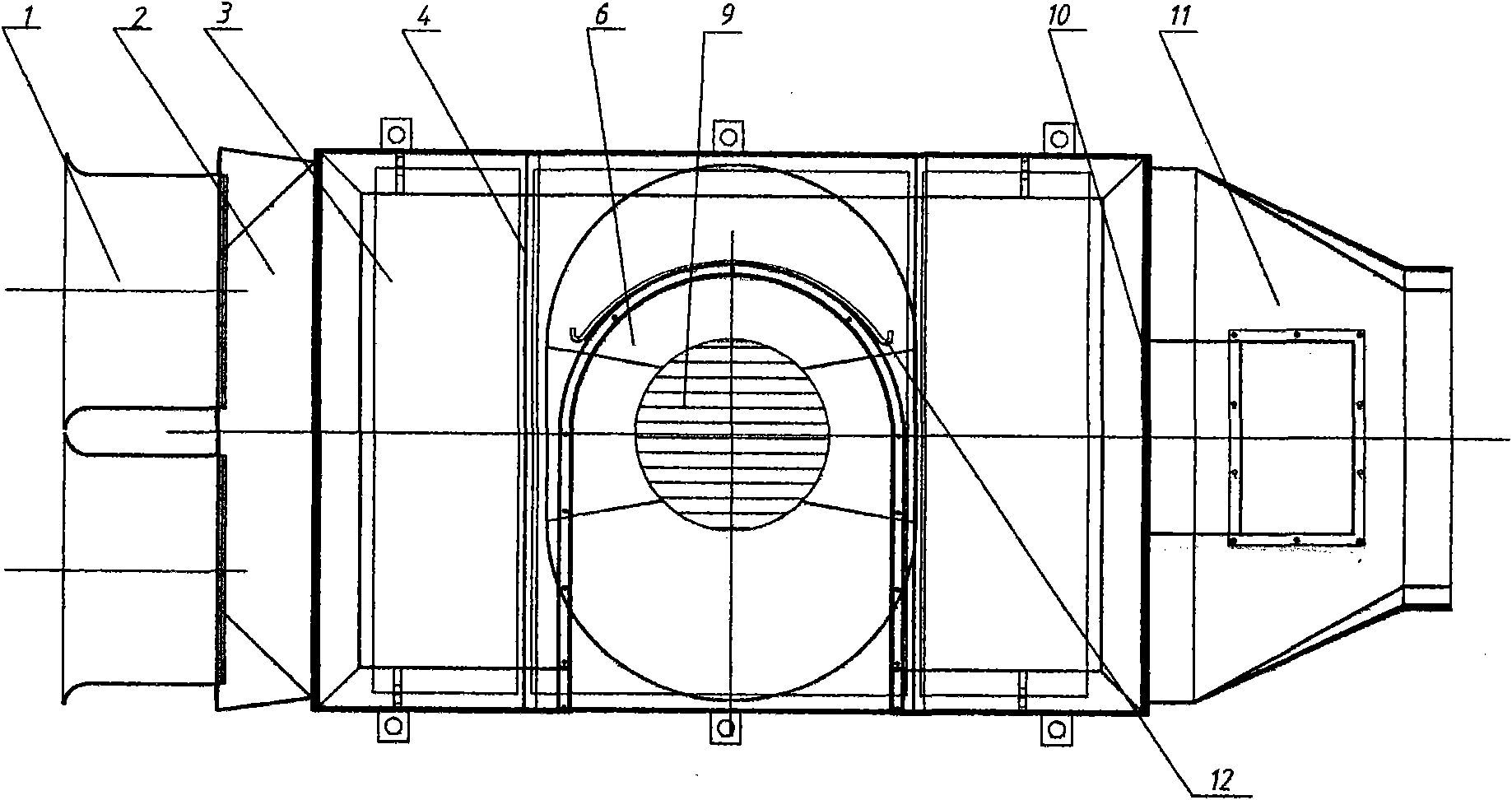

Cooler of wind power generator

ActiveCN101834490AUniform flow rateReduce wind resistanceManufacturing dynamo-electric machinesWind energy generationElectricityEngineering

The invention relates to an air-air cooler used for a wind power generator, in particular to a cooler of a wind power generator with large power. A backpack type installation way is adopted between the cooler and the wind power generator; the whole cooler is buckled on the wind power generator and comprises an outer wind path fan, a ventilating cabinet, a pipe plate, heat exchange pipes, a wind collector, a wind inlet and a wind outlet, wherein a cover plate with a moulding disk-type motor installation seat is arranged on the ventilating cabinet; an inner wind path fan comprising a centrifugal fan and a motor is installed on the cover plate; a push insertion fastening installation way is adopted between the cover plate and the ventilating cabinet; a cove disc-type machine soleplate can reduce the overall height of the wind power generator after the machine is equipped and is easy to let the cooler move and be operated in the machinery room.

Owner:ZHEJIANG ERG TECH

Cooling device, cooling system and experimental system and method of cooling device

InactiveCN107329546AEven heat dissipationImprove heat transfer efficiencyDigital data processing detailsStructural/machines measurementSilica gelMechanical engineering

The invention relates to a cooling device which comprises a pressure cavity cover piece, a perforation plate and a microchannel matrix plate in sequential sealed connection through waterproof silica gel. A first liquid collection cavity and a second liquid collection cavity are symmetrically formed on one side, connected with the perforation plate, of the microchannel matrix plate and communicated through a plurality of microchannels, and one side, connected with the pressure cavity cover piece, of the perforation plate inwards concaves to form a cavity which is sealed through the pressure cavity cover piece to form a pressure cavity; multiple perforation holes communicated with the microchannels penetrate the bottom of the pressure cavity, the perforation plate is provided with a first liquid outlet and a second liquid outlet on two sides of the cavity, and a liquid inlet communicated with the pressure cavity is formed in the middle of the pressure cavity cover piece. Cooling is realized by means of combining jet flow impact with the microchannels, so that the characteristic that the microchannels are large in heat exchange area can be utilized, the characteristic that jet flow impact is high in local heat exchange efficiency can be utilized, the problem of nonuniform cooling is solved, and heat exchange efficiency of the whole device is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

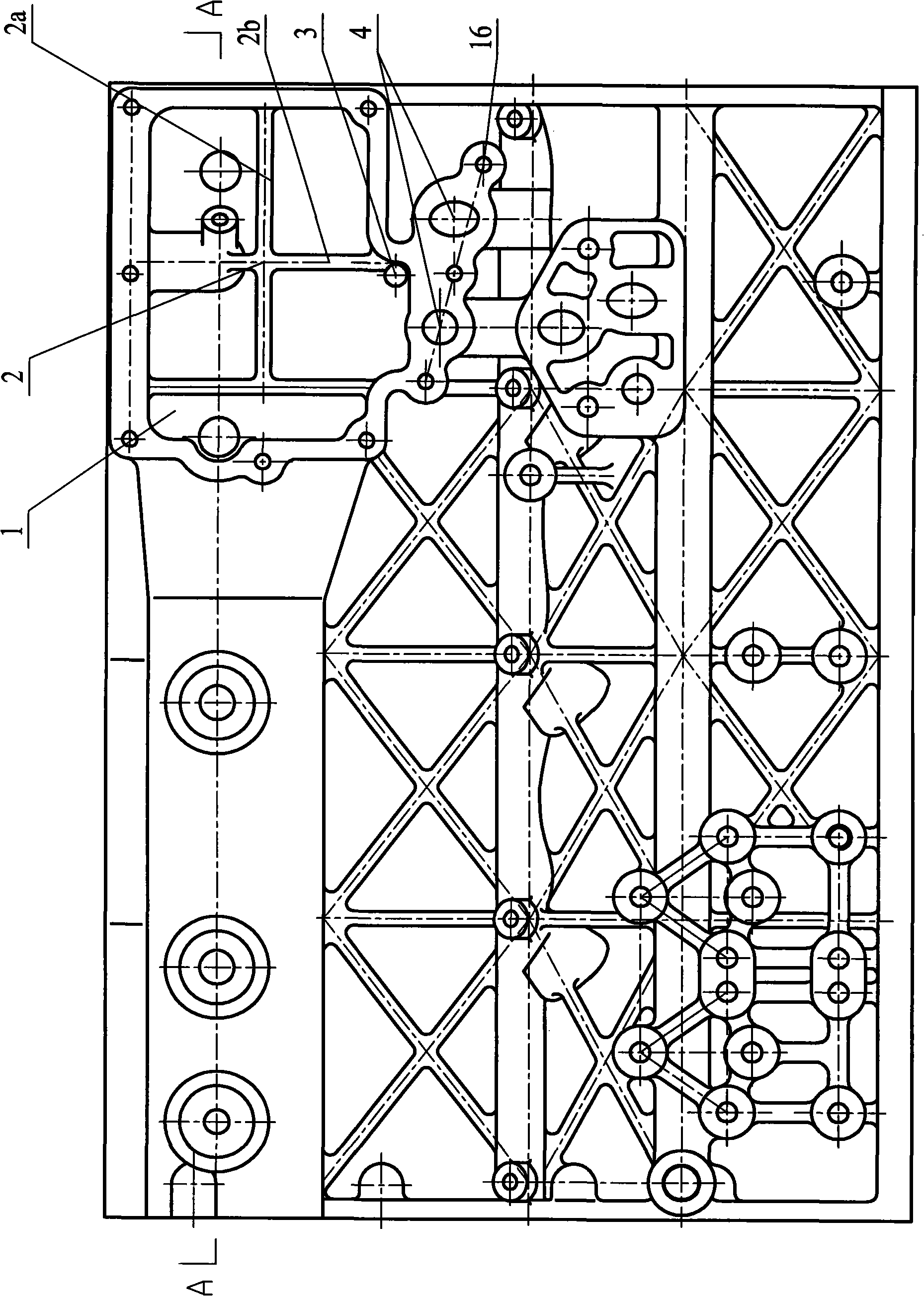

Exhaust muffler capable of automatically adjusting overflow area

InactiveCN101813017AImprove the noise reduction effectUniform flow rateExhaust apparatusSilencing apparatusEngineeringExpansion chamber

The invention discloses an exhaust muffler capable of automatically adjusting the overflow area, which comprises an air inlet pipe, an expansion chamber and an air outlet pipe, wherein the inner circle of the section (provided with radial through-holes) of the air inlet pipe is provided with a piston which can slide to and fro along the inner wall of the pipe, and the front end of the piston faces the air inlet direction, while the rear end is provided with a pressure spring which can apply pressure (with a direction opposite to the air inlet direction) to the rear end. The invention adopts a structure that the exhaust pipe section of the air inlet pipe is provided with the piston which divides the exhaust pipe section into an exhaust part and a closed part, the position of the piston can be automatically adjusted according to the exhaust pressure and the piston can reset under the action of the spring when the exhaust pressure is low; therefore, the exhaust muffler has the advantages of adjusting the area of the airflow ventilating section according to the exhaust gas flow of an engine under different working conditions, keeping the exhaust airflow in an even flow velocity, effectively lowering the exhaust backpressure, reducing the regenerated noise of the airflow, improving the erasure effect of the muffler, and having a positive significance for reducing the fuel consumption and carbon dioxide emission of an automobile.

Owner:CHONGQING UNIV

Water jacket structure of diesel cylinder block

InactiveCN101787936AAvoid cylinder liner deformationAvoid direct flushingCylinder headsCylindersCylinder blockEngineering

The invention relates to a water jacket structure of a diesel cylinder block. The upper portion of an intake side of the cylinder block is provided with a water distributing channel, the front end of which is connected with a water pump and the rear end of which is provided with an engine oil cooler cavity; a cylinder block water jacket is formed at the middle / upper portion of the cylinder block and comprises at least two transversely parallel single water jacket bodies, each of which is provided with an water intake hole and a water drainage hole, the water distributing channel is communicated with the interior of each of the single water jacket bodies through the water intake holes; the water intake hole on the first single water jacket body at the front end of the cylinder block water jacket comprises a front straight water intake hole and a rear straight water intake hole, the water intake holes on other single water jacket bodies each comprise a rear straight water intake hole, wherein all the single water jacket bodies are each provided with an oblique water intake hole except the first single water jacket body, the front straight water intake hole, the rear straight water intake hole and the oblique water intake hole are all tangential to the periphery of the single water jacket bodies. The water jacket structure, skillful and reasonable in structure, can effectively cool the cylinder block and the engine oil, increase the rigidity of the intake side of the cylinder block and lower noise.

Owner:JIANGSU SIDA POWER MECHANICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com