Pulse arc welding control method

A control method and pulsed arc technology, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems such as the limit of molten pool shaking and poor arc stability, so as to improve the effect of bubble reduction, suppress arc instability, The effect of suppressing undershoot and overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

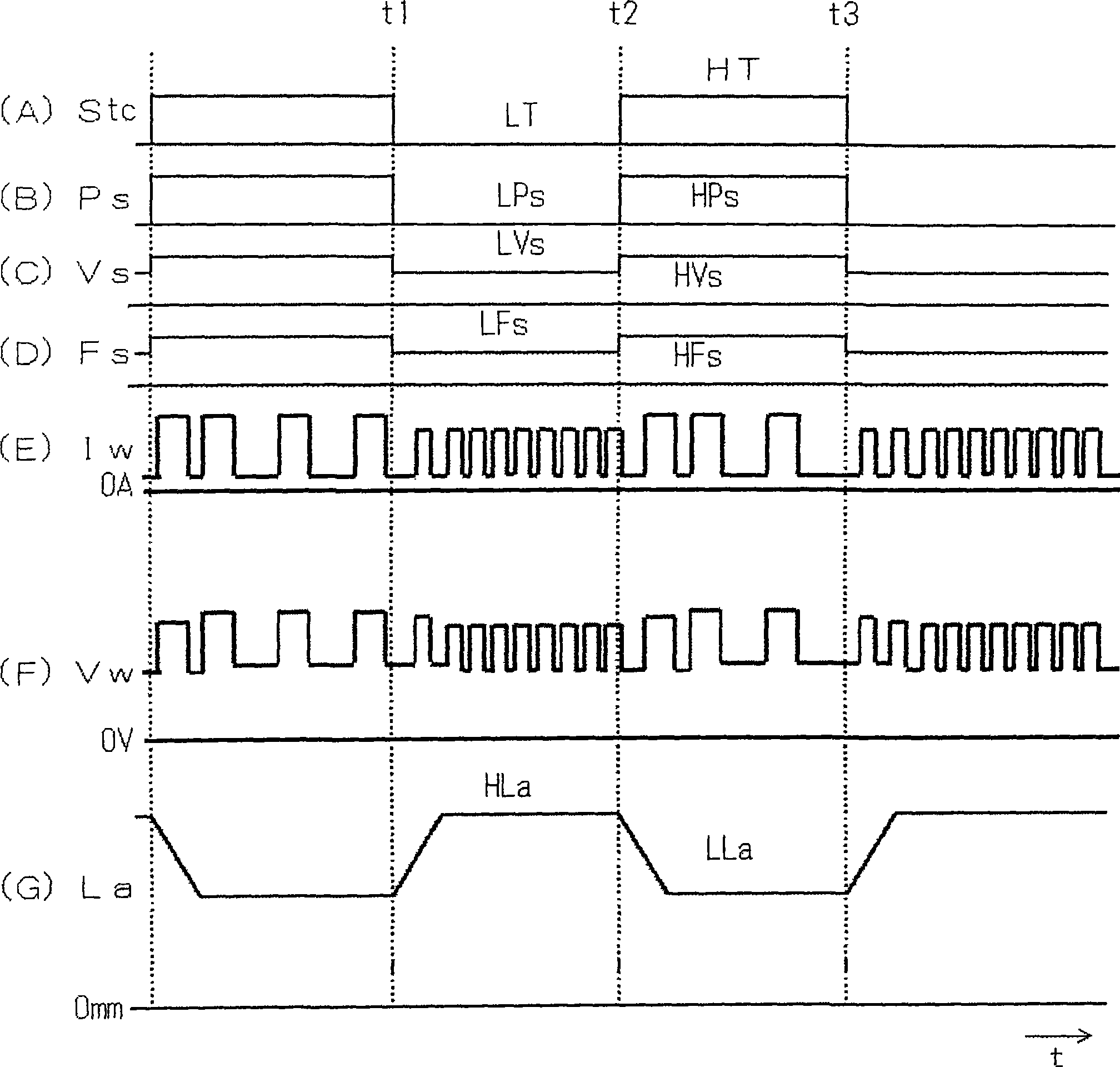

[0113] figure 1 It is a timing chart showing the pulse arc welding control method according to Embodiment 1 of the present invention. The figure (A) shows the switching signal Stc, the figure (B) shows the pulse parameter setting signal Ps, the figure (C) shows the voltage setting signal Vs, and the figure (D) shows the speed setting signal Fs, the The graph (E) shows the welding current Iw, the graph (F) shows the welding voltage Vw, and the graph (G) shows the arc length La. Hereinafter, description will be made with reference to this figure.

[0114] As shown in (A) of the figure, the switching signal Stc is at low level during the low pulse period LT at predetermined times t1 to t2, and at high level during the high pulse period HT at predetermined times t2 to t3.

[0115] The pulse parameter setting signal Ps, as shown in (B) of the figure, is the low pulse parameter setting value LPs during the low pulse period LT, and is the high pulse parameter setting value HPs dur...

Embodiment approach 2

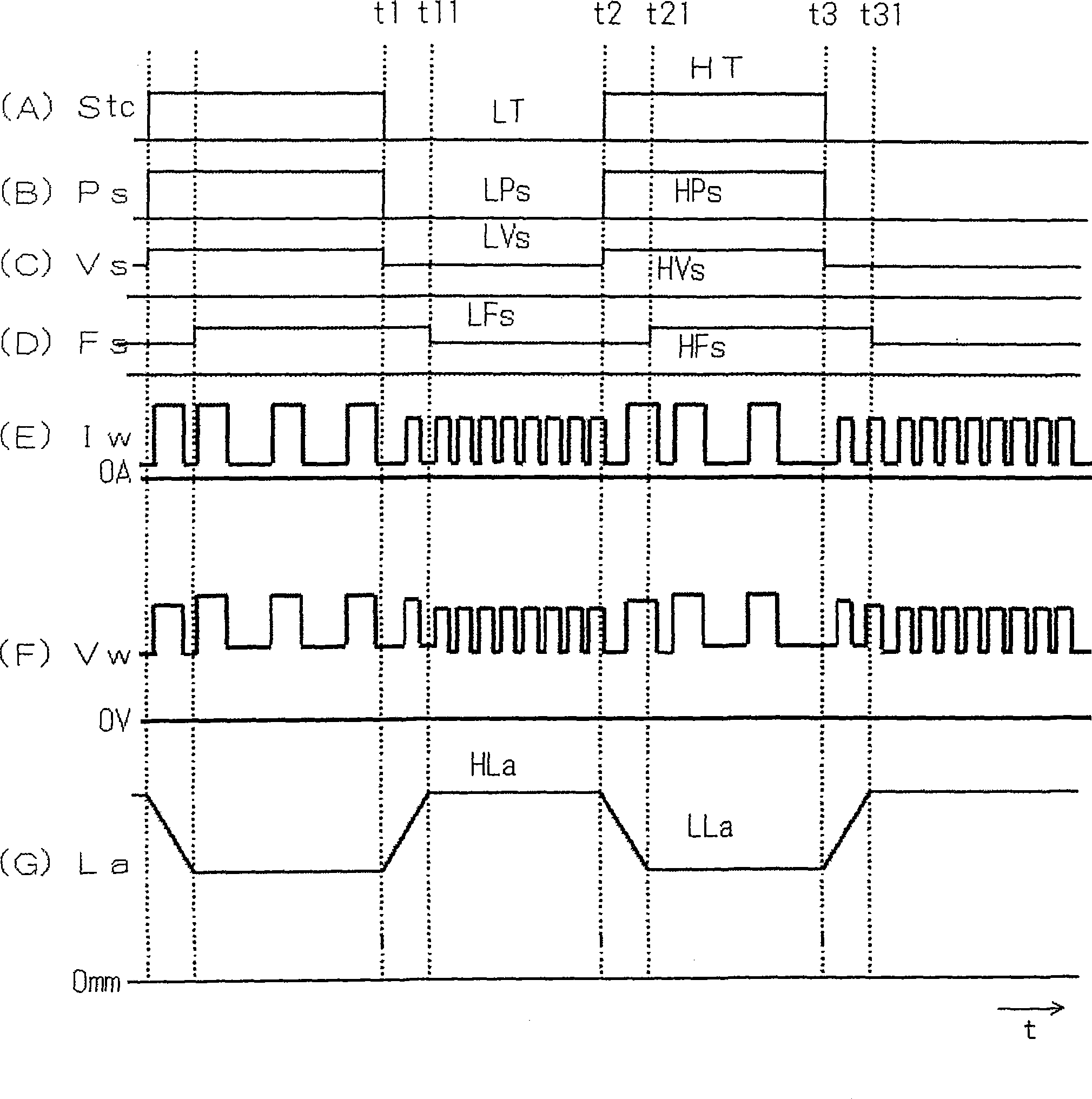

[0132] image 3 It is a timing chart showing the pulse arc welding control method according to Embodiment 2 of the present invention. This figure is similar to the above figure 1 Correspondingly, the signals shown in (A) to (G) of the figure are the same. The following pairs with figure 1 The different parts are explained with reference to this figure.

[0133] At time t1, as shown in (A) of the figure, when the switching signal Stc is at a low level (low pulse period), similarly to Embodiment 1, as shown in (B) of the figure, the pulse parameter setting signal Ps is The low pulse parameter setting value LPs, as shown in the figure (C), the voltage setting signal Vs is the low voltage setting value LVs. As a result, as shown in (G) of the figure, the arc length La changes from the low arc length LLa to the high arc length HLa, and converges from the transient state to the steady state at time t11. At time t11 when the transition state of the arc length La substantially ...

Embodiment approach 3

[0140] Figure 5 It is a time chart of the pulse arc welding control method in Embodiment 3 of this invention. This figure is similar to the above figure 1 Correspondingly, the signals shown in (A) to (G) of the figures are the same. Below, yes and figure 1 The different parts are explained with reference to this figure.

[0141] At time t1, as shown in (A) of the figure, when the switching signal Stc is at a low level (low pulse period), as in Embodiment 1, as shown in (D) of the figure, the sending speed setting signal Fs is Low feed speed setting value LFs. As a result, the feed speed changes from a speed corresponding to the high feed speed setting value HFs to a speed corresponding to the low feed speed setting value LFs, and the feed speed converges from a transient state to a steady state at time t12. At time t12 when the transitional state of the feeding speed is substantially convergent, as shown in (B) of the figure, the pulse parameter setting signal Ps becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com