Patents

Literature

1745results about How to "Avoid manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

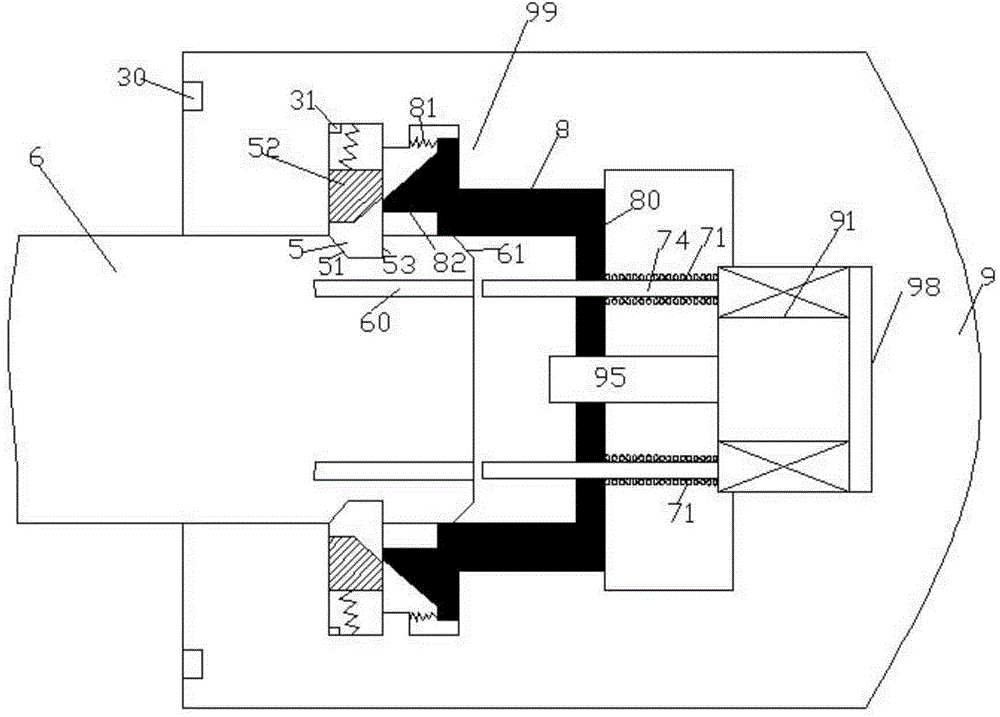

Socket with power-on indication lamp

InactiveCN105186200AAchieve orientationAvoid manual operationCoupling device detailsMechanical engineeringStator

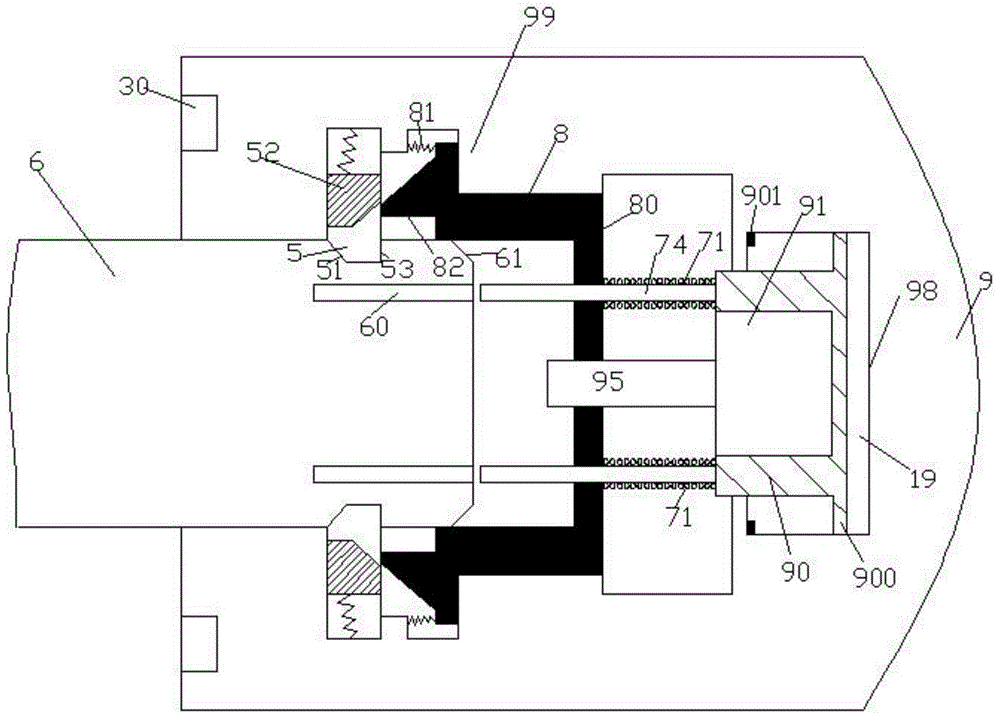

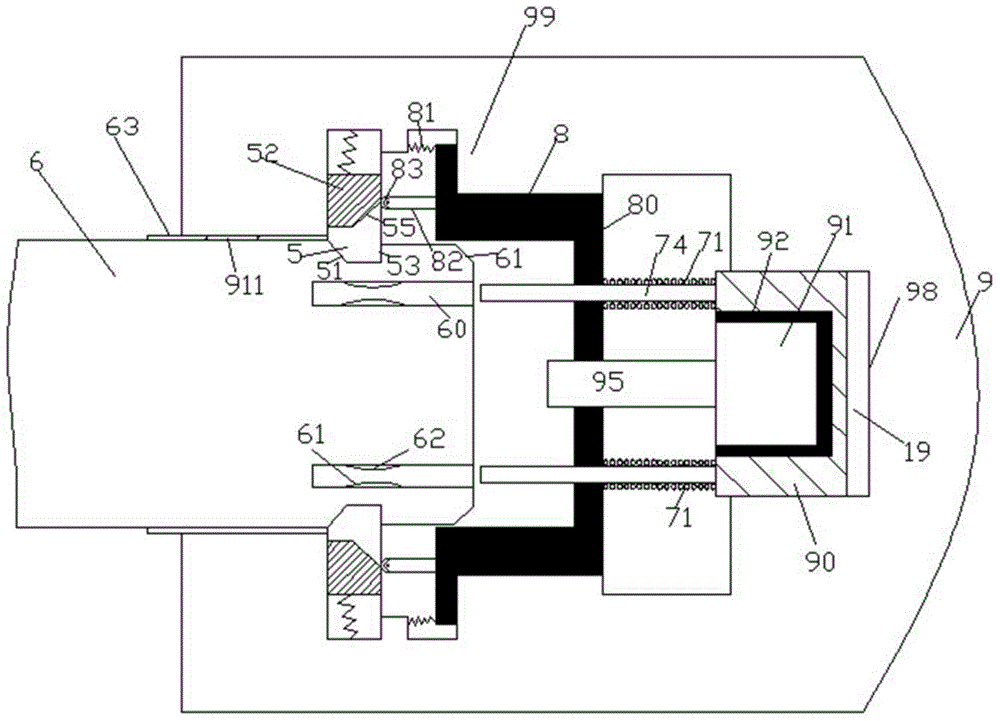

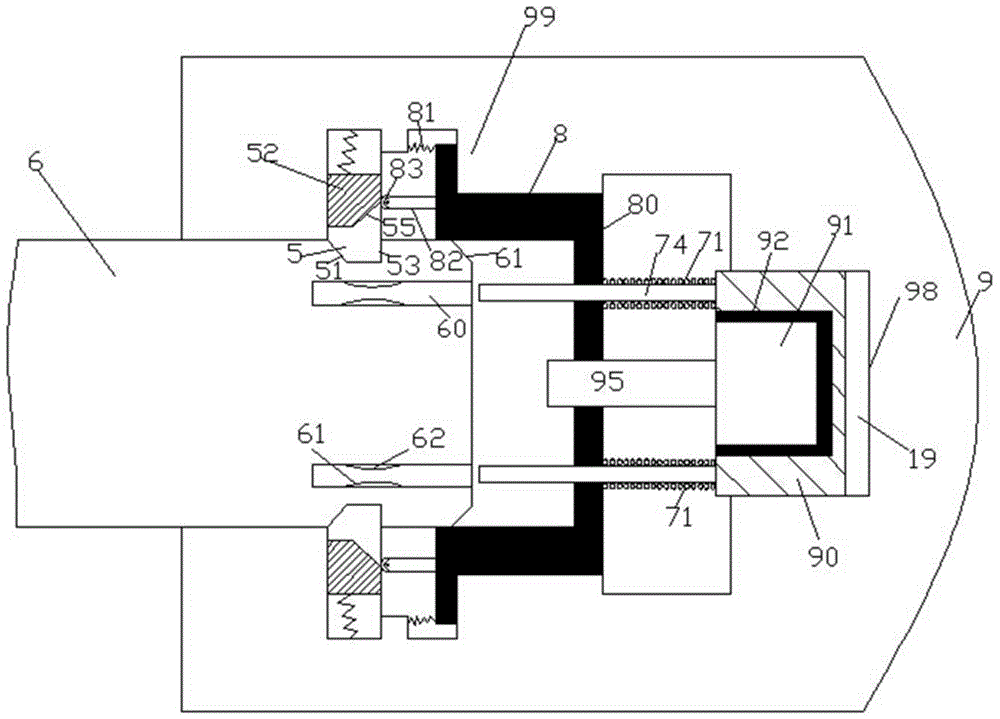

The invention provides a socket with a power-on indication lamp. The socket comprises a socket body (9) and a mounting seat (90) which is installed in the sliding groove (19) of the socket body (9) and can slide left and right. The left end of the sliding groove (19) is provided with a limit projection (92). The right end of the mounting seat (90) is provided with a limit block (900) which is matched with the limit projection (92). The mounting seat (90) is internally equipped with an execution motor (91). The rotor of the execution motor (91) and a screw rod (95) are in power connection. The screw rod (95) is cooperated with the screw hole in the transverse wall member (8) in the socket body (9). The left end wall of the mounting seat (90) is fixedly connected to power supply guide columns (74) which slidingly go through the sliding holes in the transverse wall member (8). The power supply guide columns (74) are used for connecting the power supply holes (60) in the plug (6) inserted into the jack of the socket body (9) to supply power. In each of the power supply guide columns (74), a compression spring (71) is arranged between the surface of the transverse wall member (8) facing the execution motor (91) and the stator of the execution motor.

Owner:肖白玉

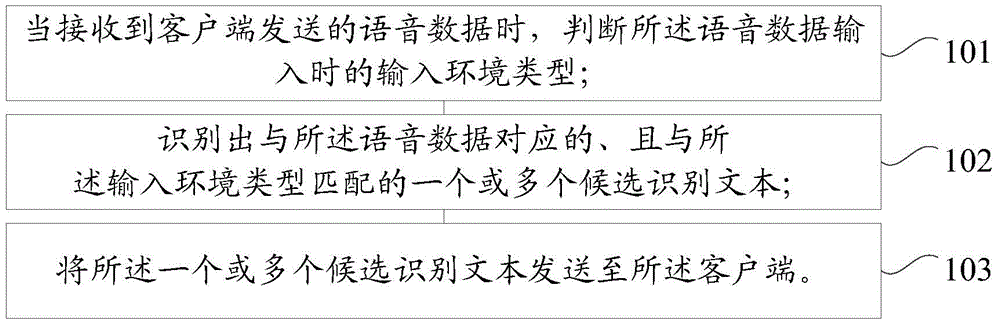

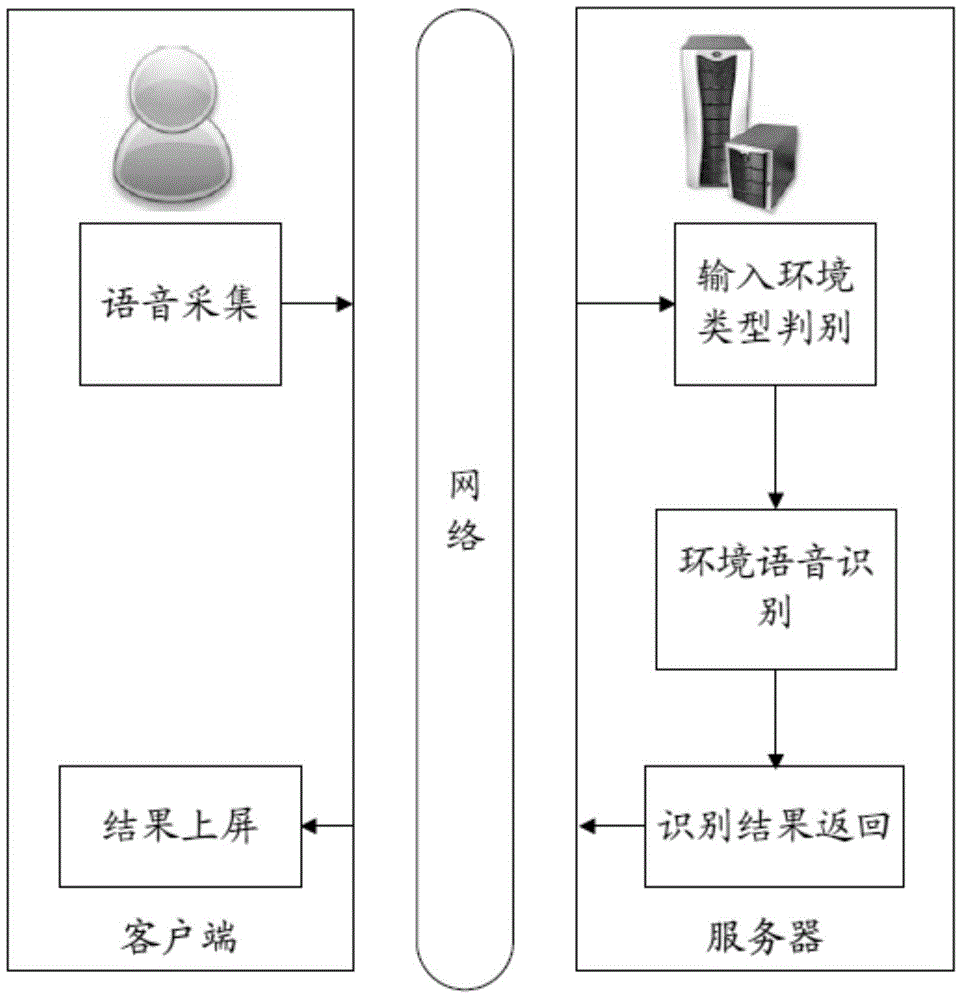

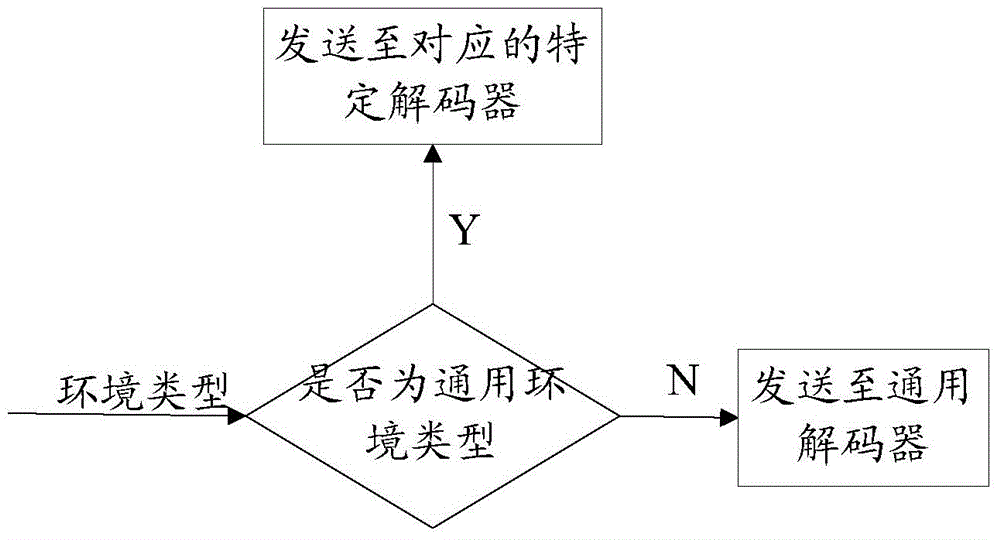

Speech input method, device and system

ActiveCN103956169AImprove performanceImprove recognition accuracySpeech recognitionSpeech inputSpeech sound

The embodiment of the invention provides a speech input method, device and system. The method comprises the steps that when speech data sent by a client terminal are received, an input environment type when the speech data are input is judged; one or more candidate recognition texts are recognized, wherein the one or more candidate recognition texts correspond to the speech data and are matched with the input environment type; the one or more candidate recognition texts are sent to the client terminal, wherein the one or more candidate recognition texts are used for being displayed in the client terminal. According to the embodiment, different input environment types have different language features, different language models are selected based on the different input environment types to carry out recognition, the performance of the language models is improved, meanwhile, the recognition accuracy of the speech data is also improved, the intension of a user is better met , and user experience is improved.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

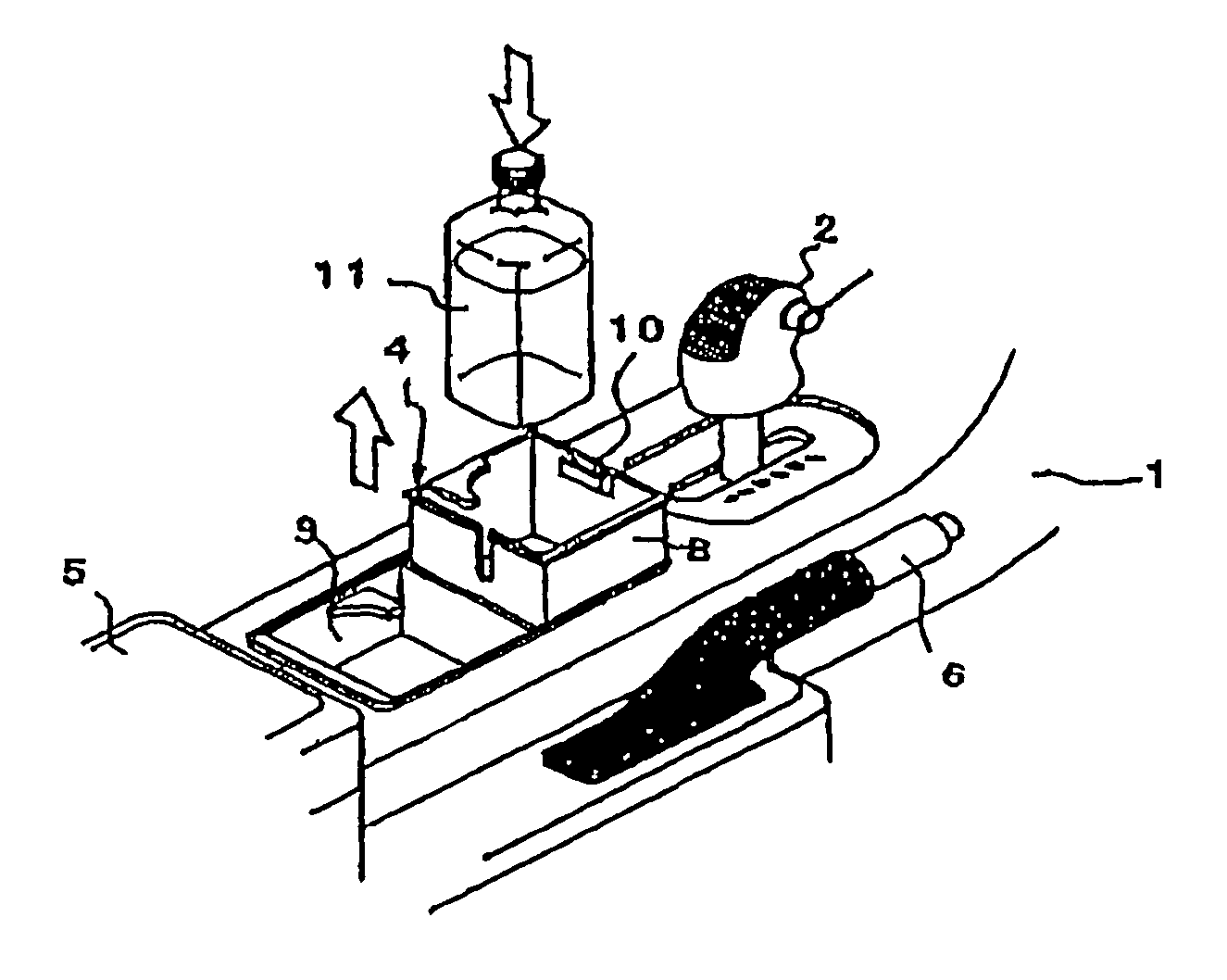

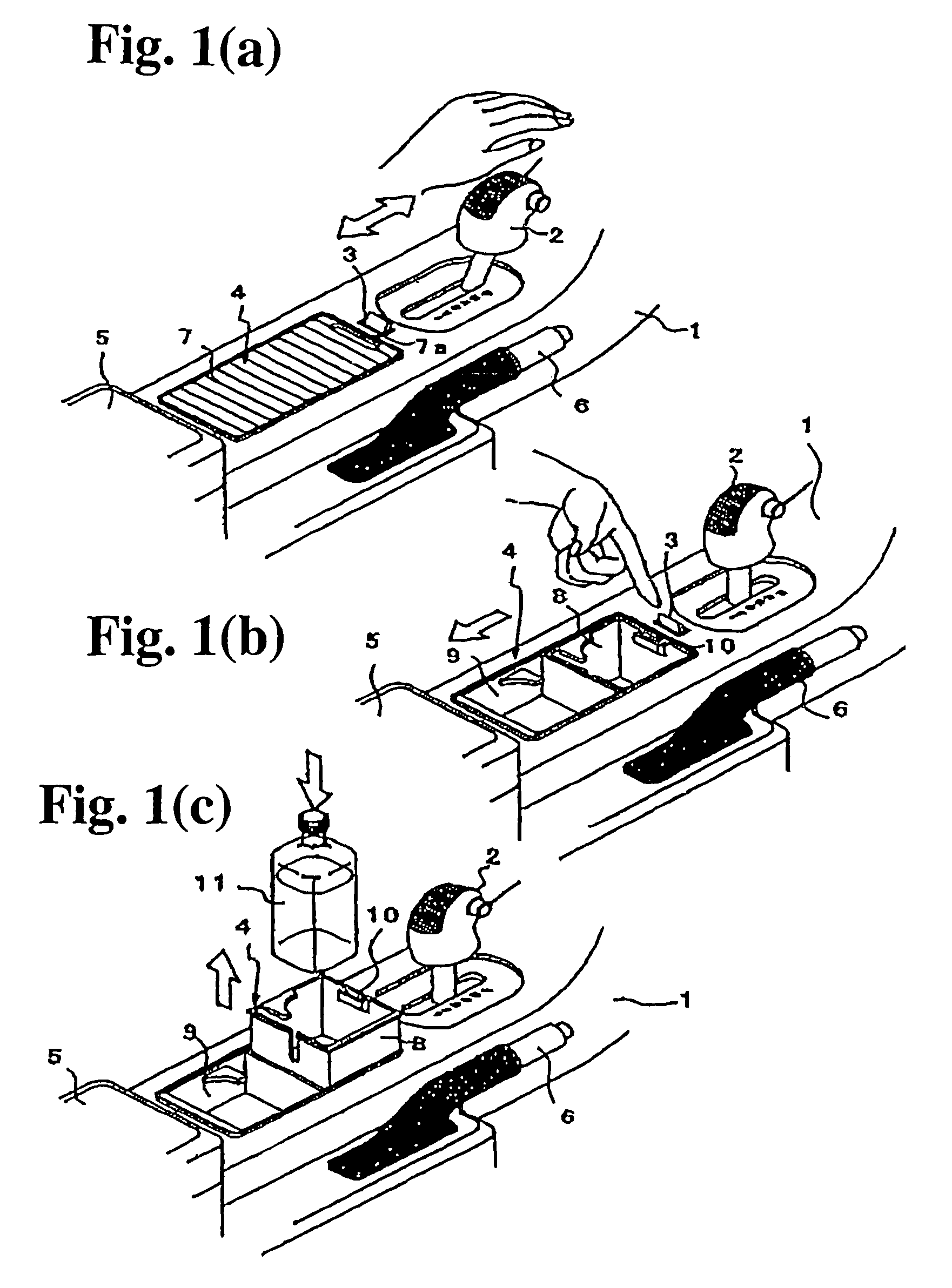

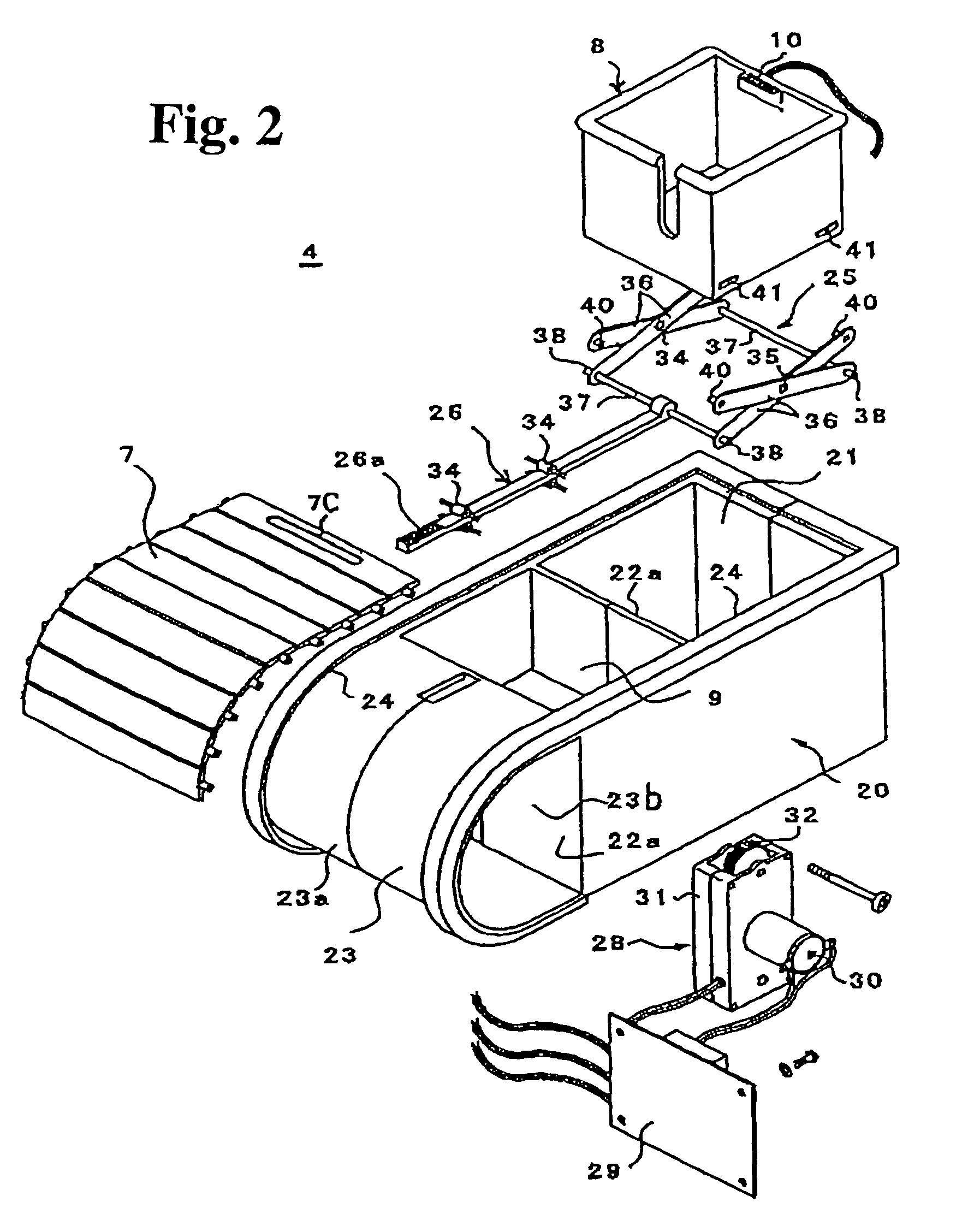

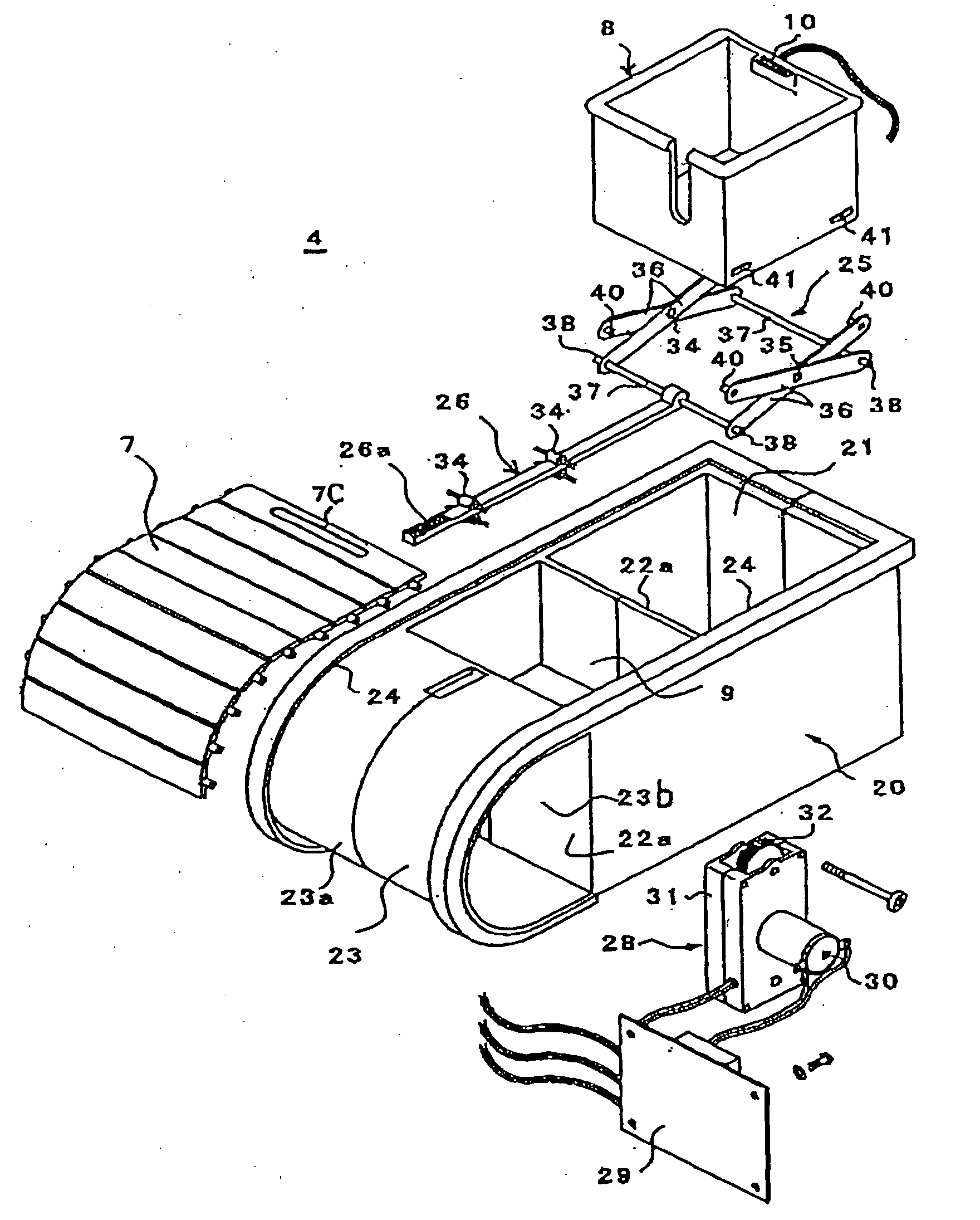

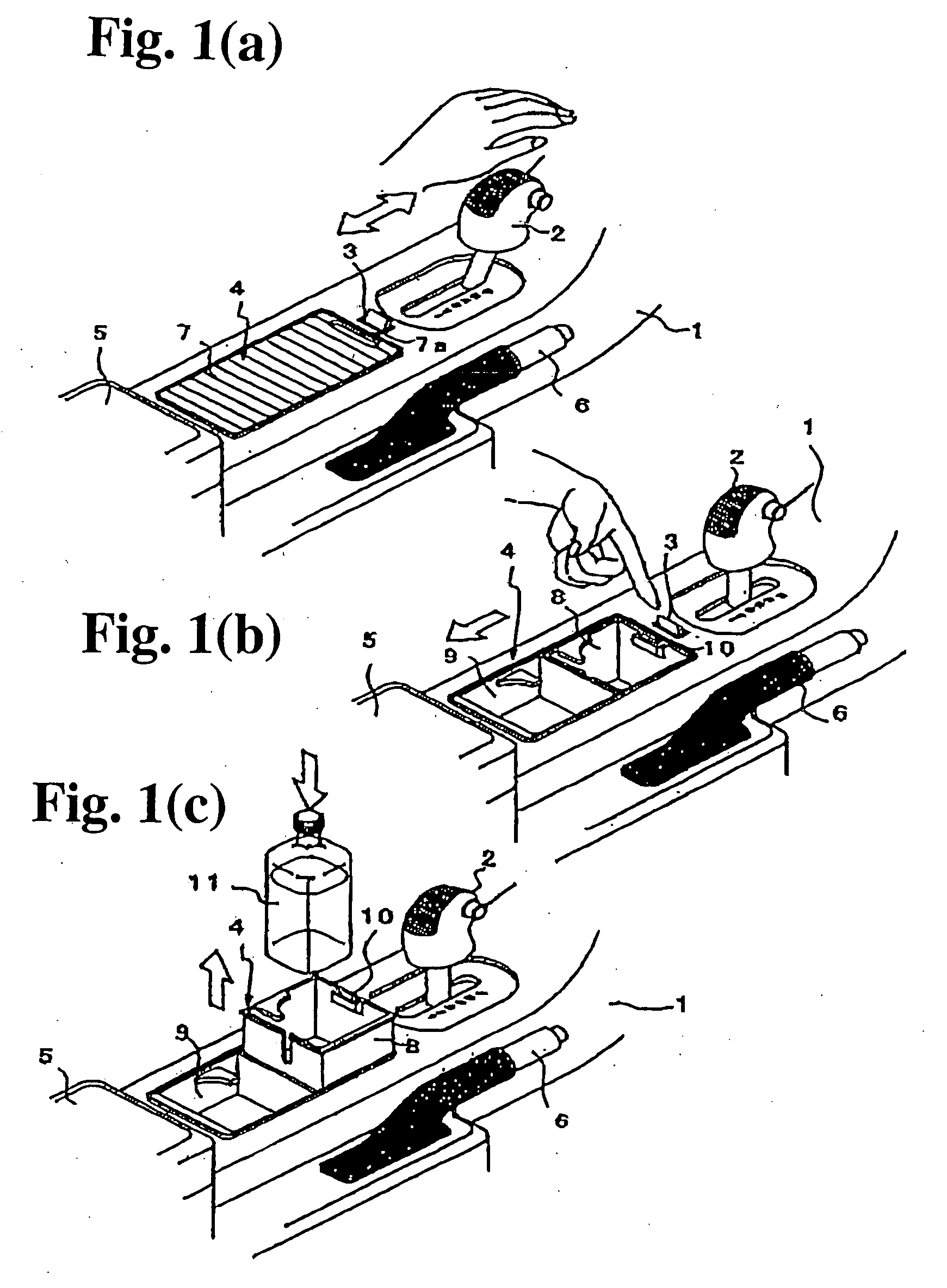

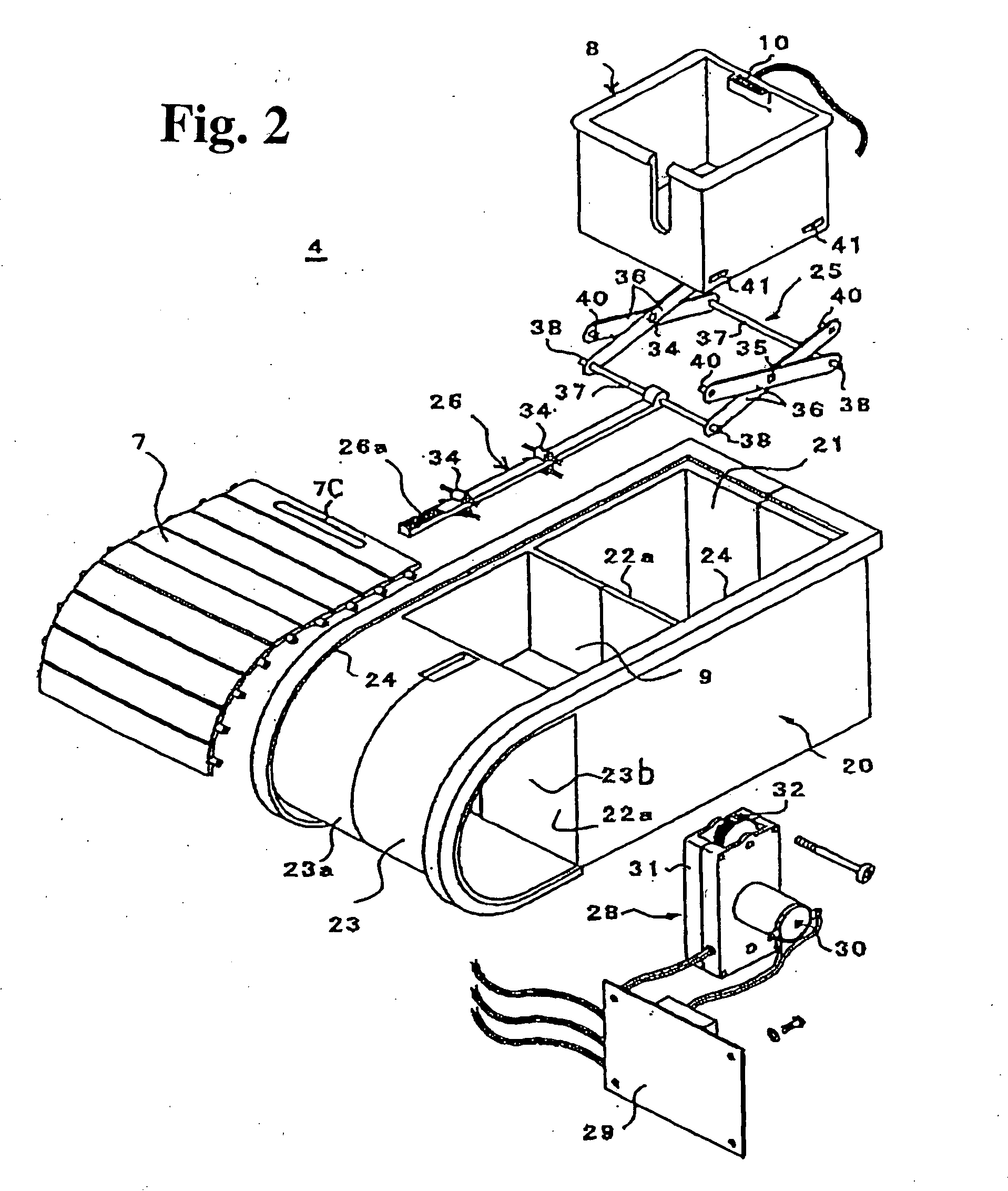

Configuration for operating interior device and cup holder using the same

InactiveUS7794000B2Ideal operabilityAvoid manual operationVehicle seatsVehicle locksStart timeInterior design

Owner:NIFCO INC

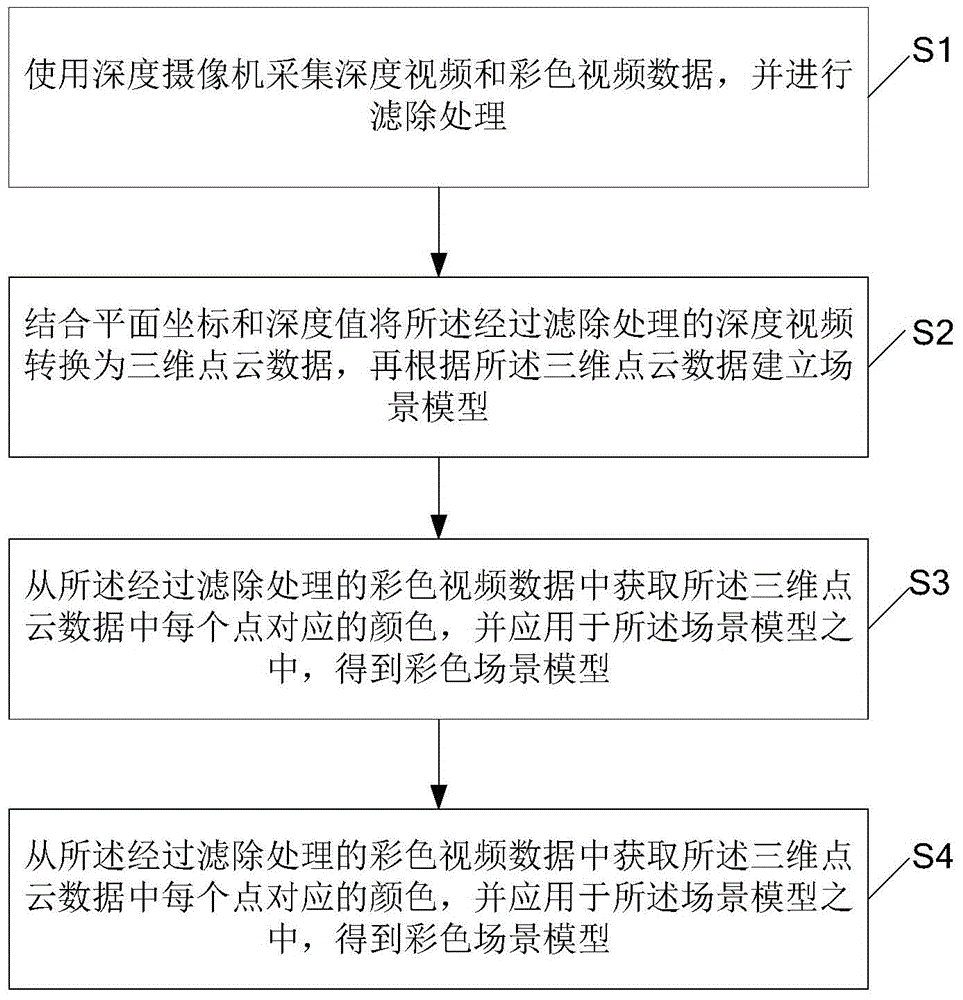

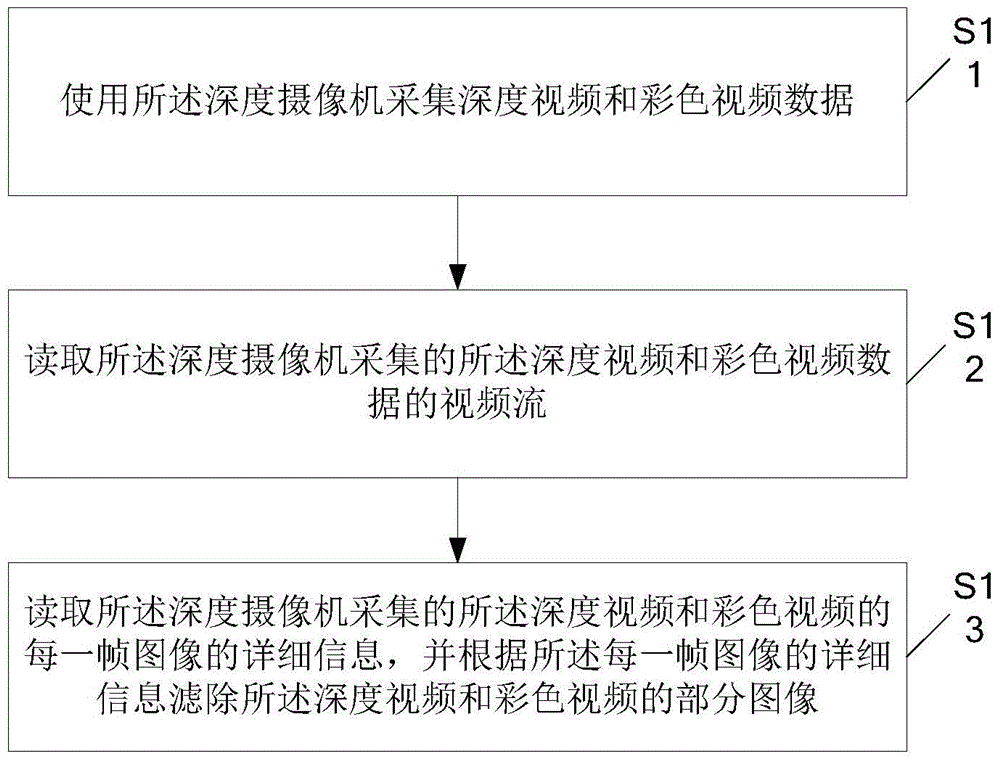

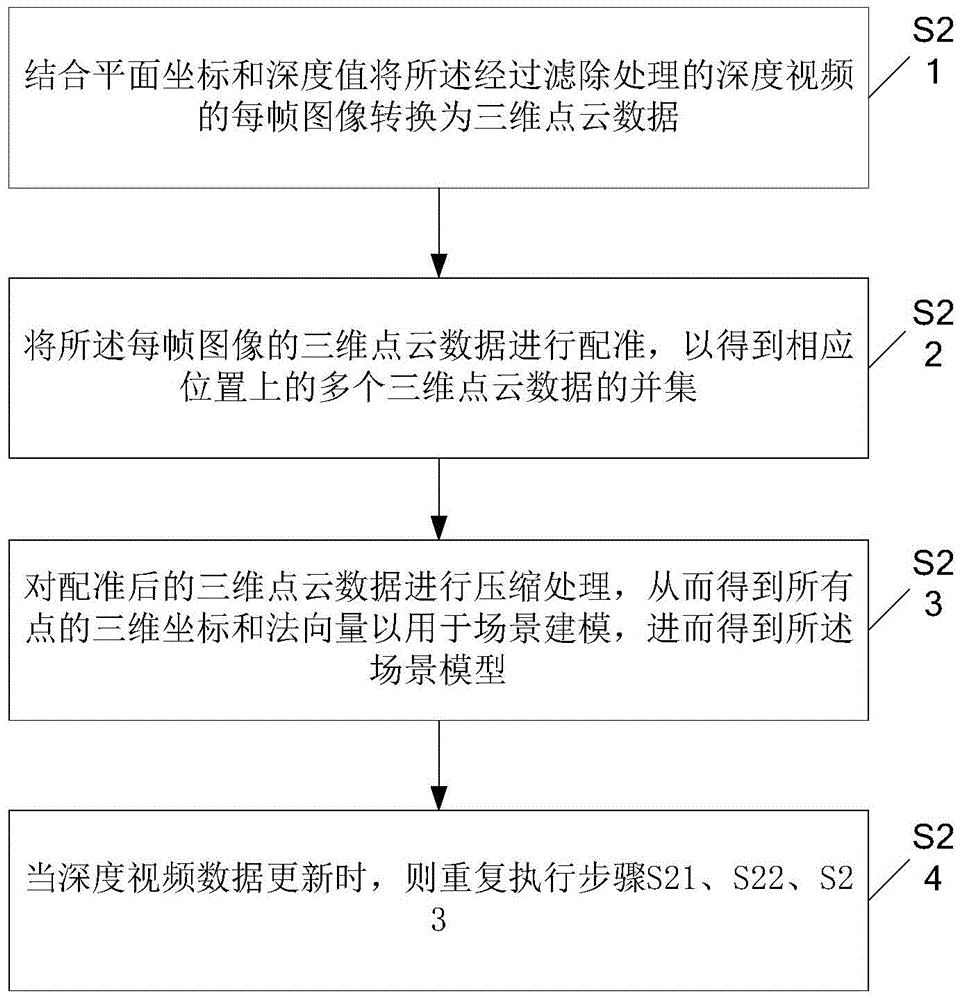

3D scene generation method based on depth video

InactiveCN104008569ARealistic effect is goodLower performance requirements3D modellingPoint cloudData conversion

The invention discloses a 3D scene generation method based on a depth video. The method comprises the following steps that S1, data of the depth video and a color video are collected by using a depth camera, and filtering out is performed; S2, the depth video on which filtering out is performed is converted into three-dimensional point cloud data by combining a plane coordinate and a depth value, and then a scene model is built according to the three-dimensional point cloud data; S3, the color corresponding to each point in the three-dimensional point cloud data is obtained from color video data on which filtering out is performed and the color is applied to the scene model so as to obtain a color scene model; S4, the format of data of the color scene model are converted into the 3D file format, and converted files are 3D scene files. The scene generated through the method is verisimilar and natural, modeling is convenient and efficient, calculation amount and memory space are small during drawing, and the method is more suitable for real-time modeling and drawing.

Owner:广东小草科技有限公司

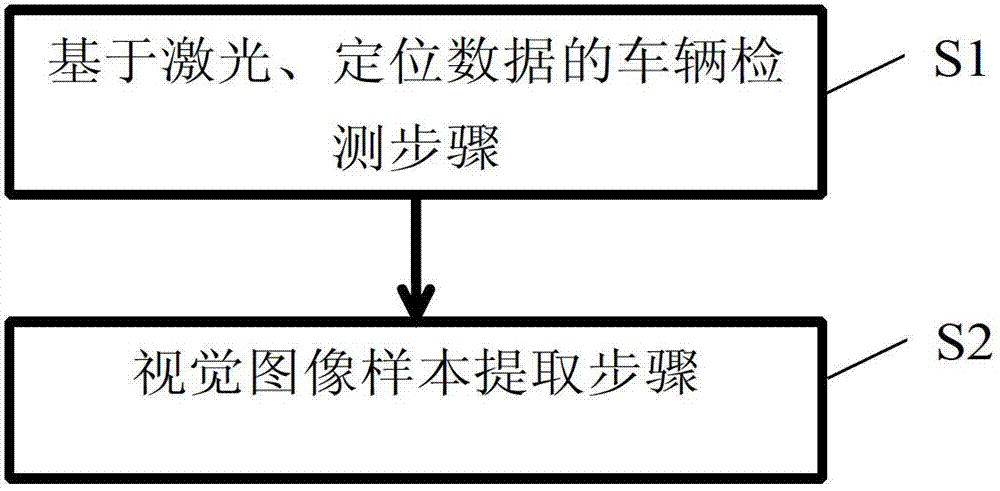

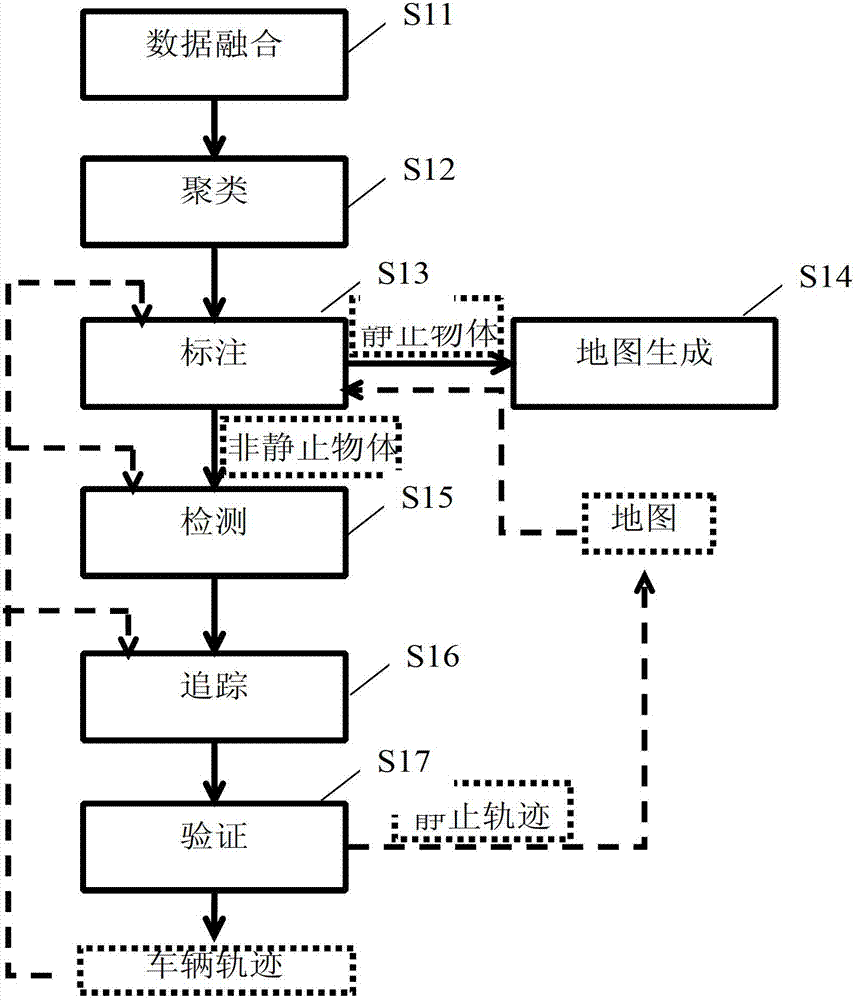

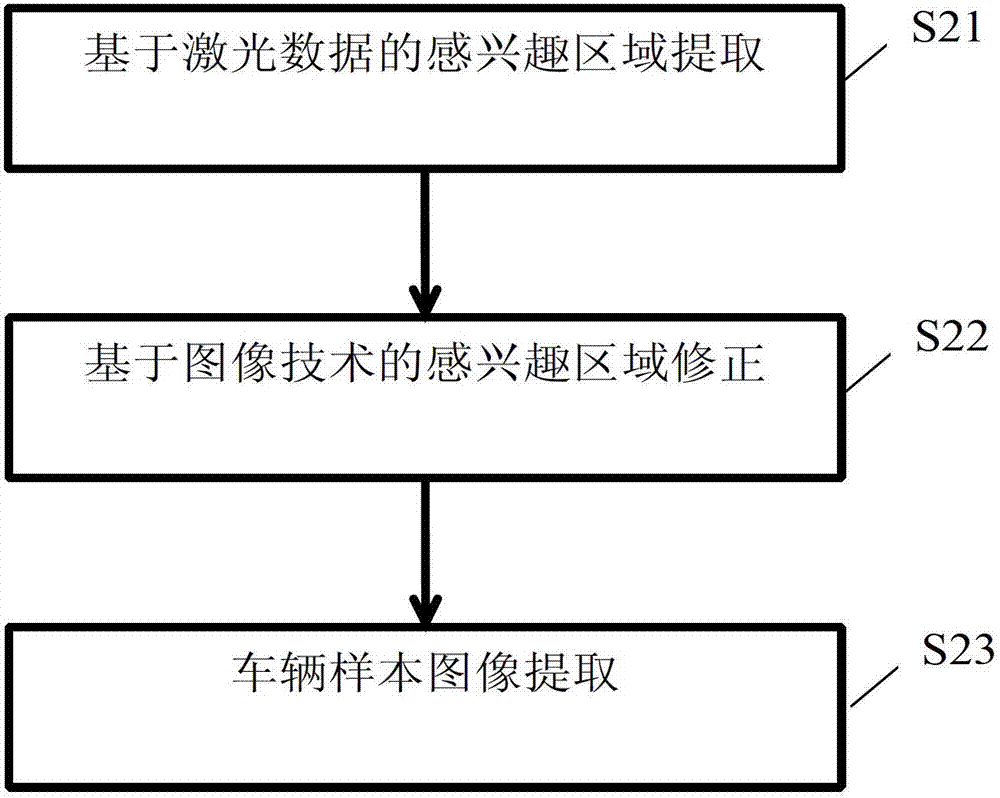

Method for automatically acquiring vehicle training sample based on multi-modal sensor data

InactiveCN102737236AAvoid manual operationReduce restrictionsCharacter and pattern recognitionData acquisitionVehicle detection

The invention discloses a method for automatically acquiring a vehicle training sample based on multi-modal sensor data. The method comprises the following steps of: detecting a vehicle based on laser data and positioning data, namely acquiring a two-dimensional coordinate relative to a data acquisition vehicle according to a distance and an angle of the laser data and a laser sensor calibration parameter so as to describe horizontal contour information of an object; and extracting a time sequence of parameters such as the position and direction of a candidate vehicle relative to the data acquisition vehicle by analyzing a shape and detecting and tracking a mobile object; and extracting a vision image sample, namely projecting the candidate vehicle into an image according to the position and direction of the candidate vehicle at each moment on the basis of a geological relation between the laser sensor and image acquisition equipment to produce a region of interest, correcting the region of interest by using a detector, calculating a relative view angle of each candidate vehicle relative to a camera according to the parameters such as position and direction, removing image frame samples with similar view angles, and automatically extracting sample pictures of the candidate vehicle under different view angles.

Owner:PEKING UNIV

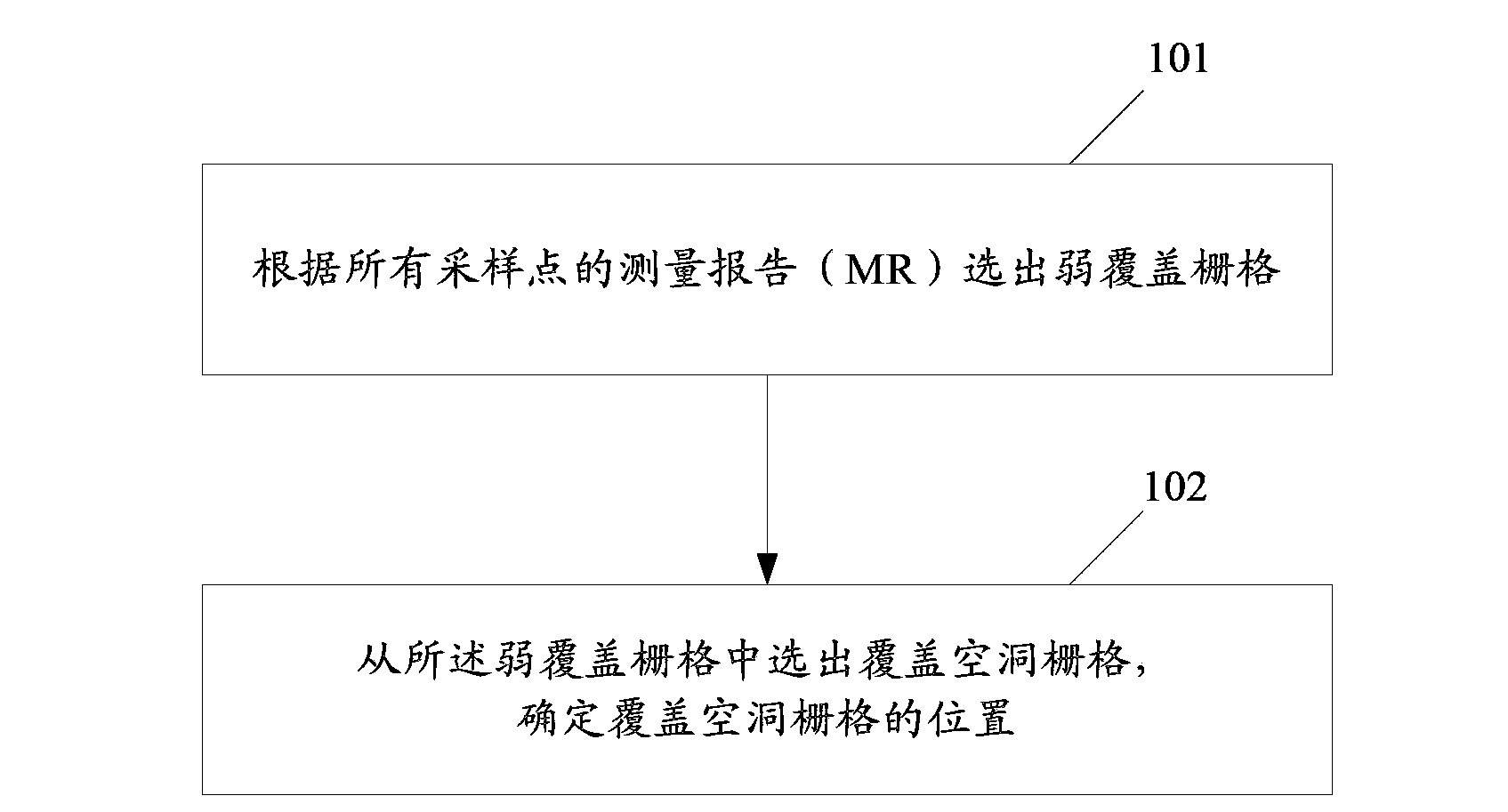

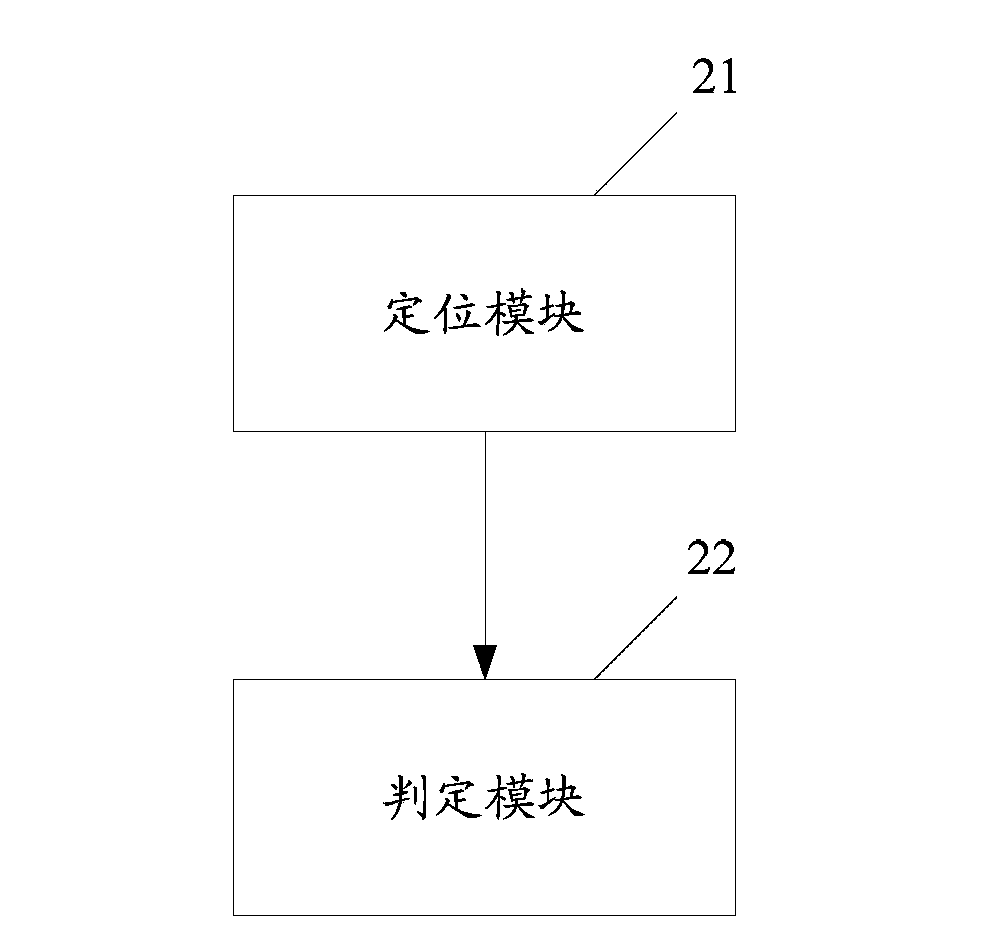

Method and device for positioning and covering hole

ActiveCN103906104AGuaranteed accuracyGuaranteed timelinessWireless communicationEnvironmental geology

Owner:中国移动通信集团内蒙古有限公司

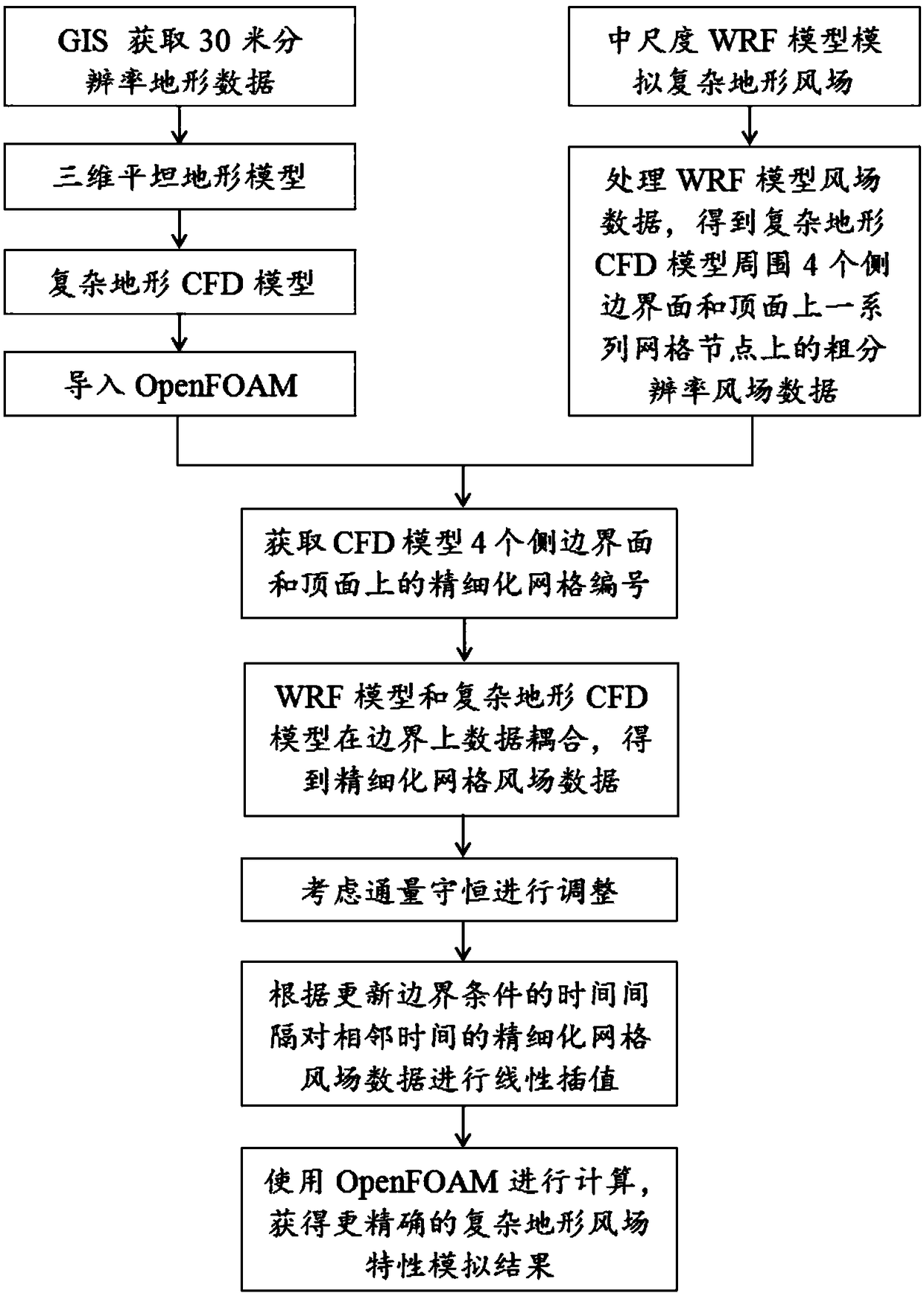

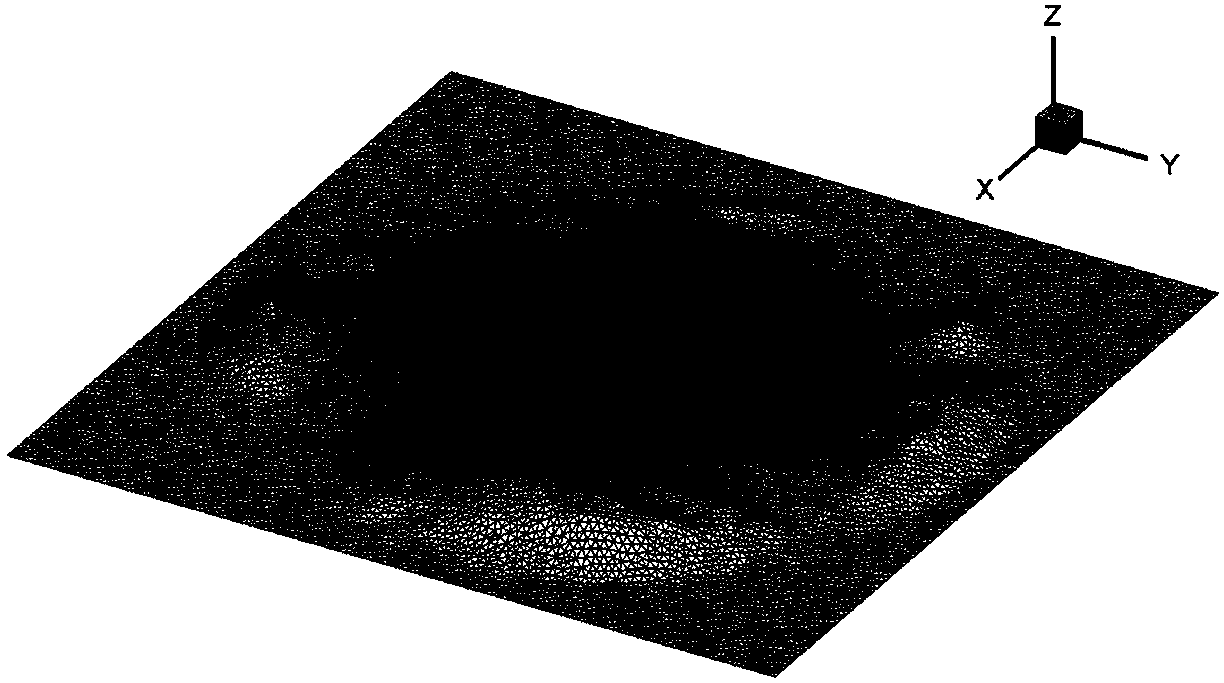

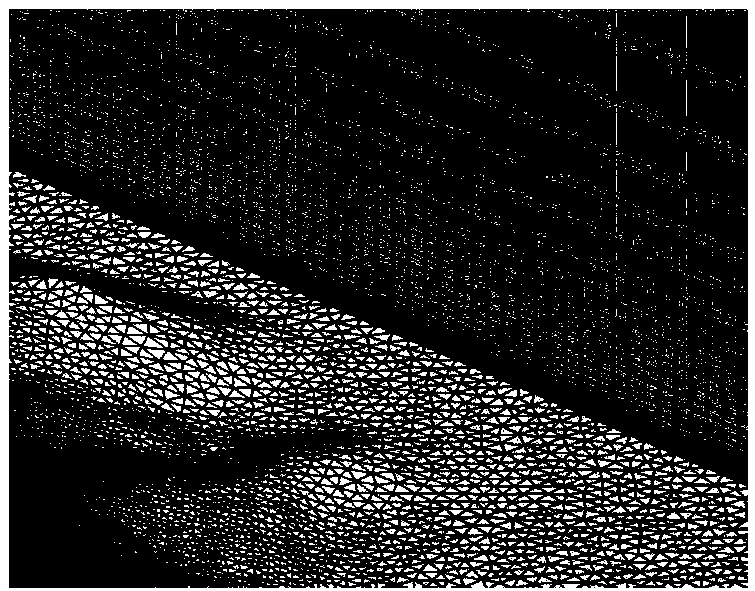

Method for achieving WRF and CFD coupled simulation wind field based on Open FOAM

InactiveCN108563867AAvoid large deviationHigh precisionDesign optimisation/simulationSpecial data processing applicationsWind resource assessmentTerrain

The present invention belongs to the field of computing wind engineering, and discloses a method for achieving WRF and CFD coupled simulation wind field based on OpenFOAM. The method comprises the following steps: 1) establishing a complex terrain CFD model to generate a refined grid; 2) establishing a mesoscale WRF model to simulate complex terrain wind fields and processing wind field data of the WRF model; 3) achieving the data coupling of the WRF model and the complex terrain CFD model on the boundary, and obtaining refined grid wind field data with time varying on the four side interfacesand the top surface of the complex terrain CFD model; 4) calculating the coupled complex terrain CFD model so as to obtain a complex terrain wind field characteristic simulation result. The method for achieving WRF and CFD coupled simulation wind field based on OpenFOAM can adopt the program language supported by the computer, achieve the data coupling on the boundary of the WRF model and the complex terrain CFD model, and facilitate to improve the precision of the complex terrain wind resource assessment and wind field numerical simulation.

Owner:HUAZHONG UNIV OF SCI & TECH

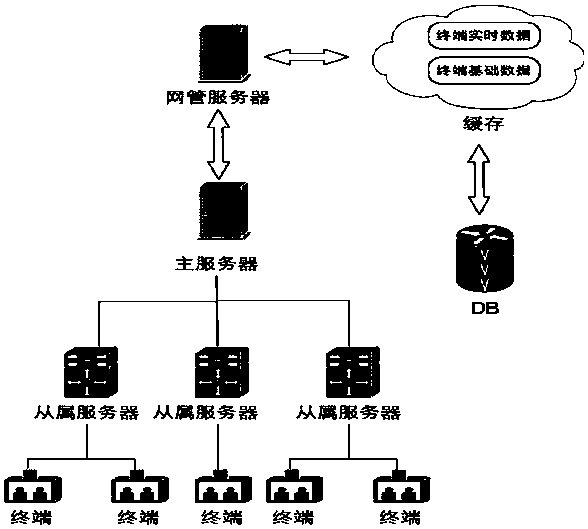

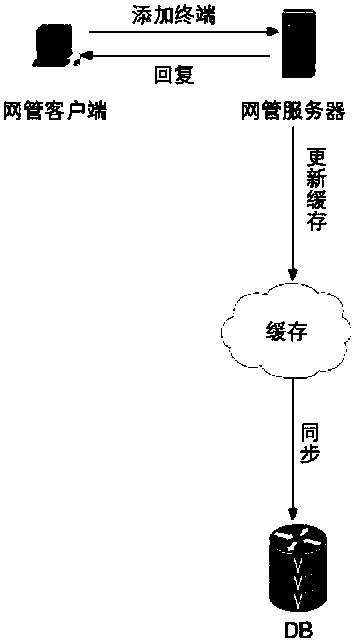

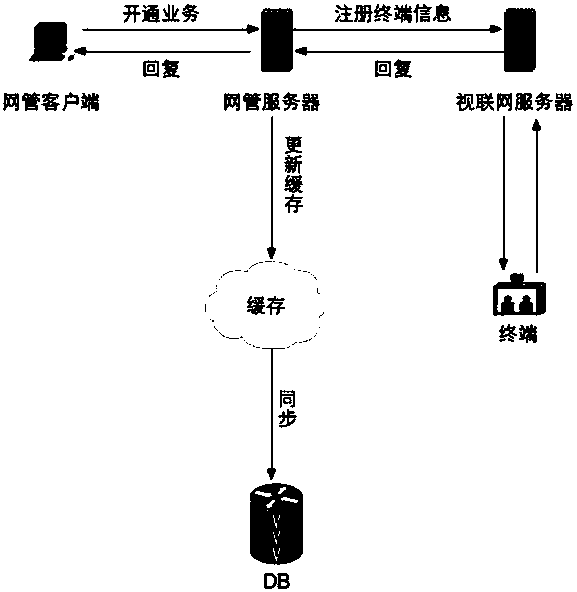

Management method and system of internet of vision terminal

ActiveCN108075920AImprove and optimize management efficiencyReduce error rateData switching networksManagement efficiencyClient-side

The embodiment of the invention provides a management method and system of an internet of vision terminal. The method comprises the following steps: a webmaster server reads non-dynamic attribute information of multiple internet of vision terminals stored in a database to a cache when the webmaster server is started; if the non-dynamic attribute information stored in the cache is changed, the webmaster server synchronously updates the non-dynamic attribute information stored in the cache to the database through an internet protocol; the webmaster server acquires dynamic attribute information of the multiple internet of vision terminals from an internet of vision main server through an internet of vision protocol, and saves the same to the cache; the webmaster server monitor the dynamic attribute information in the cache; and alarm information corresponding to the dynamic attribute is generated and send to a webmaster client to display if any dynamic attribute information exceeds a corresponding preset attribute threshold. Through the management method provided by the embodiment of the invention, the management efficiency of the internet of vision terminal can be improved and optimized.

Owner:海南乾唐视联信息技术有限公司

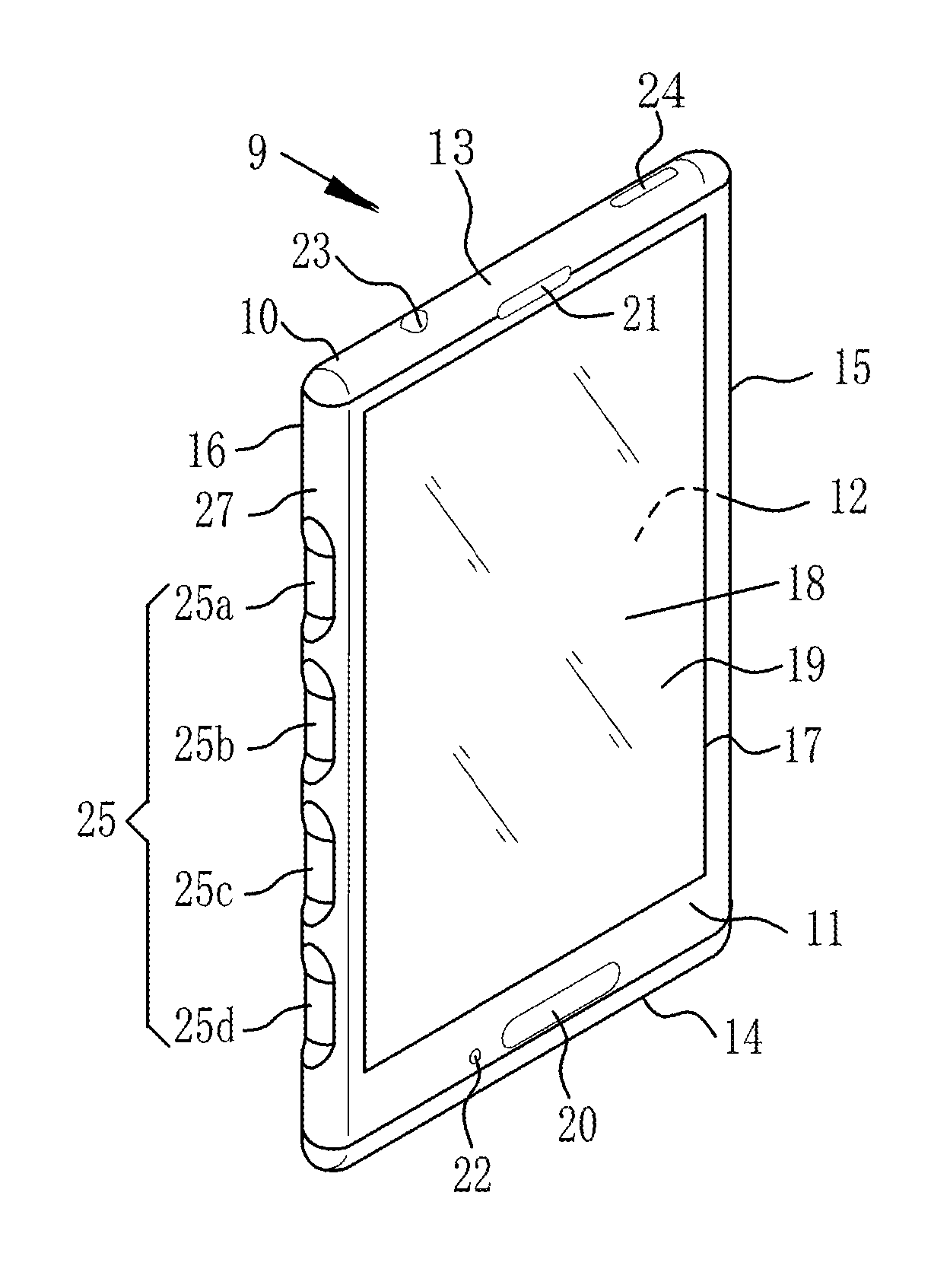

Configuration for Operating Interior Device and Cup Holder Using the Same

InactiveUS20090146444A1Ideal operabilityAvoid manual operationVehicle seatsVehicle locksControl engineeringMechanical engineering

In an operating member (2) disposed in a cabin and manually operated by the occupant of a seat and an interior device (8) such as a cup holder allowing its position to be changed with a movable mechanism disposed near the seat, the operating member (2) possesses a detecting sensor (51) for detecting a starting time of a manual operation of the operating member (2) by a hand, and a movable mechanism (25) automatically changes the interior device to a position not to interfere with the manual operation of the operating member in response to the detection signal of the detecting sensor (51).

Owner:NIFCO INC

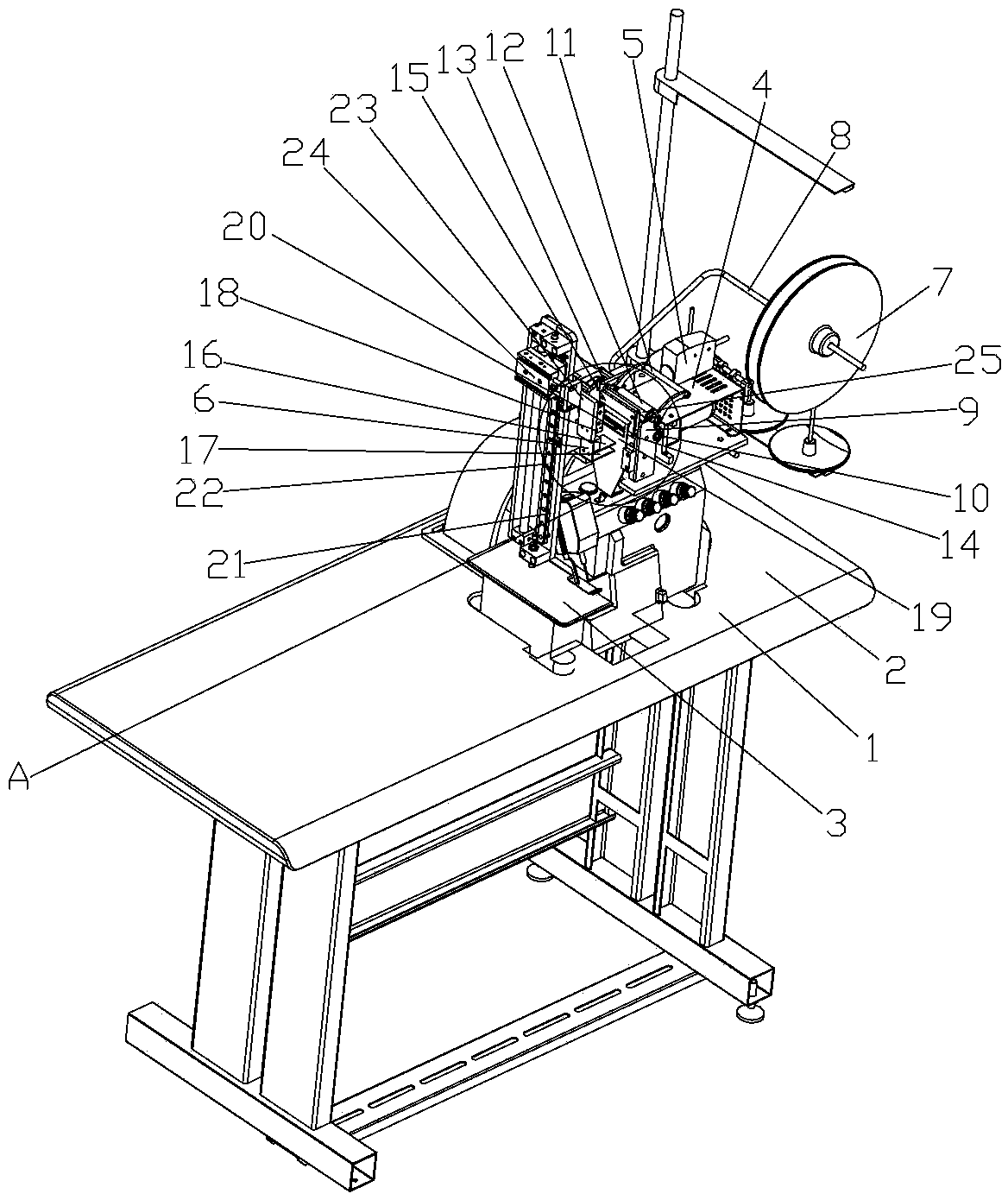

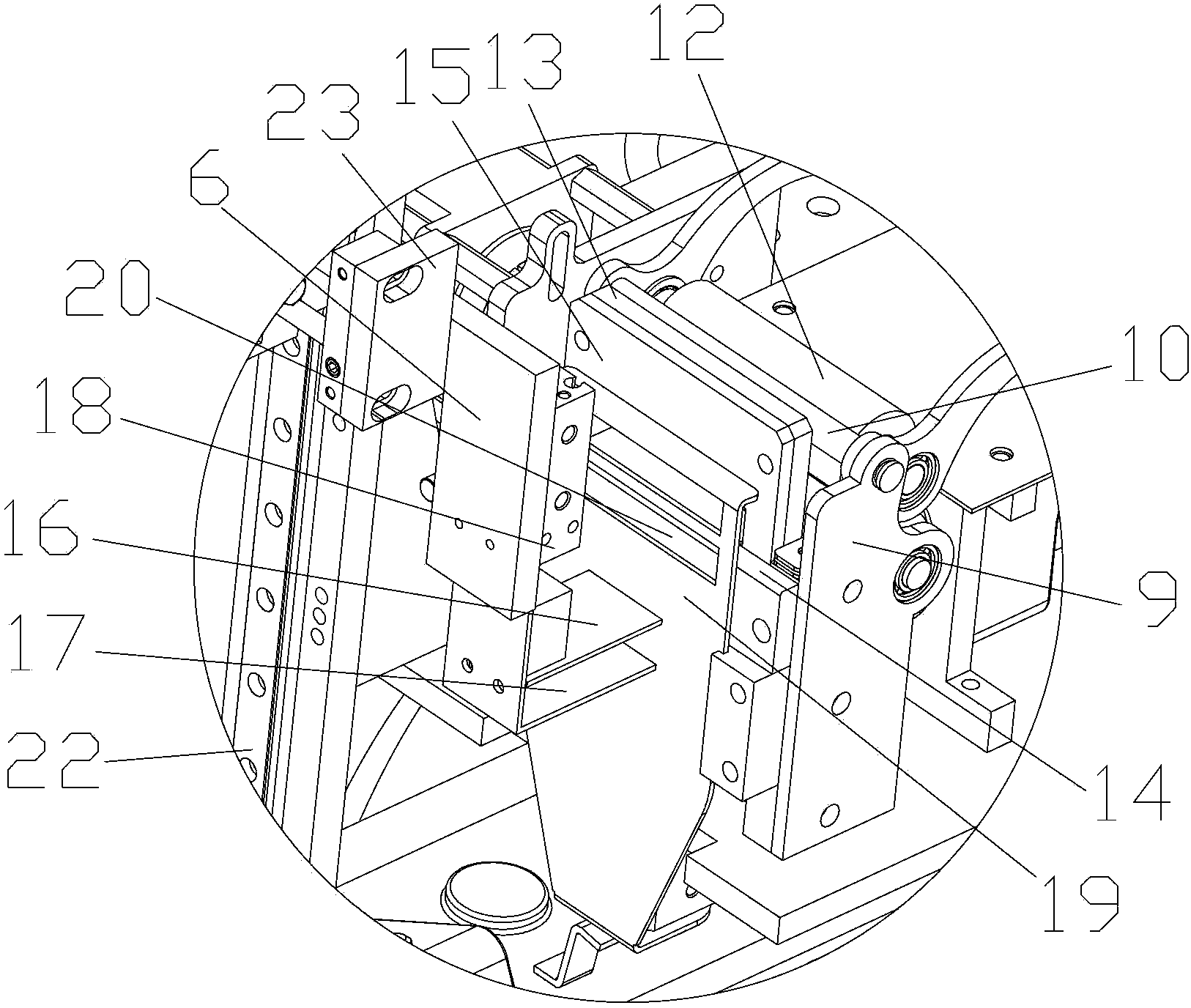

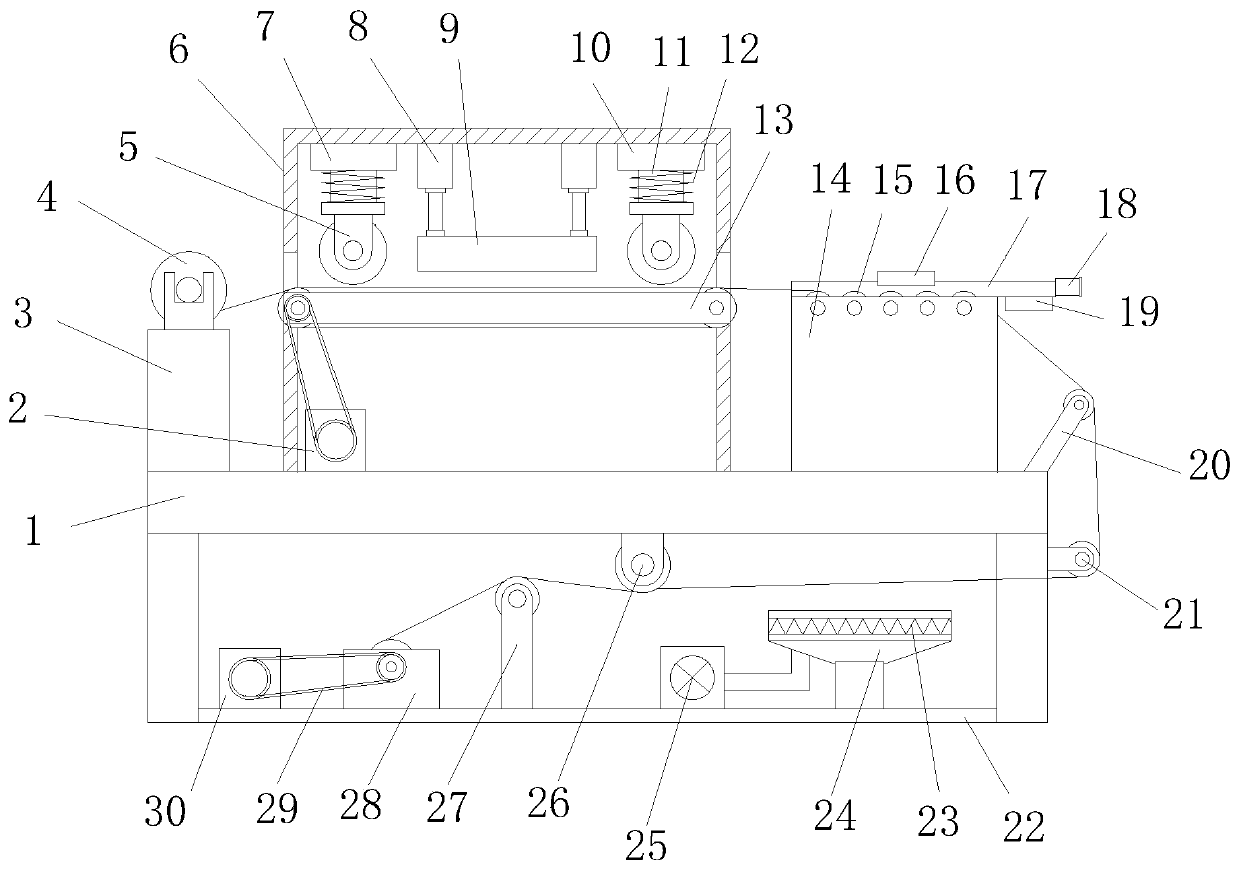

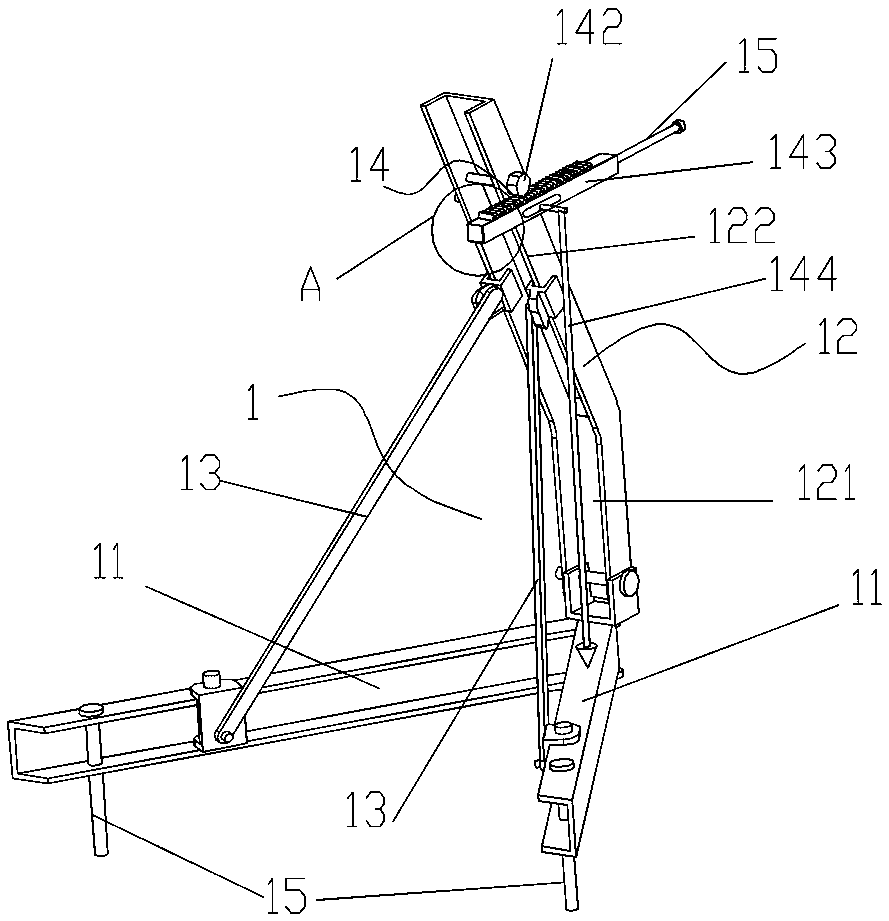

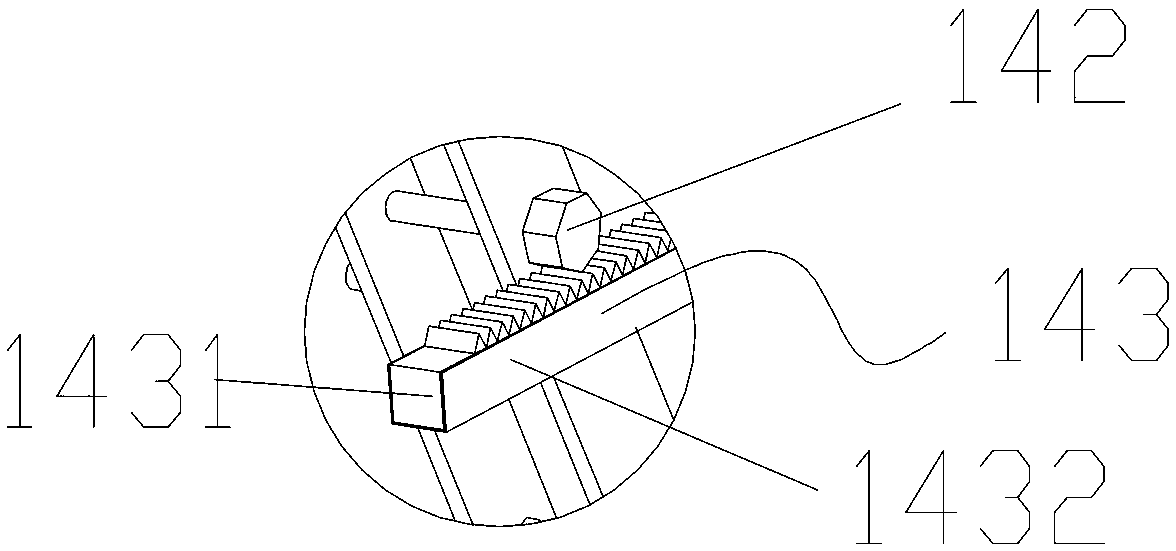

Bar tacker

The invention discloses a bar tacker. The bar tacker comprises a bar tacker body located on a machine base, an operating table face, a feeding device, an automatic detector, a pressing device, a shearing device, a folding device and a conveying device, wherein a sewing table face is arranged on the bar tacker body; the feeding device, the automatic detector, the pressing device, the shearing device, the folding device and the conveying device are fixedly arranged on the operating table face in sequence; the folding device is fixedly connected with the conveying device, shell fabric enters the operating table face through the feeding device and is conveyed into the folding device through the automatic detector, the pressing device and the shearing device; after being folded trough the folding device, the shell fabric is conveyed to the sewing table face of the bar tacker body through the conveying device to be sewn. The bar tacker is convenient to operate, manual operation is avoided, mechanical automation is achieved, production efficiency is achieved, production cost is reduced, market requirements are met, and the bar tacker is applicable to promotion and application on a large scale.

Owner:SUZHOU TRANSPARENT TECH CO LTD

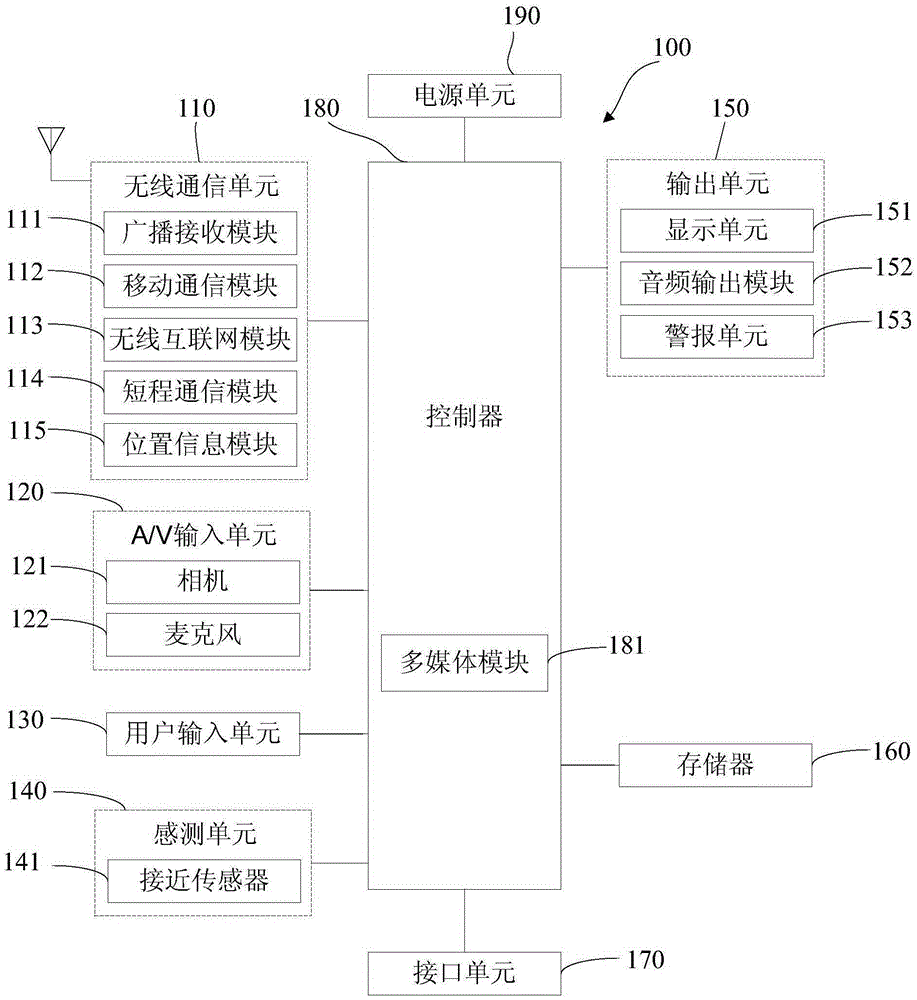

Terminal device, information issuing method and information issuing system

InactiveCN105391843AEmotions are timely and fastAvoid manual operationRespiratory organ evaluationSensorsTerminal equipmentComputer terminal

The invention discloses a terminal device. The terminal device includes: a receiving module for allowing the terminal device to receive human physiological index information acquired by a mobile terminal through a built-in biosensor; an analysis module for analyzing the human physiological index information to obtain emotional state information of a user; and an issuing module for issuing the emotional state information of the user through a social software platform. The invention also discloses an information issuing method and an information issuing system. The terminal device can timely and quickly share emotion of the user, manual operations of the user can be avoided or operation steps of the user can be reduced, and the user experience can be improved.

Owner:NUBIA TECHNOLOGY CO LTD

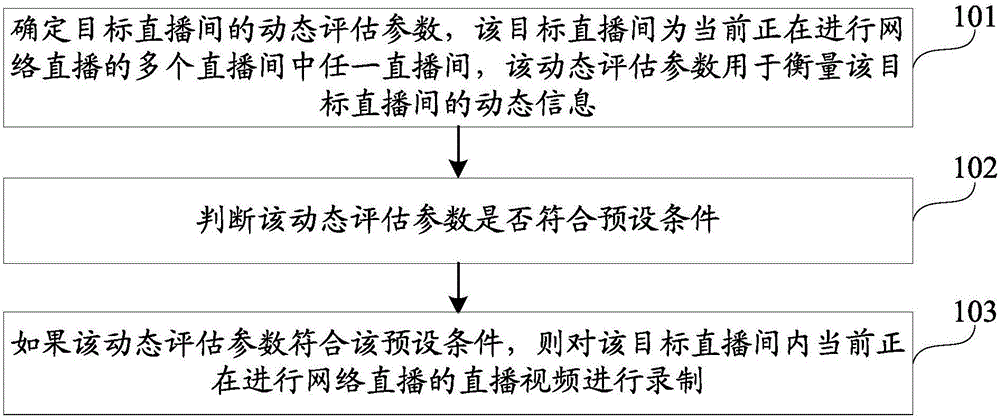

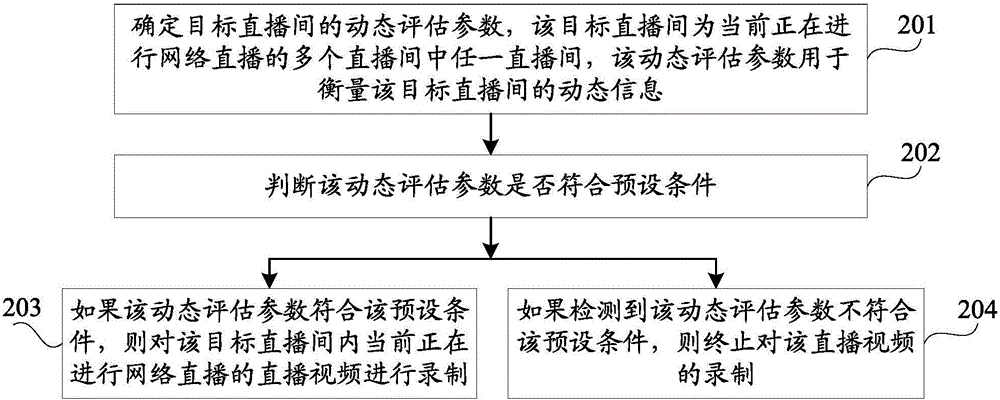

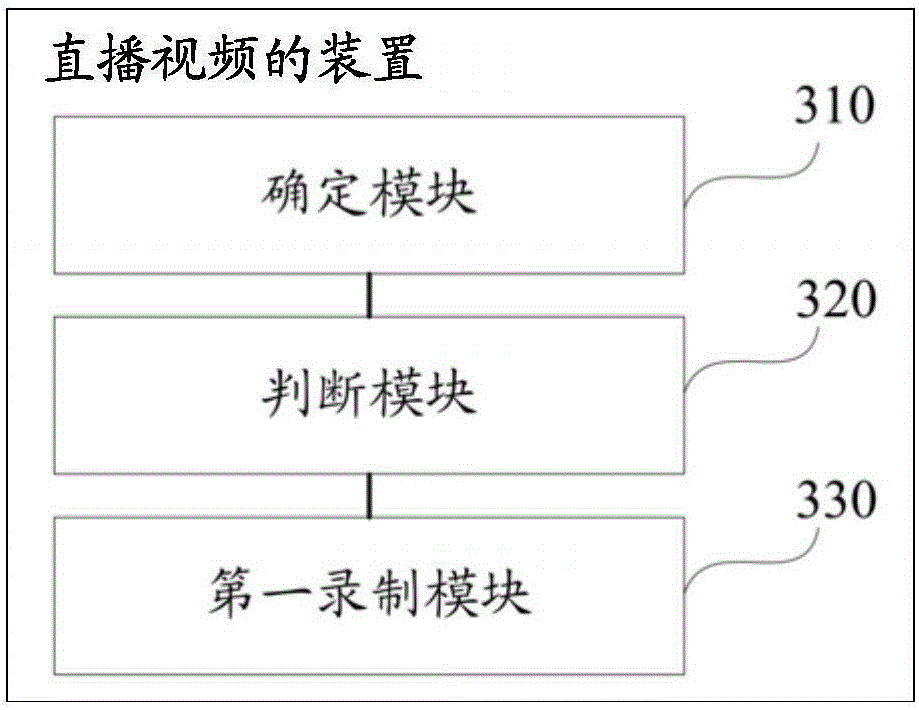

Recording method and device of live broadcast video

ActiveCN105872580AAvoid manual operationImprove convenienceSelective content distributionBroadcastingWeb technology

The invention discloses a recording method and device of a live broadcast video, and belongs to the technical field of networks. The recording method comprises the steps that dynamic evaluation parameters of a target live broadcast room are determined, wherein any one live broadcast room in multiple live broadcast rooms conducting network broadcasting at present serves as the target live broadcast room, and the dynamic evaluation parameters are used for measuring dynamic information of the target live broadcast room; whether the dynamic evaluation parameters meet the preset condition or not is judged, and if yes, the live broadcast video during network broadcasting in the target live broadcast room is recorded. Accordingly, when it is detected that the dynamic evaluation parameters of the target live broadcast room meet the preset condition, the live broadcast video is automatically recorded by a network live broadcast platform without needing manual operation of a user, and therefore the operation convenience is improved.

Owner:GUANGZHOU KUGOU TECH

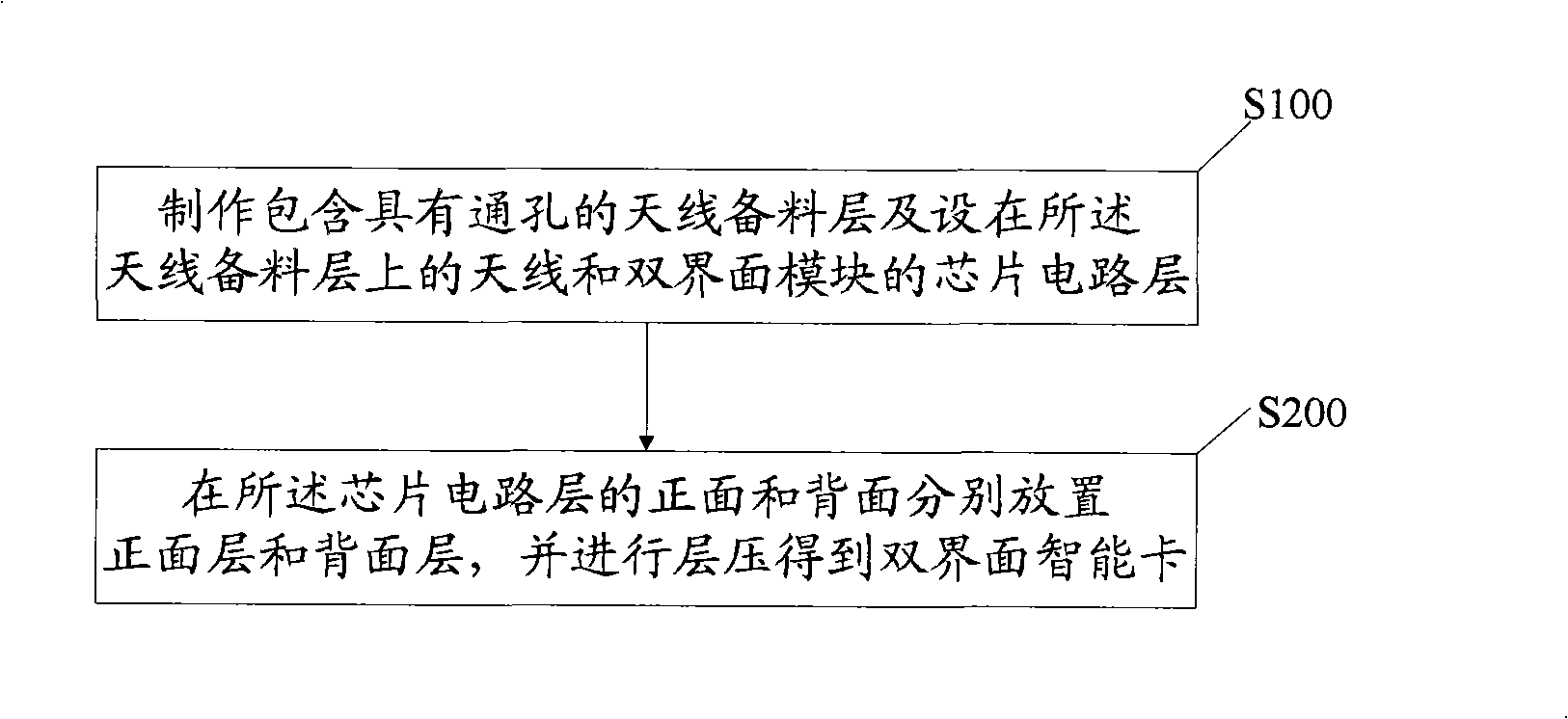

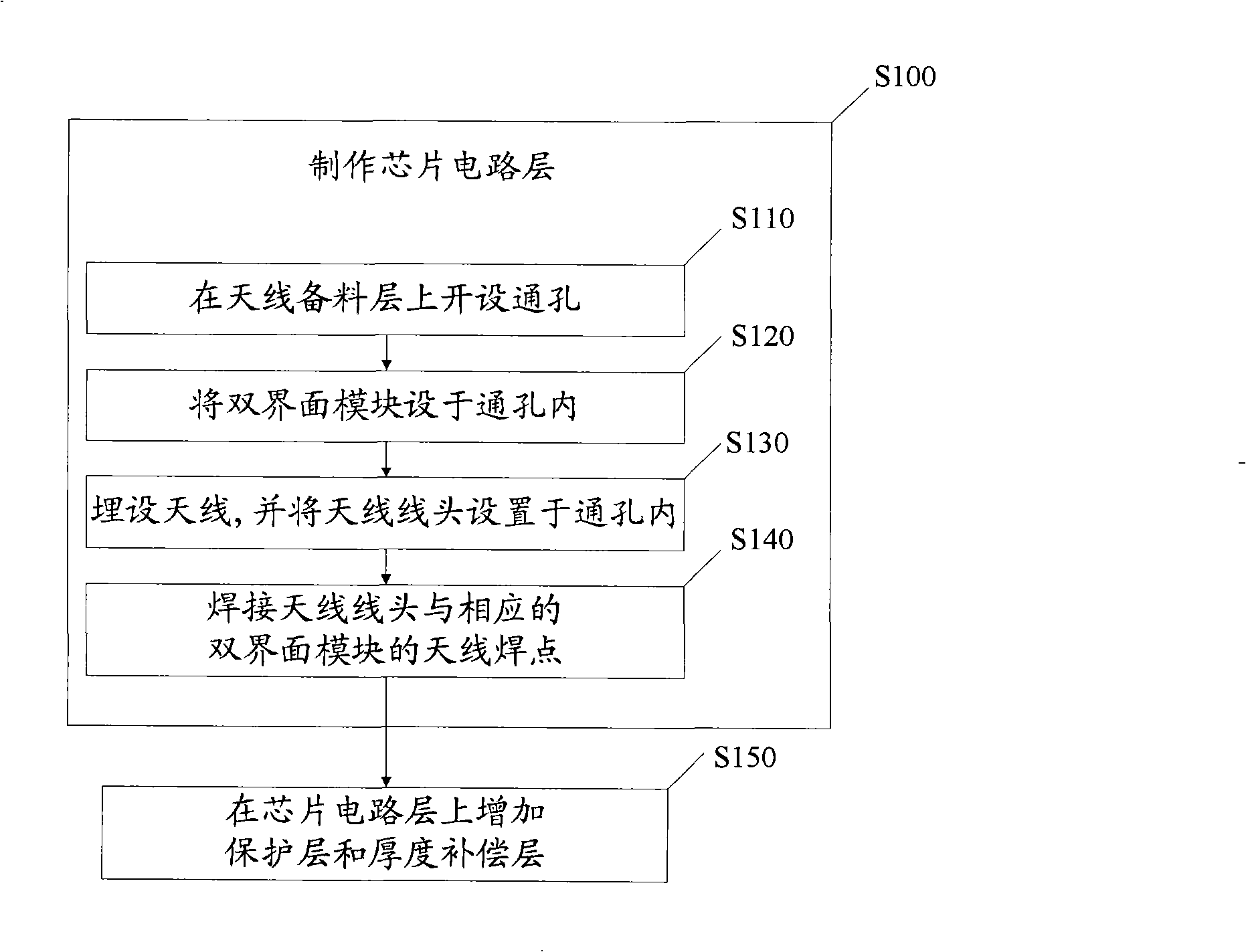

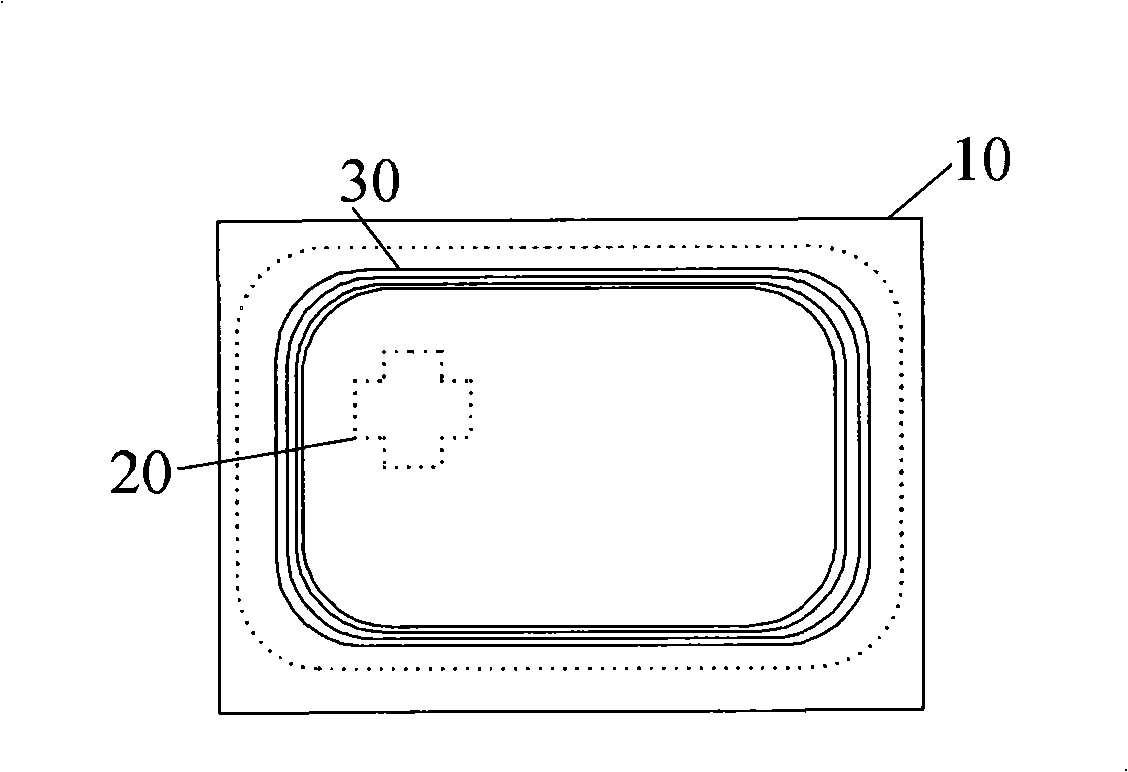

Method for producing double interfaces smart card, double interfaces smart card and antennae layer thereof

ActiveCN101350073AAutomate the machineAvoid manual operationLayered productsAntenna supports/mountingsElectrical and Electronics engineeringAntenna feed

The invention discloses a method for producing a dual-interface card, the dual-interface card and an antenna layer of the dual-interface card, which relate to the smart card manufacture field and are designed for improving the production efficiency of the dual-interface card and for lowering the reject rate of the dual-interface card. The method for producing the dual-interface card comprises: manufacturing an antenna feed preparation layer which comprises through holes, an antenna which is arranged on the antenna feed preparation layer and a chip circuit layer of a dual-interface module, wherein the antenna is electrically connected with the dual-interface module on the through holes, respectively placing a front layer and a back layer on the front and the back of the chip circuit layer, and laminating to obtain the dual-interface card. The antenna layer of the dual-interface card of the invention comprises the antenna feed preparation layer which comprises the through holes and an antenna which is arranged on the antenna feed preparation layer, wherein aerial heads of the antenna are arranged in the through holes and areas which are corresponding to an antenna solder joint of a prearranged dual-interface module.

Owner:BEIJING WATCH DATA SYST

Safety socket with guiding function

InactiveCN104916968AAchieve insertionAchieve orientationCoupling device detailsEngineeringMechanical engineering

Owner:潘燕

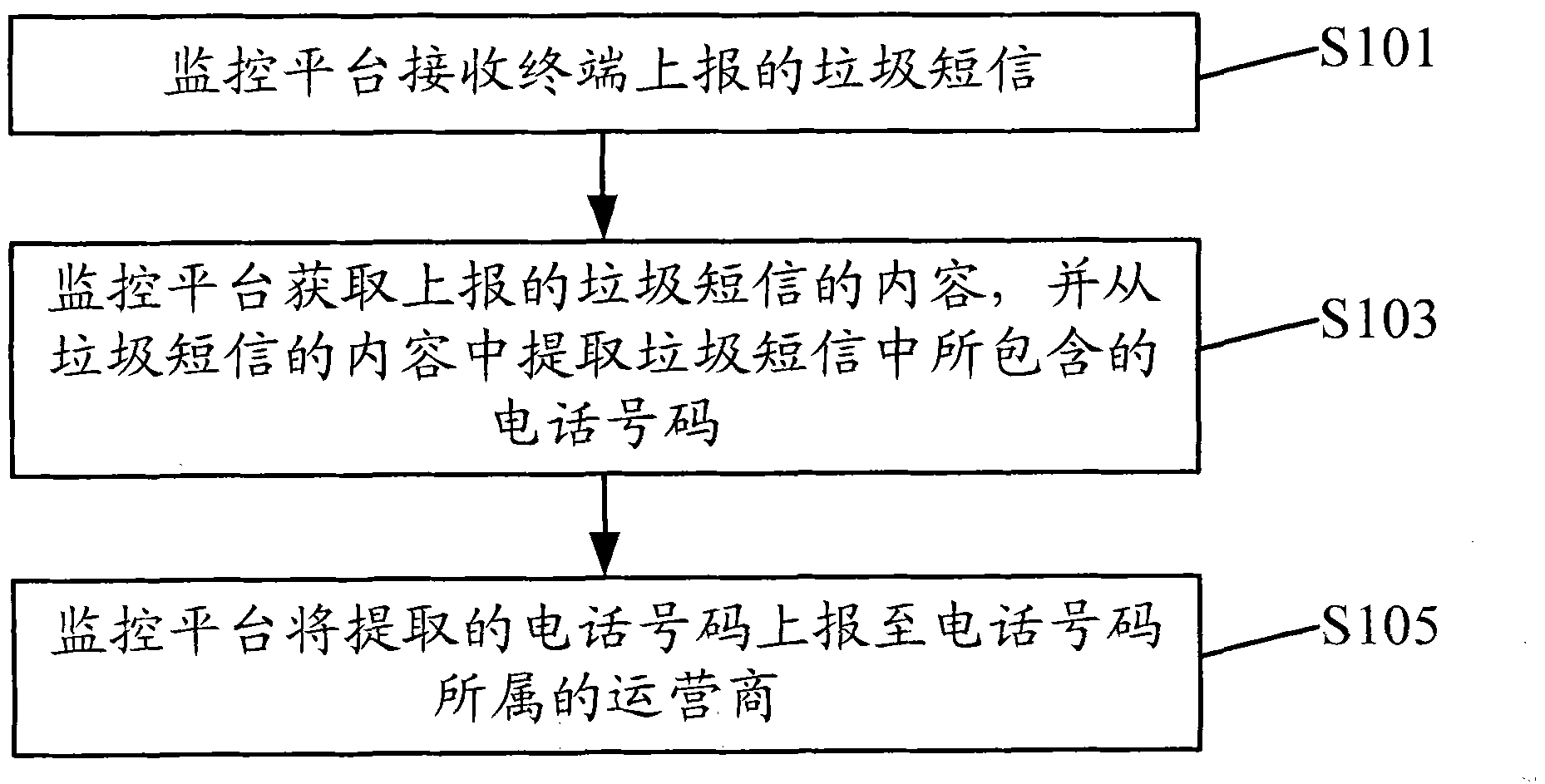

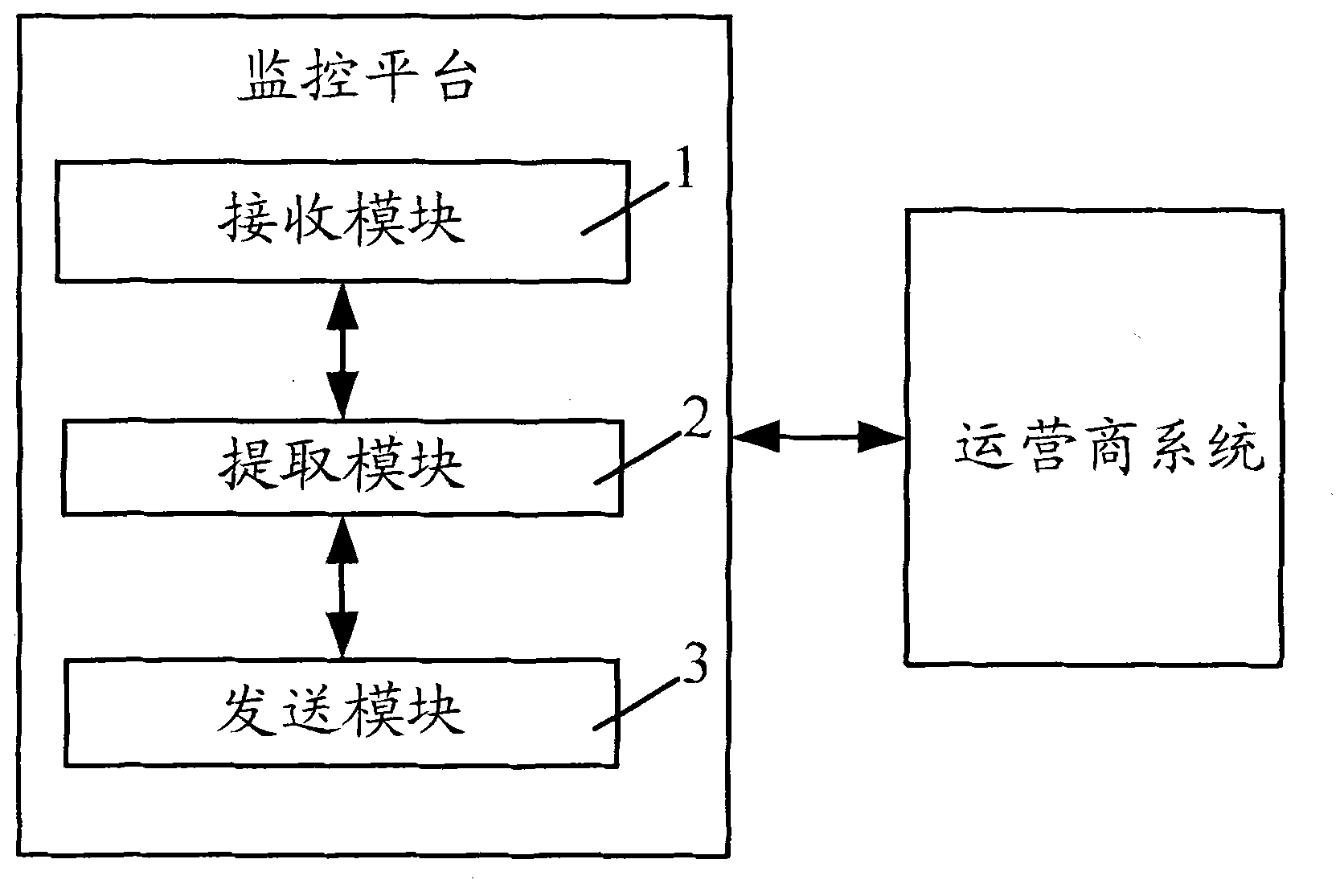

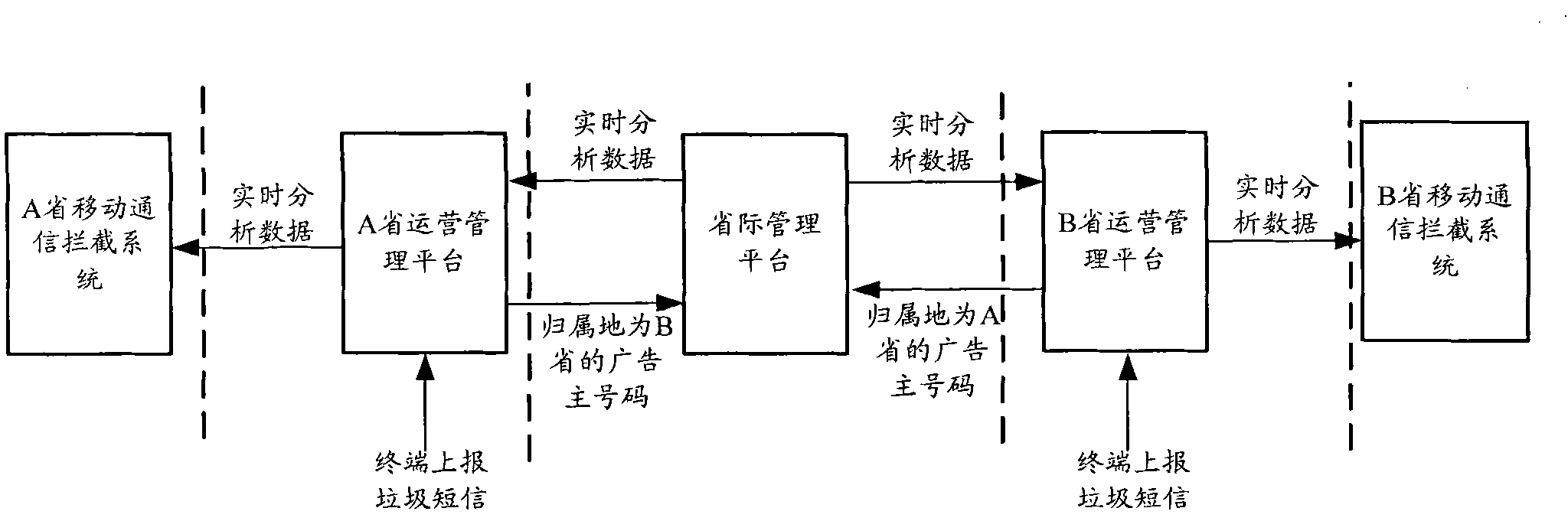

Method and system for processing spam

InactiveCN102088697AImprove performance and accuracyAvoid manual operationSecurity arrangementTelecommunicationsMaterial resources

The invention discloses a method and a system for processing spam. The method comprises the following steps: a monitoring platform receives the spam reported by a terminal; the monitoring platform acquires the content of the reported SMS spam and extracts a telephone number contained in the spam from the content of the spam; and the monitoring platform reports the extracted telephone number to an operator to which the telephone number belongs. By means of the method, the number (can be regarded as a main advertising number) contained in the content of the spam is extracted and reported to the operator; and the number of a contact person in the spam such as the advertising spam is always fixed, thus being beneficial for the operator to carry out interception or other processing from the source of the spam, improving interception effect and accuracy of the spam, avoiding a large amount of manual operation, and saving manpower and material resources.

Owner:BEIJING HUAZHONG FUSION TECH

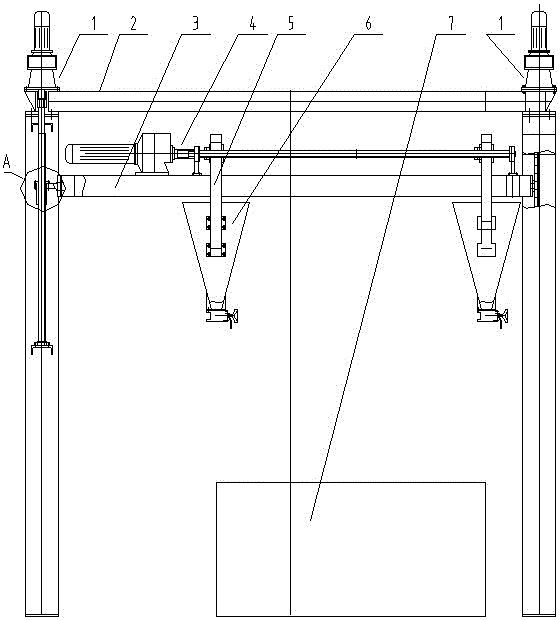

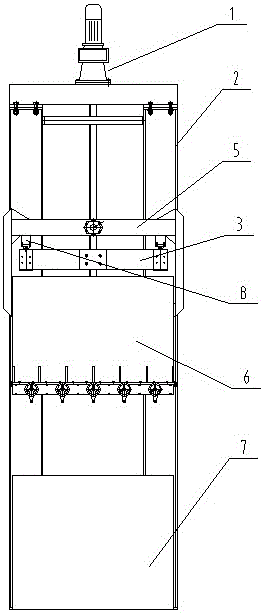

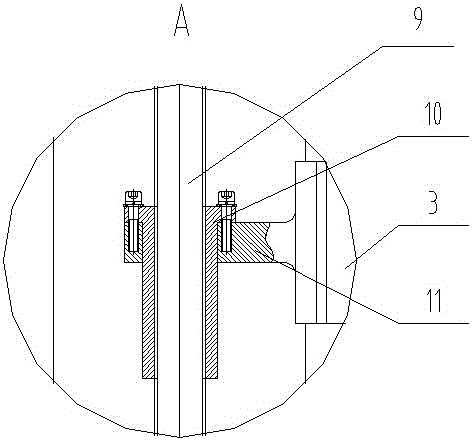

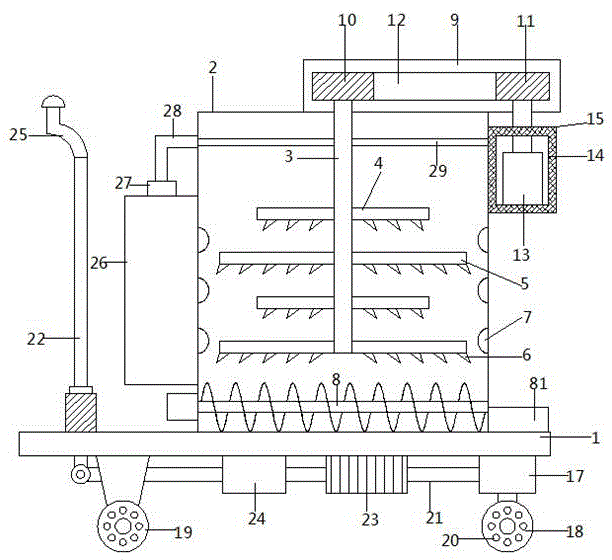

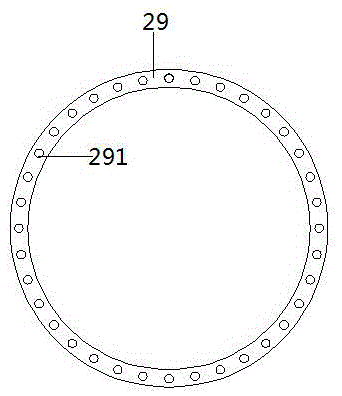

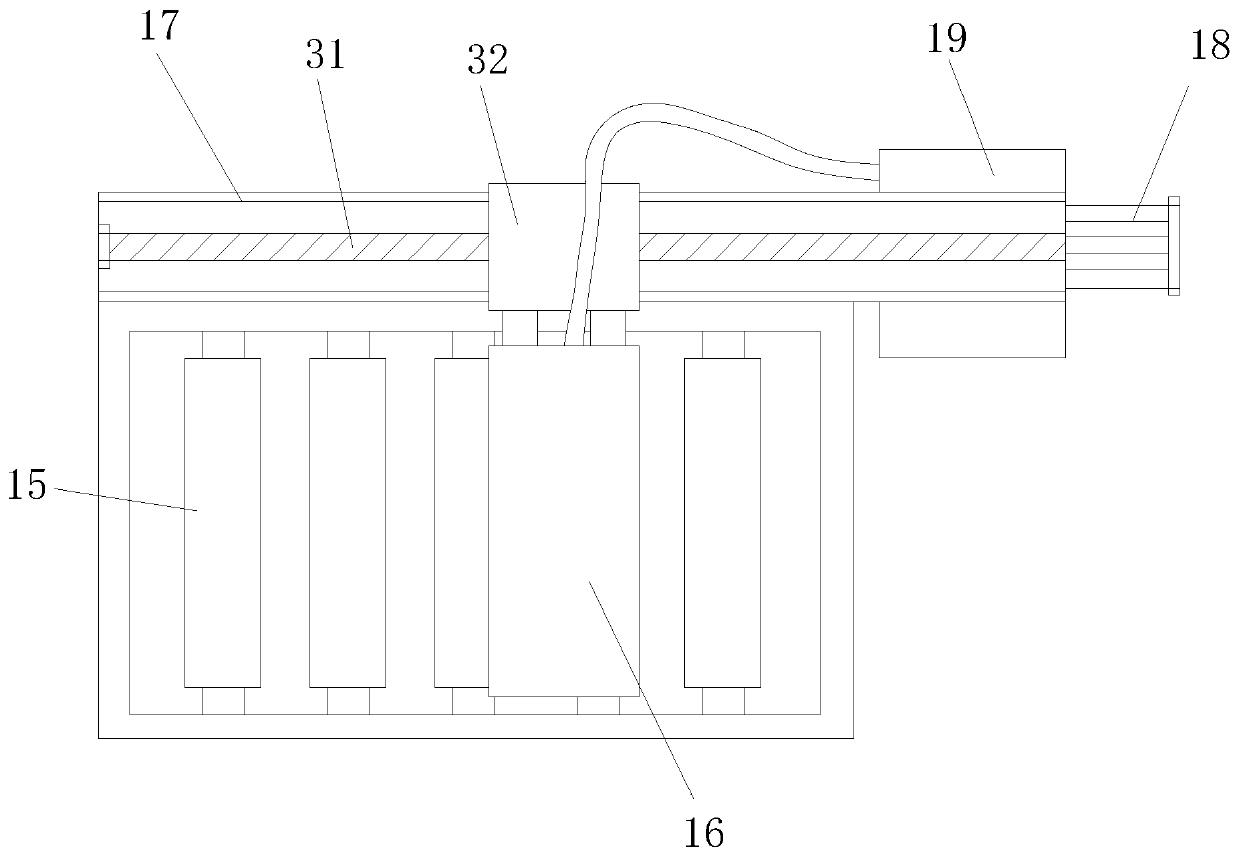

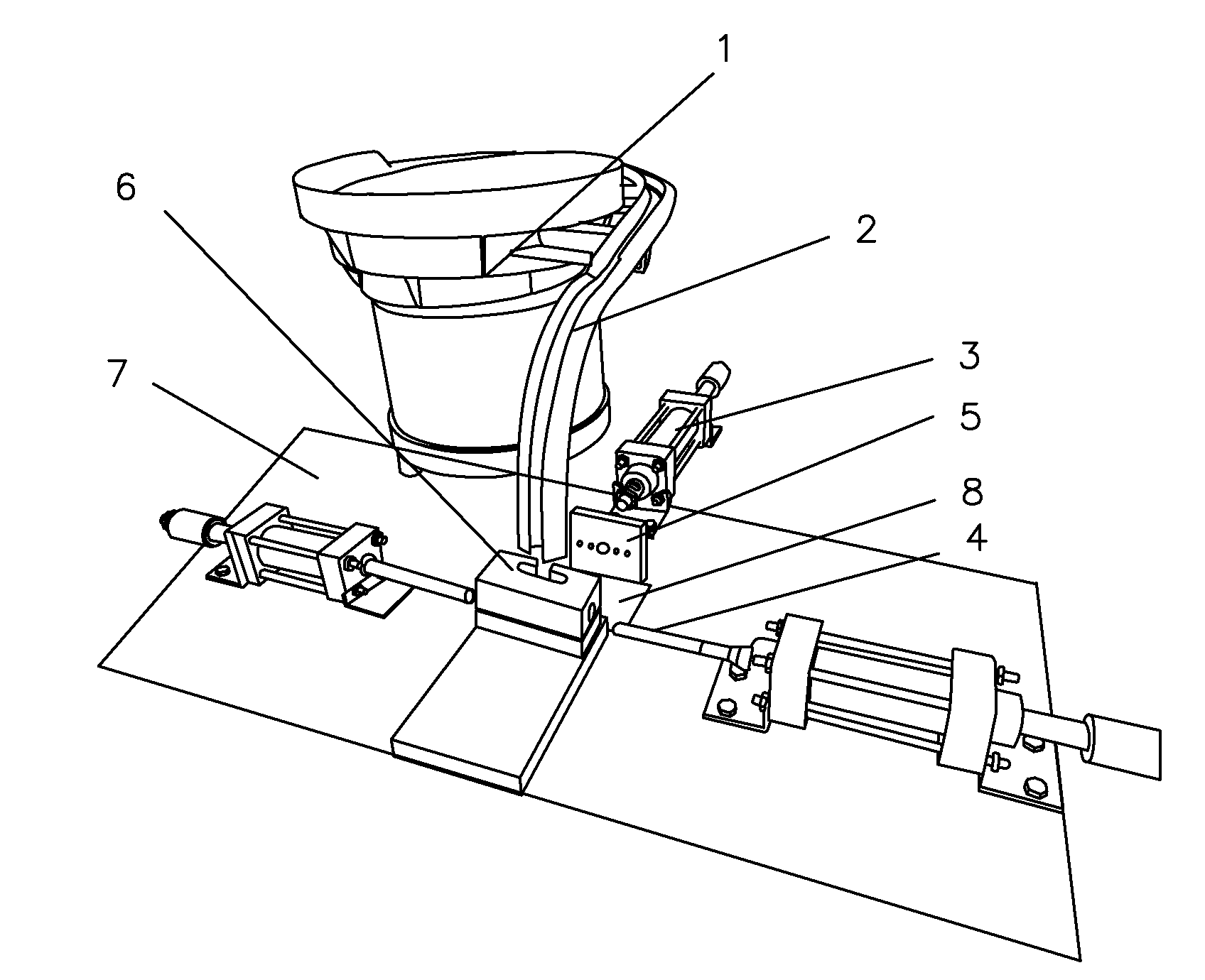

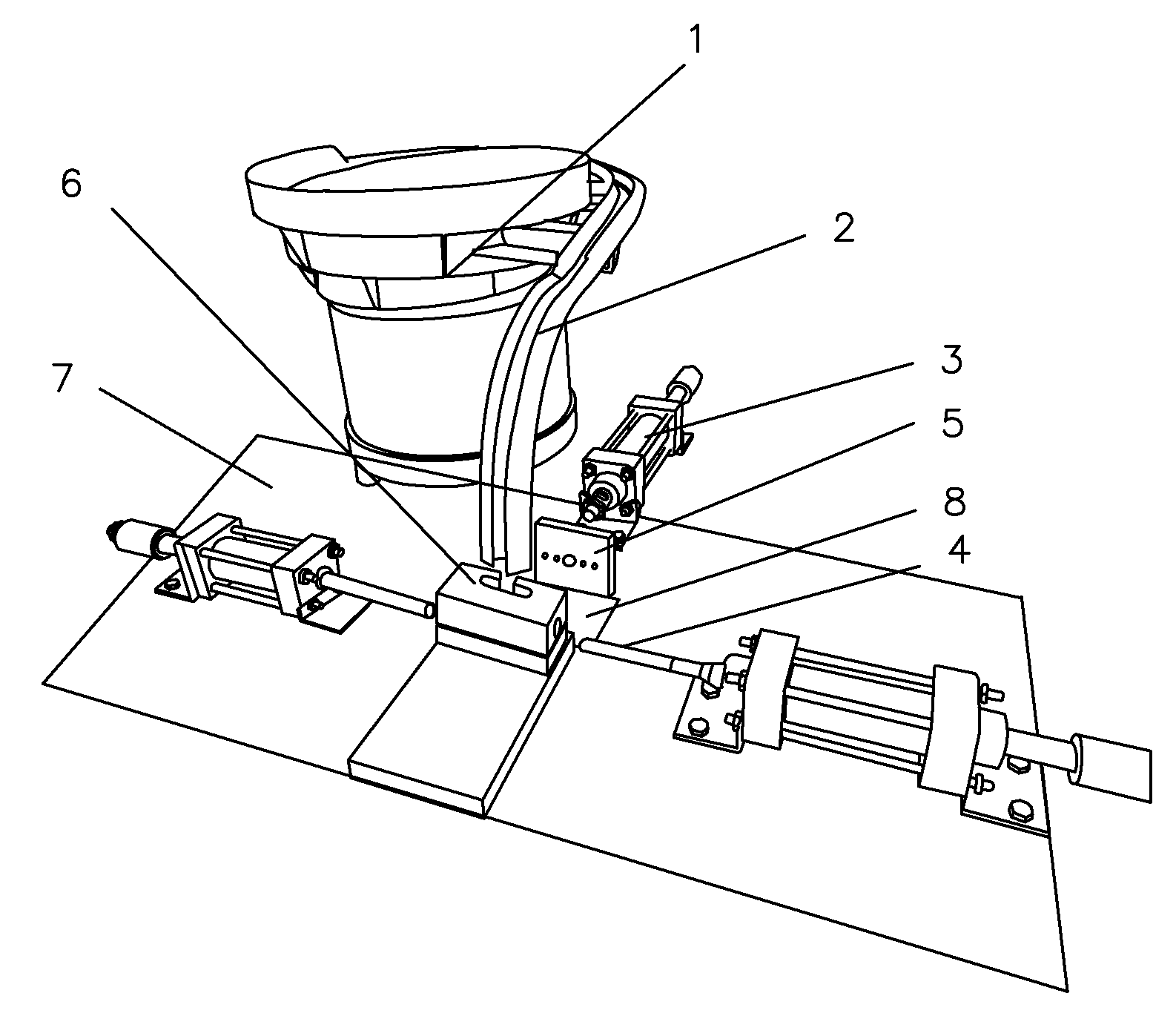

Full-automatic reciprocating sand sample preparing instrument

InactiveCN105092331APrecise control of horizontal movement speedAccurate control of horizontal movementPreparing sample for investigationProgrammable logic controllerElectric machinery

The invention relates to a full-automatic reciprocating sand sample preparing instrument which is characterized by comprising a rigid frame, wherein the rigid frame is fixedly connected with a vertical lifting system, a moving cross beam is fixedly connected with the vertical lifting system, a horizontal moving system is fixedly connected with the moving cross beam, a moving carriage is fixedly connected with the horizontal moving system, a funnel assembly is hoisted at the lower end of the moving carriage, distance measuring equipment is fixedly connected with the funnel assembly, a PLC (programmable logic controller) is fixedly connected with the rigid frame; the vertical lifting system, the horizontal moving system and the distance measuring equipment are respectively electrically connected with the PLC. According to the working process, sand in the funnel is subjected to sand rain scattering by virtue of a duckbill, the distance measuring equipment is used for monitoring the distance between the funnel assembly and the sand surface in real time, the horizontal moving system is used for driving the funnel assembly to move horizontally, a guide assembly is used for guiding for the moving carriage and the funnel assembly, the vertical lifting system is used for regulating height and controlling the falling distance of sand in sample preparation, and the PLC is used for controlling the operation of a speed control motor, thus realizing automation of the whole course of sample preparation of the system.

Owner:NORTHEAST DIANLI UNIVERSITY

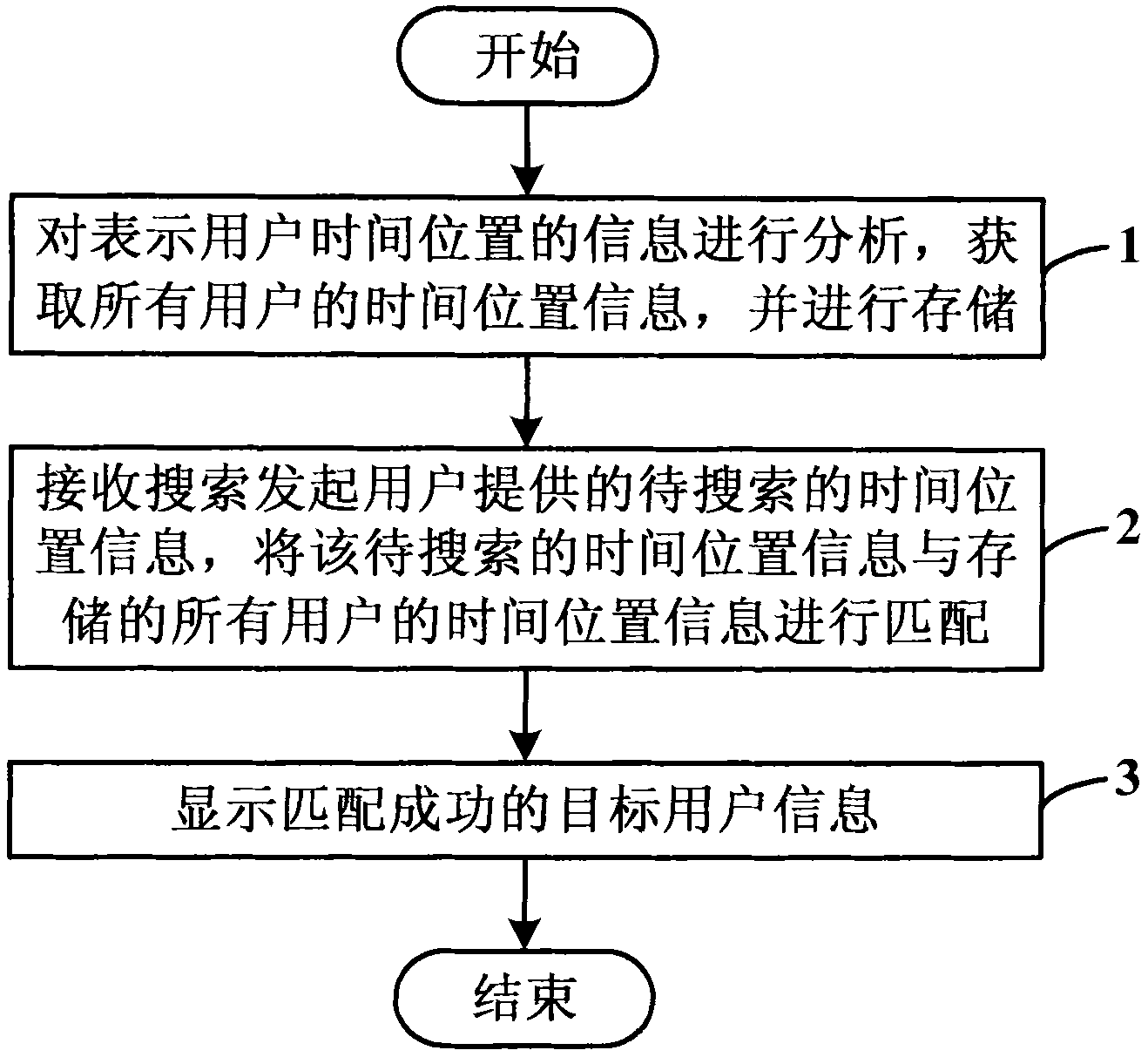

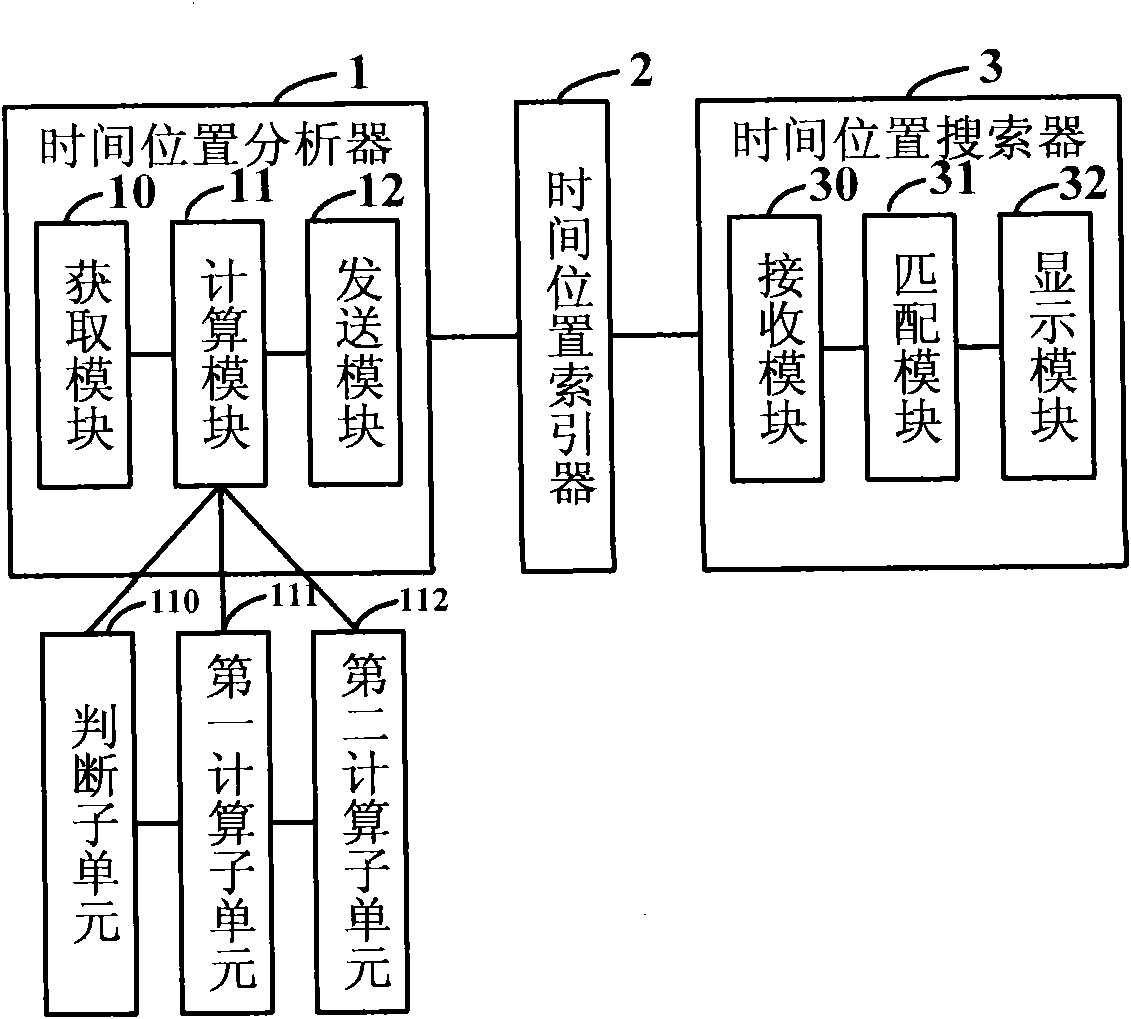

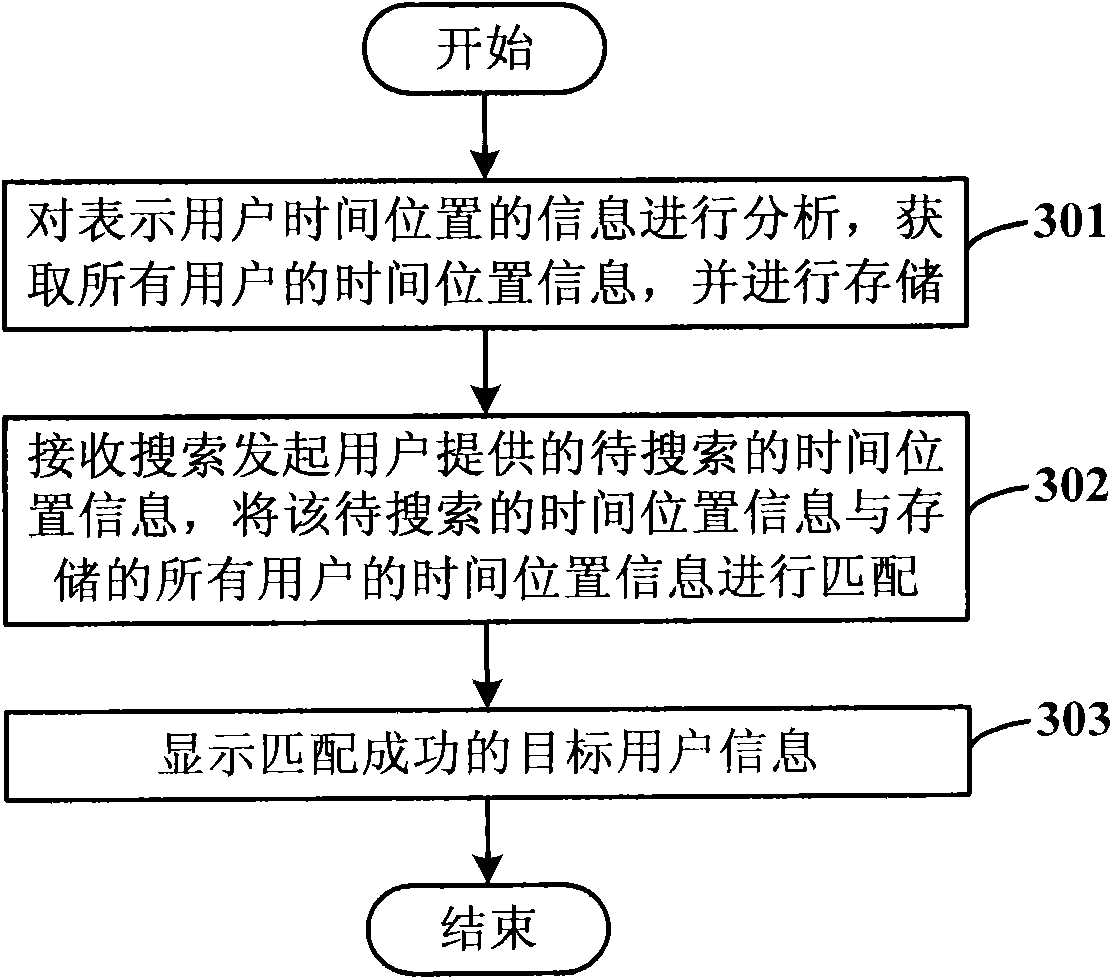

Method and system for searching target user on basis of information of time and position

InactiveCN102033918AAvoid manual operationAccurate and fast searchSpecial data processing applicationsInformation searchingReal-time computing

The invention discloses a method for searching a target user on the basis of information of time and position, comprising the following steps: carrying out analysis on the information representing the time and the position of the user, acquiring the information of the time and the position and storing the information; receiving the information of the time and the position to be searched and matching the information of the time and the position to be searched and the stored information of the time and the position of the user; and displaying the target user information with successful matching. Simultaneously, the invention discloses a system for searching the target user on the basis of the information of the time and the position. By utilizing the invention, a search initiating user can carry out selective input on areas, routes or specific sites on a map or mapped on the map in other modes, manual operation needing to inquire each included site is avoided, further the search initiating user can search the needed target user information accurately and rapidly by only needing one-time input, and therefore, the searching time is greatly saved.

Owner:武汉若鱼网络科技有限公司

Socket with indicating lamp

The invention relates to a socket with an indicating lamp. The socket with the indicating lamp comprises a socket body (9) and an actuating motor (91) arranged in the socket body (9), wherein the rotor of the actuating motor (91) is in power connection with a screw (95), the screw (95) is fit with a threaded hole in a horizontal wall part (8) in the socket body (9), the stator of the actuating motor (91) is fixedly connected with power supply guide pillars (74) which slidably penetrate through and are in sliding fit with sliding holes formed in the horizontal wall part (8), the power supply guide pillars (74) are used for being jointed with power supply holes (60) in a plug (6) inserted into jacks of the socket body (9) to supply power, and a compression spring (71) is arranged on each power supply guide pillar (74) between the side surface, facing to the actuating motor (91), of the horizontal wall part (8) and the stator of the actuating motor.

Owner:肖白玉

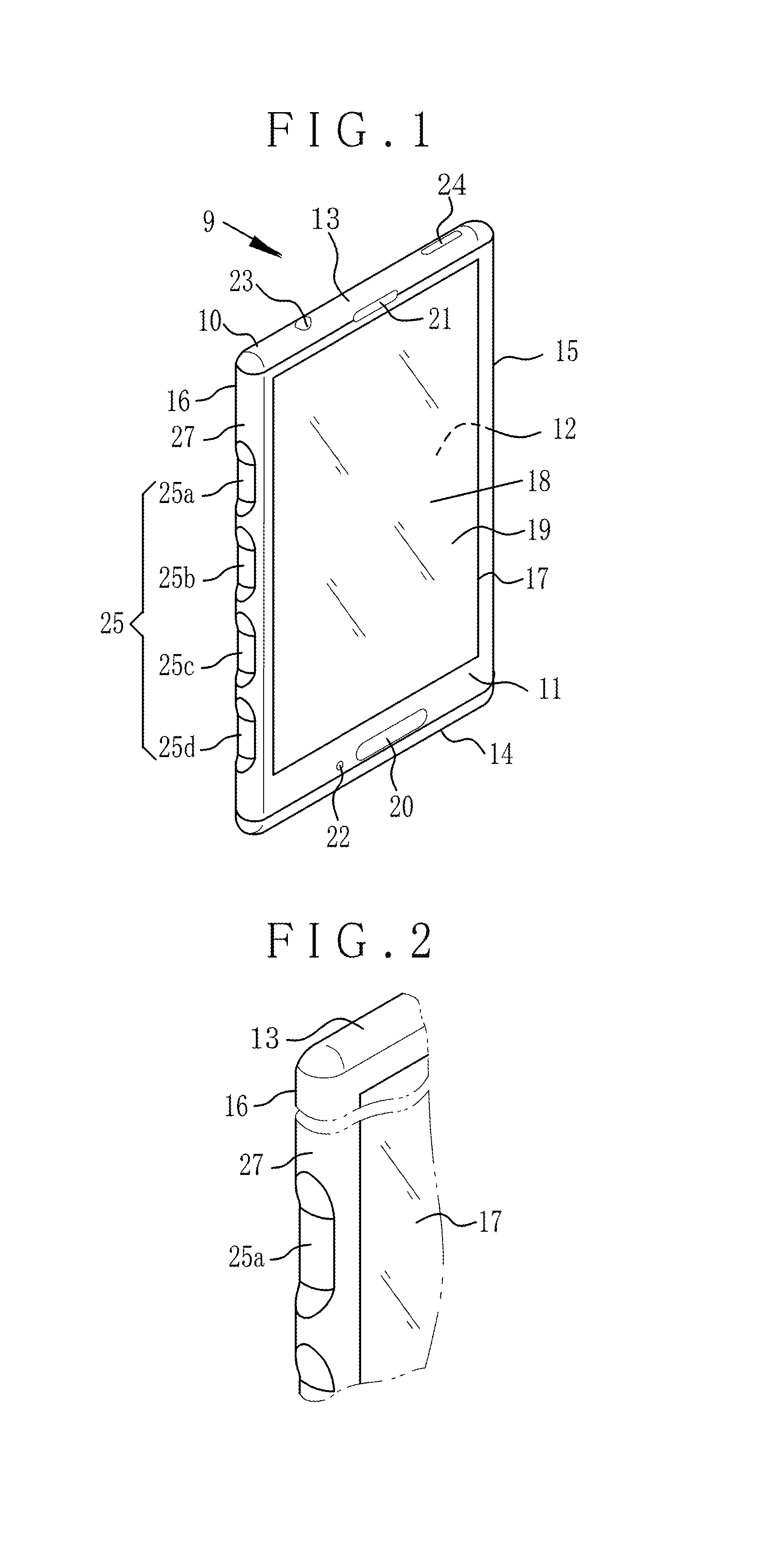

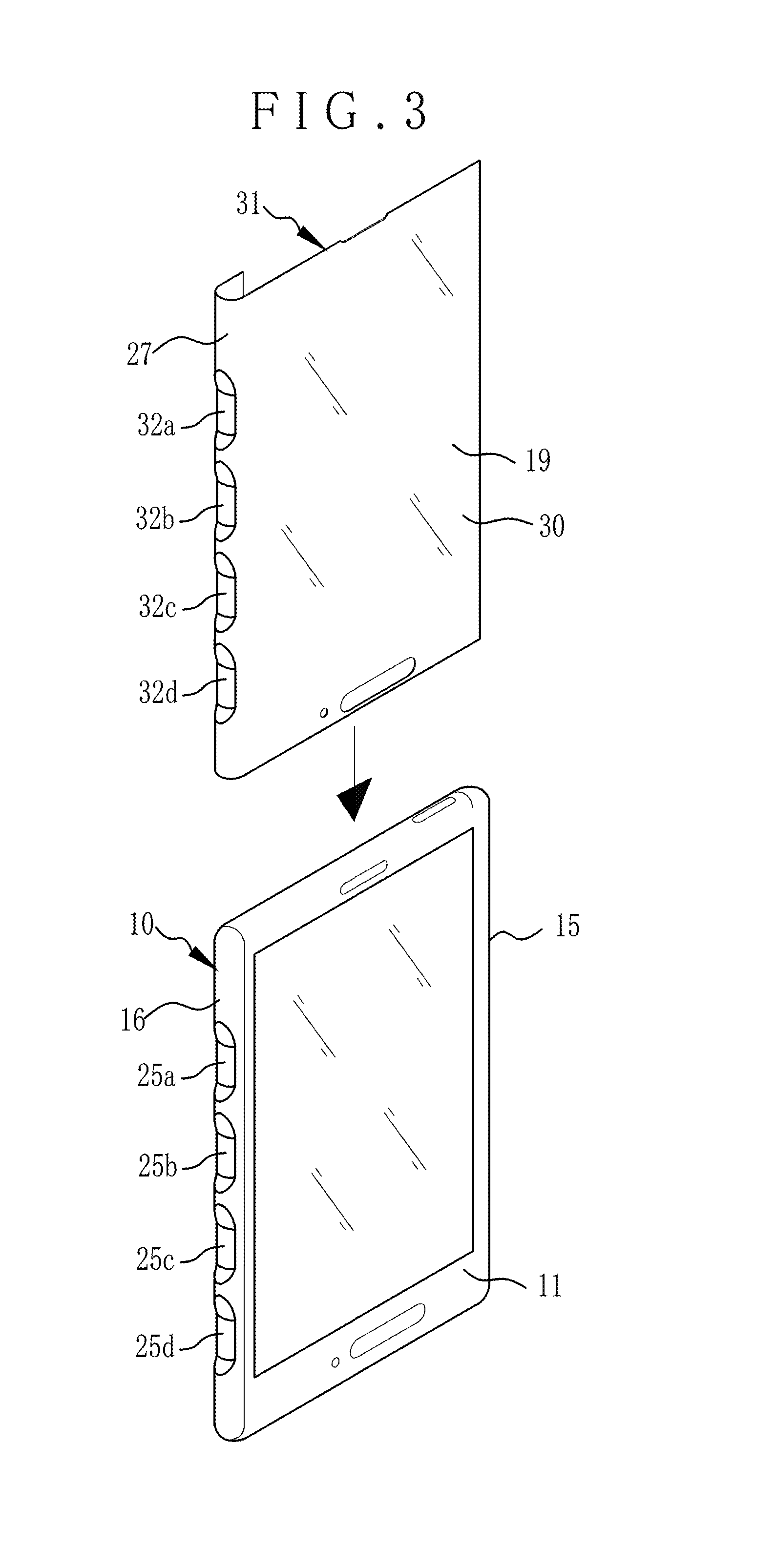

Electronic equipment with display device

ActiveUS20150355684A1Easy to operateEasy to handleDigital data processing detailsElectrical apparatus contructional detailsLateral recessTerminal equipment

Portable terminal equipment as a mobile telephone includes a display device disposed with a front surface of a housing. A first touch sensor is provided in the display device. A lateral recess is formed in at least one side surface of the housing. A side touch sensor is disposed in the housing in a range including the lateral recess. Preferably, the lateral recess is constituted by plural lateral recesses formed in the one side surface. Also, a state detection device recognizes a lateral recess where contact is detected among the plural lateral recesses by use of the side touch sensor. A disabling device disables the side touch sensor from detecting contact in a lateral recess among the lateral recesses other than the lateral recess where contact is detected, for adaptation to finger operation of one of right and left hands.

Owner:FUJIFILM CORP

Efficient mixing machine convenient to move rapidly

InactiveCN105536614ASafe and reliable workReduce noiseRotary stirring mixersTransportation and packagingEngineeringLow noise

The invention discloses an efficient mixing machine convenient to move rapidly. The efficient mixing machine comprises a base, wherein a machine body is arranged in the center of the upper side of the base, a stirring rotating shaft is vertically arranged in the machine body, a connecting box casing is arranged on the upper right side of the machine body, a first belt pulley and a second belt pulley are arranged on the left and right inside the connecting box casing and connected through a drive belt, the first belt pulley is connected with the top end of the stirring rotating shaft, and a motor case is fixed on the outer wall of the right side of the machine body. The efficient mixing machine convenient to move rapidly adopts the belt pulleys for driving, is safe, reliable and stable in work, has low noise during work and can regulate the running speed; a drive device is arranged on the upper side of the machine body, sealing is not needed to be considered, the production and use costs are reduced, the stirring effect is good, the working efficiency is high, automatic cleaning and automatic discharging can be realized, time and labor are saved, and the working efficiency is further increased; besides, the efficient mixing machine can be moved rapidly and is high in convenience.

Owner:覃艺诗

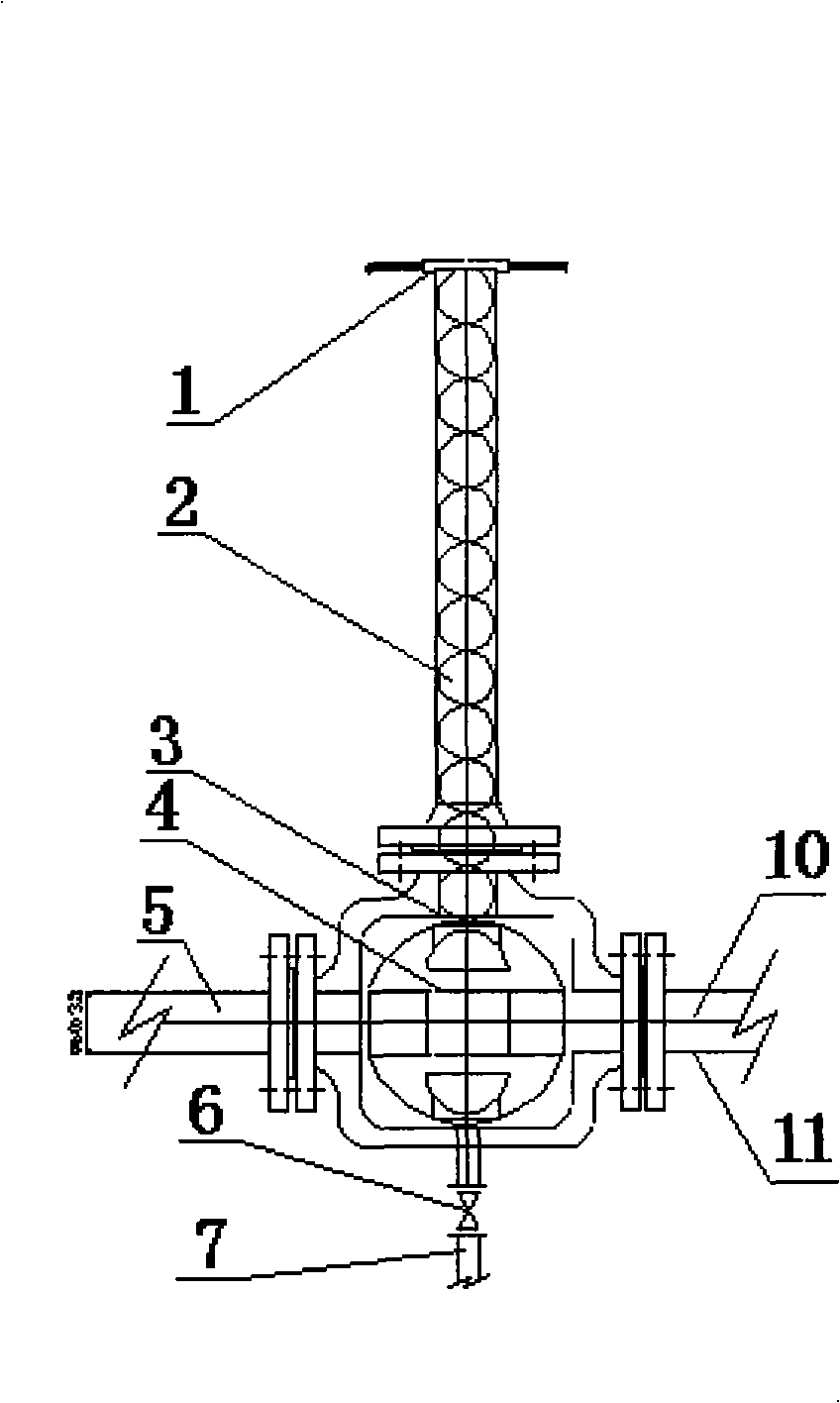

Timing automatic ball-throwing apparatus and method

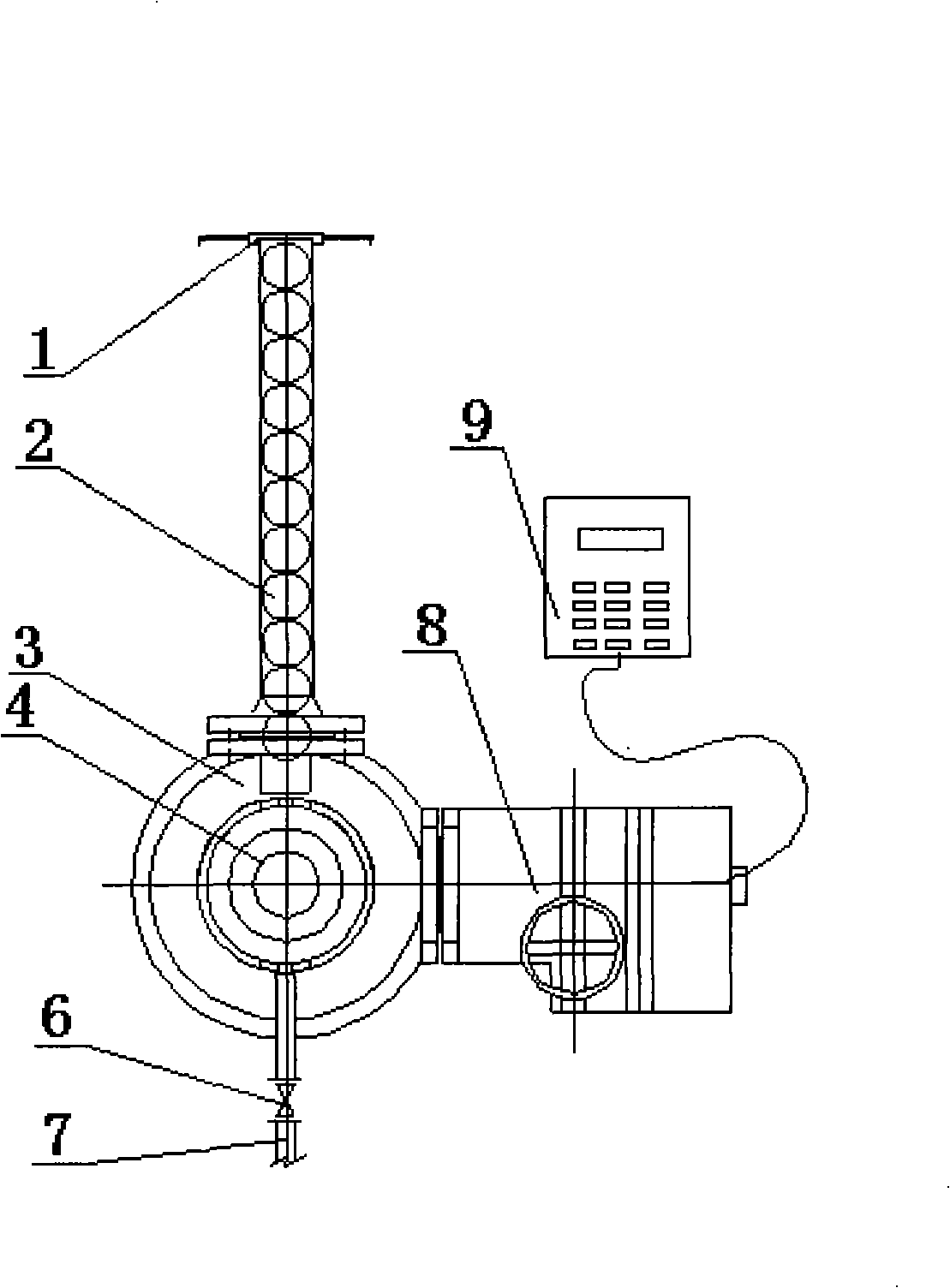

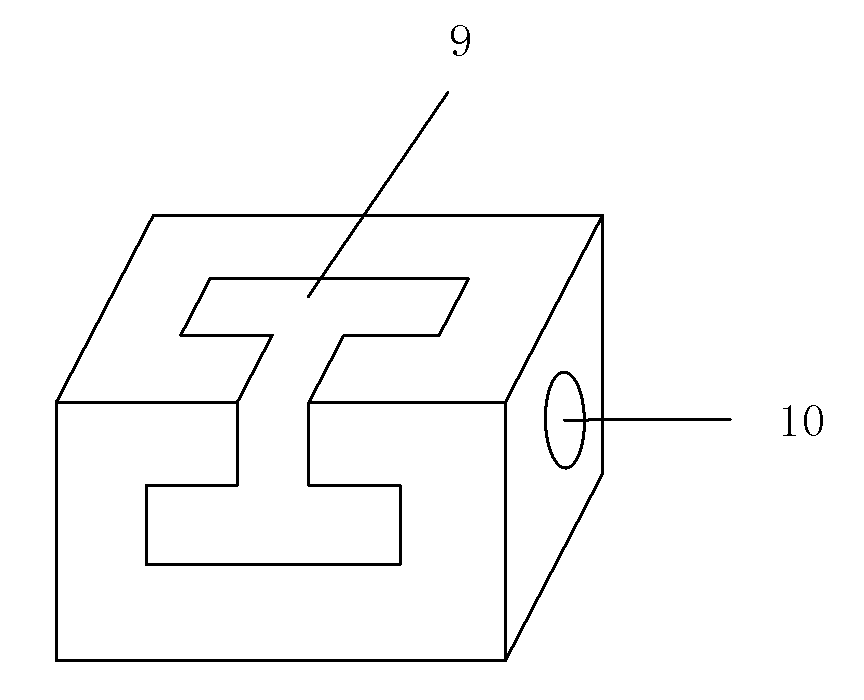

InactiveCN101408098ALow running costAvoid manual operationCleaning apparatusHollow article cleaningEngineeringOil production

The invention belongs to oil production and oil collecting equipment of an oil field, and relates to a ball injector in production and establishing engineering of the oil field, in particular to a timing automatic ball injector and a method thereof. The ball injector is characterized by comprising a ball-packing cylinder (1), a control valve (3) and a control unit (9); one end of the ball-packing cylinder (1) is an inlet for paraffin removal balls (2), and the other end thereof is an outlet for the paraffin removal balls (2); the outlet for the paraffin removal balls (2) is connected with a port of the control valve (3) of a connecting pipeline (11); the control valve (3) is a ball valve which is connected between a crude oil input pipeline (5) and a crude oil output pipeline (10); a ball valve core (4) is turned by 90 degrees through an electric head (8) of the control ball valve; the paraffin removal balls (2) of the ball-packing cylinder (1) carry out paraffin removal along the direction of the crude oil output pipeline (10); the ball valve core (4) is turned to be reset through the electric head (8) of the control ball valve; and the paraffin removal balls (2) of the ball-packing cylinder (1) are blocked. The ball injector can be used for reducing the cost of oil production and reducing the labor intensity of employees.

Owner:XIAN CHANGQING TECH ENG

Efficient embossing machine for textile wall paper production

InactiveCN110126451AAvoid damageLow investment costCovering/liningsRotary pressesPaper productionPulp and paper industry

The invention discloses an efficient embossing machine for textile wall paper production. The machine comprises a rack, a uniform pressing device, a stamping device, a drying device and a coiling device, wherein a distributing roller storing rack is fixedly arranged at the upper left end of the rack, and a distributing roller is rotatably mounted at the upper end of the distributing roller storingrack; the uniform pressing device is arranged at the right side of the distributing roller storing rack; the stamping device is arranged at the right side of the uniform pressing device and is fixedly mounted at the upper right side of the rack; a first guide roller is fixedly arranged at the upper right end of the rack; a second guide roller is arranged in the middle of the right side of the rack; a third guide roller is arranged in the middle of the bottom part of the rack; a separating plate is arranged at the inner lower part of the rack; the drying device is arranged at the upper right side of the separating plate; a fourth guide roller is arranged in the middle of the upper part of the separating plate; and the coiling device is arranged at the upper left side of the separating plate. The machine is simple in structure, multifunctional, good in use effect, and high in production efficiency; the product quality is effectively ensured; and the machine is beneficial for popularization.

Owner:苏州前航实业有限公司

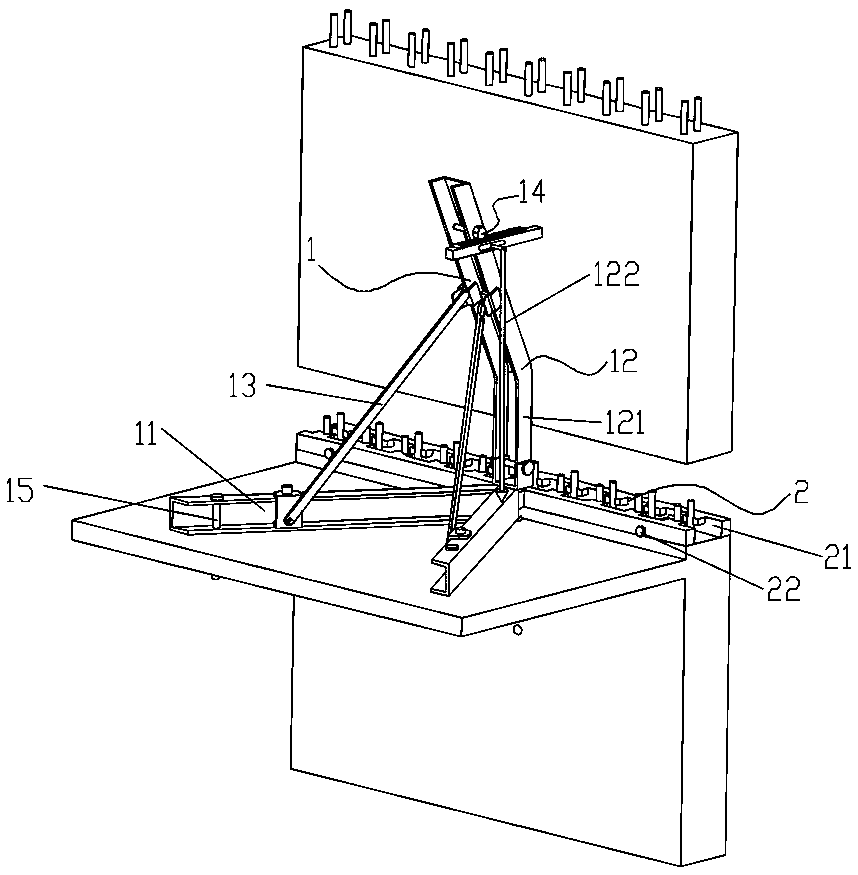

Assembled wall auxiliary mounting device and using method

Owner:北京市住宅产业化集团股份有限公司

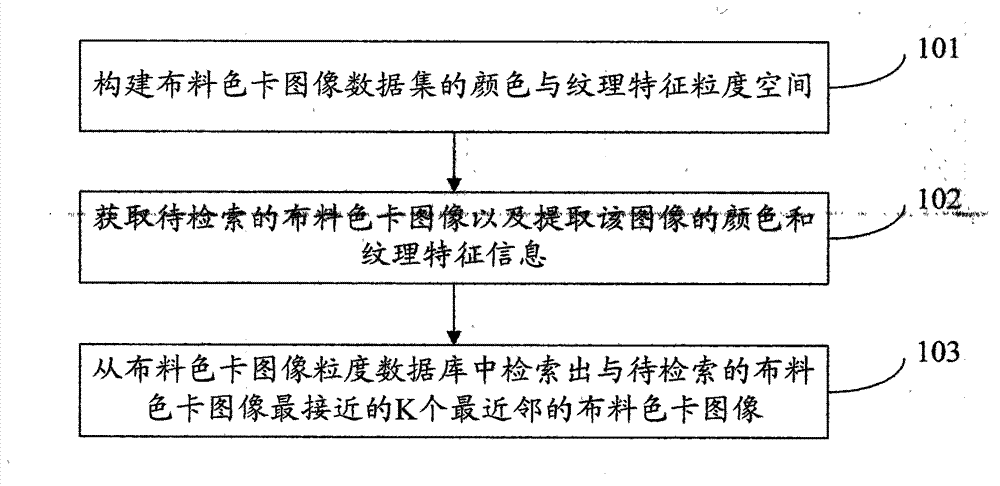

Cloth color card image retrieval method

InactiveCN104331447AAvoid manual operationEnsure consistencyCharacter and pattern recognitionSpecial data processing applicationsData setGranularity

The invention provides a cloth color card image retrieval method. The method comprises the following steps: (I) constructing a color and texture feature granular space of a cloth color card image data set; (II) acquiring a cloth color card image to be retrieved and extracting the color and texture feature information of the image; (III) retrieving K most adjacent cloth color card images which are closest to the cloth color card image to be retrieved from a cloth color card image granularity database. Cloth color card image granularity spaces of different granularities are constructed by adopting a granularity computation method following a binary relation in combination with a data mining technology, and multi-layer classification and retrieval can be performed on the images by simulating the image identification and retrieval ways of humans through an image retrieval method based on image granularity spaces of different granularities, so that the problem of difficulty in finding materials, retrieving materials and classifying in the current cloth product processing field is solved.

Owner:邱桃荣 +1

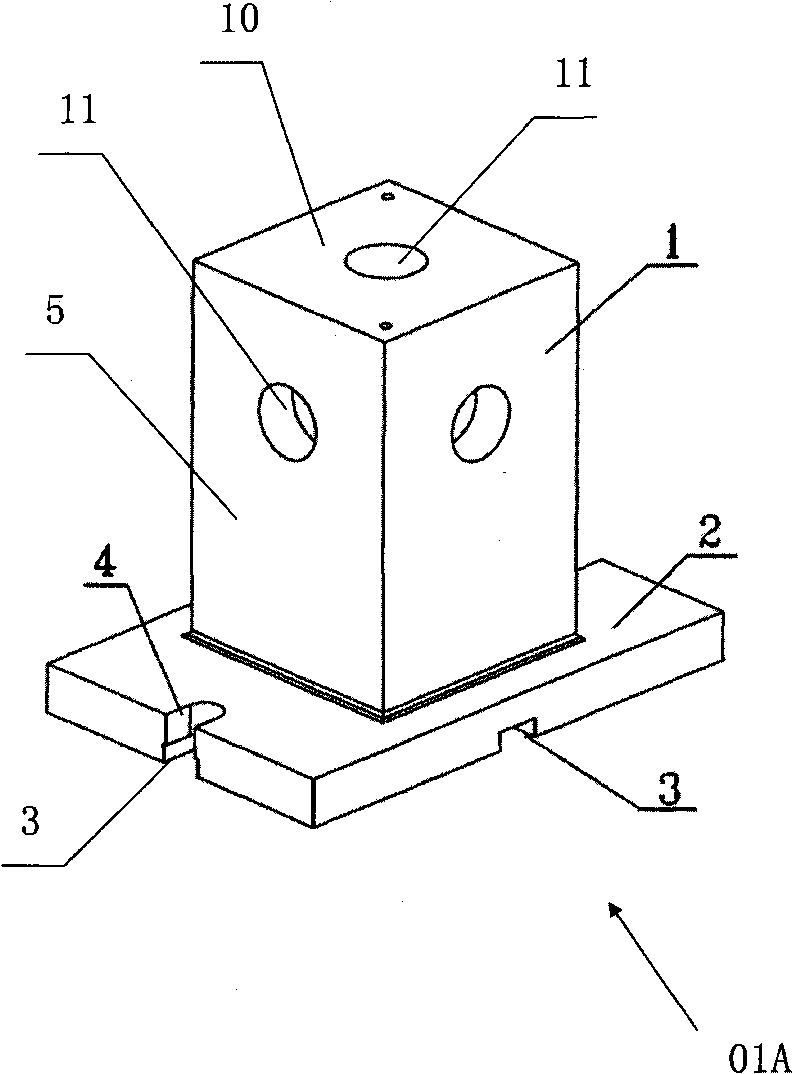

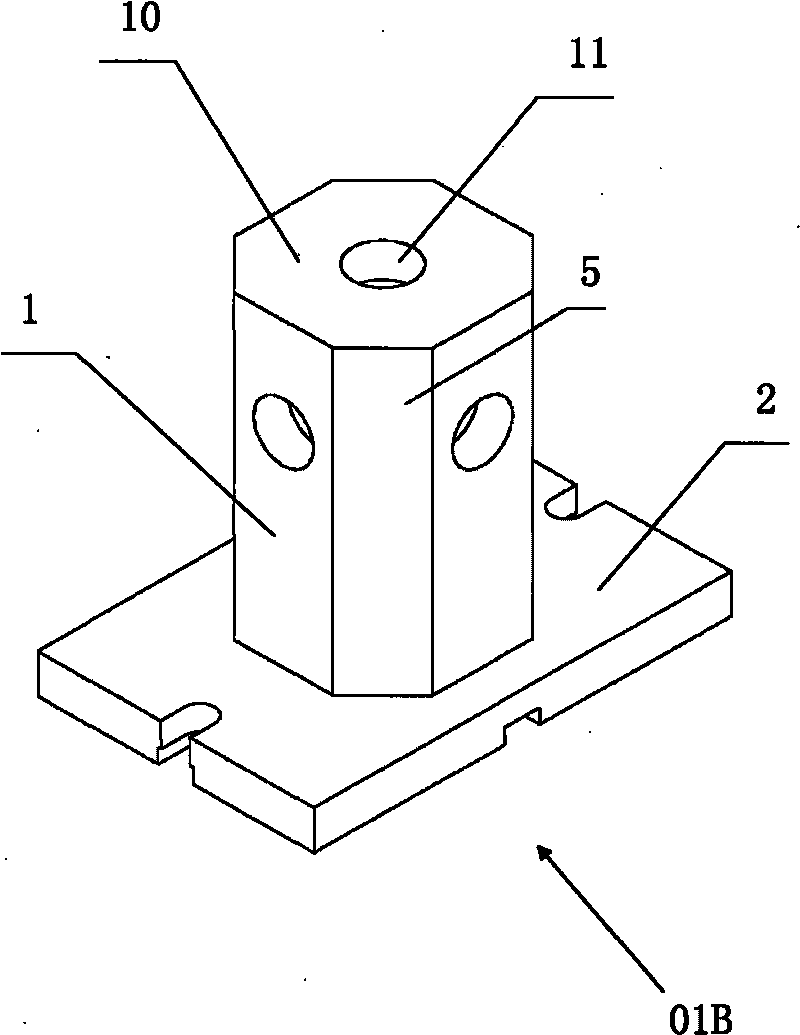

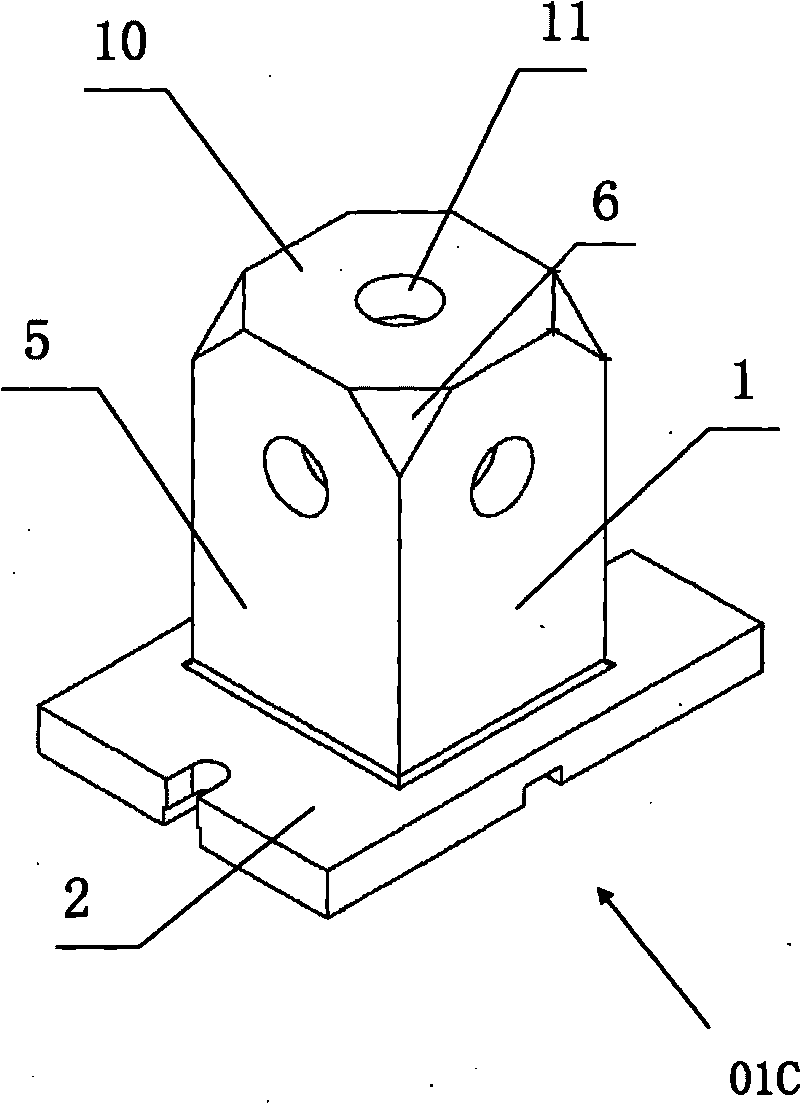

Benchmark integration processing method and multi-directional locating block thereof

ActiveCN101758421AEasy to operateAvoid safety accidentsAutomatic control devicesFeeding apparatusCost (economic)Multi directional

The invention discloses a benchmark integration processing method applied to a large numerical control planomilling machine and a multi-directional locating block thereof. In the invention, the multi-directional locating block provided with a plurality of locating elements, which is fixed on the large numerical control planomilling machine serves as a uniform benchmark of cutter calibration dead-center position in each processing step and the central points of the locating elements on the multi-directional locating block serve as the initial pint and the end point of the numerical control subprogram for controlling each processing step, the multi-directional locating block is composed of a datum body and a foundation, wherein the datum body is provided with a plurality of locating elements which comprise at least one locating plane and at least one locating circular orifice. In the invention, as the uniform benchmark is set, program control in the whole processing course is realized, manual operation is avoided, production efficiency and safety are enhanced, labor intensity and economic costs are lowered, safety and quality incidents are avoided, therefore the invention is especially suitable for processing large workpieces by the numerical control planomilling machine.

Owner:CSSC MES DIESEL

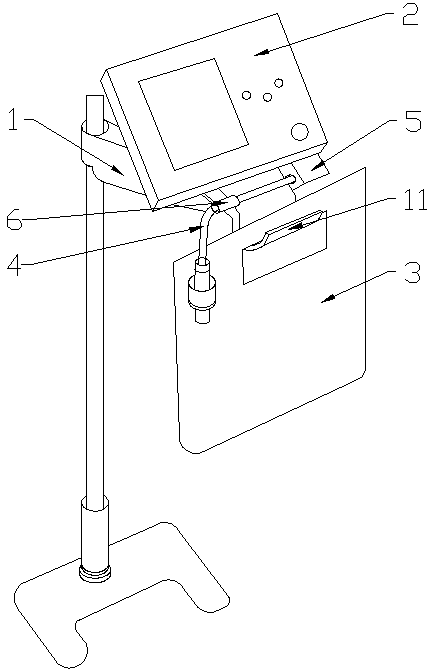

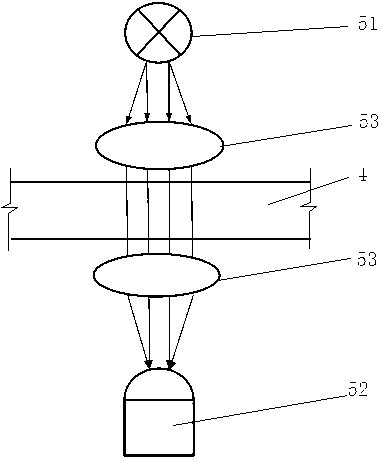

Urine volume monitor

ActiveCN103054559AAvoid influenceConvenience to workDiagnostic recording/measuringSensorsPhotovoltaic detectorsDynamic monitoring

The invention discloses a urine volume monitor. A bracket comprises a hook for hanging a drainage bag; the hook is provided with a weighing sensor which is used for transmitting information after the urine is weighed in the drainage bag to the monitor; the bracket comprises a urine detection box which can be opened or closed and can buckle a conduit in the box; a photodiode and a photoelectric detector are arranged in the urine detection box; and light emitted from the photodiode transmits through the conduit and urine flowing in the conduit in real time, then is collected by the photoelectric detector and is transmitted to the monitor. According to the urine volume monitor, the urine volume is calculated by using a urine refraction proportion analytical method, and a measuring device is not contacted with the urine when the urine is measured, so that the urine measuring accuracy is improved, the antijamming capability is strong; and besides, urine volume data of patients can be displayed or output in real time, and urine volume history information can be reviewed, the requirement of clinicians on the urine volume information dynamic monitoring is met, and the working efficiency is improved.

Owner:KEMAI CHANGZHOU ELECTRONICS

Safe socket with stable power supply

InactiveCN104934780AAchieve insertionAchieve orientationCoupling device detailsMechanical engineeringStator

A safe socket with stable power supply comprises a socket body (9) and a soleplate (90) which can be slidingly installed in a slide groove (19) of the socket body (9) along a left and right direction. The soleplate (90) is provided with an execution motor (91). A rotor of the execution motor (91) is connected to a screw (95) in a power connection mode. The screw (95) is cooperated with a screw hole in a transverse wall component (8) in the socket body (9). A left end wall of the soleplate (90) is fixedly connected to a power supply guide post (74) which slidingly passes through and forms sliding fit with a slide hole arranged in the transverse wall component (8). The power supply guide post (74) is used for jointing a power supply hole (60) in a plug (6) which is inserted into a jack of the socket body (9) so as to provide power. On each power supply guide post (74), a compression spring (71) is arranged between a side surface of the transverse wall component (8), which faces towards the execution motor (91), and a stator of the execution motor.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

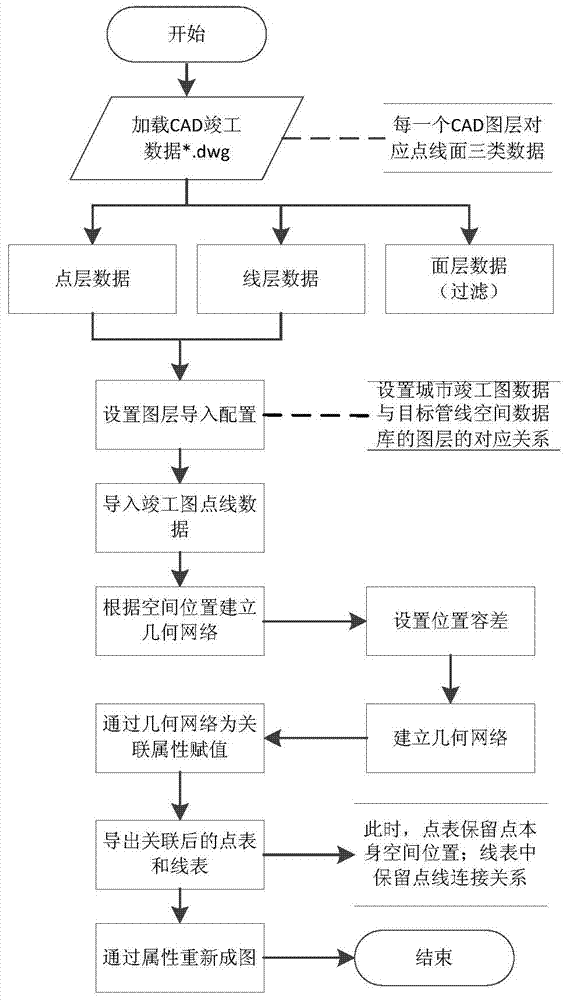

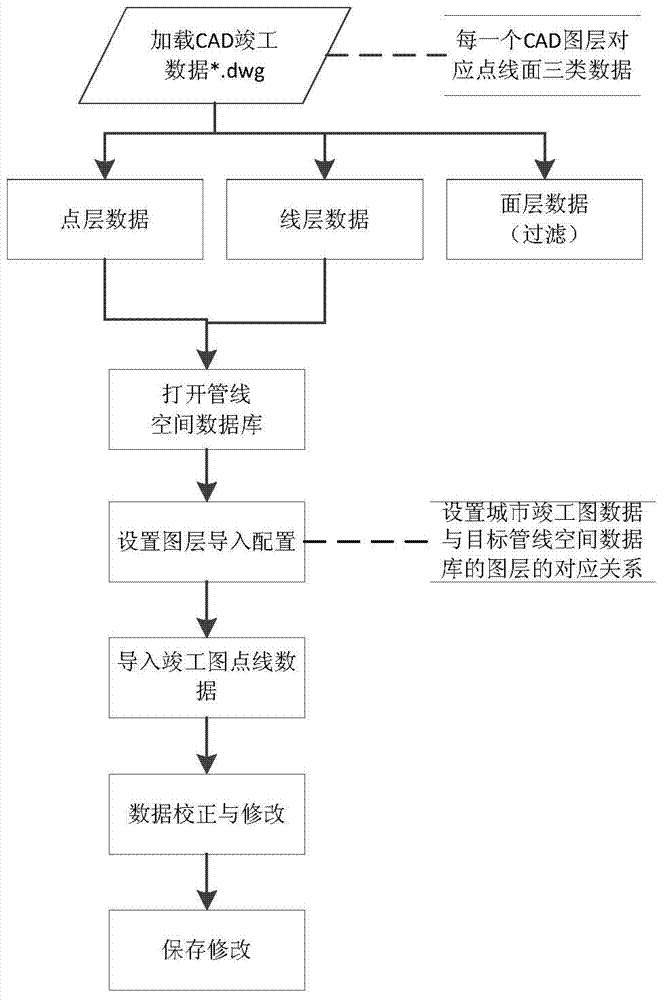

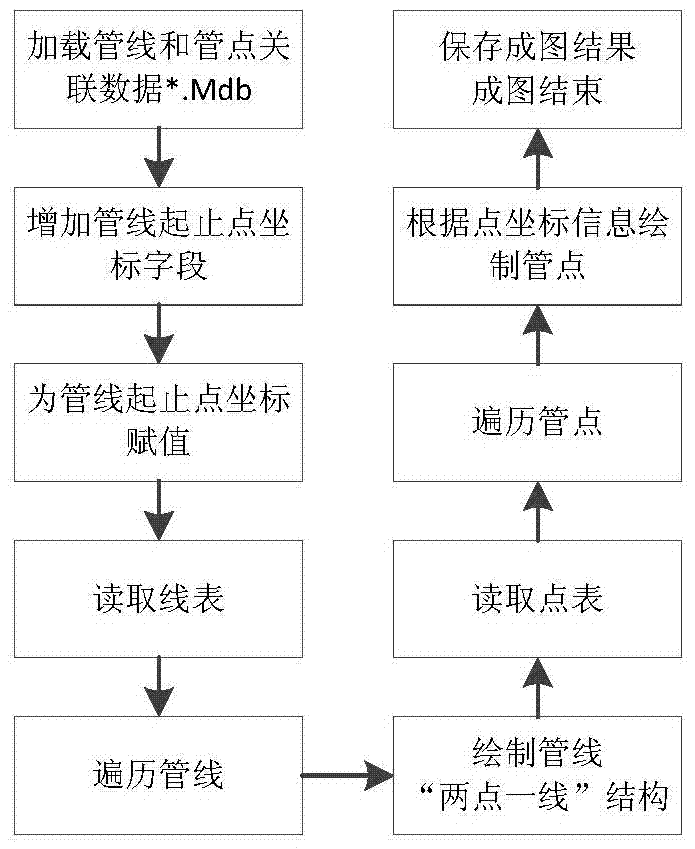

Data processing method and system for CAD urban pipeline as-built drawing based on ArcGIS platform

ActiveCN103927419AAvoid manual operationReduce errorsSpecial data processing applicationsGeometric networksSimulation

The invention discloses a data processing method and system for a CAD urban pipeline as-built drawing based on an ArcGIS platform. The method comprises the following steps of loading data of the CAD urban pipeline as-built drawing; setting layer import configuration, wherein the corresponding relation between the data of the CAD urban pipeline as-built drawing and layers of a target pipeline space database is set; guiding the data of the urban pipeline as-built drawing into the target pipeline space database according to the layer import configuration, building a geometric network through the ArcGIS in the guided target pipeline space database, associating attribute assignments for pipelines and pipe points in the urban pipeline space database through a geometric network development interface provided with an ArcGIS Engine according to the built geometric network, guiding an associated pipeline table and an associated pipe table out, and reforming a drawing by the utilization of the associated attributes of the urban pipelines and the pipe points. By the utilization of the ArcGIS geometric network technology, various problems in the process of processing the data of the urban pipeline as-built drawing are automatically solved, a large amount of manual operation is avoided, and the error rate is reduced.

Owner:TAIHUA WISDOM IND GRP CO LTD

T-shaped tee joint full-automatic orifice expanding machine and tee joint orifice expanding method thereof

InactiveCN102211127AHigh degree of automationEasy to processMetal-working feeding devicesPositioning devicesControl systemEngineering

The invention relates to a T-shaped tee joint full-automatic orifice expanding machine comprising a work table, a feeding part, a pipe expanding part and a control system, wherein the pipe-expanding part comprises a T-shaped tee joint clamp, a main pipe orifice expanding device and a branched pipe orifice expanding device, wherein the main pipe orifice expanding device and the branched pipe orifice expanding device are connected with an orifice expanding rod; an orifice expanding channel through which the orifice expanding rod can pass is arranged on the T-shaped tee joint clamp; the feeding part comprises a vibration disk and a sliding chute, wherein the vibration disk can enable T-shaped tee joints to be sequentially arrayed, and the sliding chute is connected with the vibration disk and the T-shaped tee joint clamp; and a receiving port for receiving the T-shaped tee joints conveyed from the sliding chute is arranged on the T-shaped tee joint clamp. According to the T-shaped tee joint full-automatic orifice expanding machine disclosed by the invention, a pipe to be machined is expanded in orifice in a same mould, and therefore, the automation degree is high and the current machining procedure is simplified; and automatic feeding is realized by adopting the vibration disk, therefore manual operation of placing the T-shaped tee joints on the orifice expanding machine by usinghuman hands is replaced.

Owner:珠海天达制冷设备有限公司

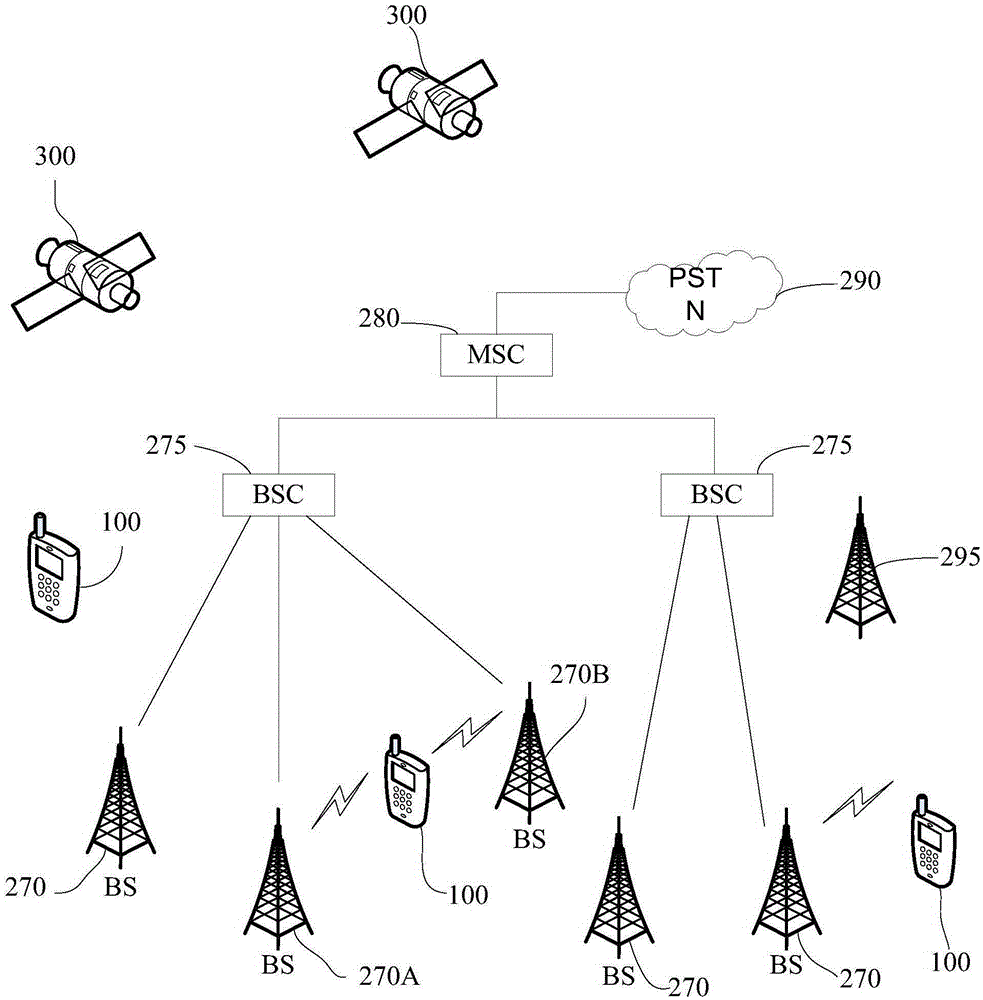

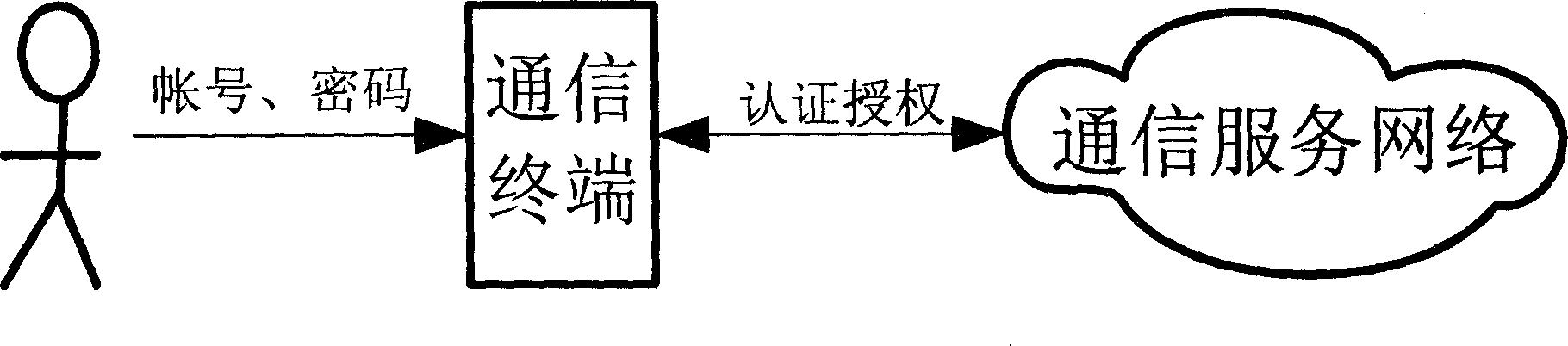

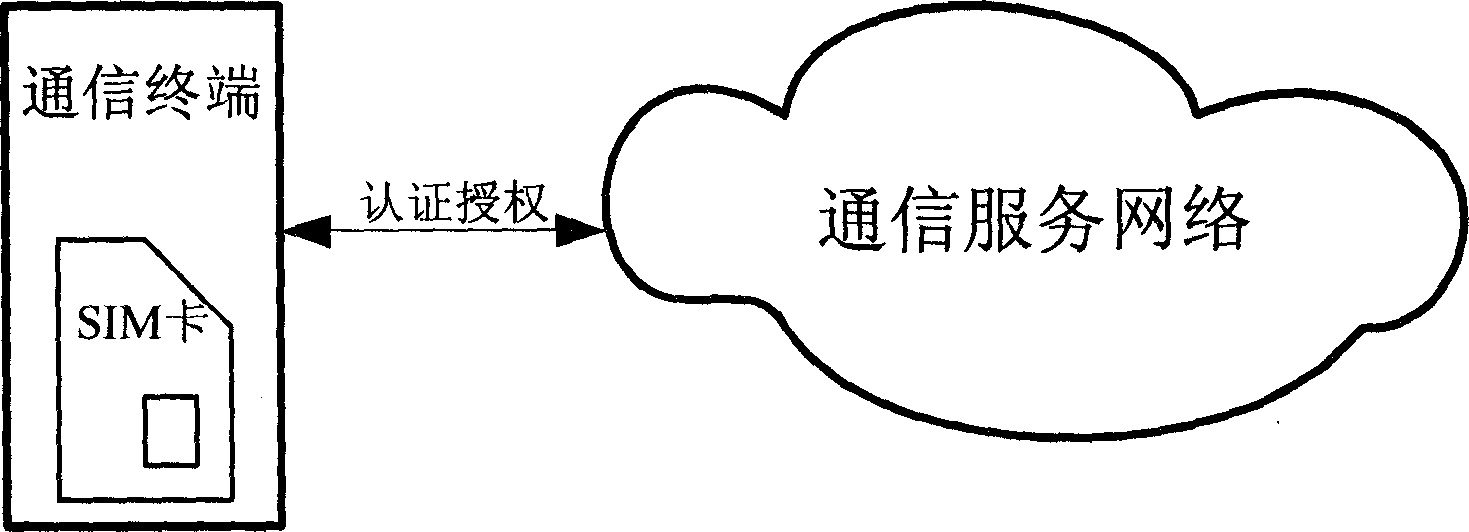

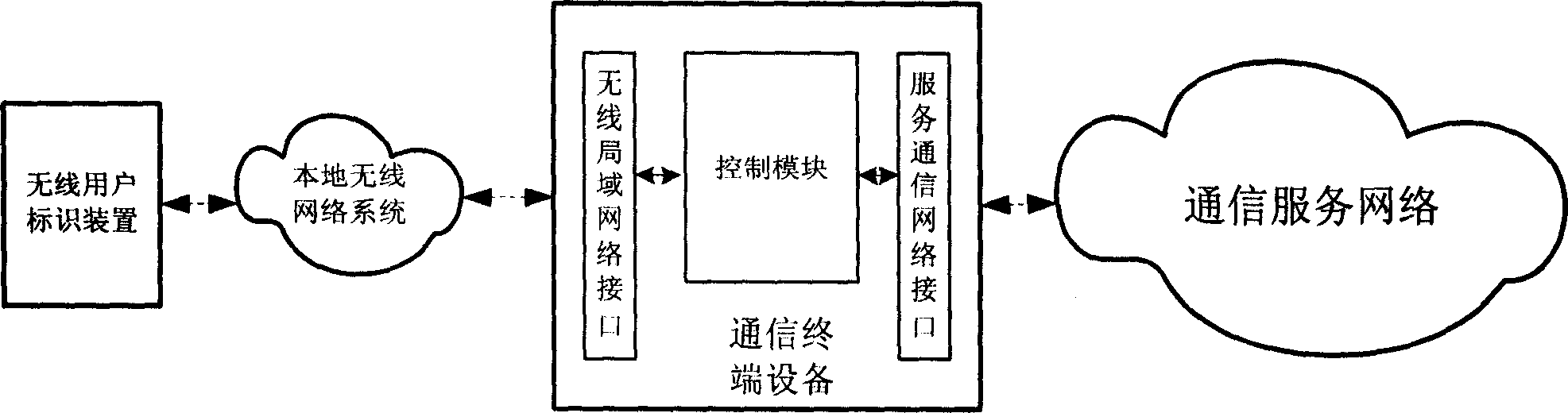

Wireless user identification module, communication terminal equipment and communication control method

InactiveCN1889730AEasy to manageSimple operation and maintenanceRadio/inductive link selection arrangementsSecurity arrangementTerminal equipmentIdentification device

An identification device of radio user consists of user identification module, interface module of radio local network and central processing module; the communication device consists of central processor, the first interface module connected to communication service network and the second interface module connected to radio local network; the communication-controlling method includes obtaining identification information of user status from identification device of radio user by central processor through the second interface module, binding the corresponding user of status identification information to let said user realize communication through communication service network.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com