Patents

Literature

148results about How to "Adjust hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy acrylate modified waterborne alkyd resin and preparation method and application thereof

The invention discloses an epoxy acrylate modified waterborne alkyd resin and a preparation method and an application thereof. The method comprises the steps: firstly, synthesizing a waterborne alkyd resin from a polyol, a polybasic acid and an oil monomer by adopting a dehydration condensation reaction; then carrying out an epoxy resin ring opening reaction to graft onto the waterborne alkyd resin so as to modify the waterborne alkyd resin; followed by carrying out free radical solution polymerization of acrylic soft and hard monomers with the modified alkyd resin, and modifying the alkyd resin by using acrylic ester; and finally pumping out a part of a polymerization solvent to neutralize the obtained waterborne alkyd resin, adding a cosolvent, and dispersing the alkyd resin to prepare an aqueous dispersion by adopting a high-speed disk dispersion machine and with water as a dispersion medium. In the addition to retaining own excellent characteristics, the modified alkyd resin also has good dryness, adhesive power and corrosion resistance of epoxy resin and the acrylic resin advantages of excellent drying, water resistance, chemical medicine resistance, high hardness, good weathering resistance and the like, and effectively improves the alkyd resin performance of water resistance, weather resistance and the like.

Owner:SOUTH CHINA UNIV OF TECH

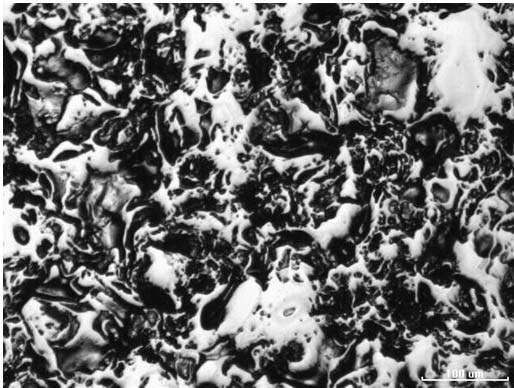

Iron-based high-titanium wear-resistant surfacing flux-cored welding wire

InactiveCN101664862AAchieving wear resistanceImprove performanceWelding/cutting media/materialsSoldering mediaBorideCrazing

The invention relates to an iron-based high-titanium wear-resistant surfacing flux-cored welding wire. Among a plurality of types of the prior wear-resistant surfacing welding wires and alloys, some alloys have favorable wearing resistance, and some alloys have great brittleness, lower toughness and easy cracking and are not suitable for the existence of low-impact grinding wear working condition.The iron-based high-titanium wear-resistant surfacing flux-cored welding wire comprises a low-carbon steel ladle clad and core powder as well as the following alloy elements in percentage by weight:1.0-3.0 C, 1.0-12.0 Ti, 0.5-9.0 V, 0.1-1.5 Si, 0.2-2.0 Mn, 0-3.0 B, 0.00-0.10 RE, 0-13.0 Cr, 0-1.0 Mo, 0-1.0 W, 0-2.0 Ni, 0-0.5 Nb and 0-0.5 Zr. The iron-based high-titanium wear-resistant surfacing flux-cored welding wire realizes the wear-resistant performance of the alloys mainly by carbides and borides formed by the alloy elements of C, Ti, V, and the like as well as a small amount of B element and adjusts the combination of the elements of C, Ti, V, Si, Mn, B, and the like to adjust the alloy hardness, enhance the toughness and lower the crack sensitivity.

Owner:王新虎

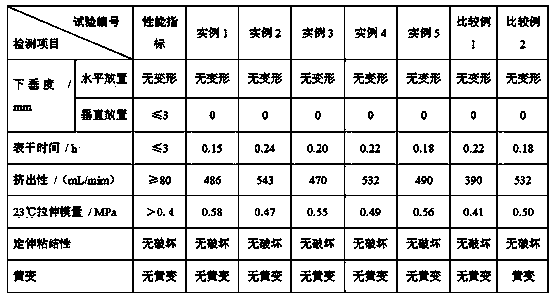

Room-temperature moisture-curable single-component flame-retardant polyurethane sealant

ActiveCN102504752AGood flame retardantNo reduction in physical propertiesNon-macromolecular adhesive additivesOther chemical processesPlasticizerRoom temperature

The invention discloses a room-temperature moisture-curable single-component flame-retardant polyurethane sealant and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 30-55 parts of liquid polyether type polyurethane pre-polymer base stock, 10-30 parts of flame-retardant plasticizer, 0.1-1 part of silane coupling agent, 15-30 parts of flame-retardant powder, 10-30 parts of filler, 0.01-0.05 part of catalyst and 0.2-3 parts of methyl benzenesulfonyl isocyanate, wherein the liquid polyether type polyurethane pre-polymer base stock is prepared from the following raw materials in parts by weight: 32.8-57.64 parts of common polyether glycol, 28.82-54.67 parts of flame-retardant polyether glycol, 12.51-13.53 parts of polyisocyanates, and 0.01 part of catalyst. The room-temperature moisture-curable single-component flame-retardant polyurethane sealant is excellent in physical performance, thixotropic property and flame-retardant performance, and convenient for construction.

Owner:SHANDONG NORTH MODERN CHEM IND

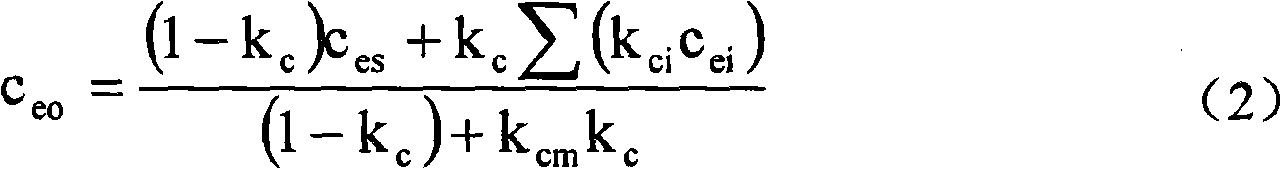

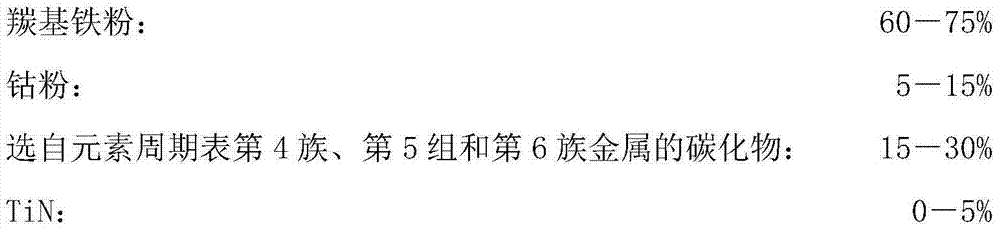

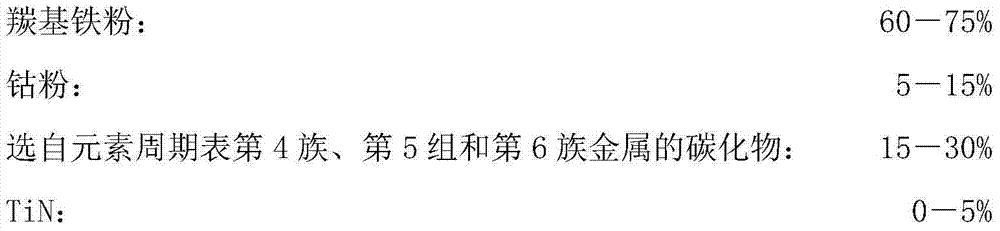

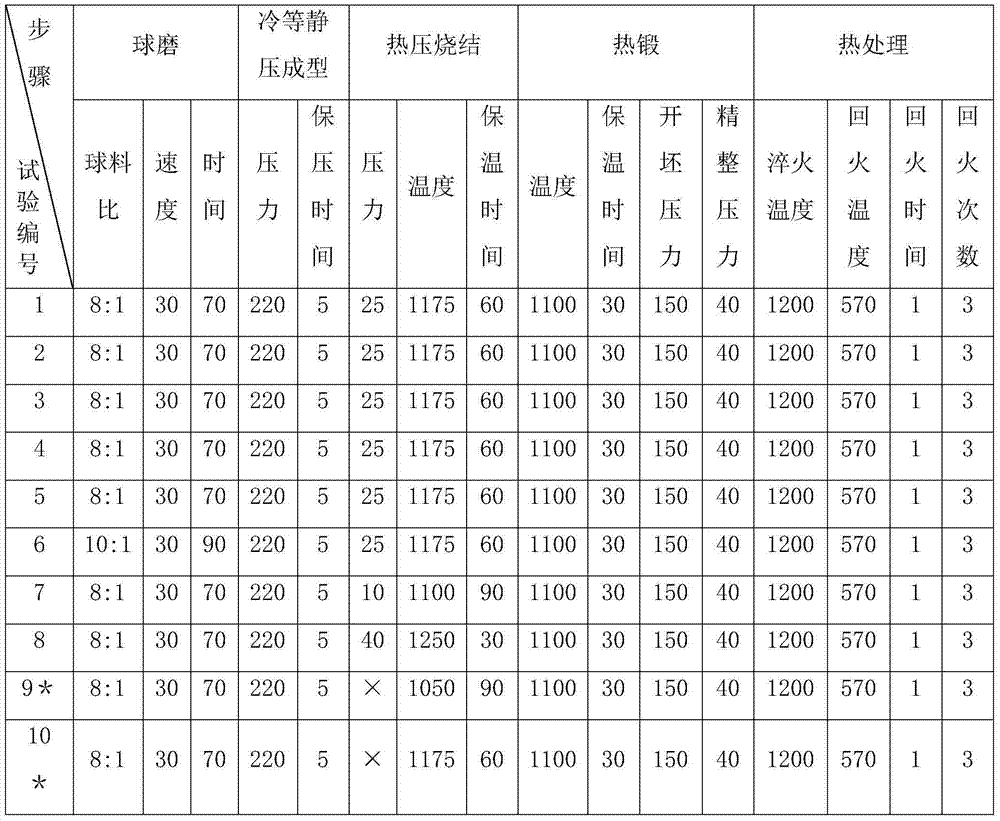

Powder metallurgy high-speed steel and preparation method thereof

The invention discloses powder metallurgy high-speed steel and a preparation method thereof. The method is simpler than the existing powder metallurgy high-speed steel preparation method, steps of high-speed steel mother alloy smelting, atomization for making powder and hot isostatic pressing are omitted, great equipment investment is not needed and the production cost of powder metallurgy high-speed steel is reduced. The impurity content of the powder metallurgy high-speed steel prepared by adopting the method provided by the invention is low and the using performance is excellent. The powder metallurgy high-speed steel provided by the invention is prepared through the steps of 1) preparing powder mixture: weighing raw materials according to set components and proportioning ratio, and mixing and ball-milling the raw materials in a roller-type ball mill to obtain the powder mixture; 2) molding: molding the powder mixture into pressed blanks through cold isostatic pressing; 3) sintering: sintering the pressed blanks in a vacuum or inert gas atmosphere by adopting a hot-pressing sintering technology, heating the pressed blanks to 1100-1250 DEG C during sintering, preserving heat for 30-90 minutes and keeping sintering pressure to be 10-40Mpa; 4) hot forging; 5) heat treatment.

Owner:长沙市萨普新材料有限公司

Damping products made from foamed rubber, and production method

A vibration damping foam rubber product with excellent vibration damping performance and antiageing nature is proportionally prepared from three-element ethylene propylene rubber, filler, softening agent, sulfurizing system and foaming system through pugging, sulfurizing at 140-180 deg.C for 5-10 min for primary sulfurizing-foaming to shape, and sulfurizing at 120-180 deg.C for 10-30 min for secondary sulfurizing-foaming to fixate its shape.

Owner:SHANGHAI JIAO TONG UNIV +1

A high-boron iron-based wear-resistant surfacing flux-cored wire

InactiveCN102284806ASmall sizeAchieving wear resistanceWelding/cutting media/materialsSoldering mediaBorideWear resistant

The invention relates to a high-boron iron-based wear-resistant surfacing flux-cored welding wire. The welding wire is composed of a low-carbon steel sheath and a core powder. It is characterized in that the iron element in the low-carbon steel sheath and the core powder are contained in the core powder. Elements include boron, carbon, manganese, and silicon. The weight percentage of boron, carbon, manganese, and silicon in the core powder of the welding wire is: boron 6 to 12%, carbon 0.1 to 3%, manganese 0.6 to 2%, silicon 0.3~1.5%, the balance is iron. It can also include Ti0.3~3.5%, Mn 0.6~2%, Si0.3~1.5%, molybdenum 0~1%, K / Na modifier 0~1%, and aluminum-magnesium alloy 0~1.5%. The high boron iron-based wear-resistant cladding flux-cored welding wire of the present invention mainly relies on boron, titanium, carbon and other alloying elements to form boride and a small amount of carbide to achieve the wear resistance of the cladding alloy, and by adding rare earth, nickel, Aluminum-magnesium alloys, etc. improve the overall performance of cladding alloys.

Owner:BEIJING UNIV OF TECH +1

Thermoplastic elastomer composition for bonding ABS and preparation method thereof

The present invention relates to a thermoplastic elastomer composition for bonding ABS and a preparation method thereof. The composition is prepared by raw materials with the following weight proportion: 40 to 70 percents of polyurethane (TPU), 5 to 20 percents of SEBS, 10 to 30 percents of extending oil, 2 to 5 percents of SEBS-g-MAH, 0 to 30 percents of active calcium carbonate and 0.1 to 0.5 percent of antioxidant. The preparation method comprises the following steps of: weighting the raw materials according to weight proportion, mixing SEBS and white oil evenly in high mixing machine, then adding other raw materials and mixing for 2 to 5 minutes, discharging; putting the raw materials mixed evenly into an extruser for prilling. The invention has the characters that the prepared thermoplastic elastomer not only has good bonding property with ABS and PC, but also has adjustable hardness according to the client requirements, and can be used for producing handle sheath, cushion pad, and the like.

Owner:SHANGHAI SUNNY

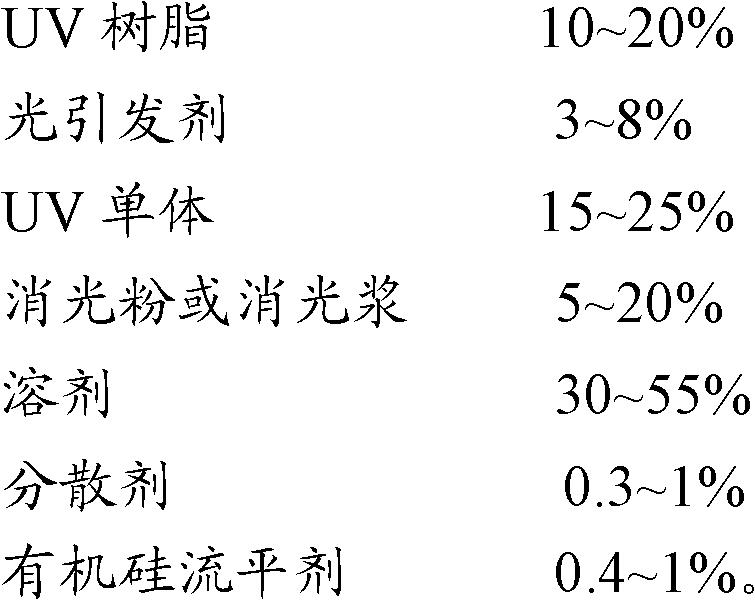

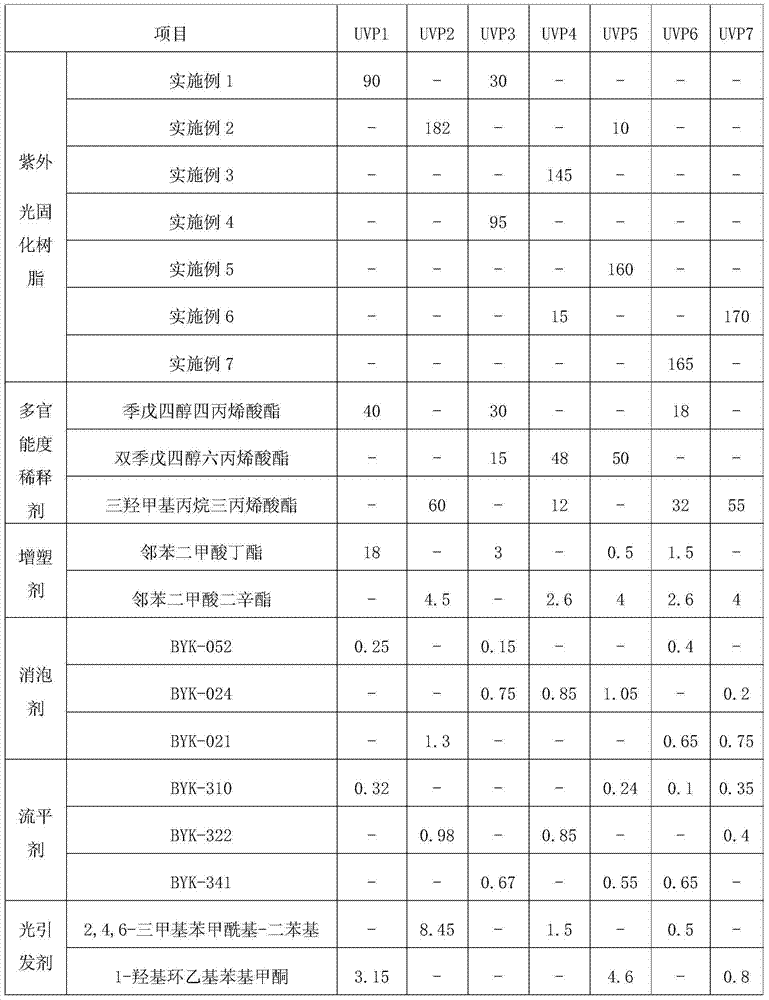

UV (Ultraviolent) deglossing paint and preparation method thereof

ActiveCN102229779ASolve the problem of uneven gloss and prone to bloomingEvenly distributed without bloomingPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceSlurry

The invention discloses a UV (Ultraviolent) deglossing paint and a preparation method thereof. The deglossing paint contains the following components by weight percent: 10 to 20% of UV resin, 3 to 8 % of light initiator, 15 to 25% of UV monomer, 5 to 20% of deglossing powder or deglossing slurry, 30 to 55% of solvent, 0.3 to 1% of dispersing agent and 0.4 to 1% of organosilicon leveling agent. The method comprises the following steps of: dispersing the light initiator, the dispersing agent and the organosilicon auxiliary into the solvent in advance, then adding the deglossing powder or the deglossing slurry, uniformly dispersing the solvent added with the deglossing powder or deglossing slurry to the fineness smaller than 25 mum, and finally adding and uniformly dispersing the UV resin and the UV monomer. In the formula provided by the invention, the hardness and brittleness of a paint film are regulated by controlling the type and amount of the UV monomer and the UV resin, and the paint film has good hardness and becomes brittle hardly. According to the invention, the solvent and the dispersing agent are firstly used to disperse the deglossing powder uniformly, thus avoiding the interaction of the deglossing powder and resin components; and since the deglossing powder is uniformly distributed in the paint film, the paint film is basically free from the floating phenomenon.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Aeroengine case seam allowance size repairing method

The invention relates to an aeroengine case seam allowance size repairing method. The porosity and hardness of a coating and the content of oxides in the coating can be effectively adjusted by controlling the plasma spraying power and the heating process of spraying powder during flying, and heat stress of the coating is reduced. The hardness and thermal expansion coefficient of the prepared nickel-aluminum coating are equivalent with those of a case, the bonding strength of the coating is far higher than the stress strength of a case seam allowance under the given working condition, and the use working condition of the aeroengine case can be met.

Owner:HARBIN DONGAN ENGINE GRP

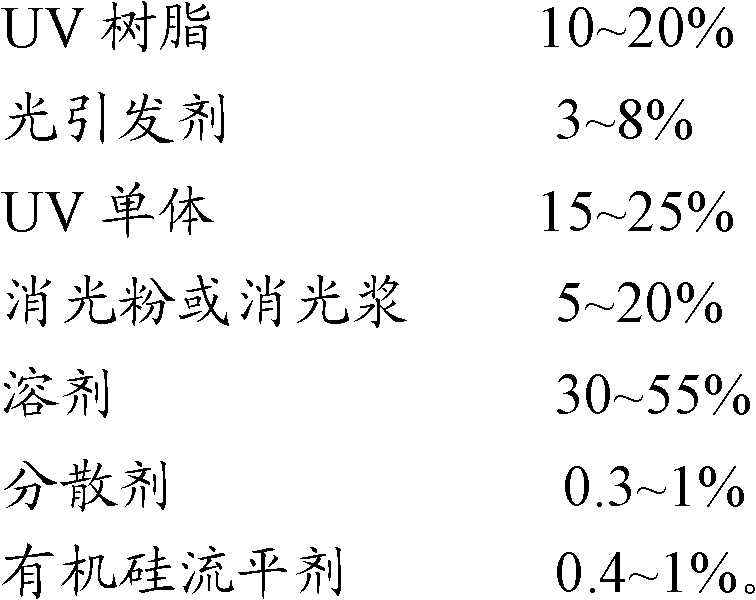

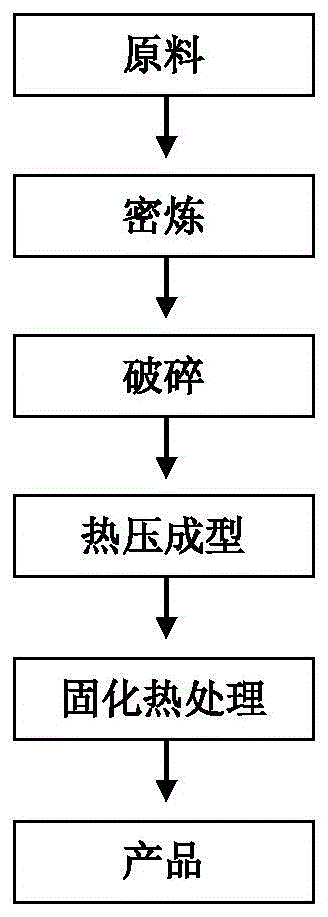

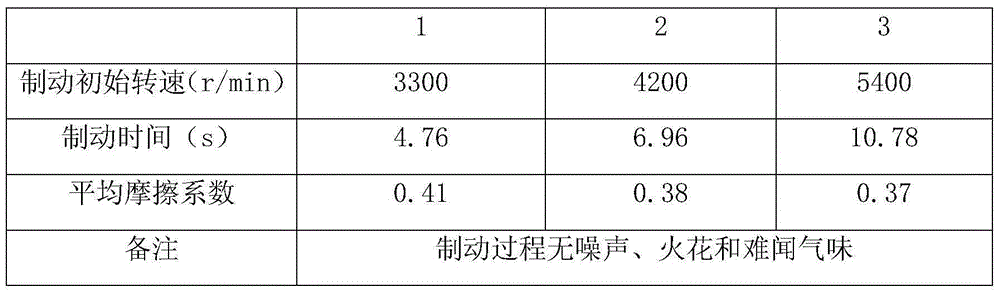

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

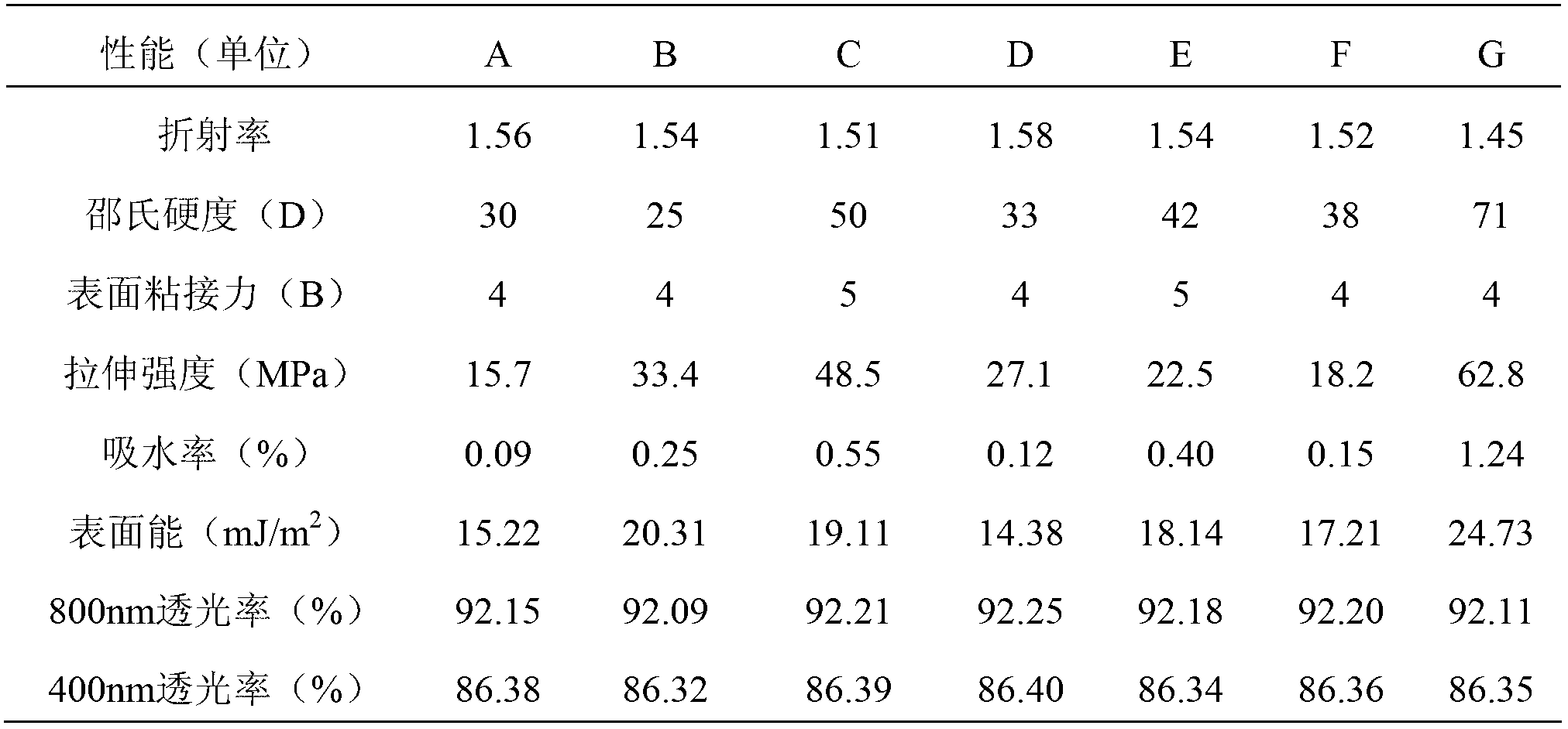

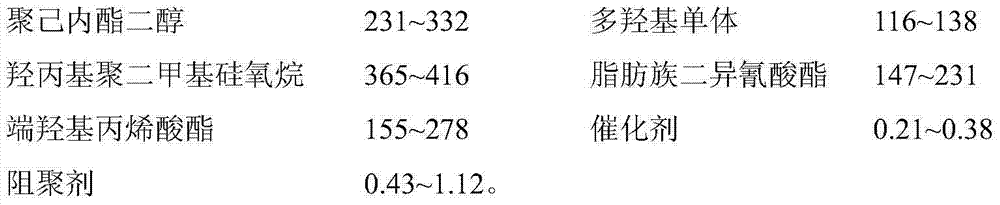

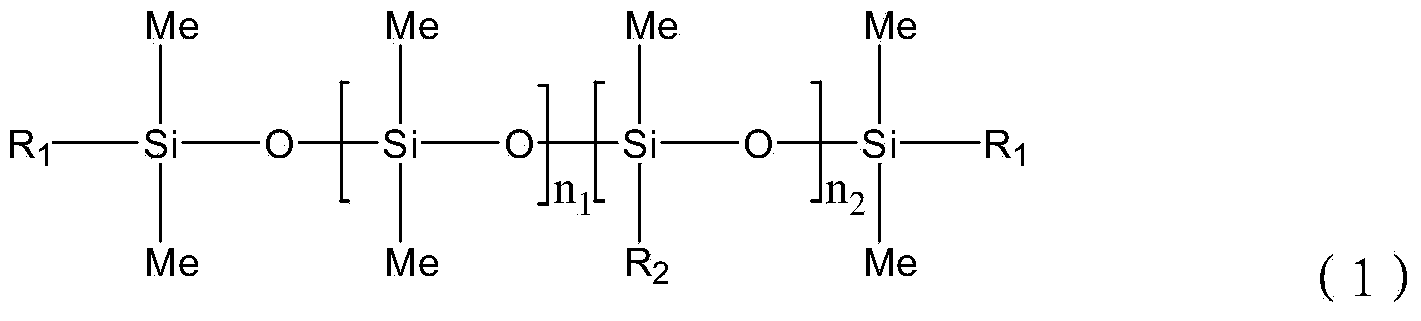

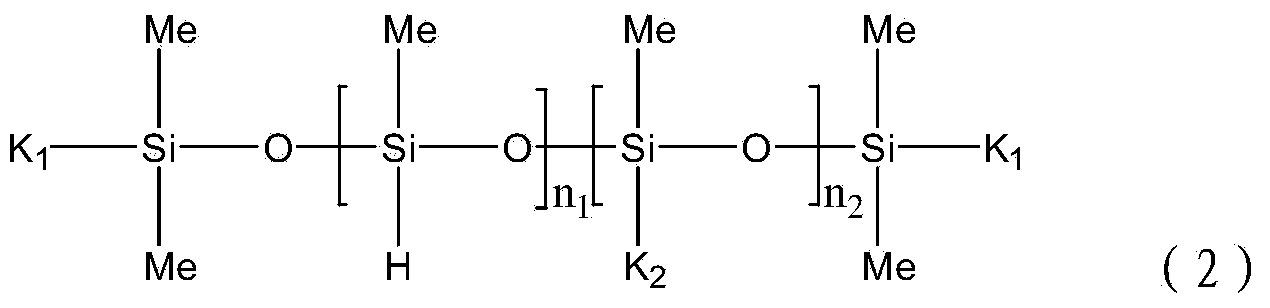

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

ActiveCN102702532AEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyAdhesive

The invention discloses a method for preparing organosilicone hybrid resin and a power type encapsulating material for light-emitting diodes (LED) thereof and application. According to the method, the organosilicone hybrid resin containing three functional groups of an epoxy group, a fluorin group and a phenyl group is prepared by a cohydrolysis condensation method, and the content of each group in the resin is optimized by controlling the ratios of fluoro alkyl silicane, epoxy alkyl silicane and phenyl silicane, so that the resin is applied to the power type encapsulating material for the LEDs. The prepared encapsulating material has the advantages of epoxy resin and organosilicone, has high performance of high light transmittance and refractive index, low hygroscopicity, high mechanical property and ageing-resistant performance and the like, and the problems of low light output rate, short service life and the like of the LEDs due to dropping caused by low bonding strength and poor mechanical property of the ordinary organosilicone material for encapsulating LEDs are solved. The method for preparing the organosilicone hybrid resin and the power type encapsulating material for the LEDs is simple, and raw materials are readily available and environment-friendly; and the organosilicone hybrid resin can also be used as the raw materials to be applied to processing and preparation of optical lens materials, photovoltaic conversion materials, integrated circuit encapsulating materials, insulating materials, coating materials, adhesives and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

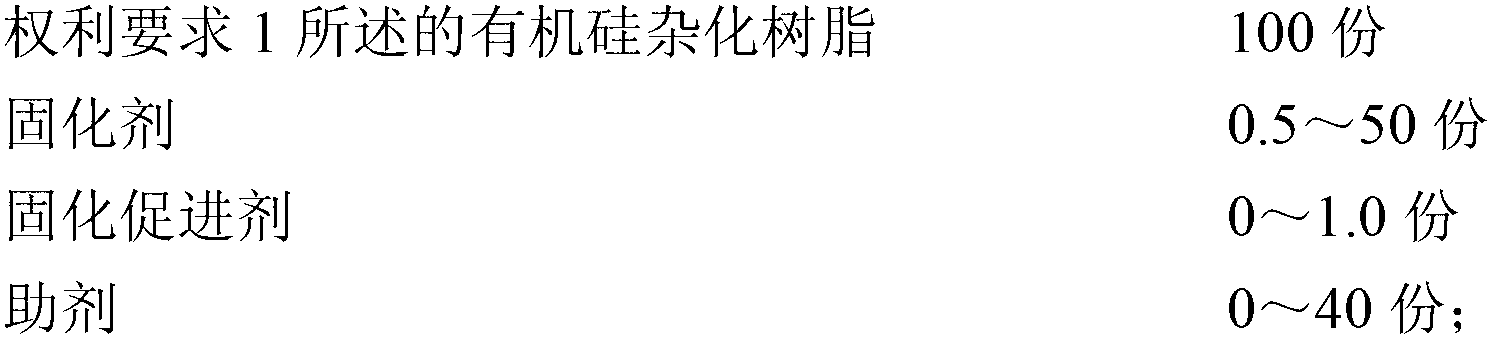

UV curing resin, preparation method thereof and coating prepared therefrom

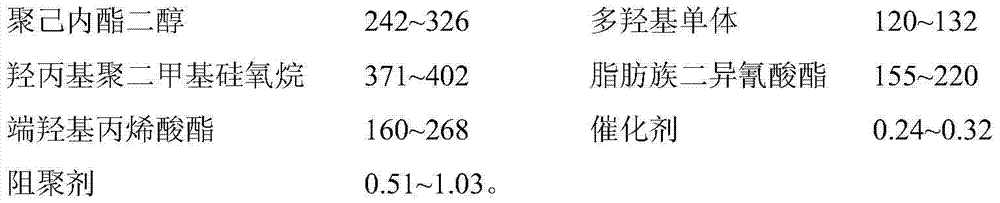

ActiveCN103483537AAdjust hardnessHigh hardnessPolyurea/polyurethane coatingsPolymer scienceBackbone chain

The invention provides a UV curing resin. The UV curing resin comprises the following raw materials: polycaprolactone glycol, a polyhydroxy monomer, hydroxypropyl polydimethylsiloxane, aliphatic diisocyanate, hydroxy-terminated acrylic ester, a catalyst and a polymerization inhibitor. The UV curing resin is aliphatic polyfunctional urethane acrylate, and the backbone structure of the resin contains an internal cross-linked structure formed by the polyhydroxy monomer and the aliphatic diisocyanate; as the aliphatic diisocyanate is used, the internal cross-linked structure can not enable a paint film to be fragile while improving the hardness of the paint film; through reaction between the hydroxypropyl polydimethylsiloxane and the aliphatic diisocyanate, a siloxane structure is introduced into the backbone of the UV curing resin, so that the UV curing resin has excellent light transmittance. The invention also discloses a preparation method for the UV curing resin, as well as a UV curing coating prepared from the UV curing resin, and the UV curing coating also has high abrasion resistance and excellent light transmittance.

Owner:HUNAN BENAN YADA NEW MATERIALS

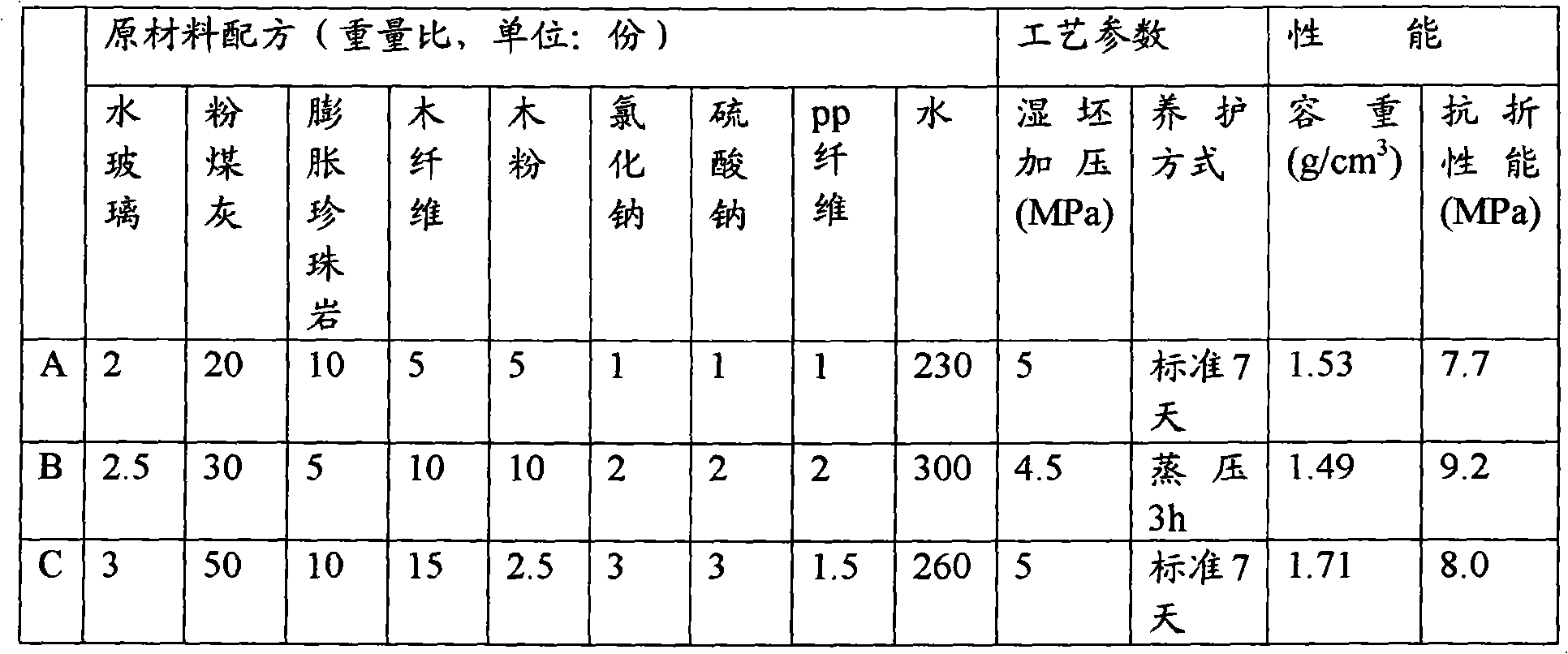

Light-weight fiber reinforced cement board and manufacturing method thereof

ActiveCN101781106AHigh tensile strengthHigh impact strengthSolid waste managementCement boardMethyl cellulose

The invention provides a light-weight fiber reinforced cement board. The light-weight fiber reinforced cement board comprises 100 parts of cement, 20 parts of silicon powder, 15 parts of calcium powder, 5 to 10 parts of expanded perlite, 4 parts of paper pulp, 5 to 15 parts of wood fibers, 5 to 10 parts of wood powder, 1 to 2 parts of polypropylene fibers, 0.8 part of methyl cellulose, 1 to 3 parts of sodium chloride, 1 to 3 parts of sodium sulphate, 2 to 3 parts of sodium silicate, and 230 to 300 parts of water. The invention also discloses a method for manufacturing the light-weight fiber reinforced cement board, which comprises the following steps of: 1, weighing each component according to formula; 2, placing the weighed dry materials into a mixer for uniformly mixing; 3, preparing wet materials, placing the mixed materials obtained by the step 2 into a kneader, adding water and the wet materials into the mixed materials, and kneading the mixture; and 4, placing the kneaded slurryinto a mold, performing compression moulding by using a plate fluidizing machine, and then demolding. The manufacturing method greatly improves the tensile strength, the impact strength, the water-retaining property, and the extrusion property of the materials.

Owner:BEIJING NEW BUILDING MATERIALS PLC

High-transparency polyurethane elastomer

InactiveCN102040720AAvoid easy to be oxidized and discoloredAvoid defects that cannot be exposed to air for a long timePolyurethane elastomerPolyol

The invention discloses a high-transparency polyurethane elastomer, which is of a system of three components, namely a prepolymer component, a polymer component and a chain extender component, wherein in the prepolymer component, diisocyanate reacts with polyalcohol to generate a prepolymer, the NCO of which is 6 to 10 percent, the diisocyanate is preferably selected from toluene diisocyanate 80 (TDI-80), and the polyalcohol is polyepoxy propane ether polyalcohol, the number average molecular weight of which is in a range of 400 to 3,000 and the functionality of which is 2; and the polymer component is prepared from polyepoxy propane ether polyalcohol, catalyst and anti-ageing agent, wherein the molecular weight of the polyepoxy propane ether polyalcohol is 1,000 to 5,000, and the functionality of the polyepoxy propane ether polyalcohol is 2 or 3. When the product is produced, the temperatures of the polymer component and the chain extender component are controlled at 30 + / - 5 DEG C, the polymer component and the chain extender are mixed in a certain ratio and stirred uniformly, then the polymer component and the chain extender are mixed with the prepolymer component in a certain ratio, and the mixture is placed and cured for 20 to 30 minutes at the temperature of between 70 and 80 DEG C to obtain a product with excellent abrasion resistance and impact resilience. The high-transparency polyurethane elastomer is mainly used for manufacturing high-elasticity ice skate wheels or skateboard wheels.

Owner:SHANDONG INOV POLYURETHANE

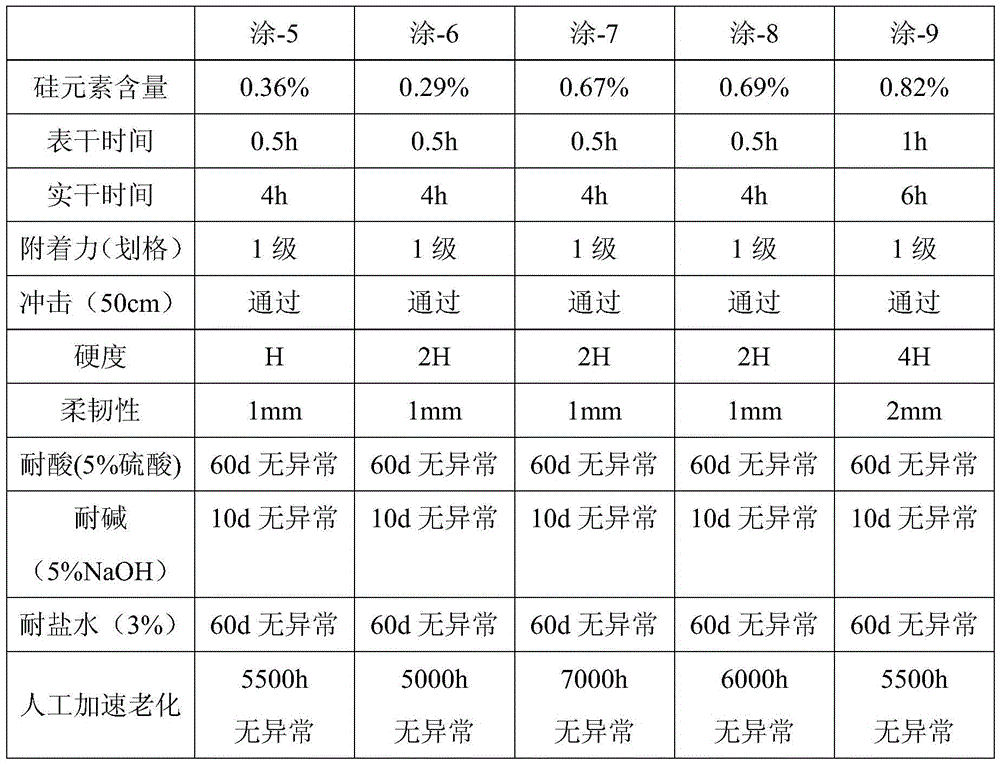

Acrylic acid modified polysiloxane resin and application thereof to self-stratifying coating

InactiveCN105482027AImprove anti-corrosion performanceGood weather resistanceAnti-corrosive paintsPolymer scienceWeather resistance

The invention relates to acrylic acid modified polysiloxane resin and application thereof to a self-stratifying coating. The resin contains two kinds of groups for a cross-linking reaction, consequently different curing agents can be selected for curing of the coating prepared from the resin according to performance requirements, and a silicon part and other parts in the resin have special compatibility. The self-stratifying coating containing the acrylic acid modified polysiloxane resin contains a component A and a component B, wherein the component A is prepared from 15-70 wt% of the acrylic acid modified polysiloxane resin, 5-40 wt% of pigment filler, 0.5-2 wt% of auxiliary and 10-45 wt% of solvent, and a coupling agent containing isocyanate groups or aminosilane can be selected for the component B according to coating performance requirements. Compared with an existing acrylic acid modified polysiloxane coating, the coating is high in surface drying speed, can achieve gradient self-stratifying in the film forming process, and has good corrosion resistance and weather resistance on the condition that the organosilicone content is extremely low.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

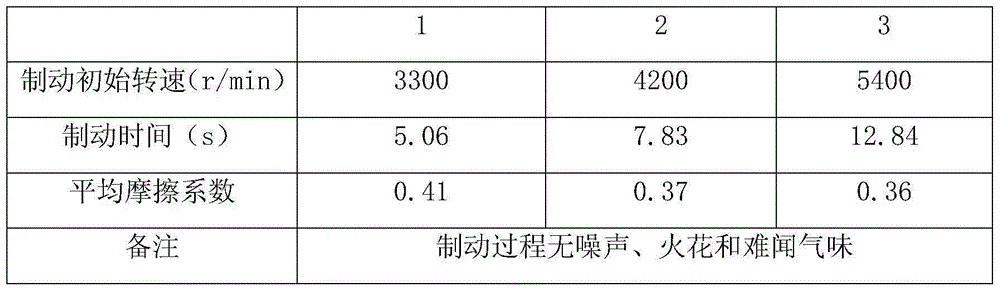

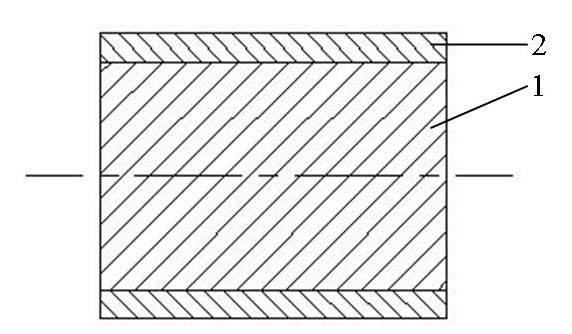

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Acidic and transparent silicone weather-resistant sealant for construction

ActiveCN104263315AAdjust the elasticityAdjust hardnessNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsCross-linkWeather resistance

The invention relates to an acidic and transparent silicone weather-resistant sealant for construction, and belongs to the technical field of adhesives. The acidic and transparent silicone weather-resistant sealant is prepared from the following components in parts by weight: 50-150 parts of hydroxyl terminated polydimethylsiloxane, 20-140 parts of methyl terminated polydimethylsiloxane, 10-60 parts of fumed silica, 5-40 parts of a cross-linking agent, 0.05-0.5 part of a catalyst and 0.05-5 parts of a composite anti-yellowing agent. The acidic and transparent silicone weather-resistant sealant has the advantages of high strength, good adhesive performance, excellent weather resistance, quick crosslinking curing at room temperature and the like, and can be widely applied to weather-resistant sealing of glass curtain walls, glass daylighting roofs and other constructional engineering.

Owner:ZHEJIANG TIME NEW MATERIAL

Preparation method of TPU and PVC blended improved composite fabrics

ActiveCN102729559AGood weather resistanceImprove wear resistanceSynthetic resin layered productsLaminationEngineeringOxygen

The invention discloses a preparation method of TPU and PVC blended improved composite fabrics. According to the method, TPU and PVC are blended to fully perform respective characteristics of TPU and PVC, so as to achieve the purpose of complementary advantages; calendaring molding is carried out by a four roll calender method to obtain a TPU and PVC blended film; and on-line lamination is carried out on the TPU and PVC blended film and glued base cloth on a calendar so as to obtain the TPU and PVC blended improved composite fabrics. The composite fabrics have characteristics of excellent mechanical property, wear resistance, environmental protection and the like. The coating of the composite fabrics is uniform and thickness error is less than 0.015mm. The composite fabrics has advantages of firm adhesion, wear resistance and flexing resistance, and can be widely used in application fields of inflatable life jacket, chemical splash suit, water pot, oil tank, sphygmomanometer, medical bed, oxygen bag, inflatable cushion, airbed, inflatable tent, air bag, air cushion ship, waterproof moisture permeable high-grade costuming and the like.

Owner:无锡翔隆高分子面料有限公司

Medicinal implant and preparation method thereof

InactiveCN101961507AHigh porosityIncrease roughnessMolten spray coatingProsthesisPorosityCeramic composite

The invention discloses a medicinal implant and a preparation method thereof, and relates to the fields of medicinal biology and material processing. The medicinal implant comprises an implant and a coating. The medicinal implant is characterized in that: the tantalum coating is coated on the surface of the implant, and the tantalum coating is made of one of tantalum elemental material and tantalum alloy material or tantalum / ceramic composite coating material. The preparation method comprises the following steps of: performing sandblast pretreatment and cleaning on a to-be-coated area of the implant by adopting a sandblast apparatus; and then coating the tantalum coating to the to-be-coated area of the implant by adopting a plasma coating device. The medicinal implant has the advantages of good biocompatibility, simple preparation process, high production efficiency, low production cost, wide matrix selection range, good process controllability, low influence of matrix tissues, high coating roughness, high thickness and wide porosity.

Owner:SICHUAN INST OF MATERIALS & TECH

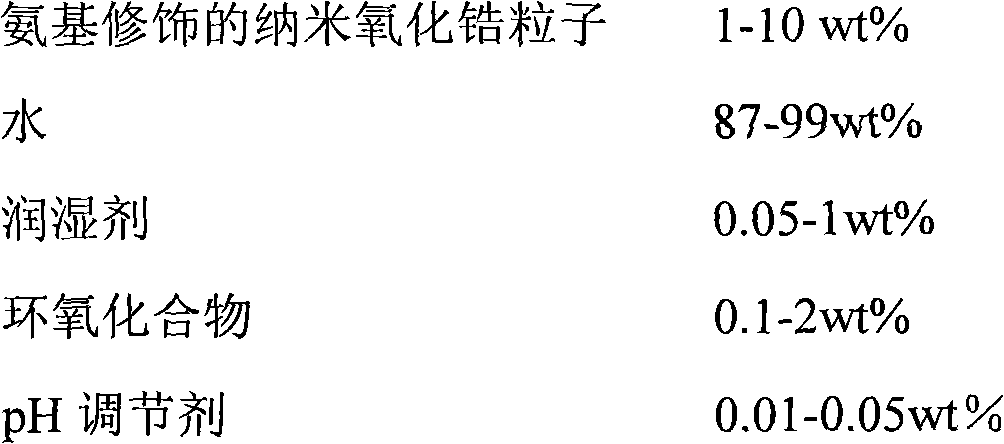

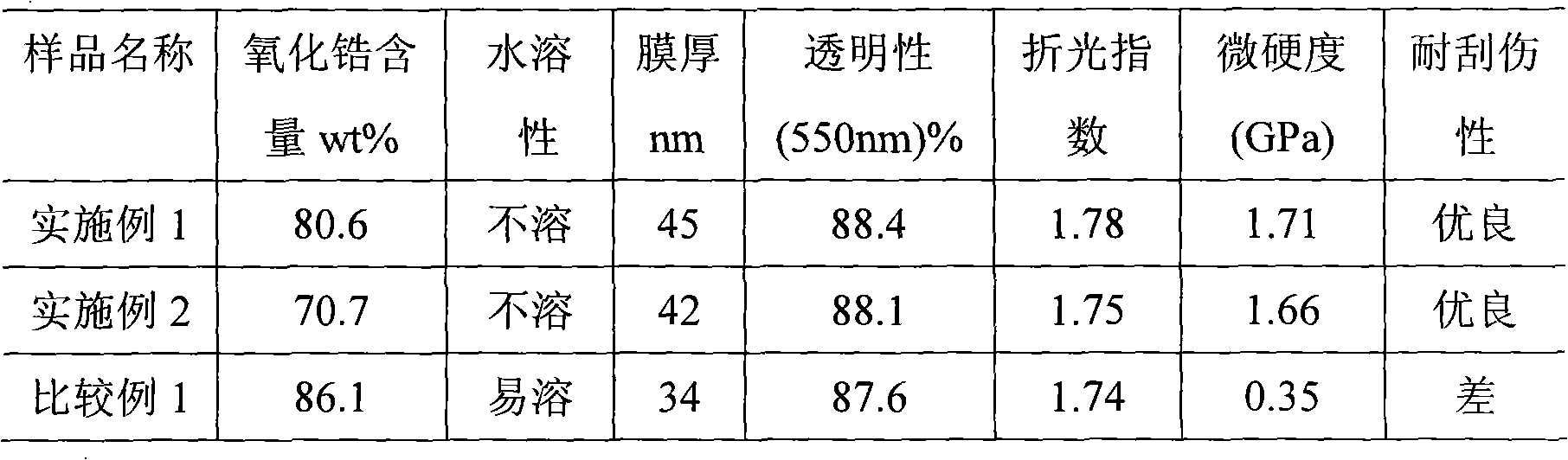

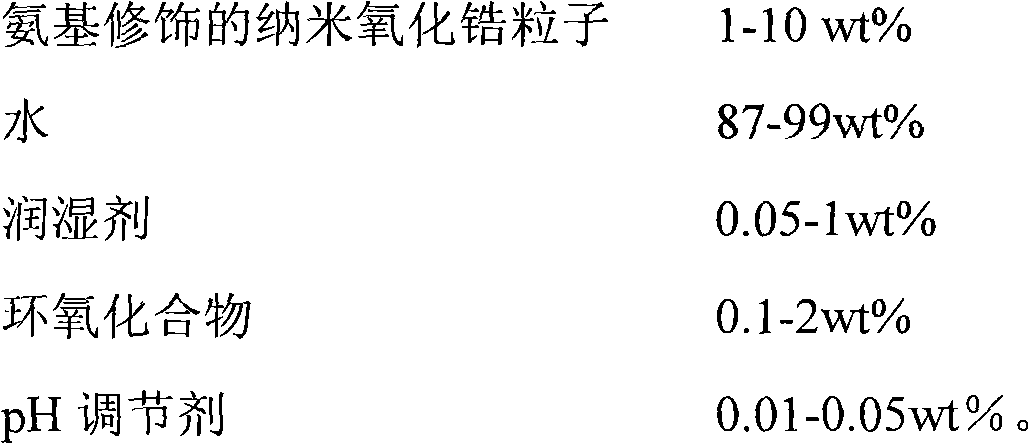

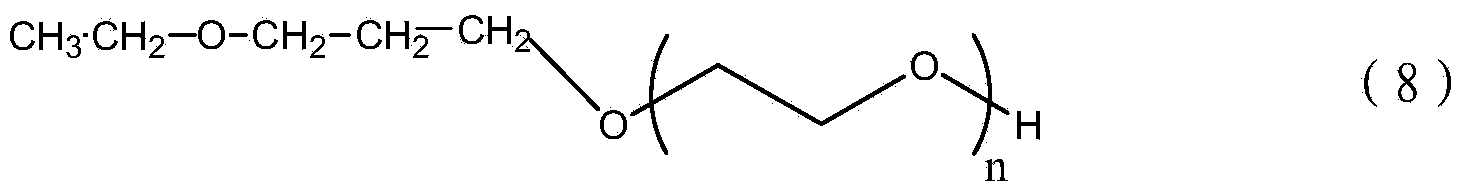

Aqueous nano zirconia particle paint and method for preparing paint film thereof

InactiveCN102031026ASimple preparation processPromote environmental protectionCoatingsEpoxyChemical industry

The invention relates to the field of chemical industry and new materials, in particular to aqueous nano zirconia particle paint and a method for preparing a paint film thereof. A preparation method of the aqueous nano zirconia particle paint comprises the steps of: with nano zirconia crystal particles as raw materials, modifying organic amino groups on nano particles with an amino silane coupling agent, dispersing the modified nano zirconia crystal particles in water, adjusting a pH value to acquire a transparent nano zirconia aqueous dispersion, and further adding aqueous double-functional groups or multi-functional groups of epoxy compound and a wetting agent to obtain the aqueous nano zirconia particle paint. The method for preparing the paint film of the aqueous nano zirconia particle paint comprises the steps of: coating the aqueous nano zirconia particle paint on the surface of a plastic substrate through dip coating, spin coating and spray finishing, and thermally treating at lower temperature to obtain an organic molecule-bridged nano zirconia particle film, wherein the thickness of the paint film can be adjusted through coating multiple times. The aqueous nano zirconia particle paint in the invention has simple and convenient preparation methods and good environmental-protection performance, and the acquired paint film has high zirconia content, good transparency, high refractive index and outstanding mechanical property and can be used as an optical paint film and a scratch-resistant paint film on the surface of the transparent plastic substrate.

Owner:FUDAN UNIV

Three-component polyurethane elastomer composition with high wear resistance

ActiveCN101747618AAvoid easy to be oxidized and discoloredAvoid defects that cannot be exposed to air for a long timePrepolymerIsocyanate

The invention relates to a three-component polyurethane elastomer composition with high wear resistance, which comprises a prepolymer component, a polymer component and a chain extender component, wherein diisocyanate reacts with polyol to obtain a prepolymer of which the NCO content is 6%-10%, wherein the diisocyanate is preferably TDI-80, and the polyoxypropylene polyol of which the molecular weight is 400-3000 and the functionality is 2 is adopted; the polymer component is prepared from polyoxypropylene polyol of which the molecular weight is 1000-5000 and the functionality is 2 or 3, reinforcing agent, catalyst and anti-aging agent; and in the process of production, the temperature of the polymer component and the temperature of the chain extender component are controlled at 30+ / -5 DEG C, after the polymer component and the chain extender component are mixed and stirred uniformly according to a certain proportion, the mixture is mixed with the prepolymer component according to a certain proportion, the mixture is placed and solidified at 70-80 DEG C for 20 minutes, and the obtained product has excellent wear resistance and impact resilience. The invention is mainly used for manufacturing high-elastic skate wheels or skateboard wheels.

Owner:SHANDONG INOV POLYURETHANE

Antistatic organosilicon gel used for heat-conducting gasket and preparation method of the organosilicon gel

The invention relates to antistatic organosilicon gel used for a heat-conducting gasket and a preparation method of the organosilicon gel. The organosilicon gel comprises an A component and a B component in a weight ratio of 1:1. The A component comprises following raw materials by weight: 95-99.84 parts of a basic material, 0.1-1 part of a catalyst, 0.05-2 parts of an adhesive and 0.01-2 parts of an antistatic agent. The B component comprises following raw materials by weight: 84-94.9 parts of the basic material, 5-15 parts of a cross-linking agent and 0.1-1 part of an inhibitor. The organosilicon gel prepared by the invention has good fluidity. After sulfuration, the organosilicon gel has excellent adhesive property, holding power and antistatic property.

Owner:YANTAI DARBOND TECH

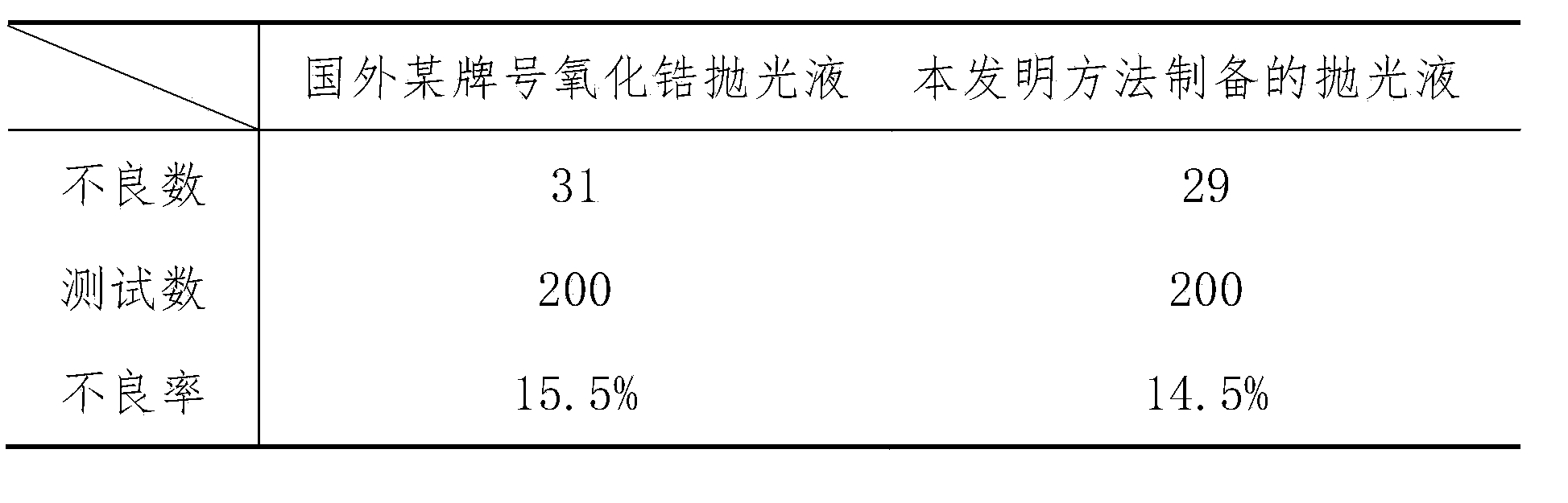

Preparation method of iron-doped zirconium oxide polishing solution

ActiveCN103450813AGood cutting rateAdjust hardnessPolishing compositions with abrasivesMaterials preparationWater soluble

The invention discloses an iron-doped zirconium oxide polishing solution, and relates to the technical field of preparation of polishing materials. The iron-doped zirconium oxide polishing solution is prepared from water-soluble inorganic zirconium salt, soluble trivalent ferric salt, alkali, zirconium carbonate, additives and a pH value modifier. The method comprises the preparation steps of material preparation, symbiotic solution preparation, symbiotic precipitate preparation, washing, drying, roasting, grinding and stirring dispersion; the method has the characteristics that the cutting rate is good and no obvious defects are generated on the surface of a polished material; the iron-doped zirconium oxide polishing solution prepared by using the method is suitable for the processing field of high-grade optical instruments, and particularly can be applied to polishing flexible glass.

Owner:HUNAN HAOZHI TECH

Special handwork plasticine for English course and preparation method thereof

The invention relates to special handwork plasticine for English course, which is used for showing English characters or words to be learned on a blackboard in forms of plasticine characters during English teaching at schools and kindergartens so as to enhance the teaching interestingness. The special handwork plasticine for English course is prepared from the following raw materials in parts by weight: 30 parts of resin clay, 10 parts of pectin, 0.5 part of bone glue, 5 parts of aloe gel, 40 parts of modified corn starch, 10 parts of glutinous rice flour, 5 parts of neodymium iron boron magnetic material powder, 3 parts of almond oil, 1 part of palm oil, 1 part of chamomile essential oil, 0.2 part of pericarpium granati extract, 0.5 part of refined salt, 3 parts of calcite powder, 20 parts of flour, 0.5 part of calcium stearoyl lactylate, 0.2 part of sodium tripolyphosphate, 0.2 part of polymethylphenyl siloxane liquid, 5 parts of kieselguhr, 0.5 part of food coloring and 10 parts of water. In the invention, the English characters or words to be learned are shown on the blackboard in forms of plasticine characters so as to enhance the teaching interestingness and realize the characteristics of environmental protection, no toxin, harm or crack, antibacterial property, good forming property, moderate hardness and convenience in demoulding.

Owner:HEBI COLLEGE OF VOCATION & TECH

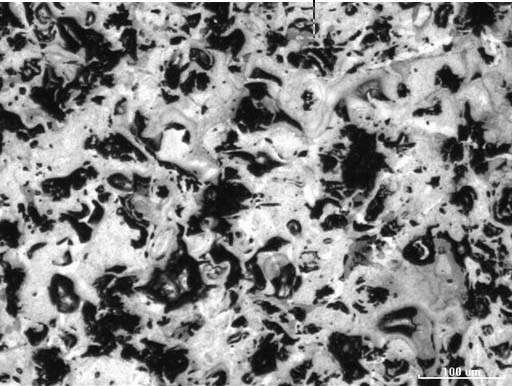

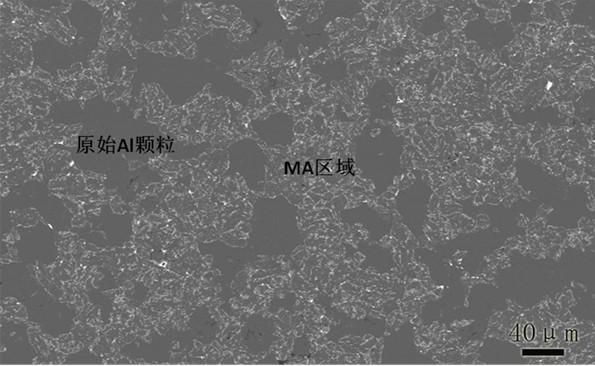

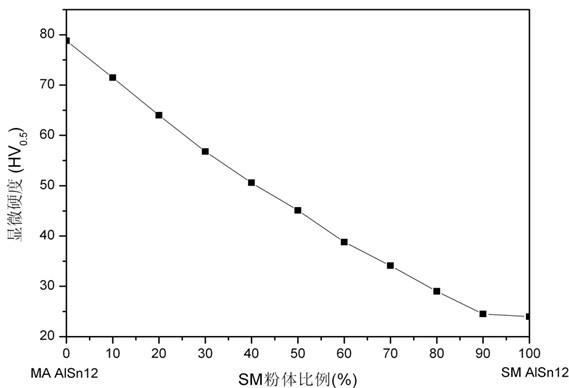

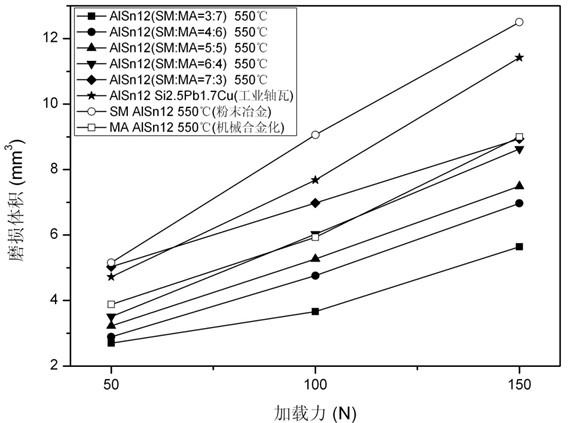

Method for manufacturing multi-scale structure aluminum/stannum-based bearing alloy

InactiveCN102134661AAvoid specific gravity segregationImprove tribological performanceAl powderHigh energy

The invention discloses a method for manufacturing a multi-scale structure aluminum / stannum-based bearing alloy, which is characterized in that coarse-crystalline raw mixed powder with the same components is added to mechanical alloying powder having a nano-phase composite structure. The method specifically comprises the steps that: high-purity Al and Sn powders with the grain size about 200 meshes are subjected to high energy ball milling based on certain mass ratio of the Al powder to the Sn powder under the protection of argon, so as to prepare Al-Sn alloy powder with the nano-phase composite structure; the Al and Sn powders are commonly mixed according to the same mass ratio above to obtain the raw mixed powder; the Al-Sn alloy powder is uniformly mixed with the raw mixed powder; the mixed powder is subjected to cold pressing molding to obtain a green compact; and the green compact is sintered under vacuum to prepare the Al-Sn bearing alloy with excellent tribological properties. The aluminum / stannum-based bearing alloy of the invention has a multi-scale structure, remarkably improved density and abrasive resistance, increased adjustable extent of hardness and high matching degree with shafts.

Owner:SOUTH CHINA UNIV OF TECH

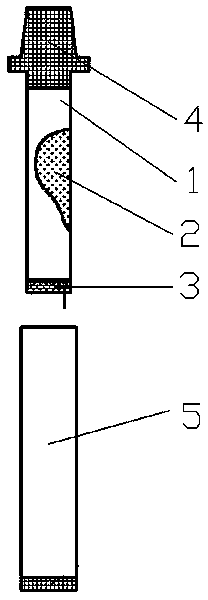

Electroless welding rod

ActiveCN103962749AMake full use of chemical energySave energyWelding/cutting media/materialsSoldering mediaEngineeringCopper

The invention belongs to the technical field of special welding and relates to an electroless welding rod. The electroless welding rod is composed of a welding agent pipe, welding agents, an ignition cap, a clamping end and a sleeve, wherein the welding agents are loaded in the welding agent pipe, one end of the welding agent pipe is connected with the clamping end, the other end of the welding agent pipe is inserted into the ignition cap to be encapsulated, and the welding agent pipe and the ignition cap are arranged in the sleeve with one end closed. The welding agents include, by mass, 58.0%-70.0% of CuO powder, 13.0%-18.0% of Al powder, 5.0%-6.7% of Si-Ca alloy powder, 5.0%-6.3% of CaF2 powder, 0.7%-1.5% of B powder, 4.8%-9.5% of Fe powder, and 0.4%-1.0% of Mn powder. The welding rod is small in size and convenient to carry, materials for manufacturing are easy to obtain, price is low, welding is easy, and welding of various materials such as ordinary steel, stainless steel and copper can be realized.

Owner:成都银河动力有限公司

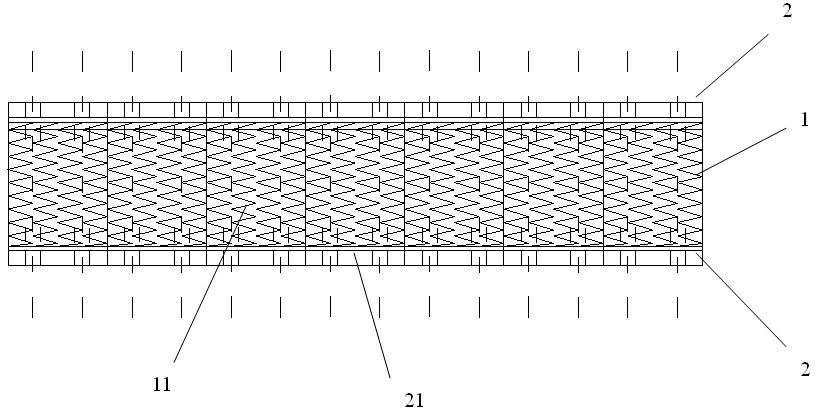

Air cushion-partitioned mattress

InactiveCN102166082AImprove comfortGuaranteed breathabilityStuffed mattressesSpring mattressesEngineeringAir content

The invention mainly discloses an air cushion-partitioned mattress, which comprises a steel wire spring layer and an air cushion, wherein the air cushion is laid outside the spring wire spring layer and is divided into a plurality of air cushion units along the length direction of the mattress. In the air cushion-partitioned mattress, the design of the mattress is simplified, the mattress can be divided into different areas aiming at different parts of human bodies, each area can be adjusted independently, and air pressure is regulated by air content to adjust the hardness of the mattress, so that the optimum comfort degree is achieved. The air cushion-partitioned mattress saves cost and is convenient to produce, operate and maintain.

Owner:XILINMEN FURNITURE

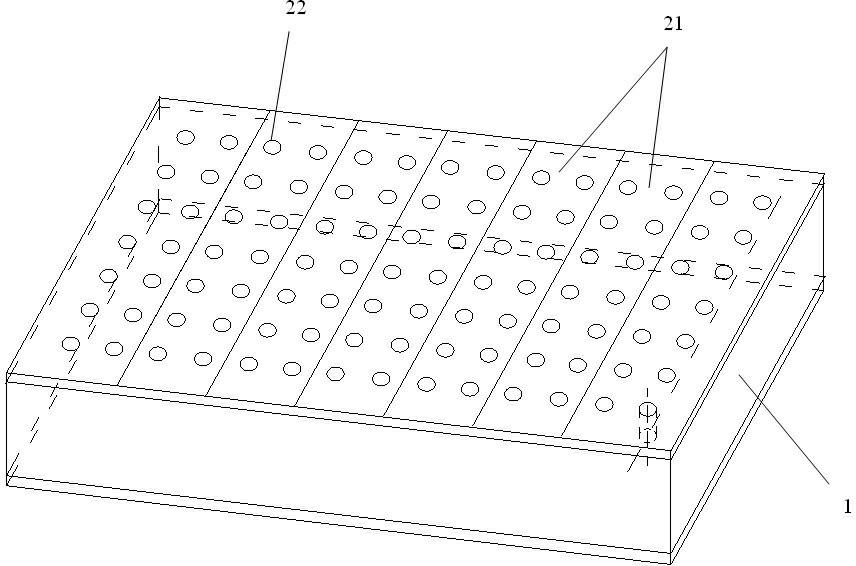

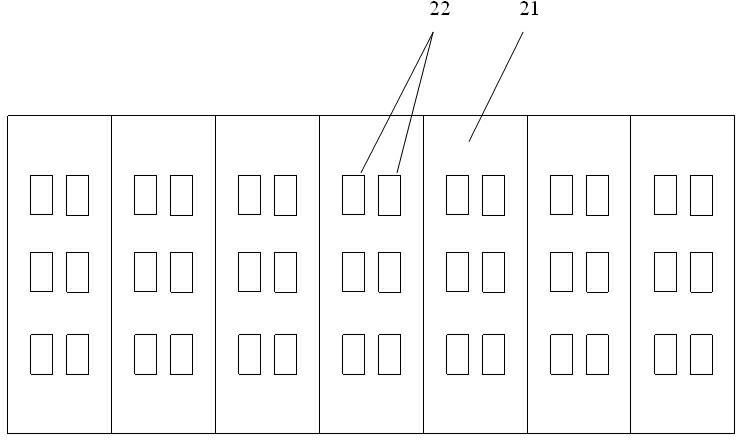

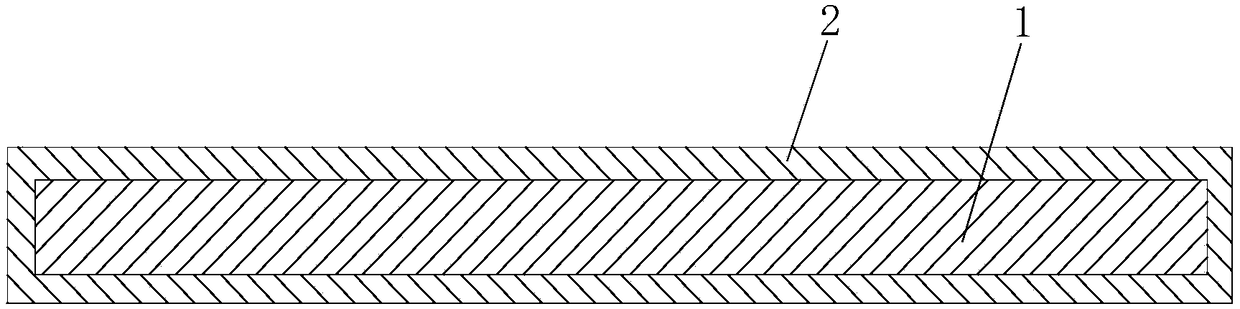

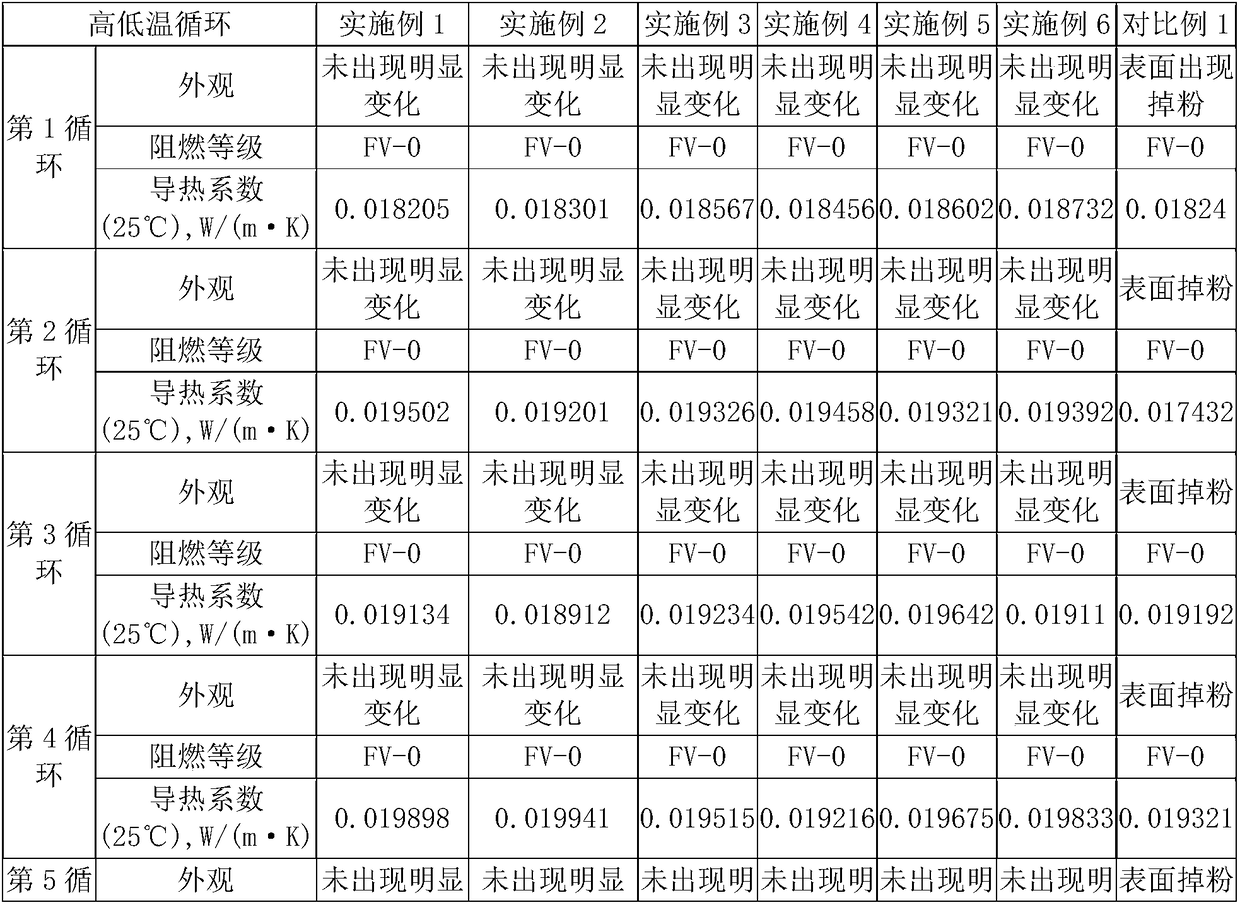

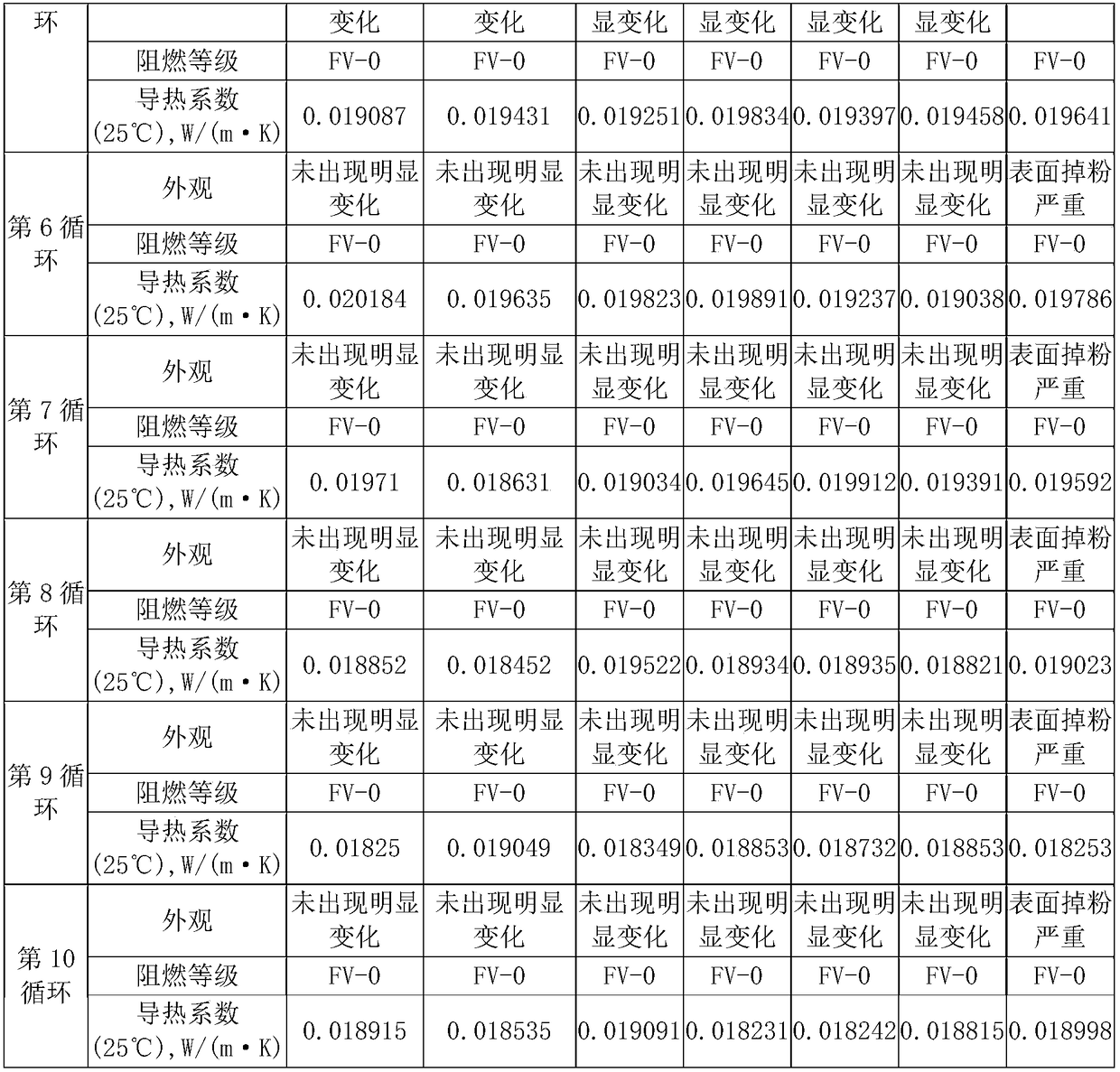

Aerogel heat insulation sheet

InactiveCN108587510ADoes not affect flame retardancyDoes not affect thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberAdhesive

The invention provides an aerogel heat insulation sheet which comprises an aerogel layer and a glue layer coating the outer surface of the aerogel layer; the glue layer covers the whole outer surfaceof the aerogel layer and is prepared from the following raw material components in part by weight: 0.03-1.5 parts of carbon powder, 0.5-5 parts of glass fiber powder, 0.2-5 parts of a flame retardantand 4-35 parts of a structural adhesive. The aerogel heat insulation sheet provided by the invention has the benefits that as the glue layer covers the whole outer surface of the aerogel layer, powderon the surface of an aerogel material is fixed in the glue layer, so that the problem of falling-off of the powder on the surface of the aerogel material is solved. Therefore, the aerogel heat insulation sheet can be applied to the automobile field, and is used as a heat insulation material for an automobile battery, and the problems of pollution and damage to an automobile product due to powderdrop of the aerogel material are effectively solved.

Owner:王宏宁 +3

Cross-linked anti-fatigue and anti-wear polyurethane rubber

The invention discloses a method for preparing cross-linked anti-fatigue and anti-wear polyurethane rubber. The cross-linked anti-fatigue and anti-wear polyurethane rubber comprises the following components in percentage by mass: 65-70% of polytetramethylene glycol, 6-10% of cyclic polypropylene oxide ether triatomic alcohol, 14-20% of toluene diisocyanate, 5-8% of 1,5-naphthalene diisocyanate, 1-3% of di-o-chlorodiphenylamine methane, 0.5-1.5% of trimethylolpropane, 0-0.5% of carbon black and 1-2% of molybdenum disulfide. The rubber has the advantages of high wear resistance, good resilience, good low-temperature resistance, high tensile strength, predominant hydrolysis resistance, good adhesion to metal, shock resistance and relatively good anti-fatigue performance.

Owner:JIANGSU GUANGDING PIPE IND TECH CO LTD

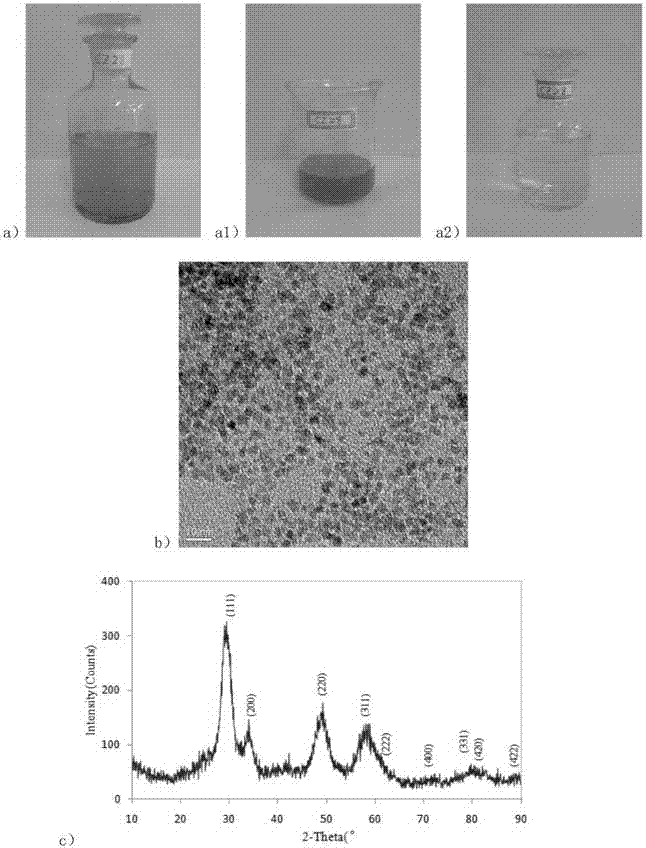

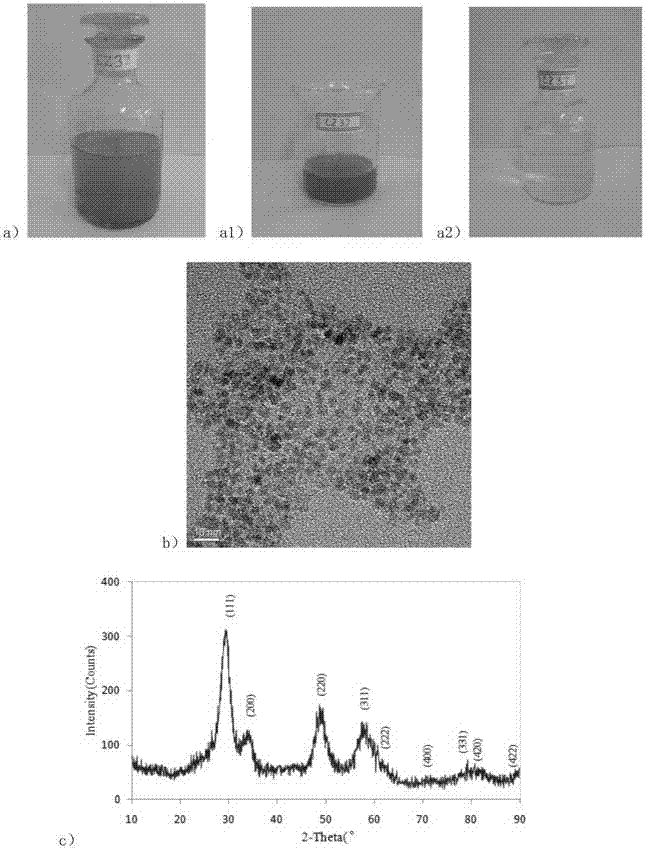

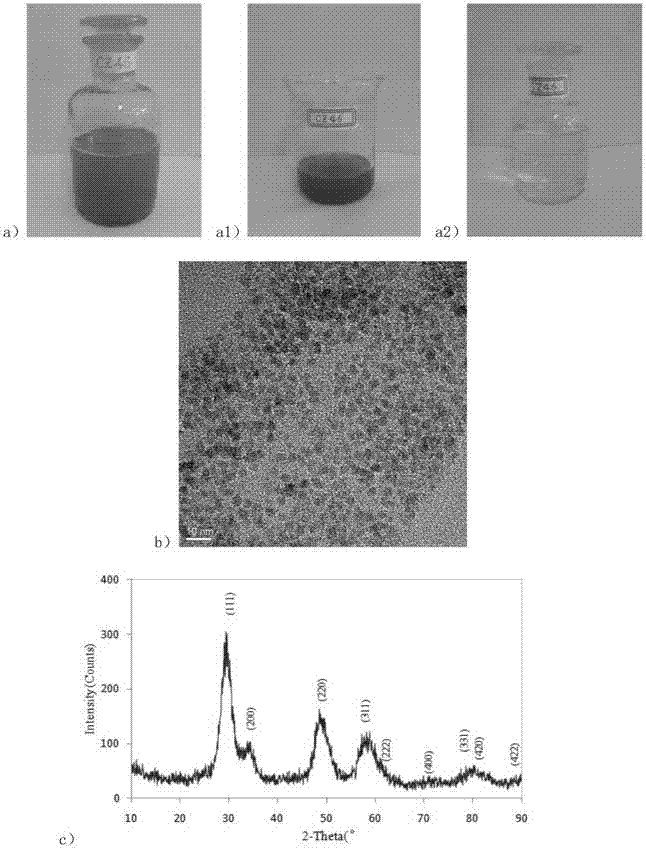

Ceria-zirconia oxide nanometer material dispersed in water medium

ActiveCN104492418AHigh mass percentageCan be stored for a long timeMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsWear resistantEvaporation

The invention provides a ceria-zirconia oxide nanometer material dispersed in water medium. Water is used as a dispersion medium, solid solution nano-particles prepared from cerium oxide and zirconium oxide are used as dispersion-phase sol, wherein the nano-particle is a single crystal with the nanoscale being 2-8nm and is singly dispersed in the water medium; the mass of the CexZr(1-x)O2 nano-particles is 0.1-30% of the volume of the nanometer material sol, the content of the CexZr(1-x)O2 nano-particles can be further increased through evaporation and concentration or water can be added freely for dilution. The prepared ceria-zirconia oxide nanometer material has the nano-meter characteristics of remarkable small size effect and surface effect and the like, and can be used for an oxygen storage / release material of a three-way catalyst for automobile exhaust gas purification, a carrier of a supported catalyst or an assisted-catalysis material, optical glass, semiconductors, LED ultra-precision polishing materials, a surface layer thermal barrier or a wear-resistant material of a special plate, a catalytic promoter of a fuel cell anode, and an optimal property modifying agent for hydrogen storage, sensing, luminous and ceramic materials and the like.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com