Patents

Literature

184results about How to "Achieve insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

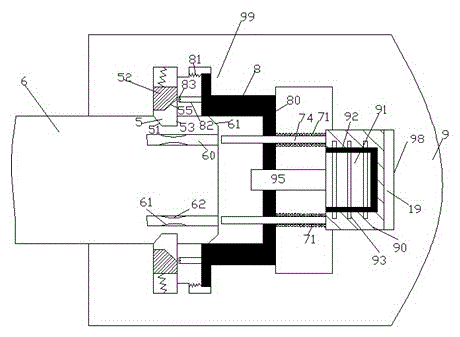

Stable power supply socket

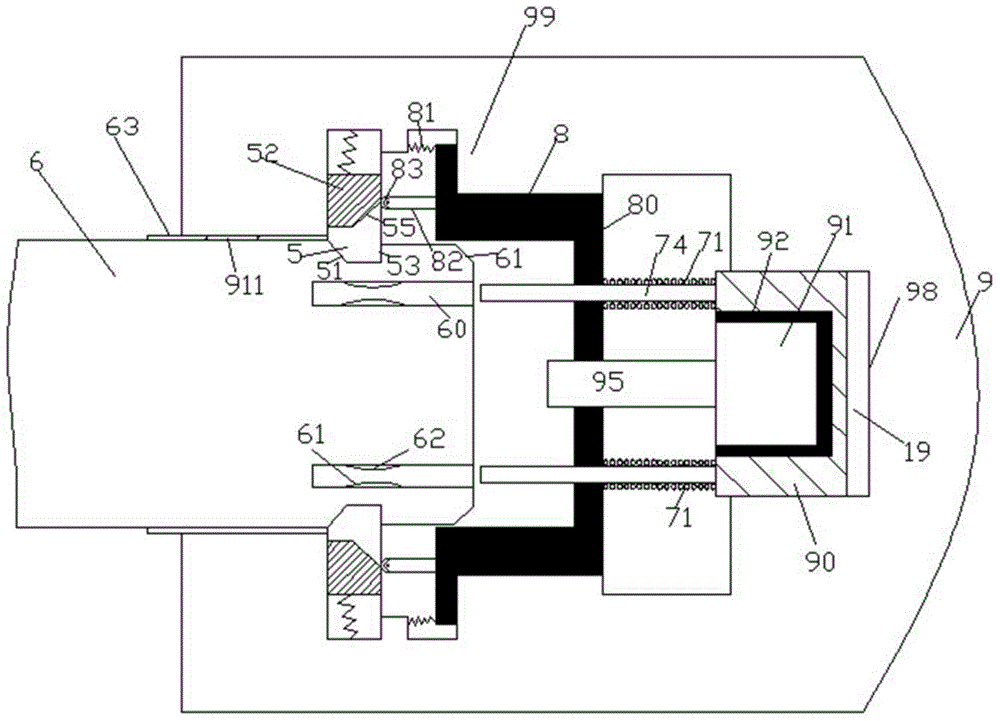

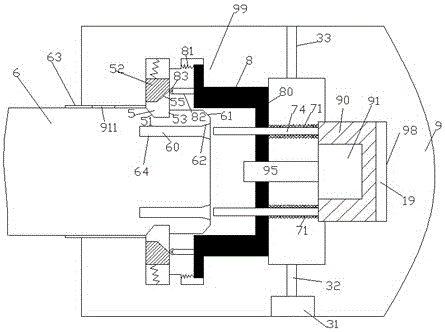

Provided is a stable power supply socket. The stable power supply socket comprises a socket body (9) and an installation base (90) which can be installed in a sliding groove (19) of the socket body (9) in a left and right sliding manner. The installation base (90) is equipped with an execution motor (91). A rotor of the execution motor (91) is in power connection with a screw rod (95). The screw rod (95) cooperates with a screw hole in a cross wall part (8) in the socket body (9). The left end wall of the installation base (90) is fixedly connected with a power supply guide post (74) going through a sliding hole arranged in the cross wall part (8) in a sliding manner in sliding cooperation. The power supply guide posts (74) are used for connection with power supply holes (60) in a plug (6) inserted into jacks of the socket body (9) for power supply. A compression spring (71) is arranged on each power supply guide post (74) and between the side surface, facing to the execution motor (91), of the cross wall part (8) and a stator of the execution motor.

Owner:舒泳军

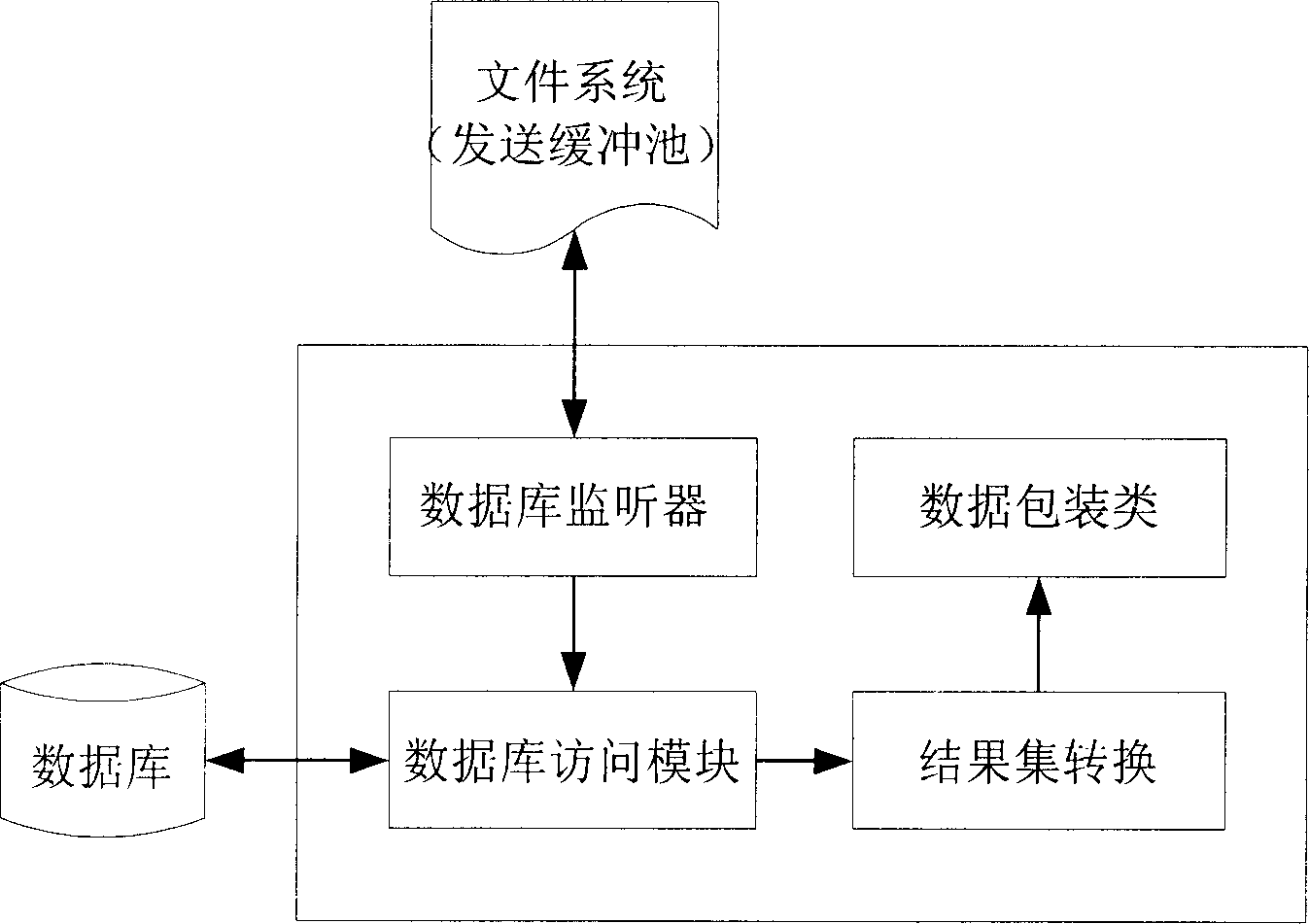

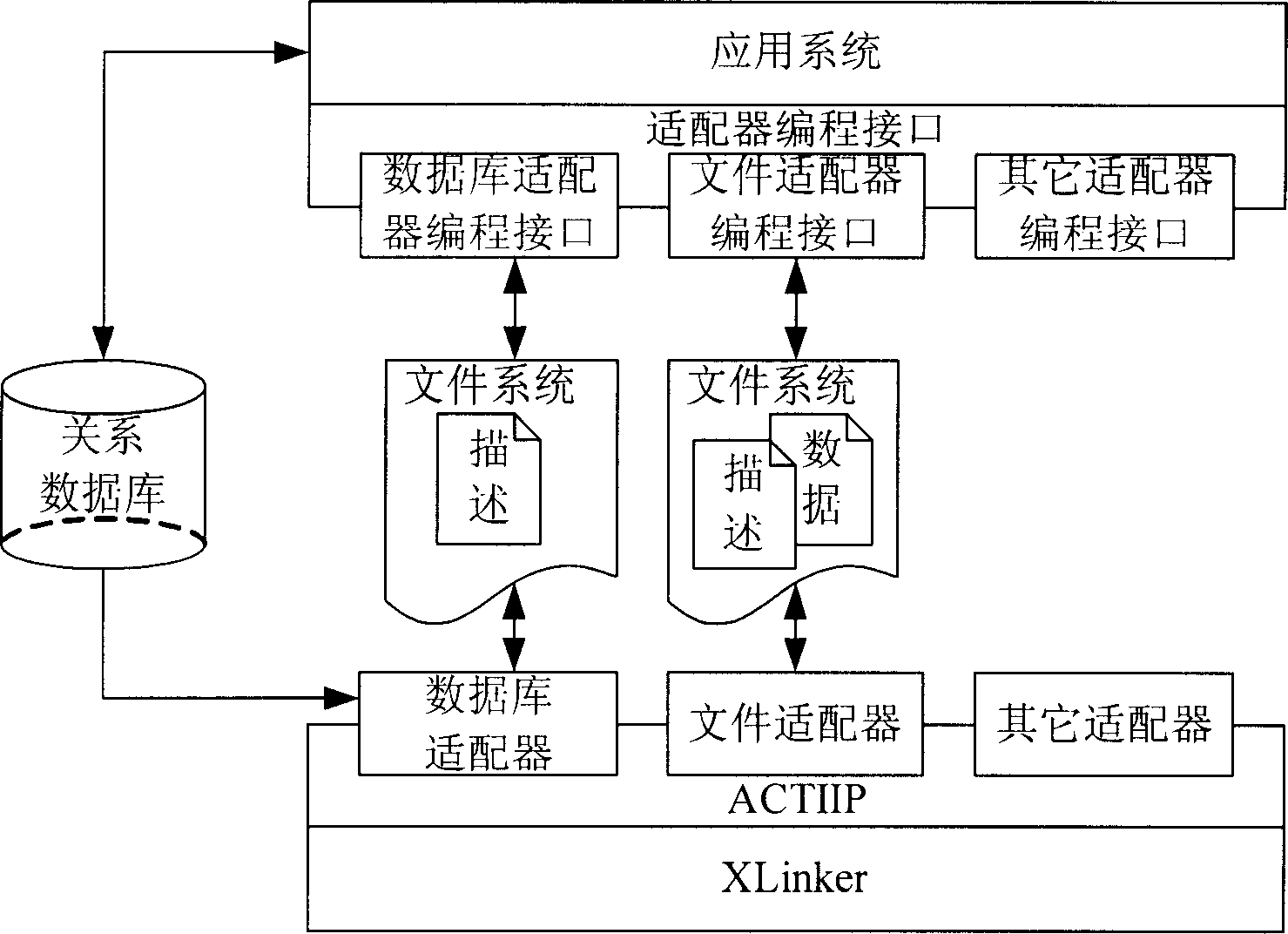

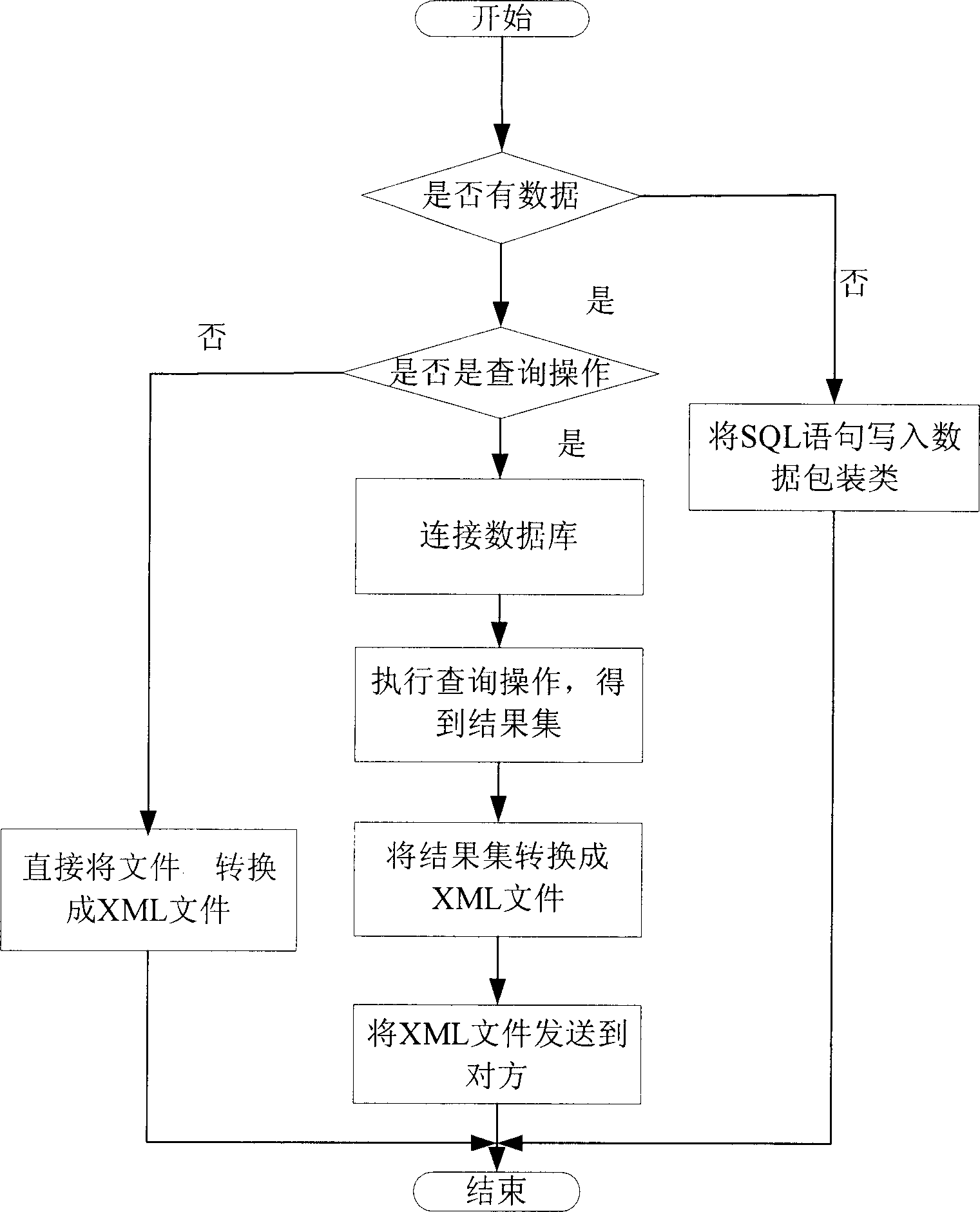

Database adapter

InactiveCN1904885AEliminate differencesImprove compatibilitySpecial data processing applicationsFile systemDatabase access

The invention discloses a new type data base adapter that is made up of database sound monitor, database access module, data packaging module and result collecting module. The sound monitor is used to monitor or poll the files in folder and analysis folder in file system sending buffer pool, and calling the database access module to take read and write operation to database. The result collecting module connects to the database access module and data packaging module. It is used to transform the result collecting and element data of different data base to universal XML format to shield the different of isomer database and transform the XML file to structurization SQL database language. The database access module would operate the database. The data package module is used to buffering application data and record path and size to record data.

Owner:BEIHANG UNIV

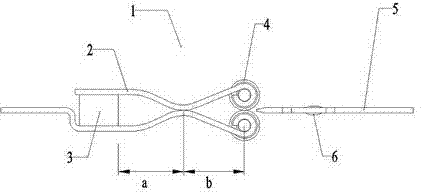

Safety socket with guiding function

InactiveCN104916968AAchieve insertionAchieve orientationCoupling device detailsEngineeringMechanical engineering

Owner:潘燕

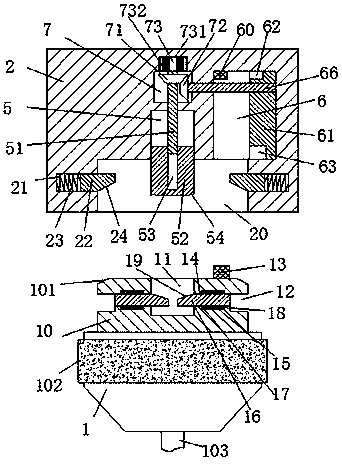

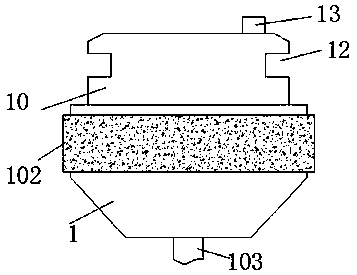

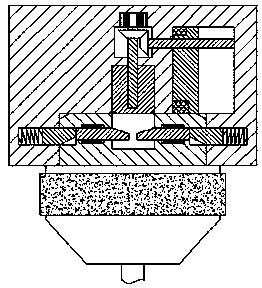

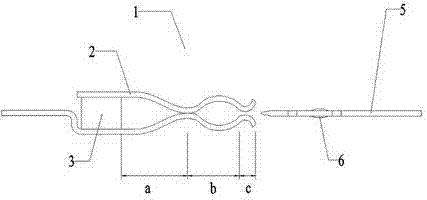

Safe socket with stable power supply

InactiveCN104934780AAchieve insertionAchieve orientationCoupling device detailsMechanical engineeringStator

A safe socket with stable power supply comprises a socket body (9) and a soleplate (90) which can be slidingly installed in a slide groove (19) of the socket body (9) along a left and right direction. The soleplate (90) is provided with an execution motor (91). A rotor of the execution motor (91) is connected to a screw (95) in a power connection mode. The screw (95) is cooperated with a screw hole in a transverse wall component (8) in the socket body (9). A left end wall of the soleplate (90) is fixedly connected to a power supply guide post (74) which slidingly passes through and forms sliding fit with a slide hole arranged in the transverse wall component (8). The power supply guide post (74) is used for jointing a power supply hole (60) in a plug (6) which is inserted into a jack of the socket body (9) so as to provide power. On each power supply guide post (74), a compression spring (71) is arranged between a side surface of the transverse wall component (8), which faces towards the execution motor (91), and a stator of the execution motor.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

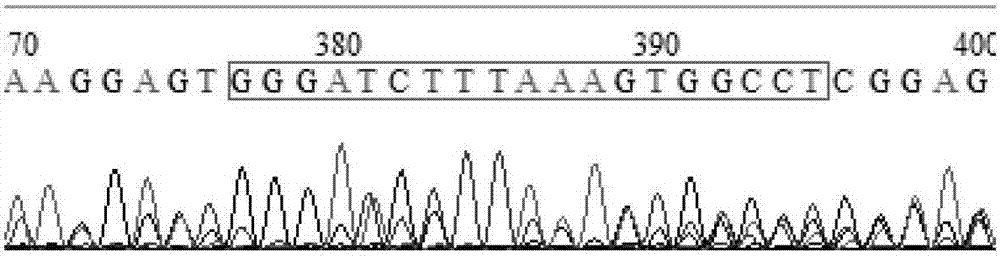

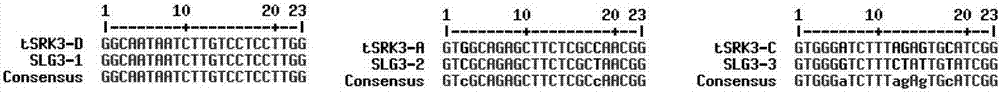

Multi-target sequence sgRNA expression vector based on endogenous tRNA processing system and application of sgRNA expression vector in plant gene editing

InactiveCN107475256ARealize editingAchieve insertionNucleic acid vectorVector-based foreign material introductionMulti siteTRNA processing

The invention provides a tRNA-sgRNA expression sequence. The expression sequence is characterized in that tRNA, type II endonuclease sites and sgRNA are sequentially connected to form a unit sequence, four unit sequences are arranged in series, and the type II endonuclease sites in the four unit sequences which are arranged in series are BbsI, BsaI, BsmBI and BfuAI sequentially. According to the tRNA-sgRNA expression sequence, multiple target sequences can be assembled in a tRNA-sgRNA expression vector step by step, and multi-site gene editing of multiple plants such as tobacco, cabbages and the like can be realized; editing of multiple genes or combined editing of different genes according to targets can be realized by repeatedly inserting tRNA-sgRNA expression sequence units on which different target sequences are assembled in a Cas9 gene expression vector.

Owner:SOUTHWEST UNIVERSITY

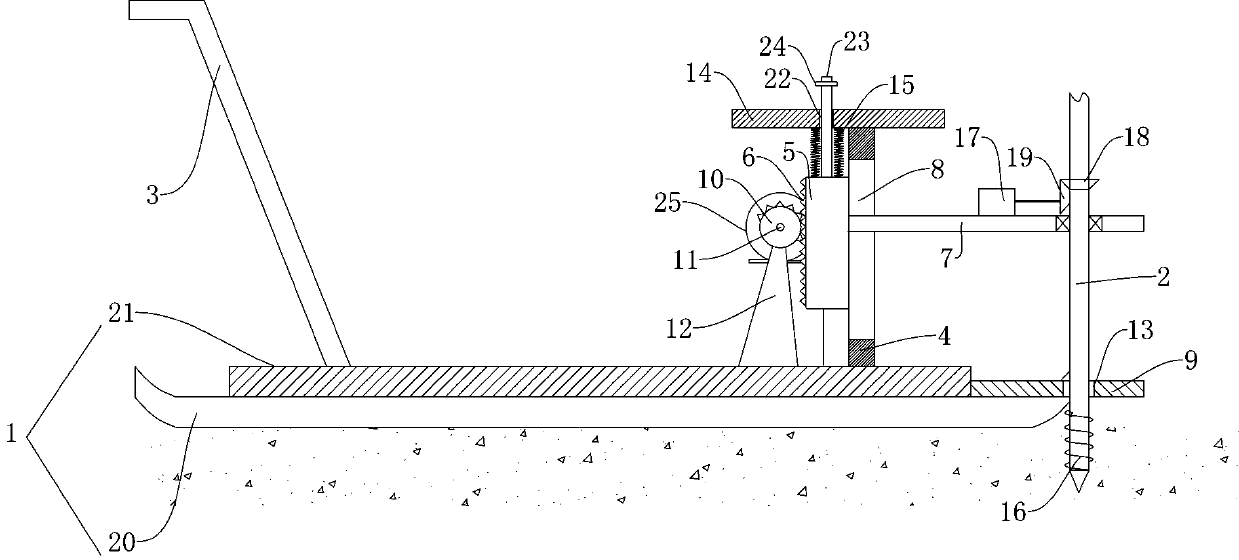

Clamping and cutting type white asparagus harvesting device and method

The invention relates to a clamping and cutting type white asparagus harvesting device and method. The clamping and cutting type white asparagus harvesting device comprises a handle, a shell, a limiting baffle, a clamping mechanism and a cutting mechanism, wherein through the handle, a person can hold the harvesting device to insert the harvesting device into soil or pull the harvesting device out of soil; the limiting baffle is used for limiting the soil insertion depth of the harvesting device; the clamping mechanism is used for clamping stems of white asparagus; the cutting mechanism is used for cutting roots of white asparagus. By adopting a blade for automatic cutting and a clamping plate for automatic clamping, harvesting of white asparagus is achieved; as the clamping plate, the blade and the shell discharge soil simultaneously, automatic soil backfilling is achieved; white asparagus is prevented from being damaged by the adoption of flexible materials. The clamping and cutting type white asparagus harvesting device is convenient to use, low in cost and convenient to maintain.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

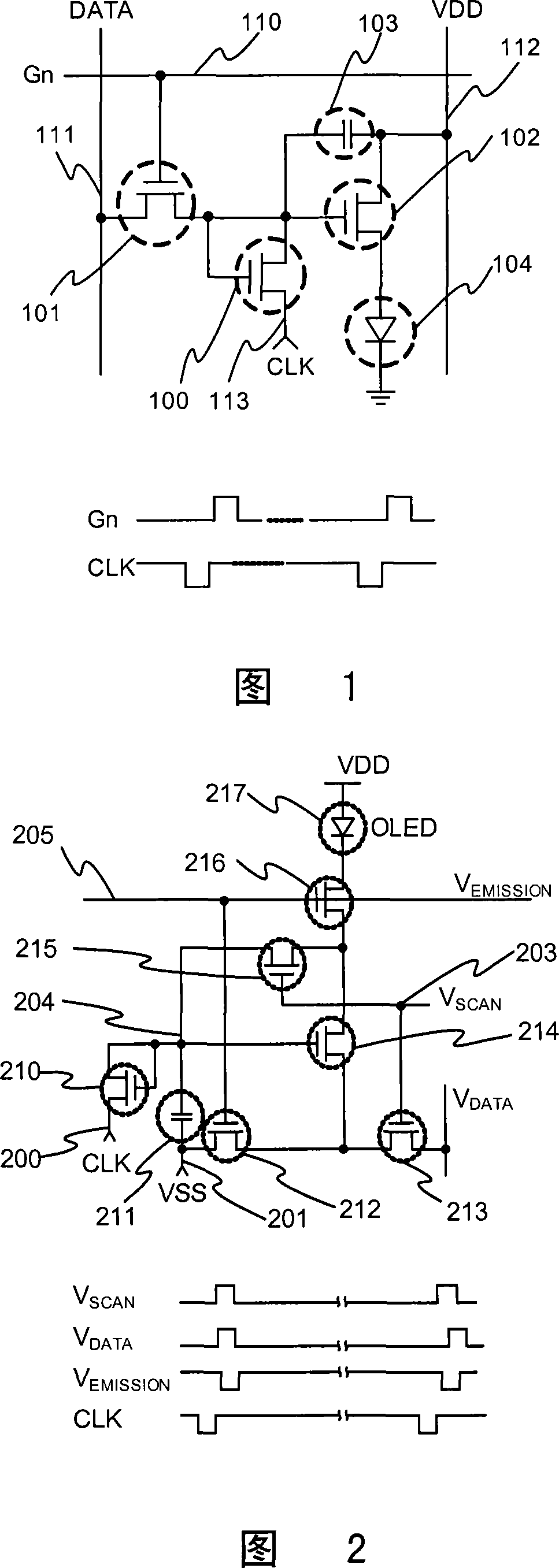

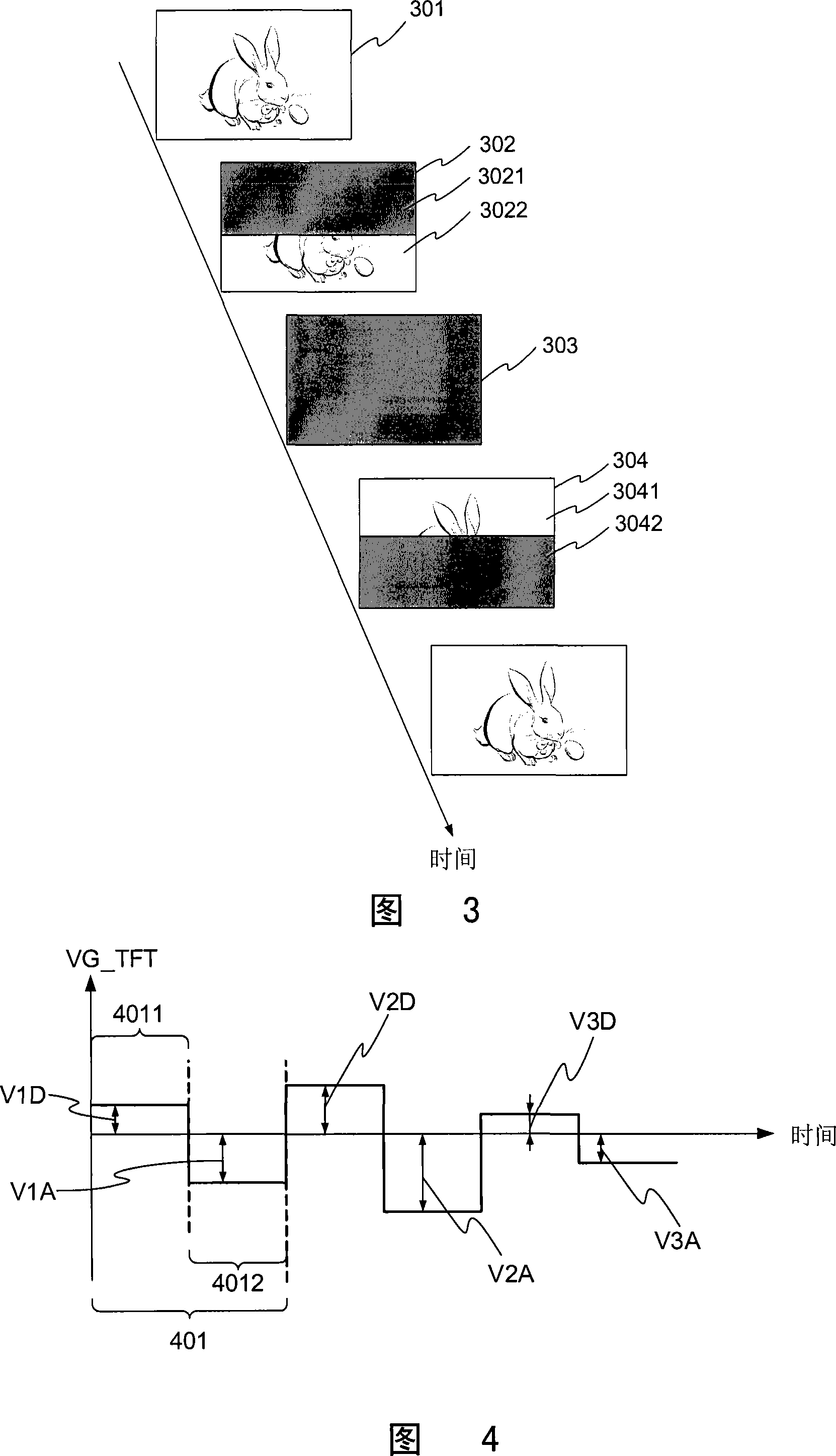

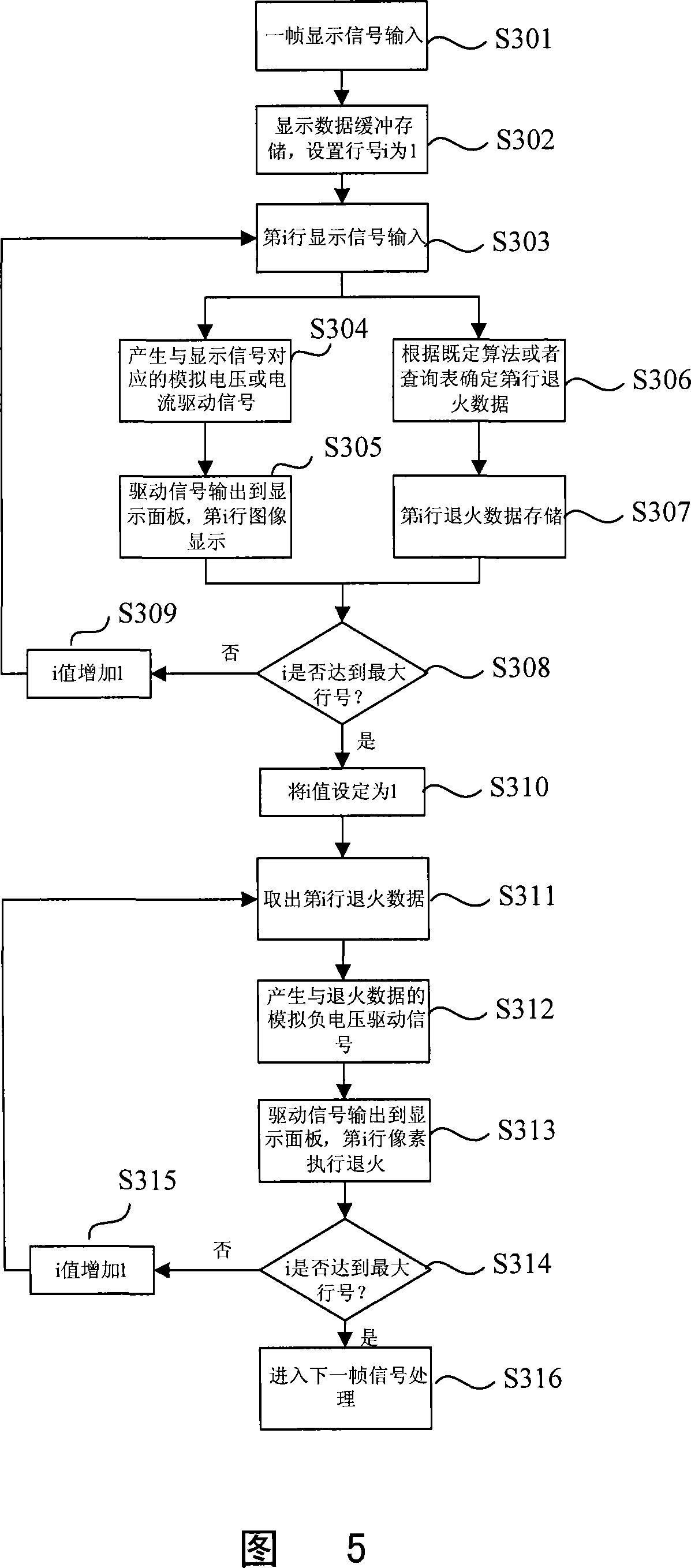

Method for accomplishing negative impulse annealing by data writing, its device and driver circuit

InactiveCN101236724ASuppresses characteristic driftExtend your lifeElectrical apparatusStatic indicating devicesDriver circuitLiquid-crystal display

The present invention discloses a method and a device for realizing negative impulse anneal by data writing, and a driving circuit thereof. The characteristic of a TFT in an active matrix driving OLED display device for driving OLED device is prevented from drifting, the service life of the device is prolonged. The technical proposal is that: within each frame display period, the method of the present invention comprises writing display data line by line for all pixels in a first scan period; writing anneal data line by line for all pixels in a second scan period. Or the method, in each frame display period, comprises writing the first part of the display data or the first part of the anneal data line by line for all pixels in the first scan period; writing the second part of the display data or the second part of the anneal data line by line for all pixels in the second scan period; wherein the display data is written into each pixel in one of the two scan periods of one frame display period, and the anneal data is written in the other scan period. The invention is applied in the liquid crystal display device field.

Owner:上海广电光电子有限公司

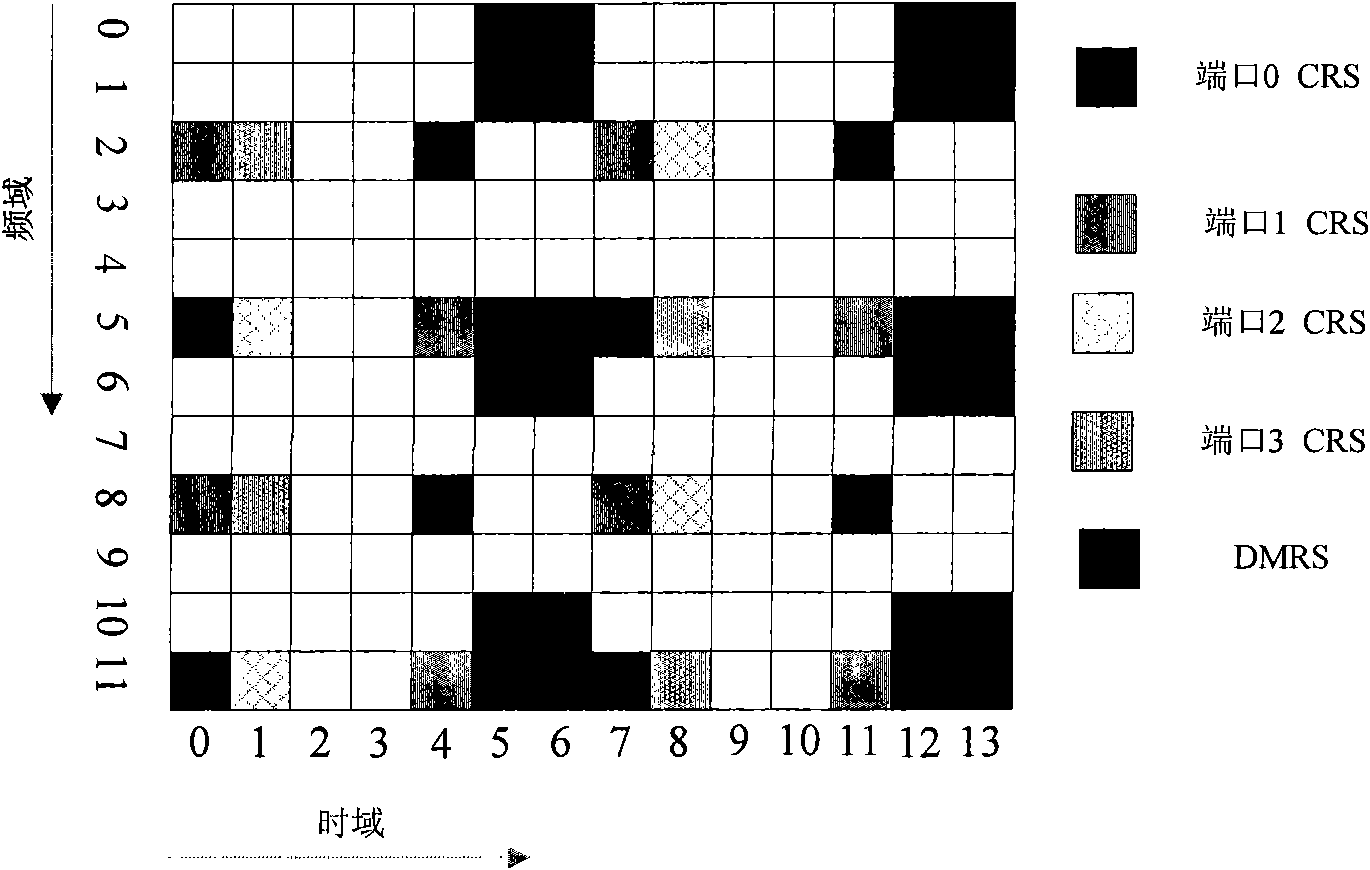

Measurement pilot transmission method and device

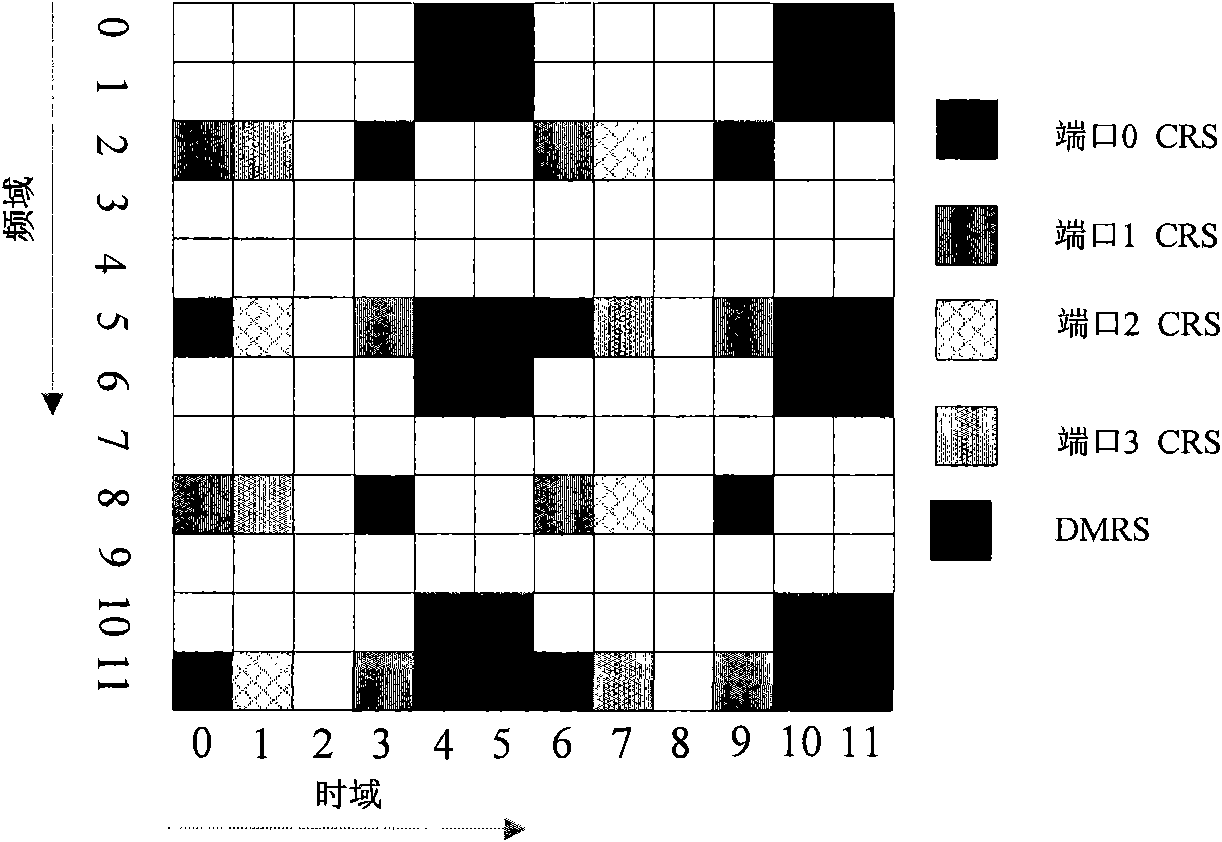

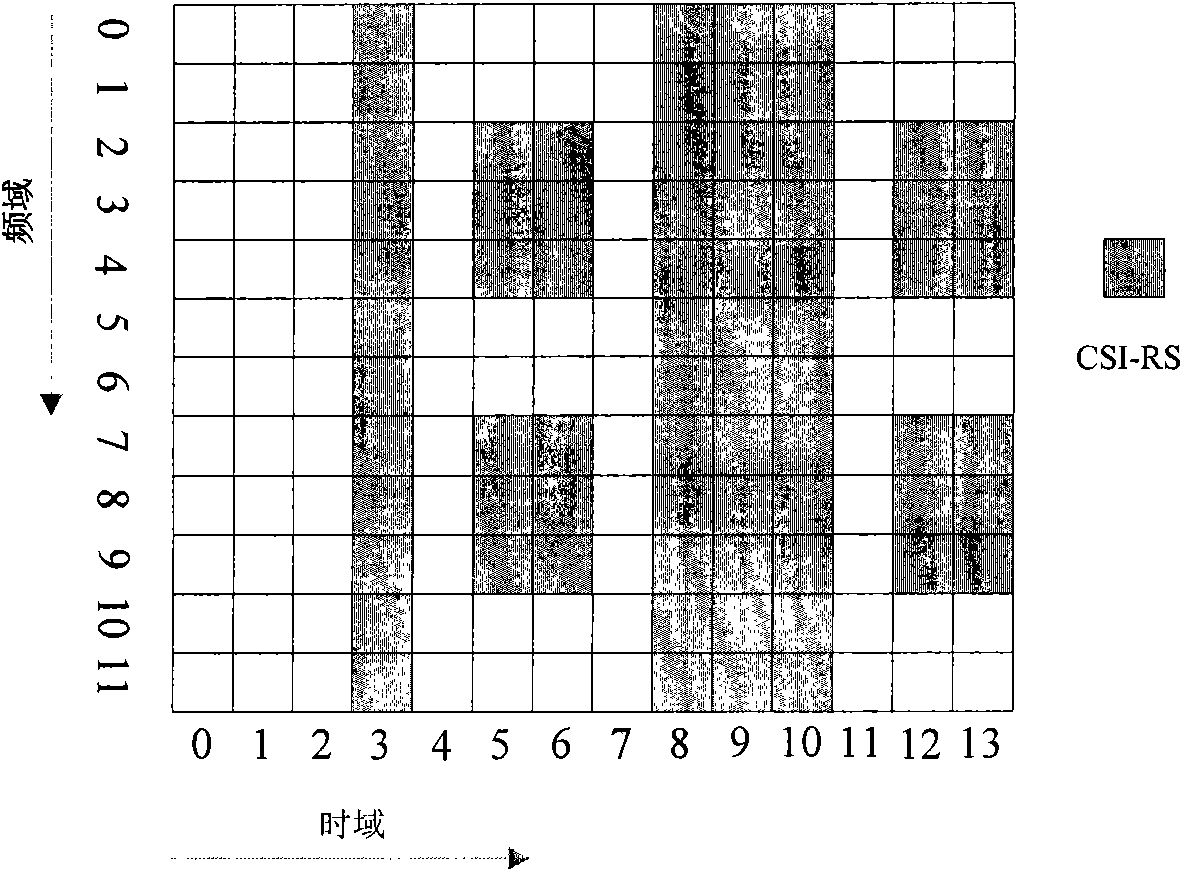

InactiveCN102118867ARealize measurementAchieve insertionMulti-frequency code systemsWireless communicationResource elementComputer science

The invention discloses a measurement pilot transmission method, which realizes the transmission of a measurement pilot. A measurement pilot area comprises more than one resource element pair (REP), each REP comprises two resource elements (RE), and the each REP corresponds to an REP identifier. The transmission method comprises the following steps of: acquiring the REP identifier allocated to each antenna port of a cell by a base station side by using cell configuration information according to a set rule; and transmitting the measurement pilot of the each antenna port of the cell on the RE corresponding to the REP identifier. In the scheme of the invention, the REs for the transmission of a channel status information reference signal (CSI-RS) are divided into the REPs, and the REP identifiers allocated to the antenna ports of the cell are acquired by utilizing the known cell configuration information of the base station side and a terminal side according to the set rule, so that the mapping of the multi-cell measurement pilot is realized, the insertion of the measurement pilot of long term evolution-advanced (LTE-A) and the measurement of a channel are further realized, and good measurement performance is obtained.

Owner:CHINA ACAD OF TELECOMM TECH

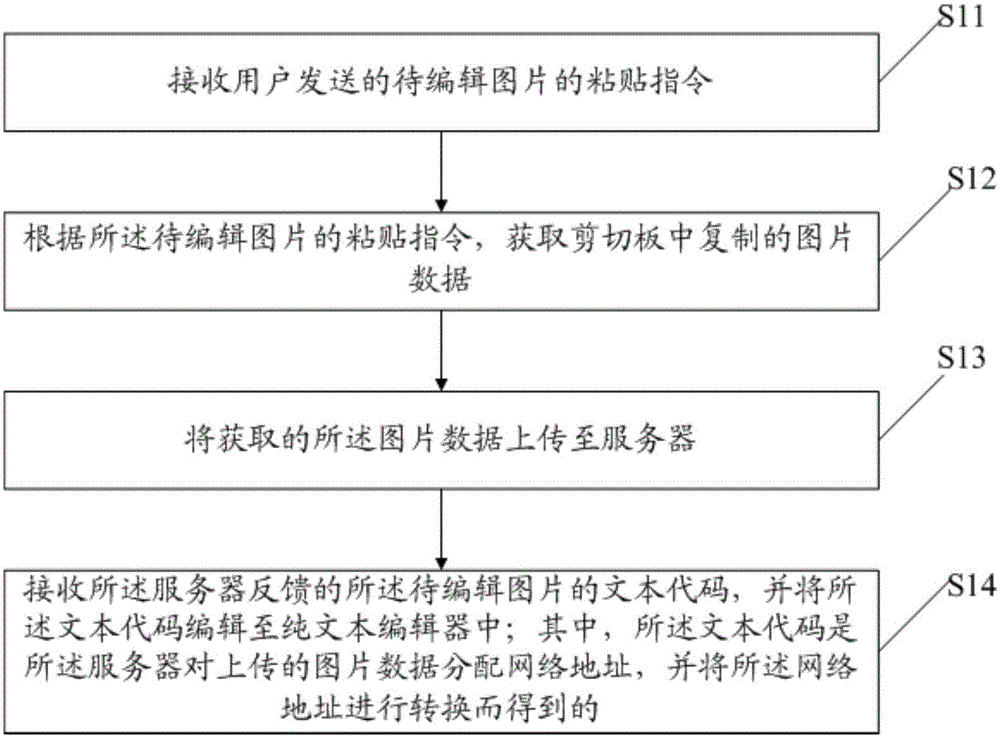

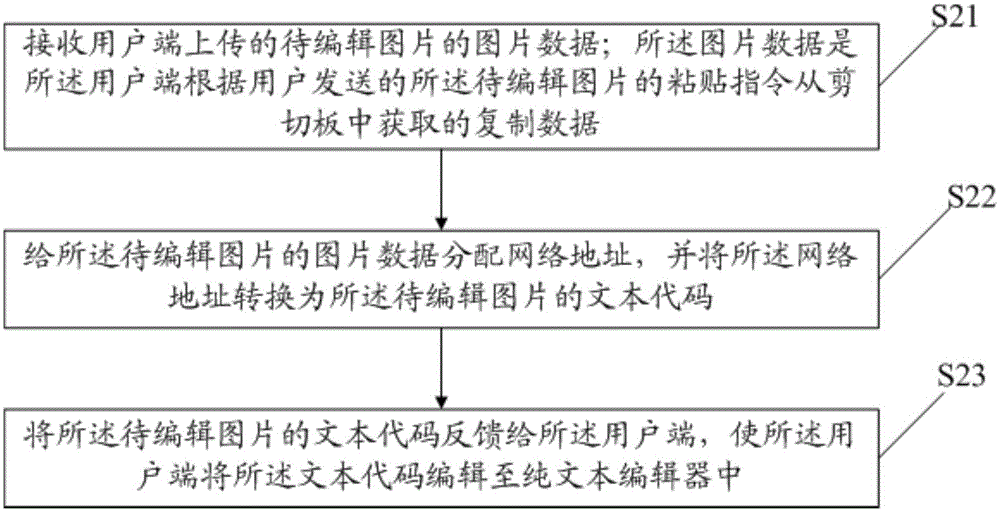

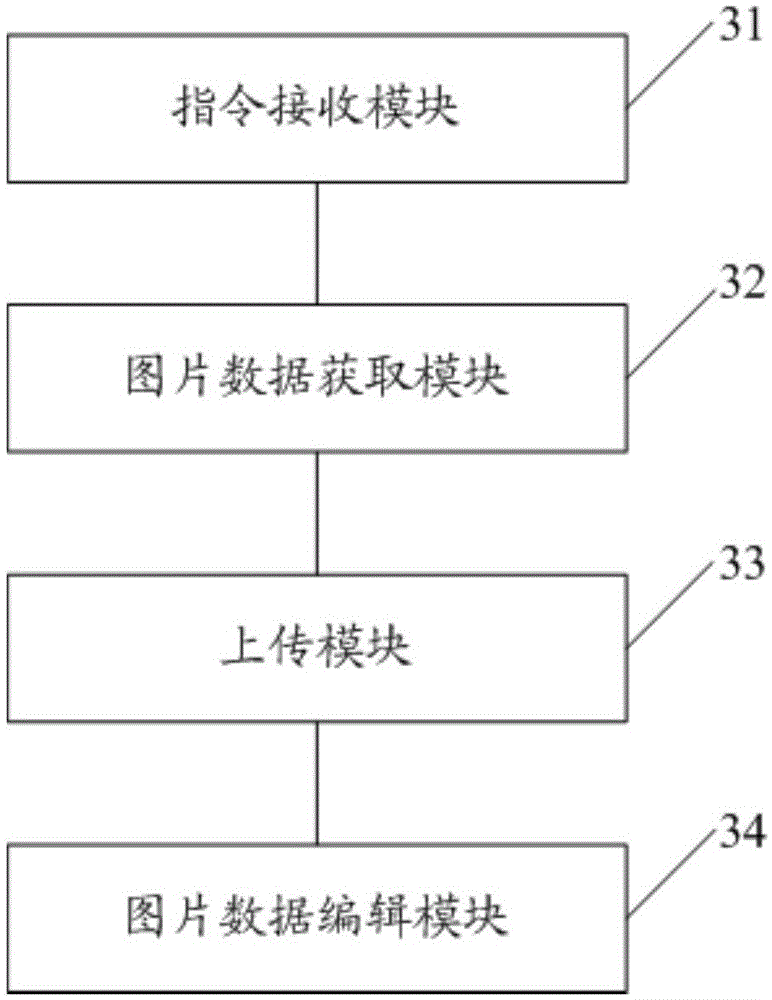

Data editing method and device

InactiveCN105138503AImprove editing efficiencyAchieve insertionSpecial data processing applicationsNetwork addressingNetwork address

The invention discloses a data editing method and device. The data editing method includes the steps that a pasting instruction, sent by a user, of a picture to be edited is received; picture data copied in a clipboard are acquired according to the pasting instruction of the picture to be edited; the acquired picture data are uploaded to a server; a text code, fed back by the server, of the picture to be edited is received and edited into a plain text editor, wherein the text code is obtained in the mode that the server distributes a network address to the uploaded picture data and then switches the network address. By adopting the embodiment of the data editing method and device, data editing efficiency can be effectively improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Stable server device

InactiveCN108232994AIncrease insertion efficiencyLock firmlyCoupling device detailsComputer periphery connectorsEngineeringElectric shock

The invention discloses a stable server device. The stable server device comprises a socket formed in a wall and a plug connected with the socket in a matching manner, wherein a socket slot is formedin the middle part of the bottom surface of the socket; a first forward driving slot is formed in the middle part of the top wall of the socket slot; a second forward driving slot is formed in the right side of the top wall of the socket slot; a third forward driving slot is formed in the socket and positioned above the first forward driving slot and on the left side of the second forward drivingslot. The plug in the data server device is firmly locked, the plug is also powered on while the plug is locked during insertion, and the plug is unlocked while the plug is powered off during extraction, so that the efficiencies of plug insertion and plug extraction are greatly improved, the plug is conveniently extracted and replaced after the plug is damaged, an electric shock accident during insertion and extraction of the plug is effectively avoided, and the life safety of people is guaranteed; in addition, the insertion and the extraction of the plug can be achieved through a motor.

Owner:郭丹枫

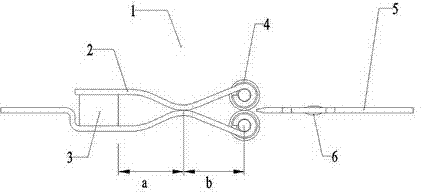

Novel power supply safety socket

InactiveCN105098524AAchieve insertionAchieve orientationCoupling device detailsEngineeringMechanical engineering

A novel power supply safety socket comprises a socket body and an installation seat (90), wherein the installation seat (90) can be arranged in a sliding groove (19) of the socket body (9) in a left-right sliding way and is provided with an execution motor (91), a rotor of the execution motor (91) is in power linkage with a screw rod (95), the screw rod (95) is matched with a screw hold in a cross wall part (8) in the socket body (9), a left end wall of the installation seat (90) is fixedly connected with power supply guide columns (74) which penetrate through and are matched with a sliding hole arranged in a cross wall part (8) in a sliding way, the power supply guide columns (74) are used for connecting with power supply holes in a plug (6) inserted into a jack of the socket body (9) for supplying power, and on each power supply guide column (74), a compression spring (71) is arranged between the side surface, facing the execution motor (91), of the cross wall part (8) and a stator of the execution motor.

Owner:诸暨市柯晶机械技术开发有限公司

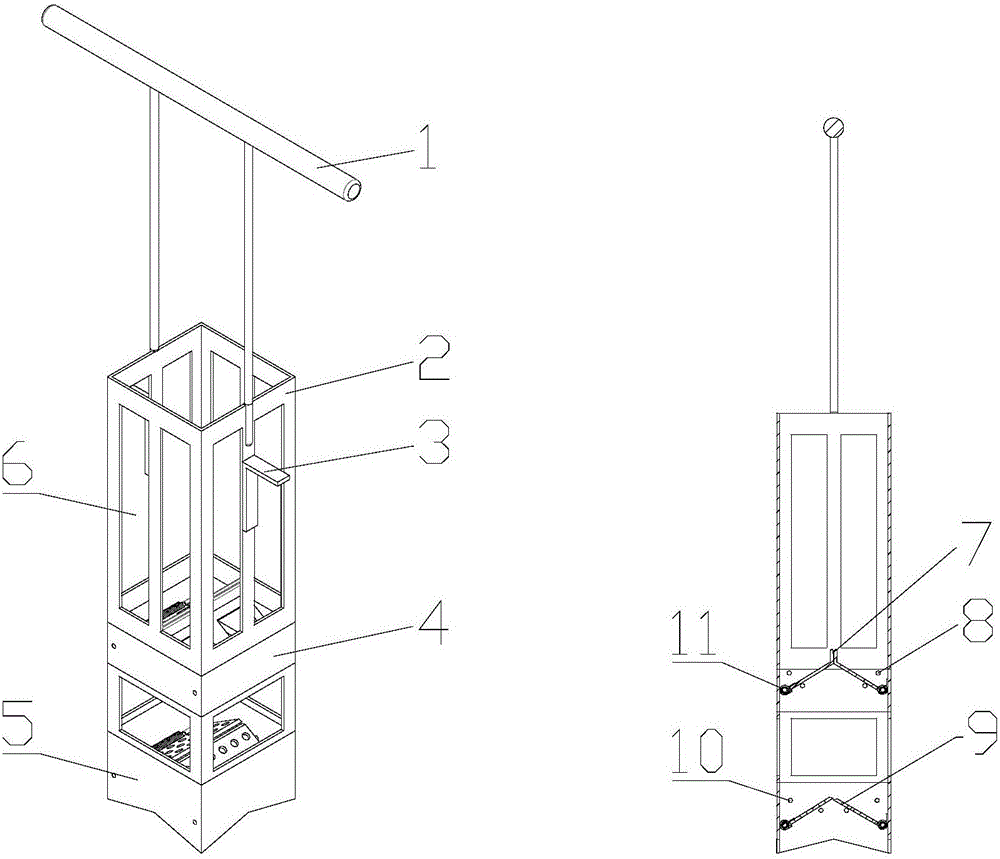

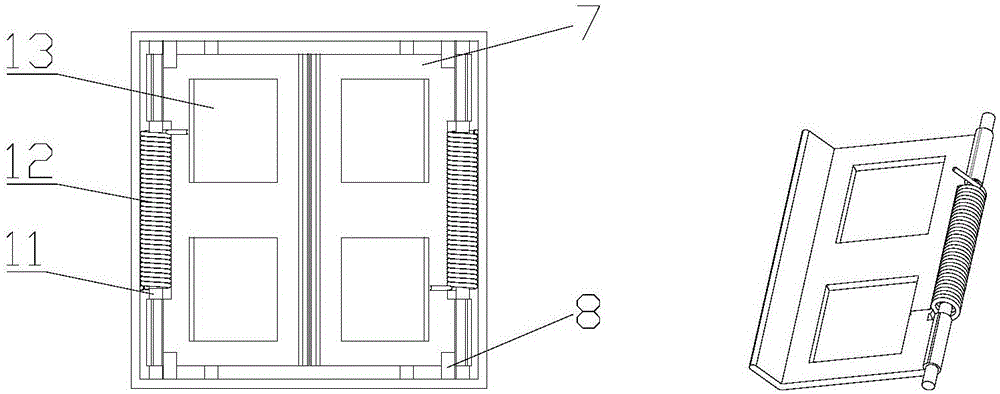

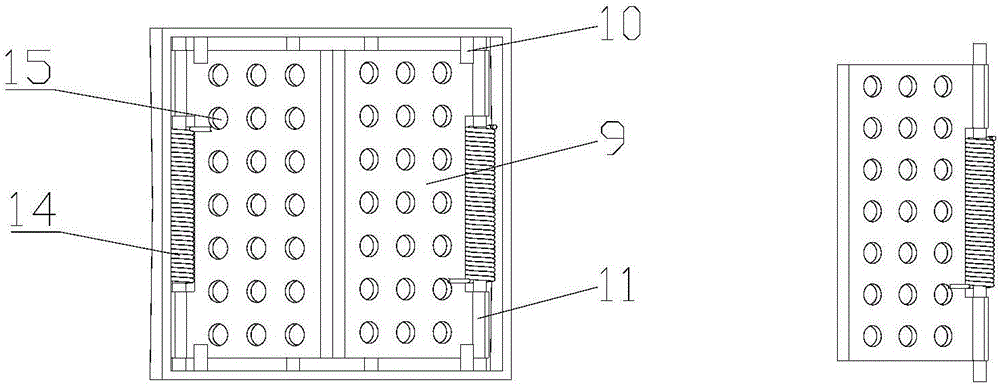

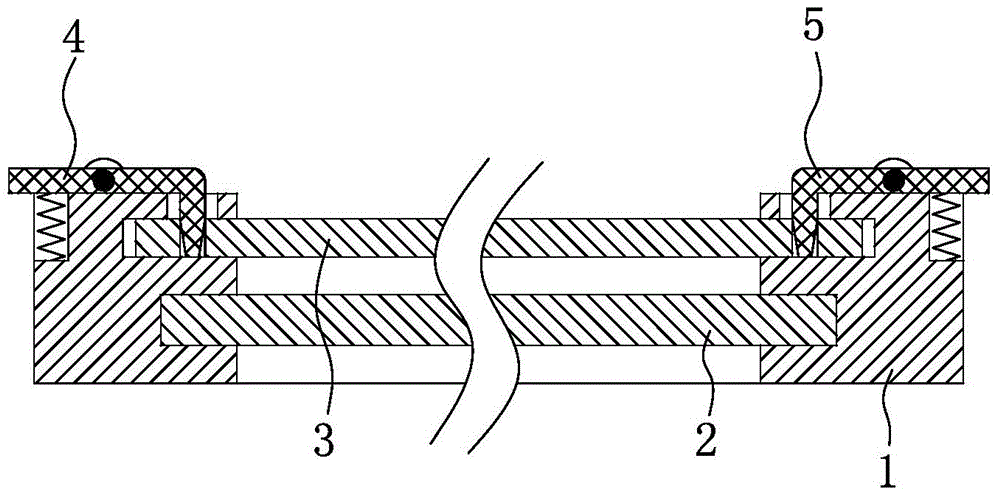

Solar energy collection device facilitating disassembling and washing

ActiveCN104579139AEasy to assemble and disassembleEasy to disassemble and washPhotovoltaicsPhotovoltaic energy generationEngineeringSolar cell

The invention relates to a solar energy collection device facilitating disassembling and washing, and belongs to the field of solar energy collection devices. A protective cover is convenient to disassemble and assemble. The solar energy collection device facilitating disassembling and washing comprises a frame and a solar cell panel arranged inside the frame. A dust cover covers the frame. A first limiting groove and a second limiting groove with the opening opposite to the opening of the first limiting groove are formed in the length direction of the frame. One end of the dust cover slides along the first limiting groove, and the other end of the dust cover slides along the second limiting groove. A first locking assembly and a second locking assembly are arranged at the lower end of the frame. The first locking assembly comprises a first locking rod, a first rotating shaft and a first elastic piece. The second locking assembly comprises a second locking rod, a second rotating shaft and a second elastic piece so that the top end of the second locking rod can be inserted into the second limiting groove and fix the other end of the dust cover.

Owner:浙江宏阳新能源科技股份有限公司

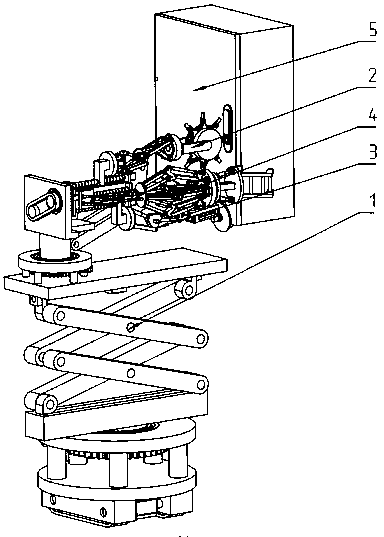

Power distribution cabinet inspection robot

InactiveCN109927045AAchieve insertionEnough degrees of freedomManipulatorSwitchgearTransmission beltEngineering

The invention provides a power distribution cabinet inspection robot. The robot comprises a machine body part, an unlocking part, a turning part and a door opening part, wherein the machine body partcomprises a rotary base, a rotating base, a first stepping motor, a second stepping motor, a third stepping motor, a T-shaped block, a first mounting plate, a first screw rod, a second screw rod, a third screw rod, a camera, a camera shooting rod, double triangular plates, a first electric actuator, camera shooting double rods, a fourth stepping motor, a main transmission belt, a first gear, a fifth stepping motor, a second gear and a rotating support, when the power distribution cabinet inspection robot is used, the machine body part moves to the vicinity of a power distribution cabinet needing inspection, the unlocking part is used for turning a lock of the power distribution cabinet, then a lock body ejects a turning block, the turning part is used for rotating the turning block by 90 degrees, at the moment, a cabinet door pops open, then the door opening part is used for opening the cabinet door, and the machine body part is used for carrying out scanning inspection on the interiorof the power distribution cabinet.

Owner:徐秀荣

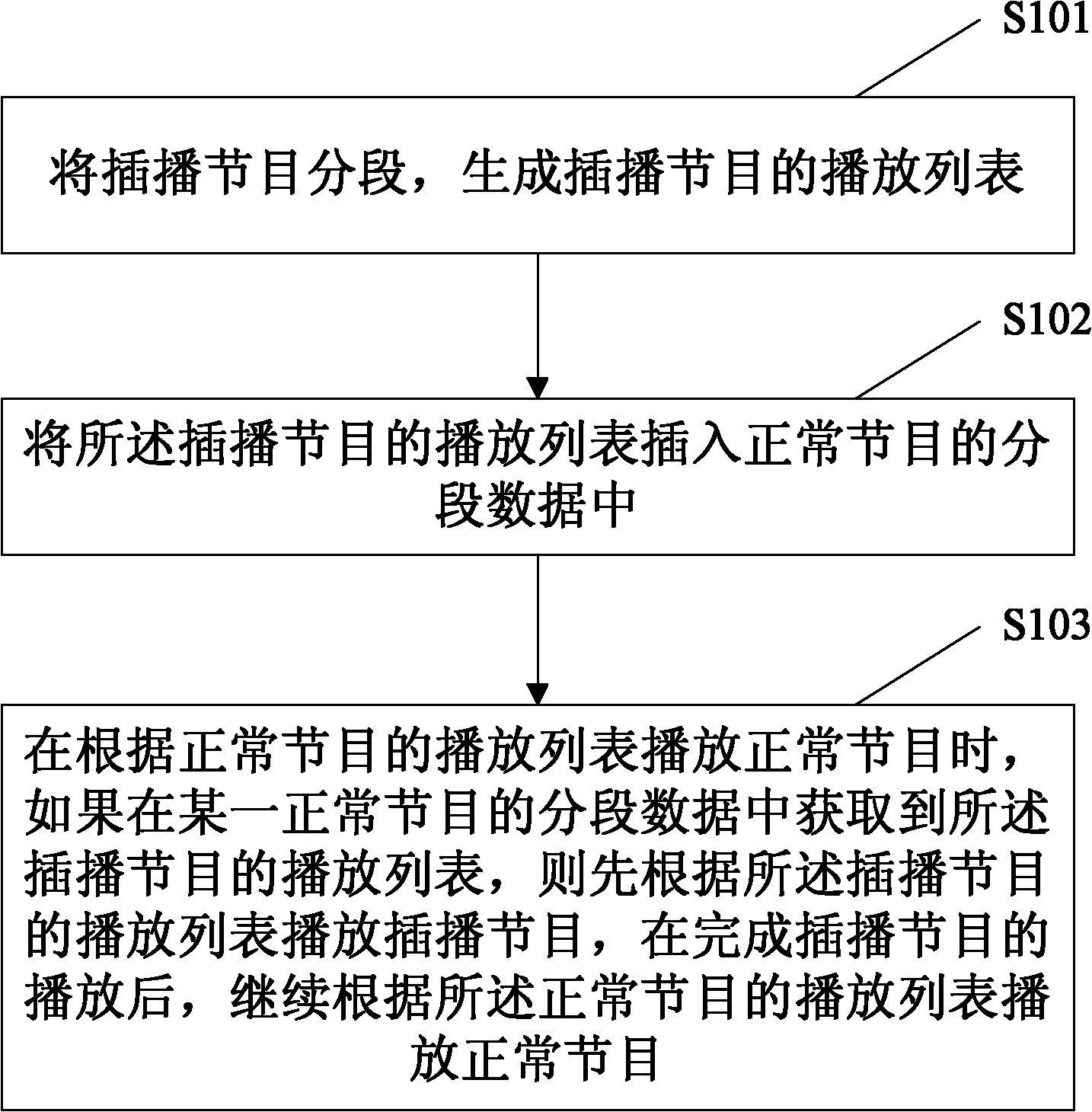

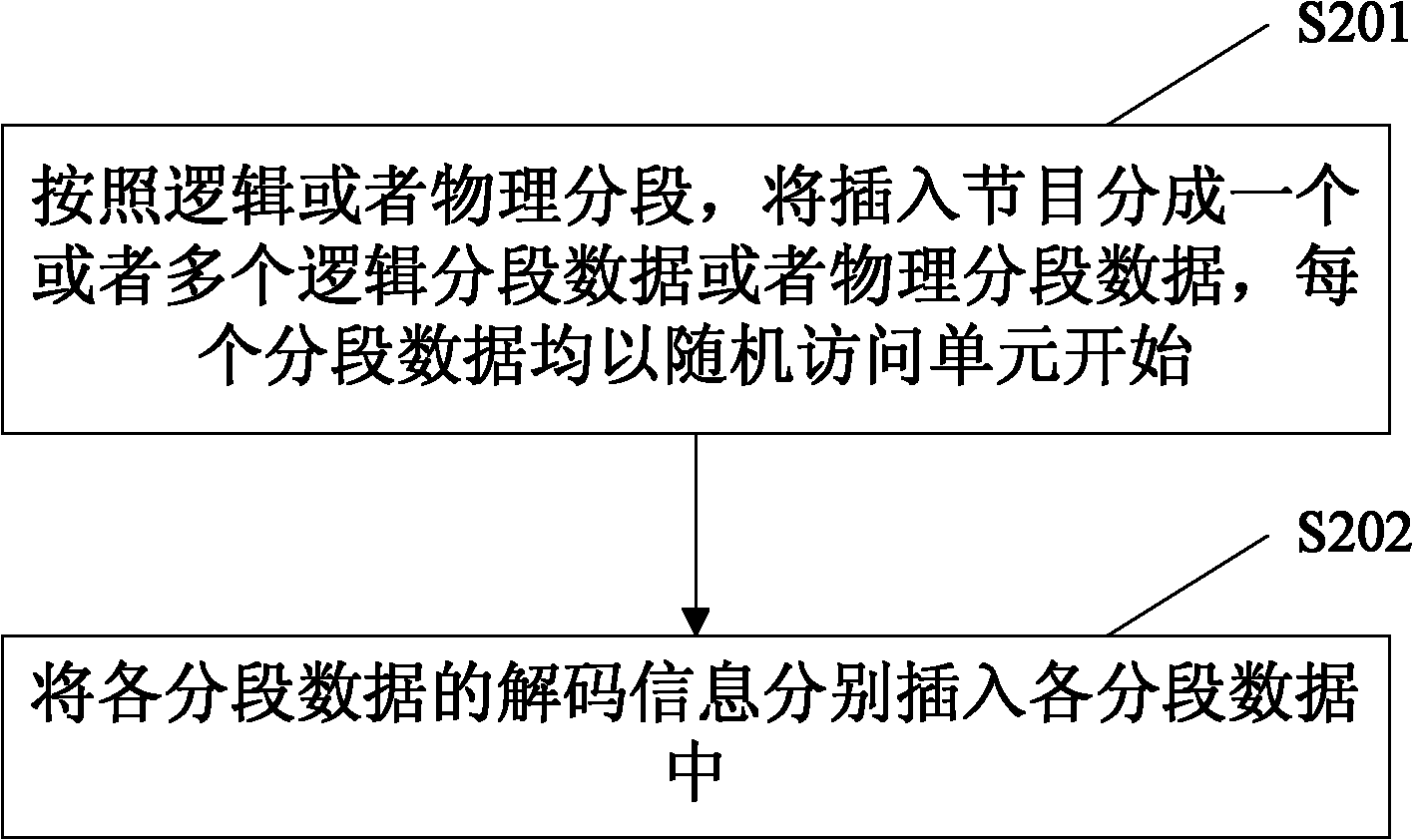

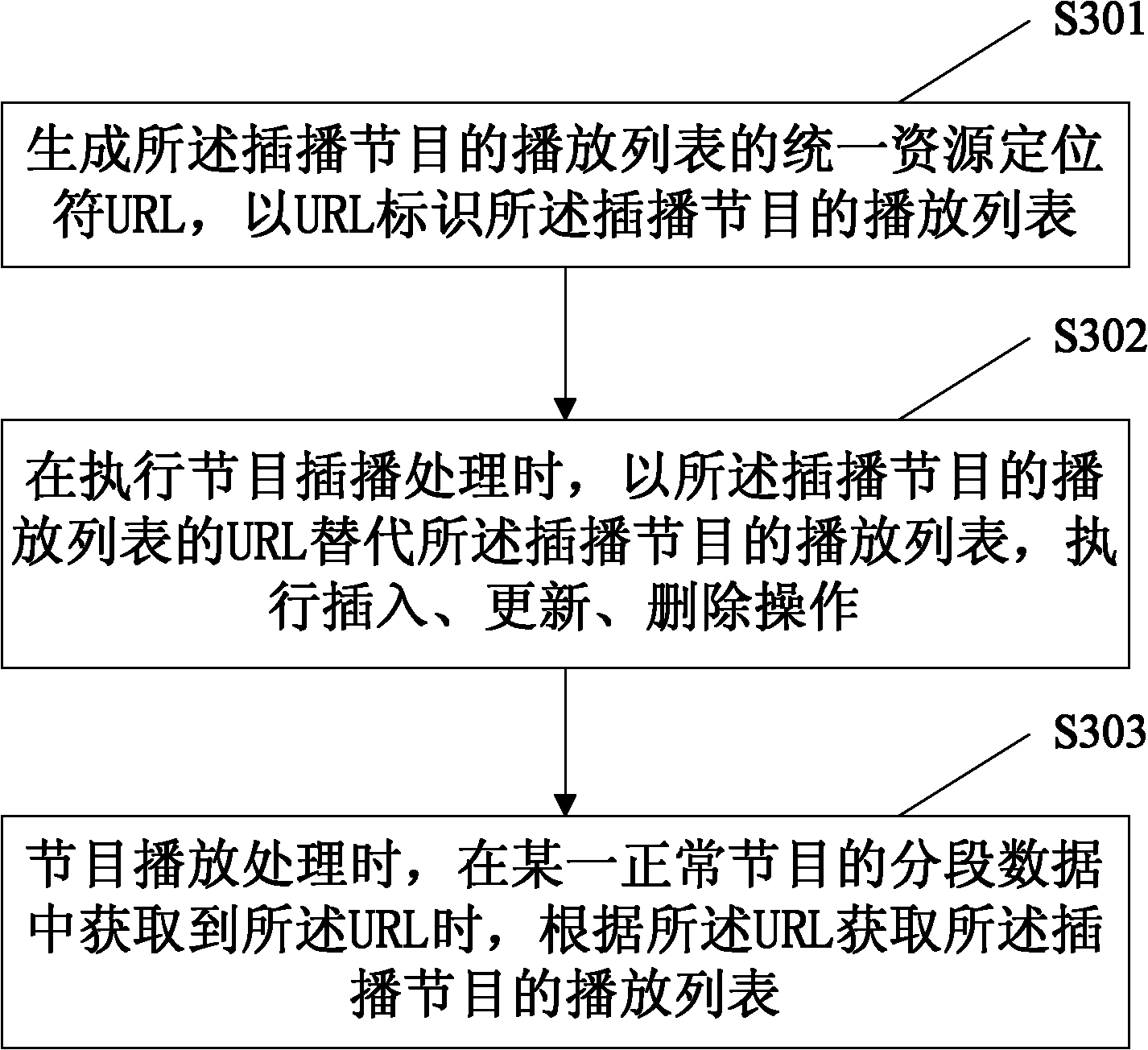

Method for dynamically inserting program in segmental program and system thereof

InactiveCN102487453ARealization of dynamic insertionAchieve insertionElectronic editing digitised analogue information signalsRecord information storageComputer engineering

The invention provides a method for dynamically inserting program in a segmental program and a system thereof. The method comprises the following steps of: segmenting an inserting program, and generating a broadcast list of the inserting program; inserting the broadcast list of the inserting program into the segment data of regular program; if the broadcast list of the inserting program is obtained in the segment data of a regular program when the regular program is broadcasted in the broadcast list of the regular program, firstly broadcasting the inserting program according to the broadcast list of the inserting program, after the broadcast of the inserting program, continually broadcasting the regular program according to the broadcast list of the regular program. With the method, the dynamical program insertion can be really realized, and the method is very flexible and practical to use.

Owner:ZTE CORP

Method for multiplexing optical marker by co-channel subcarriers

InactiveCN1383277ASimple designEasy to operateMultiplex system selection arrangementsFibre transmissionTime domainNetwork packet

This invention relates to a commom sub-carrier moultiplex optical mark method fixing and assisgning certain wavelengths of optical mark communicaltion network the mark wavelengths and further use thesubcarrier multiplex technology to realize multiple parallel common mark channels. Each mark channel is shared by every load wavelength and multi-data packet marks can be parallel delivered at the same time on time domain. The mark information passes through the data wavelength label domain, corresponding to the related data packet to realize the exchange of the data packet and plug-in of the newmarks. This invention uses the theory of frequency division multiplex to realize the extraction and rewriting of optical marks using band-pass filters directly in optical domain and electric domain with simple and mature technique.

Owner:SHANGHAI JIAO TONG UNIV

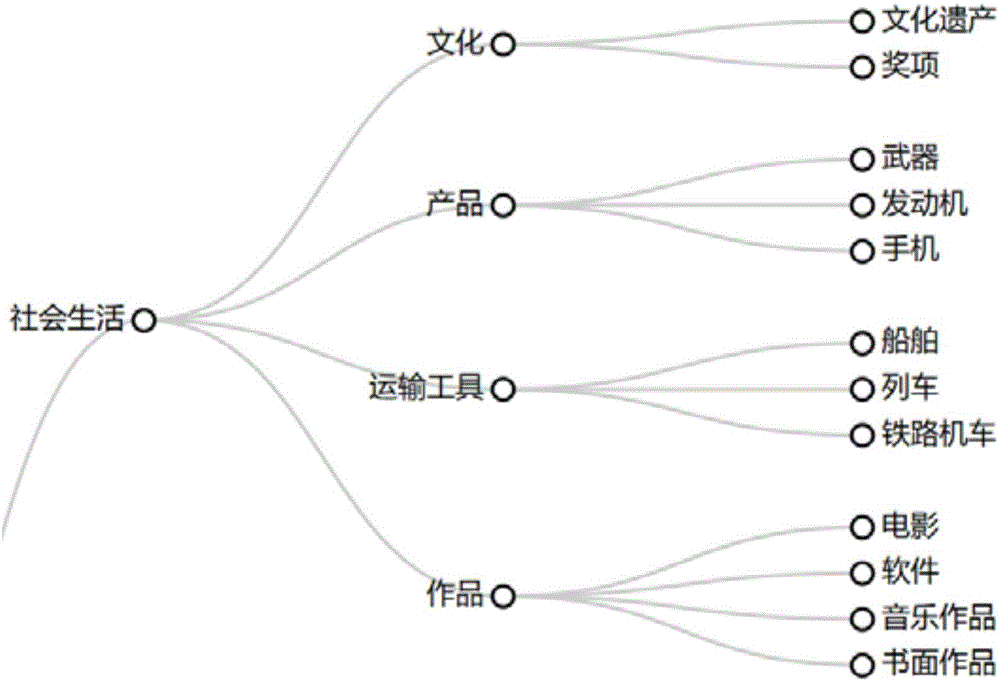

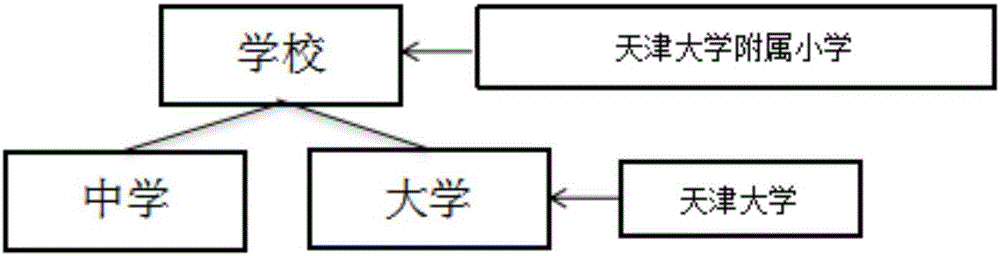

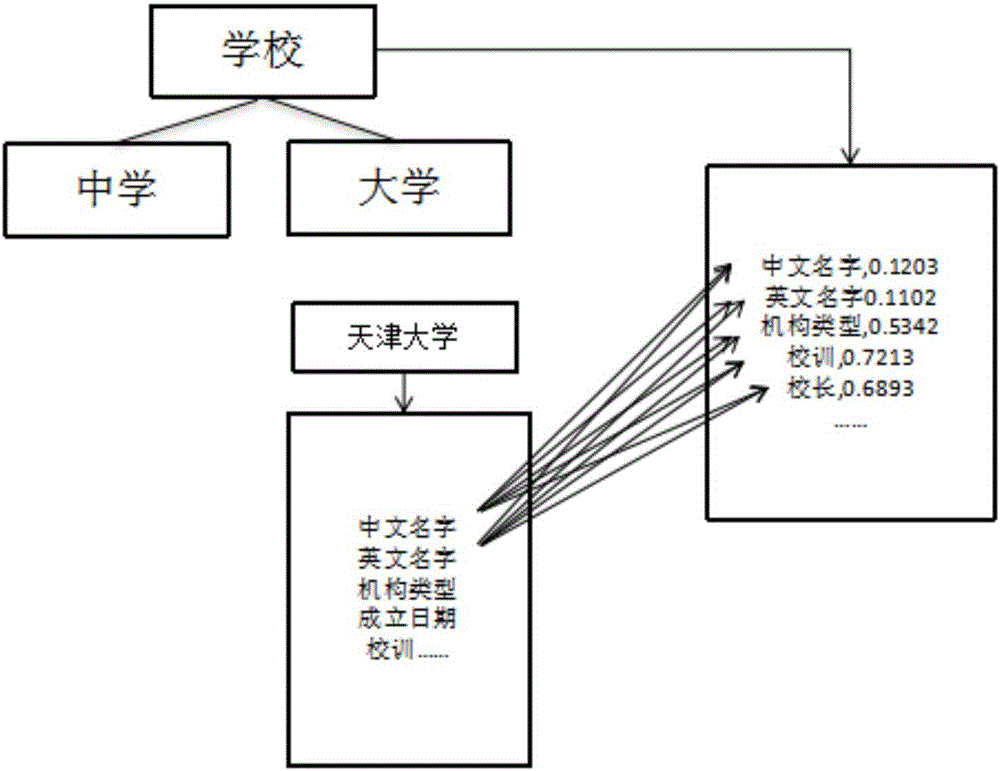

Method for automatically expanding layering ontology knowledge base

InactiveCN106776827AAchieve insertionAchieve integrationRelational databasesSpecial data processing applicationsInferenceNODAL

The invention discloses a method for automatically expanding a layering ontology knowledge base. The method comprises the steps of 1, constructing a category relationship tree for an existing layering ontology base; 2, extracting categories in the layering ontology base and characteristics of pre-plugged new entities; 3, by means of the characteristics obtained through extraction in the step 2, calculating the similarity of the category nodes in the new entities and the category relationship tree from top to bottom in the category relationship tree where the layering ontology knowledge base is located; 4, processing the pre-plugged new entities and the entities in the categories according to the situations, and therefore achieving expansion of the layering ontology knowledge base. Integration of the new entities constantly appearing in a semantic net is achieved through the layering ontology knowledge base, an ontology base with the unified standards is formed, assistances are provided for the semantic net for achieving knowledge sharing and interoperation, expression and inference based on semantics can be achieved, and a good foundation is laid for further building a credible semantic net.

Owner:TIANJIN UNIV

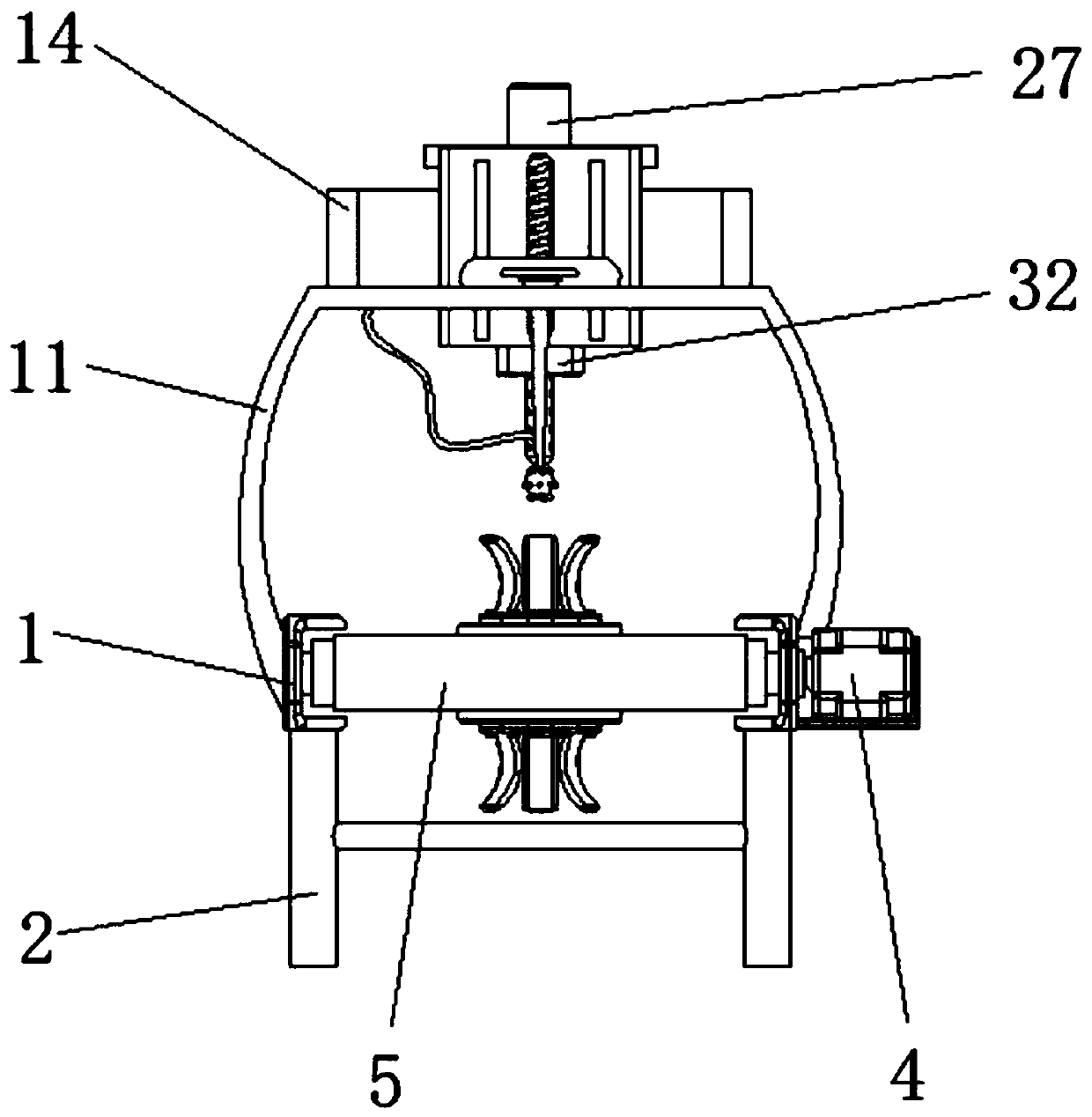

Concrete vibrator

InactiveCN110318545AVibration to achieveAchieve insertionBuilding material handlingEngineeringCantilever

The invention provides a concrete vibrator which comprises a supporting platform and a vibrating rod. A push handle and a lifting device are arranged on the supporting platform, the lifting device comprises a vertically arranged slide rail, a slide block is arranged in the slide rail, a rack is arranged on one side of the slide block, a transverse first cantilever plate is arranged on the other side, a vertical slot where the first cantilever plate moves up and down is formed in the side, far away from the rack, of the slide rail, the vertically arranged vibrating rod is arranged on the firstcantilever plate, the rack is engaged to a half gear, the half gear is mounted on a rotary shaft in a sleeving manner, the rotary shaft is rotatably mounted on a rotary shaft rack, the rotary shaft isdriven by a first driving device to rotate, a horizontal limiting plate is arranged at the top end of the slide rail, a sliding through hole is formed in the horizontal limiting plate, a sliding baris arranged on the top of the slide block, the upper end of the slide bar penetrates the sliding through hole, and a limiting block is arranged at the upper end of the slide bar. The vibrator can meetthe demand that the vibrator is inserted into concrete quickly and is pulled out of the concrete slowly, and meanwhile, the vibrator is relatively high in vibrating efficiency and guarantees the quality of a concrete member.

Owner:湖北乾奥建设工程有限公司

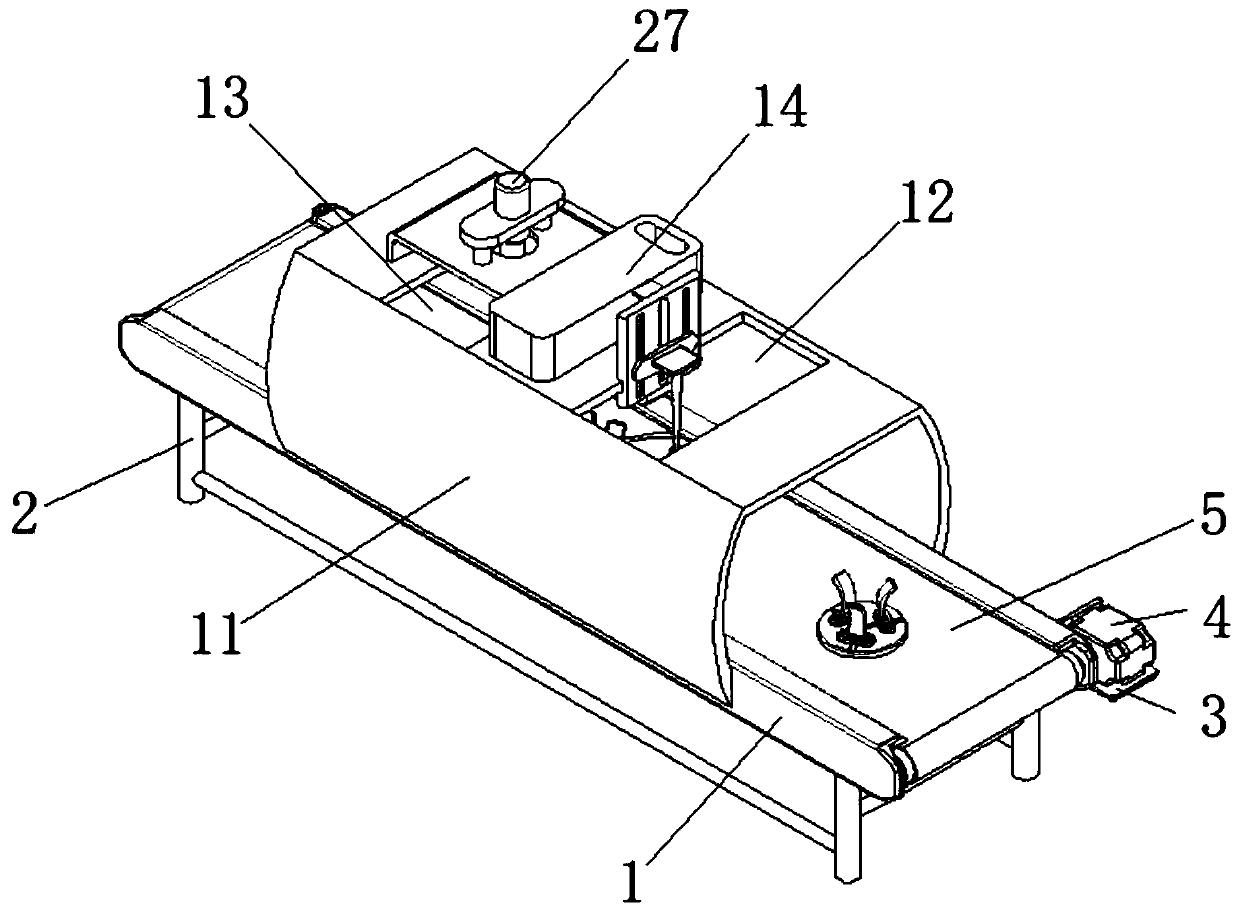

Ceramic bottle internal glaze spraying equipment for process ceramic production

ActiveCN111113649AAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

The invention belongs to the technical field of glaze spraying equipment, in particular to ceramic bottle internal glaze spraying equipment for process ceramic production. The ceramic bottle internalglaze spraying equipment comprises a protection support plate, wherein supporting legs are arranged at the bottom of the protection support plate, and an L-shaped supporting plate is arranged on one side of the protection support plate; a first motor is arranged at the top of the L-shaped supporting plate, and the output end of the first motor penetrates through the protection support plate. A ceramic bottle internal glaze spraying mechanism is arranged, on the one hand, storage and placement of glaze for glazing the surface of a ceramic bottle can be achieved through a material storage box, paint can be conveniently provided for glazing and spraying on the internal surface of the ceramic bottle, and meanwhile, the material storage box is used for storing the glaze so that the working amount of repeated adding of the glaze by an operator can be relieved; and on the other hand, a guide supporting cylinder can be conveniently inserted into the interior of the ceramic bottle through the mode that a transmission screw is adopted to move up and down for adjustment, and uniform glaze spraying treatment is carried out on the inner wall of the ceramic bottle by using a spherical glaze spraying joint.

Owner:广东金润源陶瓷股份有限公司

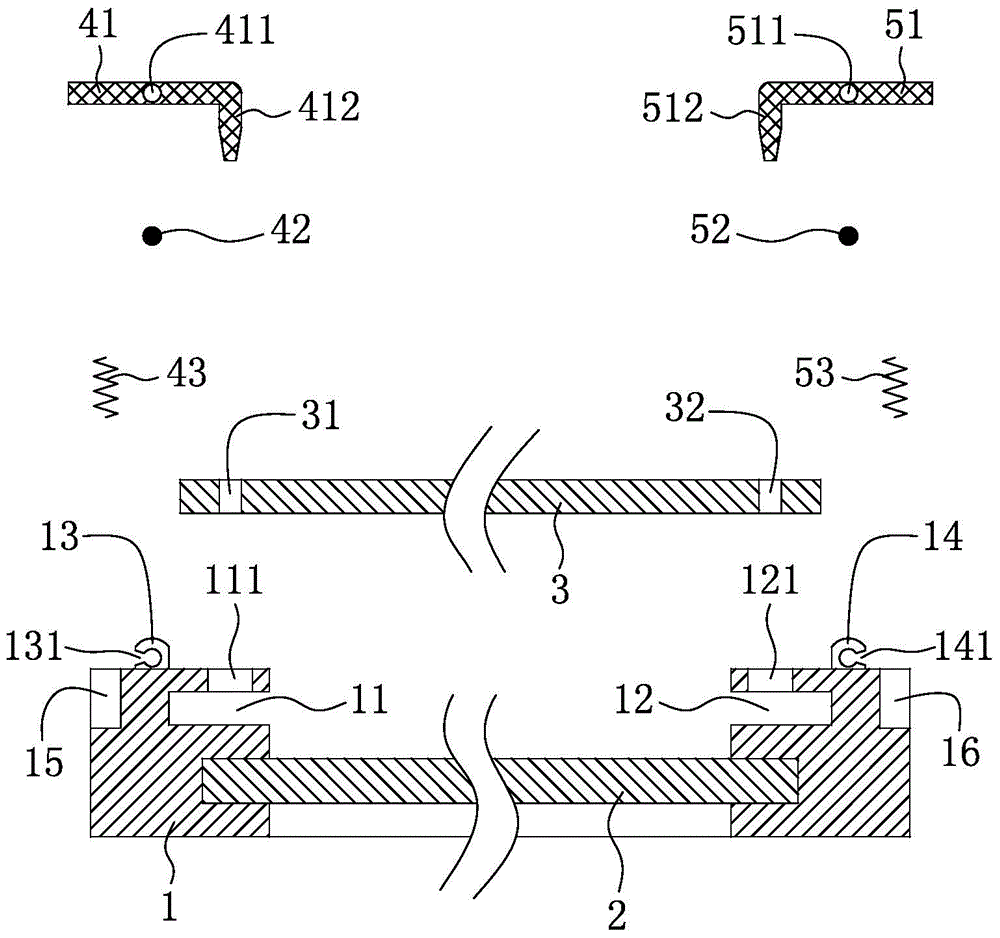

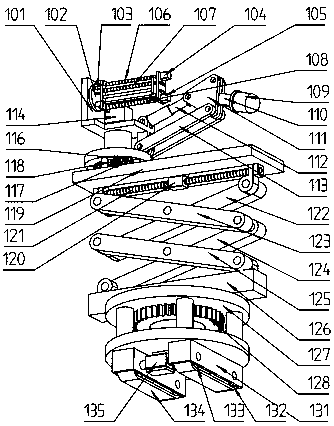

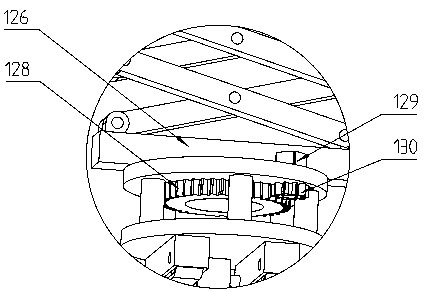

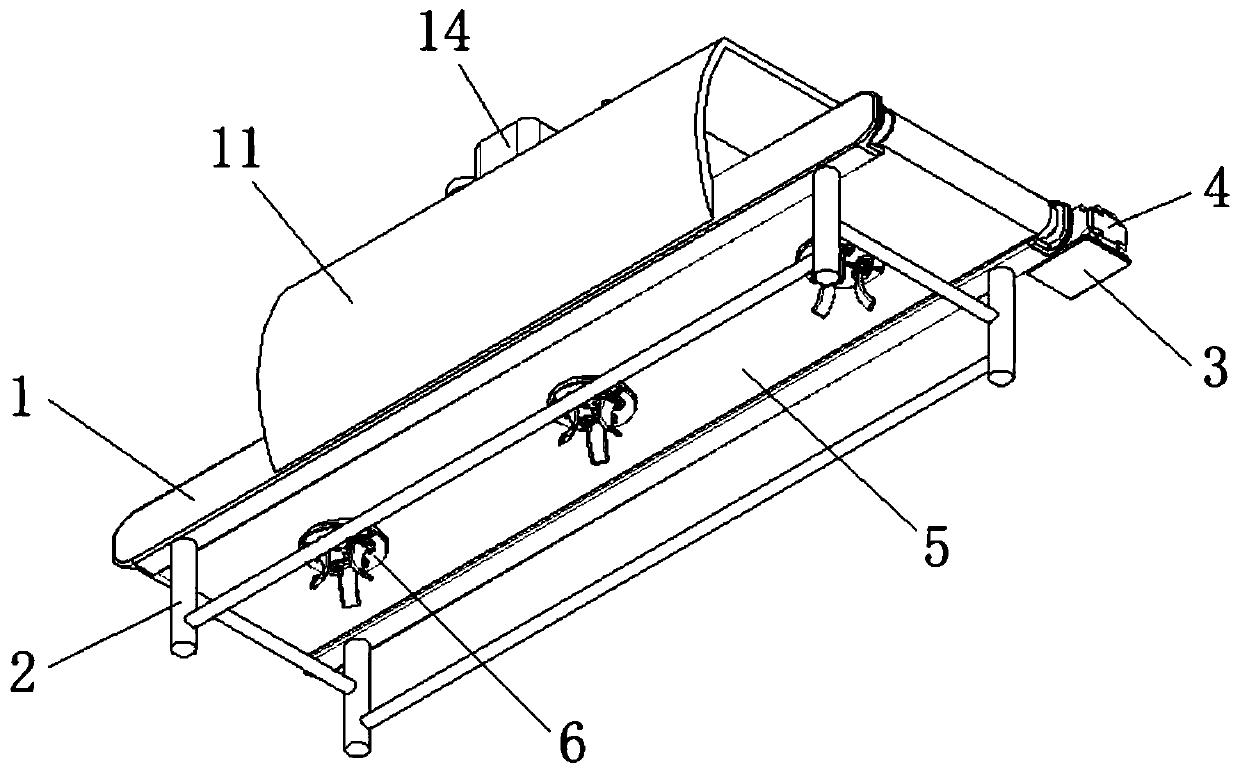

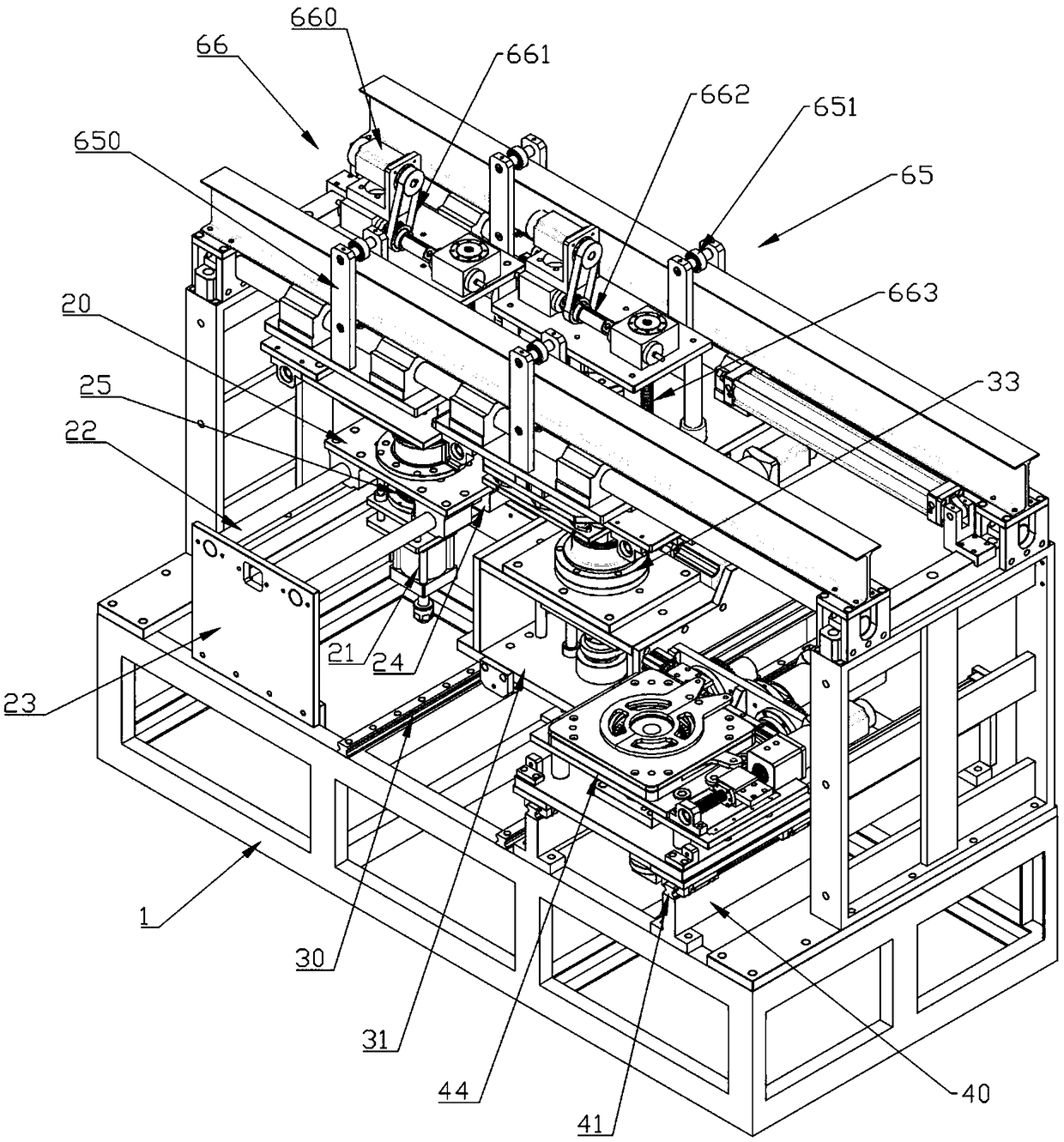

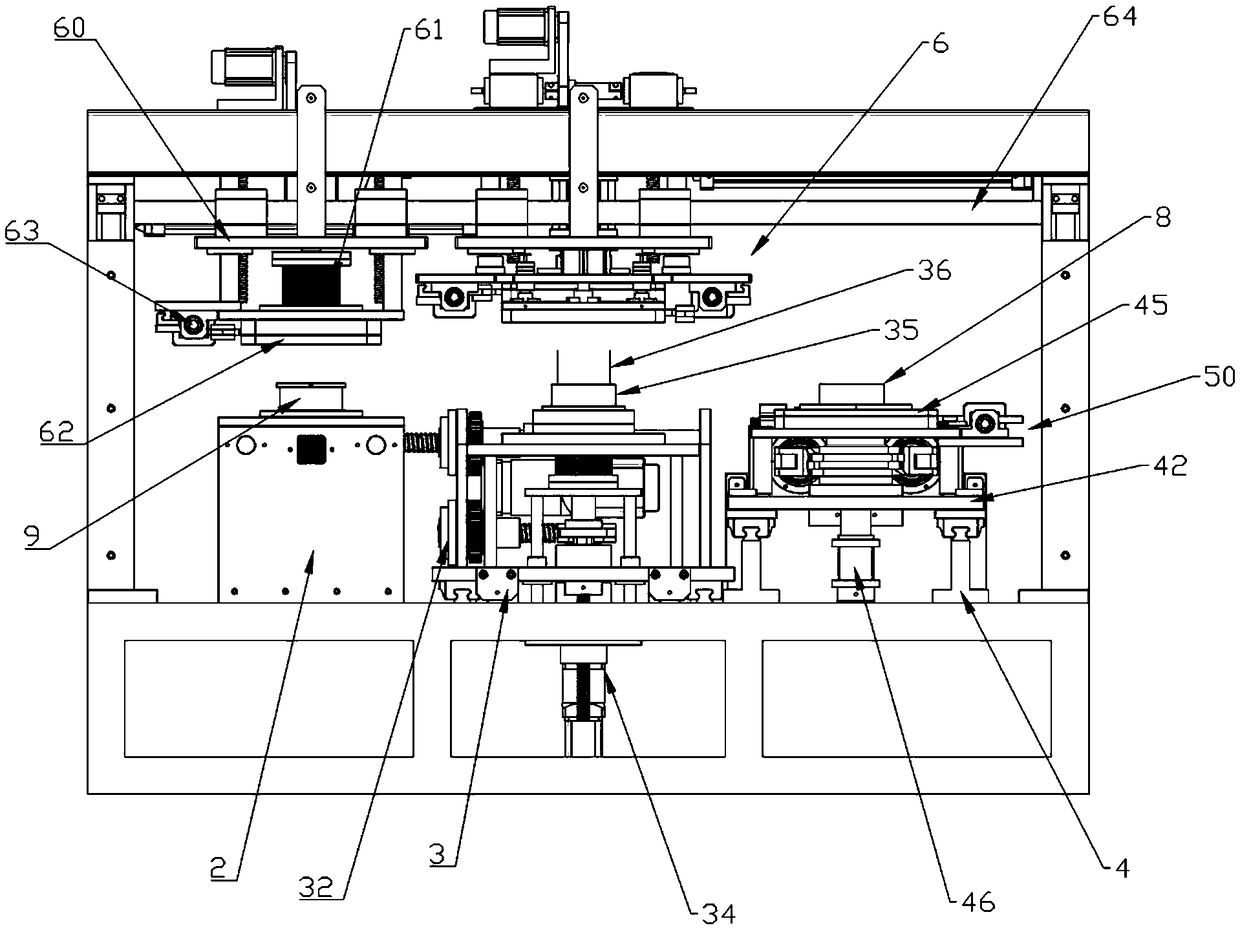

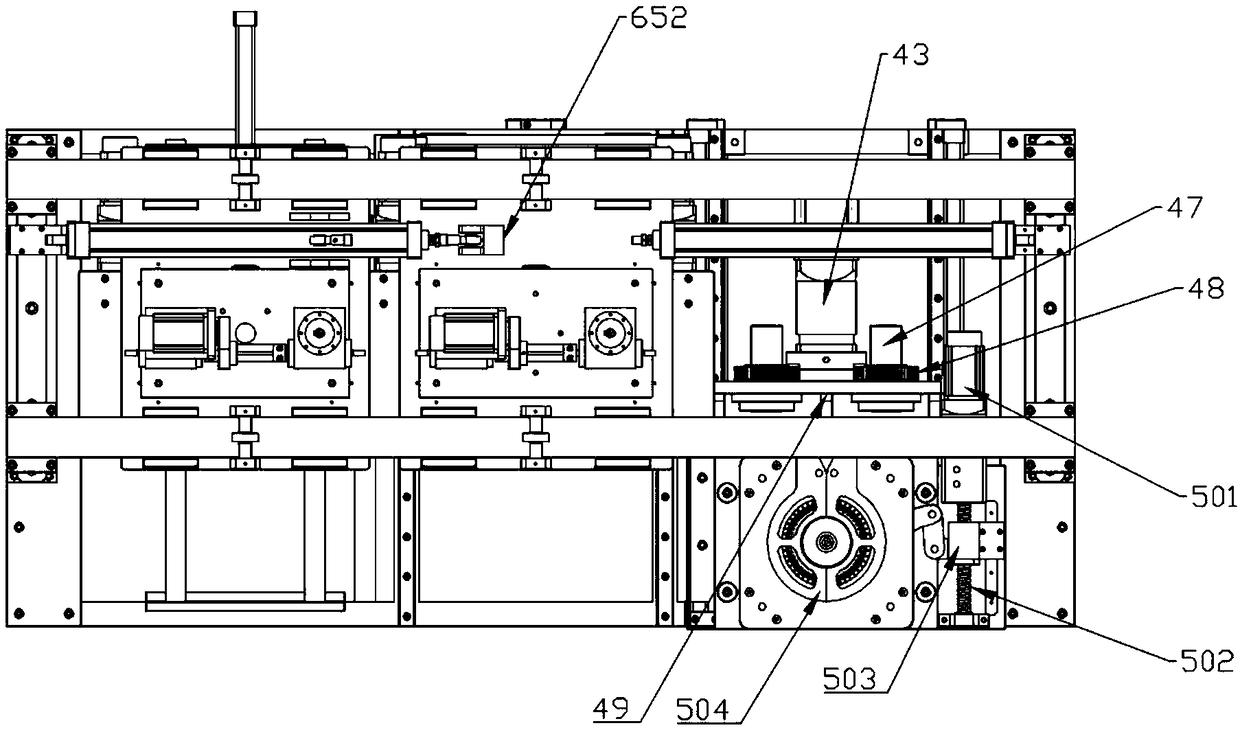

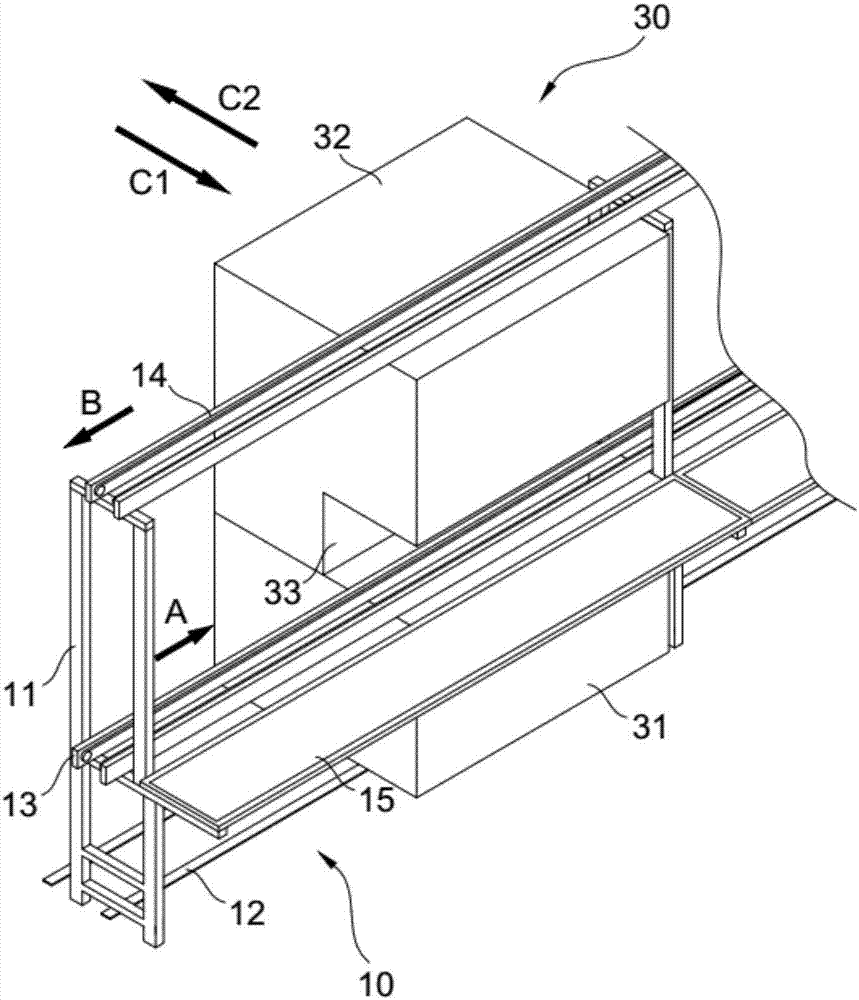

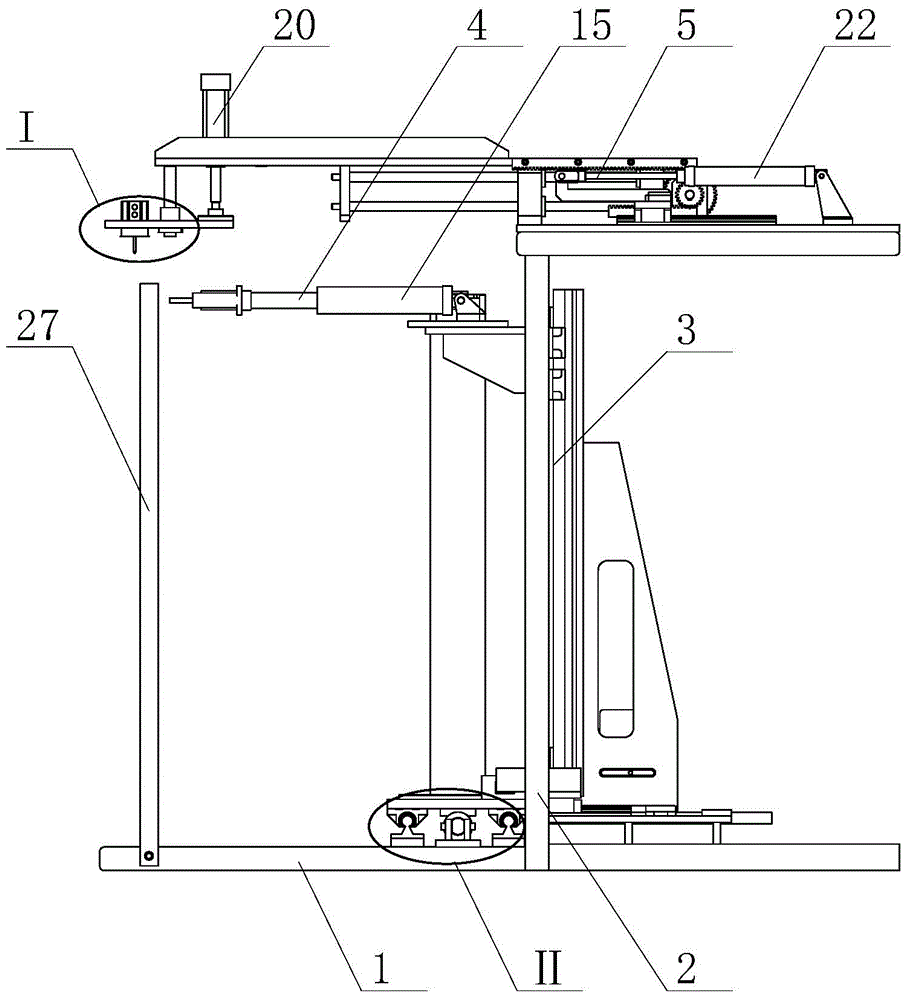

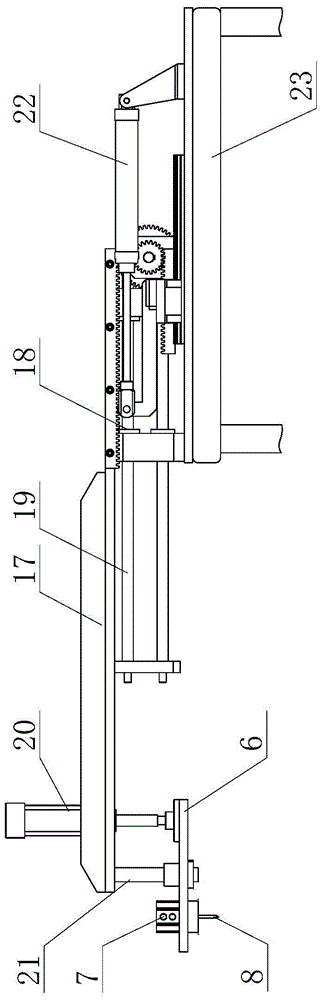

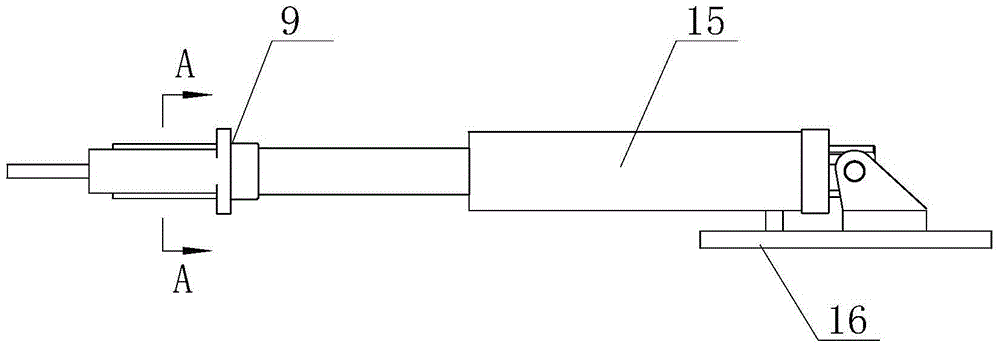

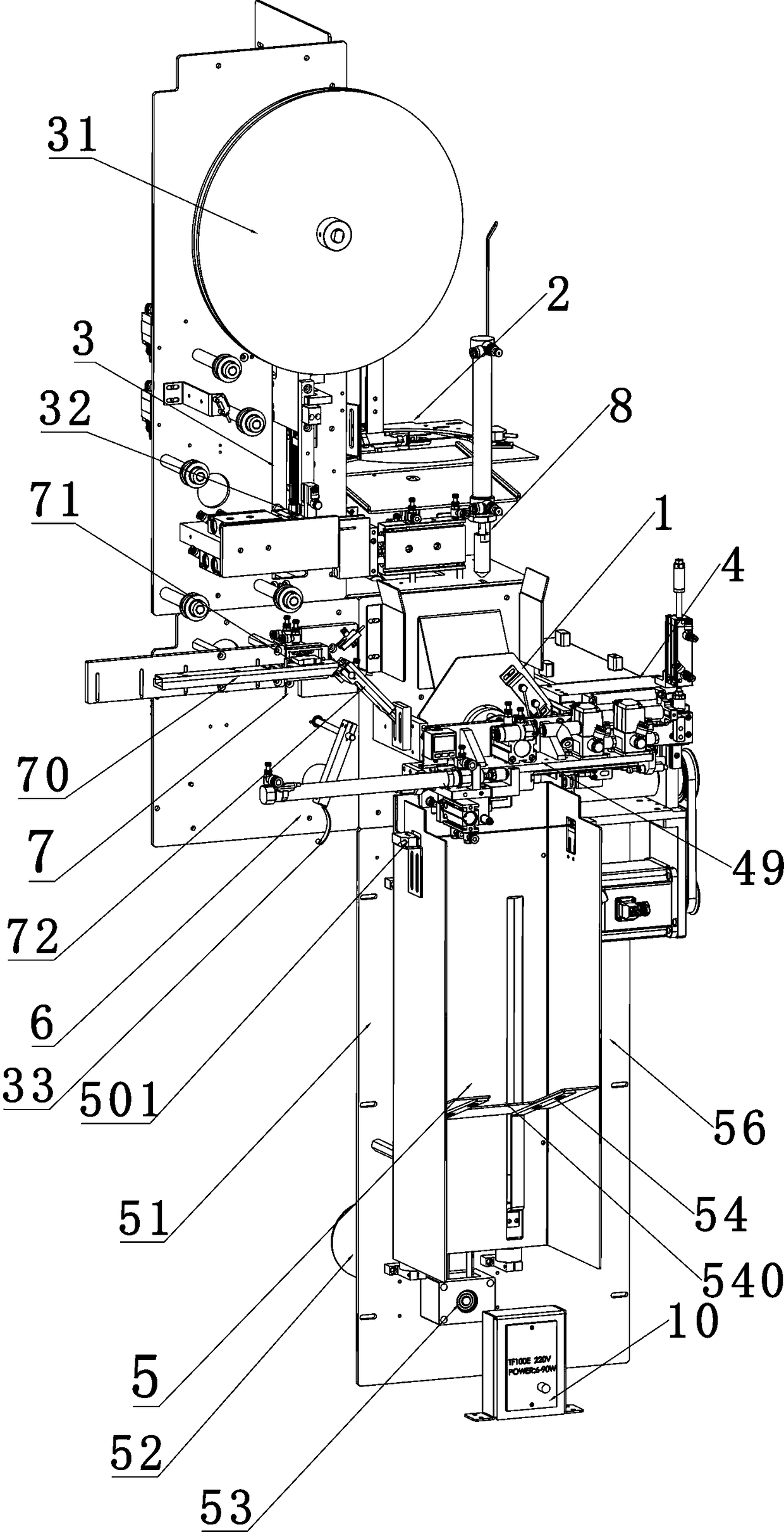

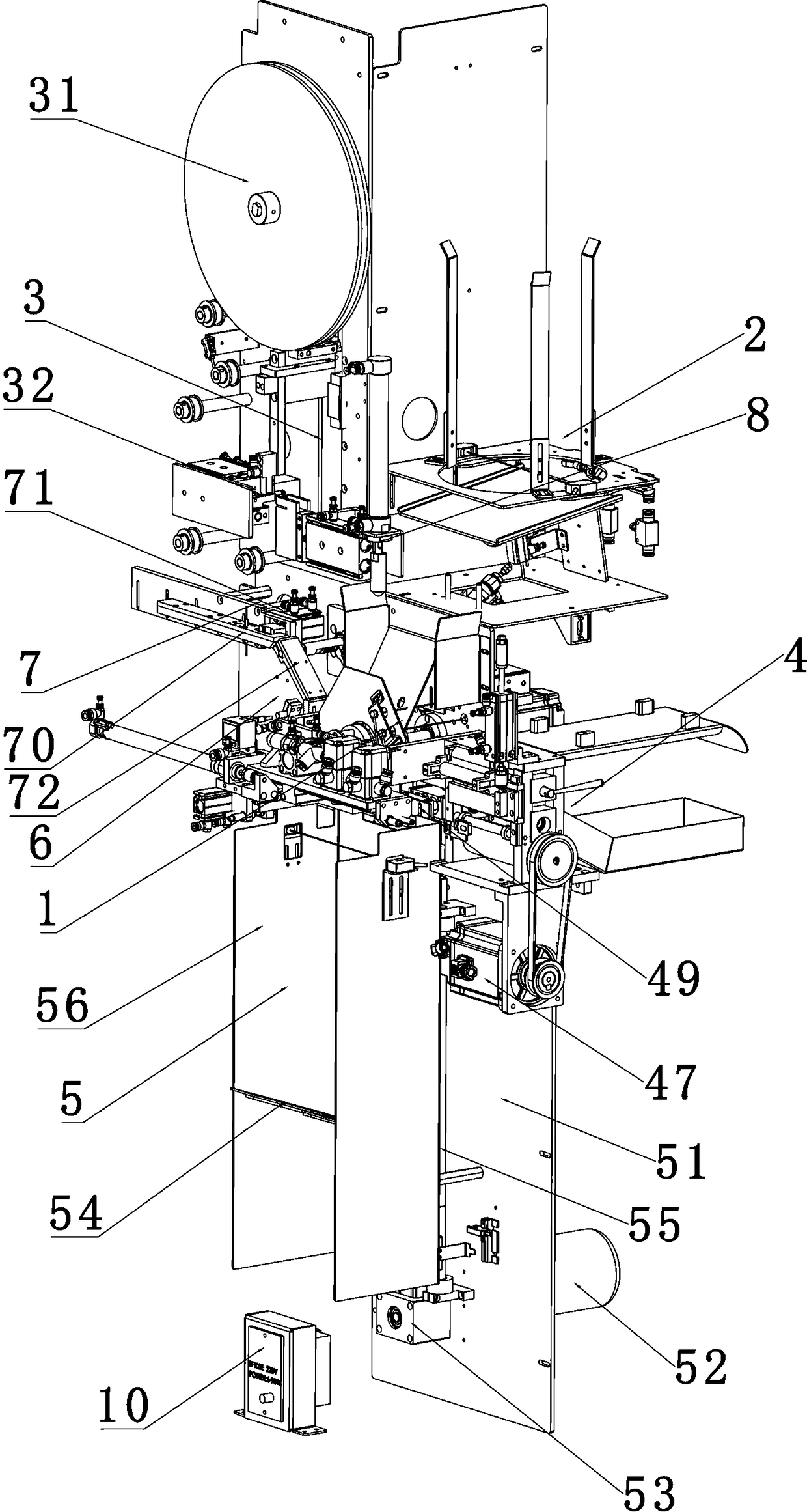

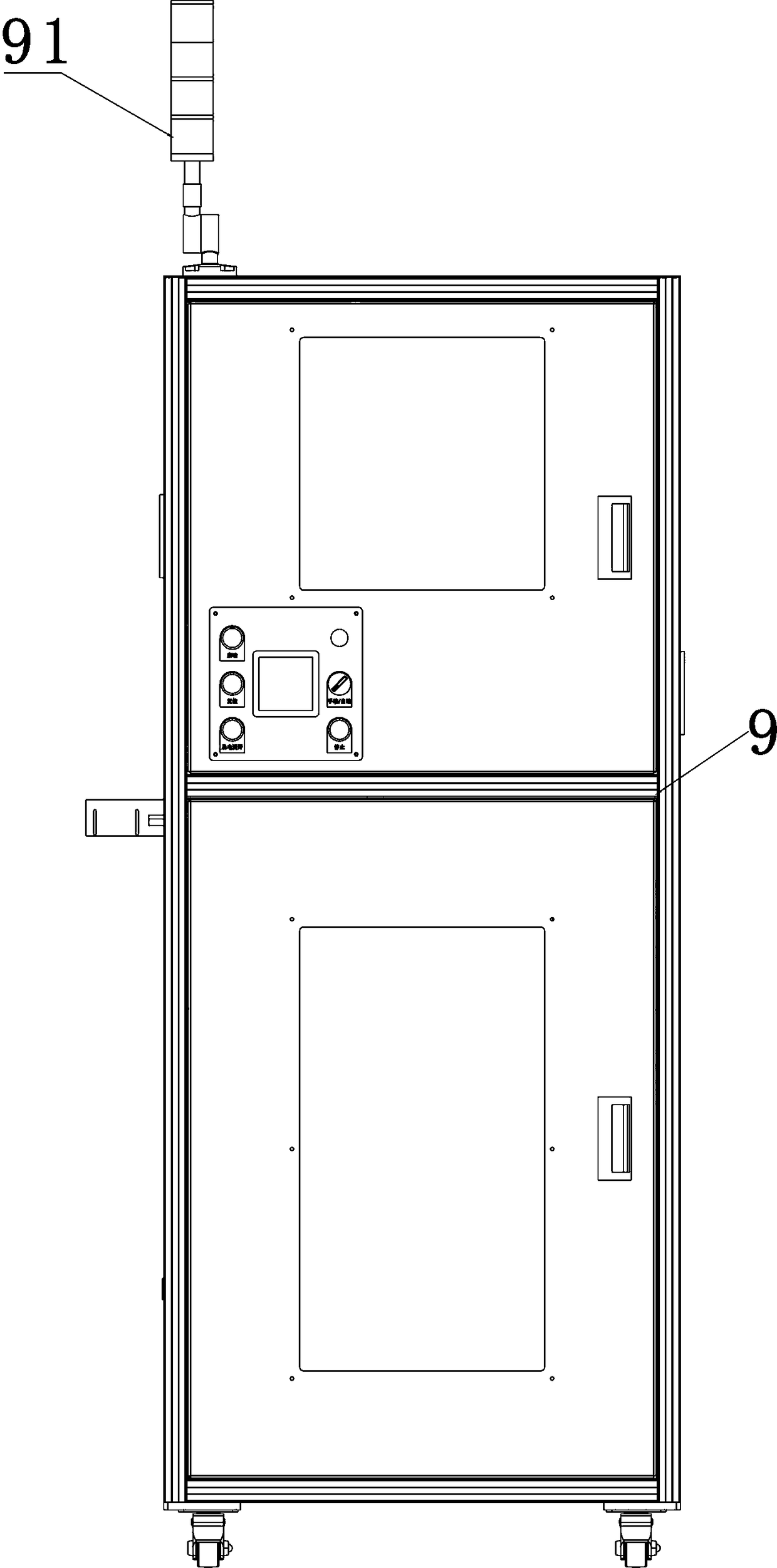

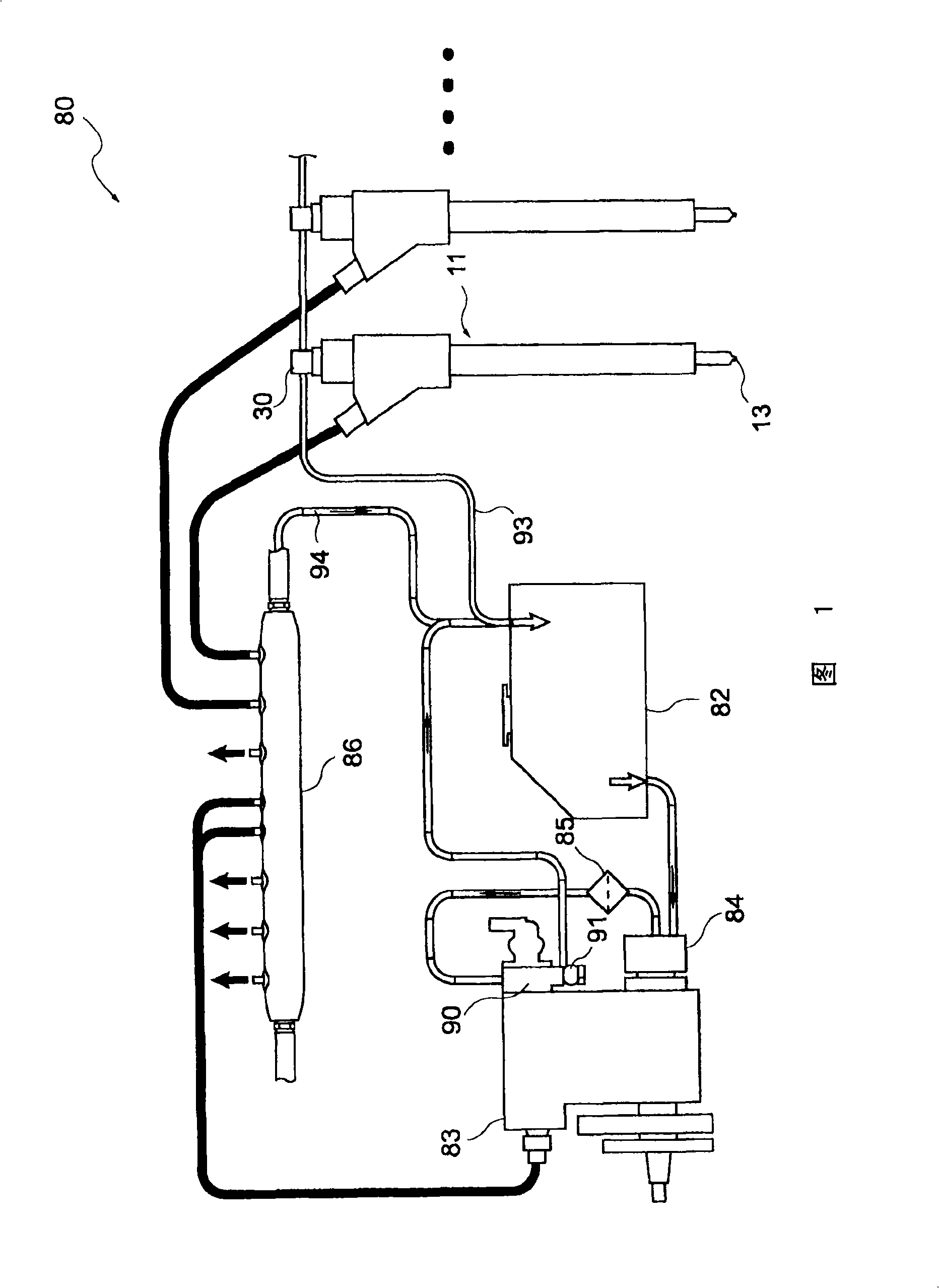

Generator HP flat wire stator automatic plugging and twisting equipment

InactiveCN109038983AAchieve insertionTo achieve up and down twistManufacturing dynamo-electric machinesFrame basedCopper wire

The invention discloses a generator HP flat wire stator automatic plugging and twisting equipment. Comprises a frame, a fixing cup device, a stator wire wrapping upper twisting head mechanism, a stator wire wrapping lower twisting head mechanism, a wire taking device and a controller; A fixing cup device, An upper twist head mechanism of a stator wire wrap, a lower twist head mechanism of that stator wire wrap are arranged on the base of the machine frame, a fixing cup device, an upper twist head mechanism of the stator wire wrap, a lower twist head mechanism of the stator wire wrap and a frame base are slidably connected, a thread taking device is arranged on the frame cross beam, the thread taking device and the frame cross beam are slidably connected, and the thread taking device is lifted and lowered in the frame and translated; The controller is respectively connected with a fixing cup device, a stator wire wrapping upper twisting head mechanism, a stator wire wrapping lower twisting head mechanism and a wire taking device through lines. The invention realizes the insertion of the copper wire in the HP flat wire stator, twists up and down, does not need to be transferred to other machines, and improves the production efficiency and the product quality.

Owner:无锡市苏盛汽车部件有限公司

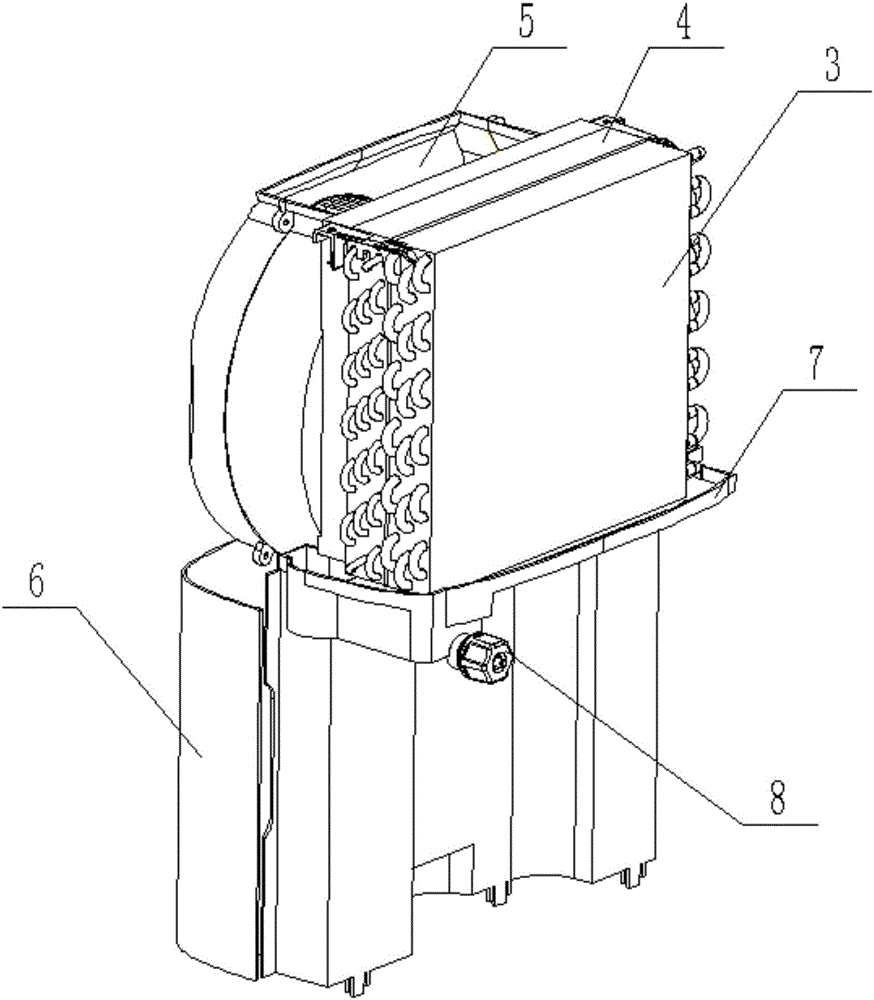

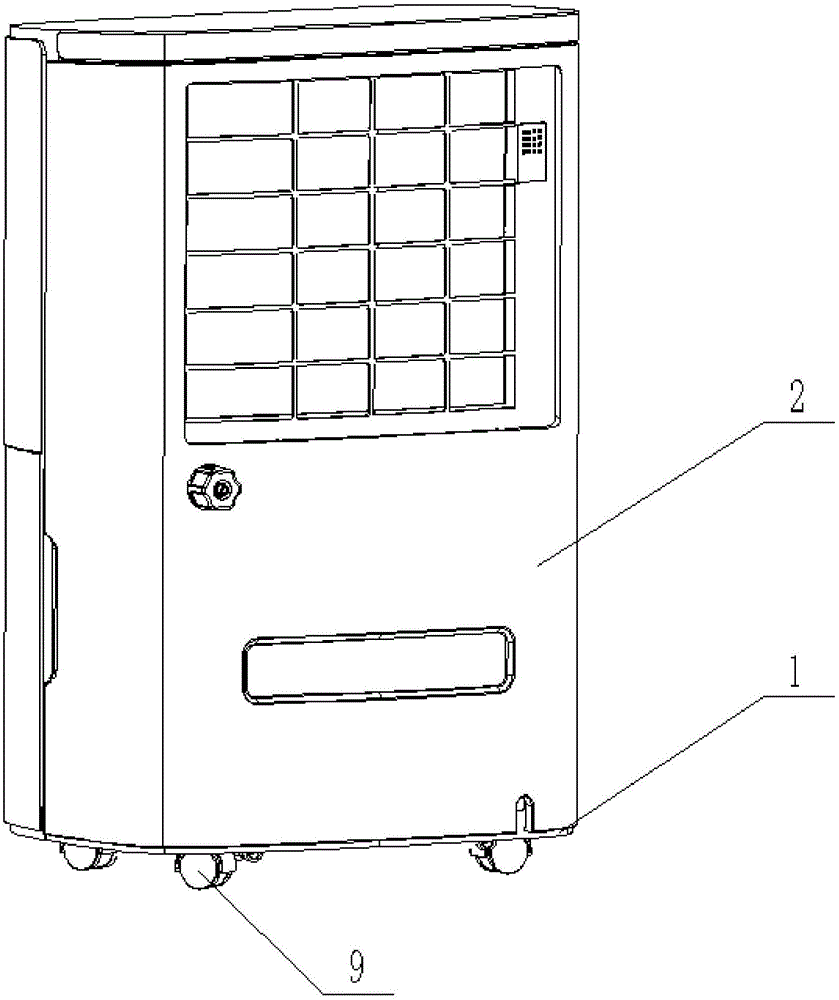

Movable dehumidifier with multipurpose integrated water drainage structure

ActiveCN106766082ASave internal spaceSimple production processCondensate preventionLighting and heating apparatusInterior spaceEngineering

The invention relates to a movable dehumidifier with a multipurpose integrated water drainage structure. The movable dehumidifier comprises a base and an outer shell installed on the base. The outer shell is internally provided with an evaporator, a condenser, an air supply system and a water tank. The water tank is located on the lower side of the outer shell. The air supply system is installed above the water tank. The condenser and the evaporator are sequentially arranged on one side of the air supply system. The movable dehumidifier further comprises the integrated water drainage structure arranged below the condenser and the evaporator. Three water drainage modes are achieved, water drainage openings are integrated on the same structure without being additionally arranged at different positions on the outer shell, the production process is greatly simplified, processing is easy, the limited internal space of the dehumidifier is effectively saved, and the overall sealing effect is greatly improved.

Owner:JIANGSU YOAU ELECTRIC CO LTD

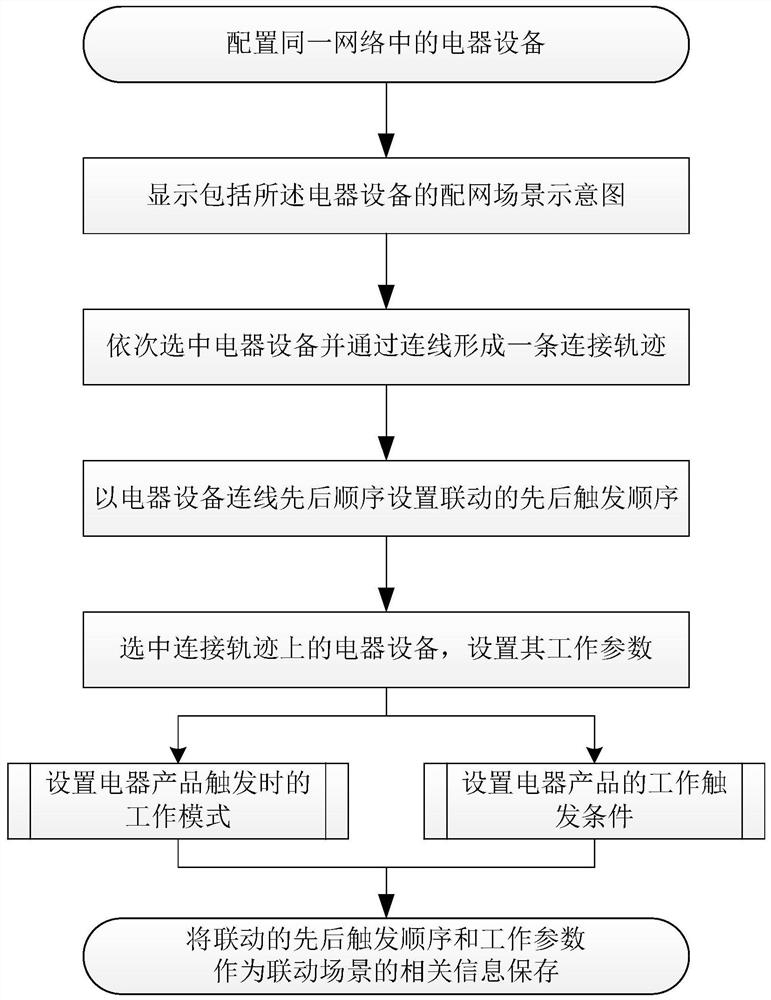

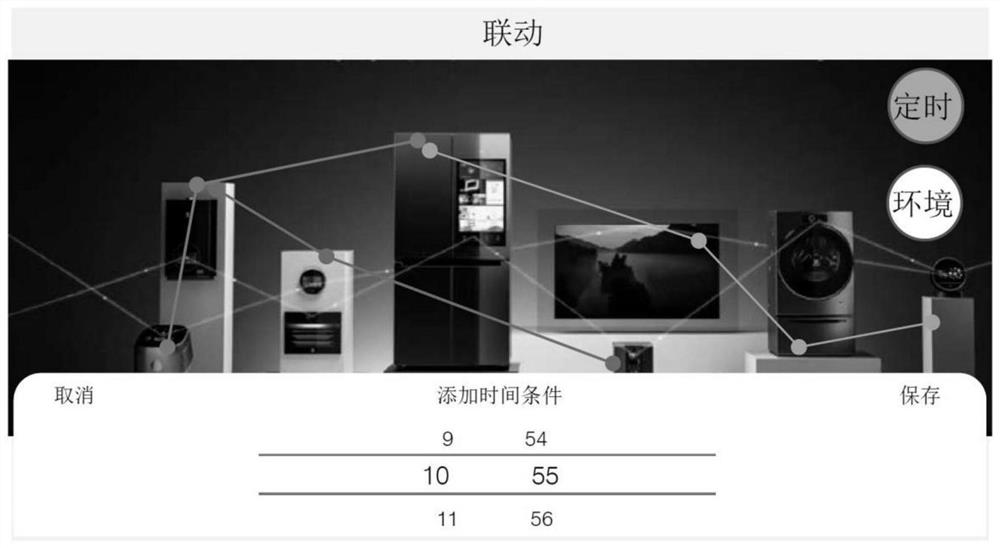

Interaction method for establishing equipment linkage scene, storage medium and electronic equipment

ActiveCN111880501AShorten the timeImprove experienceComputer controlTransmissionSimulationSchematic maps

The invention relates to the technical field of smart home linkage, in particular to an interaction method for establishing an equipment linkage scene, a storage medium and electronic equipment, and solves the problems that the display is not visual enough, the setting process is tedious, the efficiency is low and the time is wasted in the prior art. The method comprises the following steps: in adisplayed distribution network scene schematic diagram comprising electrical equipment configured in the same network, sequentially selecting the electrical equipment through connecting lines to forma connecting track, and setting a sequential triggering sequence for linkage with the electrical equipment in a linkage scene represented by the connecting track according to the sequential order of the connecting lines, selecting the electrical equipment in the connection track to set the working parameters of the electrical equipment in the linkage scene, and finally storing the related information of the linkage scene. According to the invention, the purposes of visual display, simple and rapid linkage scene setting and user experience improvement are achieved, linkage operation steps are reduced, and convenient and rapid operation of intelligent household linkage setting by a user is realized.

Owner:GREE ELECTRIC APPLIANCES INC

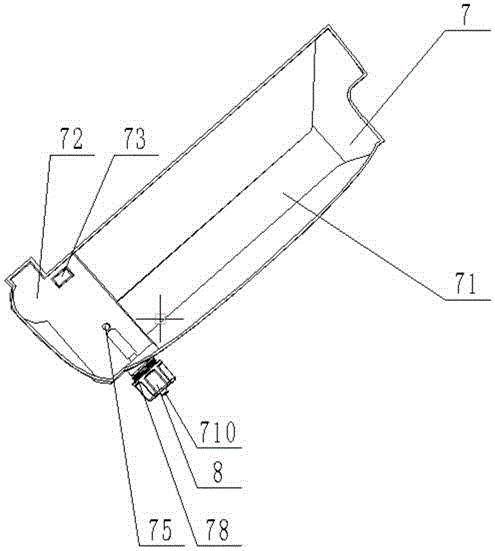

Automotive lighting device

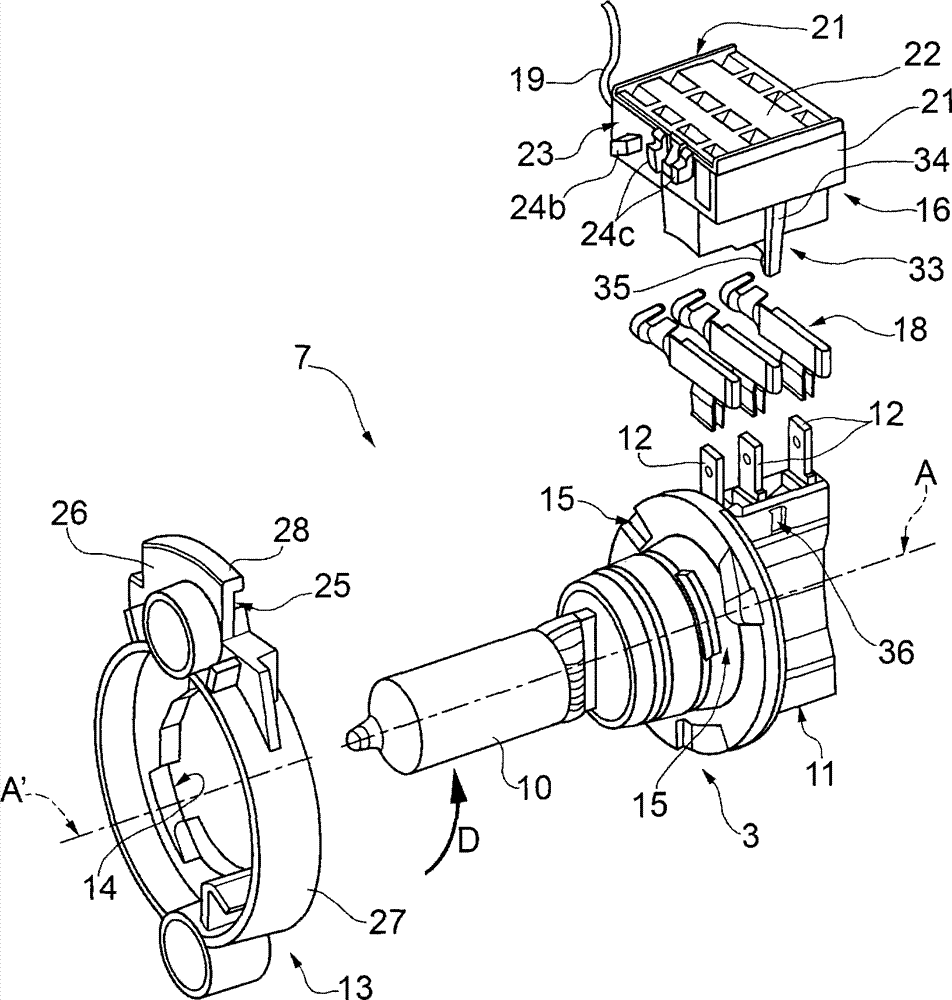

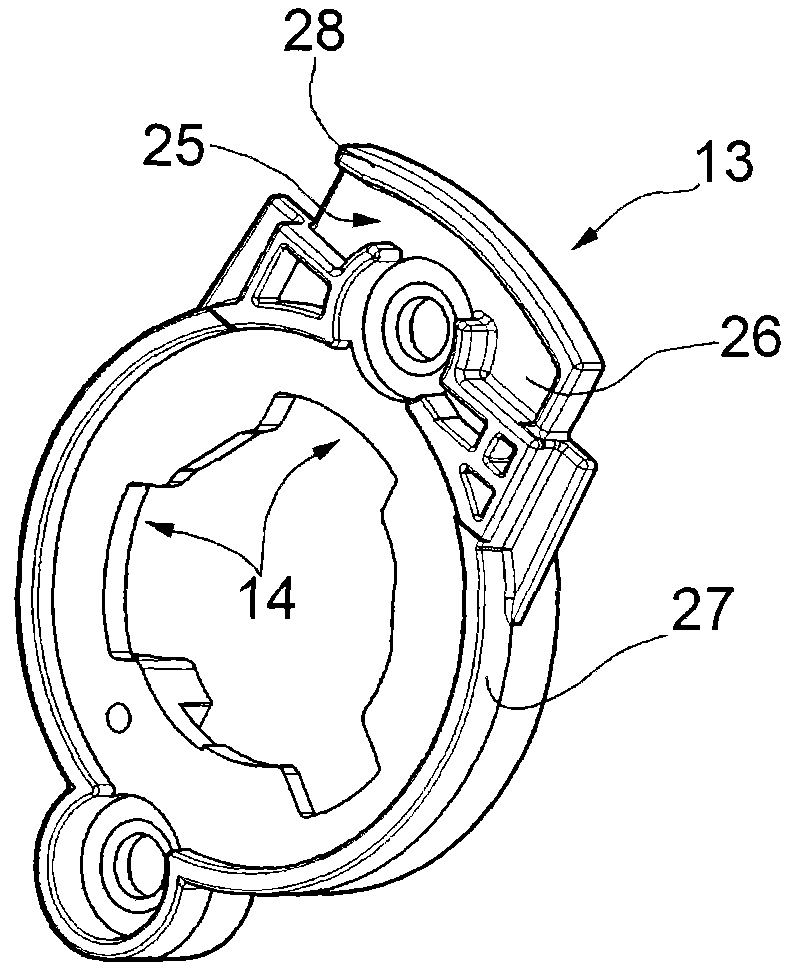

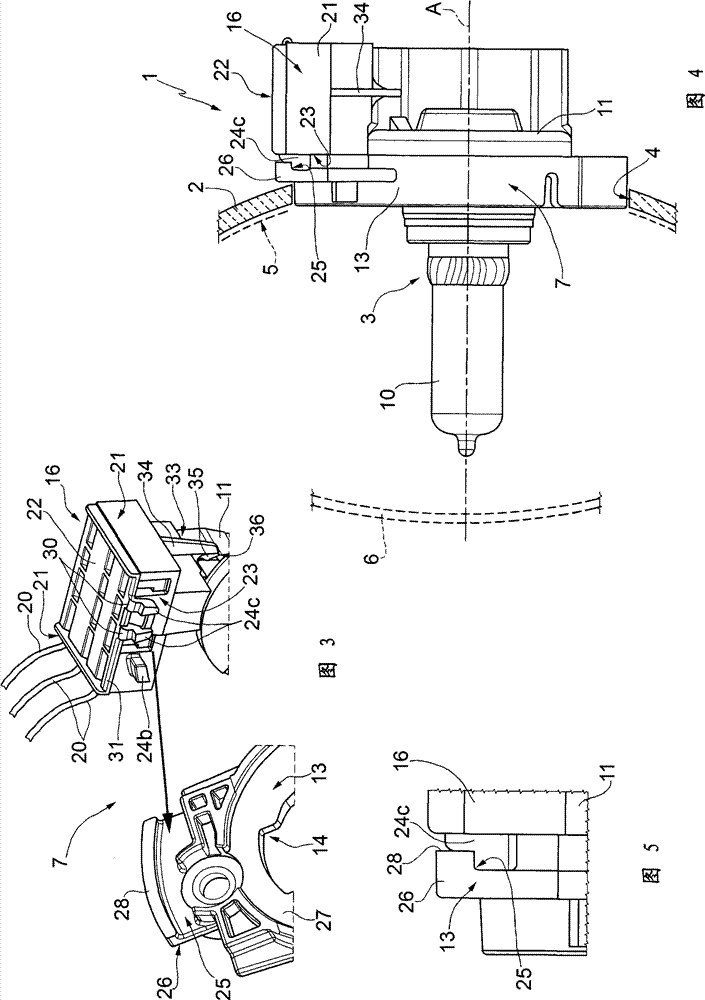

ActiveCN103568930APrevent insertionAchieve insertionVehicle headlampsPoint-like light sourceCouplingEffect light

An automotive lighting device (1) for vehicles with a headlight body, a lamp (3) including a bulb (10) and a lamp socket (11) integrally connected in one piece to the bulb and having male contacts (12) arranged so as to project at a right angle with respect to an axis (A) of the lamp, and a system (7) for assembling the lamp including a base (13), bayonet coupling means (15; 14) between lamp socket and base, and a connector (16) integrally provided with female contacts (18) which can be coupled with the male contacts by means of the movement of the connector perpendicular to the axis; the connector (16) includes at least one projecting part (24) protruding from a frontal face (23) of the connector which, with the connector being coupled to the lamp socket, faces the bulb; and the base (13), towards the lamp socket, is provided with a channel (25) arranged transversally to the axis and shaped so as to receive, in an undercut-like slidingly coupled manner, the at least one projecting part (24) when the lamp socket is bayonet coupled to the base.

Owner:AUTOMOTIVE LIGHTING ITALA

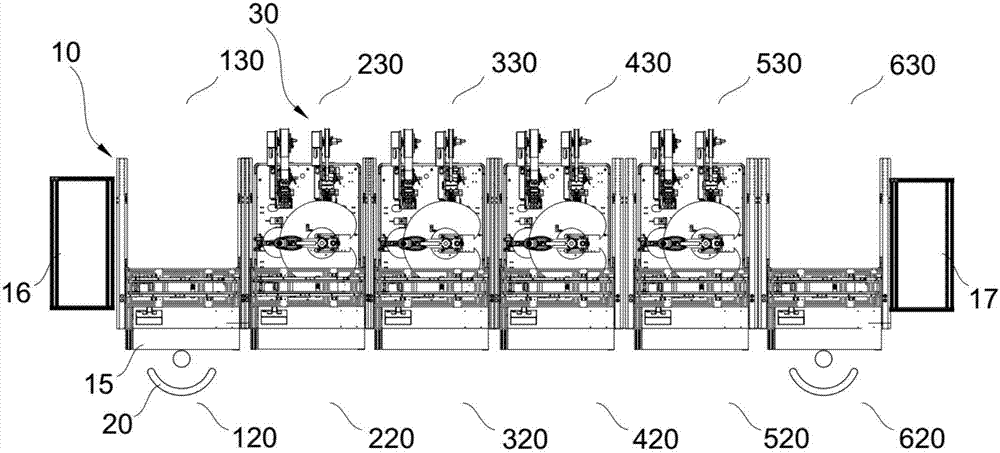

Fully-automatic flexible assembly line

The invention discloses a fully-automatic flexible assembly line. The fully-automatic flexible assembly line comprises a control system, an assembly line component, a plurality of machine platform stations and a plurality of artificial stations, wherein the machine platform stations and the artificial stations are arranged on the two sides of the assembly line component separately, different assembly machine platforms are arranged on the machine platform stations according to different assembly procedures, and the assembly line component and the assembly machine platforms are electrically connected with the control system. When the assembly machine platform on a certain machine platform station fails, the assembly machine platform is replaced, an operating worker who is used for replacing the assembly machine platform to conduct assembly operation is assigned at the artificial station corresponding to the machine platform station, artificial and automatic zero-time switching is realized, and the procedure continues until the assembly machine platform is maintained off line or a standby machine platform is replaced; after product switching or process changing, the number of the machine platforms of the whole assembly line can be increased or decreased arbitrarily and quickly according to a new process, and thus the fully-automatic flexible assembly line can be adapted to multiple product production. According to the fully-automatic flexible assembly line, assembly efficiency can be improved, line body spare part cost can be reduced, and the assembly period can be shortened.

Owner:SUZHOU RS TECH

Secondary wiring auxiliary apparatus

ActiveCN105048244AHigh speedUniform insertion lengthLine/current collector detailsCable transmissionPiston rod

The invention discloses a secondary wiring auxiliary apparatus. A base is provided with a support, the support is provided with an elevating mechanism and a cable transmission mechanism, and the cable transmission mechanism is arranged at the right side of the elevating mechanism; the front end of the right side of the cable transmission mechanism is provided with a cable clamping arm, the cable clamping arm comprises a top plate, two first vertical plates which are arranged in parallel at a front position and a rear position are installed below the top plate, a second vertical plate parallel to the two first vertical plates is arranged between the two first vertical plates, the first vertical plate at a rear side is externally provided with a longitudinal clamping cylinder, the free end of the piston rod of the clamping cylinder is vertically fixed on the rear side of the second vertical plate, the clamping cylinder can drive the second vertical plate to perform longitudinal movement between the first vertical plates, and the opposite surfaces of the second vertical plate and the first vertical plate at a front side are provided with recesses for clamping a cable. According to the invention, the secondary wiring auxiliary apparatus is a special-purpose auxiliary tool for secondary wiring, can automatically finish wire transmission, insertion and fixation in a terminal interface, replaces manually hand-actuated secondary wiring, improves the wiring efficiency and quality and saves manpower resources.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Connecting terminal assembly

InactiveCN102447183AAchieve insertionFirmly connectedCoupling contact membersEngineeringMechanical engineering

The invention discloses a connecting terminal assembly which comprises a clamping terminal, wherein two clamping pieces which are integrally formed and a connecting body used for connecting the two clamping pieces are formed on the clamping terminal; the parts extending out of the connecting body, of the two clamping pieces bend towards the directions close to each other so as to form clamping segments the distances of which are gradually reduced to the smallest; based on the smallest distance between the clamping segments as a boundary, the parts, far away from the connecting body, of the two clamping pieces bend towards the directions far away from each other so as to form separation segments; and the end parts of the separation segments are provided with end structures for shoving off the two clamping pieces when insertion is carried out. The connecting terminal assembly has the beneficial effects of providing a connecting terminal assembly capable of effectively reducing insertion and extraction force and simultaneously ensuring the reliability of connection and being used for clamping insertion pieces.

Owner:NANJING CHERVON IND

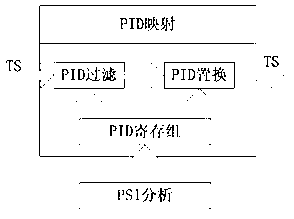

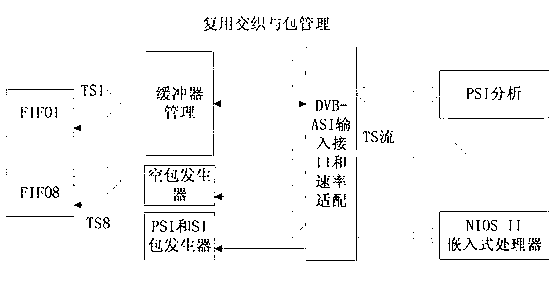

Digital television multiplexer remote control method based on Ethernet

InactiveCN103313104ARemote control and monitoring of working statusImplement remote control insertionSelective content distributionOperating instructionRemote control

The invention discloses a digital television multiplexer remote control method based on Ethernet. The method comprises the steps that 1, each subtask module sends a task request to a data sending module; 2, a control client end identifies the type of a subtask and transmits an operating instruction sent by the subtask to a multiplexer client end through the data sending module via the Ethernet; 3, the multiplexer client end analyzes and processes the operating instruction and makes a response, if the operating instruction is a parameter setting instruction, parameters for multiplex processing are set, and if the operating instruction is a current parameter monitoring instruction, data is exchanged to the control client end; 4, the control client end receives the data and analyzes and monitors the data to end. Due to the adoption of a remote control multiplexer mode, the working state of one or a plurality of multiplexer(s) can be remotely controlled and monitored, EPG (Electronic Program Guide) information insertion can be remotely controlled, the bandwidth of an input channel is not occupied, and the processed information content is larger.

Owner:GUANGZHOU ZHONGDA TELECOMM TECH

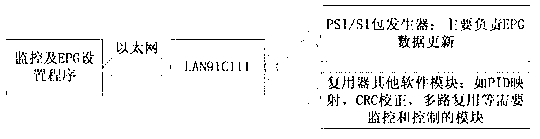

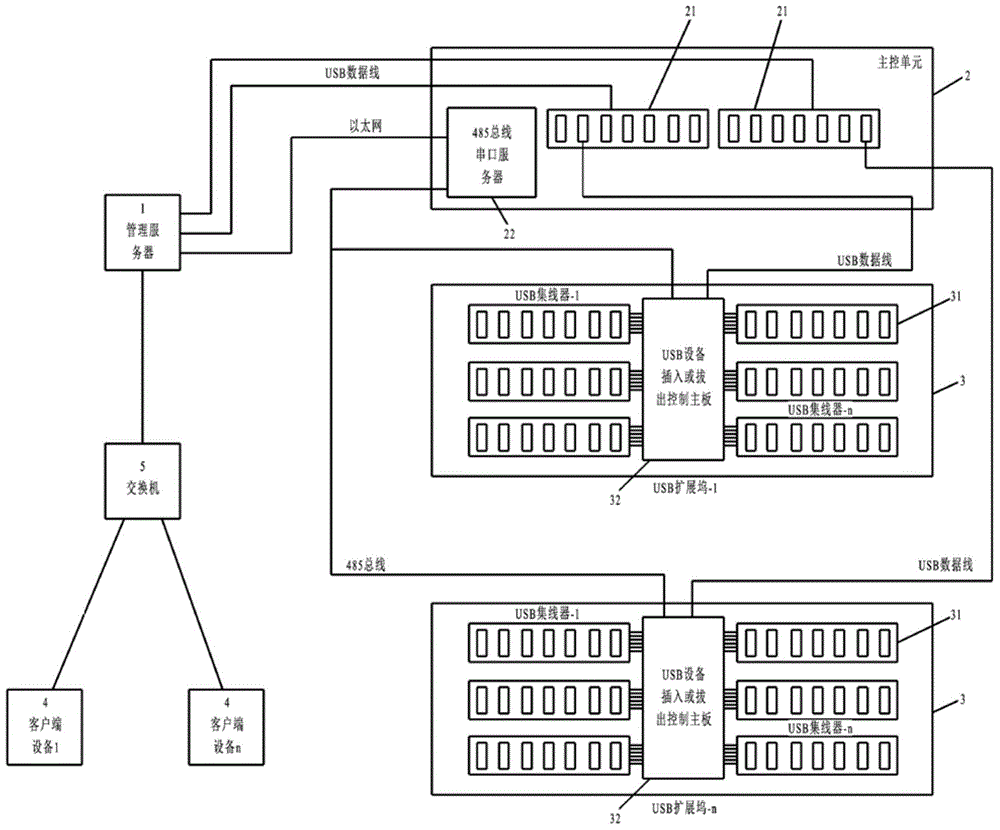

Intelligent management system for large-scale USB equipment

ActiveCN104866448AAchieve insertionAchieve pull outElectric digital data processingDocking stationManagement process

The invention relates to mobile equipment management, in particular to an intelligent management system for large-scale USB equipment, and solves the problems caused by frequent plugging and unplugging of the USB equipment and cross using of the USB equipment. The system comprises one or more USB equipment docking stations, a management server and client devices; a plurality of USB equipment are plugged into the USB equipment docking stations; the management server is communicated with the USB equipment docking stations, and is used for controlling the on-off state of the USB equipment; the client devices are communicated with the management server; an operator inputs information to the client device to ask the management server to power on or off the specific USB equipment. Through the configuration, the purpose of plugging the USB equipment into the server or unplugging the USB equipment out of the server can be realized, without physical plugging and unplugging, the service life of the USB equipment is prolonged, meanwhile, on-line concentrated management of the large-scale USB equipment can be realized, the management processes such as manual saving, searching and borrowing are simplified, and therefore, the working efficiency is improved.

Owner:众合云科信息技术集团有限公司

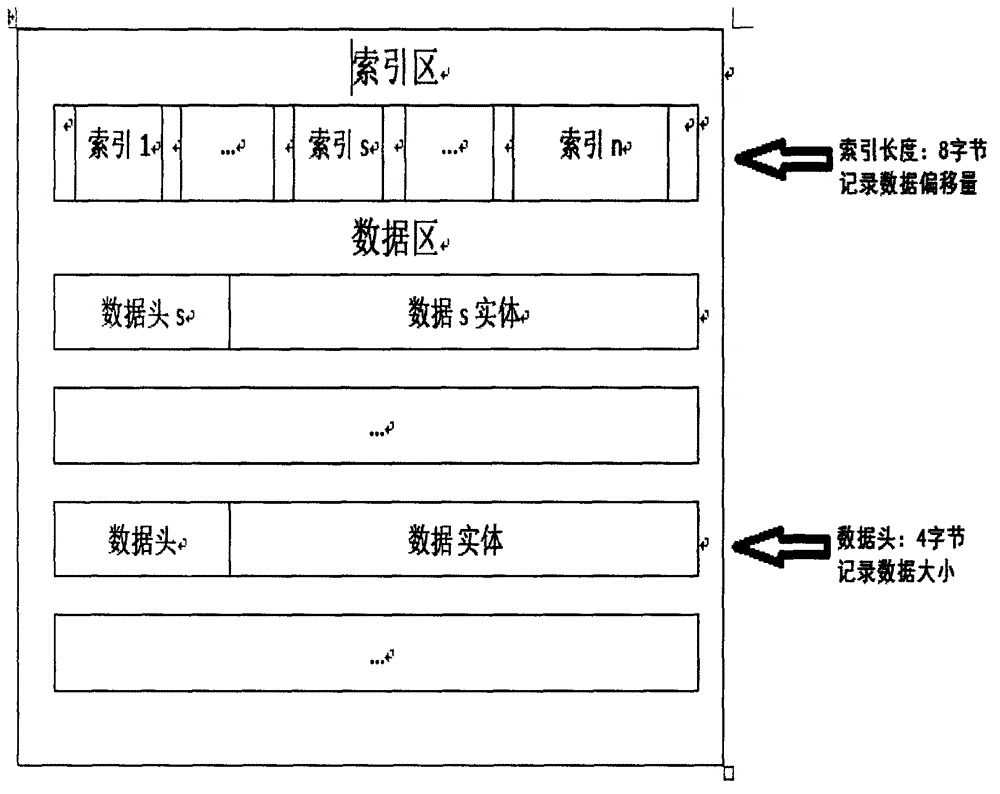

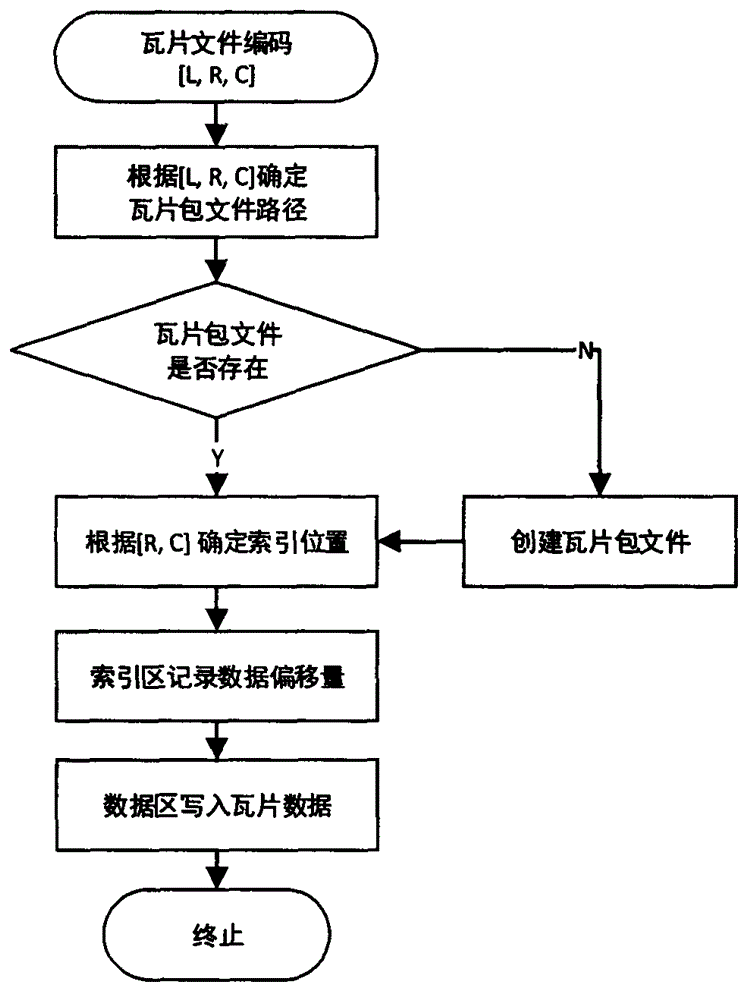

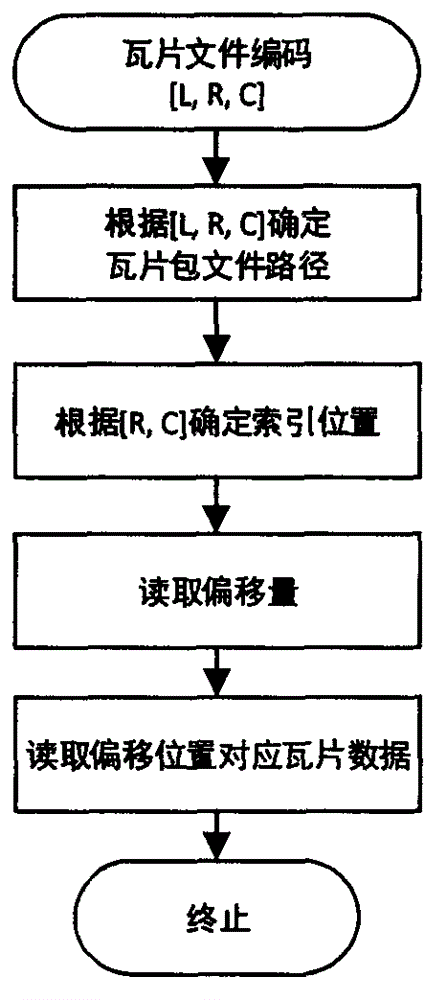

Storage method for map tile file

ActiveCN105117451AAchieve integrationAchieve insertionGeographical information databasesSpecial data processing applicationsTime complexitySmall files

The invention discloses a storage method for a map tile file. The method comprises the following steps: (1) for each layer, packaging tile data according to a fixed structure and quantity to form tile package files, wherein each tile package file comprises an index area with fixed length and an arbitrarily extendable data area, the index area records offset positions of the tile data according to a [Row, Column] sequence of the tile data, and the tile data in the corresponding [Row, Column] is stored in the offset positions recorded by indexes. For the situations of rapid increase in number of tiles generated when a measuring scale is enlarged, increment in storage space, frequent I / O operation of a disk, high time complexity and excessively high main node management pressure, the storage method for the map tile file can reduce storage space, improve retrieval efficiency, facilitate migration of lots of small files, effectively improve copy and deletion efficiency of the map tile data, and provide packaging, updating and reading operations of the tile data.

Owner:SUZHOU ZHONGKE IMAGE SKY REMOTE SENSING TECH CO LTD

Continuous full-automatic material receiving machine for semiconductor chip tape

PendingCN109368339ARealize automatic receivingAchieve insertionLabelling machinesWebs handlingSemiconductor chipEngineering

The invention discloses a continuous full-automatic material receiving machine for a semiconductor chip tape. The continuous full-automatic material receiving machine comprises a winding mechanism forwinding the semiconductor chip tape, a feeding mechanism for providing material trays, a glue pasting mechanism for pasting ending glue, a labeling mechanism for pasting labels on the material traysand a material tray lifting mechanism for collecting the material trays; the winding mechanism, the feeding mechanism, the glue pasting mechanism, the labeling mechanism and the material tray liftingmechanism are correspondingly mounted on an inner mounting plate; the winding mechanism is mounted in the middle of one side of the inner mounting plate; the material tray lifting mechanism is mountedat the lower end of the inner mounting plate and is positioned directly below the winding mechanism; the winding mechanism is positioned directly above the winding mechanism; the glue pasting mechanism is positioned on the other side of the winding mechanism; and the labeling mechanism is positioned on one side of the winding mechanism. The continuous full-automatic material receiving machine further comprises a material guiding mechanism for conveying a chip carrier tape. The output end of a material guiding rail in the material guiding mechanism extends to the winding mechanism and is butted with the winding mechanism.

Owner:深圳市恒峰锐机电设备有限公司

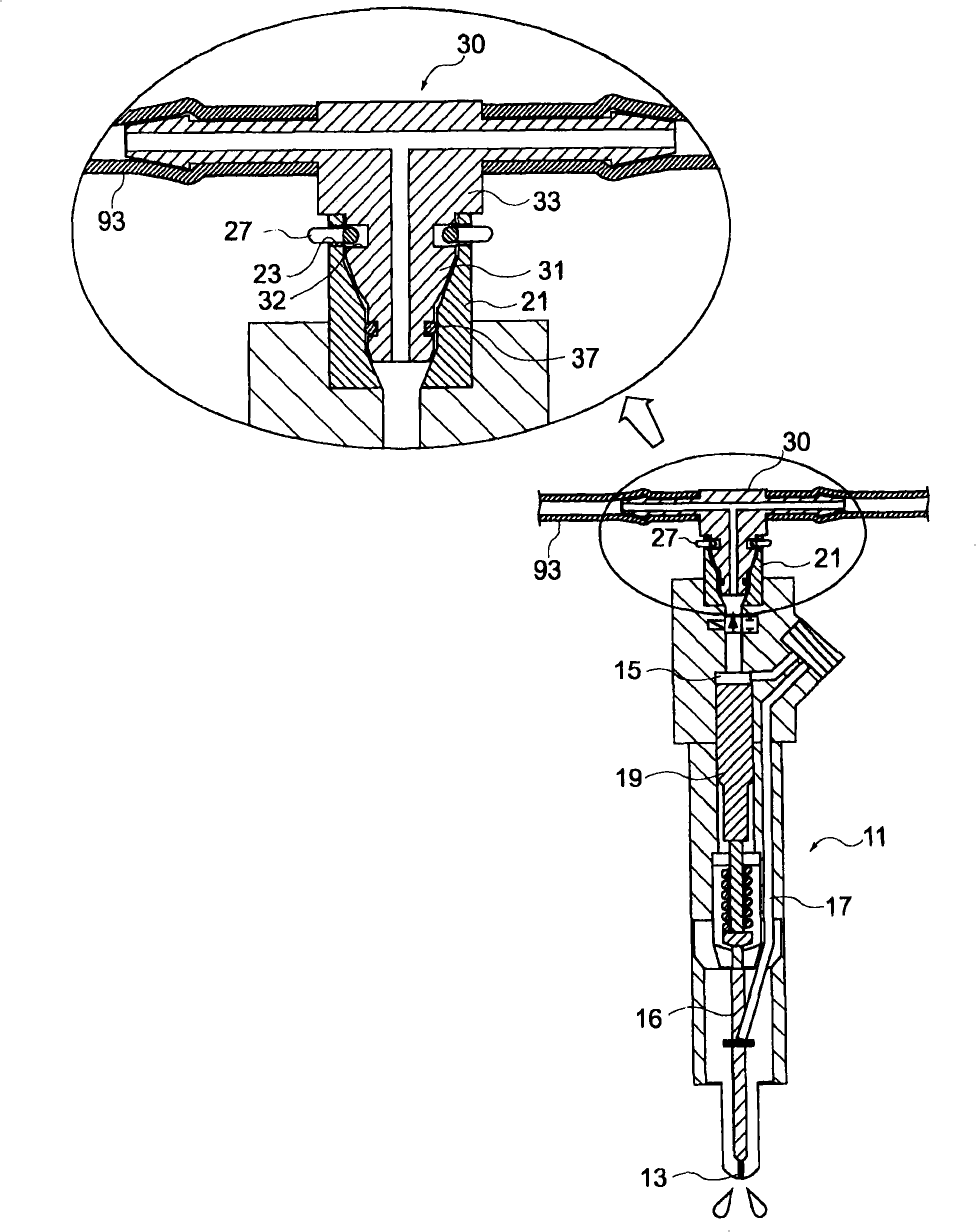

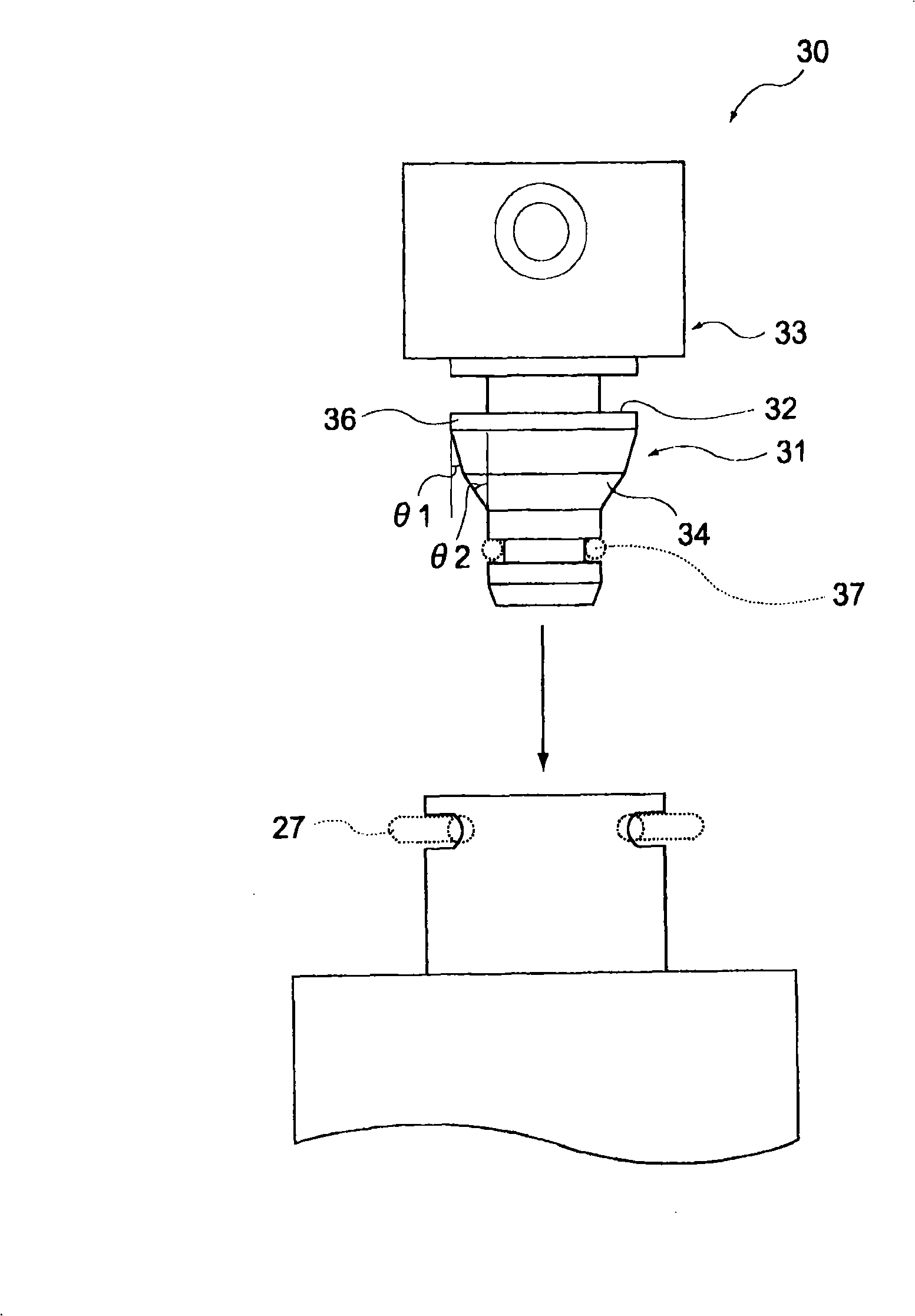

Connector for circulation, connection structure for connector for circulation, and fuel circulation system

InactiveCN101305235AReduce the burden onEasy and efficient insertionMachines/enginesCouplingsFuel tankEngineering

Provided are a connector for circulation that can be inserted into a fuel injection section with relatively small force, a connection structure for a connector for circulation, and a fuel circulation system. The connector (30) for circulation is used for a fuel circulation system in an internal combustion engine having the fuel injection section and causes fuel to flow back from the fuel injection section to a fuel tank. The connector (30) is provided between the fuel injection section and a fuel circulation hose and is joined to the fuel injection section. The connector (30) has a second groove (32) and a tapered section (34). While being inserted in the connection section, the second groove (32) is locked together with a first groove of a connection section by a clip member (27). The tapered section (34) is reduced in diameter from the second groove in the direction of insertion. The inclination angle (theta 1), relative to the insertion direction, of that side of the tapered section which is closer to the second groove is set smaller than the inclination angle (theta 2), relative to the insertion direction, of that side of the tapered section which is farther from the second groove.

Owner:BOSCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com