Exhaust muffler capable of automatically adjusting overflow area

A technology of exhaust muffler and flow area, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc. It can solve the problems of unable to adjust the cross-sectional area of air flow and complex structure, so as to improve the noise reduction effect and reduce the exhaust back Pressure, reduce the effect of air regeneration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

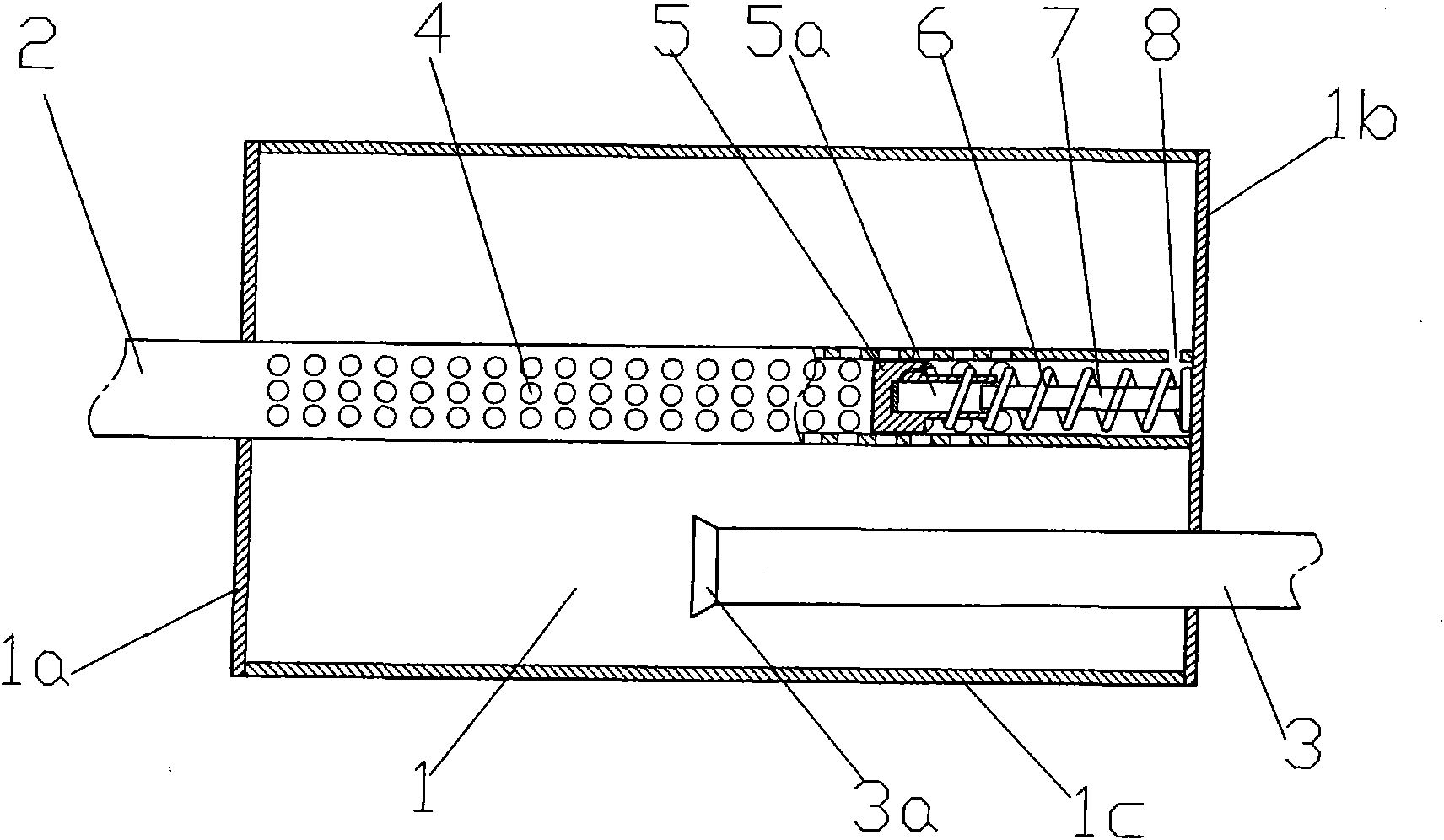

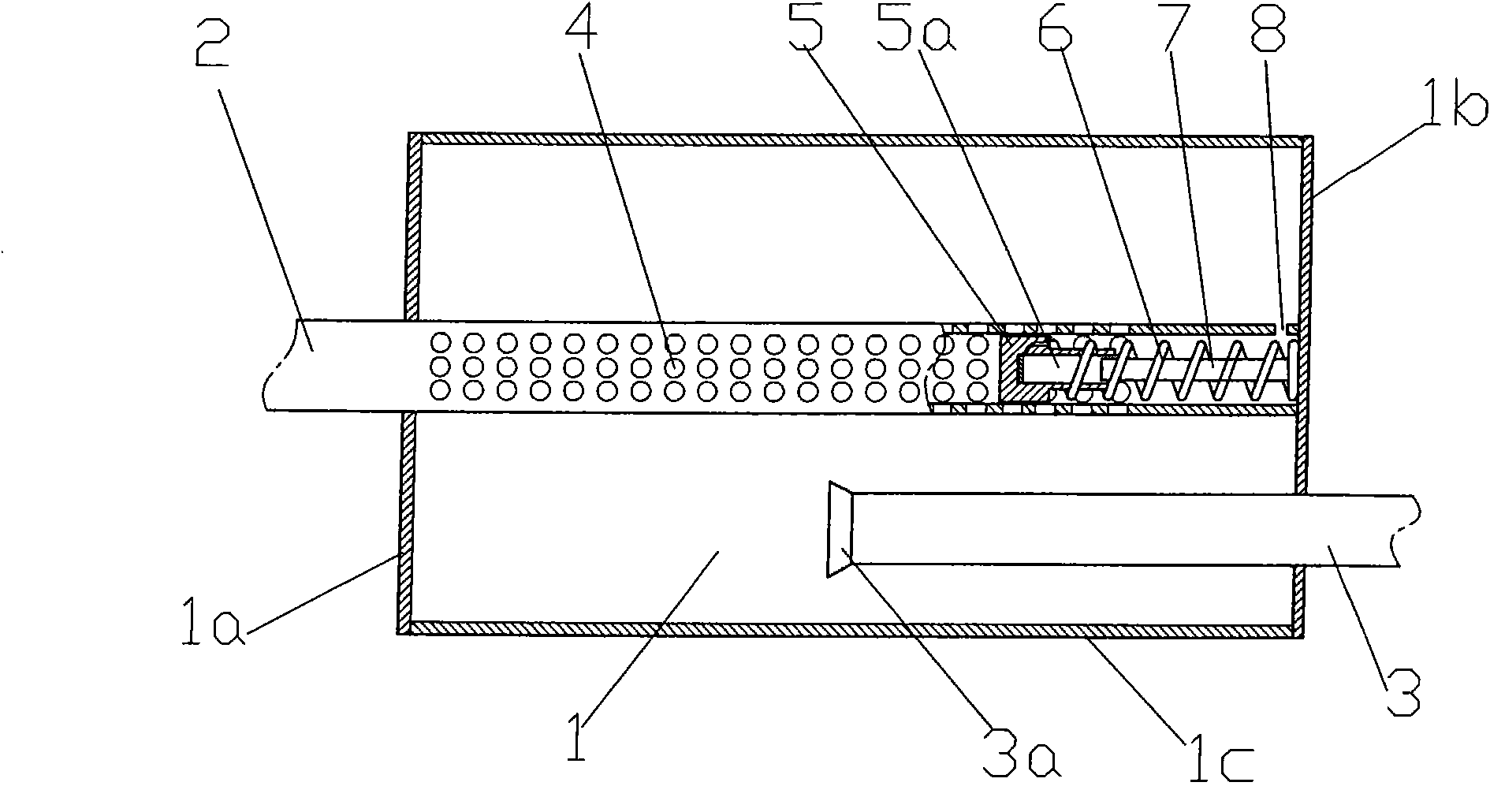

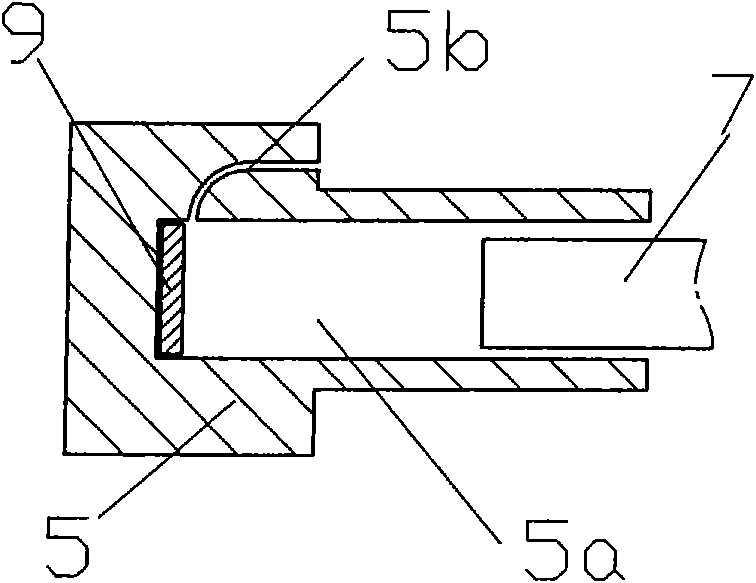

[0023] Fig. 1 is a structural schematic diagram of the first embodiment of the present invention, Fig. 2 is an enlarged view of the cooperation structure of the piston and the guide rod, and Fig. 3 is an enlarged view of the cooperation of the piston and the guide rod with a smooth transition arc surface end face, as shown in the figure: this embodiment The exhaust muffler with automatic adjustment of the flow area includes the muffler intake pipe 2, the expansion chamber 1 and the muffler exhaust pipe 3. The muffler intake pipe 2 is connected to the exhaust port of the engine through the air inlet, The air port is connected to the expansion chamber 1, and the muffler exhaust pipe 3 is connected to the expansion chamber 1 through the air inlet 3a. Through hole 4, the muffler inlet pipe 2 is provided with a piston 5 that can reciprocate and slide along the inner wall of the tube on the inner circle of the pipe section of the radial through hole 4. The front end of the piston 5 f...

Embodiment 2

[0035] Fig. 4 is a schematic structural diagram of the second embodiment of the present invention. As shown in the figure, the difference between the present embodiment and the first embodiment is only that a rear end cover of the inlet pipe 2 of the muffler and the rear end cover of the expansion chamber 1 is provided. Set distance and seal through end cap 10 instead of directly sealing through rear end cap 1b of expansion chamber 1; this structure makes full use of the volume of expansion chamber 1 and eliminates exhaust noise to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com