Patents

Literature

16259results about How to "Stable job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

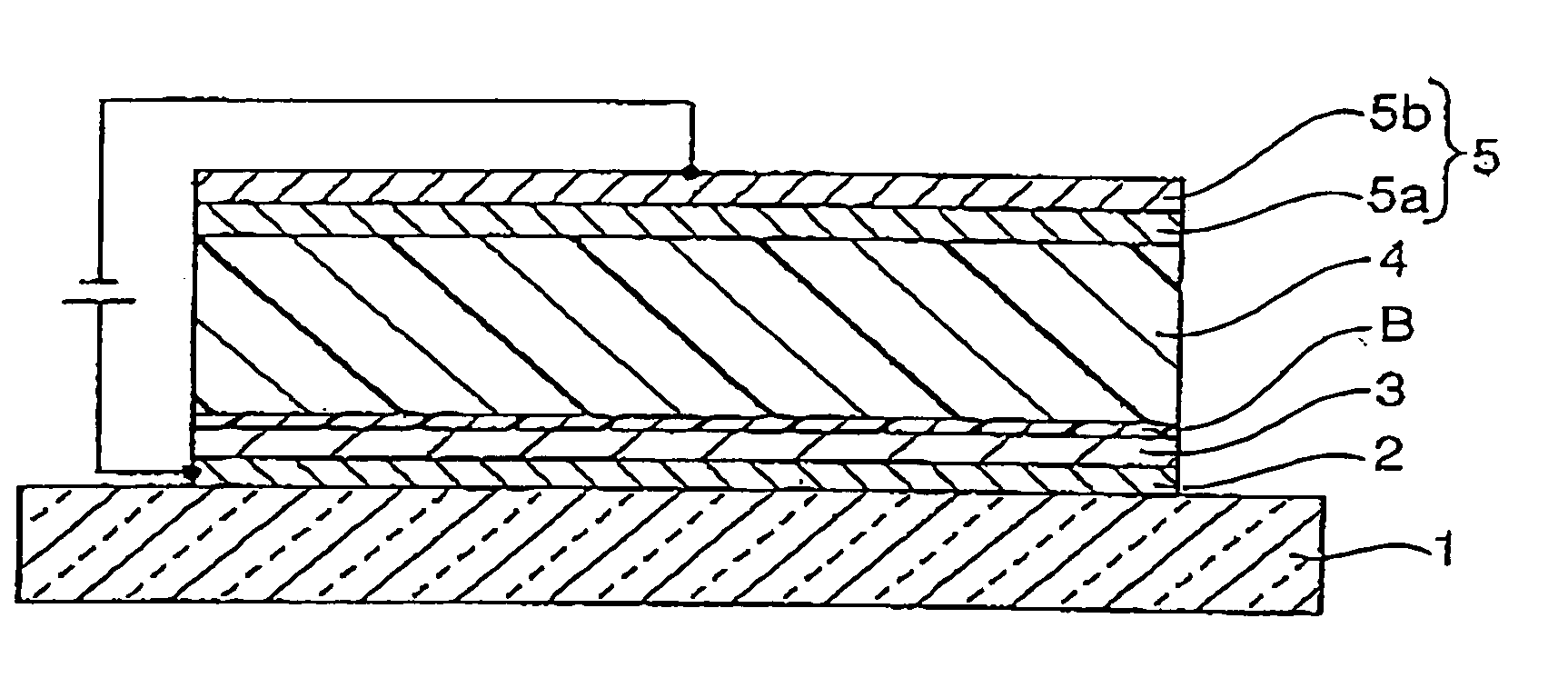

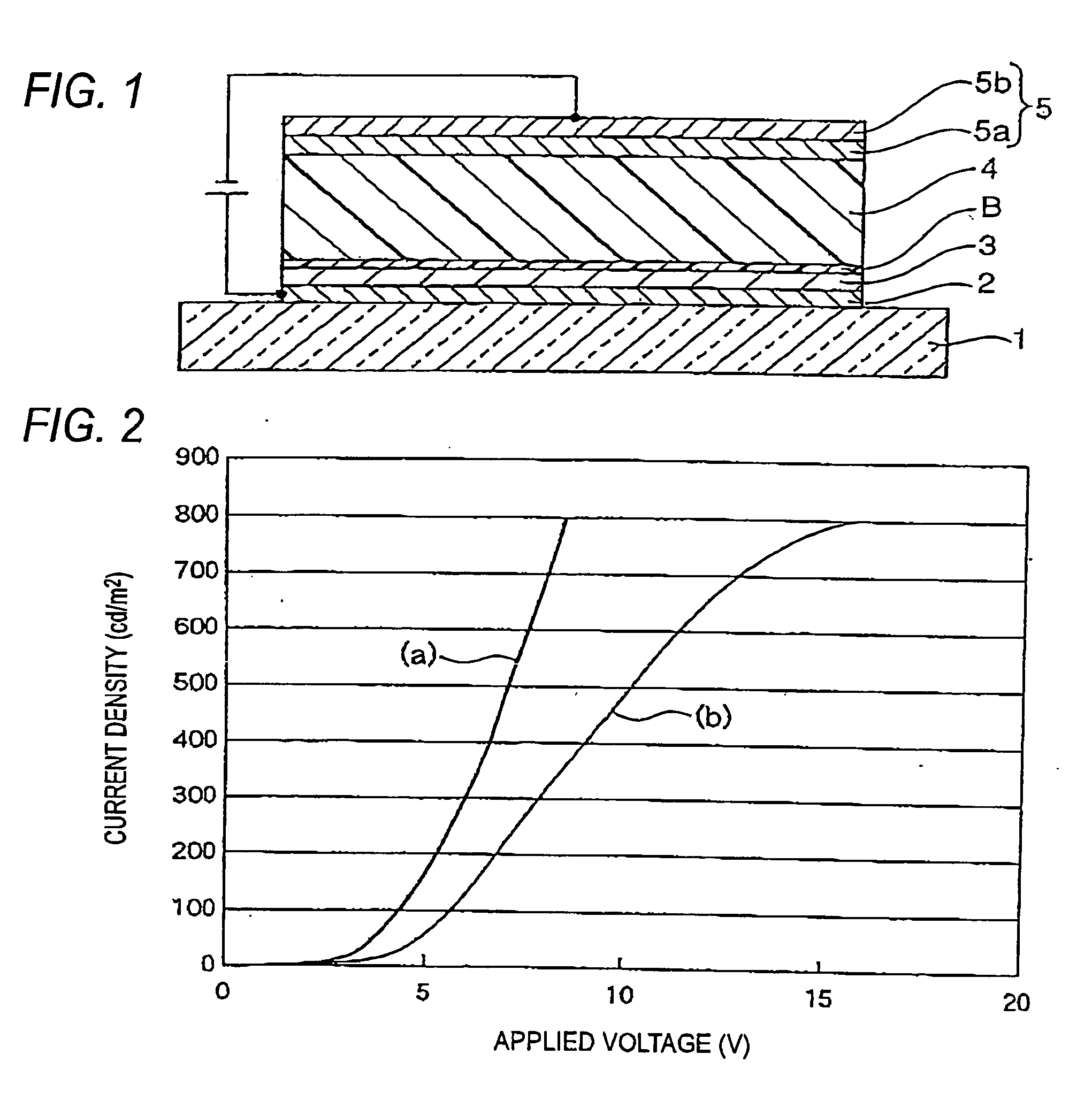

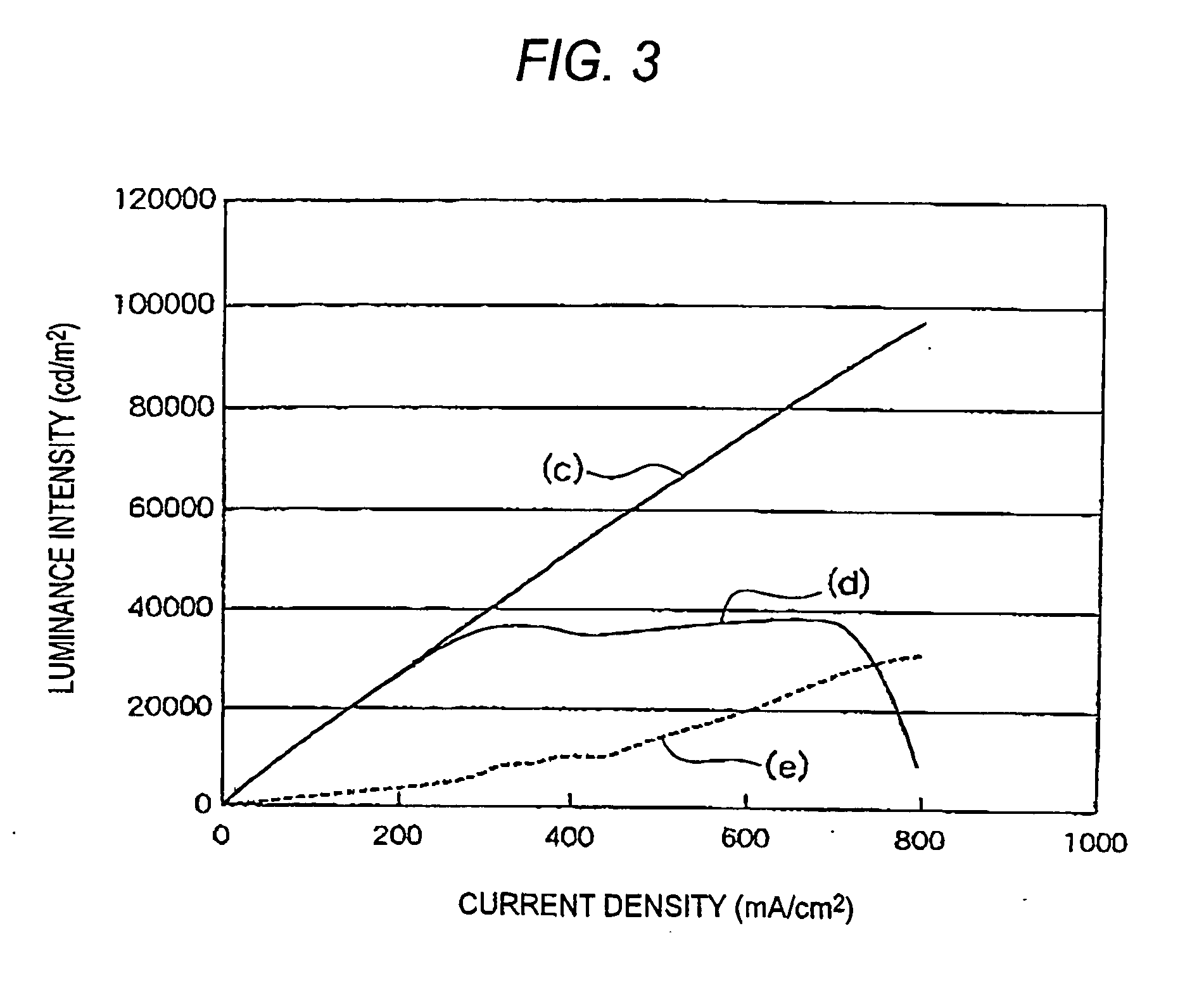

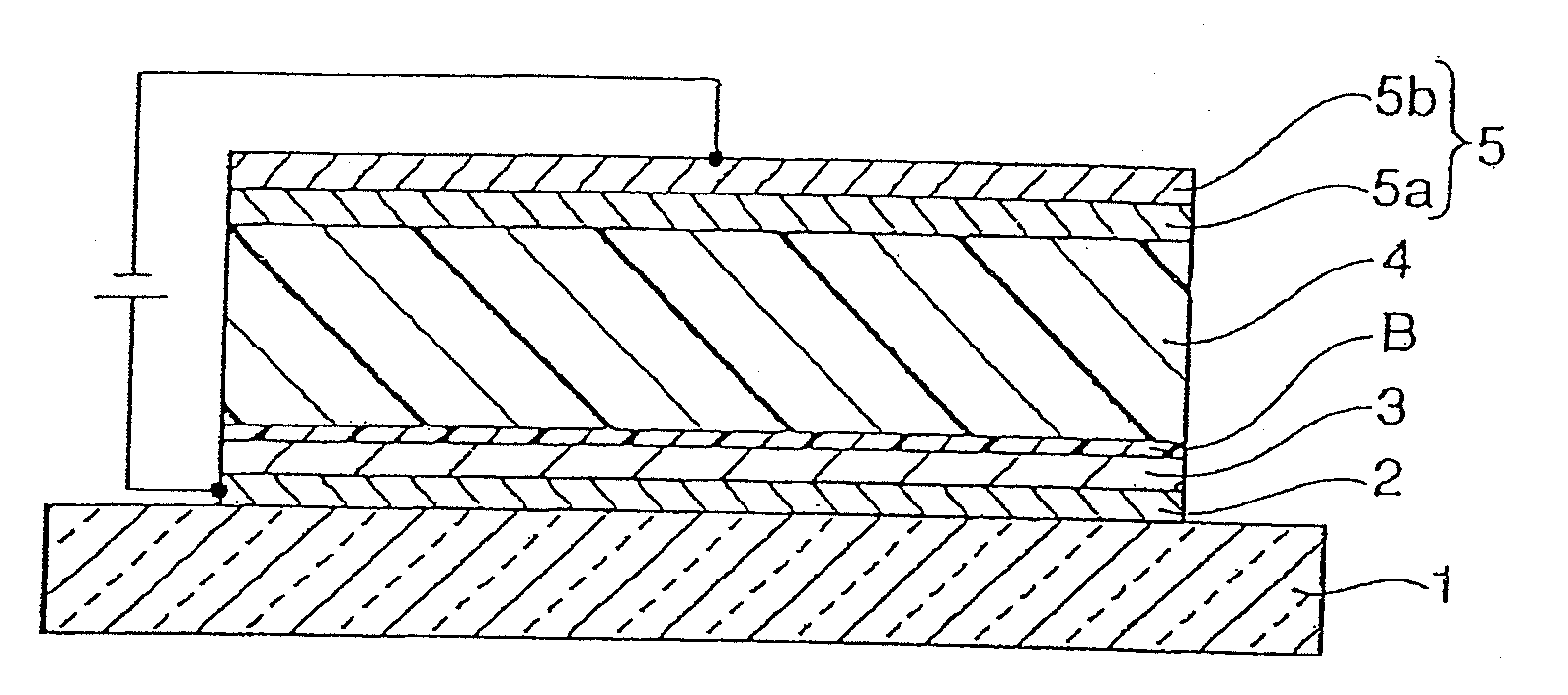

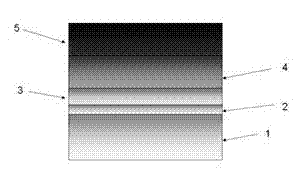

Organic electroluminescent device and method for manufacturing the same

InactiveUS20050170208A1Maintain good propertiesEasy to manufactureDischarge tube luminescnet screensElectroluminescent light sourcesCharge injectionOrganic solvent

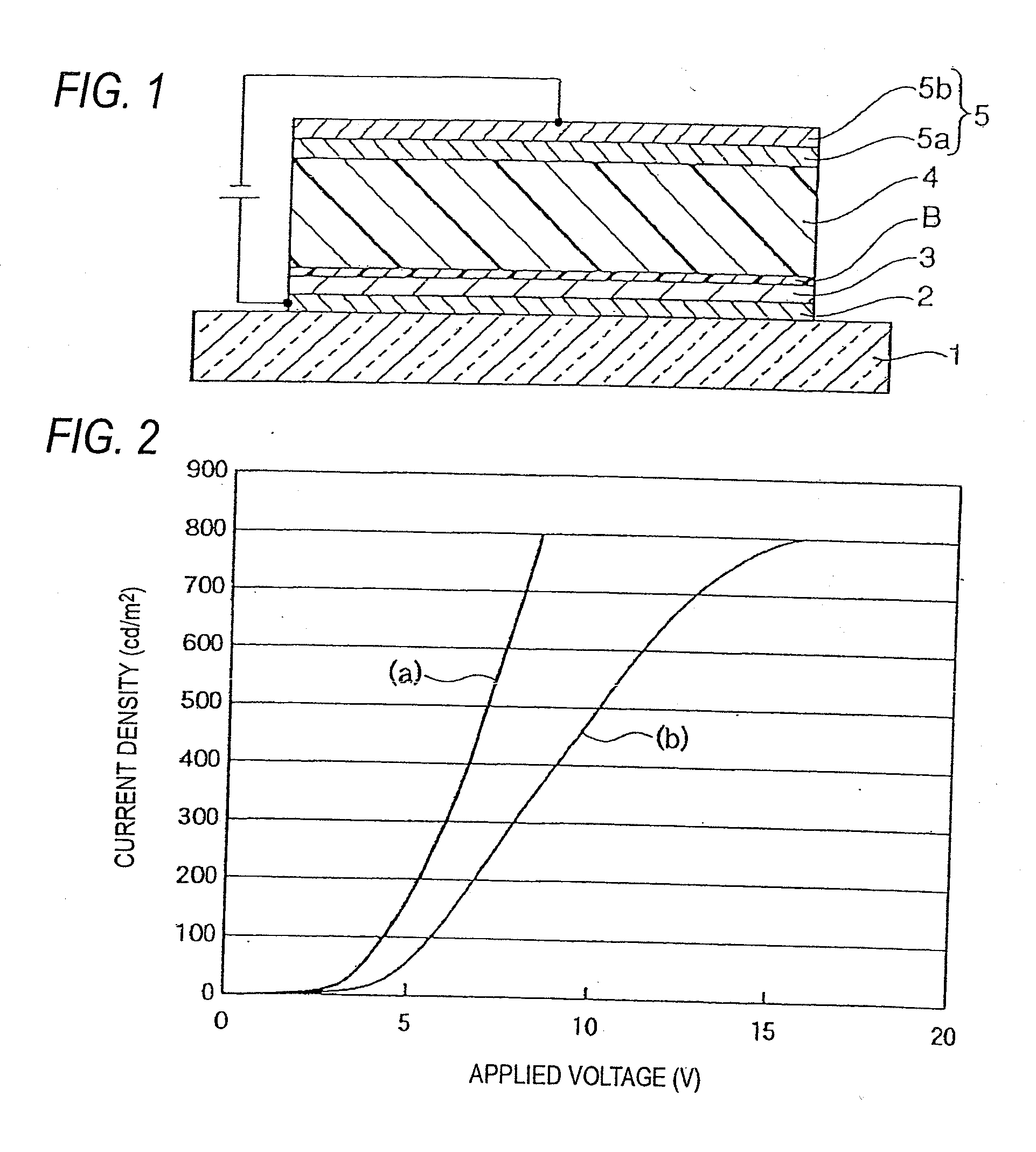

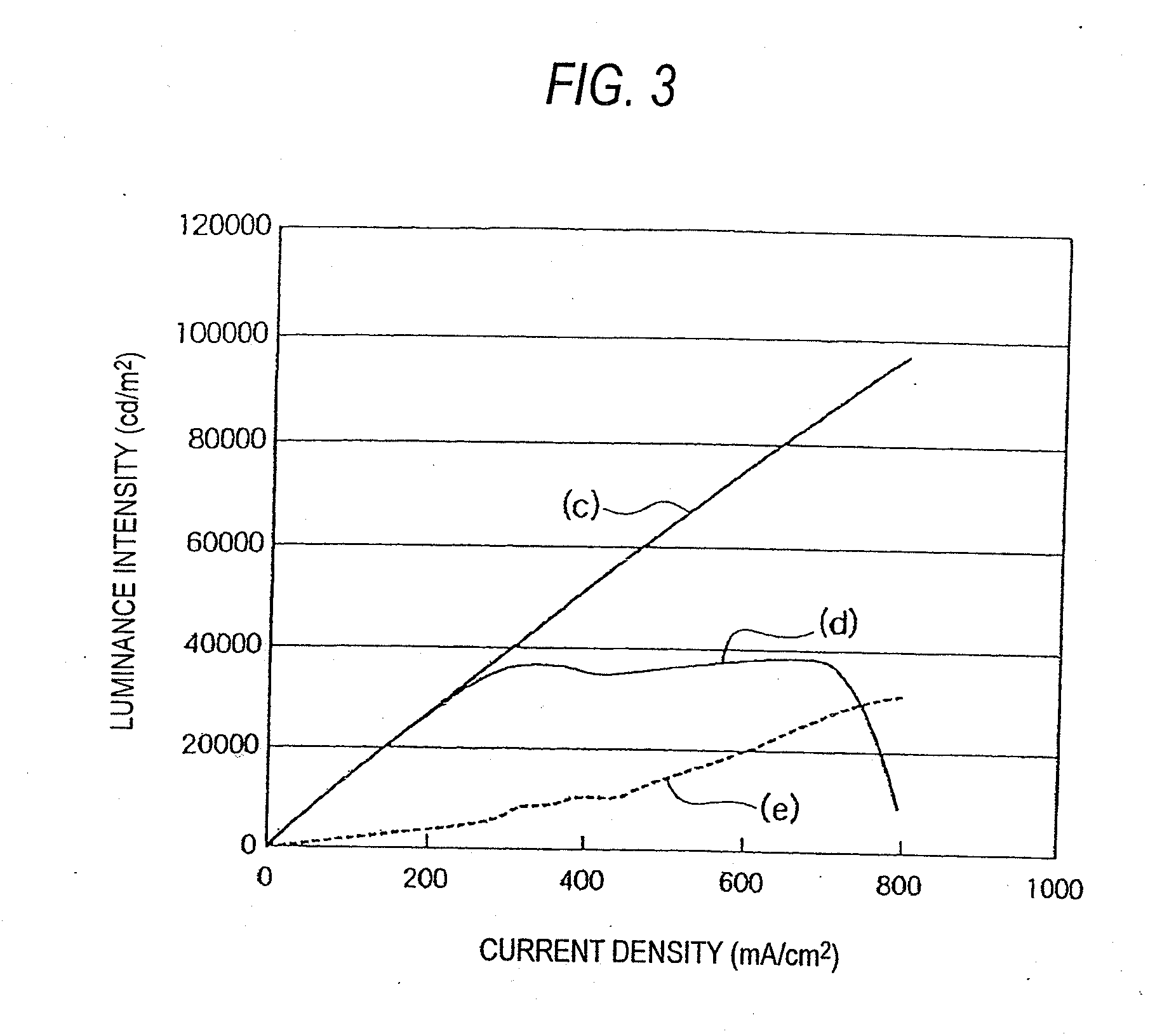

An organic EL device which drives over a wide range from low brightness to high brightness for light source applications, operates stably over a wide range of brightness and has excellent life property is provided. The device comprises at least one pair of electrodes 2 and 5, and a plurality of functional layers disposed between the electrodes 2 and 5, the functional layers comprising a layer 4 having the light emitting function, which is composed of at least one polymeric material and contains an organic solvent and a charge injection layer 3 composed of at least one inorganic material.

Owner:JOLED INC

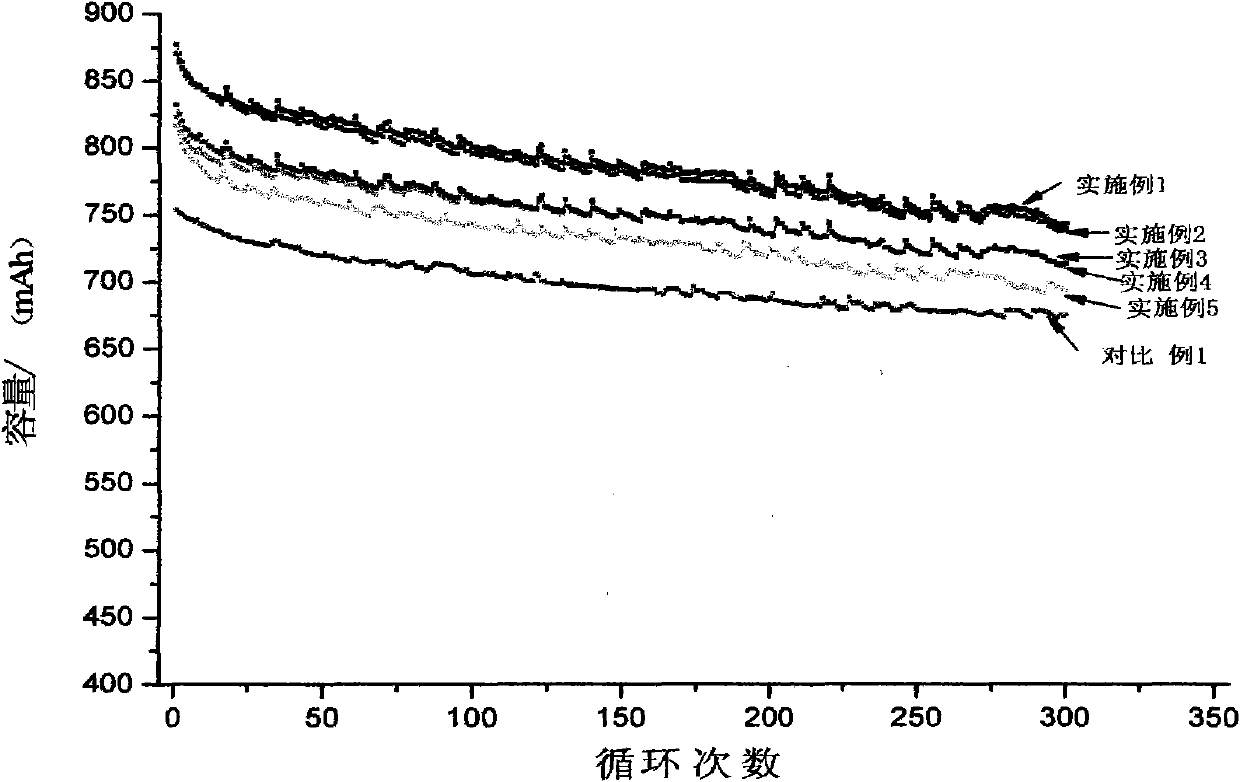

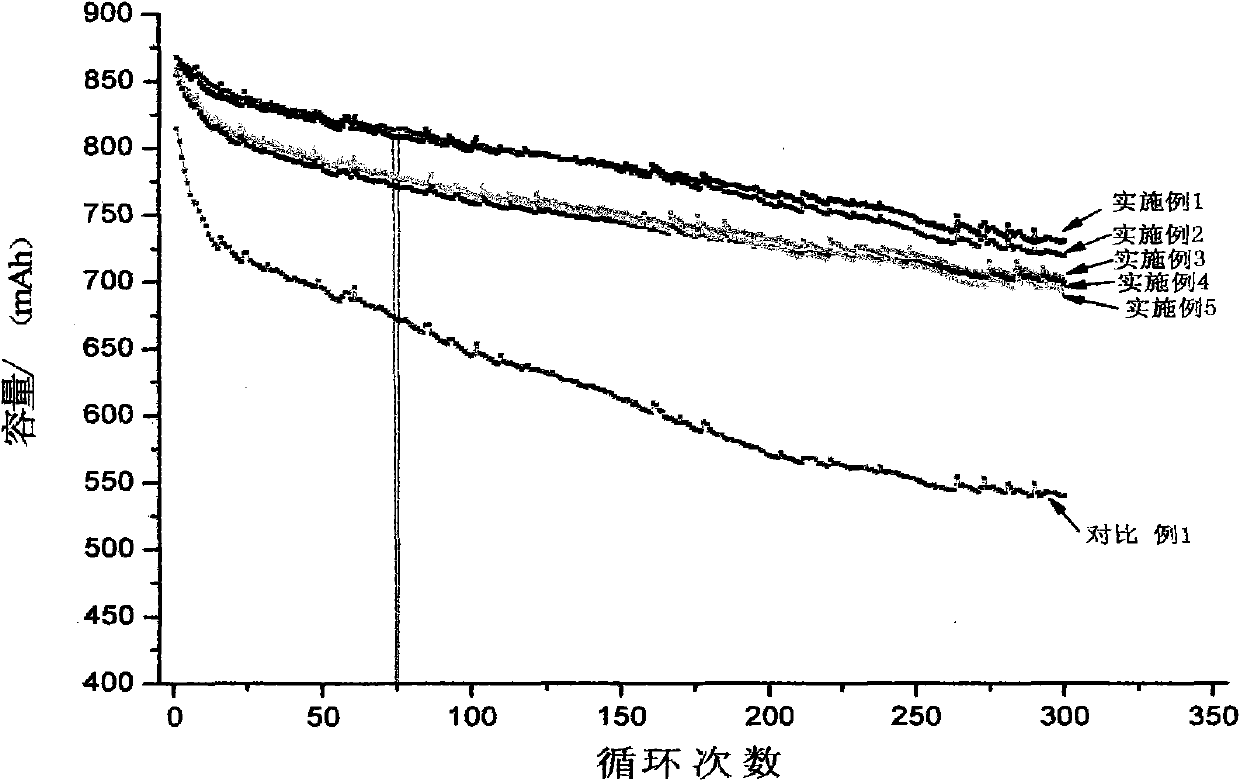

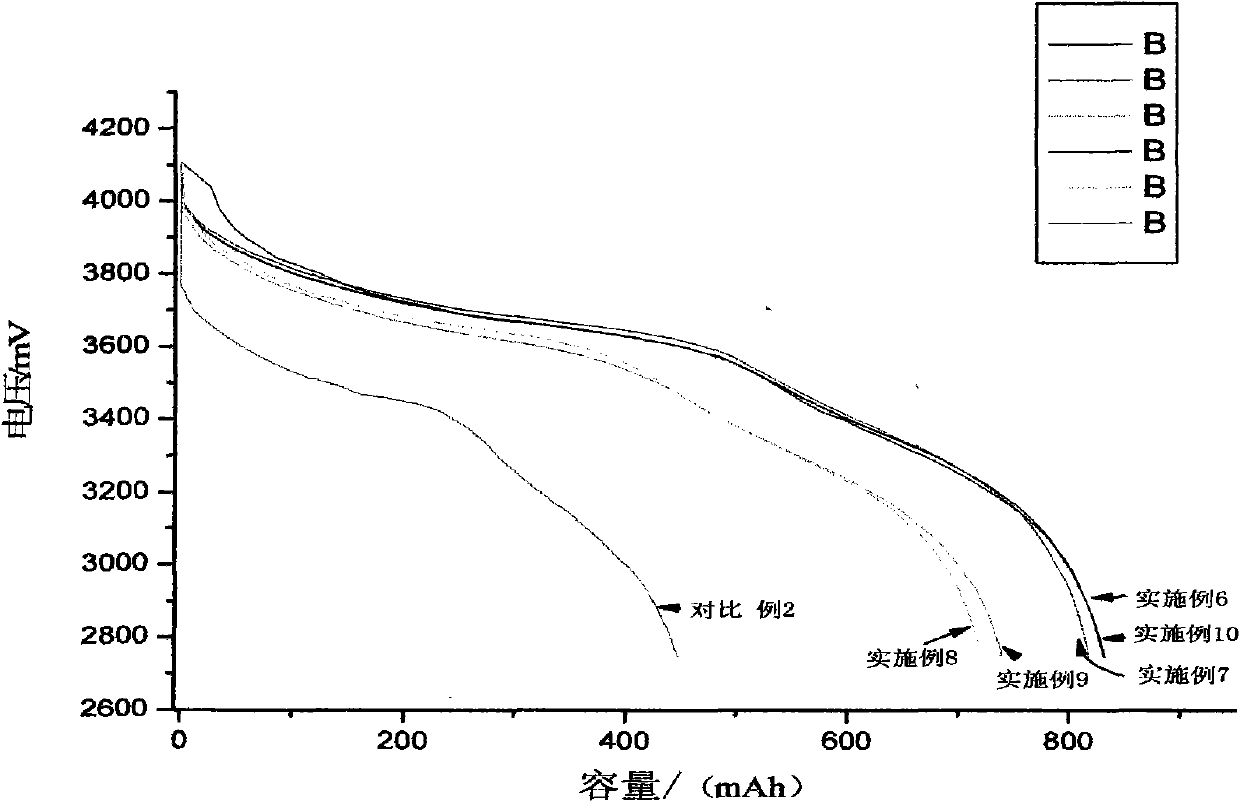

High-capacity lithium-ion electrolyte, battery and preparation method of battery

ActiveCN101771167AIncrease capacityLow costFinal product manufactureCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a high-capacity lithium-ion electrolyte, a battery and a preparation method of a battery, in particular to the high-capacity lithium-ion electrolyte and the battery using the high-capacity lithium-ion electrolyte and the preparation method of the battery. The electrolyte disclosed by the invention comprises lithium salt and non-aqueous organic solvent, and also consists of the following components in weight percent in terms of the total weight of the electrolyte: 0.5-7% of film-forming additive, 0-15% of flame-retardant additive, 2-10% of antiovefill additive, 0.01-2% of stabilizer and 0.01-1% of wetting agent; the electrolyte can enable the anode with high Ni content to work stably, and reduce the battery cost; the high-capacity lithium-ion battery can perform high ratio capacity and excellent safety and high temperature property and cyclic life fully due to the addition and synergetic functions of various functional additives.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

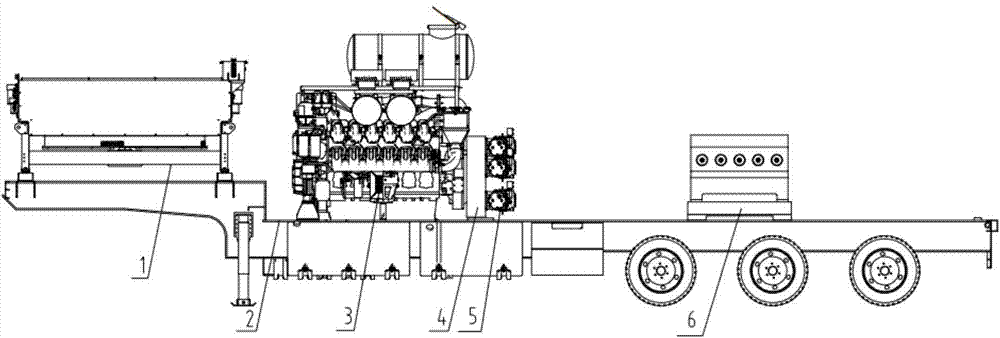

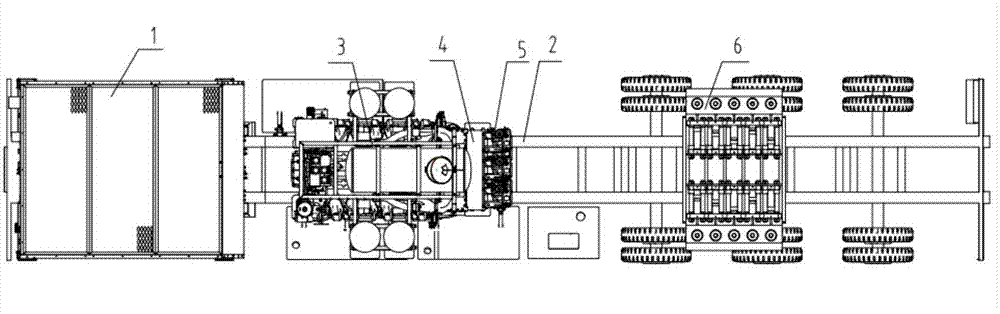

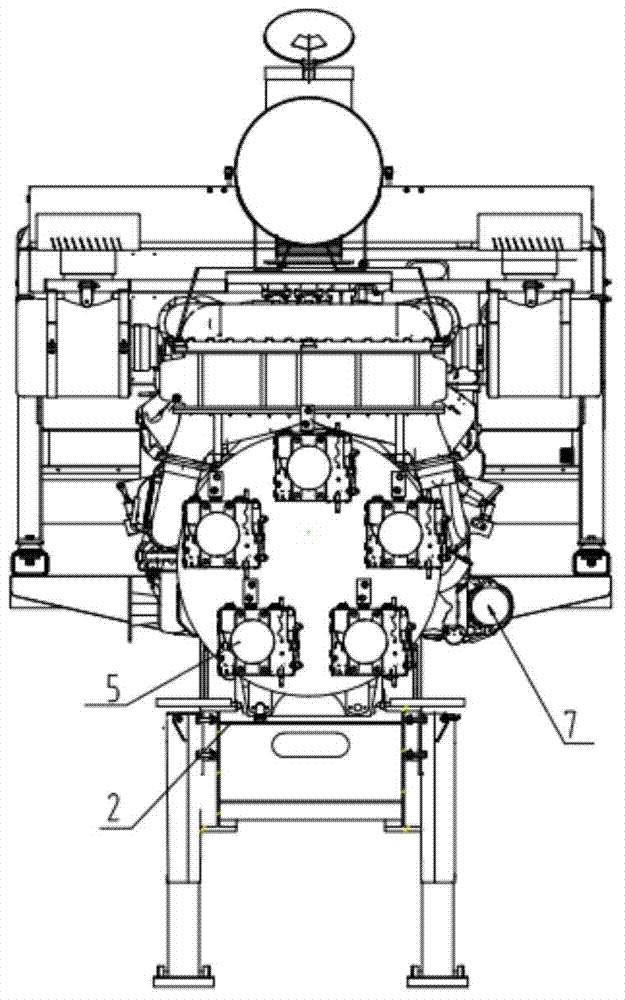

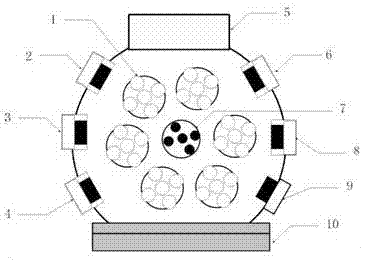

Fracturing transmission and high-pressure discharging system

InactiveCN104727797AExpand the range of selectionSave layout spaceFluid removalTransfer caseEngineering

The invention relates to a fracturing transmission and high-pressure discharging system. The fracturing transmission and high-pressure discharging system comprises a chassis and is characterized in that a high-power engine, a transfer case, a plurality of variable displacement plunger pumps and a double-acting fracturing pump are arranged on the chassis, the output end of the high-power engine is connected with the input end of the transfer case, the output end of the transfer case comprises a plurality of power take-off ports, and each power take-off port is connected with one variable displacement plunger pump; the variable displacement plunger pumps drive the double-acting fracturing pump through a hydraulic system. The fracturing transmission and high-pressure discharging system further comprises a system radiator and a heat dissipation plunger pump used for driving the system radiator, and the heat dissipation plunger pump is connected with one power take-off port of the transfer case. The power take-off ports of the transfer case and the variable displacement plunger pumps are arranged annularly. The fracturing transmission and high-pressure discharging system has the advantages that hydraulic driving replaces mechanical transmission, and working vibration is reduced; the layout space of a whole vehicle is saved, and meanwhile, operating efficiency and the stability of the whole vehicle are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

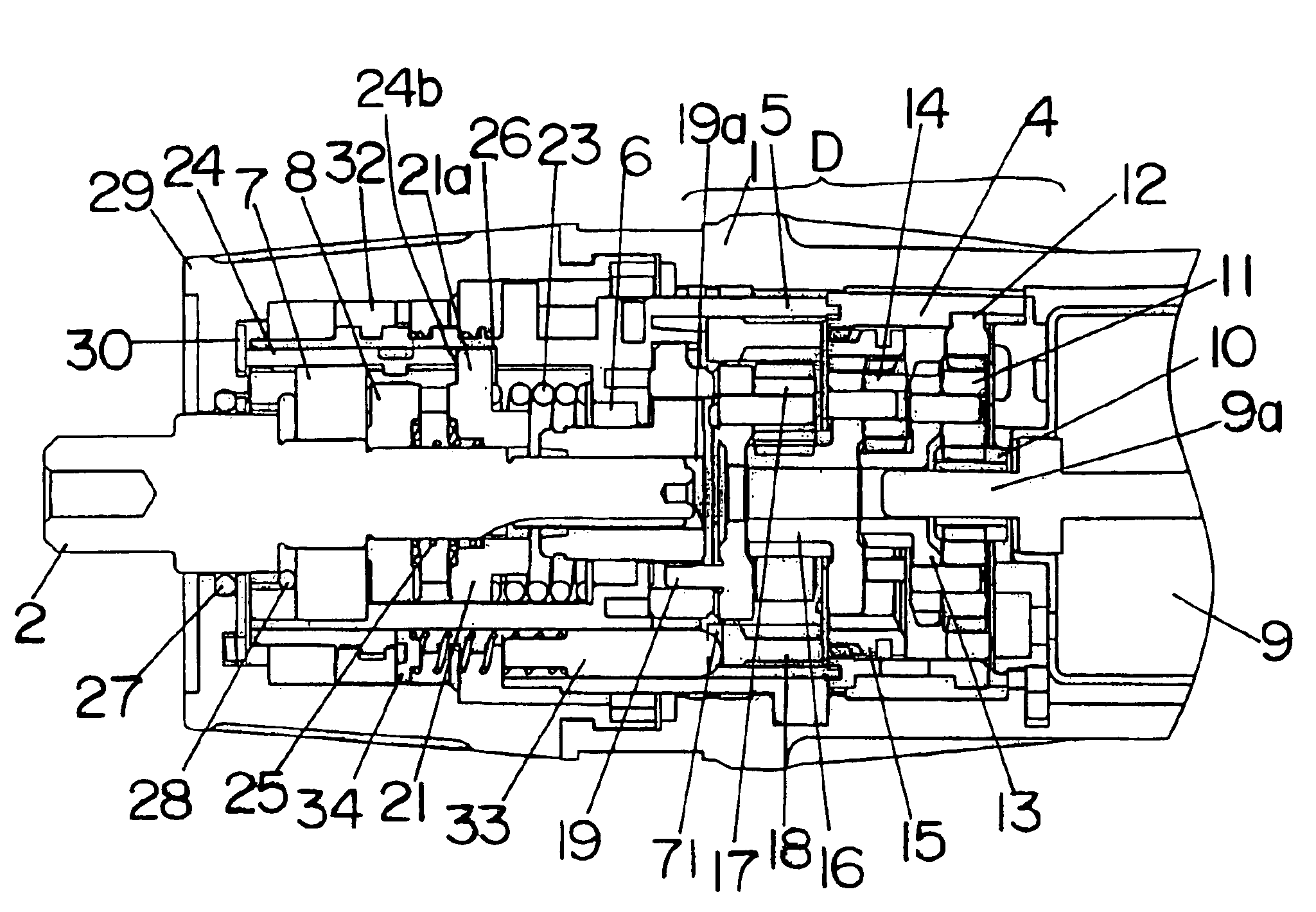

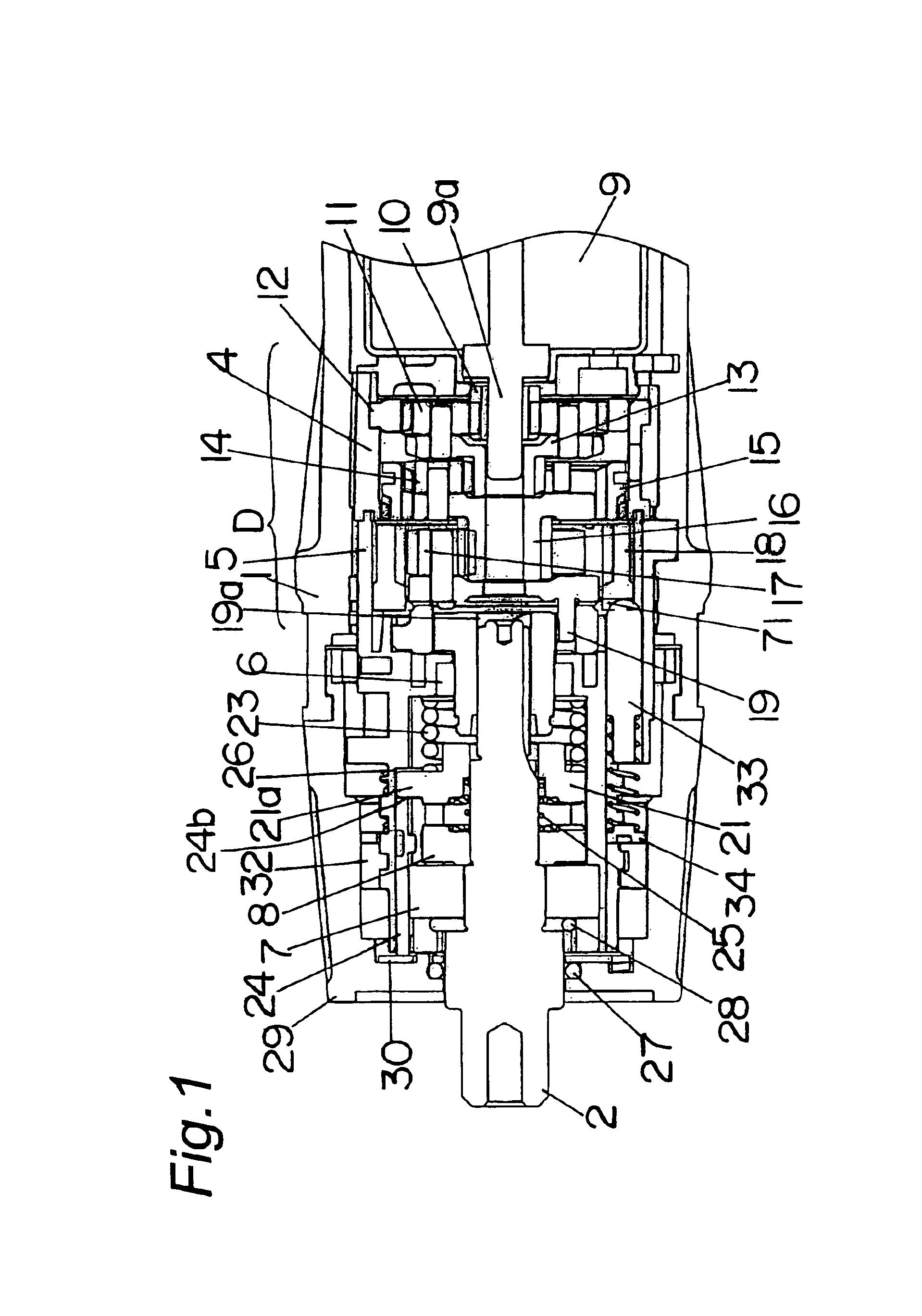

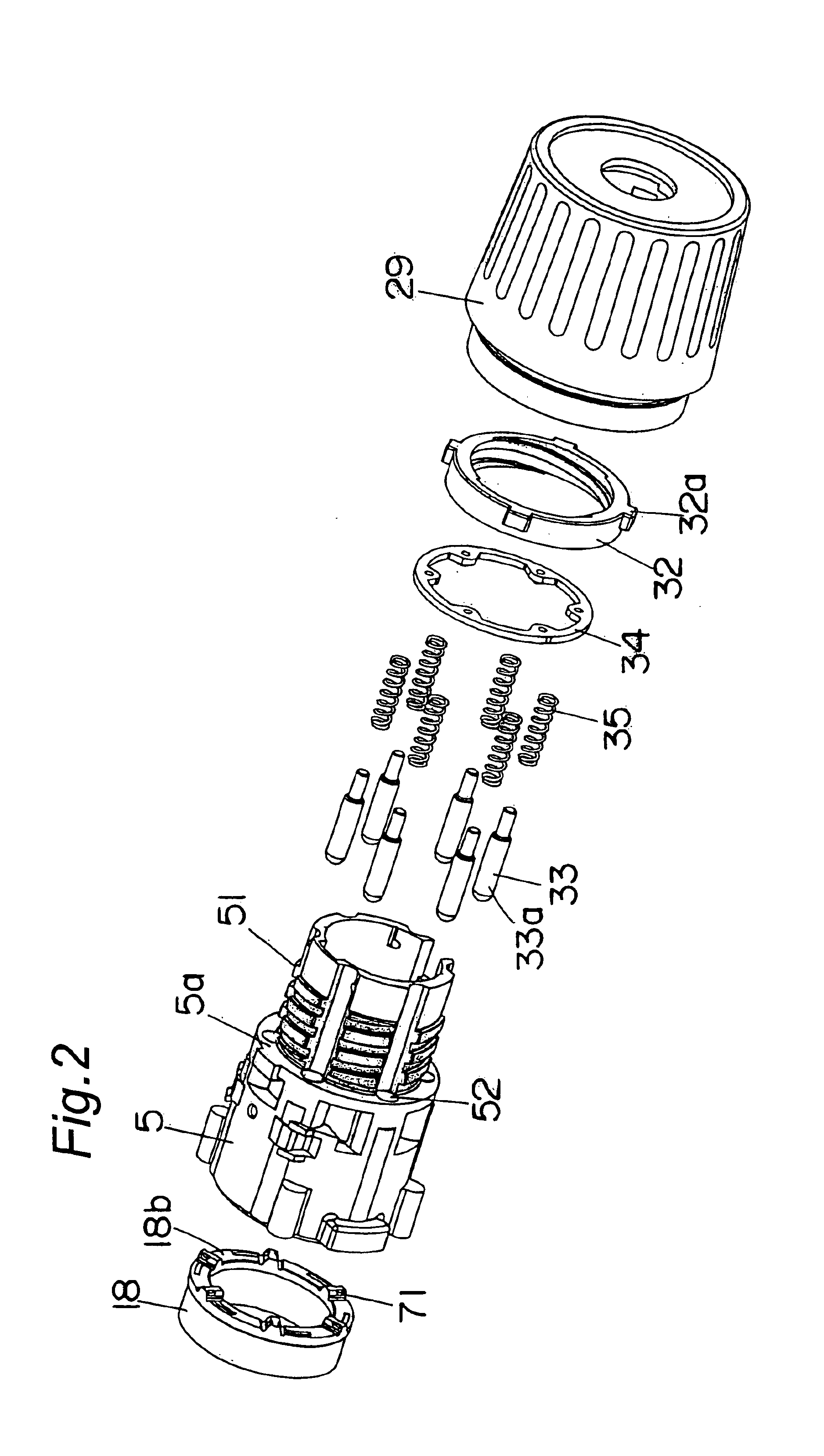

Electrically operated vibrating drill/driver

A vibrating drill / driver includes a motor for driving a spindle about the longitudinal axis thereof, a switching handle supported for rotation about a longitudinal axis thereof, a clutch mechanism for varying a working torque in dependence on rotation of the switching handle, a switching ring having a recess and capable of rotating together with the switching handle, and a switching plate having a tip for engagement in the recess. A vibrating cam mechanism is provided to be operable to undergo a slidable engagement to provide a vibration for the spindle in an axial direction thereof when the tip of the switching plate is engaged in the recess of the switching ring. With the above-described construction, the rotation of the switching handle in one direction causes the vibrating drill / driver to be set in one of a clutch mode, a vibrating mode, and a drilling mode in this order.

Owner:MATSUSHITA ELECTRIC WORKS LTD

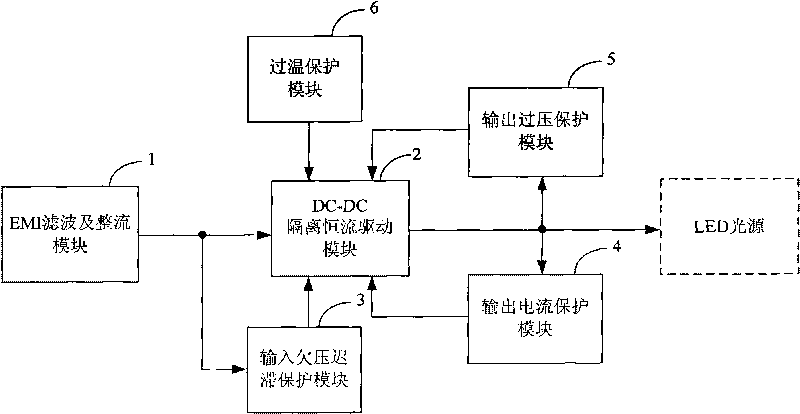

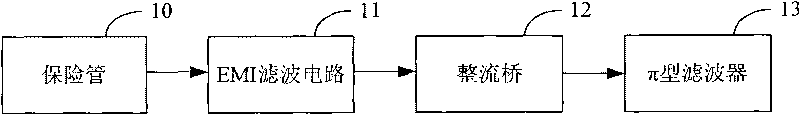

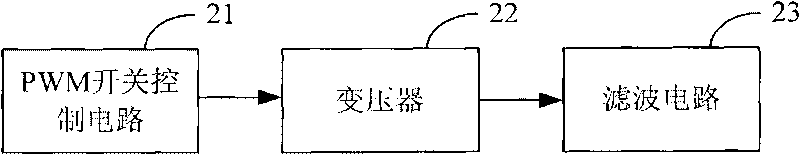

LED driving power supply control circuit and LED lamp by using same

InactiveCN101715265ALuminous stabilityStable jobAc-dc conversion without reversalElectric light circuit arrangementOvervoltageFull wave

The invention relates to an LED driving power supply control circuit. The LED driving power supply control circuit comprises an EMI filter and rectifier module, a DC-DC isolation constant current driver module, an input under-voltage lag protection module, and an output current protection module, wherein the EMI filter and rectifier module is used for performing EMI filter and full-wave rectification on an alternating-current voltage input by a power supply to generate a direct-current voltage; the DC-DC isolation constant current driver module is used for processing the direct-current voltage so as to generate a constant output current for the work of the LED power supply; the input under-voltage lag protection module is used for clamping and splitting the direct-current voltage so as togenerate an enable signal and controlling the DC-DC isolation constant current driver module to start or not to start according to the enable signal; and the output current protection module is used for detecting the constant output current and controlling the DC-DC isolation constant current driver module to stop generating the output current while the constant output current exceeds a current threshold. The invention also relates to an LED lamp. The LED driving power supply control circuit and the LED lamp realize the alternating-current inputting and constant-current outputting in a wide range and have the input clamping lag protection and the output overvoltage protection functions.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

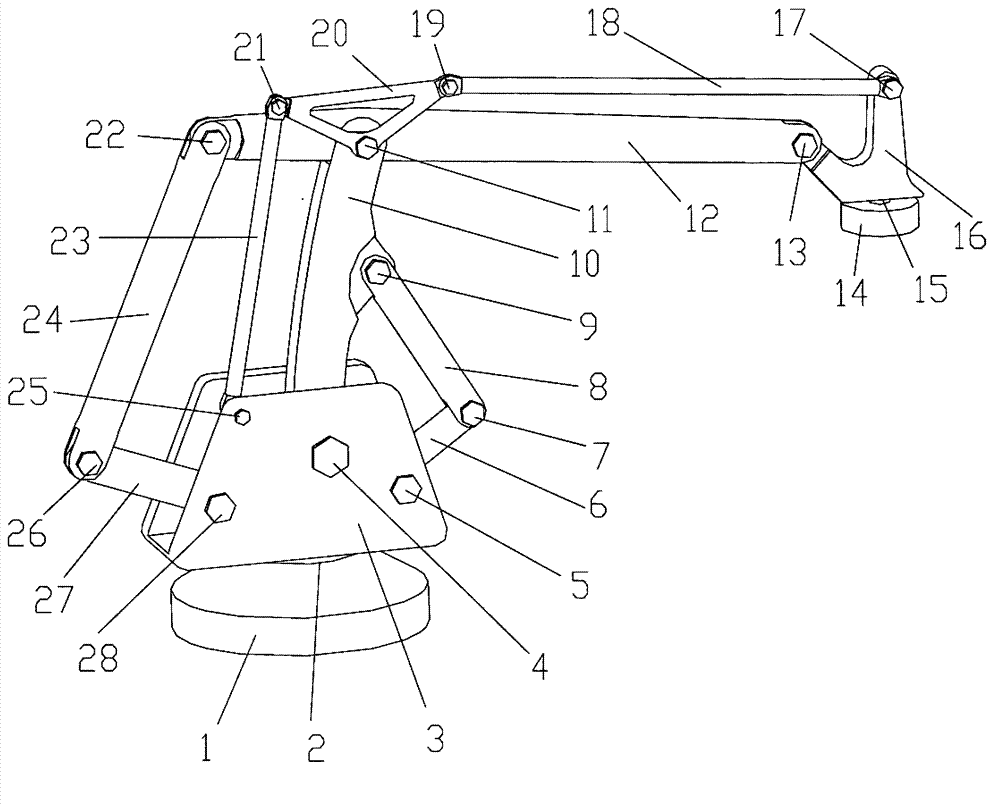

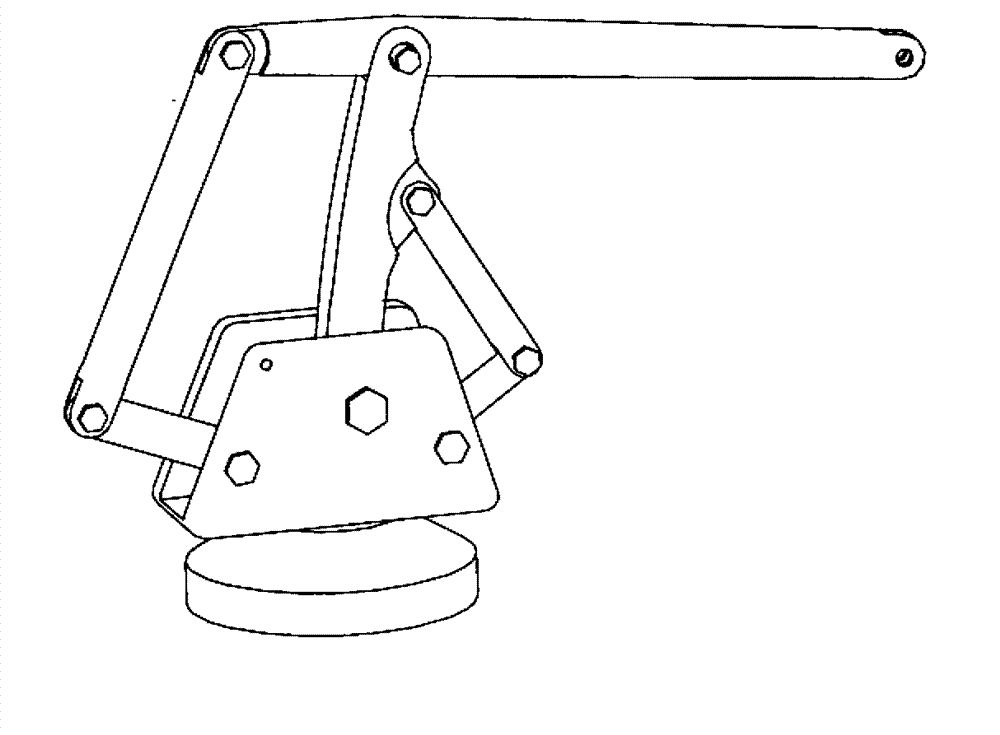

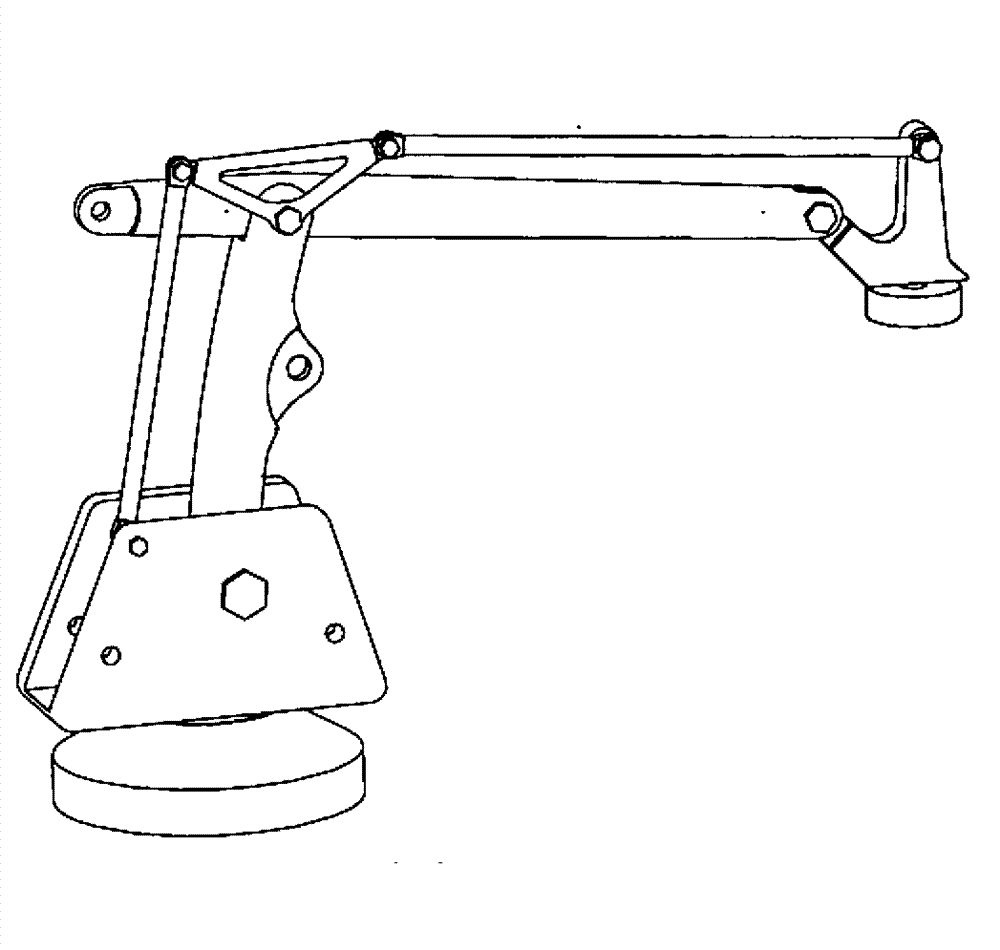

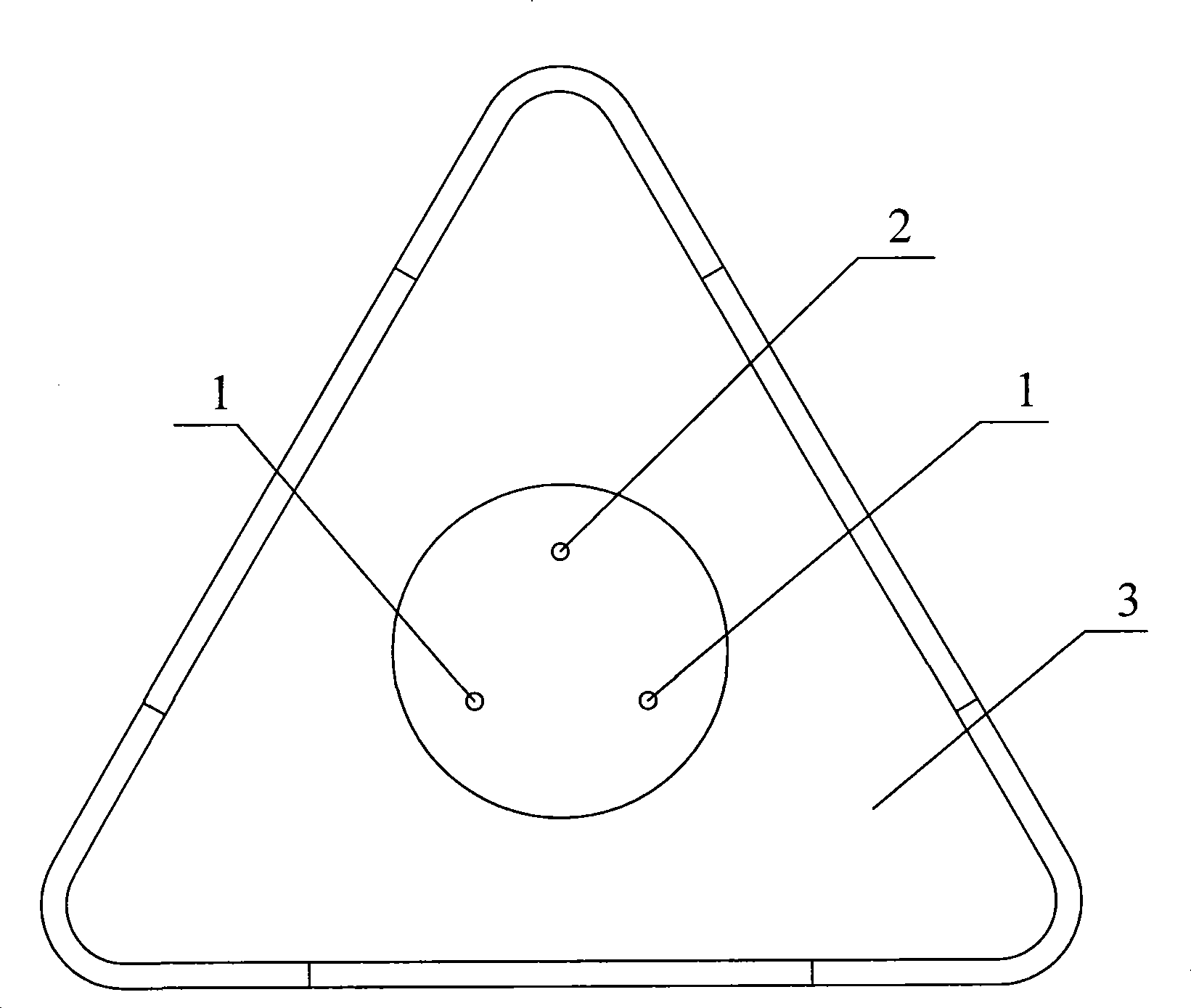

Multi-degree-of-freedom controllable mechanism type stacking robot

InactiveCN103029124AFlexible operationImprove flexibilityProgramme-controlled manipulatorGripping headsEngineeringMulti degree of freedom

The invention discloses a multi-degree-of-freedom controllable mechanism type stacking robot, which comprises a pedestal, a rotary rack, an arm lifting mechanism, an end effector translation retaining mechanism and a flange, wherein the rotary rack is connected to the pedestal through a rotary pair; the arm lifting mechanism comprises a large arm, a small arm, a first driving rod, a first connecting rod, a second driving rod and a second connecting rod; all the rods are connected through hinges; the end effector translation retaining mechanism comprises a parallelogram mechanism consisting of the large arm, a first auxiliary connecting rod, a triangular auxiliary rack and the rotary rack and a parallelogram mechanism consisting of the small arm, a second auxiliary connecting rod, a triangular auxiliary rack and an end effector translation retainer; all the rods are connected through hinges; the flange is connected to the end effector translation retainer through the rotary pair; and different end effectors can be arranged according to actual requirements. The multi-degree-of-freedom controllable mechanism type stacking robot has the advantages of simple structure, high bearing capacity, large working space, flexibility in operation, capabilities of driving through a servo motor for control, realizing intelligence and digital control and meeting handling and stacking requirements of high speed, heavy load, precision and the like and extremely broad application prospect.

Owner:GUANGXI UNIV

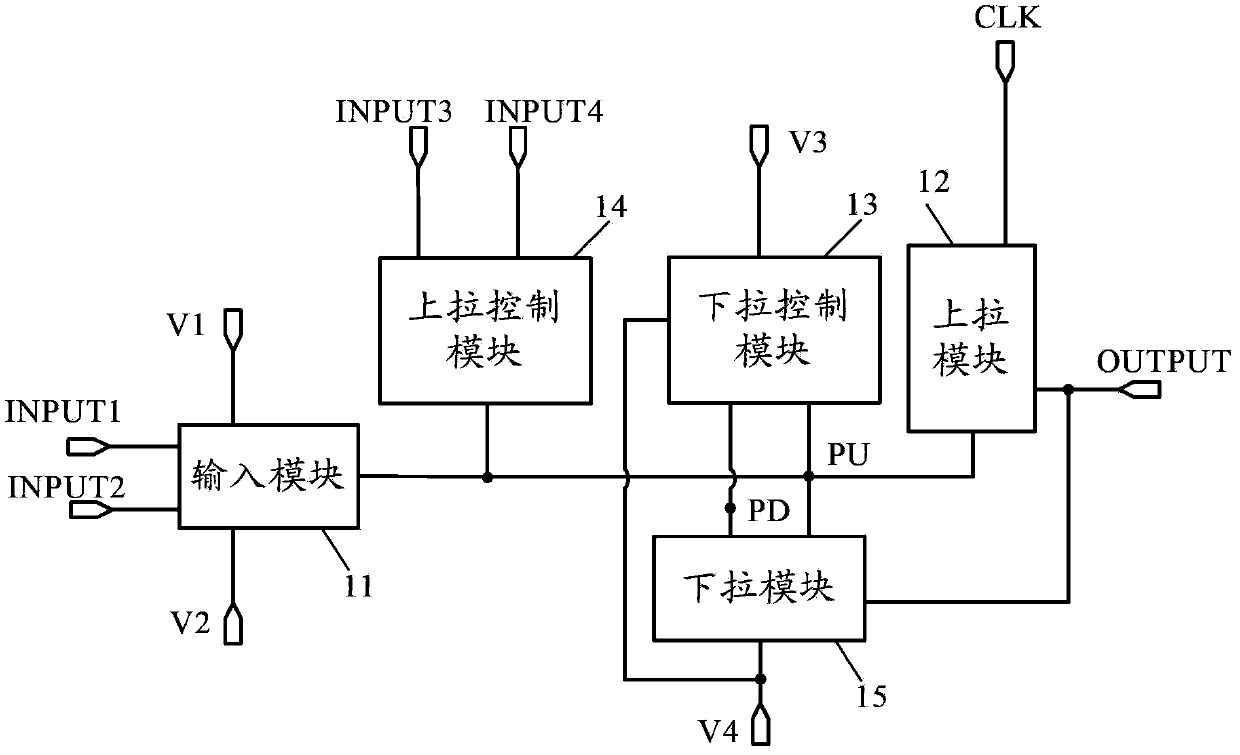

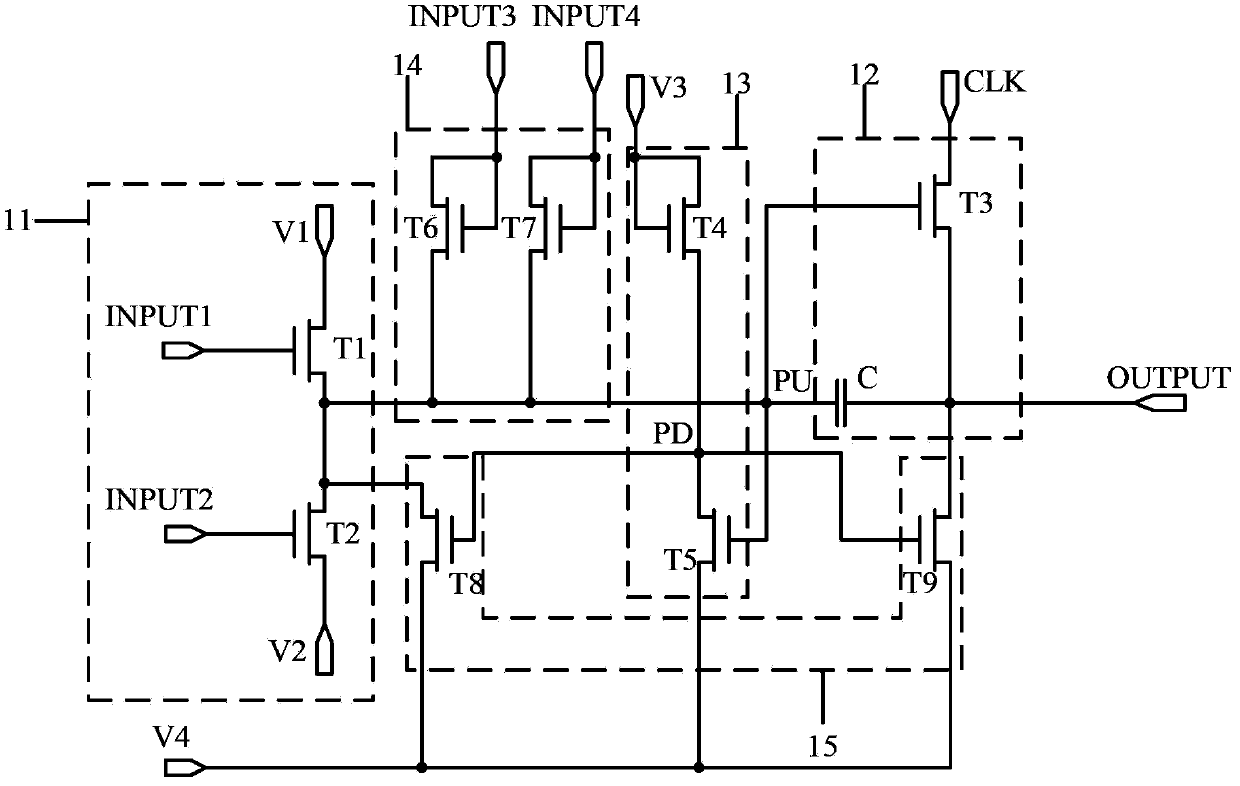

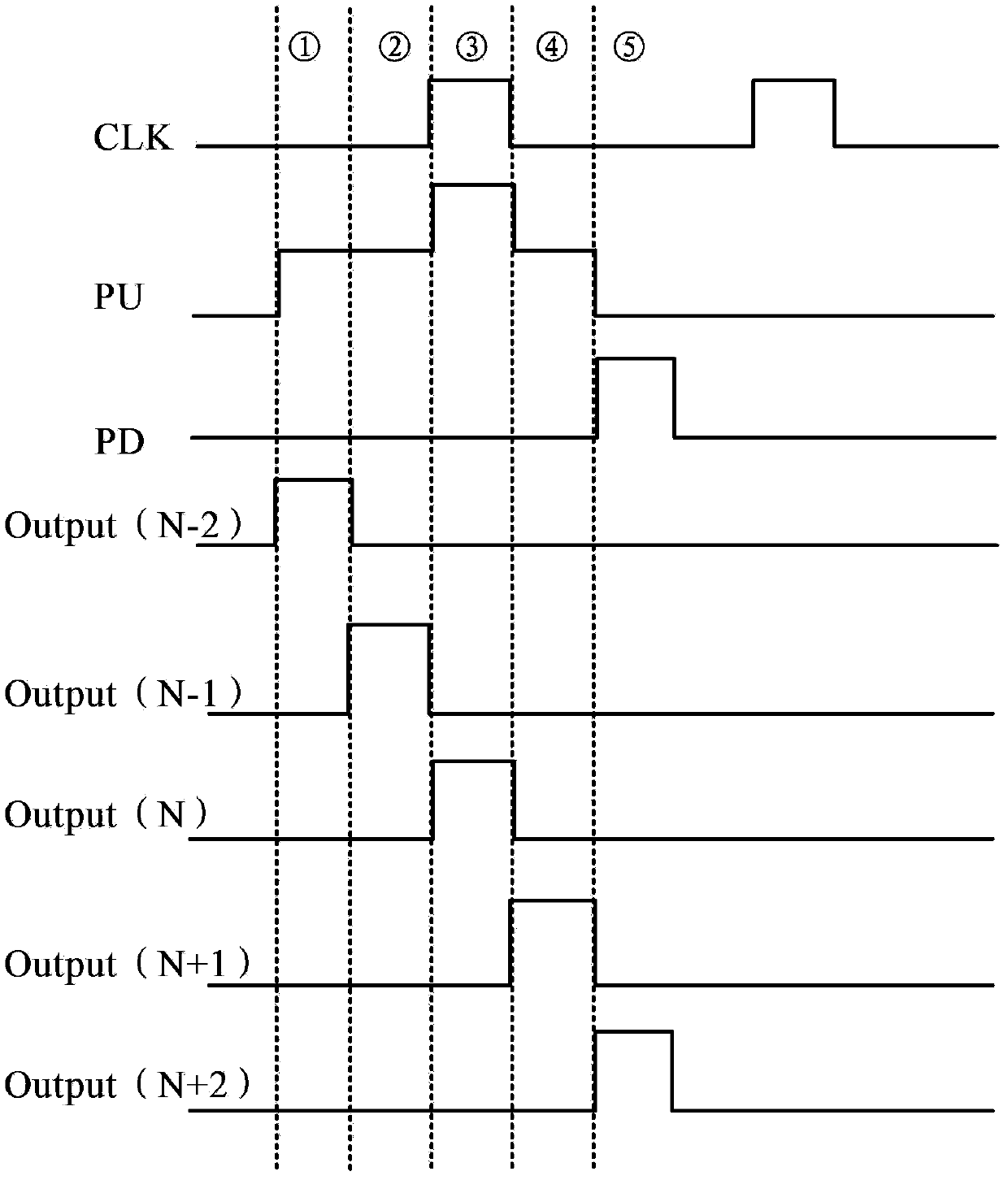

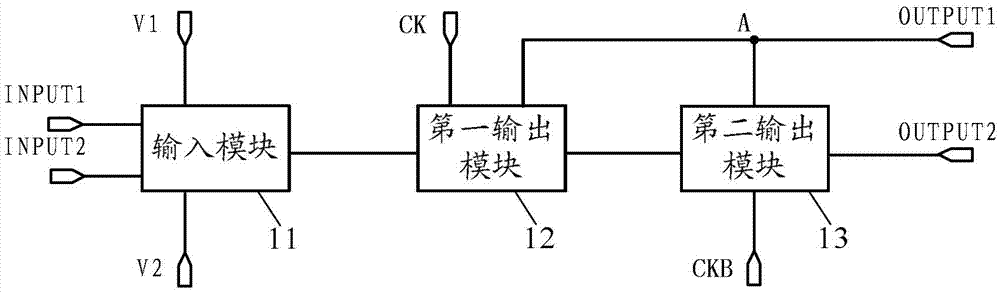

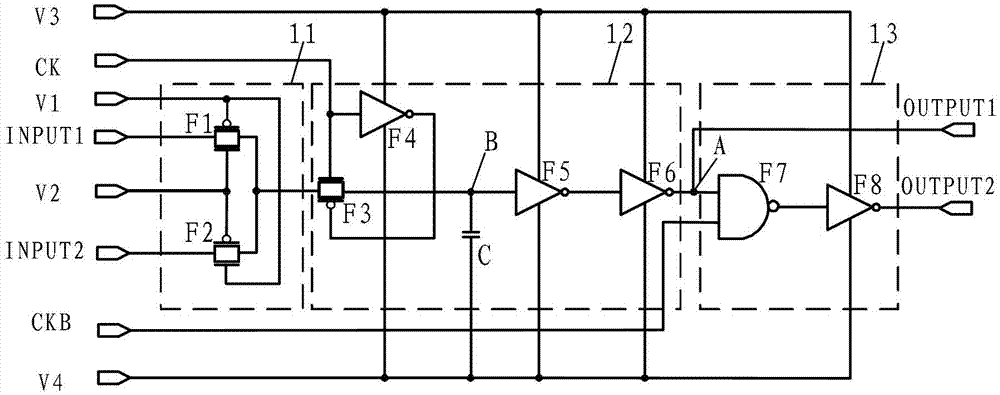

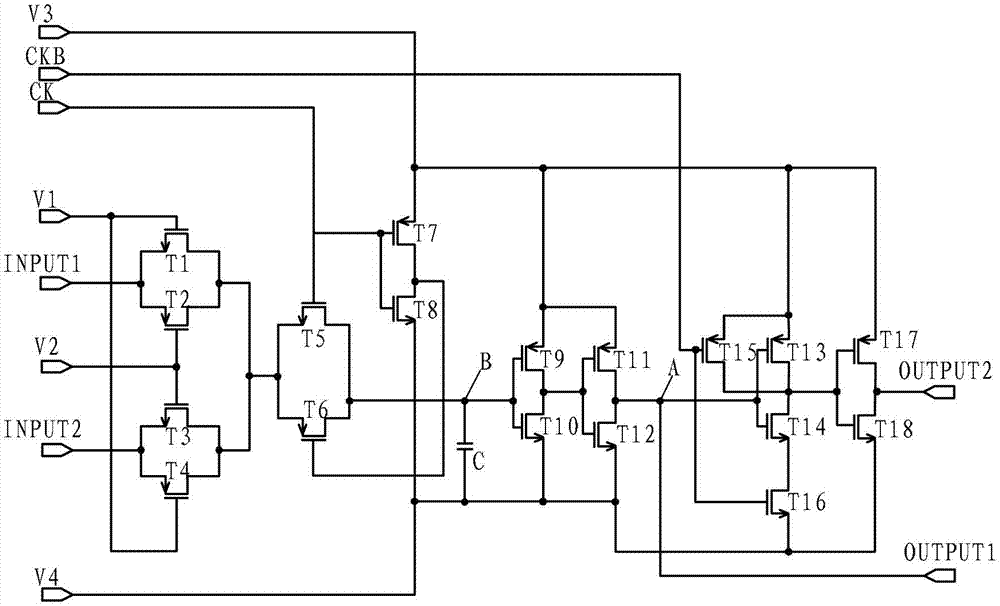

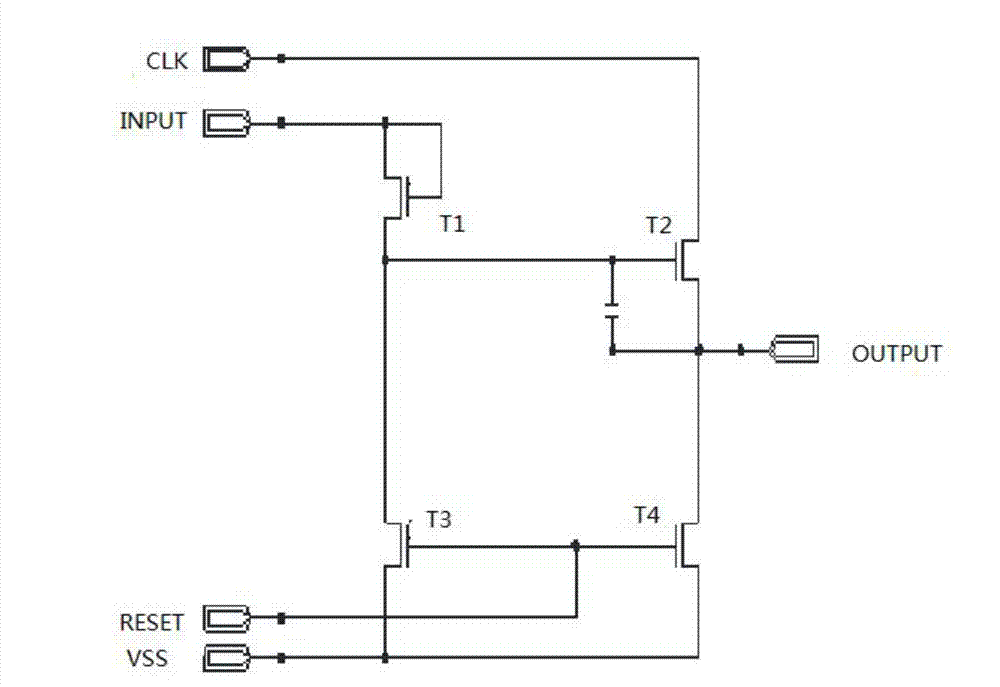

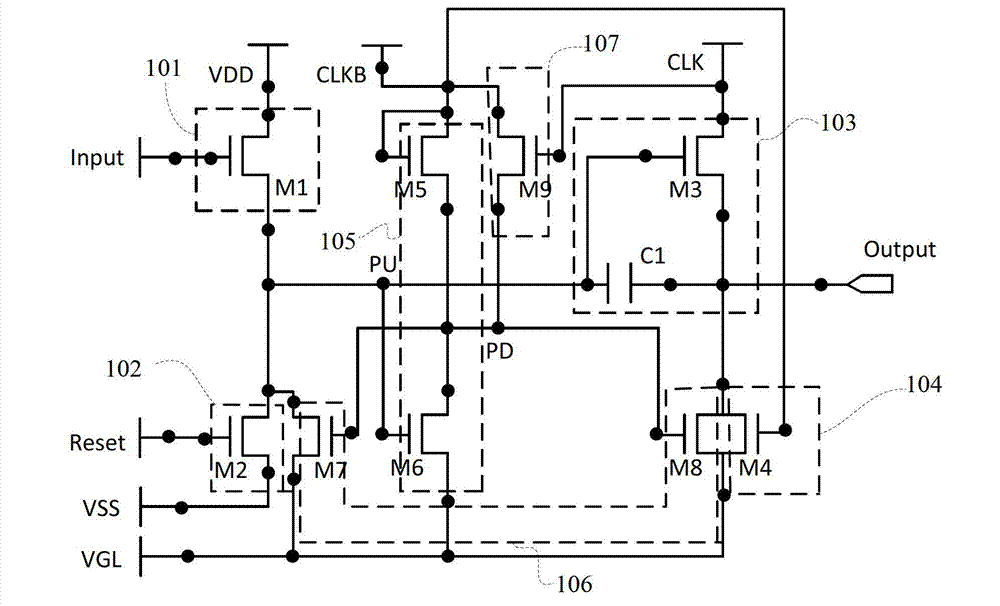

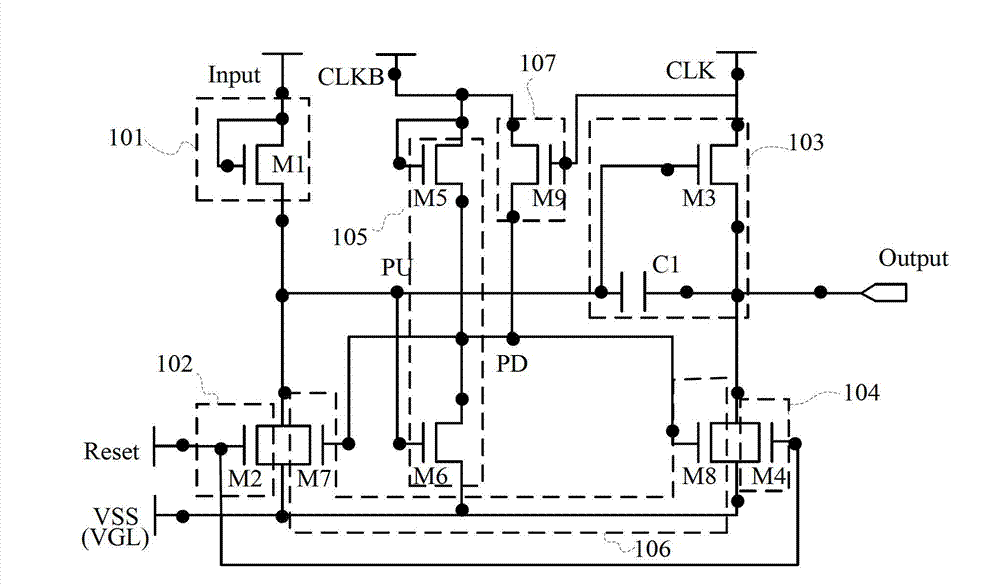

Shifting register unit and driving method thereof, gate driving circuit and display device

ActiveCN103426414AQuality improvementGuaranteed lifeStatic indicating devicesDigital storageShift registerComputer module

The invention provides a shifting register unit and a driving method thereof, a gate driving circuit and a display device. The potential of a pull-up control node is pulled up continuously by output signals of a multistage shifting register circuit, output noise of the shifting resister unit can be released through the high potential of the pull-up control node, and therefore, quality of display device products is improved, and service life and long-term performance stability of GOA (gate drive on array) circuits are guaranteed. The shifting register unit comprises an input module, a pull-up module, a pull-down control module, a pull-up control module and a pull-down module.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

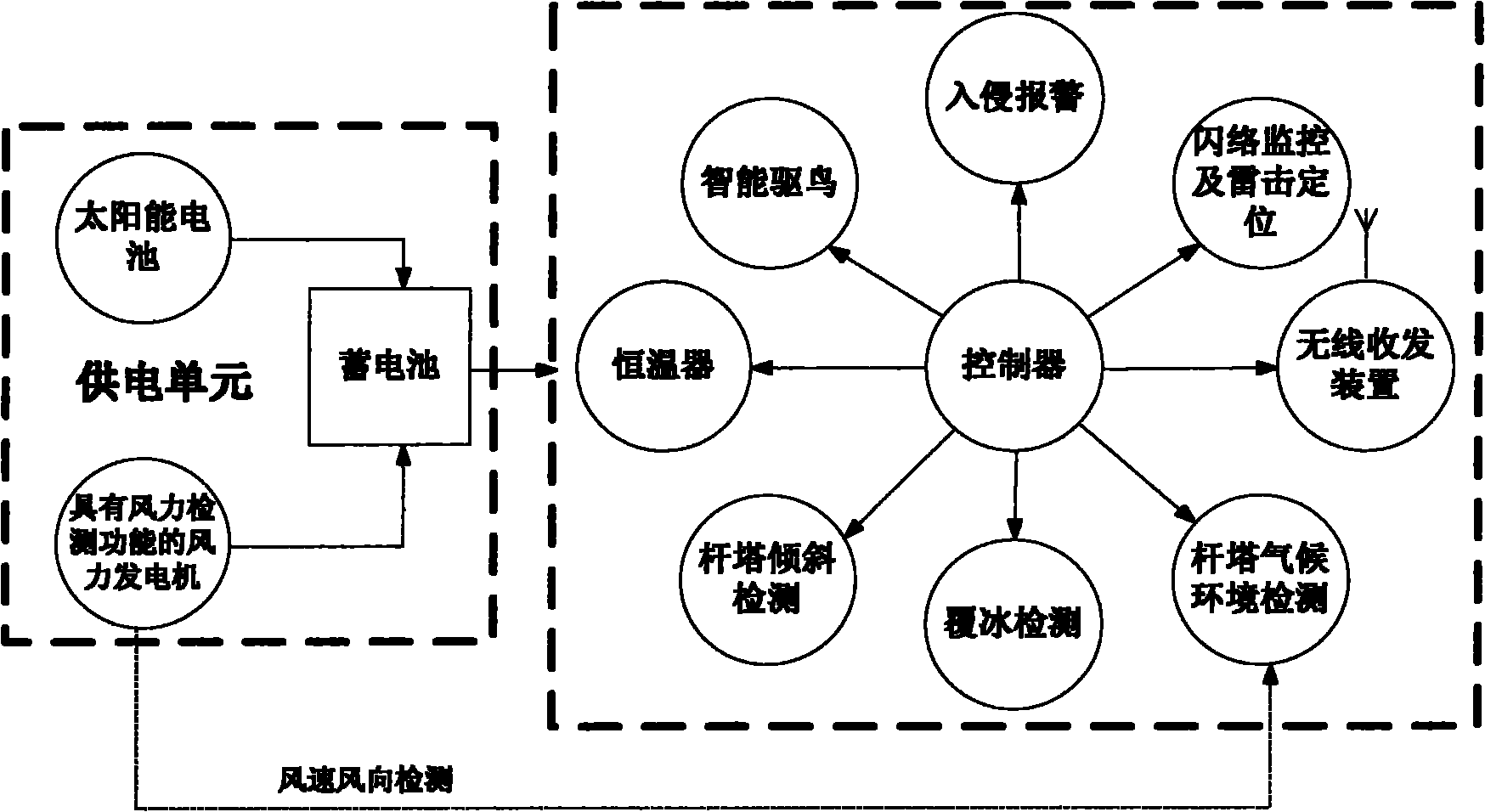

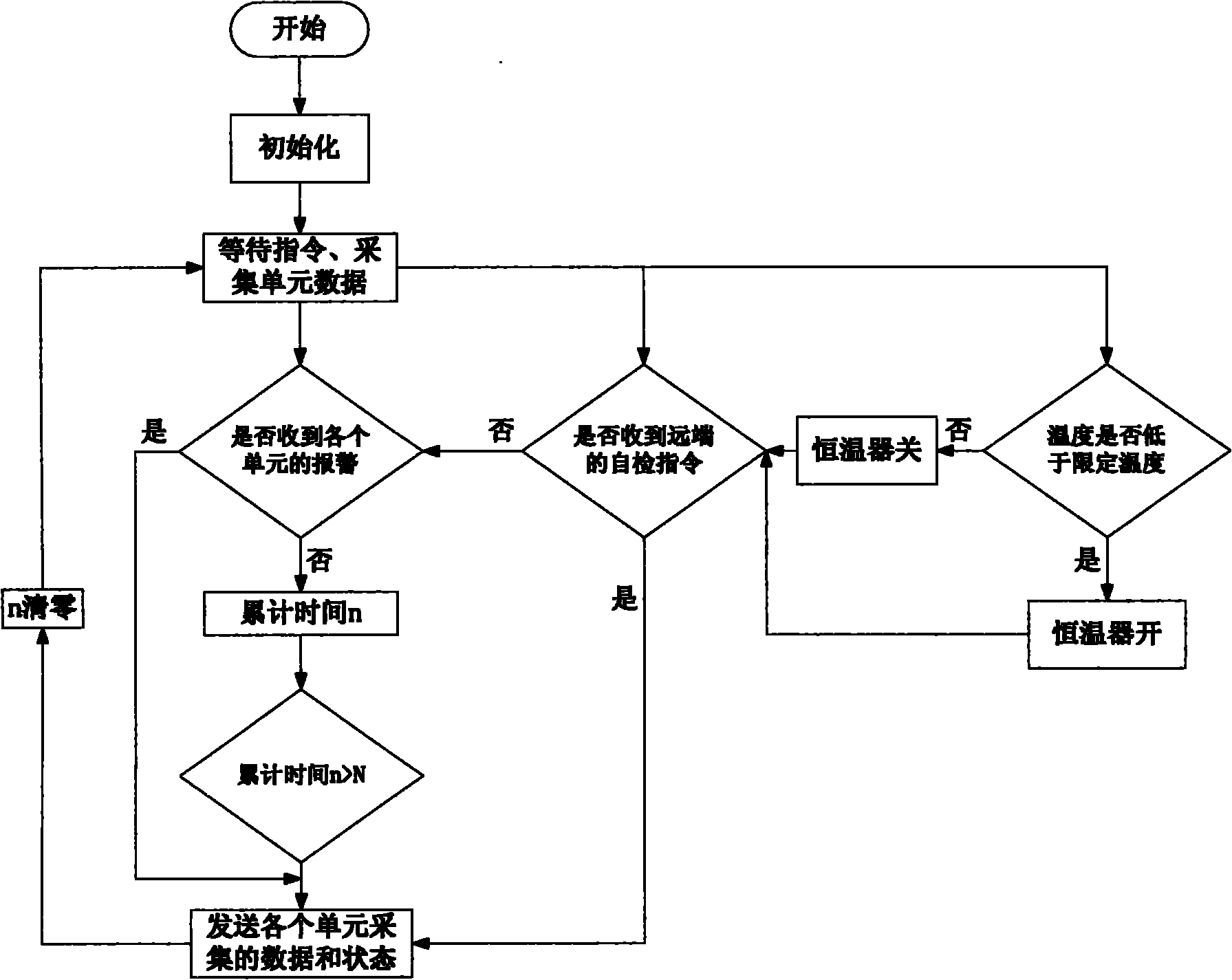

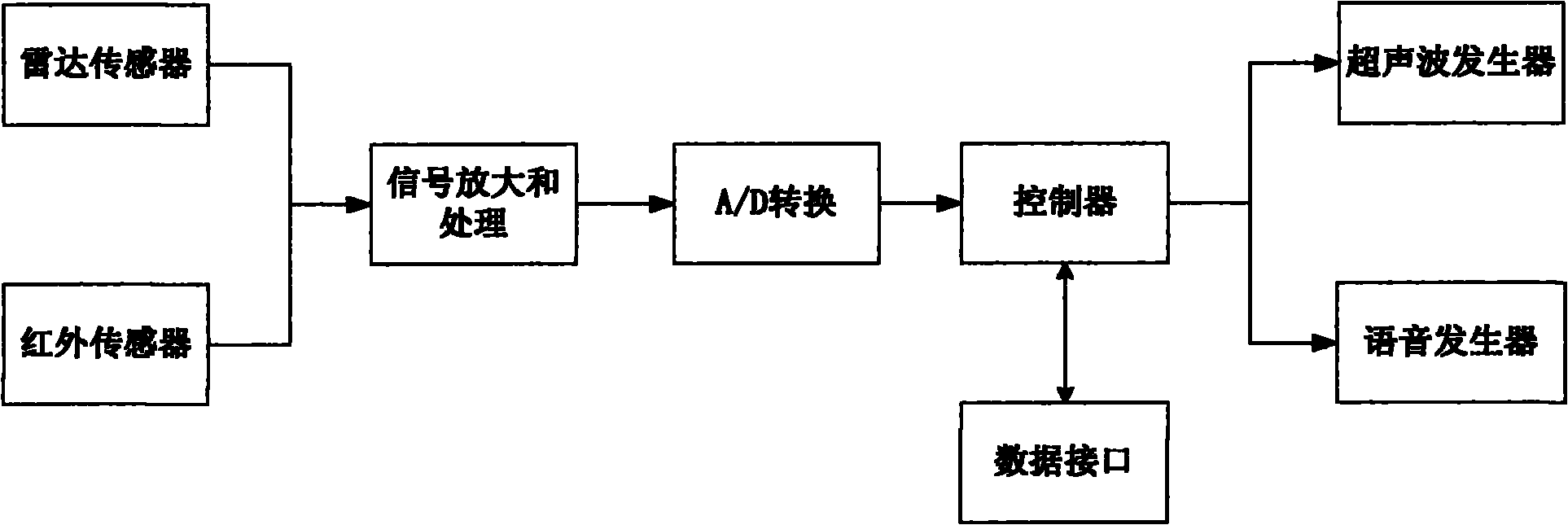

Comprehensive measuring and controlling device of high voltage pole tower

InactiveCN101989767AReduce pollutionReduce power consumptionCircuit arrangementsIndication of weather conditions using multiple variablesGeneral Packet Radio ServiceSmart grid

The invention relates to a comprehensive measuring and controlling device of a high voltage pole tower, mainly comprising a power supply unit, an intelligent bird driving unit, a flashover and lightning stroke location detection unit, a pole tower inclination detection unit, a pole tower meteorological environment detection unit, a pole tower intrusion alarm unit, an transmission line icing parameter detection unit, a central controller, a wireless transceiving device and a thermostat, wherein the power supply unit comprises two parts which are a solar battery and a wind turbine, the wind turbine also fulfills the functions of wind speed and wind direction detection and is an important component part of the pole tower meteorological environment detection unit, the power supply unit stores collected electric quantity into a storage battery through a collection circuit and supplies the power to the device, and the wireless transceiving device sends information collected in situ to a distant monitor center through a GPRS (General Packet Radio Service) or a wireless local network. The invention can fulfill the functions of intelligent bird driving, flashover and lightning stroke location, pole tower inclination detection, meteorological environment detection, intrusion alarm, icing parameter detection and the like and has strong environment adaptability because the wind power and the solar power generation accord with the environment self-powered requirement, thereby enhancing the maintenance free performance of a system. The device is an important component part of an intelligent power grid, accords with the requirement of intelligent power grid establishment of a national power grid and has higher practical value and wide application prospect.

Owner:中电国科技术有限公司 +1

Shifting register unit, gate driving circuit and display device

ActiveCN103208251AReduce in quantitySimple structureStatic indicating devicesDigital storageShift registerDisplay device

The embodiment of the invention provides a shifting register unit, a gate driving circuit and a display device, and relates to the technical field of display. The shifting register unit comprises an input module, a first output module and a second output module. Compared with the prior art, the invention has the advantages that the structure of the shifting register unit can be effectively simplified; and the using quantity of transistors is further decreased. The embodiment of the invention is used for realizing scanning driving.

Owner:BOE TECH GRP CO LTD +1

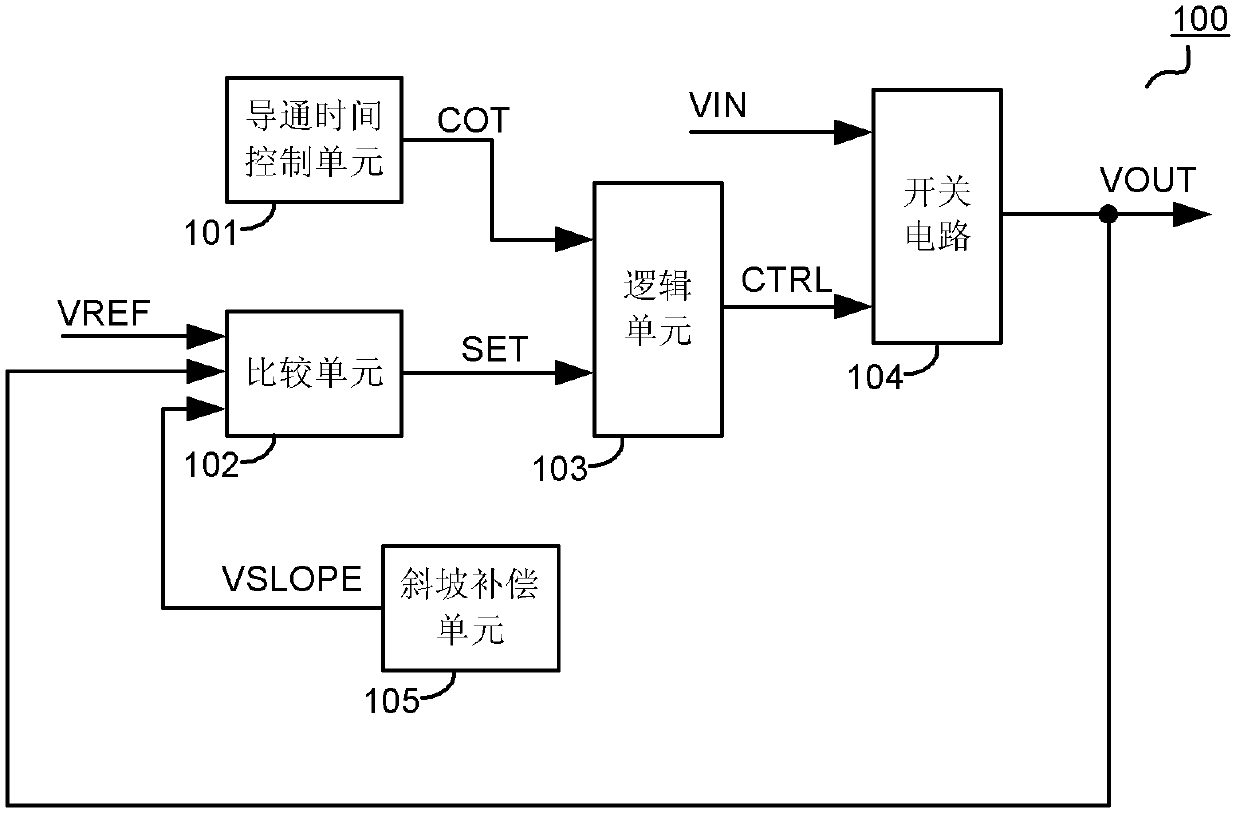

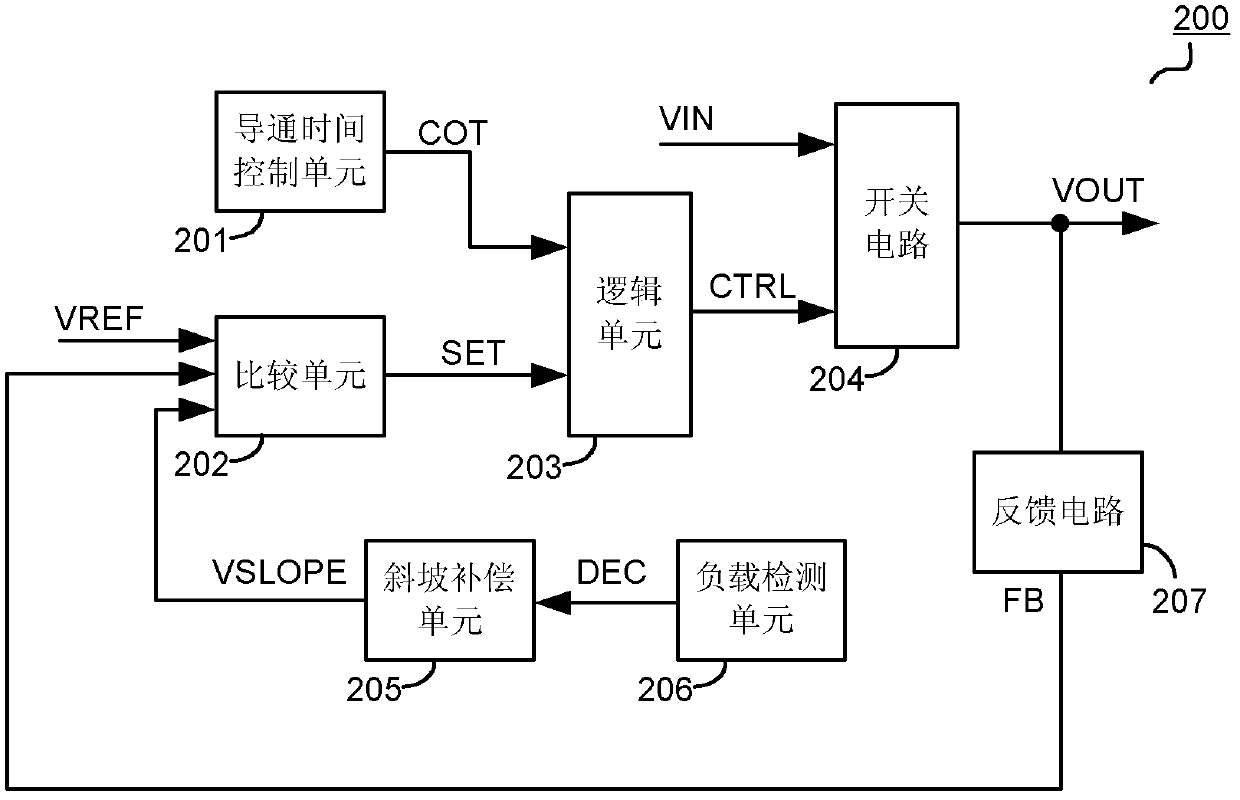

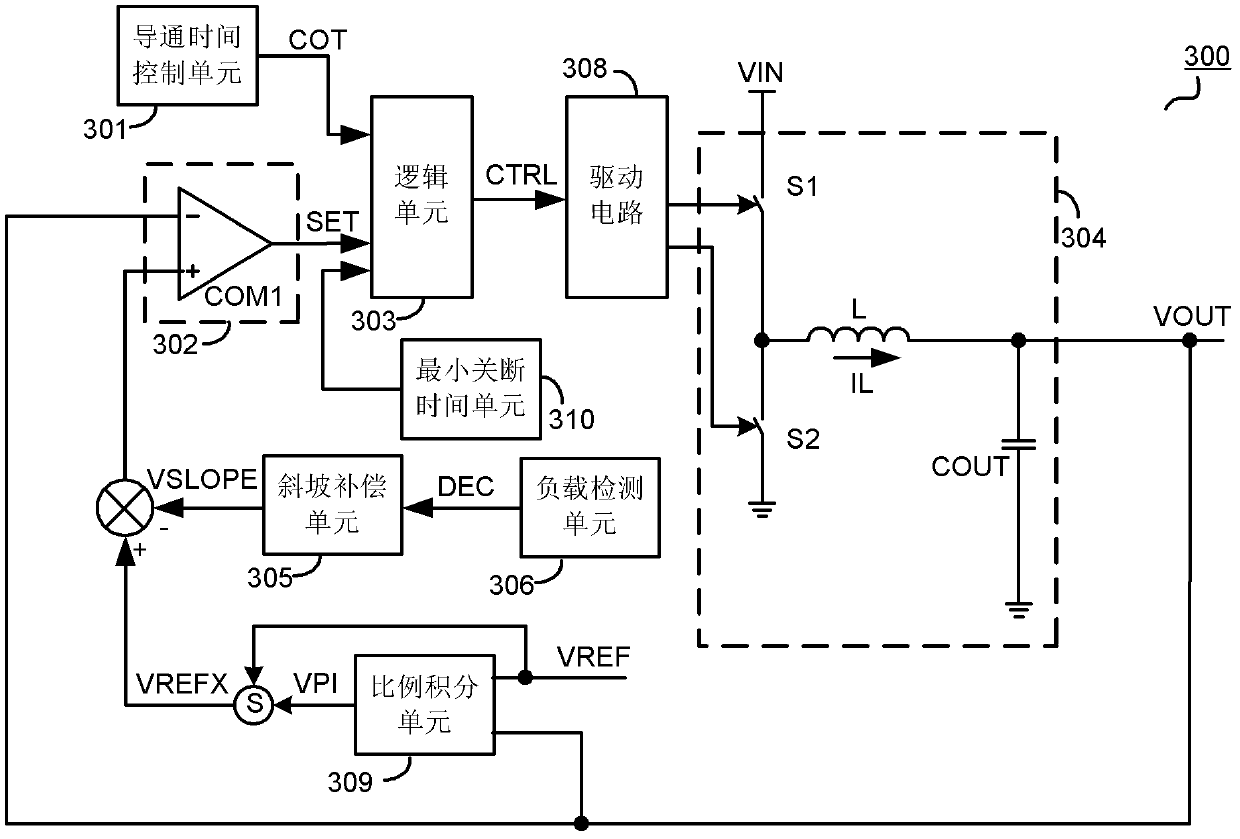

Switch converter, control circuit of switch converter and control method of switch converter

ActiveCN102611306AReduce overshootImprove transient responseEfficient power electronics conversionDc-dc conversionPhysicsControl circuit

The invention discloses a switch converter, a control circuit of the switch converter, and a control method of the switch converter. By conditioning ramp compensation signals according to the load condition, the overshoot degree of the output voltage of the switch converter is reduced during the instantaneous descending of load current while stable operation of the switch converter is maintained, and the transient response of the switch converter is improved.

Owner:CHENGDU MONOLITHIC POWER SYST

Shifting register unit and array substrate gird driving device

The invention discloses a shifting register unit and an array substrate gird driving device. With the adoption of the shifting register unit and the array substrate gird driving device, low-noise signals can be output by the shifting register unit and the shifting register unit can stably work for a long time period. The shifting register unit provided by the invention comprises an input module, a resetting module, a pull-upward module, a first pull-downward module, a first pull-downward control module, a second pull-downward module and a second pull-downward control module, wherein the input module is used for supplying a first working voltage to a pull-upward node of the pull-upward module; the resetting module is connected with the pull-upward node and is used for reducing the voltage of the pull-upward node to a second working voltage; the pull-upward module is connected with the pull-upward node, is used for storing the first working voltage and supplies a first clock signal to an output terminal; the first pull-downward module is used for supplying a third working voltage to the output terminal; the first pull-downward control module supplies a second clock signal to the pull-downward node, and supplies the third working voltage to the pull-downward node; the second pull-downward module is used for supplying the third working voltage to the pull-upward node and the output terminal; and the second pull-downward control module is used for inputting the second clock signal to the pull-downward node.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

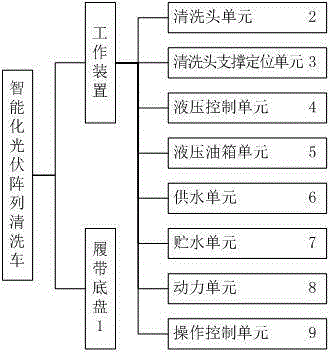

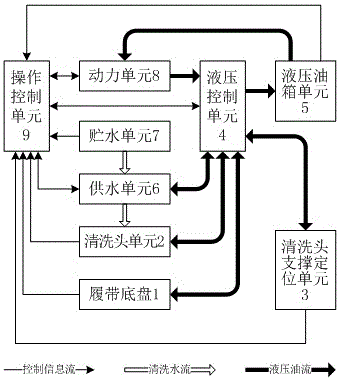

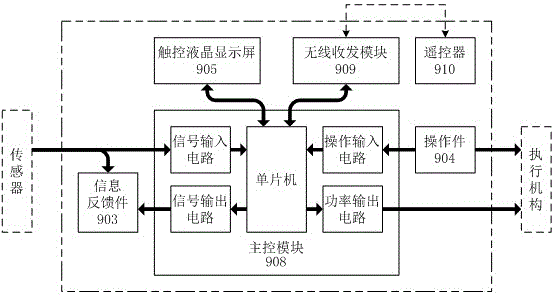

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

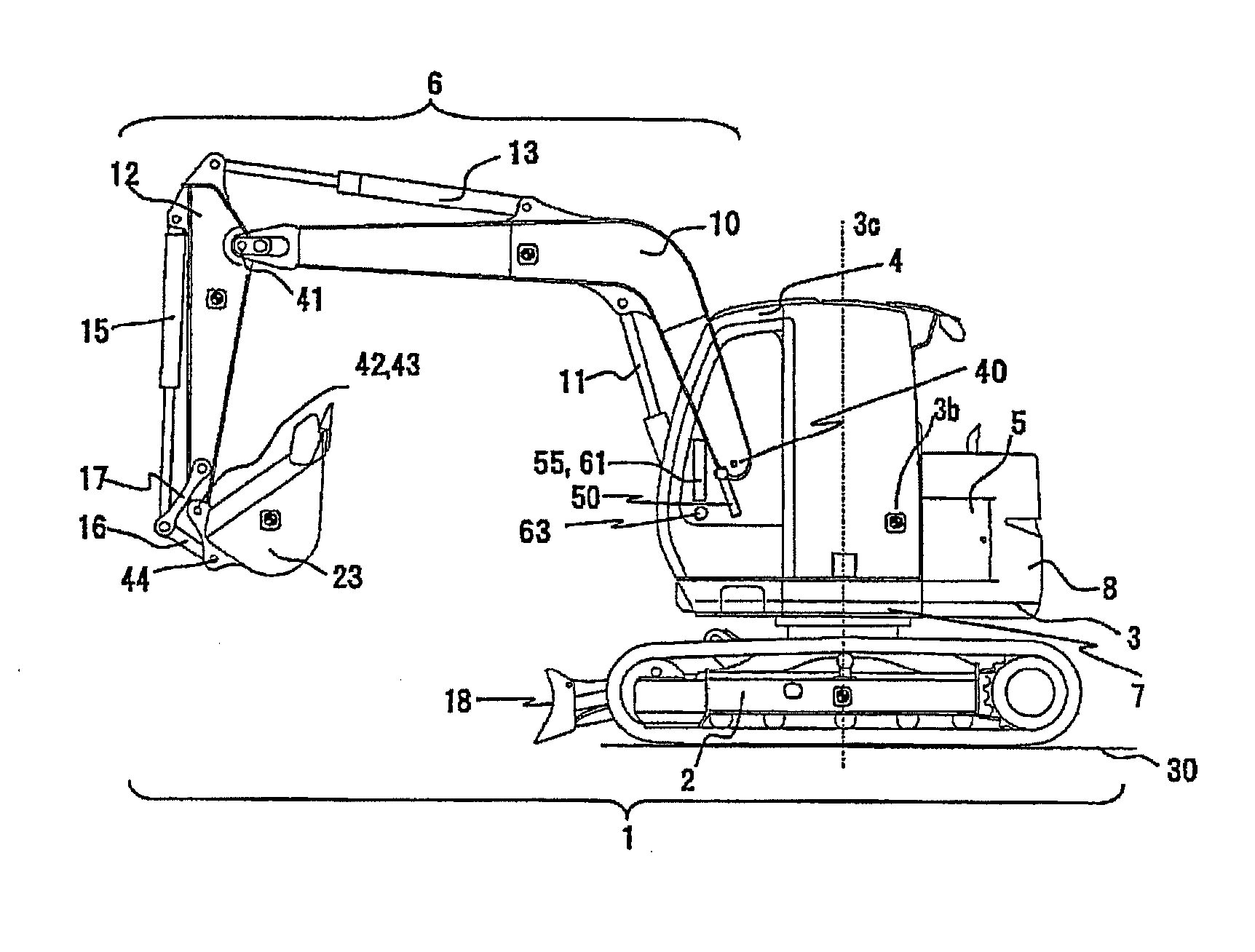

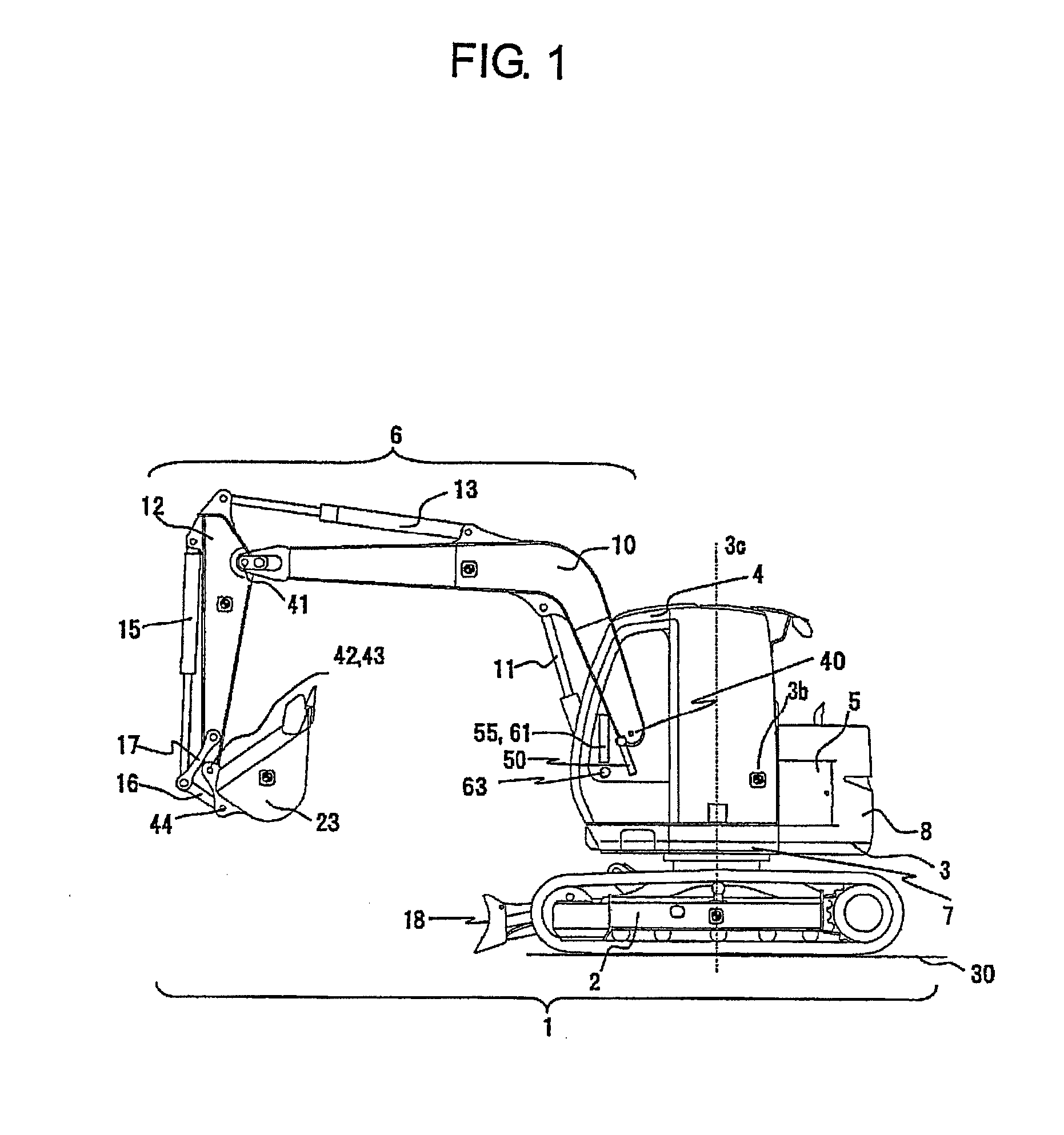

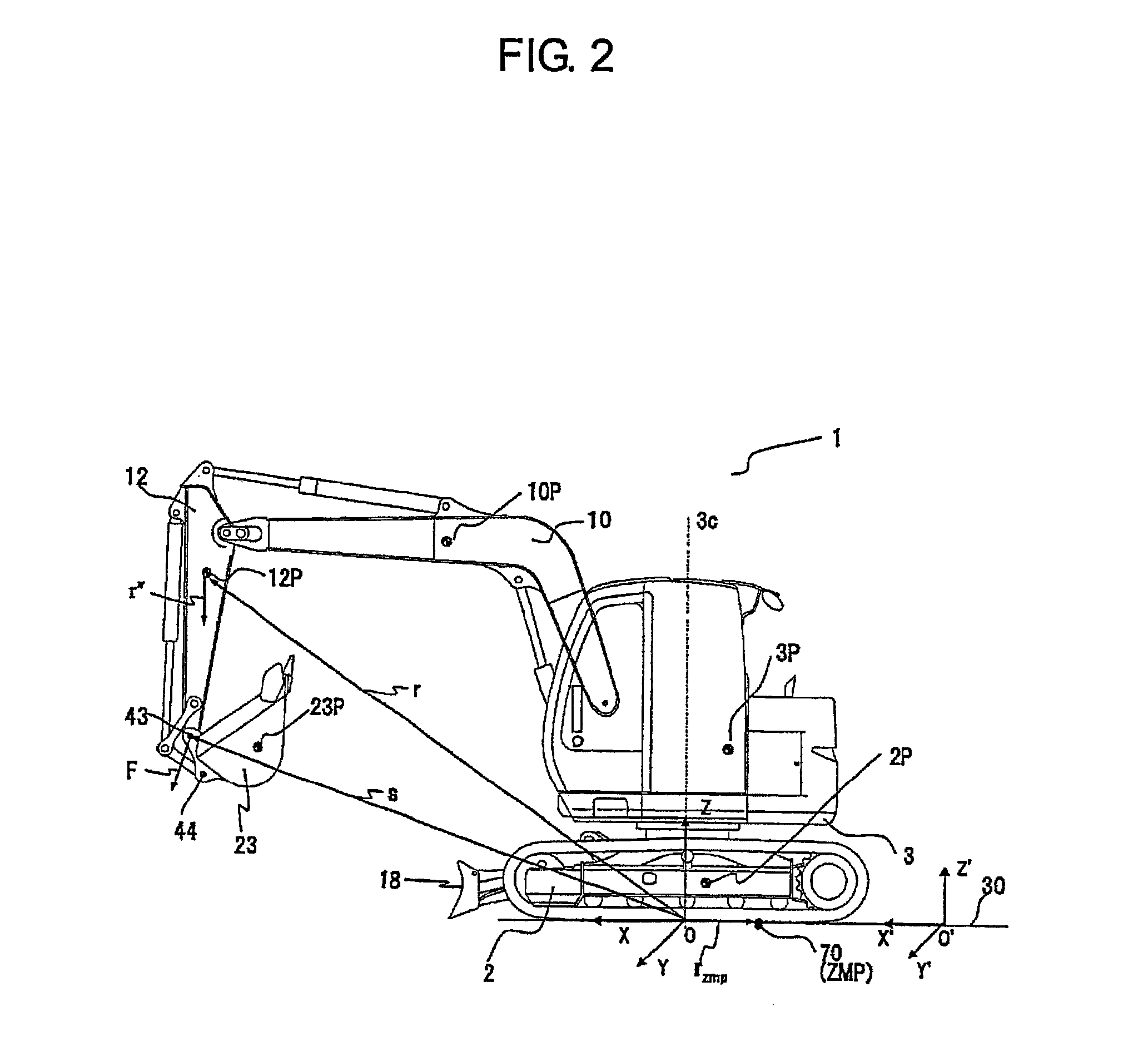

Work machine

ActiveUS20140121840A1Prevent tippingStable jobGeometric CADTemperatue controlDynamic balanceStabilization control

To provide a work machine with high stability in which a dynamic balance can be evaluated easily while the influence of a sudden stop of an travel base, an upperstructure and a work front is taken into consideration.A stabilization control calculation unit (60a) and a command value generating unit (60i) are provided in a control device (60) of the work machine. The stabilization control calculation unit (60a) uses a sudden stop model and position information of each movable portion of the travel base and a machine body including the work front (6) to predict a change of stability until reaching a complete stop when a control lever (50) in an operating state is instantaneously brought back to a stop command position, and calculates a motion limit needed to prevent destabilization from occurring at any time instant until reaching the stop. The command value generating unit (60i) corrects the command information to a drive actuator on the basis of the calculation result of the stabilization control calculation unit (60a).

Owner:NIHON KENKI CO LTD

Organic electroluminescent device and method for manufacturing the same

InactiveUS20090160325A1Maintain good propertiesEasy to manufactureDischarge tube luminescnet screensElectroluminescent light sourcesCharge injectionOrganic solvent

An organic EL device which drives over a wide range from low brightness to high brightness for light source applications, operates stably over a wide range of brightness and has excellent life property is provided. The device comprises at least one pair of electrodes 2 and 5, and a plurality of functional layers disposed between the electrodes 2 and 5, the functional layers comprising a layer 4 having the light emitting function, which is composed of at least one polymeric material and contains an organic solvent and a charge injection layer 3 composed of at least one inorganic material.

Owner:PANASONIC CORP

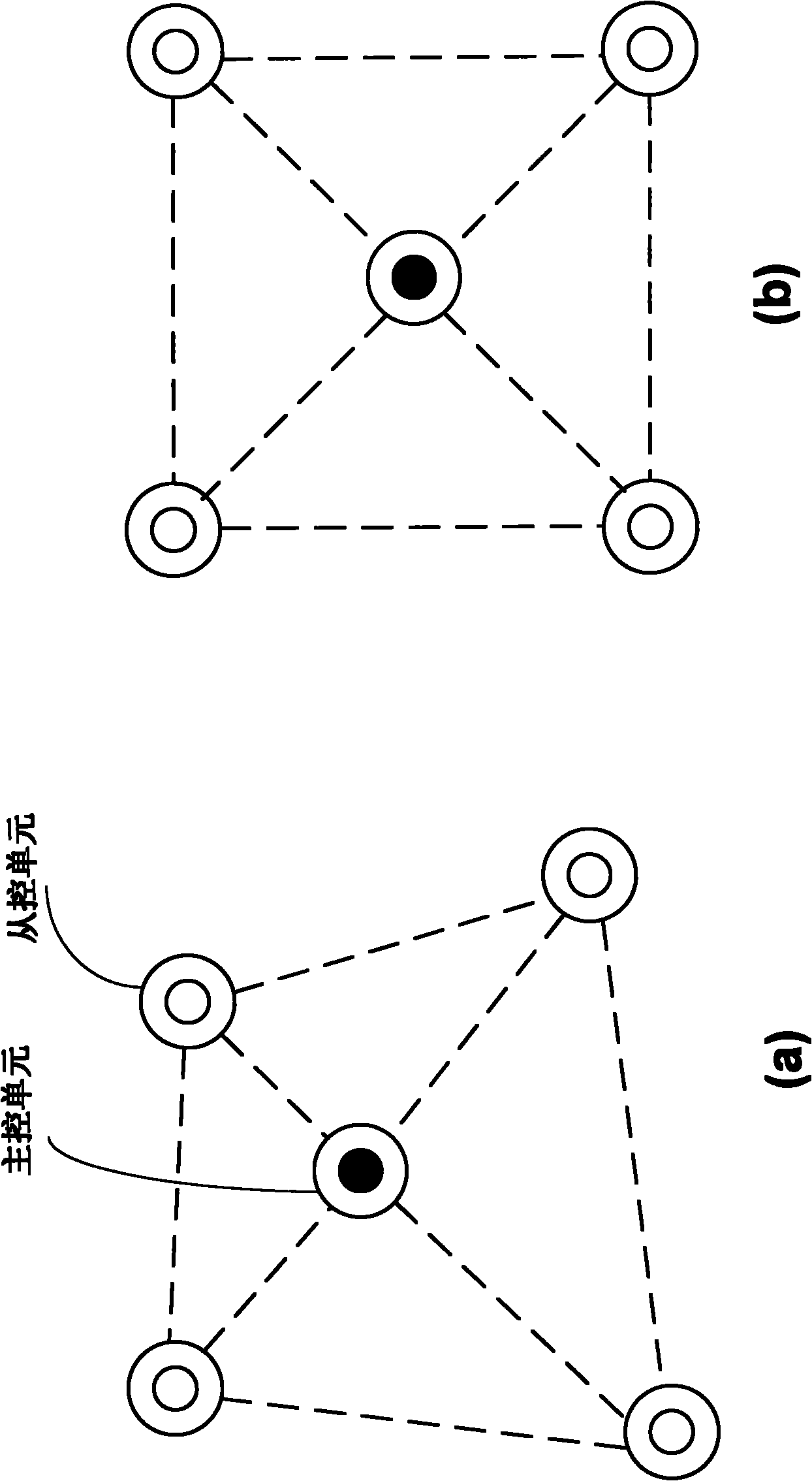

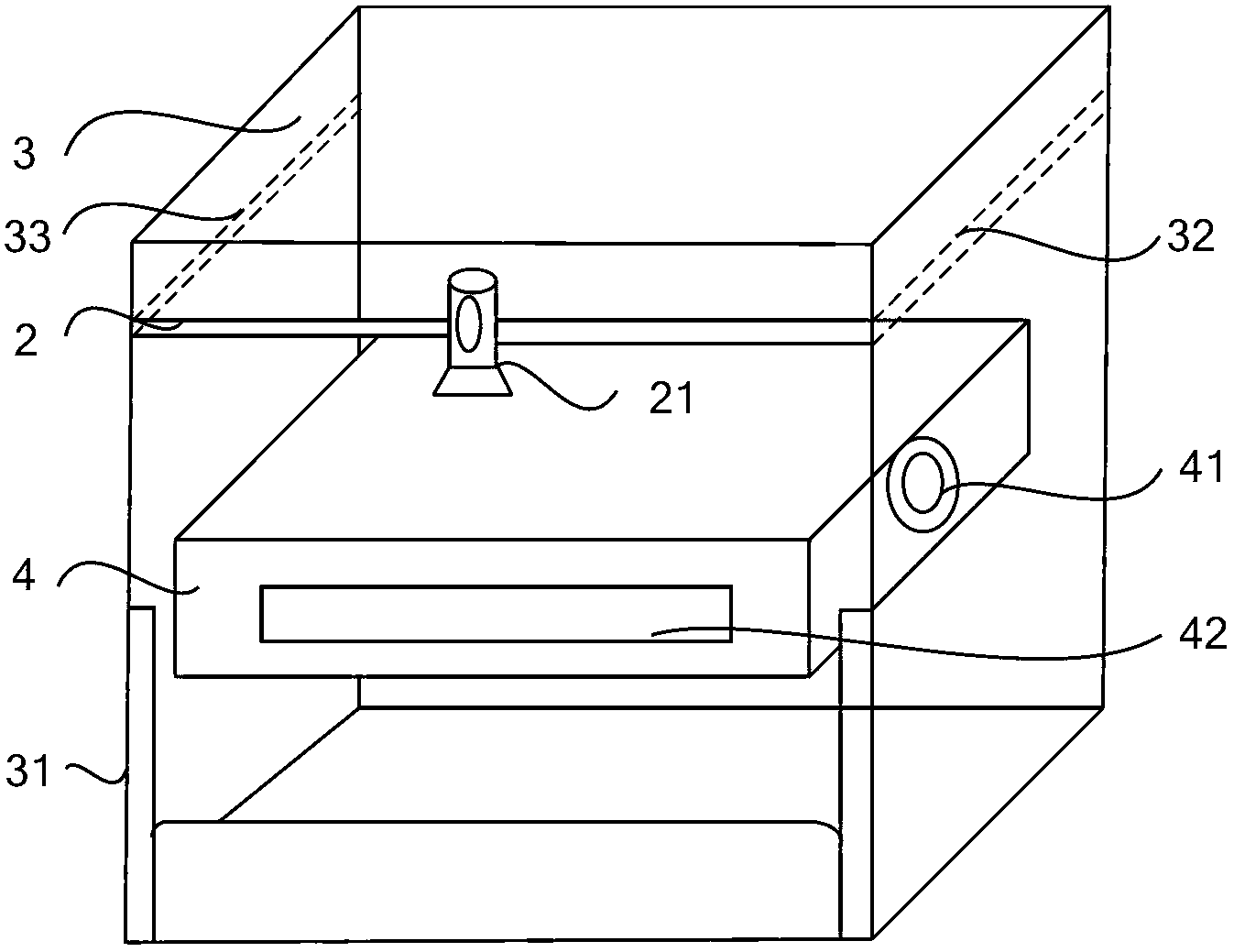

Large-scale multiple-object ultrasonic tracking and locating system and method

ActiveCN102033222AEnable indoor location trackingOvercoming intractable flawsPosition fixationSonificationEngineering

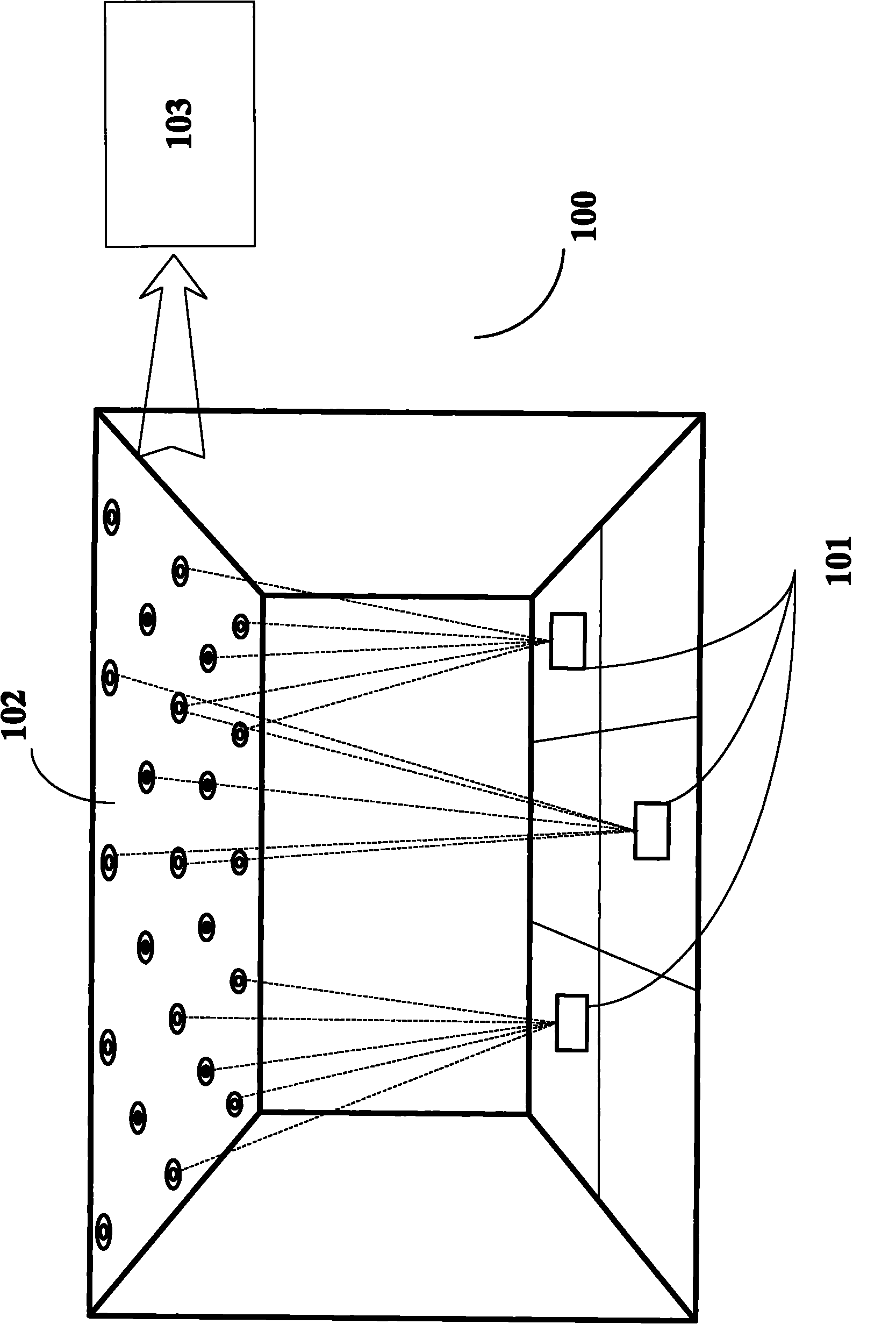

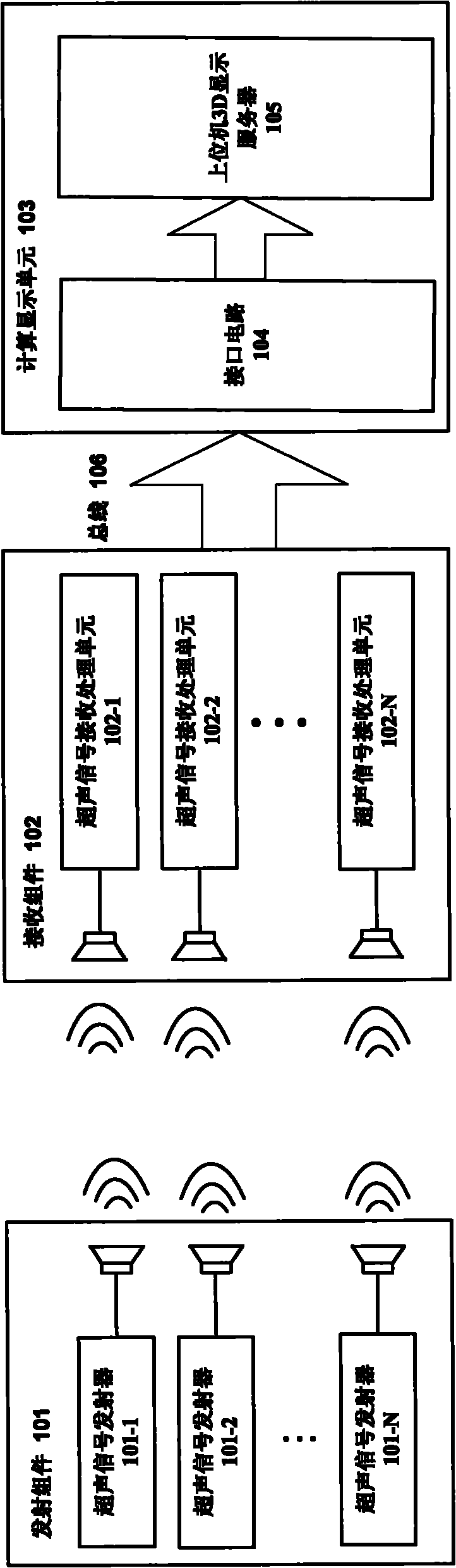

The invention provides a large-scale multiple-object ultrasonic tracking and locating system and method, relating to an indoor object tracking and locating system and method based on ultrasonic wave. The large-scale multiple-object ultrasonic tracking and locating system comprises an emitting assembly, a receiving assembly and a calculating display unit, wherein the emitting assembly comprises a plurality of ultrasonic signal emitters with different frequencies or different time slot features, and each emitter is installed on different objects and used for periodically emitting ultrasonic signals; the receiving assembly comprises a plurality of ultrasonic signal receiving and processing units for receiving and processing the ultrasonic signal emitted by the emitter; and the calculating display unit comprises a USB (Universal Serial Bus) and an upper computer three-dimensional display server. The invention realizes the tracking and the locating of large-scale multiple-object by schemesof spatial subdivision, time frequency combination, spatial handoff and the like. The locating system of the invention has the characteristics of large locating range, multiple tracking objects, no synchronous error, no need of complex network protocol, low power consumption, high stability and the like.

Owner:JILIN UNIV

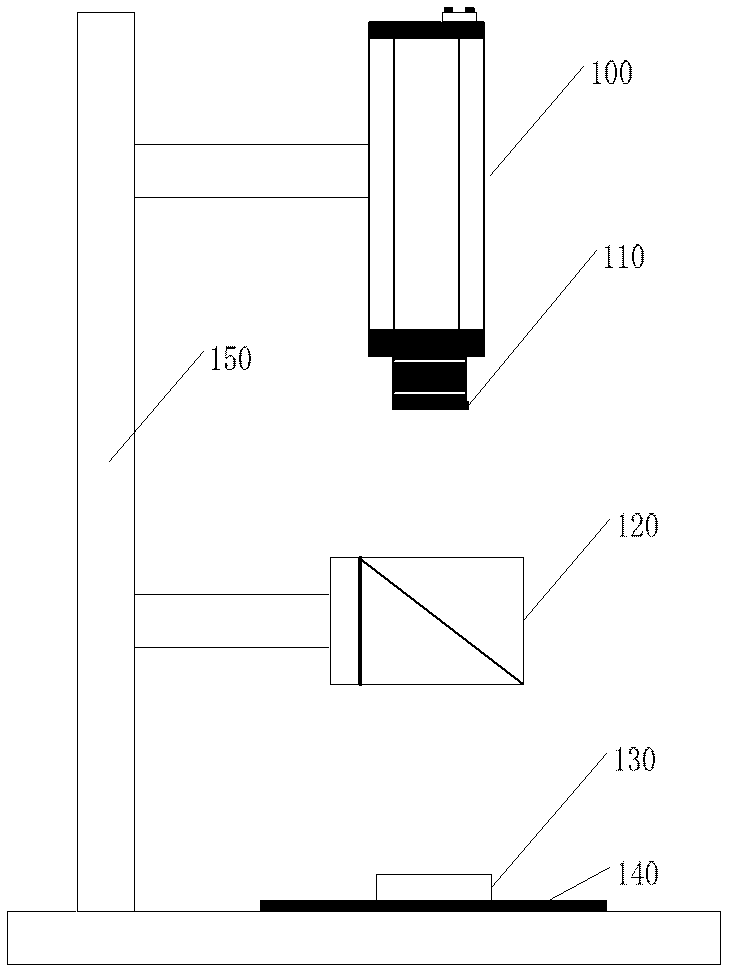

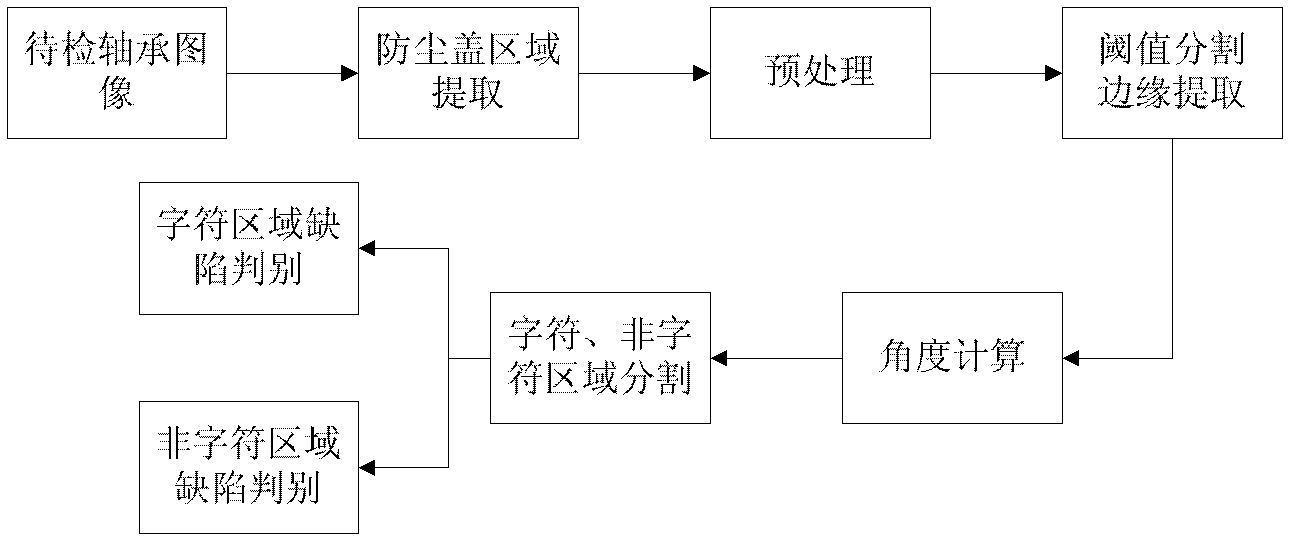

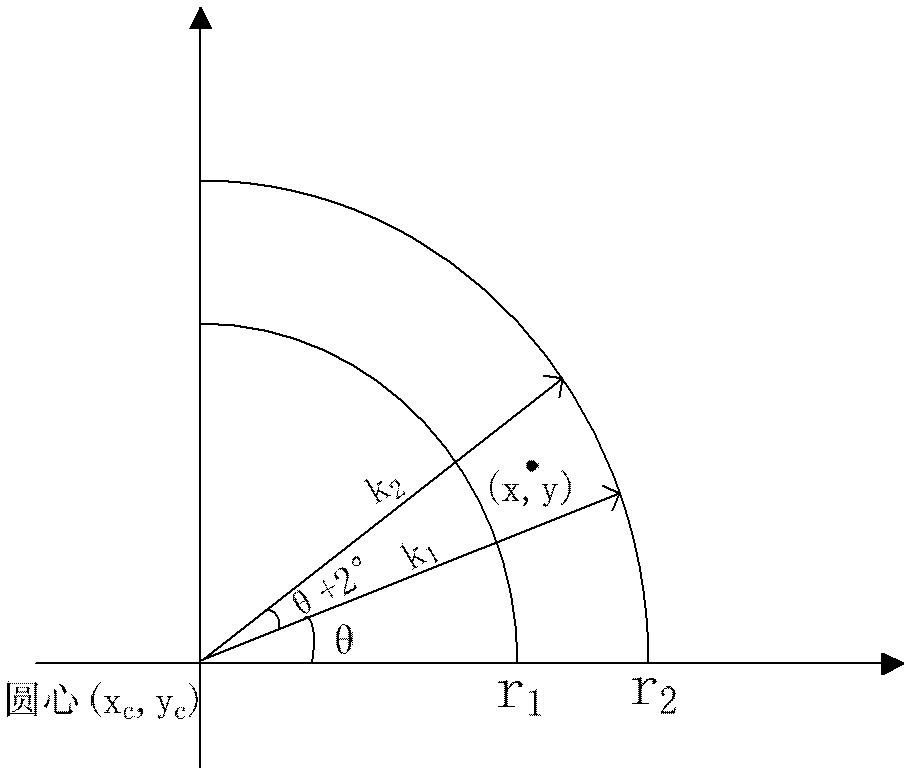

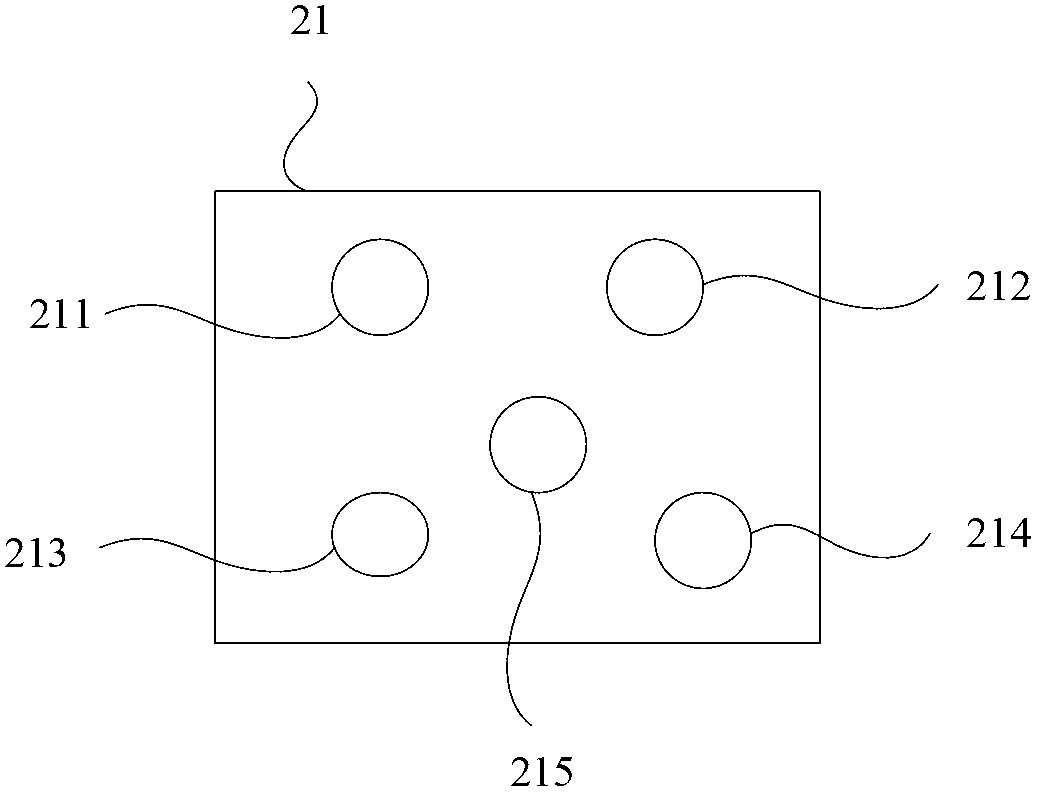

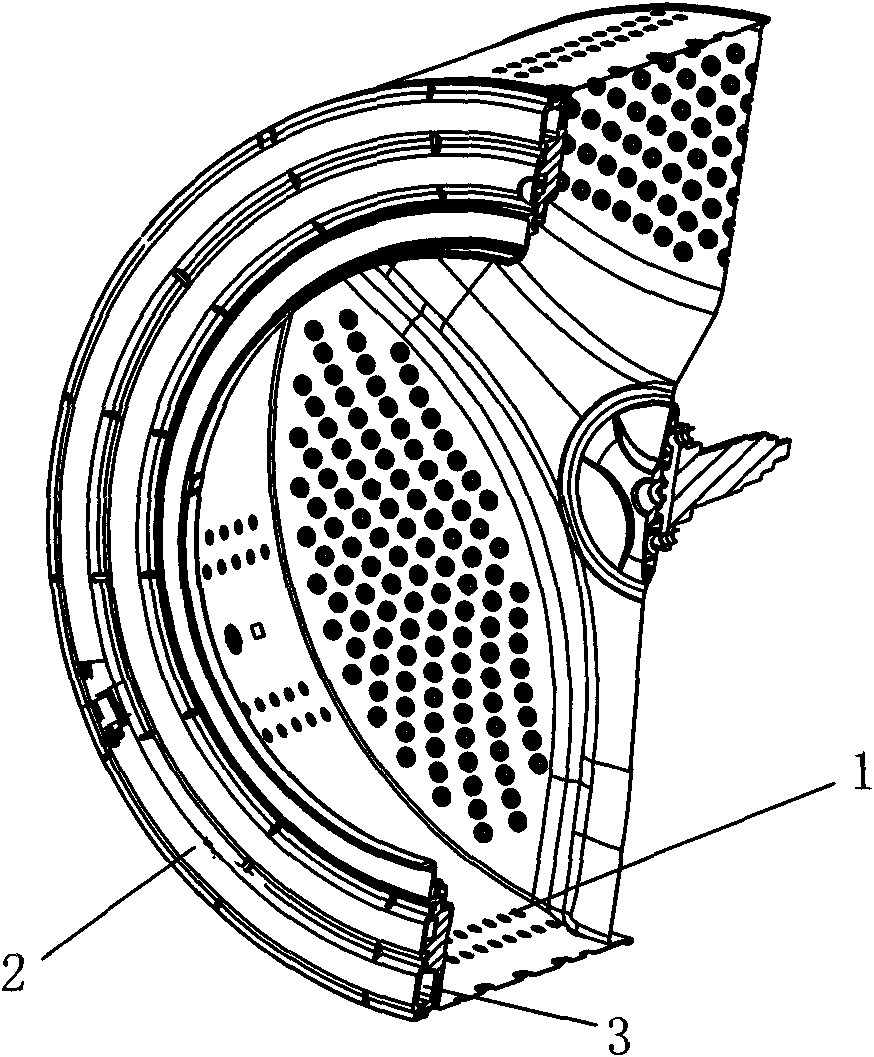

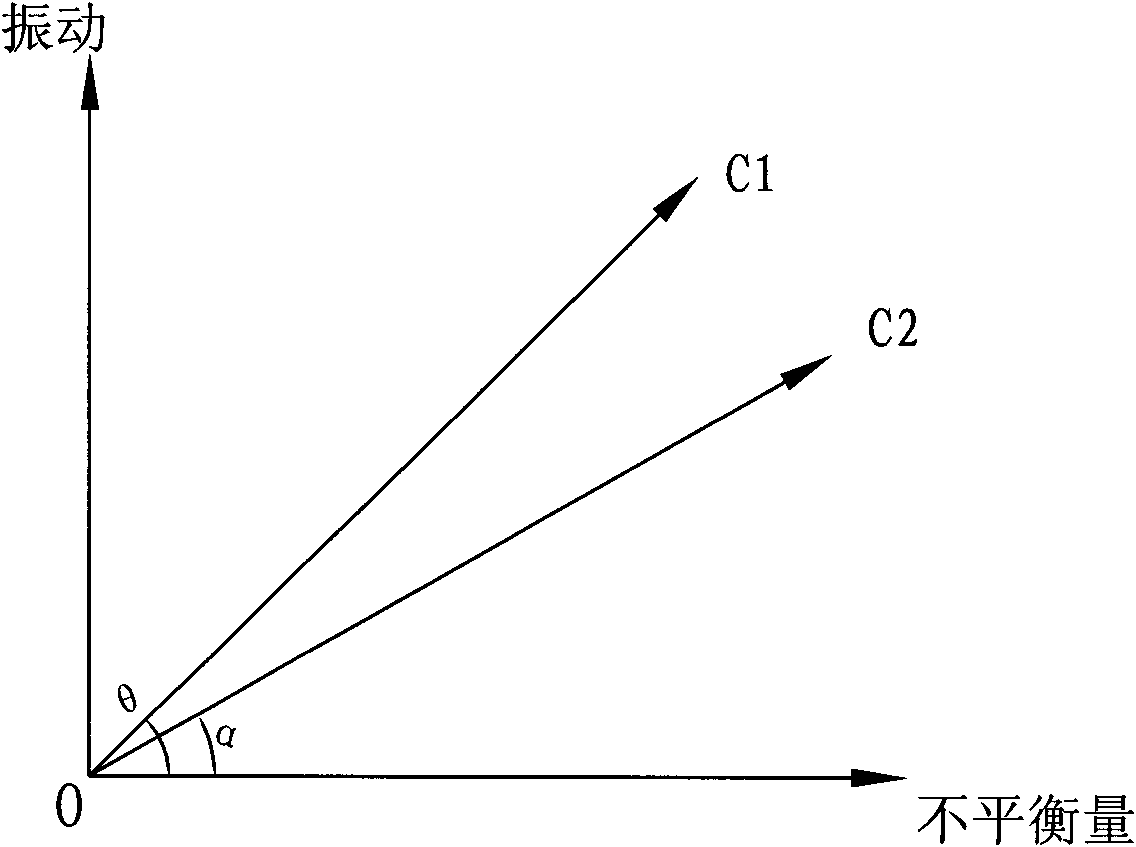

Method for detecting surface defects of dustproof cover of bearing based on machine vision

ActiveCN102636490AHigh speedAcquisition speed is fastOptically investigating flaws/contaminationMachine visionGrey level

The invention relates to a method for detecting surface defects of a dustproof cover of a bearing based on machine vision, which comprises the following steps: a, obtaining a gray level image of a to-be-detected bearing; b, carrying out separation on the gray level image so as to obtain a ring image of the dustproof cover of the bearing; c, carrying out grey level transformation and adaptive median filtering preprocessing on the ring image; d, carrying out threshold segmentation on the ring image by using a maximum interclass variance method, extracting an edge of the ring image of the dustproof cover of the bearing after threshold segmentation by using a Roberts edge detection operator; e, calculating the numbers of which the numerical values are 1 in the image area every two degrees for the ring image of the dustproof cover of the bearing; f, providing a template bearing image, and obtaining a deflection angle sigma through calculating; g, carrying out separation on the image so as to obtain character areas and non-character areas of the ring image of the dustproof cover of the bearing; and h, carrying out surface defect judgment on corresponding character areas and non-character areas in the ring image of the dustproof cover of the bearing according to the number of connected areas and the defect area. By using the method disclosed by the invention, automatic detection can be achieved, the visual detection workload of artificial detection is reduced, the detection efficiency is improved, and the method is safe and reliable.

Owner:JIANGNAN UNIV +1

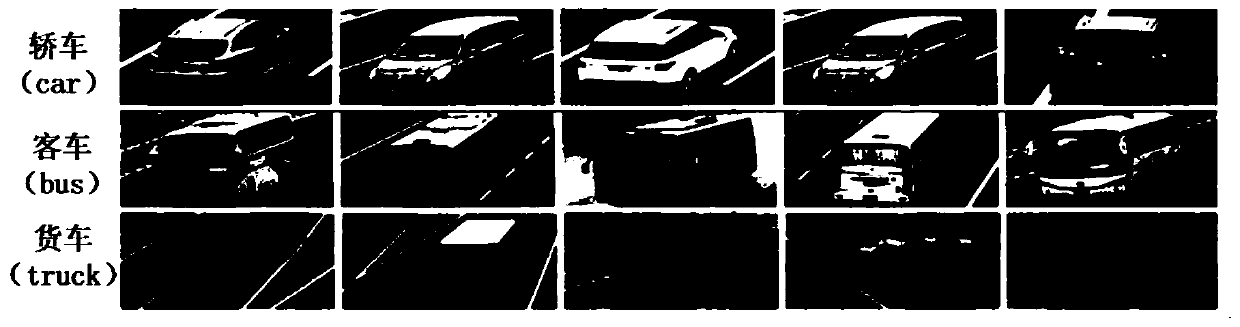

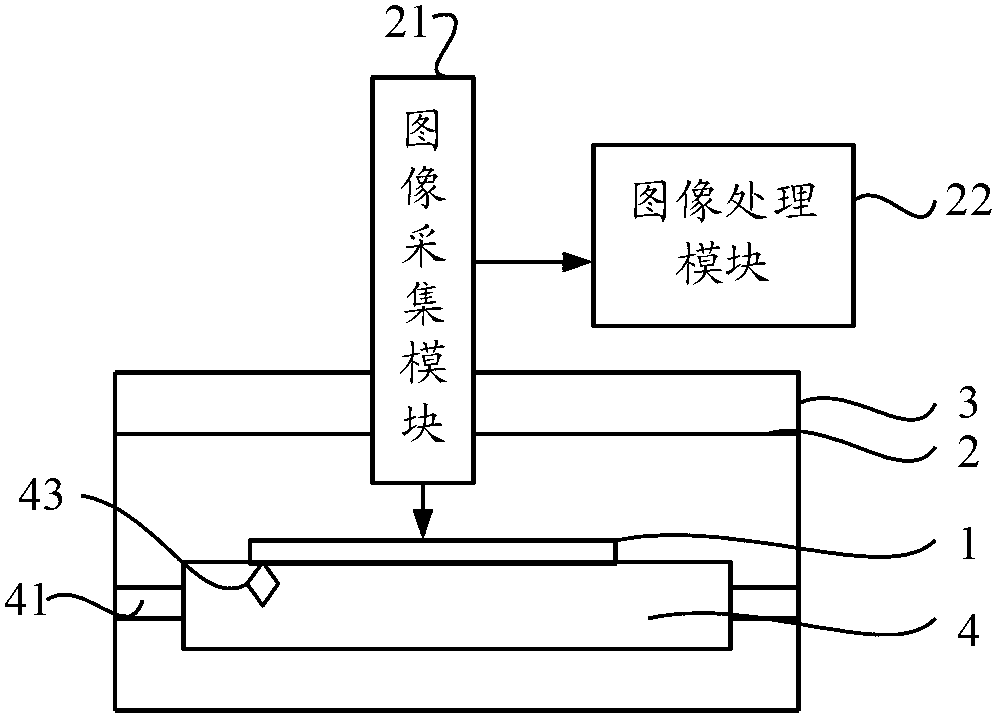

Traffic video intelligent analysis method based on target detection and tracking

ActiveCN110472496AImprove adaptabilityStable jobCharacter and pattern recognitionVisual field lossMulti target tracking

The invention discloses a traffic video intelligent analysis method based on target detection and tracking. The method specifically comprises the following steps: using highway videos acquired by using monitoring cameras; detecting vehicle target detection by using a deep learning method, acquiring target tracks by using a multi-target tracking method according to a detection result, automaticallyanalyzing the target tracks acquiring traffic flow and vehicle speed, detecting traffic congestion and parking traffic abnormal events and completing intelligent analysis of traffic videos. Vehiclescan be detected and tracked for a long time in a visual field range, so that traffic parameters are accurately obtained, and traffic events are detected. The invention provided by the invention has high stability when being used in various traffic scenes, and has certain practical value and wide market potential.

Owner:CHANGAN UNIV

Detecting device and method

InactiveCN103257465AImprove accuracyWide spectral response rangeImage enhancementImage analysisImaging processingLiquid-crystal display

The invention relates to the technical field of detection, and discloses detecting device and method. The detecting device comprises an image acquiring module and an image processing module, wherein the image acquiring module acquires image information of a liquid crystal display panel to be detected, and the image processing module is in signal connection with the image acquiring module. The image processing module compares received image information with a defect database and judges defect level of the liquid crystal display panel to be detected. During use of the detecting device, the image acquiring module can acquire image information of any position of the liquid crystal display panel to be detected, the image processing module compares received the image information acquired by the image acquiring module with the defect database and judges the defect level of the liquid crystal display panel to be detected. Accordingly, by the detecting device, defect identification rate and detection efficiency of the liquid crystal display panel are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

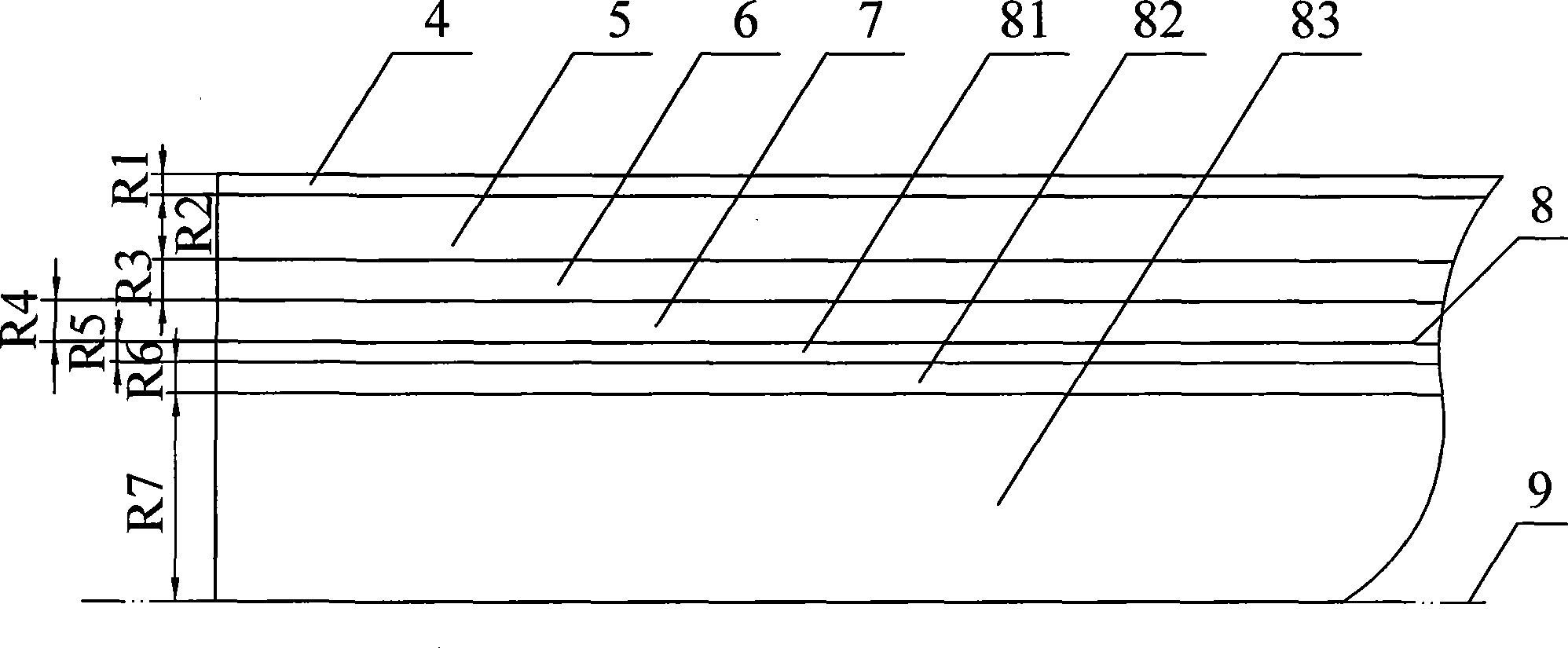

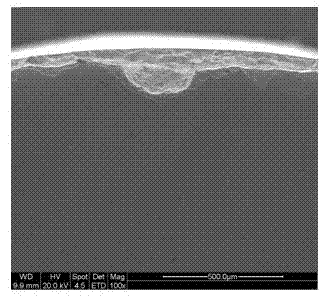

Needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof

ActiveCN101530327AShort response timeStable jobDiagnostic recording/measuringSensorsGlucose sensorsConcentrations glucose

The invention discloses a needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof. The sensor comprises a needle reference electrode (2) and at least one needle working electrode (1) including a conducting layer (8) and an enzyme membrane layer (6), and is characterized in that the working electrode (1) further comprises a polymer material inner membrane layer (7) and a polymer material control diffusion layer (5), and the conducting layer (8), the polymer material inner membrane layer (7), the enzyme membrane layer (6) and the polymer material control diffusion layer (5) are coated in turn from inner to outside. According to the manufacturing method in the invention, the glucose sensor has good stability, high flexibility, wide linear range of output current and glucose concentration, short response time, continuous real-time monitoring, good fastness and stability of enzyme bonding, high flexibility, selectivity and repeatability.

Owner:HUZHOU MEIQI MEDICAL EQUIP CO LTD

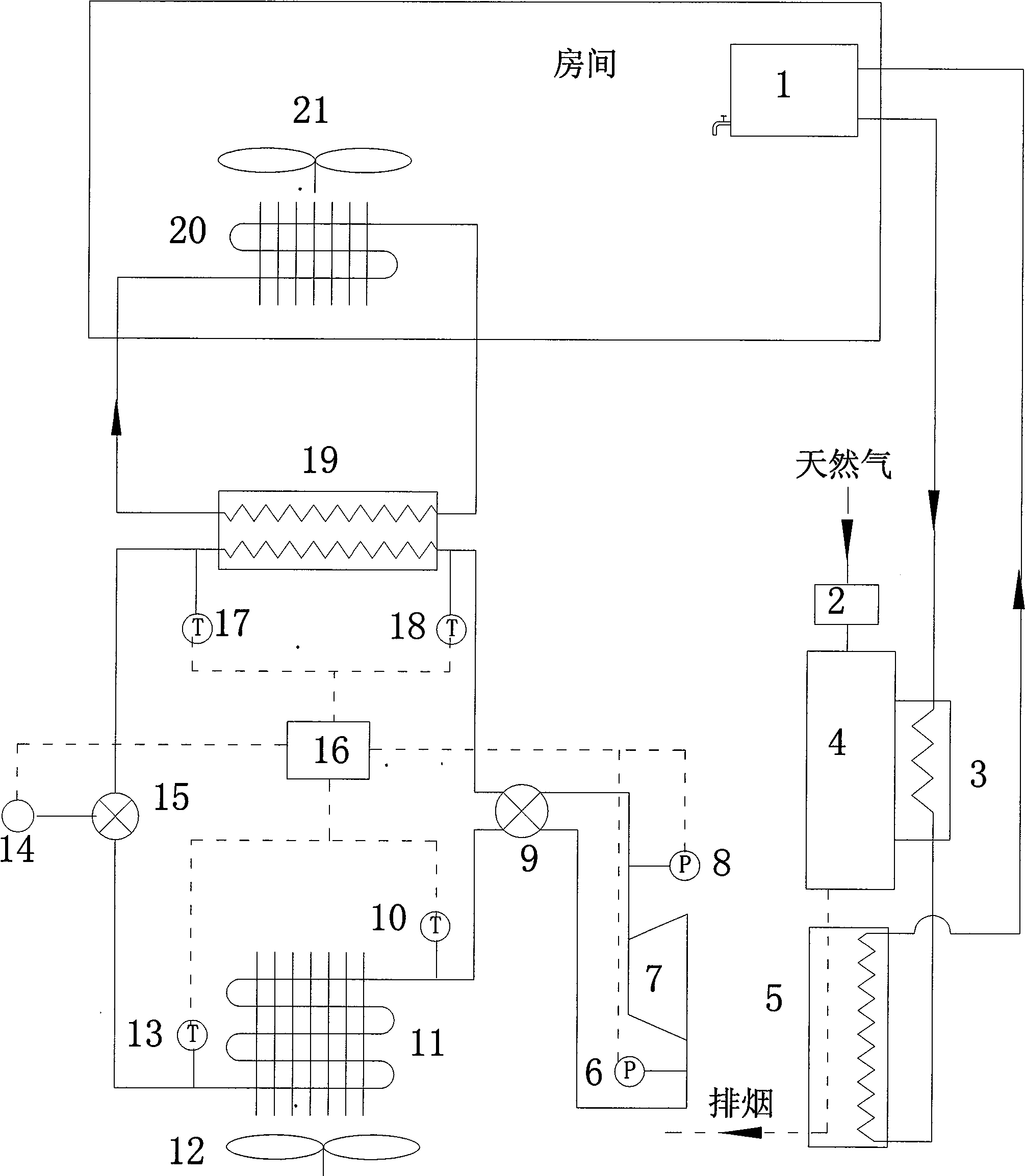

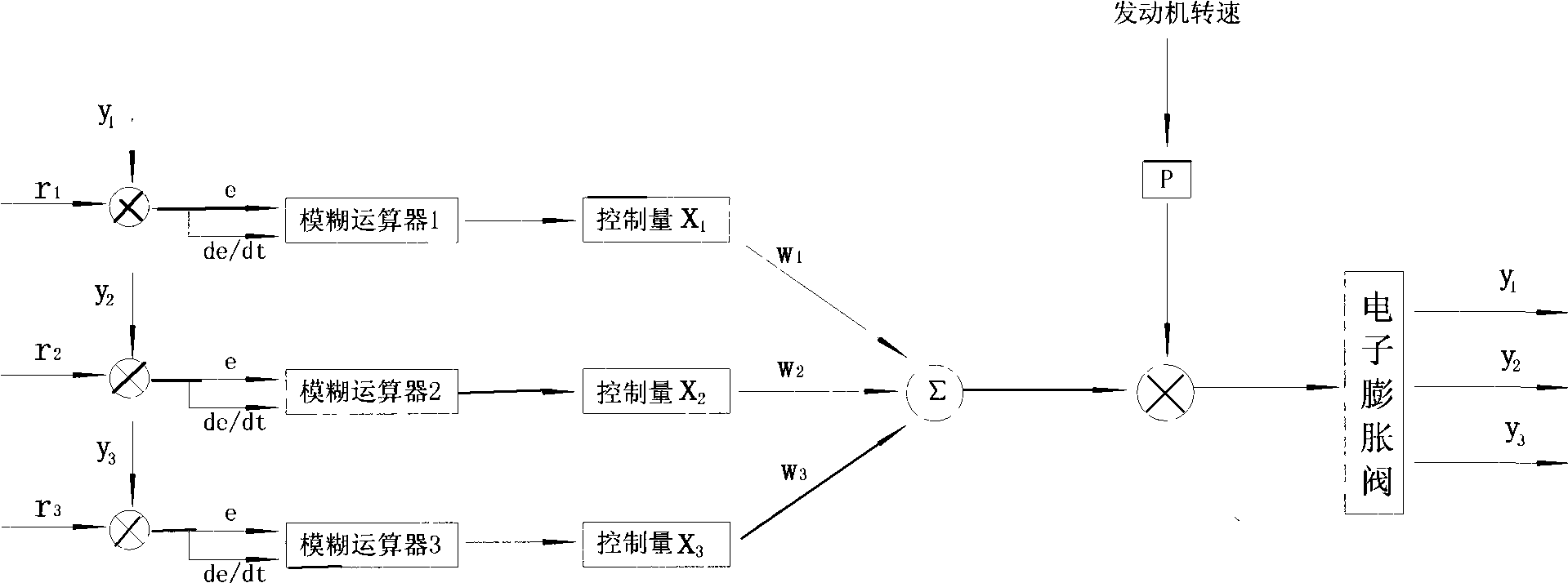

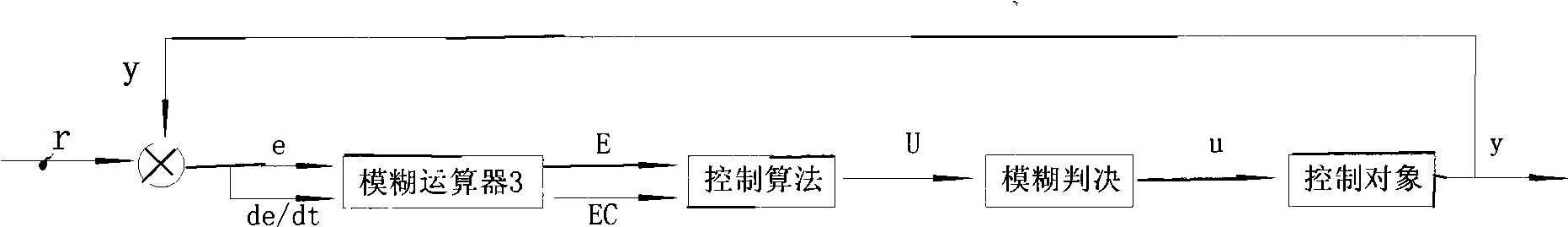

Multi-target intelligent control method for electronic expansion valve of refrigeration air conditioner heat pump system

InactiveCN101498534AStrong couplingImprove performanceRefrigeration safety arrangementAdaptive controlNeural network controllerEnergy supply

The invention relates to a multipurpose intelligent control method for an electronic expansion valve of a heat pump system of a refrigeration air-condition, belonging to the technical field of the independent heat and cold energy supply of buildings. The method comprises the steps of(1) determining two or more controlled parameters affected by the electronic expansion valve,(2) determining a set value for each controlled parameter and carrying out detection in real time, (3)comparing the detection value and the set value of each controlled parameter, calculating deviation and deviation change rate, then carrying out indistinct processing to generate the control quantity of respective electronic expansion valve,(4) obtaining the control quantity of each electronic expansion valve by being calculated by the step (3) to be taken as the input layer of a neural network controller and obtaining the right value of each controlled parameter by being trained by a single neuron neural network and (5) obtaining the feedback control quantity of the electronic expansion valve according to each controlled parameter value detected in real time. Due to the adoption of the method, operating parameters can be intelligently adjusted, so that intelligent heat and cold supply and stable and efficient operation under a variety of climatic conditions are realized.

Owner:TIANJIN UNIV

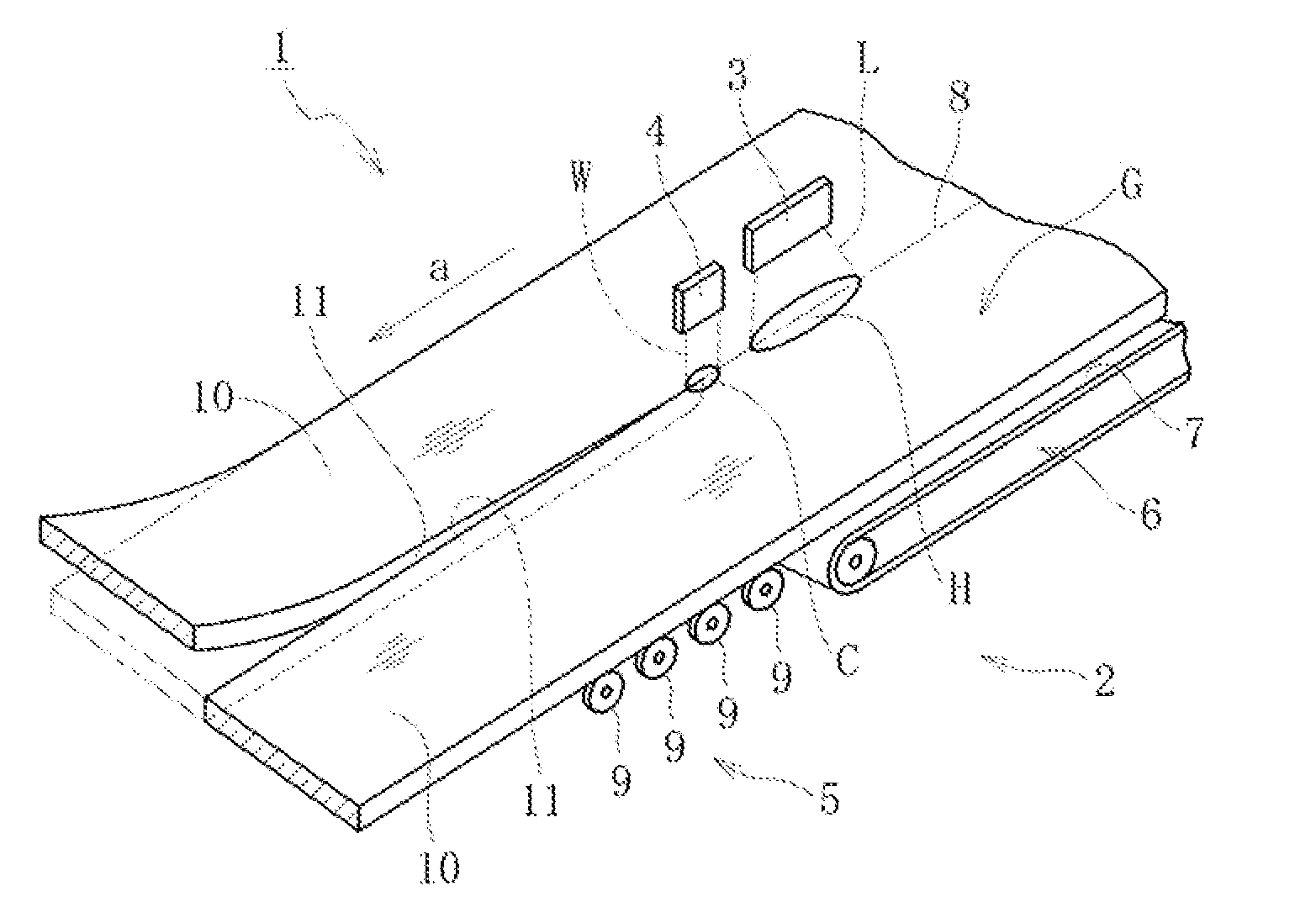

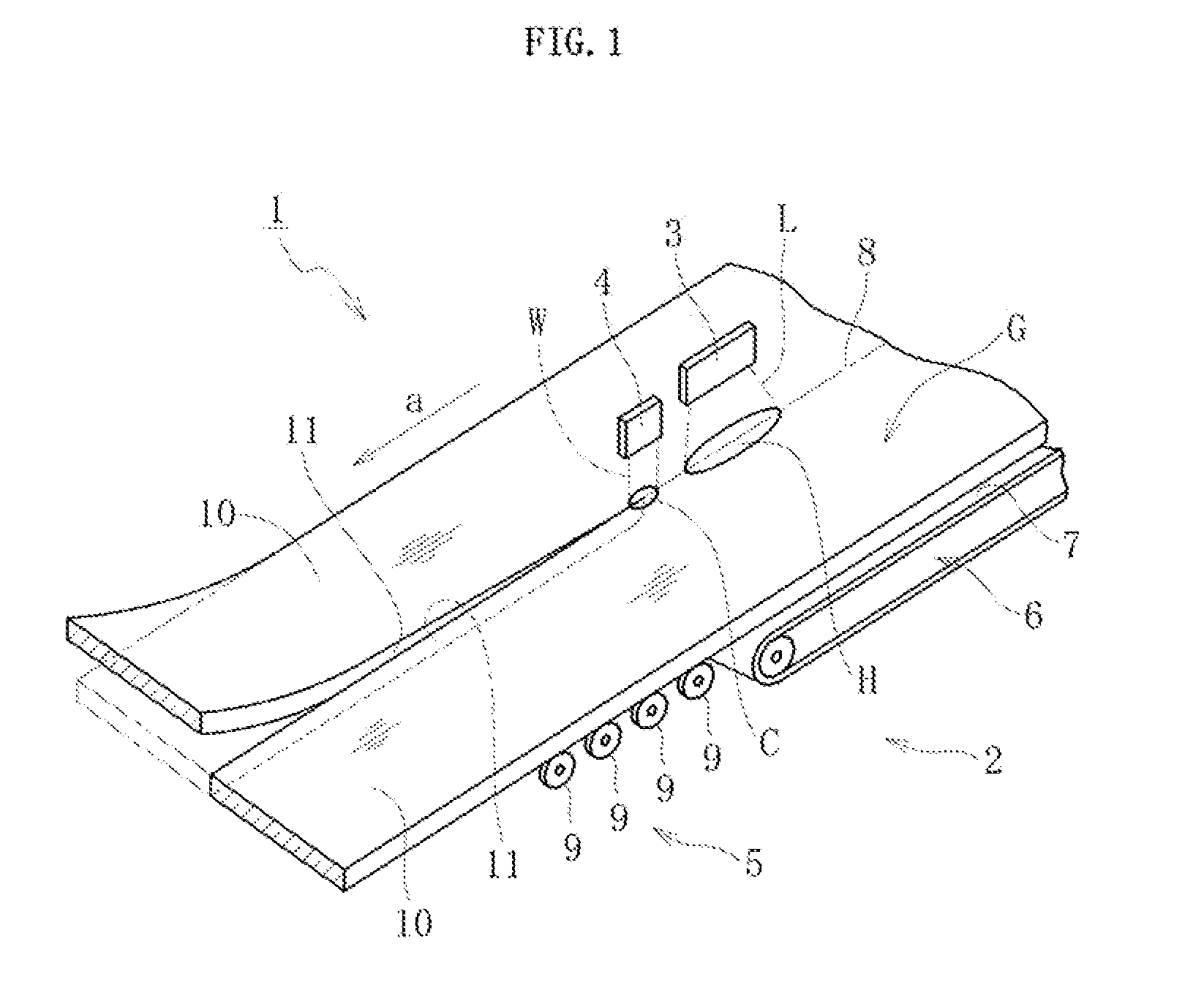

Cleaving method for a glass film

ActiveUS20120024928A1Stable jobInterferenceGlass transportation apparatusGlass severing apparatusGlass filmElectrical and Electronics engineering

Provided is a cleaving method for a glass film (G) including: cleaving, during conveyance of the glass film (G) in a predetermined direction, the glass film (G) continuously along a preset cleaving line (8) extending in a predetermined conveying direction (a) by a thermal stress generated through localized heating performed along the preset cleaving line (8) and through cooling of a locally heated region (H); dividing the glass film (G) in a width direction of the glass film (G) ; diverting, after the dividing, adjacent divided glass films (10) , which are obtained by the dividing, so that the adjacent divided glass films (10) are separated in a front and rear direction of the adjacent divided glass films; and forming a predetermined widthwise clearance between the adj acent divided glass films after the dividing of the glass film (G) and before the diverting of the adjacent divided glass films (10).

Owner:NIPPON ELECTRIC GLASS CO LTD

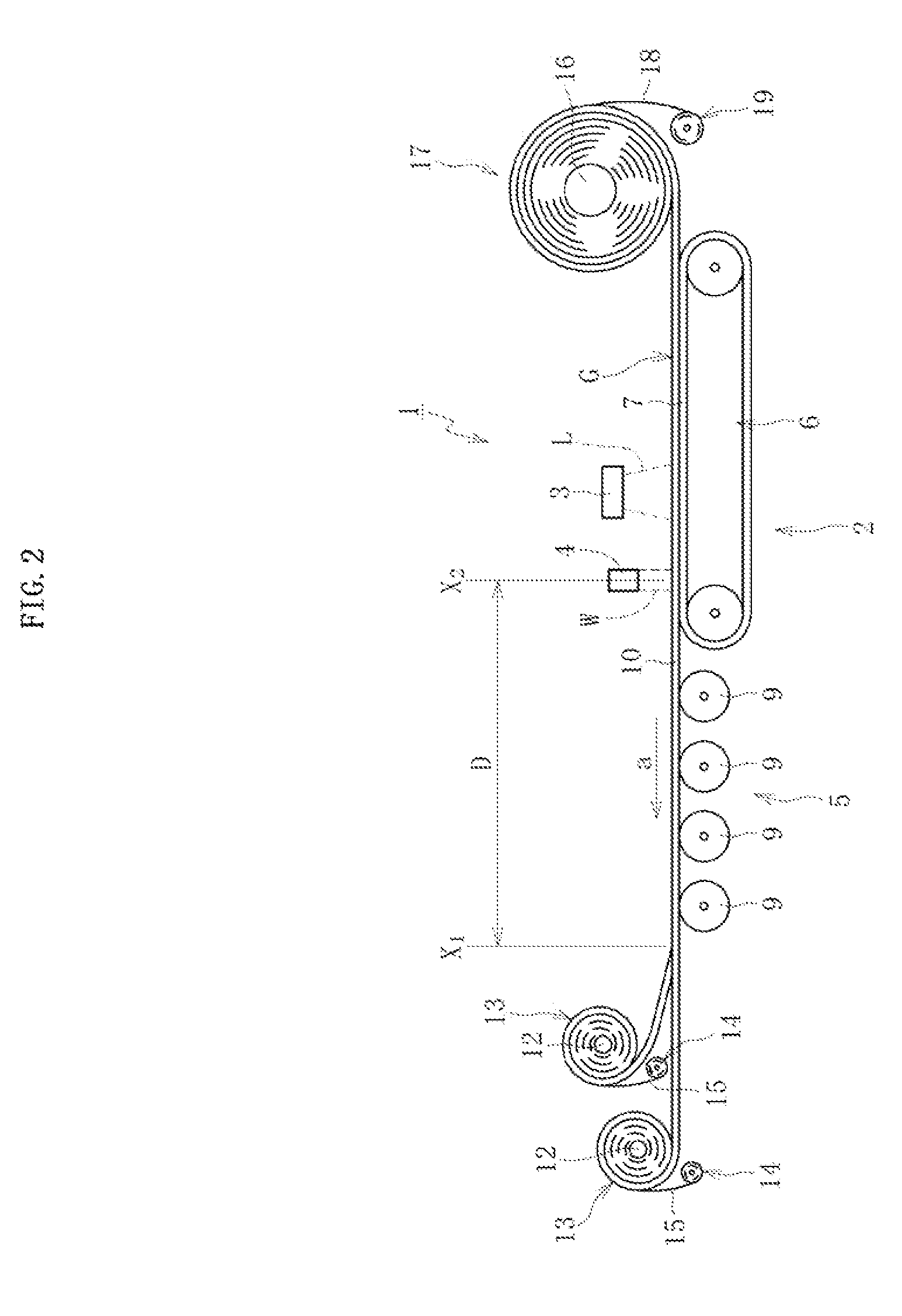

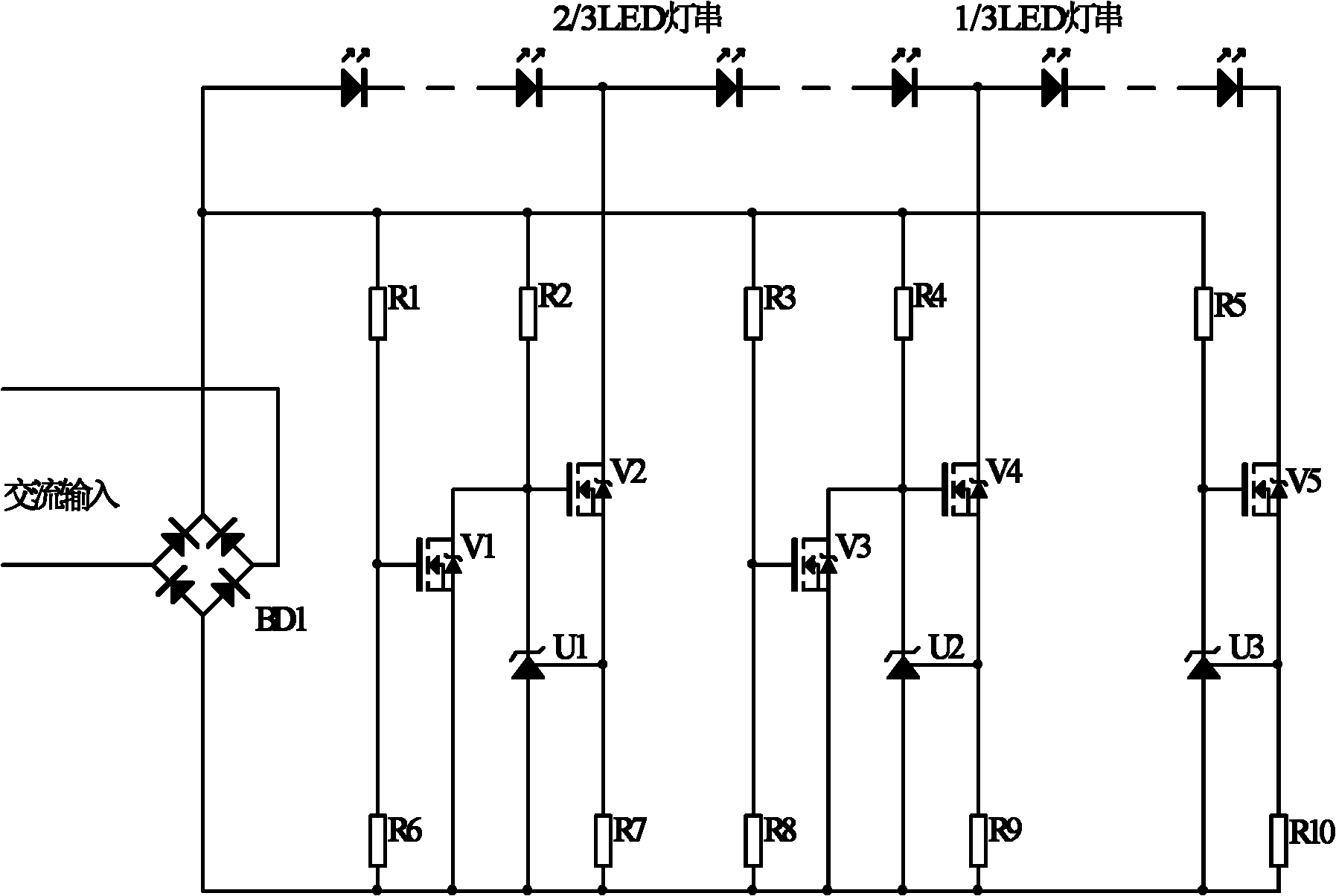

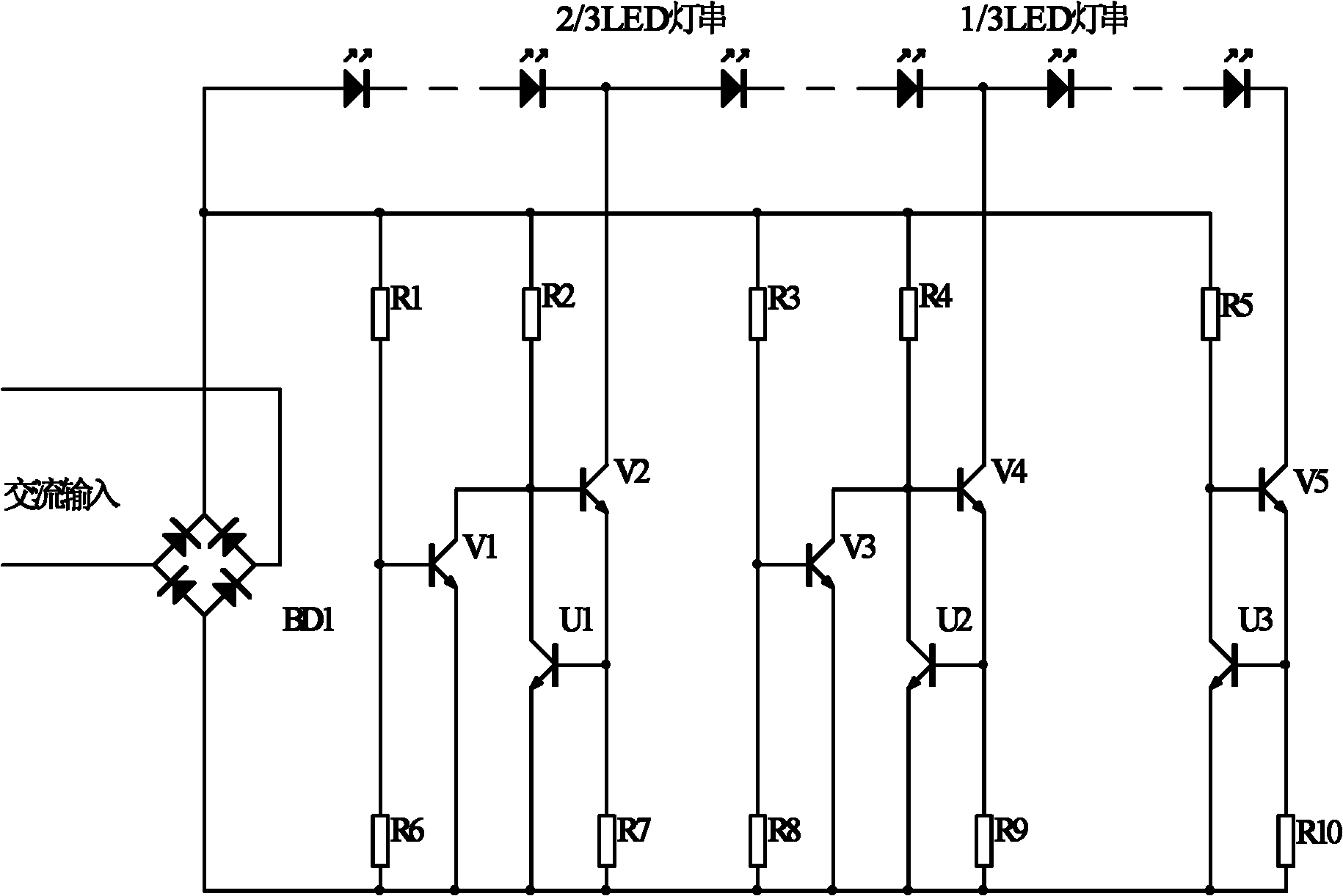

Drive circuit capable of improving power factors of alternating current light emitting diode (AC LED) lamp

ActiveCN102186282AImprove power factorReduce pollutionEfficient power electronics conversionElectric light circuit arrangementPower savingHigher Power

The invention discloses a drive circuit capable of improving power factors of an alternating current light emitting diode (AC LED) lamp. The drive circuit comprises a rectifier bridge, wherein two input terminals of the rectifier bridge are connected with AC voltage. The drive circuit is characterized in that: the positive output terminal of the rectifier bridge is connected with positive terminals of n serially connected LED lamp strings and detection terminals of n self-controlled constant-current circuits; the negative output terminal of the rectifier bridge is connected with the output terminals of the n self-controlled constant-current circuits; the negative terminal of the nth LED lamp string is connected with the input terminal of the self-controlled constant-current circuit with serial number of n, wherein n is more than or equal to 2 but less than or equal to 10; and in the n serially connected LED lamp strings, the number of LEDs in each lamp string is the same. The drive circuit uses a circuit design method of automatically controlling operating modes of the n constant-current circuits in stages by detecting AC input voltage so as to greatly improve the power factor, reliability and safety of the AC LED; and an AC / DC converter is not needed to be installed in the lamp, and then the failure rate of equipment is reduced. Furthermore, the drive circuit has the advantages of novel structure, simple circuit, high power factor, long service life, good power-saving effect and the like.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

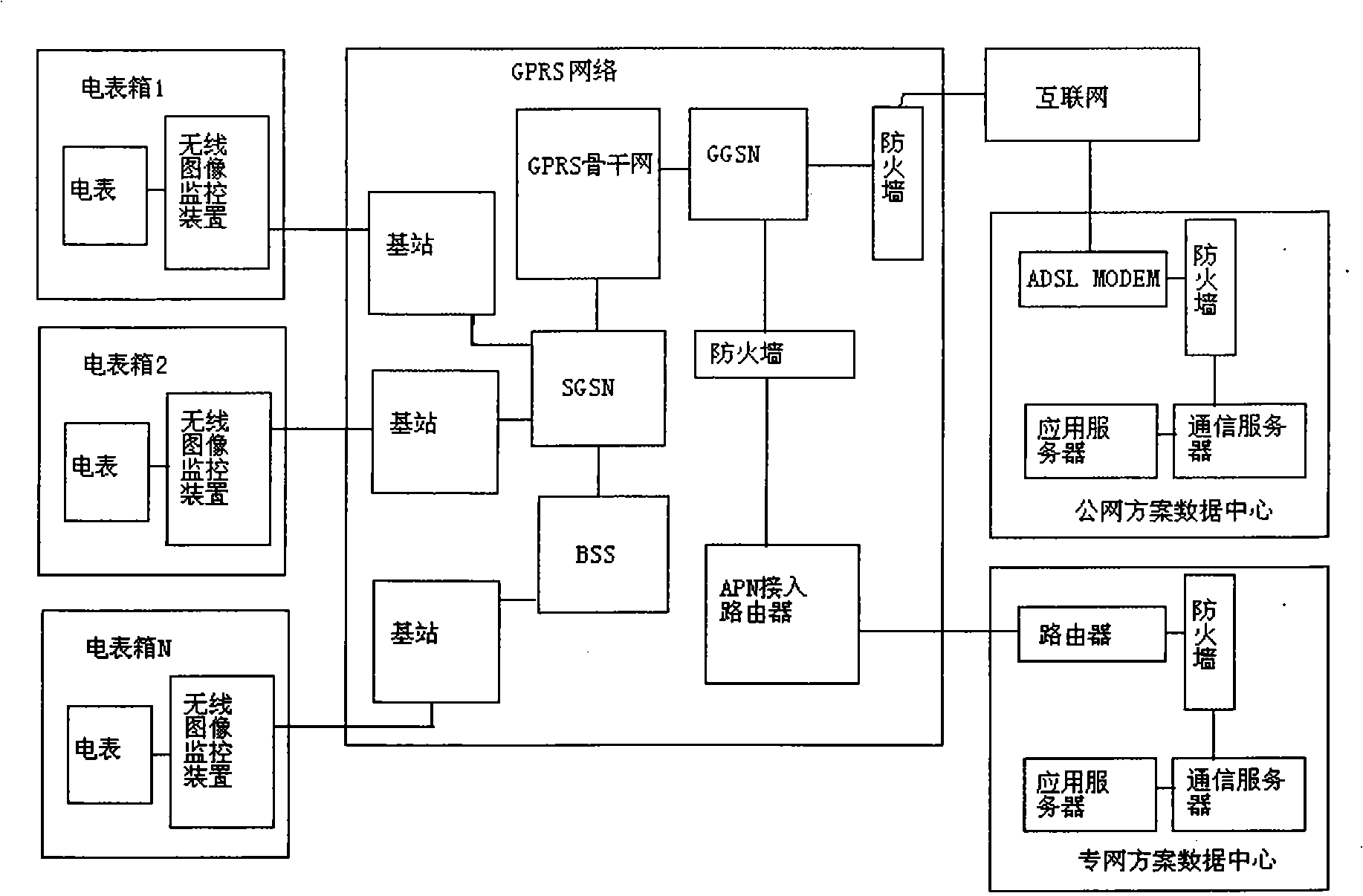

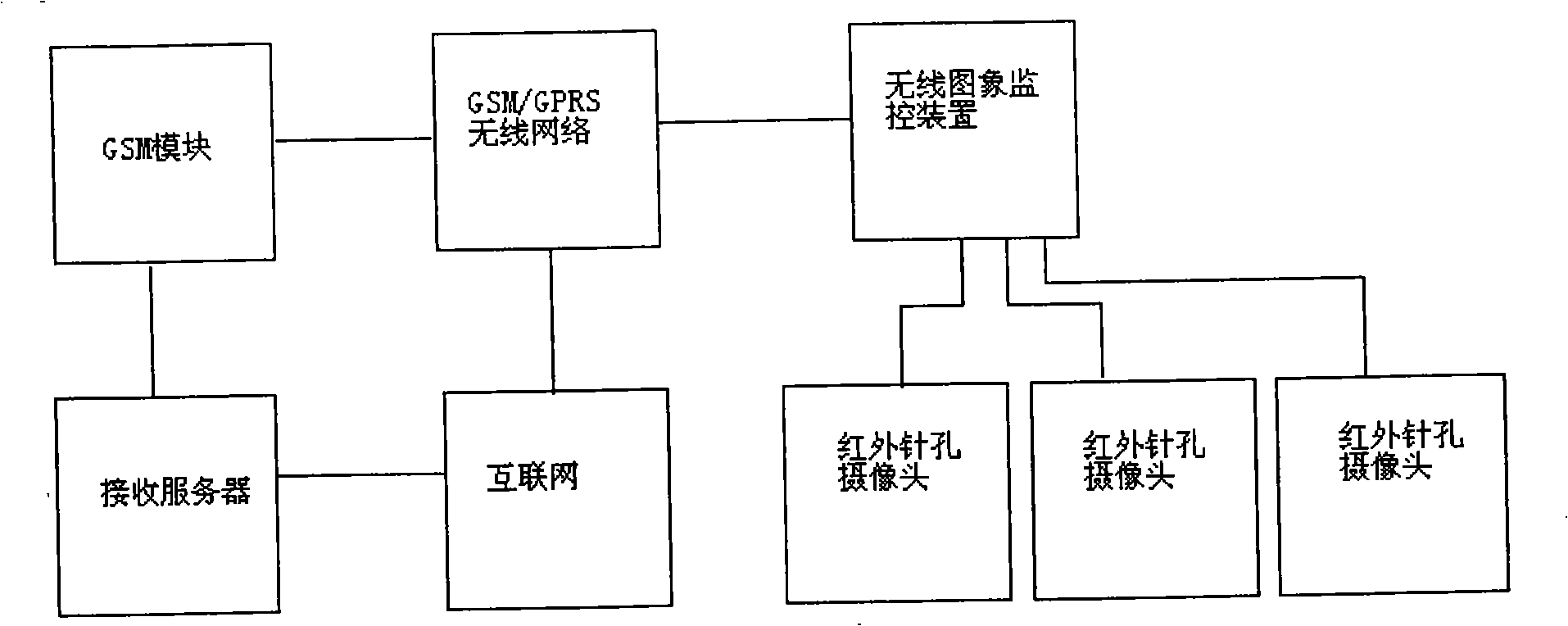

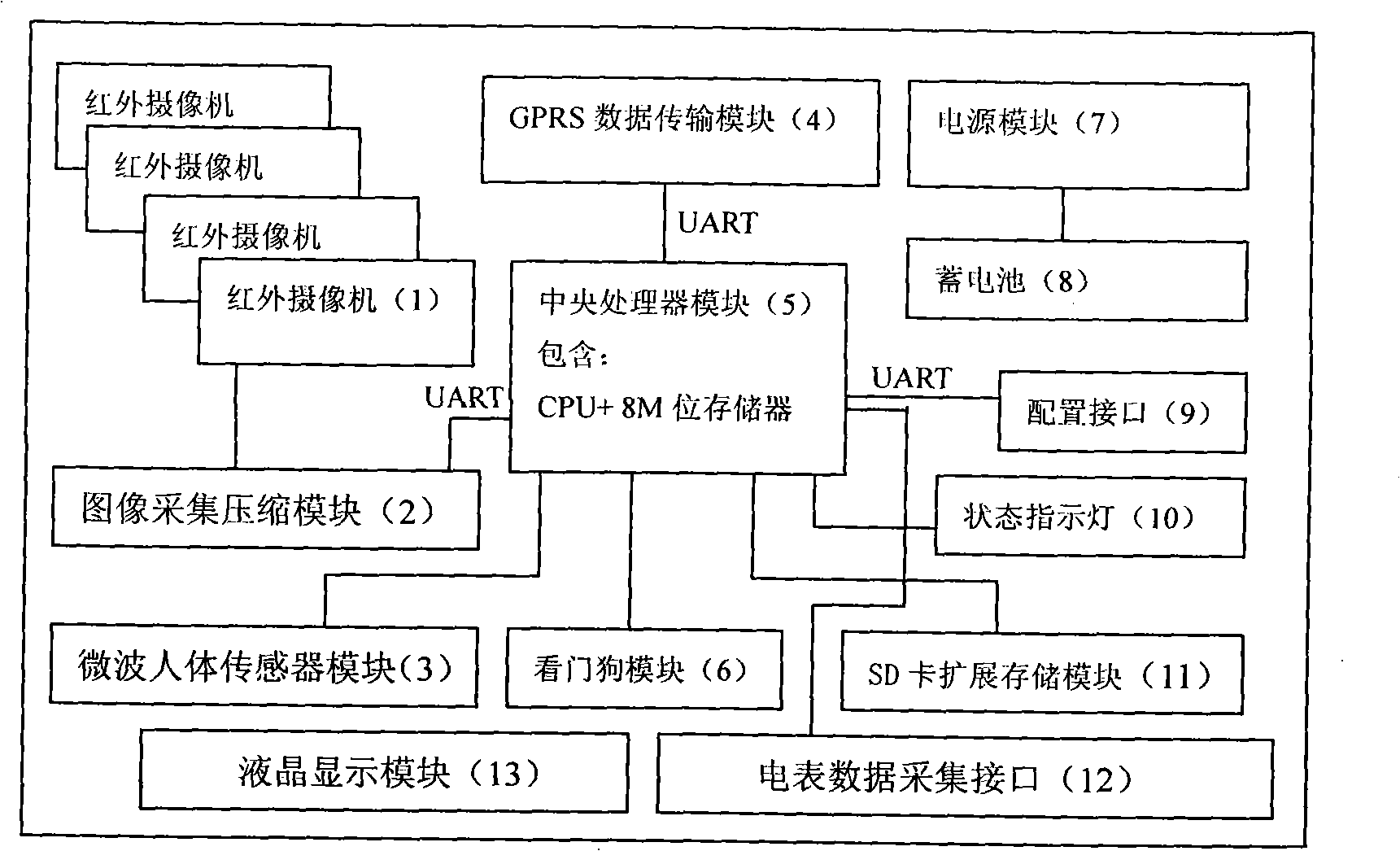

Wireless data and image double-acquisition anti-electricity theft monitoring system and method thereof

InactiveCN101320053AAcquisition timingReal-time acquisitionTransmissionBurglar alarmElectricityMicrowave

The invention discloses a wireless data-image dual acquirement anti-electricity-theft monitoring system and method which uses a microwave body sensor to conduct the real time detection to activities of people around an electricity meter box. Based on the method of the image shooting of a camera, the monitoring system provided by the invention uses a camera to continuously shoot and store the images of the activities of people around the electricity meter box and can real time transmit alarming information, electricity meter data and image information to a motoring server through GPRS network; and then, the motoring server can send the received alarming information to the mobile phones or computers of users in time, and users can read the alarming information from the mobile phones or computers of users in distance. Besides the functions of remote electricity meter data acquiring, the anti-electricity-theft monitoring and real-time alarming, the monitoring system also can transmit field images in time and obtain images stored by field equipment later for providing convincible proofs during handling the electricity theft of illegal users.

Owner:STATE GRID SHANDONG ELECTRIC POWER

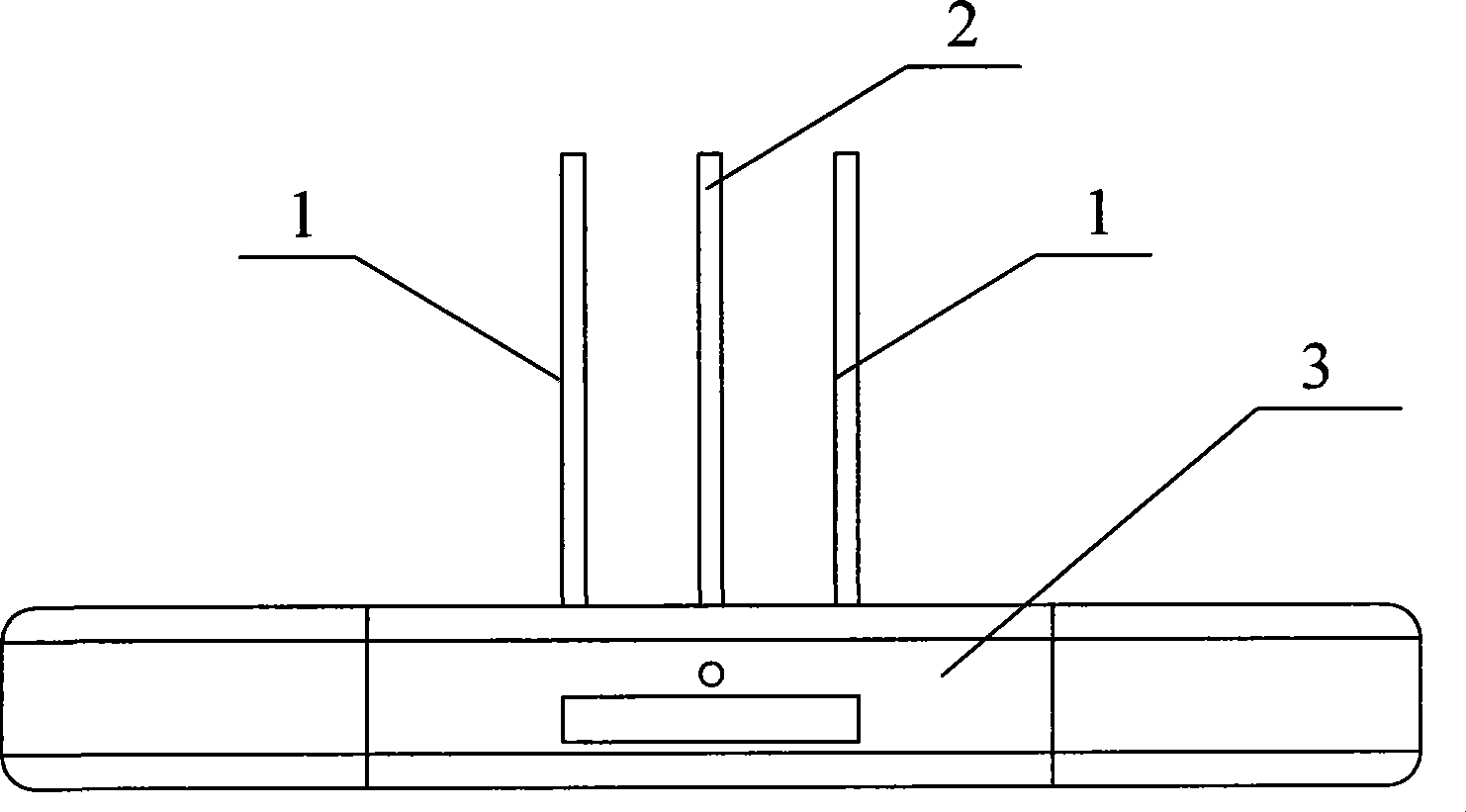

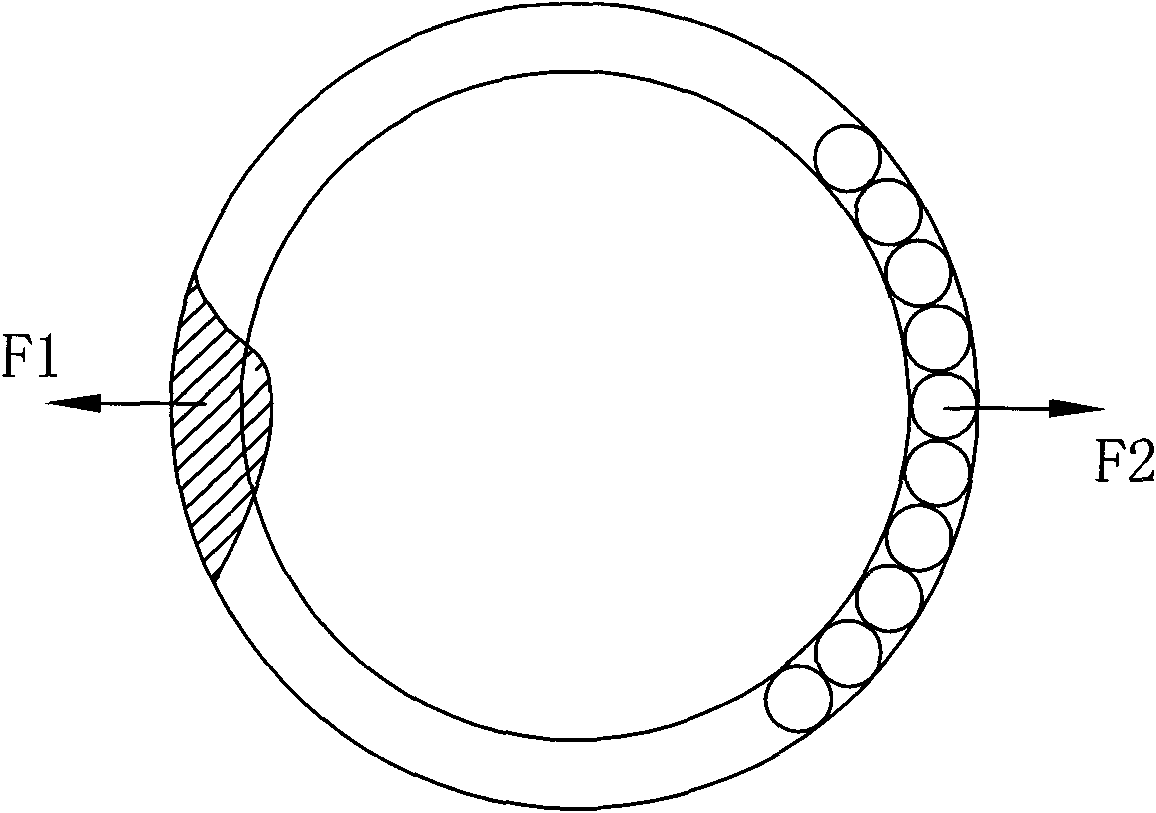

Gimbal device of rolling drum-type washing machine

ActiveCN101962901AReduce noiseLow costOther washing machinesTextiles and paperVibration amplitudeLow noise

The invention discloses a gimbal device of a rolling drum-type washing machine. The gimbal device comprises at least two annular chambers which are in coaxial with a rolling drum and are arranged at the edge of the rolling drum, wherein at least one chamber is a sphere gimbal provided with a grounder; and at least one chamber is a liquid gimbal provided with flowing liquid. The two different counterweights of the grounder and the liquid are utilized for respectively generating at least two counterbalances with different reaction speeds, thereby improving equilibrium state of rotation when the rolling drum of the washing machine dehydrates. When the rotation speed is less than the point of resonance of the rolling drum and an outer drum, the liquid gimbal absorbs vibration. When the rotation speed exceeds the point of resonance and is stabilized, the sphere gimbal generates high degree of vibration to absorb the vibration of the outer drum. For offset exceeding sphere volume, the liquid gimbal absorbs the vibration. The gimbal device can restrain vibration amplitude of the outer drum when starting and stably rotating, and realizes the purposes of low vibration, low noise and low cost.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

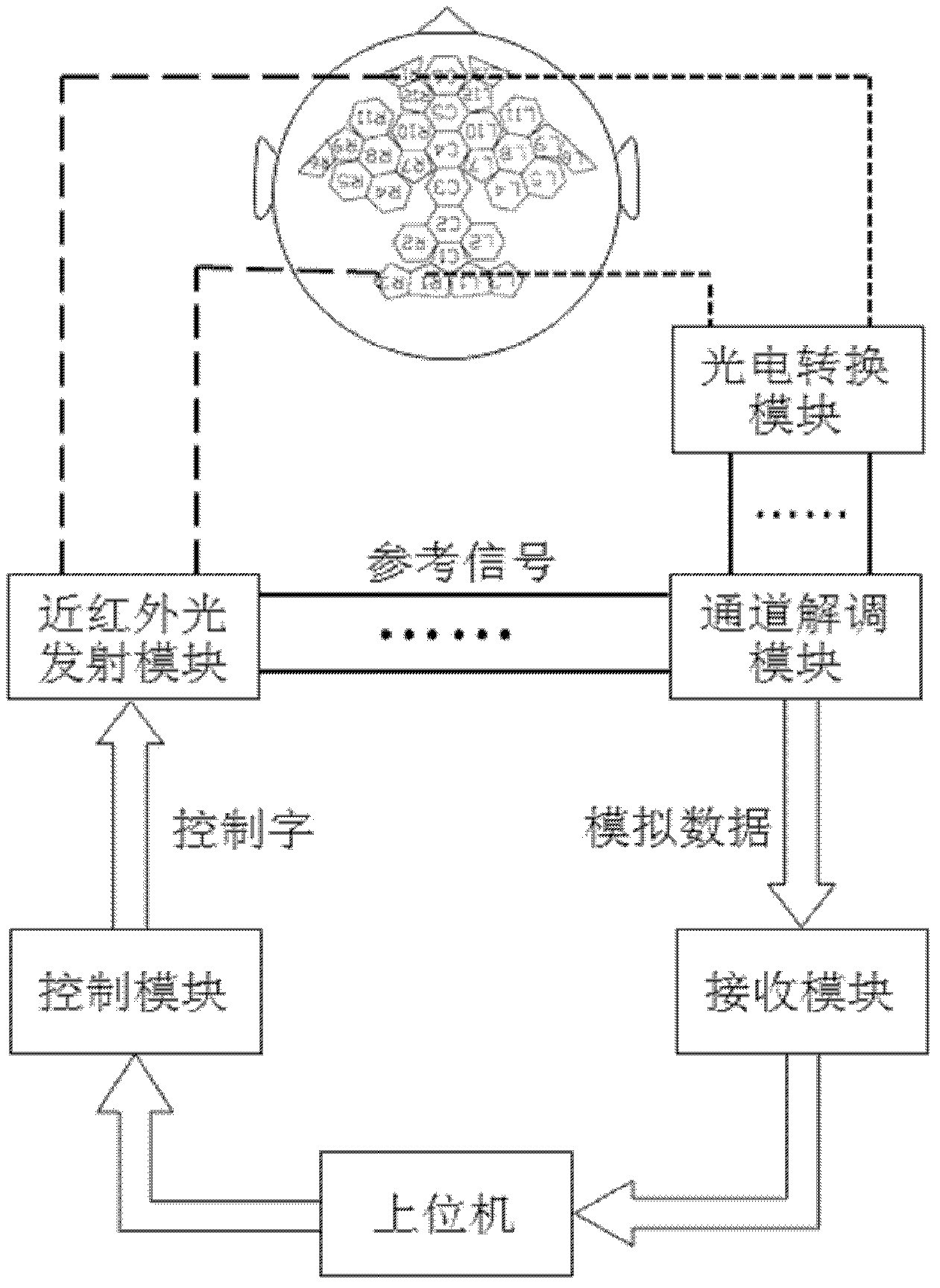

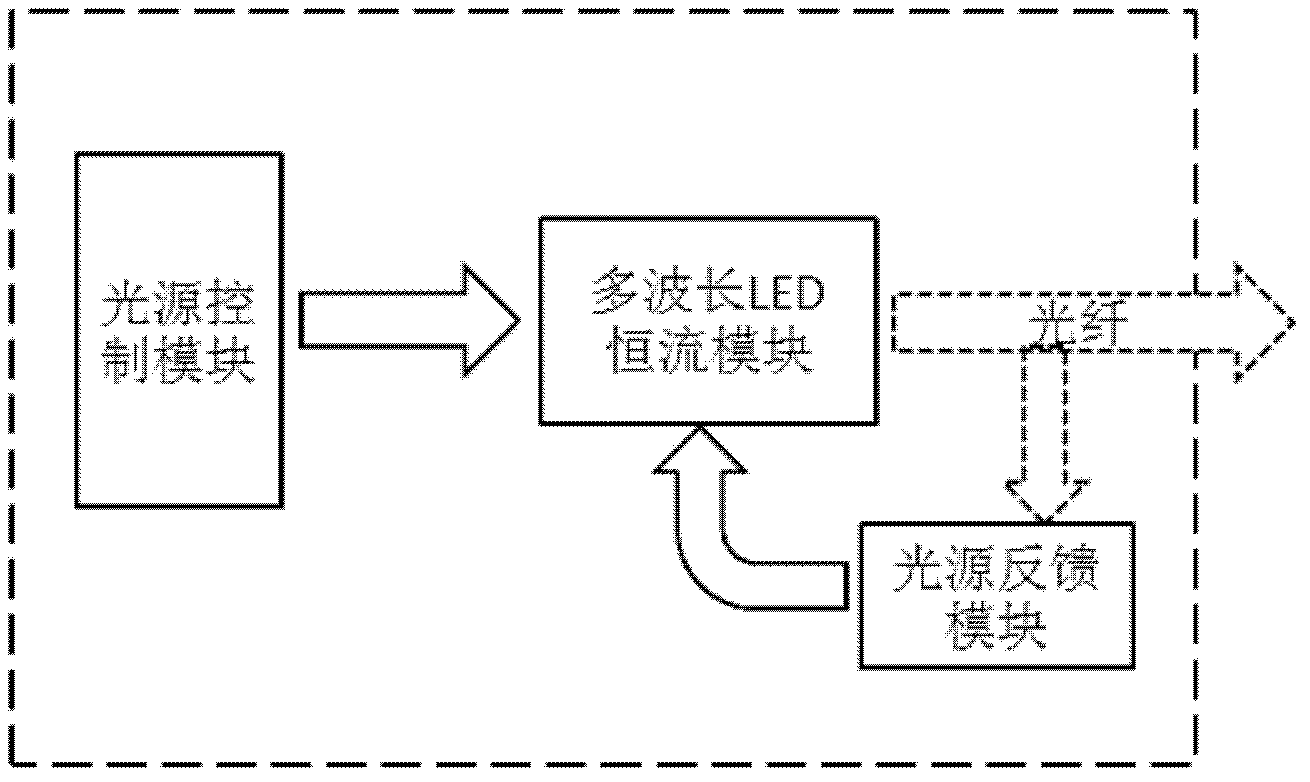

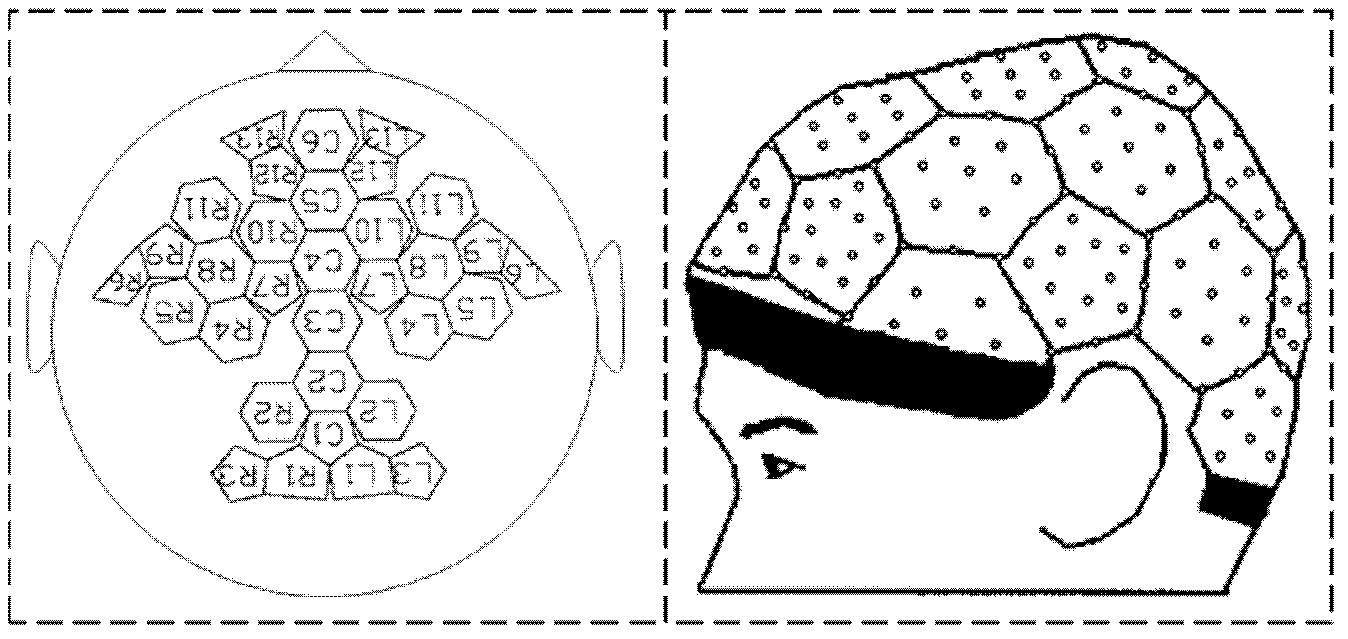

Multi-channel parallel near infrared spectrum imaging system

ActiveCN103156620ALow cost to manufacture and useHigh costDiagnostic recording/measuringSensorsMulti wavelengthInfrared

The invention discloses a multi-channel parallel near infrared spectrum imaging system. A multi-wavelength light emitting diode (LED) is applied to finishing emission of near-infrared light. An avalanche photodiode is used for detecting a weak optical signal, the simulating lock-in amplifier technology is used for achieving amplification of the signal, and a near infrared spectrum cerebral function imaging helmet disclosed in Chinese patent application CN200520002784.8 can be used for improving the partial unreasonable design of a self-adaptation head portion. The multi-channel parallel near infrared spectrum imaging system can achieve continuous rapid accurate detection and collection of cerebral blood oxygen signals, overcomes the defect of an existing functional near infrared system, and brings superiority of the near infrared spectrum imaging technology compared with other cerebral function imaging technologies into full play.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

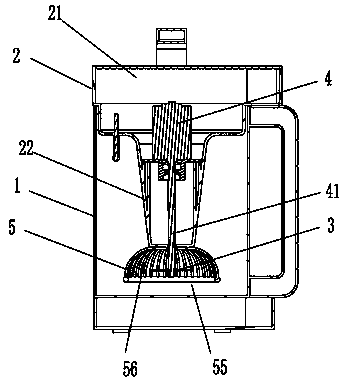

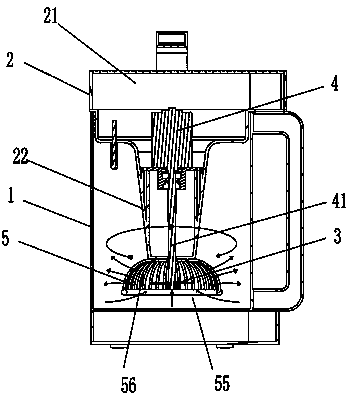

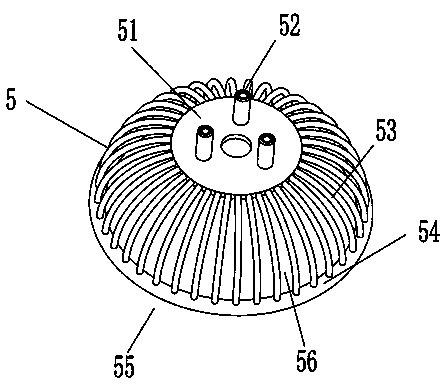

Soybean milk machine with small-space crushing cover

ActiveCN103654475AImproved material crushing effectEnsure consistencyBeverage vesselsEngineeringWater pumping

In order to solve the problems that the good material crushing effect and cleaning easiness of an existing soybean milk machine can not be achieved at the same time, and the uniformity of the crushing effect is difficult to guarantee, the invention provides a soybean milk machine with a small-space crushing cover. According to the soybean milk machine, the unsealed small-space crushing cover is arranged on the lower portion of a lower cover of a machine head, a cutter body is located inside the unsealed small-space crushing cover, the cutter body is provided with a water pumping part which enables water in a cup body to move towards the unsealed small-space crushing cover in the rotating process, the unsealed small-space crushing cover is provided with at least one bottom feed port and a plurality of discharge ports, and the maximal permission passing size of materials on the discharge ports is smaller than the original size of materials to be crushed. According to the soybean milk machine with the small-space crushing cover, material crushing is divided into the two phases of small-space concentrated crushing and cyclic crushing, the material crushing effect is made to be greatly improved, the uniformity of the crushing effect is guaranteed, meanwhile, the small-space crushing cover can be conveniently cleaned, and the problem that the good material crushing effect and cleaning easiness can not be achieved at the same time is solved.

Owner:JOYOUNG CO LTD

Super-high thermal conductivity and low thermal expansivity diamond composite material and preparation method thereof

The invention discloses a super-high thermal conductivity and low thermal expansivity diamond composite material and a preparation method thereof, and belongs to the field of high-performance functional materials. The composite material consists of at least two phases of high thermal conductivity diamond grains and high thermal conductivity metals or alloy materials. The preparation method for the composite material comprises the following steps of: putting high thermal conductivity sheet or block metals or alloy materials on the high thermal conductivity diamond powder grains, loading, sealing, performing vacuum heat treatment, and performing melt infiltration sintering at certain high temperature under high pressure to make high thermal conductivity metals melted and infiltrated in the diamond grains so as to form the super-high thermal conductivity and low thermal expansivity composite material. The method makes high thermal conductivity nonmetal materials and high thermal conductivity metal materials firmly combined, so the composite material has the compactness of over 99 percent, and the thermal conductivity of 600 to 800W / (m.K); the thermal expansivity (less than 5ppm / K) matched with an electronic device can ensure that a workpiece works stably for a long time under the condition of high heating density; and the composite material has wide industrial application prospect.

Owner:UNIV OF SCI & TECH BEIJING +1

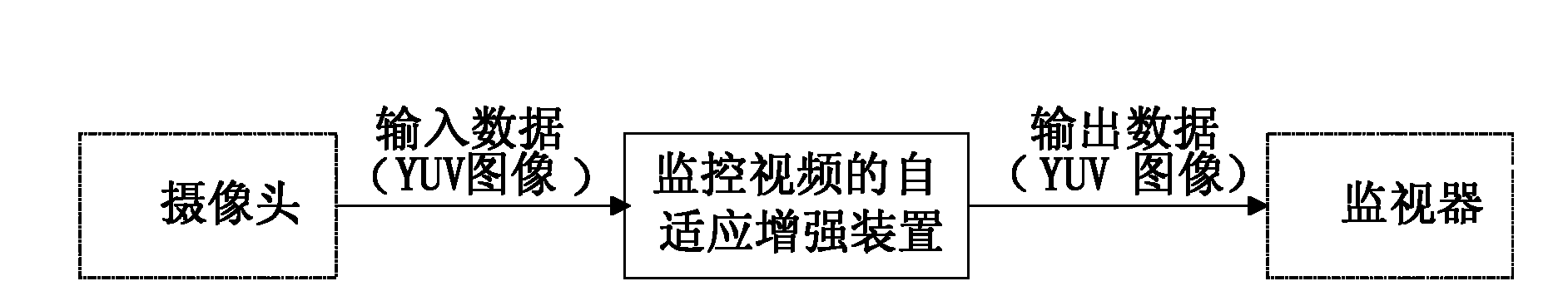

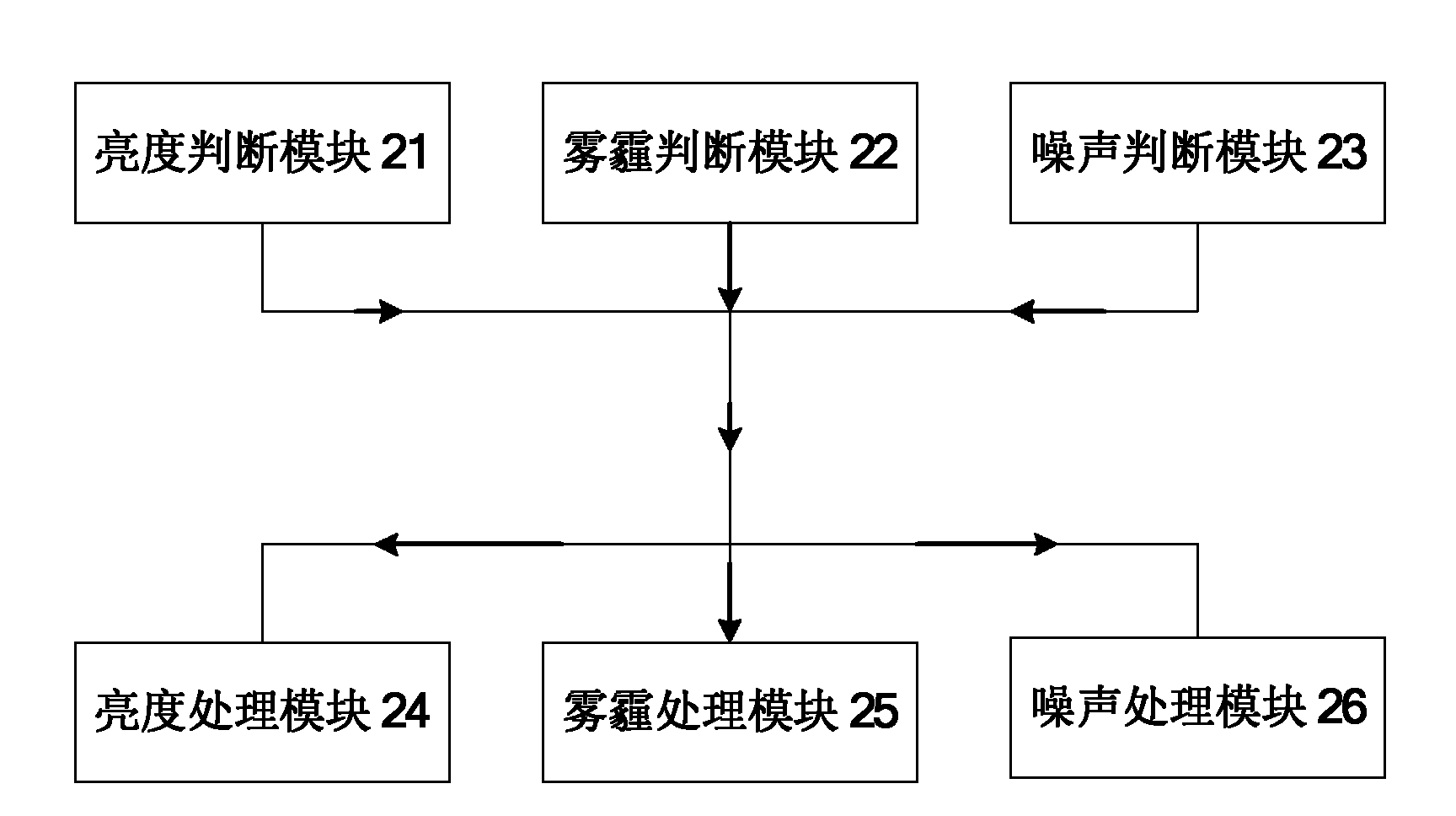

Adaptive enhancement method and device for monitored video

InactiveCN102202163AImplement Adaptive EnhancementImprove image qualityTelevision system detailsColor signal processing circuitsPattern recognitionColor saturation

The invention discloses an adaptive enhancement method for monitored video. The method comprises the steps of brightness judgment, haze judgment, noise judgment, brightness processing, haze processing and noise processing. An adaptive enhancement device for monitored video comprises a brightness judgment module, a haze judgment module, a noise judgment module, a brightness processing module, a haze processing module and a noise processing module. The brightness judgment module comprises a brightness mean calculating unit and a brightness processing and judgment unit; the haze judgment module comprises a first chrominance space conversion unit, a color saturation calculating unit, a color saturation component mean calculating unit, a haze processing and judgment unit and a second chrominance space conversion unit; and the noise judgment module comprises an edge detection unit, a binarization unit, a target statistics calculating unit and a noise processing and judgment unit.

Owner:CHENGDU WESTIMAGE TECH

Silicon-based hybrid integration laser radar chip system

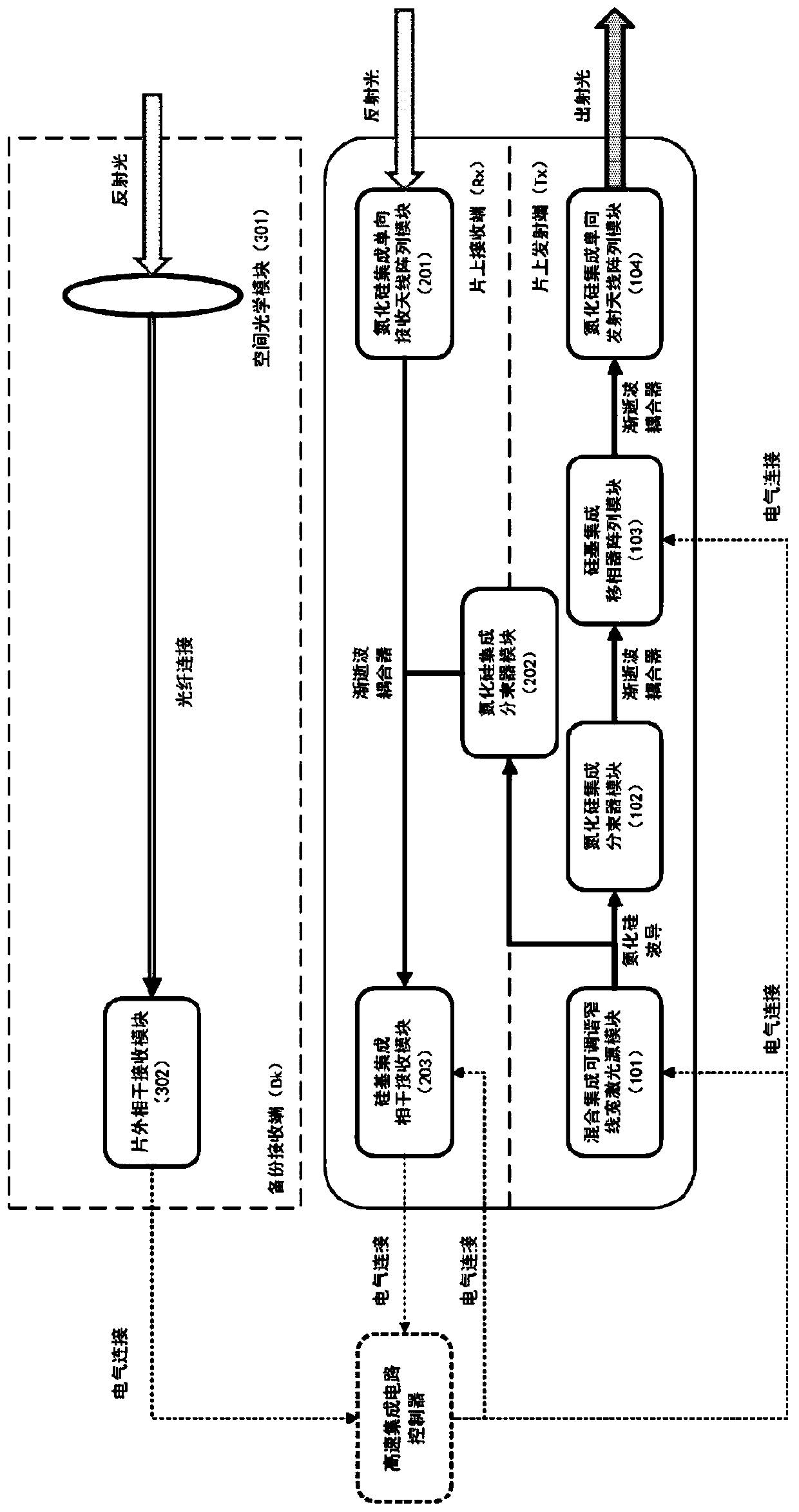

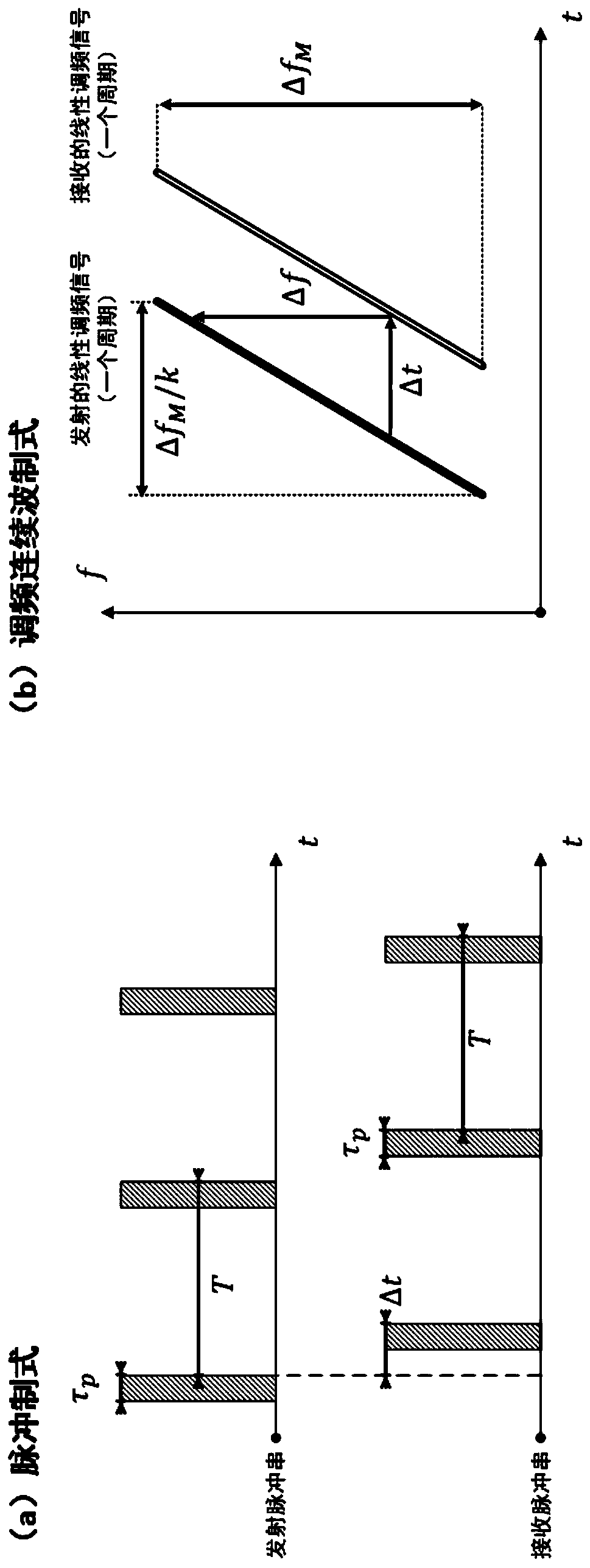

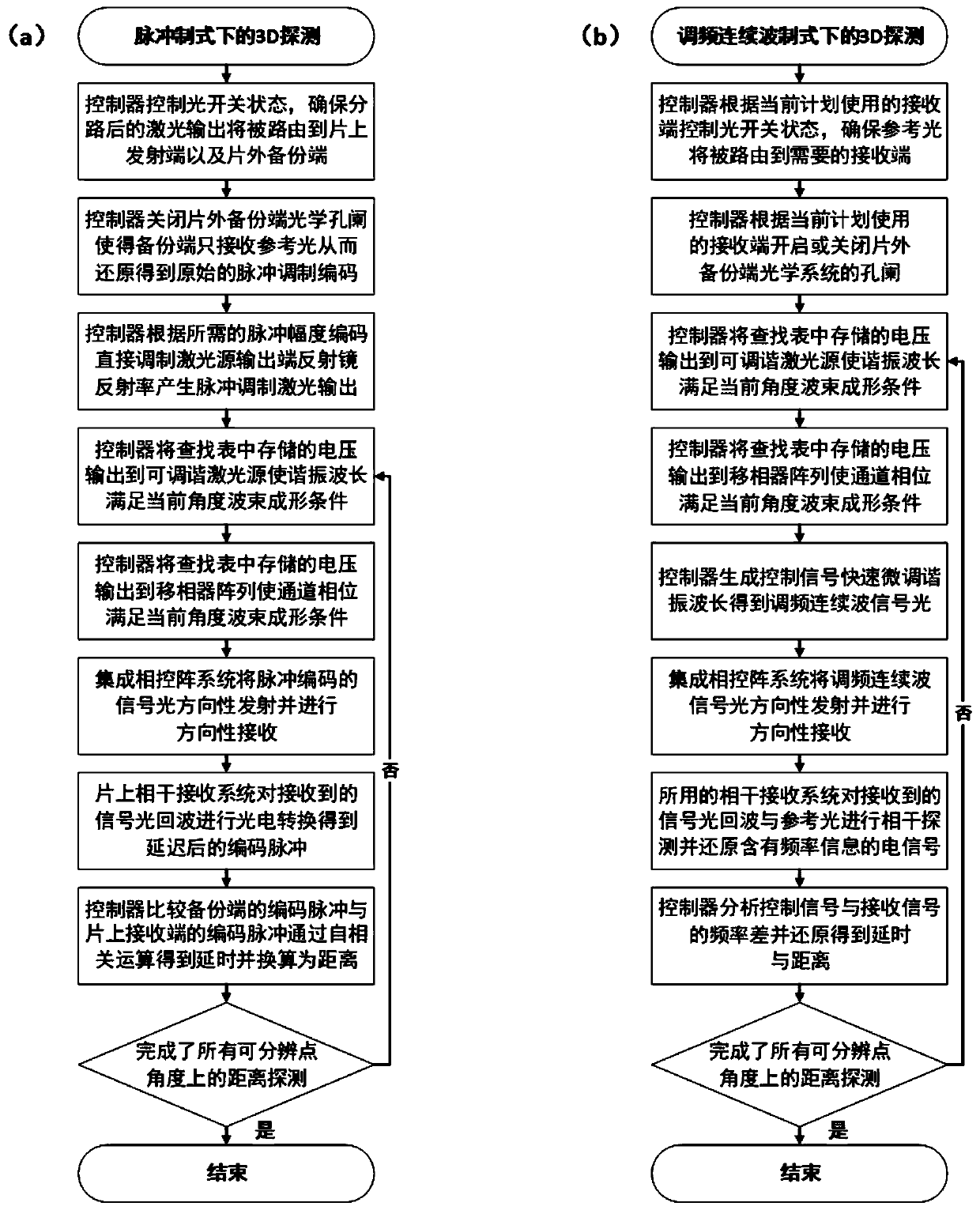

ActiveCN109991582AHigh continuous scanning speedFast scanningElectromagnetic wave reradiationNon-linear opticsBeam splitterMulti field

The invention discloses a silicon-based hybrid integration laser radar chip system. According to a light path sequence, the transmitting terminal of the system comprises a tunable narrow linewidth laser source, a silicon nitride beam splitter, a silicon-based phase shifter array and a silicon nitride one-way transmitting antenna array in sequence. According to a principle that the light path is reversible, the receiving terminal of the system comprises a silicon nitride one-way receiving antenna array, a silicon nitride beam splitter and a silicon-based coherence receiving module in sequence and also comprises a backup system and an electric domain control processing module. Each module on a silicon platform and a silicon nitride platform realizes multilayer single-chip integration with the help of a silicon / silicon nitride evanescent wave coupler, and a gain chip in a tunable laser source module and silicon nitride waveguide are subjected to hybrid integration through horizontal coupling. By use of the system, through multi-platform multi-field hybrid integration, the high-speed flexible wave beam formation, rotation and directivity receiving of a free space laser signal can be realized in a phased array way. The system does not contain movable devices, and has high integration density, good CMOS (Complementary Metal-Oxide-Semiconductor Transistor) compatibility, low large-scale volume production cost and extremely high practical value.

Owner:SHANGHAI JIAOTONG UNIV

AlTiN-AlCrN super hard nano multilayer composite coating hob and preparation method thereof

InactiveCN102922052AHigh densityImprove corrosion resistanceVacuum evaporation coatingSputtering coatingAlloyCemented carbide

The invention discloses an AlTiN-AlCrN super hard nano multilayer composite coating hob and a preparation method thereof. The hob is provided with a nano composite coating consisting of Cr, CrN, AlTiN / CrhN and AlTiN / AlCr in sequence and generated by adopting an arc ion plating technology. The coating is reasonable in structural design and has gradually changed components and gradient hardness at the same time; and the prepared AlTiN / AlCr coating has good bonding force with the high-speed steel or hard alloy hob, high hardness and excellent temperature resistance. The problems of insufficient temperature resistance and abrasion resistance of the hob are well solved, the machining performance of the hob is greatly improved, and the hob has a good industrial application prospect.

Owner:SHENZHEN YUANSIDACHENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com