Patents

Literature

1016results about How to "Improve the extrusion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium alloy profile for building template, and preparation method thereof

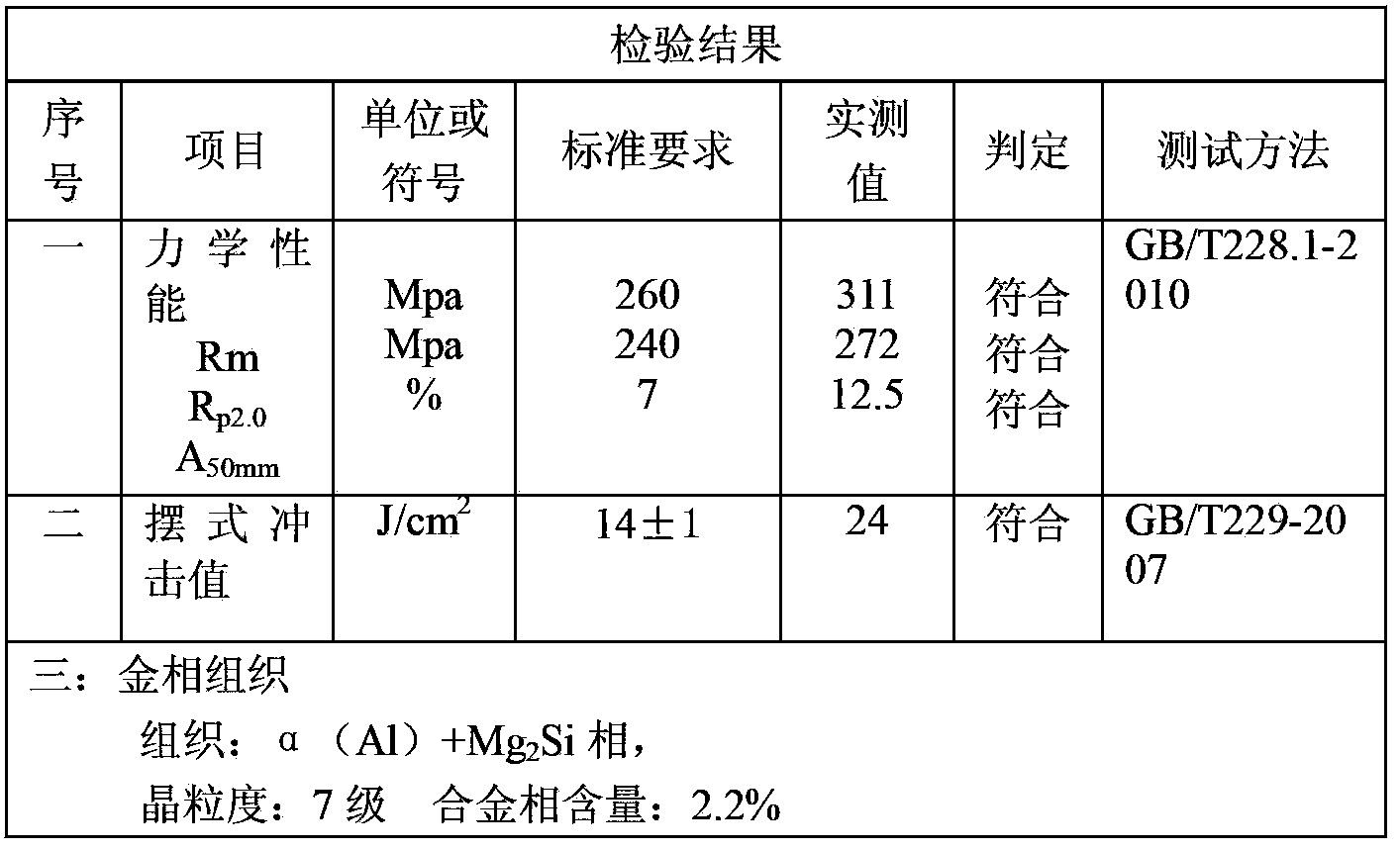

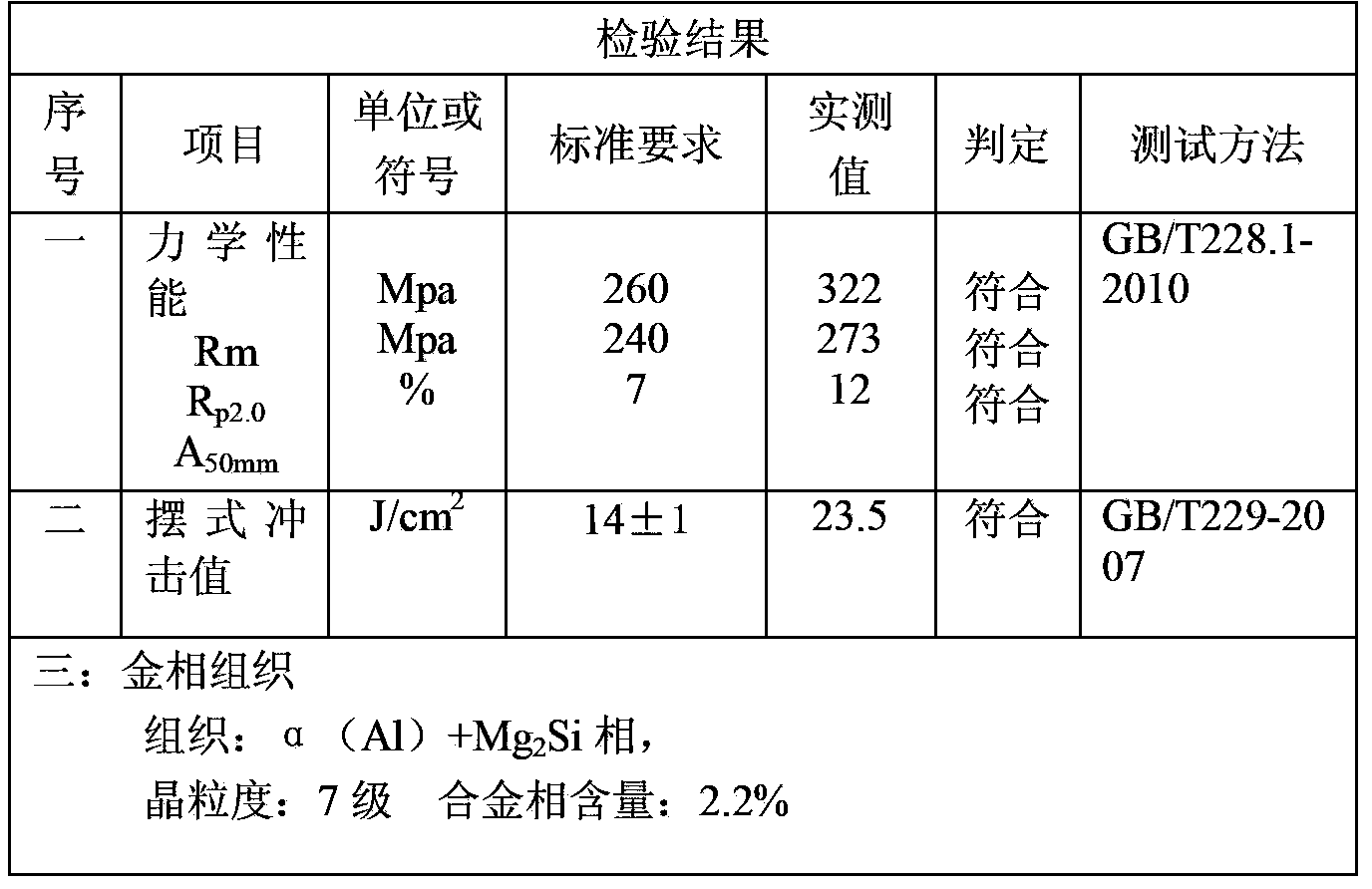

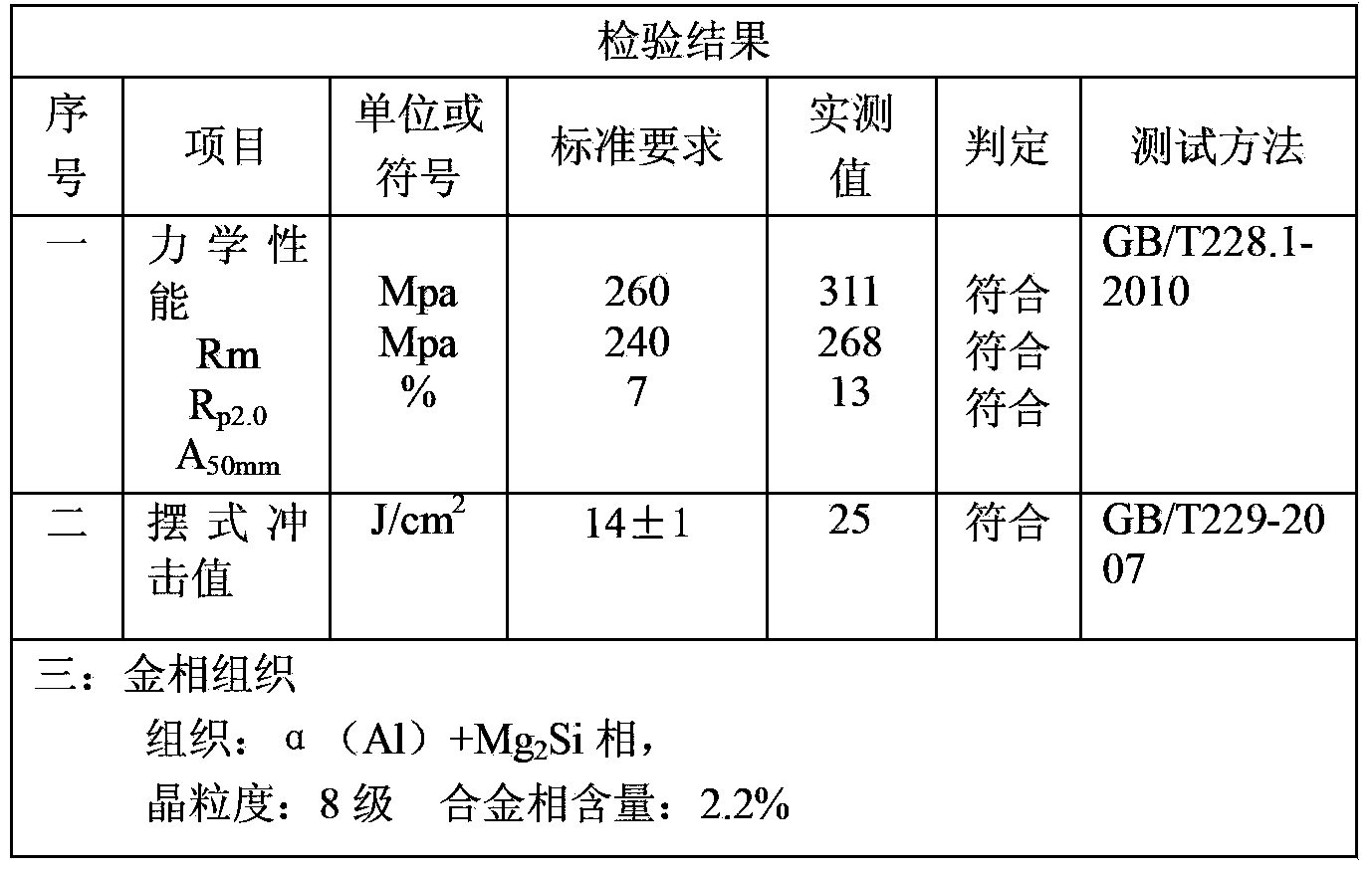

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

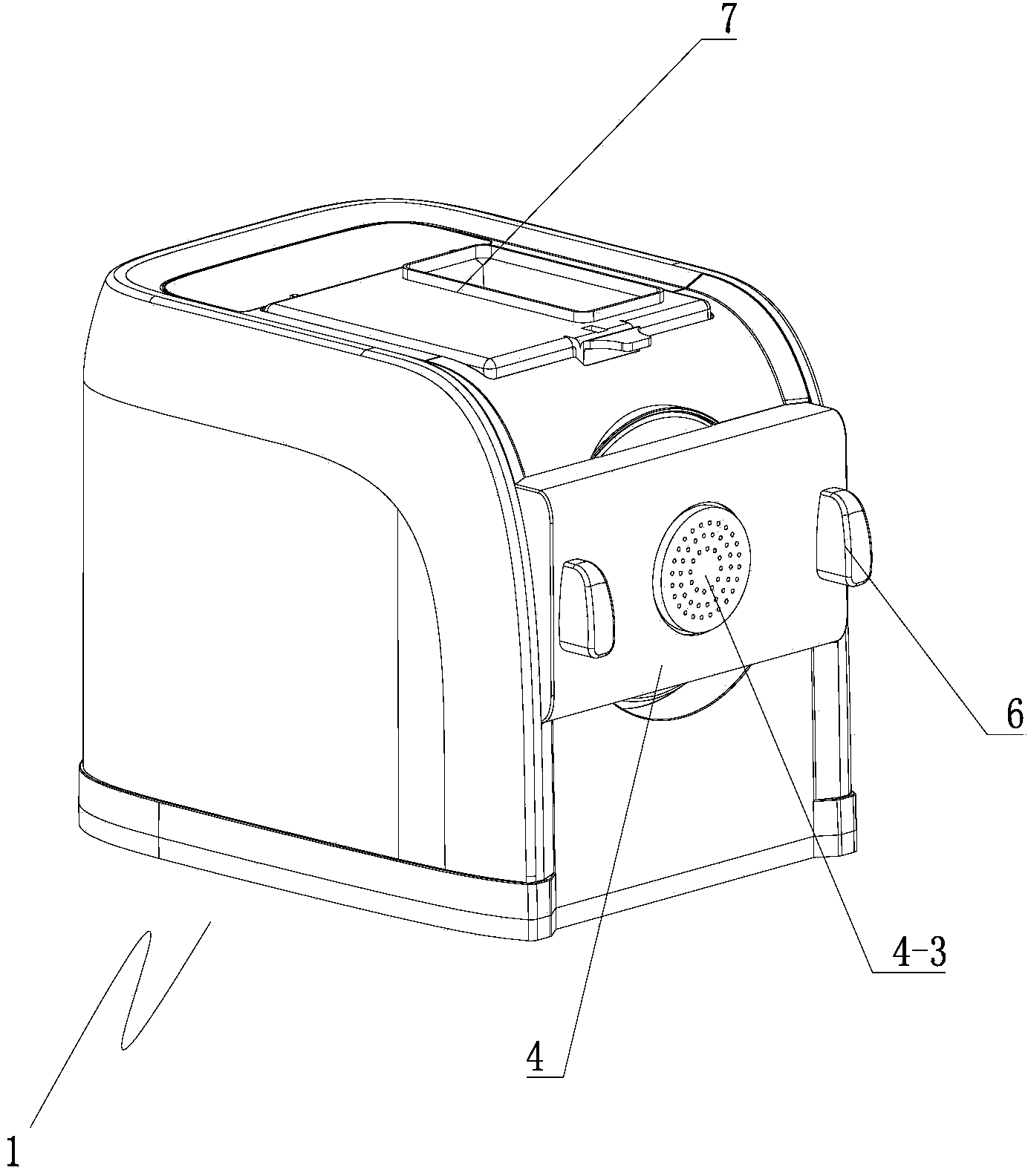

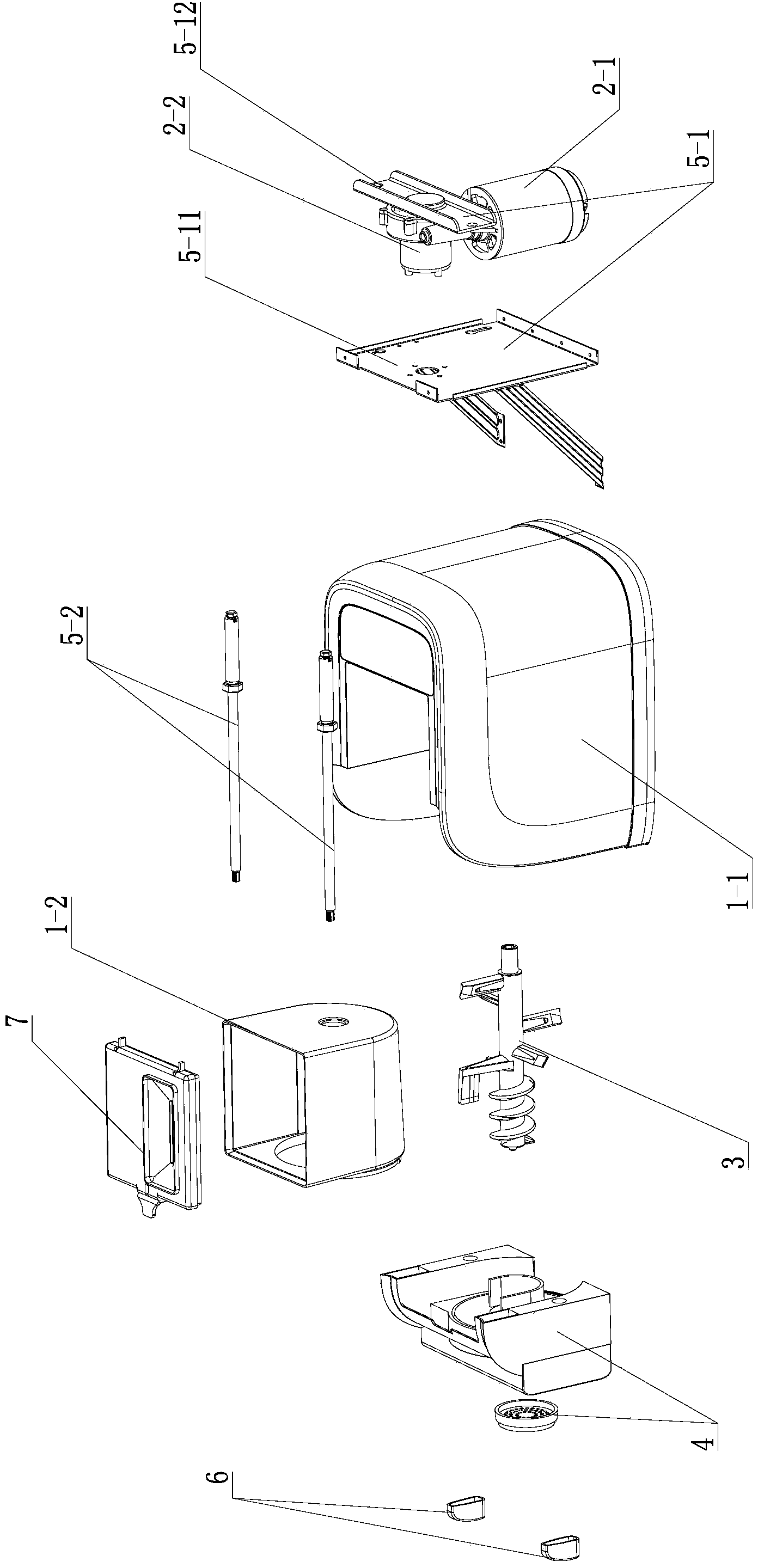

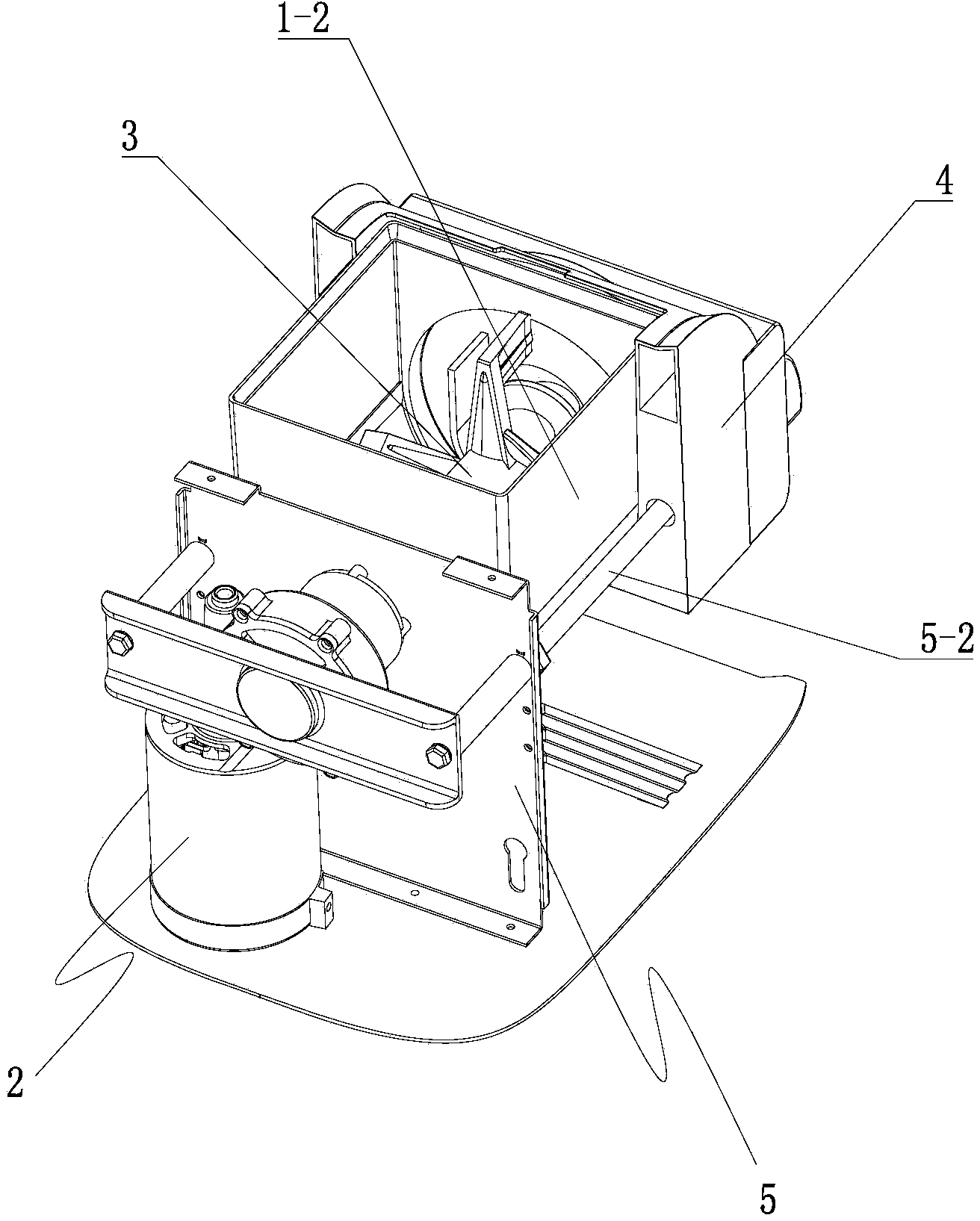

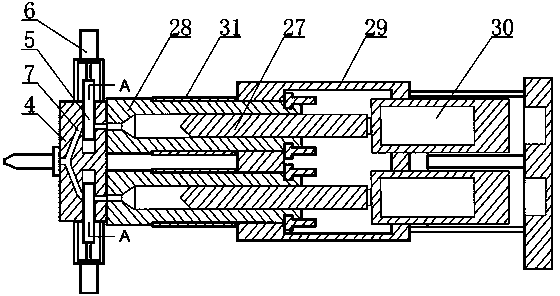

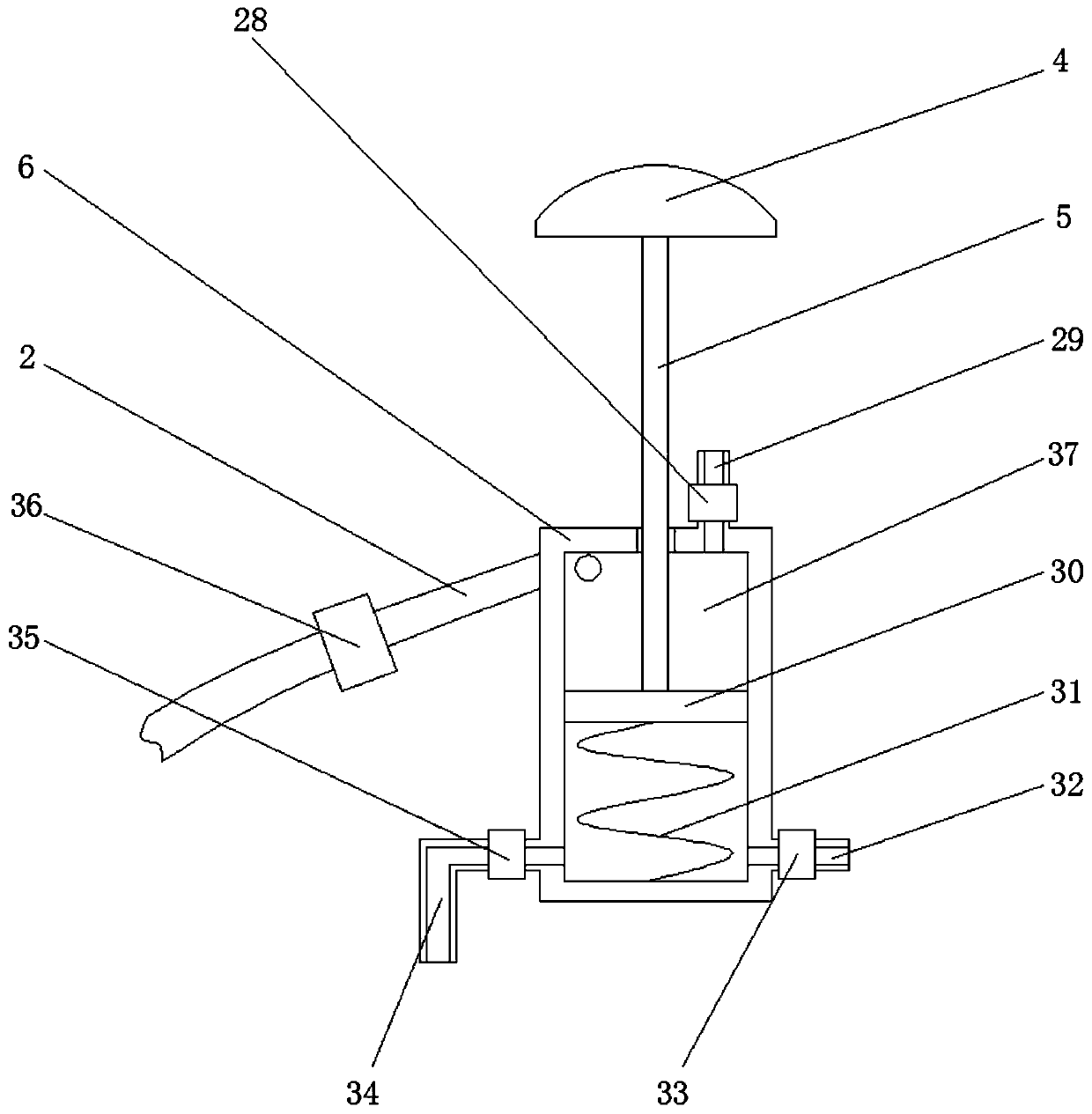

Noodle processing machine

InactiveCN103518792AReduce volumeSuitable for home useMixing/kneading with horizontally-mounted toolsDough extruding machinesEngineeringMechanical engineering

The invention discloses a noodle processing machine. The noodle processing machine comprises a shell (1), wherein a driving device (2) capable of rotating forward and reversely is arranged in the shell (1); the shell (1) comprises an outer shell (1-1) in which the driving device (2) is arranged and a stirring chamber (1-2) for mixing noodles; a stirring and extruding device (3) which is connected with the driving device (2) and used for stirring the mixed noodles and extruding the mixed paste is arranged in the stirring chamber (1-2); a blade assembly (4) is arranged at the front end of the stirring chamber (1-2); a holder (5) is arranged in the outer shell (1-1) and at one end of the outer shell (1-1), opposite to the blade assembly (4), and comprises a fixing plate (5-1) for fixing the driving device (2); a group of tensioning bolts (5-2) are arranged between the fixing plate (5-1) and the blade assembly (4).

Owner:王玉霞

Fluoropolymer composition

InactiveUS20070117929A1Increase melt viscosityImprove the extrusion effectTetrafluoroethyleneMolten state

A melt-mixed composition of non-melt flowable polytetrafluoroethylene (PTFE) and melt-fabricable perfluoropolymer is provided that exhibits thixotropy at increasing shear rate in the molten state and high elongation at break even at PTFE concentrations well above 4 wt %, based on the combined weight of the PTFE and the perfluoropolymer, e.g. at least 200% up to at least 30 wt % PTFE, the composition also exhibiting the structure of a dispersion of submicrometer-size particles of the PTFE in a continuous phase of the melt-fabricable perfluoropolymer.

Owner:EI DU PONT DE NEMOURS & CO

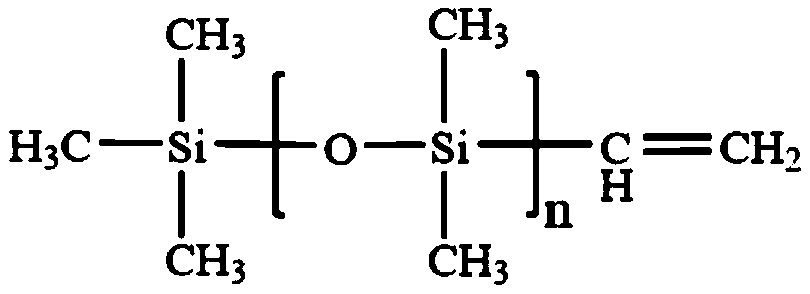

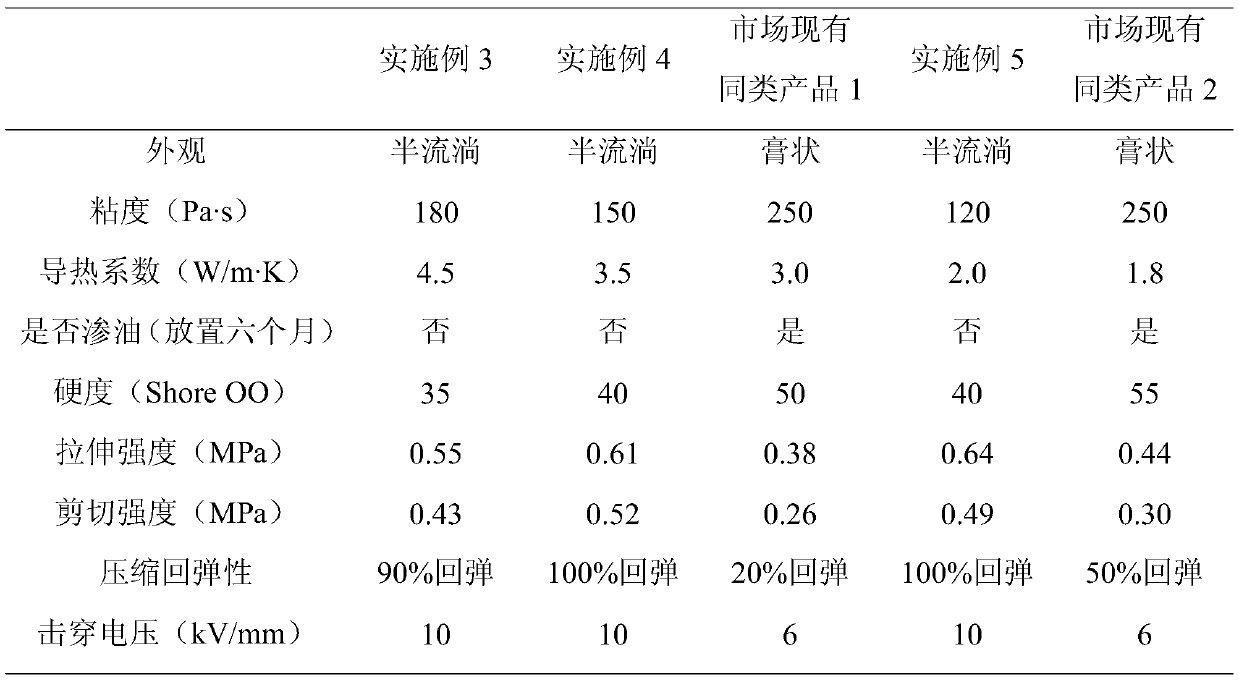

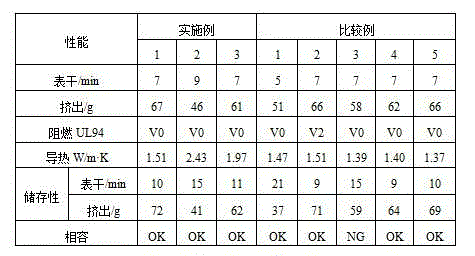

Low viscosity and high thermal conductivity organosilicon gel and preparation method thereof

Belonging to the technical field of thermal conductive interface materials, the invention relates to a low viscosity and high thermal conductivity organosilicon gel and a preparation method thereof. The low viscosity and high thermal conductivity organosilicon gel consists of a component A and a component B. Specifically, the component A comprises the following components: vinyl silicone oil, polyvinyl silicone oil, alkyl modified silicone oil, an active diluent, high thermal conductivity compound inorganic filler, a catalyst and pigment; and the component B comprises the following componentsby mass: vinyl silicone oil, polyvinyl silicone oil, alkyl modified silicone oil, an active diluent, high thermal conductivity compound inorganic filler, hydrogen-containing silicone oil, an inhibitorand a tackifier. The product provided by the invention has the characteristics of low viscosity, high extrudability and high thixotropy, and easy mixing, can be compressed into filling layers of different thicknesses and different shapes, can be quickly solidified into soft silicone gel at normal temperature and by heating, is suitable for filling the irregular gaps among various electronic devices and heat dissipators, and can play the role of heat conduction, insulation, buffering, shock absorption, etc.

Owner:GOLOHO TECH CHANGZHOU CO LTD

Heat-conducting flame-retardant room temperature vulcanized silicone rubber and preparation method thereof

InactiveCN104592763AImprove processing performanceImprove system compatibilityFire retardantHeat conducting

The invention discloses heat-conducting flame-retardant room temperature vulcanized silicone rubber. The silicone rubber consists of the following components in parts by weight: 100 parts of alpha, omega-triethoxy polydimethylsiloxane, 400-1500 parts of an inorganic heat conducting filler, 0.5-5 parts of a filler treating agent, 1-10 parts of titanium dioxide prepared by a vapor phase method, 0.5-15 parts of a cross-linking agent, 0.1-5 parts of a flame-retardant agent, 0-10 parts of a catalyst and 0-5 parts of a silane coupling agent. The silicone rubber and the preparation method use the alpha, omega-triethoxy polydimethylsiloxane so as to improve the processing property and the storing property of a composition system. Compared with the prior art, through the use of the silicone rubber and the preparation method, the compatibility, the storing property and the extrudability of the filler and the silicon rubber are improved, the flame retardance in a UL94-V0 level is realized, and the situation that because a large amount of the inorganic flame-retardant filler is used, the heat-conducting property of the system is influenced is avoided; silicon dioxide prepared by a vapor phase method is added, the thixotropy of the composition is regulated, and besides the heat-conducting property is not influenced; the silicone rubber has good system compatibility, a good regulable heat-conducting property and a good flame-retardant property and can be suitable for a glue point asking for a high heat dissipation property and a high flame-retardant property.

Owner:TONSAN ADHESIVES INC

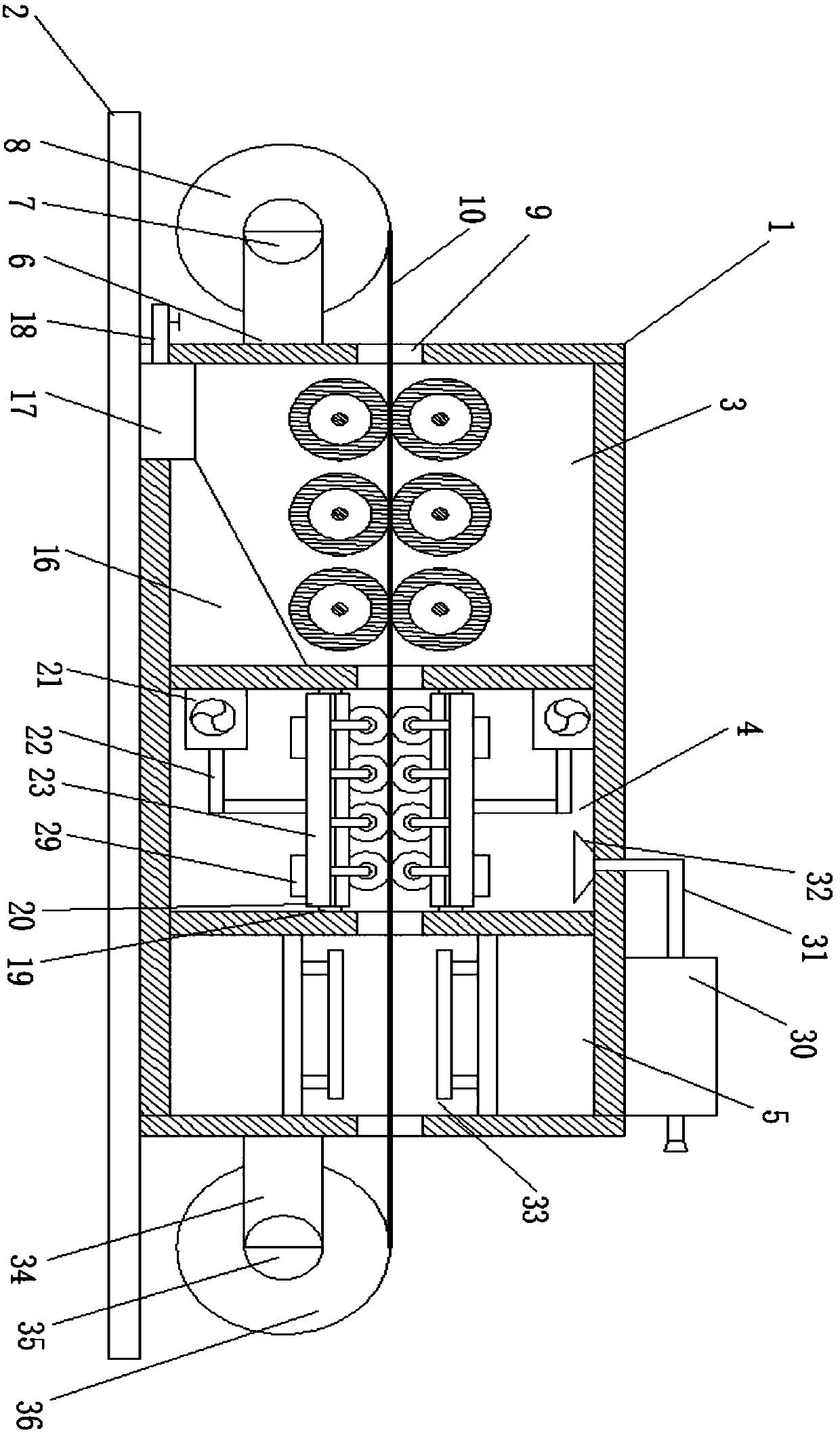

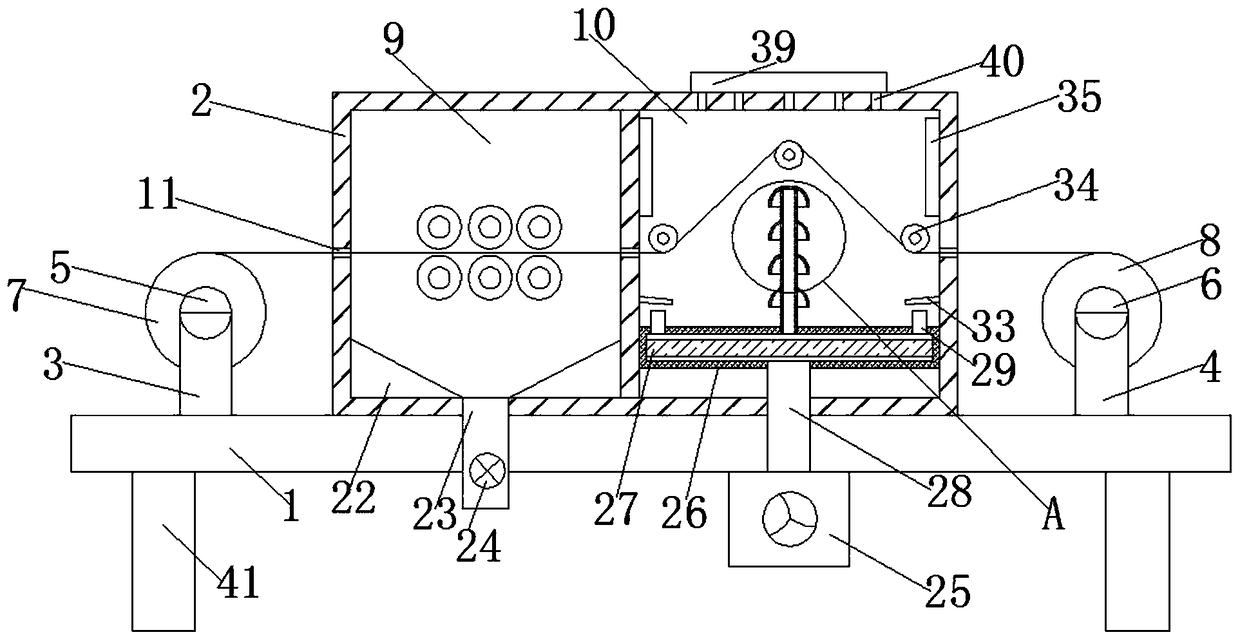

Drying device of long medical gauze

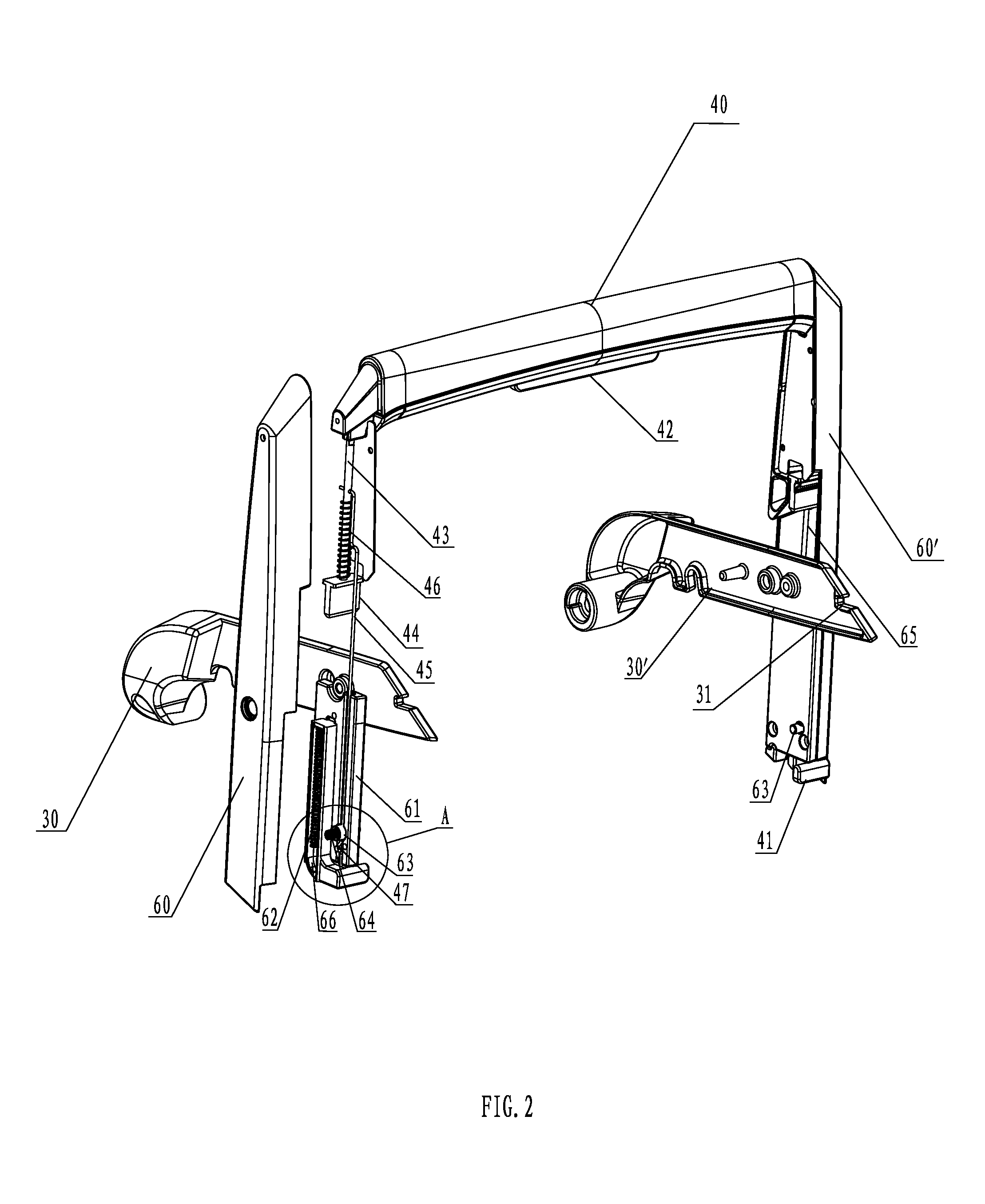

InactiveCN107620185AEasy to moveImprove the extrusion effectLiquid/gas/vapor removal by squeezing rollersIroning machinesGear driveFixed frame

The invention discloses a drying device of long medical gauze. The drying device of the long medical gauze comprises a device case and a base. A first fixing frame and a second fixing frame are installed at the front and back sides of the device case respectively. A delivery rotation shaft and a collection rotation shaft are arranged on the first fixing frame and the second fixing frame respectively in a running-through mode. A delivery wheel disc and a collection wheel disc are mounted on the delivery rotation shaft and the collection rotation shaft respectively. The device case is divided into a dehydration room, a drying room and a disinfection room. Material through holes are formed in all the middles of the front and back walls of the dehydration room, the drying room and the disinfection room. The dehydration room, the drying room and the disinfection room are communicated by the material through holes. The gauze is wound around the delivery wheel disc. The gauze runs through thedehydration room, the drying room and the disinfection room through the material through holes, and the tail end of the gauze is wound around the collection wheel disc. According to the drying deviceof the long medical gauze, a gear drives a squeeze roller to rotate to squeeze the gauze to play the role of fully dehydration; an iron cylinder and the surface of the gauze are in contact, and therefore the role of high-temperature disinfection is further played.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

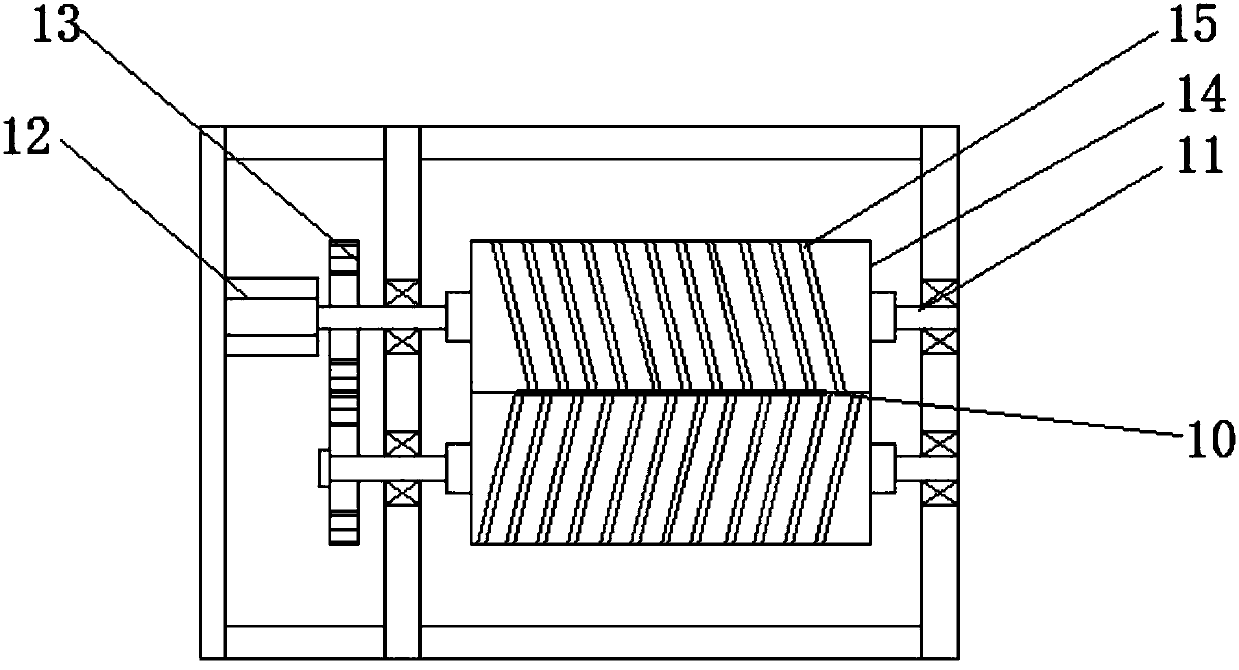

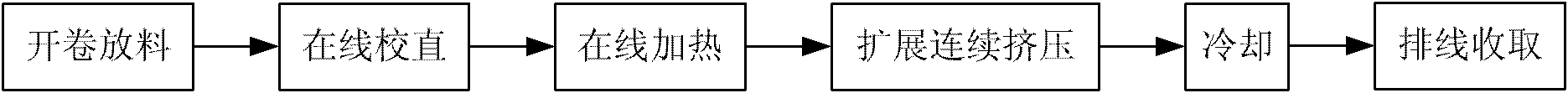

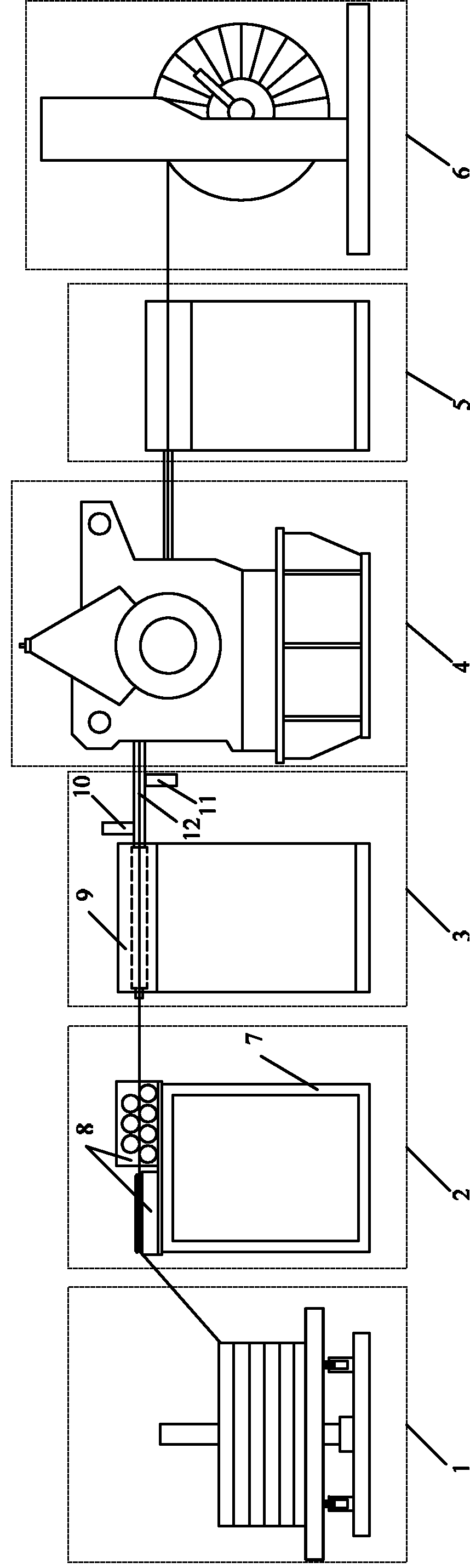

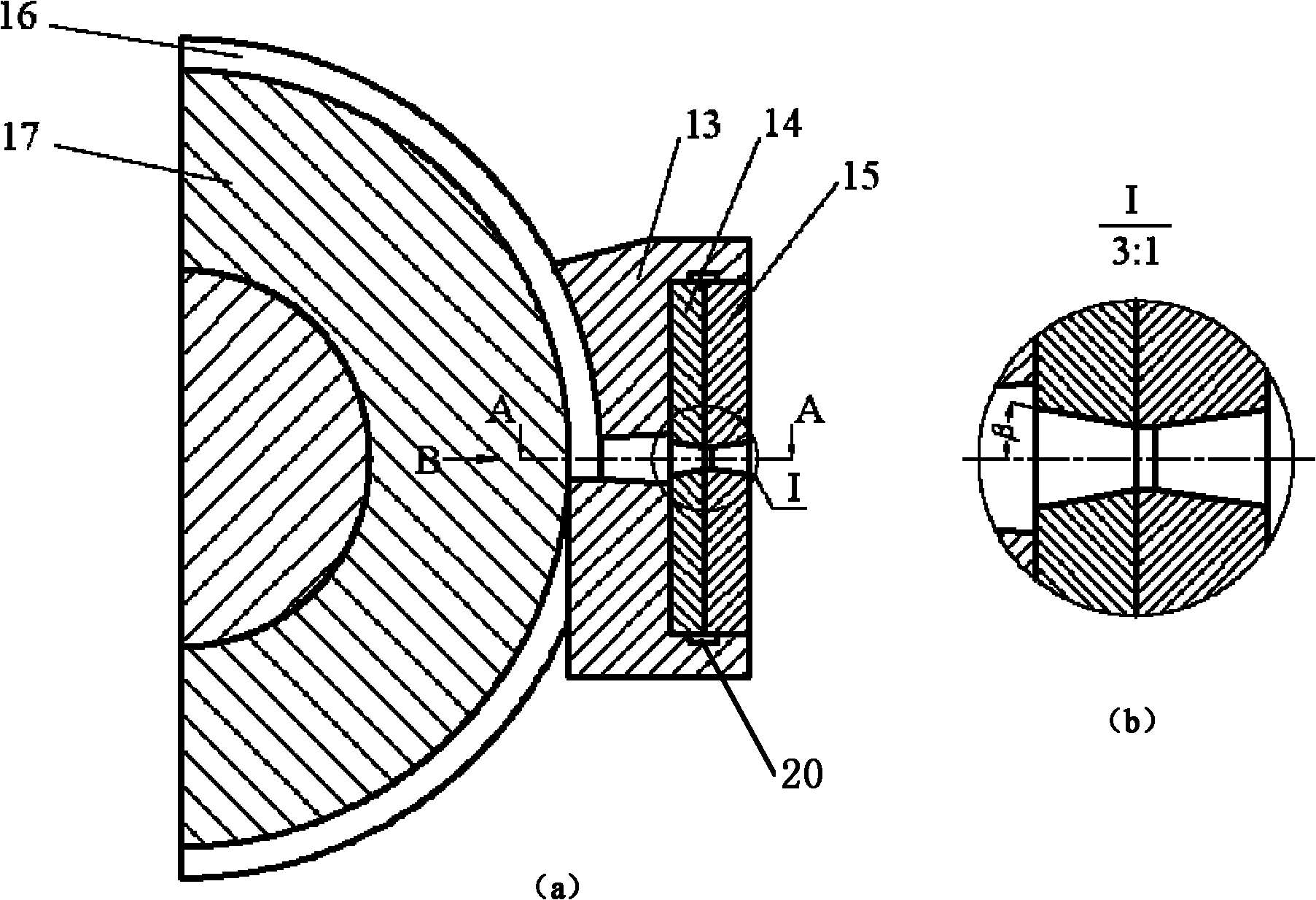

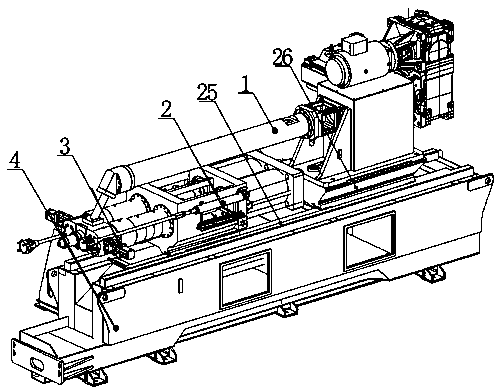

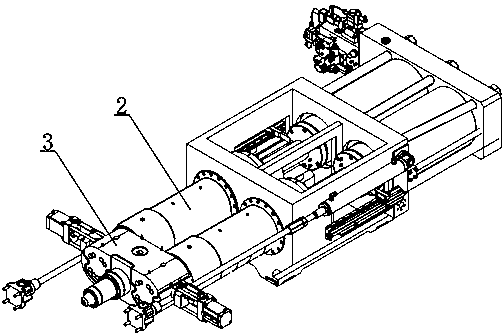

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

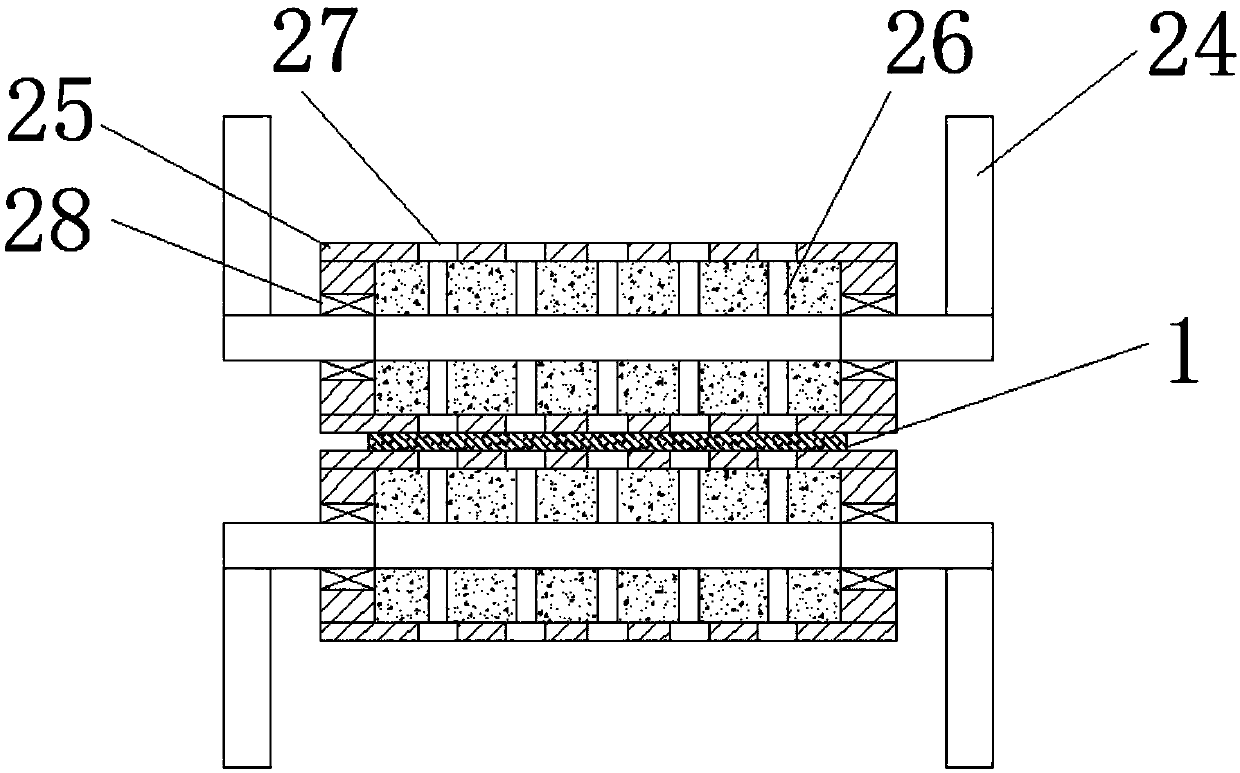

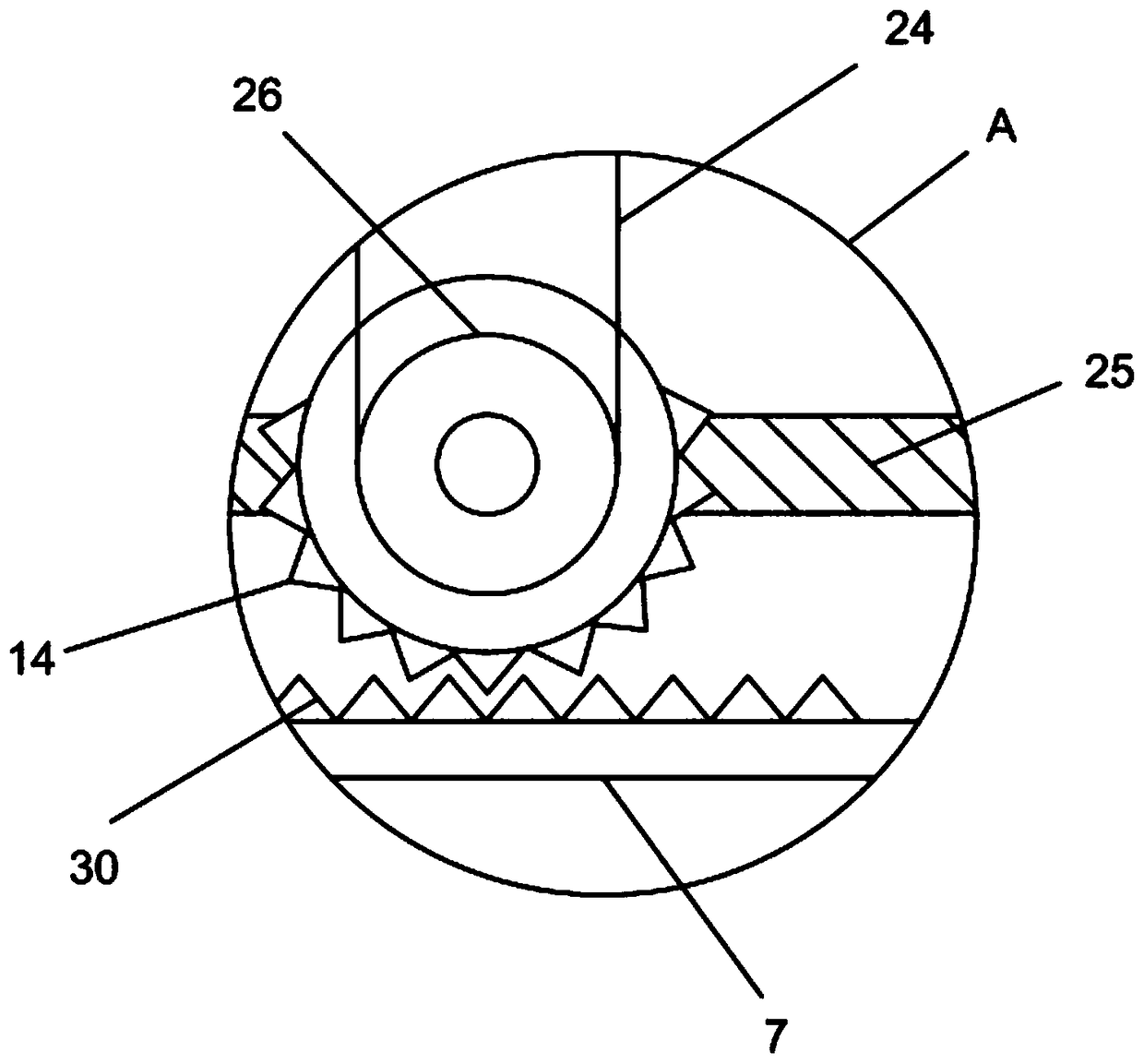

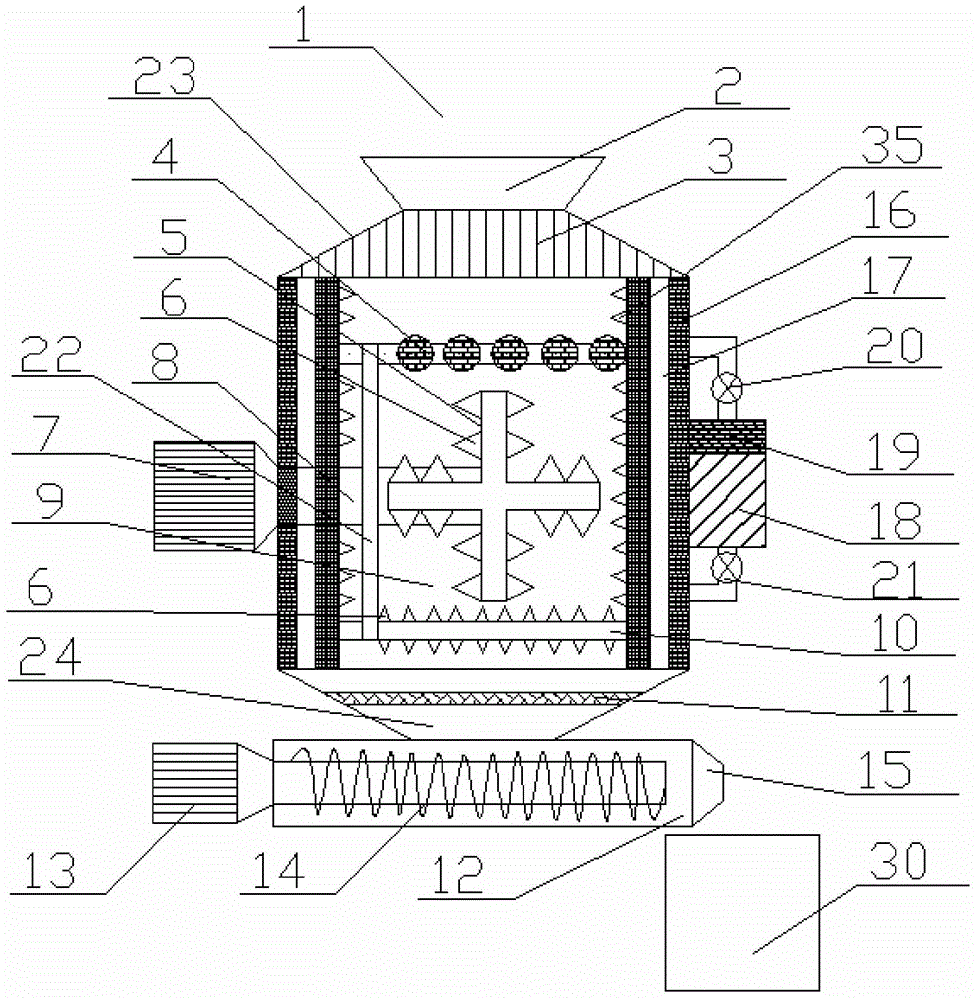

Feed extruding and granulating device for livestock feed processing

InactiveCN108654515AImprove the extrusion effectImprove work efficiencyFeeding-stuffGranulation by material expressionReciprocating motionEngineering

The invention discloses a feed extruding and granulating device for livestock feed processing. The feed extruding and granulating device is characterized in that a support rack is vertically fixedly mounted on a bottom plate, a limit extruding cylinder is fixedly mounted on the support rack, a slider is horizontally slidably arranged in the limit extruding cylinder, a slide plate is horizontally fixedly mounted at the left top end of the slider, the upper surface of the slide plate is abutted against the inner side of the limit extruding cylinder, and a feeding channel is vertically formed inthe slide plate; an air heater is fixedly mounted at the bottom of the bottom plate, and a collecting tank located at the right bottom of a conveying belt is fixedly mounted on the bottom plate. The feed extruding and granulating device has the advantages that feed intermittently enters the limit extruding cylinder is extruded into strip-shaped feed through extruding holes by the leftward and rightward reciprocating movement of the slider, and a good extruding effect and high work efficiency are achieved; the strip-shaped feed is repeated cut by a cutting blade which moves leftwards and rightwards in a reciprocating manner to achieve feed granulation, the feed is fast dried through hot air rightwards discharged by an exhaust mesh cover, feed adhesion is avoided, and the quality of feed granules is increased greatly.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

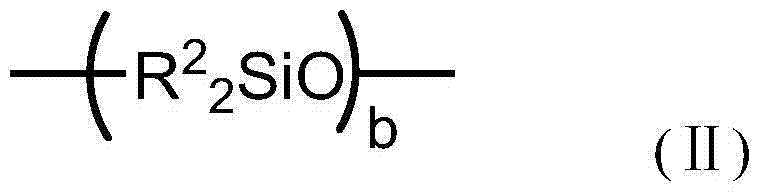

Organic silicone thixotropic agent and thixotropy addition type liquid silicone rubber

The invention discloses an organic silicone thixotropic agent and a thixotropy addition type liquid silicone rubber. The organic silicone thixotropic agent comprises modified polysiloxane and modified cyclosiloxane; and the modification groups in the modified polysiloxane and modified cyclosiloxane at least comprise one group of epoxy group, ether group, hydroxyl group, amine group, and ester group. The modification group content of the modified polysiloxane is 0.01 to 0.80 mol / 100g, and the modification group content of the modified cyclosiloxane is 0.10 to 0.60 mol / 100g. The organic silicone thixotropic agent can further comprise silicone dioxide. The invention further discloses a thixotropy addition type liquid silicone rubber containing the organic silicone thixotropic agent. After the provided organic silicone thixotropic agent is mixed with liquid silicone rubber, the thixotropy of liquid silicone rubber can be improved, and thus the liquid silicone rubber can satisfy the specific application occasion such as mould-free encapsulation, and the like.

Owner:惠州市安品新材料有限公司

Industrial grinder suitable for chemical engineering, pharmacy and food material processing

The invention discloses an industrial grinder suitable for chemical engineering, pharmacy and food material processing. The industrial grinder comprises a grinder body and a storage bin, wherein the grinder body comprises a feed port, a variable frequency motor, a grinding bin, a stirring wheel and a discharge port; the feed port is arranged above the grinding bin, and a flow guiding plate is arranged in a feed channel between the feed port and the grinding bin, an extrusion roller is arranged below the flow guiding plate, the stirring wheel and a rotating shaft are arranged in the grinding bin, and the surfaces of the stirring wheel and the rotating shaft are respectively provided with teeth; the variable frequency motor is arranged on the grinding body, and the variable frequency motor is capable of respectively driving the stirring wheel, the rotating shaft and the extrusion roller to rotate through a connecting piece and / or a transmission tape; the bottom of the grinding bin is provided with an inverted trapezoidal discharge funnel, a filter net is arranged in the discharge funnel, a material conveying cavity is arranged below the grinder body, and the discharge port is formed at one side of the material conveying cavity. The material can be completely ground, the grinding effect is good, and the grinding efficiency is high.

Owner:YANCHENG XINANZHOU PHARMA +1

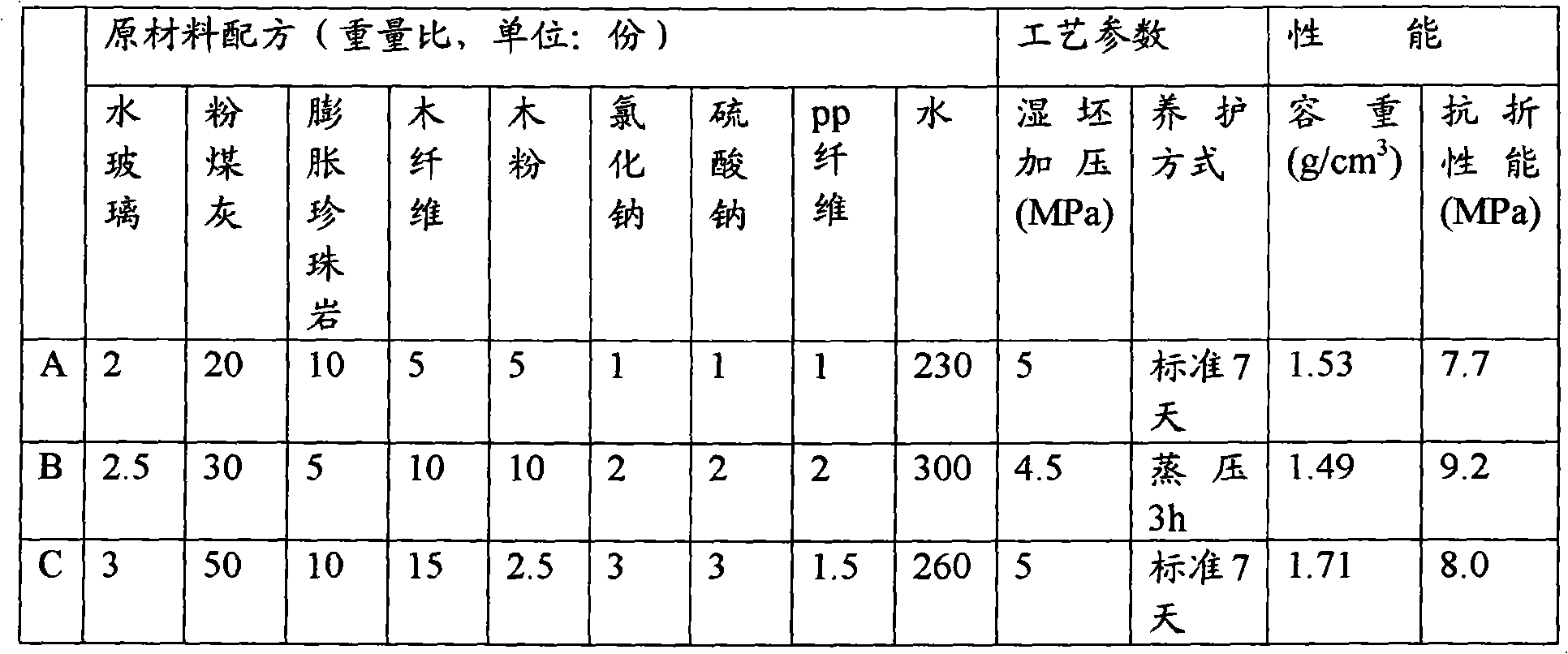

Light-weight fiber reinforced cement board and manufacturing method thereof

ActiveCN101781106AHigh tensile strengthHigh impact strengthSolid waste managementCement boardMethyl cellulose

The invention provides a light-weight fiber reinforced cement board. The light-weight fiber reinforced cement board comprises 100 parts of cement, 20 parts of silicon powder, 15 parts of calcium powder, 5 to 10 parts of expanded perlite, 4 parts of paper pulp, 5 to 15 parts of wood fibers, 5 to 10 parts of wood powder, 1 to 2 parts of polypropylene fibers, 0.8 part of methyl cellulose, 1 to 3 parts of sodium chloride, 1 to 3 parts of sodium sulphate, 2 to 3 parts of sodium silicate, and 230 to 300 parts of water. The invention also discloses a method for manufacturing the light-weight fiber reinforced cement board, which comprises the following steps of: 1, weighing each component according to formula; 2, placing the weighed dry materials into a mixer for uniformly mixing; 3, preparing wet materials, placing the mixed materials obtained by the step 2 into a kneader, adding water and the wet materials into the mixed materials, and kneading the mixture; and 4, placing the kneaded slurryinto a mold, performing compression moulding by using a plate fluidizing machine, and then demolding. The manufacturing method greatly improves the tensile strength, the impact strength, the water-retaining property, and the extrusion property of the materials.

Owner:BEIJING NEW BUILDING MATERIALS PLC

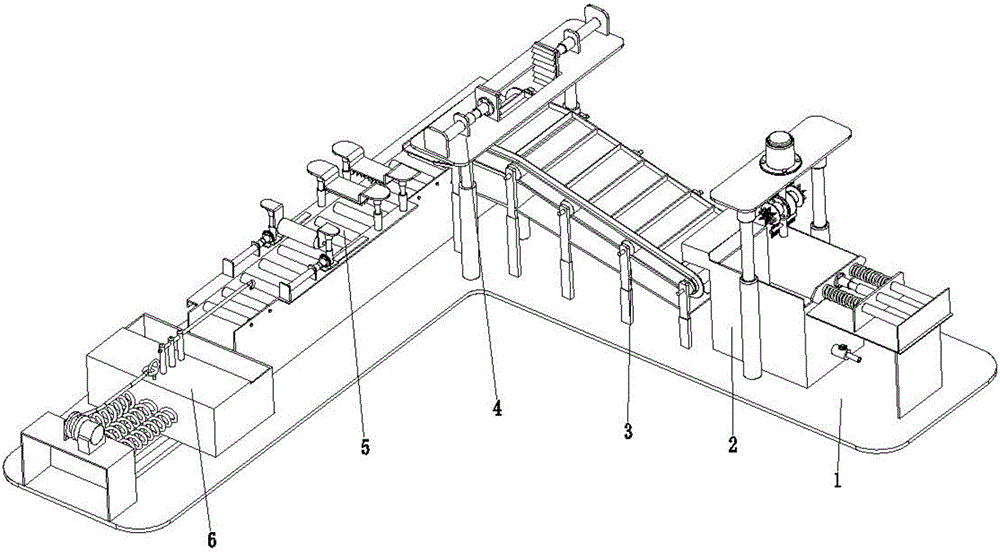

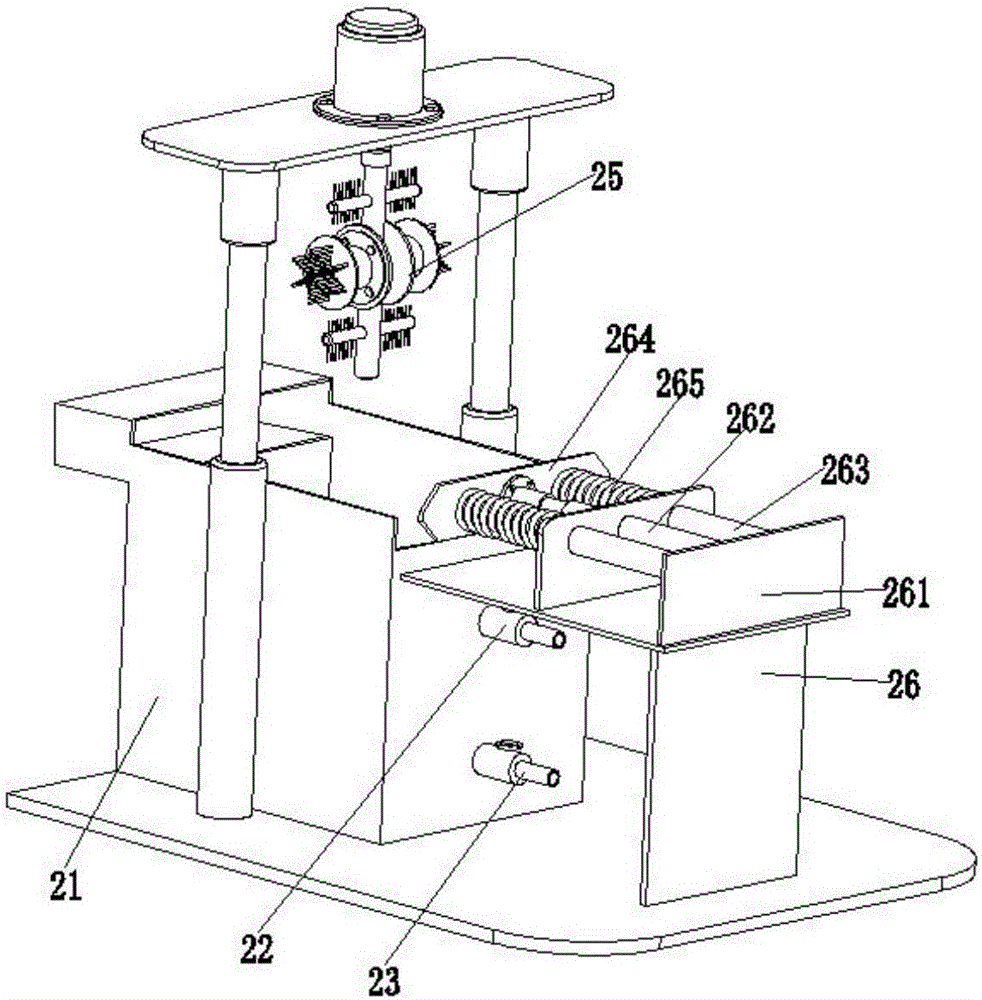

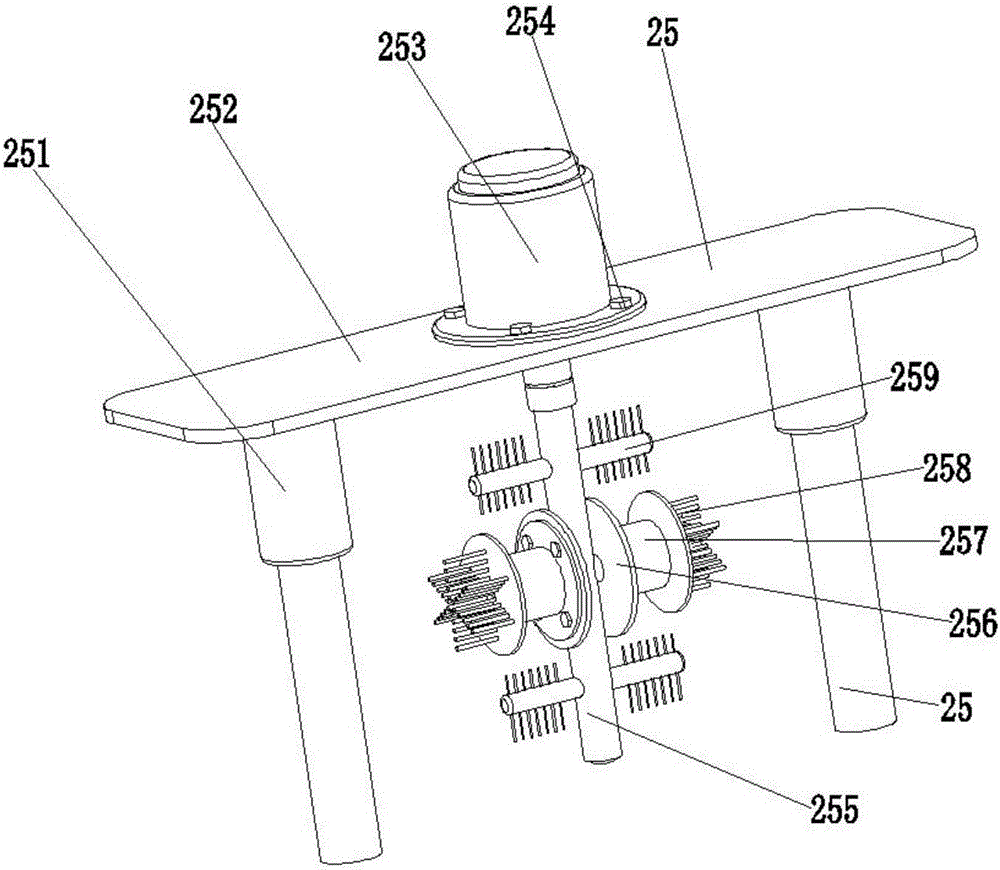

Environment-friendly recycling treatment system for waste plastic bottles

ActiveCN106608004AAvoid pollutionProtect the ecologyPlastic recyclingMechanical material recoveryPollutionMechanization

The invention relates to an environment-friendly recycling treatment system for waste plastic bottles. The environment-friendly recycling treatment system comprises a base plate, a cleaning and feeding device, a conveying device, a squeezing device, a crushing device and a storage device. The base plate is of an L-shaped structure. The cleaning and feeding device is located at the front side end of the base plate. The conveying device is located right on the rear portion of the cleaning and feeding device, and the conveying device and the cleaning and feeding device are located on the same straight line. The squeezing device is located at an outlet in the rear side of the conveying device. The crushing device and the conveying device are vertically arranged, and the crushing device is fixedly connected with the base plate. The storage device is installed at the left side of the crushing device. By means of the environment-friendly recycling treatment system, the waste plastic bottles can be cleaned, pushed, fed, conveyed, squeezed, crushed and stored, and the whole recycling treatment of the waste plastic bottles is realized; moreover, the treatment process is high in degree of mechanization, a large number of labor force is saved, and treatment efficiency is improved; and meanwhile, pollution to the environment by the waste plastic bottles is avoided, and the environment and ecology are protected.

Owner:同信生态环境科技有限公司

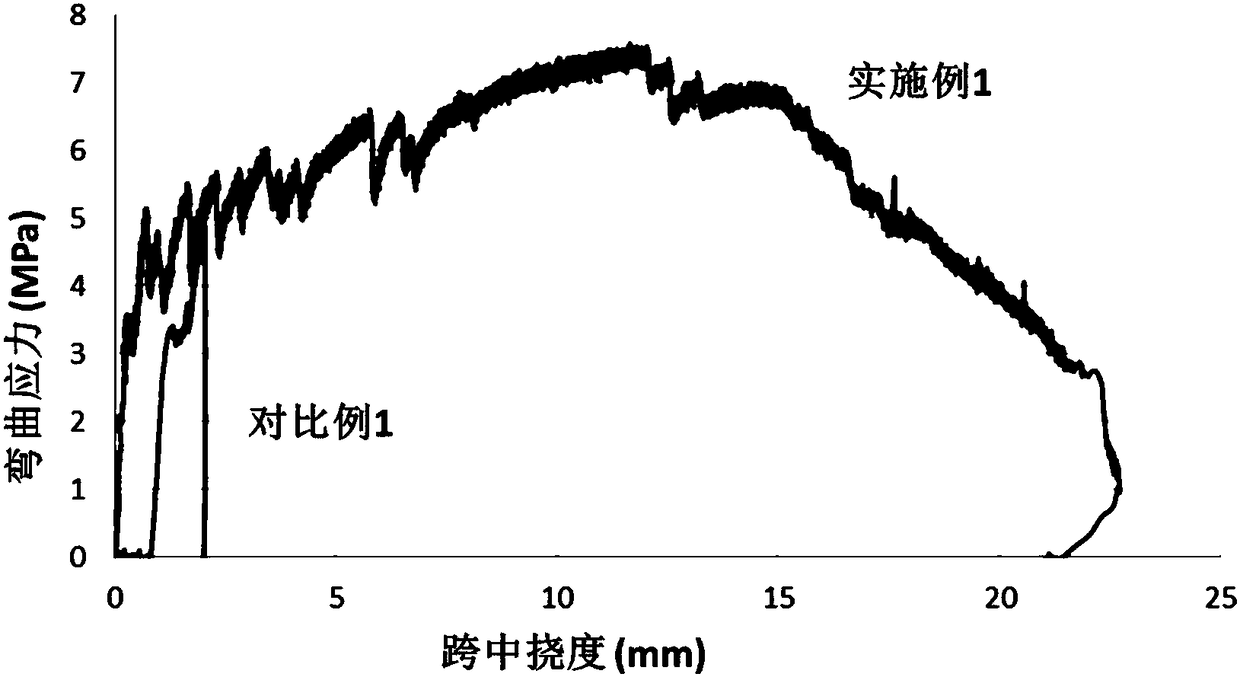

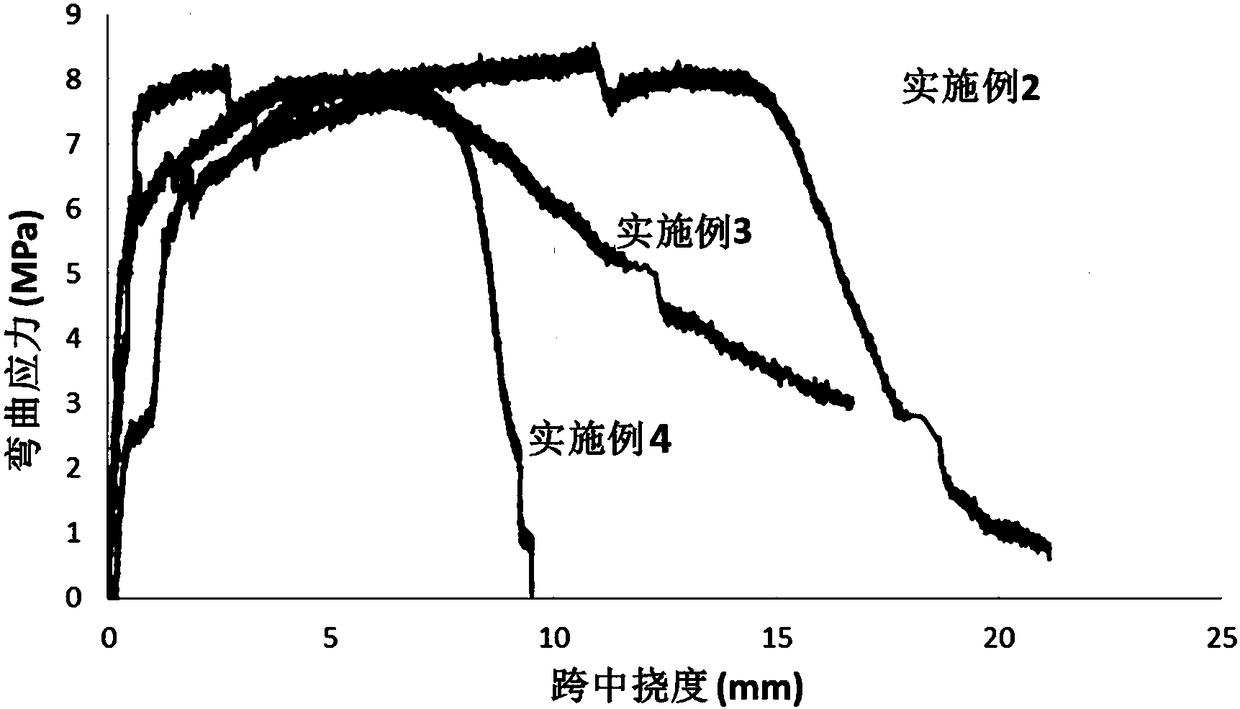

PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and use method thereof

ActiveCN108129102AHigh mechanical strengthImprove impact resistanceAdditive manufacturing apparatusAdditive ingredientPortland cement

The invention relates to PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and a use method thereof. Through being metered in parts by weight, the concrete is preparedfrom the following ingredients including 0.8 to 1.2 parts of fast hardening ordinary Portland cement, 0.96 to 1.44 parts of grade F fly ash, 0.64 to 0.96 part of quartz sand (with the particle diameter range being 0.075 to 0.15mm), 0.29 to 0.43 part of water, 0.005 to 0.01 part of water reducing agents, 0.0017 to 0.0018 part of PVA fiber and 0.0043 to 0.0078 part of basalt fiber. According to thematerials of the concrete, the PVA fiber and the basalt fiber are used for optimizing and improving the intensity and the toughness of the concrete material; the printing performance is high; the intensity is high; the cost is low; the practical engineering application of the 3D printing concrete can be favorably promoted.

Owner:HEBEI UNIV OF TECH

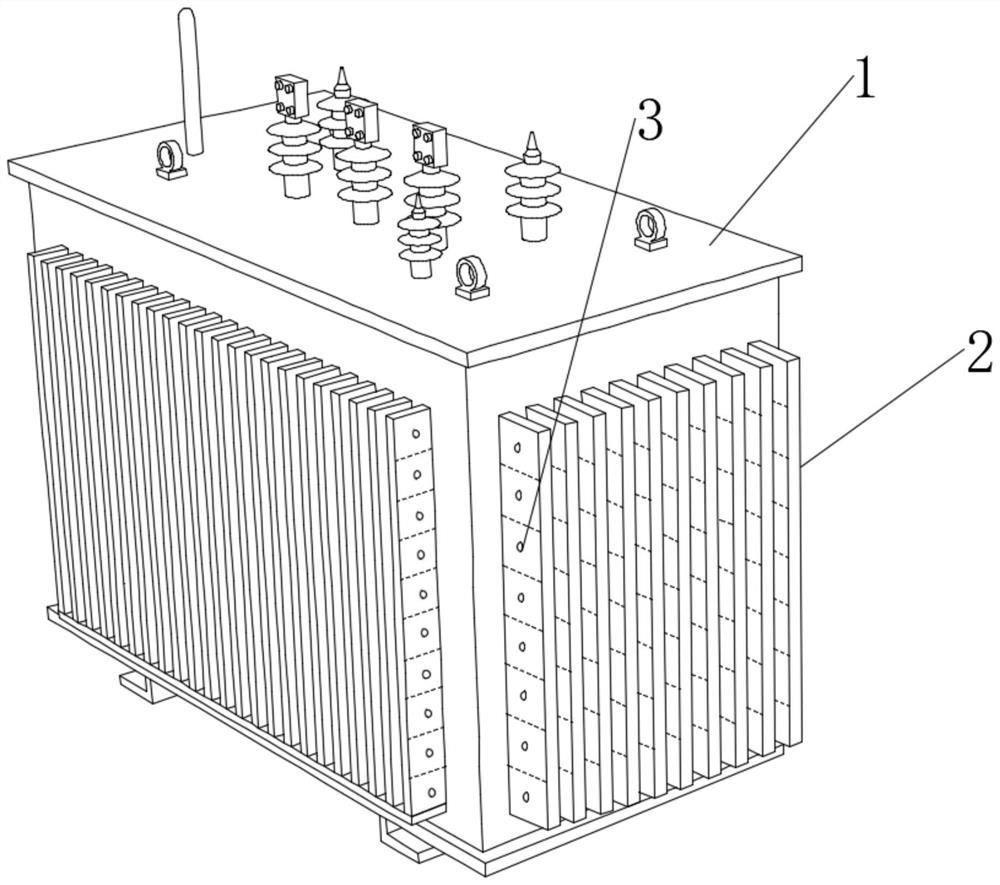

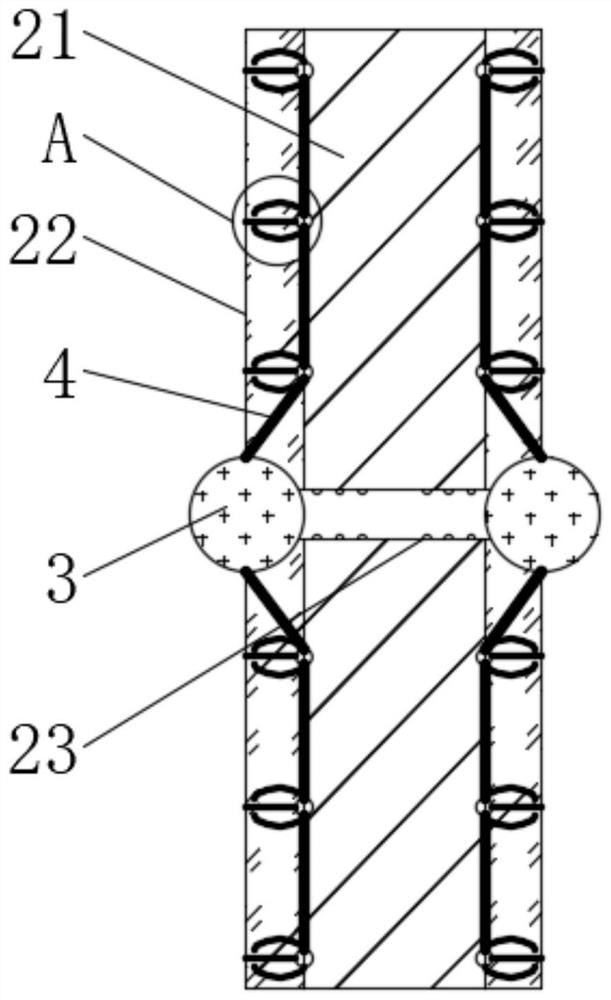

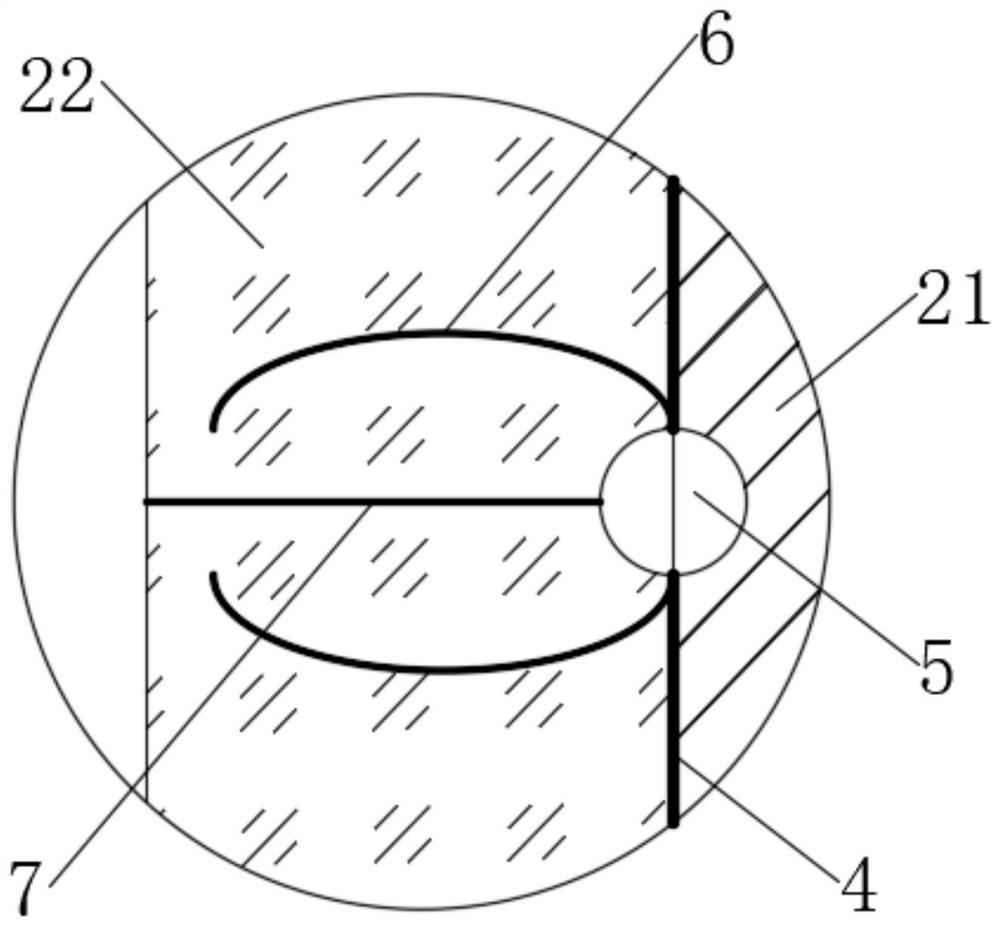

Outer-layer variable heat dissipation structure of transformer

ActiveCN111627667AImprove cooling effectPromote absorptionTransformers/inductances coolingWater useTransformer

The invention discloses an outer-layer variable heat dissipation structure of a transformer, and belongs to the technical field of transformer equipment. Composite variable cooling fins can be innovatively introduced into the transformer body. The deformable shape-change heat exchange layer is attached to the heat dissipation substrate for rapid heat conduction. An external water-absorbing water-based ball is used as a cold source. A thermal extension trigger cylinder arranged in the heat dissipation substrate generates an expansion phenomenon after sensing heat. On one hand, the water-based balls are extruded to release water, and on the other hand, the expansion action of the thermal extension trigger cylinder is continued, the water-based ball is also used for pulling the shape-change heat exchange layer to deform to form a shape similar to a tent, and performing second cooperation with the thermal extension trigger cylinder. The outer surface of the heat dissipation substrate can be exposed, water can absorb heat conveniently to achieve evaporation, meanwhile, the shape change heat exchange layer wraps the heat extension trigger cylinder and then absorbs heat away, the heat extension trigger cylinder restores to conduct the next time of variable heat dissipation, and therefore the heat dissipation effect of the transformer is remarkably improved.

Owner:河南龙键电力装备有限公司

Chemical crosslink polyethylene insulating plastic used for water tree resistant power cable and application thereof

ActiveCN101445628AIncrease internal lubricityReduce intermolecular stressPlastic/resin/waxes insulatorsInsulated cablesEngineeringCrystallinity

The invention discloses a chemical crosslink polyethylene insulating plastic used for a water tree resistant power cable and application thereof. The insulating plastic comprises the components based on the parts by weight: 100 parts of polyethylene resin, 0.5-4 parts of ethylene-acrylic ester multipolymer, 1.0-3.0 parts of peroxide, 0.02-2 parts of compound antioxidizer, 0.1-0.5 parts of nucleating agent and 0.1-1 part of siloxane. The chemical crosslink polyethylene insulating plastic used for the medium-low pressure water tree resistant power cable has good extrudability and cable forming property, less impurity content, excellent water tree resistant performance, improved internal lubricity and good surface performance; under the same current, the extruded velocity of the cable is high, the processing temperature is reduced, less low molecular gas is generated, the impurities and defects inside the material get less, the degree of crystallinity and the water tree resistant performance are improved, the production energy consumption is reduced, and the production efficiency is improved. Therefore, the invention can be used for an insulating layer or a restrictive coating of medium-low pressure power cable.

Owner:上海新上化高分子材料有限公司

Cesium-rubidium-potassium monolithic flameproof glass and preparation method

The invention discloses cesium-rubidium-potassium monolithic flameproof glass and a preparation method. The preparation method comprises a process of carrying out chemical strengthening on glass, wherein chemical strengthening is carried out by placing the glass in molten salts and carrying out ion exchange by a two-step method; in the first step, the molten salt is a mixture of potassium nitrate, rubidium nitrate, potassium fluoride and potassium hydroxide, the exchange temperature is 320-360 DEG C and the heat-insulation time is 2 hours; and in the second step, the molten salt is a mixture of potassium nitrate, cesium nitrate, aluminum oxide, boron fluoride, potassium carbonate and potassium phosphate, the exchange temperature is 500 DEG C and the heat-insulation time is 3 hours. The monolithic flameproof glass product prepared by the method is stable in quality and excellent in fire resistance; in the fire resistance test, the invalidation of the monolithic flameproof glass is caused by final softening and collapsing instead of heat bursting destruction; and the fire resistance time is 120 minutes.

Owner:SHENYANG JIANZHU UNIVERSITY

High-strength and abrasion-proof cable sheath material

InactiveCN103788434AGood physical and mechanical propertiesImprove heat resistanceInsulated cablesInsulated conductorsAntimony trioxideTalc

The invention discloses a high-strength and abrasion-proof cable sheath material, which comprises the following components in parts by weight: 15 to 30 parts of nitrile rubber, 40 to 60 parts of chloroprene rubber, 10 to 15 parts of chlorinated polyethylene, 1.5 to 4 parts of zinc oxide, 1.5 to 4 parts of magnesium oxide, 0.8 to 1.5 parts of N,N'-m-phenylene dimaleimide, 0.5 to 2 parts of calcium stearate, 0.8 to 2.5 parts of accelerator 4010NA, 1.8 to 3 parts of paraffin, 35 to 44 parts of white carbon black, 20 to 25 parts of superfine talc powder, 12 to 14 parts of active kaolin, 2 to 4 parts of dicumyl peroxide, 0.7 to 1.4 parts of diallyl isocyanate, 2 to 4 parts of antimony trioxide and 4 to 6 parts of magnesium hydroxide. The high-strength and abrasion-proof cable sheath material is high in tear resistance and abrasion-proof performance and long in service life, and has good flame-retardant effects.

Owner:ANHUI FUXING CABLE GRP

Organic silicon heat conduction bonding agent adopting high-power light emitting diode (LED) for illumination and preparation method thereof

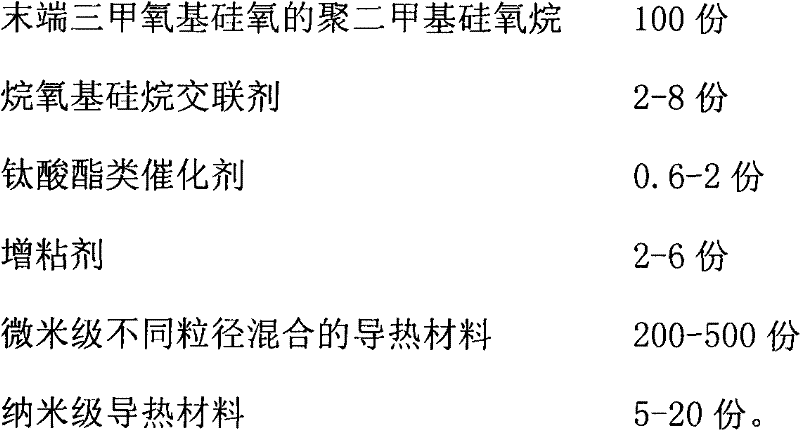

InactiveCN102352213AImprove thermal conductivityIncrease elasticityNon-macromolecular adhesive additivesSemiconductor devicesCross-linkHeat conducting

The invention discloses an organic silicon heat conduction bonding agent adopting a high-power light emitting diode (LED) for illumination and a preparation method thereof. The organic silicon heat conduction bonding agent consists of polydimethylsiloxane with trimethoxy silane oxygen at the tail end, alkoxy silane cross linking agents, titanate catalysts, adhesion promoters, micrometer level mixed heat conducting materials with different grain diameters, nanometer level heat conduction materials and the like. The preparation method of the bonding agent comprises the following steps that: the nanometer level heat conduction materials carry out lyophobic treatment, then, the polydimethylsiloxane with trimethoxy silane oxygen at the tail end, the micrometer level mixed heat conducting materials with different grain diameters and the nanometer level heat conduction materials after the lyophobic treatment are added into a high-speed dispersing stirring machine and are stirred and dewatered for 1 to 3 hours in vacuum, the alkoxy silane cross linking agents, the titanate catalysts and the adhesion promoters are added after the materials are cooled, the materials are output after the vacuum stirring for 60 minutes, and the single ingredients are sealed and packed. The organic silicon heat conduction bonding agent has the advantages that the heat conduction material filling parts are few, the heat conduction factor is high, the elasticity after the solidification is excellent, no corrosion is caused on light emitting diode (LED) electronic elements and aluminum base plates, and the like.

Owner:常州联众光电新材料有限公司

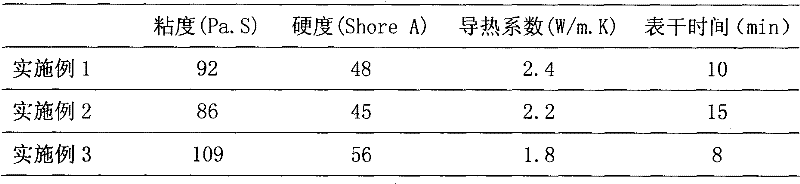

Nano-montmorillonite and PET mixture forming system

The invention discloses a nano-montmorillonite and PET mixture forming system. The system is mainly composed of a rack, a mixture extruding device, an alternative feeding device and two injection devices, wherein the mixture extruding device and the two injection devices are arranged on the rack, and the alternative feeding control device is mainly composed of a valve body, two cylindrical valve elements and two oil cylinders; the two oil cylinders drive the two cylindrical valve elements to move, respectively, one of the cylindrical valve elements is used for communicating the mixture extruding device with one injection device, and closing a material injection channel communicated with the injection device, and meanwhile, the other cylindrical valve element is used for closing a channel between the mixture extruding device and the other injection device, and opening the material injection channel communicated with the injection device. The extruder and the injectors are organically integrated by the system disclosed by the invention, and an NPET pelletizing process is omitted; the system has the characteristics of simple structure, low manufacturing cost and obvious effect.

Owner:GUANGZHOU XUNZHI MACHINERY

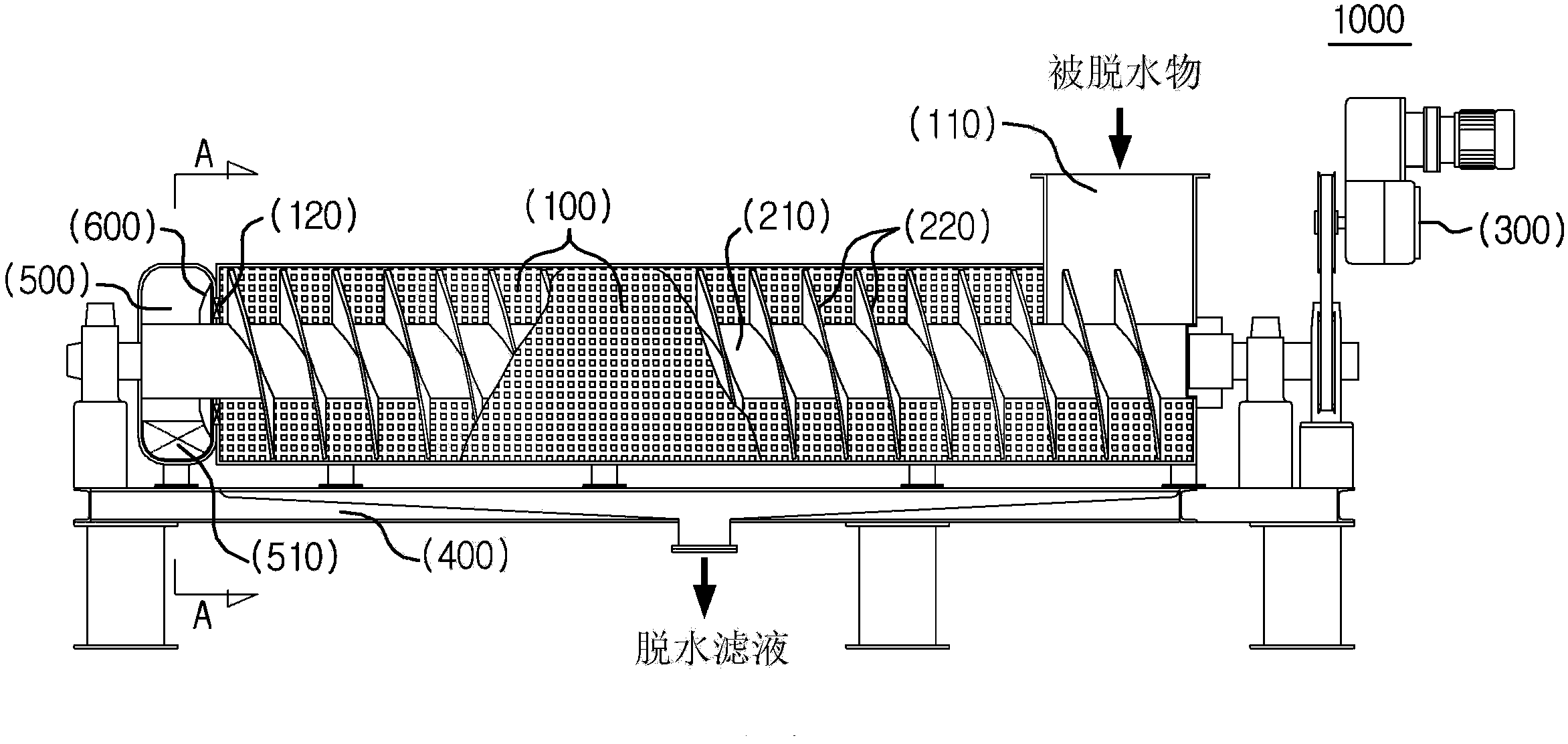

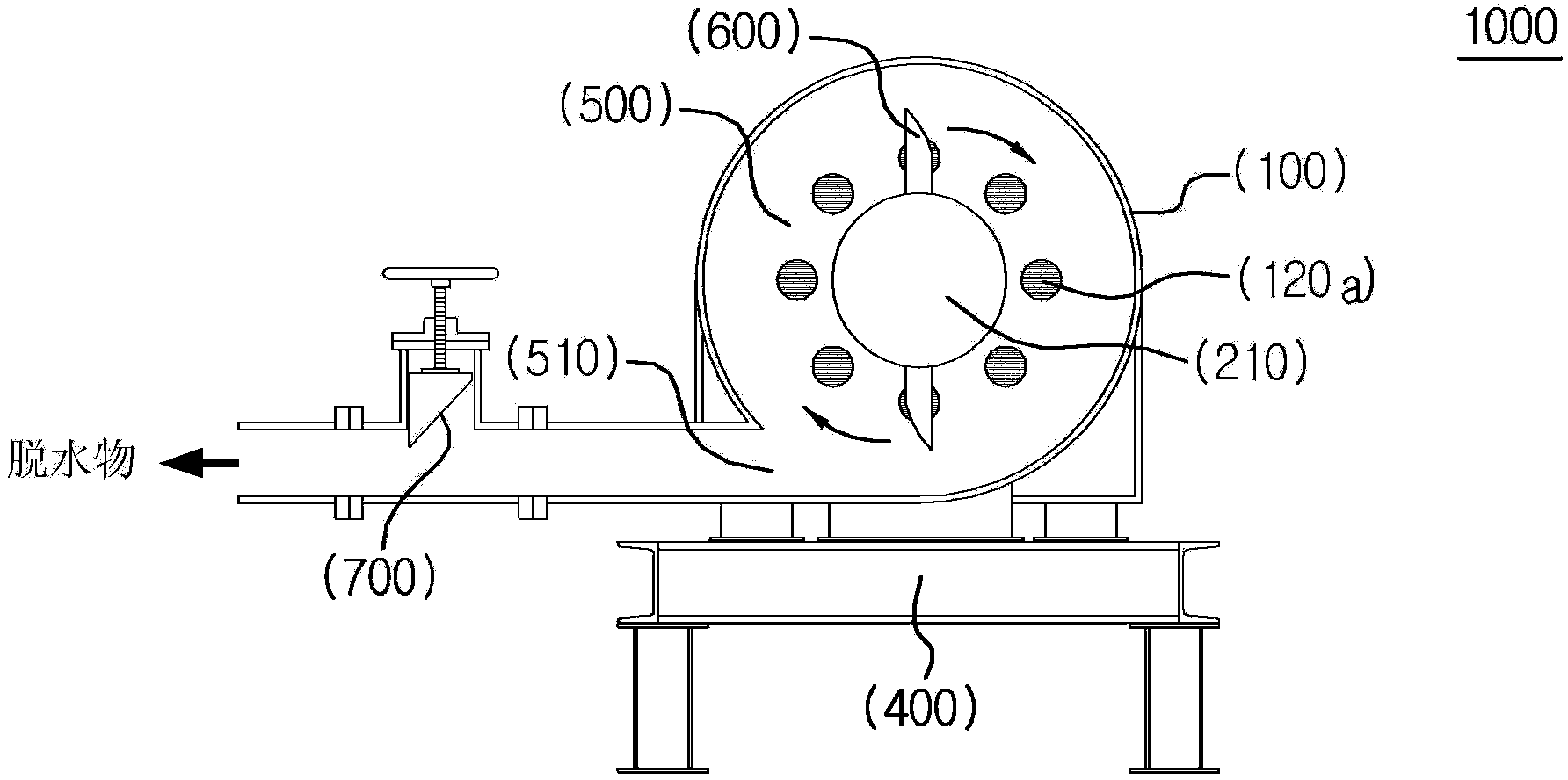

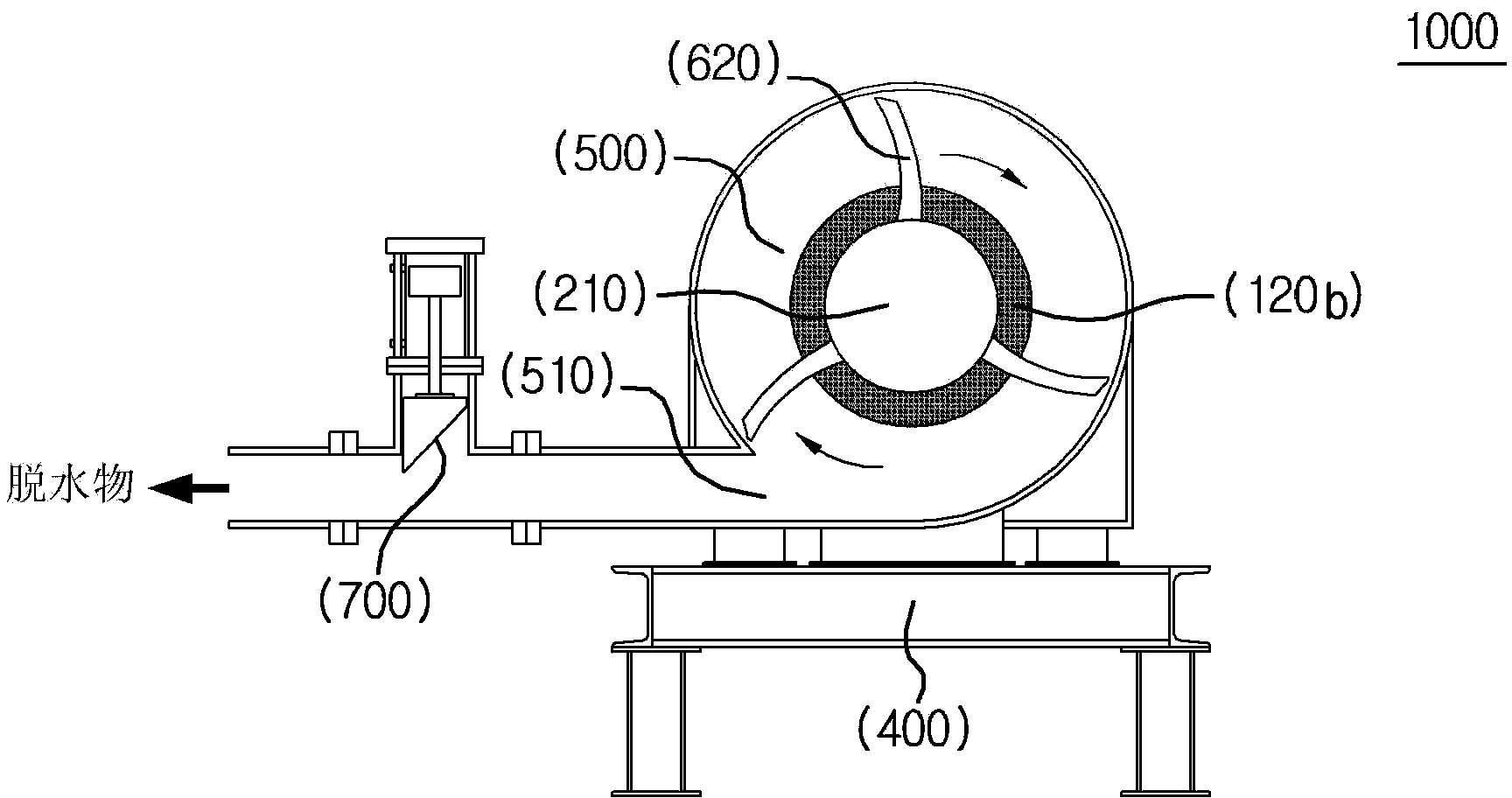

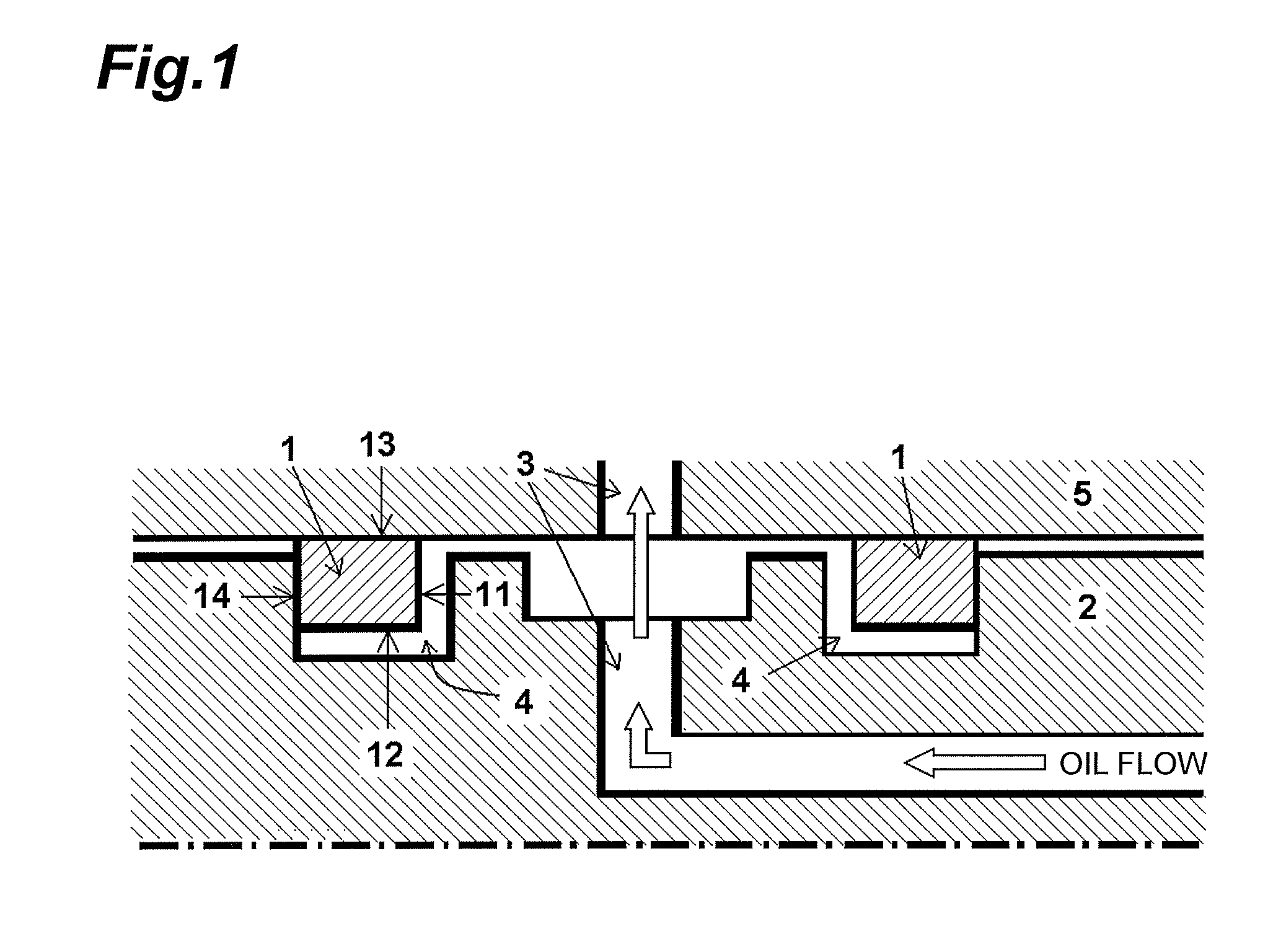

Dehydrator

InactiveCN103977614AAdjust moisture contentRising dehydration pressureStationary filtering element filtersImpellerEngineering

The present invention relates to a dehydrator dehydrating various dehydrated objects containing water and solid bodies. By means of a rotating screw in a driving portion, the dehydrator performs driving inside a cylindrical sieve equipped with an inlet and a discharge outlet such that the dehydrated objects are dehydrated by extrusion. The dehydrator may function various advantages that the discharge outlet is equipped with pressurization chamber with a discharge opening and a pressure regulating unit communicated with the discharge opening, dehydrating pressure can be regulated by simple operation, in another aspect, a push auxiliary unit is arranged on the screw so as to enhance a pressing and pushing capability, a rotary impeller is provided so as to prevent the jamming of the discharge outlet and increase discharging pressure, and the dehydrator is used as a pressure feed pump for pressing and feeding the dehydrated objects .

Owner:GREEN TEC

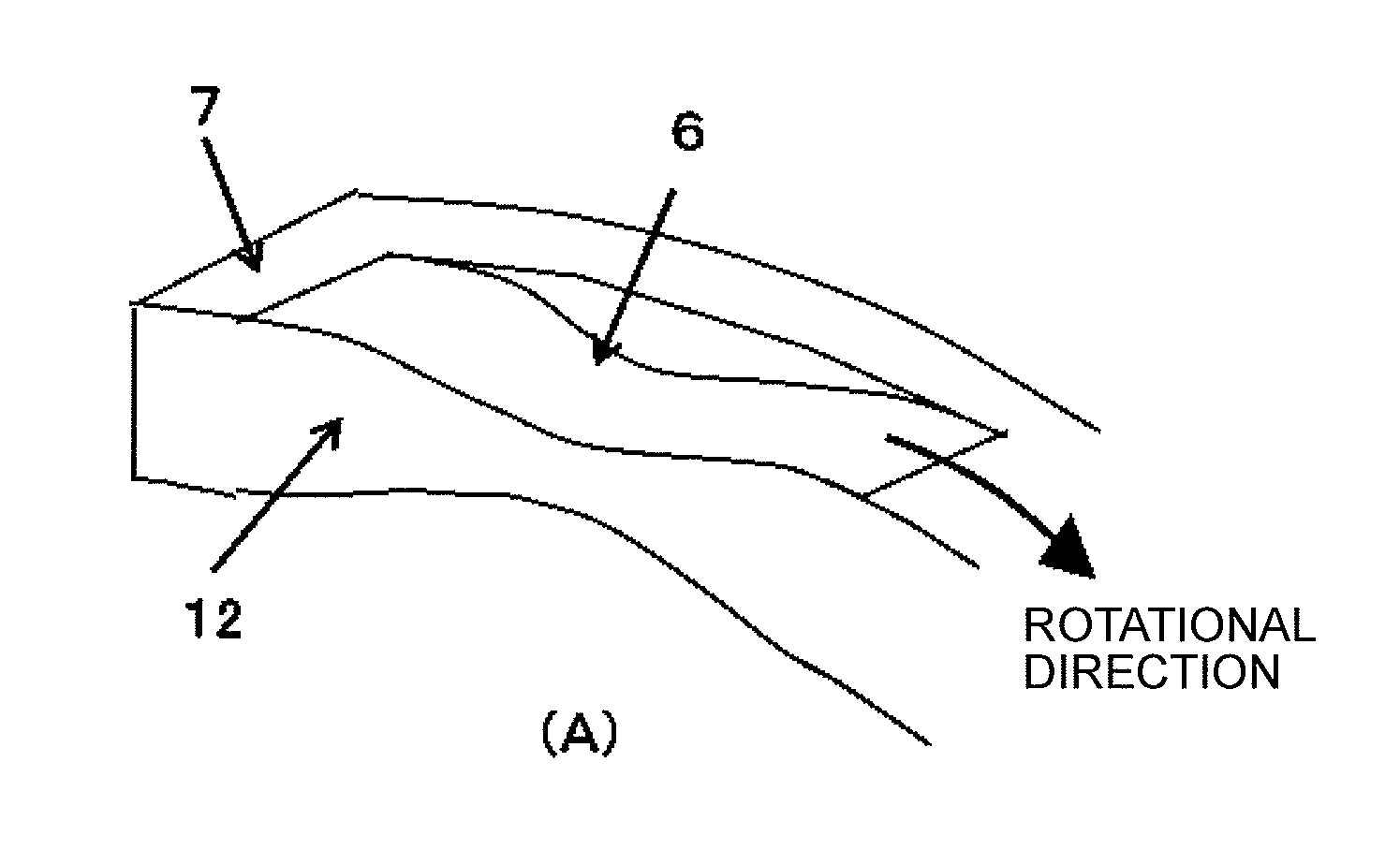

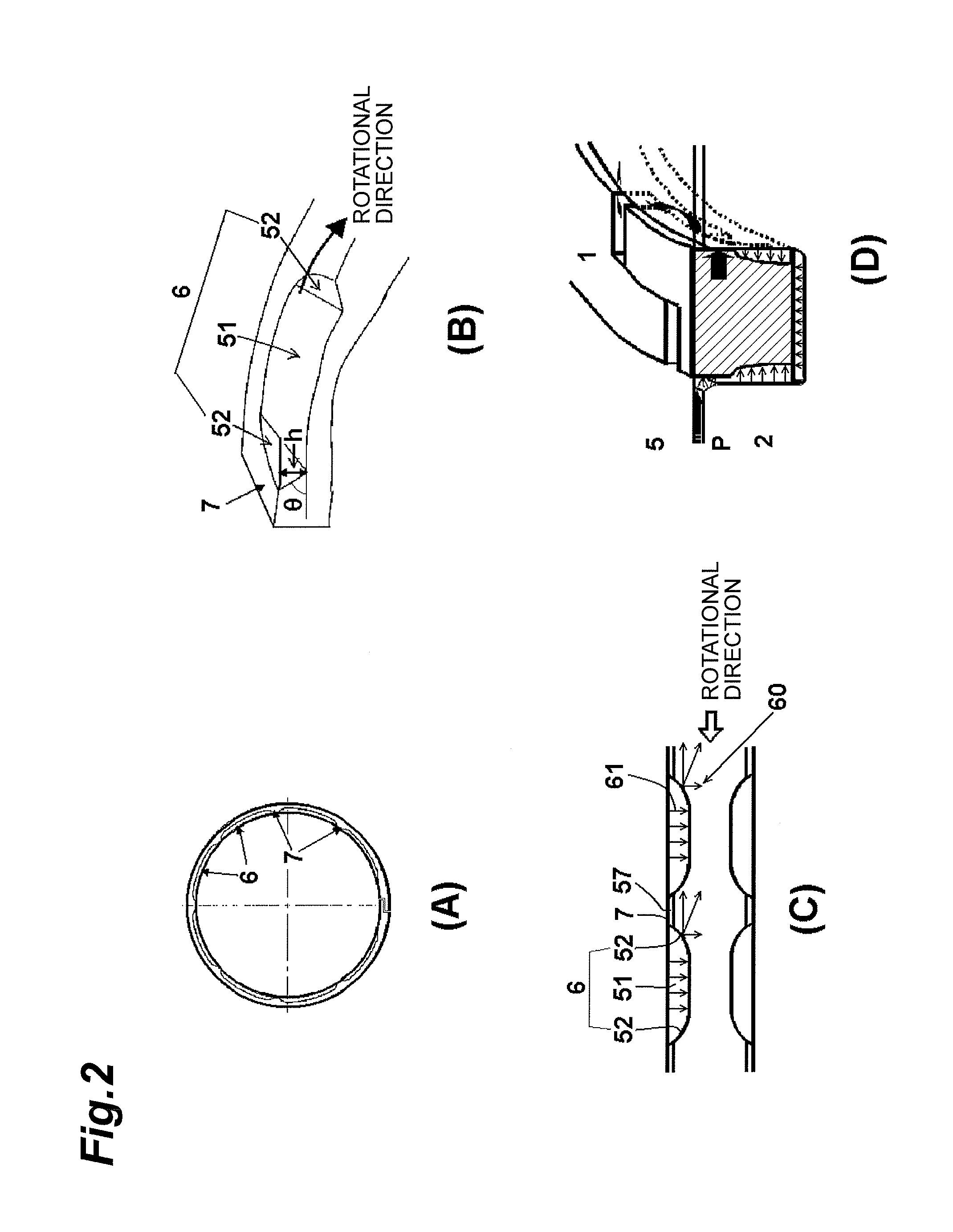

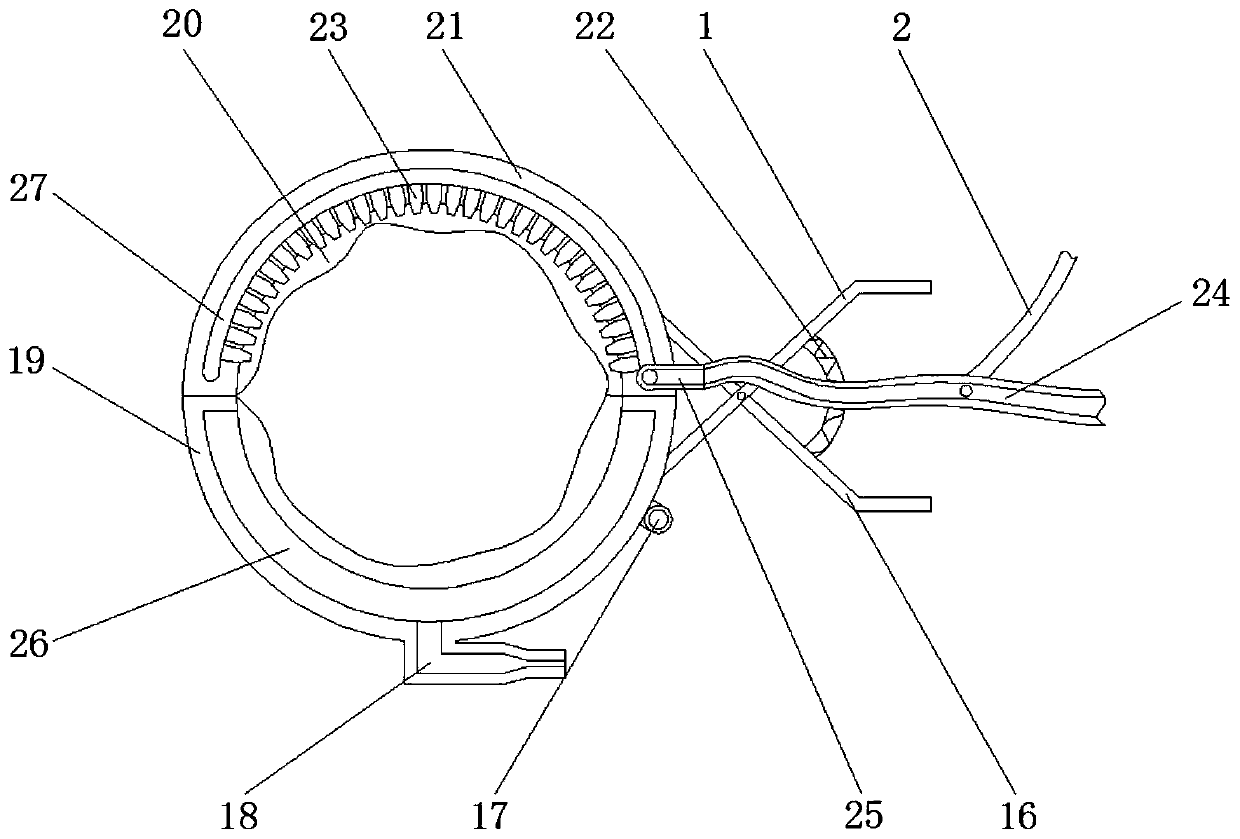

Seal ring

ActiveUS20140008876A1Oil extraction effect is goodEasy to liftEngine sealsAutomatic transmissionLow leakage

Provided is a seal ring which has low-friction characteristics and low-leakage characteristics, reduces drive loss of the automatic transmission of an automobile, and contributes to improvement in fuel consumption of the automobile. The seal ring is attached to a shaft groove on the outer peripheral surface of a shaft. A plurality of recessed sections circumferentially spaced apart from each other with pillar sections interposed therebetween are formed at least on the inner peripheral side of a side surface of the seal ring in contact with the shaft groove. The circumferential opposite ends of each of the recessed sections are formed as squeezing portions formed of curved surfaces convex toward the pillar sections. The depth “h” of a deepest portion in which the axial width of the recessed section is the largest is set in the range of 2 to 17 where the axial width of the seal ring is 100.

Owner:RIKEN CO LTD

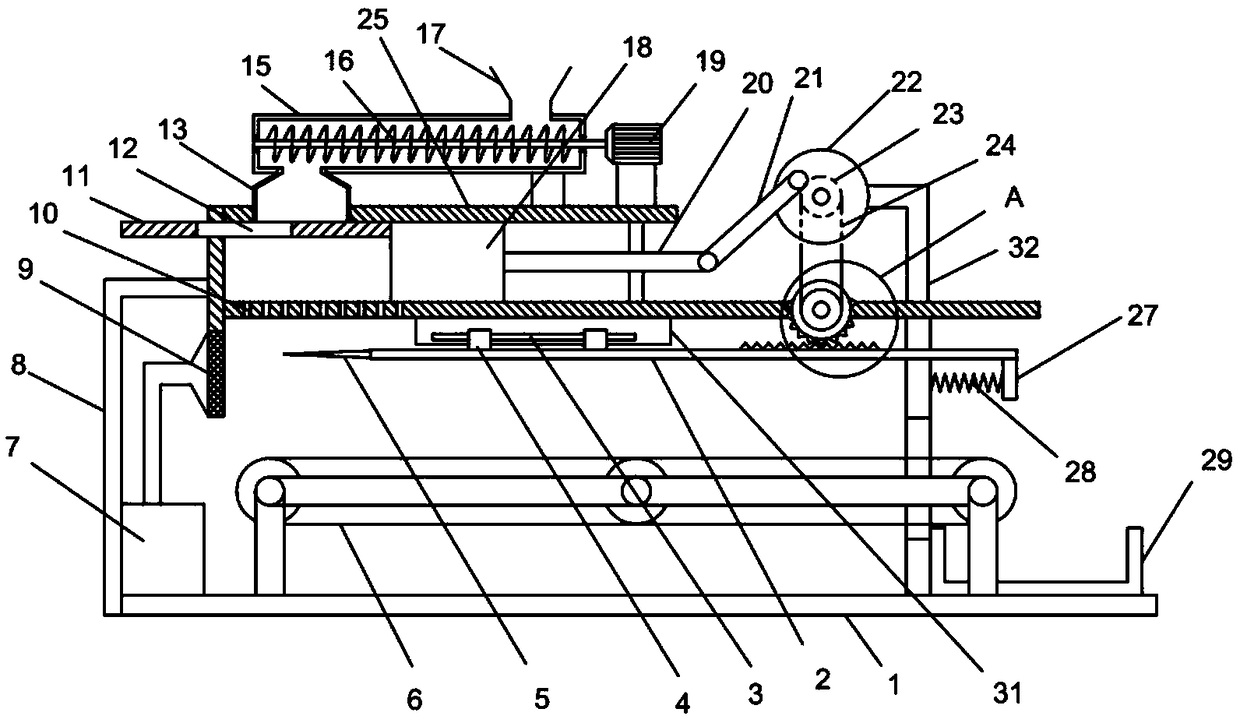

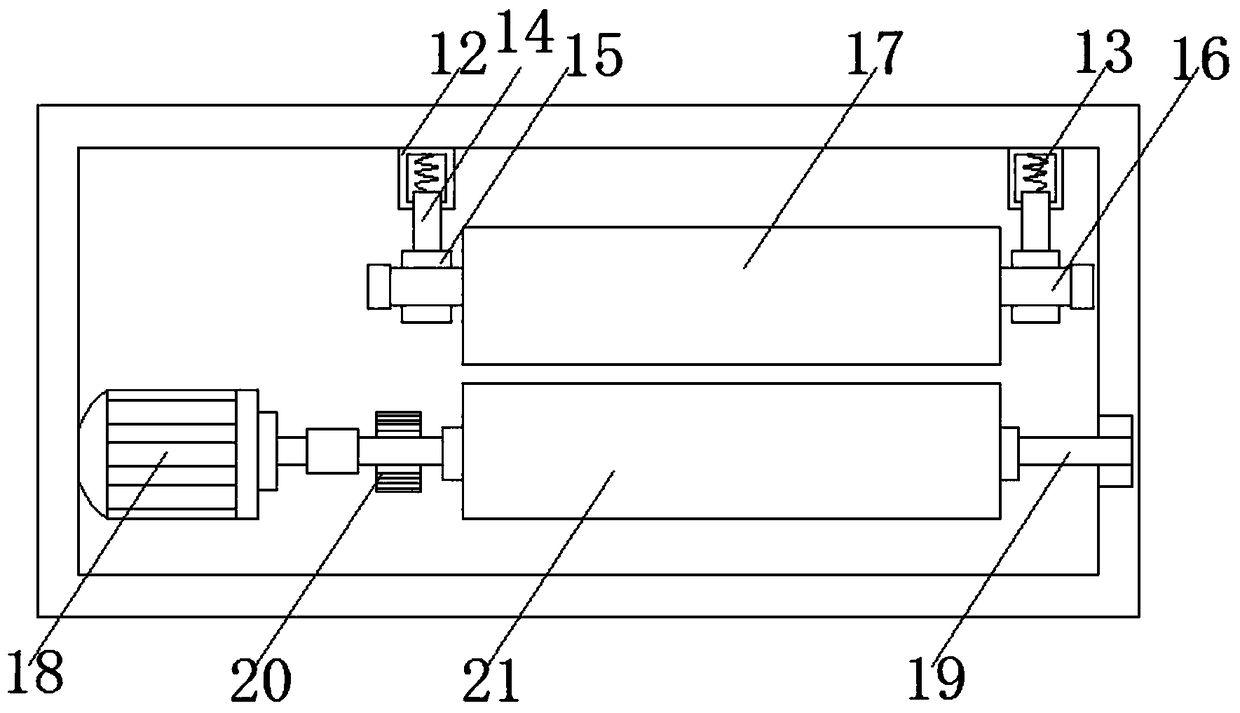

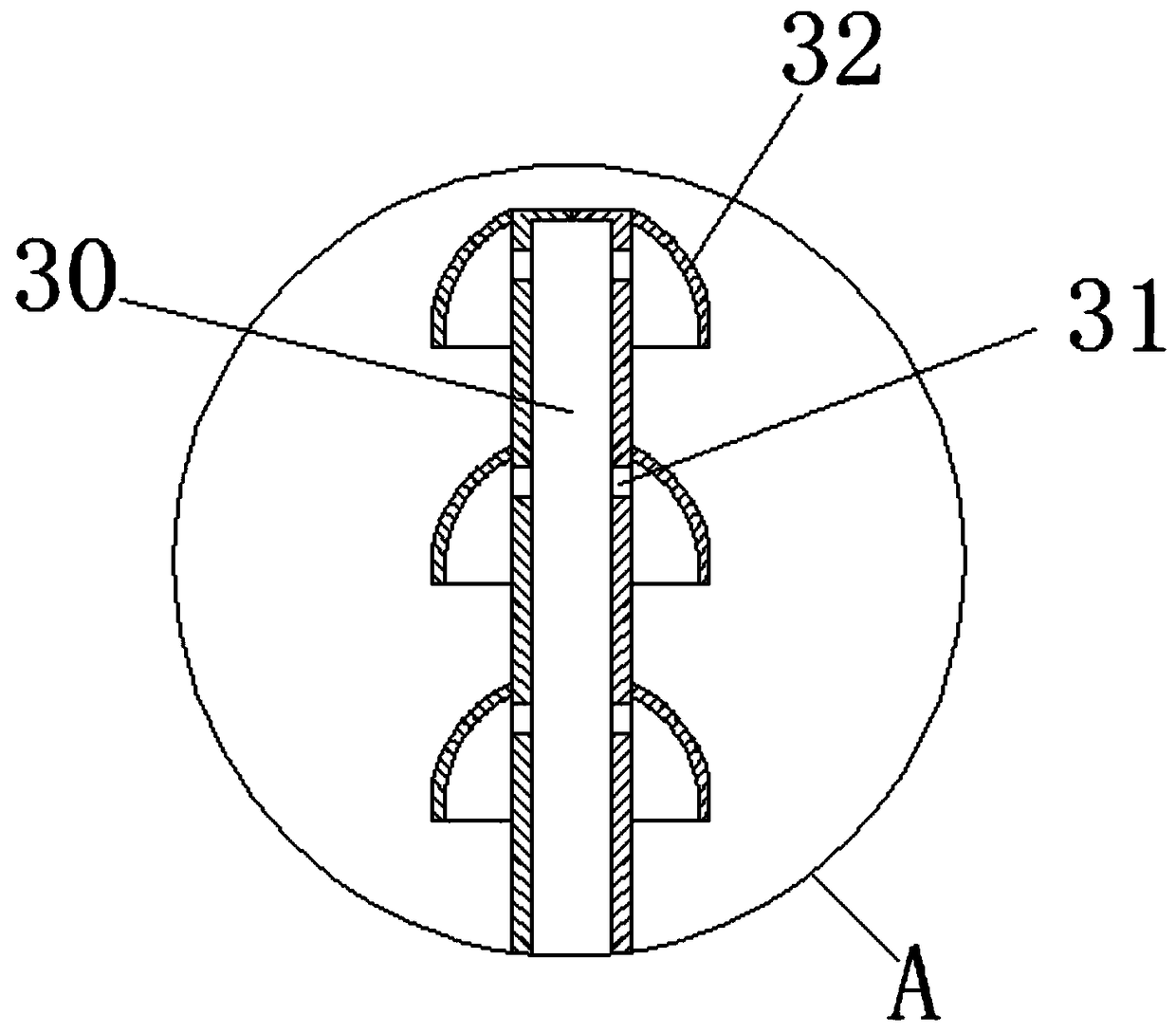

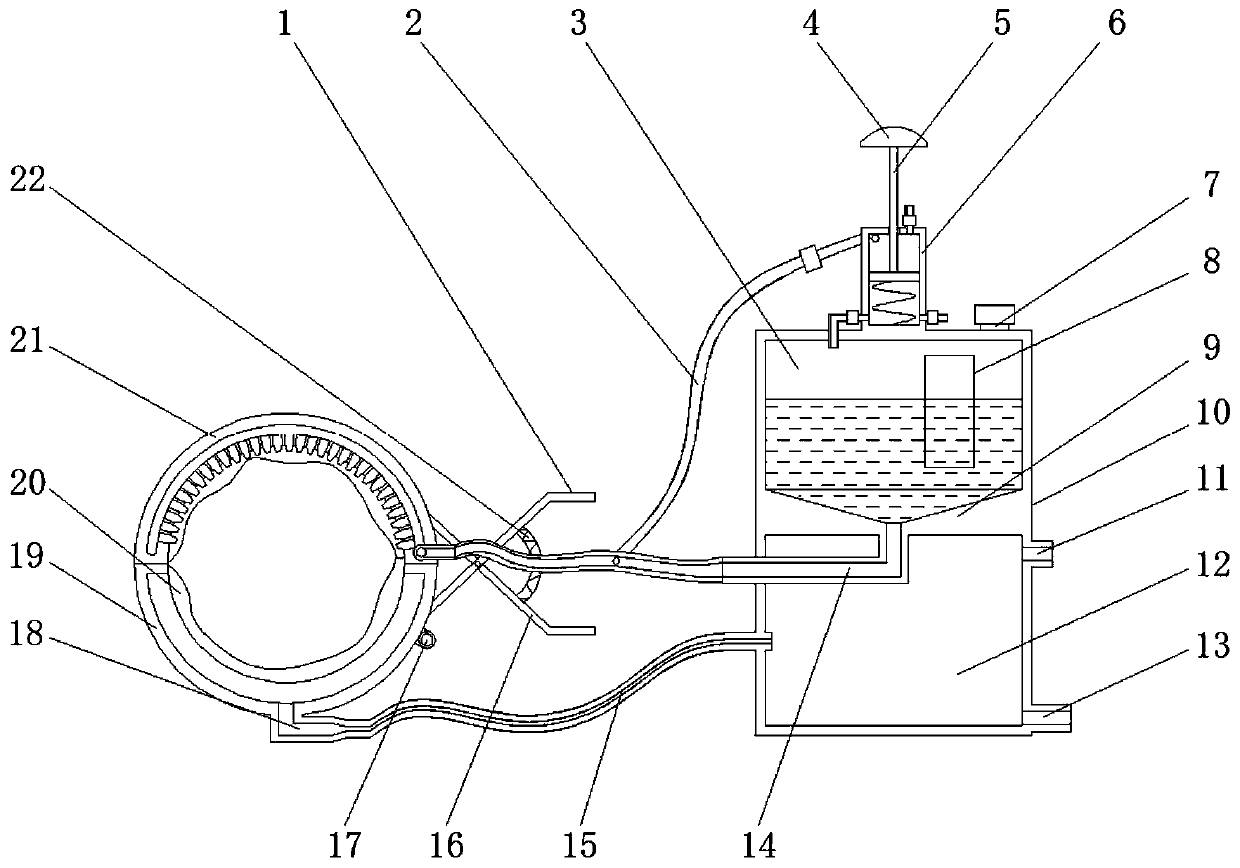

Gauze drying and disinfecting device

InactiveCN109114933AImprove the extrusion effectFully dehydratedDrying solid materials without heatDrying gas arrangementsDrive motorEngineering

The invention provides a gauze drying and disinfecting device, and relates to the technical field of textile machinery. The gauze drying and disinfecting device comprises a base, the top of the base is fixedly provided with a drying box, a first support and a second support, a material conveying rotating shaft and a material collecting rotating shaft are arranged on the first support and the second support respectively in a penetrating mode, the material conveying rotary shaft and the material collecting rotary shaft are respectively and fixedly provided with a material conveying rotary disc and a material collecting rotary disc, and the drying box is divided into a dehydrating chamber and a drying and disinfecting chamber. According to the gauze drying and disinfecting device, an upper pressing roller, a lower pressing roller, a second roller shaft, a first roller shaft, a driving motor, a transmission gear and an extrusion spring are arranged in a cooperated mode, the driving motor drives one of the second roller shafts to rotate, the lower pressing roller is driven to rotate together through the transmission gear, the corresponding upper pressing roller is driven to rotate in the rotating process of the lower pressing roller, the gauze is dehydrated, the follow-up drying work is facilitated, the squeezing effect of the gauze is increased through the squeezing spring, and dewatering is more sufficient.

Owner:江西美宝利实业有限公司

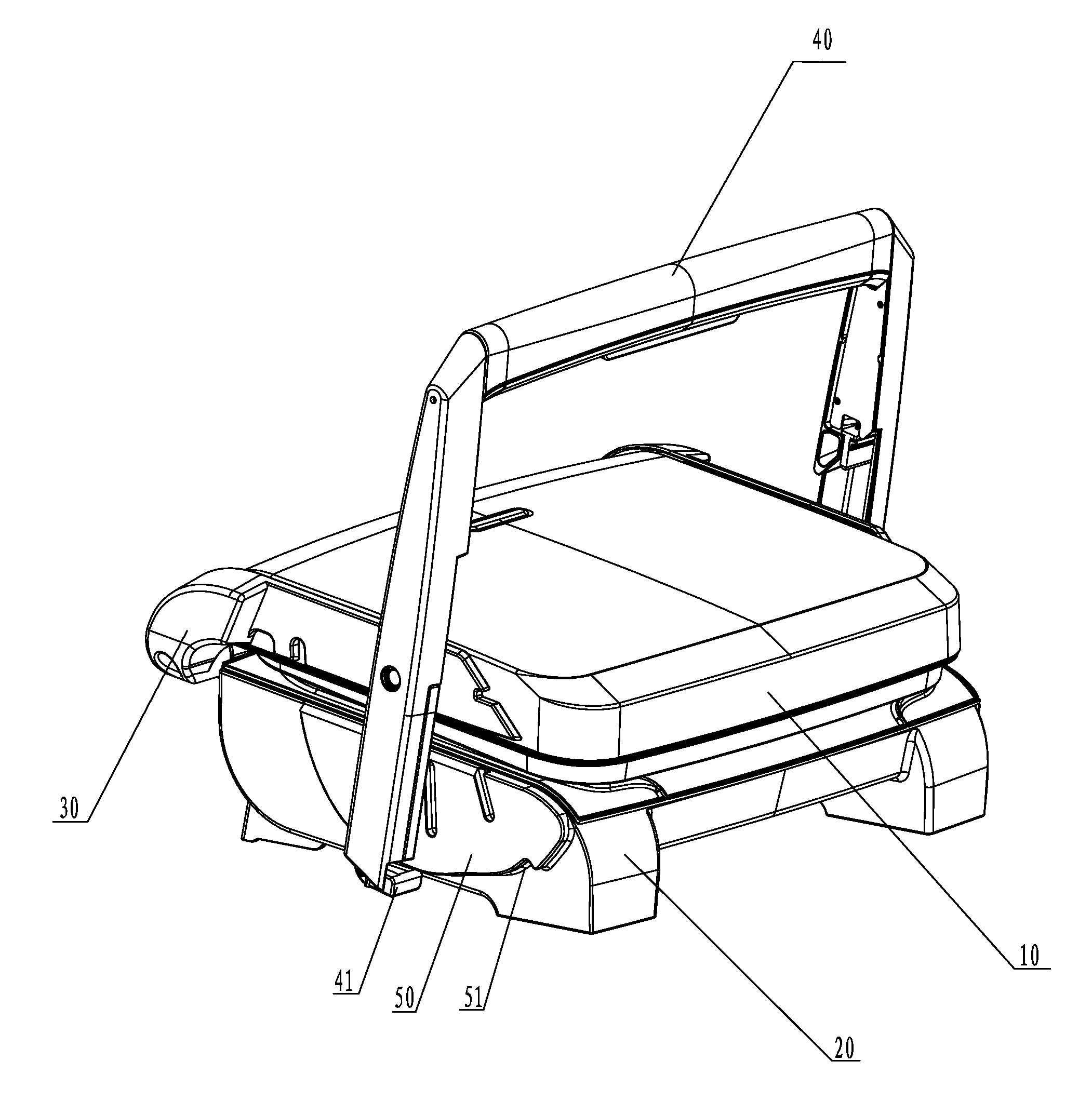

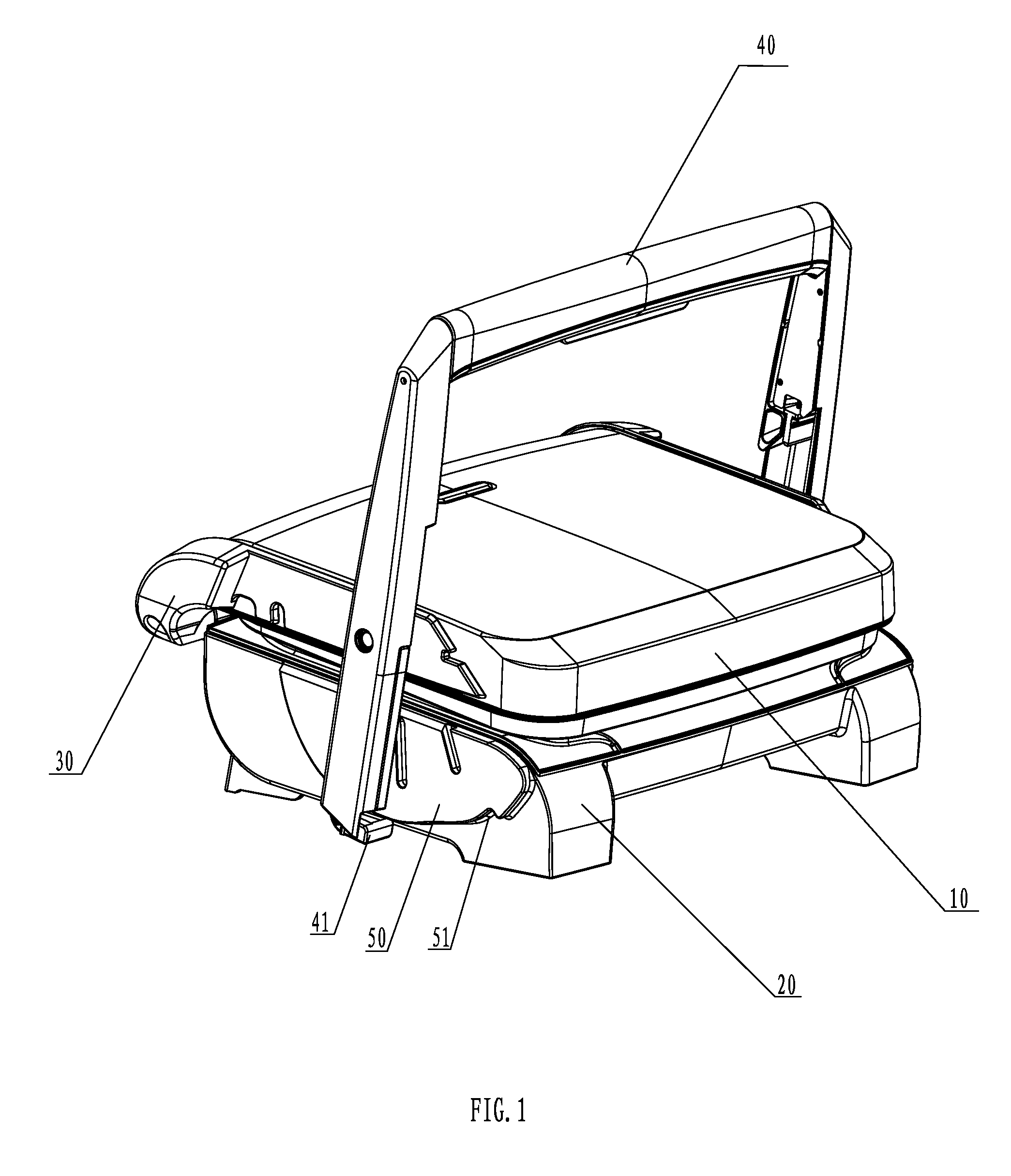

Frying and roasting device with minute-pressure

InactiveUS20140033931A1Compact structureImprove the extrusion effectHam-boilersRoasters/grillsEngineeringMechanical engineering

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

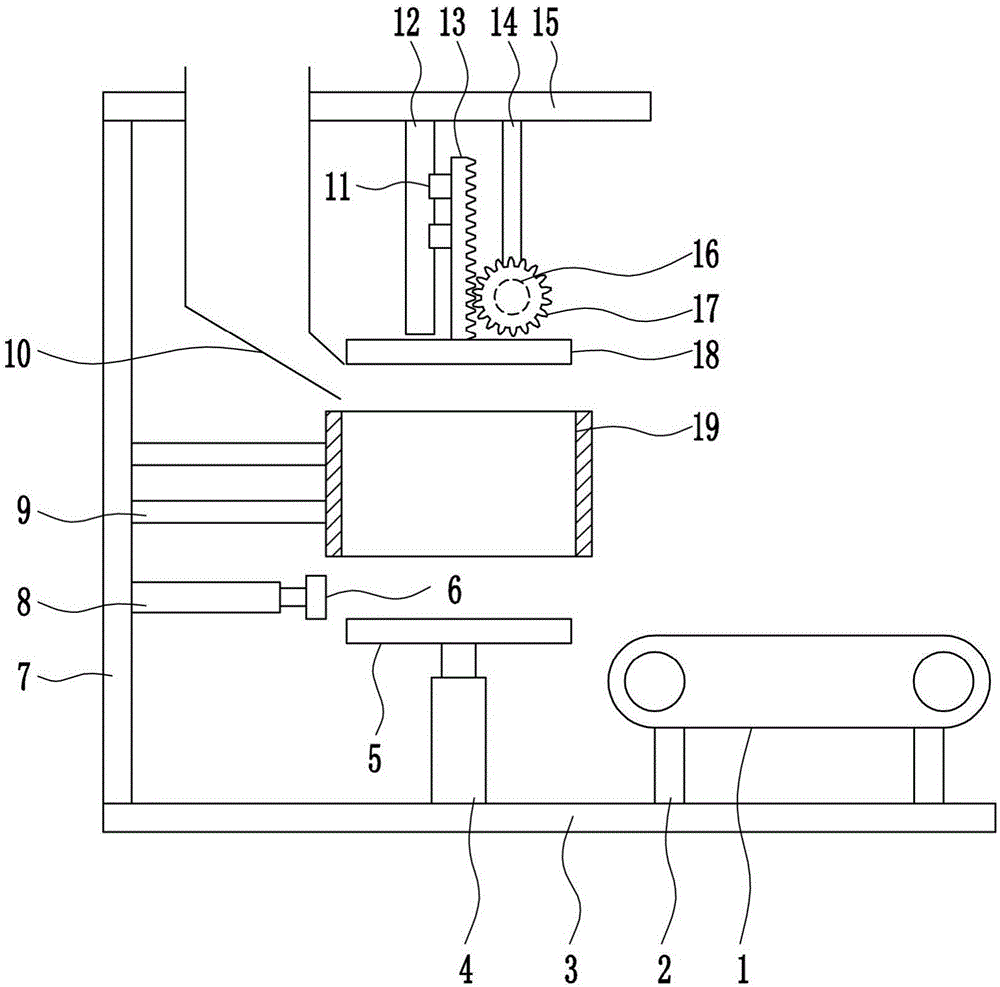

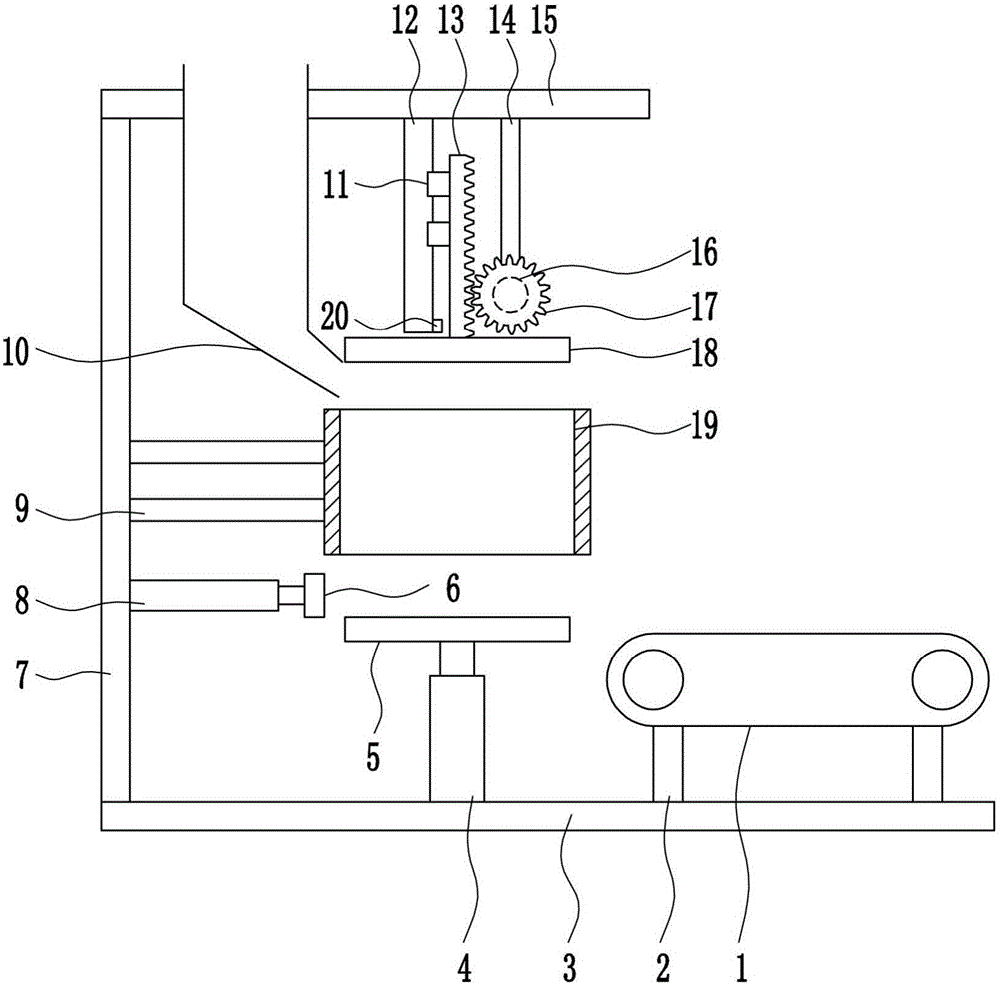

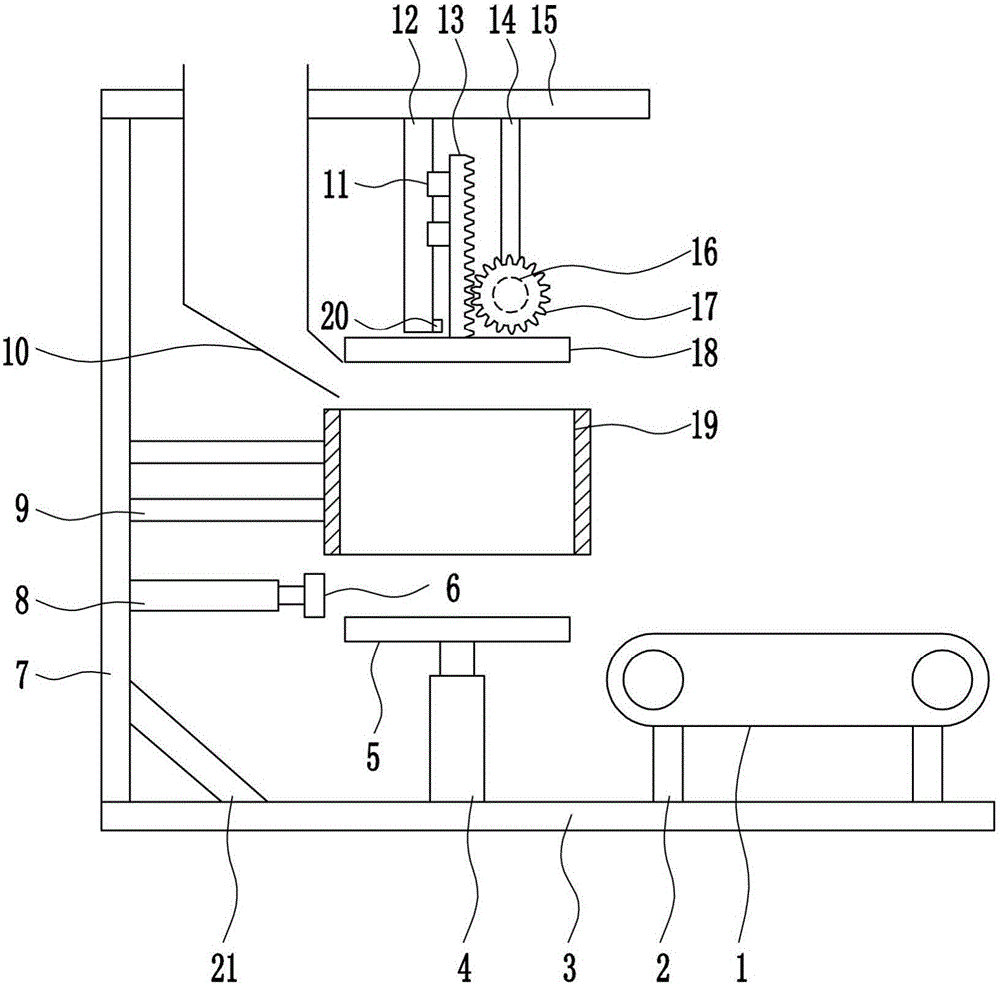

Extrusion forming equipment for haze-prevention briquette coal

InactiveCN106427031AExtrusion speed is fastUniform extrusion densitySolid fuelsShaping pressBriquetteMotor drive

The invention relates to briquette coal extrusion forming equipment, in particular to extrusion forming equipment for haze-prevention briquette coal. In order to solve the technical problems, the invention provides extrusion forming equipment for haze-prevention briquette coal, which is high in extrusion speed, is uniform in extrusion density and is convenient in operation. A first electric pushing rod is firstly controlled to extend; the first electric pushing rod drives a press plate to move upwards; when the press plate is in contact with the bottom of a mould, the first electric pushing rod is controlled to stop extension; certain amount of pulverized coal and the like is poured by a worker through an unloading hopper; pulverized coal, limestone and adhesive drop on the press plate, and a rotary motor is controlled to rotate anticlockwise; and the rotary motor drives a gear to rotate anticlockwise. The briquette coal extrusion forming equipment achieves the effects of high extrusion speed, uniform extrusion density and convenient operation; and moreover, the equipment achieves good extrusion effect, and further improves working efficiency, and is high in safety.

Owner:赵新伟

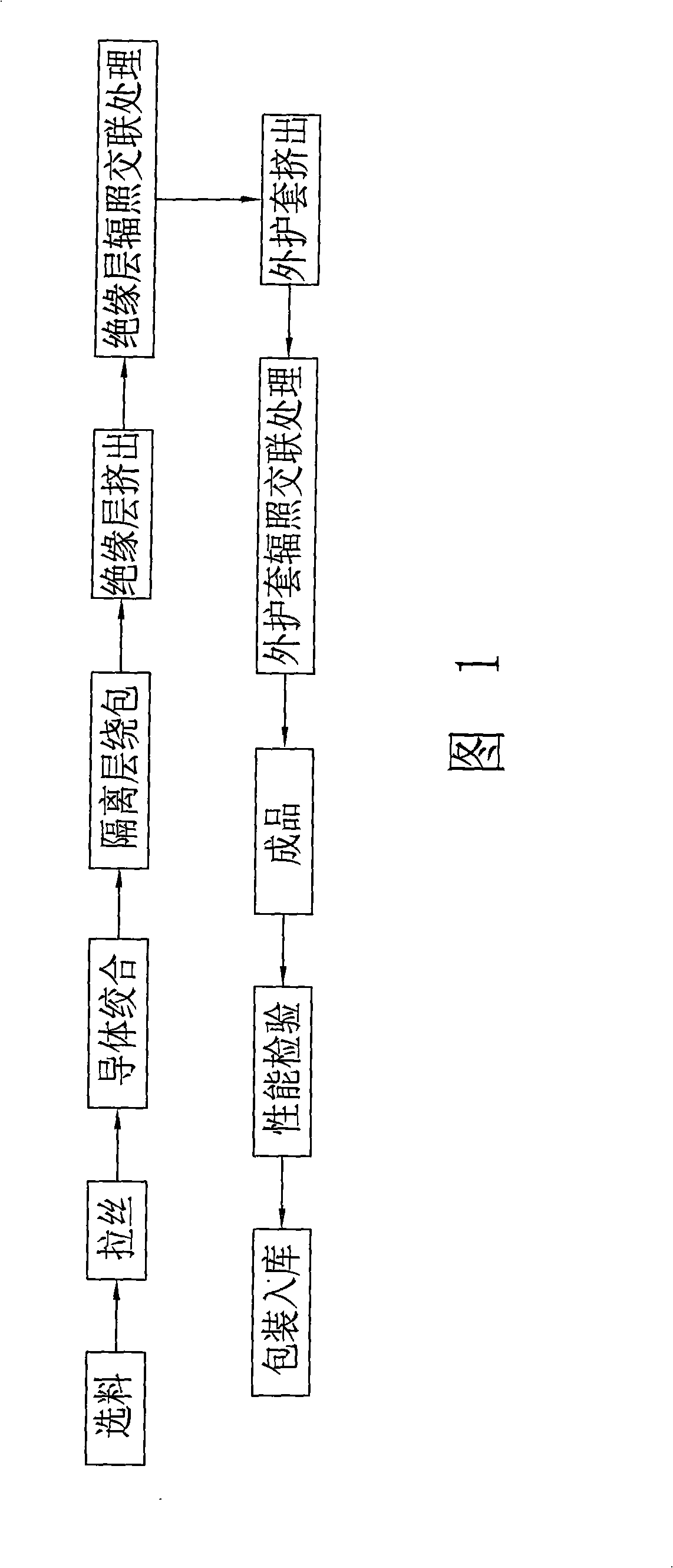

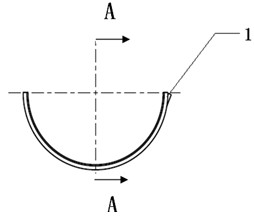

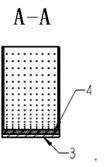

Production method of power cable for solar photovoltaic power generation assembly

ActiveCN101295562AGood weather resistanceGood UV resistanceInsulating conductors/cablesCross-linkInsulation layer

The invention discloses a manufacturing method for power cables used for solar energy photovoltaic power-generating equipment. The method is characterized in that the manufacturing process has the following steps: material selection, wire drawing, conductor twisting, isolated-layer wrapping, insulation-layer extrusion, insulation-layer radiation cross-linking processing, jacket extrusion, jacket radiation cross-linking processing and finished-product. The cable manufactured by the method has high weather resistance, high UV radiation resistance and high ozone corrosion resistance. Moreover, the resisted high temperature can reach 120 DEG C. The cable can resist atrocious weathers and mechanical impacts so as to dramatically enhance the safety and service life of the solar energy photovoltaic power-generating equipment.

Owner:SICHUAN MINGXING CABLE

Bearing bush with surface microporous structure and processing method

ActiveCN102537066AIncreasing the thicknessExtrusion effect is goodBearing componentsMicrometerStructure of the Earth

The invention provides a bearing bush with surface microporous structures and a processing method. The bearing bush includes a bearing bush body, and the body comprises a metal bearing bush back and an antifriction alloy layer, wherein the antifriction alloy layer is a friction layer between the bearing bush and a journal. The bearing bush is characterized in that microporous structures are formed on the inner surface of the antifriction alloy layer through machining. The microporous structures are micropores formed by adopting the laser micromachining technique for machining, the micro-pores are arranged regularly, the diameters range from 150 micrometers to 200 micrometers, and the depths range from 35 micrometers to 50 micrometers. The bearing bush is provided with the microporous structures on the inner surface, can effectively improve the oil film bearing capability, and remarkably improves the lubrication effect.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Electrically insulating resin composition and electric wire or cable both coated therewith

InactiveUS20030149176A1Stress resistantImprove performancePlastic/resin/waxes insulatorsPower cablesPolymer sciencePolyolefin

An object of the present invention is to provide an electrically insulative resin composition that exhibits superior electrical properties and processability and an electric wire or cable having a covering made of the resin. The electrically insulative resin composition comprises 60 to 90 percent by weight of ethylene-alpha-olefin copolymer (A) polymerized with a single-site catalyst and 40 to 10 percent by weight of another polyolefin resin (B), which is other than (A), wherein the composition contains a polyolefin having a graft-polymerized substituent with a dipole moment of not less than 4 Debye.

Owner:SUMITOMO ELECTRIC IND LTD

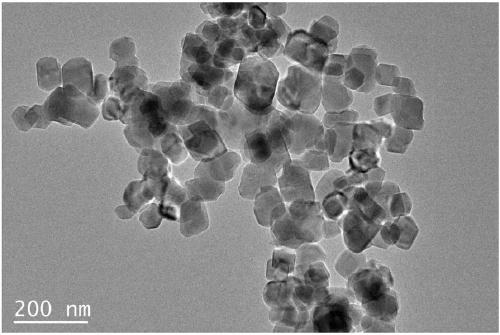

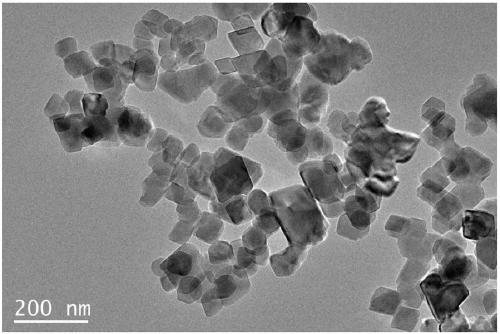

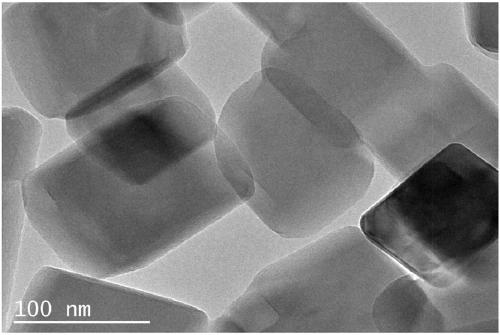

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

Aluminum alloy material and preparation method thereof

The invention discloses an aluminum alloy material which is characterized in that the material consists of the following components by weight percent: 0.6-1.3% of copper, 0.9-1.6% of magnesium, 5.3-6.7% of zinc, 0.03-0.2% of chromium, 0.03-0.2% of titanium, not more than 0.5% of iron, not more than 0.5% of silicon, not more than 0.3% of manganese and the balance of aluminum. The invention also discloses a preparation method of the aluminum alloy material. The aluminum alloy disclosed by the invention has the advantages of good oxidation performance, low copper content, low production cost, good extrusion performance, good corrosion resistance, difficult generation of cracking and good overall mechanical properties.

Owner:宁波环球输变电设备有限公司

Anti-hydrops wound irrigation syringe for general surgery department

InactiveCN110292672AEasy to collect and storeNo splashEnemata/irrigatorsIrrigation syringeEngineering

The invention discloses an anti-hydrops wound irrigation syringe for the general surgery department. The anti-hydrops wound irrigation syringe comprises a liquid storage chamber, a fixed tank, a wasteliquid chamber, a first clamping plate and a second clamping plate, wherein the middle of the inner portion of the fixed tank is provided with a partition plate, the liquid storage chamber is formedin the fixed tank above the partition plate, the waste liquid chamber is formed in the fixed tank under the partition plate, and the top of the partition plate is in a funnel shape. The anti-hydrops wound irrigation syringe for the general surgery department has the advantages that extrusion columns at the upper and lower ends of a piston are provided with a first air inlet pipe and a first air outlet pipe which cooperate with each other and a second air inlet pipe and a second air outlet pipe which cooperate with each other respectively, the air inlet pipes and the air outlet pipes are provided with one-way valves respectively, intermittent flushing of a cleaning solution and anti-hydrops flushing of air are used during wound cleaning, intermittent cleaning enables the cleaning solution of each time of flushing to be in full contact with the surface of a wound of a patient, thereby improving the cleaning effect and cleaning efficiency of the wound, and after the cleaning solution is used, the gas can be continuously ejected from a spray head, thereby improving the anti-hydrops effect.

Owner:吴军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com