Industrial grinder suitable for chemical engineering, pharmacy and food material processing

A kind of pulverizer, industrial technology, applied in the direction of grain processing, etc., can solve the problems of affecting work efficiency, increasing enterprise cost, and only doing secondary crushing, so as to achieve the effect of safe and reliable work for workers, improve work efficiency, and avoid manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

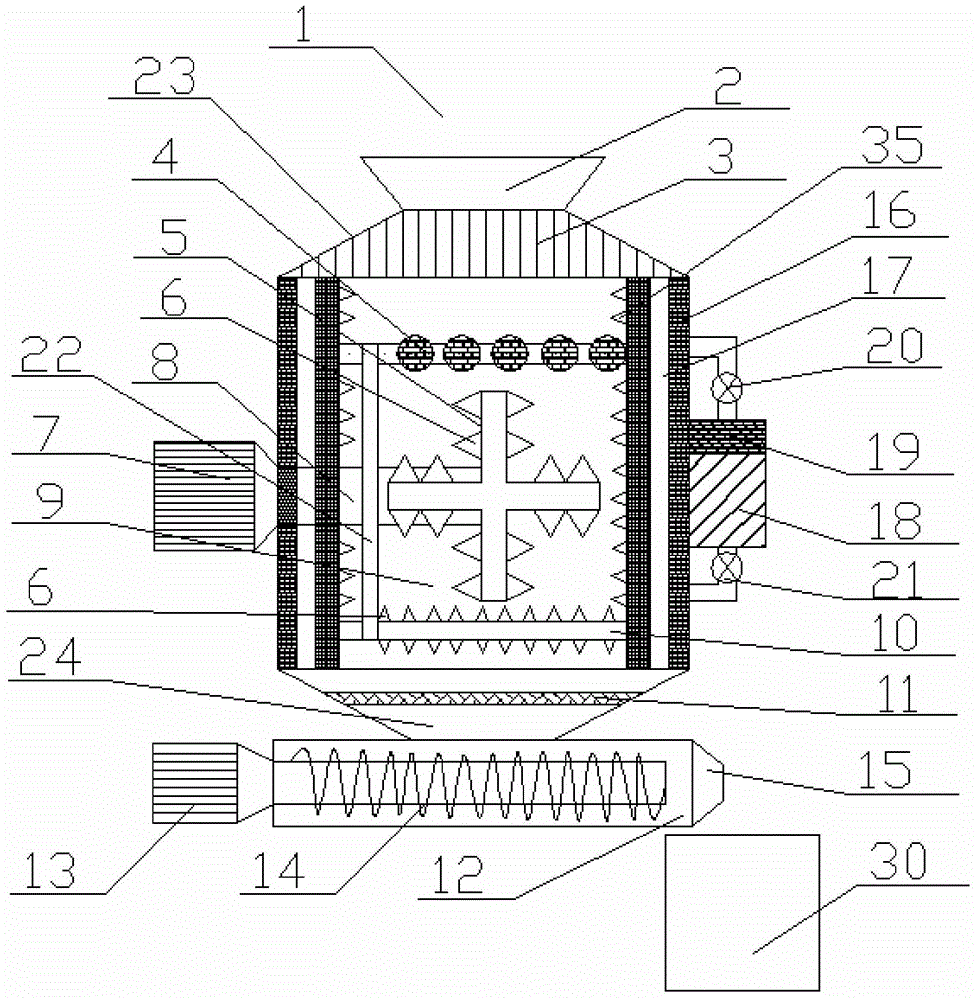

[0036] like figure 1 and figure 2As shown, the first embodiment of the present invention is: an industrial pulverizer suitable for processing chemical, pharmaceutical and food raw materials, including a pulverizer body 1 and a storage bin 30, and the pulverizer body 1 includes a feed port 2. Frequency conversion motor 7, crushing bin 9, stirring wheel 5 and discharge port 15, the feed port 2 is in an inverted trapezoidal structure, and is arranged above the crushing bin 9, between the feed port 2 and the crushing bin 9 In the feeding channel 23, twelve vertically arranged rectangular deflectors 3 are evenly arranged, and the distance between each adjacent deflector 3 is 20 to 50 millimeters. In this embodiment, the distance is preferably 30 millimeters. , the deflector 3 can ensure that the material enters the pulverizer body 1 evenly during the process of filling the material, without the phenomenon of material congestion. Eight evenly arranged cylindrical squeeze rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com