Steel surface type composite air duct and manufacturing method thereof

A technology of composite air duct and manufacturing method, which is applied in the directions of heating method, pipeline protection, and protection of pipeline through heat insulation, etc. High strength and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

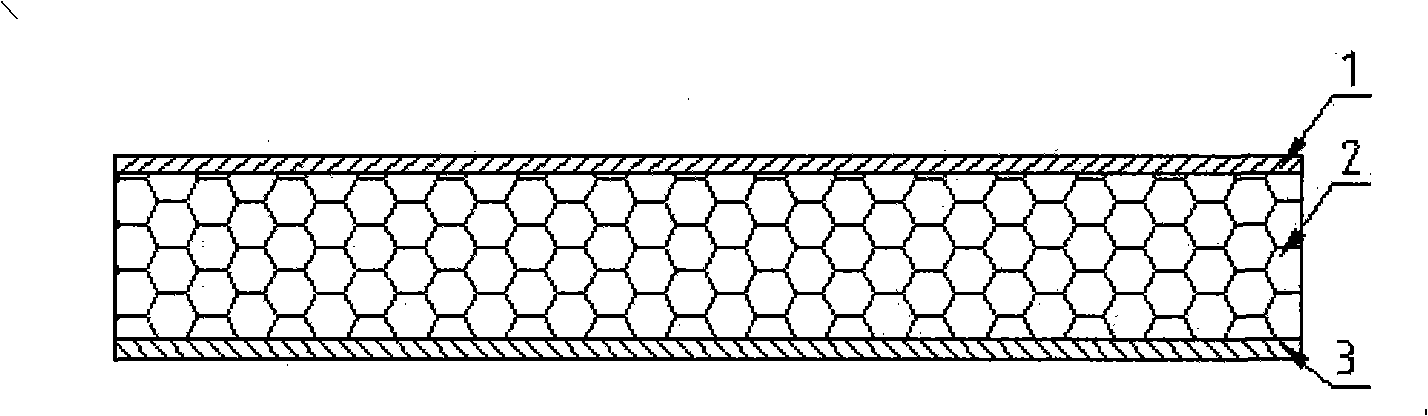

[0048] see figure 1, the preparation of the steel-faced composite air duct plate is to pass the steel-faced surface layer 1 and the inner protective layer 3 through gluing and roller rolling respectively, then the moisture in the glue is basically evaporated through an oven, and then the intermediate foam The insulation layer 2 is placed between the steel-faced surface layer and the inner protective layer, and then pressed and bonded together by the pair of rollers of the compound machine.

[0049] The specific method of pipe segment division and cutting is as follows:

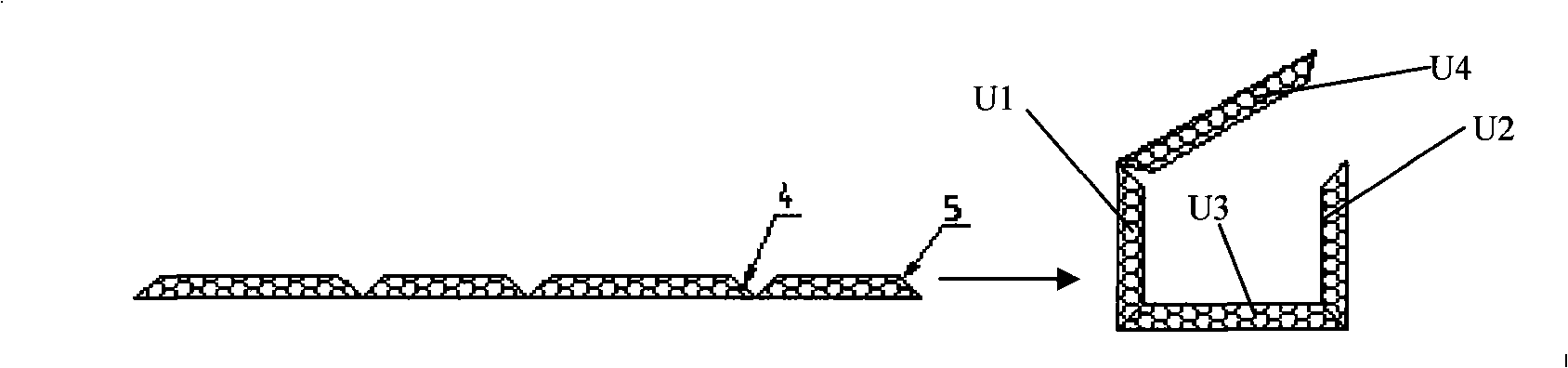

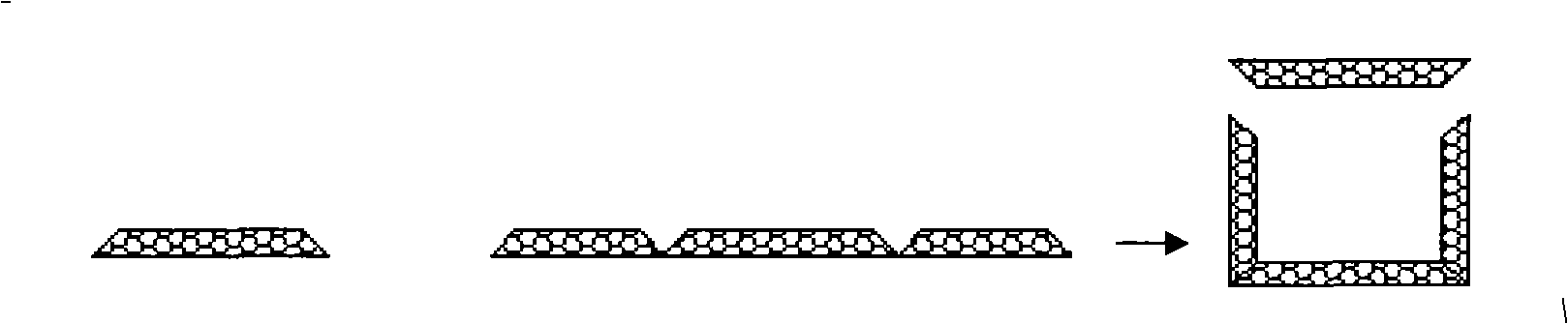

[0050] 1) When the corners are at right angles, accurately calculate the size and specification of the air duct, segment and mark the inner layer of the steel-faced composite air duct plate, and according to the width of the steel-faced composite air duct plate and the prefabricated air duct The length of the two opposite sides can be divided into 4 kinds of scribe cutting methods. figure 2 A schematic diag...

Embodiment 2

[0064] The manufacturing process of the curved pipe section of the steel surface composite air duct. The production process of pipe segment division and cutting is: use a bending machine to press the required bending place on the inner layer of the steel-faced composite air duct plate, so that the plate has a "V"-shaped groove 10, which has bendability. The pressing depth should not exceed 5mm. If the depth is too large, the plate is easy to break; if the depth is too small, it is not suitable for bending. The bending length of the sheet depends on the bending arc length of the duct. All the other structures and techniques are the same as in Example 1. Such as Figure 9 and 10 shown.

Embodiment 3

[0066] Manufacture process of 90° elbow of steel surface composite air duct. The manufacturing process of dividing and cutting is as follows: 1) cutting the left and right air duct plates 15 with a certain arc shape, the specific cutting is the same as in embodiment 1. 2) cutting the upper and lower air duct plates 16, the specific cutting is the same as in embodiment 2. All the other techniques are with embodiment 1, as Figure 14 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com