Patents

Literature

1298 results about "Arc length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arc length is the distance between two points along a section of a curve. Determining the length of an irregular arc segment is also called rectification of a curve. The advent of infinitesimal calculus led to a general formula that provides closed-form solutions in some cases.

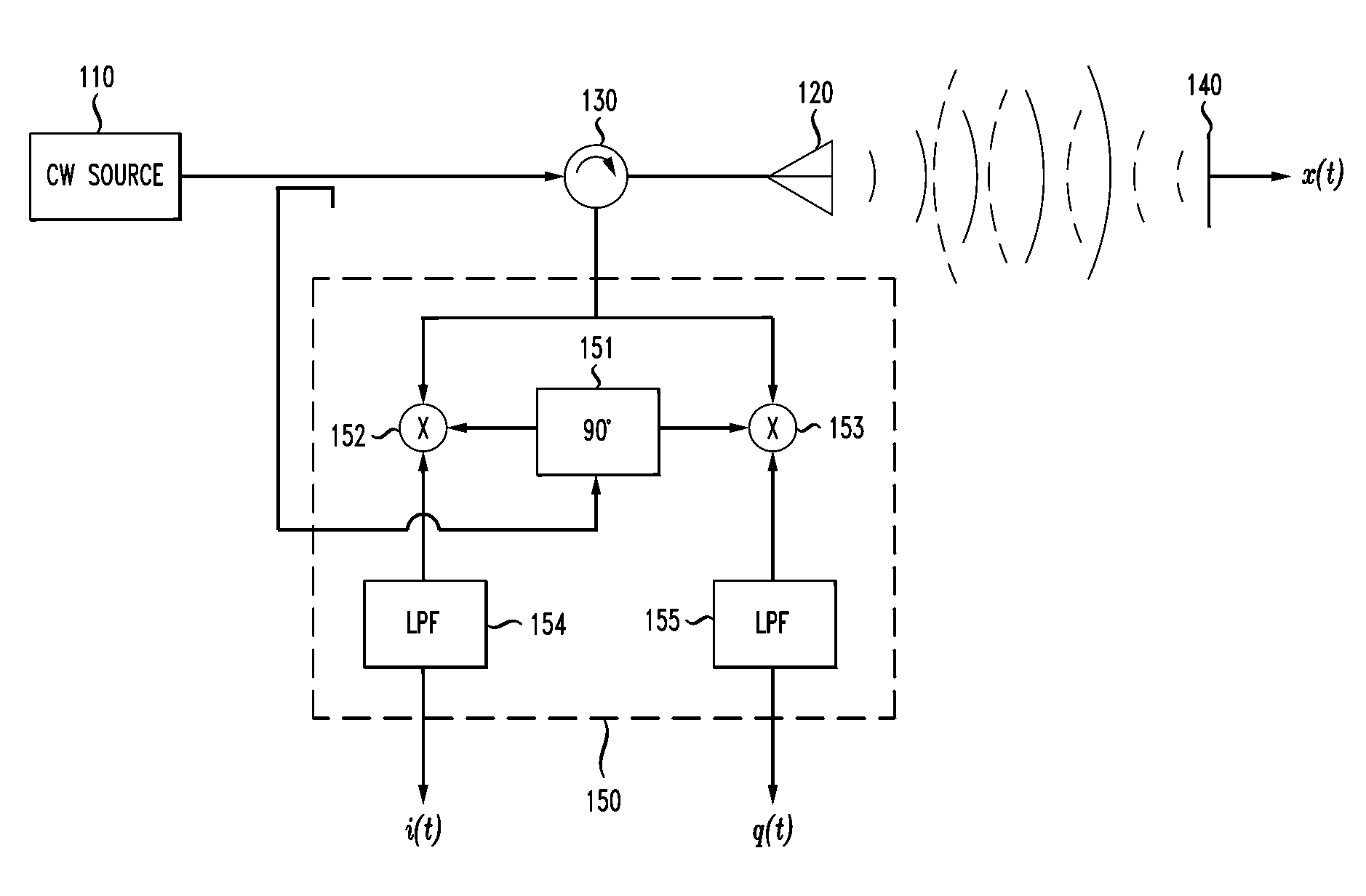

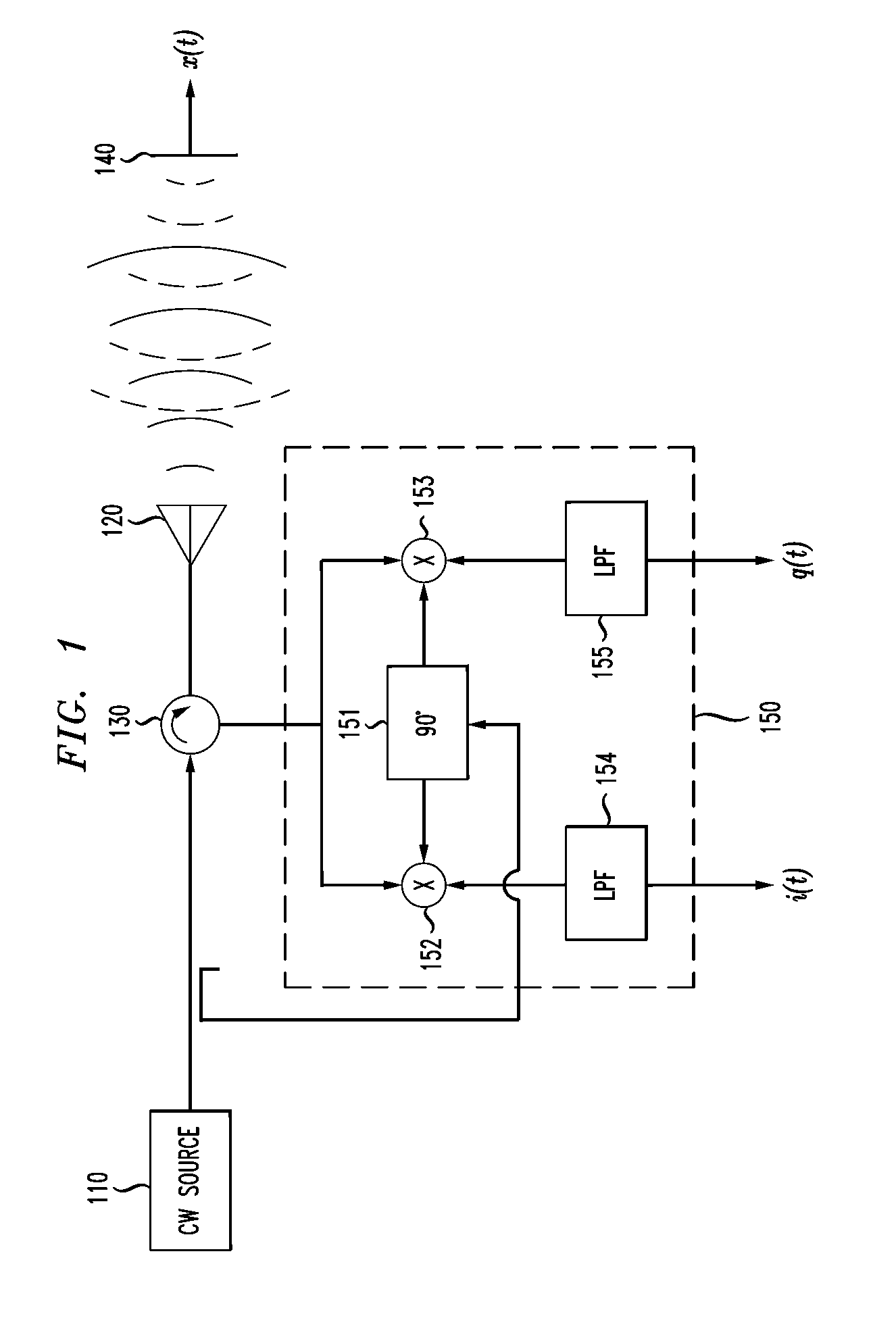

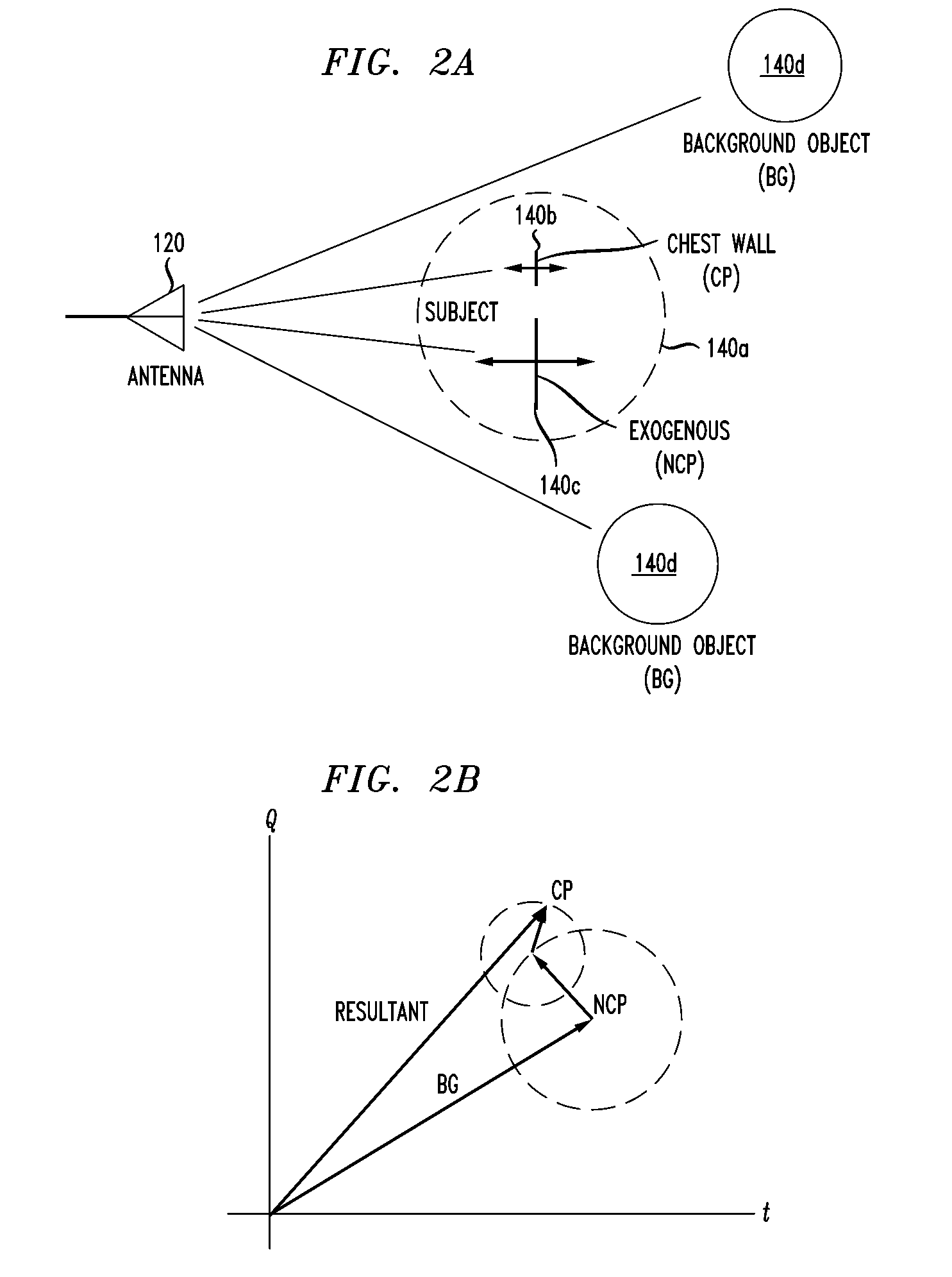

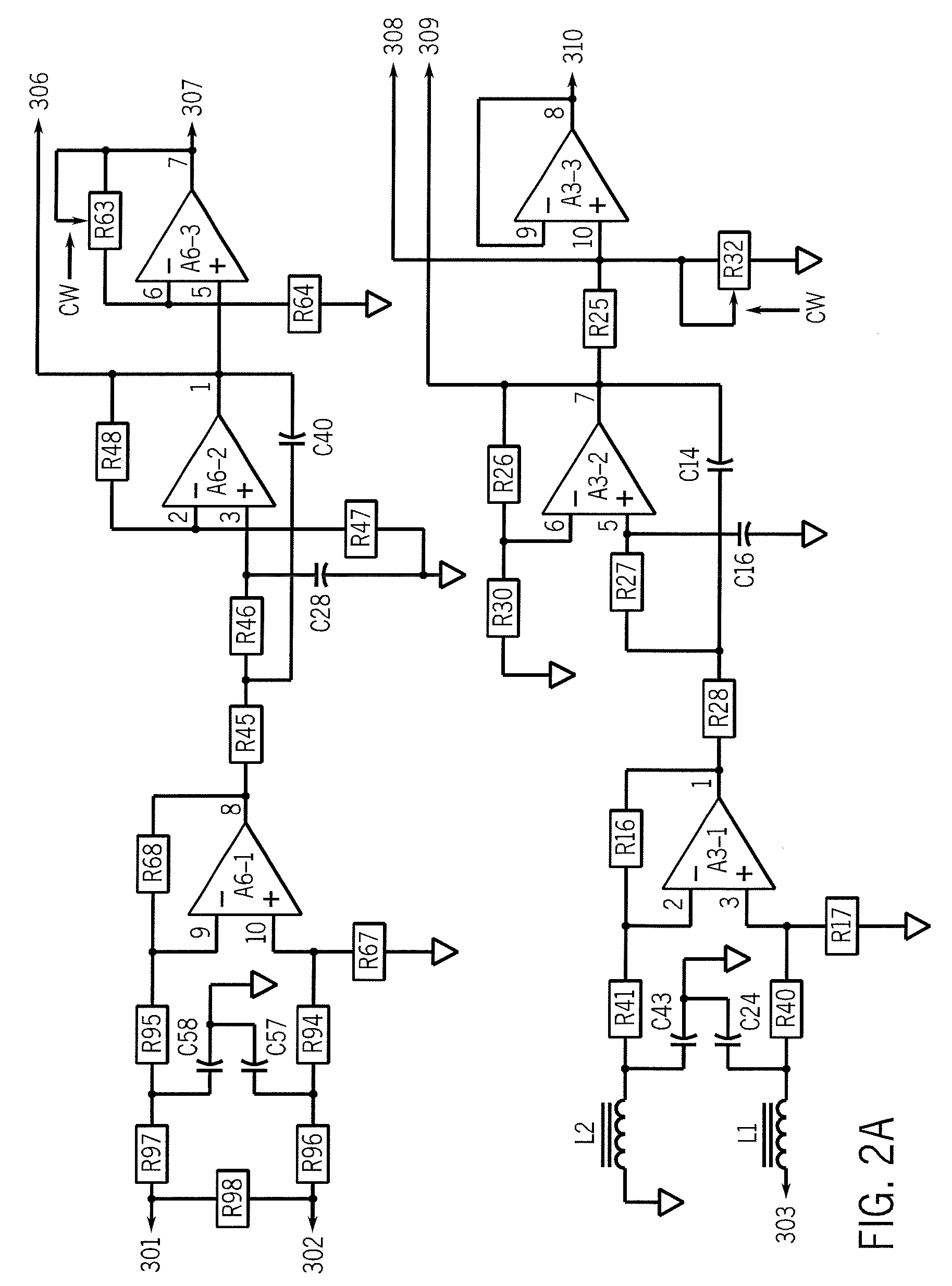

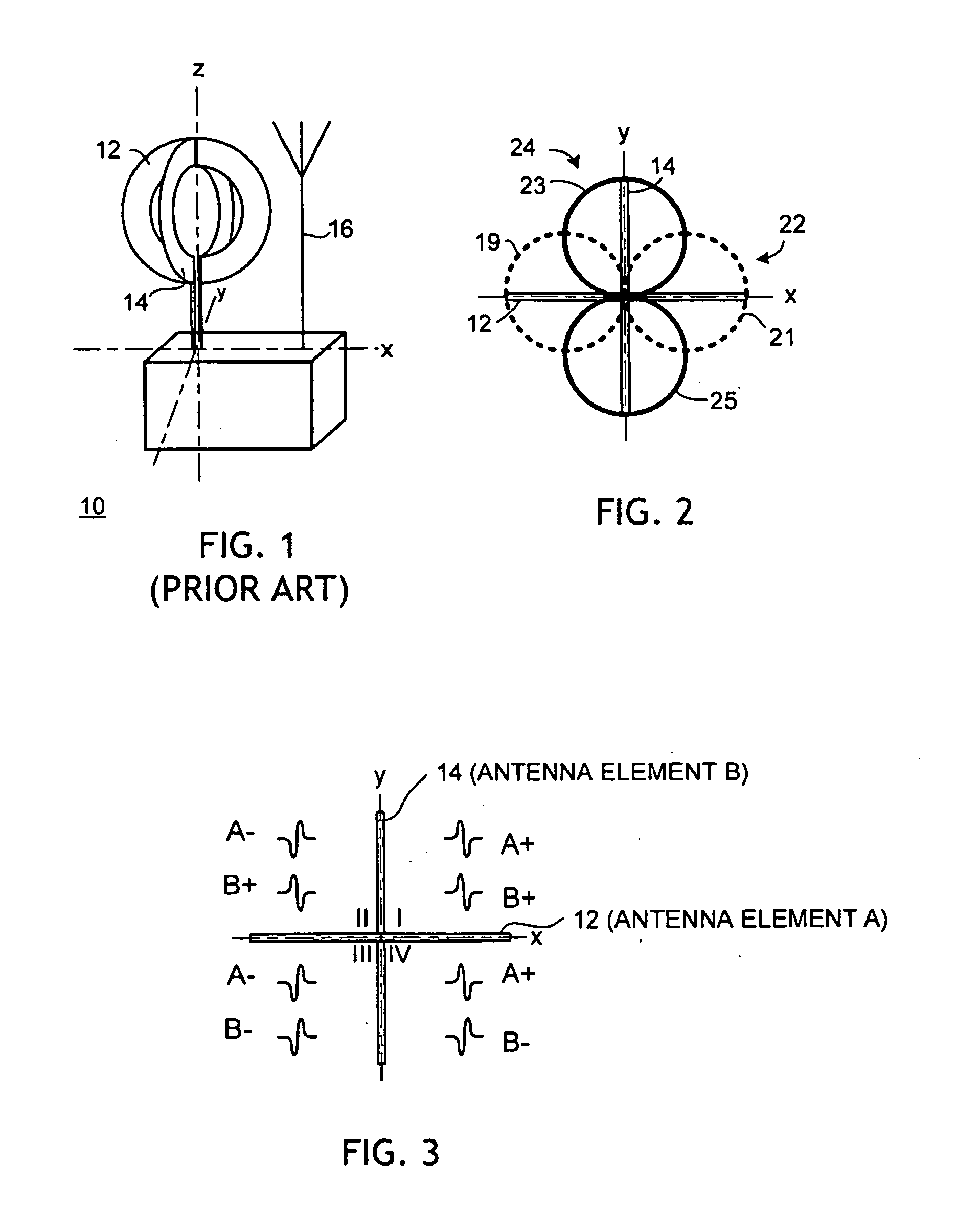

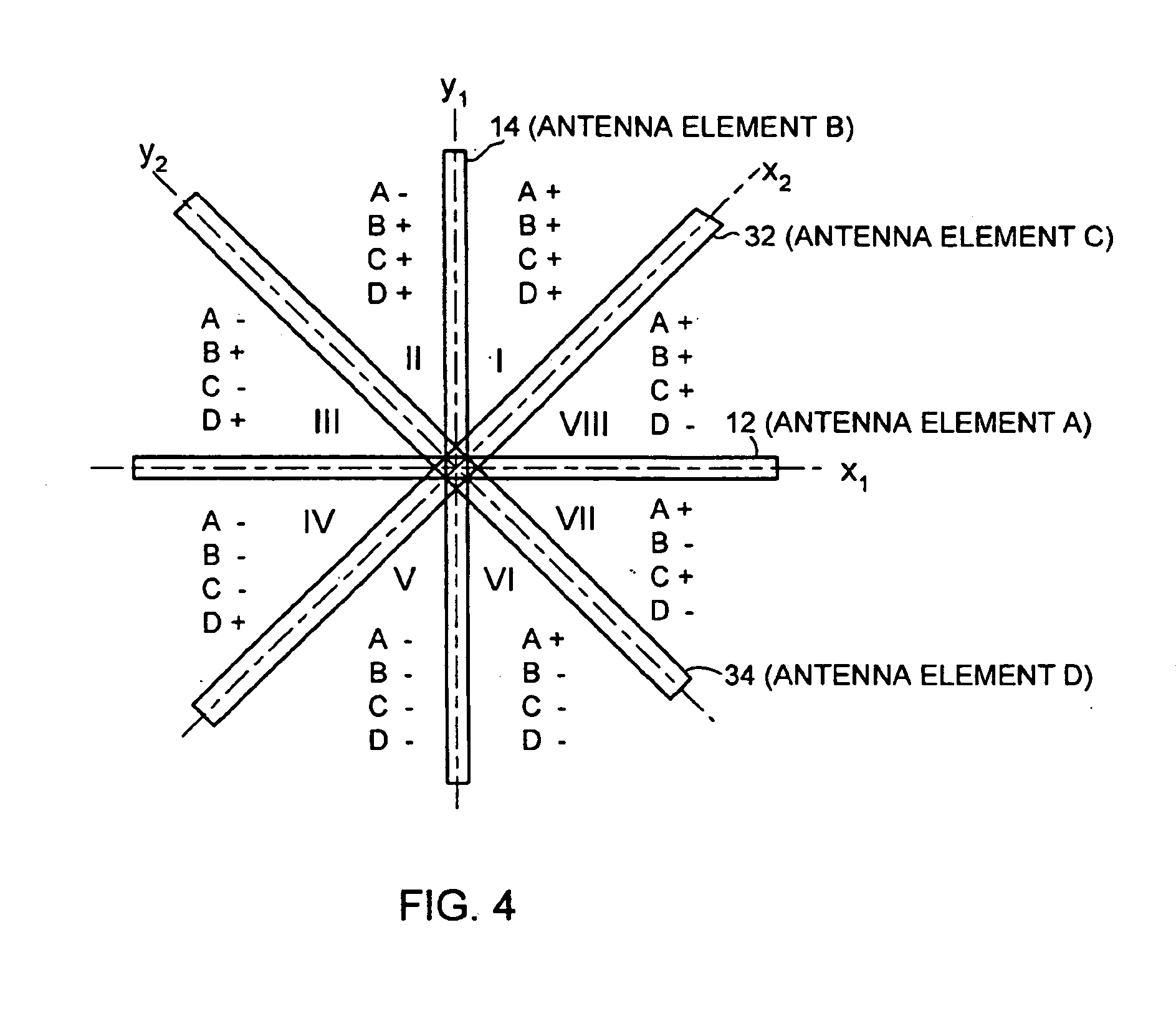

Doppler Radar Cardiopulmonary Sensor and Signal Processing System and Method for Use Therewith

A Doppler radar signal processing system and method and a Doppler radar employing the system or the method. In one embodiment, the system includes: (1) an input configured to receive at least one radar output signal representing a reflected Doppler radar signal, (2) signal processing circuitry coupled to the input and configured to produce an arc-length cardiopulmonary signal from the at least one radar output signal and employ a respiration fundamental frequency estimate to extract a heart rate signal from the arc-length cardiopulmonary signal and (3) an output coupled to the signal processing circuitry and configured to provide the heart rate signal.

Owner:ALCATEL-LUCENT USA INC

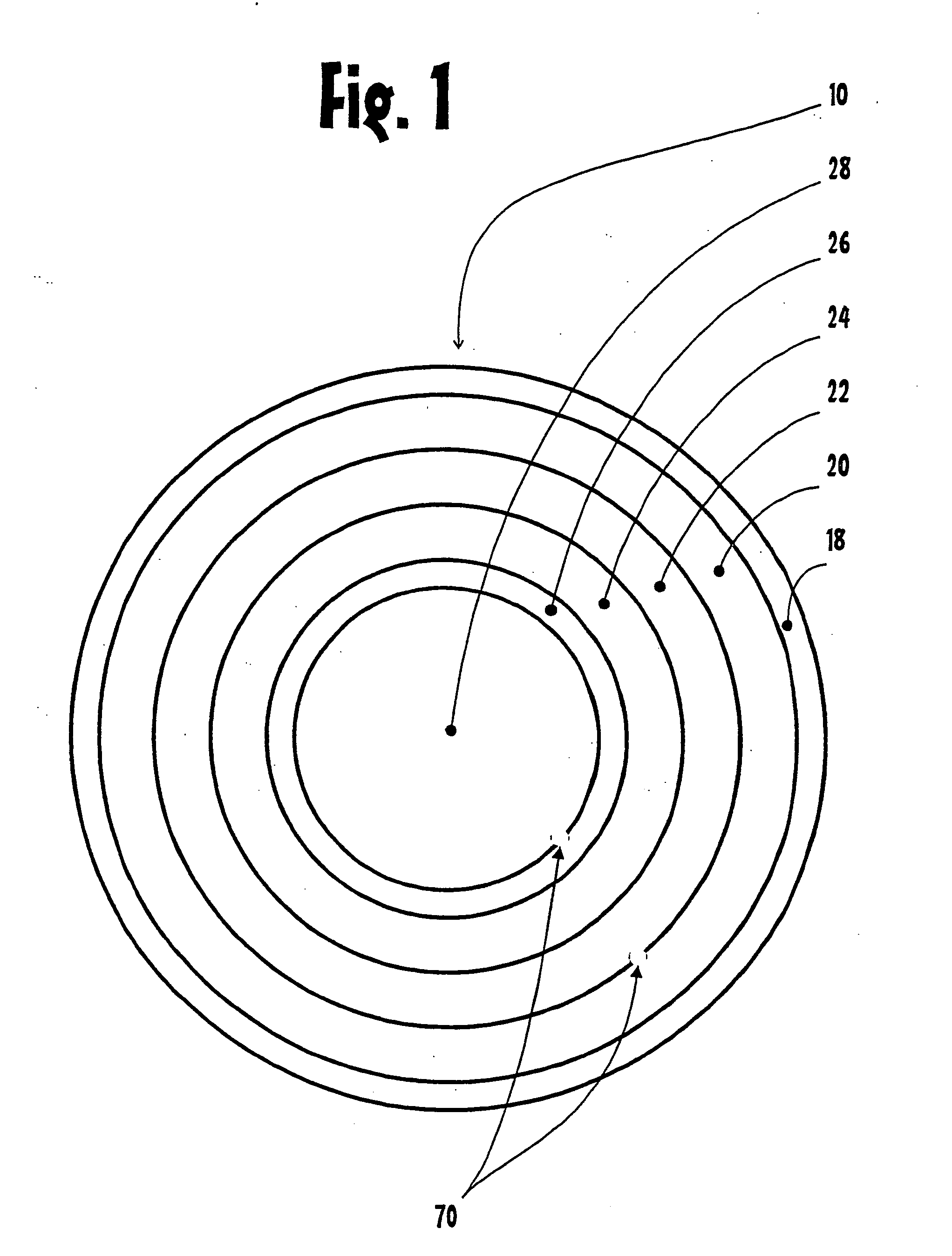

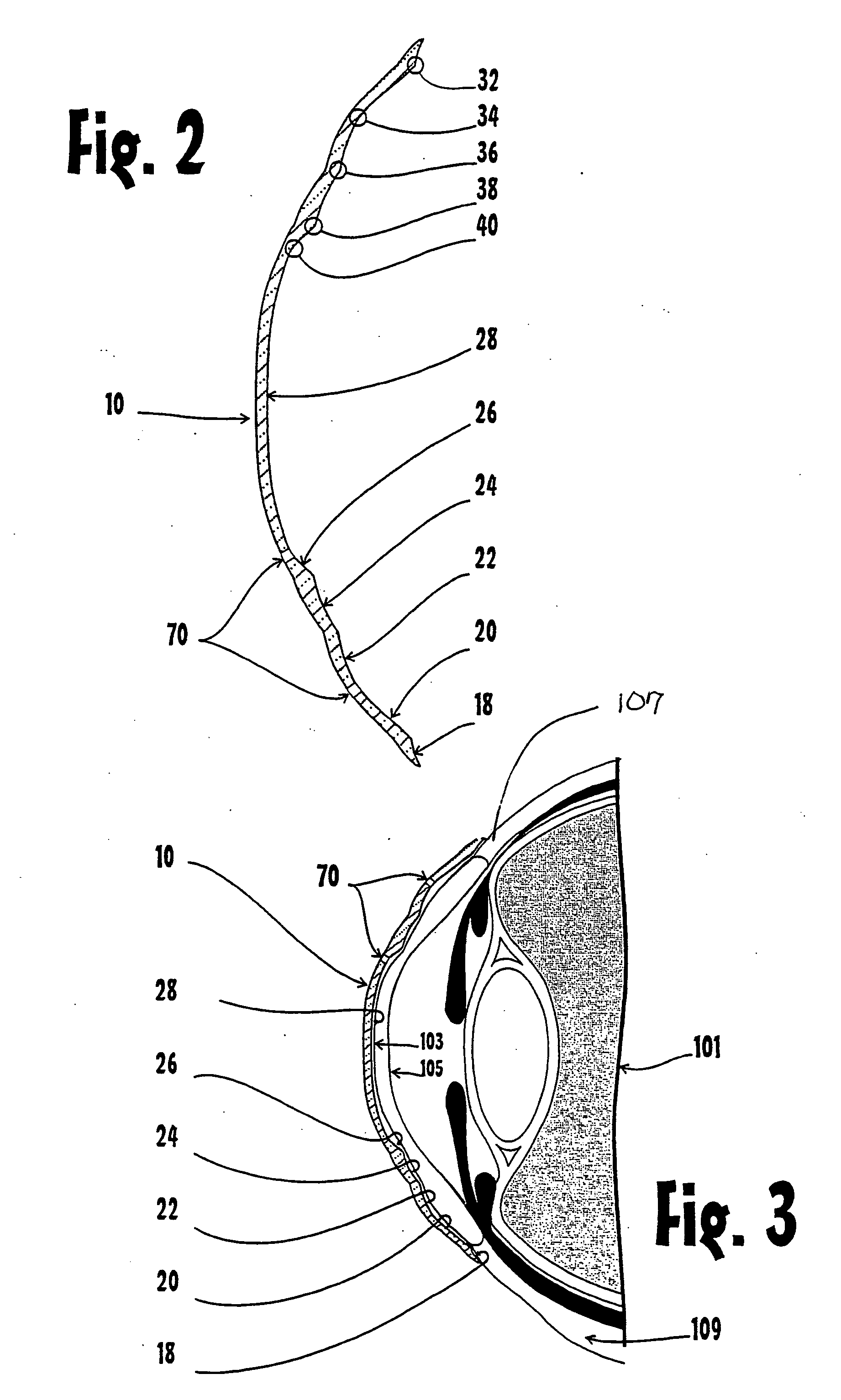

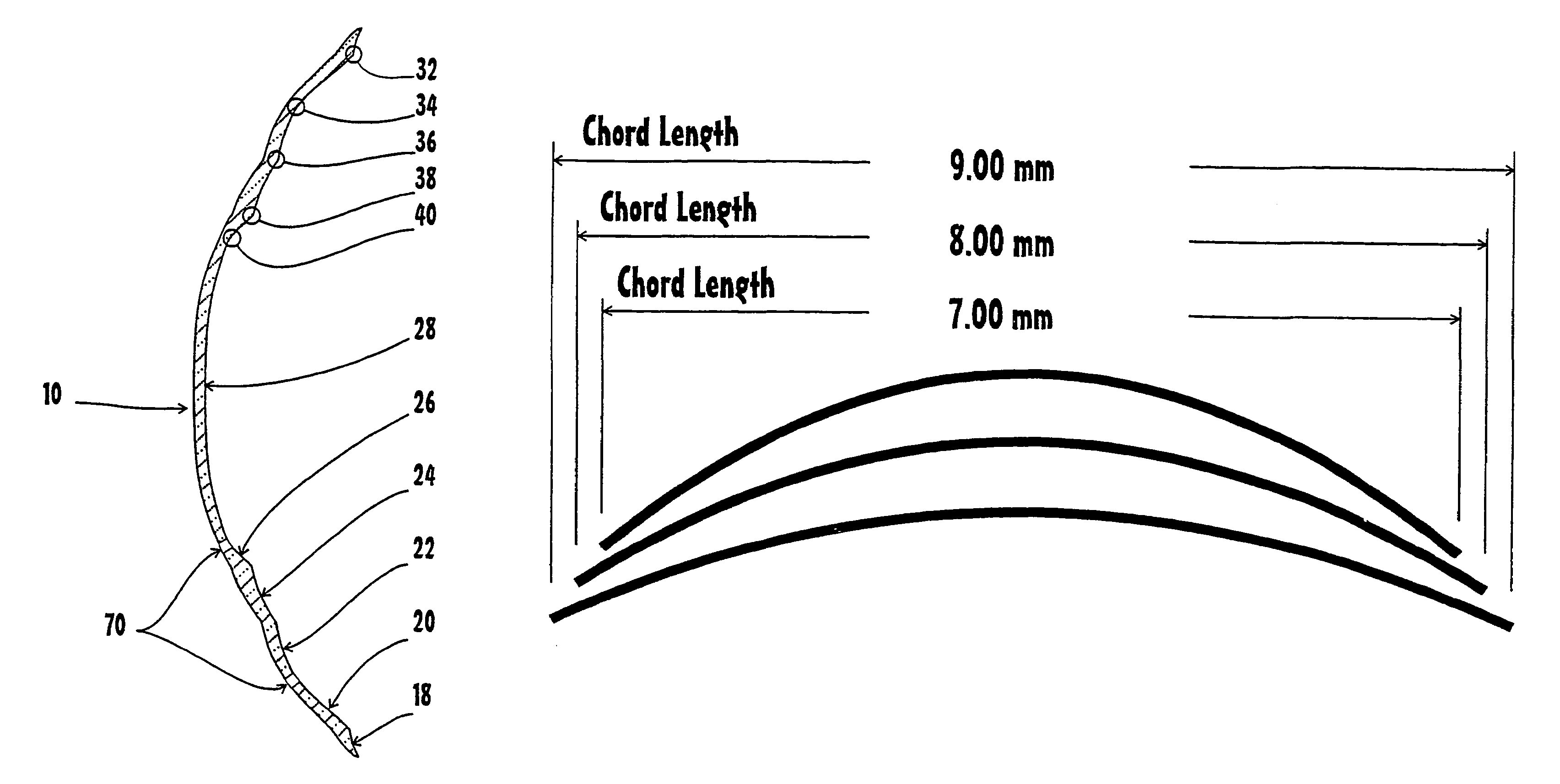

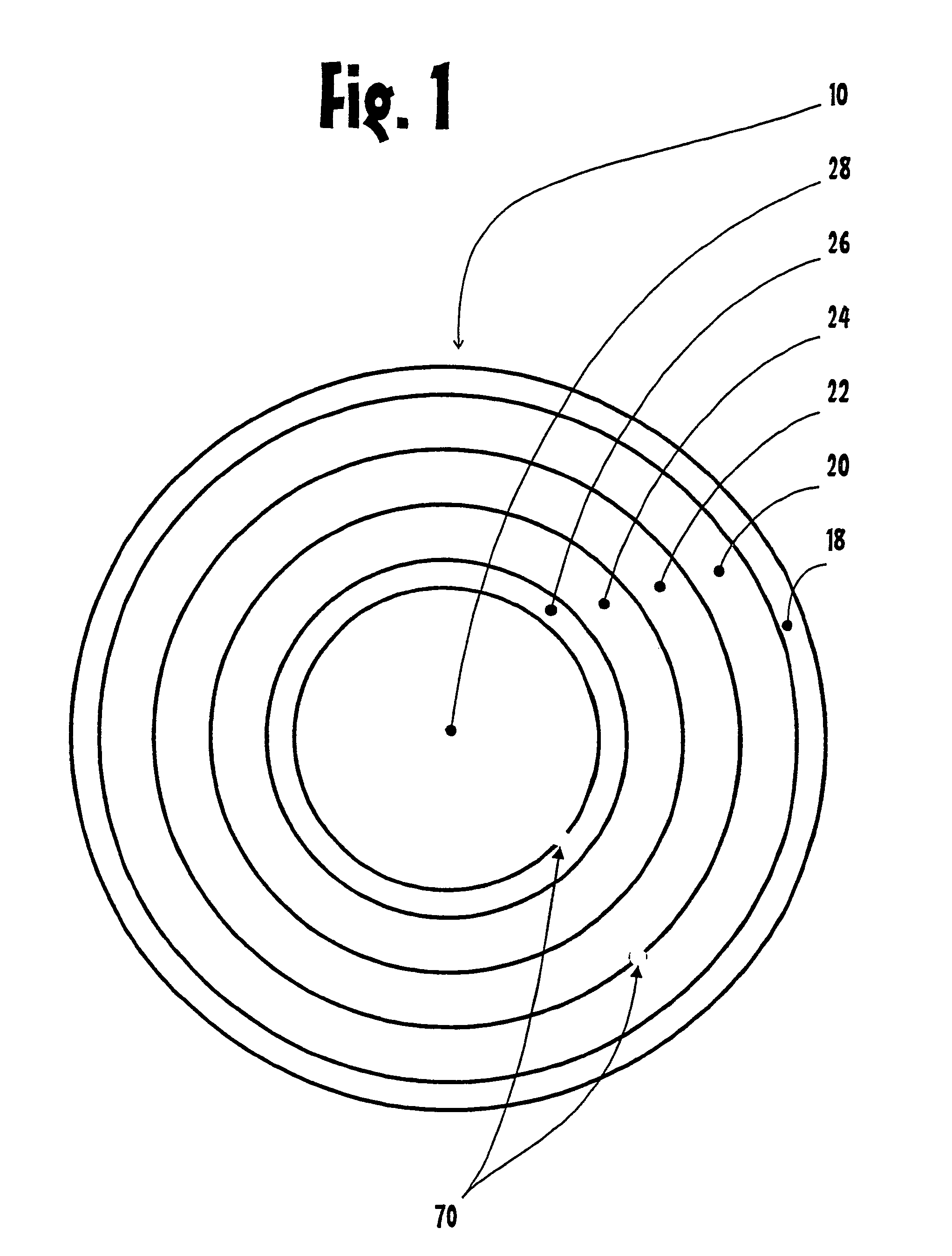

Corneal-scleral orthokeratology contact lens

ActiveUS20060152673A1Improve abilitiesFast and reliable and comfortable resultOptical partsCorneal curvatureRigid gas permeable lens

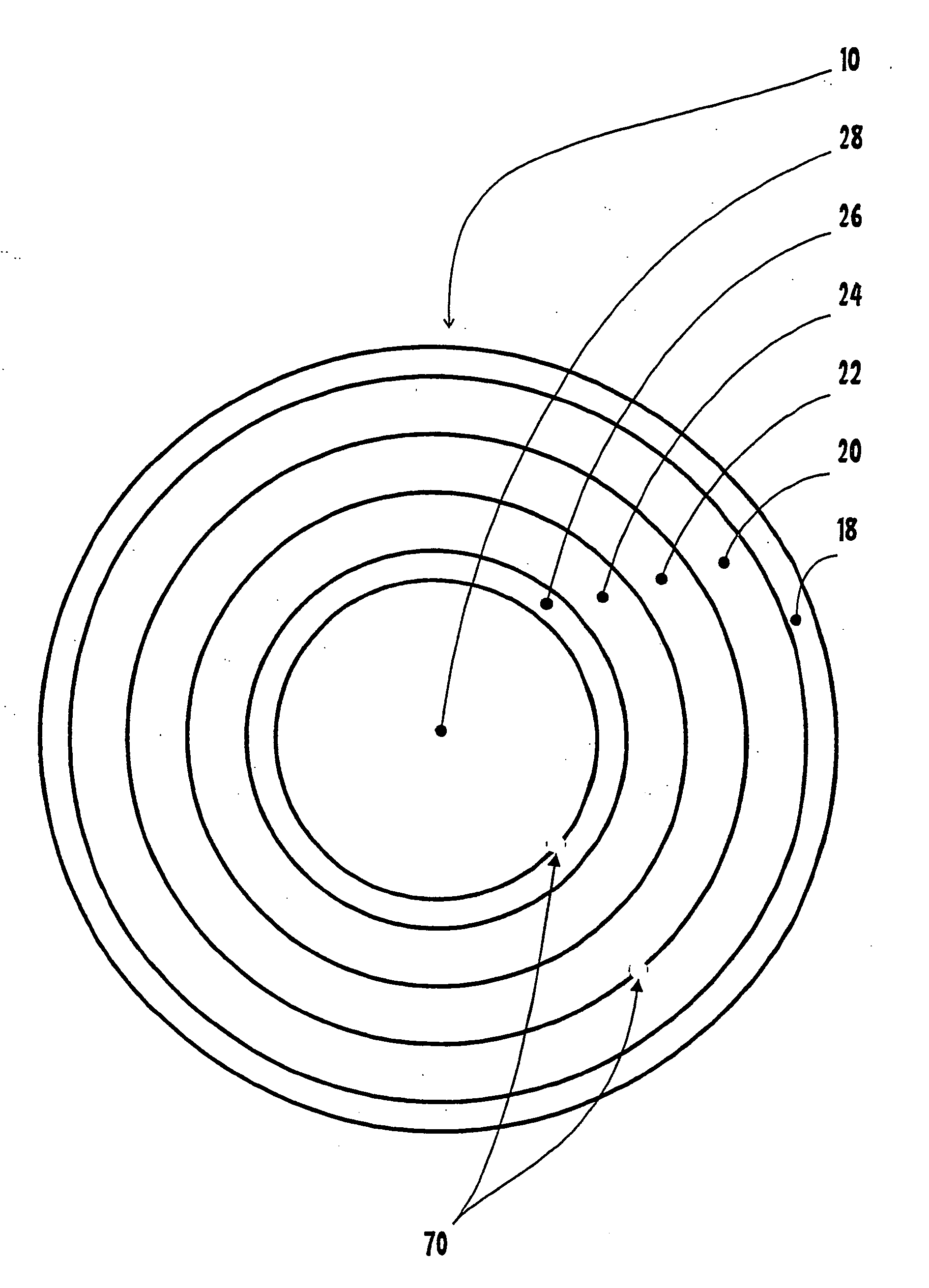

A corneal-scleral orthokeratology contact lens is formed of rigid gas permeable material with uniform arc lengths in the treatment area even when the corneal curvature varies and asymmetric blends or splines called minor zones, where the portion of the blend or spline is shorter toward the lens center and broader toward the lens edge, and relieve the treatment area of all centering responsibility, transferring it to the limbal-scleral region. The method of determining the total sagittal height of an eye at a given chord diameter to predetermine exact fitting parameters and predict unaided visual outcome trial lenses, with exact chord and sagittal height values used to match the sagittal height of an eye, the sagittal value may be obtained from some ocular topographers. A computer program can easily take the sagittal information and design an optimum lens.

Owner:DAKOTA SCI

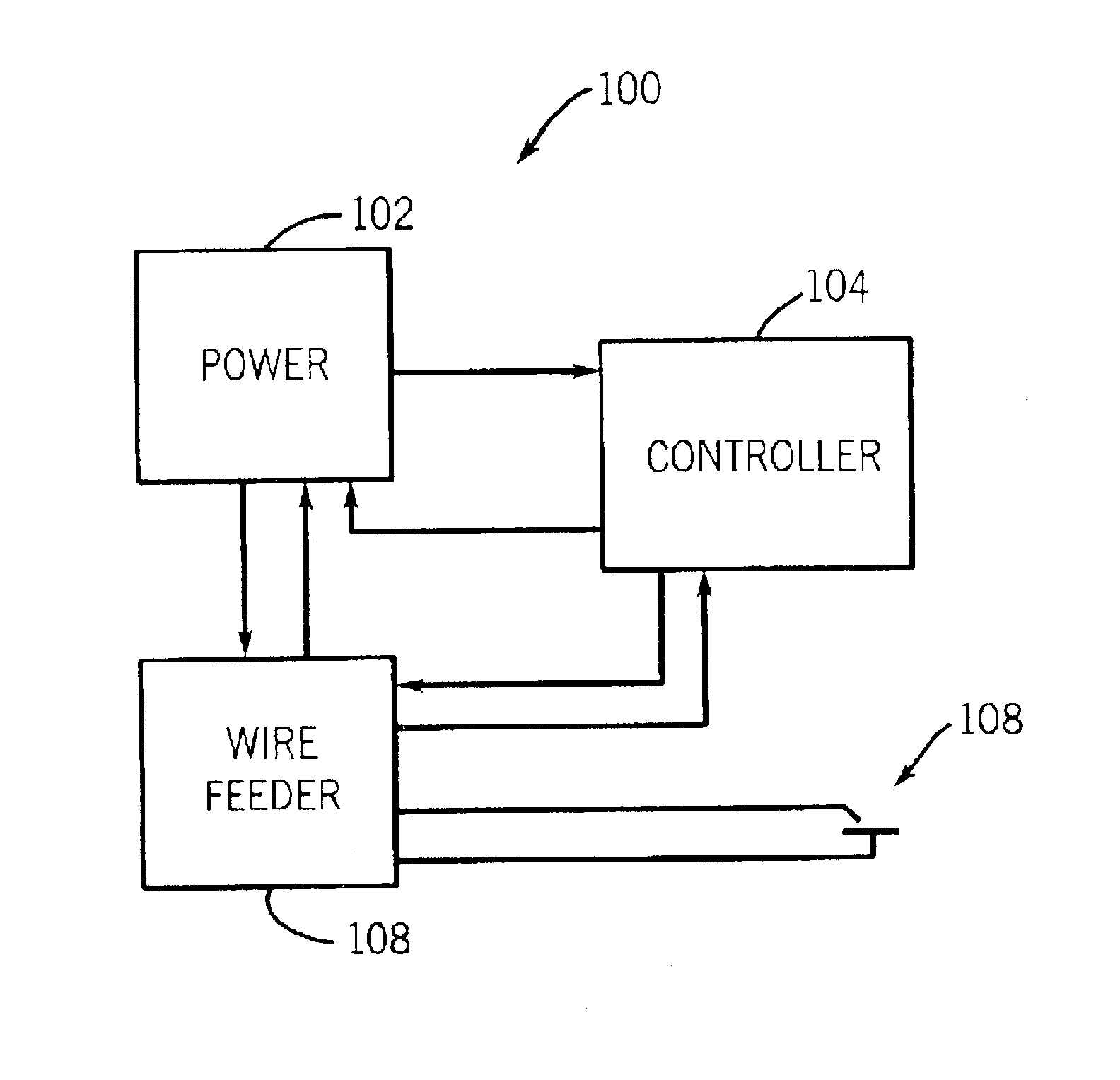

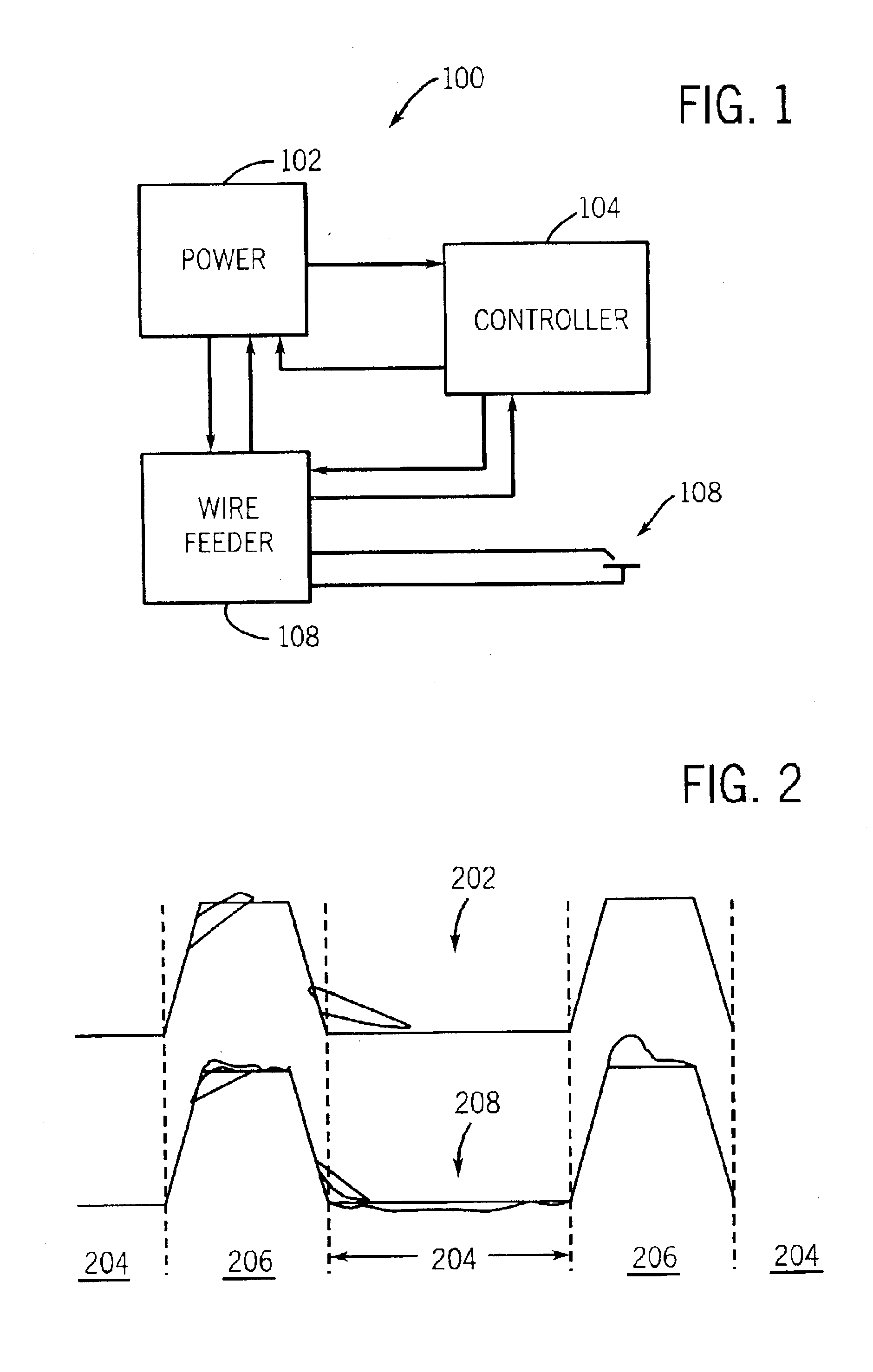

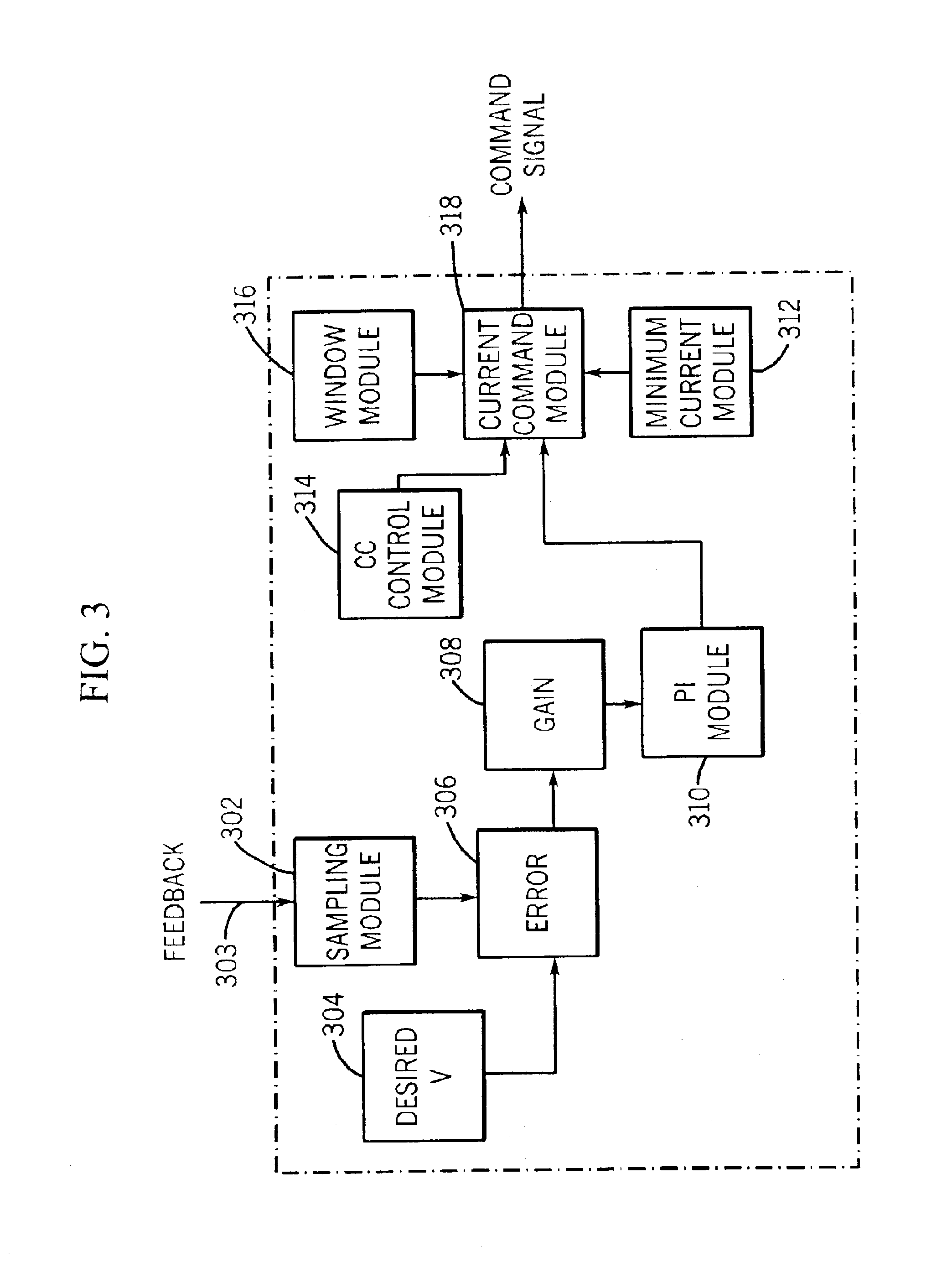

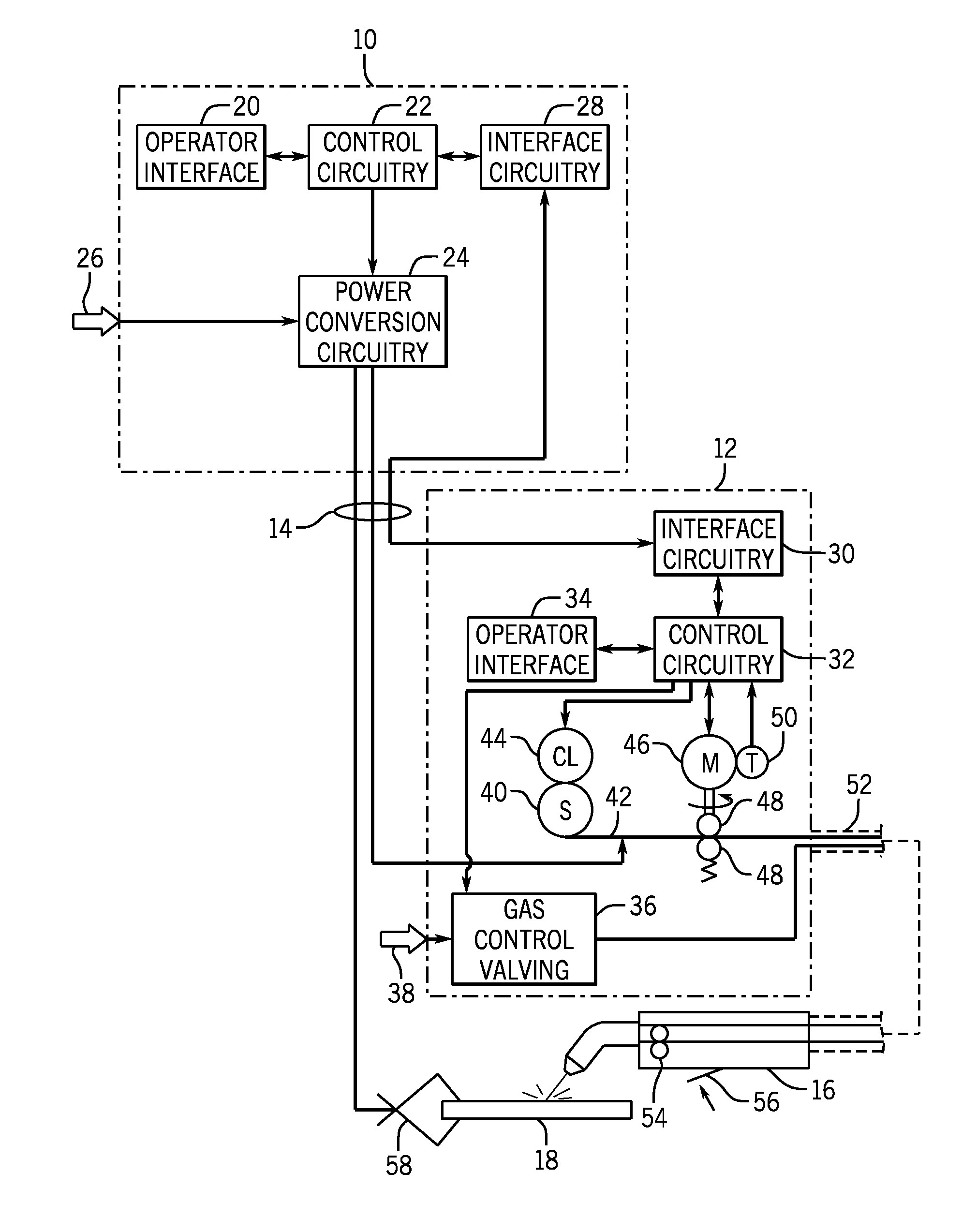

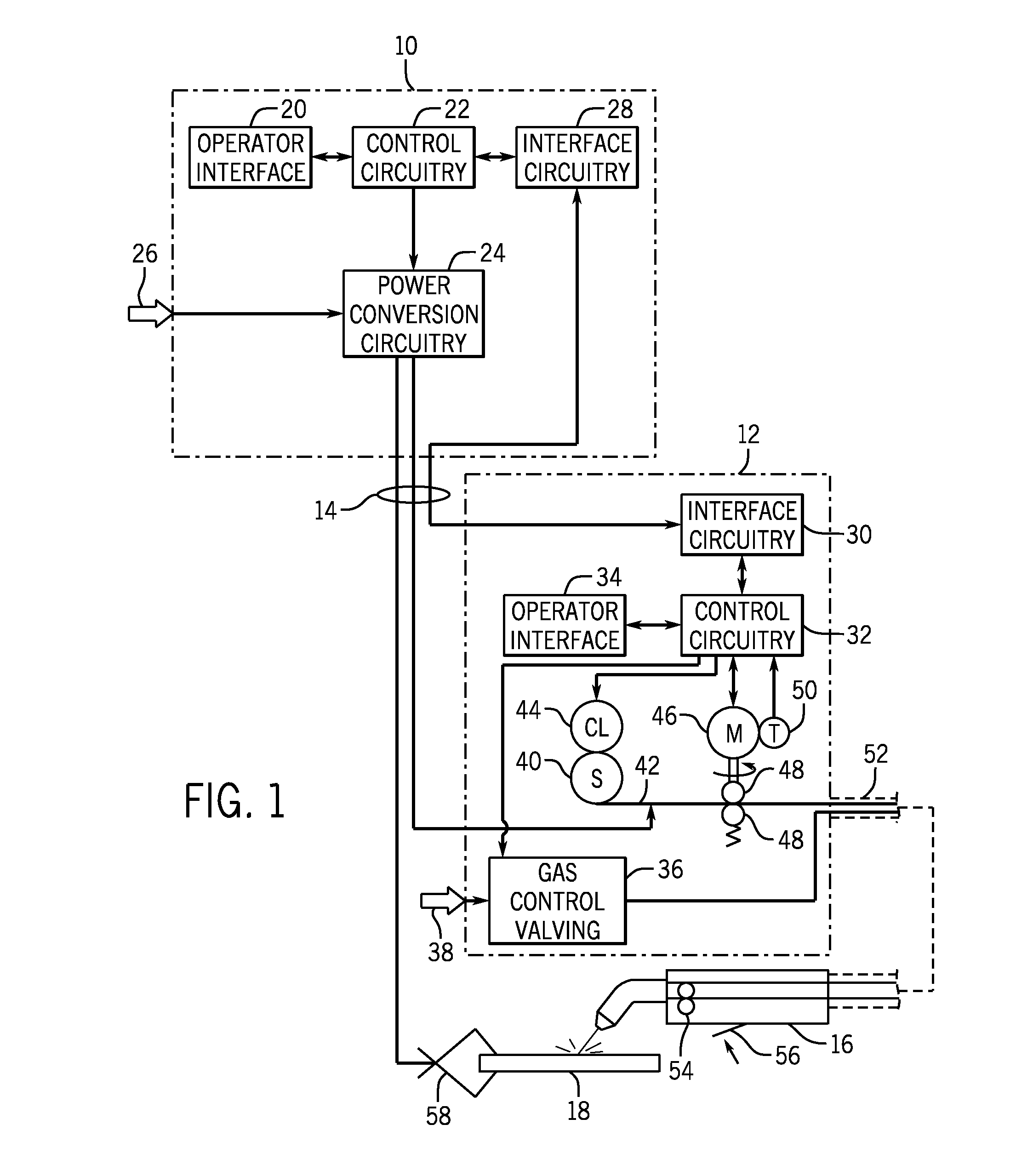

Method and apparatus for welding

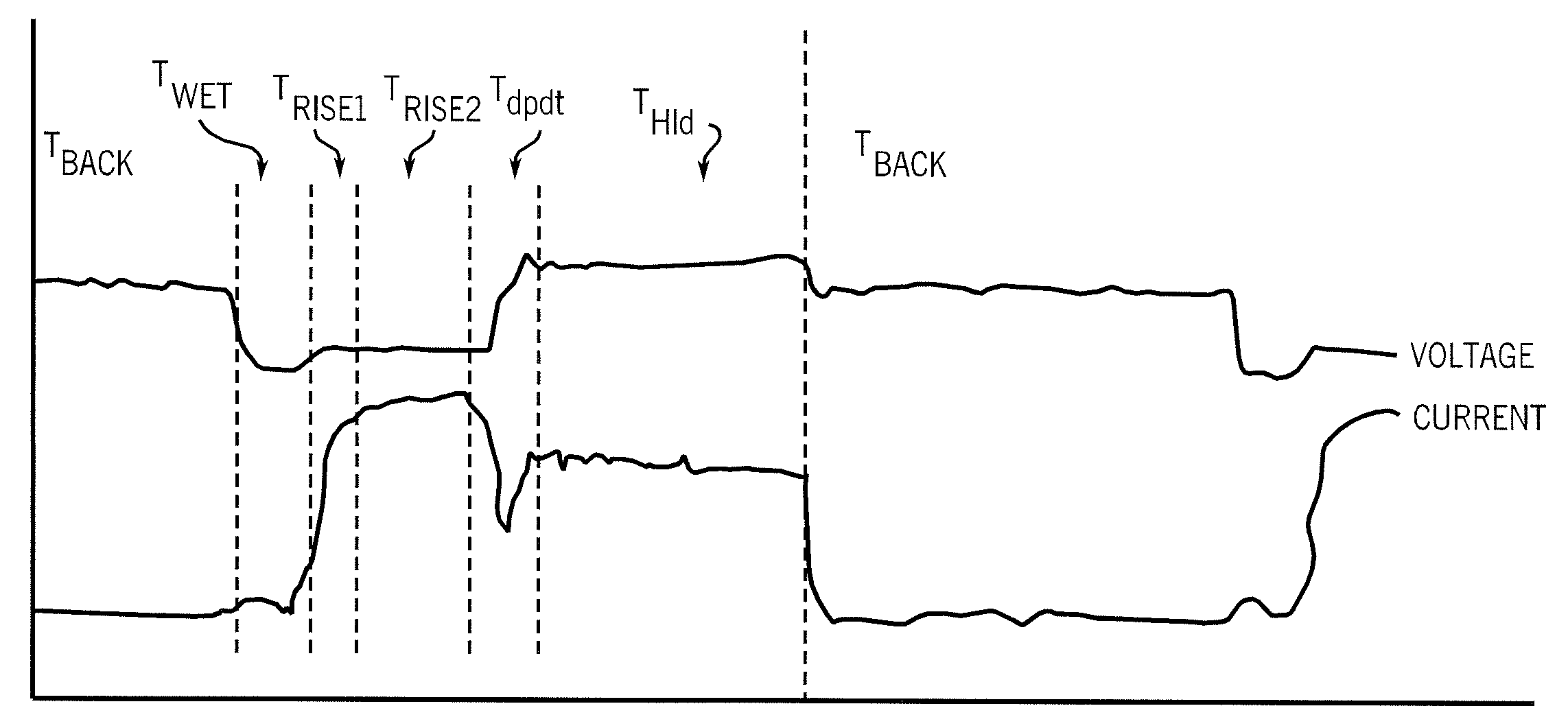

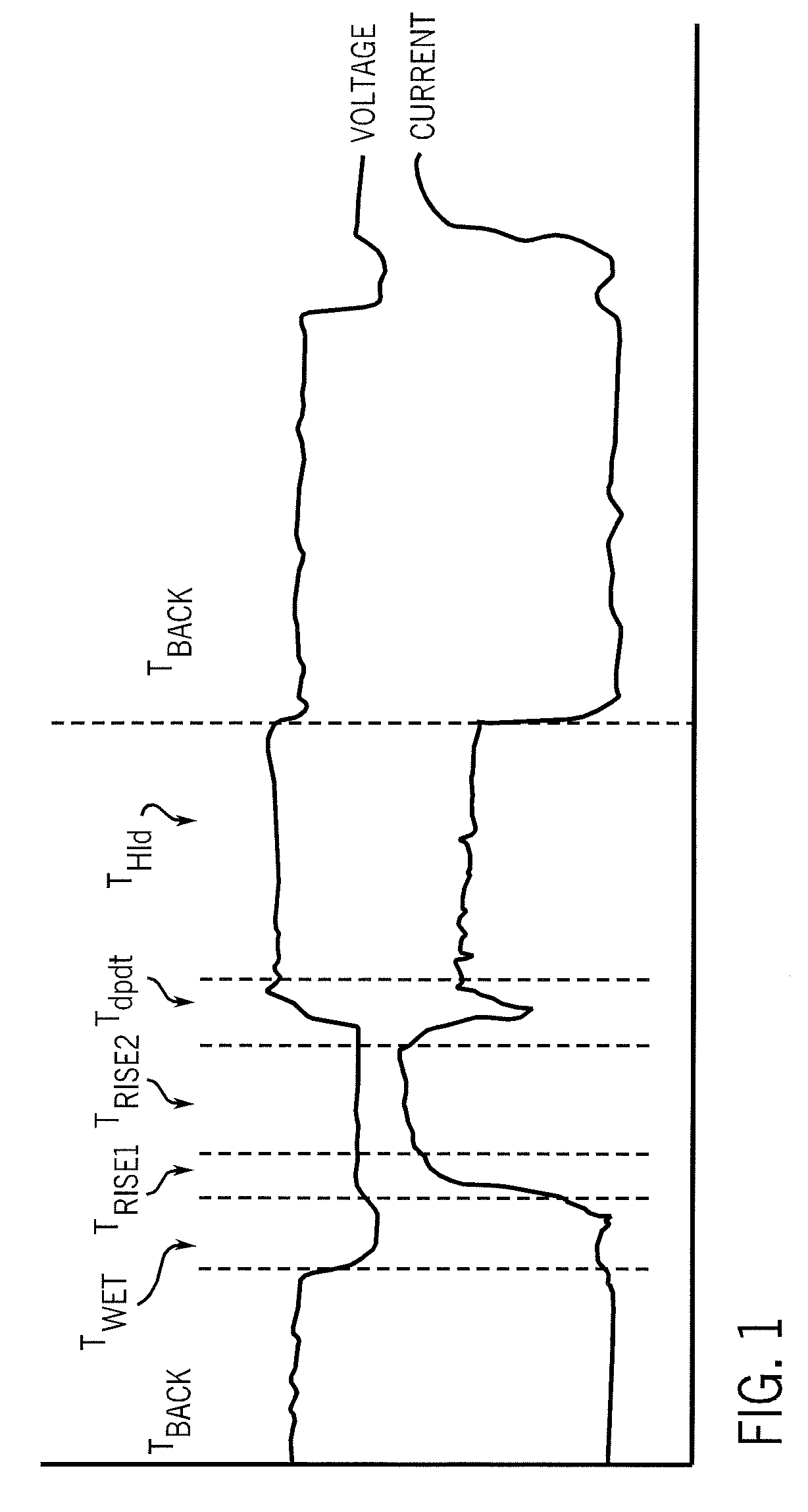

A short circuit arc welding system is disposed. The control scheme uses a current command signal to drive the output current. The command signal is comprised of a long-term current command that sets the long-term current command level and a real-time or short-by-short current command. Arc voltage feedback is used to determine if the desired arc length is present and to adjust the long-term command. The short-by-short current command is derived from real-time arc current feedback and is used to control the burn-off rate by an instantaneous, or short-by-short, adjustment of the current command. A function of the time derivative of arc power, less the time derivative of arc current, is used to detect, in real time, when the short is about to clear. A stop algorithm is employed that monitors the arc on a short-by-short basis. When the process is ending a very low current level is provided to avoid forming a ball. However, if a short is created, (indicated by a drop in arc voltage) after the low current level, a burst of energy is provided to clear of burn off the short. After the short is cleared, very low current is again provided to avoid forming a large ball. This is repeated until the wire stops and the process ends.

Owner:ILLINOIS TOOL WORKS INC

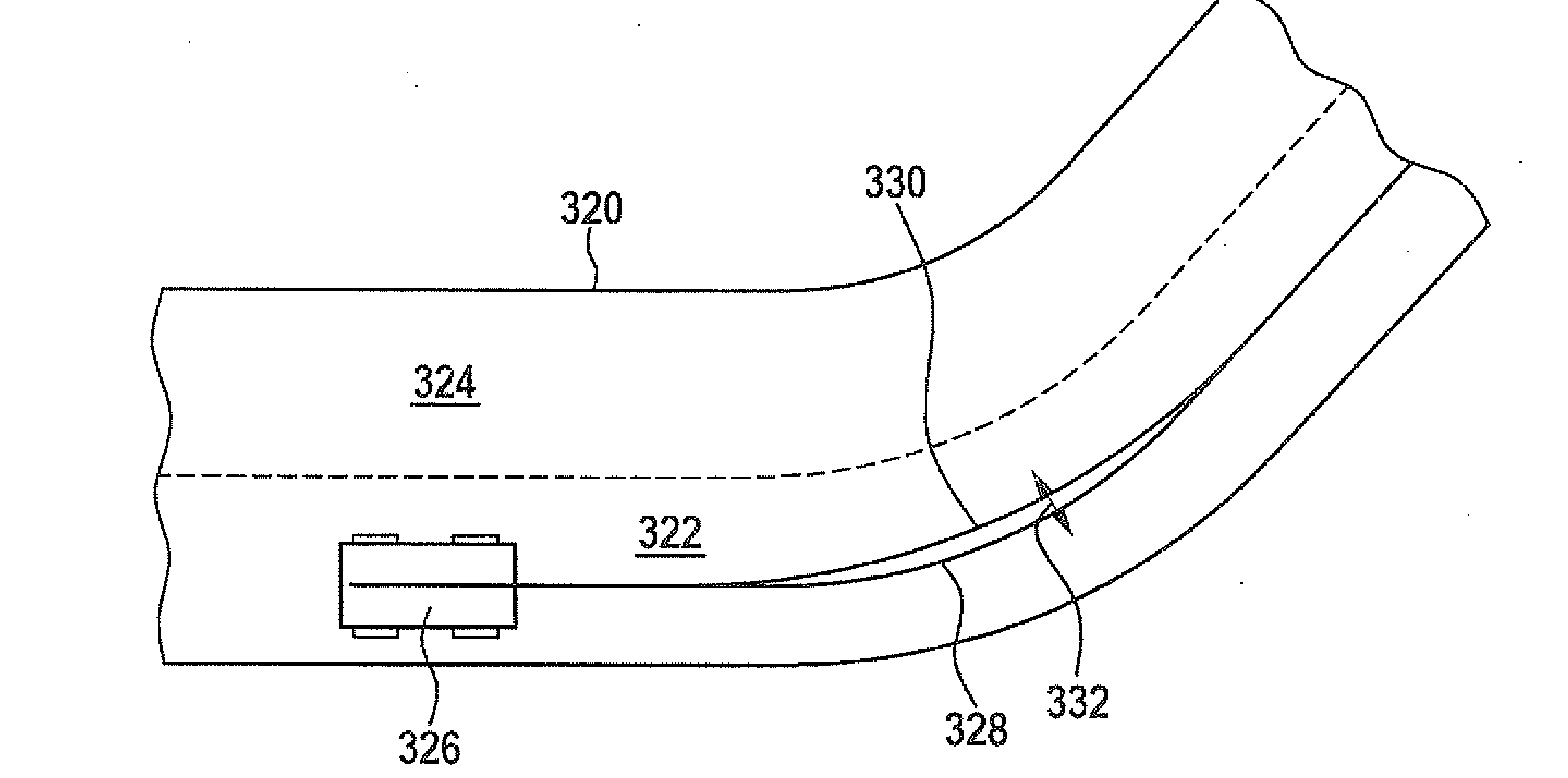

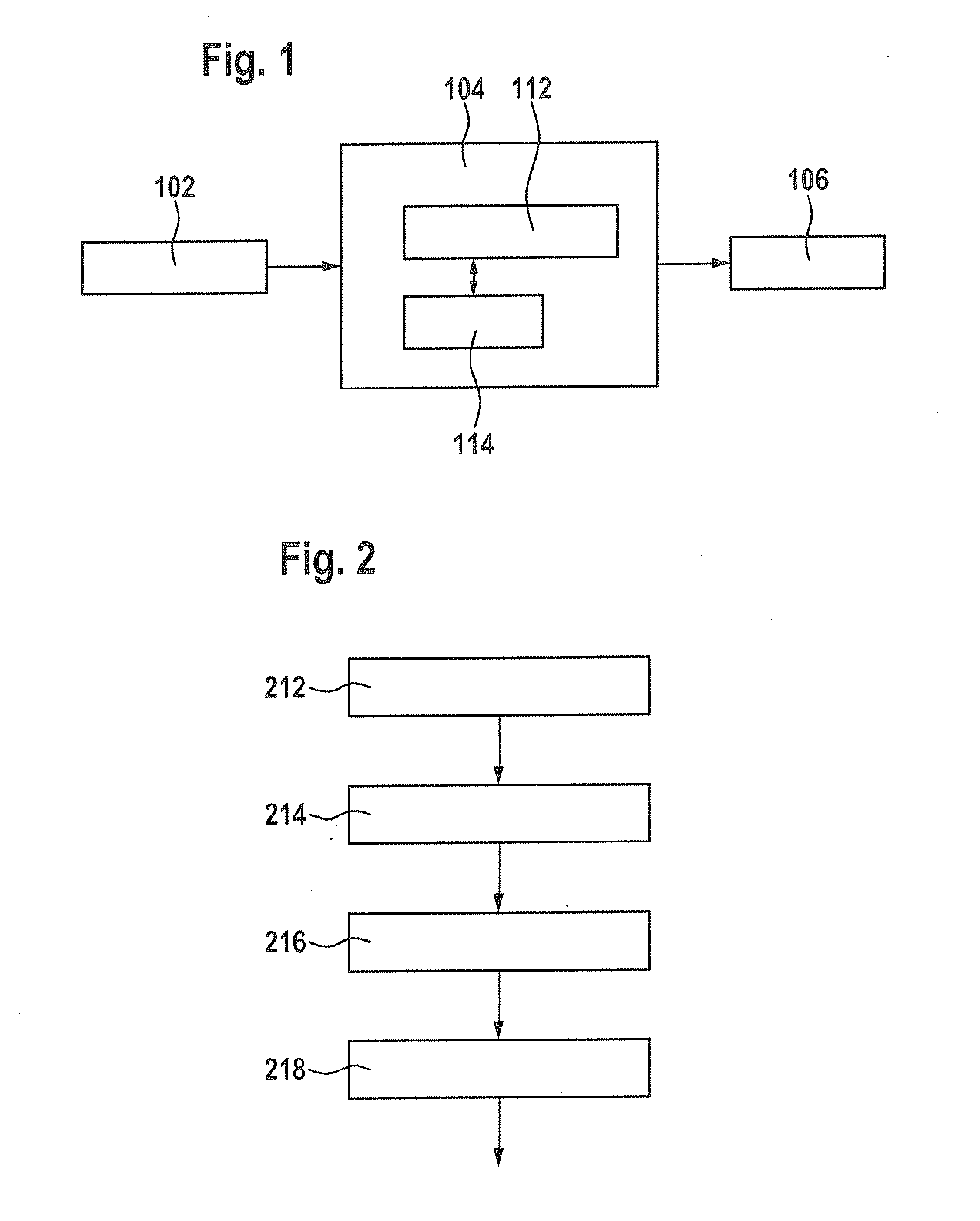

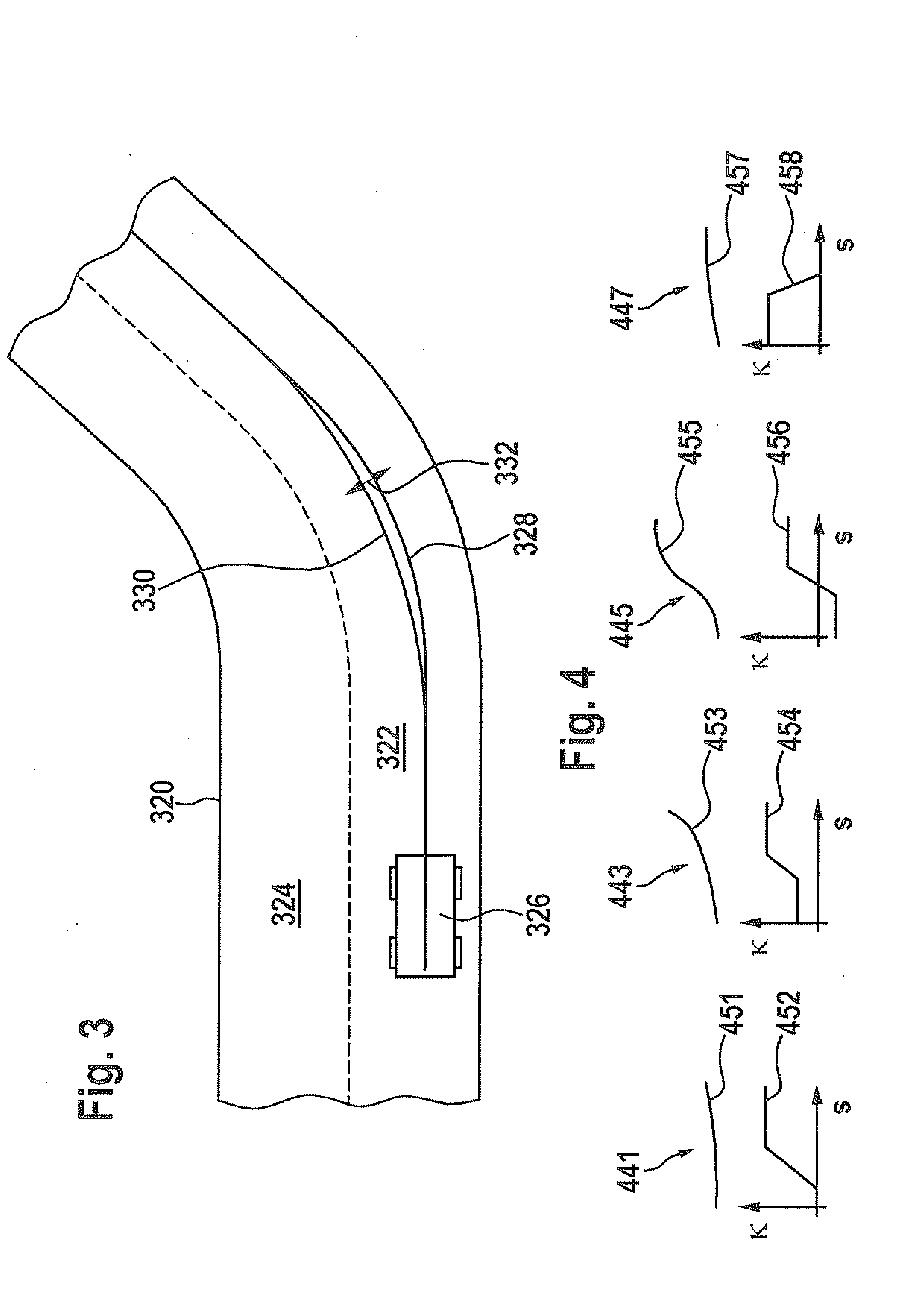

Method and control unit for determining a cutting trajectory of a curve section of a roadway

ActiveUS20130006473A1Increase radiusImprove securitySteering initiationsDigital data processing detailsMechanical engineeringLine segment

A method for determining a cutting trajectory that enables a curve section of a lane to be cut by a vehicle. In the method, information about the curve section is received, and the curve section is divided into at least one curve segment having a segment length and a start curvature, the curve segment being a straight-line segment or a circular arc segment or a curve segment whose curvature is a function of an arc length of the curve segment. This is followed by determination of a cutting trajectory from the at least one curve segment, so that, at a specific point of the curve section, the cutting trajectory has a predetermined offset relative to a center of the lane.

Owner:ROBERT BOSCH GMBH

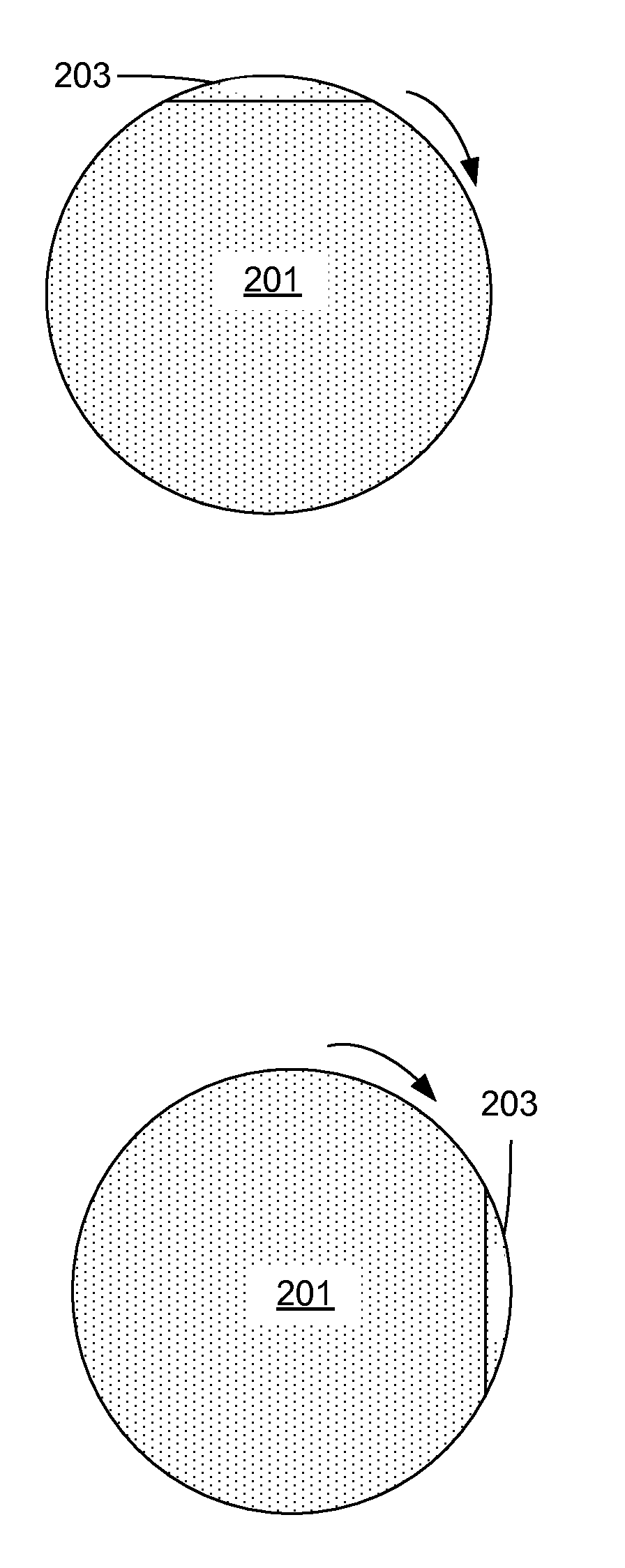

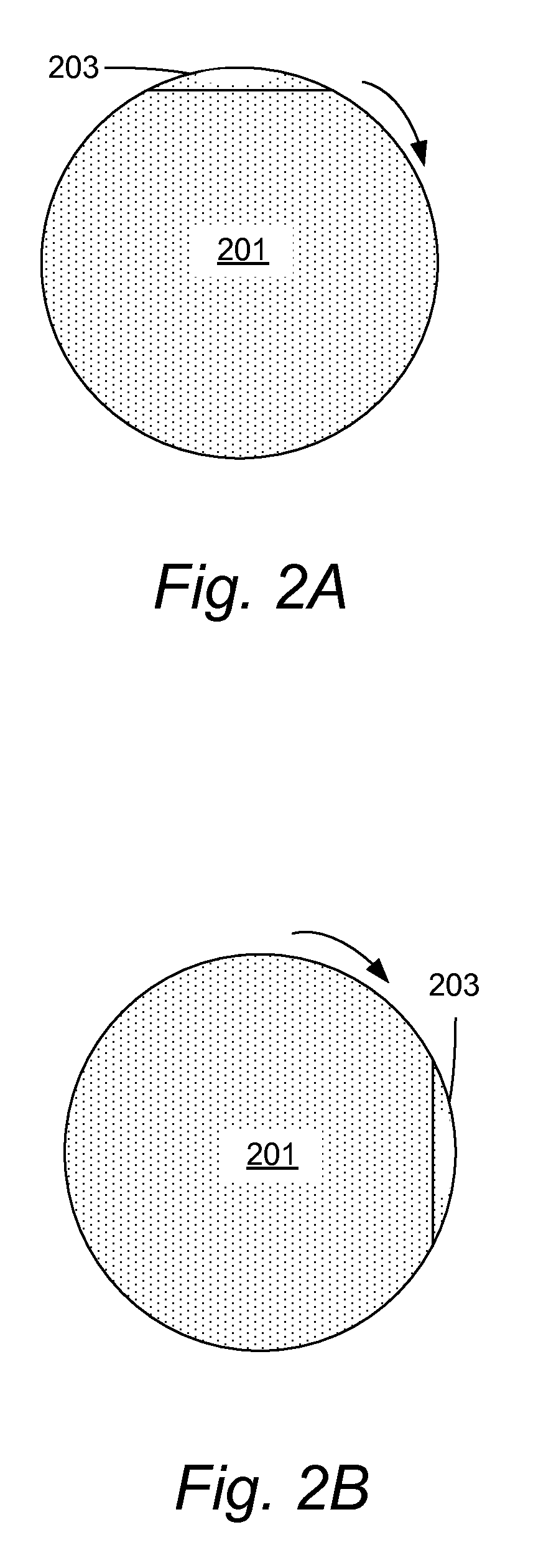

Electroplating apparatus for tailored uniformity profile

ActiveUS20120258408A1Maximizing randomization of flow patternSimple processCellsMachining electric circuitsRadial positionEngineering

Methods of electroplating metal on a substrate while controlling azimuthal uniformity, include, in one aspect, providing the substrate to the electroplating apparatus configured for rotating the substrate during electroplating, and electroplating the metal on the substrate while rotating the substrate relative to a shield such that a selected portion of the substrate at a selected azimuthal position dwells in a shielded area for a different amount of time than a second portion of the substrate having the same average arc length and the same average radial position and residing at a different angular (azimuthal) position. For example, a semiconductor wafer substrate can be rotated during electroplating slower or faster, when the selected portion of the substrate passes through the shielded area.

Owner:NOVELLUS SYSTEMS

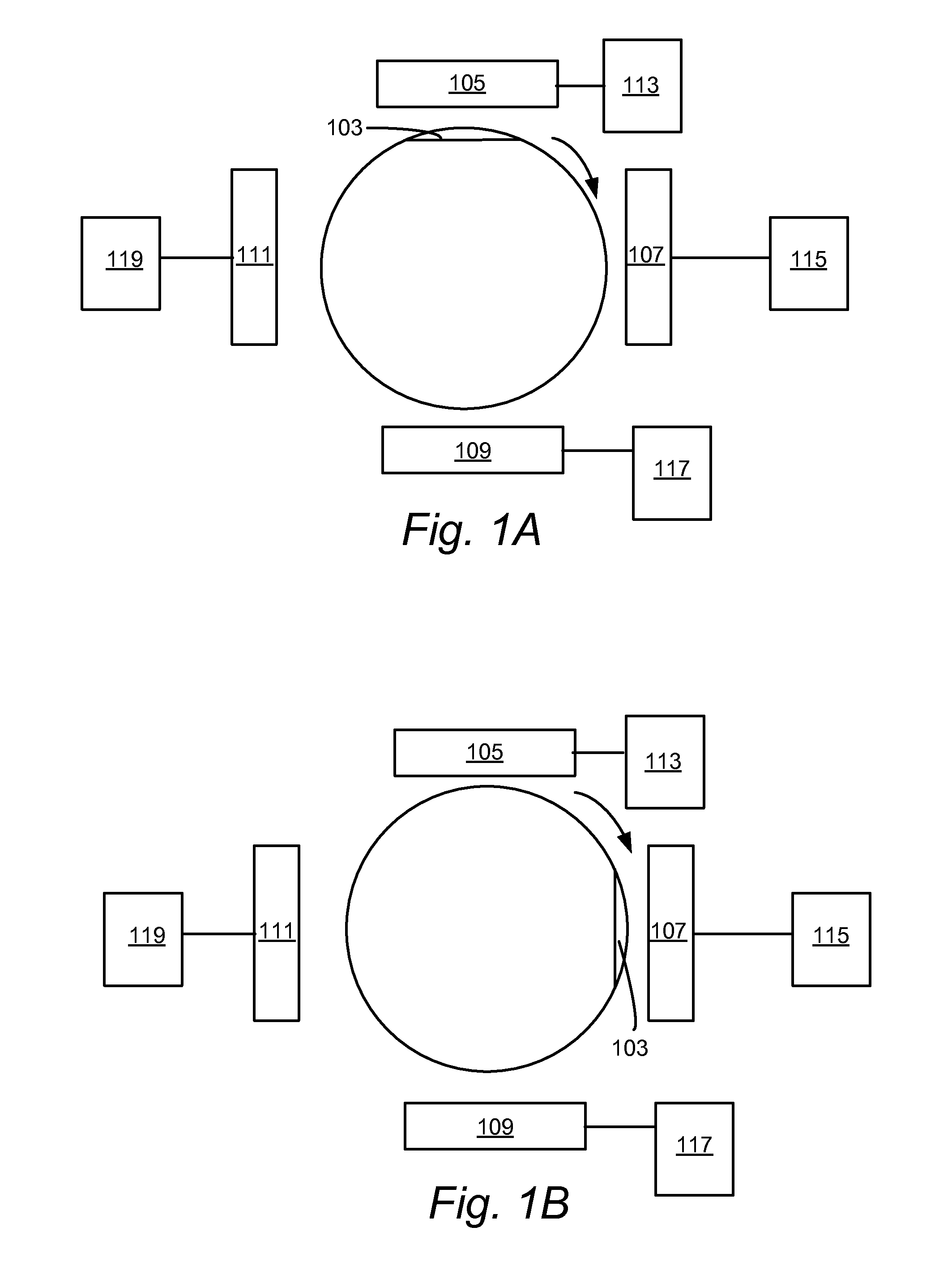

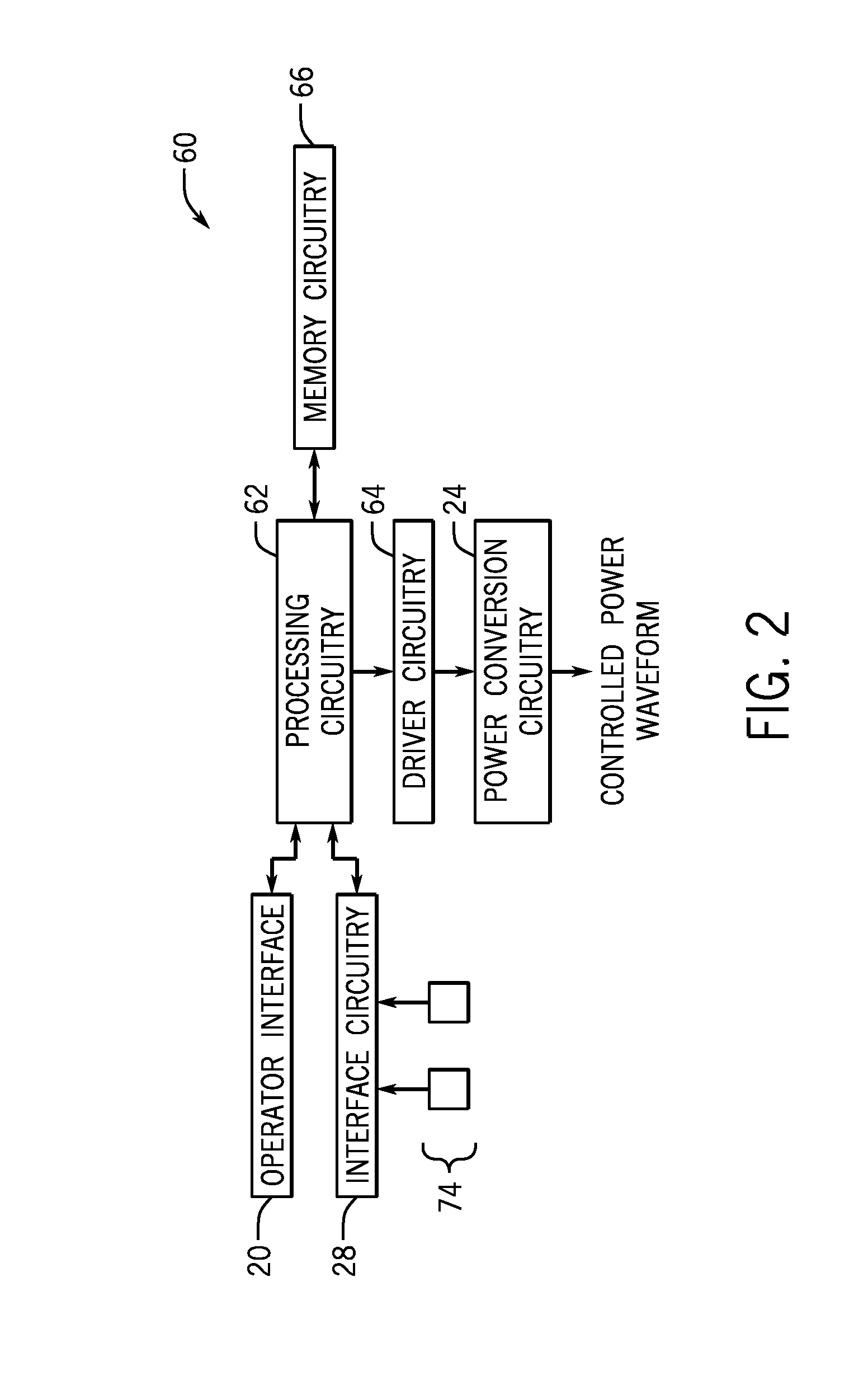

Method and apparatus for welding with CV control

A method and apparatus for welding is disclosed. The output is preferably a cyclical CV MIG output, and each cycle is divided into segments. An output parameter is sampled a plurality of times within one or more of the segments. The CV output is controlled within the at least one segment in response to the sampling. The parameter is output power, a resistance of the load, an output current, an output voltage, or functions thereof in various embodiments. The control loop is preferably a PI or PID loop. The loop may be applied only within a window. The set point may be taught or fixed. The system can be used to weld with a controlled arc length.

Owner:ILLINOIS TOOL WORKS INC

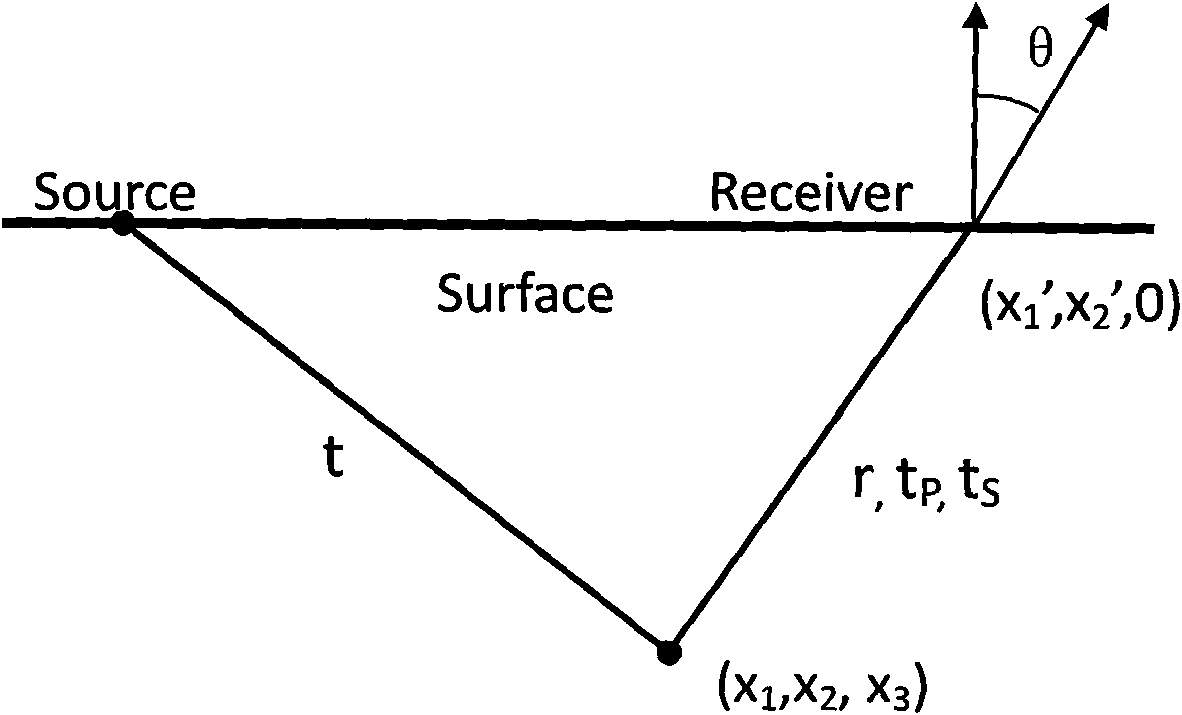

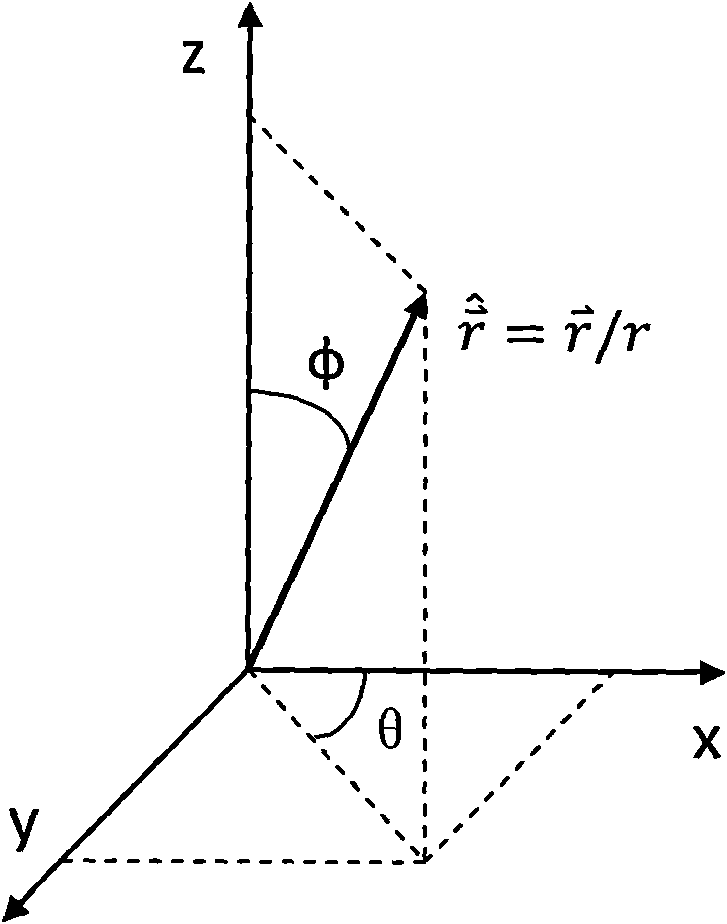

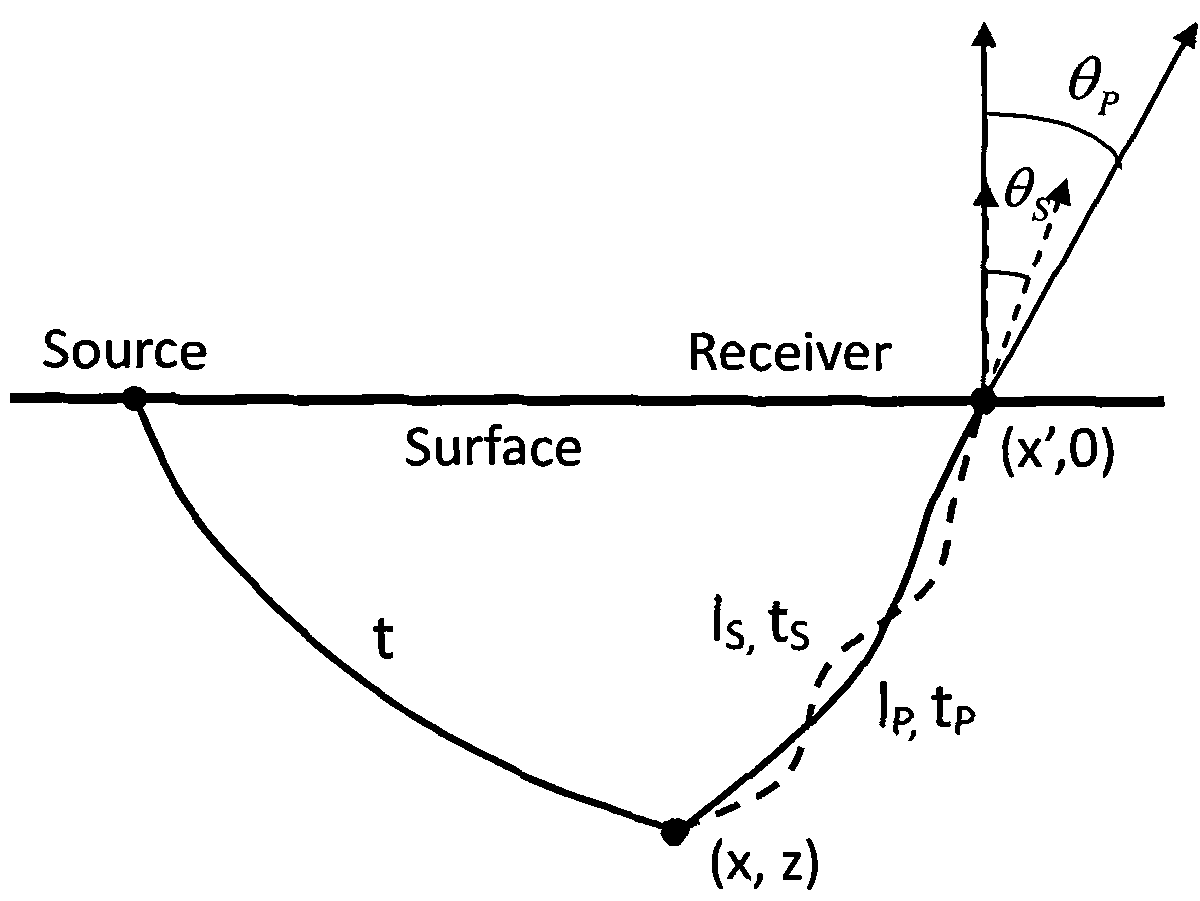

Pre-stack depth migration method

ActiveCN101937100AAccurate homingImplement multi-component migrationSeismic signal processingImage resolutionWave field

The invention relates to the field of seismic prospecting, in particular to a pre-stack depth migration method. The method comprises the following steps of: performing migration velocity analysis on seismic data; calculating travel time, arc length, emergence angle and incidence angle by ray tracing; performing migration aperture calculation; and performing pre-stack depth migration by using a Kirchhoff integration vector migration formula. The method integrates migration velocity analysis, migration aperture selection, ray tracing and Kirchhoff integration formula, does not need wave field separation, and realizes multi-component simultaneous migration and accurate homing of converted wave. Based on the practical exploration data, the pre-stack depth migration method has good surface imaging effect and high imaging resolution, the continuity of the deep reflecting in-phase axis on a converted wave imaging section is improved, and the construction is clearer.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI +1

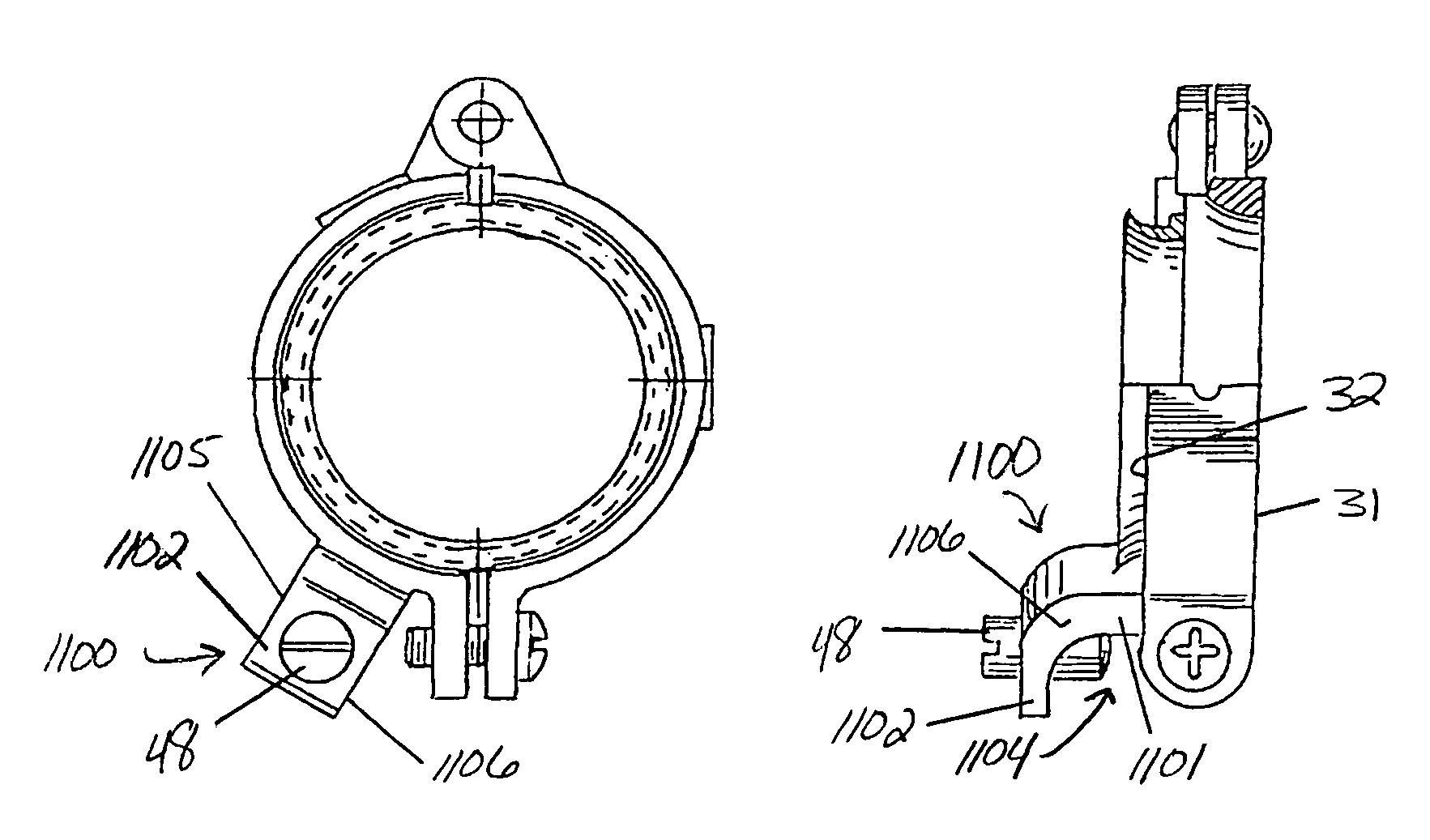

Dual-sectioned grounding bushing assembly

The present invention provides a grounding bushing assembly essentially comprising a first bushing section, a second bushing section, select pivot structure, select latch structure, and select ground conductor attachment structure. The first bushing section, second bushing section, select pivot structure, select latch structure, and select ground conductor attachment structure are all preferably constructed from electrically conductive materials for allowing electric charges to migrate through the material. The first and second sections each comprise an arc length intermediate the section ends, which are lengths together function to cooperatively form an annular, dual-sectioned, grounding bushing. The resulting grounding bushing comprises an inner annular surface, an outer annular surface, a conductor inlet end, a conductor outlet end, and unique ground conductor attachment structure. The present invention enables an installer thereof to install the same in cooperative association with a ground conductor either before or after electrical connections are finalized.

Owner:BRIDGEPORT FITTINGS LLC

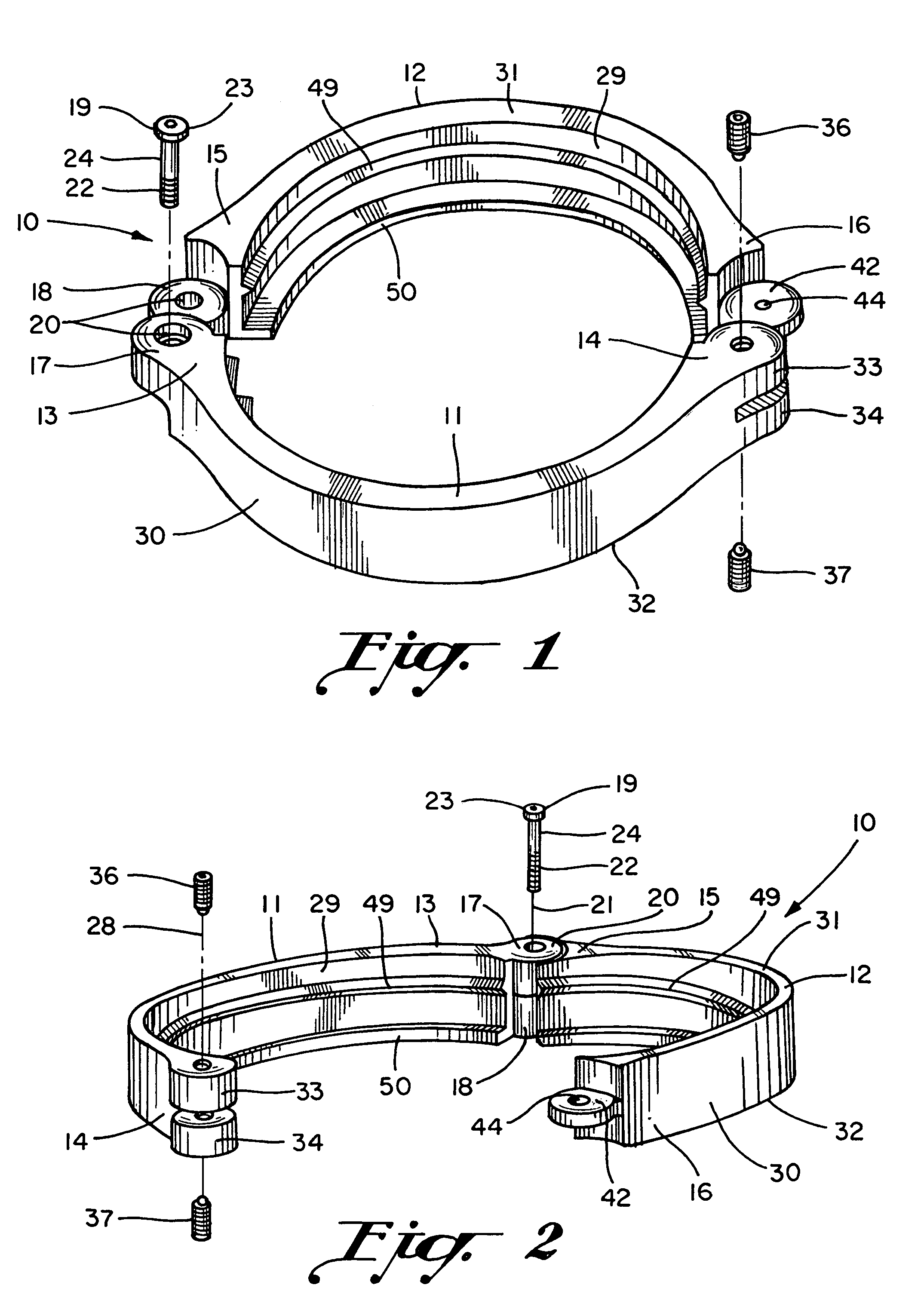

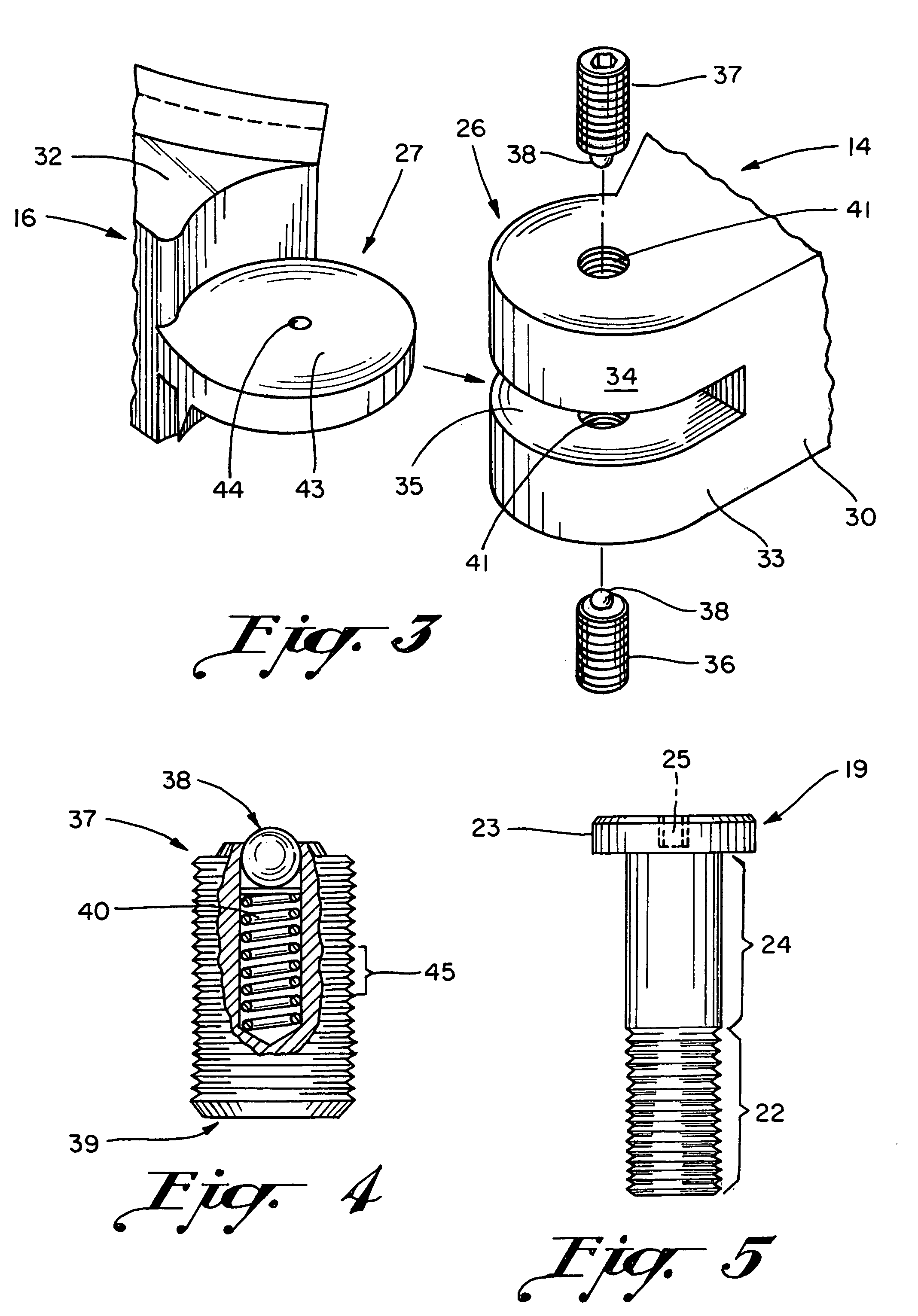

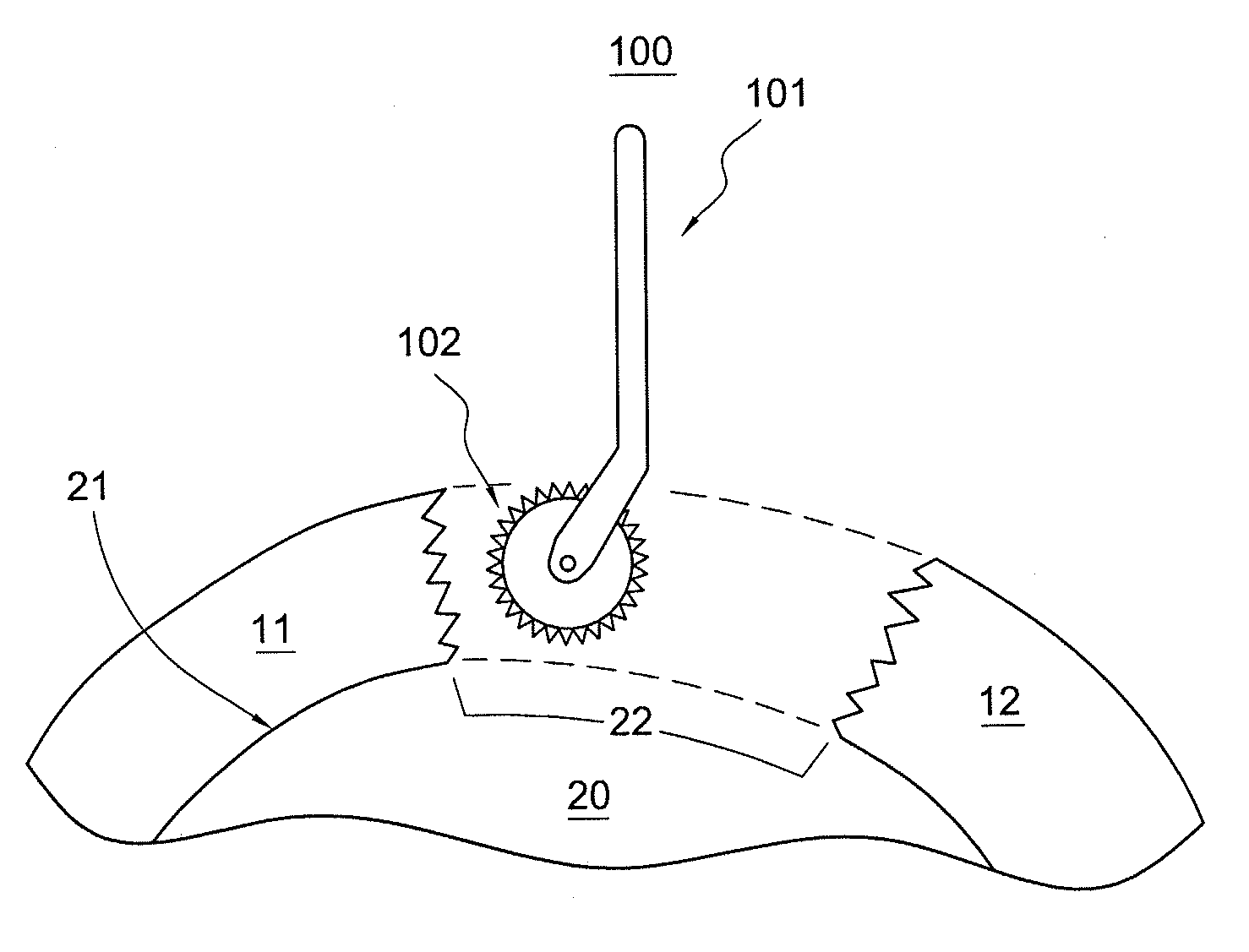

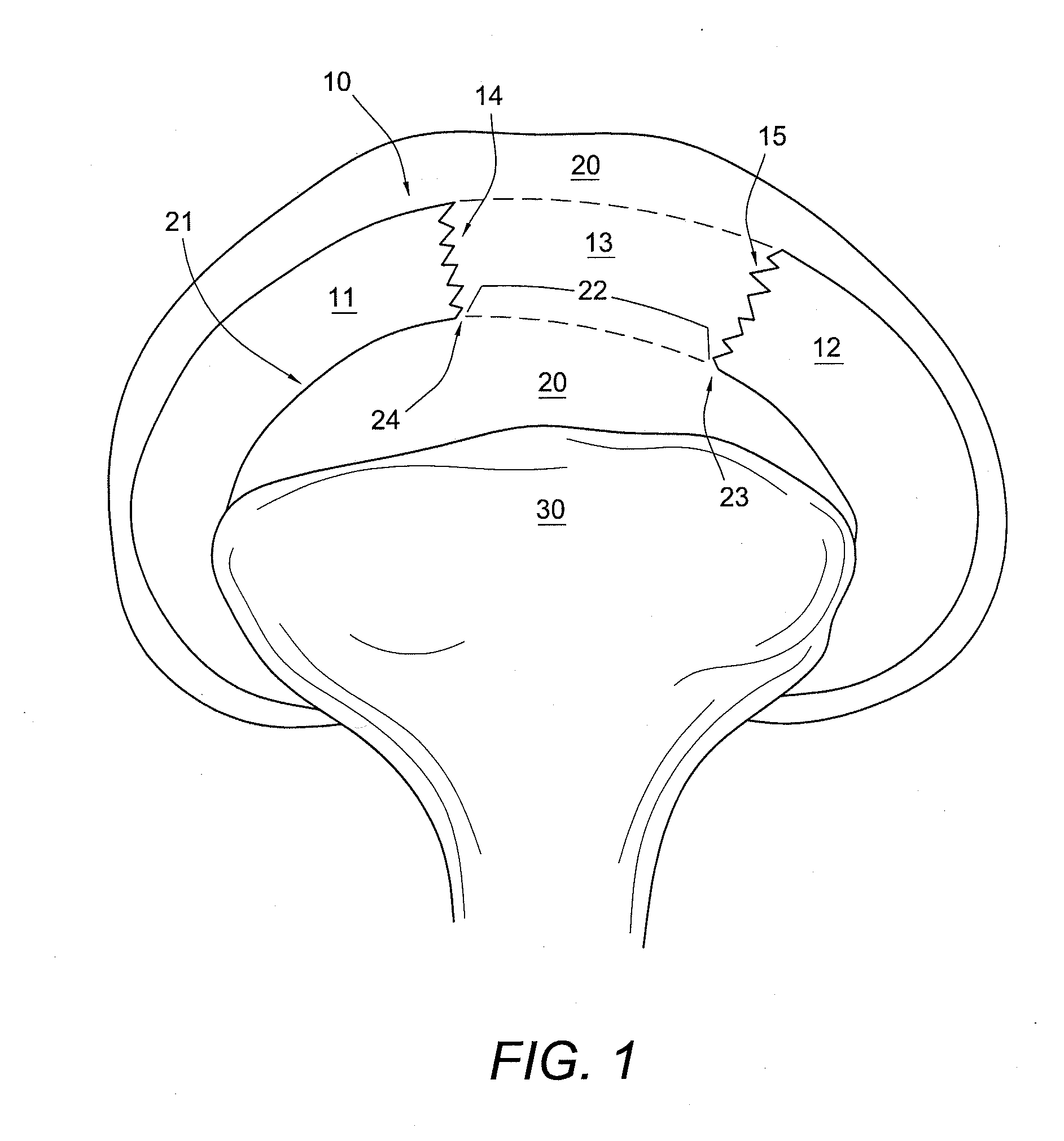

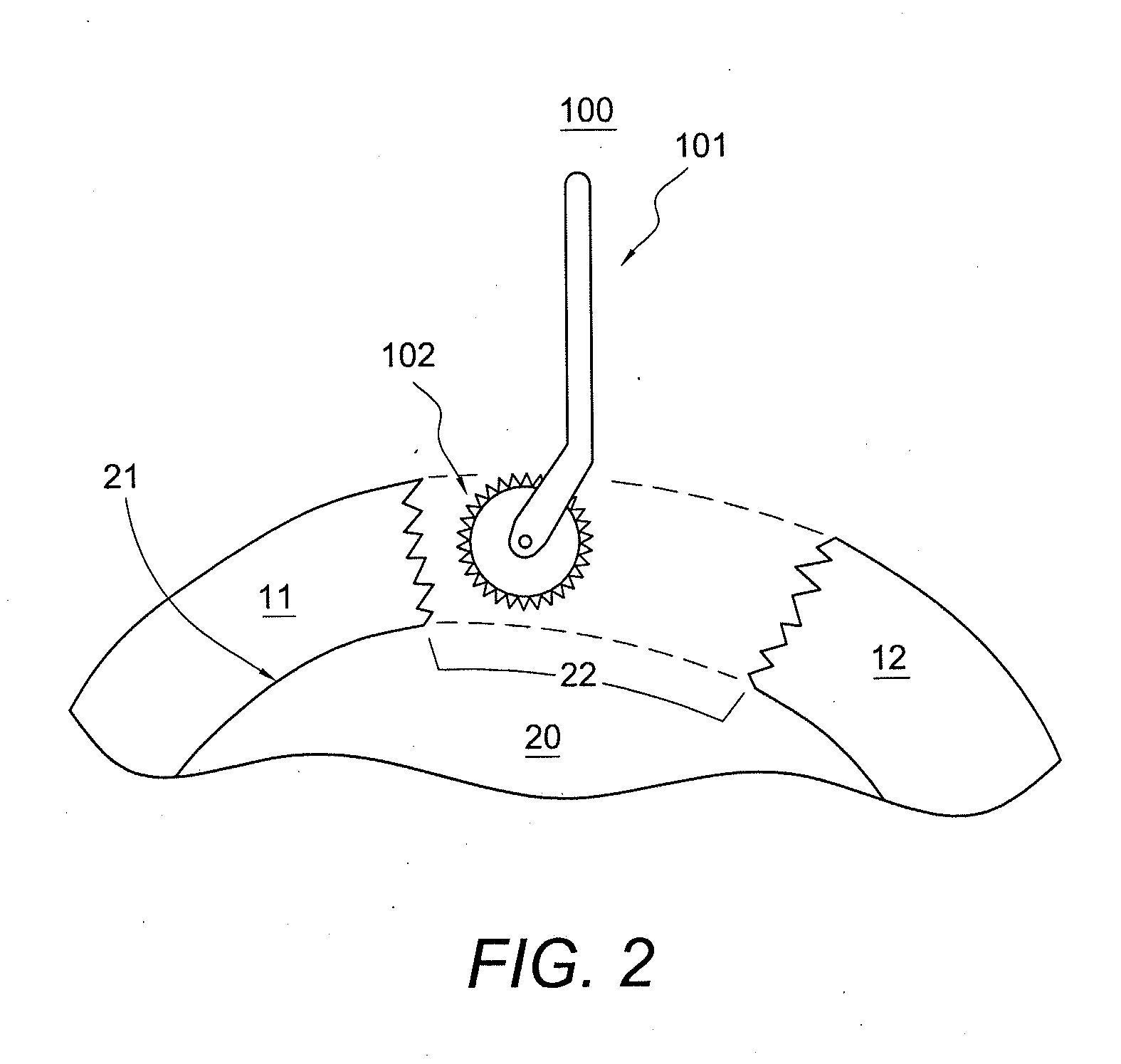

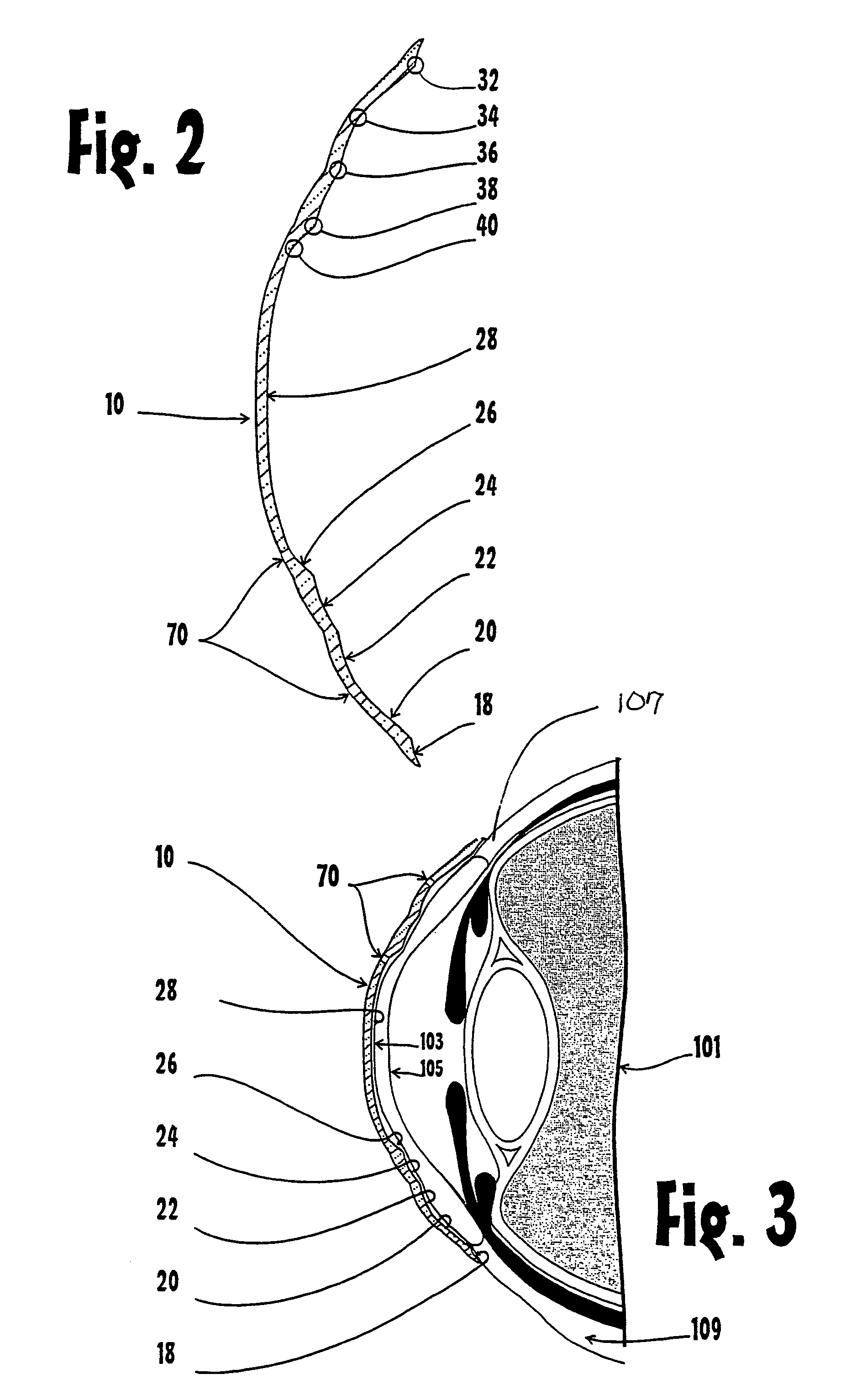

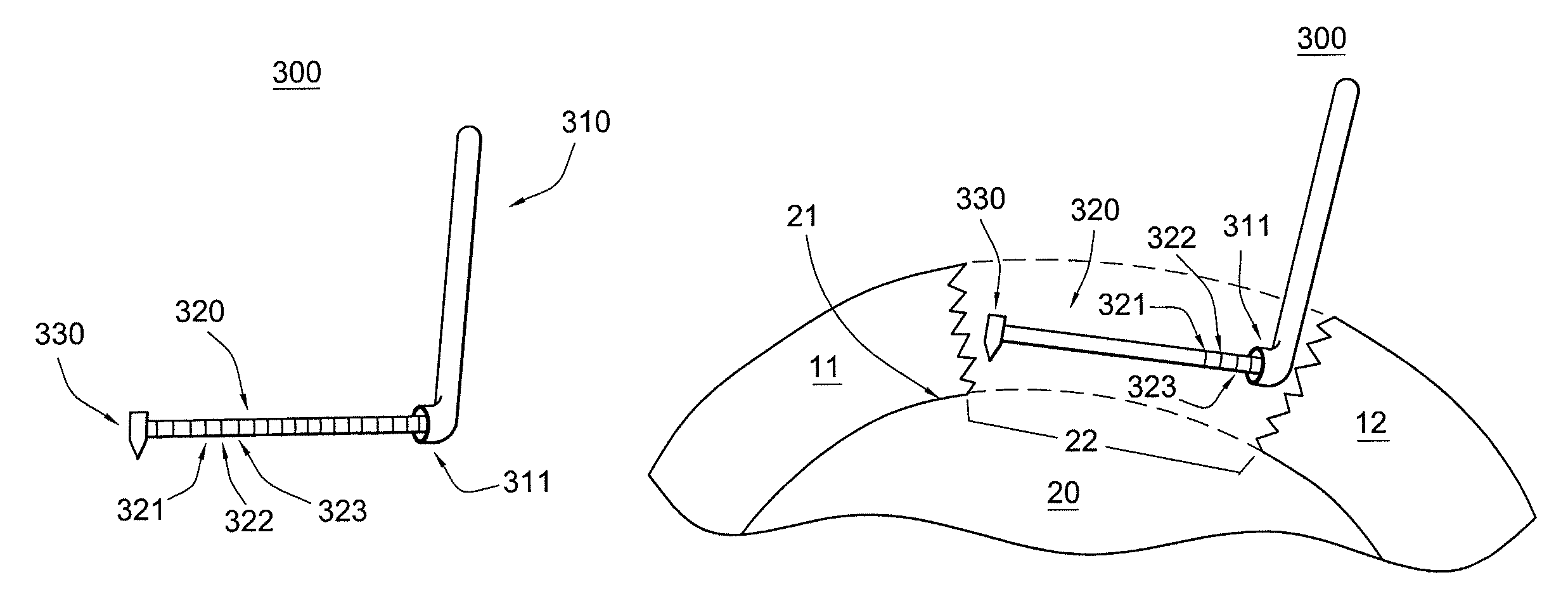

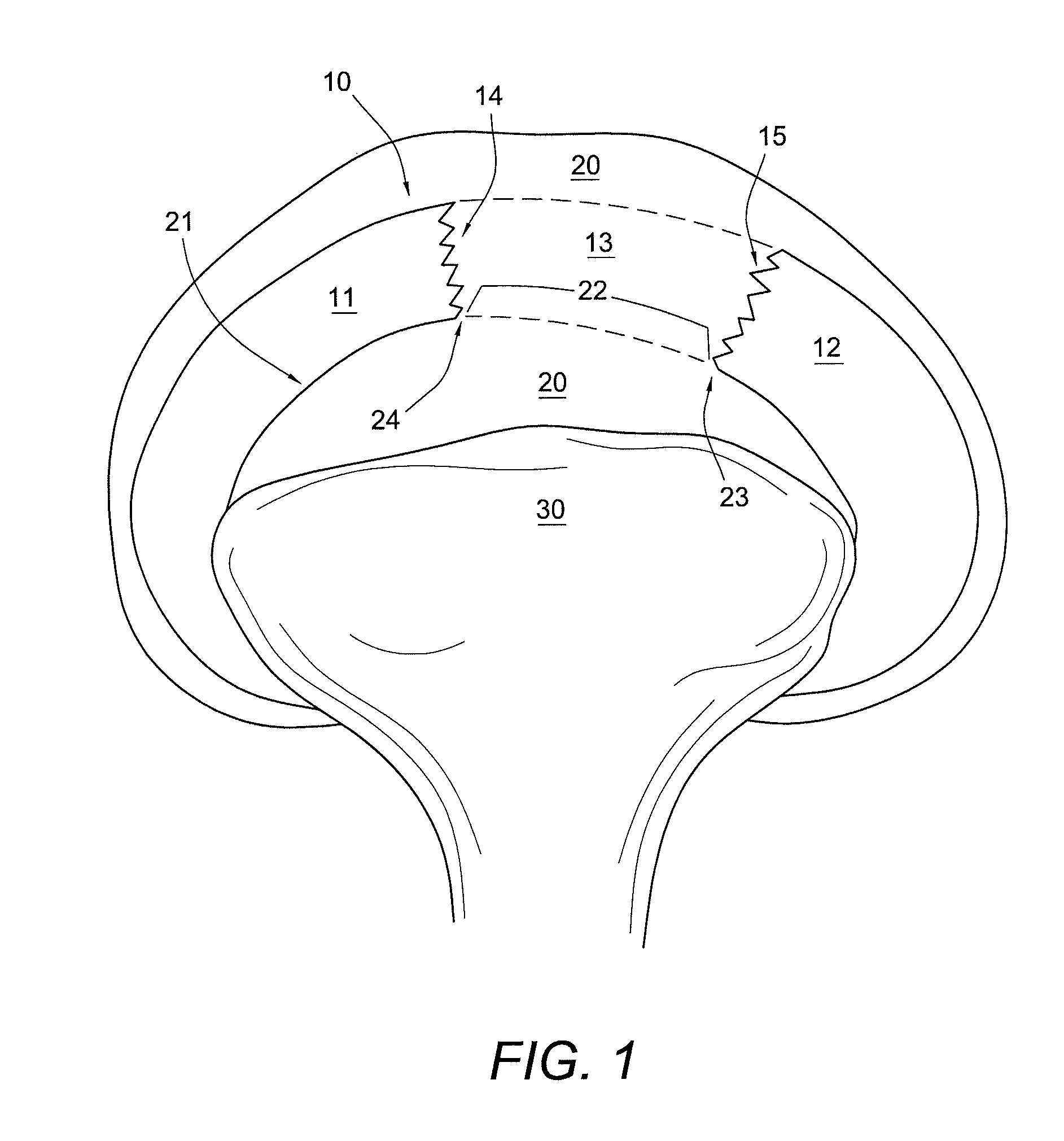

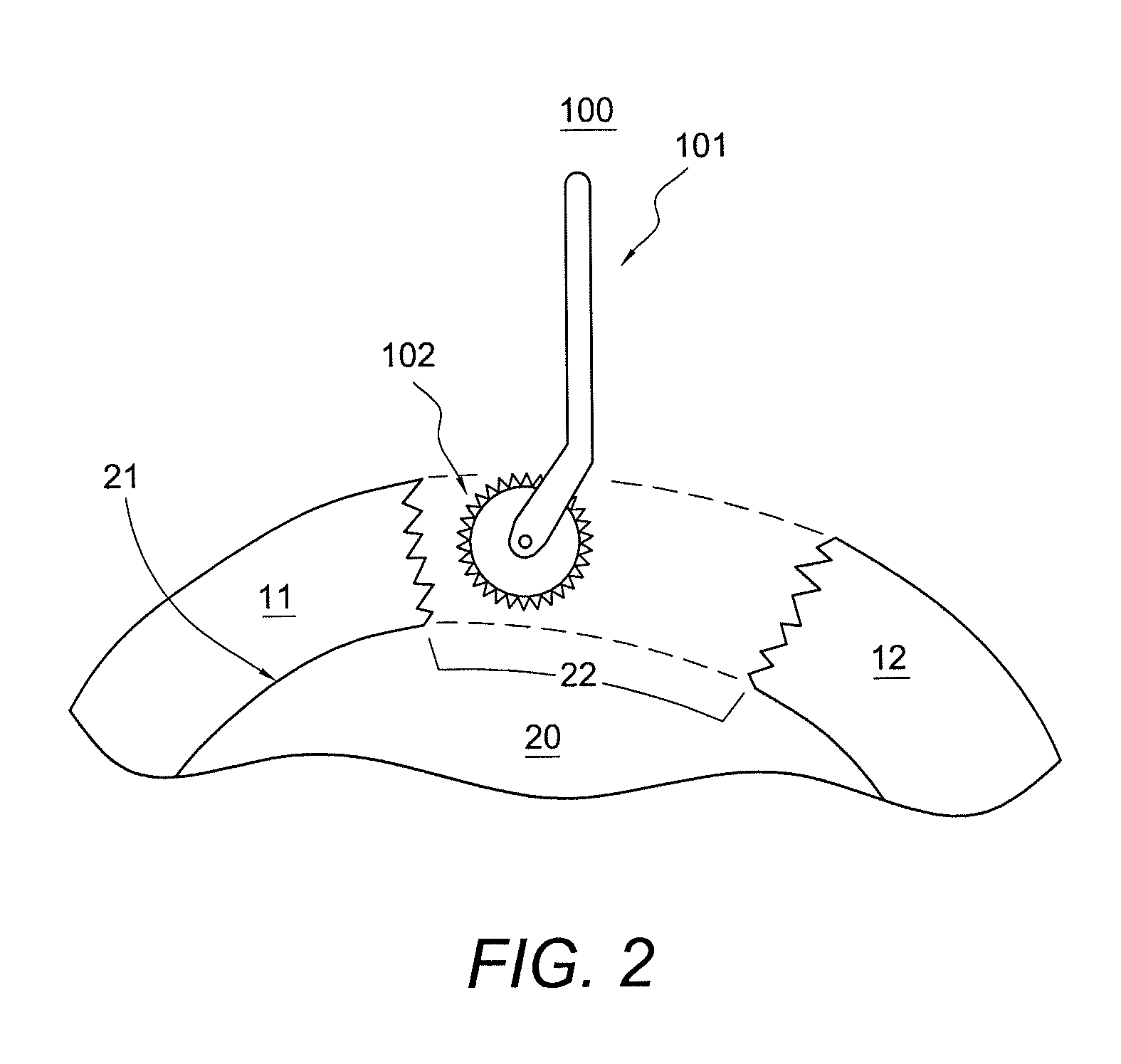

Method and instrumentation for acetabular labrum reconstruction

Methods and instruments for repairing a damaged acetabular labrum. The arc length of a portion of an acetabular rim proximal to the damaged (torn or broken) region of the acetabular labrum is measured, and a graft, such as a meniscal allograft or a gracilis autograft, is trimmed according to the measurement and secured in the damaged region of the acetabular labrum as a replacement. Various instruments, such as a wheel mounted on an arm, a measuring member with spaced tines, or a hollow arm with a graduated wire, can be used to measure the arc length of the damaged region of the acetabular labrum.

Owner:ARTHREX

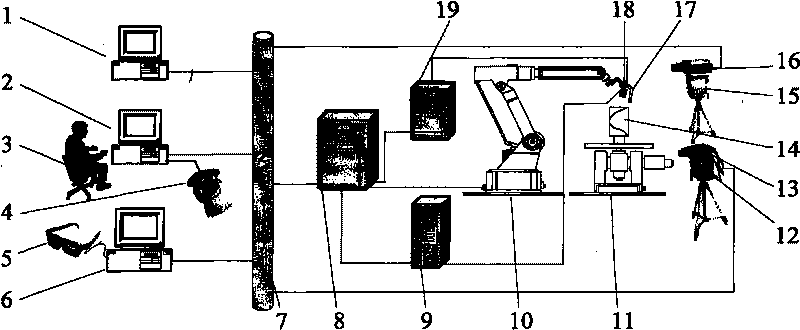

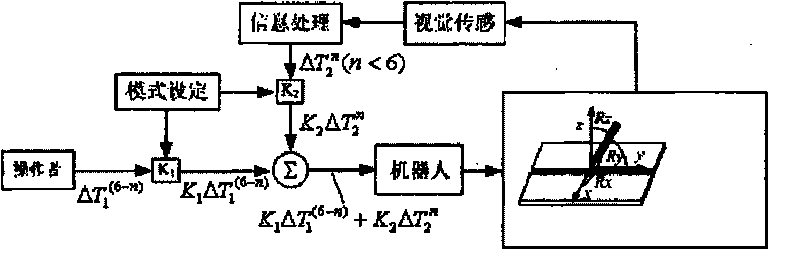

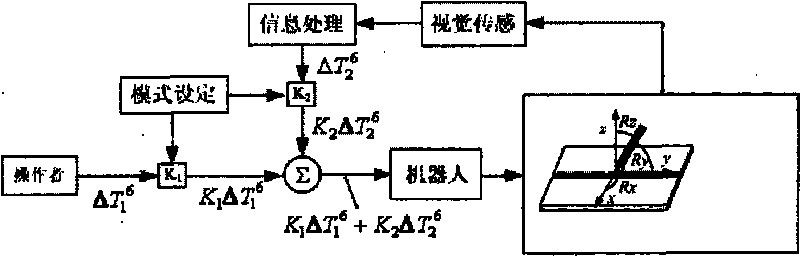

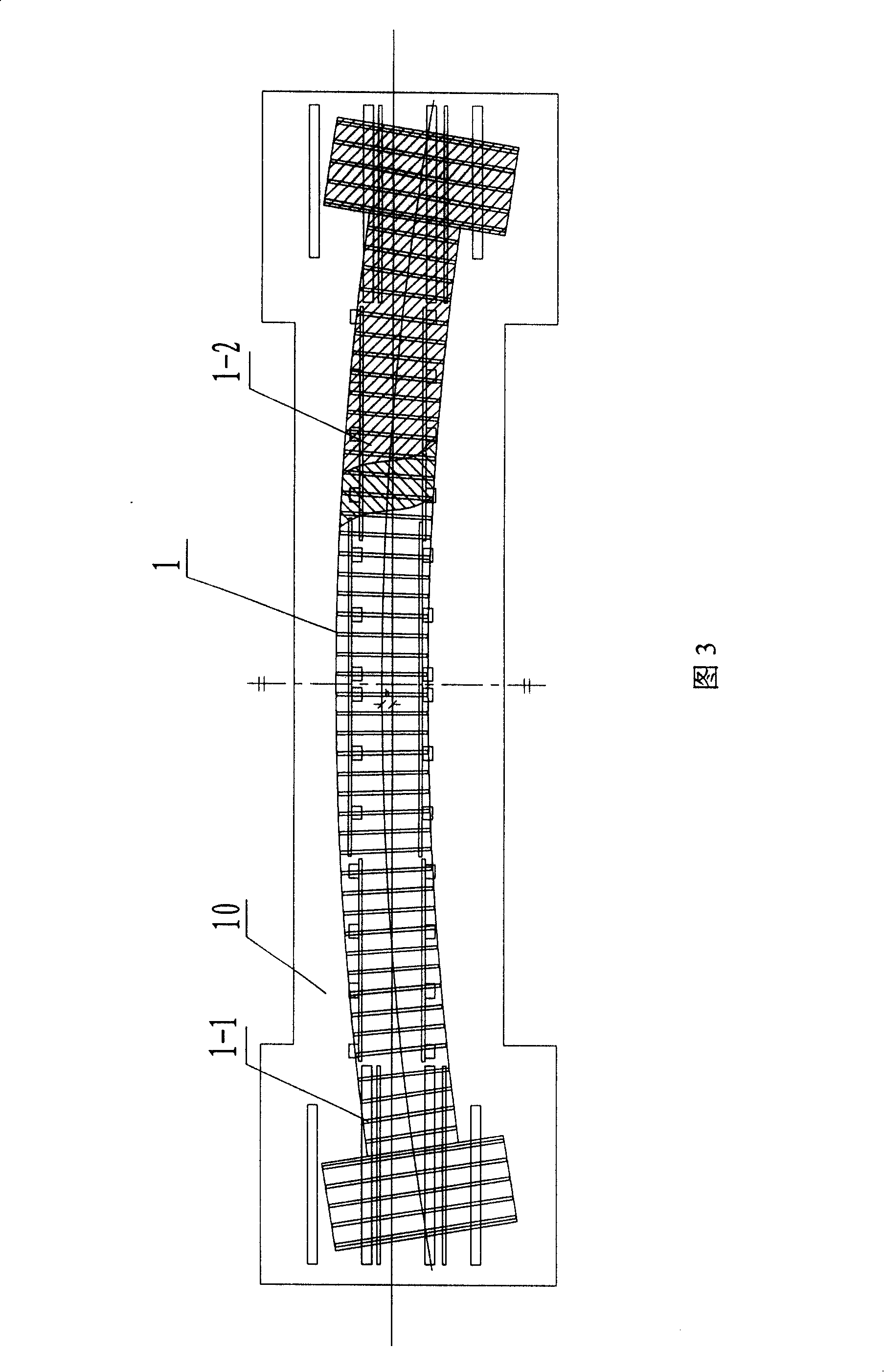

Man-machine collaboration shared control remote welding method

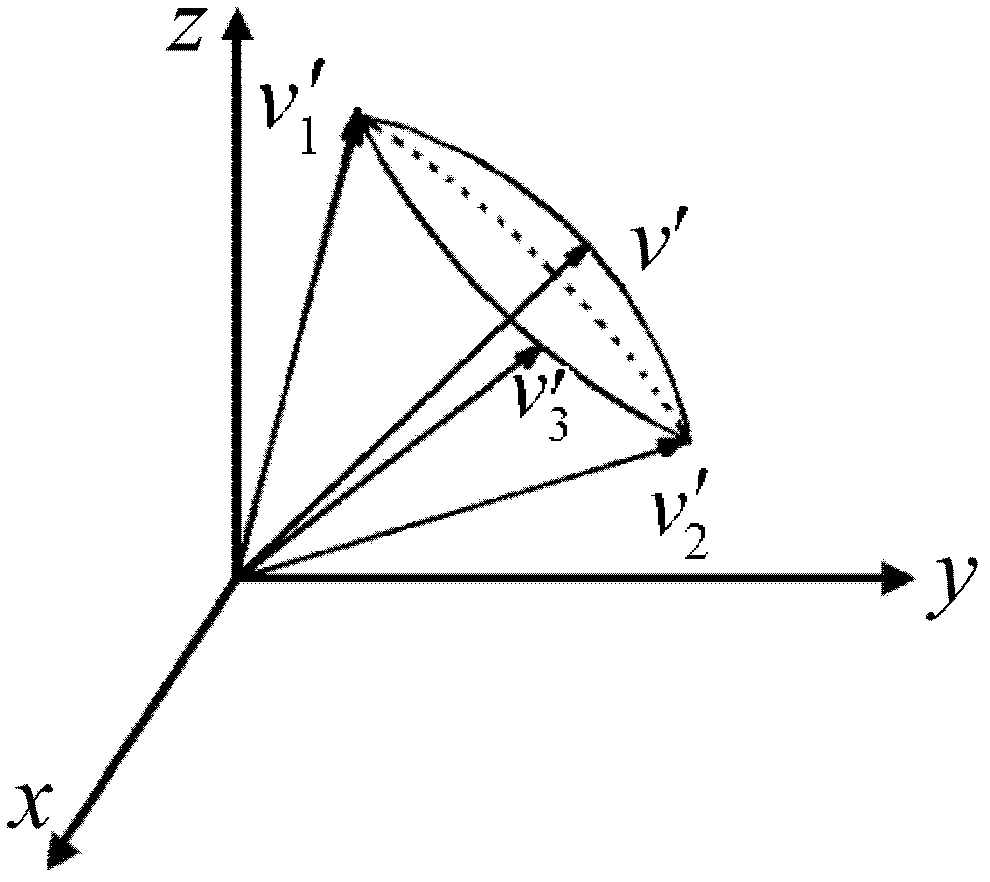

InactiveCN101745765ASolve the obstacle avoidance problemImprove environmental adaptabilityWelding/cutting auxillary devicesAuxillary welding devicesTime delaysSimulation

A man-machine collaboration shared control remote welding method relates to a remote welding method. The invention aims to solve the problems in the prior remote welding that the direct control operation can not be continuously carried out and particularly can not work under the situation of time delay, and an autonomous tracking weld seam can not be welded under the situations of complicated welding environment and irregular groove outline dimension of a weld seam. The remote welding method comprises the following steps: firstly, a macroscopic zooming camera acquires a two-dimensional video image, and the visual field of an operator is adjusted in a central monitoring man-machine interface; secondly, a robot guides a welding gun to reach the upper part of the weld seam; thirdly, the operator tracks the weld seam; fourthly, a workpiece is fixed on a working platform to form the welding environment at the remote end; fifthly, the robot moves towards an initial point of the weld seam; sixthly, the welding gun ensures that arc-length distance parameters of the workpiece are set by the central monitoring man-machine interface; and seventhly, the operator sets a shared control algorithm through the central monitoring man-machine interface.

Owner:HARBIN INST OF TECH

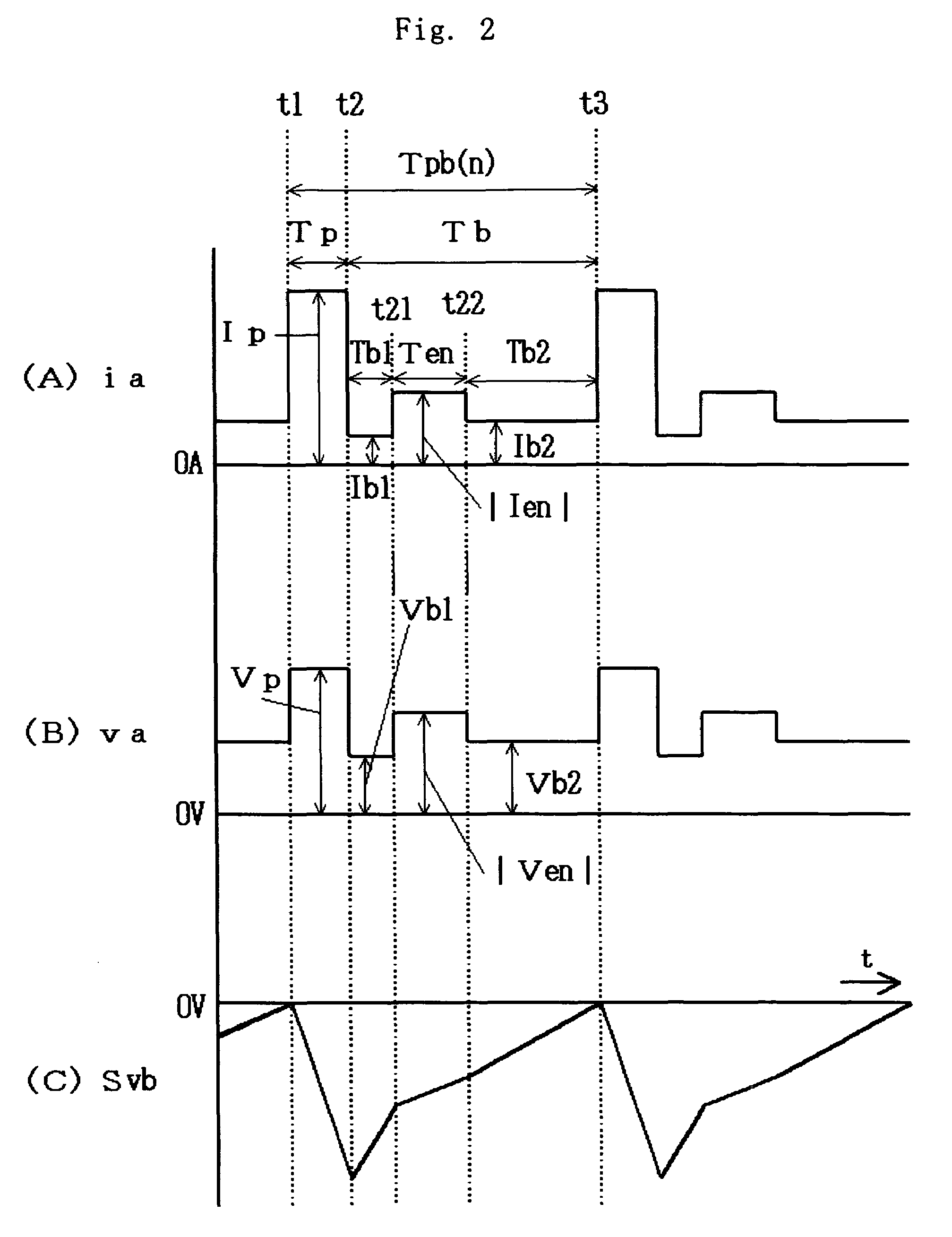

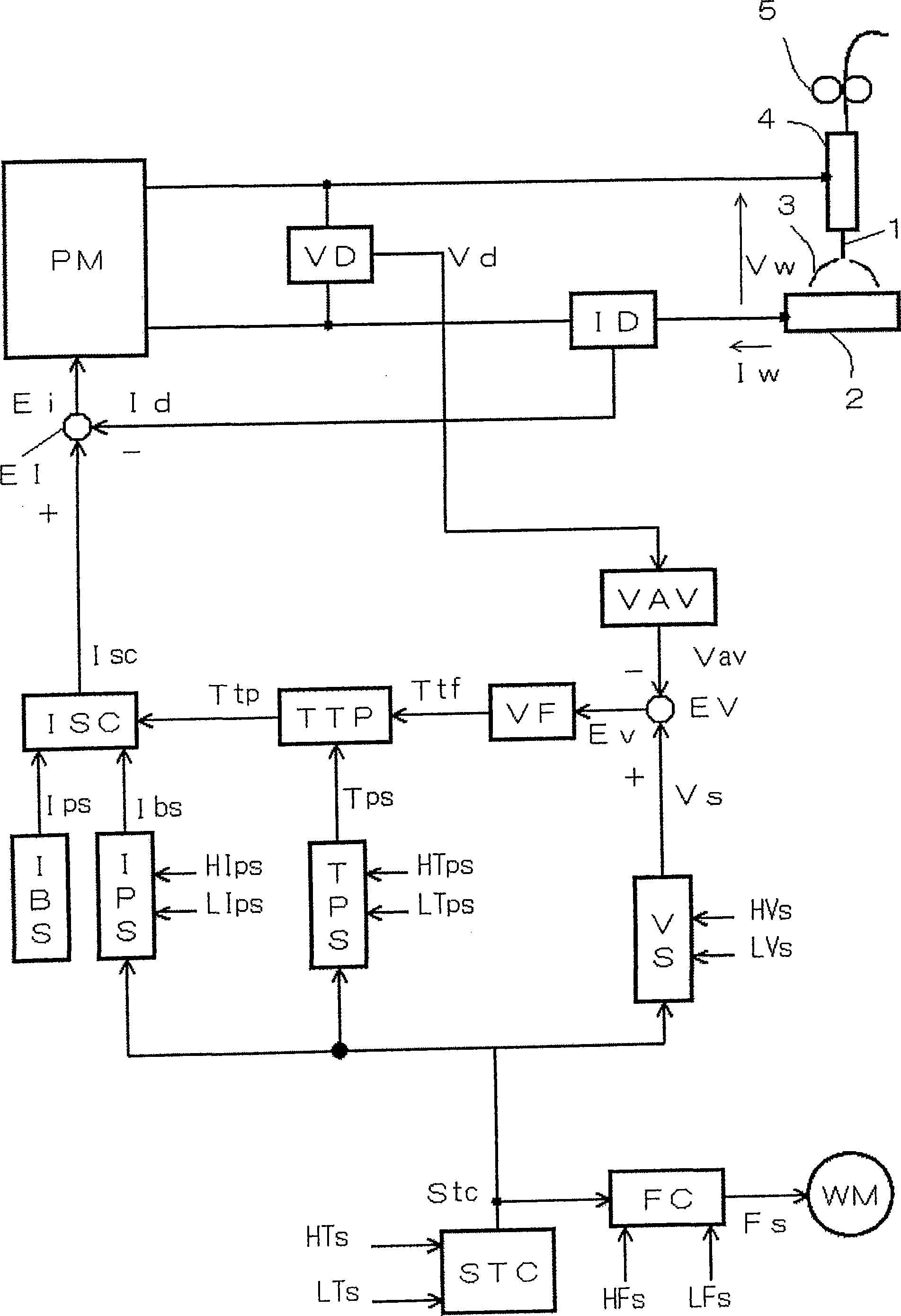

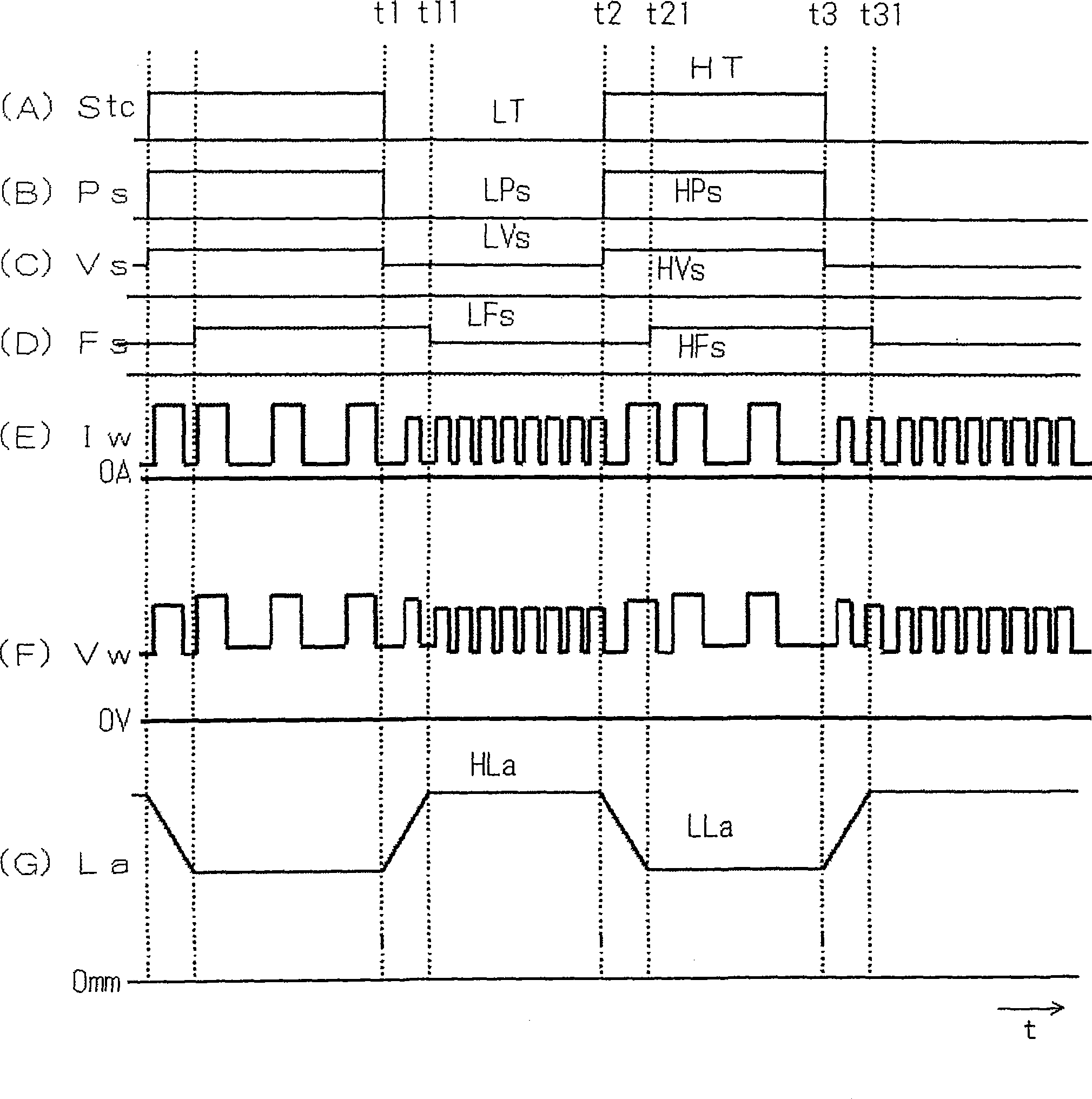

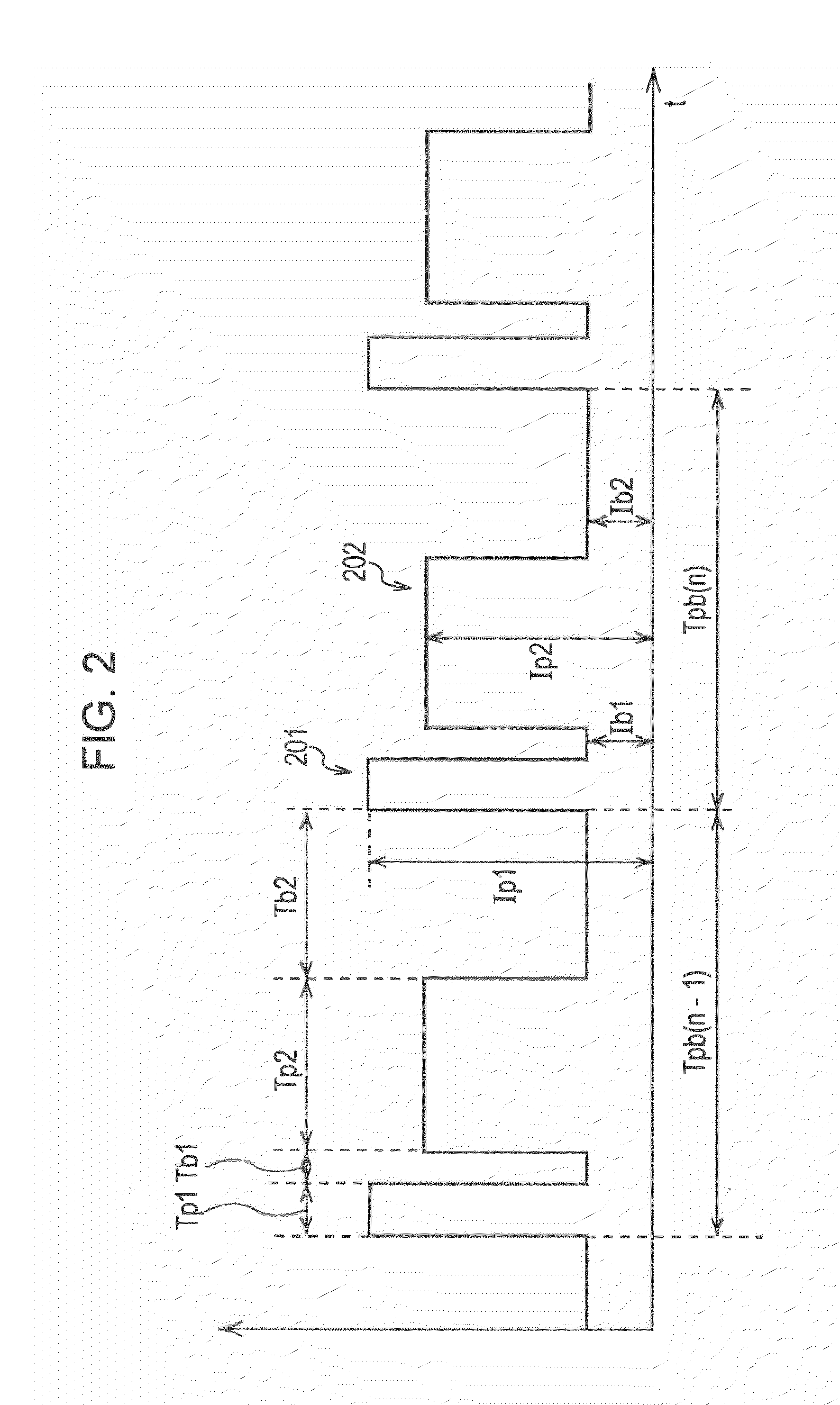

Pulse arc welding output control method and arc length variation pulse arc welding output control method

ActiveUS7145101B2Suppress fluctuationsImprove welding qualityArc welding apparatusPower flowWelding power supply

Owner:DAIHEN CORP

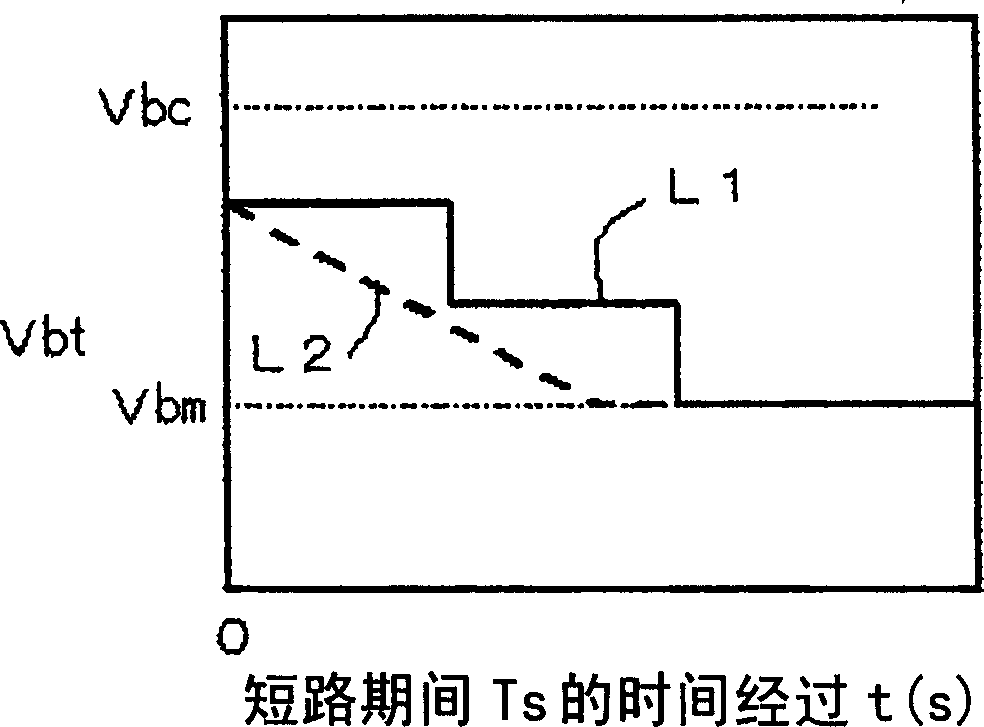

Arc length control method for impulse arc welding

In a method for controlling the arc length in pulse arc welding, the mean value of welding voltage Vw composed of peak voltage and base voltage is calculated, and the arc length is kept to be optimum by controlling the pulse period such that the mean value of the welding voltage is approximately equal to the preset value of the voltage. When a short circuit state Ts occurs during a base period and the voltage has changed from the base voltage to the short circuit voltage Vs, the mean value of the welding voltage is calculated by limiting the short circuit voltage Vs to the lower limit Vbt of the base voltage, wherein the lower limit value Vbt of the base voltage is varied so as to be furthermore low with the lapse of time in the short circuit state Ts. In consumable electrode type pulse arc welding the high speed welding, etc. are carried out with a mean arc length set to be short in order to improve the controllability of an arc length.

Owner:DAIHEN CORP

Corneal-scleral orthokeratology contact lens

ActiveUS7559649B2Fast and reliable and comfortable resultAccurately determineOptical partsCamera lensCorneal curvature

A corneal-scleral orthokeratology contact lens is formed of rigid gas permeable material with uniform arc lengths in the treatment area even when the corneal curvature varies and asymmetric blends or splines called minor zones, where the portion of the blend or spline is shorter toward the lens center and broader toward the lens edge, and relieve the treatment area of all centering responsibility, transferring it to the limbal-scleral region. The method of determining the total sagittal height of an eye at a given chord diameter to predetermine exact fitting parameters and predict unaided visual outcome trial lenses, with exact chord and sagittal height values used to match the sagittal height of an eye, the sagittal value may be obtained from some ocular topographers. A computer program can easily take the sagittal information and design an optimum lens.

Owner:DAKOTA SCI

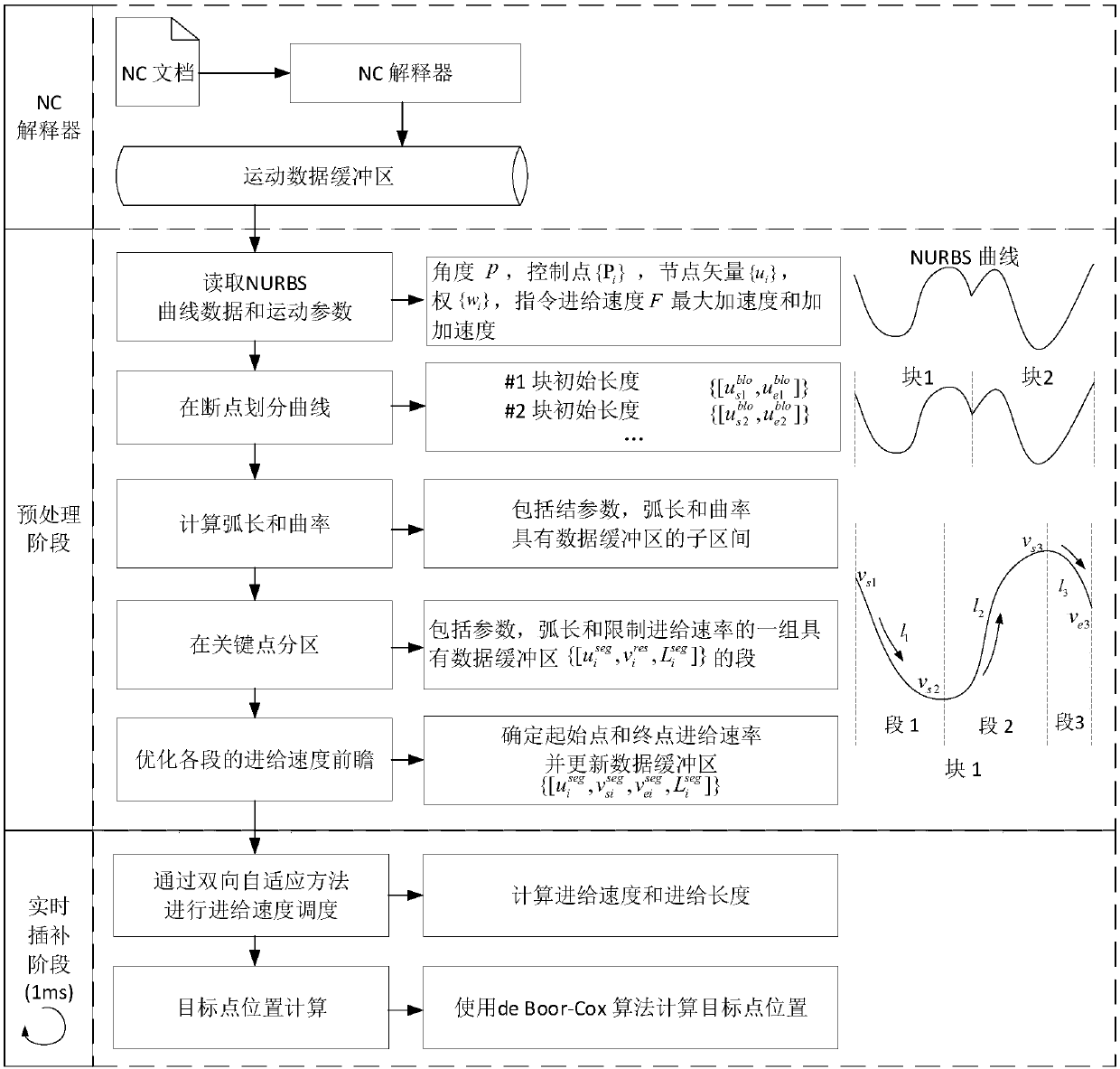

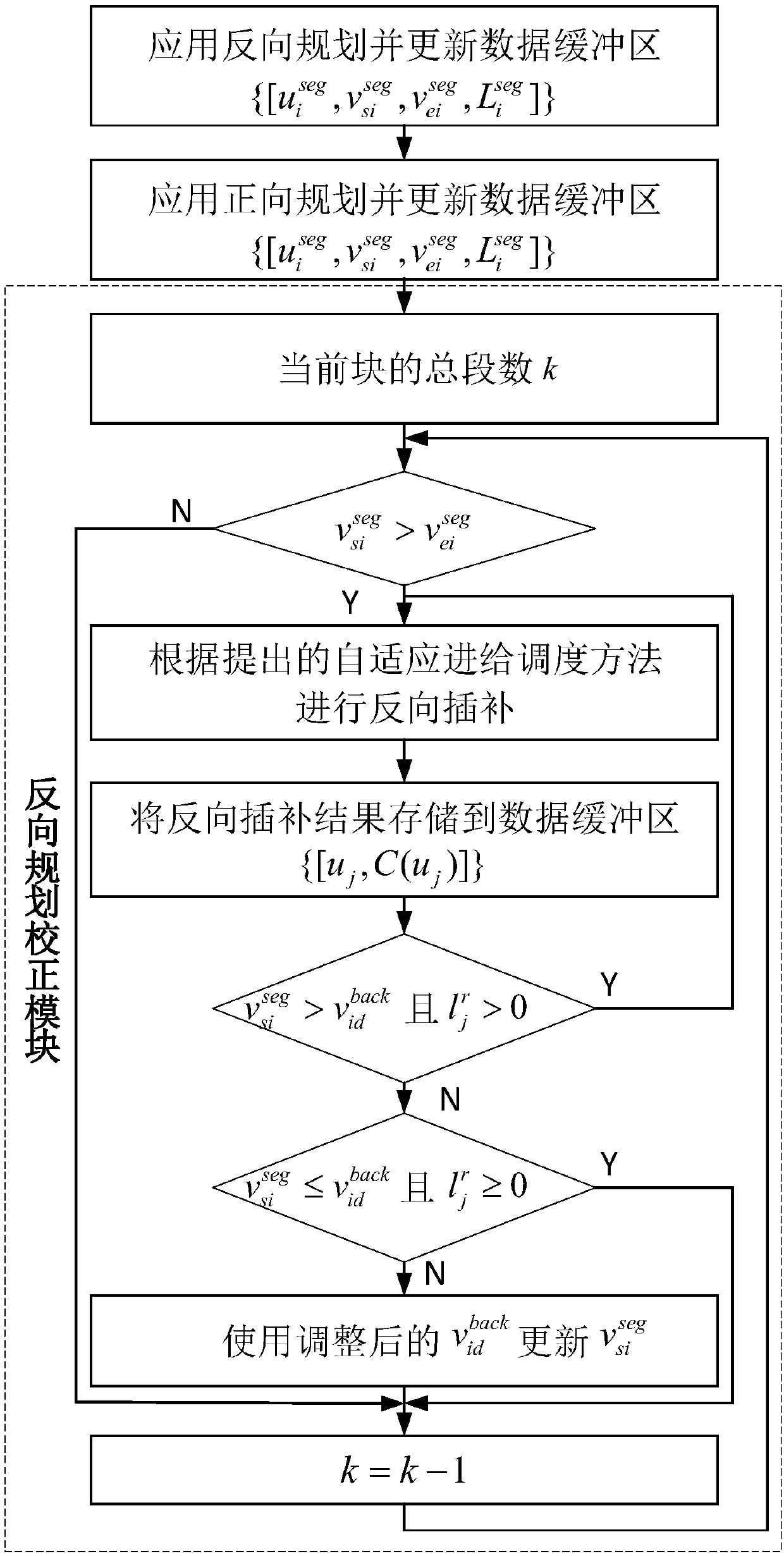

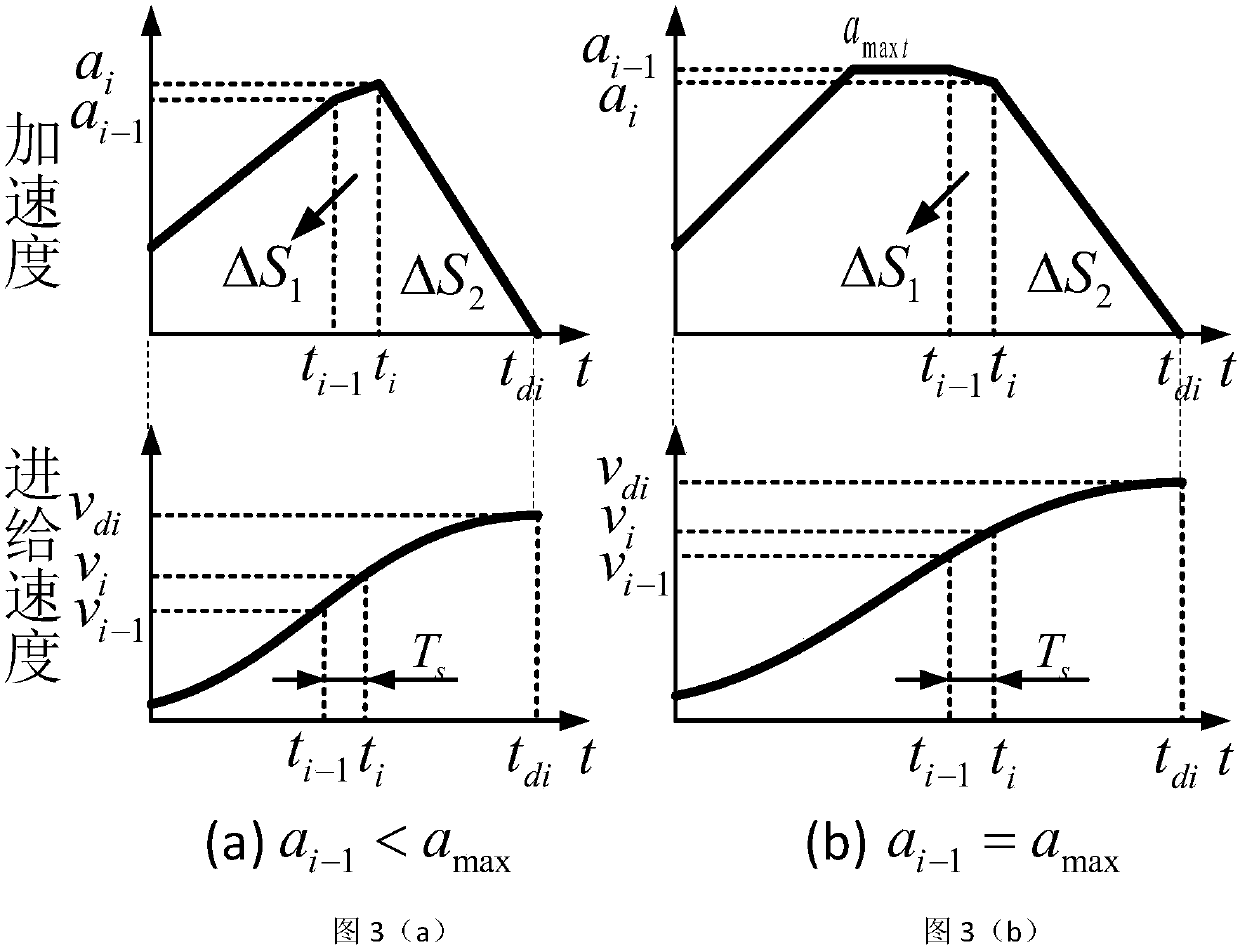

NURBS curve bi-directional adaptive interpolation algorithm based on S-curve acceleration and deceleration algorithm

ActiveCN107817764AGuaranteed speed smoothnessHigh precisionNumerical controlAlgorithmMotion parameter

The present invention relates to an NURBS curve bi-directional adaptive interpolation algorithm based on an S-curve acceleration and deceleration algorithm, belonging to the field of motion control. The method comprises the steps of: (1) employing an NC interpreter to obtain NURBS curve data and motion parameters; (2) performing scanning to obtain key characteristics of a NURBS curve, the key characteristics comprising breaking points of the NURBS curve, dividing the NURBS curve into blocks according to the breaking points, and calculating an arc length and a curvature of the NURBS curve of each block; dividing the blocks into sections according to curvature of each block; and (3) employing the curve data and motion parameters of each section obtained in the step (2) to obtain a feeding length of each period in each section, and finding new interpolating points. The NURBS curve bi-directional adaptive interpolation algorithm considers constraint of a curvature extreme point and curvatures in nearby areas thereof on the speed so as to ensure that a planning speed is in a constraint range and precision of speed planning and interpolation is improved; and moreover, interpolations in two directions can be accurately met, and speed smoothness of the whole interpolation process can be ensured.

Owner:SHANDONG UNIV

Method and instrumentation for acetabular labrum reconstruction

Methods and instruments for repairing a damaged acetabular labrum. The arc length of a portion of an acetabular rim proximal to the damaged (torn or broken) region of the acetabular labrum is measured, and a graft, such as a meniscal allograft or a gracilis autograft, is trimmed according to the measurement and secured in the damaged region of the acetabular labrum as a replacement. Various instruments, such as a wheel mounted on an arm, a measuring member with spaced tines, or a hollow arm with a graduated wire, can be used to measure the arc length of the damaged region of the acetabular labrum.

Owner:ARTHREX

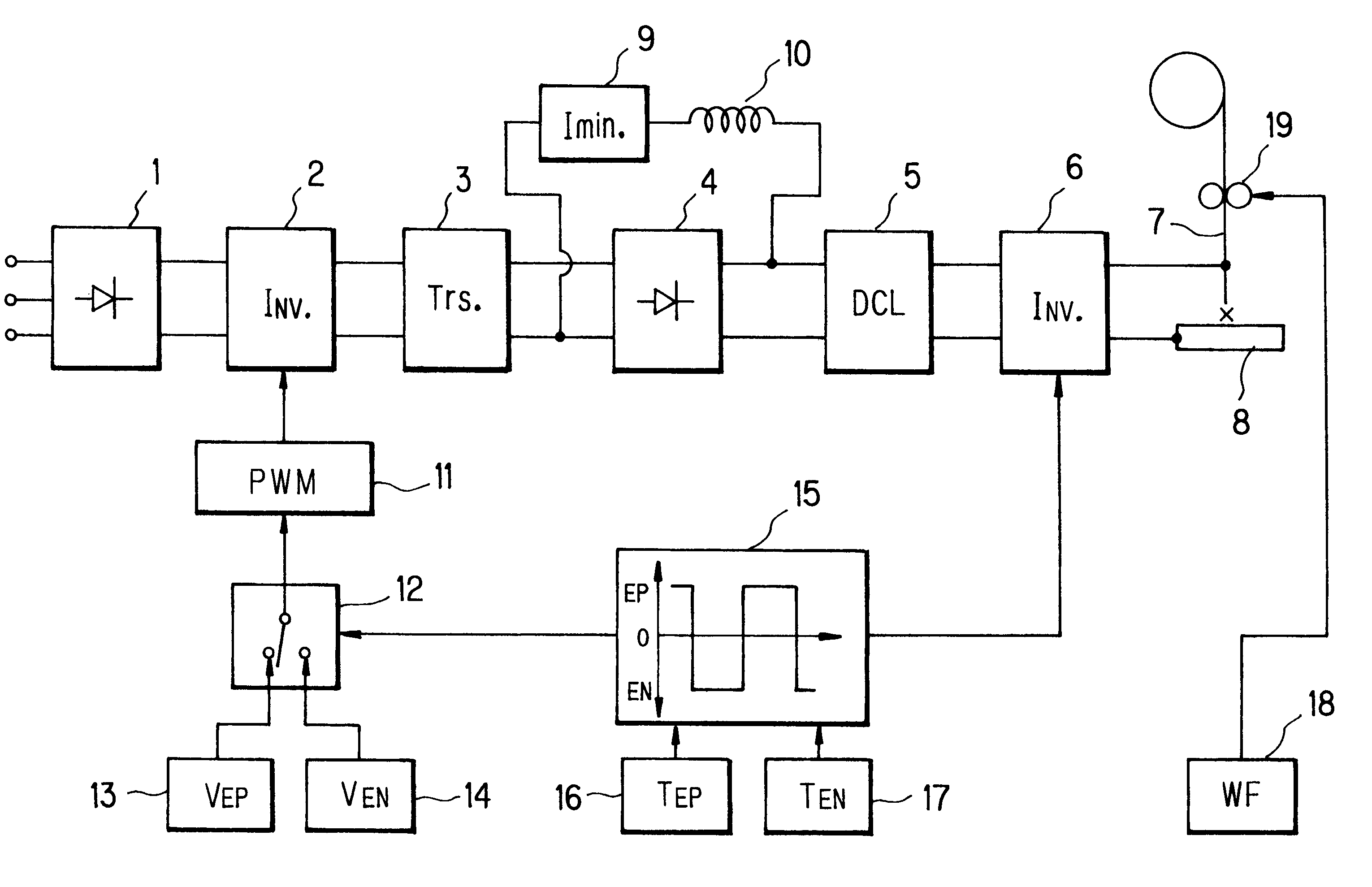

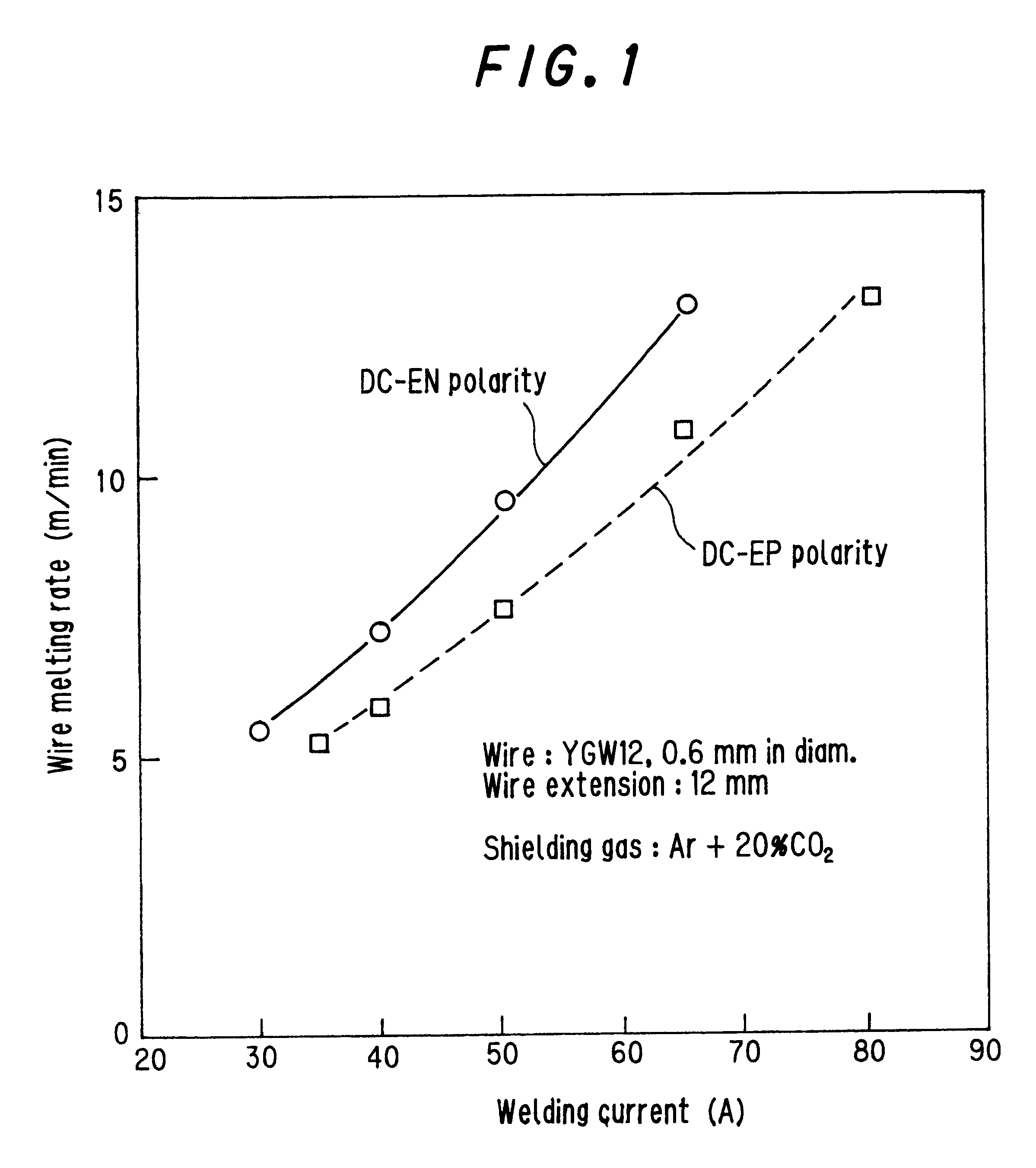

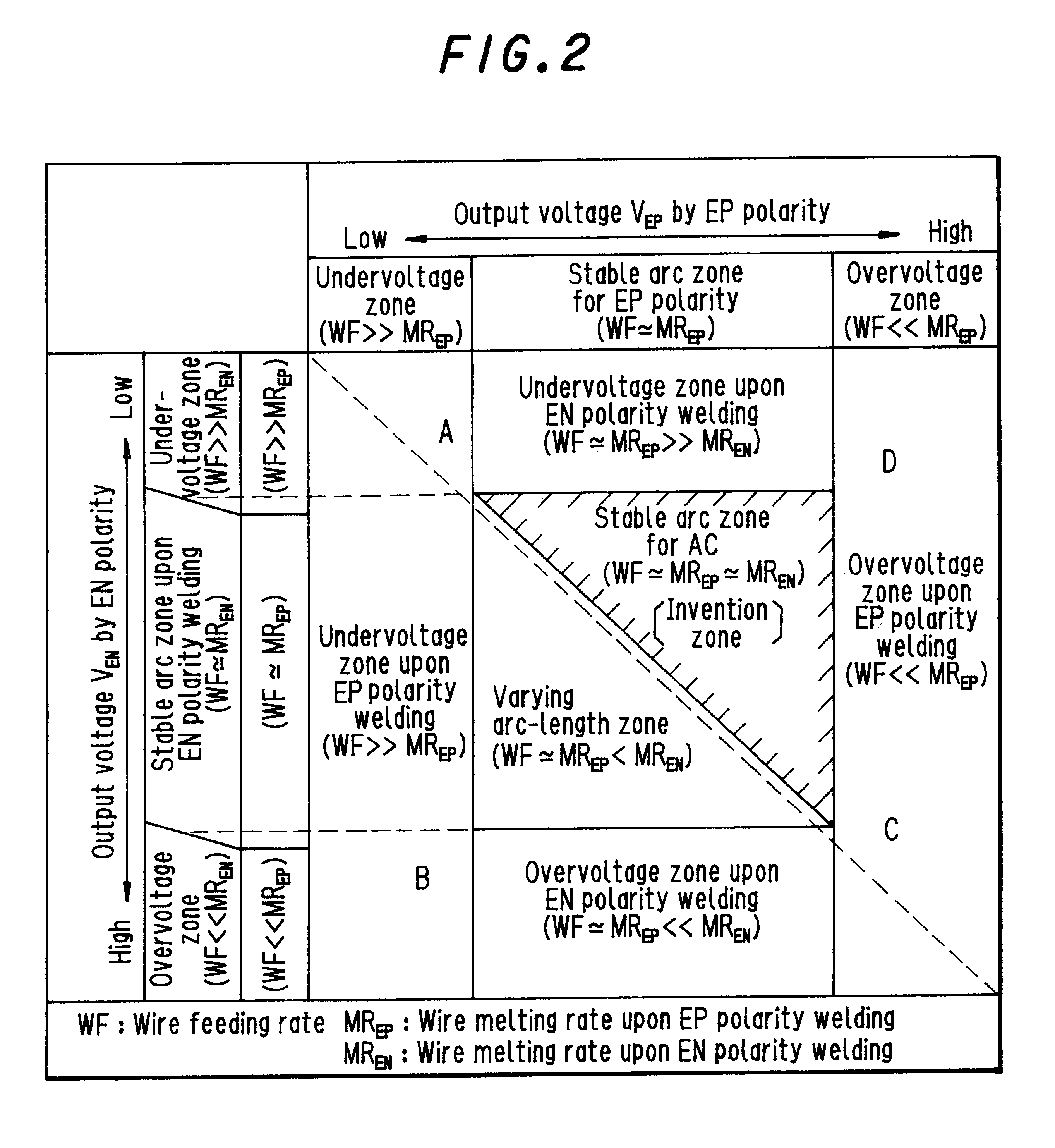

Gas-shielded AC arc welding method and machine making use of consumable electrode

An EP output voltage to be outputted during a period of EP polarity is set so that a welding current becomes equal to or lower than a critical current level, and an EN output voltage to be outputted during a period of EN polarity is set at a level lower than the EP output voltage. This makes it possible to substantially equalize a wire melting rate in the period of EN polarity and that in the period of EP polarity with each other. Even at such a short arc length as causing frequent short circuiting, gas-shielded AC arc welding making use of a consumable wire can be still performed stably so that high wire melting rate, shallow penetration, convex weld reinforcement and the like, which are characteristic features of AC welding, can each be set selectively at a desired level or in a desired shape depending on the application.

Owner:HITACHI SEIKO LTD +1

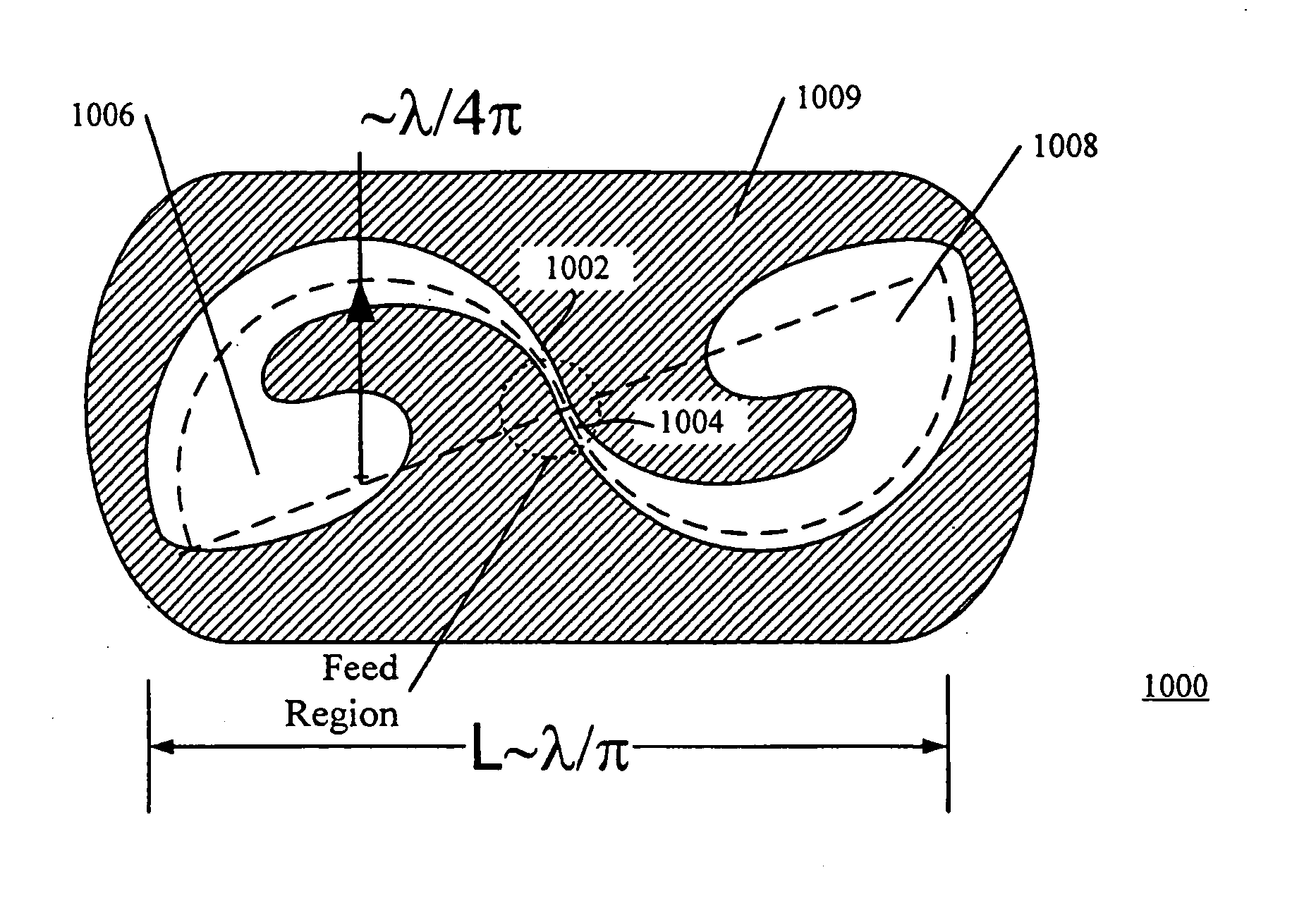

Chiral polarization ultrawideband slot antenna

Owner:NEXT RF

Dabbing pulsed welding system and method

ActiveUS20140158669A1Increase flexibilityImprove welding qualityArc welding apparatusPower flowEngineering

A pulsed welding regime includes a peak phase in which energy is added to an electrode and a weld puddle, and a molten ball begins to detach from the electrode, followed by a dabbing phase in which current is significantly reduced to place the ball in the weld puddle with addition of little or no energy. The resulting short circuit clears and the system proceeds to a background phase. The current in the dabbing phase is lower than the current during the background phase. The process may be specifically adapted for particular welding wires, and may be particularly well suited for use with cored wires. The dabbing phase allows for lower energy to be transferred to the sheath of such wires, and resets the arc length after each pulse cycle.

Owner:ILLINOIS TOOL WORKS INC

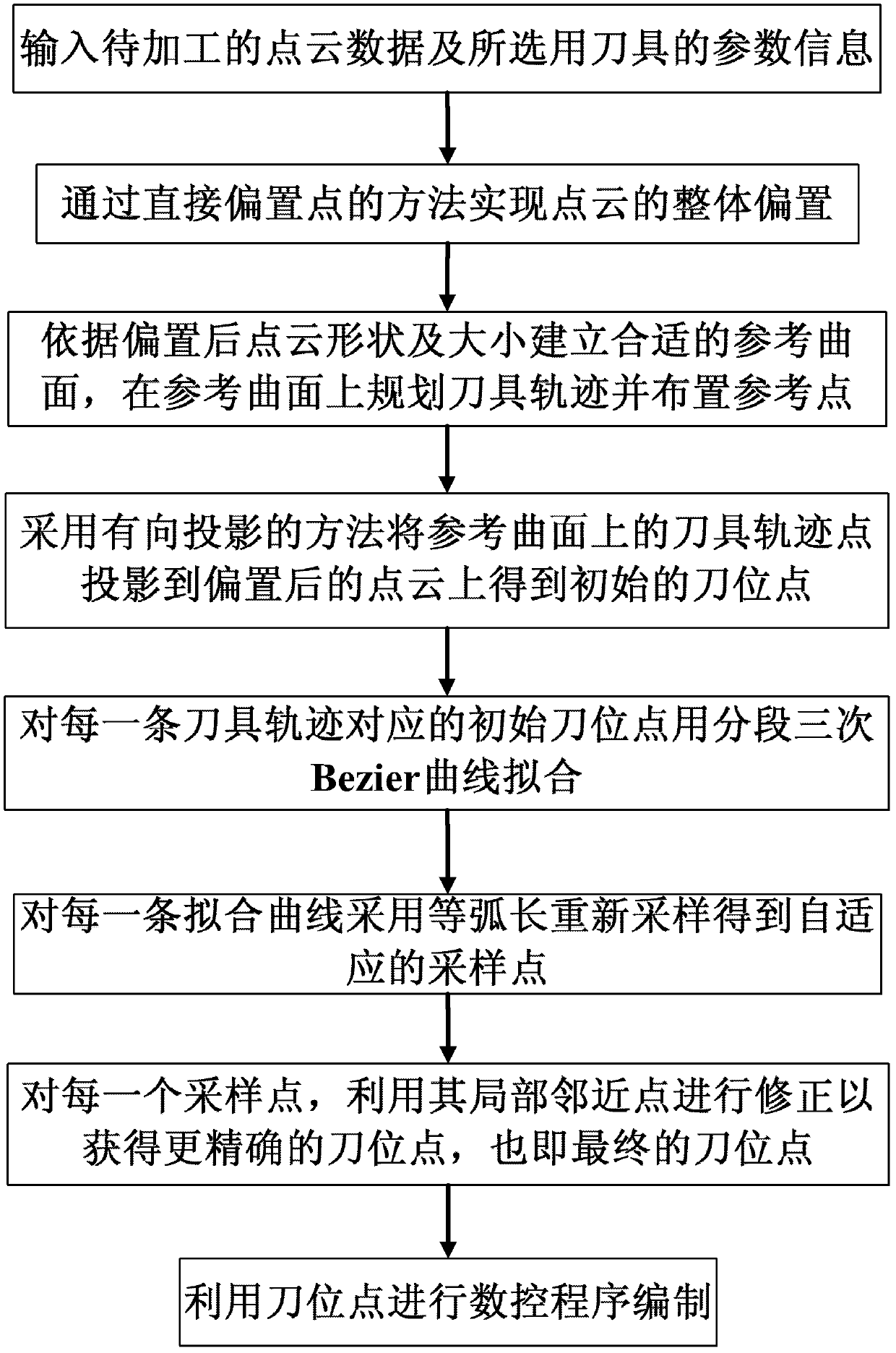

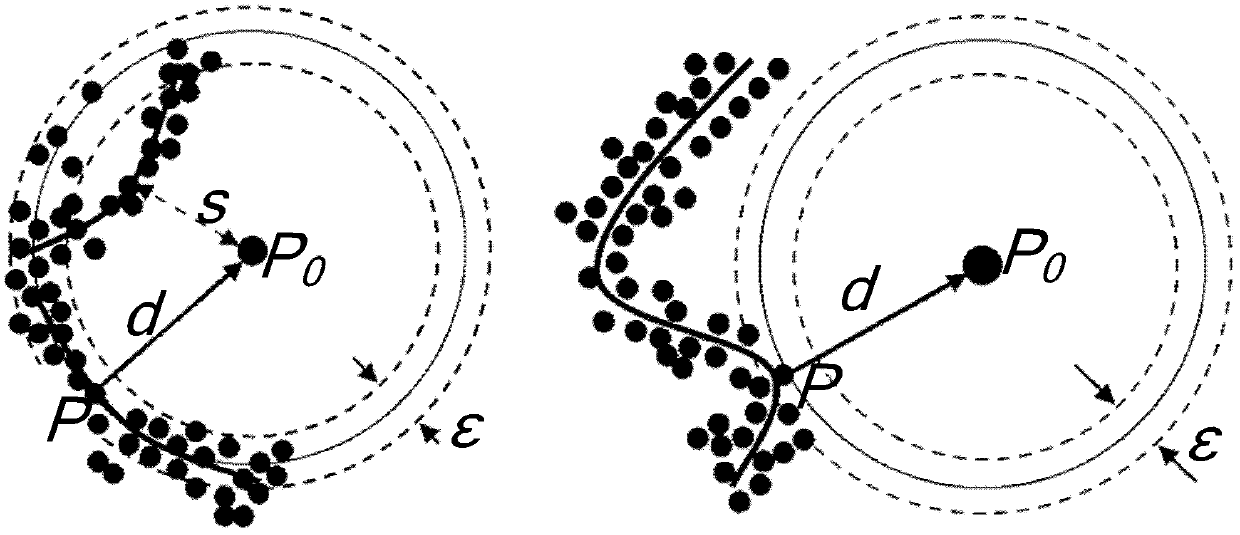

Method for directly generating tool path based on measured data

InactiveCN102608954AAvoid problems with radius compensationAvoid cumbersomeComputer controlSimulator controlNumerical controlPoint cloud

The invention discloses a method for directly generating a tool path based on measured data. The method comprises the following steps of: biasing a point cloud curved surface by means of directly biasing points; establishing a reference curved surface according to the shape and size of biased point cloud and planning the tool path on the reference curved surface; projecting a tool path point on the reference curved surface to the biased point cloud so as to obtain initial tool location information by employing a directed projection method; fitting the projection point by using a segmented triple Bezier curve, re-sampling the projection point by employing an equal arc length method to generate a self-adaptive tool path so as to improve the machining precision; and correcting the sampling point by employing point-based local neighboring orthogonal projection to improve to precision so as to obtain the final tool location point information. The numerical control machining tool path is directly generated by the measured data, a complex process of reconstructing a curved surface model is avoided, reverse engineering and a numerical control technique are effectively integrated, the manufacturing efficiency and precision are improved, and automation is conveniently realized.

Owner:XI AN JIAOTONG UNIV

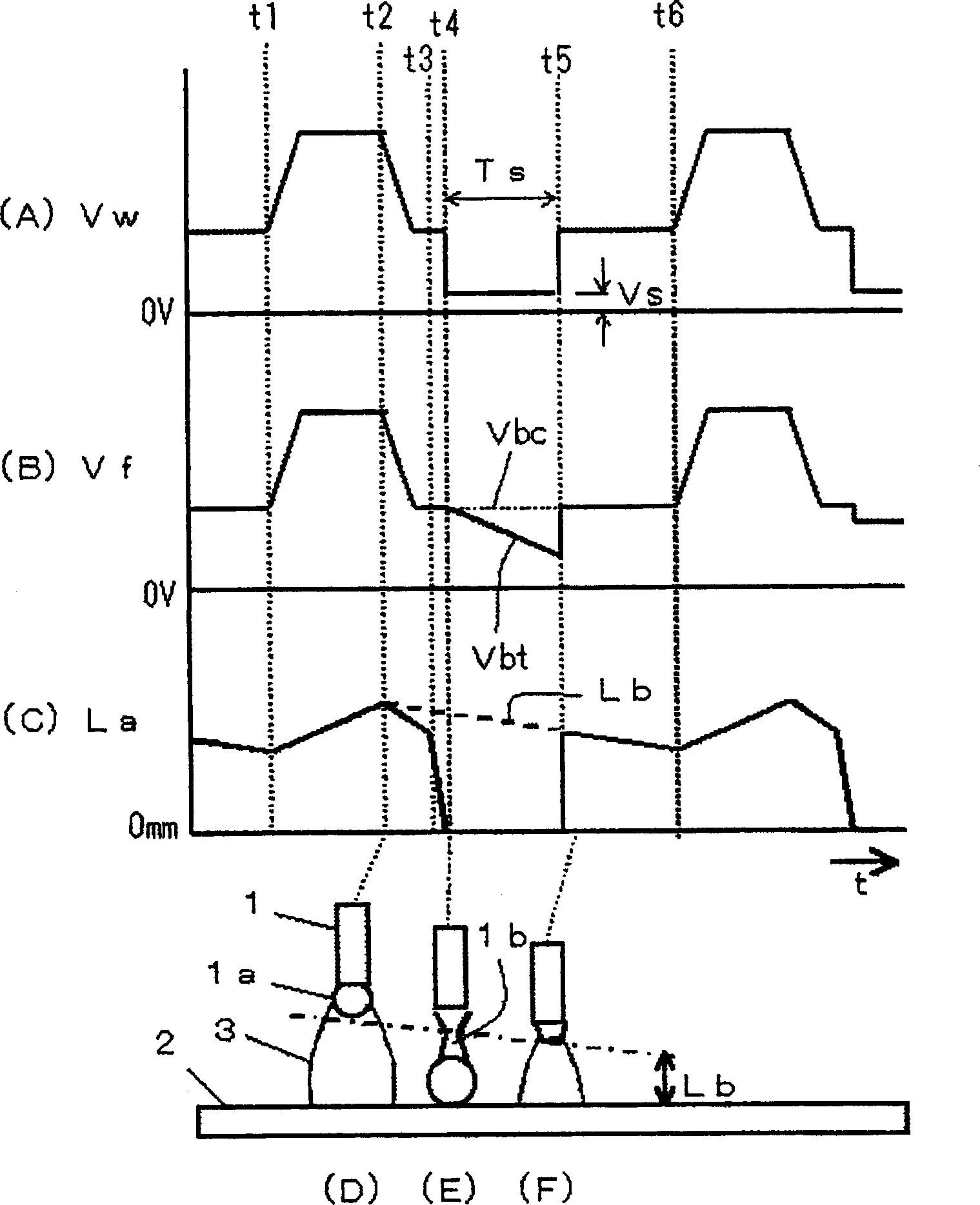

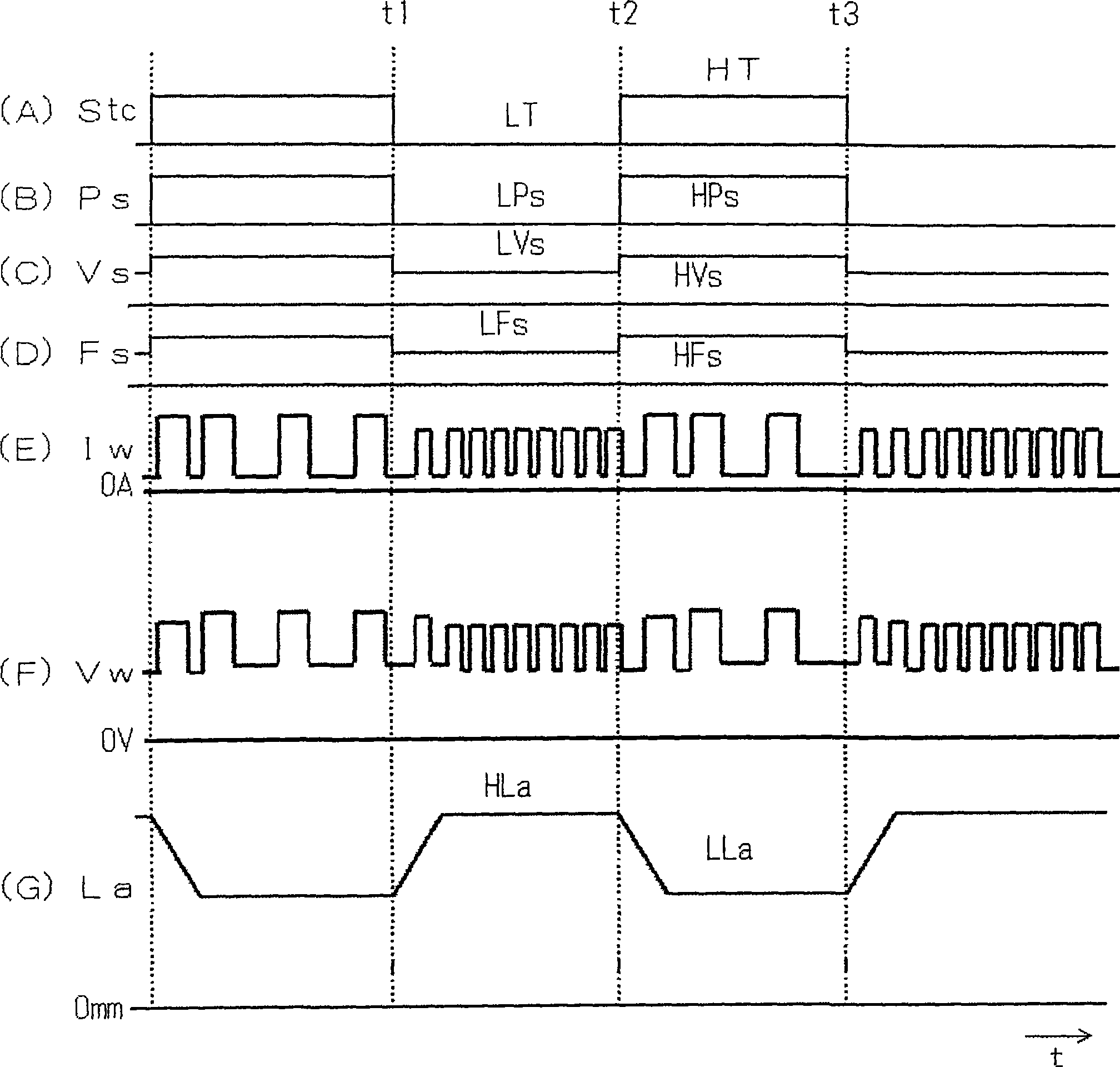

Pulse arc welding control method

ActiveCN101376191AThe arc force changes greatlyShake violentlyArc welding apparatusPower flowSwitching signal

An impulse arc welding control method comprises: repeating electrifying using the electrifying of peak current of in peak period and the electrifying of background current in background period as impulse period; controlling the arc length in the manner that the welding voltage value (Vw) is approximately equal to the set voltage value (Vs); making the arc length to vary periodically by making the set voltage value (Vs) to vary synchronistically with the switching signal (Stc); making the impulse parameter (Ps) to vary synchronistically with the switching signal (Stc); and changing the sending speed (Fs) from the time the switching signal (Stc) varying starts to the time arc length (La) transition varying approximately converges. Thus, the major varying of arc force make the shake movement of the bath becomes more intensive to improve the air bubble reducing effect. Consequently, the air bubble reducing effect is improved in the impulse arc welding method with arc length varied periodically.

Owner:DAIHEN CORP

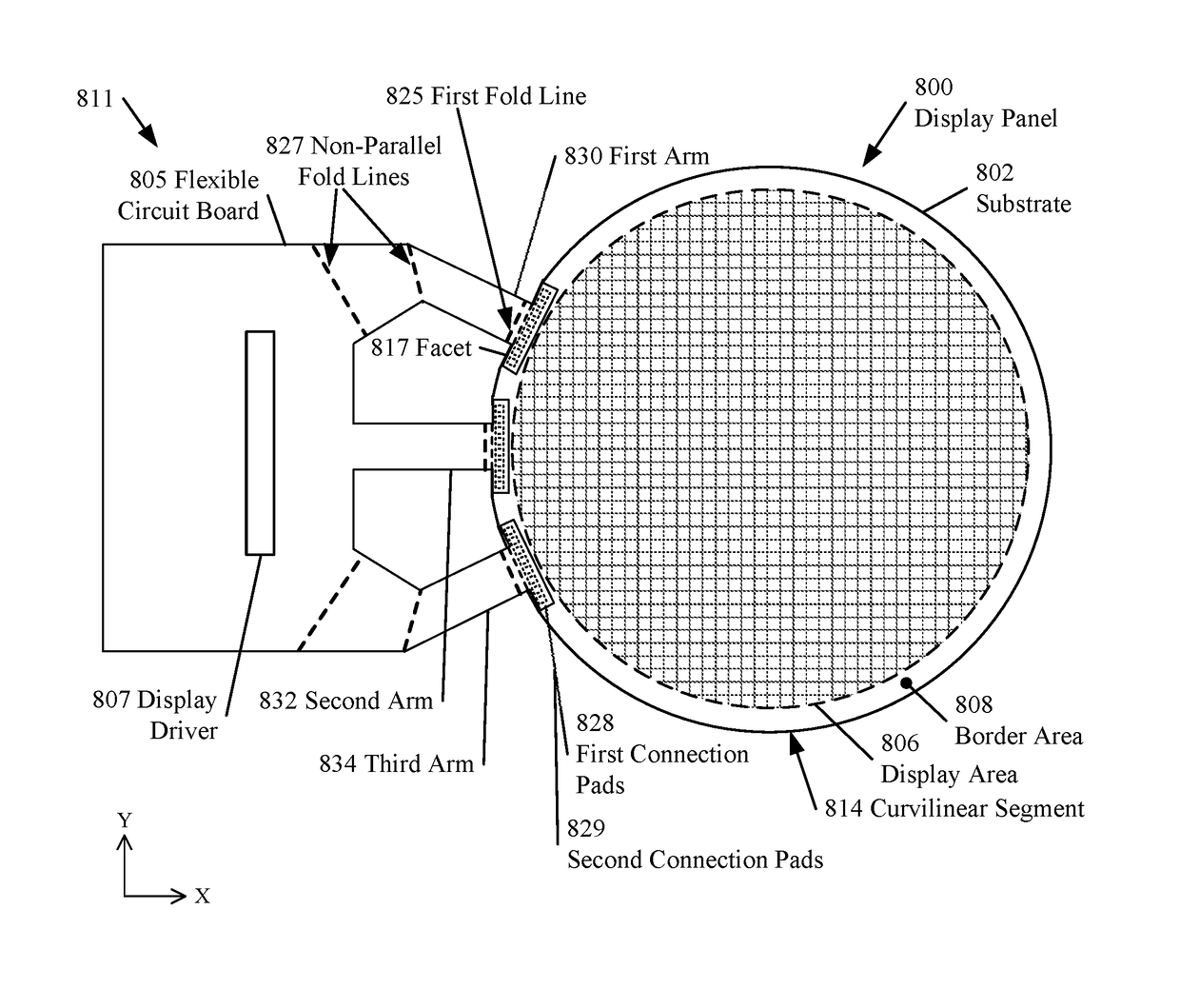

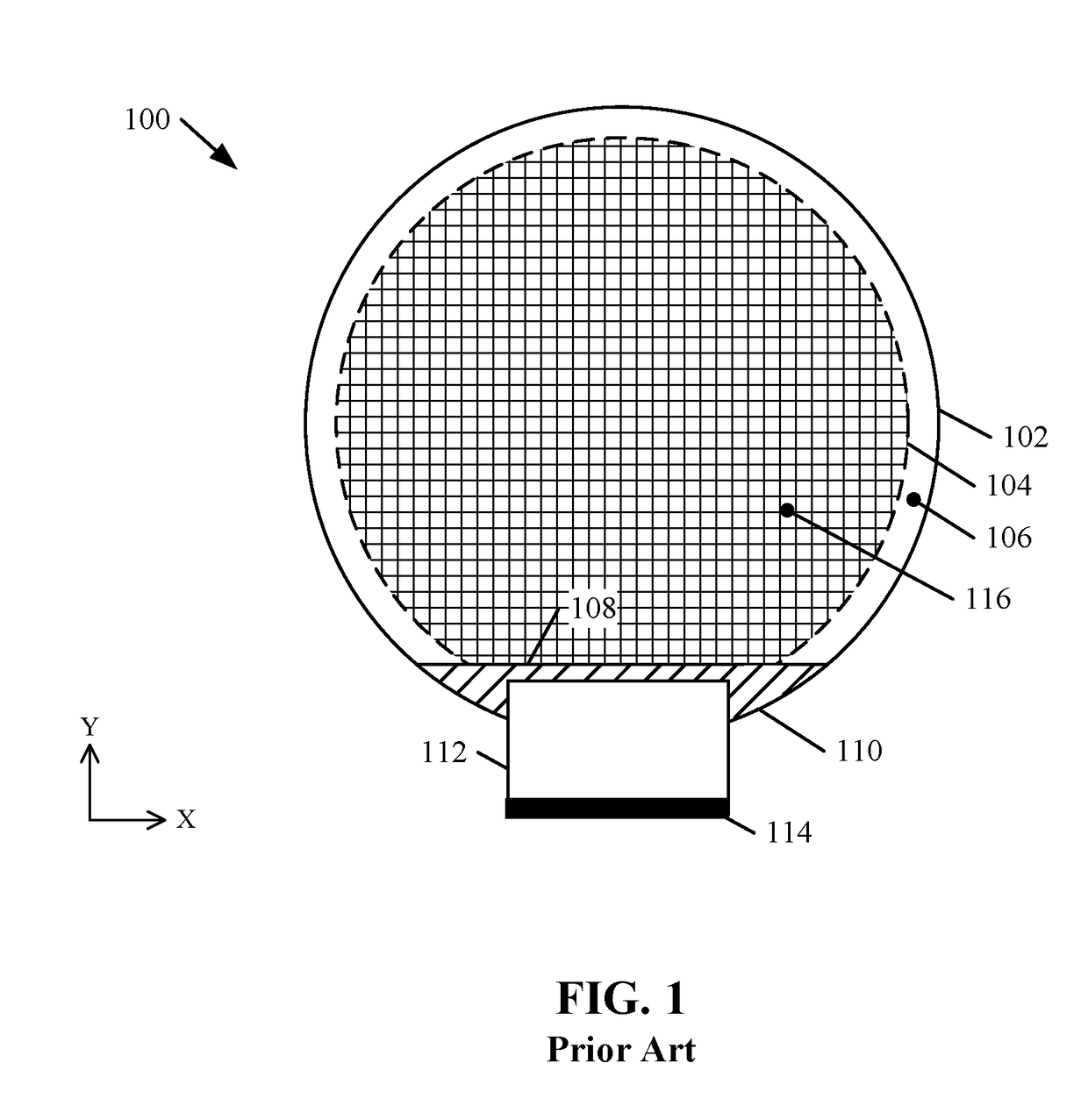

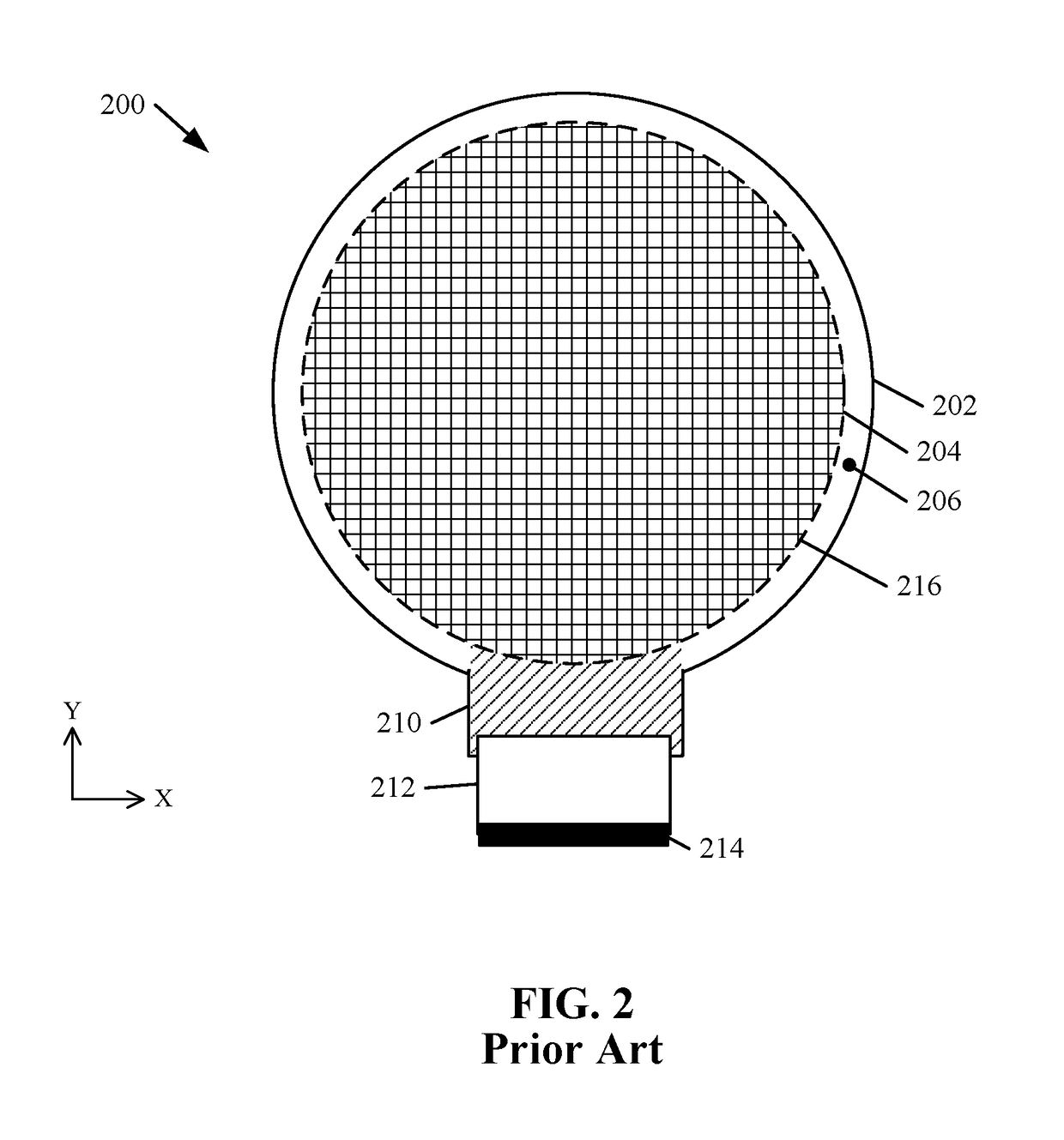

Display panel with minimum borders

ActiveUS20170168463A1Reduce border widthReduce widthElectronic time-piece structural detailsVisual indicationsFlexible circuitsEngineering

A device includes a substrate with a curvilinear perimeter segment adjoined to a plurality of facets, a display area, a border area surrounding the display area, and connection pads, divided into groups corresponding to the facets, in the border area. A flexible circuit board with arms coupled to the groups of connection pads is included. Another device includes a substrate having a display area, first connection pads within a border area peripheral to the display area, and a flexible circuit board having a first portion including second connection pads configured to be coupled to the first connection pads, and a second portion configured to accommodate a plurality of transmission lines extending from the second connection pads. An arc length of the first portion can be greater than that of the second portion and a center-to-center pitch of the second connection pads can be greater than that of the transmission lines.

Owner:QUALCOMM INC

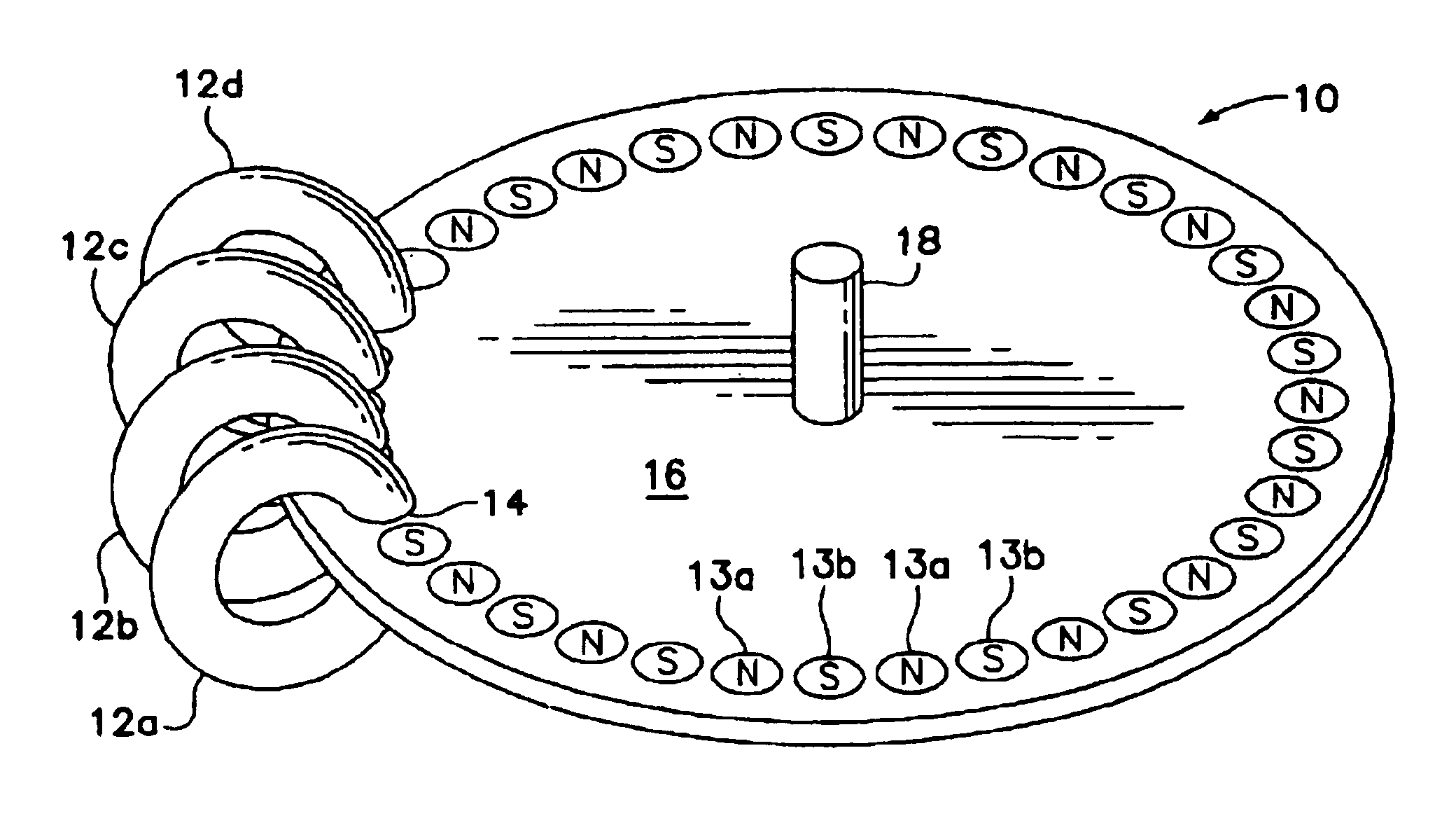

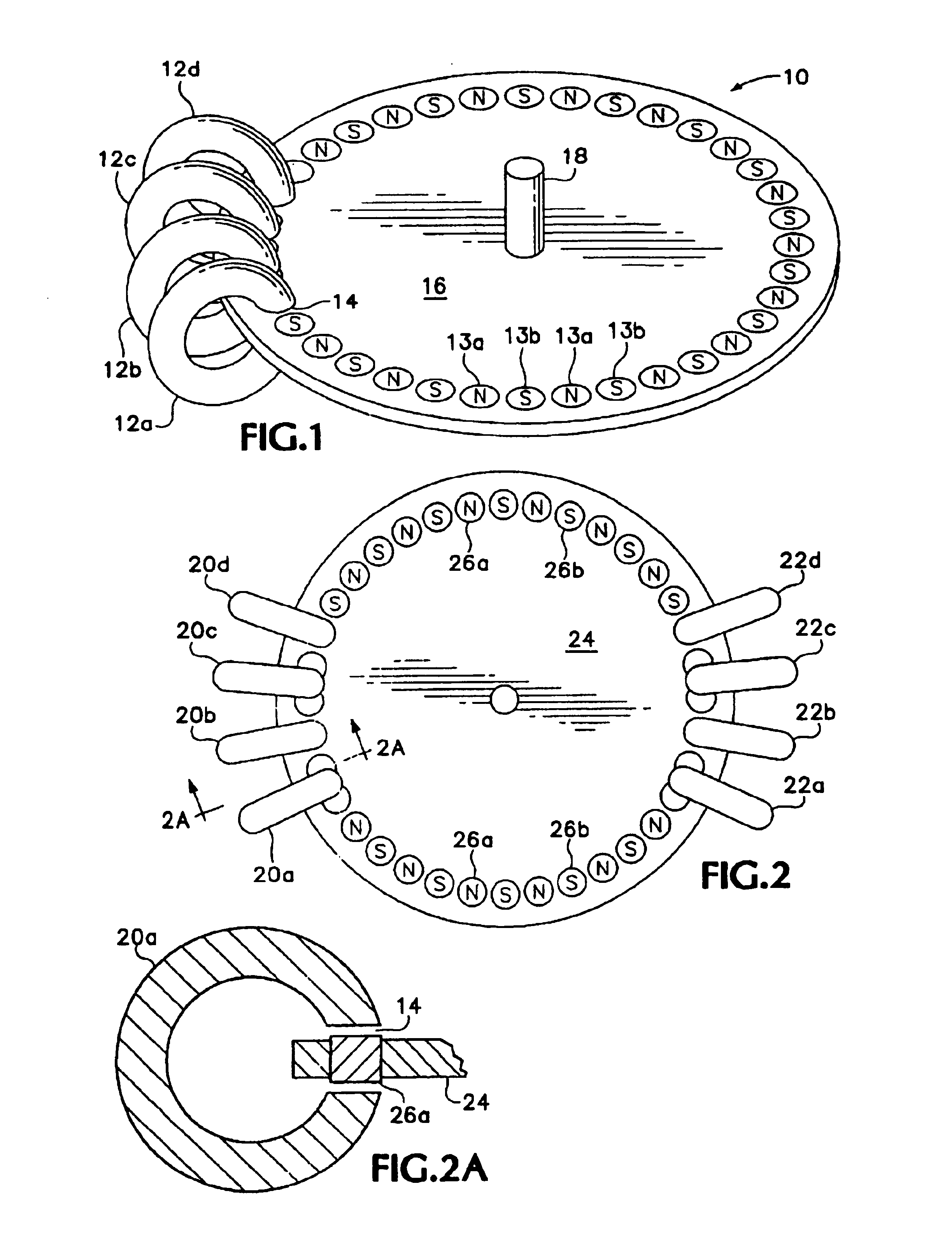

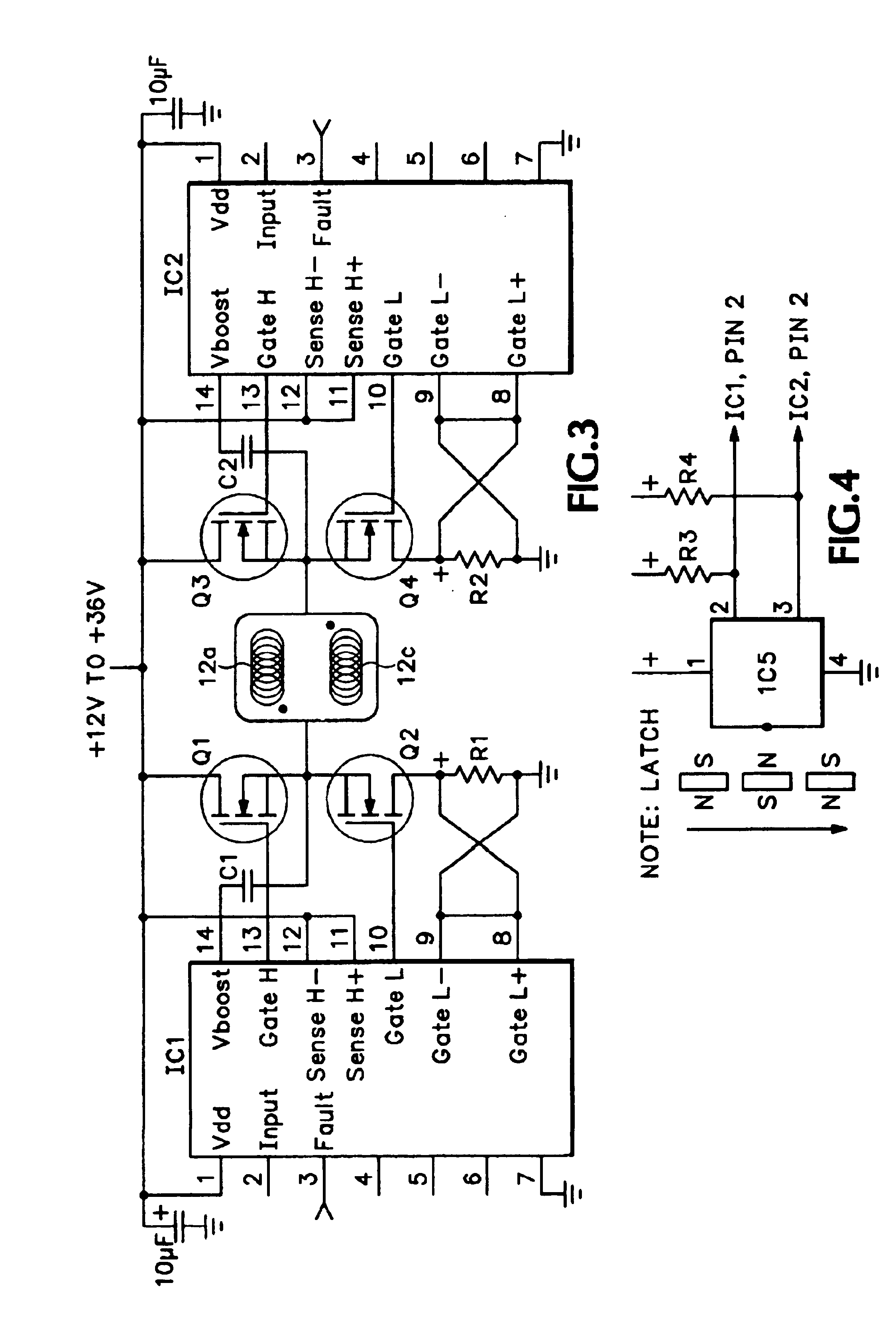

Brushless electro-mechanical device

An electromotive machine having a stator element and a rotor element, the stator element including at least one set of N preferably toroidally shaped electromagnetic members, the electromagnetic members arranged along an arc a predetermined distance apart defining a stator arc length. Each of the members has a slot, and the rotor element includes a disc adapted to pass through the slots. The disc contains a plurality of permanent magnet members spaced side by side about a periphery thereof and arranged so as to have alternating north-south polarities. These permanent magnet members are sized and spaced such that within the stator arc length the ratio of stator members to permanent magnet members is N to N+1, where N is the number of electrical excitation phases applied to the electromagnets. The electromagnetic members are energized to create high torque and smooth operation.

Owner:HIPPERT MICHAEL

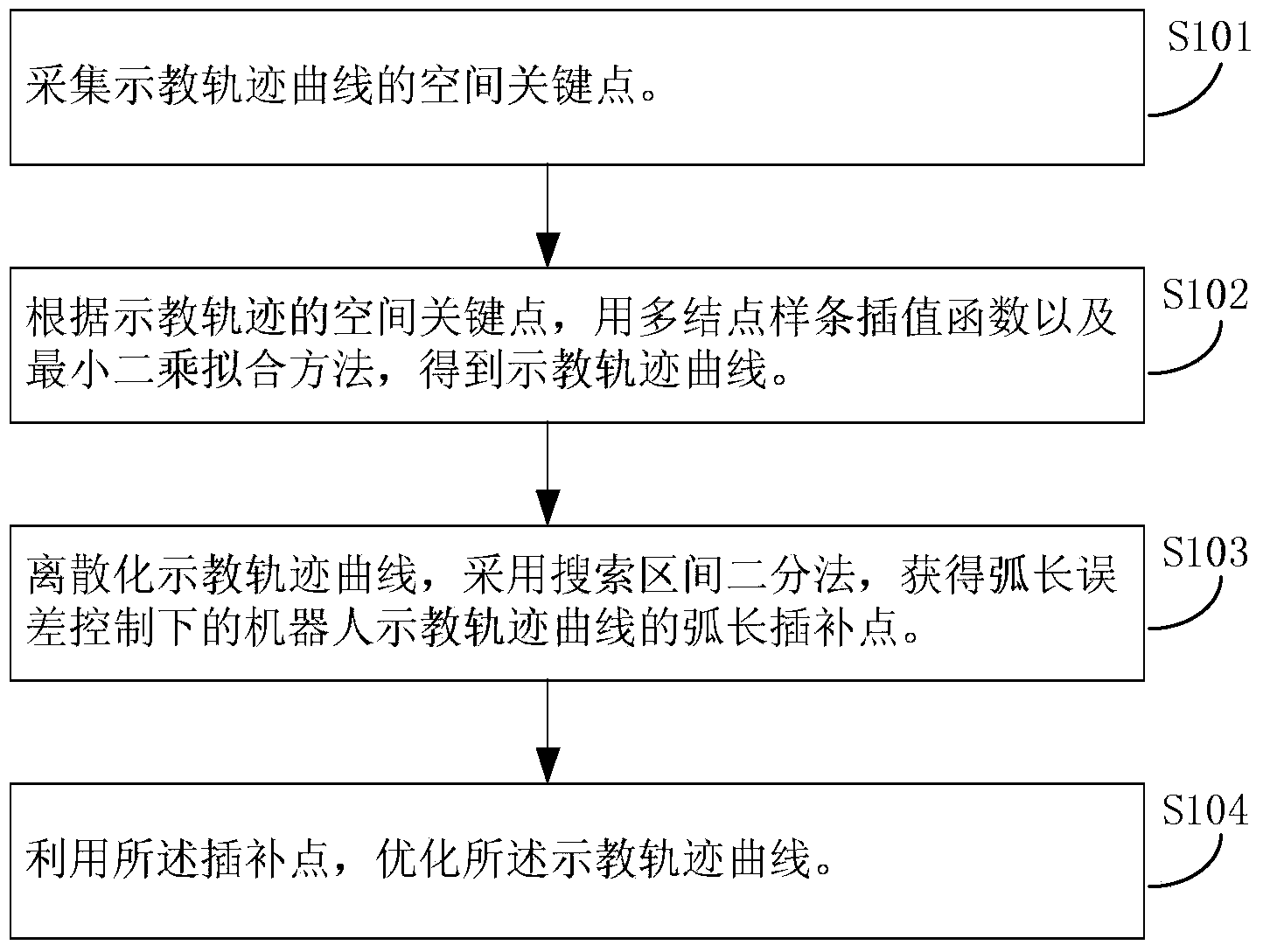

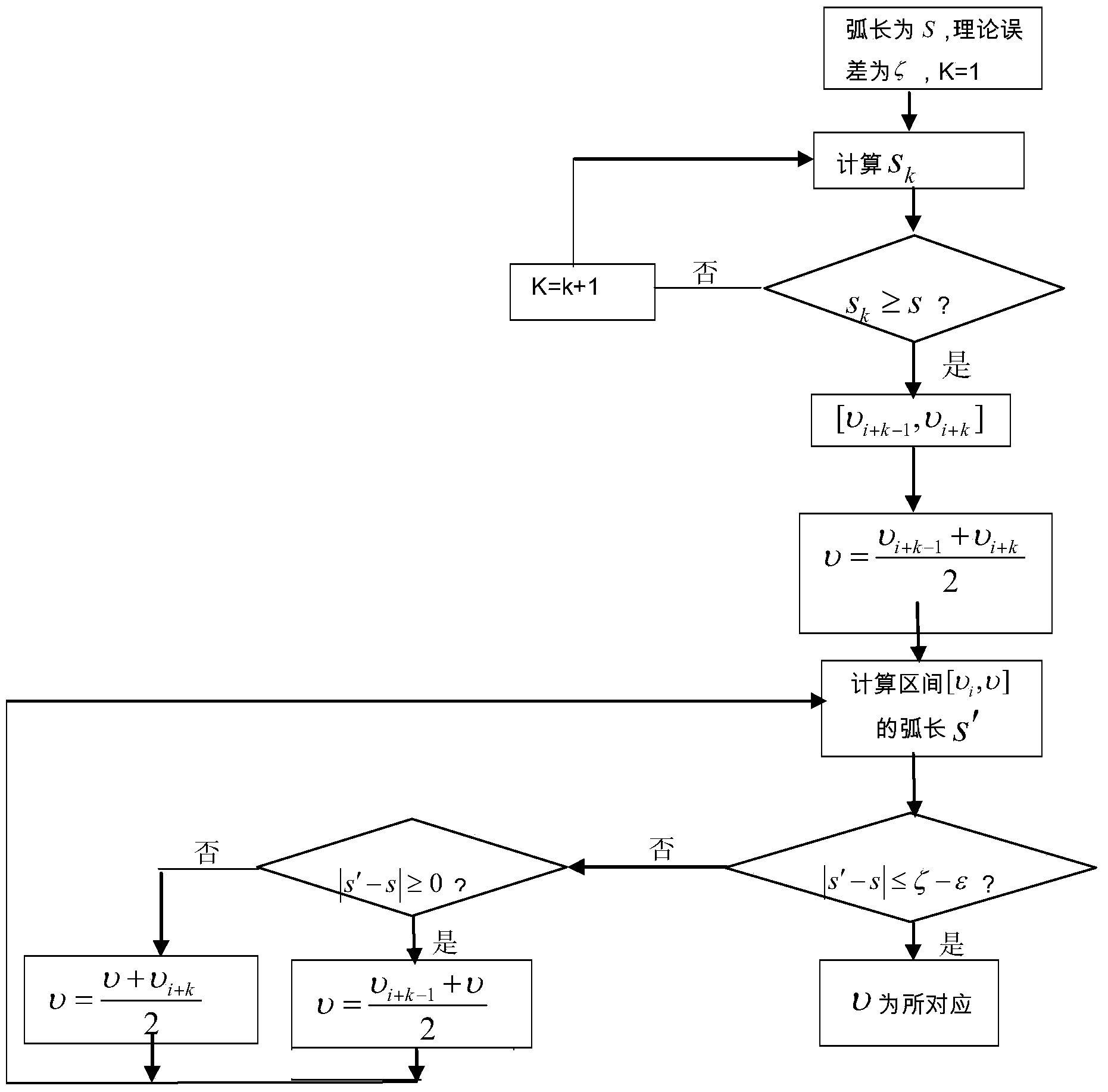

Teaching track planning method and system for robot

ActiveCN103645725APrecise motion trajectorySpace trajectory planning is accurateProgramme controlComputer controlSimulationLeast squares

The invention discloses teaching track planning method and system for a robot, and relates to the field of robot teaching in an industrial process. The teaching track planning method comprises the following steps: collecting a space key point of a teaching track in the process of teaching the robot; obtaining a teaching track curve by using a multi-knot spline interpolation function and the least square fitting method according to the space key point of the teaching track. By adopting the method, action smoothness reappearing in teaching is also achieved by adopting an arc length error control interpolation algorithm. The method and the system can be applicable to robot teaching under general conditions, and the accurate robot movement track can be obtained. The method and the system have the characteristics of accurate space track planning and smooth predictive error control and teaching action, and can be used for achieving the teaching track planning of the robot in the industrial process.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

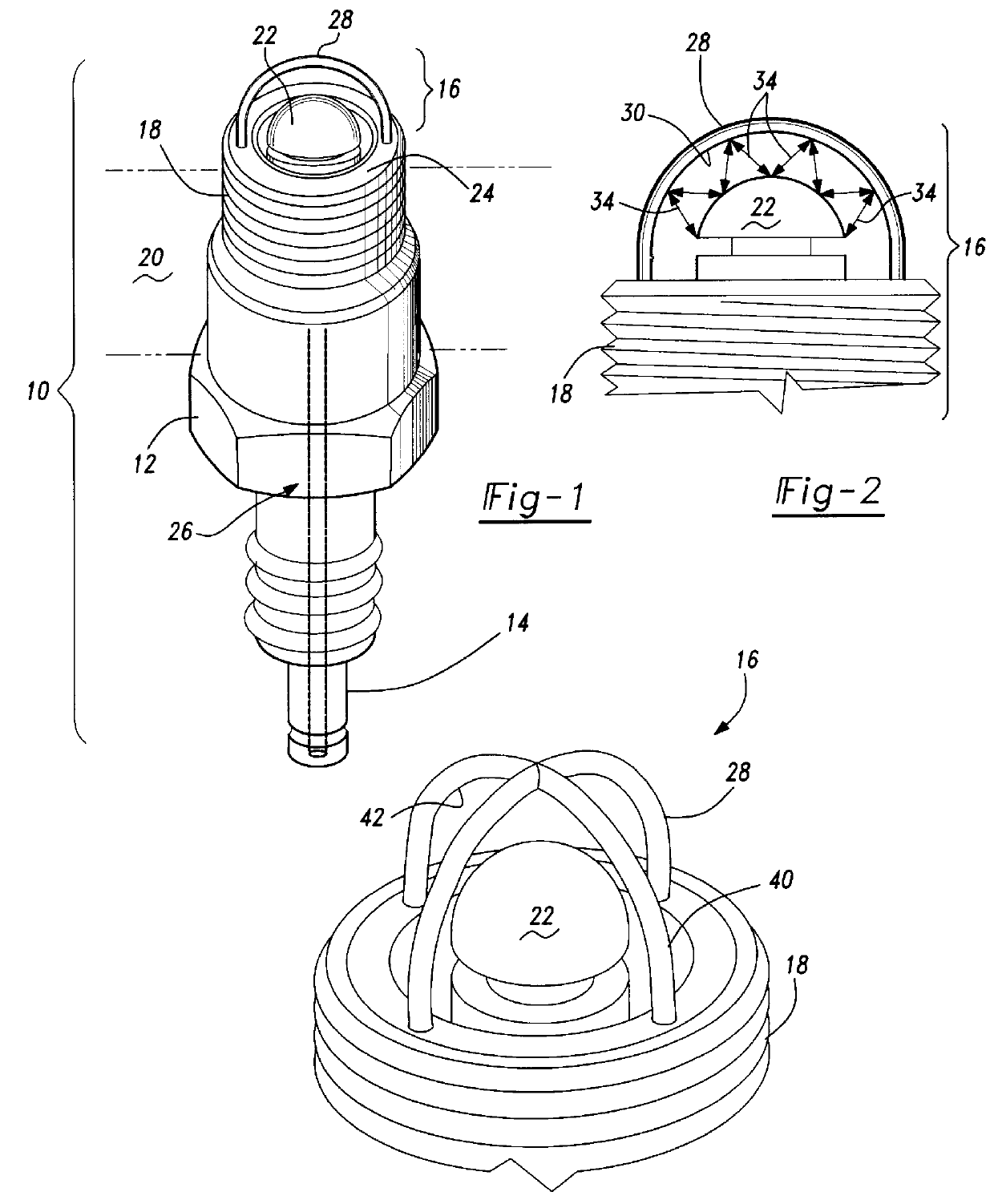

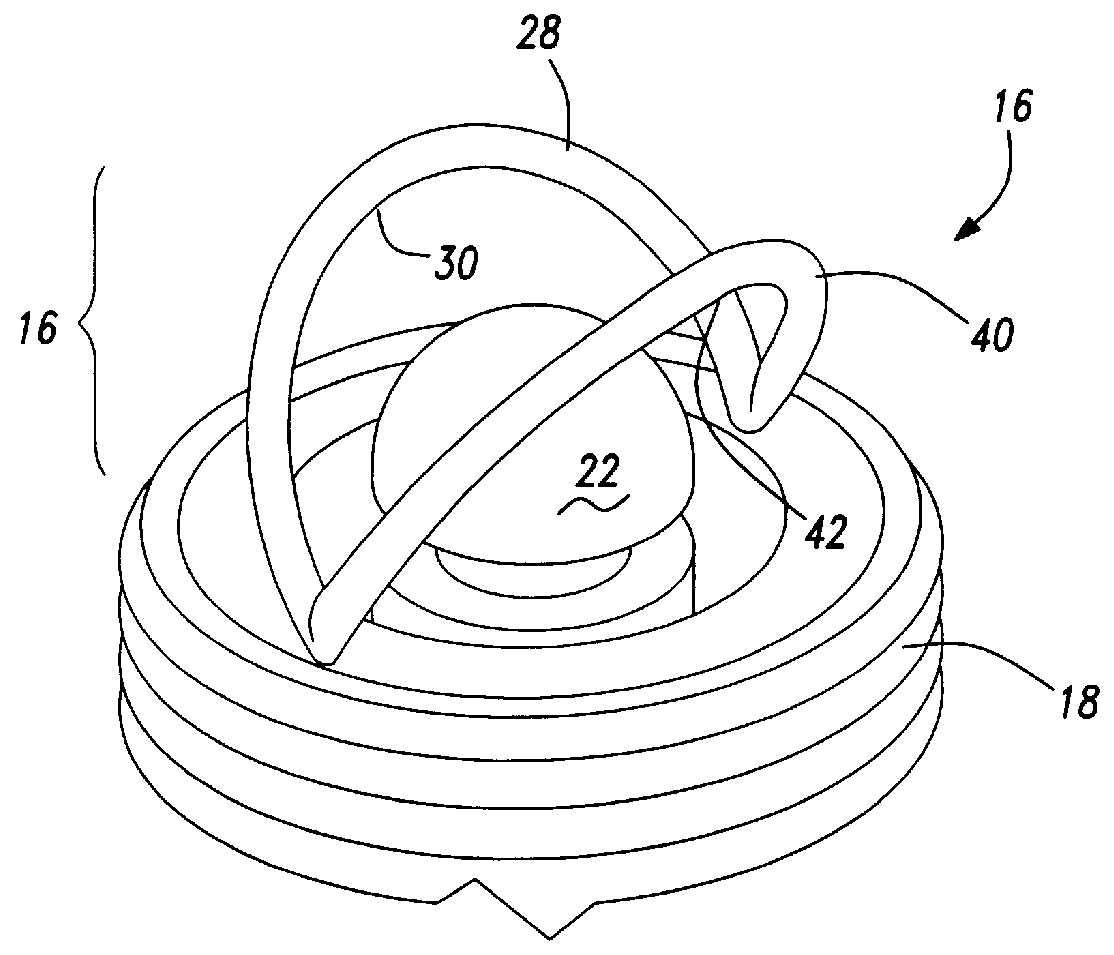

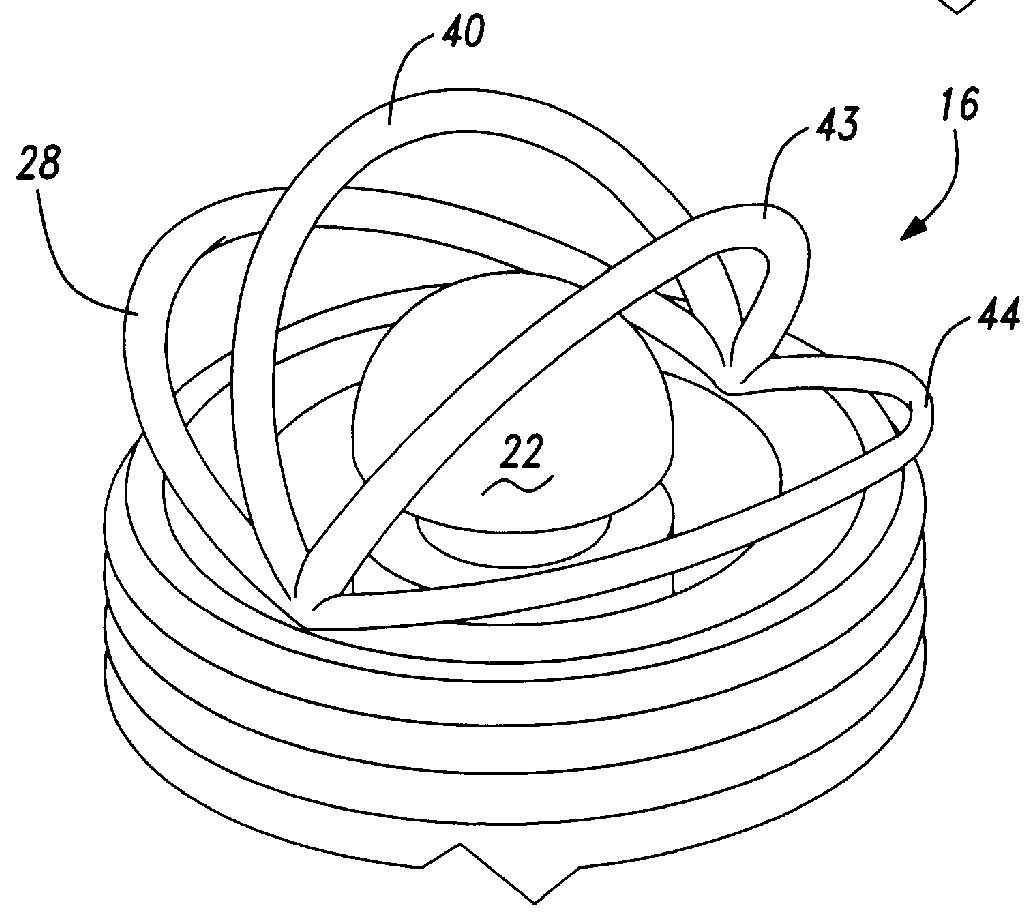

Spark plug

A very unique universal bi-directional firing spark plug for any spark ignited internal combustion engine, whether racing, industrial, truck, aeronautical, automotive, recreational or residential (for trimmers, edgers, brush cutters, leaf blowers, leaf vacuums, chain saws, augers, tillers, lawnmowers, riding mowers, tractors, generators, etc.). This spark plug eliminates misfire and improves gas mileage, peaks engine performance, horsepower, and increases the RPM range, while utilizing and enhancing current ignition systems. In addition, this spark plug serves as a low emission device that reduces the effects of global warming, acid rain, and smog via greatly reduced emissions through vastly improved fuel combustion within all internal combustion engines by operating at a 24:1 air-to-fuel ratio. This unique spark plug is comprised of an elongated or non-elongated body with an electrical connector at one end. An absolute aerodynamic semispherical dome or sphere electrode is secured to the other end of the body. At least one absolute aerodynamic semicircular electrode is also secured to the body adjacent to the dome or sphere electrode such that the semicircular electrode has its inner surface equidistantly spaced from the dome or sphere electrode's surface. The electrodes can be fabricated from various metals, alloys, and / or precious metals and can also be coated with various metals, alloys, and / or precious metals. Alternate embodiments of the invention include two, three or four or more semicircular electrodes, all of which have a surface equidistantly spaced from the aerodynamic semispherical dome or sphere electrode along its complete arc length.

Owner:CG PEGASUS HANGER

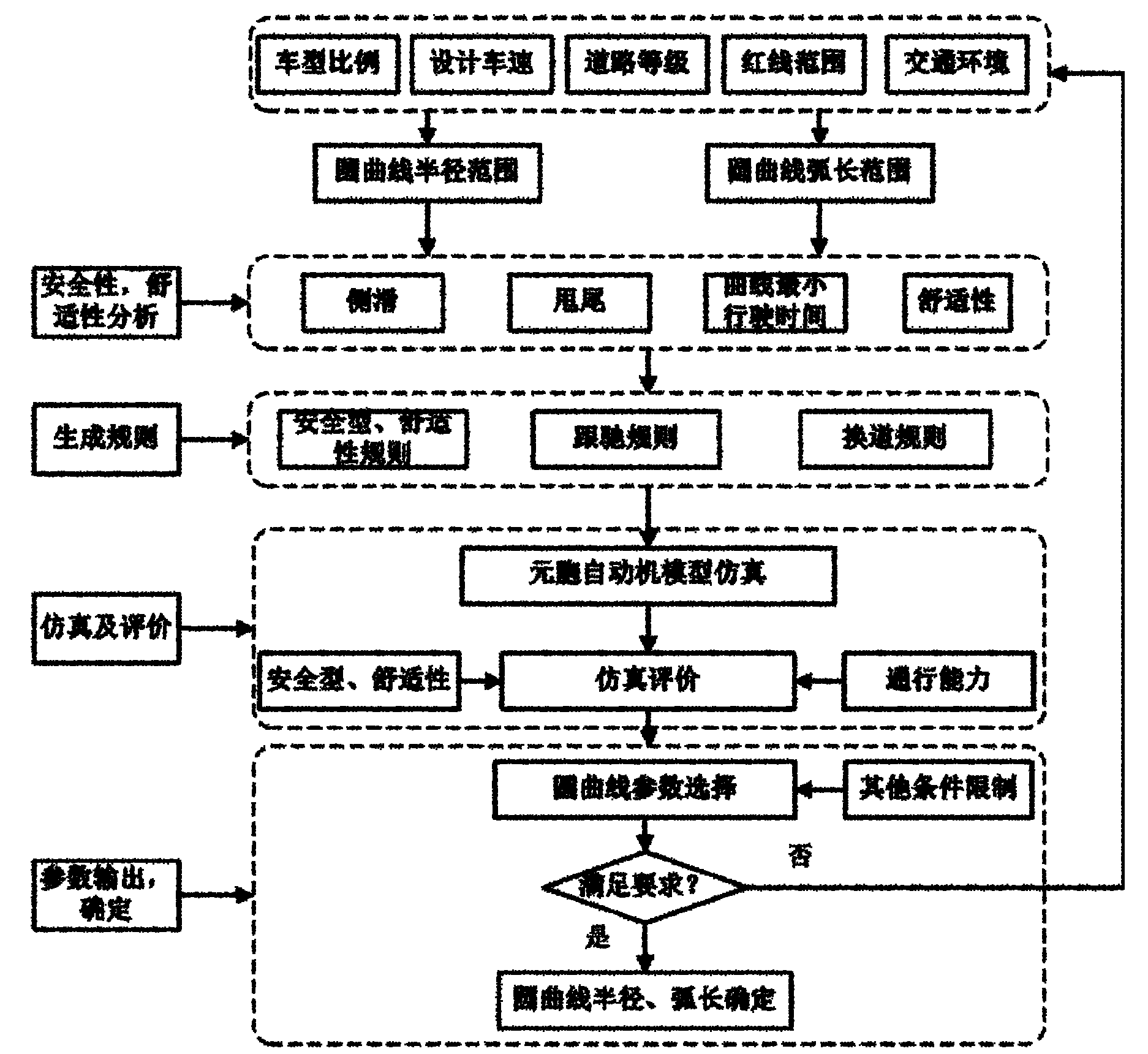

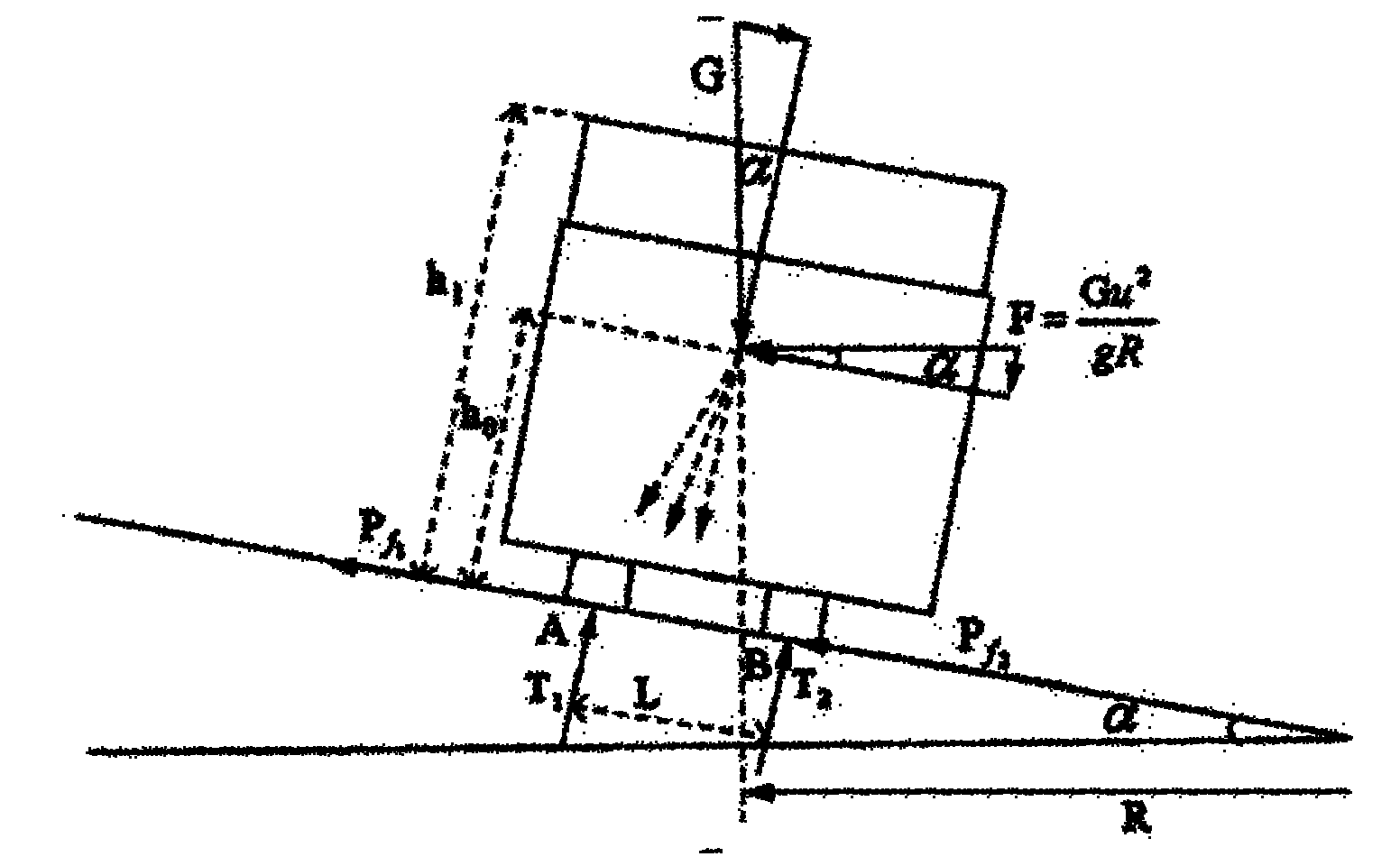

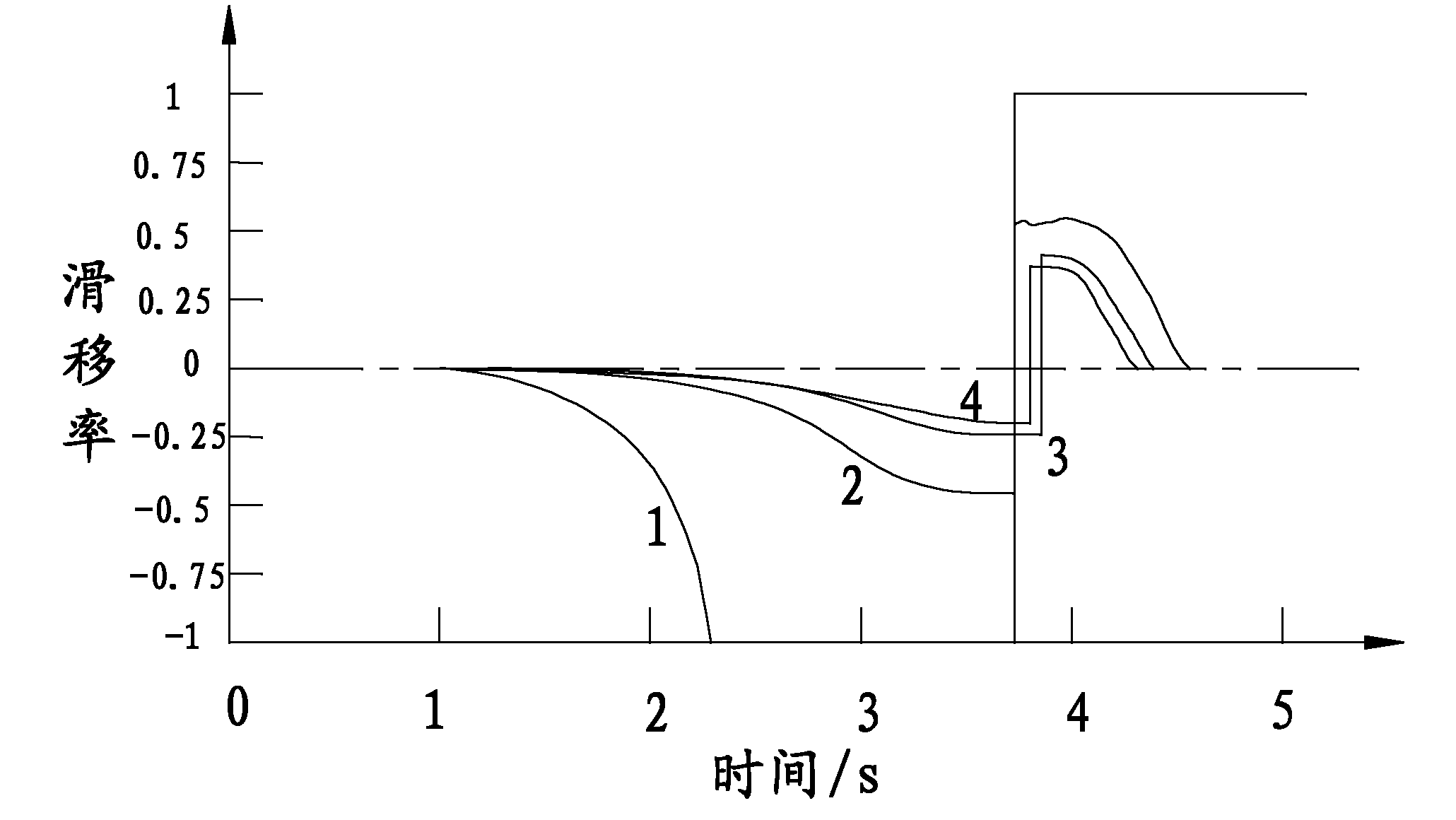

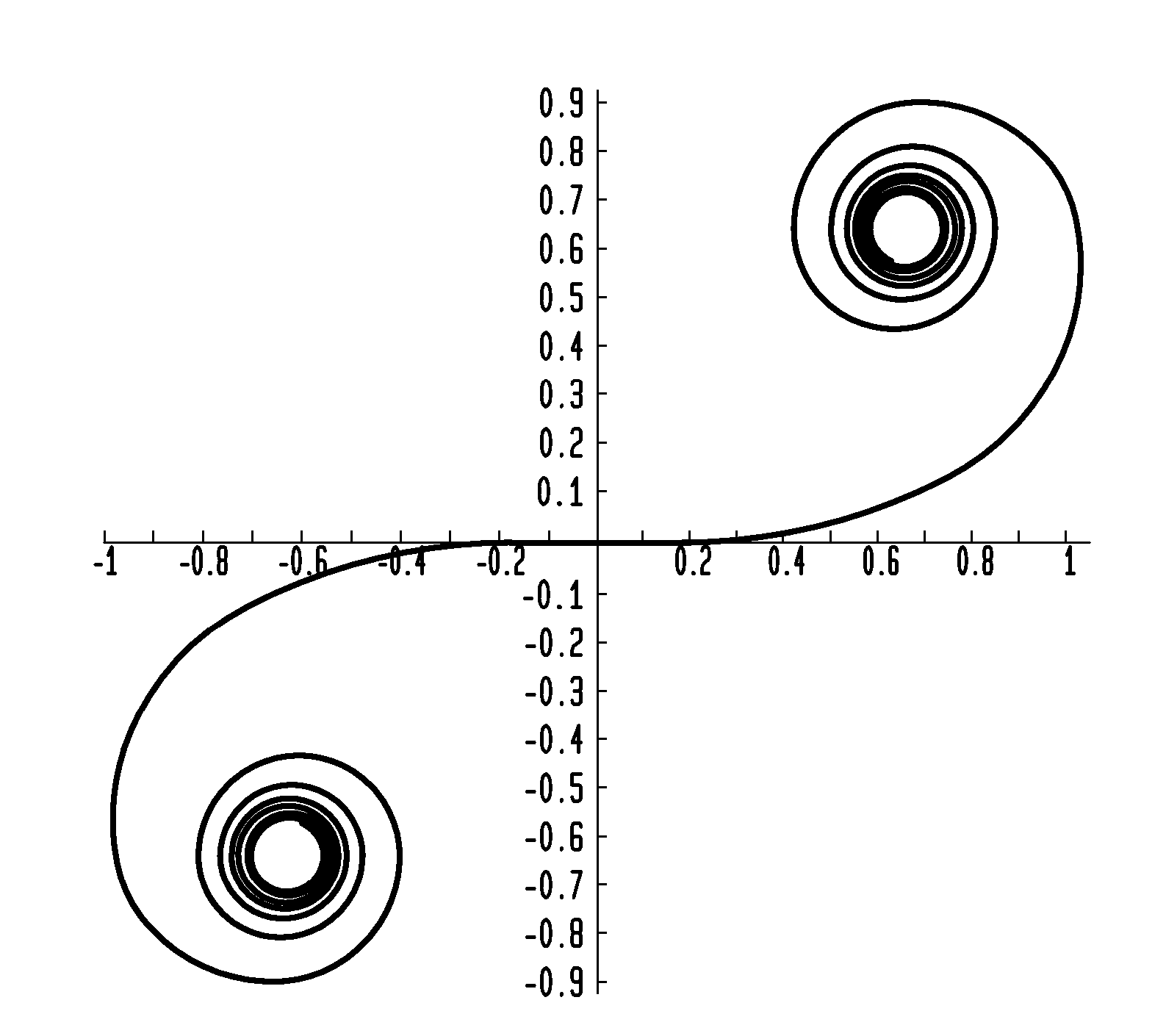

Cellular automata based design method of circular curve elements of bends of harbor roads

ActiveCN101944148AEnsure safetyPrevent sideslipAerodynamics improvementSpecial data processing applicationsTraffic characteristicTraffic capacity

The invention belongs to the technical field of harbor road design and relates to a cellular automata based design method of circular curve elements of bends of harbor roads. The method comprises the following steps: preliminarily determining the radius ranges and the arc length ranges of the circular curves to be designed; determining the maximum speeds and acceleration and deceleration probability of the vehicles by analyzing the safety and the comfort and treating the safety boundary conditions; establishing a simulation model of the cellular automata, determining the maximum speeds and acceleration and deceleration probability of the vehicles and designing car-following and lane-changing rules of the vehicles; and simplifying the types of the vehicles, converting the types of various vehicles into a single type, simulating the traffics in the harbor districts by changing the radii and the arc length of the circular curves of the bends of the harbor roads according to the established simulation model of the cellular automata, evaluating the simulation result and investigating whether the design scheme can meet the requirement of the traffic capacity. Compared with the traditional method, the design method of the invention has the advantage that the design scheme of the line shapes of the bends in the harbor districts is further consistent with the traffic characteristics in the harbor districts.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Method and apparatus for interactive curve generation

ActiveUS20080005212A1Drawing from basic elementsDigital function generatorsComputer scienceCurve design

A system of curve generation takes a sequence of control points and constraint codes for each control point, and outputs a curve in which each of the constraints is satisfied. The set of constraints is chosen from the tangent angle, curvature, first derivative of curvature, and second derivative of curvature. The interactive curve design uses as its primitive, a curve whose curvature is a polynomial function of arclength (whose intrinsic equation is a polynomial). At each control point, a choice of G2 curvature continuity (tangent angle and curvature) or G4 curvature continuity (tangent angle and curvature plus first and second derivatives of curvature are continuous) is input. The desired curve is expressed as the solution to the chosen set of constraints.

Owner:LEVIEN RAPHAEL L

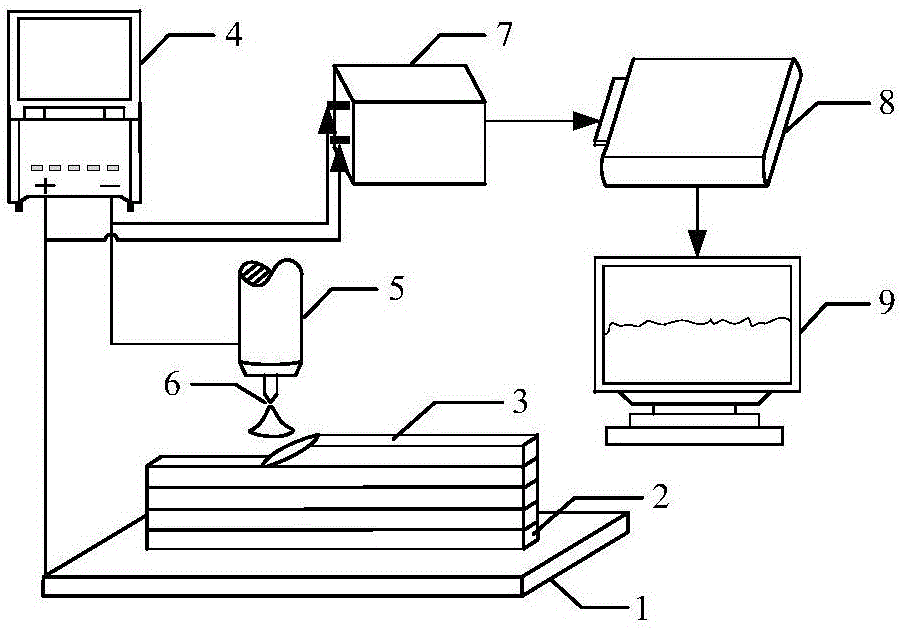

Method for detecting stability of gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback

InactiveCN106363275AImprove stabilityLess susceptible to interferenceArc welding apparatusData acquisitionEngineering

The invention provides a method for detecting the stability of the gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback. The method comprises the steps that the stability of the process is reflected through the arc length, the arc length is indirectly fed back though arc voltage, and the initial position of a GTAW gun on a substrate is adjusted; in the forming process of a first layer, a voltage sensor is matched with a data acquisition card to obtain a variation signal of the arc voltage along a forming path; the arc voltage is converted into the arc length according to a calibration relationship, a variation signal of the arc length along a forming path is obtained, and a second layer, a third layer until the n layer are formed, so that a variation signal of the n layer arc length along a forming path is obtained; and if the arc length is within a certain range, it is judged that the forming process is stable. According to the method for detecting the stability of the GTAW additive manufacturing process based on arc voltage feedback, the purpose of real-time detection of the stability of the GTAW additive manufacturing process is effectively achieved, and the detection process is easy to operate, high in stability, not prone to being interfered by intense arc light, high in calculation speed, capable of achieving automation easily and suitable for engineering application of real-time site detection.

Owner:SOUTHWEST JIAOTONG UNIV

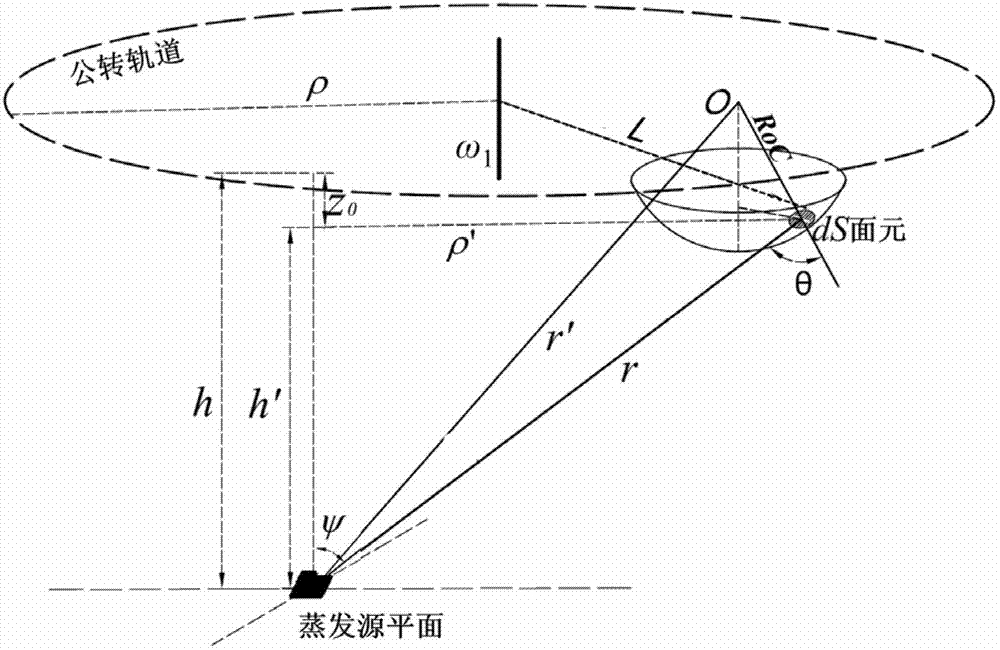

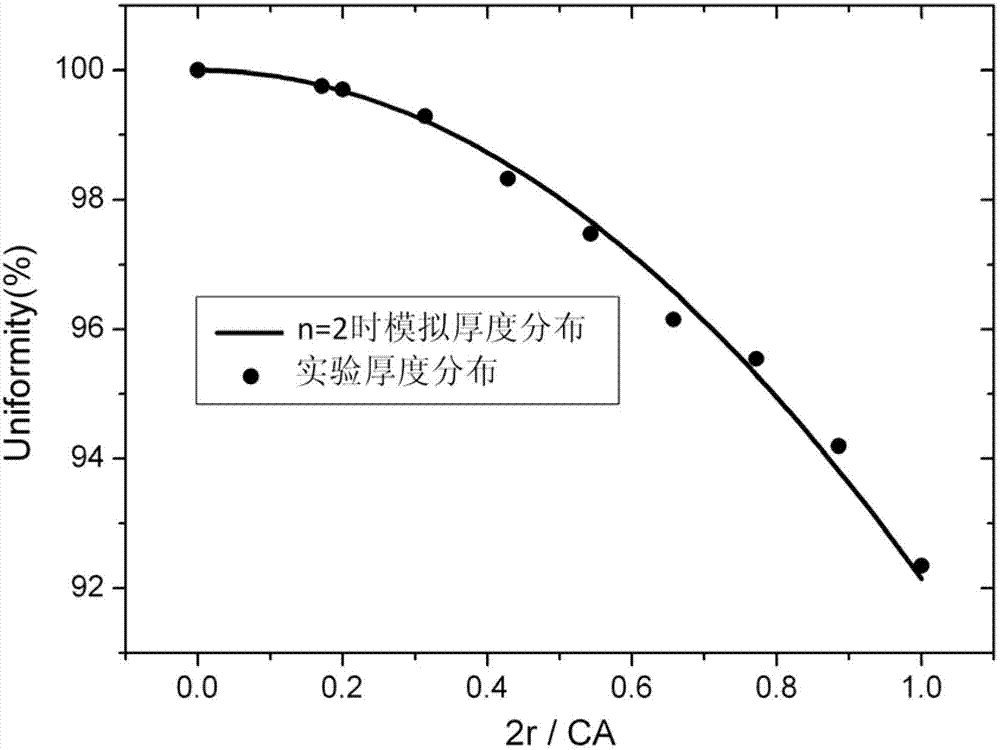

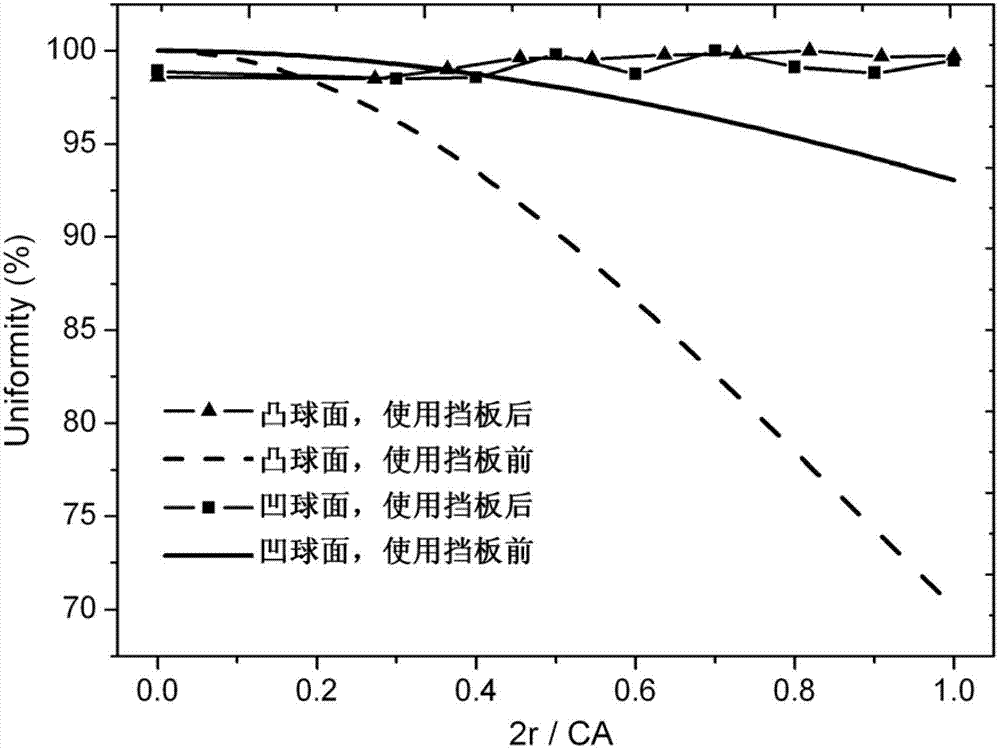

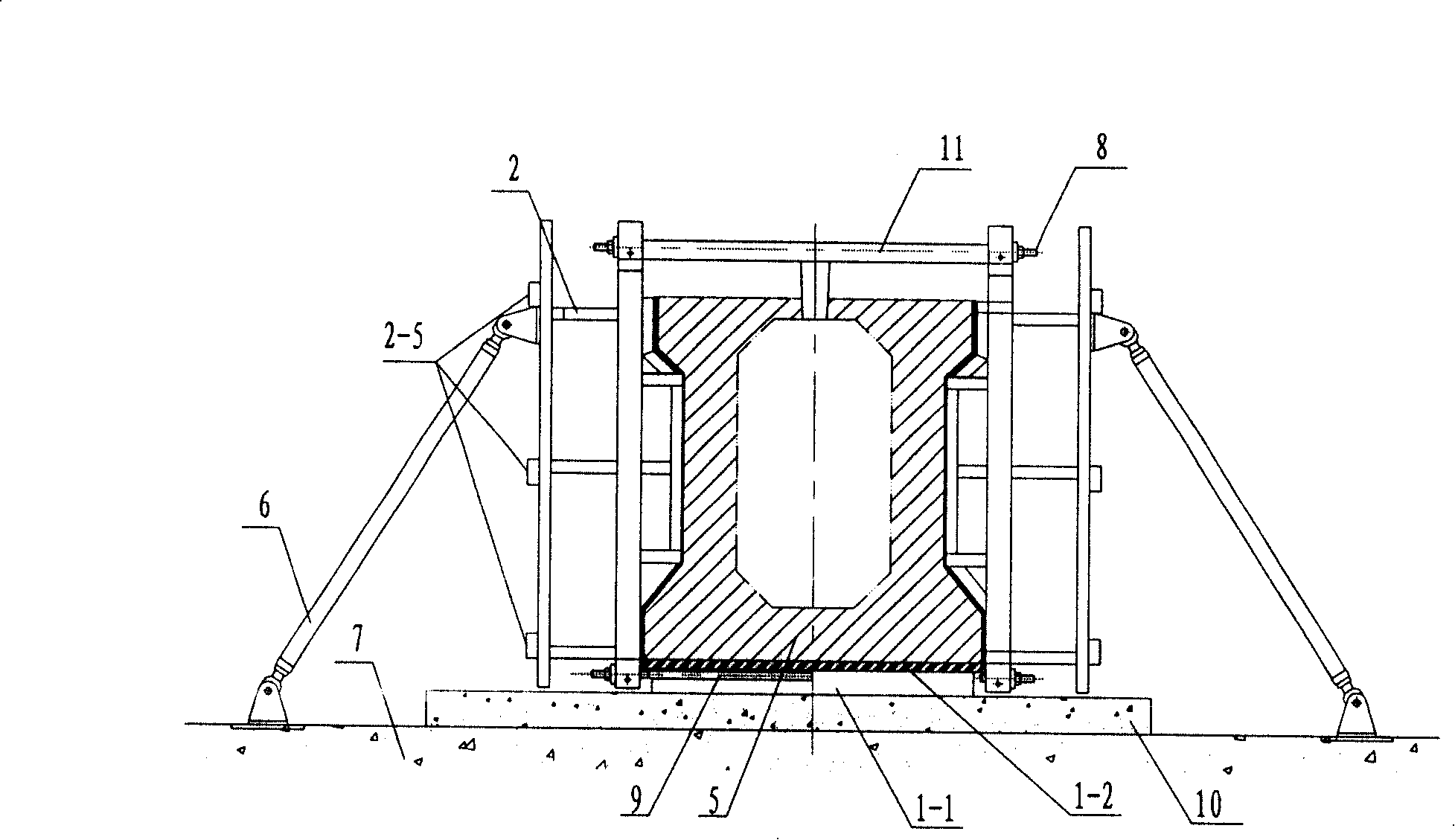

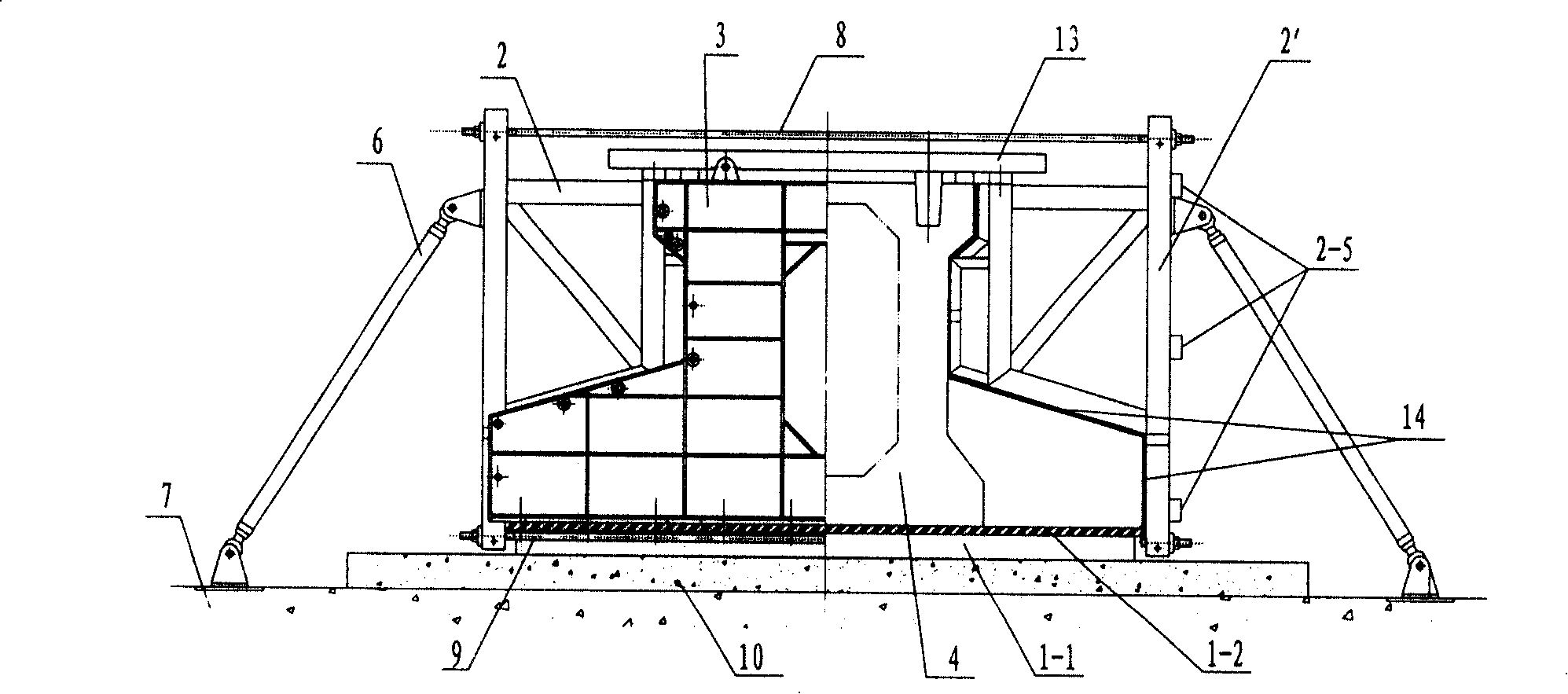

Method for designing coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines

ActiveCN102732844AImprove design efficiencyImprove thickness uniformityVacuum evaporation coatingSputtering coatingComputer optimizationMagnification

The invention discloses a method for designing a coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines, which is used for studying the film thickness distribution of a plane or spherical optical element (subjected to coating) on a planetary rotating jig through establishing a coating model in a vacuum environment. Through enabling an optical element coating process in a planetary rotating jig to be equivalent to a coating process in a simple rotating jig, the initial shape of the coating uniformity correction mask in the planetary rotating jig is designed. Through optimizing the arc length magnification factor of the correction mask by using a computer until the film thickness uniformity reaches the optimal result, the actual shape of the coating uniformity correction mask for the spherical optical elements is obtained. According to the invention, the control on the film thickness uniformity of the spherical optical element with a large caliber and a large caliber / curvature radius ratio can be realized, thereby obtaining the uniformity of multilayer-film spectral characteristics of the spherical optical element with a large caliber and a large caliber / curvature radius ratio.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Curvature radius adjustable prefabricated box-beam mold and construction method thereof

ActiveCN101181796ASmooth and beautiful surfaceReduce manufacturing costMould separation apparatusMouldsEngineeringPeriod length

The invention discloses a prefabricated box girder mold with adjustable curvature radius and an installation and construction method of the mold. The invention adopts the concept of replacing the curved line with a folded line of a fixed length, and accurately sets out the bottom mold, so that the side mold is designed by It is composed of several fixed-length fixed sections. An elastic change section is set between the fixed-length fixed sections, and an adjustment link rod is set between the fixed-length fixed sections to realize the function of adjusting the curvature of the fixed-length broken line. At the same time, the adjustment insert section is embedded in the side mold The adjustment of inner and outer arc length changes can not only meet the needs of fixed section and variable curvature prefabricated building components, but also meet the production or construction needs of continuous variable section and variable curvature prefabricated building components. The prefabricated box girder mold with adjustable curvature radius of the present invention can not only meet the overall needs and accuracy requirements of the design curvature change, but also has a smooth and beautiful surface, with as few or no traces of template joints as possible.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

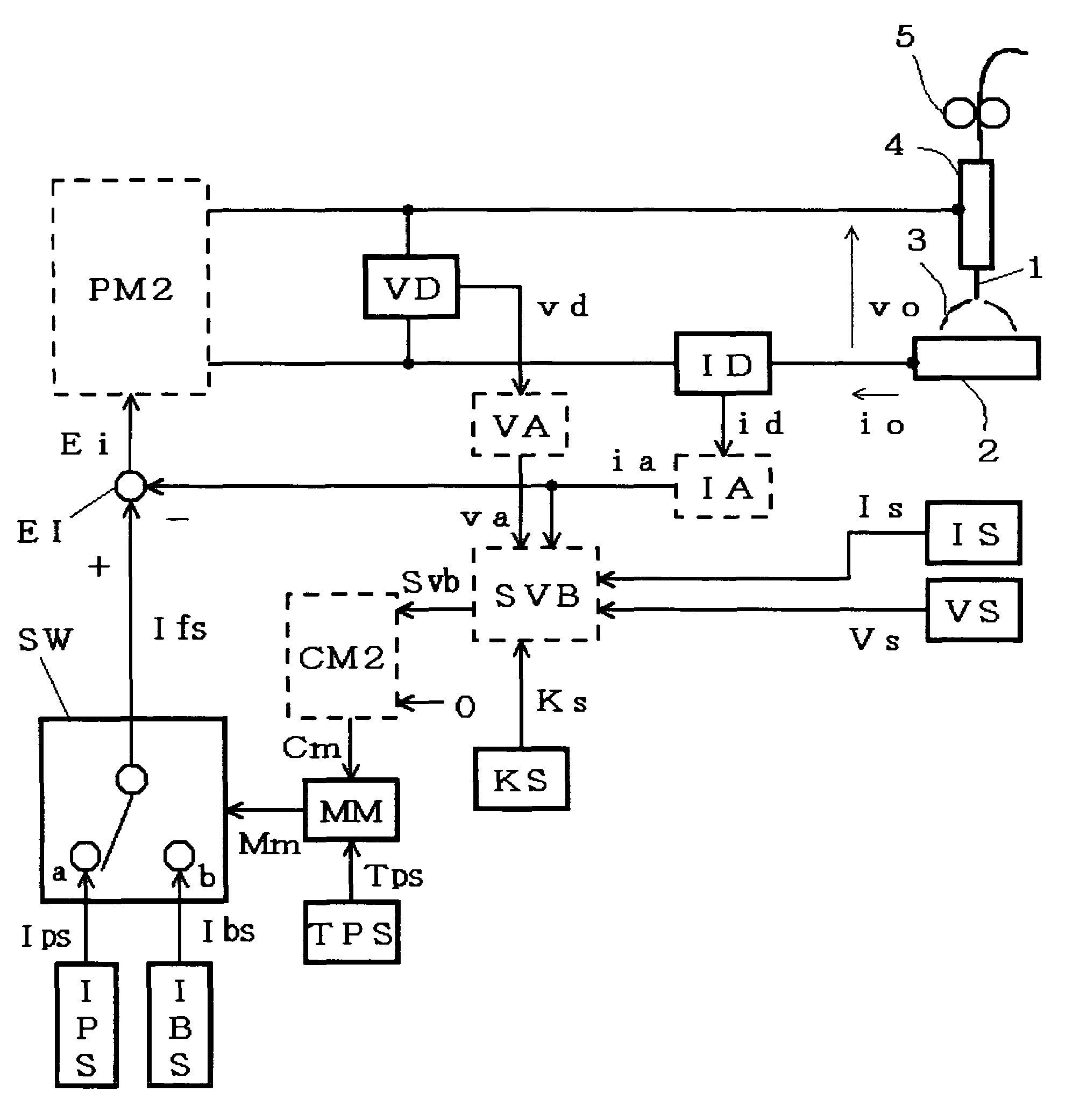

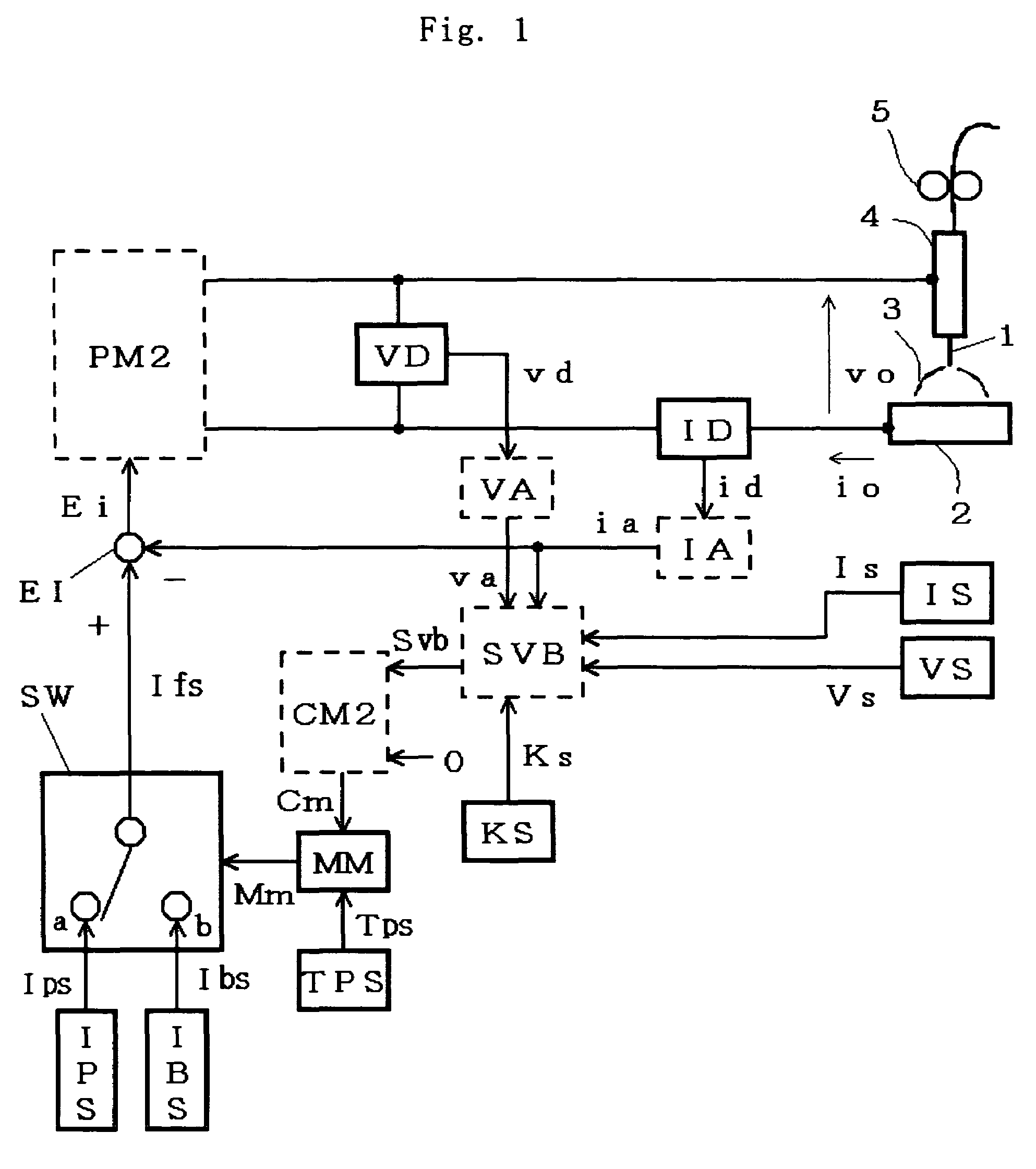

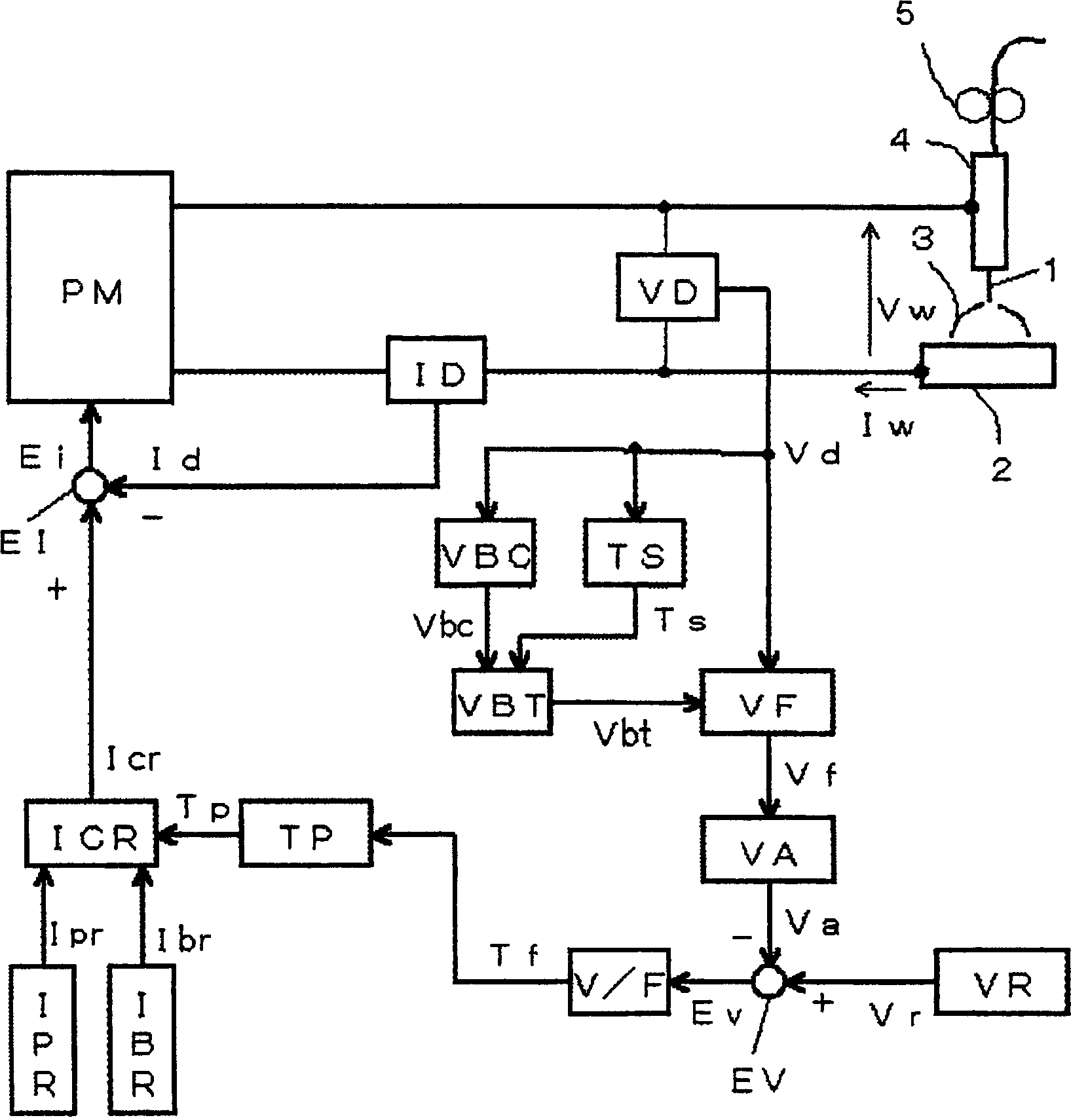

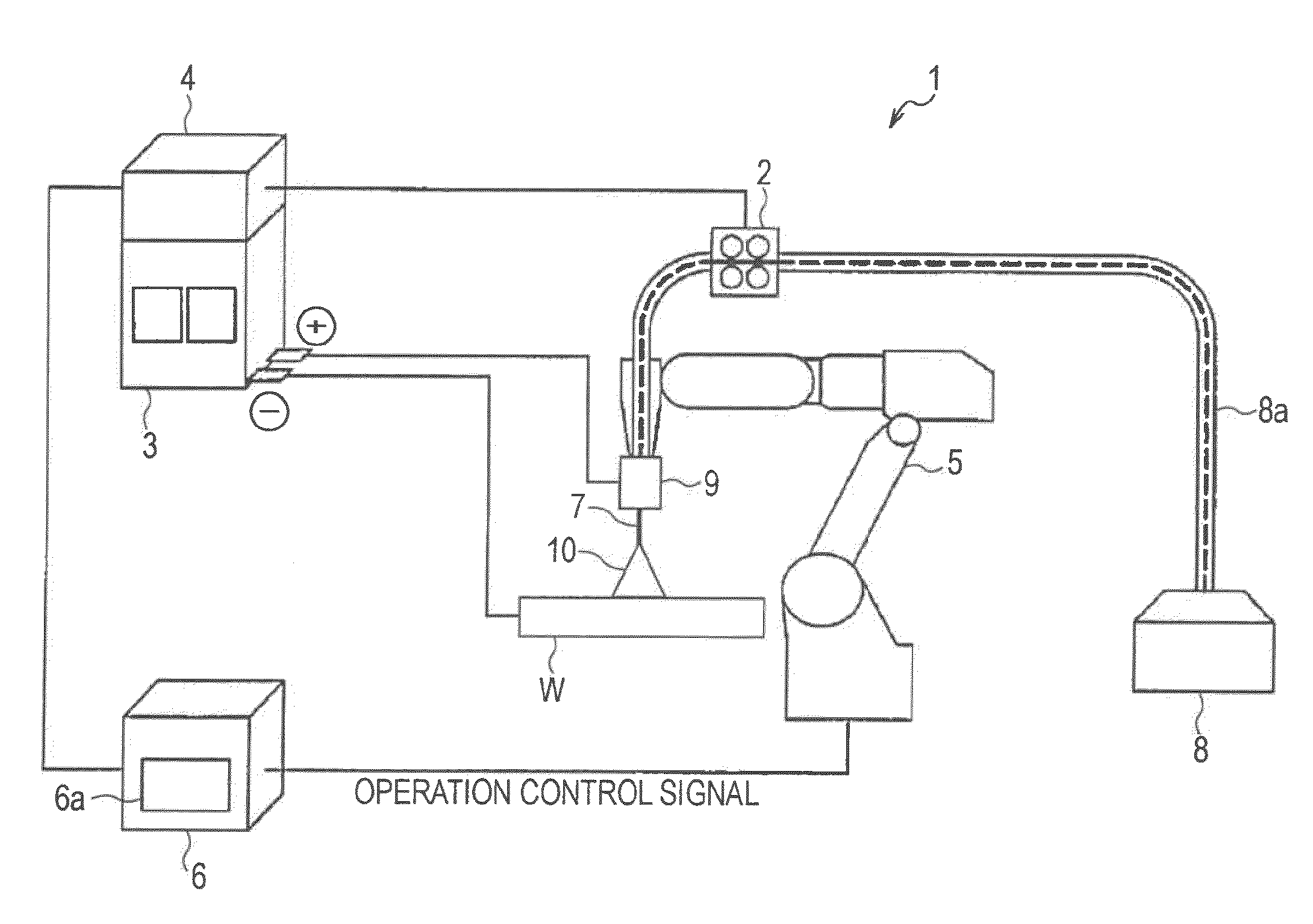

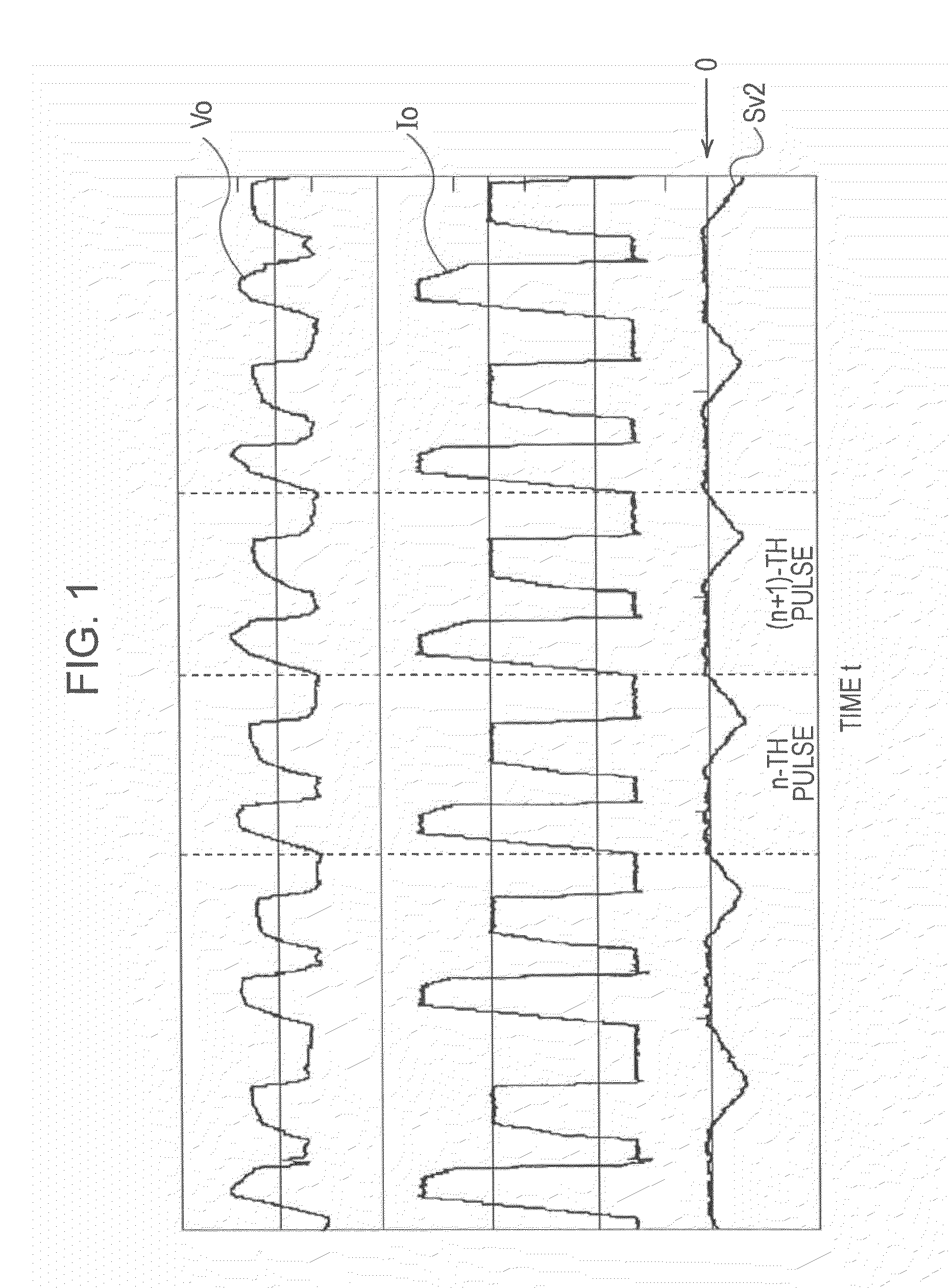

Welding control apparatus for pulse arc welding of consumed electrode type, arc length control method for use with the same, and welding system including the welding control apparatus

ActiveUS20100200553A1Suppress mutationSuppress generationArc welding apparatusIntegratorWelding power supply

A welding control apparatus according to the present invention includes an integrator for starting calculation of a voltage error integral value Sv2, expressed by a formula (1) given below, from a time when a first pulse period ends and a second pulse period starts in a pulse cycle, based on various data of information regarding a gradient Ks of an external characteristic of a welding power supply and a welding current setting value Is2 and a welding voltage setting value Vs2 both in a second pulse period, which are preset as parameters in the formula (1), as well as on an instantaneous value Io2 of a welding current and an instantaneous value Vo2 of a welding voltage both detected in the second pulse period, a comparator for comparatively determining whether a value of the voltage error integral value Sv2 provided as the calculation result has become 0, and a waveform generator for, per pulse cycle, terminating the relevant pulse cycle and starting a next pulse cycle at a time when the value of the voltage error integral value Sv2 has become 0, whereby a variation in an arc length caused by disturbances is precisely suppressed in pulse arc welding of consumed electrode type:Sv2=∫{Ks(Io2−Is2)+Vs2−Vo2}dt (1)

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com