Patents

Literature

56results about How to "Meet the operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

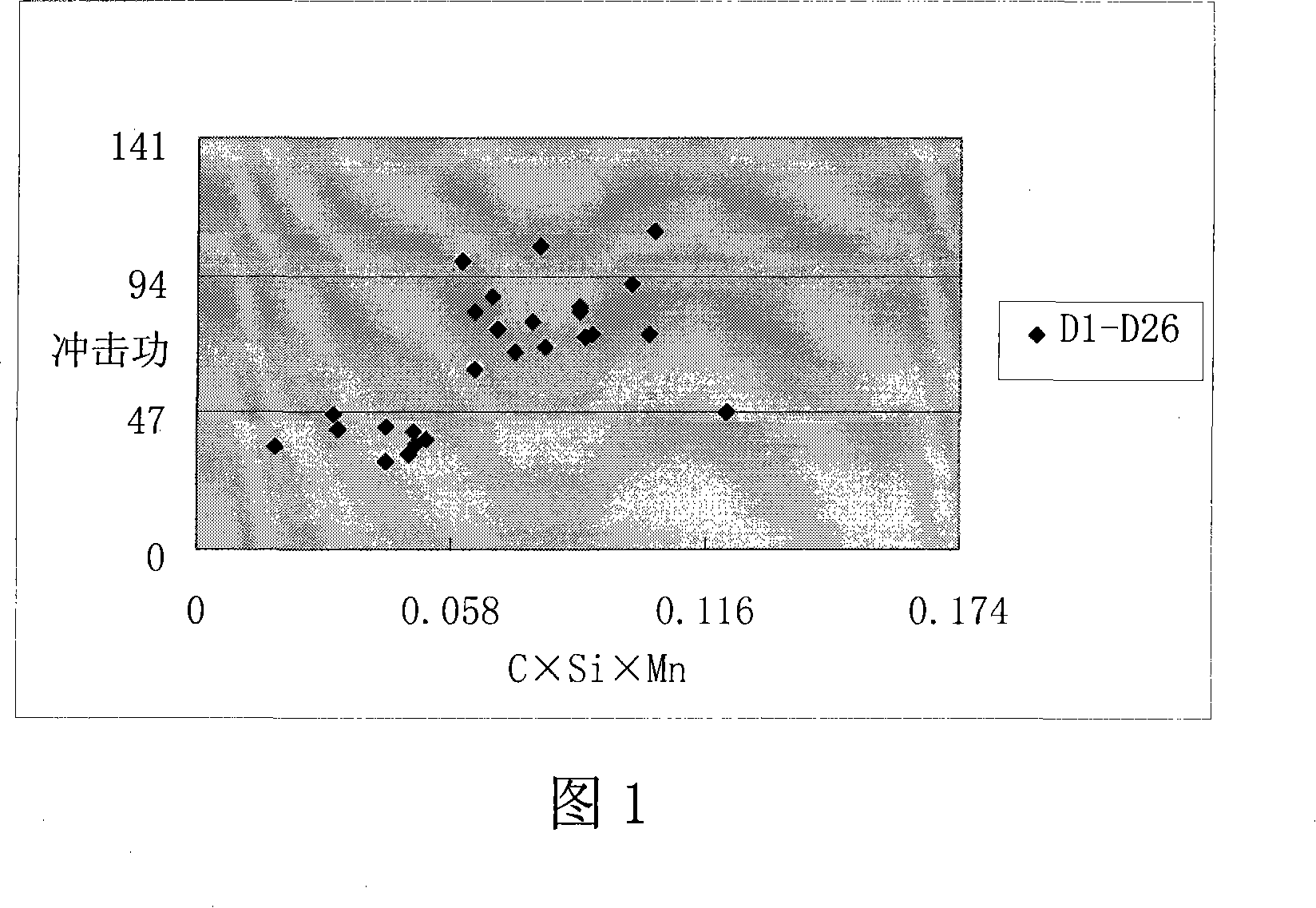

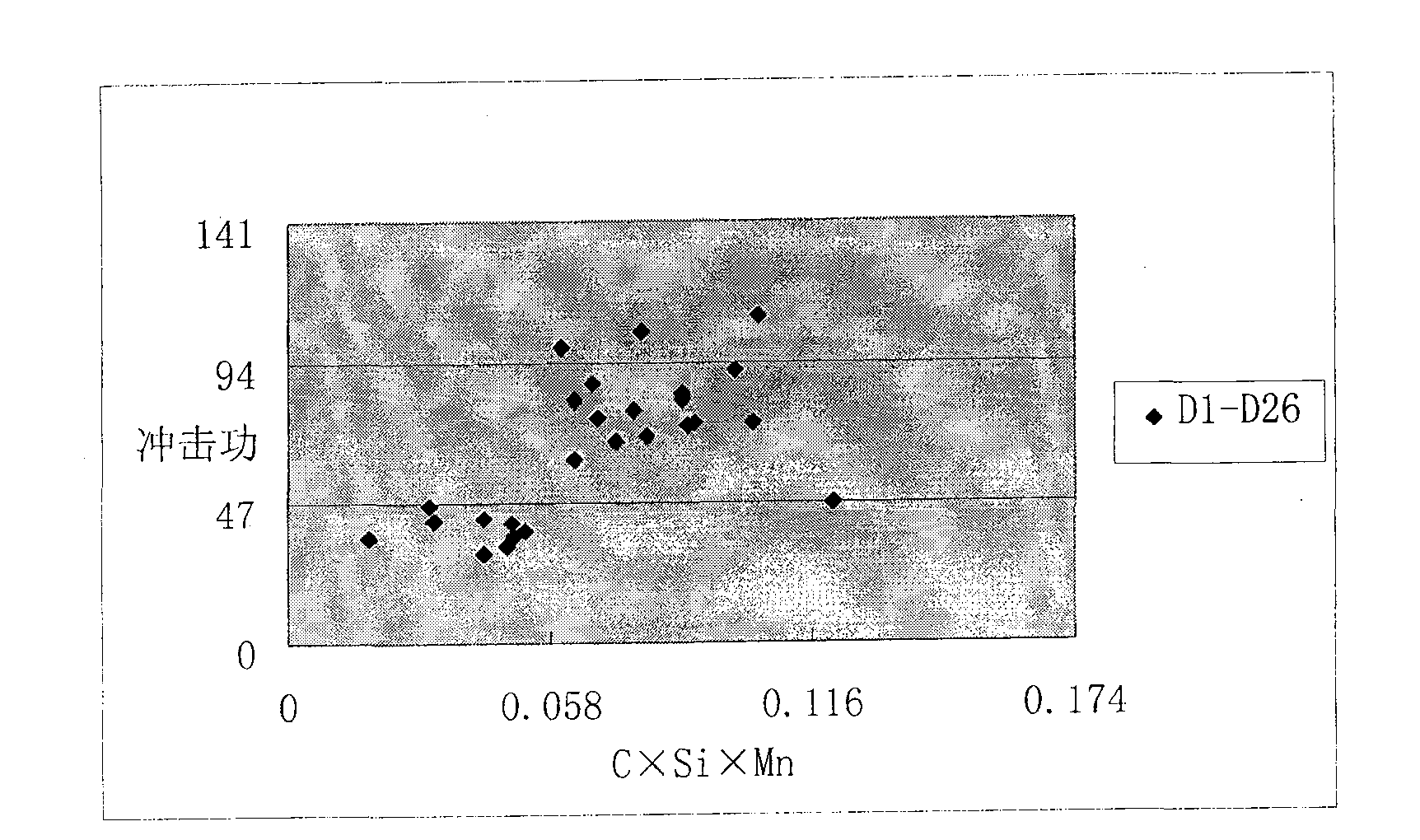

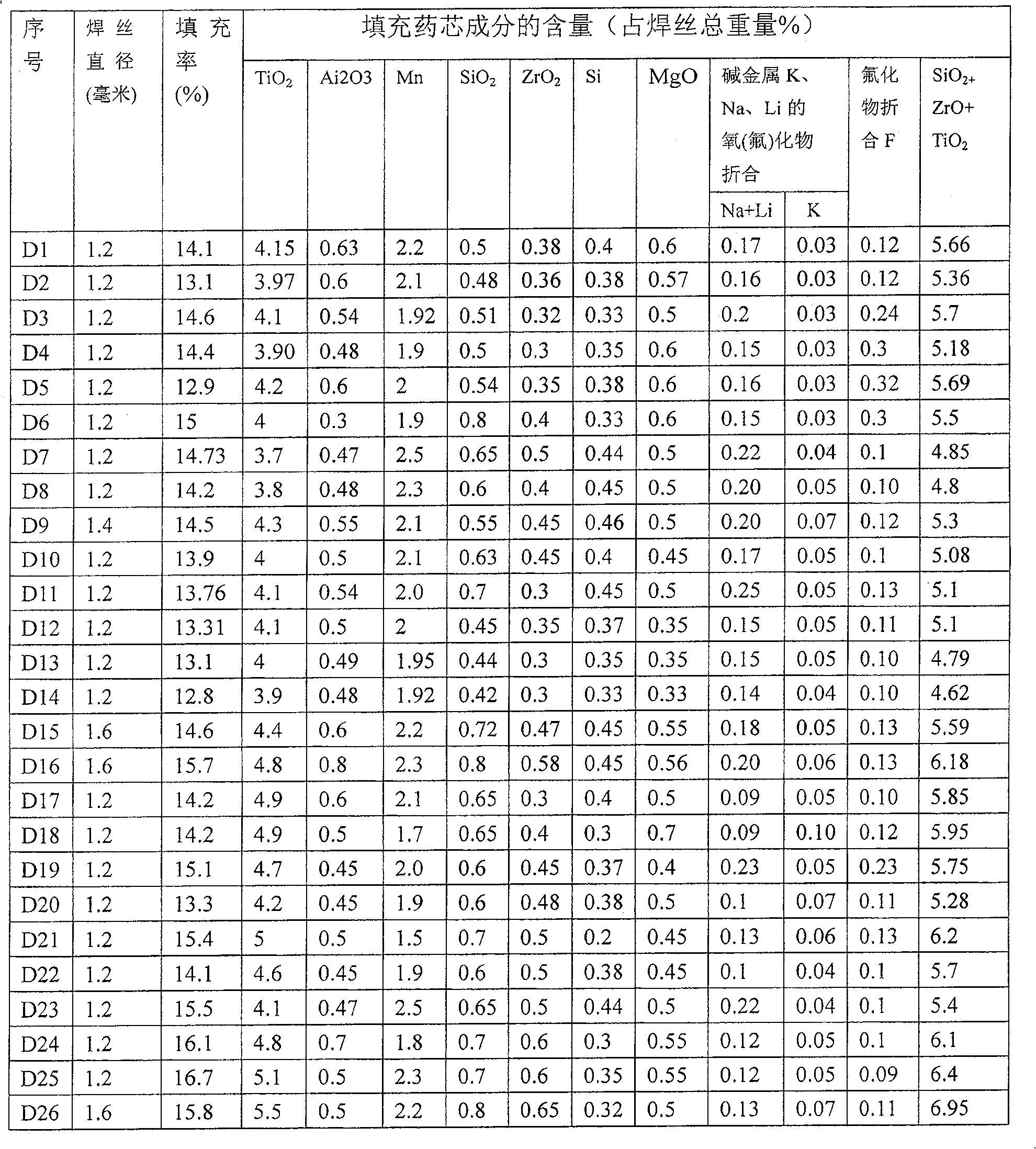

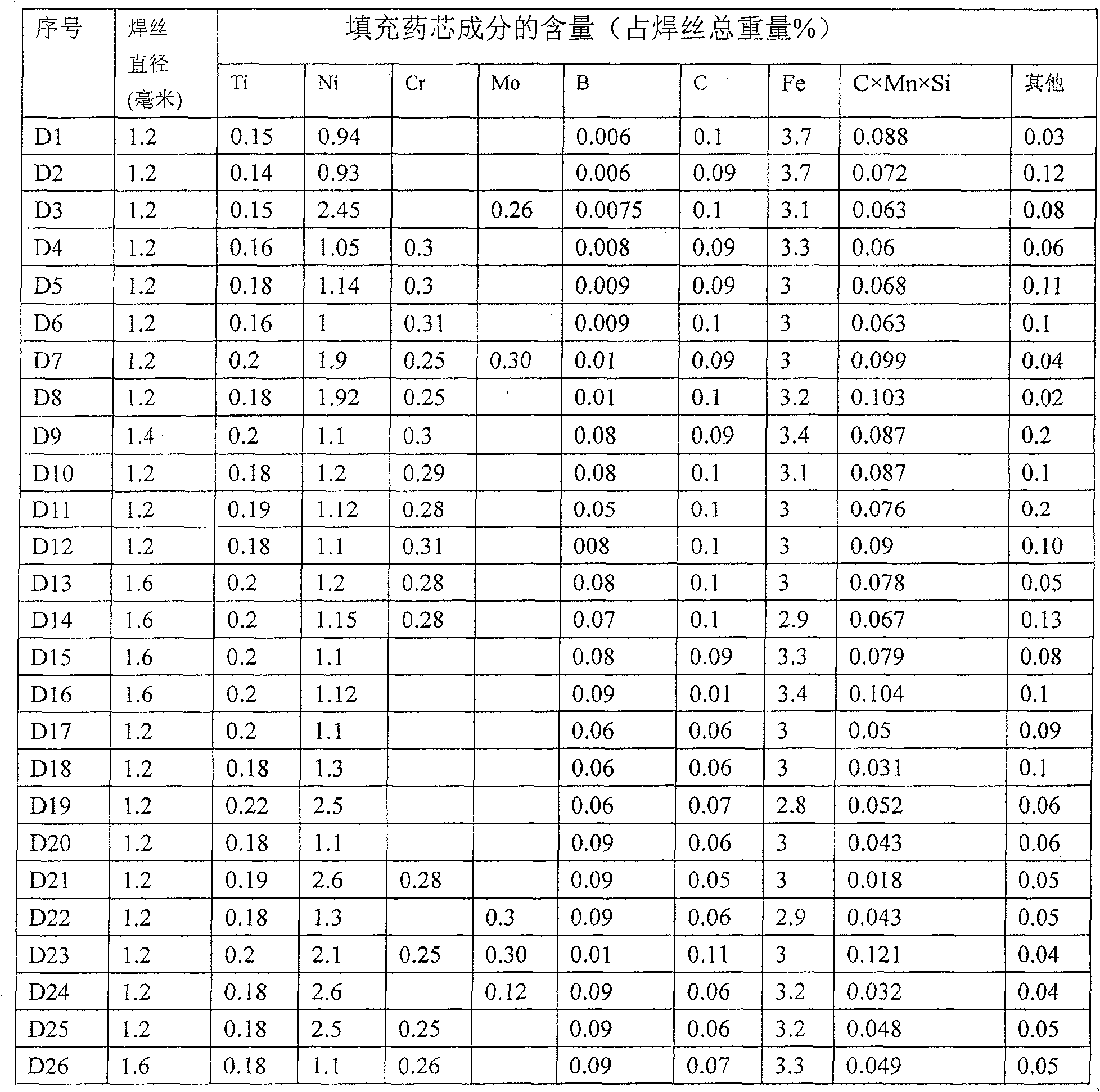

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Aeroengine case seam allowance size repairing method

The invention relates to an aeroengine case seam allowance size repairing method. The porosity and hardness of a coating and the content of oxides in the coating can be effectively adjusted by controlling the plasma spraying power and the heating process of spraying powder during flying, and heat stress of the coating is reduced. The hardness and thermal expansion coefficient of the prepared nickel-aluminum coating are equivalent with those of a case, the bonding strength of the coating is far higher than the stress strength of a case seam allowance under the given working condition, and the use working condition of the aeroengine case can be met.

Owner:HARBIN DONGAN ENGINE GRP

Micro porous friction material and its producing method

The present invention relates to one kind of microporous friction material and its production process. The friction material is produced with the raw materials including modified resin 10-35 wt%, butyronitrile powder 0-10 wt%, kaolin 20-40 wt%, precipitated barium sulfate 25-50 wt%, graphite 5-20 wt%, zinc oxide 1-10 wt%, corundum 0-1 wt%, chromite powder 0-5 wt%, iron oxide red 0-2 wt%, steel fiber 10-30 wt%, aramid fiber pulp 0.1-10 wt%, and carbon fiber 0- 10 wt%. The production process includes mixing the raw materials, reaction and forming at the temperature from room temperature to 140 deg.c and the pressure of 200-800 kg / sq cm for 20-800 sec, and final sintering in a sintering furnace at 150-200 deg.C for 2-16 hr. Compared with available technology, the present invention has the advantages of excellent friction performance, excellent physical and mechanical performance, no noise, etc.

Owner:SHANGHAI RENPHEN COMPOSITE MARERIALS

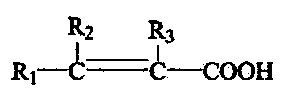

Corrosion-proof ice-covering-proof coating

InactiveCN103788831AMeet the operating conditionsMeet the working conditions, acid and alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to the field of corrosion-proof ice-covering-proof coatings, and particularly relates to a corrosion-proof ice-covering-proof coating. The corrosion-proof ice-covering-proof coating comprises the following components in percentage by weight: 15%-30% of epoxy resin, 10%-15% of fluoroolefin resin, 15%-40% of nanometer silicon oxide, 10%-20% of solidifying agents, 1%-5% of toughening resin, 5%-10% of titanium dioxide blending agents, 15%-30% of fluorinated acrylate modified polyurethane resin and 5%-15% of organic solvents, wherein each titanium dioxide blending agent comprises polyurethane, biuret, polyester J4, butyl alcohol, ethanol ethyl ester, petroleum type dimethyl benzene, titanium dioxide, fine particle calcium carbonate, talcum powder, sodium pentachlorophenate and tri-butyl alcohol, and the weight ratio of polyurethane to biuret to polyester J4 to butyl alcohol to ethanol ethyl ester to petroleum type dimethyl benzene to titanium dioxide to fine particle calcium carbonate to talcum powder to sodium pentachlorophenate to tri-butyl alcohol is (1.5-2.5):(1-2):(1.5-2):(1.5-2):(1-1.5):(2-2.5):(1.5-2):(1-2):(1-1.5):(0.1-0.3):(0.3-0.5). The corrosion-proof ice-covering-proof coating disclosed by the invention has good adhesive force, can meet the requirements for use conditions of an oil drill rod in a using process in a cold place, and has the advantages of acid resistance, alkali resistance, corrosion proofing and ice-covering proofing.

Owner:南通新昱化工有限公司

All-weather variable-working-condition compensating type high-low-temperature environment simulating test chamber

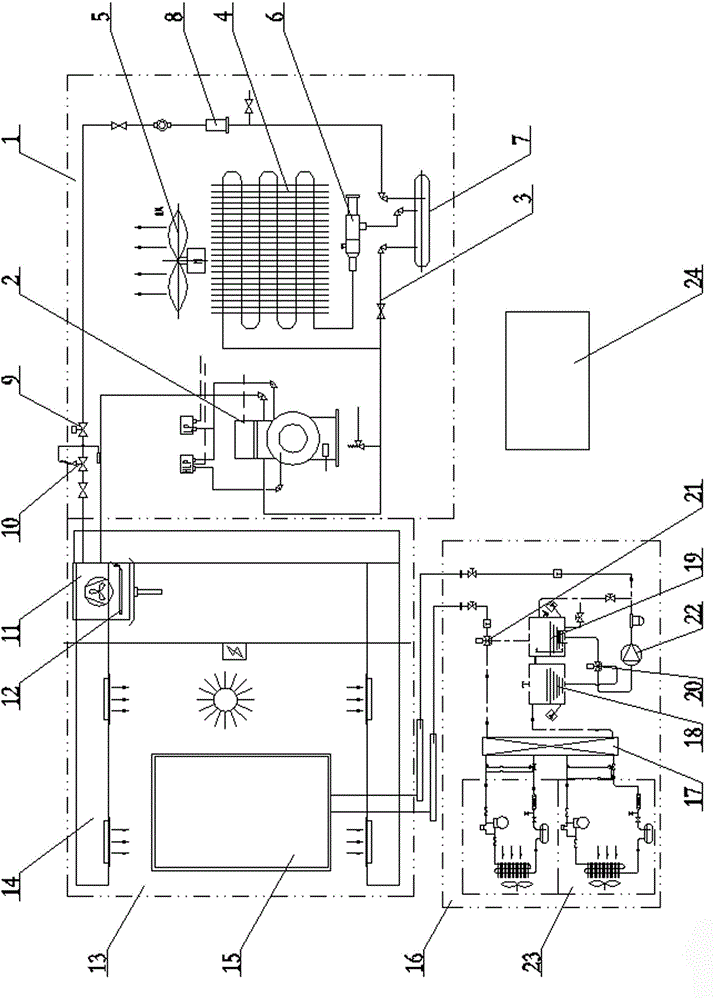

ActiveCN104549577AMeet needsHigh control precisionHeating or cooling apparatusEnclosures/chambersTest chamberControl table

The invention relates to an all-weather variable-working-condition compensating type high-low-temperature environment simulating test chamber. The test chamber comprises an environmental climate simulating chamber, an air-cooled refrigerating device, a liquid-cooled source device and a control table, wherein a constant flow air supply device is arranged on the inner wall of the environmental climate simulating chamber, tested equipment is arranged in the environmental climate simulating chamber, the air-cooled refrigerating device comprises a compressor, a condenser, a condensing pressure regulating valve, a liquid storage device, a drying filer, an electromagnetic valve, an expansion valve and an air cooler, which are sequentially connected, the air outlet of the air cooler is connected with the constant flow air supply device, the air return of the air cooler is connected with the compressor, the liquid-cooled source device is a secondary coolant refrigerating and heating system, and the secondary refrigerant refrigerating and heating system supplies coolant water and heating medium water and is connected with the tested equipment.

Owner:JIANGSU JOSUN AIR CONDITIONER

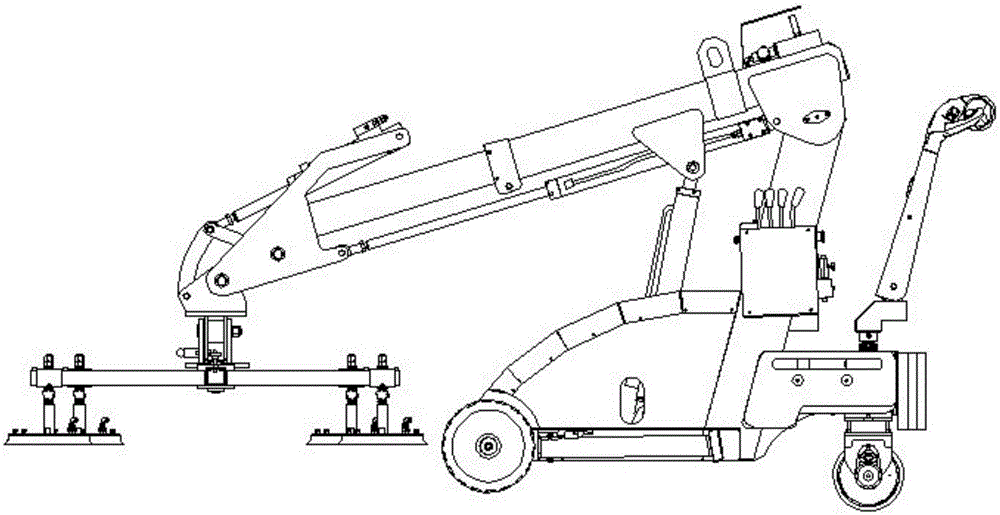

Electric transportation trolley for automatic glass mounting

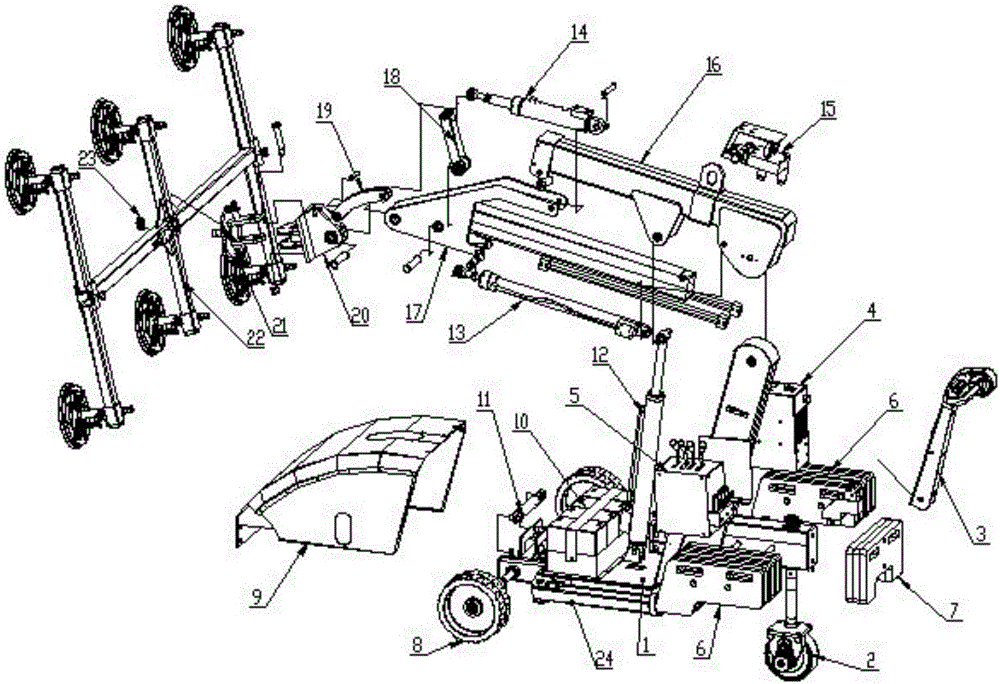

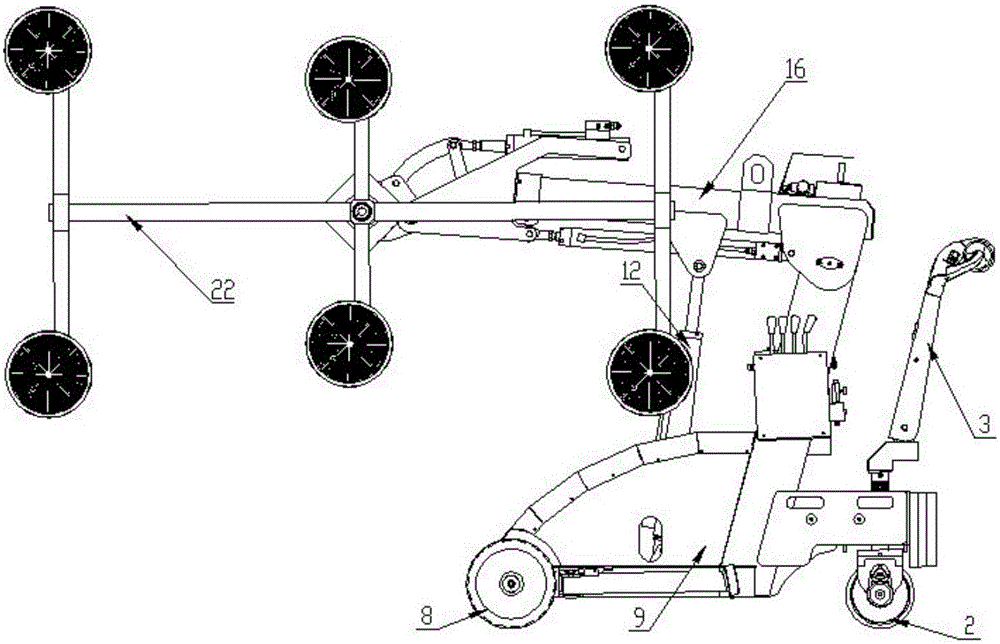

InactiveCN105152036AWon't hurtWide range of installationLoad-engaging elementsCranesHydraulic cylinderVehicle frame

The invention provides an electric transportation trolley for automatic glass mounting. The electric transportation trolley comprises a frame, a lift cylinder, a telescopic cylinder, a turnover cylinder and a suction disc frame, wherein one end of the frame is connected with a driving wheel; the driving wheel is connected with a steering handle; the other end of the frame is connected with two driven wheels; a balancing weight is arranged on the frame; the frame is hinged to one end of a telescopic fixed beam through a supporting rod; one end of the lift cylinder is hinged to the frame; the other end of the lift cylinder is hinged to the telescopic fixed beam; the other end of the telescopic fixed beam is connected with a telescopic arm; the telescopic cylinder and the telescopic fixed beam are coaxially arranged; one end of the telescopic arm is hinged to one end of a turnover seat; the other end of the turnover seat is hinged to a horizontal rotation seat; the horizontal rotation seat is connected with the suction disc frame; a plurality of suction discs are arranged on the suction disc frame. The electric transportation trolley for automatic glass mounting, provided by the invention, is simple to operate, does not cause personal injury, utilizes a DC hydraulic power unit and a hydraulic cylinder to realize turning-over, rotating, lifting and stretching out and drawing back of plates.

Owner:GUANGZHOU COWEST MACHINERY EQUIP CO LTD

High temperature resistance acid-proof alkali-proof coating

InactiveCN103773151AMeet the operating conditionsImprove adhesionAntifouling/underwater paintsPaints with biocidesAdhesion forceSilicon oxide

The invention relates to the field of coating, and particularly relates to high temperature resistance acid-proof alkali-proof coating. The high temperature resistance acid-proof alkali-proof coating is obtained by uniformly mixing a mixture of nanometer silicon oxide, organic silicon modified sodium polyacrylate, a forming substance, a forming additive, an accelerant, a solvent, filler and acid, wherein the content of the nanometer silicon oxide is 50-100g / l, the content of the organic silicon modified sodium polyacrylate is 50-100g / l, the content of the forming substance is 80-100g / l, the content of the forming additive is 20-40g / l, the content of the accelerant is 10-20g / l, the content of the solvent is 30-80g / l, the content of the filler is 10-30g / l, the content of the acid is 25-40g / l, and the average particle diameter of the nanometer silicon oxide is less than 50 nanometers; and the pH value of the high temperature resistance acid-proof alkali-proof coating is in the range of 3 to13. The high temperature resistance acid-proof alkali-proof coating has good adhesion force, can be used at a high temperature, can resists acid, alkaline and corrosion, can resist cold in a cold working condition and meets the use conditions of beam hangers and drill stems, and the usage range pH value of the coating is in the range of 3 to 13.

Owner:南通新昱化工有限公司

Three-hole parallel magnetic levitation vacuum tunnel structure

PendingCN110985039AAdaptableEfficient evacuationMining devicesRailway tunnelsStructural engineeringLow vacuum

The invention discloses a three-hole parallel magnetic levitation vacuum tunnel structure. The structure comprises running tunnels on the two sides and a service tunnel on the middle. The running tunnels and the service tunnel are connected through a connection channel, the interiors of the running tunnels are vacuum environments, the bottoms of the running tunnels are in under-rail filling, a magnetic levitation rail beam is placed on the filling face, a magnetic levitation train runs on the magnetic levitation rail beam, the interior of the service tunnel is the normal pressure environment,the bottom of the service tunnel is in filling under equipment, equipment needed by magnetic levitation running is placed on the filling face, other spaces serve as evacuation channels, one end of theconnection channel communicates with the running tunnels, the other end of the connection channel communicates with the service tunnel, and a vacuum isolation wall and a vacuum isolation door are arranged on the connecting position of the communication channel and the running tunnels. The low-vacuum environment can be ensured, the ground space use can be reduced, adaptation to the terrain is high, the tunnel structure with good passenger evacuation, personal inspection and equipment arranging capacity is achieved, and meanwhile, practicability, safety and economy are all considered.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN100515655CImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsCrack resistanceArc stability

A low-alloy steel flux-cored welding wire for carbon dioxide gas shielded welding, the composition and content of the flux core in % of the total weight of the welding wire are as follows: TiO2: 3-6, Si: 0.3-0.5, Mn: 1.5-3.2, SiO2: 0.1 -0.8, ZrO2: 0.1-0.5, Fe: 2-7, Al+Mg: 0.5-1.2, Ni: 0.5-5, B: 0.002-0.015, Ti: 0.1-0.3, oxidation of alkali metal K, Na, Li The content of fluoride or fluoride equivalent to K, Na, and Li is 0.1-0.35, the content of fluoride F is 0.05-0.2, the fluoride or oxide of rare earth metal is equivalent to 0.005-0.2 of rare earth metal, and the content of C, Si, and Mn in the welding wire The product of the contents is 0.058-0.11. For high-strength low-alloy steel all-position welding process performance is good, it can maintain good arc stability and welding operation performance under the condition of high current and fast welding, the weld seam is smooth, the connection strength is high and it has a good -40 ℃ low temperature Impact toughness and excellent crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

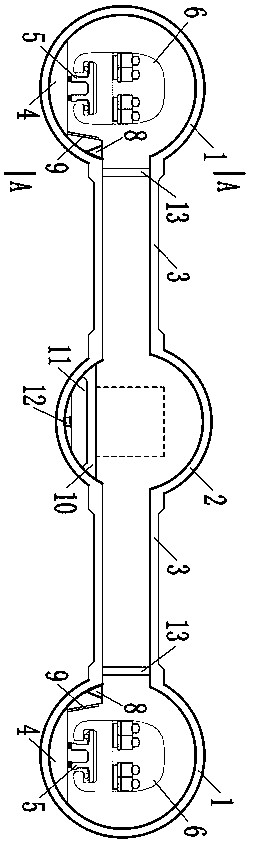

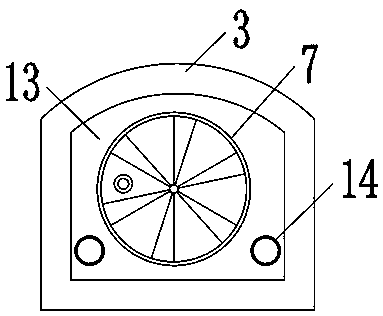

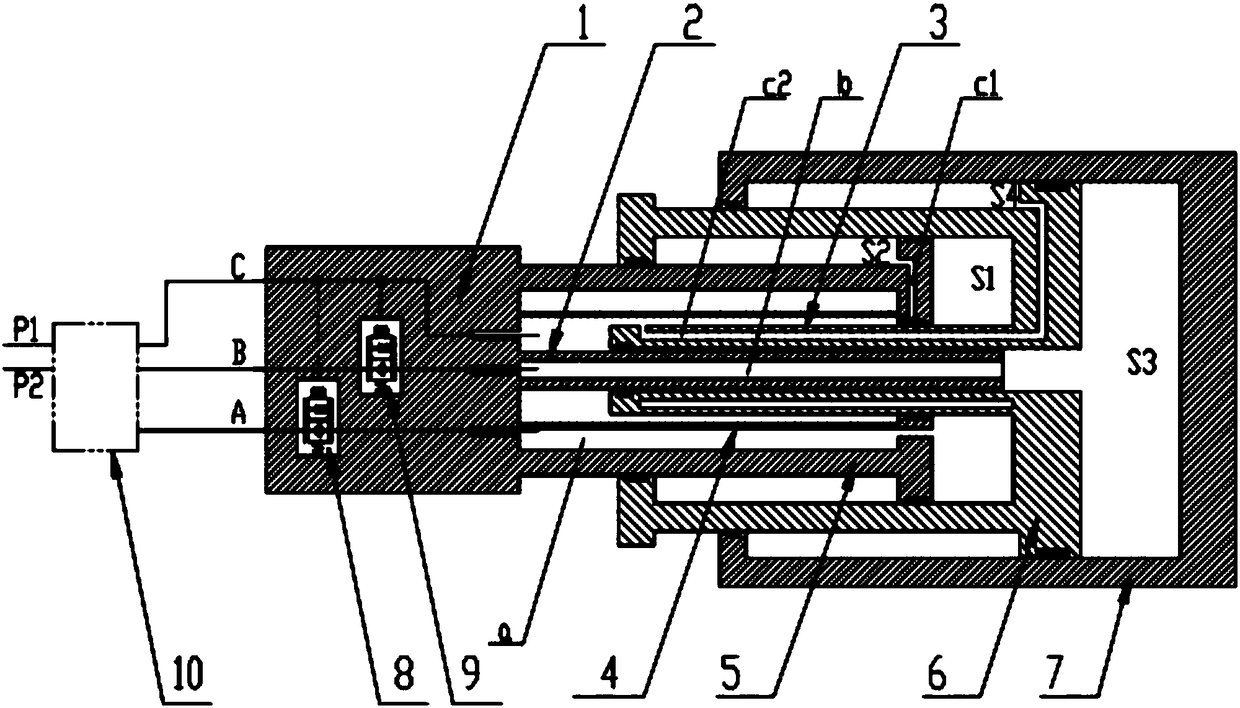

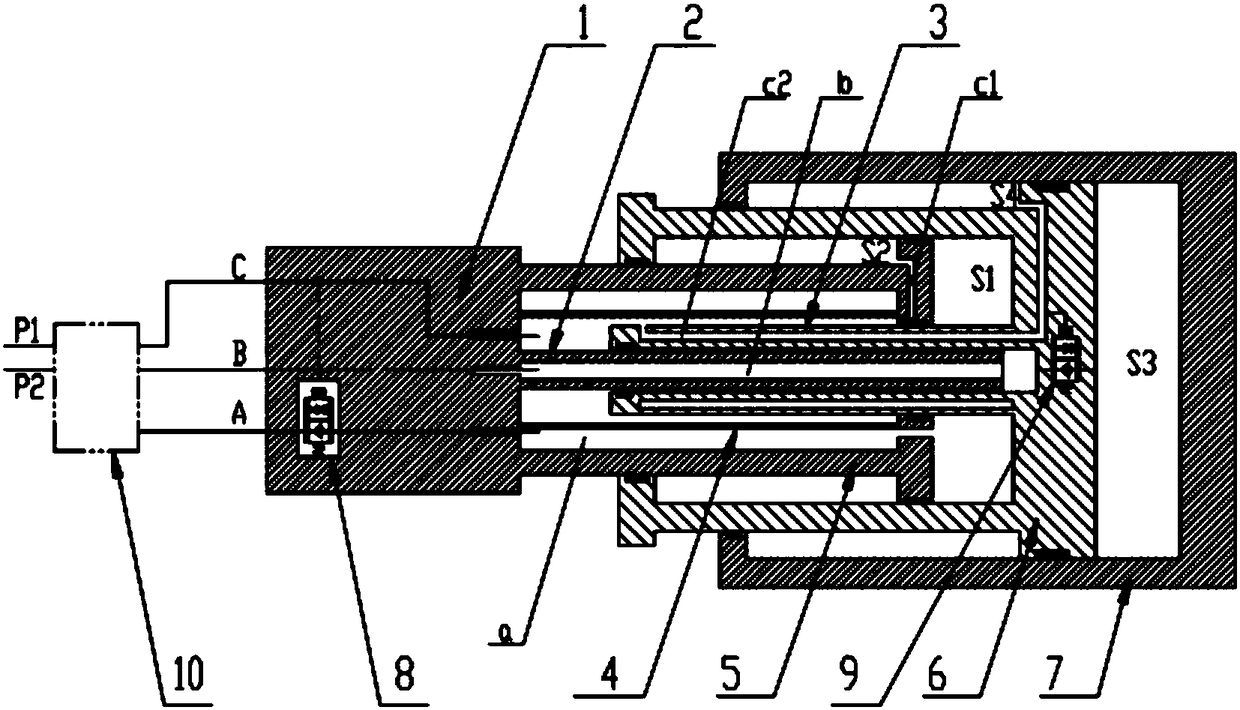

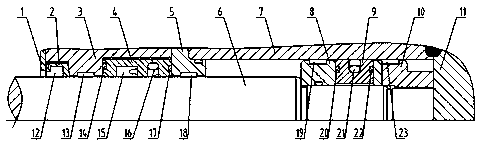

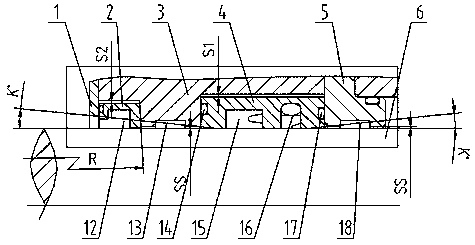

Two-stage hydraulic cylinder with multi-layer core tube and crane

InactiveCN108302090AReduce cylinder weightImprove the performance of the boom and the stability of the whole machineFluid-pressure actuatorsHydraulic cylinderPiston rod

The invention discloses two-stage hydraulic cylinder with multi-layer core tubes and a crane, and belongs to the technical field of engineering machinery. The two-stage hydraulic cylinder with the multi-layer core tubes comprises a piston rod head, an inner telescopic core tube, a sleeve, a piston rod assembly, a first-stage cylinder barrel and a second-stage cylinder barrel, wherein one end of the inner telescopic core tube, one end of the sleeve and one end of the piston rod assembly are connected to the piston rod head; the first-stage cylinder barrel is provided with an outer telescopic core tube, multiple working oil ports are formed in the piston rod head, the first-stage cylinder barrel is arranged in the second-stage cylinder barrel, and the first-stage cylinder barrel is providedwith an outer cavity connected to the sleeve and the piston rod assembly and an inner cavity connected to the inner telescopic core tube; and the working oil ports can independently control extensionand retraction of the first-stage cylinder barrel and the second-stage cylinder barrel. According to the two-stage hydraulic cylinder with multi-layer core tubes and the crane, all stages of the cylinders can be independently controlled and are not limited in sequence, various working conditions of the device are met, the weight of an oil cylinder is greatly reduced, the performance of a suspension arm and the stability of the whole machine are improved, the arrangement space is saved, and arrangement and optimization of a rope arrangement mechanism are facilitated.

Owner:XUZHOU HEAVY MASCH CO LTD

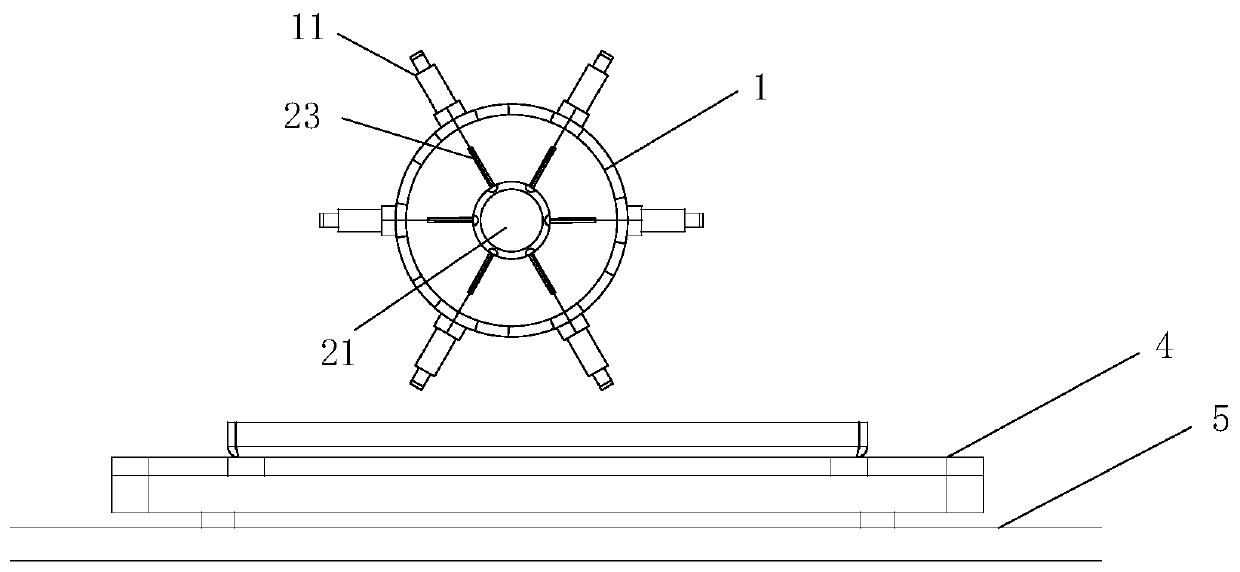

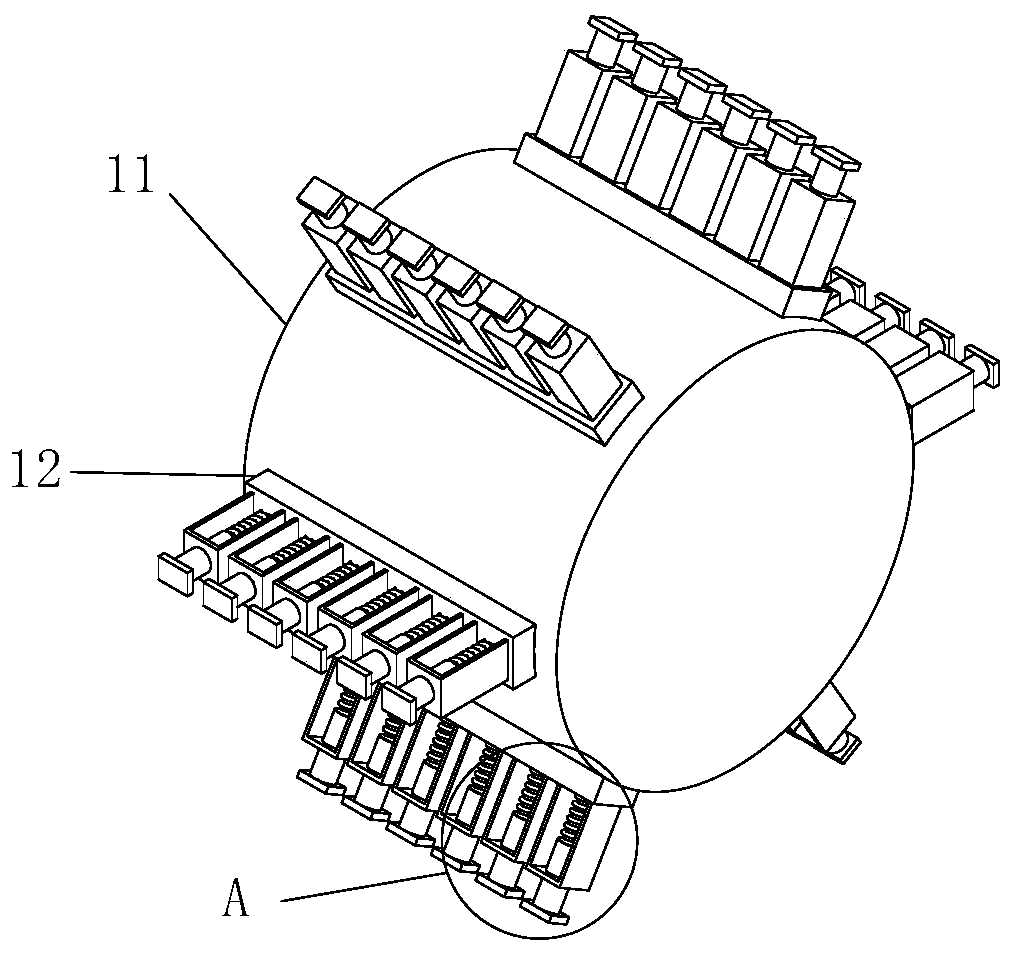

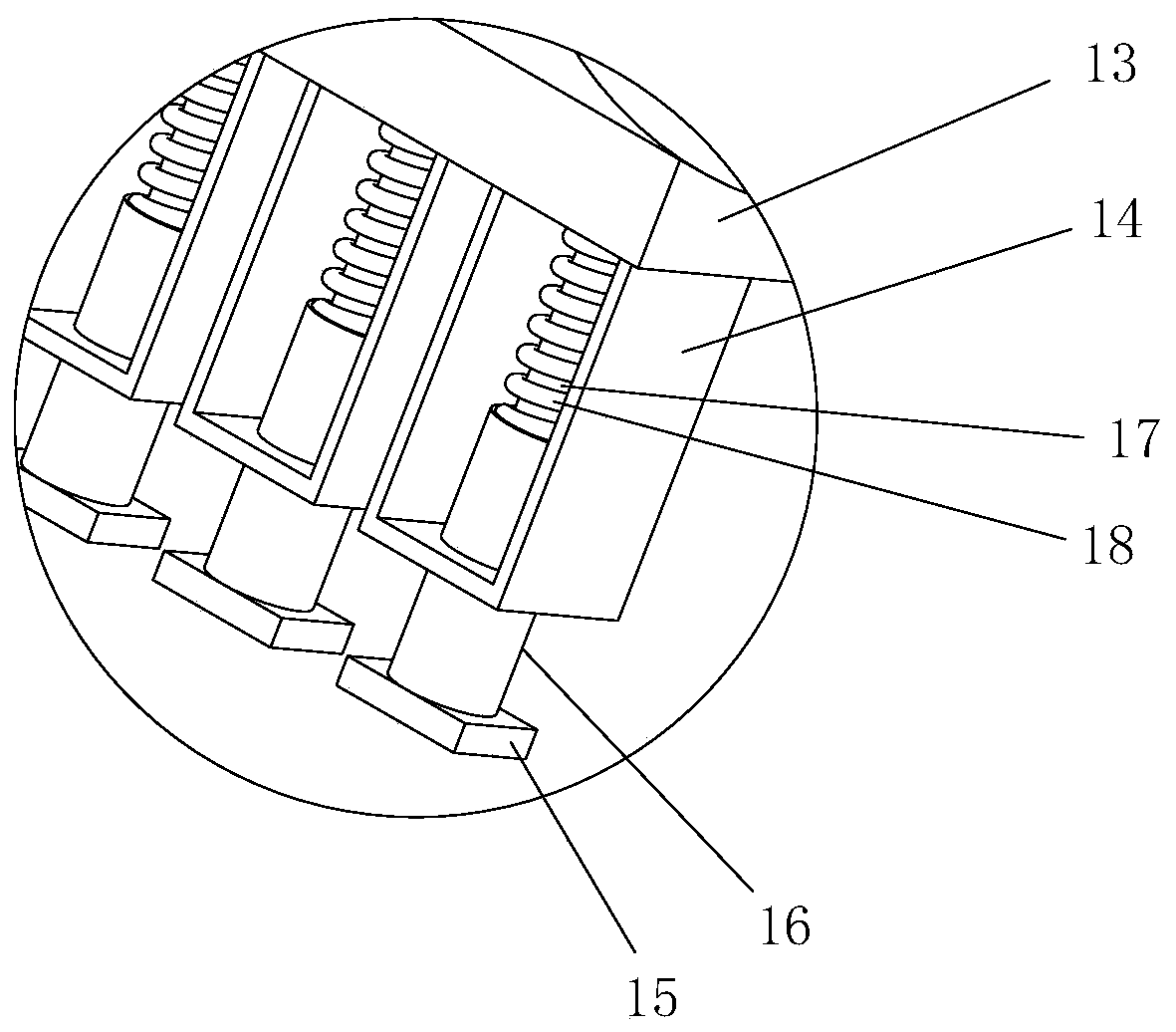

Roughness detection robot for precision machining and detection method thereof

InactiveCN110500987AGuaranteed precisionEffective Flatness AnalysisMeasurement devicesManipulatorEngineeringMachining process

The invention relates to the field of precision machining processes, and specifically relates to a roughness detection robot for precision machining and a detection method thereof. The roughness detection robot comprises a transmission frame and a material conveying belt, wherein the transmission frame is equipped with a detection mechanism, the main body of the detection mechanism is a detectionmachine barrel, and the outer barrel wall of the detection machine barrel is equipped with a plurality of detection frames at equal intervals, each detection frame is mounted on the outer wall of thedetection machine barrel through a fixed base plate, a plurality of detection brackets are independently arranged on each detection frame, the front end of each detection bracket is equipped with a detection head, each detection head is installed on the detection bracket in a penetrating mode through a movable sleeve, the inner cavity of the detection bracket is provided with a fixed rod, the movable sleeve is arranged on the fixed rod in a sleeving mode, each fixed rod is wound with an extrusion spring, a plurality of elasticity detectors are arranged in the detection machine barrel, and theextrusion springs are respectively connected with the elastic detectors. According to the invention, the surface is converted into points on the whole during the detection, and then the points are integrated into the surface, thereby achieving the effects of high-efficiency operation and high-efficiency analysis.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

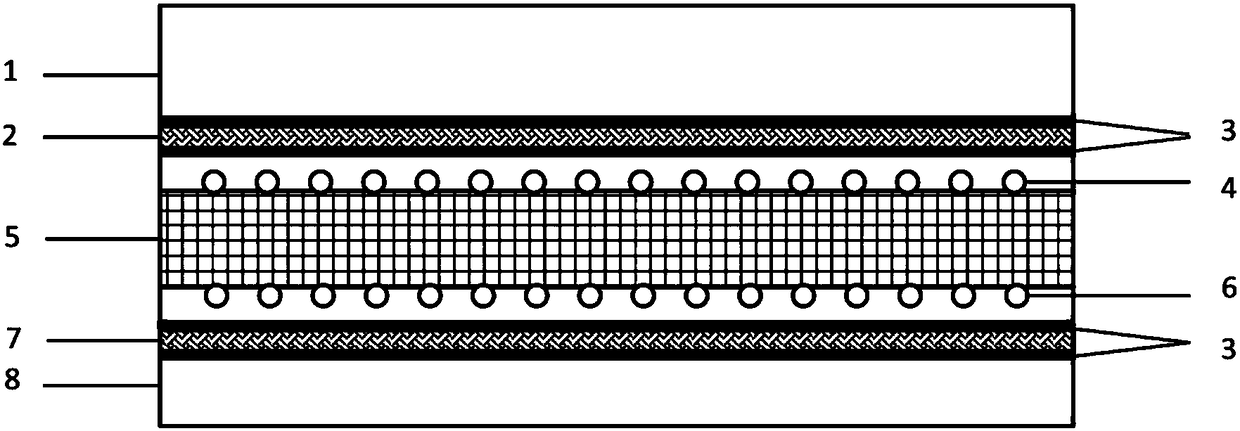

Preparation method of carbon-ceramic friction material

InactiveCN110713385AMeet the operating conditionsIncrease coefficient of frictionFriction liningActuatorsPorous substrateGraphite

The invention provides a preparation method of a carbon-ceramic friction material, which comprises the following steps: A) with propylene as a carbon source and nitrogen as a diluent gas, carrying outchemical vapor deposition densification on a C / C preform, and carrying out graphitization heat treatment to obtain a C / C matrix; B) immersing the C / C matrix into the impregnation liquid for impregnation under a vacuum condition, and then sequentially carrying out heating curing, high-temperature carbonization treatment and graphitization treatment to obtain a C / C porous matrix; C) processing a plurality of grooves on the friction surface of the C / C porous substrate; D) siliconizing the processed C / C porous matrix obtained in the step C) by adopting an embedding method infiltration process toobtain a siliconized matrix; and E) immersing the siliconized matrix into a coating solution, carrying out coating impregnation, and heating the matrix for curing treatment to obtain the carbon-ceramic friction material. The wet attenuation of the friction material prepared by the method is less than or equal to 5%, so that the friction material completely satisfies the use conditions of amphibious aircrafts.

Owner:HUNAN BOYUN NEW MATERIALS

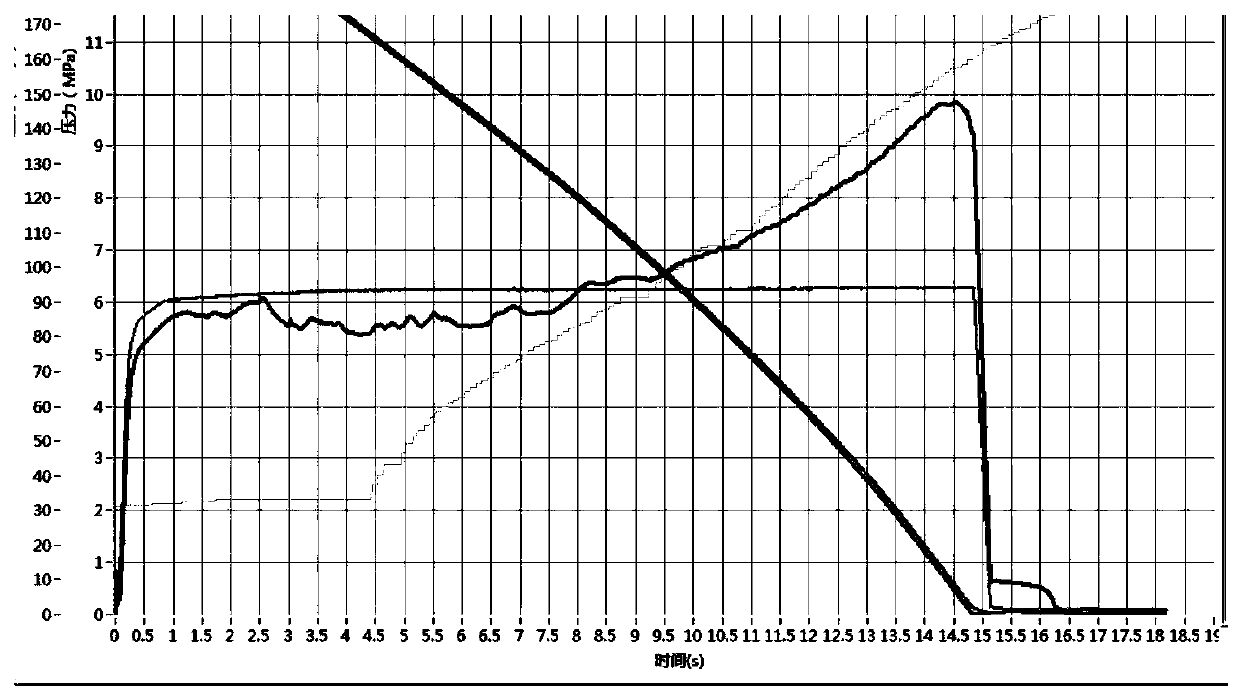

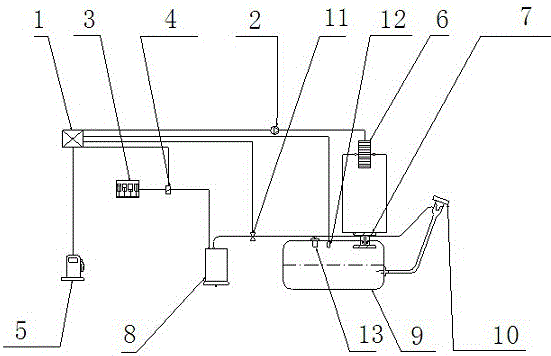

Internal-pressure-adjusting fuel system and control method

ActiveCN105114225AReduce volumeImprove adsorption capacityElectrical controlNon-fuel substance addition to fuelThermodynamicsFuel tank

The invention relates to an internal-pressure-adjusting fuel system. The internal-pressure-adjusting fuel system is characterized by comprising an ECU, an engine, a battery, a carbon pump, a lock cover and an oil tank assembly; the ECU is connected with the battery, the engine and the carbon pump through lines, the carbon pump is connected with the oil tank assembly through a pipe, and the lock cover is connected with the oil tank assembly through a pipe; the fuel system further comprises a semiconductor refrigerating / heating device, and the semiconductor refrigerating / heating device is arranged on the oil tank assembly, connected with the battery through a line and connected with the carbon pump through a pipe. According to the technical scheme, the pressure inside an oil tank can be adjusted, the whole structure is simple, design is ingenious, the oil tank is small in weight, cost is low, and outward emission of hydrocarbon steam is effectively suppressed.

Owner:YAPP AUTOMOTIVE PARTS

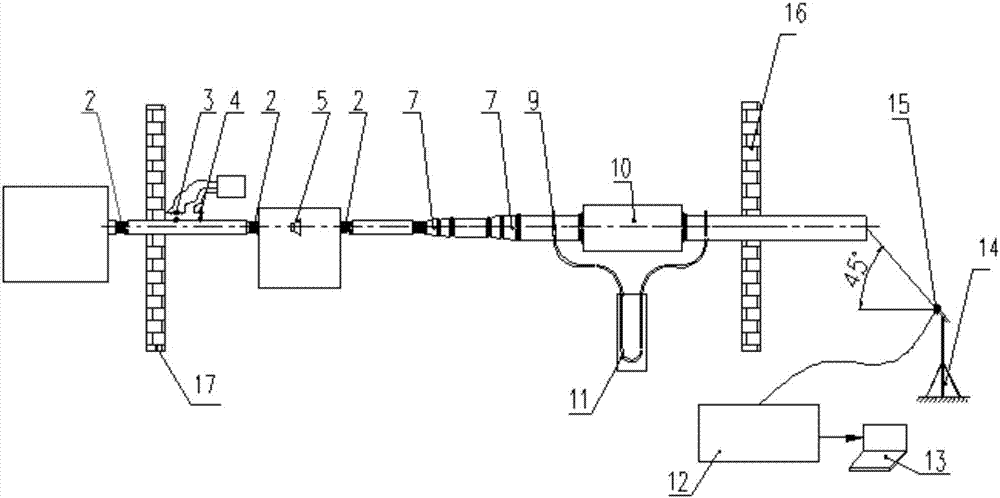

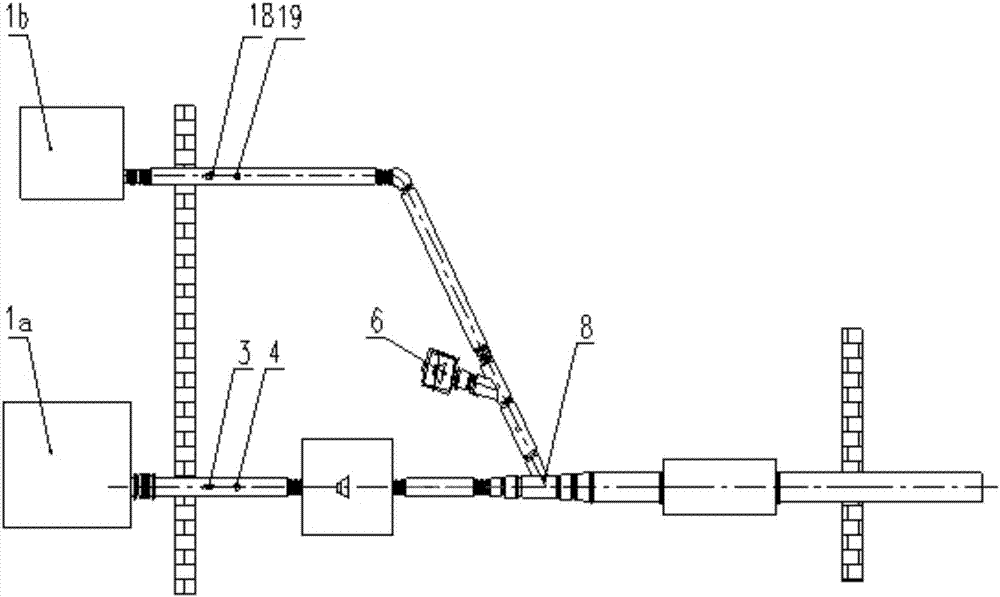

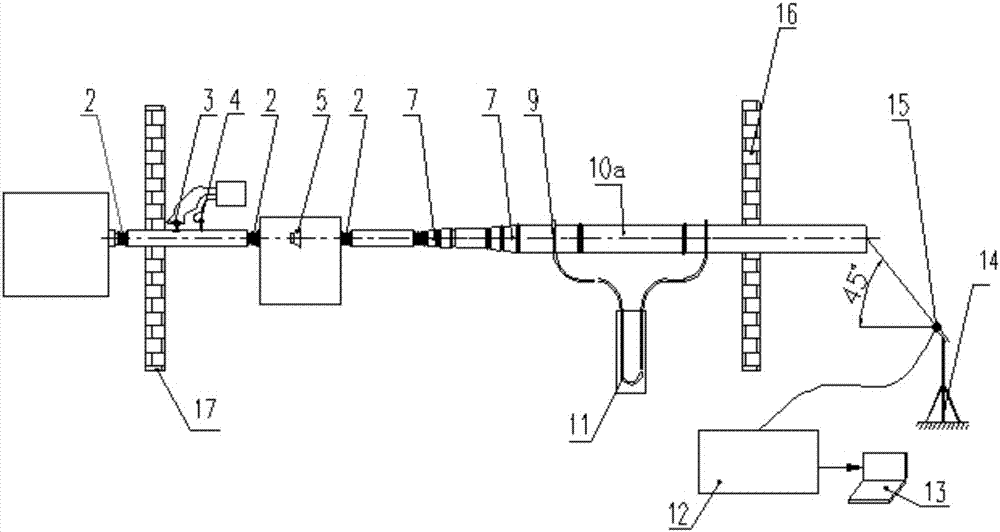

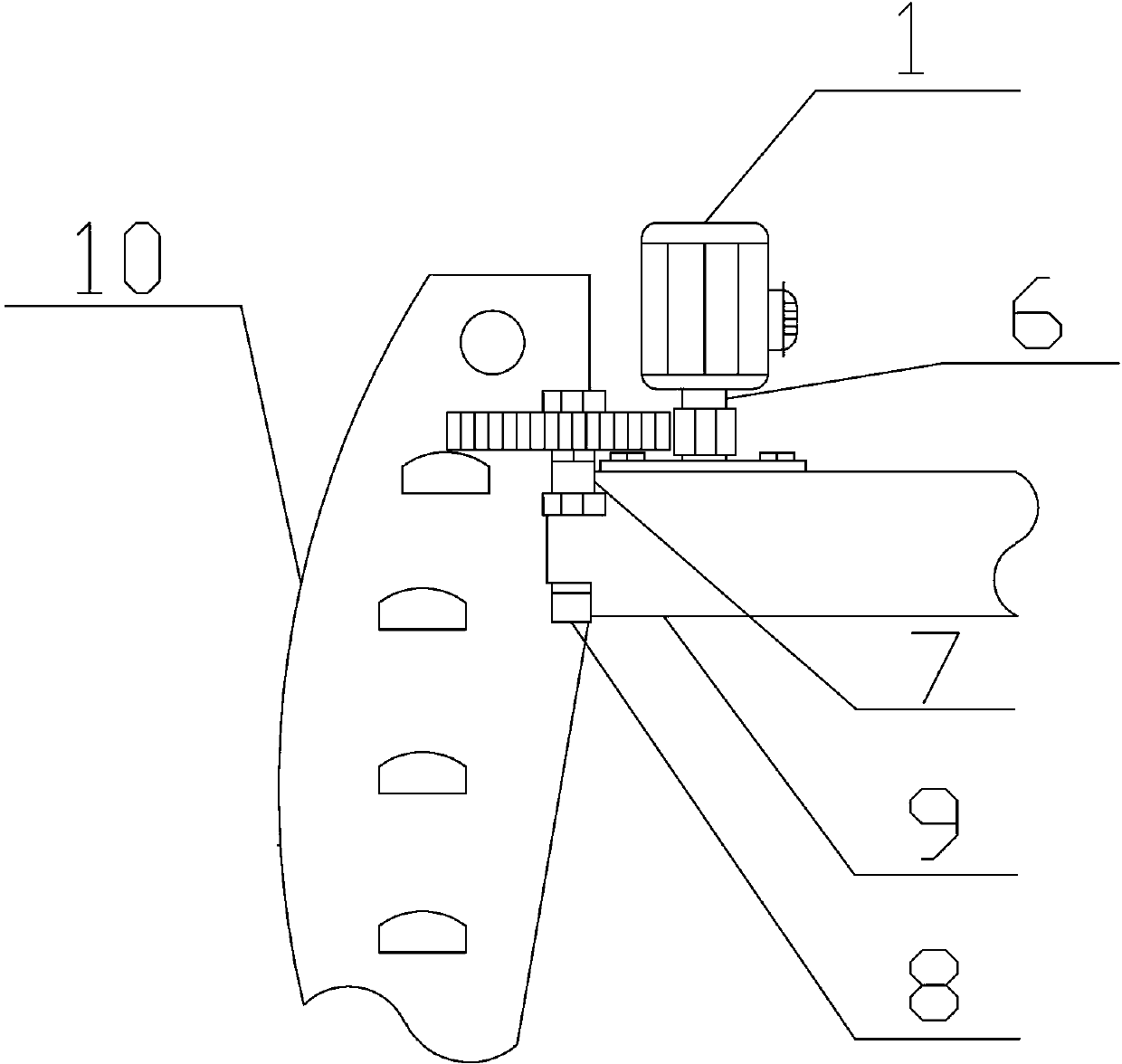

Silencer test device based on airflow temperature and flow matching

ActiveCN107490473AGuaranteed accuracy and data reliabilityGood noise reduction performanceMachine part testingFrequency bandTraffic volume

The invention provides a silencer test device based on airflow temperature and flow matching, which belongs to the technical field of silencer test. A diesel test bench 1a and a kerosene test bench 1b are used as hot and cold gas sources. By adjusting the air flow and the oil ratio, the operating conditions of a silencer 10 at different temperatures and flows are simulated. A mechanical sound source 5 and an electro-acoustic source 6 are combined, and acoustic performance measuring is carried out on the silencer 10 in the frequency band range from 10 Hz to 20 kHz. According to the invention, the acoustic performance measurement and resistance performance measurement of the silencer are realized based on airflow temperature and flow matching; the test results are accurate; the measurement results have an important guiding significance for the structure optimization and noise reduction design of the silencer; and the silencer test device can be widely applied to the acoustic performance measurement and resistance performance measurement of a marine silencer and an automobile silencer.

Owner:HARBIN ENG UNIV

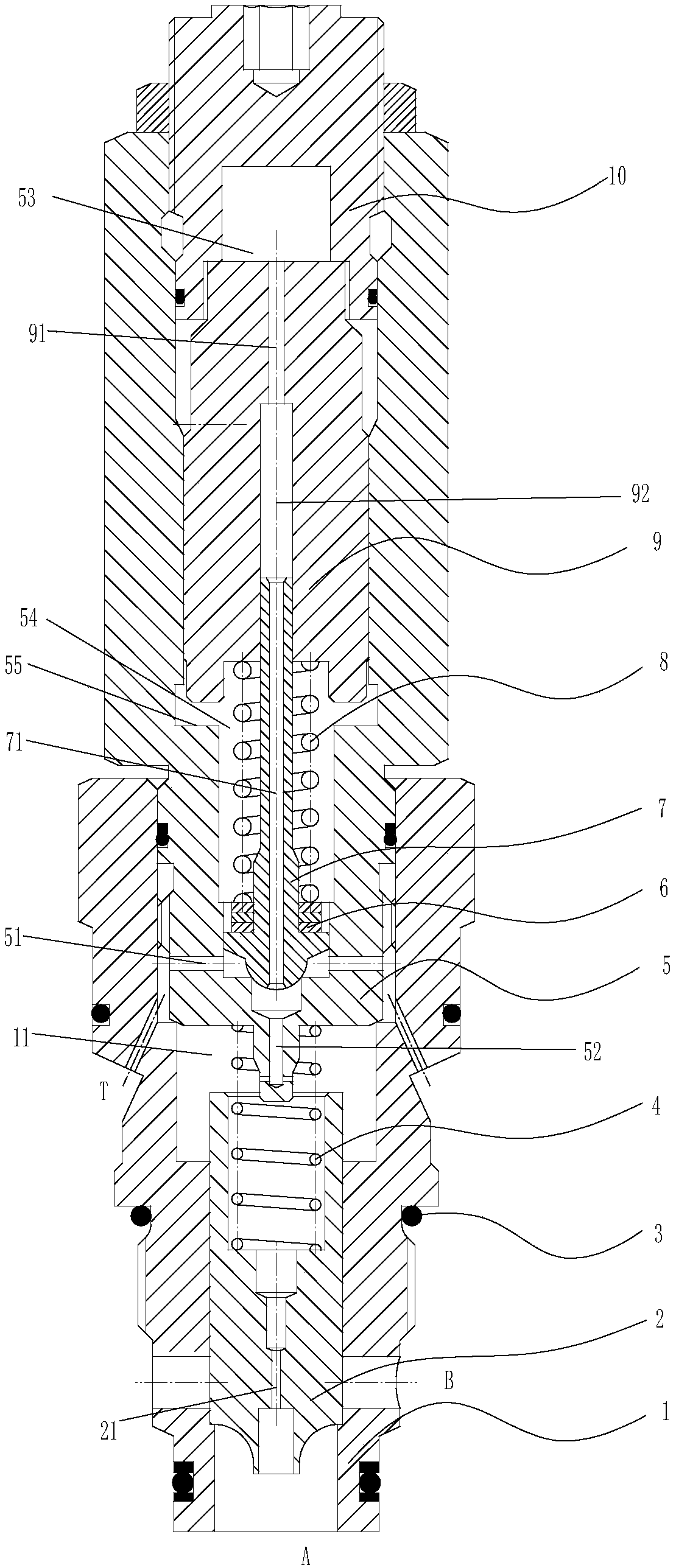

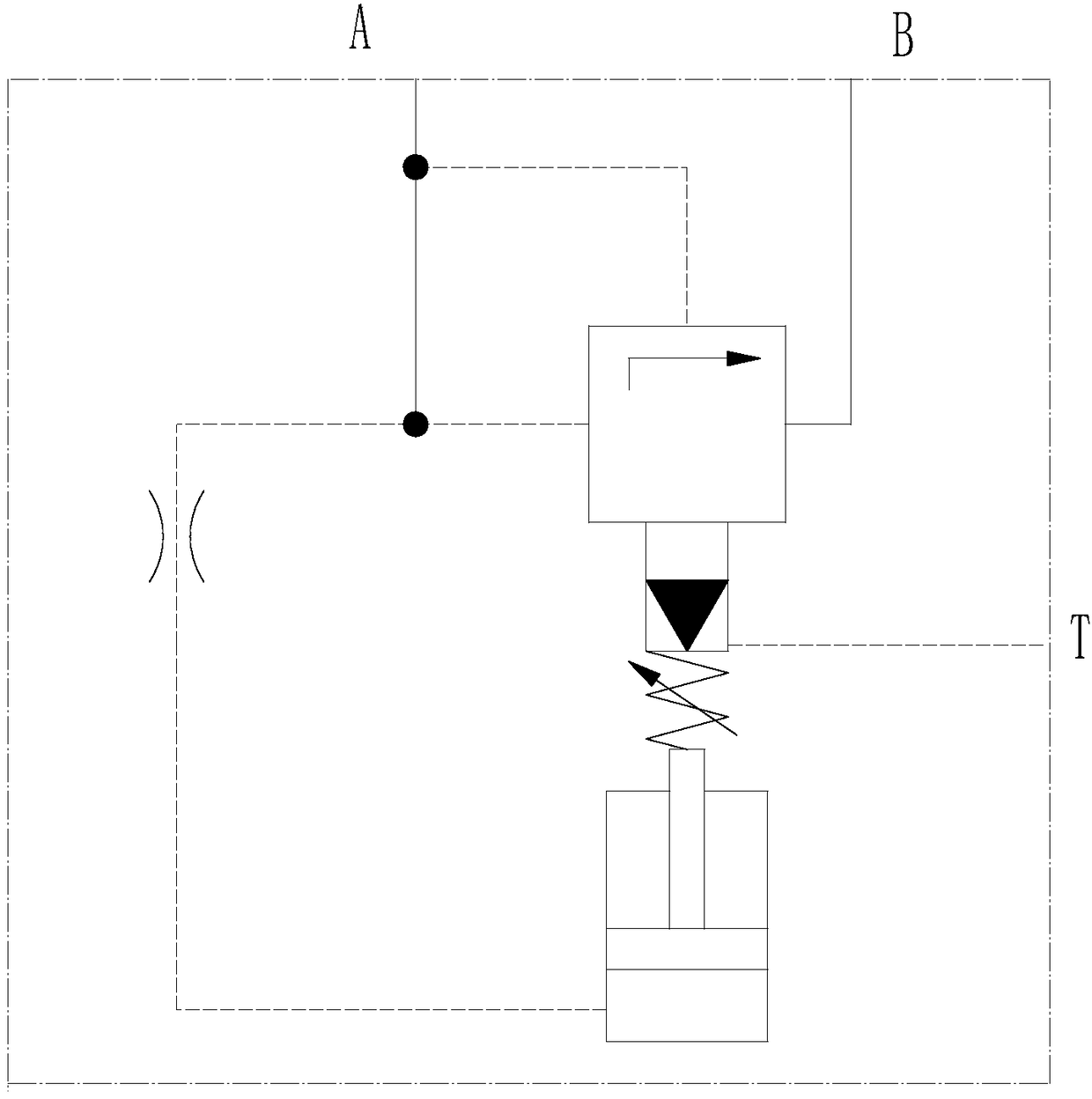

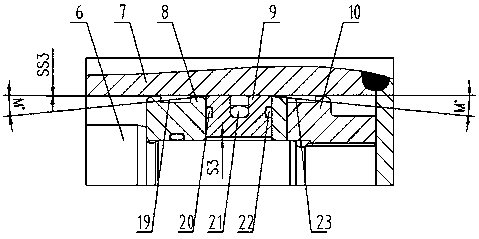

Plug-in type buffer valve

InactiveCN108167256AMeet the operating conditionsEffective cushioning of impact pressureOperating means/releasing devices for valvesServomotor componentsEngineeringPiston

The invention provides a plug-in type buffer valve, which comprises a valve body, a main valve element, a thread sleeve, and a buffer piston, a pilot valve element and a second elastic element built in the thread sleeve. An oil port A, an oil port B and an oil port T are formed in the valve body; the oil port A is formed in one end of the valve body; the oil port B is formed in one end side face close to the oil port A; the oil port T is formed in the other end side face far away from the oil port A; the main valve element is movably arranged in the valve body and seals the oil port B; and a first damping channel leading to a control cavity from the oil port A is arranged on the main valve element. The plug-in type buffer valve meets a high-flow use condition, can be beneficial to effectively buffering impact pressure, and is simple in structure and low in cost.

Owner:邵立坤

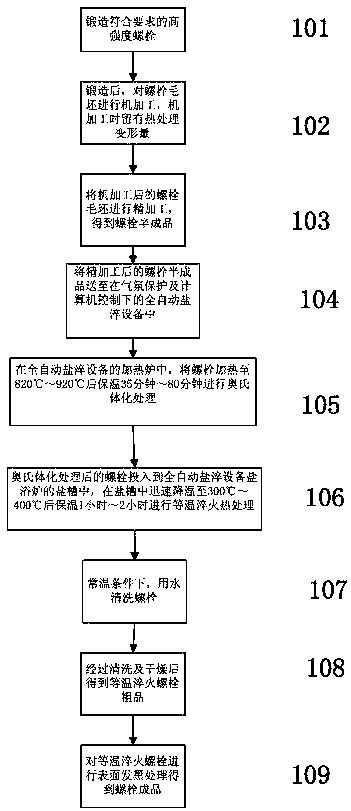

Heat treatment method of high-strength bolt for electric tool

ActiveCN108103297ASmall amount of deformationImprove wear resistanceFurnace typesQuenching agentsHigh intensityWork in process

The invention discloses a heat treatment method of a high-strength bolt for an electric tool. The heat treatment method comprises the following steps: bolt forging: a bolt blank is machined; and a heat treatment deformation is remained; bolt finish machining: a bolt semi-finished product is sent to full-automatic salt quenching equipment under atmospheric protection and computer control, is heatedto 820-920 DEG C for insulation by 35-80 minutes for austenizing, and is put in a salt tank of a salt bath furnace of the full-automatic salt quenching equipment to quickly cool to 300-400 DEG C forinsulation by 1-2 hours for isothermal quenching heat treatment; the bolt is washed by water under normal-temperature condition; an isothermal-quenched bolt is obtained after drying; and the surface of the bolt is blackened. After salt bath and isothermal quenching heat treatment of a traditional 12.9-grade bolt, the strength is improved to 14.9 grade, the tensile strength reaches 1500-1600 MPa, and the use working conditions of high-power electric tools are met; and meanwhile, the high-strength bolt after heat treatment achieves low deformation, improved wear resistance and prolonged servicelife.

Owner:艾普零件制造(苏州)股份有限公司

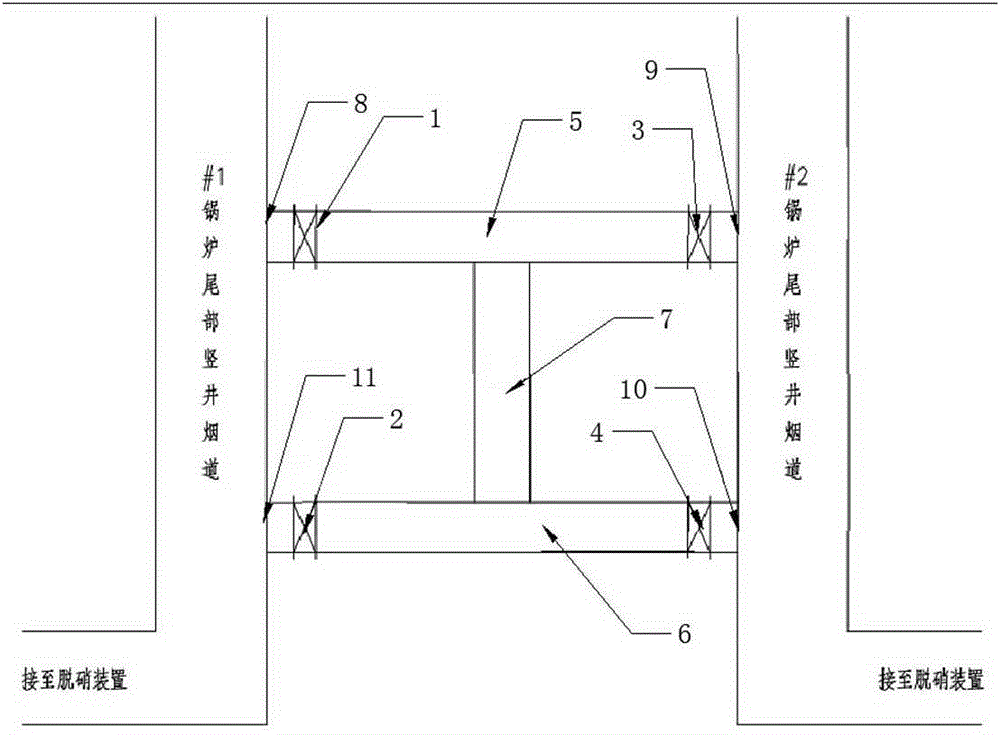

Low-load system increasing denitration flue gas temperature

ActiveCN105423322AIncrease temperatureGuaranteed temperatureLighting and heating apparatusThermodynamicsFlue gas

The invention relates to a low-load system increasing the inlet flue gas temperature of a boiler denitration device. The system comprises two boiler tail vertical flues, and bypass flues are arranged on the two boiler tail vertical flues, are communicated and are provided with flue baffles. Compared with the prior art, the two boiler tail vertical flues are directly provided with the bypass flues capable of being communicated, when one boiler is at the start-up stage or at the low-load operation stage, the bypass flues can be opened, partial high-temperature flue gas of the one in normal operation of the two boiler tail vertical flues enters the tail vertical flue of the boiler at the low-load operation stage, and therefore the inlet flue gas temperature of the denitration device can be increased, and the NOx emission in flue gas can reach the standard. The system is flexible to operate, can meet various complex operation conditions of power plants and can guarantee that the denitration inlet flue gas temperature can meet the requirement no matter which one unit is at the low-load stage or at the start-up stage.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

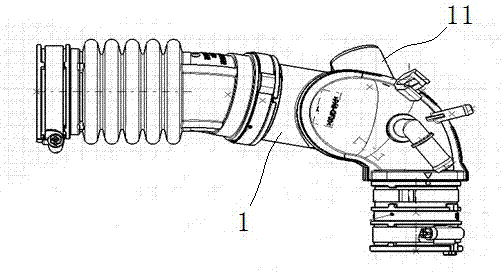

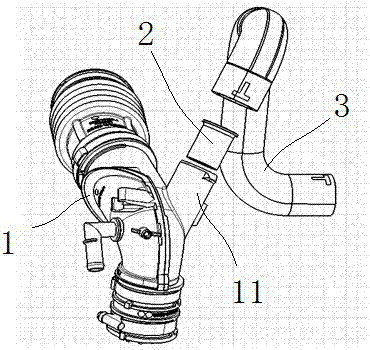

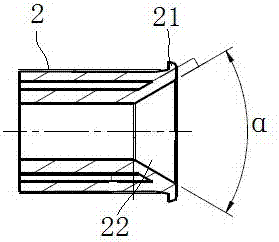

Exhaust and noise elimination structure of pressure release valve of automobile

ActiveCN107255056AReduce noiseReduce noise valueInternal combustion piston enginesIntake silencers for fuelAir filterAgricultural engineering

The invention discloses an exhaust and noise elimination structure of a pressure release valve of an automobile. The exhaust and noise elimination structure comprises a pressure release valve exhaust pipe and an air filter air outlet pipe. A connector connected with one end of the pressure release valve exhaust pipe is formed in the air filter air outlet pipe. The other end of the pressure release valve exhaust pipe is used for being fixedly connected with the pressure release valve. The exhaust and noise elimination structure further comprises a noise elimination pipe arranged in the pressure release valve exhaust pipe. The outer diameter of the noise elimination pipe is matched with the inner diameter of the pressure release valve exhaust pipe. The end, facing the connector, of the noise elimination pipe is inserted into the connector, an inner hole in the other end of the noise elimination pipe is a conic hole with the diameter being gradually shrunk inwards from an end opening, and the angle of the conic hole is 45-75 degrees. The exhaust and noise elimination structure can reduce noise generated when the pressure release valve of the automobile exhausts air.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Structure and method for anti-corrosive treatment of pure titanium plates of chimney steel inner cylinder and steel structure flue

ActiveCN103850514AExcellent anti-scourabilityReduce construction costsTowersVertical ductsArc weldingStrip steel

The invention discloses a structure and a method for anti-corrosive treatment of pure titanium plates of a chimney steel inner cylinder and a steel structure flue. An anti-corrosive layer which is respectively attached to the inner walls of a steel inner cylinder and a steel flue consists of a pure titanium plate and a steel plate keel, the pure titanium plates are sequentially overlapped along the edges in the peripheral and axial directions of the inner walls, and the overlapping part is welded by an argon arc welding way to form a protecting layer; for a connection method of each pure titanium plate and each steel plate keel, a strip steel plate keel is compounded onto all or part of four edges of the same side of each pure titanium plate through electric resistance sealing welding, so as to form different structures which are respectively provided with the keels at the periphery, the keels at the three edges, the keels at the two right edges, the keels at the left two edges, the keels at the upper and lower edges or the keels at the lower edges; the edge of one side, without the keel, of one pure titanium plate is mutually overlapped and connected with the edge of one side, with the keel, of the other pure titanium plate. The structure and the method can solve the technical problems of the traditional steel inner cylinder wall anti-corrosive structure after chimney wet process desulfurizing that the construction is complicated, the period is long, the cost is high, the anti-corrosive service life is short, and the like.

Owner:北京赛奥防腐技术有限公司

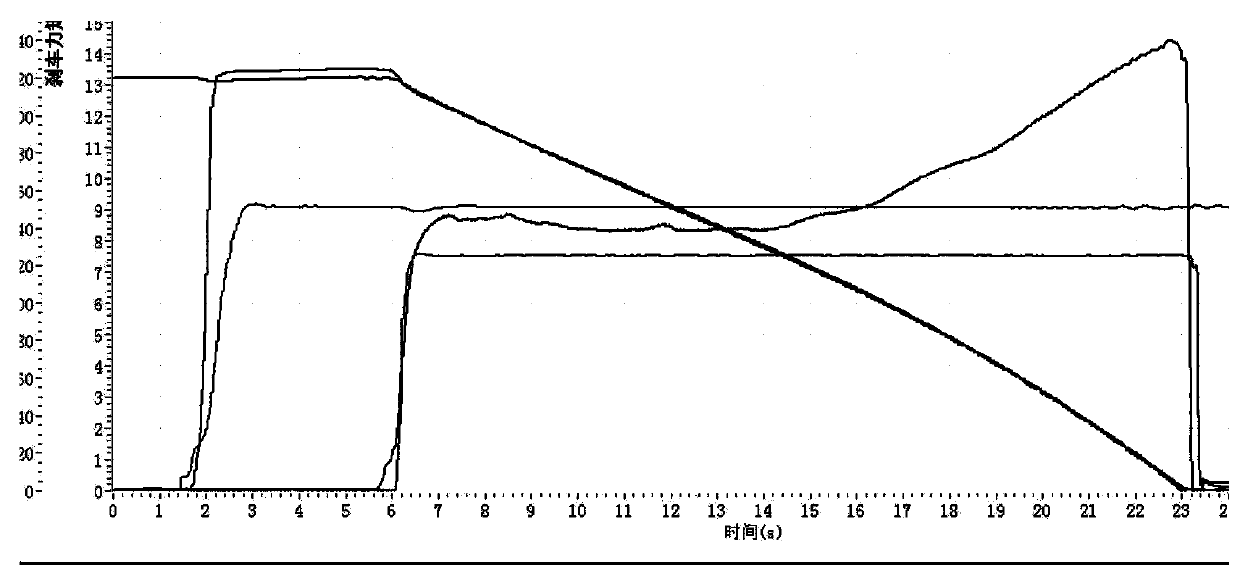

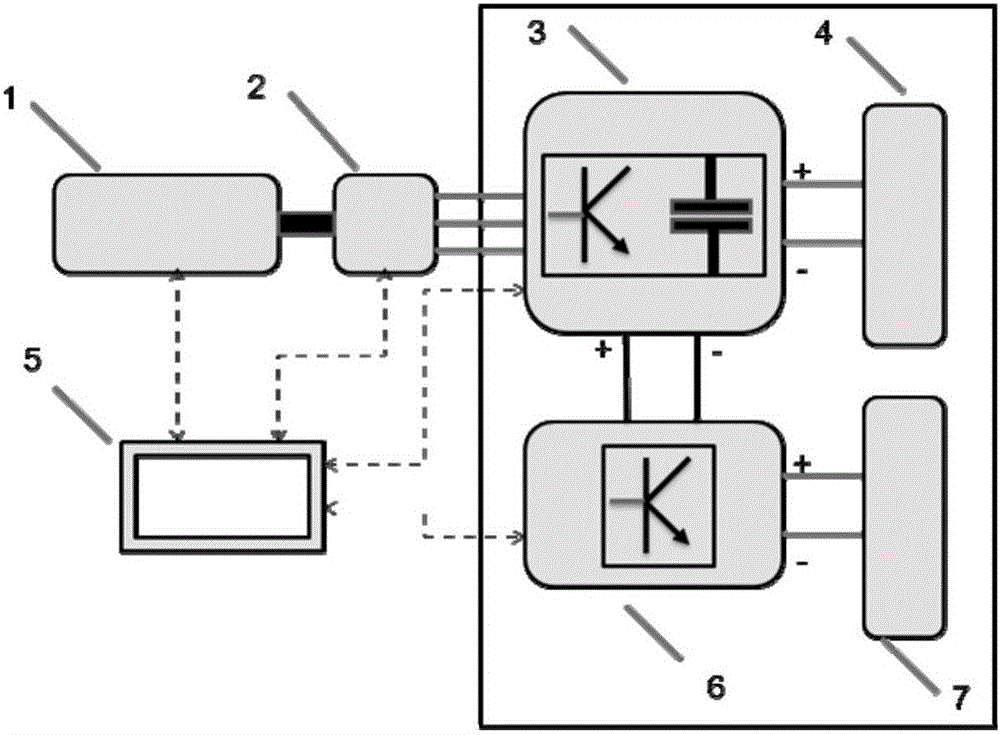

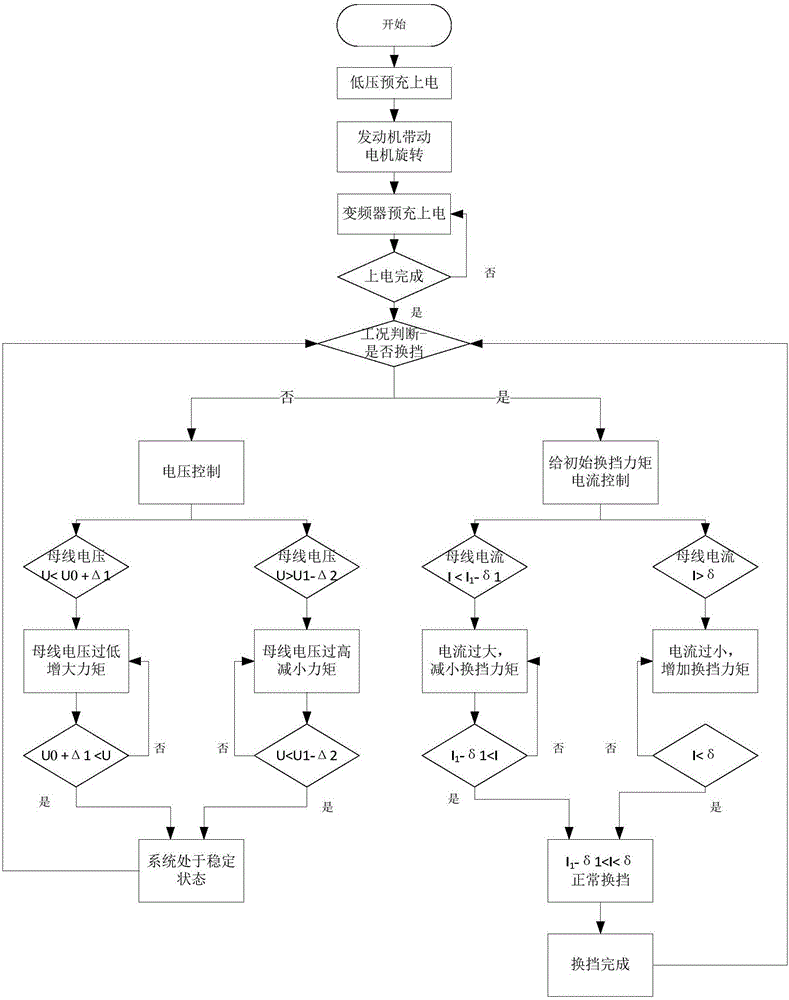

An energy feedback system and method for an electric drive automatic transmission

ActiveCN105383309BMeet the operating conditionsSimple structureElectrodynamic brake systemsElectric energy managementCapacitanceFrequency changer

Owner:武汉理工通宇新源动力有限公司

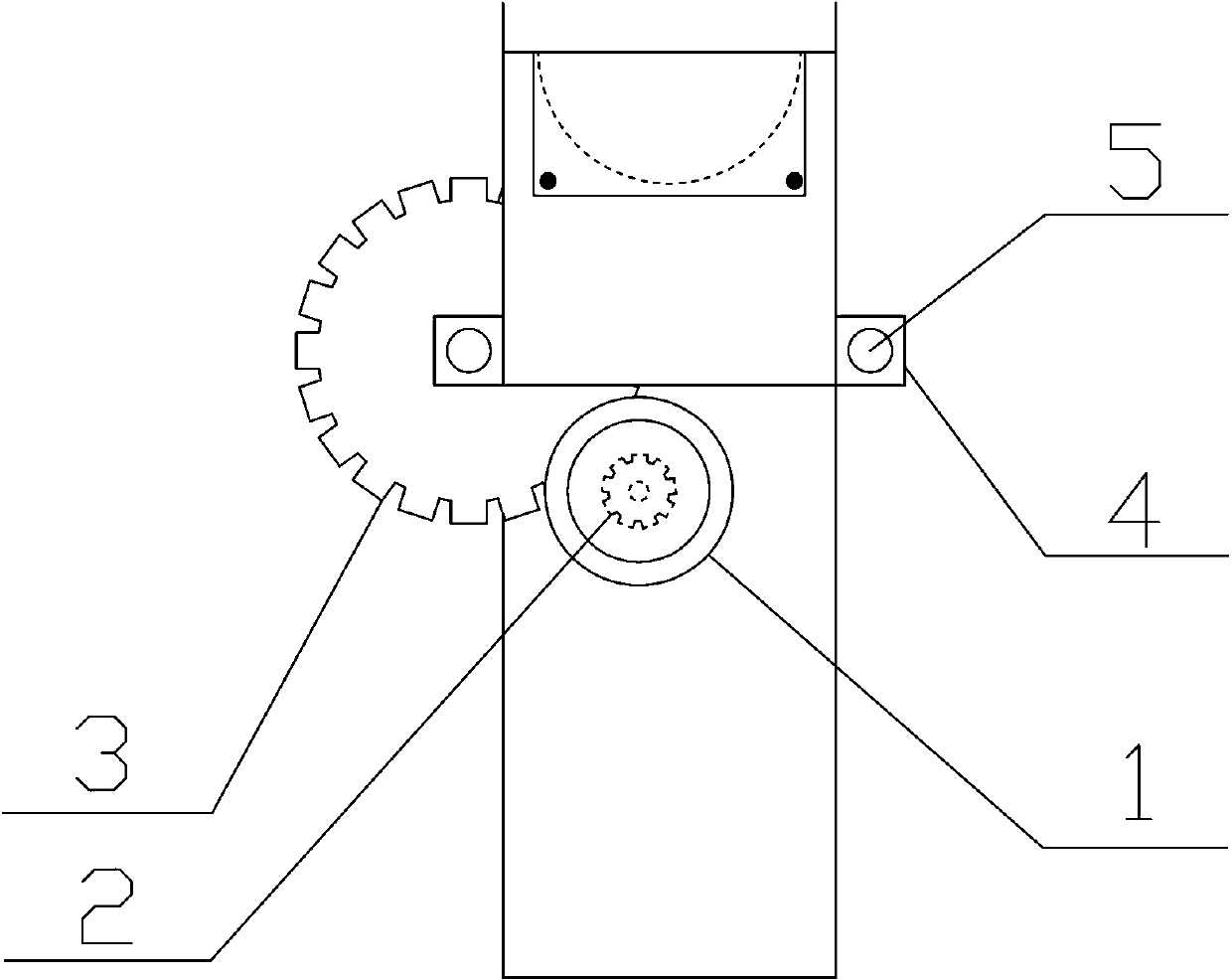

Horse-head overturning device of walking-beam type oil pumping unit

The invention discloses a horse-head overturning device of a walking-beam type oil pumping unit. The horse-head overturning device comprises an oil-pumping-machine horse head, an oil-pumping-machine walking beam, a motor, a horse-head pin seat and a horse-head pin, wherein the horse head is hinged to the walking beam by a pin shaft; the motor is arranged on the upper surface of the walking beam; the horse-head pin seat is fixed on the side surface of the horse head; the horse-head pin seat is matched with the horse-head pin; an output shaft of the motor is provided with a first gear; the upper end of the pin shaft is connected with a gear shaft of a second gear; the second gear is arranged on the other side surface of the horse head; and the first gear is meshed with the second gear. The horse-head overturning device disclosed by the invention has the beneficial effect that the motor is utilized for driving the horse head to overturn, so that the purpose of reducing the high-altitude operation of personnel is achieved; compared with the prior art, the horse-head overturning device disclosed by the invention has the advantages that the operation is simple, the use is safe, the workload of the personnel is reduced, and the like.

Owner:张健

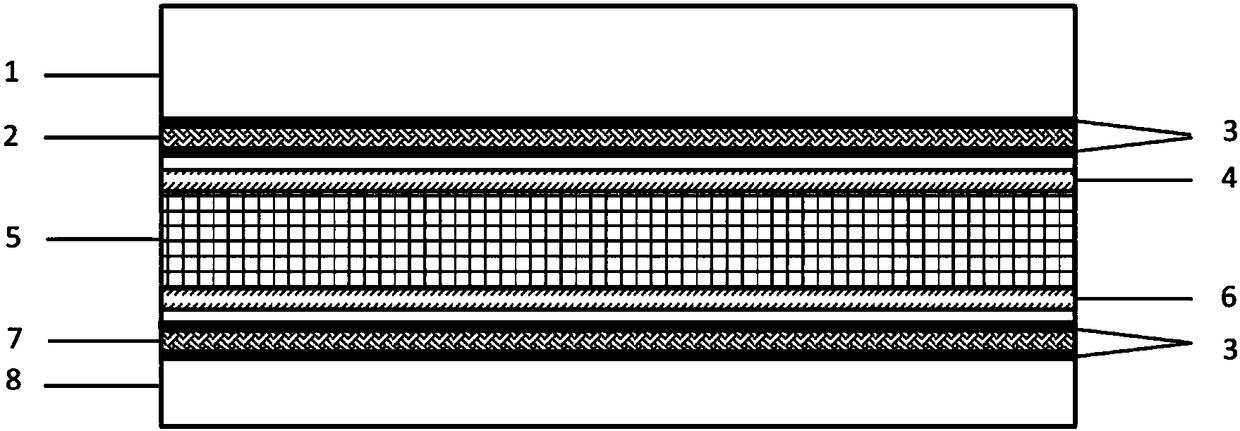

High-temperature-resistant wear-resistant lifter belt and preparation method thereof

ActiveCN108249100AMeet the operating conditionsImprove wear resistanceConveyorsWear resistantHigh intensity

The invention relates to a high-temperature-resistant wear-resistant lifter belt and a preparation method thereof and belongs to the technical field of rubber products. The high-temperature-resistantwear-resistant lifter belt is successively provided with an upper cover rubber layer, an upper canvas layer, an upper steel net layer, a middle framework layer, a lower steel net layer, a lower canvaslayer and a lower cover rubber layer from top to bottom. The high-temperature-resistant wear-resistant lifter belt also comprises adhesive rubber layers which are compounded to the upper and lower surfaces of the upper and lower canvas layers. The high-temperature-resistant wear-resistant lifter belt product is prepared by the following steps: mixing, calendering, extruding, forming and vulcanizing a conventional conveyor belt. In a continuous high-temperature working condition, the belt body can keep high strength, and does not stretch after long-term use; the steel nets are paved above andbelow the framework, so that the belt body is effectively prevented from being damaged by a hopper after the lifter belt is perforated and the hopper is mounted; the high-temperature-resistant canvaslayers play roles of isolating heat and buffering, so that the framework layer of the belt body is further protected, and bolts are favorably fastened when the hopper is mounted; the high-temperature-resistant canvas layers adopt a rubberizing formula of pure ethylene propylene rubber, so that the high-temperature-resistant wear-resistant lifter belt has a good temperature-resistant characteristic. The canvas layers and the cover rubber are adhered together well at continuous high temperatures.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

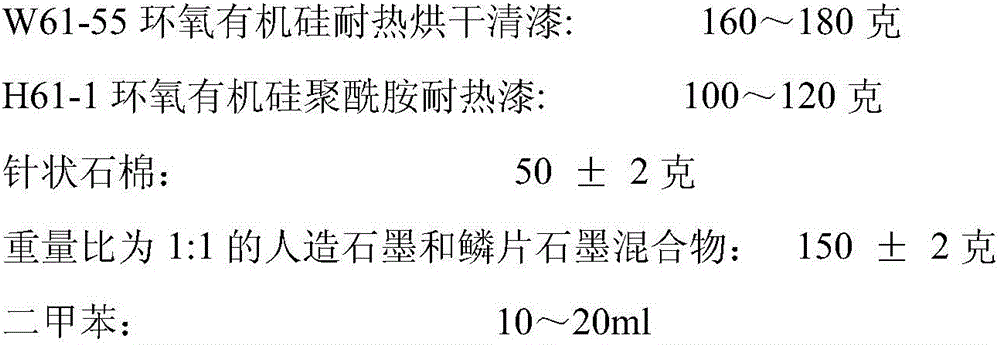

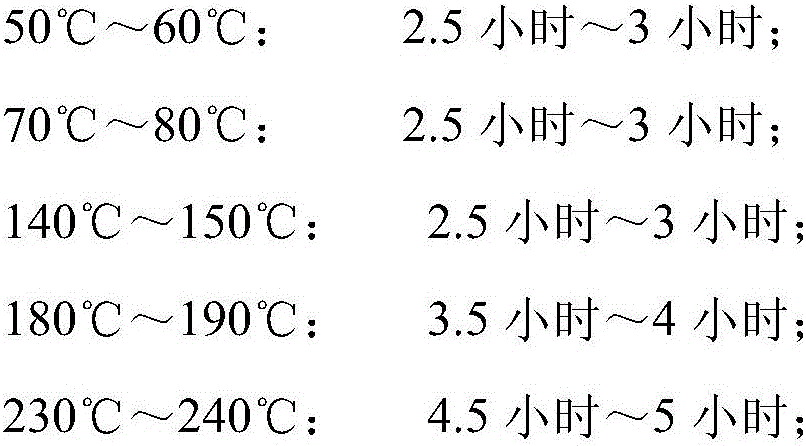

Method for coating asbestos-graphite seal coating on surface of titanium alloy parts

InactiveCN106583202AImprove heat resistanceHigh coefficient of thermal expansionFireproof paintsPretreated surfacesHeat resistanceGraphite

The invention relates to a method for coating an asbestos graphite seal coating on the surface of a titanium alloy parts. Through the steps of protecting, coating, heating curing and the like, asbestos and graphite are coated on the surface of the titanium alloy parts in a sealing way, wherein a coating material has an anti-high-low temperature cycle performance and favorable heat resistance, and can enable the coating to be more spongy. According to the method for coating the asbestos graphite seal coating on the surface of the titanium alloy parts provided by the invention, the bonding strength of the seal coating can be higher than or equal to 1MPa; and after the coating is coated on the surface of a titanium alloy gas-sealing ring, a disbonding phenomenon is avoided during subsequent processing.

Owner:HARBIN DONGAN ENGINE GRP

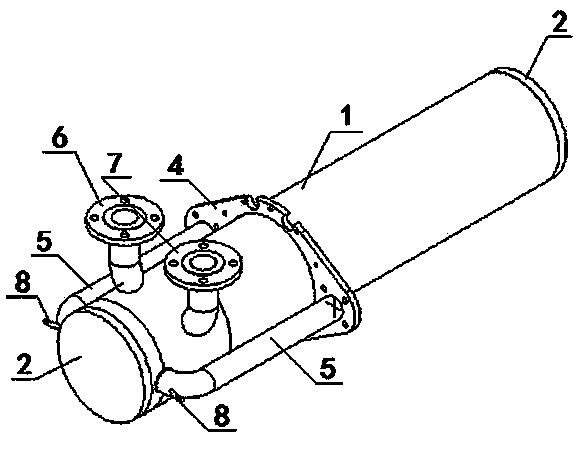

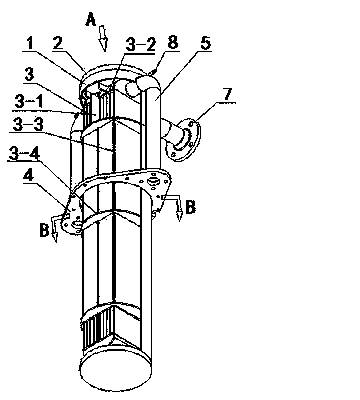

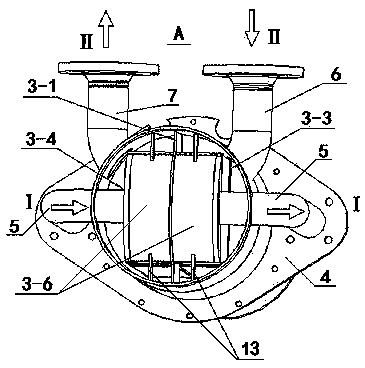

Main pump lubricating oil cooler

ActiveCN103424016AReduce resistanceNot suitable for scalingHeat exhanger sealing arrangementHeat exchanger casingsEngineeringHeat transfer efficiency

The invention relates to heat exchange equipment, in particular to a main pump lubricating oil cooler. The heat exchanger is heat exchange equipment developed specially for a nuclear power reactor main pump lubricating oil system. The heat exchanger comprises a barrel body, an upper end cover, a lower end cover, a plate bunch, a connecting flange, pipelines, an inlet flange and an outlet flange, wherein the barrel body, the upper end cover and the lower end cover form a sealed cavity of the heat exchanger, the connecting flange of a rhombic structure is arranged in the middle of the barrel body, the two L-shaped pipelines with discharge oil compensating ports are symmetrically arranged at the two sides of the barrel body, one end of each pipeline is communicated with the barrel body, the other end of each pipeline is arranged on the connecting flange, the inlet flange and the outlet flange are perpendicular to the axial direction of the pipelines and are arranged on the barrel body, and the plate bunch is arranged in the sealed cavity of the barrel body. The main pump lubricating oil cooler is simple and reasonable in structure, high in heat transferring efficiency, and convenient to install and use.

Owner:四平市巨元瀚洋板式换热器有限公司

Self-adaption lateral-bending-wear-resisting oil cylinder structure

PendingCN110259758AReduce performance requirementsAvoid unilateral stressFluid-pressure actuatorsEngineeringLateral bending

The invention belongs to the technical field of oil cylinders and particularly relates to a self-adaption lateral-bending-wear-resisting oil cylinder structure comprising a cylinder barrel, a piston rod end structure and a piston end structure. A piston rod is arranged in the cylinder barrel. The piston rod end structure and the piston end structure between the cylinder barrel and the piston rod are provided with a separated type supporting structure and a seal structure correspondingly. The piston end structure is located at the end, close to the cylinder bottom, of the piston rod in the cylinder barrel. The piston rod end structure located at the other end of the piston rod is located at the cylinder barrel. A guide sleeve is arranged between a gland and the cylinder barrel. The seal structure is located between the guide sleeve and the piston rod. The self-adaption lateral-bending-wear-resisting oil cylinder structure has the beneficial effects that the independent seal structure is adopted and does not participate in support, a seal piece fluctuates along with the piston rod and the cylinder barrel, and the situation that the seal piece is stressed unilaterally can be effectively avoided; the independent support structure is adopted, so that a larger matching interval can be adopted, and the possibility that relative movement parts except a guide ring make contact due to flexure is effectively lowered.

Owner:无锡市汉为液压气动有限公司

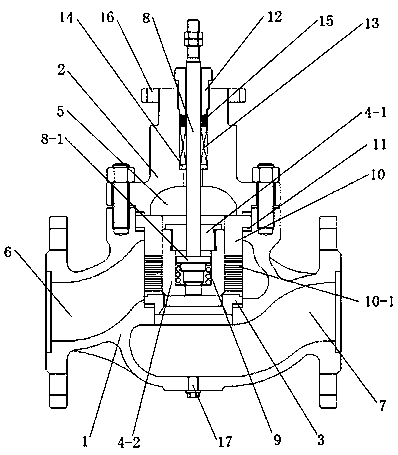

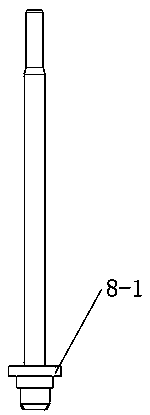

High-performance single-clack dual-seal pneumatic adjusting valve for nuclear power

InactiveCN111022667ASimple structureReasonable designSpindle sealingsOperating means/releasing devices for valvesStructural engineeringOutlet Port Valve

The invention relates to a high-performance single-clack dual-seal pneumatic adjusting valve for nuclear power. The high-performance single-clack dual-seal pneumatic adjusting valve comprises a valvebody, a valve cover, a valve seat and a valve clack assembly. The valve cover is mounted on the valve body, and a valve cavity is formed. An inlet and an outlet are arranged at the two ends of the valve body correspondingly. The valve seat and the valve clack assembly are mounted in the valve cavity in a cooperation manner, and the valve clack assembly is driven by a valve element shaft to move upand down in the valve cavity, so that the valve is opened or closed. The valve clack assembly comprises a first valve clack and a second valve clack, the first valve clack and the valve seat are opposite and are in seal fit to form outer seal, a round groove is formed in the top of the second valve clack, a round hole is formed in the bottom of the round groove, and the first valve clack covers the second valve clack. The valve element shaft sequentially penetrates through the valve cover, the valve cavity and the first valve clack in the vertical direction to stretch into the round groove, aring protrusion is arranged on the valve element shaft, the lower end of the valve element shaft is opposite to the round hole, and the valve element shaft and the round hole are in seal fit to forminner seal. The valve element shaft is further sleeved with a spring, and the two ends of the spring are fixed to the ring protrusion and the second valve clack correspondingly. The sealing performance is good, the operation torque is small, the service life is long, the cost is reduced, benefits are increased, and the use conditions of a nuclear unit are met.

Owner:南通国电阀门科技有限公司

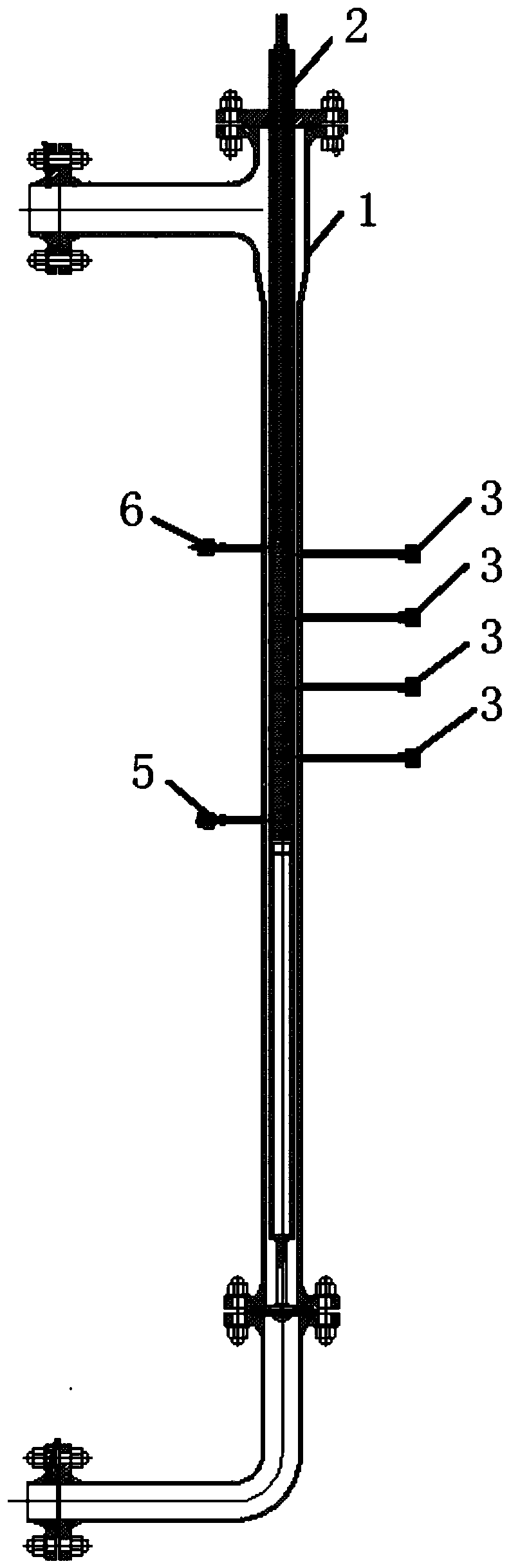

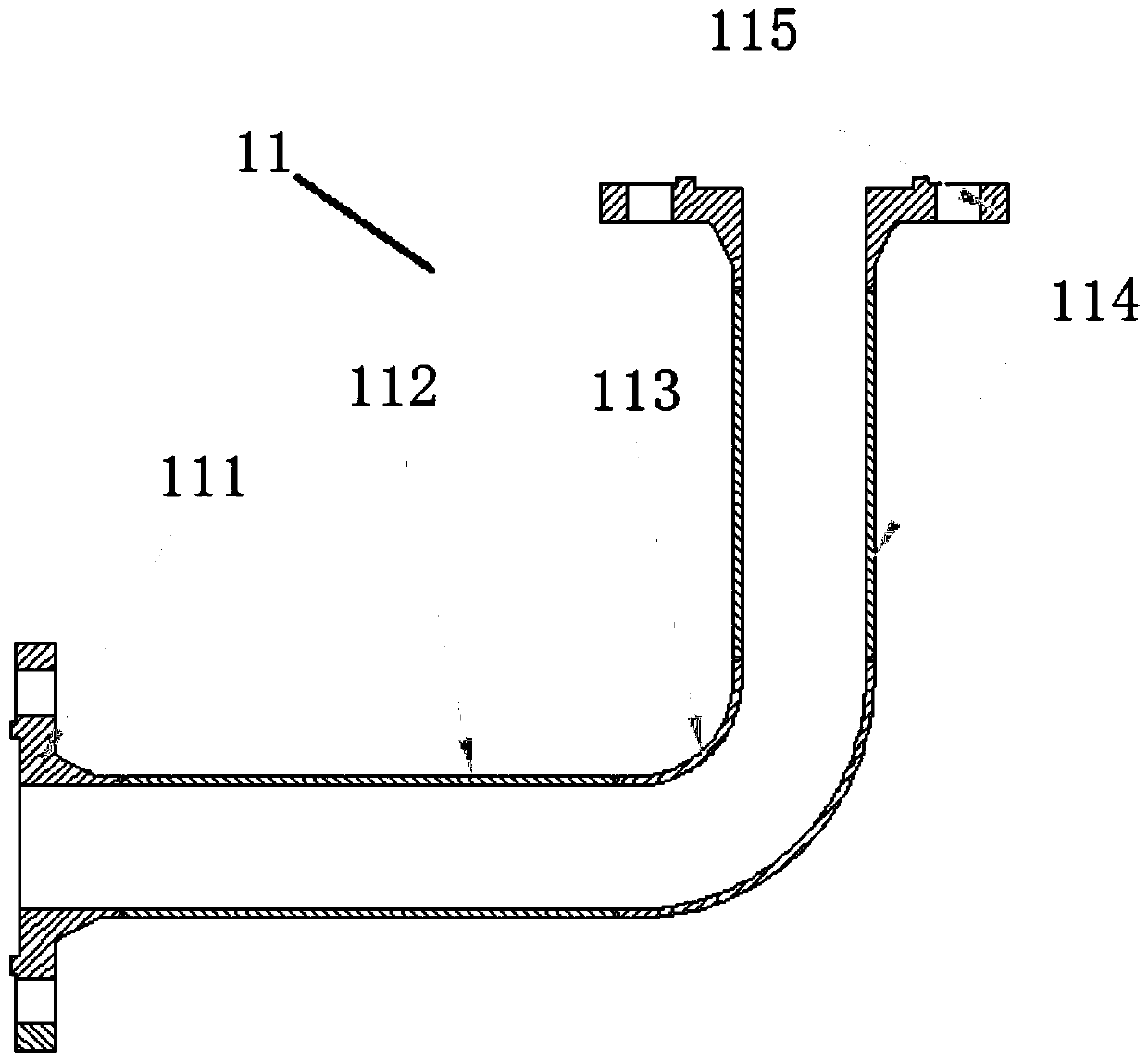

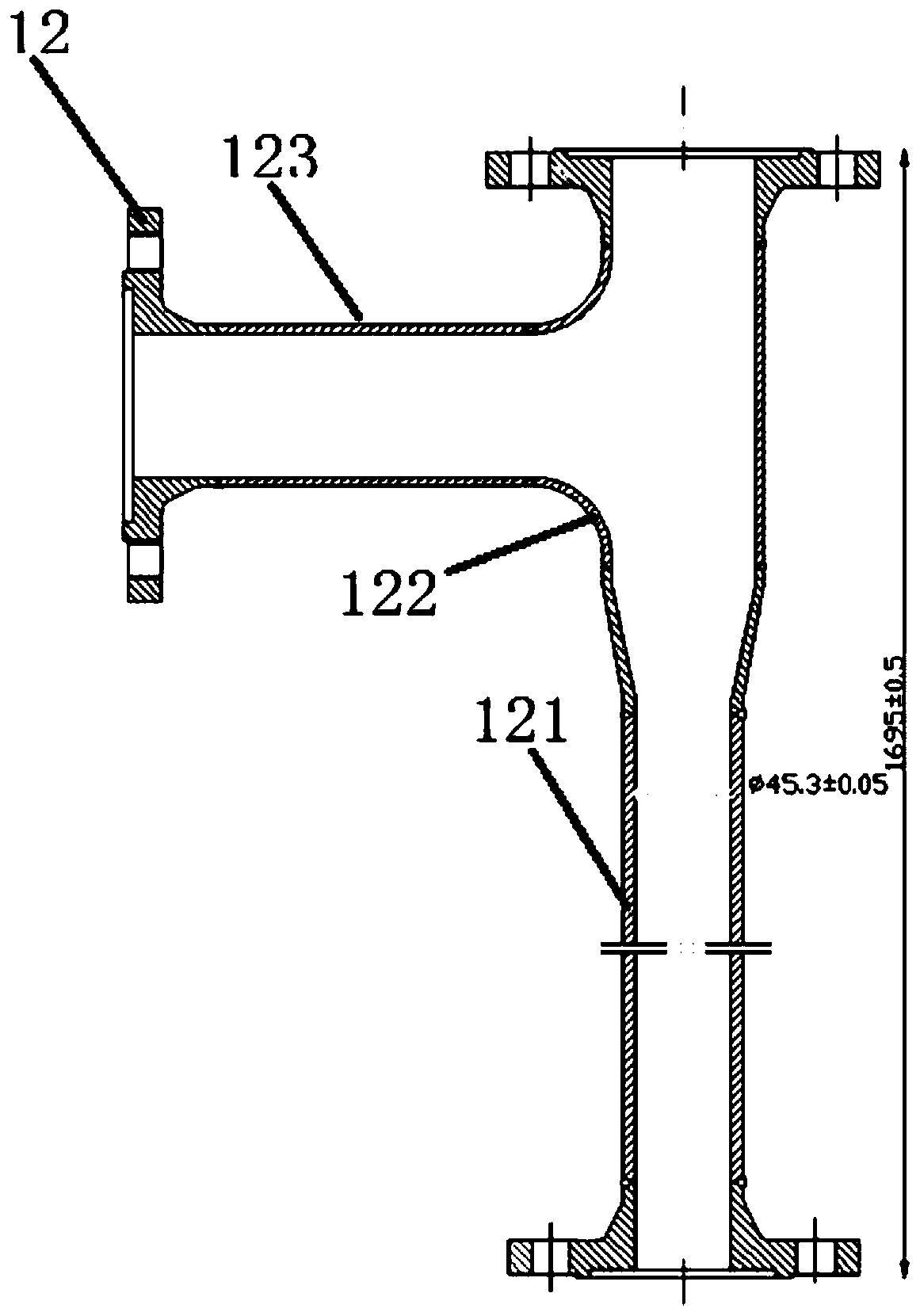

High-power thick rod fuel element simulation device

ActiveCN111161897AAvoid burningIncrease in sizeNuclear energy generationNuclear monitoringElectrically conductiveHeat flow

The invention relates to a high-power thick rod fuel element simulation device. The device comprises a heating assembly and a cylinder body; the heating assembly is sleeved in the cylinder body, and amedium circulation channel is formed between the heating assembly and the cylinder body; and the heating assembly comprises a heat conduction core rod, a screw plug, an outer conductive tube, a ceramic inner tube, a ceramic outer tube, a connecting tube and a positioning head. By reasonably arranging the interface positions of a thermocouple, a pressure gauge and a differential pressure gauge andarranging a heating section and a non-heating section in the heat conduction core rod, the operation condition of a pool type research reactor is met, high-power stable operation can be achieved, andresearch on the critical heat flux density of the pool type research reactor is achieved.

Owner:NORTHWEST INST OF NUCLEAR TECH

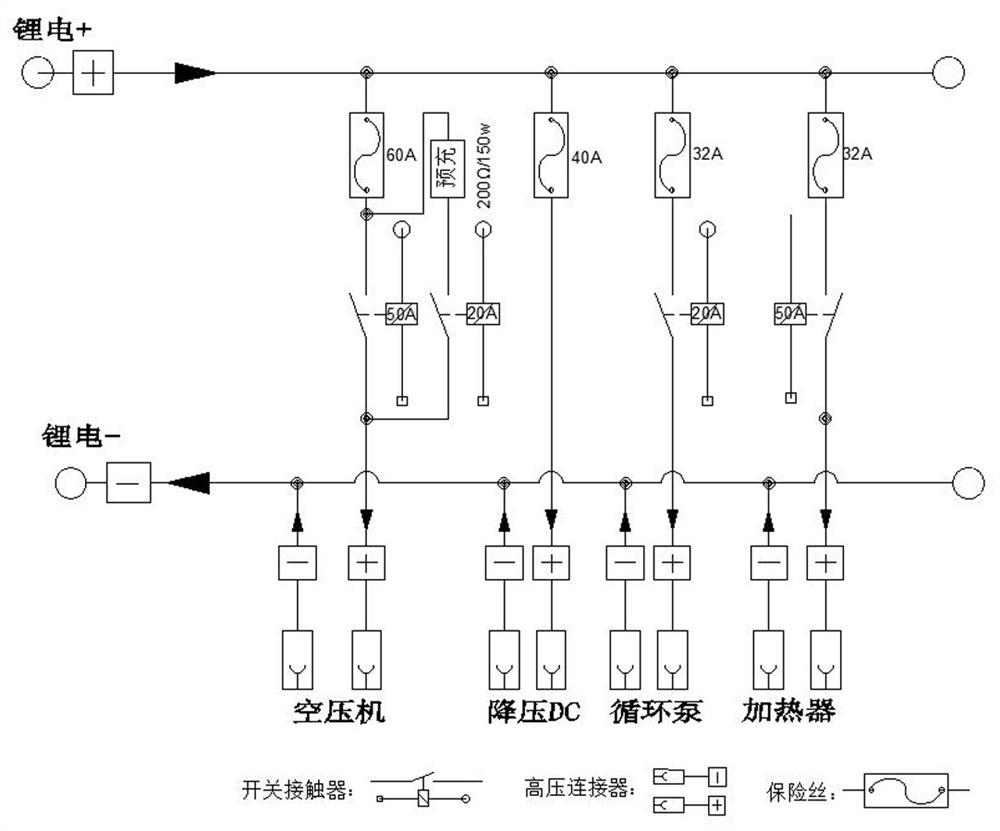

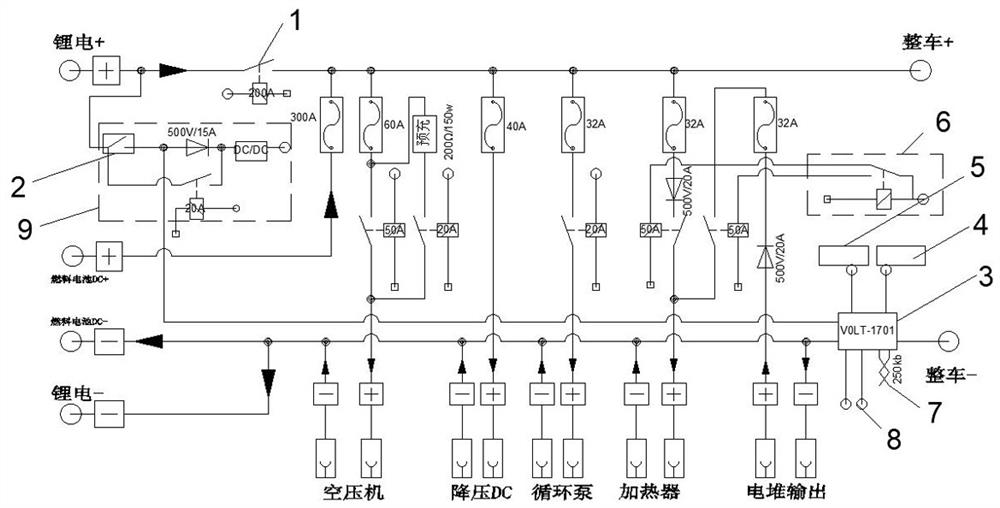

High-integration-level multifunctional high-voltage distribution box for forklift

PendingCN113479066ASolve matching puzzlesHigh system integrationBoards/switchyards circuit arrangementsElectric devicesForklift truckFuel cells

The invention relates to a high-integration-level multifunctional high-voltage distribution box for forklift, which comprises a lithium battery interface, the lithium battery interface is connected with a whole vehicle interface through a bus, and a lithium battery main contactor is arranged at the front end of the bus; the bus is provided with a fuel cell branch connected with a fuel cell interface and a plurality of power device branches used for connecting power devices, the tail end of each power device branch is provided with a high-voltage connector, and the bus is provided with a power acquisition module used for detecting voltage and current. A lithium battery interface and a fuel battery interface are designed, in the system starting stage, a lithium battery serves as a main energy source of the whole forklift system, and a starting power source of a fuel battery is provided by the lithium battery; along with the gradual increase of the output power of the fuel cell, the main energy source is the fuel cell, and the fuel cell not only can provide power for the operation of the whole vehicle, but also can charge the lithium battery, so that the matching problem of the double-source hybrid power system is solved, the system integration degree is higher, and the flexibility is higher.

Owner:金华氢途科技有限公司

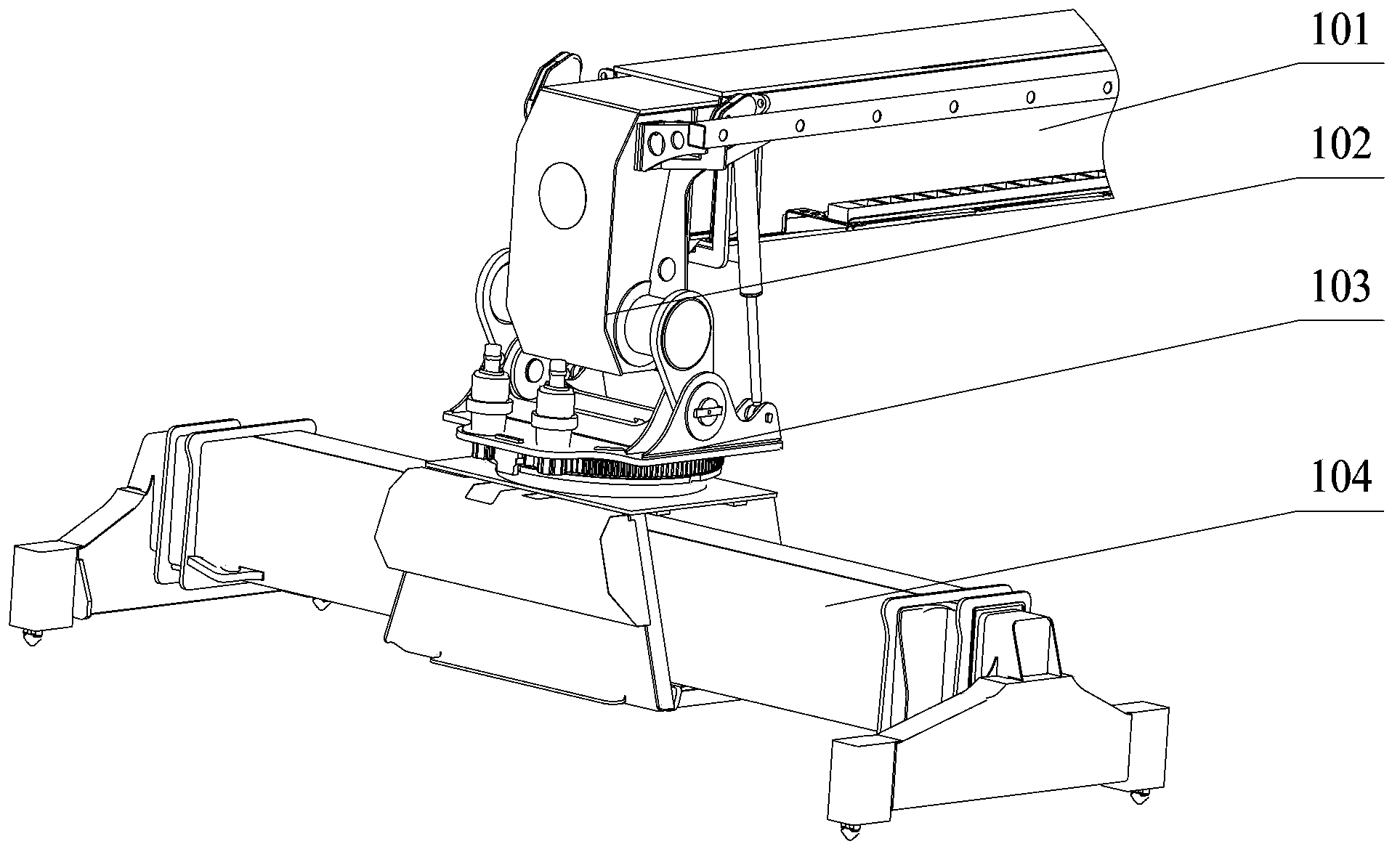

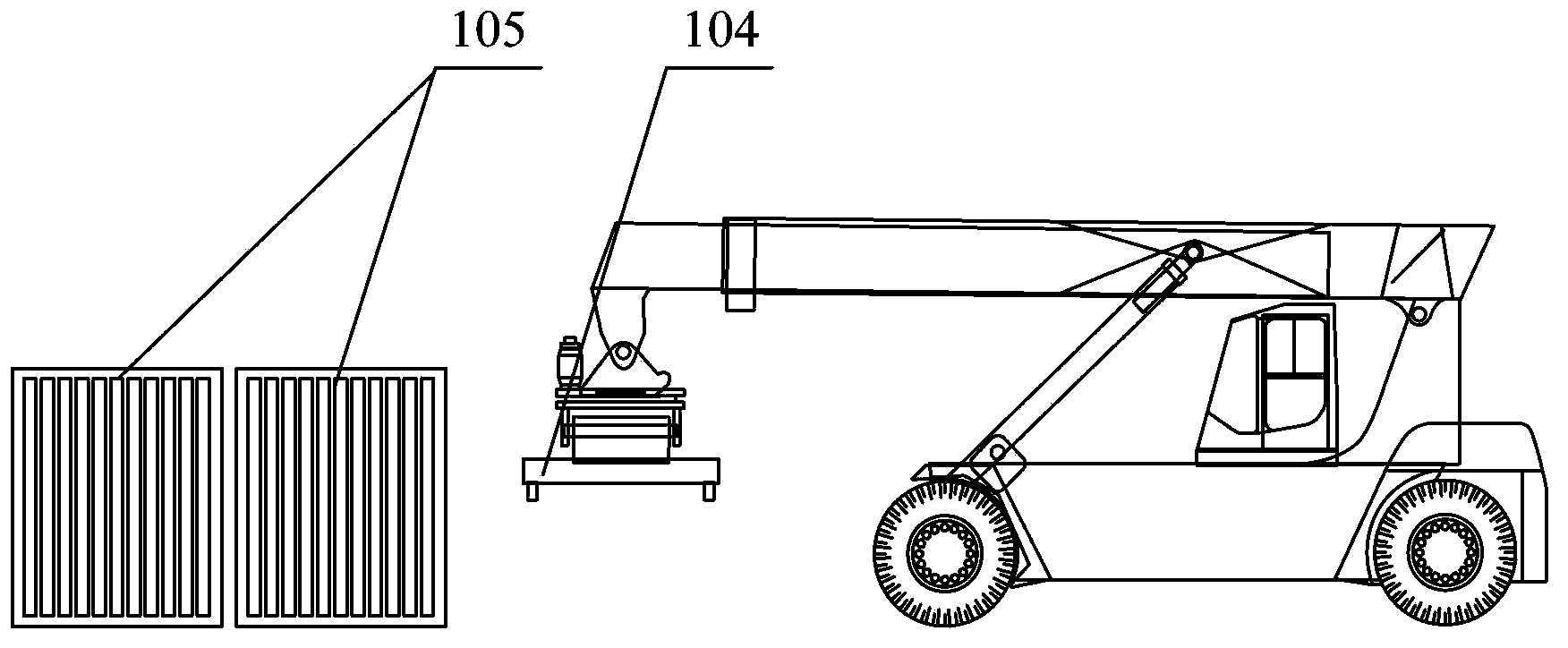

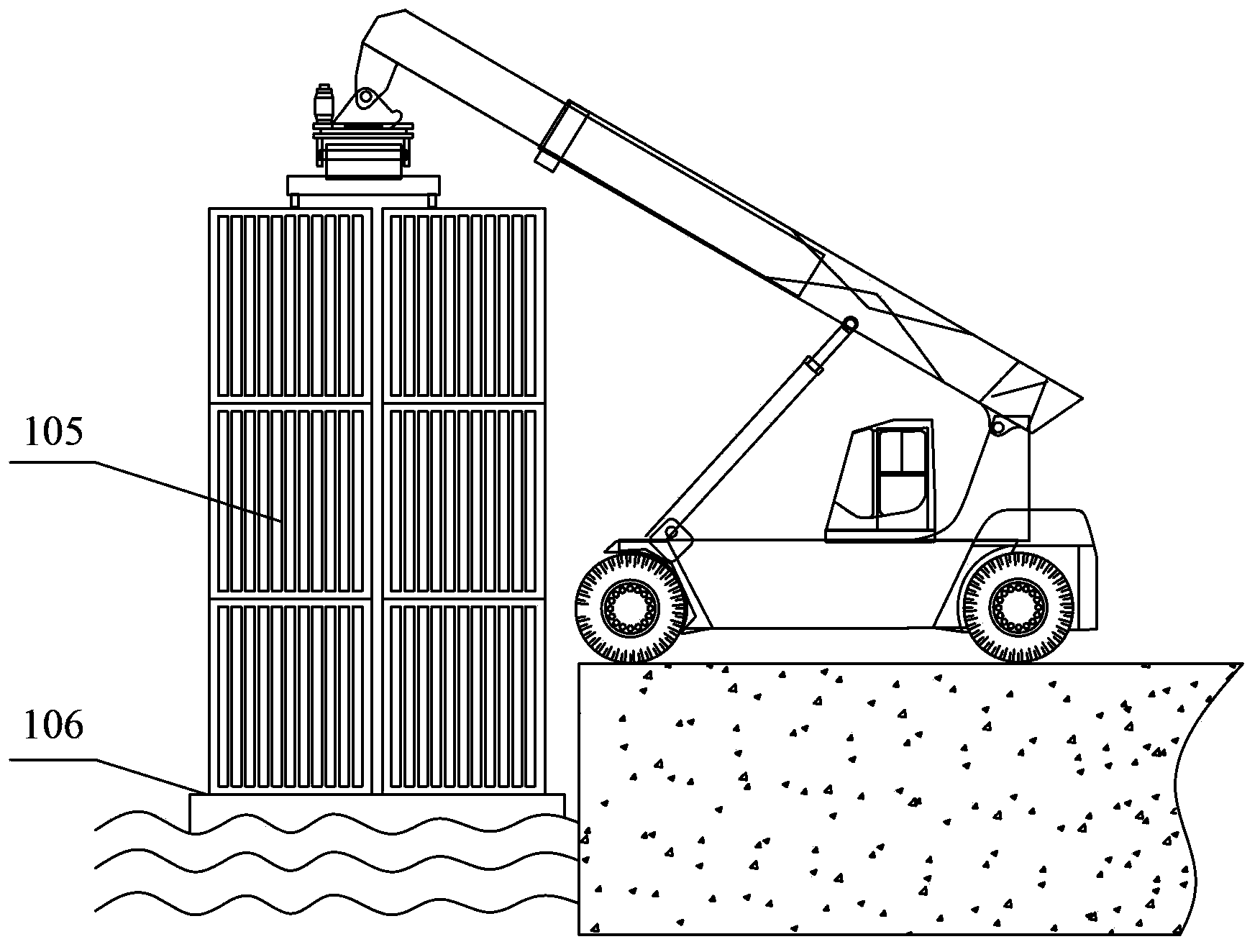

Crane boom head system and crane

The invention discloses a crane boom head system which comprises a crane boom head and a hanger connecting structure, and further comprises an expansion device, one end of the expansion device is connected with the crane boom head, and the other end of the expansion device is connected with the hanger connecting structure. The crane boom head system provided by the invention can meet the requirements of a traditional operation site, is also suitable for sites requiring negative angle operation, and meets the operating conditions of sites such as railroad relay stations, barge berths and the like. According to the invention, on the basis of not increasing auxiliary devices such as special hangers and the like, whole vehicle working condition and application range are expanded. The invention further discloses a crane provided with the crane boom head system.

Owner:XUZHOU HEAVY MASCH CO LTD

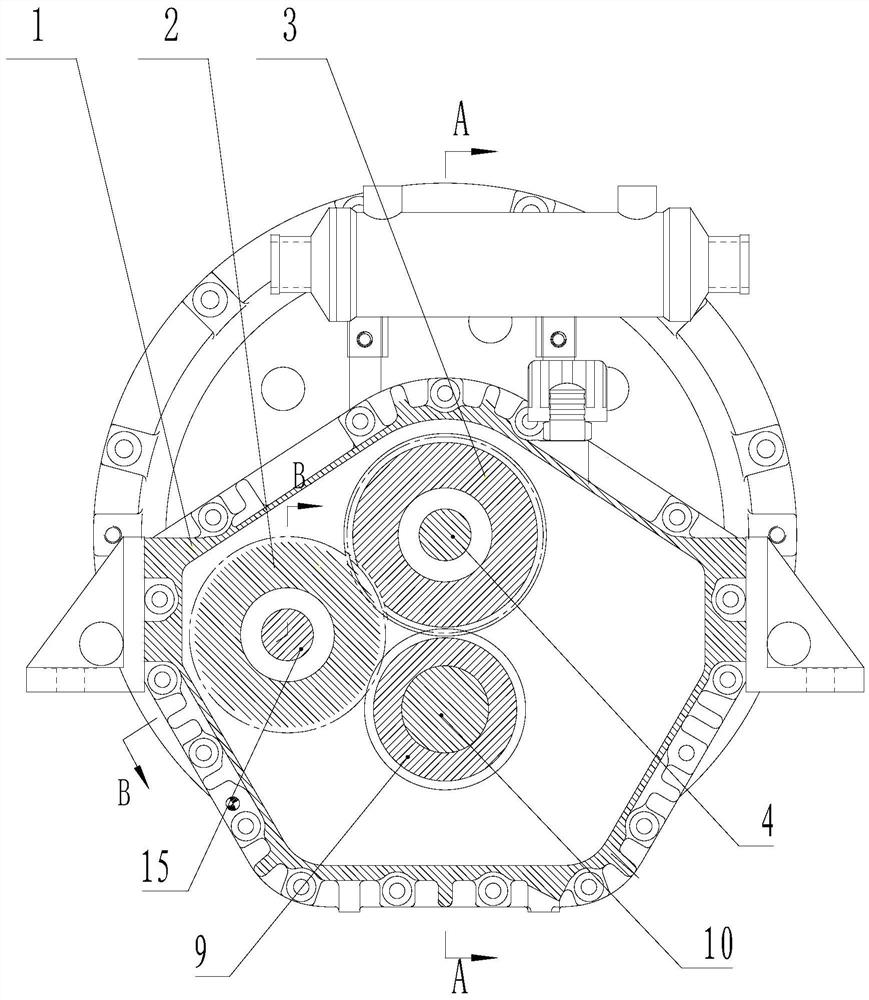

Gearbox special speed ratio structure

PendingCN111853174AMeet the operating conditionsResolve mutual interferenceToothed gearingsDrive shaftGear wheel

The invention discloses a gearbox special speed ratio structure, and relates to the field of transmission devices. The gearbox special speed ratio structure comprises a box body, wherein an ahead running transmission gear is fixedly arranged in an input shaft of the box body, an ahead running clutch is arranged in the ahead running transmission gear, an ahead running driving gear sleeves the inputshaft, the ahead running driving gear is engaged with the ahead running transmission gear fixedly mounted on an output shaft, a driven gear is meshed with a reversing driving gear, the reversing driving gear sleeves a transmission shaft, a reversing clutch is arranged in a reversing transmission gear fixedly mounted on the transmission shaft, and the output end of the output shaft is provided with an output shaft joint for outputting power; and the ahead running transmission gear meshes with the reversing transmission gear. The gearbox special speed ratio structure has the beneficial effectsthat when the rotating speed of a diesel engine of an existing yacht, a working boat and a speed yacht is not enough, the speed can be improved by connecting a gearbox, so that the working condition of a high-speed propulsion device is met.

Owner:杭州萧山江南通用机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com