Automatic insertion machine of magnetic steel of motor

A technology of automatic insertion and insertion machine, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of uneven magnetic field distribution, low work efficiency, unstable motor operation, etc., to ensure the uniformity of distribution and improve the effect of insertion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

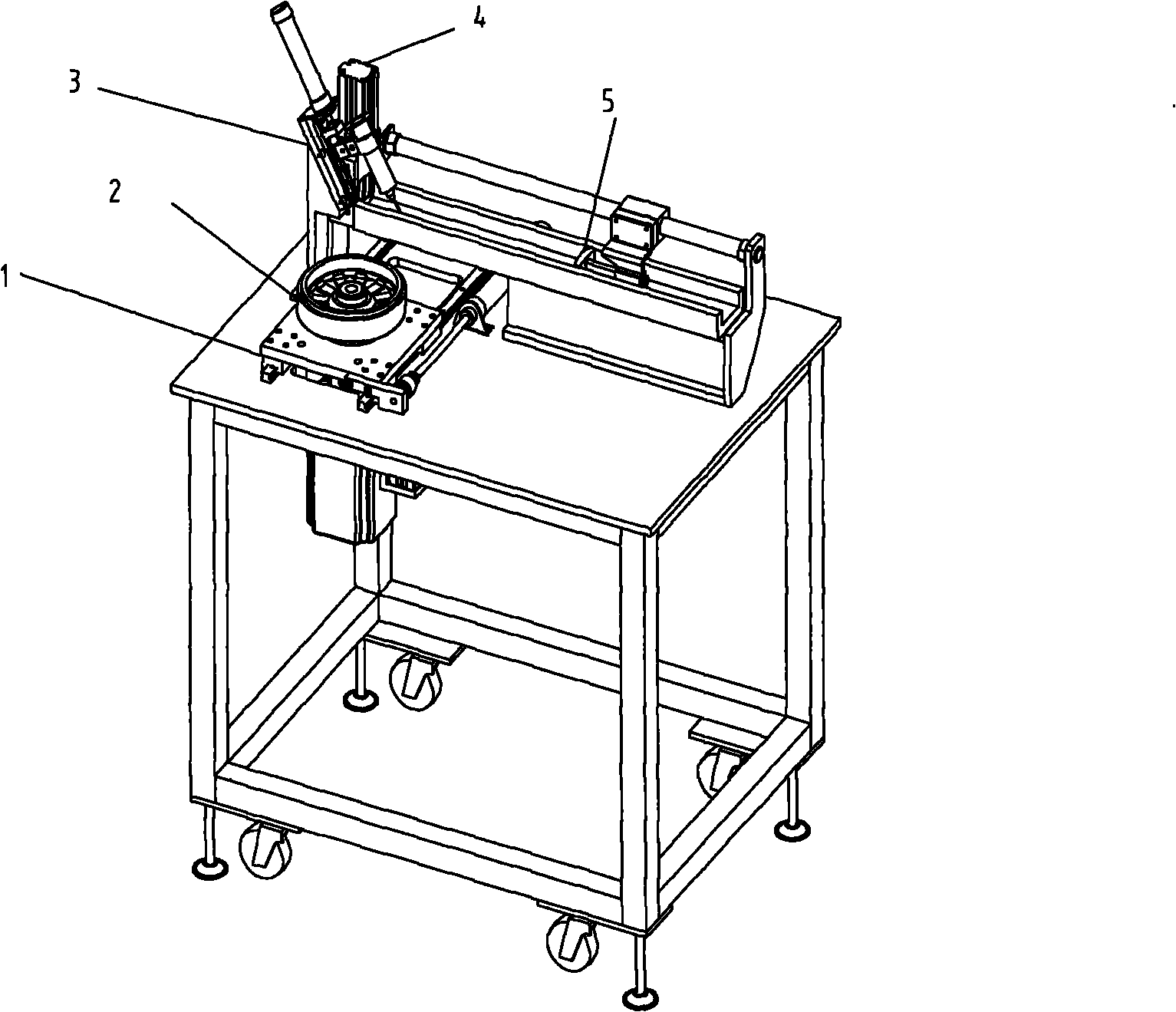

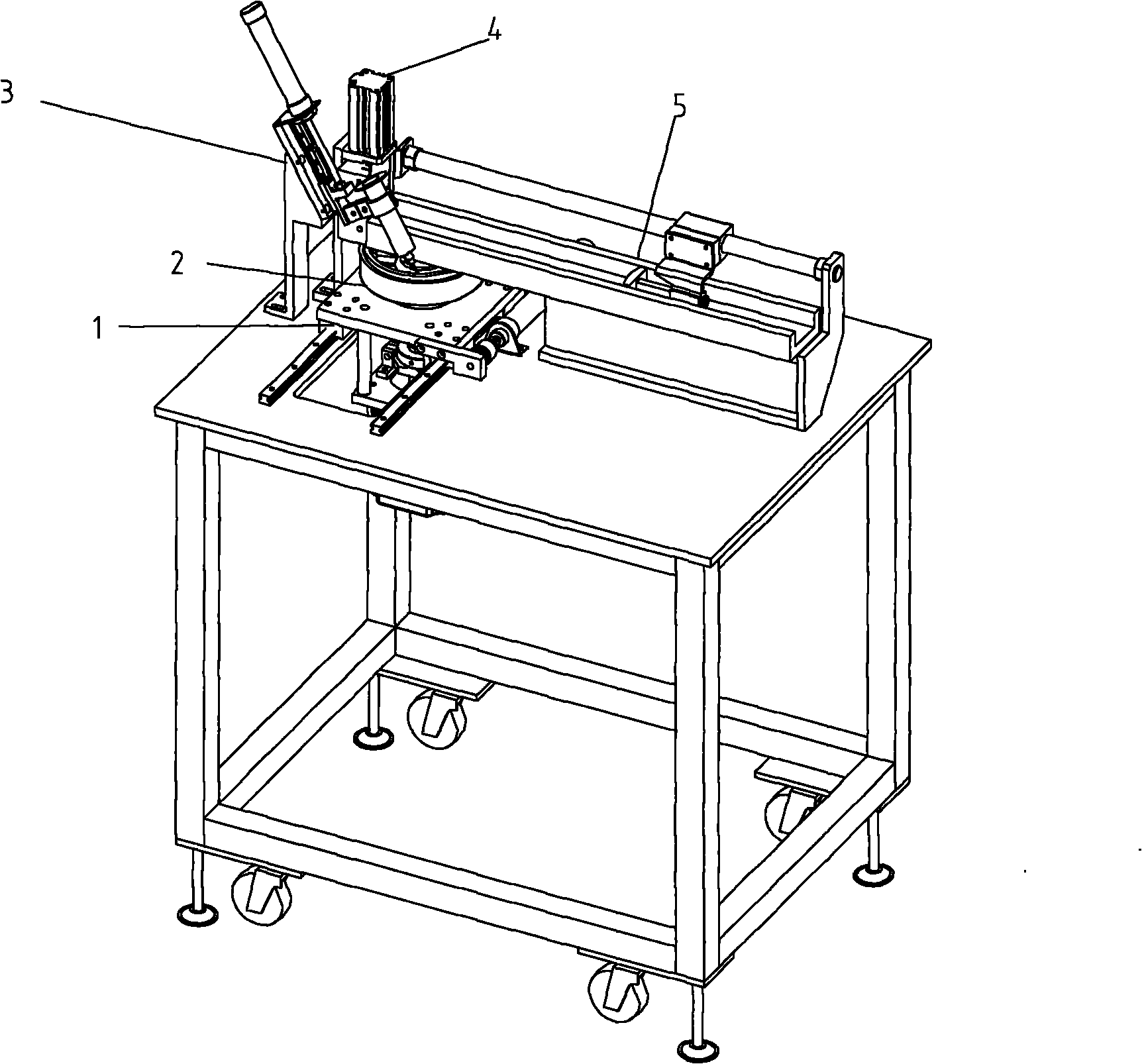

[0012] Such as figure 2 Shown, the work of the motor magnetic steel automatic insertion machine of the present invention is controlled automatically by program completely, and the driving device on it is fixedly connected with the carrier (1) that is loaded with stator (2), and drives the expansion and contraction of carrier; Stator (2) ) is driven by a motor below it to rotate intermittently at a certain frequency in a clockwise direction; a track is set above the carrier (1), such as figure 1 The shown magnetic steel (5) is adsorbed on the slider in the track, and one end of the track is connected with a magnet (3) and two glue guns, and the position of the glue guns is set so that when working, the glue gun head The glue can be sprayed in alignment with the gap between the magnetic steel (5) and the inner surface of the stator (2). The air cylinder (4) is placed above the mounting position where said magnetic steel (5) is inserted into the stator.

[0013] Such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com