Patents

Literature

279results about How to "Improved arc stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardfacing electrode

ActiveUS20060165552A1Prolong lifeTrend downMolten spray coatingWelding/cutting media/materialsMetalMaterials science

An electrode to form a hardfacing alloy for use as a surfacing on metal that is subjected to high thermal and mechanical stresses. The electrode includes chromium, a metal sensitization inhibitor, and iron to form a hardfacing alloy.

Owner:LINCOLN GLOBAL INC

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

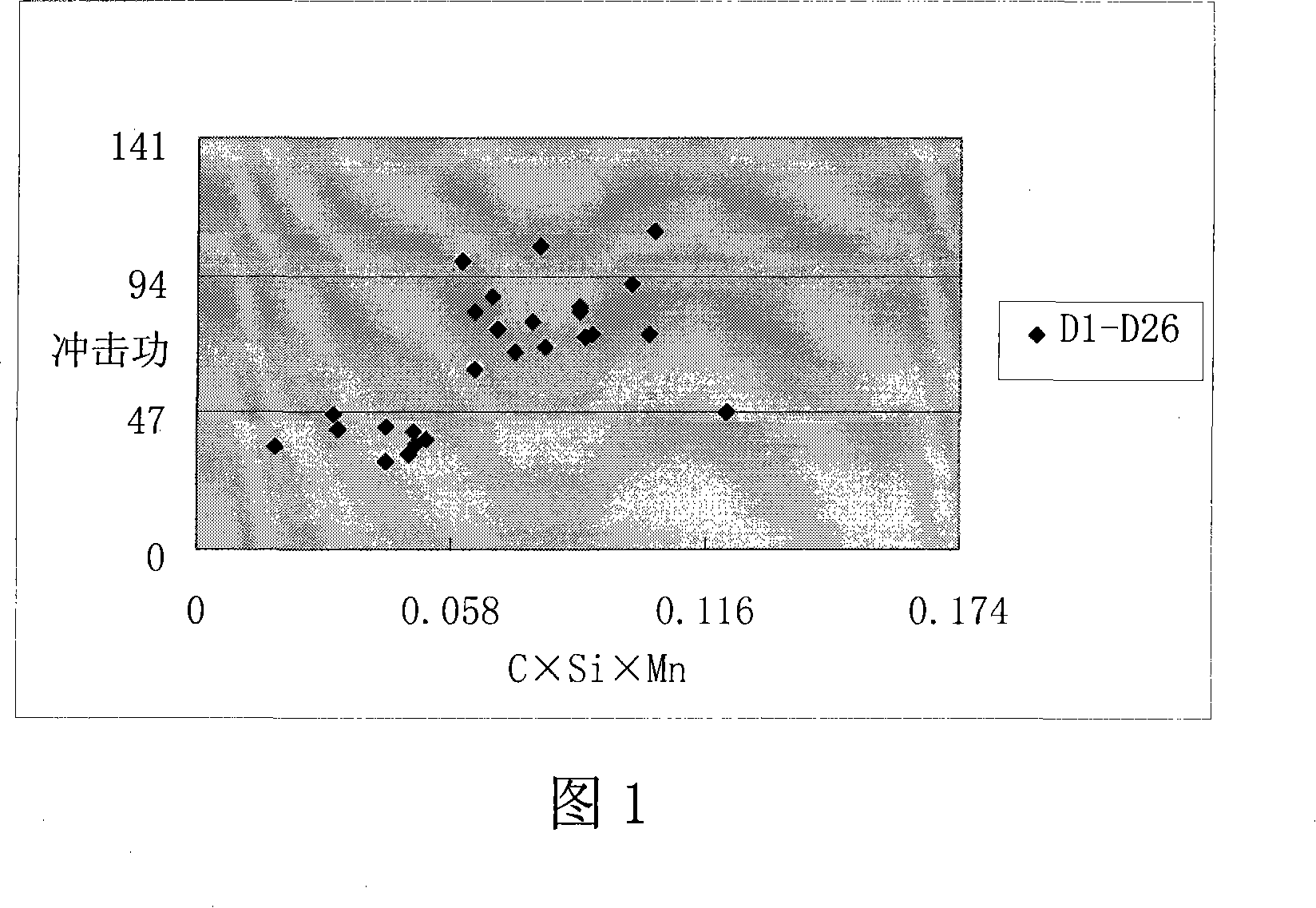

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

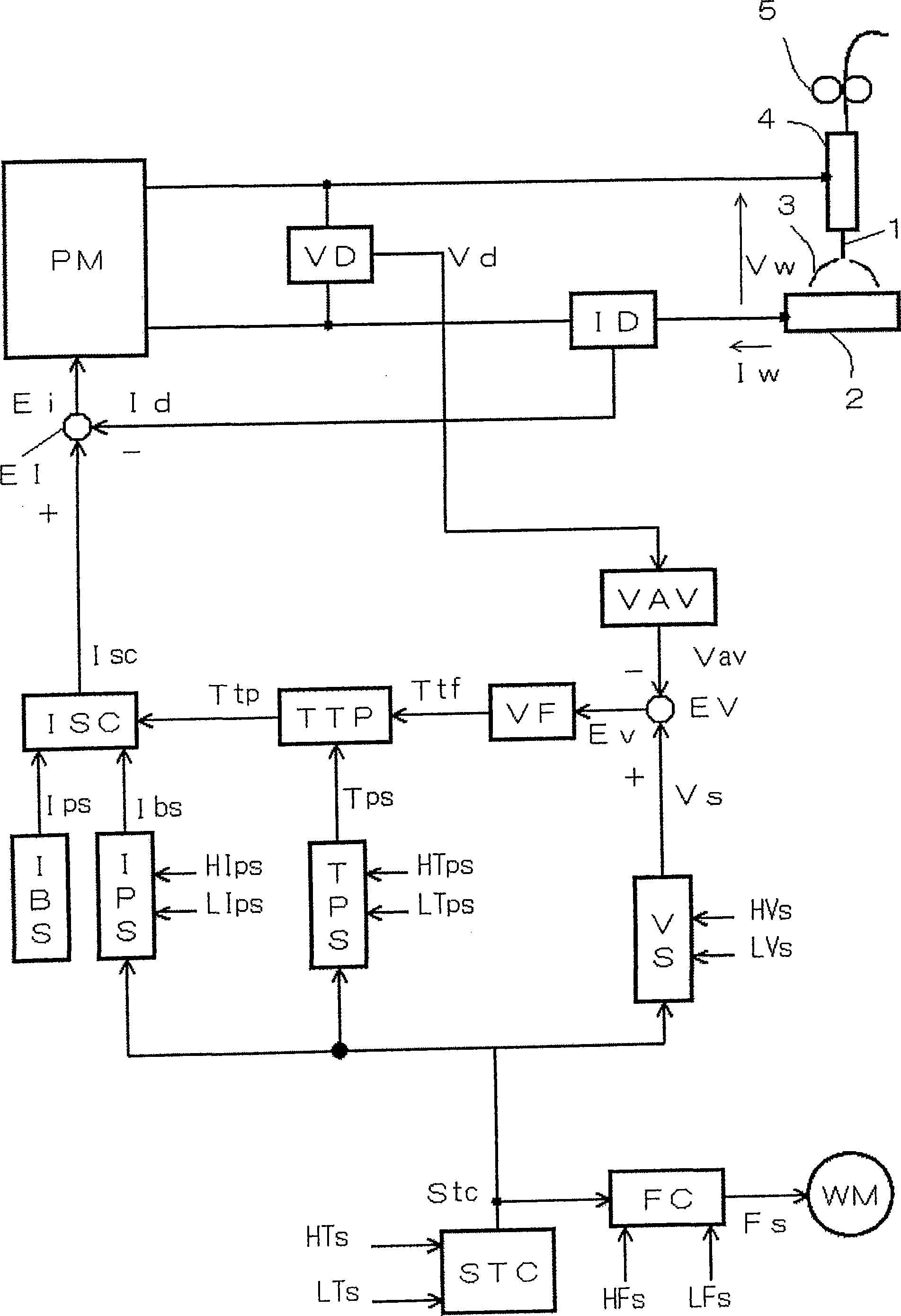

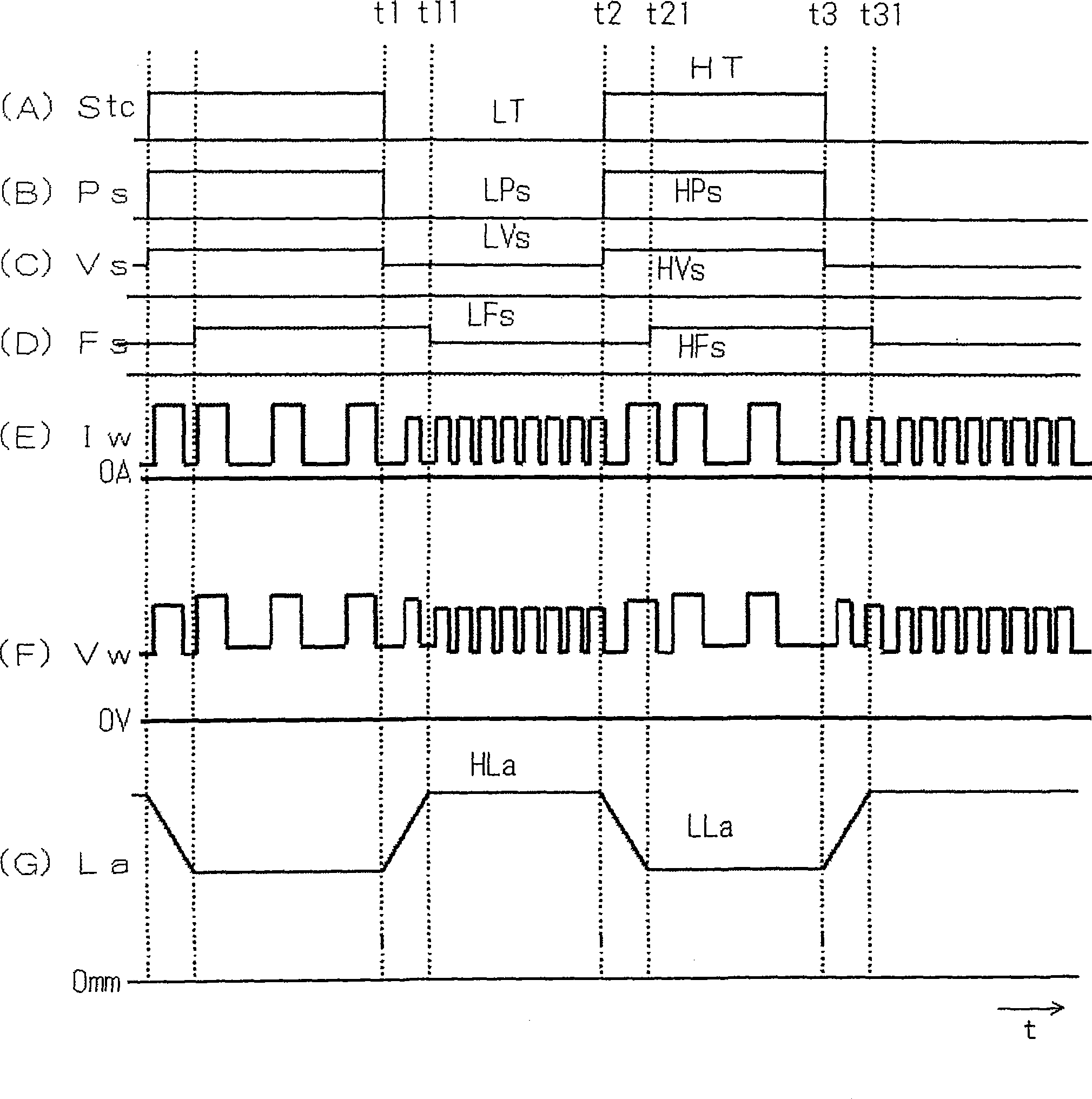

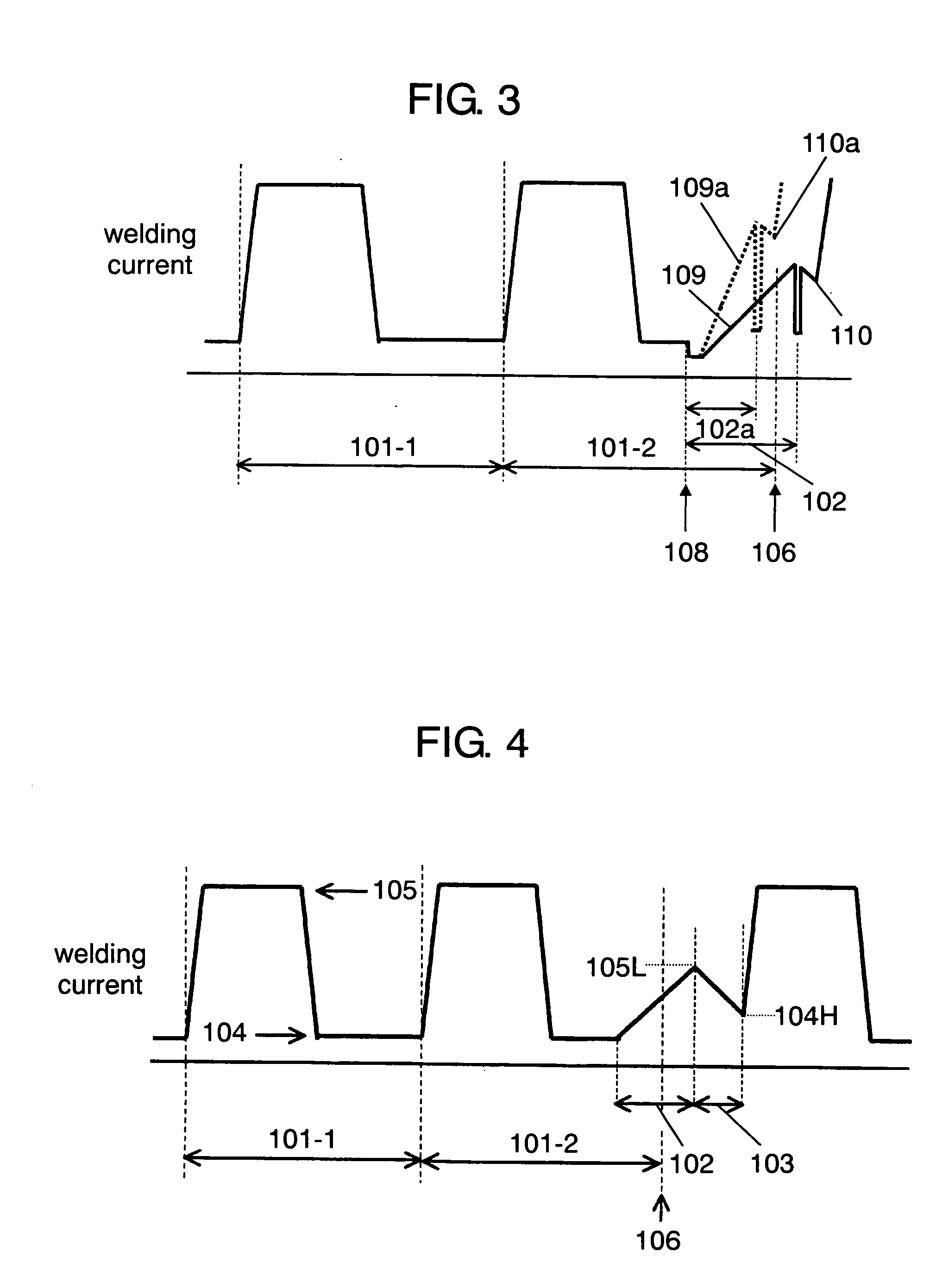

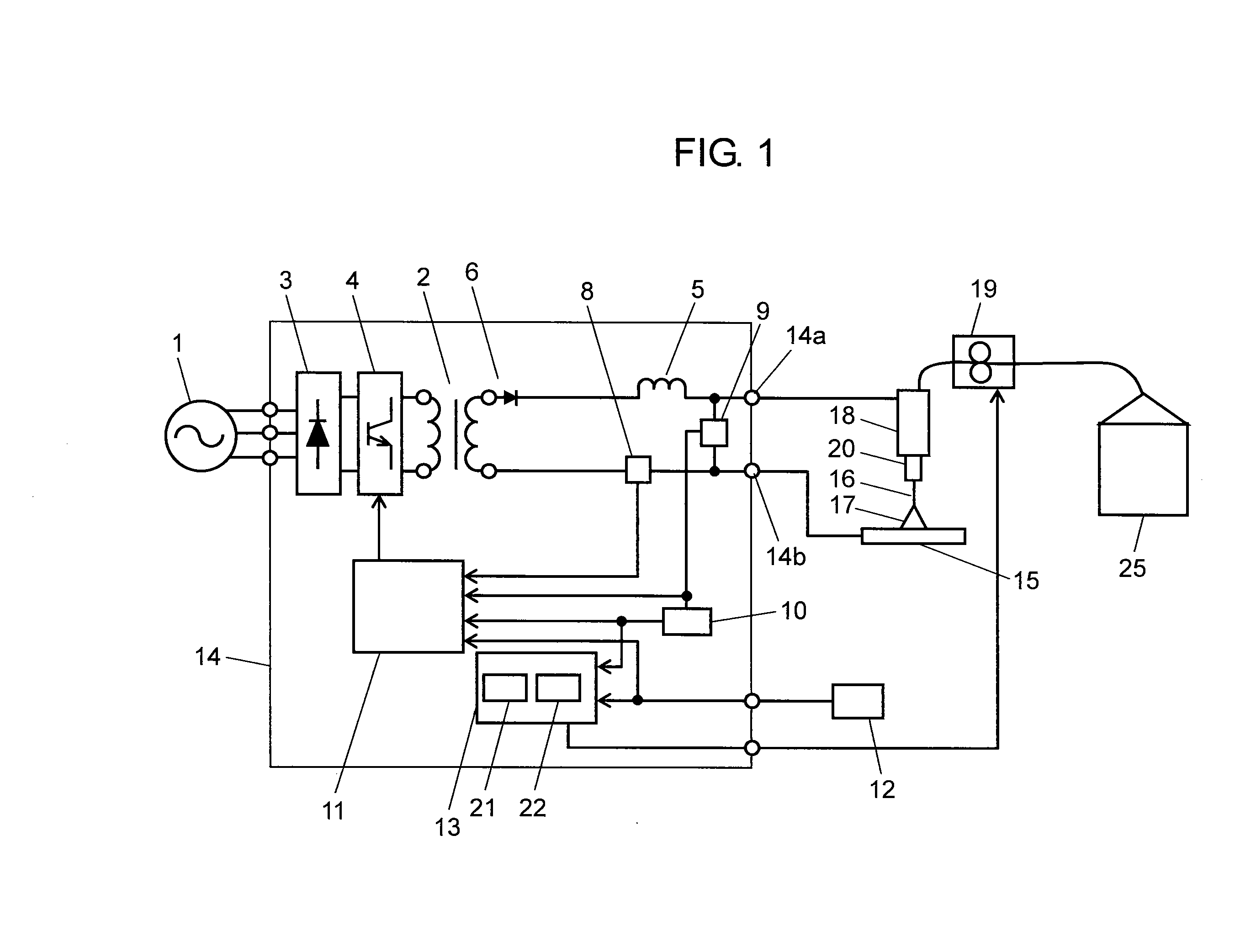

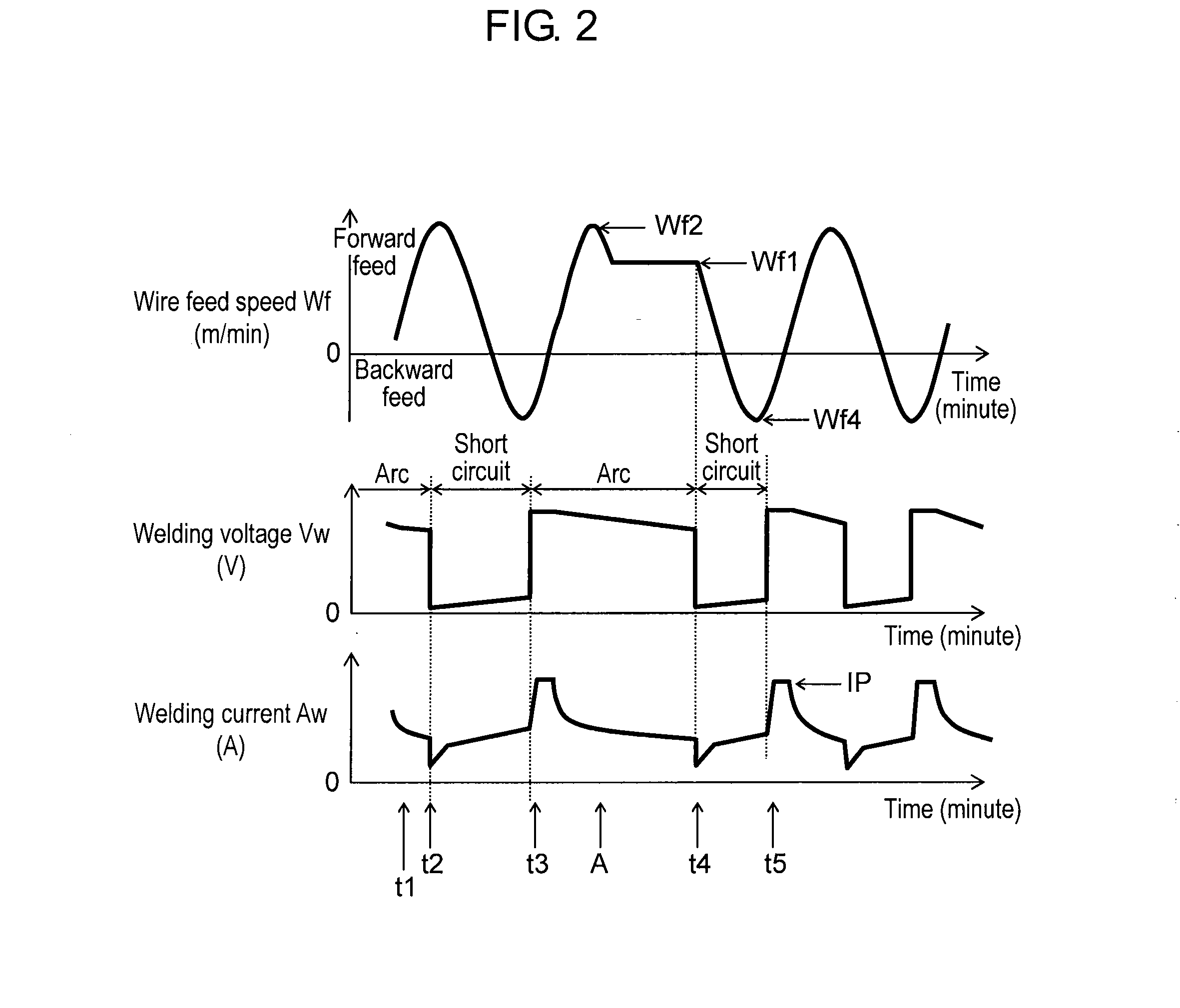

Consumable electrode arc welding method and consumable electrode arc welding device

ActiveUS20120074114A1Uniform beadImproved arc stabilityWelding/cutting media/materialsWelding electrode featuresMechanical engineeringElectric arc

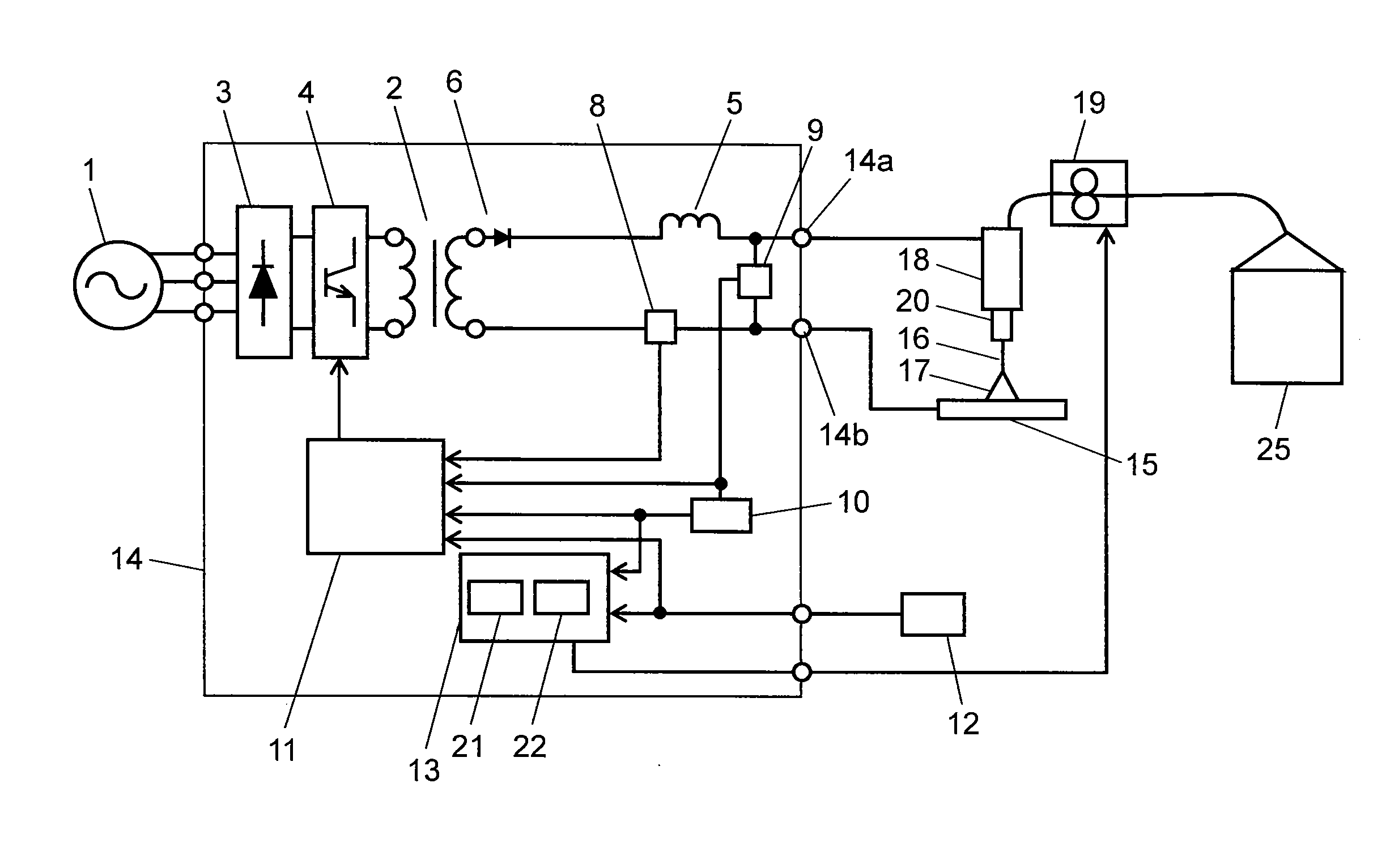

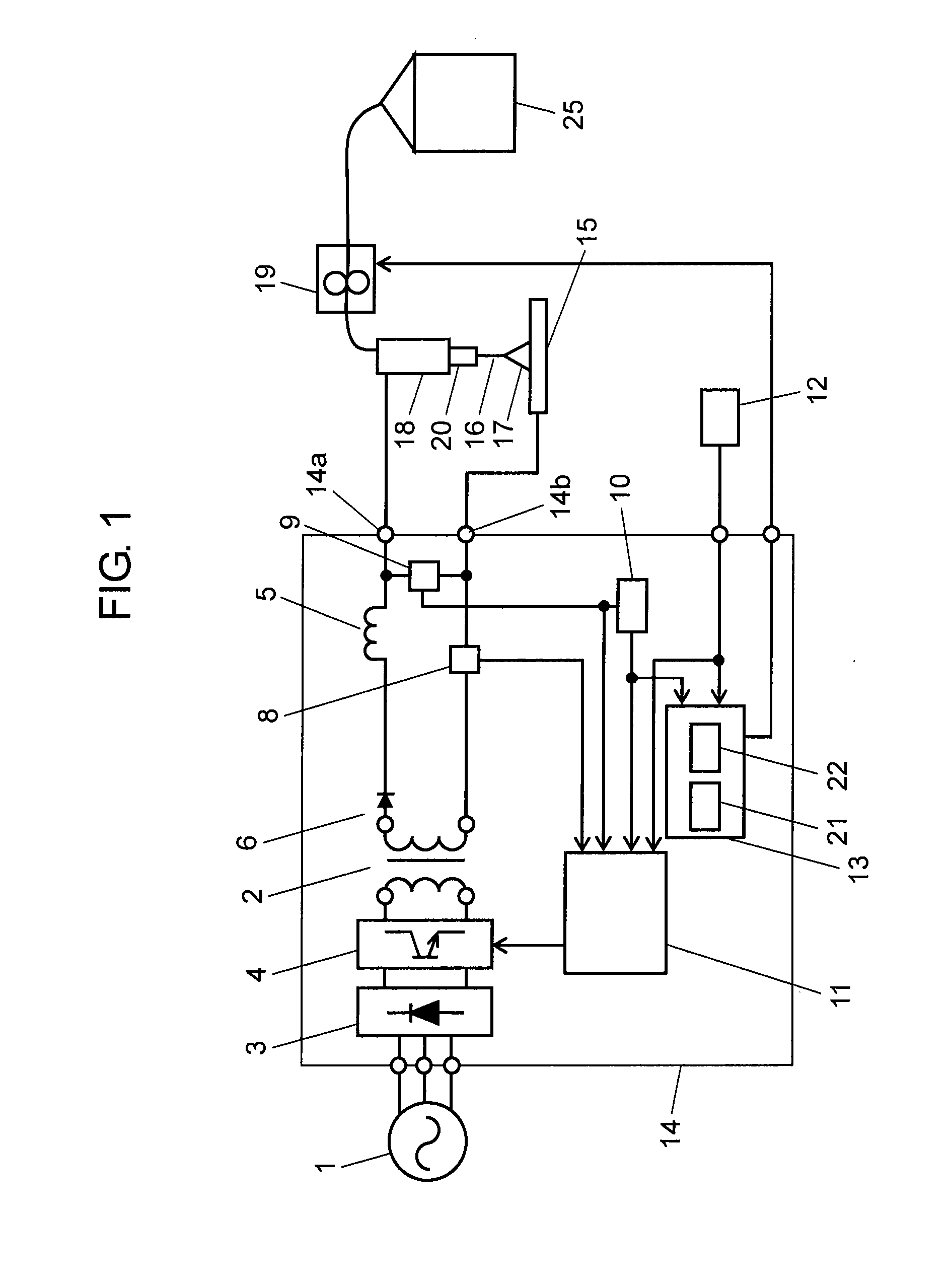

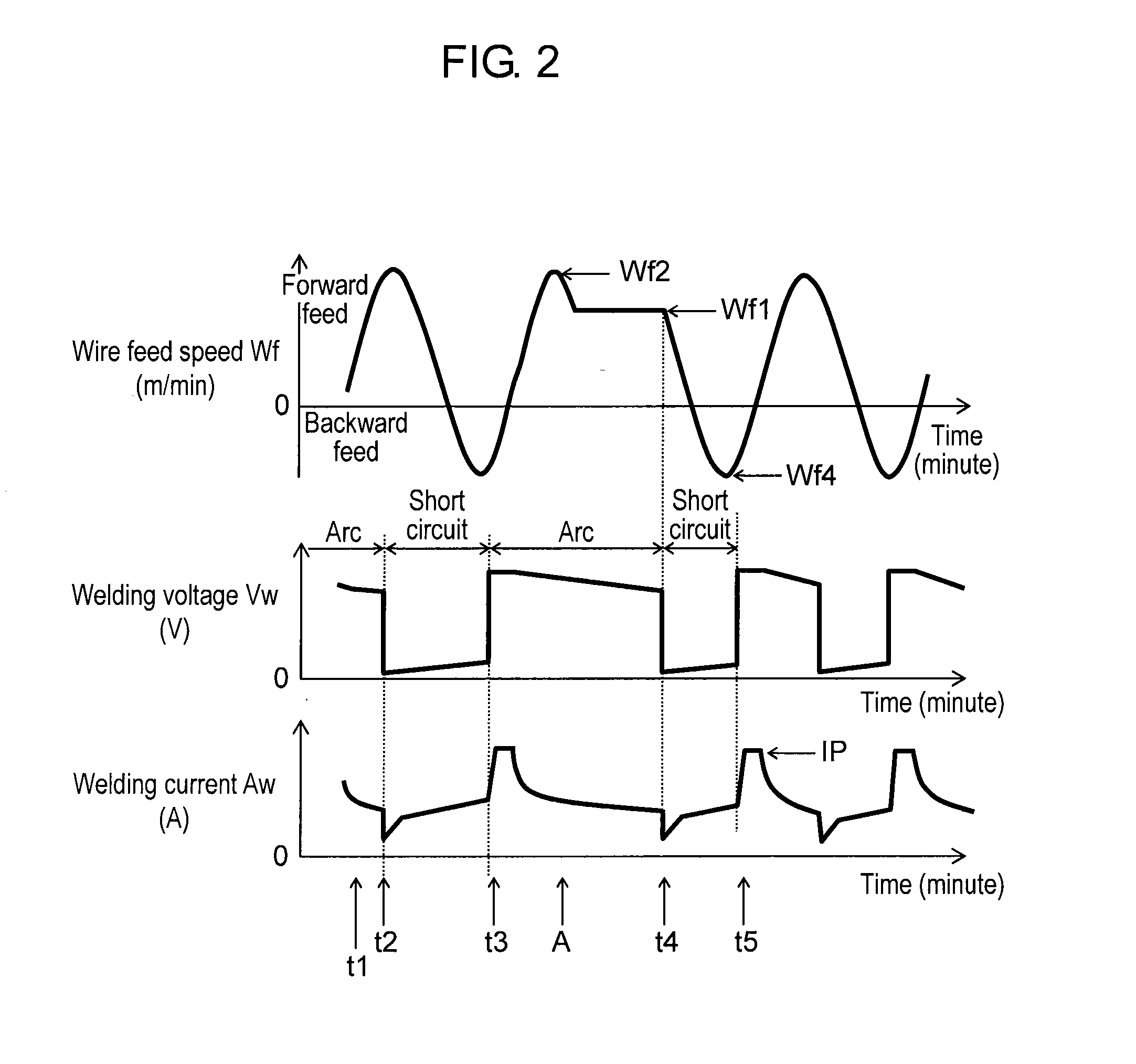

If a short circuit does not occur during deceleration of a wire feed speed in forward feed of a welding wire before the wire feed speed reaches a predetermined wire feed speed, a cyclic change is stopped and the wire feed speed is constantly controlled at the first feed speed. If a short circuit occurs during forward feed at the first feed speed, deceleration from the first feed speed starts, and the cyclic change is resumed for welding. This achieves uniform weld bead without increasing spatters even if any external disturbance such as change of distance between a tip and base material occurs.

Owner:PANASONIC CORP

Hardfacing electrode

ActiveUS7491910B2Improved arc stabilityModification to compositionMolten spray coatingWelding/cutting media/materialsMetalChromium

An electrode to form a hardfacing alloy for use as a surfacing on metal that is subjected to high thermal and mechanical stresses. The electrode includes chromium, a metal sensitization inhibitor, and iron to form a hardfacing alloy.

Owner:LINCOLN GLOBAL INC

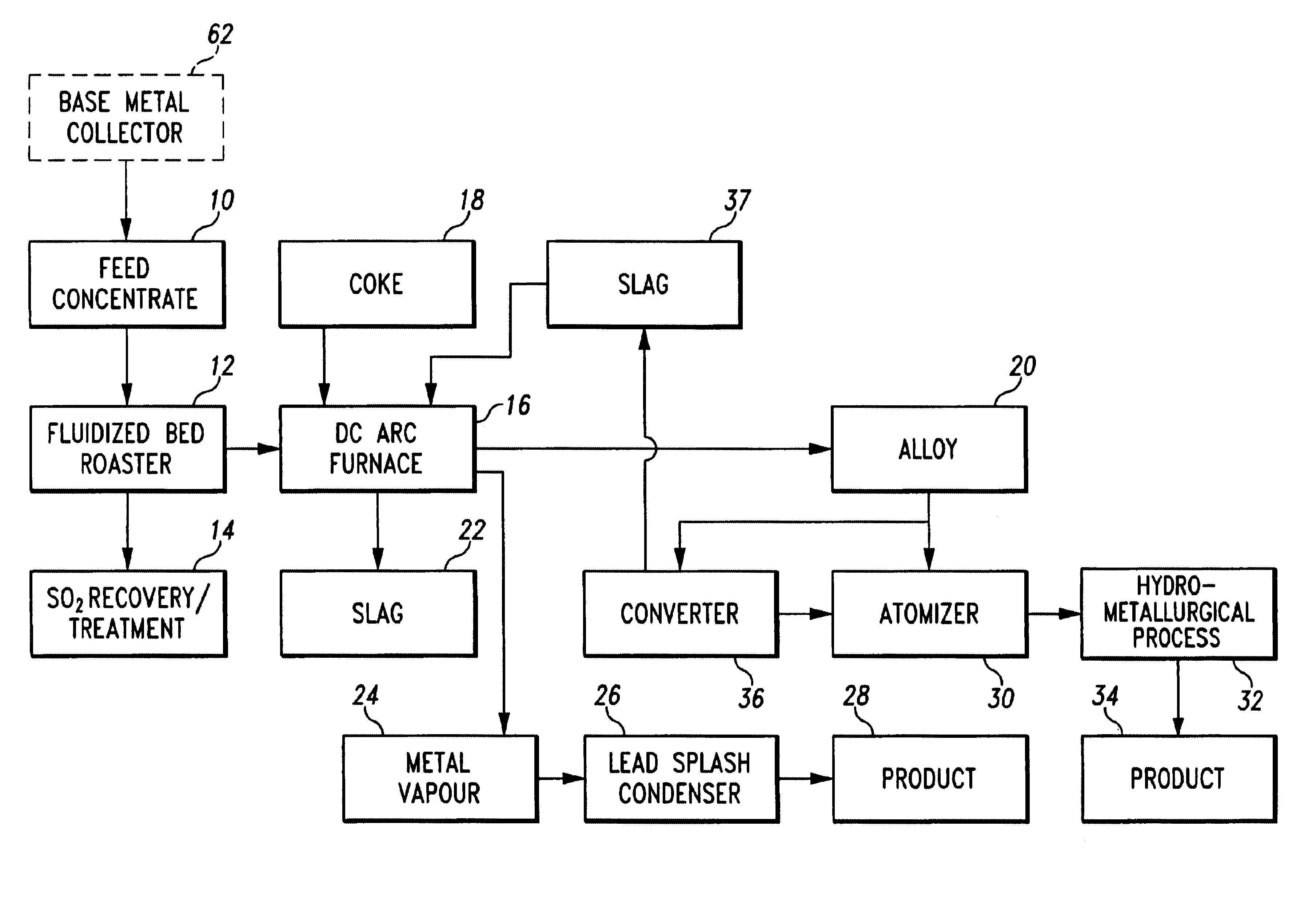

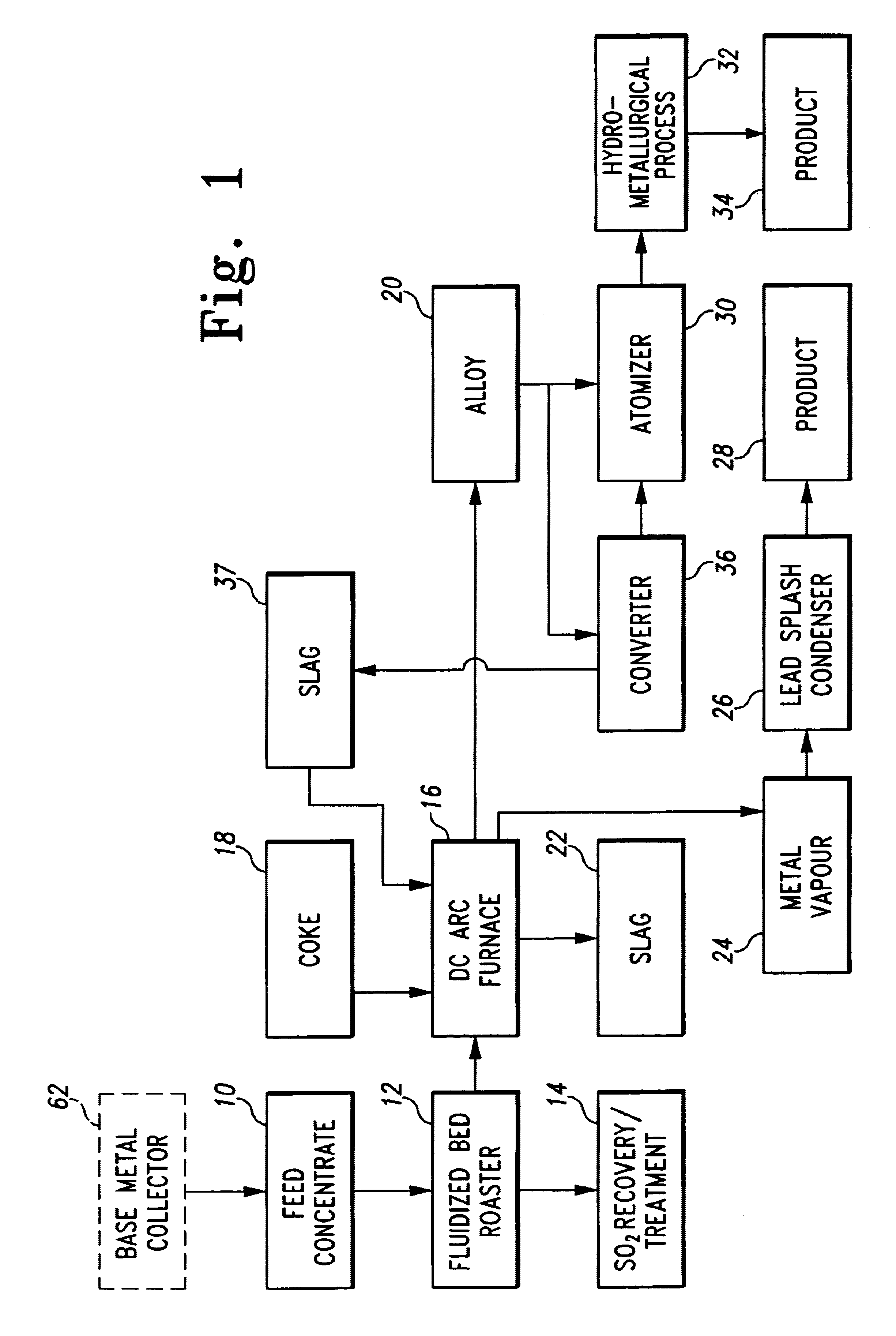

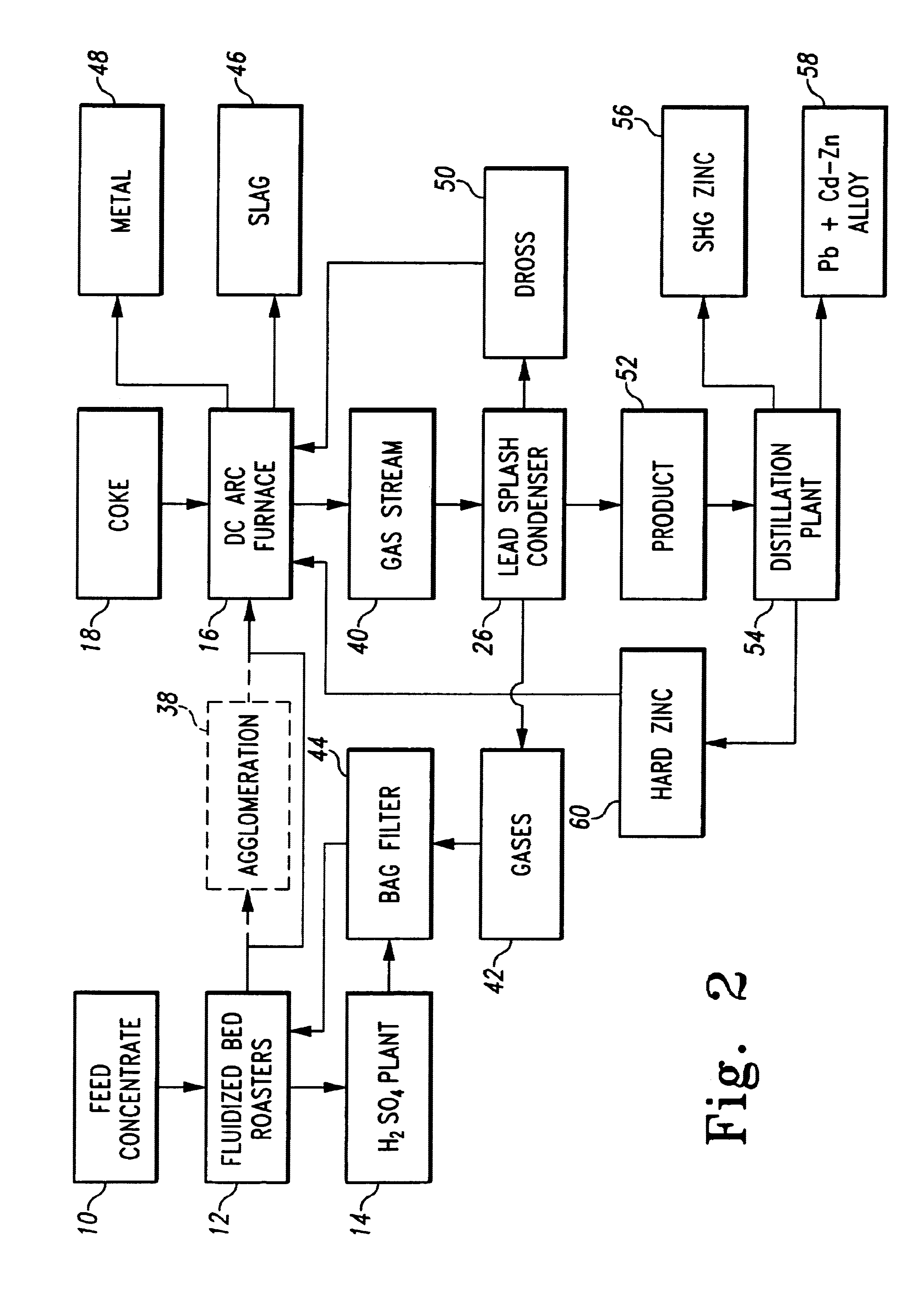

Treatment of metal sulphide concentrates by roasting and electrically stabilized open-arc furnace smelt reduction

InactiveUS6699302B1Improved arc stabilityIncreased energy lossProcess efficiency improvementElectric furnaceDc arc furnaceMetallic sulfide

A process for treating a metal sulphide concentrate which includes the steps of: a) roasting the concentrate to reduce the sulphide content of the concentrate, to a negligible value and b) melting the concentrate, under reducing conditions, in an electrically stabilized open-arc furnace, in particular a DC arc furnace.

Owner:MINTEK

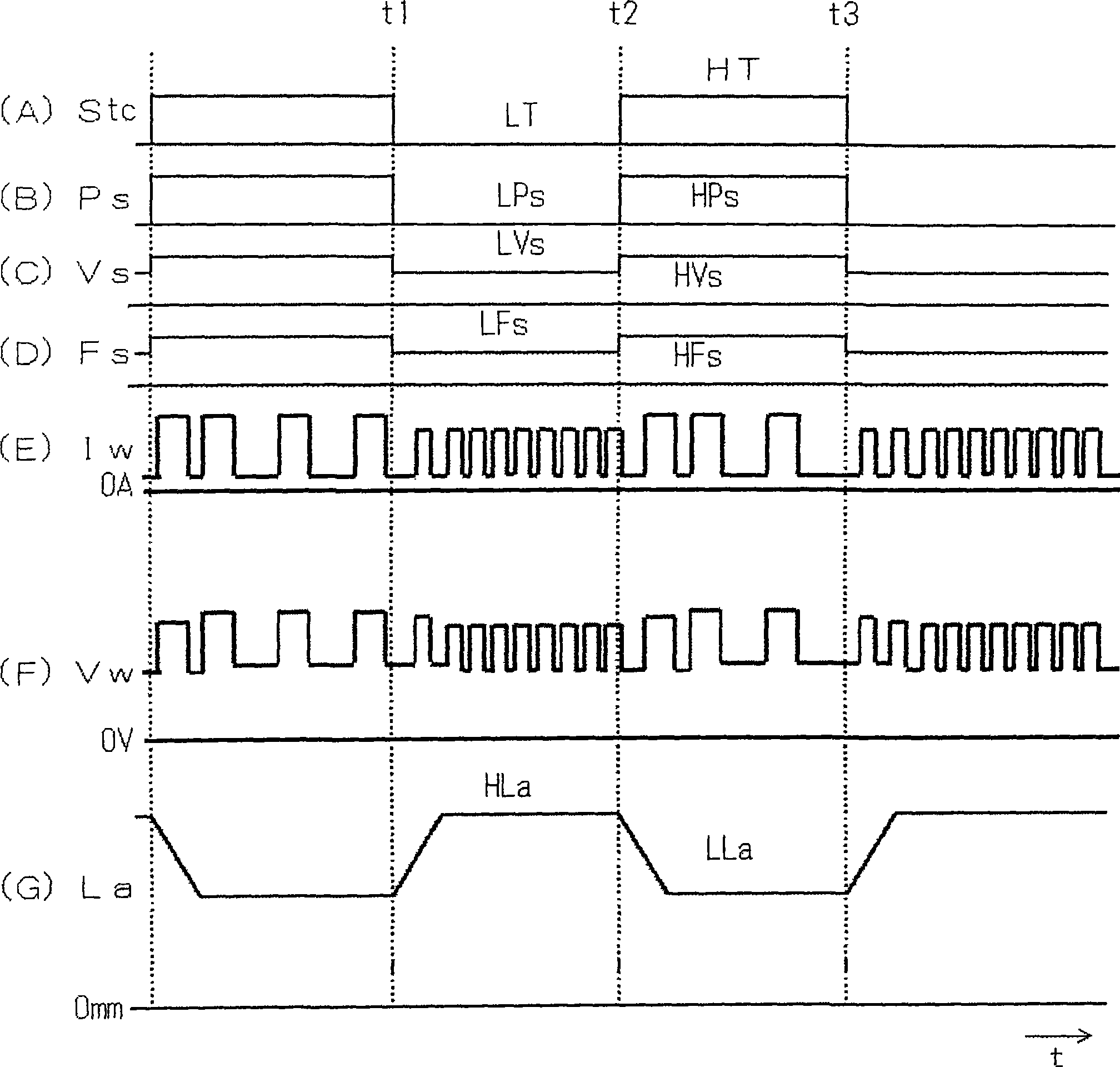

Pulse arc welding control method

ActiveCN101376191AThe arc force changes greatlyShake violentlyArc welding apparatusPower flowSwitching signal

An impulse arc welding control method comprises: repeating electrifying using the electrifying of peak current of in peak period and the electrifying of background current in background period as impulse period; controlling the arc length in the manner that the welding voltage value (Vw) is approximately equal to the set voltage value (Vs); making the arc length to vary periodically by making the set voltage value (Vs) to vary synchronistically with the switching signal (Stc); making the impulse parameter (Ps) to vary synchronistically with the switching signal (Stc); and changing the sending speed (Fs) from the time the switching signal (Stc) varying starts to the time arc length (La) transition varying approximately converges. Thus, the major varying of arc force make the shake movement of the bath becomes more intensive to improve the air bubble reducing effect. Consequently, the air bubble reducing effect is improved in the impulse arc welding method with arc length varied periodically.

Owner:DAIHEN CORP

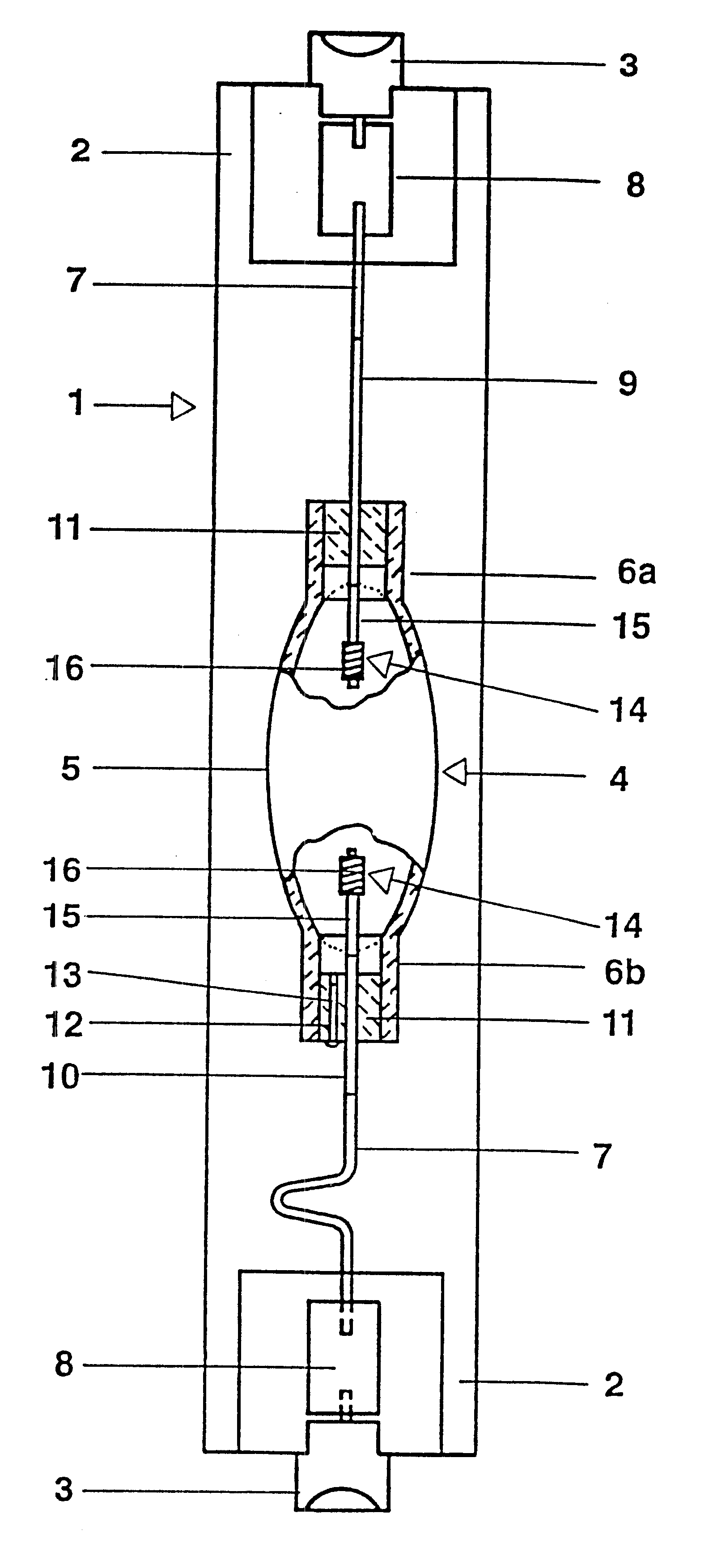

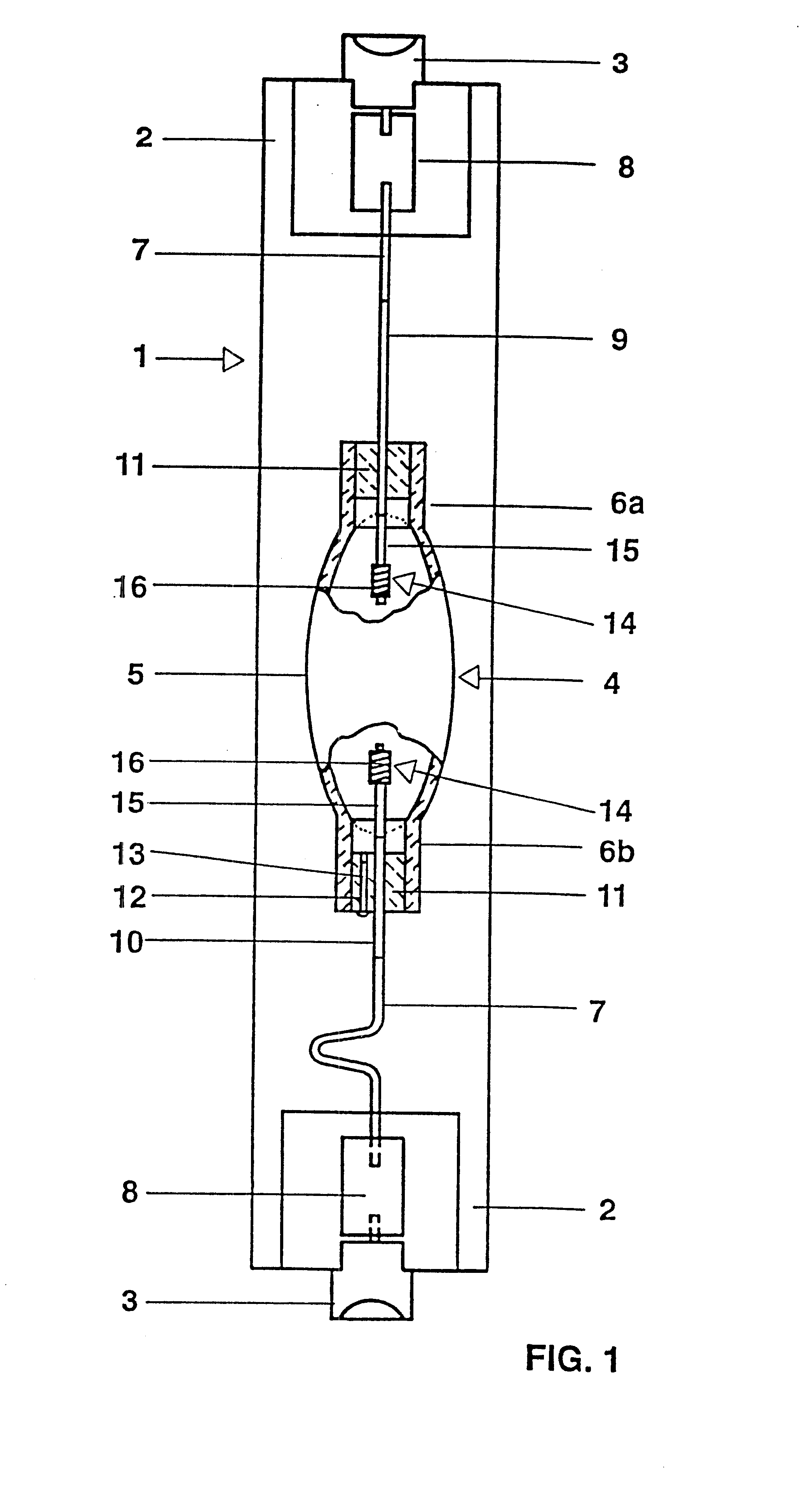

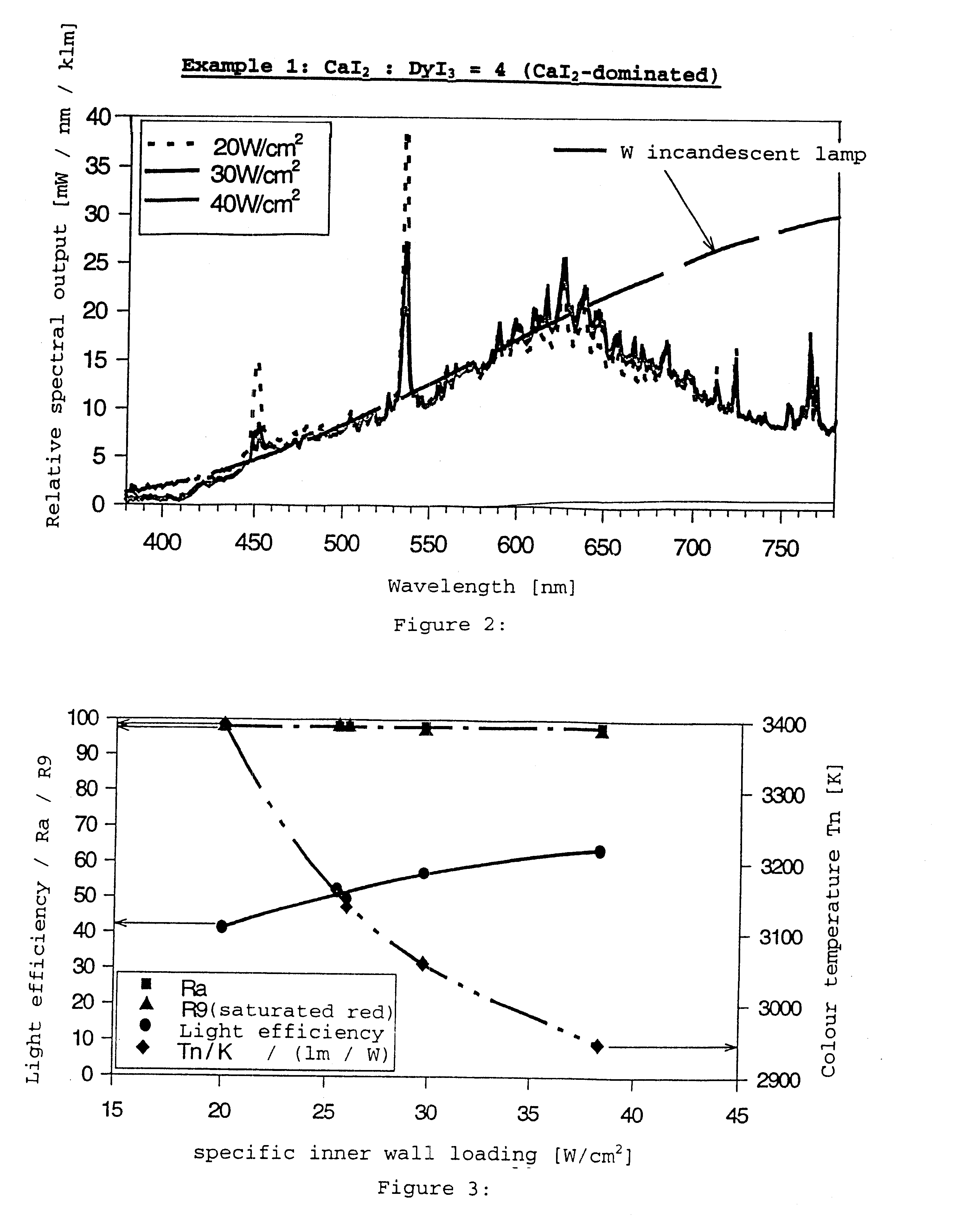

Mercury-free metal halide lamp

InactiveUS6469446B1Improve stabilityGood dimming effectSolid cathode detailsGas discharge lamp detailsBoiling pointMetal-halide lamp

Mercury-free metal halide lamp with a warm white luminous color, the fill of which comprises the following components: an inert gas which acts as a buffer gas; a first group of metal halides (MH), the boiling point of which is above 1000° C. (preferably above 1150° C.), the first group comprising at least Dy and Ca used simultaneously as metals, and the molar ratio of the two metal halides Ca-MH:Dy-MH being between 0.1 and 10; these are components with a low volatility which are present in saturated form; a second group of metal halides, the boiling point of which is below 1000° C. (preferably below 900° C.), the second group comprising at least one of the elements In, Zn, Hf, Zr as metals; these are volatile components which are mostly present in unsaturated form; the total fill quantity of the first group of metal halides being between 5 and 100 mumol / cm3; the total fill quantity of the second group of metal halides being between 1 and 50 mumol / cm3; and the color temperature being between 2700 and 3500 K; the general color rendering index being at least Ra=90, while at the same time the red rendering index is at least R9=60.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

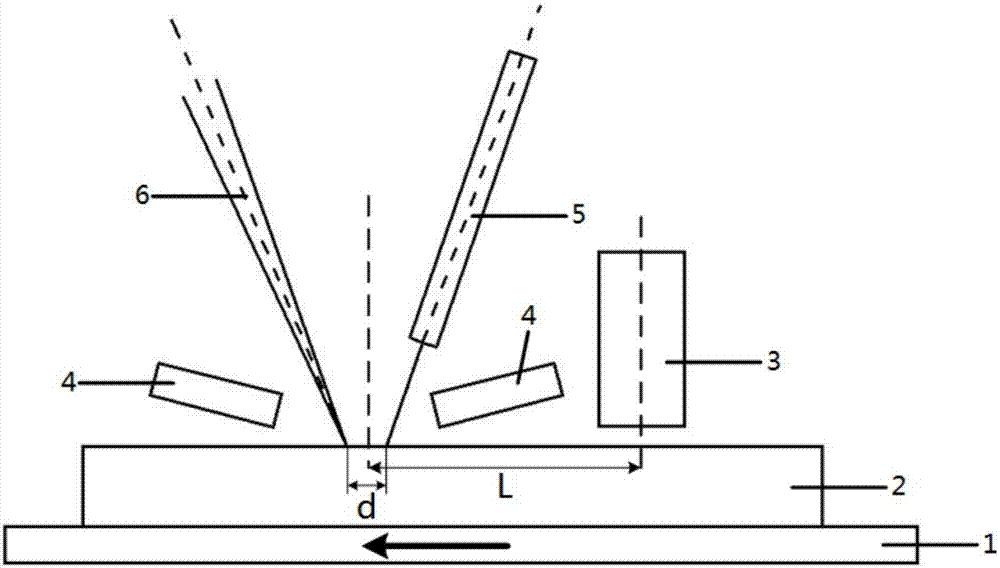

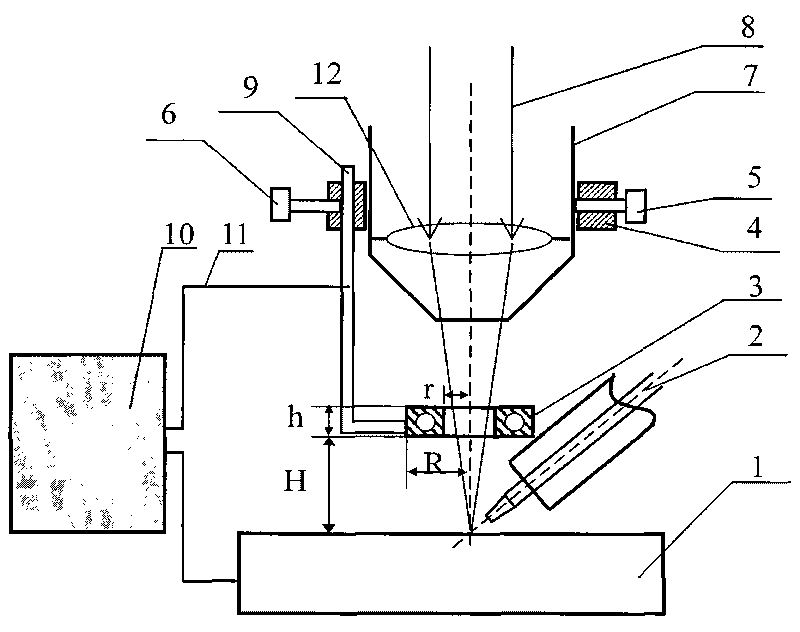

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

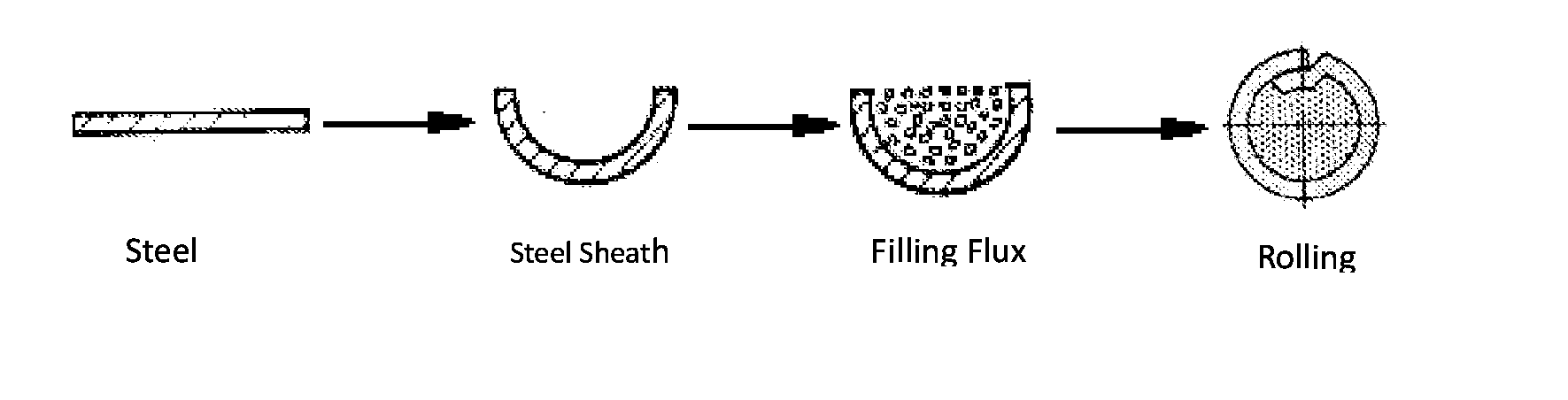

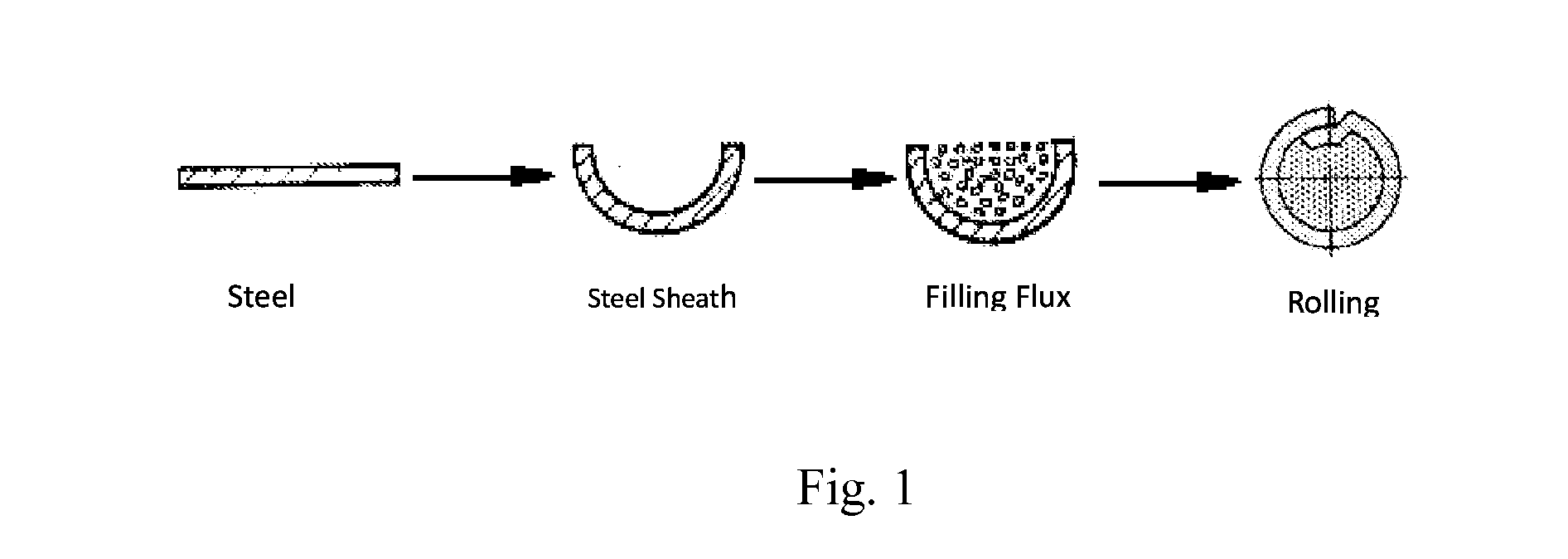

Aluminum metal-core weld wire and method for forming the same

InactiveUS6933468B2Reduce porosityImprove permeabilityWelding/cutting media/materialsSoldering mediaAluminum metalNitride

An aluminum metal-core weld wire, the sheath being aluminum, the metal-core having a composition that contains primarily metallic alloying powders e.g. Manganese nitride and / or barium. A method for manufacturing aluminum metal-core wire, the method including depositing a core composition onto strip of aluminum, forming strip of aluminum into a tube containing core composition, and applying an inorganic lube to surface of tube, and drawing tube through reducing dies.

Owner:HOBART BROS

Low-temperature steel flux-cored wire

InactiveCN101450426AExcellent Oxygen Content Diffusion Hydrogen ContentOxygen Diffusion Good Hydrogen ContentWelding/cutting media/materialsSoldering mediaArc stabilitySlag

The invention discloses a low-temperature steel flux cored wire. Flux core of the flux cored wire comprises the following raw materials by weight percentage: 28 to 33 percent of rutile, 1 to 3 percent of aedelforsite, 14 to 18 percent of silicon-manganese alloy, 16 to 21 percent of ferrous powder, 2 to 4 percent of nickel powder, 1 to 2 percent of cryolite, 5 to 7 percent of feldspar, 1.5 to 2.5 percent of ferrotitanium, 0.5 to 1 percent of ferroboron, 5 to 6 percent of mid-carbon ferromanganese, 2.5 to 4 percent of magnesite, 4 to 6 percent of quartz and 1.5 to 3.5 percent of fluorite. Compared with the similar product of the prior art, the flux cored wire belongs to the meta-acid slag series, and has the advantages of good electric arc stability, less splash, easy slag removal, good low-temperature impact ductility, good low-temperature crack resisting performance, high efficiency and low cost.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

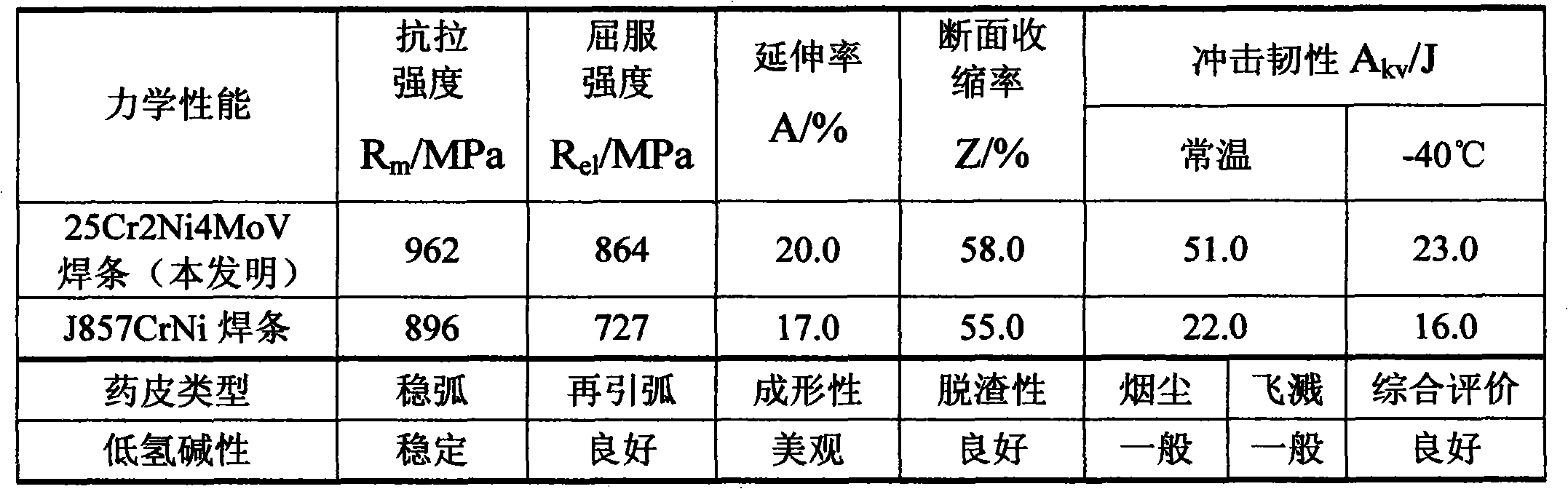

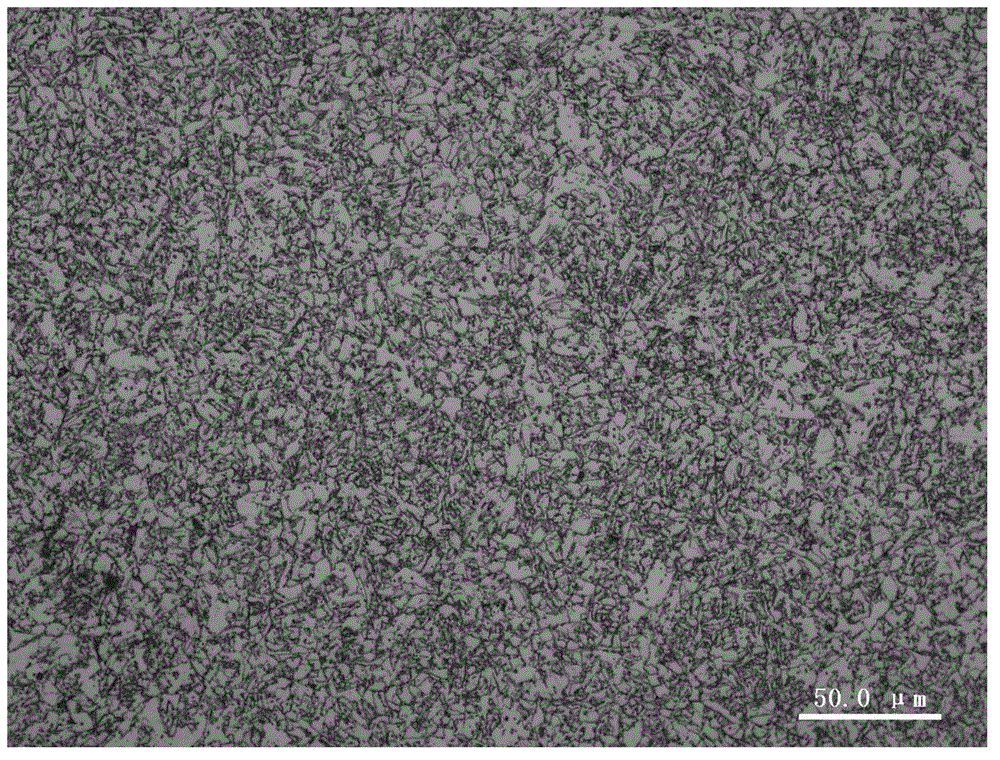

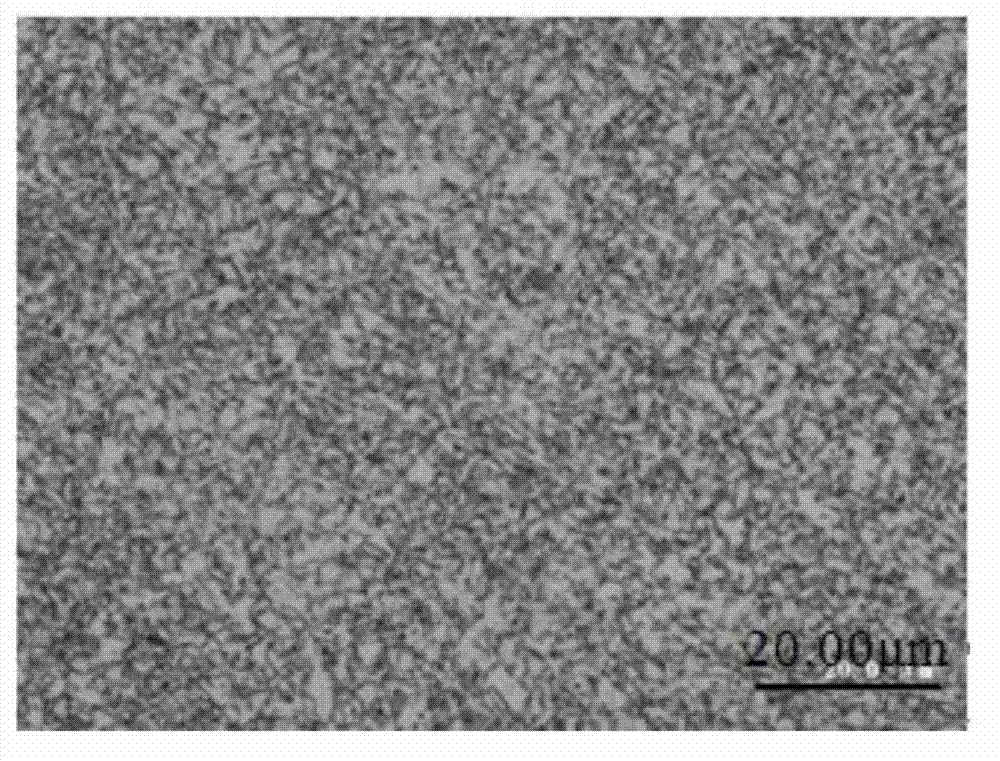

Low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding

InactiveCN101890594AGood arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFerrosiliconFerrotitanium

The invention discloses a low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding, which comprises a core wire and a coating, wherein the coating is prepared from the following materials in percentage by weight: 40-47% of marble, 16-24% of fluorite, 3-6% of quartz, 3-6% of zircon sand, 4-12% of rutile, 6-11% of ferrotitanium, 4-8% of low-carbon ferromanganese, 2-5% of ferrosilicon, 1-3% of rare earth ferrosilicon, 2.8-3.2% of synthetic mica and 0.5-1.5% of soda ash, and the sum of the weight percentage of all the components is 100%.The electrode prepared from the coating has the advantages of high arc stabilizing performance, good molten pool fluidity, fine splashing particles, easier deslagging after welding, uniform slag covering and delicate and attractive molded weld. Besides, the diffusible hydrogen content of the deposited metal of the prepared electrode is effectively limited.

Owner:XIAN UNIV OF TECH

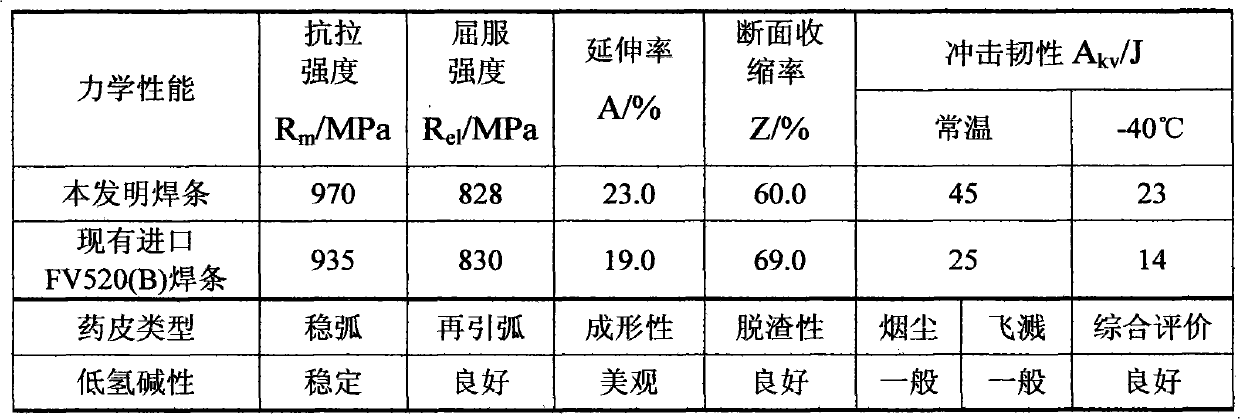

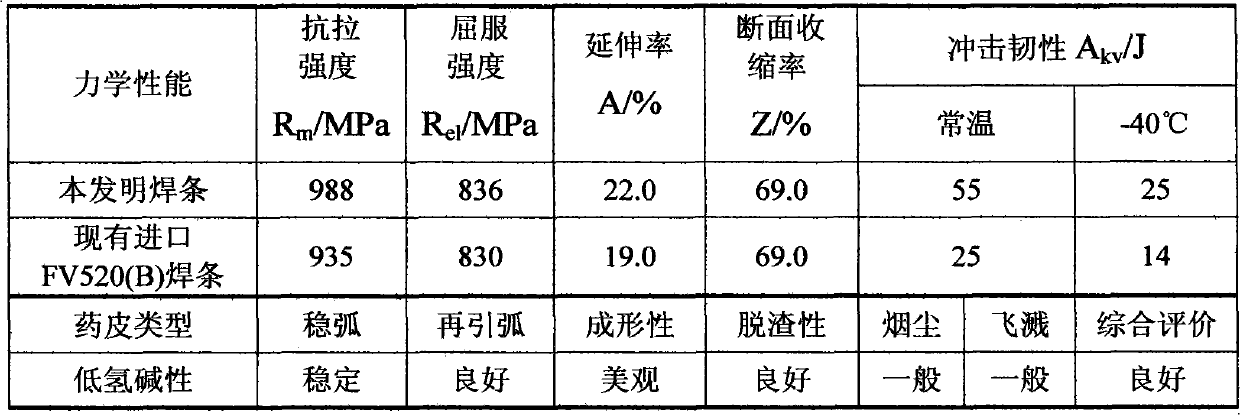

Low-hydrogen basic electrode for welding FV520 (B) stainless steel

ActiveCN101905395AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a low-hydrogen basic electrode for welding FV520 (B) stainless steel, comprising a core wire and an electrod covering, wherein the electrode covering comprises the following materials in weight percentage: 35%-45% of marble, 18%-26% of fluorite, 6%-9% of quartz, 3%-6% of zircon sand, 6%-12% of rutile, 1%-3% of ferrosilicon, 6%-10% of ferrotitanium, 5%-11% of low-carbon ferromanganese, 1%-3% of rare-earth ferrosilicon and 0.5%-1.5% of sodium carbonate, and the sum of the weight percentages of the components is 100%. Compared with the traditional special imported electrode for the FV520 (B) stainless steel, the electrode made of the electrode covering has the advantages of favorable arc stabilization performance, good fluidity of a molten bath, less splash and dust, easier slag removal after welding, uniform slag coverage, and delicate and attractive welding joint formation. The content of diffusible hydrogen generated by using the developed electrode for depositing metal is effectively controlled and meets the requirements of low-carbon contents.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

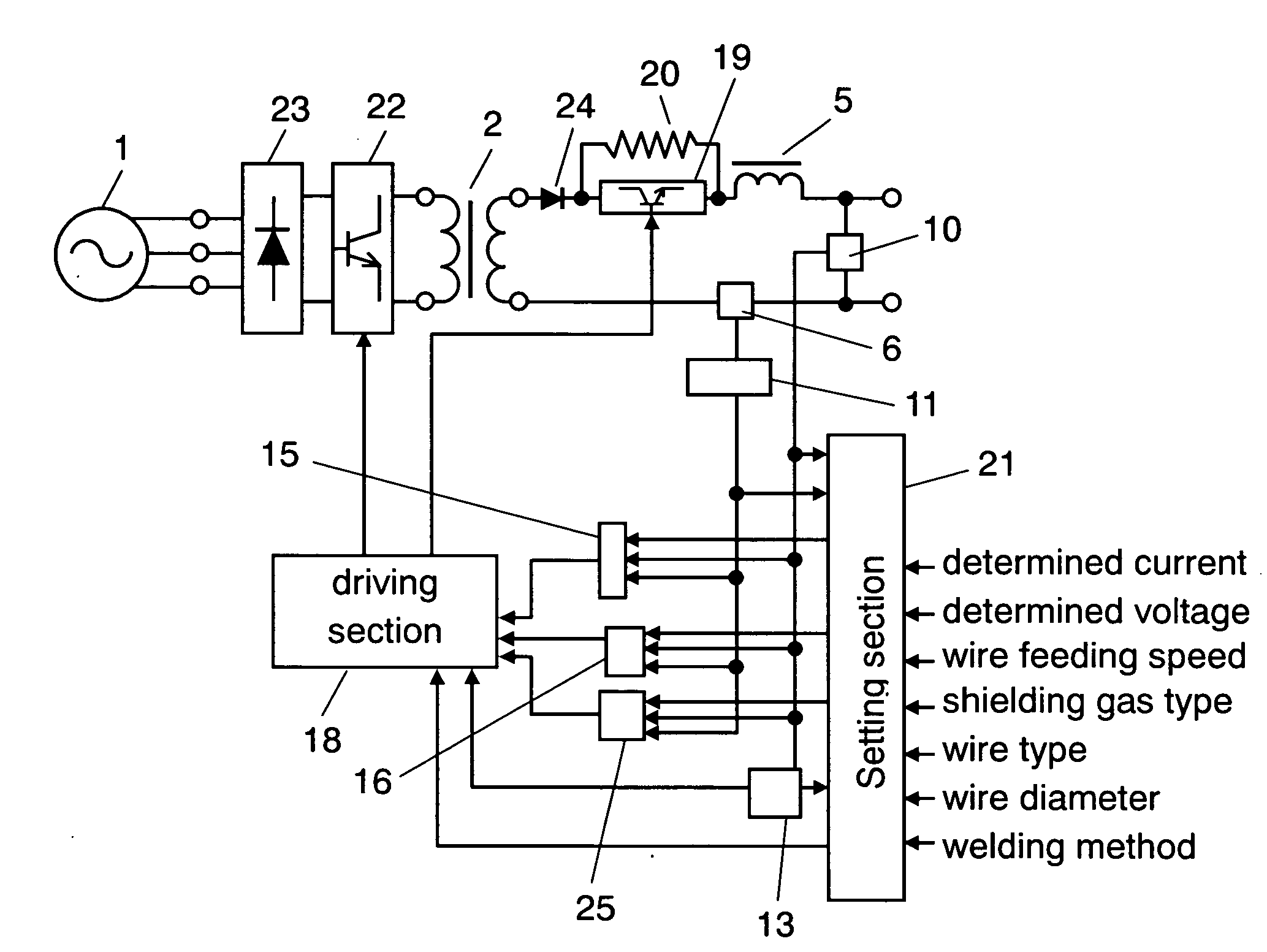

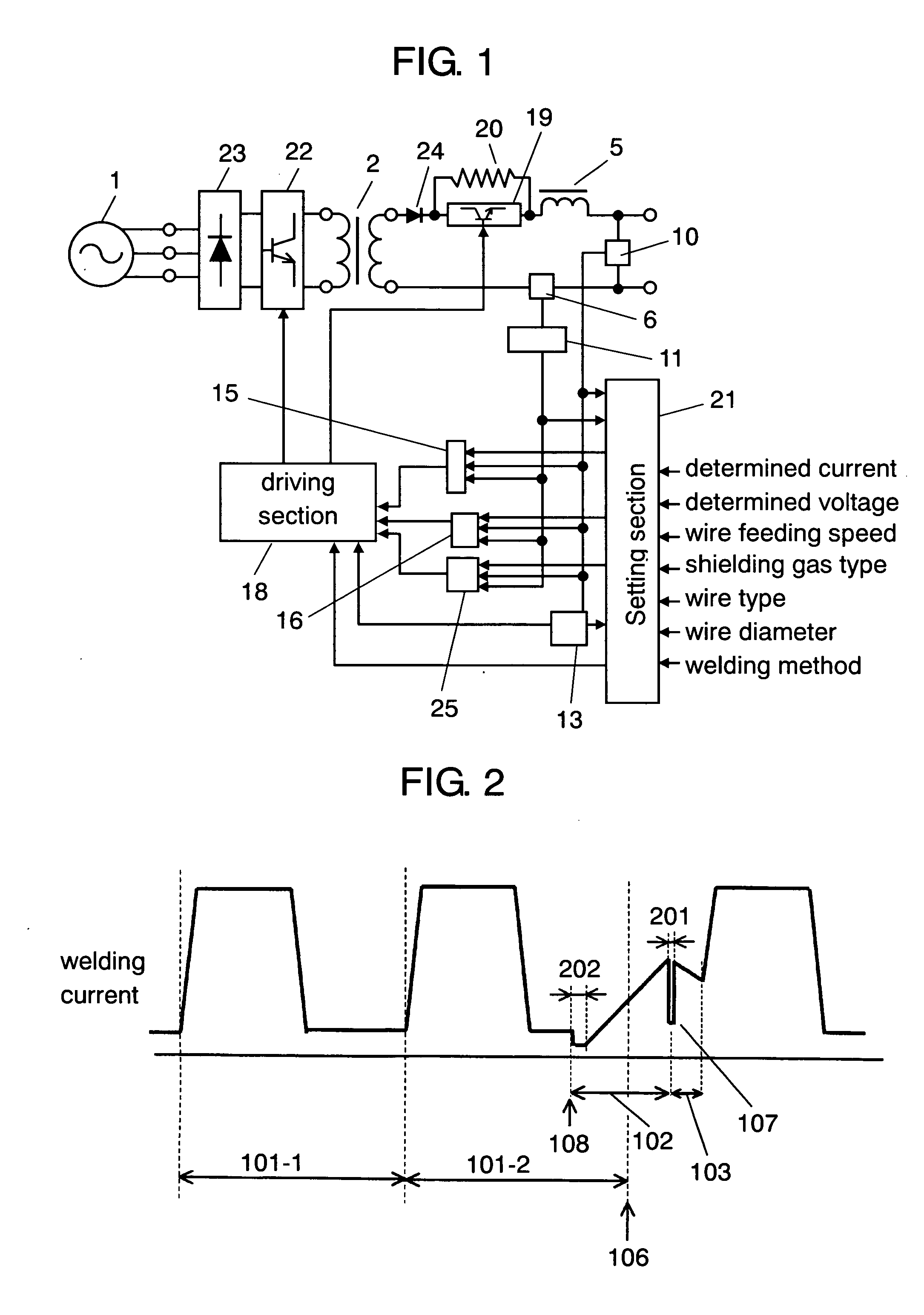

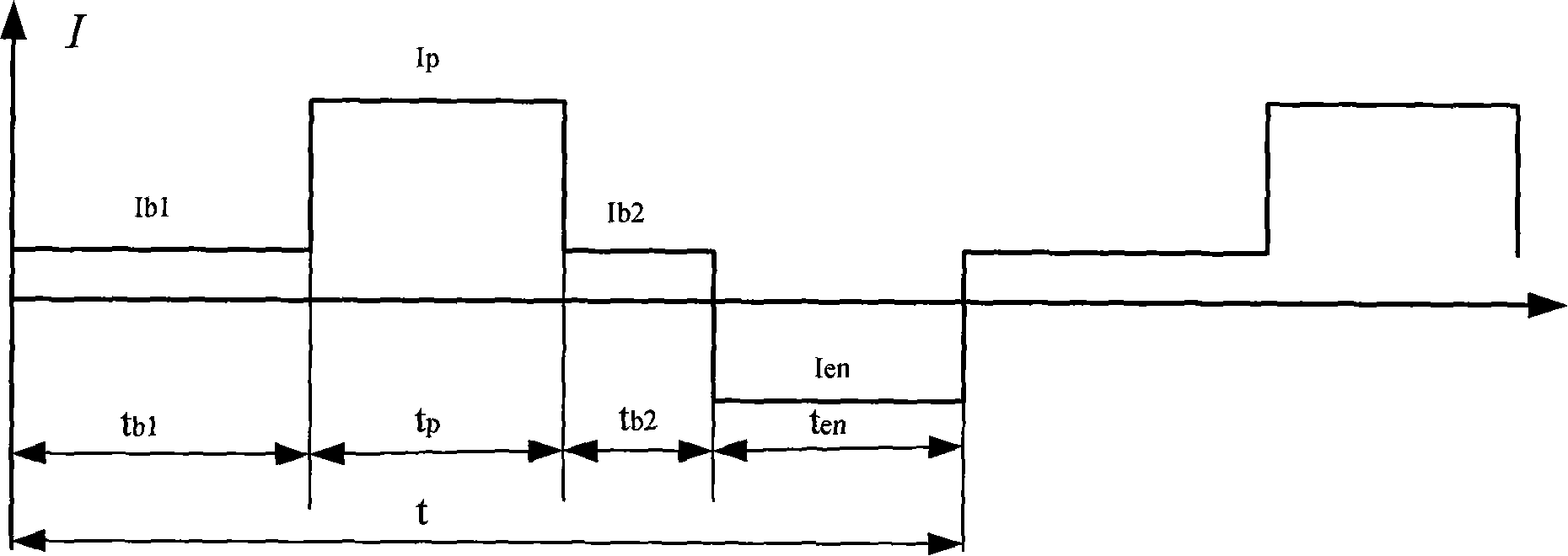

Pulse arc welding control method and pulse arc welding device

ActiveUS20090152252A1Shortens short-circuit durationImproved arc stabilityArc welding apparatusArc stabilityVoltage

Disclosed here is a pulse welding control method and a pulse arc welding device capable of improving arc stability, and decreasing the amount of spatters. The structure contains arc short-circuit judging section (13) for judging a welding state; setting section (21) for defining parameters used for a short-circuit period and an arc period; secondary control section (25); and driving section (18). Secondary control section (25) sharply decreases welding current on detecting a moment when the tip of a wire has a neck just before recovery from the short circuit, according to at least any one of outputs from a welding current value detector, a welding voltage value detector, and the setting section. Driving section (18) selects from outputs of a pulse-waveform circuit section and a dip-waveform circuit section according to the signal from the setting section and the output from the arc short-circuit section, and outputs the selected data to a switching element.

Owner:PANASONIC CORP

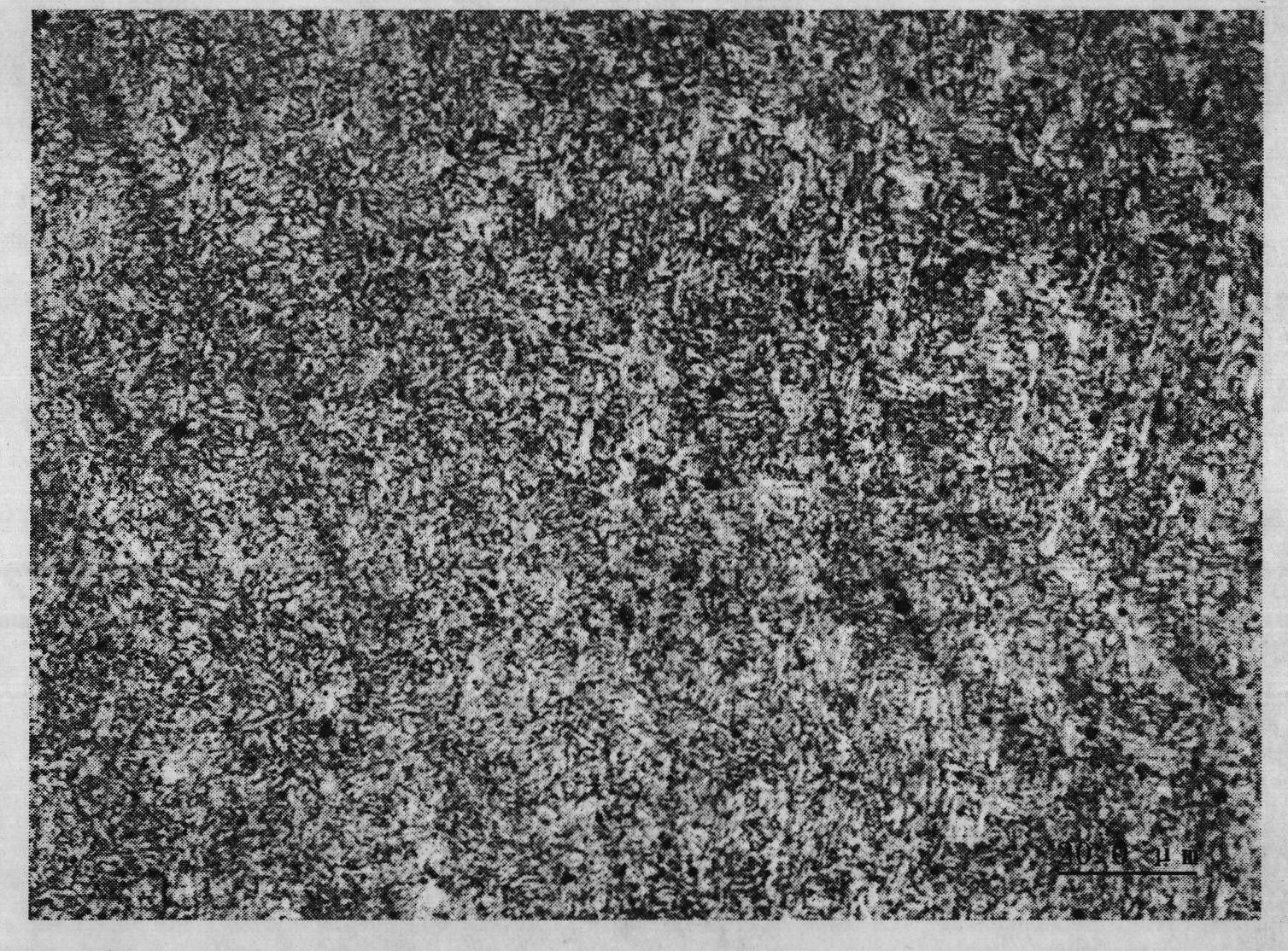

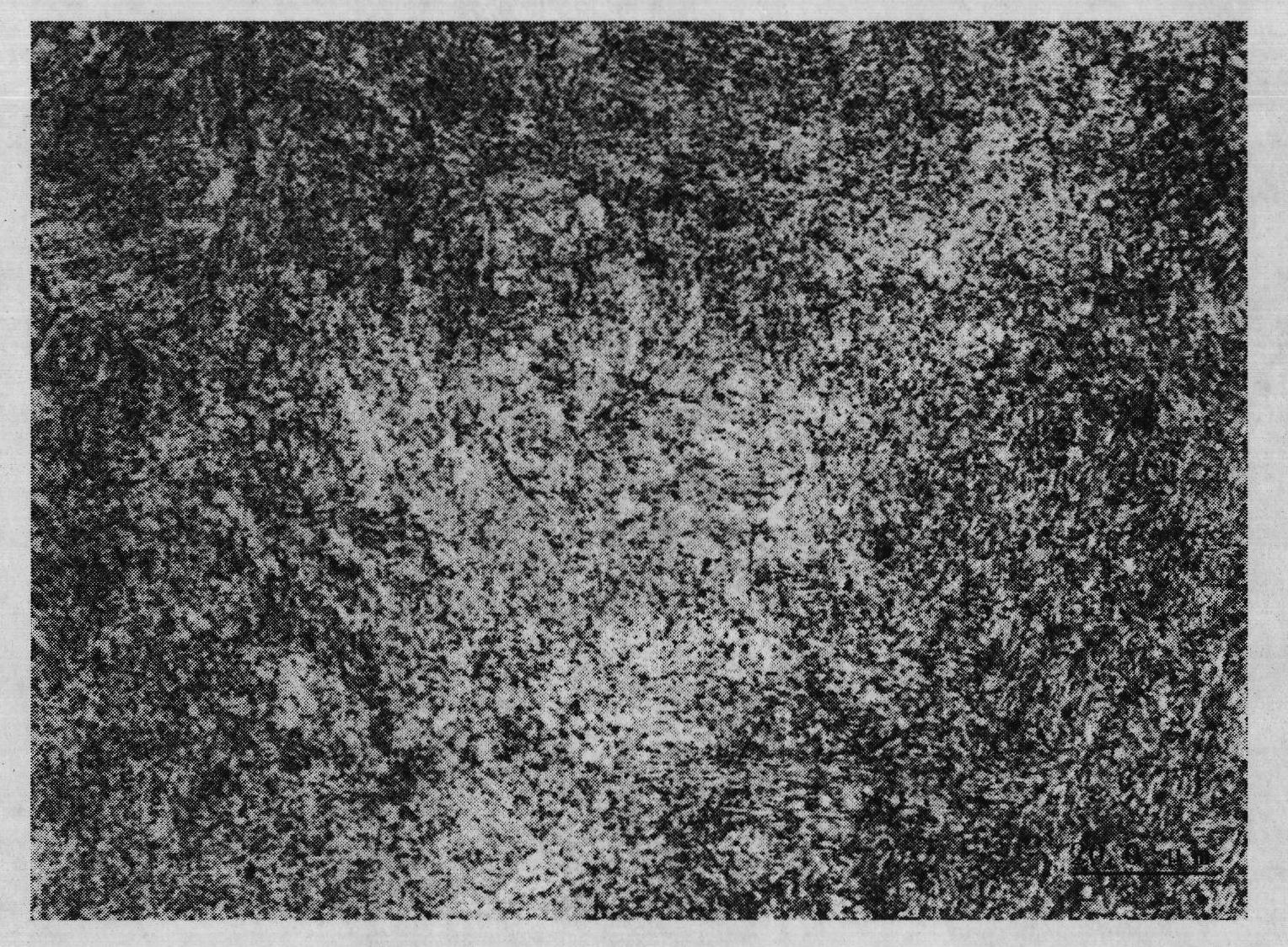

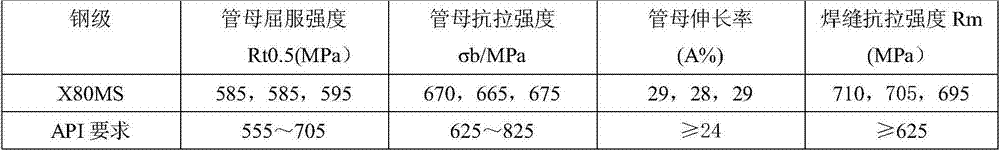

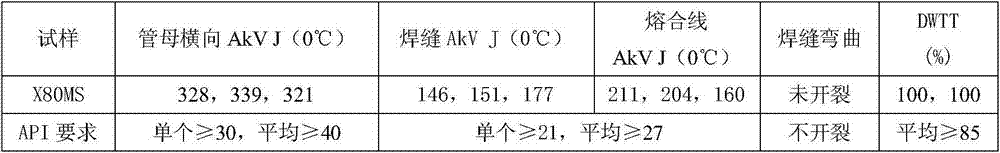

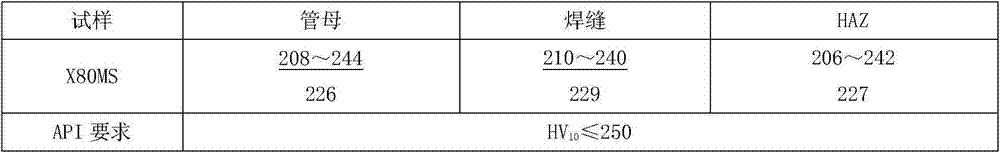

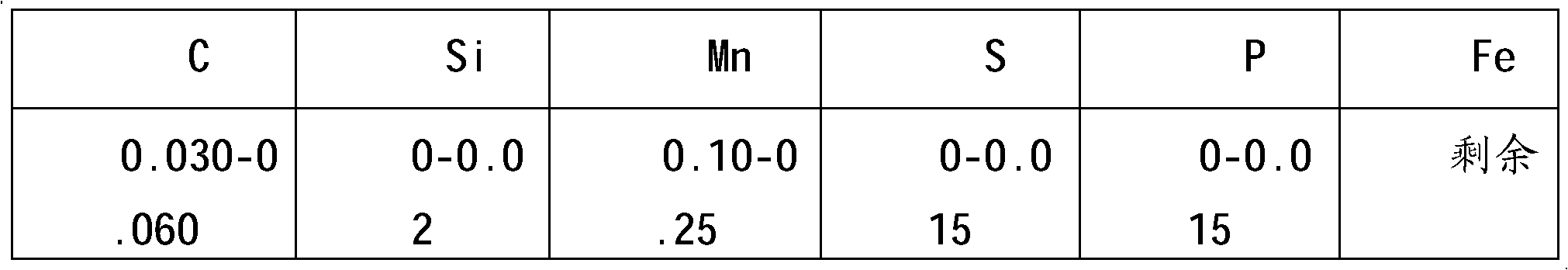

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

The invention discloses an X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as a manufacturing method thereof. The straight seam submerged-arc welded pipe comprises a welding seam and a welded pipe body, and is characterized in that the welded pipe body consists of the following elements in percent by mass: not greater than 0.04% of C, 0.20%-0.40% of Si, 1.20%-1.80% of Mn, not greater than 0.008% of P, not greater than 0.002% of S, 0.10%-0.30% of Ni, not greater than 0.15% of Cr, not greater than 0.15% of Cu, 0.01%-0.10% of Nb, 0.01%-0.10% of Ti, 0.10%-0.30% of Mo, 0.04%-0.10% of Al, not greater than 0.0005% of B, not greater than 0.002% of Ca, and the balance of Fe and inevitable impurities. According to the X80-level straight seam submerged-arc welded pipe and the manufacturing method thereof disclosed by the invention, the X80 straight seam submerged-arc welded pipe disclosed by the invention has good strength, toughness, welding performance, ductility and corrosion resistance through reasonably deploying and controlling material components, a manufacturing process, a manufacturing technology and subsequent processing. Besides, high-pressure large-flow conveying requirements of oil gas under an acidic environment are satisfied.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Gas-shielded flux-cored wire with recyclable welding slag

InactiveCN102139424ALow diffusible hydrogen contentReduce sensitivityWelding/cutting media/materialsSoldering mediaCrack resistanceHydrogen

A gas-shielded flux-cored wire with recyclable welding slag belongs to the welding field. In the invention, the skin of the gas-shielded flux-cored wire is made from a mild steel strip, and welding slag powder is partially or completely instead of natural rutile, thus the purposes of saving the resource and reducing the cost are achieved. The powder of the flux-cored wire comprises the following chemical components in percentage by weight: 15-35% of the welding slag powder of the flux-cored wire (including 20-65% of TiO2, 5-15% of MnO, 5-15% of MgO, 5-15% of SiO2, 1-10% of Fe2O3 and 1-10% of Al2O3), 15-35% of TiO2, 2-7% of Si, 3-8% of Mn, 0.5-5% of Al-Mg, 0-5% of Na, 0-5% of K, 1-5% of Mg and the balance of ferrous powder. When the flux-cored wire manufactured by adopting the welding slag powder is applied to welding, the gas-shielded flux-cored wire has the advantages of excellent technical performance of welding and omnibearing welding adaptability, attractive appearance good humidity resistance, low content of diffusible hydrogen in a welding seam, excellent crack resistance, high connection strength and good low-temperature impact toughness.

Owner:BEIJING UNIV OF TECH

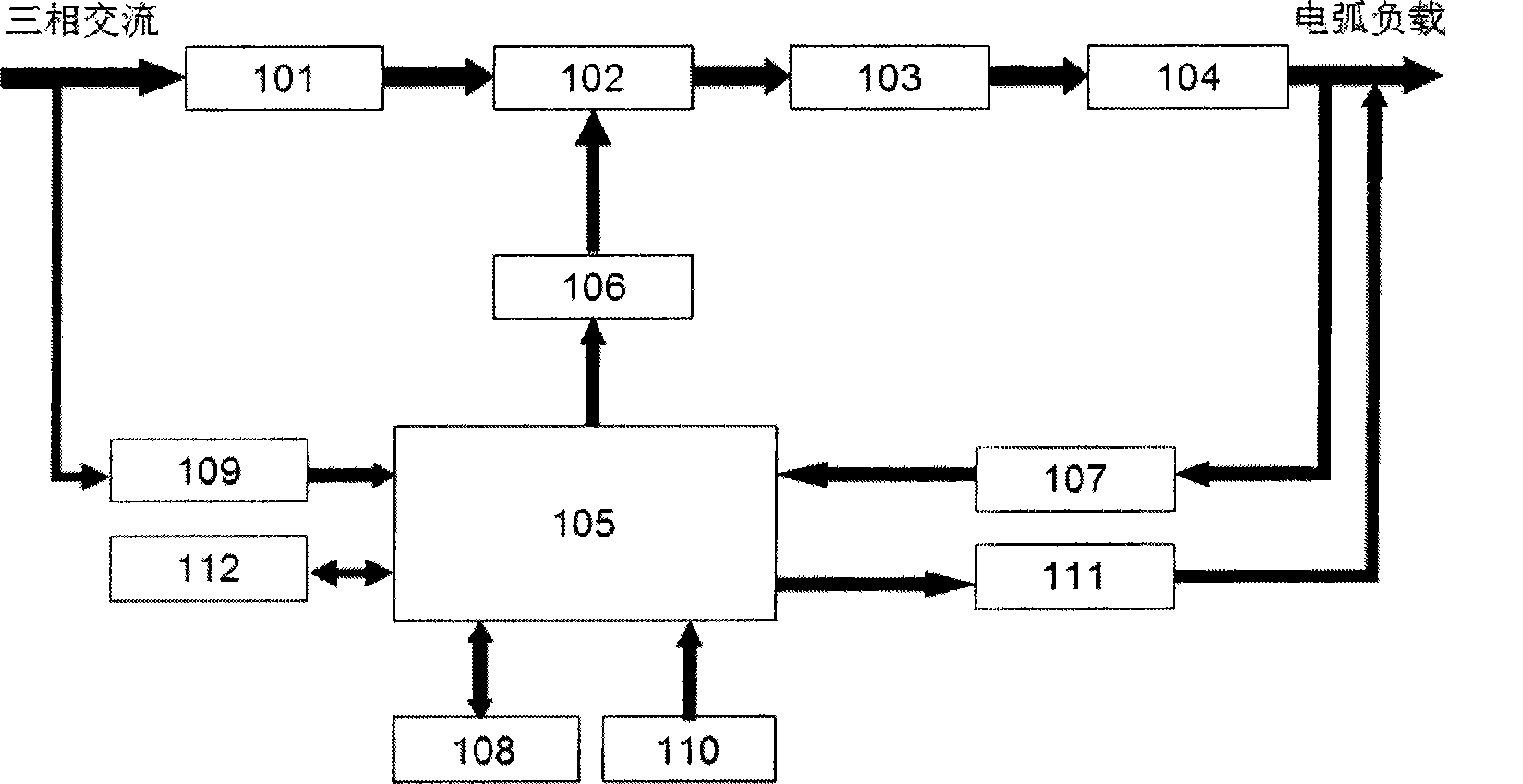

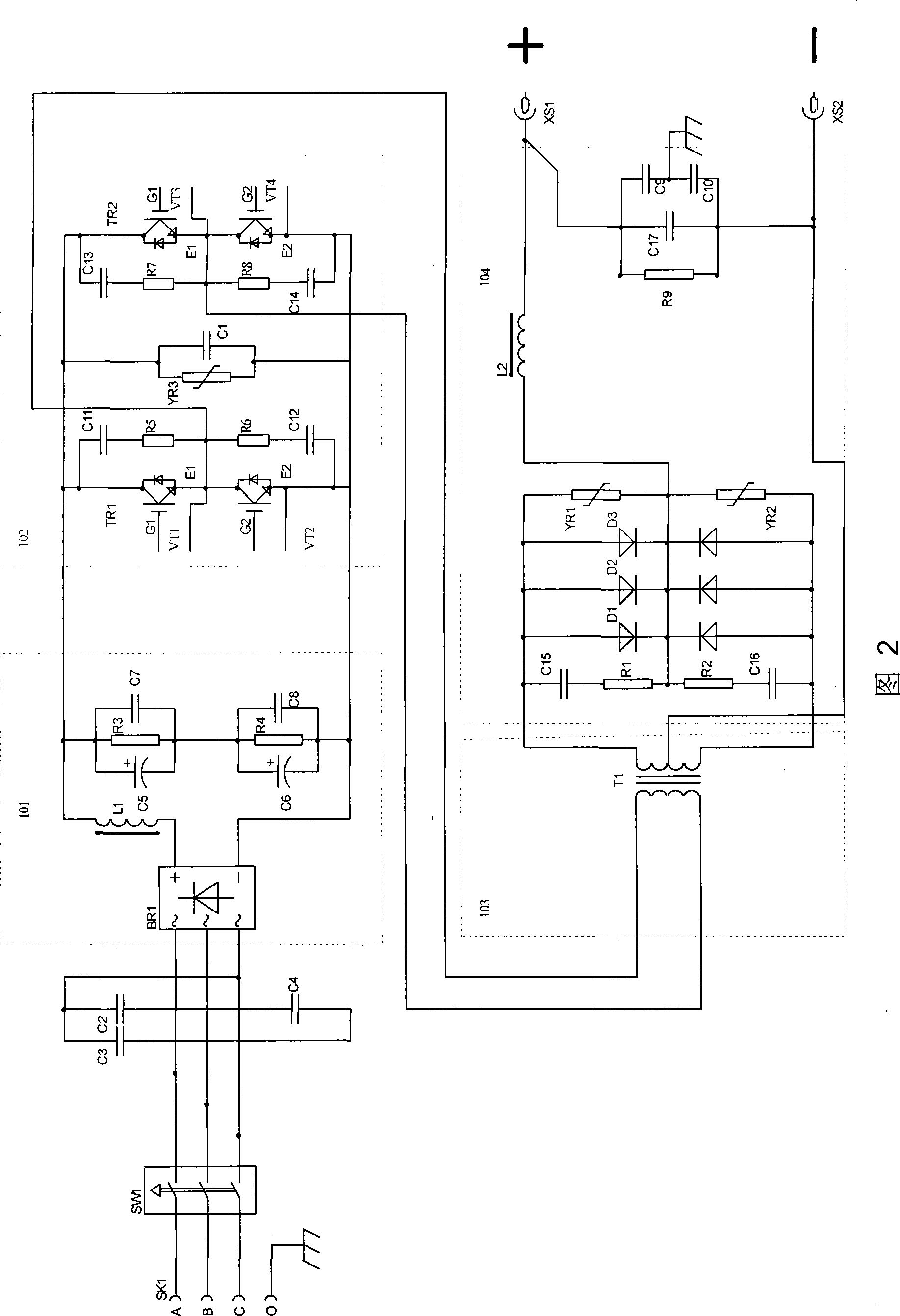

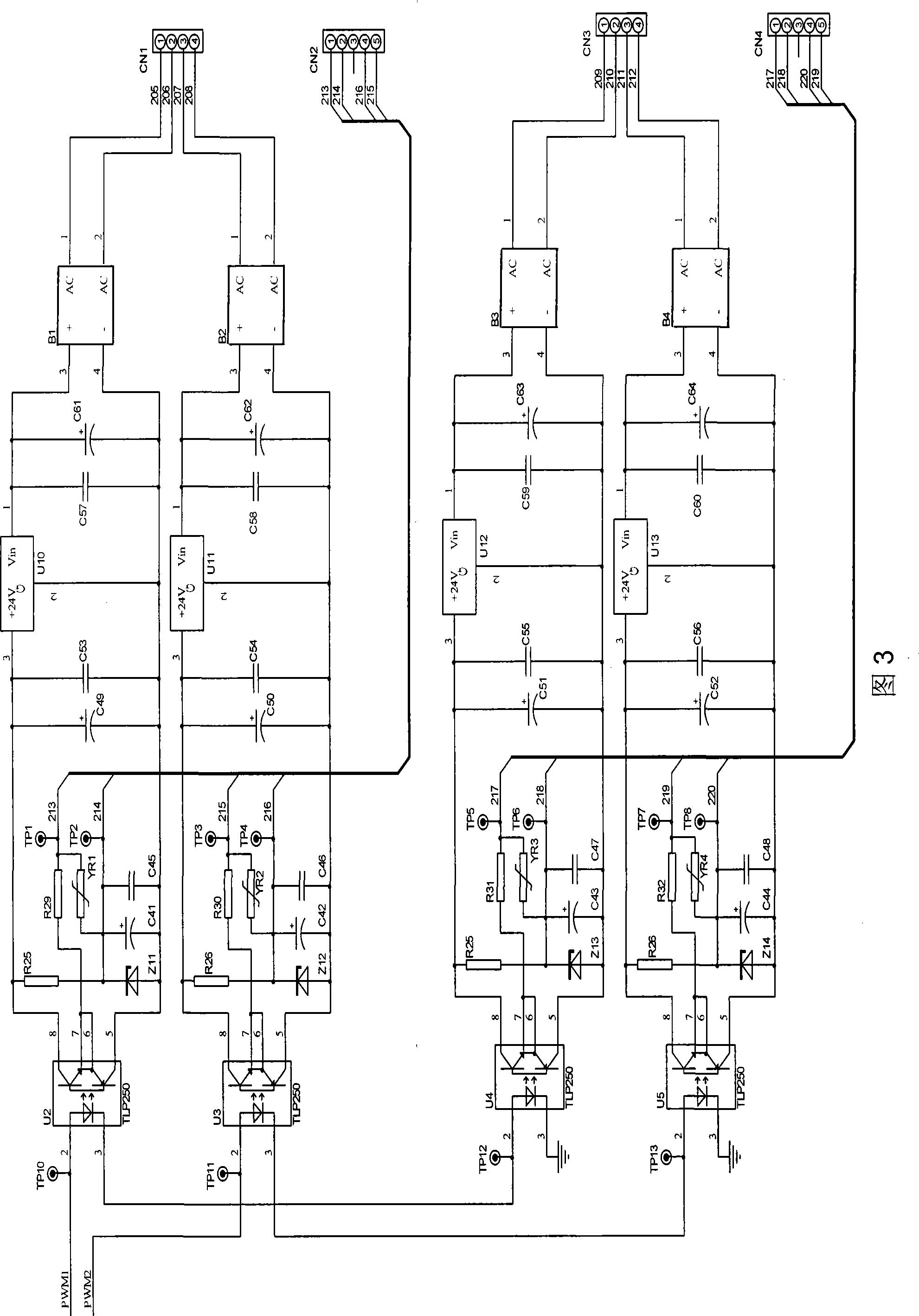

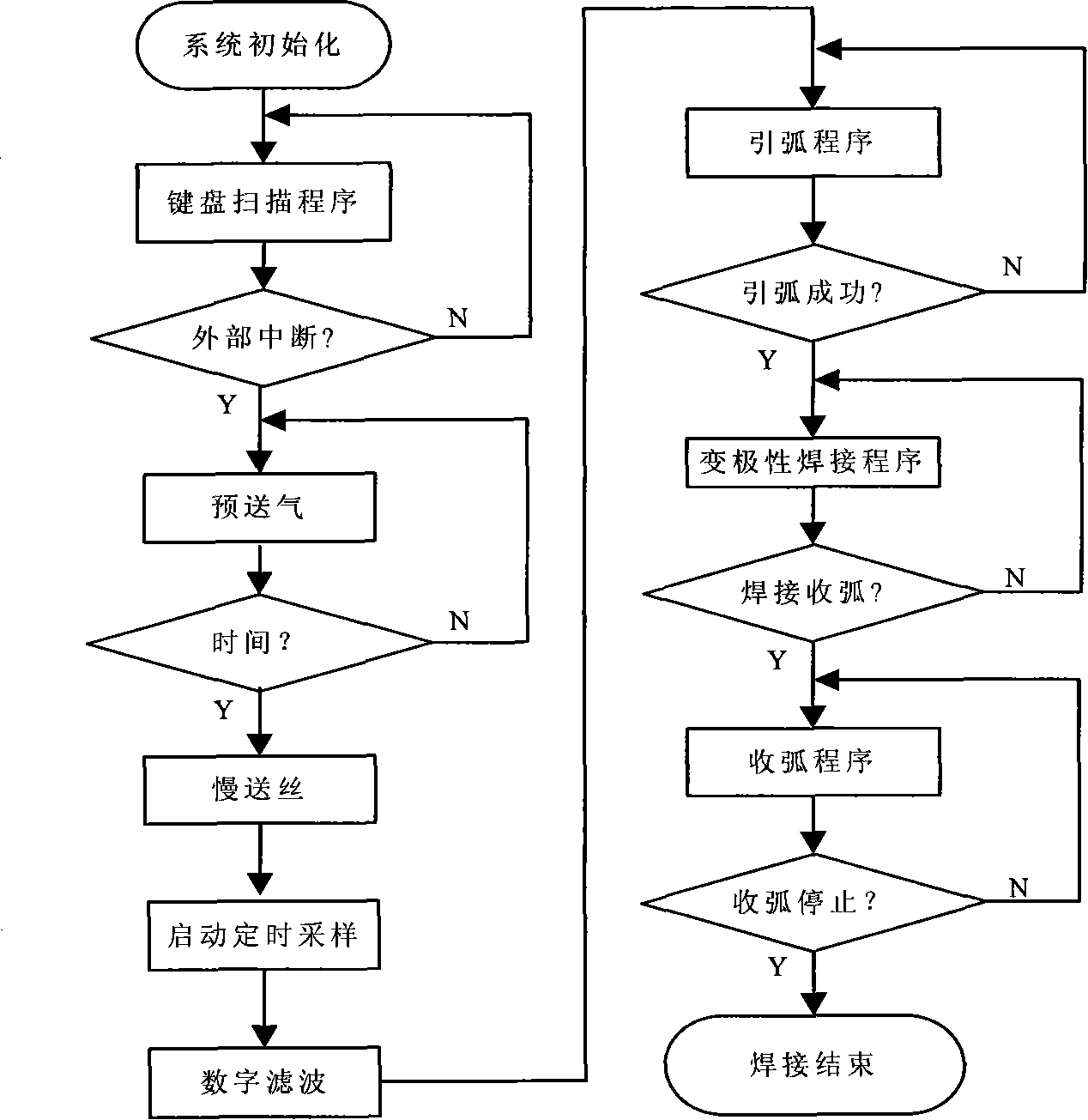

Embedded digitization controlled tube-plate all-position automatic welding inverter

InactiveCN101391336AGood consistencyGuaranteed arc stability and stiffnessArc welding apparatusDc-ac conversion without reversalThree-phaseHigh frequency

The invention is an embedded digital control inverter power source used in tube and plate overall position automatic welding, which comprises a main circuit, a control circuit and a high frequency arc-ignition circuit. The main circuit comprises a rectifying wave filter module, a high frequency inverter module, a power voltage-transforming module and a rectifying smooth module which are connected sequentially. The rectifying wave filter module is connected with a three-phase alternating current (AC) input power, and the rectifying smooth module is connected with a load. The control circuit includes an over-voltage and under-voltage protective testing module, a voltage and current sample testing and feedback module, an ARM microprocessor and a high frequency drive module. The over-voltage and under-voltage protective testing module is respectively connected with the three-phase AC input power and the ARM microprocessor. The voltage and current sample testing and feedback module is respectively connected with the ARM microprocessor and the load. The ARM microprocessor is also connected with the high frequency drive module and the high frequency arc-ignition circuit. The high frequency drive module is also connected with the high frequency inverter module, and the high frequency arc-ignition circuit is also connected with the load. The invention can realize the overall digital control of the tube and plate automatic welding inverter power source.

Owner:GUANGDONG POWER ENG +1

Heat-resisting steel flux-cored wire

InactiveCN101450425ASimple welding processImproved arc stabilityArc welding apparatusWelding/cutting media/materialsFerrochromeRutile

The invention discloses a flux cored wire for heat resistant steel. Flux cored powder of the flux cored wire is formed by mixing the following components by weight percentage: 21 to 23 percent of rutile, 1.5 to 2.5 percent of aedelforsite, 19 to 21 percent of silicon-manganese alloy, 8.5 to 10.5 percent of ferrous powder, 1.5 to 2.5 percent of nickel powder, 2.5 to 3.5 percent of cryolite, 7 to 9 percent of feldspar, 13 to 14 percent of ferrochrome, 6 to 7 percent of ferromolybdenum, 6 to 7 percent of mid-carbon ferromanganese, 2.5 to 4.5 percent of magnesite, 6 to 7.5 percent of quartz, 0.5 to 2 percent of fluorite, 1.5 to 3 percent of aluminum-magnesium alloy and 0.5 to 2 percent of ferrotitanium. During the welding, the flux cored wire not only uses CO2 to protect shielded welding, but also has the advantages of small splash, easy slag removal, stable electric arc burning, and spray transfer as a droplet transfer form.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

Consumable electrode arc welding method and consumable electrode arc welding device

ActiveUS20130082041A1Spatter can be reducedUniform beadArc welding apparatusMechanical engineeringElectric arc

If a short circuit does not occur during deceleration of a wire feed speed in forward feed of a welding wire before the wire feed speed reaches a predetermined wire feed speed, a cyclic change is stopped and the wire feed speed is constantly controlled at the first feed speed. If a short circuit occurs during forward feed at the first feed speed, deceleration from the first feed speed starts, and the cyclic change is resumed for welding. This achieves uniform weld bead without increasing spatters even if any external disturbance such as change of distance between a tip and base material occurs.

Owner:PANASONIC CORP

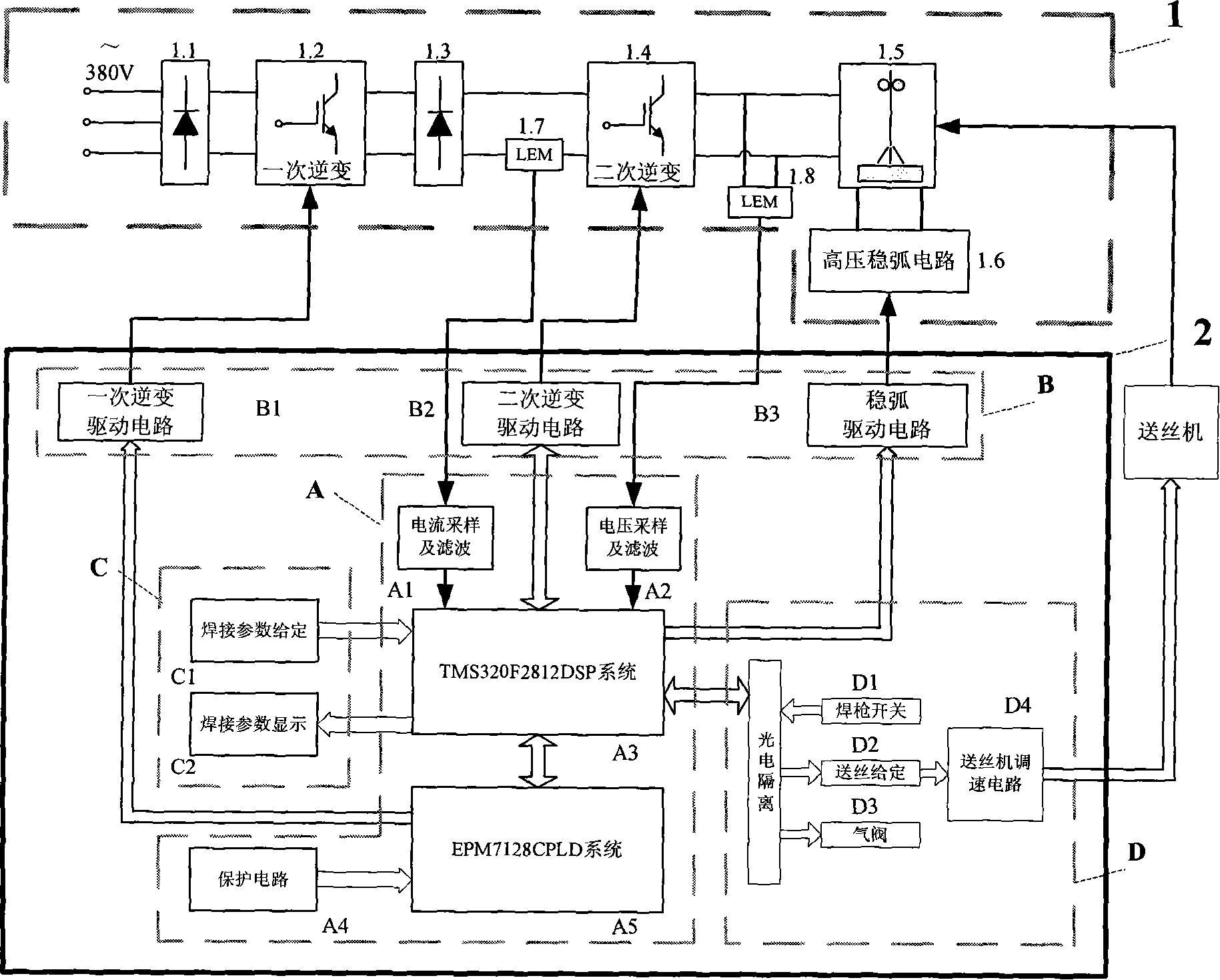

Complete digital PWM controlled AC pulse MIG welding system

InactiveCN101249582AControllable welding processStrong arc stabilityArc welding apparatusNumerical controlPower flow

The invention relates to a full-digital PWM-controlled AC pulse MIG welding system, which belongs to the field of welding equipment and automation. The full-digital PWM-controlled AC pulse MIG welding system comprises a main circuit and a control circuit, wherein the control circuit comprises a kernel control section, a control execution section, etc. The kernel control section comprises a DSP system, a current sampling and filtering circuit, a voltage sampling and filtering circuit, a CPLD system and a protection circuit. The DSP system is respectively connected with the CPLD system, a welding parameter setting signal and a welding parameter display signal in a front panel input and display section, a welding torch switch signal in a wire feeding system, a valve switch quantity signal and a wire feeding setting signal, and the CPLD system is also connected with the protection circuit and a primary inversion drive circuit in the control execution section. By combining the DSP system and the CPLD system, the welding system can achieve full-numerical control, which has flexible control and accurate control in comparison with the analog control manner of D / A+SG3526.

Owner:BEIJING UNIV OF TECH

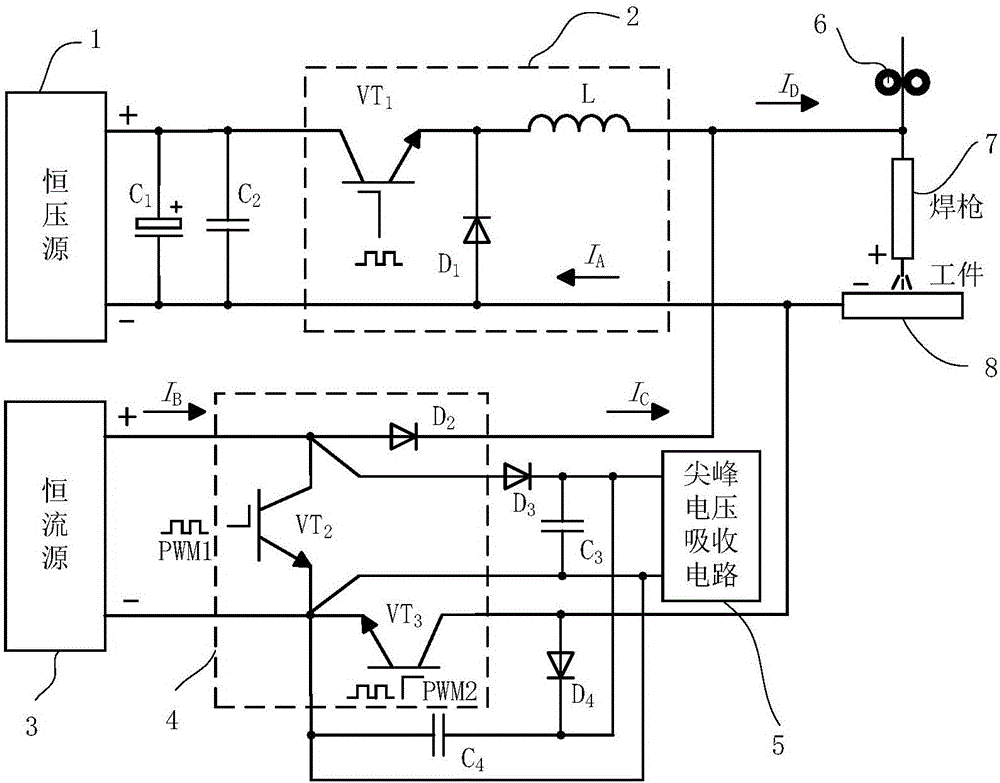

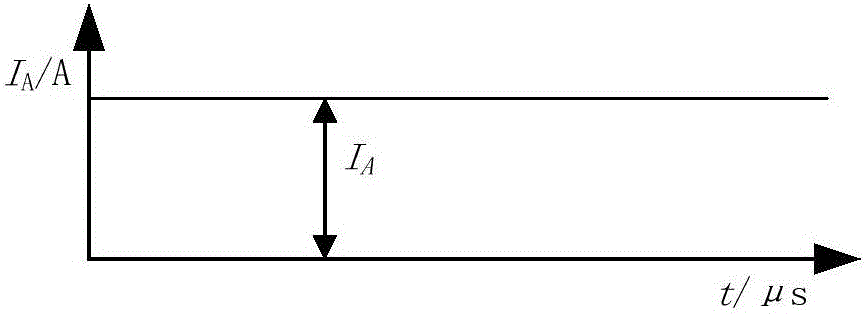

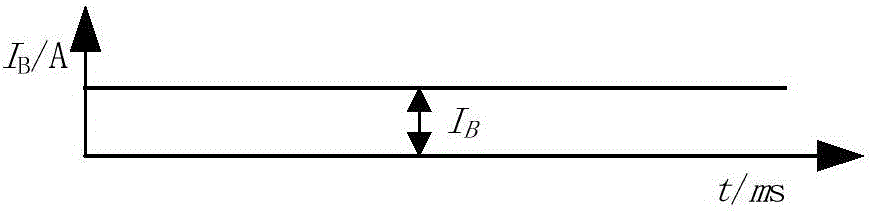

Ultrasonic-frequency composite pulse GMAW welding power source device

ActiveCN105880802AImproved droplet transfer behaviorImprove stiffnessDc-dc conversionArc welding apparatusConstant current sourceArc stability

The invention provides an ultrasonic-frequency composite pulse GMAW welding power source device which comprises a constant-voltage source used for providing constant voltage for a BUCK type main circuit, the BUCK type main circuit, a constant-current source used for providing constant current for an ultrasonic-frequency pulse current switching circuit, and an ultrasonic-frequency pulse current switching circuit. The constant-voltage source is connected with the BUCK type main circuit. The constant-current source is connected with the ultrasonic-frequency pulse current switching circuit. The BUCK type main circuit is connected with the ultrasonic-frequency pulse current switching circuit in parallel. The BUCK type main circuit is used for providing first output current for welding, wherein the first output current is in a direct current form or a pulse form. The ultrasonic-frequency pulse current switching circuit is used for providing second output current for welding, wherein the second output current is ultrasonic-frequency pulse current. By means of the above ultrasonic-frequency composite pulse GMAW welding power source device, the ultrasonic-frequency pulse current and the current in the direct current form or the pulse form are superimposed, the behavior of metal transfer of traditional direct current or pulse GMAW is improved, electric arc energy is concentrated, the electric arc stability is greatly improved, and the influences of electric arc magnetic flow are reduced.

Owner:BEIHANG UNIV

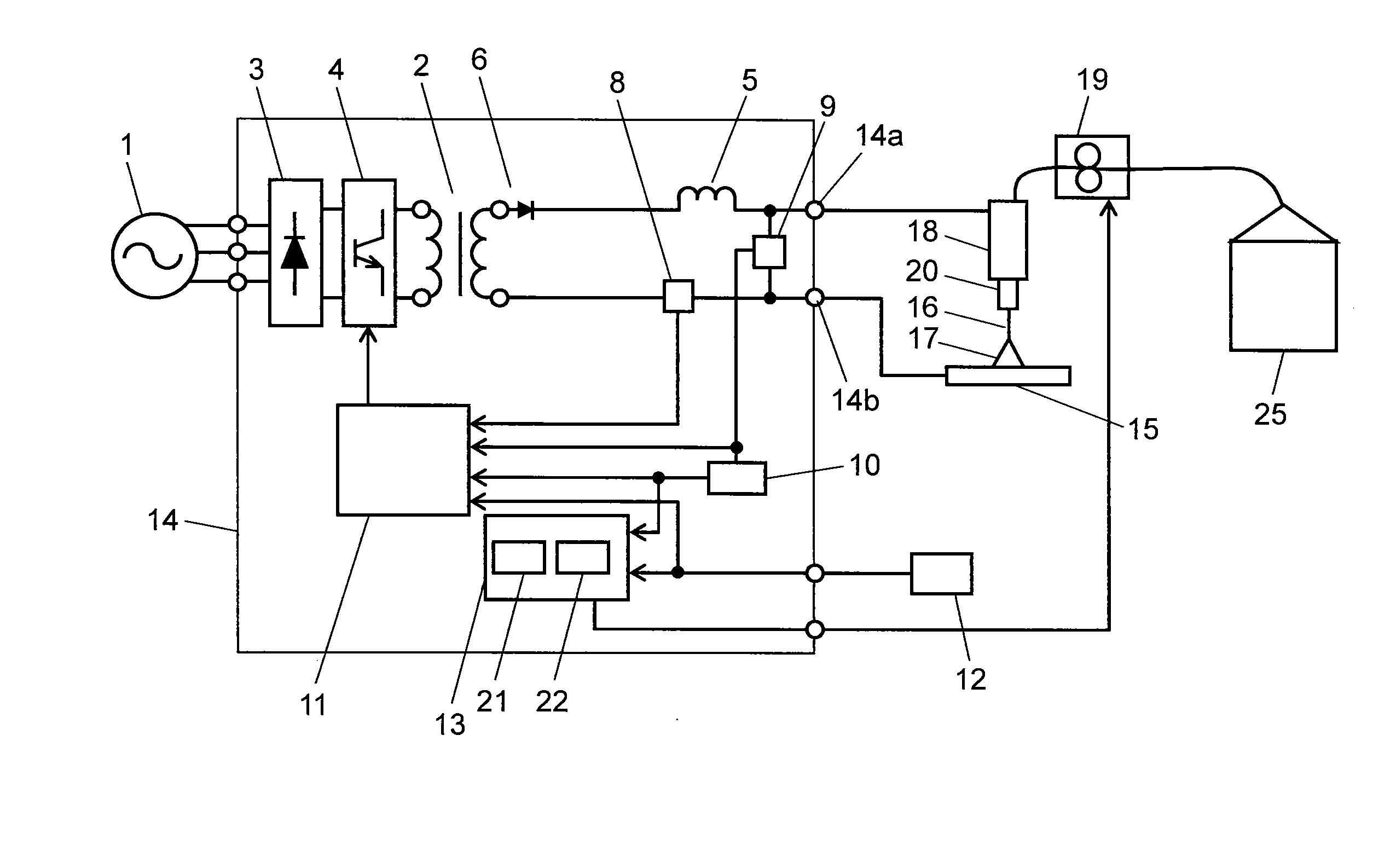

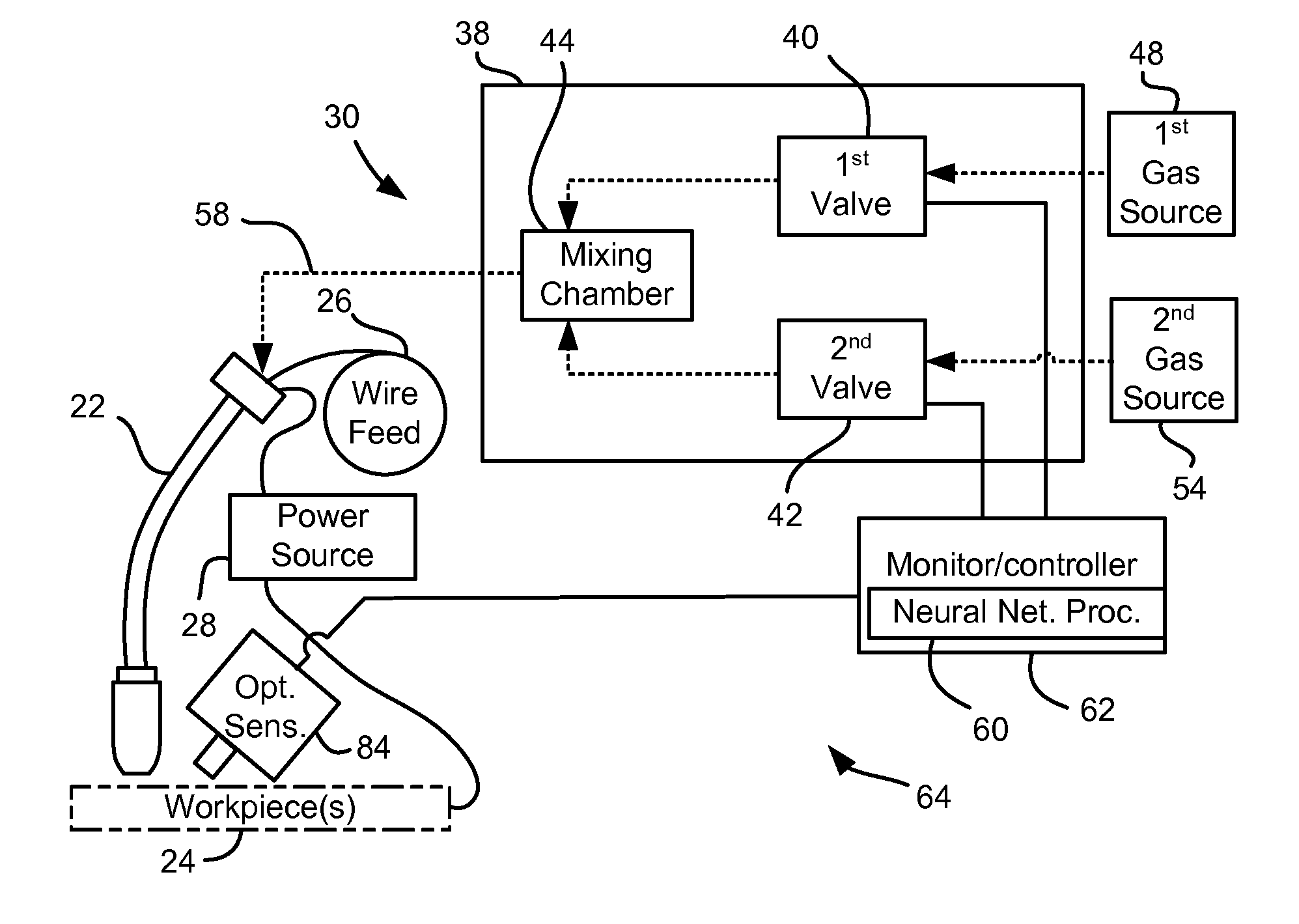

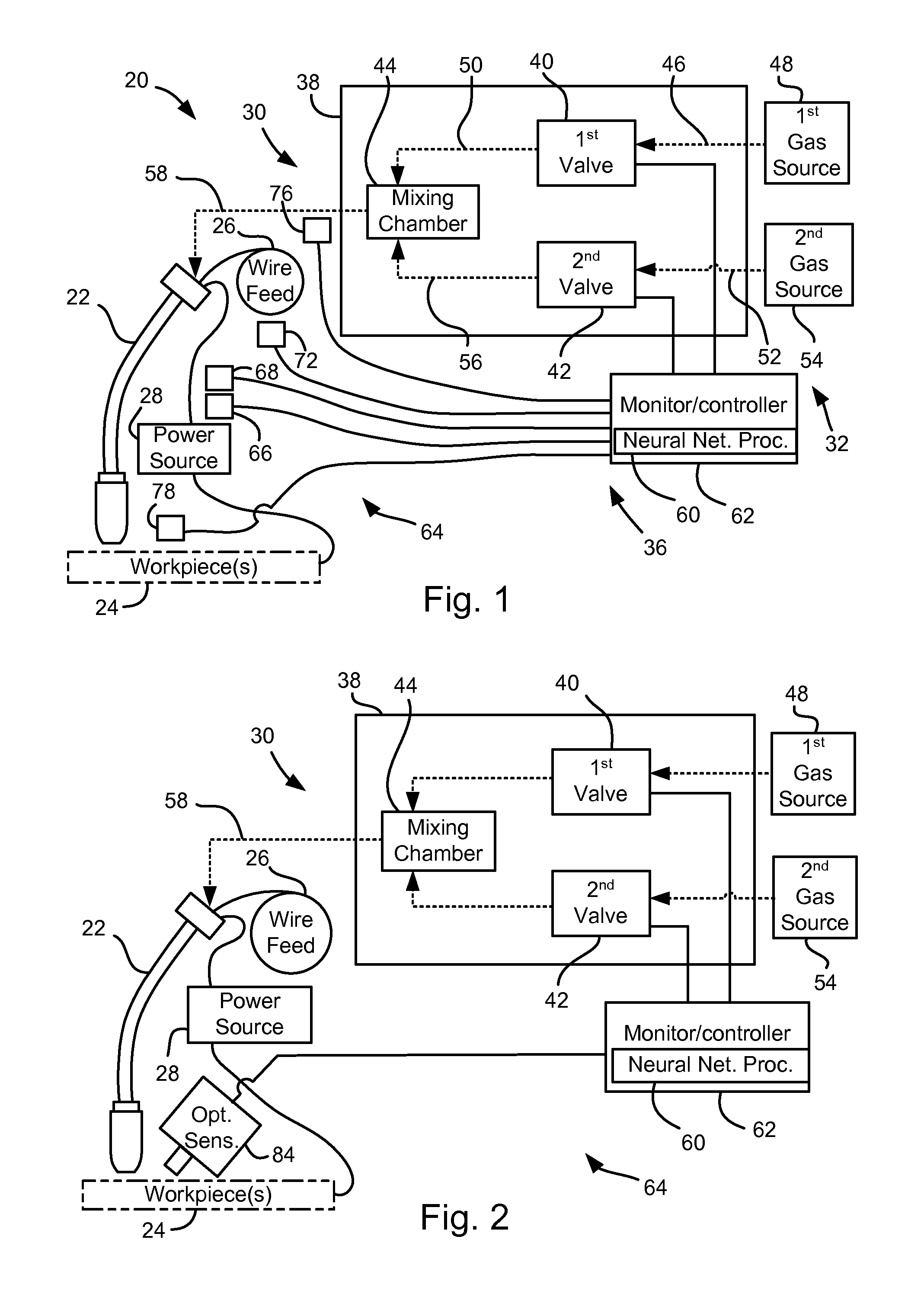

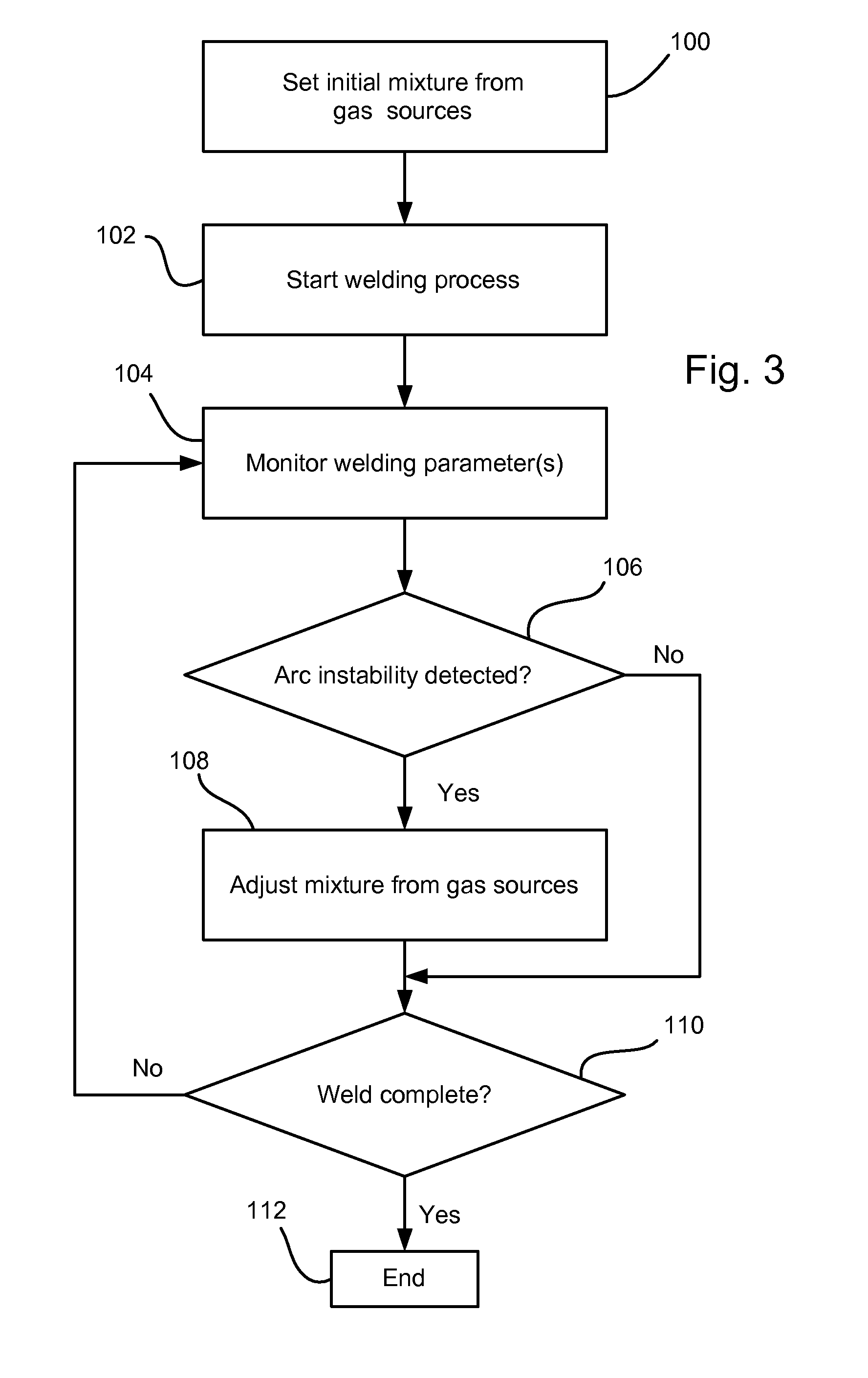

Welding stability system and method

ActiveUS8129652B2Improved arc stabilityReduce the amount requiredElectrode supporting devicesPlasma welding apparatusShielding gasCarbon Dioxide / Helium

A weld stability system for an arc welding apparatus and method of operation is disclosed. The weld stability system may comprise a shielding gas supply and a control assembly. The shielding gas supply may include a first source of gas, a second source of gas, a mixing chamber, a first valve selectively connecting the first source of gas to the mixing chamber, a second valve selectively connecting the second source of gas to the mixing chamber, and a shielding gas supply line configured to direct gas from the mixing chamber to a weld gun. The control assembly may include a controller operatively engaging the first and second valves, and at least one sensor configured to monitor a parameter of an arc welding process and communicate with the controller.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding process of ultrahigh-strength steel and heterogeneous high-strength steel

InactiveCN101954524AHigh degree of automationEasy to operateArc welding apparatusWelding/cutting media/materialsWelding defectManufacturing engineering

The invention relates to a welding process of ultrahigh-strength steel and heterogeneous high-strength steel, belonging to the field of welding and processing. For solving problems, the invention provides a welding process of ultrahigh-strength steel and heterogeneous high-strength steel to ensure that welded joints have favorable formation and no welding defects and the mechanical properties can meet the requirement on the product. The welding process comprises the following steps of: (1) groove form: setting the groove angle on the end surface of the ultrahigh-strength steel to 37 DEG-45 DEG, setting the end face of a heterogeneous high-strength steel forging to a vertical plane, and adopting appropriate root gaps and truncated edges; (2) selection of a welding method and a welding material: bottoming by adopting melting pole mixed gas metal arc welding (GMAW) with a Lincoln STT (Short Time Test) technology, wherein the welding requires single-face welding and double-face formation, welding wires adopt AWSA5.28ER80S-G, the protective gas is formed by mixing 80% of AR and 20% of CO2, and the gas flow is15-20 L / Min; and the filling and the cover face, wherein low-hydrogen shielded metal arc welding (SMAW) is adopted, and AWSA5.5E11018M is selected as a welding rod. The welding process is used for welding and processing the ultrahigh-strength steel and the heterogeneous high-strength steel.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Low-cost gas shielded flux-cored wire with recycled welding slag

InactiveUS20120241432A1Low costSave resourcesWelding/cutting media/materialsSoldering mediaIron powderSlag

A gas shielded flux-cored wire (FCW) comprises s steel sheath and core flux, in which recycled welding slag powder is used to partially replace the natural rutile. The core flux contains (by weight): 10-50% recycling welding slag powder, 10-45% TiO2, 2-7% Si, 5-20% Mn, 0.5-5% Al—Mg (Al / Mg=1), 0-11.52% Na2CO3, 0-8.85% K2CO3, 0-10% MgO, 0.5-10% fluoride, and iron powder as balance. The recycling welding contains (by weight): TiO2: 20-65%, MnO: 5%-15%, MgO: 5%-15%, SiO2: 5%-15%, Fe2O3: 1%-10%, Al2O3: 1%-10%.

Owner:BEIJING UNIV OF TECH

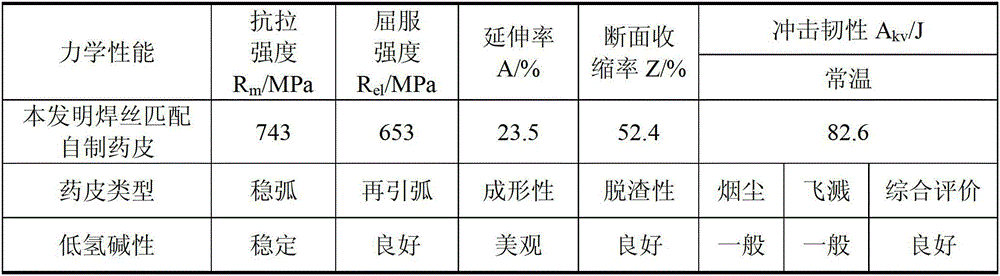

Gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of gas protection solid welding wire

ActiveCN106312372AHigh strengthImprove impact toughnessArc welding apparatusWelding/cutting media/materialsSocial benefitsPower station

The invention discloses a gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of the gas protection solid welding wire. Chemical ingredients of the welding wire include, by weight, 0.07-0.13 part of C, 0.3-0.5 part of Si, 1.8-2.3 parts of Mn, 2.7-3.2 parts of Ni, 0.3-1.2 parts of Cr, 0.4-0.85 part of Mo, 0.01-0.1 part of Ti, 0.01-0.03 part of Al, 0.008 part or below of P, 0.005-0.010 part of S, 0.3 part or below of Cu, 0.01-0.035 part of Nb and the balance Fe. The welding wire can replace an imported welding wire, the construction cost of high-strength steel for large hydropower stations, water pumping and energy storage power stations and the like can be remarkably reduced, and remarkable economic benefits and social benefits are achieved.

Owner:SICHUAN XIYE NEW MATERIAL

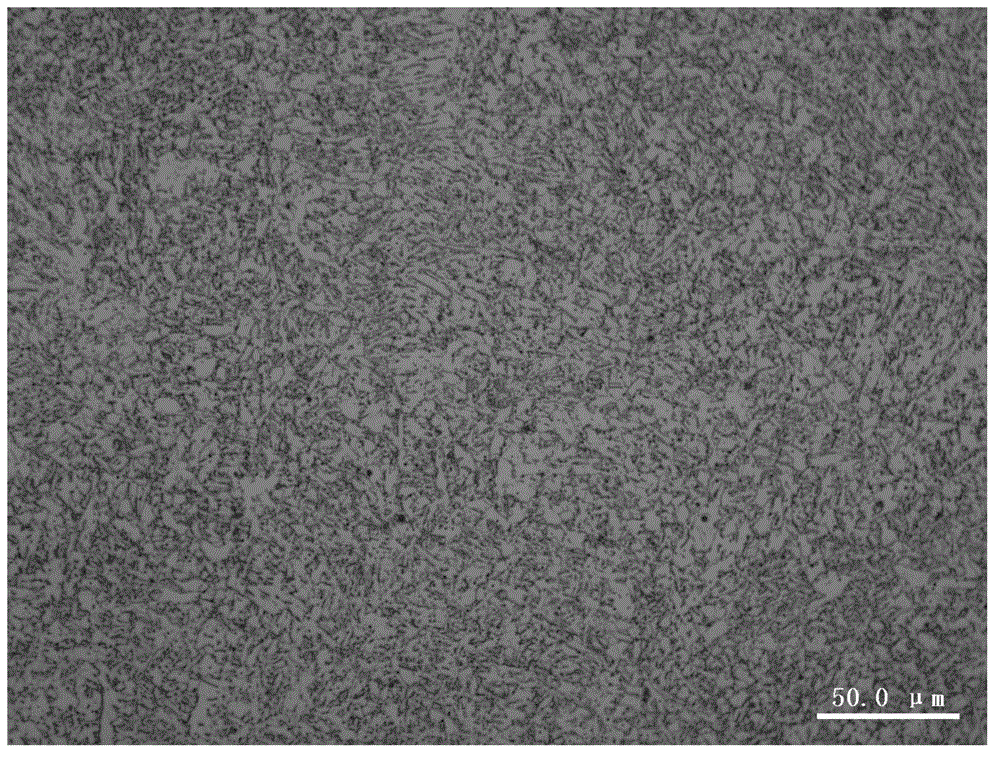

Low-hydrogen alkaline electrode for online welding of X80 pipeline steel

InactiveCN102873473AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFerrosiliconFerrotitanium

The invention discloses a low-hydrogen alkaline electrode for online welding of X80 pipeline steel. The low-hydrogen alkaline electrode comprises a core wire and a coating. The coating comprises, by weight, from 40% to 45% of marble, from 15% to 20% of fluorite, from 2% to 4% of titanium dioxide, from 6% to 10% of rutile, from 7% to 10% of ferrotitanium, from 4% to 7% of low-carbon ferromanganese, from 2% to 5% of ferrosilicon, from 6% to 10% of iron powder, from 2.5% to 3% of synthetic mica, from 1.8% to 2.2% of rare earth and from 2% to 2.4% of microcrystal fibers, and the sum of the weight percents of the components is 100%. The electrode made from the coating is good in arc stabilization performance, a molten pool is good in flowability, splashing particles are tiny, post-welding slag detachability is good, slag coverage is uniform, and formed weld joints are delicate and attractive. Besides, the content of diffusible hydrogen in deposited metal of the manufactured electrode is effectively controlled.

Owner:XIAN UNIV OF TECH

High-tenacity low-hydrogen alkaline welding rod and preparation method thereof

InactiveCN103084757AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberMisch metal

The invention discloses a high-tenacity low-hydrogen alkaline welding rod which comprises a coating and a welding core, wherein the coating comprises, by weight, 38%-44% of marble, 20%-25% of fluorite, 3%-5% of zircon sand, 1%-5% of ferrosilicon, 10%-15% of ferrotitanium, 5%-7% of mid-carbon ferromanganese, 2%-4% of titanium dioxide, 3%-6% of mica, 1.5%-2% of microcrystalline fiber, 1.2%-1.8% of nickel powder, and 1%-1.5% of misch metal, wherein sum of weight percentages of all components is 100%. The invention further discloses a preparation method of the high-tenacity low-hydrogen alkaline welding rod. The preparation method of the high-tenacity low-hydrogen alkaline welding rod includes the steps: enabling coating materials and K-Na mixing water glass to be mixed, crushing the mixture into a power ball with a cylindrical shape, putting the power ball into a pressing coating machine, coating the power ball with the cylindrical shape on a H08A welding core to form the welding rod, and then grinding the head and the tail and getting the high-tenacity low-hydrogen alkaline welding rod after drying. When the high-tenacity low-hydrogen alkaline welding rod is used for welding high-strength steel, no preheating is needed before welding, no heat treatment is needed after welding, content of diffusible hydrogen of deposited metal is controlled effectively, and the preparation method is simple.

Owner:XIAN UNIV OF TECH

Laser-electric arc composite welding method through extra electric field

InactiveCN101745747AHigh strengthFacilitated ionizationLaser beam welding apparatusElectrical field strengthMaterials processing

The invention belongs to the technical field of material processing, which relates to a laser-electric arc composite welding method. The method comprises the following steps: installing an extra electrode in the position with the distance of 4 to 100 mm higher from the surface of a work piece to be welded in the direction vertical to the laser beam; forming a hole in the center of the extra electrode for passing the laser beam; and respectively connecting the extra electrode and the work piece to be welded to both ends of a DC stabilized voltage supply with the output voltage between 1 and 220 V at the electric field intensity between 1 and 220 V / cm. When the laser power is between 300 W and 500 W, the electric arc current is between 100 A and 300 A, and the electric arc current is between 20 V and 35 V, the optimum range of the extra electric field intensity is between 30 V / cm and 60 V / cm. The invention can fully utilize the energy of the laser and the electric arc, and can realize the effect of obtaining large composite hot source welding fusion depth under the condition of lower laser output power. Compared with the existing laser-electric arc composite welding method under the same process condition, the invention has the advantage that the fusion depth is increased by 15 percent to 40 percent.

Owner:DALIAN UNIV OF TECH

Micro-plasma arc welding for heat-resistant casting alloy and austenitic stainless steel

InactiveCN101774070AImprove performanceSmooth appearancePlasma welding apparatusProcess equipmentAlloy

The invention discloses a micro-plasma arc welding method for dissimilar metals of a heat-resistant casting alloy and austenitic steel, which realizes rapid welding of the heat-resistant casting alloy and the austenitic steel by adopting micro-plasma arc welding technology and proper process equipment, and strictly controlling welding process parameters, and is particularly suitable for the places where the thickness difference between the heat-resistant casting alloy and the stainless steel is great. Due to the micro-plasma arc welding method for the heat-resistant casting alloy and the austenitic stainless steel, the application range of heterogeneous structural parts of the heat-resistant casting alloy and the austenitic stainless steel is enlarged, and the micro-plasma arc welding method has the advantages of effectively improving the welding production efficiency, along with stable and reliable welding quality. Compared with the argon tungsten-arc process, the production efficiency of the micro-plasma arc welding is improved by more than 2 times.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com