Light-weight fiber reinforced cement board and manufacturing method thereof

A lightweight fiber and cement board technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of insufficient thermal insulation ability to meet requirements, bottlenecks in achieving goals, and high labor intensity. The effect of solving the problem of pan-alkali, simple manufacturing process and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preparation process of the lightweight fiber reinforced cement board of the present invention is carried out according to the following steps

[0036] (1) Weigh each material according to the following proportion:

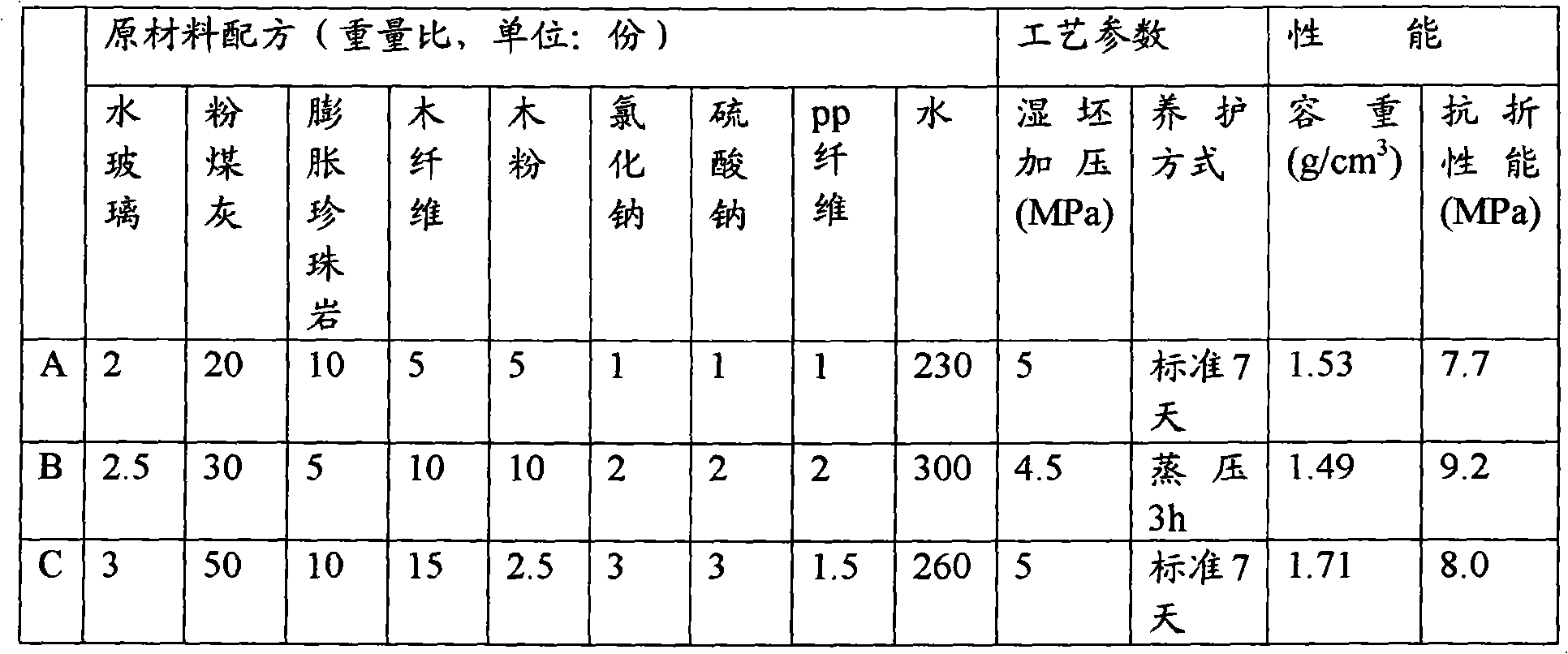

[0037] Table 1 Process formula

[0038] raw material name

Dosage (weight ratio)

Remarks

cement

pulp

Wood fiber

Polypropylene fiber

Calcium powder

Expanded perlite

Methyl Cellulose (MC)

Water glass

water

100 servings

4 parts

5~15 copies

1~2 copies

20 servings

15 servings

5~10 copies

5~10 copies

0.8 copies

1~3 copies

1~3 copies

2~3 copies

230~300 copies

20-50 copies

Low alkalinity cement: sulphoaluminate cement

Length is 5~10mm, diameter

<1mm, water content is 6.96%

Short cut PP (polypropylene) fiber, long

Degree between 5~200mm

Grade: 95%, 200 mesh

Grade: 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com