Safe socket with stable power supply

A safety socket and stable technology, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve problems such as troublesome operation, easy ignition, and impact on operator safety, so as to save space, avoid danger, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

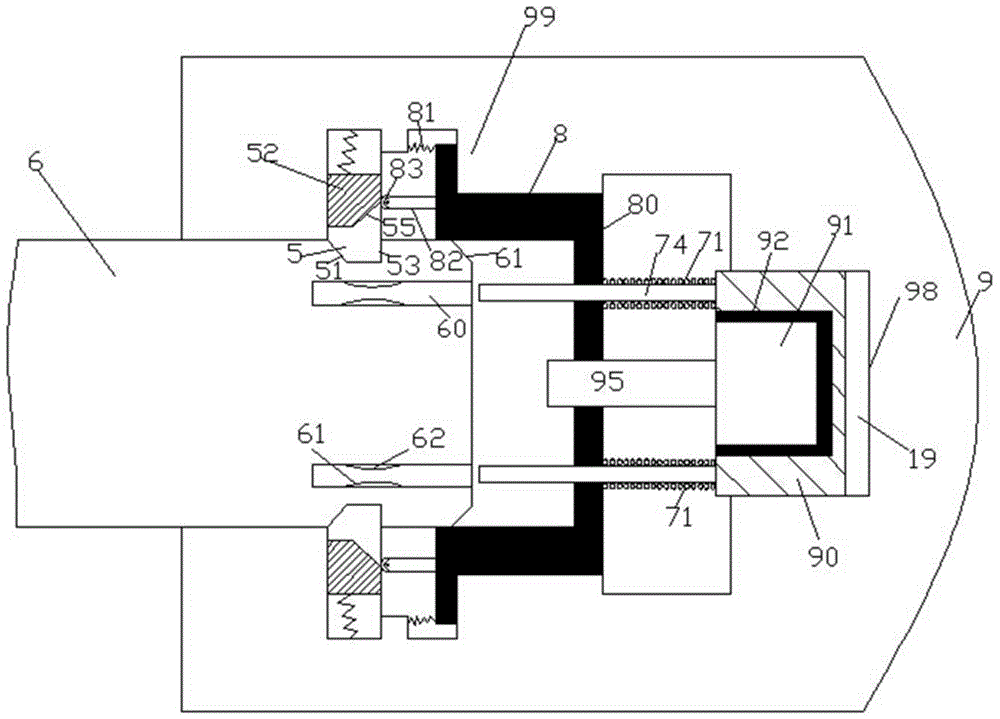

[0008] The present invention will be described in detail below by means of specific examples and in conjunction with the accompanying drawings.

[0009] According to the embodiment, combining figure 1 , a safety socket with stable power supply, including a socket body 9 and a mounting base 90 slidably installed in the sliding groove 19 of the socket body 9 left and right, the mounting base 90 is equipped with an actuator motor 91, and the actuator motor 91 The rotor is power-coupled with the screw rod 95, and the screw rod 95 cooperates with the screw hole in the cross wall part 8 in the socket body 9, and the left end wall of the mounting seat 90 slides through the slide hole provided in the cross wall part 8 The sliding fit power supply guide post 74 is fixedly connected, and the power supply guide post 74 is used to engage with the power supply hole 60 in the plug 6 inserted into the jack of the socket body 9 to supply power, each of the power supply guide posts 74 A compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com