Patents

Literature

397results about How to "Increase insertion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

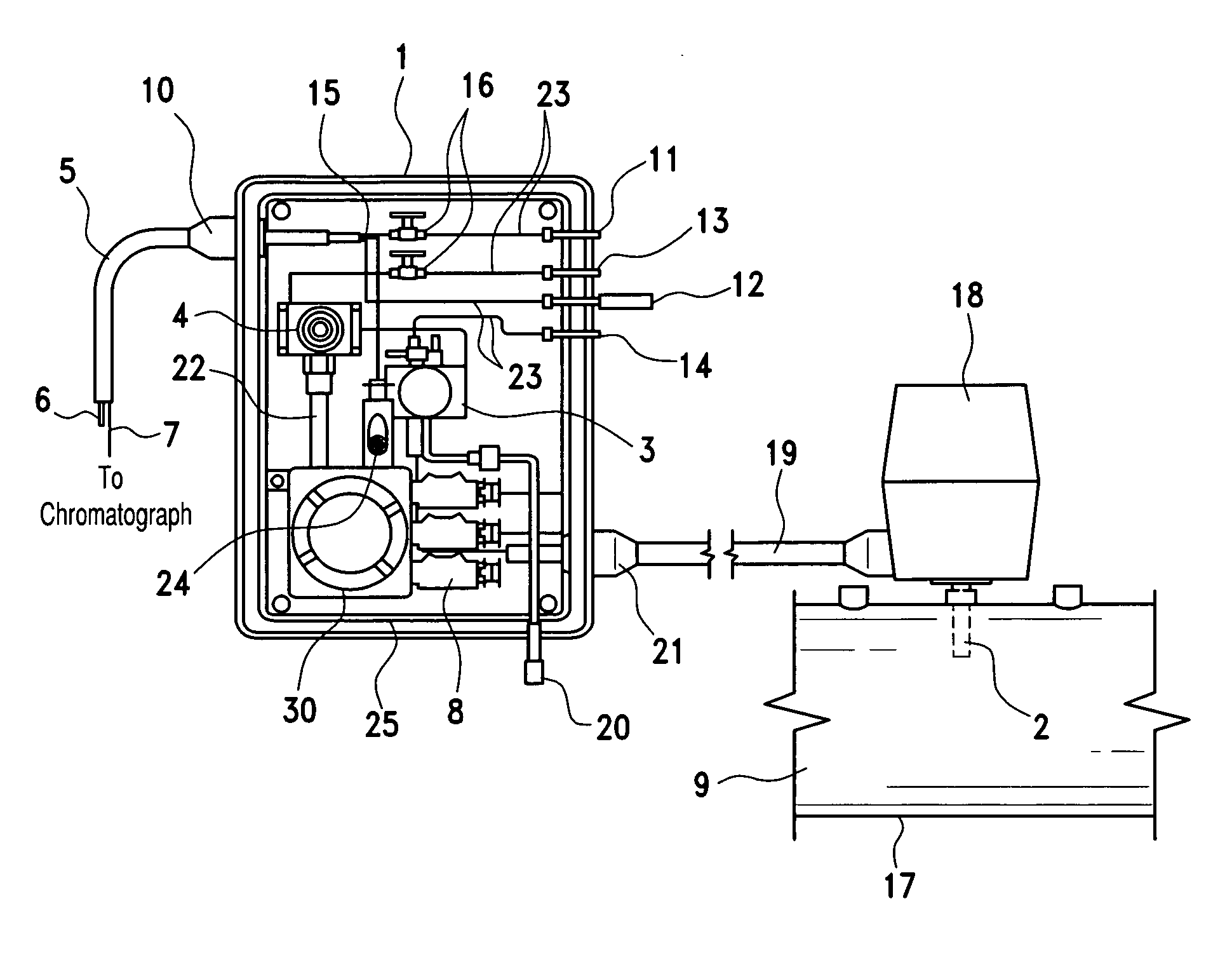

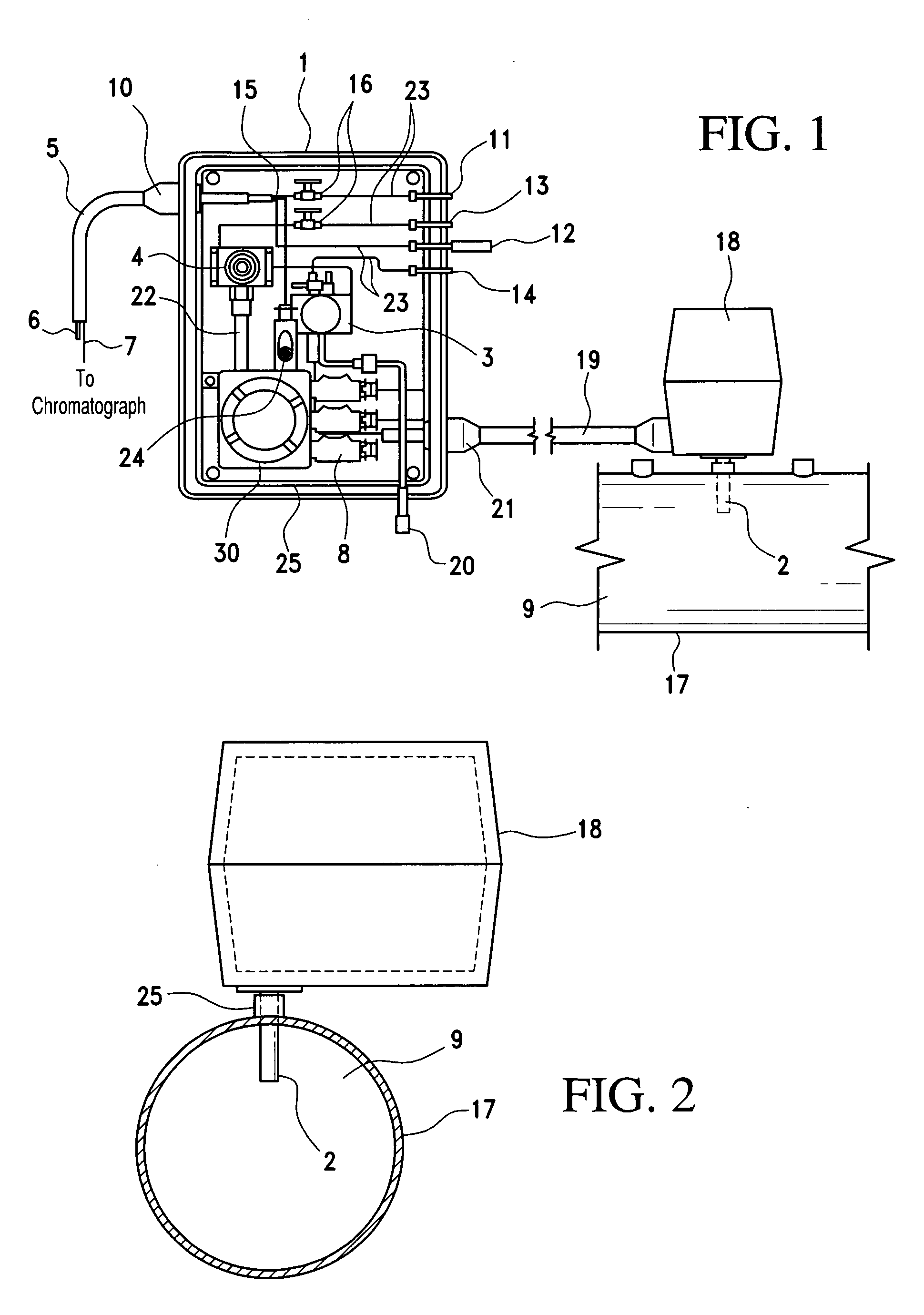

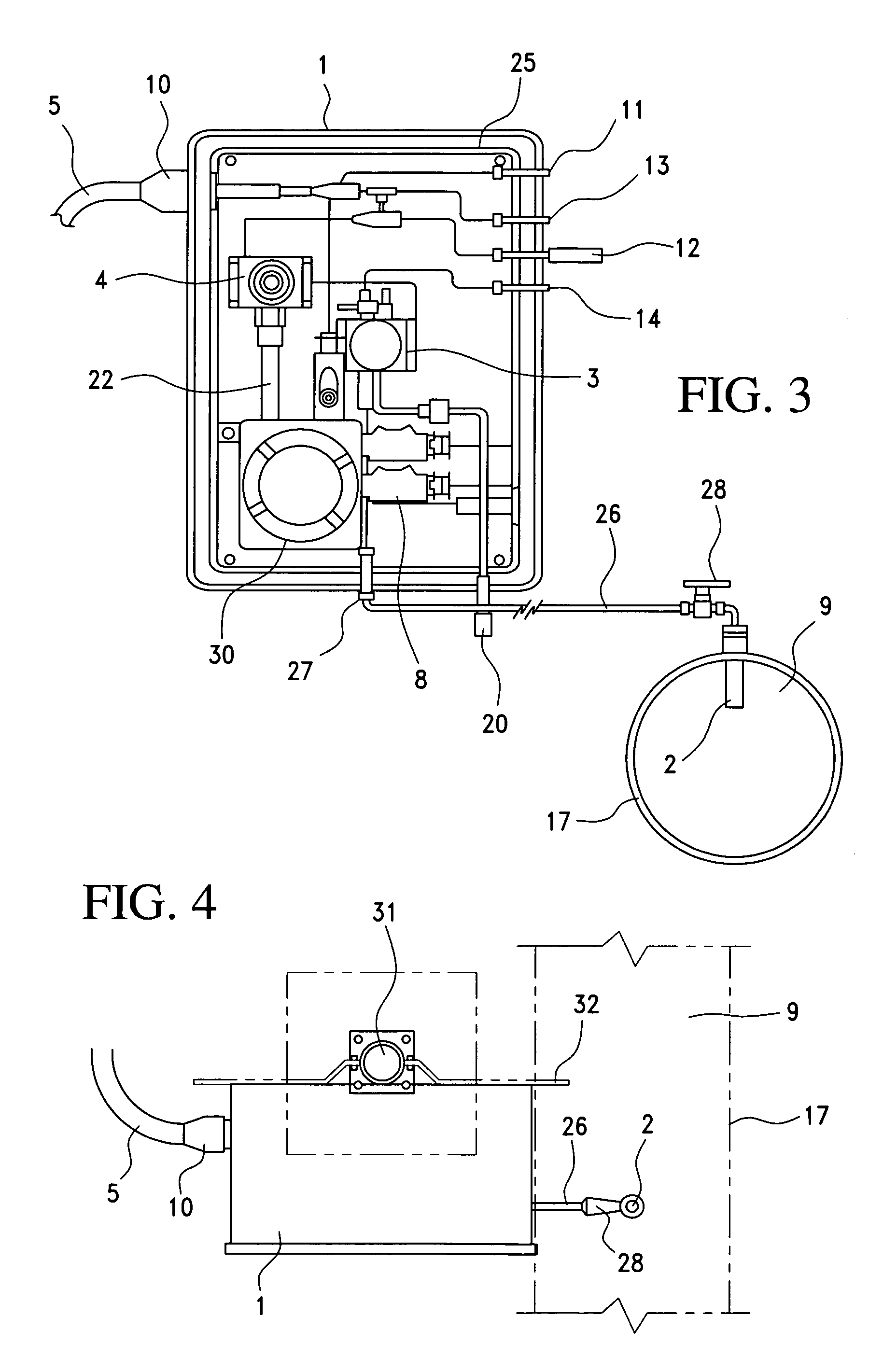

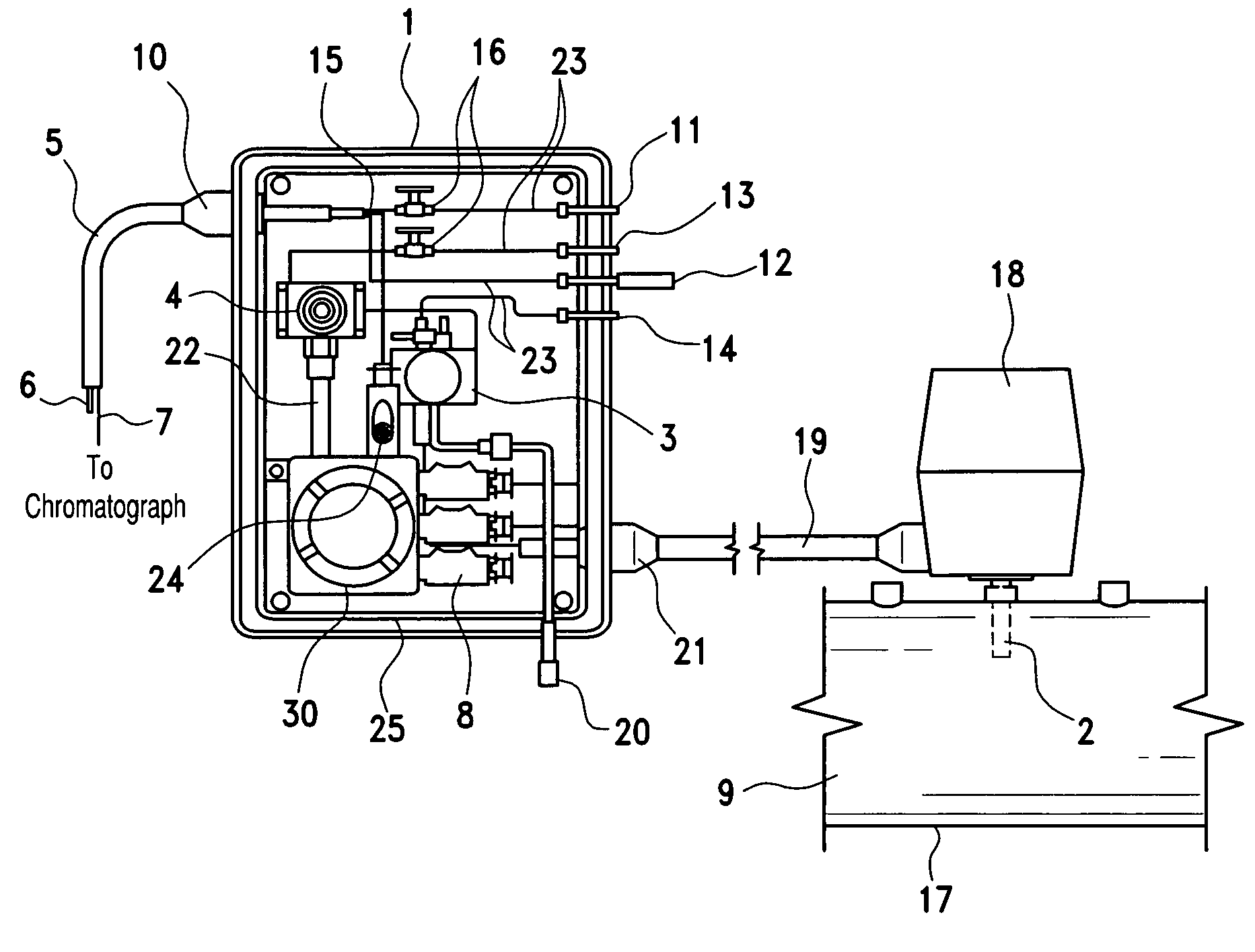

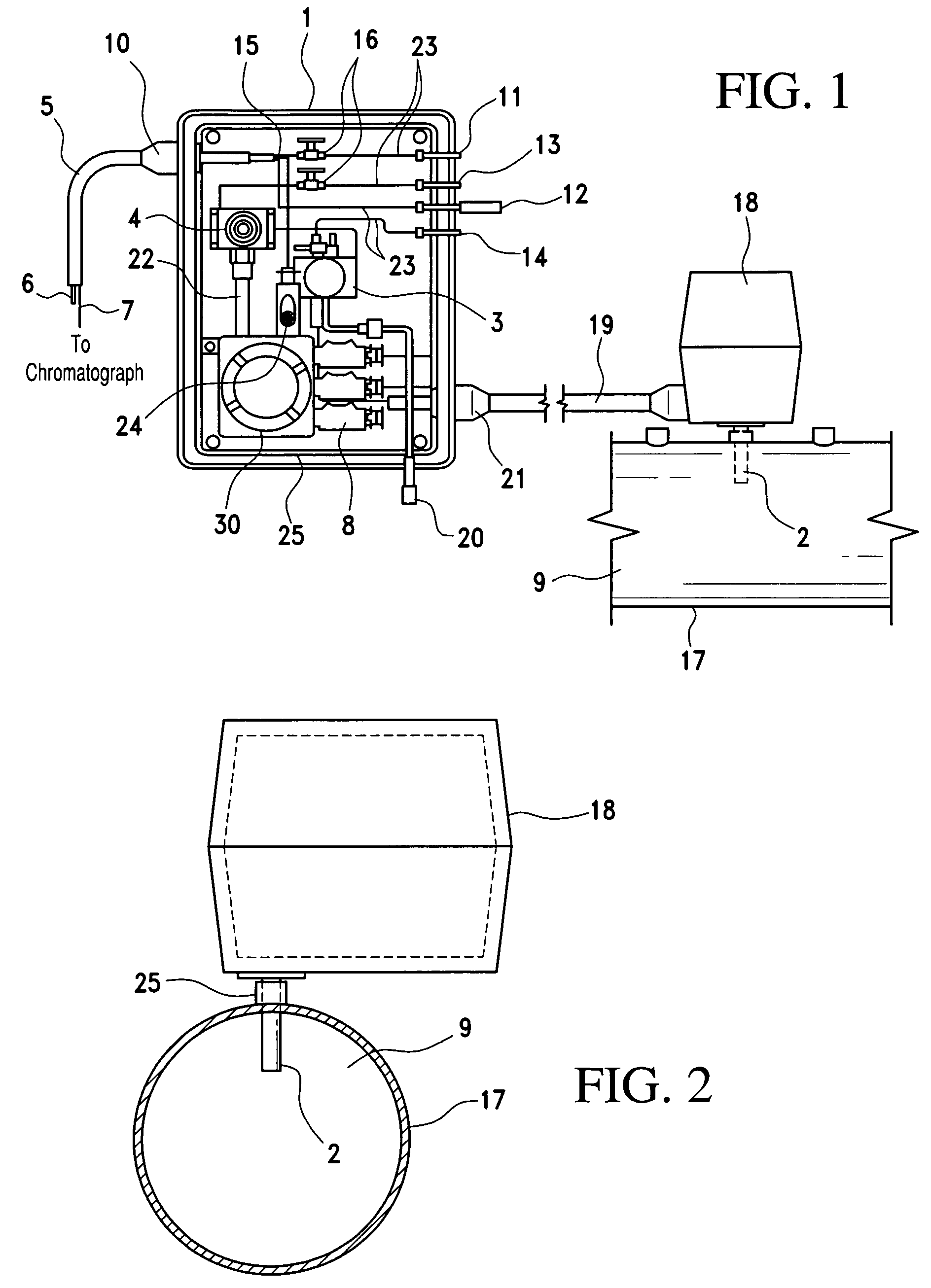

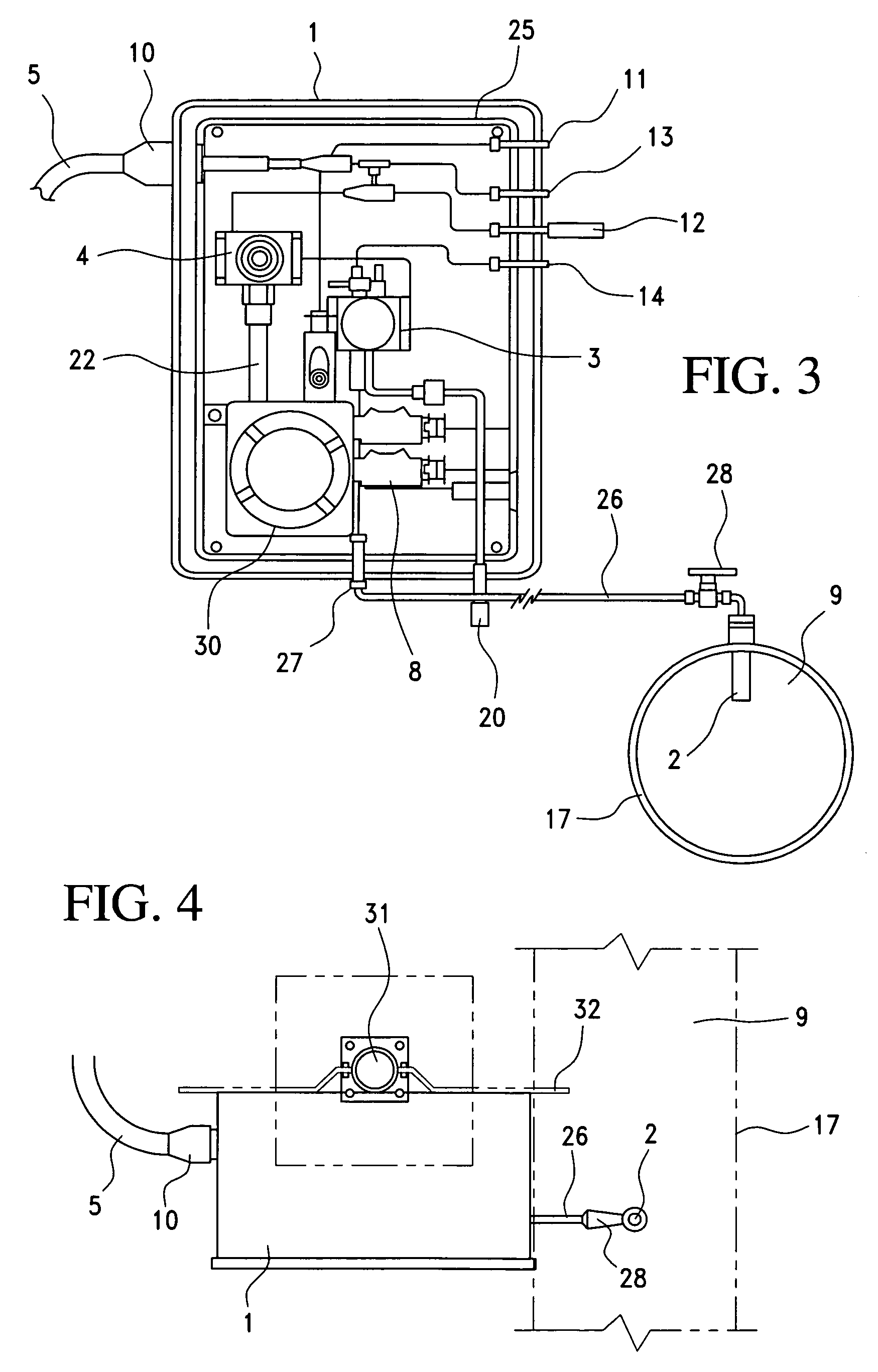

Gas sample conditioning system

ActiveUS20060000298A1Enhance gas line sample insertion efficiencyReducing inherent risk attendantComponent separationWithdrawing sample devicesEngineeringTemperature and pressure

A gas sample and conditioning device for sampling gas in a storage or transport device and conditioning the gas to avoid dew point dropout of the gas. A chamber for regulating the temperature and the pressure of the gas is provided with external A.C. or D.C. power using the leads of existing heat tracing cables to avoid the need for additional power sources to power the temperature and pressure regulating devices within the chamber.

Owner:MUSTANG SAMPLING

Gas sample conditioning system

ActiveUS7162933B2Increase insertion efficiencyInherent riskComponent separationWithdrawing sample devicesEngineeringTemperature and pressure

A gas sample and conditioning device for sampling gas in a storage or transport device and conditioning the gas to avoid dew point dropout of the gas. A chamber for regulating the temperature and the pressure of the gas is provided with external A.C. or D.C. power using the leads of existing heat tracing cables to avoid the need for additional power sources to power the temperature and pressure regulating devices within the chamber.

Owner:MUSTANG SAMPLING

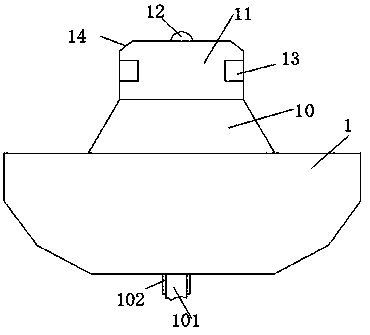

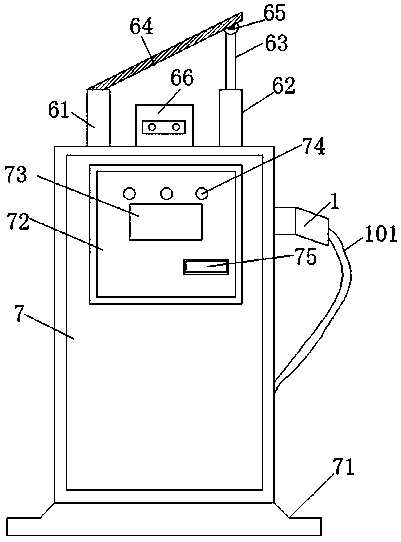

Fast charging device of new energy automobile

ActiveCN106864302AReduce personnel operationsImprove insertion efficiencyCharging stationsCoupling device detailsAutomatic controlElectricity

The invention discloses a fast charging device of a new energy automobile. The device comprises a transmission part and a charging pile body which is composed of a charging part and fixed on the bottom end surface of the right side of the transmission part, the end surface of the bottom of the left side of the transmission part is internally provided with a first slide groove, the first slide groove is internally provided with a first threaded rod, the right side end of the first threaded rod is connected to a first motor, the first threaded rod is in screw-thread fit connection with a first slide block, a charging gun head is arranged below the first slide block, the end surface of the left side of the charging part opposite to the right side of the charging gun head is internally provided with a plug-in groove, the right side, in the charging part, of the plug-in groove is internally provided with a circular slide groove, the rear side, in the charging part, of the circular slide groove is internally provided with a first transmission cavity, a clapboard is arranged between the first transmission cavity and the circular slide groove, and the right side, in the transmission part, of the first slide groove is internally provided with a second transmission cavity. The fast charging device of the new energy automobile is simple in structure and convenient to operate, can automatically control and achieve plug-in work and automatically control exposure and hiding work of a jack socket, and improve the overall safety of a charging pile.

Owner:泰州市海通资产管理有限公司

High-safety power supply apparatus

ActiveCN106877071AImprove insertion efficiencySimple structureCoupling device detailsMechanical engineeringEngineering

Owner:STATE GRID SHANDONG ELECTRIC POWER

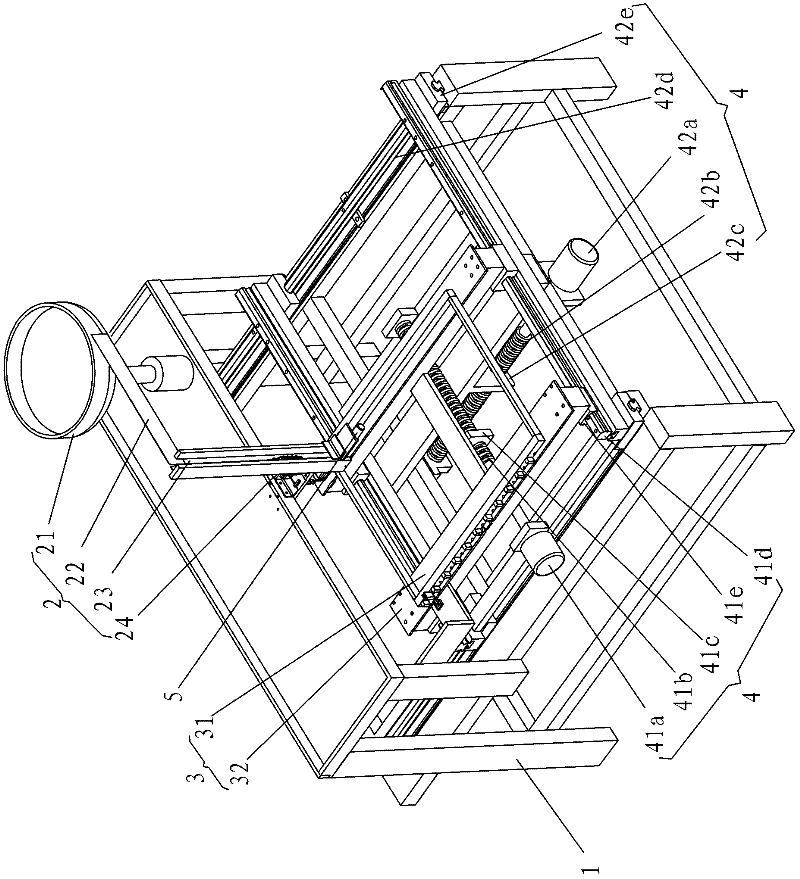

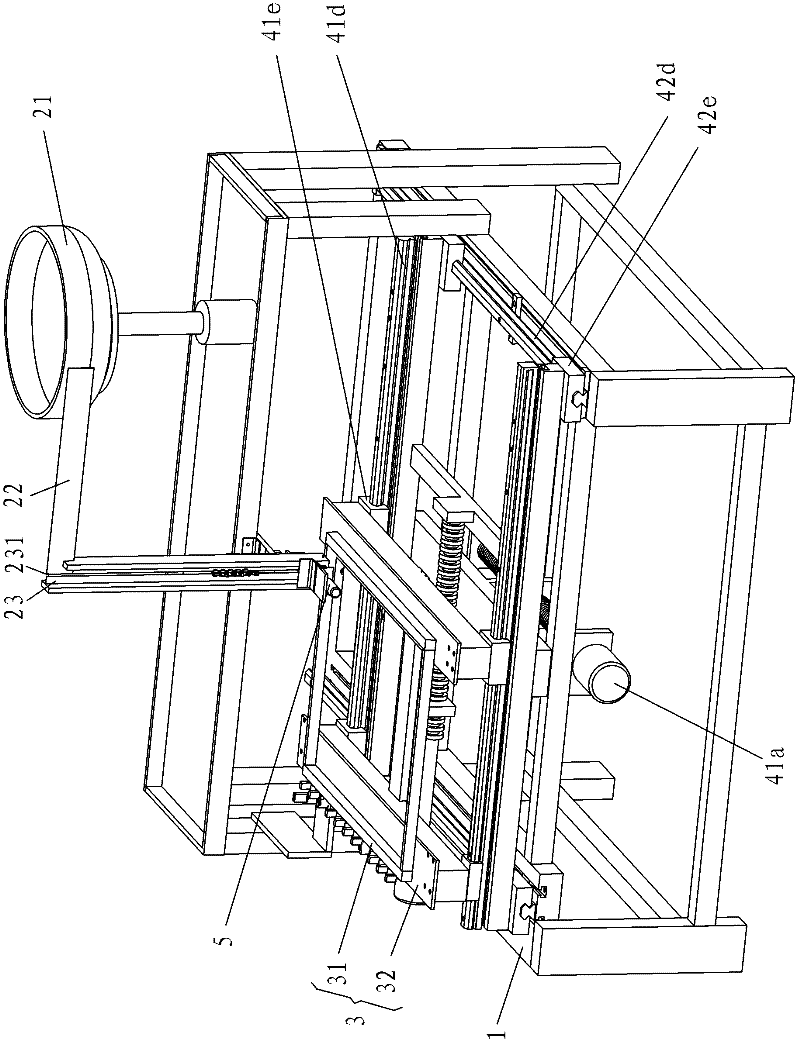

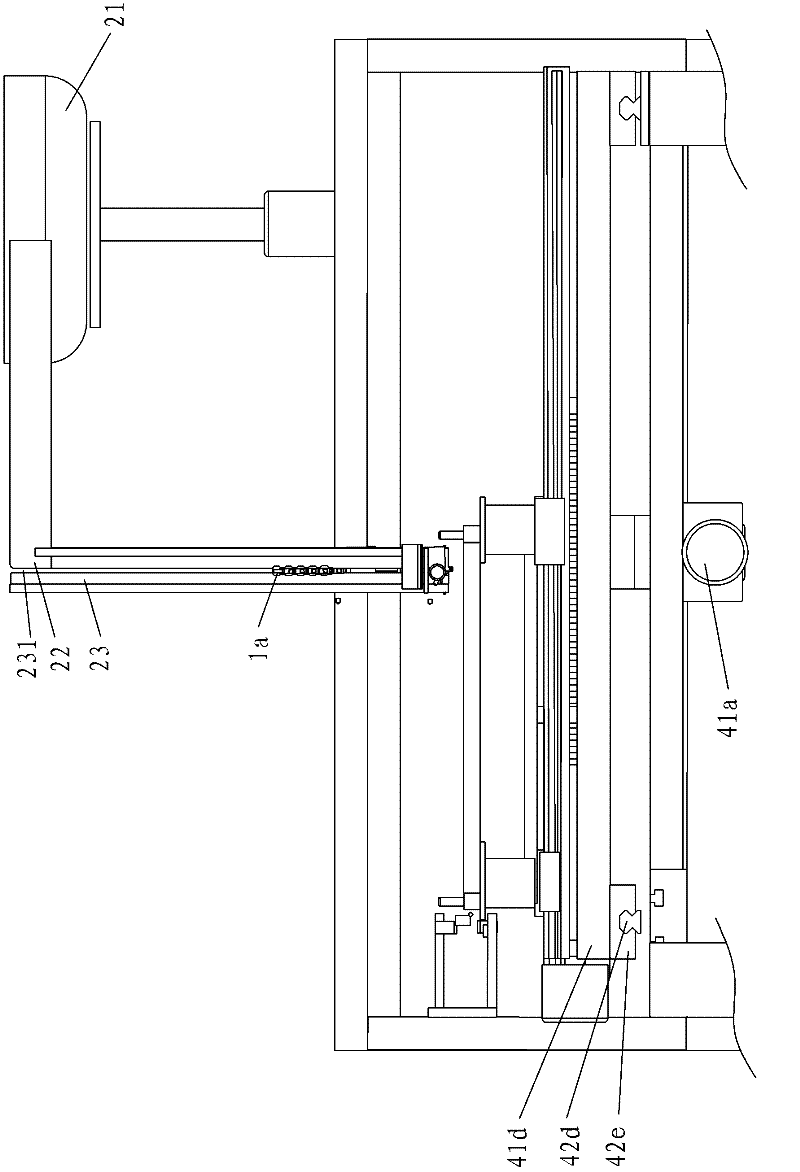

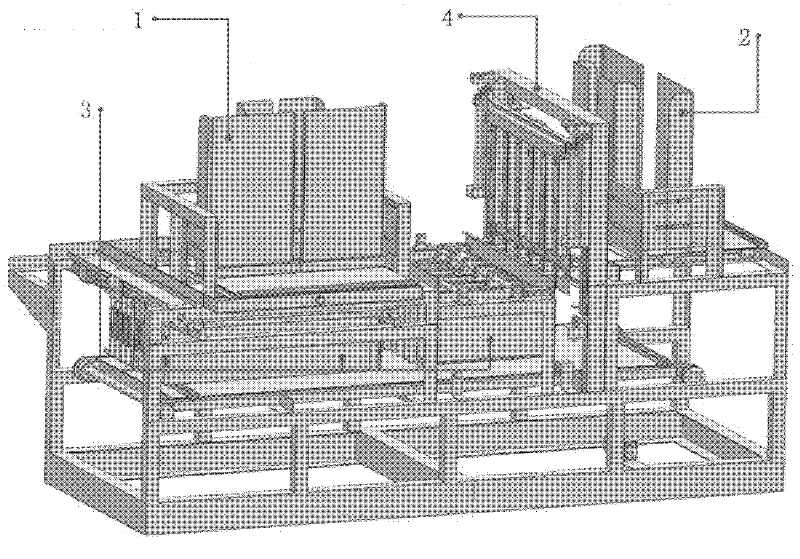

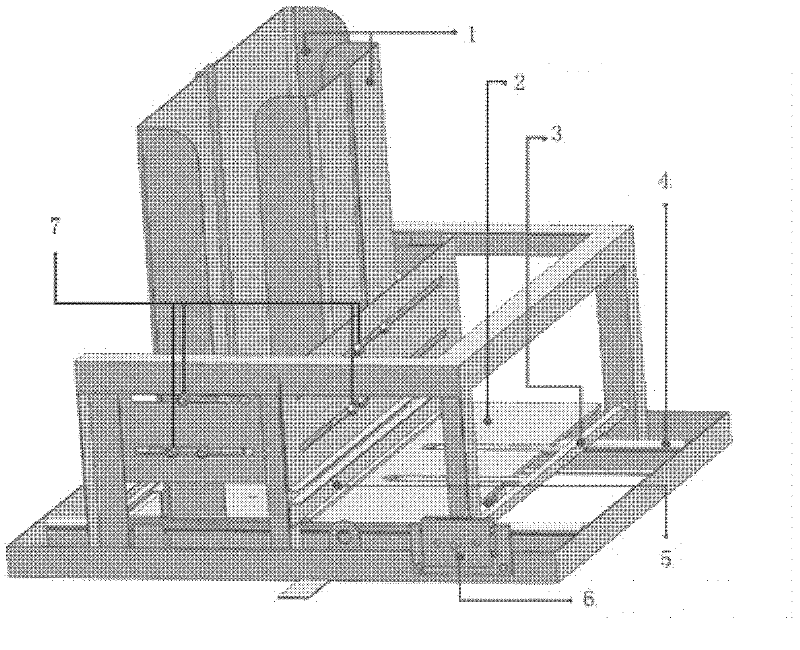

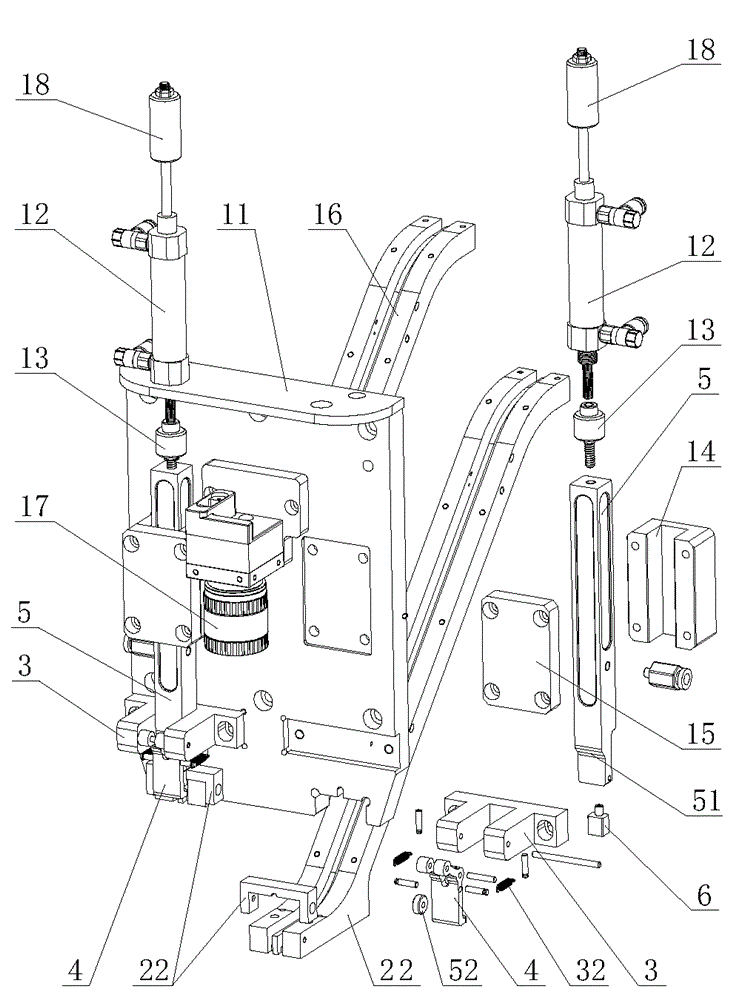

Automatic hanging machine of pullers

ActiveCN102556679ARealize automatic process insertion operationAvoid deformationStacking articlesRelative displacementControl system

The invention discloses an automatic hanging machine of pullers, which comprises a feeding device outputting pullers one by one, an insertion board provided with a plurality of insertion teeth, a material insertion device inserting the pullers on the insertion teeth on the insertion board, a driving mechanism controlling sequential relative displacement of the insertion board and the material insertion device and a control system. Output ends of the control system are respectively and correspondingly connected with the corresponding ends of the feeding device, the corresponding ends of the material insertion device and the driving mechanism, and the material insertion device comprises a hook pull mechanism and a material insertion mechanism. The control system respectively corresponds to the corresponding ends of the feeding device, the corresponding ends of the material insertion device and the driving mechanism, the driving mechanism enables the insertion board and a material insertion mechanism of the material insertion device to shift sequentially and relatively, the feeding device outputs the pullers one by one, and the material insertion device inserts the pullers on the insertion board one by one. The automatic hanging machine of pullers can achieve insertion operation in high degree automation mode. Each group of inserted pullers can reach about 120, and the automatic hanging machine of pullers can conduct 24-hour ongoing continuous insertion.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

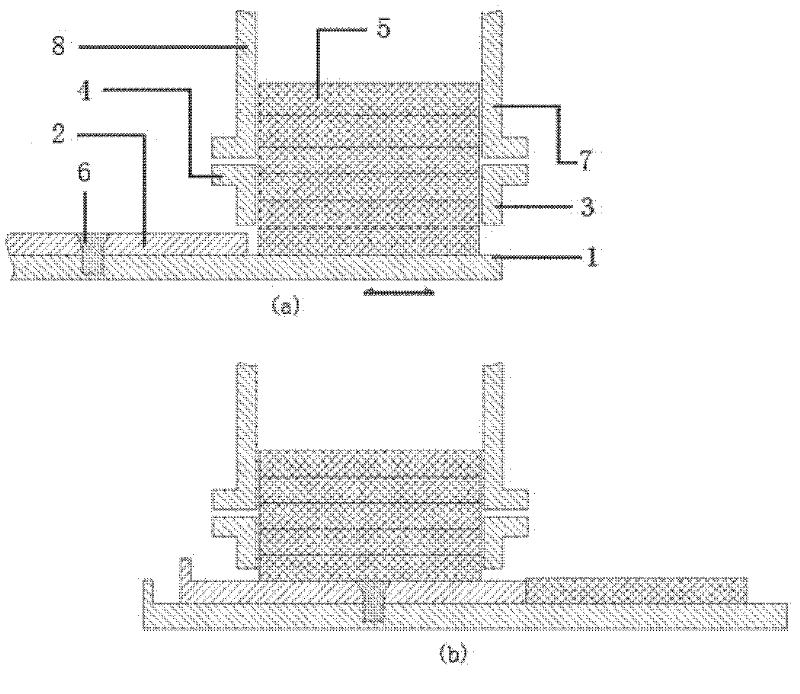

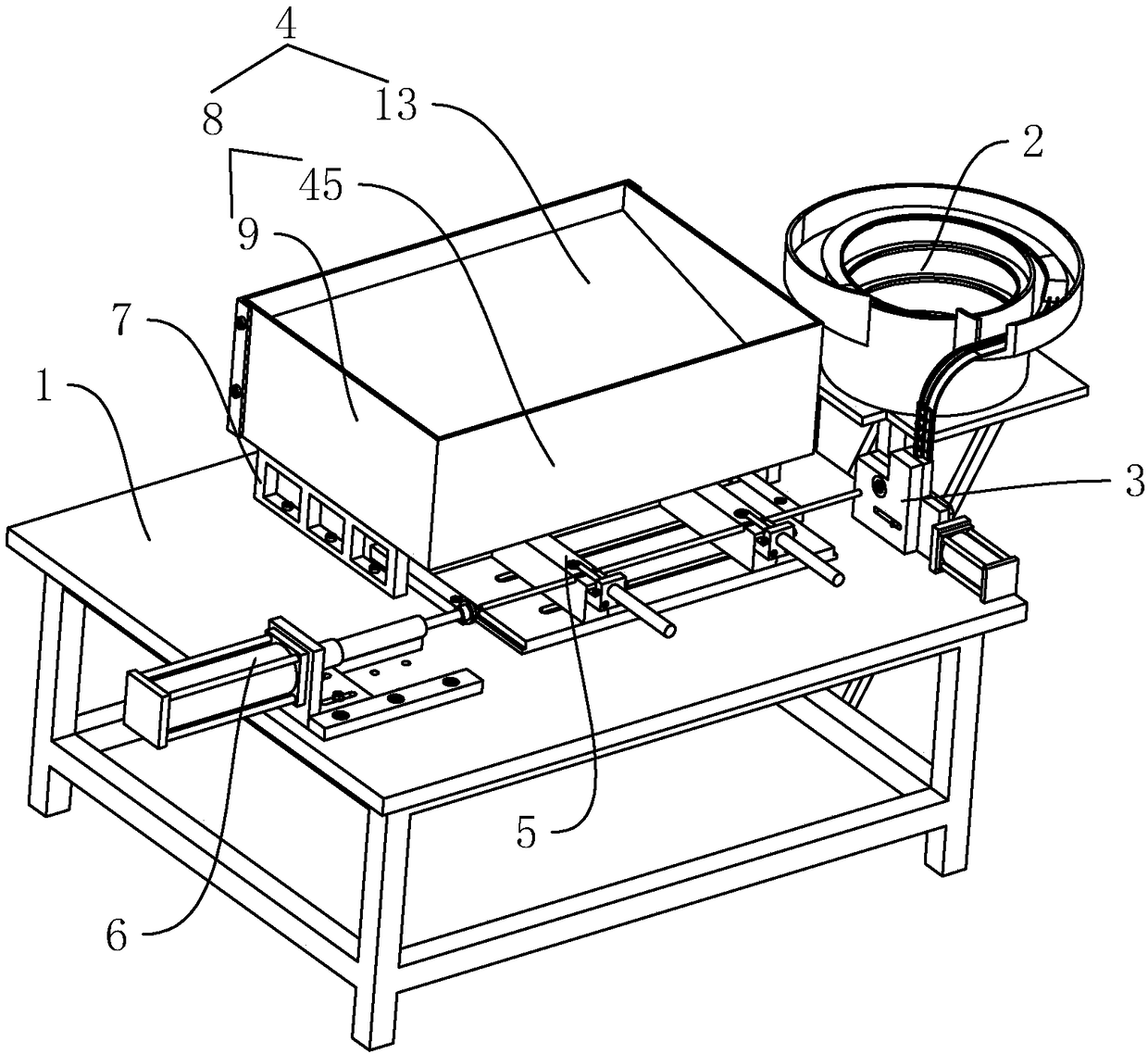

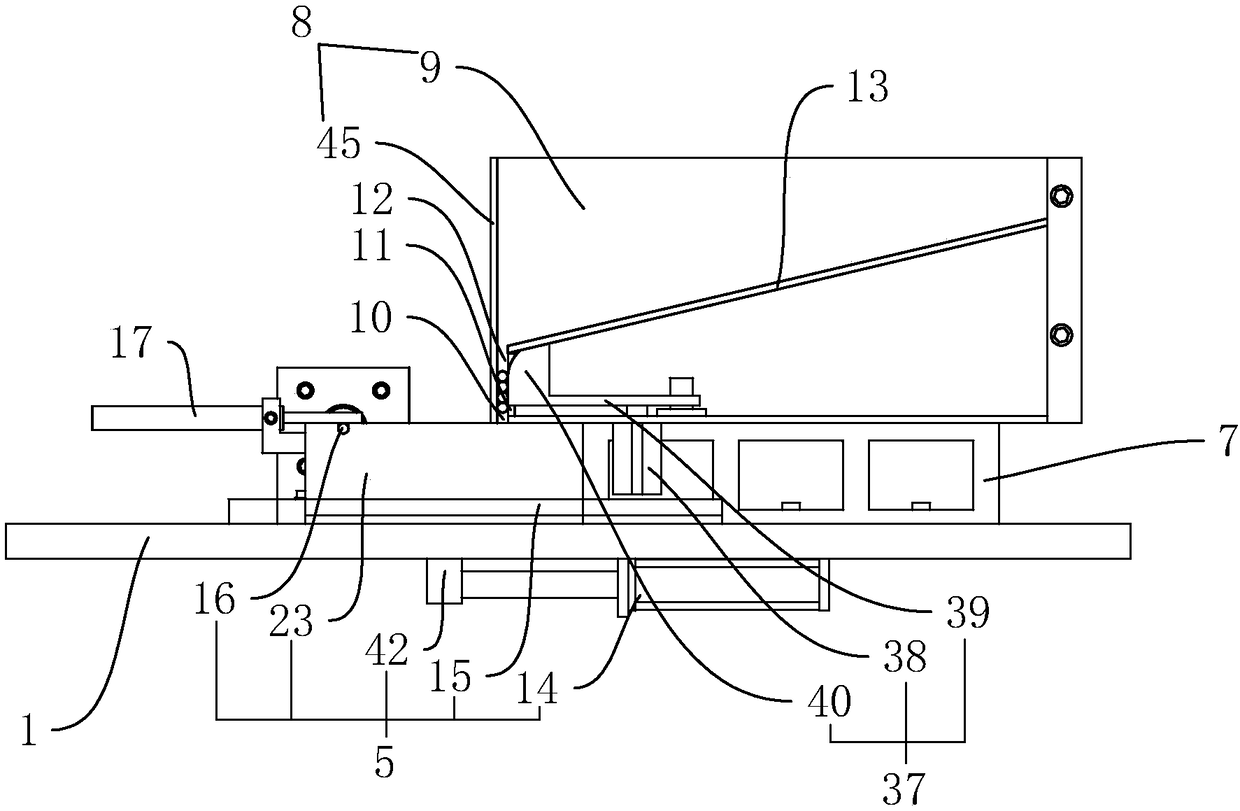

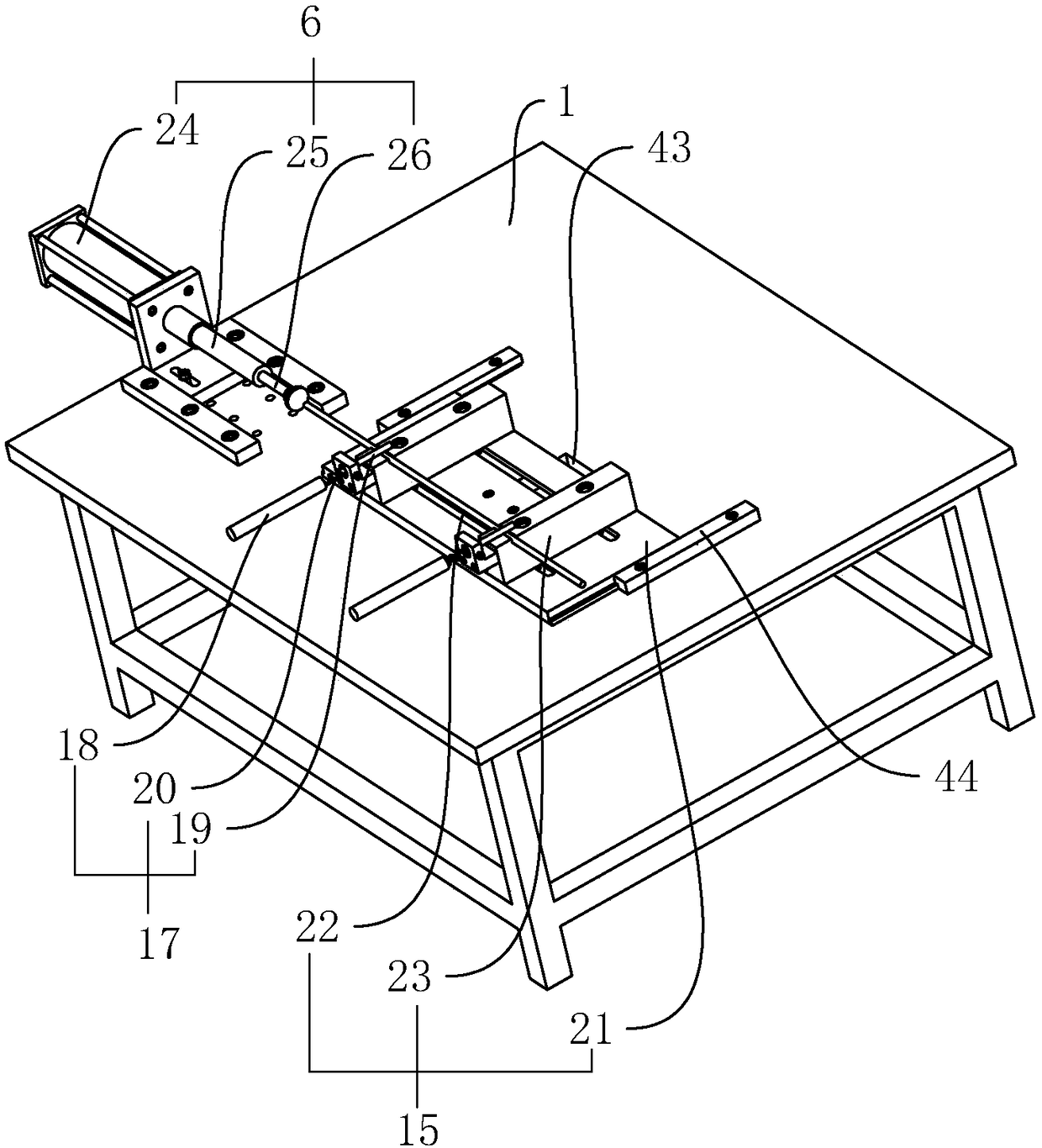

Automatic insertion machine of carton clapboard

InactiveCN102529165AIncrease insertion efficiencyContainer making machineryControl systemProgrammable logic controller

The invention designs an automatic insertion machine of a carton clapboard, which belongs to an automatic packaging machine and relates to a mechanical-electrical integration machine enabling compression molded packaging carton cutting boards to be automatically assembled into the packaging carton clapboard. The automatic insertion machine is composed of a material charging and dividing bin, an insertion material dividing bin, a longitudinal cutting board assembly transmission material channel, a transverse cutting board inserting head and the like. A cutting board material dividing bin structure is composed of a material scraping board assembly, a front clapboard, a back clapboard and a material turning-over board. A structure of the longitudinal cutting board assembly transmission material channel is composed of a fixed material channel and a movable material channel. The transverse cutting board inserting head is a mechanism for locating, absorbing, inserting and the like a transverse cutting board, insertion of the cutting board is achieved, and the carton clapboard is formed. A control system adopts a programmable logic controller (PLC), each location sensor adopts an inductance approach switch or a more accurate photoelectric sensor to be connected with a switch quantity input point of the PLC, so that the cylinder is controlled to execute movements of board pushing, board turning-over, location, insertion and the like.

Owner:QIQIHAR UNIVERSITY

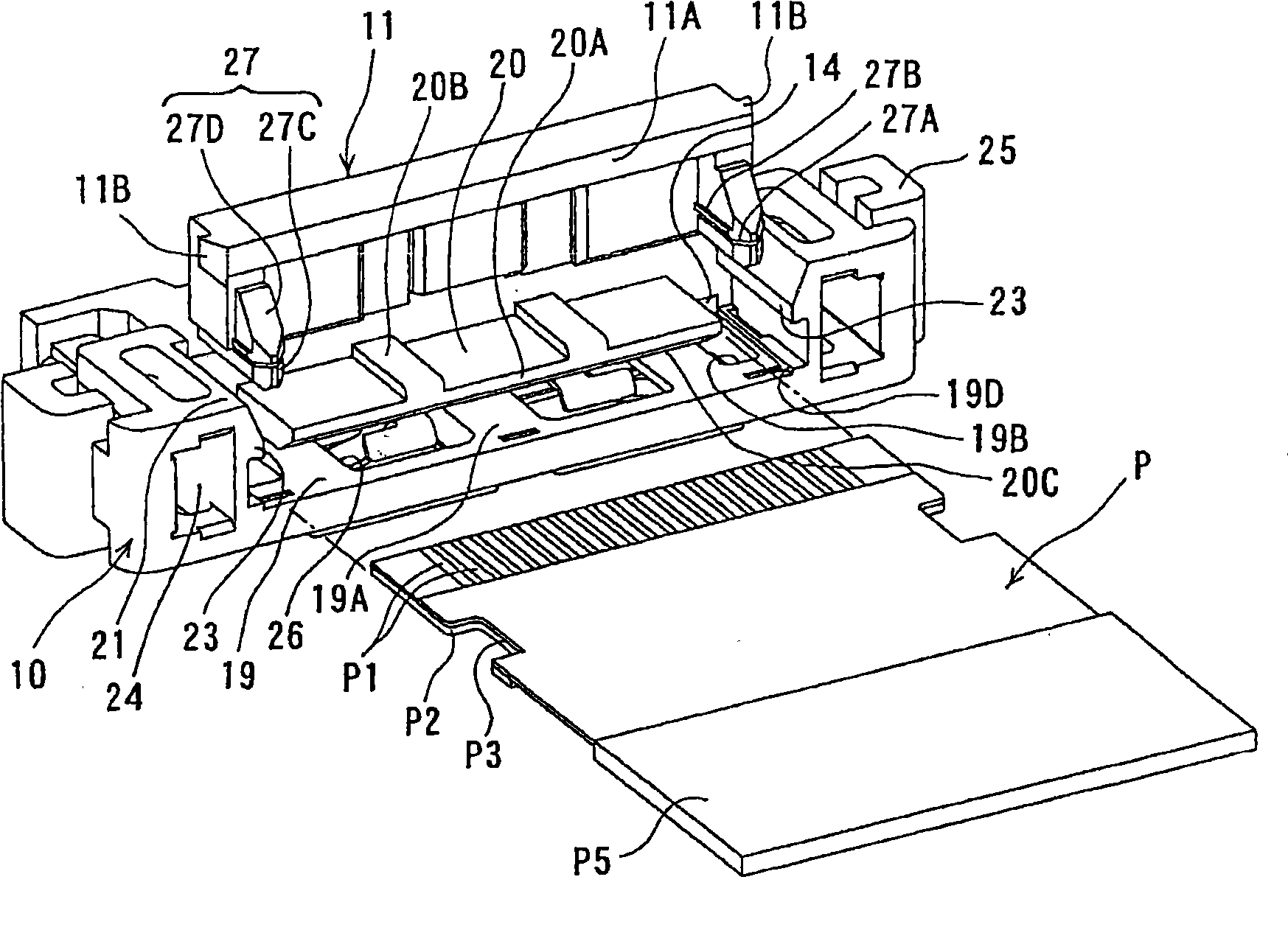

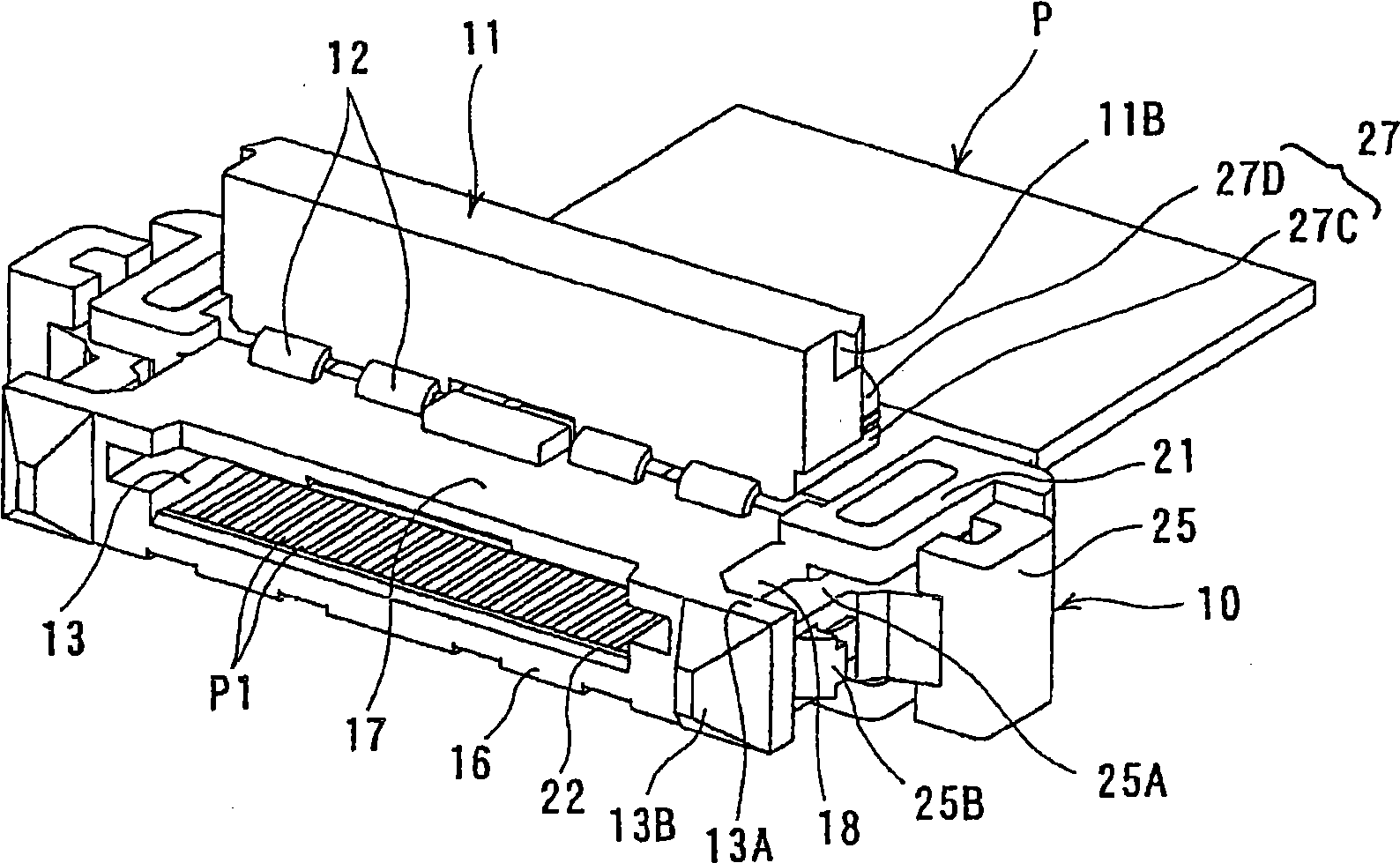

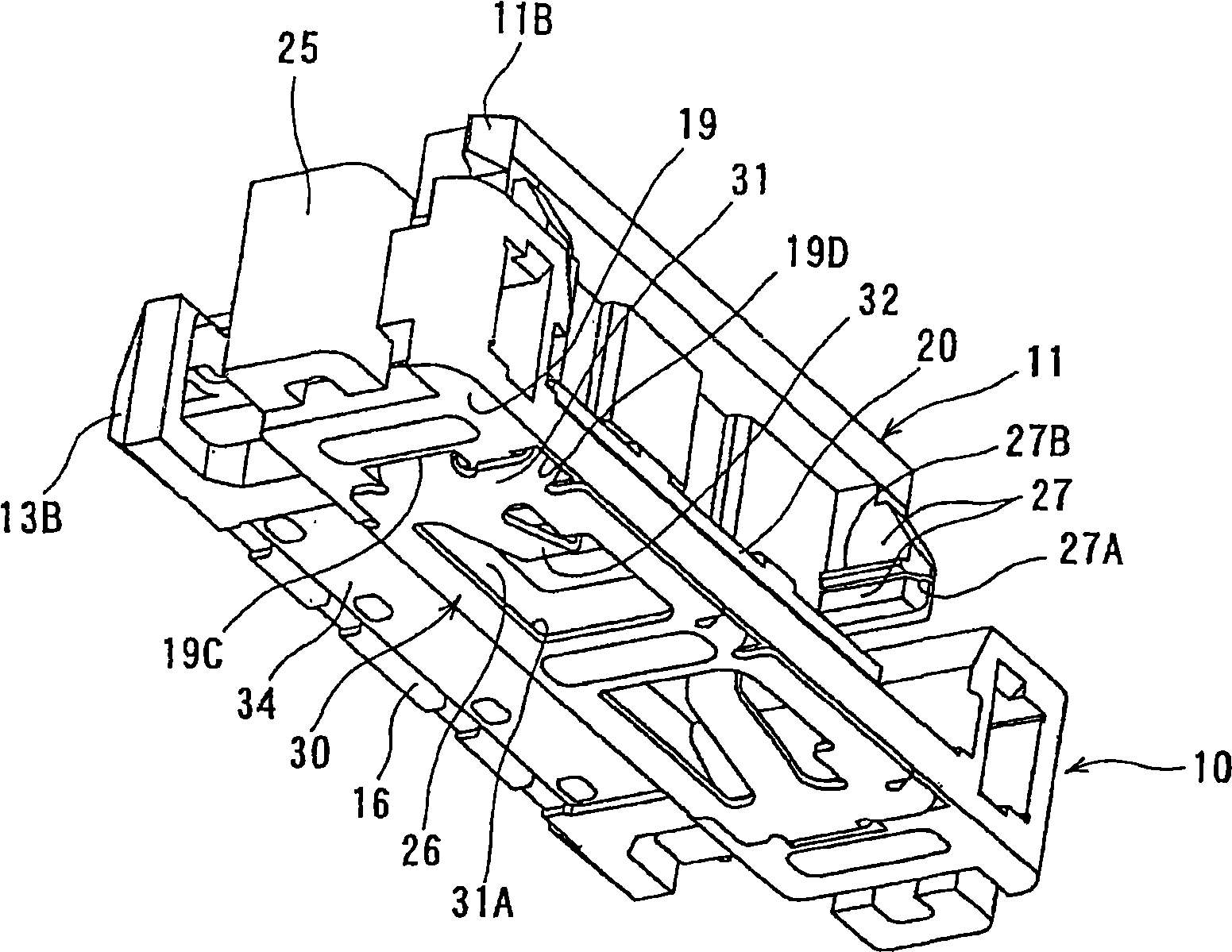

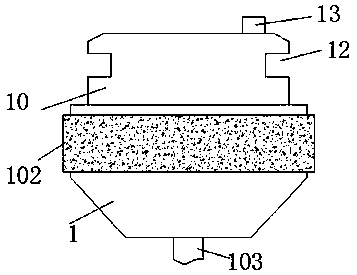

Electric connector for flat type conductor

ActiveCN101505014ALocking is effectiveImprove rigidityCoupling device detailsEngineeringElectrical conductor

A flat conductor-grade electric connector is disclosed, which is provided with: a housing body (10) of a guide space for guiding a flat conductor (P), and a pressing member (11) fixable on the housing body; one side of the housing body (10) is formed with an insertion hole (14) in which the flat conductor is inserted, the opposite other side is formed with a jointing part (13) for jointing with the connector of the other side, the insertion hole (14) is communicated with the jointing part (13), by utilizing the fixation of the pressing member (11) on the housing body (10), the pressing memberis provided with a pressing part that presses the flat conductor on a support surface, the upper edge of an opening circumference part of the insertion hole (14) at one side of the housing body (10) is more adjacent to the other side of the housing body than the lower edge and the side edge, and the pressing member (11) is provided with a protrusion part (27) which penetrates at a gap part P1 of the flat conductor P in a thickness direction of the flat conductor P when being fixed on the housing body (10). The invention can enable the flat conductor to reach a connection location easily, and even if the location is appreciably deviated, the flat conductor can still be corrected automatically and is easily inserted into the insertion hole of the housing.

Owner:HIROSE ELECTRIC GROUP

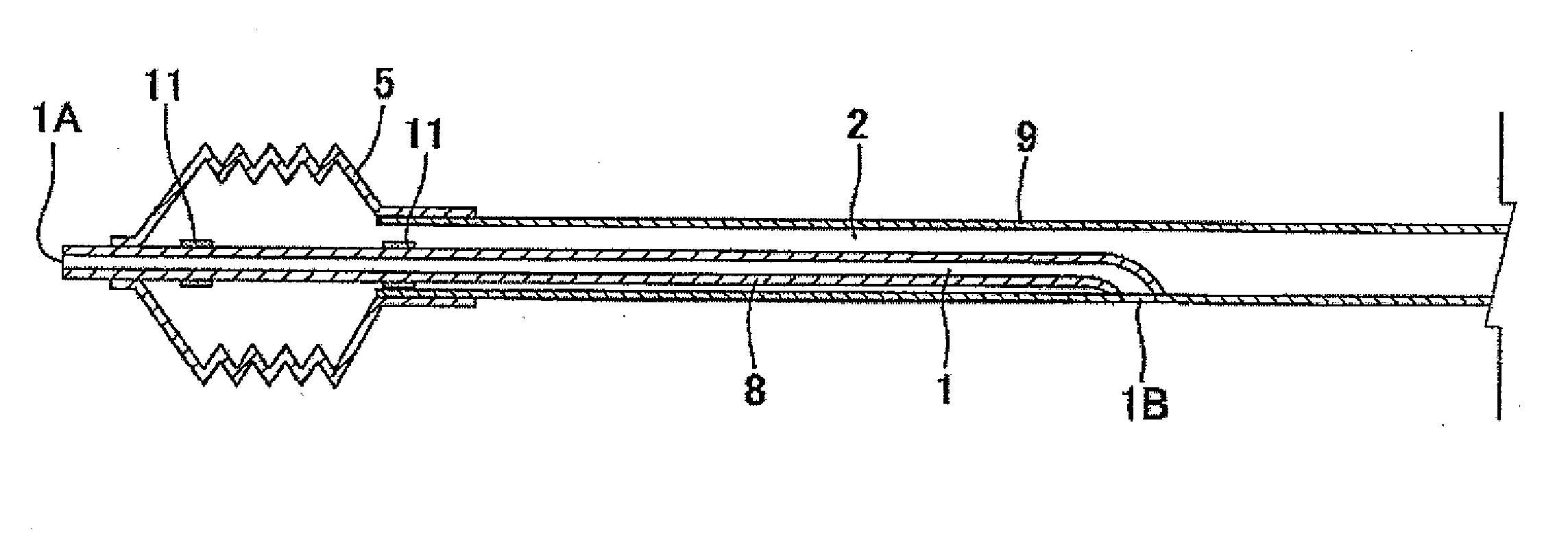

Catheter

InactiveUS20090270801A1Increase insertion efficiencyAvoid deformationStentsBalloon catheterCatheter device

A catheter having a proximal shaft and a distal shaft each having a proximal end section and a distal end section. The distal end of the proximal shaft and the proximal end of the distal shaft are connected to each other, a catheter holding hub is connected to the proximal end of the proximal shaft, and a part of at least the distal shaft is constructed from an inner shaft and an outer shaft coaxially surrounding the inner shaft. The inner shaft is extended out from the outer shaft to the distal side. The lumen of the inner shaft forms a guidewire lumen. The catheter has a means for restricting relative movement of the outer shaft and the inner shaft occurring when pressing force exceeding a predetermined level is applied to the catheter.

Owner:KANEKA CORP

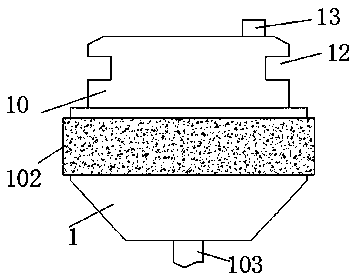

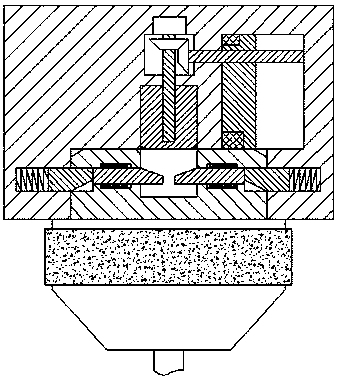

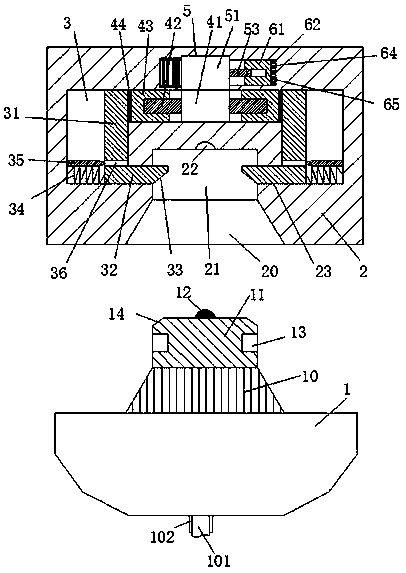

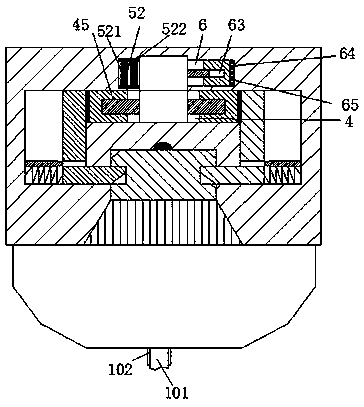

Novel kettle

InactiveCN107374260AOvercome elastic forceInhibit sheddingDrinking vesselsElectrical connectionEngineering

The invention discloses a new type of water cup, which includes a joint head connected to the cup body through a line and a cup holder mated with the joint head. The left end surface of the cup body is fixedly equipped with a handle, and the right end surface is provided with a The outlet of the water outlet, the middle point of the bottom end surface of the cup holder is provided with a slot, and the middle point of the top of the slot is provided with an electrical connection column, and the bottom end surface of the cup holder is located at the left and right ends of the slot. A locking groove, located above the slots, a first chute is connected between the two locking grooves, a cavity is arranged in the top of the first chute, and the first chute The midpoint is provided with a guide rod that expands upwards and pushes into the cavity. The overall structure of the present invention is simple, and the operation is safe and convenient.

Owner:黄均杰

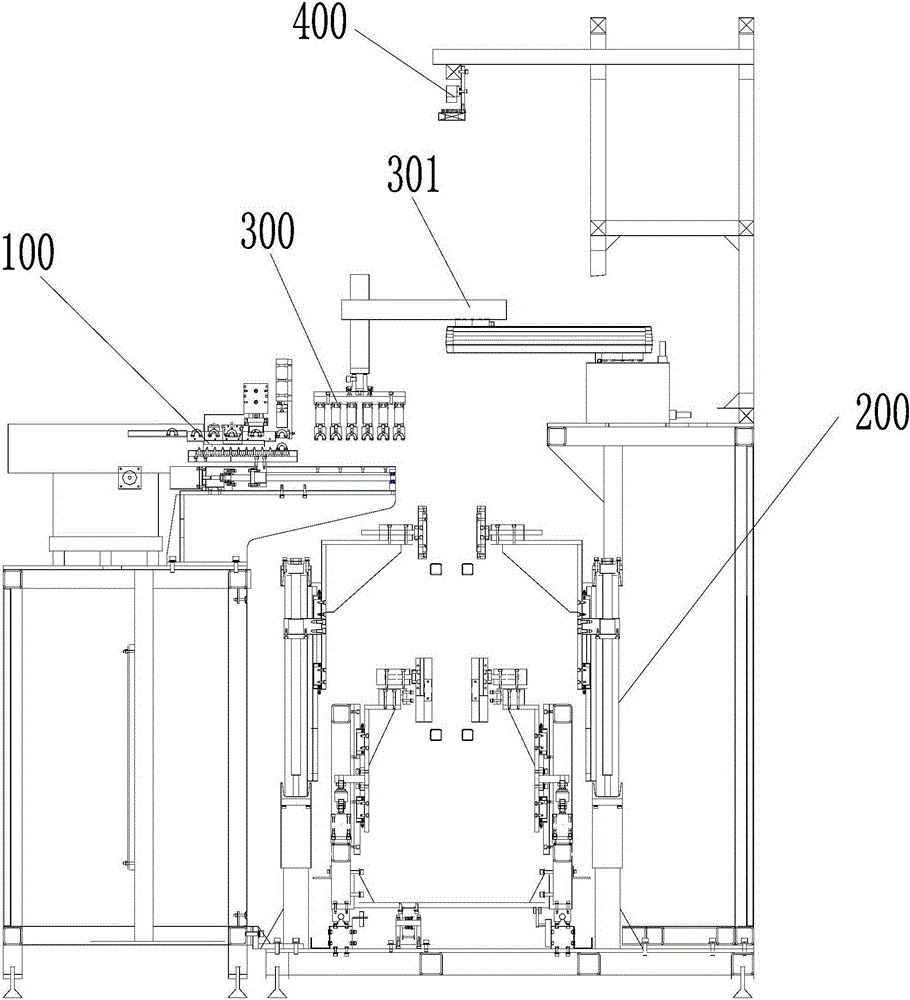

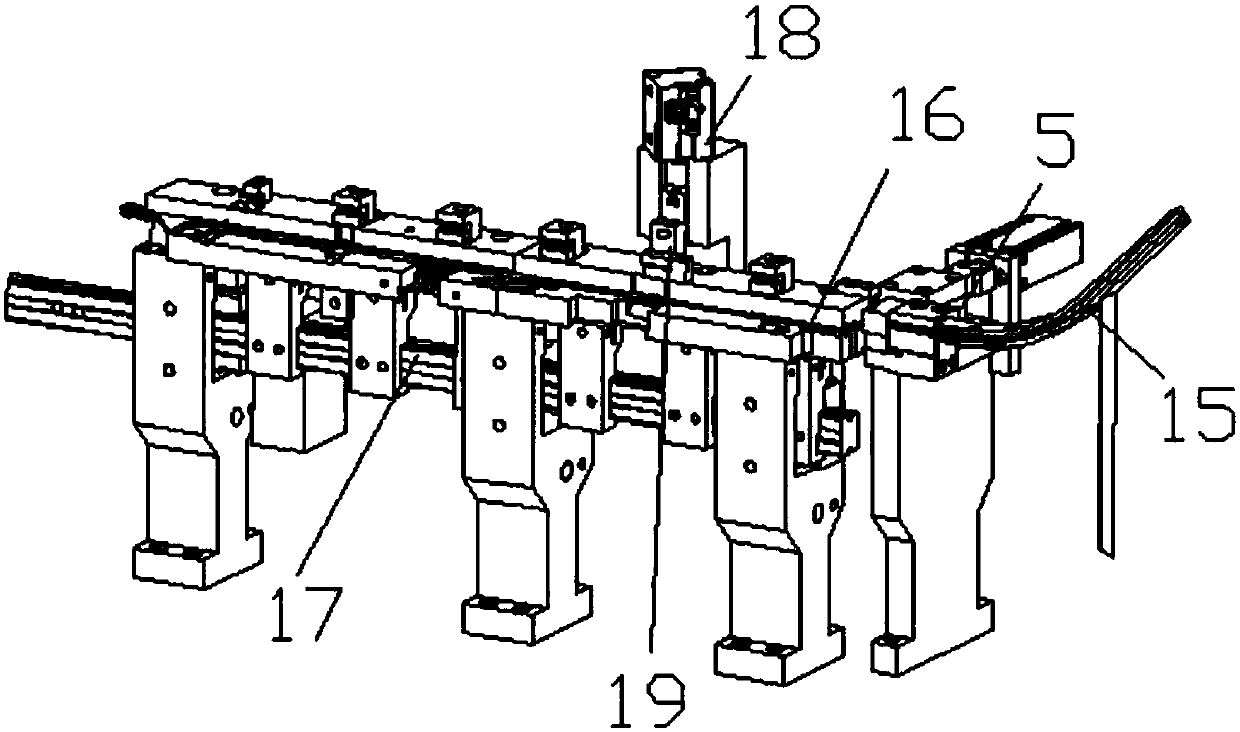

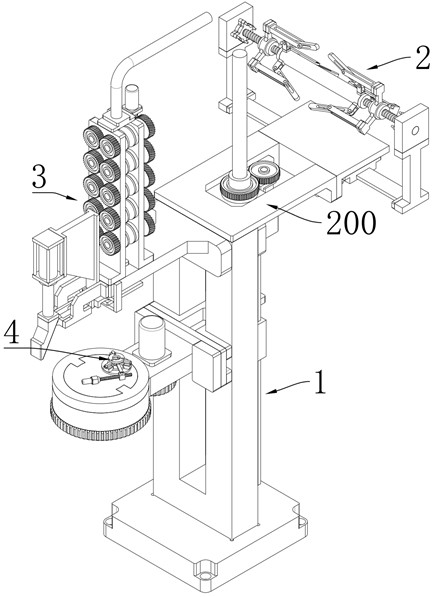

Online automatic U pipe inserting system

ActiveCN105215649AImprove U insertion accuracyImprove the efficiency of clamping and positioningMetal working apparatusEngineeringMechanical engineering

The invention discloses an online automatic U pipe inserting system. The online automatic U pipe inserting system comprises a screening and shaping mechanism used for screening and shaping short U pipes, an online positioning mechanism used for positioning and adjusting an air conditioner condenser, and an automatic clamping claw floating mechanism used for inserting the short U pipes into the air conditioner condenser. The initial position of the automatic clamping claw floating mechanism corresponds to the travel terminal of the screening and shaping mechanism, and the ending position of the automatic clamping claw floating mechanism corresponds to the travel terminal of the online positioning mechanism. According to the online automatic U pipe inserting system, the consistency of the short U pipes is improved through the screening and shaping mechanism, and automatic insertion of the short U pipes is facilitated; the online positioning mechanism is provided with an adjusting component and a horizontal limiting portion to carry out pose adjustment on workpieces before clamping and locating of the workpieces, so that the positions of the clamped workpieces meet the positioning requirement of U pipe inserting assembling, and the U pipe inserting precision is improved; the automatic clamping claw floating mechanism is used for automatically inserting the short U pipes into the air conditioner condenser.

Owner:思睿智能医学科技(武汉)有限公司

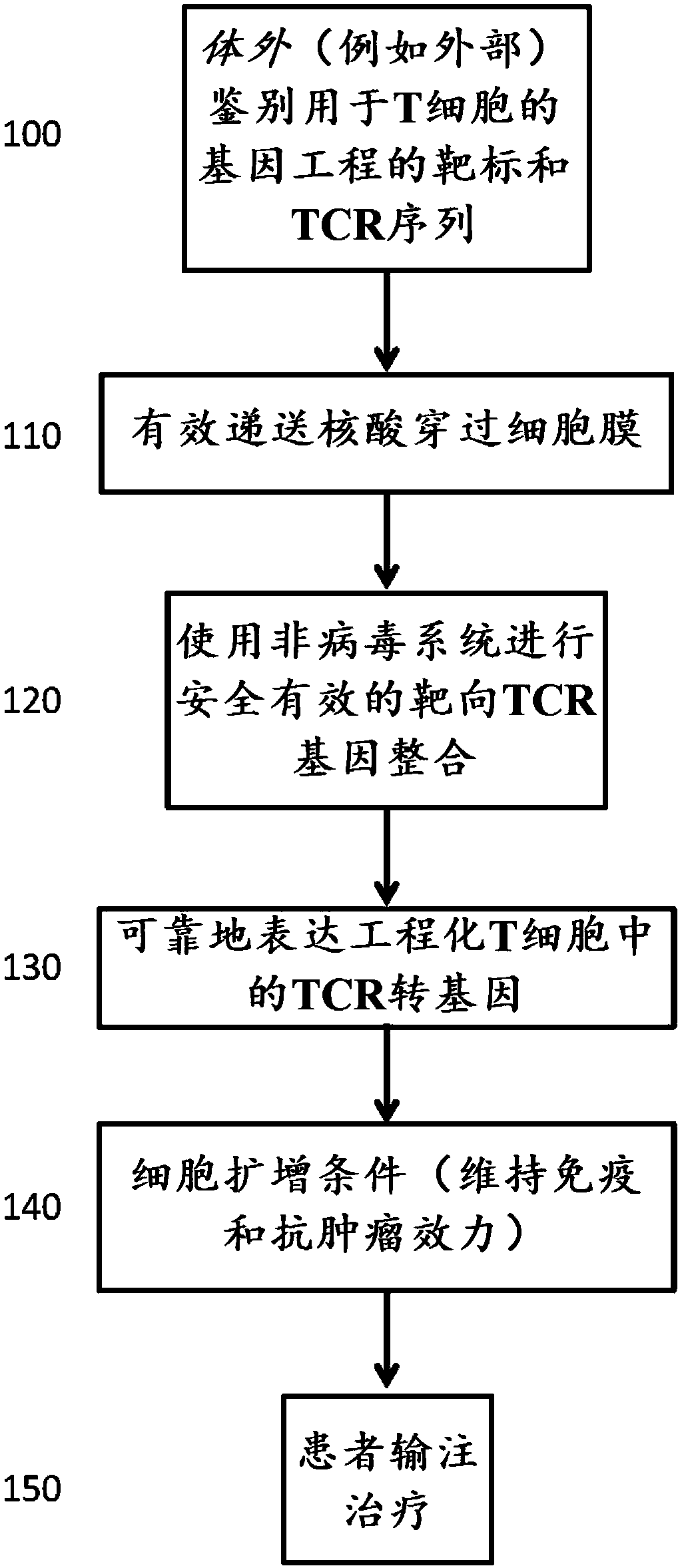

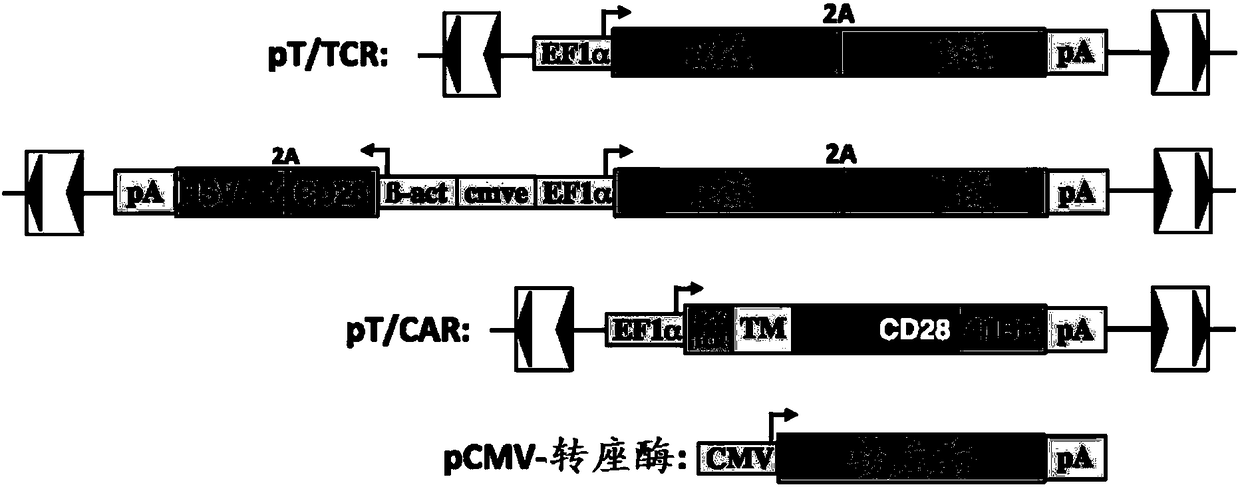

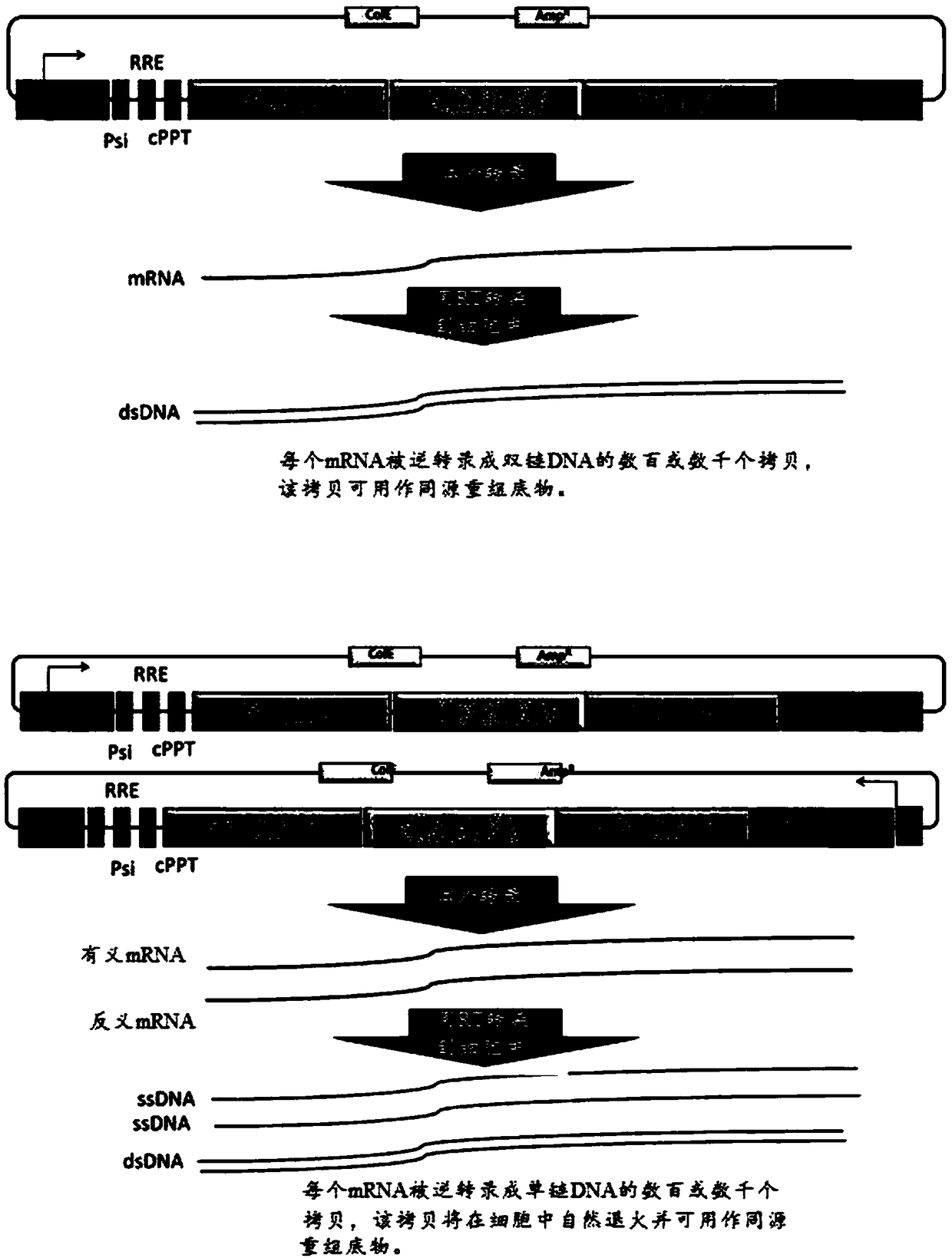

Modified cells and methods of therapy

PendingCN108472314AIncrease insertion efficiencyLow toxicityCytokine-induced proteinsFusion with DNA-binding domainOncologyT cell

Owner:RGT UNIV OF MINNESOTA +2

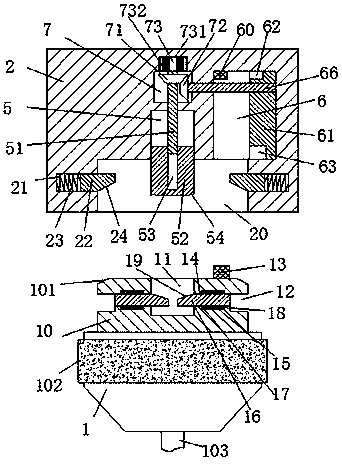

Stable server device

InactiveCN108232994AIncrease insertion efficiencyLock firmlyCoupling device detailsComputer periphery connectorsEngineeringElectric shock

The invention discloses a stable server device. The stable server device comprises a socket formed in a wall and a plug connected with the socket in a matching manner, wherein a socket slot is formedin the middle part of the bottom surface of the socket; a first forward driving slot is formed in the middle part of the top wall of the socket slot; a second forward driving slot is formed in the right side of the top wall of the socket slot; a third forward driving slot is formed in the socket and positioned above the first forward driving slot and on the left side of the second forward drivingslot. The plug in the data server device is firmly locked, the plug is also powered on while the plug is locked during insertion, and the plug is unlocked while the plug is powered off during extraction, so that the efficiencies of plug insertion and plug extraction are greatly improved, the plug is conveniently extracted and replaced after the plug is damaged, an electric shock accident during insertion and extraction of the plug is effectively avoided, and the life safety of people is guaranteed; in addition, the insertion and the extraction of the plug can be achieved through a motor.

Owner:郭丹枫

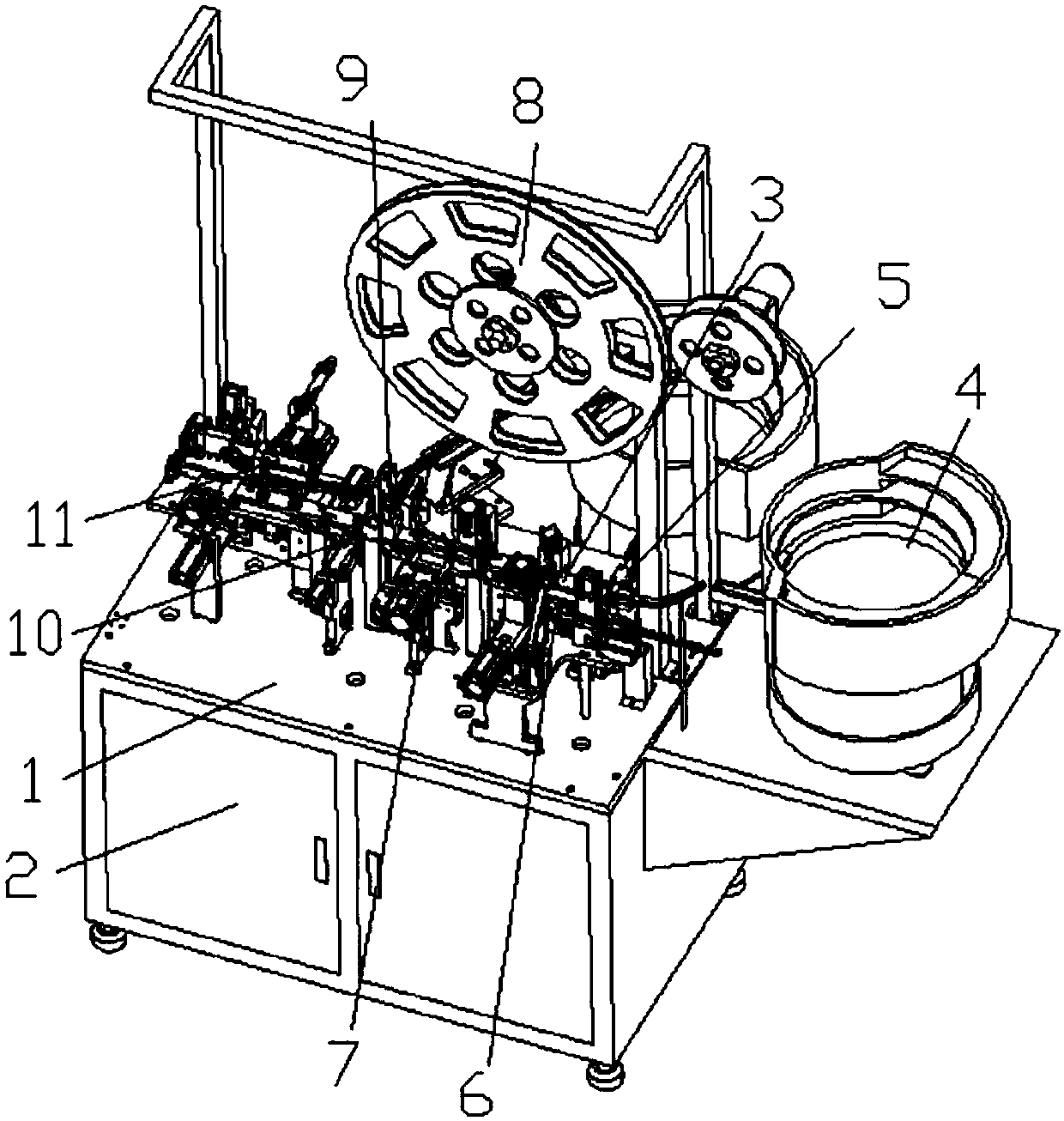

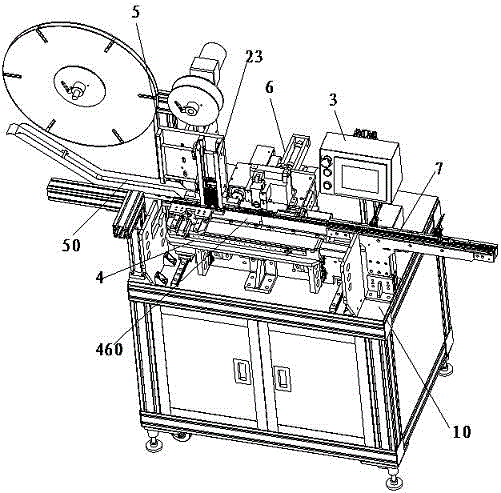

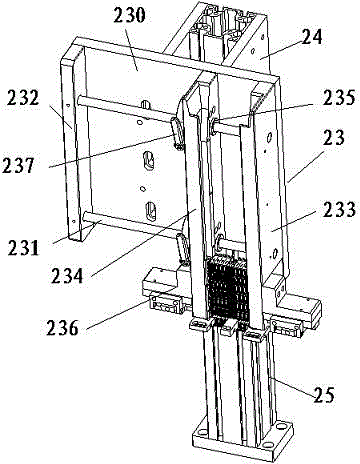

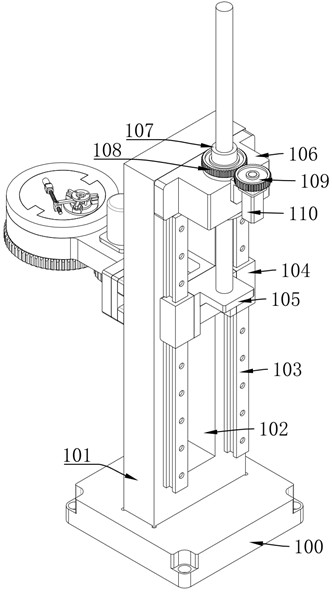

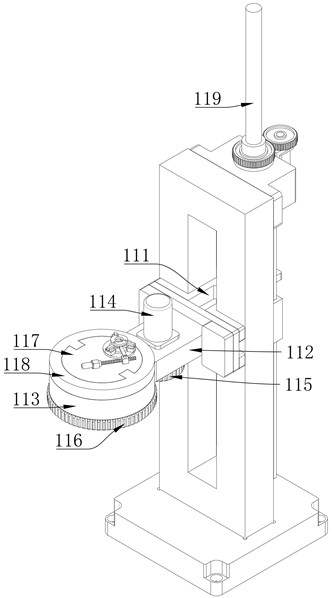

Automatic assembling machine for connector

ActiveCN107553085AAccurate jackingRealize automated assemblyOther manufacturing equipments/toolsMetal working apparatusMechanical engineering

The invention relates to an automatic assembling machine for a connector. A rack is provided with a rubber core conveying device and a shell conveying groove; a shell feeding device is arranged on theupper portion of the shell conveying groove, a shell material feeding device is matched with the right side of the shell conveying groove, and a rubber core ejecting-in port is formed in the front side of the shell conveying groove and is matched with a rubber core ejecting-in device; the shell material feeding device is connected with a shell vibration material feeding disk through a shell material feeding groove; the shell feeding device comprises a shell feeding lifting cylinder which is connected with a shell reciprocating feeding pull rod; the shell reciprocating feeding pull rod is connected with a shell feeding block; and feeding grooves matched with the left and right length of the shell are uniformly formed in the lower portion of the shell feeding block. According to the automatic assembling machine for the connector, by means of the shell feeding device in fixed distance feeding guarantees the fixed distance feeding of a shell, the fixed rubber core ejecting-in port is formed in the shell conveying groove, it is guaranteed that a rubber core is accurately ejected in from the rubber core ejecting-in port, automatic assembling of the connector rubber core and the shell isachieved, meanwhile the positioning and assembling structure is simplified, and the work efficiency is improved.

Owner:TONGXIANG YAORUN ELECTRONICS

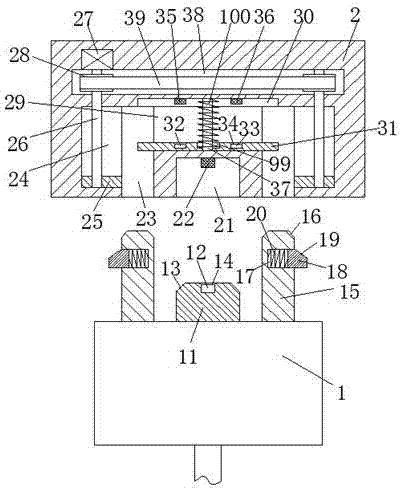

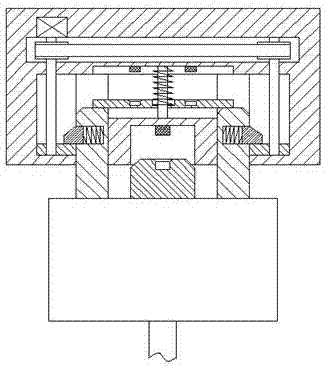

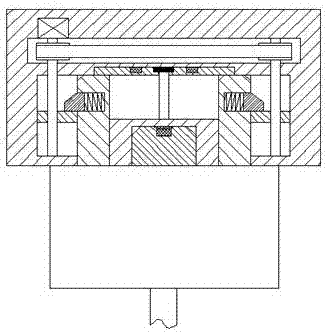

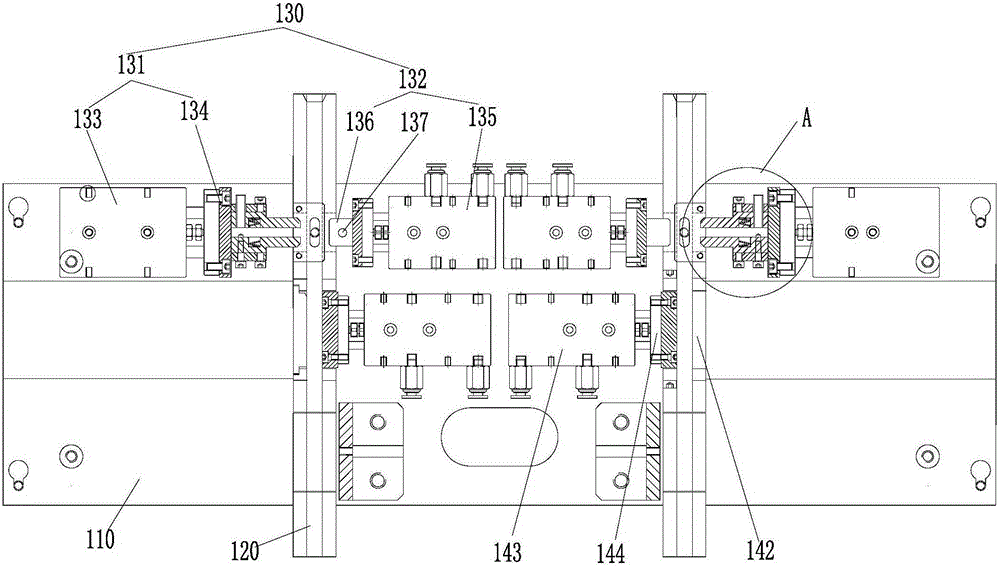

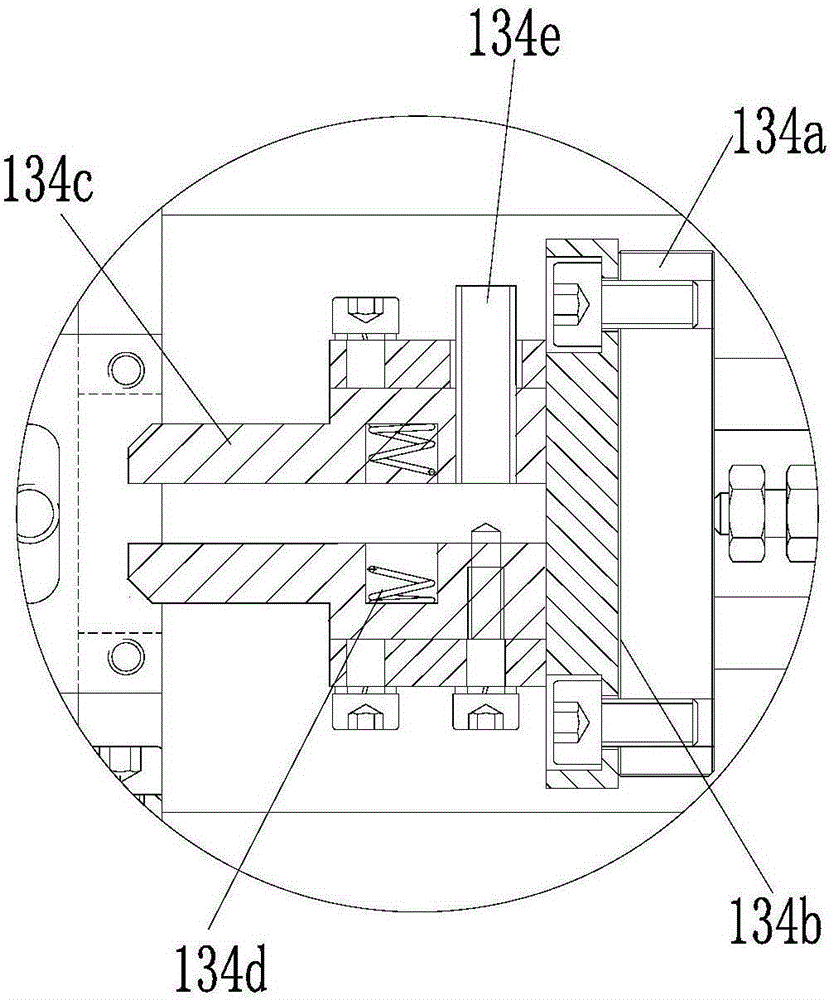

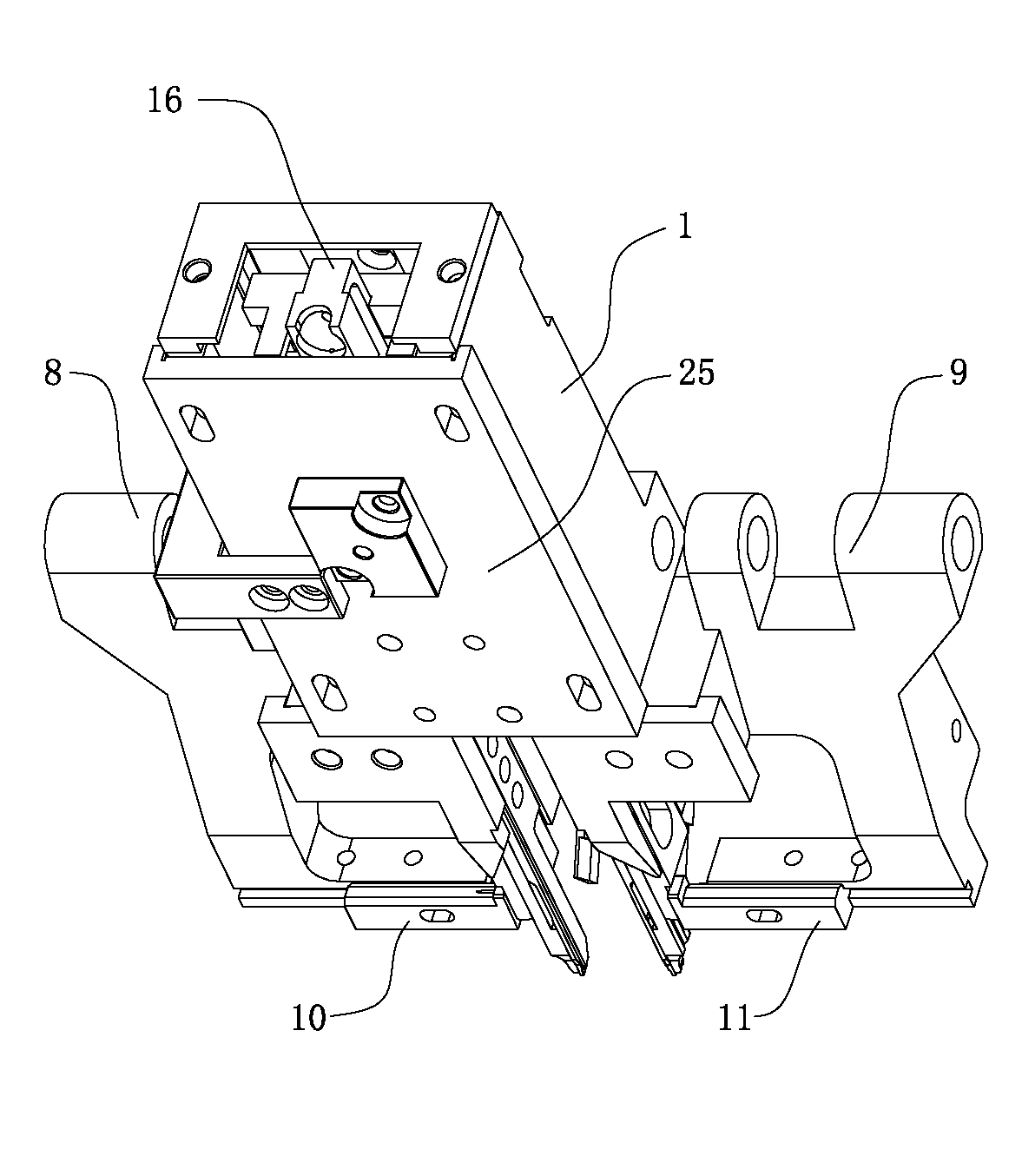

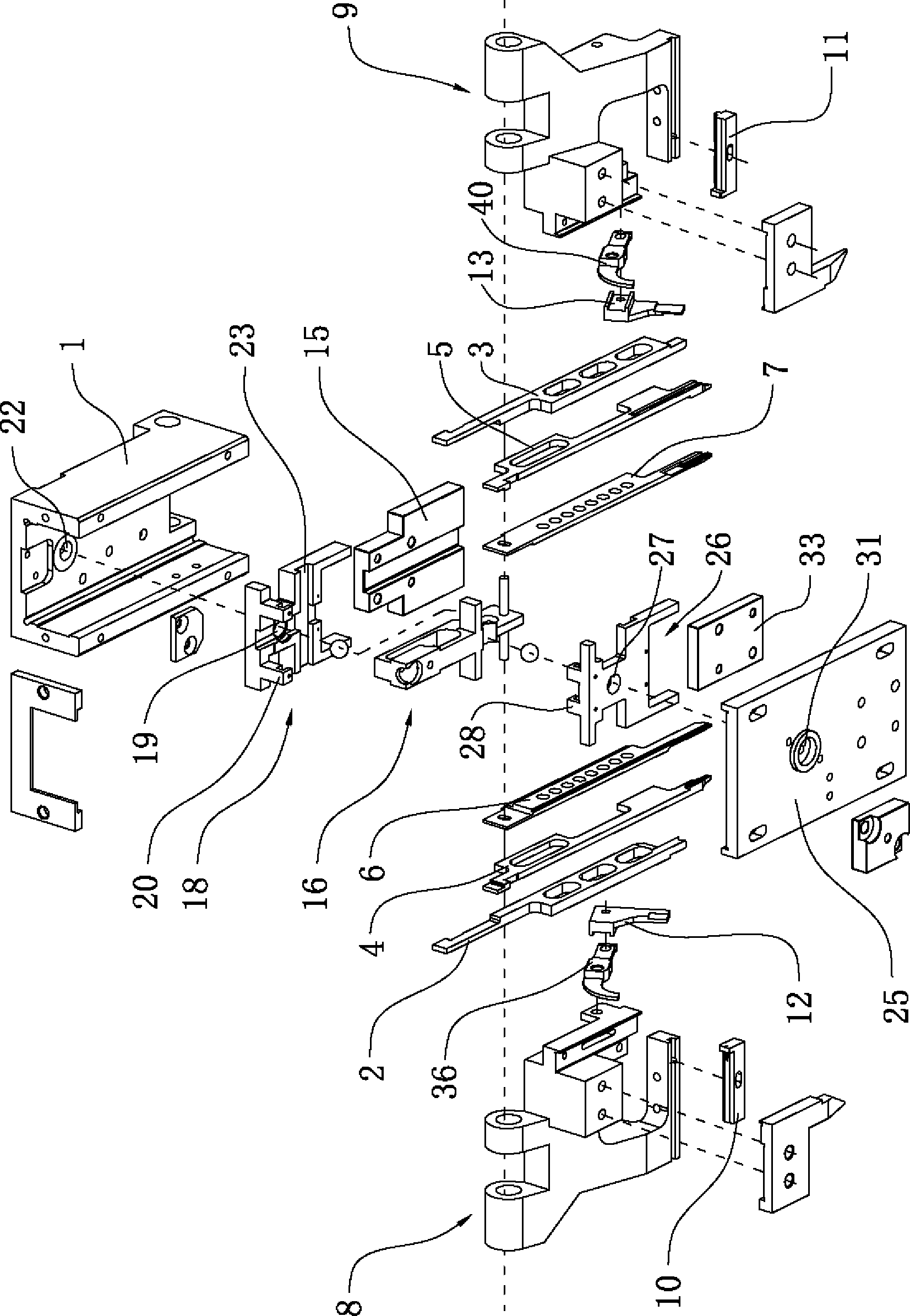

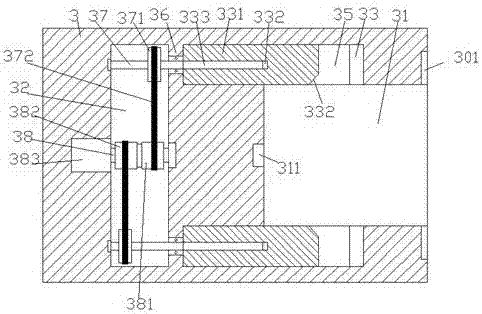

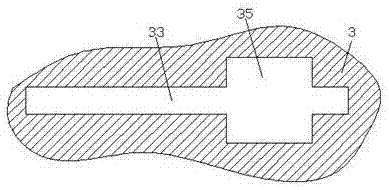

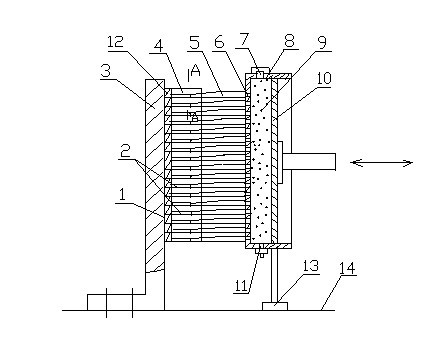

Component shaping and inserting mechanism for component inserting machine

InactiveCN102427717AIncrease insertion efficiencySimple structureElectrical componentsEngineeringElectronic component

The invention relates to the technical field of electronic component insertion, in particular to a component shaping and inserting mechanism for a component inserting machine. The component shaping and inserting mechanism comprises a tool box, a tool group and a link gear, wherein the tool group comprises a left-cut tool, a right-cut tool, a left molding tool, a right molding tool, a left push-type broach and a right push-type broach, wherein the left-cut tool, the left molding tool, the left push-type broach, the right push-type broach, the right molding tool and the right-cut tool are sequentially and movably arranged in the tool box from left to right; a left tool rest and a right tool rest are arranged at the lower part of the tool box, a left undercut tool and a right undercut tool are respectively assembled at the lower part of the left tool rest and the right tool rest, and the left tool rest and the right tool rest are respectively and movably provided with a left auxiliary molding tool and a right auxiliary molding tool; and pin guiding slots are respectively formed at the inner sides of the lower end parts of the lower end parts of the left molding tool and the right molding tool. The component shaping and inserting mechanism for the component inserting machine, disclosed by the invention, has the advantages of simple structure, low manufacturing cost, and no equipment locking phenomenon in a machining process, thus, the stability during component shaping and inserting machining is greatly increased, the inserting efficiency of the component inserting machine is increased, and the practicability is strong.

Owner:DONGGUAN SCIENCGO MACHINERY MFG

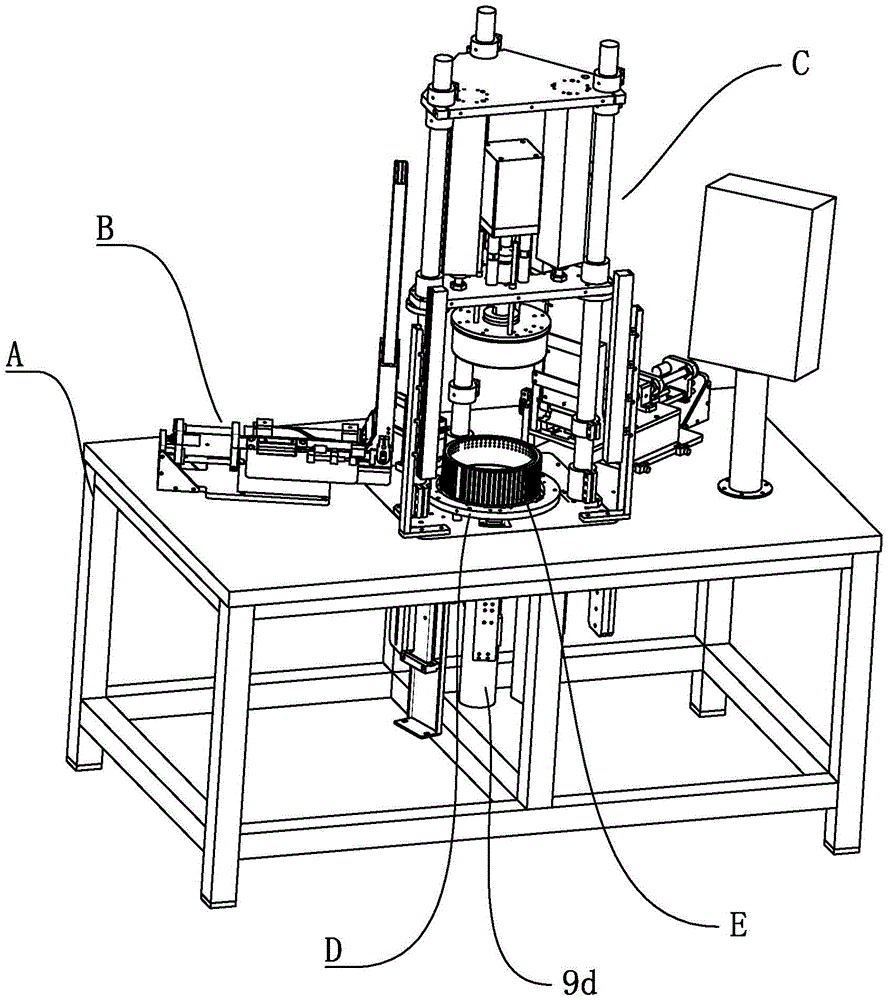

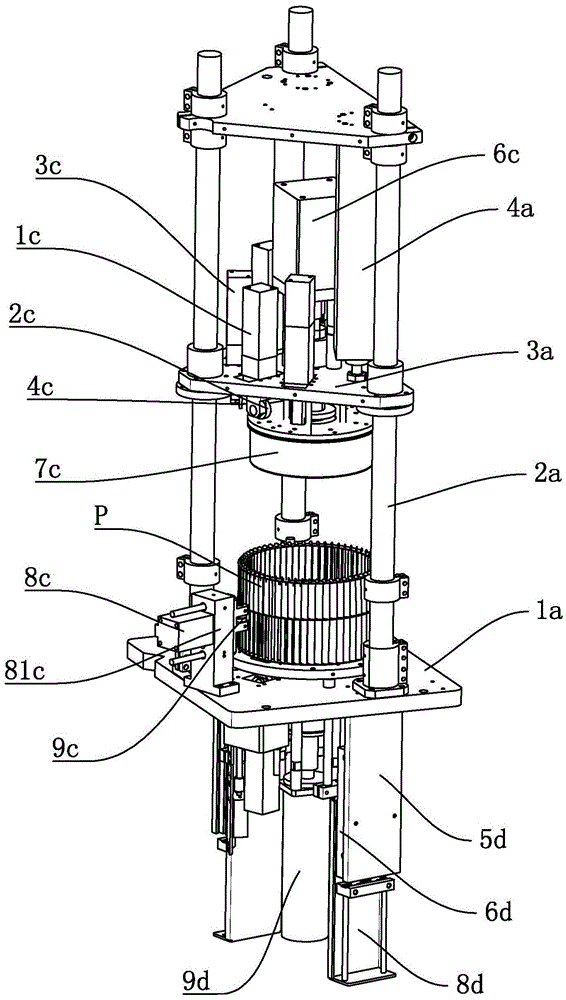

Impeller assembly machine

InactiveCN105485060AImprove work efficiencyImprove processing efficiencyPump componentsPumpsImpellerEngineering

The invention discloses an impeller assembly machine which comprises a machine base, a mold arranged on the machine base and allowing blades of an impeller to be inserted therein, a push mechanism arranged on the machine base and used for pushing the blades to the mold and a rolling and riveting mechanism for riveting the impeller. The height of the mold is equal to half of the length of the blades. The rolling and riveting mechanism comprises an upper riveting mechanism for bending and fixing an upper gland of the impeller and insertion pieces of the blades and a middle riveting mechanism for riveting the blade in the middle of the impeller and a reinforcing partition plate arranged in the middle of the impeller. The middle riveting mechanism capable of riveting the reinforcing partition plate of the double-layer impeller is additionally arranged on the basis that only the upper gland and a lower gland of the impeller can be riveted to the impeller, so that only one working procedure is added without affecting the original riveting efficiency, and the machining efficiency of the double-layer impeller is improved greatly.

Owner:南通市京山锦纶有限公司

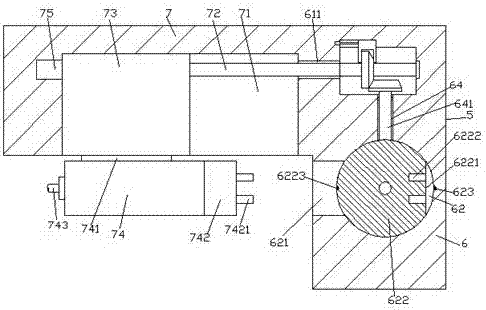

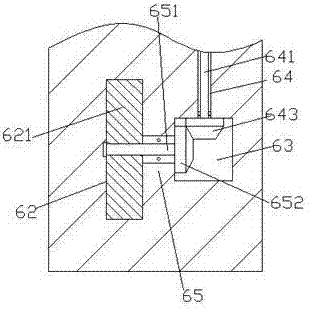

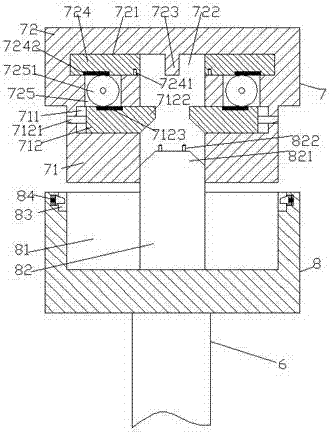

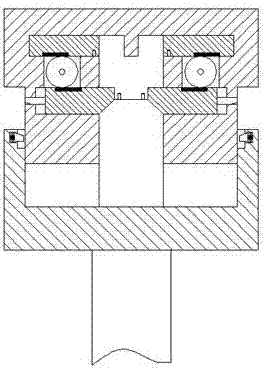

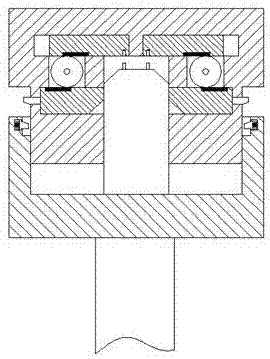

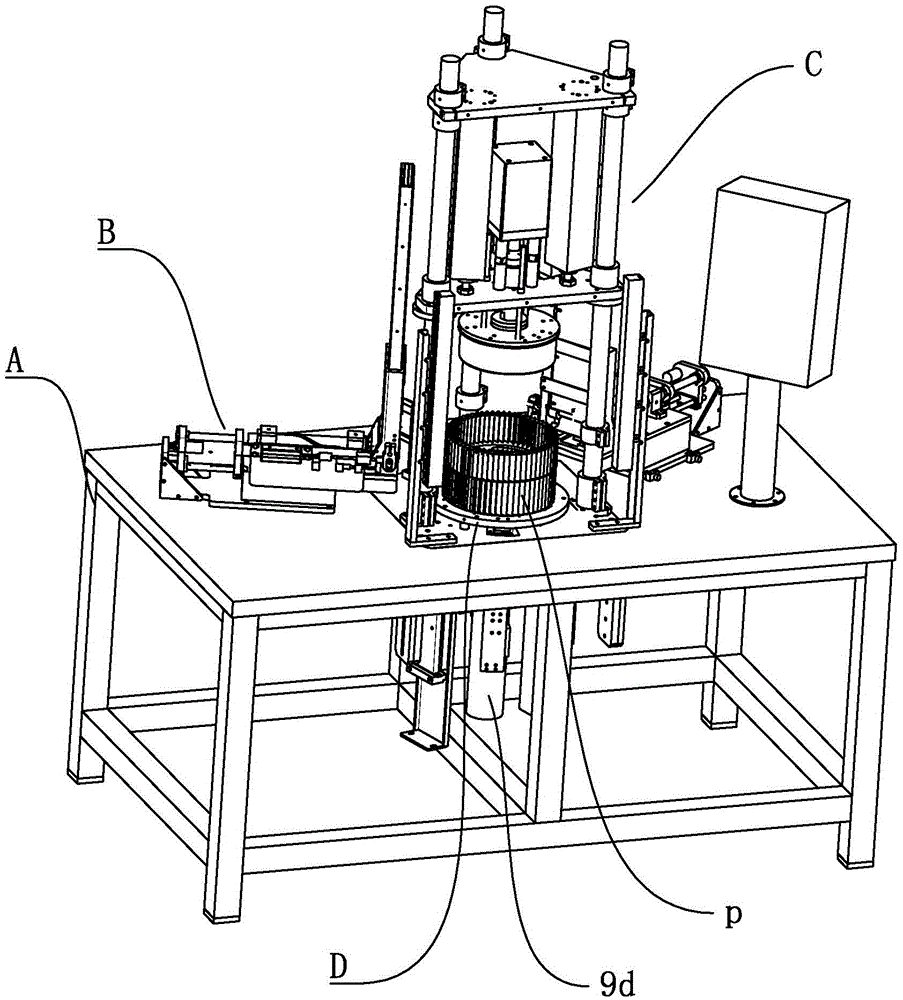

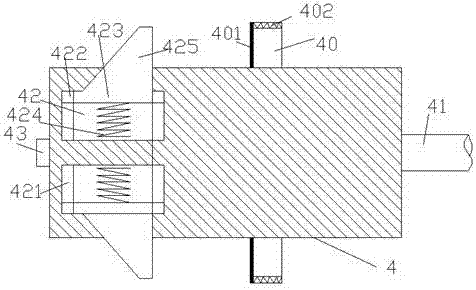

Automatic insertion machine of magnetic steel of motor

InactiveCN101877516AImprove insertion efficiencyGuaranteed uniformity of distributionManufacturing stator/rotor bodiesMagnetStator

The invention relates to an automatic insertion machine of magnetic steel of a motor, which comprises a telescopic platform with a stator, a motor driving the stator to rotate and a track erected above the platform and used for conveying the magnetic steel. The automatic insertion machine is characterized in that one end of the track is provided with a magnet used for attracting the magnetic steel above the stator, and a cylinder used for pressing the magnetic steel into the installing position inside the stator is arranged above the installing position; and the operation of the insertion machine is controlled by program, thereby realizing automatic operation.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

Novel bridge device

InactiveCN107104323ARealize automatic controlReduced mating stepsLive contact access preventionPush upsEngineering

Owner:杭州秀资机械科技有限公司

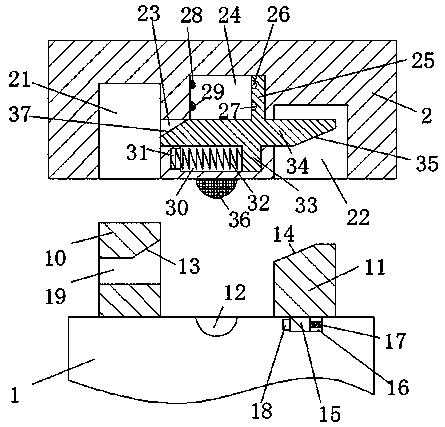

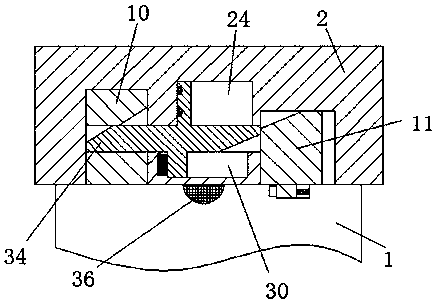

Server device

InactiveCN107768923AIncrease insertion efficiencyLock firmlyTwo-part coupling devicesLive contact access preventionElectric shock

The invention discloses a server device. The server device comprises a socket and a plug, wherein the socket is arranged in a wall, the plug is connected with the socket in a matching way, a slot is formed in a middle position of a bottom surface of the socket, a first front driving groove is formed in a middle position of a top wall of the slot, a second front driving groove is formed in a rightside of the top wall of the slot, and a third front driving groove is formed in a position, above the first front driving groove and at a left side of the second front driving groove, of the socket. The plug is fixedly and firmly locked, power also can be supplied to the plug when the plug is fixedly locked during plug-in, the plug is also unlocked when being powered off during plug-out, the plug-in and plug-out efficiency of the plug is greatly improved, the plug is convenient to replace when being damaged, an electric shock accident is effectively prevented during the plug-in and plug-out process, life safety of people is guaranteed, and the plug can be plugged in and plugged out by a motor.

Owner:郑必达

Novel household electric water heater

InactiveCN108232767ALock firmlyIncrease insertion efficiencyCoupling device detailsElectricityElectric shock

The invention discloses a novel household electric water heater which comprises a socket arranged in a wall body and a plug connected with the socket in a matched manner, and is characterized in thata guide block is arranged at the top of the plug; a locking block is arranged on the top end surface of the guide block; an electrifying head is arranged in the middle of the top end surface of the locking block; two locking cavities are correspondingly formed in the left and right end surfaces of the locking block. The plug in the novel household electric water heater is firmly locked, so that electrification is safe and stable; during plugging, the plug is electrified while being locked; during unplugging, the plug is unlocked while being powered off; the whole device is convenient and quickto operate; the efficiency of plugging and unplugging the plug is greatly improved; an electric shock accident occurring during plugging and unplugging of the plug is effectively avoided, and the life safety of workers is guaranteed.

Owner:广州迅速光电科技有限公司

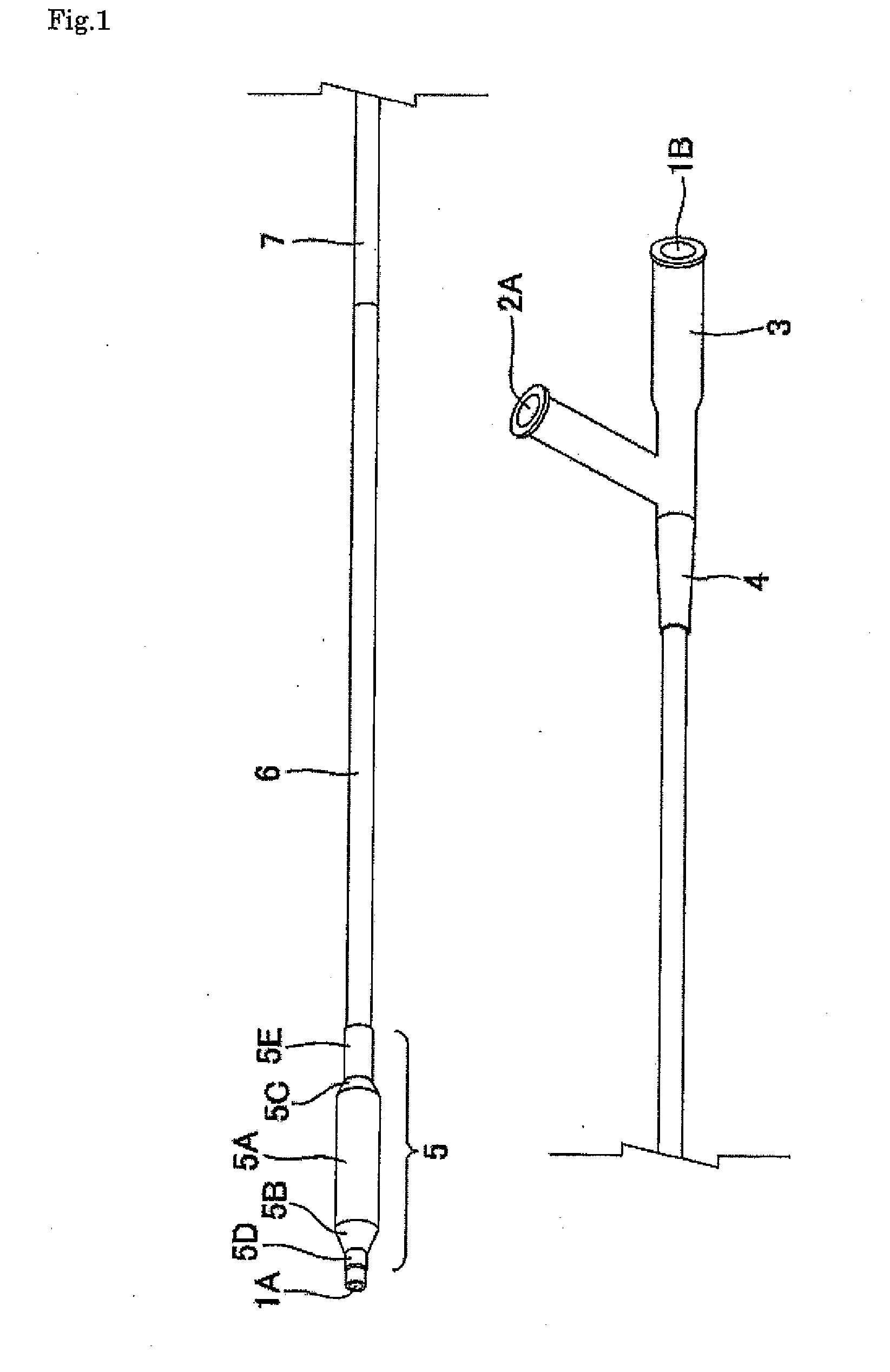

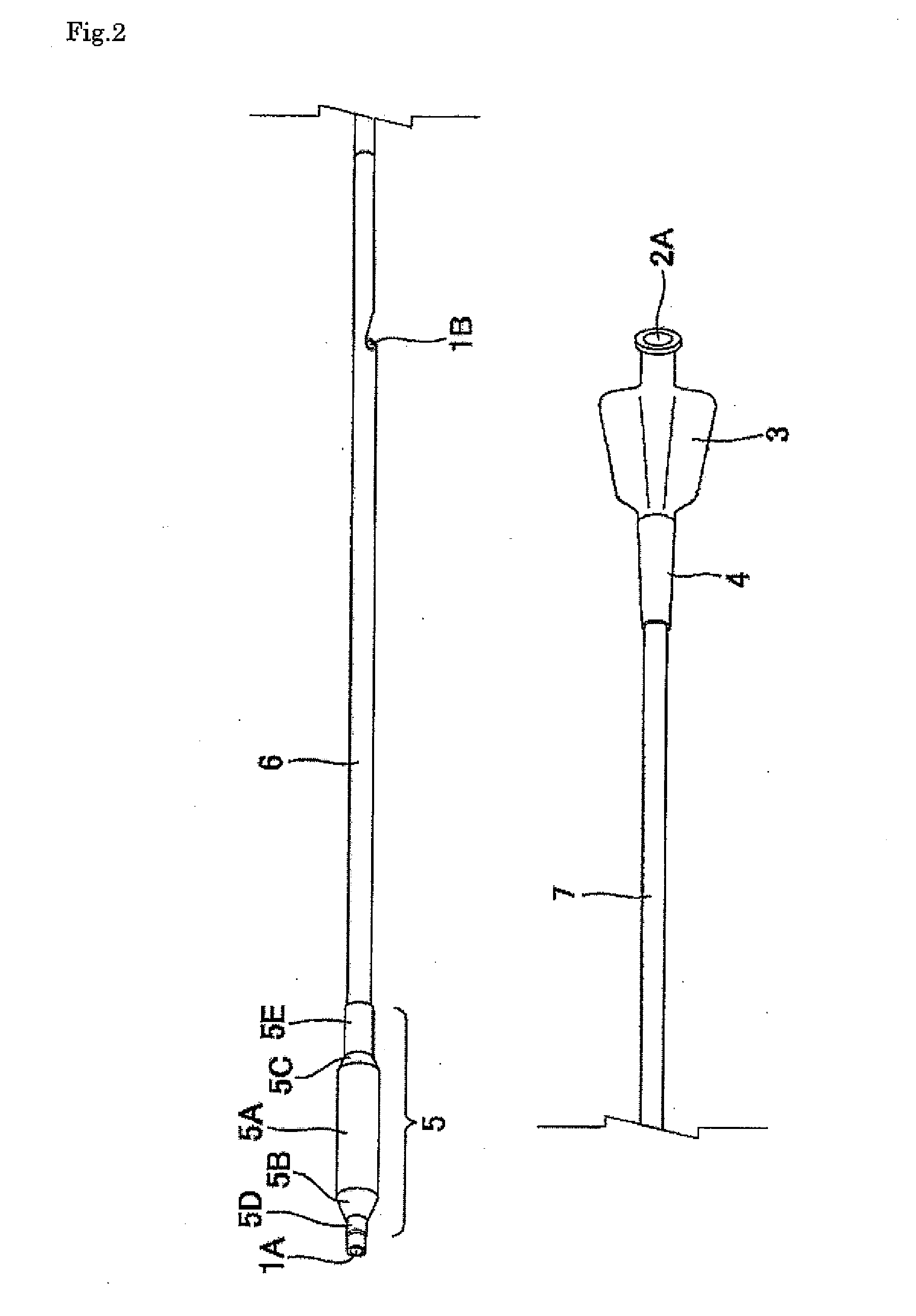

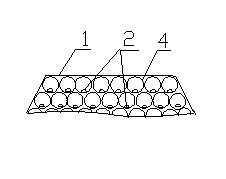

Firecracker pouring leading line technology method

ActiveCN102679822ATo achieve the discharge effectImprove ergonomicsFireworksFirecrackerEconomic benefits

The invention discloses a firecracker pouring leading line technology method that a bottom-sealed firecracker cake (1) is vertically fixed on a mold plate (3); a pouring and leading device is arranged in the axis direction of the firecracker cake; pouring and leading needles (5) correspond with the paper cylinders on the firecracker cake in number and position; the pouring leading line needles (5) can extend into the paper cylinders (4); and when the leading line slurry (9) in the pouring leading line needles flows into the inner walls of the paper cylinders in line shape under the pressure, the pouring leading line needles move from inside to outside till the pouring leading line needles move out of the firecracker cake, and the solidified line-shaped leading line slurry can be fixed on the inner walls of the paper cylinders to serve as the leading lines (2). According to the firecracker pouring leading line technology method, the leading lines are safe to make, the material consumption and waste are reduced, the making cost of the leading lines is reduced; and as the leading lines are uniform in size and correct in position, leading line breaking and splitting are avoided, the fire joining performance is excellent, and all the paper cylinders of the firecracker cake can be simultaneously poured and led once for all, the inserting leading line procedure is reduced, the inserting leading line efficiency of the firecrackers is improved, the inserting leading line cost is reduced, and the economic benefits are improved.

Owner:崔立波

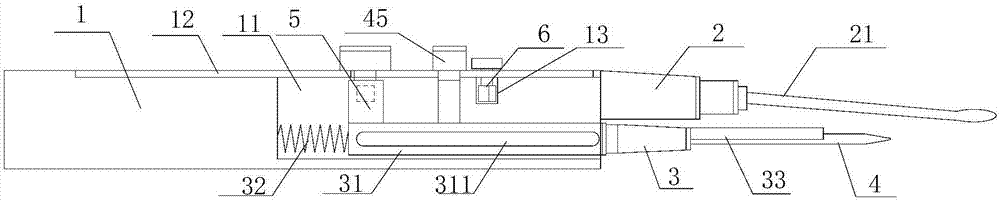

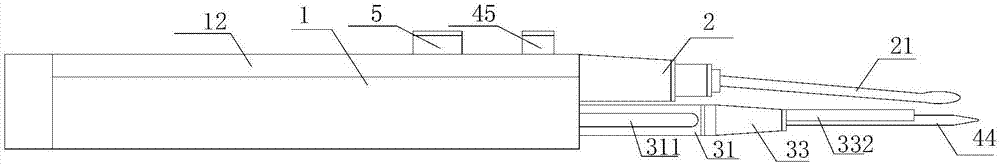

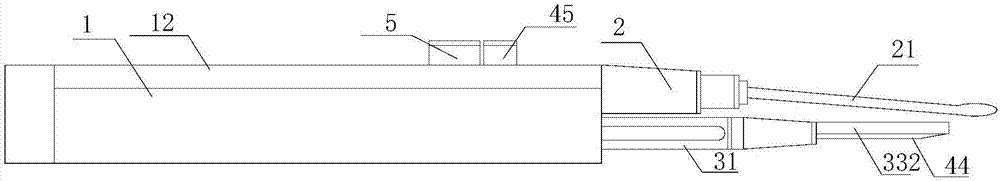

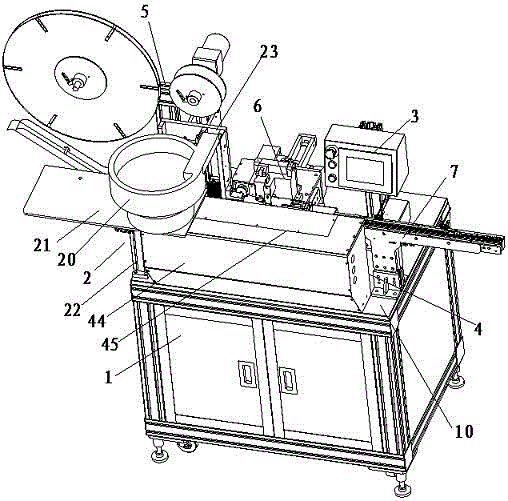

Nucleus inserting tool for freshwater mussel breeding pearls

PendingCN107494359AImplanted accuratelyReduce implantationClimate change adaptationPisciculture and aquariaFresh water organismEngineering

The invention provides a nucleus inserting tool for freshwater mussel breeding pearls. The tool comprises a handle, a conducting component, a pearl nucleus pike-off driving component, a guide rod inserting component, a telescopic driving component and a return trigger component, wherein a first mounting groove is formed in the handle, the pearl nucleus poke-off driving component is movably mounted in the first mounting groove through a first spring, and a material poke U-shaped tune is arranged at one end of the pearl nucleus poke-off driving component; a positioning groove is formed in the side wall of the telescopic driving component, the return trigger component is matched with the positioning groove, and an auxiliary driving push block component is arranged on the guide rod inserting component; a needle is arranged at the end of the guide rod inserting component, and the material U-shaped tube is matched with the needle. The conducting component is used for guiding and positioning, the guide rod inserting component conducts positioning on a pearl nucleus to which cell small pieces adhere, and the pearl nucleus poke-off driving component conveys the pearl nucleus to the nucleus inserting position. The nucleus inserting tool is easy to operate, combines conducting, positioning and nucleus inserting, does not need to be replaced by operating tools and can improve the nucleus inserting efficiency.

Owner:戚鸟定

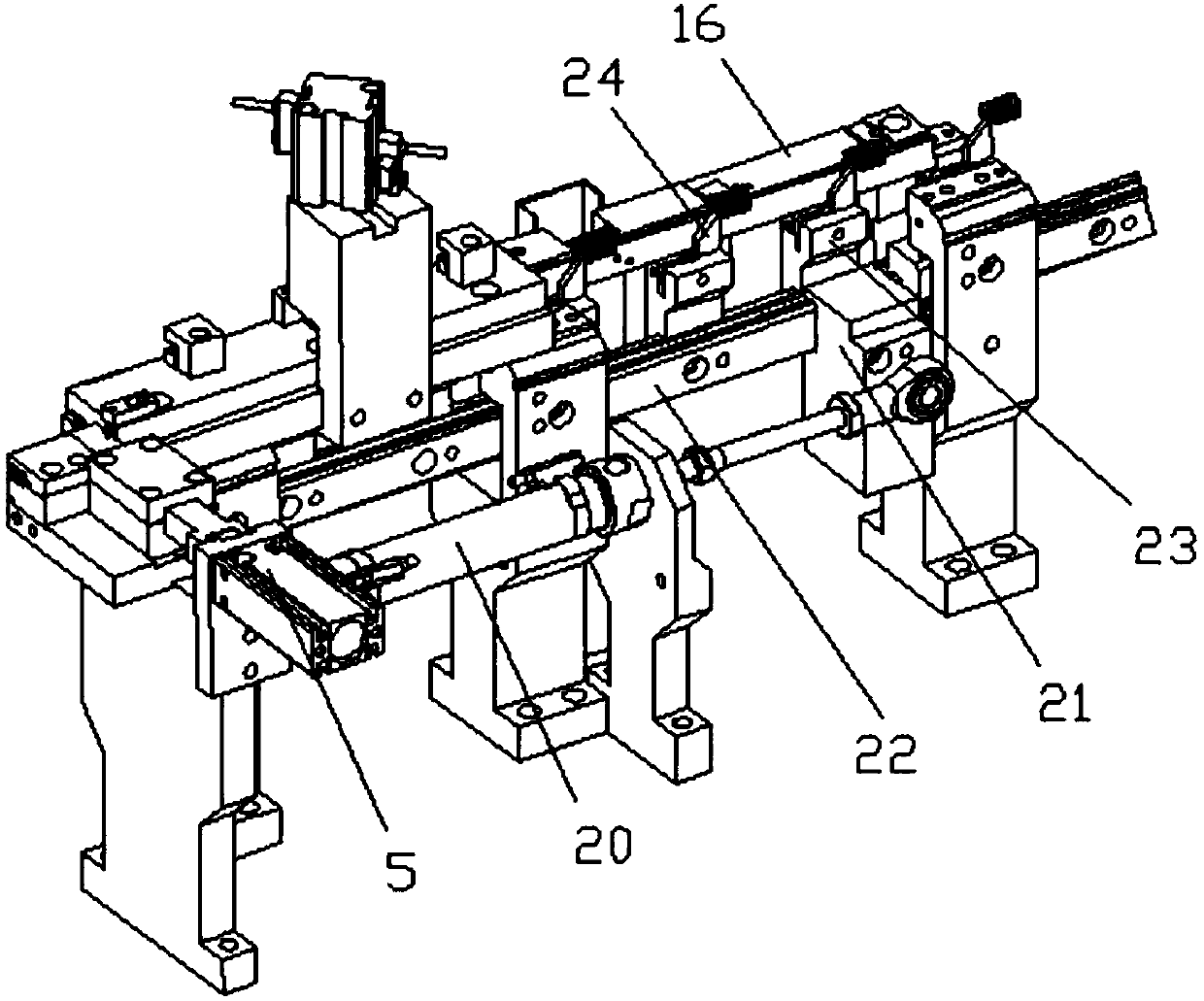

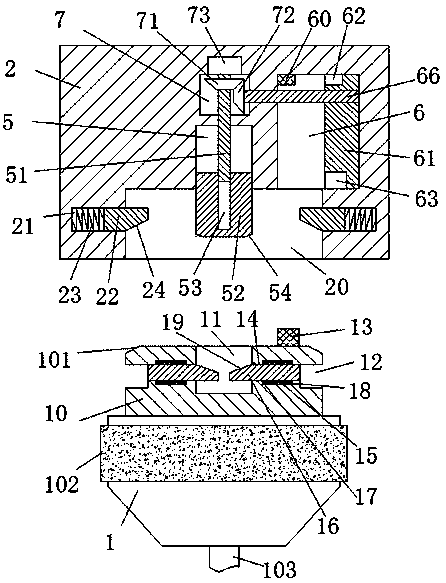

Adjustable pin inserting machine

InactiveCN104917033AImprove general performanceIncrease insertion efficiencyContact member assembly/disassemblyMan machineControl circuit

The invention discloses an adjustable pin inserting machine comprising a plug body feeding mechanism, a man-machine controller, a plug body servo shifting mechanism, a pin rolling and supplying mechanism, a pin inserting mechanism, and a micro belt conveying mechanism which are installed on the working surface of a box type frame. The discharging port of the plug body feeding mechanism is disposed at the left end of a segmented plug body shifting slot of the plug body servo shifting mechanism. The right end of the segmented plug body shifting slot of the plug body servo shifting mechanism faces the micro belt conveying mechanism. The rear side of the segmented plug body shifting slot of the plug body servo shifting mechanism is equipped with the pin inserting mechanism. The rear side of the plug body feeding mechanism is equipped with the pin rolling and supplying mechanism. A pin rolling and distributing slot of the pin rolling and supplying mechanism faces a pin feeding port of the pin inserting mechanism. The box type frame is internally provided with a main control circuit. Through the technical scheme, the adjustable pin inserting machine is applicable to electronic connecting plugs of the same structure, is highly universal, and has high inserting efficiency.

Owner:吴中区横泾博尔机械厂

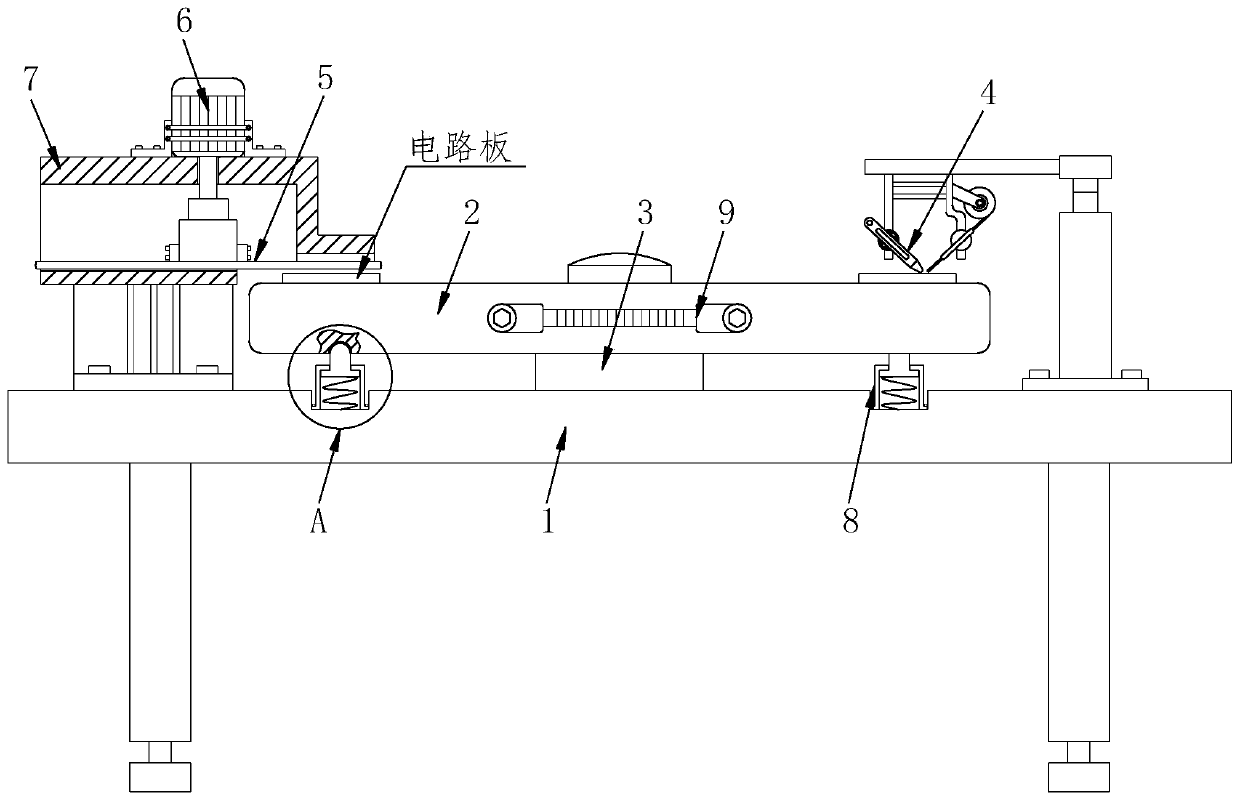

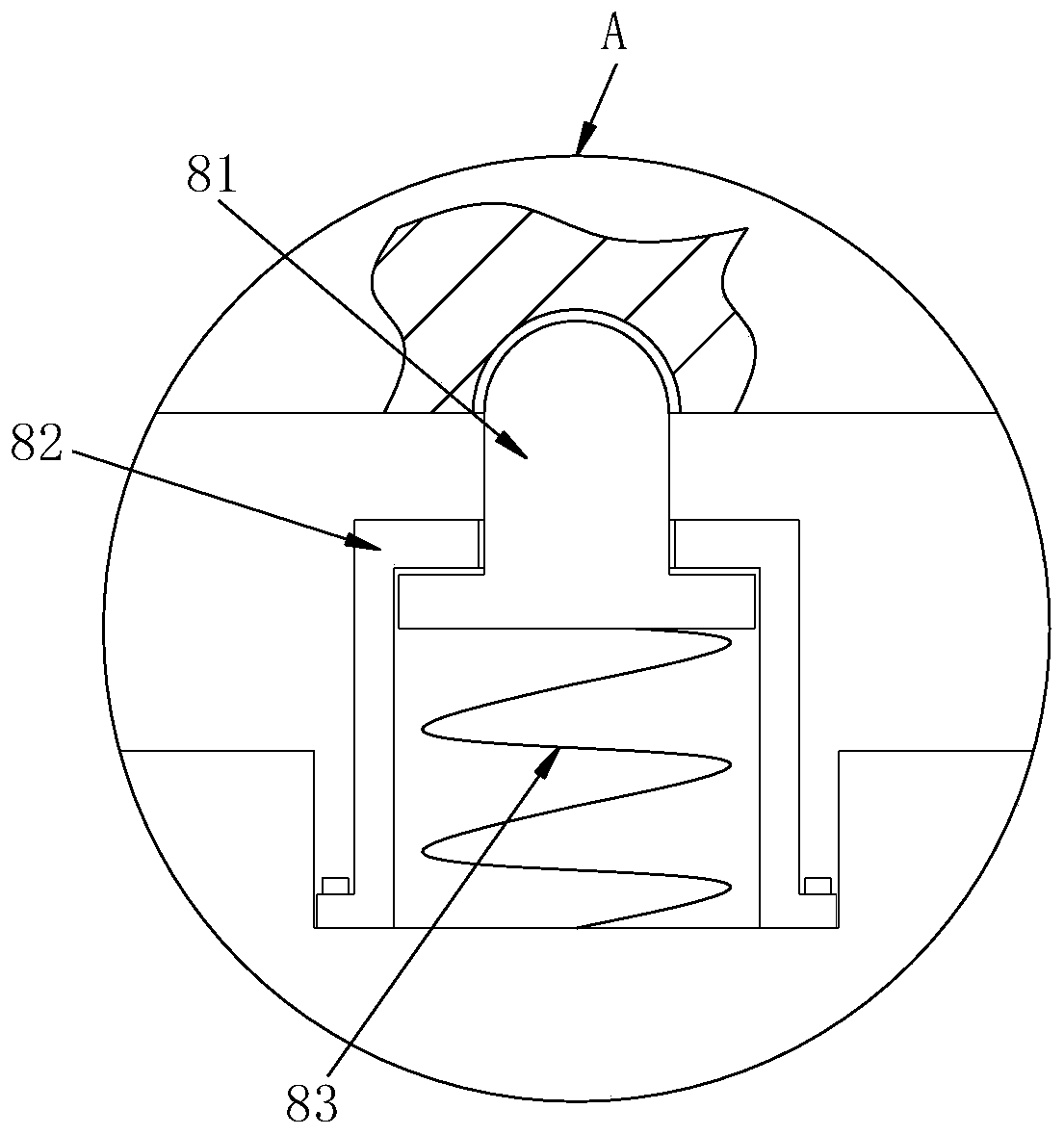

Location-welding all-in-one machine for electrical apparatus element pins of assembled circuit board

ActiveCN110899892AWon't fall intoPrevent fallingMetal working apparatusSoldering auxillary devicesElectric machineCoupling

The invention relates to a location-welding all-in-one machine for electrical apparatus element pins of an assembled circuit board. The location-welding all-in-one machine for the electrical apparatuselement pins of the assembled circuit board comprises a workbench surface, a placement rotary disc, a rotary shaft, a welding gun, a cutting assembly, a drive motor, a fixed frame, a location assembly and rotary handles, wherein the rotary shaft is installed at the central position of the top of the workbench surface; the placement rotary disc is installed at the upper end of the rotary shaft; the rotary handles are equidistantly arranged on the sidewall of the placement rotary disc; the location assembly is arranged at the top of the workbench surface and in an area on the lower end surfaceof the placement rotary disc; the welding gun is installed at one end of the placement rotary disc; the fixed frame is installed at the other end of the placement rotary disc; the drive motor is installed at the central position of the top of the fixed frame; the cutting assembly is connected to the bottom of the drive motor through a shaft coupling; and a circular rail is formed at the bottom ofthe placement rotary disc. According to the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board, the electrical apparatus element pins can be rapidly inserted into metal through holes; and moreover, the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board is appliable to different typesof circuit boards, and capable of rapidly and effectively cutting redundant pins.

Owner:东莞市硕动自动化设备有限公司

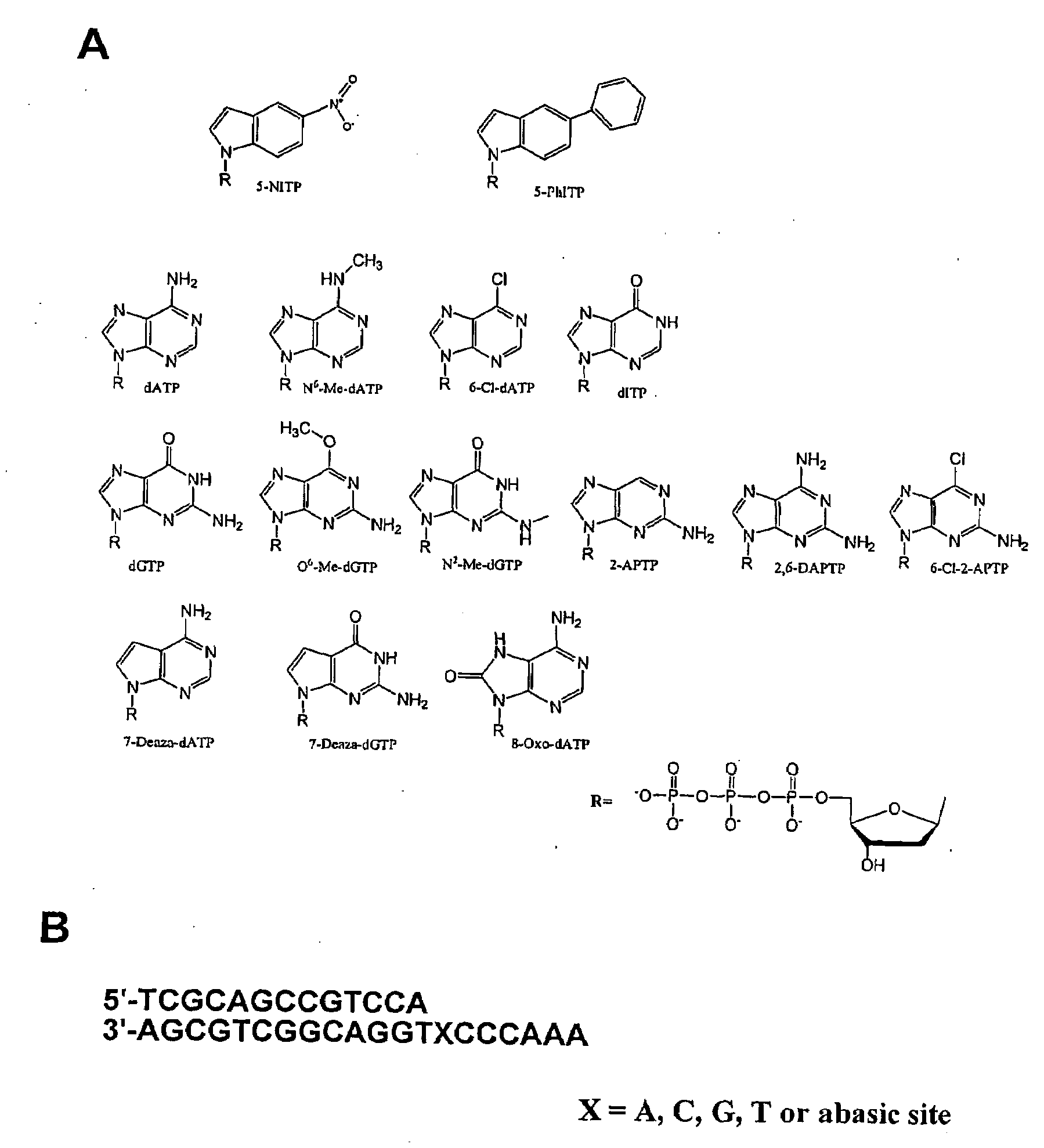

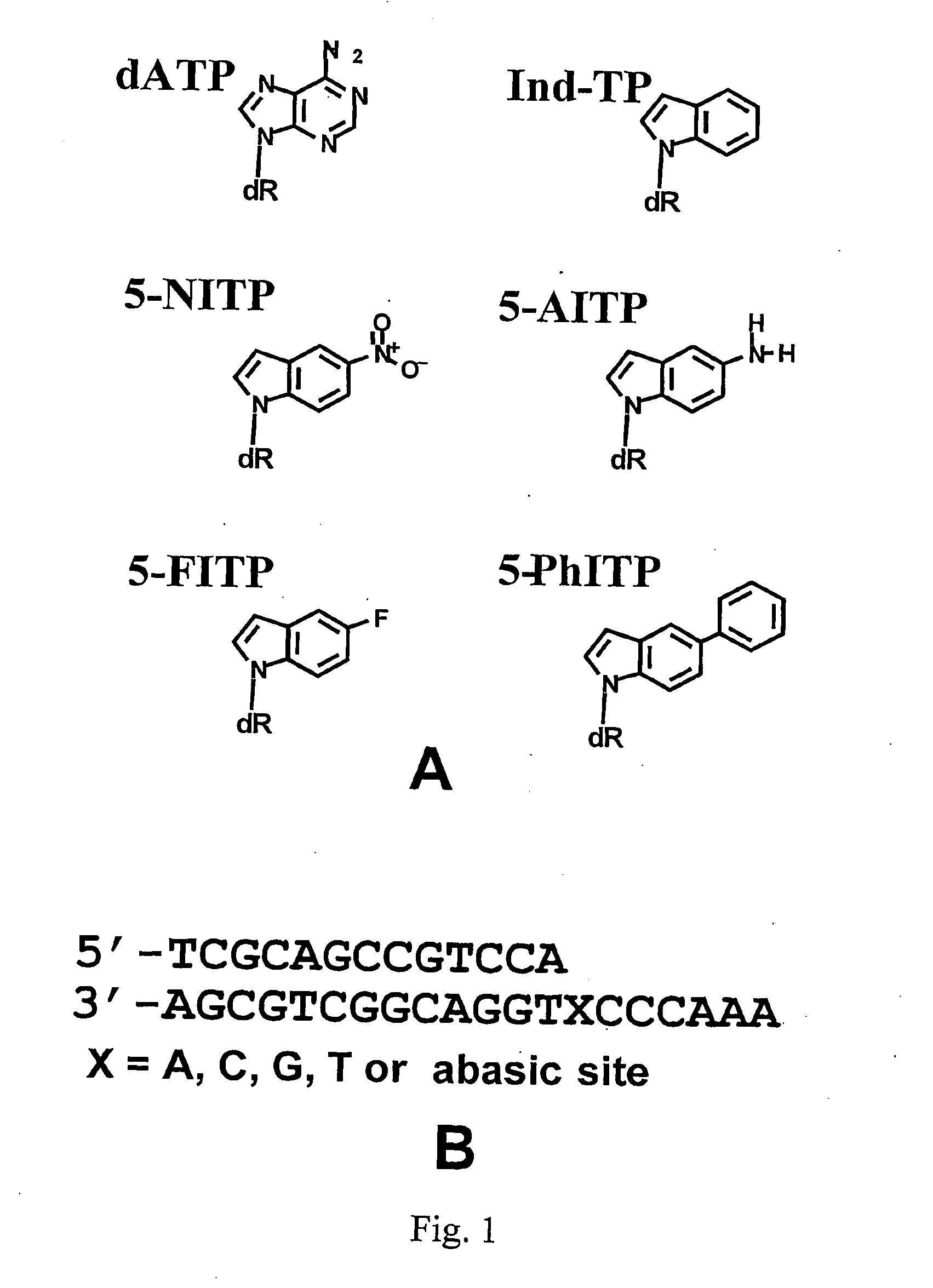

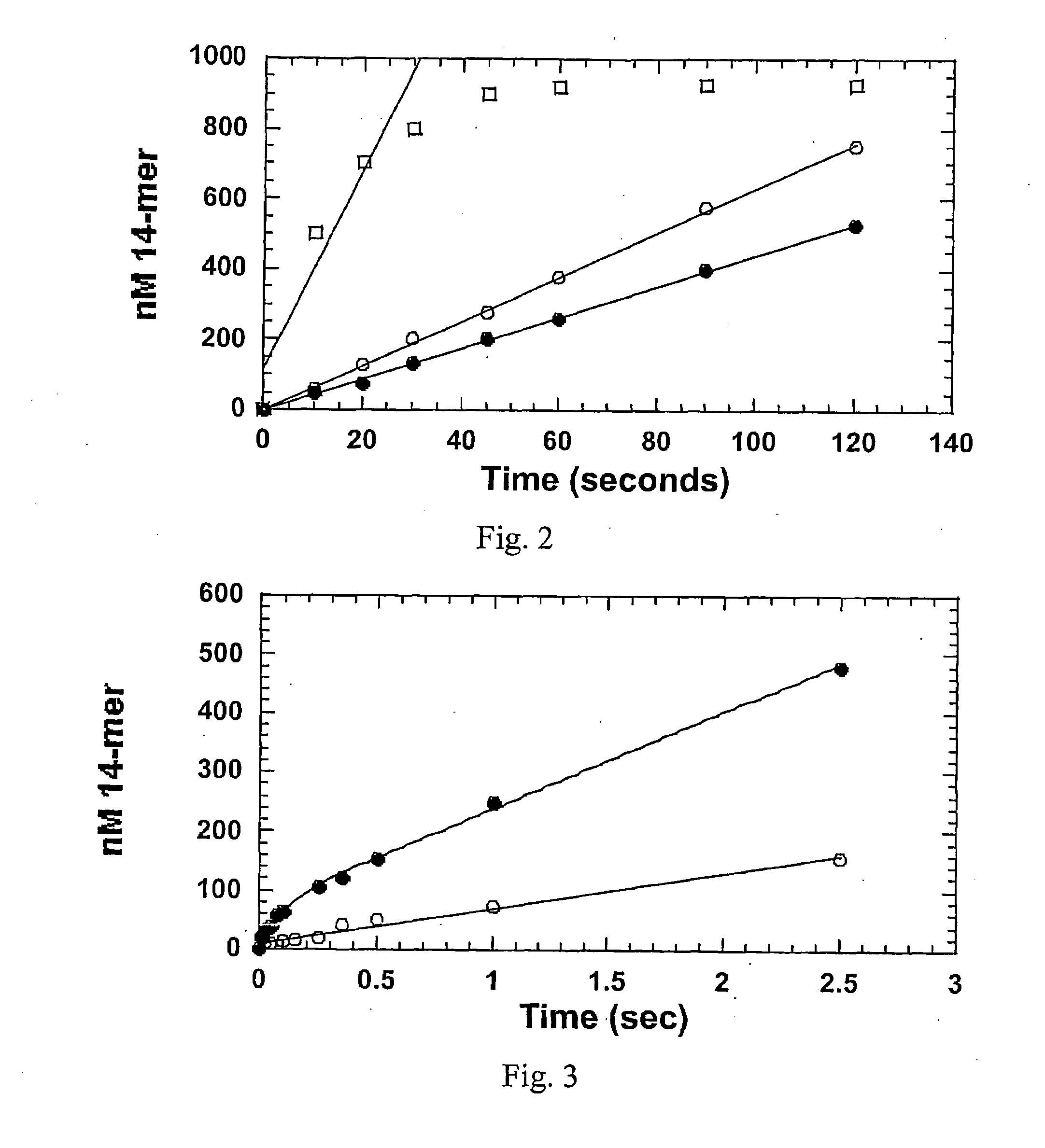

Selective inhibitors of translesion DNA replication

InactiveUS20090048202A1High binding affinityFast aggregationBiocideSugar derivativesRiboseDNA replication

Owner:CASE WESTERN RESERVE UNIV

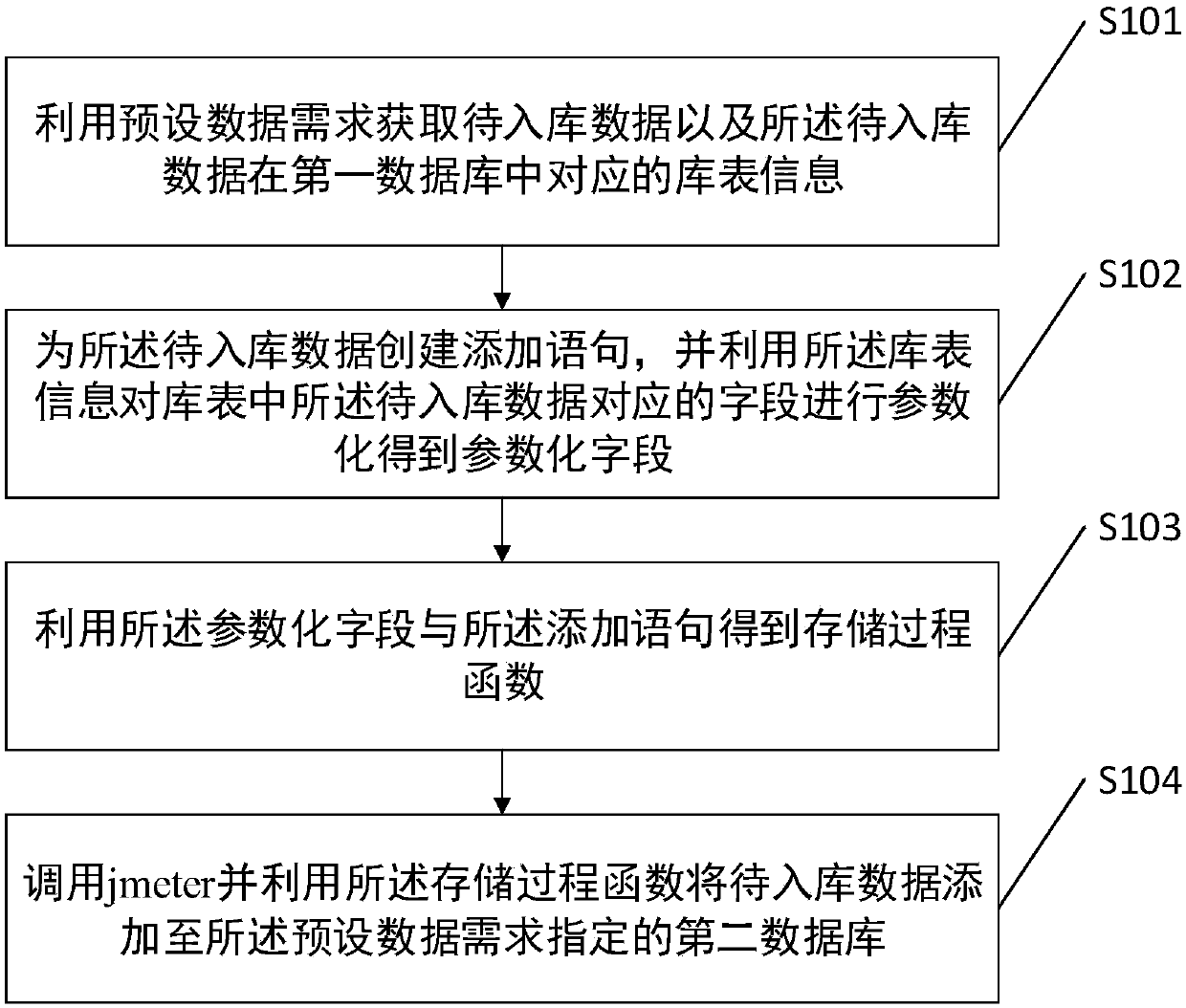

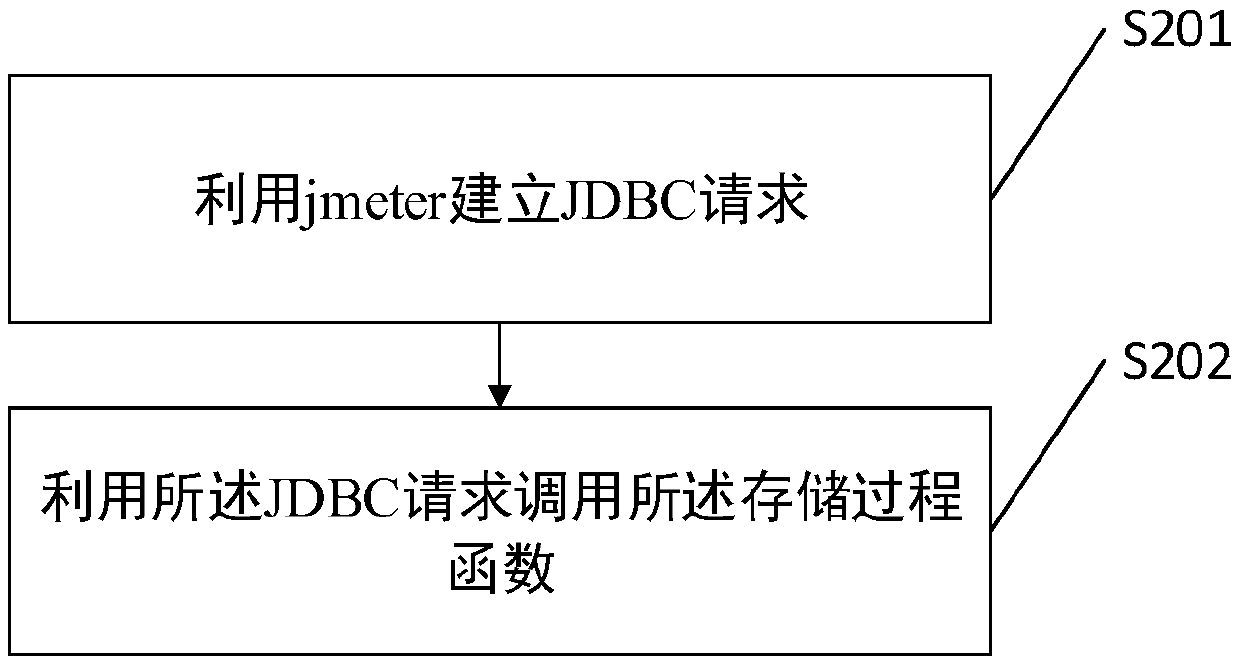

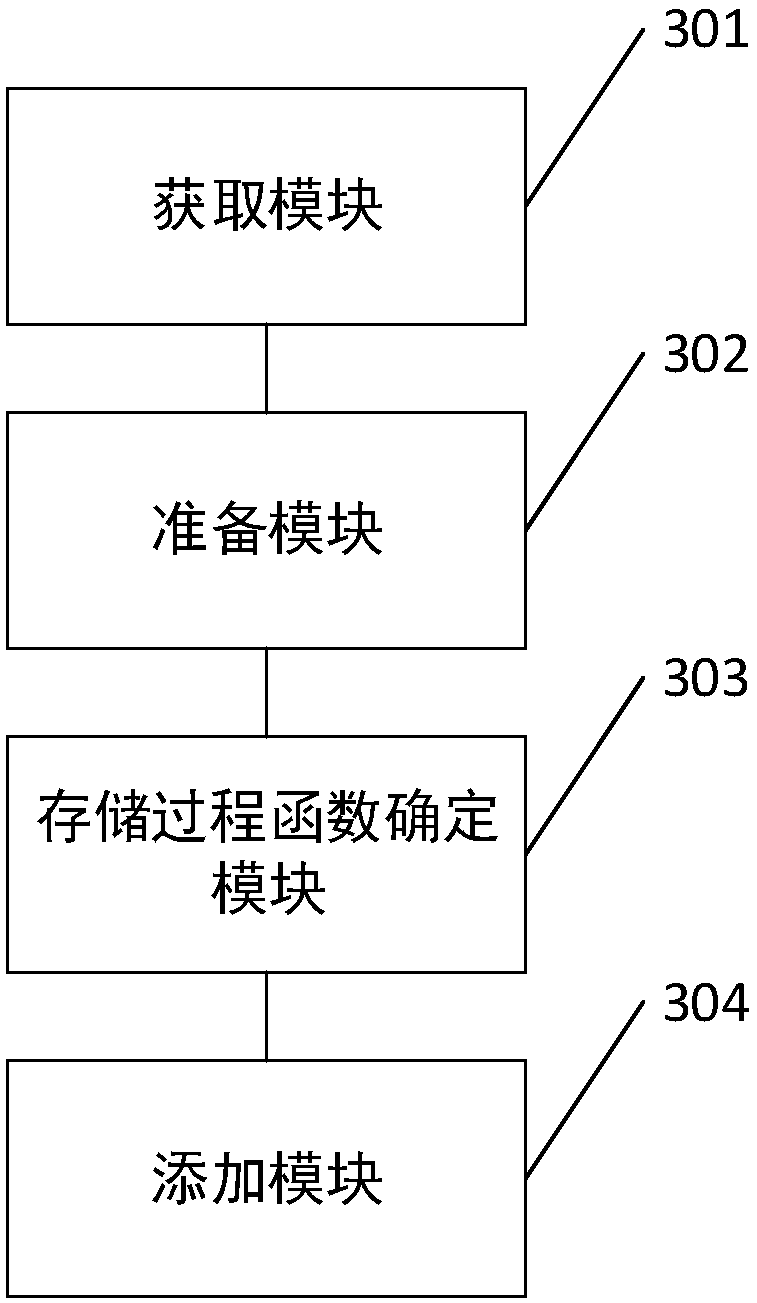

Test data addition method and apparatus

ActiveCN107704568AQuick storageEnsure consistencyDatabase management systemsSoftware testing/debuggingProcess functionStored procedure

The invention discloses a data addition method. The method comprises the steps of firstly determining to-be-stored data according to a demand and which database is added with the to-be-stored data, and determining database table information of the to-be-stored data; secondly creating an addition statement for the to-be-stored data, determining a parametric field of the to-be-stored data, and determining a storage process function by utilizing the addition statement and the parametric field; and finally calling the storage process function by utilizing jmeter to store the to-be-stored data in atarget second database. The data consistency is ensured through the parametric field in the storage process function; quick data storage is realized by using the jmeter tool; and the data insertion efficiency is effectively improved. An embodiment of the invention furthermore provides another data addition method, which also has the abovementioned technical effects.

Owner:MASHANG CONSUMER FINANCE CO LTD

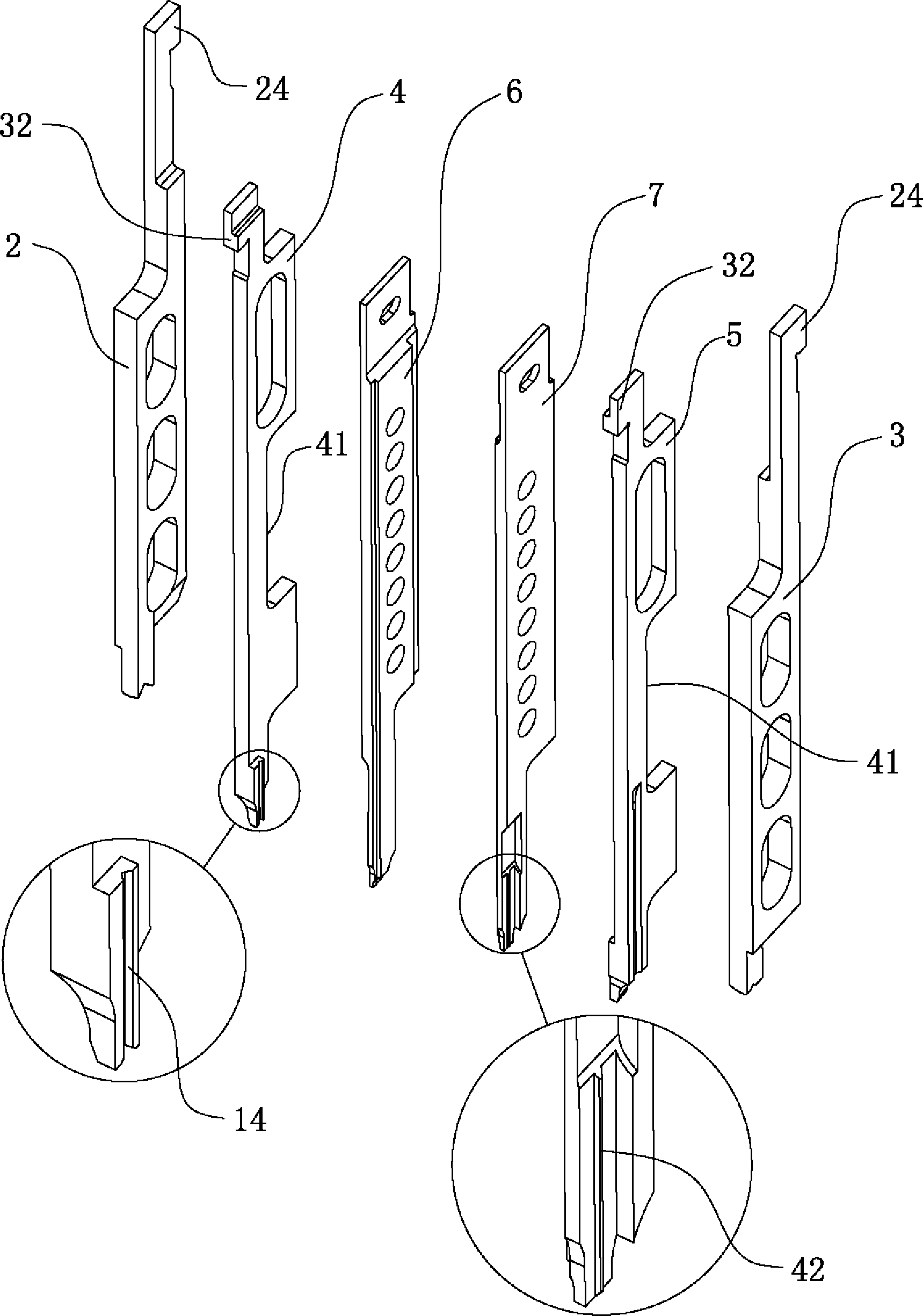

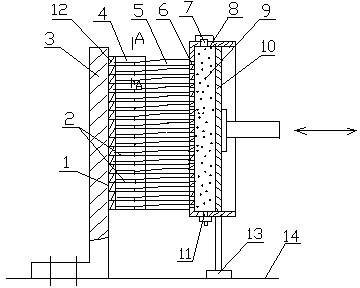

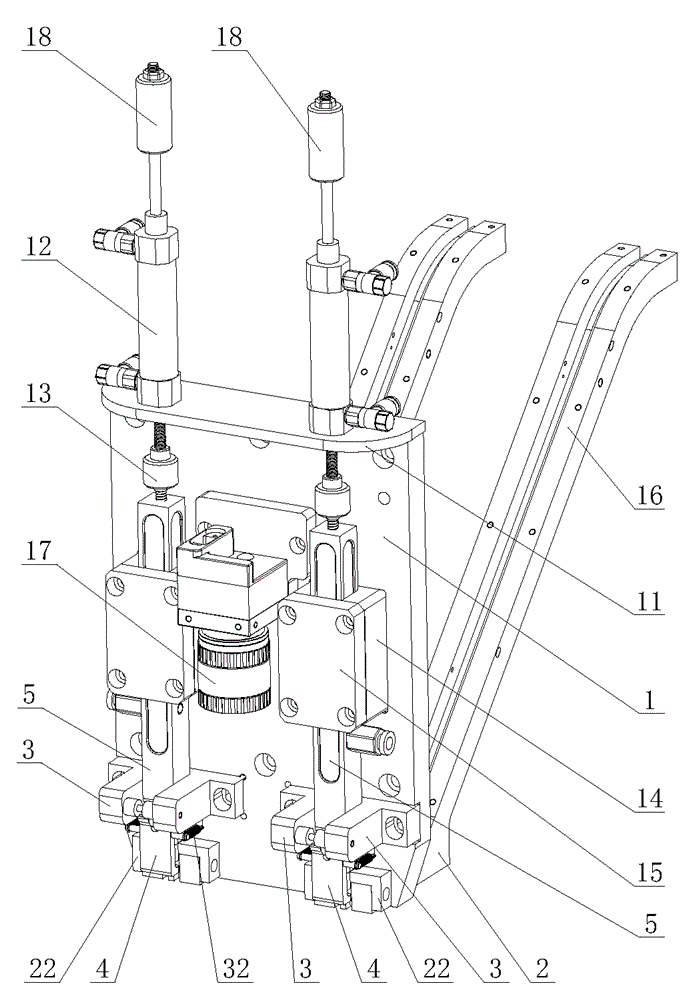

Head component inserting mechanism of straight insert type component inserting machine

ActiveCN104105393AIncrease insertion efficiencyImprove processing qualityElectrical componentsEngineeringTurning action

The invention relates to the technical field of upright component inserting machine equipment, in particular to a head component inserting mechanism of a straight insert type component inserting machine. The head component inserting mechanism of the straight insert type component inserting machine comprises a head mounting seat, a feed lead rail and a linkage mechanism, the head mounting seat is fixed with a material hook seat, a material receiving hook is hinged to the material hook seat, the hook part of the material receiving hook is abutted to the discharge end of the feed lead rail, the head mounting seat is movably provided with a main component inserting rod and a drive mechanism, a sucker is arranged at the lower end of the main component inserting rod, and the sucker is located above the hook part of the material receiving hook. The head component inserting mechanism is specially used for a PCB board, components of which are inserted in an accordant direction, a turning action is not needed when inserting, and accordingly the inserting efficiency of the component inserting machine is greatly improved; and in addition, because the function is reduced, the component inserting part of the component inserting machine is re-designed, the equipment structure is greatly simplified, the equipment production cost is lowered, and the processing quality and the component inserting stability of the component inserting machine are greatly improved.

Owner:海宁经开产业园区开发建设有限公司

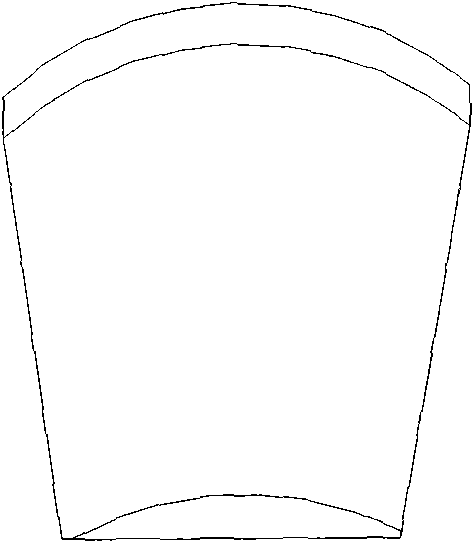

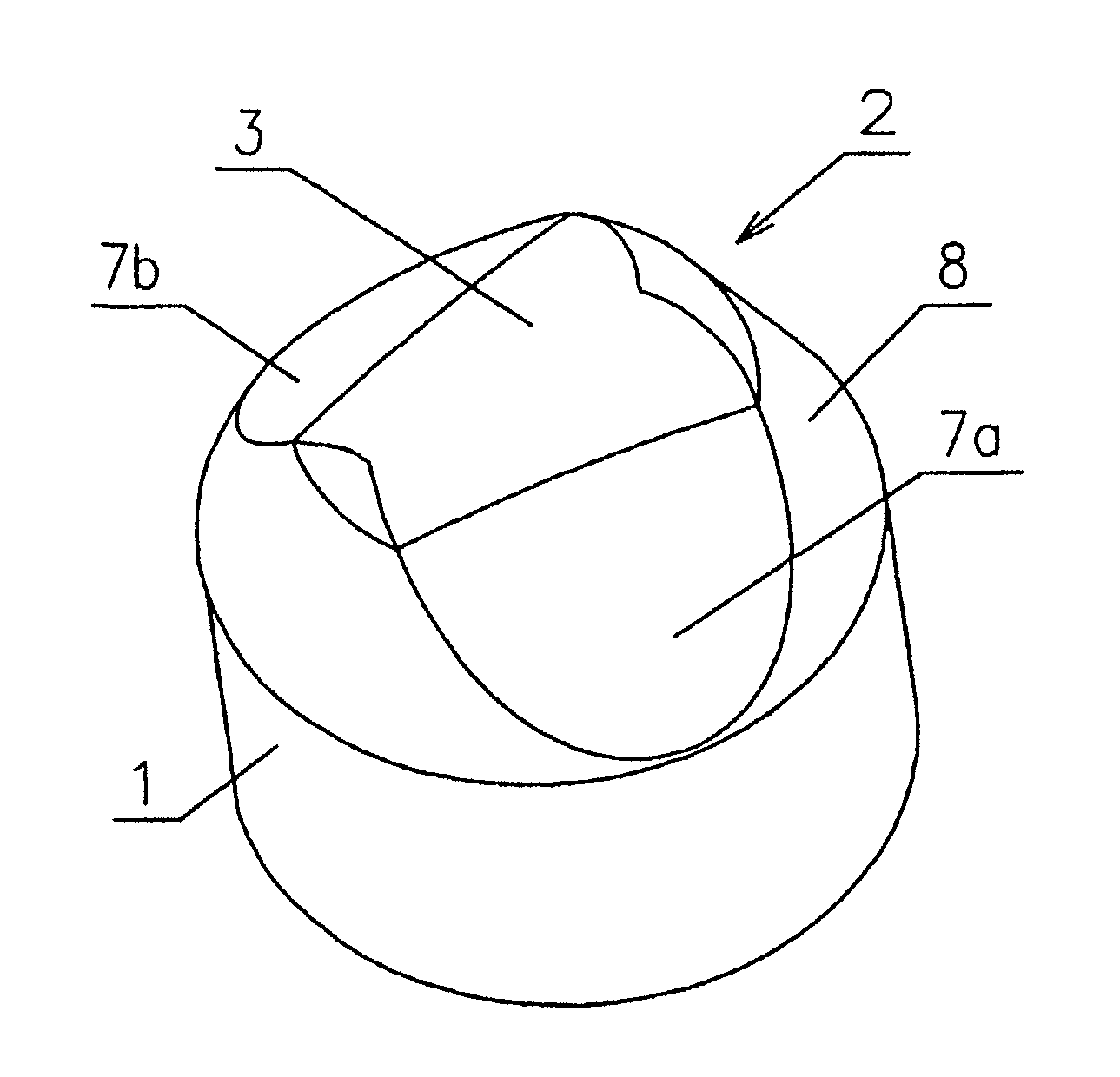

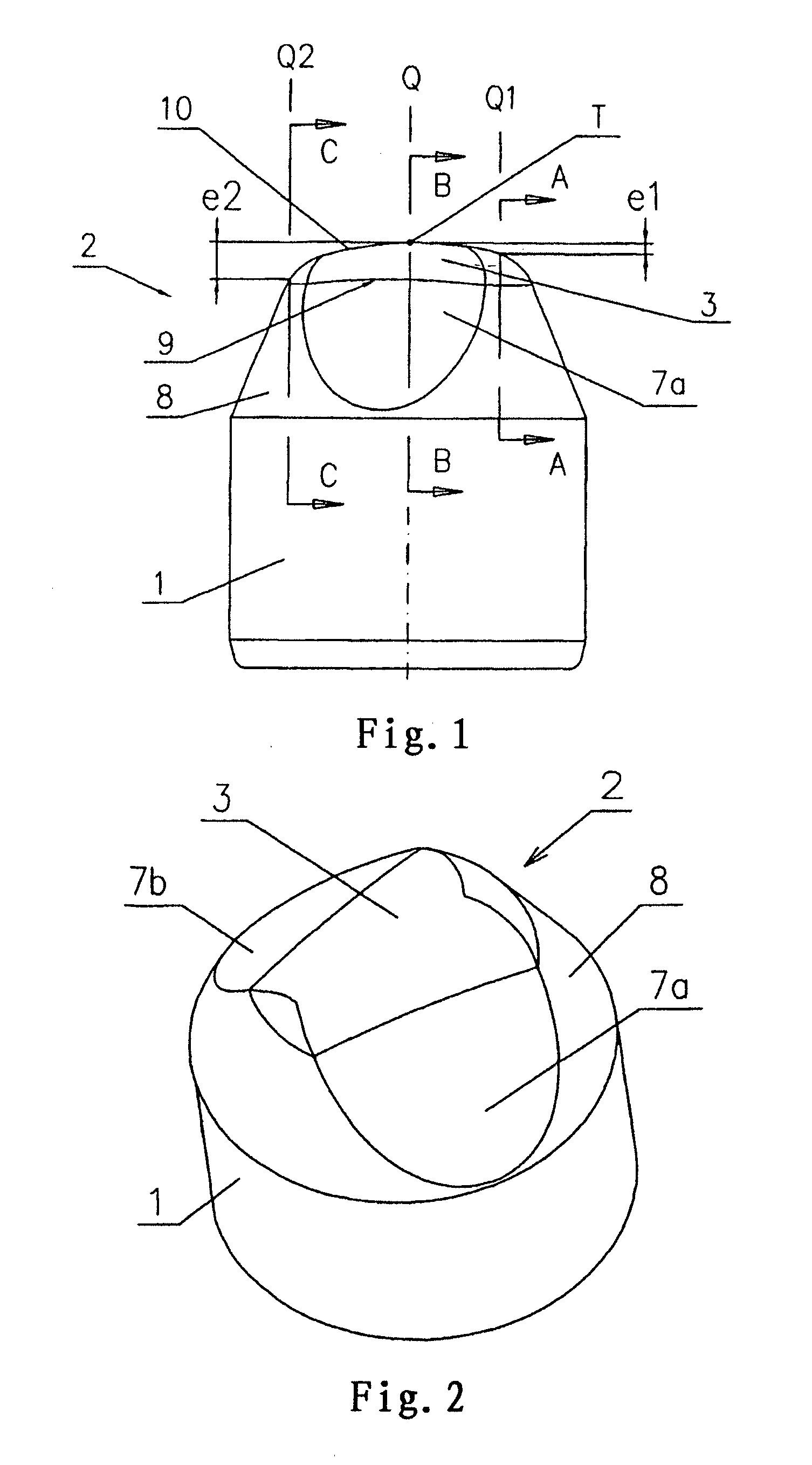

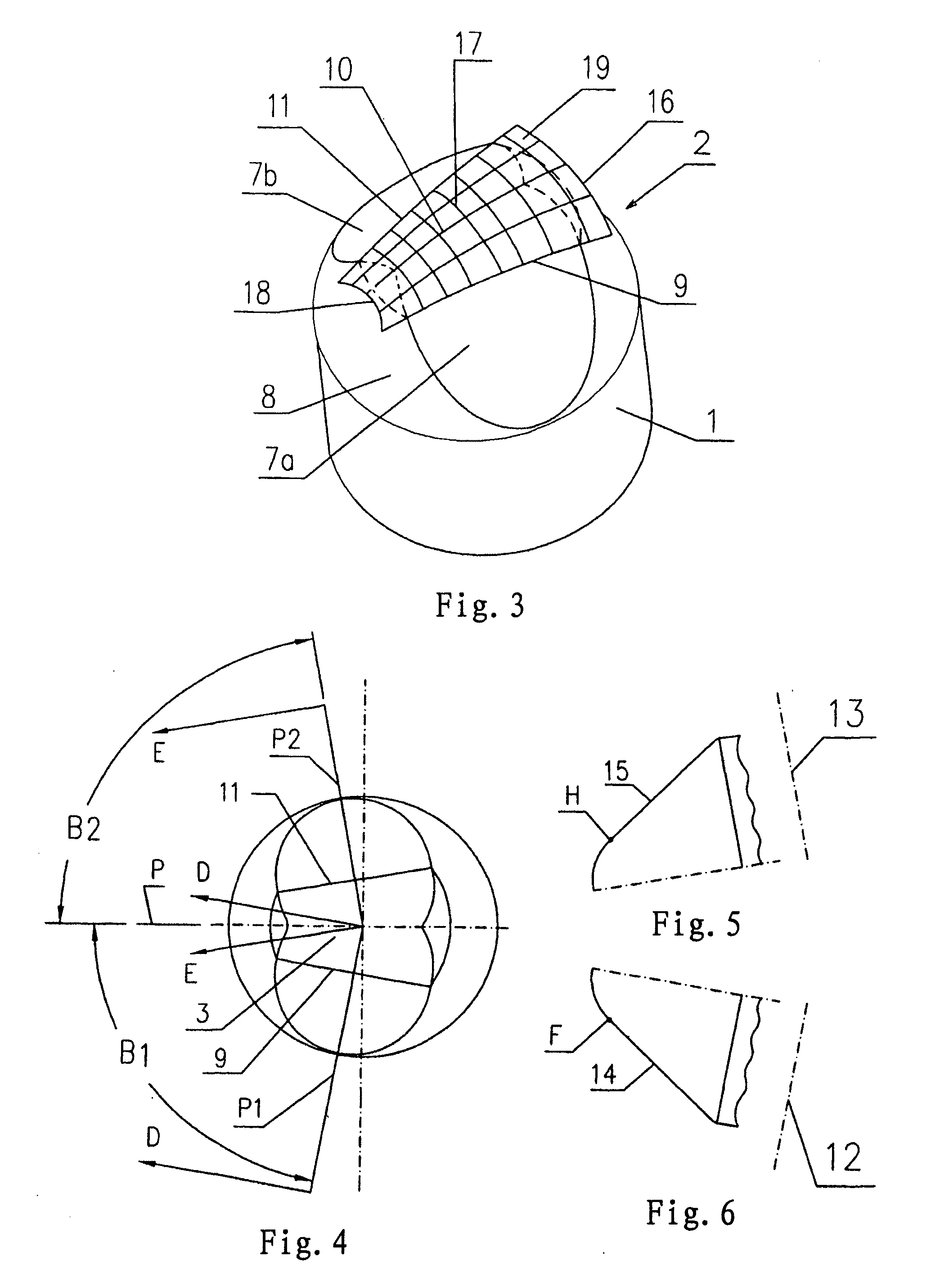

Convex Crested Insert With Deflected Wedge Surfaces

This invention relates to carbide inserts used on roller cone bits for oil and gas drilling applications as well as for other geological drilling applications, and more specifically, relates to the convex crested insert with deflected wedge surfaces. The insert comprises a cylindrical portion and a crest portion. Said crest portion is composed of a conical crest base, a top surface and two opposing wedge surfaces. Upper ends of the two wedge surfaces are merged smoothly with top surface of the insert. The specific feature of the structure is that top surface of the crest portion is convexed outwardly and forms a smooth curve surface which is higher in the middle and lowers down gradually to each end. Said two wedge surfaces are slant wedge surfaces, so that a width of the top surface and therefore a width of the insert crest are tapered from one end to the other. Advantages of this invention include: 1. Help for rock breaking and therefore, it can increase drilling efficiency of the cutters and lower the overall drilling cost; 2. higher anti-breakage capability and longer working life; and 3. when inserts of this invention are used as heel row cutting elements on bit, contact area between wider end of the top surface of the insert and borehole wall is larger and therefore the gouging action applied on the borehole wall is higher and can also achieve better gage protection of the bit.

Owner:KINGDREAM PLC CO

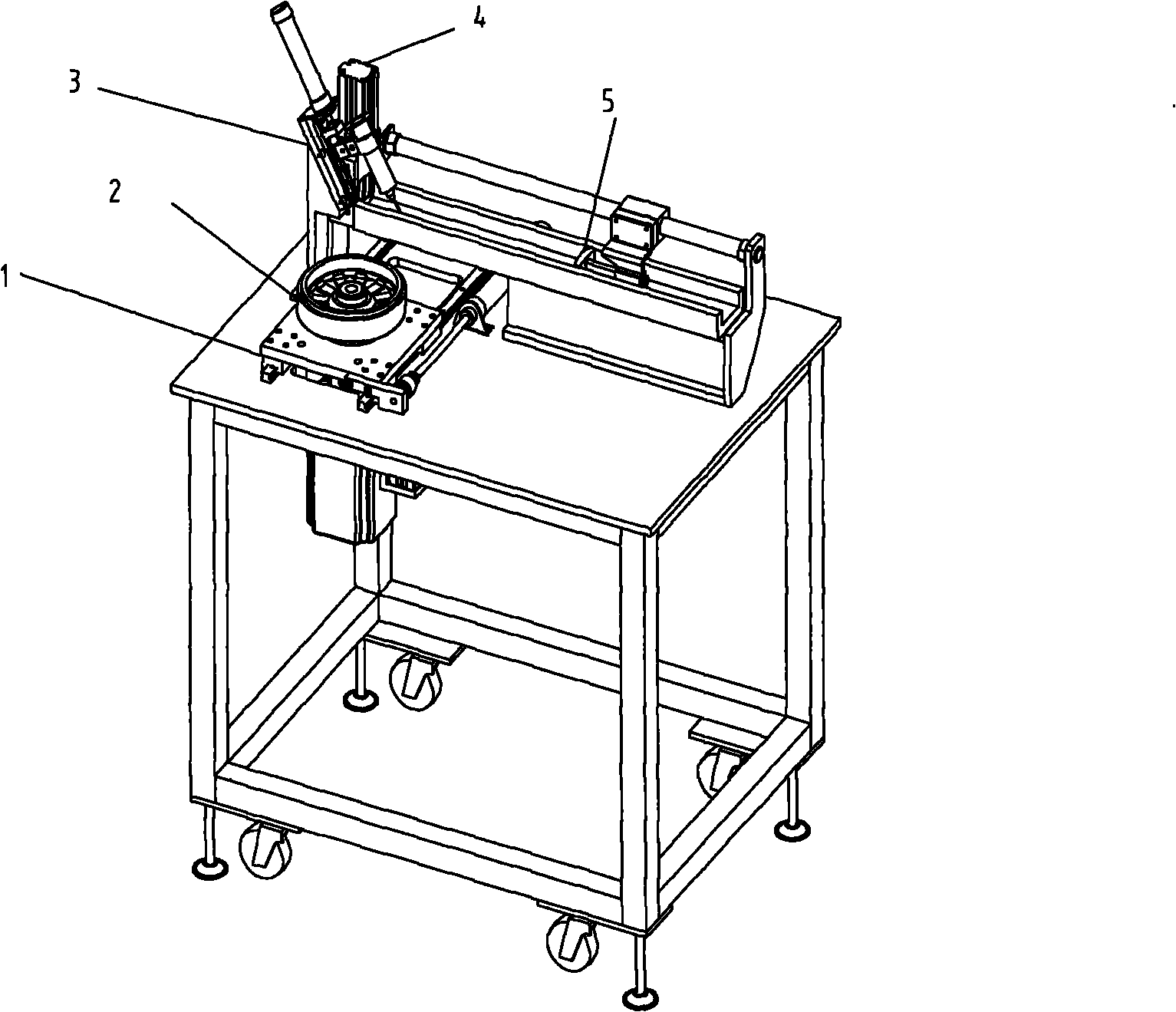

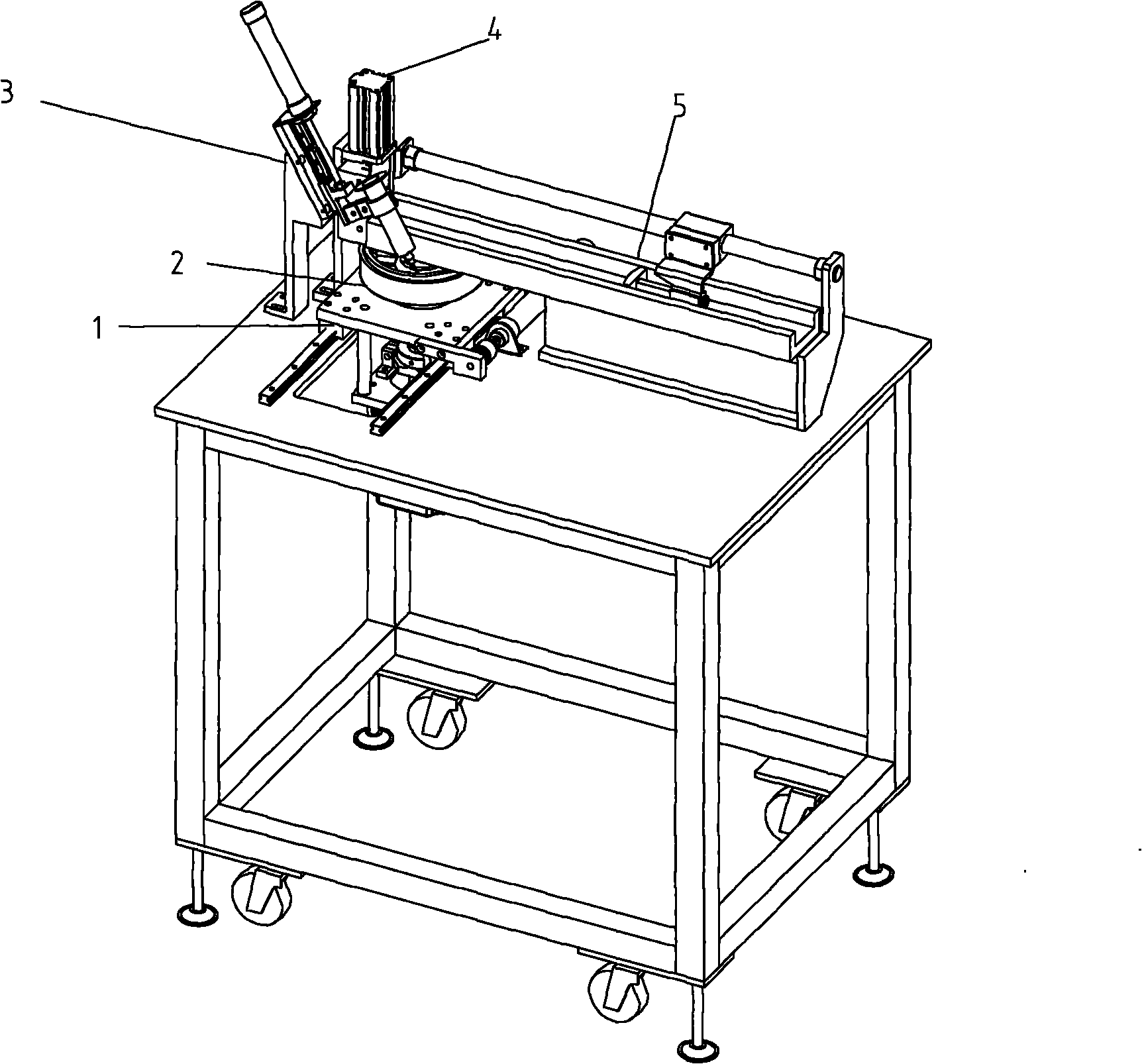

Automatic steel strip end cap sleeving machine

ActiveCN108213906ARealize feedingAchieve continuous feedingMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic steel strip end cap sleeving machine, and aims at solving the problems that during traditional manual steel strip and end cap installation, efficiency is low, andmanpower is wasted. According to the technical scheme, the automatic steel strip end cap sleeving machine is characterized by comprising a rack, a vibration material disc arranged on one side of the rack, a clamping assembly connected to the discharging end of the vibration material disc and used for clamping an end cap, a feeding mechanism arranged on the rack and used for arranging steel strips,a conveying assembly arranged below the feeding mechanism and used for pushing one steel strip out, and a drive mechanism which is arranged on the rack and is collinear to the discharging position ofthe conveying assembly. According to the automatic steel strip end cap sleeving machine, through automatic steel strip and end cap installation, manpower is greatly liberated, labor force consumptionis reduced, and the installing efficiency is improved.

Owner:徐锋

TO-CAN assembly PIN pin plugging device

PendingCN114245604AImprove qualityEasy to plug inPrinted circuit assemblingClassical mechanicsStructural engineering

A TO-CAN assembly PIN pin plugging device comprises a posture adjusting mechanism, one side of the upper end of the posture adjusting mechanism is provided with a conveying mechanism, the other end of the posture adjusting mechanism is provided with a cutting mechanism, and the posture adjusting mechanism is provided with a clamping mechanism; the posture adjusting mechanism is used for adjusting the height and the direction of the contact pin and comprises a lifting component, and a rotating component is arranged on the lifting component; the conveying mechanism is used for placing and conveying continuous pin wires and comprises an end locking component, and a placing component is arranged at the upper end of the end locking component; the cutting mechanism is used for straightening and cutting pin wires and comprises a straightening component, and a cutting component is arranged at the output end of the straightening component; and the clamping mechanism is used for clamping the pin wire. According to the invention, when the TO-CAN assembly is assembled, the pin can be automatically and accurately plugged conveniently, so that the quality of the TO-CAN assembly is improved.

Owner:四川九州光电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com